High-strength high-corrosion resistance thallium-based nickel base superalloy and preparation method thereof

A nickel-based superalloy, high corrosion resistance technology, applied in the field of yttrium-containing nickel-based superalloy, can solve problems such as damage to economic value, safety hazards, fracture of metal components, etc., to improve corrosion resistance, internal uniformity, and impurity content. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

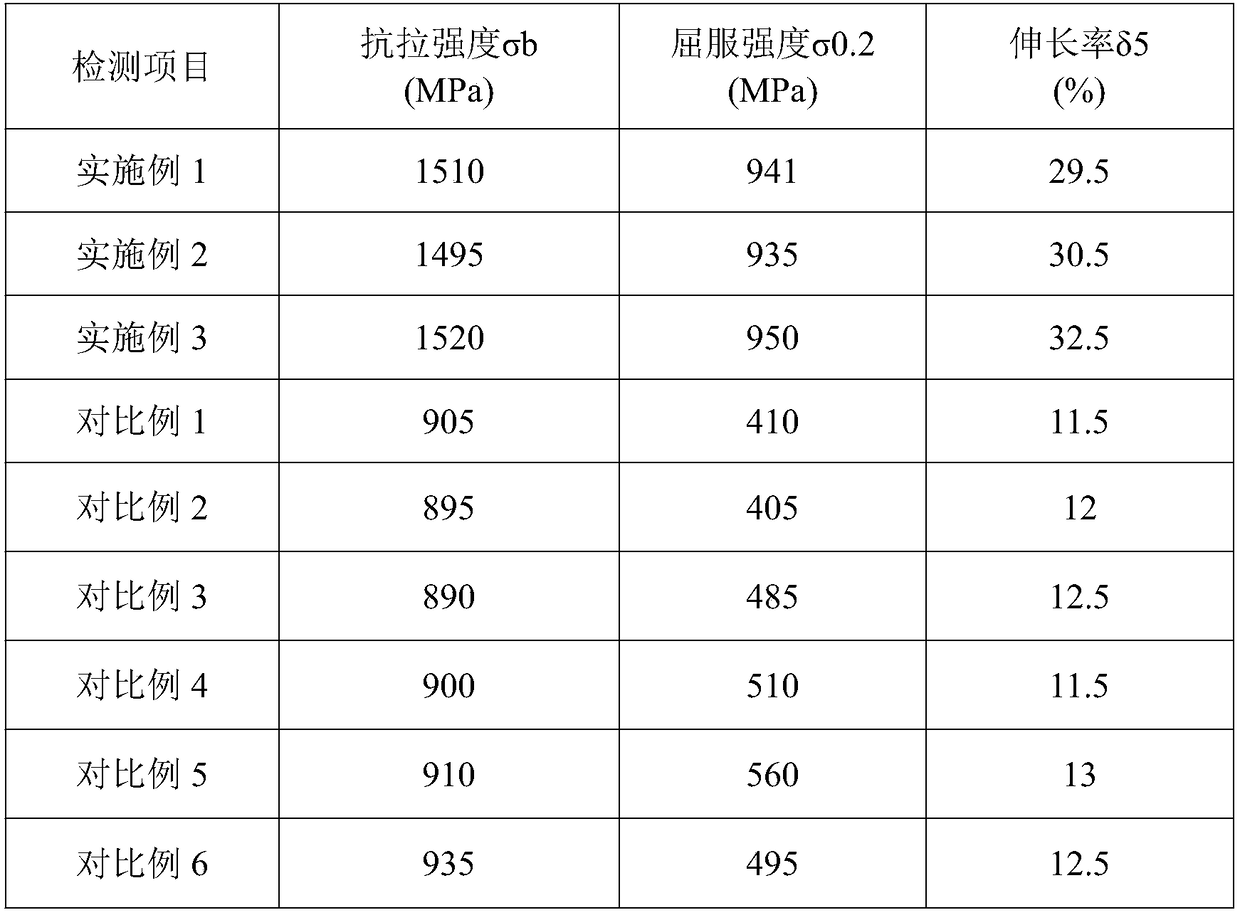

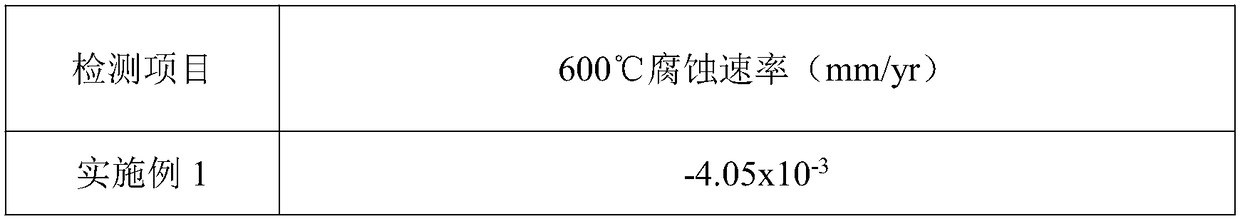

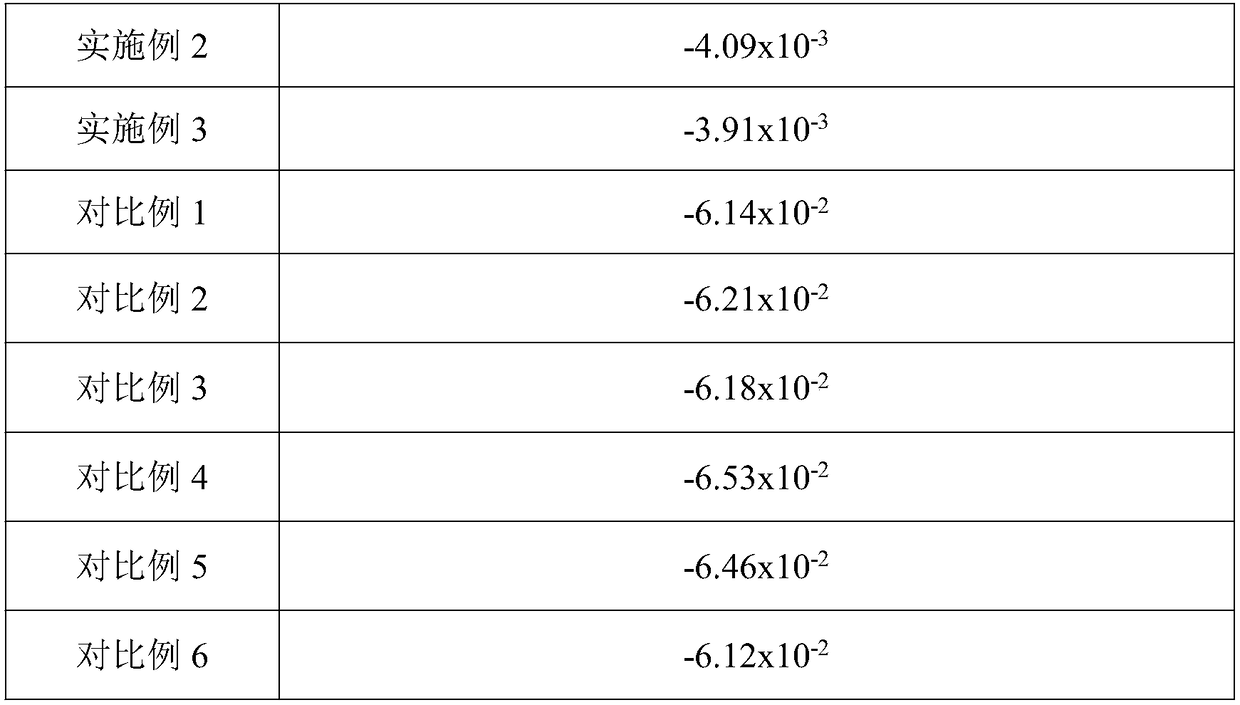

Examples

Embodiment 1

[0032] A high-strength and high-corrosion-resistant thallium-containing nickel-based superalloy is characterized in that, in percentage terms, the alloy includes: Cr: 8%; Tl: 4.5%; Fe: 16%; Mo: 11%; C Al: 1.5%; Cu: 4%; Nb: 0.01%; the balance is Ni and unavoidable impurities.

[0033] The preparation method of above-mentioned alloy material is as follows:

[0034] (1) Weigh the raw materials according to the proportion of the components, and then smelt them in a vacuum induction furnace to ensure that the smelting temperature is 1480°C, and pour them into consumable electrodes after smelting;

[0035] (2) The consumable electrode obtained in step (1) is remelted and refined in a vacuum consumable furnace, and the five-element slag remelting system is: CaF 2 :56%, Al 2 o 3 :20%, CaO:15%, MgO:4%, SiO 2 : 3%; after refining, forced cooling and remelting into electroslag ingots, the refining temperature is 1380°C, and the refining time is: 10 minutes; the cooling temperature is...

Embodiment 2

[0043] A high-strength and high-corrosion-resistant thallium-containing nickel-based superalloy is characterized in that, in percentage terms, the alloy includes: Cr: 11%; Tl: 6%; Fe: 18%; Mo: 17%; C Al: 2%; Cu: 6%; Nb: 0.25%; the balance is Ni and unavoidable impurities.

[0044] The preparation method of above-mentioned alloy material is as follows:

[0045] (1) Weigh the raw materials according to the proportion of the components, and then smelt them in a vacuum induction furnace to ensure that the smelting temperature is 1490°C, and pour them into consumable electrodes after smelting;

[0046] (2) The consumable electrode obtained in step (1) is remelted and refined in a vacuum consumable furnace, and the five-element slag remelting system is: CaF 2 :59%, Al 2 o 3 :2%, CaO:17%, MgO:7%, SiO 2 : 6%; after refining, forced cooling and remelting into electroslag ingots, the refining temperature is 1400°C, and the refining time is: 14 minutes; the cooling temperature is 43°C;...

Embodiment 3

[0054] A high-strength and high-corrosion-resistant thallium-containing nickel-based superalloy is characterized in that, in percentage terms, the alloy includes: Cr: 9.8%; Tl: 4.25%; Fe: 16.8%; Mo: 13.25%; C Al: 1.55%; Cu: 4.95%; Nb: 0.15%; the balance is Ni and unavoidable impurities.

[0055] The preparation method of above-mentioned alloy material is as follows:

[0056] (1) Weigh the raw materials according to the proportion of the components, and then smelt them in a vacuum induction furnace to ensure that the smelting temperature is 1485°C, and pour them into consumable electrodes after smelting;

[0057] (2) The consumable electrode obtained in step (1) is remelted and refined in a vacuum consumable furnace, and the five-element slag remelting system is: CaF 2 :58%, Al 2 o 3 : 21%, CaO: 16%, MgO: 6%, SiO 2 : 4.5%; after refining, forced cooling and remelting into electroslag ingots, the refining temperature is 1390°C, and the refining time is: 12 minutes; the cooli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com