Ether anticorrosive polycarboxylate superplasticizer and preparation method thereof

A technology of anti-corrosion type polycarboxylic acid and water reducing agent, applied in the field of building materials, can solve the problems of lack of water reduction, poor water solubility, low polymerization efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

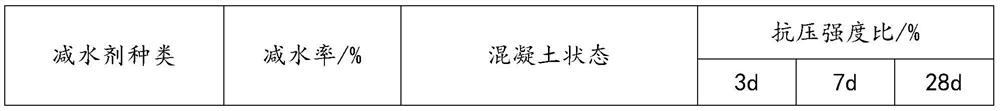

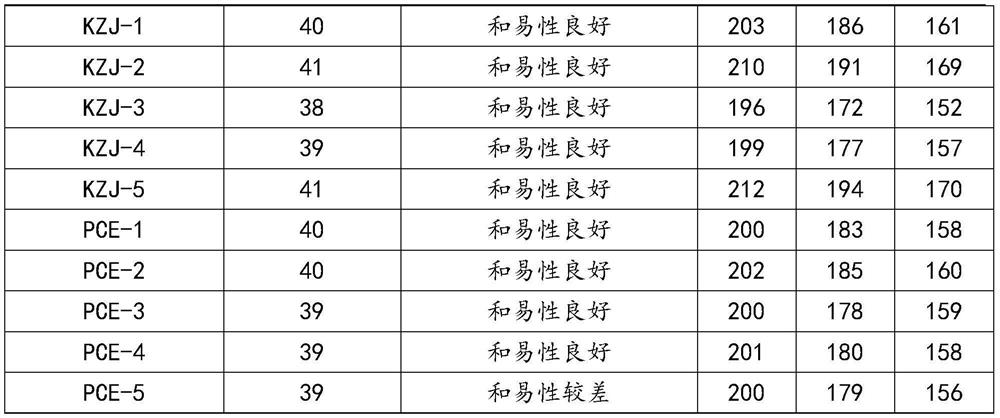

Examples

Embodiment 1

[0036] (1) 180.00g molecular weight is 2400 3-methyl-3-butene-1-polyethylene glycol, 2.40g monomethyl fumarate, 2.00g acrylamide and 145.00g water are added in the reactor, Turn on the agitator and the temperature control device, and when the materials are mixed evenly, start to drop an aqueous acrylic acid solution (wherein, 20.00 g of acrylic acid, 20.00 g of water), an aqueous solution of hydrogen peroxide (wherein, 1.50 g of hydrogen peroxide, and 20.00 g of water), and an aqueous solution of mercaptopropionic acid (wherein , mercaptopropionic acid 0.80g, water 20.00g), ascorbic acid aqueous solution (among them, ascorbic acid 0.40, water 20.00g), the reaction temperature is 40 ℃, the time of dropping is 3.0h, after the dropping is completed, keep warm for 0.5h to obtain the copolymerization product;

[0037](2) Add 11 g of 32% aqueous sodium hydroxide solution to the copolymerized product obtained in step (1) to obtain the ether anti-corrosion polycarboxylate water reducer...

Embodiment 2

[0039] (1) 180.00g molecular weight is 2400 2-methallyl polyethylene glycol, 2.50g diethyl maleate, 3.00g methacryl tartrate and 145.00g water are added in the reactor, open Stirrer and temperature control device, until the materials are mixed evenly, start to drop acrylic acid aqueous solution (wherein, acrylic acid 22.00g, water 20.00g), hydrogen peroxide aqueous solution (wherein, hydrogen peroxide 1.70g, water 20.00g), thioglycolic acid aqueous solution (wherein, mercapto Acetic acid 0.90g, water 20.00g), ascorbic acid aqueous solution (among them, ascorbic acid 0.40, water 20.00g), the reaction temperature is 40°C, the dropwise addition time is 2.5h, after the dropwise addition is completed, keep warm for 1h to obtain the copolymerization product;

[0040] (2) Add 11 g of 32% aqueous sodium hydroxide solution to the copolymerized product obtained in step (1) to obtain the ether anti-corrosion polycarboxylate water reducer, which is designated as KZJ-2.

Embodiment 3

[0042] (1) 60.00g molecular weight is 2400 3-methyl-3-butene-1-polyethylene glycol, 120.00g molecular weight is 2400 2-methallyl polyethylene glycol, 3.00g fumaric acid Add monoethyl ester, 1.50g methyl methacrylate and 145.00g water into the reactor, turn on the stirrer and the temperature control device, and wait for the materials to mix evenly, start to drop the mixed aqueous solution of acrylic acid and maleic anhydride (wherein, 15.00g of acrylic acid , maleic anhydride 5.00g, water 20.00g), hydrogen peroxide aqueous solution (among them, hydrogen peroxide 1.70g, water 20.00g), mercaptoethanol aqueous solution (among them, mercaptoethanol 0.70g, water 20.00g), chrysanthemum block aqueous solution (among them, white block 0.50, water 20.00g), the reaction temperature is 45°C, the dropwise addition time is 2.0h, after the dropwise addition is completed, keep warm for 1h to obtain the copolymerized product;

[0043] (2) Add 12g of 32% aqueous sodium hydroxide solution to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com