Porous alloy filter element used in high temperature environment and preparation method thereof

A filter element and high-temperature environment technology, applied in the field of porous alloy filter element and its preparation, can solve the problems of affecting the service life of materials, difficulty in recycling, high cost of raw materials, etc., and achieve good filtering effect, long service life and small pressure drop Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

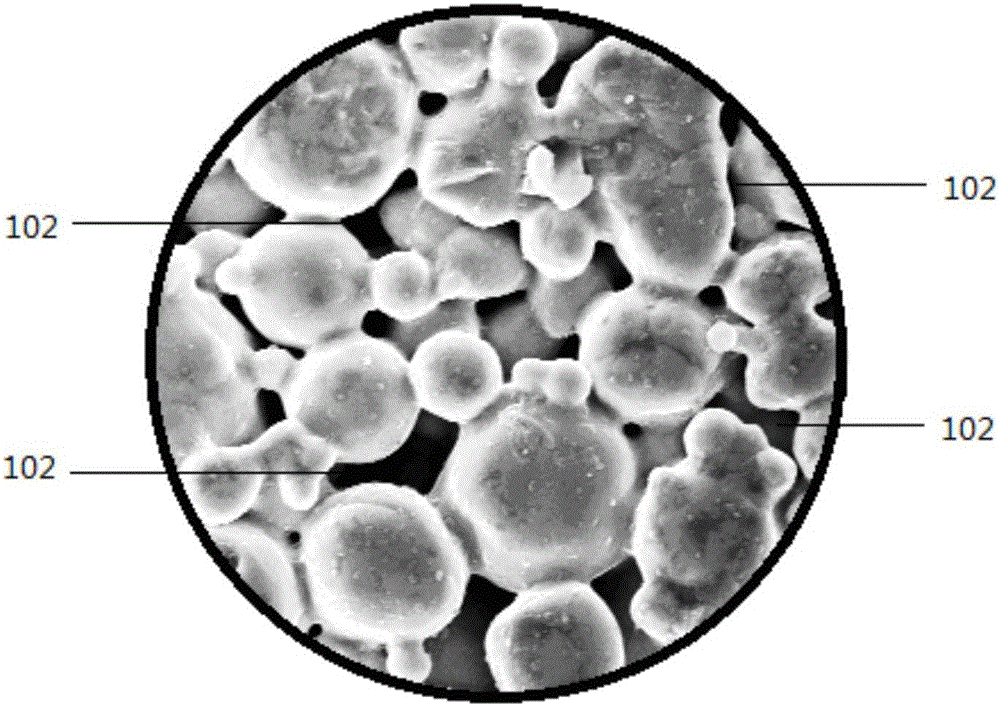

[0057] Preparation of Fe-Cr-Al-Based Porous Metal Filter Elements for Purification of High-temperature Dusty Gas Used in IGCC Power Generation

[0058] The porous alloy filter element prepared in this embodiment is made of iron-chromium-aluminum-based composite porous alloy material, and is composed as follows by mass percentage:

[0059] 3wt% of aluminum, 15wt% of chromium, 2wt% of silicon carbide, 0.038wt% of lanthanum-cerium mixed rare earth, and the balance is iron;

[0060] The filter element preparation method of the present embodiment comprises the following steps:

[0061] Step 1: Preparation of rare earth-containing iron-silicon carbide sintered block

[0062] According to the mass ratio of silicon carbide and rare earth in the designed iron-chromium-aluminum-based porous metal material, the mass ratio of silicon carbide and rare earth is enlarged by 5 times, and the silicon carbide powder with a particle size below 1um is weighed 10Kg, and the rare earth is 0.19. K...

Embodiment 2

[0076] Preparation of Fe-Cr-Al-based porous metal filter element for direct purification of PM2.5 in high-temperature flue gas

[0077] The porous alloy filter element used in the high-temperature environment prepared in this embodiment is made of iron-chromium-aluminum-based composite porous alloy material, and its composition includes the following components, which are composed by mass percentage:

[0078] Aluminum 5wt%, chromium 20wt%, silicon carbide 8wt%, rare earth yttrium 0.49wt%, the balance is iron;

[0079] The filter element preparation method of the present embodiment comprises the following steps:

[0080] Step 1: Preparation of rare earth-containing iron-silicon carbide sintered block

[0081] According to the mass ratio of silicon carbide and rare earth in the designed iron-chromium-aluminum-based porous metal material, the mass ratio of silicon carbide and rare earth enlarged by 5 times, respectively weigh 40Kg of silicon carbide powder with a particle size o...

Embodiment 3

[0095] Preparation of Fe-Cr-Al-Based Porous Metal Filter Elements for Purification of Aluminum Melts

[0096] The porous alloy filter element used in the high-temperature environment prepared in this embodiment is made of iron-chromium-aluminum-based composite porous alloy material, and its composition includes the following components, which are composed by mass percentage:

[0097] 7wt% of aluminum, 25wt% of chromium, 10wt% of silicon carbide, 0.25wt% of lanthanum-cerium mixed rare earth, and the balance is iron;

[0098] The filter element preparation method of the present embodiment comprises the following steps:

[0099] Step 1: Preparation of rare earth-containing iron-silicon carbide sintered block

[0100] According to the mass ratio of silicon carbide and rare earth in the designed iron-chromium-aluminum-based porous metal material, the mass ratio of silicon carbide and rare earth enlarged by 5 times, respectively weigh 50Kg of silicon carbide powder, 1.25Kg of rare ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com