Filter tube for high-temperature gas-solid separation and filter with same

一种过滤管、固分离的技术,应用在膜过滤器、分散颗粒过滤、分离方法等方向,能够解决生产成本和维护费用高、易堵塞过滤管多孔通道、降低滤管使用寿命等问题,达到降低生产成本和维护费用、提高清灰效率、提高除尘效果的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

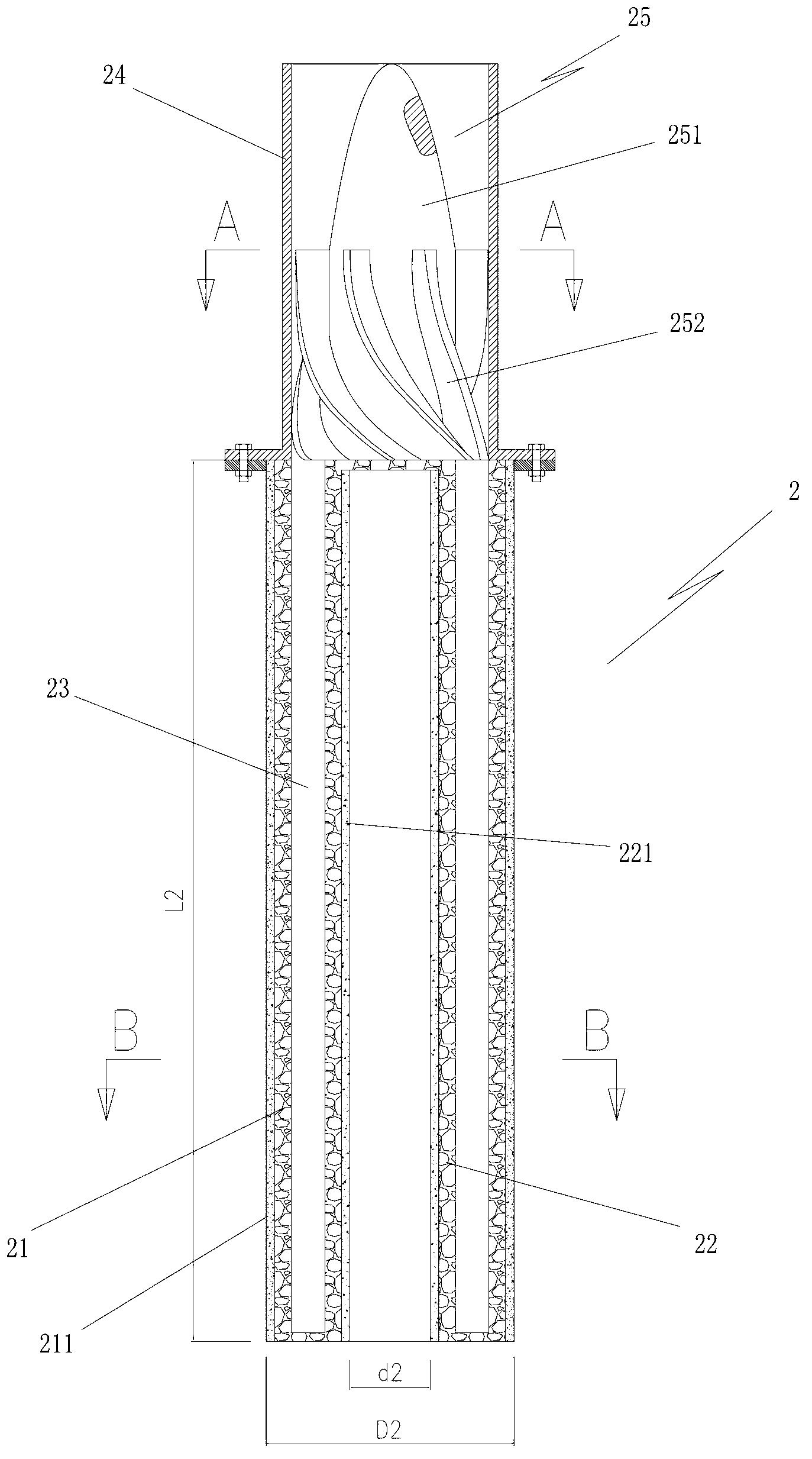

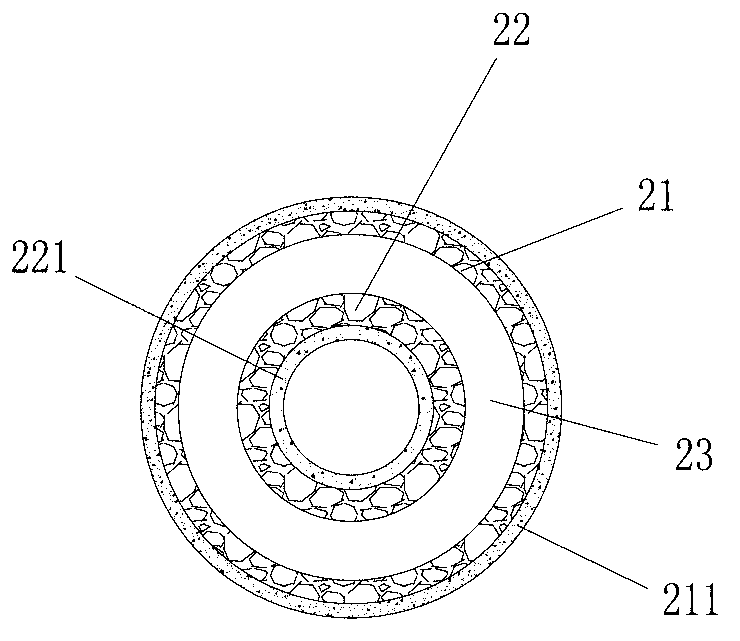

[0043] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

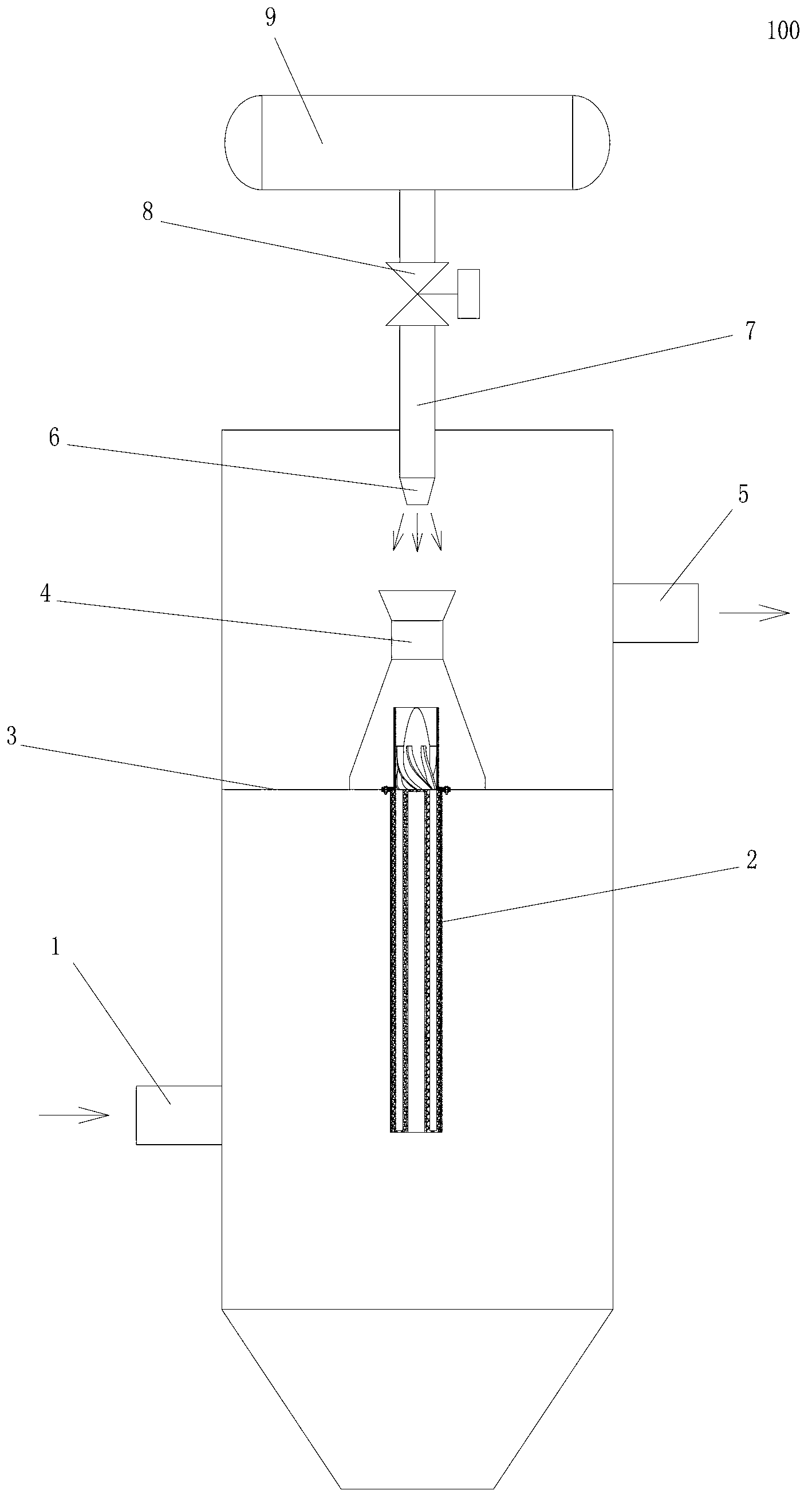

[0044] Such as figure 1 As shown, the present invention proposes a filter 100 for high-temperature gas-solid separation, a filter unit is provided on the tube sheet 3 of the filter, and at least one filter tube 2 is included in the filter unit, and the tube sheet 3 will filter The filter unit is sealed and separated into an upper clean gas chamber and a lower dusty gas chamber; the upper part of the filter unit is provided with an ejector 4 and a blowback pipeline 7 corresponding to the ejector 4, and one end of the blowback pipeline 7 is passed through a pulse The blowback valve 8 is connected to the blowback gas storage tank 9, the other end of the blowback pipeline 7 is provided with a nozzle 6 corresponding to the top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com