Patents

Literature

88results about How to "Inhibition of grain growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

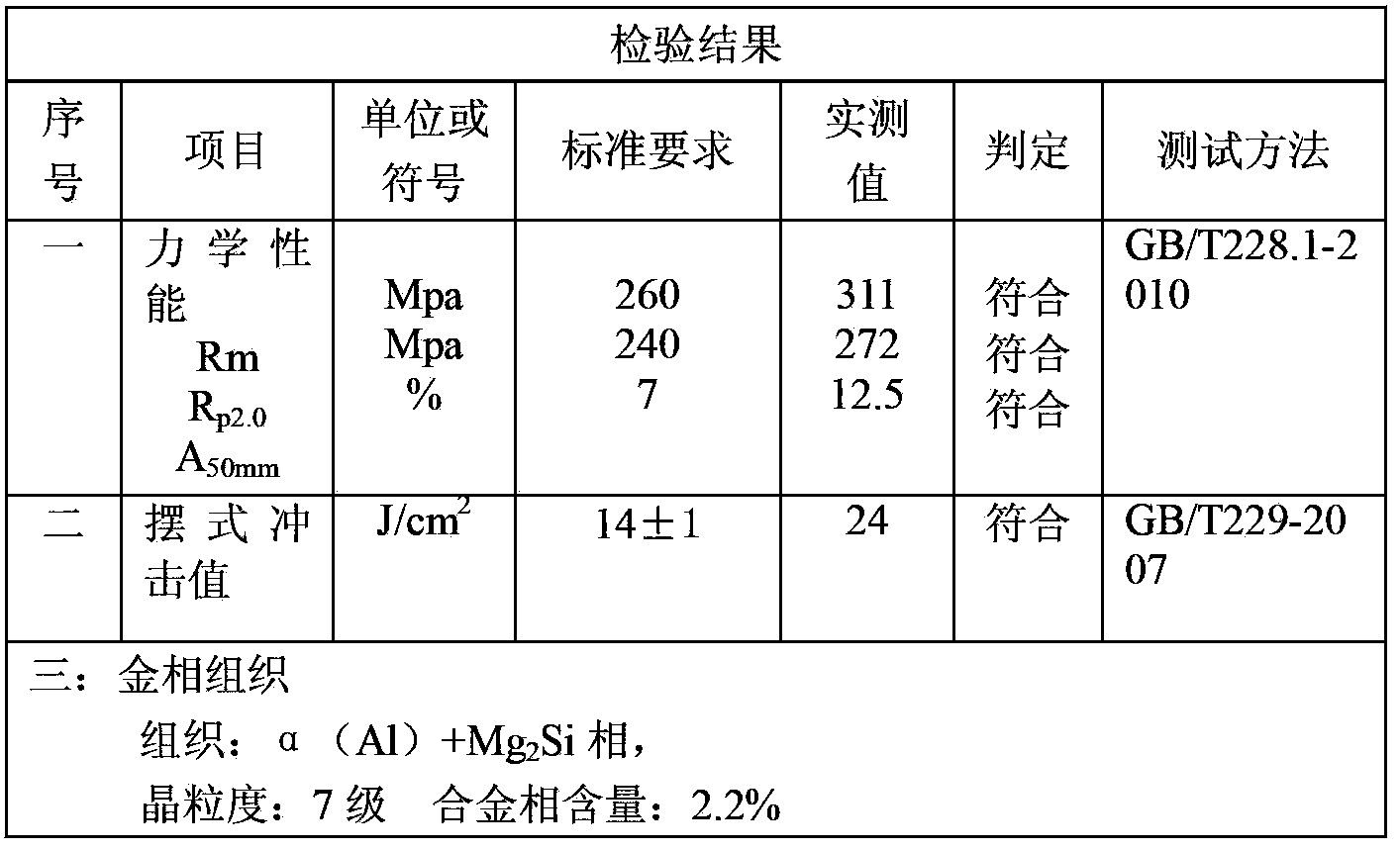

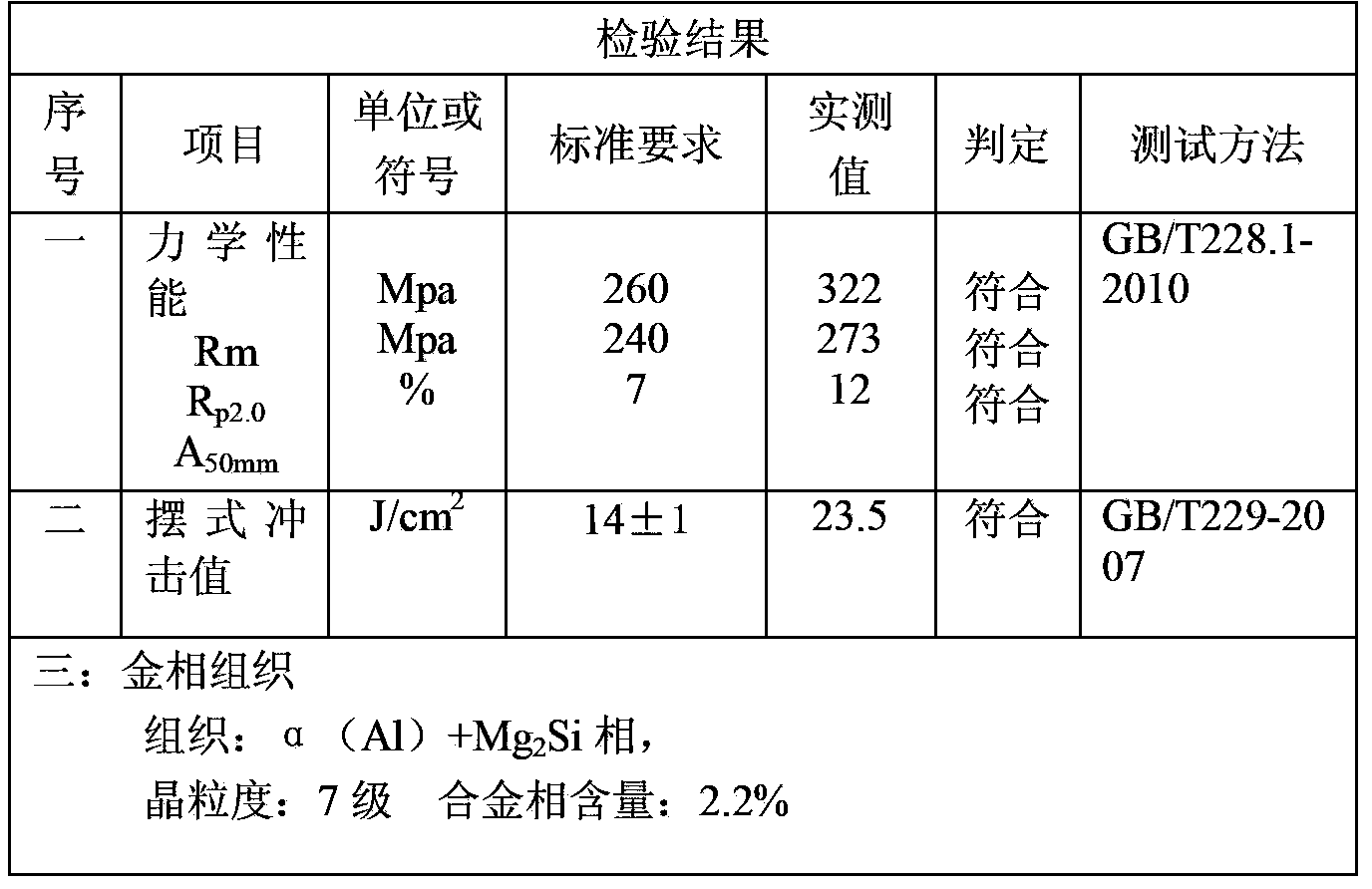

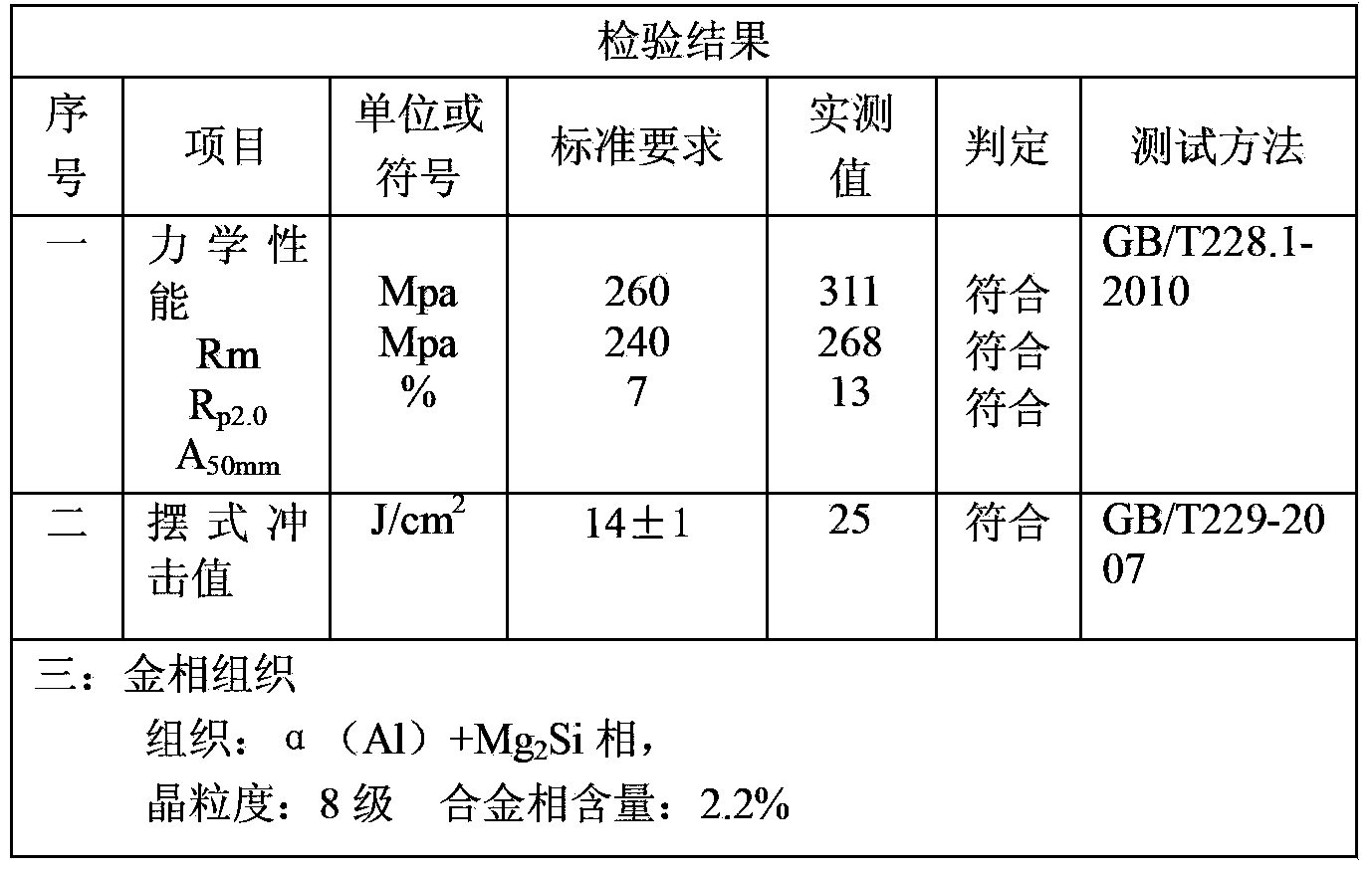

Aluminium alloy profile for building template, and preparation method thereof

The invention discloses an aluminium alloy profile for a building template, and a preparation method thereof. The aluminium alloy profile comprises the following components in percentage by weight: 0.85-0.95 percent of magnesium, 0.06-0.65 percent of silicone, 0.15-0.20 percent of copper, 0.05-0.08 percent of manganese, 0.03-0.05 percent of zirconium, 0.04-0.06 percent of chromium, 0.008-0.012 percent of titanium, 0-0.2 percent of iron, 0-0.10 percent of zinc and the balance of aluminium. The aluminium alloy profile provided by the invention has the advantages that the tensile strength is more than 300 MPa, the yield strength is more than 260 MPa, the breakage elongation percentage is more than 12 percent, the tenacity, the weldability and the corrosion resistance are obviously improved compared with that of an original 6061 alloy, the pendulum impact value is more than 20 J / cm<2>, the welding coefficient is not less than 0.6, smaller quench sensitivity is provided, and critical quenching speed is dropped from 10 DEG C / S of the original alloy to 7 DEG C / S; during the processing of the aluminium alloy profile, air cooling is adopted to process an extrusion outlet with the temperature of 450 DEG C in a high-temperature segment as well as an extrusion outlet with the temperature of being smaller than or equal to 25 DEG C in a low-temperature segment, while a moderate-temperature segment, namely a quench sensitive area with the temperature of 450-250 DEG C utilizes water mist to replace direct water-cooling, so that the difficulty for controlling cross section deformation of the profile in the production field is greatly reduced.

Owner:GUANGDONG WEIYE ALUMINUM FACTORY GRP

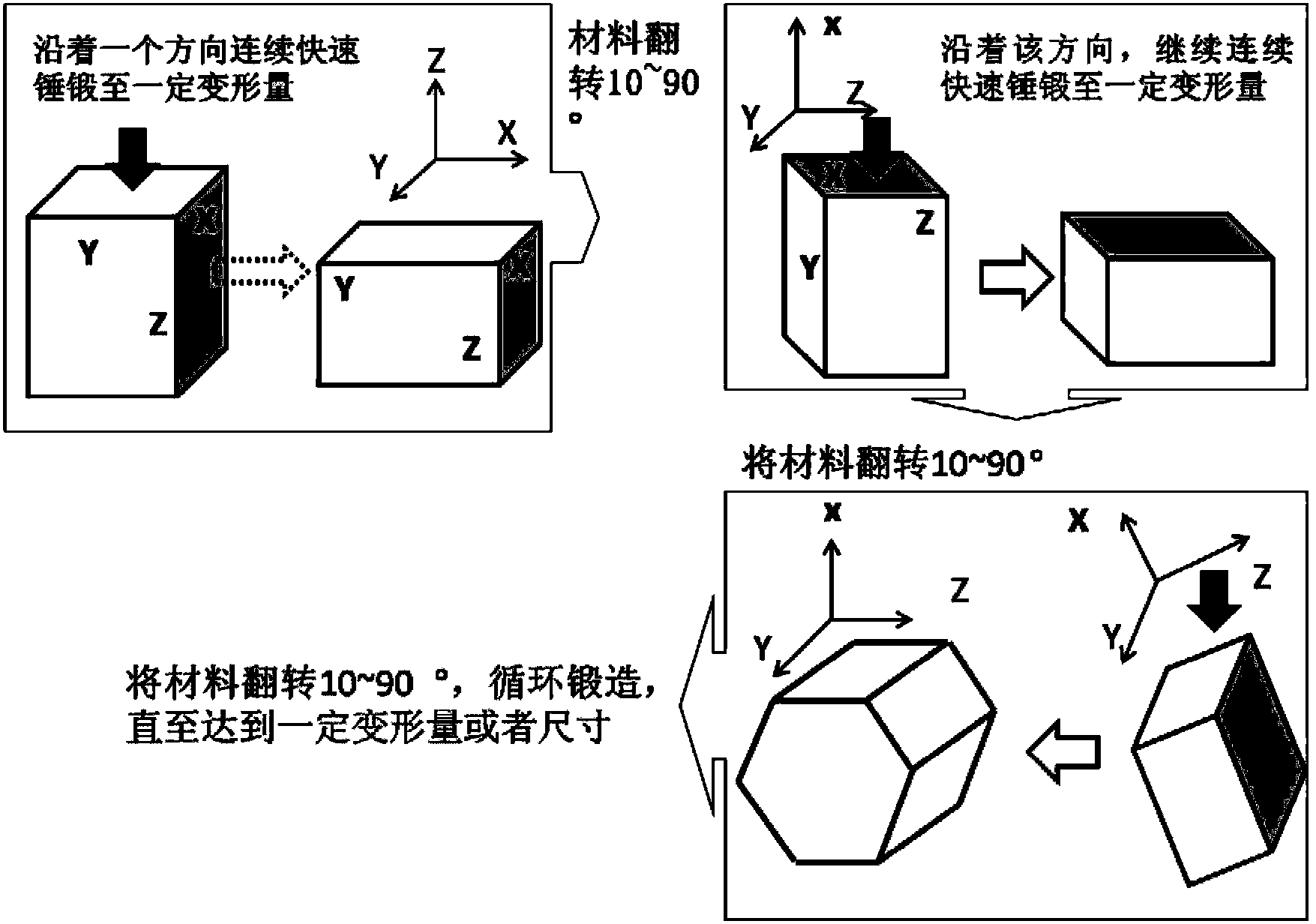

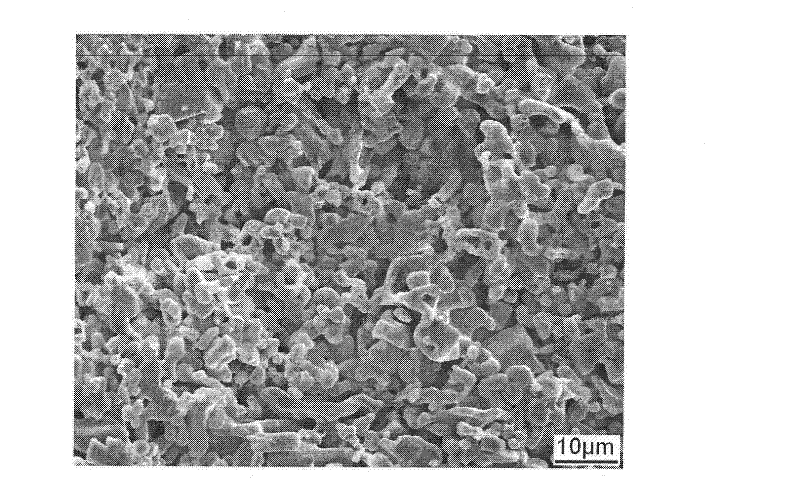

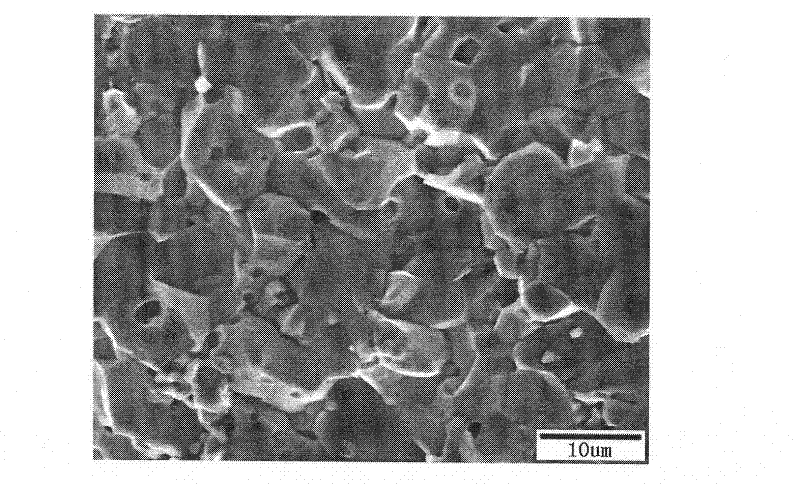

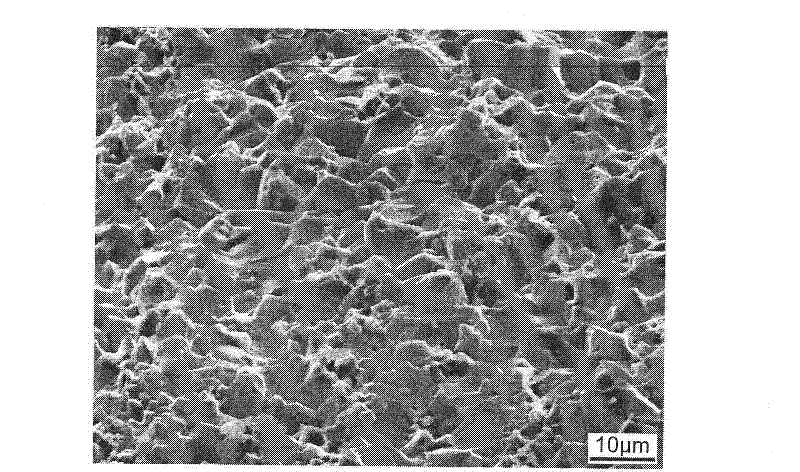

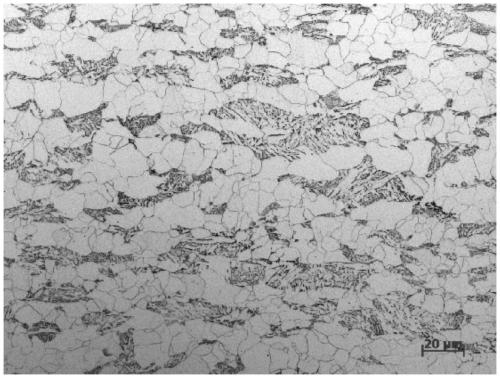

Forging method for multi-direction, circulatory and high-speed hammer forging of magnesium alloy

ActiveCN103805923AOvercome the shortcomings of poor plastic processing performanceLess slipHigh velocityHeat treated

The invention relates to a magnesium alloy plastic processing technology, and relates to a forging method for multi-direction, circulatory and high-speed hammer forging of a magnesium alloy. The method comprises the specific steps: after carrying out homogenization annealing of a casting-state or deformation-state magnesium alloy, carrying out continuous high-speed hammer forging along one direction of the bulk material at a certain temperature; after a certain deformation amount is reached, overturning the material, and continuing to carry out continuous high-speed hammer forging along another direction to reach a certain deformation amount; then overturning the material to another direction, and carrying out such circulatory hammer forging until the material reaches a predetermined deformation amount and size; and finally, carrying out heat treatment on the material. The method utilizes the textured micostructure formed during the processes of high-speed hammer forging of the magnesium alloy to be combined to change the hammer forging direction, thereby improving the ultimate deformation amount that the magnesium alloy can withstand and is not cracked during forging, and improving the plastic processing performance of the magnesium alloy. The method is suitable for magnesium and the alloy material thereof, and improves the forging processing production efficiency of magnesium and the alloy material thereof.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

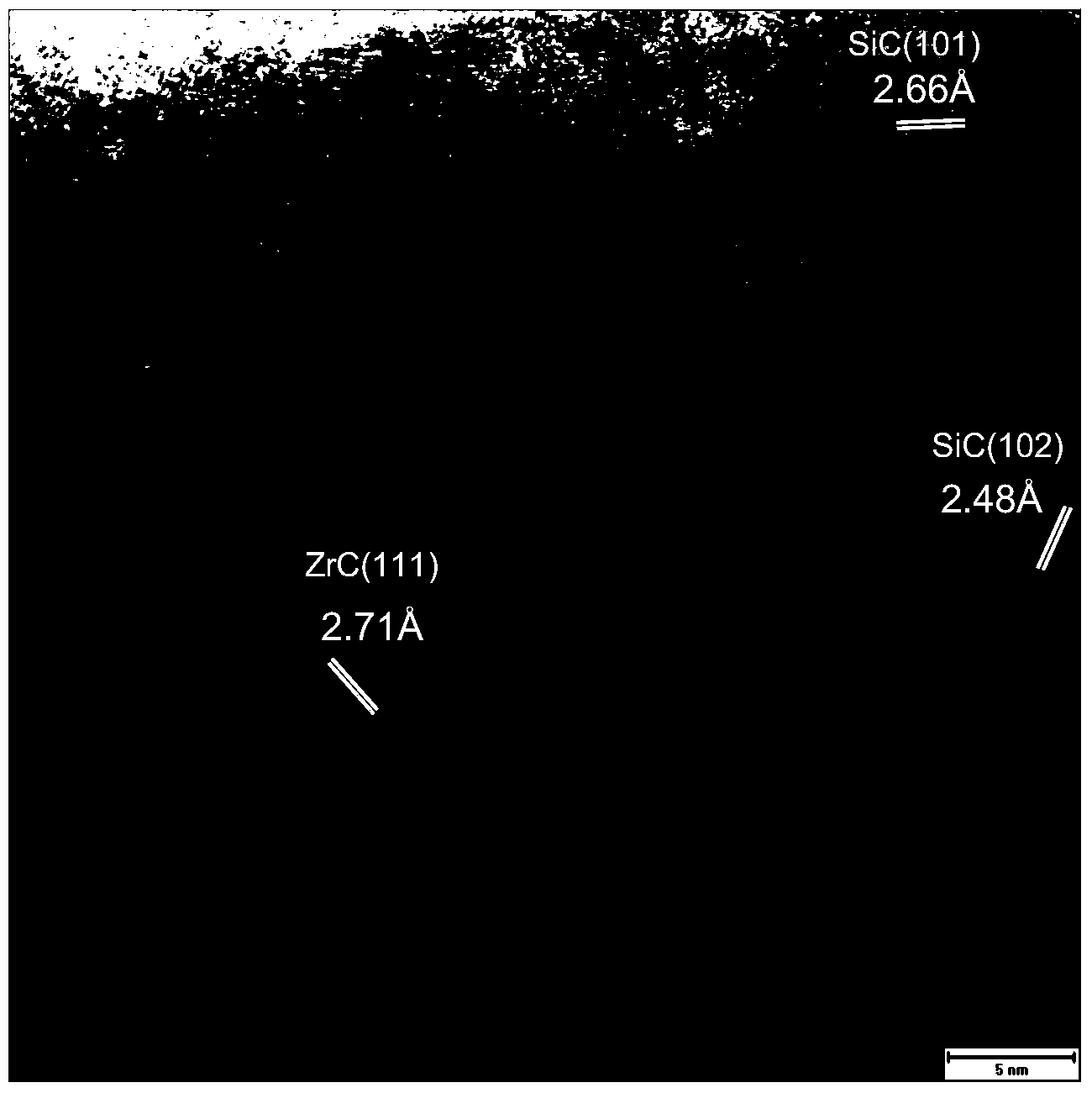

Preparation method for promoting to sinter zirconium boride or zirconium carbide ceramics by using reaction aids

The invention provides a preparation method for promoting to sinter zirconium boride or zirconium carbide ceramics by using reaction aids. Two-phase sintering aids capable of being reacted, namely Zr powder and C powder, or Zr powder and B4C powder, are added, and a material is promoted to be compact and crystals of a matrix are inhibited from growing by zirconium carbide / zirconium boride second phase particles with higher sintering activity, which are generated through in-situ reaction between the sintering aids. The ZrB2 or ZrC-based bulk material prepared by the method has the relative density of over 97 percent, the room temperature bending strength of 500-800MPa, the fracture toughness of 3.5-6.5MPa.ml / 2, and the hardness of 14-20GPa. The second phase generated through the in-situ reaction has the same melting point as the matrix, and the sintering acids cannot bring adverse effect to the high temperature mechanical properties of the material.

Owner:江苏先进无机材料研究院

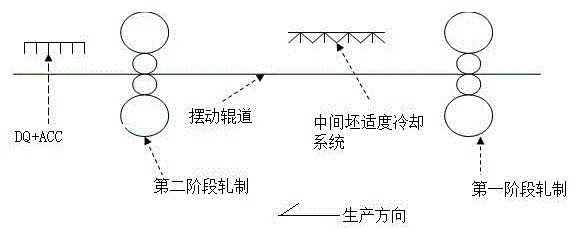

Large-wall-thickness X52MS acid-resistant pipeline steel plate produced by LF-RH refining process and manufacturing method thereof

The invention relates to a large-wall-thickness X52MS acid-resistant pipeline steel plate produced by an LF-RH refining process. The steel plate is characterized by being manufactured from the following chemical component percentage by weight: 0.03%-0.07% of C, 0.2%-0.4% of Si, 1.0%-1.4% of Mn, 0.02%-0.04% of Al, 0.02%-0.05% of Nb, less than or equal to 0.02% of V, 0.004%-0.012% of Ti, 0.1%-0.4% of Cr, 0.1%-0.2% of Mo, less than or equal to 0.0005% of B, less than or equal to 0.012% of P, less than or equal to 0.001% of S, less than or equal to 0.005% of [N], less than or equal to 0.005% of [O], less than or equal to 0.0015% of [H] and the balance being Fe and inevitable impurities, wherein the cold crack sensitivity coefficient Pcm is less than or equal to 0.19. The manufacturing method comprises the sequential steps of KR molten iron pretreatment, converter smelting, LF and RH refining, plate blank continuous casting, plate blank heating, rough rolling, intermediate blank cooling, finish rolling, ACC cooling and the like. The manufactured steel plate has thickness being 35.1-44.2 mm, yield strength being 380-440 MPa, tensile strength being 490-570 MPa, and elongation being greater than or equal to 33%, yield ratio being less than or equal to 0.09; an average shear plane ratio of drop hammer under the temperature of minus 5 DEG C is 85% or more; and the large-wall-thickness X52MS pipeline steel can meet the requirement of being used in an acidic environment, and has good HIC resistance and low-temperature toughness.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Composite ceramic fiber and preparation method thereof

ActiveCN104233512AHigh compositionExpand the scope ofFibre chemical featuresCompound organicComposite ceramic

The invention relates to a composite ceramic fiber and a preparation method thereof. The composite ceramic fiber comprises the components of SiC (silicon carbide), MC and / or MB2, SiC which are evenly diffused and distributed, wherein M is one or more of Ti, Zr and Hf. The composite ceramic fiber uses a single or composite organic macromolecule precursor containing M, Si, C, H and a selectable B element as a raw material, a melt spinning technology is used, and the polybasic composite ceramic fiber is prepared from fiber stabilization and ceramic. The composite ceramic fiber disclosed by the invention has excellent mechanical and high-temperature-resistant antioxygenic properties, and can be used as a reinforcement body for preparing ceramic fiber reinforced composite materials.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

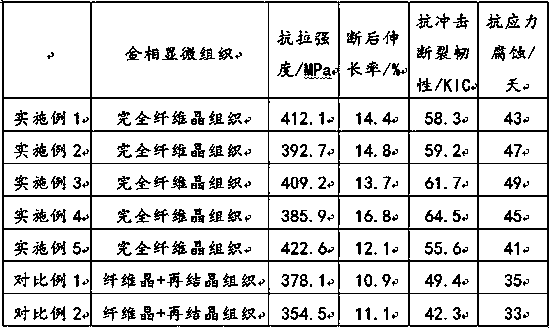

High-strength corrosion resistant Al-Zn-Mg series aluminum alloy and preparation method thereof

The invention discloses a high-strength corrosion resistant Al-Zn-Mg series aluminum alloy and a preparation method of the high-strength corrosion resistant Al-Zn-Mg series aluminum alloy, the aluminum alloy comprises main alloy elements of Zn, Mg and Cu and microalloying elements of Mn, Cr, Er, Ti and B, others are Al and inevitable impurity elements. The preparation method of the high-strength corrosion resistant Al-Zn-Mg series aluminum alloy comprises melting an aluminum alloy solution, spraying, blowing and refining in a furnace, refining a grain online, degassing and filtering online, casting semi-continuously, homogenizing a cast ingot, heating, extruding, quenching online, and implementing artificial ageing treatment. The ingredient composition and the preparation process of the alloy are optimized and designed, the recrystallization and the grain growth are controlled, so that a fibrous crystal tissue is acquired by processing the Al-Zn-Mg series aluminum alloy in the extruding direction, the breaking tenacity and the corrosion resistance of an aluminum alloy extruding material are improved, the aluminum alloy extruding material has excellent comprehensive performances andis suitable for manufacturing light-weight aluminum materials of transportation means like automobiles, railway vehicles, ships and airplanes.

Owner:GUANGDONG INST OF NEW MATERIALS

High-strength high-toughness anti-corrosion aluminum alloy for rail traffic and extrusion method of high-strength high-toughness anti-corrosion aluminum alloy

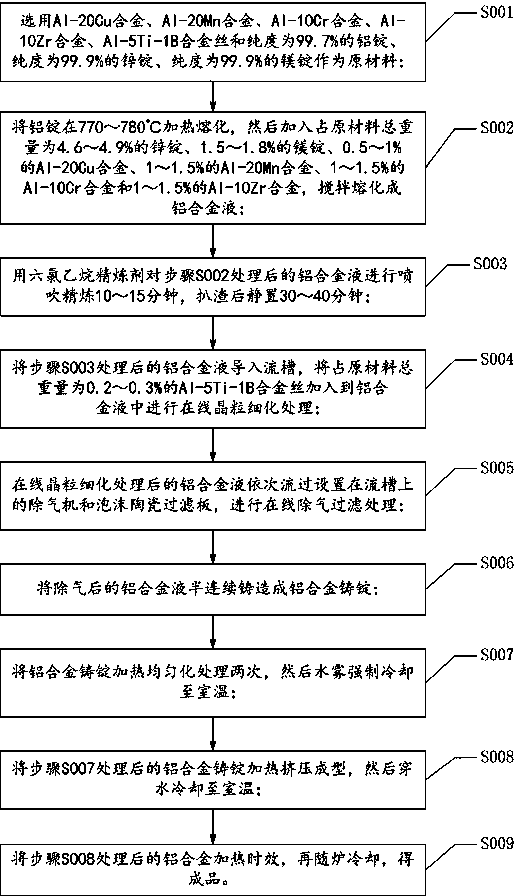

The invention discloses high-strength high-toughness anti-corrosion aluminum alloy for rail traffic and an extrusion method of the high-strength high-toughness anti-corrosion aluminum alloy. The high-strength high-toughness anti-corrosion aluminum alloy is prepared from the following components in percentage by mass: 4.6 to 4.9 percent of Zn, 1.5 to 1.8 percent of Mg, 0.1 to 0.2 percent of Cu, 0.2to 0.3 percent of Mn, 0.1 to 0.15 percent of Cr, 0.1 to 0.15 percent of Zr, 0.01 to 0.015 percent of Ti, 0.002 to 0.003 percent of B, less than or equal to 0.15 percent of Fe, less than or equal to 0.1 percent of Si and the balance of Al and other inevitable impurities. The extrusion method comprises the following steps: melting of aluminum alloy liquid, in-furnace spray blowing refining, onlinegrain refining, online degassing and filtering, semicontinuous casting, ingot homogenizing, heating and extruding, online quenching and artificial ageing treatment. The high-strength high-toughness anti-corrosion aluminum alloy disclosed by the invention is high in strength and good in plasticity, has excellent impact fracture toughness and excellent stress corrosion resistance, and is suitable for rail traffic vehicles.

Owner:佛山市三水凤铝铝业有限公司 +1

Binary nanometer cooperative reinforcing and toughening silicon carbide ceramics and preparing method thereof

The invention discloses a method for preparing binary nanometer cooperative reinforcing and toughening silicon carbide ceramics, and silicon carbide powder, yttrium aluminum garnet, nano particles and nano crystal whickers are taken as the main raw materials. The method comprises the following steps: 1) the main raw materials, a binder and a dispersant are added into de-ionized water, after being ball-milled and mixed, water-base silicon carbide slurry is prepared; 2) the water-base silicon carbide slurry is sprayed and dried by adopting a spray granulation technology; 3) the obtained silicon carbide granulating powder is formed by adopting pre-pressing of dry pressing and final pressing of cold isostatic pressing; and 4) the obtained green body of silicon carbide is put in a vacuum non-pressure sintering furnace to be treated, thus obtaining the binary nanometer cooperative reinforcing and toughening silicon carbide ceramics. The invention also discloses the binary nanometer cooperative reinforcing and toughening silicon carbide ceramics prepared in the method. The silicon carbide ceramics have the advantages of large flexural strength, good fracture toughness and the like.

Owner:ZHEJIANG UNIV

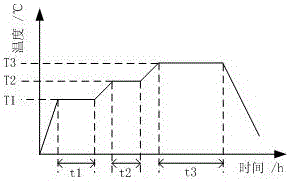

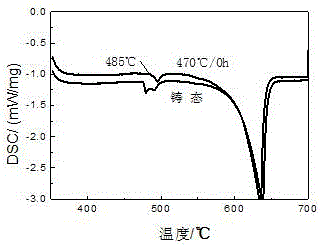

Homogenization heat treatment method of Al-Zn-Mg-Cu-Zr aluminum alloy

The invention relates to a homogenization heat treatment method of Al-Zn-Mg-Cu-Zr aluminum alloy. The homogenization heat treatment method of the Al-Zn-Mg-Cu-Zr aluminum alloy is characterized in that a three-level homogenization heat treatment process for controlling a heating process is used for homogenization heat treatment, and the homogenization heat treatment method comprises the following steps: (1) carrying out low-temperature pre-precipitation, and carrying out a first-level homogenization heat treatment process for promoting precipitation of Al3Zr as a dispersed phase; (2) insulating, and carrying out a second-level homogenization heat treatment process for increasing the overburnt temperature of a structure; and (3) carrying out a long-term uniform insulating process, and carrying out a third-level homogenization heat treatment process for eliminating high-melting-point Al2CuMg. By the heat treatment process, the problem of insufficient soaking in large cast ingots of 7xxx series aluminum alloy can be solved well, a coarse phase does not dissolve in a microscopic structure, an S phase is fully re-dissolved, and meanwhile, uniform precipitation of Al3Zr as the dispersed phase can be regulated and controlled. More importantly, the homogenization heat treatment method is suitable for industrial production of large cast ingots, and has good operability; meanwhile, homogenization heat treatment time can be shortened; and energy consumption of heat treatment is reduced.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

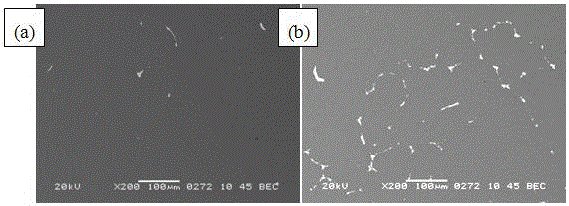

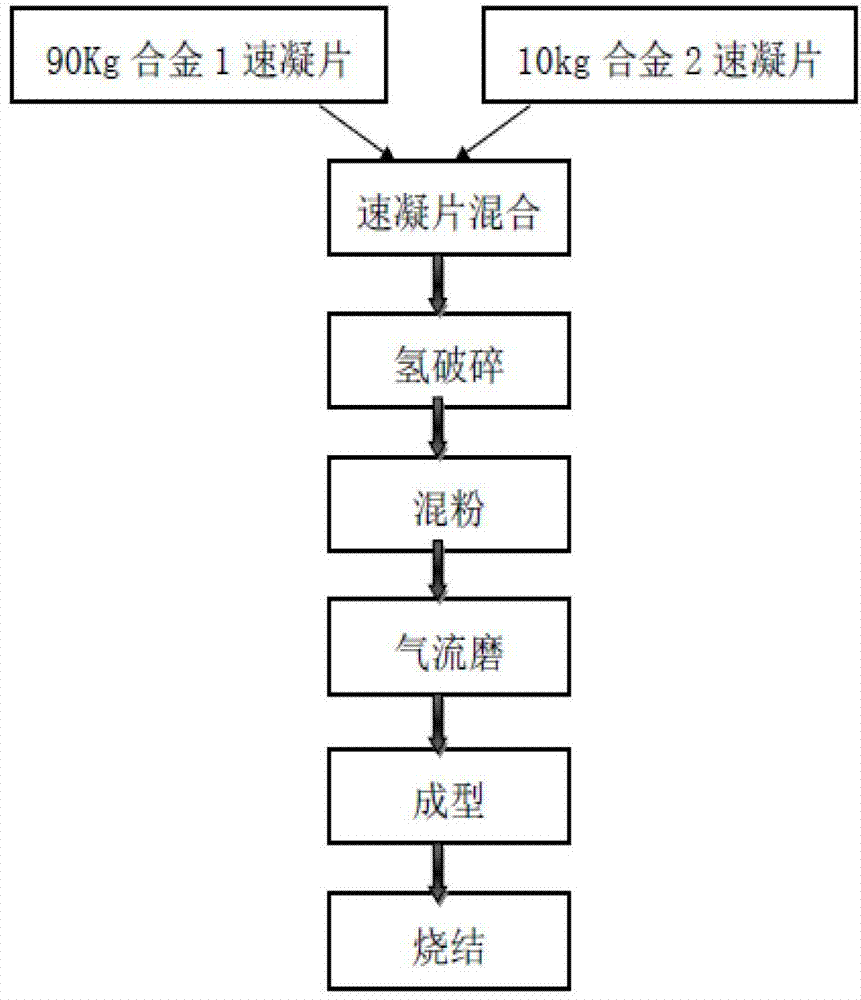

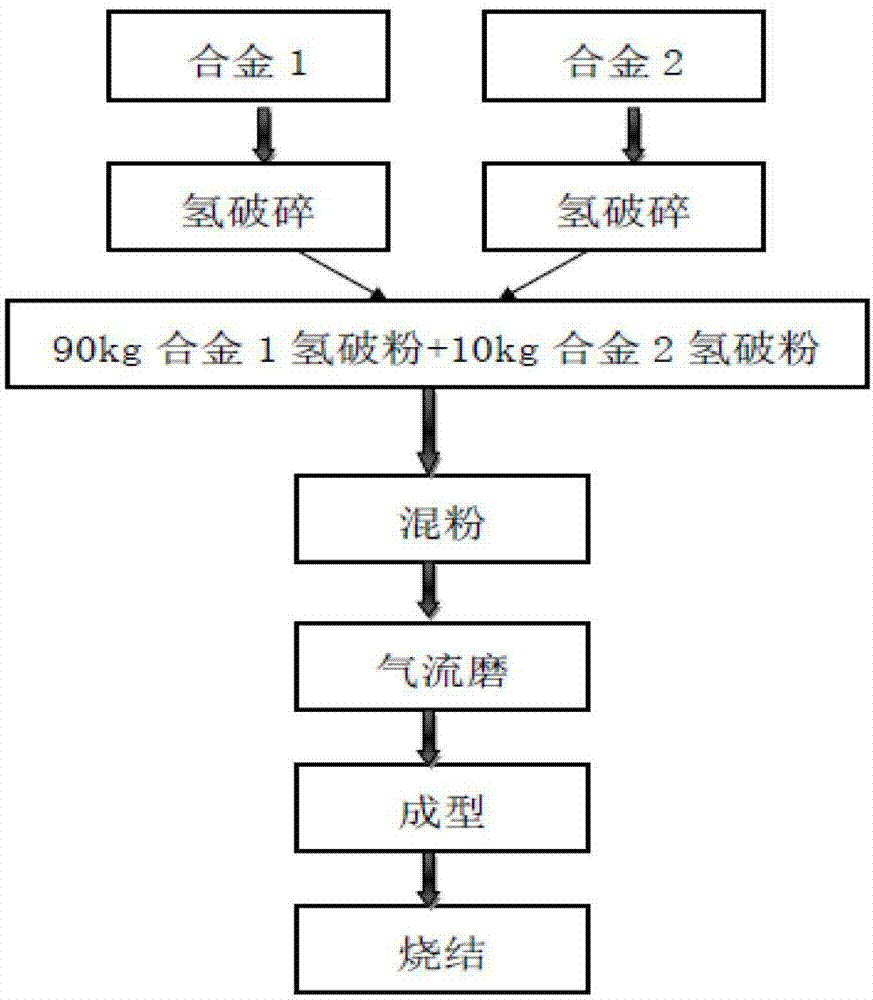

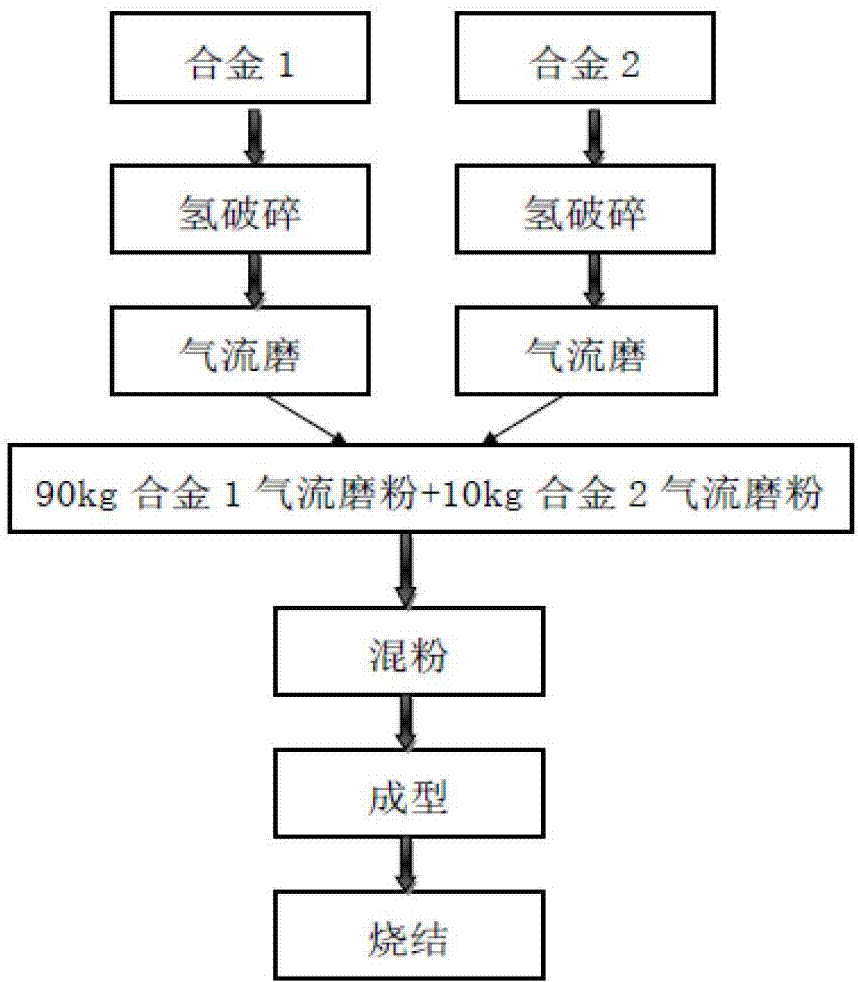

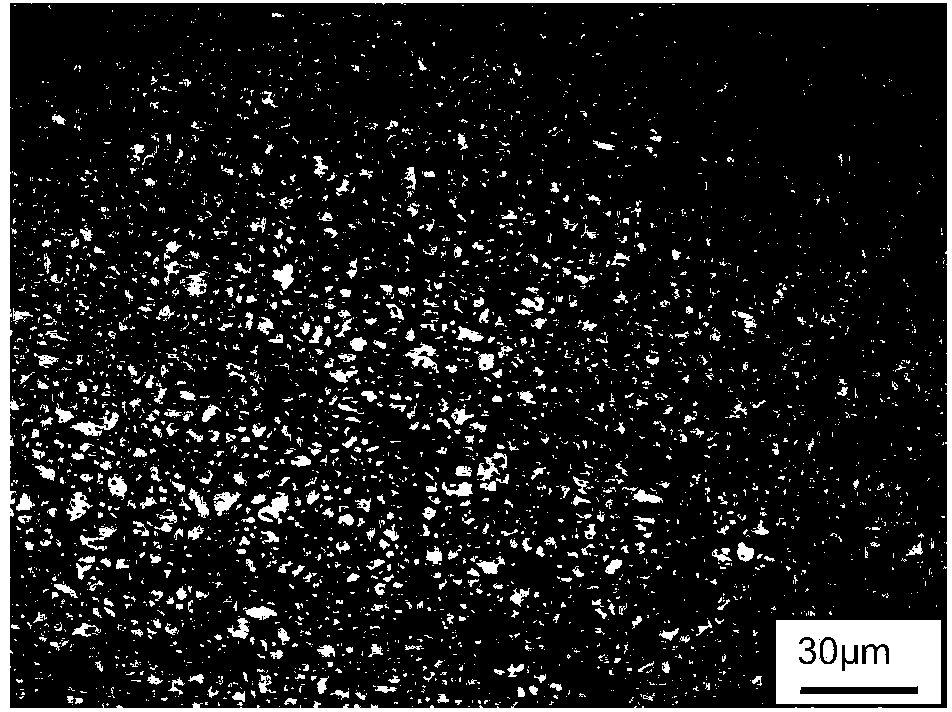

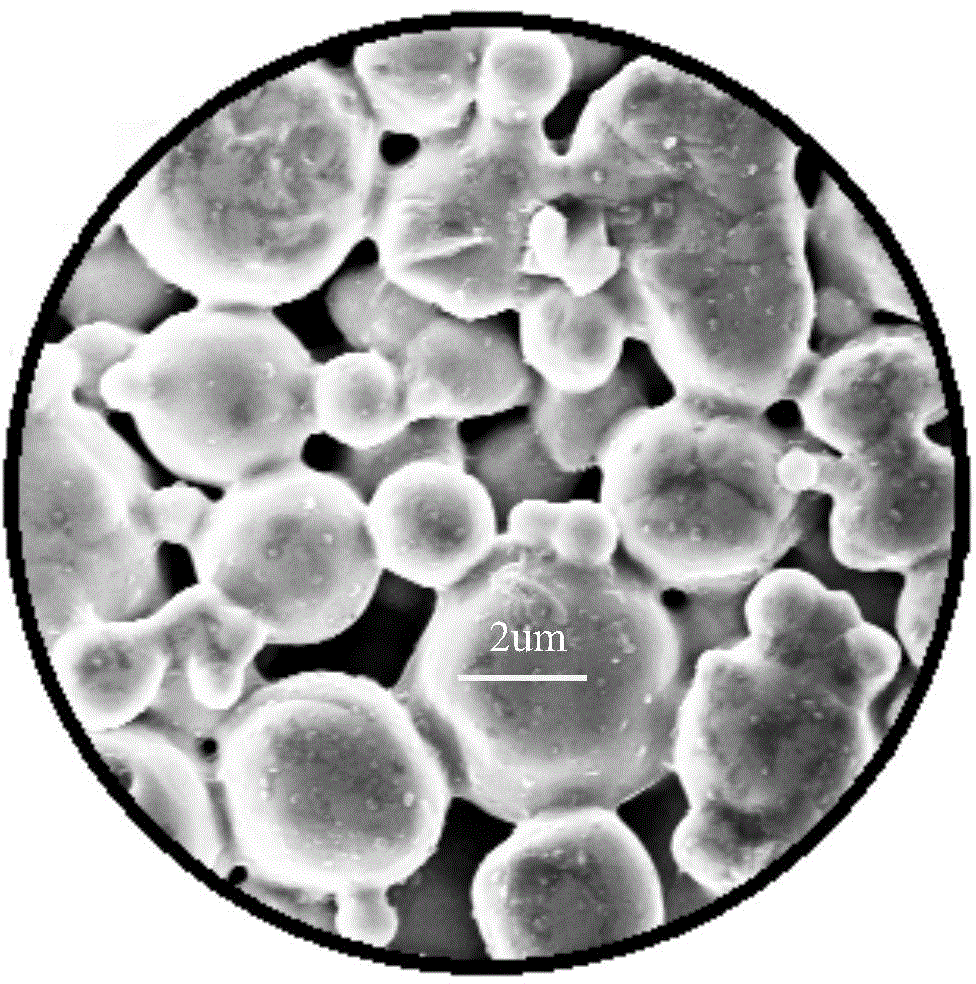

Powder for sintering rare-earth permanent magnet

ActiveCN103093911AEasy to wrapInhibition of grain growthPermanent magnetsInorganic material magnetismAdditive ingredientMetallurgy

The invention relates to powder for preparing and sintering a rare-earth permanent magnet. The powder is obtained by mixing two kinds of powder with different ingredients, different average particle sizes and different melting points. By that the powder is used for preparing and sintering the rare-earth permanent magnet, the temperature endurance of the magnet can be improved, production cost is reduced, and heavy rare earth resources are saved.

Owner:ORIENT MAGNET TECH OMT

Aluminum alloy welding wire for automobile fuel tank and preparation method of aluminum alloy welding wire

InactiveCN107414339AInhibition of recrystallizationInhibition of grain growthWelding/cutting media/materialsSoldering mediaFuel tankAluminium alloy

The invention discloses an aluminum alloy welding wire for an automobile fuel tank. The raw materials of the aluminum alloy welding wire comprise, by weight, 6.3-6.7% of Mg, 0.5-0.8% of Mn, 0.16-0.18% of Ti, 0.0001-0.005% of Be, 0.2-0.4% of Fe, 0.01-0.08% of B, 0.22-0.25% of Cr, 0.3-0.4% of Si, 0.16-0.25% of Zr, 0.15-0.2% of V, 0.2-0.3% of Sc, less than or equal to 0.1% of Cu, less than or equal to 0.2% of Zn, less than or equal to 0.05% of the single content of other impurity elements, less than or equal to 0.1% of the total content of other impurity elements and the balance Al. The invention further discloses a preparation method of the aluminum alloy welding wire for the automobile fuel tank. The aluminum alloy welding wire for the automobile fuel tank is compact in welding joint tissue, good in impact resistance, toughness and tension strength, good in crack resistance, and good in fatigue resistant property.

Owner:安徽飞弧焊业股份有限公司

Technique method for manufacturing oriented silicon steel

ActiveCN106755843AReduce carbon contentAvoid stickingSolid state diffusion coatingFurnace typesInsulation layerNitrogen

The invention discloses a technique method for manufacturing oriented silicon steel. A full hard coil is subjected to decarburizing annealing so as to reduce the band steel carbon content; aluminum nitride is formed through nitrizing, and crystalline grains of steel are restrained from growing up; a magnesium silicate film is formed through magnesium oxide coating, and bonding between band steel is prevented; a magnesium oxide base layer and purified steel are formed through high-temperature annealing secondary recrystallization; and the band steel is subjected to insulation layer coating for eddy prevention and heat stretching leveling treatment, and the plate shape is more level. The obtained oriented silicon steel is more level in surface, stable in quality and high in percent of pass.

Owner:NINGBO YINGZHAN PRECISION SHEET

High magnesium aluminum alloy cold draw bar material and preparation method thereof

ActiveCN103898378APrevent grain boundary migrationInhibition of grain growthHigh magnesiumAluminium alloy

The invention relates to a high magnesium aluminum alloy cold draw bar material and a preparation method thereof, solving the problems of low tensile strength and poor plasticity of the existing magnesium aluminum alloy bar material. The high magnesium aluminum alloy bar material is prepared from the following smelting materials: 9.2%-10.4% of Mg, 0.5%-0.7% of Mn, 0.05%-0.10% of Ti, less than or equal to 0.3% of Fe, less than or equal to 0.3% of Si, less than or equal to 0.15% of Zn, less than or equal to 0.05% of Cu, less than or equal to 0.08% of Ni, and the balance of Al. The preparation method comprises steps of firstly, smelting the raw materials; secondly, casting into a bar; thirdly, cutting off; fourthly, removing oxide skin; fifthly, homogenizing annealing; sixthly, ingoting and heating up; seventhly, upsetting; eighthly, extruding; ninthly, intermediate annealing; tenthly, cold drawing. The prepared high magnesium aluminum alloy cold draw bar material has the tensile strength of 410-420MPa and the elongation greater than or equal to 12%, thus meeting the requirement of aerospace products.

Owner:HEILONGJIANG INST OF TECH

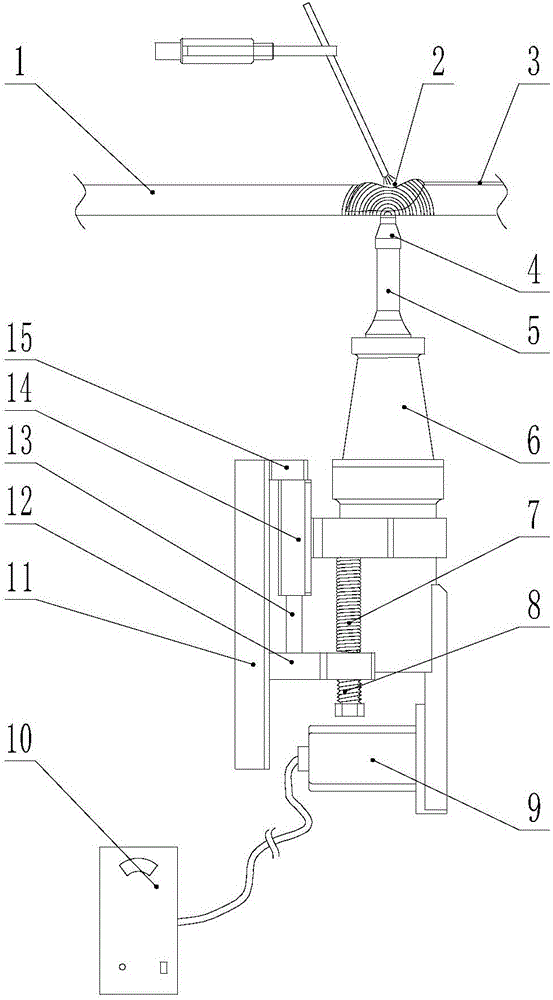

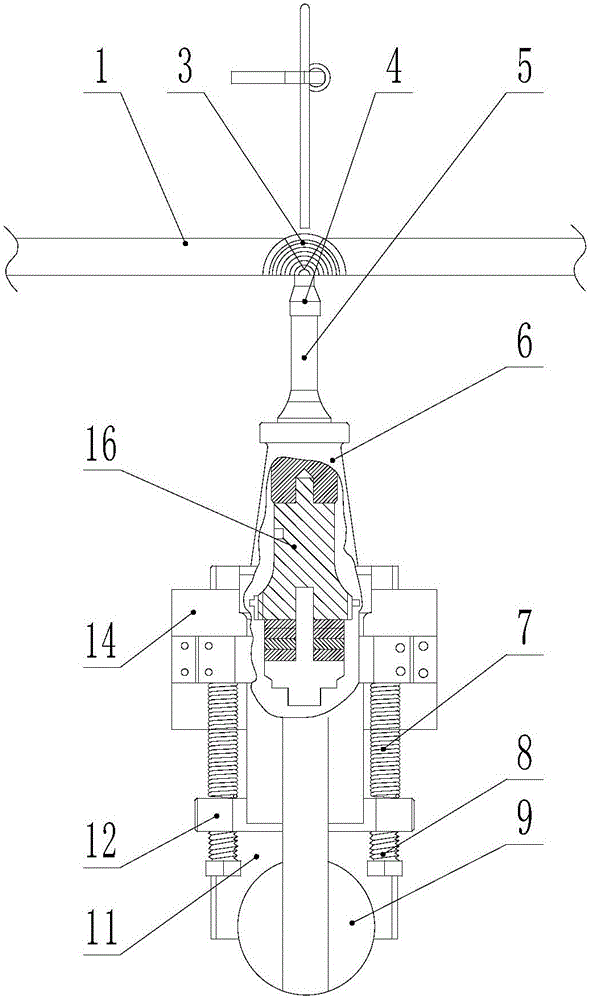

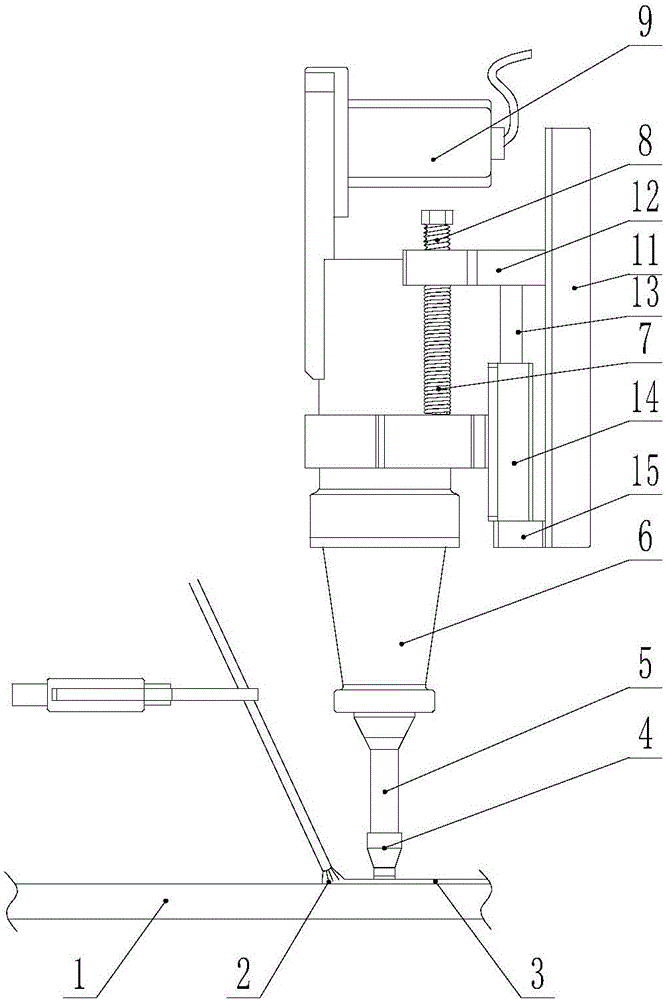

Ultrasonic vibration assisted welding method

ActiveCN105728930AIncrease the number ofInhibition of grain growthNon-electric welding apparatusMetalCrystal

The invention relates to the field of welding and in particular relates to an ultrasonic vibration assisted welding method. The method comprises the following steps: in a welding process of fusion welding, providing an ultrasonic vibration force through an ultrasonic excitation vibration device; introducing ultrasonic frequency stress wave into a welding fusion tank; finally, transmitting vibration to a welding part. With the adoption of the configuration, the quantity of crystal nucleuses can be effectively increased, the size of crystal grains is prevented from growing, dendritic crystals are crushed and a crystal shape is changed, so that condensed welding line metal crystal grains are thinned; gas, impurities and the like in the fusion tank are prompted to rapidly float up, and defects of air pores and slag adding are reduced; welding residual stress and welding deformation are reduced; components are more uniform so that a welding line metal structure is improved; a fusion region becomes narrow and is uniformly transited, and non-fusion defects are reduced; comprehensive mechanical properties of welding lines are improved through the effects above.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

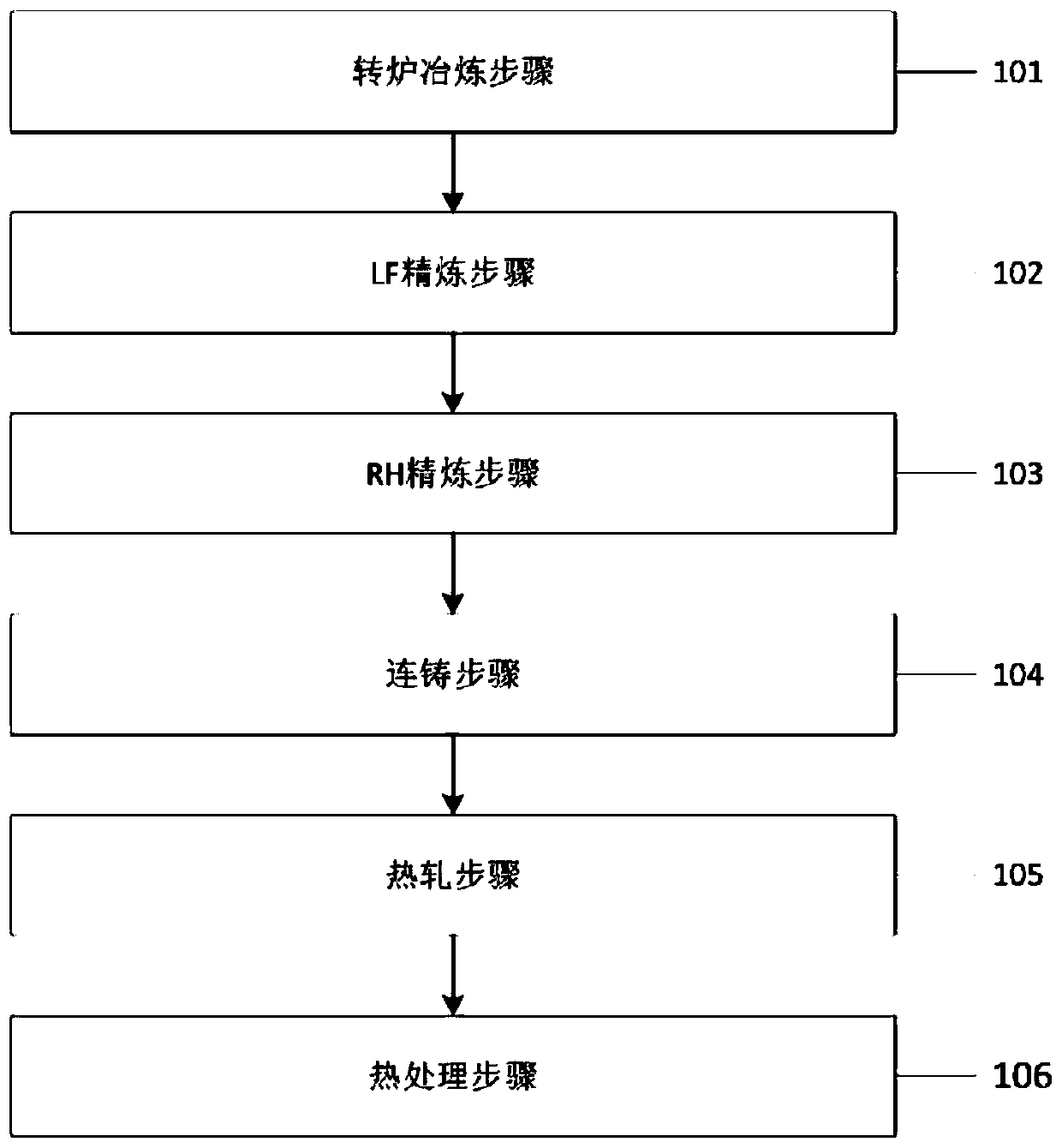

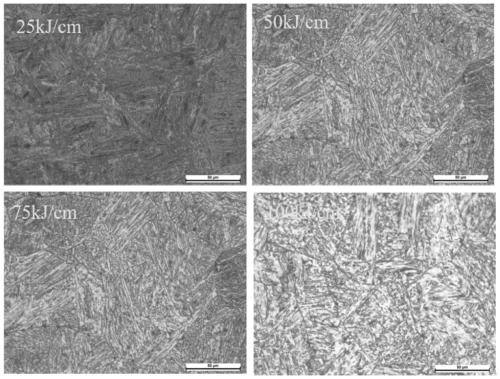

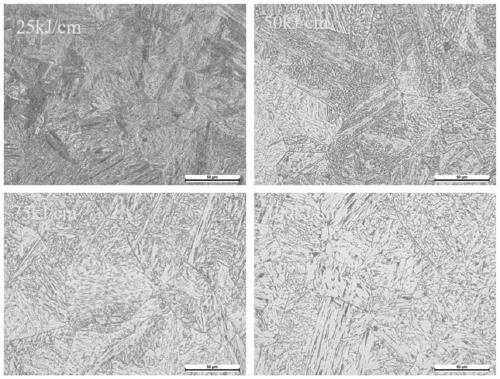

Method for improving toughness of high-carbon equivalent steel plate welding heat affected zone through rare earth

ActiveCN109868342AInhibition of grain growthImprove performanceManufacturing convertersProcess efficiency improvementHigh intensitySmelting

The invention relates to a method for improving toughness of a high-carbon equivalent steel plate welding heat affected zone through rare earth, and belongs to the technical field of high-strength steel plates for welding. The method sequentially comprises the converter smelting step, LF refining step, RH refining step, continuous casting step, hot rolling step and thermal treatment step. According to the method, a certain amount of rare earth Ce alloy is added into molten steel during the RH refining process, inclusions in molten steel are modified into rare earth inclusions through rare earth, tiny new rare earth inclusions are generated in molten steel, and dispersed distribution of the rare earth inclusions is controlled; the tiny dispersed distribution rare earth Ce inclusions and original inclusions modified by rare earth newly generated in molten steel inhibit original austenite grains in the heat affected zone from growing during the welding process; and bainite transformationof the welding heat affected zone is delayed through addition of rare earth, formation of bainite is inhibited, and toughness of the high-carbon equivalent steel plate welding heat affected zone is greatly improved.

Owner:UNIV OF SCI & TECH BEIJING +1

Aluminum alloy extrusion material with impact-resistant energy absorption characteristic and manufacturing method thereof

The invention provides an aluminum alloy extrusion material with an impact-resistant energy absorption characteristic and a manufacturing method thereof. The aluminum alloy is Al-Mg-Si-Mn alloy, and comprises main alloy elements Mg, Si, Mn and microelements Cr, Er, La, Sr, Ti and B. The manufacturing method comprises the following steps of smelting and preparing aluminum alloy liquid, blowing andrefining in a furnace, online refining and modification, online degassing and filtering, semi-continuous casting, ingot casting homogenization, heating extrusion, on-line quenching and artificial aging. According to the manufacturing method, the modified needle-shaped beta-Fe-rich phase and the excess Si phase are refined and converted into fine and uniform particles and dispersed and distributedin an alpha-Al substrate, so that the harm of the relative strength and plasticity of the needle-shaped Fe-rich phase and the excess Si is eliminated. By forming the multi-element co-lattice dispersedphase particles, recrystallization and crystal grain growth are inhibited, the aluminum alloy extruded material keeps fine fiber crystal tissues, and the impact toughness and the corrosion resistanceare improved. The aluminum alloy extrusion material has an excellent impact-resistant energy absorption effect and is suitable for manufacturing an energy absorption component subjected to impact collision.

Owner:GUANGDONG INST OF NEW MATERIALS

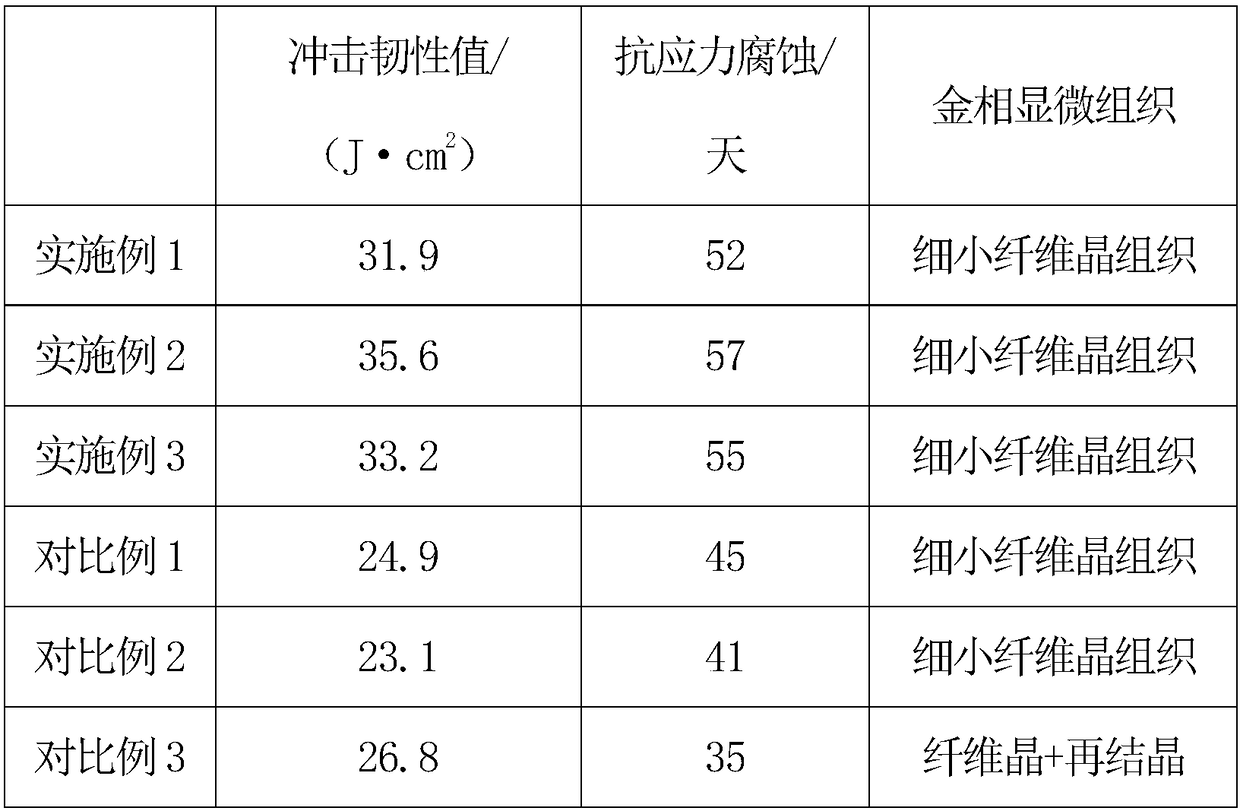

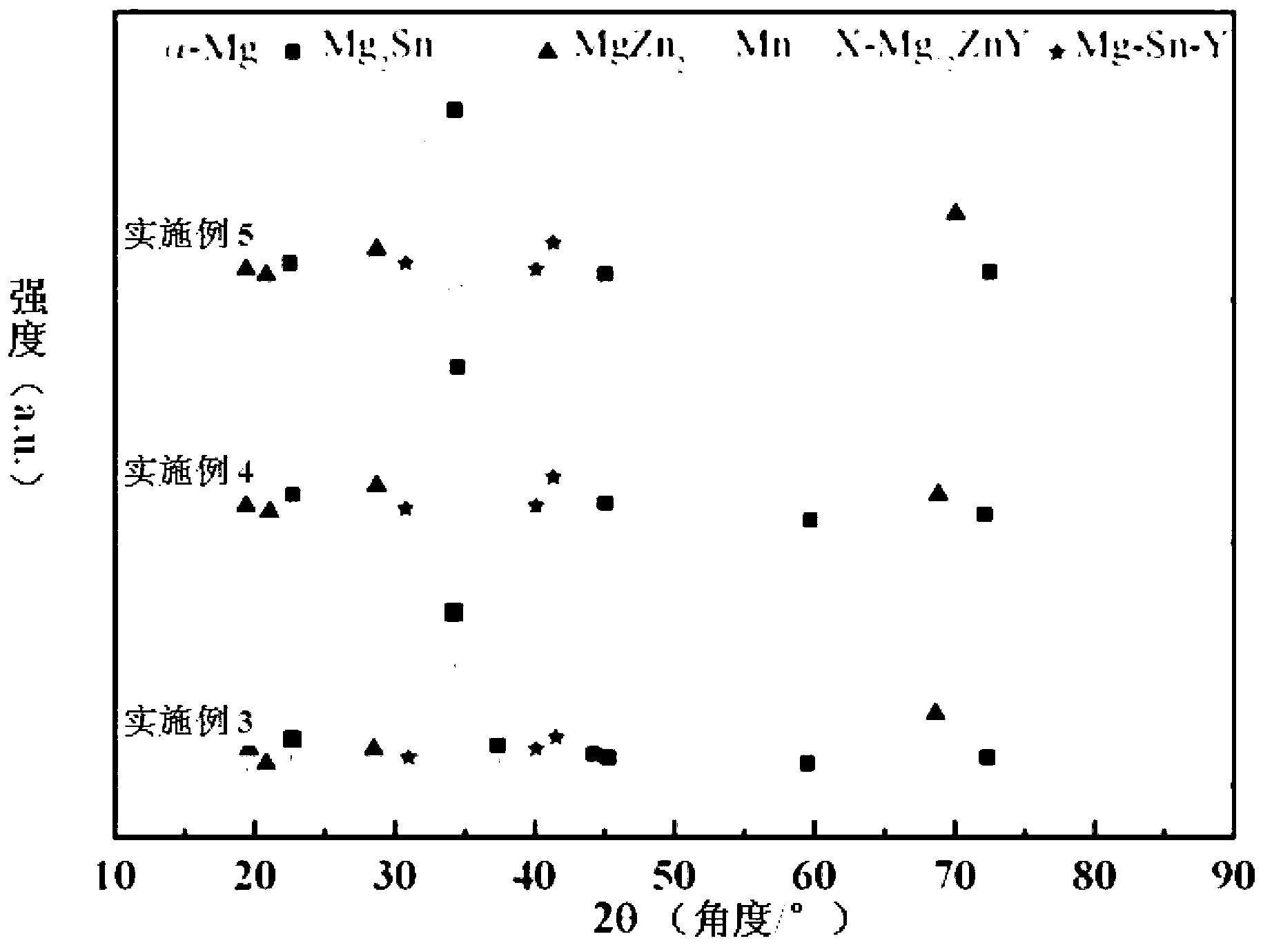

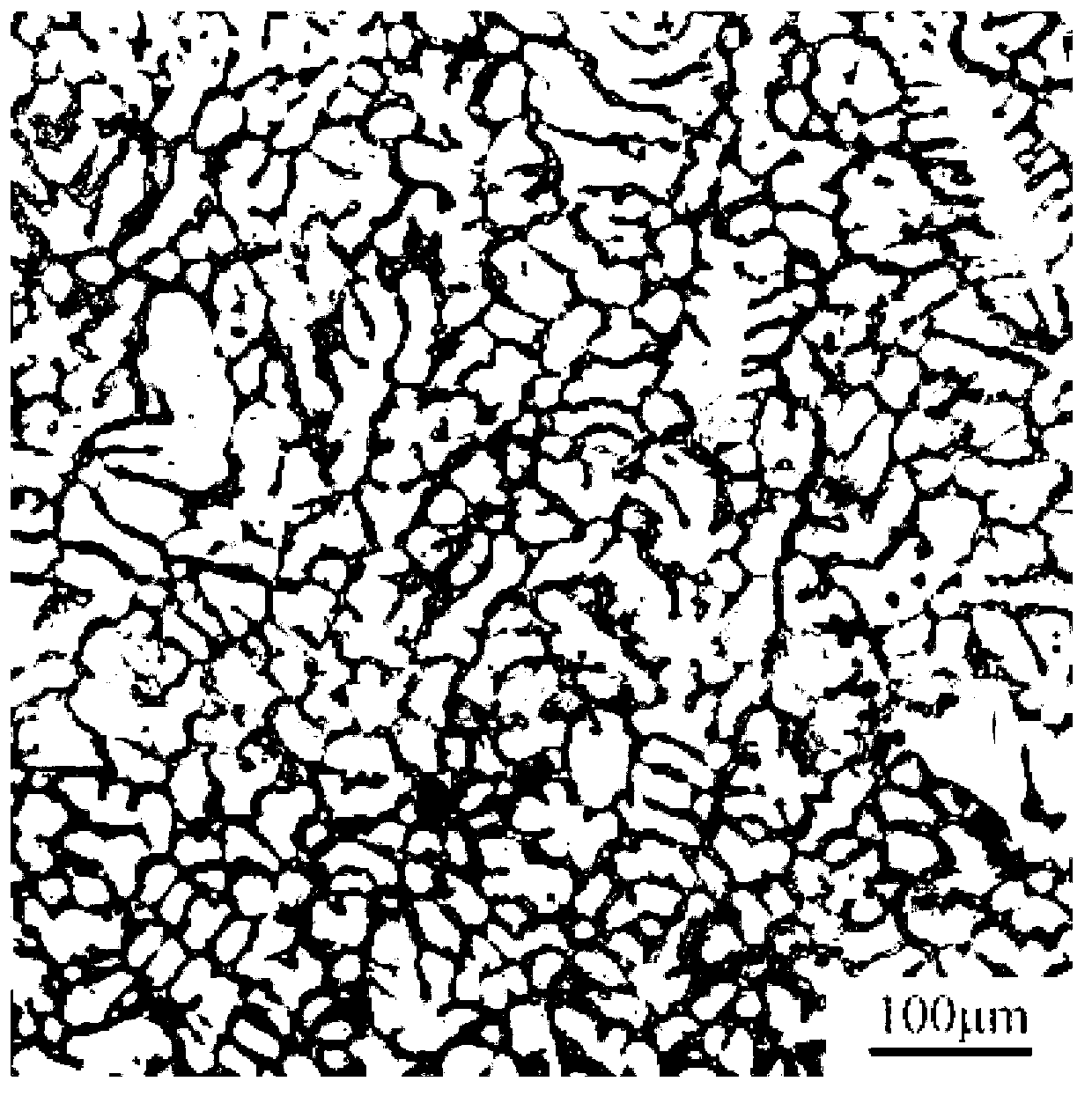

Magnesium-zinc-manganese-tin-yttrium alloy and preparation method of same

The invention discloses a magnesium-zinc-manganese-tin-yttrium alloy and a preparation method of the same. The mass percentage content of each component of the magnesium-zinc-manganese-tin-yttrium alloy is as follows: Zn: 2-8%, Mn: 0.1-3%, Sn: 1-6%, Y: 0.1-4%, the inevitable impurities of not more than 0.15%, and the balance of magnesium. The preparation method comprises the following steps of: firstly, adding the selected raw materials in a vacuum induction furnace, smelting and cooling with water, then, machining the smelted alloy to a proper size in a rolling mill, annealing the machined alloy, and finally extruding the annealed alloy into bars. The alloy provided by the invention contains very little rare earth yttrium, during smelting and hot working, crystalline grains can be refined, and sequentially, the comprehensive mechanical property of the alloy is improved; with the yttrium, the hot machining temperature of the alloy can be raised, the resistance to deformation in hot machining is reduced, and the machining efficiency is improved. The magnesium alloy provided by the invention needs simple preparation technology, and has low requirement on production equipment.

Owner:CHONGQING UNIV

Cold-rolled steel sheet with 420 MPa grade yield strength and preparation method of steel sheet

ActiveCN106636898AImproved recrystallization kineticsGrain refinementChemical compositionSheet steel

The invention discloses a cold-rolled steel sheet with the 420 MPa grade yield strength and a preparation method of the steel sheet and belongs to the technical field of metallurgy. The steel sheet is prepared from components in percentage by mass as follows: 0.06%-0.09% of C, 0-0.2% of Si, 0.8%-1.0% of Mn, 0-0.02% of Ti, 0.01%-0.025% of Nb and the balance of Fe and inevitable impurity elements. The preparation method comprises steps as follows: (1) according to the ratio of the chemical components of the cold-rolled steel sheet, a steel ingot is obtained through smelting and is forged to form a slab; (2) heat preservation is performed on the slab, hot rolling is performed, and a hot-rolled sheet is prepared and is cooled to the proper temperature at a certain cooling rate for coiling; (3) the coiled hot-rolled sheet is pickled and then cold-rolled, and the cold-rolled sheet is prepared; (4) the cold-rolled sheet is subjected to continuous annealing treatment of low-temperature soaking and step cooling. According to the cold-rolled steel sheet, the microstructure mainly comprises ferrite, pearlite and cementite, the yield strength of the steel sheet ranges from 435 MPa to 450 MPa, the tensile strength ranges from 518 MPa to 548 MPa, and the ductility A80 ranges from 25.0% to 26.3%.

Owner:NORTHEASTERN UNIV LIAONING

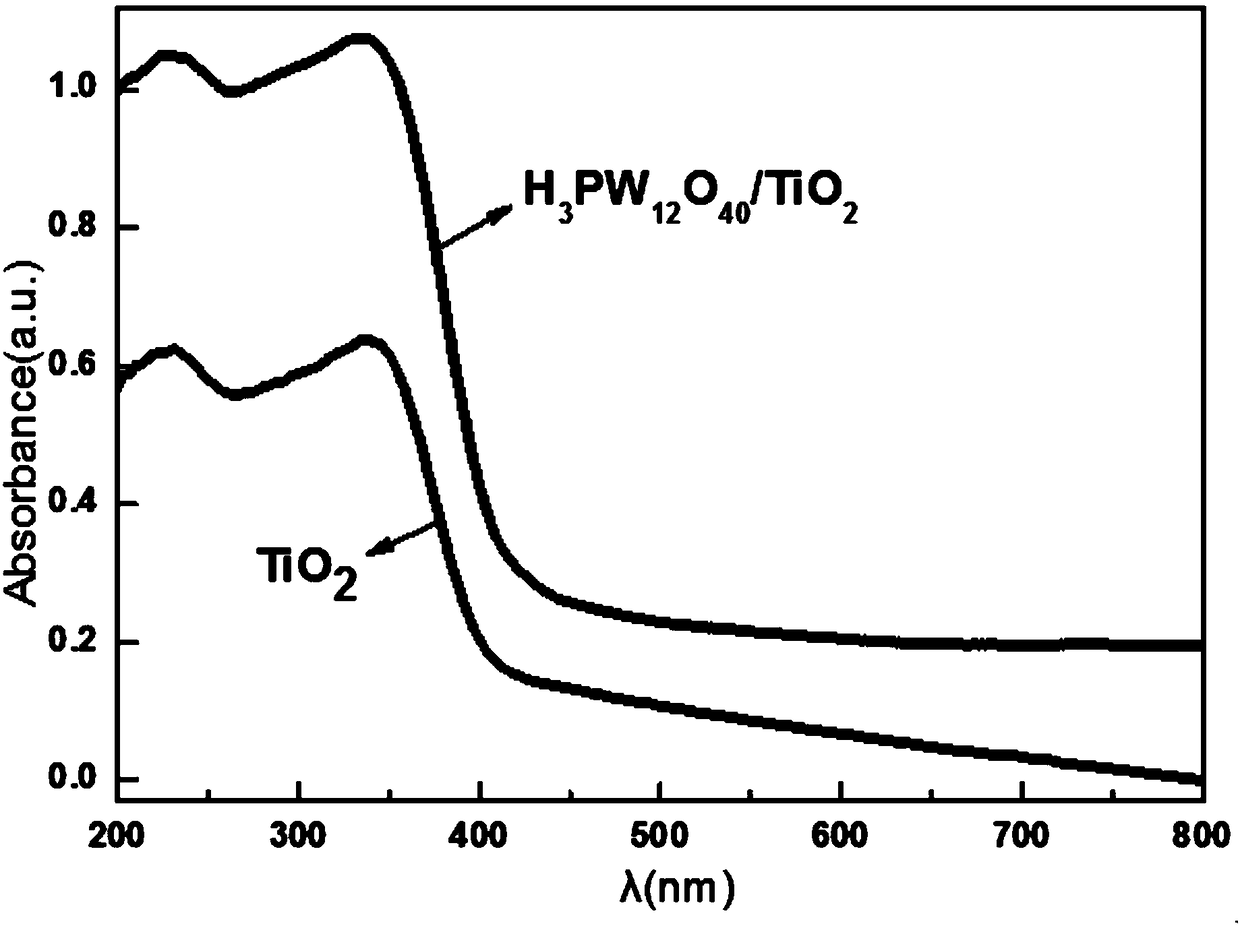

Preparation method of phosphotungstic acid doped titanium dioxide photocatalyst

InactiveCN108126719AEasy transitionImprove separation efficiencyPhysical/chemical process catalystsAcetic acidDistilled water

The invention discloses a preparation method of a phosphotungstic acid doped titanium dioxide photocatalyst. The preparation method comprises the steps: firstly, dropwise adding a certain amount of butyl titanate into absolute ethanol to make butyl titanate uniformly dispersed, dropwise adding a small deal of acetic acid and triethanolamine, and carrying out stirring and standing to obtain a liquid marked as a liquid A; then, adding a certain amount of absolute ethanol into a small deal of mixed solution of distilled water and acetic acid, and carrying out stirring and standing to obtain a liquid marked as a liquid B; secondly, slowly dropwise adding the liquid B into the liquid A, slowly dropwise adding a certain amount of phosphotungstic acid solution into the mixed solution, firstly, carrying out magnetic stirring to uniformly disperse the solution, and then, carrying out ultrasonic treatment for 30-50min to obtain a uniform, transparent and white sol; and finally, carrying out ageing, drying, heat treatment and grinding on the sol to obtain a light gray phosphotungstic acid doped titanium dioxide powder. By using the preparation method, the problem that a method for doping phosphotungstic acid into titanium dioxide is relatively complex in step and relatively high in energy consumption in the prior art is solved.

Owner:XIAN UNIV OF TECH

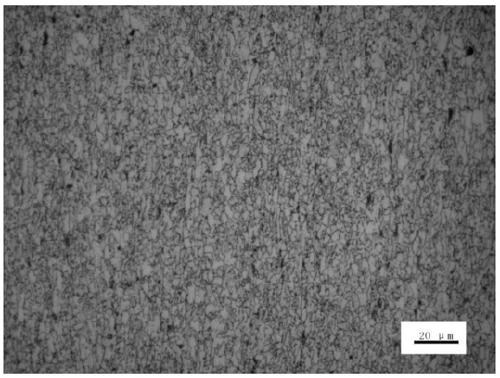

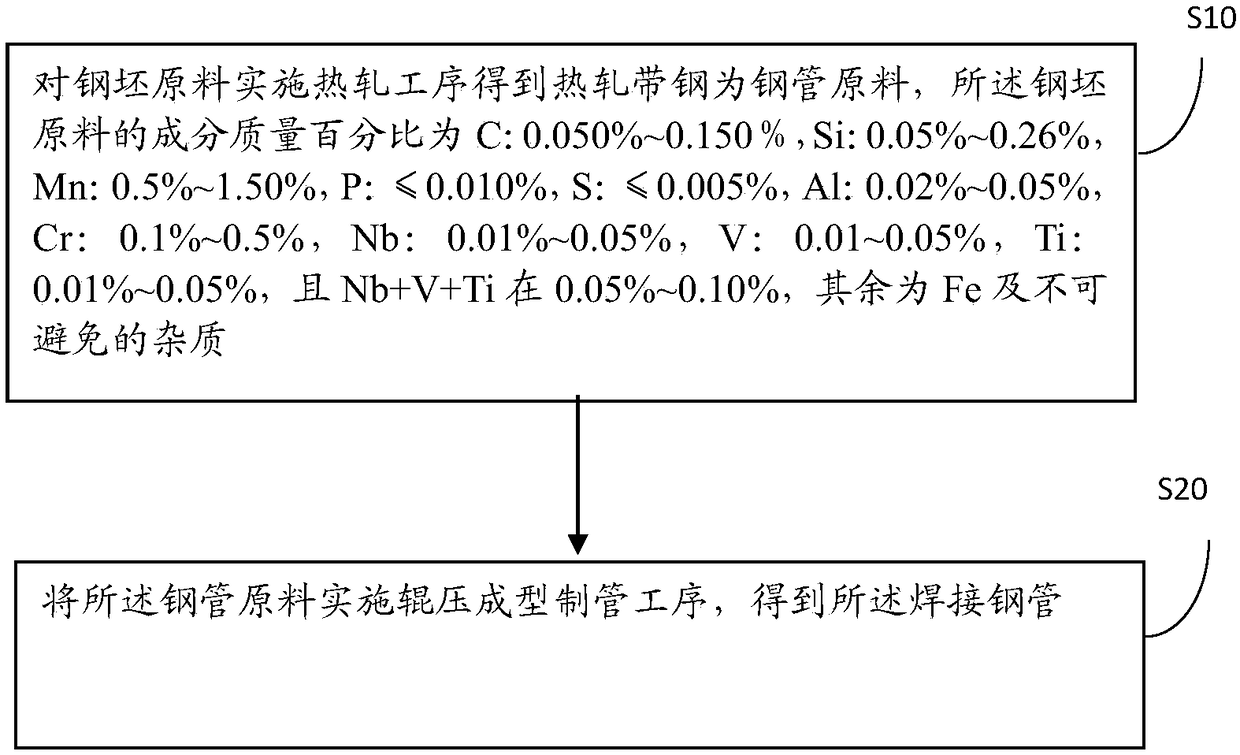

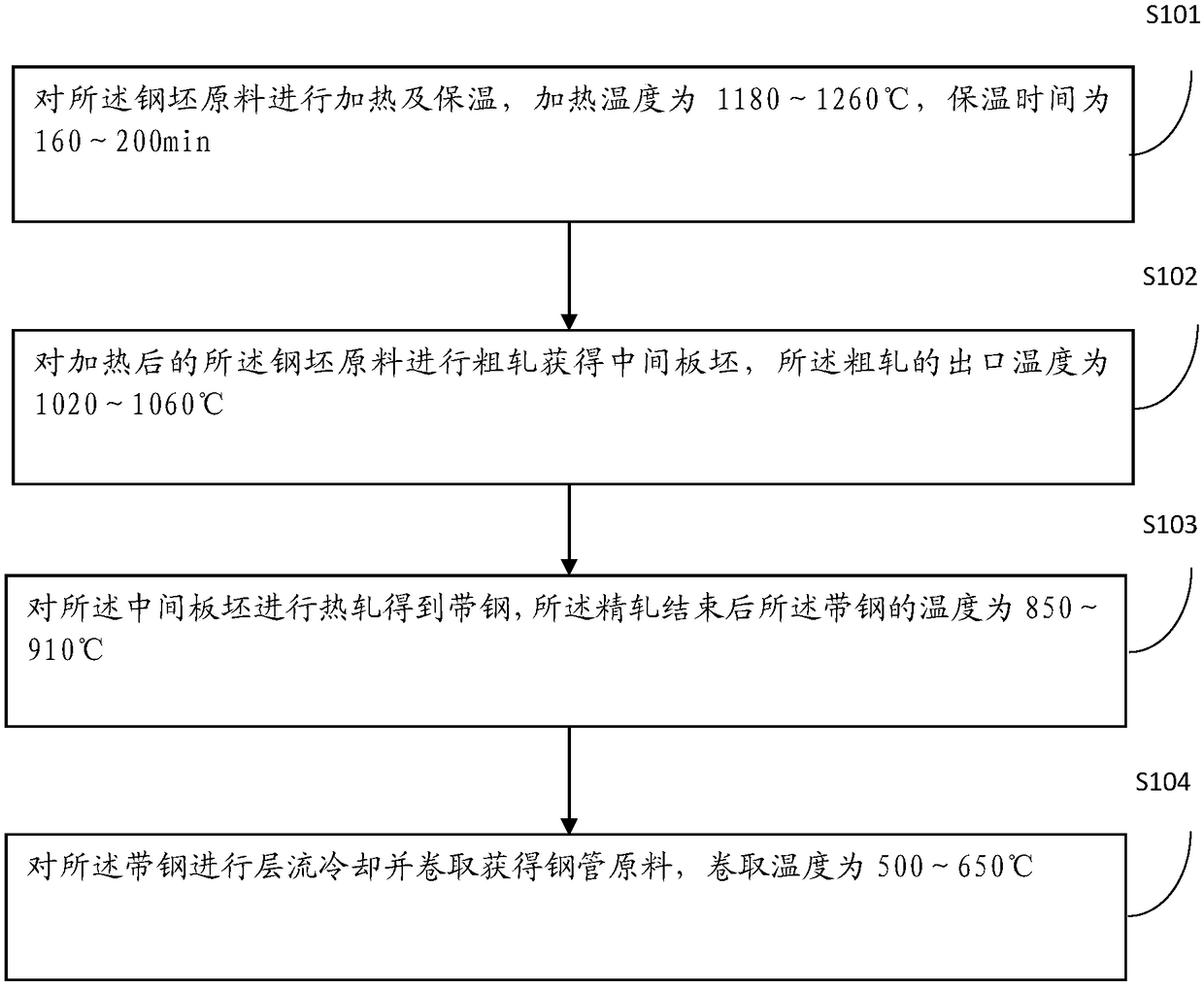

Welded steel tube for carrier roller and manufacturing method thereof

The invention discloses a welded steel tube for a carrier roller and a manufacturing method thereof. The welded steel tube comprises the compositions of, by mass, 0.050%-0.150% of C, 0.05%-0.26% of Si, 0.5%-1.50% of Mn, less than or equal to 0.010% of P, less than or equal to 0.005% of S, 0.02%-0.05% of Al, 0.1%-0.5% of Cr, 0.01%-0.05% of Nb, 0.01%-0.05% of V, 0.01%-0.05% of Ti and the balance Feand unavoidable impurities, a carbon equivalent Ceq is less than or equal to 0.4%, and a cold crack sensitivity index Pcm is less than or equal to 0.2%. The technical problems that machinability and the usage requirements of the welded steel tube for the carrier roller are inconsistent in the prior art, forming precision control is insufficient and the production requirements of the carrier rollercannot be met are solved. The technical effects that chemical elements of reasonable proportions are used, excellent cold-forming property and welding properties are achieved, the cracking of base metal or weld joints in pipe making is avoided effectively, and through reasonable hot rolling process design, the finished steel coil of hot rolling strip used for produced carrier rollers has a good shape and surface quality, good formability and abrasion resistance to adapt to the processing requirements of welded steel tubes used for the carrier rollers and meet the requirements for the use of welded steel tubes for the carrier rollers.

Owner:SHOUGANG CORPORATION +1

Iron-chromium-aluminum-based porous metal material and preparation method thereof

InactiveCN104630635AExtended service lifeImprove heat transfer performanceCompression moldingIron powder

The invention relates to an iron-chromium-aluminum-based porous metal material and a preparation method thereof. The material comprises through-holes having a pore size of 500nm-40um. The iron-chromium-aluminum-based porous metal material is prepared from the following raw materials: aluminum powder, chromium powder, iron powder, silicon carbide and rare earths. The preparation method of the iron-chromium-aluminum-based porous metal material comprises the following steps: firstly, carrying out vacuum sintering silicon carbide powder, rare earth and iron powder to obtain iron-silicon carbide sintering blocks containing rare earth, smelting the iron-silicon carbide sintering blocks, aluminum ingots, chromium powder and balance iron powder together under the protection of argon to obtain iron-chromium-aluminum-based alloy ingots, crushing the alloy ingots, carrying out vacuum ball milling to obtain alloy powder and finally uniformly mixing alloy powder, a pore-forming agent and a binder, carrying out compression molding and sintering to obtain the iron-chromium-aluminum-based porous metal material. The material has the advantages of long service life at high temperature and the like and furthermore, the large-scale industrialization can be achieved by the preparation method.

Owner:北京绿洁美科技有限公司

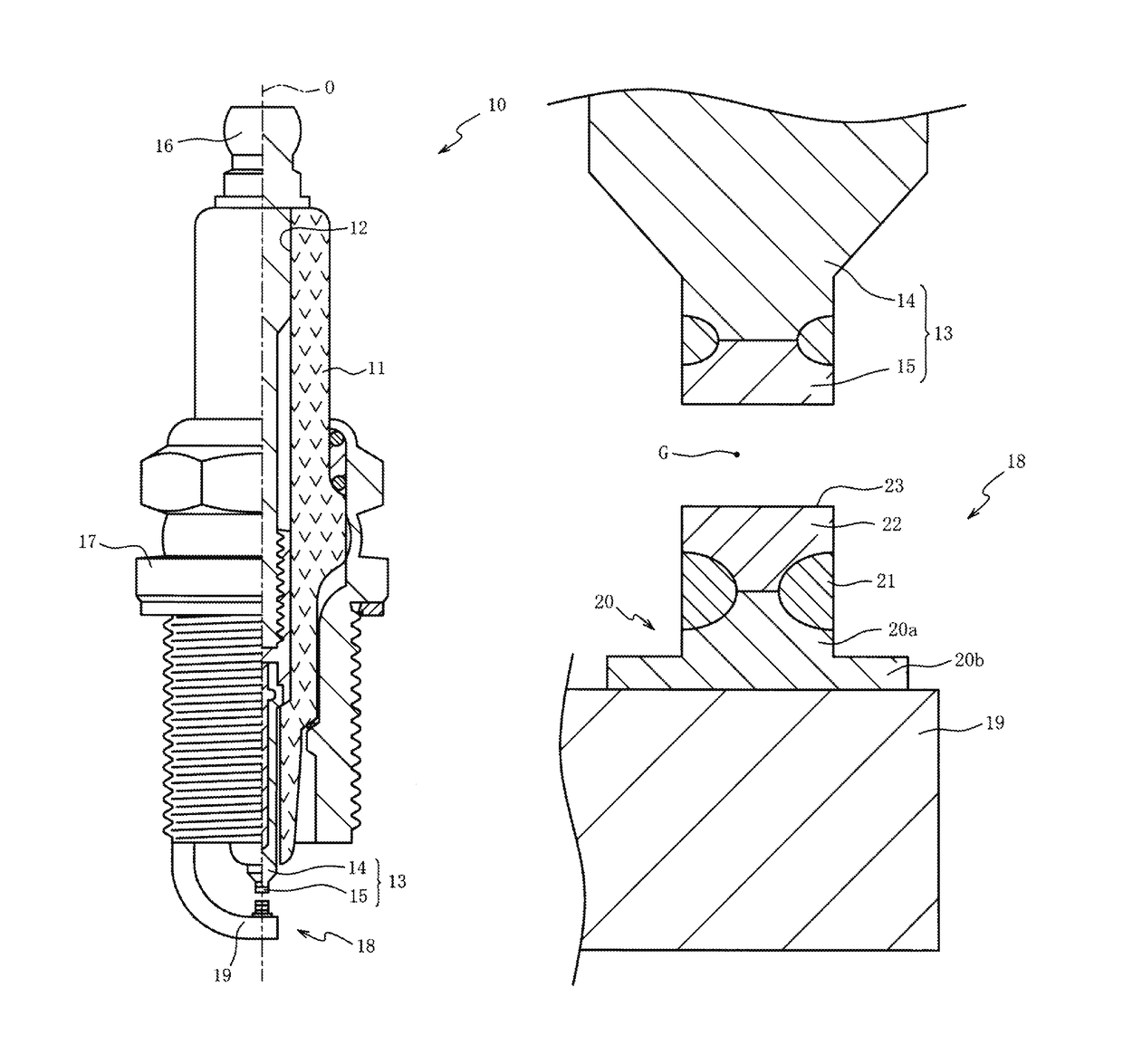

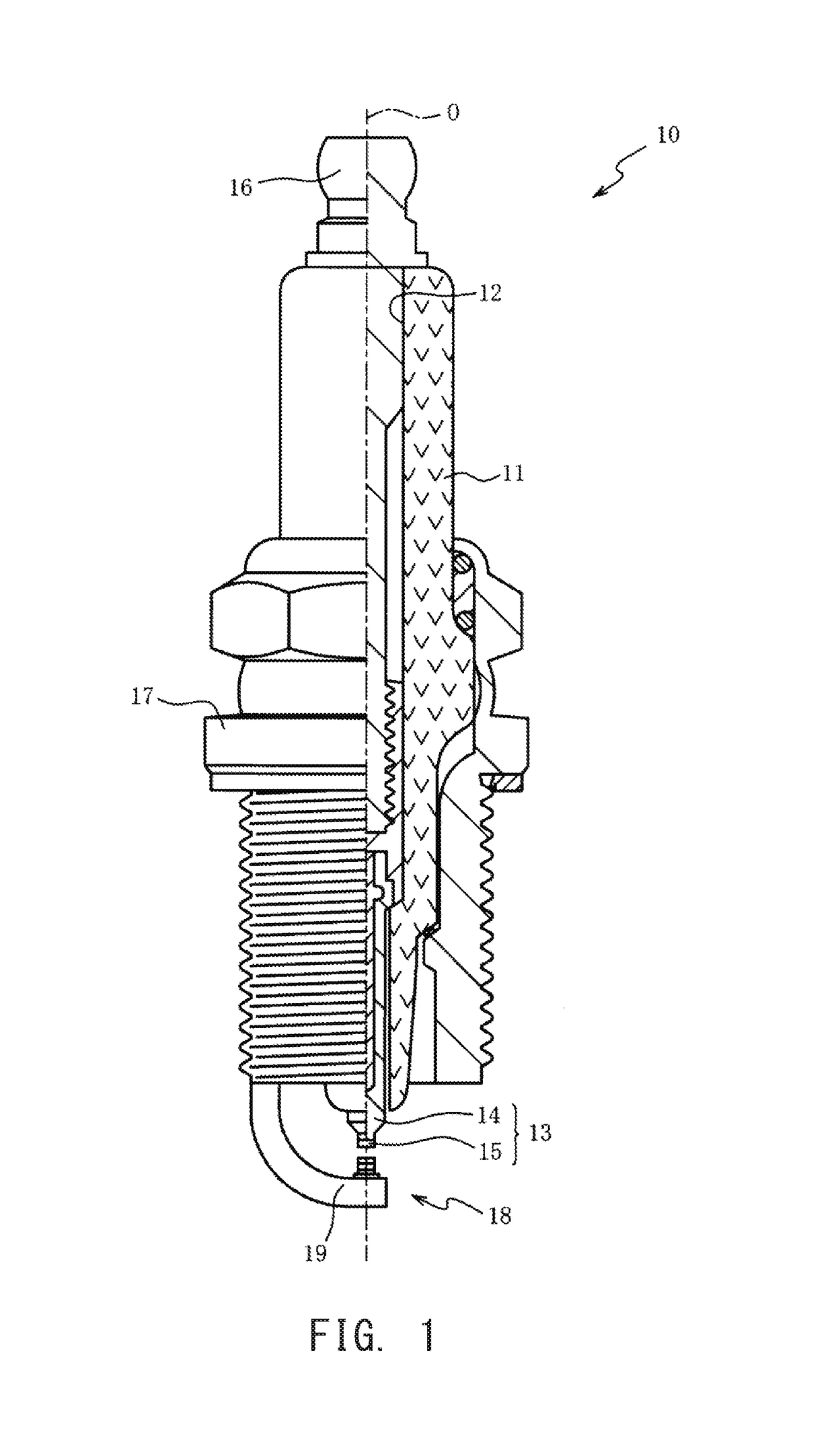

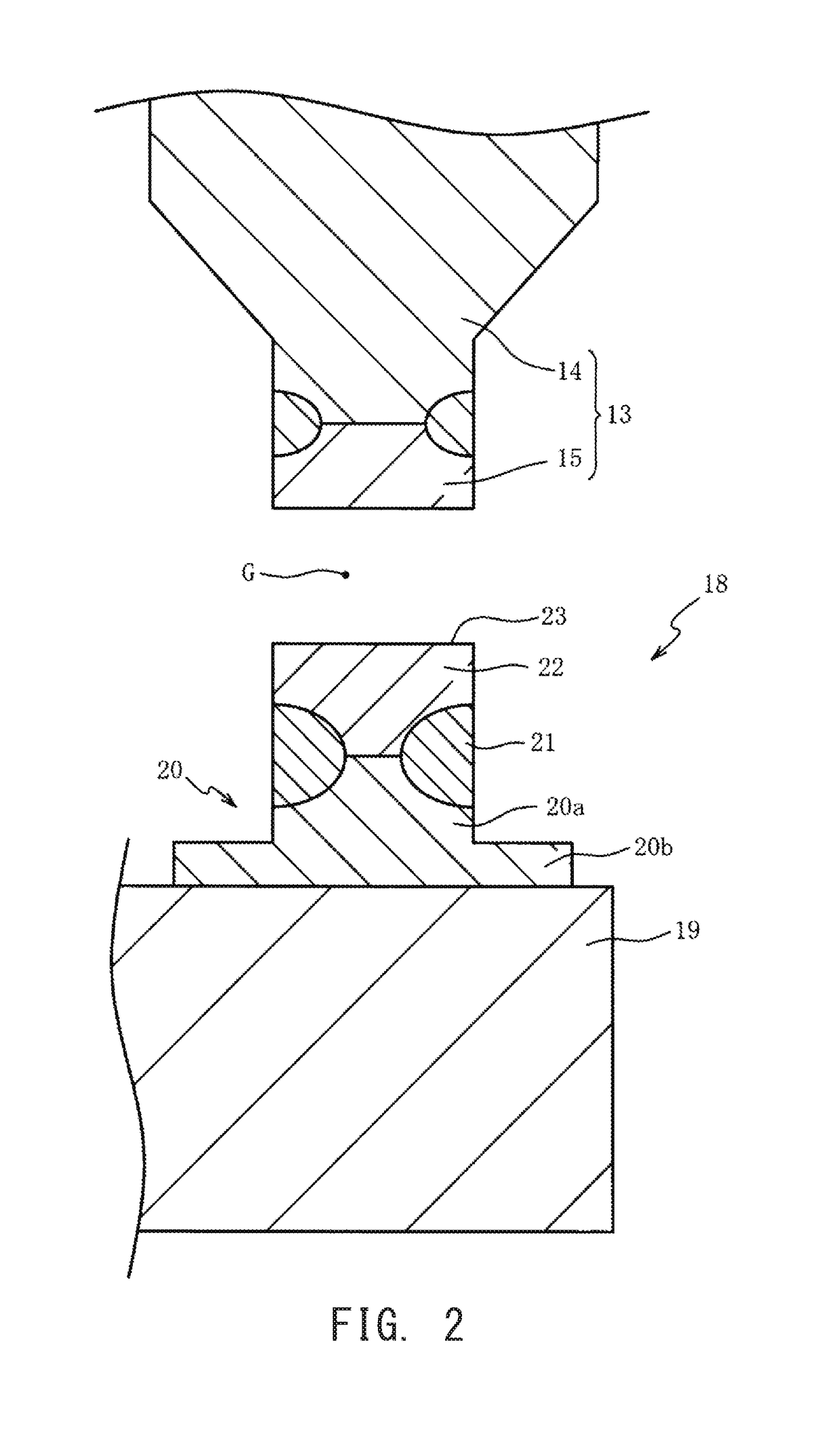

Spark plug

A spark plug having a tip formed of an alloy containing Pt. The tip contains not less than 6 mass % of Rh, at least one element selected from an R group consisting of Rh, Re, Ir, Ru, W, Mo, and Nb, not less than 5 mass % of Ni, and at least one element selected from an N group consisting of Ni, Co, Fe, and Cu. The tip contains Rh most among the elements of the R group, and contains Ni most among the elements of the N group. The total of contents of Pt, Rh, and Ni is not less than 91 mass %, and the total of contents of Pt, the R group, and the N group is not less than 95 mass %. A value obtained by dividing the content of the R group by the content of the N group is not less than 0.7 and not greater than 8.

Owner:NGK SPARK PLUG CO LTD

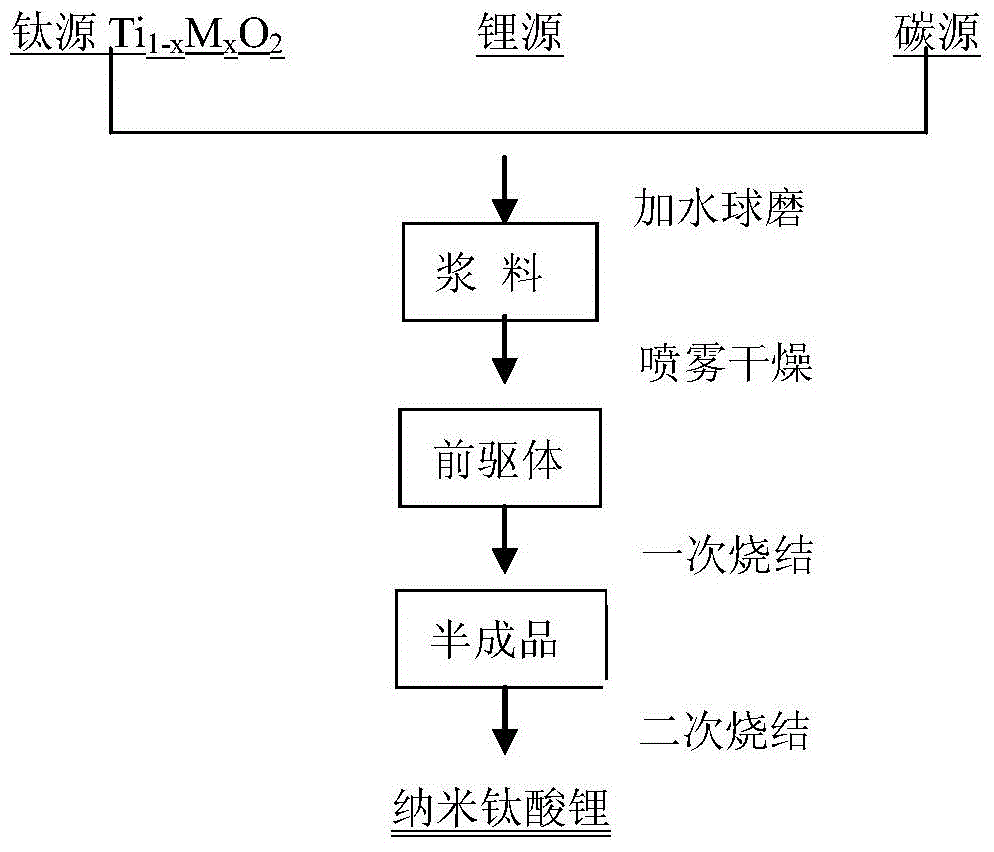

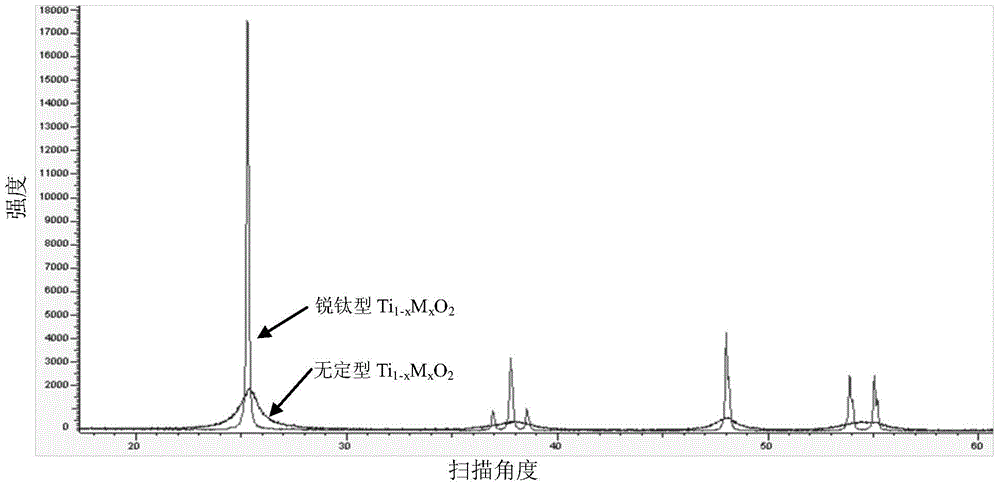

Preparation method suitable for industrial production and used for nano lithium titanate

InactiveCN106159249AIncrease lithium titanate crystal nucleusInhibition of grain growthCell electrodesSecondary cellsCarbon sourceTemperature treatment

The invention provides a preparation method suitable for industrial production and used for a lithium ion battery anode material nano lithium titanate. The preparation method comprises steps as follows: nanoscale Ti<1-x>MxO2(M is Al, Mg, Ag, Zr, Na, K, Zn or Ca; x is larger than or equal to 0 and smaller than or equal to 0.2) is selected as a titanium source, a lithium source and organic carbon source are added in proportion, water is adopted as a dispersant, wet ball milling and mixing are performed, a precursor is obtained with a pray drying technology, and a doped nano spinel lithium titanate material is obtained through high-temperature treatment. The method adopts cheap raw materials, adopts a simple technology and short processes, is environment-friendly, has low equipment requirement and is suitable for industrial production of the nano lithium titanate material.

Owner:RISESUN MENGGULI NEW ENERGY SCIENCE & TECHNOLOGY CO LTD

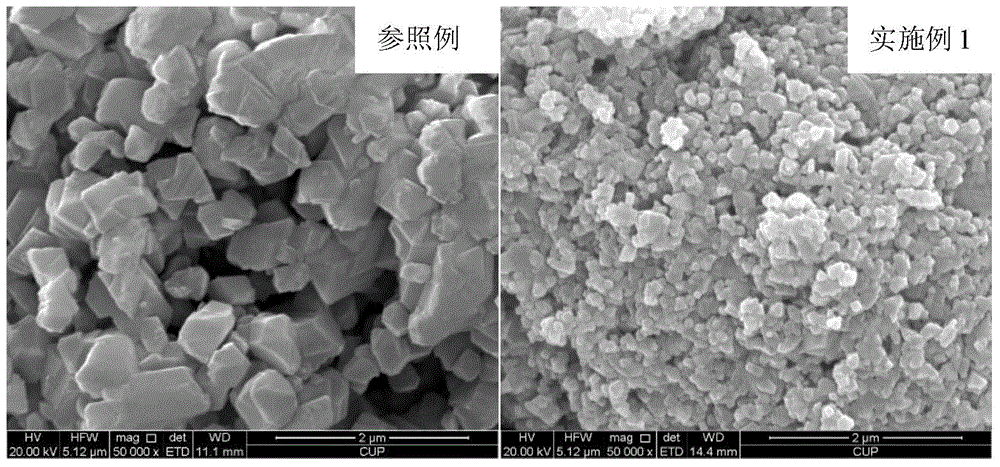

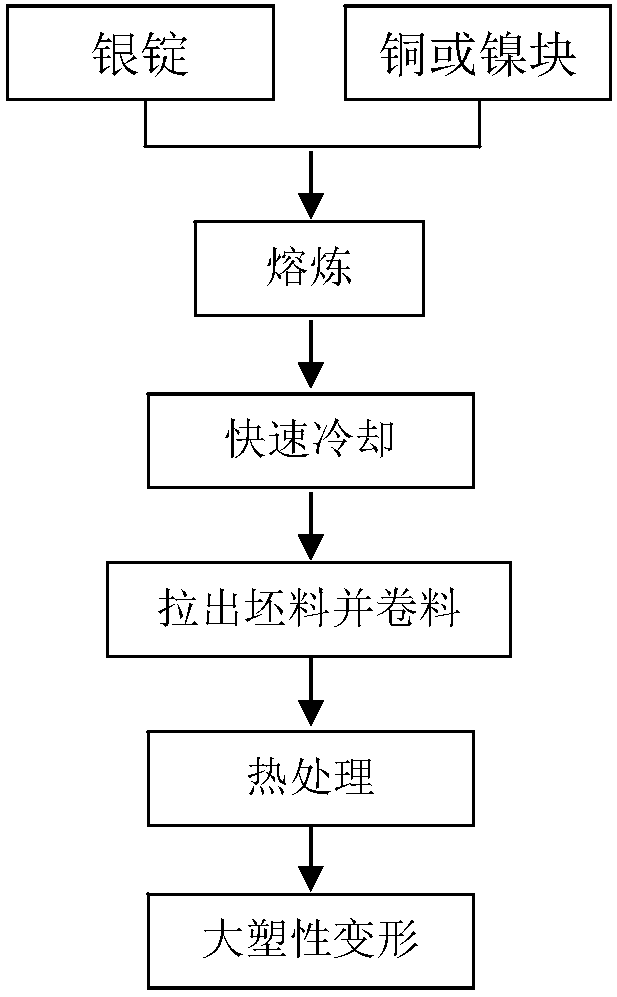

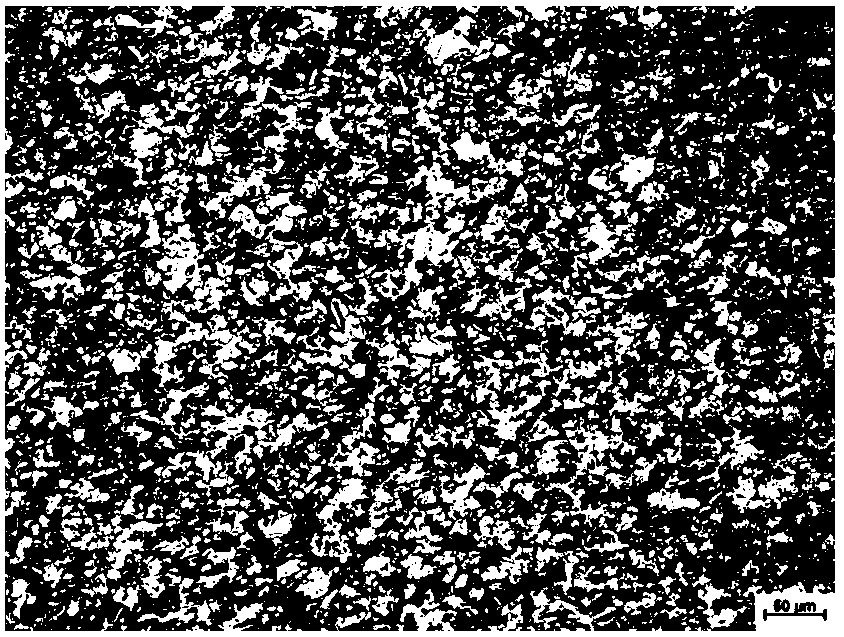

Fine-grained silver-based electrical contact material and preparation method thereof

InactiveCN107740019AAvoid uneven tissue distributionInhibition of grain growthPlastic propertyCopper

The invention provides a fine-grained silver-based electrical contact material and a preparation method thereof. The method comprises the following steps of 1, carrying out smelting and insulating onmetal silver and copper or silver and nickel so as to obtain the molten metal; 2, rapidly cooling the molten metal into a blank so as to inhibiting the grain growth in the alloy structure; 3, pullingout the blank to form a wire; 4, carrying out heat treatment on the wire; 5, performing large-plastic deformation on the heat-treated wire to obtain the fine-grained silver-based electric contact material. According to the fine-grained silver-based electrical contact material and the preparation method thereof, the horizontal continuous casting and large-plastic deformation technologies are combined, the prepared silver-based electric contact material has the advantages of being fine in crystal grain, compact in structure and good in mechanical property, the electric performance is greatly improved, and the material can be widely applied to a self-control switch, a thermostat, a thermostat, a baking machine, a baking oven timer, a computer and the like.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

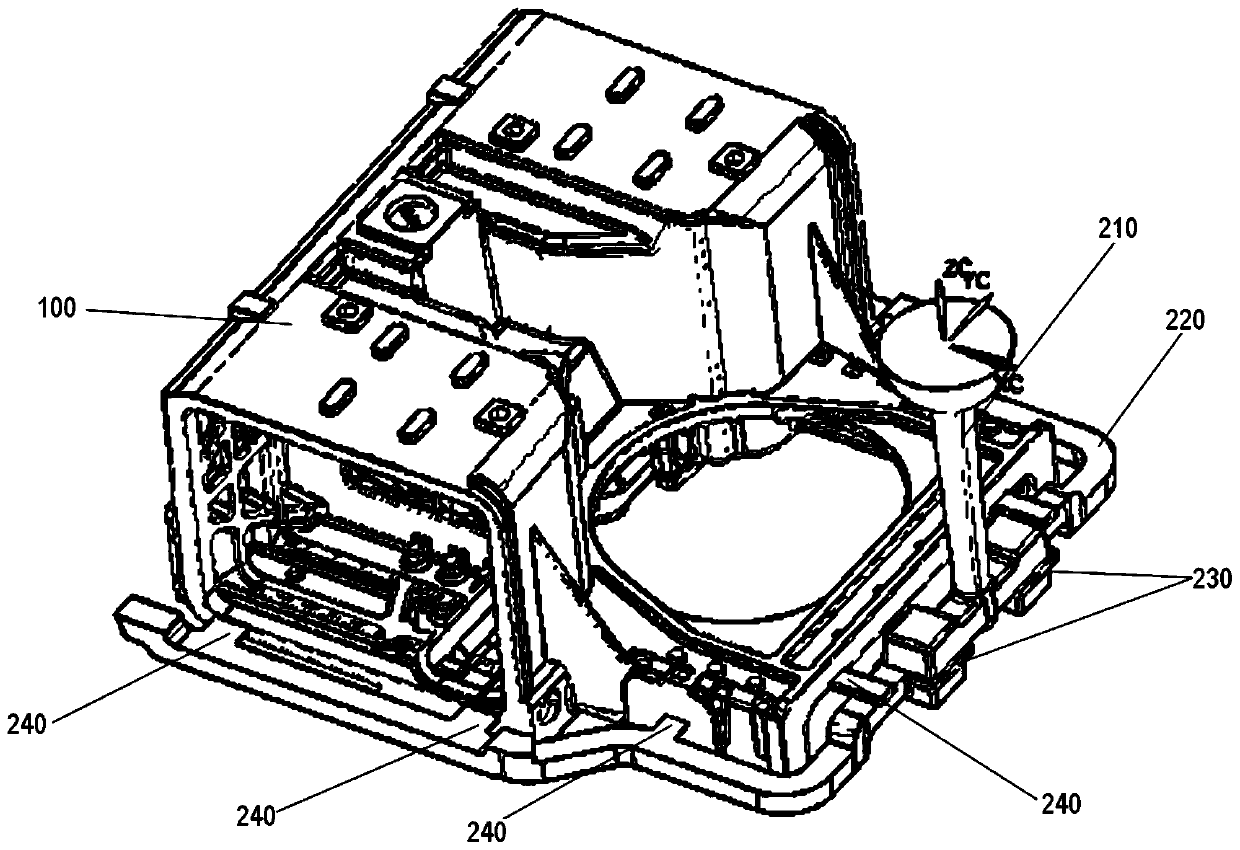

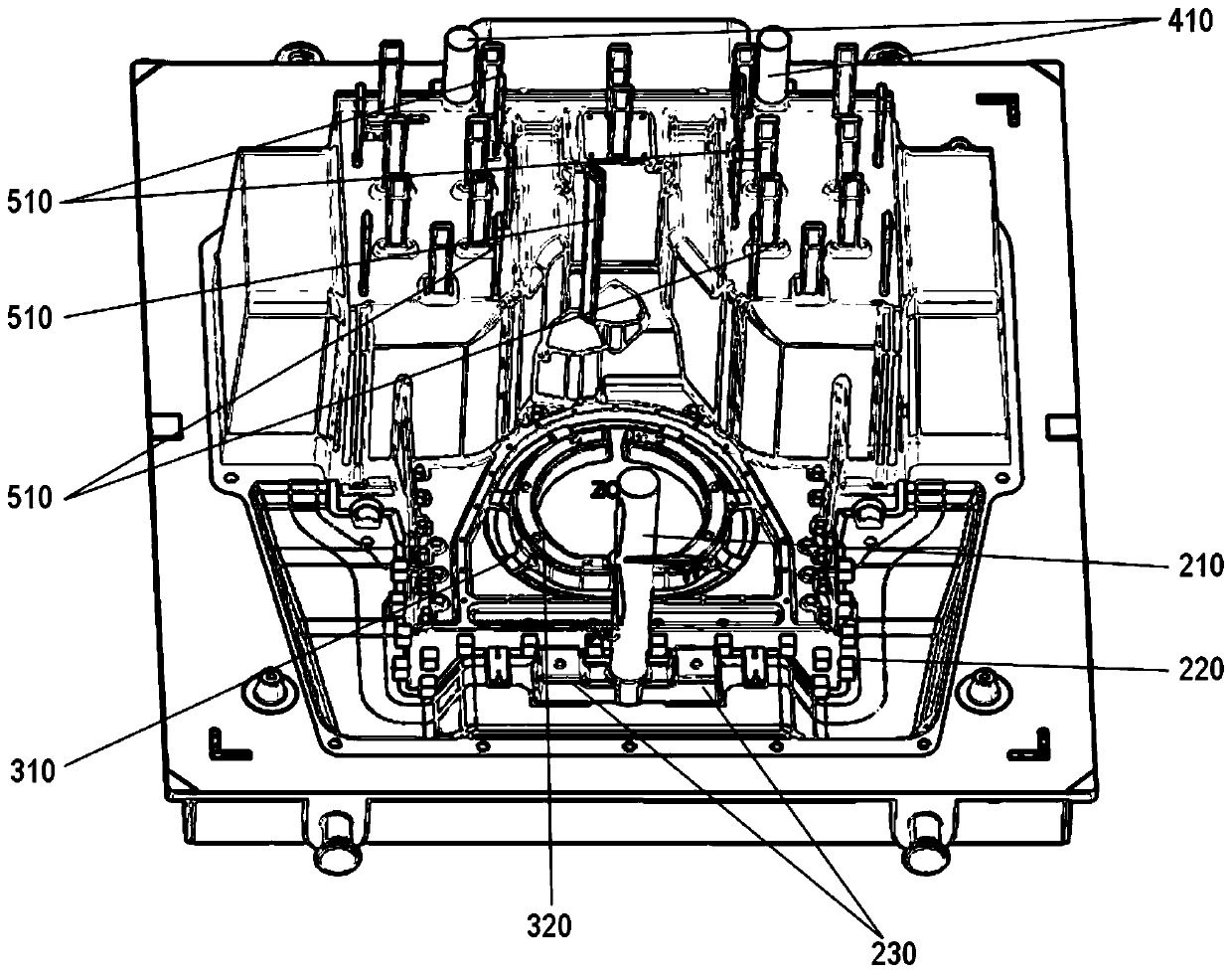

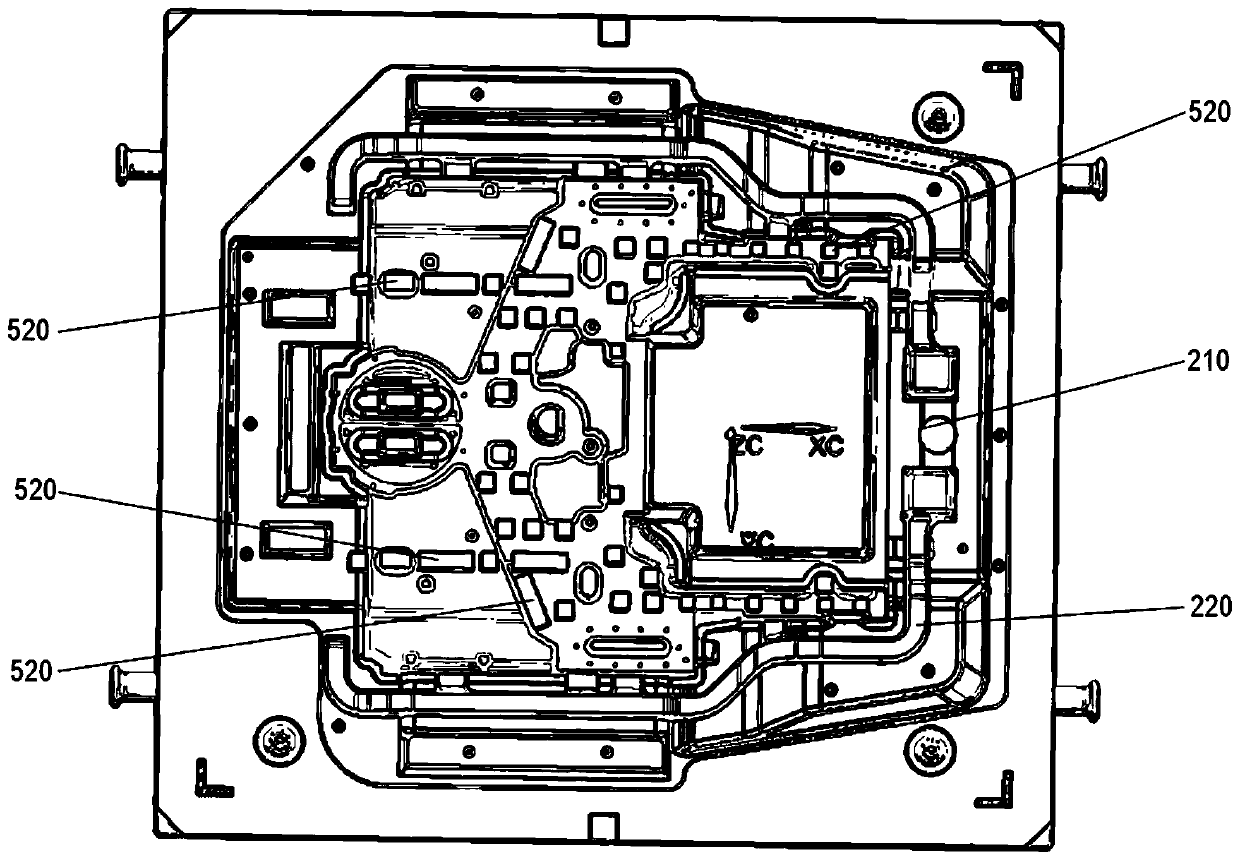

Casting method of high-powered engine box casting

PendingCN111451444AQuality improvementImprove yieldFoundry mouldsFoundry coresTemperature controlIndustrial engineering

The invention discloses a casting method of a high-powered engine box casting. The casting method comprises the steps of preparing moulding sand, performing modeling and core making to obtain a sand mould, preparing pouring iron liquid, taking pig iron, foundry returns and waste steel as raw materials to be fed into a smelting furnace to be smelted, carrying out in-package inoculation and spheroidization on the smelted iron liquid, carrying out stream inoculation before tapping, then carrying out tapping, pouring the iron liquid into the sand mould, carrying out stream inoculation, adopting acold iron riser process for feeding and temperature control, forming a casting after pouring is finished, and carrying out treatment on the formed casting. The obtained casting is good in quality, andquality problems of core clamping, shrinkage, cracks and the like are not prone to happening.

Owner:宜宾普什联动科技有限公司 +1

Thick-specification X80 pipeline steel plate with process time being shortened and manufacturing method thereof

The invention discloses a thick-specification X80 pipeline steel plate with the process time being shortened. The thick-specification X80 pipeline steel plate is characterized in that the steel plate comprises, by mass, 0.02%-0.06% of C, 1.6%-1.9% of Mn, 0.1%-0.35% of Si, 0-0.0006% of S, 0-0.010% of P, 0.055%-0.08% of Nb, 0.008%-0.03% of Ti, 0-0.008% of V, 0-0.06% of Alt, 0-0.010% of N, 0-0.006% of O, 0-0.15% of Mo, 0-0.20% of Cu, 0.2%-0.4% of Ni, 0-0.35% of Cr, 0-0.01% of Ca, the balance Fe and inevitable impurities. The main process of the thick-specification X80 pipeline steel plate comprises the steps of molten steel smelting, continuous casting, plate blank reheating and hot rolling; and the hot rolling process comprises the steps of intermediate blank cooling, water cooling, stack cooling and straightening. According to the thick-specification X80 pipeline steel plate with the process time being shortened and the main processes, an intermediate blank is uniformly cooled through an intermediate blank moderate cooling system and is cooled to the rolling starting temperature of second-stage finish rolling, thus, the process time can be substantially shortened, and the production efficiency is improved.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Alumina ceramics composite containing novel four-component sintering adjuvant

InactiveCN101767981AImproved high temperature strength and oxidation resistanceInhibition of grain growthRare-earth elementAdjuvant

The invention discloses an alumina ceramics composite containing a novel four-component sintering adjuvant, which is characterized in that the four-component adjuvant is MO-CaO-SiO2-L2O3, wherein M is one of Mg, Ba and Be, and L is a rare earth element which is one of Ce, La and Lu. The alumina ceramics composite has the following components in percentage by weight: (1), 75%-90% of alumina powder; (2), 3%-6% of nano MO (M is one of Mg, Ba and Be); (3), 2%-6% of nano SiO2; (4), 2%-6% of nano CaO; and (5), 3%-7% of nano L2O3 (L is the rare earth element which is one of Ce, La and Lu). The particle size of the four-component sintering adjuvant is less than 300 nanometers, and the particle size of main alumina powder is at nanometer scale, namely 1-10 nanometers. By forming liquid phase and gradually forming spinel-like matter (the melting point thereof is more than 2100 DEG C) at later sintering stage to eliminate the liquid phase, sintering is promoted and simultaneously the growth of grain is inhibited, air hole elimination is promoted, density is improved and fine and even alumina ceramics grain and grain boundary air hole are formed, thereby ensuring the alumina ceramics material to have better high-temperature mechanical performance and wear resistance.

Owner:NINGBO UNIV

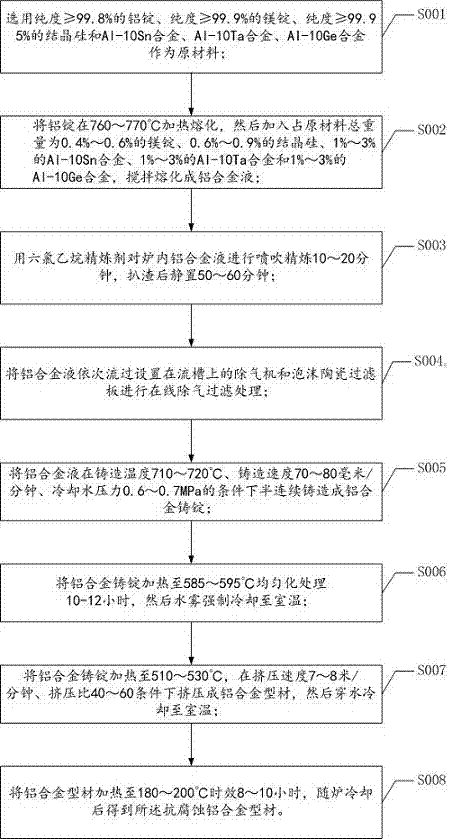

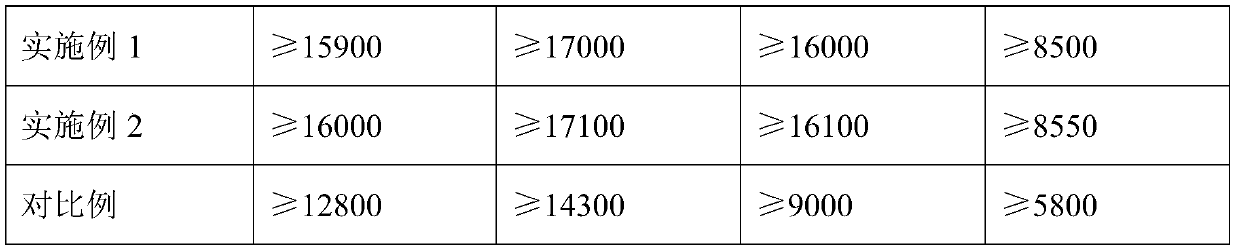

Corrosion-resistant aluminum alloy profile and extrusion method thereof

The invention discloses a corrosion-resistant aluminum alloy profile and an extrusion method thereof. The corrosion-resistant aluminum alloy profile is composed of, by mass, 0.4%-0.6% of Mg, 0.6%-0.9% of Si, 0.1%-0.3% of SN, 0.1%-0.3% of Ta, 0.1%-0.3% of Ge, not larger than 0.15% of Fe and the balance Al, wherein 0.4%<=(Sn+Ta+Ge)<=0.6%. According to the corrosion-resistant aluminum alloy profile, the specific alloy composition constituting and the extrusion method of the corrosion-resistant aluminum alloy profile are designed, recrystallization and grain growth are restrained, the aluminum alloy profile obtains single fiber grain structures in the extruding direction, the strength, breaking tenacity and stress corrosion resistance property of the aluminum alloy profile are improved, the beneficial effect of high combination property is achieved, the corrosion-resistant aluminum alloy profile can be widely applied to buildings, electric products, mechanized equipment, transportation, aerospace and other fields, and the wide application prospect is achieved.

Owner:佛山市三水凤铝铝业有限公司 +1

Preparation method of nickel-manganese zinc ferrite material with high impedance and magnetic property

InactiveCN109748579AImproved oxygen distributionInhibition of grain growthInorganic material magnetismInductances/transformers/magnets manufactureCvd grapheneChemistry

The invention provides a preparation method of a nickel-manganese zinc ferrite material with a high impedance and magnetic property. The preparation method comprises the following steps: preparing a meta nitrate solution from metal salt containing Ni<2+>, Mn<2+> and Fe<2+> to obtain a mixed solution A, adding an alkali solution of graphene into the mixed solution A, adding ethylene diamine tetraacetic acid under magnetic stirring, adding ammonia water dropwise to adjust the pH value to 4 to 6, heating to 80 to 110 DEG C, reacting for 1 to 2 hours and standing for 3 to 5 hours; performing suction filtration, washing and drying to obtain a first material; adding a dicyclopentadienyl ferromagnetic powder, polyvinyl alcohol (PVA) and bisphenol A epoxy resin into the first material, mixing andball-milling to obtain a second material; and performing pressing formation on the second material, performing microwave sintering and cooling to obtain the nickel-manganese zinc ferrite material. According to the method and through the improvement of the process and the addition of the materials, low loss and high impedance within high-frequency range are realized and the application range of themanganese zinc ferrite material is enlarged.

Owner:NANTONG HUAXING MAGNETIC MATERIAL

Preparation method of ultra-fine tungsten carbide powder

InactiveCN105537606AControllable granularityInhibition of grain growthDicobalt octacarbonylUltra fine

The invention discloses a preparation method of ultra-fine tungsten carbide powder and belongs to the technical field of powder metallurgy. The preparation method of the ultra-fine tungsten carbide powder comprises the technological steps that 100 mass parts of tungsten hexacarbonyl W(CO)6 and 3-5 mass parts of dicobalt octacarbonyl Co2(CO)8 are dissolved in diethyl ether in a three-opening bottle and stirred to be completely dissolved, and the diethyl ether is evaporated through vacuum distillation, so that a solid uniform mixture of the ungsten hexacarbonyl W(CO)6 and the dicobalt octacarbonyl Co2(CO)8 is obtained; the three-opening bottle is heated to the temperature of 50-90 DEG C, carrier gas is introduced to carry the gasified W(CO)6 mixture into a pyrolyzing furnace, methane gas preheated to the temperature of 300-450 DEG C is introduced into the pyrolyzing furnace at the same time, the temperature of the pyrolyzing furnace is kept being 300-450 DEG C, and the reaction time is 30-120 minutes; and the ultra-fine tungsten carbide powder which contains 1.0%-6.5% of cobalt by mass is finally obtained, and the granularity D50 of the powder is 50-600 nm. By the adoption of the method, the granularity of the tungsten carbide powder can be controlled; in addition, due to the fact that the tungsten carbide powder is doped with certain cobalt, abnormal growth of the tungsten carbide powder during high-temperature sintering can be restrained, and the excellent performance of the tungsten carbide powder is kept.

Owner:CENT IRON & STEEL RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com