Large-wall-thickness X52MS acid-resistant pipeline steel plate produced by LF-RH refining process and manufacturing method thereof

A LF-RH, process technology, applied in the field of metallurgy, can solve the problems not mentioned in the drop hammer performance of large thick-walled acid-resistant and corrosion-resistant pipeline steel, achieve good low-temperature toughness and corrosion resistance, and suppress austenite grains The effect of growing and improving the uniformity of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

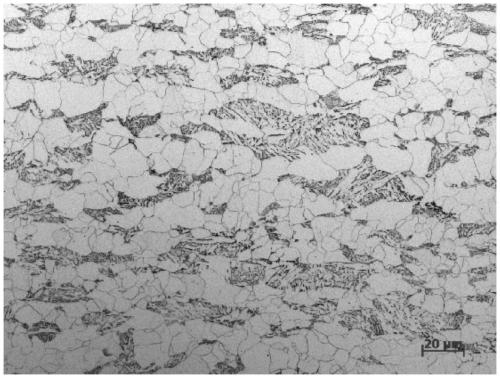

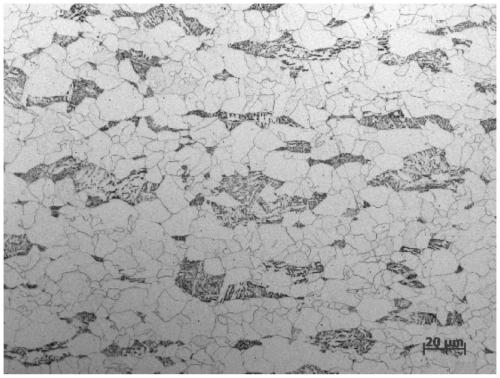

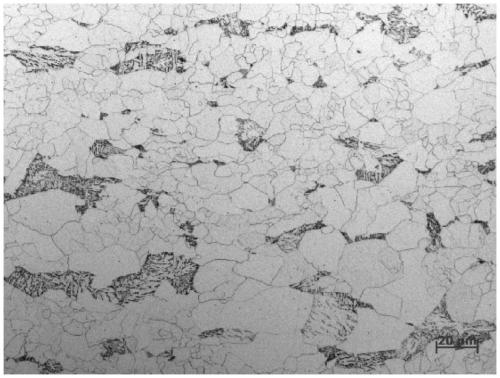

[0037] According to the scope of chemical composition and manufacturing method of the present invention, pretreatment of molten iron by KR—converter smelting—LF refining—RH vacuum degassing—continuous casting—continuous casting slab covered and slow cooling—continuous casting slab inspection and cleaning—slab heating—high pressure Process steps such as water descaling-rough rolling-intermediate billet cooling-finish rolling-ACC cooling, used under the acidic conditions of manufacturing thickness 35.1mm (embodiment 1), 38.3mm (embodiment 2) and 44.2mm (embodiment 3) steel plate.

[0038] The specific process of the above-mentioned heating, rolling and cooling stages is: heating the continuous casting slab with a thickness of 370mm to 1180°C and holding it for 180min (Example 1, 2) or heating the continuous casting slab with a thickness of 450mm to 1200°C and holding it for 210min (Example 3 ), use high-pressure water descaling after the continuous casting slab is out of the fur...

Embodiment 1

[0044] The anti-HIC performance of X52MS steel plate in table 3 embodiment 1, 2 and 3

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com