Patents

Literature

406results about How to "Squeeze fully" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

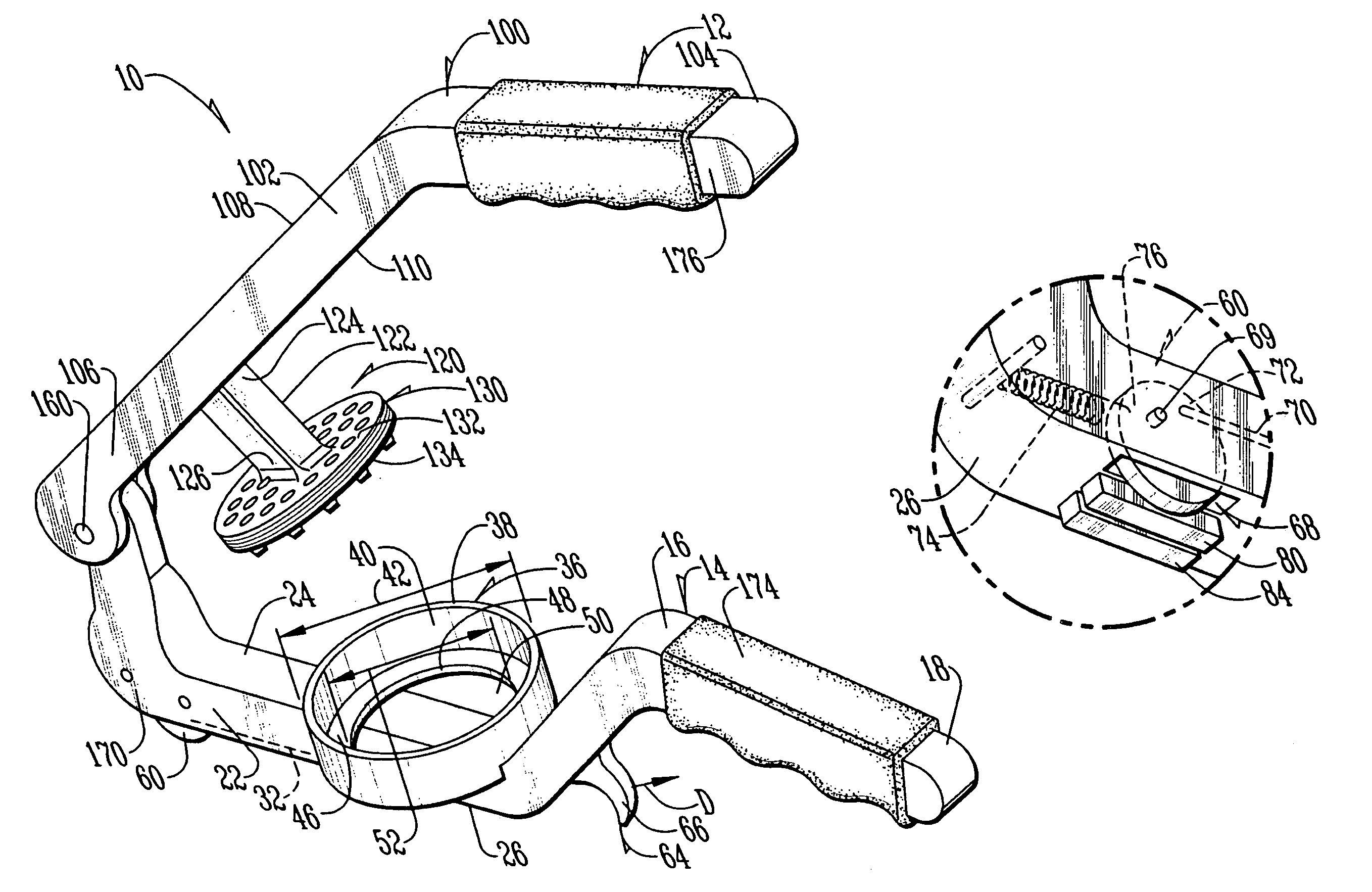

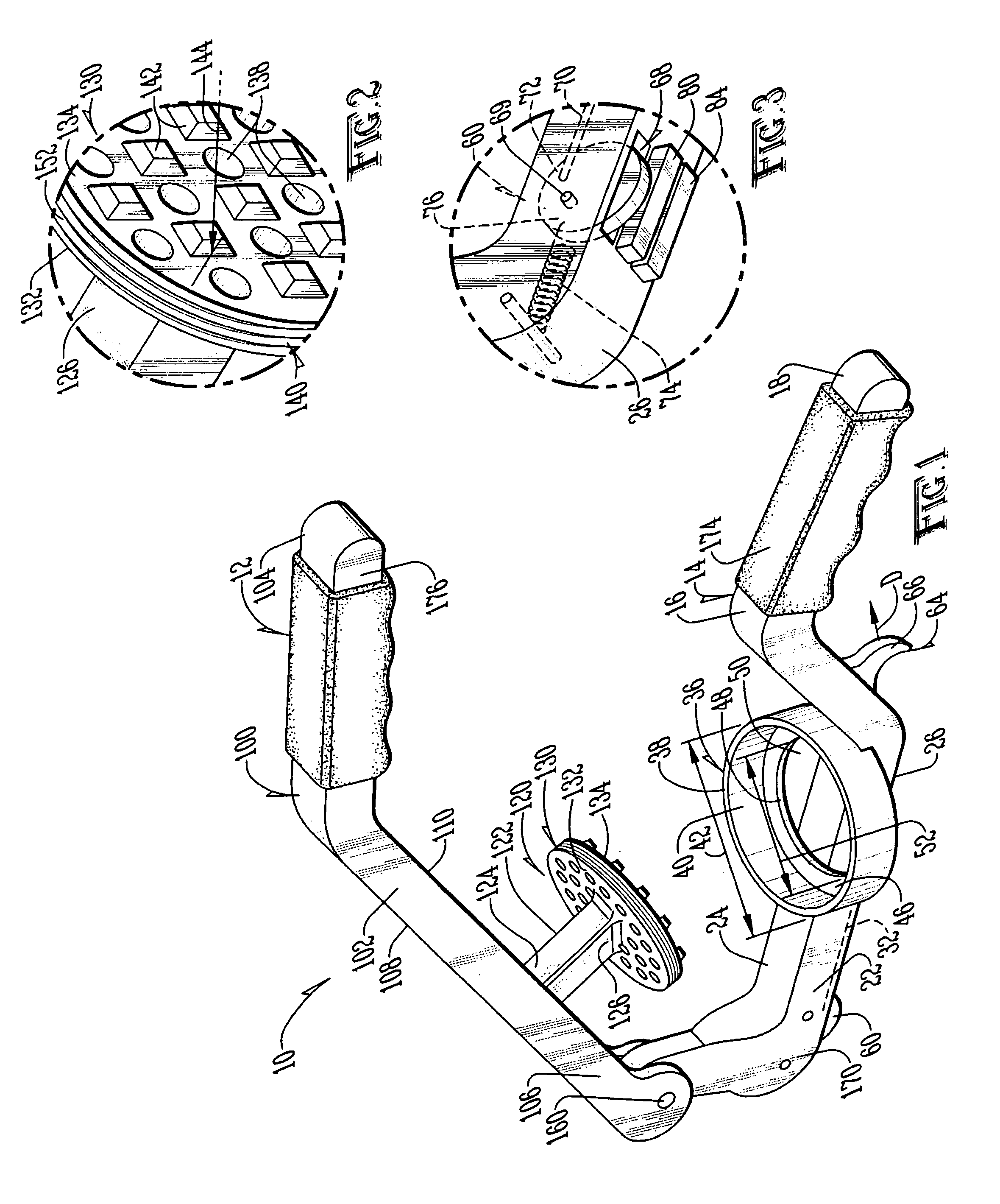

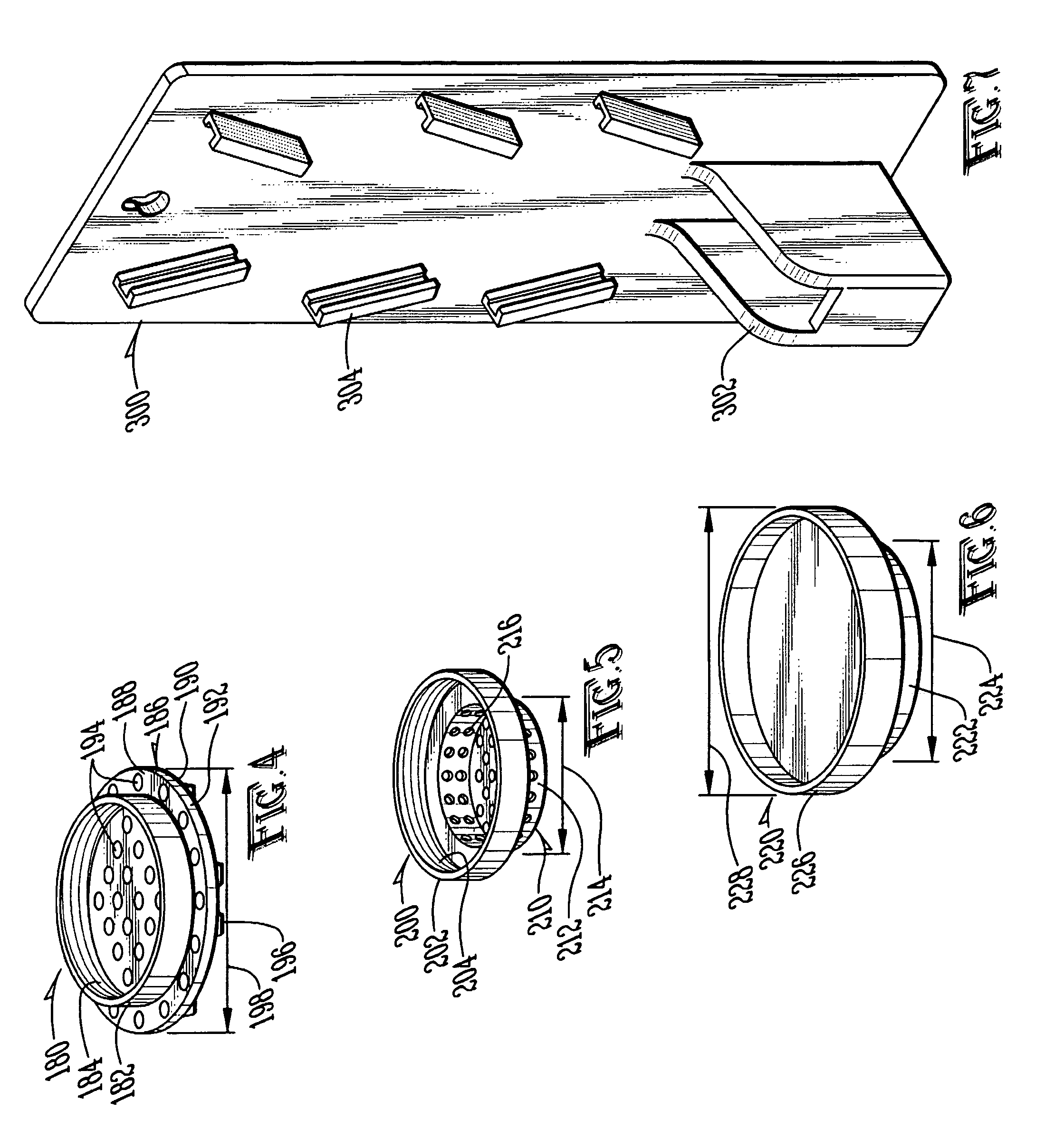

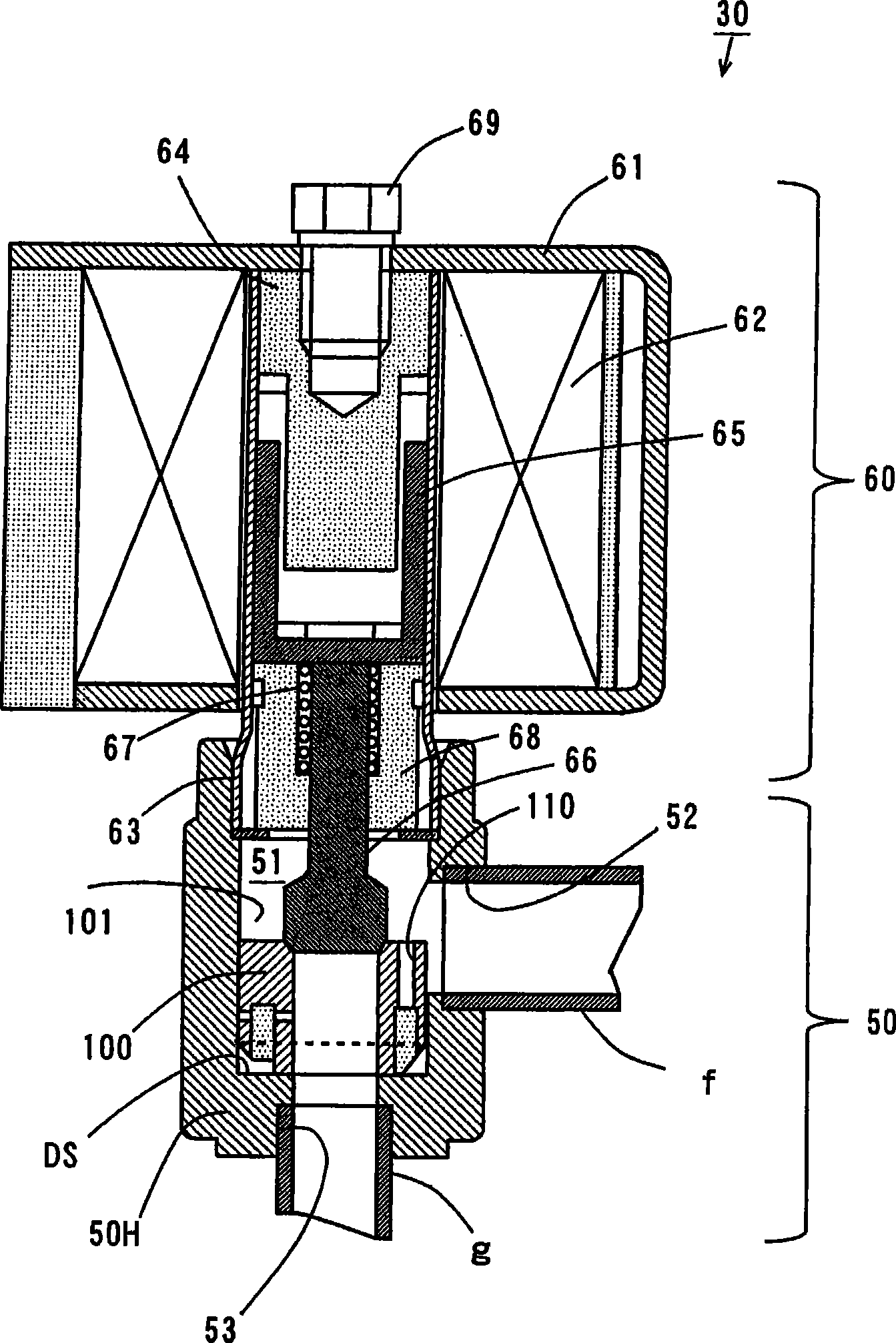

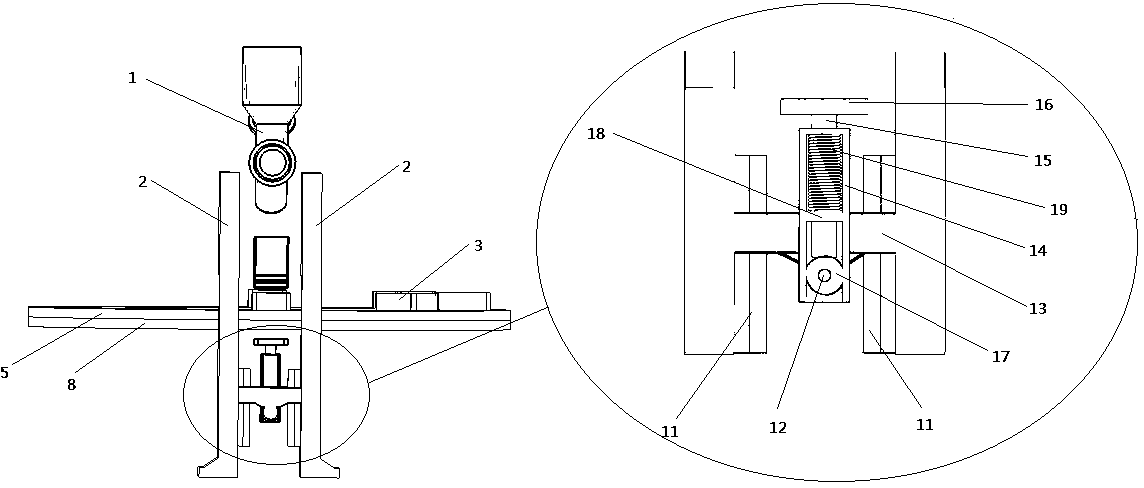

Device for squeezing fluid from a container of food packed in fluid

InactiveUS7162952B1Increased mechanical advantageSqueeze fullyJuice extractionGripping headsMechanical engineeringIngested food

A device includes two handle elements with a can support on one handle and a can contents engaging unit on the other handle element. A trigger mechanism is included to ensure complete draining of the fluid from the can and various adapter elements are also included so the device can be used with cans of various sizes. A wall mounting element is also included.

Owner:MICHAUD LEO

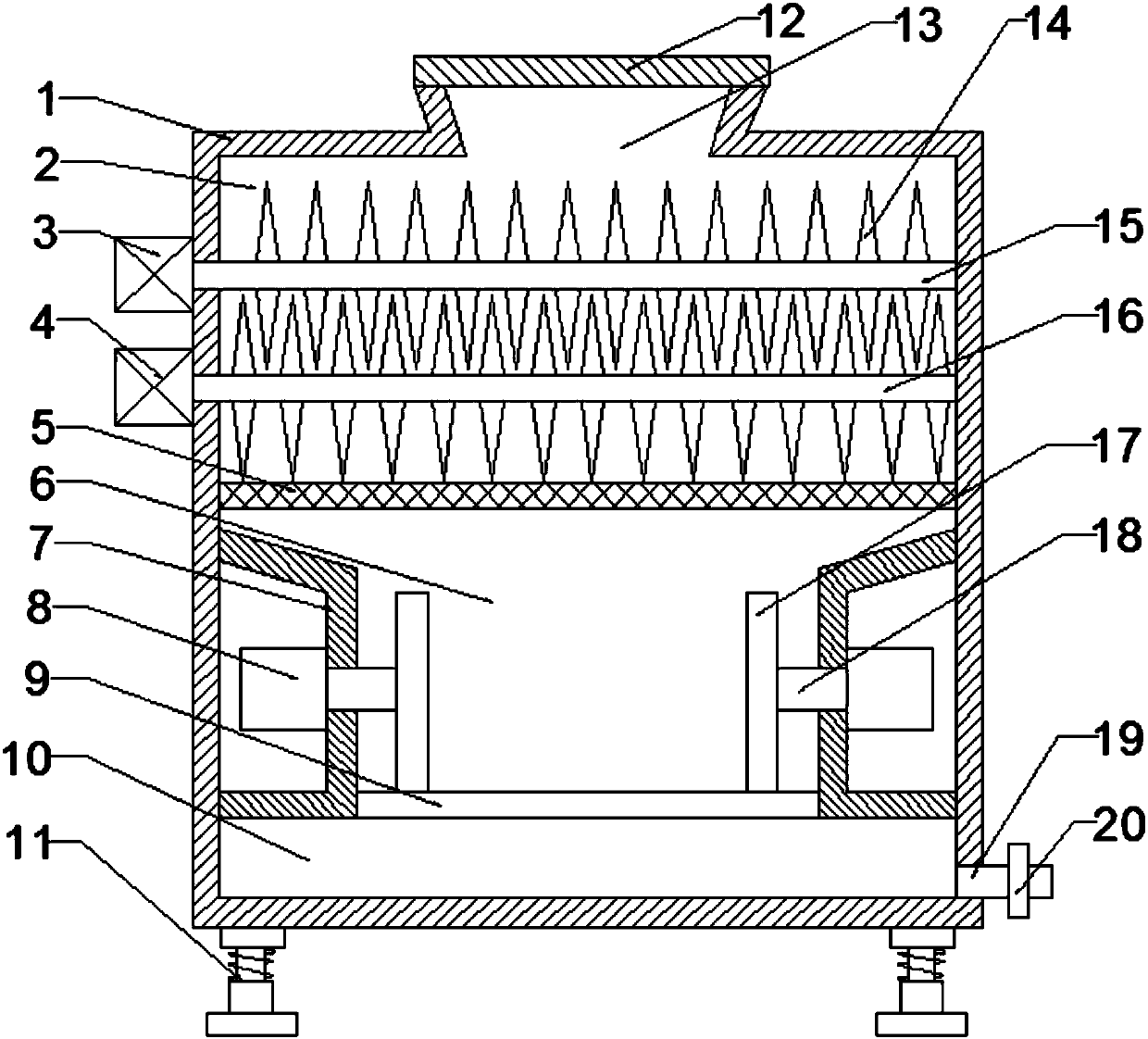

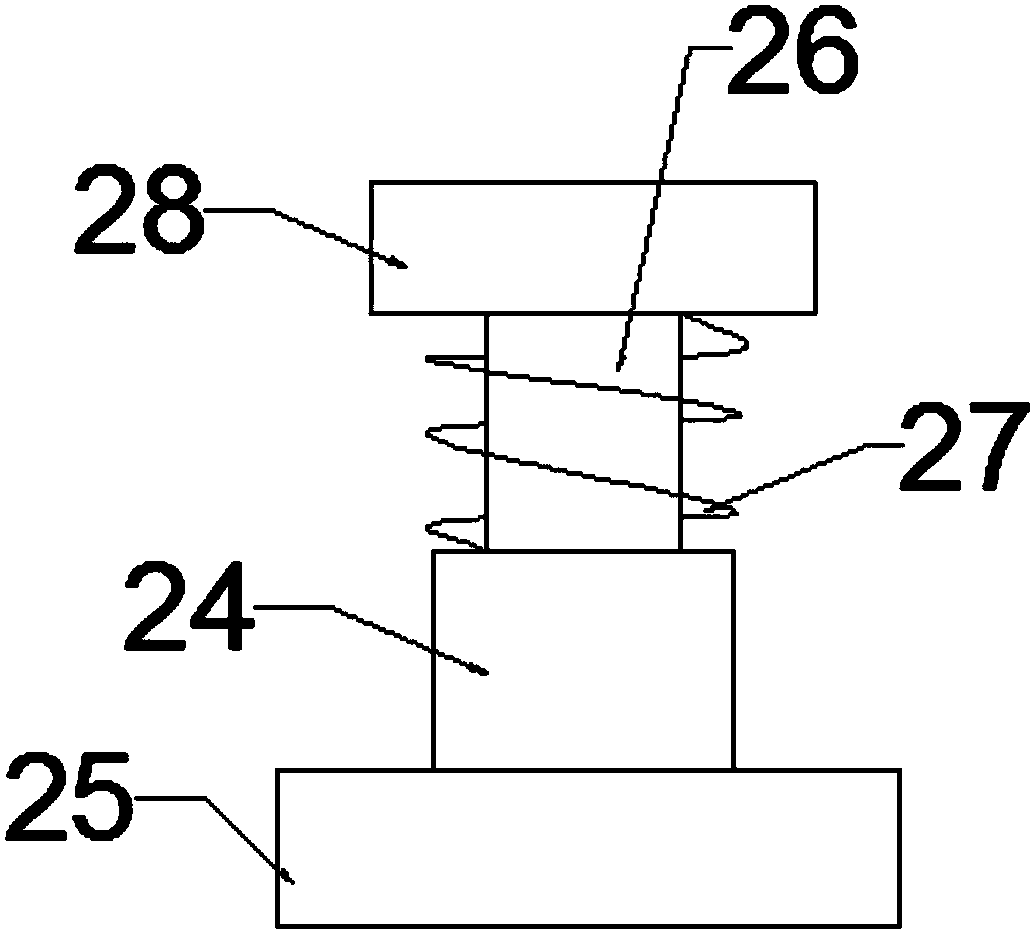

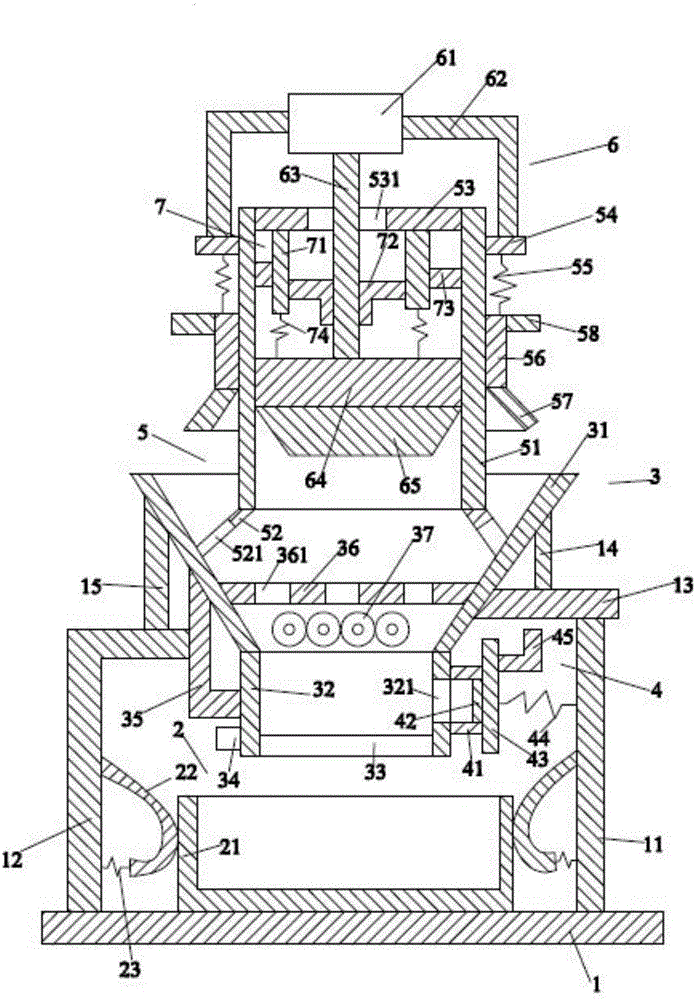

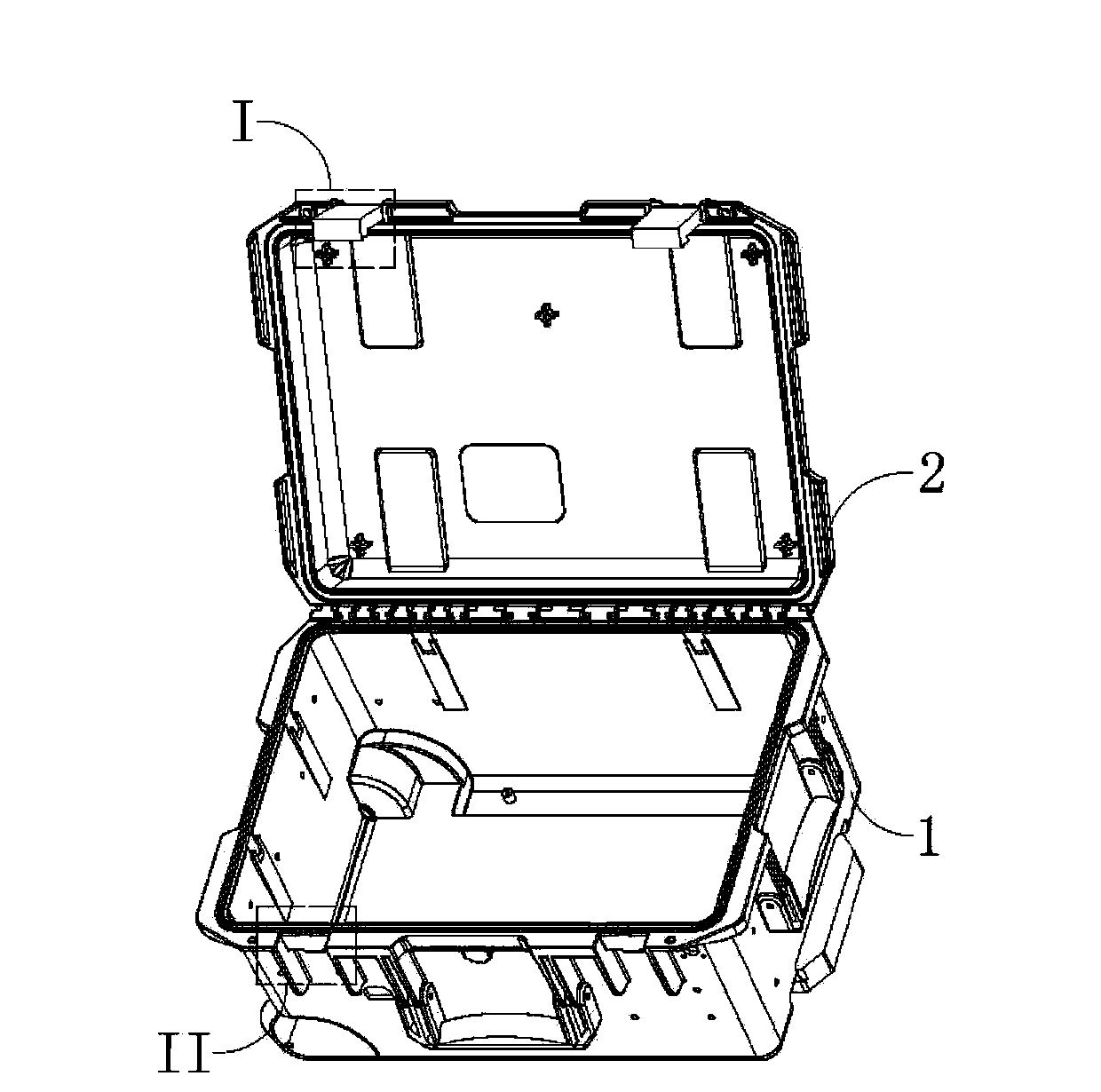

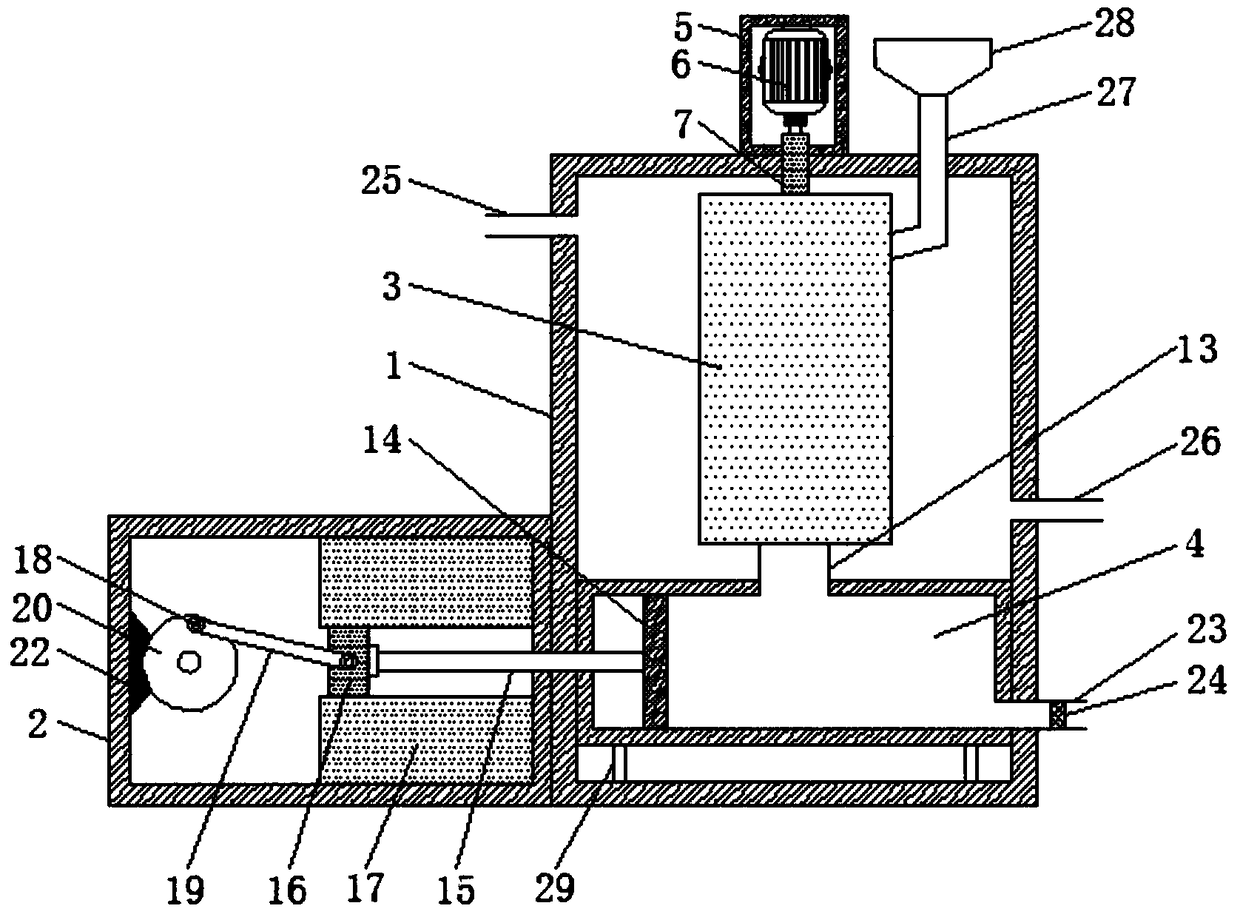

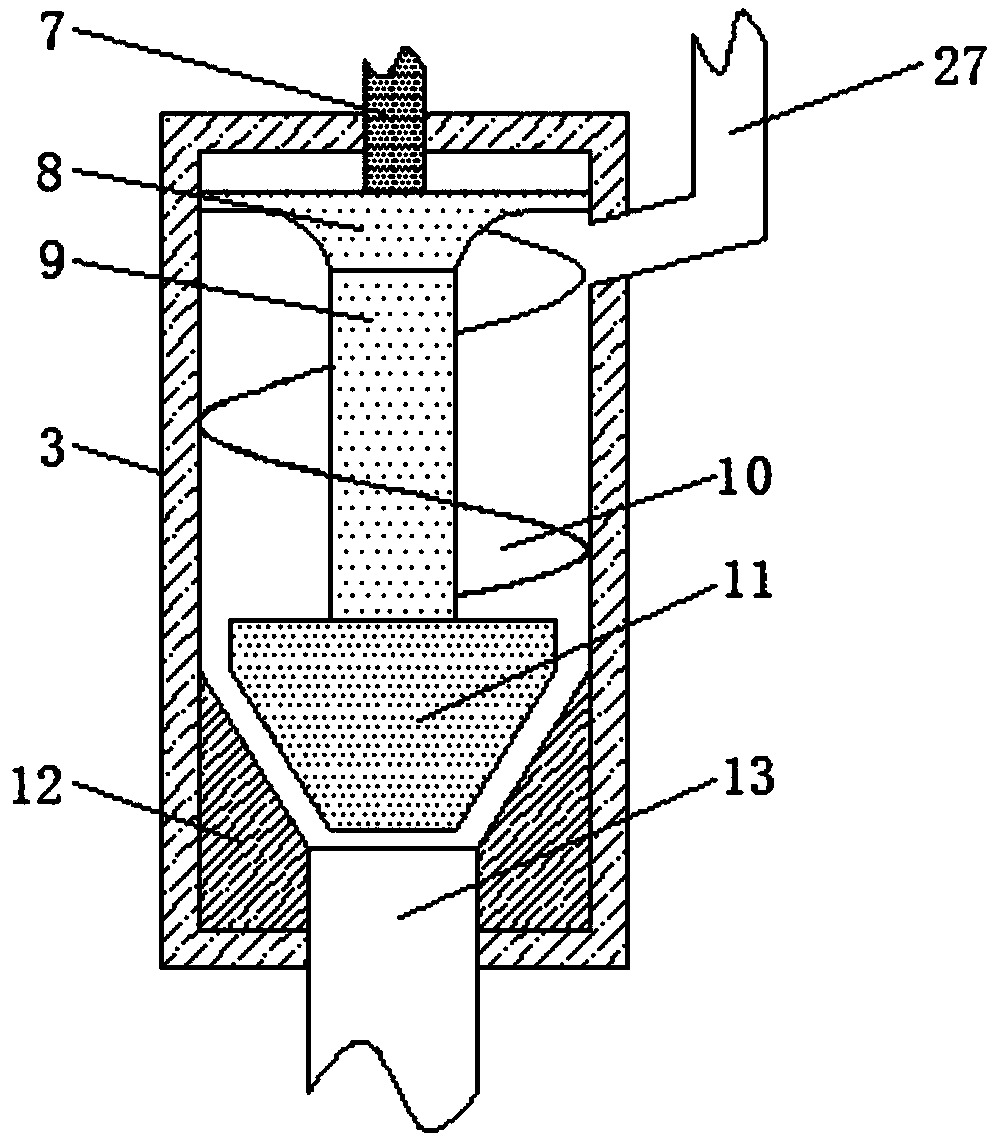

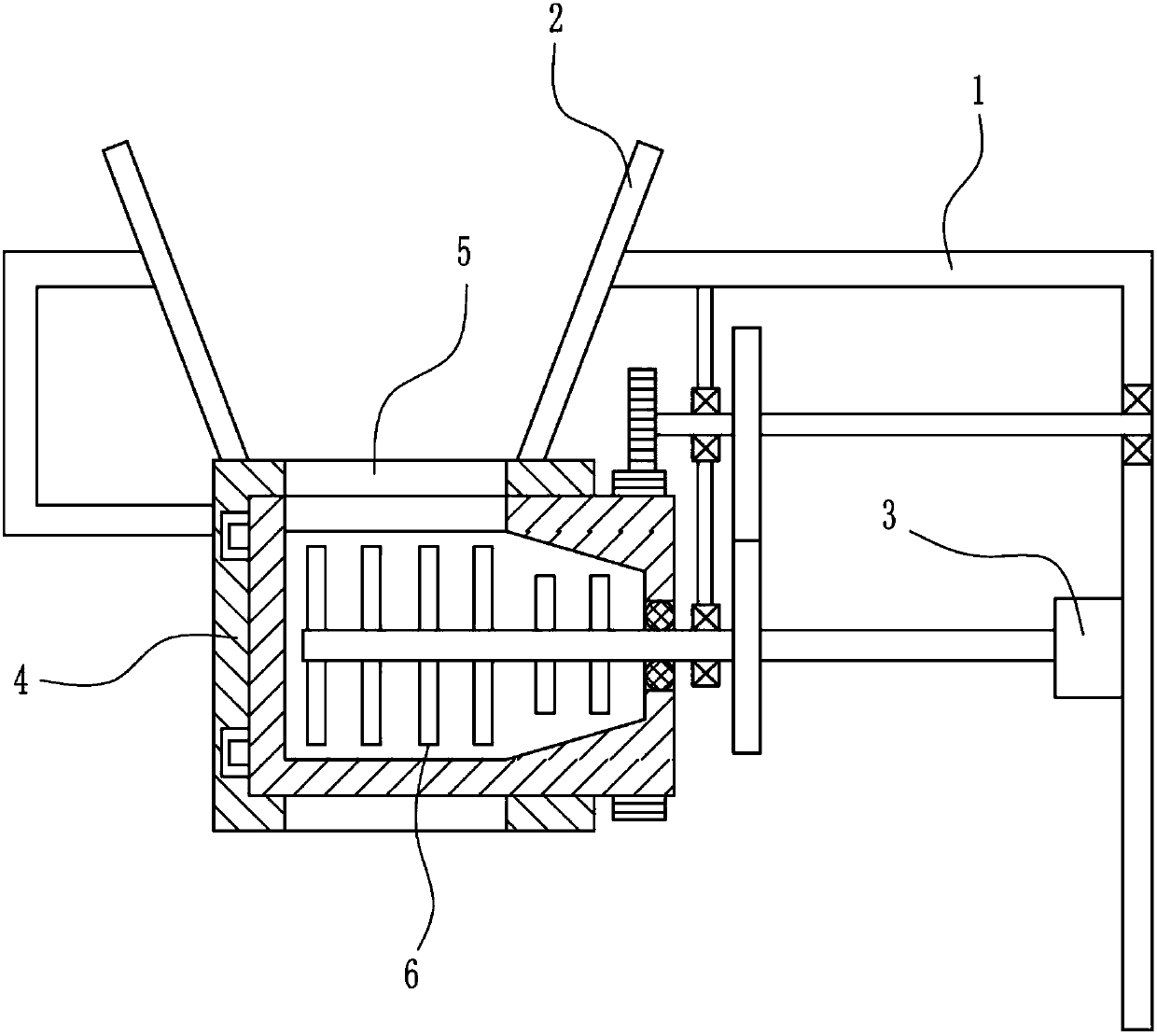

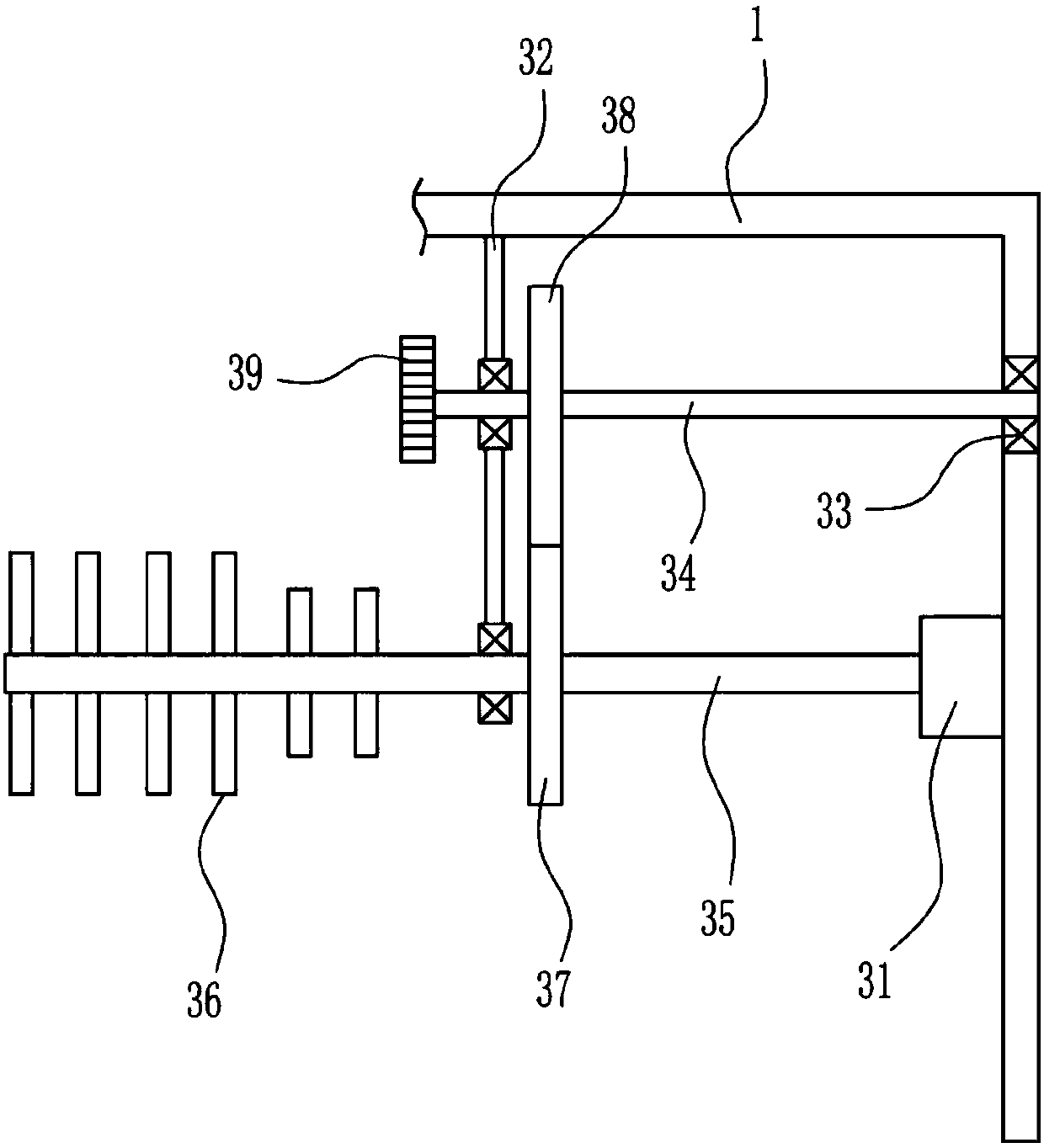

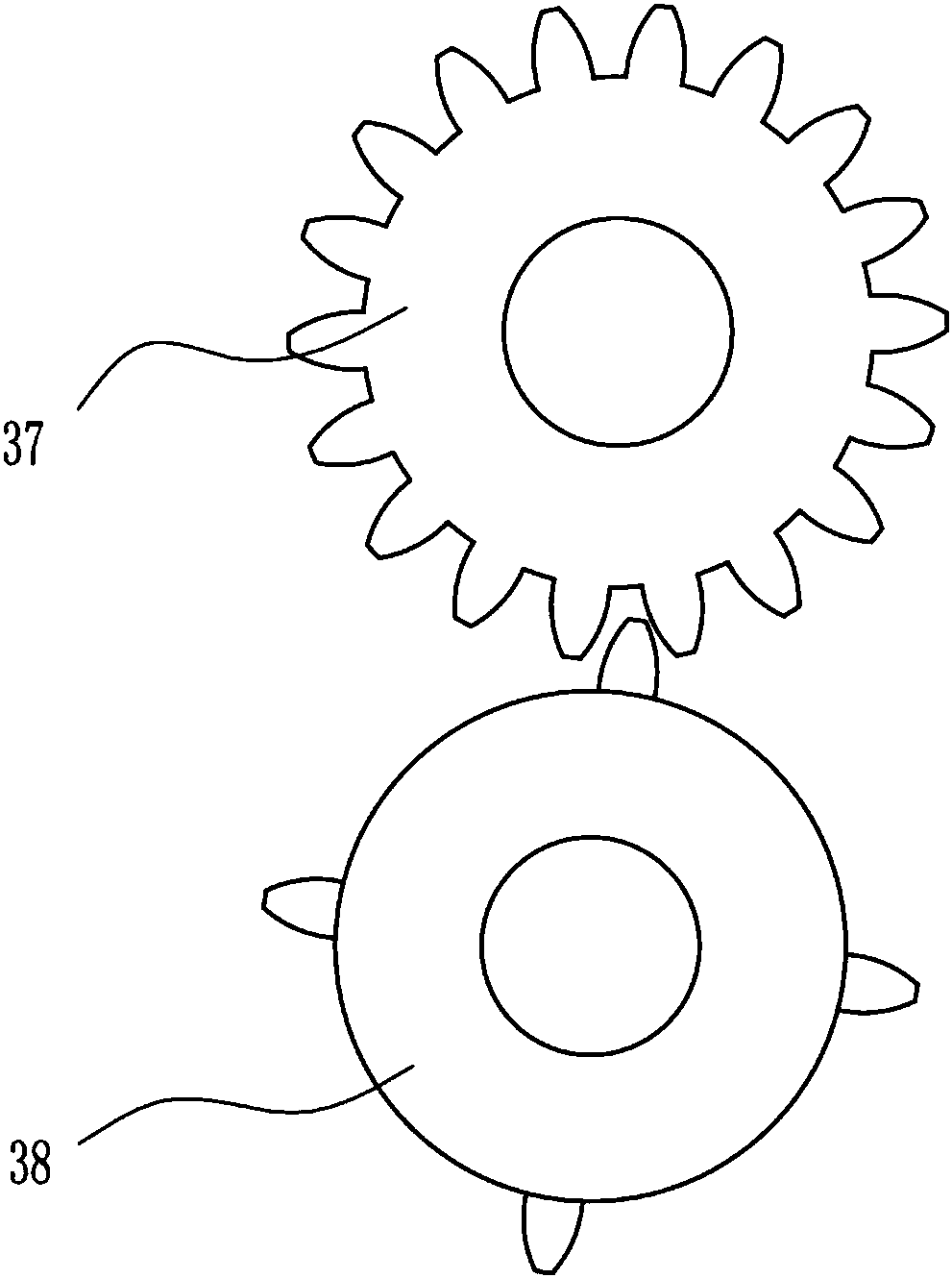

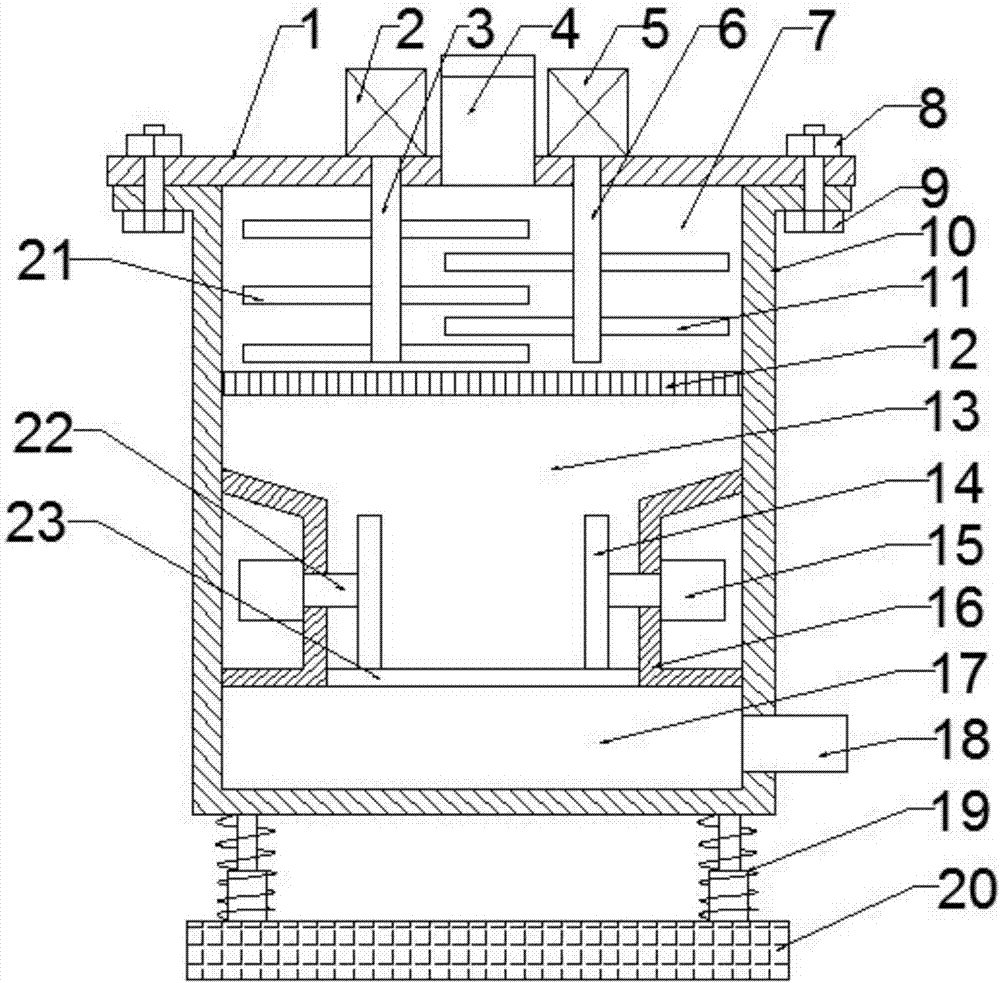

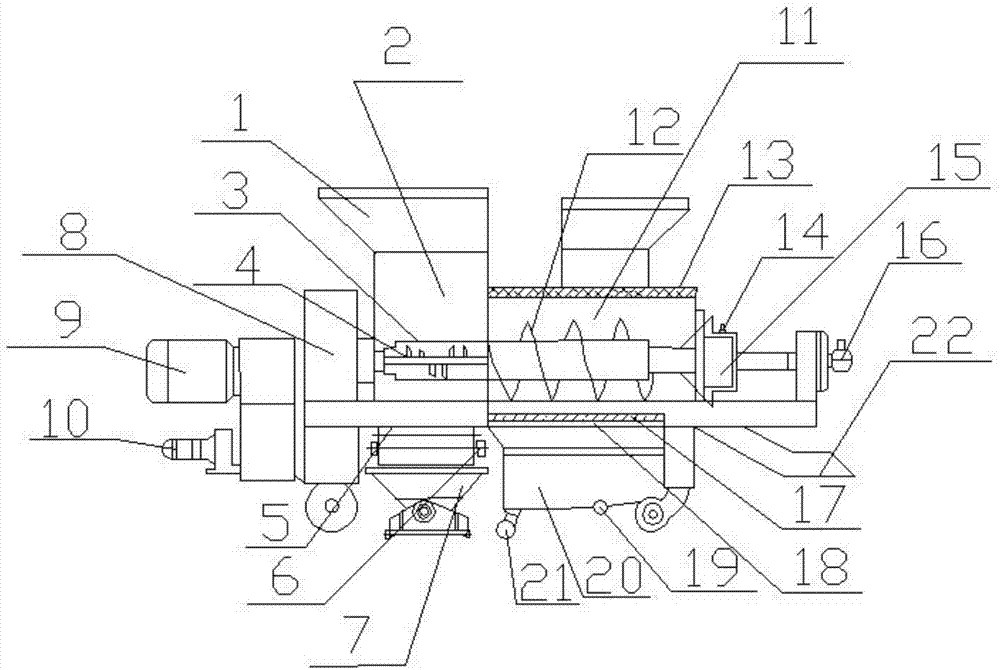

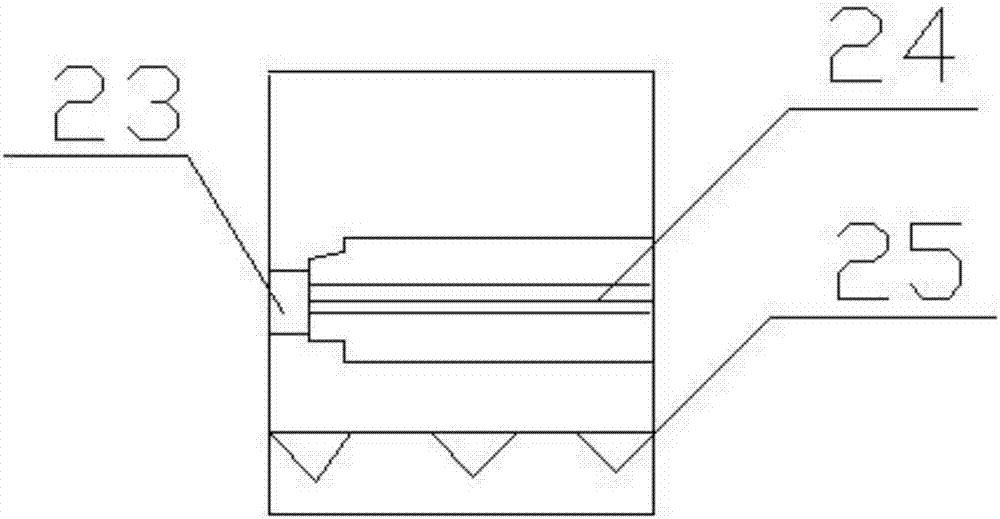

Medical garbage smashing and extrusion-forming device

InactiveCN107552537ASqueeze fullyFast crushingSolid waste disposalGrain treatmentsElectric machineryLiquid storage tank

The invention discloses a medical garbage smashing and extrusion-forming device and belongs to the technical field of medical garbage treatment. The medical garbage smashing and extrusion-forming device comprises a box body. A smashing cavity, an extruding cavity and a liquid storage tank are formed inside the box body; a feeding hopper is arranged at the bottom of the box body and communicates with the smashing cavity; a cover plate is arranged on the top of the feeding hopper through a hinge; smashing blades, a first rotating shaft and a second rotating shaft are arranged in the smashing cavity; the first rotating shaft is horizontally arranged on the upper side of the smashing cavity, and the left end of the first rotating shaft is connected with an output shaft of a first motor; and the second rotating shaft is horizontally arranged below the first rotating shaft, and the left end of the second rotating shaft is connected with an output shaft of a second motor. The structural design is reasonable, an arranged double-smashing device can smash medical garbage thoroughly, and the smashing efficiency is high; and arranged extruding plates fully extrude the medical garbage, so thatthe garbage is flattened, and subsequent machining can be conveniently conducted.

Owner:郑州莉迪亚医药科技有限公司

Road surface crack sealing and mending tape and preparation and construction process thereof

The invention relates to a road surface crack sealing and mending tape and a preparation and construction process thereof. The road surface crack sealing and mending tape is mainly used for processing thermal contraction cracks and partial structural cracks. The raw material formula of the road surface crack sealing and mending tapeis as follows: 50-70g of petroleum asphalt, 6-8g of 1301SBS, 8-10g of methyl methacrylate, 10-15g of butyl acrylate, 5-8g of acroleic acid, 1-2g of styrene, 10-15g of calcium carbonate, 3-5g of softening agent, 2-3g of polyester fiber, 3-4g of tackifying resin, 0.6-0.88g of benzoyl peroxide (BPO), 10-20mg of antioxidant and 24-32g of mixed solvent. The road surface crack sealing and mending tape has excellent high and low temperature resistance, the glass transition temperature can reach below minus 25 DEG C, the high-temperature flowing temperature can reach more than 180 DEG C, the breaking elongation can reach 300-400%, the peel strength can reach 3-5MPa, the road surface crack sealing and mending tape can perform the autohesion at the temperature above 10 DEG C, and the road surface crack sealing and mending tape and the road surface can be formed into a whole by the rolling compaction of wheels after the crack is bonded, thereby achieving favorable crack sealing effect. The invention can actually mend the road surface crack at a very high efficiency, thereby greatly improving the service performance of the road surface and prolonging the service life of the road surface. The invention can be simultaneously used for fast mending the cracks in asphalt and cement concrete road surfaces, and has the advantages of good mending quality and low cost.

Owner:SHANGHAI UNIV

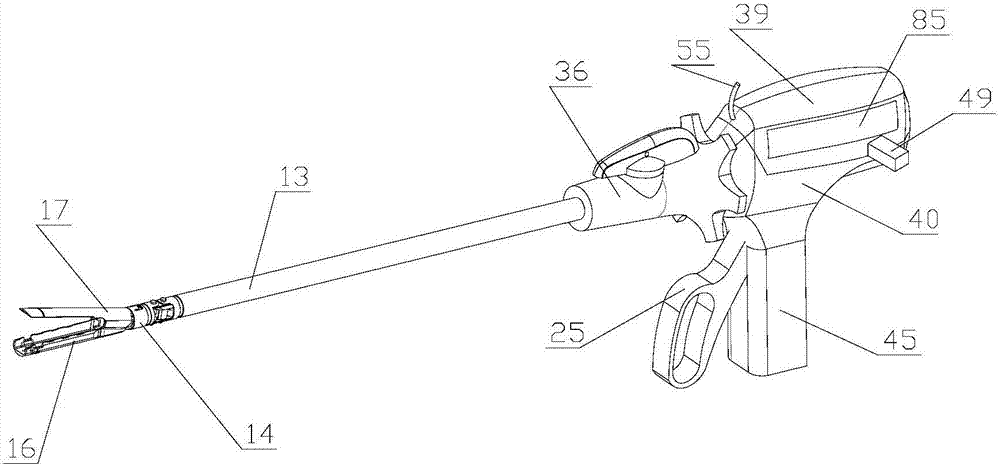

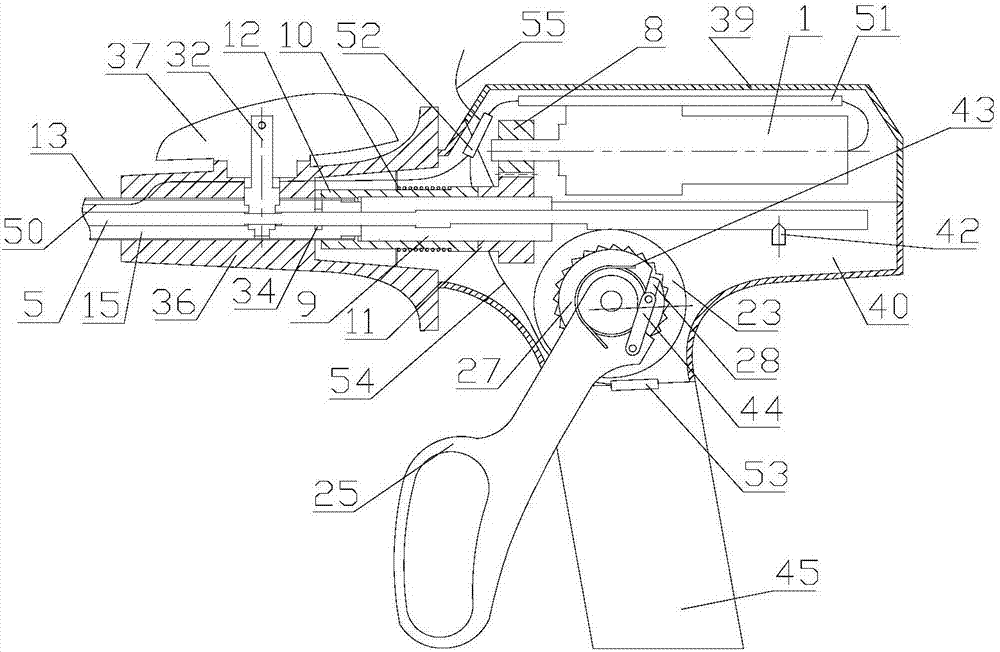

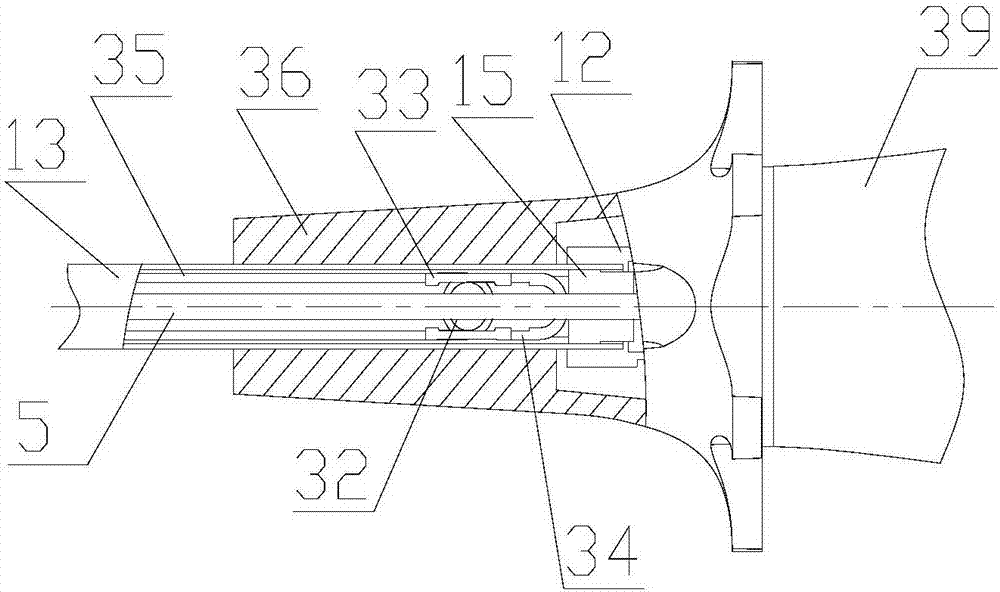

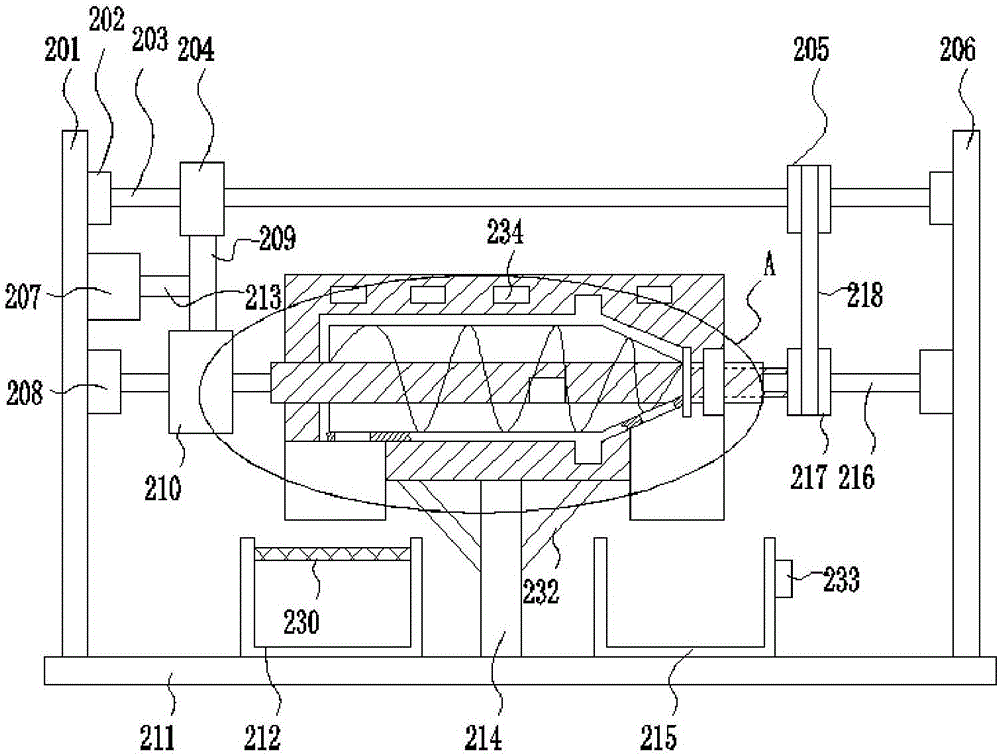

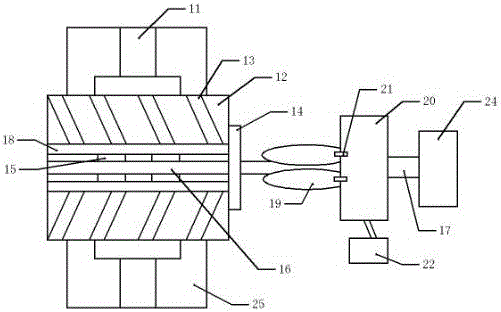

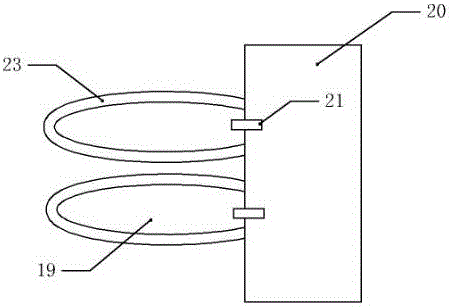

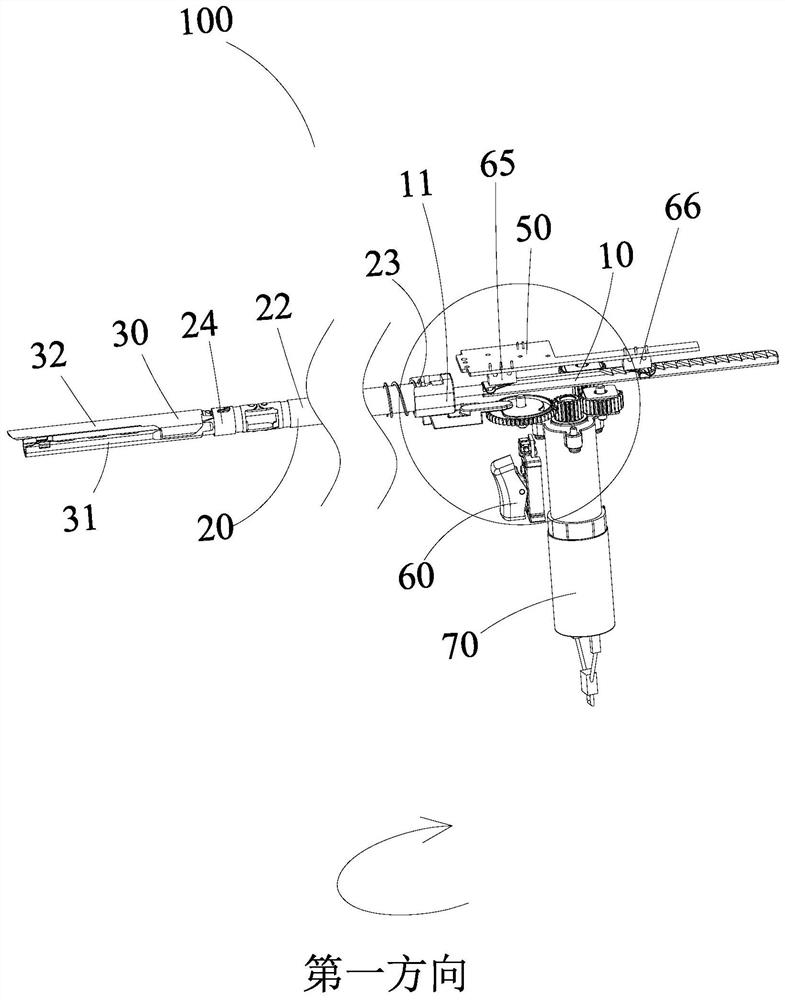

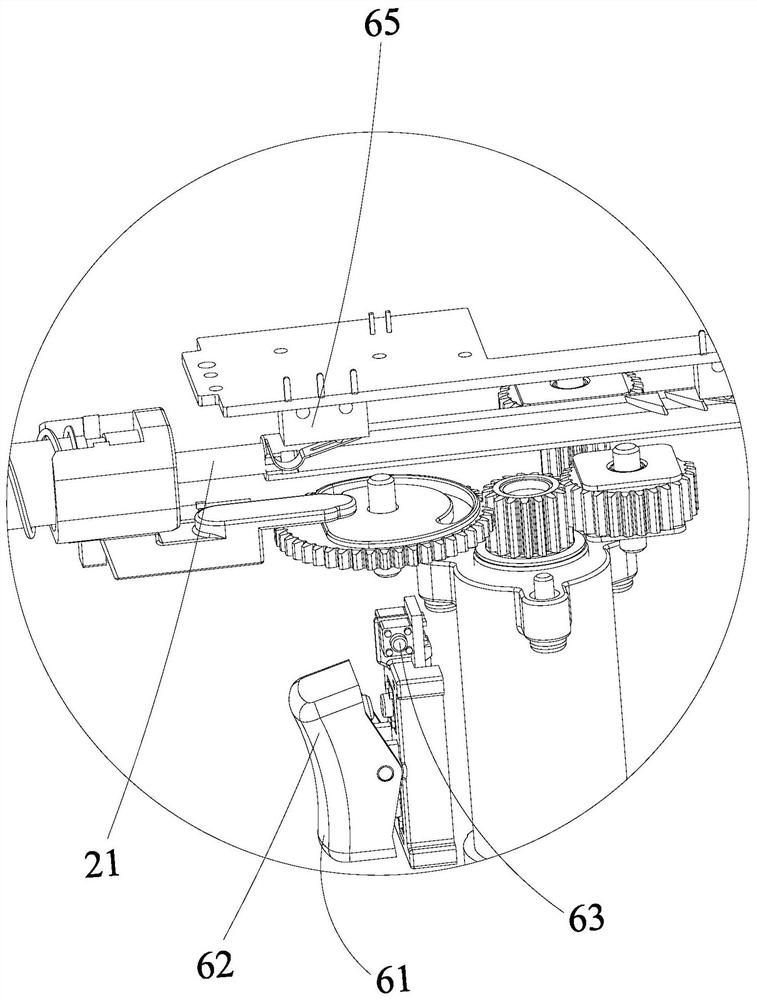

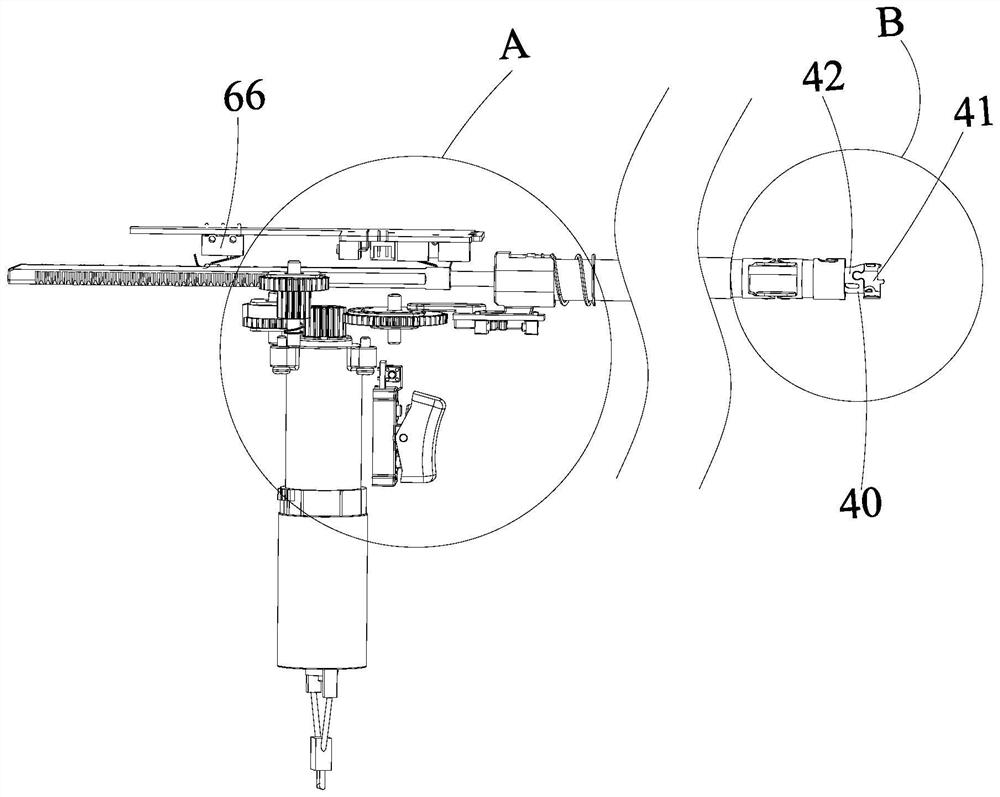

Intelligent anastomat

ActiveCN107981900AReduce subjective involvementMeet the requirementsSurgical staplesEngineeringActuator

The invention relates to an intelligent anastomat which comprises an electric clamping transmission component, a manual excision-closed transmission component, an executor steering transmission component, a nail bin support (16), a nail supporting seat (17), a short connecting pipe (14), a connecting pipe (13), a movable handle (39) and a fixed handle (40), a control module is arranged on the nailsupporting seat (17), the short connecting pipe (14) and the connecting pipe (13) are connected with the nail bin support (16) and an adjusting shell (36), the movable handle (39) and the fixed handle (40) are arranged at the rear end of the adjusting shell (36), a handle (25) and a battery (45) are connected below the fixed handle (40), and a pull-back block (49) and an external power supply line (55) are arranged on the movable handle (39). Compared with the prior art, the intelligent anastomat can really reduce subjective participation of doctors, use of the anastomat is more standardized,so that harmful effects caused by lack of experience of users are avoided, and anastomosis success rate is increased.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Kerve-free sublevel filling mining method

ActiveCN104453904ASqueeze fullyFlexible control of exposure areaUnderground miningSurface miningEngineeringOperating time

The invention provides a kerve-free sublevel filling mining method. The kerve-free sublevel filling mining method specifically comprises the following steps: dividing sublevel chambers and splitting ore blocks, carrying out mining preparation and cutting engineering arrangement, carrying out kerve explosion, firstly carrying out extraction and filling operation of splitting ore blocks, carrying out extrusion groove explosion to form a cutting groove during extraction of adjacent ore blocks, utilizing a compensation space formed by extrusion explosion to carry out normal explosion extraction operation, after the extraction of a second splitting ore block, entering the next adjacent splitting ore block, forming the cutting groove through extrusion groove explosion, carrying out extraction, and cycling the extraction process of the adjacent ore blocks. Kerve-free explosion is adopted from the second splitting ore to form a stope cutting groove; compared with a normal cutting kerve method, the engineering of cutting a level and cutting a dooryard is eliminated, the operating time is reduced, the stope extraction period is reduced, the mining operation cost is reduced, the stope labor efficiency is improved, the method is suitable for mining ore deposits with poor stability of surrounding rock, and stope top base plate and hanging side surrounding rock collapse can be effectively controlled.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

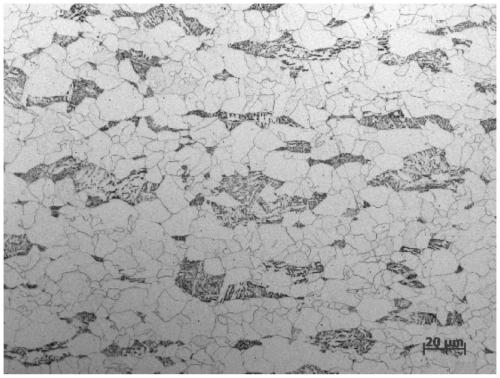

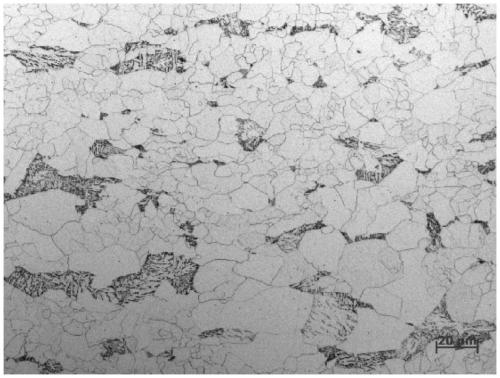

Large-wall-thickness X52MS acid-resistant pipeline steel plate produced by LF-RH refining process and manufacturing method thereof

The invention relates to a large-wall-thickness X52MS acid-resistant pipeline steel plate produced by an LF-RH refining process. The steel plate is characterized by being manufactured from the following chemical component percentage by weight: 0.03%-0.07% of C, 0.2%-0.4% of Si, 1.0%-1.4% of Mn, 0.02%-0.04% of Al, 0.02%-0.05% of Nb, less than or equal to 0.02% of V, 0.004%-0.012% of Ti, 0.1%-0.4% of Cr, 0.1%-0.2% of Mo, less than or equal to 0.0005% of B, less than or equal to 0.012% of P, less than or equal to 0.001% of S, less than or equal to 0.005% of [N], less than or equal to 0.005% of [O], less than or equal to 0.0015% of [H] and the balance being Fe and inevitable impurities, wherein the cold crack sensitivity coefficient Pcm is less than or equal to 0.19. The manufacturing method comprises the sequential steps of KR molten iron pretreatment, converter smelting, LF and RH refining, plate blank continuous casting, plate blank heating, rough rolling, intermediate blank cooling, finish rolling, ACC cooling and the like. The manufactured steel plate has thickness being 35.1-44.2 mm, yield strength being 380-440 MPa, tensile strength being 490-570 MPa, and elongation being greater than or equal to 33%, yield ratio being less than or equal to 0.09; an average shear plane ratio of drop hammer under the temperature of minus 5 DEG C is 85% or more; and the large-wall-thickness X52MS pipeline steel can meet the requirement of being used in an acidic environment, and has good HIC resistance and low-temperature toughness.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

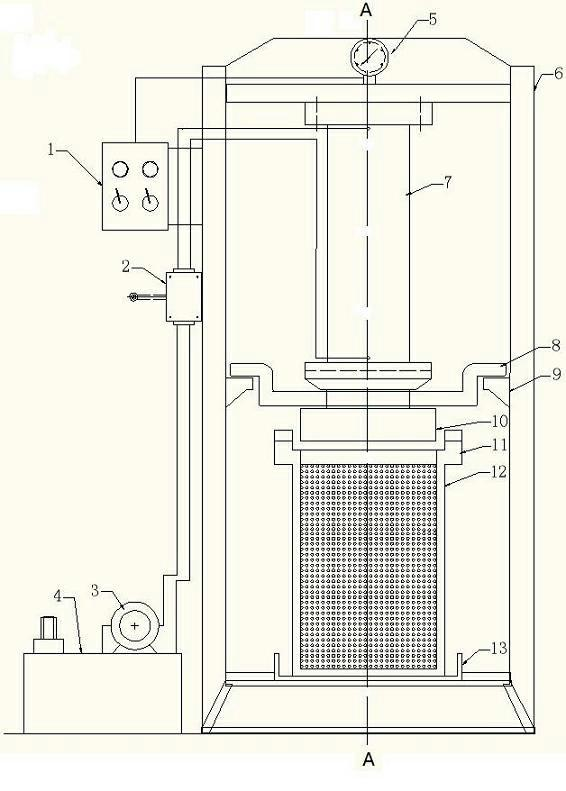

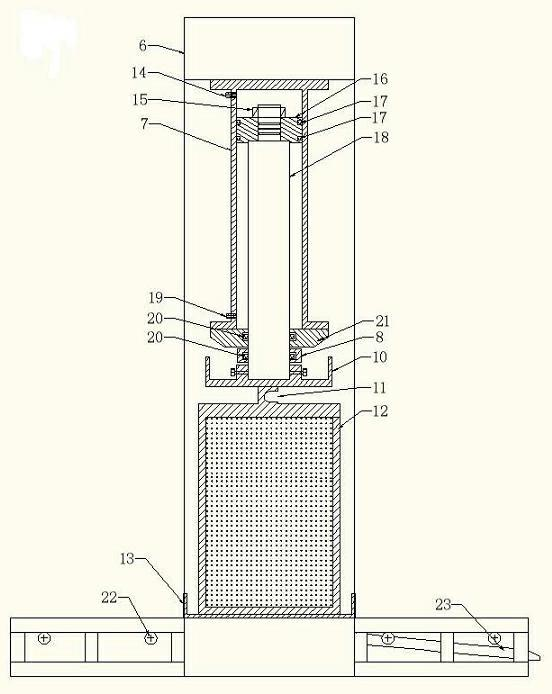

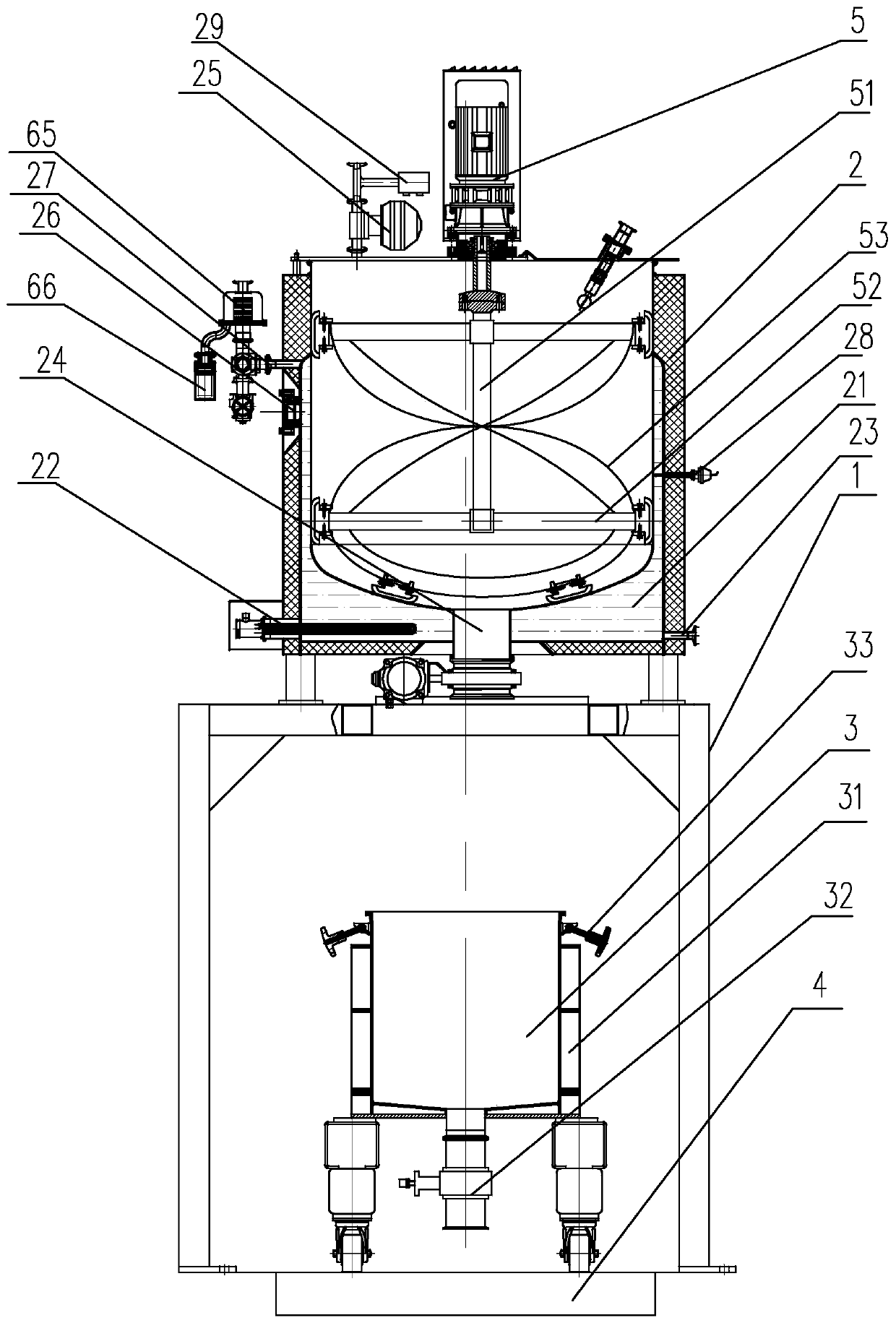

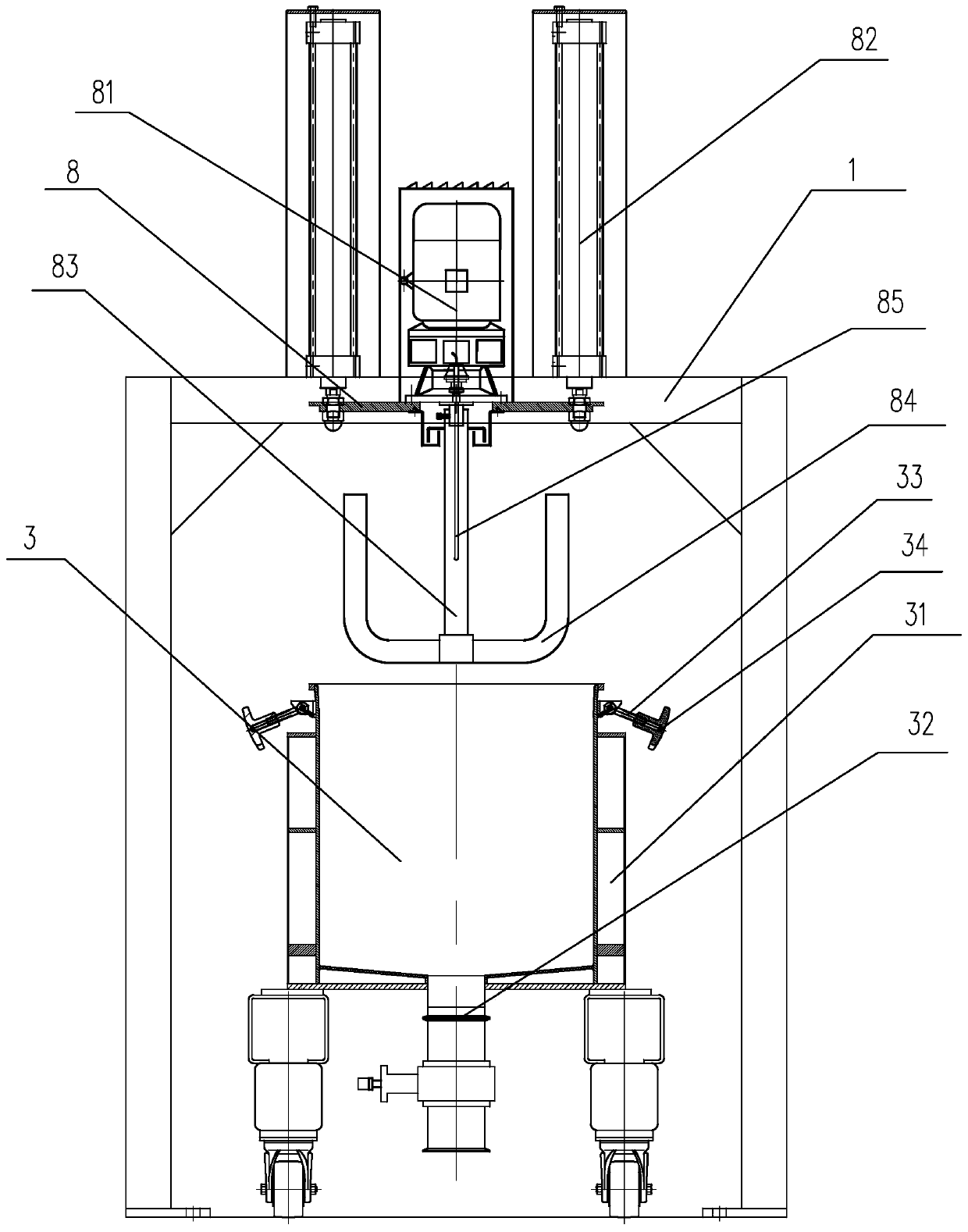

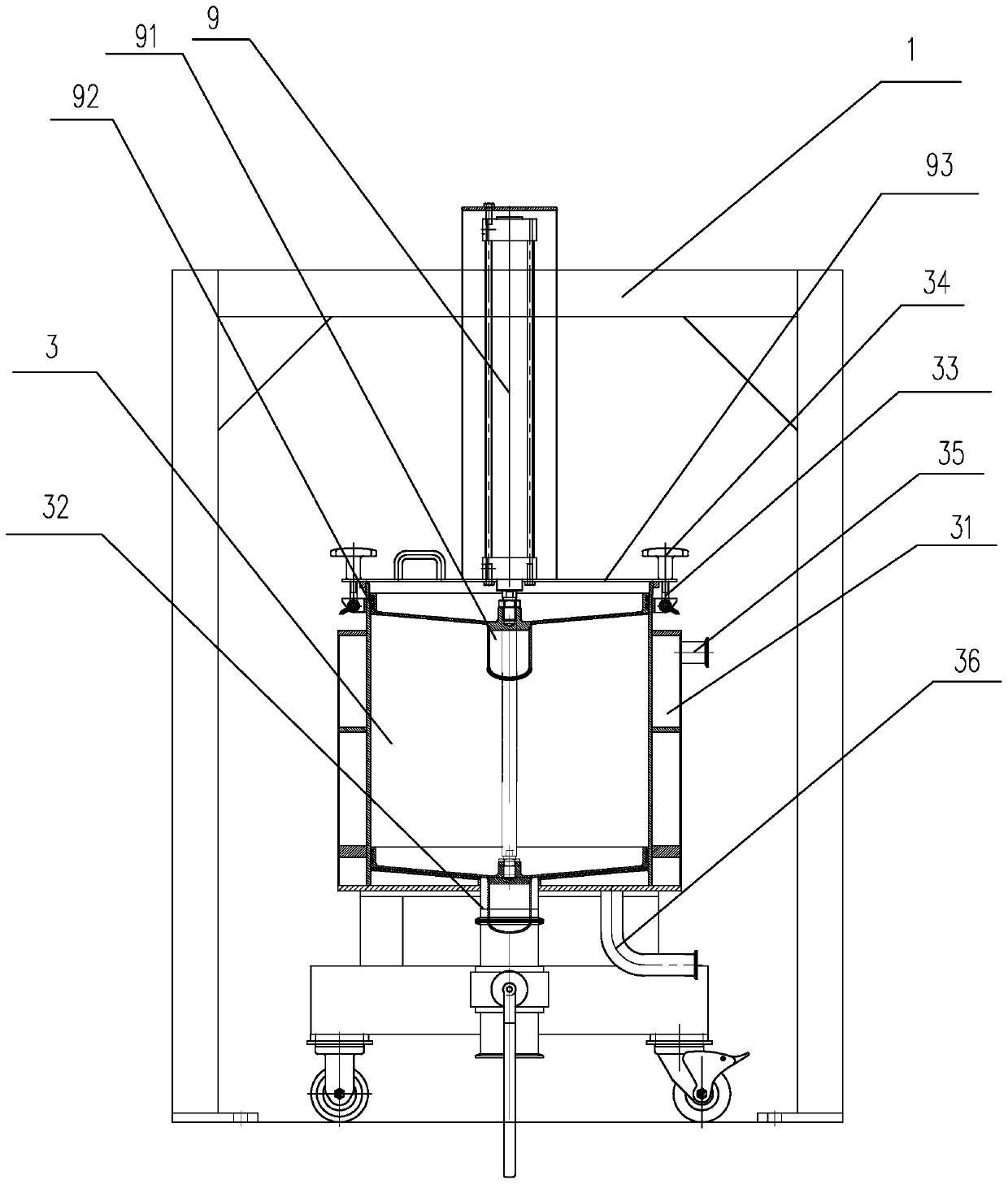

Vertical microporous oil press and control device thereof

The invention relates to a vertical microporous oil press and a control device thereof. The vertical microporous oil press comprises a frame erected on the horizontal ground, a cylinder in a hydraulic system is fixed to the center of the upper portion of the frame, a connector at the upper end and a connector at the lower end of the cylinder are connected with a manual reversing valve through pipelines, a shock-proof pressure gauge with electric contact of a control device is mounted at another connector which is arranged at the upper end of the cylinder, a squeezing drum which is a hollow drum is arranged on the lower portion of the cylinder, two hooks are welded to an opening of the drum, and a plurality of oil micropores are uniformly distributed all over the wall of the squeezing drum. The vertical microporous oil press and the control device thereof have the advantages that firstly, manual caking is not needed so that efficiency is improved; secondly, since no caking is needed, wrappers such as straws and the like are not needed, and the sanitation requirement can be better met; thirdly, the squeezing pressure is fed back to a programmable controller through electric contact pressure signals, and the squeezing pressure can be protected within a normal range to avoid accidents; and fourthly, seeds are directly squeezed during squeezing so that the cake ring problem is avoided, the squeezing pressure of the vertical microporous oil press is larger than that of traditional oil presses, squeezing is more thorough, and oil yield is evidently improved.

Owner:常德市恒德机械制造有限公司

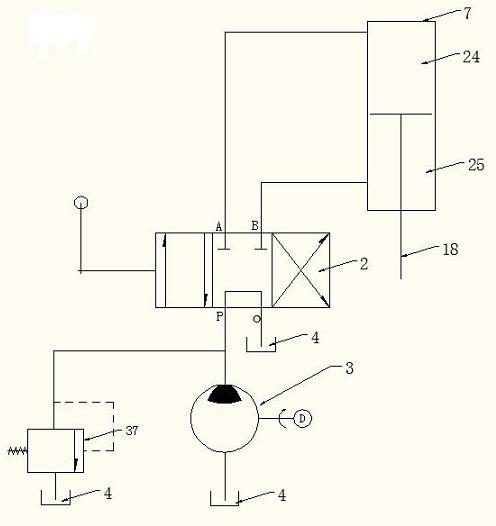

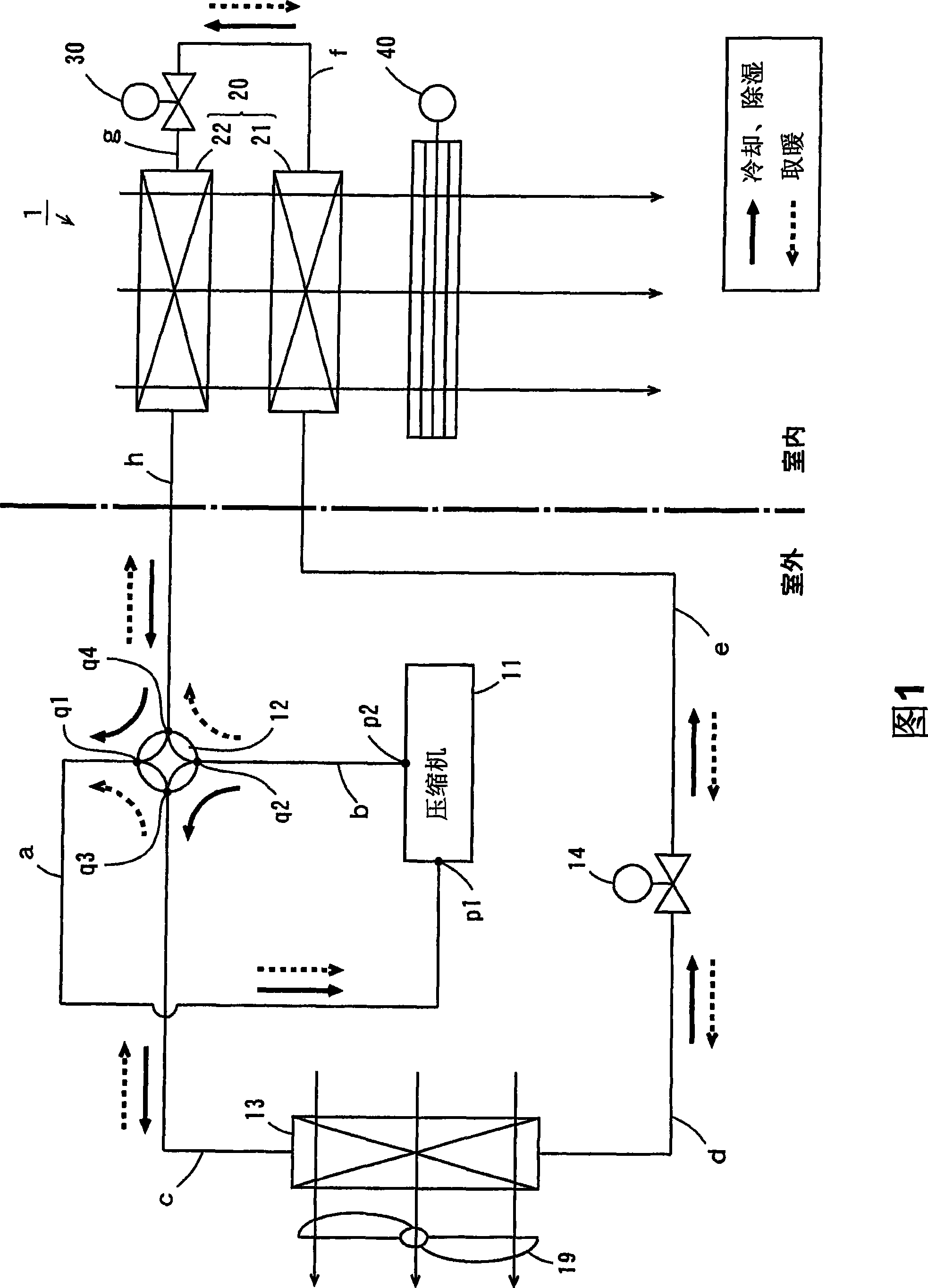

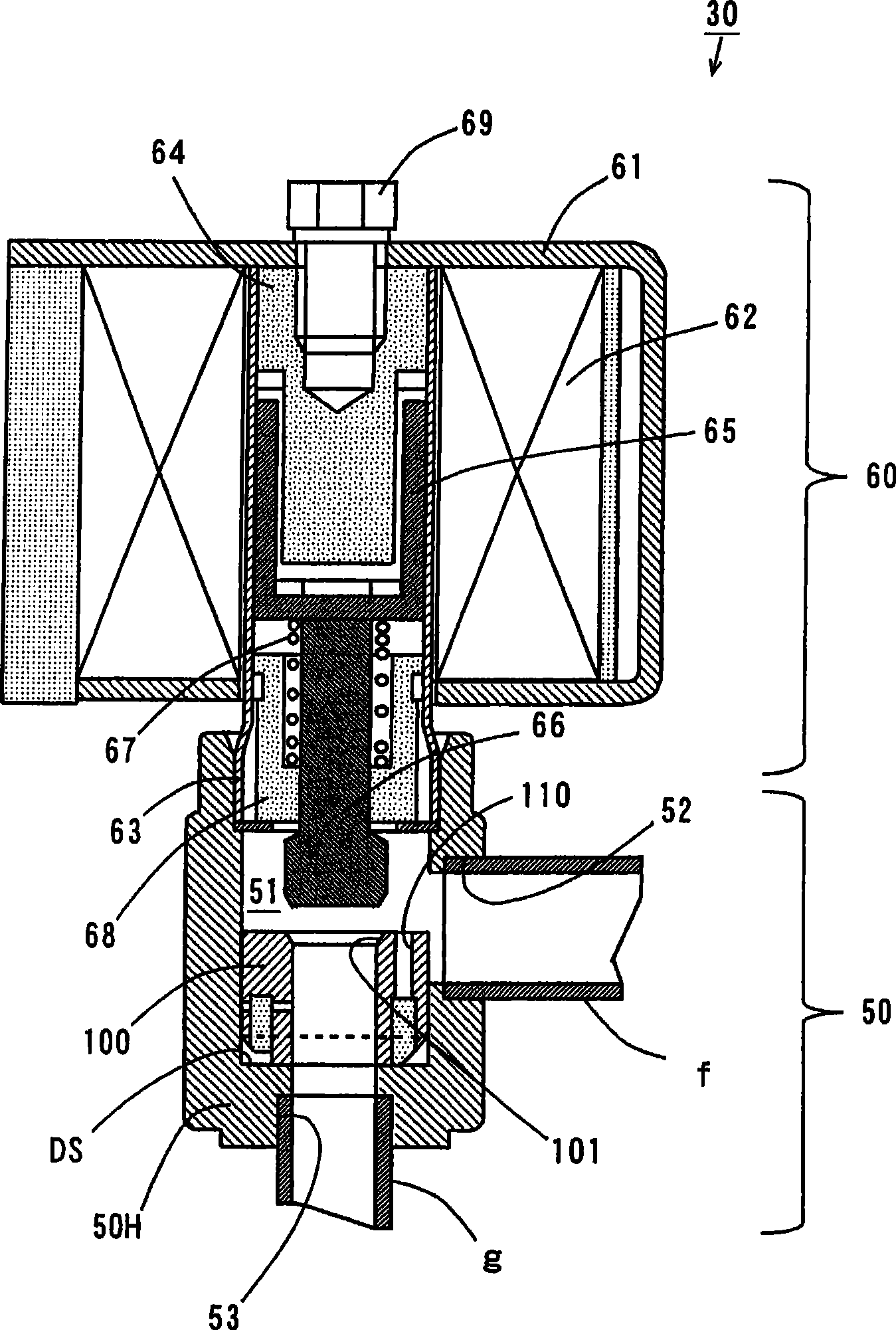

Valve device and air regulator equipped with the same

InactiveCN101441012AReduce flow soundSqueeze fullyOperating means/releasing devices for valvesCompression machines with non-reversible cycleInterior spaceEngineering

The invention provides a valve device and an air adjustor for the valve device. An indentation in the use of dry-type valve installed in the valve chamber in the upper parts of the valve seat within the department of weeks the Ministry of the edge of the formation of the valve seat. The components in the valve seat inside the walls of the upper part of the department of forming a vertical hole. The components in the valve seat inside the walls of the lower part of the department of the formation of the first and second filter port space. The vertical hole, as well as the first filter port connected space. The components in the seat bottom peripheral edge of the department of chamfering processing through the conical surface forming a ring. The components in the valve seat surface within weeks of the provisions of the location of the valve seat forming a part connected to the internal space and the second space filter through the port hole.

Owner:PANASONIC CORP

Efficient and rapid squeezing and extracting device for traditional Chinese medicinal materials

The invention provides an efficient and rapid squeezing and extracting device for traditional Chinese medicinal materials. The efficient and rapid squeezing and extracting device for traditional Chinese medicinal materials comprises a bottom plate, a recovery device, a squeezing device, a discharging device, a frame device, a crushing device and a positioning device. A first supporting rod, a first support, a first cross rod, a second supporting rod and a third supporting rod are arranged on the bottom plate. The recovery device comprises a recovery box, first bent rods and first springs. The squeezing device comprises a feeding hopper, a first frame, a first filter screen, a vibrator, a second support, a transverse plate and idler wheels. The discharging device comprises a discharging frame, a baffle, a blocking block, a third spring and a handheld rod. The frame device comprises a second frame, an oblique plate, a sealing plate, a fixed block, a second spring, a movable block, a shielding block and a handheld block. The crushing device comprises an electric cylinder, a third support, a pushing rod, a positioning block and a pressing block. The positioning device comprises a vertical rod, a positioning frame, a second cross rod and a fourth spring located under the vertical rod. The efficient and rapid squeezing and extracting device can effectively squeeze traditional Chinese medicinal materials for liquid preparation, and the liquid preparation efficiency is high.

Owner:SHANDONG KONGFU PHARMA

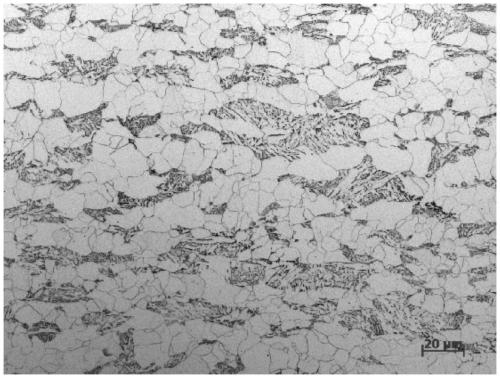

Method for manufacturing high carbon chromium bearing steel

ActiveCN110777300AImprove original tissue morphologyReduce segregationCondensation processMolten steel

The invention relates to a method for manufacturing high carbon chromium bearing steel, and belongs to the field of steel manufacturing. The method comprises the following steps that electromagnetic stirring at the head end and electromagnetic stirring at the tail end are separately carried out in the process of molten steel crystallization, the total amount of reduction in the soft reduction zoneis controlled at the tail end of molten steel solidification, then, a slab is heated in a heating furnace, the temperature of the core and surface of the slab is homogenized, so that a segregation structure in the slab is effectively diffused, and the slab is subjected to be rolled directly after being discharged from the furnace. In the example, the condensation process of the molten steel, theheating process of the slab in the heating furnace and the rolling process can be selectively adjusted, so that the cold working performance and hot working performance of the obtained steel are improved and the fatigue life of the bearing is also prolonged.

Owner:BAOSTEEL SPECIAL STEEL SHAOGUAN CO LTD

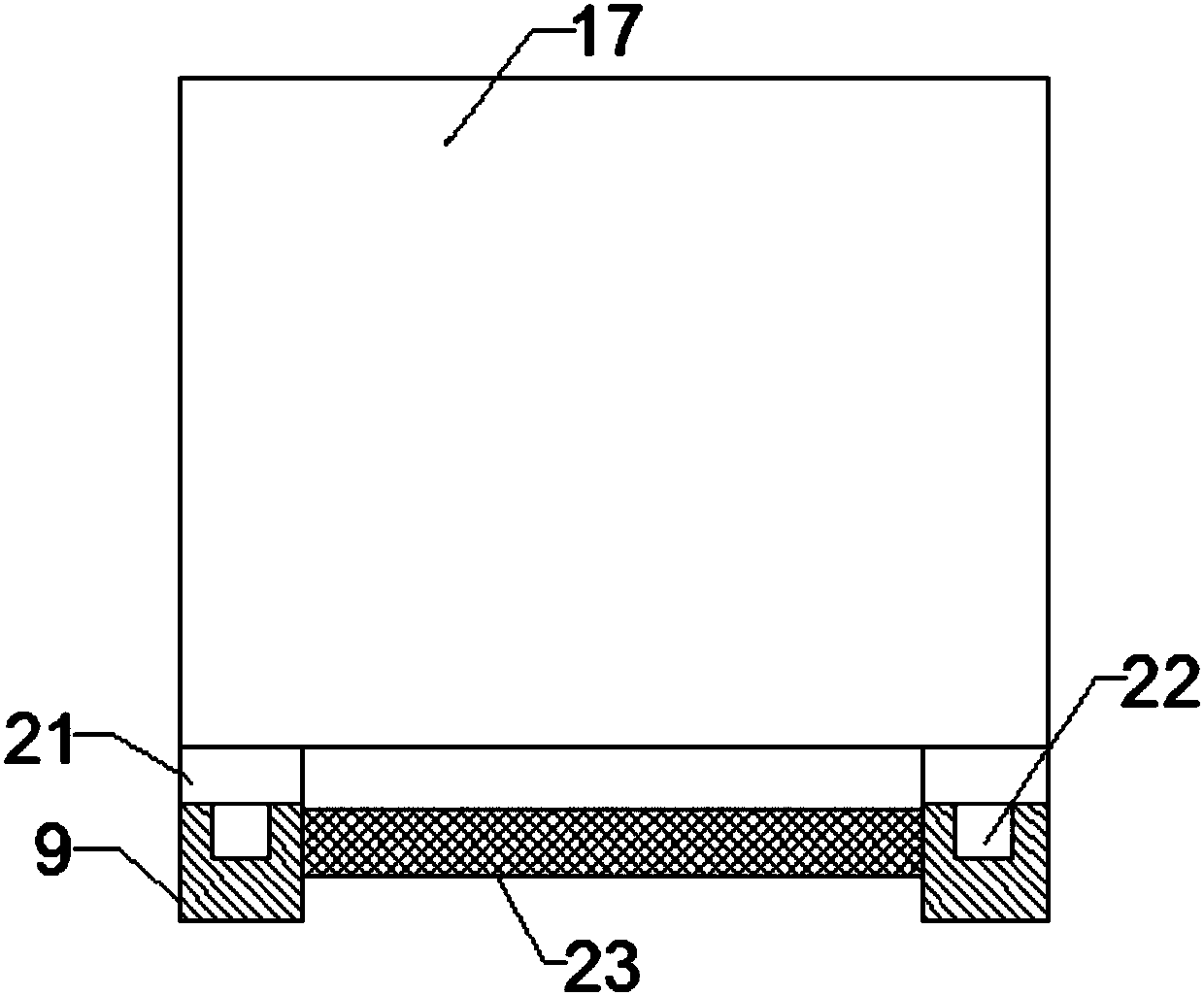

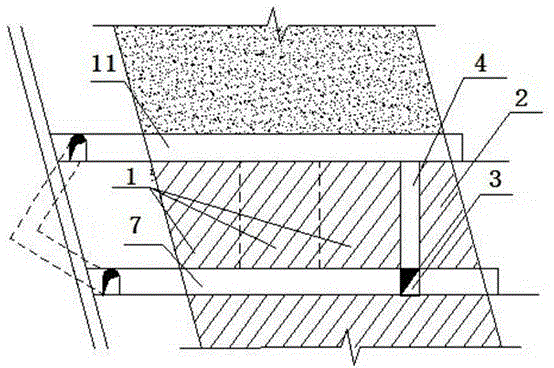

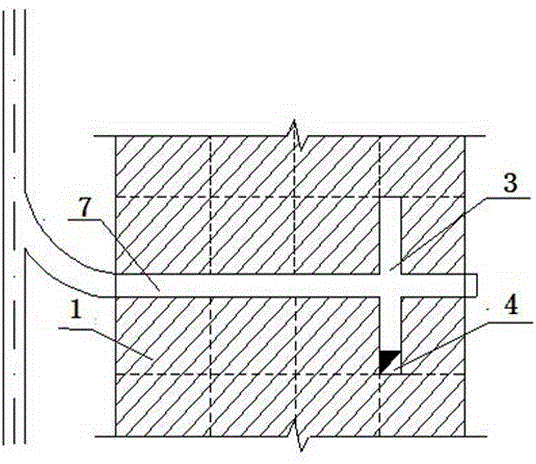

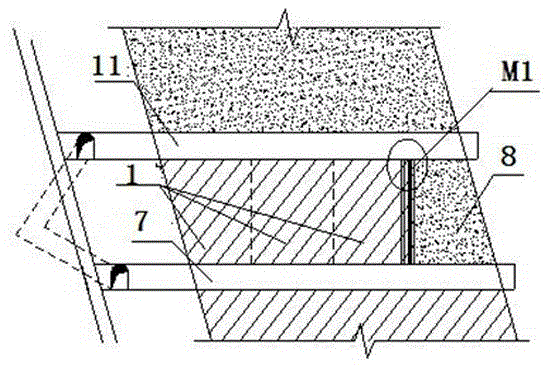

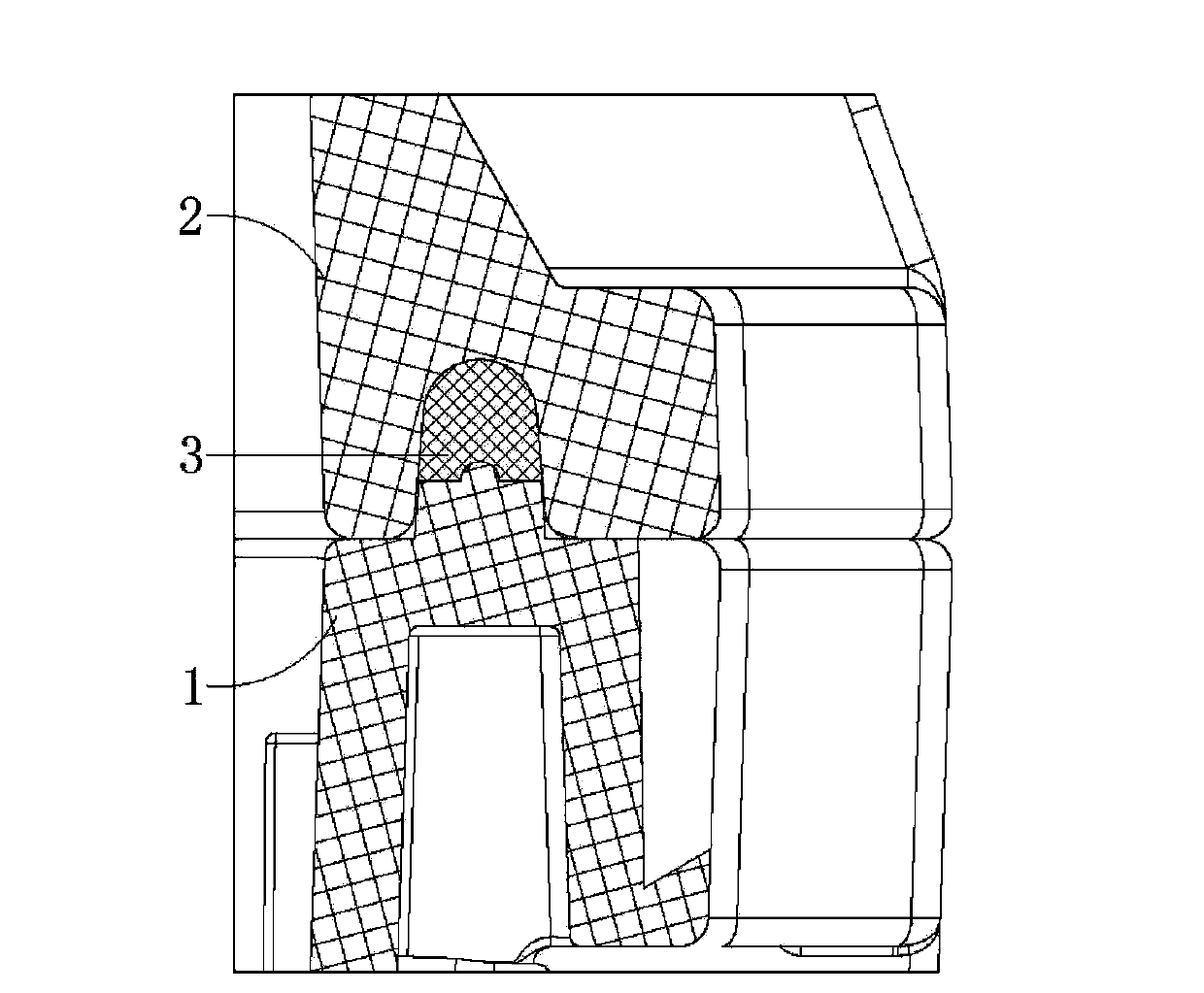

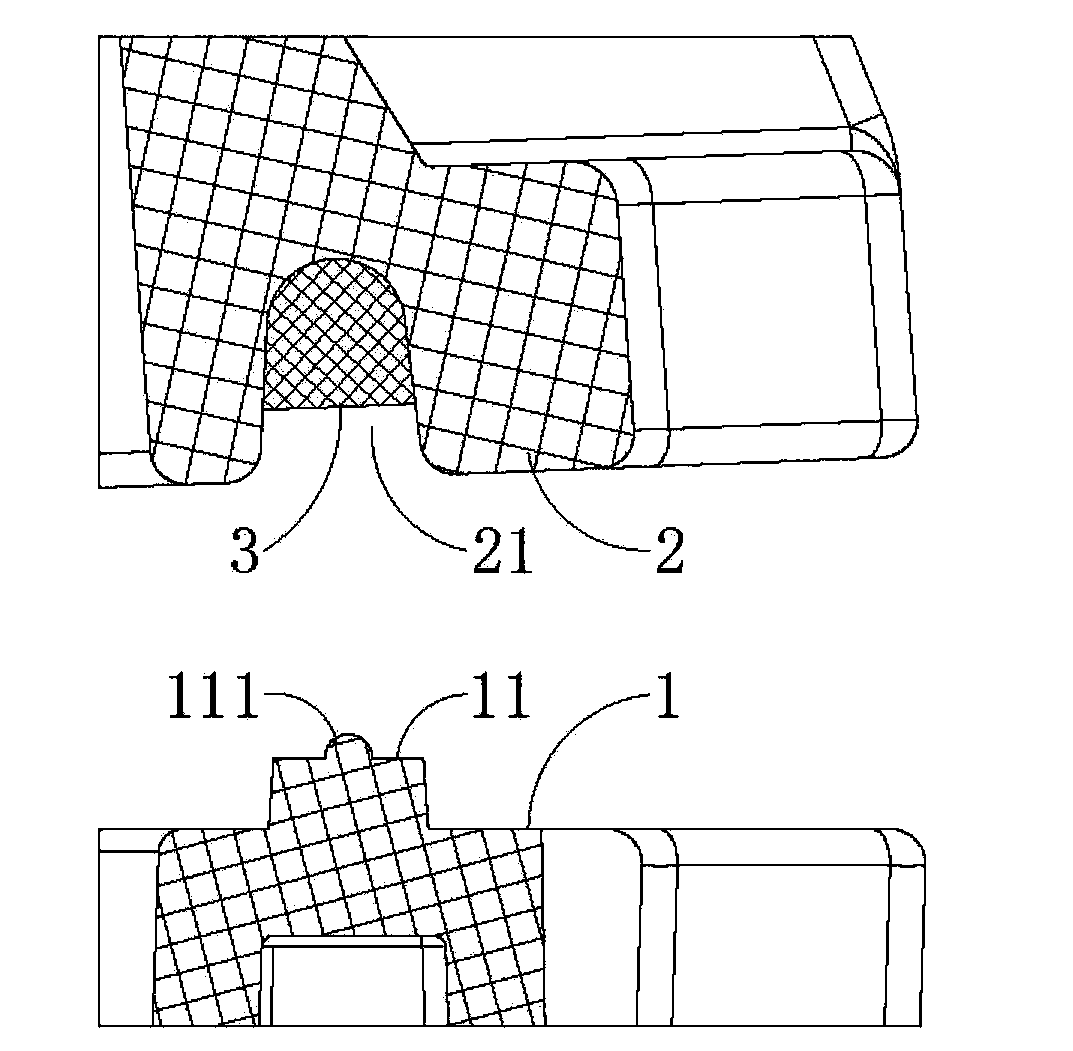

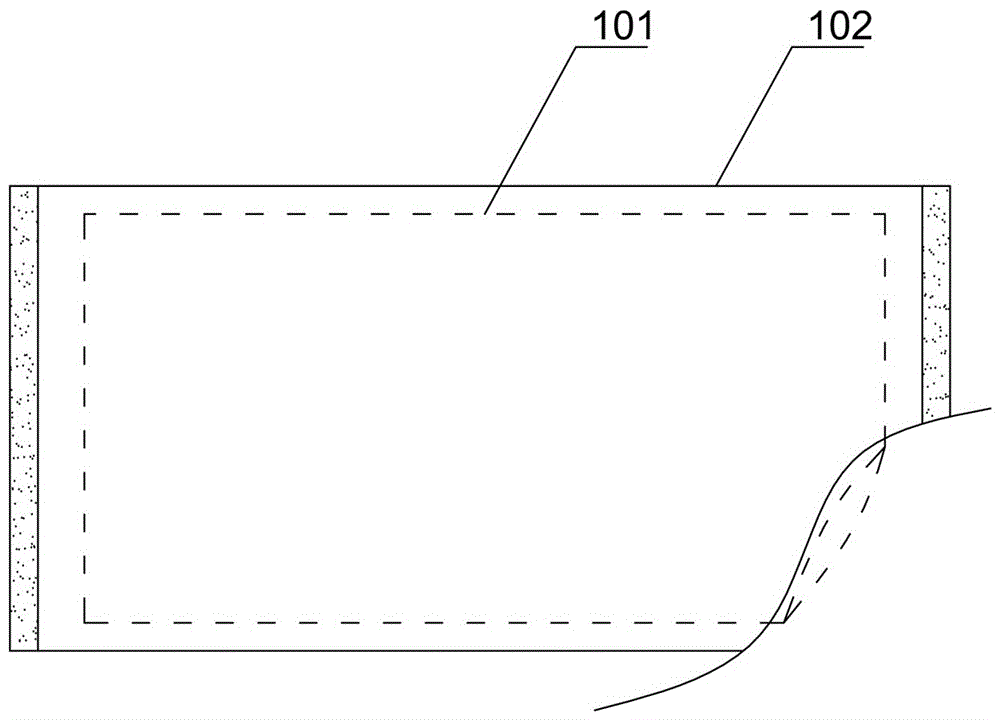

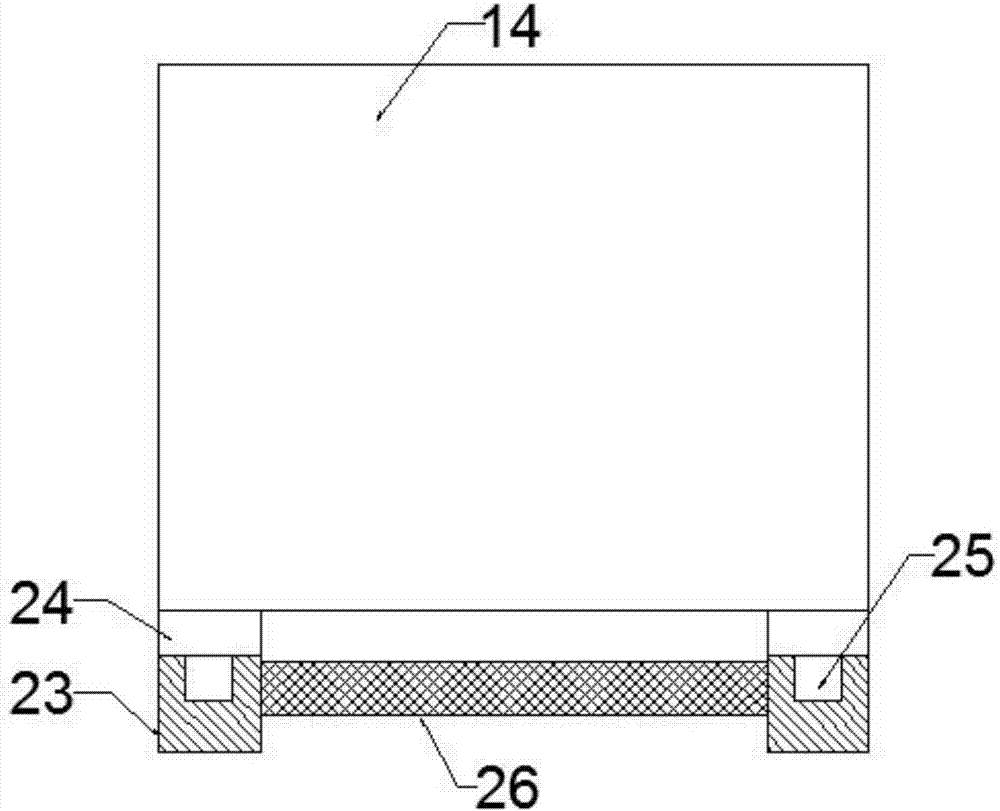

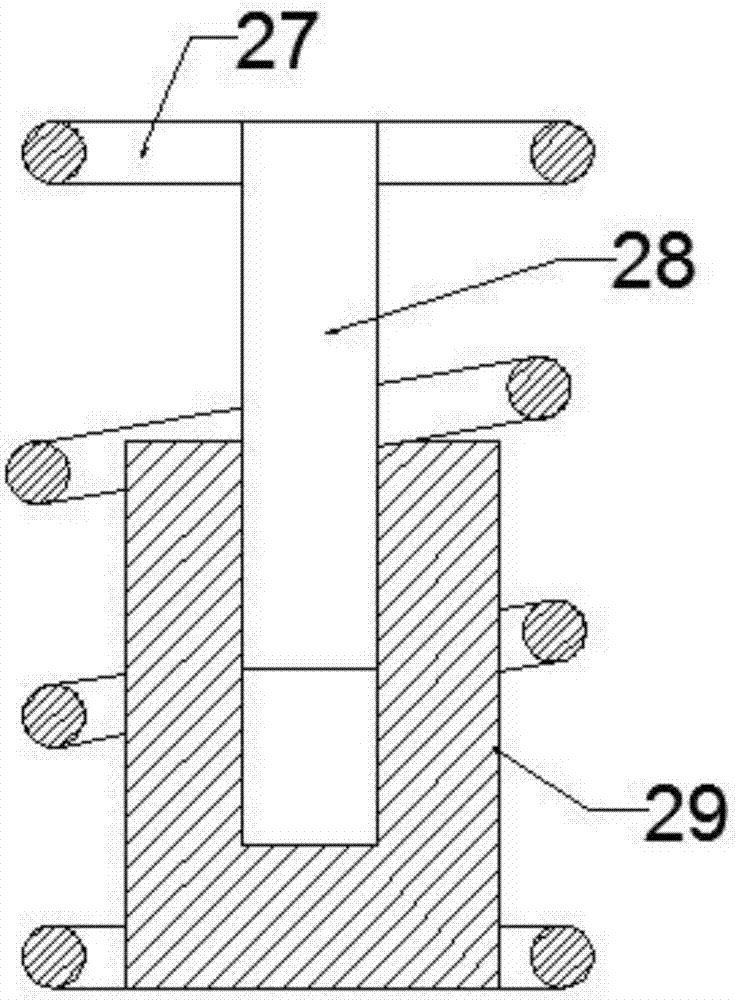

Sealing box and box body sealing structure thereof

The invention provides a box body sealing structure. The box body sealing structure comprises a box body, a box cover and a seal ring, wherein the box body is covered with the box cover, and the seal ring is arranged on the junction surface of the box body and the box cover. The box body is matched with the box cover through an annular groove and an annular flange, the seal ring is arranged in the annular groove, and the annular flange is connected into the annular groove in a mortise joint mode and squeezes the seal ring. The annular groove is formed in the box cover or the box body, and the annular flange is arranged on the box body or the box cover. An annular protrusion which abuts against the bottom of the seal ring is further arranged on the annular flange, the cross section of the annular protrusion is in a semicircular shape, chamfers are arranged on the annular groove and the annular flange respectively, and the bottom of the annular groove is in an arc shape. The sealing structure is simple in structure and good in sealing performance, and the problem that the sealing effect is not good due to the fact that dislocation of the junction surface occurs when the box body is covered with the box cover is effectively solved. The invention further provides a sealing box. The sealing box comprises the box body and the box cover, the sealing structure is adopted between the box body and the box cover, and the box body is fixedly connected with the box cover in a mode that hooks are arrange on the periphery.

Owner:SHENZHEN OCEANS KING LIGHTING ENG CO LTD +1

Preparation device of fructus hippophae juice

The present invention discloses a preparation device of a fructus hippophae juice. The preparation method comprises a squeezing device, a horizontal screw centrifuging device, a concentrating device and a filling device. A material outlet of the squeezing machine is connected with a material inlet of the horizontal screw centrifuging machine; a material inlet of the concentrating device is located at the lower part of a liquid collecting box of the horizontal screw centrifuging machine and a material inlet of the filling device is connected to a material outlet of the concentrating device; and the horizontal screw device comprises a horizontal screw main body, a rotary drum and a screw inside, a material feeding tube with a material inlet, a speed reduction motor, a liquid collection tank, and a residue discharge port and a pressure sensor arranged on the residue discharge port used for controlling the outflow of the residues. The device can effectively remove pectin and fibers in the fructus hippophae juice and realizes the automatic production of the fructus hippophae juice.

Owner:新疆慧华沙棘生物科技有限公司

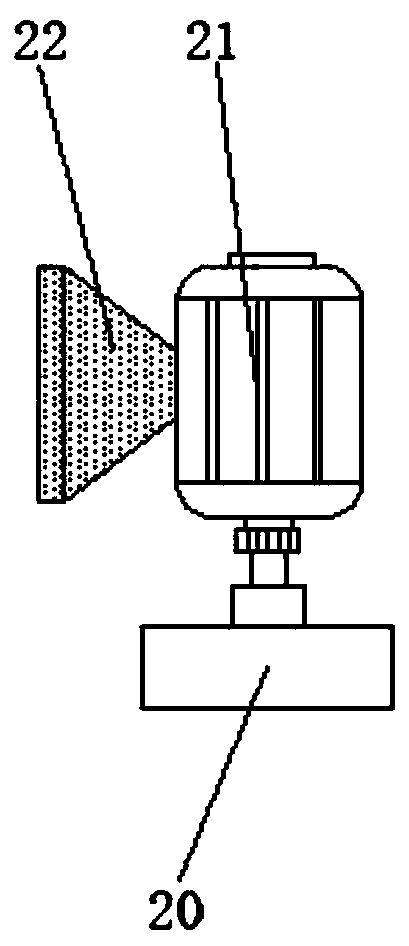

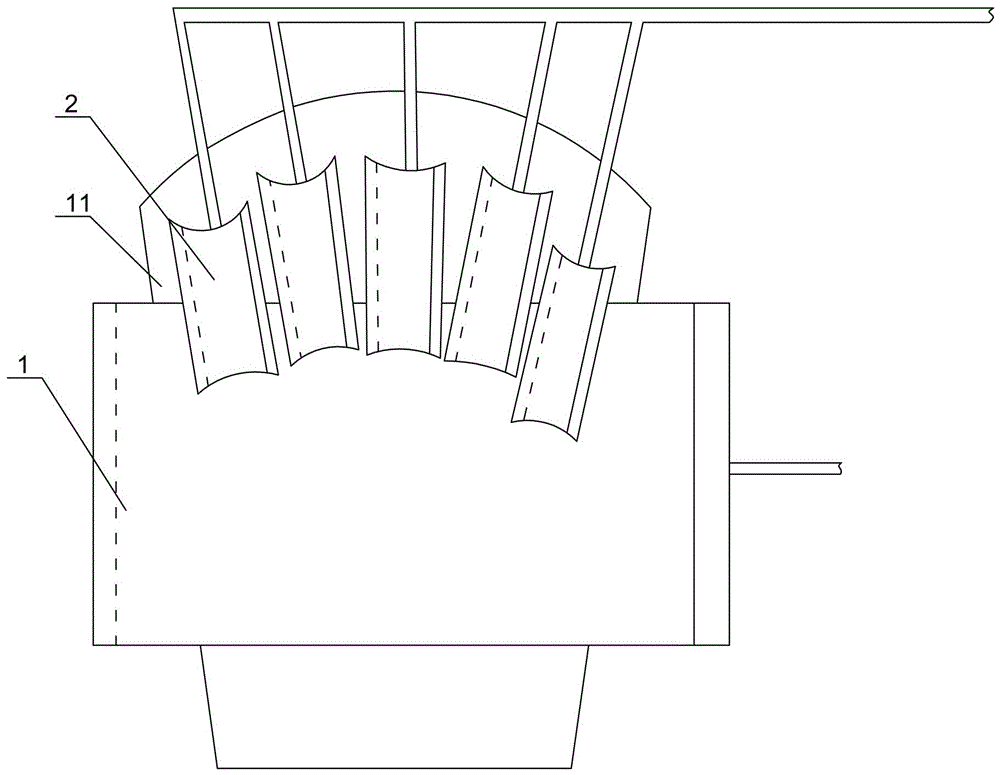

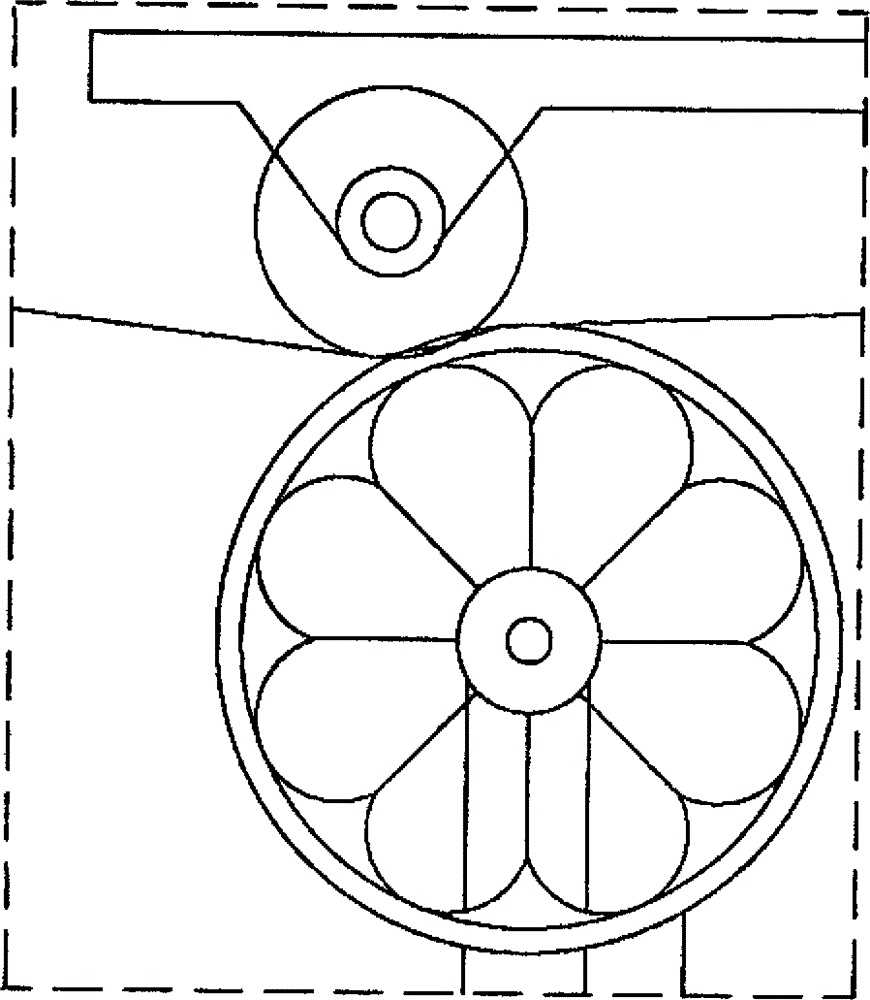

Novel squeezing device for tea oil processing

InactiveCN109094082ASimple structureEasy to useFatty-oils/fats productionPressesAgricultural engineeringOil processing

The invention discloses a novel squeezing device for tea oil processing. The novel squeezing device comprises a shell, and one side of the shell is fixedly connected with a driving box. A grinding binand an extruding bin are formed in the shell, and a motor box is arranged at the top of the shell. A first motor is arranged in the motor box, and a rotary shaft of the first motor is in transmissionconnection with one end of a connecting rod. According to the novel squeezing device for tea oil processing, tea seeds are ground through the grinding bin firstly, the ground tea seeds enter the extruding bin through a discharging channel and extruded in the extruding bin, and then tea oil is filtered through a filter net and discharged through an oil outlet; meanwhile, cooling water is pumped into the shell through a water inlet, the device is cooled, and influences of heat generated in the squeezing process on the quality of the tea oil are prevented; and the whole device is simple in structure and convenient to use, the tea seeds are squeezed more thoroughly, the oil yield is increased, the situation that in the squeezing process, the temperature of the tea oil is too high is avoided,and thus the quality of the tea oil is ensured.

Owner:湖南省阳雀湖农业开发有限公司

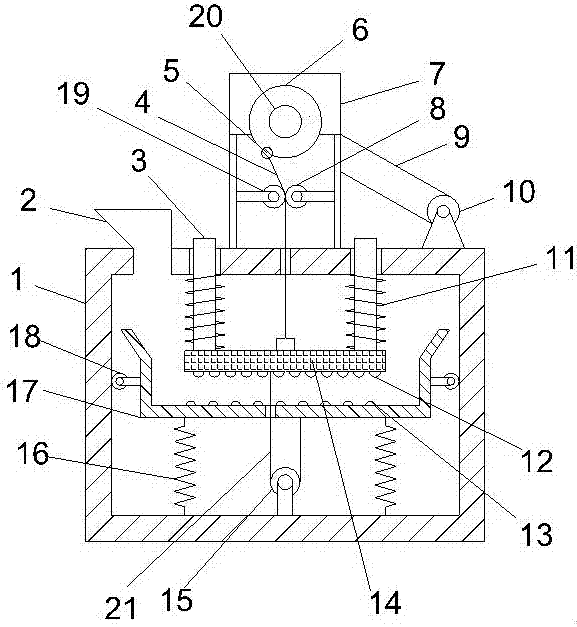

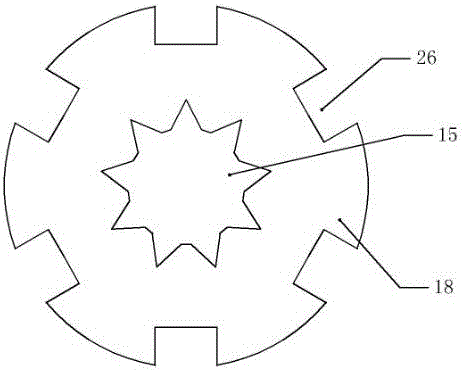

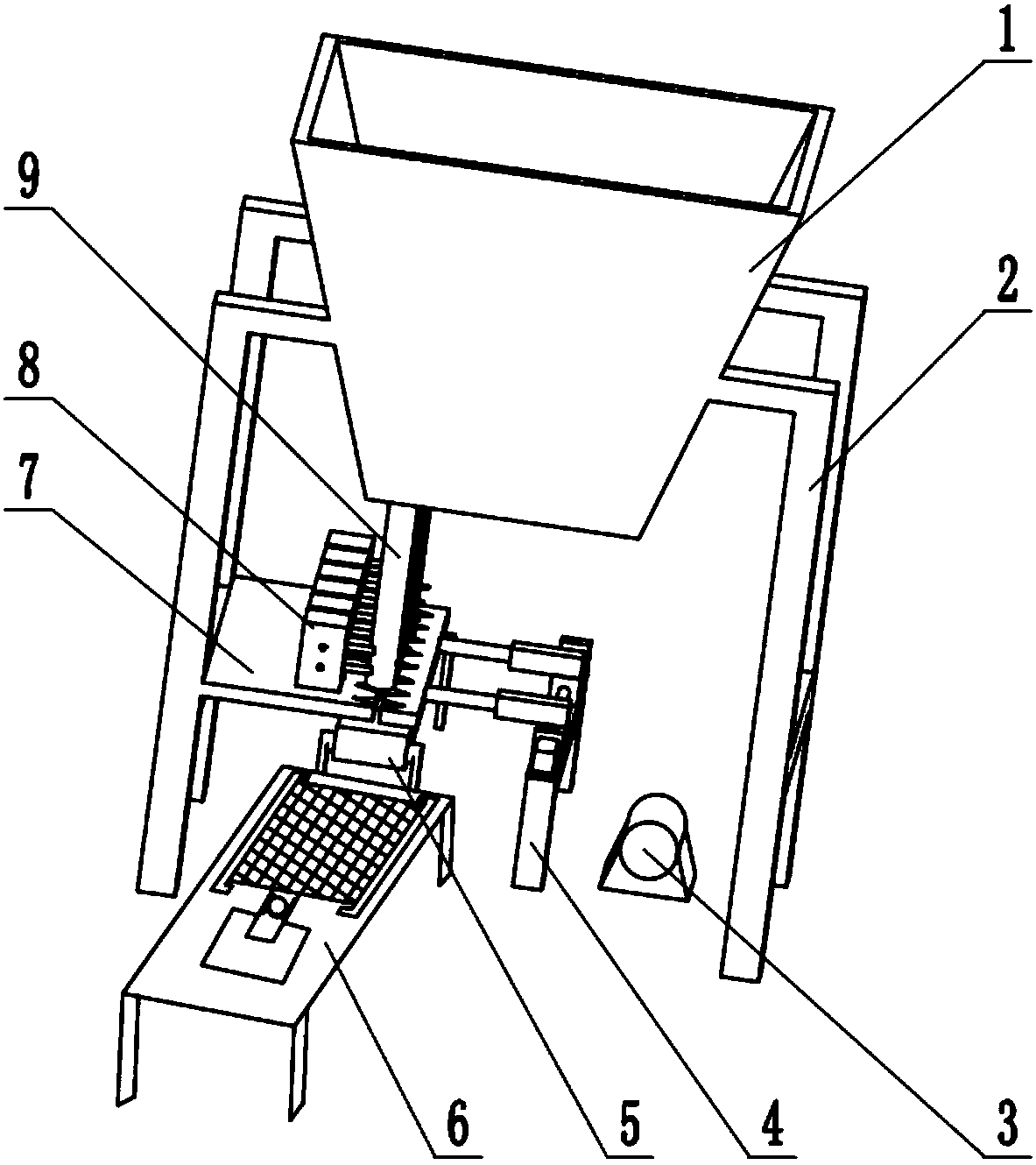

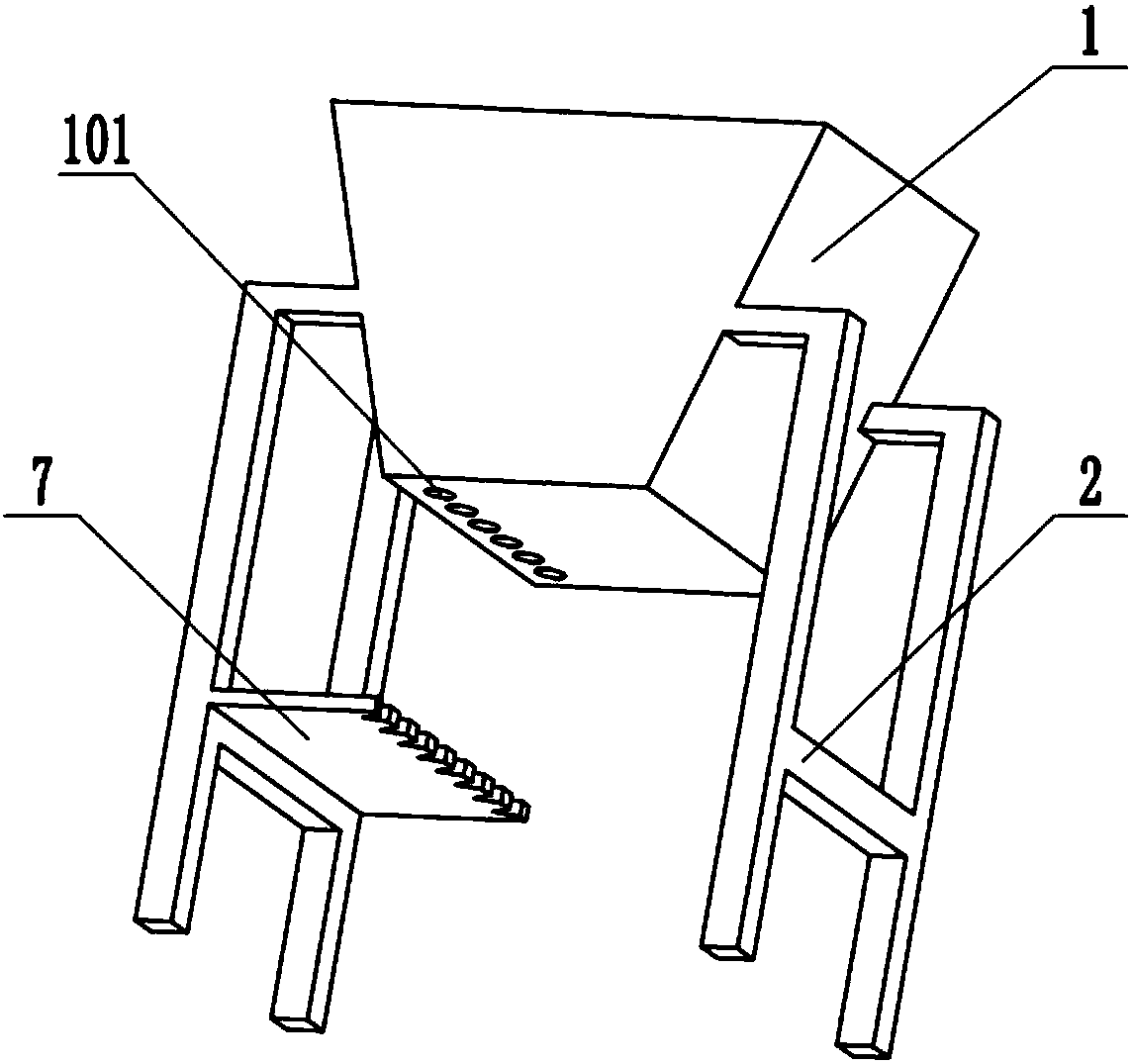

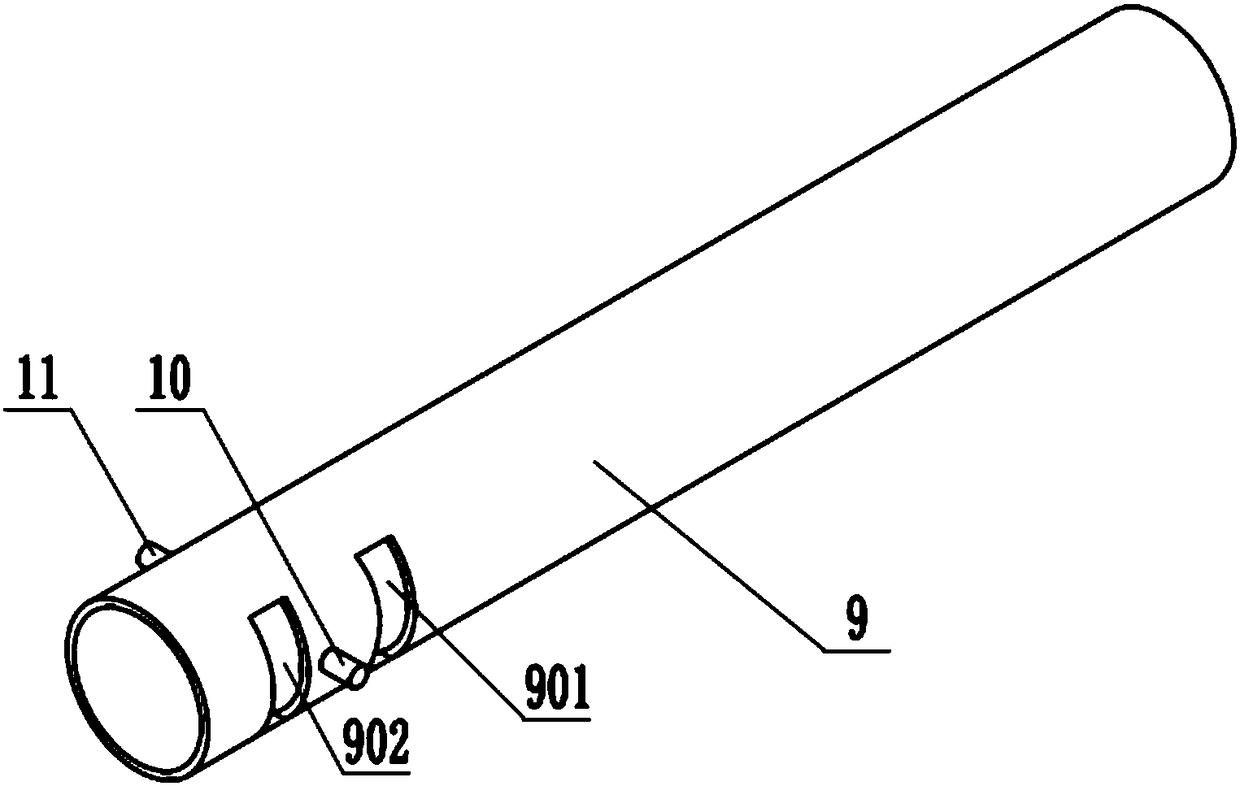

Cereal grain extruding and crushing device

InactiveCN107377063ASqueeze fullyFully brokenNon-rotating vibration suppressionGrain treatmentsEngineeringCereal grain

A grain grain crushing device, comprising a main body, characterized in that a loading frame is arranged in the body, guide pulleys are fixedly installed on the left outer wall and the right outer wall of the loading frame, and the inner bottom of the loading frame Several lower pressing blocks are evenly arranged, two return springs B are arranged inside the body, a pressure plate is arranged inside the body, two sliding columns are vertically arranged on the pressure plate, and a return spring A is set on the sliding column, A second wire rope is wound around the reversing pulley, a door-shaped bracket is fixedly installed on the body, a runner is installed on the door-shaped bracket, and the lower end of the first wire rope is fixedly installed on the pressing plate; the grains located inside the loading frame are fully squeezed. Pressure, return spring A and return spring B not only provide force for crushing the grain, but also play a good role in buffering and shock absorption, and at the same time promote the uniform dispersion of grain particles in the loading frame, the crushing process is stable and efficient, and the grain crushing is more efficient. full.

Owner:盐城千之诺机械有限公司

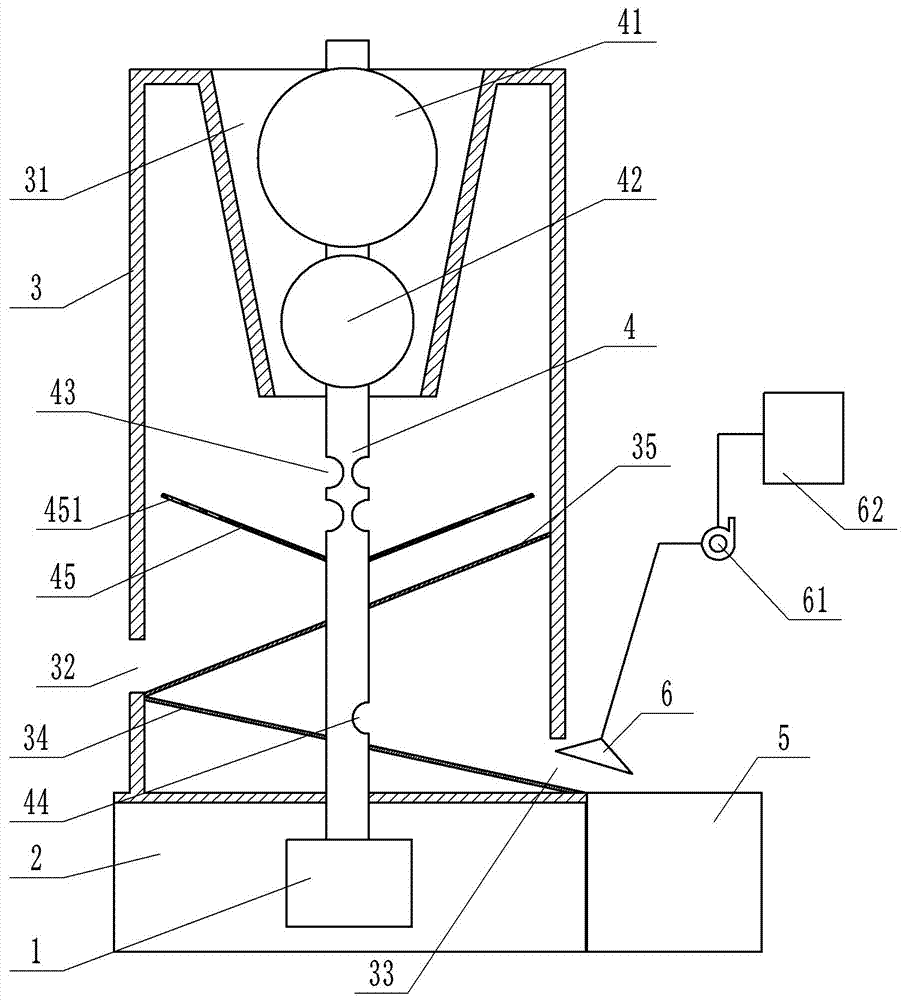

Peanut husking and skin removing device

The invention belongs to machines for husking or hulling or nut breaking, and particularly discloses a peanut husking and skin removing device. The peanut husking and skin removing device comprises a supporting table, a rack, a motor and a rotating shaft, wherein the motor is fixed in the supporting table, and the rack is fixed to the supporting table; a groove is formed in the upper part of the rack, and the opening area of the groove is gradually reduced from top to bottom; one end of the rotating shaft penetrates through the rack to be located in the middle of the groove, and a first grinding ball and a second grinding ball are connected to the upper part of the rotating shaft in sequence; a screen is fixed to the middle of the rotating shaft, and a plurality of openings are formed in the side, away from the rotating shaft, of the screen; a cavity is formed in the middle section of the rotating shaft; an inlet and an outlet are formed in the rotating shaft, the inlet is located above the screen, and the outlet is located in the lower part of the cavity; a helical blade is arranged in the cavity; a separating plate located below the screen is arranged in the rack in an inclined mode, and a discharging port is formed in the rack. By means of the technical scheme, peanuts of different sizes can be husked, and red skins on peanut kernels can be removed in the husking process.

Owner:CHONGQING ZHOUYI FOOD CO LTD

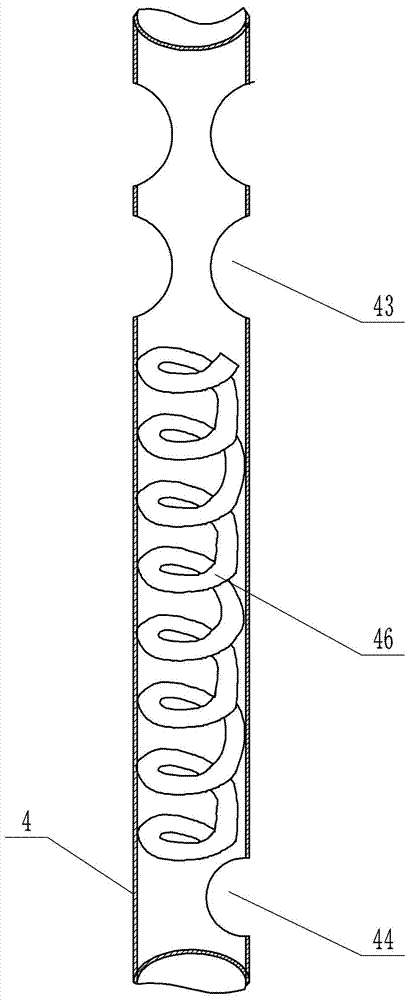

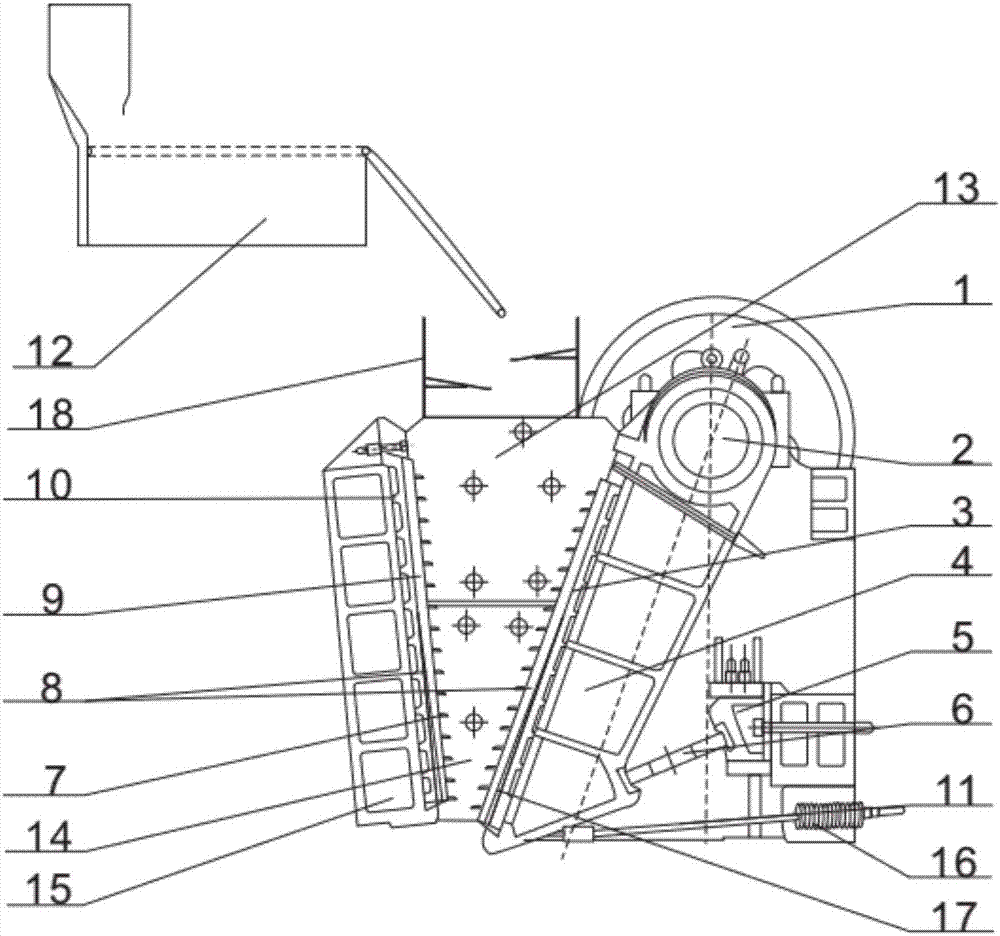

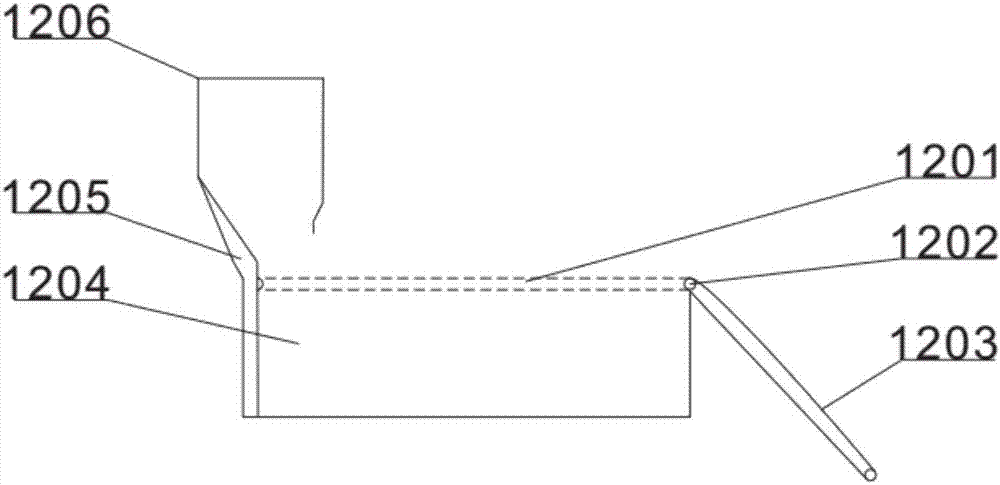

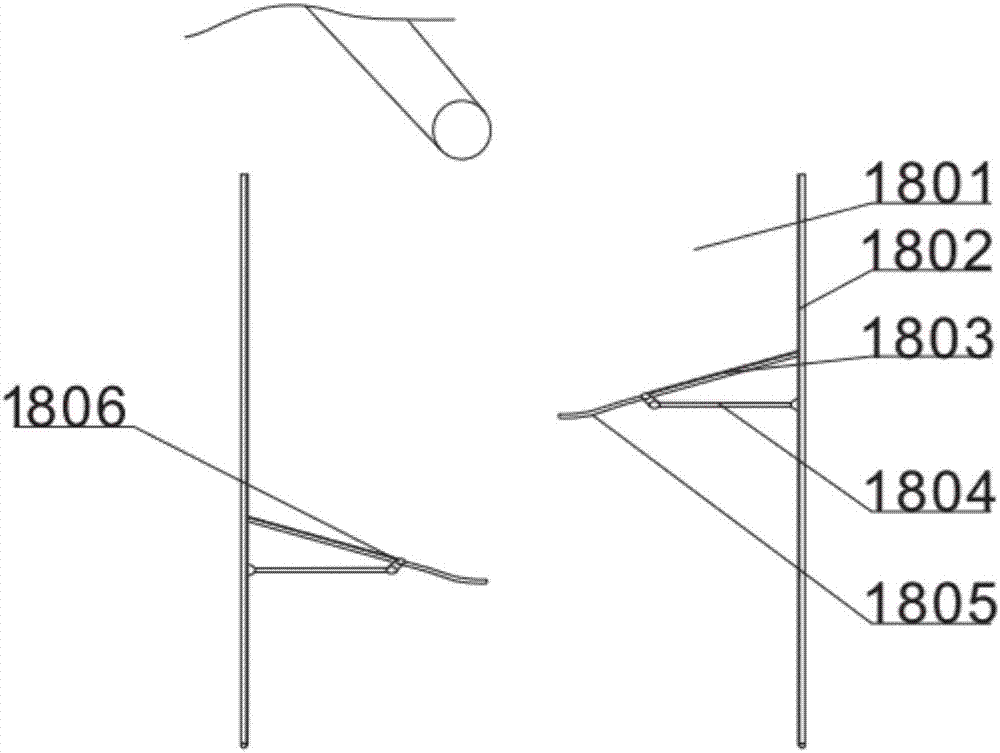

Intermittent-feeding juicing apparatus used for hawthorn fruit deep-processing

InactiveCN107594548AIncrease the speed of stirring the hawthornImprove work efficiencyJuice extractionEngineeringMechanical engineering

The invention relates to a juicing apparatus, and especially relates to an intermittent-feeding juicing apparatus used for hawthorn fruit deep-processing. The technical problem to be solved by the invention is to provide an intermittent-feeding juicing apparatus used for hawthorn fruit deep-processing which is capable of intermittently feeding materials and achieving full squeezing. In order to solve the technical problem, the invention provides an intermittent-feeding juicing apparatus used for hawthorn fruit deep-processing. The intermittent-feeding juicing apparatus used for hawthorn fruitdeep-processing comprises a support and so on; a driving mechanism is connected to an inner wall of the support; a feeding hopper is connected to a left side of a top of the support; a placing bucketis connected to a left side of the support; a top of the placing bucket is connected with a top of the feeding hopper; first through holes are formed at both upper and lower sides of the placing bucket; a crushing mechanism is connected into the placing bucket; and the crushing mechanism and the driving mechanism are connected. The intermittent-feeding juicing apparatus is capable of intermittently feeding and discharging materials, as well as fully squeezing hawthorn fruits so as to improve utilization ratio of the hawthorn fruits; moreover, a first movable rod and a press plate are arrangedso as to increase juice yield of the hawthorn fruits, and thus, waste is reduced.

Owner:王翠翠

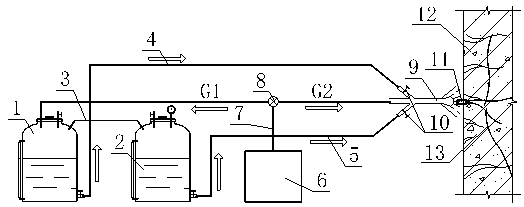

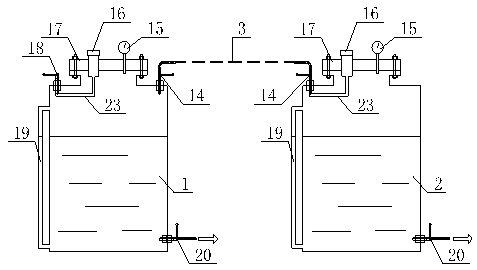

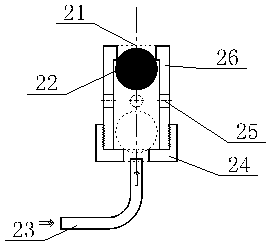

Double-fluid single-system air pressure energy storage grouting machine and grouting process

PendingCN108374567ASmooth entryEliminate the effects of dilutionBuilding repairsWater leakageEngineering

The invention discloses a double-fluid single-system air pressure energy storage grouting machine and a grouting process. The objective of the invention is to provide the structurally simple groutingmachine capable of efficiently controlling the water leakage of underground buildings and the grouting process. The grouting machine mainly comprises an energy storage grouting tank for first fluid, an energy storage grouting tank for second fluid, an air compressor, a proportioning mixer, intake opening and closing valves, liquid level indicators, a pressure-balancing communicating pipe, balancing communicating valves, an expansion grouting nozzle and the like. The flow of the grouting process is as follows: the expansion grouting nozzle is buried; a two-way valve is switched to a position G1of an air supply pipe; the air compressor is opened to supply pressured air to the energy storage grouting tanks; the two-way valve is switched to a position G2 of the air supply pipe; the air compressor applies pressure to the air supply pipe; high-pressure air is directly pressurized into water leakage cracks of a grouted body via the expansion grouting nozzle; grout outlet valves of the energystorage grouting tank for the first fluid and the energy storage grouting tank for the second fluid are opened to start grouting; the grouting proportion of the first fluid and the second fluid is controlled by the proportioning mixer; after pressure reaches a set termination pressure, grouting is kept for a certain period of time; the expansion grouting nozzle is taken out; and the grouting opening is sealed.

Owner:安徽国信建设集团有限公司 +2

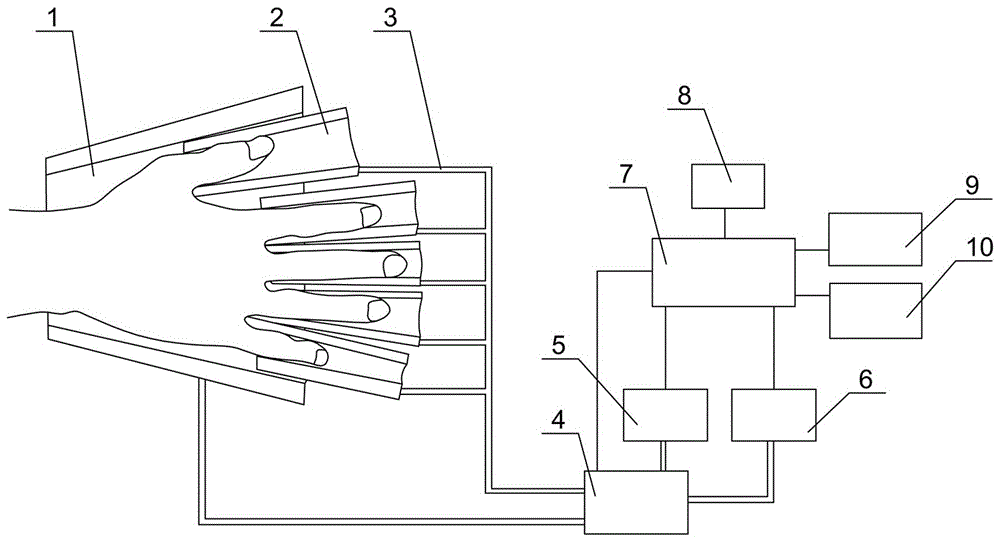

Rehabilitation device for treating hand edema of stroke patient

The invention relates to a medical rehabilitation device, in particular to a rehabilitation device for treating hand edema of a stroke patient. The medical rehabilitation device comprises an extrusion system and a control system, wherein the extrusion system comprises an outer covering air bag, five finger air bags, inflating tubes, an electromagnetic valve group and an air pump, wherein the outer covering air bag and the finger air bags are all of open structures; the unfolding shapes are rectangular shapes; connecting elements are arranged at the two ends of each rectangular shape; each rectangular shape is connected through the connecting elements to from a tubular shape; the outer covering air bag is sequentially connected with the electromagnetic valve group and the air pump through the air inflating tube; the five finger air bags are communicated through the inflating tubes and are then sequentially connected with the electromagnetic valve group and the air pump; the control system comprises an air pressure sensor, a CPU (Central Processing Unit) control circuit, a power supply module, an input module and an output module; the CPU control circuit is respectively connected with the electromagnetic valve group, the air pump, the air pressure sensor, the power supply module, the input module and the output module; and the air pressure sensor is connected with the electromagnetic valve group arranged in the extrusion system.

Owner:刘志成

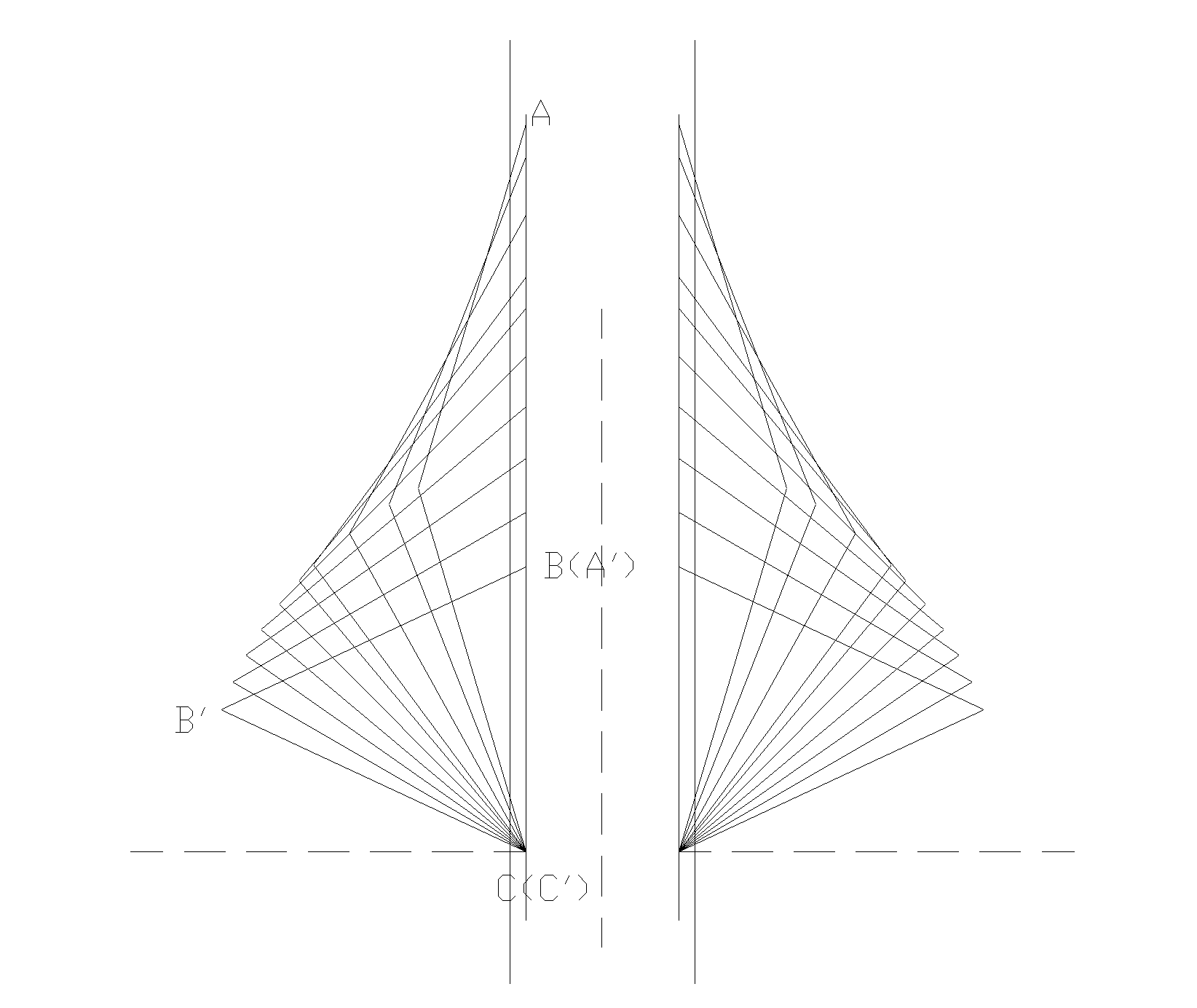

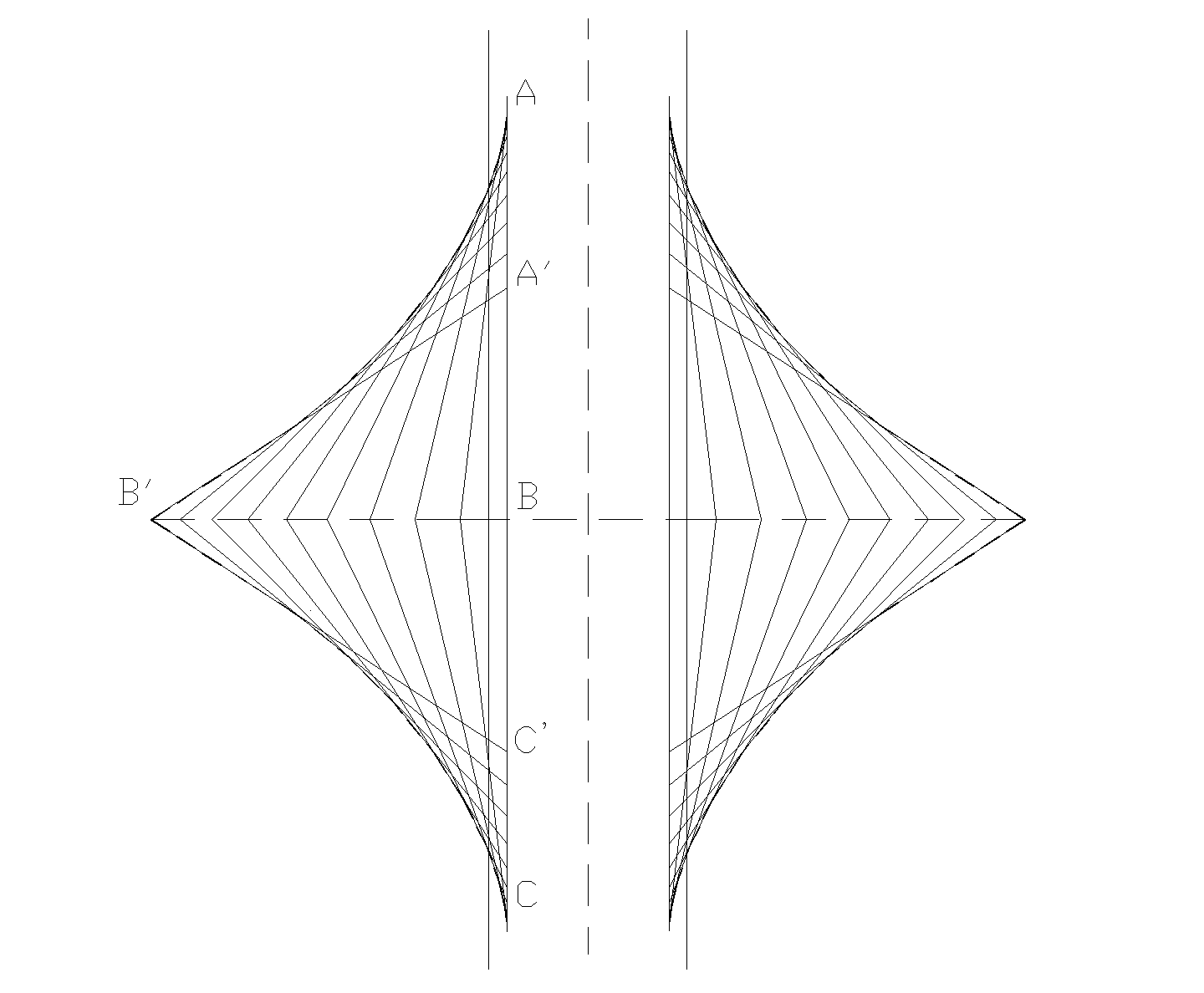

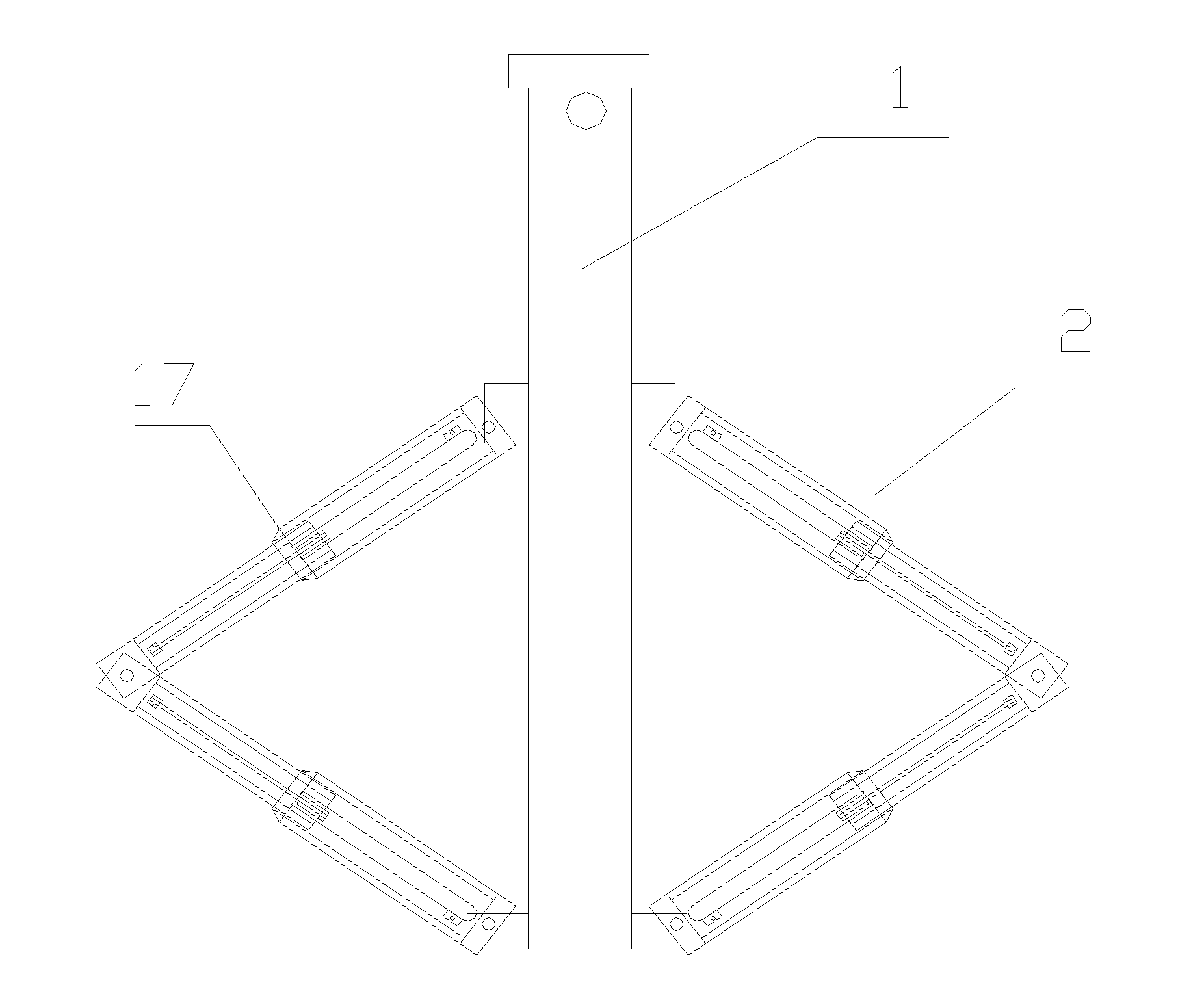

Extruding-expanding device and method for pile foundation

The invention relates extruding-expanding device and method for a pile foundation. The device comprises a supporting device and an extruding-expanding arm connected with the supporting device, wherein the extruding-expanding arm comprises a telescopic expanding arm. The extruding-expanding device and method for the pile foundation overcome the defects of a single-cylinder one-way extruding-expanding device and a double-cylinder two-way extruding-expanding device and prevent the soil mass from falling in an arm with a box-shaped section; the telescopic extruding-expanding arm always contacts the soil mass, and the soil mass is fully compacted; the horizontally-projected area of an extruded disk cavity is larger; and the bearing capacity of an extruding-expanding pile is larger.

Owner:李征 +2

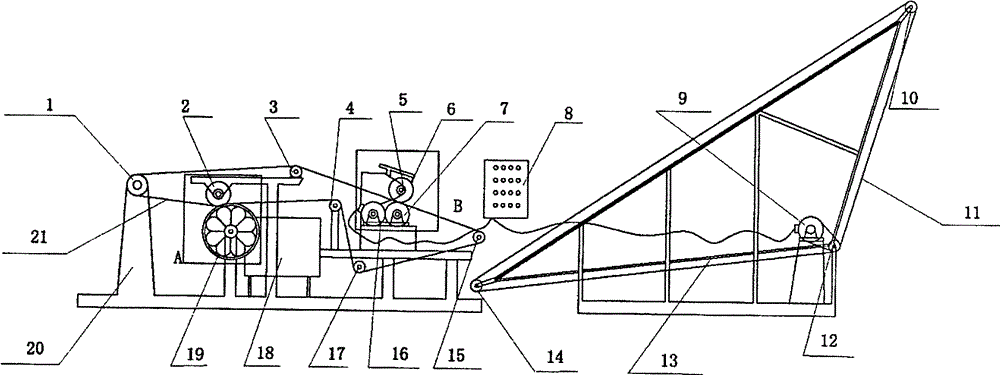

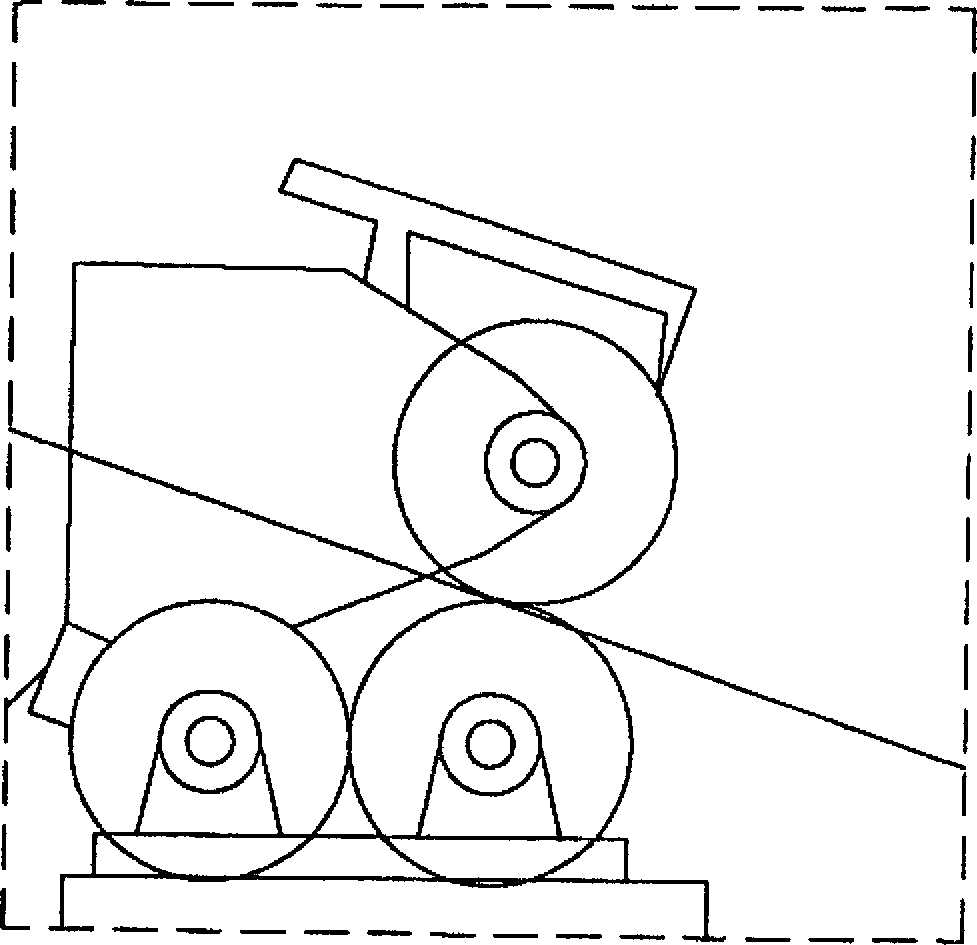

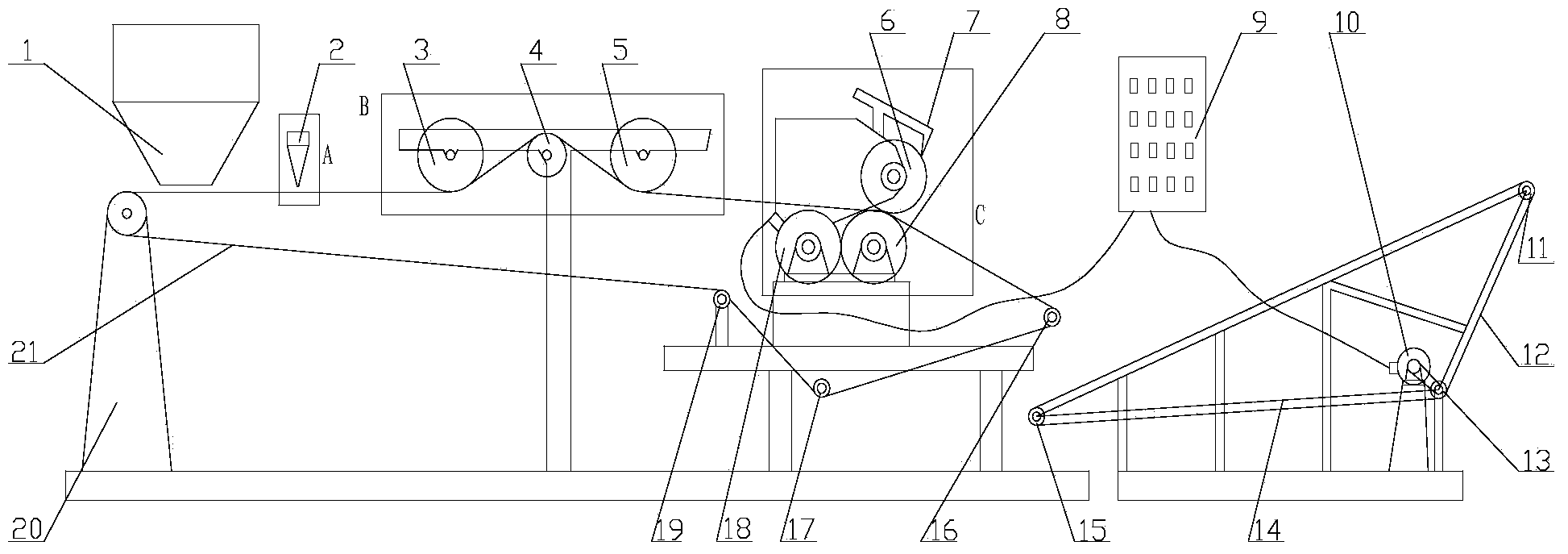

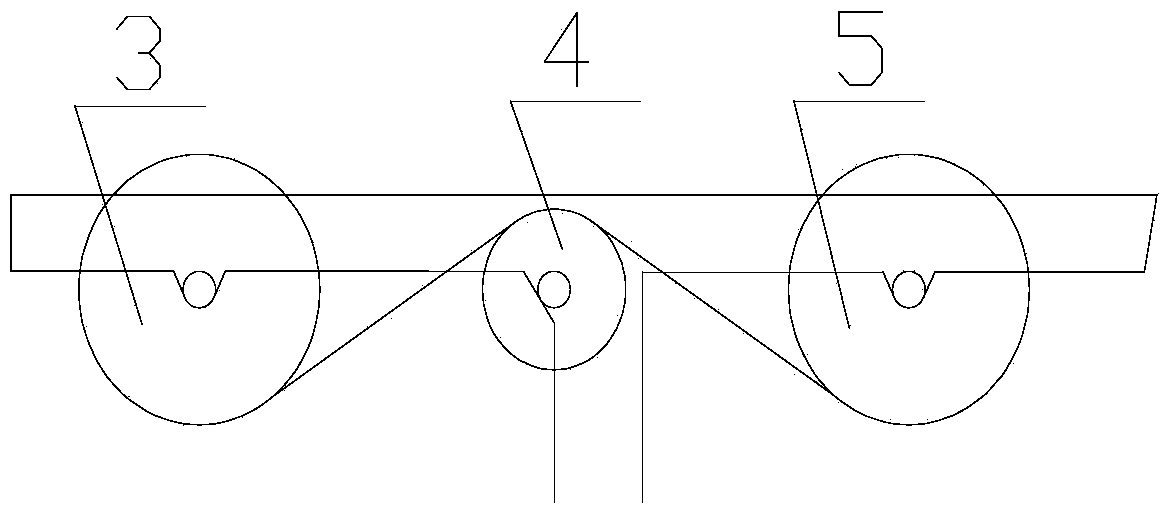

Belt filter press for manioc waste

InactiveCN103055580ARealize automatic loadingSqueeze fullyMoving filtering element filtersHigh energyFiltration

The invention relates to a belt filter press of manioc waste. The belt filter press comprises a rack, a motor, a container slot, a large roller, a middle roller group, a small roller group, a conveying belt, a scraper, a controller, a load conveying rack, a load motor, a load conveying belt and a load roller group, wherein the motor, the container slot, the large roller, the middle roller group and the small roller group are fixedly arranged on the rack; a conveying mechanism is formed by the conveying belt, the large roller, the middle roller group, the small roller group and the motor; the middle roller group is formed by a first middle roller, a second middle roller, a third middle roller and a fourth middle roller, the large roller is in counter-rolling contact with the first middle roller, and the second middle roller is in counter-rolling contact with the third middle roller; the motor is controlled by the controller; and a load conveying mechanism is formed by the load conveying belt, the load roller group and the load motor. Compared with an existing dehydration technology, such as vacuum roller rotation and plate-frame pressure filtration, the belt filter press provided by the invention has the advantages of small size, simple structure and high energy efficiency. The belt filter press can be applied to dehydration processing of waste liquid materials of opacified microparticle materials in industries of manioc processing, sewage treatment, paper making and the like.

Owner:GUANGXI UNIV

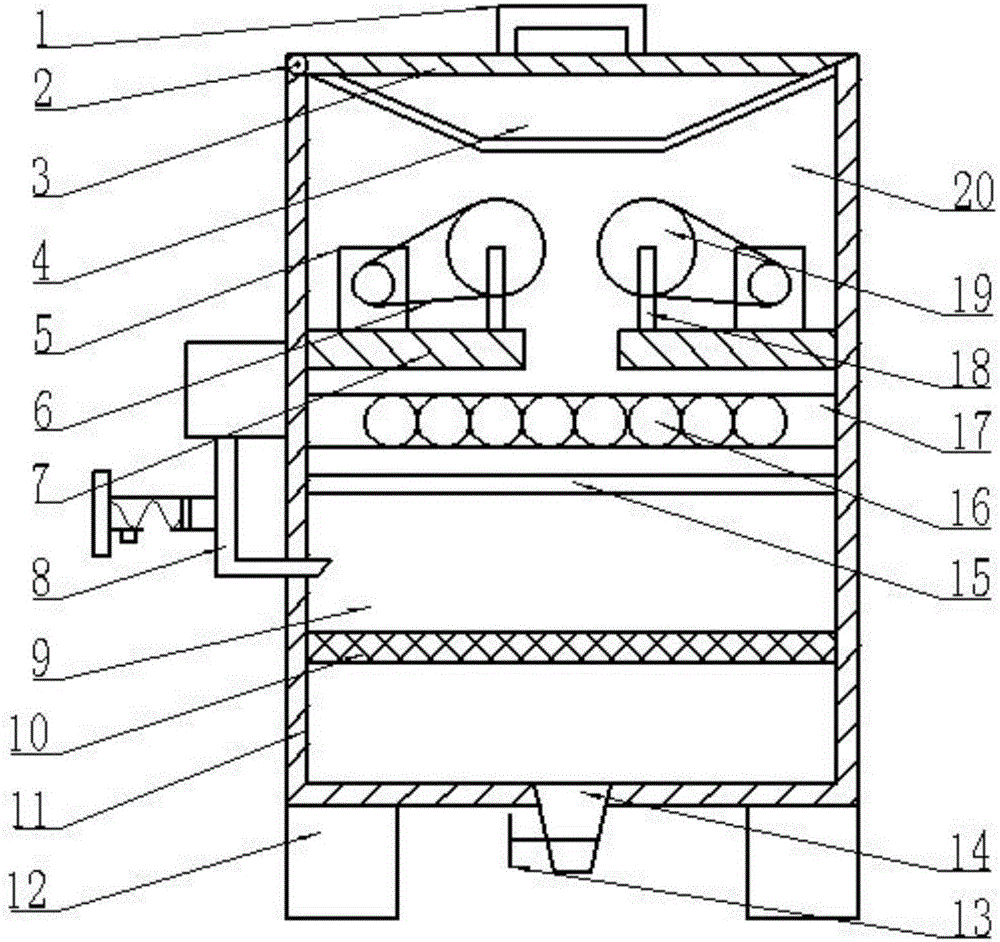

Environmental-friendly multifunctional sludge treatment device

InactiveCN107512844ASqueeze fullySmash thoroughlySludge treatment by de-watering/drying/thickeningWater/sewage treatment apparatusSewageEngineering

The invention discloses an environmental-friendly multifunctional sludge treatment device and belongs to the field of environmental protection equipment. The environmental-friendly multifunctional sludge treatment device comprises a shell, wherein a grinding chamber, an extrusion chamber and a sewage chamber are formed inside the shell; an upper end cover is arranged on the top of the shell; the upper end cover is mutually screwed with a bolt through nuts and is fixedly connected with the shell; a feed hopper is arranged on a center line of the upper end cover and communicated with the grinding chamber; and a first grinding motor is fixedly arranged at the left side of the top of the upper end cover and fixedly connected with a first grinding shaft. The environmental-friendly multifunctional sludge treatment device disclosed by the invention is reasonable in structural design, and due to first grinding blades and second grinding blades arranged in the grinding chamber in a cross manner, solid wastes in sludge can be completely ground; the ground sludge is fully extruded by two extrusion plates, so that the sludge is flattened and then conveniently subjected to subsequent treatment; and the sewage in the sludge treatment process can be collected by the sewage chamber, so that solid-liquid separation during sludge treatment is realized.

Owner:王书愚

Bevel gear polishing device

InactiveCN106826515AAchieve grindingSqueeze fullyGrinding carriagesPolishing machinesGear wheelEngineering

The invention relates to the technical field of gear machining, in particular to a bevel gear polishing device. The bevel gear polishing device comprises a rotating shaft and a collecting tank; the rotating shaft is fixedly mounted on the collecting tank, and is sleeved with two rotating discs; a saw gear is arranged between the rotating discs; bevel gears are respectively arranged on the outer sides, far from the saw gear, of the two rotating discs; tooth grooves of the two bevel gears are distributed in a herringbone manner; the rotating discs are provided with guide grooves communicated with the tooth grooves of the bevel gears; a rack engaged with the saw gear is arranged on the outer side of the saw gear; one end, far from the rotating discs, of the rack is fixedly connected with an extension rod; one end, far from the bevel gears, of the extension rod is connected with a second airbag and a cylinder in sequence; the second airbag is inserted in the extension rod; one side, far from the cylinder, of the second airbag is connected with two first airbags; the first airbags are coated with elastic fine abrasive papers; and one-way intake holes are formed in the connecting places of the second airbag and the first airbags. The bevel gear polishing device solves the problem that the tooth roots of the bevel gears are not liable to polish.

Owner:滁州伏特威电气技术有限公司

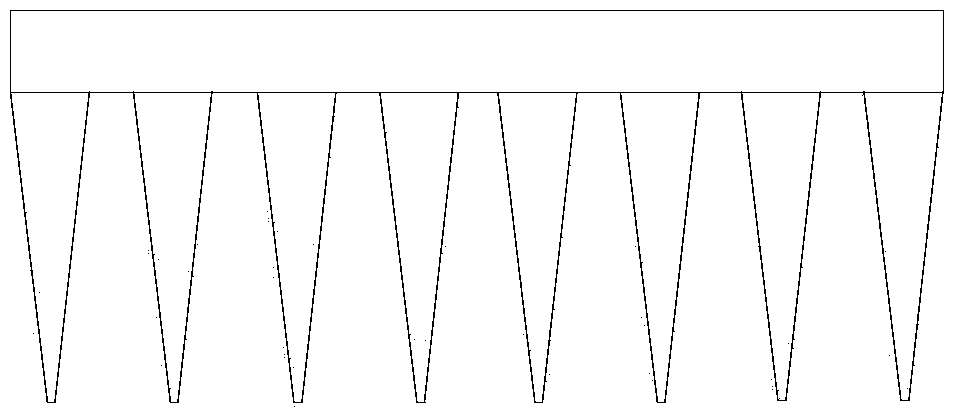

Barbell type manioc waste belt pressure filter with mud carding device

InactiveCN103623633ARealize automatic loadingSqueeze fullyMoving filtering element filtersEmulsionPapermaking

The invention discloses a barbell type manioc waste belt pressure filter with a mud carding device. The barbell type manioc waste belt pressure filter comprises a rack, a motor, a feeding groove, the mud carding device, a pressure filter roller group, an auxiliary roller group, a conveying belt, a scraper, a controller, a loading conveying rack, a loading motor, a loading conveying belt and a loading roller group, wherein the motor, the feeding groove, the mud carding device, the pressure filter roller group, the auxiliary roller group and the motor are fixedly arranged on the rack. The barbell type manioc waste belt pressure filter has the advantages that a dehydration link is added; the dehydration efficiency is improved. The barbell type manioc waste belt pressure filter can be applied to dehydration treatment of micro-particle emulsion waste liquor materials in the industries of manioc processing, sewage treatment, papermaking and the like.

Owner:GUANGXI UNIV

Walnut shelling device

The invention provides a walnut shelling device, and belongs to the field of walnut shelling devices. The device comprises a discharging tank, a rack, an air pump, an extrusion mechanism, a conveyingbelt, a screening mechanism, a fixed extrusion plate, a small air cylinder, a falling pipe, an optoelectronic switch receiver, an optoelectronic switch transmitter and a controller, wherein the discharging tank is soldered at the top end of the rack; a falling hole is formed in the bottom of the discharging tank, and is connected with the falling pipe; an upper telescopic arm hole and a lower telescopic arm hole are formed in one side of the lower part of the falling pipe; optoelectronic detection devices are arranged on two sides of a middle lower part, corresponding to the upper telescopic arm hole and the lower telescopic arm hole, of the falling pipe; the fixed extrusion plate is arranged at the bottom of the rack, and the extrusion mechanism is arranged at the opposite side of the fixed extrusion plate; the conveying belt is arranged at the lower part of the fixed extrusion plate; a vibrating screen is arranged in front of the conveying belt; and the air pump is arranged on the side of the extrusion mechanism. The device is simple in structure and easy to operate, and can be used for effectively removing shells of walnuts, so that labor and materials can be greatly reduced.

Owner:邵博文

American ginseng pulverizing and grinding device convenient to maintain

InactiveCN106582941AImprove crushing efficiencyImprove use valueSievingScreeningAerospace engineeringExtrusion

The invention provides an American ginseng pulverizing and grinding device convenient to maintain. The American ginseng pulverizing and grinding device comprises a box cover and a box. The box is provided with a pulverizing bin, an extrusion bin, a screening bin and landing legs. A feeding port and motor bases are arranged in the pulverizing bin. The extrusion bin is arranged at the lower ends of the motor bases. Extrusion rollers are arranged in the extrusion bin. The screening bin is arranged at the lower end of the extrusion bin. An iron removing plate and a filtering net are arranged in the screening bin, an air supply device is arranged at the left end of the screening bin, and a discharging pipe is arranged at the bottom end of the screening bin. The iron removing plate is fixed to the inner wall of the box. The iron removing plate is provided with an outer ring, an inner ring and iron removing rods. The air supply device comprises an air blower, an air blowing channel and an air leakage device. The air leakage device is connected with the air blowing channel. The air leakage device comprises an exhaust pipe communicating with the air blowing channel. A sealing plate, an air outlet, a whistle, a spring and a sealing cover are arranged in the exhaust pipe. The two landing legs are arranged. The American ginseng pulverizing and grinding device is efficient and sufficient in pulverizing, convenient to maintain and capable of removing iron and screening particles according to the size.

Owner:河南常青藤信息科技有限公司

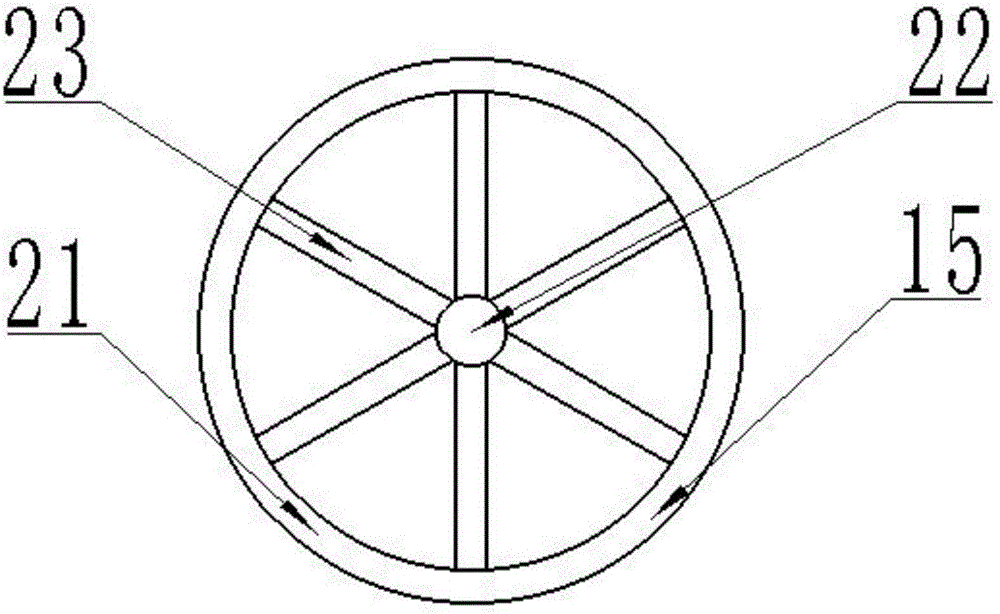

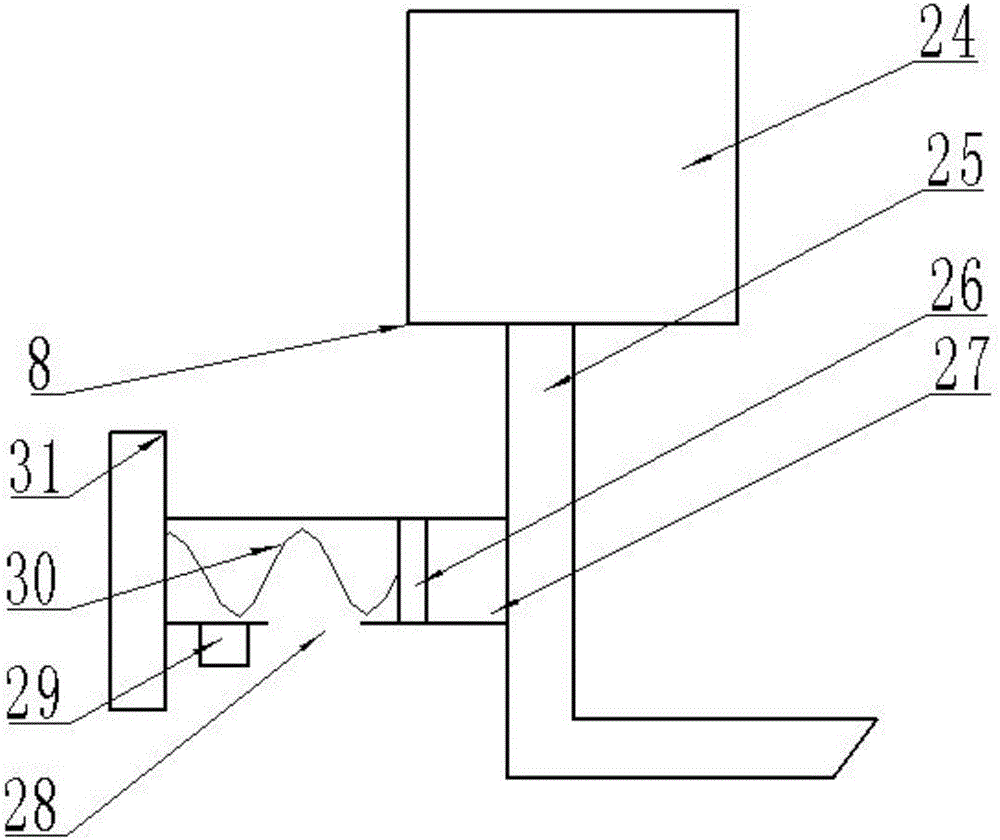

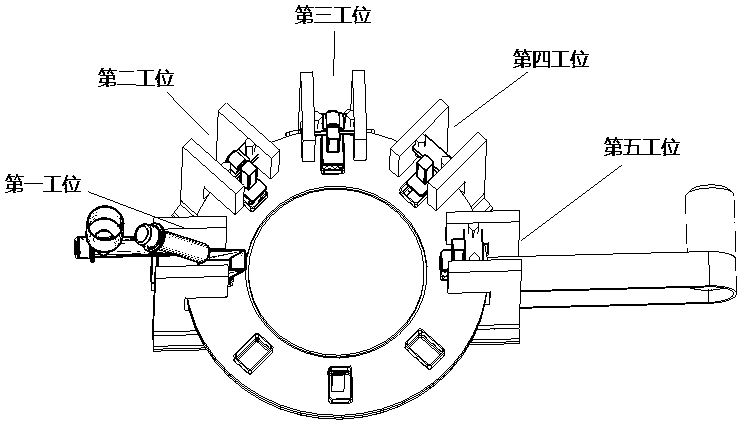

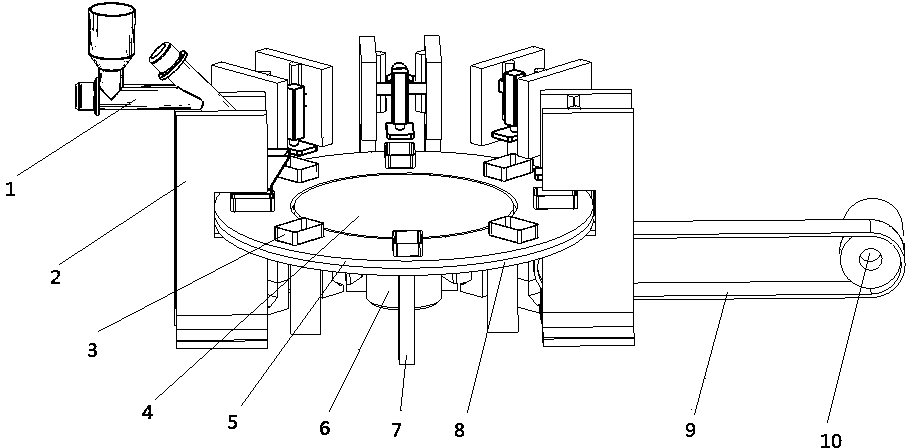

Rotary variable-frequency vibrating-compacting leaven making machine

InactiveCN103865716AEvenly filledEasy to demouldAlcoholic beverage preparationEngineeringUltimate tensile strength

The invention discloses a rotary type variable-frequency vibration-compaction leaven making machine. Five phases are balanced at the circumferential side of a workbench, wherein a leaven mould loading mechanism, a low-frequency vibrating-compacting mechanism, a beating-syrup purifying mechanism, a leaven blank forming mechanism and a leaven blank discharging mechanism which are connected with a control cabinet to integrally form the rotary variable-frequency vibrating-compacting leaven making machine are respectively and sequentially arranged on adjacent continuous five phases by virtue of brackets. The leaven making machine is used for simulating manual leaven making, the prepared leaven is formed by virtue of dual-direction variable-frequency vibrating-compacting, variable pressure is transmitted from upper and lower directions to flexibly and repeatedly squeeze and rub a leaven blank while the leaven blank is formed, flour syrup is lifted to the surface of the leaven blank by virtue of variable-frequency vibration, and the conventional manual operation is replaced by mechanical production, so that problems such as great labor intensity, low working efficiency and poor production environment of manual leaven preparation are solved.

Owner:JIANGSU FOOD & PHARMA SCI COLLEGE

Feeding buffer device of jaw crusher

The invention provides a jaw crusher feeding buffer device, which includes a frame, an upper guard plate, a lower guard plate, a fixed jaw assembly, a movable jaw assembly, an eccentric wheel, a toggle plate, an adjustment seat and a spring rod, and the movable jaw There is a buffer structure between the plate and the movable jaw assembly, teeth are arranged in parallel on the fixed jaw plate and the movable jaw plate, and a screening device is installed above the movable jaw assembly and the fixed jaw assembly. The screening device includes material Box, material receiving box, transmission screen and conveyor belt, the material box and transmission screen are all set above the material receiving box, the lower part of the conveyor belt near the end of the upper guard plate is equipped with a feeding buffer device, the feeding buffer device and the upper guard plate Fixedly connected, the feeding buffer device includes a buffer bucket body, a wear-resistant plate and two buffer components. The buffer components are respectively fixed on the two inner plates of the buffer bucket body. The buffer component includes a sloping plate, a wear-resistant plate, a rubber body and a support plate. The inclined plate is connected with the rubber body through a connecting shaft, and the rubber body is arranged on the side away from the inner plate of the buffer bucket; the invention has low cost and long life.

Owner:张家港明惠金属制品有限公司

Pulp mixing device

PendingCN110193320AAvoid cloggingAvoid badRotary stirring mixersTransportation and packagingPulp and paper industryMixing effect

The invention discloses a pulp mixing device, which comprises a mounting frame, a pulp mixing tank, a pulp adding tank, a cooling mechanism and a pulp discharging mechanism, wherein a pulp adding tankis movably arranged below the pulp mixing tank, the cooling mechanism and the pulp discharging mechanism; a mass scale is arranged below the pulp adding tank; a stirring cavity is formed in the pulpmixing tank; a stirring valve is arranged in the stirring cavity; a stirring motor is arranged on the pulp mixing tank; a discharge port is arranged at the bottom of the stirring cavity; an oil bath cavity is formed between the pulp mixing tank and the stirring cavity; and the cooling mechanism comprises a lifting cylinder and a lifting seat. The lifting seat is provided with a rotating paddle anda rotating motor, the lifting cylinder is arranged on a mounting frame, the output end of the lifting cylinder is connected with the lifting seat, the pulp discharging mechanism comprises a piston and a driving cylinder, the piston is connected with the output end of the driving cylinder, the piston is provided with an elastic sealing ring along the circumferential direction, and the bottom of the pulp adding tank is provided with a pulp outlet. The pulp mixing device has simple structure, good pulp mixing effect, and simultaneously has the functions of conveying, cooling and extruding pulp,thereby improving the production and processing efficiency.

Owner:ZHEJIANG CANAAN TECH

Control device of surgical instrument, surgical instrument and control method of surgical instrument

PendingCN111870318APress Time GuaranteeSqueeze fullyIncision instrumentsSurgical staplesSurgical instrumentationElectric machinery

The invention discloses a control device of a surgical instrument, the surgical instrument and a control method of the surgical instrument. The surgical instrument comprises an end effector, a cuttingknife assembly, a transmission mechanism and a motor, wherein the control device comprises a signal source module and a control module; the signal source module is electrically connected to the control module, and the control module is electrically connected to the motor; and the motor drives the end effector and the cutting knife assembly through the transmission mechanism. After the control module receives a signal that the end effector is closed in place, the signal source module sends out a first signal, and after receiving the first signal, the control module starts a squeezing keeping mode; in a squeezing keeping mode, no matter whether a second signal sent by the signal source module is received or not, the control module does not send out a third signal used for instructing the motor to operate so as to drive the cutting knife assembly to move forwards through the transmission mechanism.

Owner:FENGH MEDICAL CO LTD

Presser

InactiveCN107364170ASolve the shortcomings of single functionSolve problems that cannot be automatically dischargedGrain treatmentsPressesEngineeringReducer

The invention discloses a squeezer, the structure of which comprises a feed inlet, a rotary sieve, a destemming blade, a support, a crushing device, a pulp delivery pump, a pressing screw, a juice collection tank, and a liquid outlet. It is movably connected with the rotary screen, the rotary screen is fixedly connected with the destemming blade, the rotary screen is connected with the crushing equipment through the support, the crushing equipment is connected with the slurry pump, and one end of the crushing device is connected with the reduction box The reduction box is connected with the reducer through the support, the squeezing screw is connected with the screen drum assembly, the screen drum assembly is connected with the filter screen through the frame, and the squeezing screw is connected with the tail cone. The tail cone is movably connected with the adjusting handwheel. Through the design of the crushing device, the press can not only realize the pressing function but also destem, which solves the shortcoming of the single function of the press on the market at present. Through the curved design of the slag outlet , can solve the problem that the residue cannot be discharged automatically.

Owner:天津捷茂亨科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com