Patents

Literature

432results about How to "Not easy to crush" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recovery plus-negative plate material from waste and old electrode plate

InactiveCN1758478AImprove adhesionImprove ductilityReclaiming serviceable partsWaste accumulators reclaimingMaterials scienceNickel–metal hydride battery

This invention relates to a method for recovering positive and negative materials from waste pole plates including a high temperature method and a specific gravity method, in which, the high temperature method includes putting the waste positive and negative pole plates under high temperature to dissolve the PVDF and break the positive and negative materials from the matrix and separate them from the conduction agent, then separating the PVDF with water, which applies a physical method to recover the materials and does not change the physical and chemical targets of the materials.

Owner:朱明明

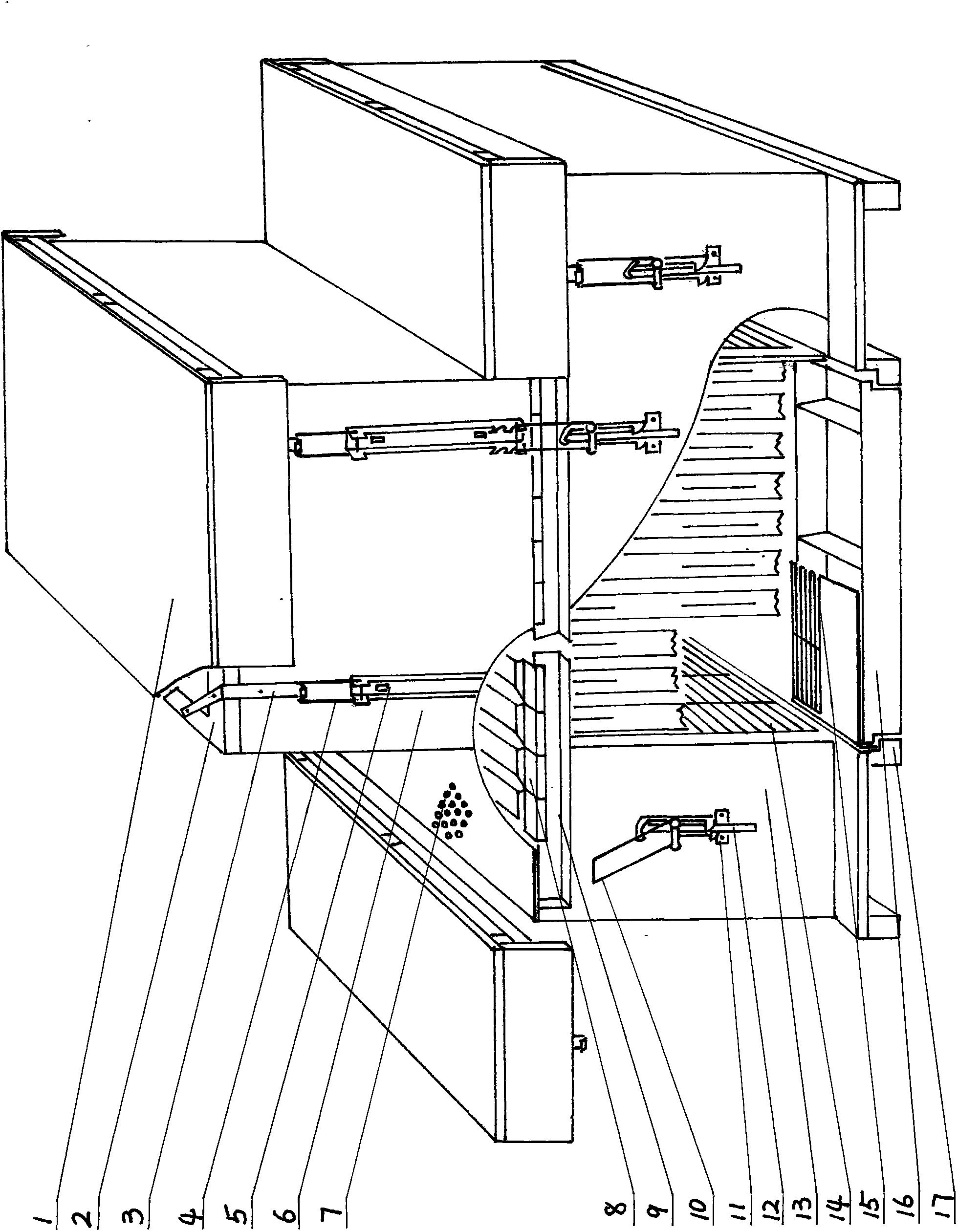

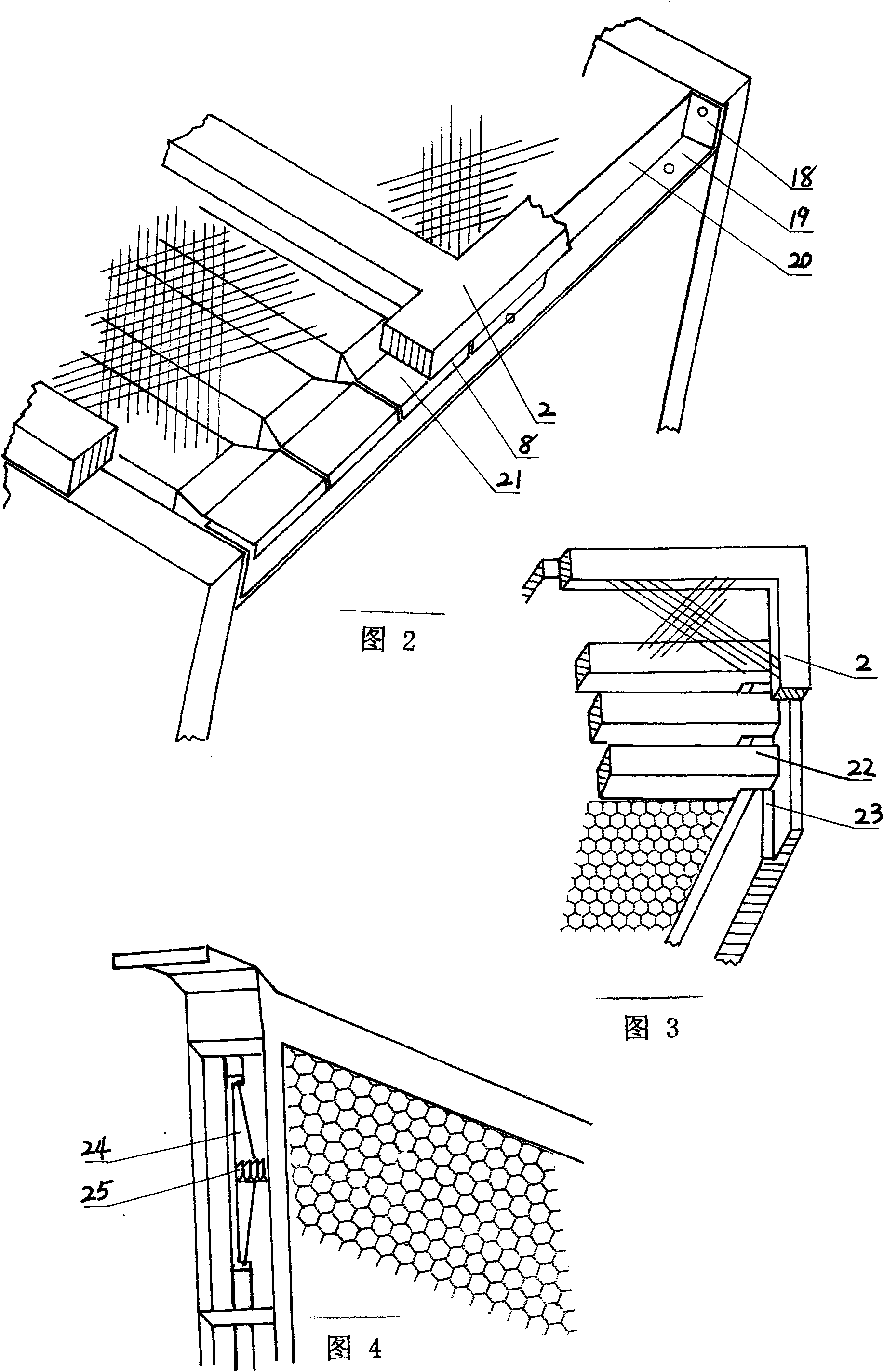

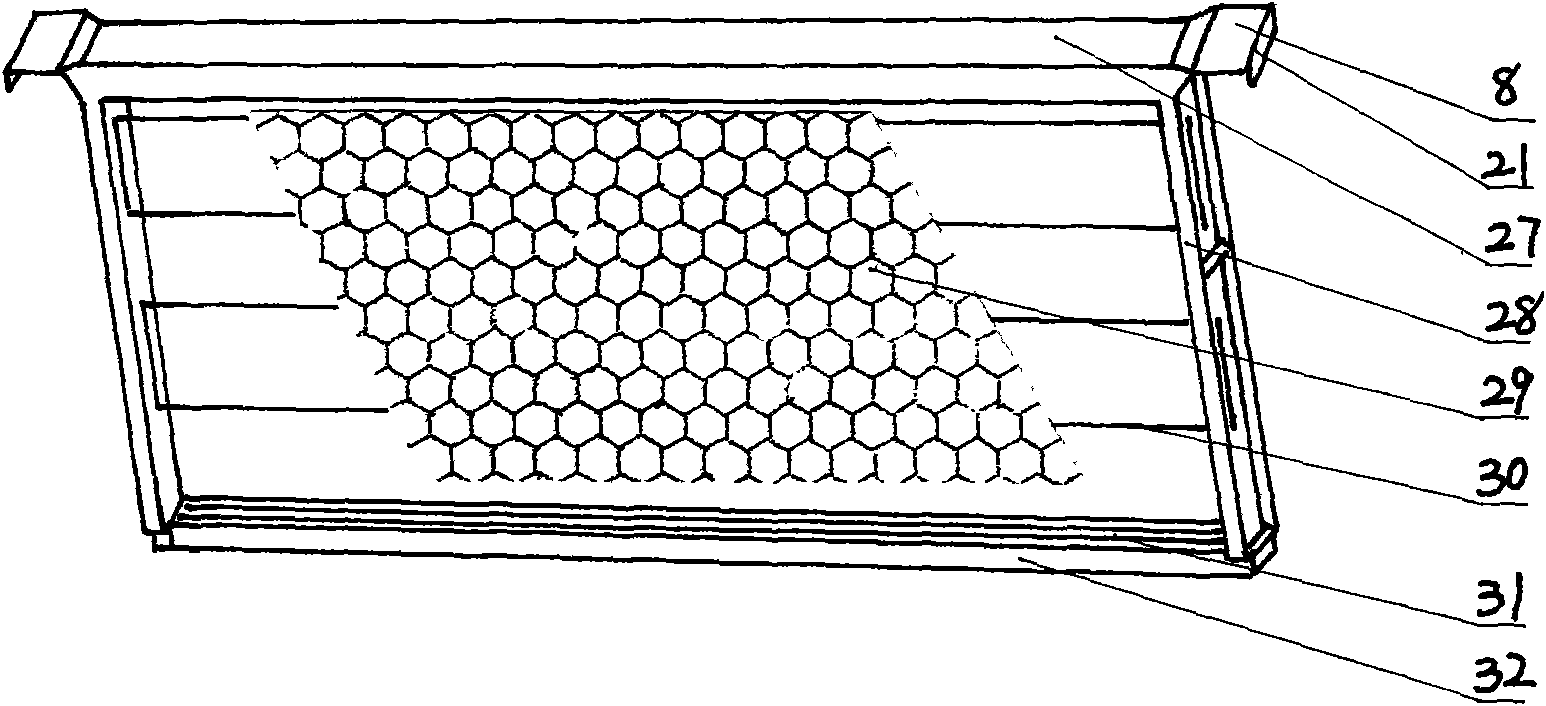

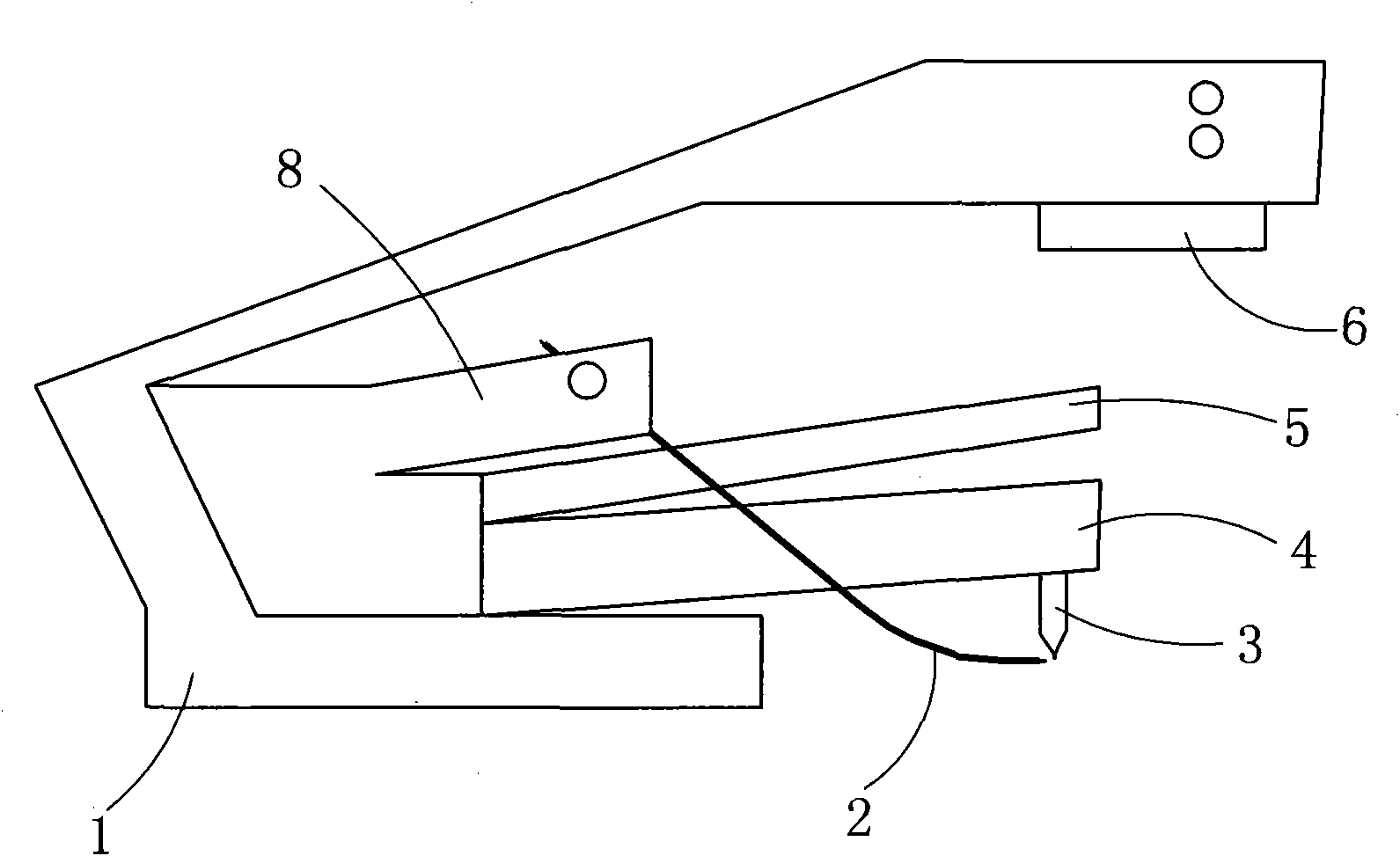

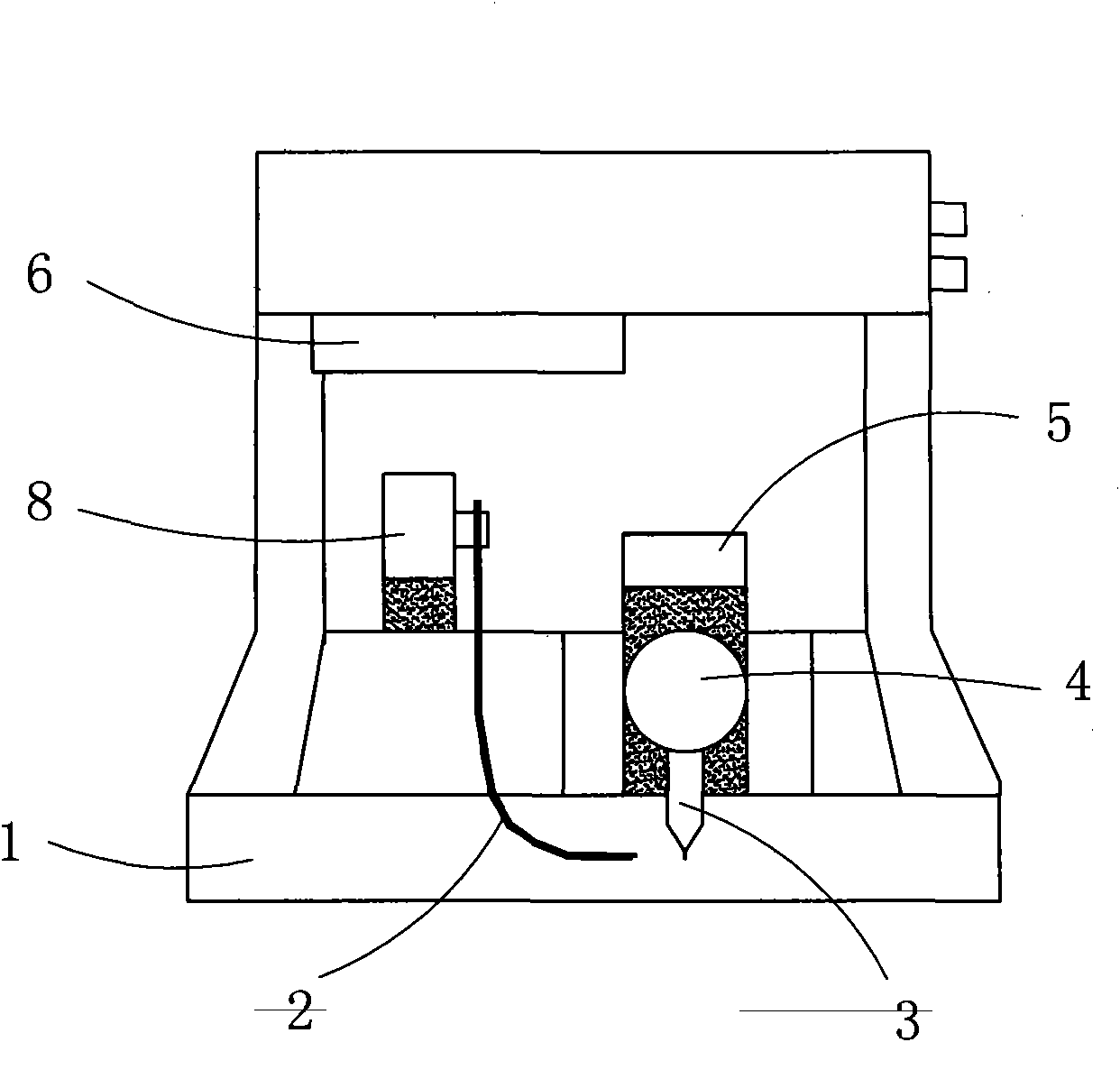

Horizontal and super combined beehive

InactiveCN101897300AImprove work efficiencyIncrease productionBeehivesHoney collectionWaxEngineering

A horizontal and super combined beehive comprises a wide-comb box, a frame support, a powder-releasing cover, a pollen box, a connector, a degummed drape, an inserted frame, an integrated frame and a wax comb foundation with suspension loops. The wide-comb box is characterized in that the both ends of the box are used as the breeding areas for two swarms of bees, a super is supported above the middle production area, frame queen excluders are used to form a working bee centralized production area, the areas are covered; the powder-releasing cover is bottomless, pollens and honey on a powder-leaking railing pedal with anti-theft gantry boxes on both sides directly leak in the pollen box at the bottom; the connected box is coarsely adjusted by a multi-teeth hook and finely adjusted and connected firmly by a screw crow bar through screws; the laps and edgings of the inserted frame are integrated, an upper beam and a lower beam are inserted in the upper and lower grooves of two edgings to integrate, the upper beam is thin, the lower beam and the edgings are provided with grooves to be inserted in the comb foundation; a wide hook with the same width and an adjuster are hung on the wax comb foundation for tightening; the laps are integrated with a frame-distance clip and connected with the upper beam through a downward slope, the tops of comb-forming frame supports are butted to each other and are tightly pressed by the degummed drape and the inner frame of the box cover, the distance of the frames is standard so that people can not stung by bees; and the top of each lap is provided with a handle, thus the laps can be fast gripped outside the box. The wide-comb box can be used to multiply the efficiency, thus being suitable to be used for beekeeping around the world.

Owner:汪修建

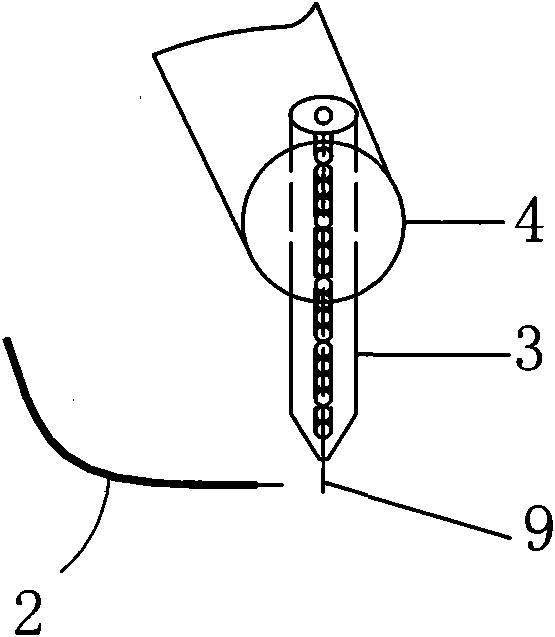

Method for bonding copper wire of power device

InactiveCN101862897AImprove conductivityLow costSolid-state devicesSemiconductor/solid-state device manufacturingCopper wireUltrasonic welding

The invention provides a method for bonding a copper wire of a power device, in particular to a method for bonding the copper wire (91) with the welding joints of a chip (511). The method comprises the following steps: burning the lower end (9) of the copper wire into a spherical shape; applying the pre-pressure on the spherical end of the copper wire, i.e., flattening the spherical end of the copper wire to increase the contact area of the spherical end of the copper wire and the chip; and welding the spherical end of the copper wire to the bonding area of the chip on an ultrasonic-welding basis, wherein the pre-pressure is preferably 80g to 120g, and the time for applying the pre-pressure is preferably 80ms to 150ms. By increasing the contact area, the invention can improve the stability and reliability in welding the copper wire and the chip; the bonding production can be smooth without breaking the copper wire, breaking the welding joints or shutting down; the chip cannot be damaged by bonding; and the bonding strength of the copper wire, the chip and the pin is high. By substituting the copper wire for the gold wire for bonding, the invention can reduce the cost for the bonding metal wire by about 84%, reduce the overall cost for the product by 5.7% to 8.6%, reduce the saturation voltage drop parameter of the product and improve the reliability of the product; and compared with the gold wire, the conductivity of the copper wire is increased by about 20%, thus improving the reliability of the product.

Owner:深圳市贵鸿达电子有限公司

Construction process for repairing concrete ground

InactiveCN102261034AStable structureNot easy to damageRoads maintainenceHigh intensityMaterial resources

The invention relates to a ground repairing technology and discloses a construction process for repairing concrete ground. The construction process for repairing the concrete ground comprises the following steps of: selecting the concrete ground, planing a deterioration layer, removing dust, cleaning and moistening by the use of water, mixing a high-strength non-shrinkage grouting material and water which accounts for 10-15% of the total weight with stirring to obtain a slurry, pouring the slurry into ground defect positions to repair and smoothen the ground, flattening the ground after solidification, pouring the slurry onto the surface of the whole concrete substrate to form a layer of 0.3cm-3cm thick, naturally drying for 10-14 hours, covering the layer with a maintenance pad, watering, followed by wet curing for several days, and removing the maintenance pad to finish the construction process. According to the technical scheme provided by the invention, apart from the full consideration of concrete ground situation and the impact of external environment such as temperature, climate and the like during the construction process, the high-strength non-shrinkage grouting material with high strength and good viscosity is used such that the repaired ground has a high hardening strength and is not easy to crush and damage, and manpower and material resources are saved.

Owner:张学

Novel organic sulfur hydrogenation catalyst carrier and preparation method thereof

ActiveCN102489336AReduce catalysisImprove adsorption capacityCatalyst carriersDispersed particle separationPseudoboehmitePtru catalyst

The invention relates to a novel organic sulfur hydrogenation catalyst carrier. A preparation method of the carrier comprises steps that: a neutralization material, pseudoboehmite (gamma-alumina), an adhesive, a hole expansion agent and a metal additive are mixed; the mixture is subject to knead-molding, drying, and roasting, such that a finished product is obtained. The method is characterized in that the neutralization material is prepared through steps that: pseudoboehmite is soaked by using an alkaline solution, and is neutralized by using an acid solution; and the pseudoboehmite is subject to washing and press-filtrating, such that the neutralization material is obtained. Therefore, impurity content in the pores is greatly reduced, such that the loading of active components is promoted. A catalyst prepared by using the carrier is suitable to be used in hydrogenation catalyzing of organic sulfur in natural gas, coke oven gas, exhaust gas, and the like. Organic sulfur is converted into inorganic sulfides; and the sulfides are removed with the cooperation of an inorganic sulfur desulfurizing agent.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD +1

Preparation technology of butadiene catalyst by oxidative dehydrogenation of butene

ActiveCN102580749AAvoid secondary pollutionHigh mechanical strengthHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsActivated carbonCalcium hydroxide

The invention provides a preparation technology of butadiene catalyst by oxidative dehydrogenation of butane, which comprises the following steps of: dissolving an iron sheet by dilute nitric acid to prepare ferric nitrate solution, adding mixed serous fluid of calcium chloride, calcium hydroxide and zinc oxide, taking ammonia water as precipitator to gelatinize ferric nitrate solution, adding binder and activated carbon to age, cooling to be room temperature, filtering and washing, and retaining a filter cake; performing spray granulation for the filter cake; and activating in a rotary kiln in a roasting way, and screening out catalyst spherical particles with the particle size from 40 mu m to 200 mu m by a vibrating screen after roasting. The catalyst prepared by the preparation technology is high in yield, even in particle size, hard to smash, and good in wear resistance, so that the loss of the catalyst can be reduced, the use quantity of the catalyst can be saved, and the economic benefit can be improved.

Owner:中国石油集团东北炼化工程有限公司锦州设计院

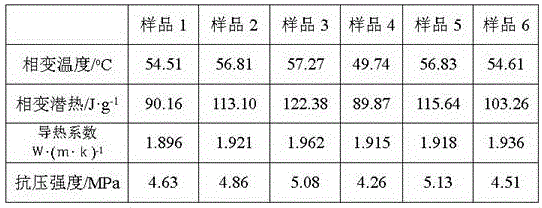

Phase change temperature-adjusting asphalt compound material for traffic pavement and preparation method thereof

ActiveCN106517894AHigh strengthHigh densityHeat-exchange elementsClaywaresPolypropyleneComposite phase change material

The invention relates to a phase change temperature-adjusting asphalt compound material for a traffic pavement and a preparation method thereof. The compound material is prepared from aggregate, base asphalt, a compound phase change material, an asphalt modifying material, a stabilizer and an antioxidant. The asphalt modifying material is composed of a polyethylene or polypropylene waste material, waste tyre powder and medium powder. The compound phase change material is composed of metal powder and a ceramic-based phase change material. The metal powder is formed by mixing nickel powder and copper powder. The ceramic-based phase change material is prepared from a supporting material and capric acid. The supporting material is formed by sintering kaolin, montmorillonite clay, zirconite, cordierite fine powder, magnesium oxide micropowder, modified nano titanium dioxide, silicon carbide fine powder, sodium hydrogen carbonate and calcium carbonate. The ceramic-based phase change material provided by the invention can be coated with an EVA resin on the surface, so that the leakage problem of the phase change material in a solid-liquid transformation process is further reduced, the stability of the ceramic-based phase change material is improved, and the phase change temperature-adjusting stability of the asphalt compound material is further improved.

Owner:王丽丽

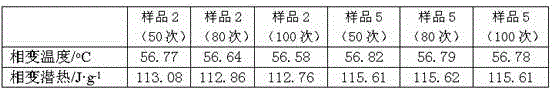

Low-carbon olefin catalyst prepared from low-carbon alkane through dehydrogenation and preparation method thereof

ActiveCN103055856AImprove performanceImprove technical effectHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkanePlatinum

The invention relates to a low-carbon olefin catalyst prepared from low-carbon alkane through dehydrogenation and a preparation method of the catalyst, and mainly solves the problem of low mechanical strength of the catalyst after a carrier is formed in the prior art. The technical scheme comprises the following that: a pseudo-boehmite raw powder or aluminum oxide raw powder is doped with pseudo-boehmite or aluminum oxide raw powder with smaller average particle size, a forming assistant such as Sesbania and the like is added, and a cylindrical carrier is obtained by kneading and squeezing; and a platinum-tin catalyst is obtained by loading the obtained carrier with a platinum component and a tin component by an impregnation method, namely, impregnating aqueous solutions of soluble salts of the platinum component and the tin component, and drying and roasting and processing with water vapour. According to the technical scheme, the problem of the low mechanical strength of the catalyst after the carrier is formed is solved well. The catalyst can be used for industrial production of preparing low-carbon olefin catalyst from low-carbon alkane through dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

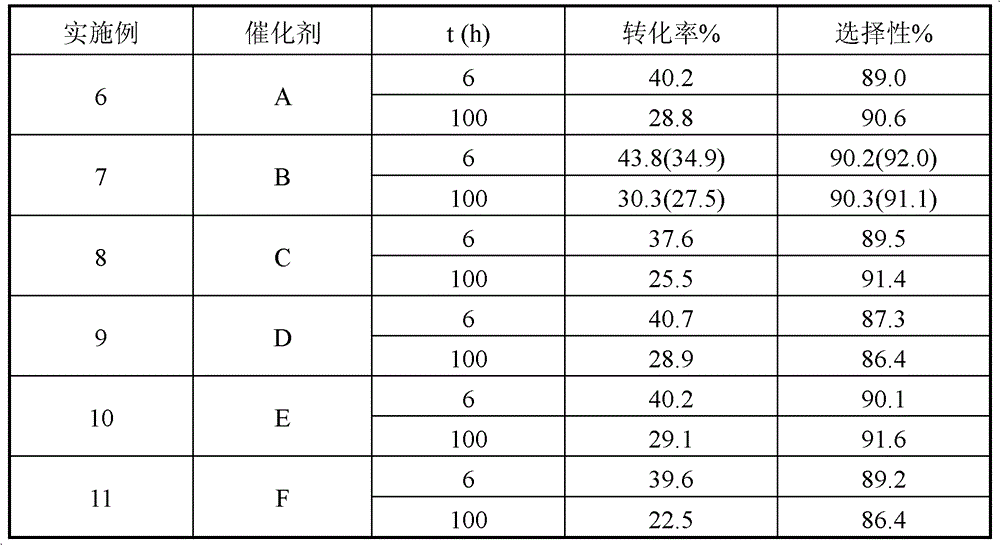

Injected supermolecule hydrogel and preparing method thereof

InactiveCN105664245AStrong adhesionStrong injectabilityTissue regenerationProsthesisSupramolecular hydrogelsGelatin

The invention belongs to the technical field of hydrogel and provides injected supermolecule hydrogel and a preparing method thereof. The injected supermolecule hydrogel comprises beta-cyclodextrin, gelatin and a coupling agent. Beta-cyclodextrin and a benzene ring in gelatin are combined in a subject and object mode by means of the hydrophobicity effect. The coupling agent is a silane coupling agent containing amino and / or epoxy bonds. Gelatin and the end, containing amino or epoxy bonds, of the coupling agent form covalent cross linking. The other end of the coupling agent is subjected to self-crosslinking to form a silicon dioxide network.

Owner:THE SECOND PEOPLES HOSPITAL OF SHENZHEN

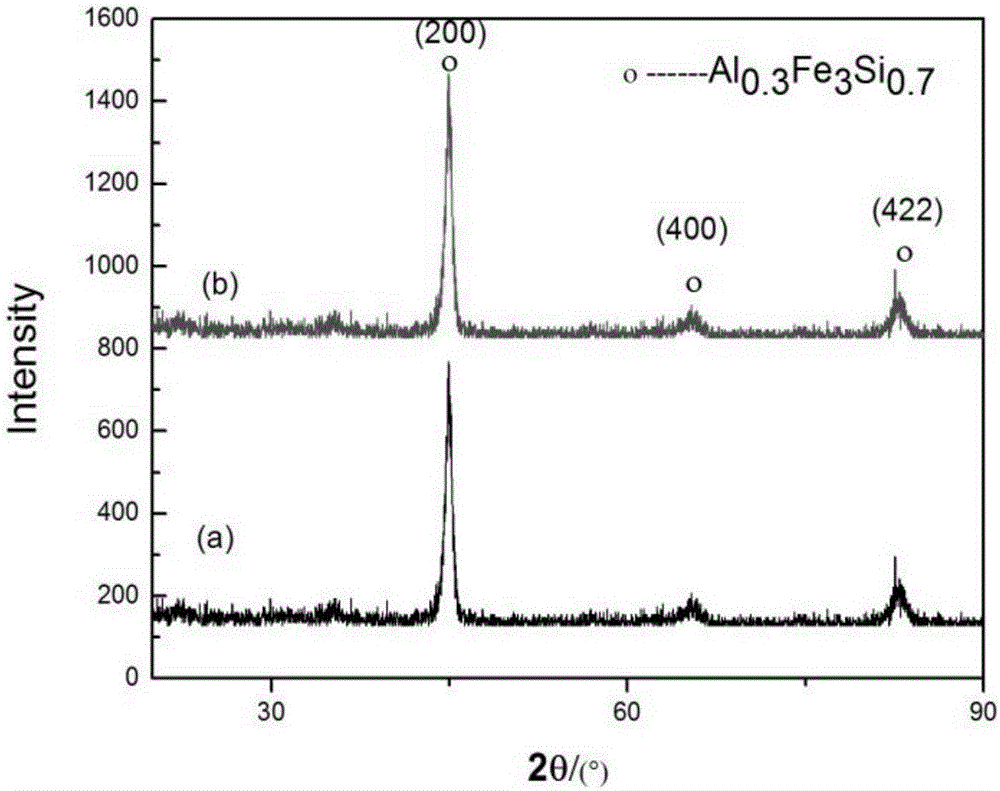

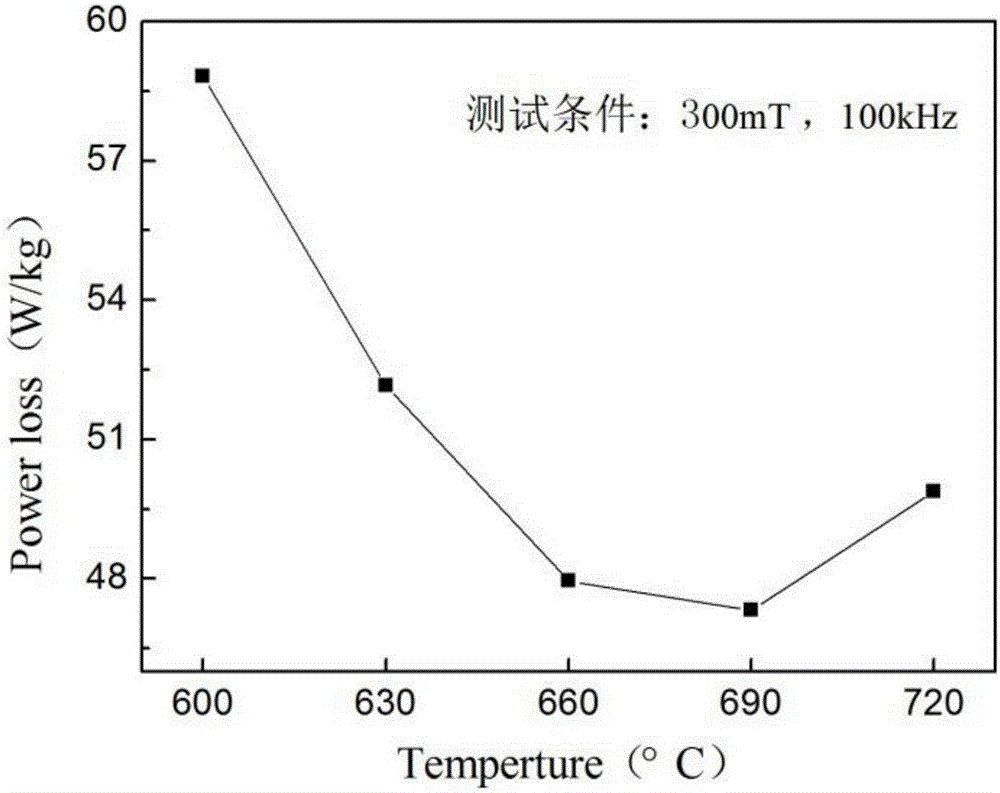

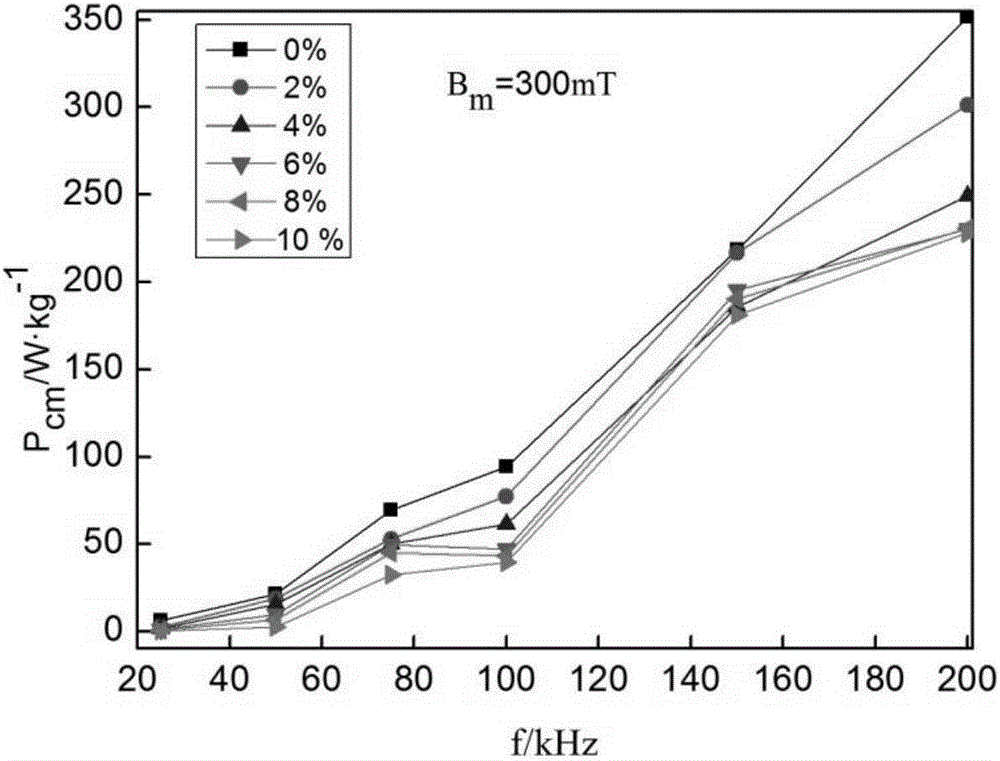

Preparation method of FeSiAl/Mn-Zn ferrite composite magnetic powder core

InactiveCN106373697AHigh temperature stabilitySolve the magnetic dilution problem of non-magnetic phaseTransportation and packagingMetal-working apparatusEpoxyManganese

The invention discloses a preparation method of an FeSiAl / Mn-Zn ferrite composite magnetic powder core. The method comprises the steps of carrying out in-situ synthesis on a ferric salt, a zinc salt and a manganese salt as raw materials and an NaOH solution as a precipitant through a chemical codeposition method on the surface of FeSiAl magnetic powder at 50-80 DEG C to form an Mn-Zn ferrite precursor and carrying out high-temperature roasting to obtain FeSiAl / Mn-Zn ferrite composite magnetic powder; and mixing the FeSiAl / Mn-Zn ferrite composite magnetic powder with epoxy resin and magnesium stearate evenly and then preparing the FeSiAl / Mn-Zn ferrite composite magnetic powder core through cold press molding. According to the method, a uniform and complete ferrite coating layer is formed on the surface of the FeSiAl magnetic powder, so that electric contact among metal magnetic powder particles is blocked; the resistivity of the composite magnetic powder core is improved; the eddy current loss of the composite magnetic powder core at a high frequency is effectively reduced; the prepared magnetic powder core is low in loss and high in magnetic conductivity; and the application field of the FeSiAl magnetic powder core is expanded.

Owner:GUANGDONG UNIV OF TECH

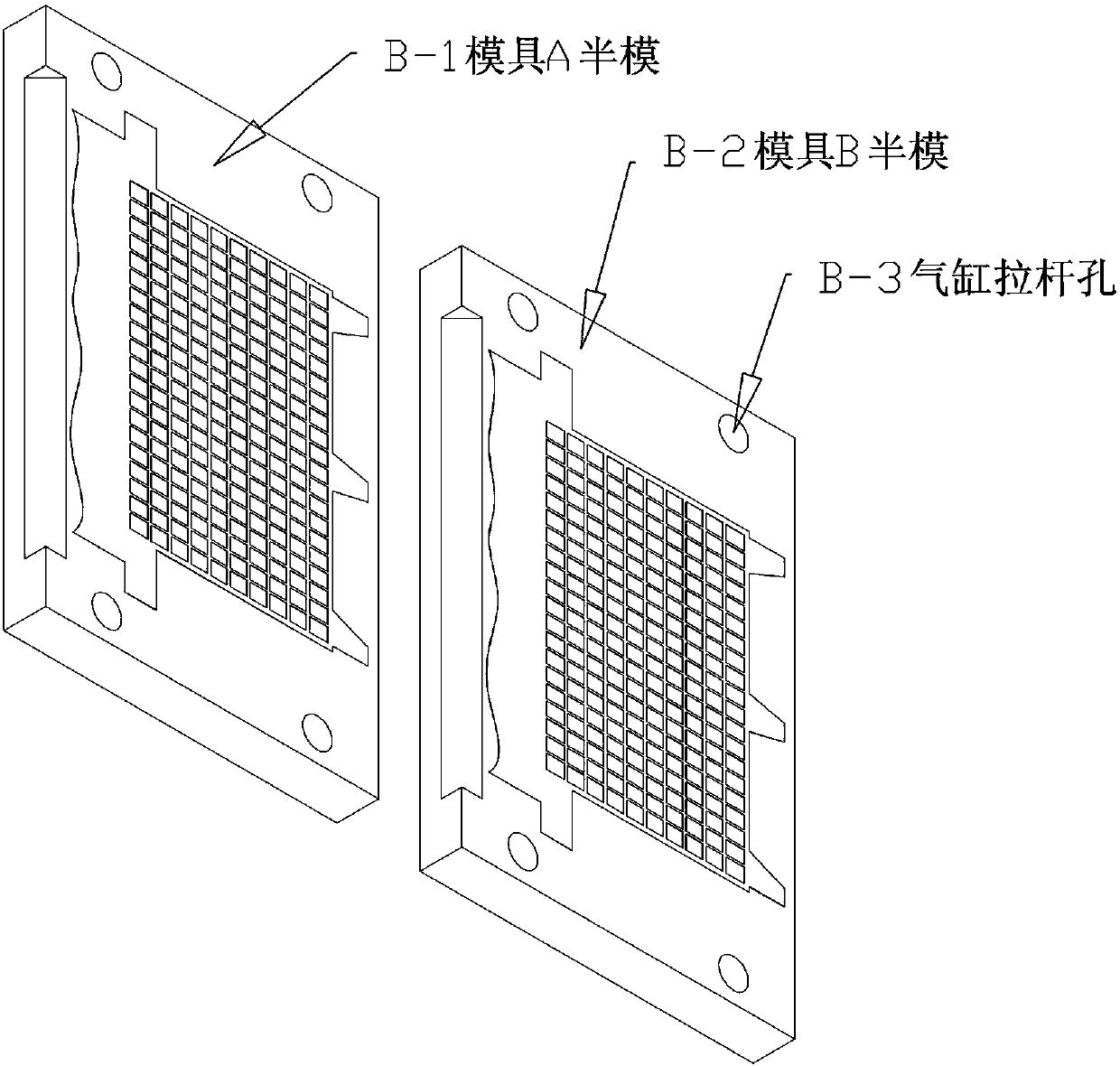

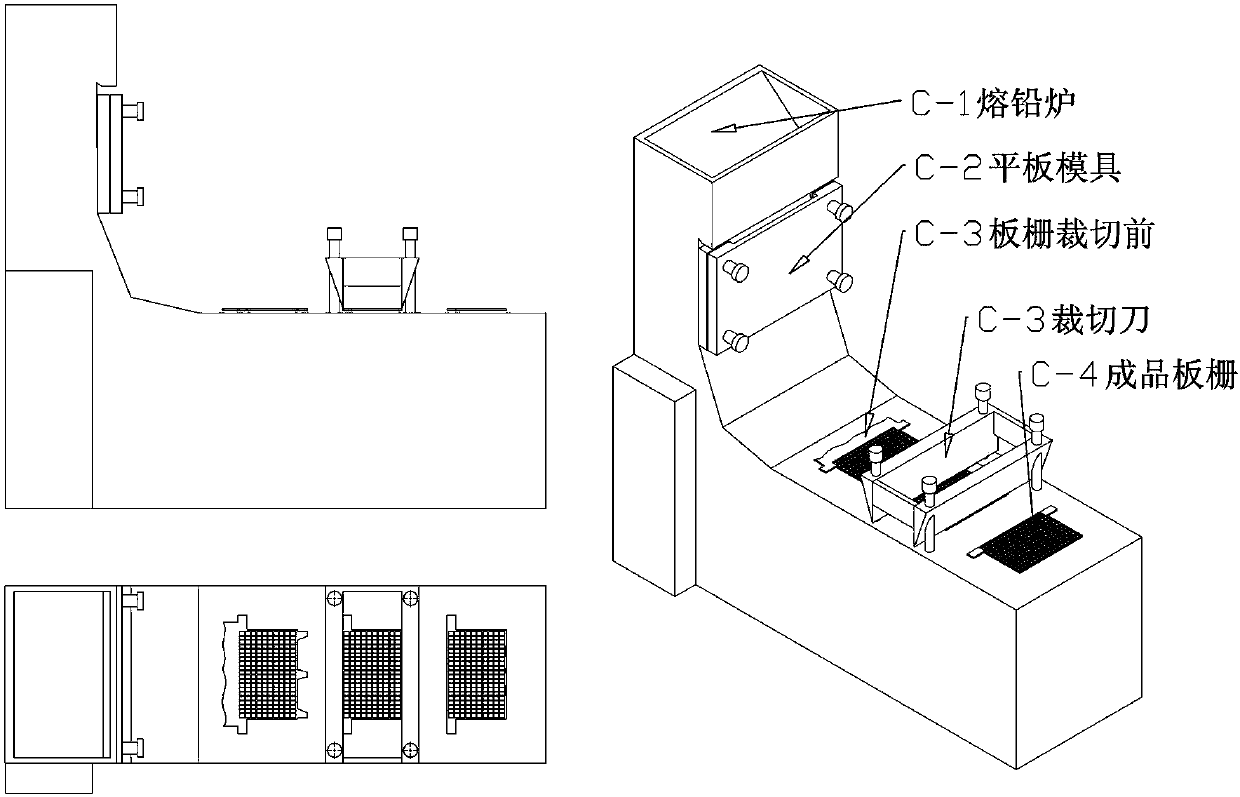

Storage battery grid mold release agent and preparation method thereof

ActiveCN103624211AHeat dissipation fastIncrease productivityFoundry mouldsFoundry coresCell fabricationManufacturing engineering

The invention belongs to the field of storage battery manufacturing technology, and particularly relates to a storage battery grid mold release agent and a preparation method thereof. The storage battery grid mold release agent is prepared from the following raw materials in parts by weight: 0.3-0.7 part of bone glue, 0.4-0.8 part of polyethylene, 0.4-0.8 part of kieselguhr, 0.2-0.5 part of glass water, 0.3-0.7 part of aluminum dihydrogen phosphate, 2-4 parts of cork powder of 200-300 meshes, 2-4 parts of cork powder of 700-800 meshes, and 88.5-94.4 parts of water. The storage battery grid mold release agent is easy to bond, high-temperature-resistant and smooth to exhaust; the prepared grid has fewer pores, thus being easily formed in casting.

Owner:HENAN CHAOWEI POWER SUPPLY

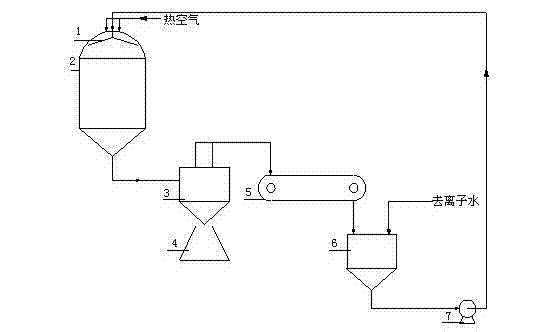

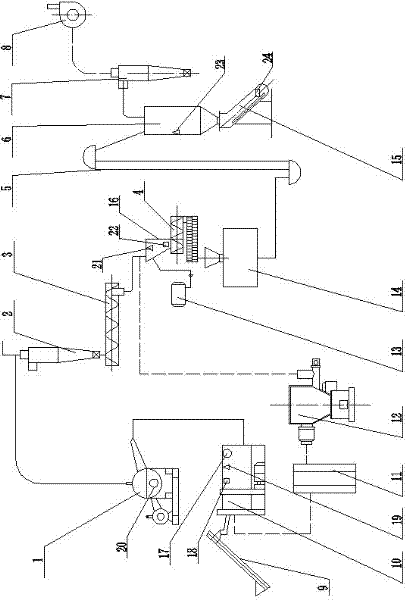

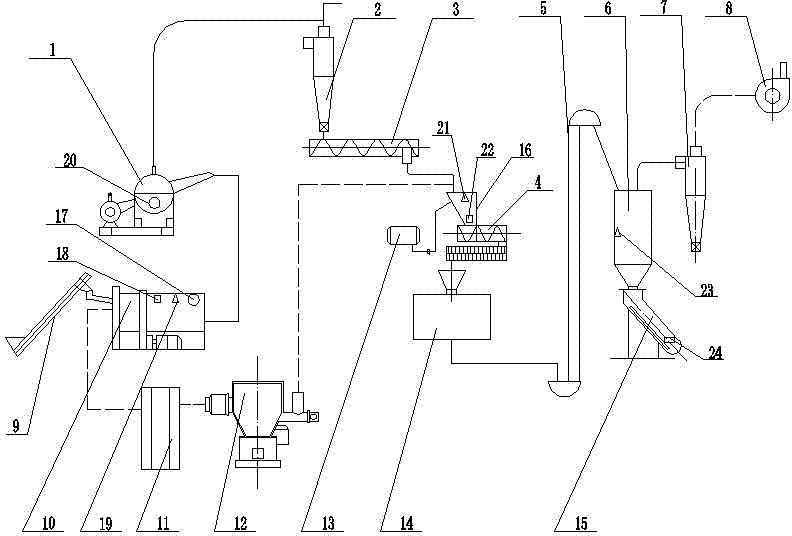

Automatic molding system for biomass flat-die particle

InactiveCN102517112AIn line with the actual operating mechanismReduce wearBiofuelsSolid fuelsAutomatic controlProcess engineering

The invention discloses an automatic molding system for a biomass flat-die particle, which comprises a drying part, a crushing part, a material conveying part, a molding part and a cooling and drying separating part, wherein the discharge hole of the drying part is connected with the feeding hole of the crushing part; the discharge hole of the crushing part is connected with the feeding hole of the molding part through the material conveying part; and the discharge hole of the molding part is connected with the feeding hole of the cooling and drying separating part. The automatic molding system for the biomass flat-die particle includes a set of intelligent and automatic large-scale energy treatment process routes integrating straw drying, straw crushing and straw cold-state compact molding. According to the automatic molding system for the biomass flat-die particle, the automatic operation of all links of biomass molding is realized by adopting an integral automatic control system, thereby, manual operations are reduced, and the automatic operation of the system under optimized working conditions is ensured; energy consumption and labor cost are low; and a heat source is provided by adopting the fluidized-bed combustion technology in the biomass drying process without consuming traditional energy sources, and the heat utilization efficiency of equipment can reach over 60 percent.

Owner:ENERGY RES INST CO LTD HENAN ACADEMY OF SCI

Microwave enzyme-deactivating process for green tea

ActiveCN103380829AStop metabolismNot easy to crushPre-extraction tea treatmentGreen teasMicrowave power

The invention discloses a microwave enzyme-deactivating process for green tea. The process comprises the following steps: setting the temperature of a microwave warehouse to be more than 200 DEG C and preheating the microwave warehouse; placing 1.5 to 2 kg of fresh tea leaves into the microwave warehouse, adjusting microwave power to be 1500 to 1800 W, stirring the fresh tea leaves, allowing leaf temperature to rapidly rise to more than 80 DEG C and maintaining the temperature for 5 min; shaking the leaves, throwing the enzyme-deactivated leaves upwardly to allow the leaves to scatter in the air and then to naturally fall into the microwave warehouse and repeatedly throwing the leaves until leaf temperature drops to less than 42 DEG C; adjusting the microwave power to be 2000 to 2200 W and stewing the leaves; and taking the enzyme-deactivated leaves out of the microwave warehouse when water content in the leaves is in a range of 55 to 60%. The process provided by the invention terminates metabolism of the tea leaves, allows substances related to tea quality to maintain optimal, removes grassy smell and retains original tea fragrance of the green tea; the prepared green tea has a good color, almost being dark blue, and has no burnt leaves; moisture in the leaves gradually decreases, the tea is soft and is difficult to triturate during rolling, and the tea naturally curls to form cords.

Owner:绍兴健茗茶业有限公司

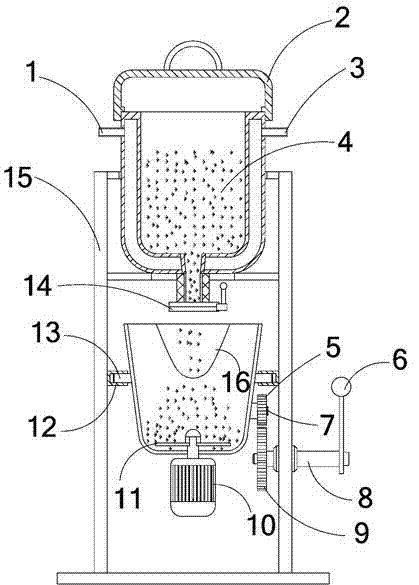

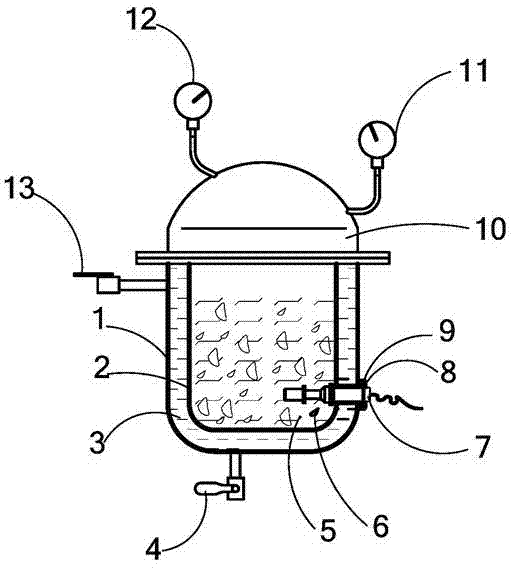

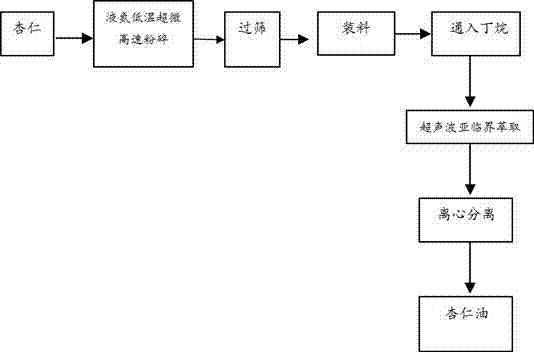

Method with combination of low-temperature superfine grinding and ultrasonic subcritical extracting for almond oil

InactiveCN103497826AEasy to crushNot easy to crush and sieveFatty-oils/fats productionMetallurgyPhysical chemistry

The invention discloses a method with combination of low-temperature superfine grinding and ultrasonic subcritical extracting for almond oil. The method comprises the steps of carrying out low-temperature grinding on peeled almonds of which the water content is 1-3% by using a low-temperature liquid nitrogen superfine grinding device, screening by a 20-60-mesh screen, paving in a 200-mesh bolting silk, and then rolling into an ultrasonic subcritical extracting kettle; with liquefied butane as a solvent, under the conditions that the material-solvent ratio is 1: (4.5-8.5), the extracting temperature is 25-55 DEG C, the pressure is 0.45-0.65MPa, the ultrasonic power is 250-500W and the ultrasonic frequency is 40KHZ, reacting for 20-60min, extracting for one time, reducing the pressure to remove the solvent, and finally, centrifuging so as to obtain the almond oil. The extracting rate in one time can reach 98.26%, the extracting time is shortened by about 40% than that in the existing extraction method, and is shortened by about 20% than that in the supercritical extraction technology; the harmful residual solvent is avoided; the large-scale industrial continuous production of the almond oil is realized, and furthermore, the method has wide practicability in production.

Owner:新疆农业科学院农产品贮藏加工研究所

Asphalt composition particle and preparation method thereof

ActiveCN103804926AHigh oxidation reactivity and reaction self-exothermic abilityImprove product softening pointDrilling compositionBuilding insulationsLignosulfonatesWater soluble

The invention discloses an asphalt composition particle and a preparation method thereof. The asphalt composition particle comprises the following components by weight percentage: 80wt%-95wt% of high-softening point asphalt, 4.9wt%-15wt% of modified starch and / or water soluble fiber, and 0.1wt%-5wt% of a promoter. Specifically, the high-softening point asphalt is the asphalt with a softening point at 120-220DEG C, the promoter is one or more of sulfate, quaternary ammonium salt or lignosulfonate. The preparation method includes: mixing and crushing the high-softening point asphalt, the modified starch and / or water soluble fiber and the promoter to obtain the asphalt composition particle. With high softening point and excellent high temperature performance, the asphalt composition particle provided by the invention can be used under high temperature drilling operation conditions. The preparation method is simple and is convenient to operate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Asphalt composition granule suitable for wider temperature drilling and preparation method thereof

ActiveCN103804922AHigh softening pointGood high temperature performanceDrilling compositionBuilding insulationsFiberSulfate

The invention discloses an asphalt composition granule suitable for wider temperature drilling and a preparation method thereof. The asphalt composition granule comprises the following components by weight percentage: 80wt%-95wt% of a high-softening point asphalt composition, 4.9wt%-15wt% of modified starch and / or water soluble fiber, and 0.1wt%-5wt% of a promoter. Specifically, the high-softening point asphalt composition is a mixture of two or more of high-softening point asphalt with a softening point of 120-220DEG C, and the softening point difference between adjacent high-softening point asphalt ranged according to the softening point from low to high is 5-50DEG C. The promoter is one or several of sulfate, quaternary ammonium salt, or lignosulfonate. The preparation method includes: mixing and crushing the high-softening point asphalt composition, the modified starch, the water soluble fiber and the promoter to obtain the asphalt composition granule. The asphalt composition granule provided by the invention has high softening point and excellent high temperature performance, and can continuously play a part under wide-temperature range drilling operation conditions. And the preparation method is simple, and is convenient to operate.

Owner:CHINA PETROLEUM & CHEM CORP +1

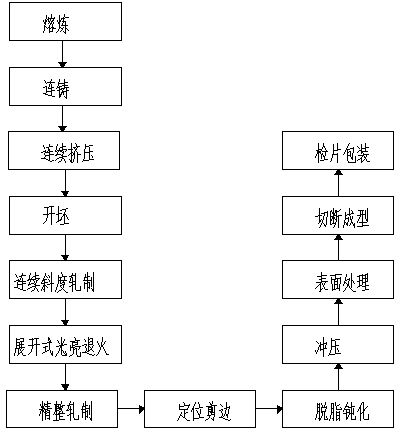

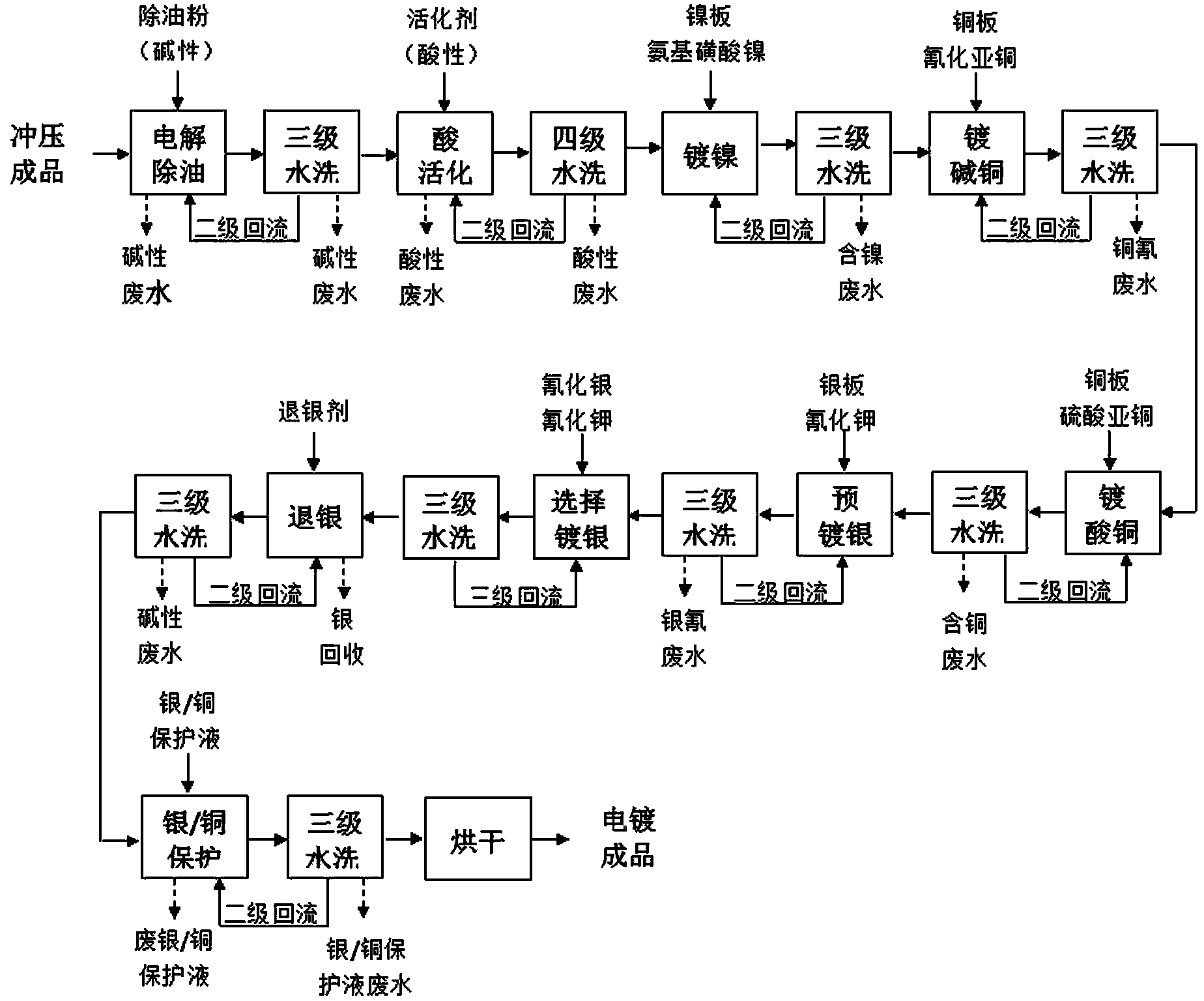

Semi-conductor lead framework production process

ActiveCN103928351AExact widthAdequate heat dissipationSemiconductor/solid-state device manufacturingMechanical engineeringSemiconductor

The invention relates to a semi-conductor lead framework production process which includes the steps of smelting, continuous casting, continuous extrusion, cogging, severe convection annealing, continuous inclination rolling, spreading-type bright annealing, finishing rolling, positioning-type edge shearing, degreasing passivation, stamping, surface processing, cutting forming and detection piece packaging. The production process is characterized in that the two work procedures of finishing rolling and positioning-type edge shearing are provided with continuous grooving procedures, when continuous grooving is carried out, precise grooving processing is carried out through a grooving machine, the rotation speed of the grooving machine is 1800-2000 r / min, the flow of cooling liquid is 45-50 L / min, and dovetail groove forming achieving through the process cannot cause strip width changes after forming, and the size of a formed semi-conductor lead framework is accurate.

Owner:SICHUAN JINGJIAN ELECTRONICS MATERIAL

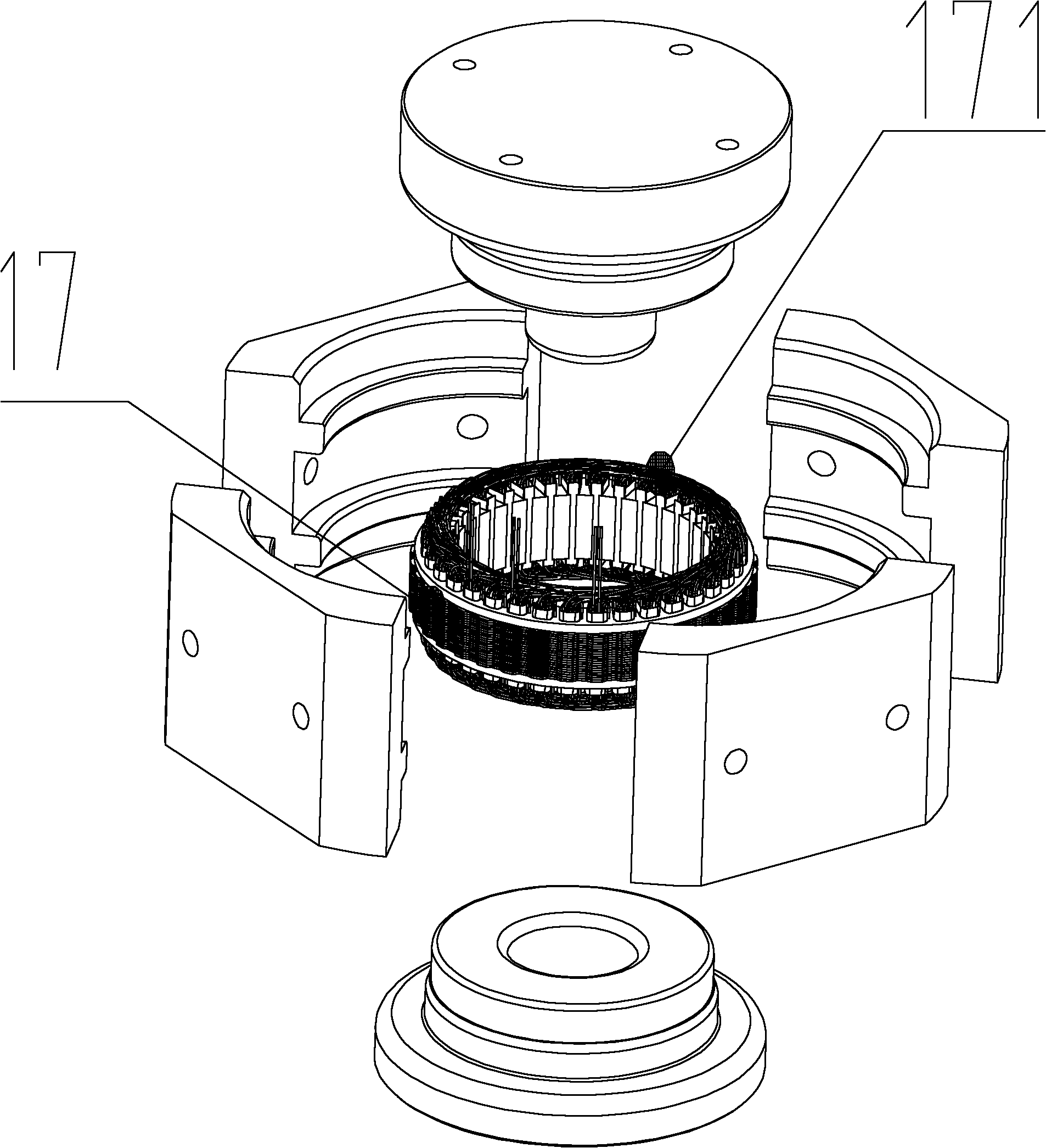

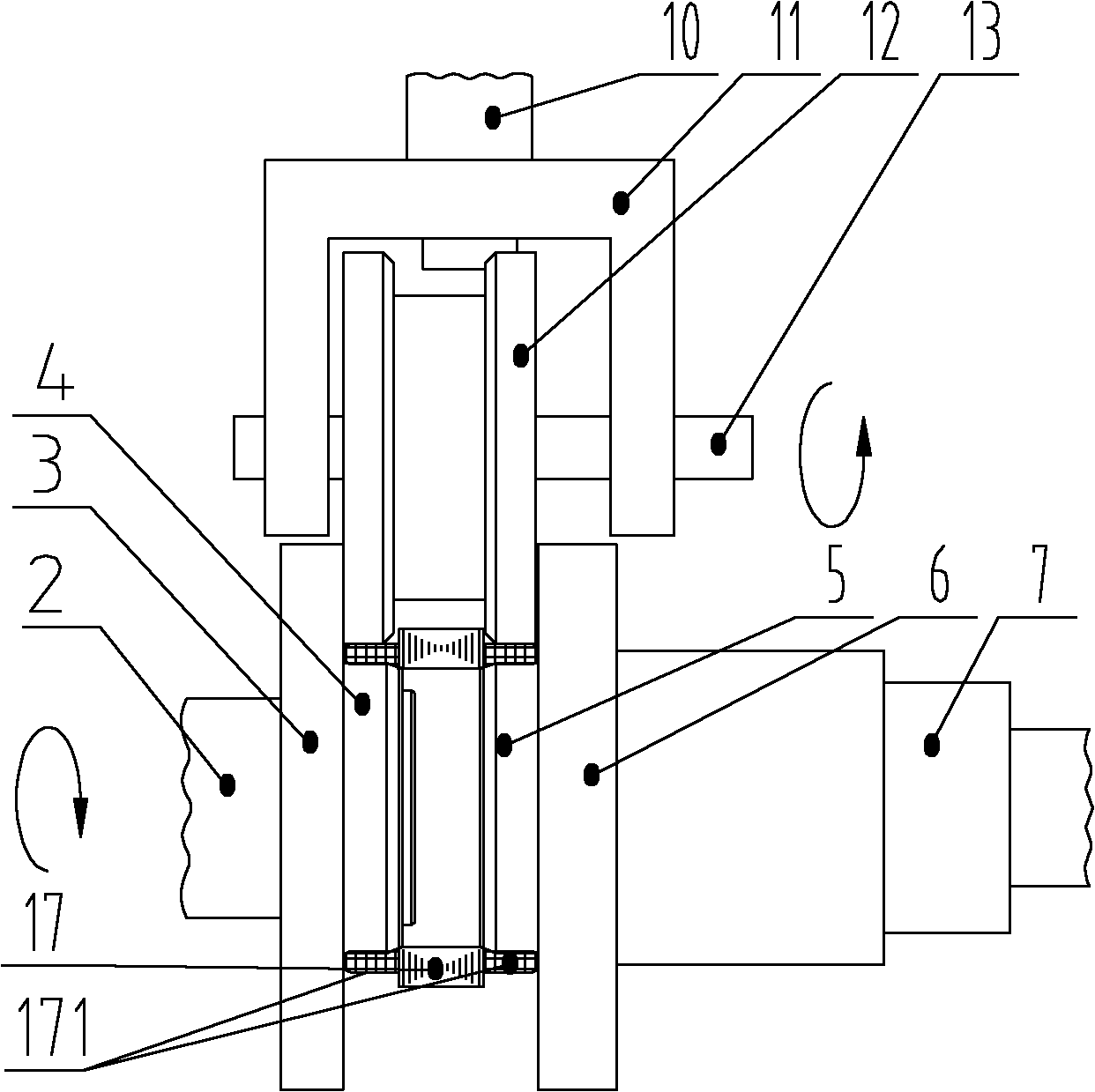

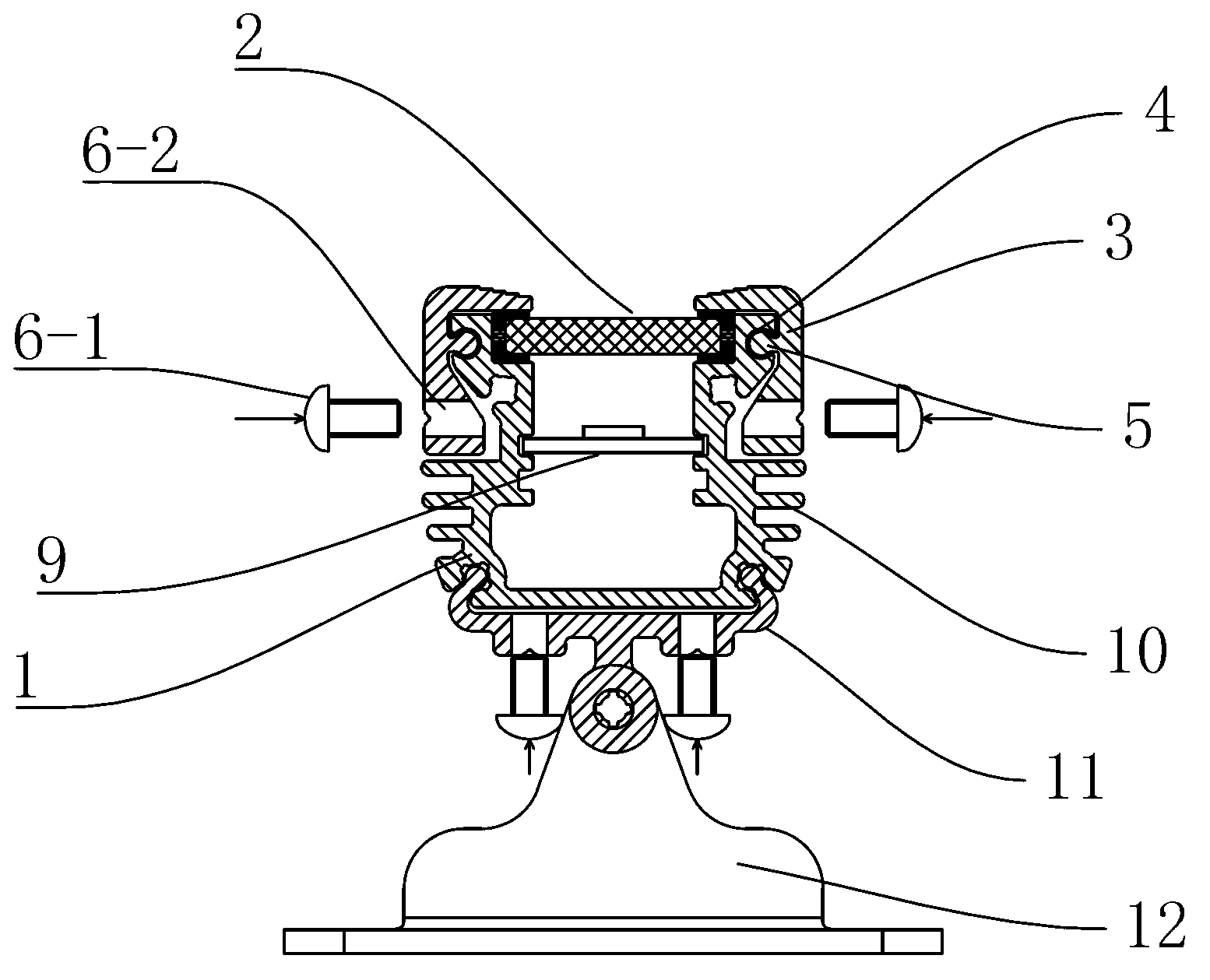

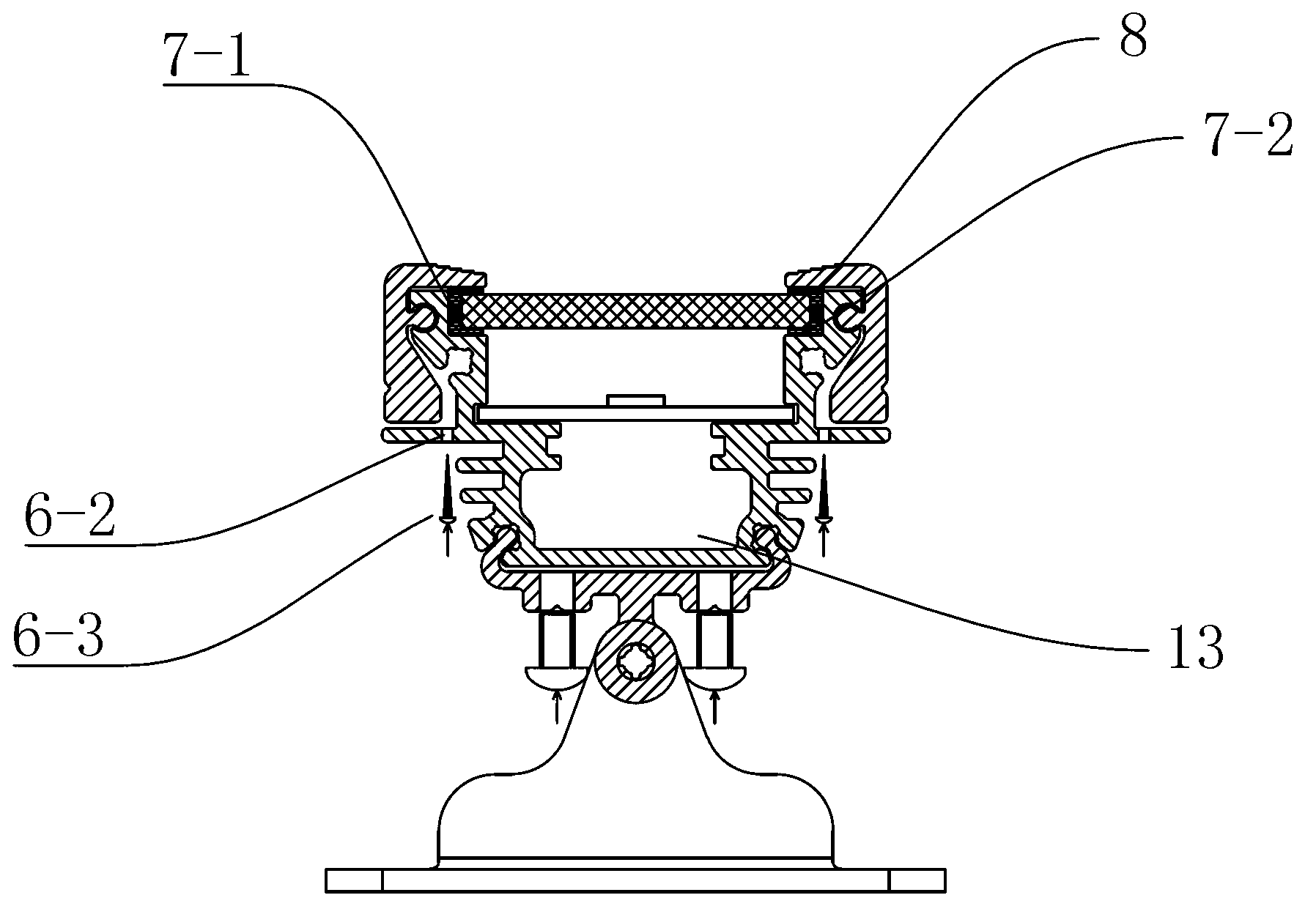

Motor stator coil reshaping method and device

ActiveCN101877519ABeautiful appearanceClosely arrangedManufacturing dynamo-electric machinesDrive shaftStator coil

The invention relates to a motor stator coil reshaping device which comprises a reshaping clamp, a driving mechanism, a transverse motion mechanism and a longitudinal motion mechanism, wherein the reshaping clamp comprises a left flange, a rolling wheel, a right flange, a fixed mandrel and a roller assembly; the right flange is fixed to the moving member of the transverse motion mechanism; the fixed mandrel is fixed on one side of the axial line of the right flange; the left flange is connected with the driving shaft of the driving mechanism; the rolling wheel is fixed on one side of the axial line of the left flange; the rolling wheel and the fixed mandrel are arranged on the same axial line; the left flange is over against the right flange; the roller assembly is fixed on the moving member of the longitudinal motion mechanism; and the roller is over against a position between the left flange and the right hand flange. Conductors in the reshaped coil are compact, can not easily loosen, and have the advantages of favorable dimensional uniformity and small degree of roundness. The invention increases the percent of pass of stator reshaping, and maximally reduces the slippage between the roller and the coil, thereby reducing the damage of the roller on the insulating layer of the coil. The invention has the advantages of simple reshaping operation, high reshaping efficiency and good product quality.

Owner:NINGBO YUNSHENG +2

Textured multicolor paint and preparation method thereof

InactiveCN110628278AHigh degree of stone imitationImprove integrationMulticolor effect coatingsSlurryMaterials science

The invention discloses a textured multicolor paint and a preparation method thereof, and belongs to the technical field of coatings. The textured multicolor paint comprises protective glue, a color matching base material, textured paint pre-slurry, natural colored sand and a continuous phase. According to the preparation method, stone like coating and a sand-in-water multicolor coating are combined, the coating has higher stone imitation degree, the texture of the stone like coating and stone imitation color spots of the sand-in-water multicolor coating, the fusion degree of the stone like coating and the sand-in-water multicolor coating is high, and the paint film effect is close to that of real stone materials; and meanwhile, the coating can be constructed by using a stone like coatingspray gun, construction can be completed in one time; compared with the sand-in-water multicolor coating, the advantages are that labor cost and construction difficulty can be reduced greatly.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

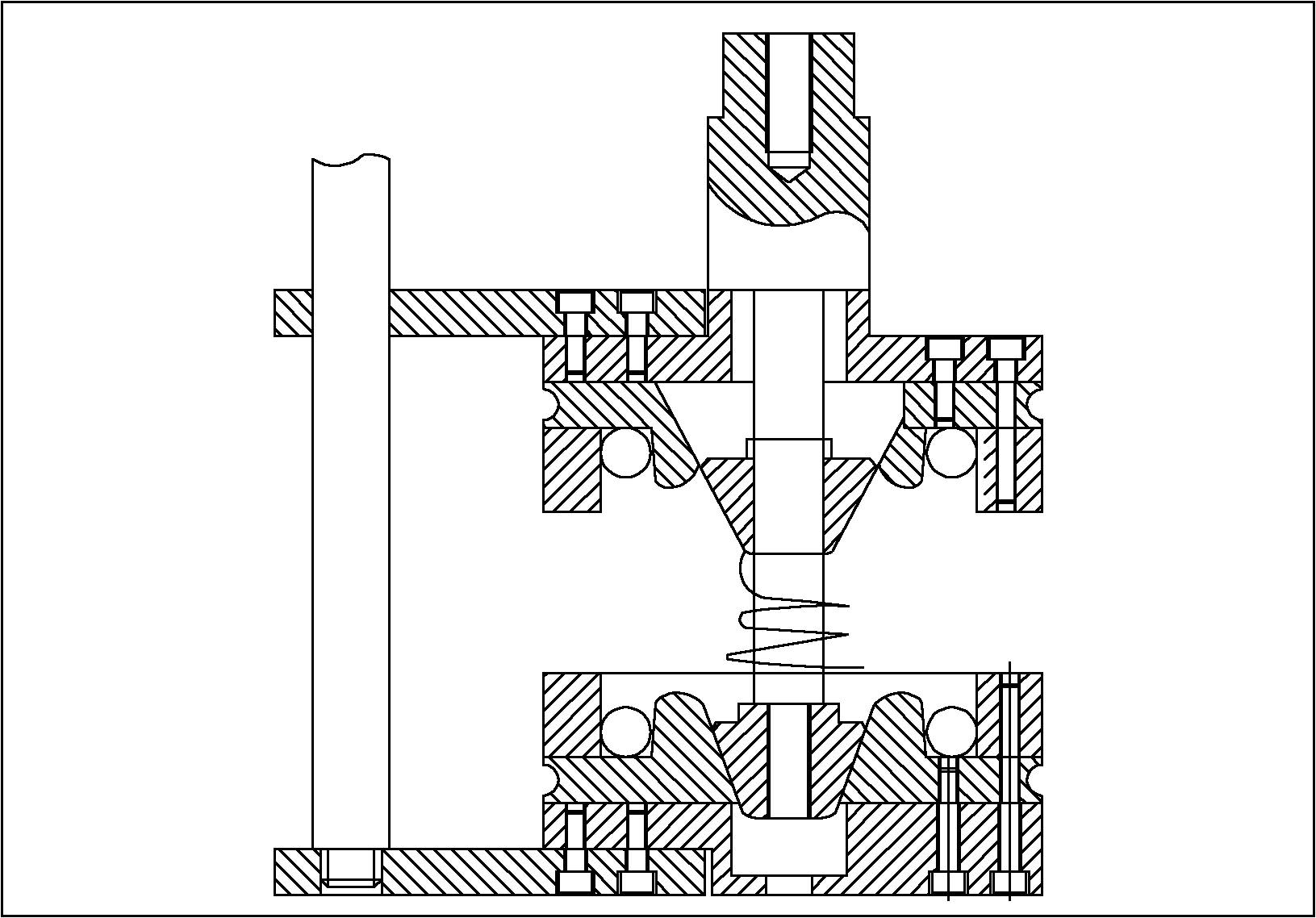

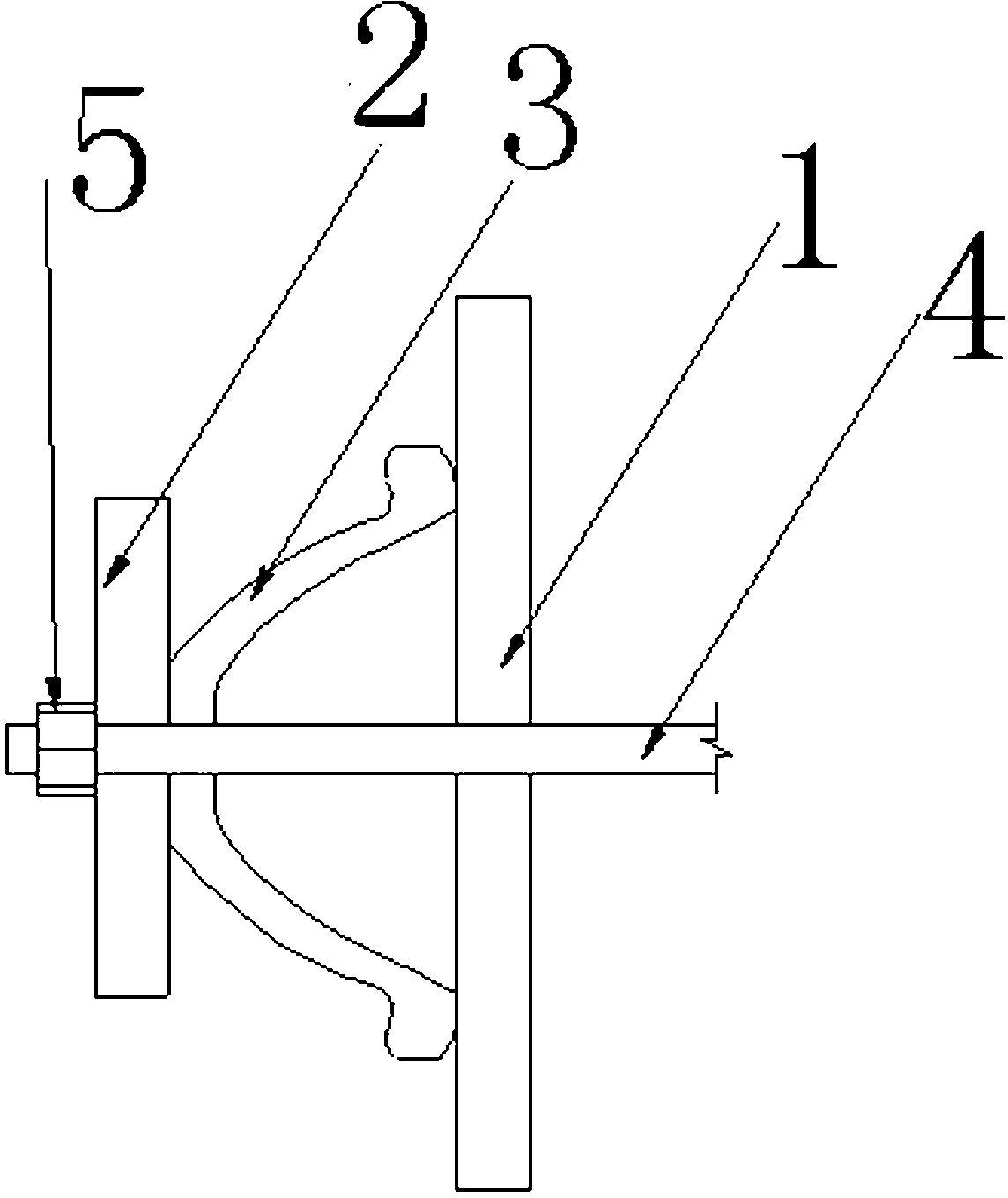

Pipe bender

The invention discloses a pipe bender comprising a frame and a power transmission mechanism fixedly arranged on the frame. A driving wheel is arranged on the frame. The power transmission mechanism comprises a hydraulic cylinder and a damping cylinder. The driving wheel is connected with the hydraulic cylinder. A driven module is arranged at one end, corresponding to the driving wheel, of the frame. An arc-shaped groove is formed in one side, corresponding to the driving wheel, of the driven module and is matched with the outer edge of the driving wheel. The driven module can be slidably arranged on a die holder which can be rotationally arranged on the frame. The lower portion of the die holder is connected with the damping cylinder. A pipe is positioned between the driving wheel and the arc-shaped groove of the driven module when the pipe bender is used for bending the pipe, and the driven module rotates along with the driving wheel during operation of the driving wheel, so that the pipe is not easy to flatten; the pipe bender is compact in structural design and low in size, and production cost is greatly reduced.

Owner:SHANGHAI SUQIAO MECHANICAL EQUIP

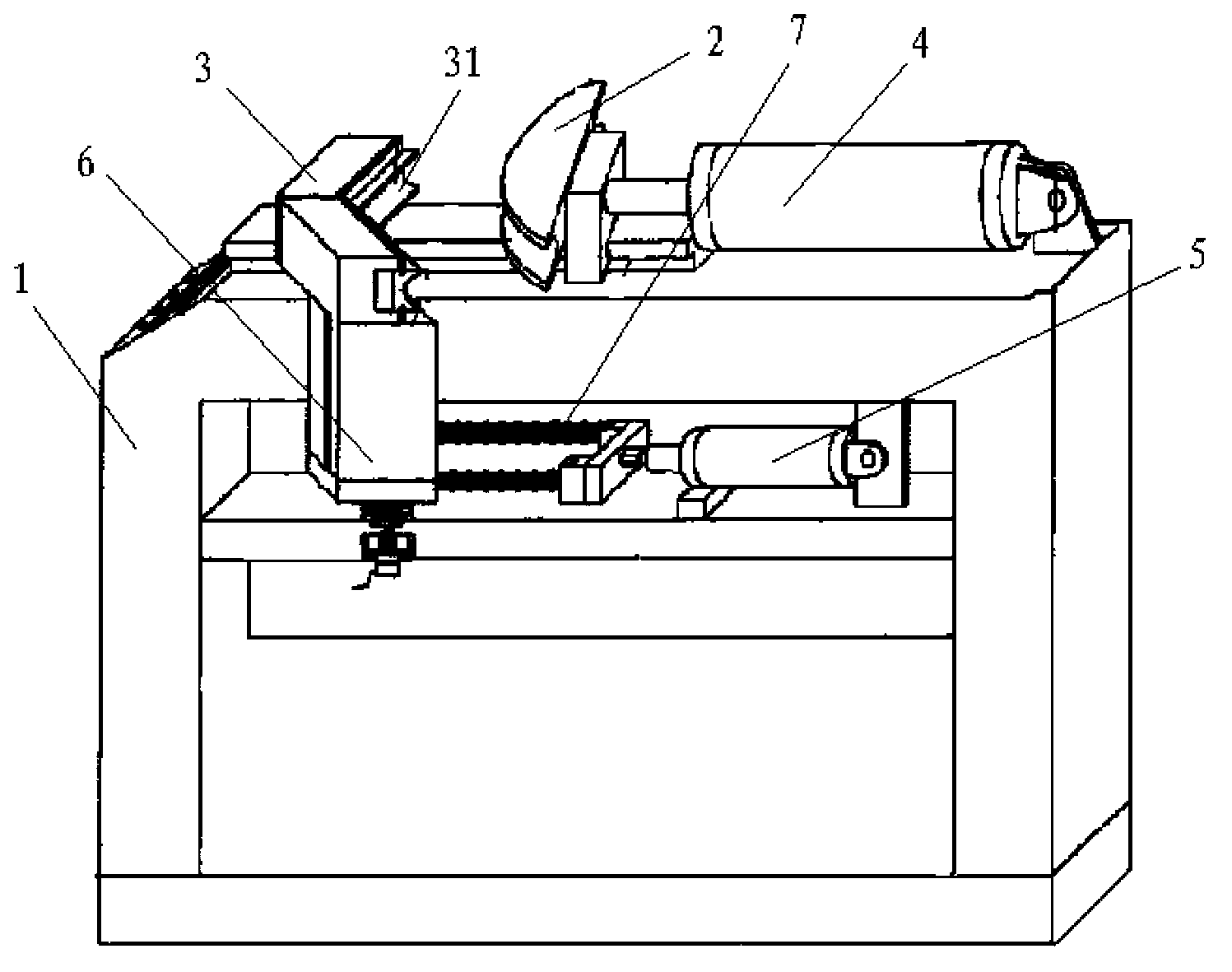

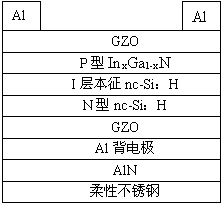

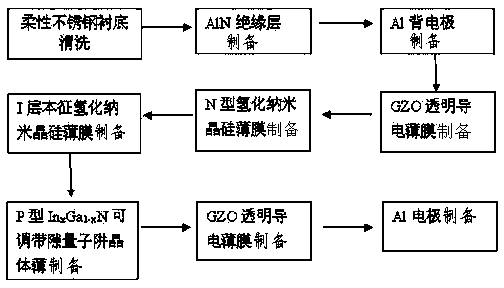

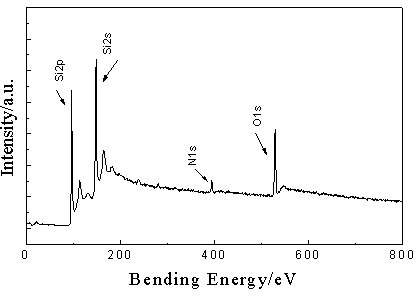

Stainless steel substrate solar battery in adjustable-band-gap quantum well structure and preparation method thereof

ActiveCN103746016AReduce weightImprove conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingInsulation layerSolar battery

The invention belongs to the technical field of flexible solar battery manufacturing, and particularly relates to a stainless steel substrate solar battery in an adjustable-band-gap quantum well structure and a preparation method thereof. The stainless steel substrate solar battery provided by the invention is of the following concrete structure: Al electrode / GZO (gallium zinc oxide) / P type In<x>Ga<1-x>N / I layer intrinsic nc-Si:H / N type nc-Si:H / GZO / Al back electrode / AlN insulation layer / flexible stainless steel substrate. The preparation method of the stainless steel substrate solar battery comprises the steps that firstly, magnetron sputtering is carried out for preparing an AlN insulation layer and an Al back electrode, then, ECR-PEMOCVD is adopted for sequentially depositing a GZO based transparent conducting film, an N type nc-Si:H film, an I layer intrinsic nc-Si:H film, a P type In<x>Ga<1-x>N film and a GZO film, and finally, the metal Al electrode is prepared. The stainless steel substrate solar battery in the adjustable-band-gap quantum well structure has the advantages that the flexibleness is excellent, the weight is light, the carrying is convenient, the industrialization potential and the market space are realized, in addition, the preparation process is simple, and the scale production can be realized.

Owner:SHENYANG INST OF ENG

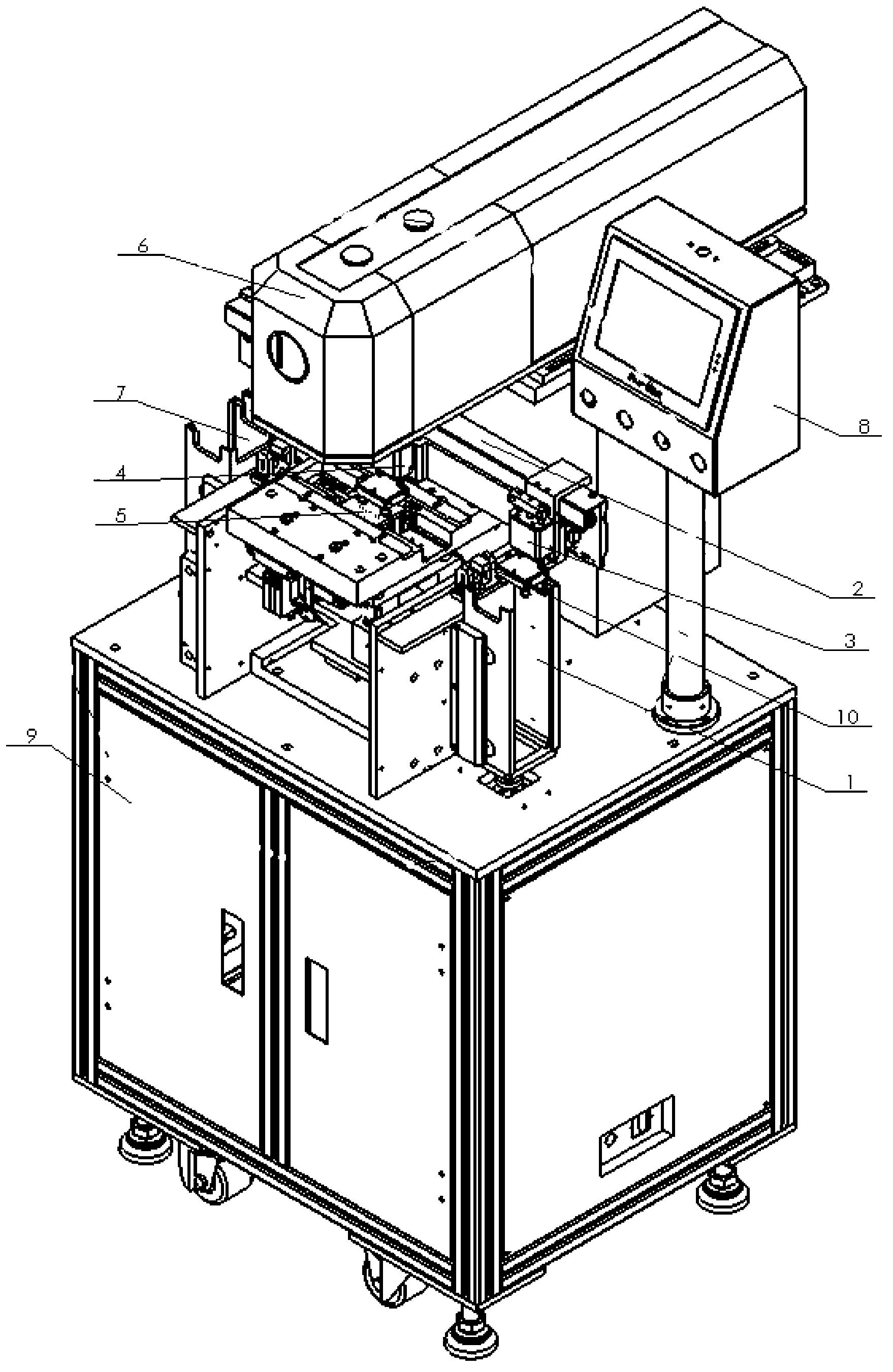

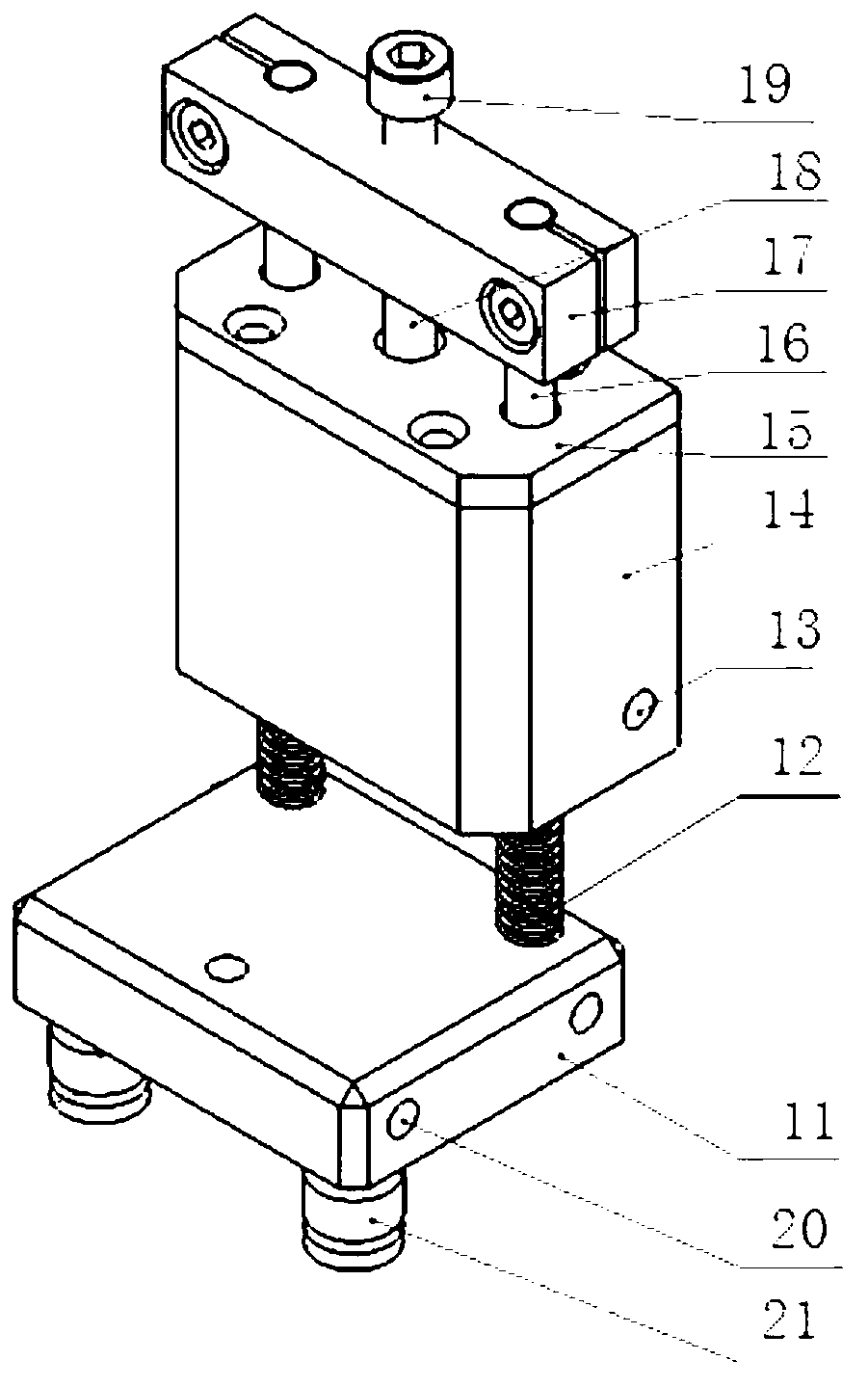

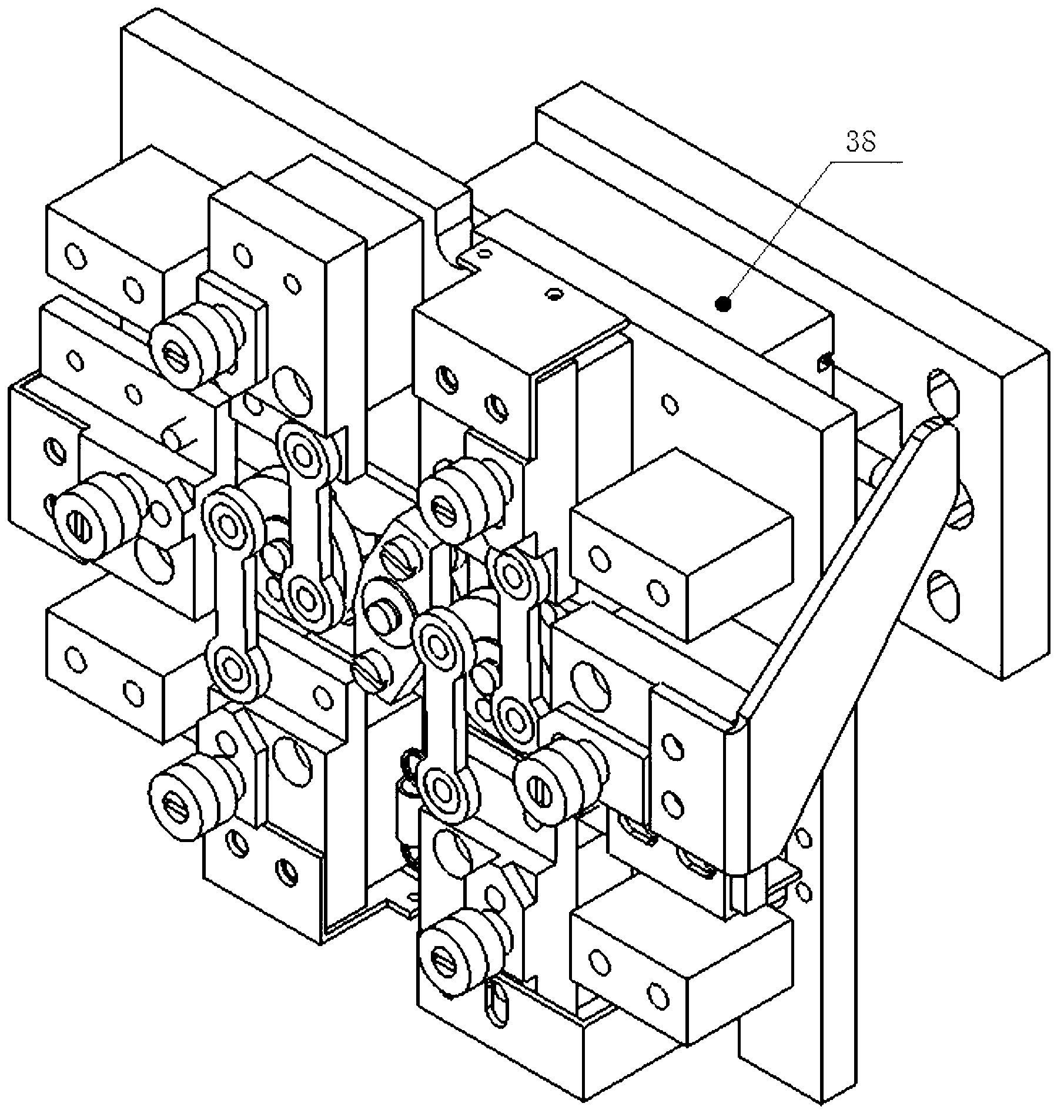

Automatic laser marking device for wafer resistor

ActiveCN102794569AImprove manufacturing qualityRealize elastic operationLaser beam welding apparatusMechanical engineeringLaser

The invention discloses an automatic laser marking device for a wafer resistor, which comprises a frame, a receiving mechanism, a conveying mechanism, an air blowing mechanism, a six-wheel eccentric link center positioning mechanism, an optical fiber laser device and a control box, wherein the receiving mechanism is used for holding a to-be-processed base plate or conveying the processed base plate to a receiving bin; the receiving mechanism is moveably connected with the conveying mechanism; the receiving mechanism can move on the conveying mechanism; a conveying bin is arranged on the lower part at one end of the conveying mechanism; the receiving bin is arranged on the lower part at the other end of the conveying mechanism; the six-wheel eccentric link center positioning mechanism is arranged at the lower end on the middle part of the conveying mechanism; the air blowing mechanism is used for performing air-blowing dust-removing treatment on the to-be-processed base plate held by the receiving mechanism; the six-wheel eccentric link center positioning mechanism is used for positioning the to-be-processed base plate held by the receiving mechanism; the optical fiber laser device is used for cutting lines for the base plate positioned by the six-wheel eccentric link center positioning mechanism; and the control box is used for controlling the receiving mechanism, the conveying mechanism, the air blowing mechanism, the six-wheel eccentric link center positioning mechanism and the optical fiber laser device to work.

Owner:昆山市和博电子科技有限公司

Method for preparing sanitary scent using with cassava powder

InactiveCN101125059AProtect forest resourcesHigh strengthGaseous substancesReligious equipmentAdditive ingredientEngineering

The present invention relates to a method of making fragrant incense by using cassava flour. The method comprises the steps that: the raw material is crashed, filtered, mixed, stirred, made into stripe, parched or aired, sprayed for spice, and all procedures make out stripe shape or disk shape finished products, wherein, the raw material takes the cassava flour as the agglomerant and the ratio are 15 to 75 percent of cassava flour, 20 to 80 percent of the other bamboo and grass powder, and the other ingredients are fire accelerant and colorant, etc.; the optimized ratio of the raw material are 30 to 60 percent of cassava flour, 35 to 65 percent of the other bamboo and grass powder, and the other ingredients are fire accelerant and colorant, etc. The present invention has the beneficial effects that the ixonanthes chinensis material such as Machilus can be replaced entirely to protect the forest resource; while the product has much higher intensity and is difficult to be broken off and crashed, thus being convenient for transportation; the ash of the product is gray without peculiar smell and the quality is better.

Owner:许景盛

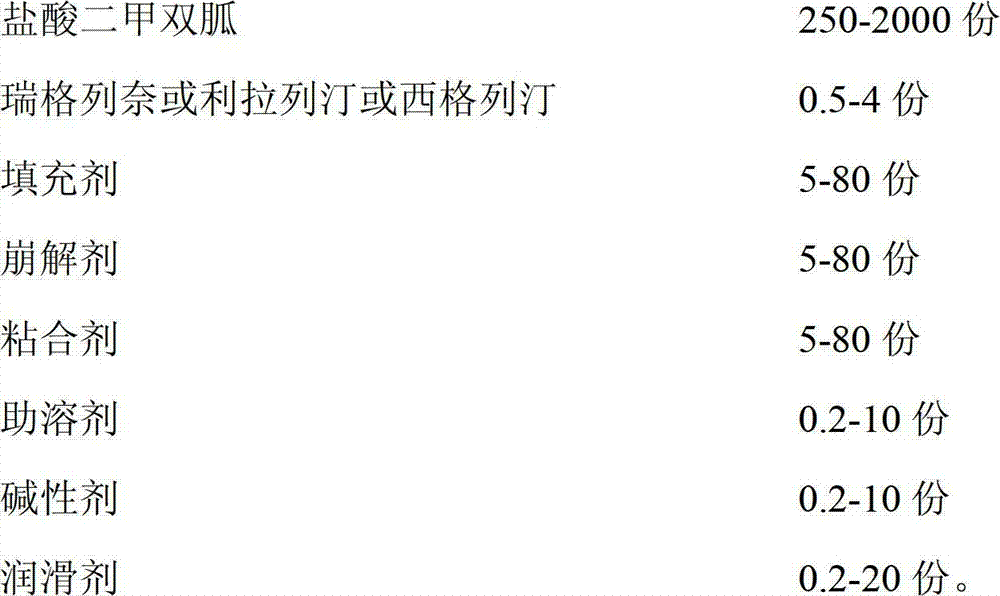

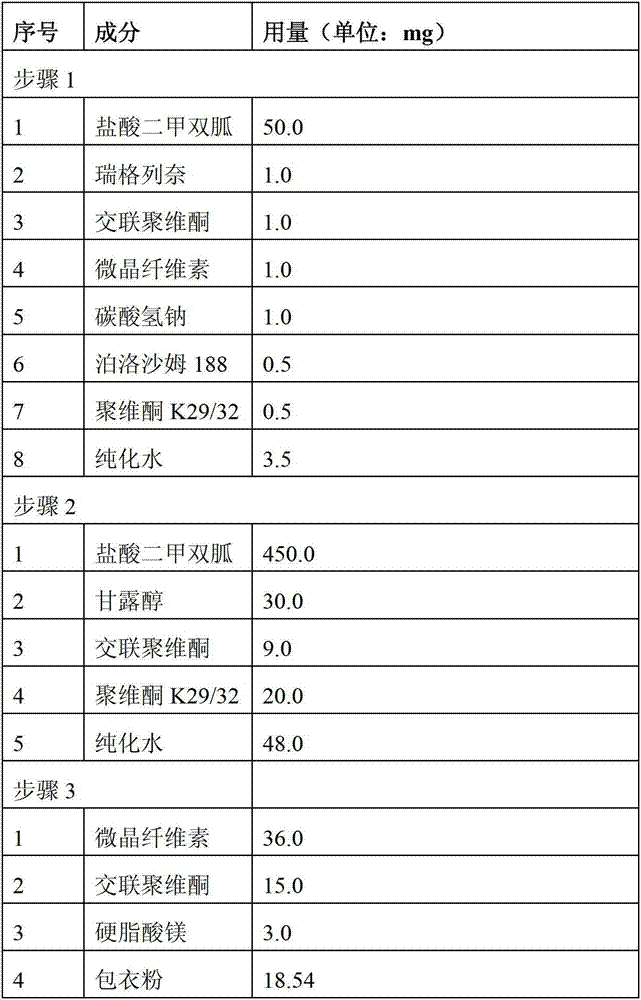

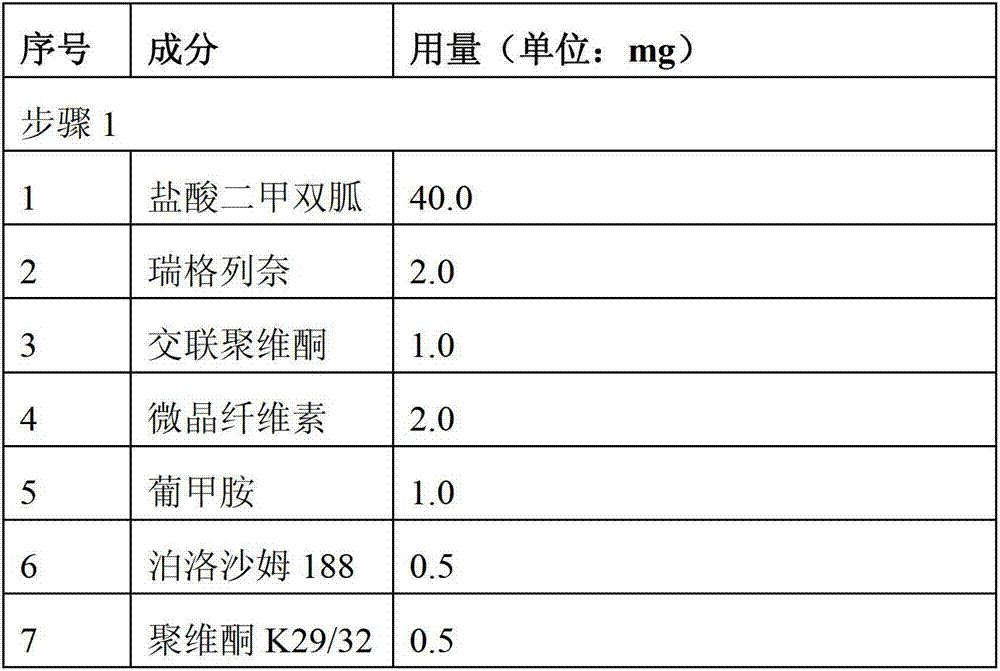

Metformin compound pharmaceutical composition and preparation method thereof

InactiveCN103239719AUniform contentSimple preparation processOrganic active ingredientsMetabolism disorderLarge doseDiabrezide

The invention provides a metformin compound pharmaceutical composition for treating type II diabetes and a preparation method thereof. The pharmaceutical composition contains a small dose of anti-diabetic medicine and a relatively large dose of metformin hydrochloride as active ingredients. The preparation method has a simple process, does not need special auxiliary materials, and is suitable for industrial production. Two active ingredients in the prepared pharmaceutical composition have the advantages of uniform content and good dissolubility.

Owner:2Y CHEM

Lysine hydrochloride/zinc gluconate composite particle and preparation method of composite particle

InactiveCN103976992ASuitable for a wide range of peopleLittle complianceOrganic active ingredientsMetabolism disorderFiller ExcipientGluconates

The invention discloses a lysine hydrochloride / zinc gluconate composite particle and a preparation method of the composite particle. The lysine hydrochloride / zinc gluconate composite particle is prepared from the following components in parts by weight: 10-15 parts of lysine hydrochloride, 3-4 parts of zinc gluconate, 0.5-2 parts of sweetening agent, 1.0-2.5 parts of citric acid, 60-90 parts of filling agent, 3-5 parts of povidone K30 and 0.5-1.0 part of essence. The composite particle is free of sugar and especially suitable for patients with diabetes mellitus. In addition, the composite particle is small in difference of weight ratios between raw material amount and accessory material amount; the prepared particle is uniform; after packaging, the content in each bag is relatively uniform; the granularity is changed from 10-13% to 5-8%; due to the adoption of the povidone K30, the strength of the particle is changed from 8-13N to 15-20N; the particle is good in pressure resistance and has a small possibility of being crushed in the packaging process and the transportation process; meanwhile, the particle is excellent in mobility; a repose angle is changed from 35-45 degrees to 25-30 degrees; carr index is changed from 20-30% to 10-20%.

Owner:海南慧谷药业有限公司

LED (light-emitting diode) wall wash lamp and assembling method thereof

ActiveCN103017035AEffective coolingNot easy to crushFlexible AC transmissionMechanical apparatusNeck partsEngineering

The invention relates to an LED (light-emitting diode) wall wash lamp, which comprises a lamp body, a light-transmitting plate and two hinge pressing bars, wherein the light-transmitting plate is arranged on a light-emitting opening at the top of the lamp body; the two hinge pressing bars are symmetrically arranged at the two sides of the lamp body, and are distributed along the length direction of the lamp body; circular grooves are arranged near outside of the top of the lamp body; the circular grooves are distributed along the length direction of the lamp body; ribs which are distributed along the length direction are arranged near the inner side surface of a neck part of the hinge pressing bar; the ribs are in a cylindrical shape, and are in running fit with the circular grooves; the tail end extending inwards at the top of each hinge pressing bar is suitable for compressing the edge of the light-transmitting plate; the lower end part of each hinge pressing bar is provided with a bolt used for controlling the tail end to compress the light-transmitting plate; under the action of the bolt, the lower end part of each hinge pressing bar is suitable for the side away from the lamp body; and the ribs rotate in the circular grooves, so that the light-transmitting plate is compressed by the tail end.

Owner:CHANGZHOU INST OF LIGHT IND TECH +1

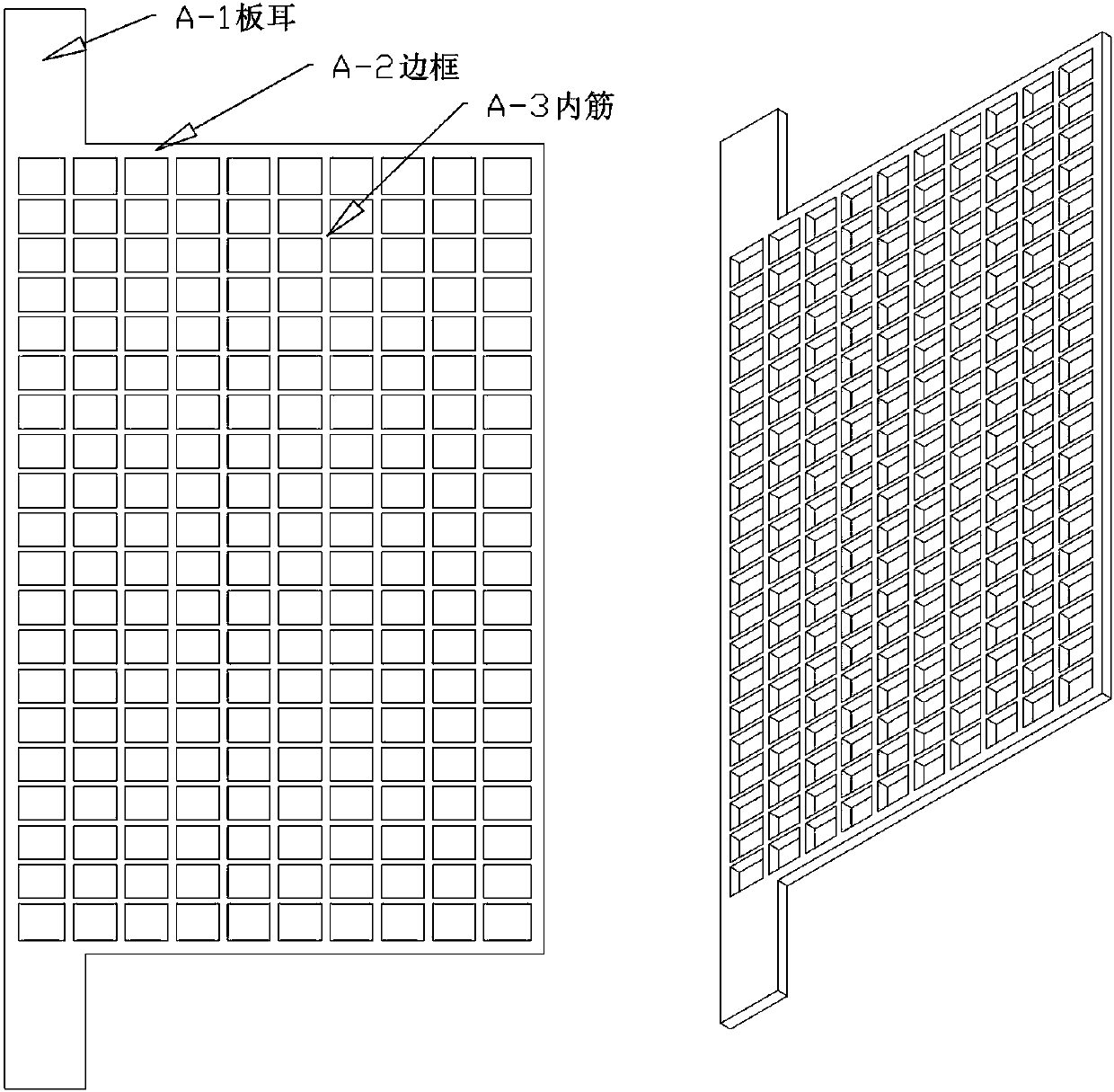

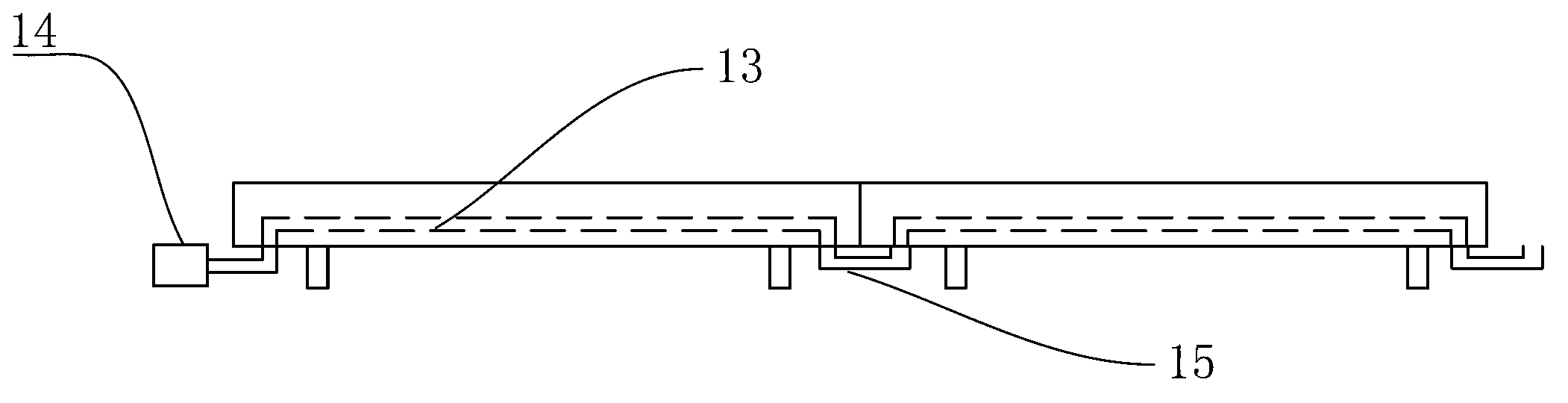

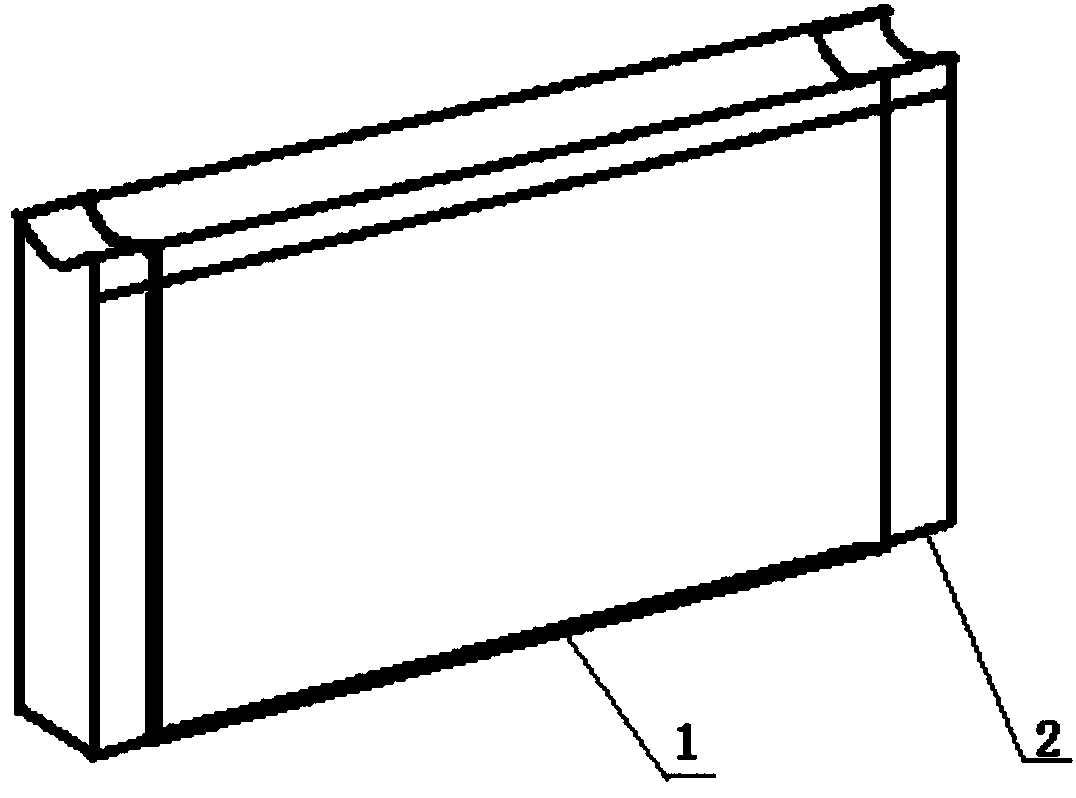

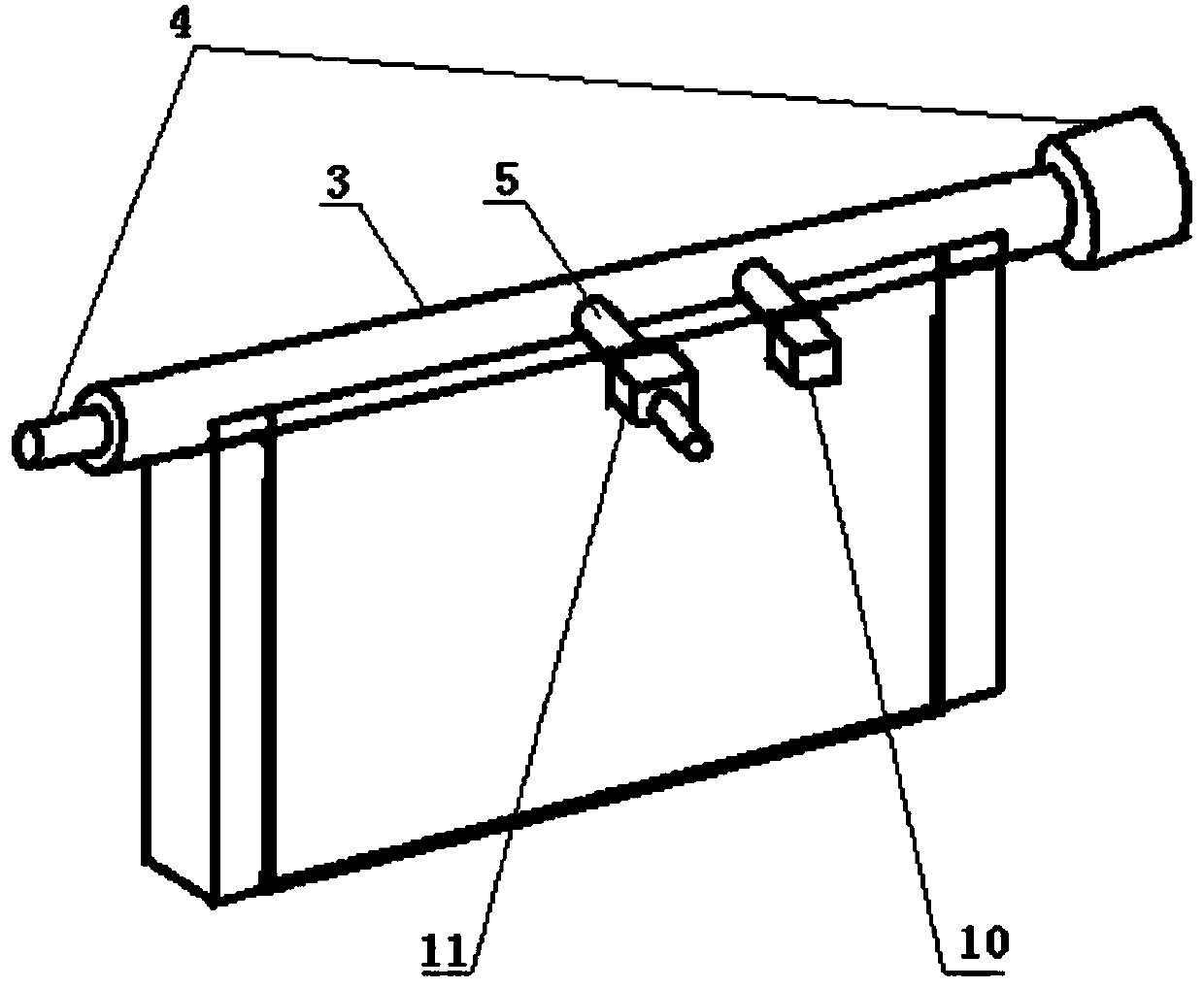

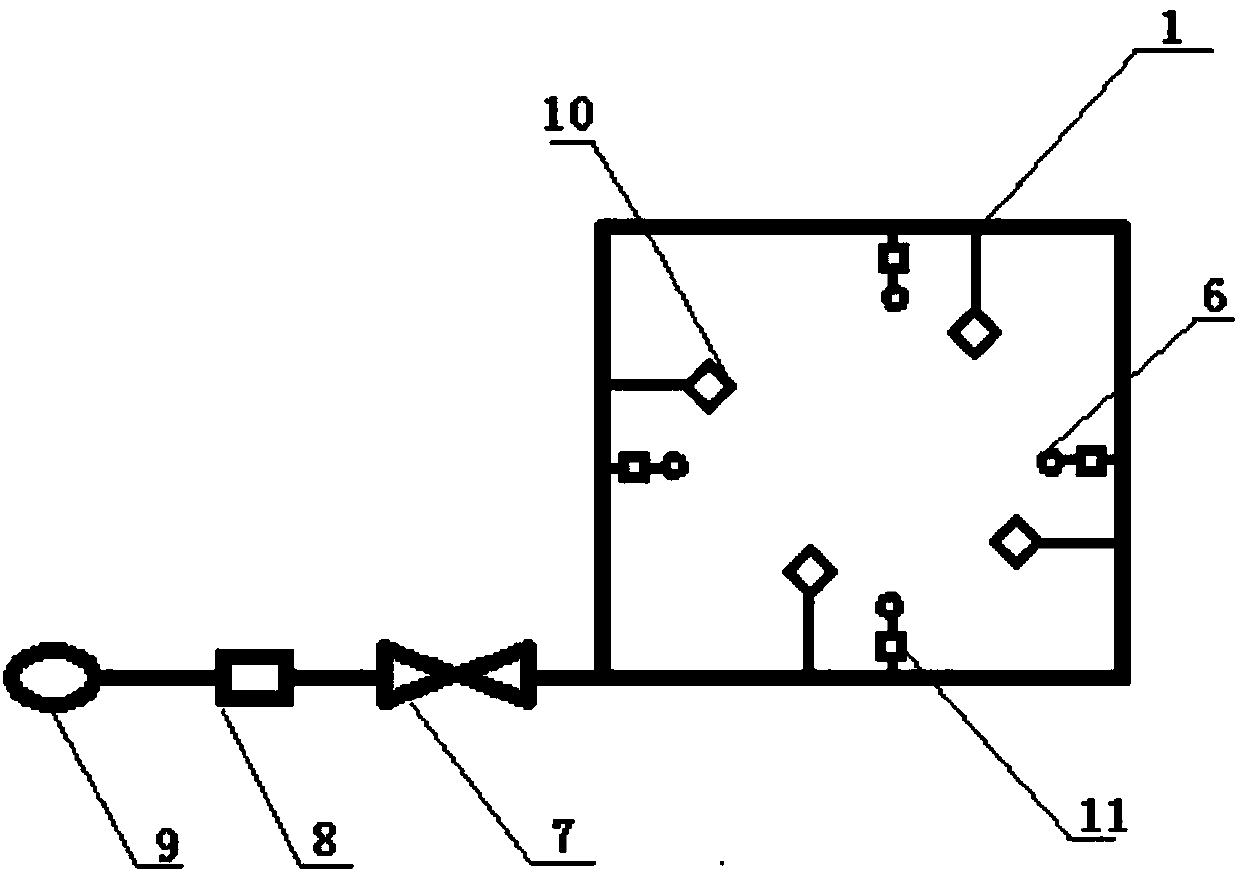

Method for constructing fence with automatic spraying device and fence module

InactiveCN107620280AEasy to assembleNeatly assembledUsing liquid separation agentRoad cleaningEngineeringElectromagnetic valve

The invention relates to the field of construction site dust fall, in particular to a method for constructing a fence with an automatic spraying device and a fence module. The fence module at least comprises a fence plate, fence columns and a spraying pipe, wherein the spraying pipe is a hose and / or a hard pipe, one ore more connecting pipes are arranged in the middle of the pipe wall of the spraying pipe, the connecting pipe is provided with an electromagnetic valve, quick joints are arranged at the two ends of the spraying pipe, the two ends of the fence plate are connected with the fence columns, grooves are formed in the upper end of the fence plate and the upper ends of the fence columns, the grooves are matched with the spraying pipe in size, a dust sensor is arranged on the pipe wall of the spraying pipe, and the dust sensor and the electromagnetic valve are connected with a control module. According to the technical scheme, the dust sensor on the spraying pipe monitors the dustflying condition near the fence in real time, when it is monitored that the flying dust exceeds a set numerical value, spraying is started on a construction site, the area needing to be sprayed can be subjected to dust fall in a targeted mode, the situation that a lot of accumulated water is generated in other areas and influences construction operation is avoided, management automation is achieved, energy conservation and environmental protection are achieved.

Owner:WUHAN CUIYU ENVIRONMENTAL TECH

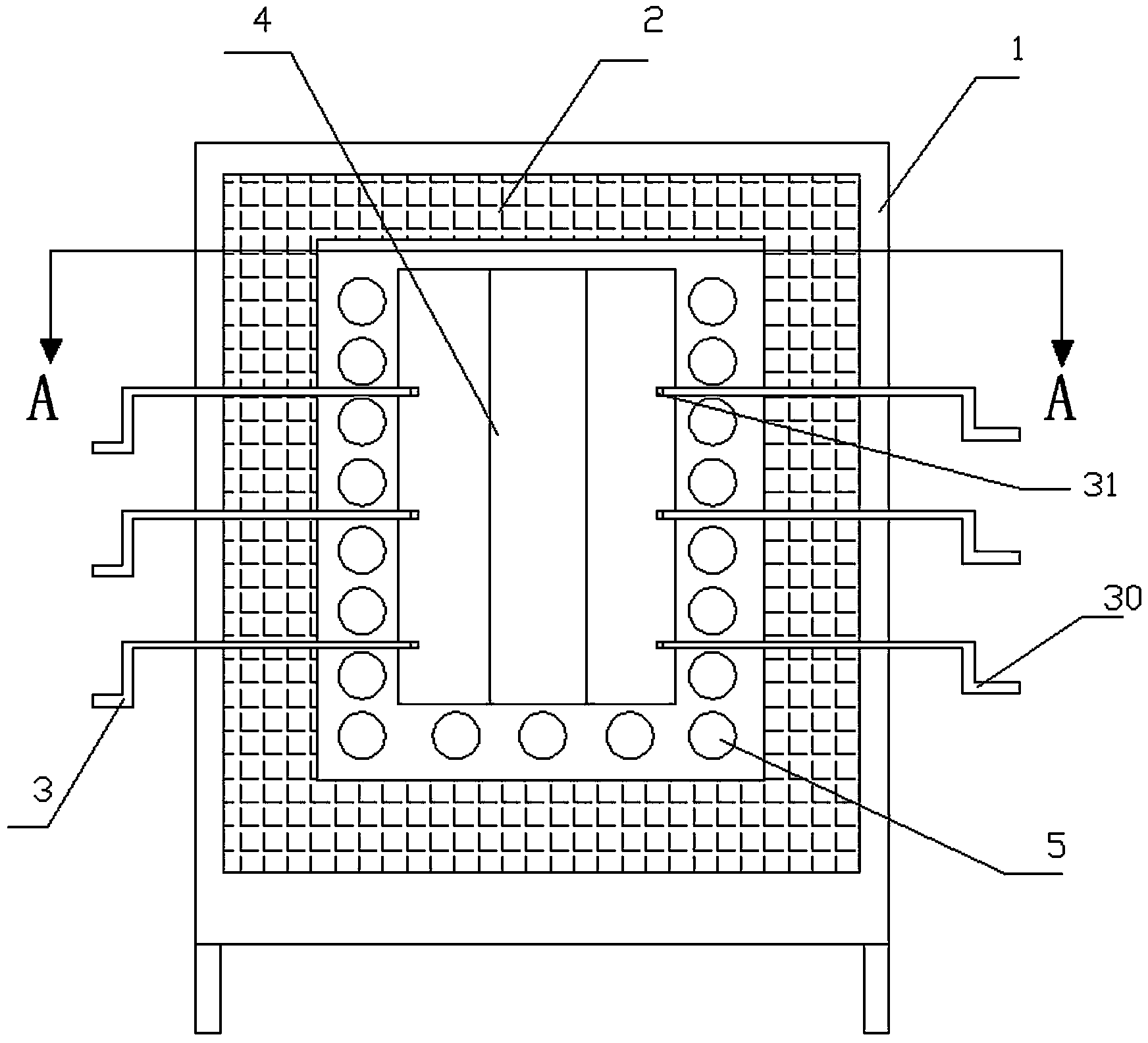

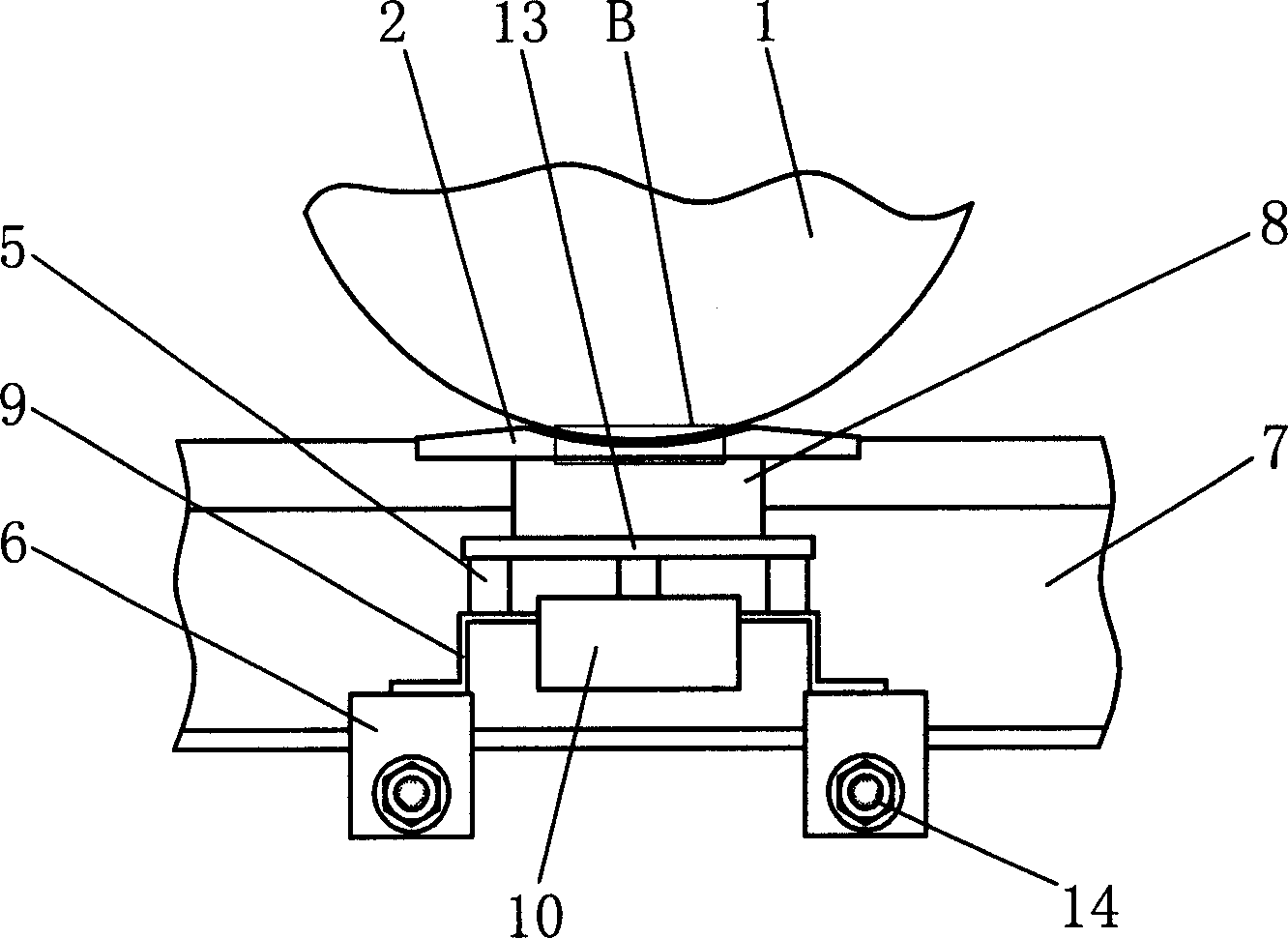

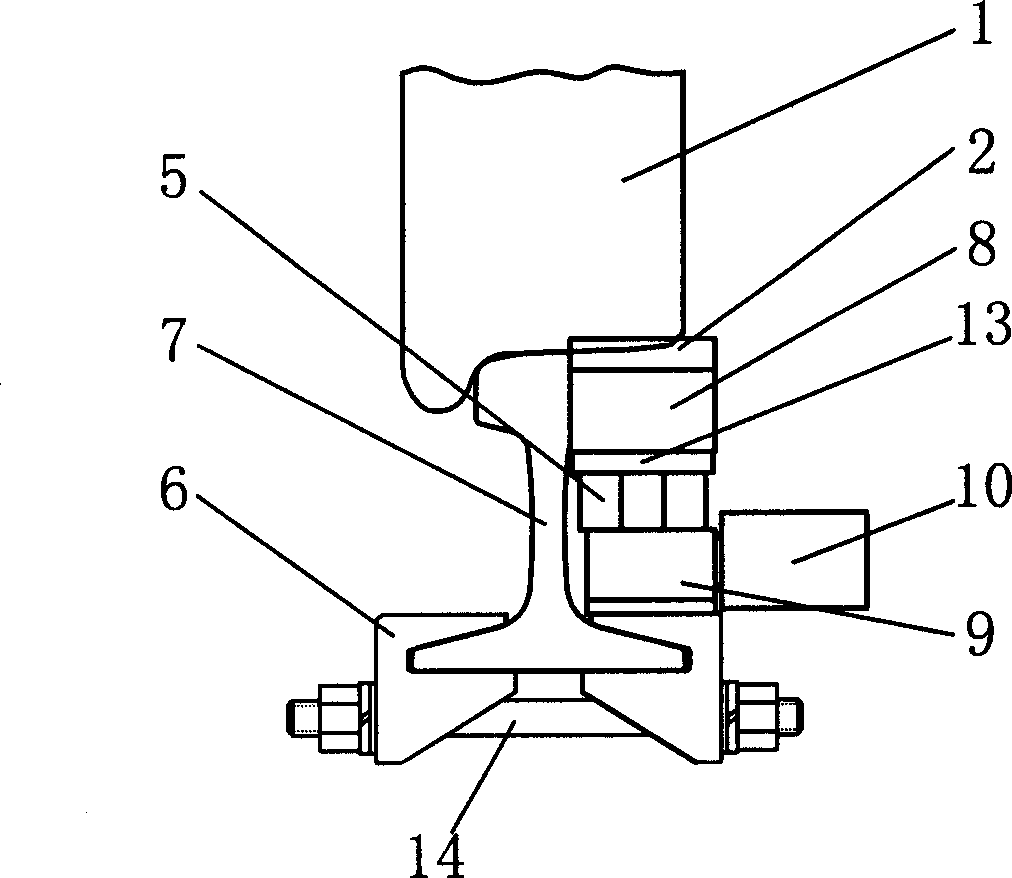

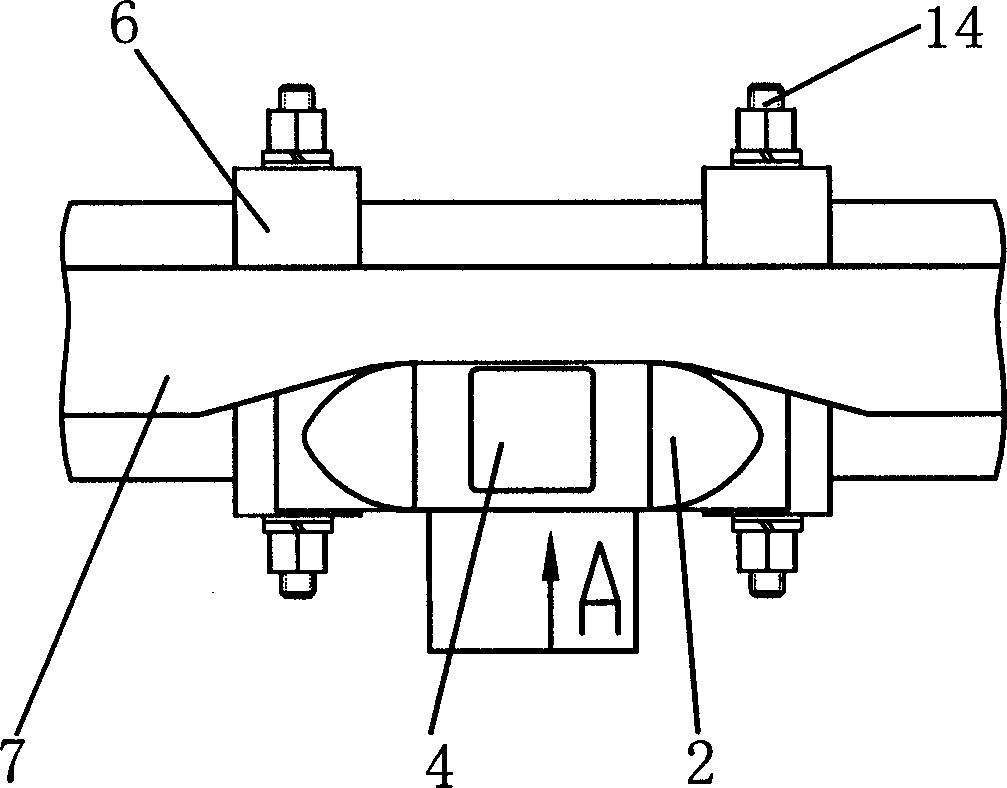

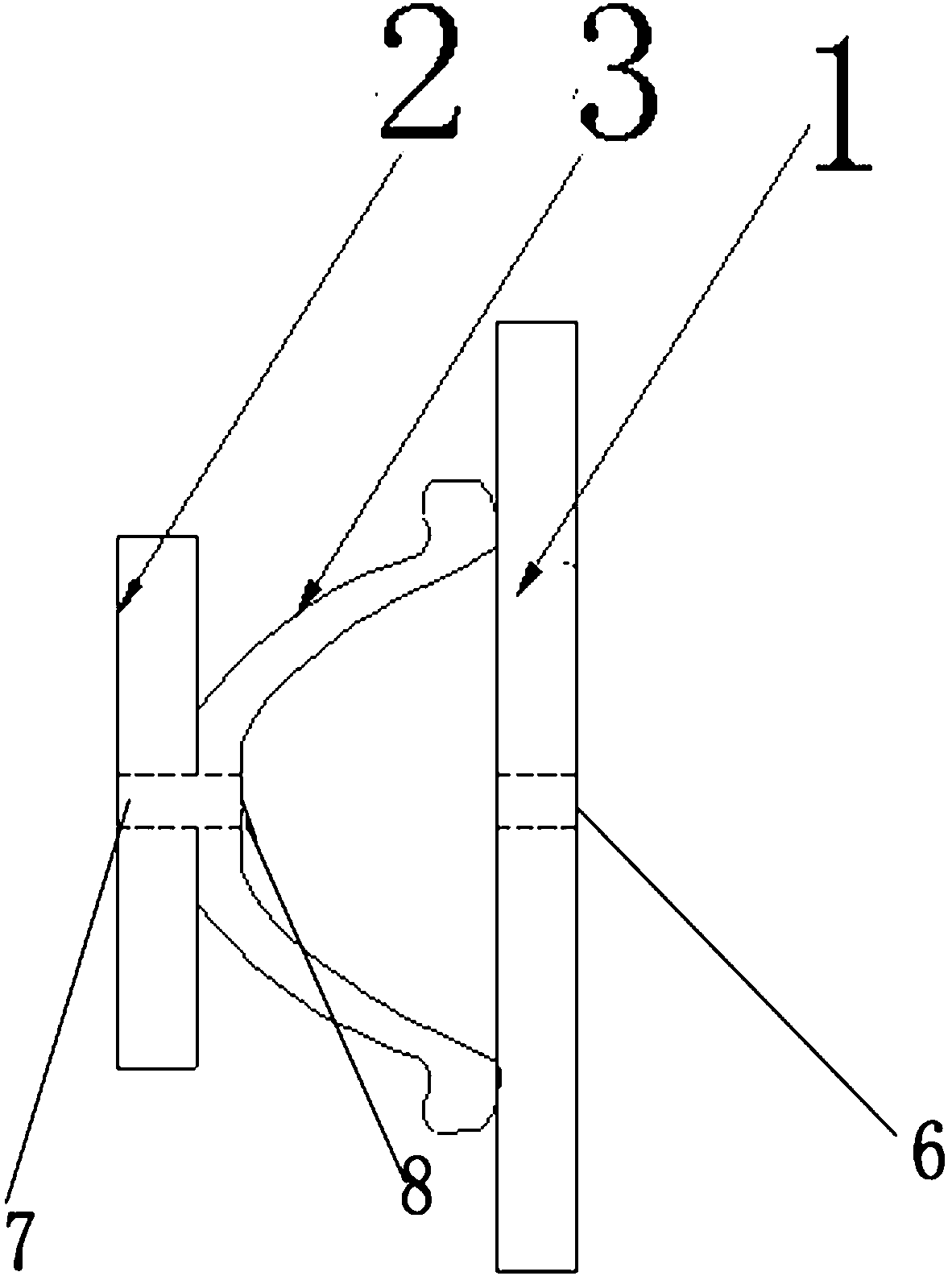

Electromagnet ultrasonic changer of on-line dynamic detection for defect of rolling stock wheel set

ActiveCN1869584AReduce impactClose contactUsing subsonic/sonic/ultrasonic vibration meansVehicle wheel testingElectromagnetic couplingUltrasonic sensor

The invention discloses electromagnetic ultrasonic transducer used to do online dynamic measure for rolling stock wheel defect. Its framework is made by medium whole casting or milling. Its E shape groove gap is down on which high frequency coil is rolled. Its upper superficial is arc concave. And its base plate is set supporting which are connected by damping spring. Its high frequency coil has long useful life, high electromagnetic coupling efficiency, and high measuring precision and reliability.

Owner:王黎 +4

Compressible base plate device and anchor cable anchorage method by device

InactiveCN103244162AHigh strengthGood compressibilityBuilding reinforcementsAnchoring boltsPre stressPre stressing

The invention discloses a compressible base plate device and an anchor cable anchorage method by the device. The compressible base plate device comprises an inner base plate (1), an outer base plate (2) and U-shaped steel (3), the centers of the inner base plate, the outer base plate and the U-shaped steel are provided with through holes, a convex surface of the U-shaped steel (3) corresponds to the outer base plate (2), the bottom of the U-shaped steel corresponds to the inner base plate (1), and the U-shaped steel (3) can generate plastic deformation. The anchor cable anchorage method by the device includes the steps: drilling a hole inside surrounding rock; placing an anchoring agent cartridge at the bottom end of the drilled hole and placing an anchor cable (4) into the drilled hole; and mounting the compressible base plate device at a projecting end of the anchor cable (4), locking a lock (5) by the aid of an anchoring pre-tightening jack and applying a certain pre-stress. The compressible base plate device is simple in structure, mounting and matching of other devices are omitted when the device is used, the supported surrounding rock can generate a certain deformation when the device is used, and the device overcomes the shortcoming that a surrounding rock supported by a traditional anchorage method cannot generate controllable deformation to release a certain stress.

Owner:HUNAN UNIV OF SCI & TECH

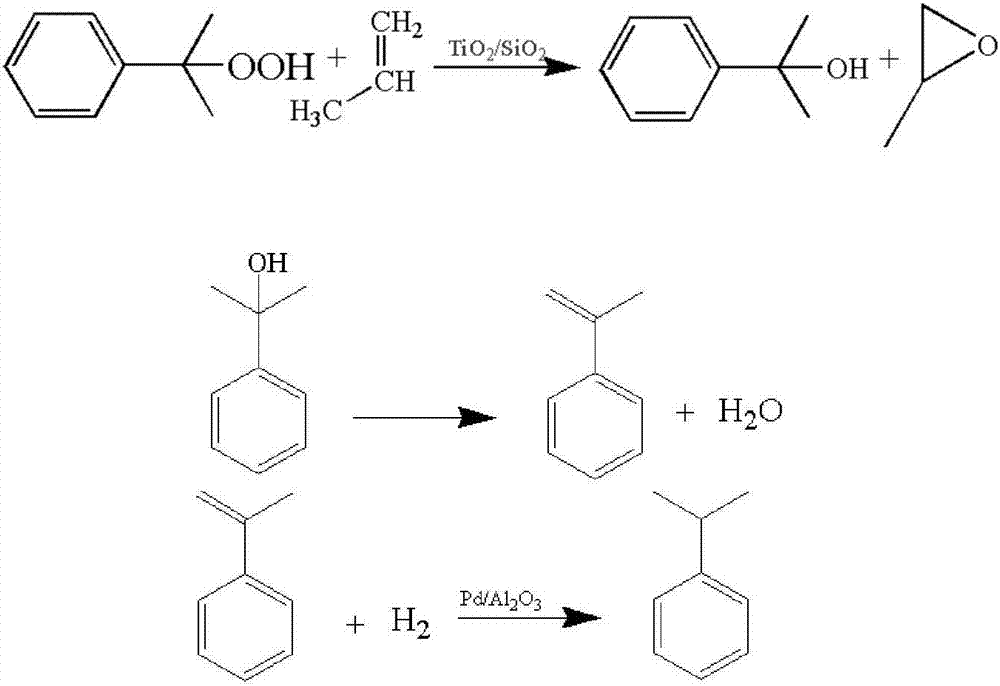

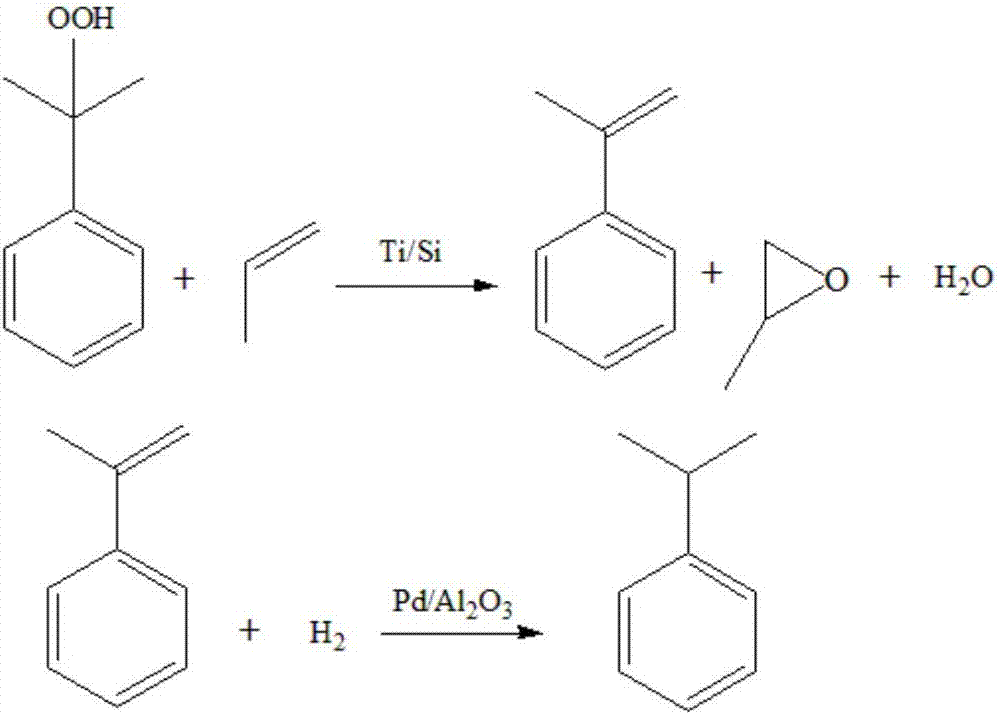

Titanium-silicon molecular sieve catalyst, preparation method thereof and application thereof in production of propylene oxide

InactiveCN107008494AHigh activityNot easy to crushOrganic chemistryMolecular sieve catalystsMolecular sieveTitanium

The invention discloses a titanium-silicon molecular sieve catalyst, a preparation method thereof and application thereof in the production of propylene oxide. Titanium in the titanium-silicon molecular sieve catalyst of the invention has mass fraction of 0.5-5%, particle size of 0.5-10 nm, specific surface area of 50-500 m<2>, particle size of 0.3-0.6 mm and bulk density of 0.1-0.6 g / cm<3>. The particles of the titanium-silicon molecular sieve catalyst are rarely break and have high activity. The titanium-silicon molecular sieve catalyst prepared herein breaks rarely; by applying the titanium-silicon molecular sieve catalyst to the production of propylene oxide, high activity is exhibited, the yield of propylene oxide can be increased, the procedure of equipment is simplified, and equipment investment is 1 / 3 lower than oxidation process in terms of investment cost.

Owner:江苏道尔顿石化科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com