Patents

Literature

949results about "Vehicle wheel testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

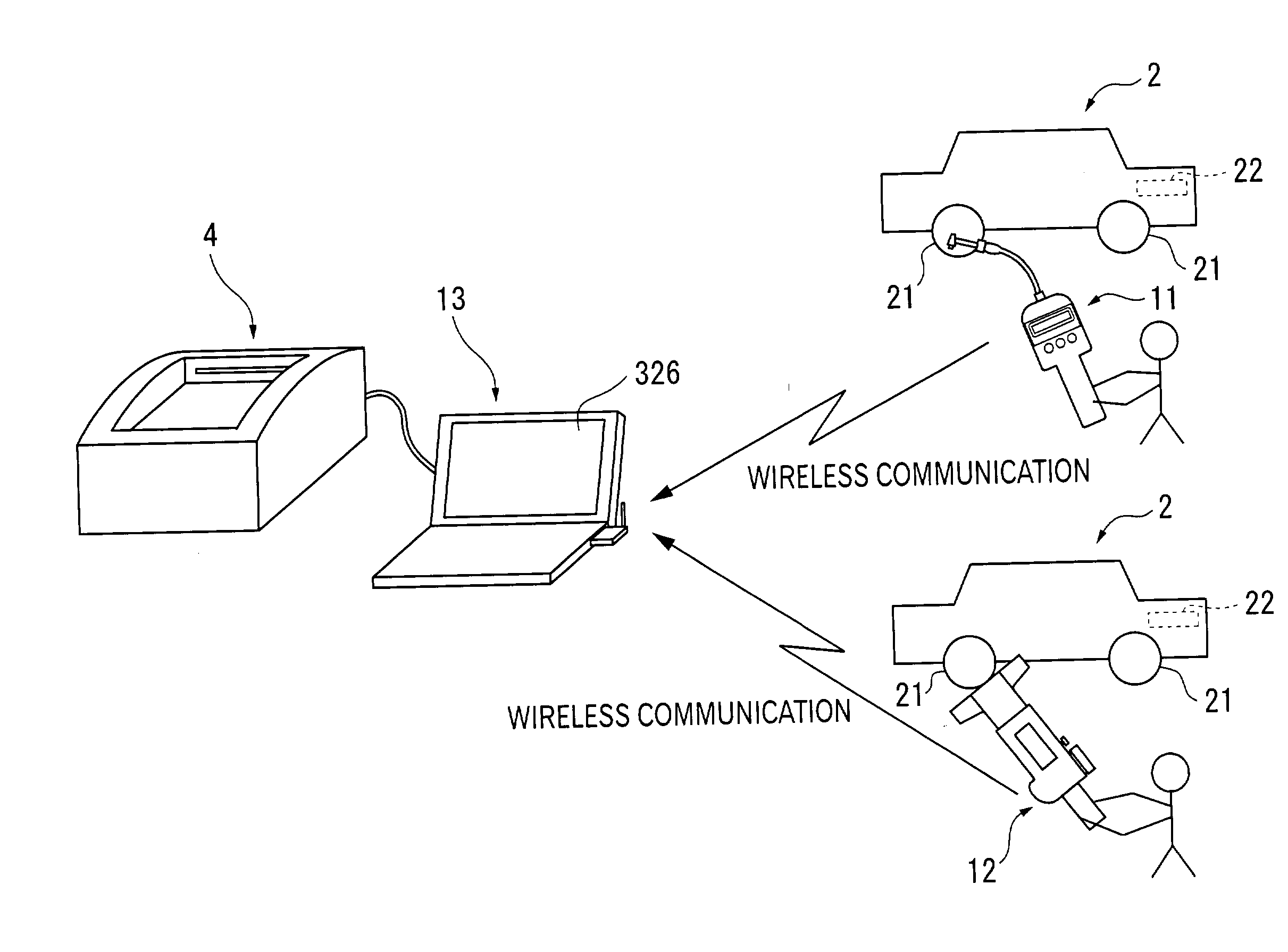

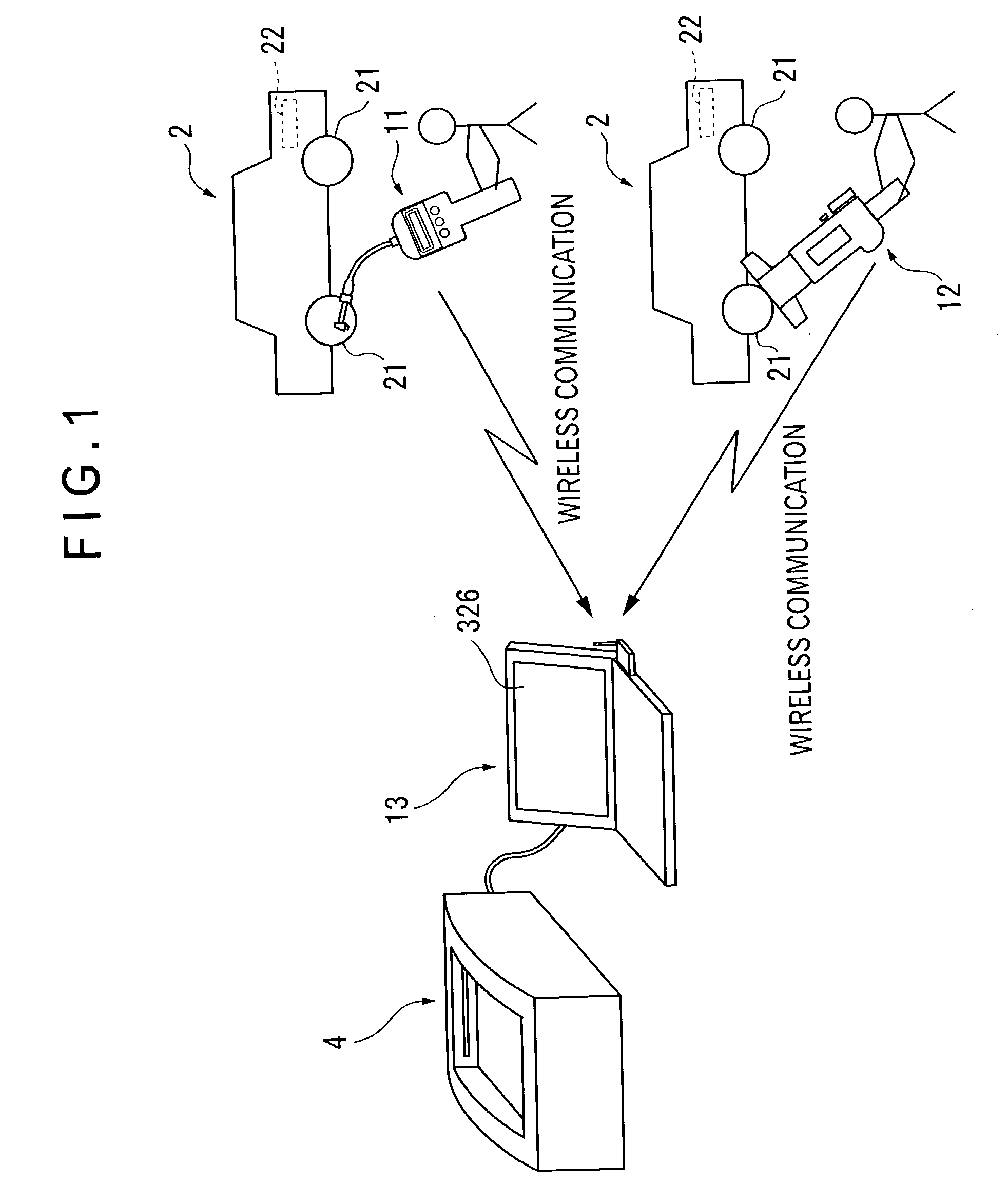

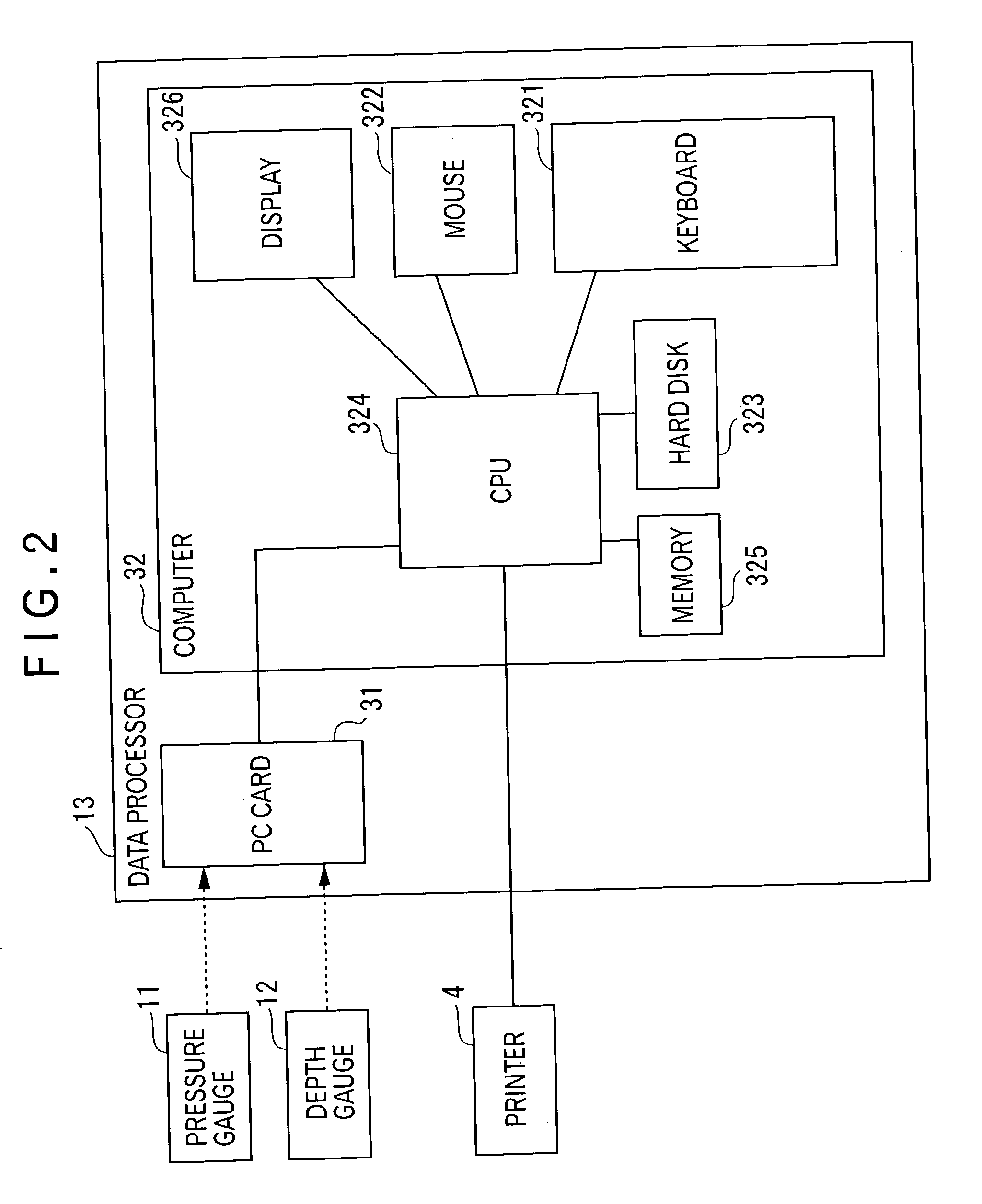

Wheel measuring system, wheel measuring method and wheel-related product sales method

InactiveUS20030187556A1Eliminate needBusiness can be proceeded more smoothlyInflated body pressure measurementTransmission systemsDisplay deviceEngineering

A data processor (13) has a receiver for receiving measurement data on tires (21, 22) attached to an automobile (2) from a tire gauge (11, 12), and a data displaying portion for processing and displaying the received measurement data on a display (326) in a predetermined form. The received measurement data includes pressure value and tread depth of the tires (21, 22). The tread depth is measured on three points of inside, middle and outside in width direction of a tread surface of the tire. The received data is displayed in graphic representing positions of the tires (21, 22) of the automobile (2) and in a graph coloured corresponding to the measurement value.

Owner:MITUTOYO CORP

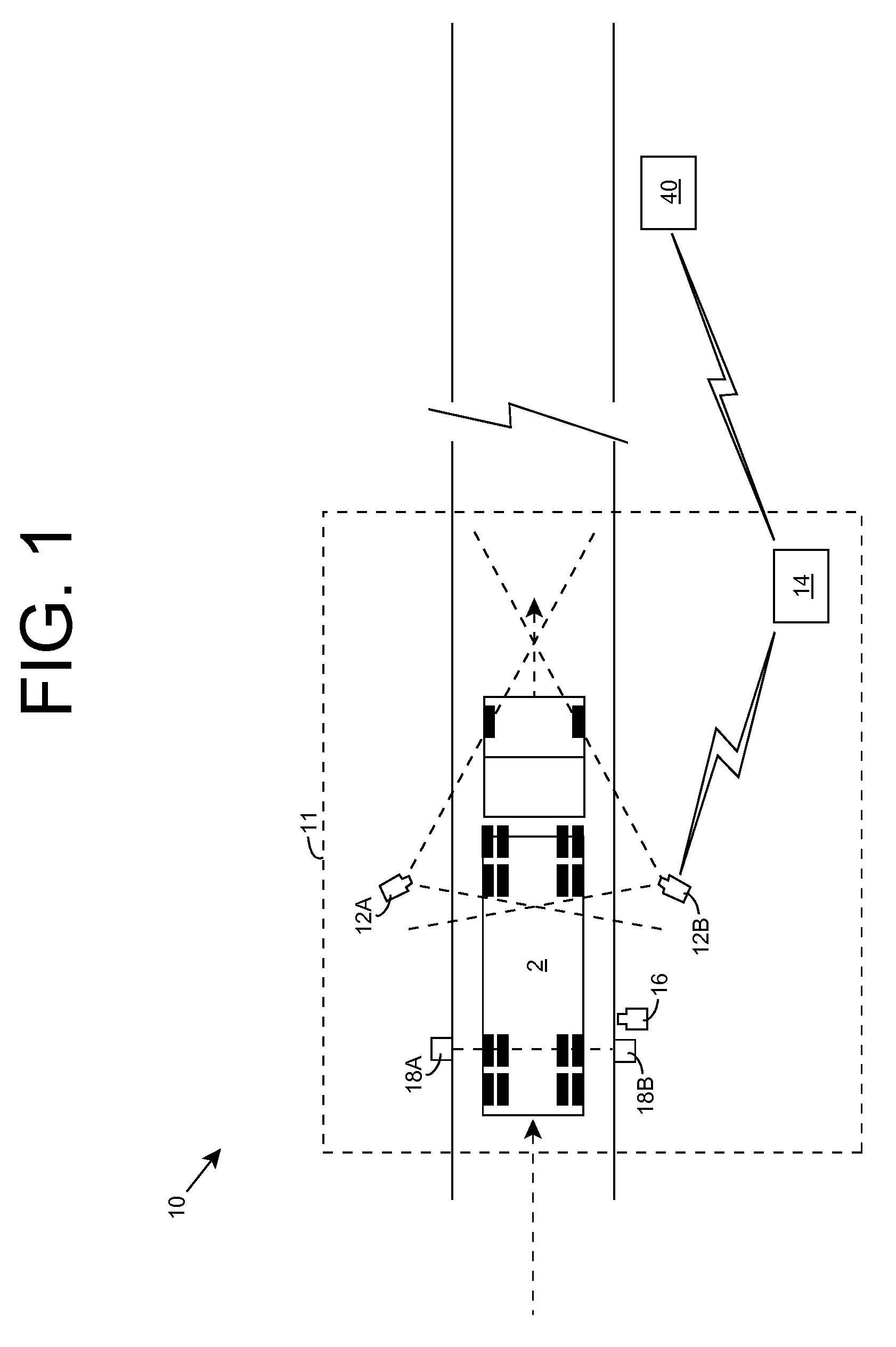

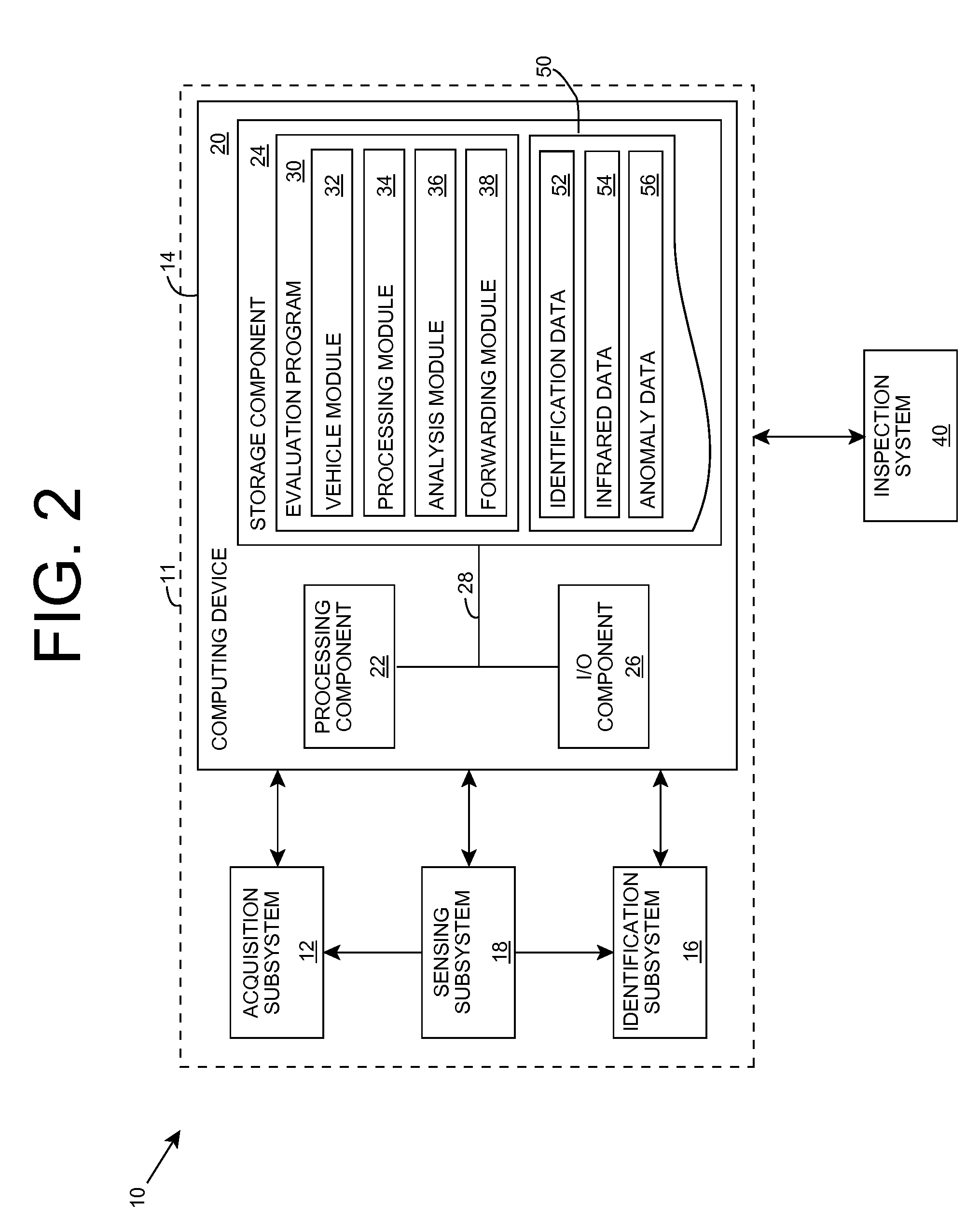

Vehicle evaluation using infrared data

ActiveUS20090018721A1Add settingsVehicle testingMangetographic processAutomotive engineeringVehicle identification

A solution for evaluating a vehicle using infrared data is provided. In particular, evaluation data for the vehicle is obtained, which includes infrared data for a plurality of sides of the vehicle as well as vehicle identification data for distinguishing the vehicle from another vehicle. The infrared data is processed to enhance a set of signal features. Additional non-infrared based data also can be obtained for evaluating the vehicle. The evaluation data is analyzed to determine whether one or more anomalies are present. The anomaly(ies) can be correlated with a possible problem with a component of the vehicle. Data on the anomaly, problem, and / or vehicle identification can be provided for use on another system, such as a remote inspection station, maintenance system, and / or the like.

Owner:INT ELECTRONICS MACHINES

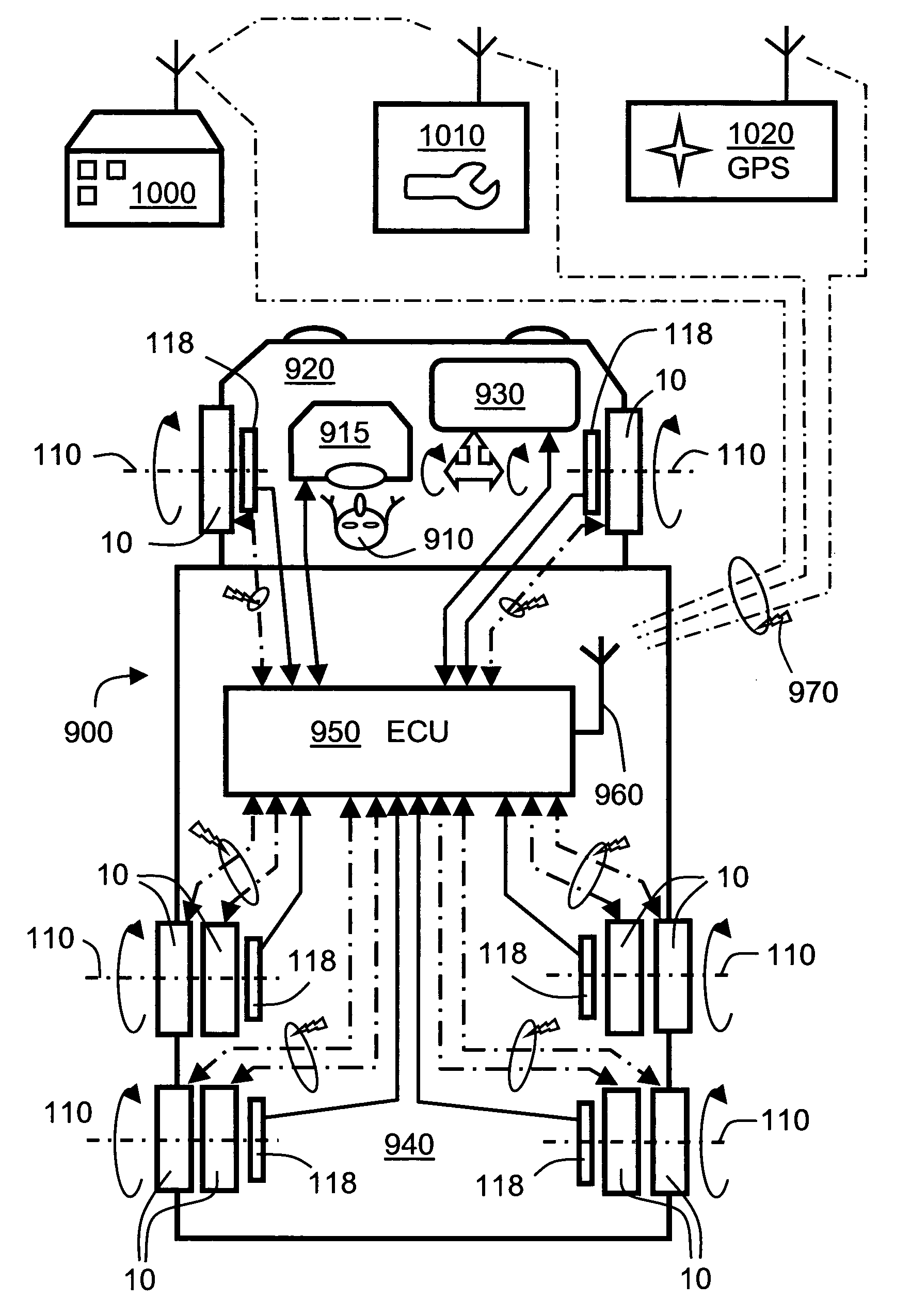

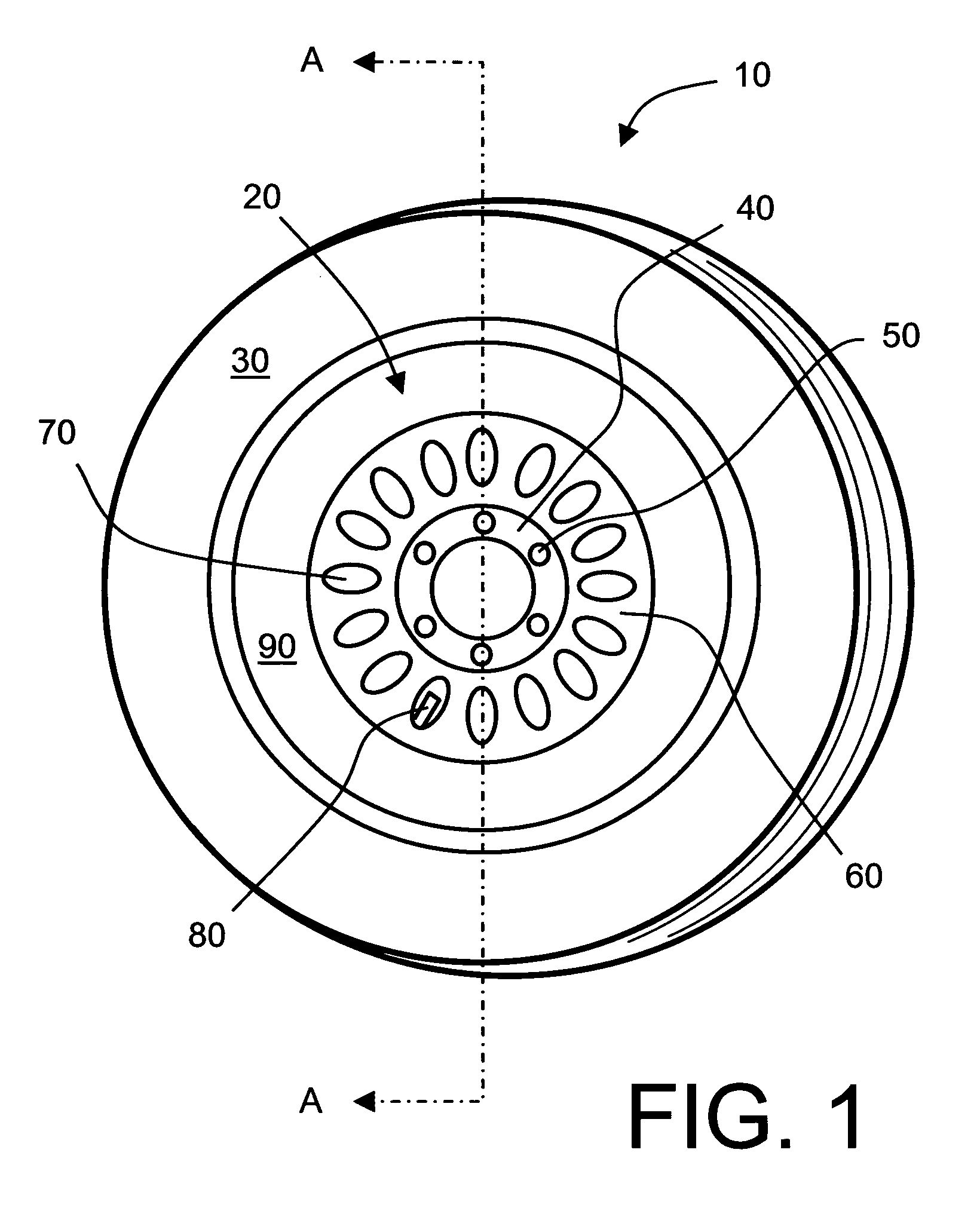

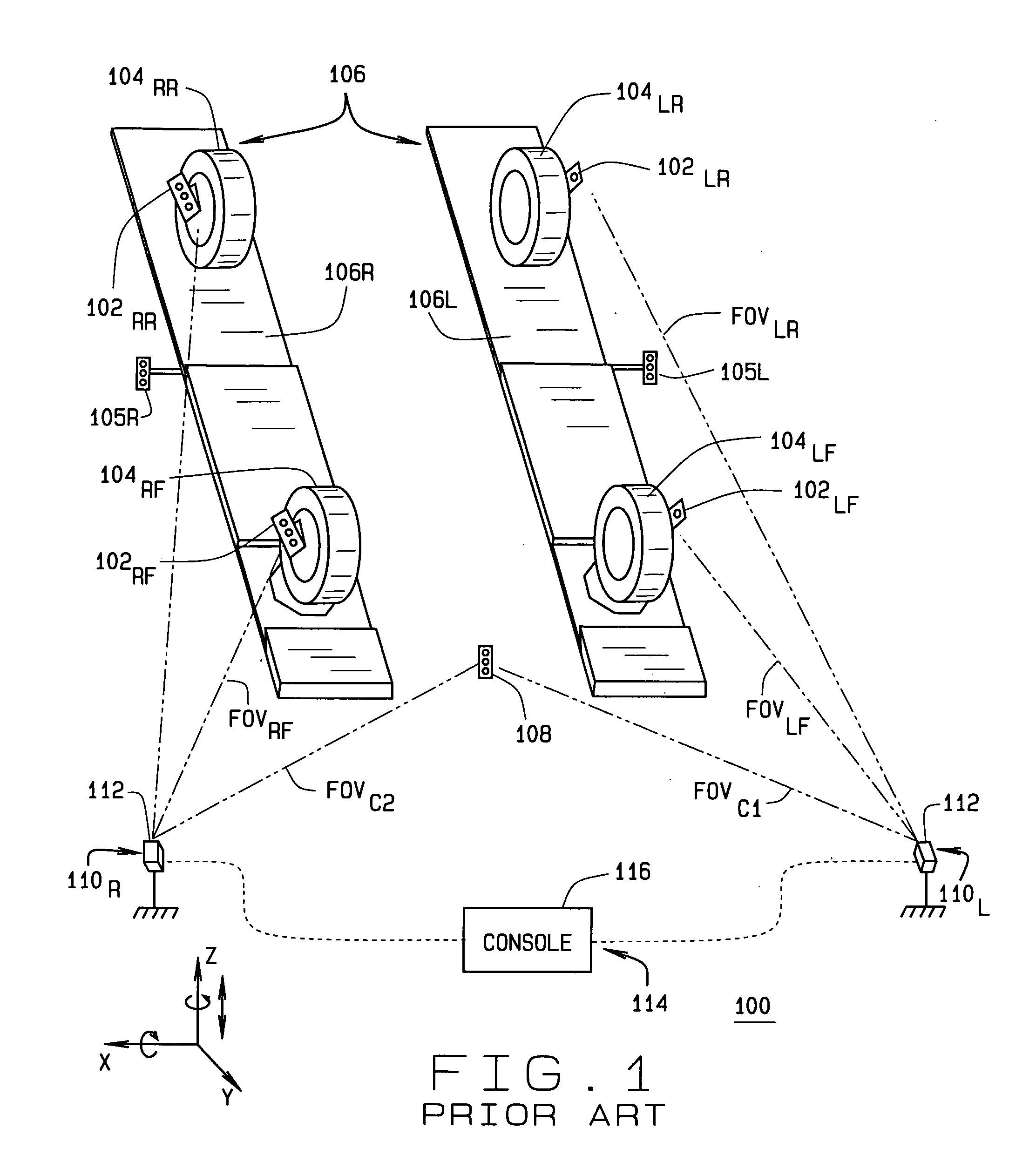

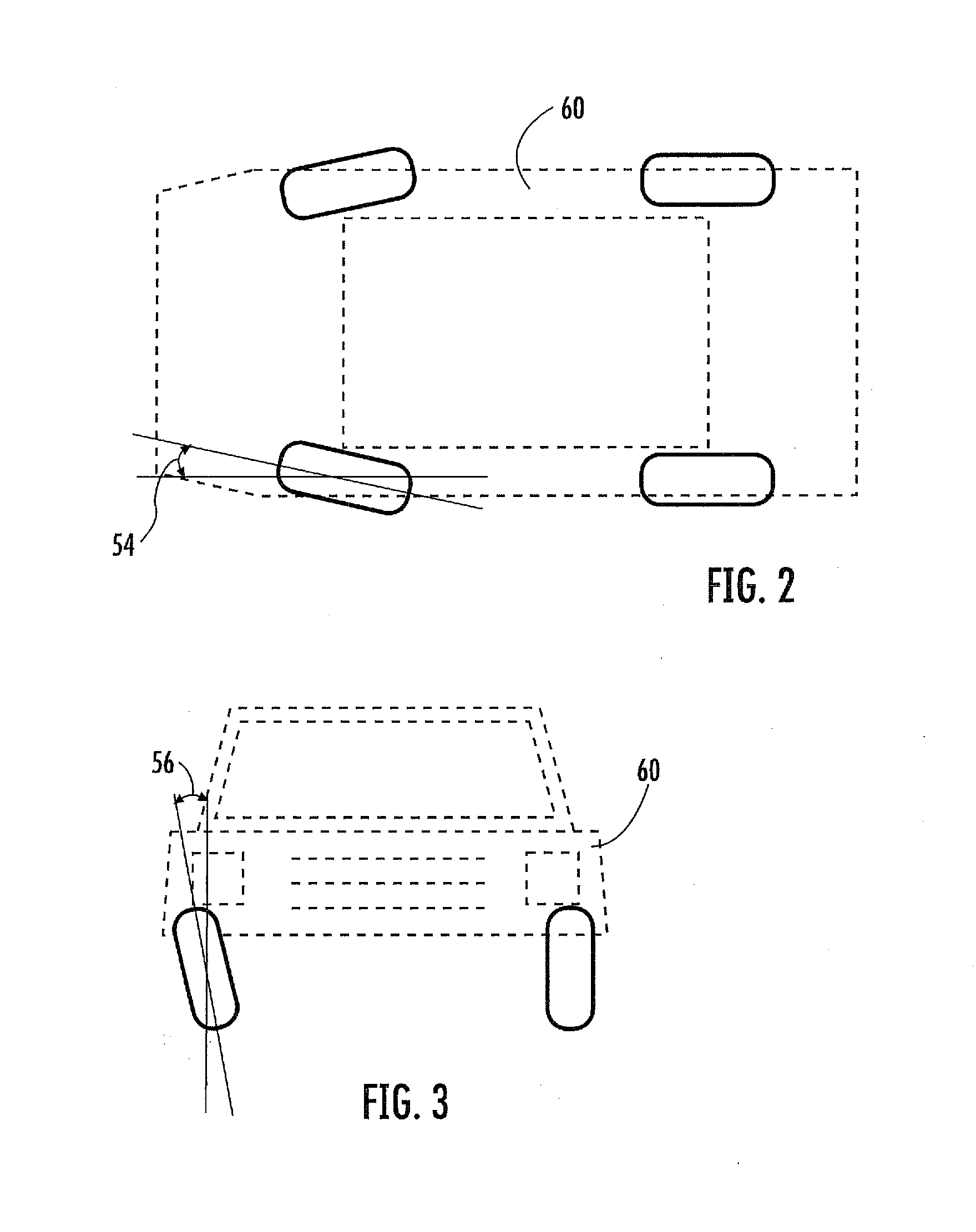

Method of identifying positions of wheel modules

ActiveUS20100274607A1Improve securityImprove reliabilityRegistering/indicating working of vehiclesDigital data processing detailsEngineeringAngular orientation

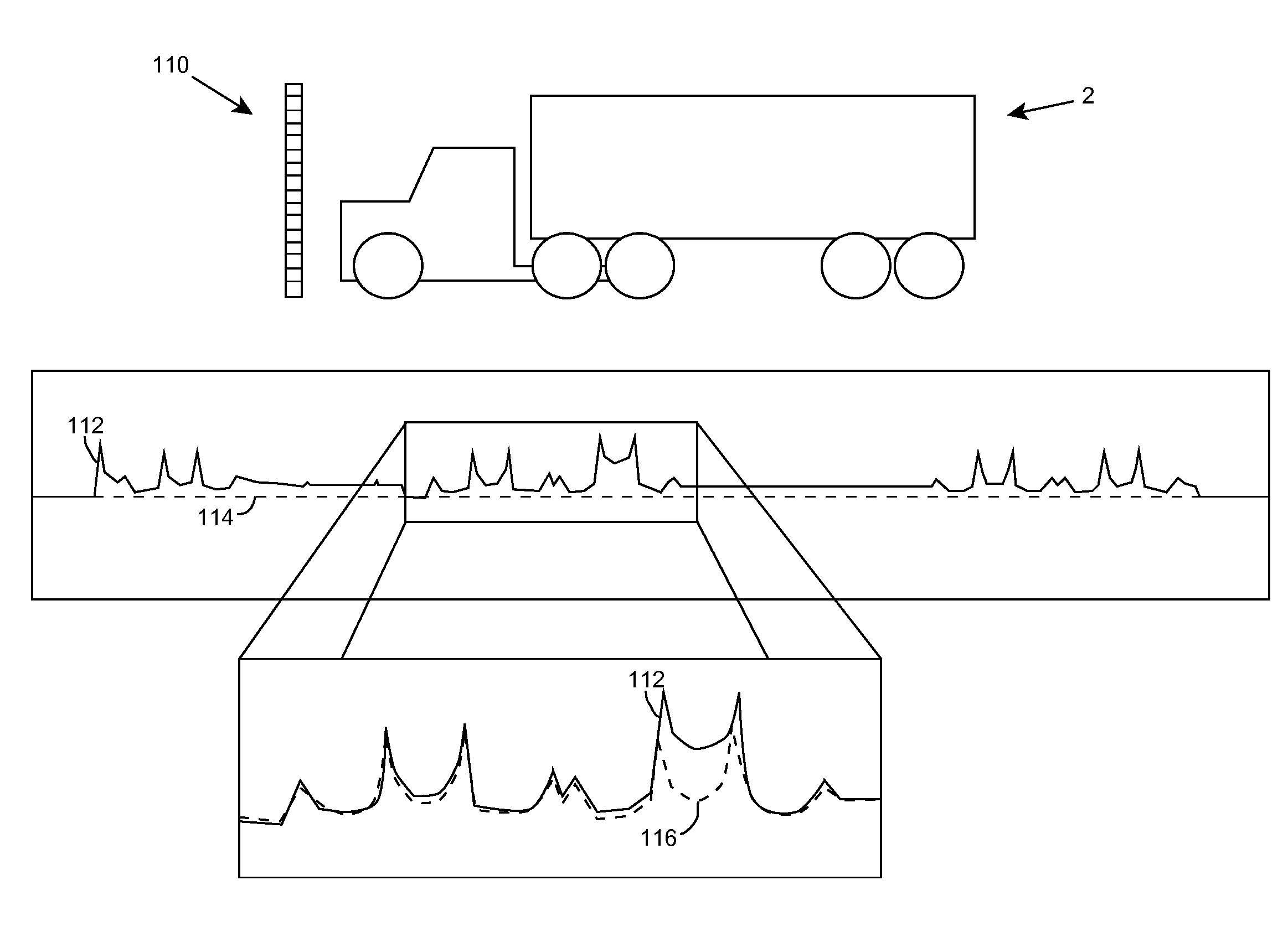

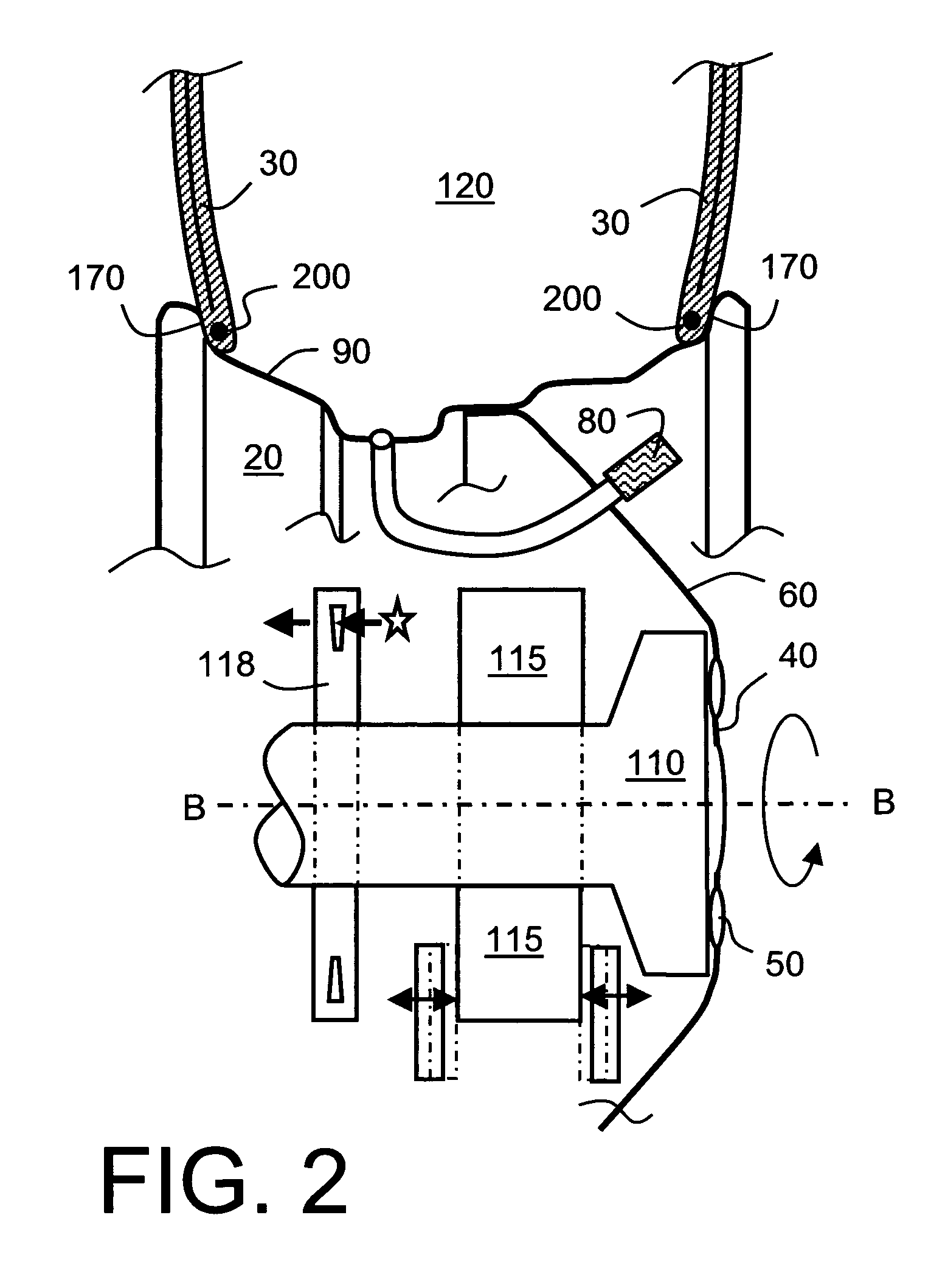

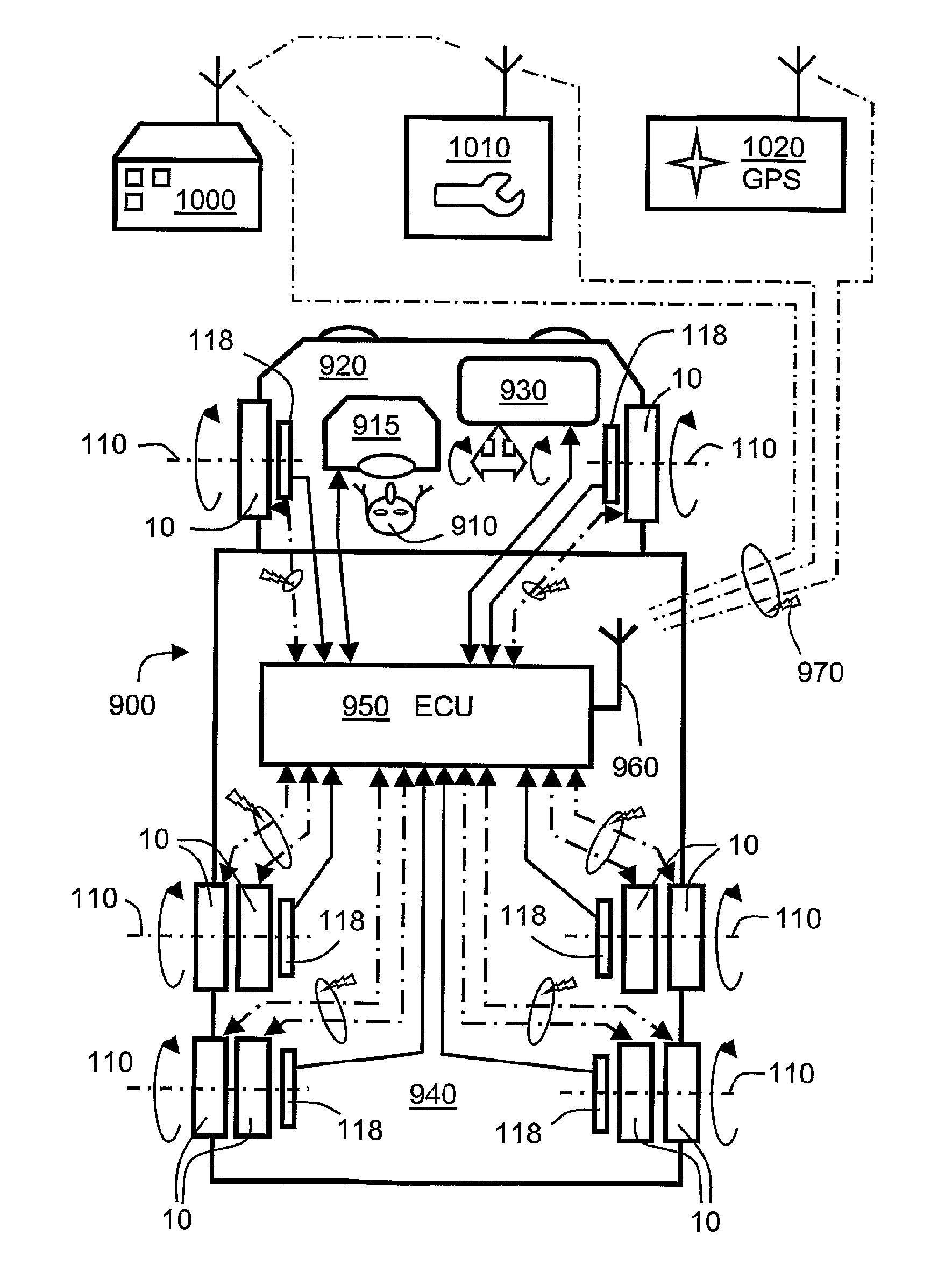

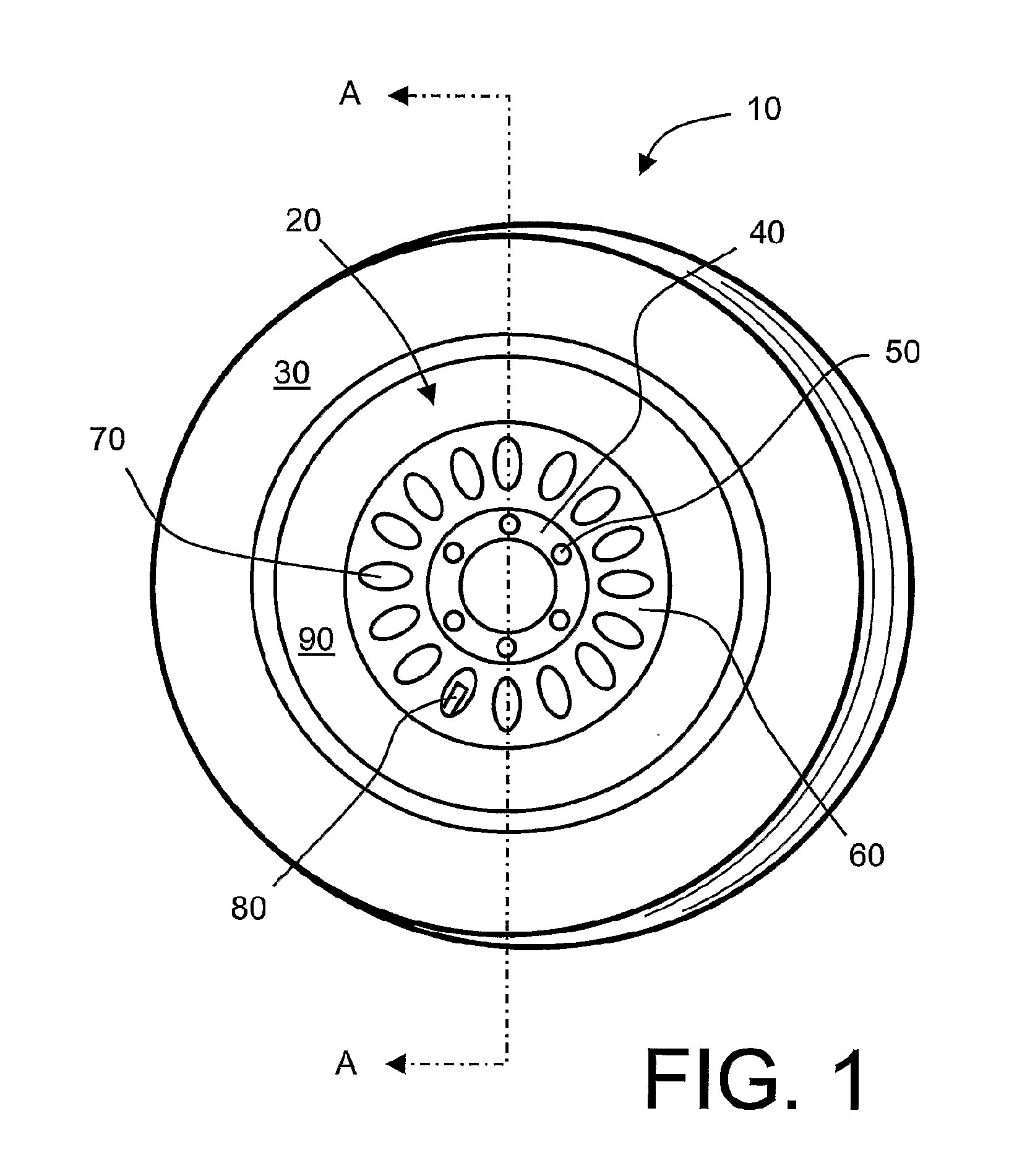

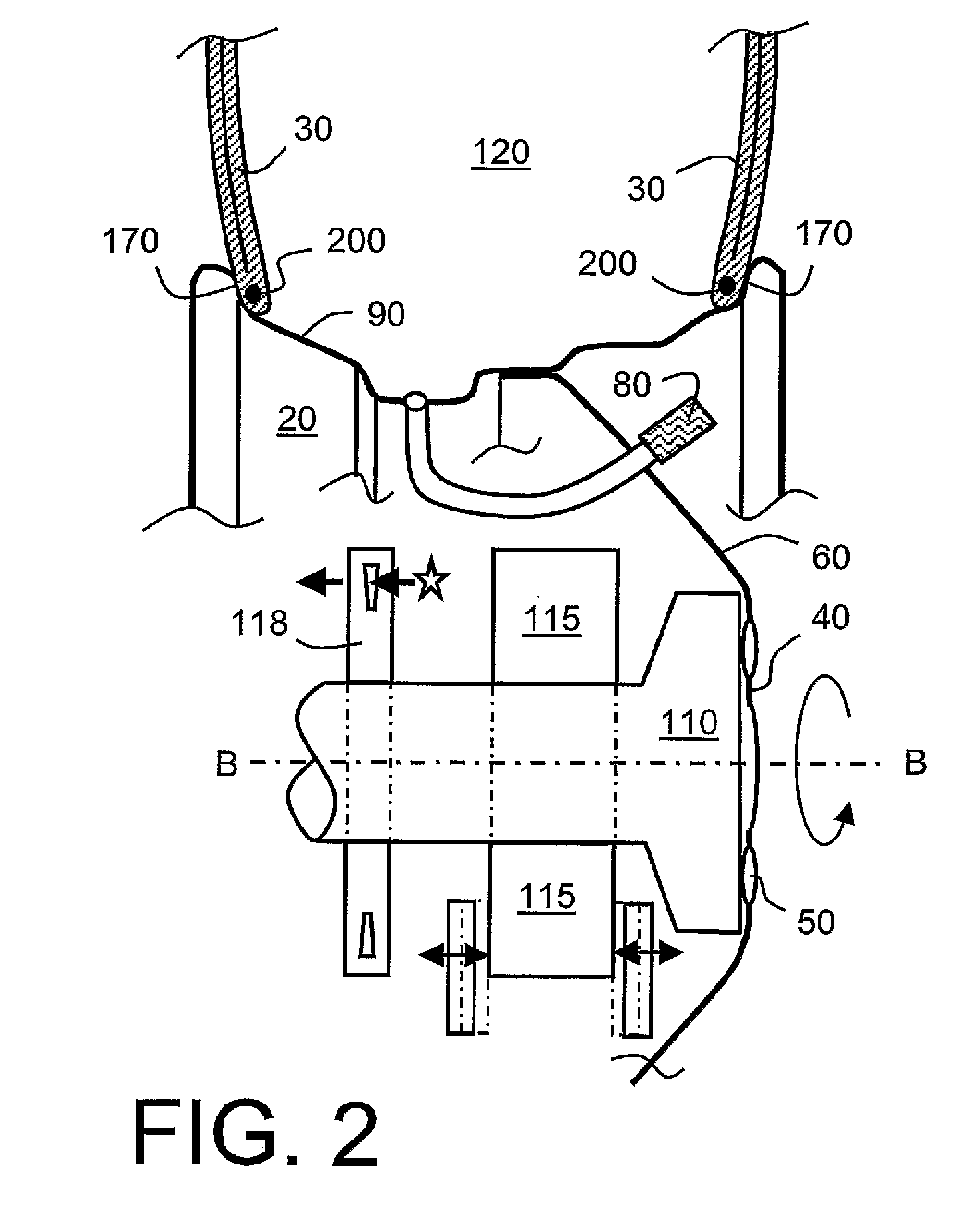

There is provided a method of identifying locations of modules (400) of an apparatus (600, 680, 690, 2200) for monitoring wheels (10) of a vehicle (900). The sensor modules (400) operatively revolving with the wheels (10). The modules (400) communicate with a processing arrangement (710, ECU 950) of the vehicle (900). The modules (400) sense a physical parameter of the wheels (10) and generate corresponding sensor signals for the processing arrangement (950). The processing arrangement (710, ECU 950) processes the sensor signals to compute information indicative of operation of the wheels (10). The apparatus (1) also includes a sensor arrangement (118) for sensing an angular orientation (0) of the wheels (10). The method includes steps of: (b) arranging an elongate feature (1100) in an at least partially transverse direction relative to a direction of travel of the vehicle (900); (c) driving the vehicle (900) over the elongate feature (1100) to cause the wheels (10), together with their associated modules (400), to contact momentarily onto the elongate feature (1100) and communicating signals including signal components stimulated by contact of the wheels (10) onto the elongate feature (1100) to the processing arrangement (950), the signals identifying a time at which their wheels (10) contacted onto the elongate feature (1100) and identification codes (ID) of the modules (400); and (d) from a temporal sequence of the signals received at the processing arrangement (950), identifying whereat modules (400) are located on the wheels (10) of the vehicle (900).

Owner:VOLVO LASTVAGNAR AB

Method of identifying positions of wheel modules

InactiveUS20100274441A1ProcessingAvoid performanceRegistering/indicating working of vehiclesDigital data processing detailsEngineeringAcceleration Unit

There is provided a method of identifying locations of one or more modules of an apparatus implemented in a vehicle for monitoring operation of at least one wheel of the vehicle, the one or more modules operatively mounted to revolve with the at least one wheel, the one or more modules being operatively coupled in communication with a processing arrangement of the vehicle, the one or more modules being operable to sense at least one physical parameter of the wheel and to generate at least one corresponding sensor signal for the processing arrangement, the processing arrangement being operable to process the at least one sensor signal to compute information indicative of operation of the at least one wheel. The method includes steps of:(a) driving the vehicle for a period of time whilst recording a number of rotations executed for each of at least one wheel of the vehicle by employing a rotation sensing arrangement associated with the at least one wheel;(b) during the period of time, sensing at the one or more modules components of acceleration at the at least one wheel and communicating signals including signal components representative of the components of acceleration to the processing arrangement and deriving therefrom a measure of a number of rotations the at least one wheel has undergone in the period of time; and(c) for each of the one or more modules, matching the number of rotations recorded in step (b) with the measure of the number of rotation undergone by the at least one wheel as determined in step (b) and thereby associating identification codes of the one or more modules with corresponding at least one wheel of the vehicle.

Owner:VOLVO LASTVAGNAR AB

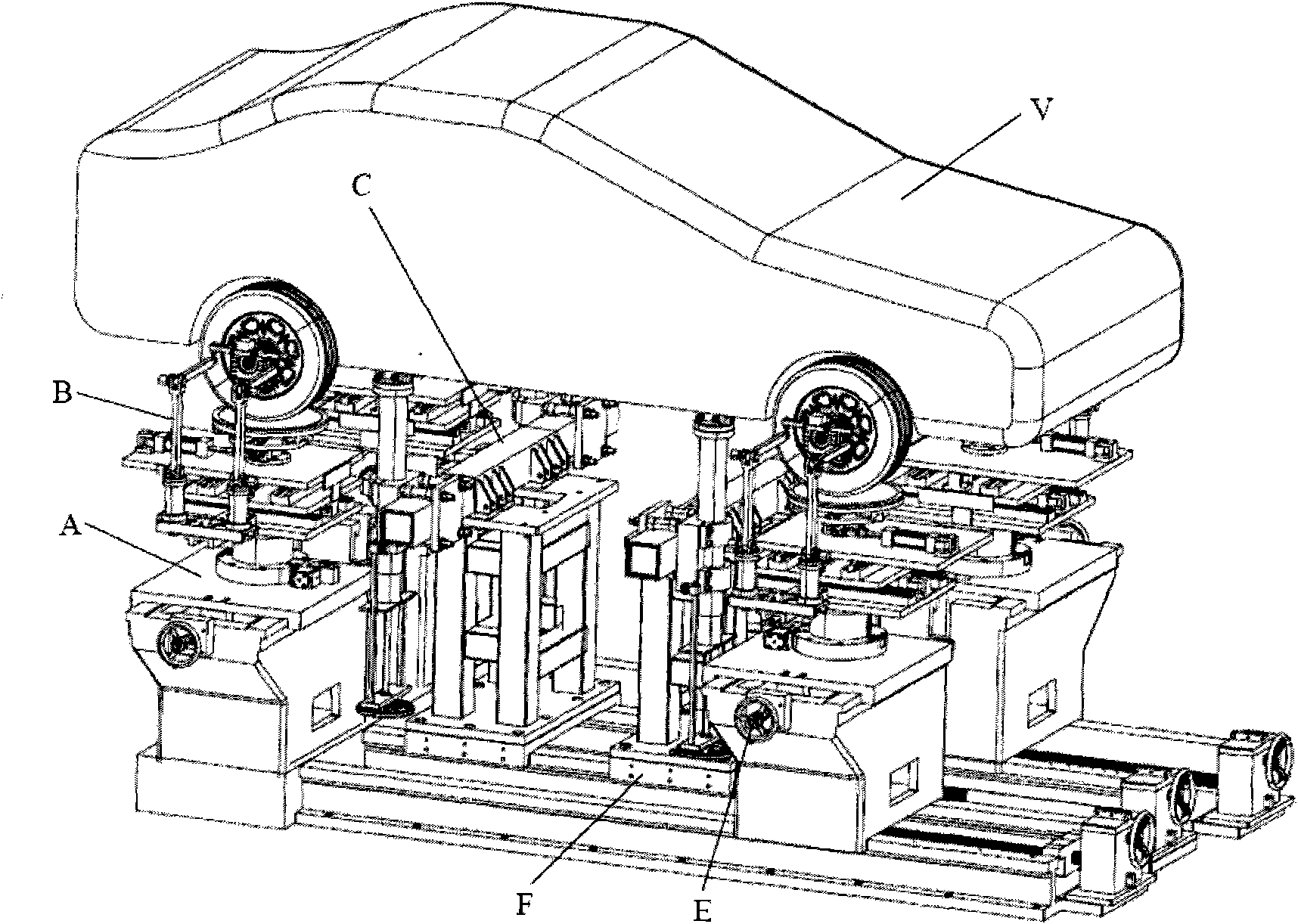

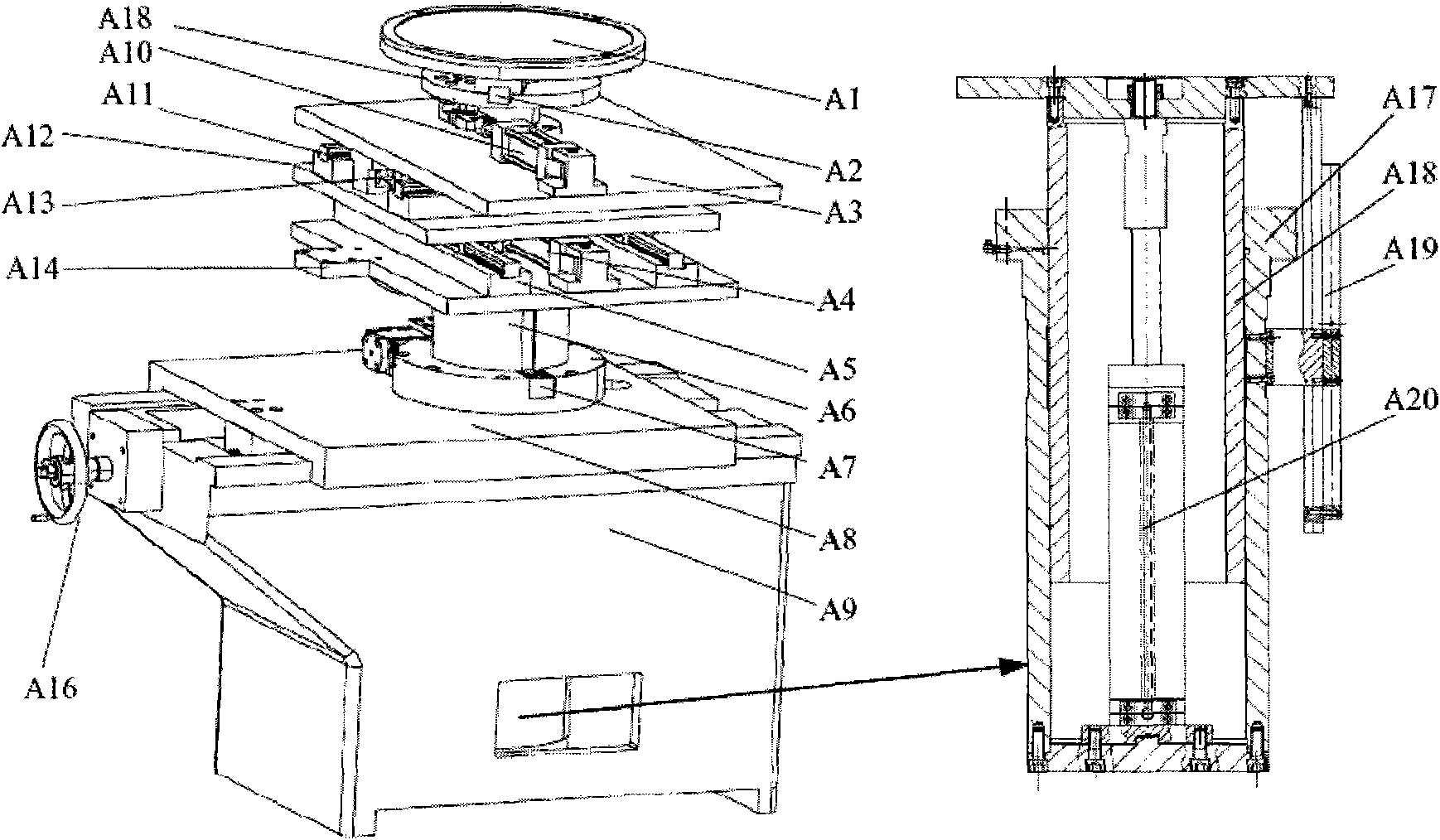

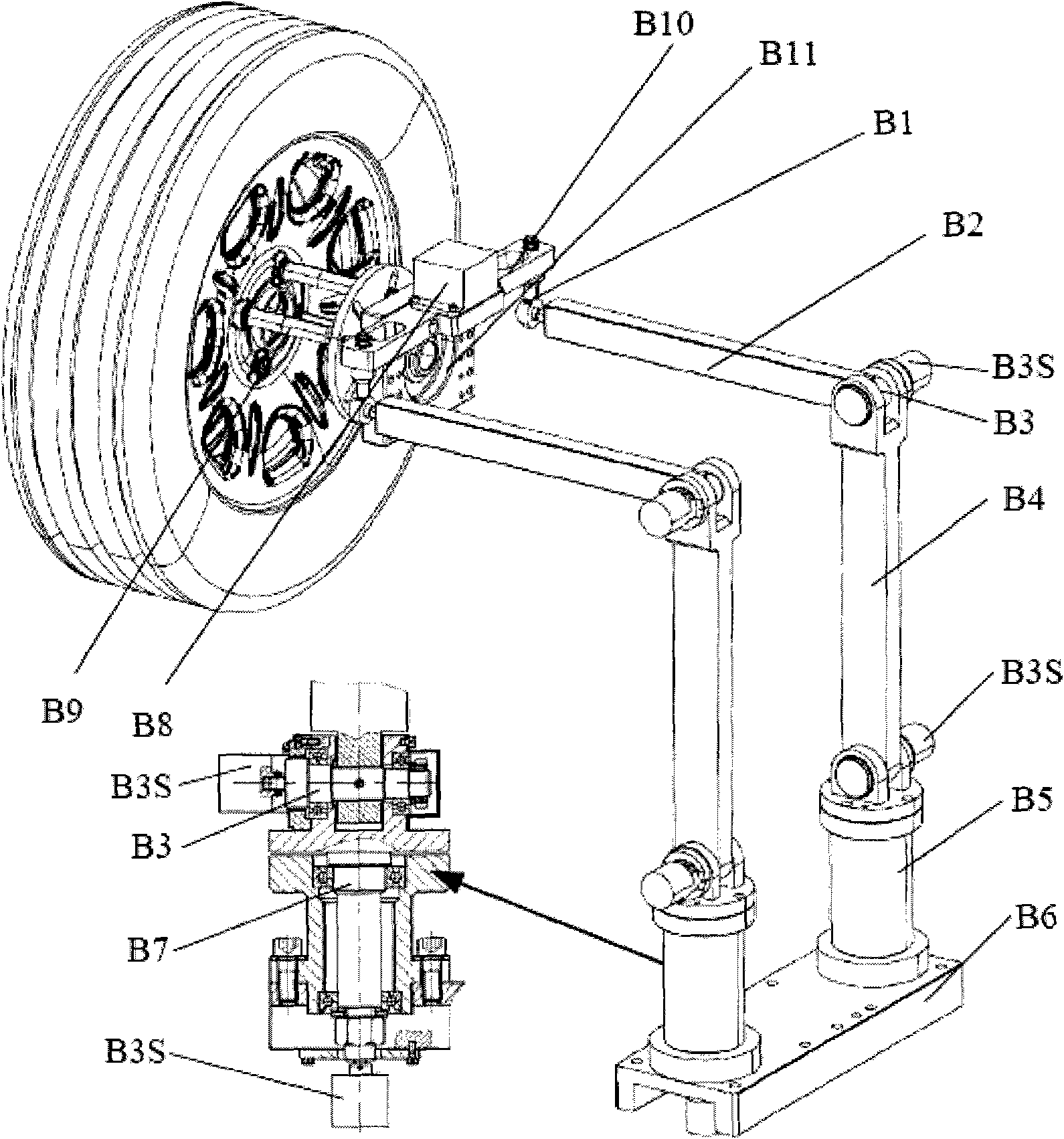

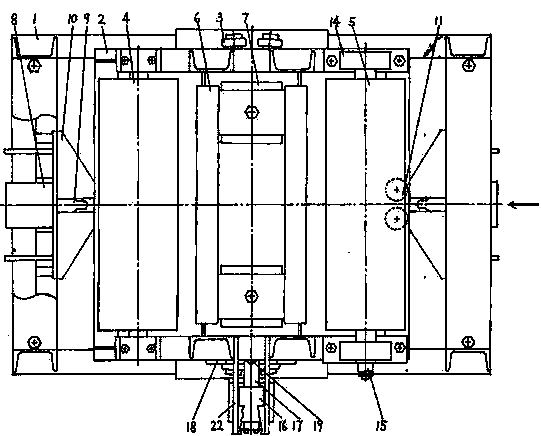

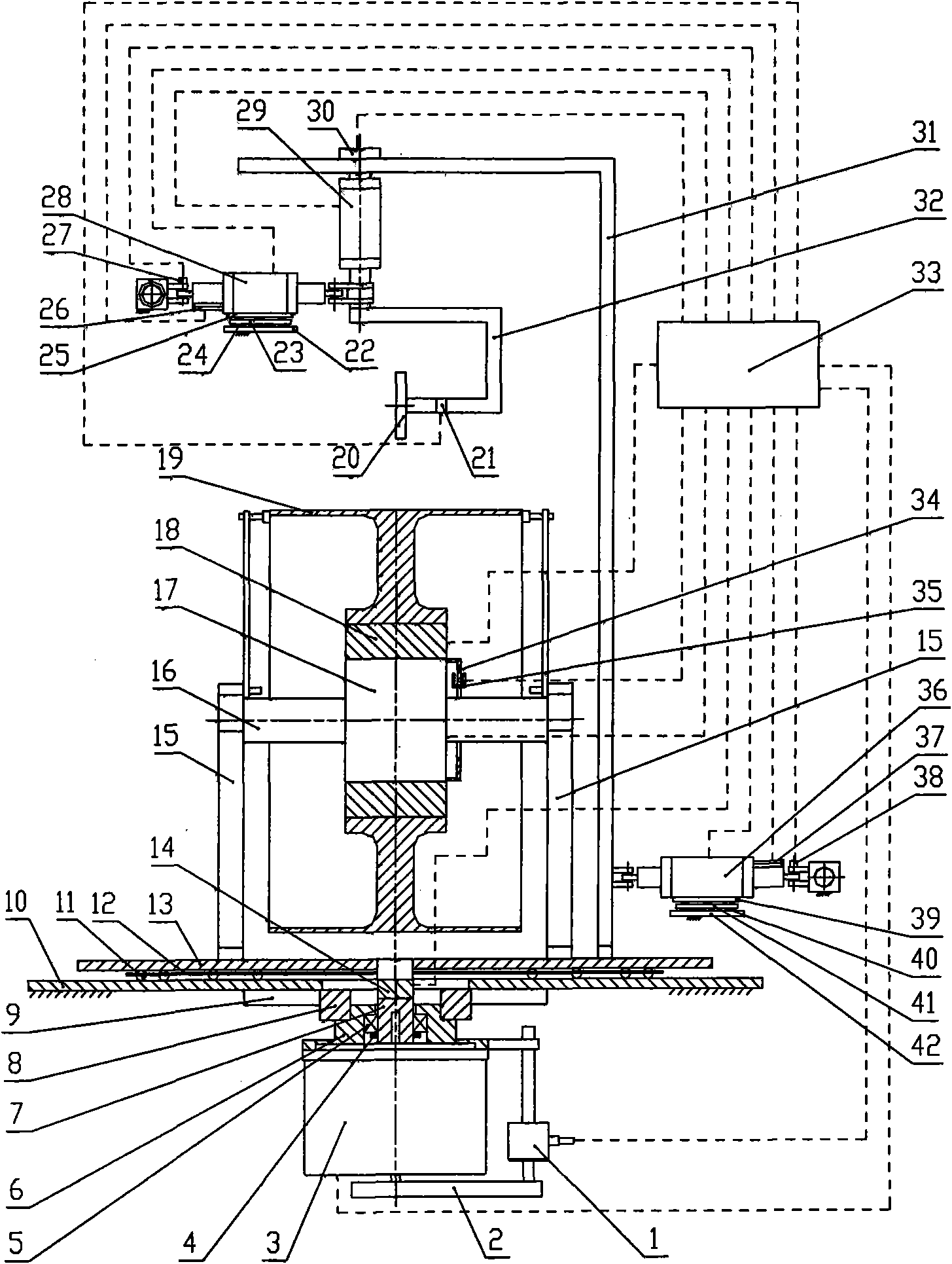

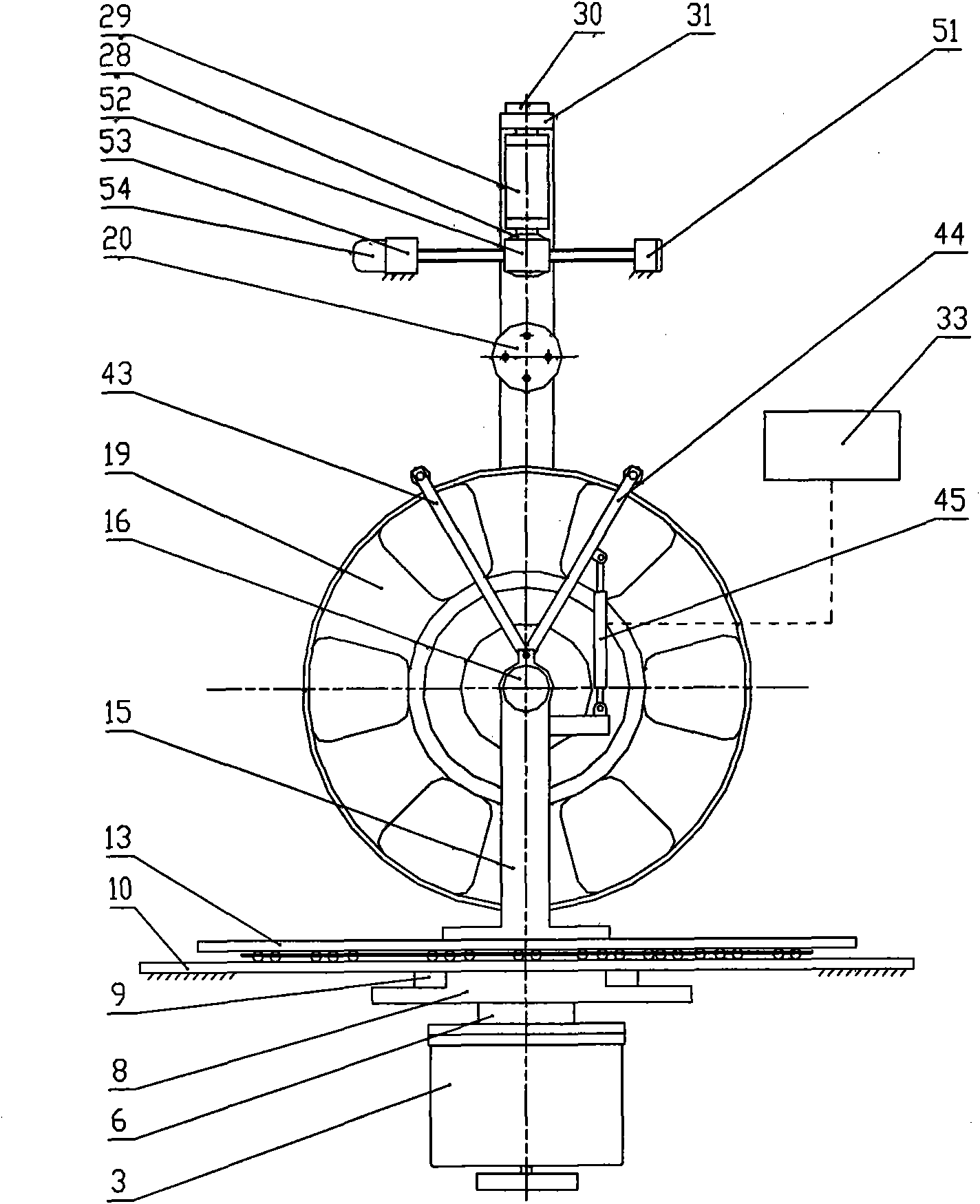

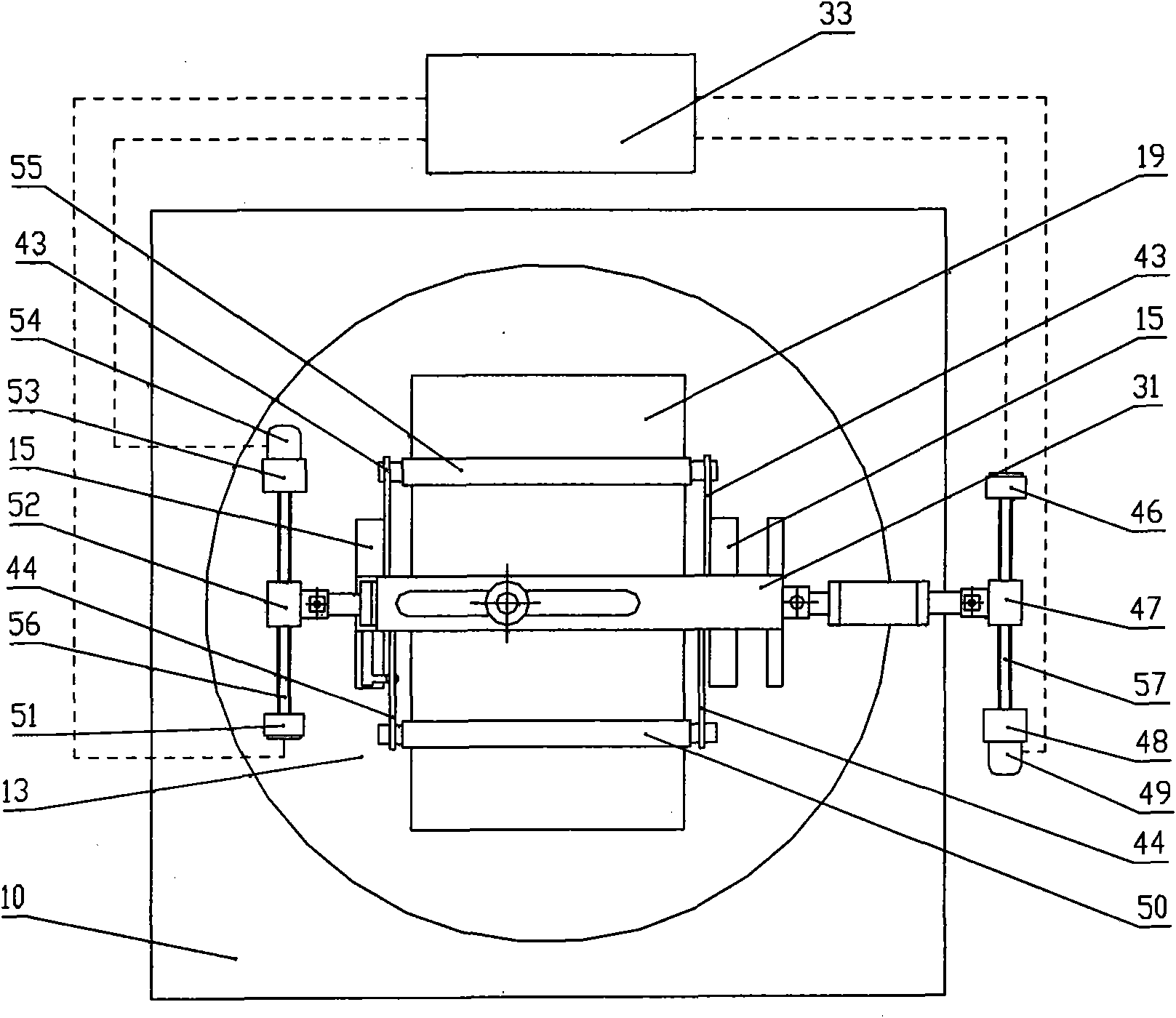

Kinematics and total working condition elastic tester of suspension bracket

A kinematics and total working condition elastic tester of a suspension bracket comprises a loading platform (A) capable of testing six component forces, a six-degree-of-freedom movement measuring mechanism (B) of a wheel, a vehicle body clamping system (C), a wheel distance adjusting system (E) and a data collecting and processing system, further comprising an axle distance adjusting system (F). A tester for a whole vehicle and a tester for a separated suspension bracket system can be assembled according to different user requirements and different clamping manners so as to satisfy different requirements on the test of the all-directional kinematics characteristic and the total working condition deformation characteristic.

Owner:KH AUTOMOTIVE TECH CHANGCHUN

Non contact wheel alignment sensor and method

ActiveUS7864309B2Good precisionHigh sensitivityAngle measurementImage analysisEngineeringWheel alignment

Owner:VERHAERT NEW PROD & SERVICES +1

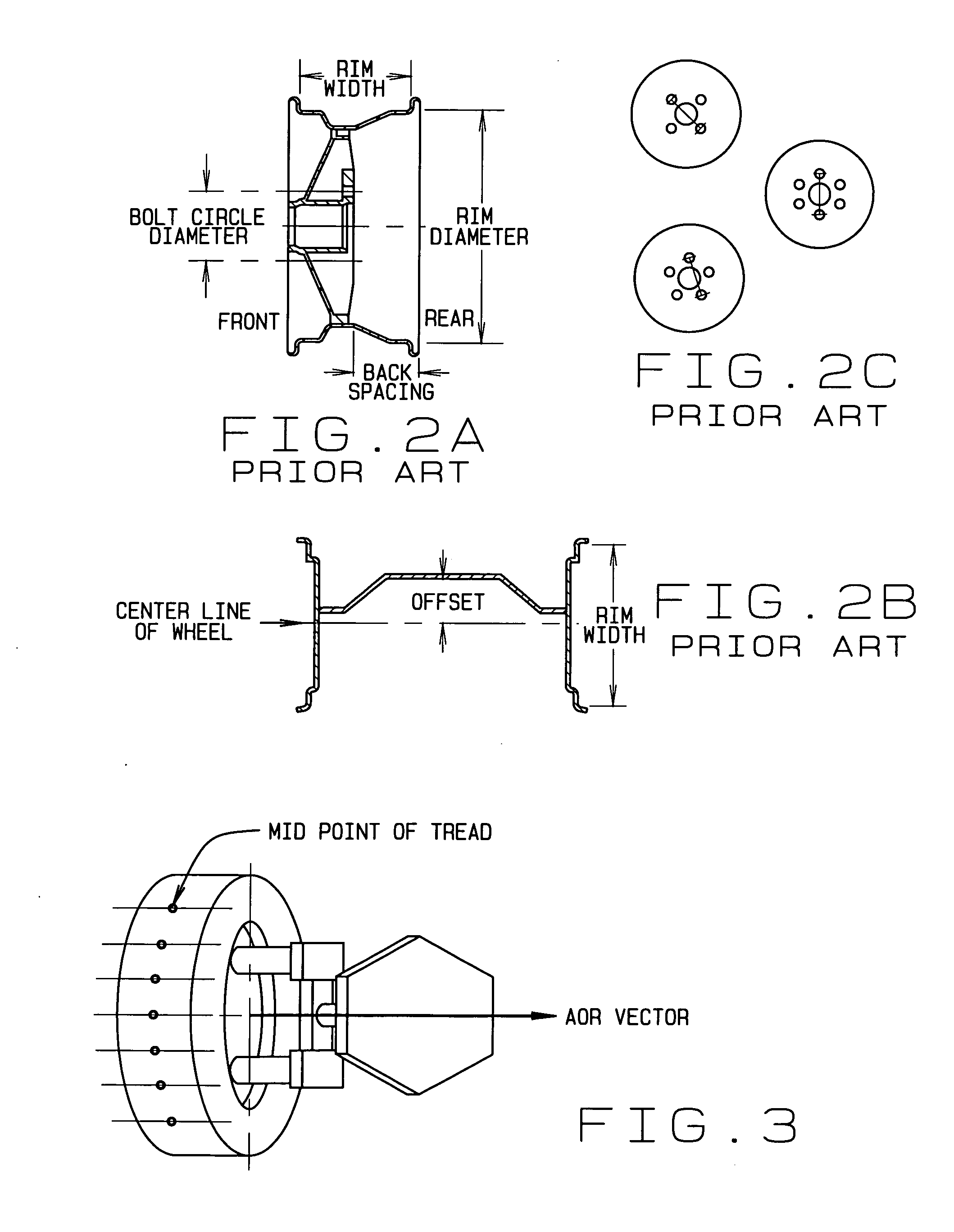

Method and Apparatus For Wheel Assembly Force Moment Arm Measurement

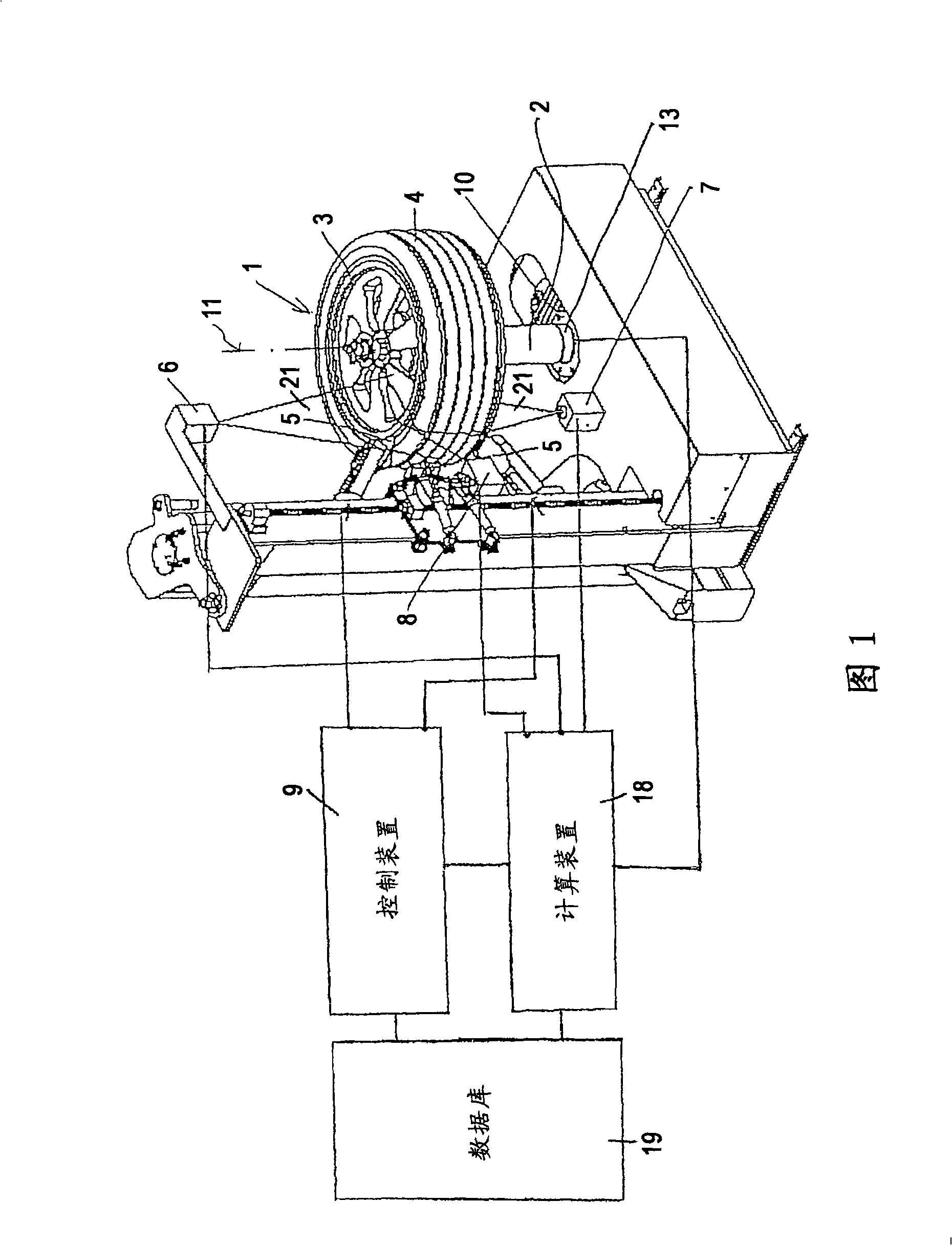

InactiveUS20080119978A1Registering/indicating working of vehiclesDigital data processing detailsMachine visionMeasurement point

A machine vision vehicle wheel alignment system configured to measure non-traditional vehicle wheel alignment angles and to determine dynamic behavior of a vehicle suspension system by observing optical targets or visible features, attached to points of interest on the vehicle body or vehicle wheels. The vehicle wheel alignment system characterizes the suspension geometry with respect to the body of the vehicle and to a rolling surface by measuring, in three-dimensions, points and / or angles on the vehicle body as well as the vehicle wheels, enabling measurement of specific non-traditional vehicle parameters, including wheel assembly braking force and lateral force moment arms.

Owner:HUNTER ENG

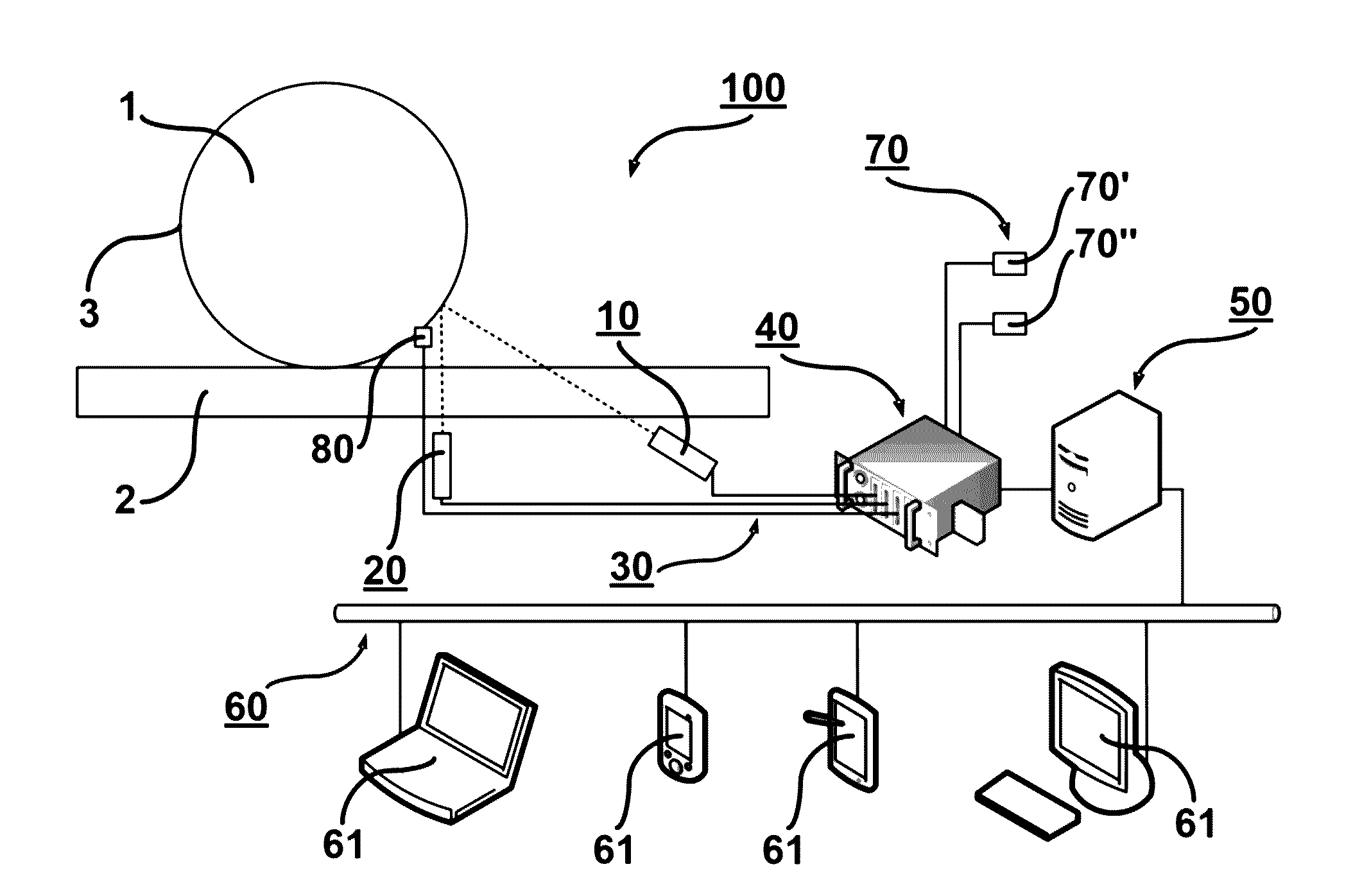

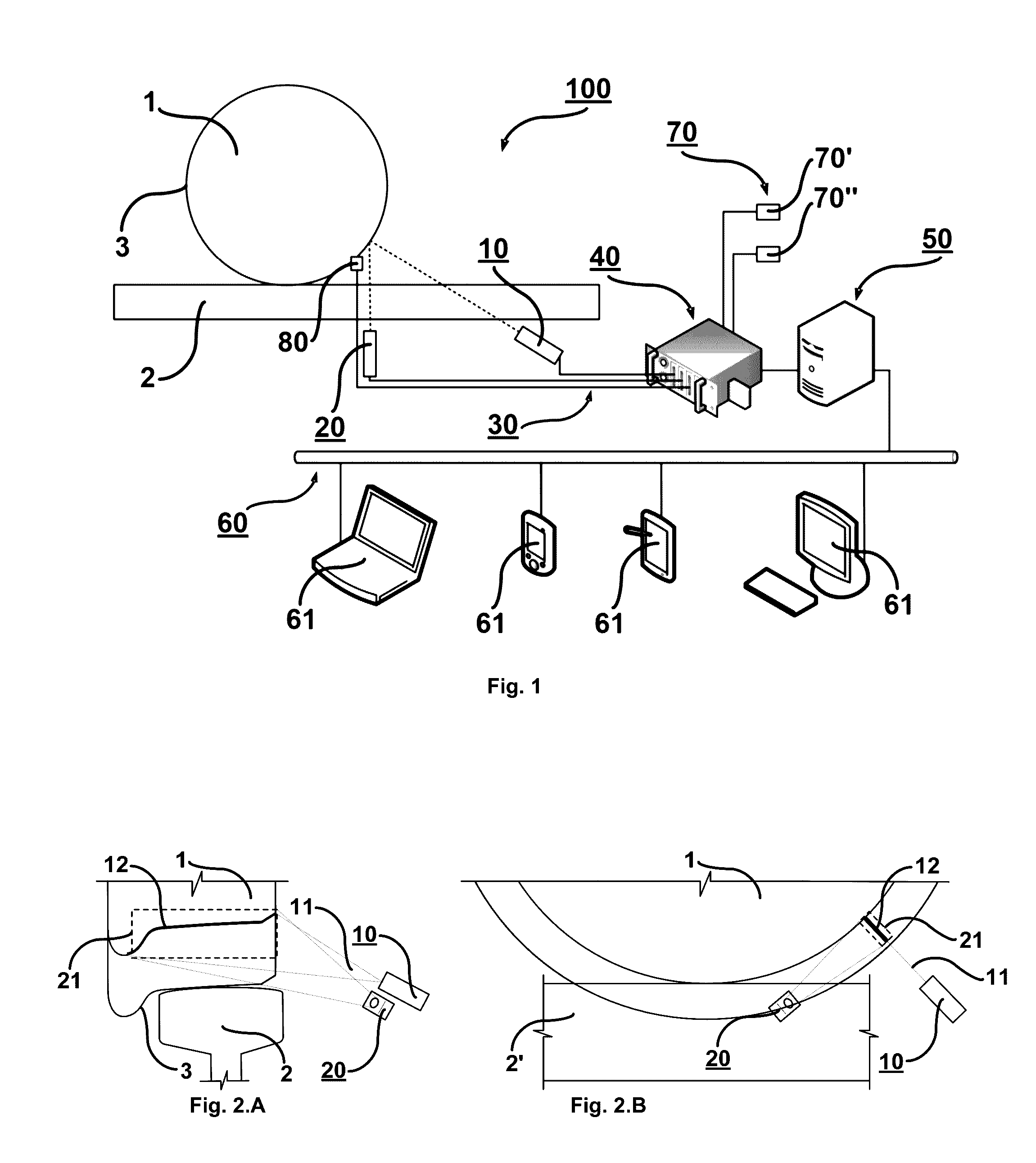

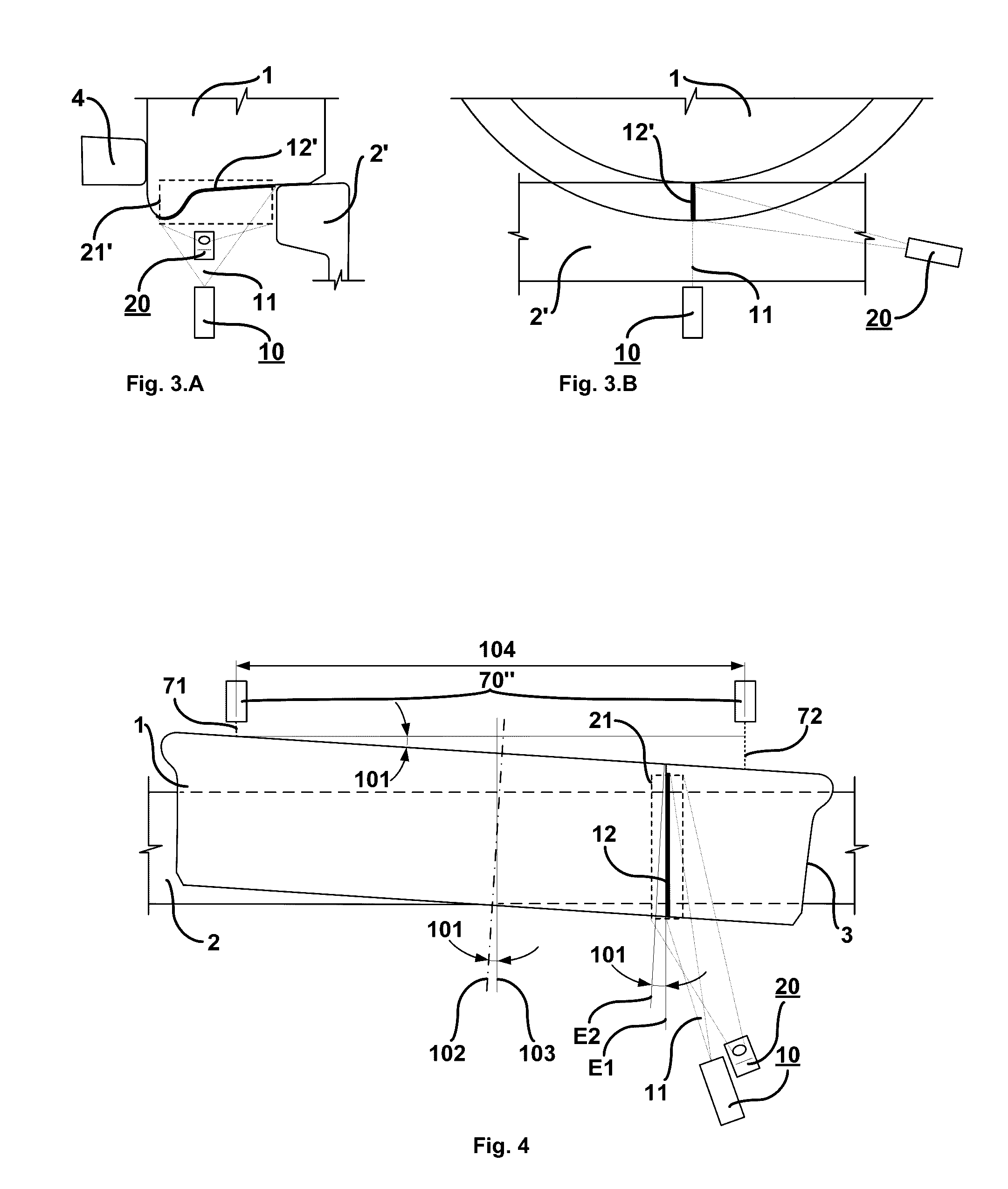

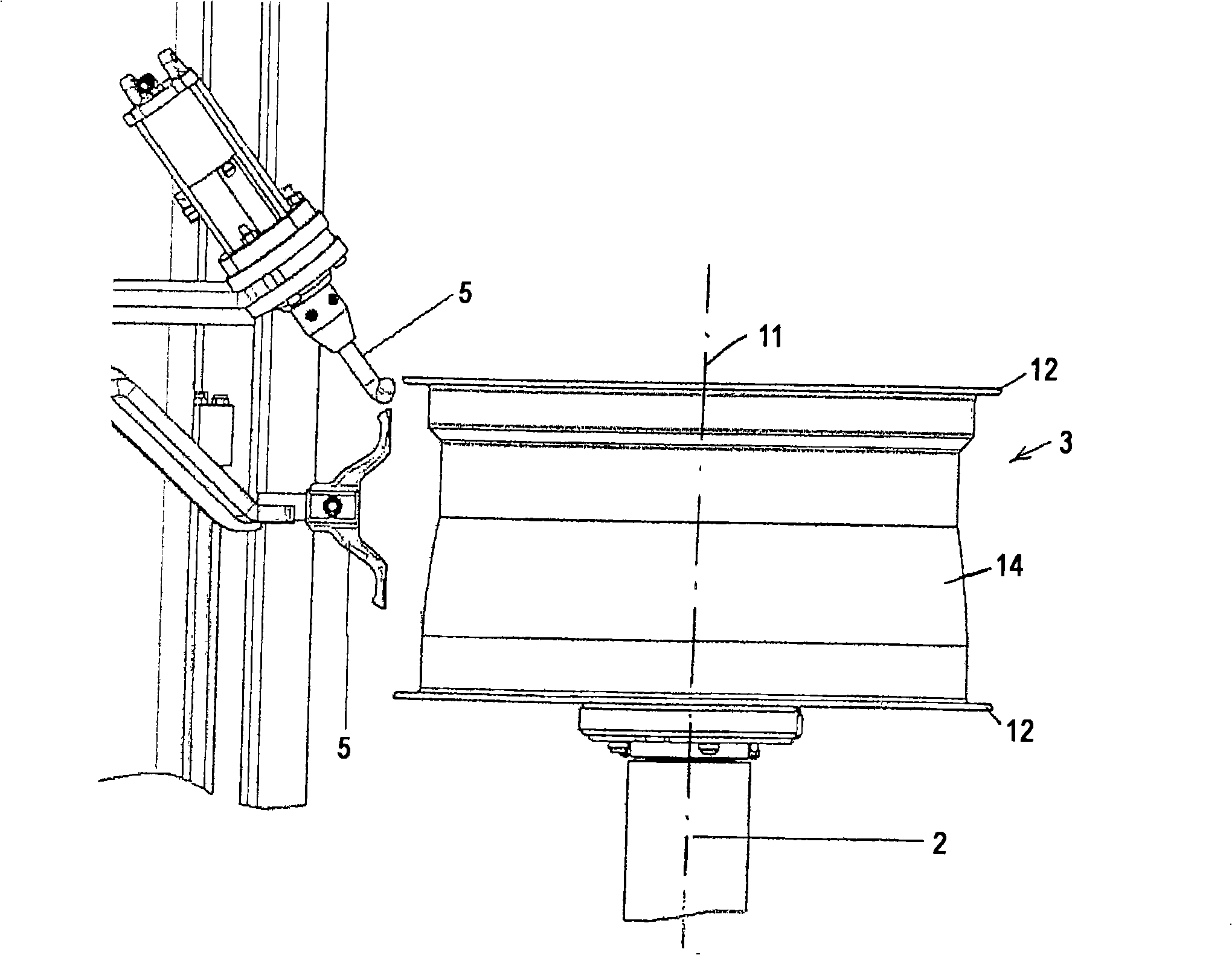

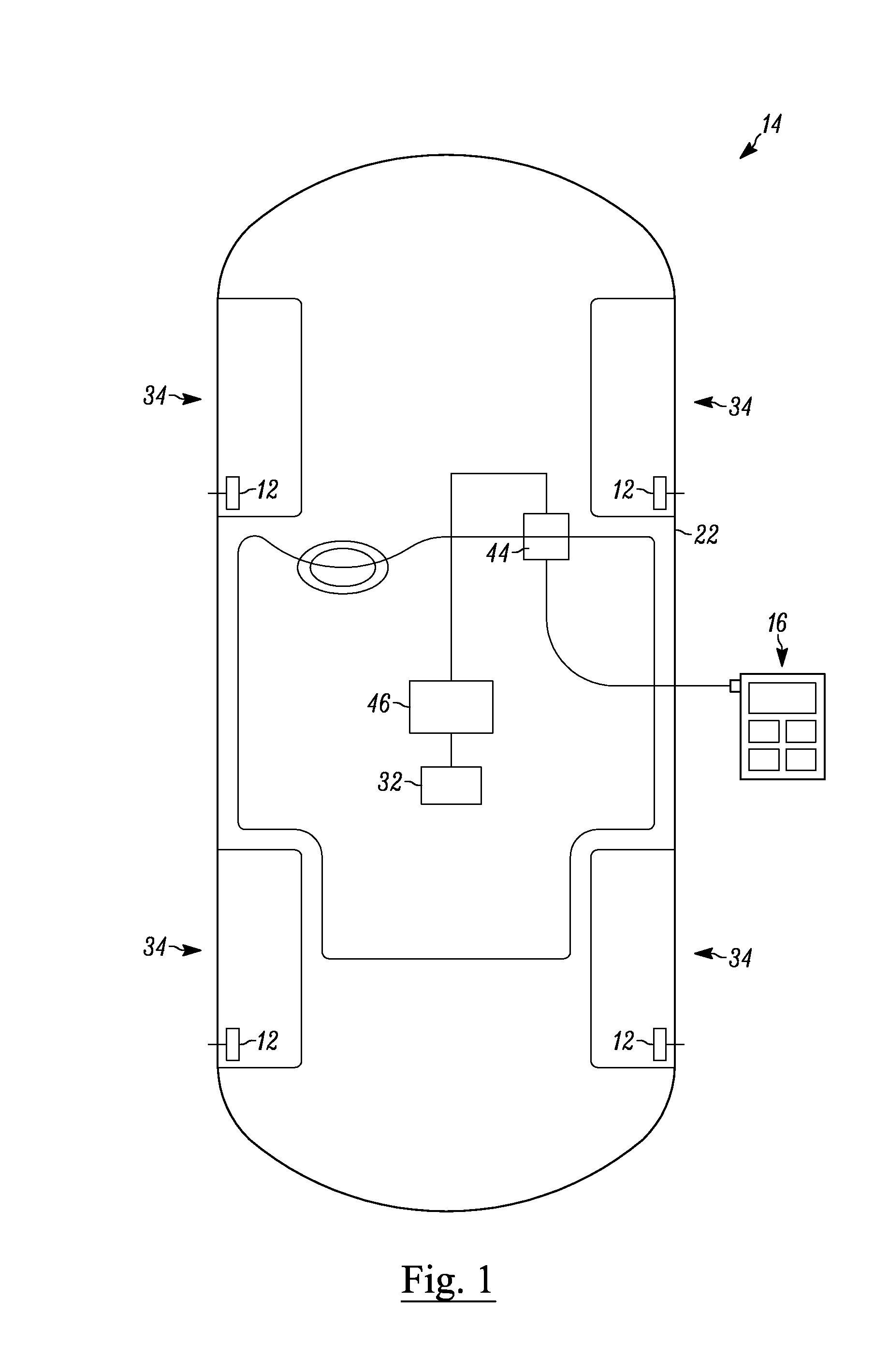

System and method for inspecting the geometric parameters of the wheels of railway vehicles

The present invention relates to a system and method for the automated inspection of geometric parameters of railway wheels rolling on a track by artificial vision techniques. The present invention uses a structured light source (10) that illuminates a line of light (12) upon a fraction of the surface of revolution (3) of a wheel (1), a CCD camera (20), which captures an image (21) of the illuminated area, and a data processing system that records, digitalizes, geometrically corrects and reconstructs information of the surface of revolution (3) that is not recorded in the image (21), in order to obtain a numeric description of the complete transverse section of the wheel (1) represented by a reconstructed profilogram (500) for calculating the geometric parameters of the wheel (1).

Owner:EMPRESA DE TRANSPORTE MASIVO DEL VALLE DE ABURRA LTDA METRO DE MEDELLIN LTDA

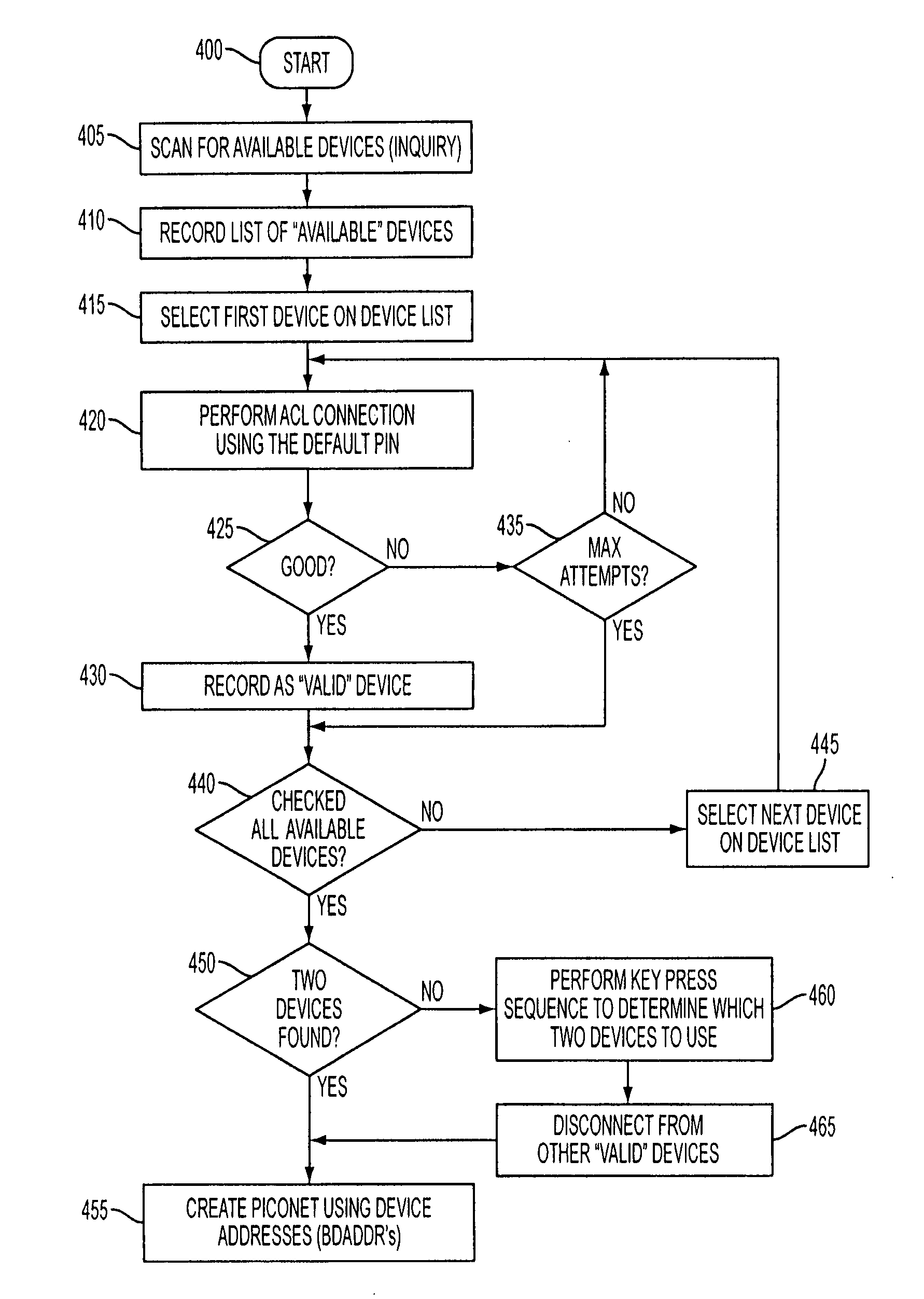

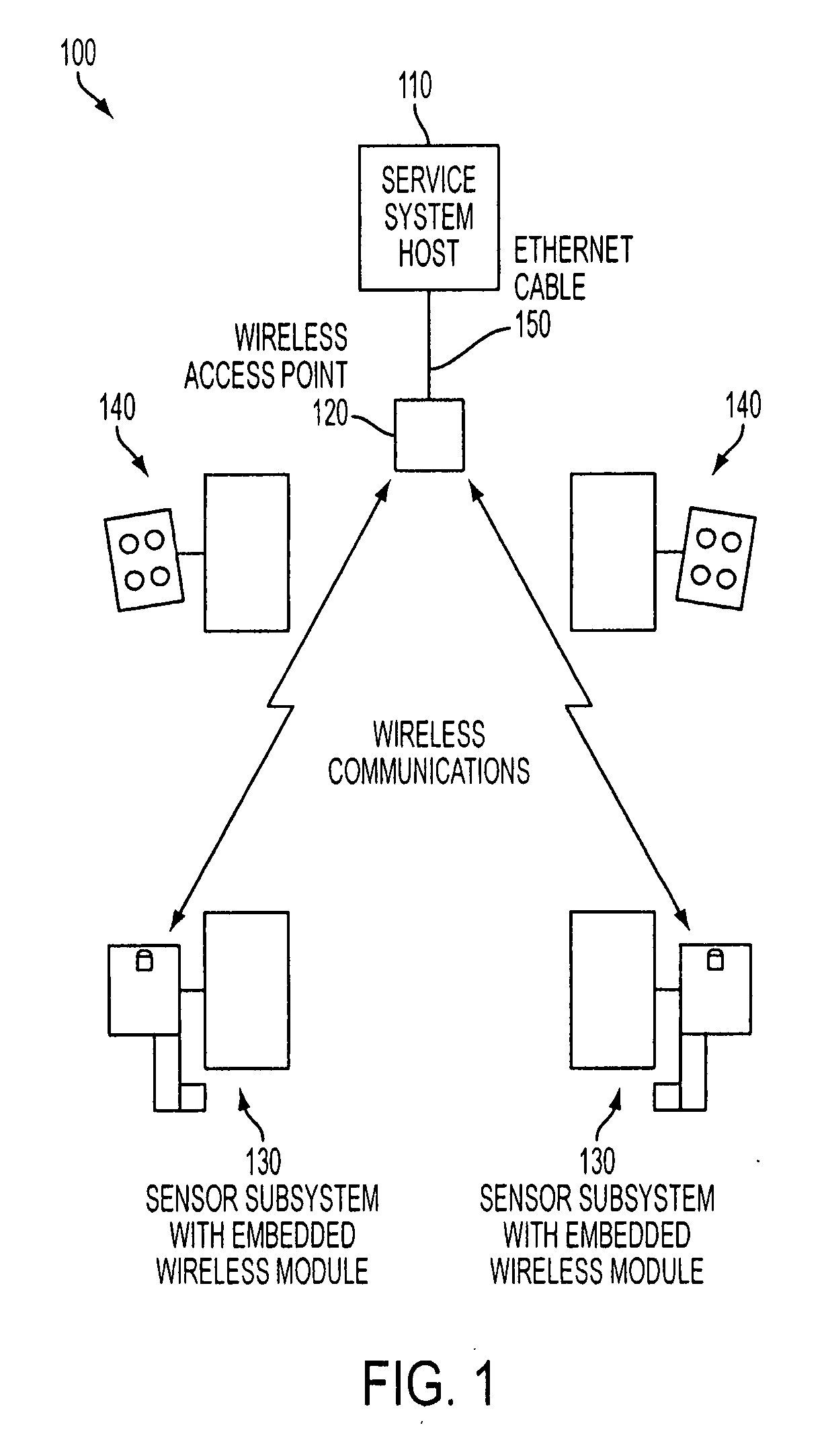

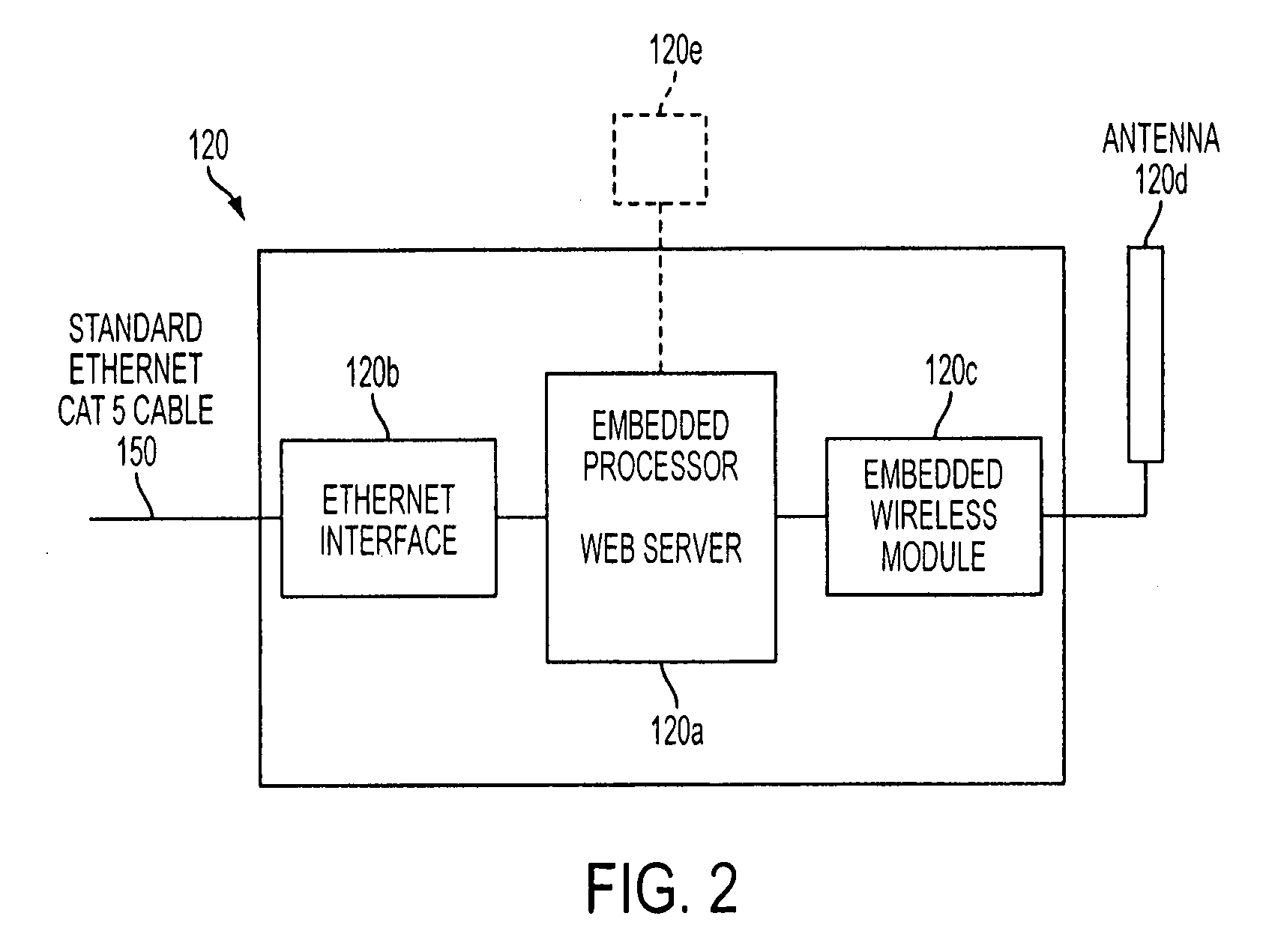

Wireless network and methodology for automotive service systems

ActiveUS20090024272A1Registering/indicating working of vehiclesDigital data processing detailsMaster controllerCommunication link

A method and apparatus are provided for forming a wireless communications network using a standard communications link between a master controller and at least one slave device. In one example, a list of available slave devices for the network is generated, valid slave devices are determined from the list of available slave devices based on an identification protocol of the standard communications link, and the at least one slave device is selected from the valid slave devices. A network identification is established between the master controller and the at least one slave device, and the network identification is used to establish a network comprising only the master controller and the at least one slave device.

Owner:SNAP ON INC

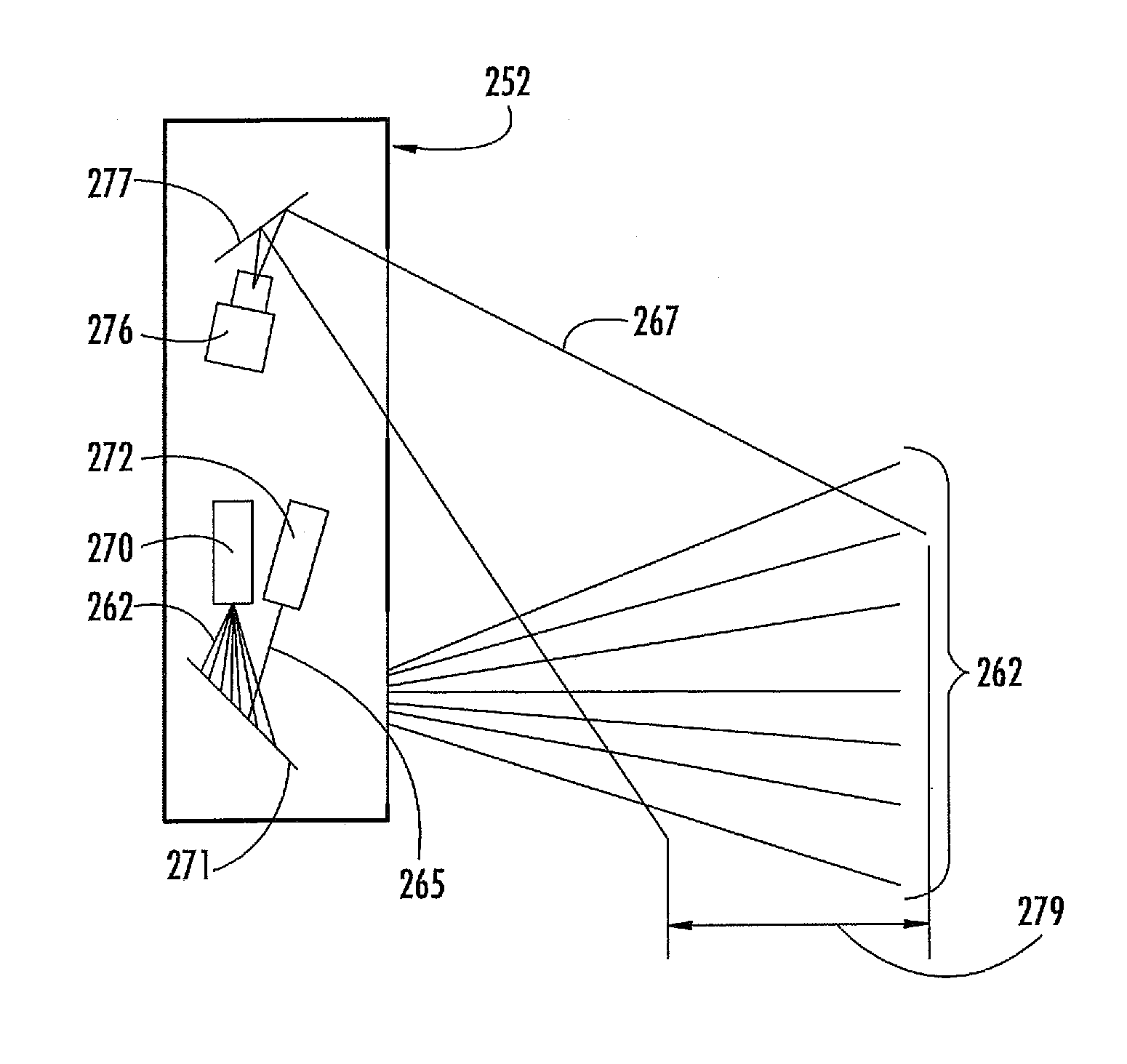

Non contact wheel alignment sensor and method

ActiveUS20080273194A1Good precisionHigh sensitivityAngle measurementImage analysisEngineeringWheel alignment

A sensor and method of determining the orientation of an object, such as the alignment characteristics of a tire and wheel assembly mounted on a vehicle, includes projecting a plurality of light planes from a first light projector onto a tire and wheel assembly to form a plurality of generally parallel illumination lines on a tire of the tire and wheel assembly, receiving a reflected image of at least some of the illumination lines with a photo electric device reflected from the tire at an angle relative to a projecting angle of the first light projector, and determining a plane defined by spatial coordinates from a selected point located on each illumination line imaged by the photo electric device, with the plane representing the orientation of the tire and wheel assembly.

Owner:VERHAERT NEW PROD & SERVICES +1

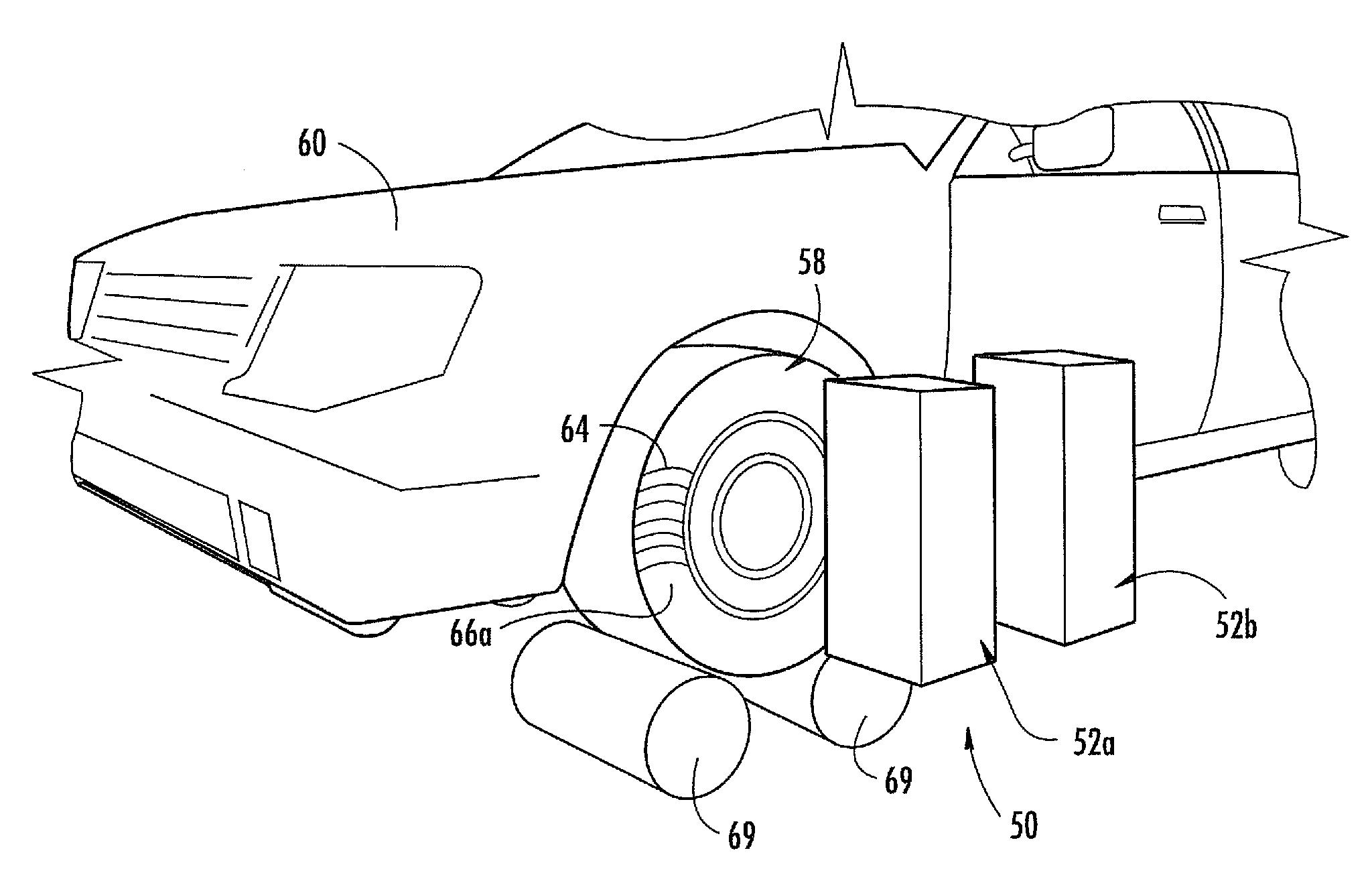

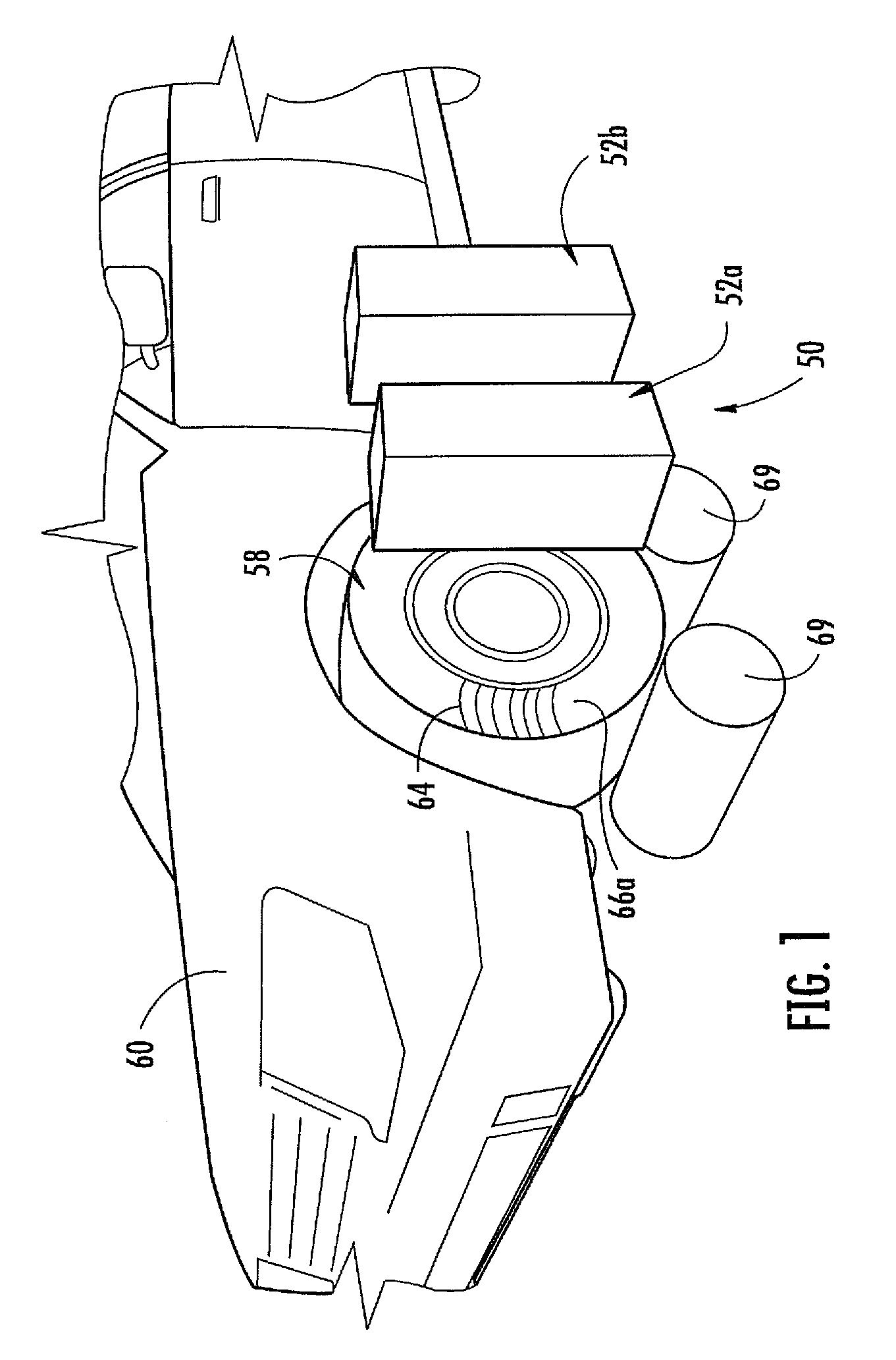

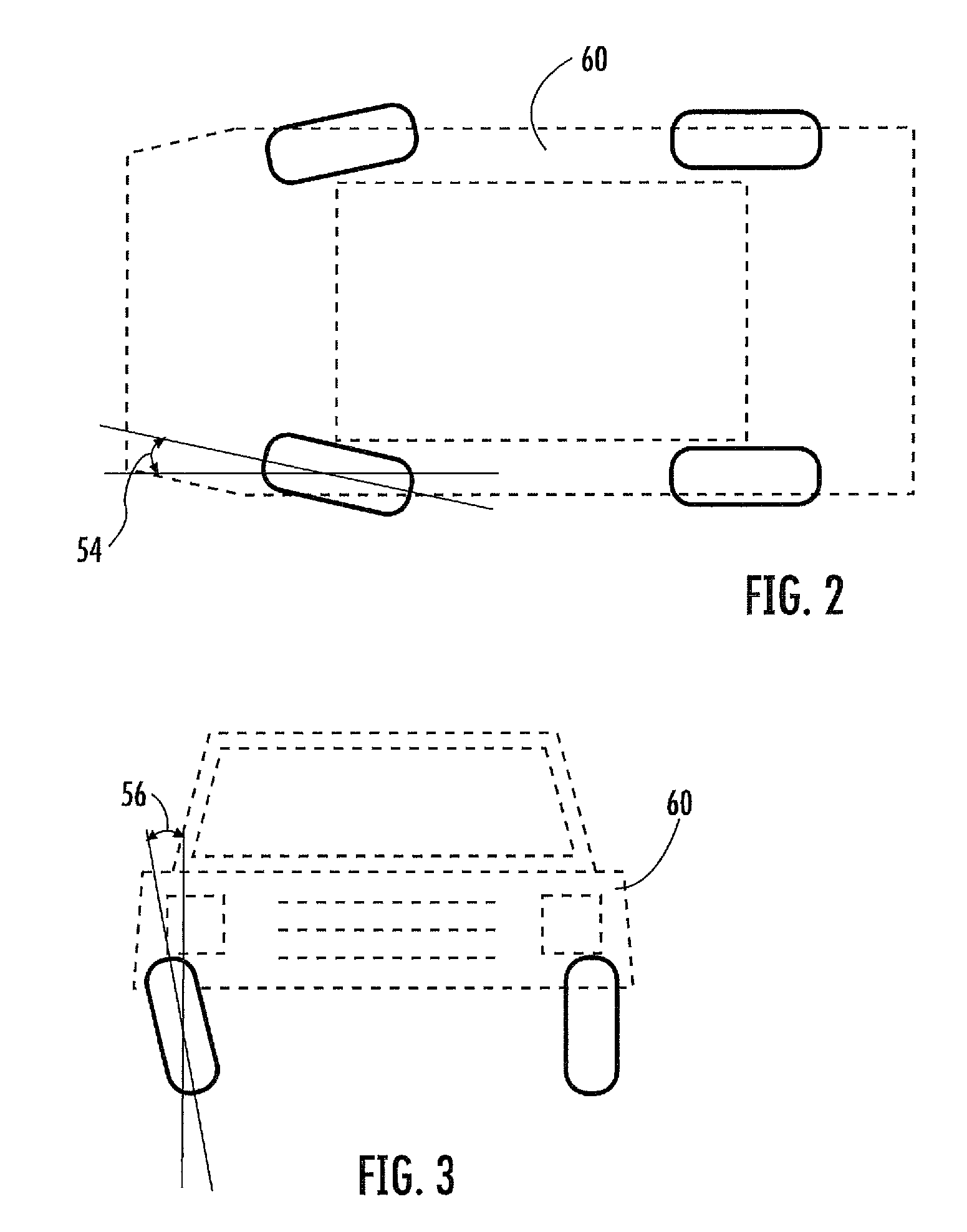

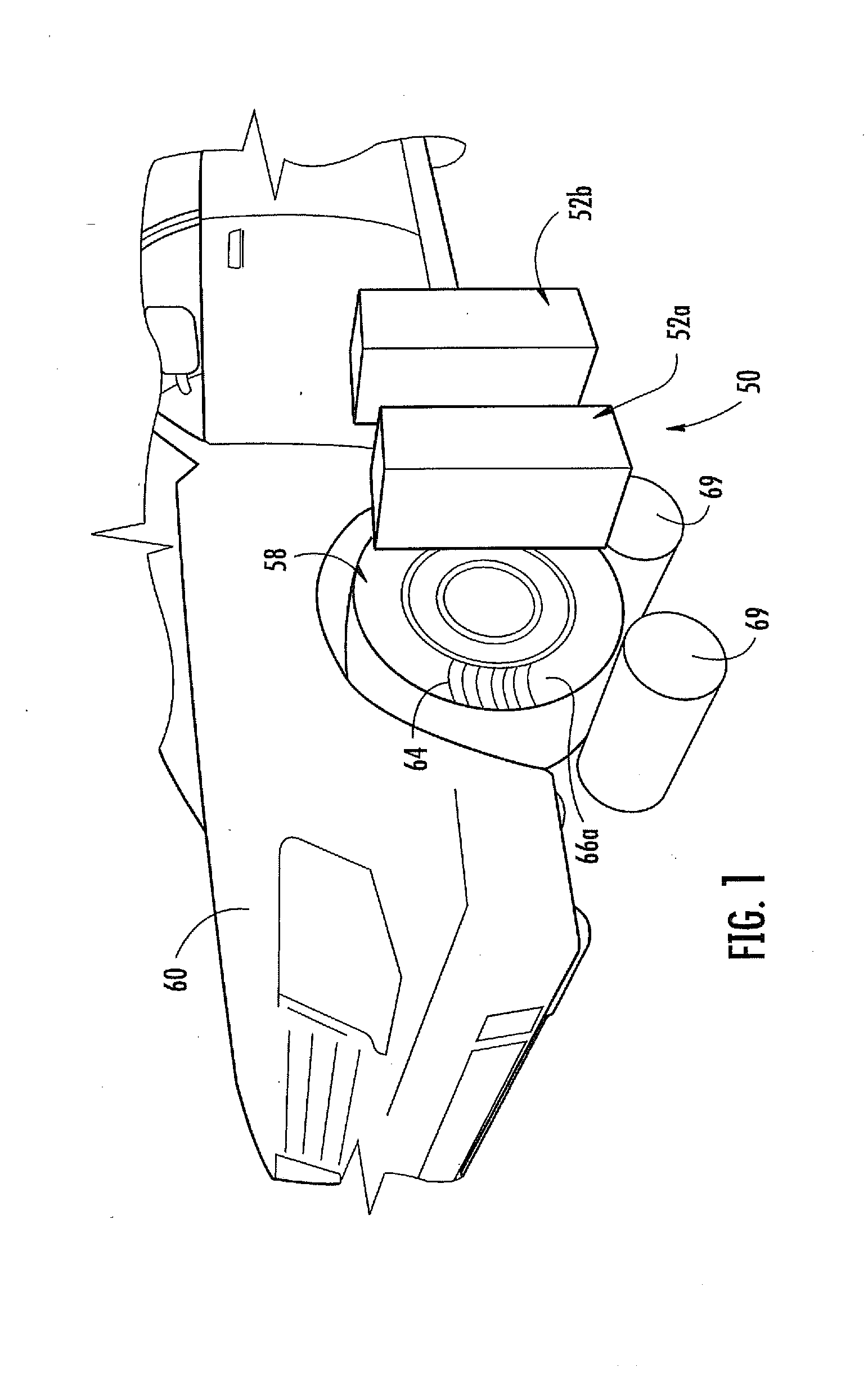

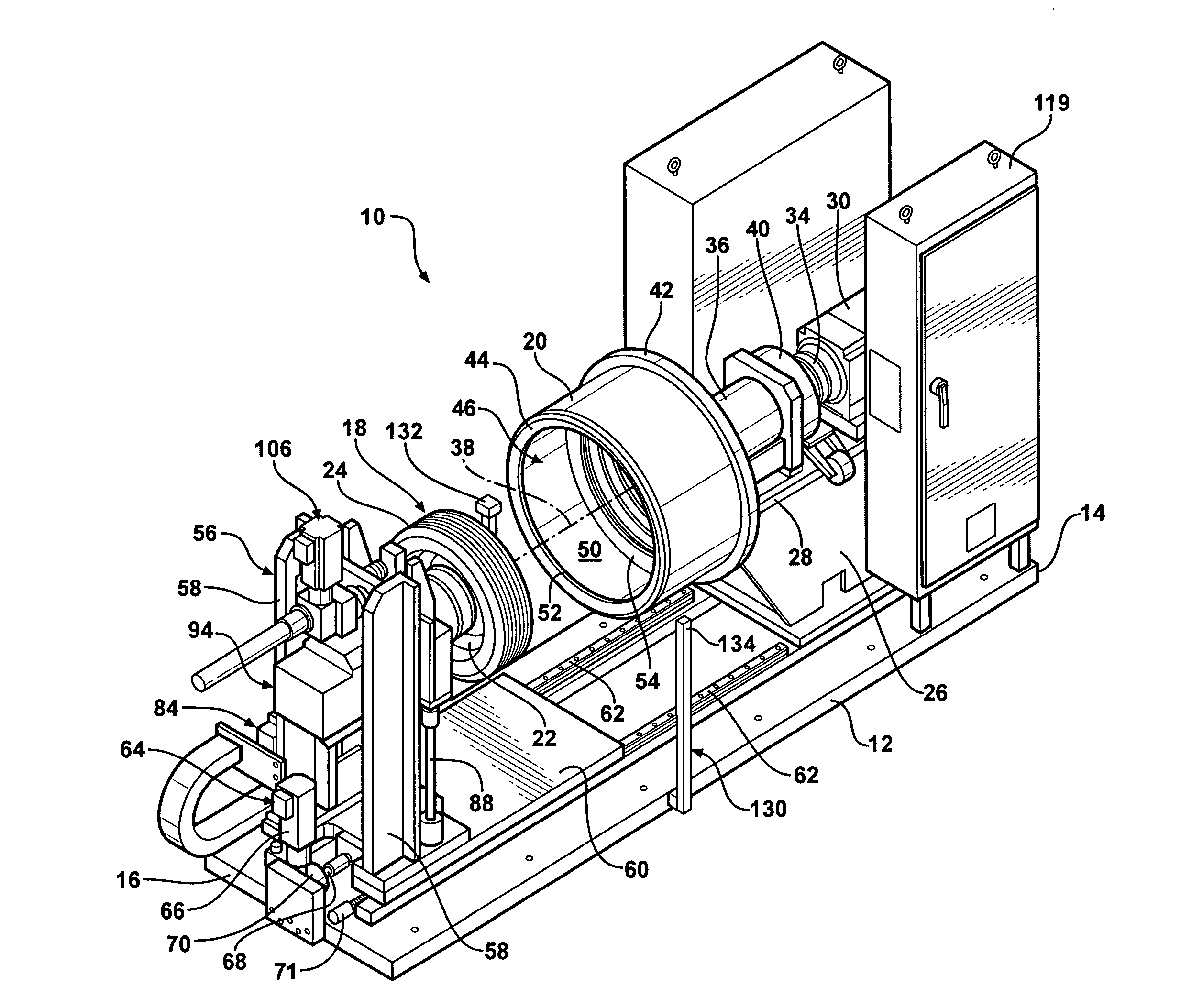

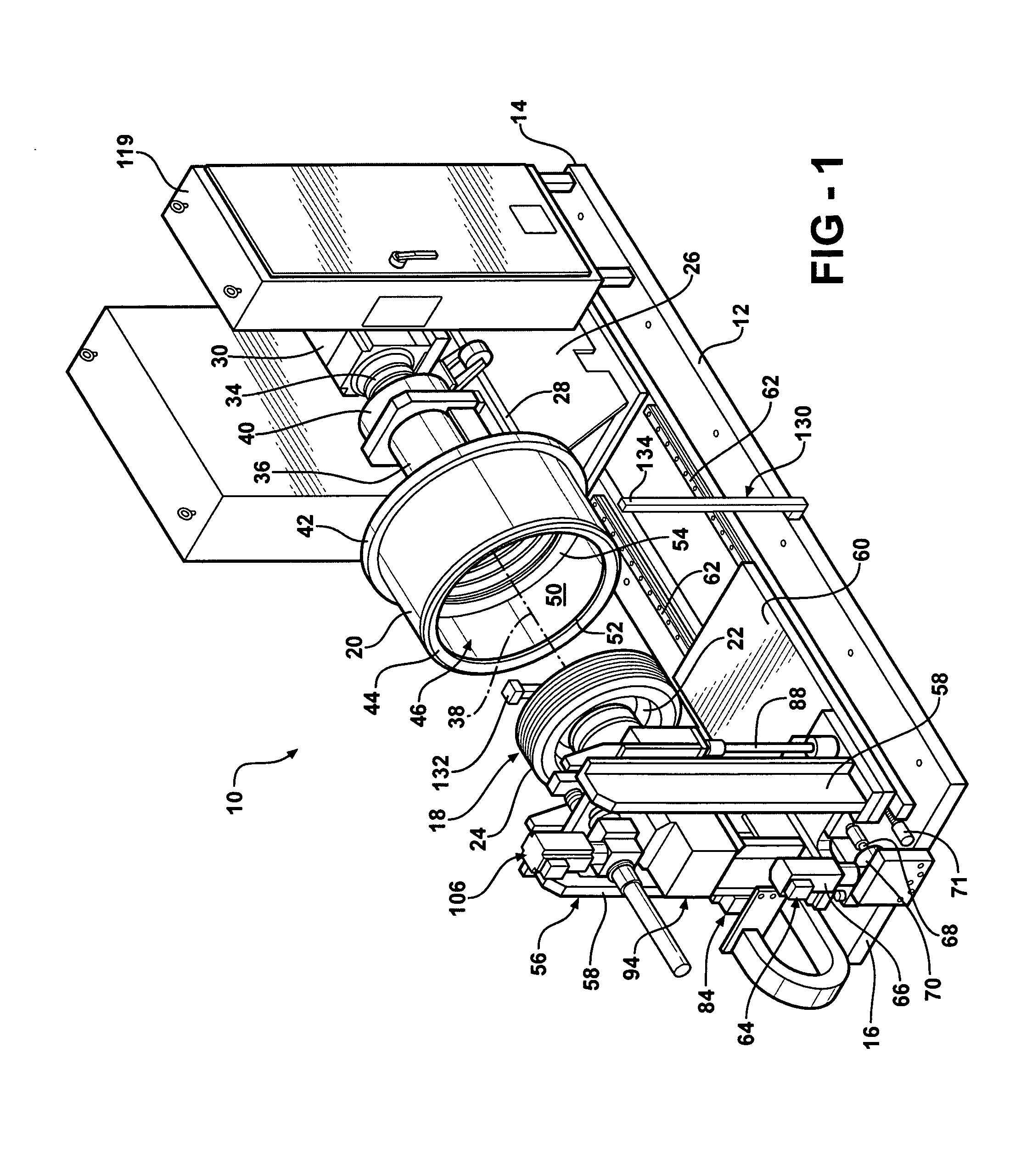

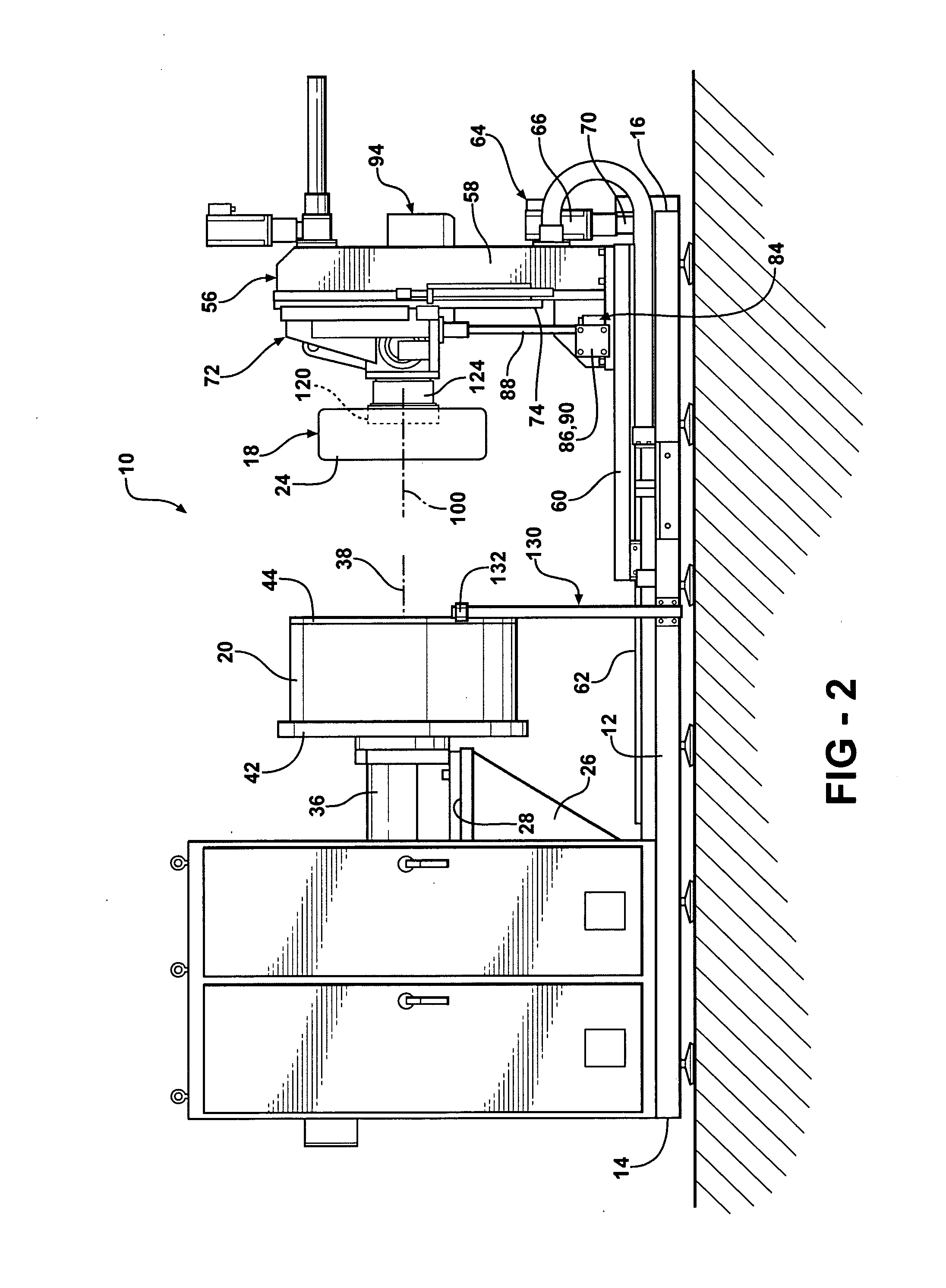

Biaxial wheel test assembly

A wheel test assembly for testing a wheel-and-tire assembly includes a drum operatively mounted to a base for rotation of the drum. The drum includes an inner circumferential surface. A tailstock assembly is slidably coupled to the base for movement in a lateral direction relative to the drum. A support assembly is slidably coupled to the tailstock assembly for movement in a vertical direction for positioning the wheel-and-tire assembly into rolling contact with the inner circumferential surface of the drum. A spindle assembly is pivotally coupled to the support assembly to adjust a camber angle of the wheel-and-tire assembly. The wheel-and-tire assembly is mounted to the spindle assembly for rotation of the wheel-and-tire assembly.

Owner:LINK ENG

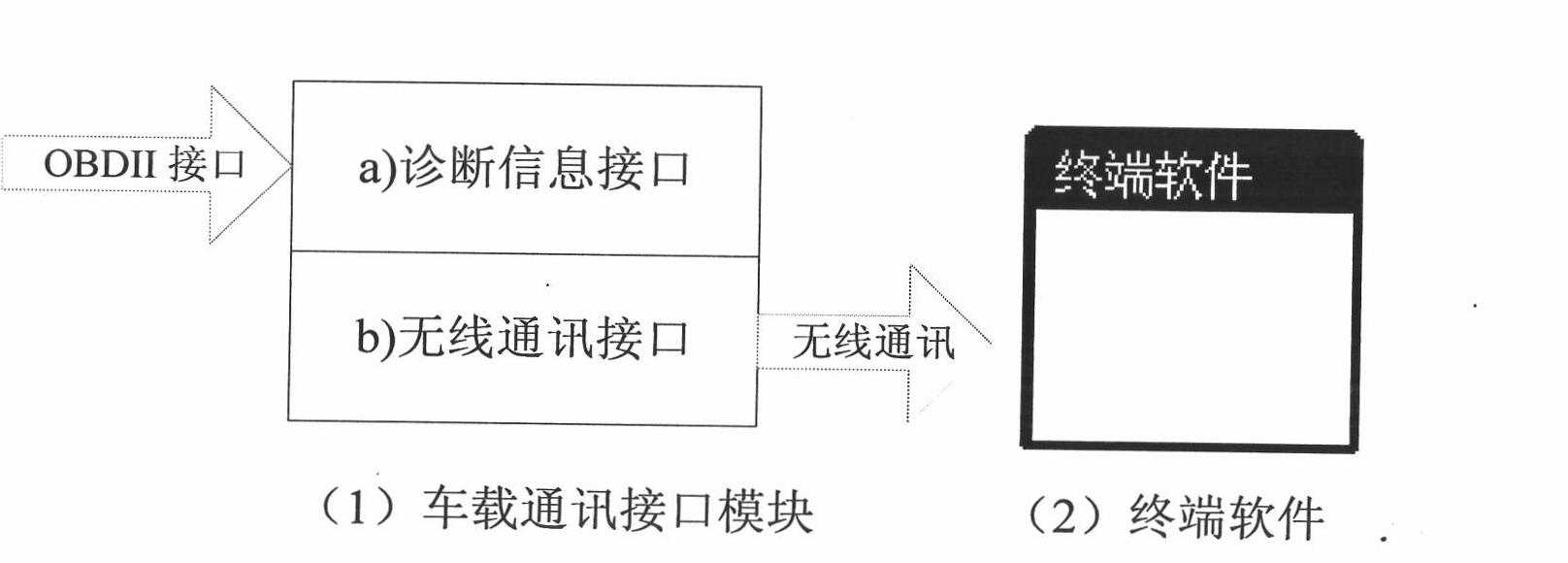

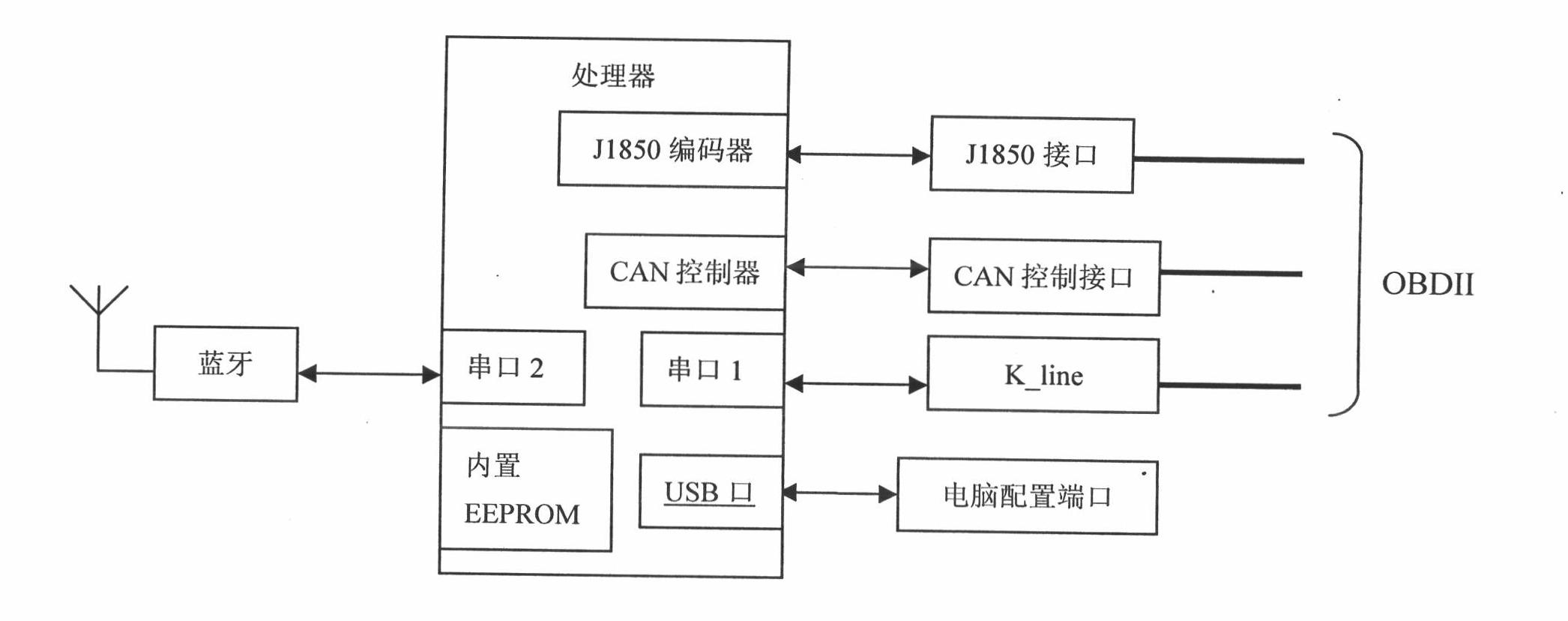

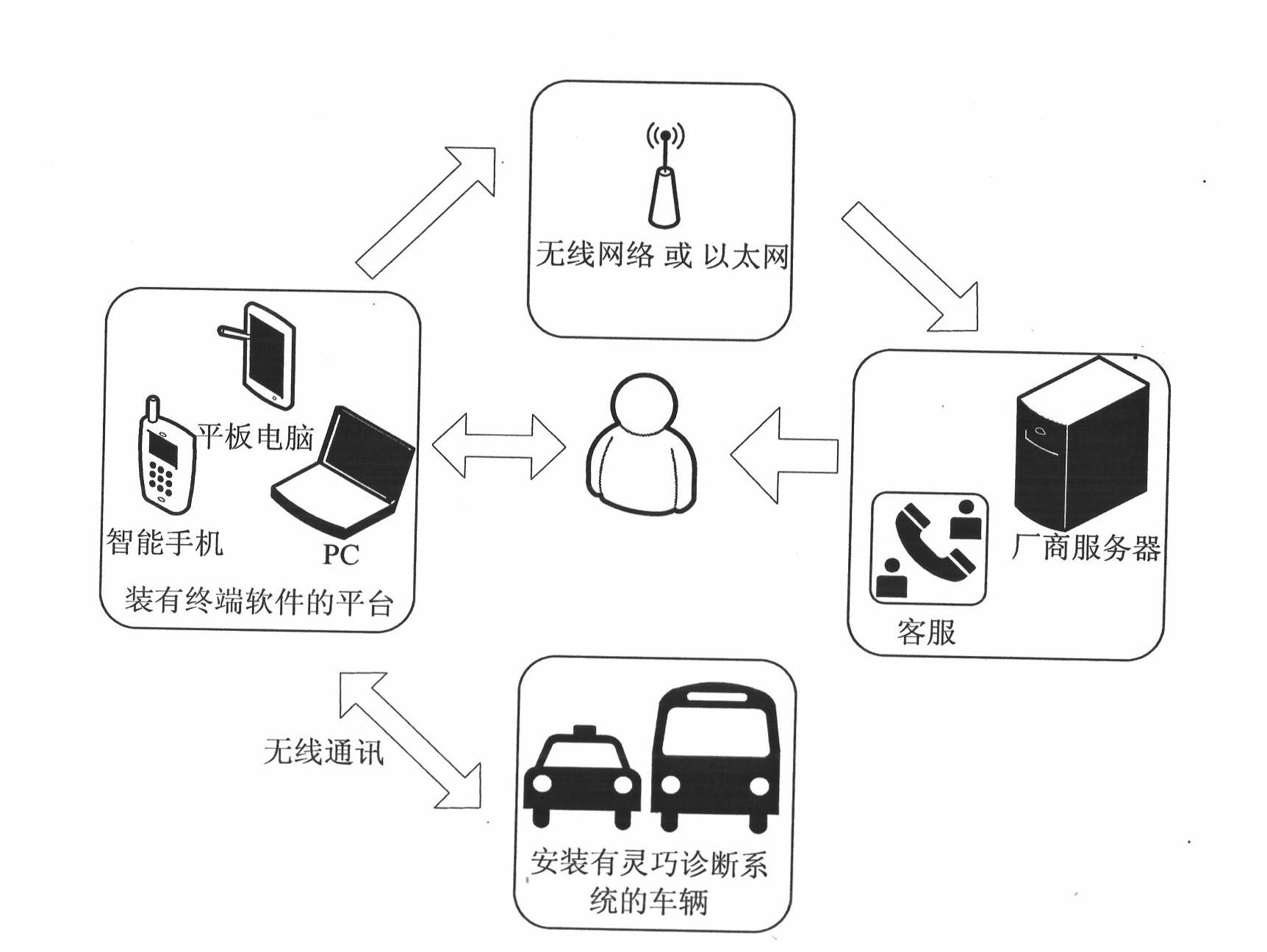

Smart diagnosis system for passenger vehicles

ActiveCN102120441AWith remoteEasy to moveRegistering/indicating working of vehiclesVehicle servicing/repairingChannel state informationTablet computer

The invention discloses a diagnosis system and a diagnosis method for passenger vehicles. The diagnosis system for passenger vehicles comprises a vehicle-mounted communication module, a vehicle standard OBDII diagnosis module, a wireless communication module and client terminal software. The diagnosis method comprises the steps of connecting the vehicle-mounted communication module with the vehicle standard OBDII diagnosis module to receive the state information of a vehicle; and transmitting the received information to an intelligent mobile phone, a personal computer or a tablet computer provided with the client terminal software by means of the wireless communication module. The intelligent mobile phone, the personal computer and the tablet computer are connected with a manufacturer's service center. Thus, a client can know the information such as vehicle state, fuel economy, loss, emission, faults and the like through the terminal software. The terminal software can analyze the data, evaluate whether the vehicle is needed to be maintained and whether a driver has good driving habits, and display information such as monthly or annual carbon discharge and the like for a user. The terminal software also can provide professional diagnosis service. If the client does not understand professional information, the client can send the data to the manufacturer service center so as to obtain high-efficiency diagnosis and service.

Owner:ACTIA SHANGHAI AUTOMOTIVE VEHICLE ELECTRONICS & DIAGNOSTICS CO LTD

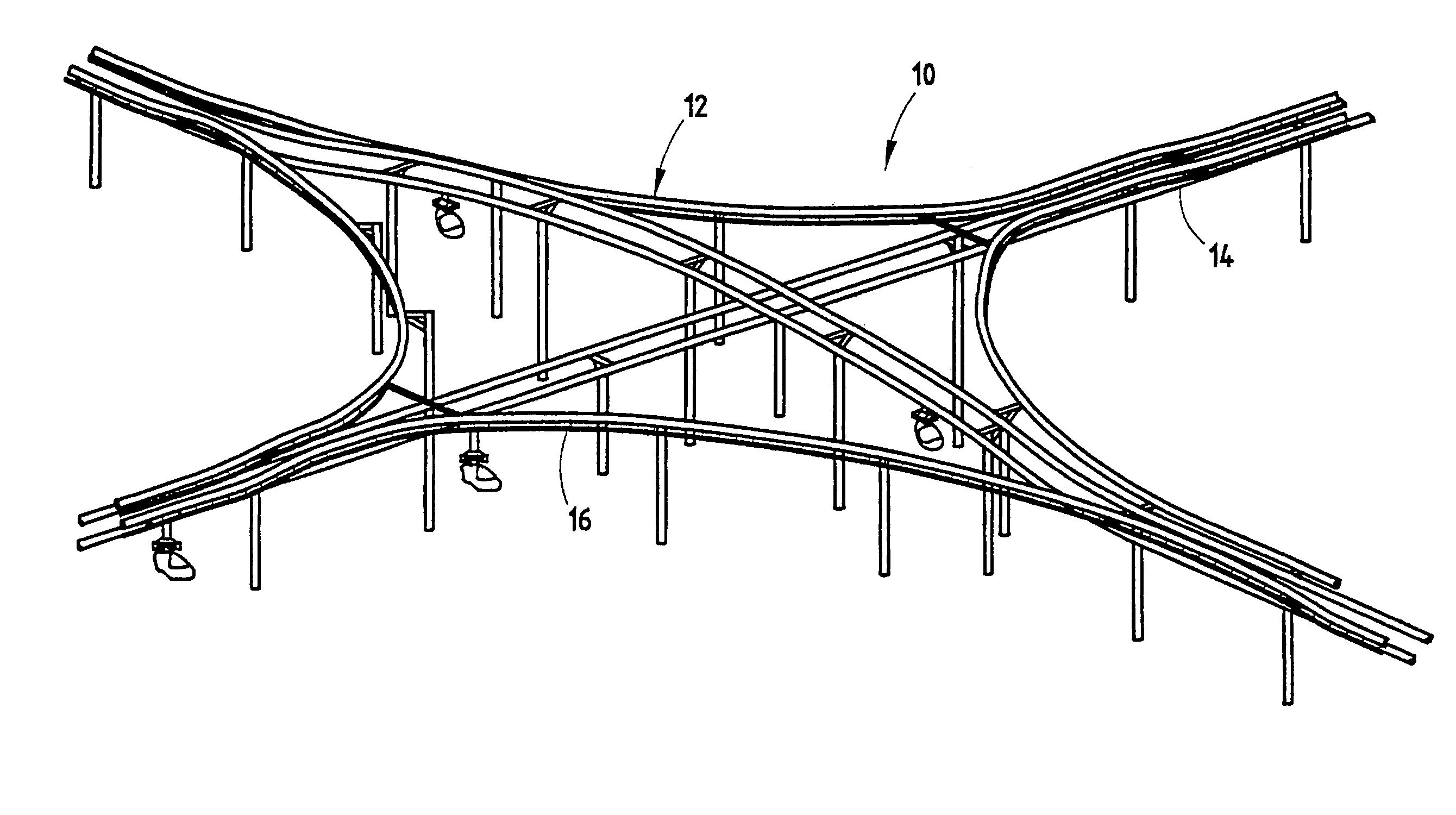

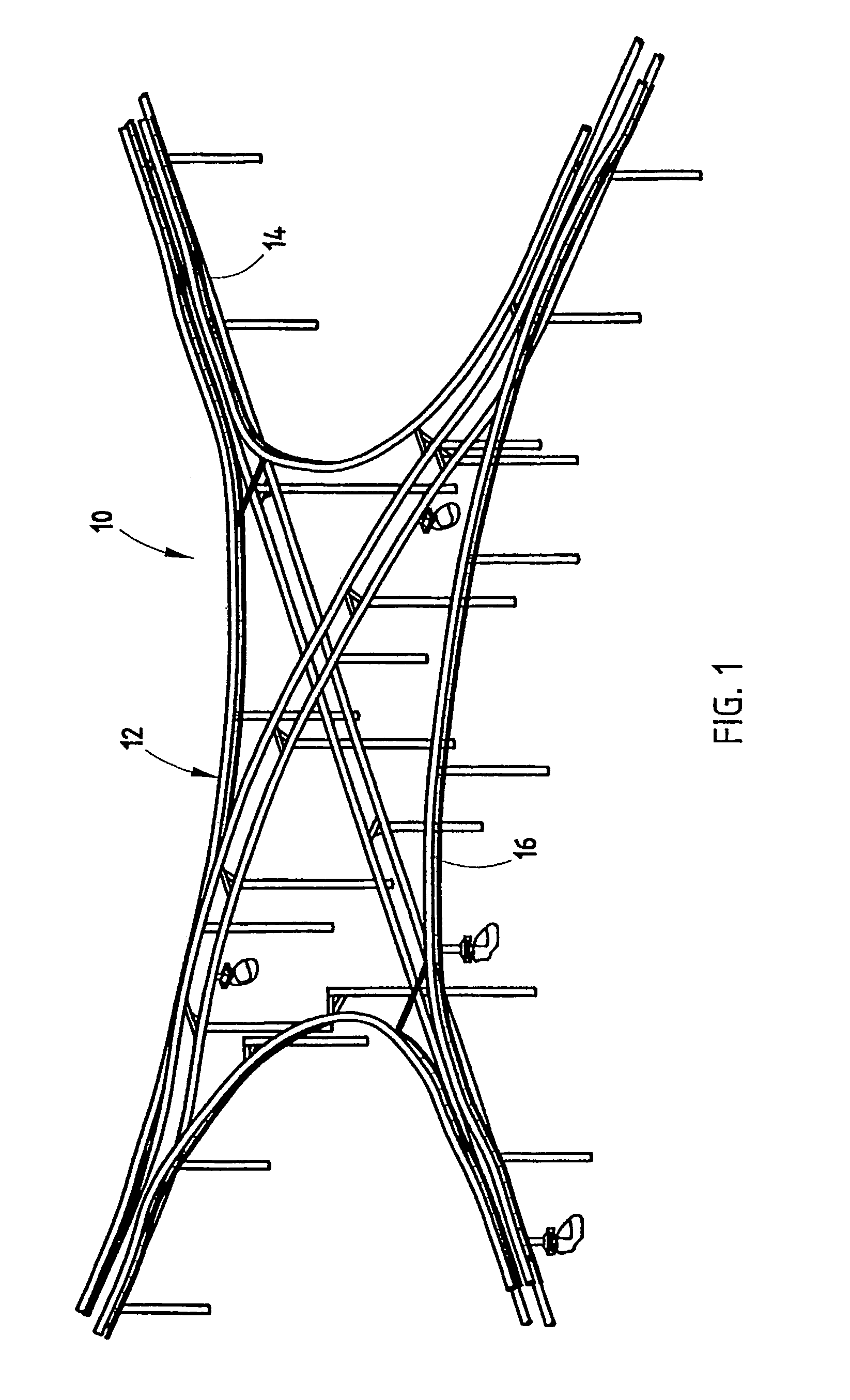

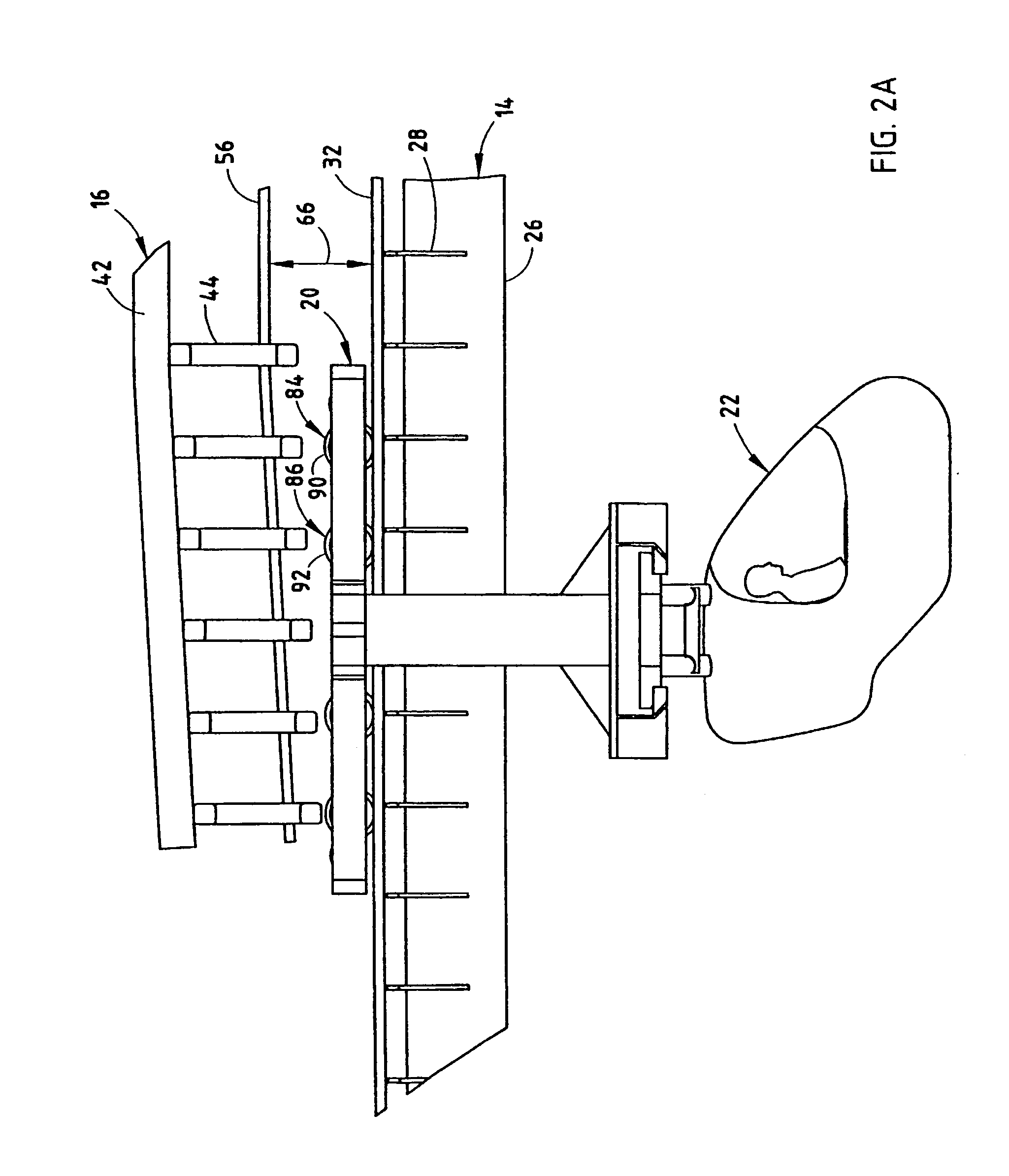

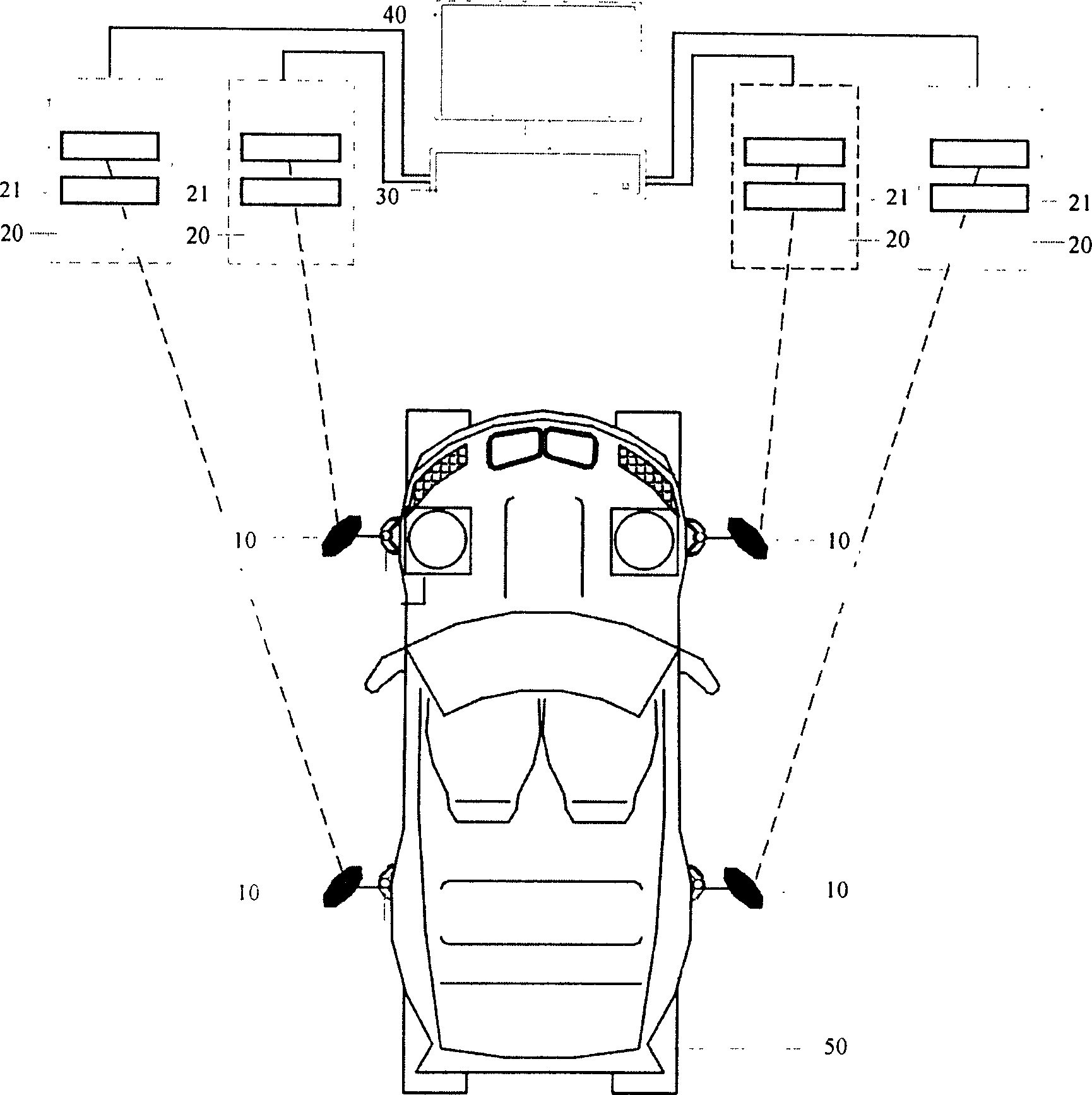

Individual transport control and communication system

InactiveUS7286934B2Maximize throughputAccurate spacingVehicle fittingsDigital data processing detailsCommunications systemMonitoring system

An automated transportation (10) system includes a plurality of vehicles (22) adapted to travel along a pathway, and a monitoring system (70) located within each vehicle and adapted to monitor a location and a speed between an associated vehicle and the pathway. The automated transportation system (10) also includes a transmitter (72) located within each vehicle (22) and adapted to transmit a signal that includes data on the location and the speed monitored, and a receiver (76) located within each vehicle and adapted to receive the signal from each of the other vehicles. The automated transportation system (10) further includes a controller (78) located within each vehicle and adapted to interpret the signal received by the receiver and control the associated vehicle to provide proper spacing between the remaining vehicles to avoid collisions therebetween and maximize throughput of the vehicles along the pathway.

Owner:CASCADE ENG

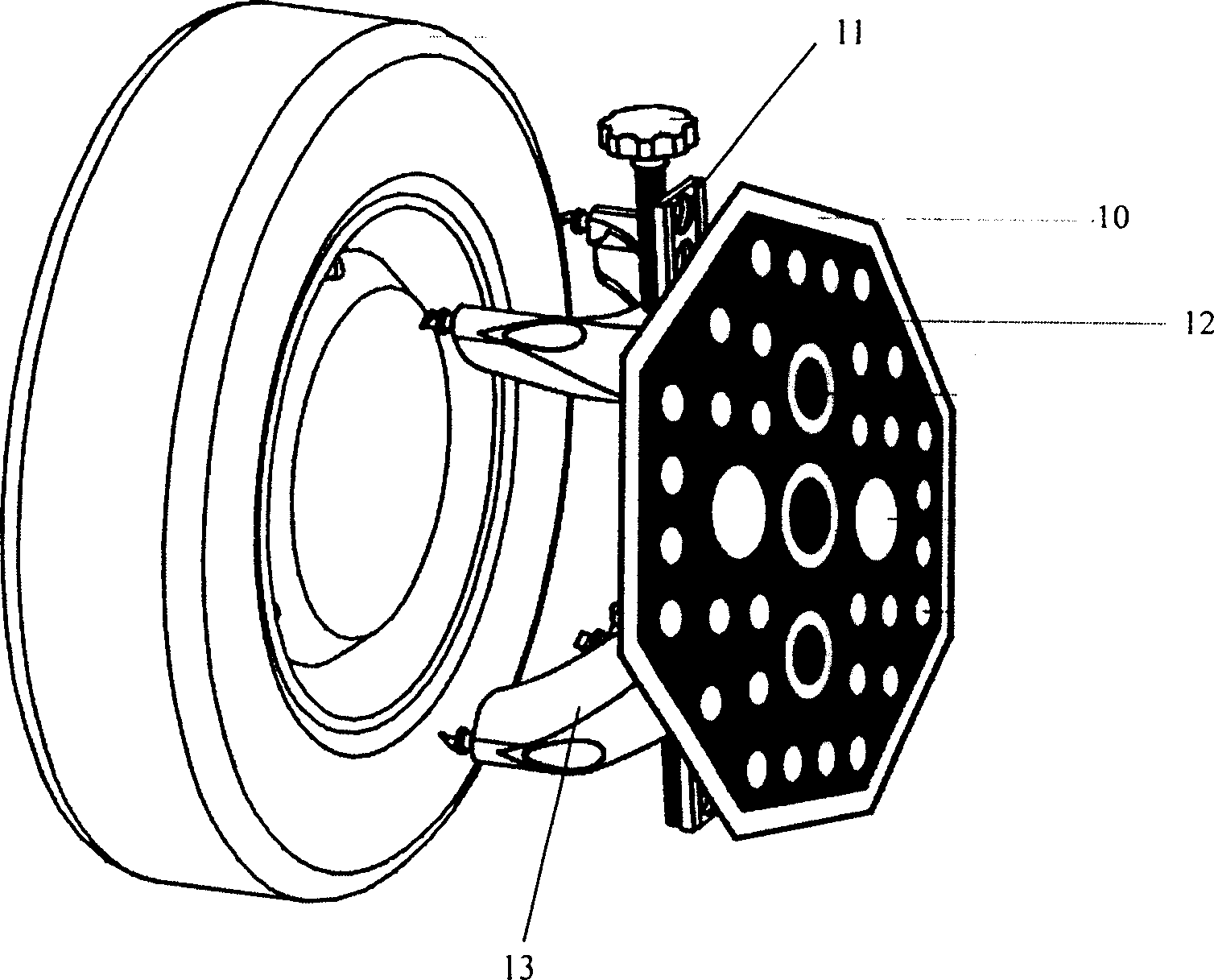

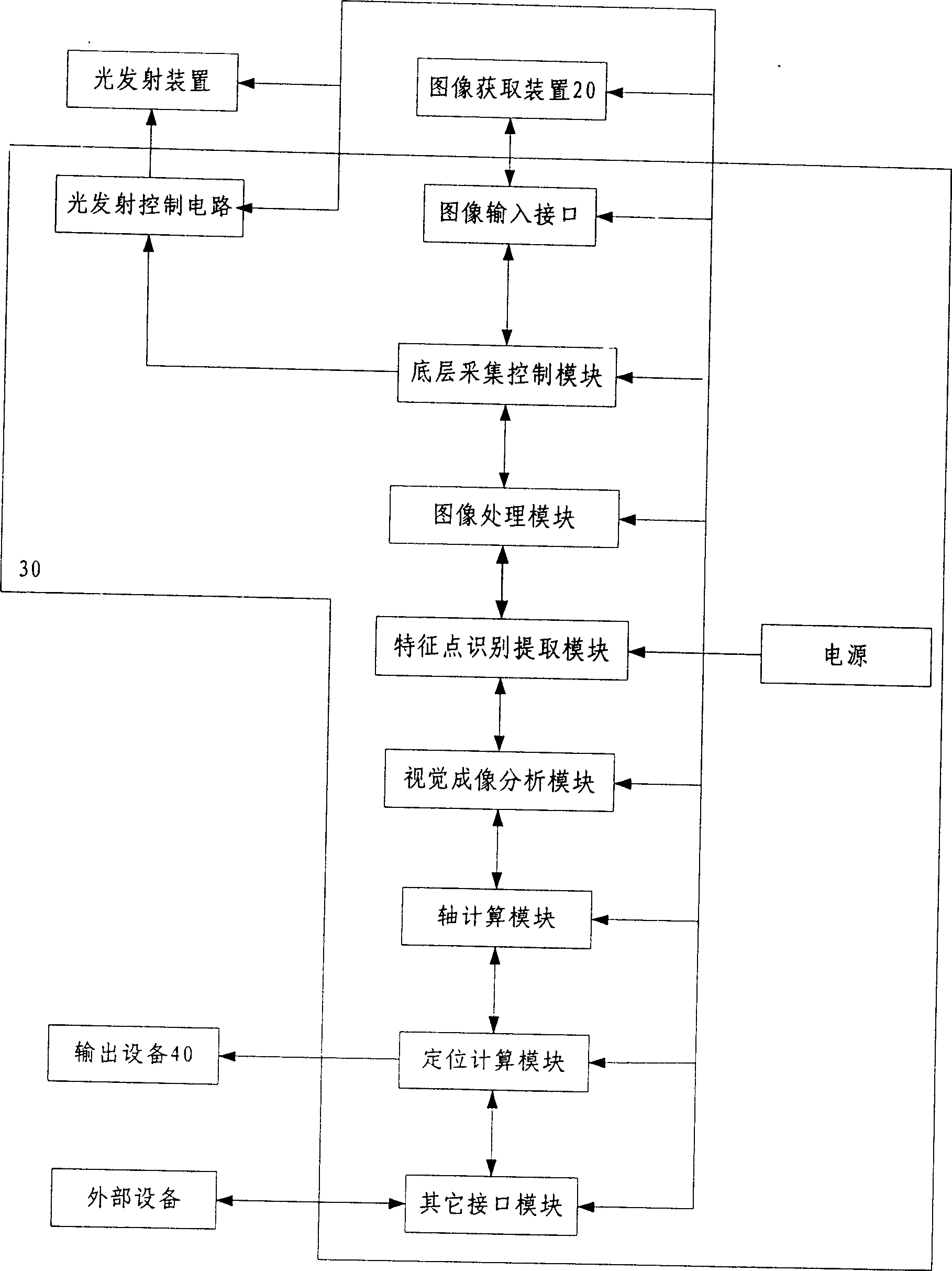

Vehicle wheel alignment check method and system

Owner:SHENZHEN SMARTSAFE TECH CO LTD

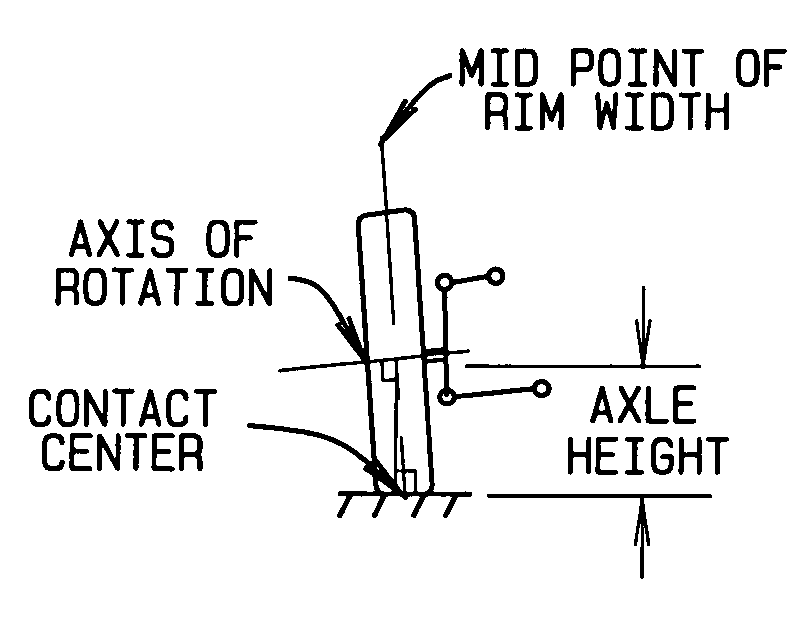

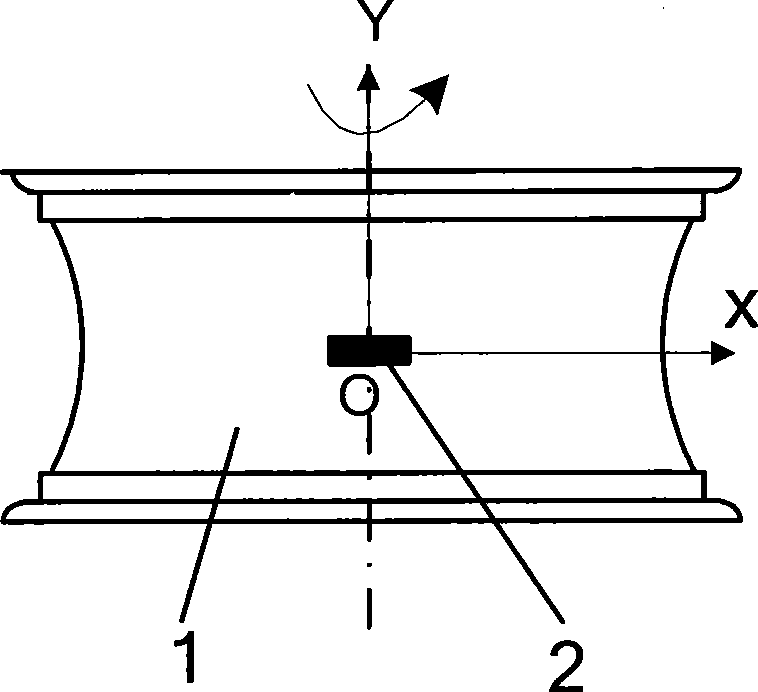

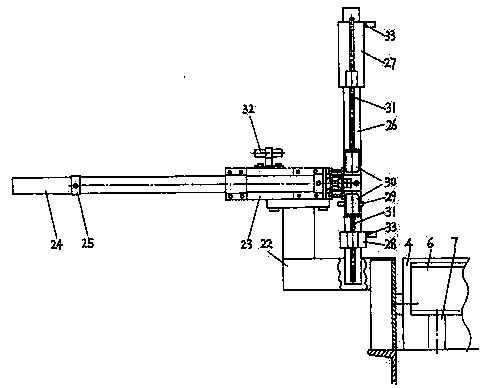

Method of and apparatus for determining geometrical dimensions of a vehicle wheel

The invention discloses a method and an apparatus of determining geometrical dimensions of a motor vehicle wheel; in particular, the invention discloses a method and an apparatus of determining geometrical dimensions of a motor vehicle wheel (rim / tyre assembly) (1) by contact-less sensing, wherein the wheel is fixed on wheel receiving means (2) of a tyre changer, that at least one light beam (21) is emitted on to the wheel or at least a part of the wheel, wherein the light beam reflected at the impingement area is detected, and wherein the directions of the emitted and reflected light beams are evaluated for determining the shape and / or position of the respective impingement area on the wheel.

Owner:SNAP ON EQUIP

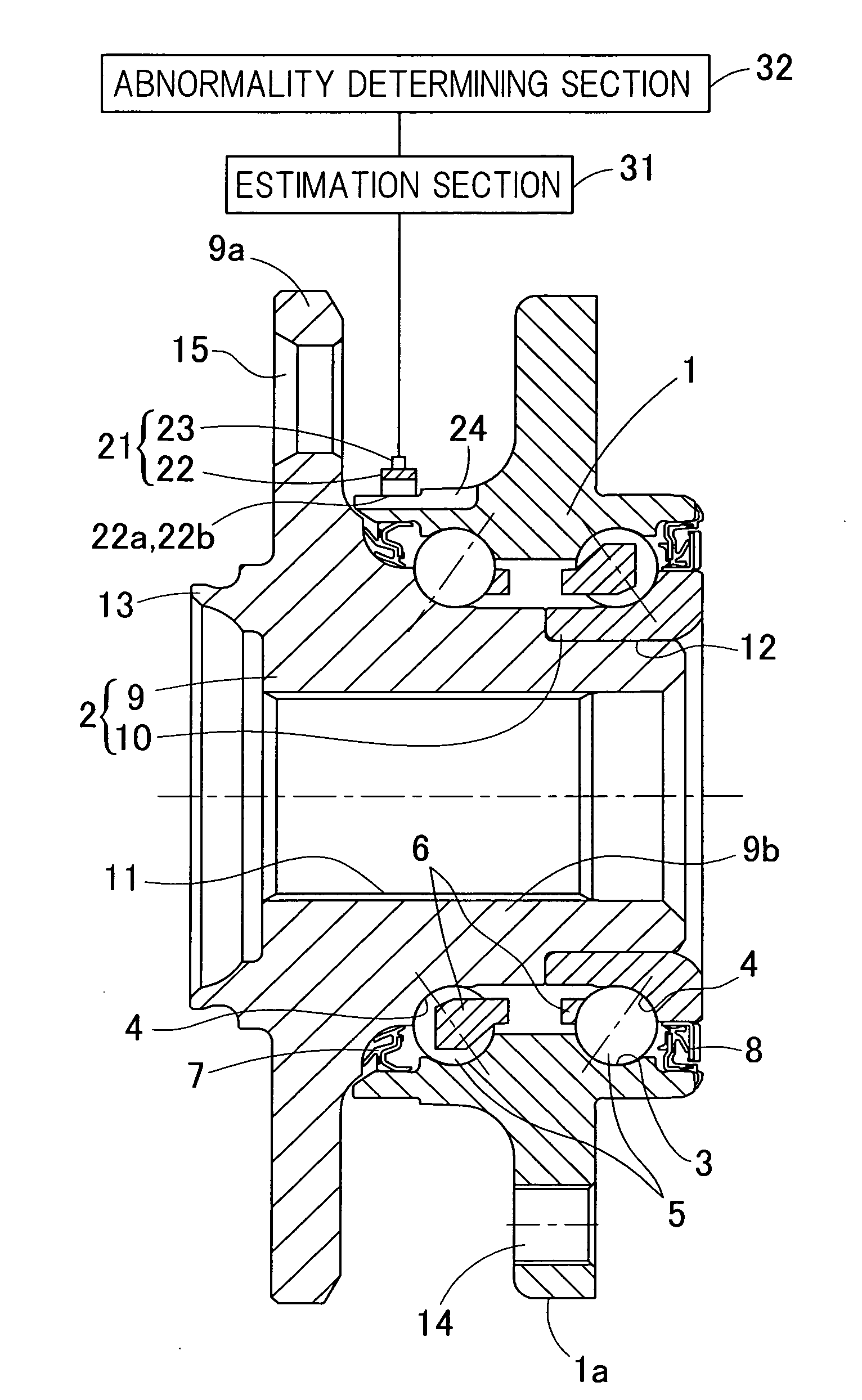

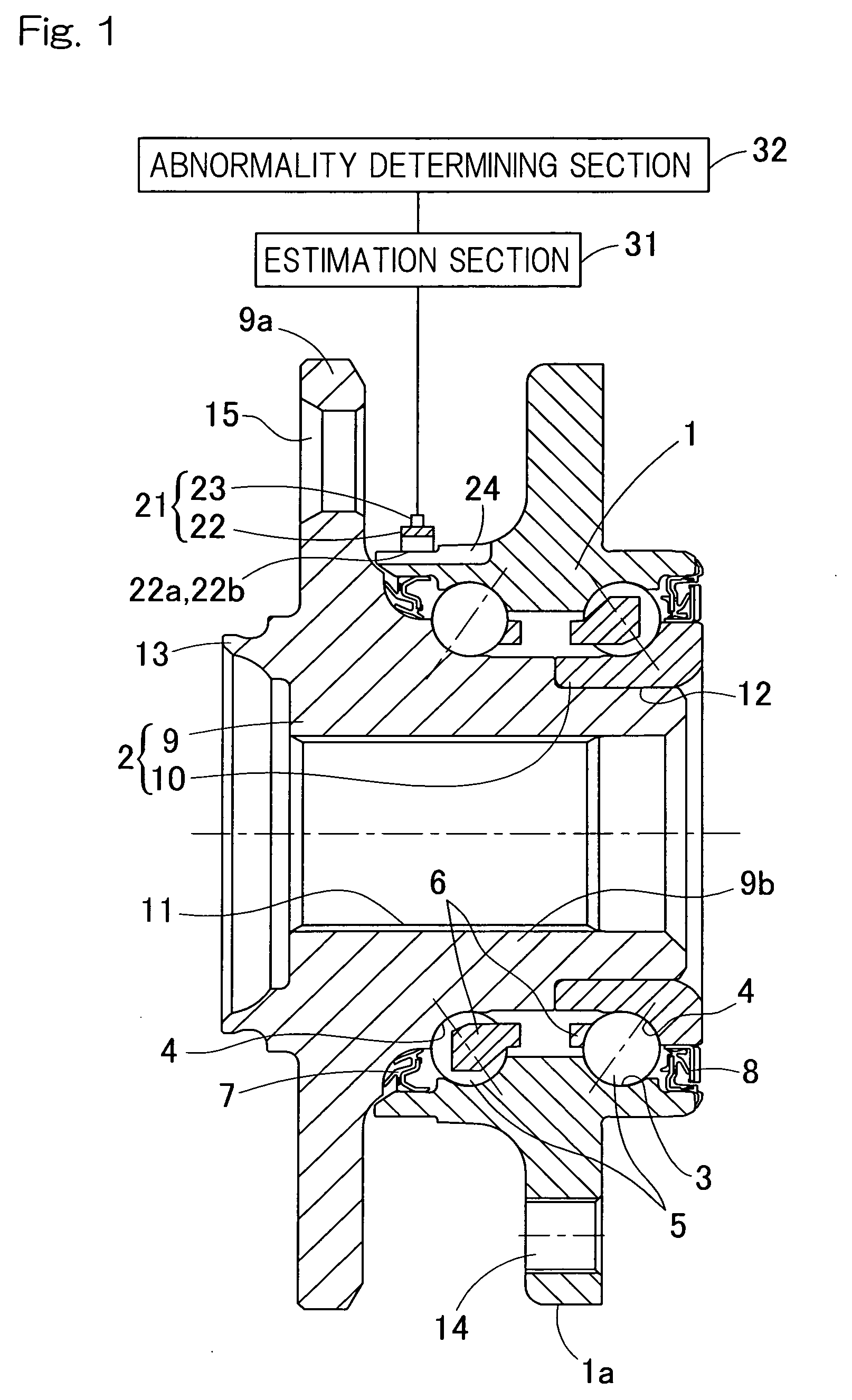

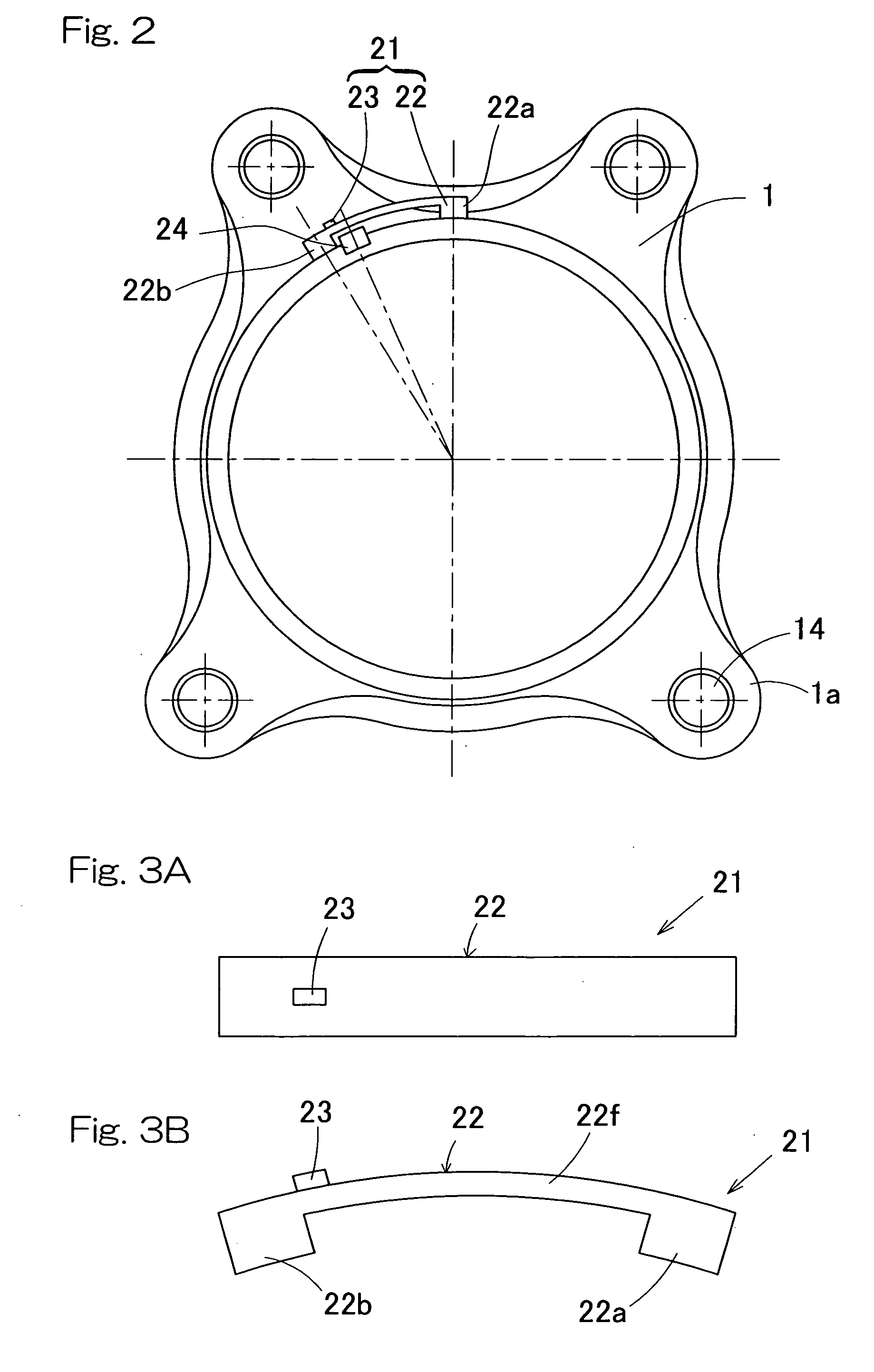

Wheel Support Bearing Assembly Equiped with Sensor

InactiveUS20090114004A1High sensitivityReduce manufacturing costRolling contact bearingsBearing assemblyEngineeringMechanical engineering

In a wheel support bearing assembly including a plurality of rolling elements (5) interposed between an outer member (1) and an inner member (2), a sensor unit (21) is fitted to one of the outer member and the inner member, which serves as a stationary member. The sensor unit includes a sensor mounting member (22) and a strain sensor (23) fitted to the sensor mounting member. The sensor mounting member has a plurality of contact fixing portions (22a, 22b) that are fixed to at least two locations spaced a distant from each other in a direction circumferentially of the outer member. A cutout (24) is provided in the outer member at respective positions corresponding to the neighboring contact fixing portions of the sensor mounting member, so as to extend in an axial direction. The strain sensor is arranged intermediate between the neighboring contact fixing portions.

Owner:NTN CORP

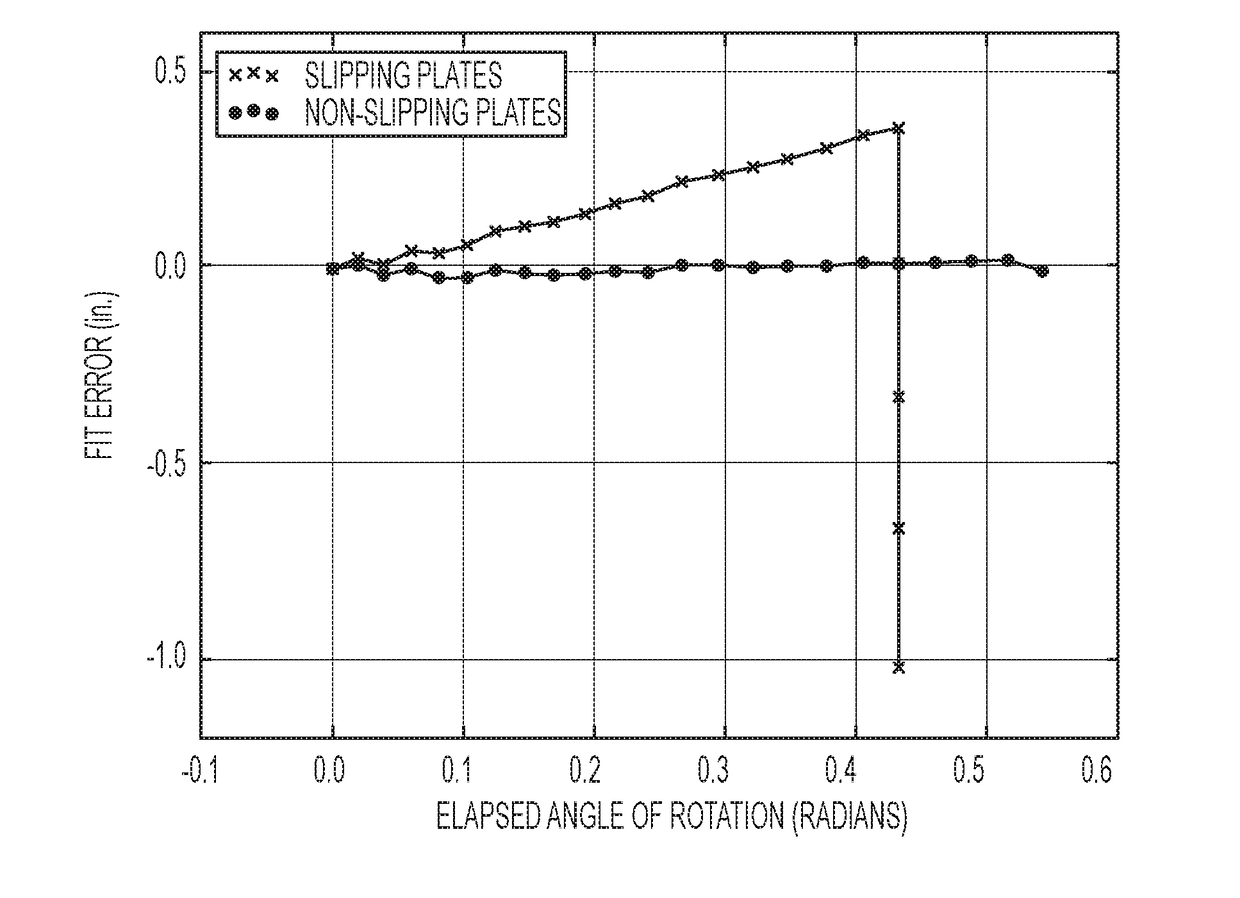

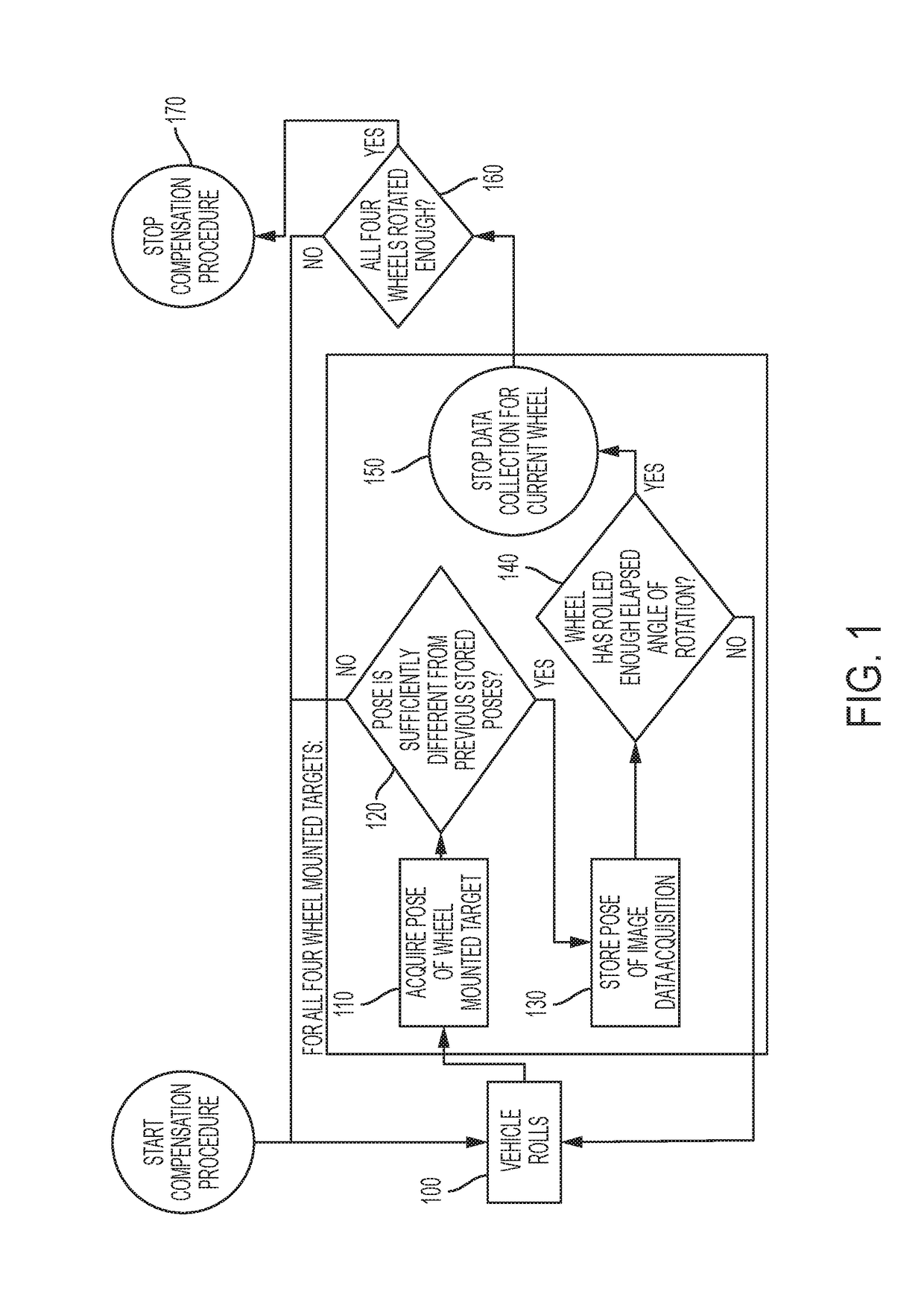

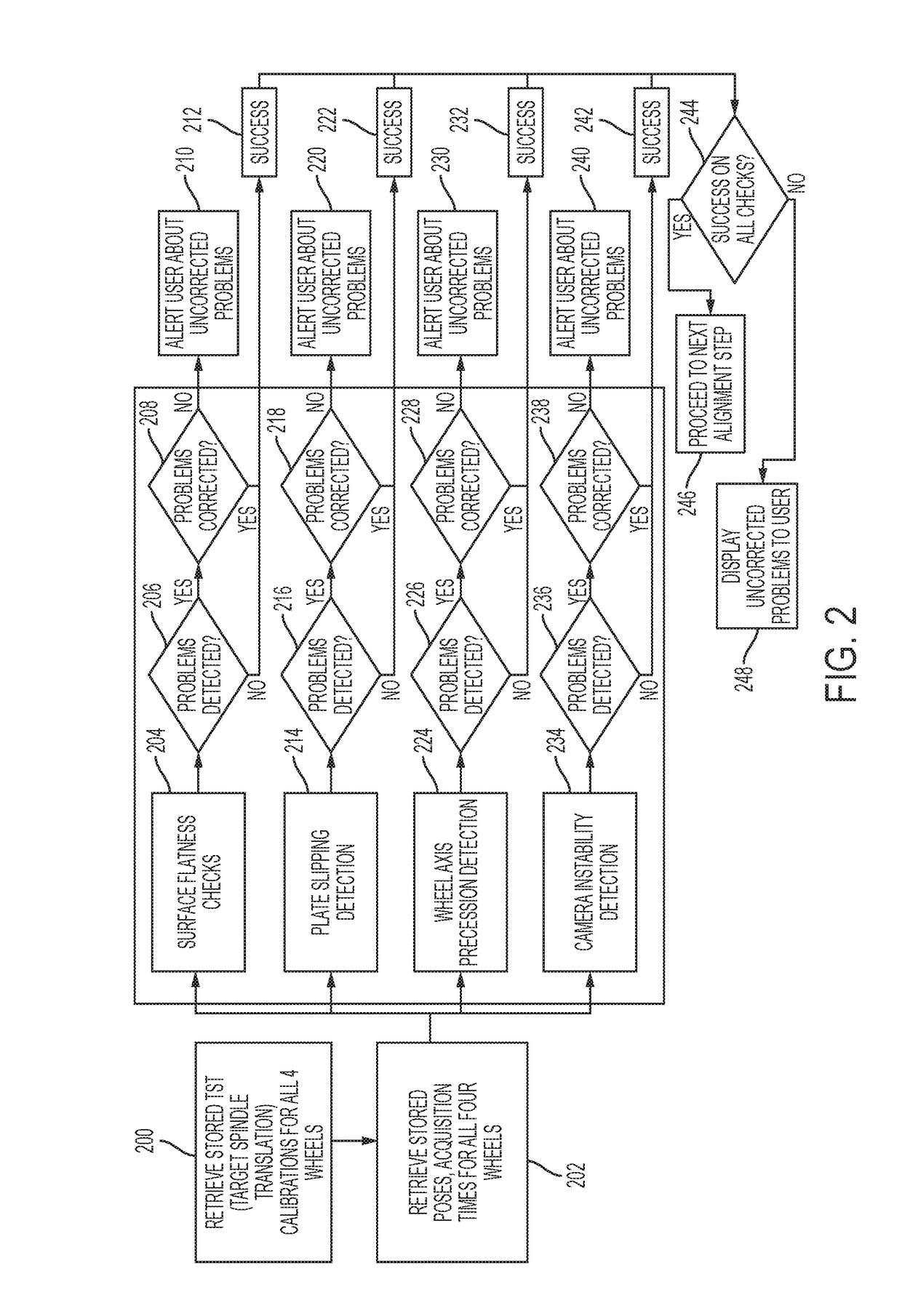

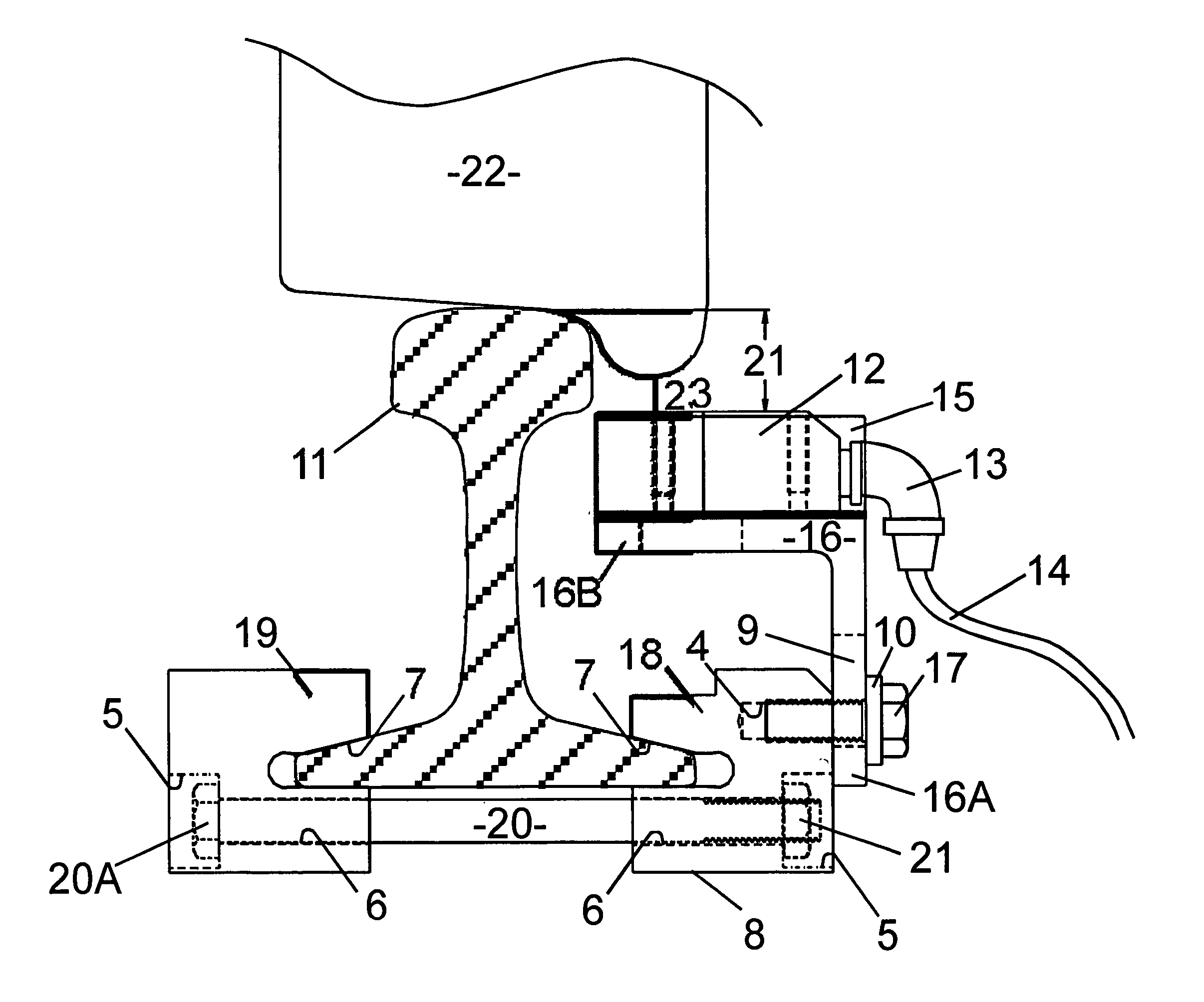

Wheel aligner with advanced diagnostics and no-stop positioning

InactiveUS20170097229A1Reduce weightLow costTelevision system detailsImage enhancementEngineeringImaging data

A vehicle wheel alignment system has a plurality of cameras, each camera for viewing a respective target disposed at a respective wheel of the vehicle and capturing image data of the target as the wheel and target are continuously rotated a number of degrees of rotation without a pause. The image data is used to calculate a minimum number of poses of the target of at least one pose for every five degrees of rotation as the wheel and target are continuously rotated the number of degrees of rotation without a pause. At least one of the cameras comprises a data processor for performing the steps of preprocessing the image data, and calculating an alignment parameter for the vehicle based on the preprocessed image data.

Owner:SNAP ON INC

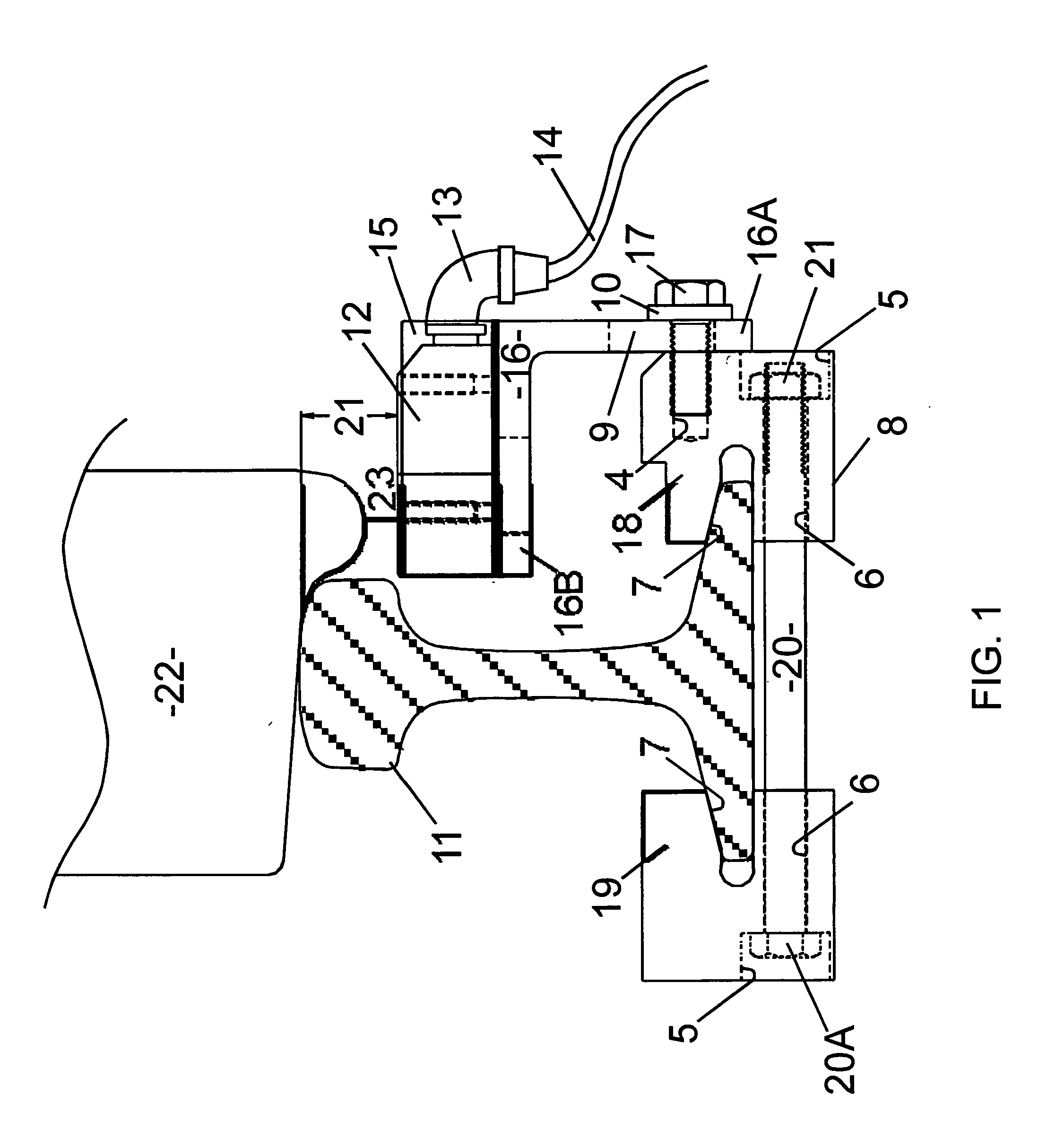

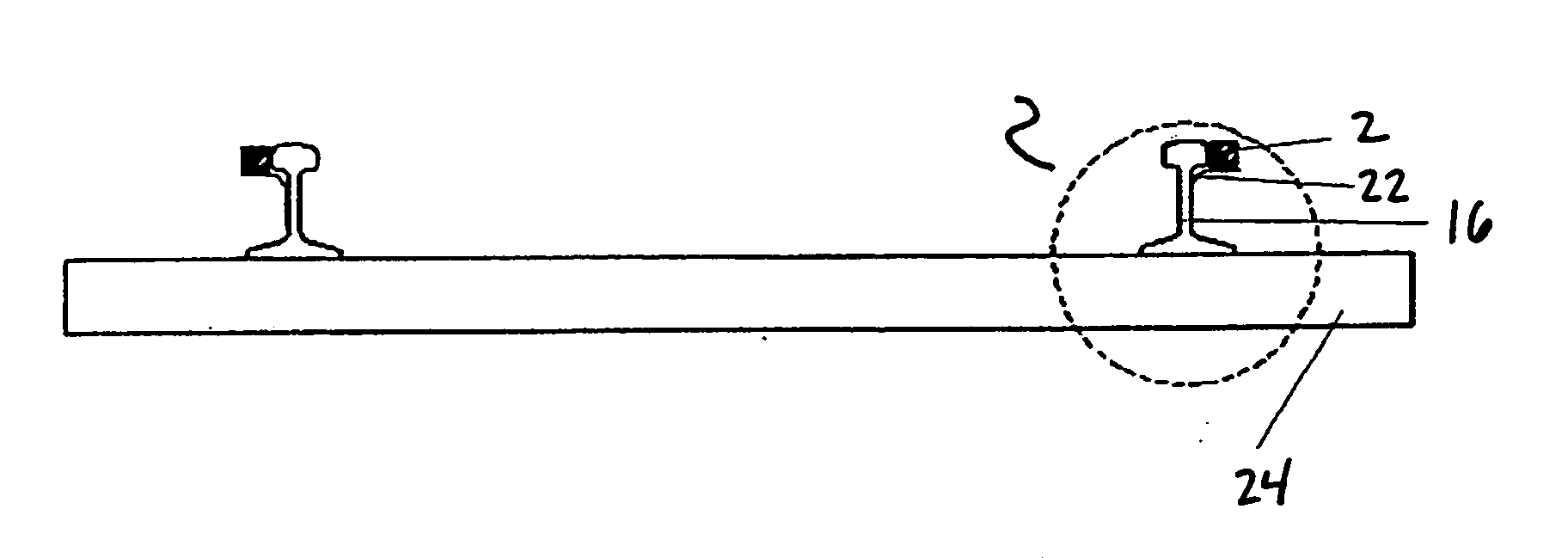

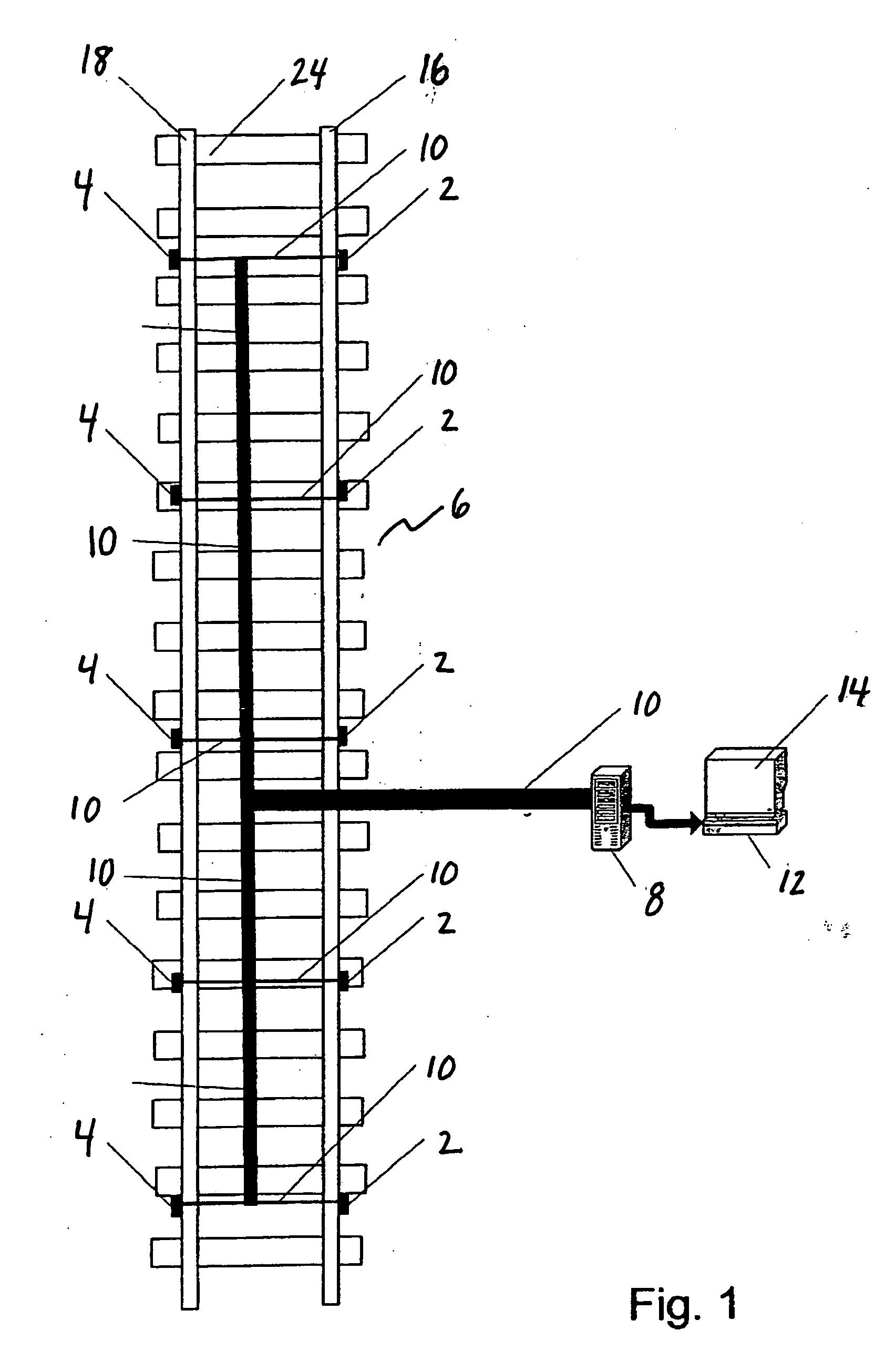

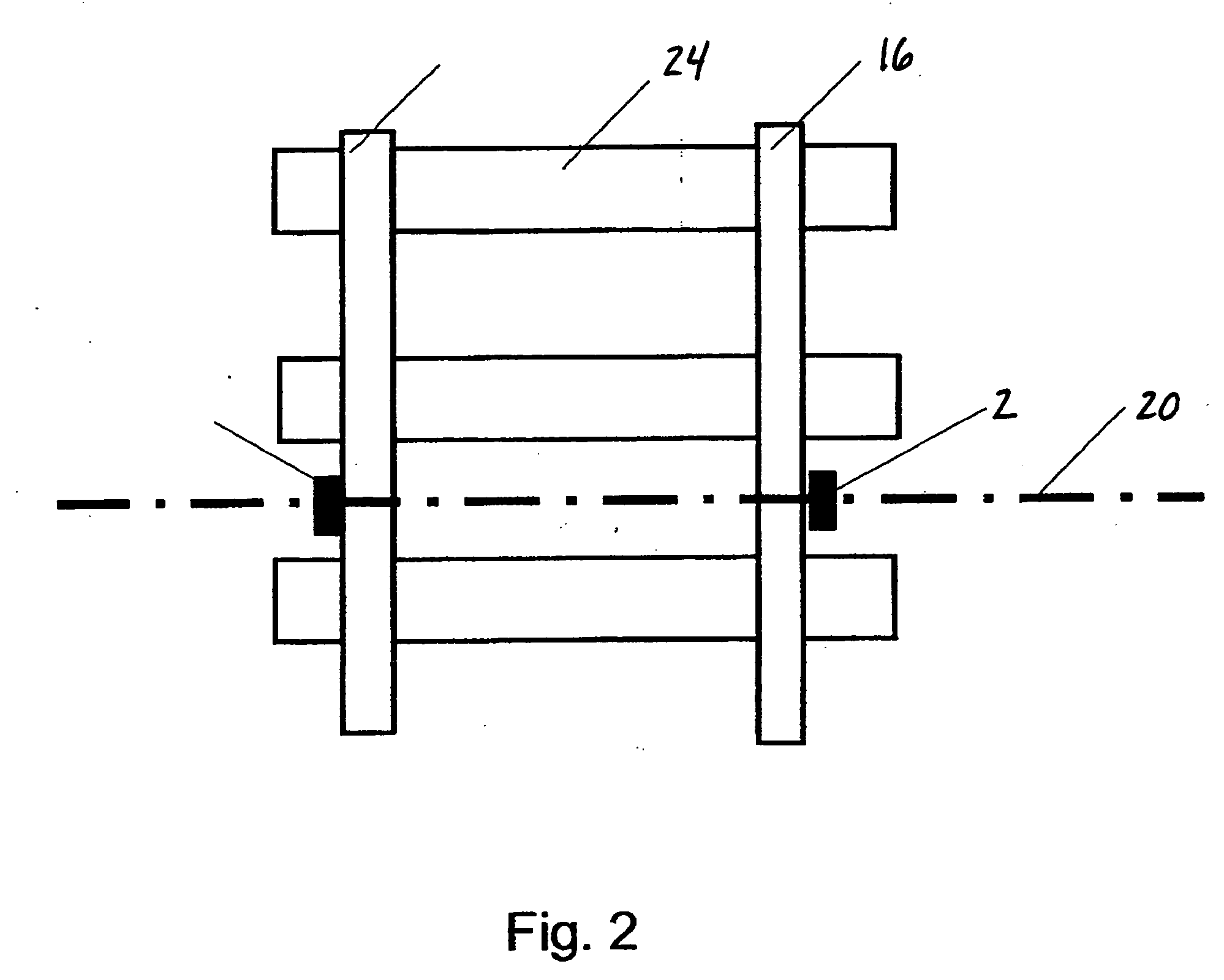

Wheel sensor assembly for rail base mounting

InactiveUS20050072252A1Easy to installLow priceVehicle route interaction devicesVehicle wheel testingMechanical engineeringSensing system

A rail-mounted, wheel-sensing system is shown having a wheel sensor and a rail mounting platform. The system includes a rugged steel rail clamp including two blocks mounted on the base of the rail by a pair of bolt extending under the rail. One block is connected to a vertically adjustable mounting bracket for carrying a sensor or other device. The mounting bracket includes a platform for the sensor. Two shields on the platform protecting a sensor mounted between them. An adapter plate may be added between the mounting bracket and the clamp for installation on lighter or heavier rails.

Owner:TRANERGY CORP

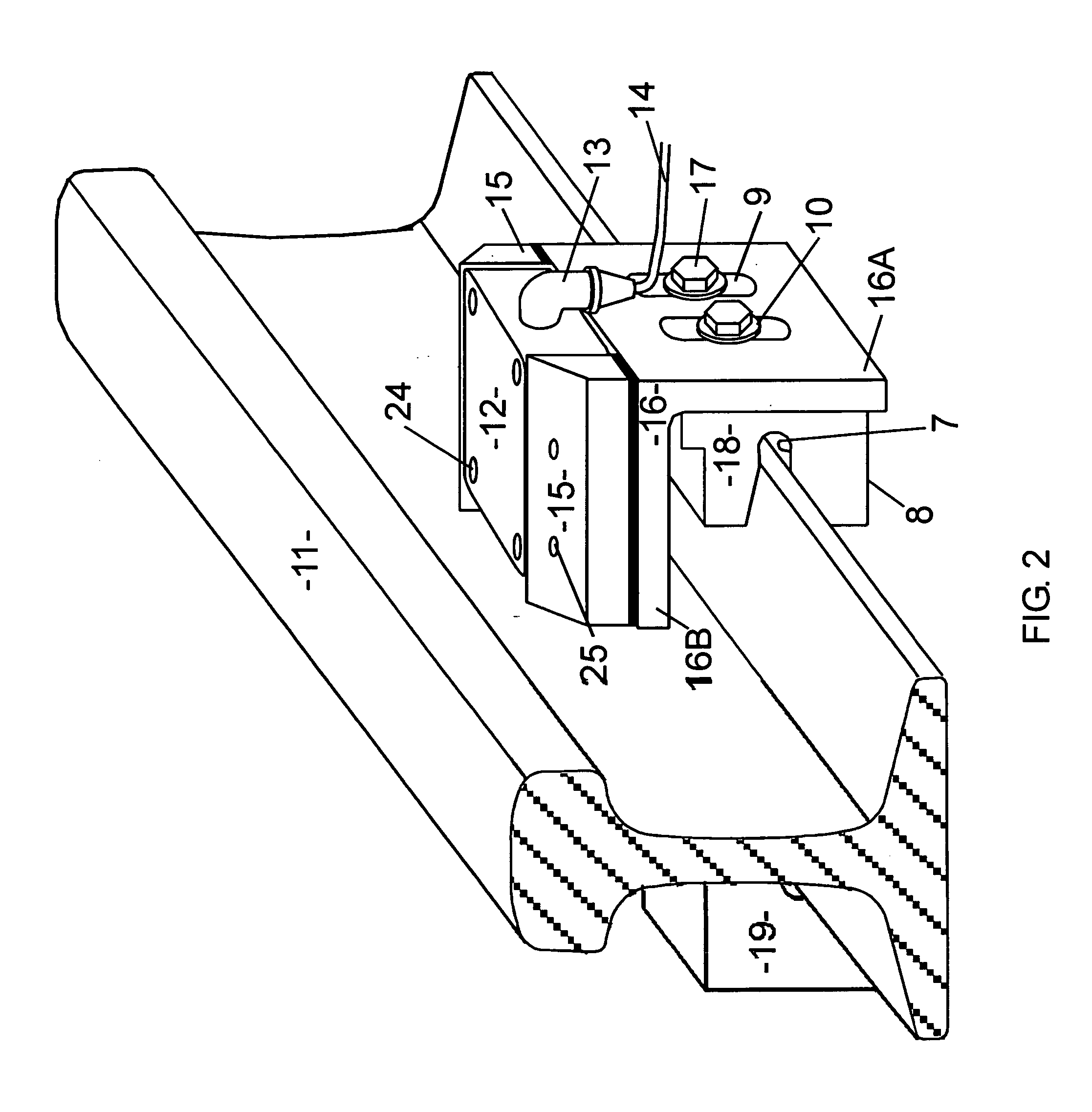

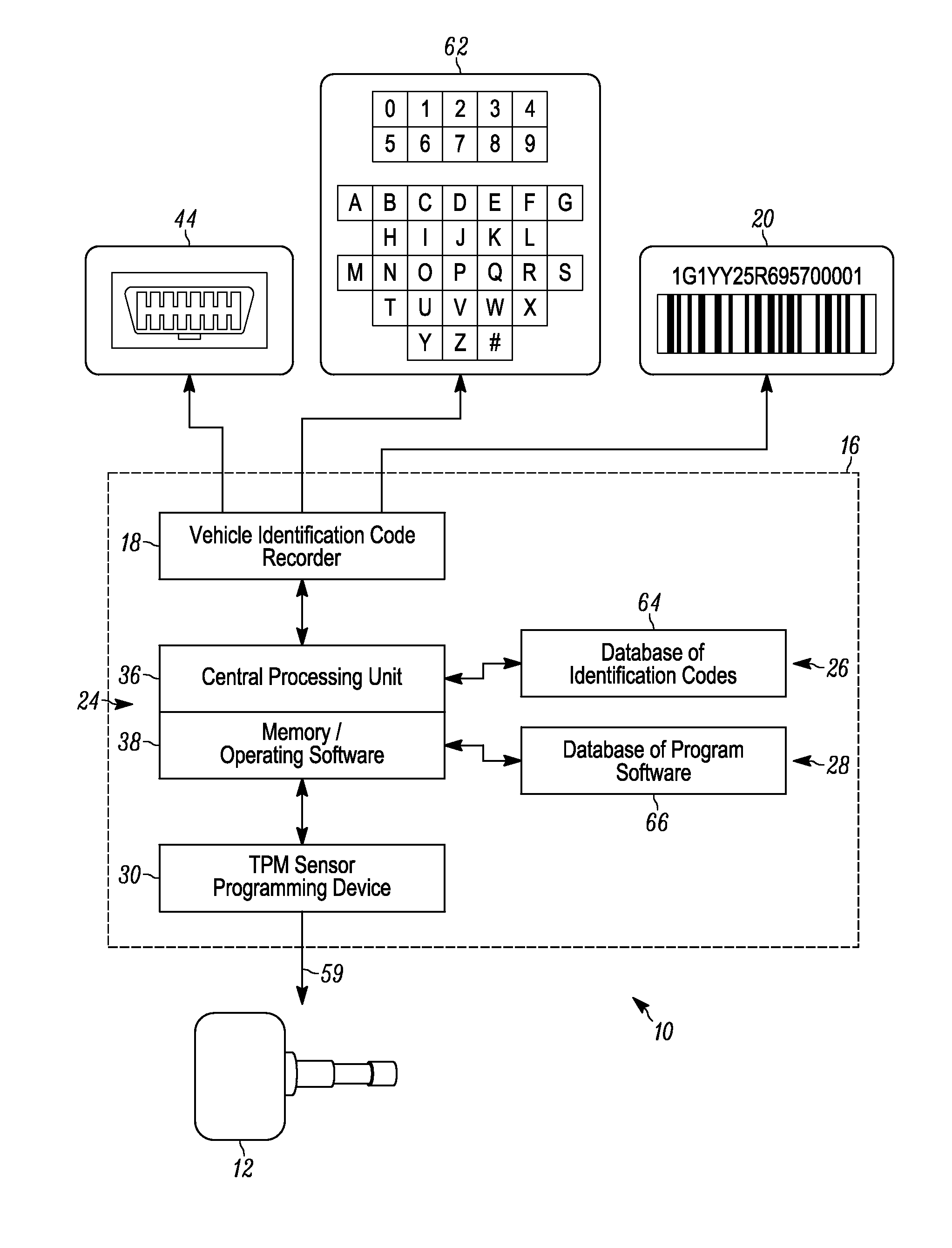

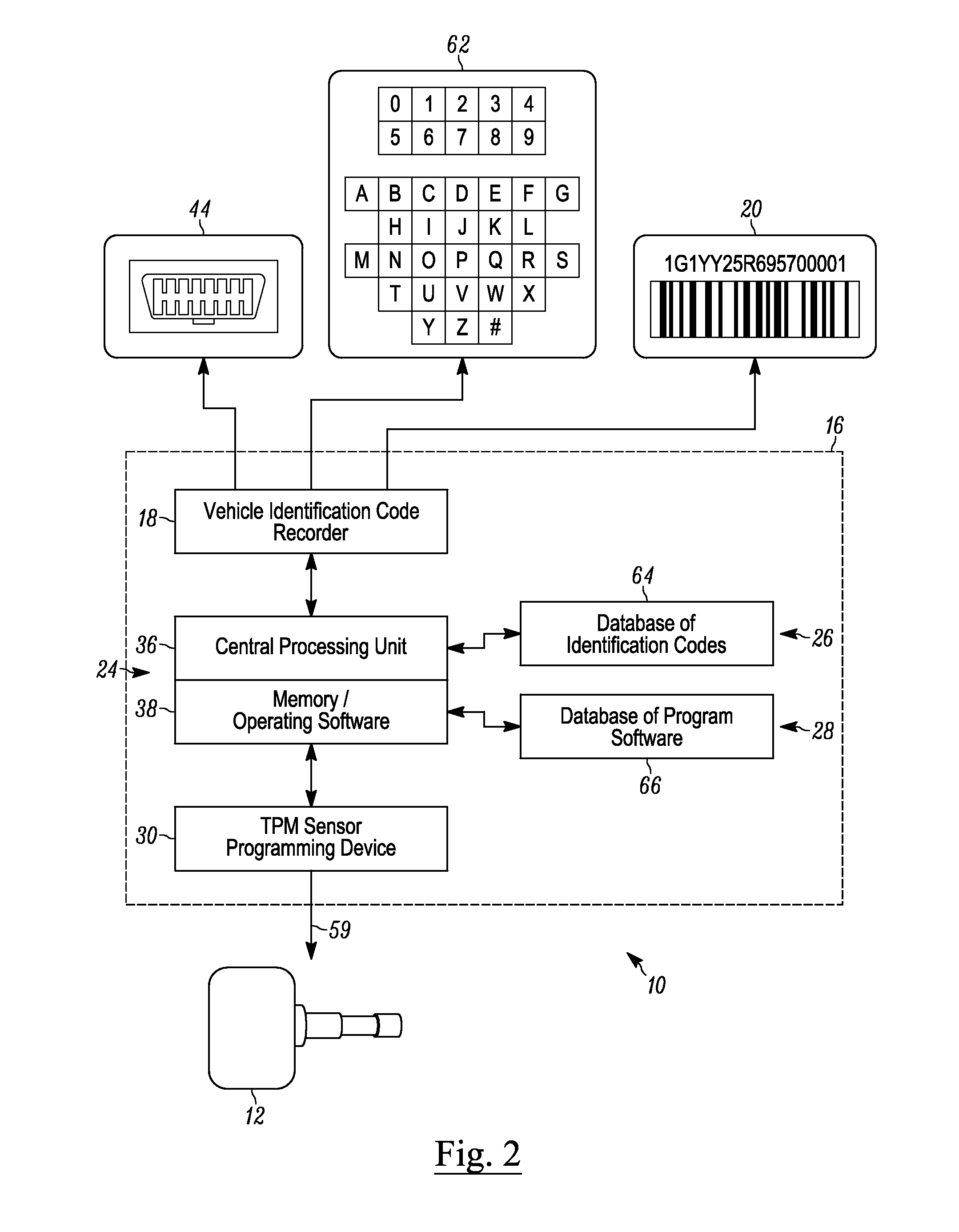

Methods, systems and tools for programming tire pressure monitoring sensors

ActiveUS20140165026A1Reduce stepsShorten the construction periodTyre measurementsRequirement analysisVehicle identificationSoftware

The present invention relates to methods, systems and tools for programming tire pressure monitoring sensors based upon ascertained vehicle identification numbers. In one aspect, the present invention provides a method of programming a tire pressure monitoring sensor of a vehicle wheel unit. The method includes obtaining identification information of a vehicle with a programming tool for a tire pressure monitoring sensor. The method further includes comparing the identification information with a database of identification information to determine a program software that is compatible with the vehicle. The method further includes programming the tire pressure monitoring sensor with the program software.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

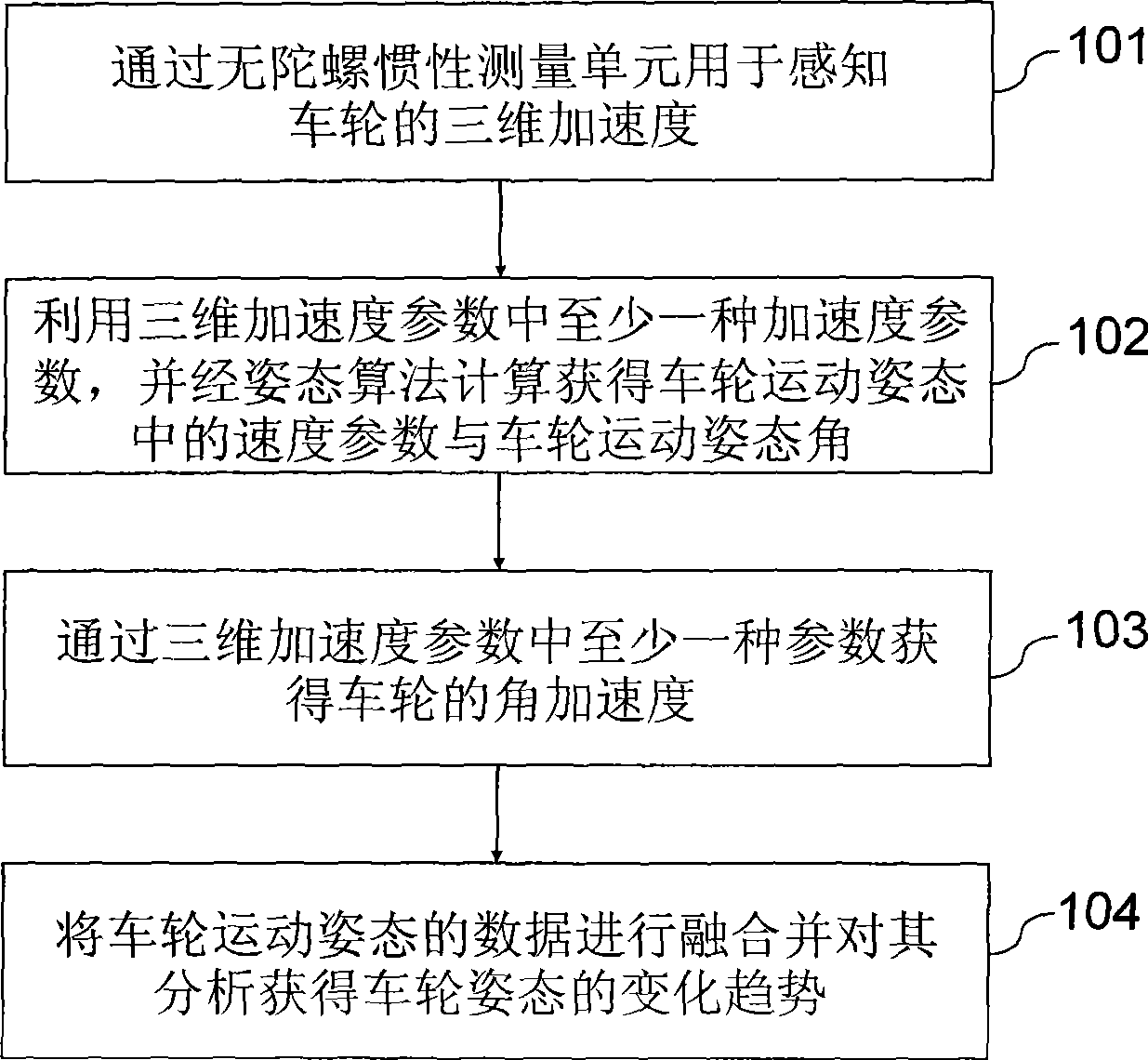

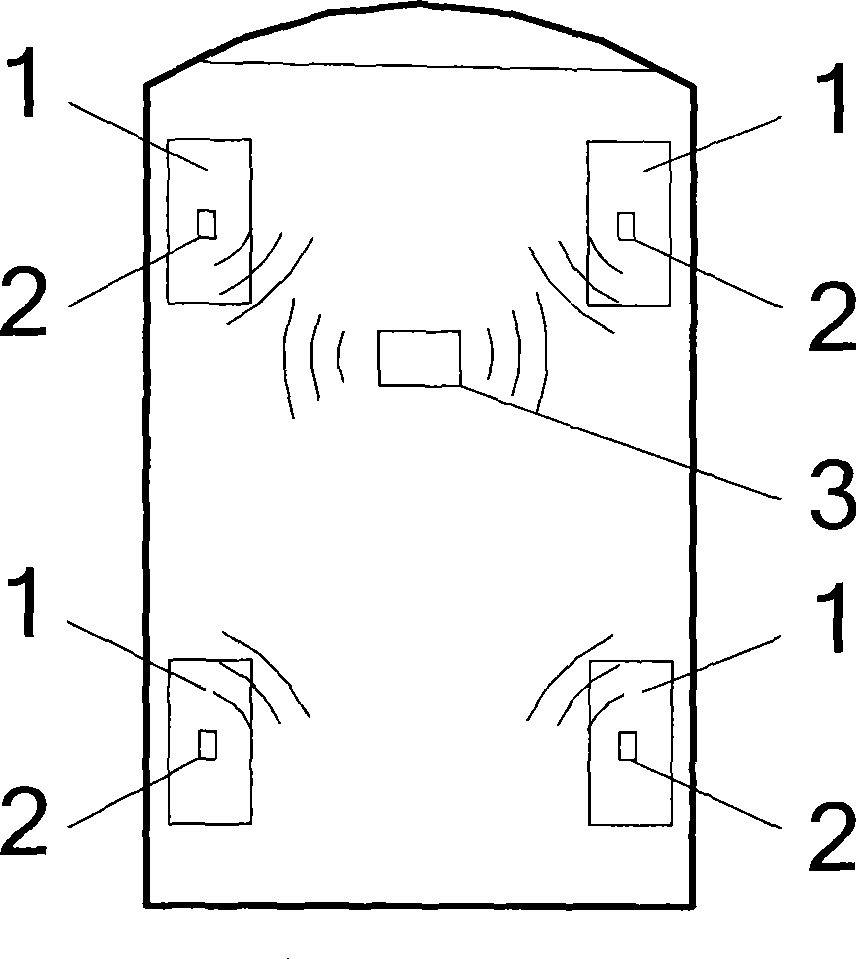

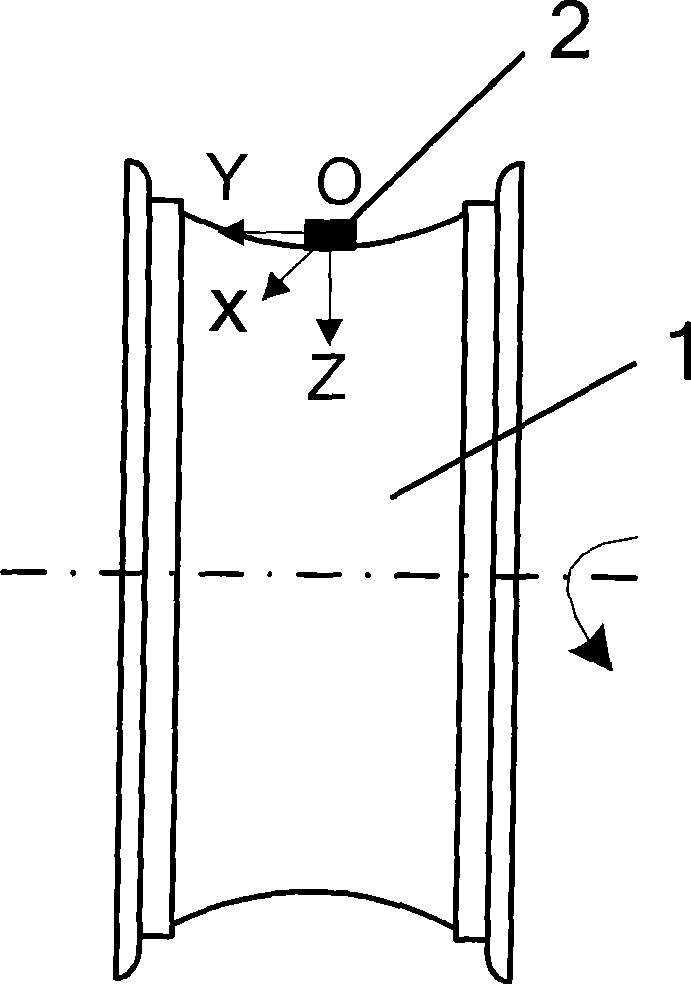

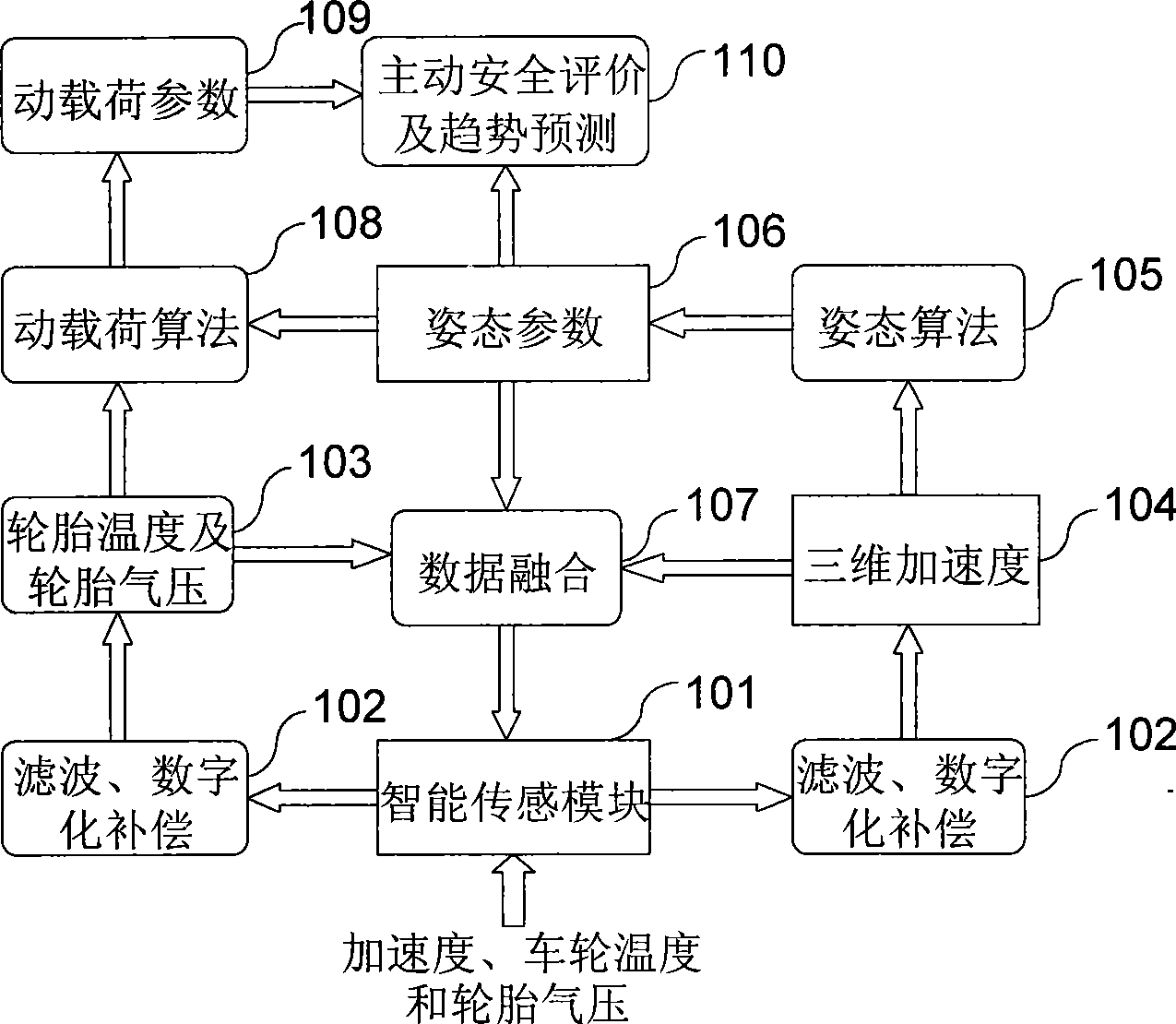

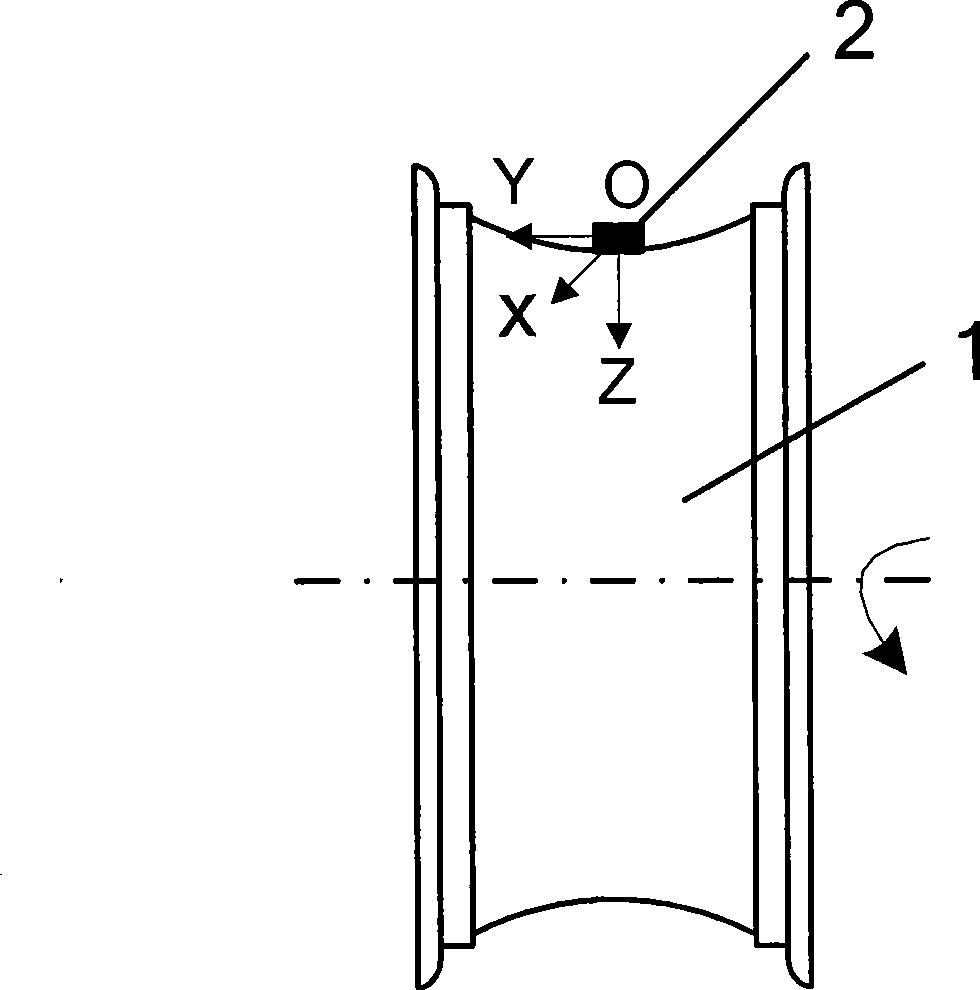

Wheel-loaded intelligent sensing wheel movement attitude monitoring method

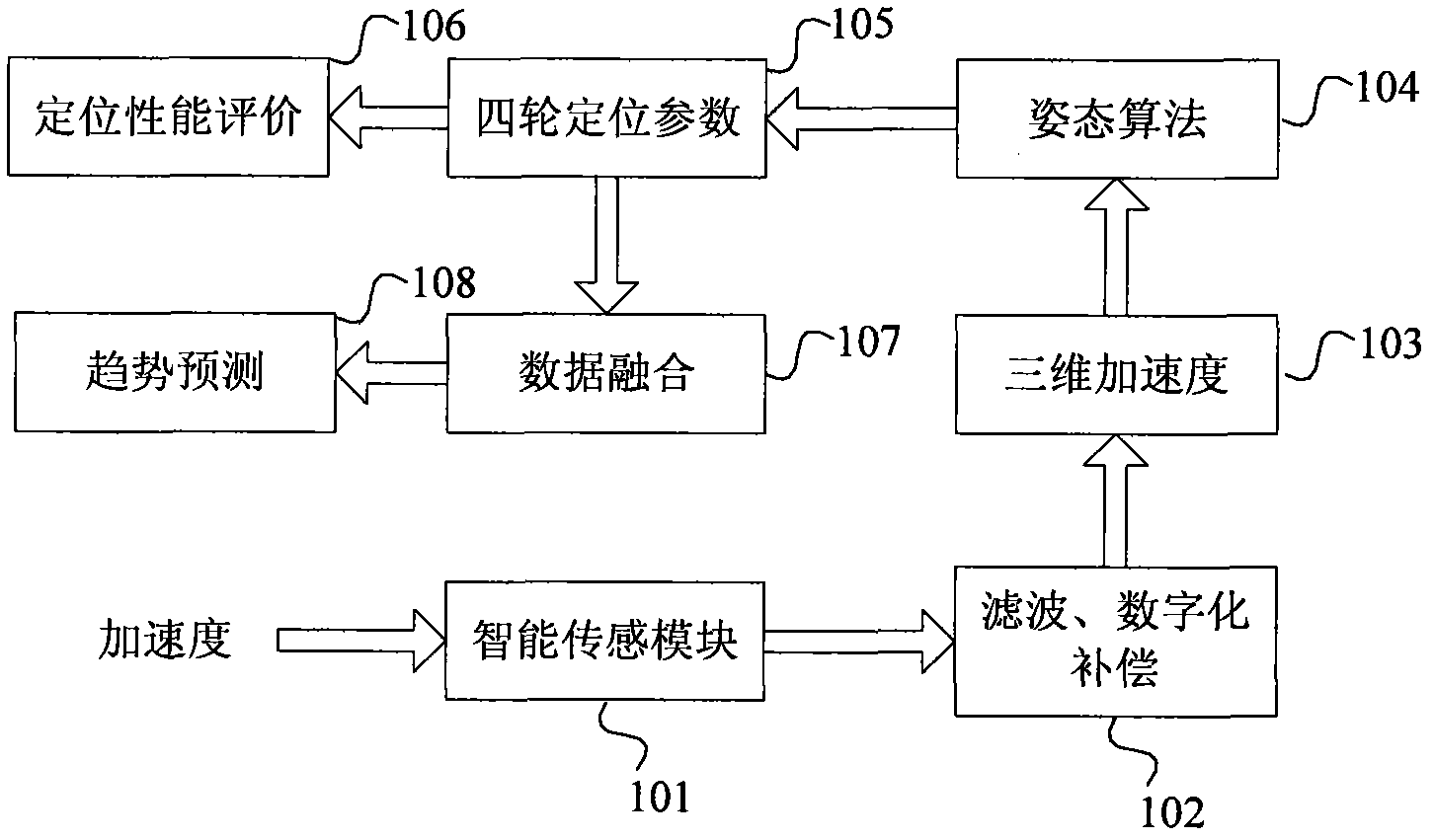

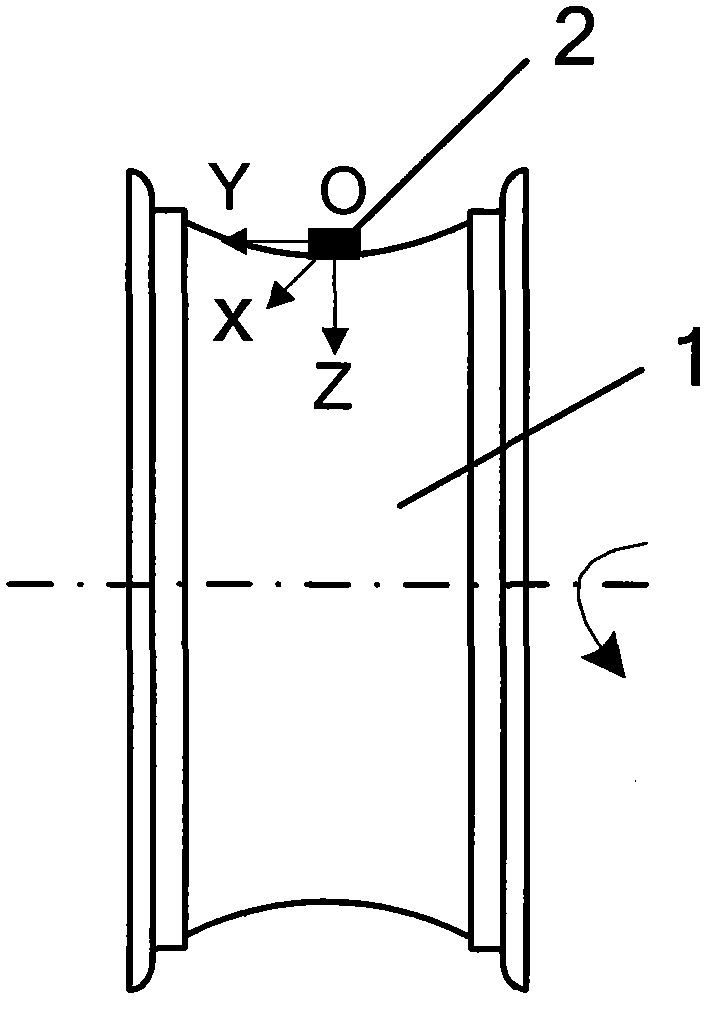

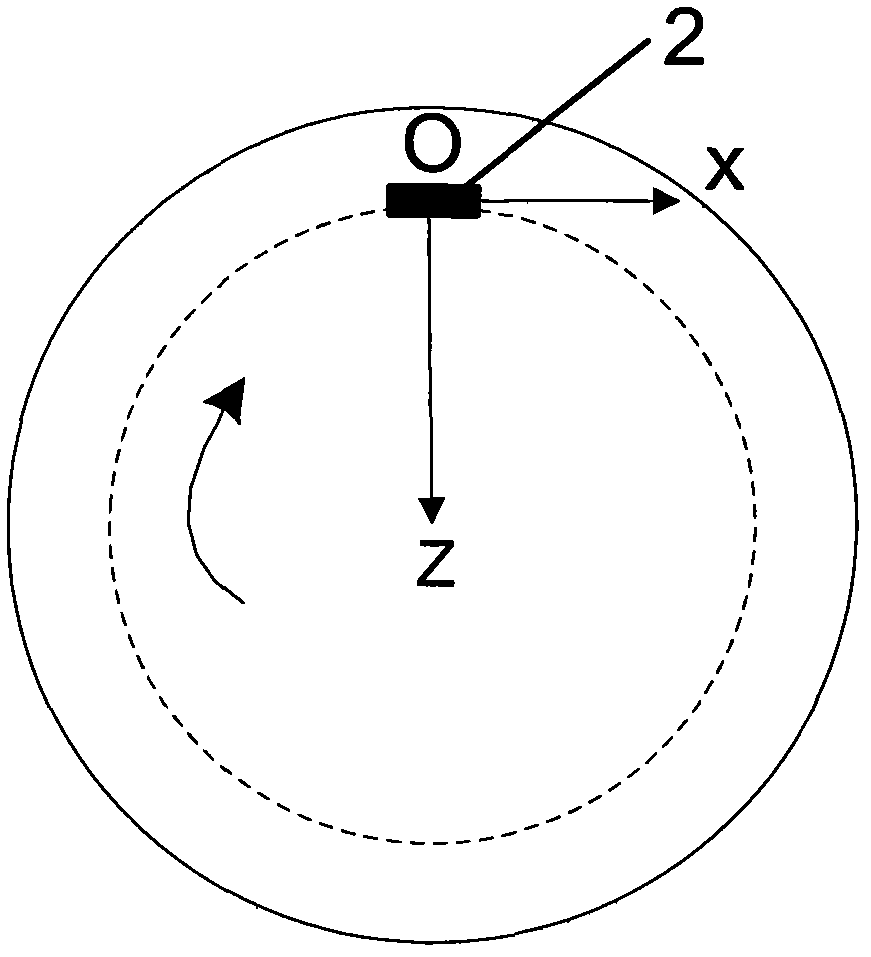

InactiveCN101498621ASports attitude monitoringAdd prediction functionTyre measurementsVehicle wheel testingSimulationAngular acceleration

The invention discloses a movement posture monitoring method based on a wheeled intelligent sensing wheel, which comprises the following steps: an equatorial plane of a hub of each wheel of a vehicle is provided with a top-free microinertia measuring unit, sensing signals are conditioned, digitized and calculated by a posture algorithm way, and main movement posture parameters of the wheels are obtained; the main movement posture parameters of the monitored wheels comprise tangential acceleration, sideward acceleration, acceleration centripetal, advance speed, side velocity, angular acceleration, camber angles, slip angles, heading angles, and the like; after the parameters are inosculated and analyzed through a plurality of sending data, the movement safety condition of the wheels such as the unbalanced degree, looseness, fly off, slippage, and the like of wheels can be monitored and actively estimated, thereby being favorable for preventing and reducing the occurrence of traffic accidents.

Owner:SOUTH CHINA UNIV OF TECH

Wheel load-based type intelligent sensing four-wheel positioning measurement method

The invention discloses a wheel load-based type intelligent sensing four-wheel positioning measurement method. The method comprises the following steps of: sensing the three-dimensional accelerations of specific points of wheels by using an intelligent sensing module; acquiring initial attitude angles of the wheels by using the three-dimensional acceleration parameters of the specific points of the wheels and an attitude algorithm and solving positioning parameters of the camber and the front wheel toe-in among the four wheels; establishing a kingpin caster angle and kingpin inclination computation model and solving positioning parameters of the kingpin caster and the kingpin inclination among the four wheels; and merging and analyzing four-wheel positioning parameters of the wheels, namely the camber, the front wheel toe-in, the kingpin caster and the kingpin inclination, to acquire a variation trend of the four-wheel positioning parameters of the wheels. By performing multi-sensor data merging and analysis on the parameters, the wheel load-based type intelligent sensing four-wheel positioning measurement method has the advantages of fully monitoring and predicating a wheel positioning state, ensuring the stability and the safety of automobile driving, reducing the abrasion and the oil consumption of automobiles, improving the steering performance of vehicles and ensuring automatic aligning of steering systems, and is a novel method for wheel positioning measurement.

Owner:SOUTH CHINA UNIV OF TECH

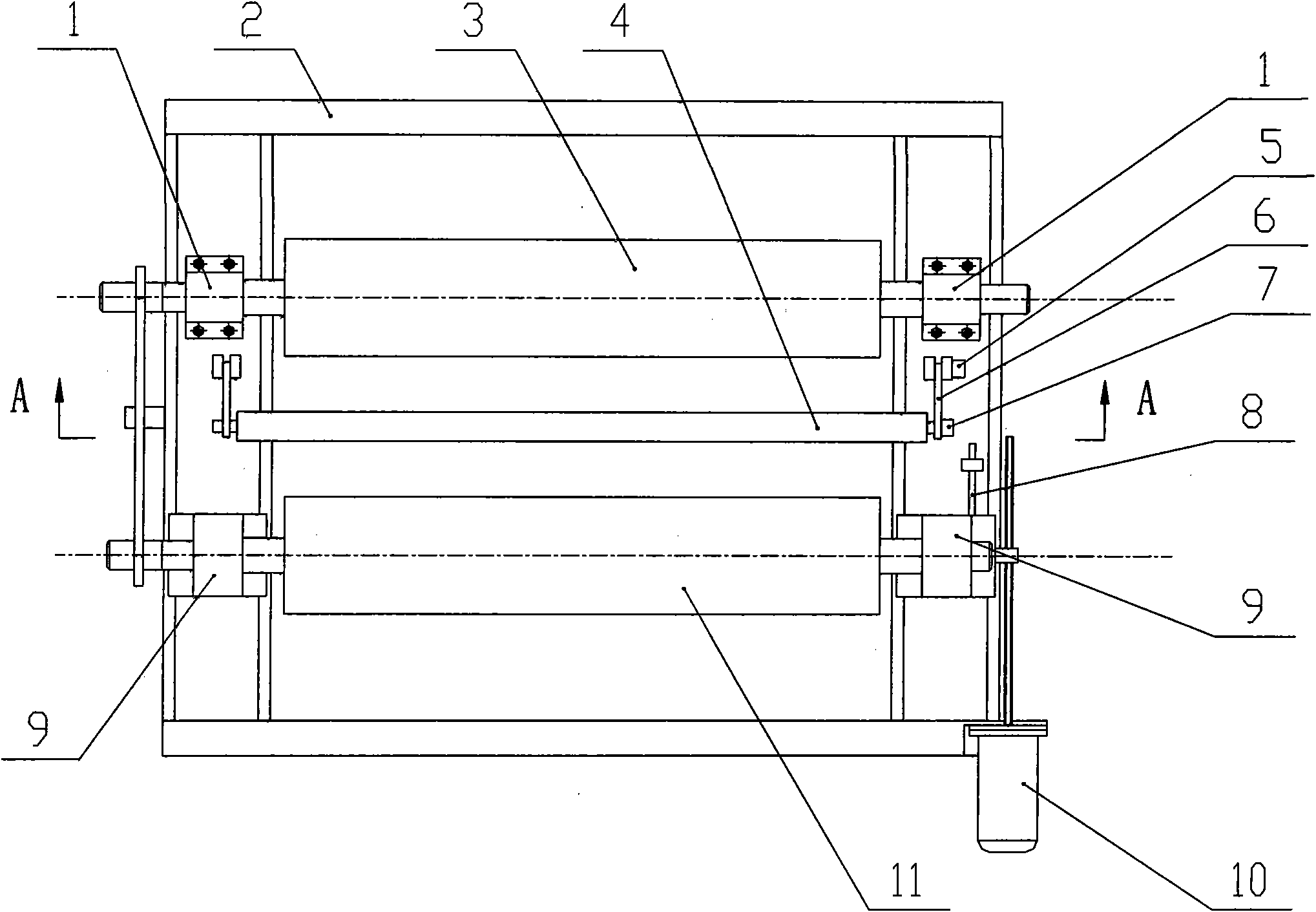

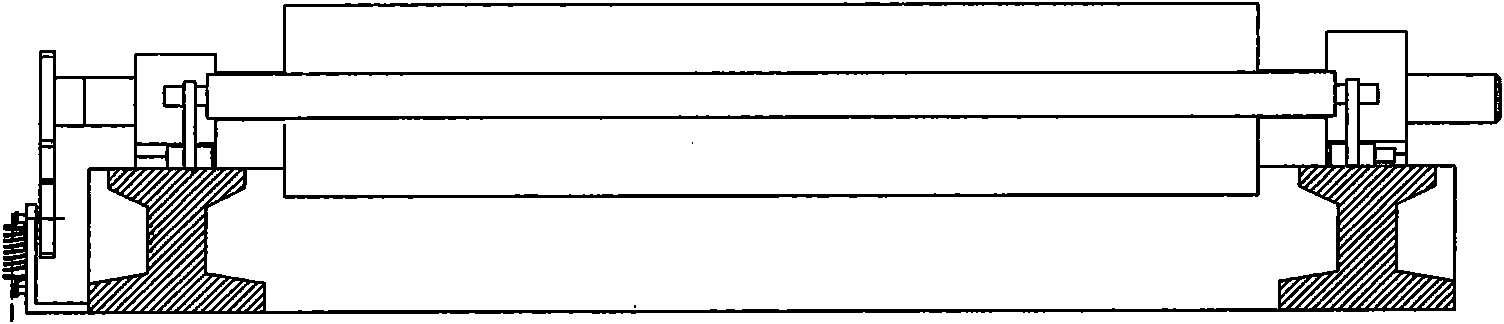

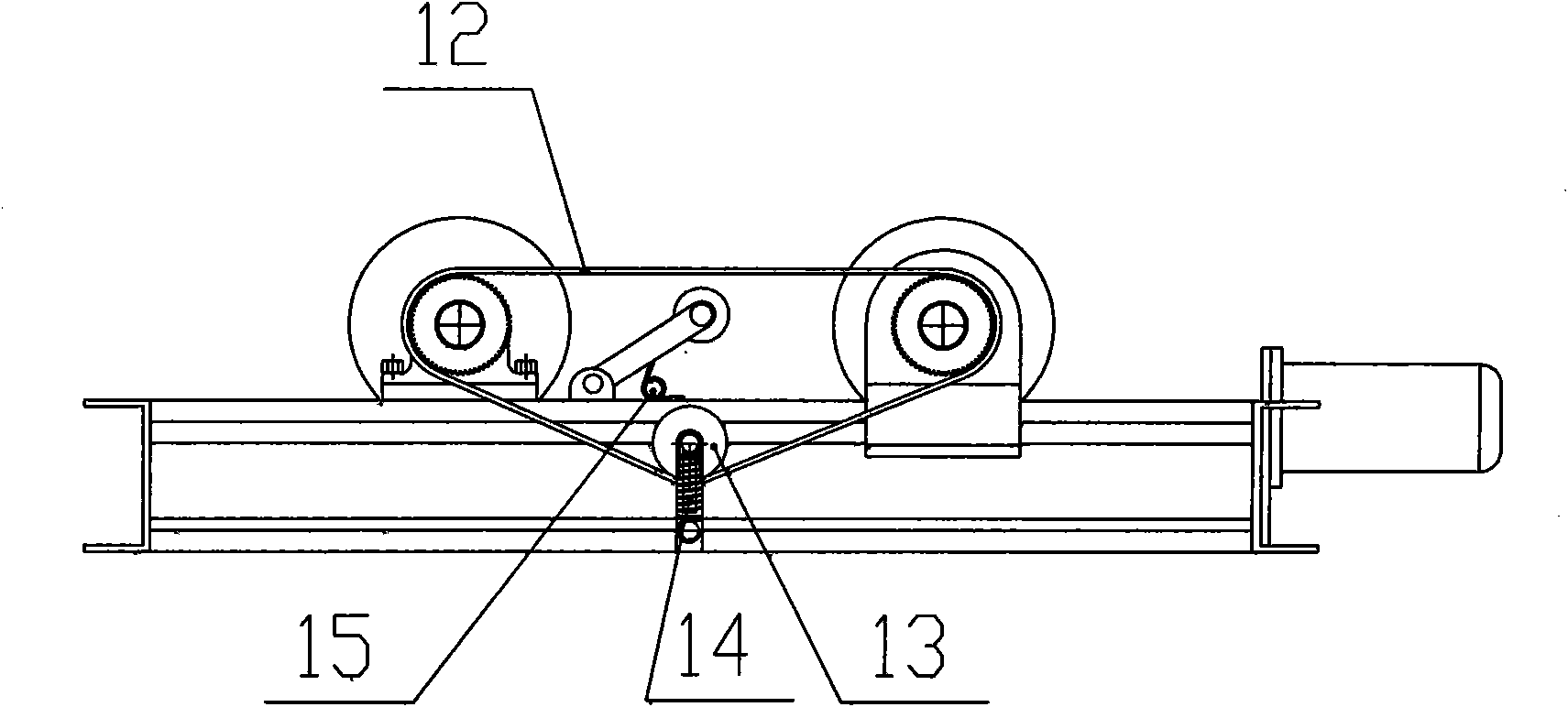

Adjustable-axle distance roller device

InactiveCN101886981AEasy to drive outRealize automatic adjustmentWork measurementTesting/calibration of speed/acceleration/shock measurement devicesAdhesion coefficientDistance detection

The invention discloses an adjustable-axle distance roller device, which comprises a machine frame, a primary roller, a secondary roller, a tire diameter detection device, a roller axle-distance detection and regulation device, a transmission device and a tensioning mechanism. When the device is used, vehicle detection equipment, such as braking detection platforms, chassis dynamometers and speedometer calibration consoles, can realize the automatic adjustment of the axle distance of rollers, the requirements for the longitudinal positioning of tires of different diameters and the adjustment of an adhesive force in a detection process are met, the detection accuracy and efficiency are improved, and the range of vehicles detected is enlarged; a wheel lifting mechanism is not required to be arranged between the primary and secondary rollers; and the adhesive force can be regulated by changing the sum of the supporting forces applied by the rollers onto the wheels in a normal direction so as to realize the simulation of different adhesion coefficients.

Owner:SHANDONG JIAOTONG UNIV

Method for monitoring dynamic load of intelligent sensing wheel based on wheel load

InactiveCN101480904ARealize real-time monitoringRealize evaluationTyre measurementsVehicle wheel testingSensing dataSignal conditioning

The invention discloses a monitoring method based on wheel load type intelligent sensing wheel dynamic load. The method comprises the following steps: an intelligent sensing module is arranged on a hub equatorial plane of each wheel of a motor vehicle, an intelligent sensing unit without gyroscopic inertia is arranged in the vehicle, and an intelligent sensing unit is hung in the vehicle to carry out complete inspection of the driving condition of the vehicle. Signal conditioning, digitalization, posture algorithm and dynamic load algorithm are carried out to various sensing signals to obtain main dynamic load parameters of the wheel. The dynamic load parameters are merged and analyzed by multiple sensing data and can be used for monitoring and actively evaluating the driving safety condition of a motor vehicle. The method can previously warn overload, tyre burst, brake performance fault, and the like of the motor vehicle, and is beneficial to avoiding and reducing the occurrence of traffic accidents.

Owner:SOUTH CHINA UNIV OF TECH

General wheel location detecting set and detecting method thereof

InactiveCN104215464AImprove versatilityGood repeatabilityVehicle wheel testingSteering angleRepeatability

Owner:吉安市吉州区华大机电工程研究所

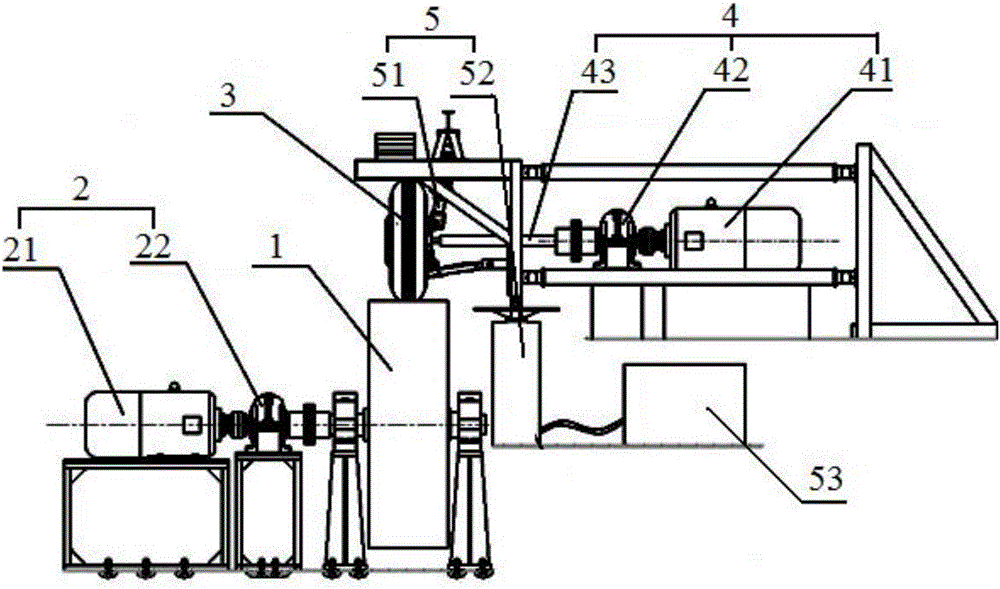

Road simulation testbed for wheel

InactiveCN105806633ARealize bench testRealize the loadVehicle wheel testingRoad surfaceRoad condition

The invention relates to the technical field of vehicle experiments, in particular to a road simulation testbed for a wheel.The road simulation testbed comprises a vertical excitation system coaxially connected with a wheel to be tested and a revolving drum system arranged below the wheel to be tested; the revolving drum system comprises a revolving drum and a first drive device for driving the revolving drum to rotate, and the outer cylindrical face of the revolving drum is in rolling contact connection with the outer circumferential face of the wheel to be tested so that the driving state on a road of a vehicle can be stimulated; the vertical excitation system comprises a hanger bracket system, the wheel to be tested is mounted on the hanger bracket system, so that the dynamic load of the wheel to be tested in the driving process of the vehicle in the vertical direction is stimulated by exerting perpendicular drive on the hanger bracket system.The first drive device drives the revolving drum, drive and loading of the torque of the wheel to be tested are achieved, the complex dynamic load of the wheel in the vertical direction is represented through the hanger bracket system, targeted to the characteristic of complex dynamic load of an off-road vehicle, the stress of the wheel passing through complex cross-country road conditions is stimulated, and the straight travel working condition of wheels of the off-road vehicle is effectively stimulated.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

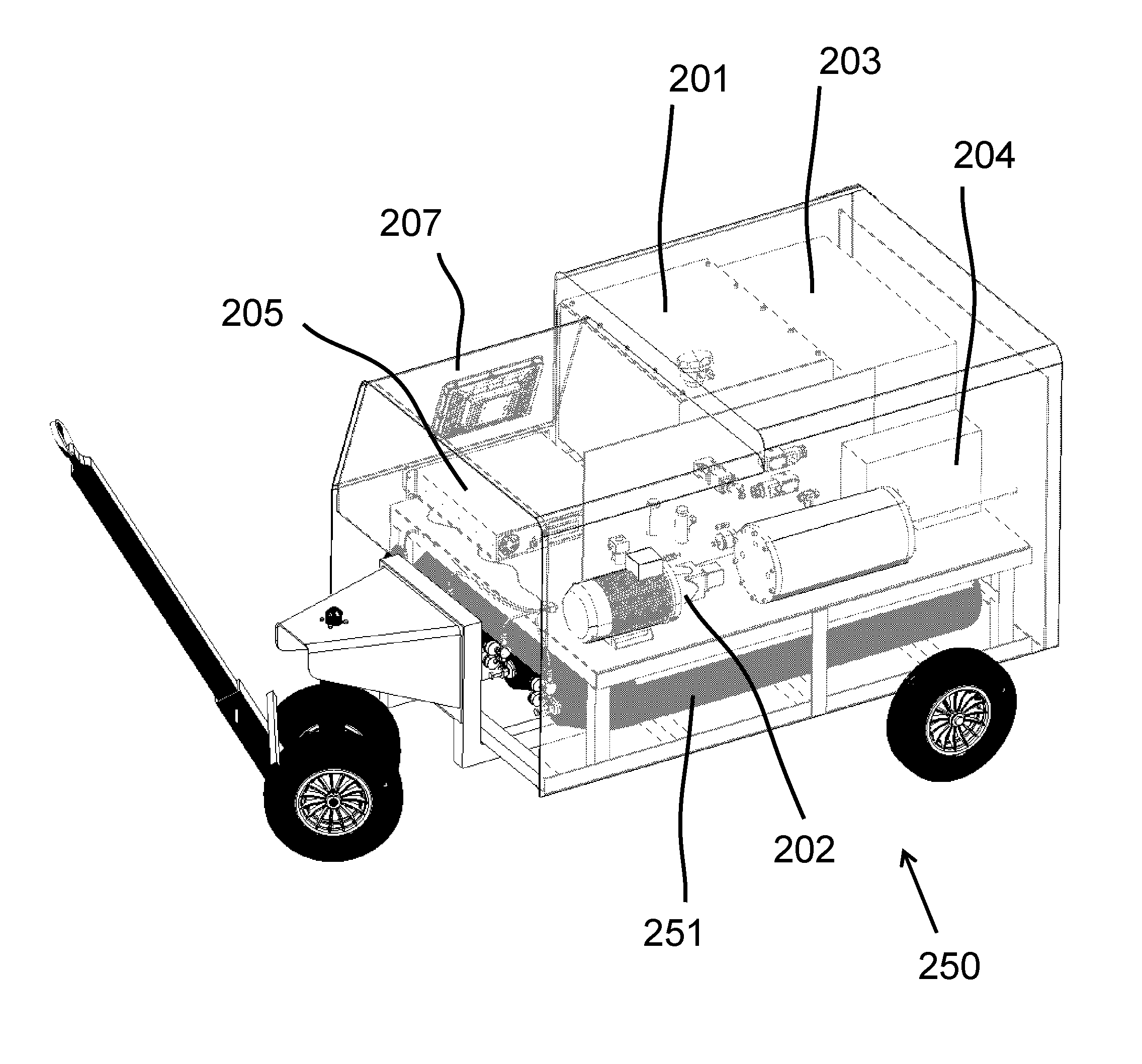

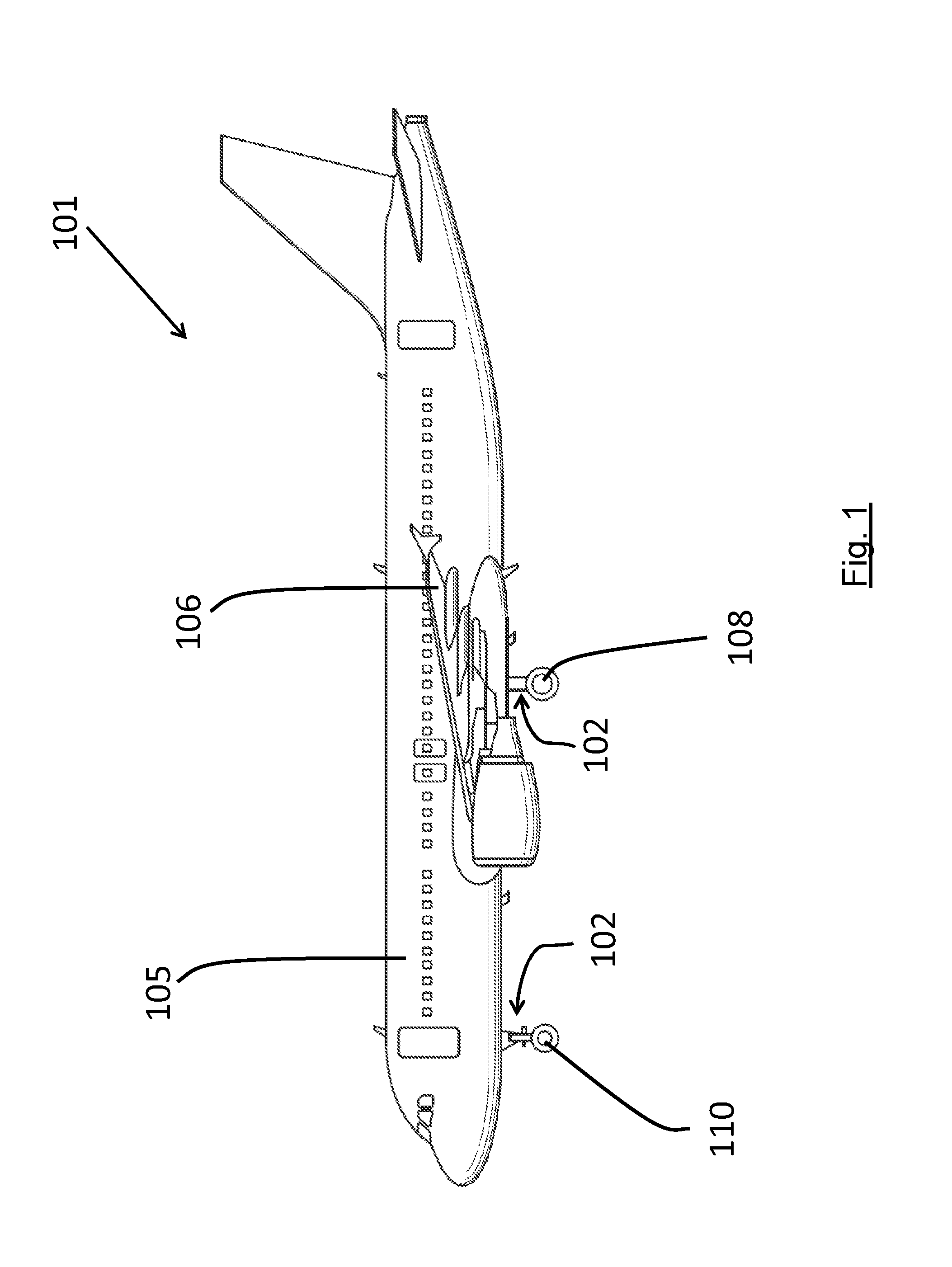

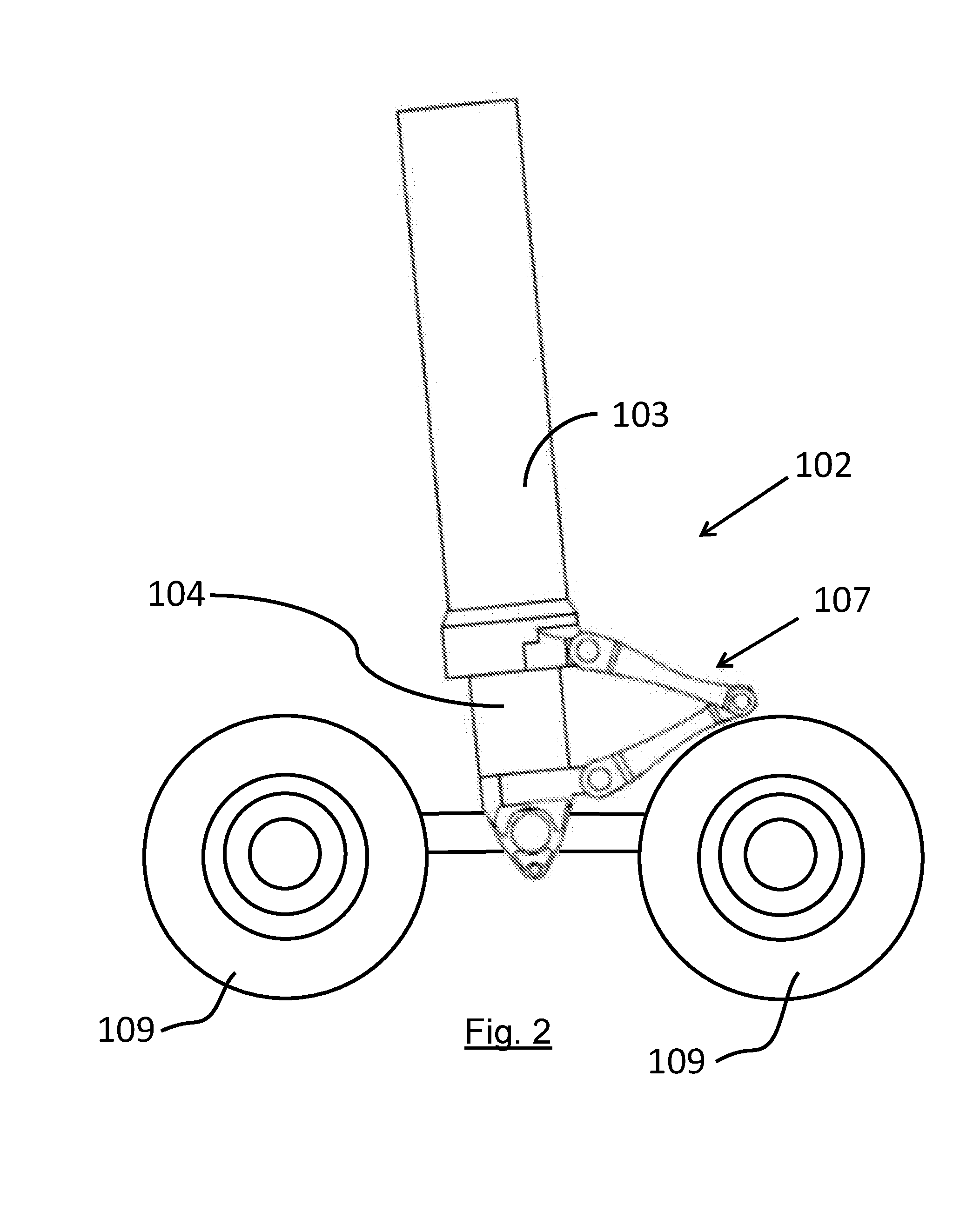

Servicing of landing gear shock absorbers

A method and portable apparatus for servicing a shock absorber on a landing gear assembly of an aircraft in a weight-on-wheels state is disclosed. The shock absorber includes at least one chamber containing both hydraulic fluid and a gas in fluid communication with each other. The apparatus includes a source of gas and a source of hydraulic fluid. The amount of hydraulic fluid in the chamber is corrected, preferably such that the chamber is then filled with a known amount of degassed hydraulic fluid. A pre-set mass of gas is then delivered into the chamber under the control of a gas delivery system of the portable apparatus. More accurate servicing of a shock absorber may thus be provided since account is additionally taken of gas dissolved in hydraulic fluid. By delivering a pre-set mass of gas into the chamber, there is no need to rely on a measure of gas pressure or H-dimension (h) when servicing the shock absorber.

Owner:AIRBUS OPERATIONS LTD

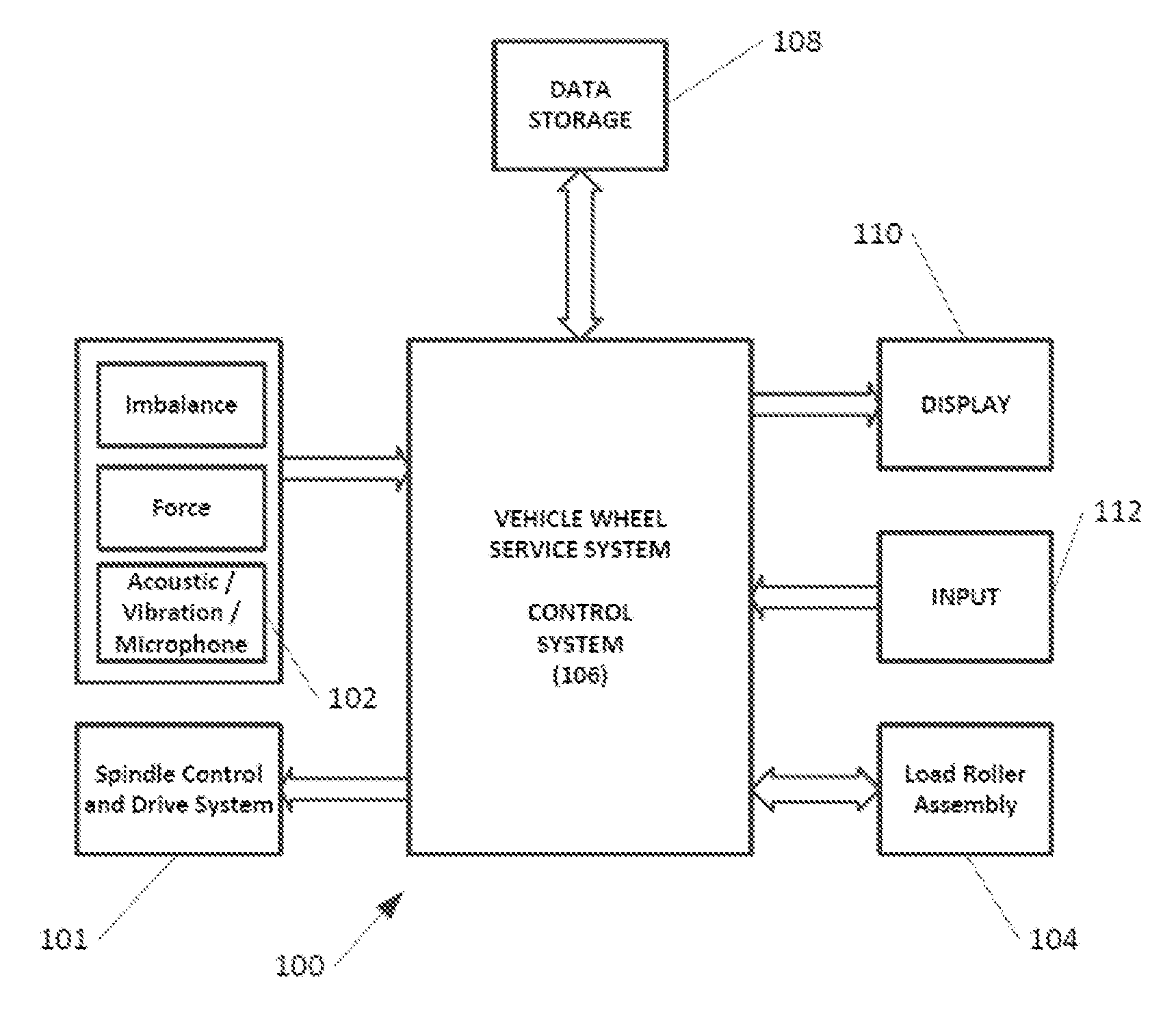

System and Method For Wheel Assembly Acoustical Evaluation

InactiveUS20140025251A1Registering/indicating working of vehiclesDigital data processing detailsAcoustic energyFigure of merit

A vehicle service or inspection system including a load roller for applying a radial load to a vehicle wheel assembly consisting of a tire mounted to a rim, with at least one sensor for acquiring measurements of acoustical energy generated by the wheel assembly during loaded rotational movement. The vehicle service or inspection system is configured with a programmed processor to evaluate the acquired measurements to provide a measure of tire road noise, identification of tire defects, and / or identification of sources of noise, vibrations, or acoustical energy on the tire surface such as tire flat spots, cupping, bubbles, embedded foreign objects, or other defects. The processor is further configured with software instructions to utilize the acquired measurements to provide a consumer with a figure of merit associated with the acoustics of the tire undergoing testing

Owner:HUNTER ENG

Apparatus for detecting hunting and angle of attack of a rail vehicle wheelset

ActiveUS20060010971A1Easy to installEasy maintenanceVehicle route interaction devicesRailway vehicle testingEngineeringBiological activation

An apparatus and method for estimating the angle of attack of wheels, wheelsets, trucks and railway vehicles traveling over a track employing a wayside system having a plurality of sensors, adjacent to the rails of the track, for detecting the passing of each wheelset of each truck. Each sensor communicates its moment of activation and length of activation caused by a passing wheel to a sensor monitoring unit for use in determining the angle of attack of the passing wheel, wheelset, truck and railway vehicle. The estimated angle of attack of the wheelset at different locations along the track may be used to detect a hunting wheelset, truck or railway vehicle.

Owner:WABTEC CONTROL SYST PTY LTD

Detection process for run-out amount of steel ring rim and equipment structure

InactiveCN101398285AImprove product qualityConsolidation of product qualityAngles/taper measurementsMechanical counters/curvatures measurementsPulse rateEconomic benefits

The invention discloses a wheel felloe pulse rate detecting process and equipment construction thereof, which comprises the construction of a steel ring wheel felloe pulse rate detecting platform and the steel ring wheel felloe pulse rate detecting process. The construction of the steel ring wheel felloe pulse rate detecting platform constructs a machine that consists of two main parts of a steel ring wheel felloe pulse rate detecting clamp and an instrument stand component as well as a mandrel component, a rotary disk component, a press block component and a platform bench component, the mandrel component is connected with the platform bench component and the rotary disk component, the press block component is connected with the mandrel component and the rotary disk component, and the instrument stand component is connected with the platform bench component, thus forming the integrated the steel ring wheel felloe pulse rate detecting platform, and the steel ring wheel felloe pulse rate detecting process can be adopted for detecting whether a wheel felloe is qualified before the forming of steel ring products. The technical proposal of the steel ring wheel felloe pulse rate detecting platform and the steel ring wheel felloe pulse rate detecting process not only further refine production equipments of the steel ring products, but also further standardize production techniques of the steel ring products, and provide required technical conditions for steel ring product plants which can ensure the quality of the steel ring products, lower the material loss in the steel ring production and raise economic benefits.

Owner:徐国林

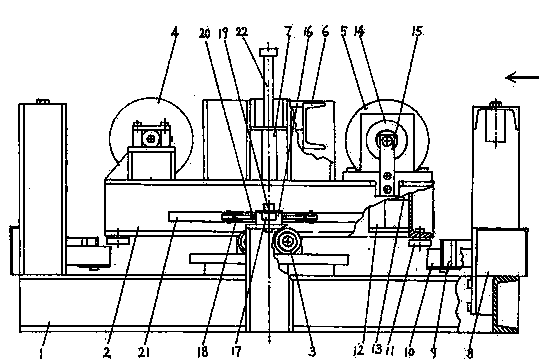

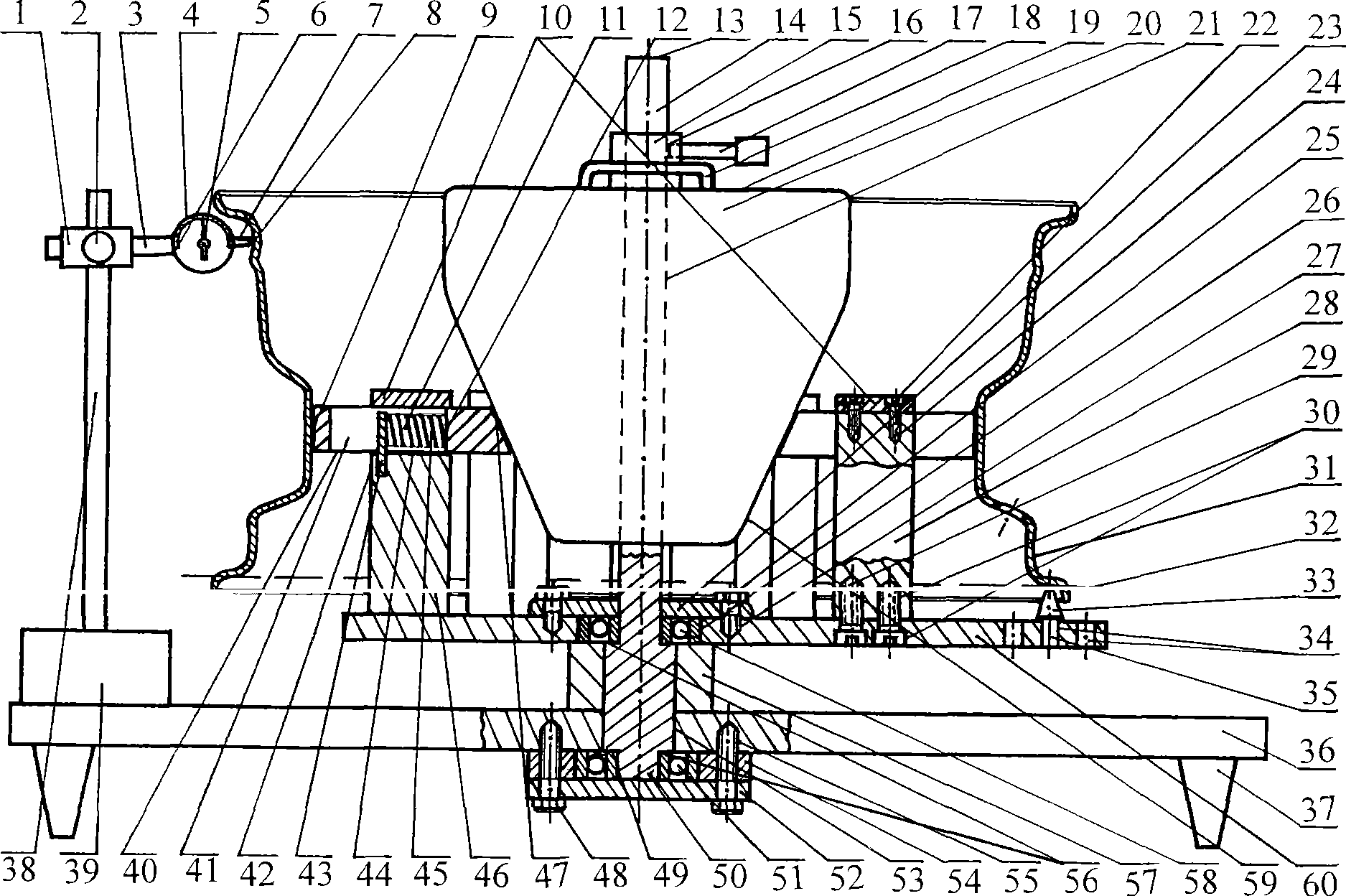

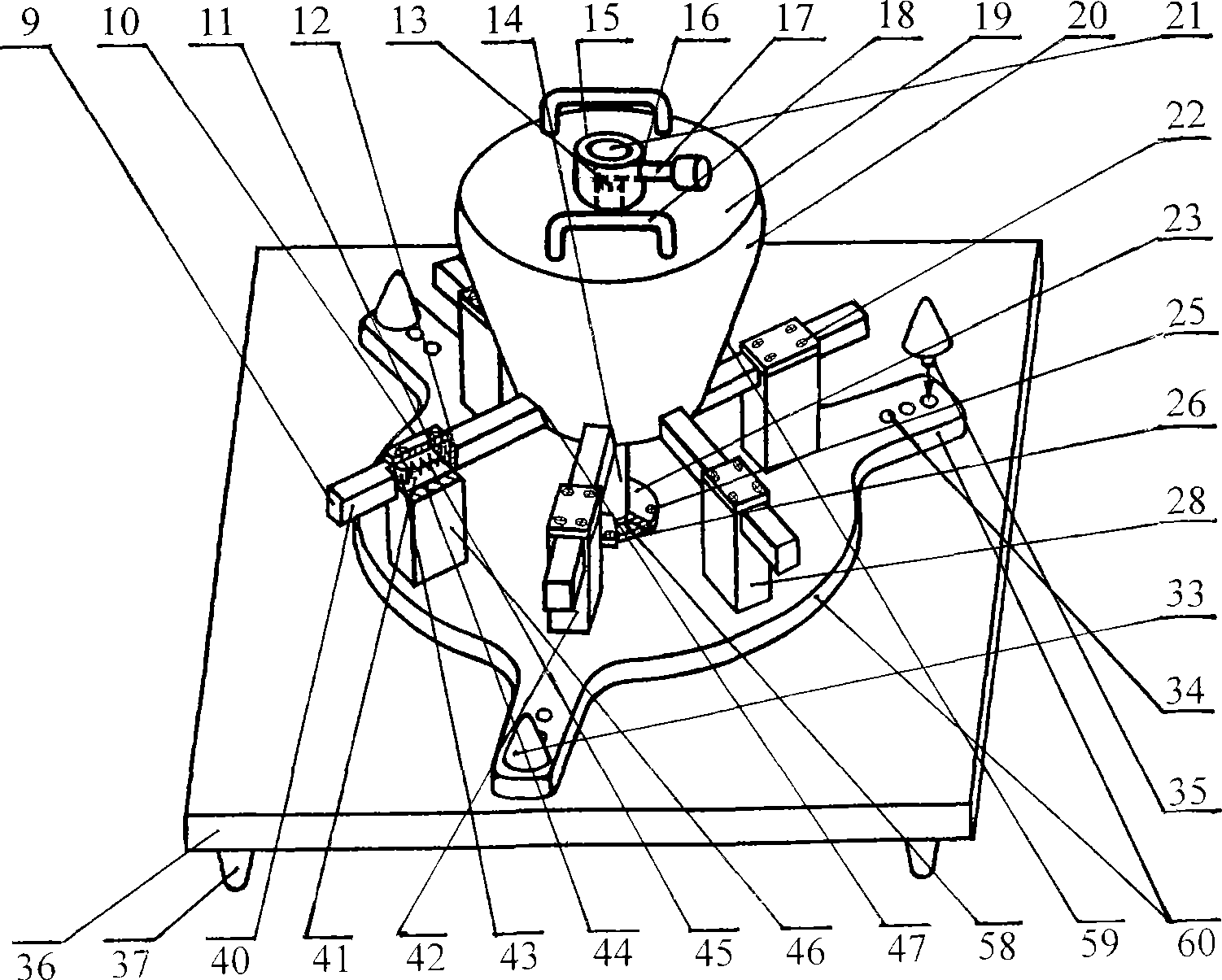

Multifunctional vehicle dynamics dynamical characteristic test bed with loading device

InactiveCN101886982AHigh simulationRealize researchForce measurementWork measurementVehicle dynamicsTorque motor

The invention discloses a multifunctional vehicle dynamics dynamical characteristic test bed with a loading device, comprising a rotary encoder, a torque motor, a longitudinal guide rail, a horizontal guide rail, a rotating disc, an outer rotor motor, a force sensor and a torque sensor, a rotary drum, a tyre flange, a horizontal loading hydraulic cylinder with the force sensor, a horizontal loading matching hydraulic cylinder with the force sensor, a vertical loading hydraulic cylinder with the force sensor, an angle sensor, a loading bracket, a rotating speed sensor, a centering roller lifter, a centering roller, a motor, a measurement and control system, and the like. The invention can be used for exerting longitudinal force and vertical force on vehicle wheels and loading horizontal force and aligning resistance torque at the same time, simulating the turning driving of a vehicle by turning the vehicle wheels with the rotary drum together, measuring the turning angles of the vehicle wheels, better simulating the actual driving work conditions of the vehicle and realizing the comprehensive research of integral vehicle dynamics, and provides the vehicle dynamics test bed which has better performance.

Owner:SHANDONG JIAOTONG UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com