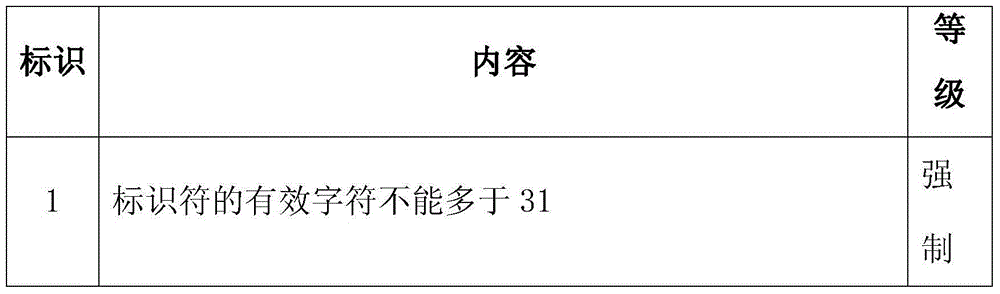

Patents

Literature

244 results about "Testbed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A testbed (also spelled test bed) is a platform for conducting rigorous, transparent, and replicable testing of scientific theories, computational tools, and new technologies. The term is used across many disciplines to describe experimental research and new product development platforms and environments. They may vary from hands-on prototype development in manufacturing industries such as automobiles (known as "mules"), aircraft engines or systems and to intellectual property refinement in such fields as computer software development shielded from the hazards of testing live.

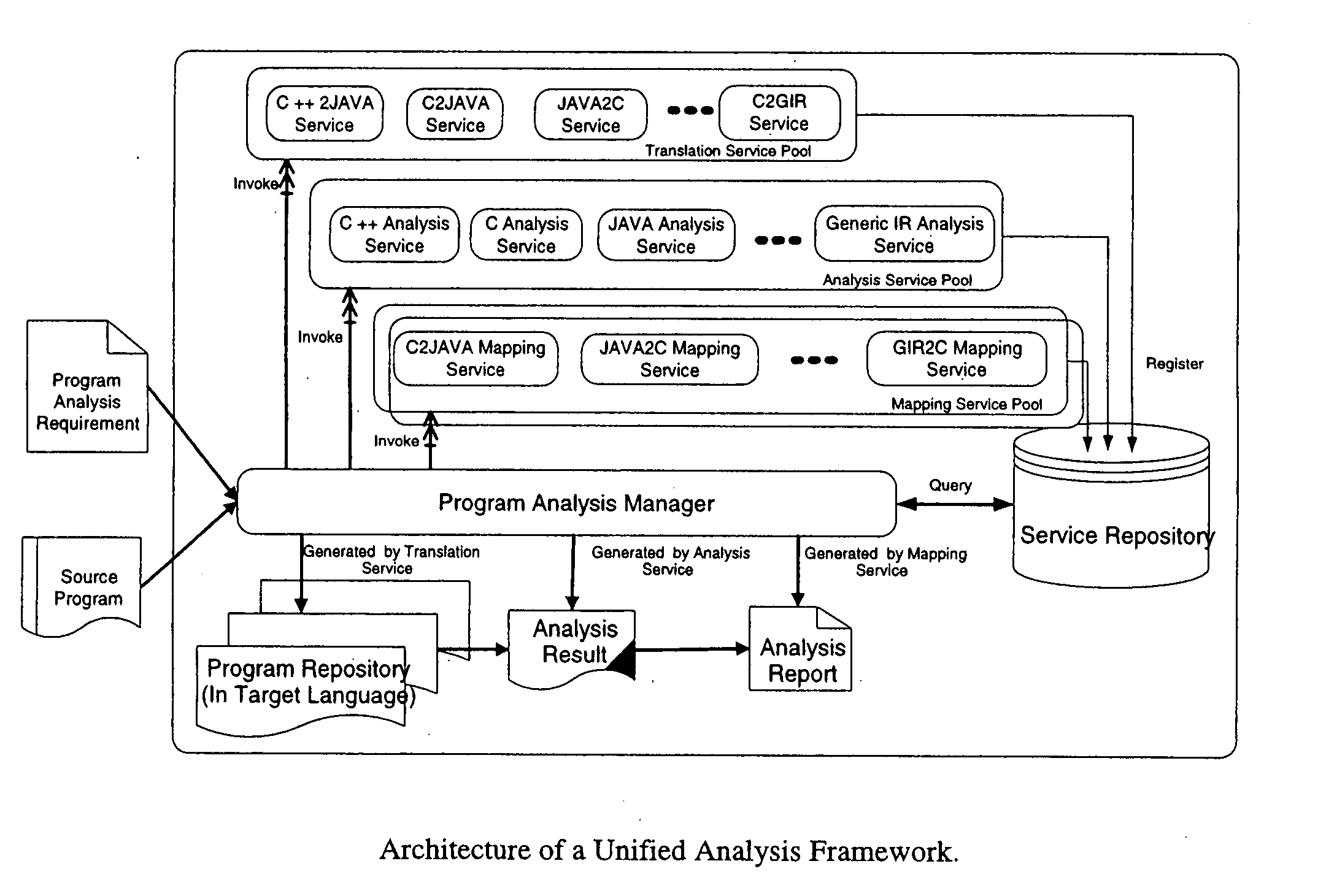

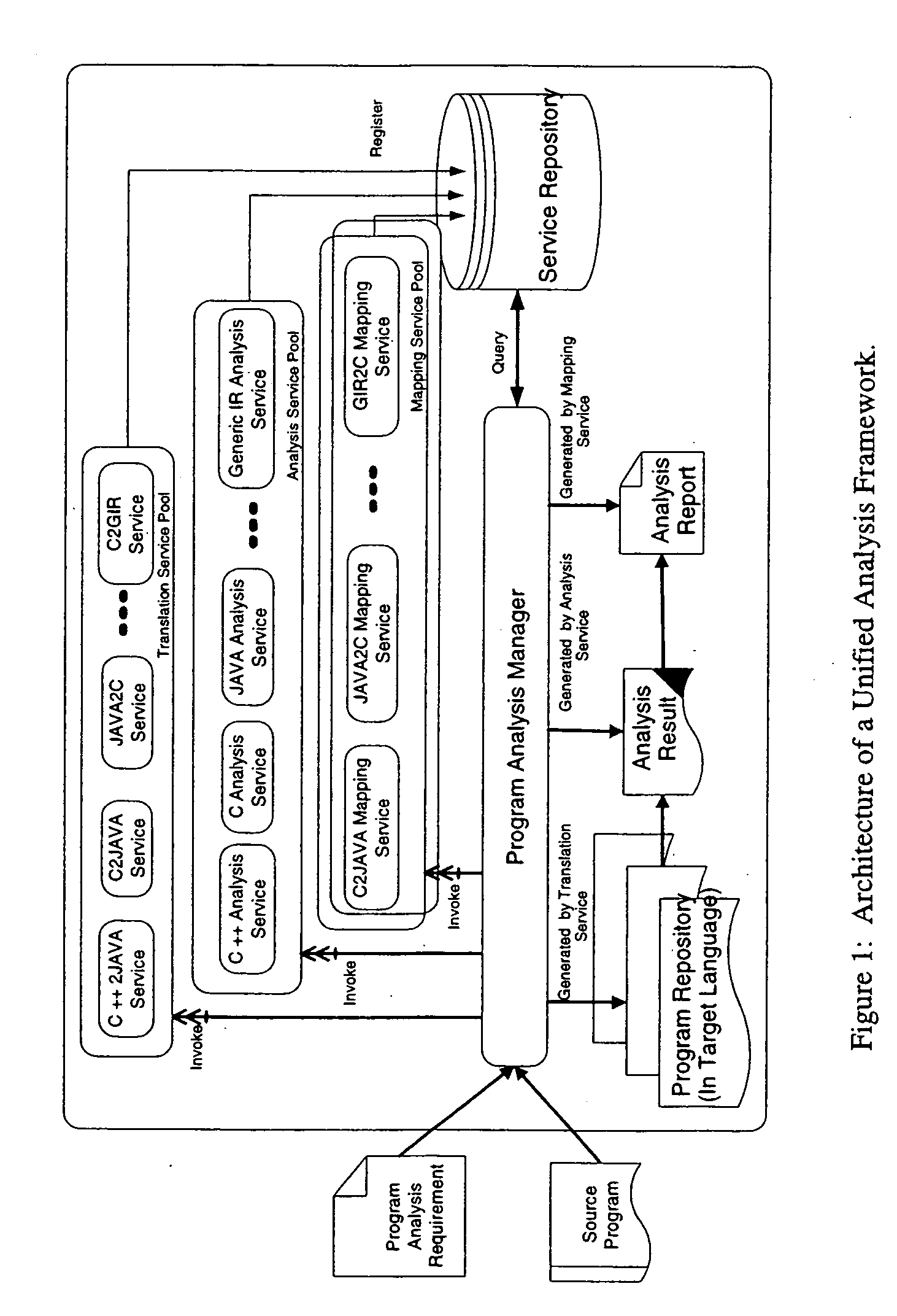

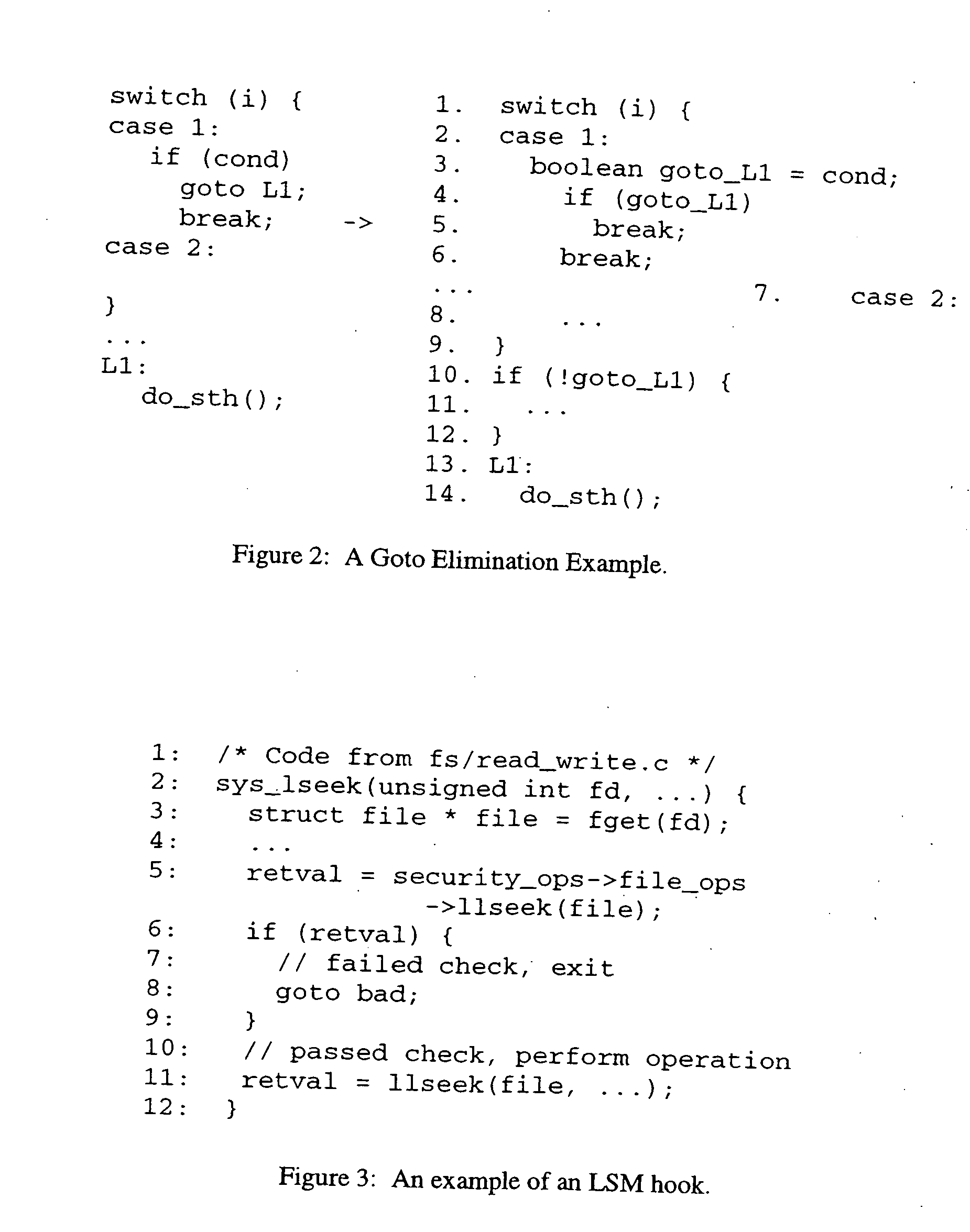

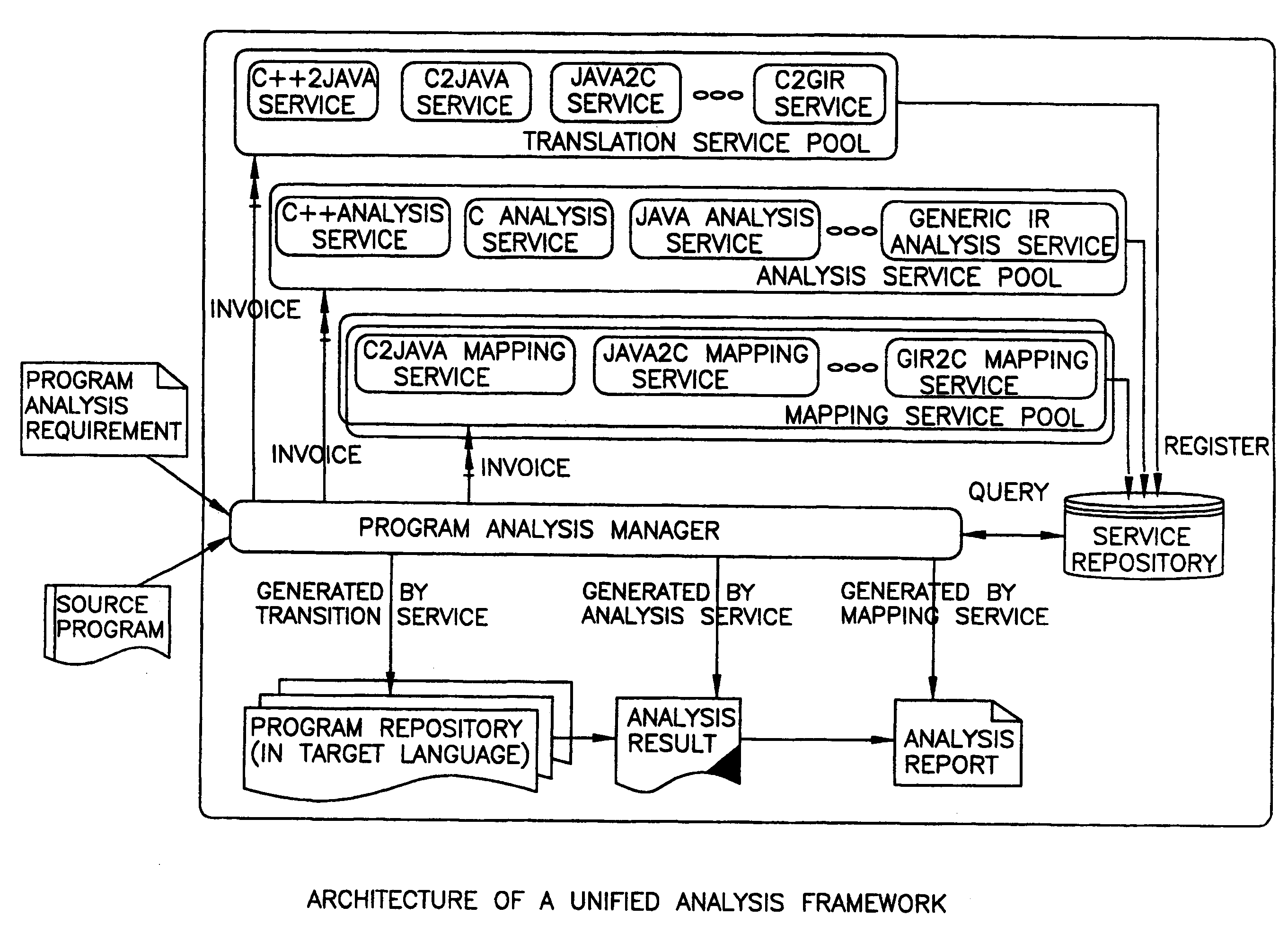

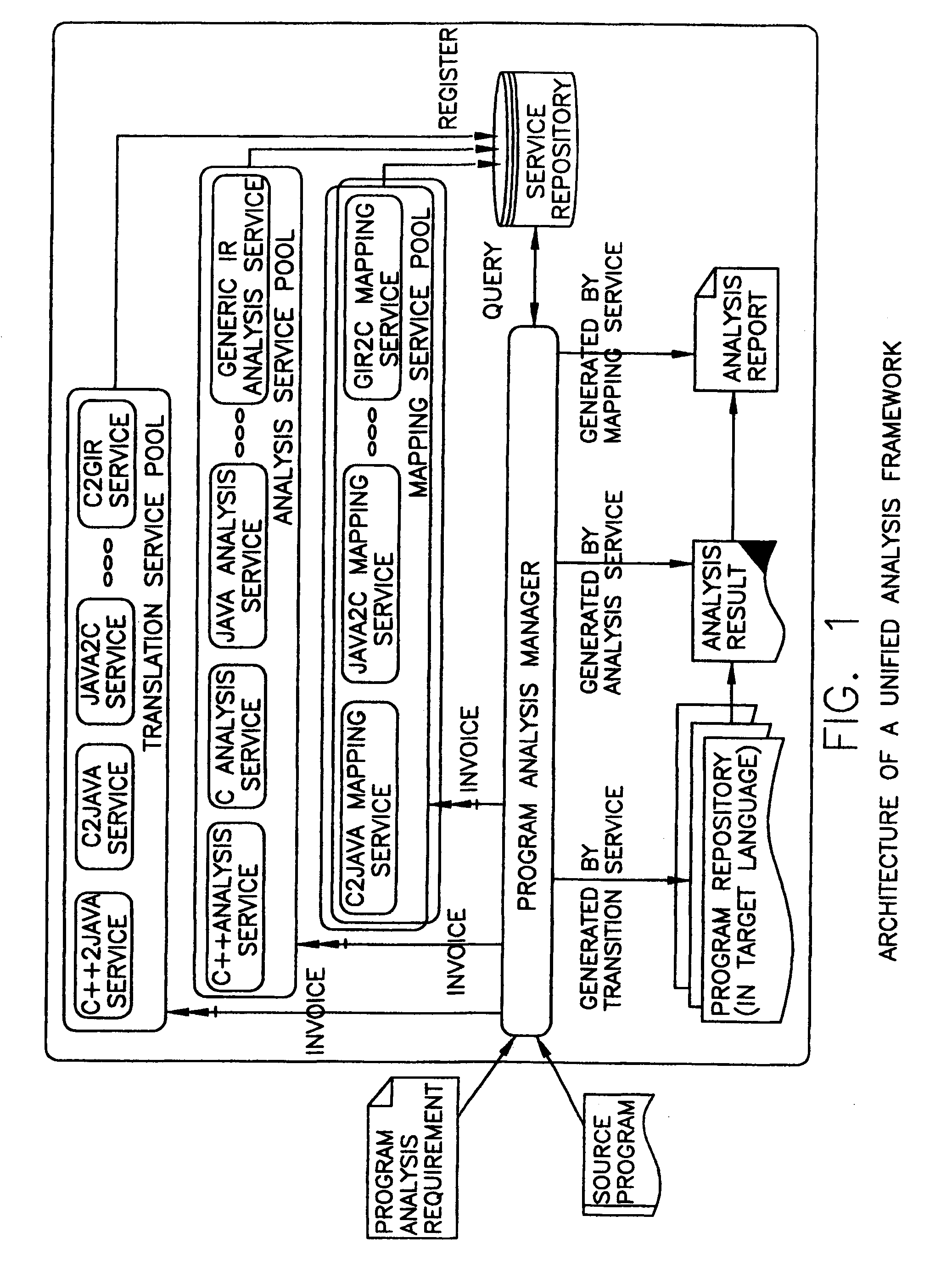

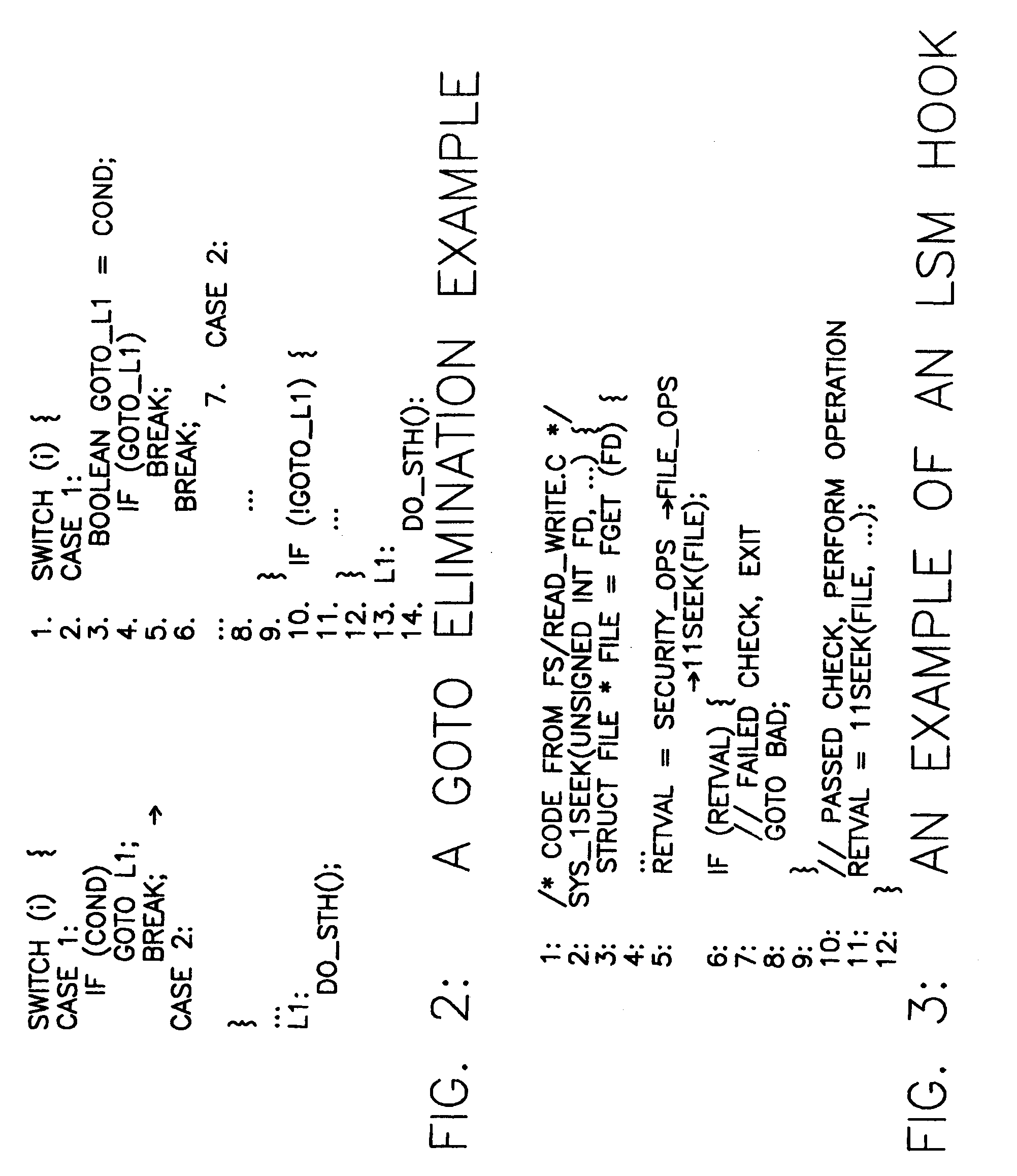

Methods and arrangements for unified program analysis

InactiveUS20060248519A1Low costMaximize returnError detection/correctionSpecific program execution arrangementsMulti languageSoftware system

A unified program analysis framework that facilitates the analysis of complex multi-language software systems, analysis reuse, and analysis comparison, by employing techniques such as program translation and automatic results mapping, is presented. The feasibility and effectiveness of such a framework are demonstrated using a sample application of the framework. The comparison yields new insights into the effectiveness of the techniques employed in both analysis tools. These encouraging results yield the observation that such a unified program analysis framework will prove to be valuable both as a testbed for examining different language analysis techniques, and as a unified toolset for broad program analysis.

Owner:IBM CORP

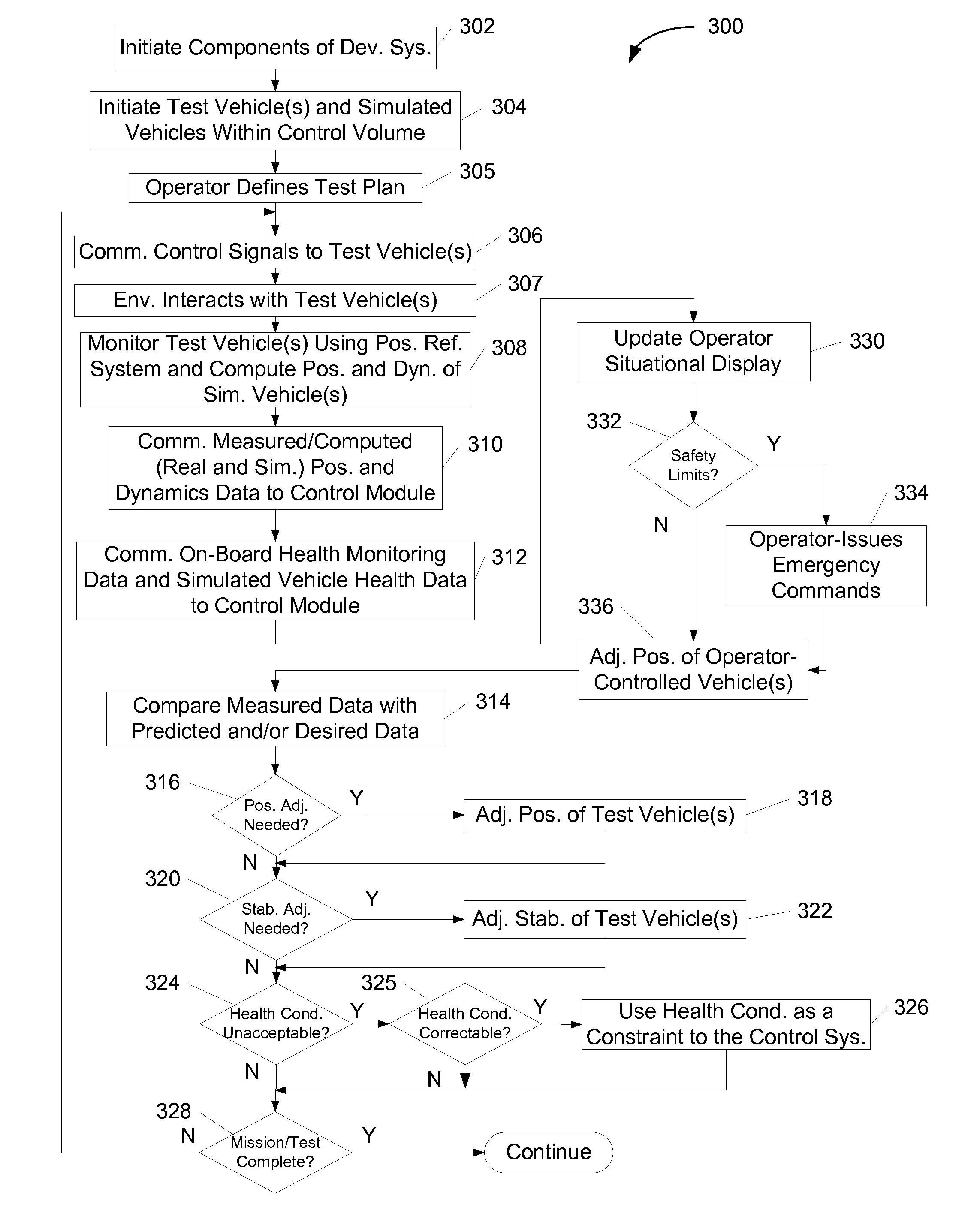

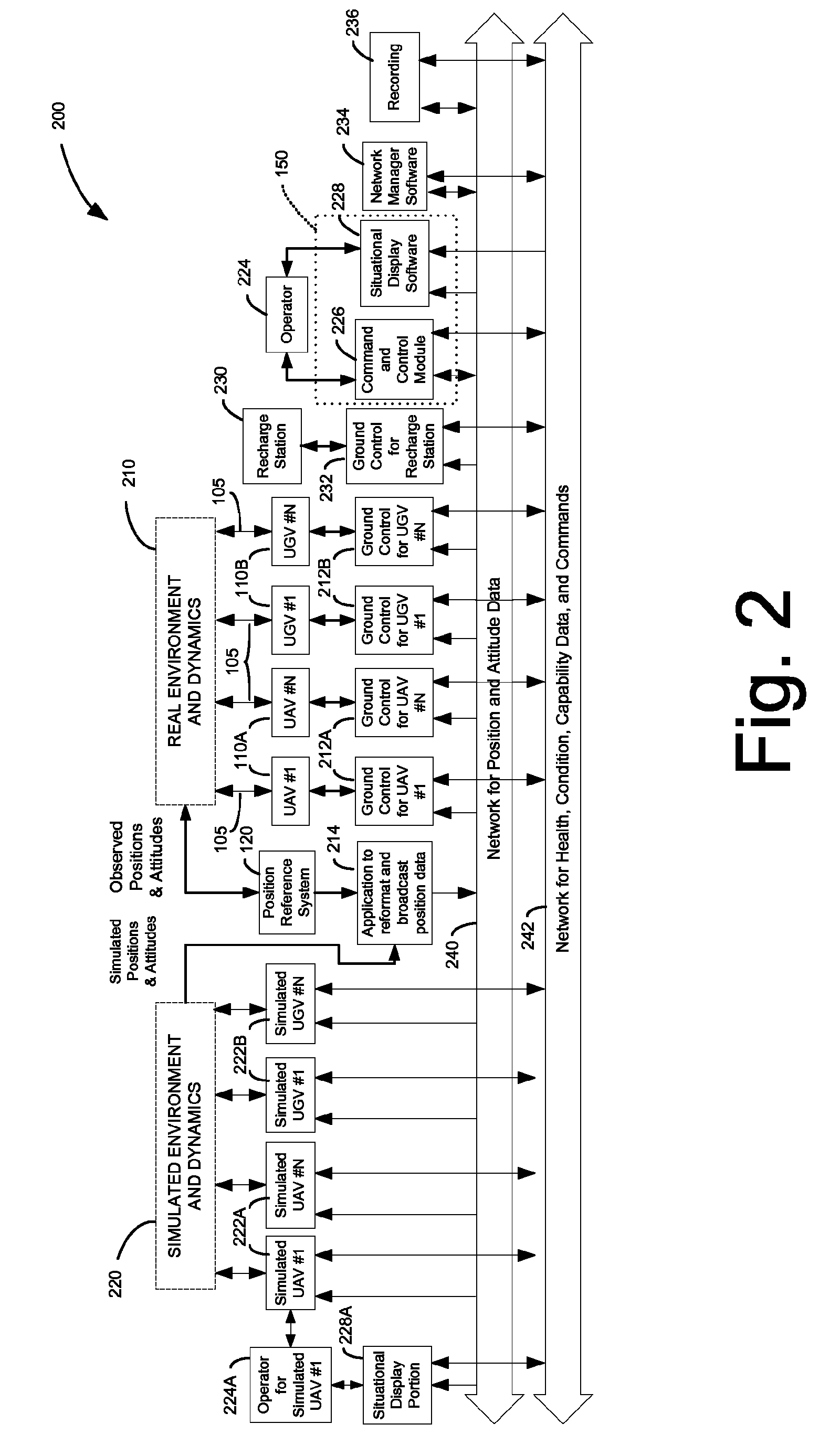

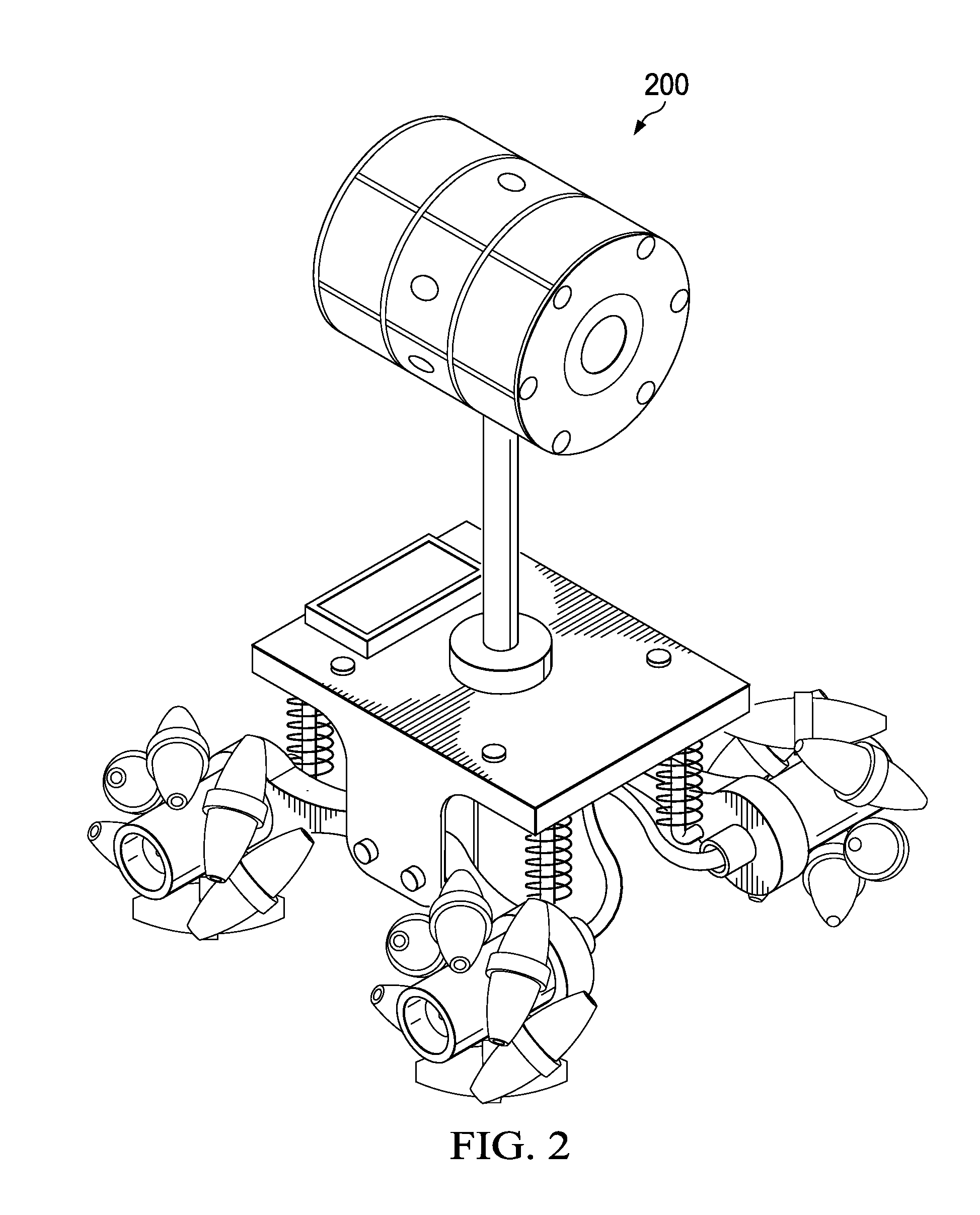

Autonomous Vehicle Rapid Development Testbed Systems and Methods

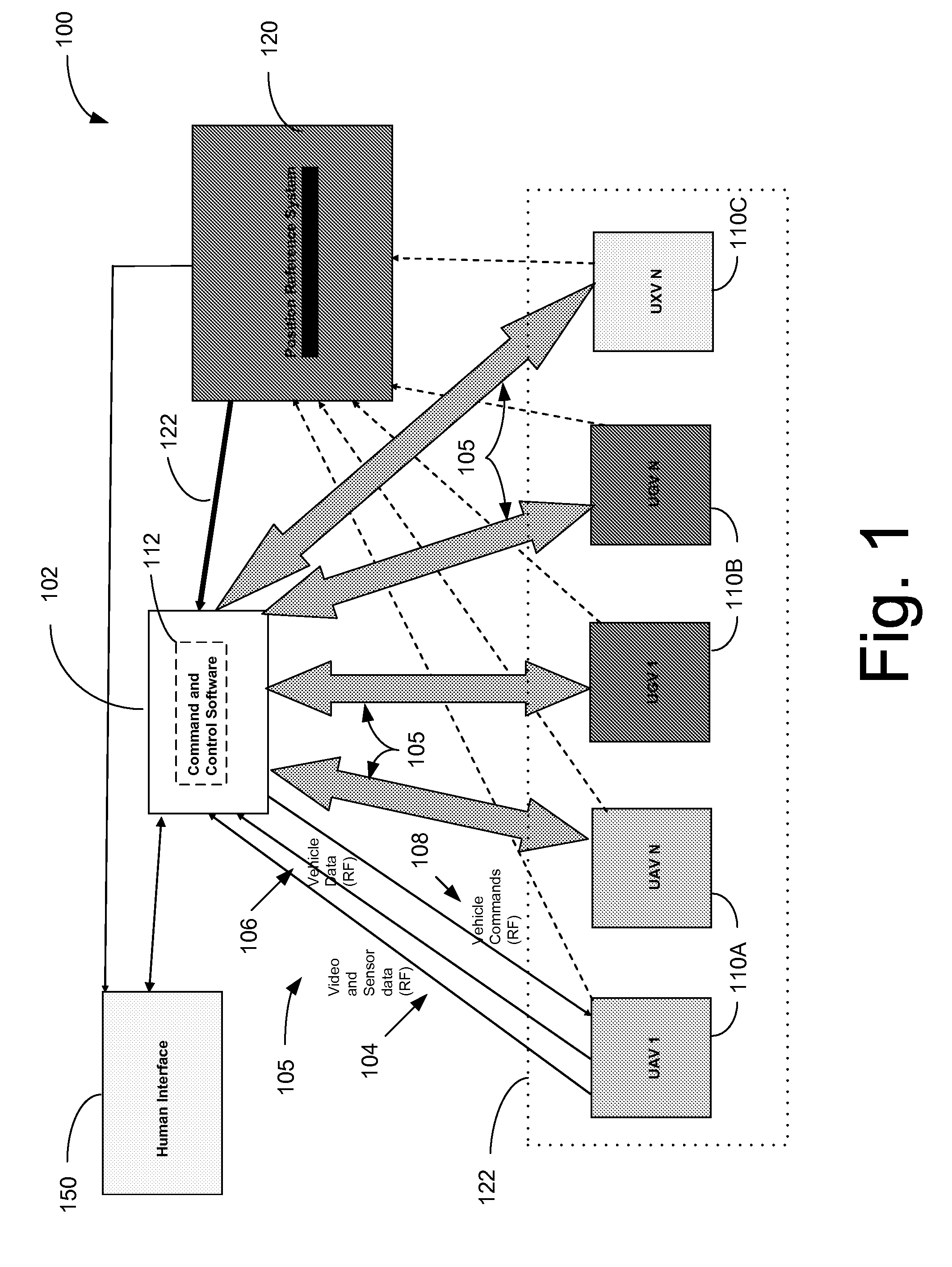

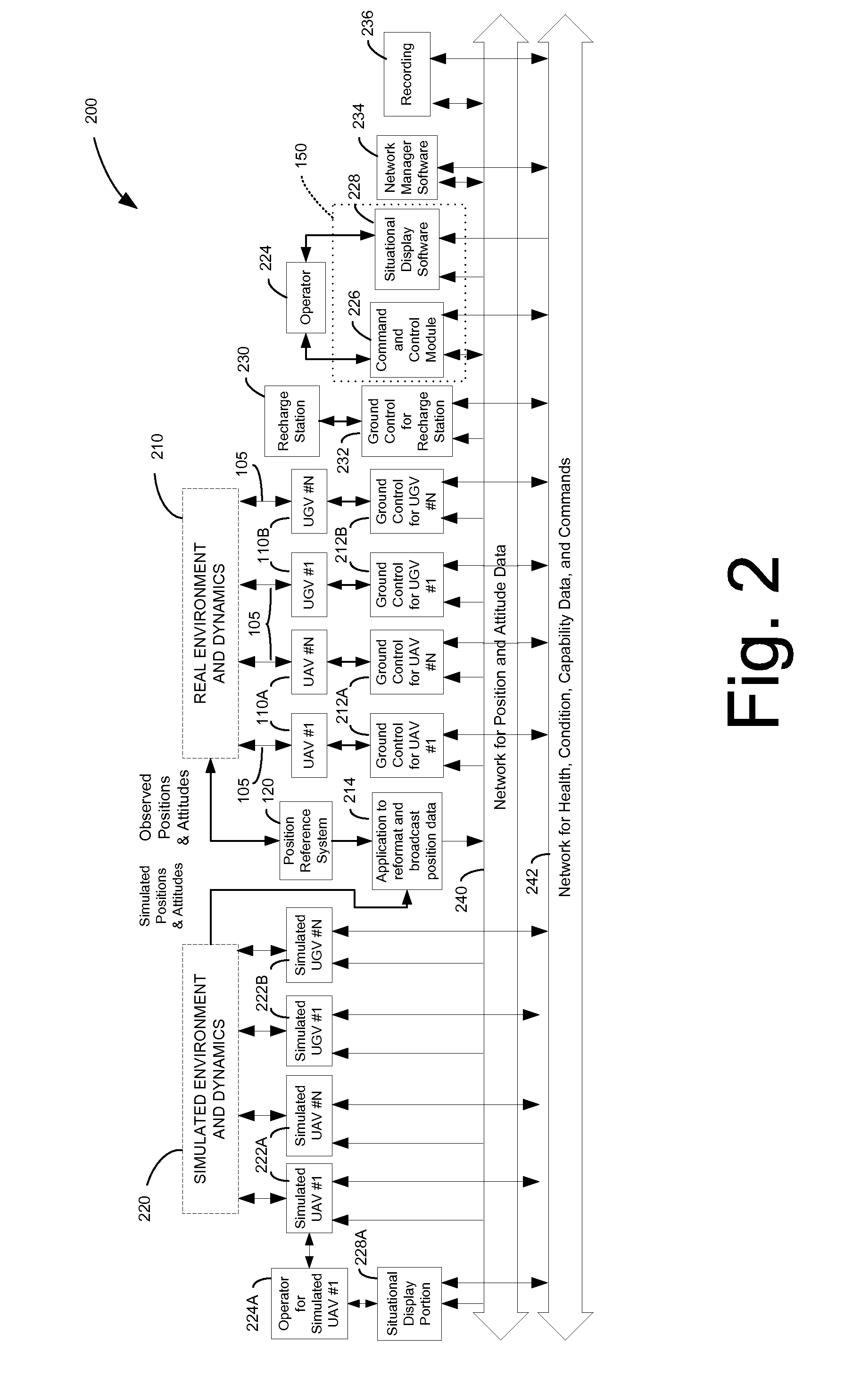

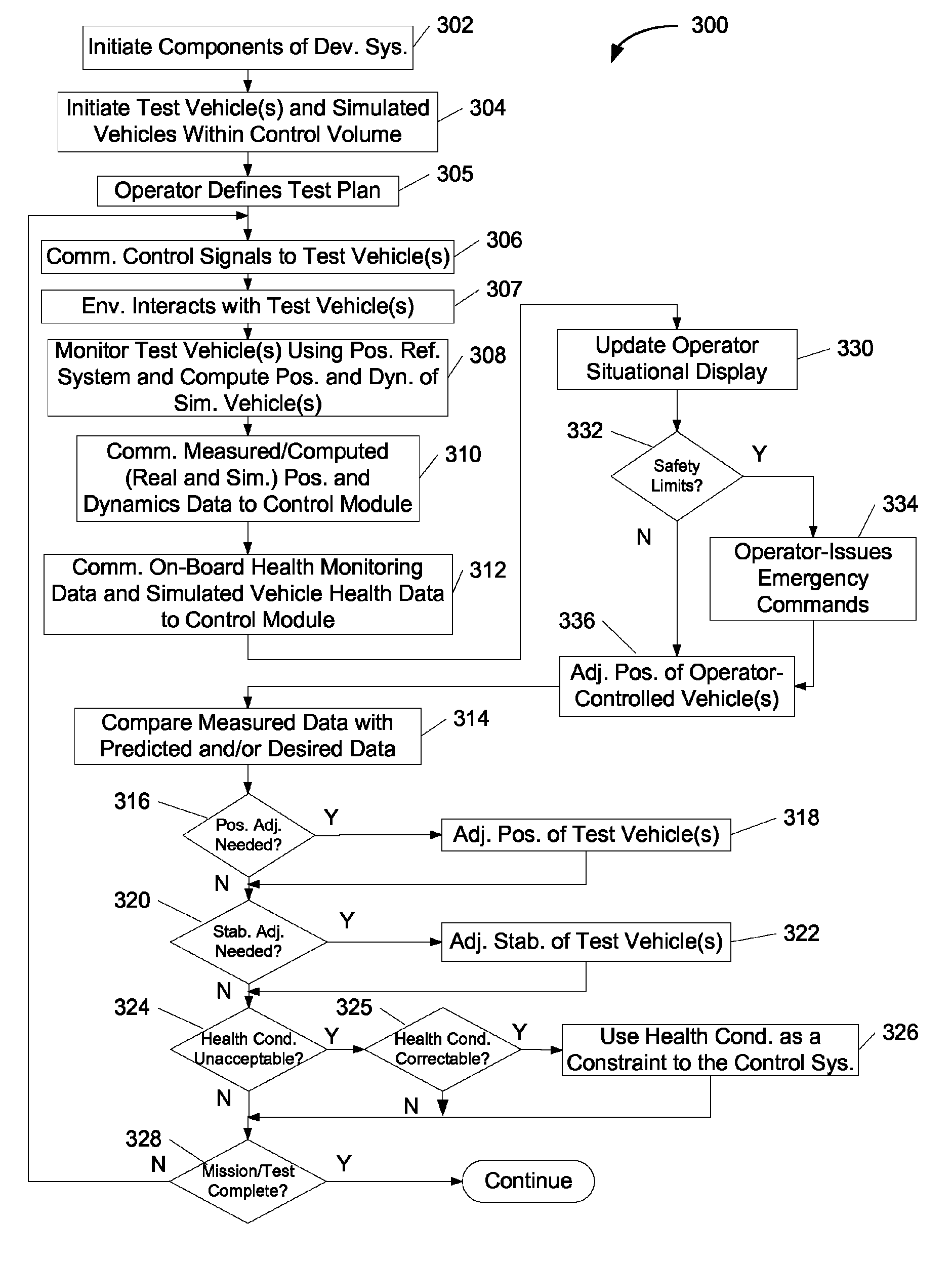

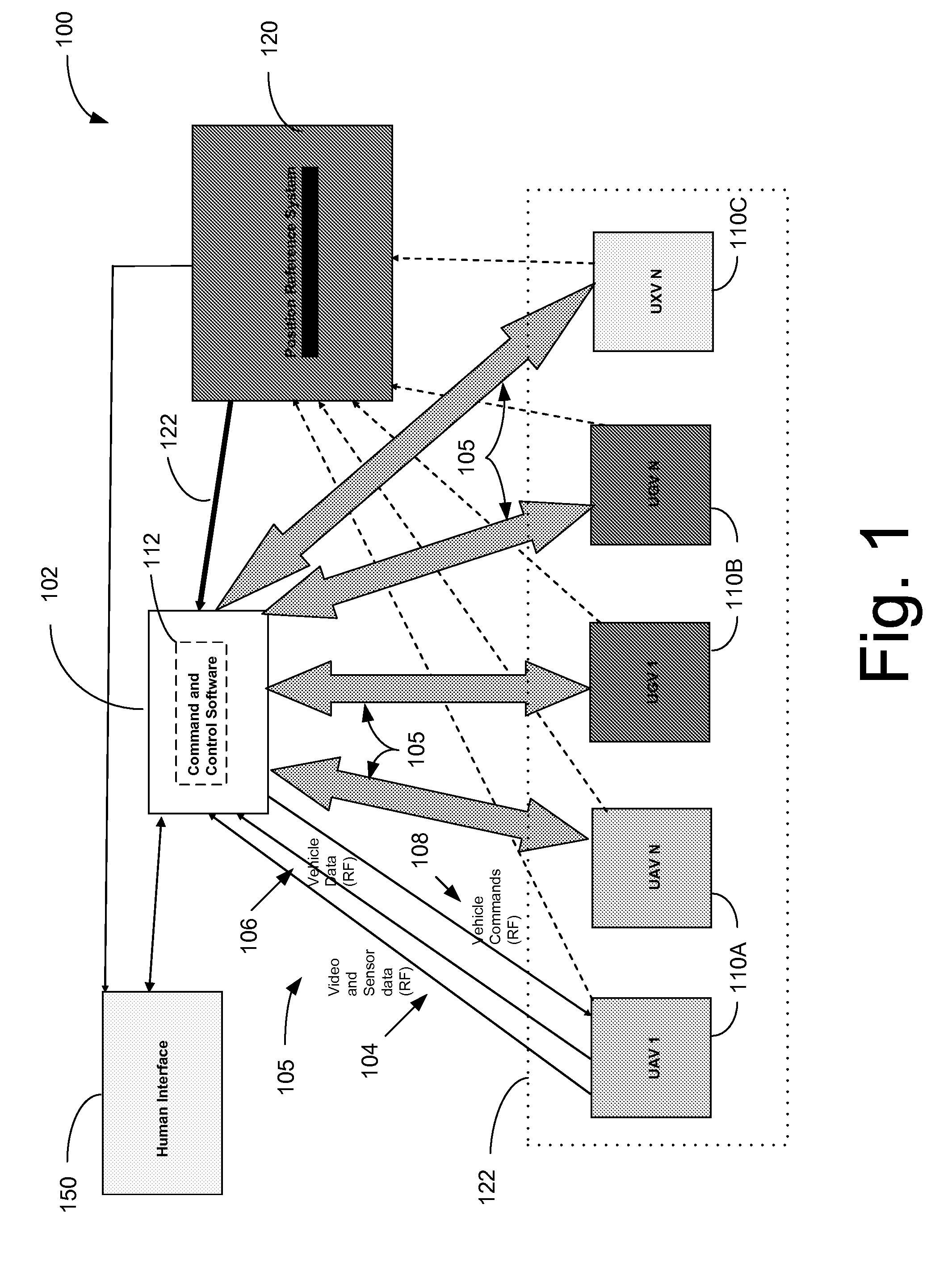

ActiveUS20080033684A1Easy to detectRapid development and testingVehicle testingDigital data processing detailsCommand and controlControl signal

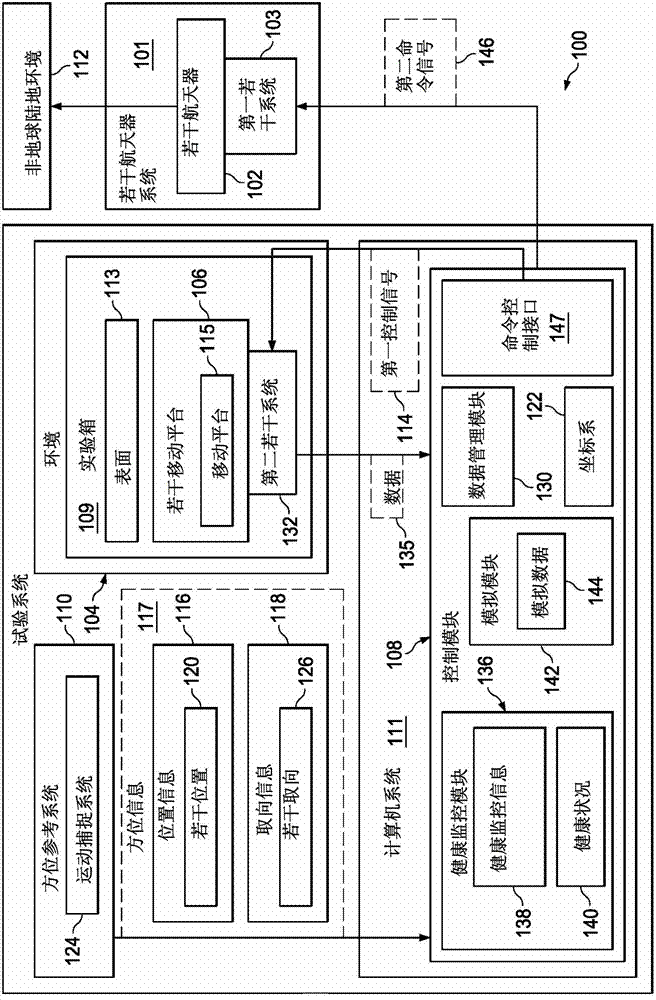

Systems and methods for development testing of vehicles and components are disclosed. In one embodiment, a system includes a position reference system and a command and control architecture. The position reference system is configured to repetitively measure one or more position and motion characteristics of one or more vehicles operating within a control volume. The command and control architecture is configured to receive the repetitively measured characteristics from the position reference system, and to determine corresponding control signals based thereon. The control signals are then transmitted to the one or more vehicles to control at least one of position, movement, and stabilization of the one or more vehicles in a closed-loop feedback manner. The system may further include a health monitoring component configured to monitor health conditions of the one or more vehicles, the control signals being determined at least in part on the health conditions.

Owner:THE BOEING CO

Autonomous vehicle rapid development testbed systems and methods

ActiveUS7813888B2Rapid development and testingEasy to detectVehicle testingElectrical measurementsControl signalCommand and control

Systems and methods for development testing of vehicles and components are disclosed. In one embodiment, a system includes a position reference system and a command and control architecture. The position reference system is configured to repetitively measure one or more position and motion characteristics of one or more vehicles operating within a control volume. The command and control architecture is configured to receive the repetitively measured characteristics from the position reference system, and to determine corresponding control signals based thereon. The control signals are then transmitted to the one or more vehicles to control at least one of position, movement, and stabilization of the one or more vehicles in a closed-loop feedback manner. The system may further include a health monitoring component configured to monitor health conditions of the one or more vehicles, the control signals being determined at least in part on the health conditions.

Owner:THE BOEING CO

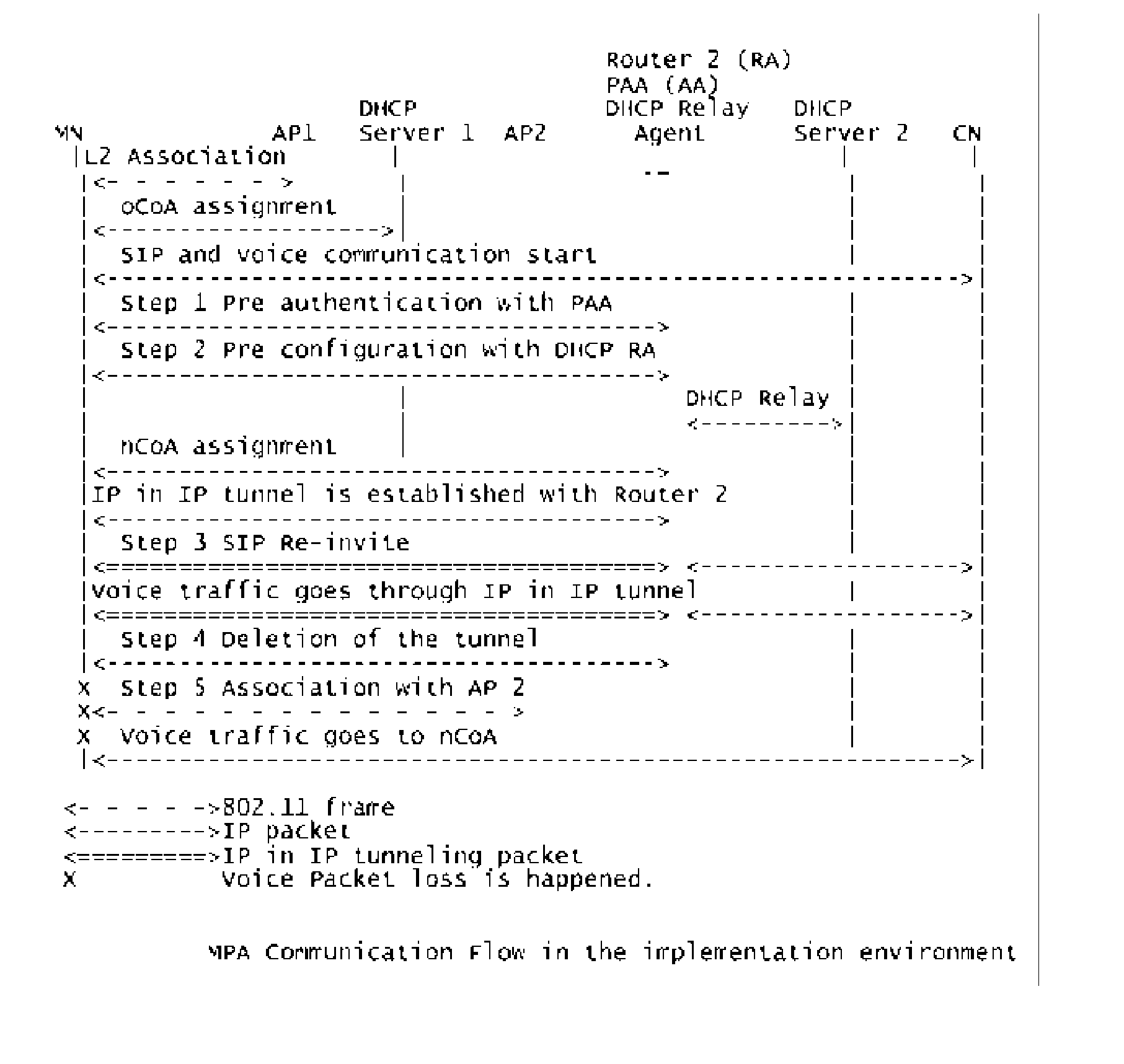

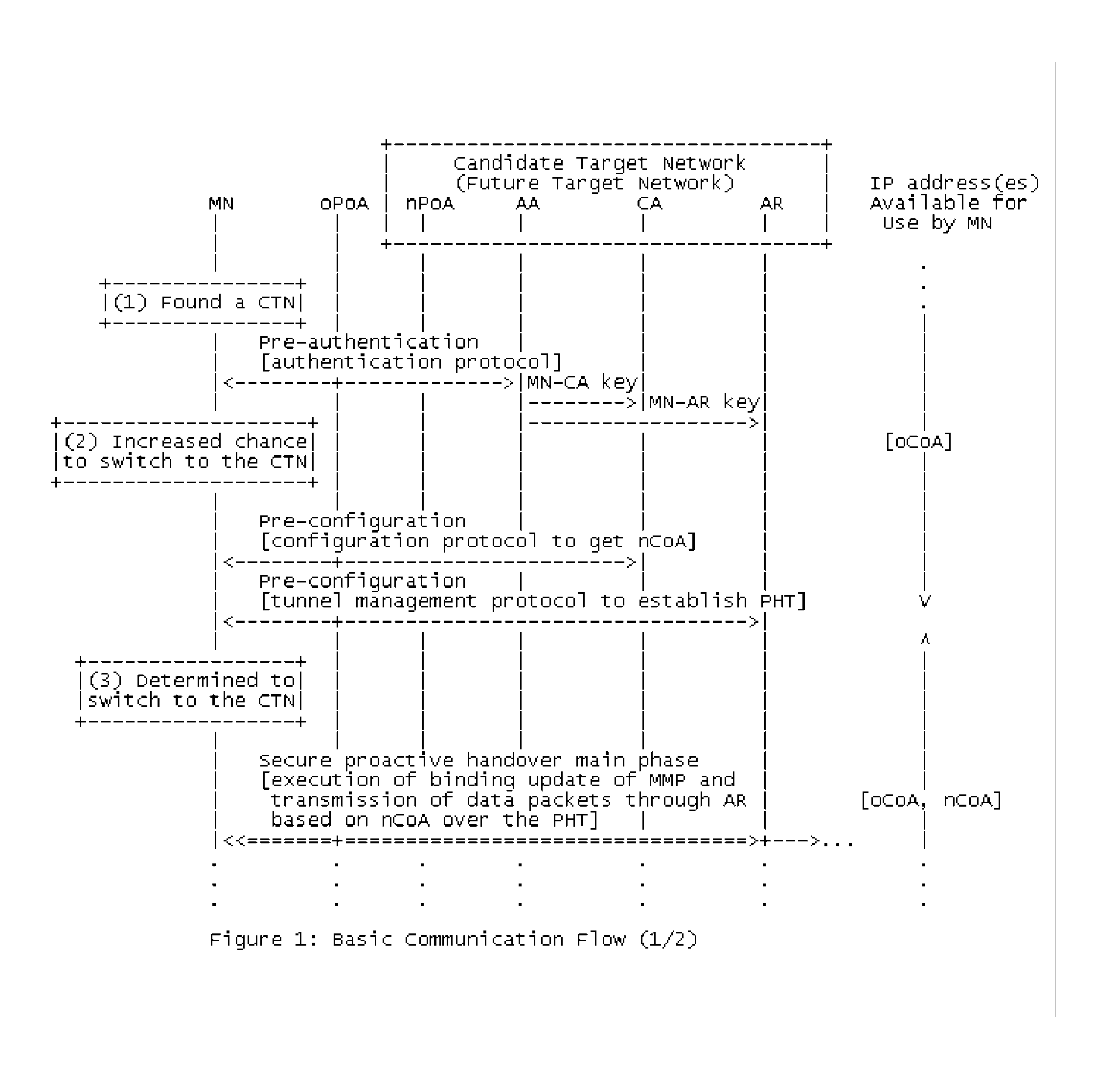

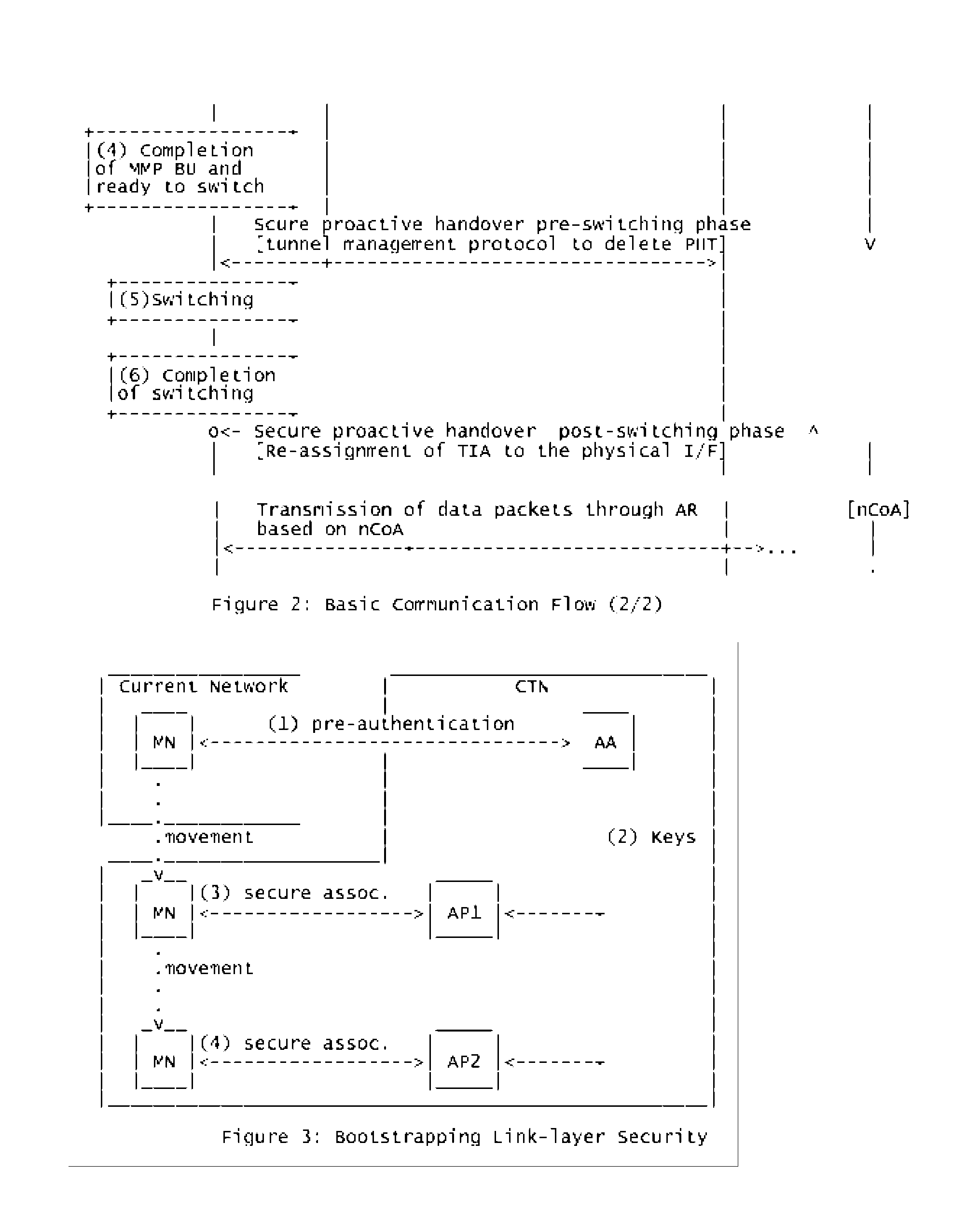

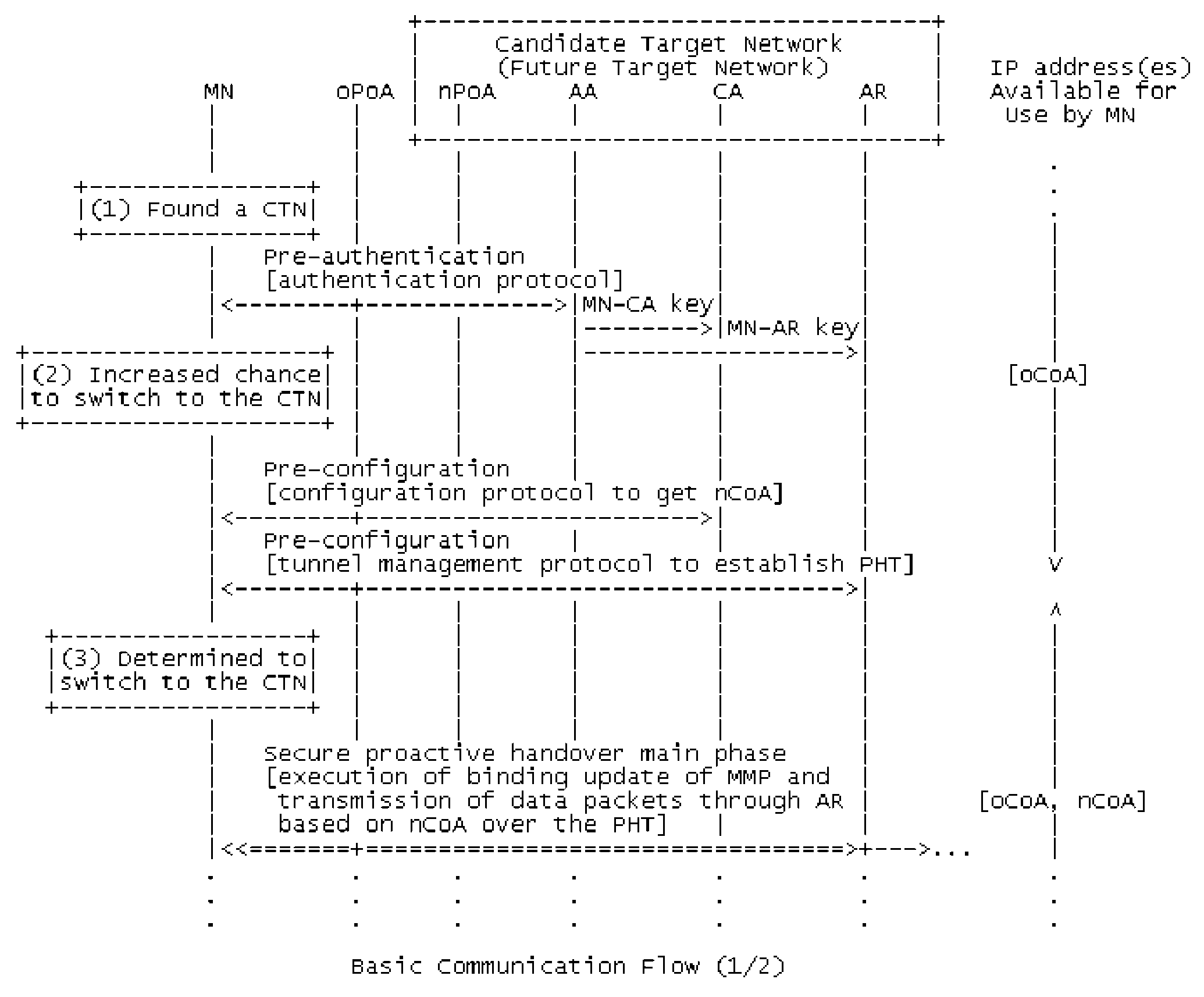

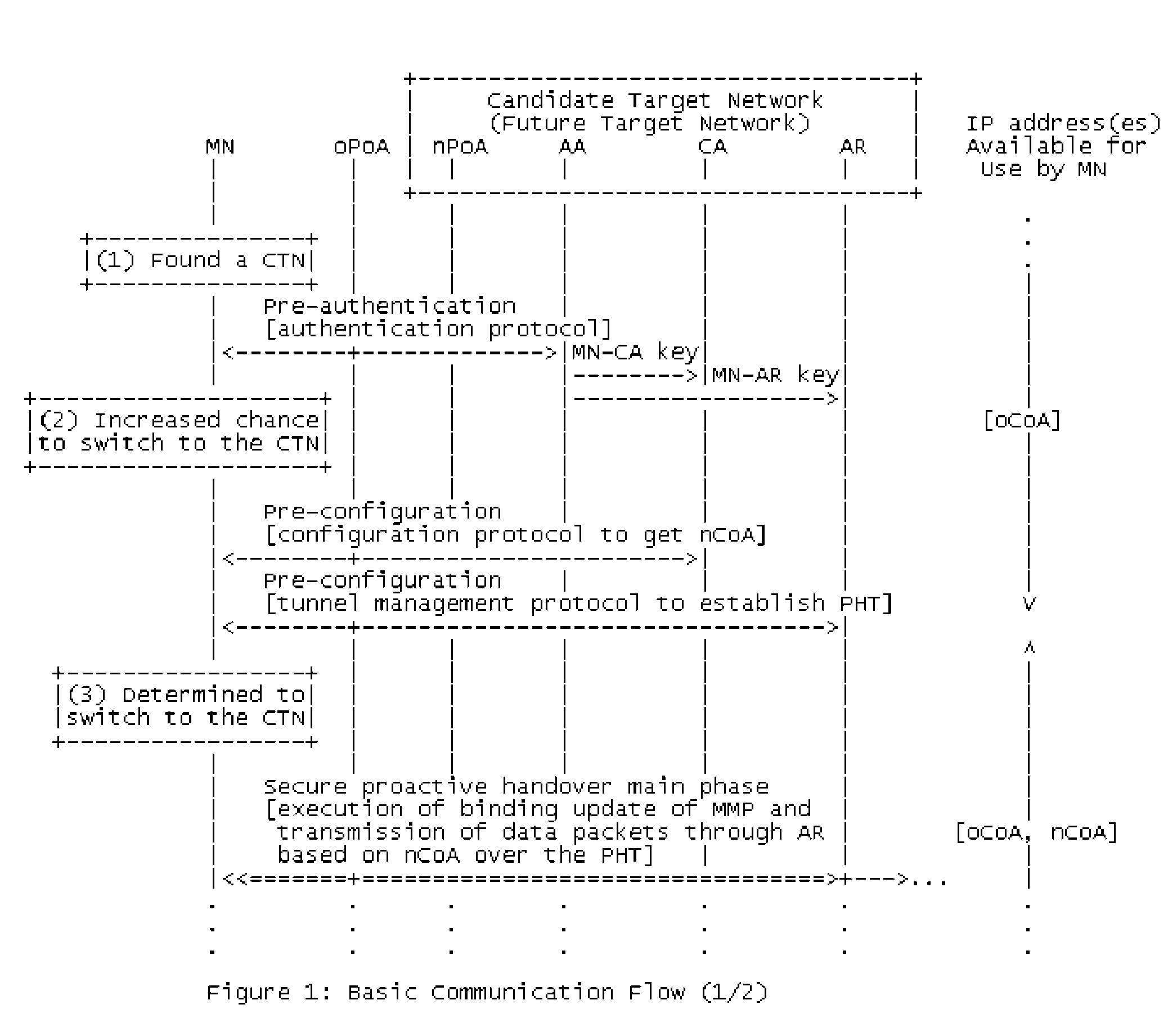

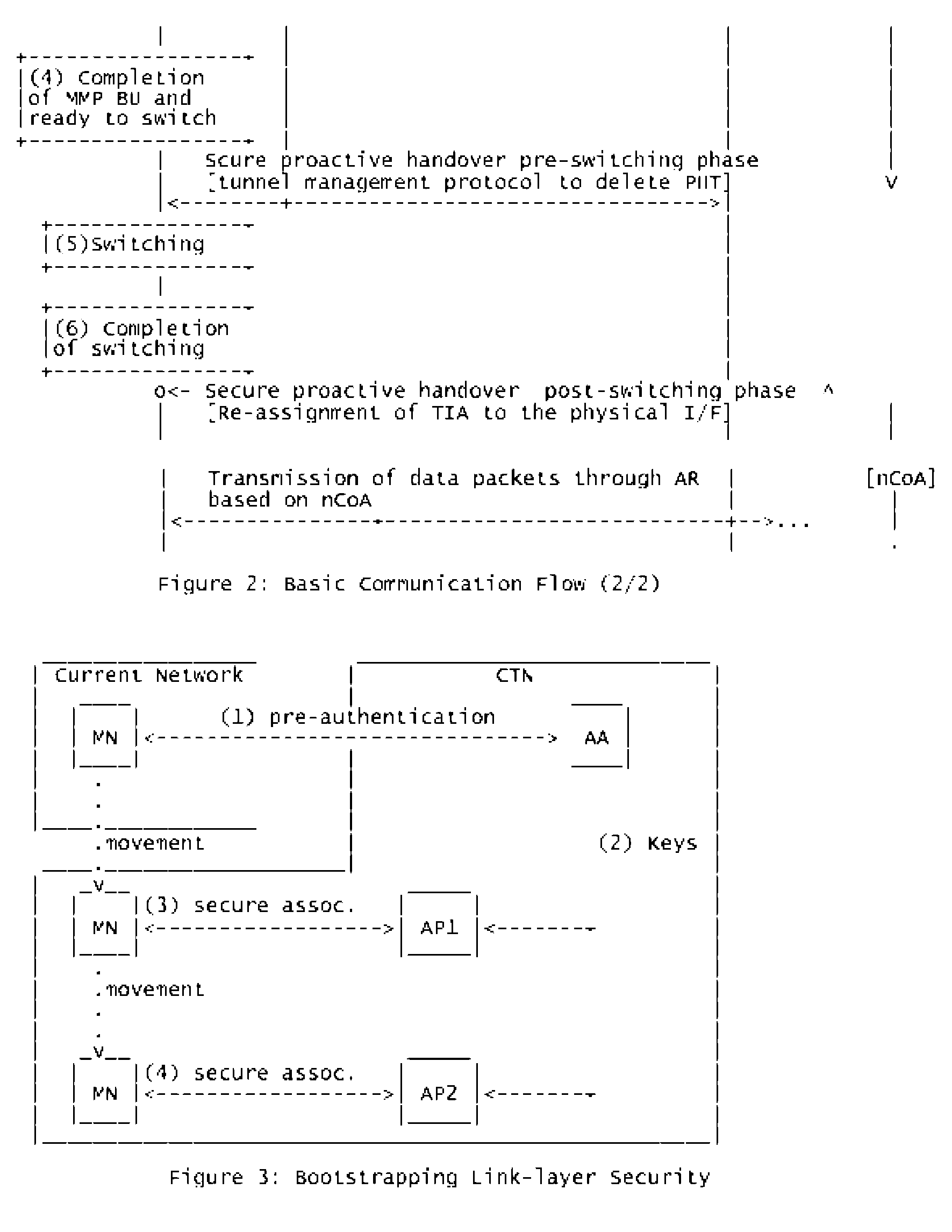

Framework of Media-Independent Pre-Authentication

ActiveUS20070204155A1Minimize and eliminate packet lossAvoid lostUser identity/authority verificationWireless network protocolsMediaFLOEngineering

This application describes, among other things, a framework of Media-independent Pre-Authentication (MPA), a new handover optimization mechanism that has a potential to address issues on existing mobility management protocols and mobility optimization mechanisms. MPA is a mobile-assisted, secure handover optimization scheme that works over any link-layer and with any mobility management protocol. This application also shows, among other things, an initial implementation of MPA in our testbed and some performance results to show how existing protocols could be leveraged to realize the functionalities of MPA.

Owner:TELCORDIA TECHNOLOGIES INC

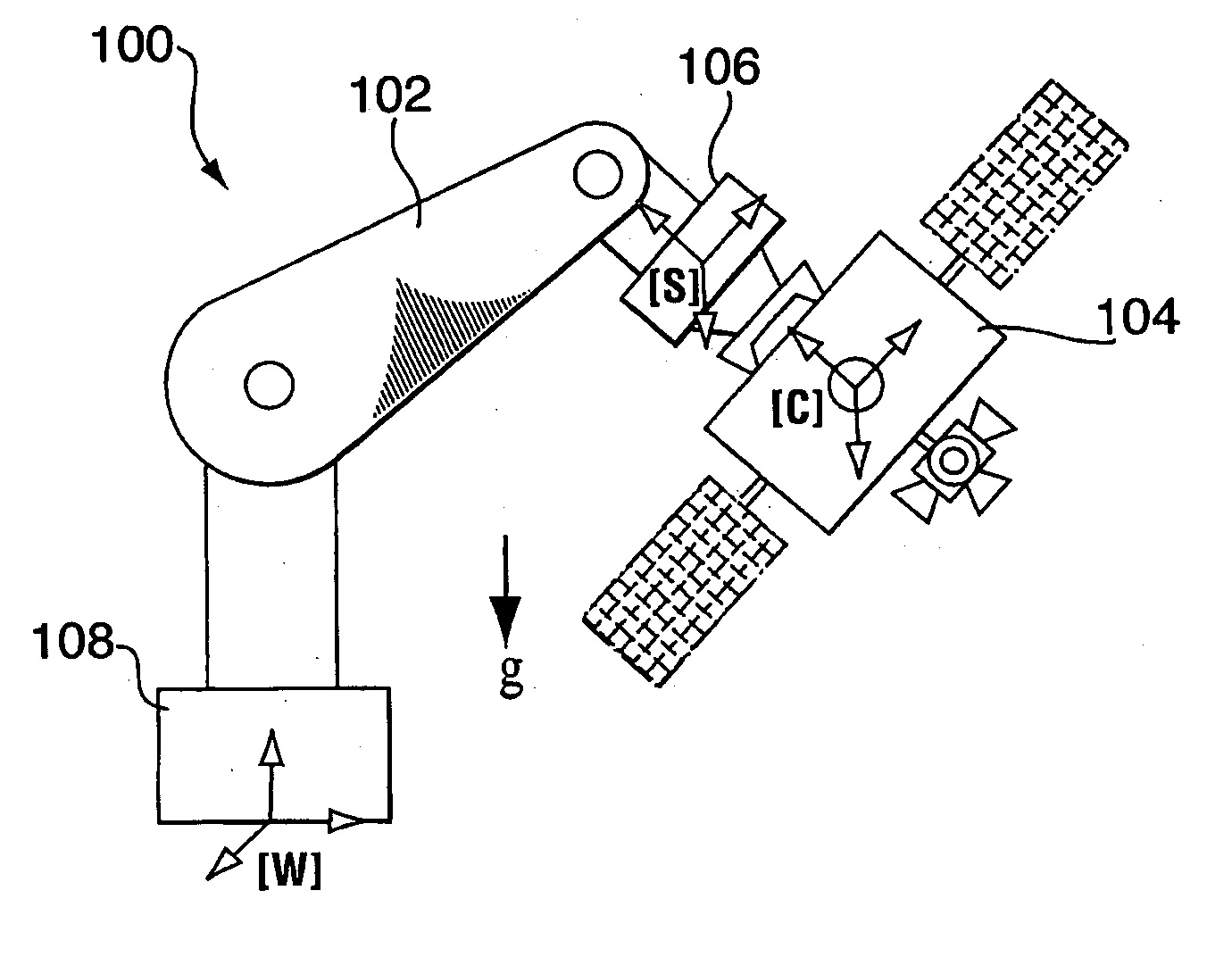

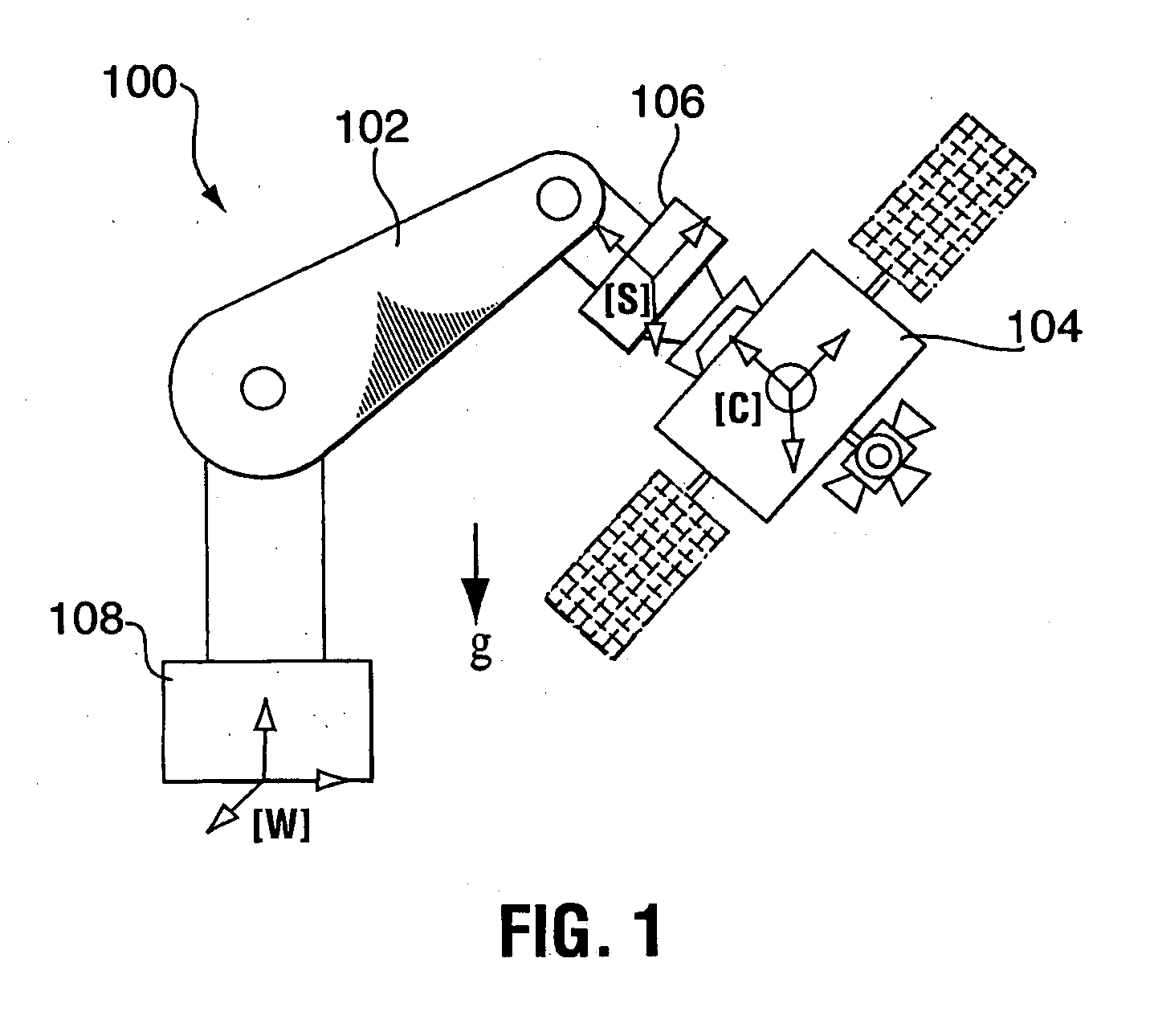

Zero-G emulating testbed for spacecraft control system

InactiveUS20050230557A1Reduces system uncertaintyReduce frictionCosmonautic condition simulationsCosmonautic ground equipmentsControl systemSpace vehicle control

The present invention provides an emulation system having a control system that allows the testing of a satellite control system with all of its hardware in place, i.e. fully integrated. The emulation methodology is applicable to the case of either a rigid spacecraft or a flexible spacecraft, provided that the spacecraft's sensors and actuators are stowed to the rigid part of spacecraft in the case of a flexible spacecraft. Practically, the latter condition is not restrictive, as the actuators and sensors are usually placed rigidly in the satellite bus, while the satellite solar panels constitute the flexible elements. The control system is used to tune the mass properties and dynamic behaviour of a rigid ground-spacecraft in a 1-G environment to those of a flight-spacecraft in 0-G. A six-axis force / moment sensor is placed at an interface of the ground-spacecraft and a manipulator. Signals received from the force / moment sensor, and in some cases signals relating to the position and velocity of manipulator joints, are received into the control system.

Owner:CANADIAN SPACE AGENCY

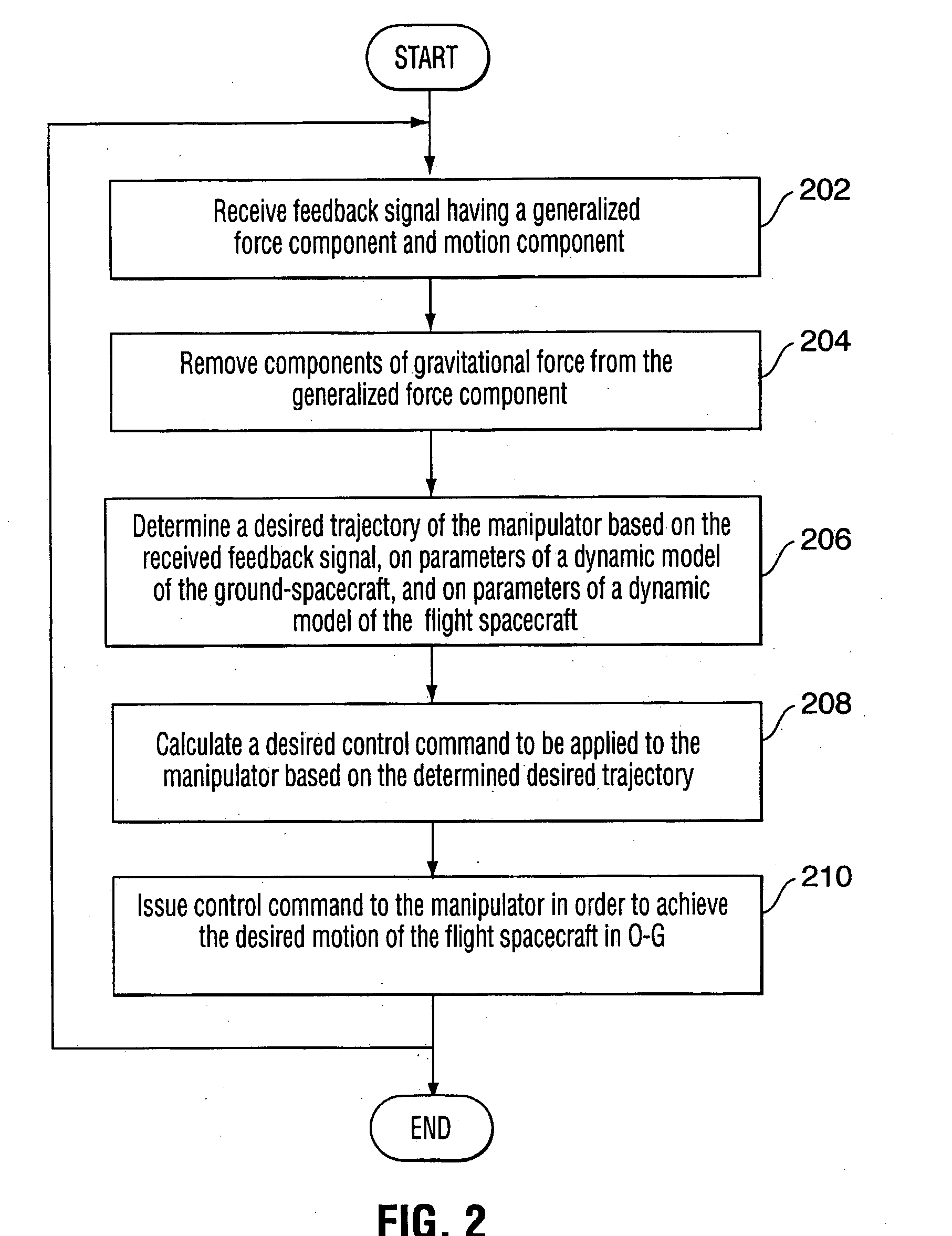

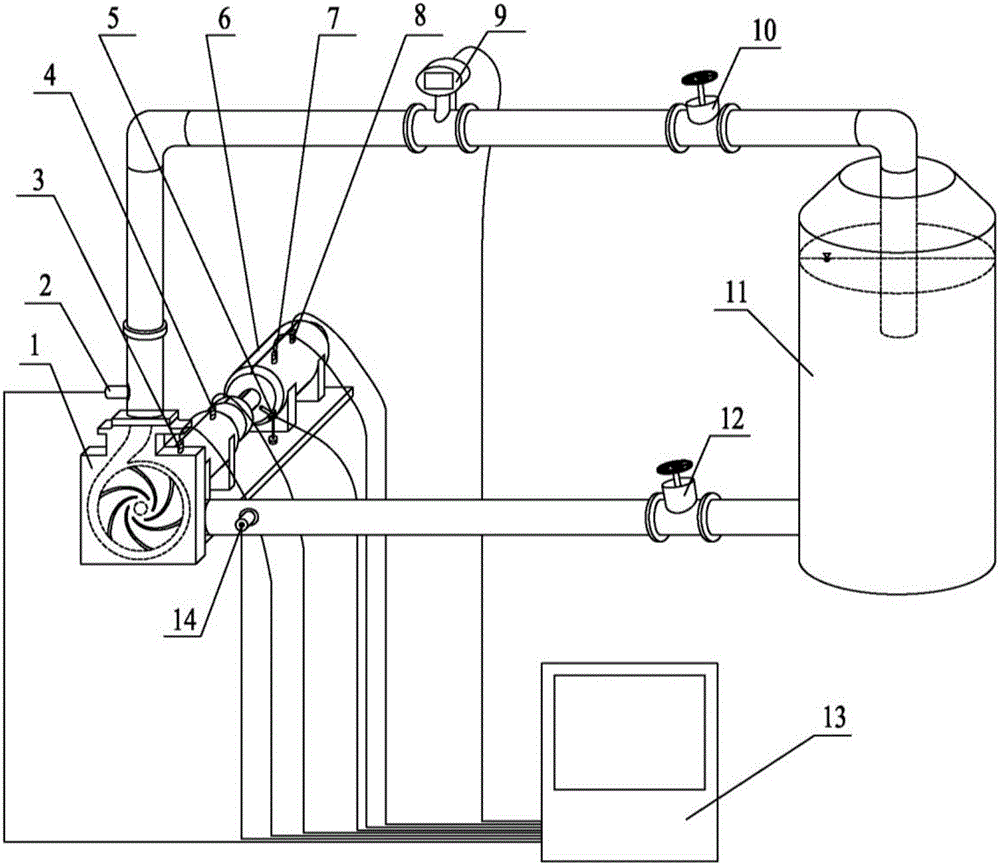

Intelligent water pump set monitoring and fault early warning method based on internet of things

ActiveCN106015028AGuaranteed uptimeAchieve early warningPump controlNon-positive displacement fluid enginesAxial-flow pumpFrequency spectrum

The invention belongs to the technical field of fluid mechanical and intelligent diagnosis, and particularly discloses an intelligent water pump set monitoring and fault early warning method based on internet of things. According to the technical scheme, a water pump set testbed is built; a touch screen serves as site monitoring equipment, a PC machine serves as a monitoring platform, a data collection module is used for collecting signals of all sensors, and the touch screen and the PC machine read the data of the data collection module in real time and store and backup the data; The water pump set internet-of-things monitoring system is designed through an HMI, and remote intelligent monitoring of water pump sets on the basis of internet of things is achieved; and monitoring signals of the water pump sets are subjected to data analysis in real time, operational diagnosis and fault early warning. The internet of things technology, the spectral analysis technology and the fault diagnosis technology are effectively combined, early warning of faults of various water pump sets like centrifugal pumps, mixed-flow pumps, axial flow pumps and submersible electric pumps is achieved, and the water pump sets can operate safely and reliably.

Owner:JIANGSU UNIV

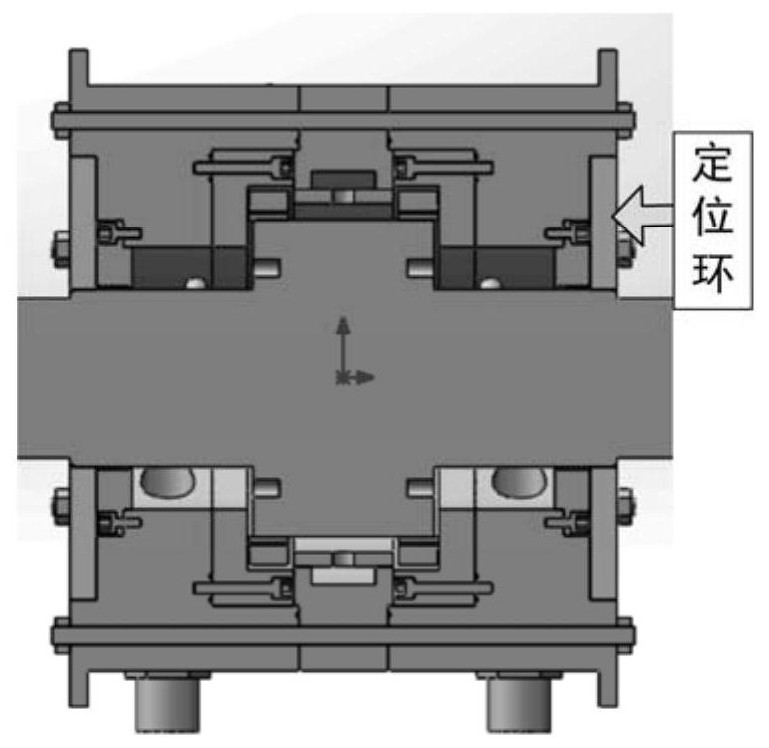

Buffer testbed of space docking mechanism

The invention discloses a buffer test bench for a space docking mechanism, which comprises an active end and a passive end arranged opposite to each other, connected with respective translational braking mechanisms through a synchronous braking link; the active end is equipped with a tracking aircraft simulation piece and Its active docking mechanism; the target aircraft simulation part and its passive docking mechanism are installed on the passive end; the gravity balance device of the docking ring is also installed on the active end. Except for the above differences, the other structures of the active end and the passive end are exactly the same. The mass, inertia, length, and position of the center of mass of the simulated aircraft are the same as those of the real aircraft. The present invention can set the docking pose and initial velocity of the two aircrafts according to the test, because the motion process of the object under the condition of weightlessness is simulated by adopting the air flotation and low-friction technology, the simulation parts of the two aircrafts can be set under the force of inertia. Attitude and speed are docked to achieve the beneficial effect of the so-called "1:1 full physical simulation".

Owner:SHANGHAI AEROSPACE SYST ENG INST

Framework of media-independent pre-authentication

ActiveUS7813319B2Avoid lostEliminate packet lossUser identity/authority verificationWireless network protocolsPerformance resultsTestbed

This application describes, among other things, a framework of Media-independent Pre-Authentication (MPA), a new handover optimization mechanism that has a potential to address issues on existing mobility management protocols and mobility optimization mechanisms. MPA is a mobile-assisted, secure handover optimization scheme that works over any link-layer and with any mobility management protocol. This application also shows, among other things, an initial implementation of MPA in our testbed and some performance results to show how existing protocols could be leveraged to realize the functionalities of MPA.

Owner:TELCORDIA TECHNOLOGIES INC

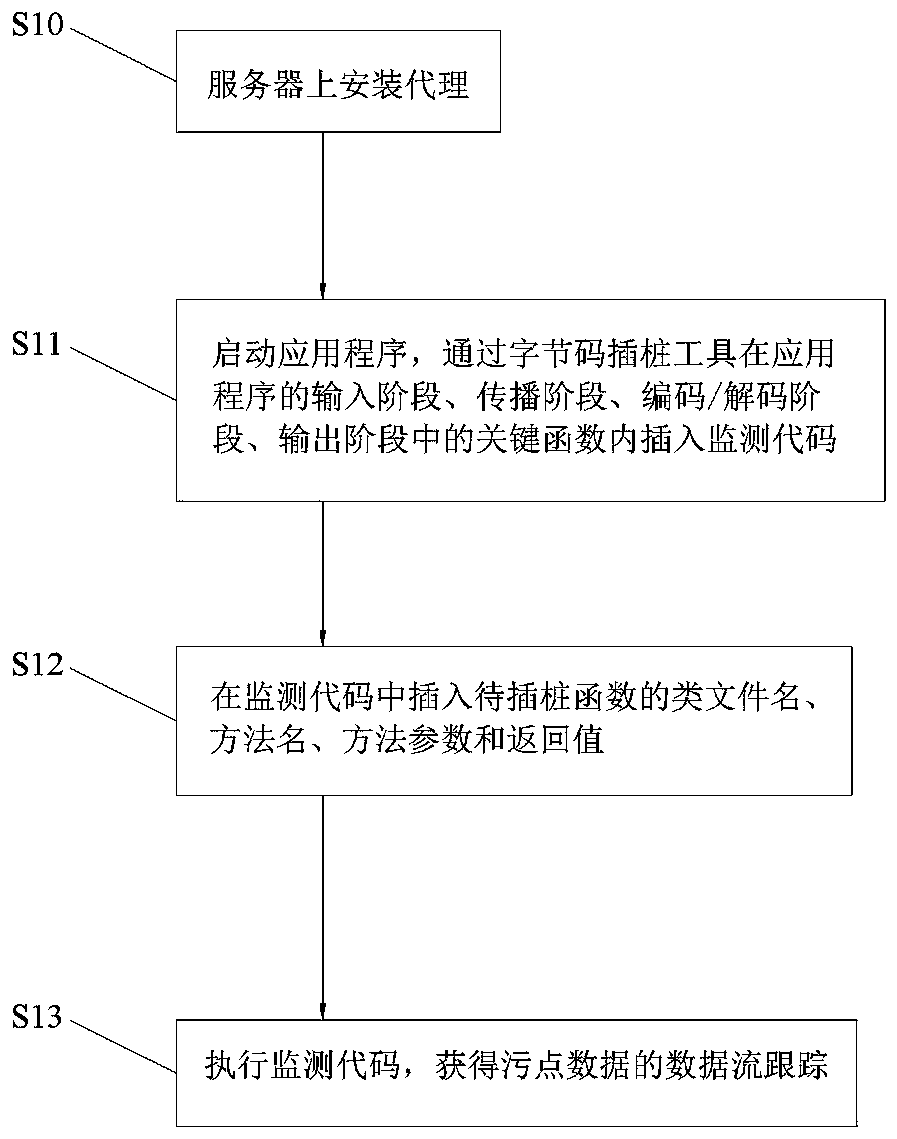

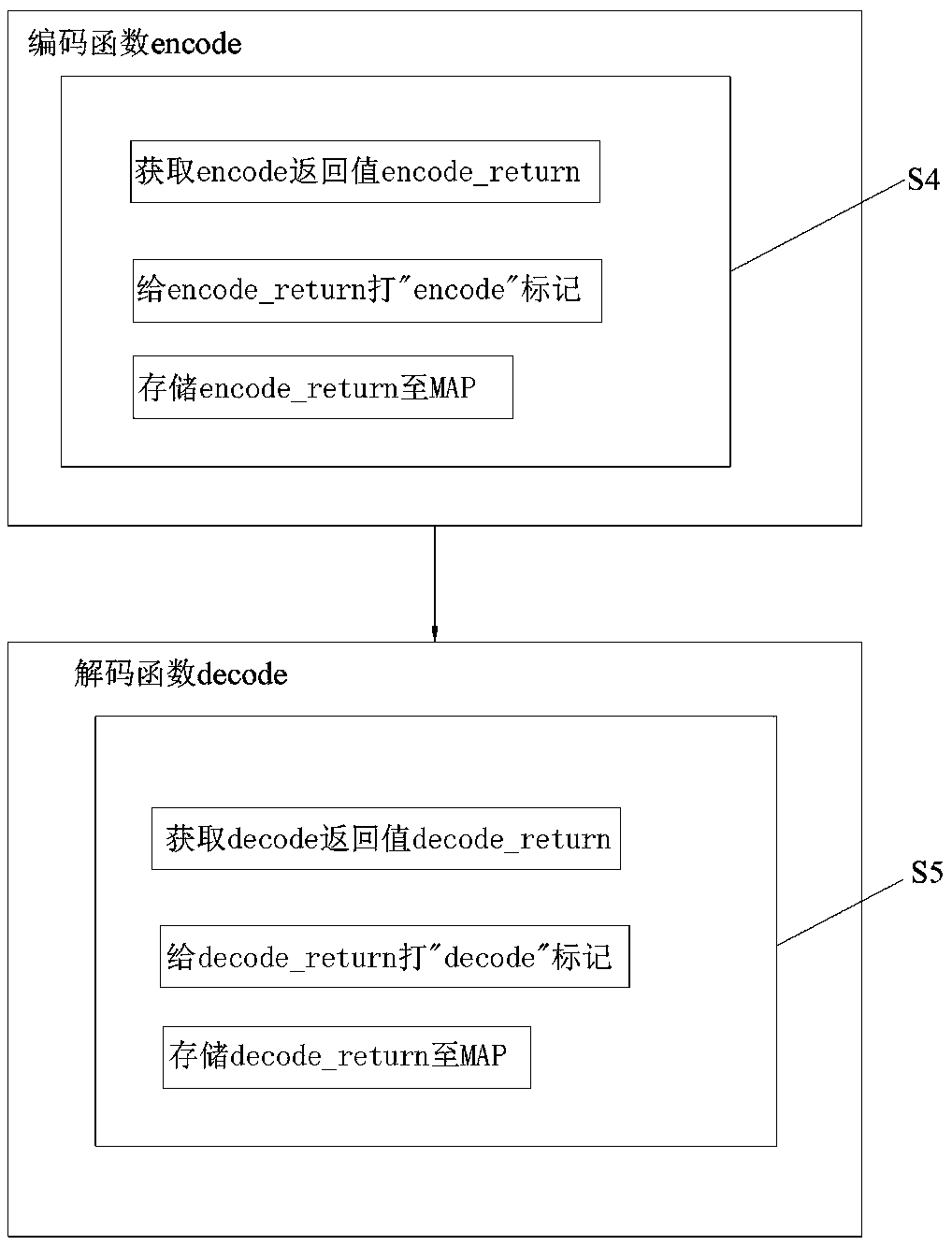

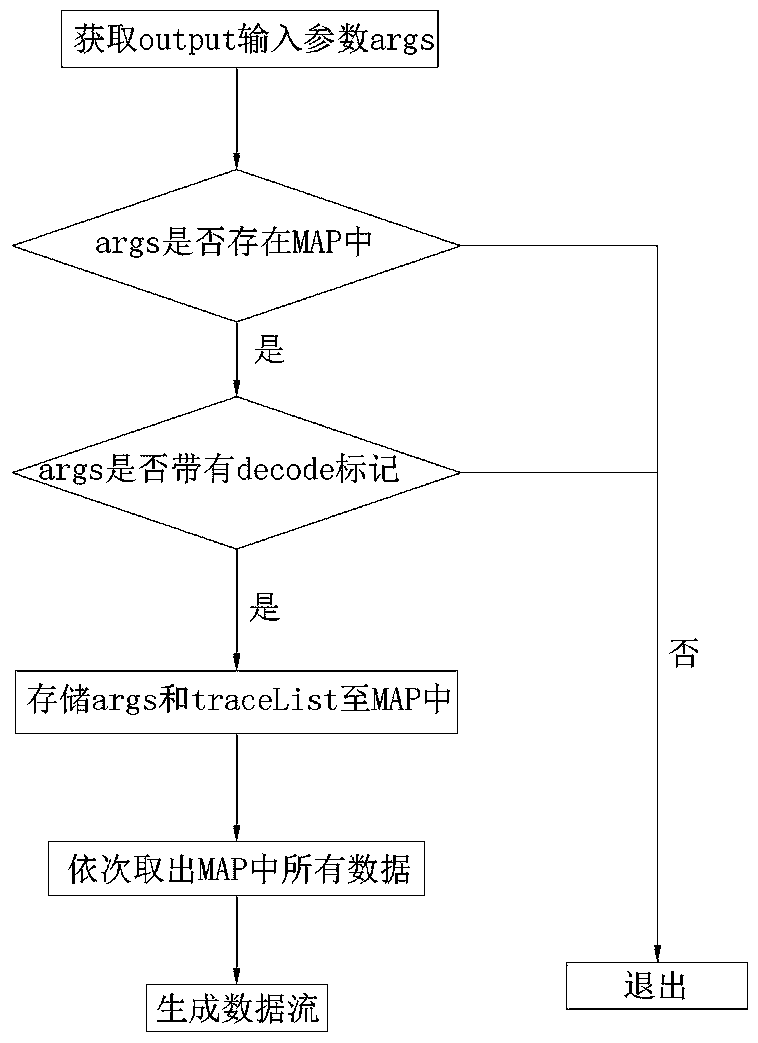

Web application test data flow tracking method and system

ActiveCN111046396APrecise positioningFast iterationSoftware testing/debuggingPlatform integrity maintainanceResponse processInstrument function

The invention discloses a web application test data flow tracking method and system based on an IAST test platform. The data flow tracking method comprises the following steps: installing an agent program on a server where the tested application program is located, wherein the agent program is used for communicating with a virtual machine running the application program; after the application program is started, inserting monitoring codes into key functions in the input stage and the output stage of the application program through the agent program and the byte code instrumentation tool; and when the monitoring code is instrumented, introducing a class file name, a method name, a method parameter and a return value of a to-be-instrumented function into the monitoring code, obtaining a propagation path of stain data in the application program through the monitoring code, wherein the stain data is data input by a user in the testing process. by adopting the data flow tracking method, real-time tracking of taint data can be realized, and an execution method chain in a request-response process can be accurately obtained based on an actual request.

Owner:SECZONE TECH CO LTD

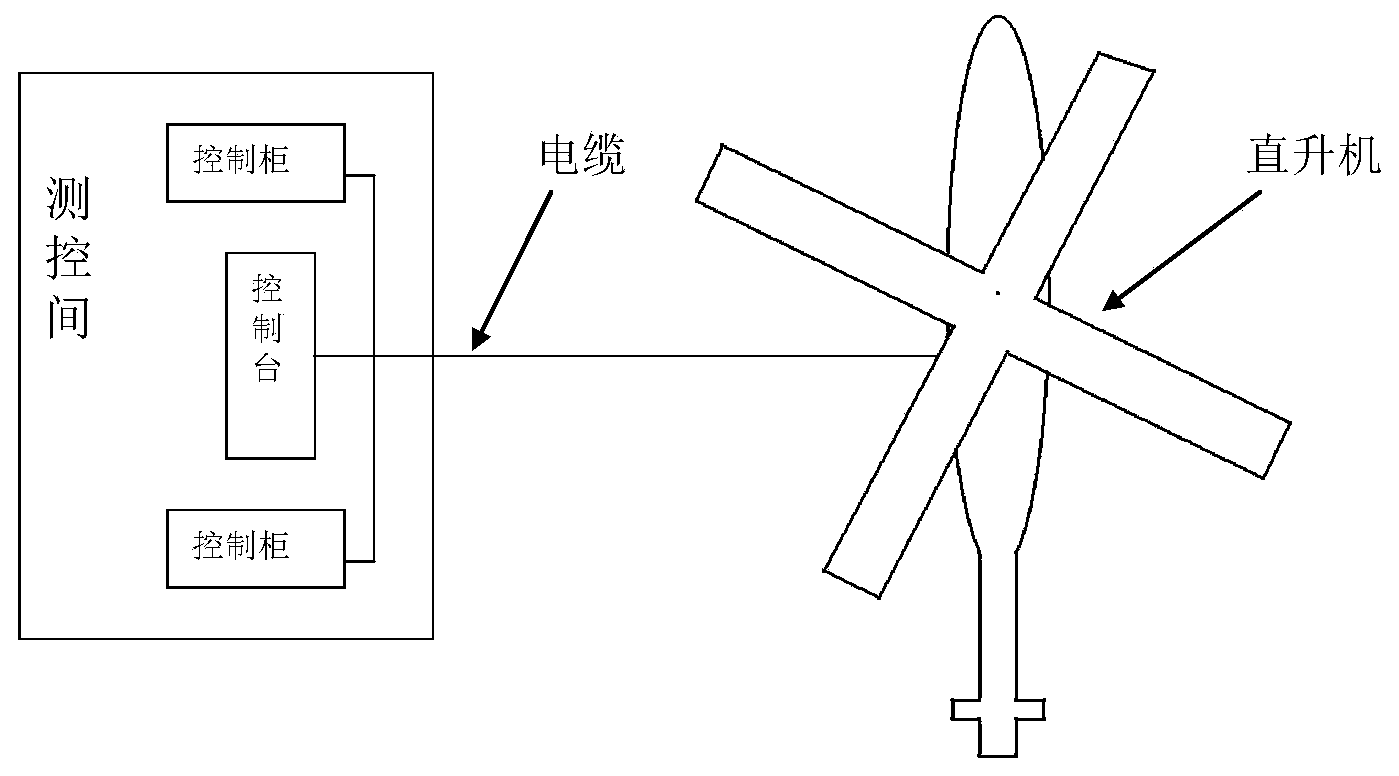

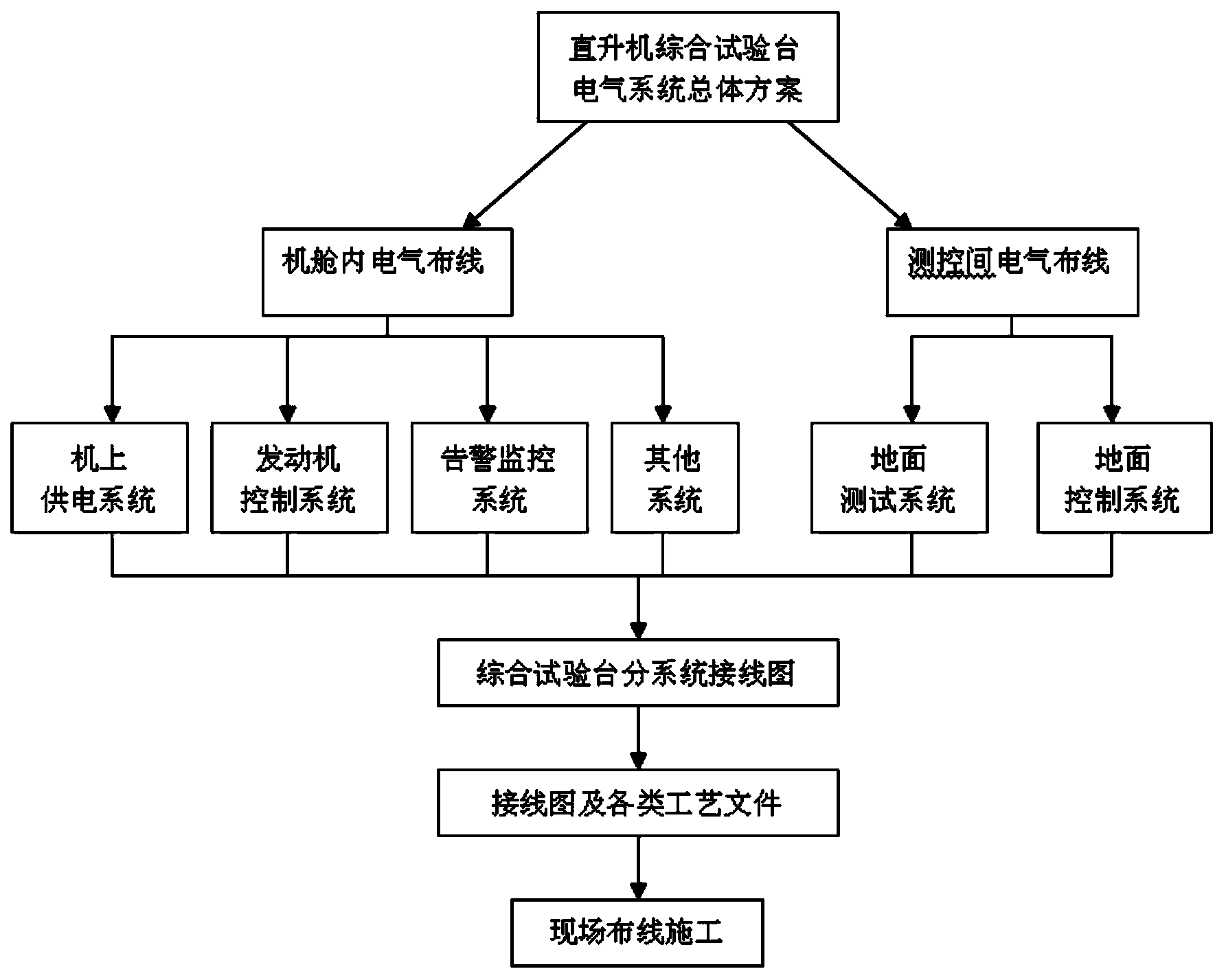

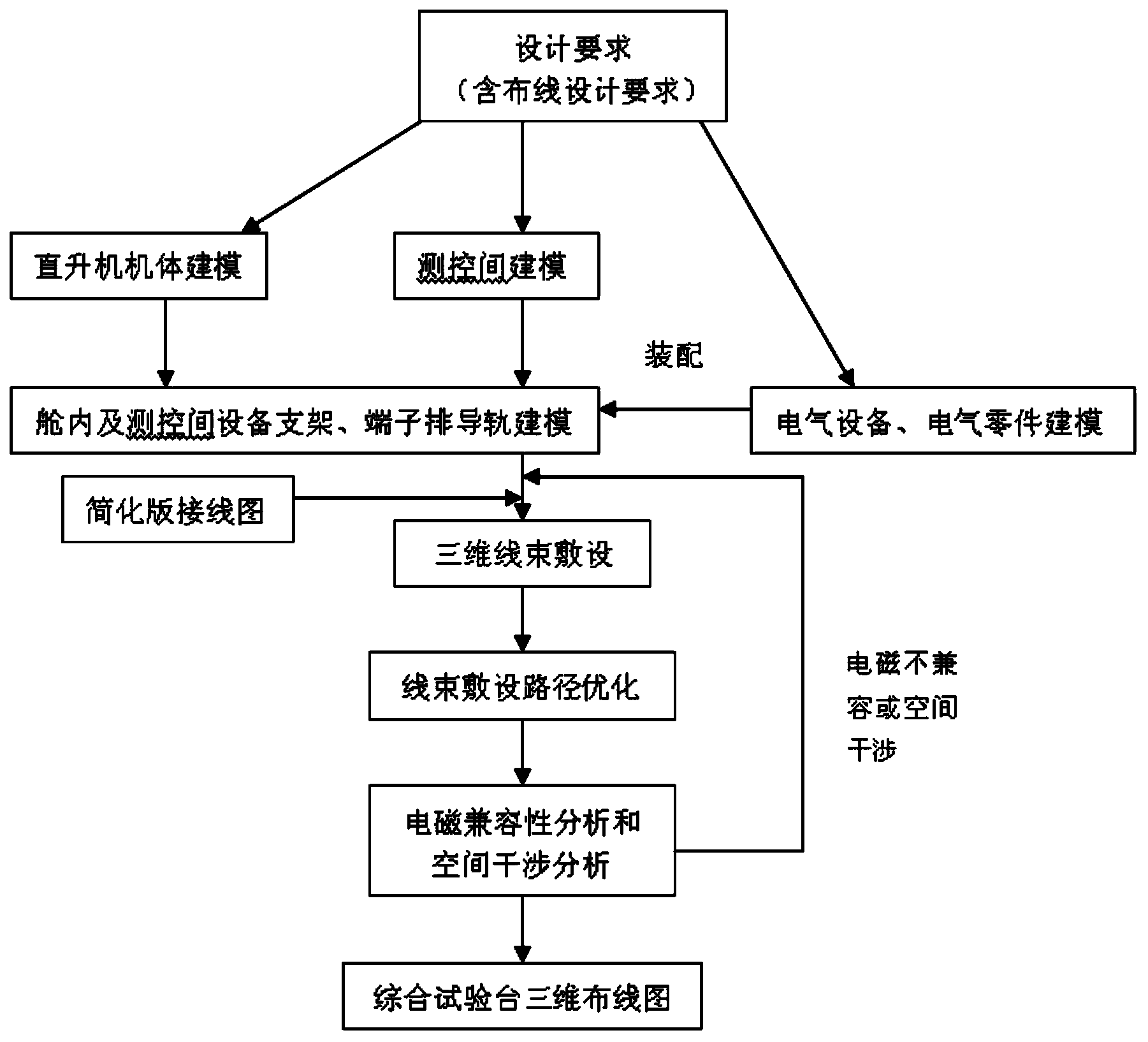

Three-dimensional wiring design method of helicopter comprehensive testbed

InactiveCN104239610ARealize wiring visualization assemblyMake up for the difficulty in expressing the wiring harness routingSpecial data processing applicationsWiring diagramTestbed

The invention provides a three-dimensional wiring design method of a helicopter comprehensive testbed and belongs to the field of helicopter comprehensive tests. The three-dimensional wiring design method is characterized by comprising the following steps of drawing a two-dimensional wiring diagram, defining electrical equipment numbers, electrical apparatus components, cable types and mutual wiring relations; modeling a mechanical structure; modeling and assembling electric parts and assembling the electrical parts and the mechanical structure model obtained in the step 2 according to constraint conditions; connecting the electrical parts obtained in the step 3 by virtue of three-dimension wiring; performing electromagnetic compatibility and spatial interference inspection on the helicopter comprehensive testbed subjected to three-dimensional wiring, and regulating wiring paths according to the inspection result. According to the method, three-dimensional wiring is adopted to simulate assembly sizes of objects, so that visual assembly during wiring of the helicopter comprehensive testbed can be realized, and the defects that the wiring path cannot be expressed by two-dimensional diagram and interference analysis cannot be performed on parts and wires can be overcome.

Owner:CHINA HELICOPTER RES & DEV INST

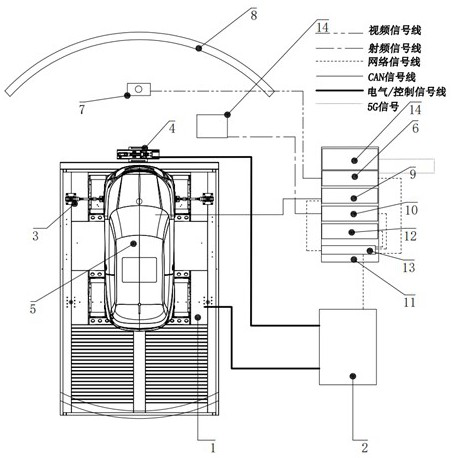

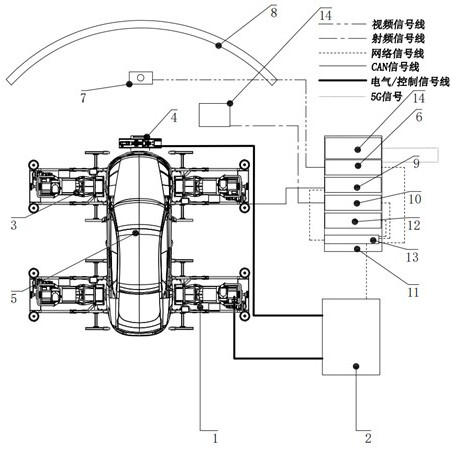

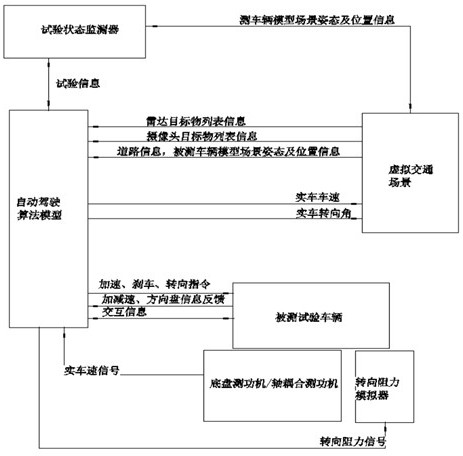

Development and test system and method for whole vehicle in-the-loop automatic driving in laboratory

ActiveCN112987703AGroundbreakingRun accuratelyVehicle testingElectric testing/monitoringNetwork communicationDynamometer

The invention provides a development and test system and method for whole vehicle in-the-loop automatic driving in a laboratory. The system comprises a four-wheel-drive road simulation dynamometer, a dynamometer control system, a front wheel restraint system, a steering resistance simulation system, a vehicle, a virtual scene simulation system, a scene projector, an annular curtain automatic driving real-time controller, a radar signal simulation system, a test system control cabinet, an automatic driving algorithm development and test management system, a network communication switch, a radar simulation signal camera obscura, and a 5G Internet of Things information simulation system. Accurate road load simulation, including simulation of different loads of wheels under different road surfaces, is realized by using a real tested vehicle and utilizing a road load simulation system, and an automatic ADAS test result and a control algorithm based on a VIL environment are closest to a real application scene. The development of the VIL automatic driving platform and the application of the test platform can greatly shorten the time and cost of the ADAS vehicle road test.

Owner:BBK TEST SYST CO LTD

Methods and arrangements for unified program analysis

InactiveUS20090019430A1Low costMaximize returnError detection/correctionSpecific program execution arrangementsMulti languageSoftware system

A unified program analysis framework that facilitates the analysis of complex multi-language software systems, analysis reuse, and analysis comparison, by employing techniques such as program translation and automatic results mapping, is presented. The feasibility and effectiveness of such a framework are demonstrated using a sample application of the framework. The comparison yields new insights into the effectiveness of the techniques employed in both analysis tools. These encouraging results yield the observation that such a unified program analysis framework will prove to be valuable both as a testbed for examining different language analysis techniques, and as a unified toolset for broad program analysis.

Owner:INT BUSINESS MASCH CORP

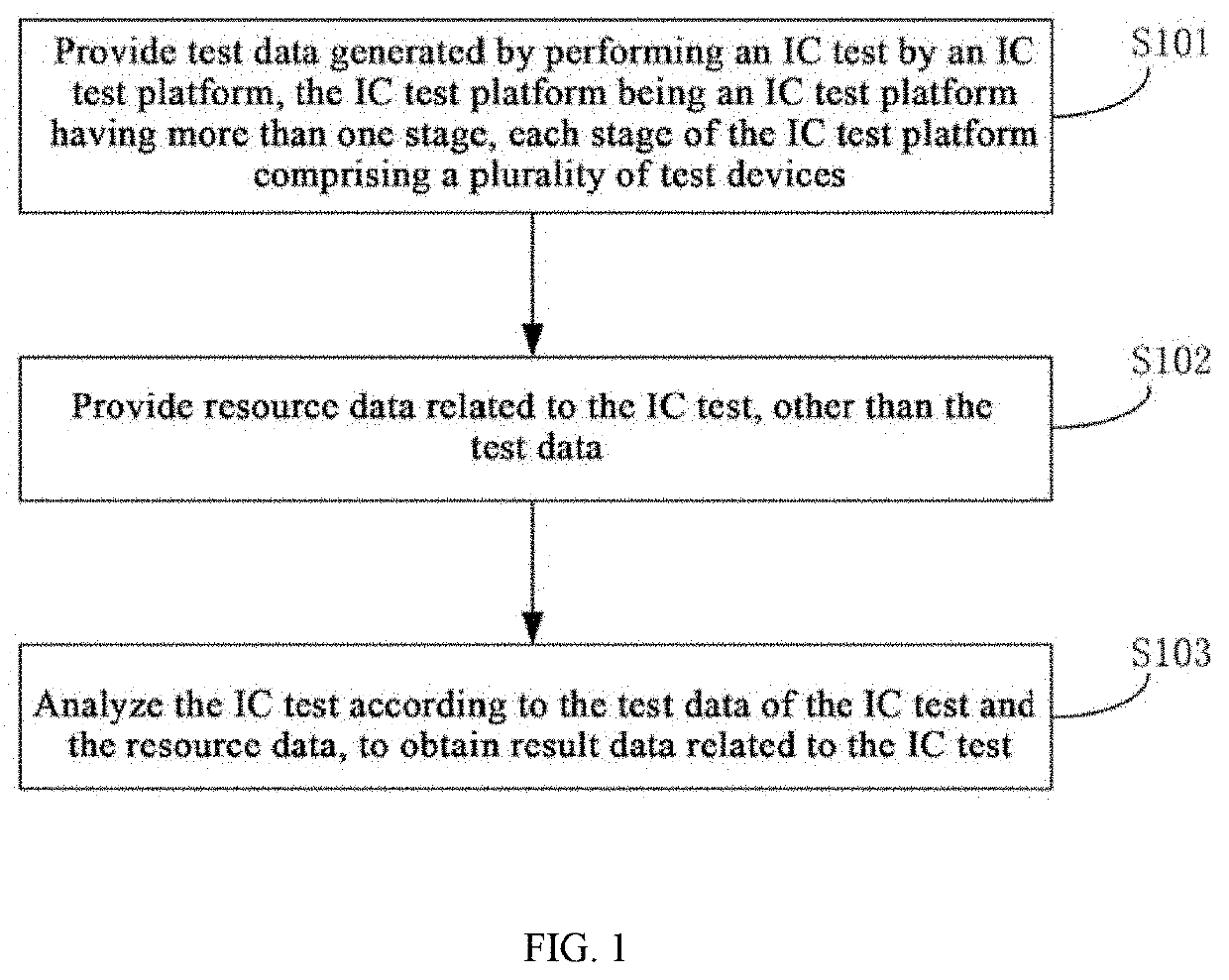

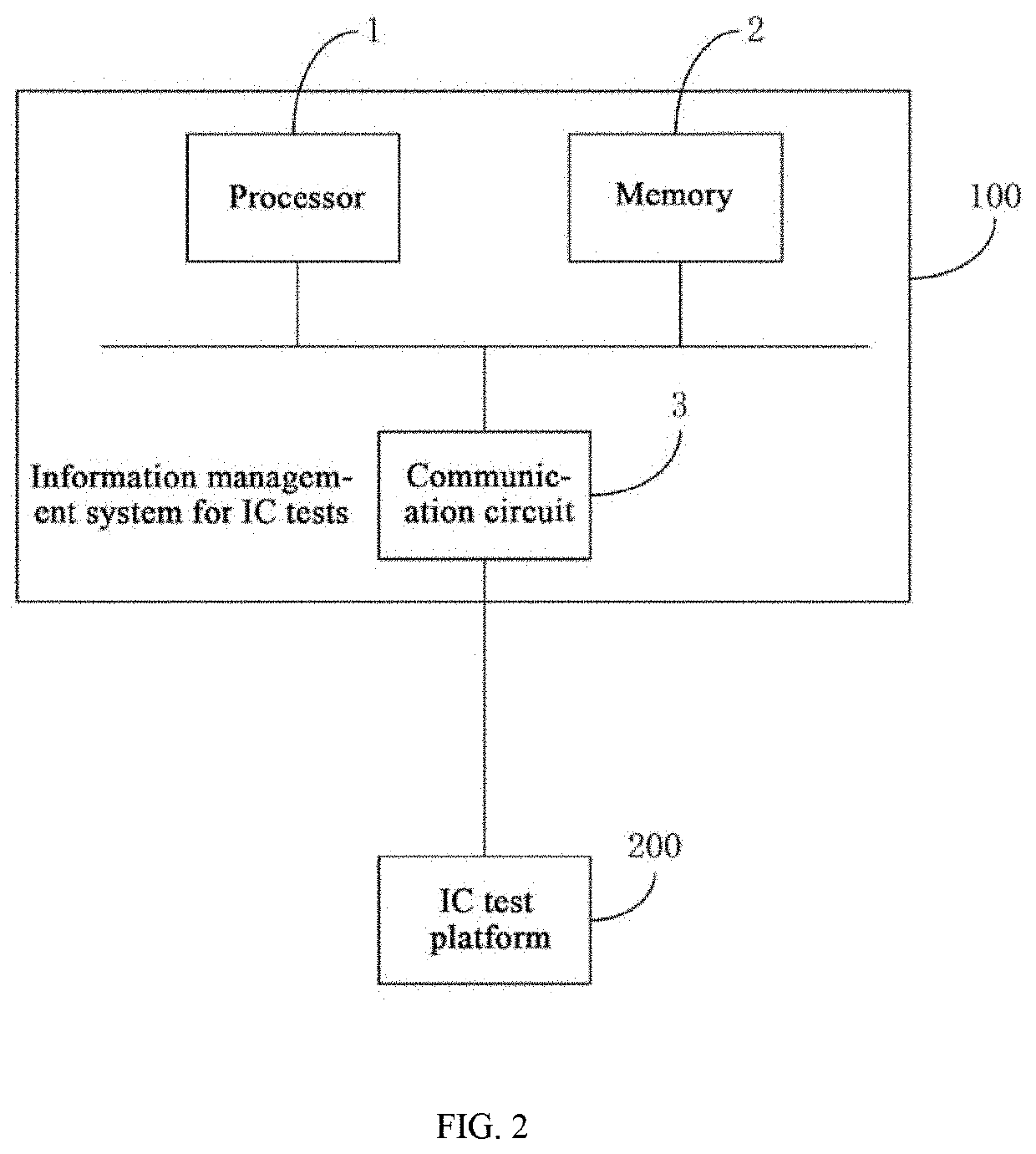

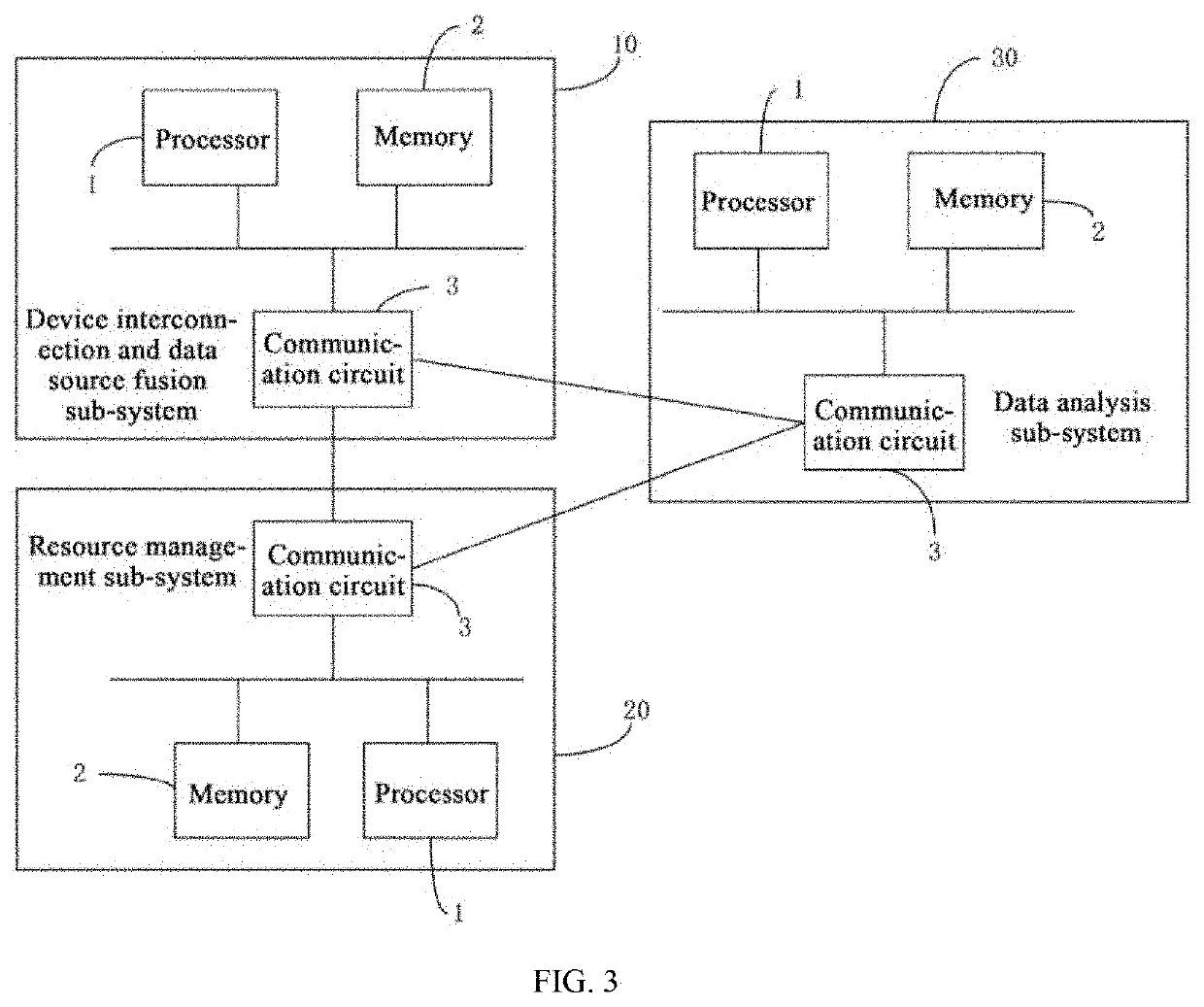

IC test information management system based on industrial internet

ActiveUS20200089820A1Utility valueDatabase management systemsElectrical testingThe InternetIndustrial Internet

The present invention discloses an information management method and system for IC tests, and a storage medium. The method comprises steps of: providing test data generated by performing an IC test by an IC test platform, the IC test platform being an IC test platform having more than one stage, each stage of the IC test platform comprising a plurality of test devices: providing resource data related to the IC test, other than the test data; and analyzing the IC test according to the test data of the IC test and the resource data, to obtain result data related to the IC test. In this way, the present invention can provide technical support for utilizing the value of test data generated in IC tests.

Owner:SINO IC TECH

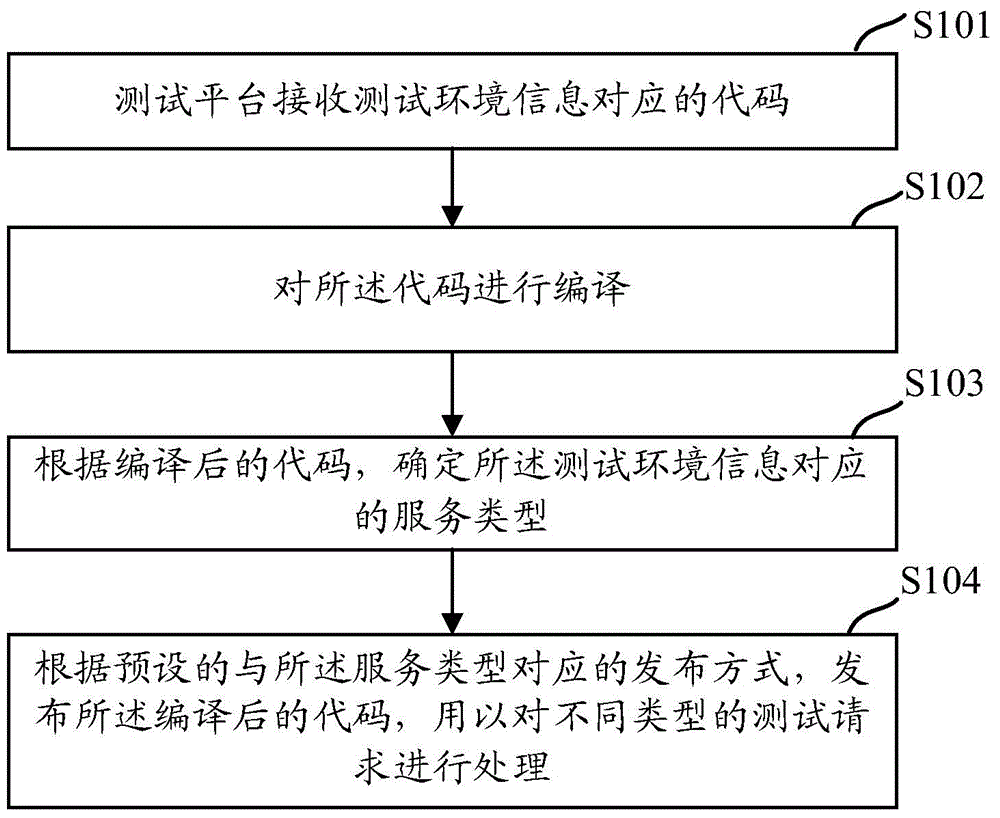

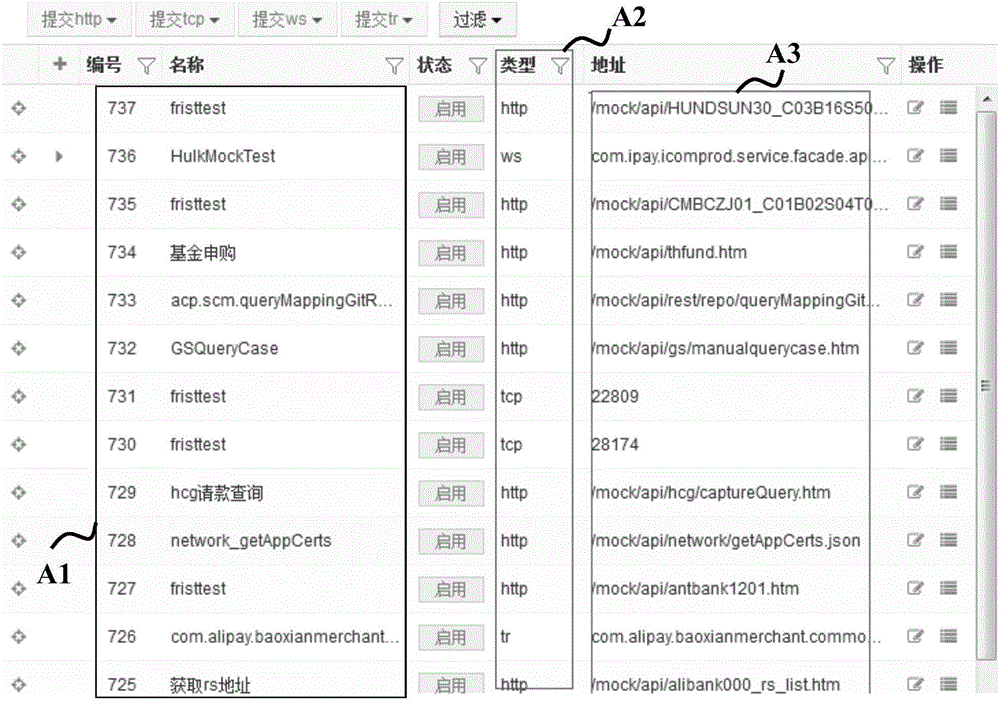

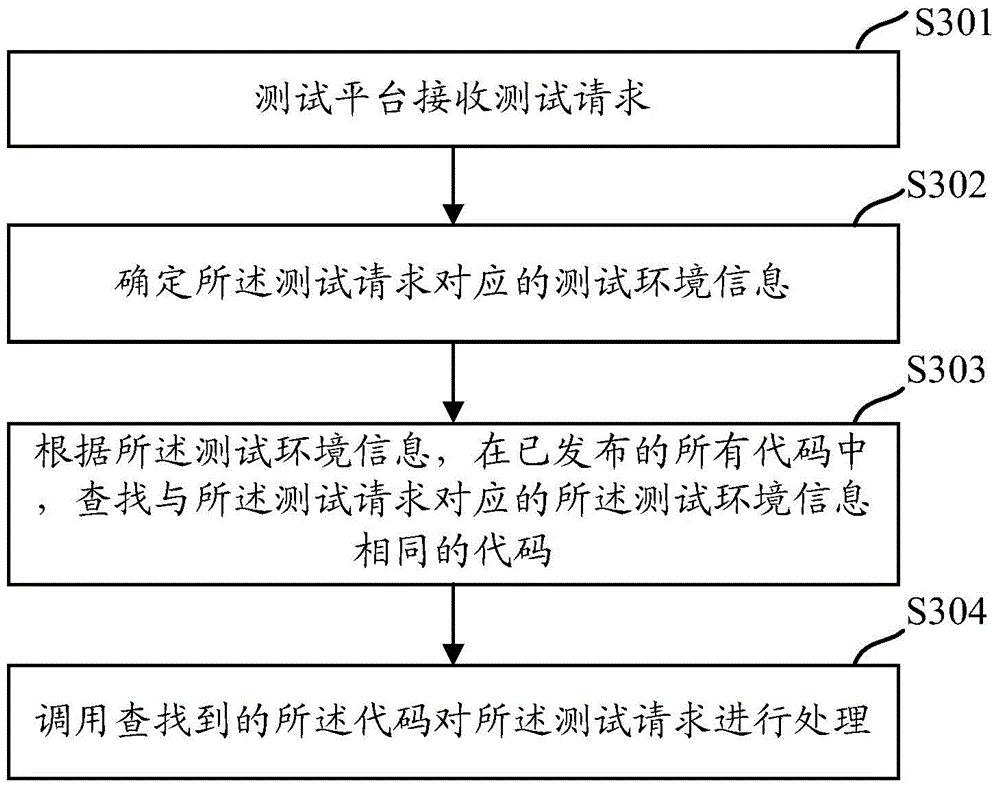

Programmable test service-based creation method and apparatus

ActiveCN106294113AChanging defects that cannot use the same test codeImproving Simulation Test EfficiencySoftware testing/debuggingSoftware engineeringTest requirements

The invention discloses a programmable test service-based creation method and apparatus. The method comprises the steps of receiving a code corresponding to test environment information by a test platform; compiling the code; determining a service type corresponding to the test environment information according to the compiled code; and releasing the compiled code according to a preset release mode corresponding to the service type, thereby processing different types of test requests. Through the method, differing from a test code and business code binding and coupling mode in the prior art, a developer can not only search for released and suitable codes to perform simulation testing but also perform testing on other business services with the same test scenes according to the test environment information corresponding to the released codes, so that the defect that different business services with the same running scenes cannot use the same test code in the prior art is overcome and the simulation testing efficiency under the condition of a large amount of development tests is effectively improved.

Owner:ADVANCED NEW TECH CO LTD

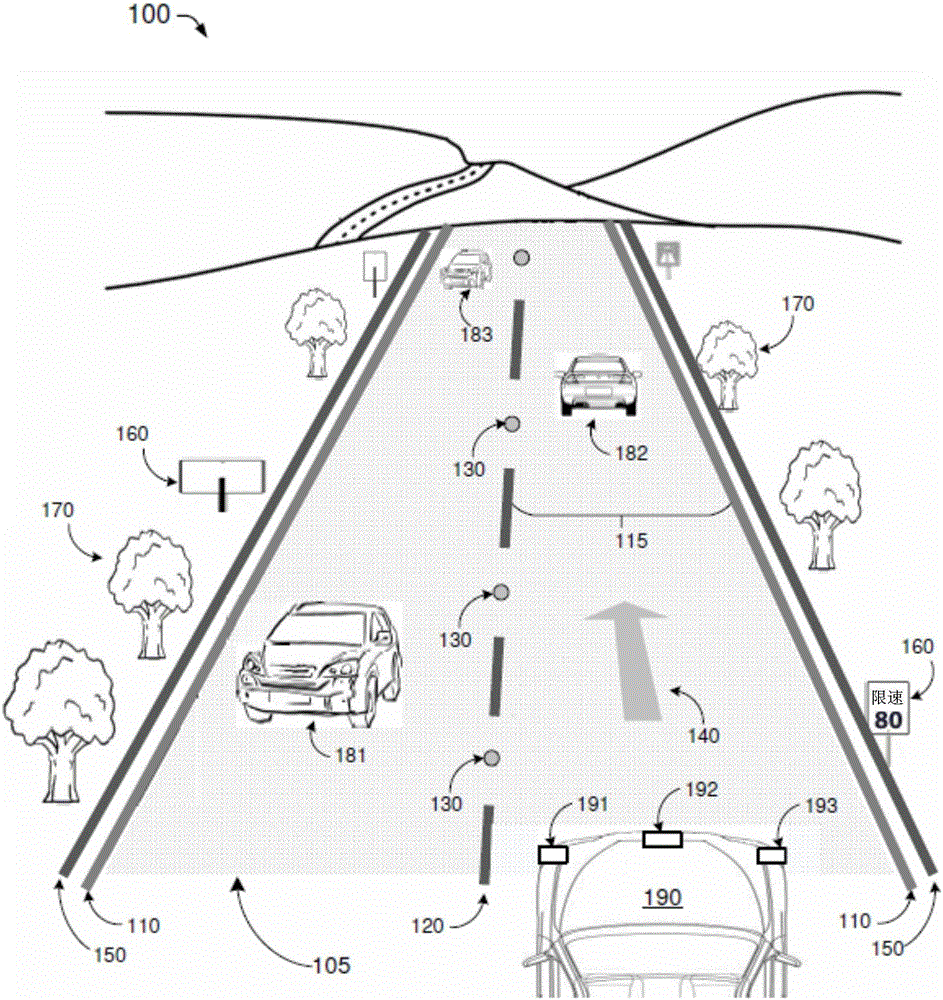

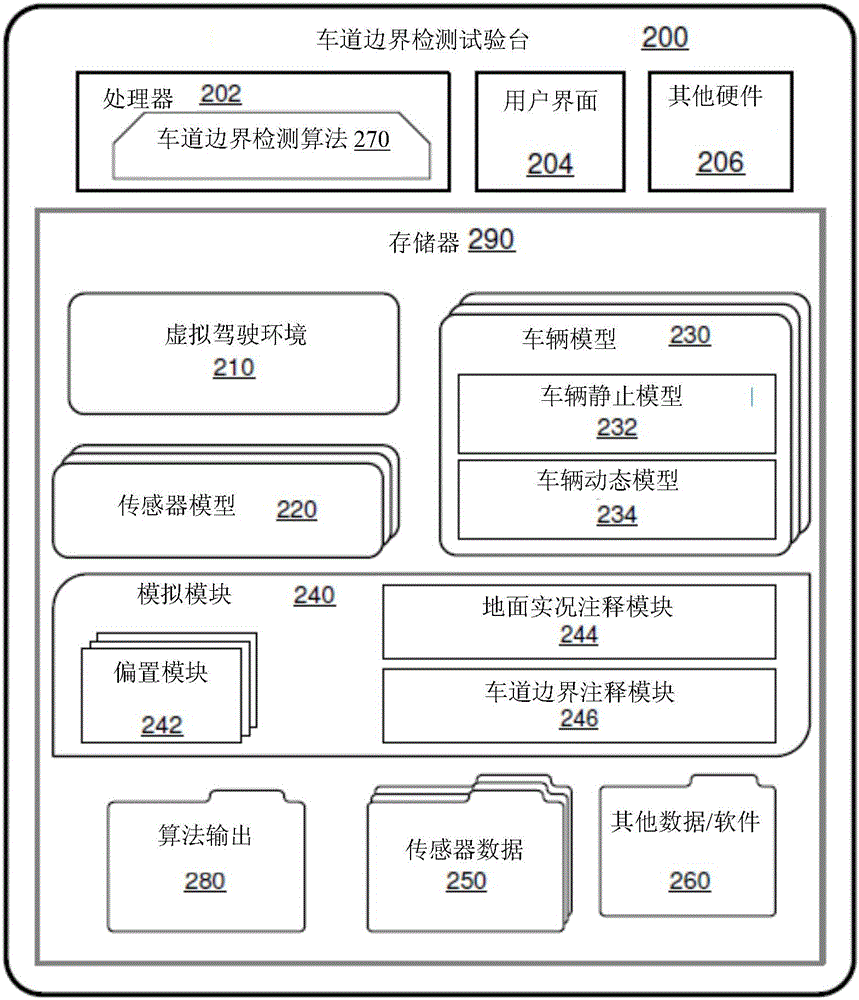

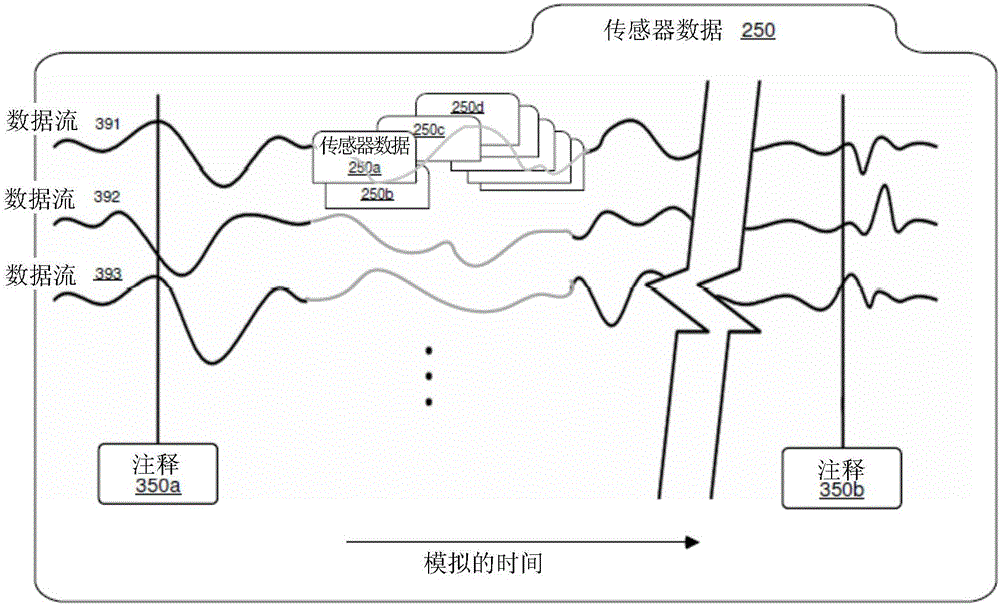

Testbed for lane boundary detection in virtual driving environment

Methods and apparatus pertaining to a testbed for lane boundary detection in a virtual driving environment are provided. A method may involve generating, by a processor, a virtual driving environment comprising one or more driving lanes, a virtual vehicle, and one or more virtual sensors mounted on the virtual vehicle configured to generate simulated data as the virtual vehicle traverses within the virtual environment. The method may also involve executing an algorithm to process the simulated data to detect the one or more driving lanes. The method may further involve recording an output of the algorithm. The method may additionally involve annotating the simulated data with the output of the algorithm.

Owner:FORD GLOBAL TECH LLC

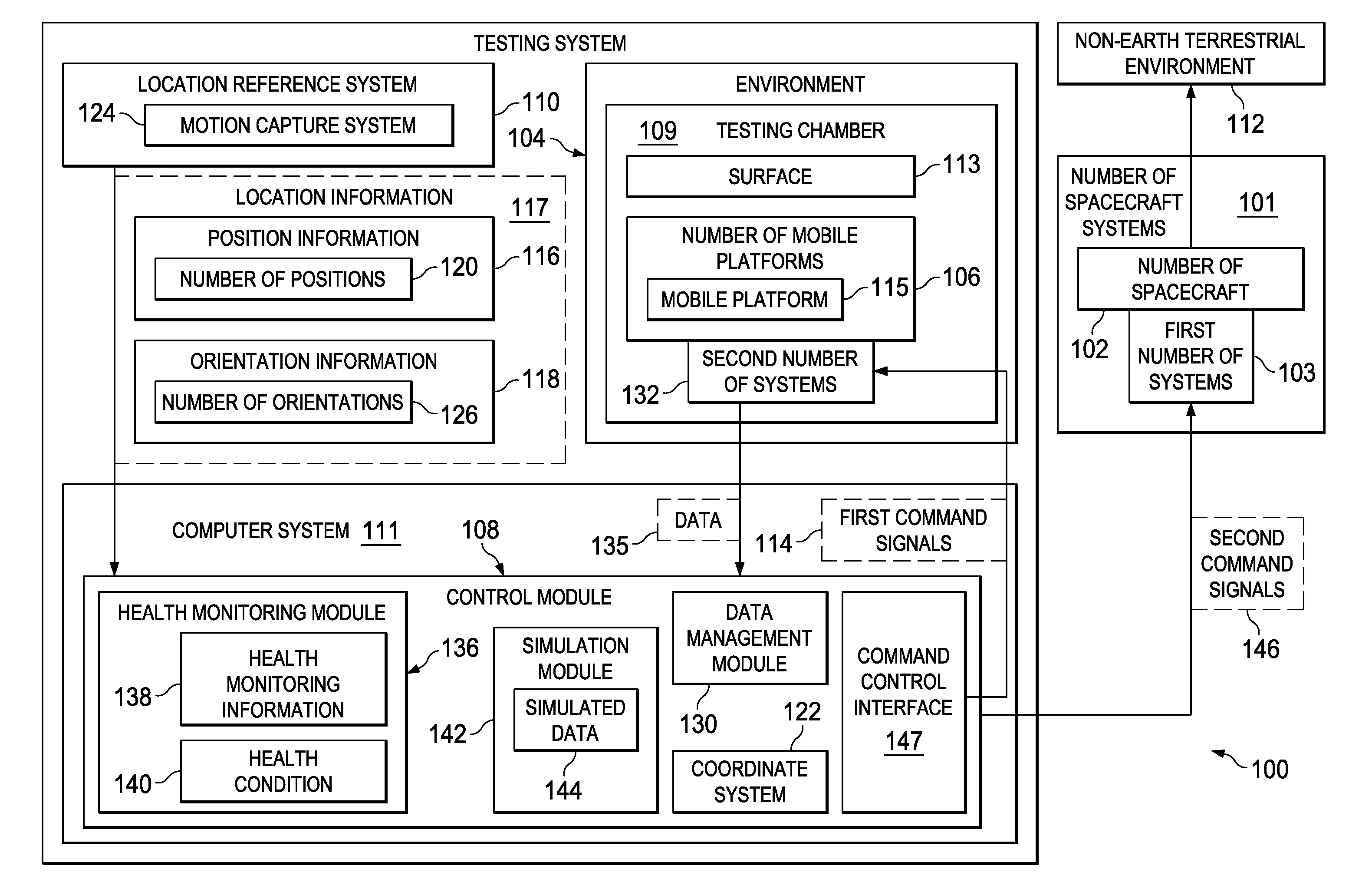

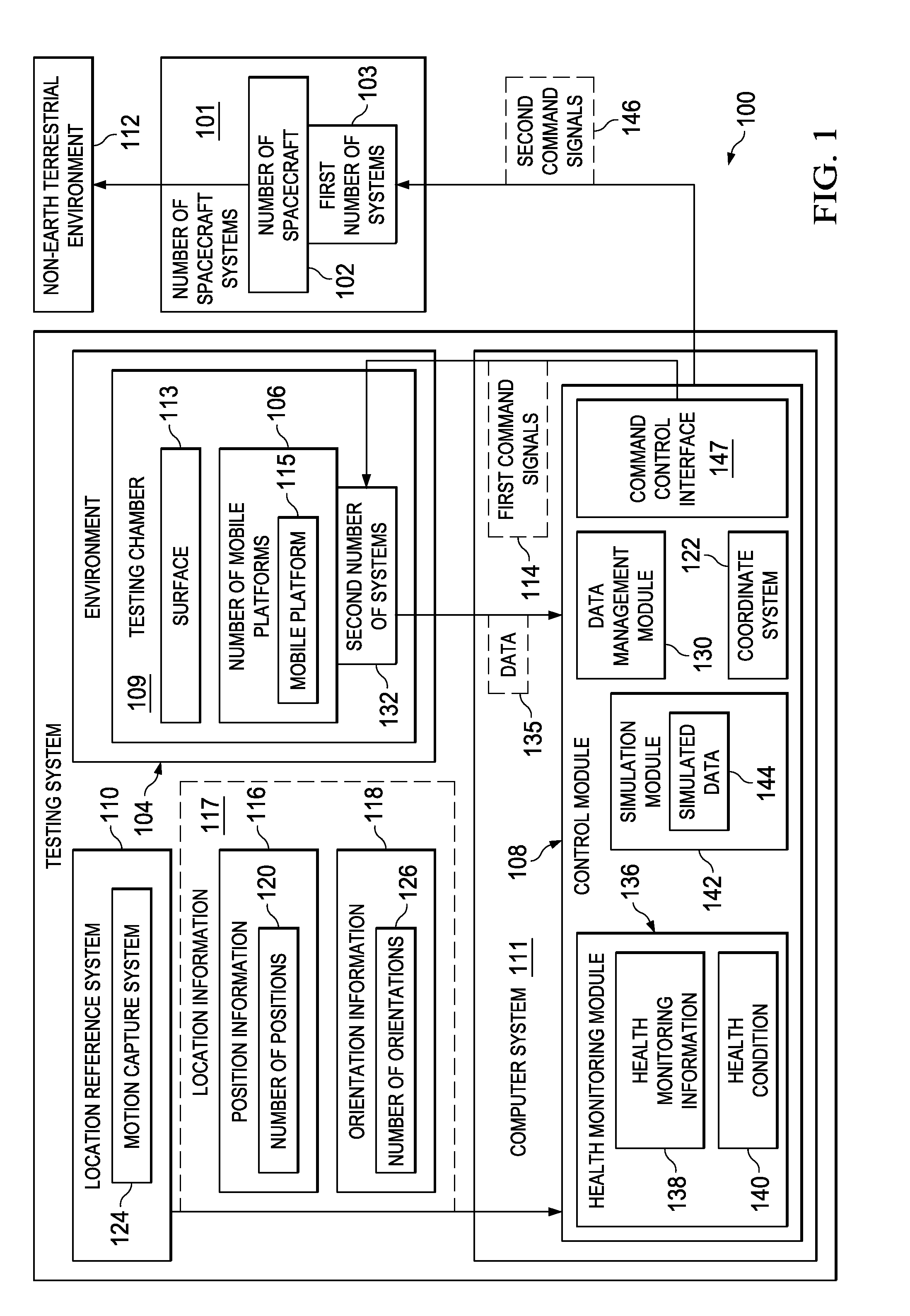

Spacecraft development testbed system

ActiveCN102880193ACosmonautic condition simulationsProgramme total factory controlComputer moduleTestbed

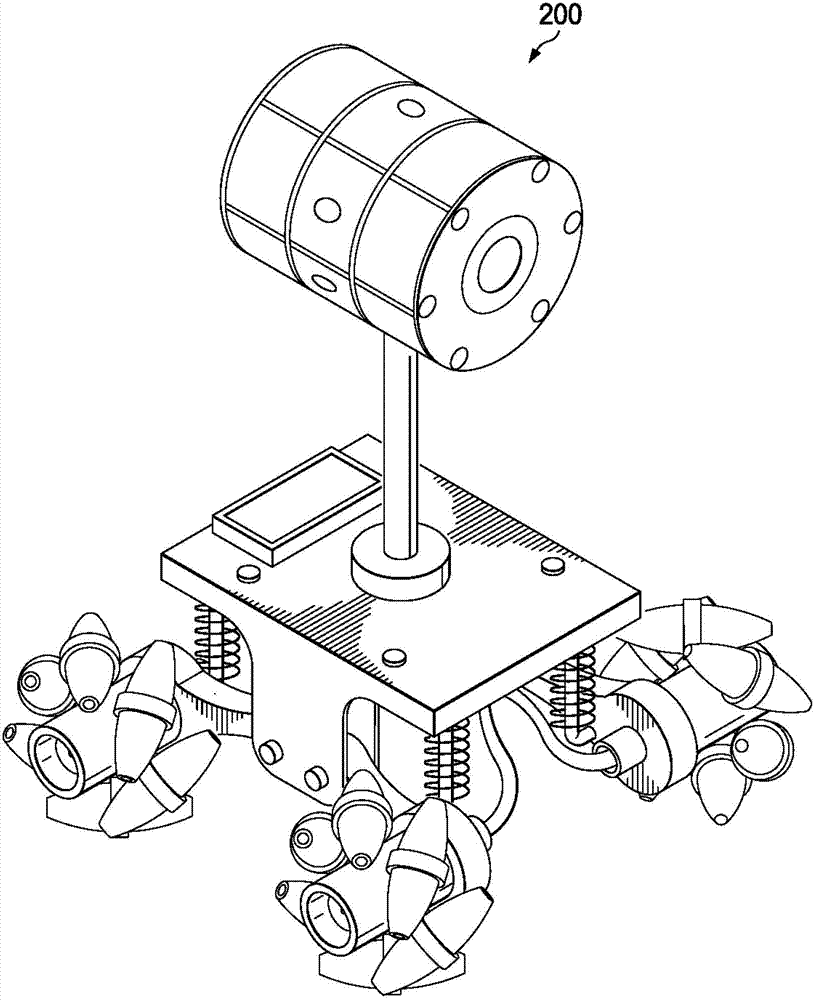

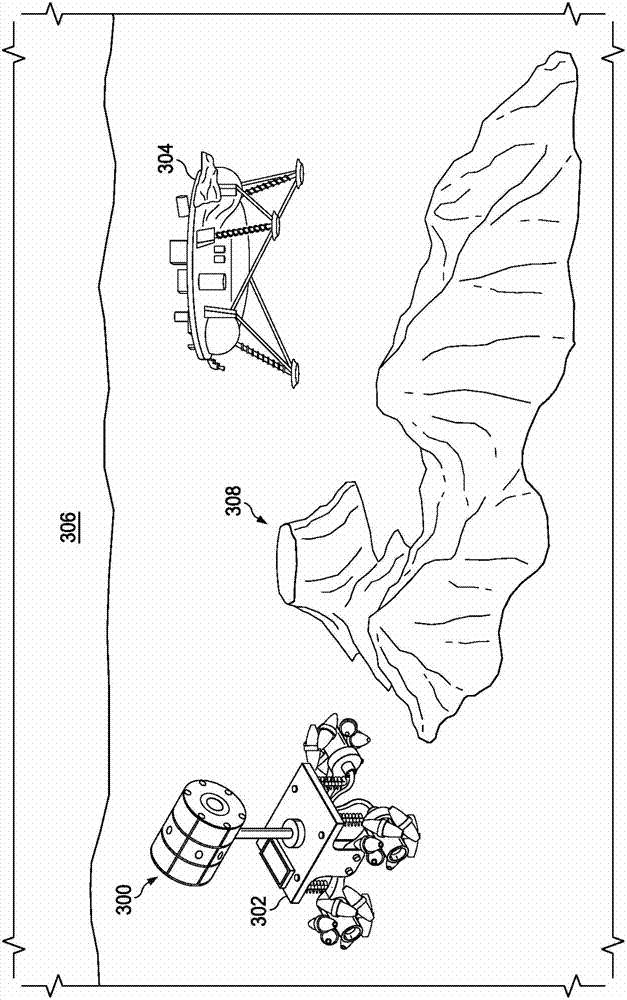

A method and apparatus comprising a location reference system (110) and a control module (108). The location reference system (110) is configured to generate location information for a number of mobile platforms (106) in an environment. The control module (108) is configured to receive the location information for the number of mobile platforms (106) from the location reference system (110). The control module (108) is further configured to generate command signals for the number of mobile platforms (106) using the location information. The control module (108) is further configured to send the command signals to the number of mobile platforms (106) to operate the number of mobile platforms (106) in the environment such that operation of the number of mobile platforms (106) emulates the operation of a number of spacecraft systems (101) in a non-Earth terrestrial environment.

Owner:THE BOEING CO

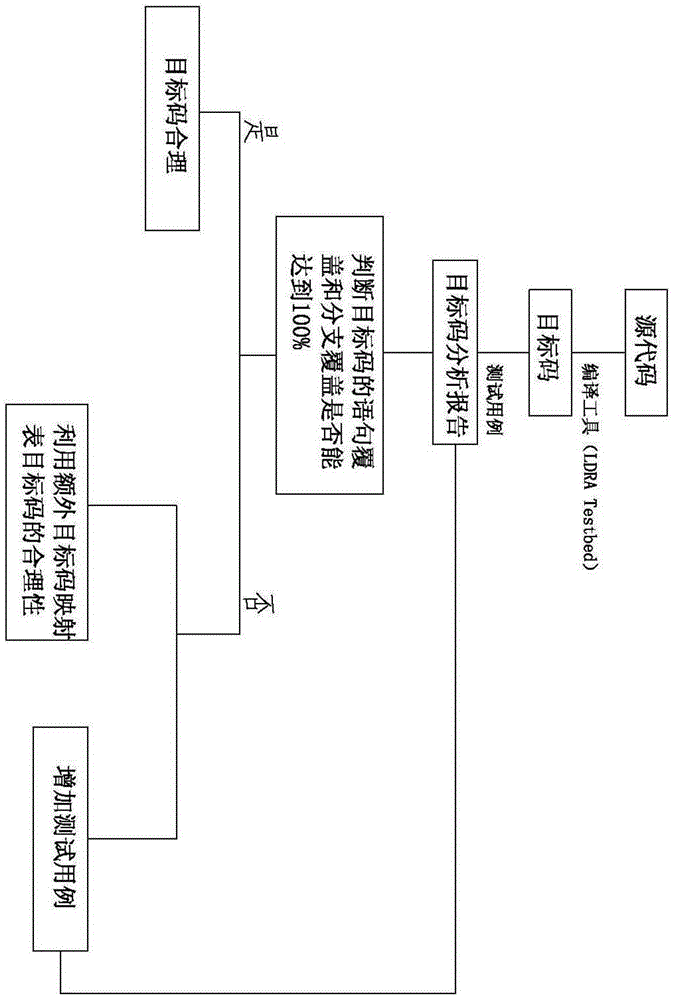

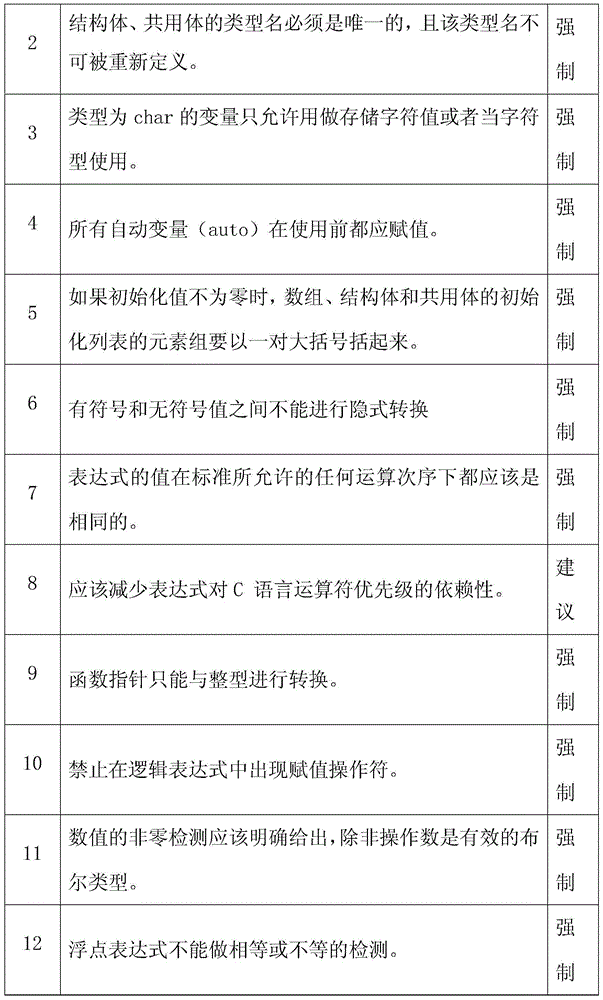

A-grade software object code coverage analysis method conforming to DO-178B/C

ActiveCN104360949AImprove efficiencyIncrease credibilitySoftware testing/debuggingAviationObject code

The invention belongs to the technical field of comprehensive avionics system software, and particularly relates to an A-grade software object code coverage analysis method conforming to DO-178B / C. By adopting a compilation tool LDRA (Liverpool Data Research Associates) Testbed or Verocel VeroCode, the method comprises the main steps of (1) adopting a source code and object code tracer technique to make a coding rule table; (2) making an extra object code mapping table for source codes breaking a coding rule; (3) carrying out coverage analysis on object codes. The application of the method needs neither the support of an object code coverage analysis tool and a hardware simulation device passing FAA certification, nor thorough manual evaluation and analysis carried out on the software, so that the efficiency and the credibility of object code coverage analysis are greatly improved.

Owner:AVIC NO 631 RES INST

Spacecraft Development Testbed System

A method and apparatus comprising a location reference system and a control module. The location reference system is configured to generate location information for a number of mobile platforms in an environment. The control module is configured to receive the location information for the number of mobile platforms from the location reference system. The control module is further configured to generate command signals for the number of mobile platforms using the location information. The control module is further configured to send the command signals to the number of mobile platforms to operate the number of mobile platforms in the environment such that operation of the number of mobile platforms emulates the operation of a number of spacecraft systems in a non-Earth terrestrial environment.

Owner:THE BOEING CO

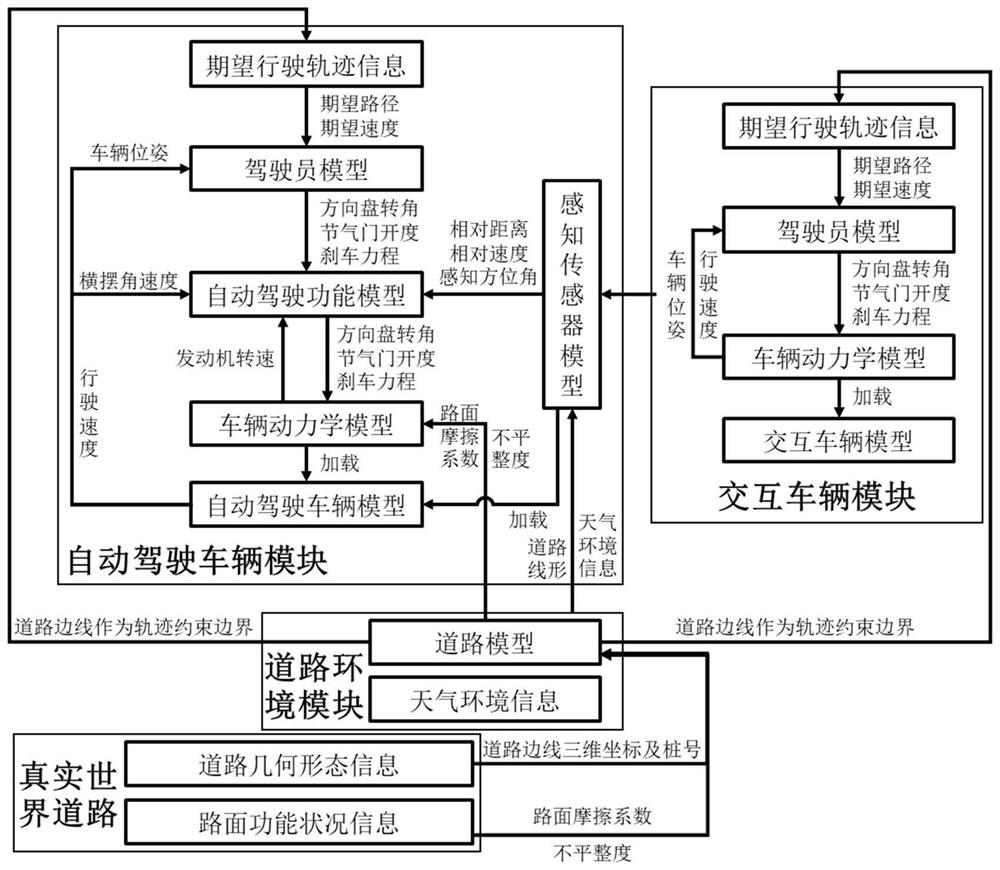

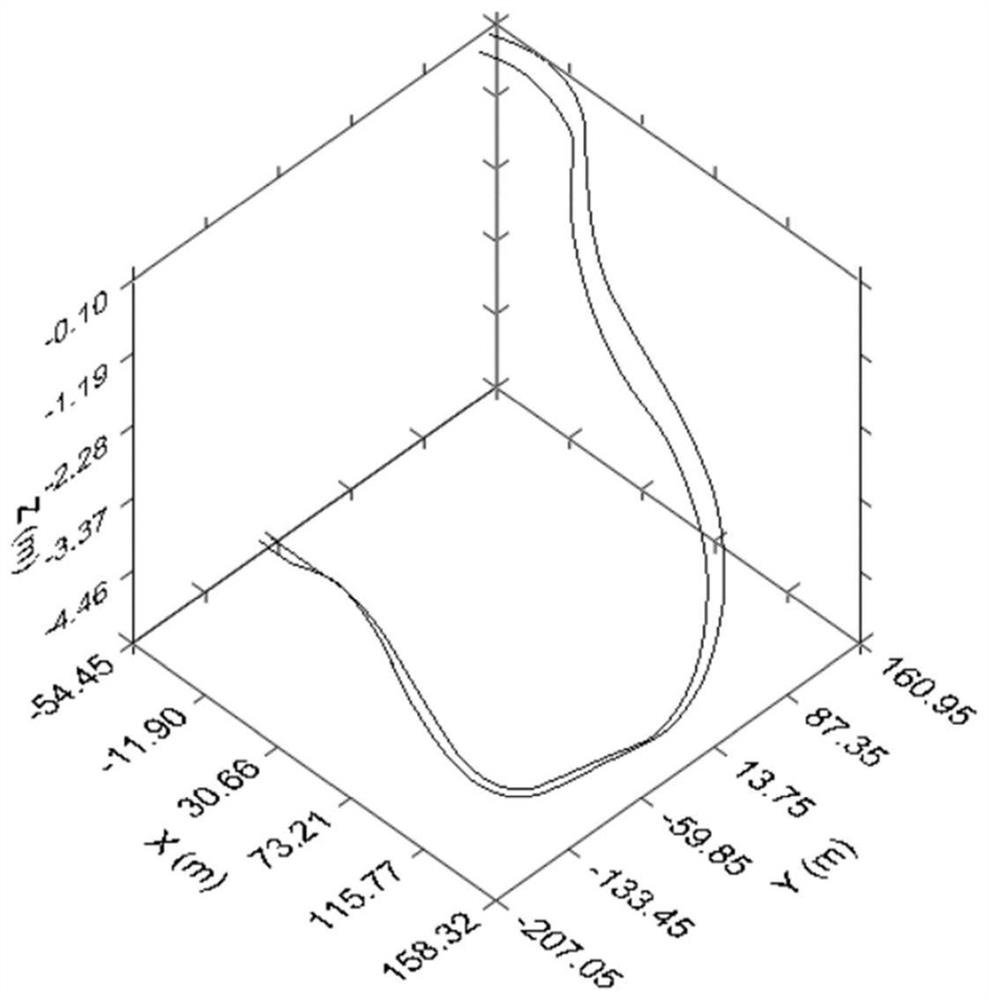

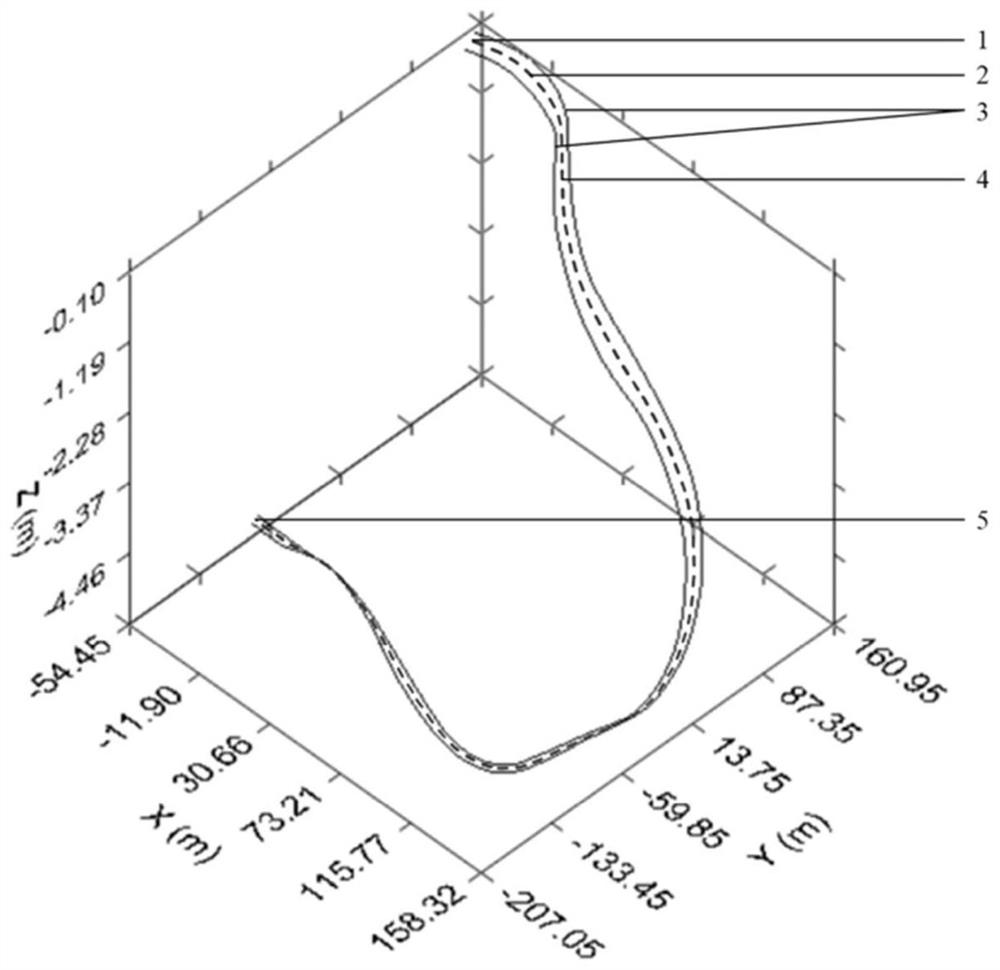

Automatic driving virtual test platform building method for mapping real-world road conditions

ActiveCN112526968AQuick Test Run StatusAddressing the needs of autonomous driving test trialsVehicle testingElectric testing/monitoringTestbedSensor model

The invention discloses an automatic driving virtual test platform building method for mapping real-world road conditions. The method comprises the following steps of: acquiring real-world road condition information; establishing a road environment module for mapping real-world road conditions; constructing an automatic driving vehicle module and an interactive vehicle module; integrating the roadenvironment module, the automatic driving vehicle module and the interactive vehicle module to realize information interconnection, and building an automatic driving virtual test platform capable ofmapping real world road conditions. According to the method, the running state of the automatic driving vehicle under the real world road conditions can be rapidly tested, and an interactive vehicle running track, a automatic driving perception sensor model and an automatic driving function model can be conveniently adjusted so as to meet the requirements of different automatic driving test working conditions.

Owner:SOUTHEAST UNIV

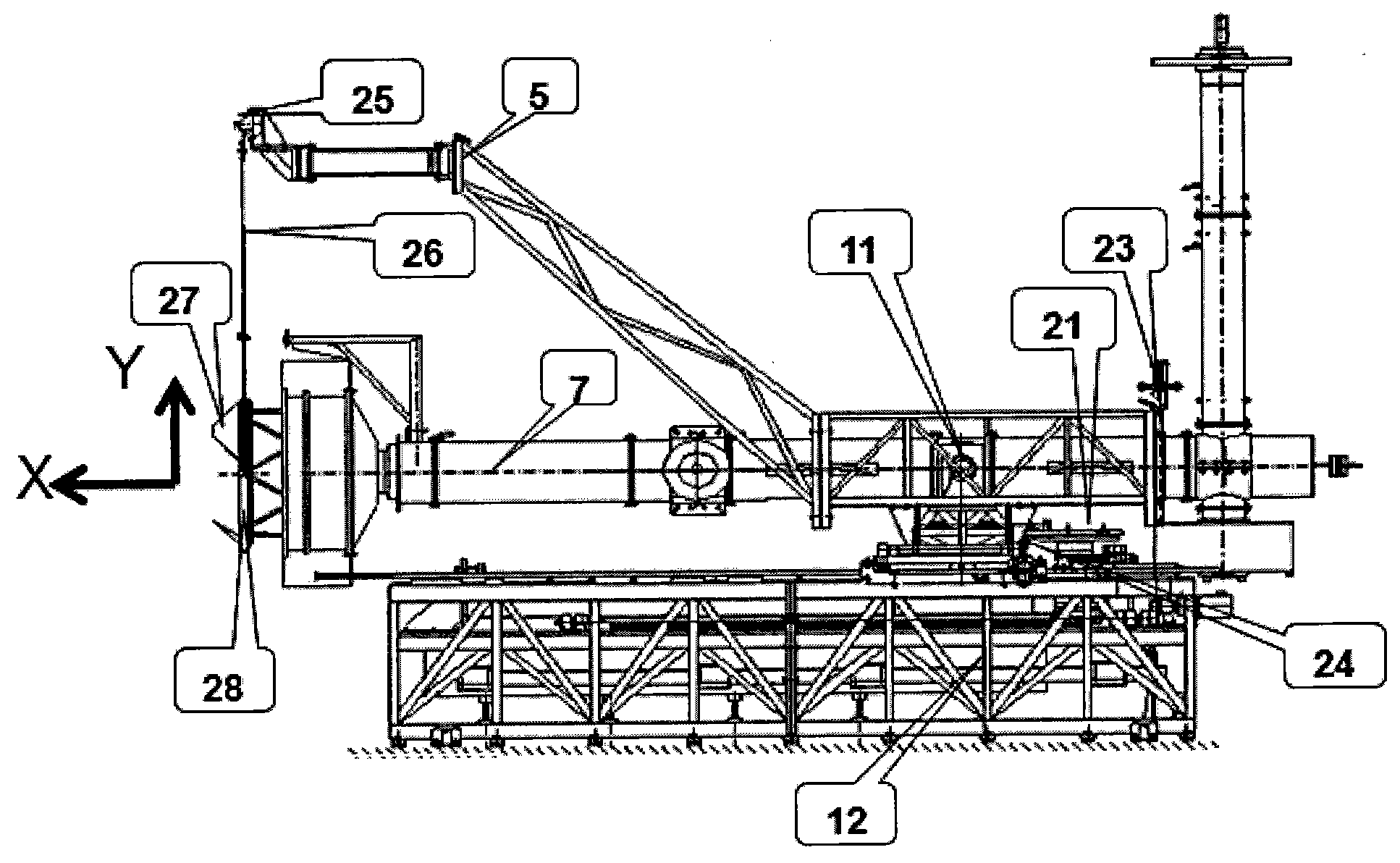

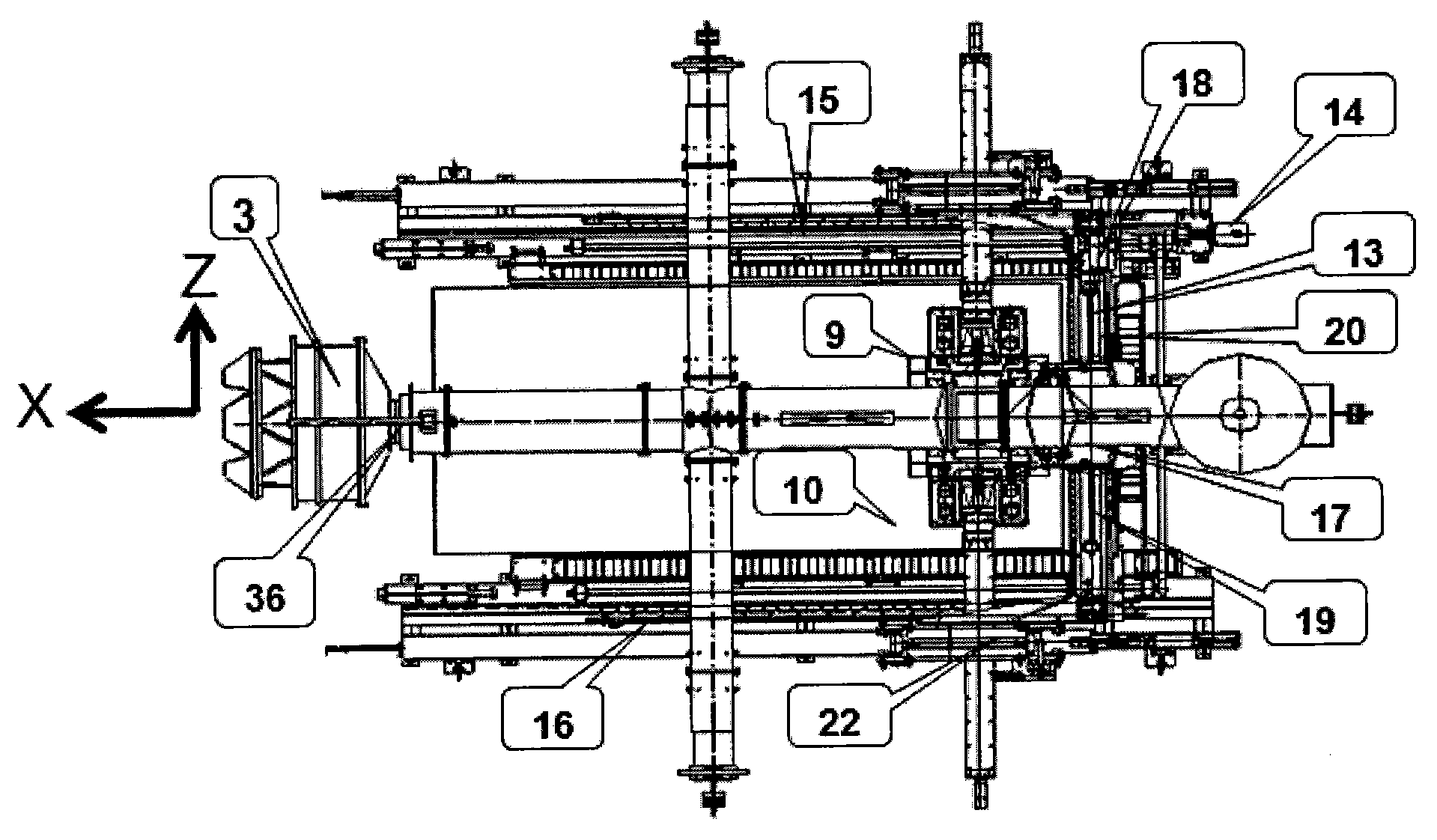

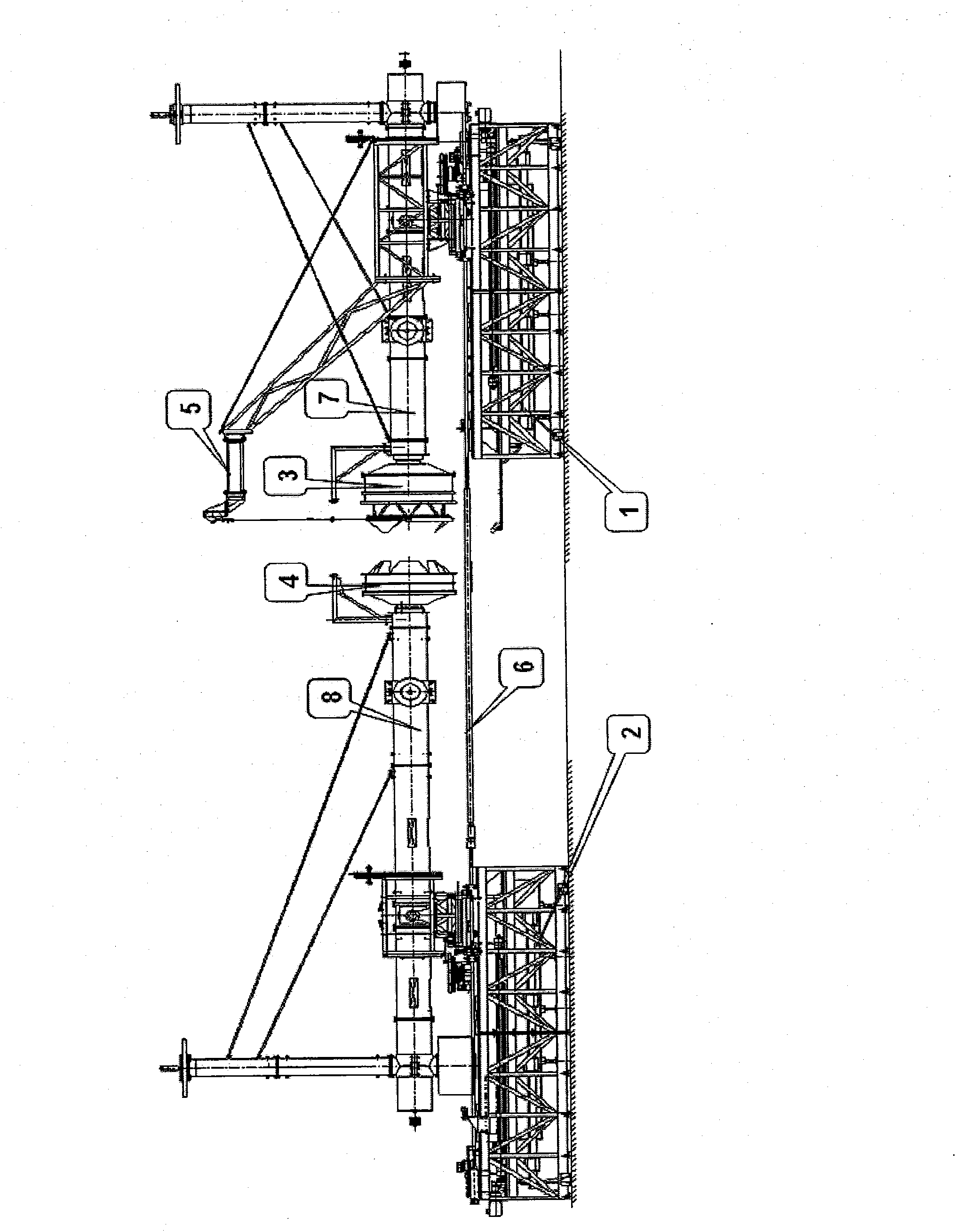

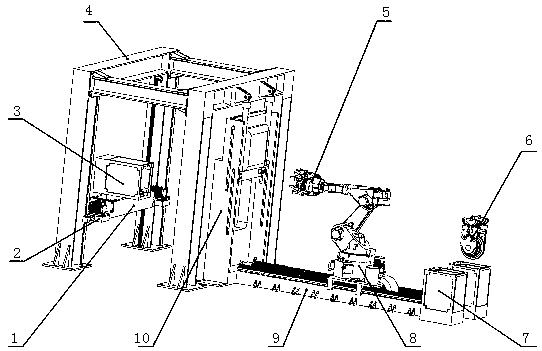

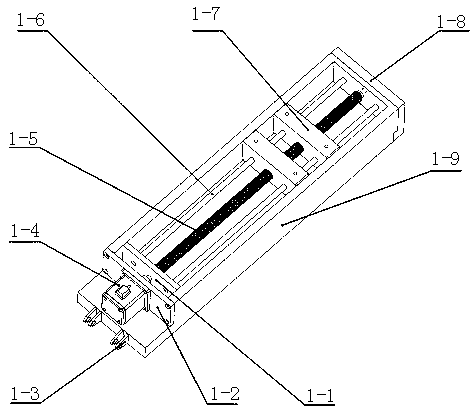

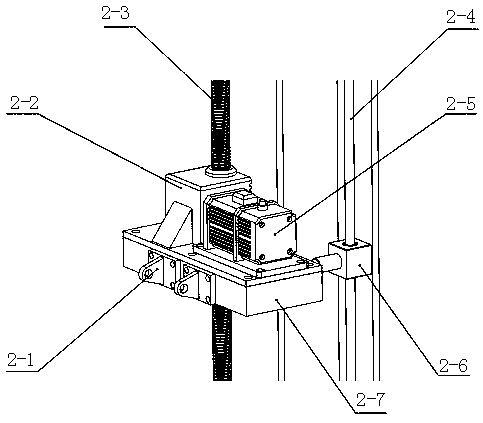

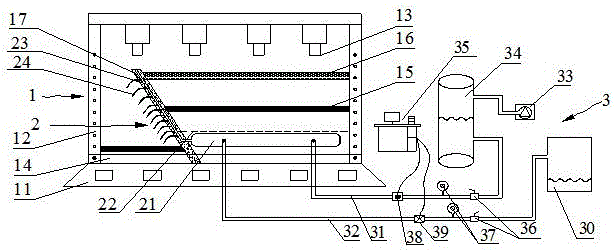

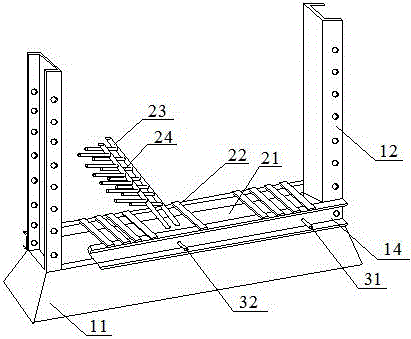

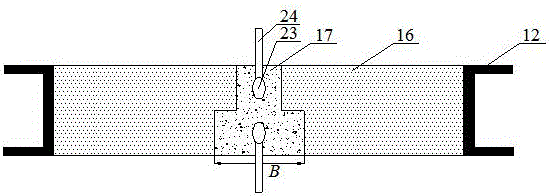

Full cross-section tunneling machine tool changing robot testbed and tool changing simulation method

ActiveCN110625626AAchieve lateral movementReduce R&D costsTunnelsManipulatorProcess simulationTestbed

The invention discloses a full cross-section tunneling machine tool changing robot testbed and a tool changing simulation method. Through the full cross-section tunneling machine tool changing robot testbed and the tool changing simulation method, the problem that the tool changing process simulation condition of a tool changing robot is not good in the prior art is solved. The full cross-sectiontunneling machine tool changing robot testbed comprises a beam frame and a tool storage box used for storing tools. A lifting device and a chamber door mechanism are arranged on the two opposite sidefaces of the beam frame correspondingly. The lifting device is provided with a tool transverse adjusting device. A tool box is arranged on the tool transverse adjusting device. A moving guide rail isarranged between the tool storage box and the chamber door mechanism. A six-axis mechanical arm is arranged on the moving guide rail. The six-axis mechanical arm is provided with a robot end executionmechanism. The full cross-section tunneling machine tool changing robot testbed can simulate different positions and postures of a set to tools on a cutterhead, greatly reduces the research and development cost of the full cross-section tunneling machine tool changing robot automatic tool changing technology and lays the foundation for success research and development of the full cross-section tunneling machine tool changing robot automatic tool changing technology.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

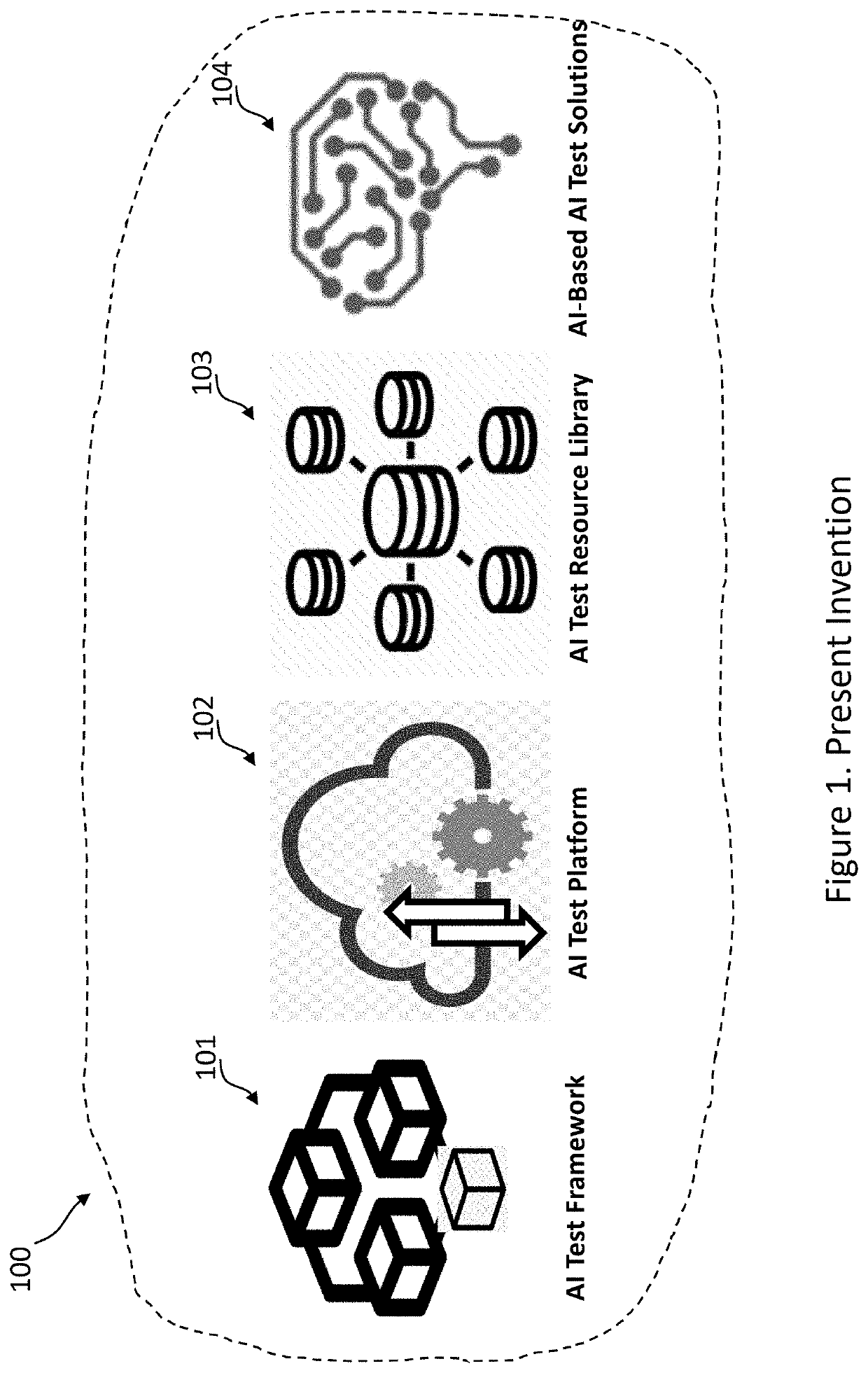

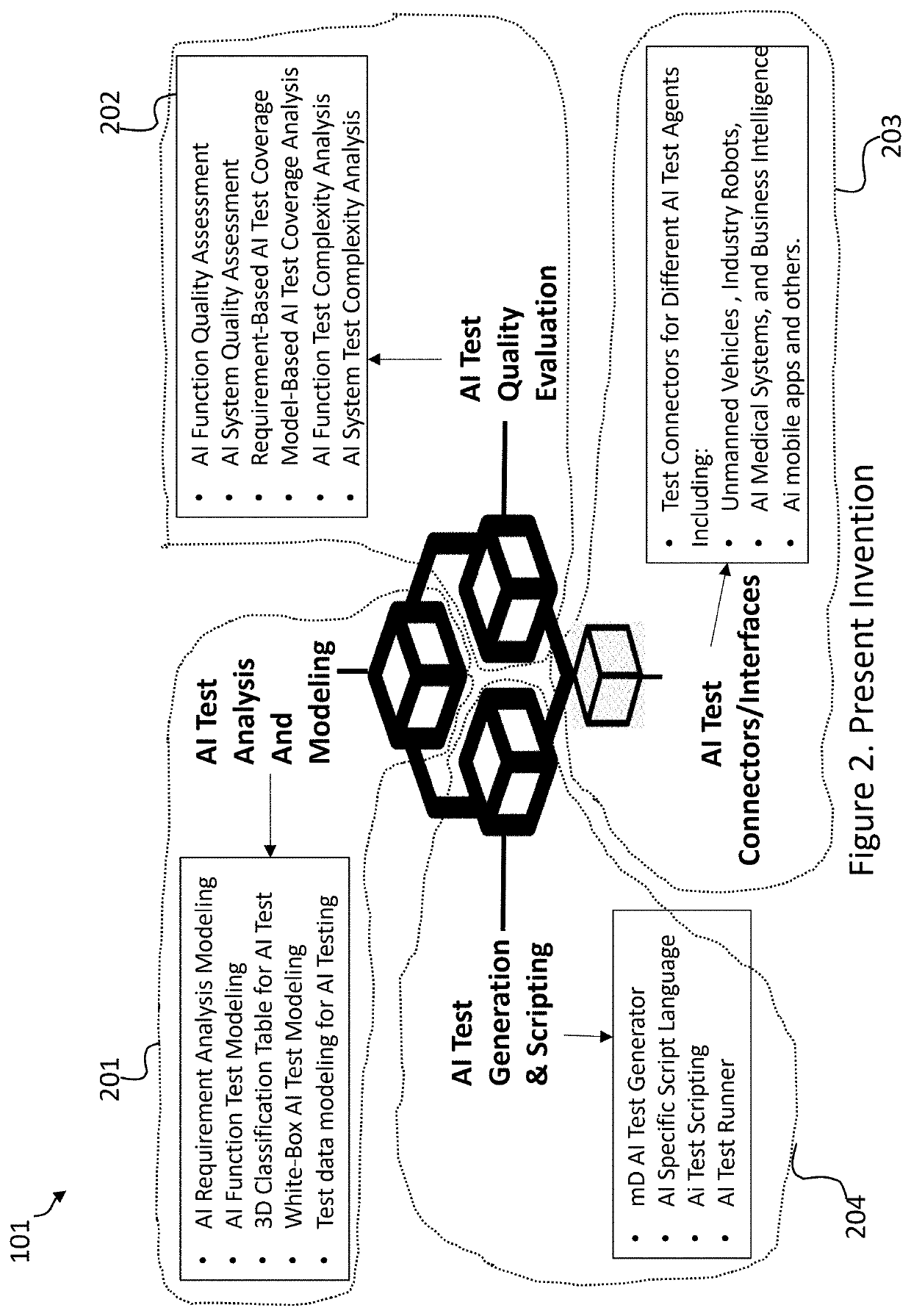

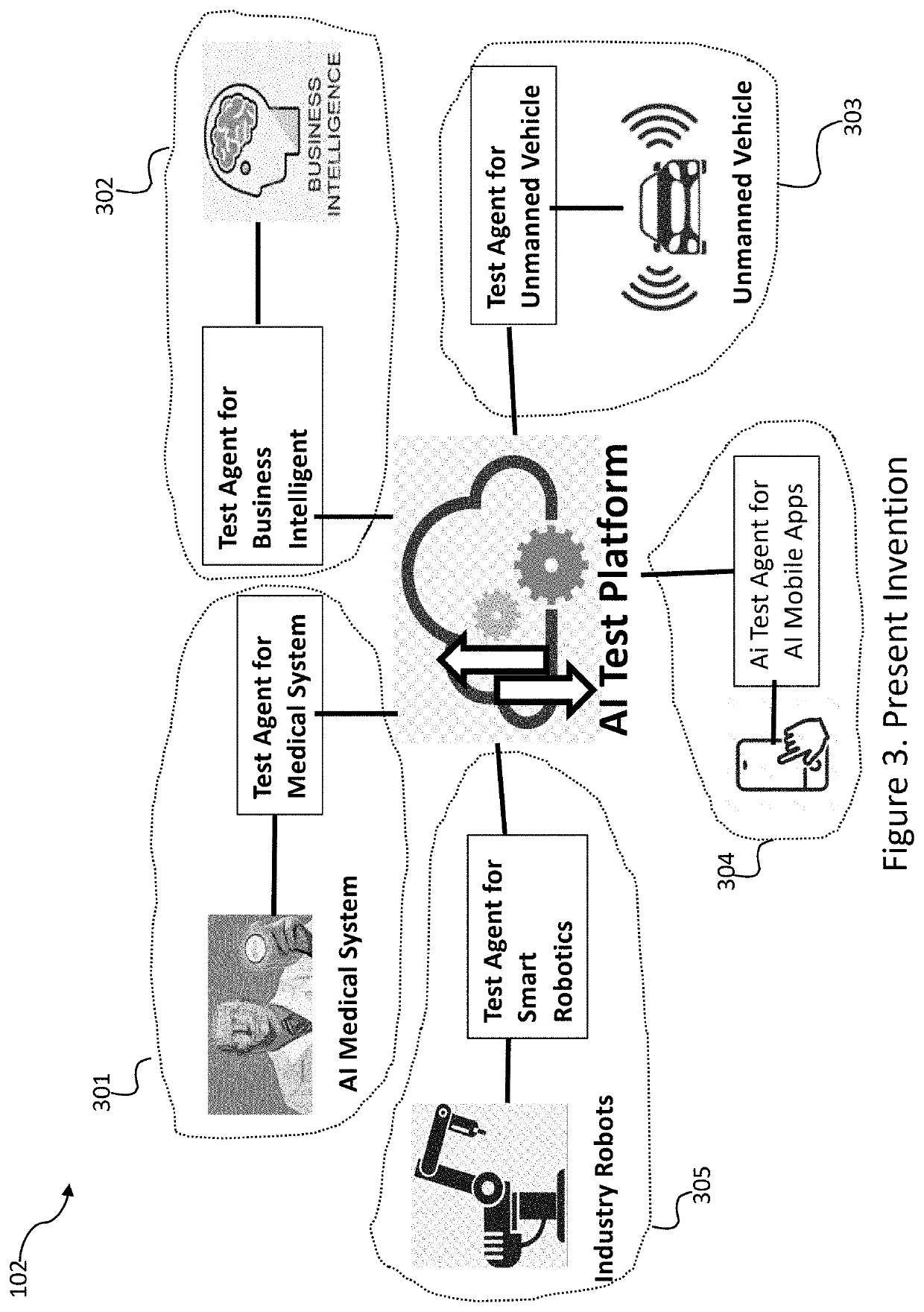

System and Method for Testing Artificial Intelligence Systems

A method and a system are provided of testing AI applications / systems on a System for testing one or more artificial intelligence System (STAIS) connectable to under-test AI systems (UTAIS) via the AI test connectors / interfaces through AI test platform. The method includes test modeling, data preparation, testing script generation, testing automation, and quality assurance. The system automatically identifies, analyzes, and displays all quality issues of UTAIS.

Owner:GAO ZEYU

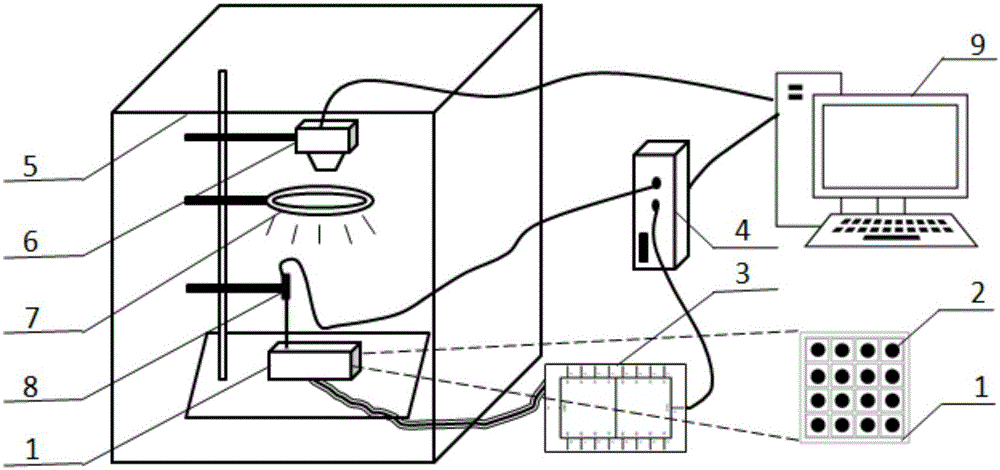

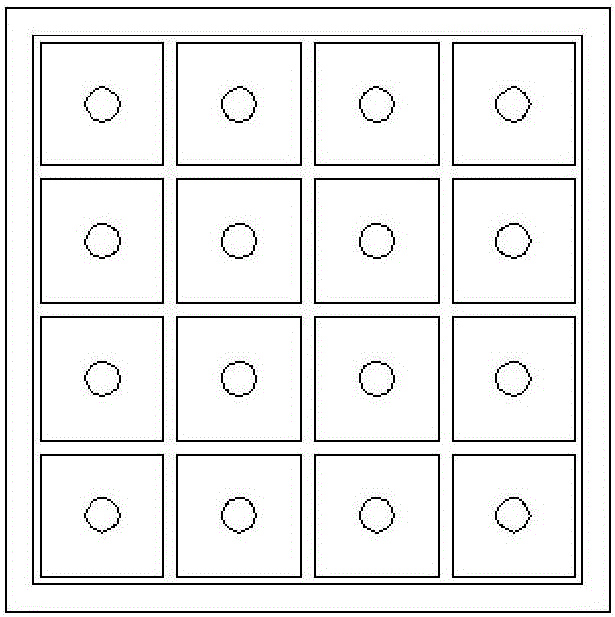

Metal corrosion high-throughput characterization experimental apparatus based on image

ActiveCN105092461AReal-time acquisitionImprove relevanceWeather/light/corrosion resistanceTestbedMetal electrodes

The invention provides a metal corrosion high-throughput characterization experimental apparatus based on an image, belonging to the technical field of metal electrochemical corrosion. The experimental apparatus comprises a high-throughput electrolytic tank, a metal electrode, an electrochemical signal acquisition device, an image signal acquisition device and a data processing device, wherein the high-throughput electrolytic tank is mounted on a testbed, the bottom of the high-throughput electrolytic tank is connected with the electrochemical signal acquisition device through a lead, the upper part of the high-throughput electrolytic tank is connected with the electrochemical signal acquisition device through a reference electrode, the image signal acquisition device is arranged above the high-throughput electrolytic tank, and both the image signal acquisition device and the electrochemical signal acquisition device are connected with the data processing device. The metal corrosion high-throughput characterization experimental apparatus is used for metal corrosion tests, synchronous reaction of a plurality of samples can be carried out at the same time, and meanwhile, the real-time acquisition of electrochemical signals and image signals is realized, so that repeated experiments are reduced, the correlation of experimental data is improved, and the accuracy and the efficiency of the metal corrosion tests are finally improved.

Owner:UNIV OF SCI & TECH BEIJING

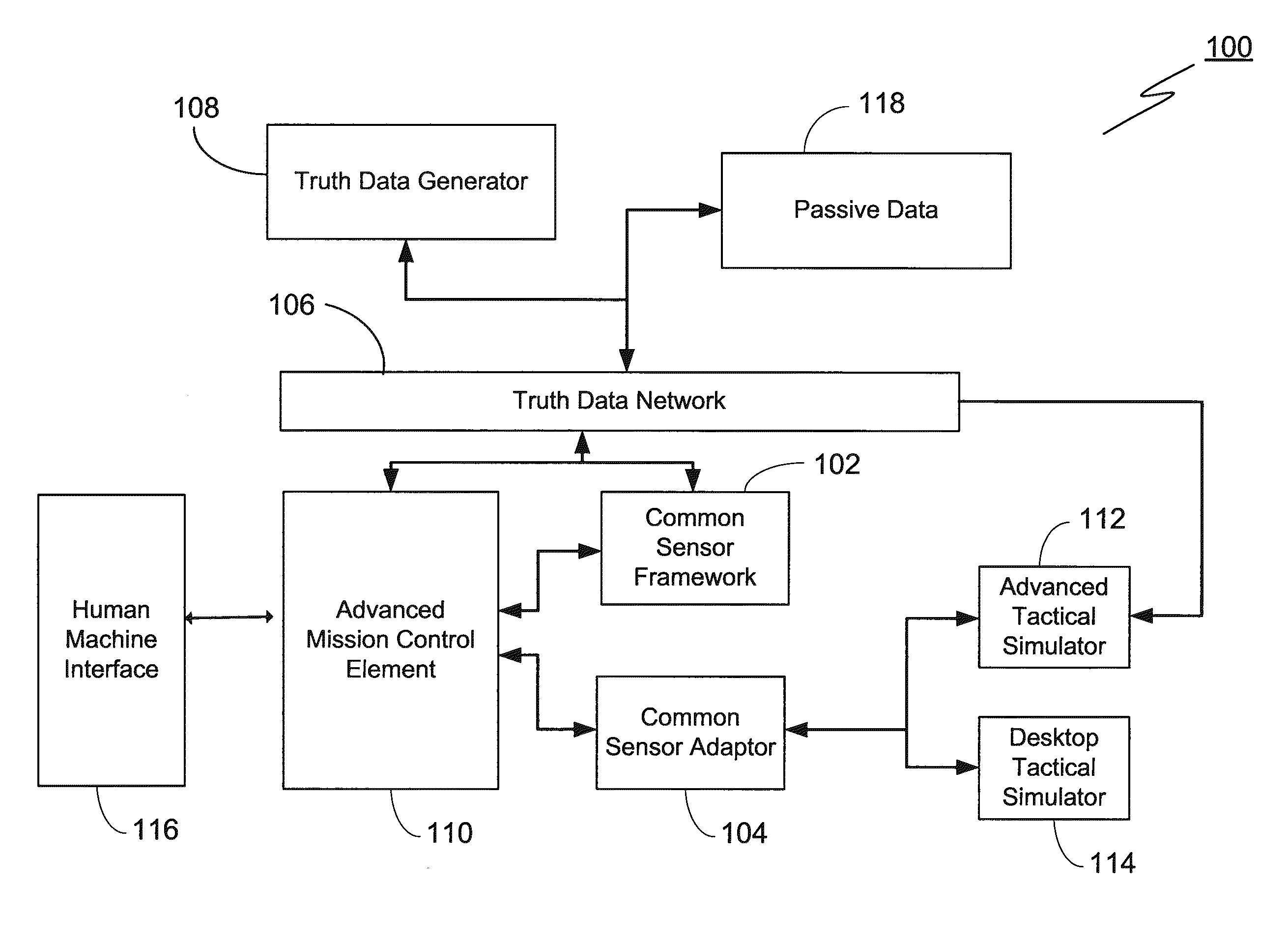

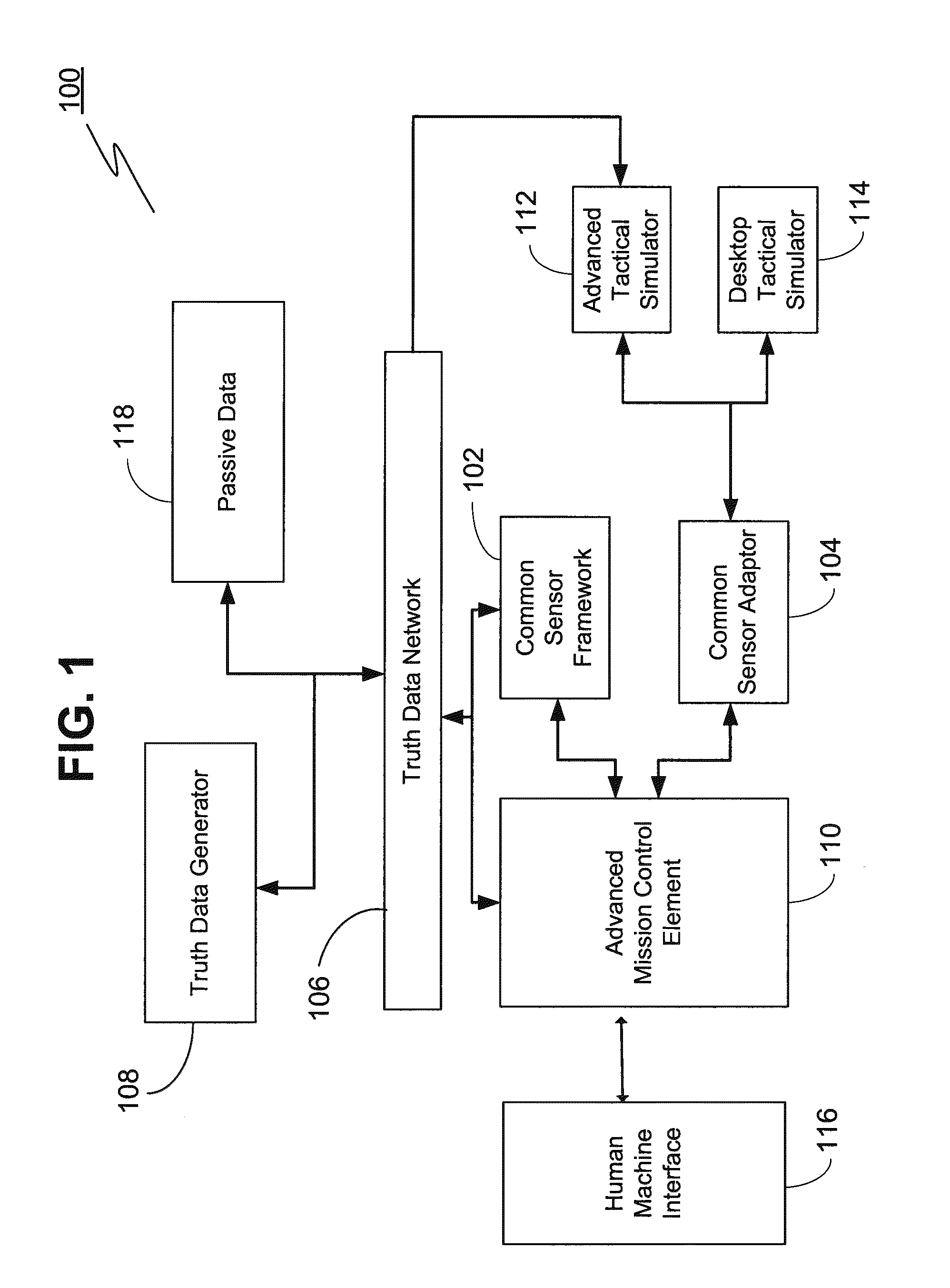

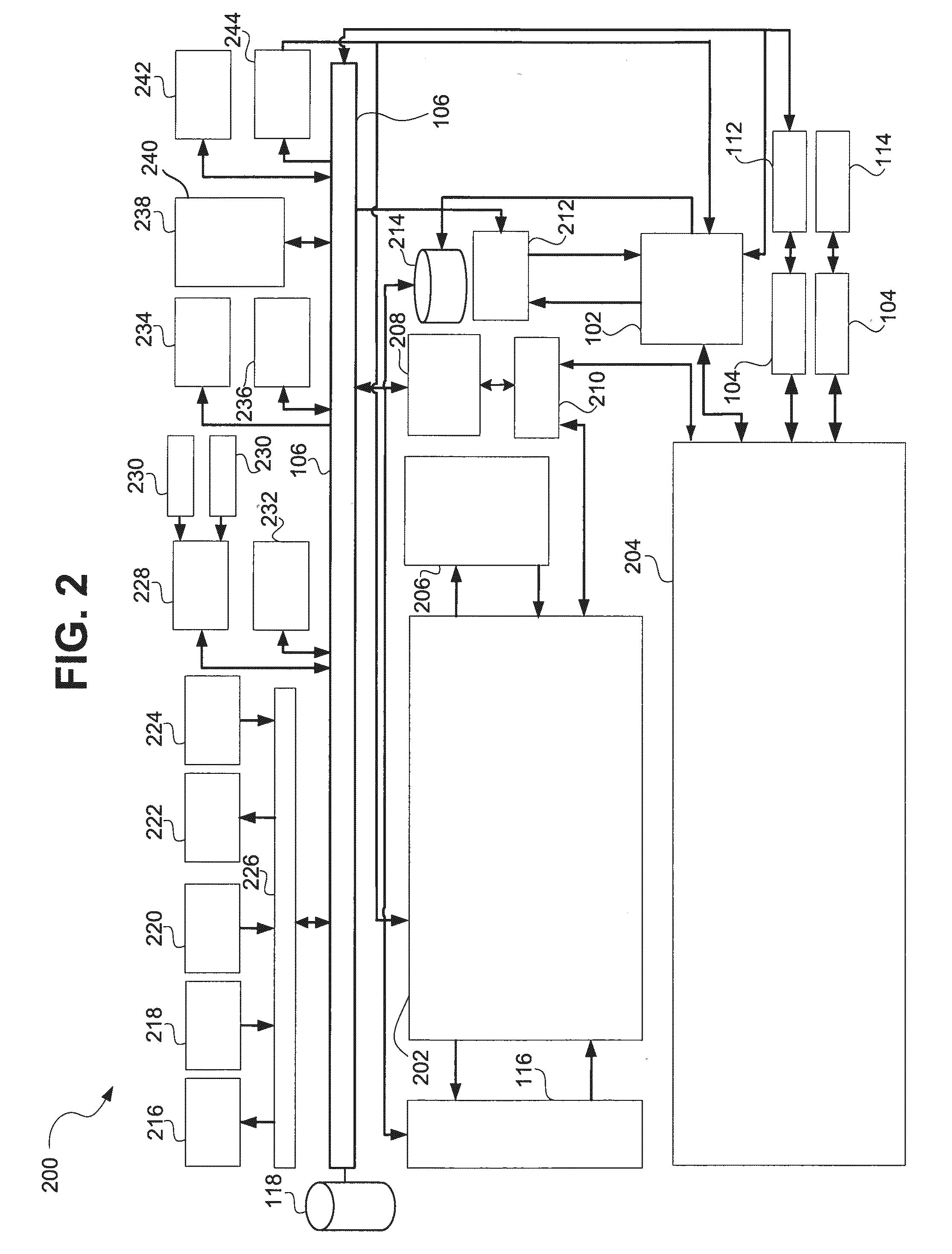

Aerospace-ground integration testbed

An aerospace-ground integration testbed may include a truth data scheme, a common sensor adaptor, a common sensor framework, a visualization scheme and a communications scheme. The truth data scheme may generate truth data configured to provide data of at least one of threats, terrain, targets and offensive and defensive systems. The common sensor adaptor may provide sensed data generated from at least the truth data. The common sensor framework may provide modeled sensed data generated from at least the truth data utilizing sensor models. The visualization scheme may generate visual data to be displayed from the sensed data and the modeled sensed data. The communications scheme may provide communication and testbed messaging infrastructure between the truth data scheme, the common sensor adaptor, the common sensor framework, and the visualization scheme.

Owner:RAYTHEON CO

Fault and secondary fault activated induced confined water gushing test method and system

The invention discloses a fault and secondary fault activated induced confined water gushing test method and a system. The specific structure of the system comprises a similar material simulator stand, a confined water loading system, and a confined water rising guiding system; the similar material simulator stand is a universal two-dimensional testbed; the confined water loading system is composed of a confined water pressurizing device, a water injection pipeline, a water return pipeline, and a computer-control system; the confined water rising guiding system is composed of a water bag, a water insulation layer steel plate, a rising guiding rubber tube, and a thin drain pipe; an original non-water permeability fault is arranged on the similar material simulator stand; the confined water loading system is used for stimulating floor pressurized water; the confined water rising guiding system is used for stimulating flow of confined water along the fault; the influences of experiment parameters on the fault and secondary fault reactivation-induced water-conducting are achieved via changing the experiment parameters such as confined water pressure, fault zone width, advance speed, and distances, and simulated reconstruction of the whole process of water gushing is realized.

Owner:SHANDONG UNIV OF SCI & TECH

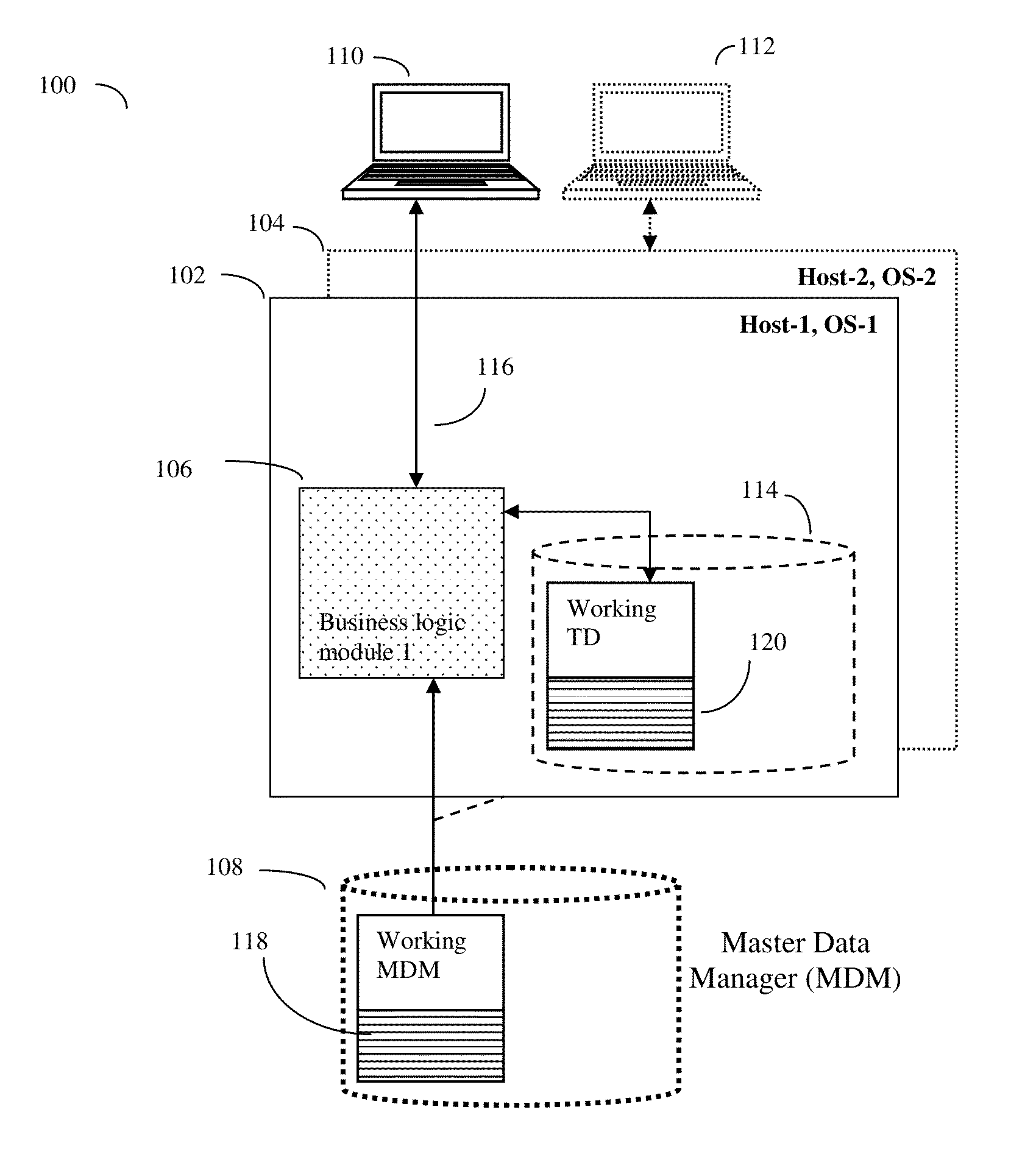

System to plan, execute, store and query automation tests

ActiveUS8645326B2Solve low usageReduce test costsError detection/correctionDigital data processing detailsOperational systemProgram planning

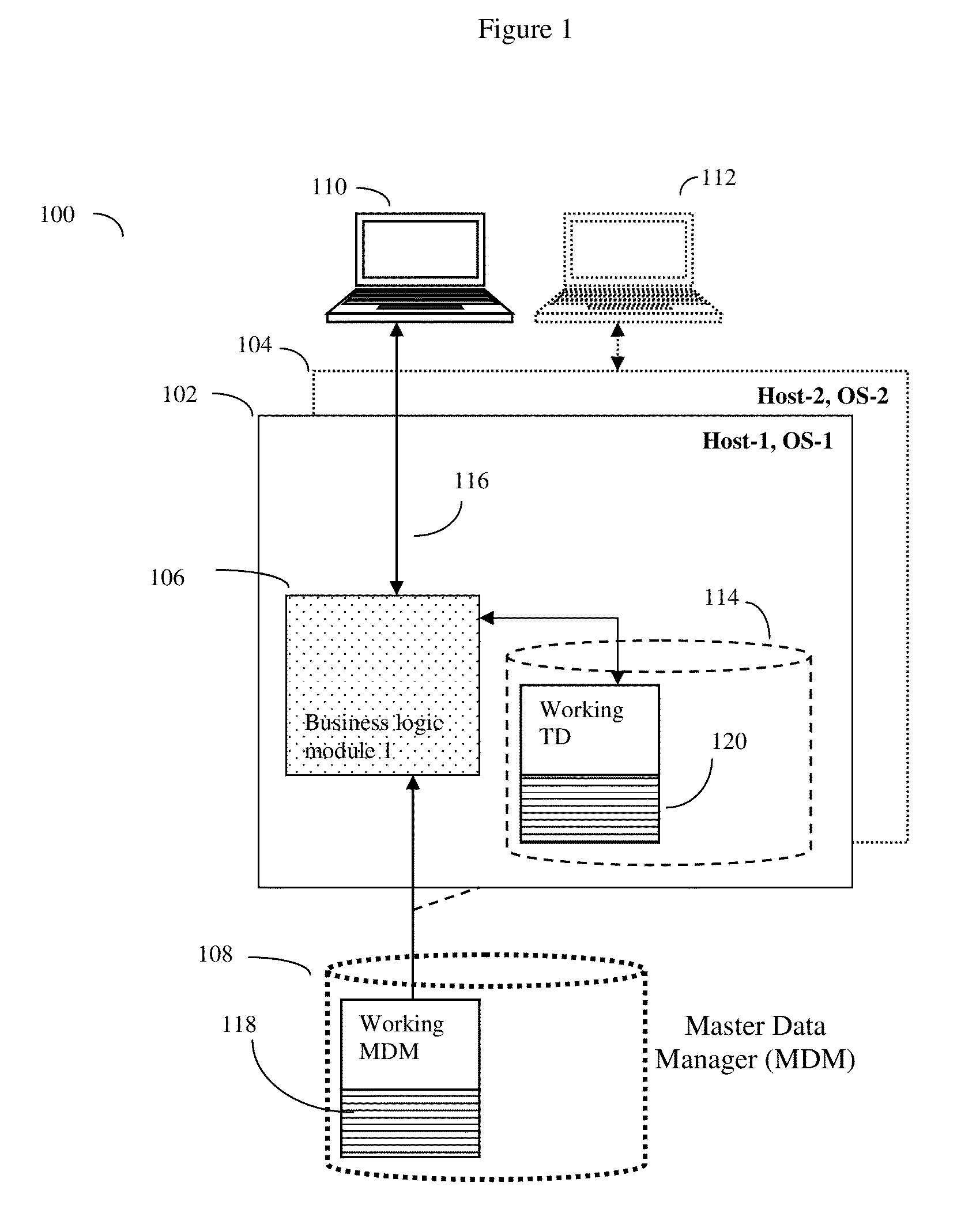

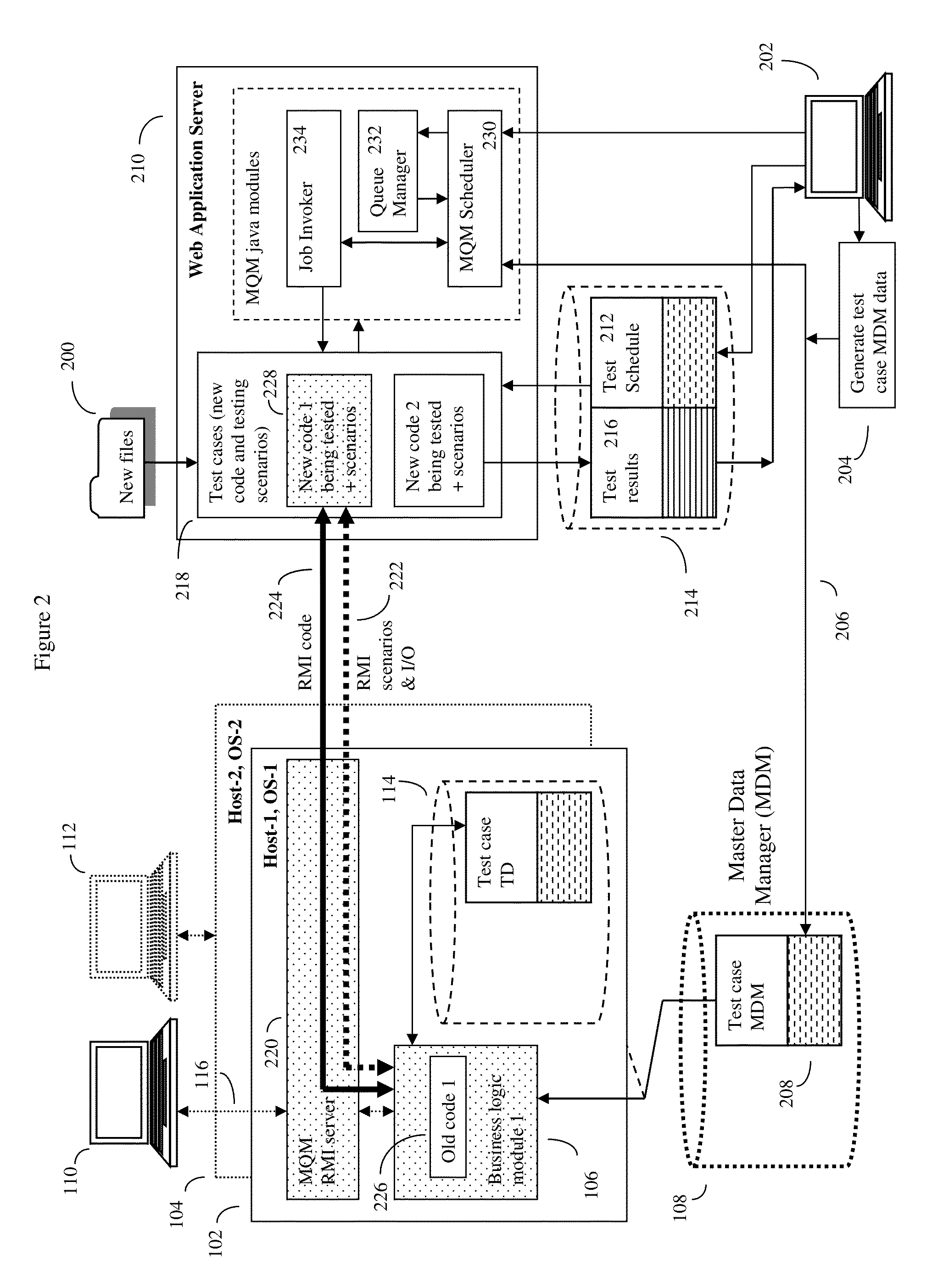

An automation testing platform that will enable simultaneous testing of new product code over variety of Operating Systems by calling remote machines. In one embodiment, the system is an SAP master data management based system such as NetWeaver, and the testing platform places important testing information onto the master data database itself. The platform then calls and controls the remote machines using distributed computing methodology such as the Java RMI protocol. The system provides the ability to run automated tests according to different technologies, OS, platforms and codelines, and allows for an automatic test portfolio to be managed from a single test catalog. The results can be represented by a variety of configurable user interface reports. The system has an ability to use legacy automation code, and can report on the quality, reliability and stability of the new product code along various configurable key performance indicators.

Owner:SAP AG

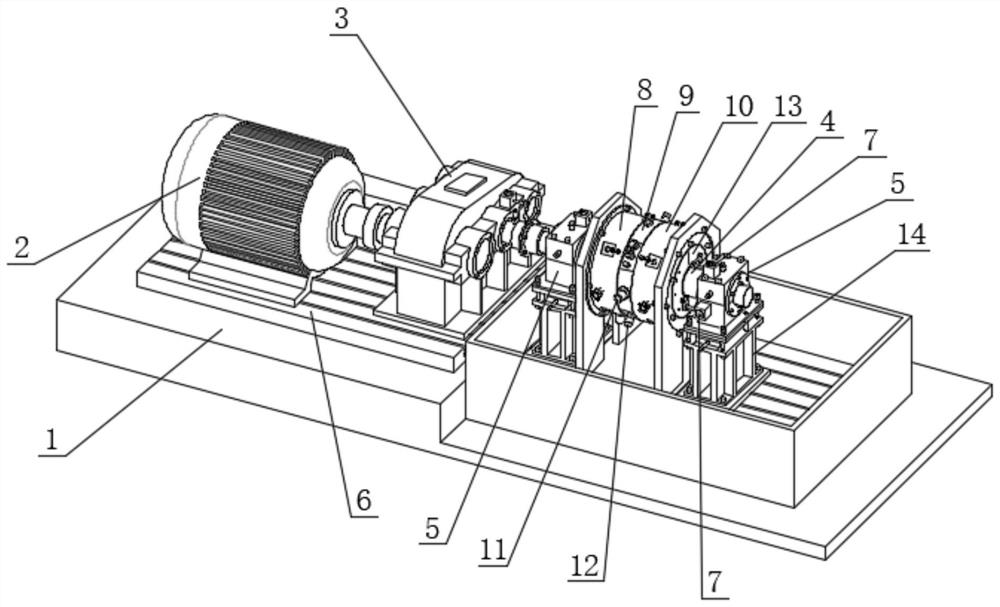

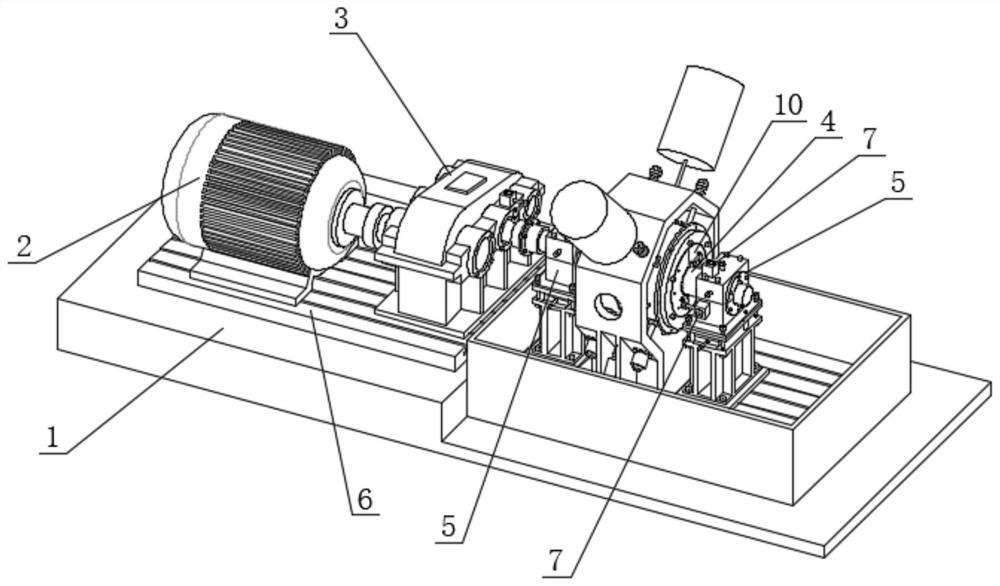

Rocket turbopump floating ring seal testing testbed

The invention discloses a testbed, in particular to a rocket turbopump floating ring seal testbed. The rocket turbopump floating ring seal testbed solves the problems that in the running process of anexisting turbopump rotor, the phenomenon of flow-induced vibration instability is likely to happen, rotor vibration is increased, oxygen-enriched combustion is extremely likely to happen under the oxygen-enriched condition of a turbopump, and a rocket engine is low in stability and reliability. Positioning rings and cavity labyrinth seals are arranged at the two ends of a testbed body, the outerring faces and the side end faces of the positioning rings are matched with a front cavity or a rear cavity in a high-precision mode, the positioning rings and the testbed body are sealed through thecavity labyrinth seals, circular beads are arranged on the inner side of the front cavity and the inner side of the rear cavity, the circular beads of the front cavity and the rear cavity and a middlecavity form a high-pressure chamber where a floating ring works, the floating ring is limited in the high-pressure chamber, hole channels are machined in the front cavity and the rear cavity and communicate with a channel of the floating ring, and eddy current displacement sensors are installed on the floating ring and a bearing pedestal. The rocket turbopump floating ring seal testing testbed isused for a rocket turbopump floating ring seal test.

Owner:HARBIN INST OF TECH

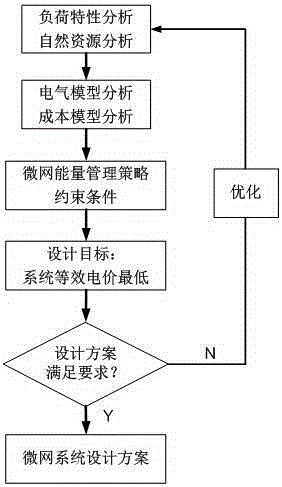

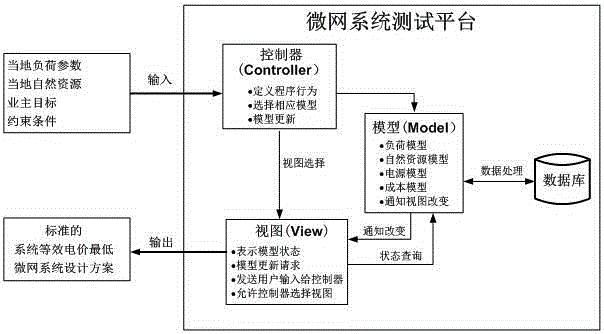

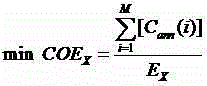

Lowest equivalent electrovalence-of-system-based microgrid system design scheme and test platform

ActiveCN105226639AMeet economic requirementsLow electricity priceElectrical testingSingle network parallel feeding arrangementsSystems designMicrogrid

The invention provides a lowest equivalent electrovalence-of-system-based microgrid system design scheme and a test platform. Each subsystem of a microgrid system at least comprises a wind generator set, a photovoltaic set, an energy storage device, a water turbine set, a diesel engine set or a gas engine set. The structure of the microgrid system is determined through analyzing different load characteristics, natural resources and power supply types of the subsystems of the microgrid system; electric cost models of the subsystems of a microgrid are established; change parameters such as the investment cost of microgrid construction, the equivalent cost of power generation and load power demand increases are comprehensively considered to carry out distributed generation power supply selection and capacity configuration; and the microgrid system is established employing the lowest equivalent electrovalence of the system as the target, so that the microgrid system design scheme meeting the economic requirements is rapidly obtained; and the microgrid system test platform is formed by adopting an MVC mode.

Owner:中国东方电气集团有限公司

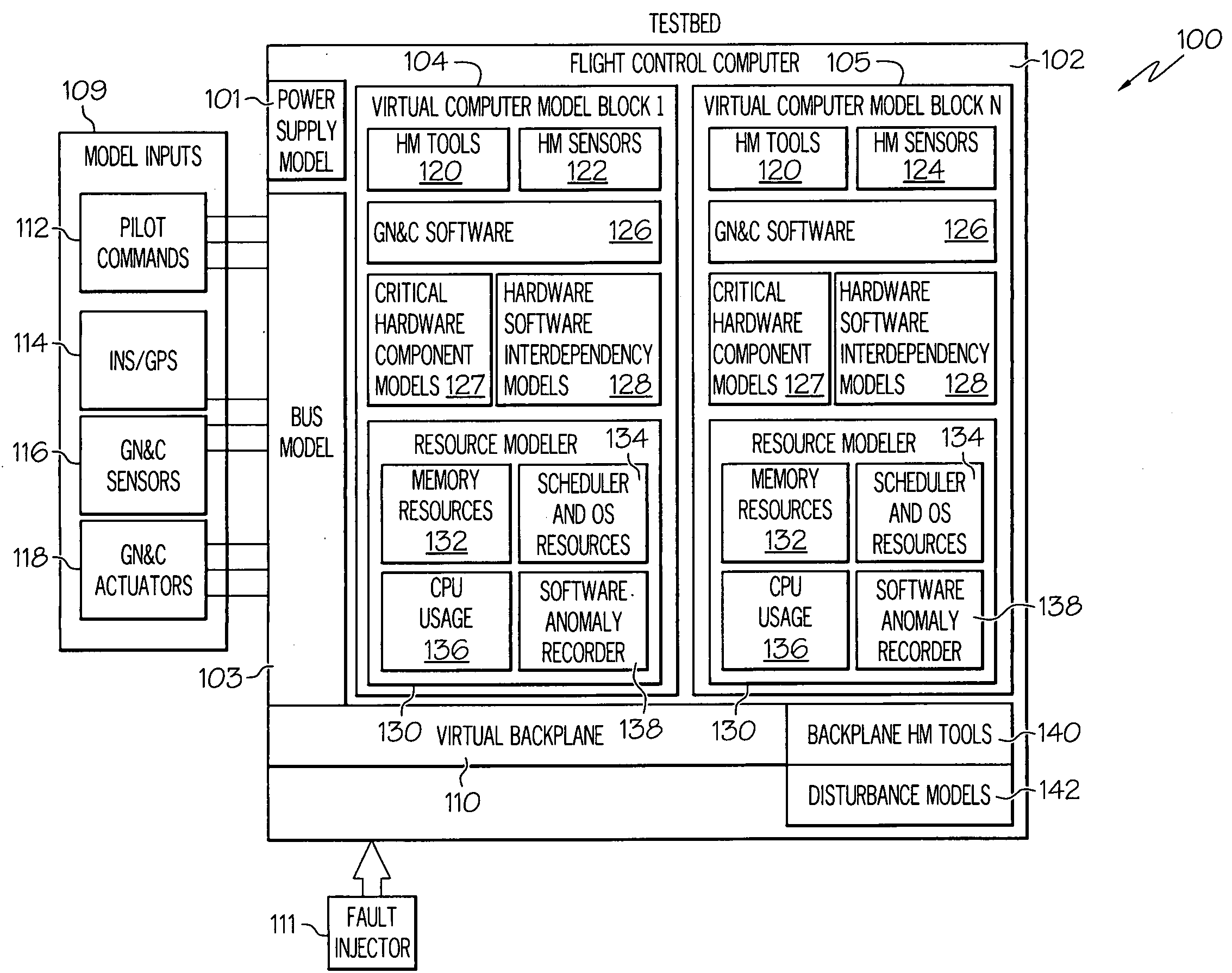

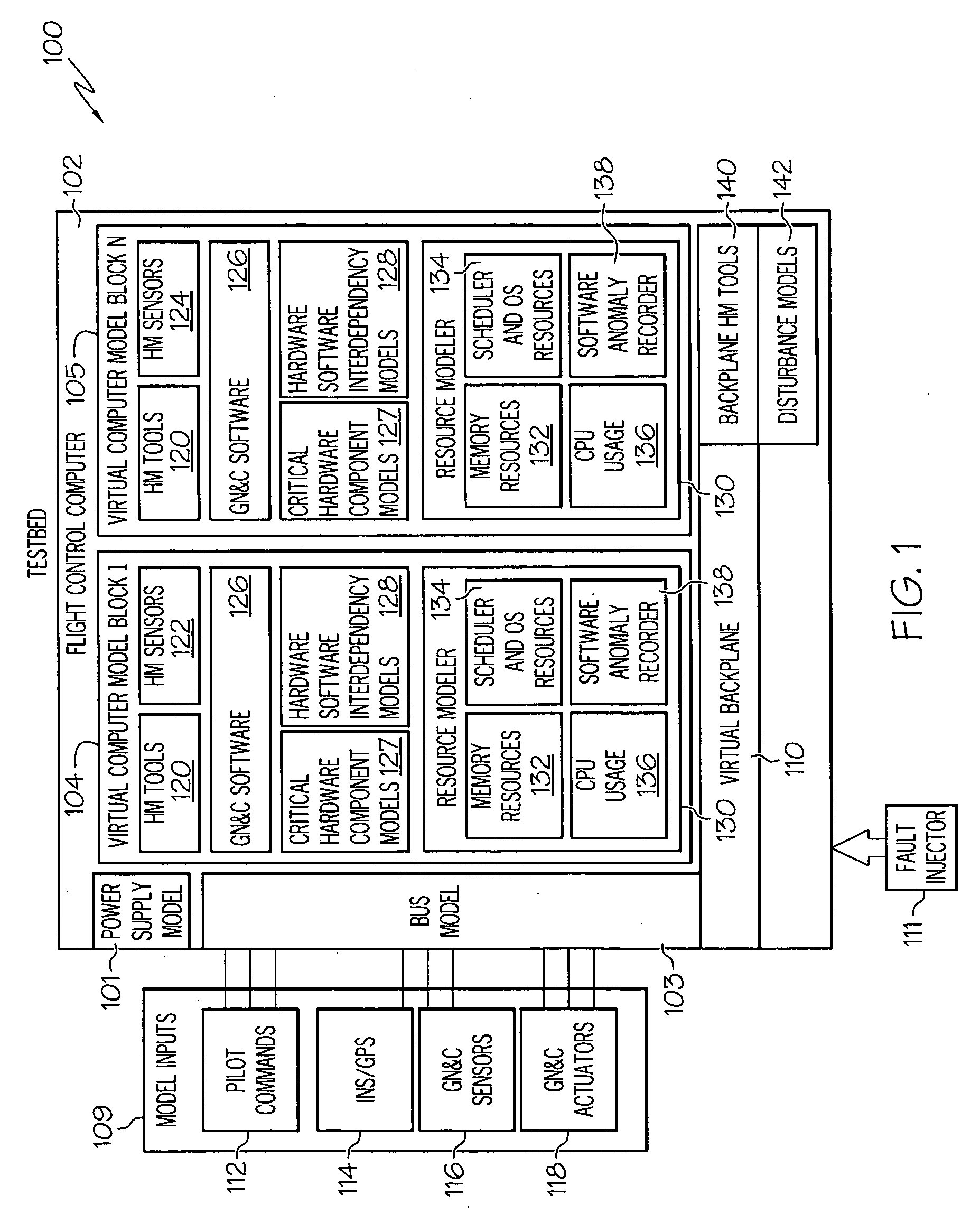

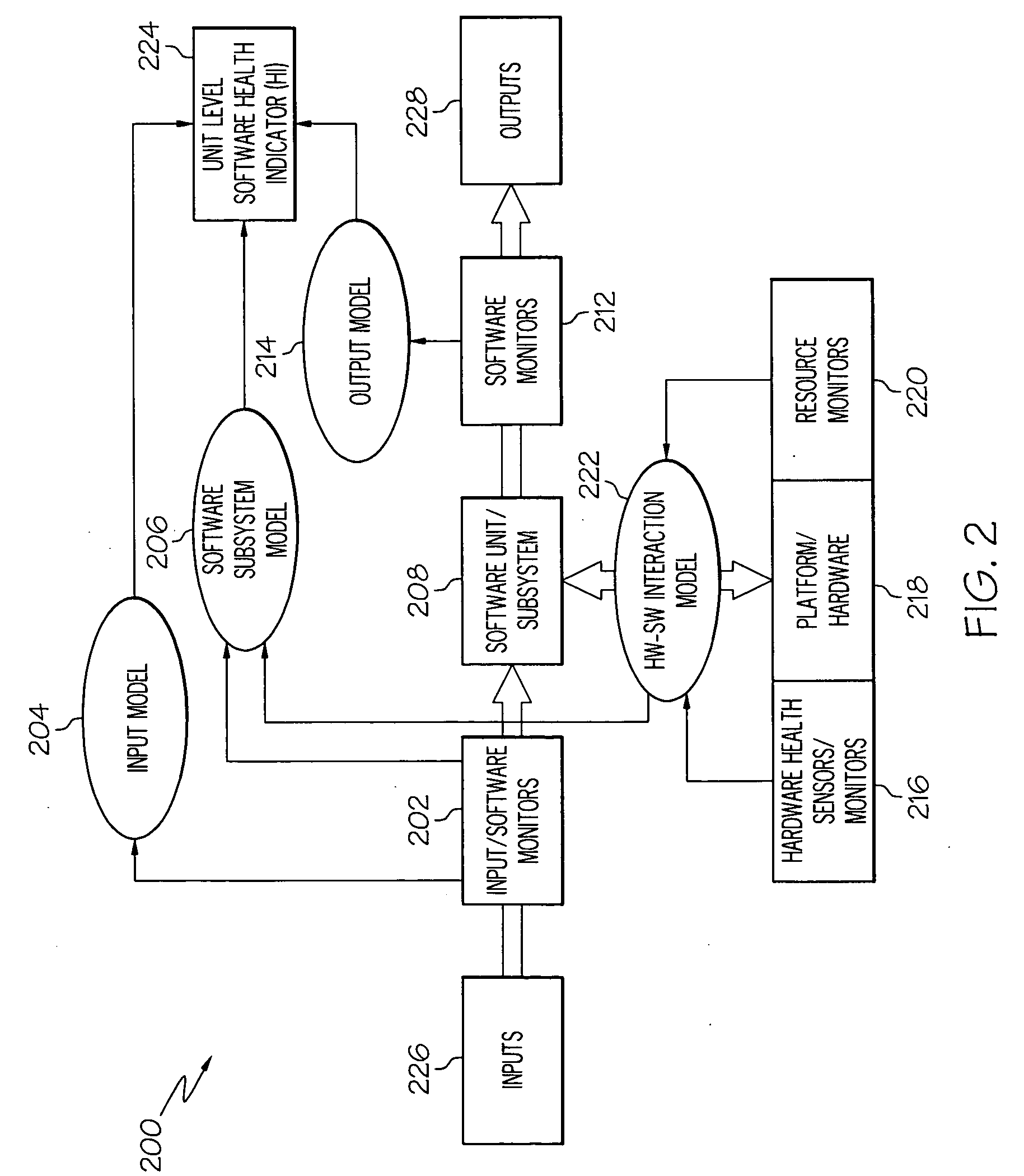

Software health management testbed

InactiveUS20100161307A1Data representation error detection/correctionError detection/correctionTestbedTesting software

A testbed for testing health of software includes an input model, a hardware model, and a resource modeler. The input model represents an input system used in conjunction with the software. The hardware model represents one or more hardware components used in conjunction with the software. The resource modeler is coupled to the input model and the hardware model, and is configured to estimate effects on the software of conditions of the hardware components, the input system, or both.

Owner:HONEYWELL INT INC

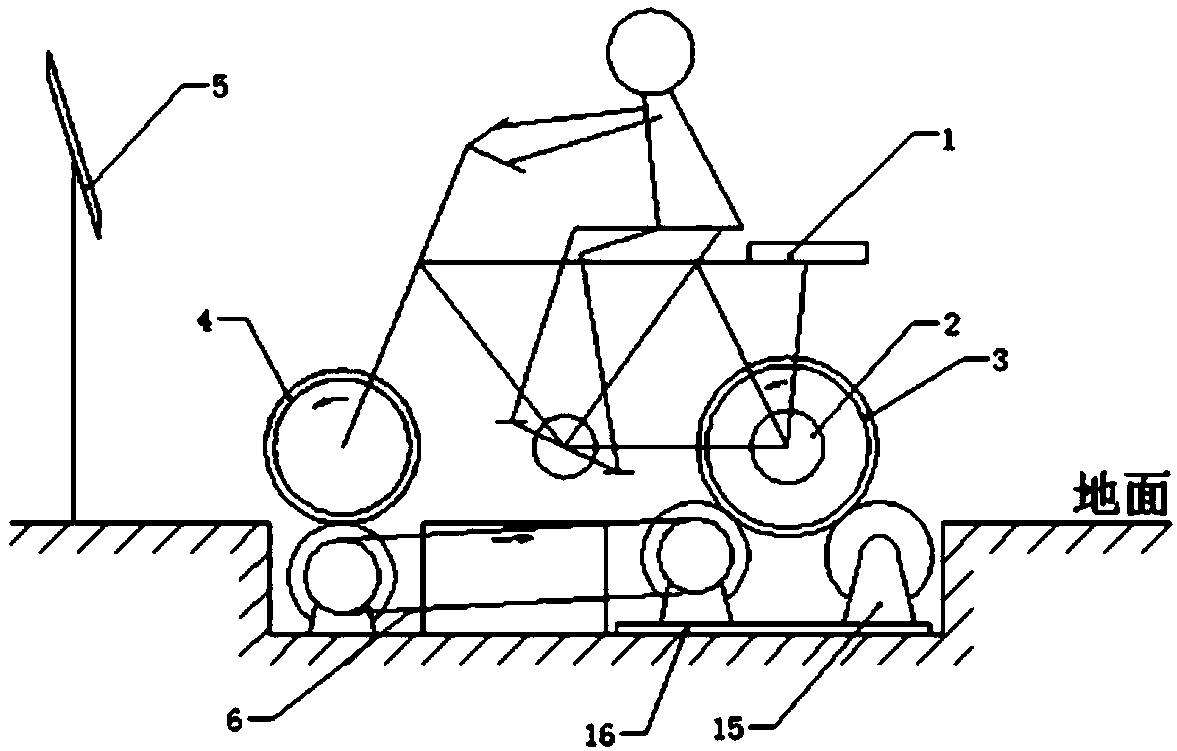

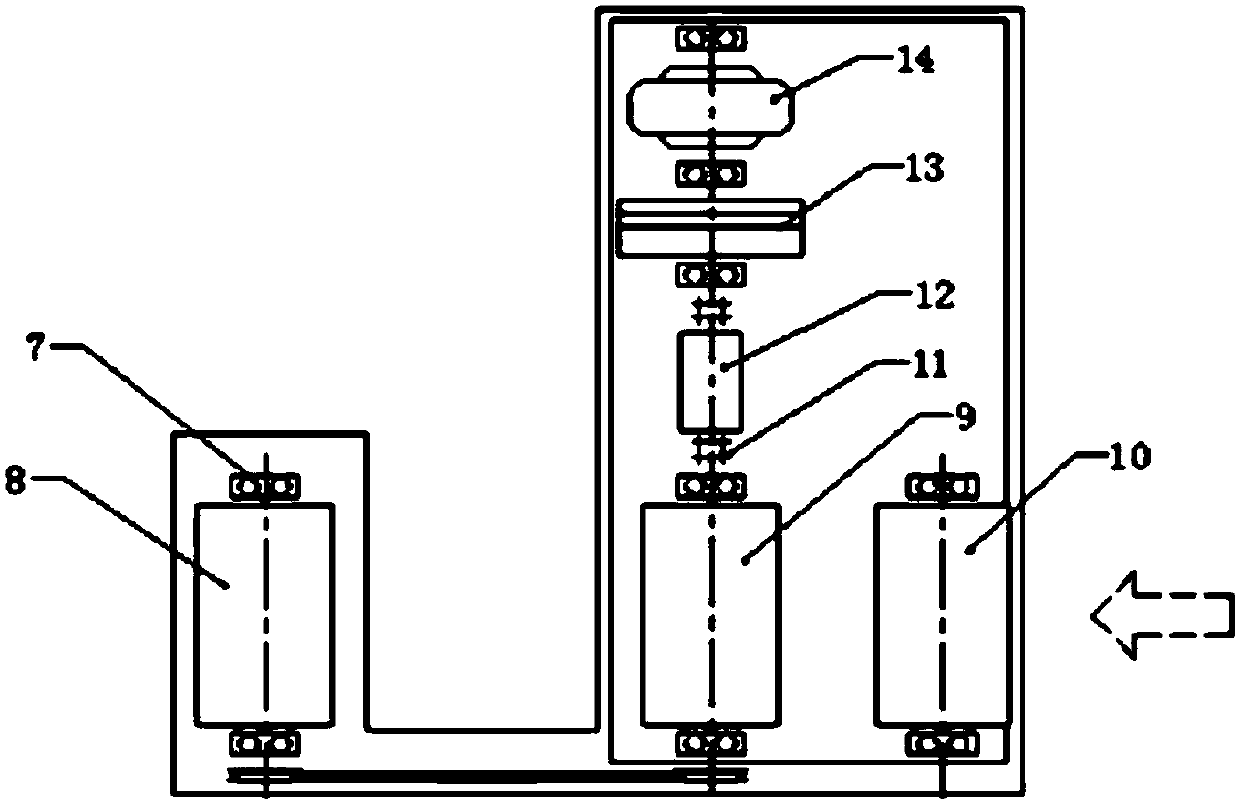

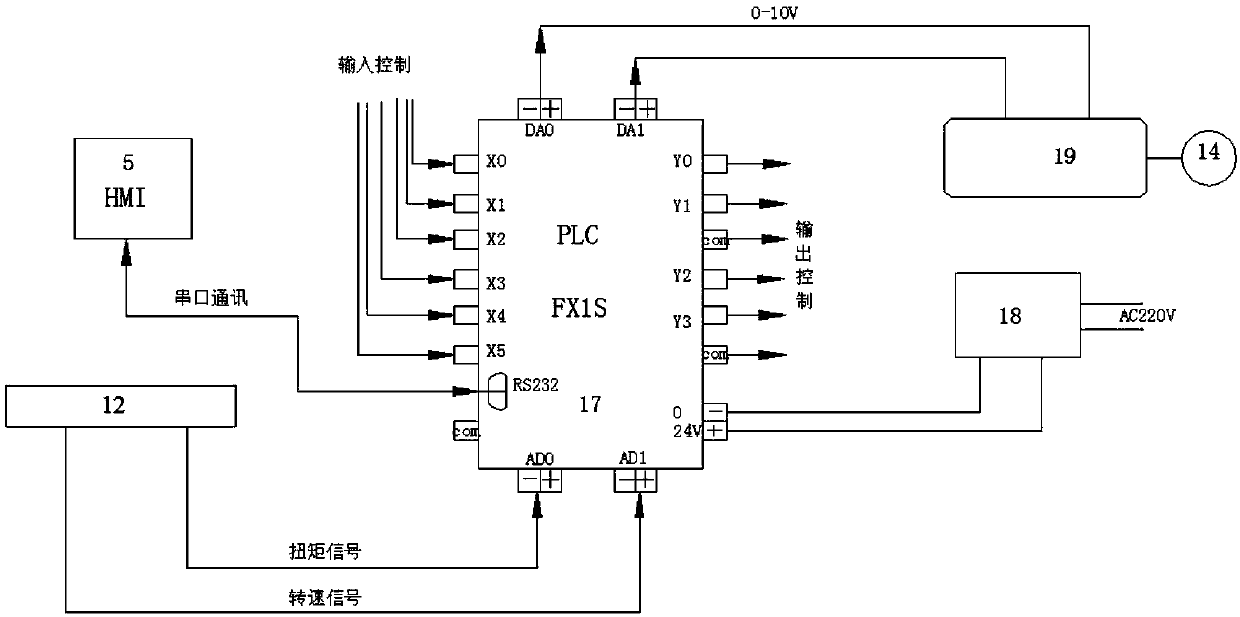

Electric two-wheeled vehicle performance detection method

The invention discloses an electric two-wheeled vehicle performance detection method. The method comprises the steps of: detecting rated continuous output power of an electric two-wheeled vehicle; testing overall braking performance of the electric two-wheeled vehicle; and testing 100-kilometer energy consumption of the electric two-wheeled vehicle, wherein the step of testing the rated continuousoutput power of the electric two-wheeled vehicle is adjusting an electric bicycle by an electric two-wheeled vehicle inspector to ensure that the electric two-wheeled vehicle runs on a detection testbed at a highest speed, transmitting real-time signals of a torque T and a rotation speed n to a programmable controller by a torque sensor of a built-in encoder, carrying out data processing by the programmable controller, and calculating the rated continuous output power P of the electric two-wheeled vehicle according to a formula. The method is capable of simulating riding states in practical roads, avoiding the influences of human factors, road factors and climatic factors during the road test, and providing good overall detection result repeatability and high credibility for two-wheeled carrying tools.

Owner:GUANGZHOU HUAGONG MOTOR VEHICLE INSPECTION TECH +1

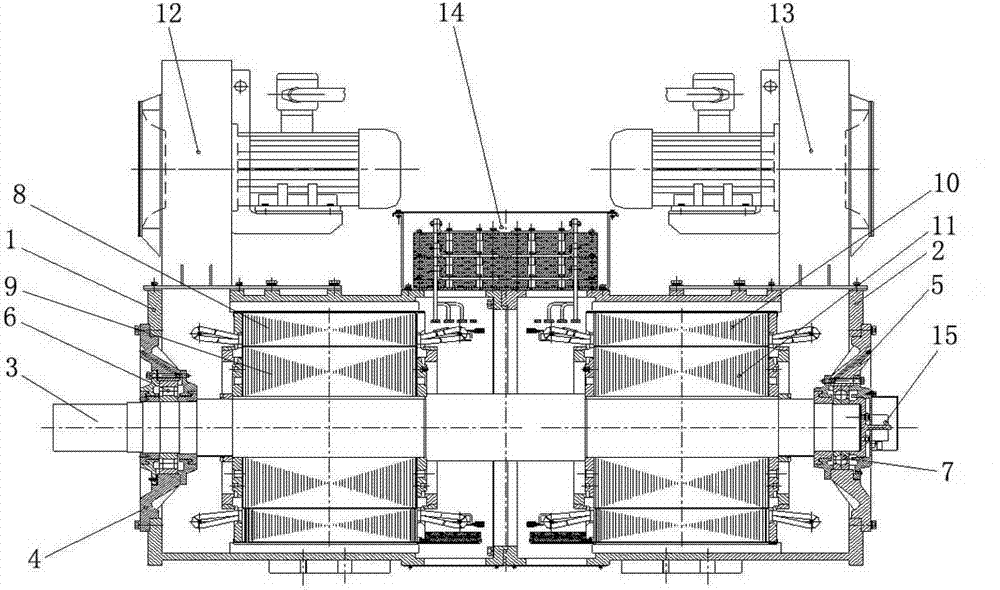

Double-stator variable frequency speed regulation asynchronous motor

InactiveCN104767330AIncrease load capacityMeet the operating environment requirementsDynamo-electric machinesConstant powerEngineering

The invention provides a double-stator variable frequency speed regulation asynchronous motor and solves the problems that a current load motor used for a testbed is large in power and wide in constant power range. The motor is a dual independent coil, namely independent stators and independent rotors, the independent stators and the independent rotors share a motor seat, double overhead draught fans force ventilation and cooling, an ejection wire box structure is used in common, import bearings are adopted, a velocity measurement encoder is installed at the non-transmission end of the motor, and the motor bearings and the coil are each provided with a temperature sensor. According to the motor, by selecting the electromagnetism parameters and mechanical structure of the motor reasonably, the requirements of large power (2 * 1200 kW) and wide constant power range (41.6 - 106 Hz) are satisfied, the load capacity of the motor at a high velocity section is improved, the operating environment requirements of the experimental motor are satisfied, and relevant technological standards of the asynchronous motor are satisfied. The motor has a certain potential market, and by referring to the designing and manufacturing experience of the motor, certain economic benefits can be obtained by applying the experience to other fields.

Owner:CRRC YONGJI ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com