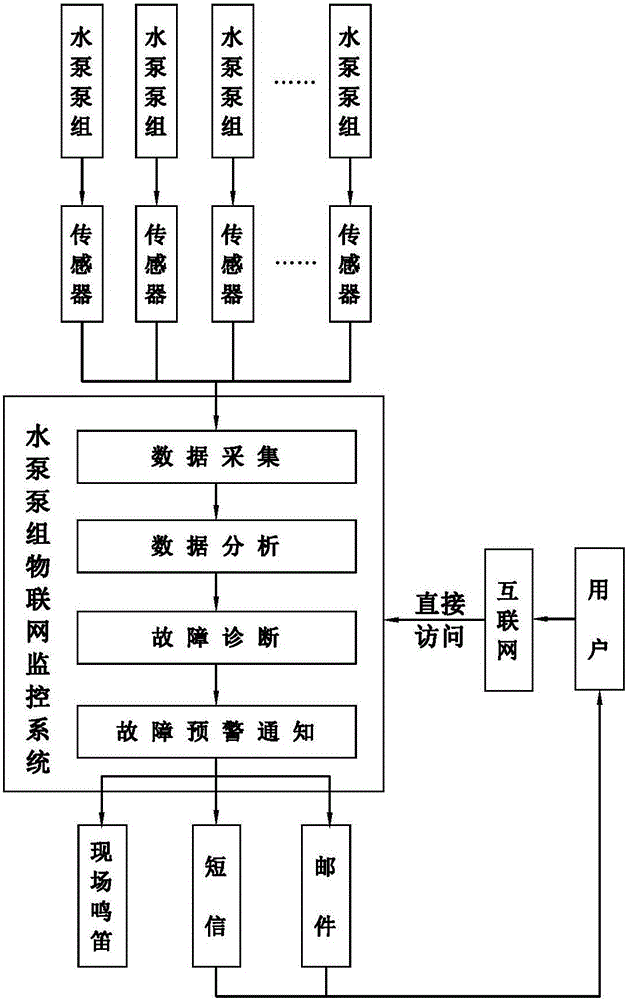

Intelligent water pump set monitoring and fault early warning method based on internet of things

A fault warning and intelligent monitoring technology, applied in pump control, non-variable-capacity pumps, machines/engines, etc., can solve the problems of single function, low reasoning efficiency, immature intelligent monitoring and fault warning methods, etc., and reduce maintenance. Cost, effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] A centrifugal pump with a specific speed of 73 has a design flow of Q d =27m 3 / h, design head H d =11m, speed n=1450r / min.

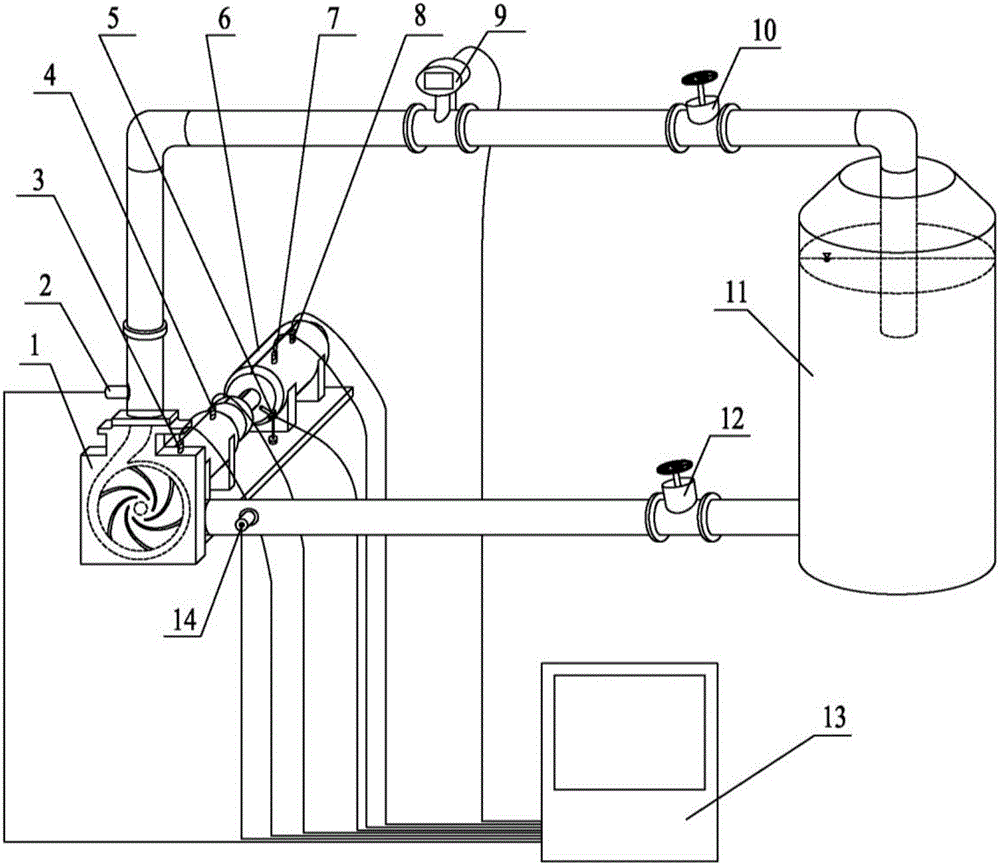

[0035] (1) Build a water pump test bench based on the electrical measurement method, such as figure 2 shown. Measure the no-load loss of the three-phase motor, draw the no-load characteristic curve of the three-phase motor, and separate the iron loss and mechanical loss. The separated iron loss and mechanical loss are 356.93W and 121.47W respectively.

[0036] The speed n of the pump is measured by the photoelectric sensor, the flow Q is measured by the electromagnetic flowmeter on the outlet pipeline system of the pump group, and the inlet pressure P i Measured by the pressure sensor on the pump inlet pipeline, the outlet pressure P o Measured by the pressure sensor on the pump outlet line. Bearing temperature and motor temperature are measured by temperature sensor, motor vibration and pump vibration are measured by vibration sensor.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com