Patents

Literature

781 results about "Axial-flow pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An axial-flow pump, or AFP, is a common type of pump that essentially consists of a propeller (an axial impeller) in a pipe. The propeller can be driven directly by a sealed motor in the pipe or by electric motor or petrol/diesel engines mounted to the pipe from the outside or by a right-angle drive shaft that pierces the pipe.

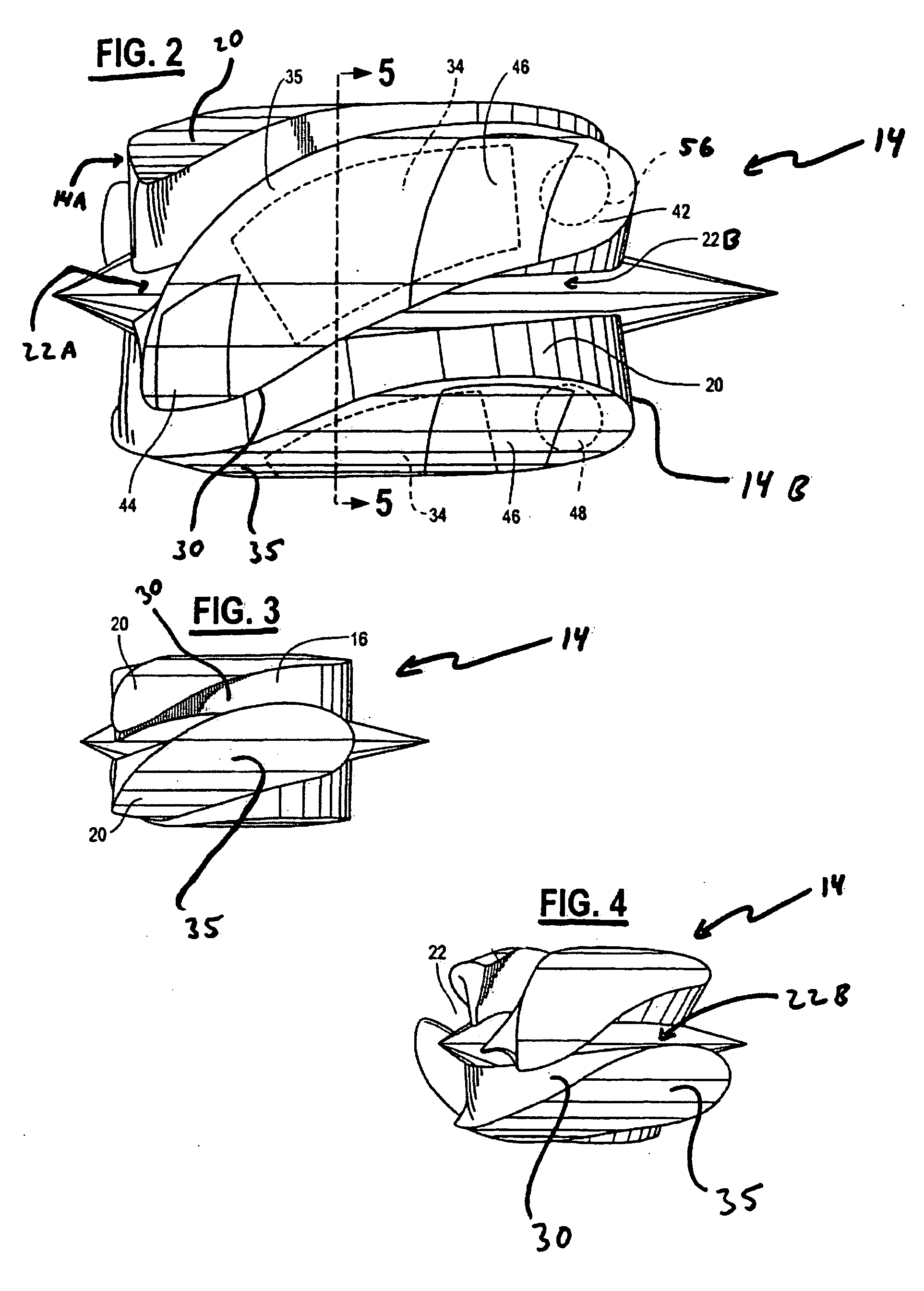

Wide blade, axial flow pump

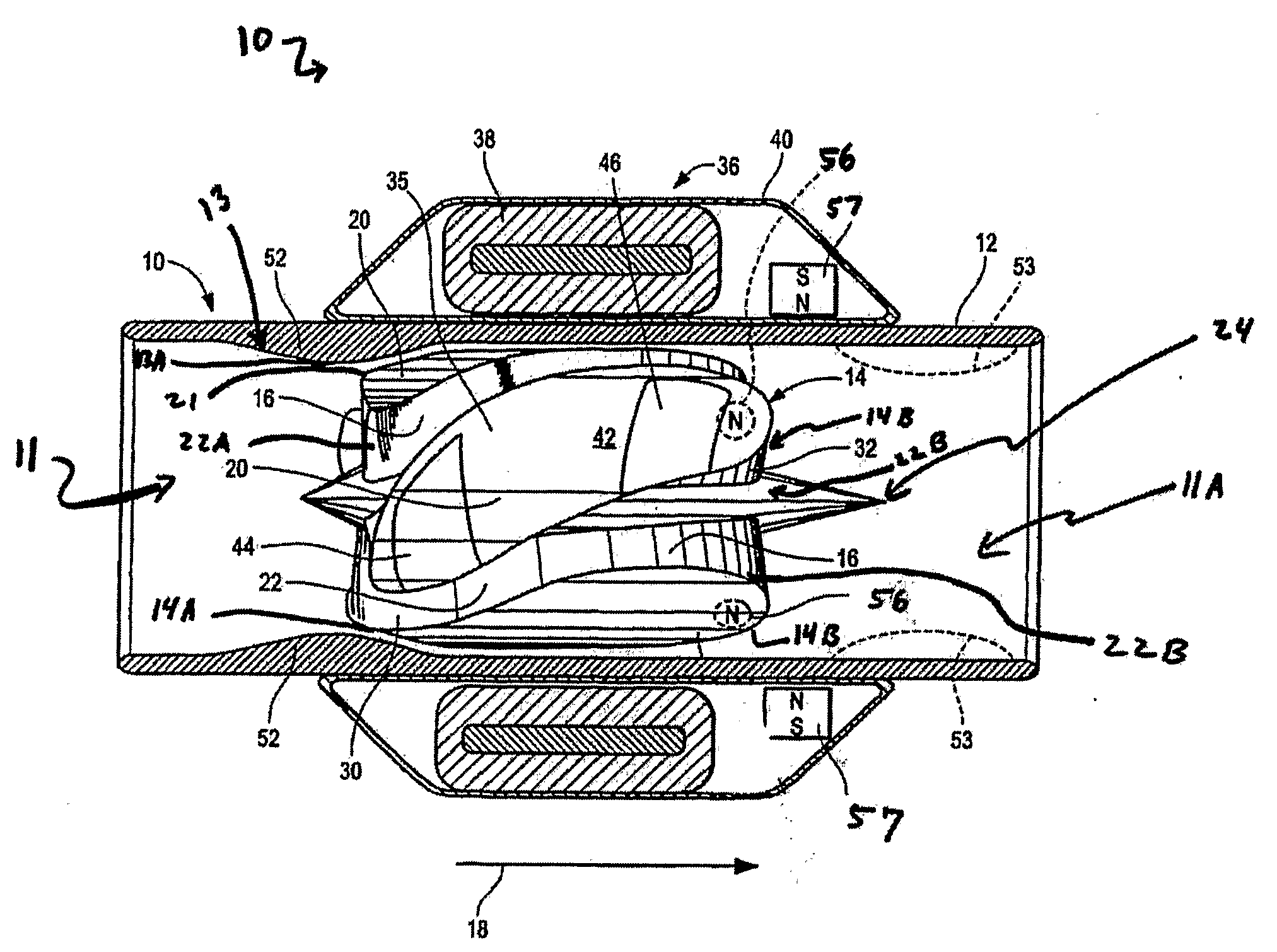

ActiveUS7699586B2Increase the magnetic fluxReduce air gapControl devicesBlood pumpsAxial-flow pumpImpeller

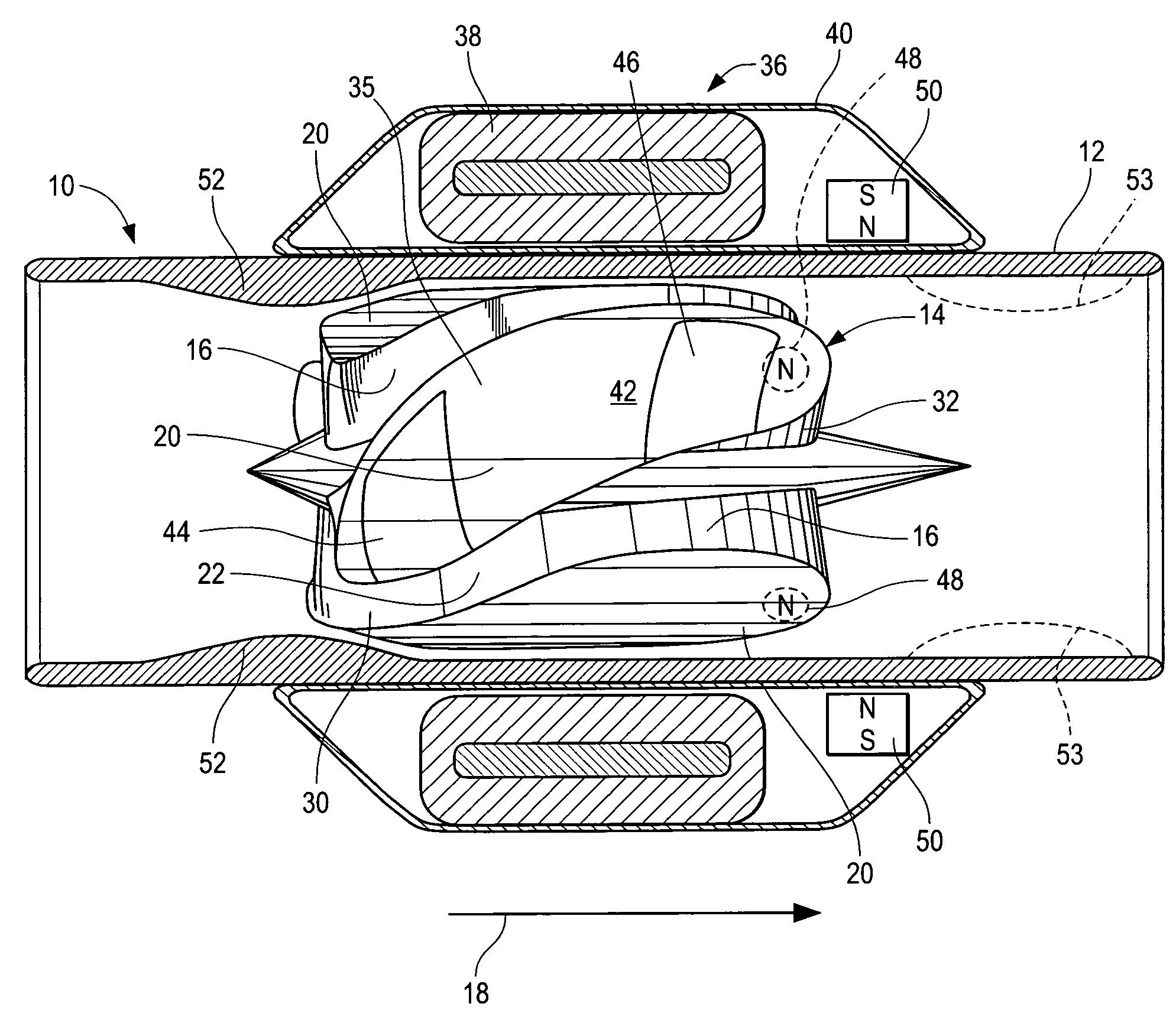

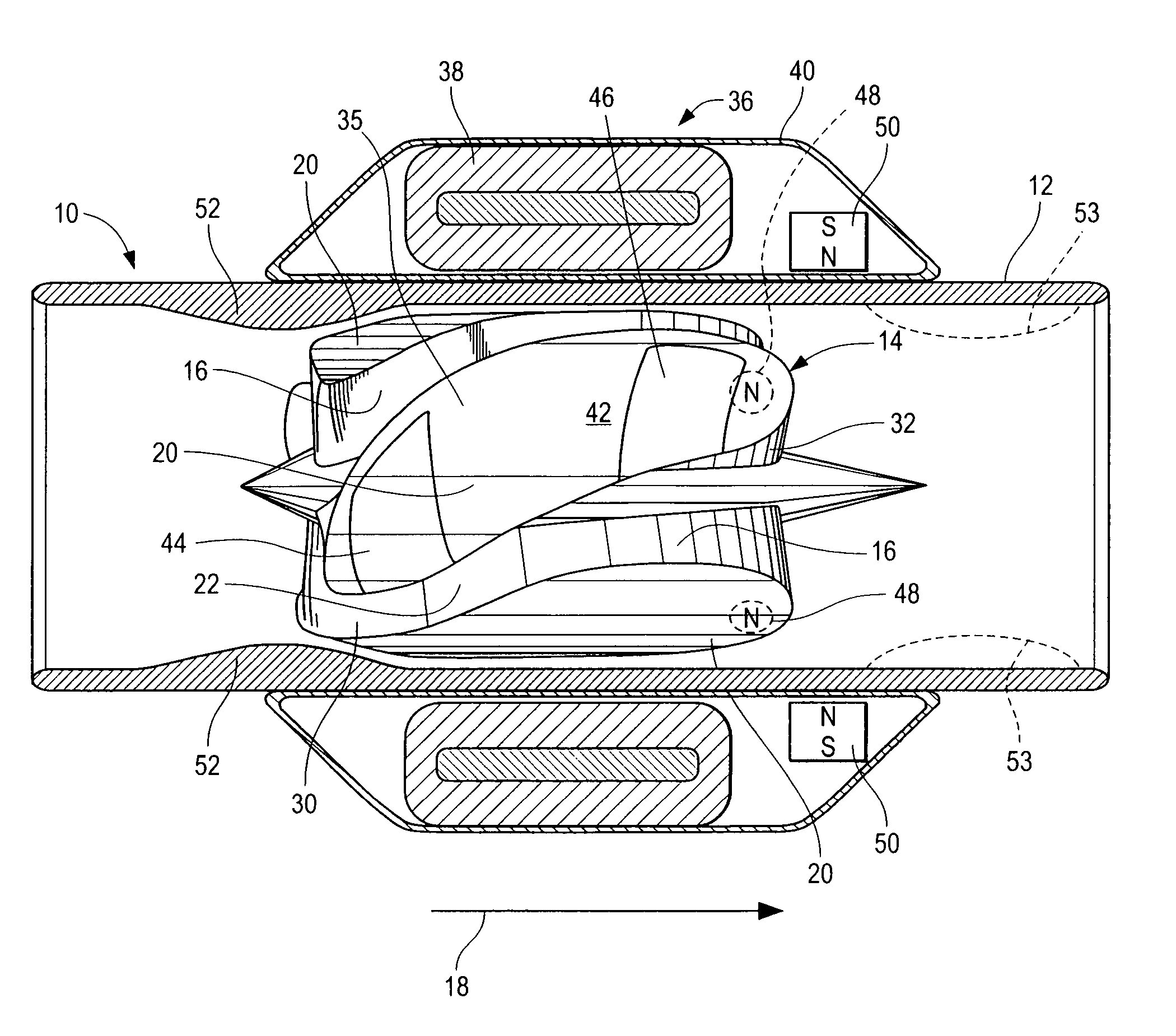

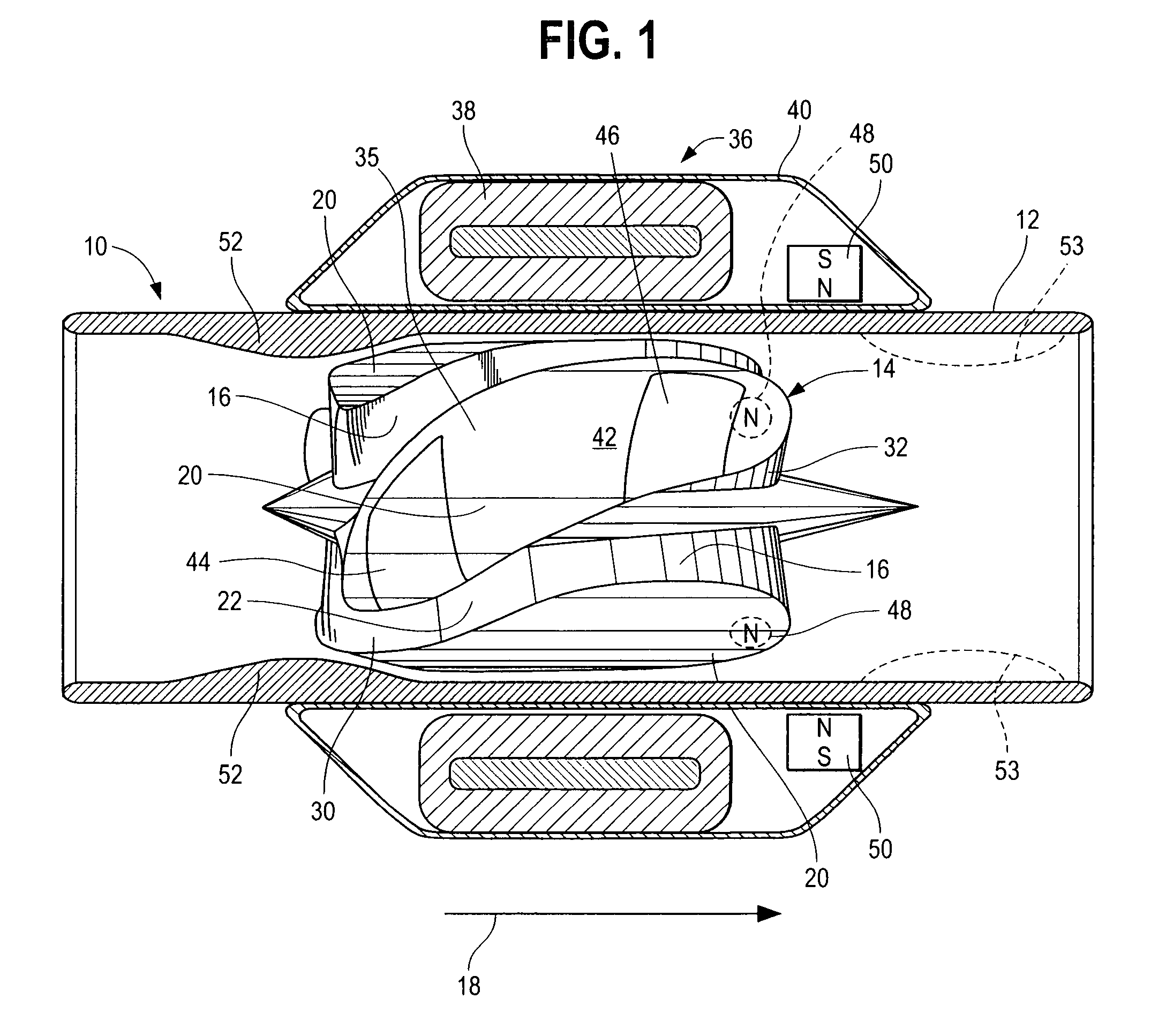

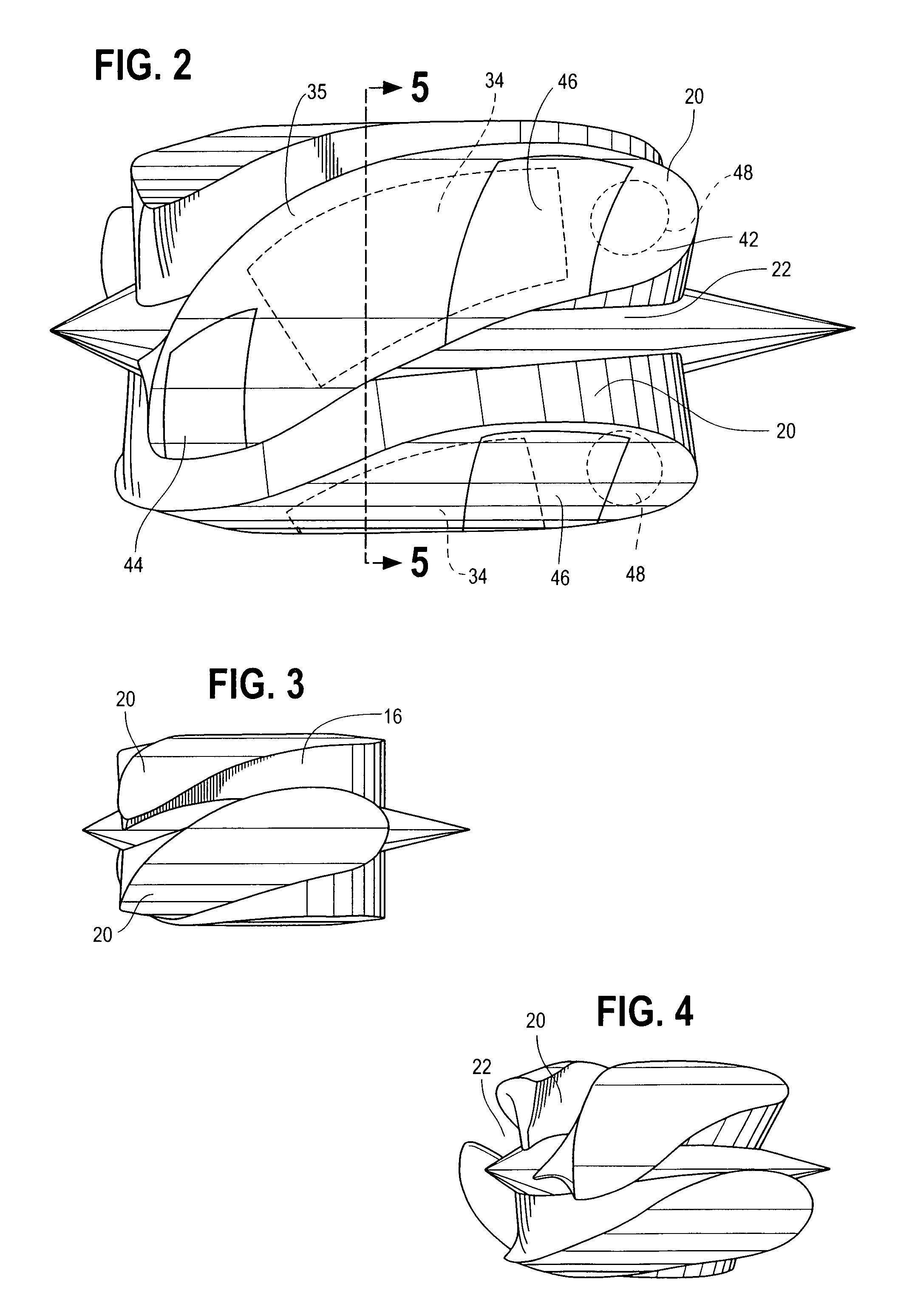

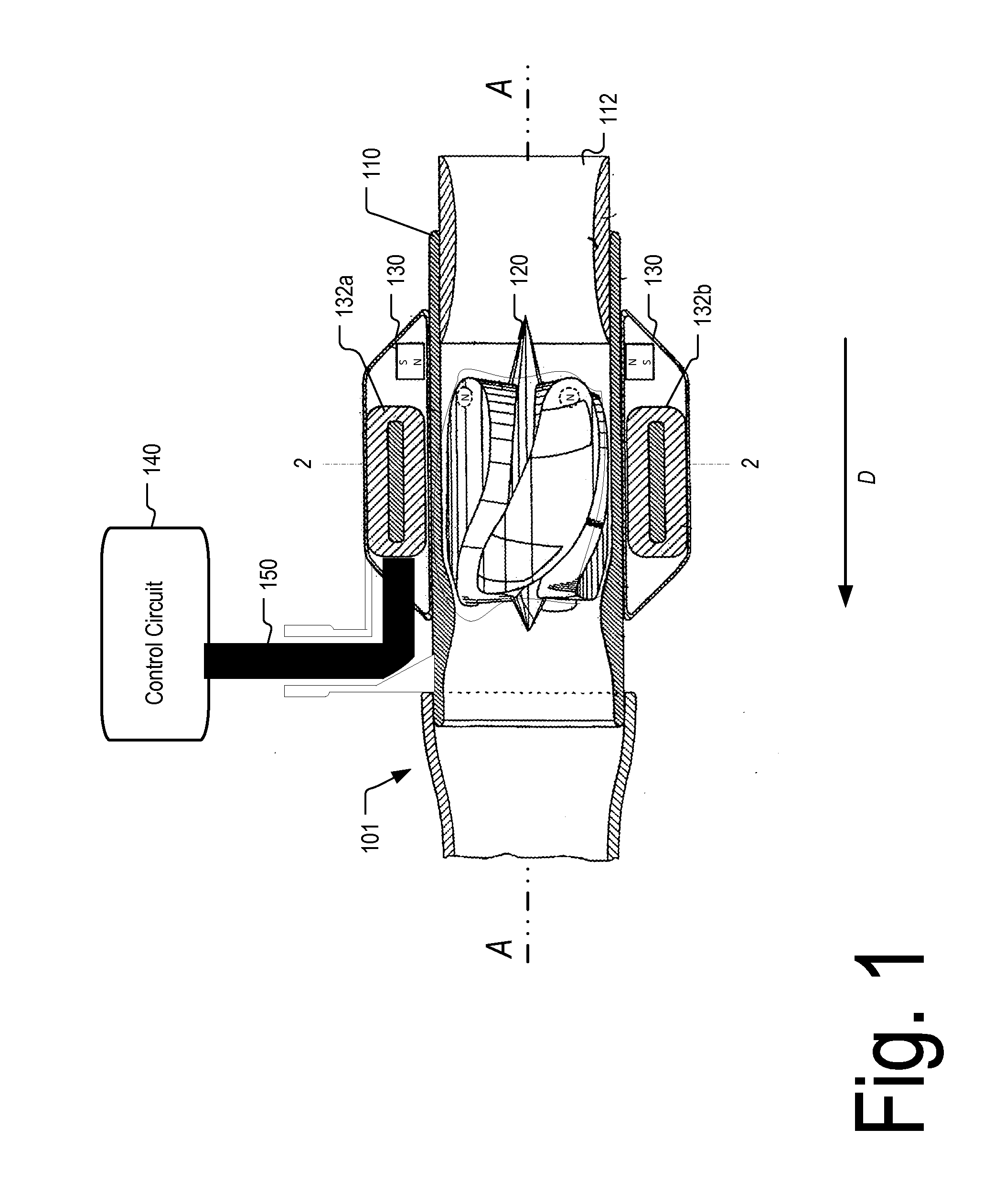

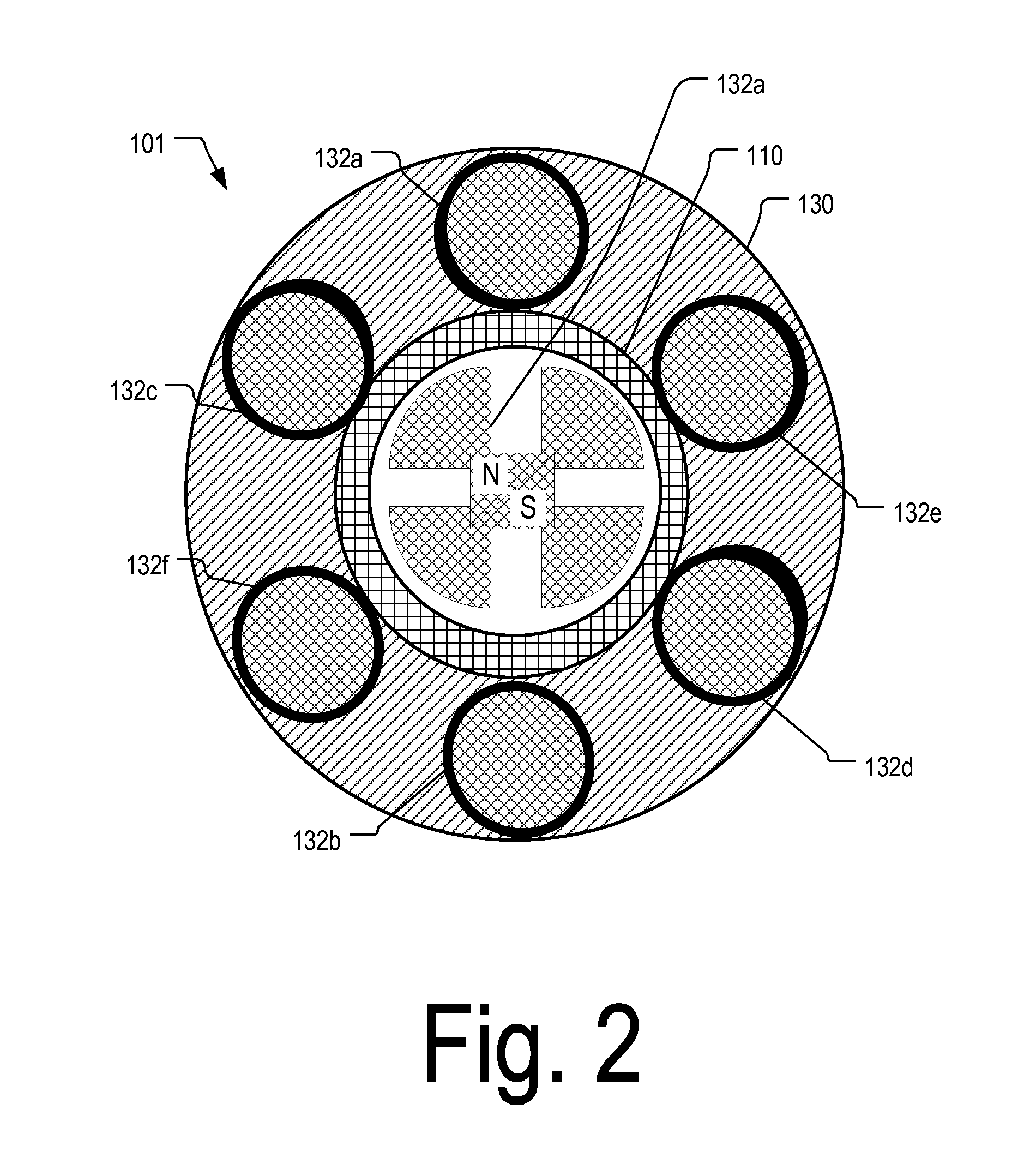

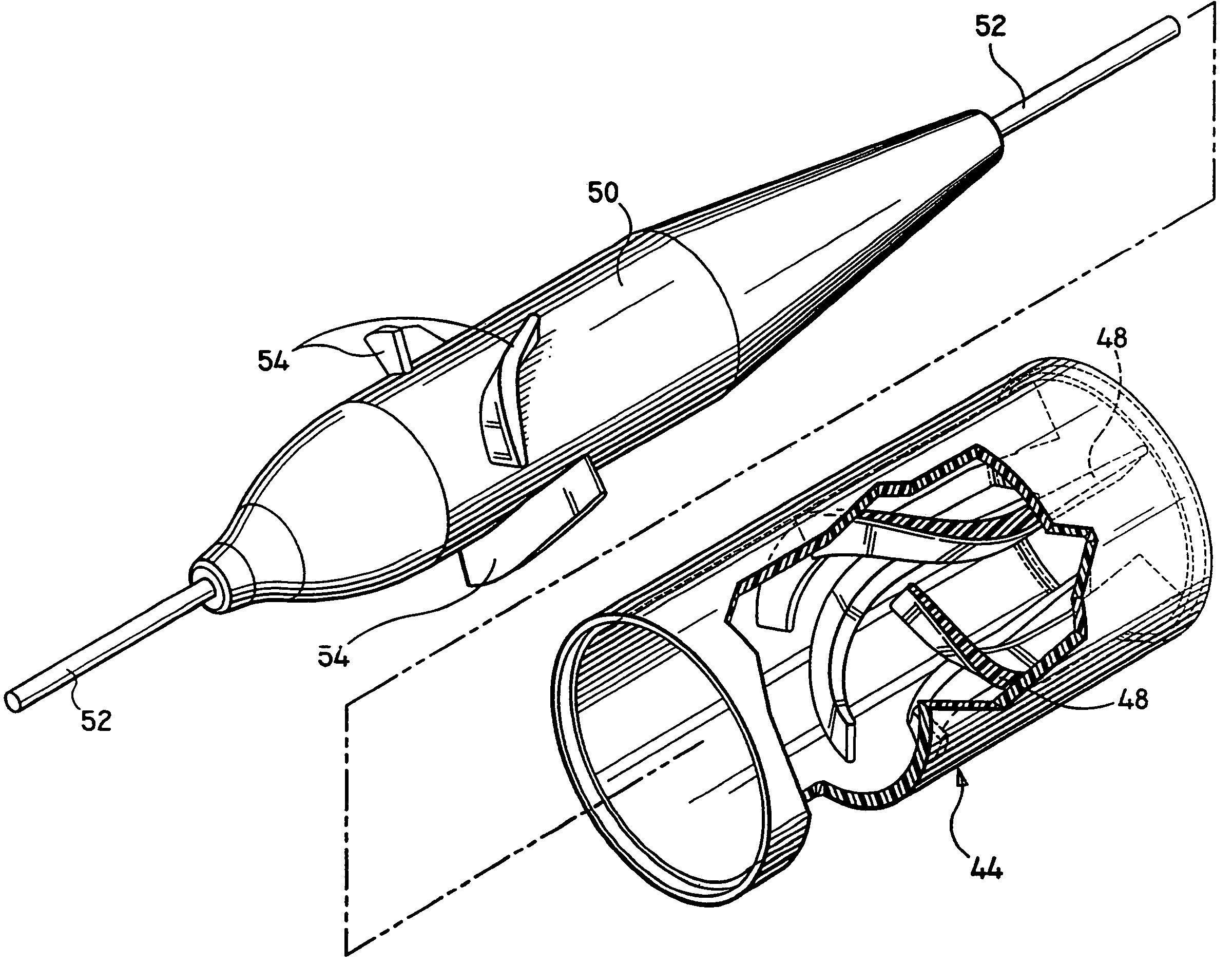

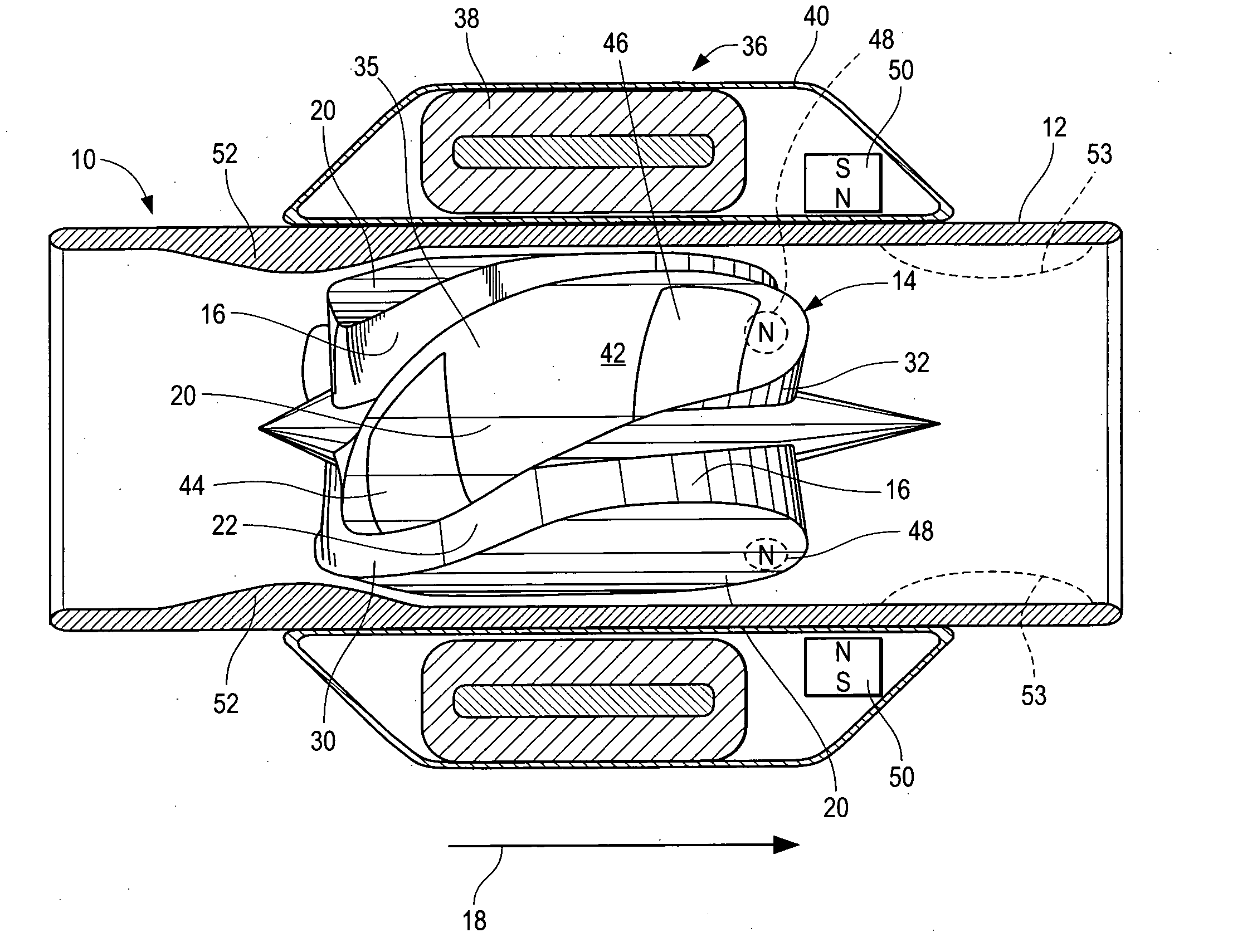

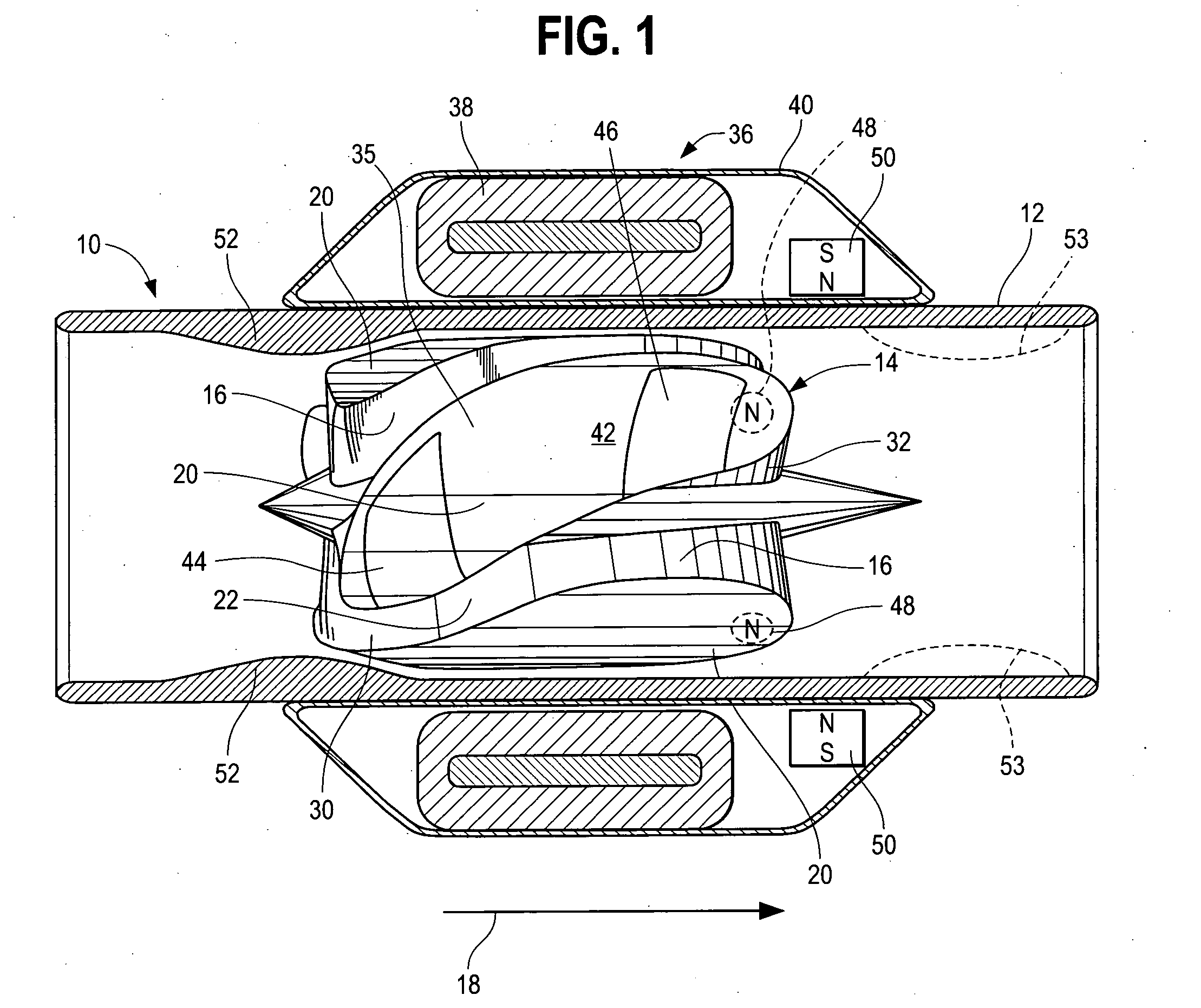

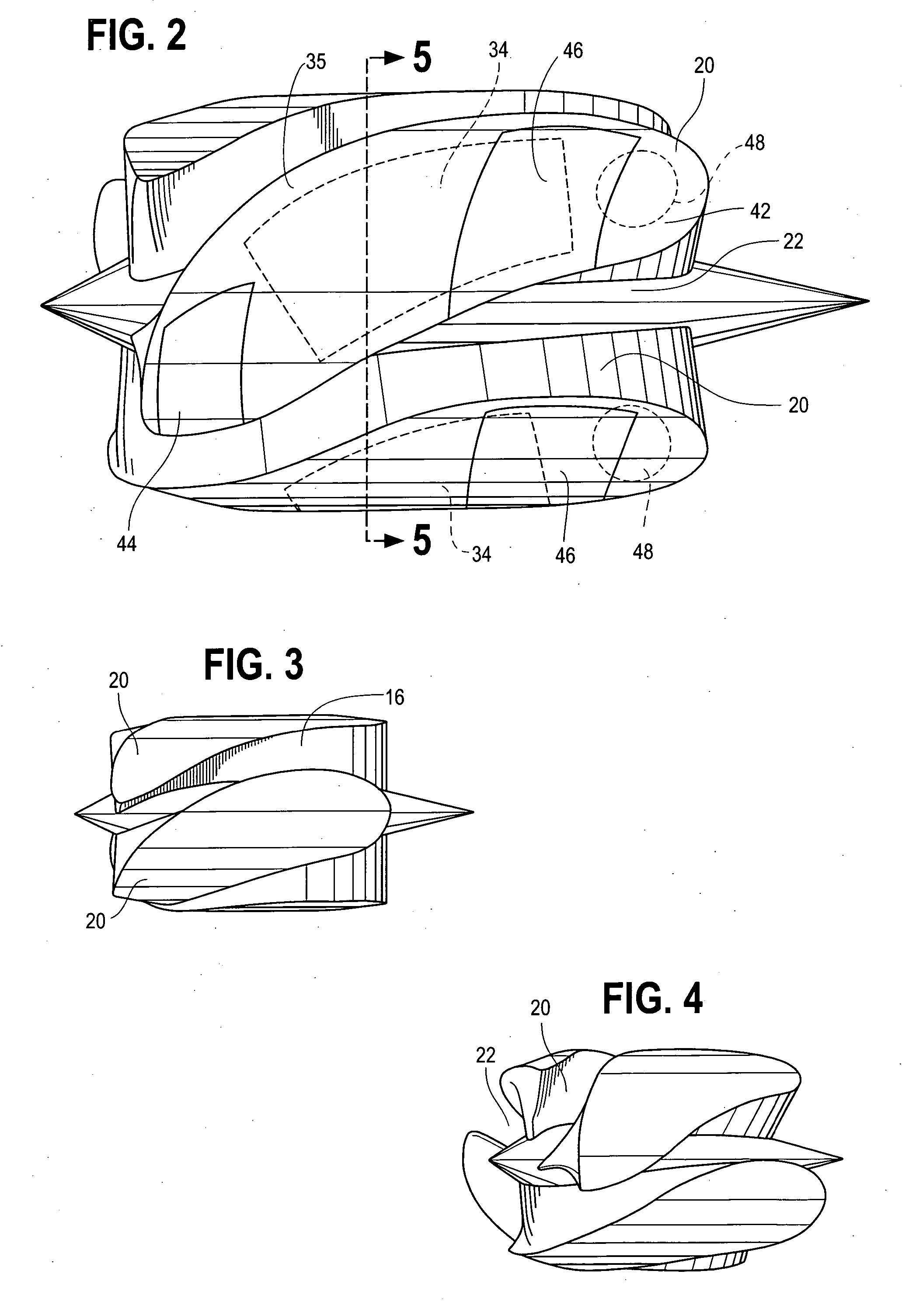

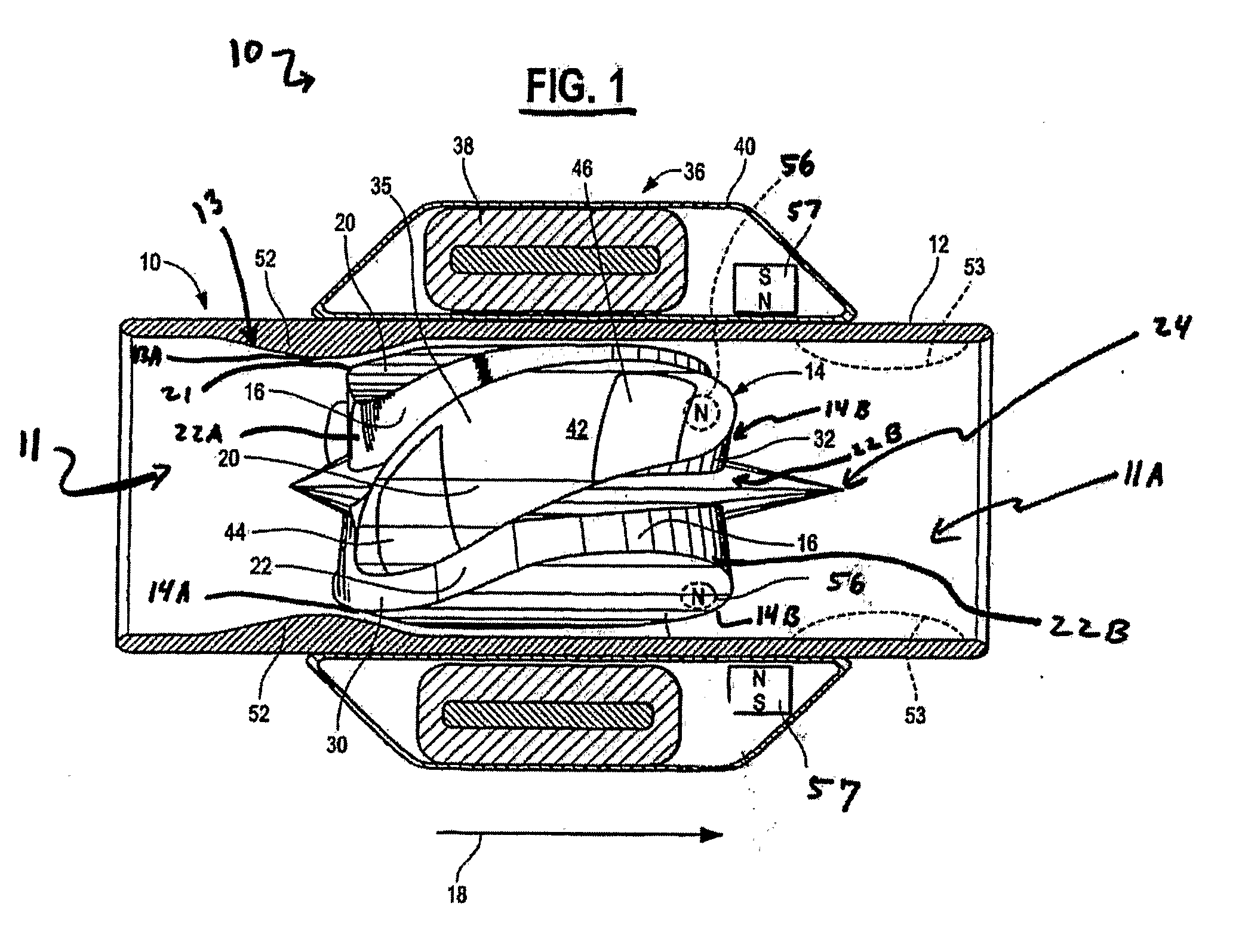

A blood pump comprises a pump housing; a rotor positioned in the housing and comprising an impeller having a hydrodynamic surface for pumping blood; and a motor including a plurality of magnets carried by the impeller, plus a rotor stator, including an electrically conductive coil located adjacent to or within the housing. The impeller comprises radially outwardly extending, bladelike projections that define generally longitudinally extending spaces between the projections. The shape of the projections and the spaces therebetween tend to drive blood in the spaces in an axial direction as the impeller is rotated. The spaces collectively have a total width along most of their lengths at the radial periphery of the rotor, that is substantially equal to or less than the collective width of the projections along most of their lengths at the radial periphery. Thus, the bladelike projections are thicker, achieving significant advantages.

Owner:HEARTWARE INC

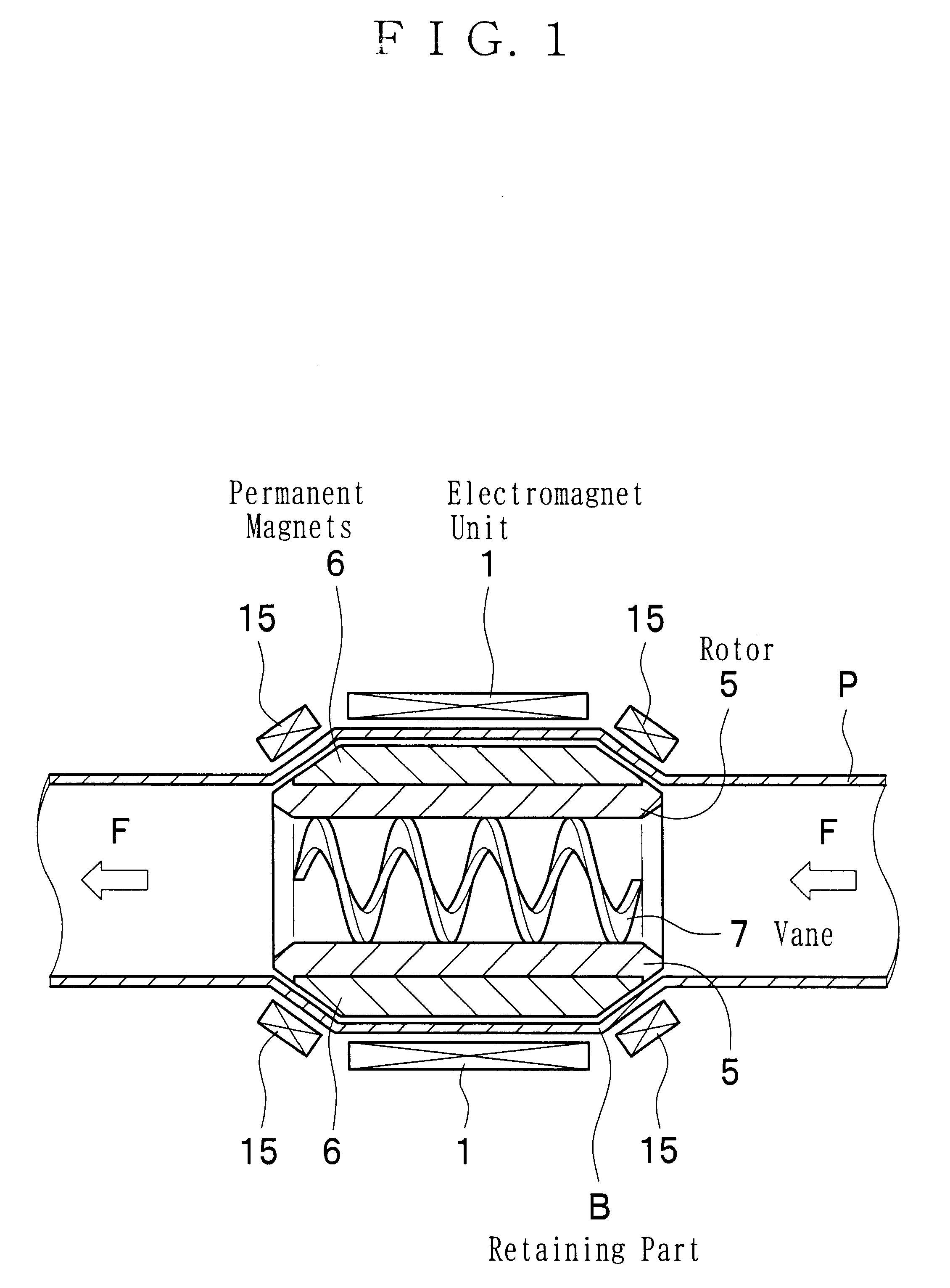

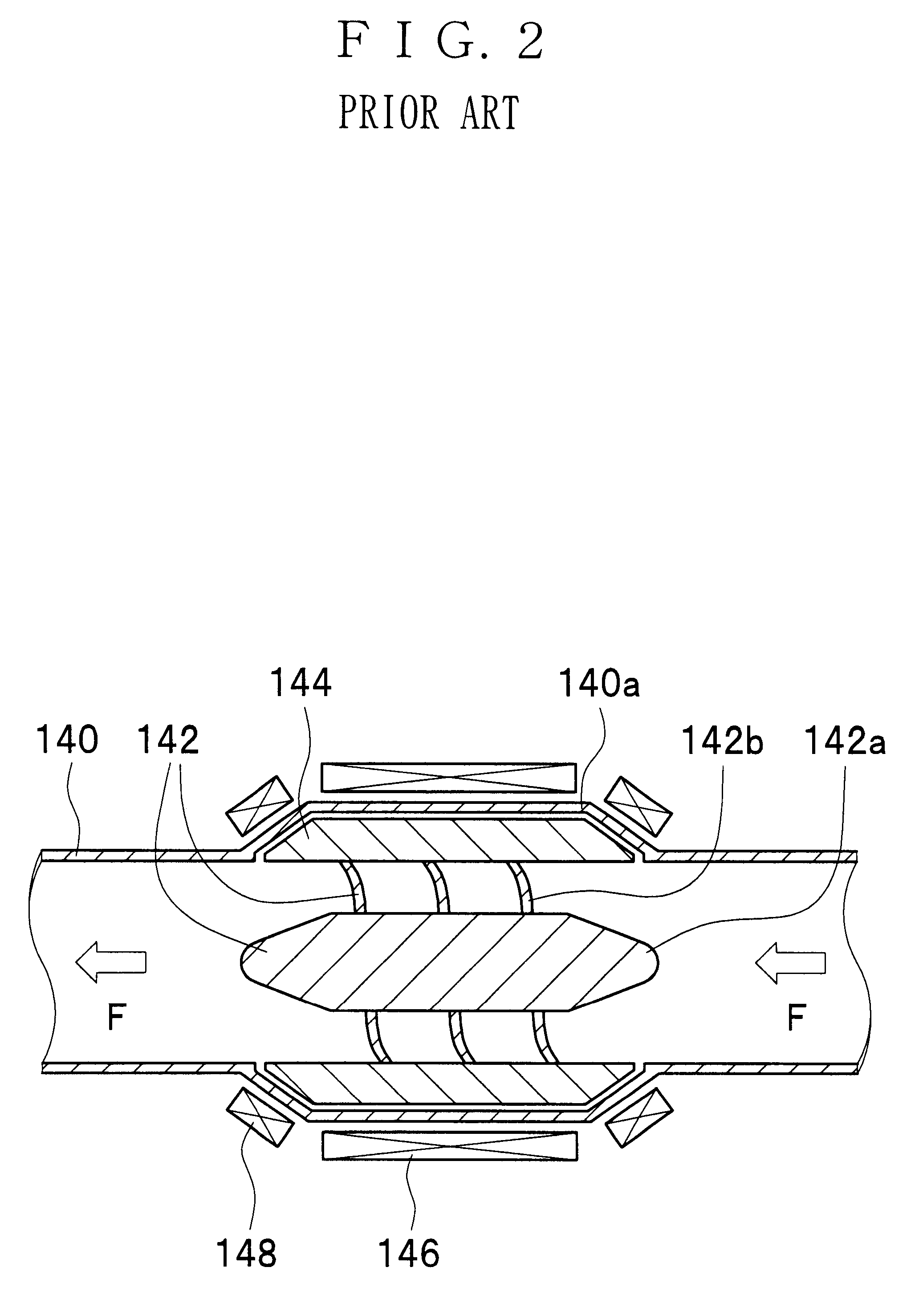

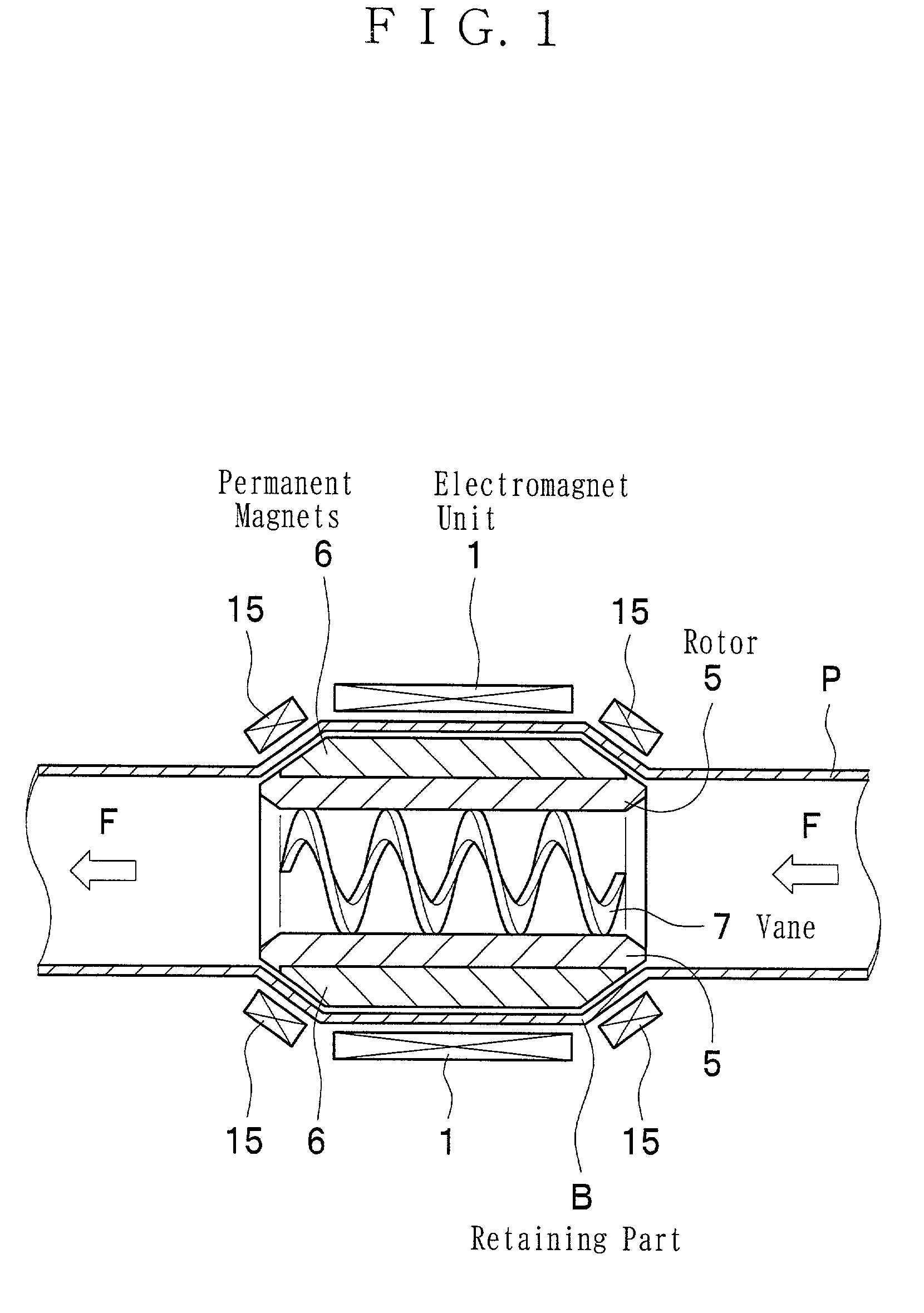

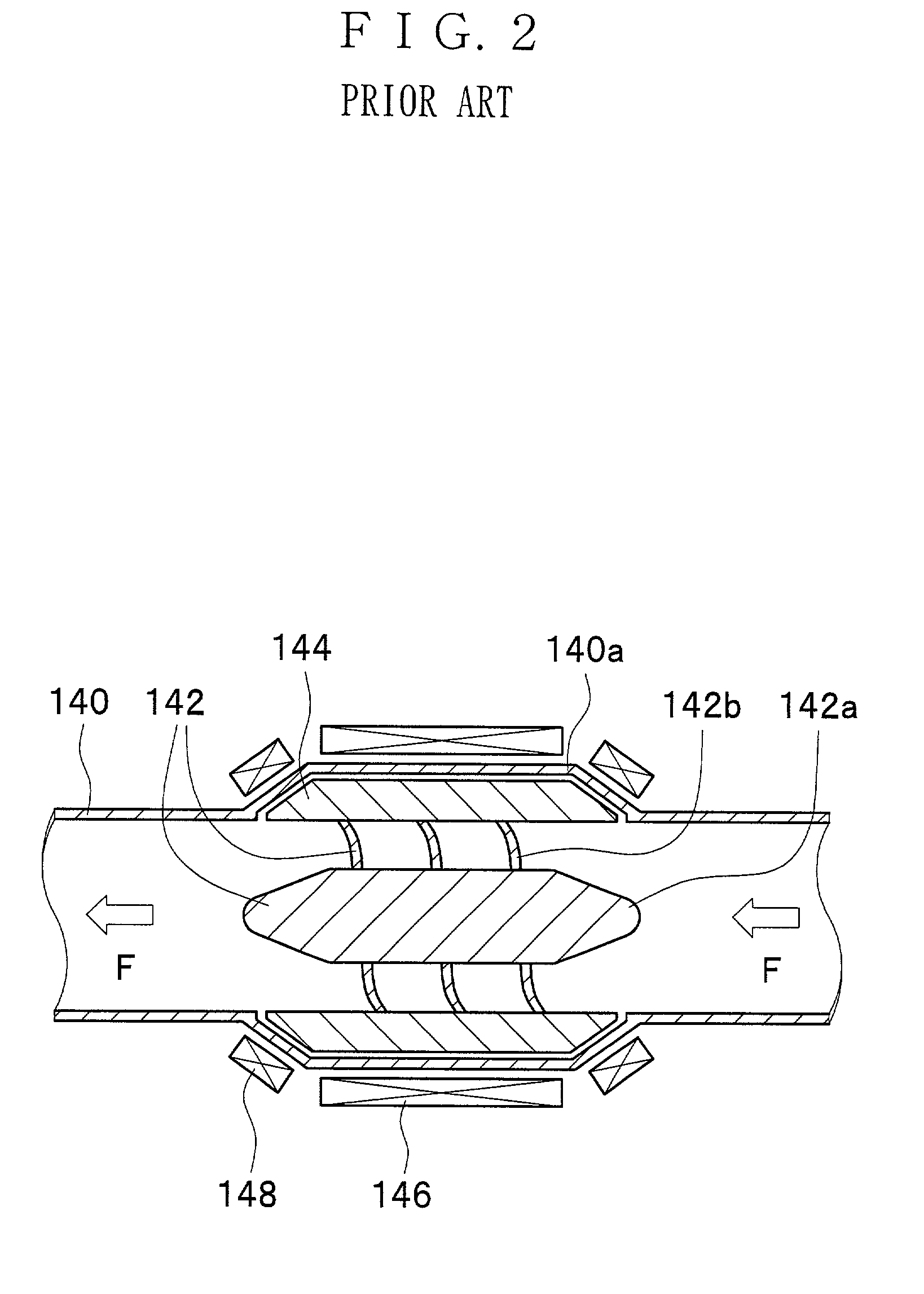

Magnetically driven axial-flow pump

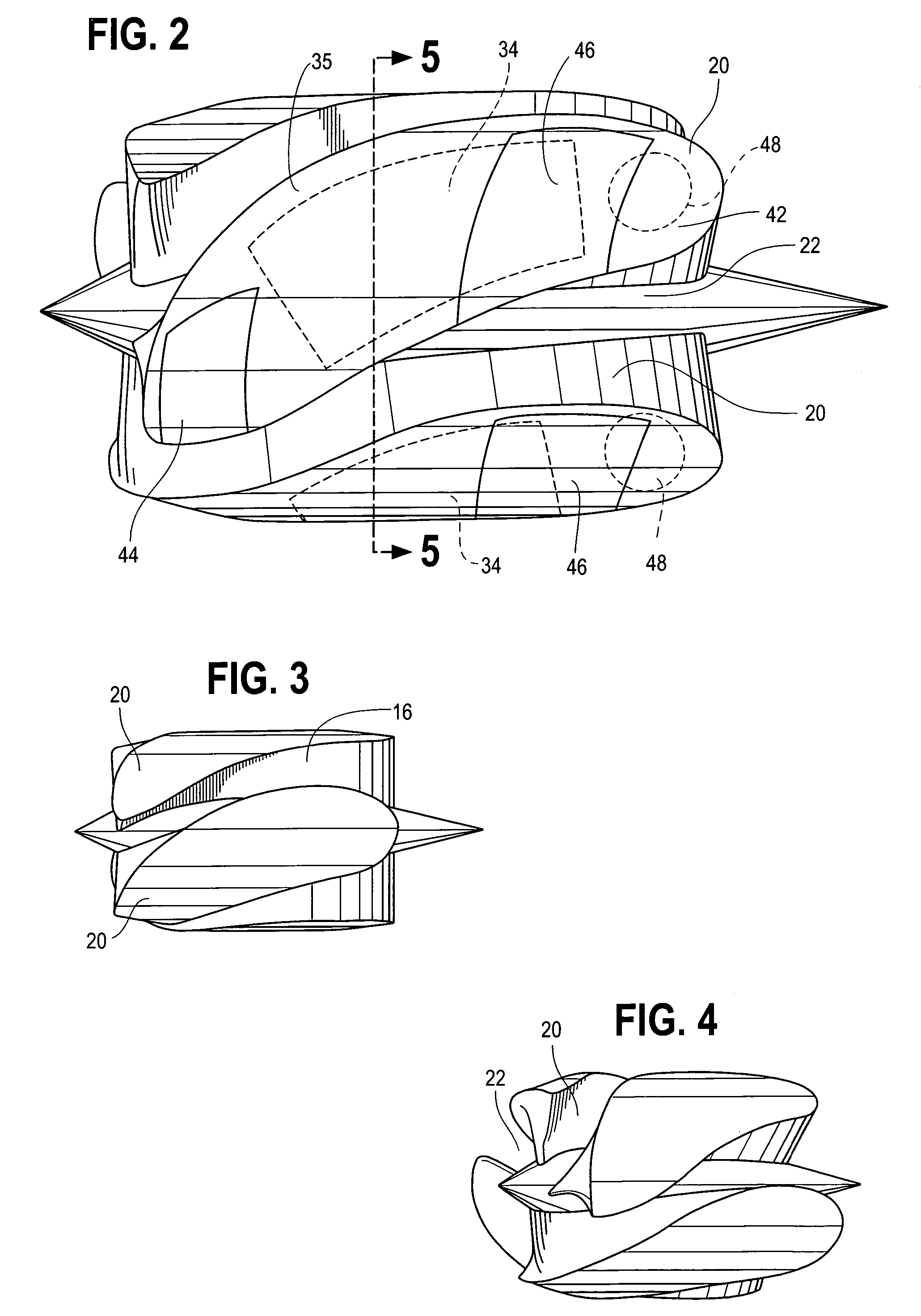

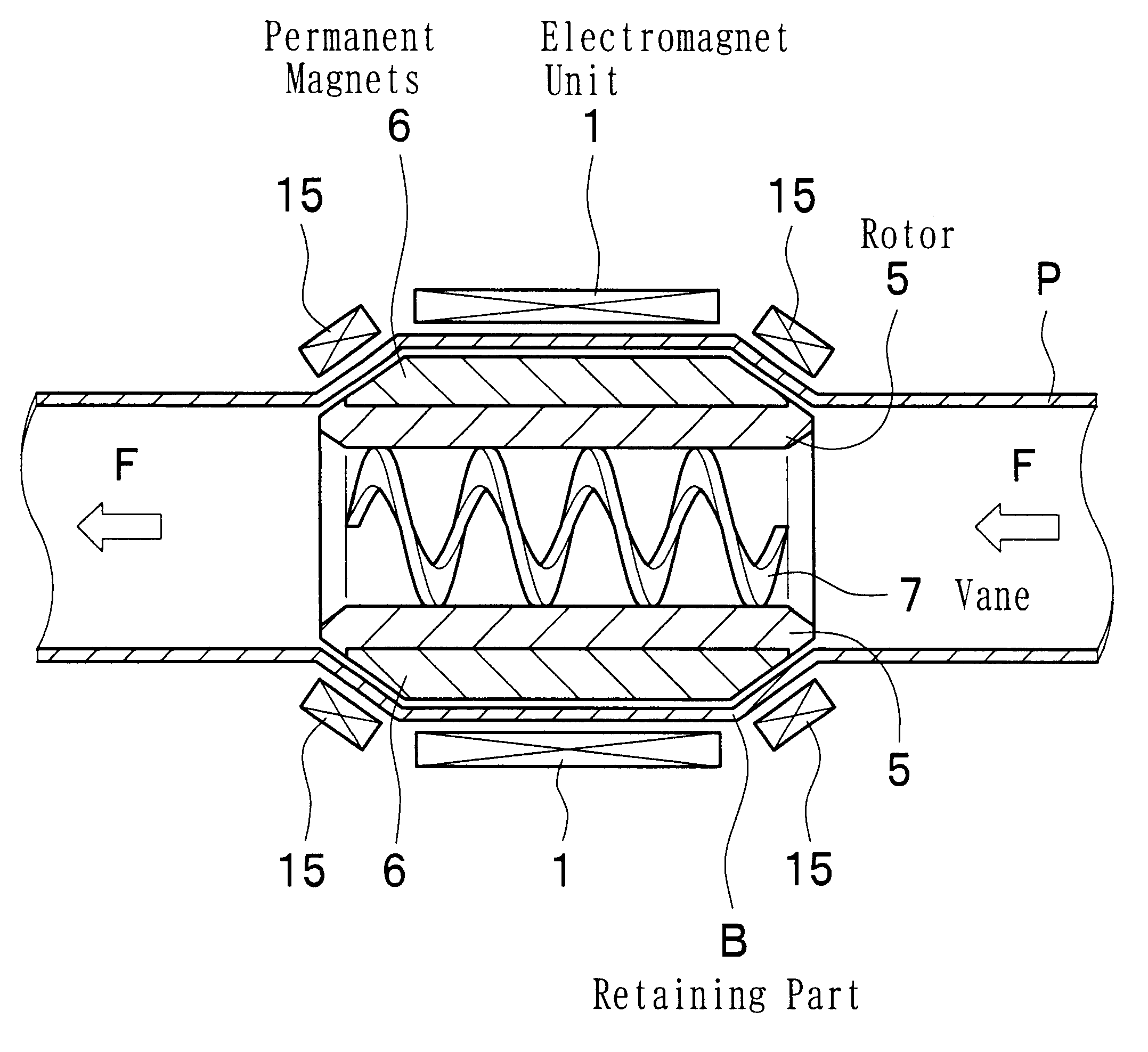

A magnetically driven, axial flow pump comprises an electromagnetic unit arranged about the periphery of a pipe. A cylindrical rotor is accommodated within the pipe and is equipped with permanent magnets mounted on the periphery. A spiral, hollow vane is formed on an inner surface of the rotor by either casting or by cutting, such as with a NC machine, thus precluding the occurrence of gaps between the rotor and the vane. The lack of gaps within the pump makes the pump suitable for use as a blood pump.

Owner:NIPRO CORP

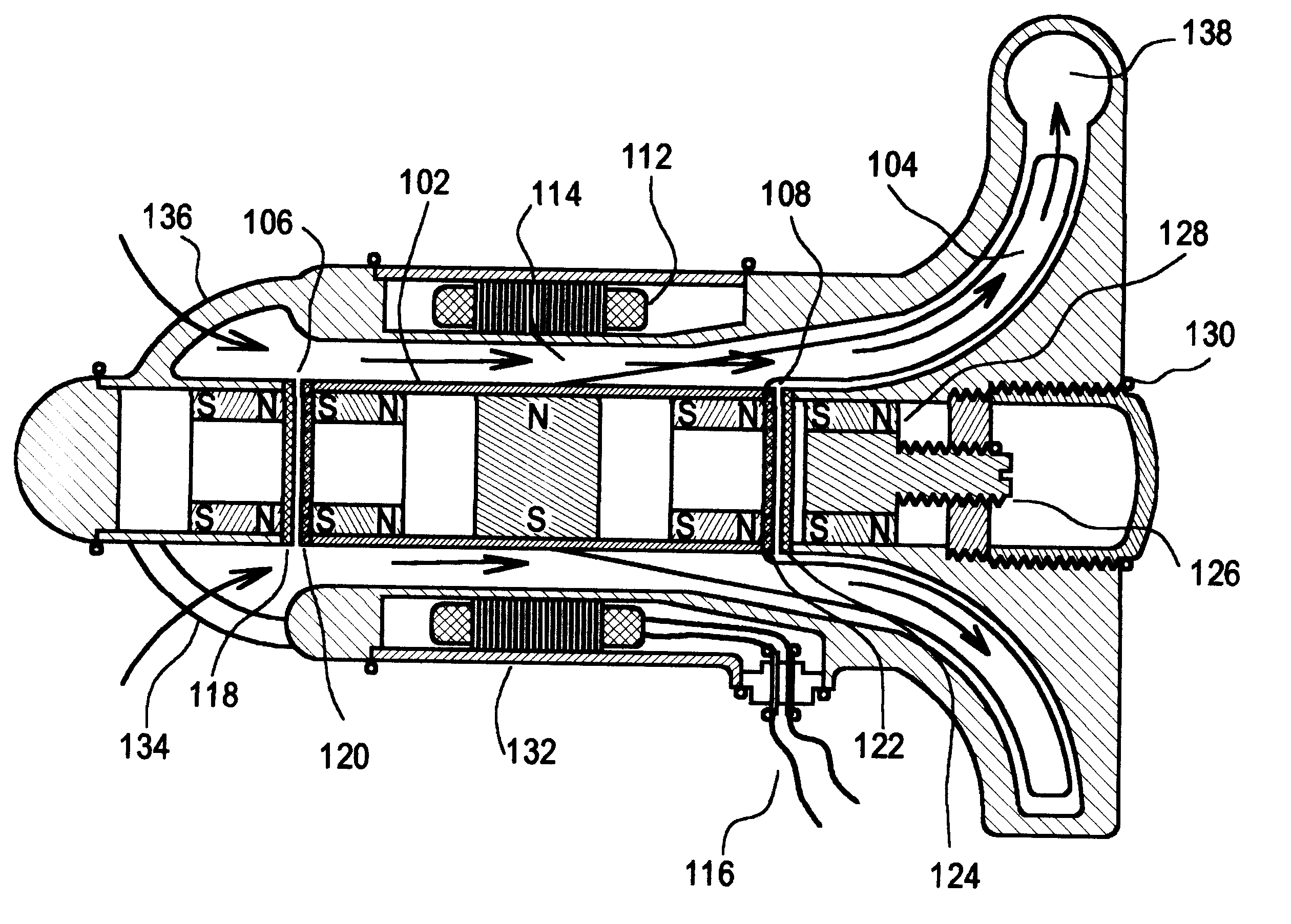

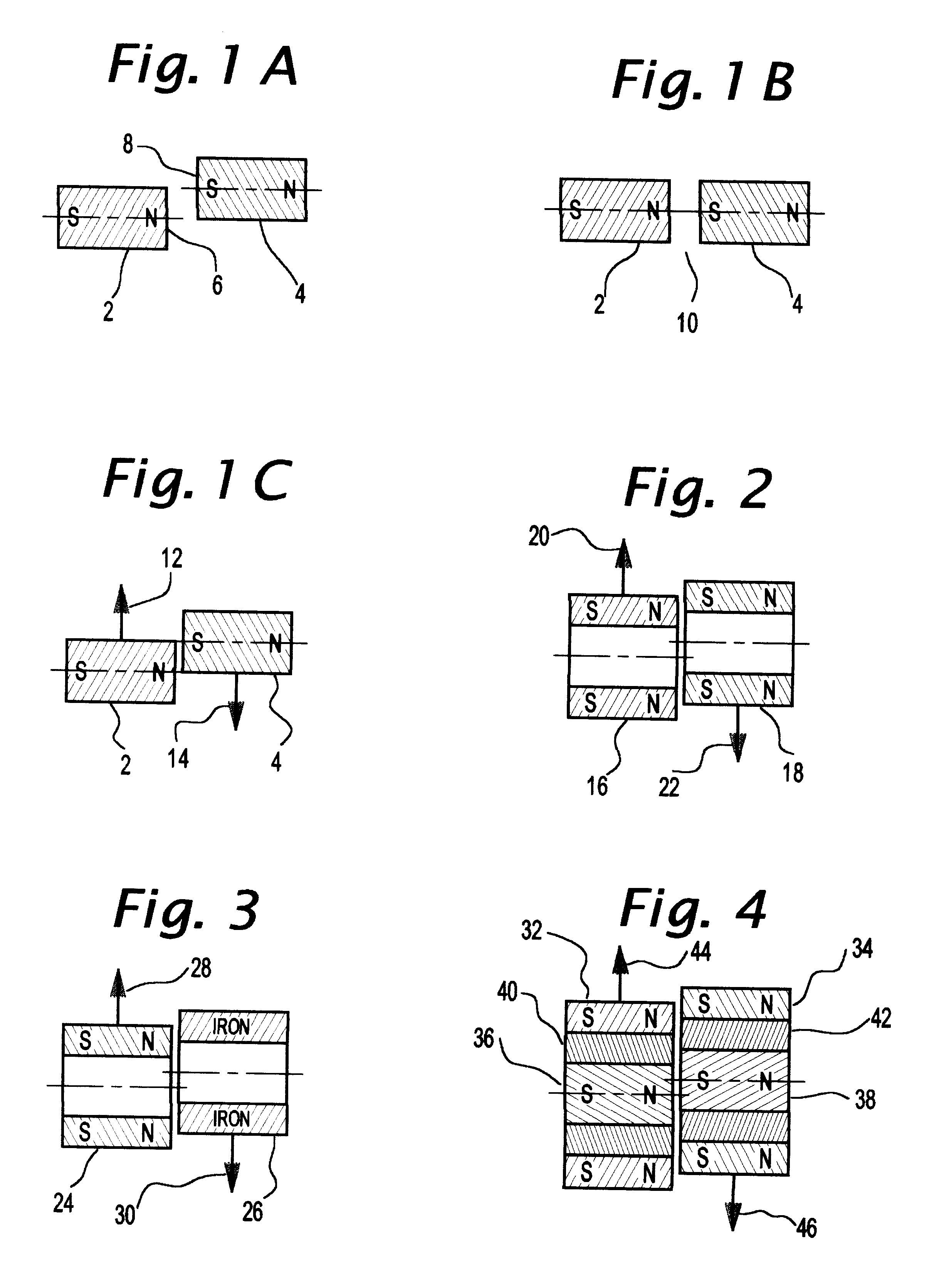

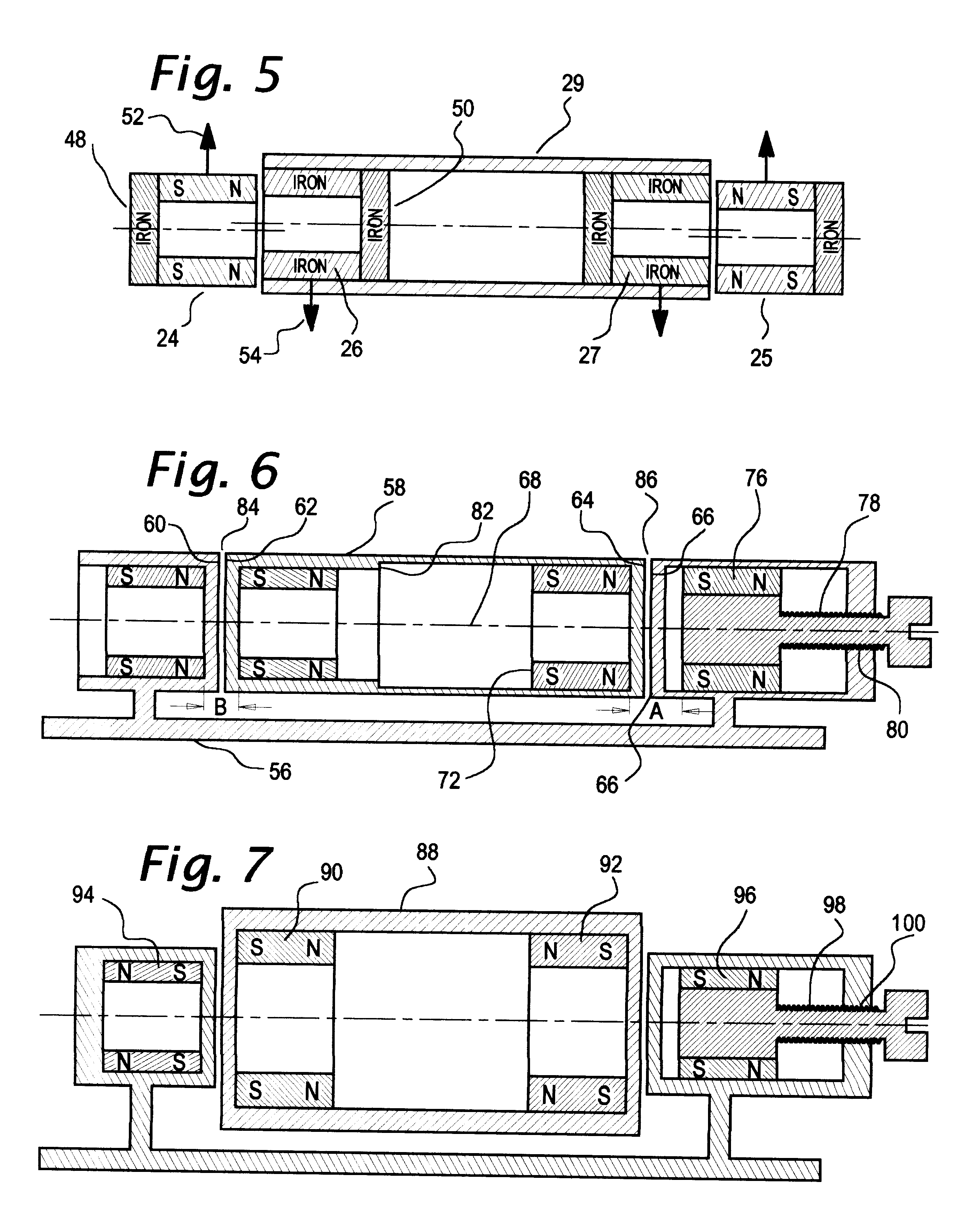

Axial force null position magnetic bearing and rotary blood pumps which use them

InactiveUS6227820B1Improve radial stiffnessSimple designPump componentsSurgeryAxial-flow pumpMagnetic tension force

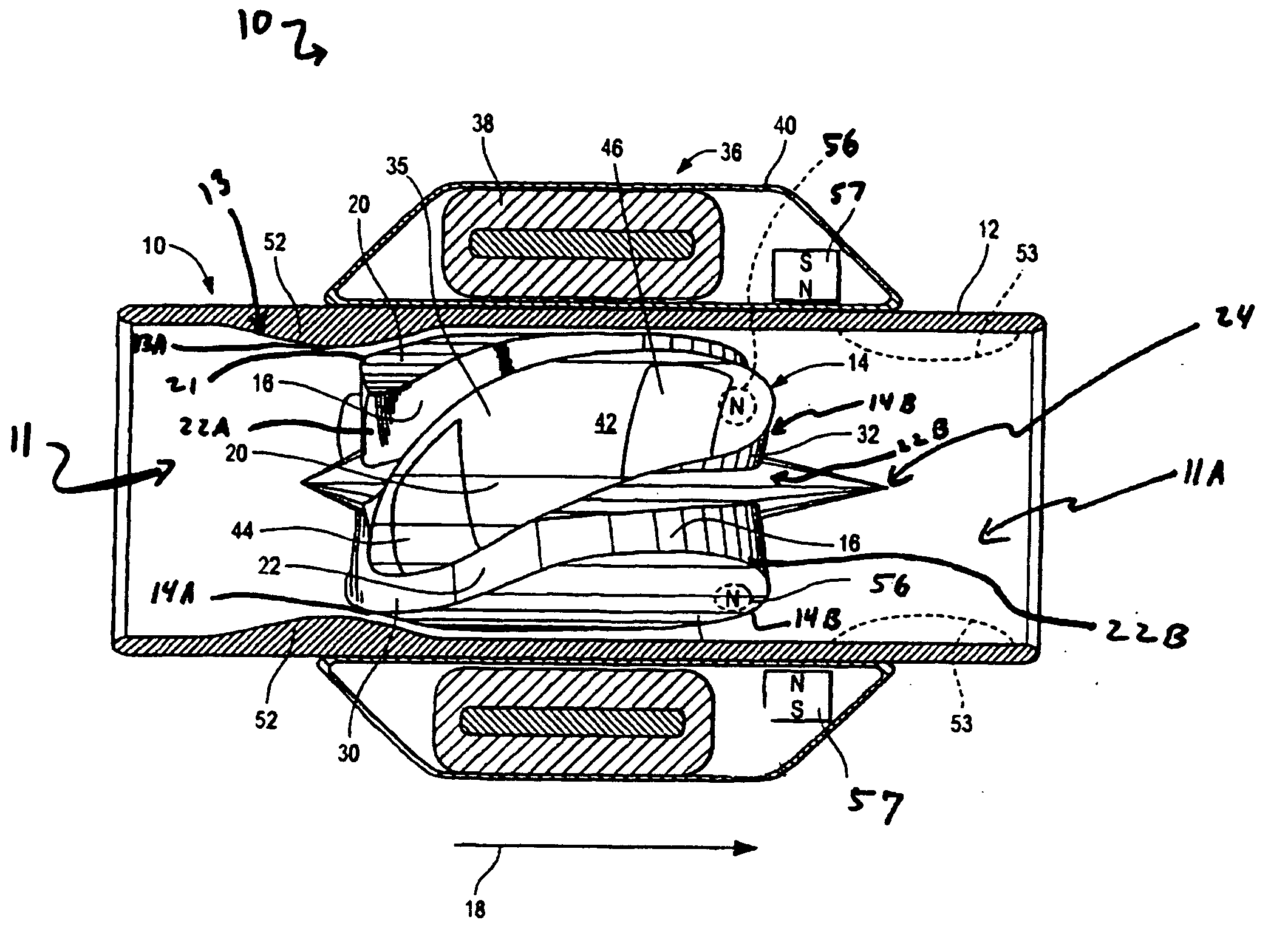

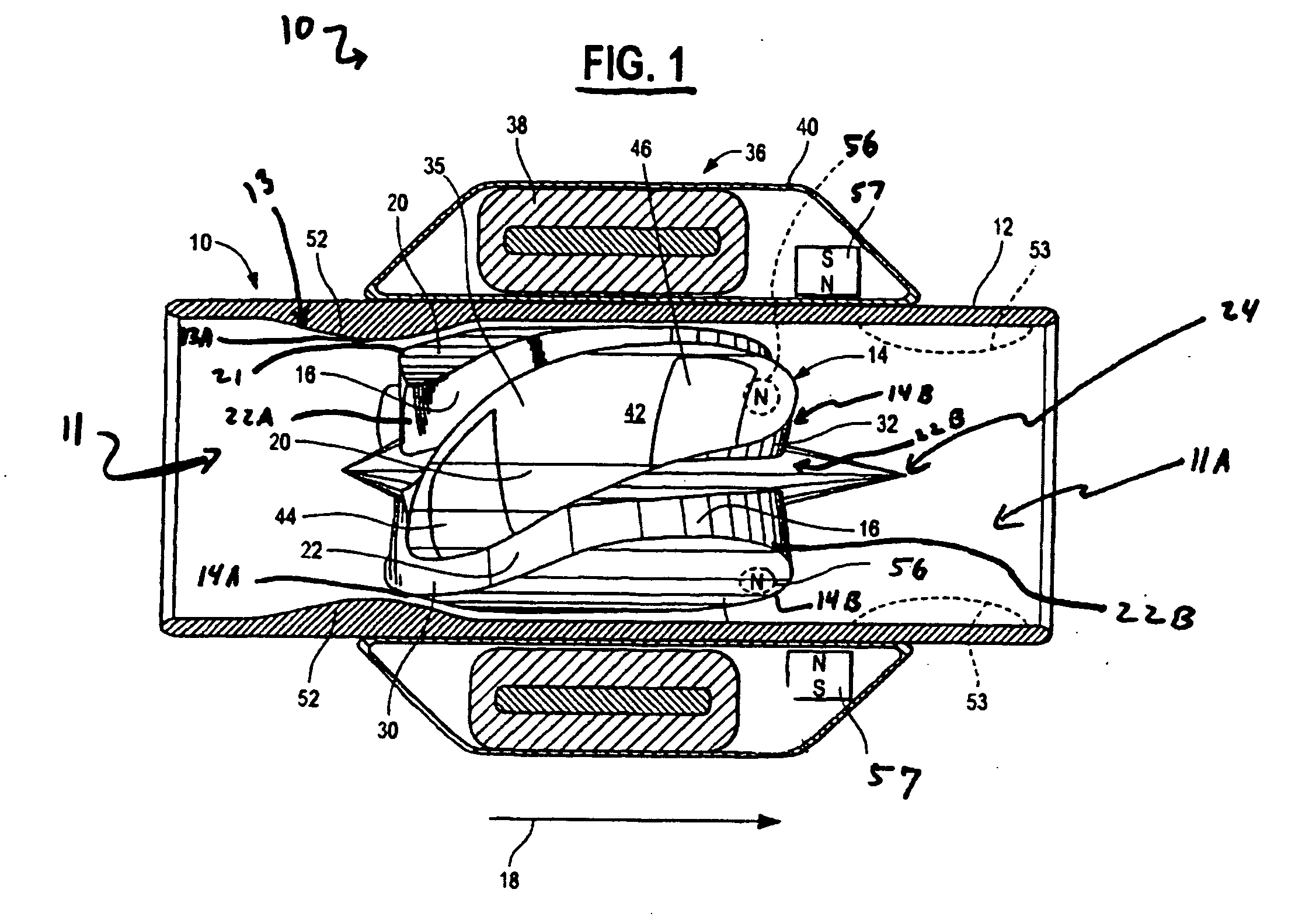

A generally cylindrical rotor very closely confined between two rigid thrust bearing surfaces is radially suspended by an array of attracting or repelling magnets or by a combination of permanent magnets and ring shaped members composed of ferromagnetic material. The geometry permits very small spacing between magnetic components to achieve high radial stiffness. High magnetic axial forces exerted between the rotor and stationary component on one end of the rotor are counter-balanced by equal and opposite forces at the other end of the rotor. Precise positioning of the rotor in the location where the opposing axial magnetic forces counterballance each other yields a net magnetic axial force on the rotor of near zero, hence the reference to this as the null position. Wear resistant mechanical thrust bearings confine the rotor axially to maintain this position during rotatioin. Precisely balance the magnetic axial forces in the proper geometry with relation to the mechanical thrust bearings. Blood pumps utilizing this type of bearing are disclosed, including both axial flow pump and centrifugal flow pump configurations with high flow washing of the junction of the rotating and stationary parts to prevent thrombus accumulation.

Owner:JARVIK ROBERT

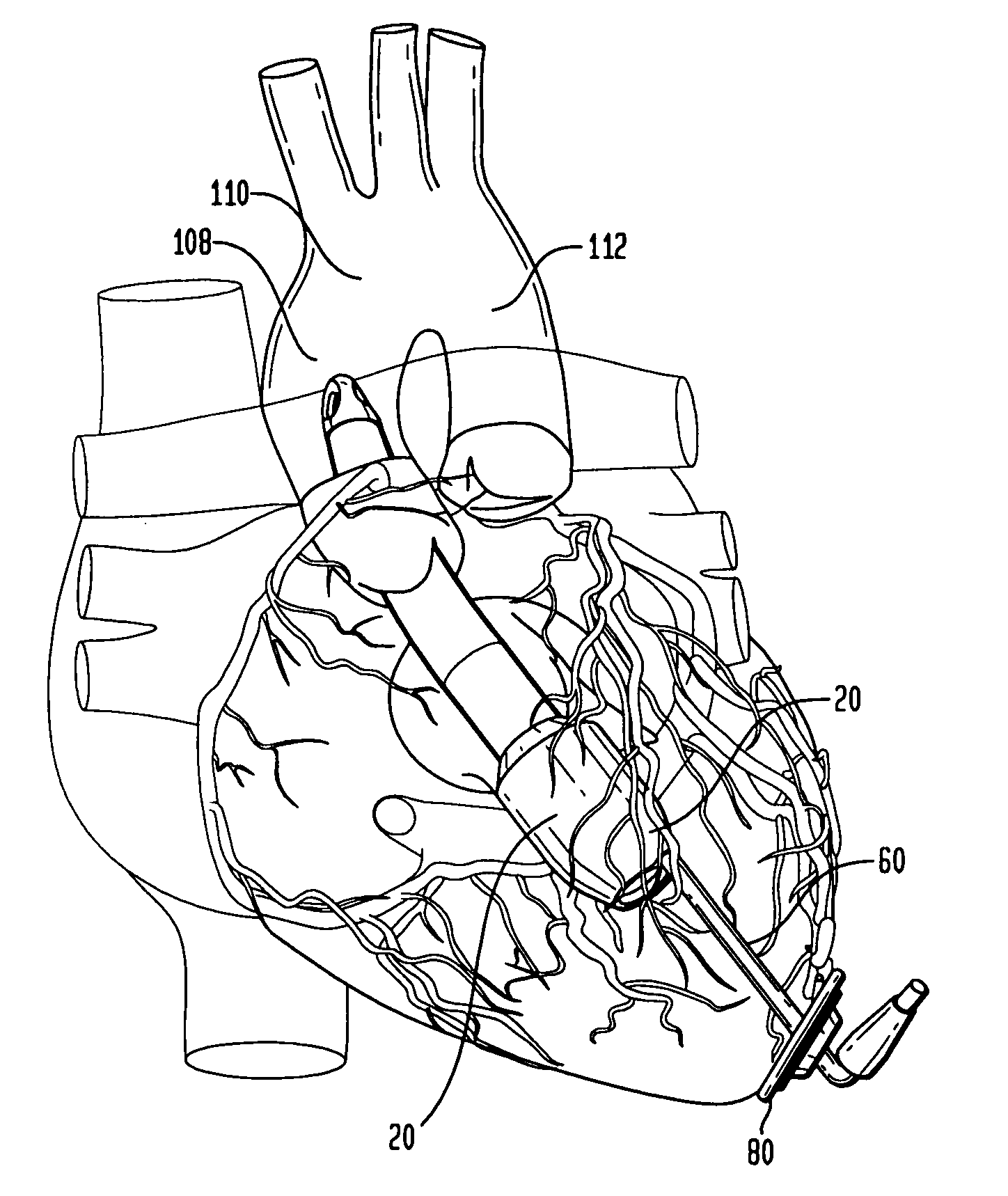

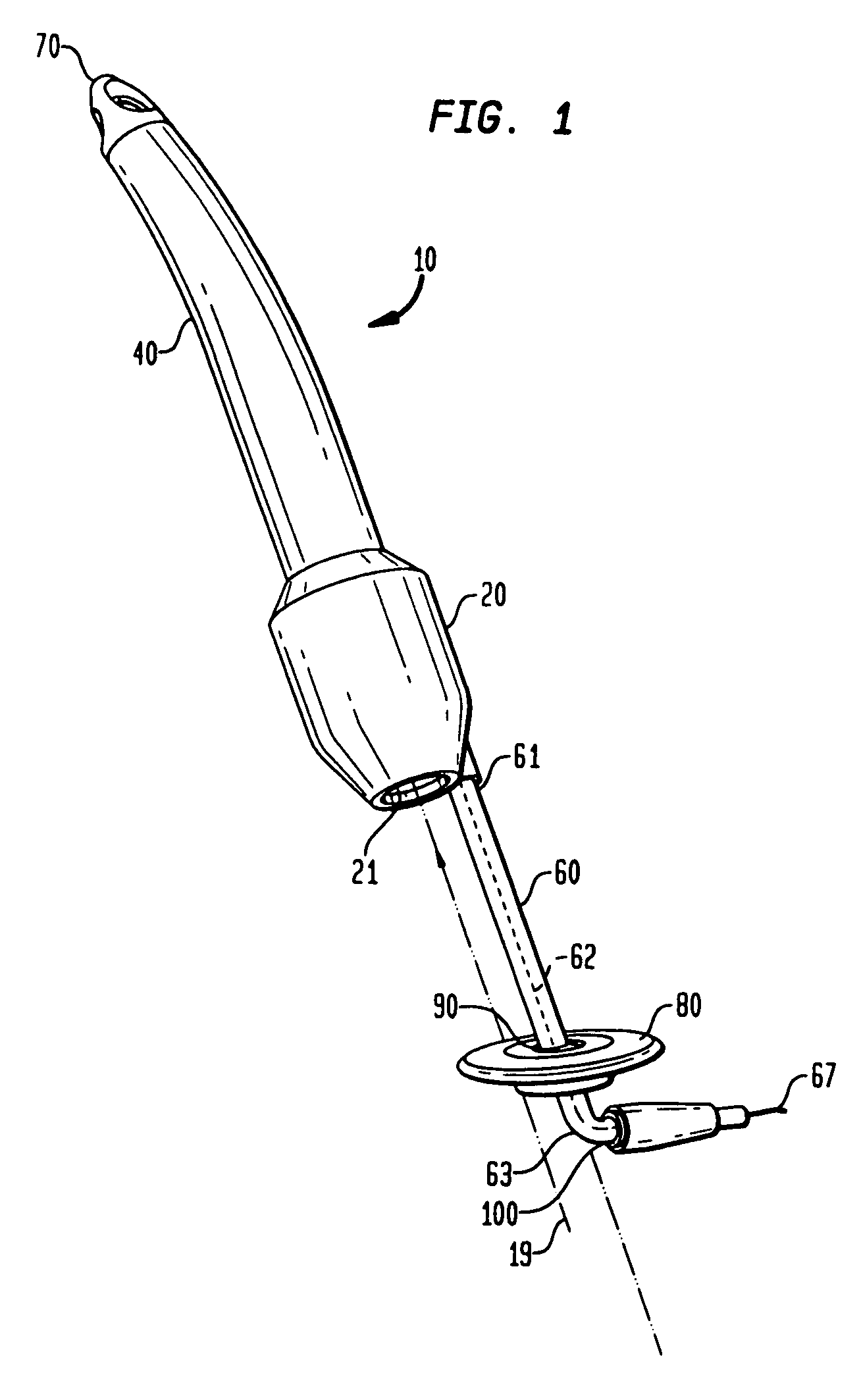

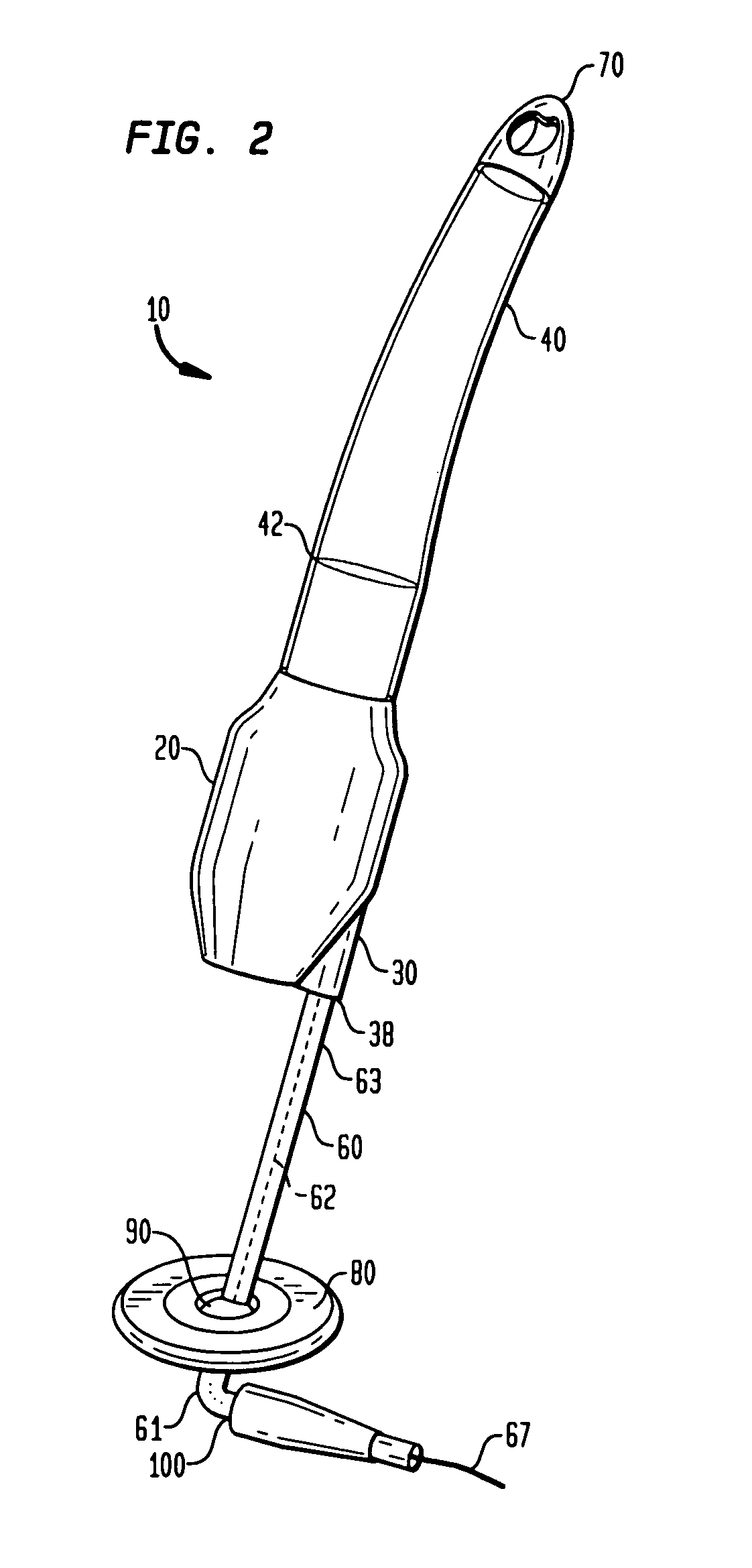

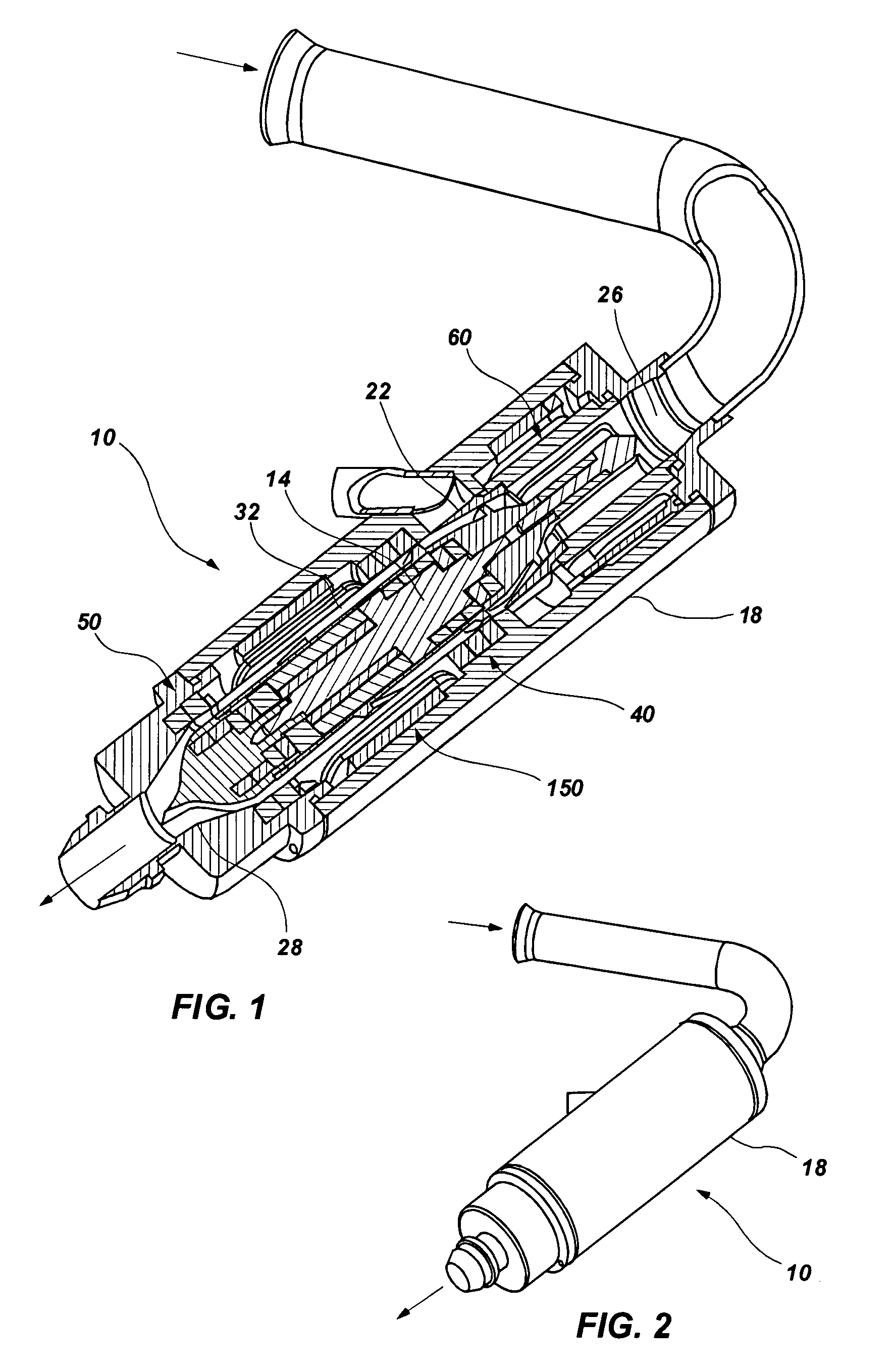

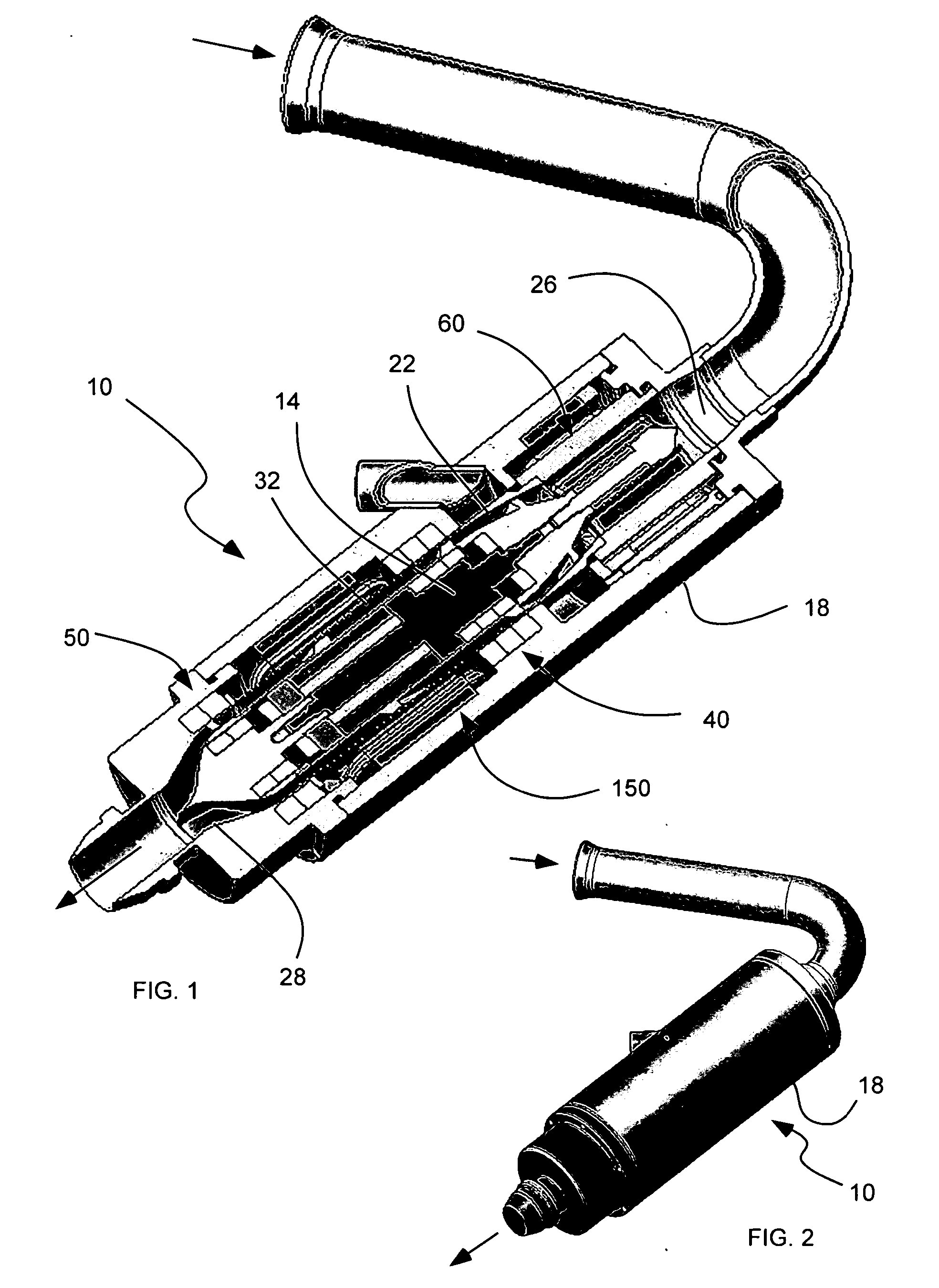

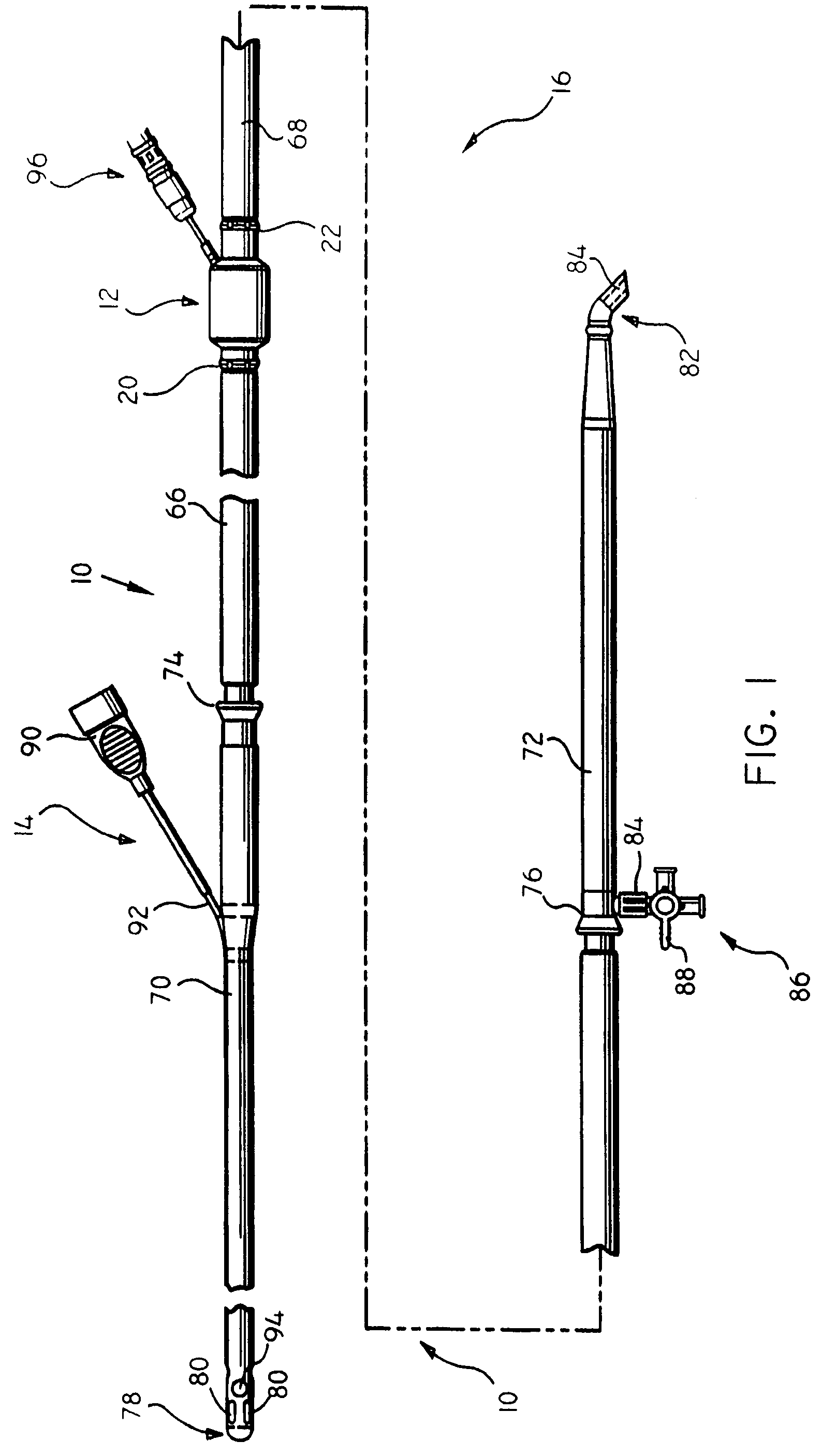

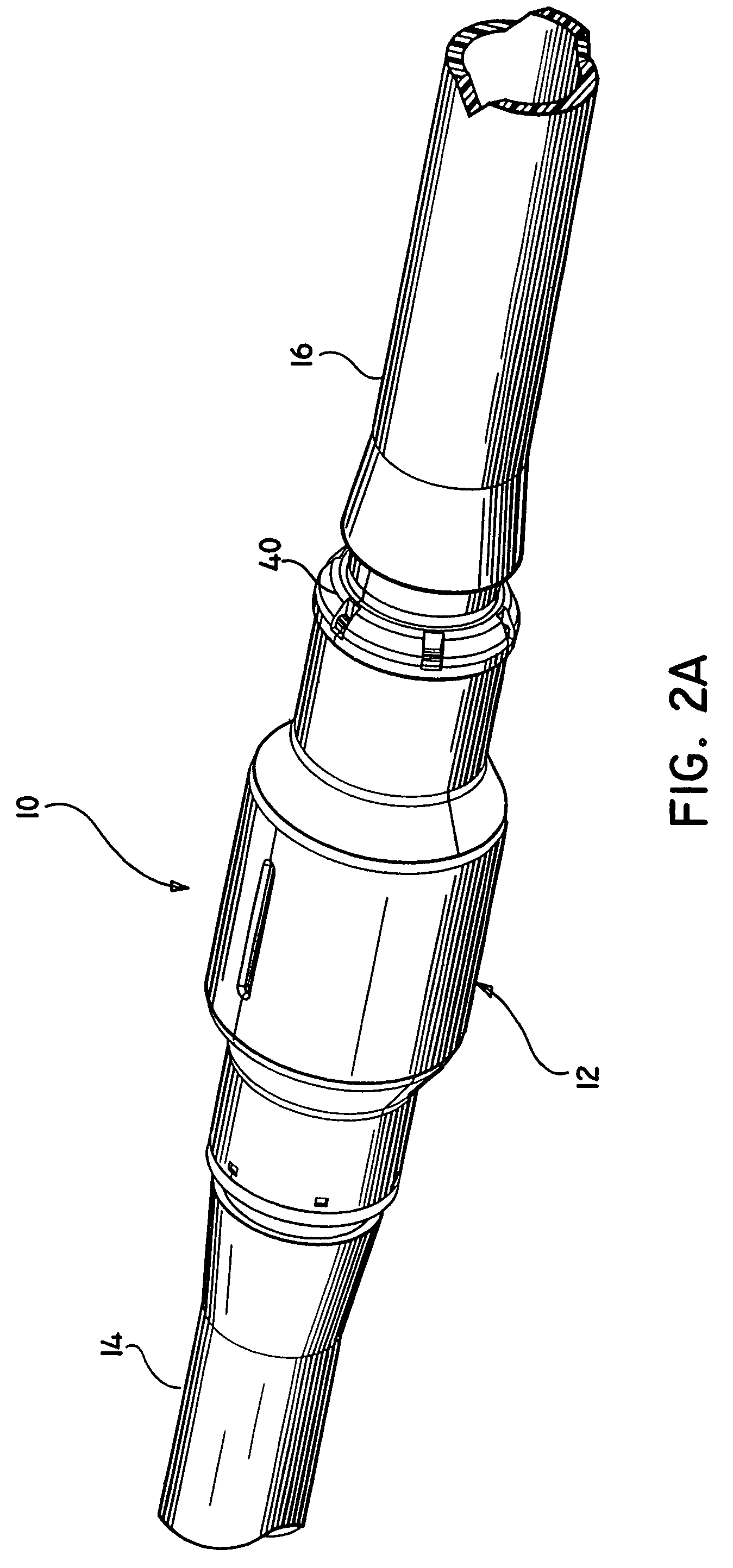

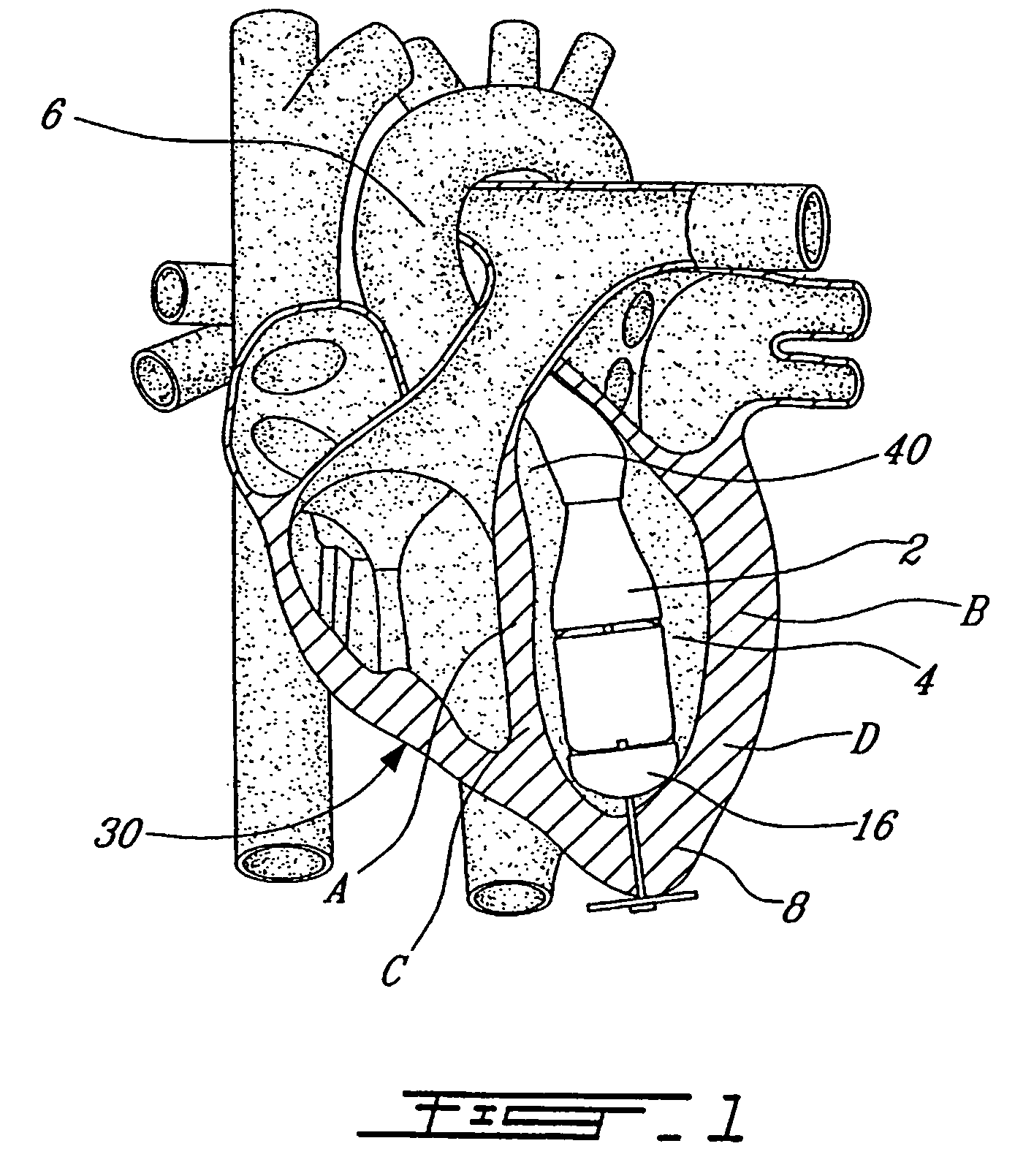

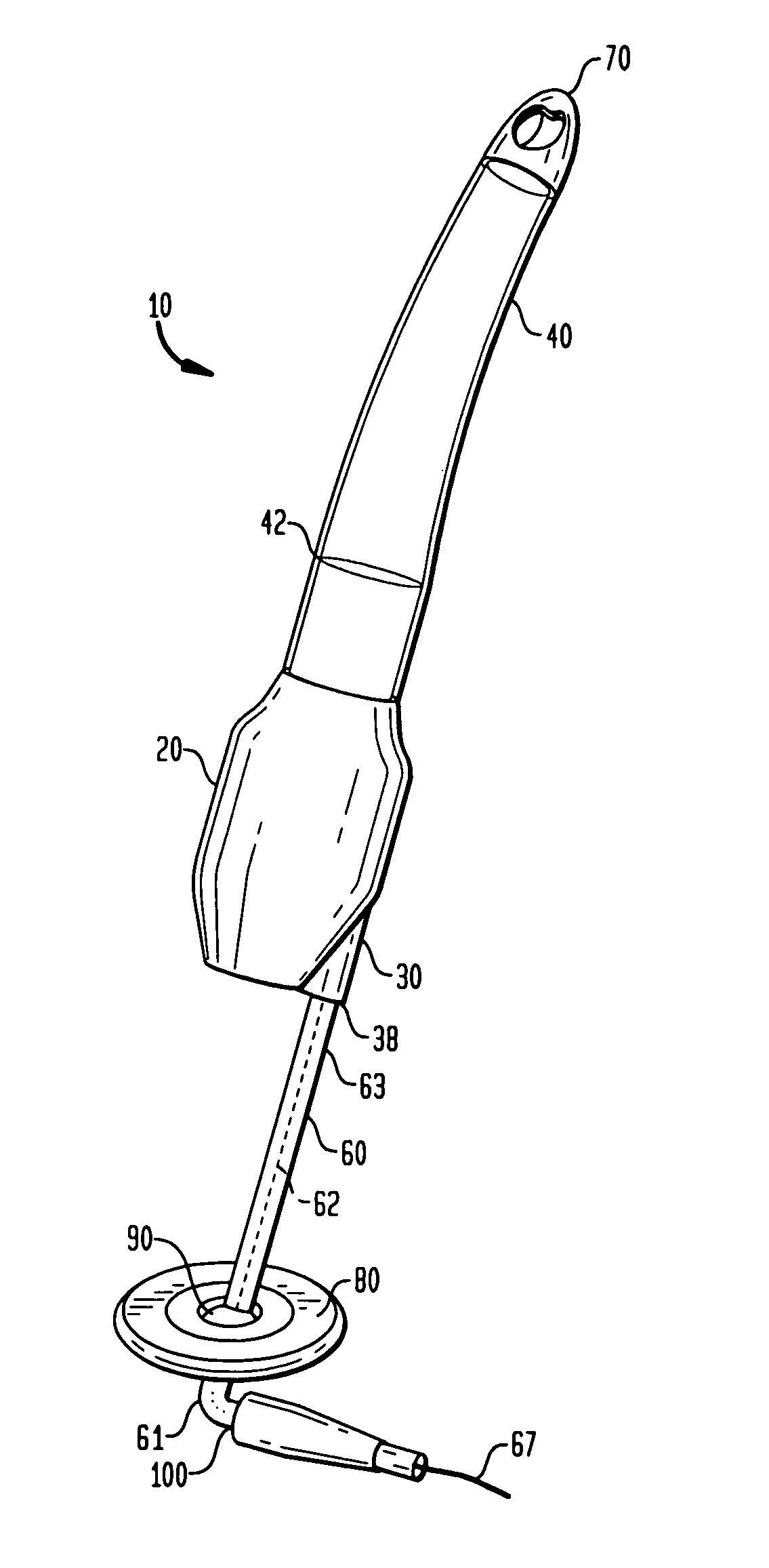

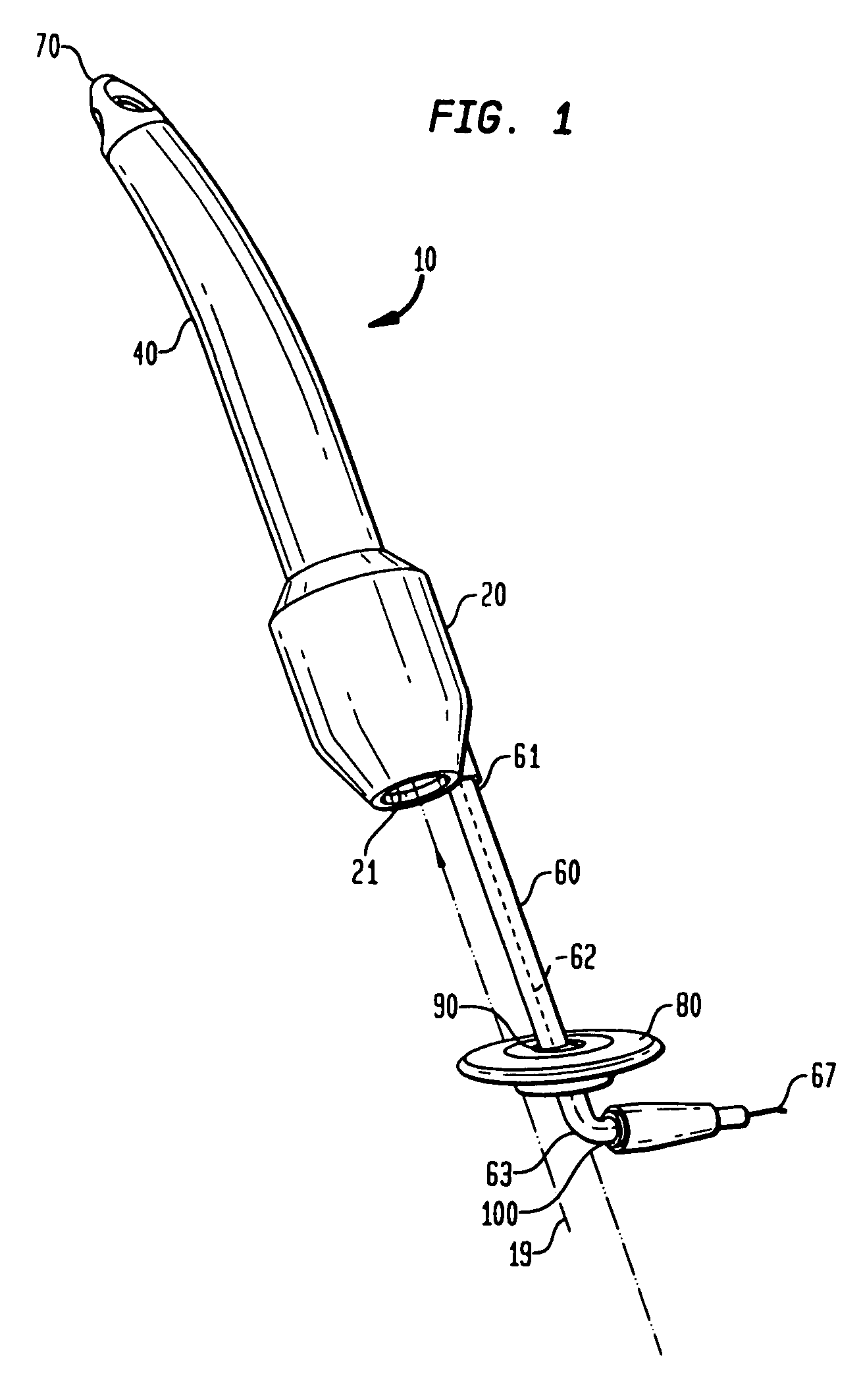

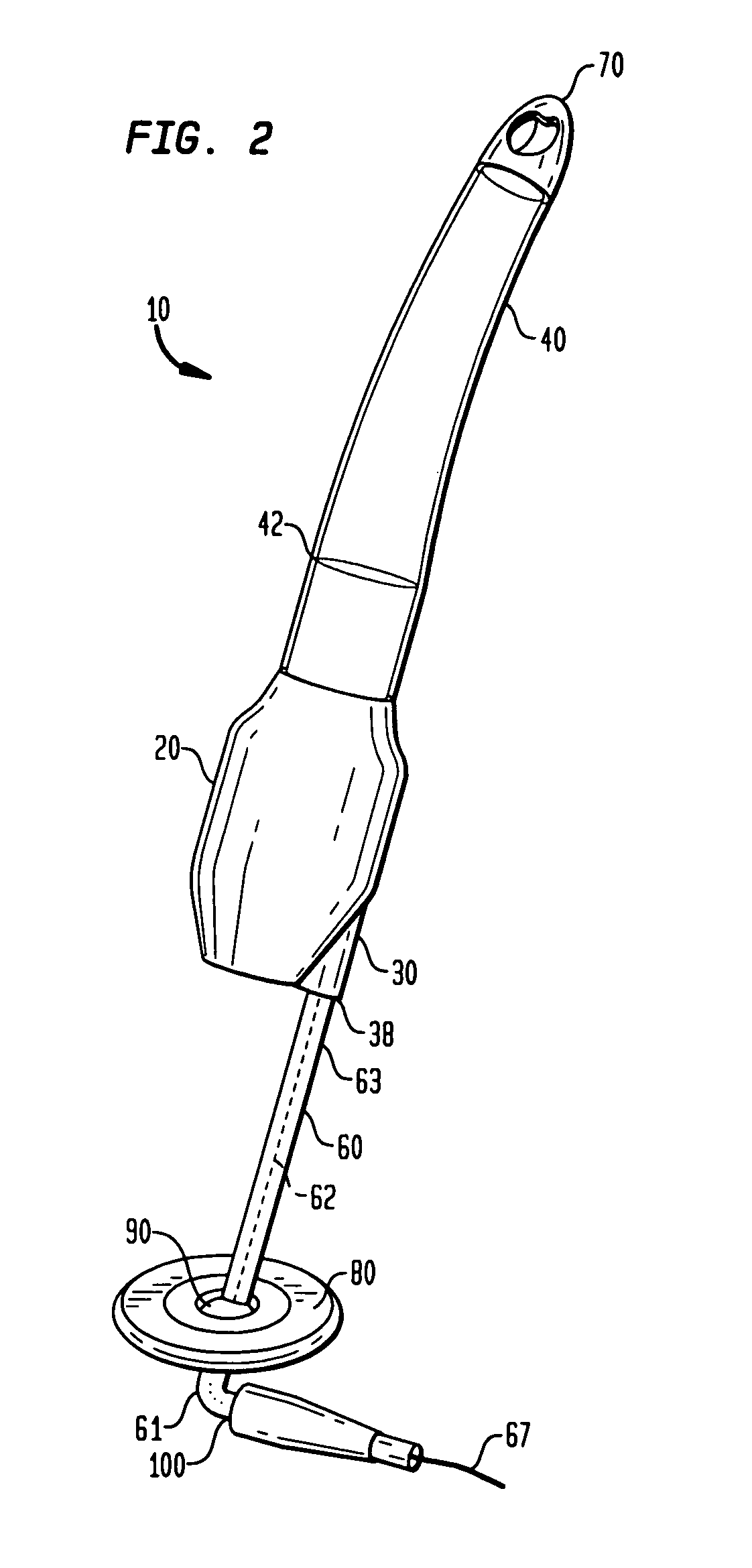

Ventricular assist device for intraventricular placement

A ventricular assist device includes a pump such as an axial flow pump, an outflow cannula connected to the outlet of the pump, and an anchor element. The anchor element is physically connected to the pump, as by an elongate element. The pump is implanted within the left ventricle with the outflow cannula projecting through the aortic valve but desirably terminating short of the aortic arch. The anchor element is fixed to the wall of the heart near the apex of the heart so that the anchor element holds the pump and outflow cannula in position.

Owner:HEARTWARE INC

Streamlined unobstructed one-pass axial-flow pump

InactiveUS7229258B2Small sizeIncreased operating lifeBlood pumpsIntravenous devicesAxial-flow pumpOne pass

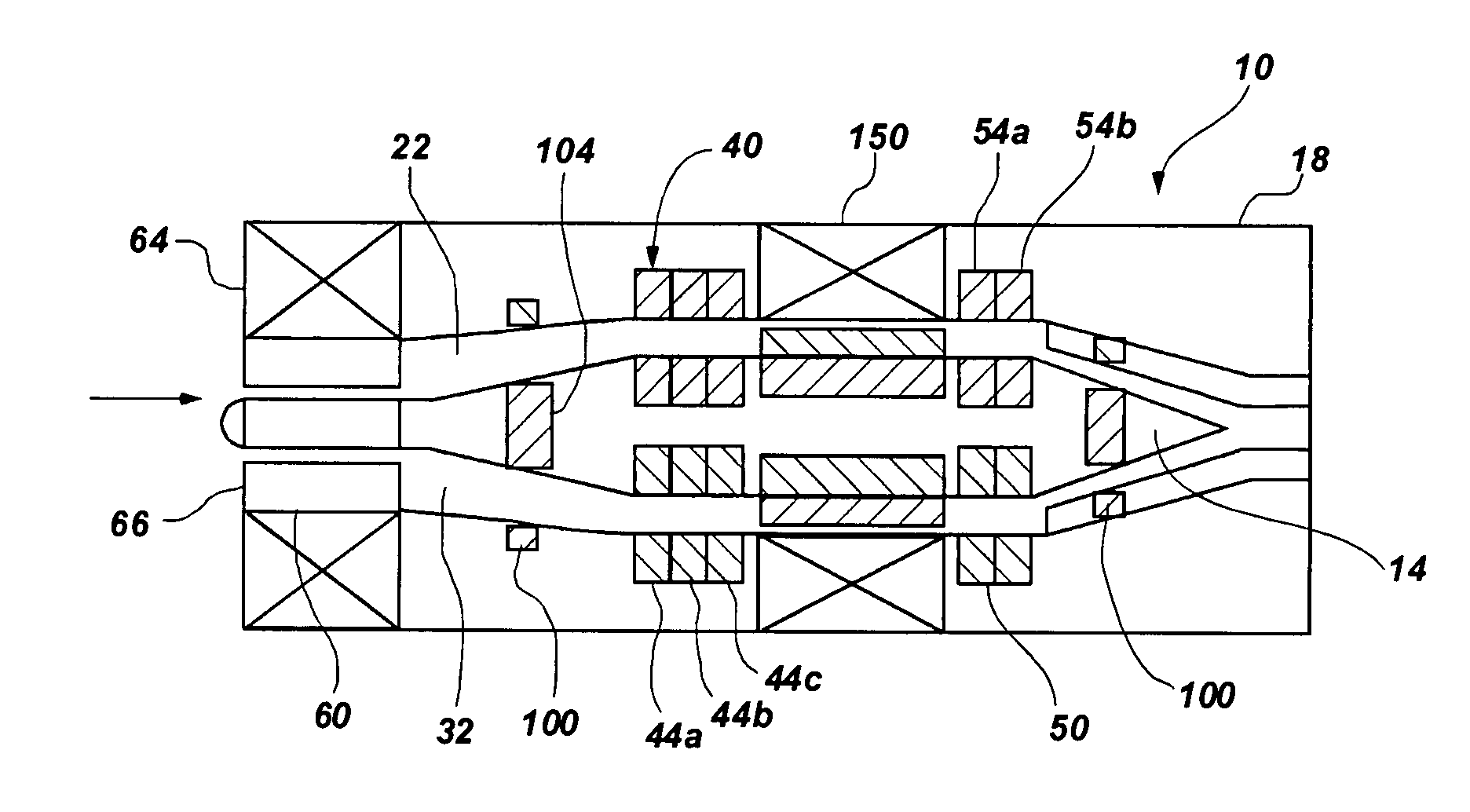

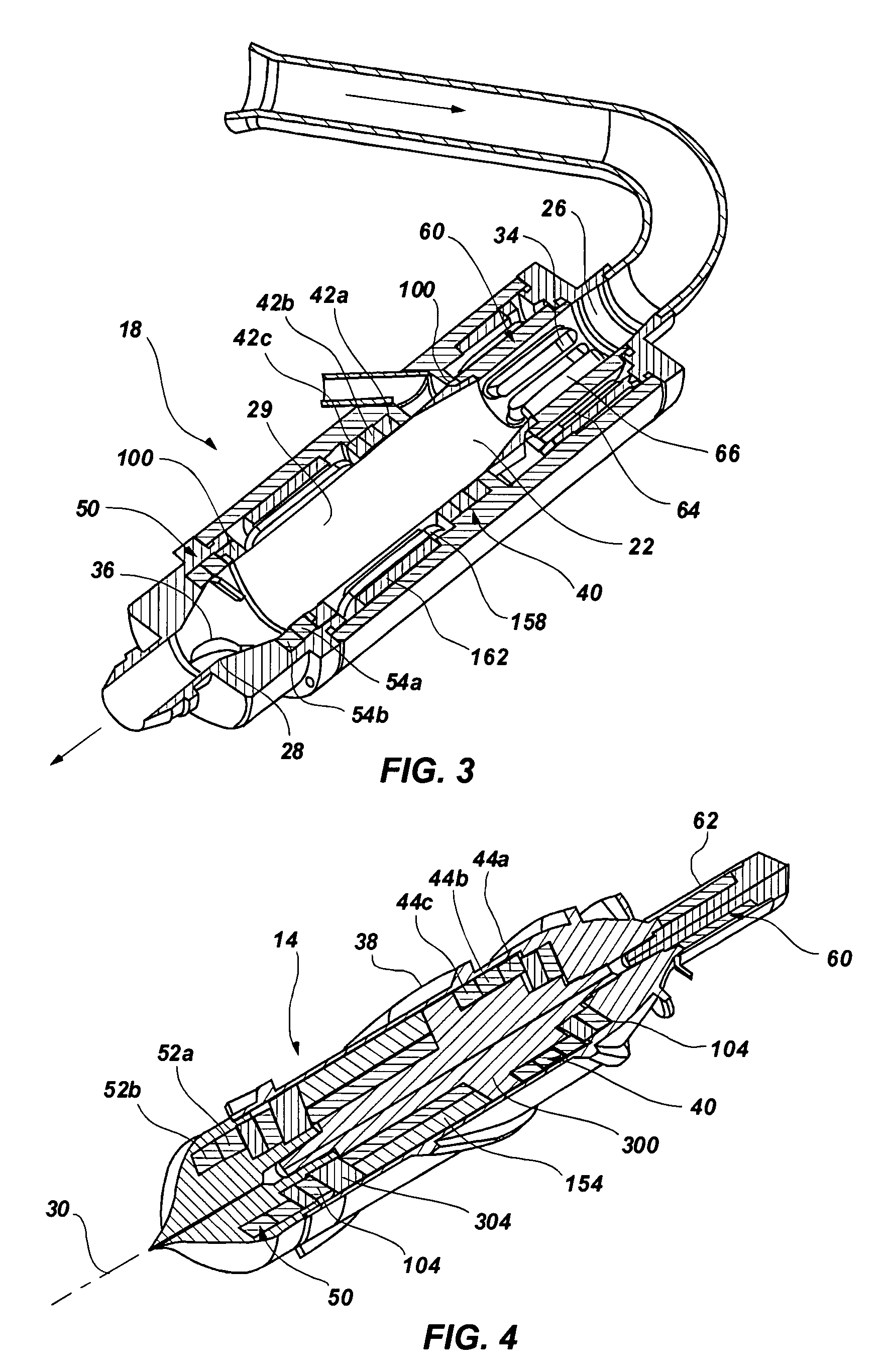

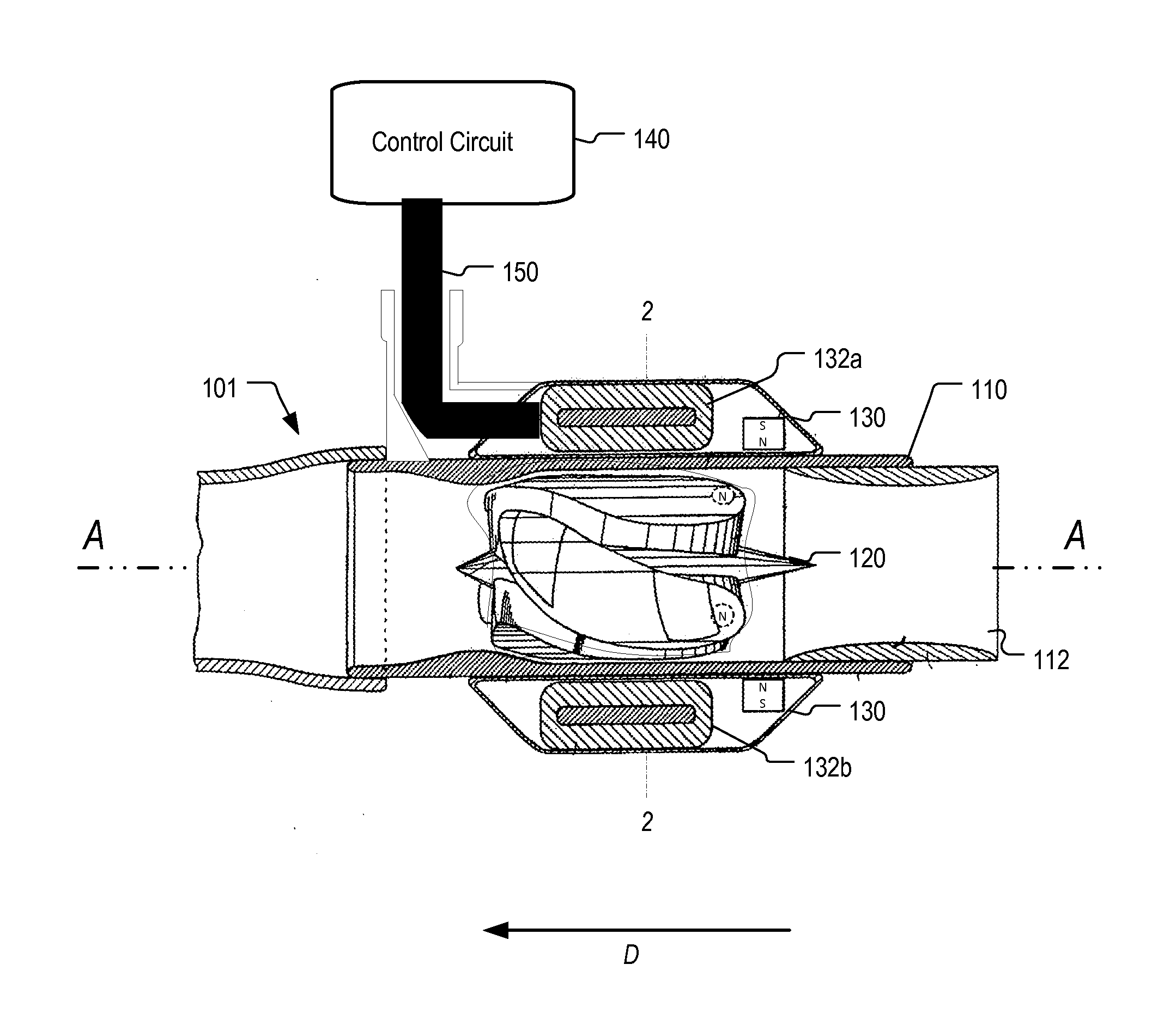

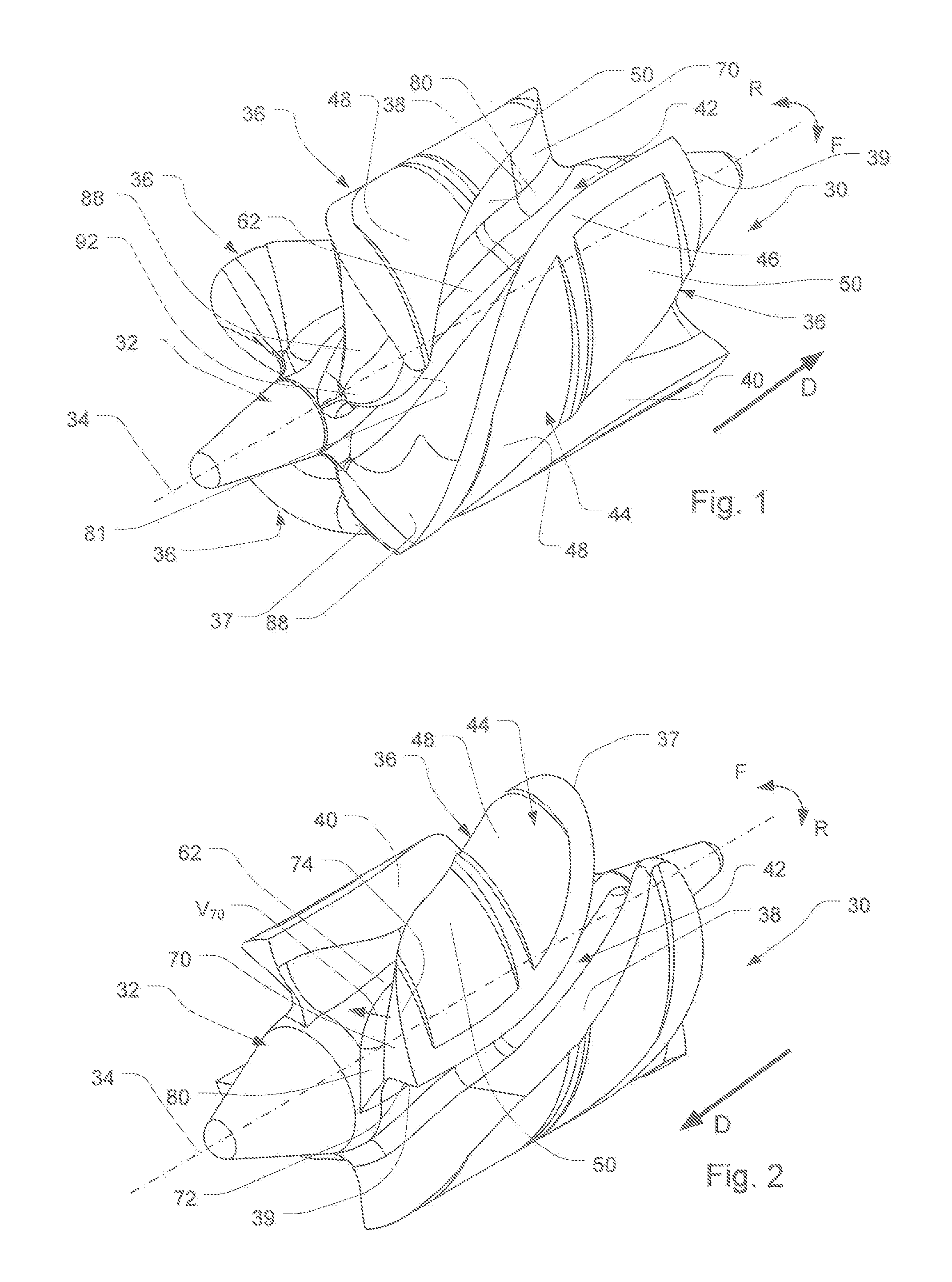

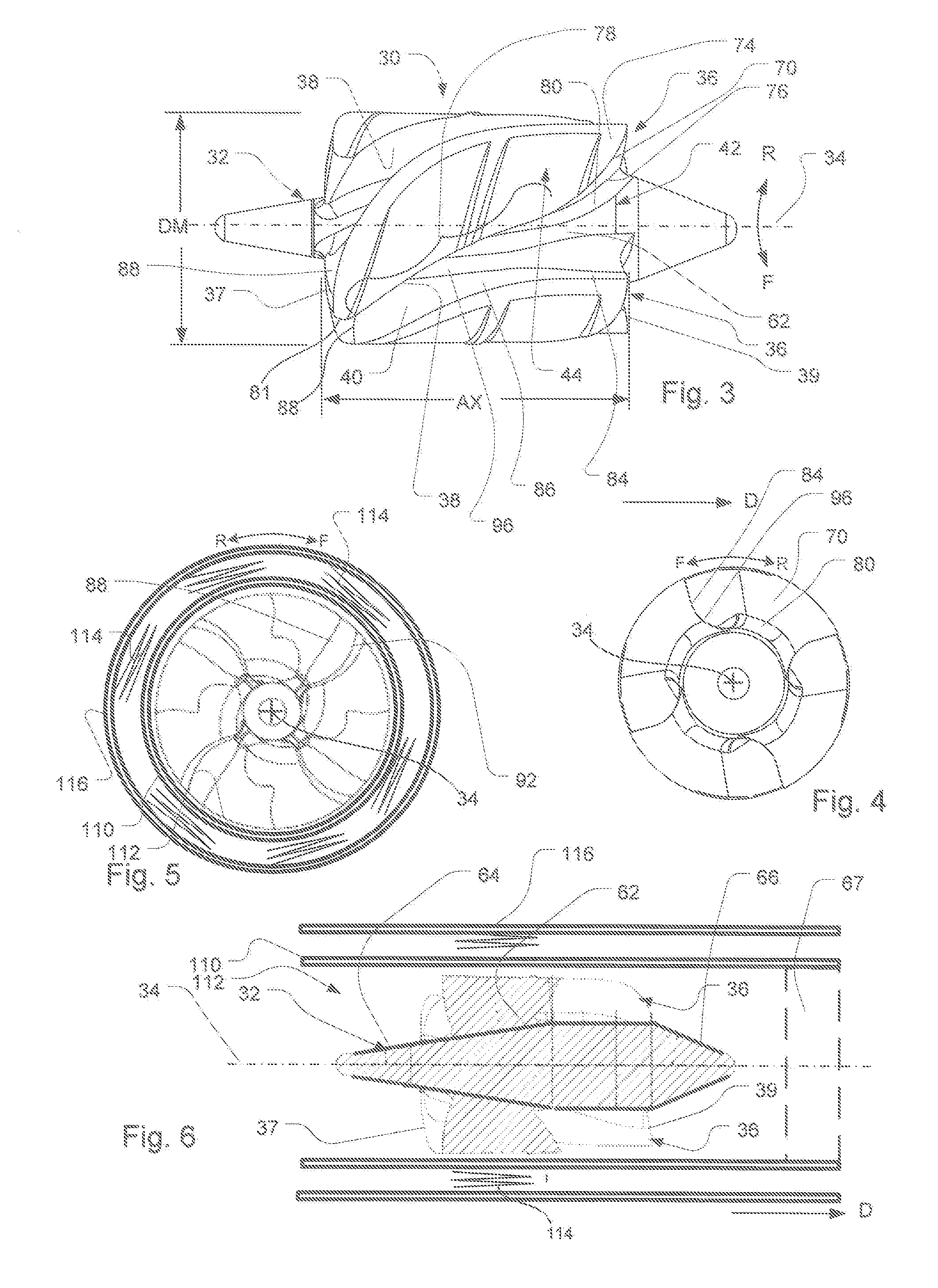

A blood pump has an impeller rotatably disposed and magnetically suspended within a cavity of a stator by a plurality of magnetic bearings (passive permanent and active electromagnetic) having impeller magnets on the impeller and stator magnets or coils / poles on the stator. A motor includes impeller magnets on the impeller and coils / poles associated with the stator. A single, annular blood flow path extends axially through the cavity between the impeller and the stator, and between the impeller magnets on the impeller and the stator magnets or the coils / poles on the stator.

Owner:MEDFORTE RES FOUND +1

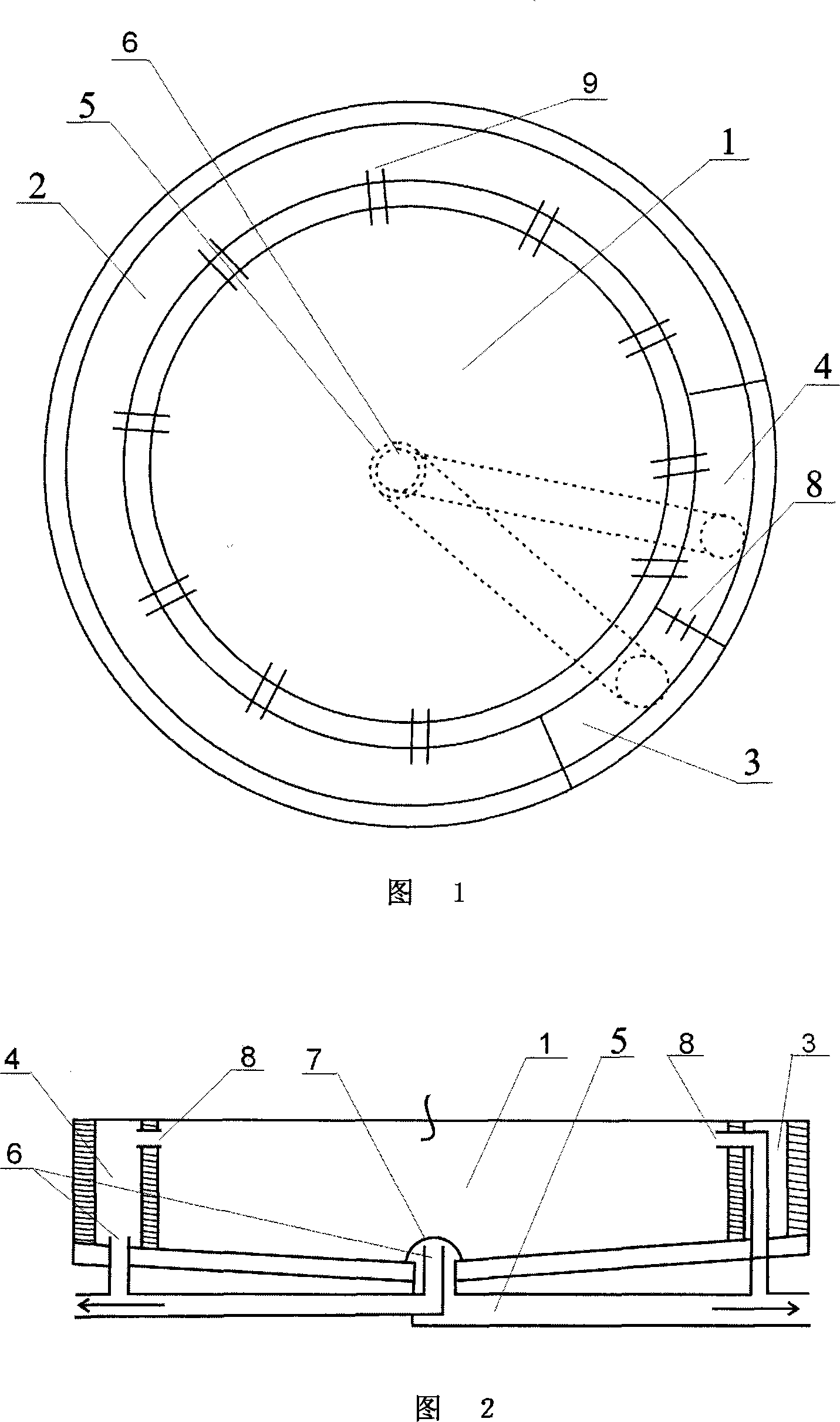

Magnetically driven axial-flow pump

A magnetically driven axial-flow pump comprising (i) an electromagnet unit 1 arranged about the periphery of a pipe "P", (ii) a cylindrical rotor 5 accommodated in the pipe "P", (iii) permanent magnets 6 mounted on the periphery of the rotor 5, and (iv) a spiral vane 7 formed on the inner surface of the rotor 5. A hollow is formed in the axial center portion of the vane 7. Because the rotor 5 and the vane 7 can be made as one piece with an NC machine, precluding the occurrence of gaps in the otherwise-inevitable joint between them, it is easy to make the rotor 5 and the vane 7. Because there are no gaps between the rotor 5 and the vane 7 as mentioned above and there is no object in contact with blood in the center portion of the vane, various germs do not enter blood, no thrombi are formed, blood tissues are not destroyed, and hence the pump is suitable as a blood pump.

Owner:NIPRO CORP

Streamlined unobstructed one-pass axial-flow pump

InactiveUS20050135942A1Reduce coagulationSmall sizeBlood pumpsIntravenous devicesAxial-flow pumpImpeller

A blood pump has an impeller rotatably disposed and magnetically suspended within a cavity of a stator by a plurality of magnetic bearings (passive permanent and active electromagnetic) having impeller magnets on the impeller and stator magnets or coils / poles on the stator. A motor includes impeller magnets on the impeller and coils / poles associated with the stator. A single, annular blood flow path extends axially through the cavity between the impeller and the stator, and between the impeller magnets on the impeller and the stator magnets or the coils / poles on the stator.

Owner:MEDFORTE RES FOUND +1

Multiple rotor, wide blade, axial flow pump

InactiveUS7972122B2Simple procedureReduce patient surgical traumaPump componentsBlood pumpsAxial-flow pumpImpeller

A blood pump comprises a pump housing; a plurality of rotors positioned in said housing, each rotor comprising an impeller having a hydrodynamic surface for pumping blood; and a motor including a plurality of magnetic poles carried by each impeller, having motor stators, each including electrically conductive coils located adjacent to or within the housing. At least one of the rotors is adopted to rotate clockwise, and at least one of rotors is adopted to rotate counterclockwise. By this means, stator or stationary blades between the rotors may not be needed.

Owner:HEARTWARE INC

Axial flow pump pressure algorithm

ActiveUS20140357937A1Shorten speedIncrease speedControl devicesBlood pumpsAxial-flow pumpDifferential pressure

The presence or absence of a high pressure condition in an implantable blood pump is determined at least in part based on a comparison between a determined amount of differential pressure across the pump and a pressure threshold value. The amount of differential pressure parameter may be determined based at least in part on a parameter related to flow, such as a parameter related to thrust on the rotor of the pump. In response to determining the presence of a high pressure condition, an updated speed of rotation of the rotor that is less than the rotor's initial speed may be determined. The rotor's speed may be increased when the flow rate of blood is determined to be at least equal to a flow recovery threshold value.

Owner:HEARTWARE INC

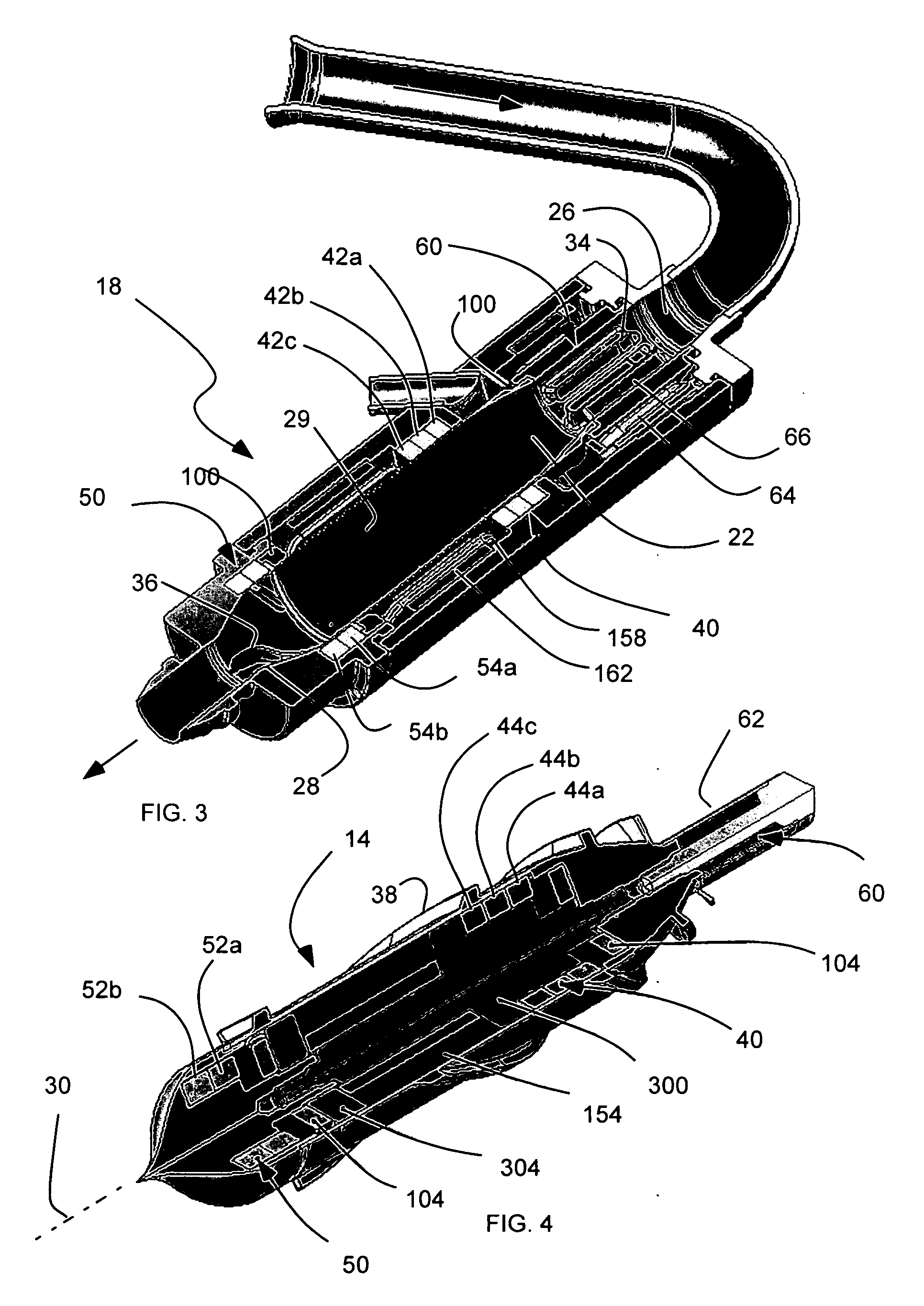

Axial flow pump with mult-grooved rotor

InactiveUS20070100196A1Improve the immunityEasy to washPump componentsControl devicesAxial-flow pumpImpeller

An axial-flow blood pump for pumping blood includes a substantially cylindrical outer enclosure. A tubular housing concentric with and located within the outer enclosure has at one end an inlet and at an opposite end an outlet. A motor stator is concentric with and located between the outer enclosure and the tubular housing. An impeller is concentric with and located within the tubular housing. The impeller is suspended in operation by a combination of passive magnetic forces between magnets within the impeller or magnetized regions of the impeller and the motor stator and hydrodynamic thrust forces generated as blood flows between the tubular housing and a plurality of hydrodynamic thrust bearing surfaces located on the impeller. A volute may be in fluid-tight connection with the outlet of the tubular housing for receiving blood in the axial direction and directing blood in a direction normal to the axial direction. The volute has a flow-improving member extending axially from the volute and into and coaxially with the tubular housing.

Owner:HEARTWARE INC

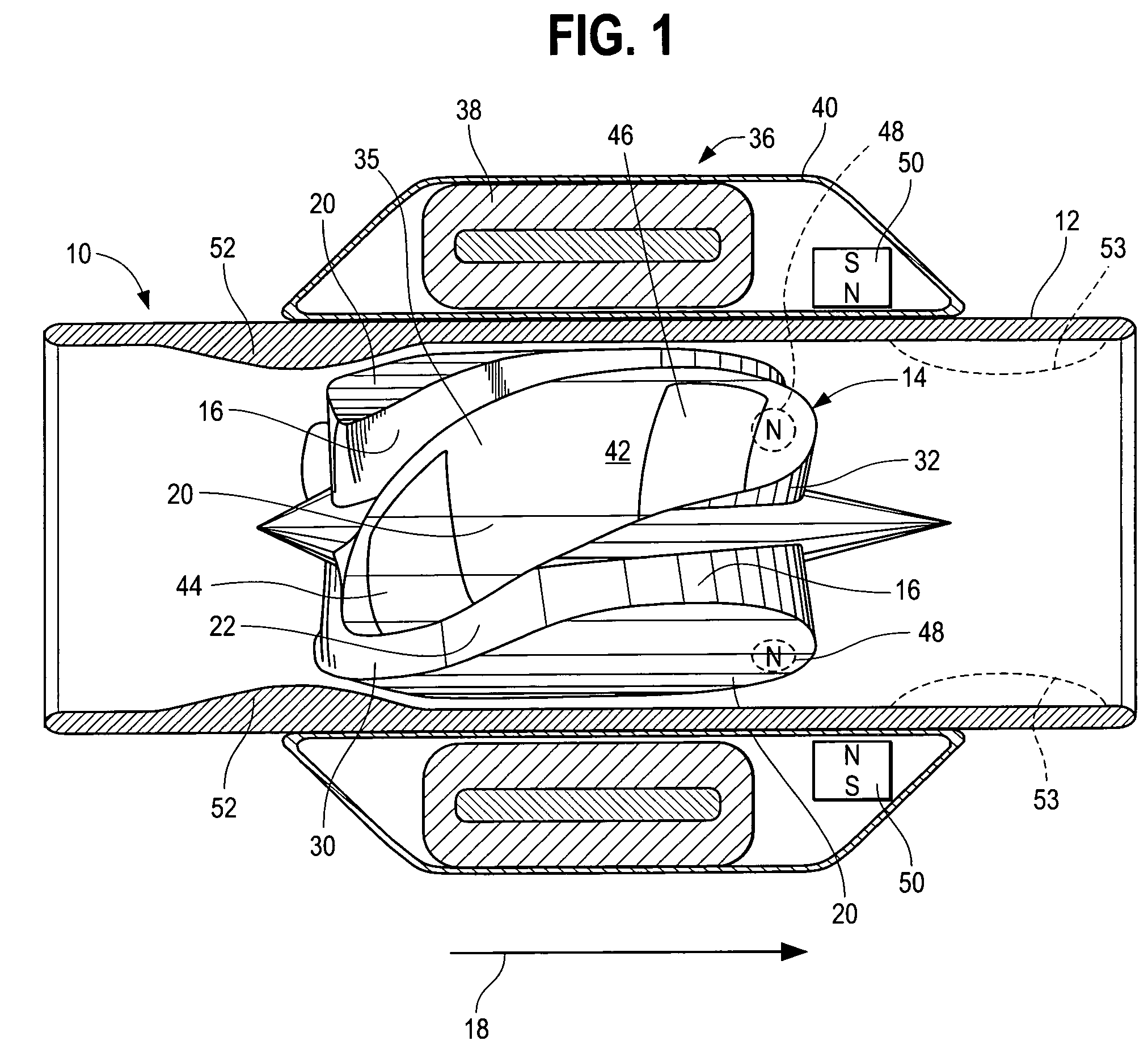

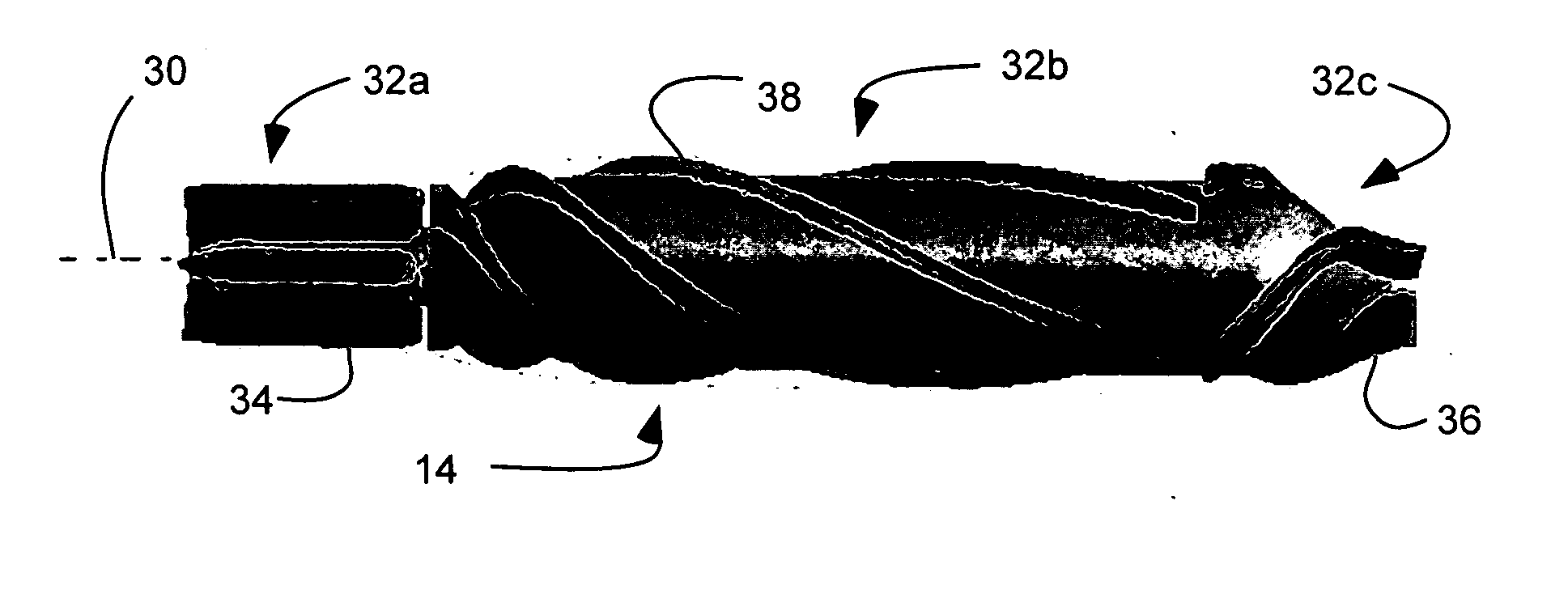

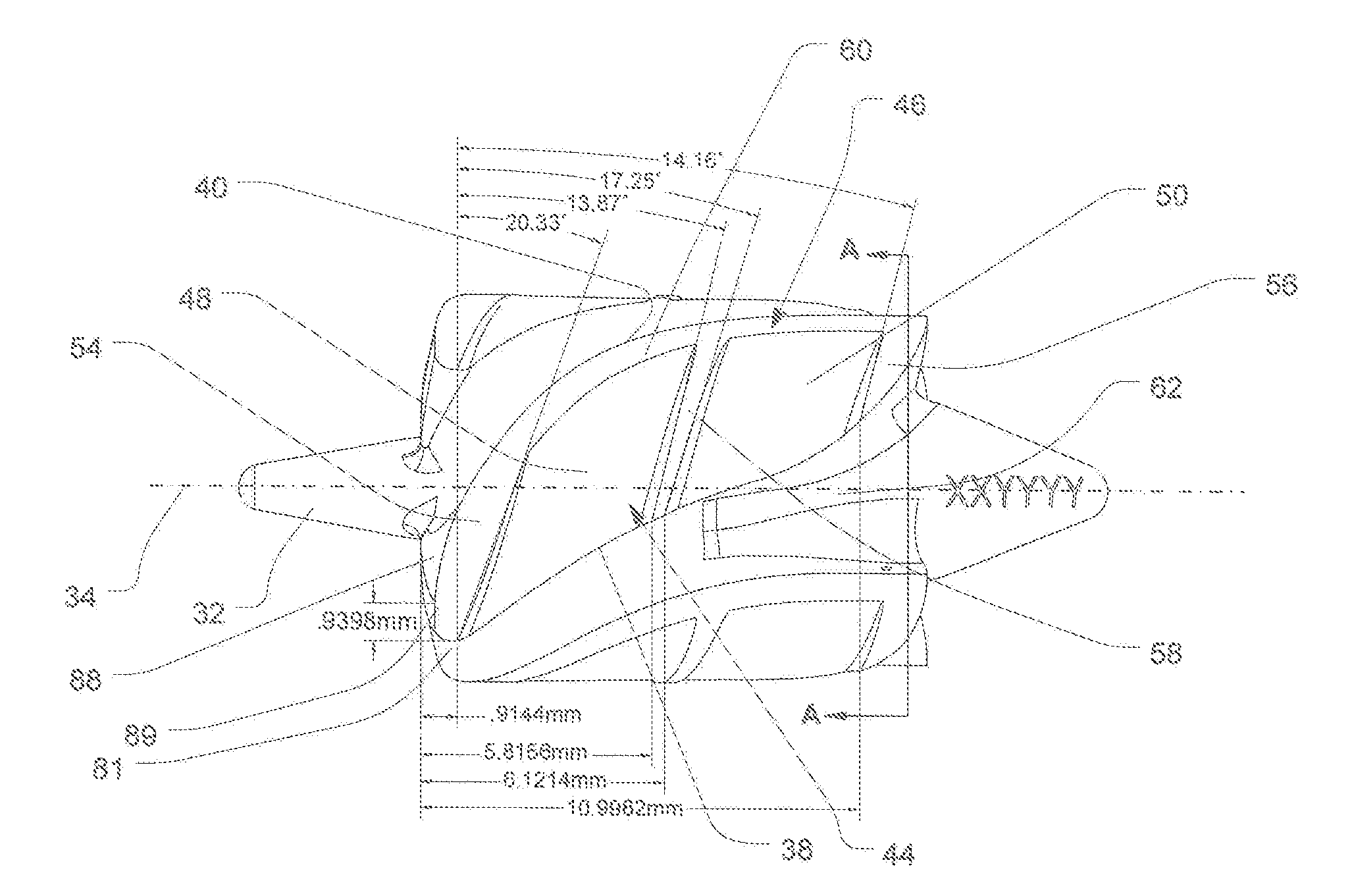

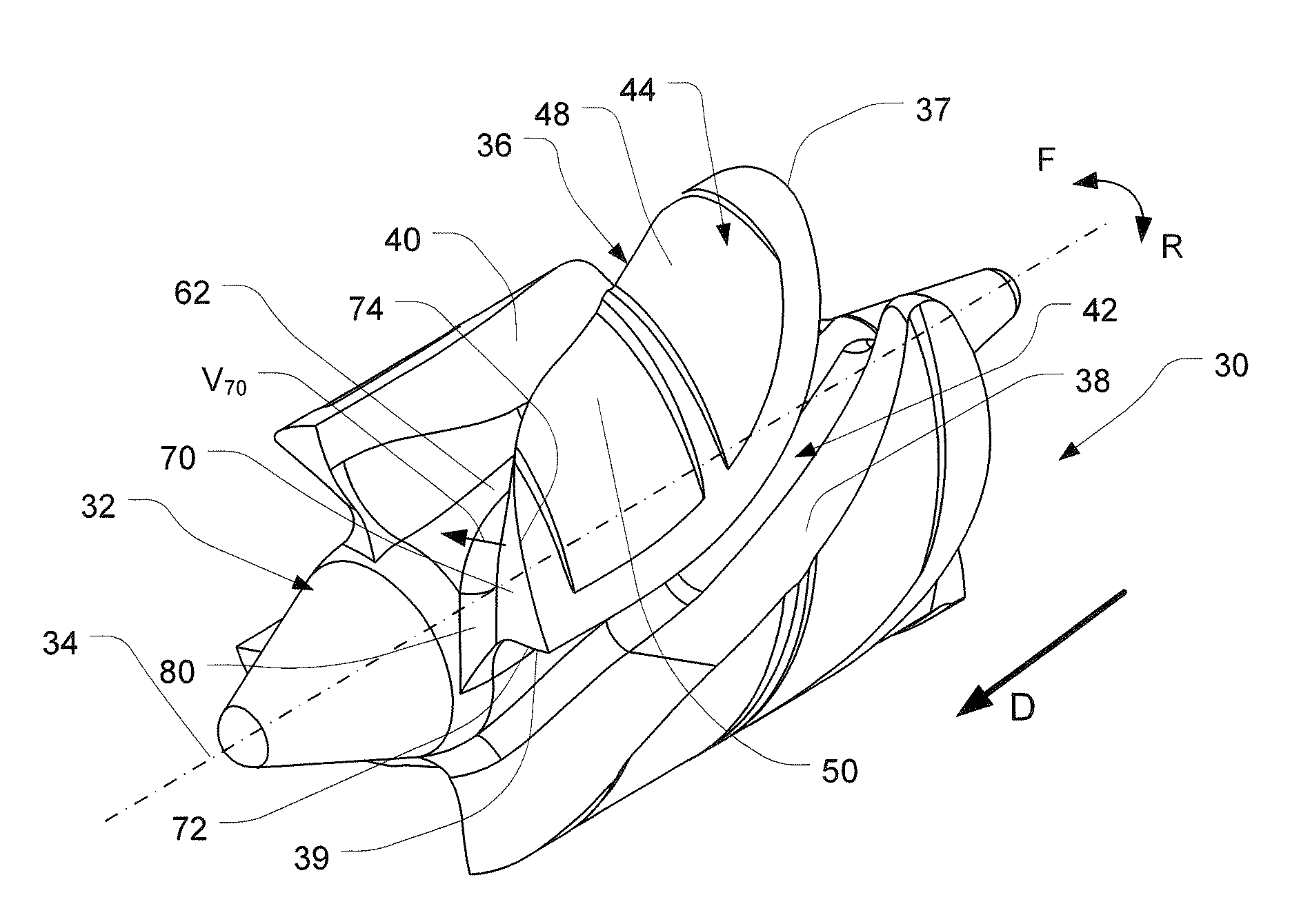

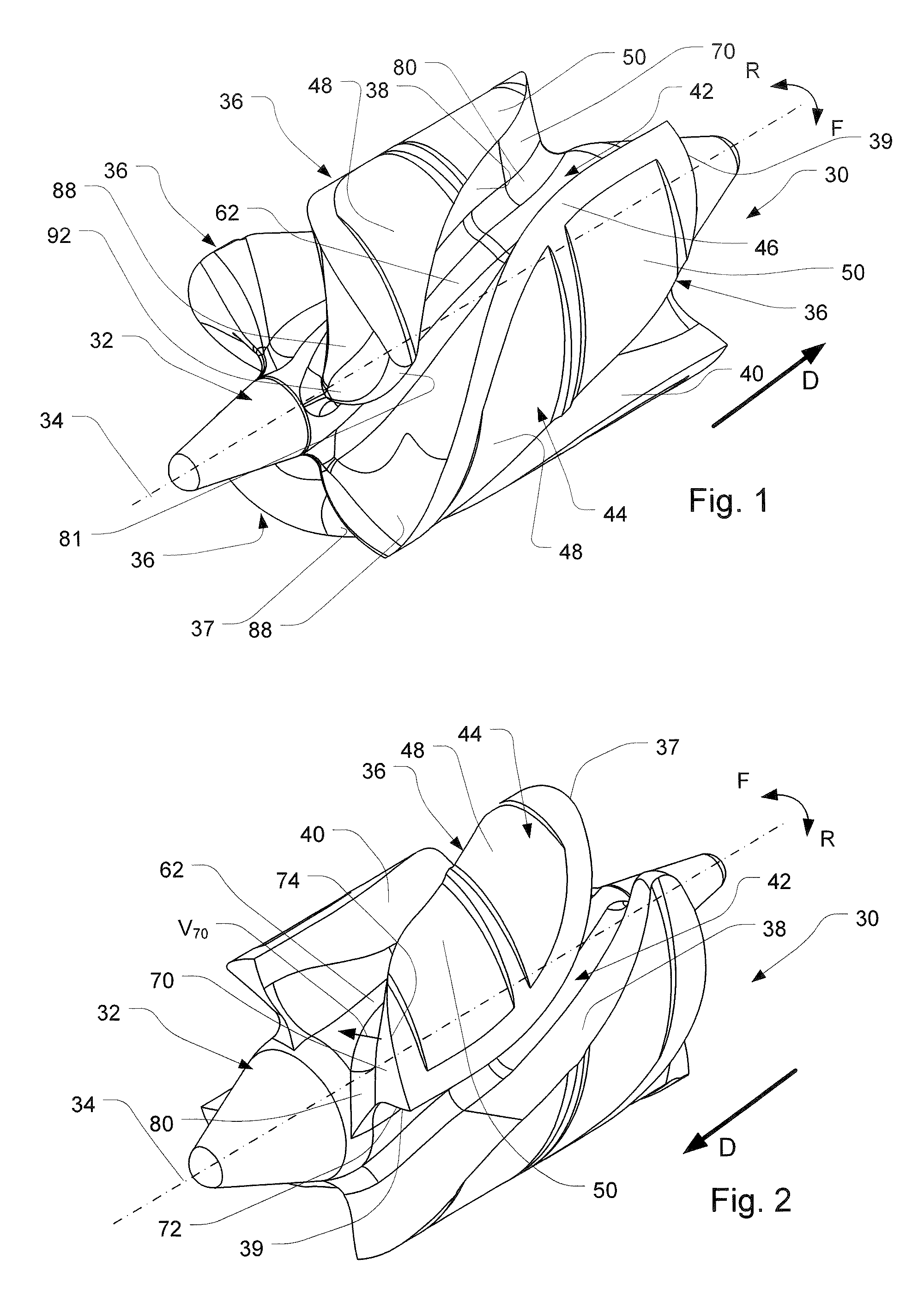

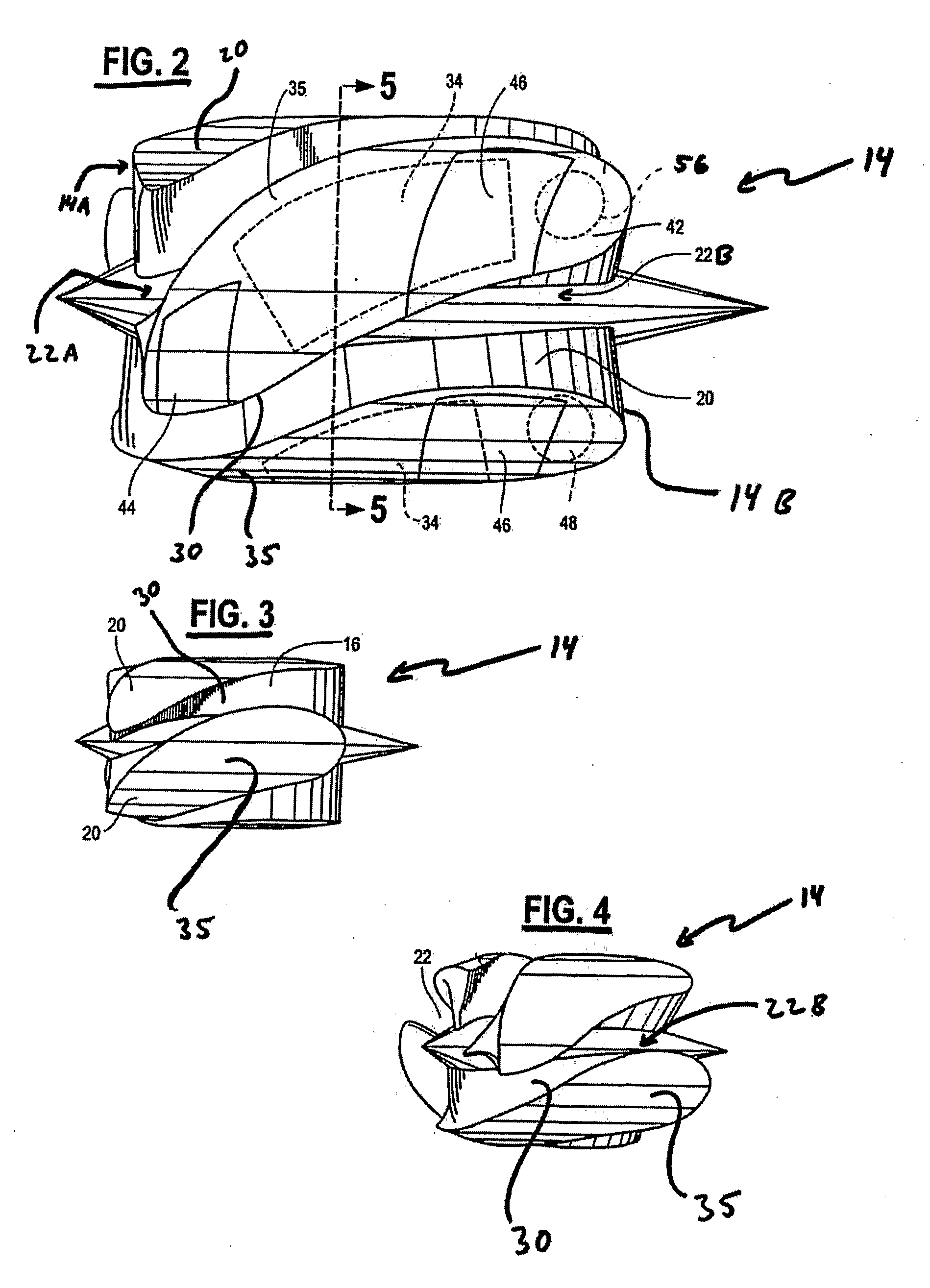

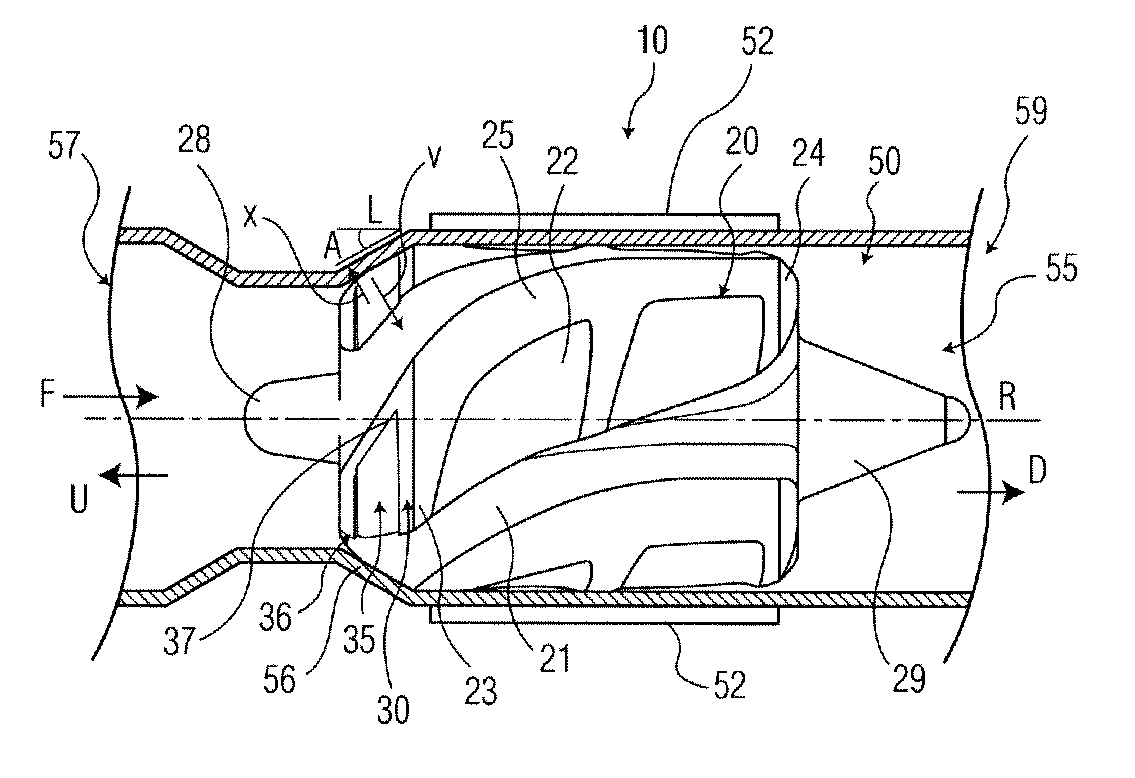

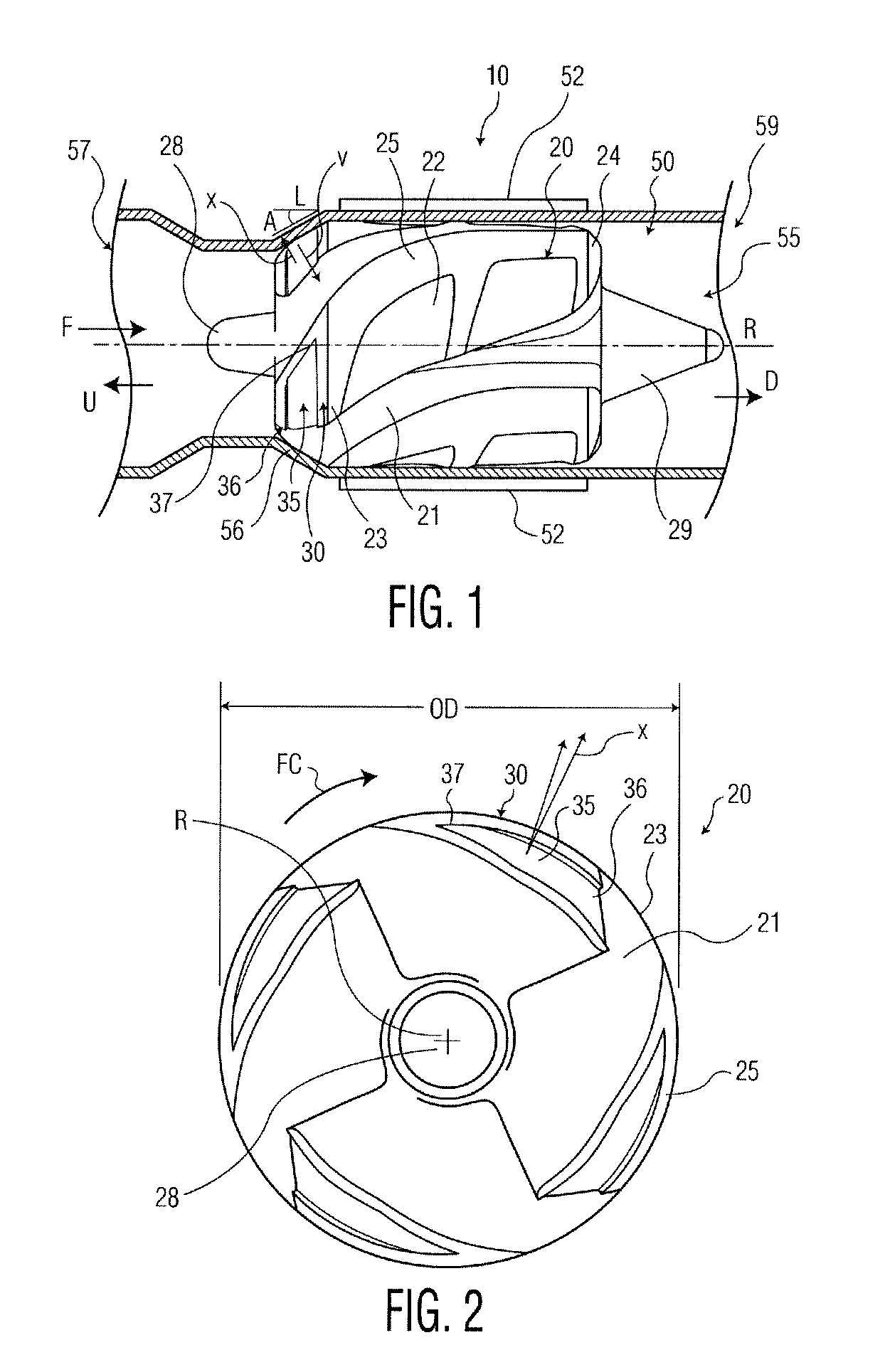

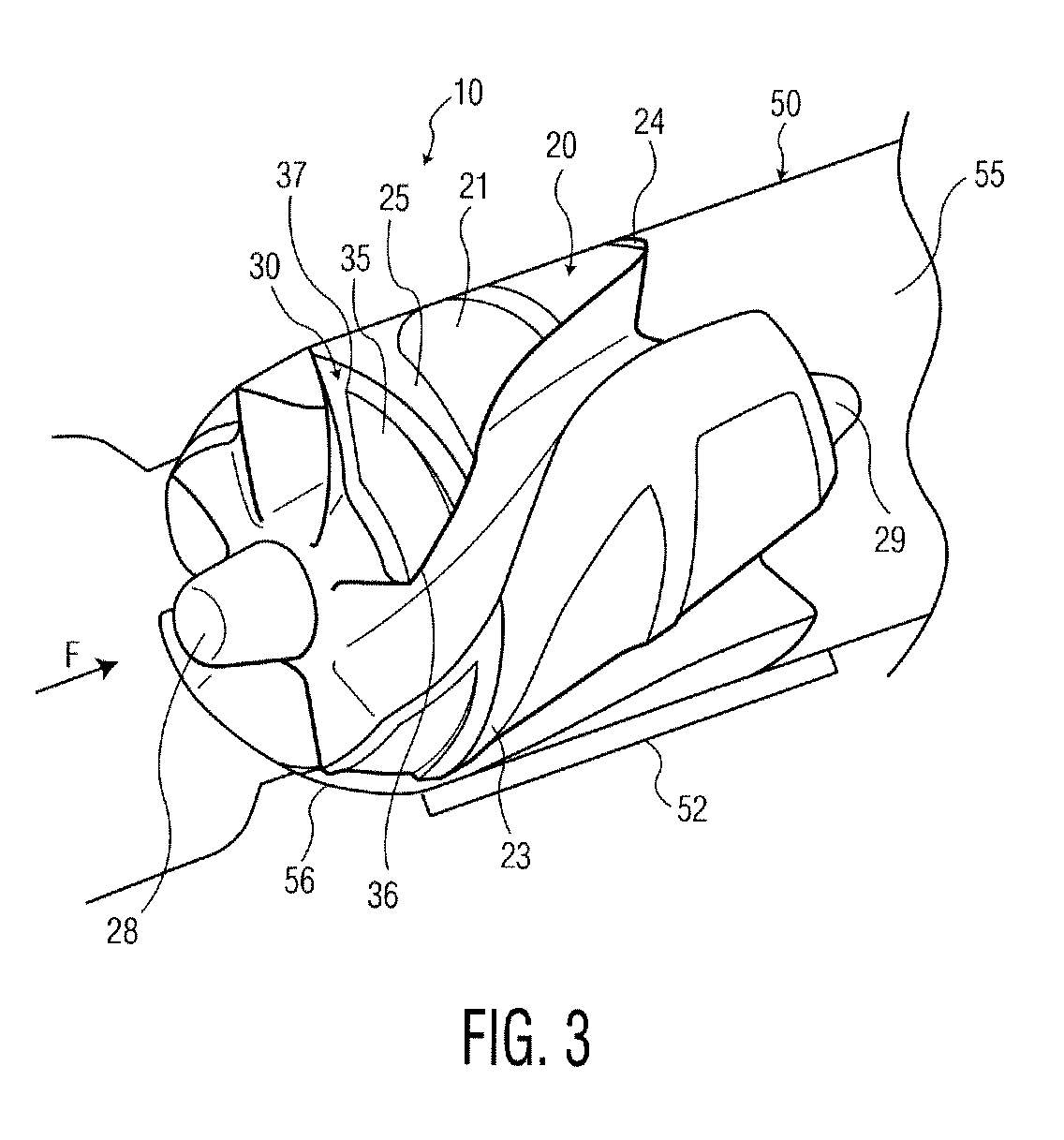

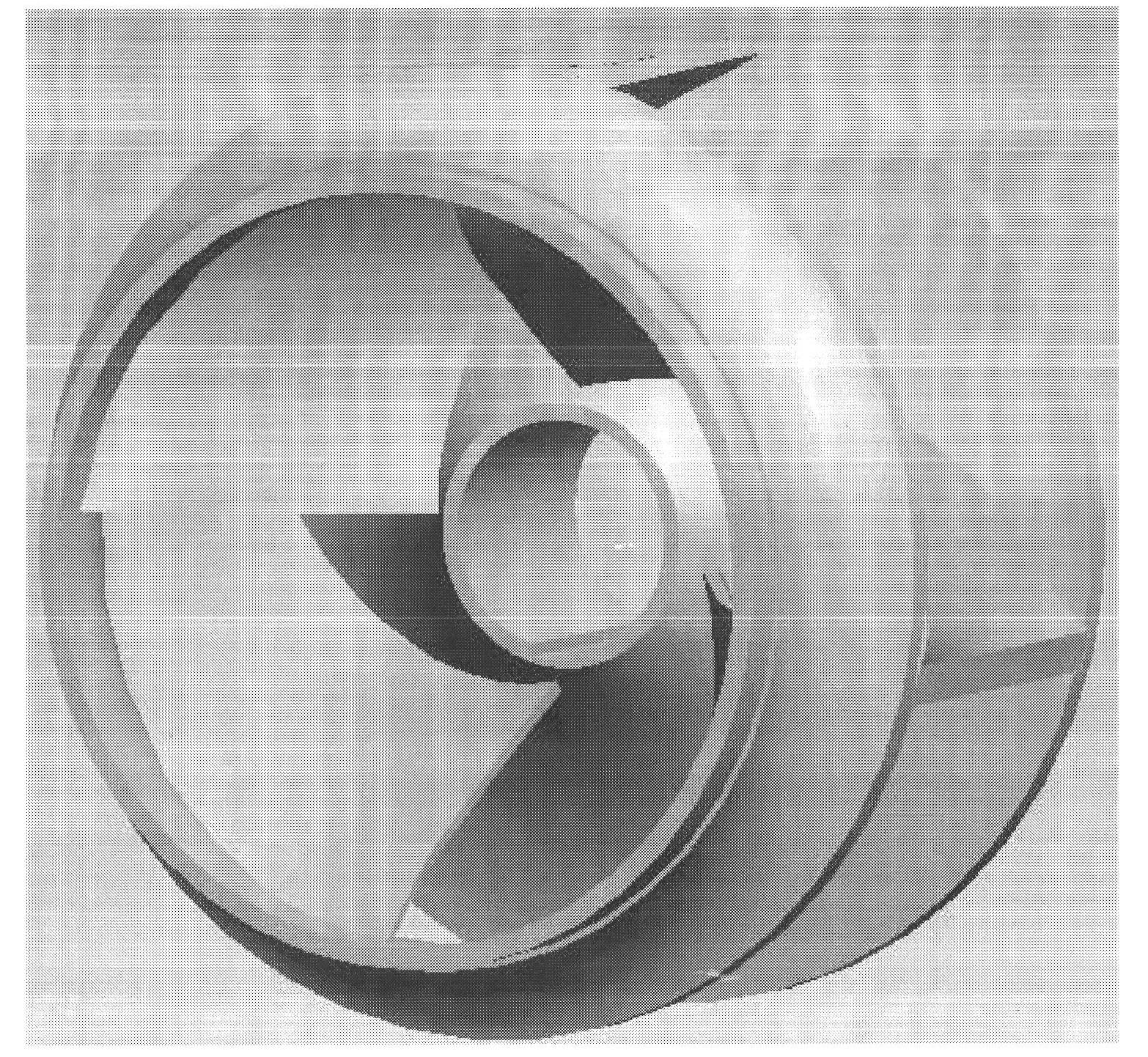

Impeller for axial flow pump

A rotor for an axial-flow blood pump has blades projecting outwardly from a hub and channels between the blades. The blades incorporate hydrodynamic bearing surfaces capable of suspending the rotor during operation. The rotor has a configuration which provides superior pumping action and reduced shear of blood passing through the pump. The forwardly facing pressure surfaces of the blades may include outflow corner surface at their downstream ends. The outflow corner surfaces desirably slope rearwardly and intersect the rearwardly-facing suction surfaces of the blades at outflow ends of the blades.

Owner:HEARTWARE INC

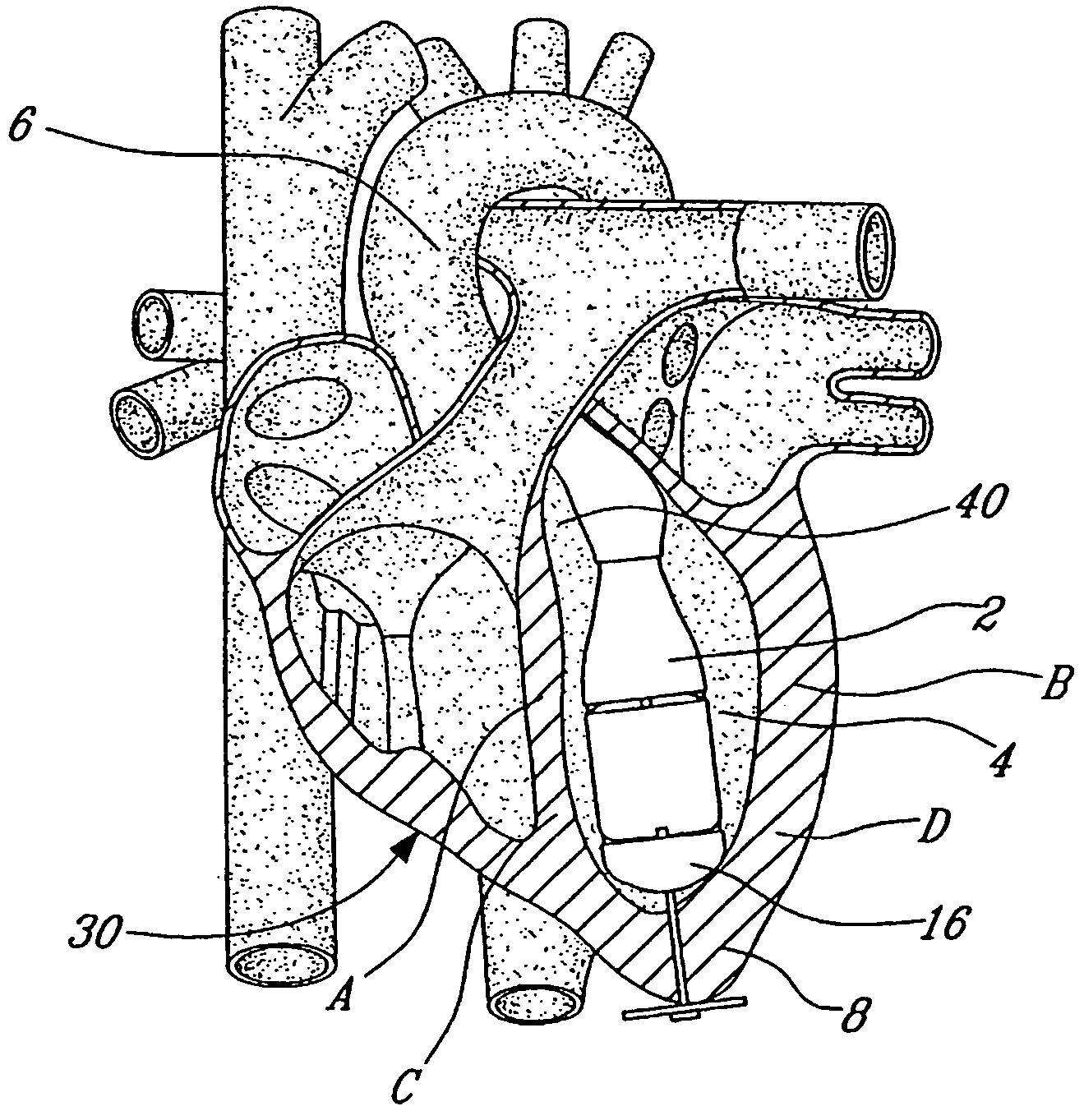

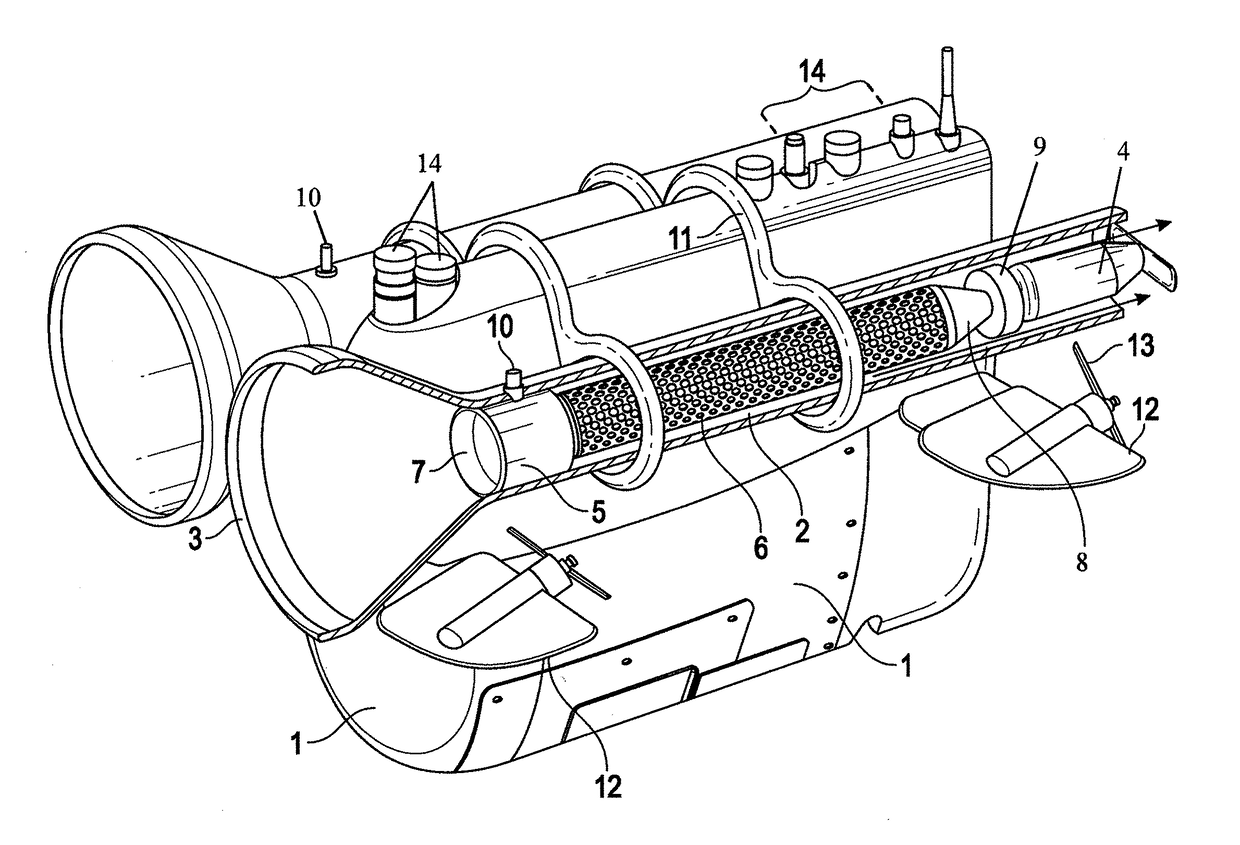

Circulatory support system

InactiveUS7264606B2Facilitate pumping functionFacilitate functioningOther blood circulation devicesBlood pumpsAxial-flow pumpPulmonary vasculature

A method for providing at least partial bypass of the heart to supplement the pumping function of the heart to thereby enable the surgeon to perform various surgical procedures thereon includes providing a circulatory assist system having a portable extracorporeal axial flow pump with a pump housing, a rotating pumping member disposed in the pump housing and inlet and outlet cannulated tubes respectively connected to inlet and outlet ports of the pump housing, accessing the patient's left atrium of the heart with the inlet cannulated tube, accessing the aorta with the outlet cannulated tube, actuating the rotating pumping member to draw oxygenated blood from the left atrium of the heart through the lumen of the inlet cannulated tube and into the inlet port of the pump housing whereby the pumping member imparts mechanical energy to the oxygenated blood passing through the pump housing and directs the oxygenated blood through the outlet port and through the lumen of the outlet cannulated tube to be transferred by the aorta to the systemic arteries and permitting the right side of the heart to function whereby oxygen-depleted blood returning through the systemic veins to the right atrium is directed through the right ventricle to the patient's lungs for oxygenation and subsequent pulmonary circulation.

Owner:UNITED STATES SURGICAL CORP

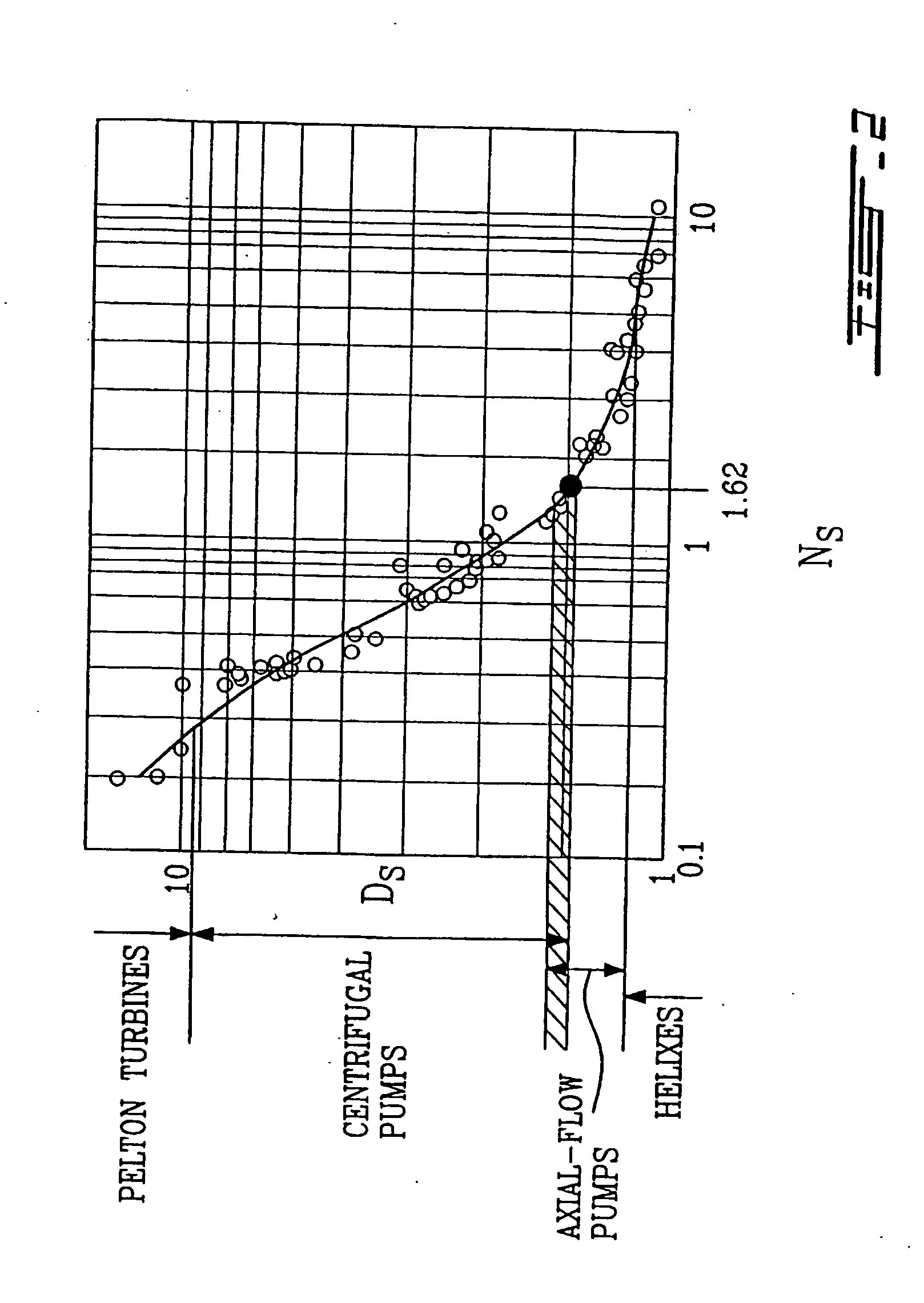

Dual inlet mixed-flow blood pump

A mixed-flow blood pump presents features of both axial-flow and radial-flow pumps. This mixed-flow blood pump comprises a stationary housing structure defining at least one blood inlet, a blood outlet, and a blood conduit between the at least one blood inlet and the blood outlet, and a rotative impeller mounted in the blood conduit. The at least one blood inlet, the blood outlet, the blood conduit and the rotative impeller have respective structures and configurations that operate the mixed-flow blood pump at a given point of a maximum hydraulic efficiency curve relating a specific pump rotational speed and a specific pump diameter. This given point is located within a transition region of the maximum hydraulic efficiency curve between axial-flow and radial-flow pumps.

Owner:CARDIANOVE

Impeller for axial flow pump

A rotor for an axial-flow blood pump has blades projecting outwardly from a hub and channels between the blades. The blades incorporate hydrodynamic bearing surfaces capable of suspending the rotor during operation. The rotor has a configuration which provides superior pumping action and reduced shear of blood passing through the pump. The forwardly facing pressure surfaces of the blades may include outflow corner surface at their downstream ends. The outflow corner surfaces desirably slope rearwardly and intersect the rearwardly-facing suction surfaces of the blades at outflow ends of the blades.

Owner:HEARTWARE INC

Wide blade, axial flow pump

ActiveUS20060122456A1Increase the magnetic fluxReduce air gapControl devicesBlood pumpsAxial-flow pumpImpeller

Owner:HEARTWARE INC

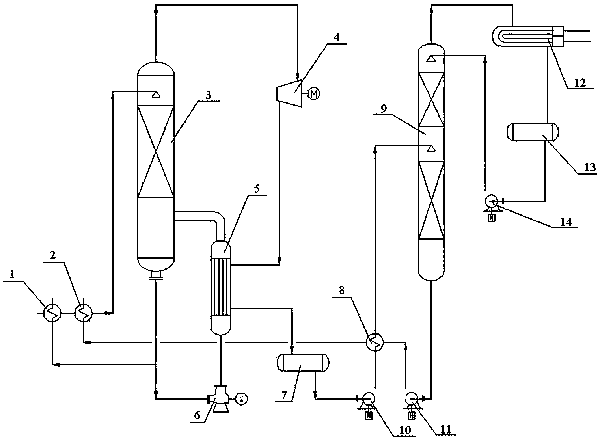

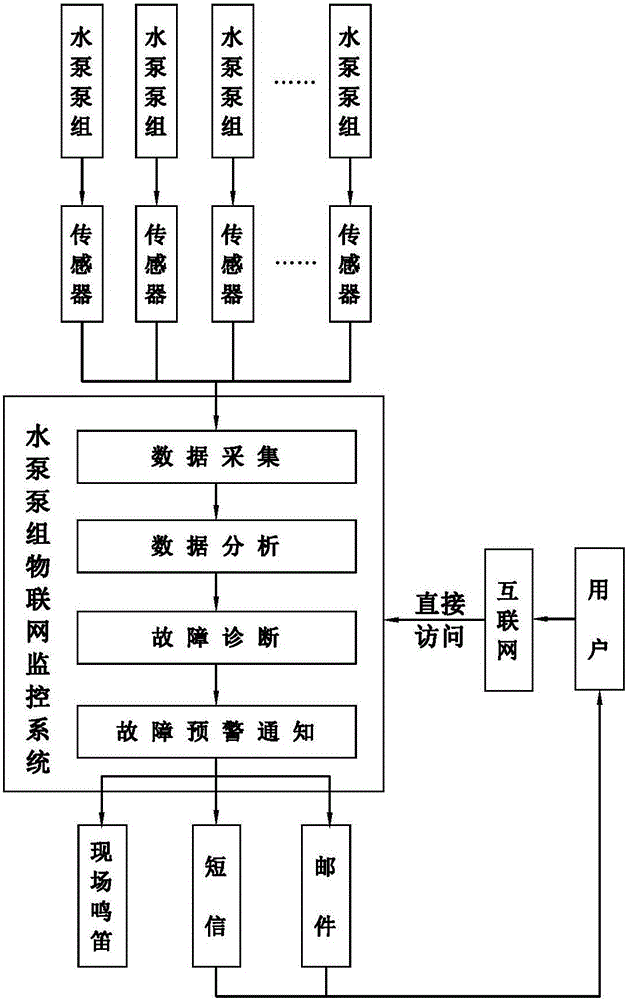

MVR (Mechanical Vapor Recompression) vapor-stripping deamination system and application method thereof

InactiveCN103408086AIncrease pressureIncrease temperatureWater/sewage treatment by degassingAmmonia preparation/separationAxial-flow pumpWater discharge

The invention relates to an MVR vapor-stripping deamination system. The MVR (Mechanical Vapor Recompression) vapor-stripping deamination system comprises a vapor-stripping deamination tower, an ammonia water rectification tower and a condenser, wherein a high-ammonia-nitrogen sewage input pipe, a vapor input pipe I, a post-deamination waste water discharge port and an ammonia-containing vapor discharge port I are arranged on the vapor-stripping deamination tower; the vapor-stripping deamination tower is connected with a reboiler; the high-ammonia-nitrogen sewage input pipe is connected with waste water feed preheaters (II and I); the post-deamination waste water discharge port is connected with the waste water feed preheater I and an axial flow pump respectively; the ammonia-containing vapor discharge port I is connected with the reboiler through a mechanical vapor compressor; the reboiler is connected with a dilute ammonia water storage tank connected with the ammonia water rectification tower; a discharge port, an ammonia-containing vapor discharge port II and a vapor input pipe are arranged on the ammonia water rectification tower; the discharge port is connected with a rectification tower kettle discharge pump and the waste water feed preheater II; the ammonia-containing vapor discharge port II is connected with the condenser; a strong ammonia water discharge port is connected with a strong ammonia water storage tank connected with the ammonia water rectification tower. Meanwhile, the invention further discloses an application method of the MVR vapor-stripping deamination system. The MVR vapor-stripping deamination system has the advantages of less investment, high feasibility and high comprehensive utilization ration.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

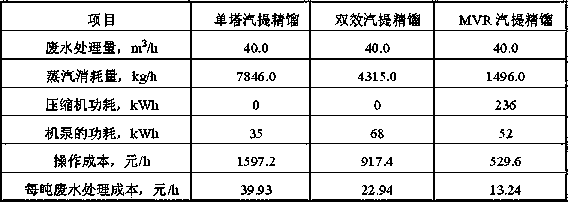

Intelligent water pump set monitoring and fault early warning method based on internet of things

ActiveCN106015028AGuaranteed uptimeAchieve early warningPump controlNon-positive displacement fluid enginesAxial-flow pumpFrequency spectrum

The invention belongs to the technical field of fluid mechanical and intelligent diagnosis, and particularly discloses an intelligent water pump set monitoring and fault early warning method based on internet of things. According to the technical scheme, a water pump set testbed is built; a touch screen serves as site monitoring equipment, a PC machine serves as a monitoring platform, a data collection module is used for collecting signals of all sensors, and the touch screen and the PC machine read the data of the data collection module in real time and store and backup the data; The water pump set internet-of-things monitoring system is designed through an HMI, and remote intelligent monitoring of water pump sets on the basis of internet of things is achieved; and monitoring signals of the water pump sets are subjected to data analysis in real time, operational diagnosis and fault early warning. The internet of things technology, the spectral analysis technology and the fault diagnosis technology are effectively combined, early warning of faults of various water pump sets like centrifugal pumps, mixed-flow pumps, axial flow pumps and submersible electric pumps is achieved, and the water pump sets can operate safely and reliably.

Owner:JIANGSU UNIV

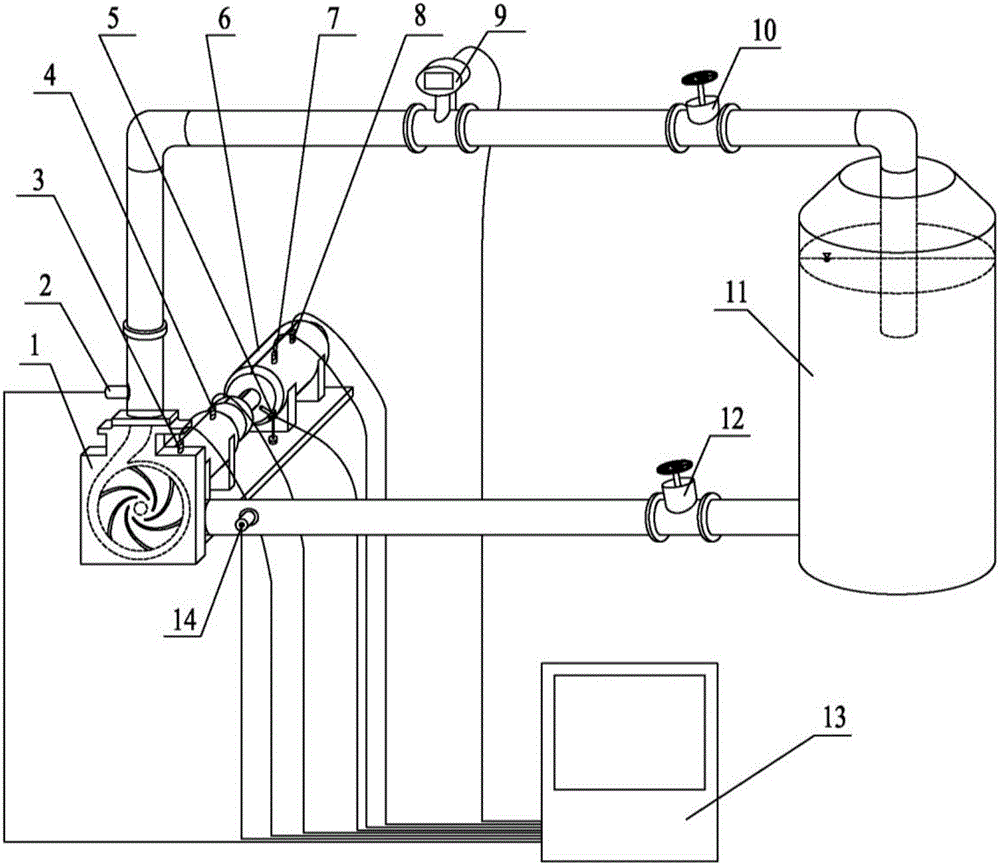

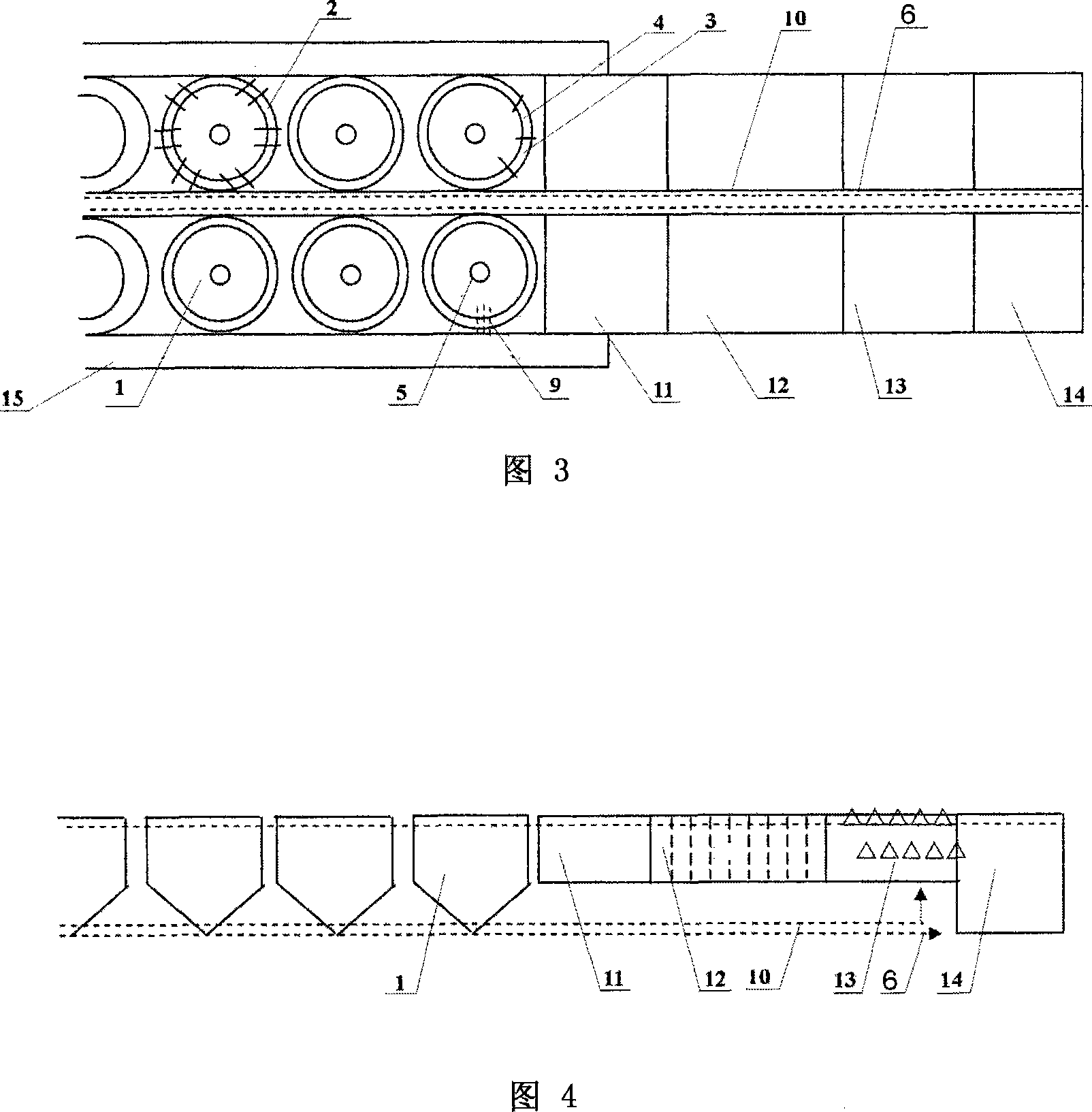

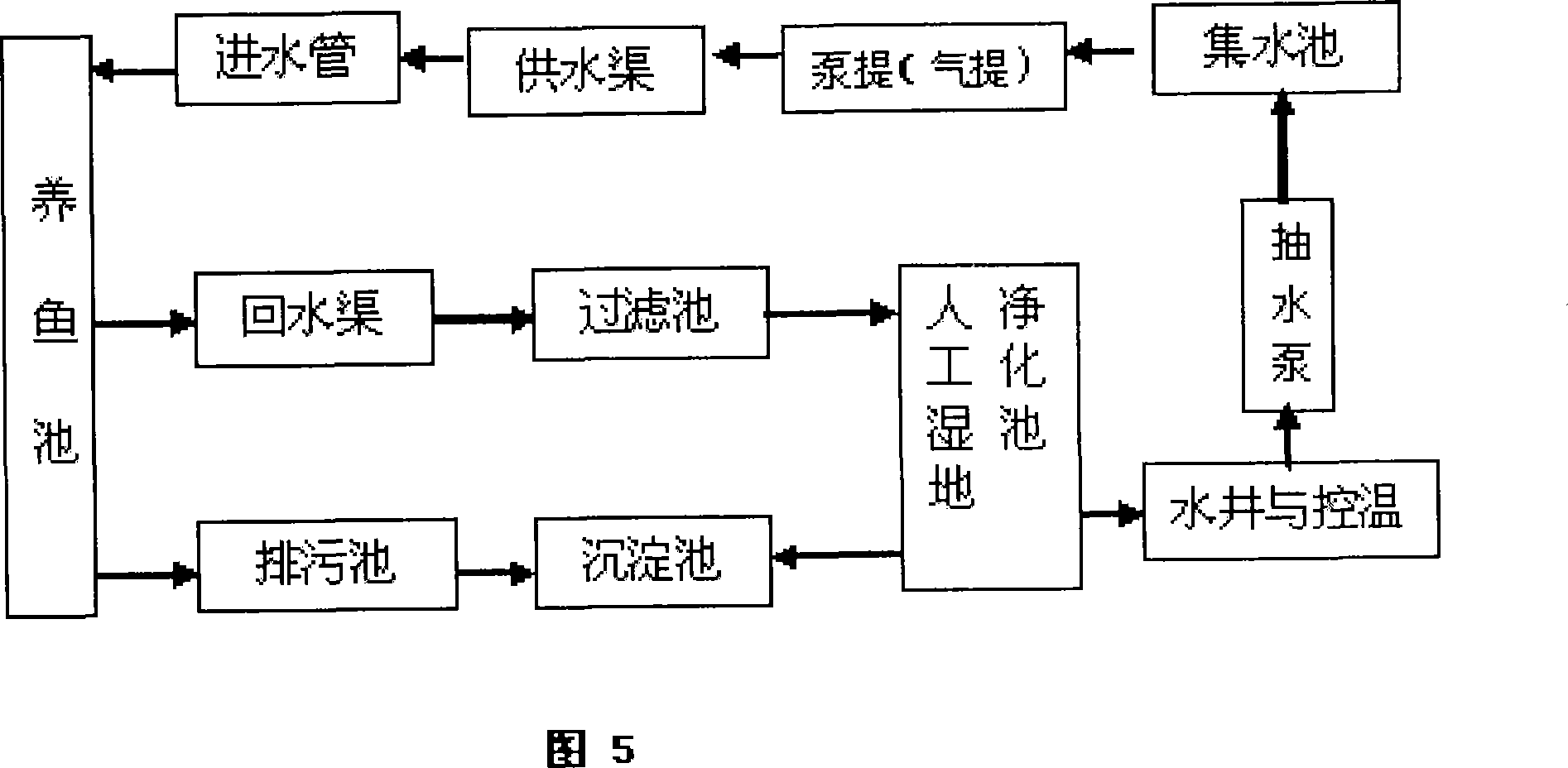

Industrialization ecological treatment circulation utilization system for fish culture waste water

InactiveCN101215069AImprove processing efficiencyReduce energy consumptionMultistage water/sewage treatmentSustainable biological treatmentAxial-flow pumpConstructed wetland

Disclosed is an ecological treatment and recycling system for factory fish-farming wastewater, which belongs to the field of fishery cultivation. The system comprises facilities and devices for treating recycle water like a fish pond, an ultra-low axial flow pump, a jet aeration oxygenation facility, a foam separating facility, a pure oxygen supplying device, a temperature control device, artificial wetland and the like, using an open type high-volume feed canal and a backwater canal to replace sealed pipes, using the foam separating facility to replace a protein separator, using the temperature control device of deep well to replace a heating-up and cool-down device, using the jet aeration oxygenation facility to replace an automatic aerator, a gas relay rock and an air pipe, using water plants of the artificial wetland and economic filtering materials to replace purifying filtration devices like a solid-liquid separation device and the like. The invention achieves functions like water lift, aeration, oxygenation, defoaming, temperature control and the like. The invention optimizes and combines a facility engineering technique and a biologic technology to replace expensive and complex water-treating equipment, and has the advantages of safety and dependability, simple management, energy-saving and environment protection, high yield and high grade and the like.

Owner:宜都天峡特种渔业有限公司

Axial Flow-Pump With Multi-Grooved Rotor

ActiveUS20100069847A1Improve the immunityEasy to washPump componentsBlood pumpAxial-flow pumpImpeller

Owner:HEARTWARE INC

Ventricular assist device for intraventricular placement

A ventricular assist device includes a pump such as an axial flow pump, an outflow cannula connected to the outlet of the pump, and an anchor element. The anchor element is physically connected to the pump, as by an elongate element. The pump is implanted within the left ventricle with the outflow cannula projecting through the aortic valve but desirably terminating short of the aortic arch. The anchor element is fixed to the wall of the heart near the apex of the heart so that the anchor element holds the pump and outflow cannula in position.

Owner:HEARTWARE INC

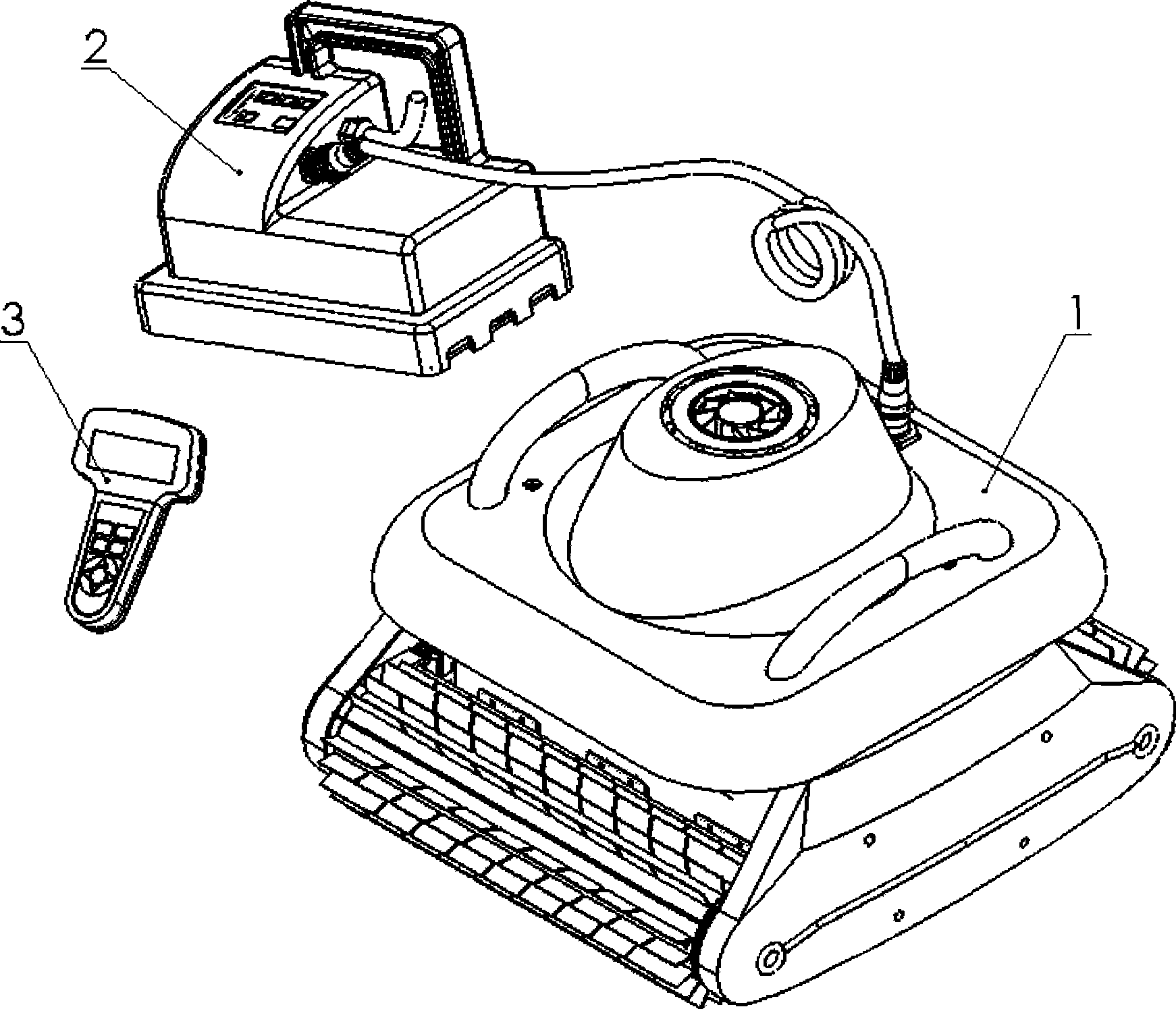

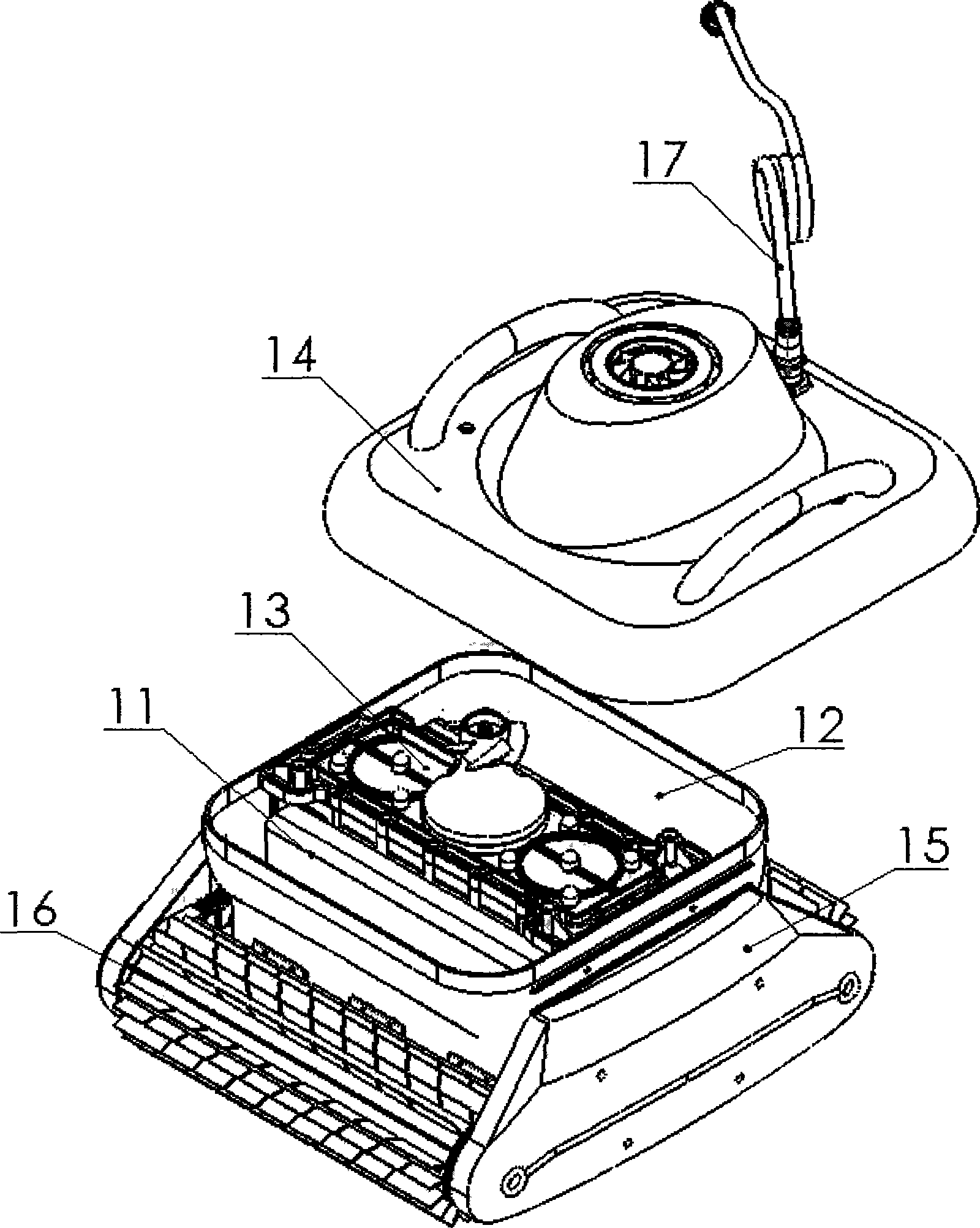

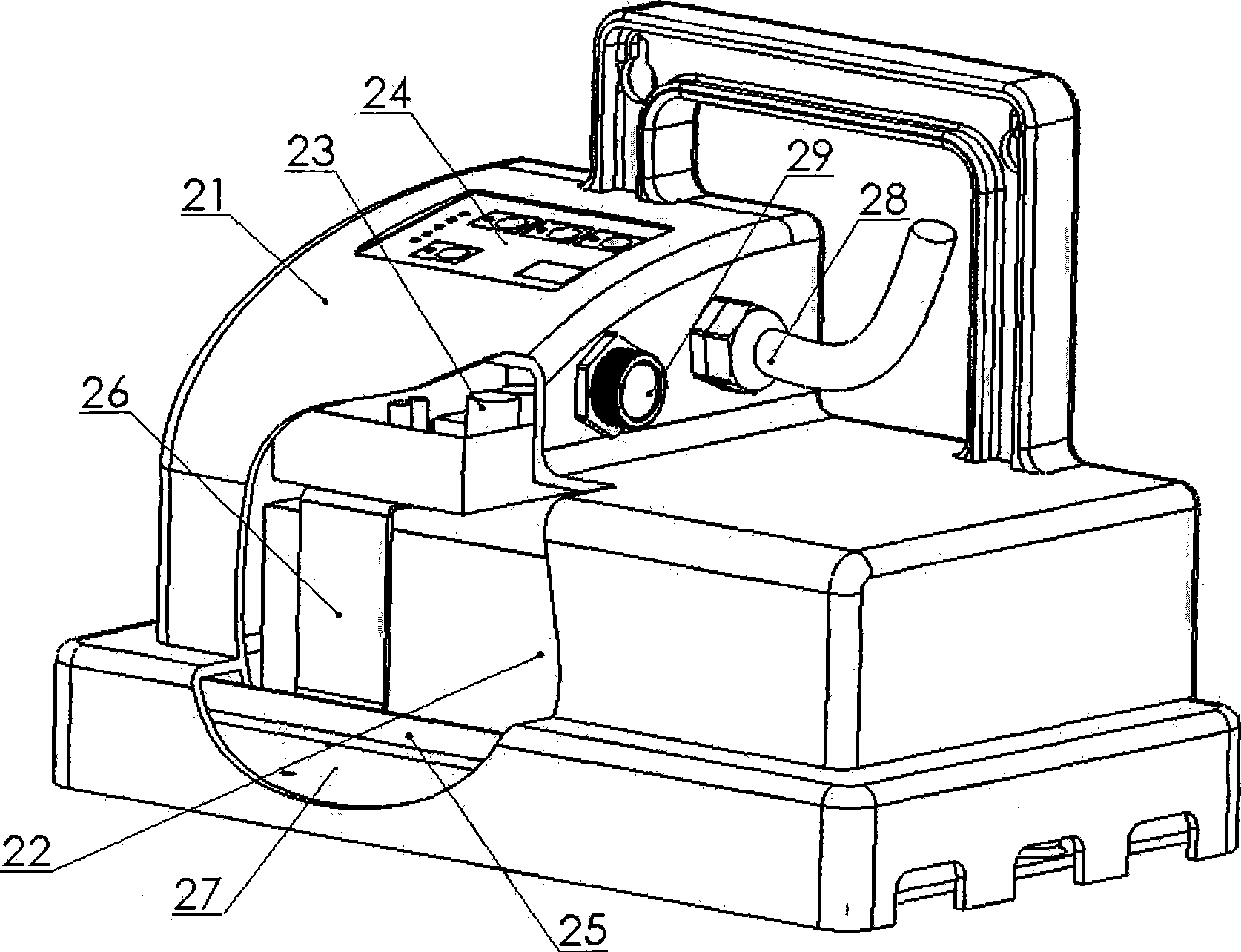

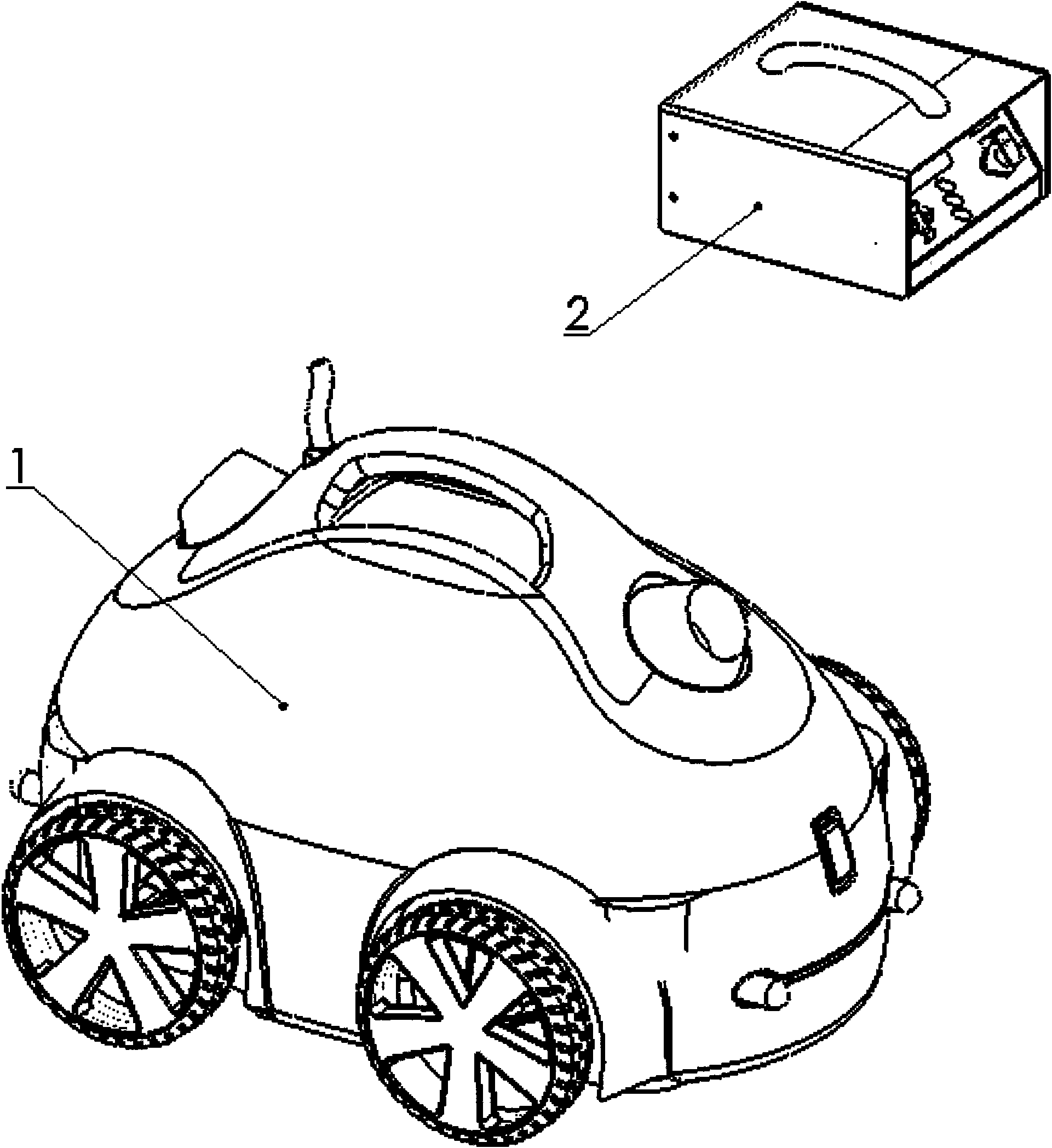

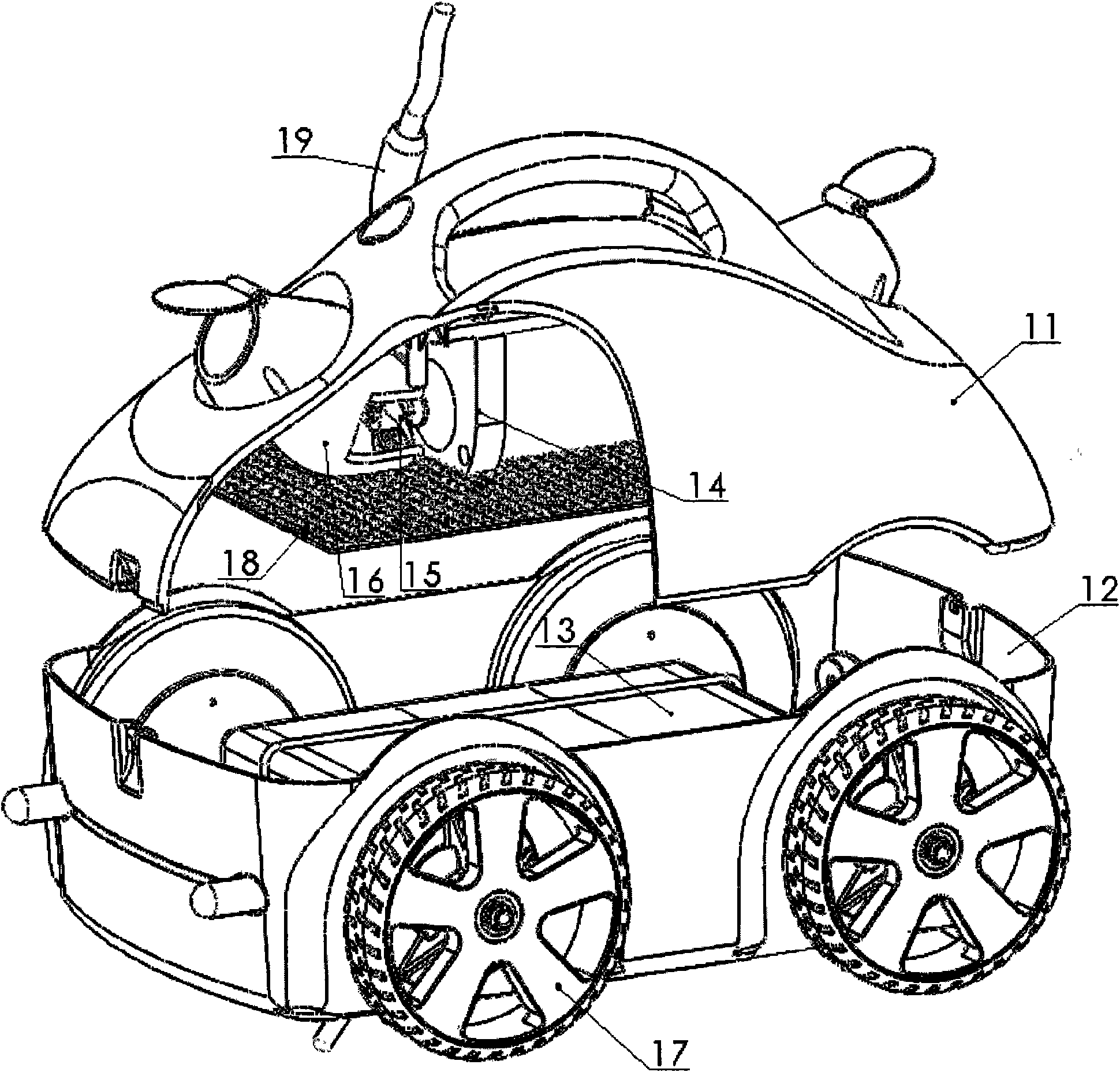

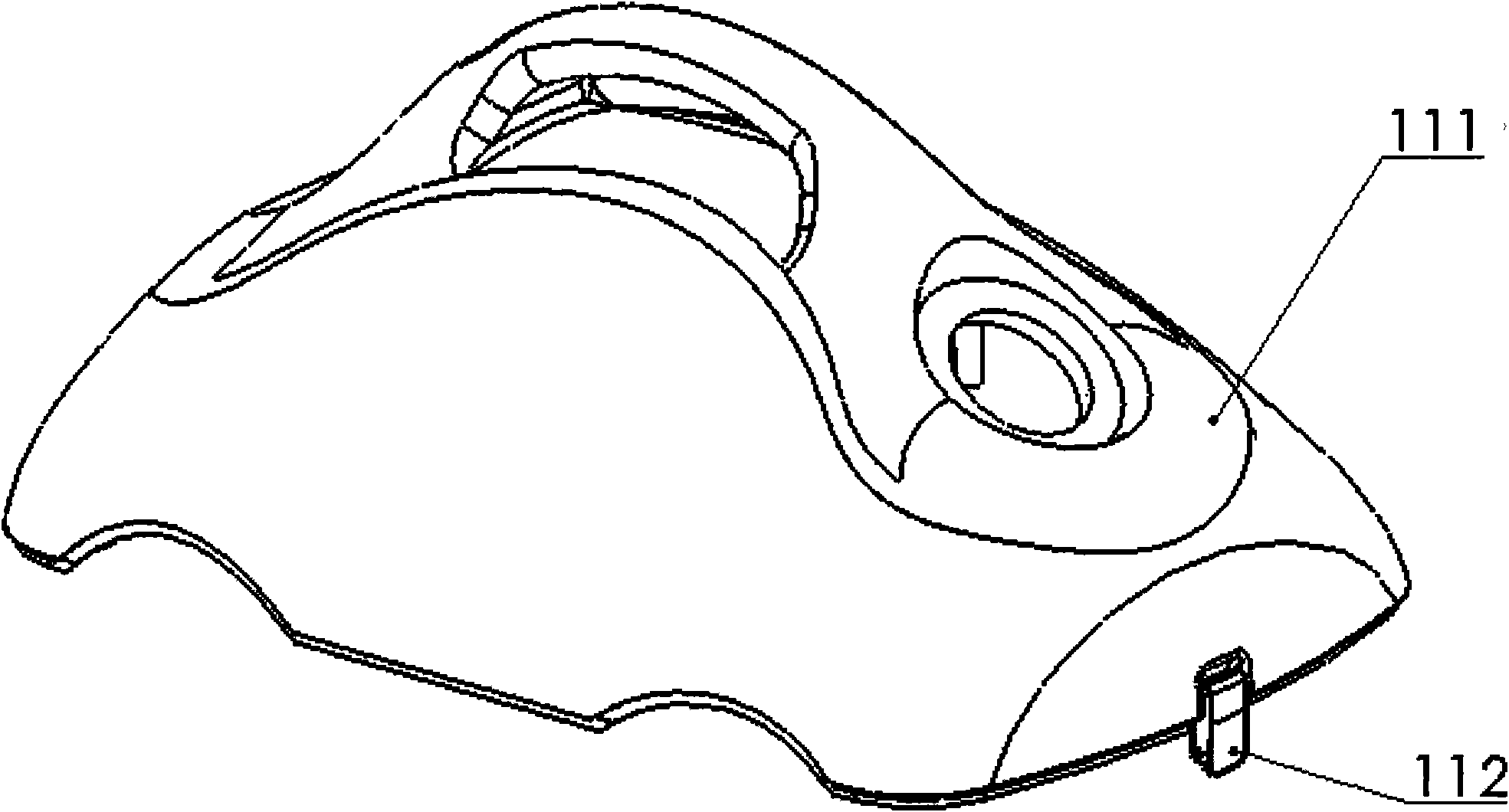

Remote control ordered swimming pool cleaning robot and ordered cleaning method thereof

ActiveCN101481957AWith turning functionOrderly cleaningGymnasiumSwimming poolsAxial-flow pumpControl system

The invention relates to a swimming pool cleaning robot with orderly remote control, comprising a cleaning robot main machine, a power supply control box and a remote controller, wherein the cleaning robot main machine comprises a filter, machine housing components, an axial flow pump, a seal box, left and right transmission systems, clearer rollers and self-suspension cables; the left and right transmission systems respectively drive the front and rear cleaner rollers to rotate, thereby synchronously driving external teeth to contact the bottom of a wall of the pool so as to drive the robot to creep; sliding friction is generated between the outer edges of cleaning belts on the cleaner rollers and the bottom or the wall of the pool, thereby carrying out the operation of cleaning; an overload sensor is arranged in a control system of the cleaning robot and is used for detecting and judging the wall contact state during creeping cleaning, and corresponding signals are sent to cause the cleaning robot to be switched to a next program to work; and the remote controller has the functions of bidirectional communication, and a display screen can display working conditions and has the function of malfunction alarm. The robot carries out path planning design for the swimming pools with different shapes, and adopts the path method of entire journey back turning and the path method of half journey back turning, thereby realizing the orderly and full coverage cleaning of the swimming pools with different shapes.

Owner:TIANJIN WANGYUAN ENVIRONMENTAL PROTECTION & TECH CO LTD

Hydrodynamic chamfer thrust bearing

An axial flow pump for a blood circulating pump for the circulation of blood, the rotor the rotor being constructed and arranged to impel blood in a downstream direction upon rotation of the rotor about its axis in a forward circumferential direction. The rotor is provided with hydrodynamic thrust bearing surfaces, each such thrust bearing surface being constructed and arranged to apply a hydrodynamic force to the rotor with a component of the force in the downstream direction upon rotation of the rotor in the forward circumferential direction.

Owner:HEARTWARE INC

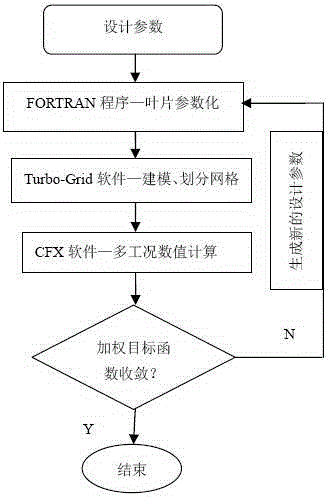

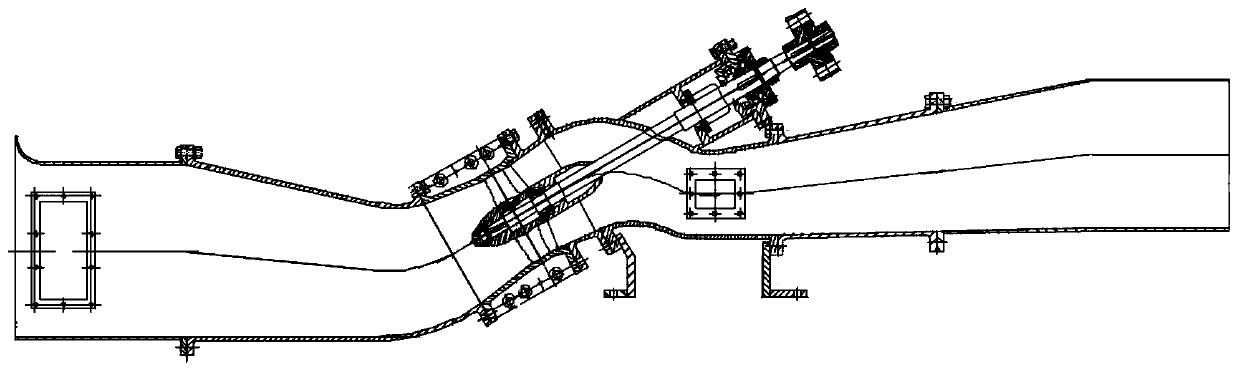

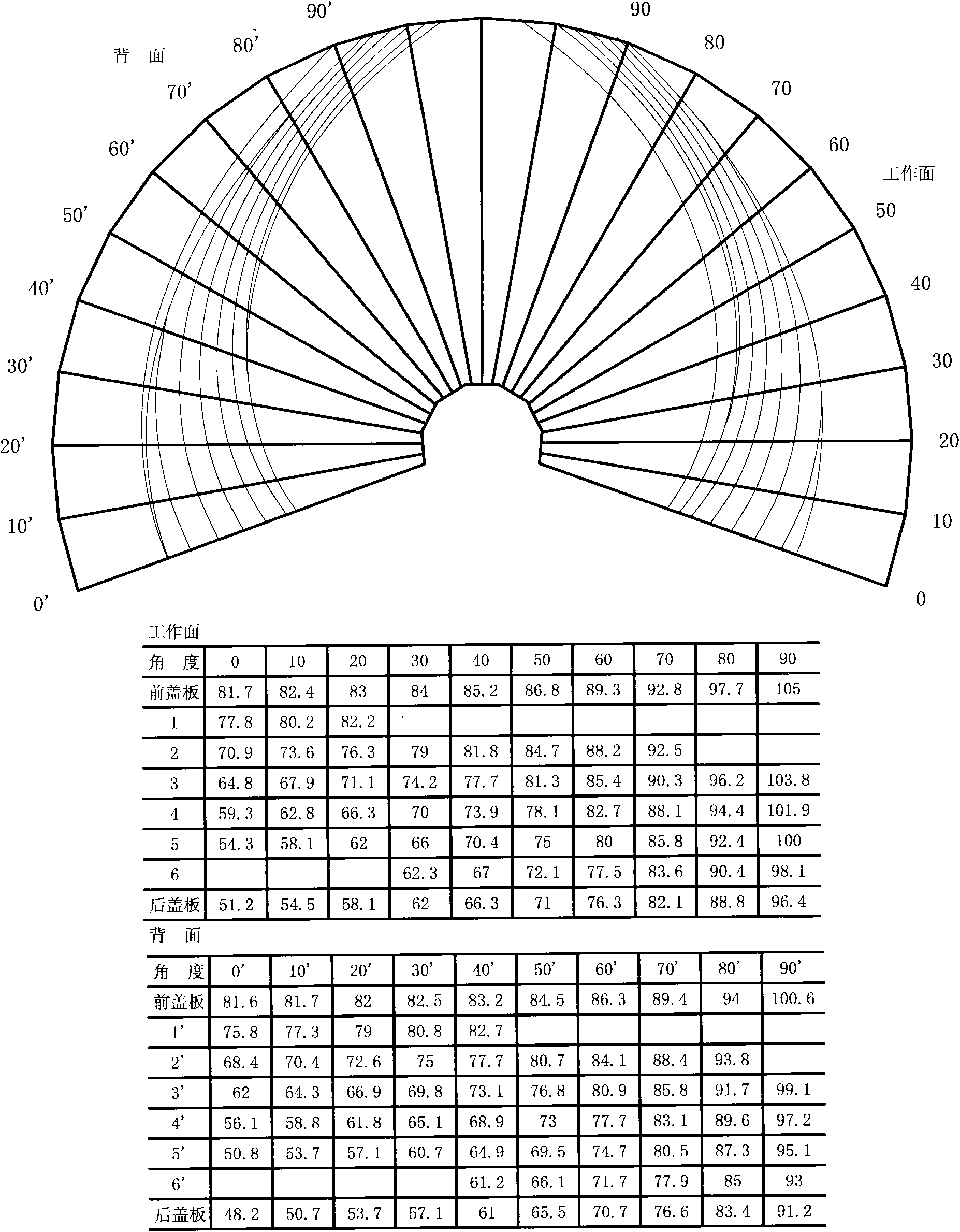

Axial flow pump impeller all-operating-condition design method

ActiveCN105179303AImprove efficiencyWide efficiency curvePump componentsPumpsAxial-flow pumpImpeller

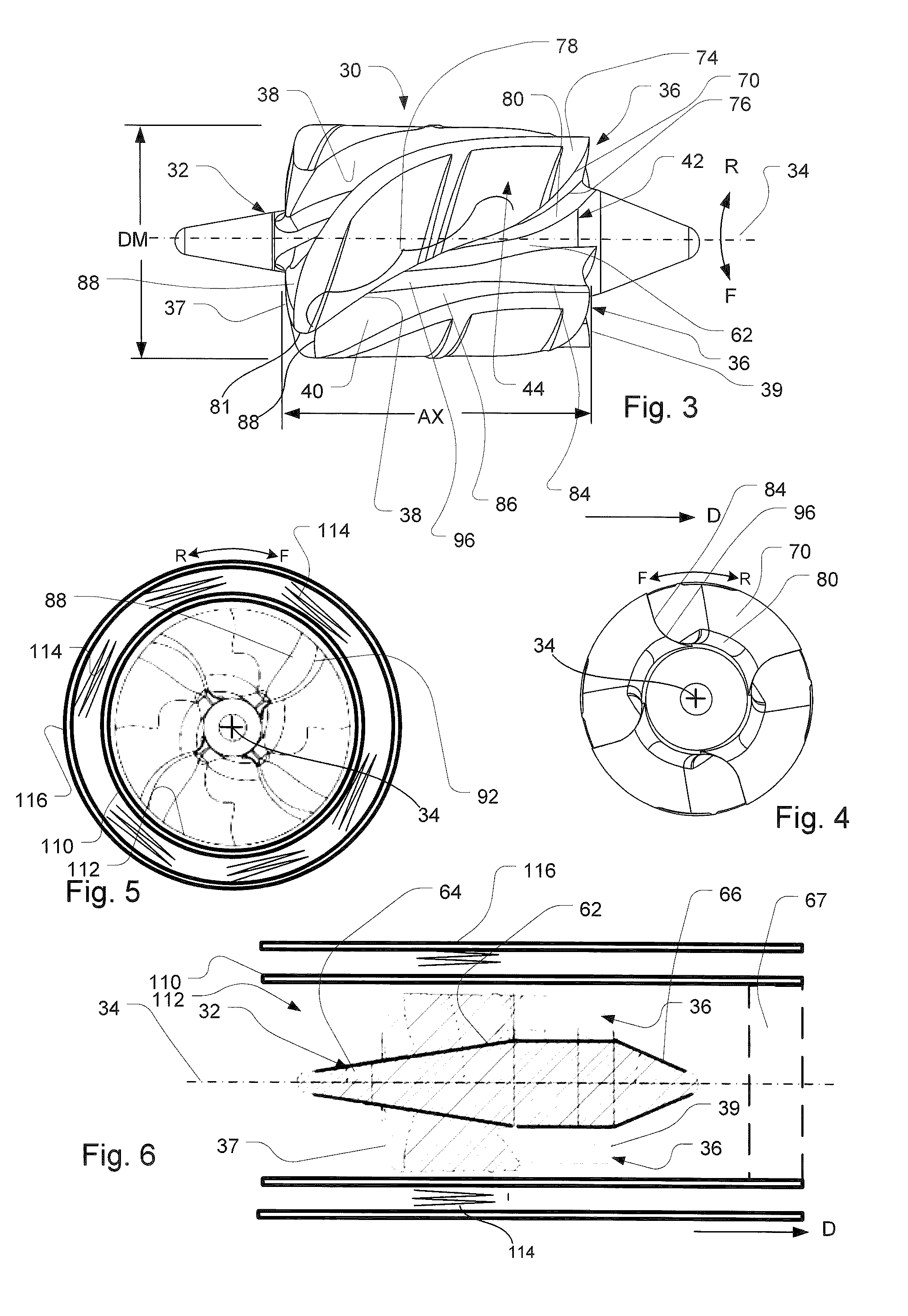

An axial flow pump impeller all-operating-condition design method comprises the following steps that 1, parametric modeling of an axial flow pump impeller is performed, namely 2k design parameters including k wing section cascade solidities and wing placement angle values of the axial flow pump impeller are selected; 2, all-operating-condition optimal design is performed: firstly, conventional design parameters of the impeller are dertemined, then numerical calculation is conducted on the design conditions of the axial flow pump impeller and various losses in a pump are comprehensively analyzed to preliminarily design the axial flow pump impeller having better hydraulic performance under the design conditions in a total-loss minimization mode; secondly, guide blades, a water guide cone and water inlet and outlet flowing channels of the impeller are designed; thirdly, the optimal all-operating-condition weighted average effciency of the pump device is regarded as a target, a lift is regarded as a constraint condition, and a seqential quadratic programming method of a gradient optimum algorithm is adopted to constantly change the design parameters of the axial flow pump impeller and perform iterative numerical calculation of the pump device. The axial flow pump impeller all-operating-condition design method adopts CFD numerical calculation, the design accuray is high, and optimization results are reliable.

Owner:YANGZHOU UNIV

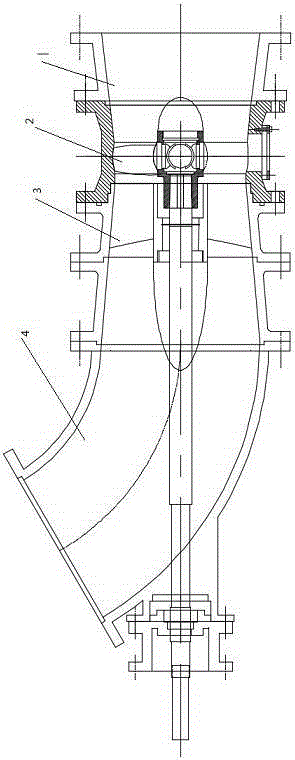

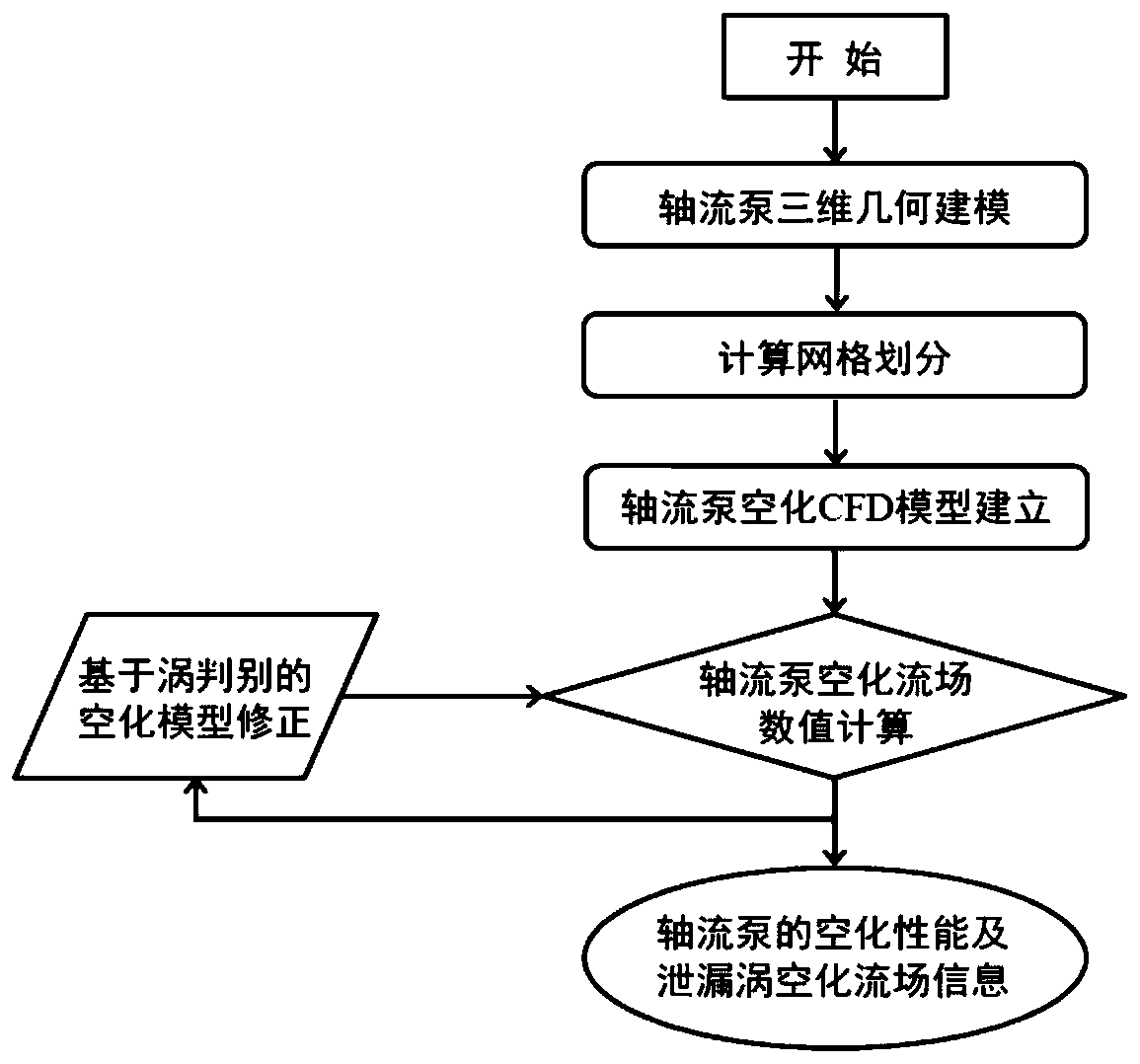

Numerical simulation method for axial flow pump blade tip gap leakage vortex cavitation

ActiveCN109977345AFast numerical predictionIncrease credibilityDesign optimisation/simulationCAD numerical modellingAxial-flow pumpMixed flow

The invention discloses a numerical simulation method for axial flow pump blade tip gap leakage vortex cavitation. An axial flow pump cavitation flow field is subjected to numerical calculation by performing three-dimensional geometric modeling on the axial flow pump, dividing calculation grids and establishing a cavitation flow calculation fluid dynamics model and adopting a cavitation model corrected based on a vortex discrimination method, and the cavitation performance of the axial flow pump and the blade top gap leakage vortex cavitation flow characteristic are obtained through analysis.According to the method, the influence of vortex flow on the cavitation phase change process is fully considered, the reliability of a vortex cavitation numerical calculation result is improved, rapidand high-precision numerical prediction of axial flow pump blade tip gap leakage vortex cavitation is realized, and a good mathematical basis is laid for research on a flowing mechanism and an inhibition measure of axial flow pump blade top gap leakage vortex cavitation. meanwhile, the method can also be popularized and applied to numerical simulation research on blade top gap leakage vortex cavitation of other blade type hydraulic machines such as a mixed flow pump and a water turbine.

Owner:HOHAI UNIV

Design method for centrifugal pump impeller with high specific revolution number

InactiveCN102062118AGuaranteed uptimeHigh efficiency and wide operating rangePump componentsPumpsAxial-flow pumpMixed flow

The invention discloses a design method for a centrifugal pump impeller with a high specific revolution number, belonging to the technical field of pumps. In the invention, the design formulas and the numerical ranges of geometric parameters, such as impeller outlet diameter, impeller front cover plate dip angle, impeller rear cover plate dip angle, blade quantity, outlet location angle and the like are provided, a high-flow low-lift pump with the specific revolution number being 400-600 is designed into a centrifugal pump, compared with the traditional design theory that a pump with the specific revolution number being 400-600 is designed into a mixed-flow pump or an axial-flow pump, the design method provided by the invention achieves the advantages of stable performance during variable working condition running and wide efficient zone; meanwhile, the centrifugal pump impeller in the design method is easy to process and has a certain popularization value.

Owner:JIANGSU UNIV

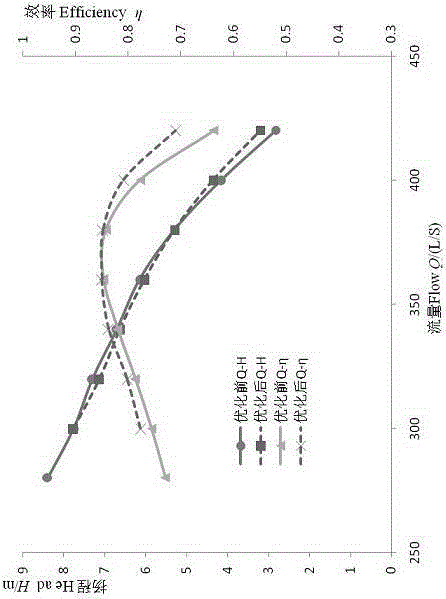

Design method for mixed-flow pump impeller

ActiveCN106650105AImprove running stabilityLow running costGeometric CADPump componentsAxial-flow pumpImpeller

The invention discloses a design method for a mixed-flow pump impeller. The method comprises the following steps that 1, the mixed-flow pump impeller is converted from a two-dimensional wooden pattern to a three-dimensional geometrical model; 2, parameterization conversion is performed on the three-dimensional geometrical model; 3, CFD numerical simulation is performed on a parameterization mixed-flow pump; 4, a CAD geometrical modeling module, a CFD numerical simulation module and numerical optimization software are integrated by designing an optimizing platform, and the impeller is optimized. The method can avoid repeated manual work, the lift and efficiency curves of the axial-flow pump obtained through the method are improved on the original basis, the lift of each operating point is increased by 5 m or above, and the efficiency is improved by about 2%; the optimized efficiency curve is lifted on the whole, the range of a high efficiency area becomes wider, the operational stability of a pump station is improved, the operating cost of the pump station is lowered, the pump device optimizing effect is quite obvious, and the method has the good market prospect.

Owner:南京天洑软件有限公司

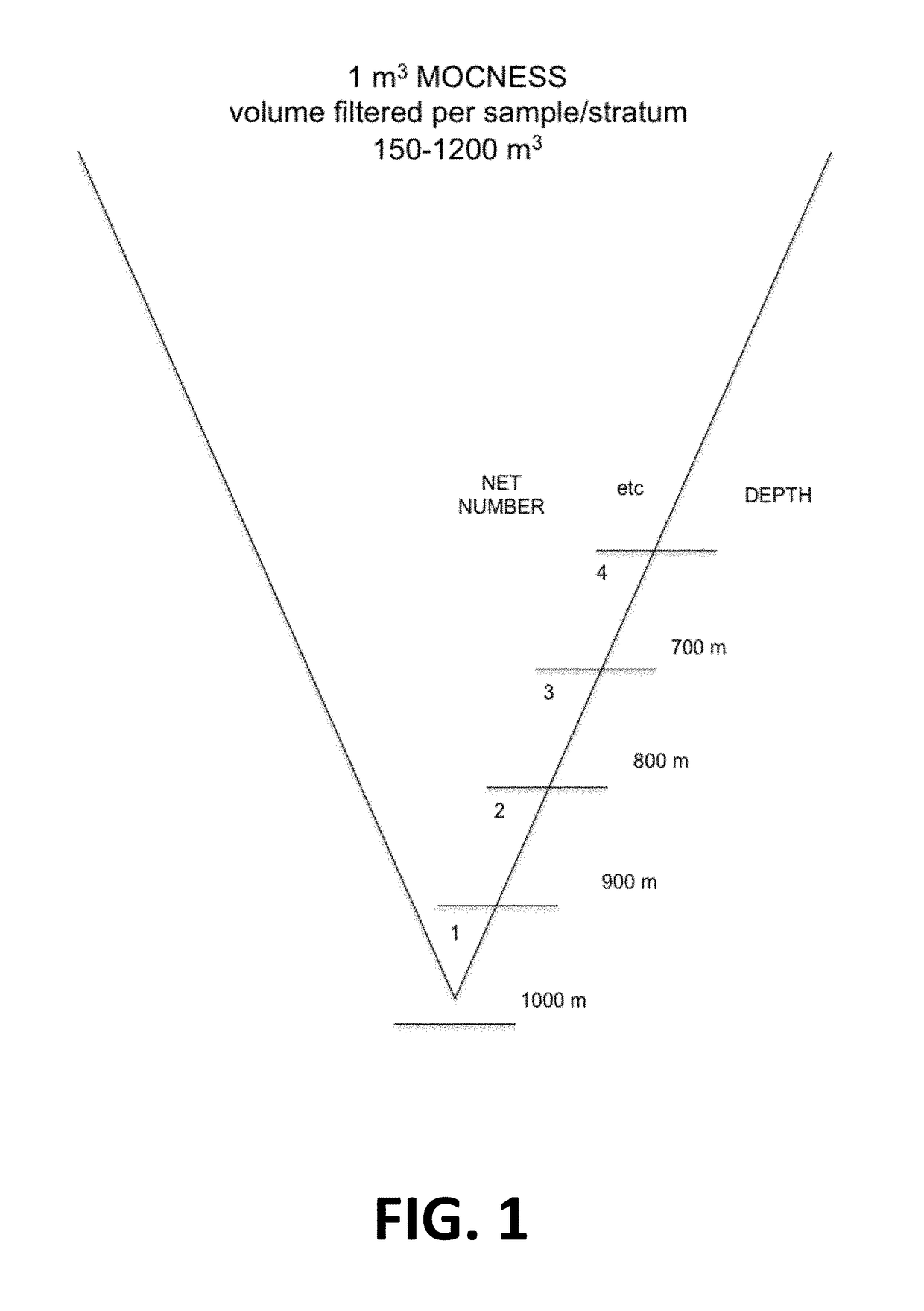

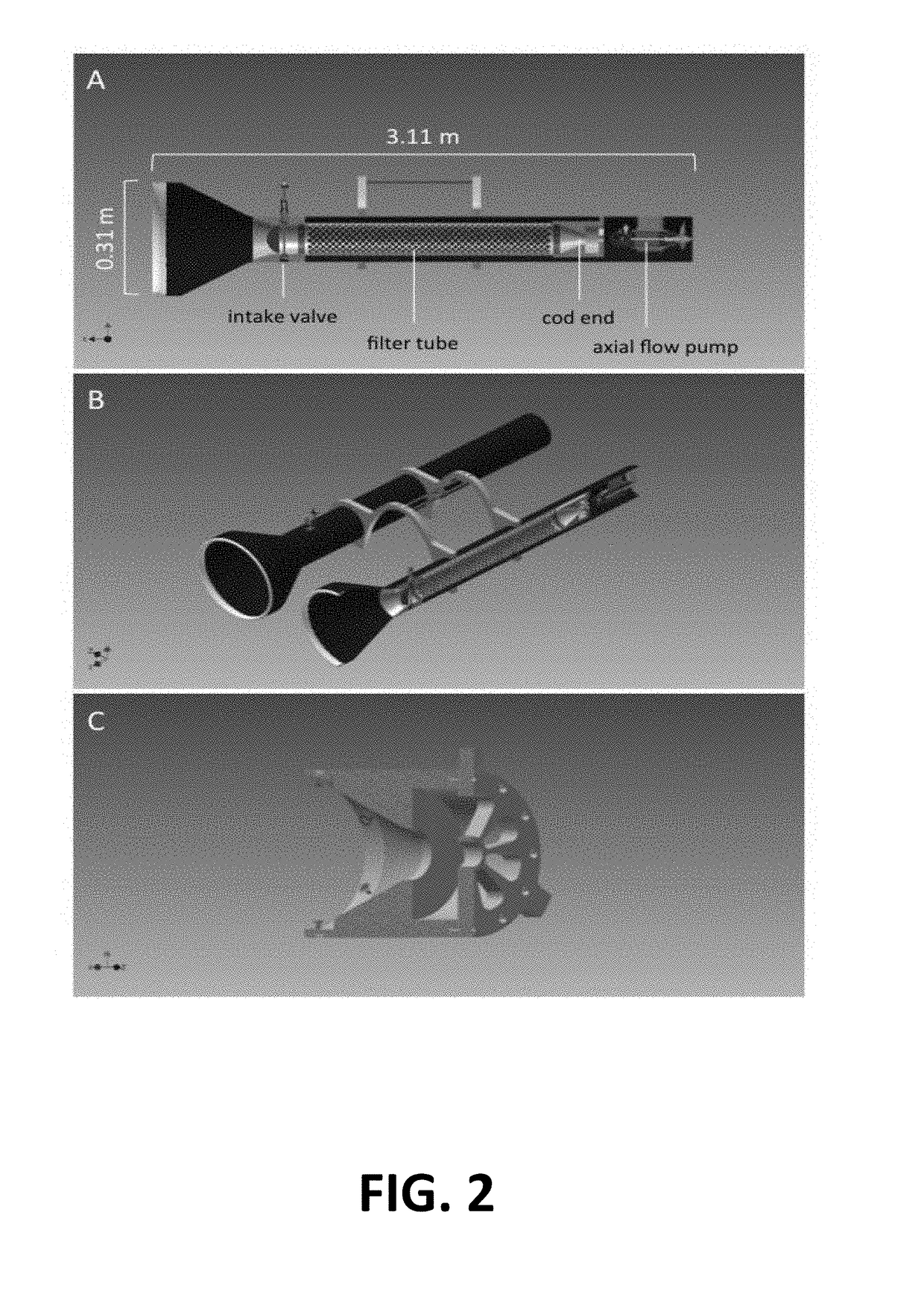

Aquatic Sampler and Collection Apparatus

An aquatic particle sampling and collection apparatus comprising a tube within a tube cylindrical collection system wherein an inner tube is housed within an outer tube wherein the outer tube has a front end that is flared in a frustum shape to collect water. The inner tube defines an open chamber lined with a net or other collection apparatus which concludes with a conical cod end. An axial flow pump is situated within the collection system to facilitate the movement of water through the system thereby drawing particles in to be collected. The apparatus is paired with a subsea vehicle that allows for controlled collection and sampling. In various embodiments, the apparatus can be used to collect both bio particles such as plankton and non-bio particles such as plastics from the ocean. Where sampling is desired, the apparatus may include a disk after the conical cod end upon which the samples are collected.

Owner:WOODS HOLE OCEANOGRAPHIC INSTITUTION

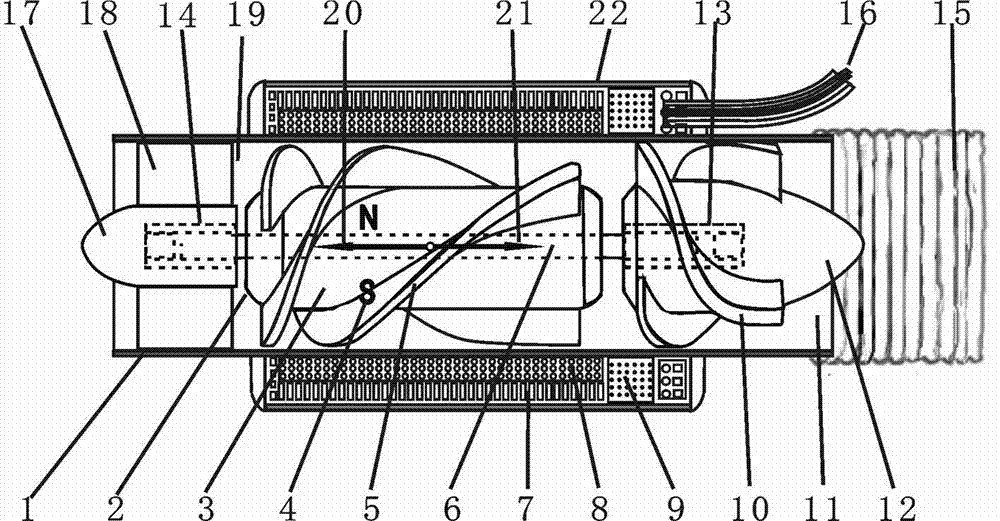

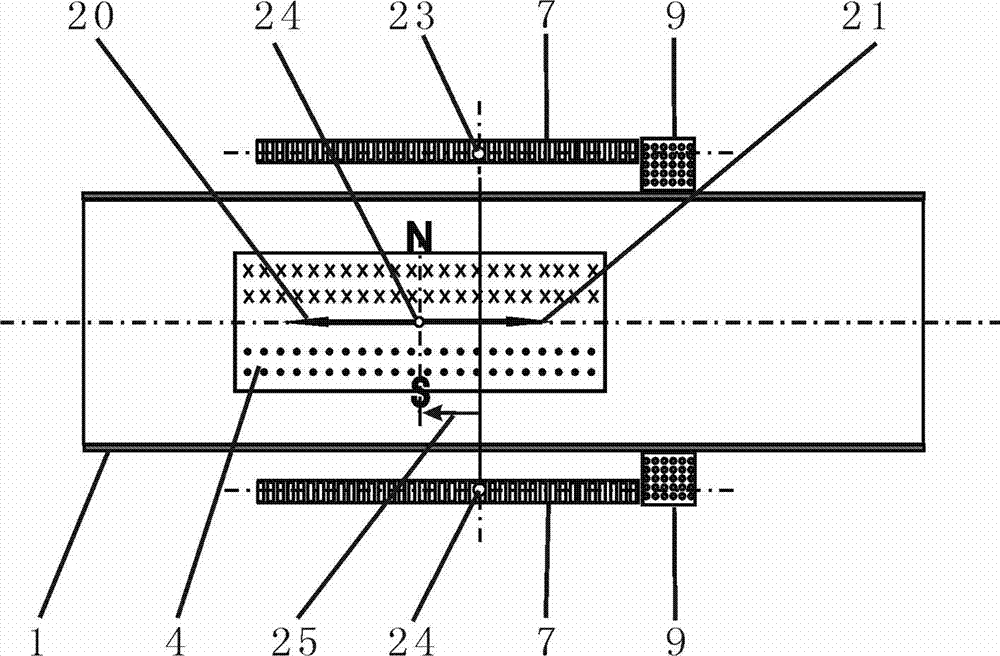

Heart auxiliary device of axial magnetic force unloading type axial flow pump

ActiveCN103877630AHigh output pressureImprove energy conversion efficiencyIntravenous devicesSuction devicesAxial-flow pumpMagnetic tension force

The invention relates to a special axial flow pump, in particular to a heart auxiliary device of an axial magnetic force unloading type axial flow pump in the field of biomedical engineering. The heart auxiliary device is implanted into the human body. The auxiliary device is a pump-machine combination body and is composed of a pump system and a motor system. The heart auxiliary device is characterized in that an impeller position control soft magnet is installed at the rear end of a stator core, when an impeller moves forwards or backwards due to external force in a pump cylinder, the impeller position control soft magnet and the stator core generate magnetic constraining force on a permanent magnet rotor in an impeller hub, and the direction of force is opposite to the axial moving direction of the impeller. When the axial flow pump works, the magnetic constraining force can form partial and even whole axial magnetic force unloading on axial force loads of the impeller and a shaft, and axial magnetic levitation of the impeller is achieved. According to the heart auxiliary device of the axial magnetic force unloading device, mechanical abrasion and the friction heat effect can be reduced, the thrombus in the pump is prevented from being formed, complications are reduced, the service life of the axial flow pump is prolonged, and stability of continuous work is improved.

Owner:CHANGZHI JIUAN ARTIFICIAL HEART TECH DEV

Swimming pool bottom hydro power pushed automatic cleaner

ActiveCN101666168ARealize work status changeChange water jetGymnasiumSwimming poolsAxial-flow pumpHydraulic action

The invention relates to a swimming pool bottom hydro power pushed automatic cleaner, comprising an underwater cleaner and a control power supply which are connected by a buoyancy cable; wherein the underwater cleaner comprises a shell cover part, a shell body part, a filter, a double extension motor assembly, a hydro power driven jaw clutch pulley assembly, a water flow channel, a wheel and support, an isolated hood and a cable with a buoy. Along with the rotating direction of the motor, the hydro power driven jaw clutch pulley assembly is reliably meshed or separated under the action of hydro power; the pulley changes working condition, so as to realize jet water to be flowed out and further change travel direction of the cleaner; the shell touches wall to cause the cleaner to automatically adjust direction after touching the wall, so as to change travel route after touching the wall; and an arranged suction tube and a unidirectional drainage valve avoid eddy diffusion of travel of the cleaner on sewage at the bottom and reduce the weight of the cleaner when being taken out from water. In addition, two or multiple axial-flow pumps are arranged horizontally, so that the cleaner has turning function and ordered full cover washing is realized.

Owner:TIANJIN WANGYUAN ENVIRONMENTAL PROTECTION & TECH CO LTD

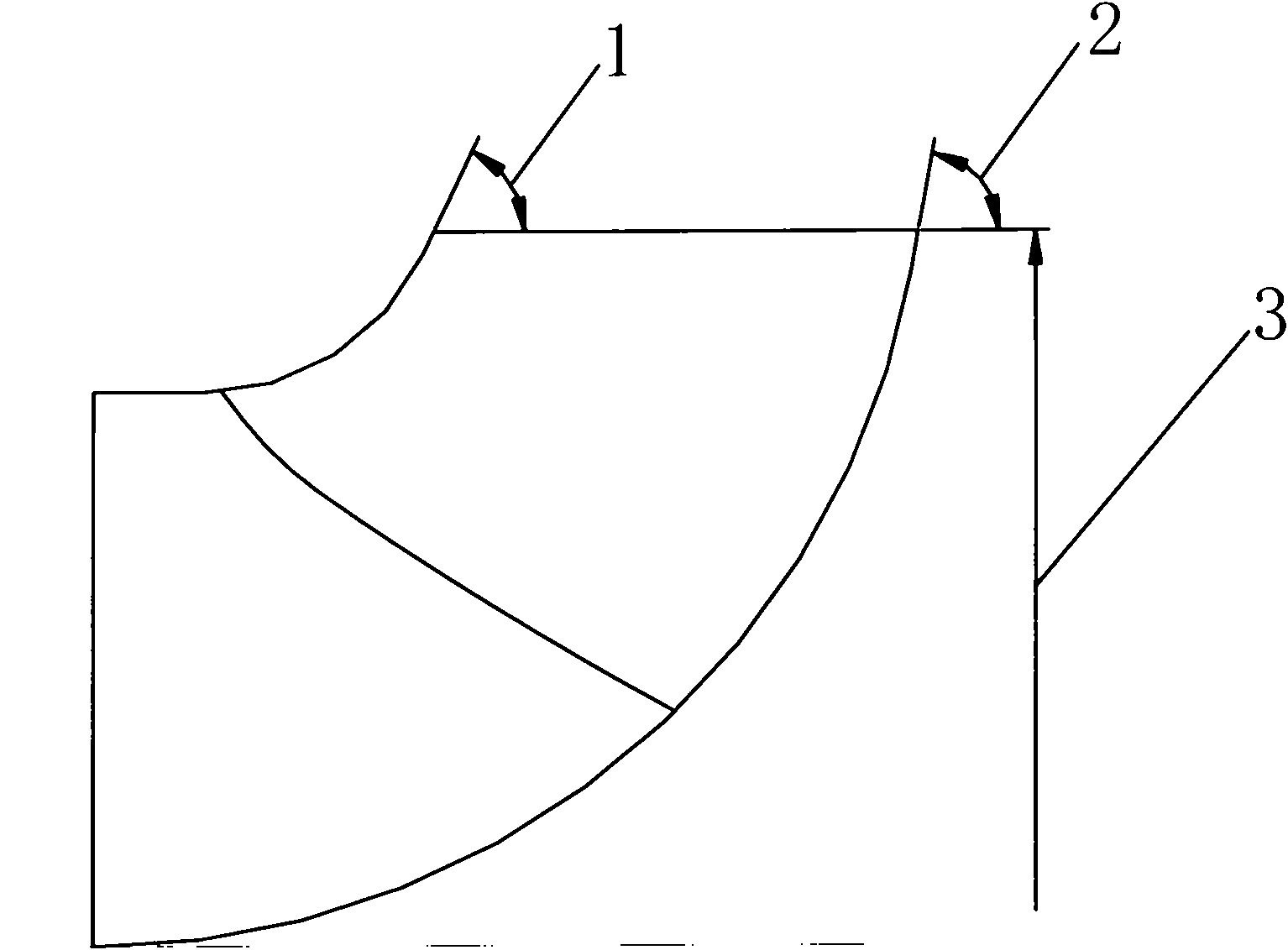

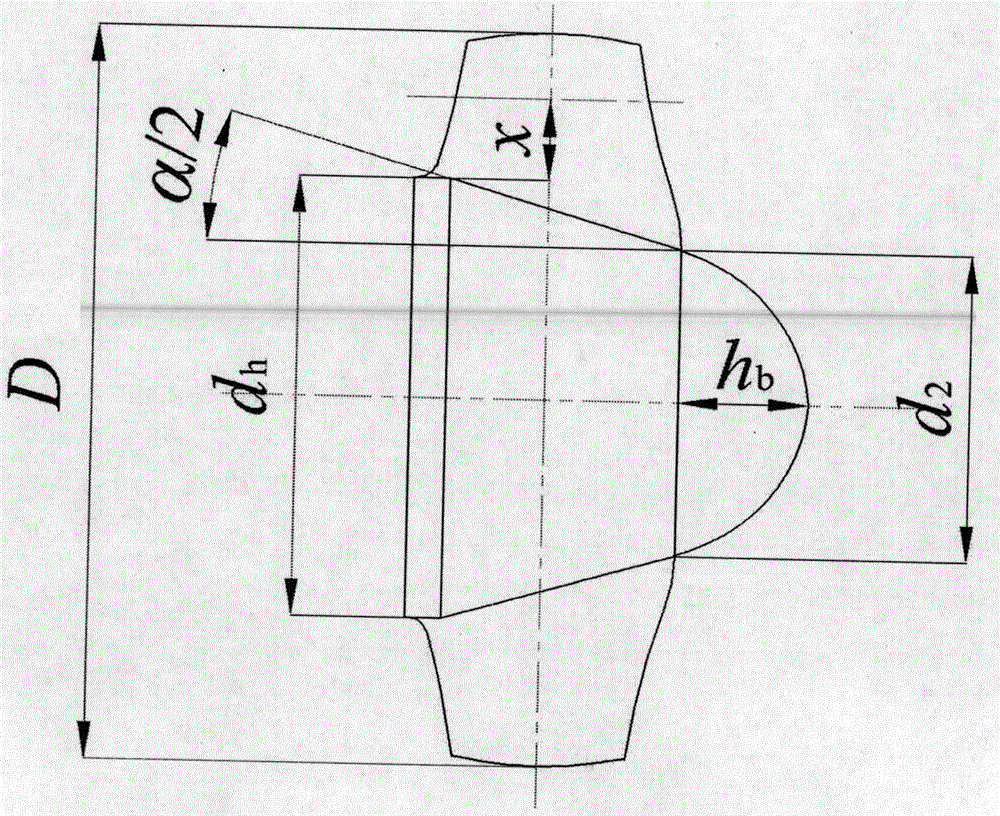

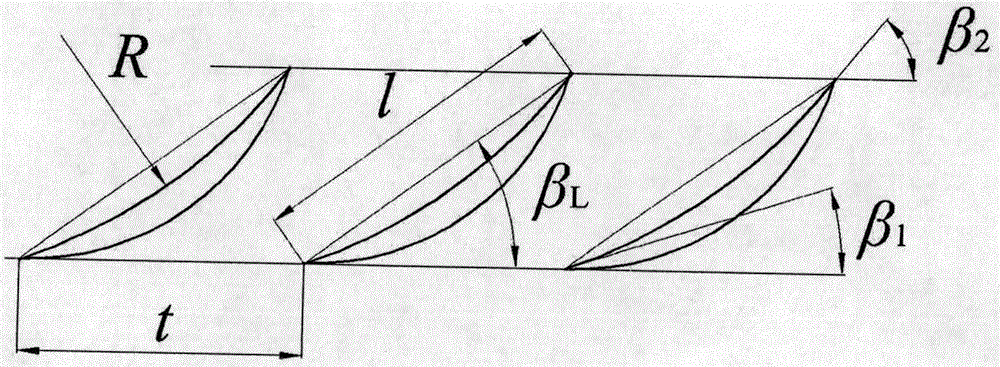

Hydraulic design method of high-lift axial flow pump impeller

The invention relates to a hydraulic design method of a high-lift axial flow pump impeller. Main geometric parameters of the impeller are provided, and include a maximum thickness delta max of axial flow pump blades, a molded line radius R, an impeller blade number z, an impeller hub side cascade solidity Sh, an impeller rim side cascade solidity S0, a blade inlet placing angle beta 1, a blade outlet placing angle beta 2, a blade inlet axial surface speed vm1, a blade outlet axial surface speed vm2, a blade outlet peripheral component speed vu2, an impeller diameter D, an impeller hub ratio Rd, an impeller lift coefficient psi, an impeller inlet hub diameter d2, an impeller hub dispersion angle alpha, an impeller round nut height hb, a blade outlet placing angle coefficient K beta 2, a blade inlet placing angle coefficient K beta 1, selection of wing sections with different sections of blades and the like. The designed axial flow pump impeller improves both the impeller lift and the cavitation resistance of an axial flow pump, facilitates computer programming, and can replace traditional similar design method and speed coefficient method of the axial flow pump to a greater extent.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com