Axial flow pump impeller all-operating-condition design method

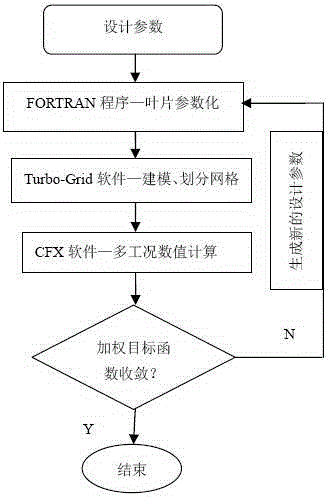

A design method and technology for axial flow pumps, which are applied to the components, pumps, and pump components of pumping devices for elastic fluids, which can solve the problem that the flow velocity field and pressure field are not analyzed, and the performance of the axial flow pump is not considered. It can achieve the effects of large economic and social benefits, reliable optimization results, and high design accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

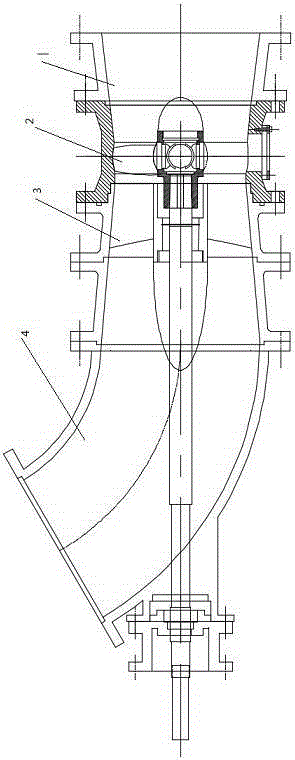

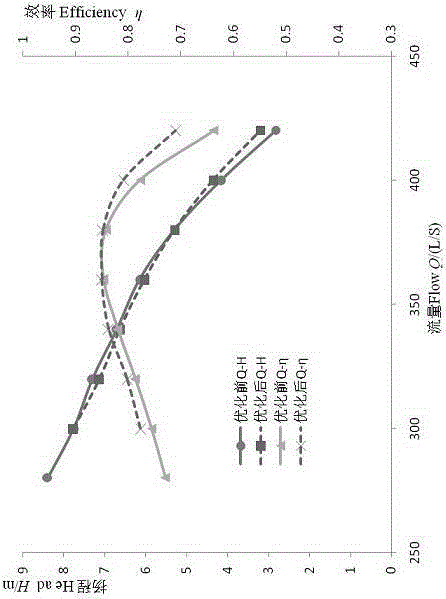

[0070] Using the patented optimization design method of the present invention, the multi-objective optimization design of the full working condition is carried out for an axial flow pump impeller with a nominal specific speed of 800. Design parameters: design flow Q=360L / s, design head H=6.0m, speed n=1450r / min, unilateral clearance of blade top is 0.2mm. The rear guide vane body is designed for the design conditions of the impeller. The divergence angle of the guide vane body is 6°, the number of guide vane blades is 7 pieces, the number of impeller blades is 4 pieces, and the hub ratio of the axial flow pump impeller is 0.4333. The water inlet straight pipe section and the water outlet elbow pipe section are modeled by Proe, and the impeller and guide vane body are modeled by Turbo-Grid according to their three-dimensional coordinate data points. The calculation model of the axial flow pump device is as follows: figure 2 shown.

[0071] 1. Numerical simulation

[0072] M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com