Patents

Literature

549 results about "Wing section" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

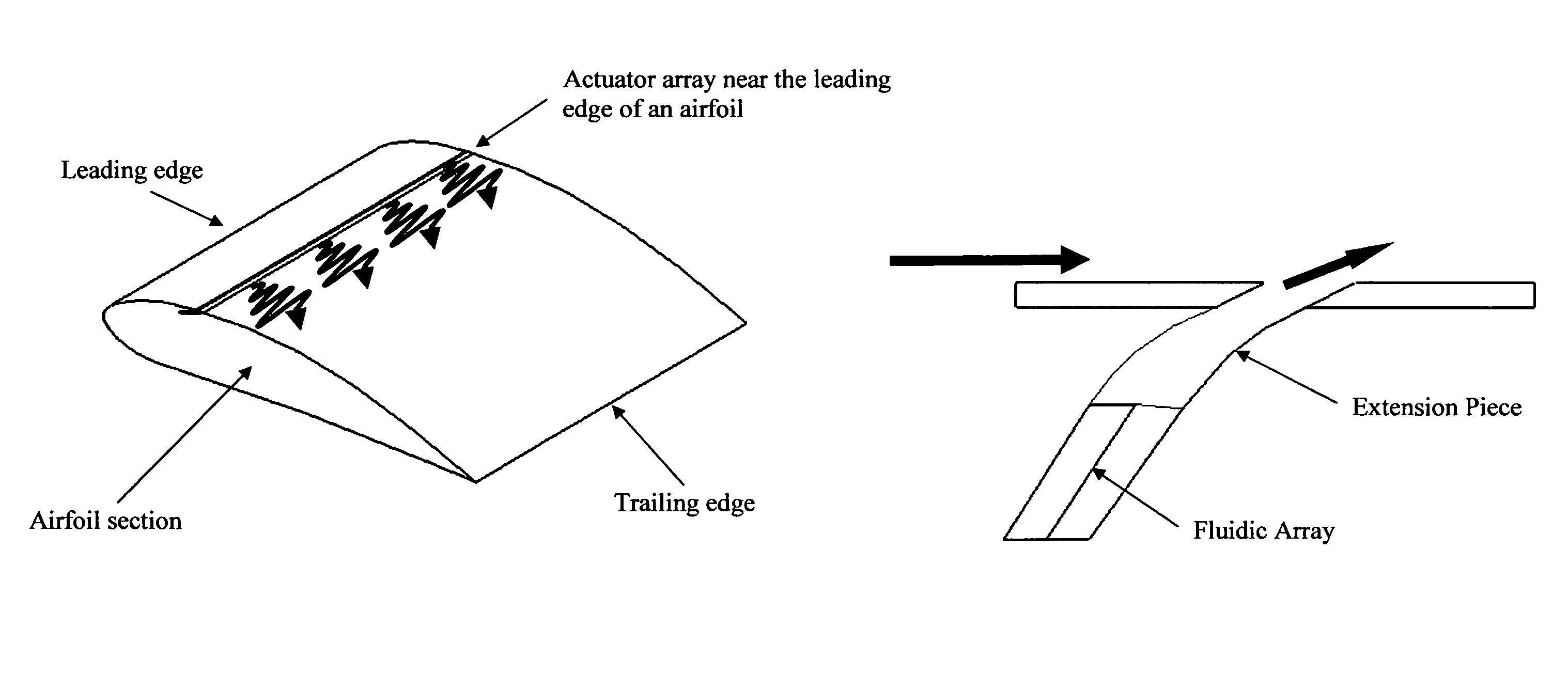

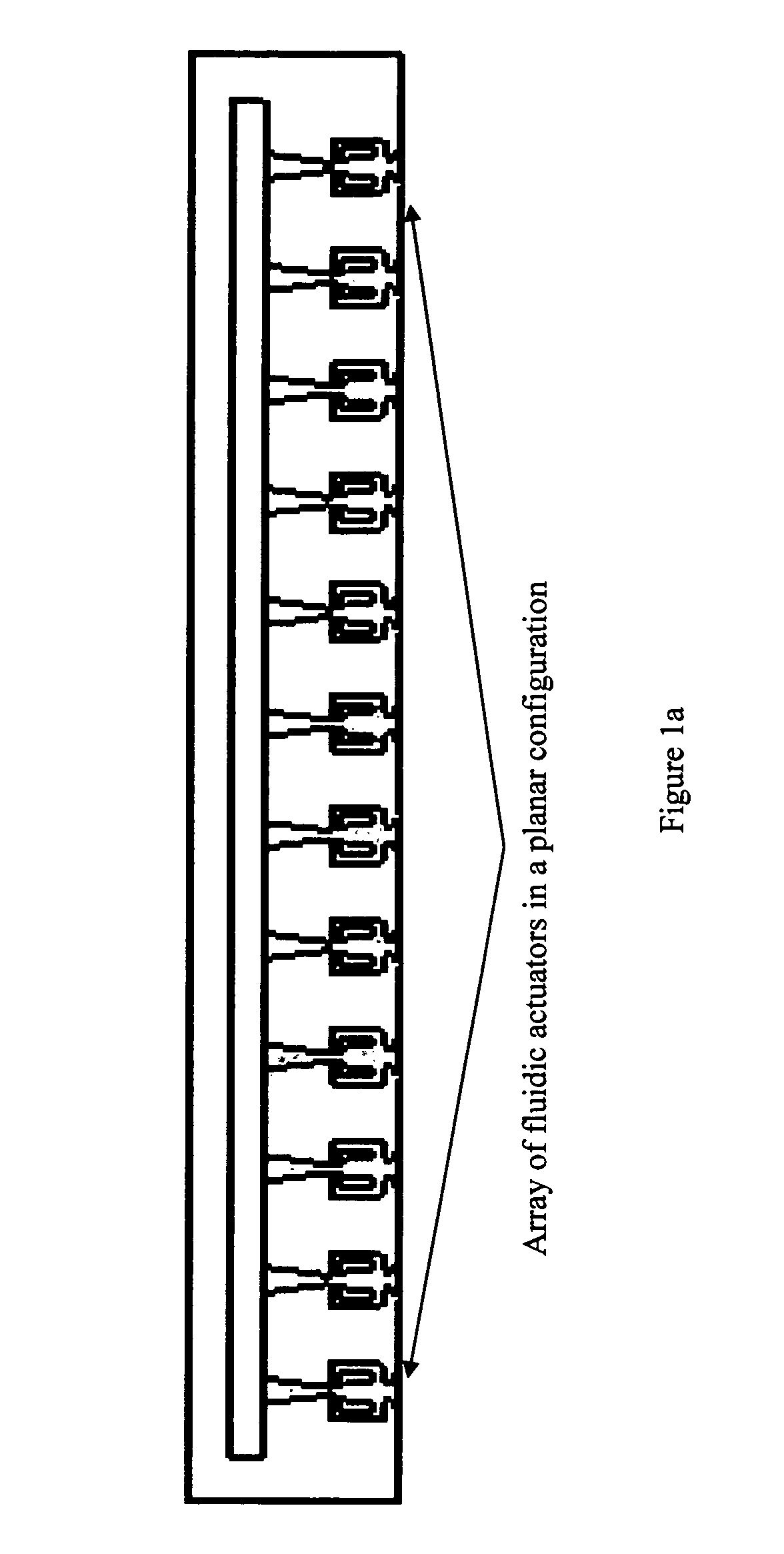

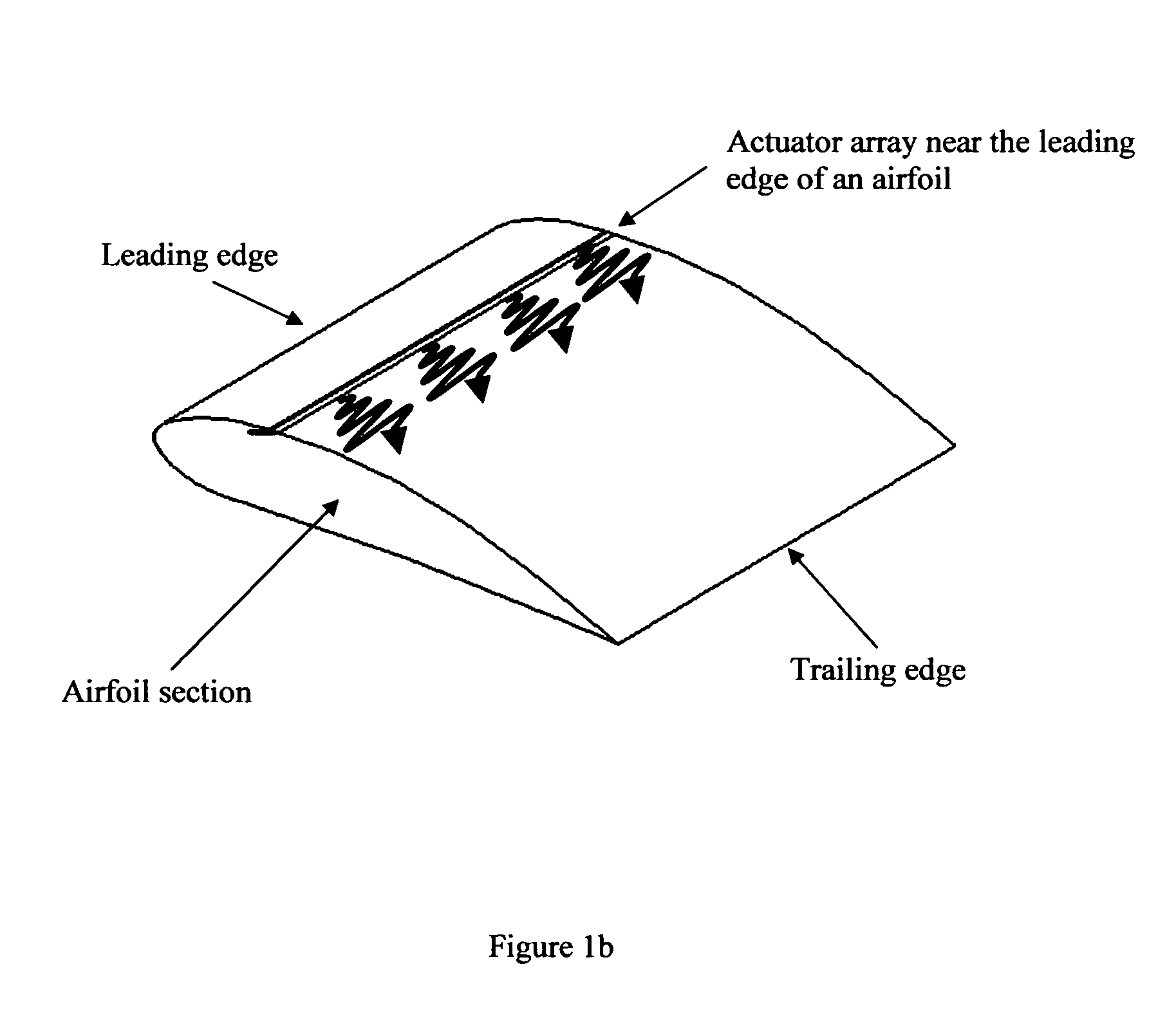

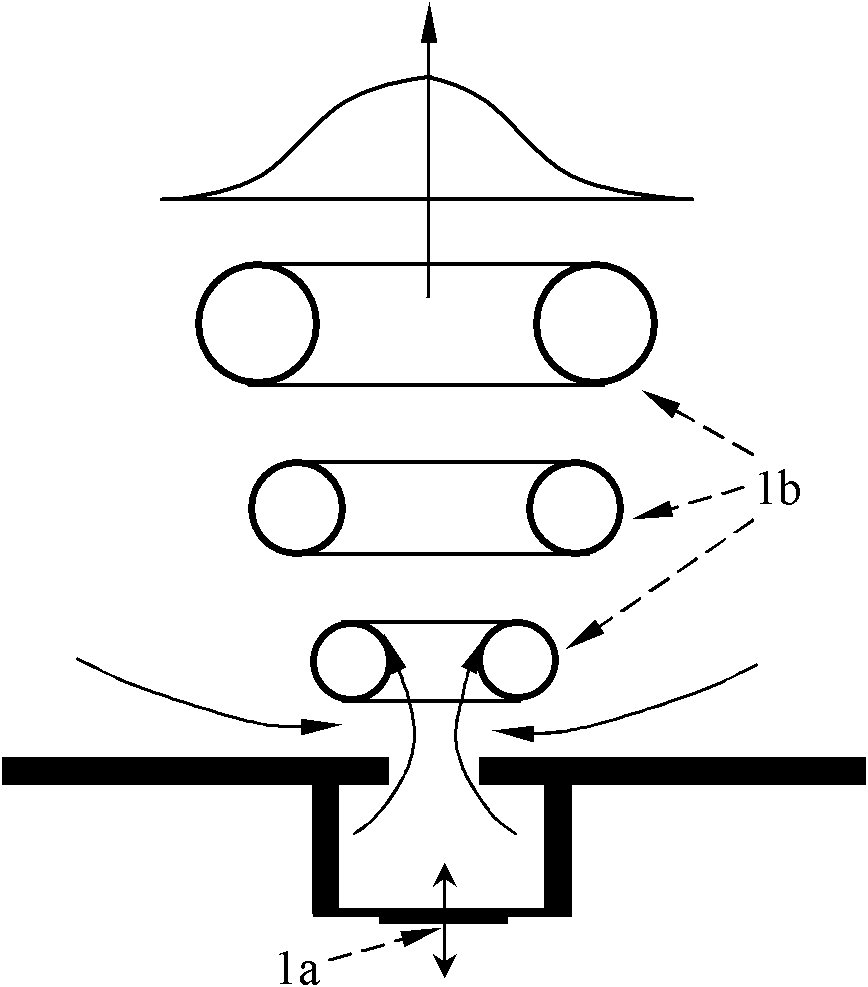

Method and apparatus for aerodynamic flow control using compact high-frequency fluidic actuator arrays

ActiveUS8382043B1Even air distributionAvoid separationBoundary layer controlsWingsJet engineEngineering

The present invention is directed to the manufacture of and the use of an aerodynamic flow control device having a compact array of a plurality of fluidic actuators in planar, curved, circular and annular configurations. The compact array of fluidic actuators of the invention may be designed to produce oscillating or pulsed jets at the exit ports with frequencies in the range of 1-22 kHz. They may be integrally manufactured along with the wing sections, flaps, tail and rudder of airplane, the inlet or exit geometries of a jet engine. When supplied with a source of fluid such as air, these arrays of actuators produce a set of fluid jets of random phase of high velocity and influence the main stream of air over the subject surface. The beneficial effects of modifying flow using the present invention include increased lift, reduced drag, improved performance and noise reduction in jet engines.

Owner:RAGHU SURYA

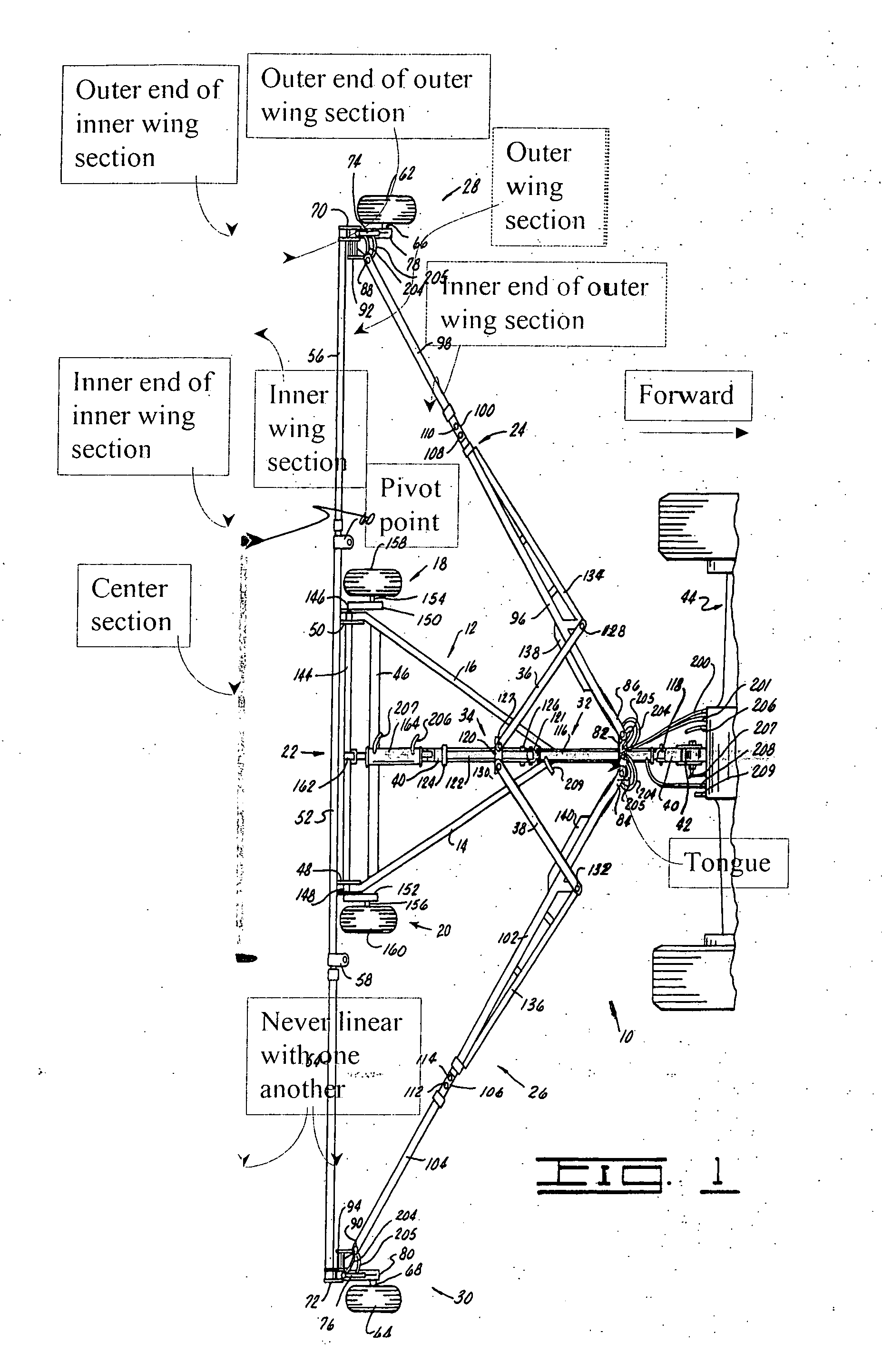

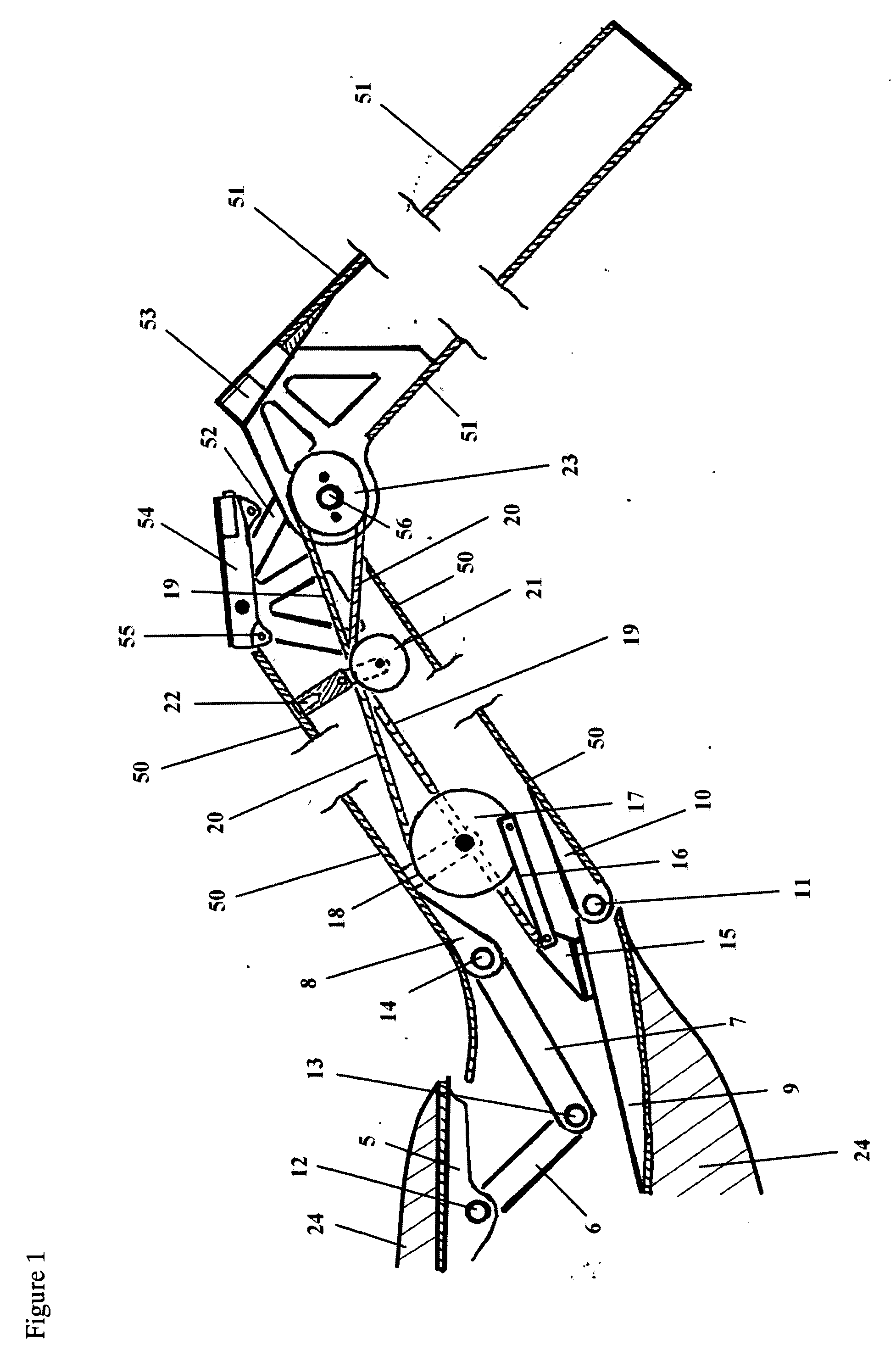

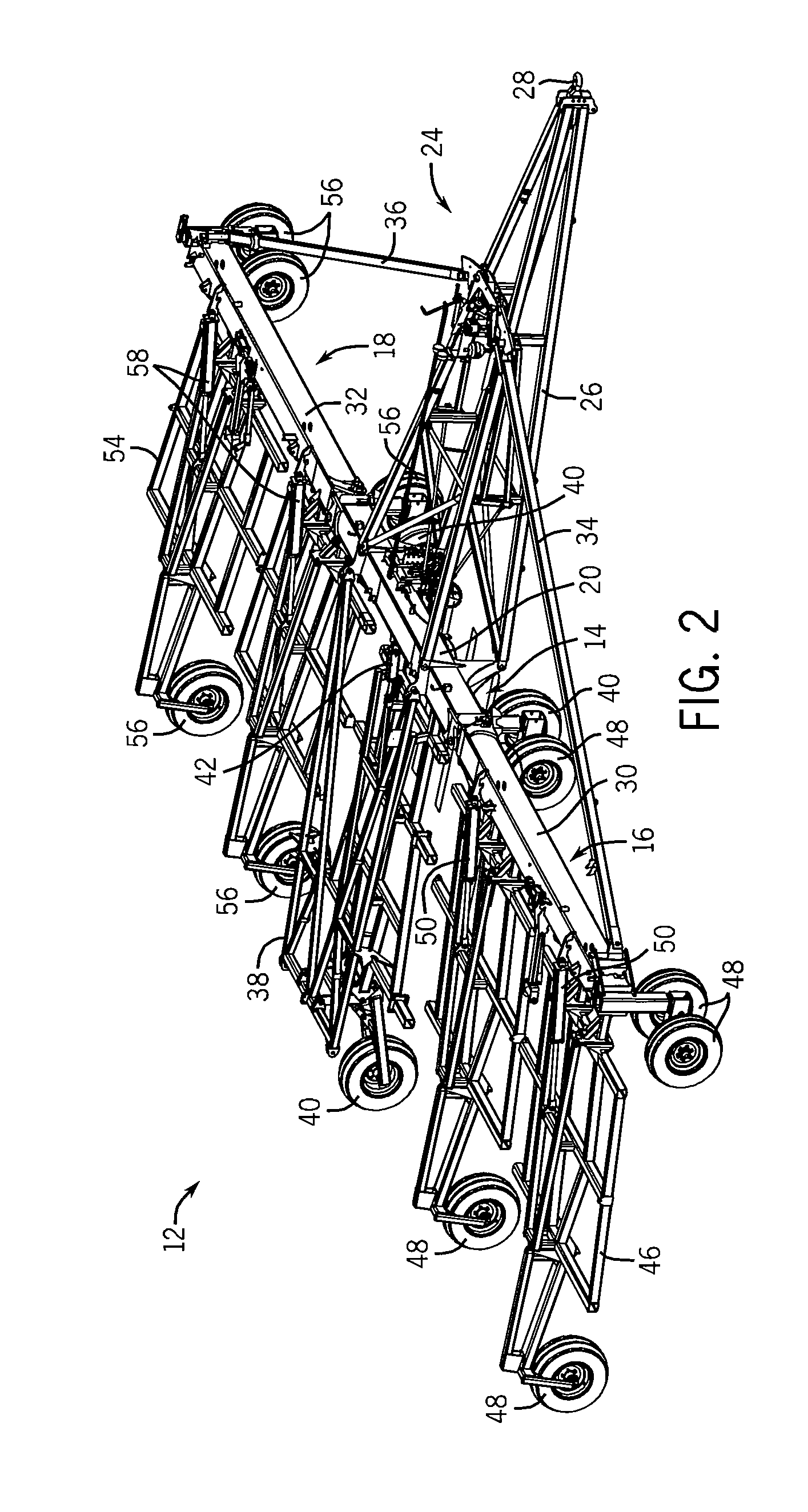

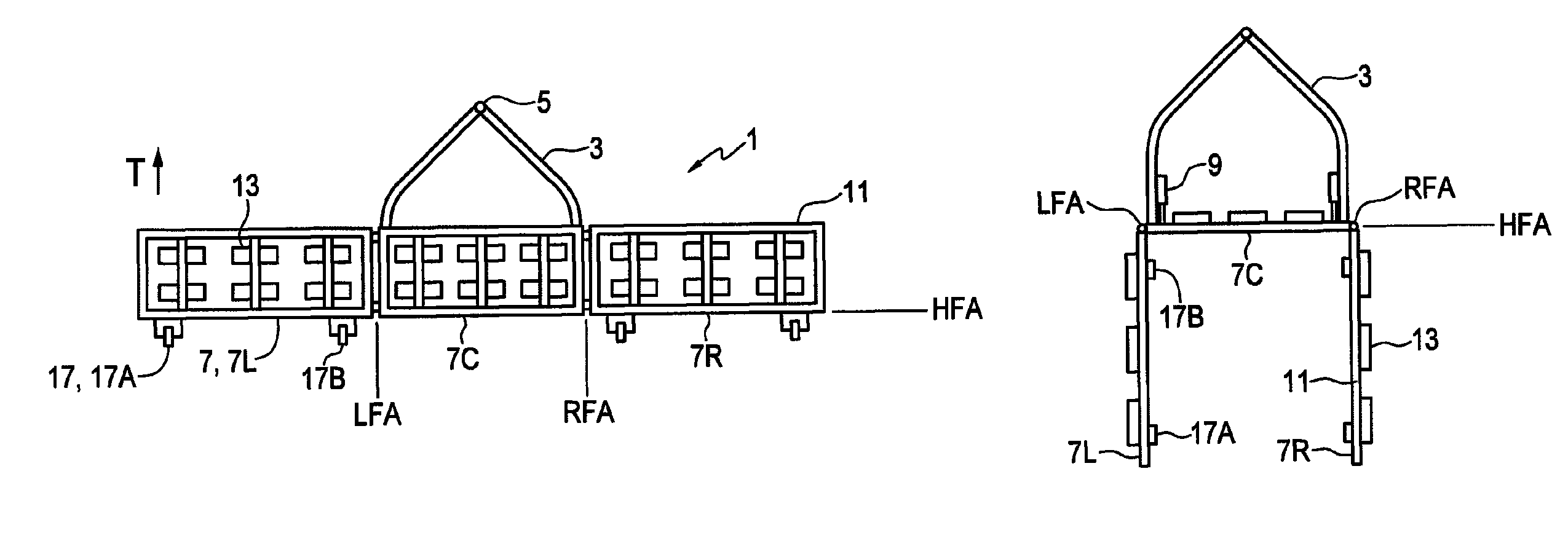

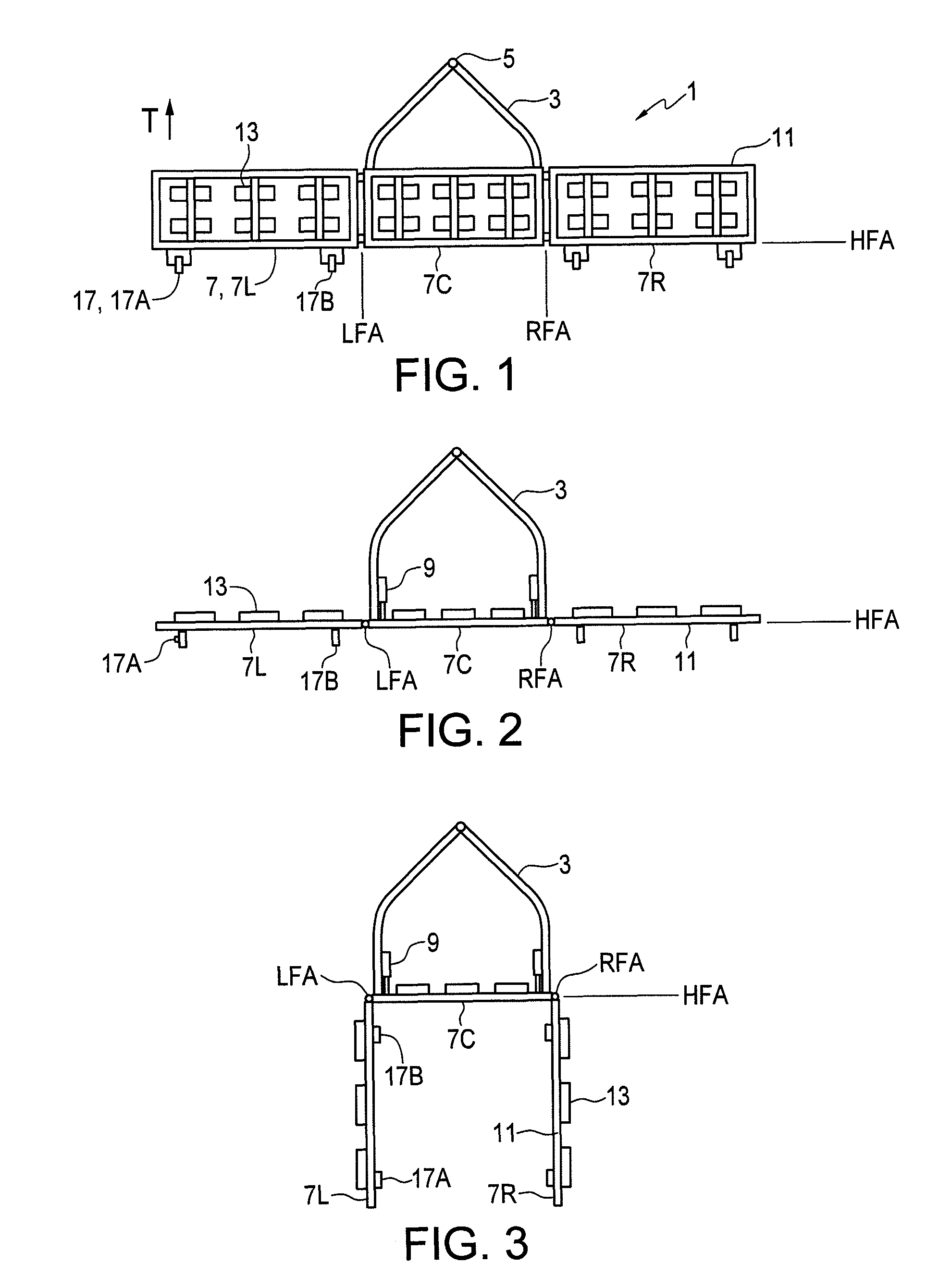

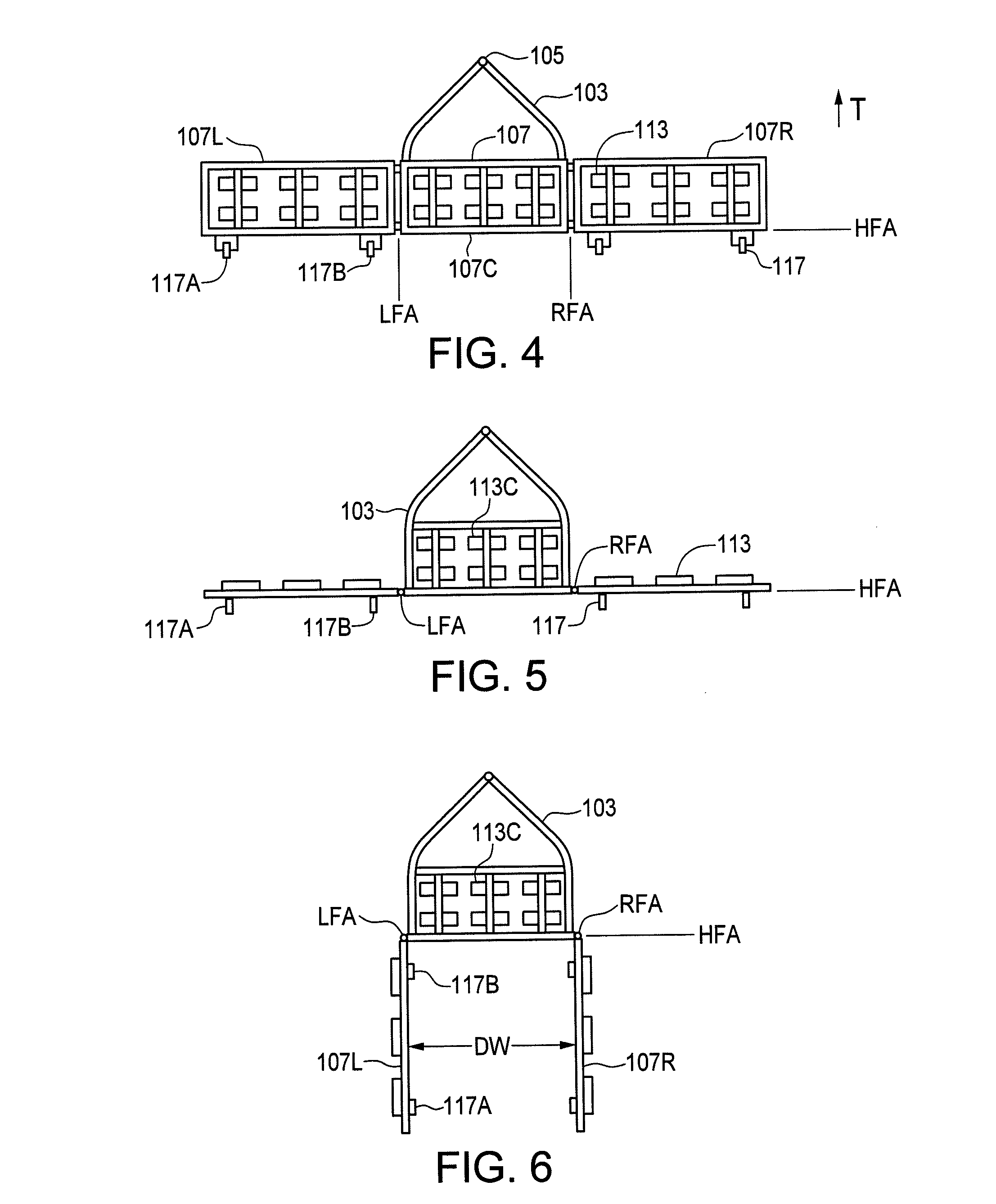

Sectional toolbar for a planter

InactiveUS20050087350A1High maintenanceImprove reliabilitySpadesAgricultural machinesSeederGround contact

Implement toolbars as used for planters have become very long in recent years. In order to assure good ground contact, the long toolbar of the present invention is divided up into more than three sections, including a center section and wing sections. The wing sections fold forward for transport on public roads, over field accesses, and through gates. The resulting planter can be longer than prior art planters while providing sound ground contact and a compact transport mode.

Owner:BAUER VAUGHN L

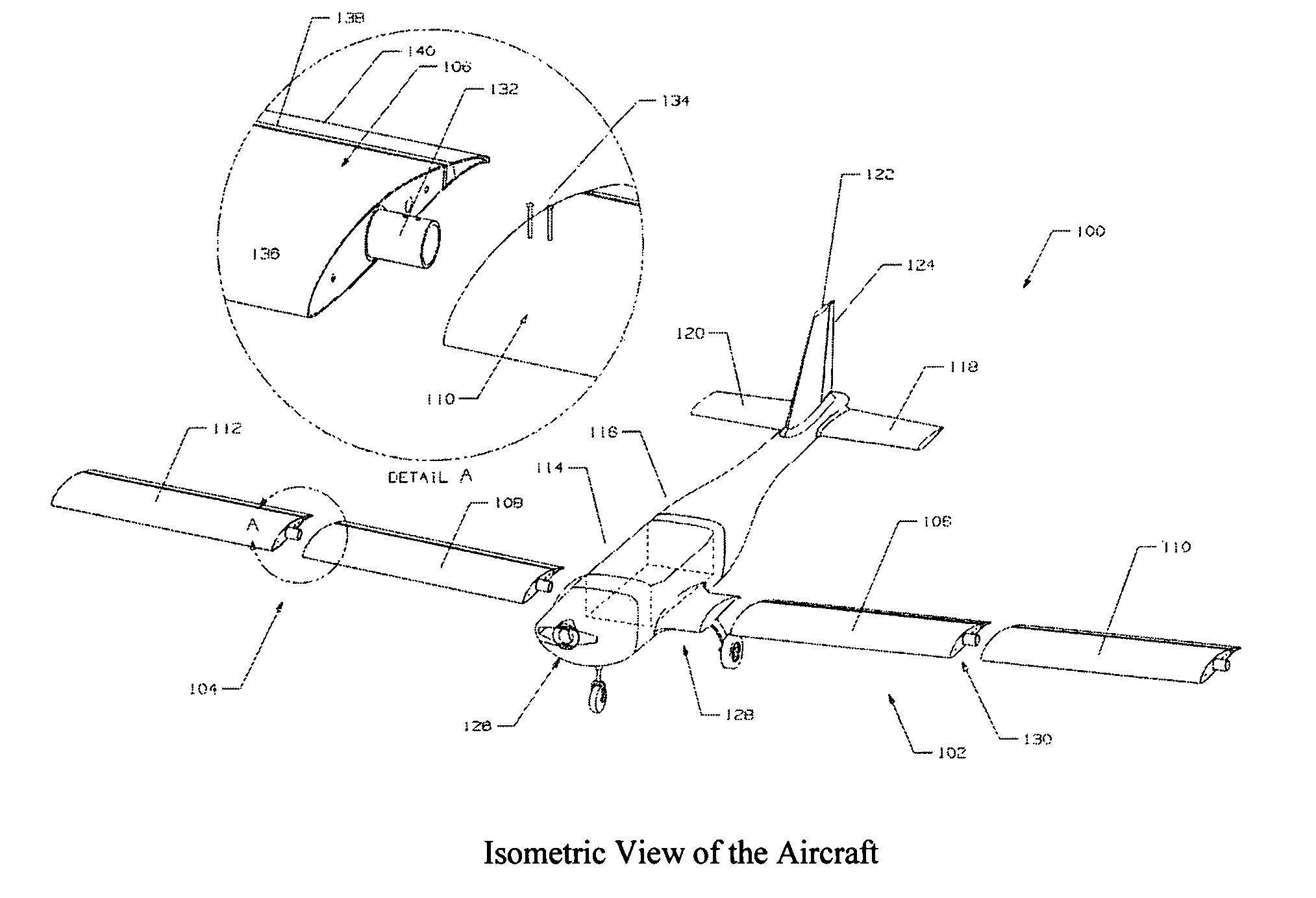

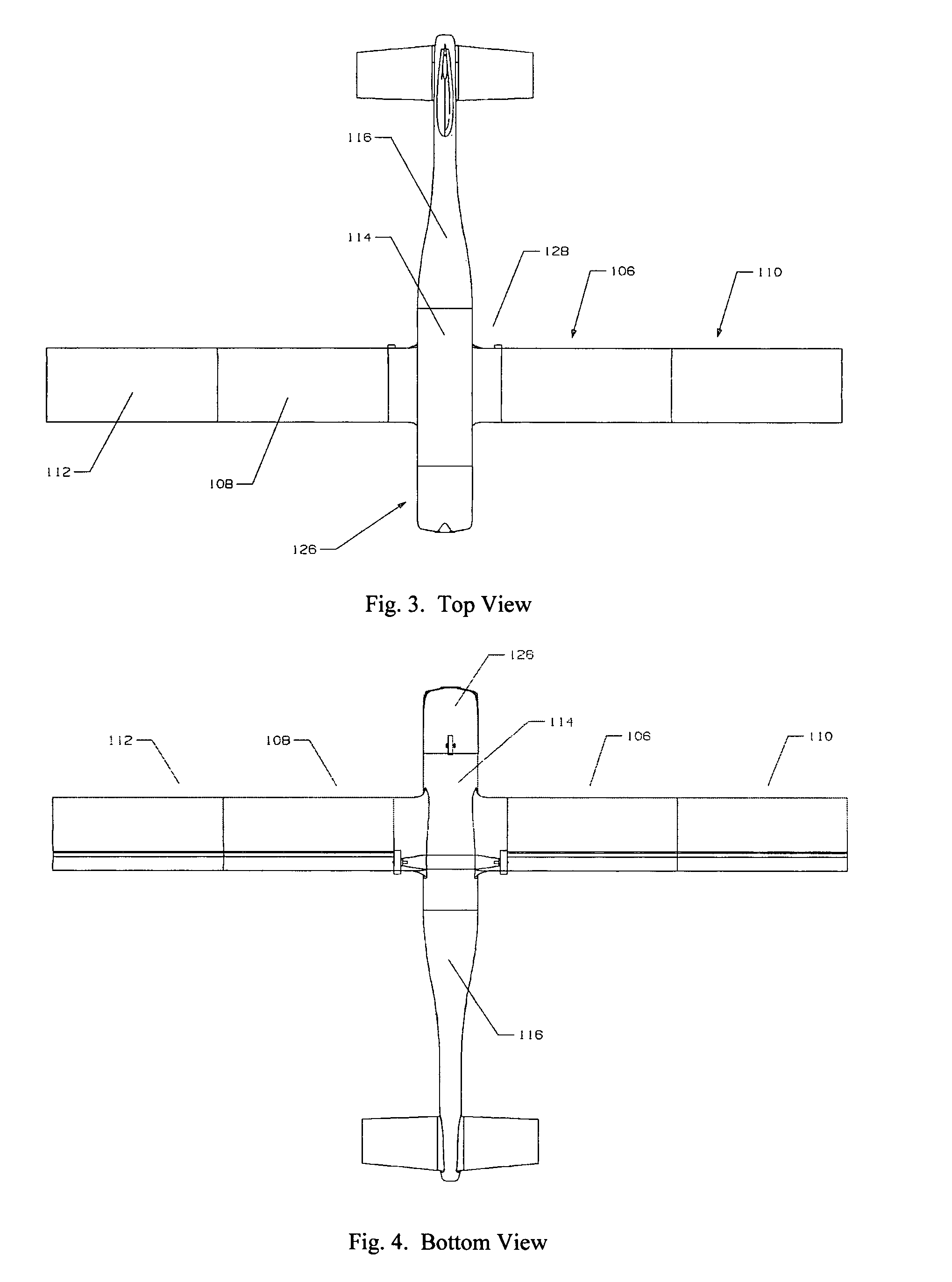

Modular unmanned air-vehicle

InactiveUS7922115B2Lower life cycle costsEasy to transportAircraft stabilisationUnmanned aerial vehiclesJet aeroplaneFlight vehicle

The present invention is an unmanned air vehicle designed for reconnaissance, surveillance, data acquisition, and general research. The air vehicle is a monoplane that consists of several pieces that can easily be assembled using a minimal amount of tools. The air vehicle consists of a forward and aft fuselage section, two identical horizontal stabilizers, and four identical wing sections. The aircraft can fly with all four wing sections, or with just two wing sections (the short wing configuration). Each of the four wing sections of the air vehicle can be interchanged with any of the other wing sections for the purpose of minimizing assembly time and spare parts.

Owner:COLGREN RICHARD D +2

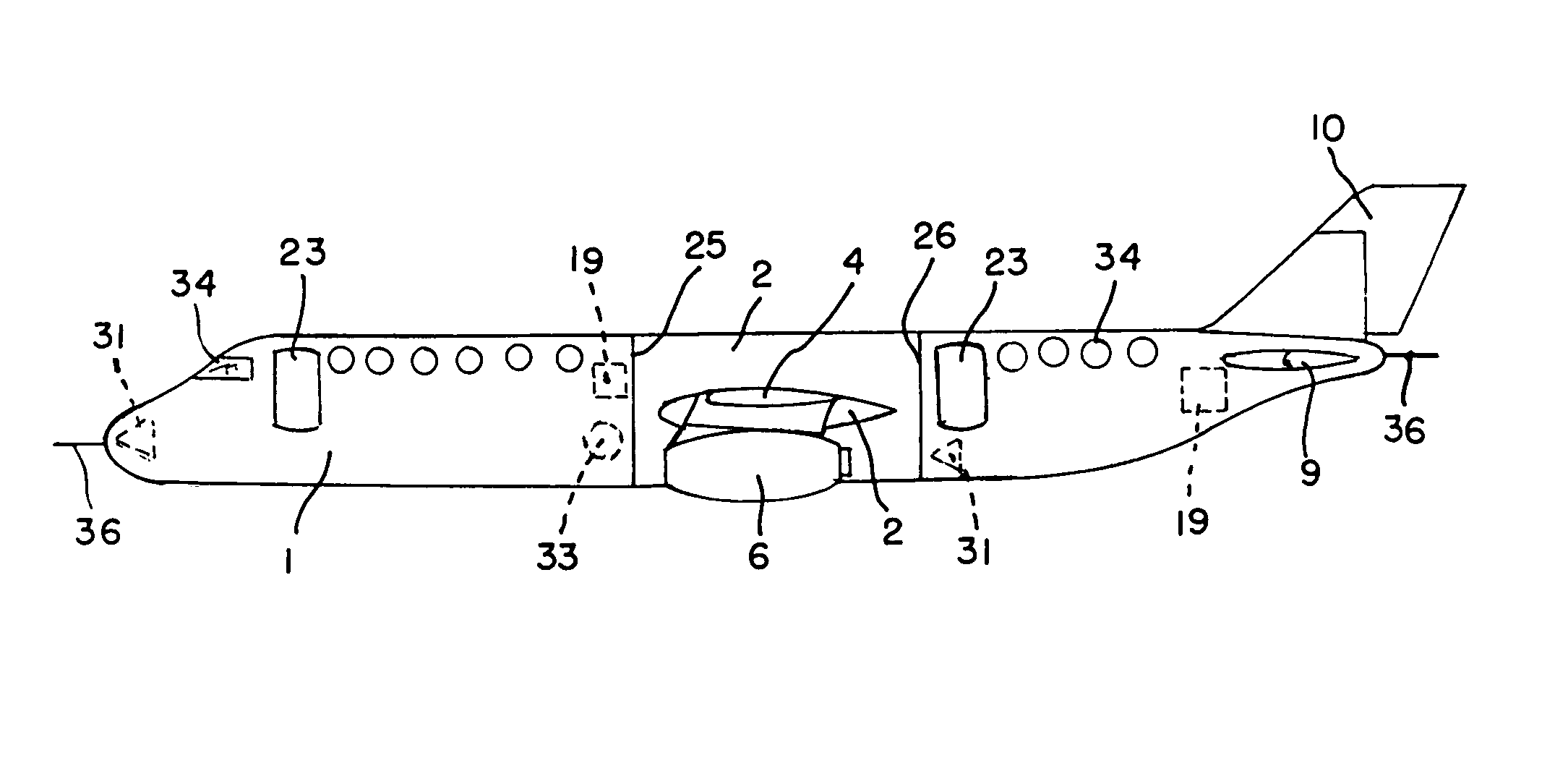

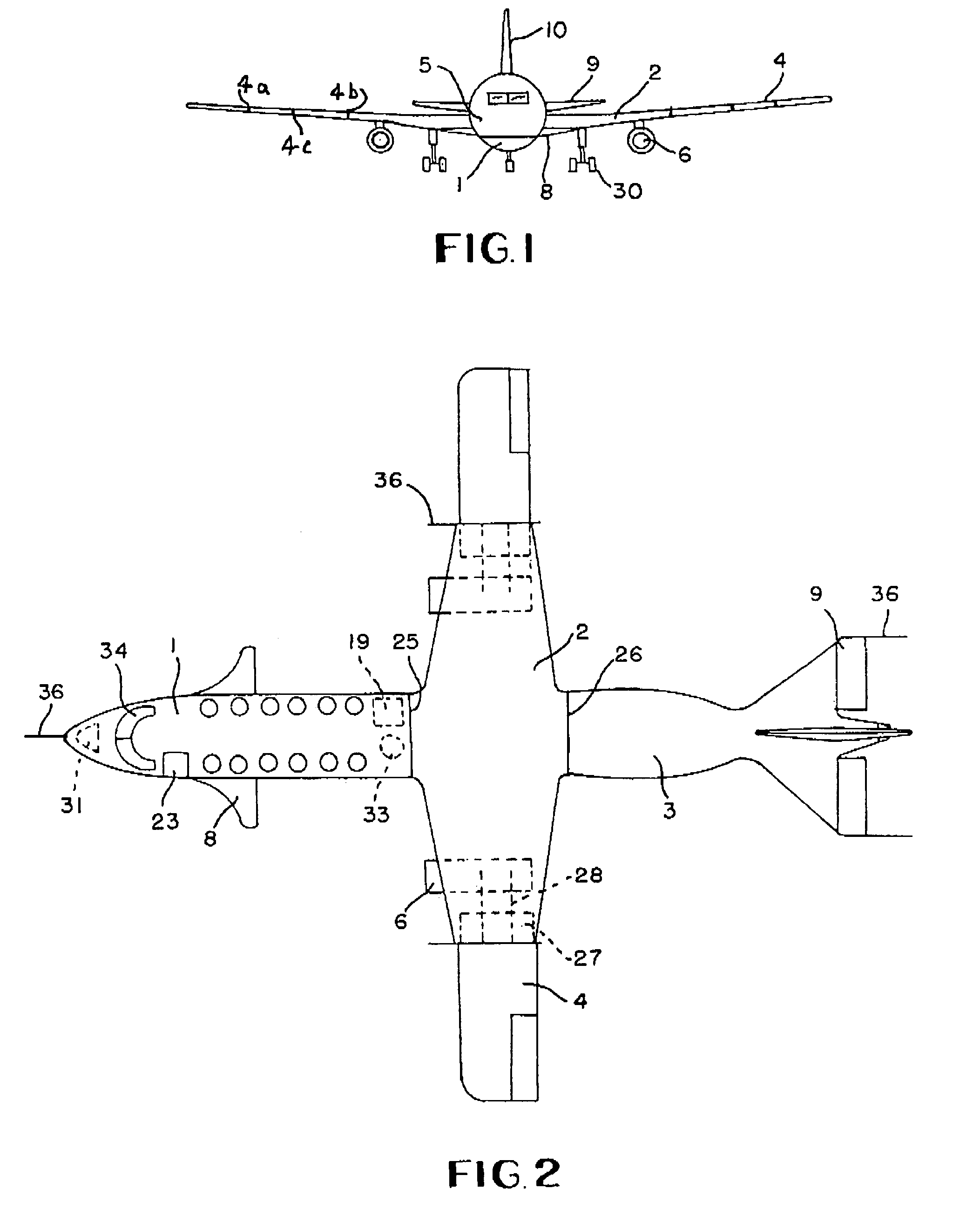

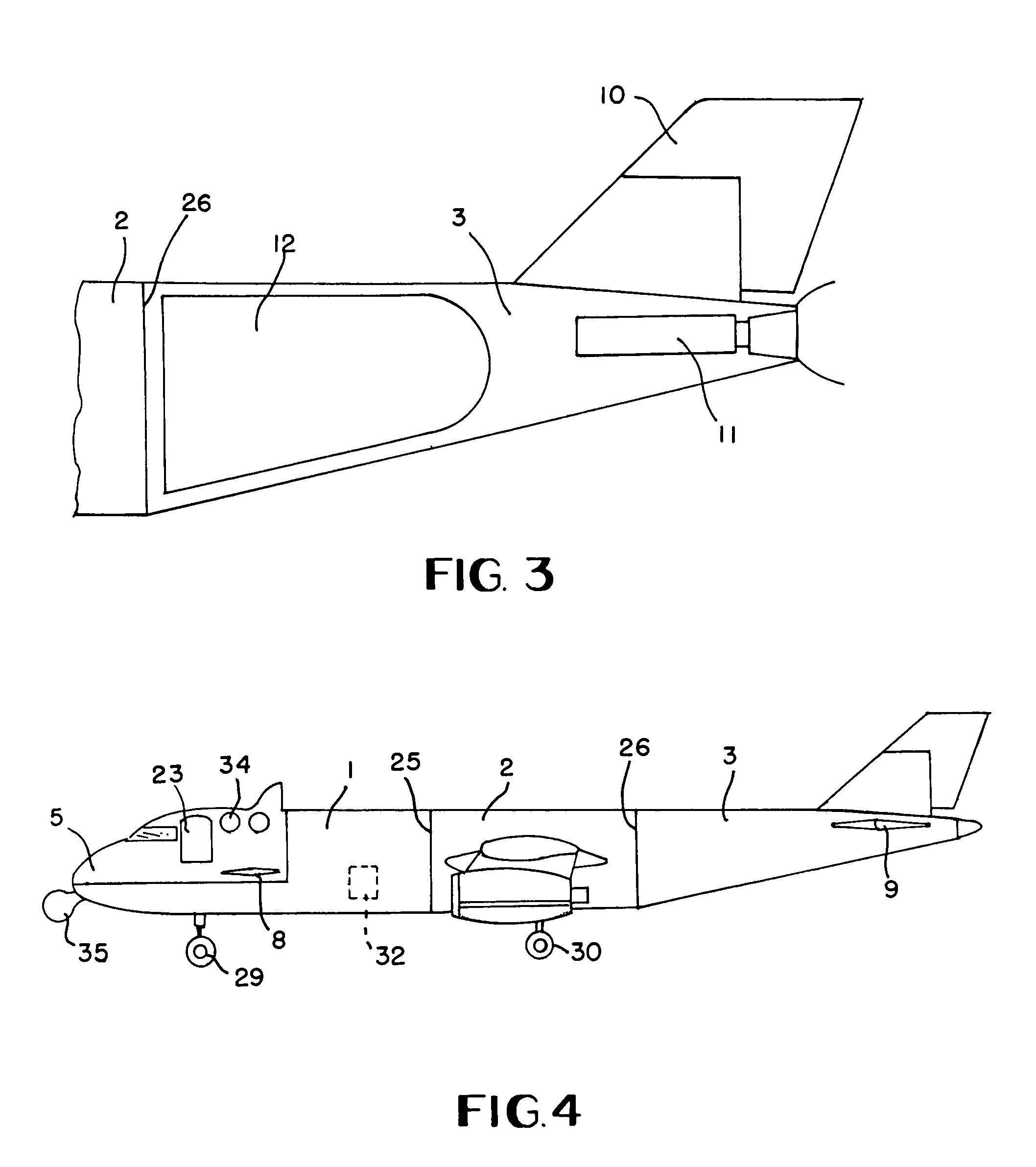

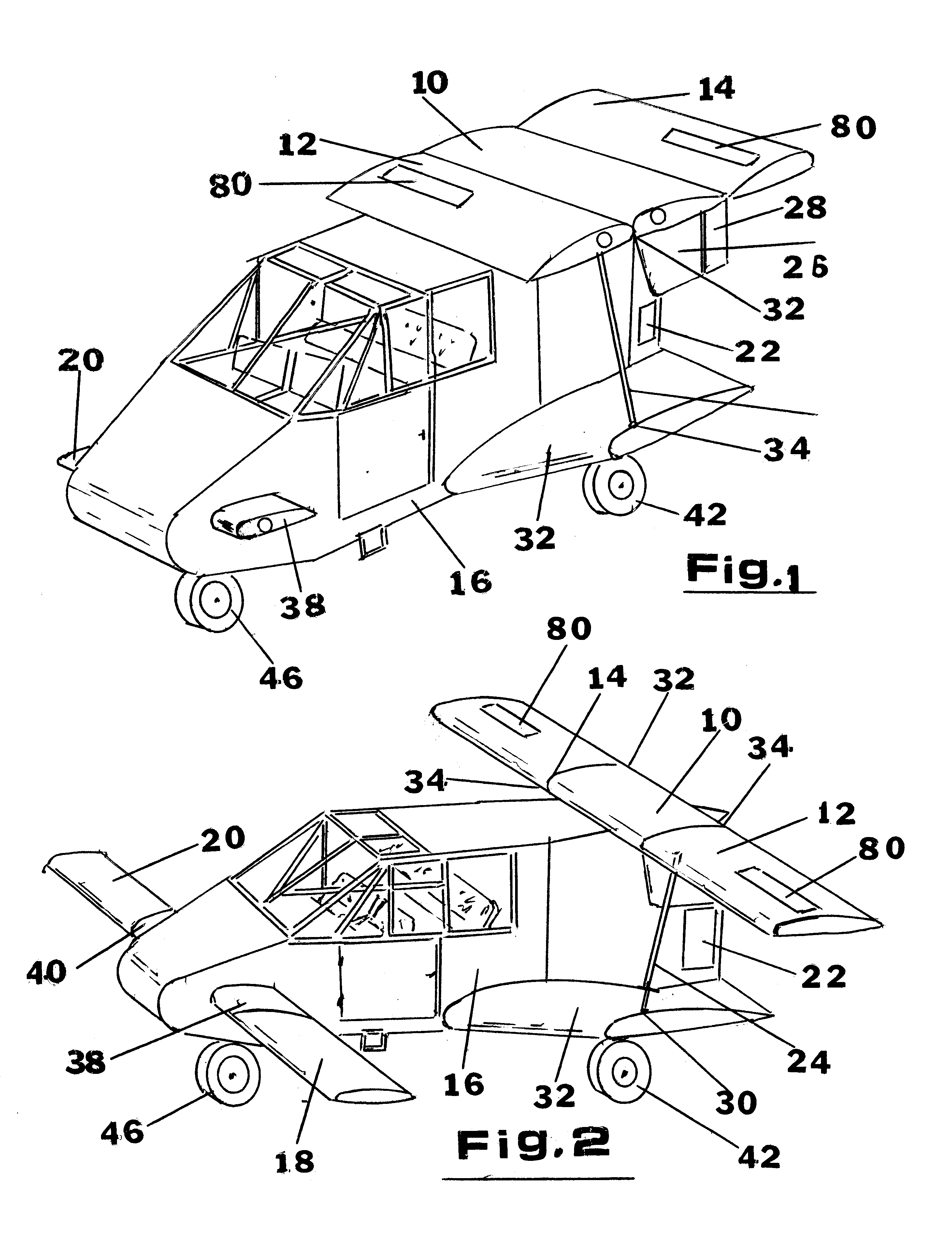

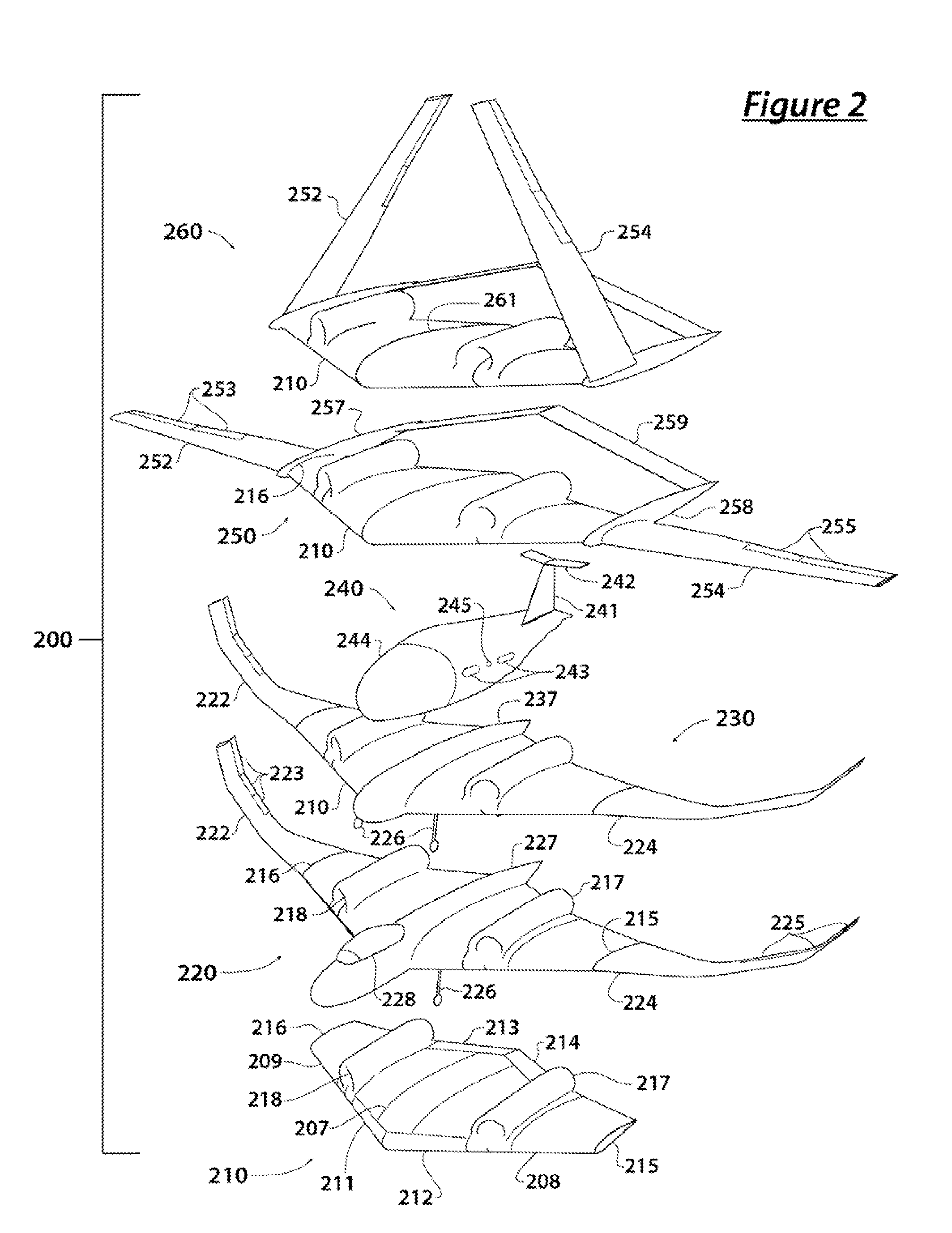

Modular aerospace plane

InactiveUS7234667B1Improve securityImprove performanceAircraft ejection meansRemote controlled aircraftAviationModularity

This invention relates to the design of a Modular Aerospace Plane (MAP) comprising a forward fuselage section, a main wing section, a tail section and wing attachments. Various sections can be integrated to offer a variety of aircraft characteristics, performance and missions. This modular design offers a new method of aircraft fabrication, maintenance, repair and ground handling to reduce costs for the manufacturers, owners and operators. The forward fuselage and tail sections may utilize a parachute device whereby these sections can separate in an emergency and safely lower the occupants to the ground.

Owner:TALMAGE JR ROBERT N

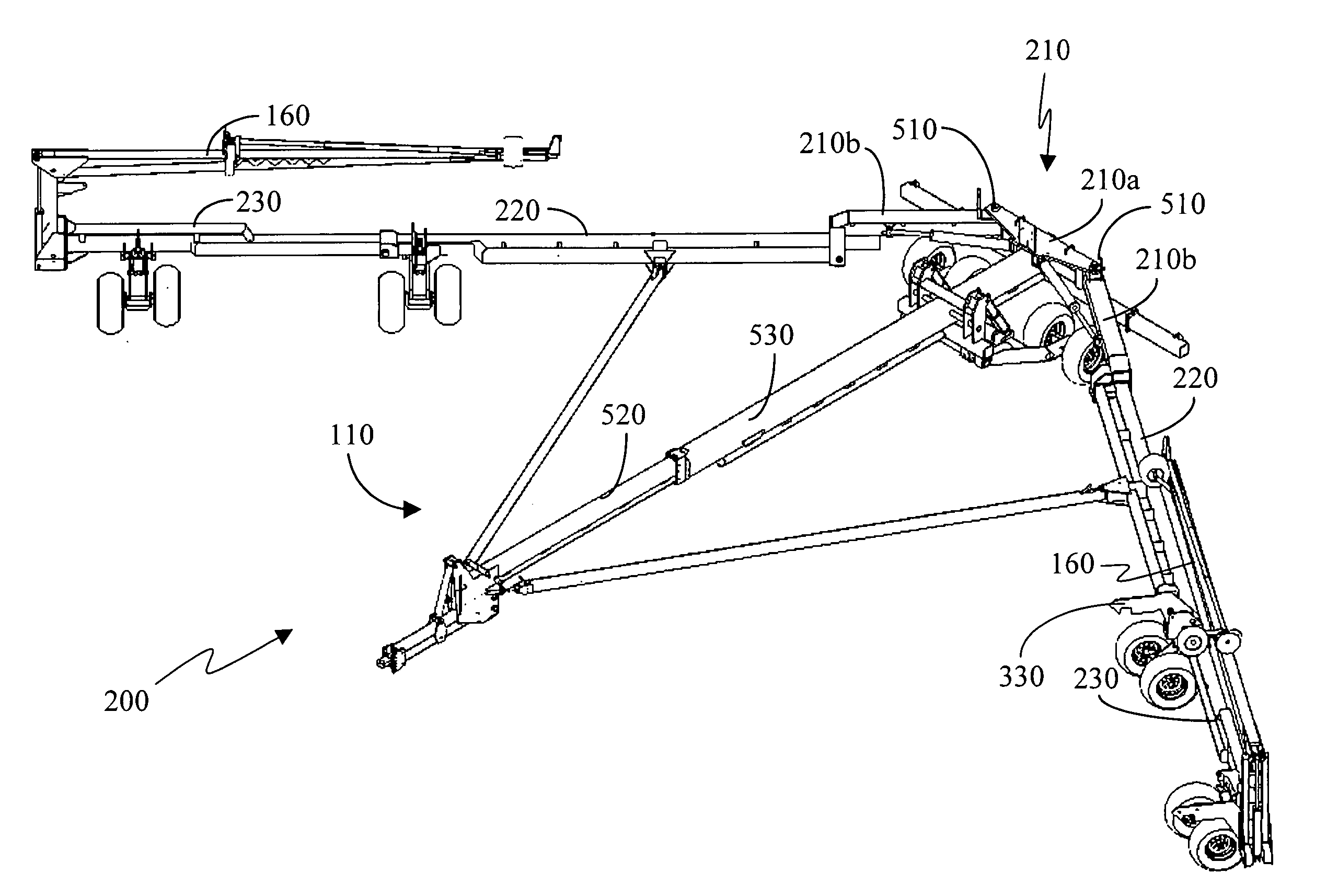

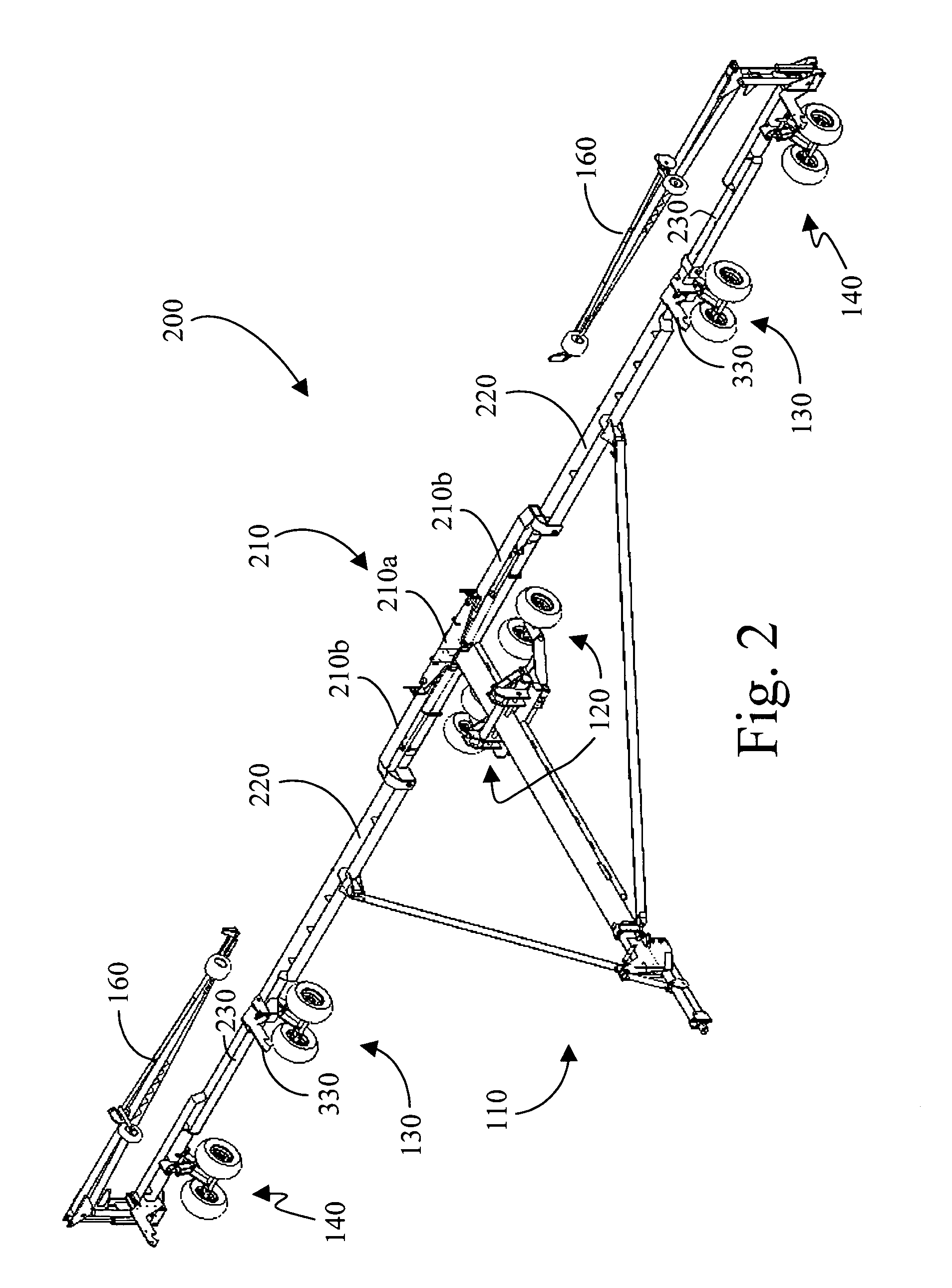

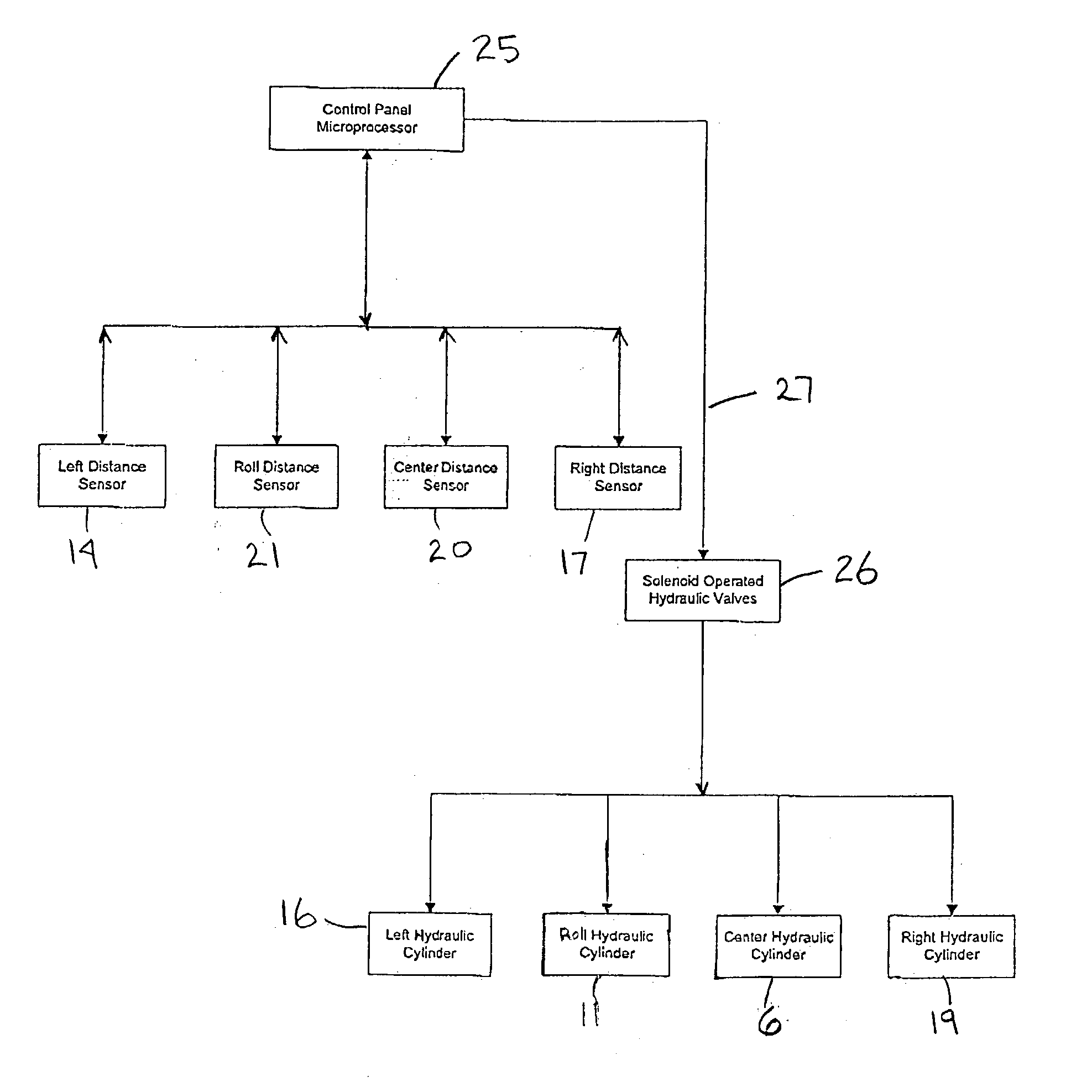

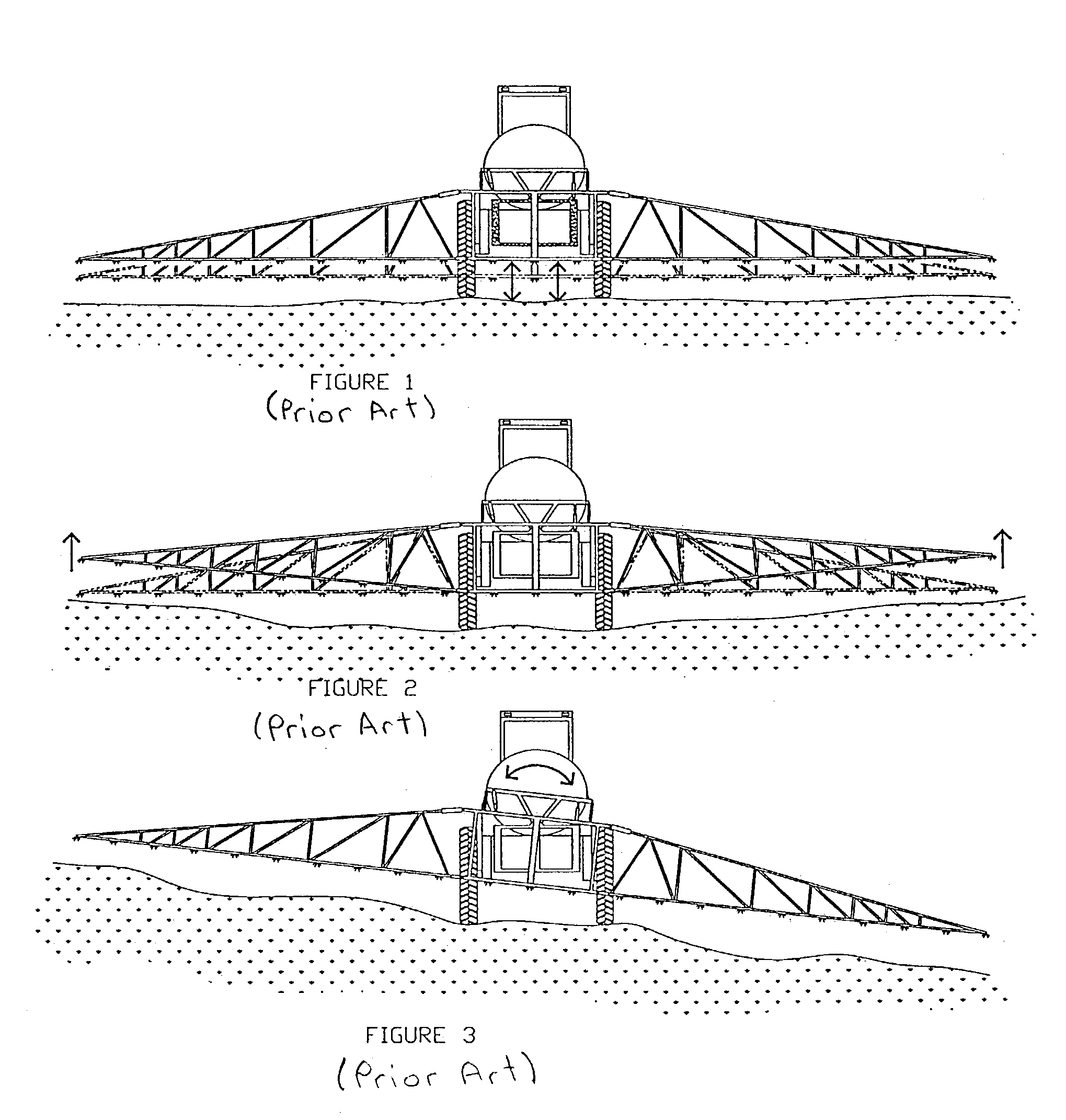

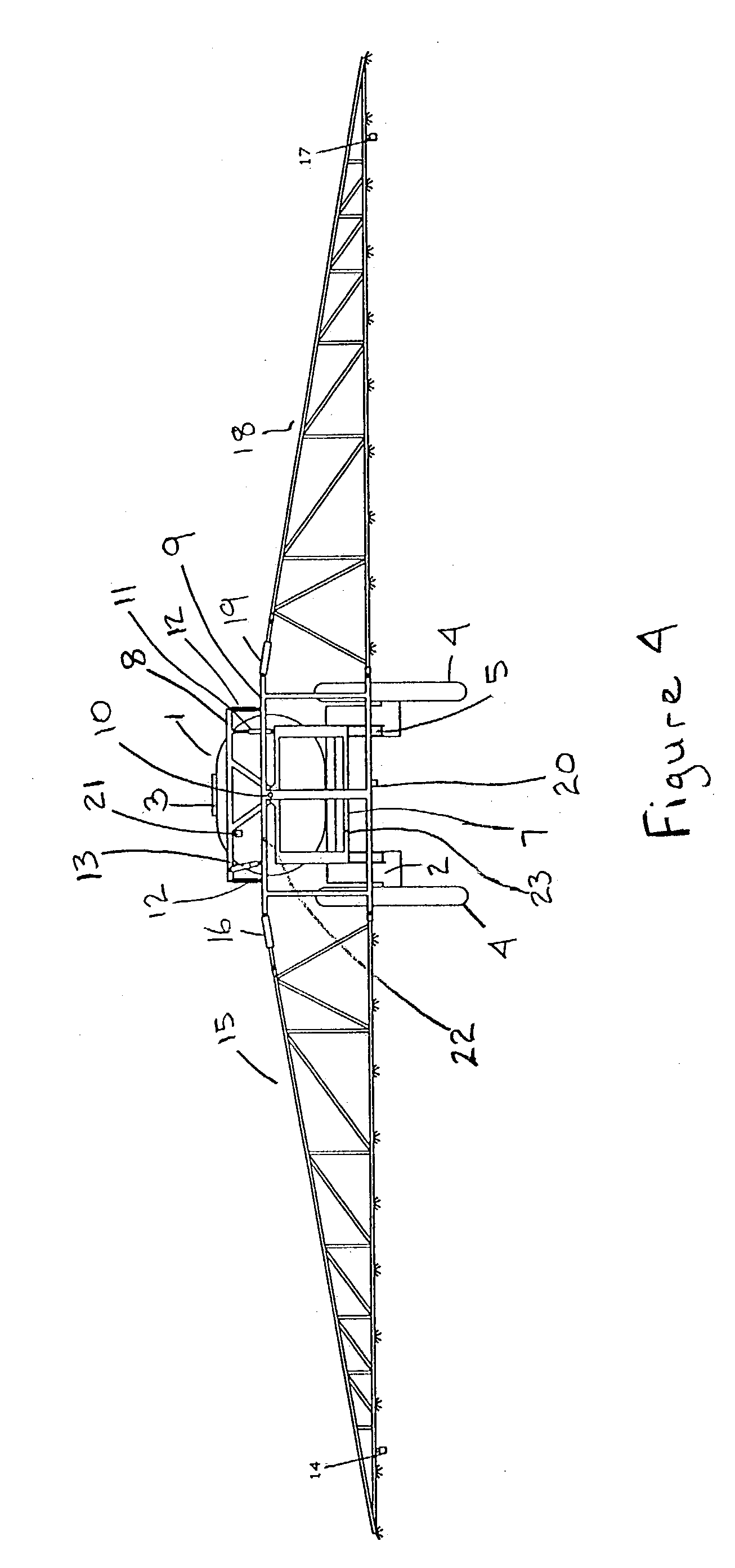

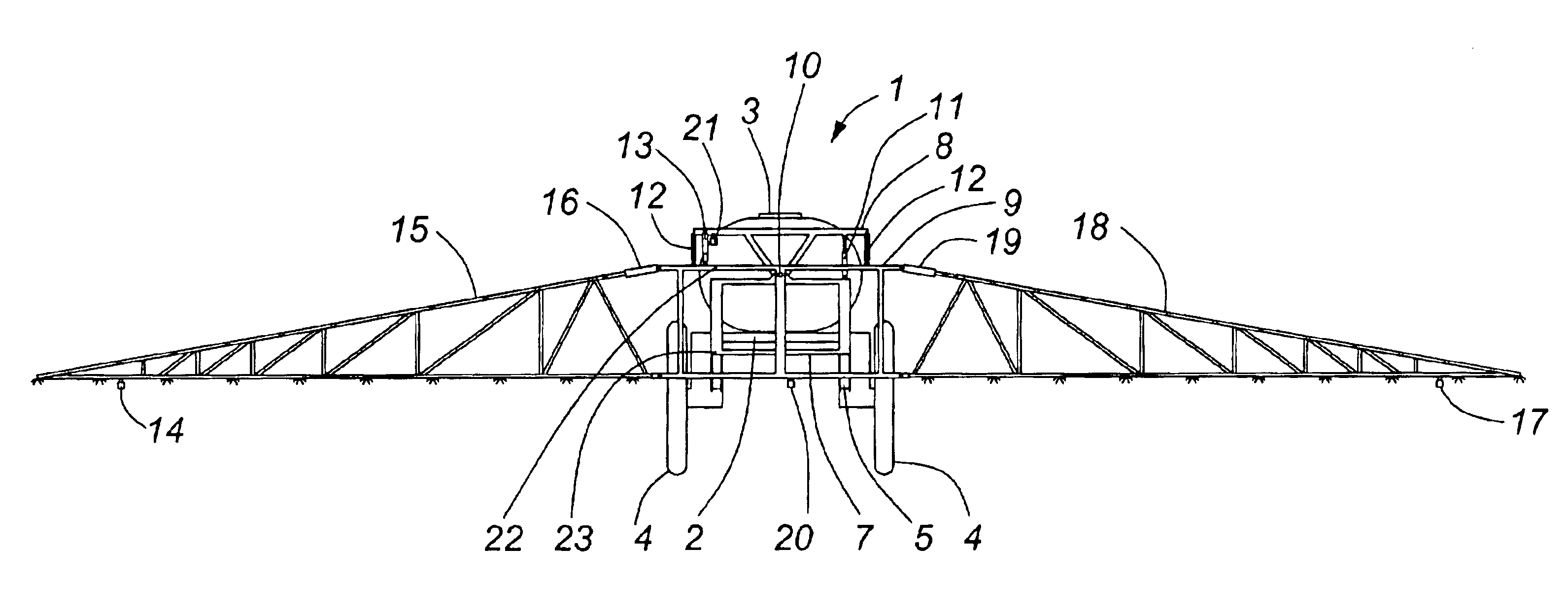

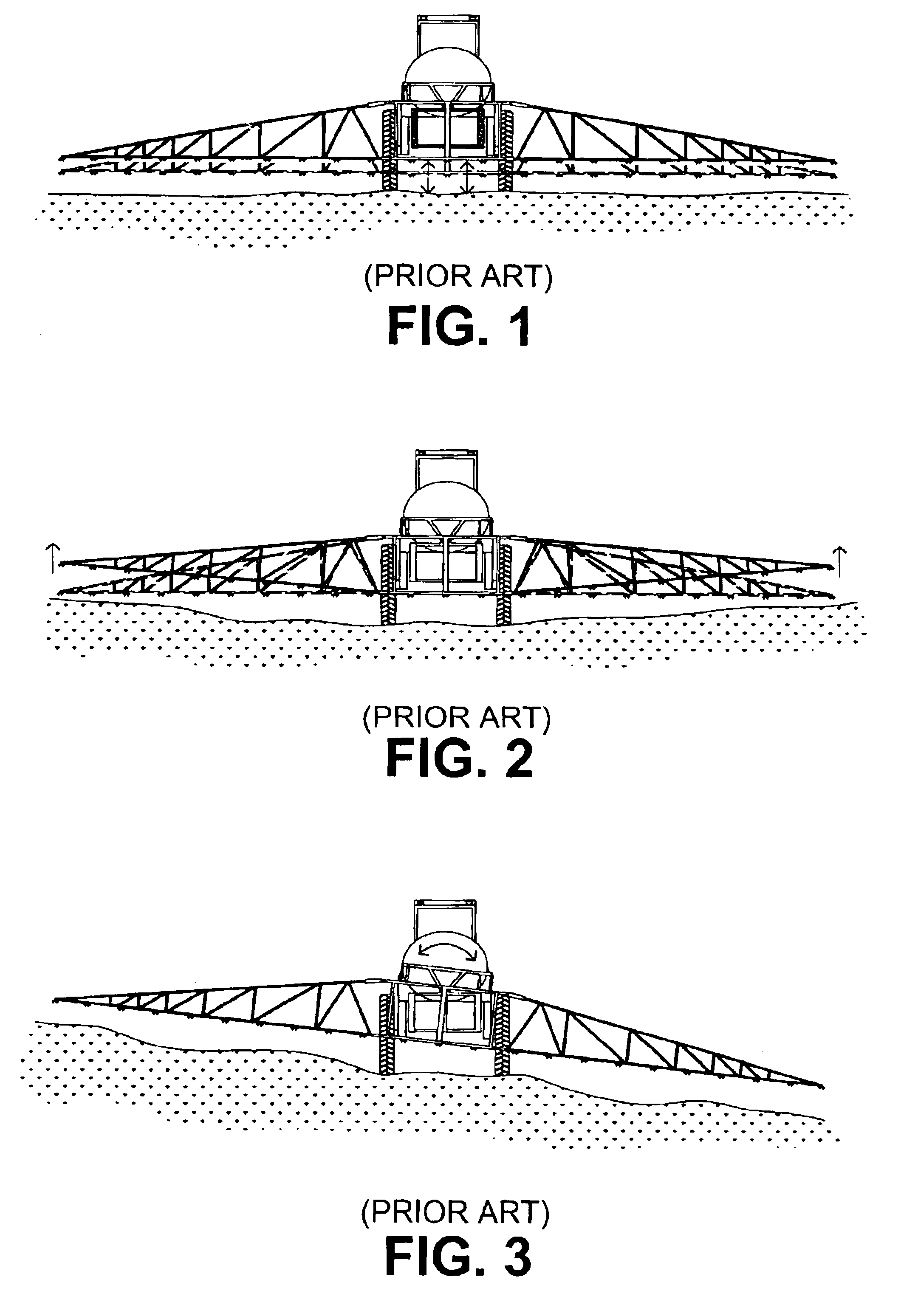

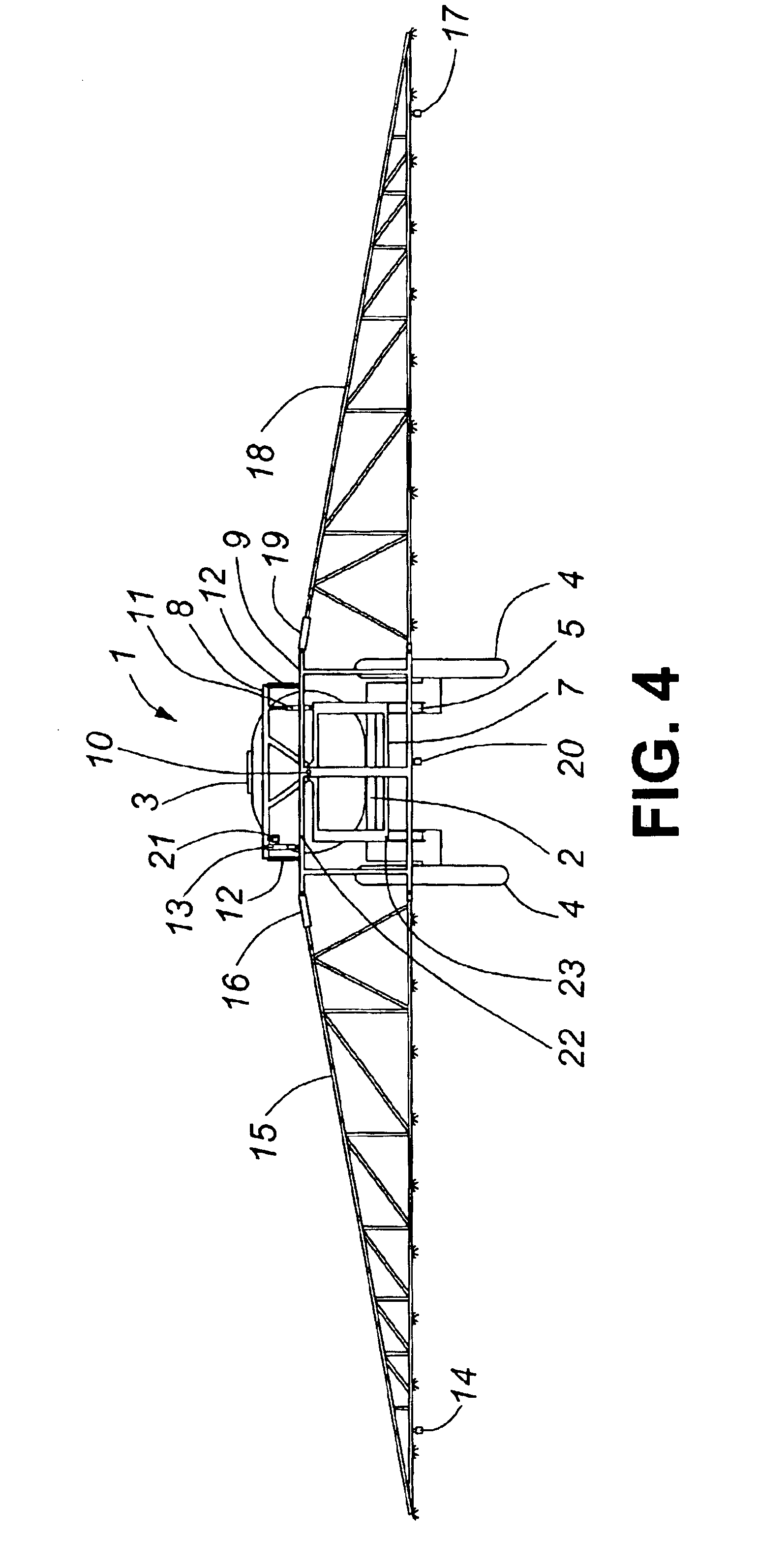

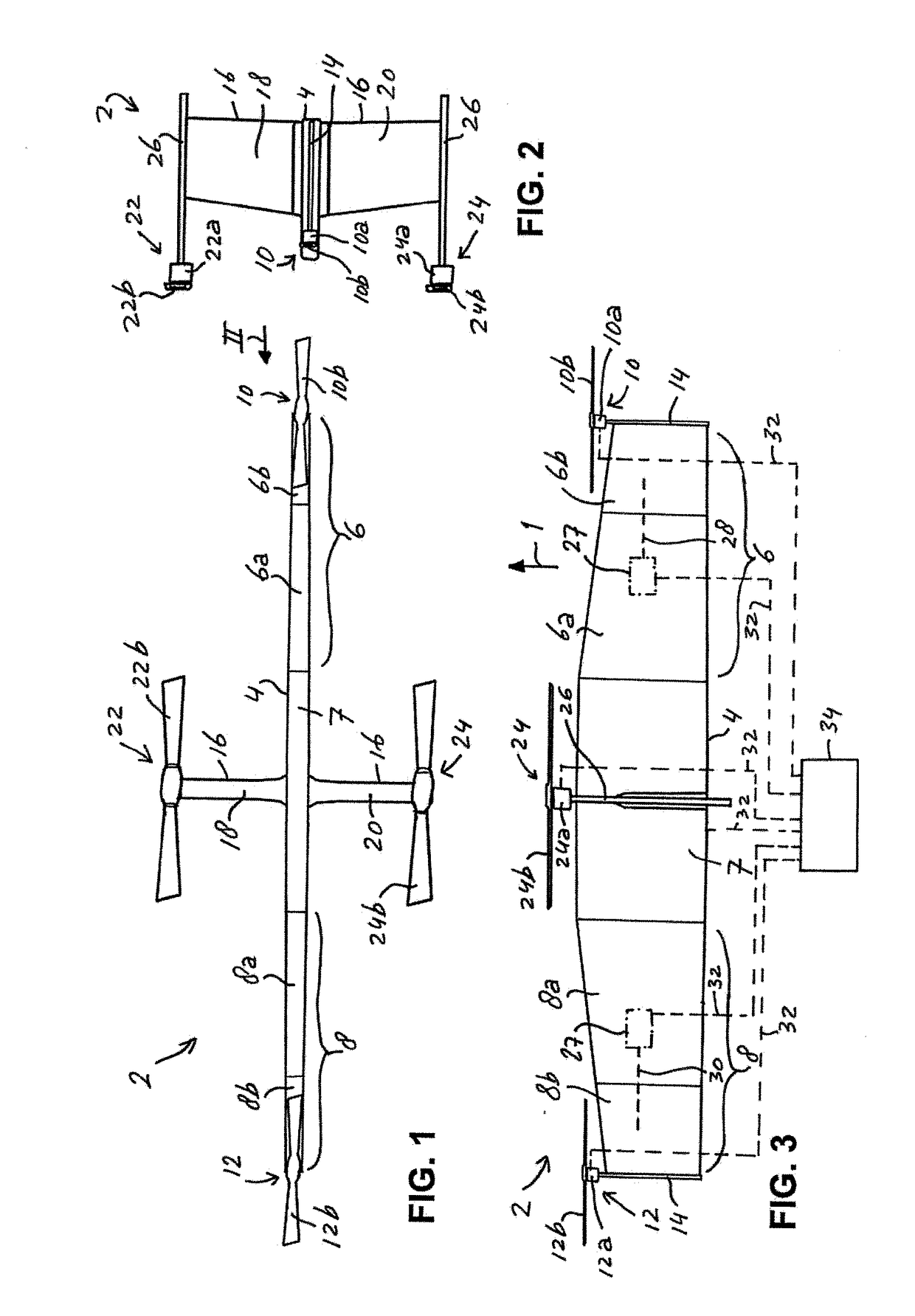

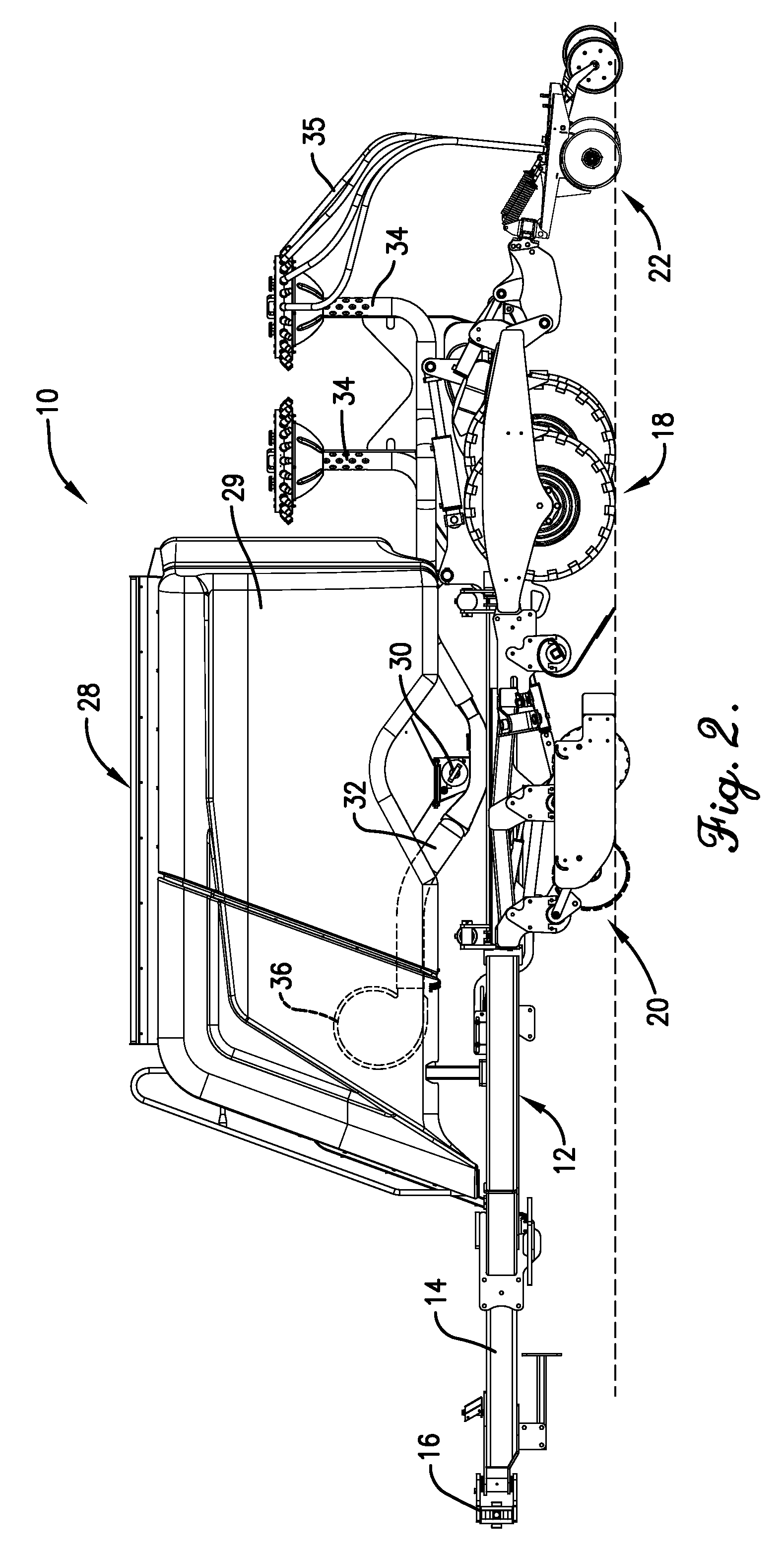

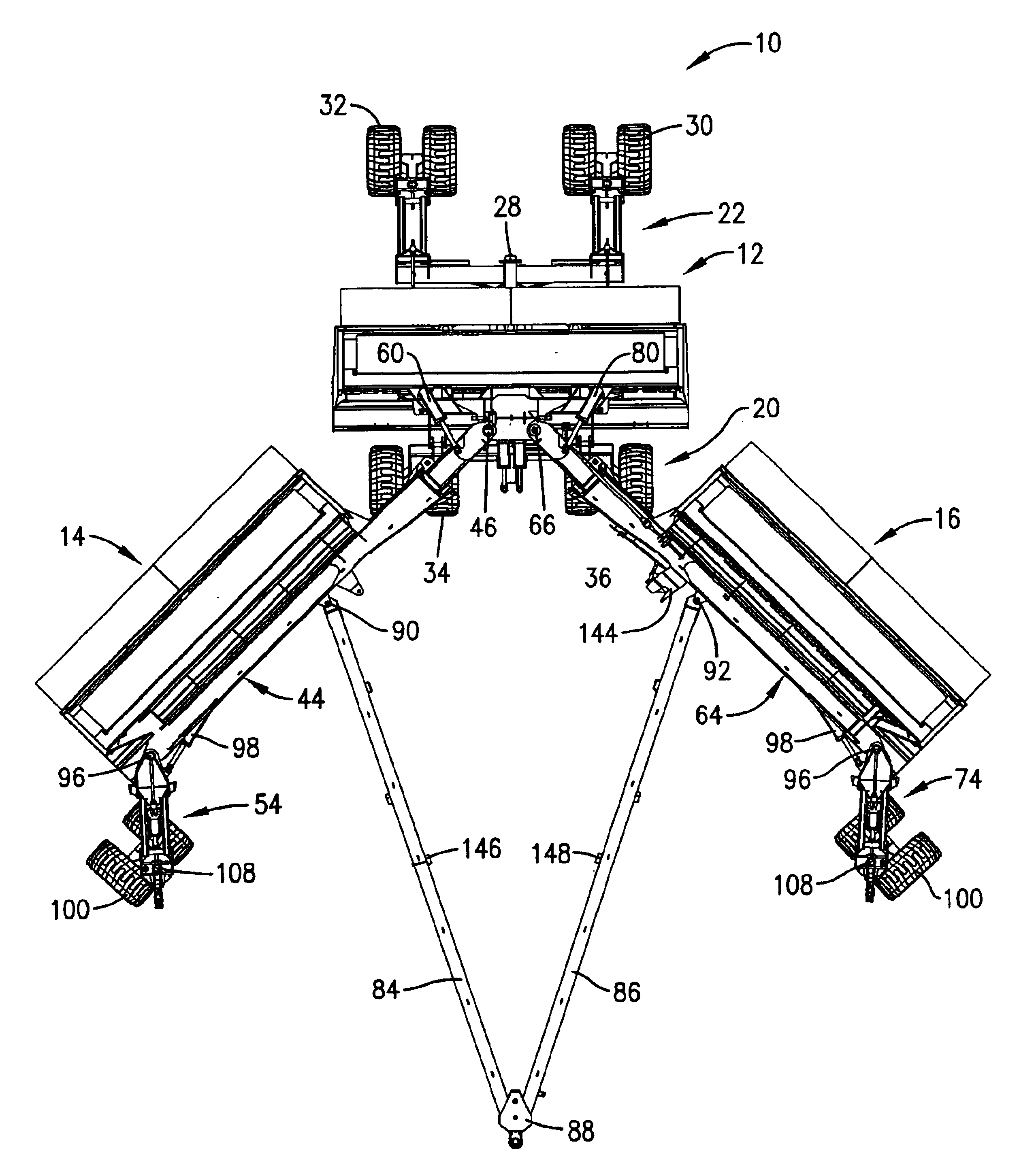

Roll control system and method for a suspended boom

A roll control system is provided for controlling a roll position of a boom rotatably coupled to a support frame, the boom comprising left and right wing sections (where the roll of the boom refers to a clockwise or counterclockwise rotation of said boom relative to the support frame). A roll control mechanism is configured for rotating the boom relative to the support frame in response to a roll control signal. Wing section position measuring apparatus is configured for producing a right wing signal correlatable to a distance between the right wing section and a right wing reference position and a left wing signal correlatable to a distance between the left wing section and a left wing reference position. Boom roll position measuring apparatus is configured for producing a boom roll signal correlatable to a roll position of the boom relative to a boom roll reference position. A controller is configured for: (i) identifying a wing section differential value and a boom roll value derived from the right and left wing signals and the boom roll signal, respectively; (ii) identifying a boom roll control error value derived from the wing section differential value and the boom roll value, the boom roll error control value being configured for deriving therefrom the roll control signal. Advantageously, the roll control system of the invention takes into account both the height differential (relative to a ground reference) between the left and right wings and the boom roll position relative to a neutral (reference) position.

Owner:NORAC SYST INT

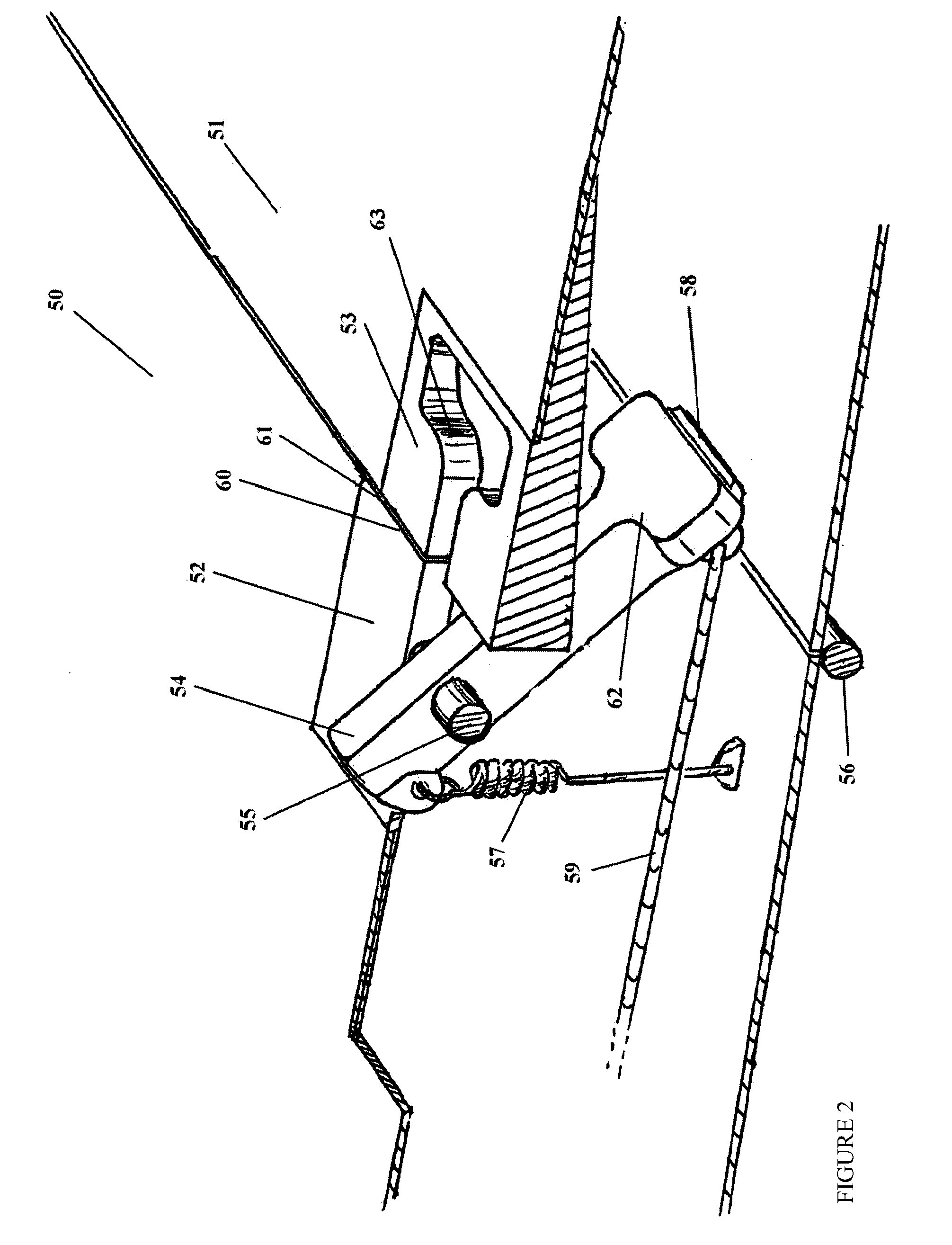

Folding Wing & Locking Mechanism

InactiveUS20100051742A1Reduce changesPrevent rotationWing adjustmentsControl systemLocking mechanism

Improved mechanisms for folding and locking an aircraft wing and controlling the wing's aileron through a wing fold have been motivated by development of a roadable aircraft. Applicable to a broader class of aircraft, these mechanisms allow for a safer, lighter-weight solution to the wing-folding challenge than currently available. The cable control system allows an outer wing section to be moved in concert with an actuated inner wing section. The locking mechanism allows for automated operation and visual inspection. The aileron control mechanism provides centering and locking in addition to flight control through the hinge axis.

Owner:TERRAFUGIA

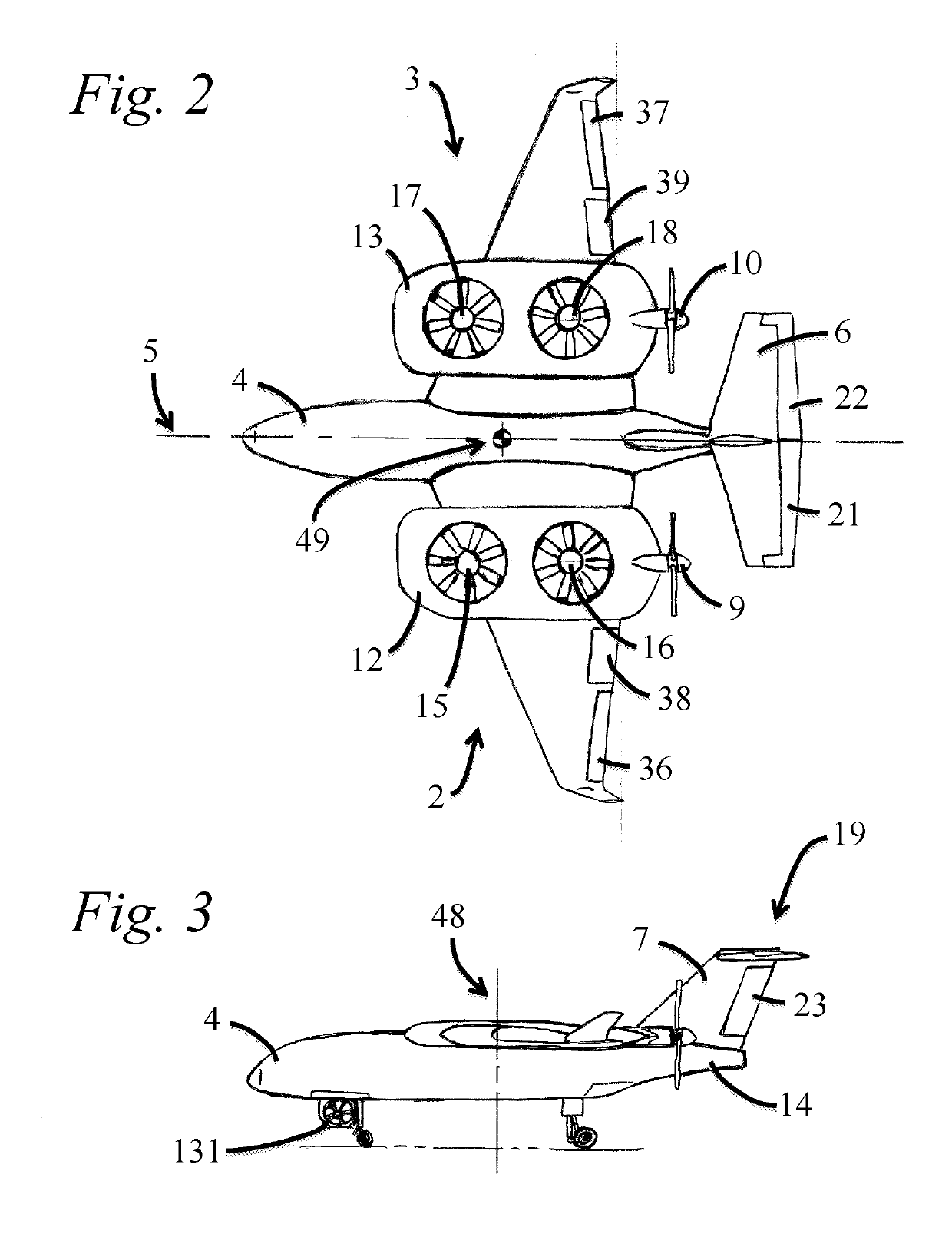

Vertical take-off and landing aircraft and control method

InactiveUS20190291860A1Reduce resistanceMore dragAircraft navigation controlAircraft stabilisationJet aeroplaneRotary wing

A vertical take-off and landing aircraft, and a control method for the aircraft, are disclosed. The aircraft has a vertical motion mode and a forward thrust mode. The aircraft comprises an airframe, having a wing section; a forward thrust means, for use during the forward thrust mode; a vertical lift rotor system, the rotor system being housed in a portion of the airframe; and a rotor control component configured to, during forward thrust, actuate the rotor system to modify the aerodynamic flow around the portion of the airframe housing the rotor system. Forward thrust may occur during the forward thrust mode, or other flight modes, such as transition phases to / from vertical motion and forward thrust modes. Modification of the aerodynamic flow may be used to optimize the aerodynamic flow around the portion of the airframe housing the rotor system.

Owner:VEROPLANE INC

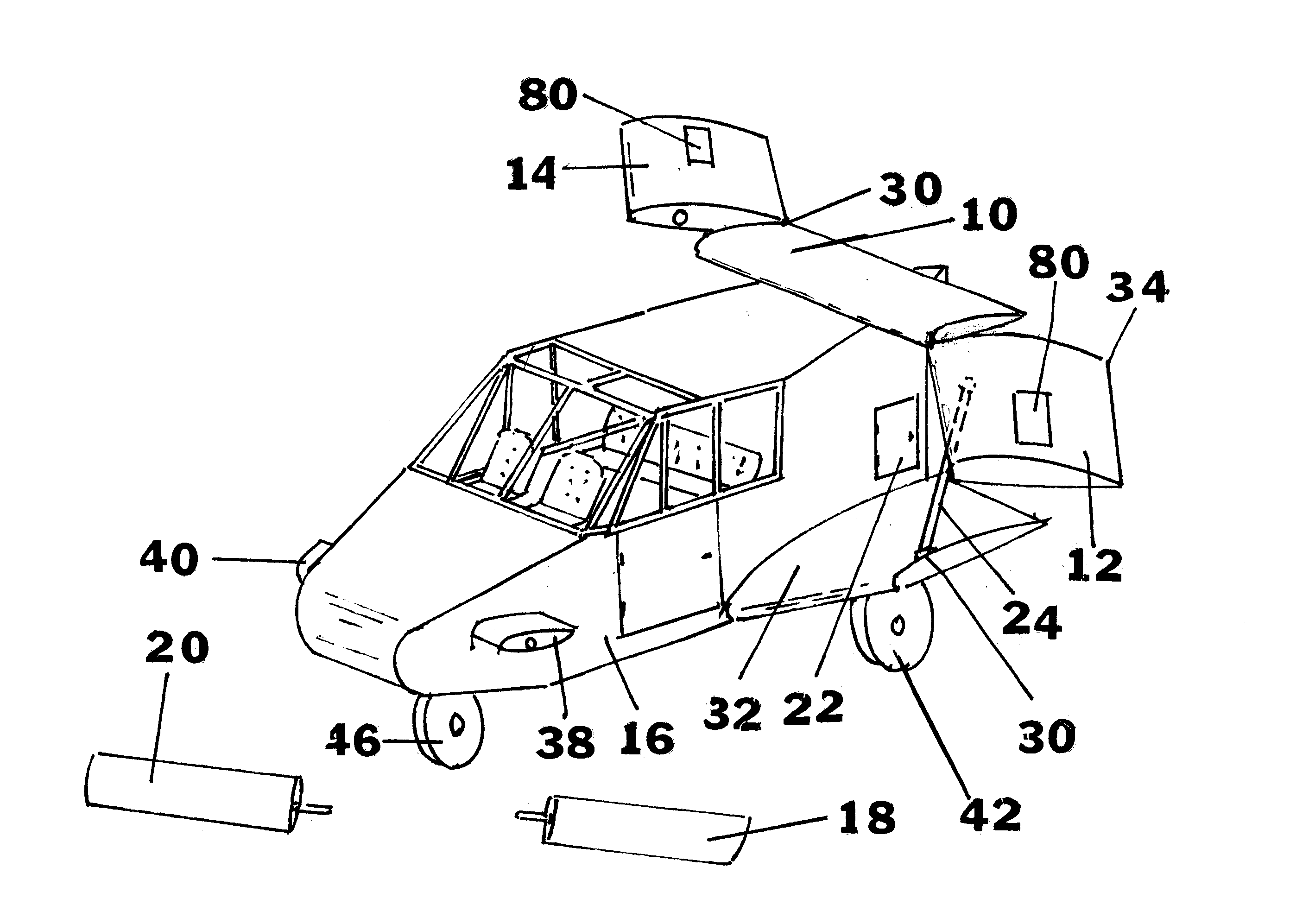

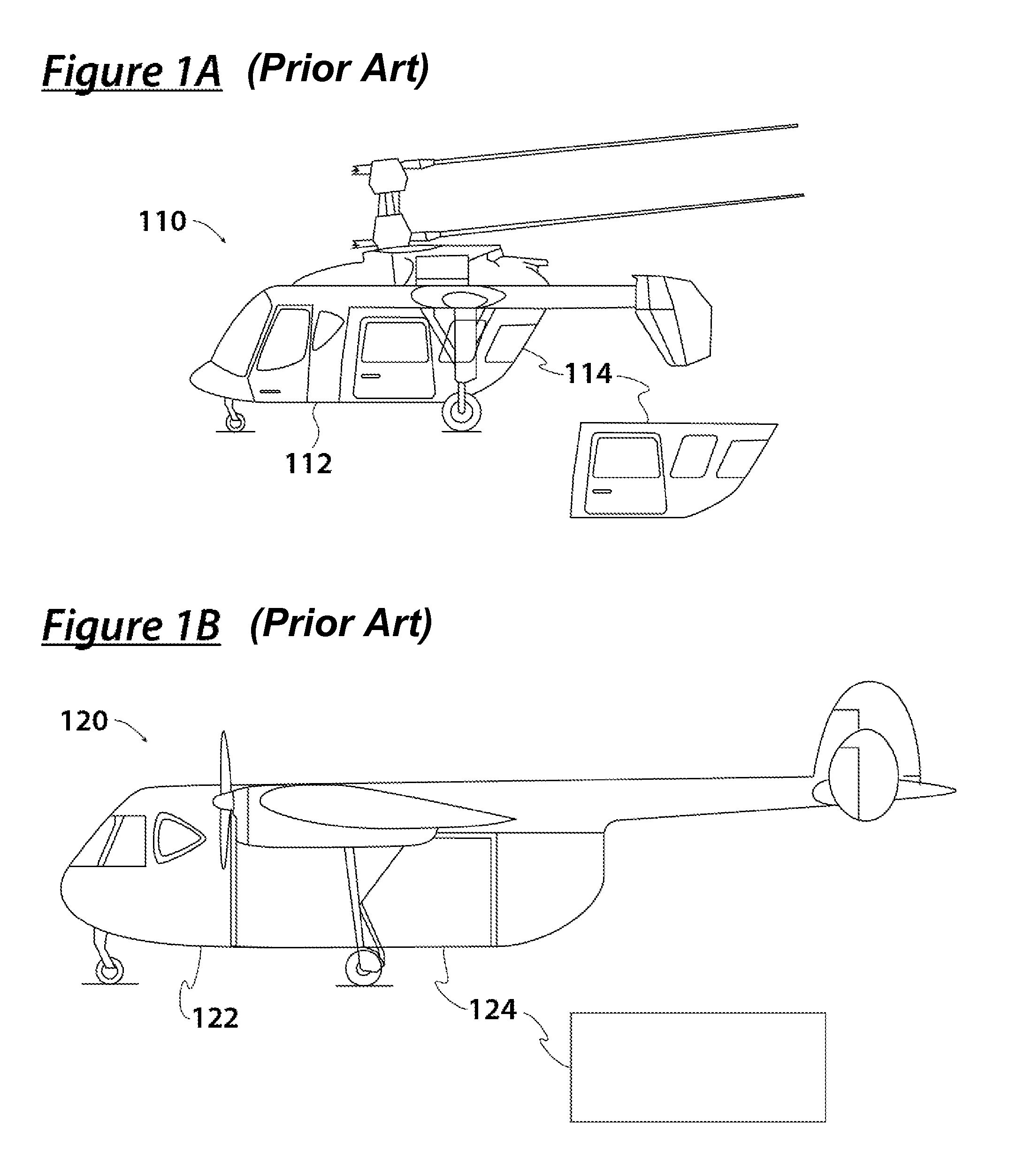

Rapidly-convertible roadable aircraft

InactiveUS6786450B1Small hangar spaceReduce resistanceConvertible aircraftsAircraft stabilisationJet aeroplaneHydraulic motor

A pusher canard aircraft convertible for road use. Canard outer sections are removable and are stored within the aircraft fuselage and the outer main wing sections rotate horizontally for storage on the fuselage top. The fuselage is designed as a lifting body which gives the aircraft three lifting surfaces. The lifting body takes advantage of ground effect, resulting in a lower landing speed. In road mode the vehicle as a 2 or 4 passenger model is smaller than a full size automobile. Hydraulic motor wheels propel the aircraft / vehicle for road use. An internal combustion engine within the fuselage drives the propeller for air operation. The propeller is disengaged, not removed, for land operation and the engine is used to drive an hydraulic pump to power the motor wheels for road use. A single nose wheel or two front wheels are used for both steering in landing / taxiing and for road use. In road mode, the appearance is as much like a van than as an aircraft. In flying mode, the appearance is not to unconventional.

Owner:EINSTEIN HARRY

Roll control system and method for a suspended boom

A roll control system is provided for controlling a roll position of a boom rotatably coupled to a support frame, the boom comprising left and right wing sections (where the roll of the boom refers to a clockwise or counterclockwise rotation of said boom relative to the support frame). A roll control mechanism is configured for rotating the boom relative to the support frame in response to a roll control signal. Wing section position measuring apparatus is configured for producing a right wing signal correlatable to a distance between the right wing section and a rightwing reference position and a left wing signal correlatable to a distance between the left wing section and a left wing reference position. Boom roll position measuring apparatus is configured for producing a boom roll signal correlatable to a roll position of the boom relative to a boom roll reference position. A controller is configured for: (i) identifying a wing section differential value and a boom roll value derived from the right and left wing signals and the boom roll signal, respectively; (ii) identifying a boom roll control error value derived from the wing section differential value and the boom roll value, the boom roll error control value being configured for deriving therefrom the roll control signal. Advantageously, the roll control system of the invention takes into account both the height differential (relative to a ground reference) between the left and right wings and the boom roll position relative to a neutral (reference) position.

Owner:NORAC SYST INT

Multi-Role Aircraft with Interchangeable Mission Modules

A flight-operable, truly modular aircraft has an aircraft core to which one or more of outer wings members, fuselage, cockpit, leading and trailing edge couplings, and empennage and tail sections can be removably coupled and / or replaced during the operating life span of the aircraft. In preferred embodiments the aircraft core houses the propulsive engines, avionics, at least 80% of the fuel, and all of the landing gear. The aircraft core is preferably constructed with curved forward and aft composite spars, that couple to outer wing sections and possibly other sections using hardpoints. The aircraft core preferably has a large central cavity dimensioned to interchangeably carry an ordnance launcher, a surveillance payload, electronic countermeasures, and other types of cargo. Contemplated aircraft can be quite large, for example having a wing span of at least 80 ft.

Owner:KAREM ABE

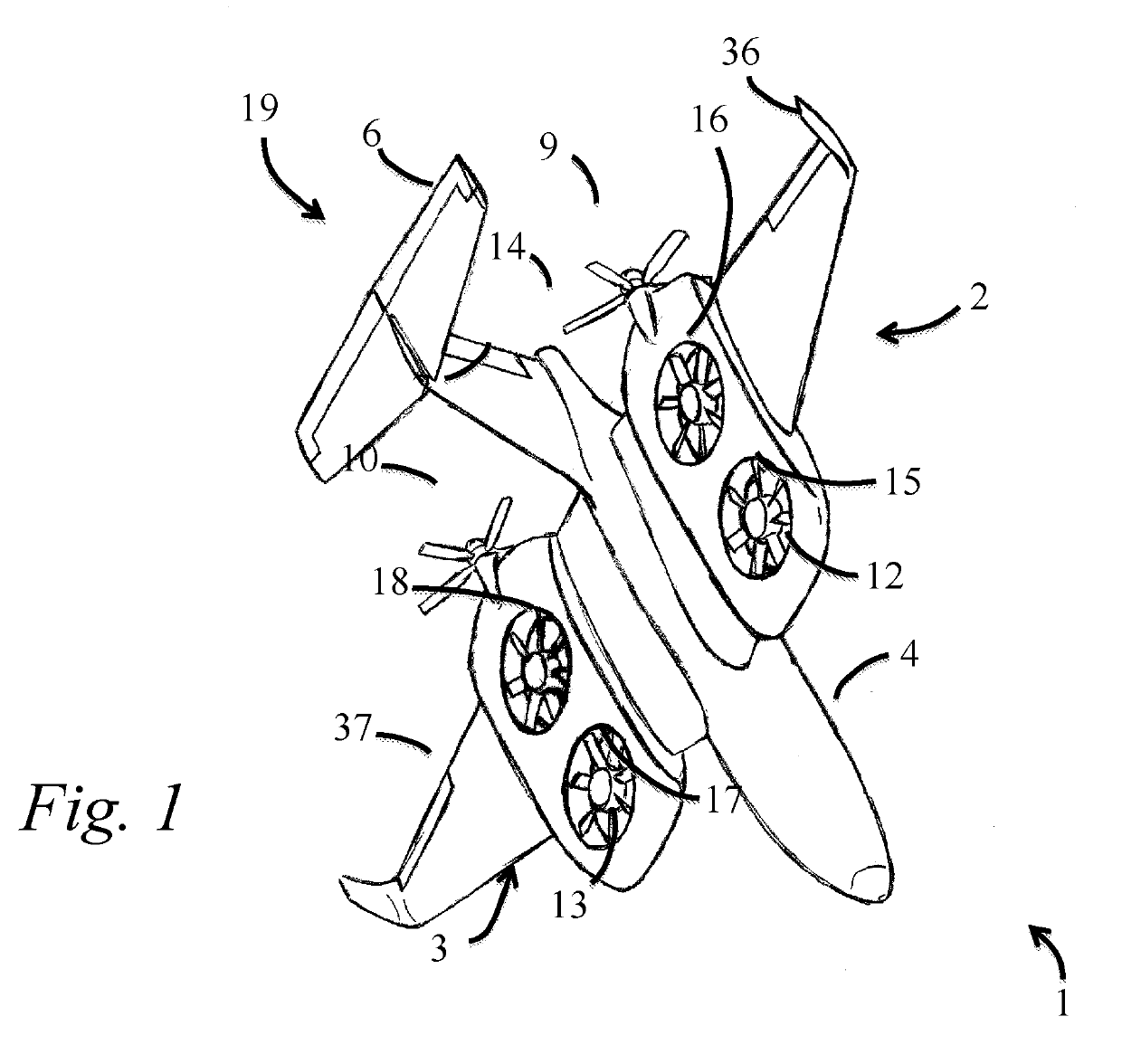

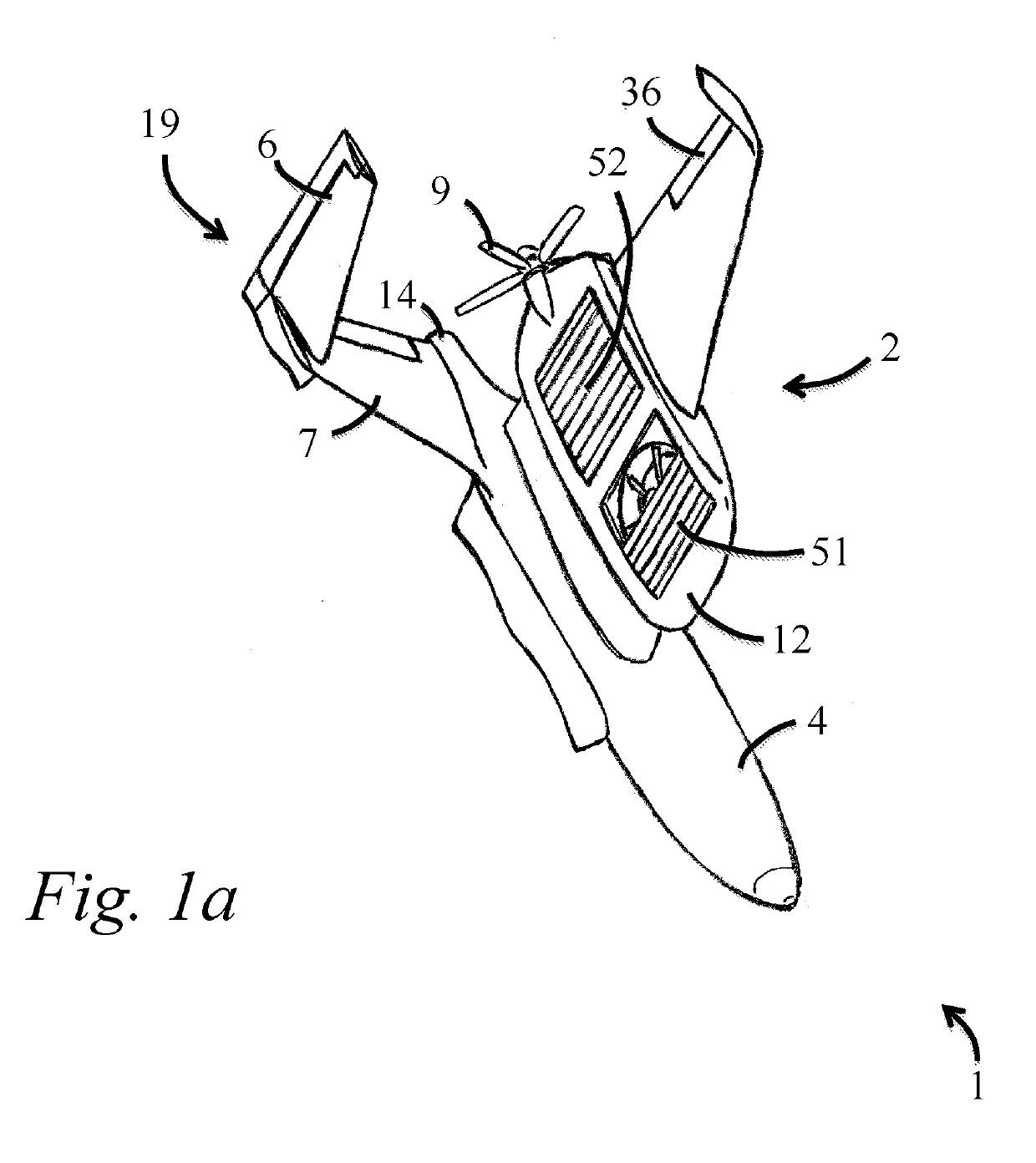

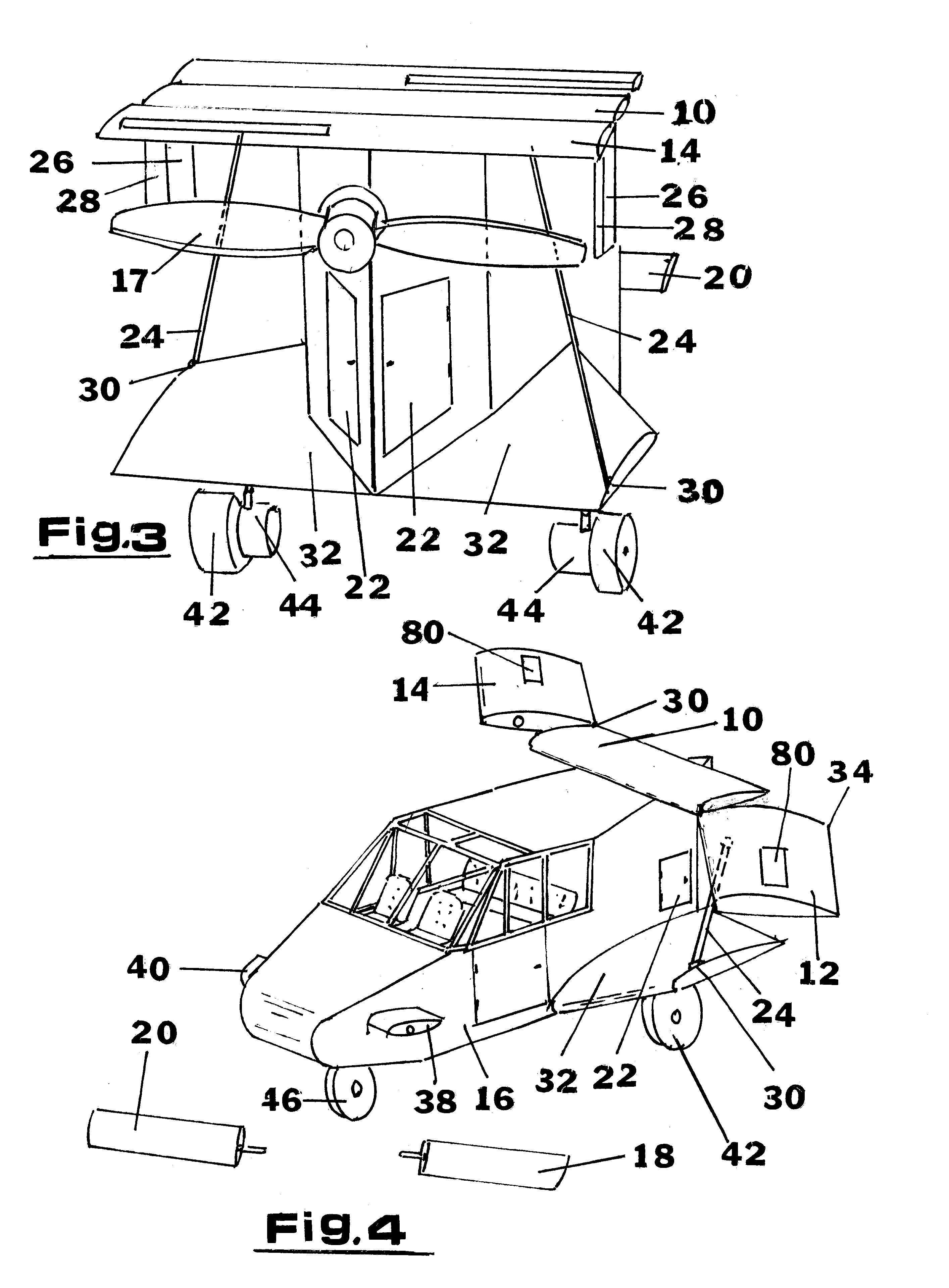

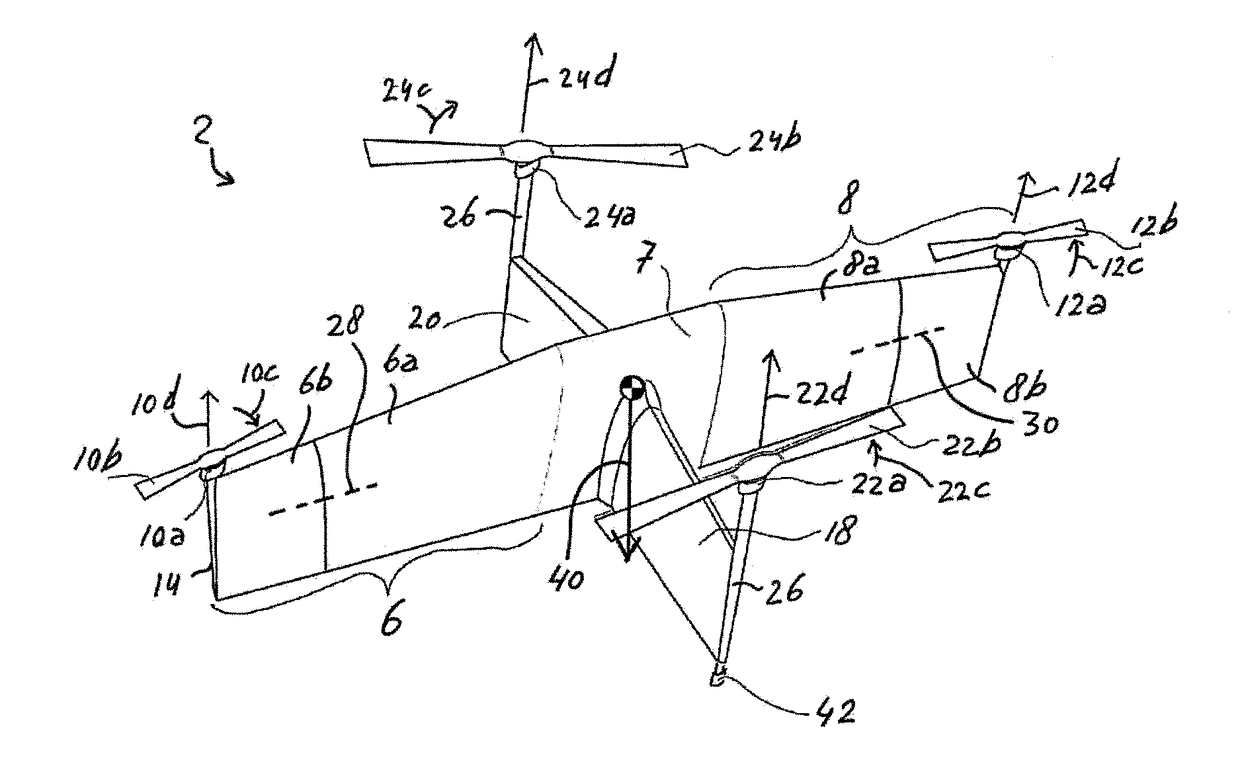

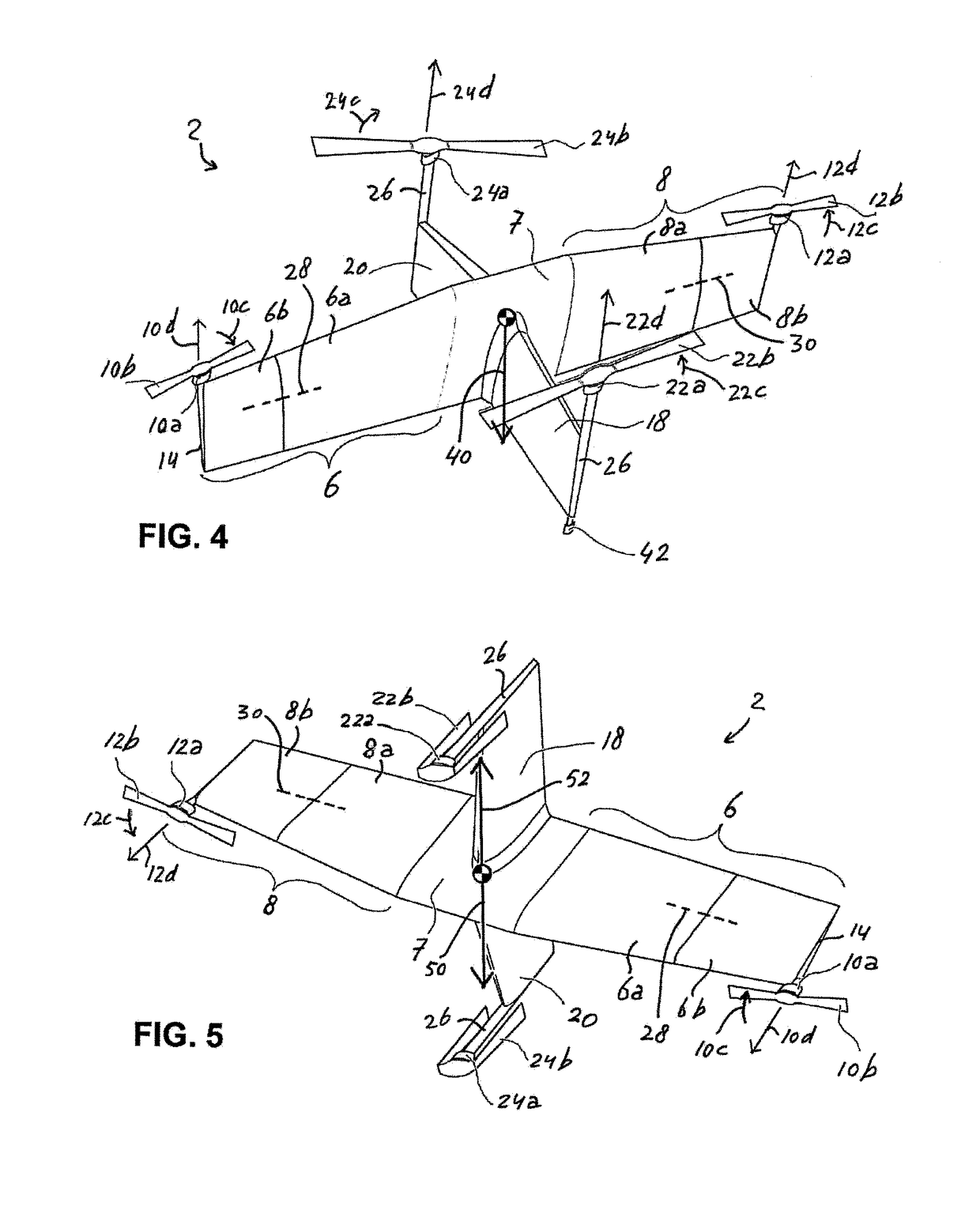

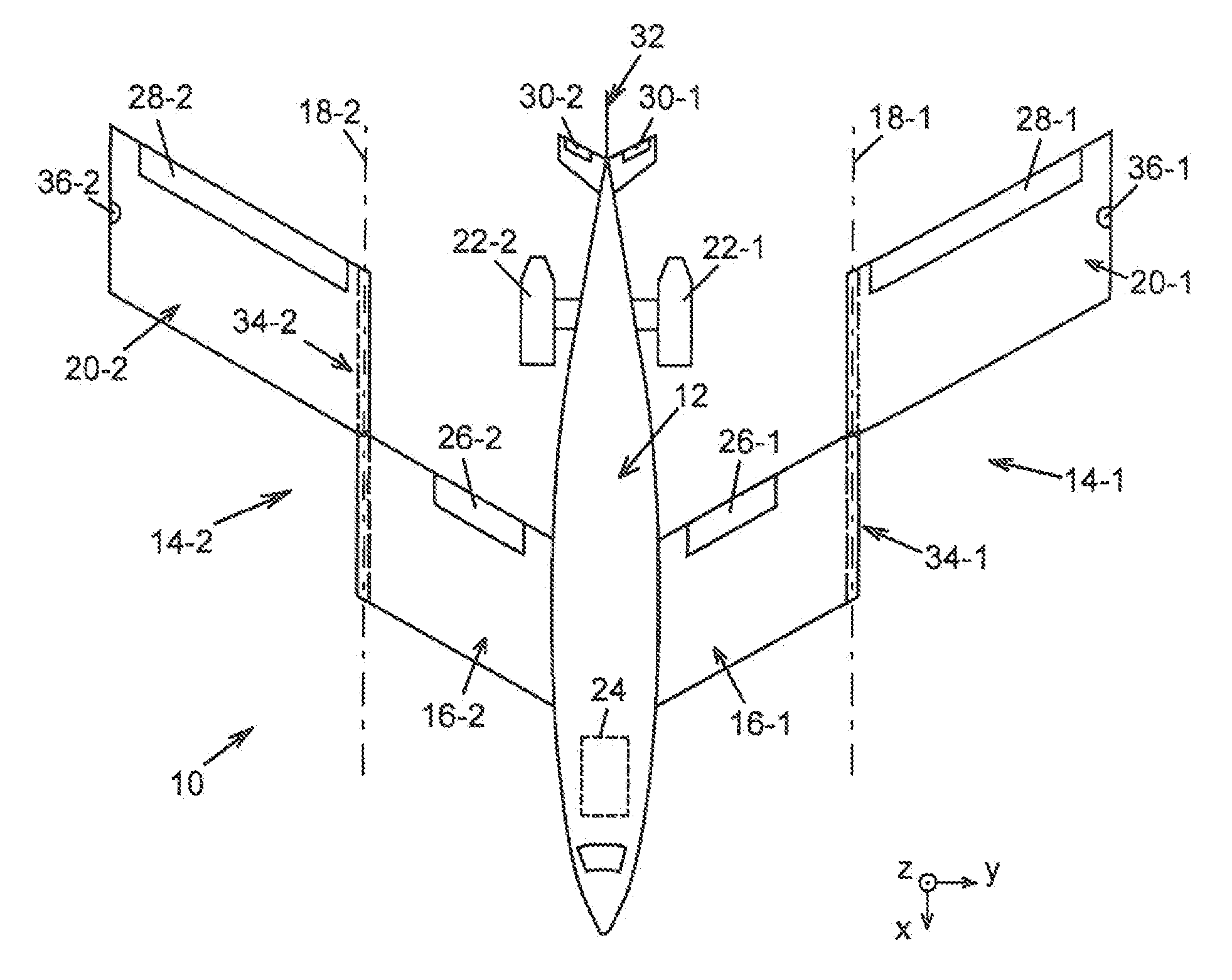

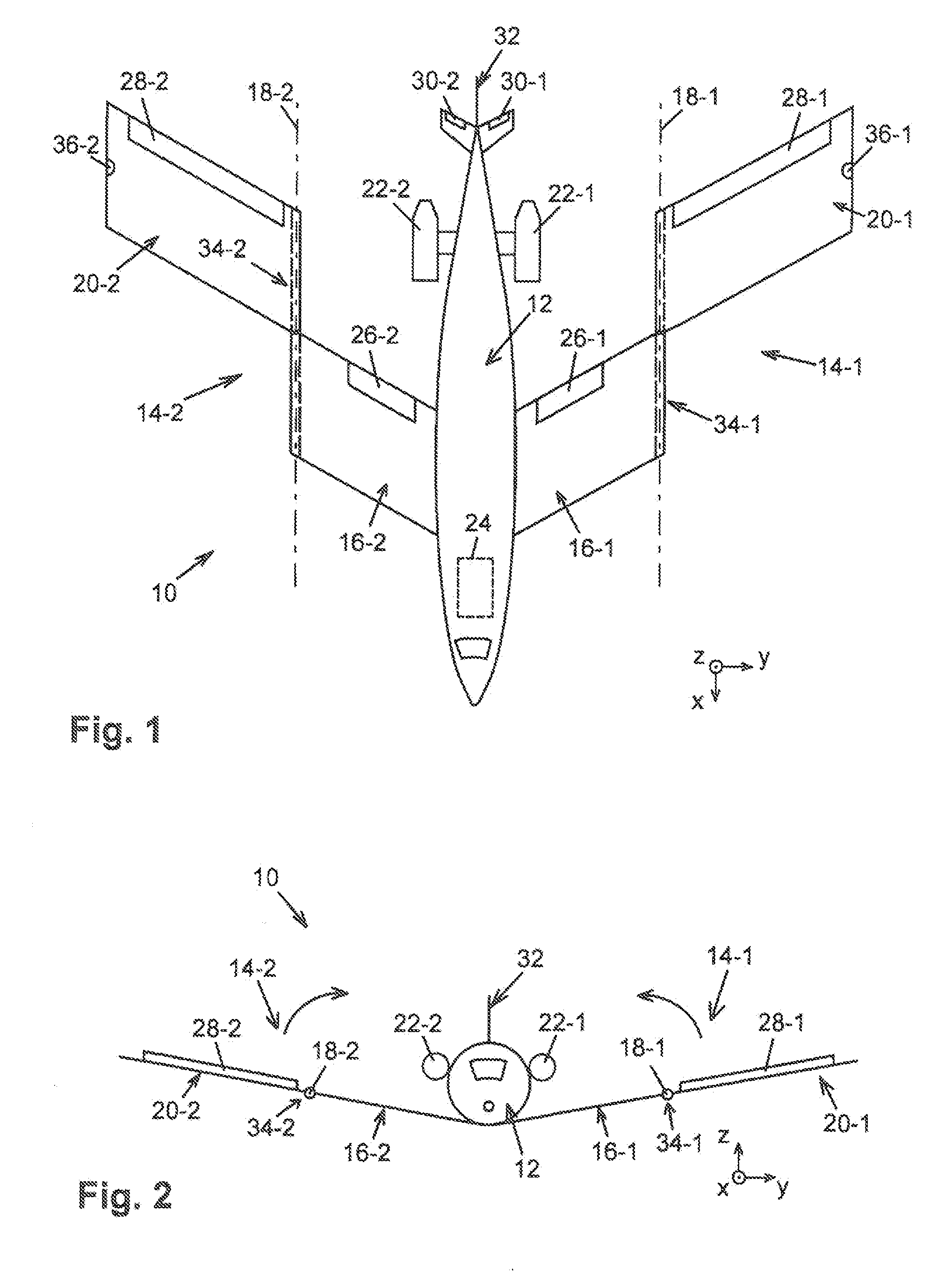

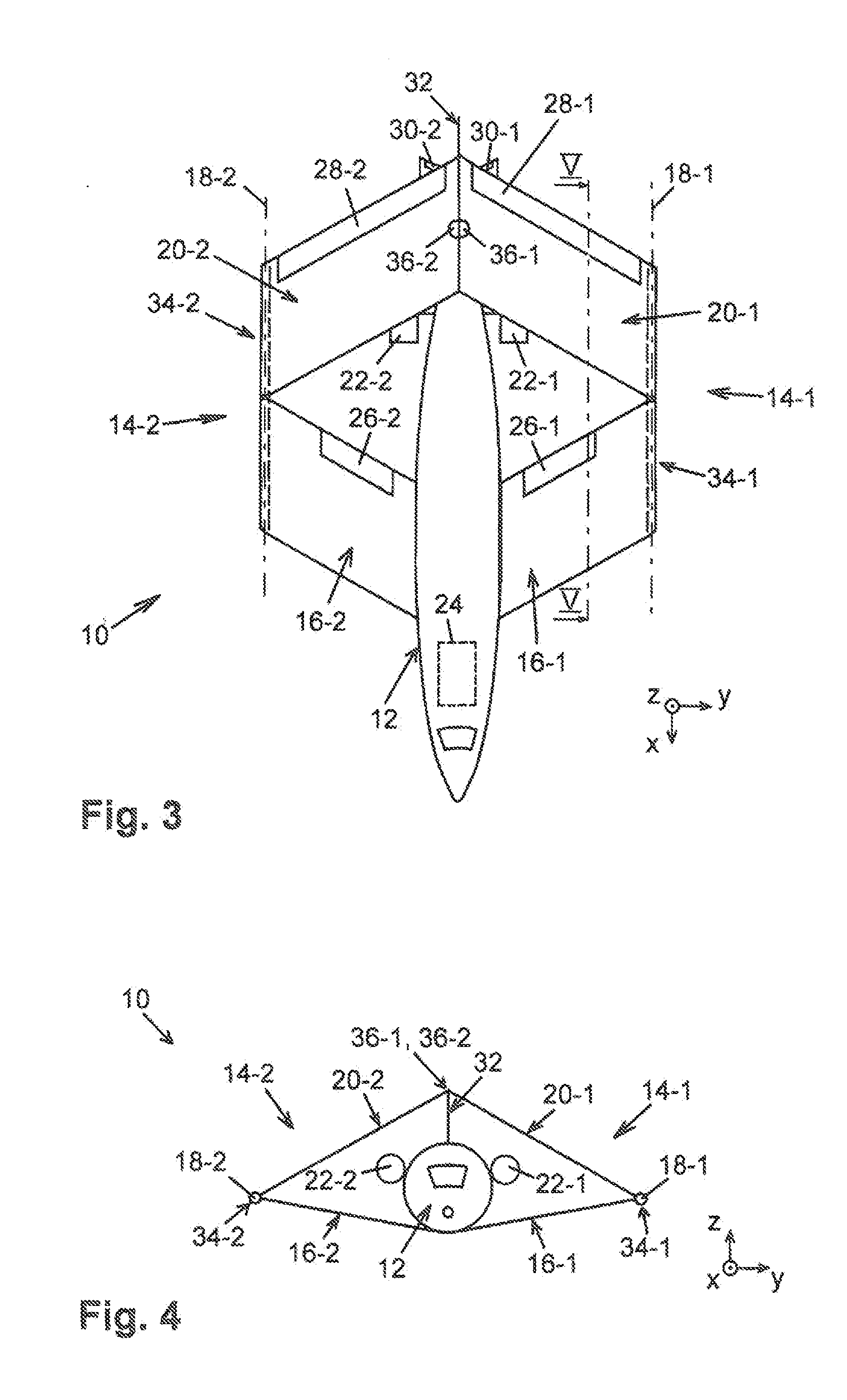

Aircraft with wing-borne flight mode and hover flight mode

ActiveUS20170217585A1Improve mobilityMore (energy) efficientUnmanned aerial vehiclesRemote controlled aircraftJet aeroplaneAirplane

An aircraft, in particular an unmanned aerial vehicle with wing-borne flight mode and hover flight mode, comprises a wing structure (4) having a left (6), middle (7), and right wing section (8). A support structure extends from the wing structure (4), and has an upper and lower support section. Each one of the left and right wing section (6, 8), and upper and lower support section (18, 20) has a thrust unit (10, 12, 22, 24). Left and right wingtip sections are rotatable relative to a left and right wing base section, respectively, around an axis extending substantially in a lengthwise direction of the wing structure. The thrust units (10,12) of the left and right wing sections(6, 8) are provided at the respective wingtip sections, in particular at the extremities thereof.

Owner:ATMOS UAV

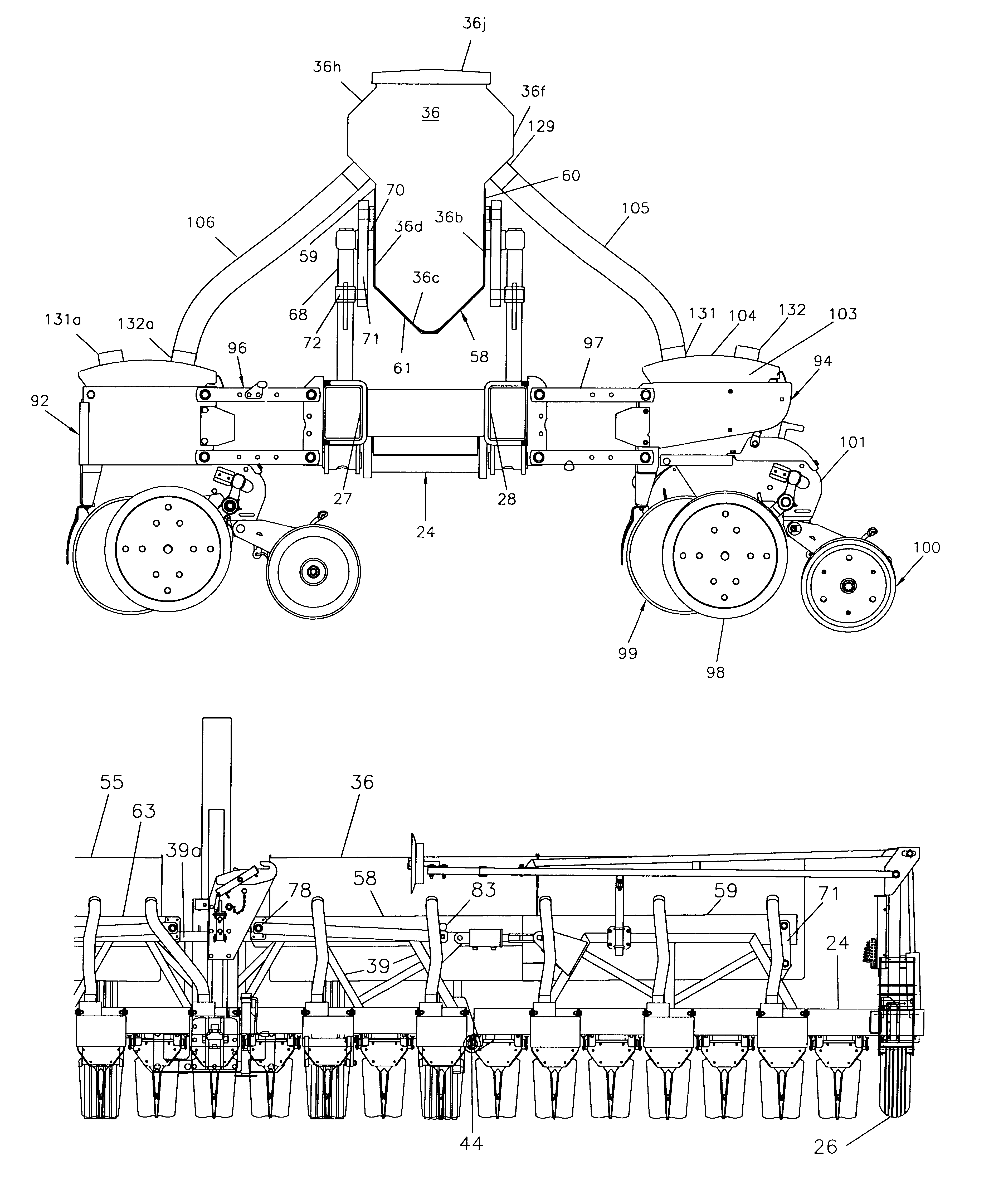

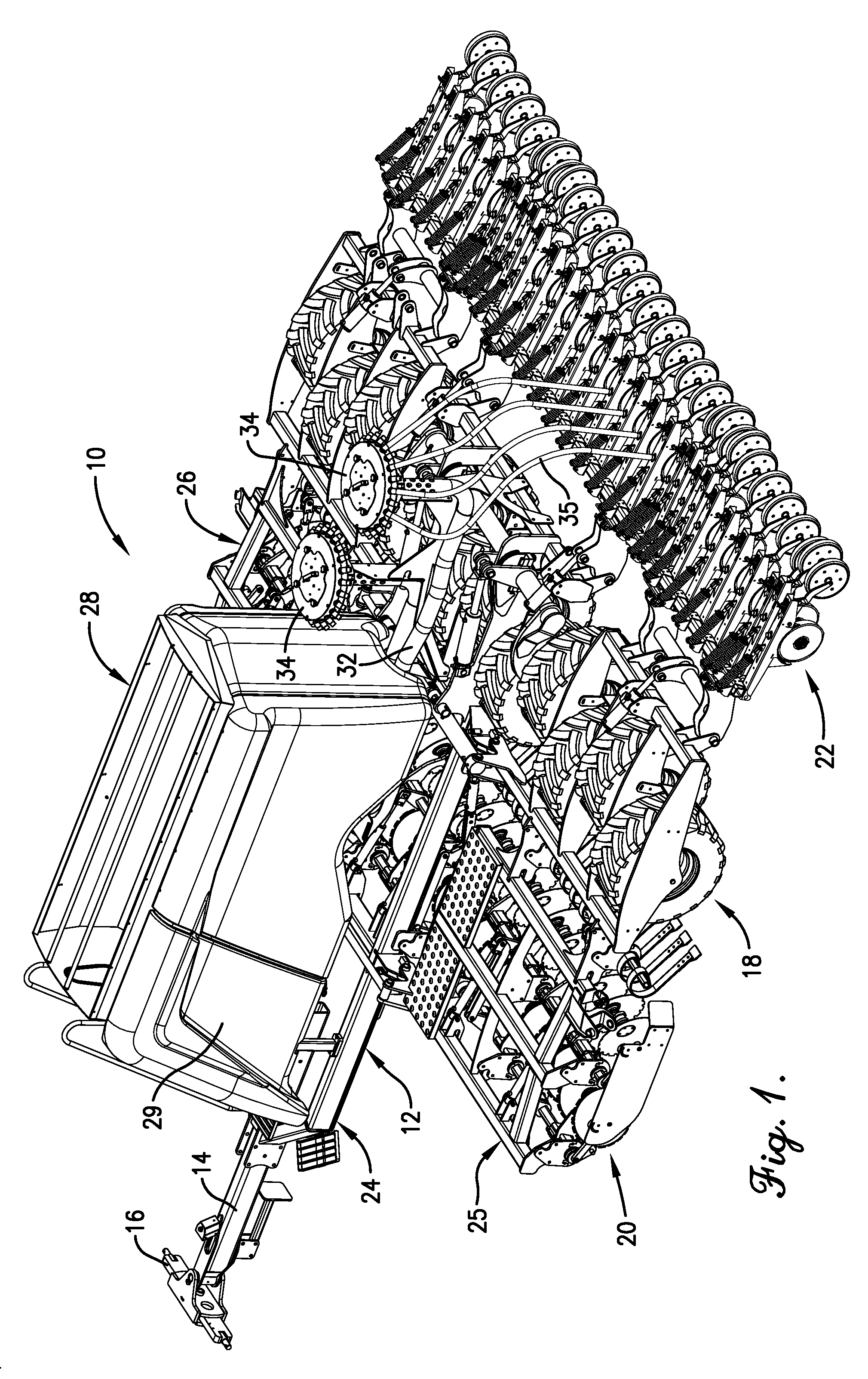

Centralized seed distribution system for planter

InactiveUS6494154B2Depth accurateReduce the overall heightSpadesAgricultural machinesDistribution systemGuide tube

Owner:KINZE MFG INC

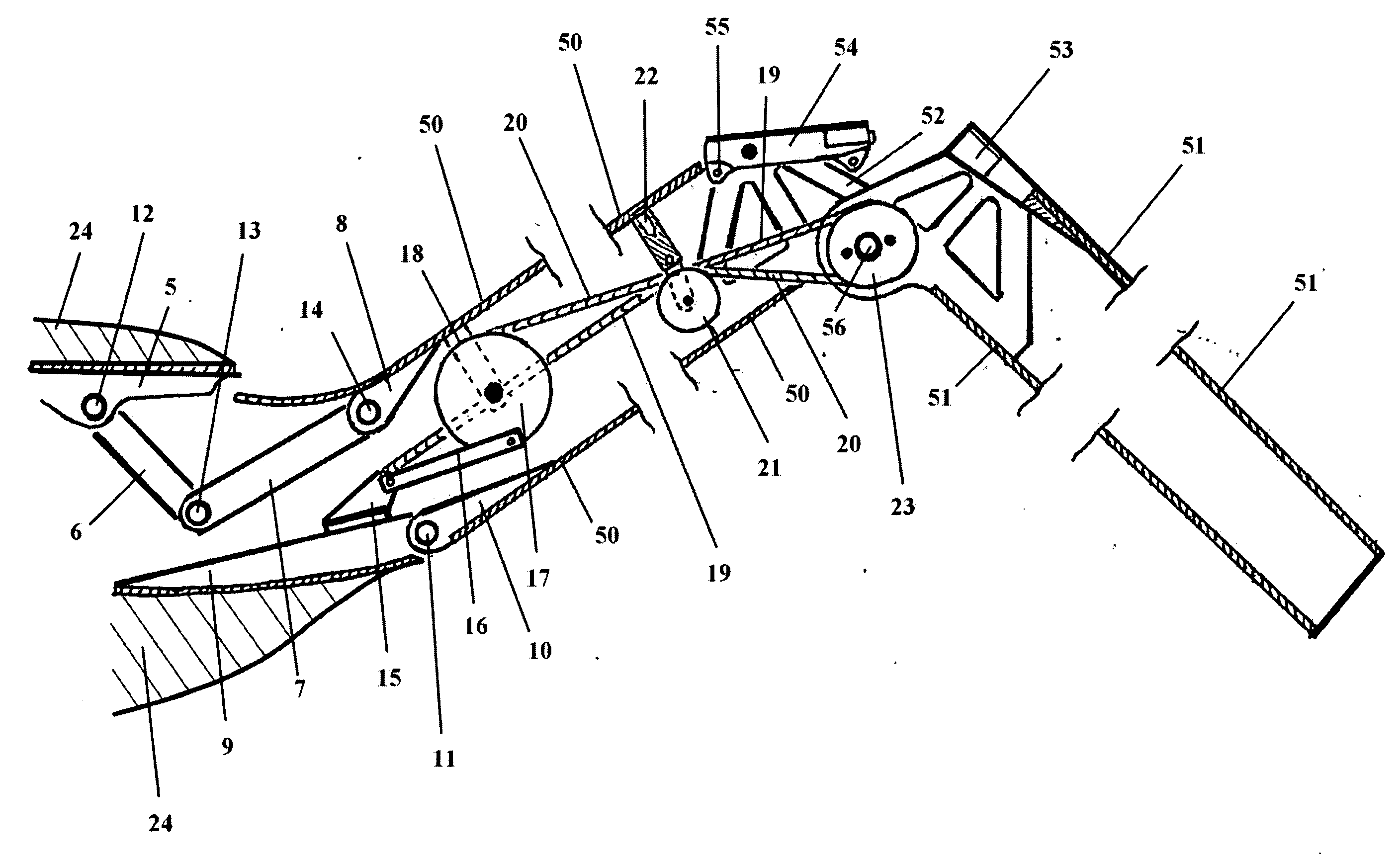

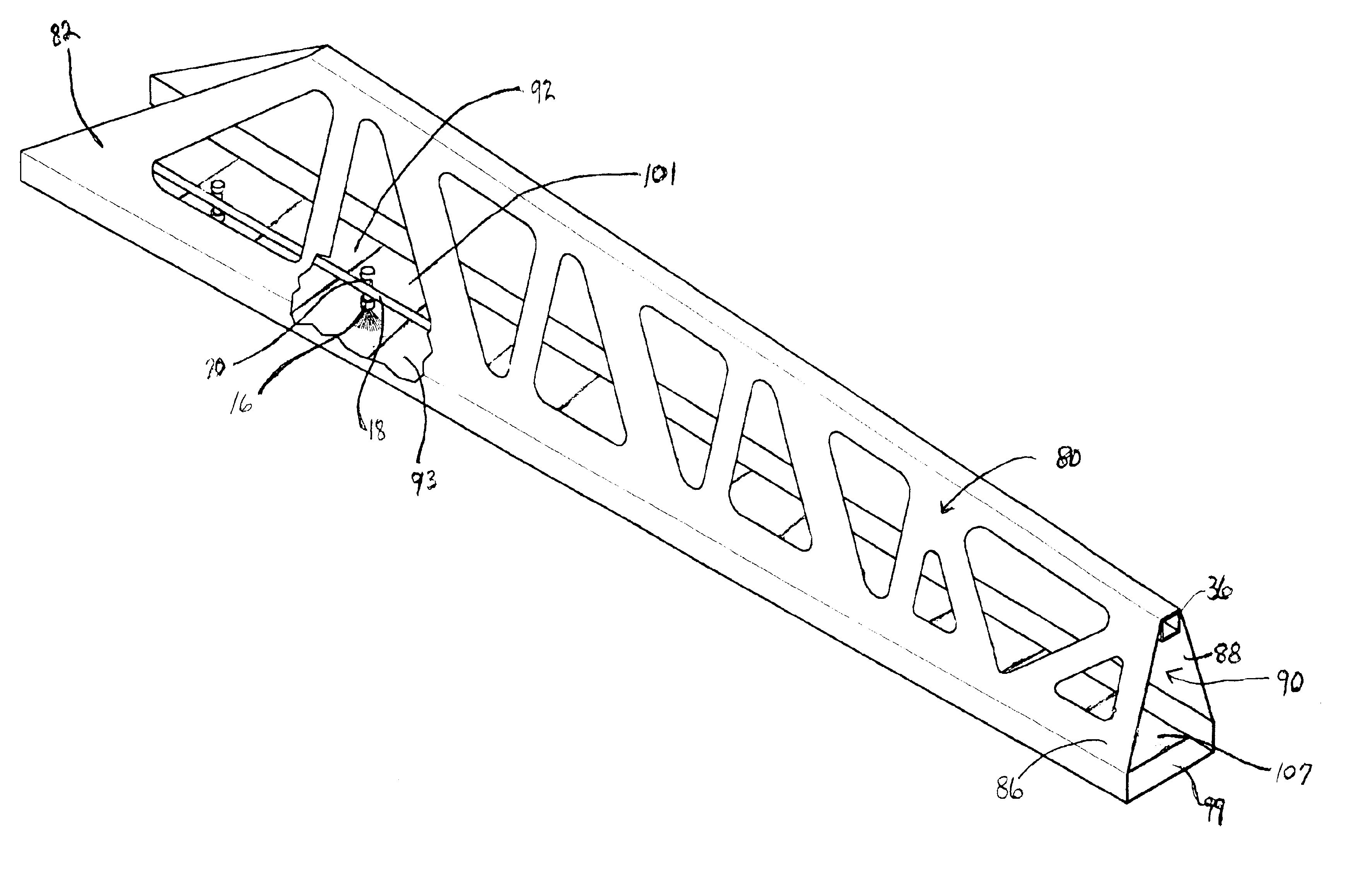

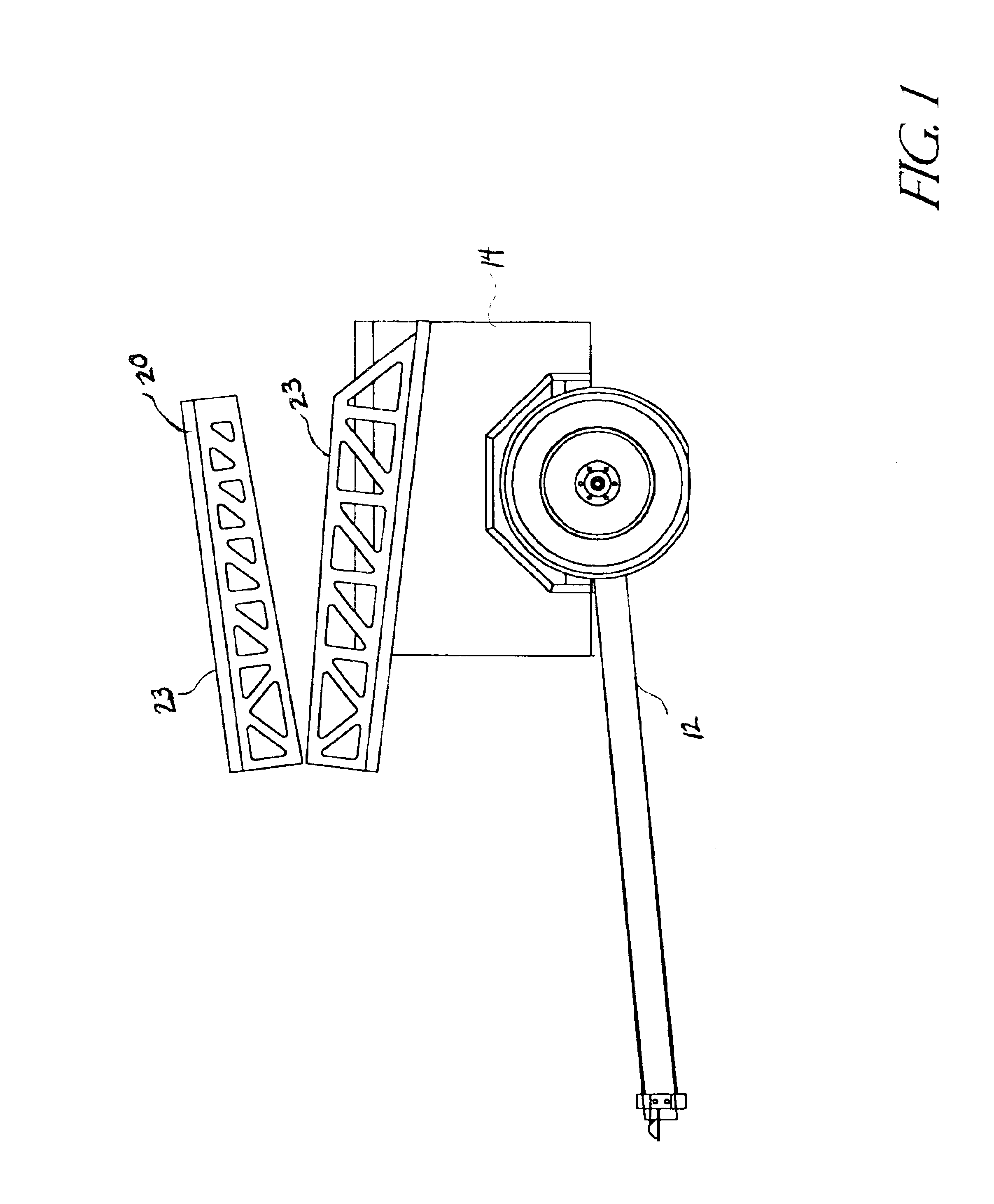

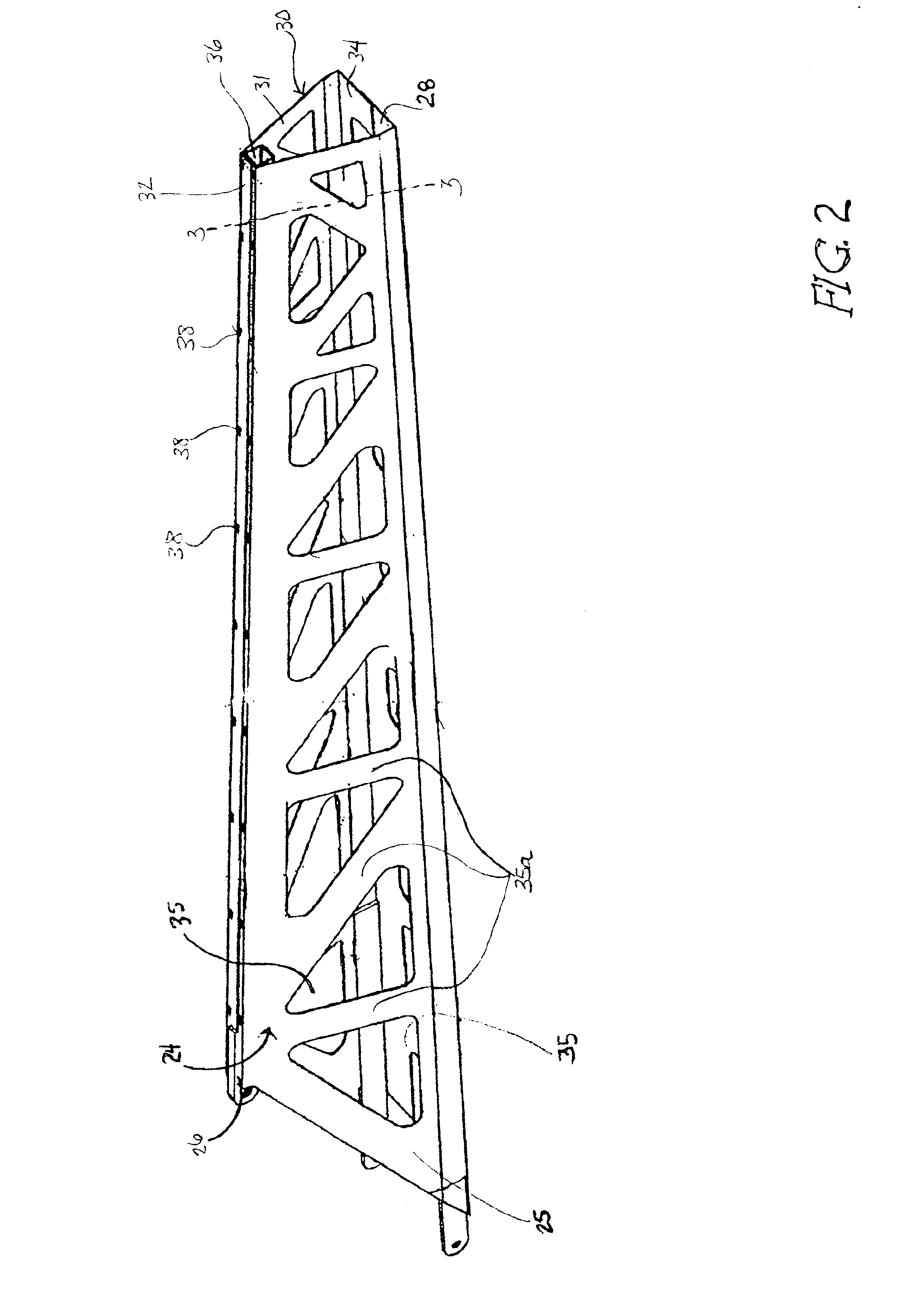

Unitary boom structure

InactiveUS6837446B1Improve accuracyImprove efficiencyLiquid fertiliser distributionFloorsSprayerEngineering

The present invention comprises a sprayer boom and is incorporated in a spraying apparatus which includes a vehicle, a tank, hoses connected to nozzles, and the sprayer boom. The sprayer boom includes a number of wing sections each including at least one single-piece component cut from a sheet of metal to form a web or truss structure which replaces the usual rods and welds support provided to sprayer booms of this nature. Obtaining the single-piece component by cutting it from a sheet of metal rather than constructing the truss-structure by use of many rods reduces material and labor costs. Spaced apart rungs or tabs on the bottom of the sprayer boom provide openings through which sprayer nozzles are aimed while the nozzles, hoses and connectors remain mostly recessed within the boom which provides physical protection from wind and other damage and still allows easy access for repair.

Owner:JESSE LYNN

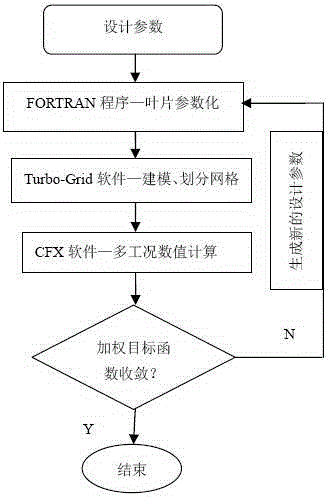

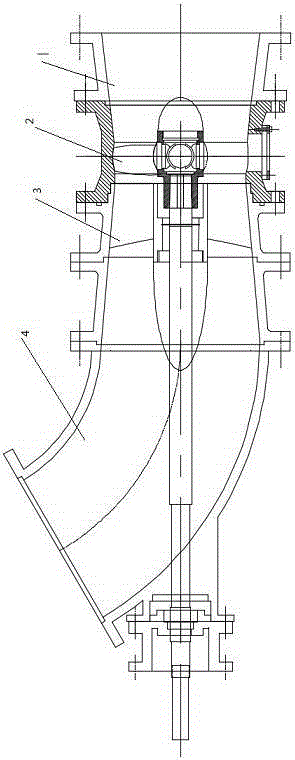

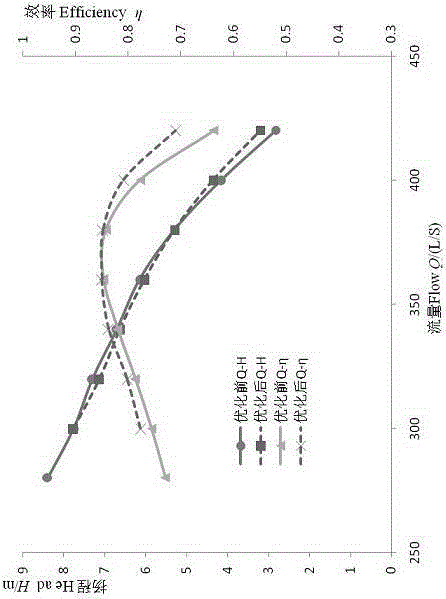

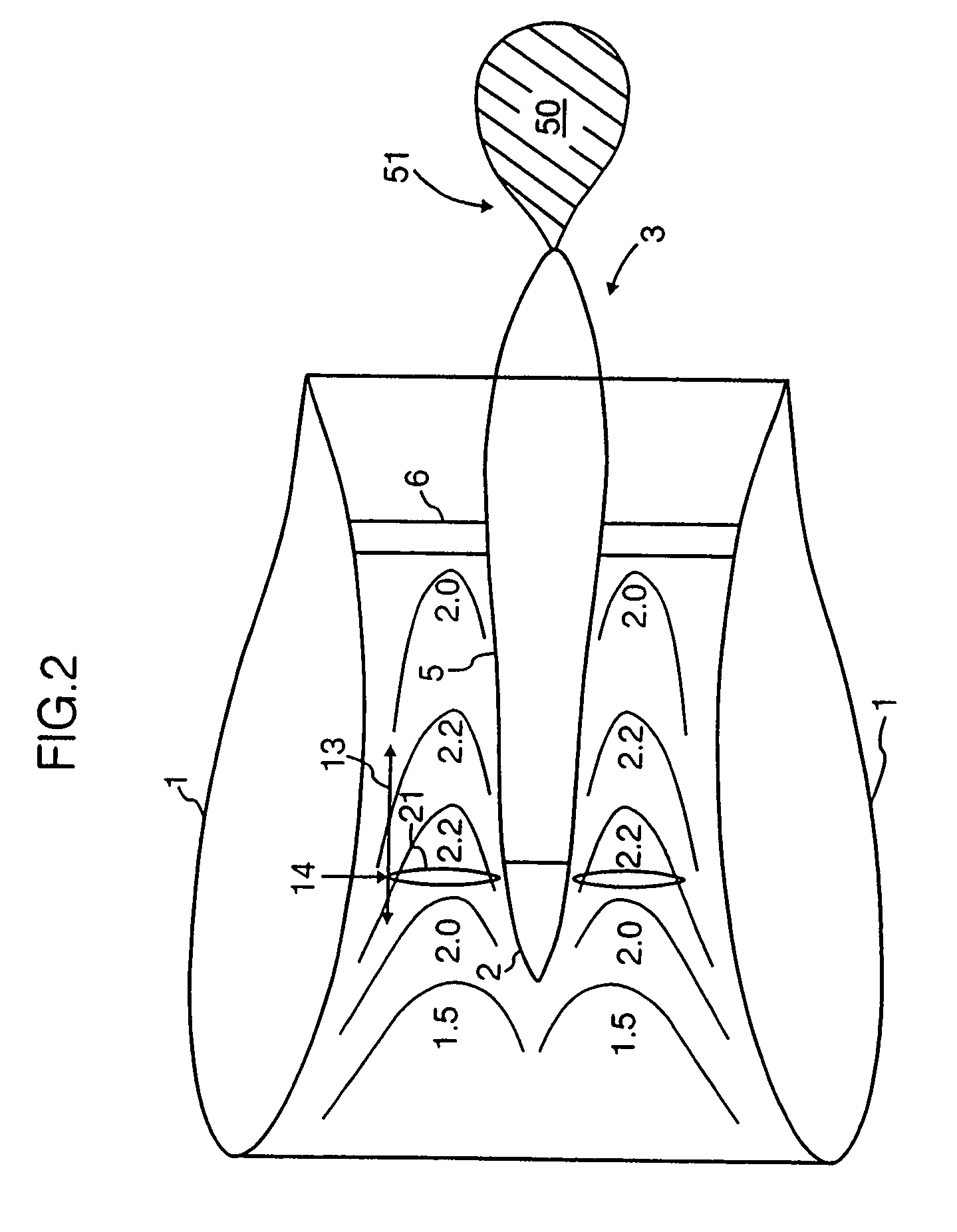

Axial flow pump impeller all-operating-condition design method

ActiveCN105179303AImprove efficiencyWide efficiency curvePump componentsPumpsAxial-flow pumpImpeller

An axial flow pump impeller all-operating-condition design method comprises the following steps that 1, parametric modeling of an axial flow pump impeller is performed, namely 2k design parameters including k wing section cascade solidities and wing placement angle values of the axial flow pump impeller are selected; 2, all-operating-condition optimal design is performed: firstly, conventional design parameters of the impeller are dertemined, then numerical calculation is conducted on the design conditions of the axial flow pump impeller and various losses in a pump are comprehensively analyzed to preliminarily design the axial flow pump impeller having better hydraulic performance under the design conditions in a total-loss minimization mode; secondly, guide blades, a water guide cone and water inlet and outlet flowing channels of the impeller are designed; thirdly, the optimal all-operating-condition weighted average effciency of the pump device is regarded as a target, a lift is regarded as a constraint condition, and a seqential quadratic programming method of a gradient optimum algorithm is adopted to constantly change the design parameters of the axial flow pump impeller and perform iterative numerical calculation of the pump device. The axial flow pump impeller all-operating-condition design method adopts CFD numerical calculation, the design accuray is high, and optimization results are reliable.

Owner:YANGZHOU UNIV

Agricultural implement having hopper weighing system

ActiveUS20120316673A1Seed supplyReduce weightSpadesFertiliser distributersAgricultural engineeringWing section

An agricultural seeding implement has a seed hopper that is weighed continuously during field operations as the seed volume in the hopper progressively diminishes. The weight information is used to perform ongoing control functions on the implement. One embodiment uses the weight information to reduce the down pressure on compaction wheels of a wing section of the machine as a function of the diminishing weight of the hopper on the main section.

Owner:GREAT PLAINS MFG INC

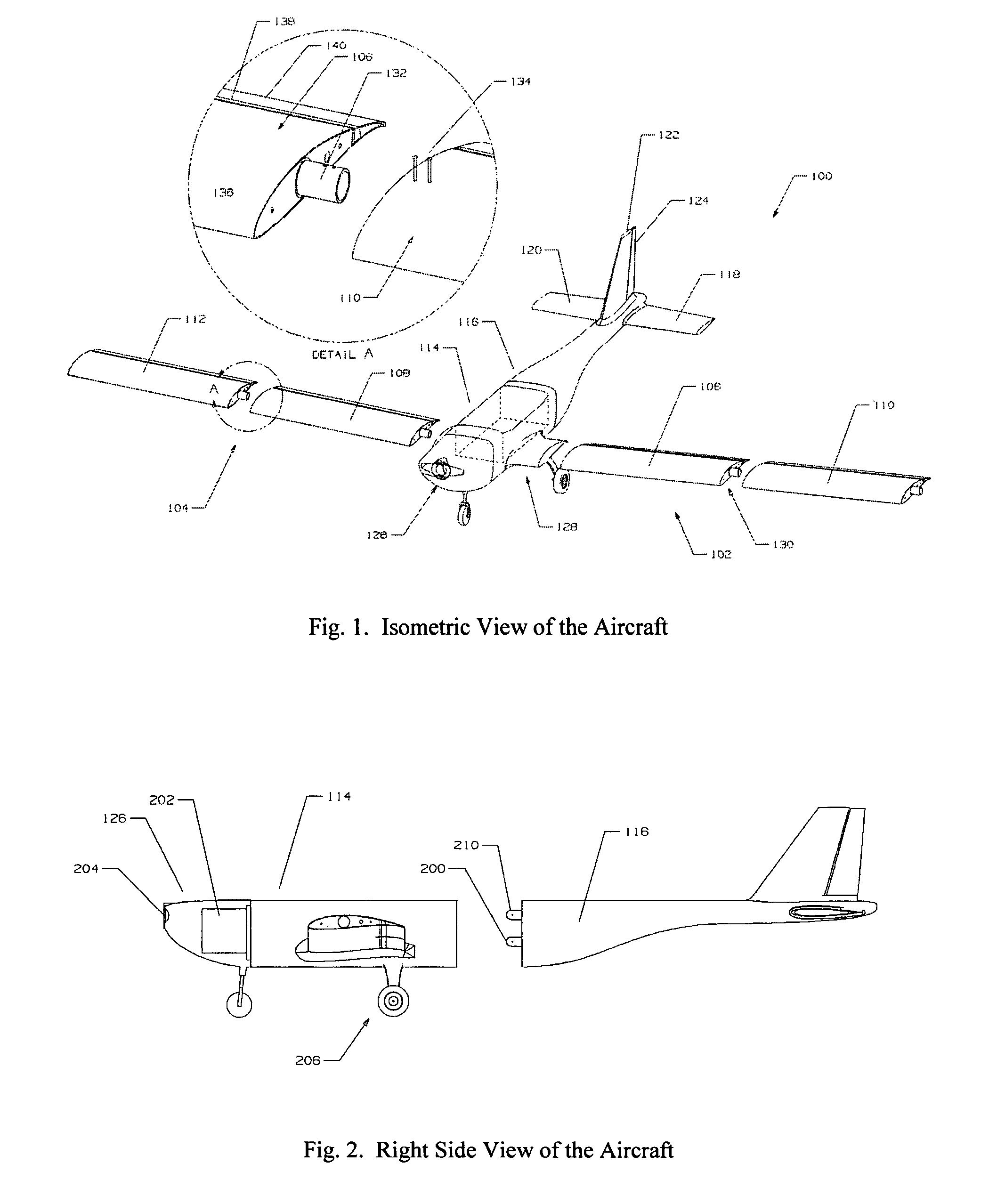

Aircraft Having a Variable Geometry

ActiveUS20120085858A1Reduce aerodynamic forceLower requirementWing shapesWing adjustmentsJet aeroplaneVariable geometry

An aircraft having a variable geometry for adapting the flight characteristics to different flight situations includes a fuselage with a pair of wings projecting on both sides of the fuselage in the transverse direction (y), each of which wings has an inner wing section arranged stationarily with respect to the fuselage and an outer wing section adjacent thereto and pivotable about a pivot axis. The pivot axis is oriented in a direction deviating from the longitudinal direction (x) of the aircraft by a maximum of 40°.

Owner:AIRBUS DEFENCE & SPACE

Check valve turbine

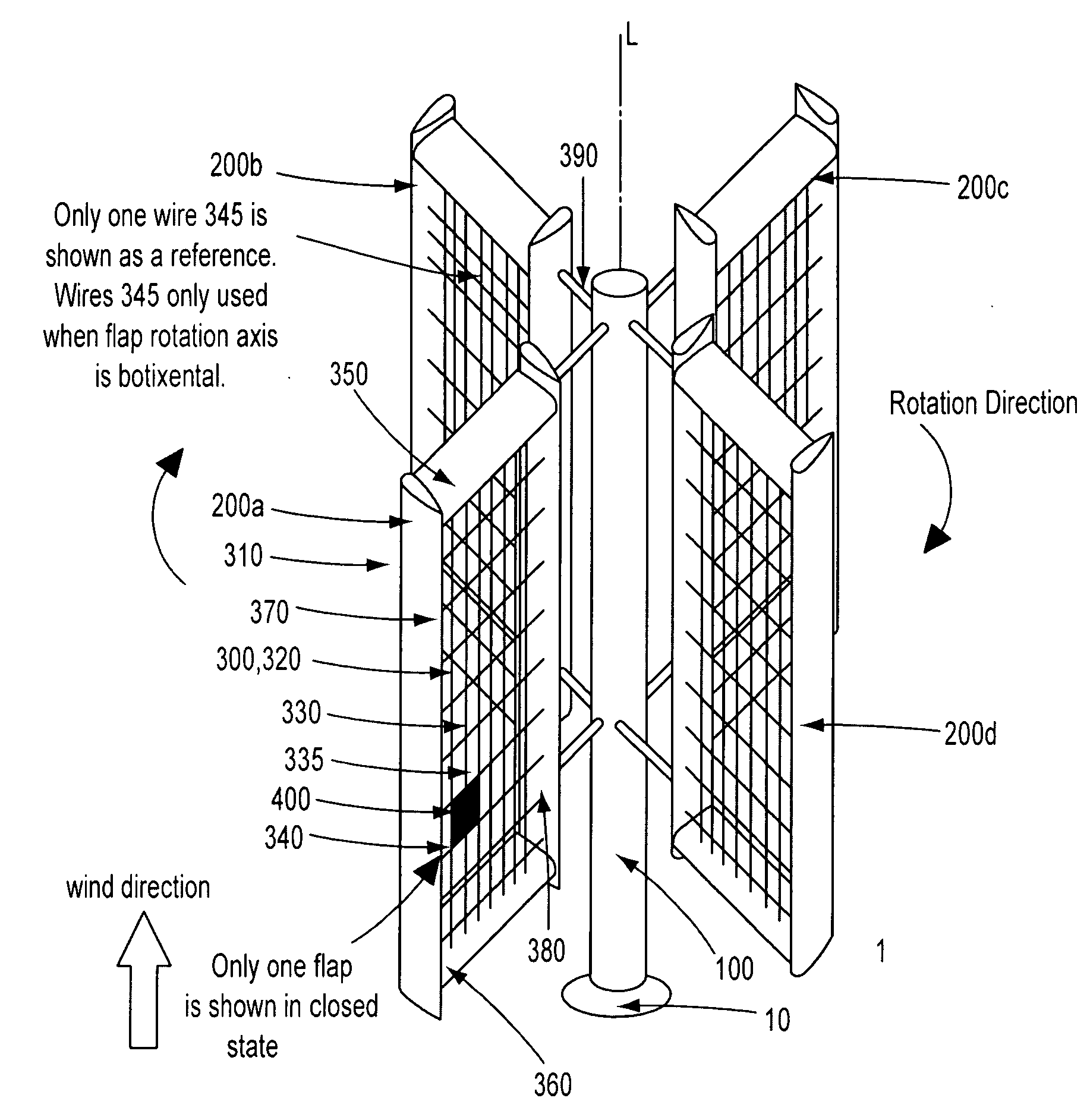

A check valve turbine assembly includes an assembly base, a vertical member rotatable relative to the base, and a sail assembly attached to the vertical member, wherein the sail assembly has a frame with parallel horizontal airfoil members and parallel vertical airfoil members, a sub frame connected to the horizontal and vertical airfoil members, and a plurality of flaps rotatably attached to the sub frame. In another aspect of the disclosure a turbine assembly includes an assembly base, a vertical member rotatable relative to the base, and at least one flexible sail assembly attached to the vertical member. In another aspect of the disclosure, a turbine system includes a a floating platform, a generator, a gearbox connected to the generator; and a check valve turbine assembly that drives the gearbox. Another aspect of the disclosure includes a check valve assembly with a longitudinal center section and a wing section.

Owner:ERSOY SEYHAN

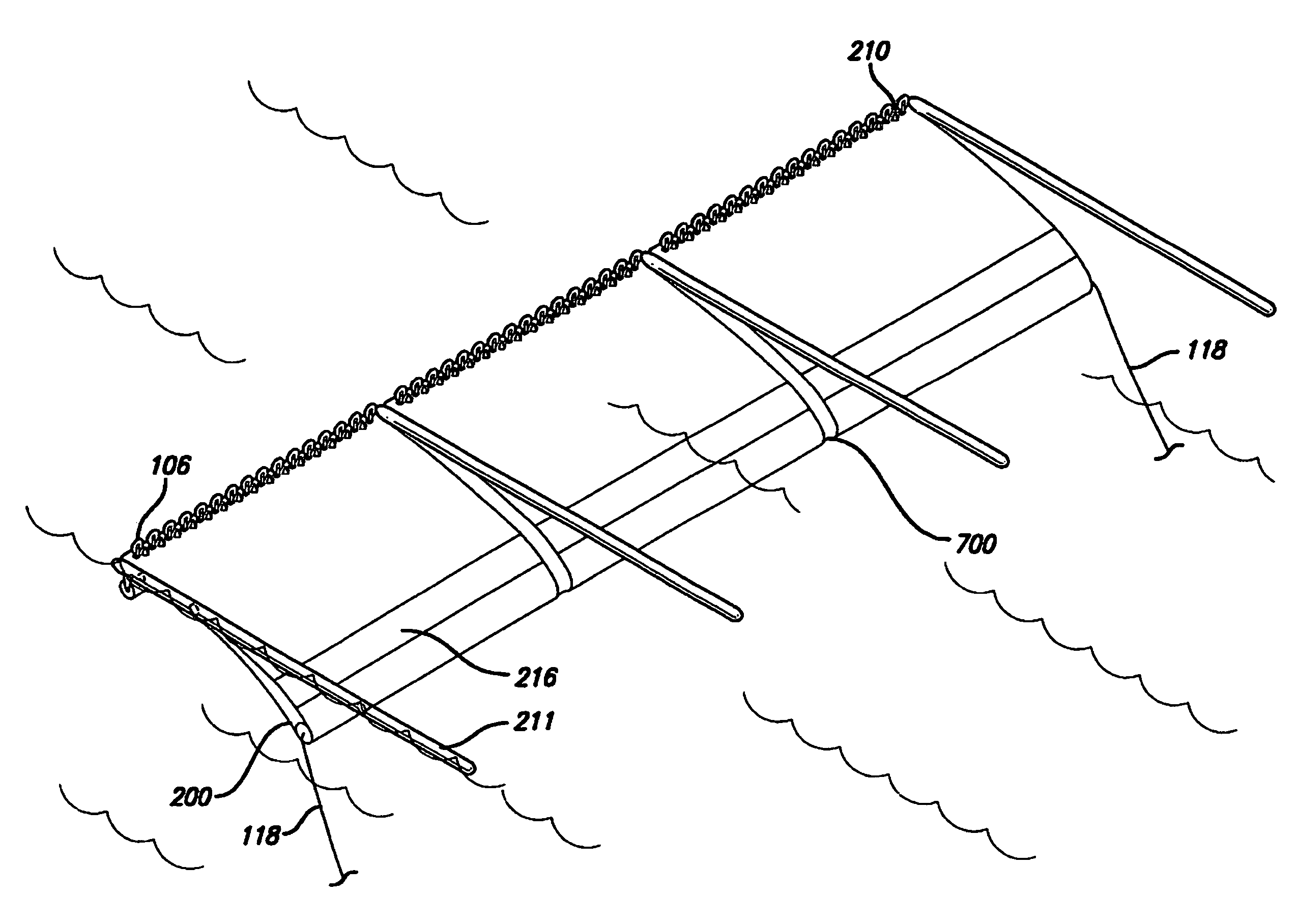

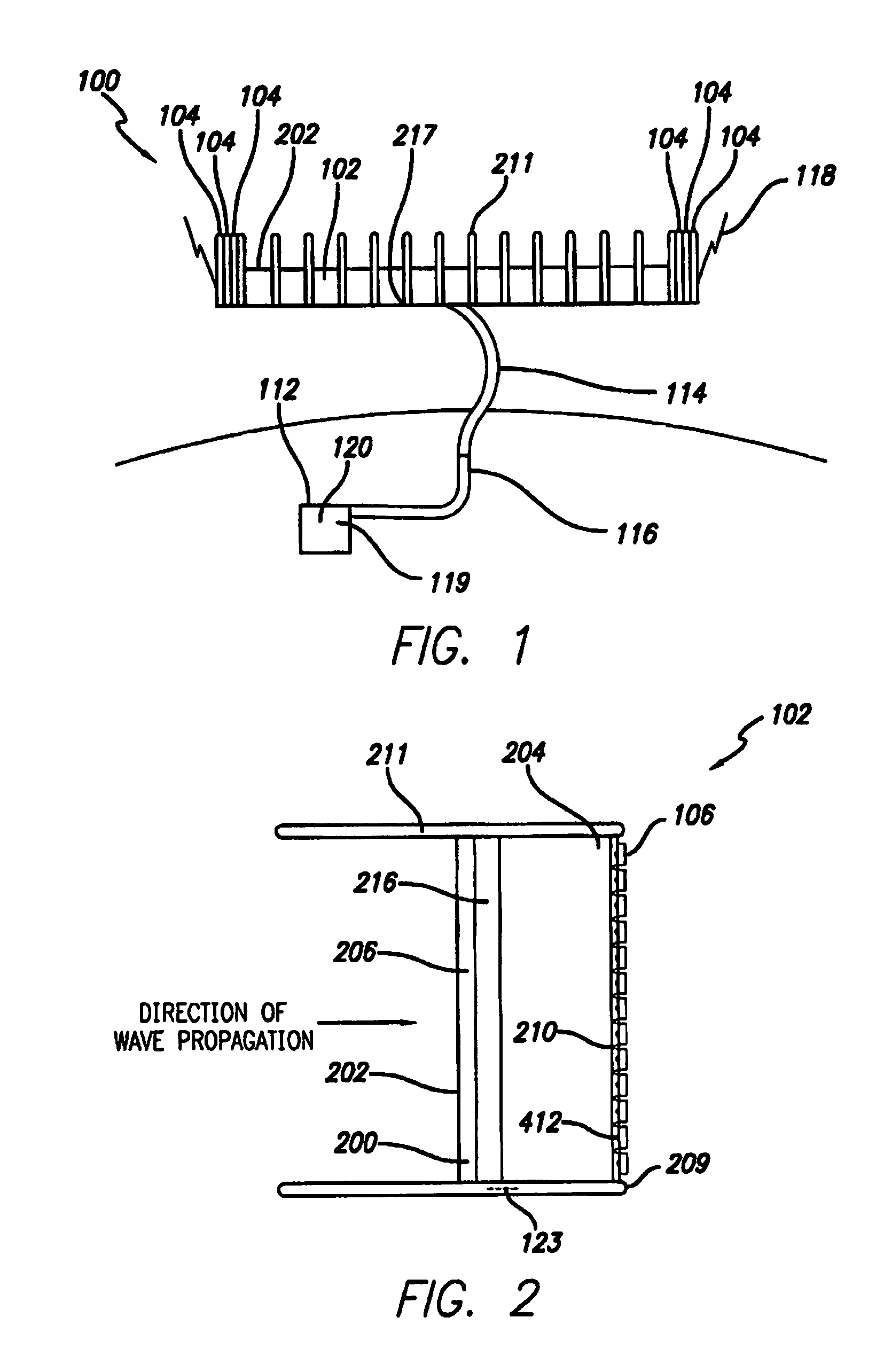

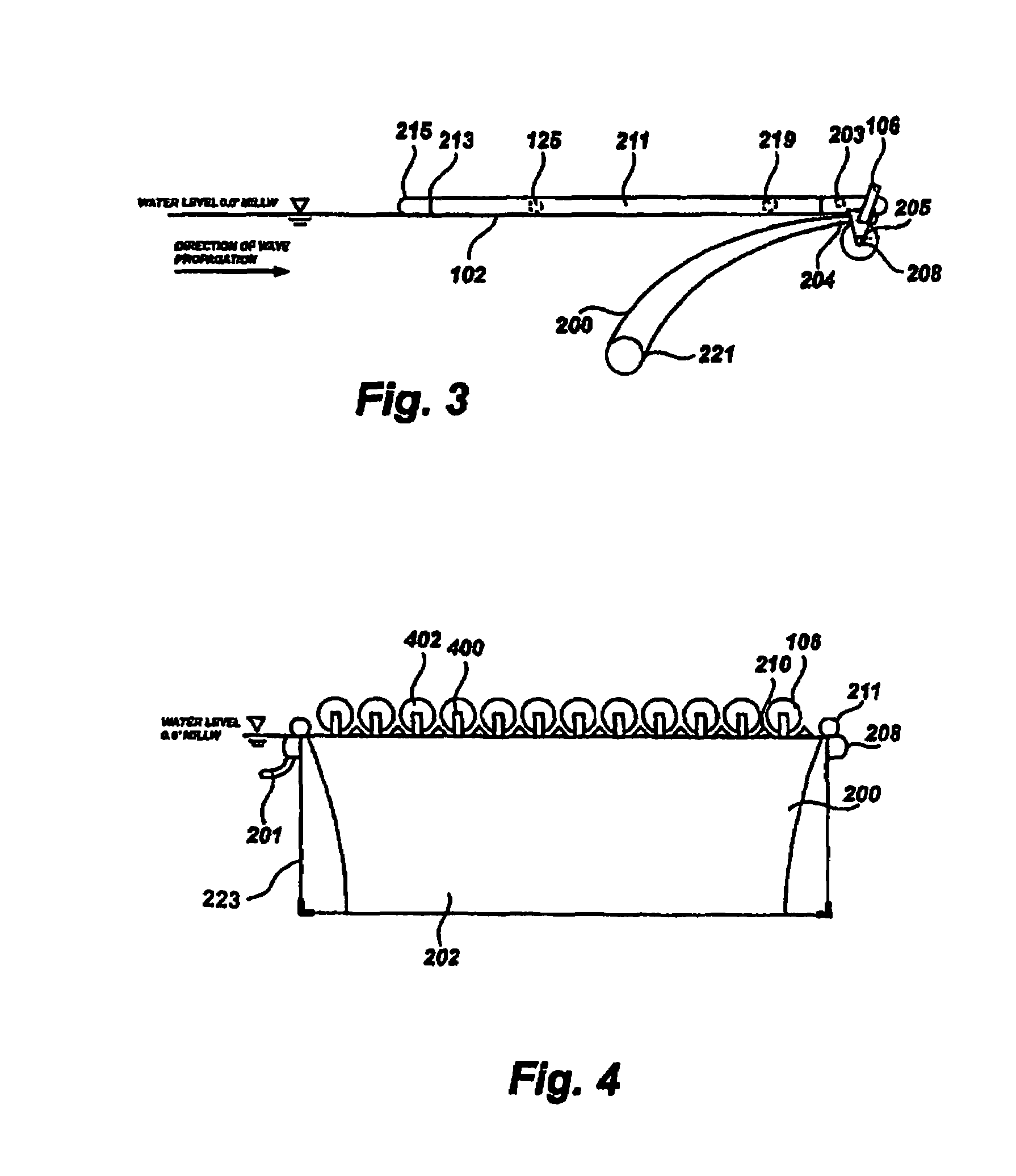

Ocean power harvester

InactiveUS7525212B1Increase conversionsIncrease heightMachines/enginesEngine componentsSea wavesEngineering

An improved ocean energy converter having a semi-submerged device designed to harvest energy from the ocean. Each device is connected to others to form long lines forming an interconnected array of ocean energy devices that are anchored at right angles to the prevailing ocean waves. The front and back sections of each energy module have internal ballast. Each device has a submerged inverse curved wing sections attached to floating stabilizer tubes. The trailing edge of the wings has several struts attached which support propellers that drive internal air compressors. The air compressors are connected together and connected to the other air compressors in the array of devices and those in turn are connected to a high pressure line leading underwater to an onshore air turbine electric generator connected to the local power grid.

Owner:CATLIN CHRIS S

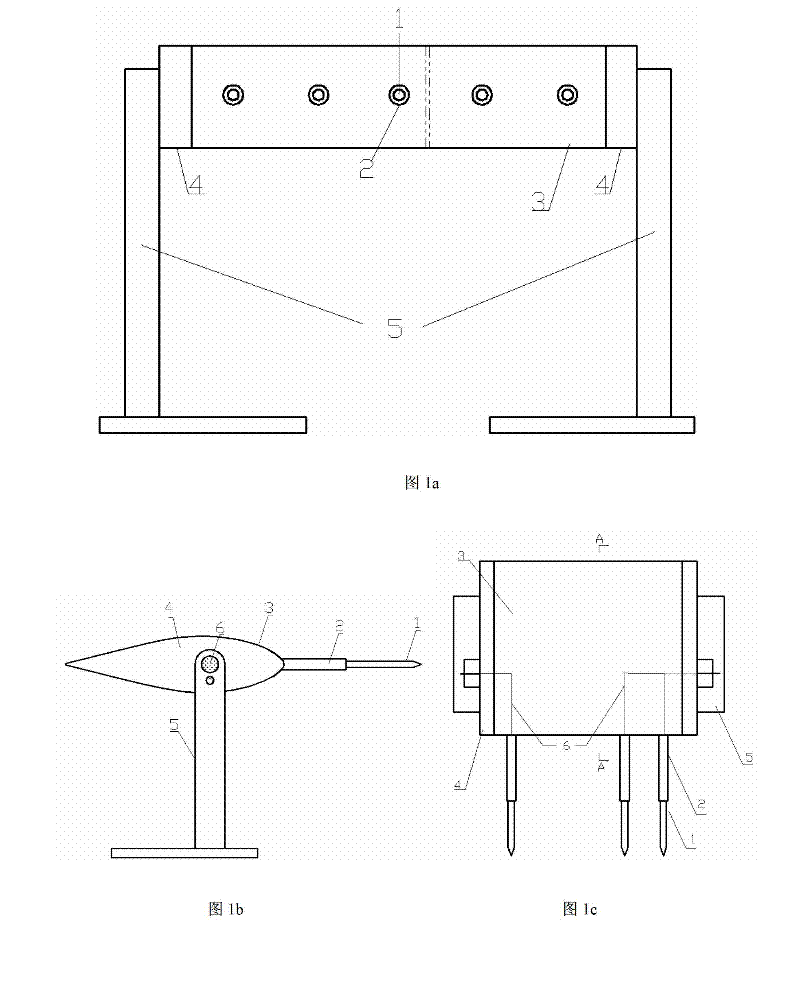

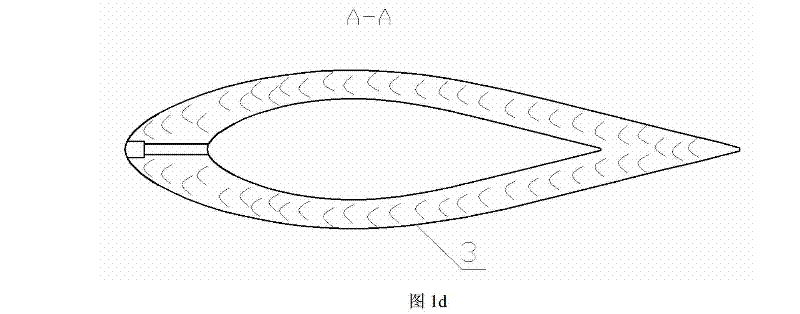

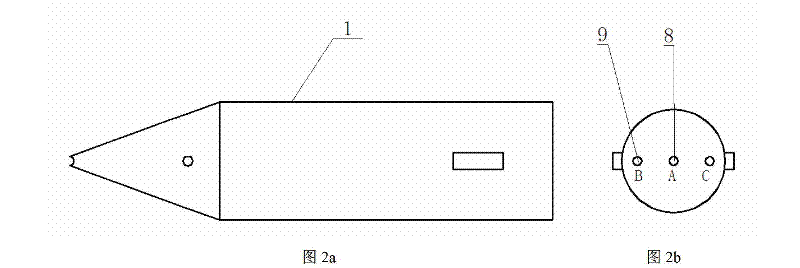

Three-hole probe type pressure measurement tail rake for wind tunnel test

ActiveCN102692310AAccurate calculation of velocity componentsAccurate calculationAerodynamic testingLeading edgeProbe type

The invention provides a three-hole probe type pressure measurement tail rake for a wind tunnel test. A plurality of connecting rods are distributed at the top end of a support platform; a three-hole probe is fixed on each connecting rod; a total pressure hole is arranged at the conical top end of each three-hole probe, and two static pressure holes symmetrically distributed on the conical surface of the three-hole probe, and the central line of the total pressure hole and the central lines of the two static pressure holes are in the same horizontal plane. According to the three-hole probe type pressure measurement tail rake, the actual total pressure, static pressure and airflow drift angle at each probe can be obtained through one total pressure hole and two static pressure holes on each probe; then, two velocity components u and v at each probe in the axial direction of a tunnel and in the horizontal plane of the height center of the tunnel can be obtained in combination with measurement of fluid density; according to the obtained static pressure distribution and the distribution of the two velocity components u and v at each three-hole probes, the resistance of a wing section can be obtained on the basis of the momentum theory, so that the two-dimensional velocity and speed drift angles of all points of wake flow can be captured at the same time. The three-hole probe type pressure measurement tail rake for the wind tunnel test is suitable for the situation that the lift force is large and the wake flow inclines to a lower wing face greatly.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

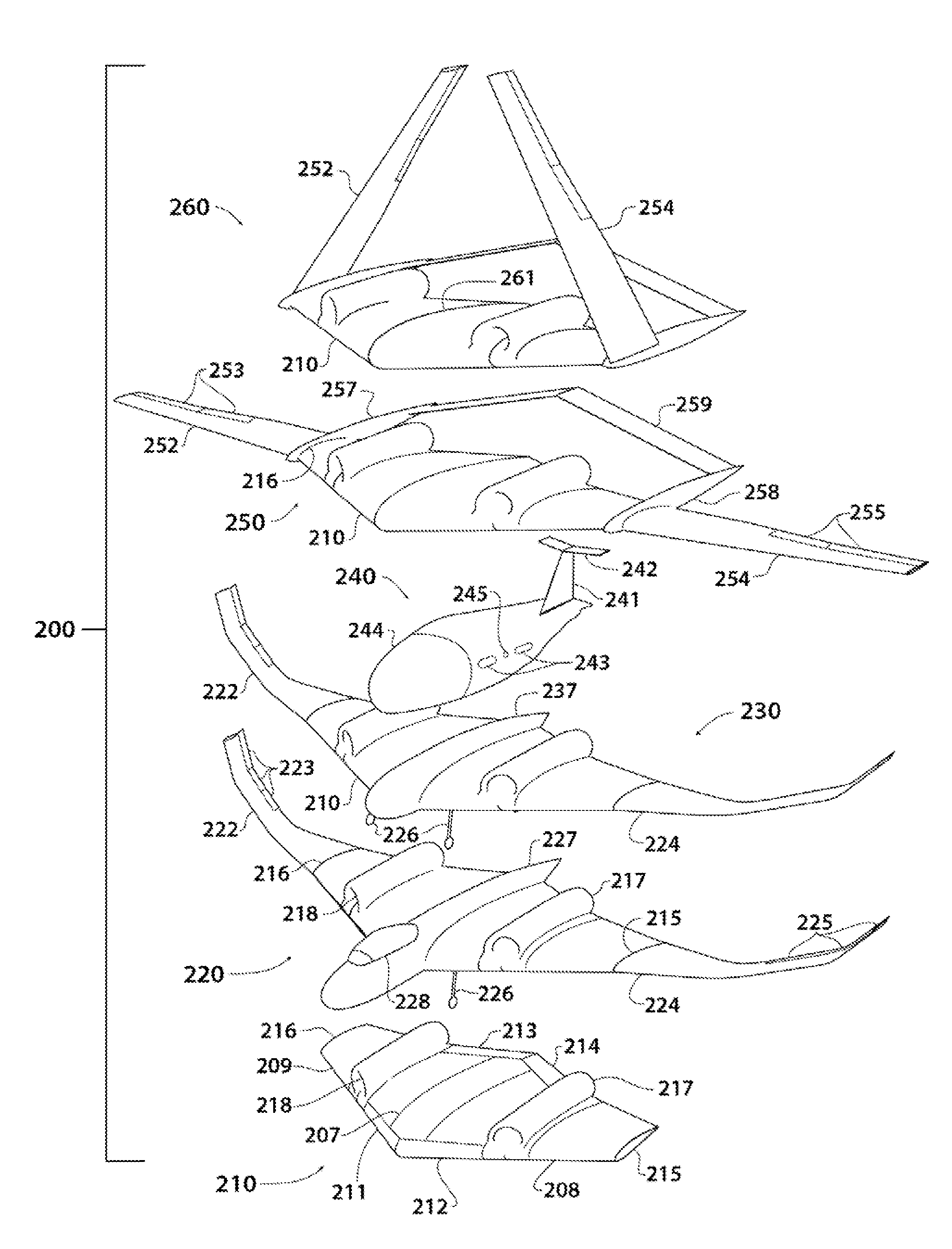

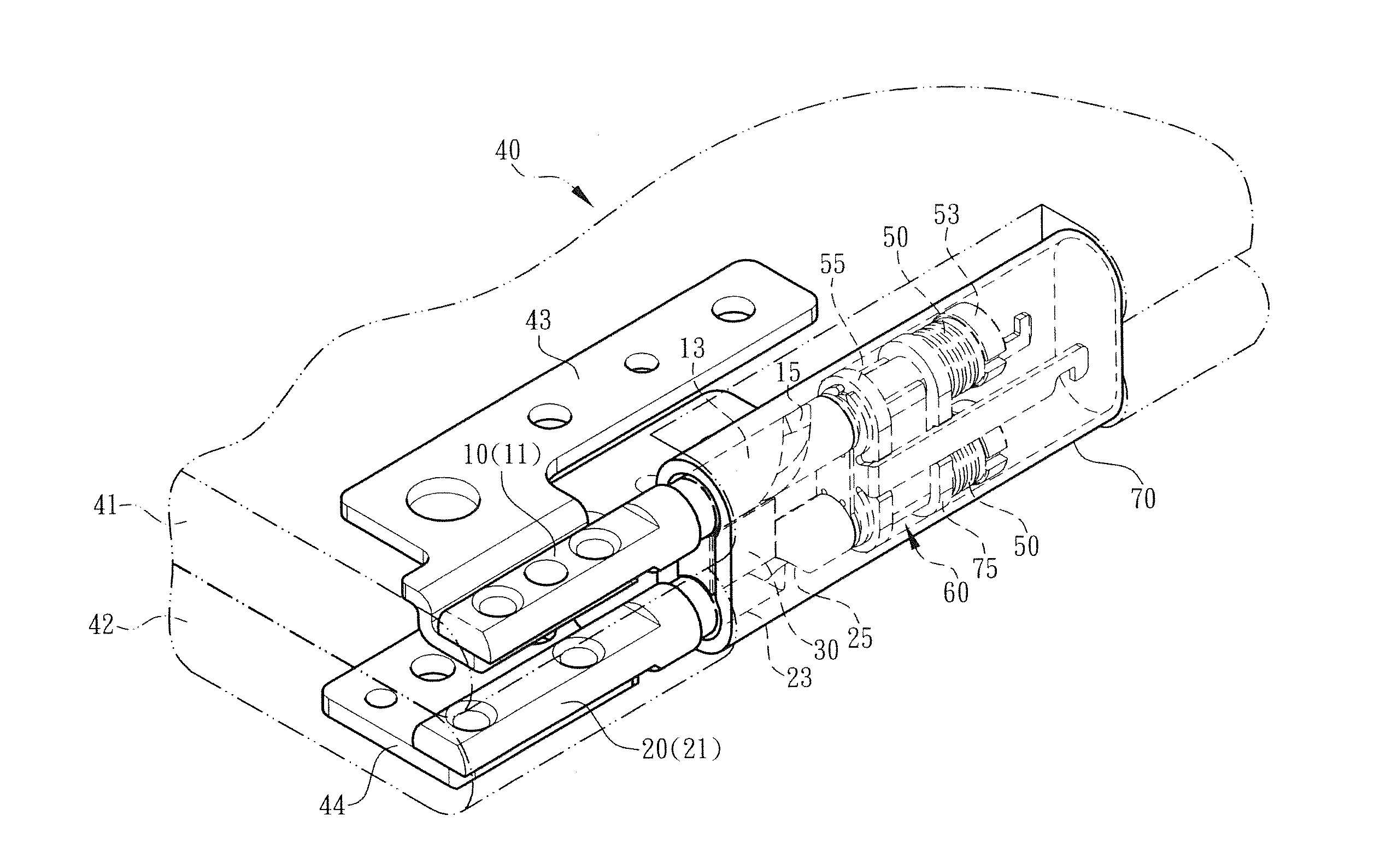

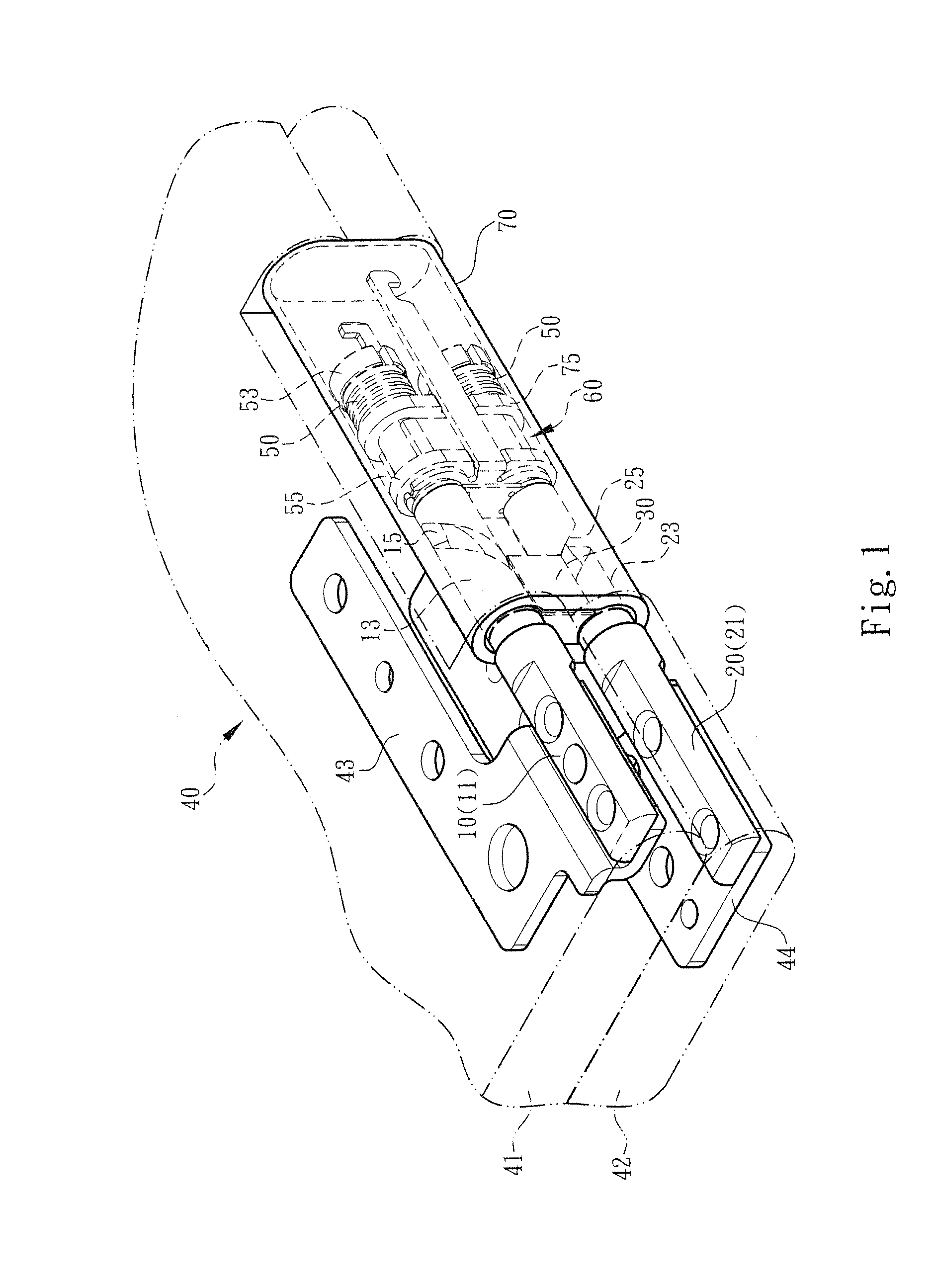

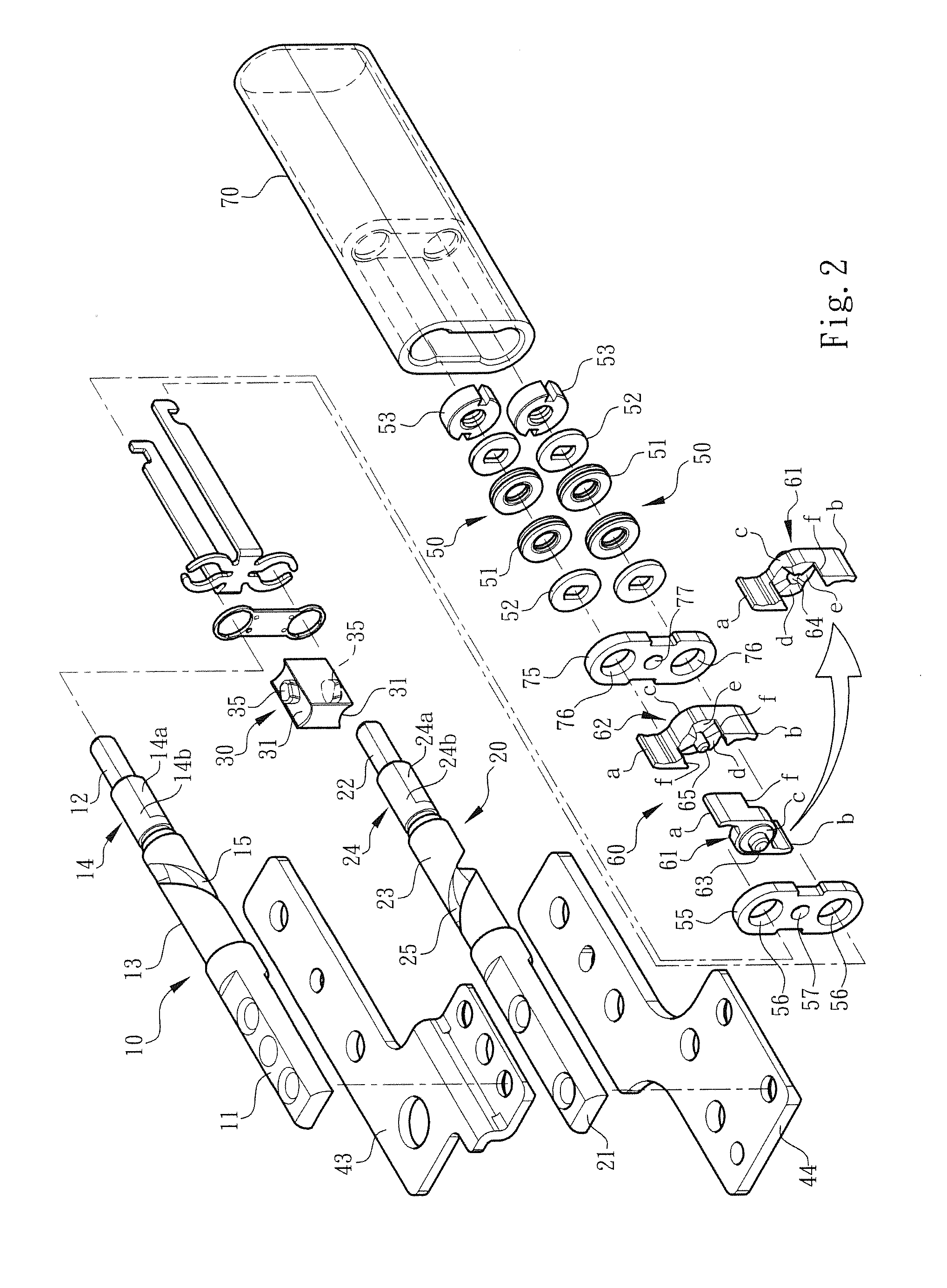

Torque balancing device applied to synchronous dual-shaft system

InactiveUS20150327383A1Prevent slippingAvoid transmission delaysCasings/cabinets/drawers detailsPin hingesEngineeringWing section

A torque balancing device applied to synchronous dual-shaft system for making the rotary shafts bear the same torque or pressure and avoiding slippage thereof. The torque balancing device includes a first rotary shaft, a second rotary shaft and a torque balancing unit. Each of the first and second rotary shafts has a fixed section mounted on an electronic apparatus and a drive section assembled with the torque balancing unit. The torque balancing unit includes a reactor and a responder assembled with each other. Each of the reactor and the responder has wing sections for together holding the drive sections of the first and second rotary shafts in normal state. When the first and second rotary shafts rotate, the wing sections are elastically forcedly biased and opened and the reactor and the responder are moved in an axial direction relative to each other.

Owner:FIRST DOME

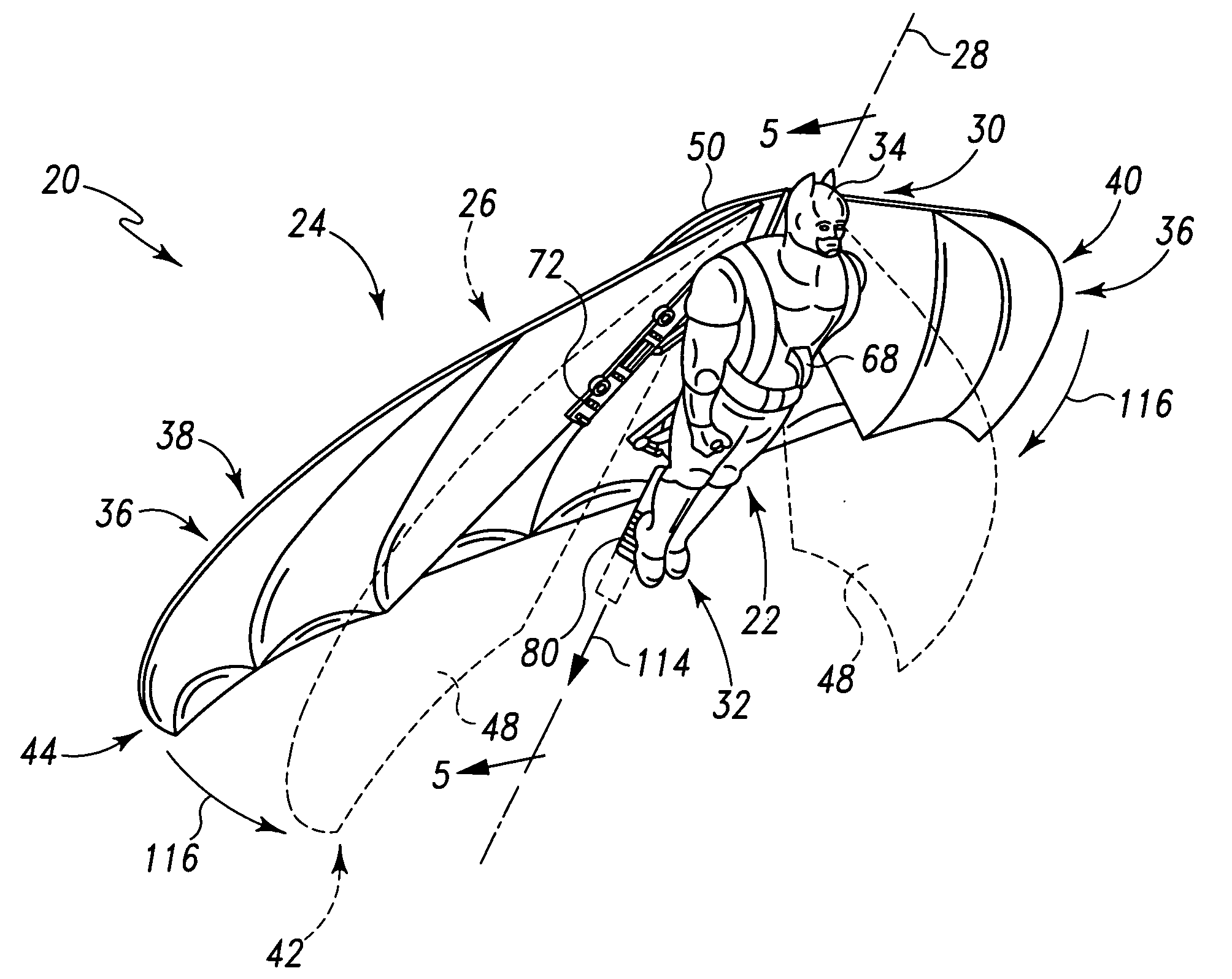

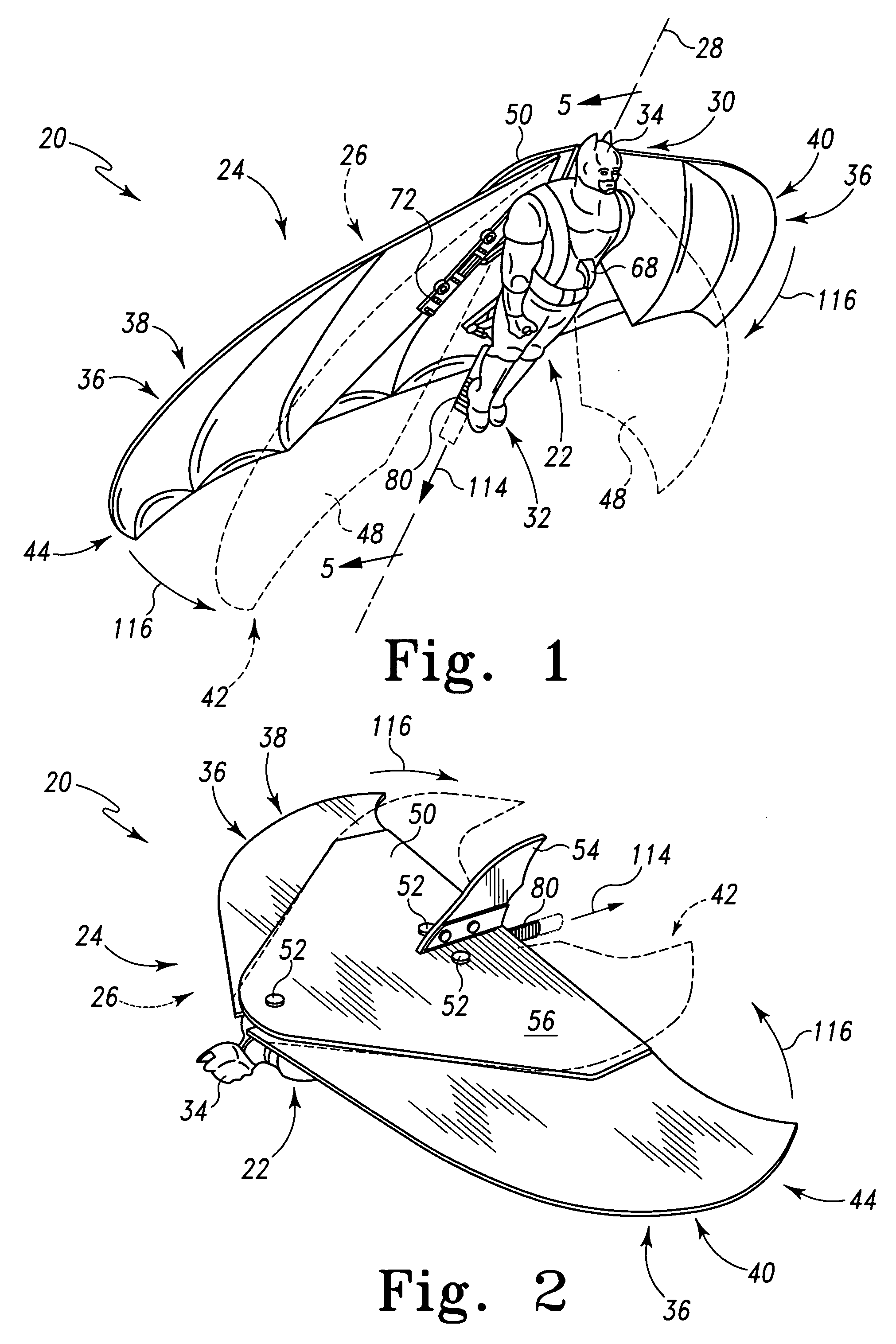

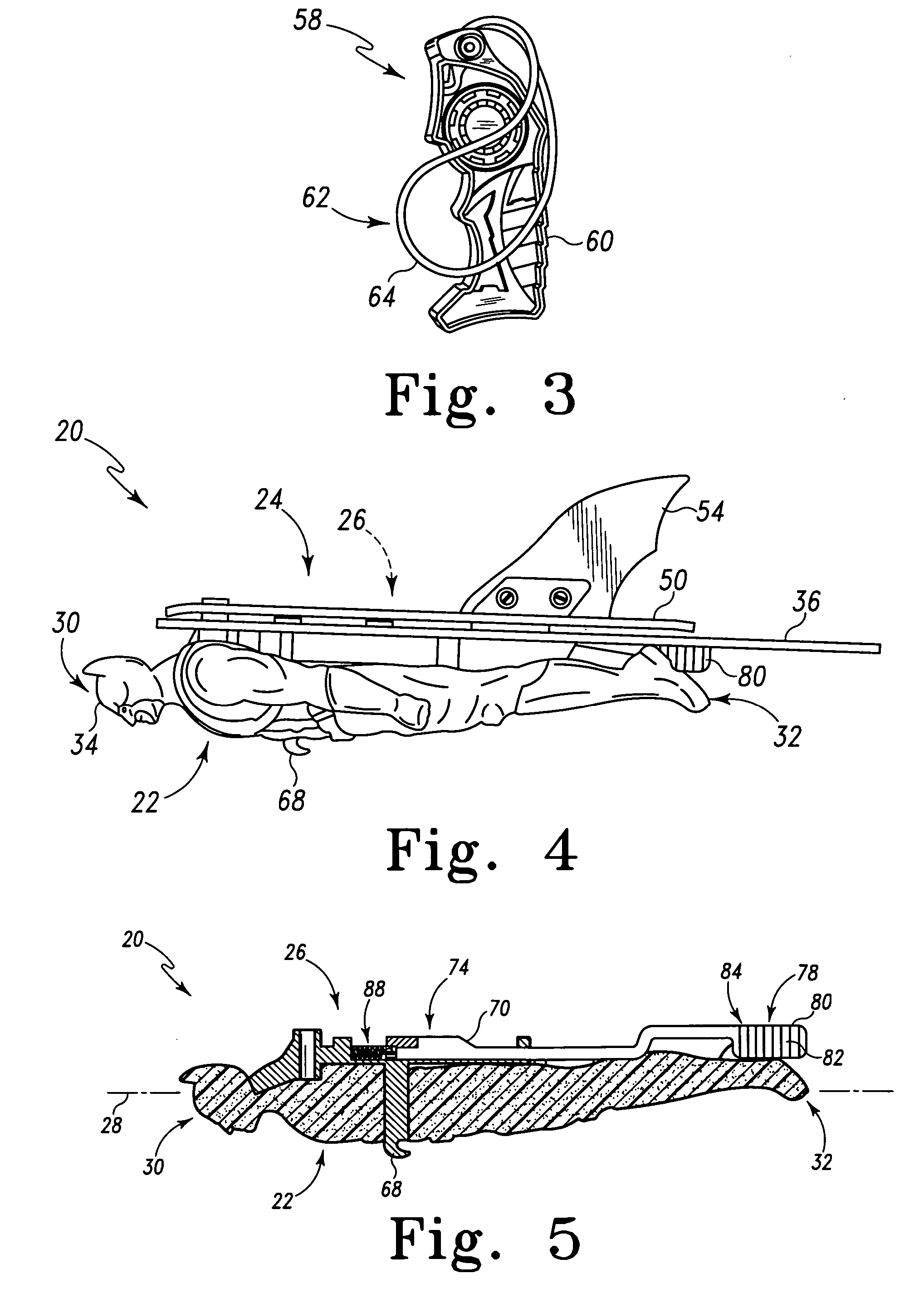

Flying toy with extending wings

A flying toy may comprise an elongate body extending along a body axis from a forward end to a rearward end. The flying toy may comprise a wing assembly, comprising a wing adapted to move relative to the body between an extended position in which at least a portion of the wing extends away from the body and a retracted position in which the wing portion is closer to the body. The flying toy may comprise an actuator movable along the body between a forward position and a rearward position. One of the wing assembly and the actuator may comprise a contact element, and the other of the wing assembly and the actuator may comprise an elongate contact surface extending obliquely relative to the body axis. The contact element may move along the contact surface as the actuator moves between the rearward position and the forward position, thereby moving the wing between the retracted position and the extended position.

Owner:MATTEL INC

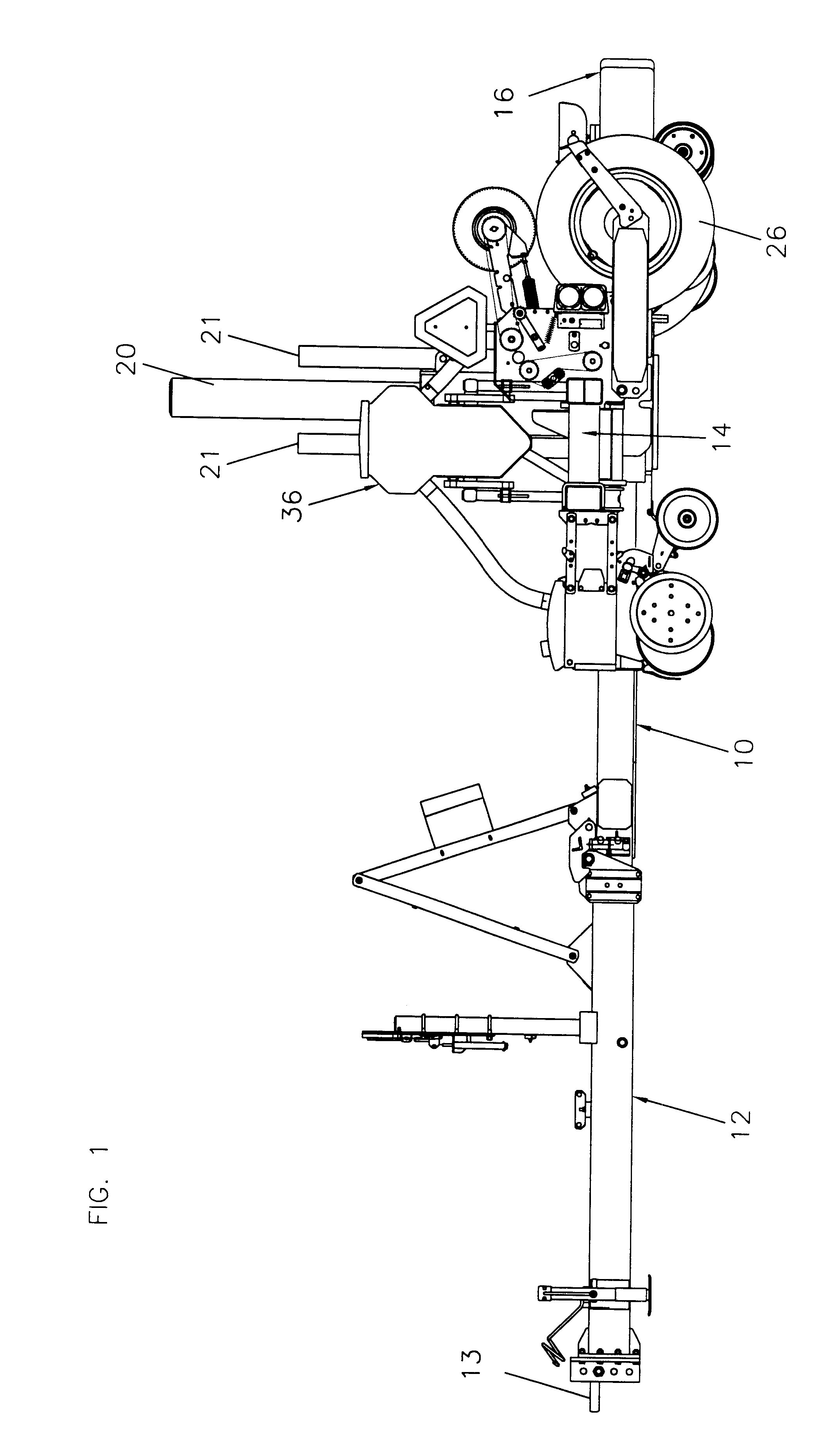

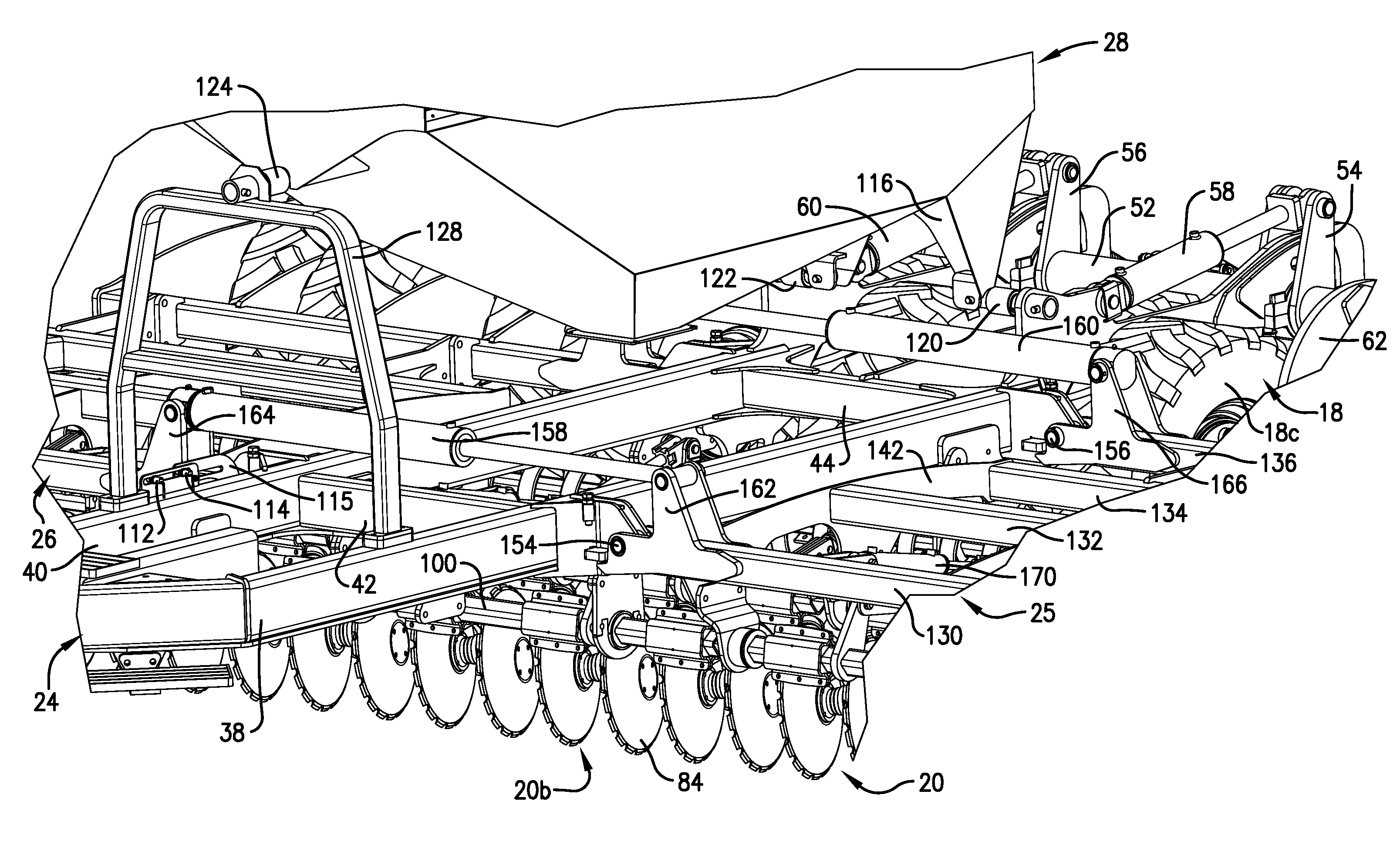

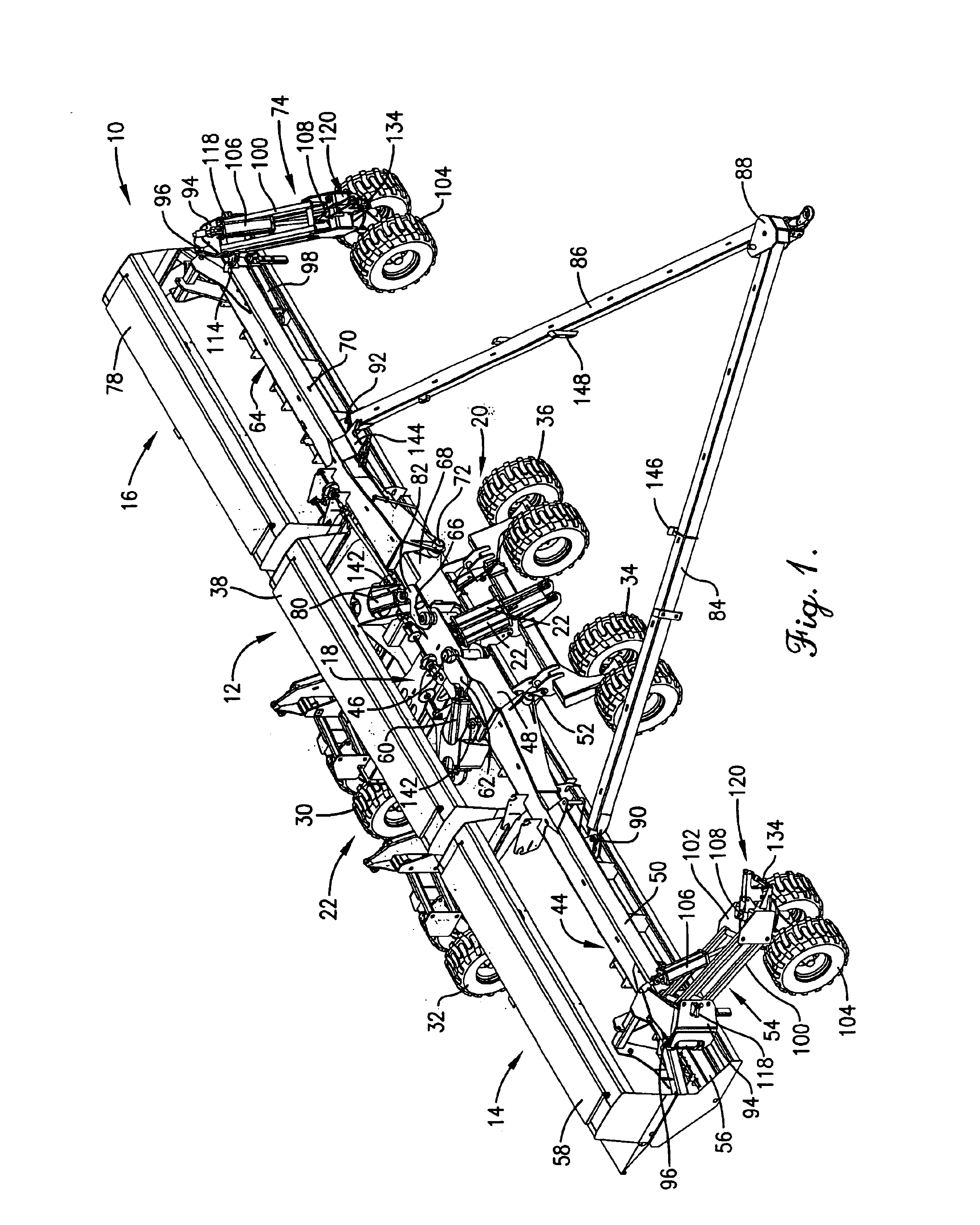

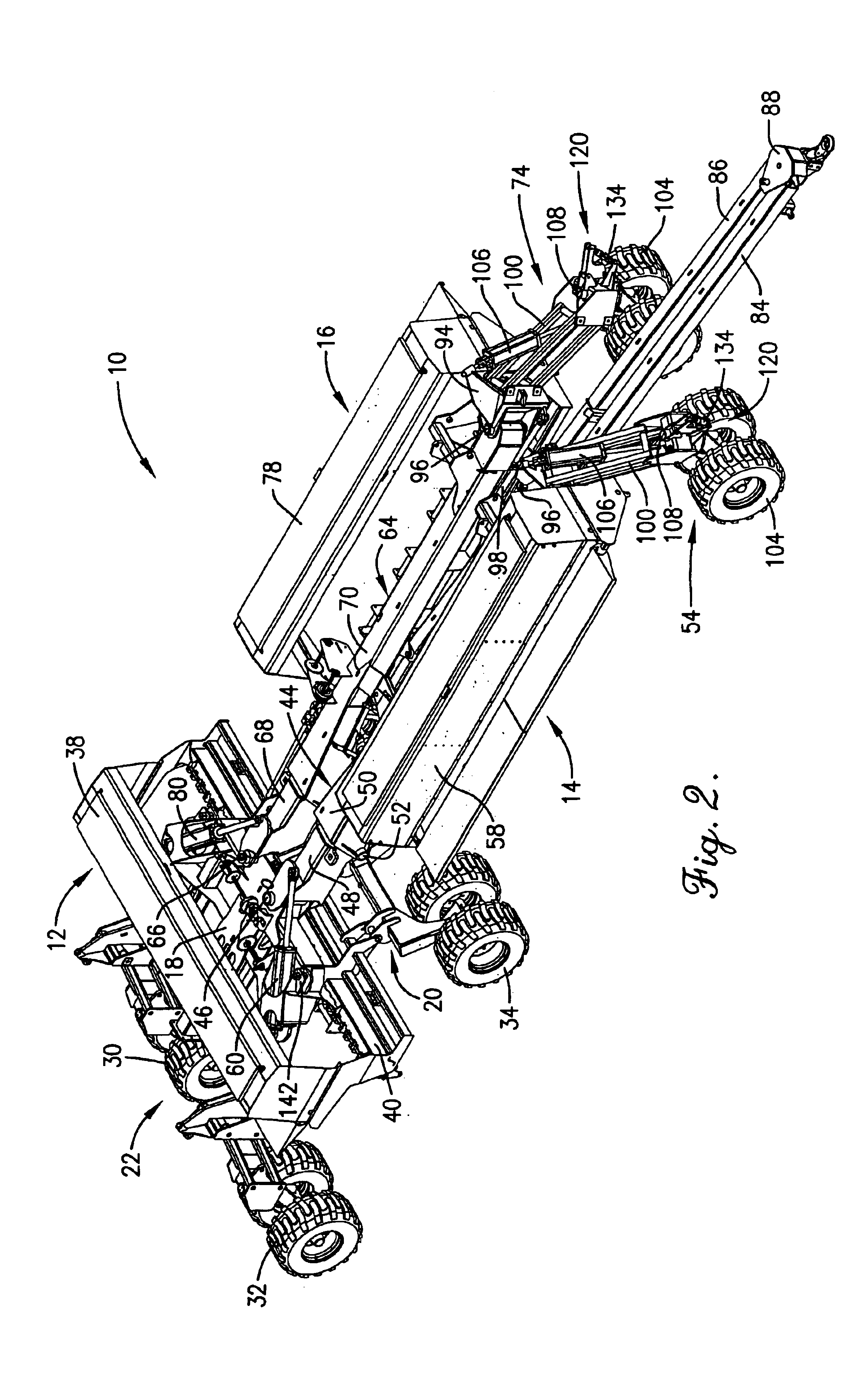

Front folding agricultural implement

InactiveUS6860335B2Increase widthReduce widthSpadesAgricultural machinesEngineeringMechanical engineering

A multiple section, front-folding implement has gauge wheel assemblies located on the front side of laterally extending beams of the sections during field operations. As the wing sections are folded forwardly to prepare the machine for transport, the gauge wheel assemblies are simultaneously swung around to the ends of the beams into outboard positions so that they extend generally forwardly from the beams when the beams are fully folded. Thus, instead of taking up space between the folded beams, the gauge wheel assemblies are moved into clearance positions that enable the wing sections to be folded more closely together, reducing the overall roading width of the machine when folded.

Owner:GREAT PLAINS MFG INC

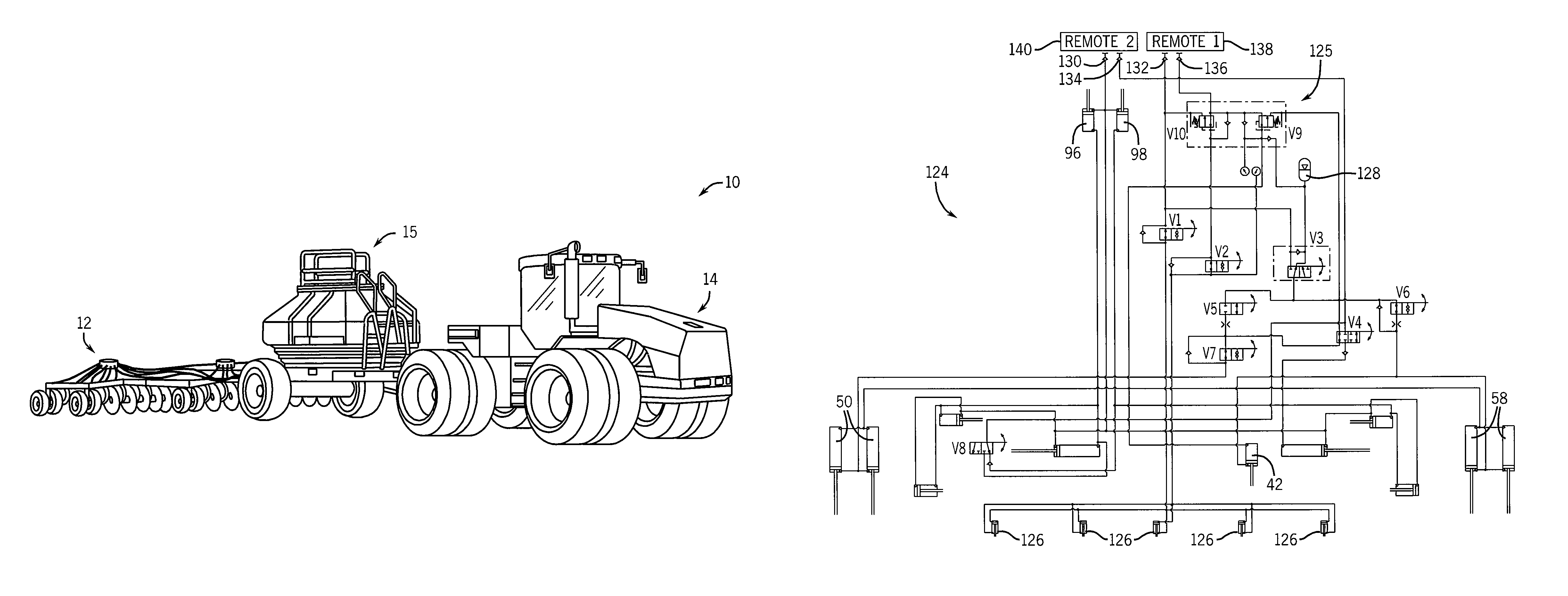

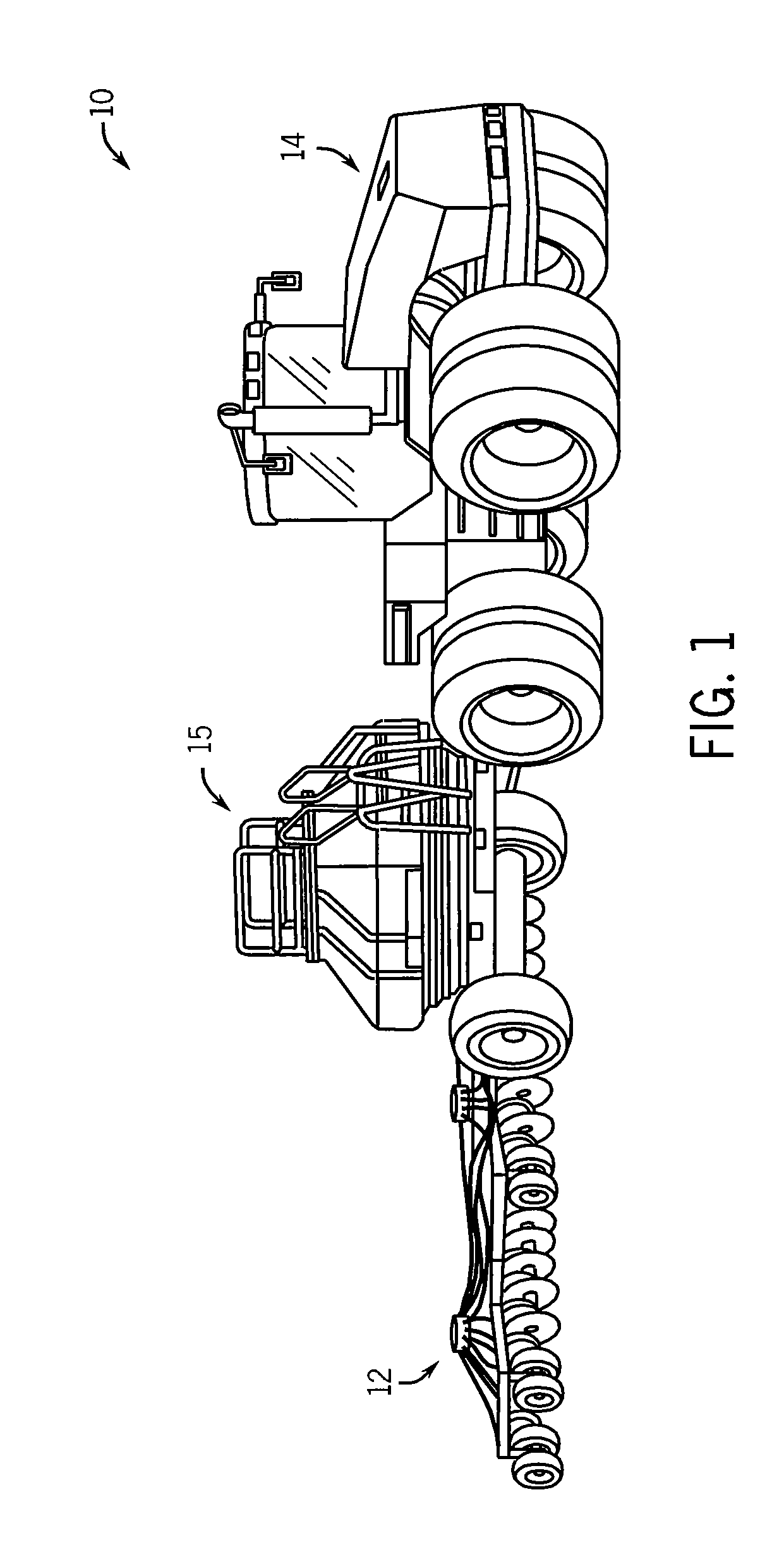

Electronically controlled hydraulic system for an agricultural implement

ActiveUS8176992B2Less complex hydraulic controlAvoid foldingSpadesAgricultural machinesWeight transferControl valves

A hydraulic control apparatus for a foldable farm includes first hydraulic control system is used to control weight transfer to ground engaging tools mounted to a stationary and foldable wing frame sections. A second hydraulic system is used to fold and unfold the wing sections. A hydraulic control is provided that interfaces with both hydraulic systems to control sequencing of the functions provided by the first and second hydraulic systems. The first and second hydraulic systems have electronically controlled valves to control the flow of hydraulic fluid to various lifting, folding, and down pressure cylinders.

Owner:CNH IND CANADA

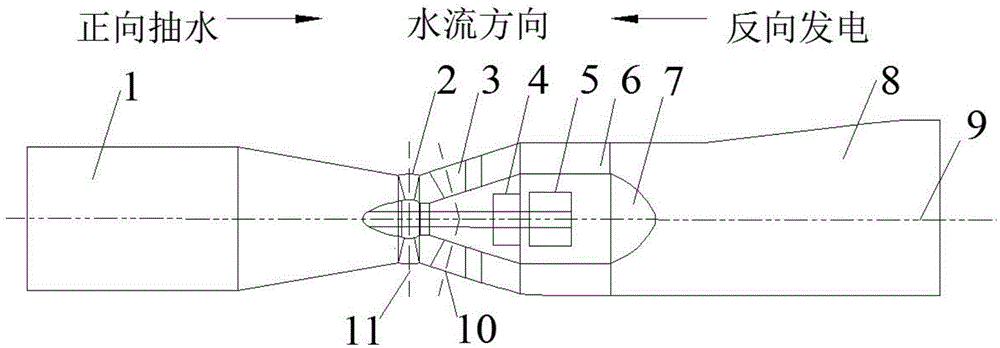

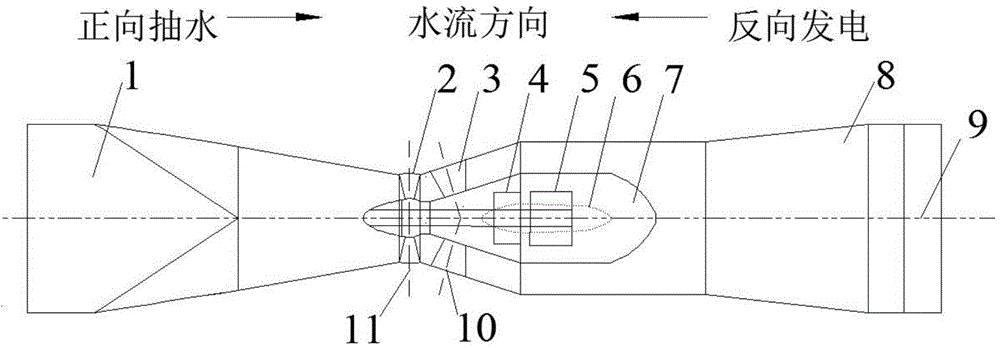

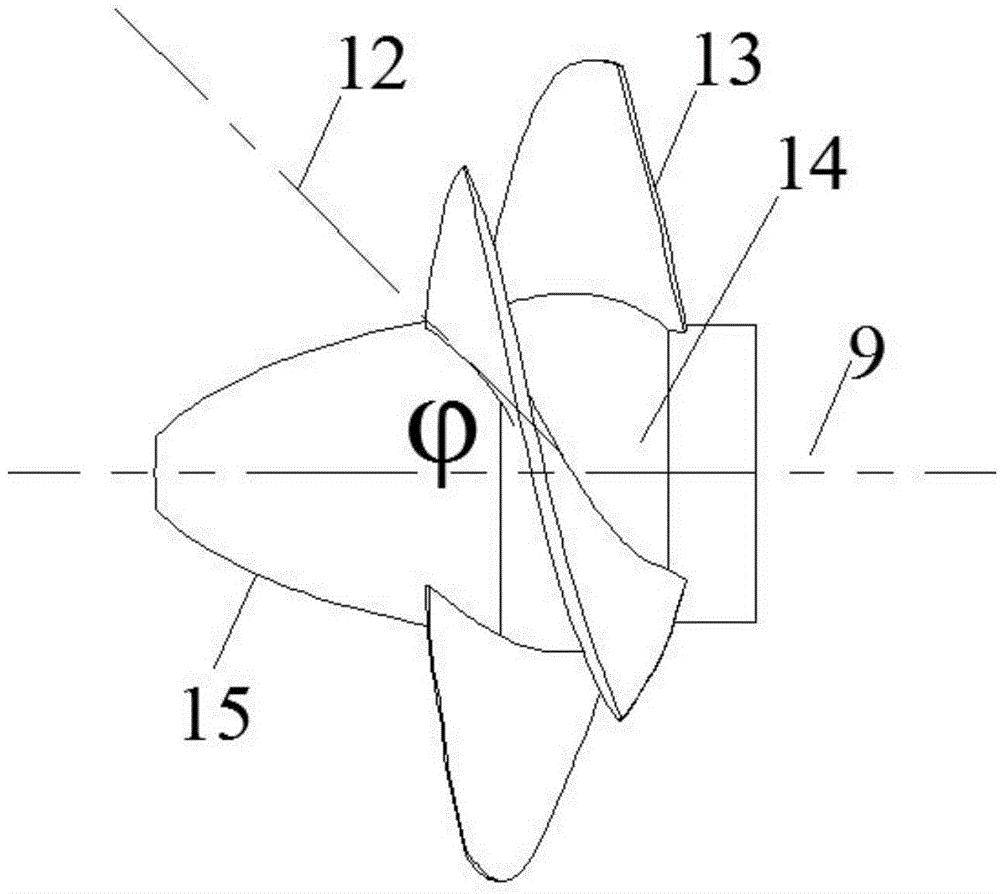

Low-lift high-flow reversible tubular pump with asymmetric SX type blades

ActiveCN104454631AImprove water conductivityAdjustable anglePump componentsHydro energy generationWater flowWater resources

The invention relates to a low-lift high-flow reversible tubular pump with asymmetric SX type blades. The low-lift high-flow reversible tubular pump comprises a forward water inlet runner, a rotating wheel, a guide blade, a gear box, a reversible motor, a bulb body, a sleeve pipe and a reverse water inlet runner. The low-lift high-flow reversible tubular pump is characterized in that the rotating wheel comprises the blades, a hub and a runner cone, wherein the blades are evenly arranged on the hub in the circumferential direction, and the runner cone is arranged on the reverse sluicing side of the hub; the blades are in a spatial warping SX shape, the axial midsection wing sections of the blades are in an asymmetric S shape, the guide blade is a movable guide blade oblique relative to the spatial curved surface, and the guide blade and the rotating paddle-type blades achieve the cooperation function. According to the low-lift high-flow reversible tubular pump, the demands that the water flow in a water pumping working condition and the water flow in a power generating working condition of the reversible tubular pump are opposite and the dual working conditions of water pumping and power generating can be met by one rotating wheel are met, and it is ensured that the efficiency in the two working conditions reaches the best. The reversible tubular pump is suitable for various reversible tubular pump stations with the water table drop ranging from 2 m to 5 m, and the efficient development and utilization of water resources can be achieved.

Owner:HOHAI UNIV

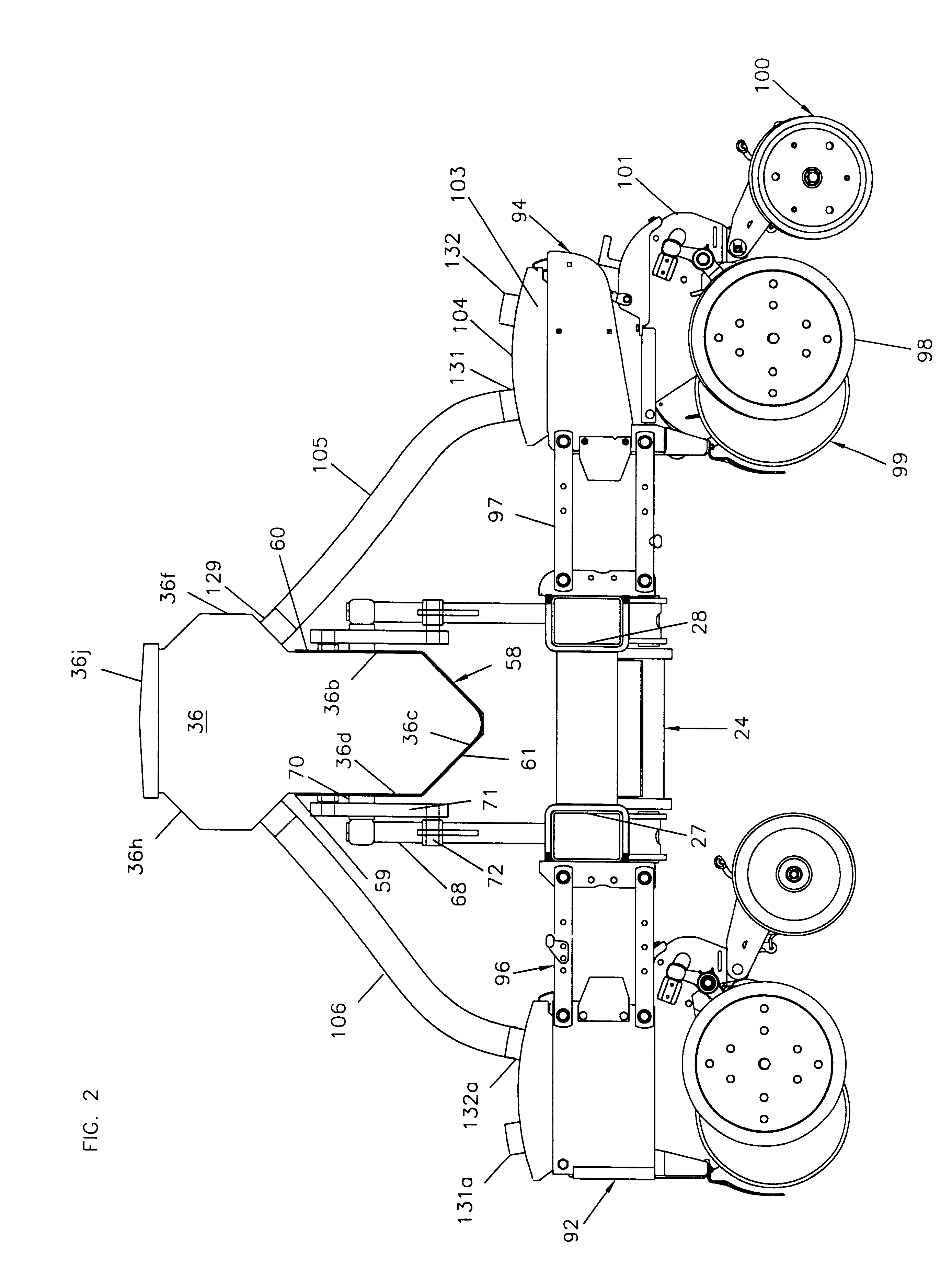

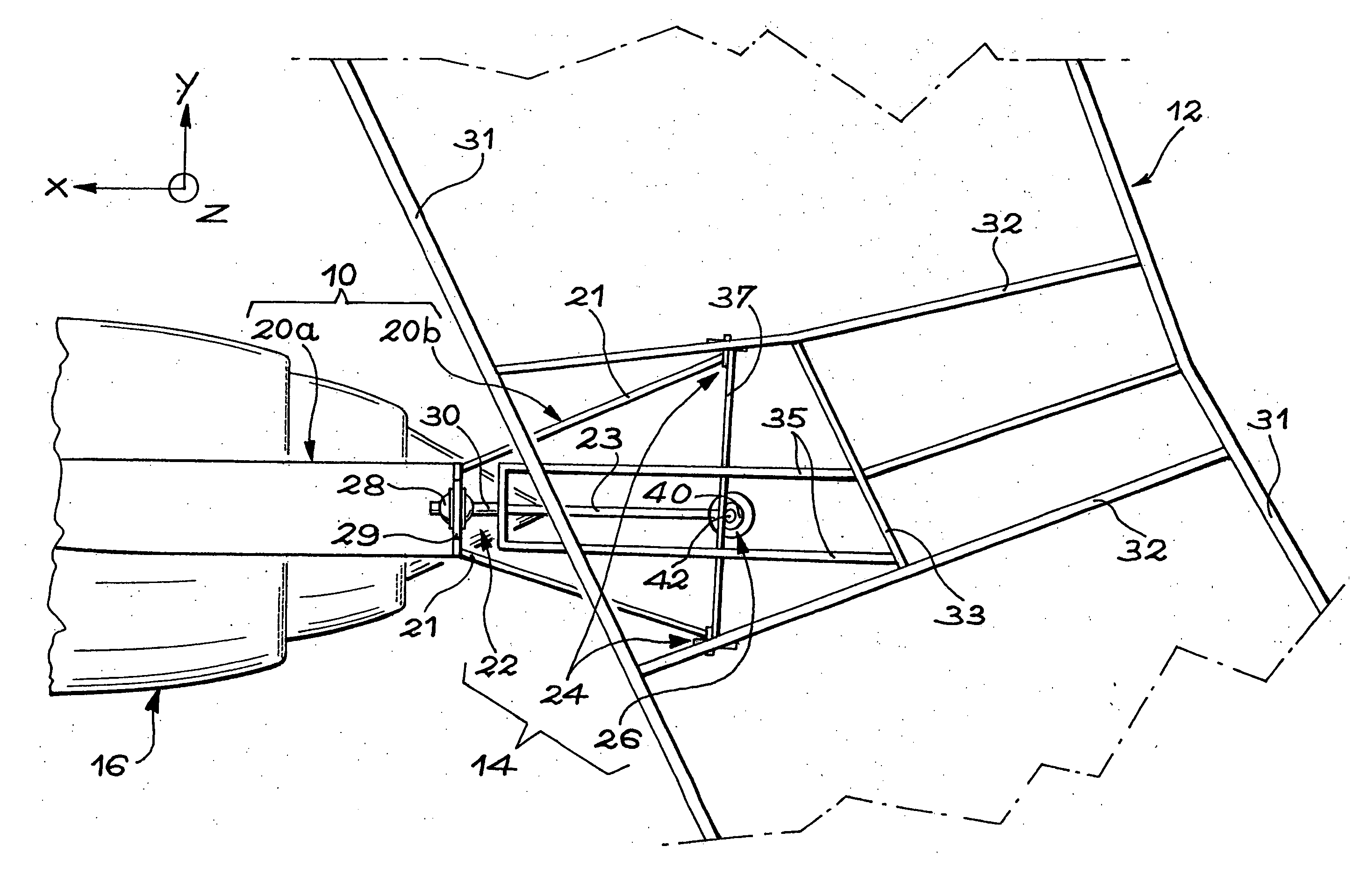

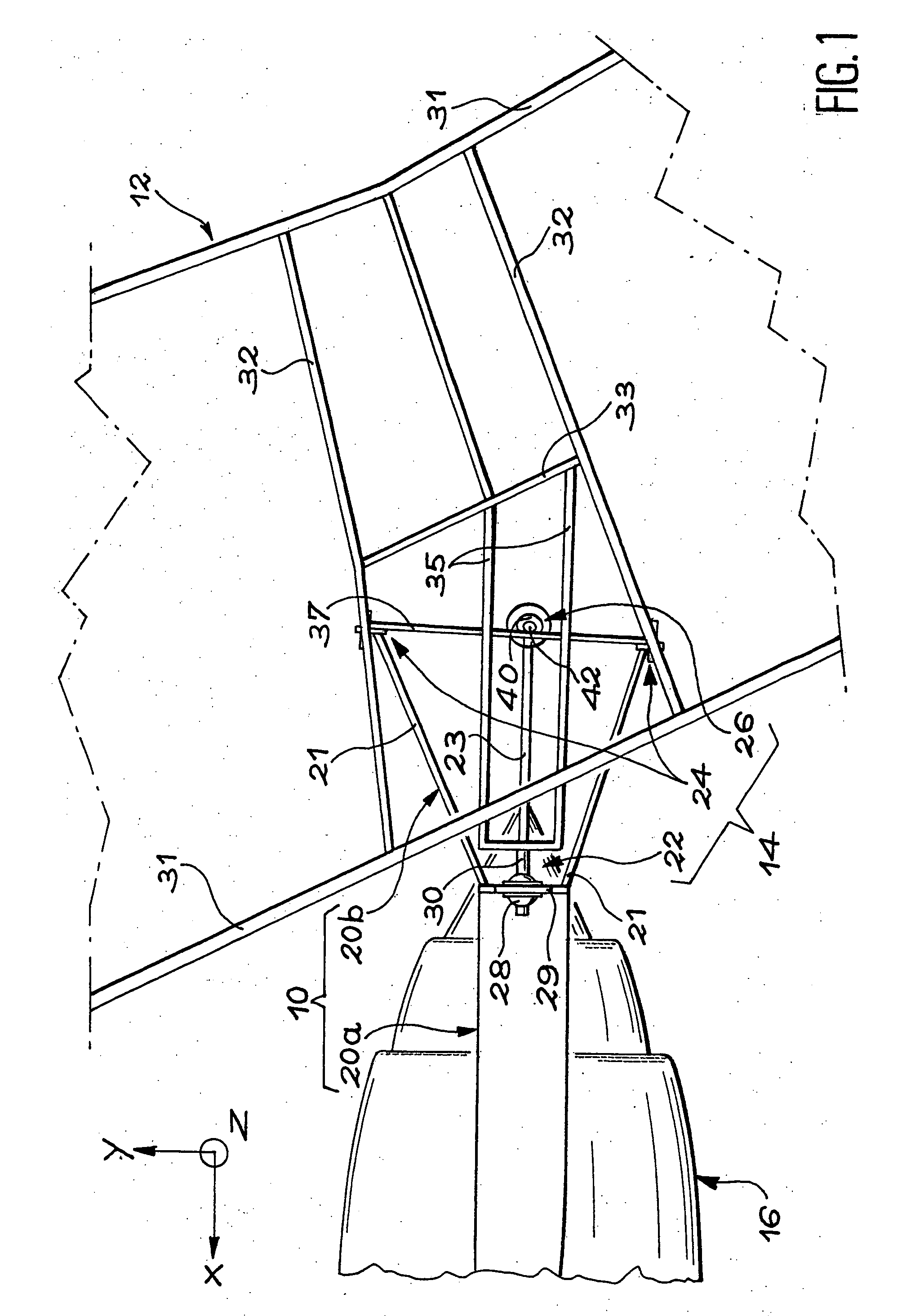

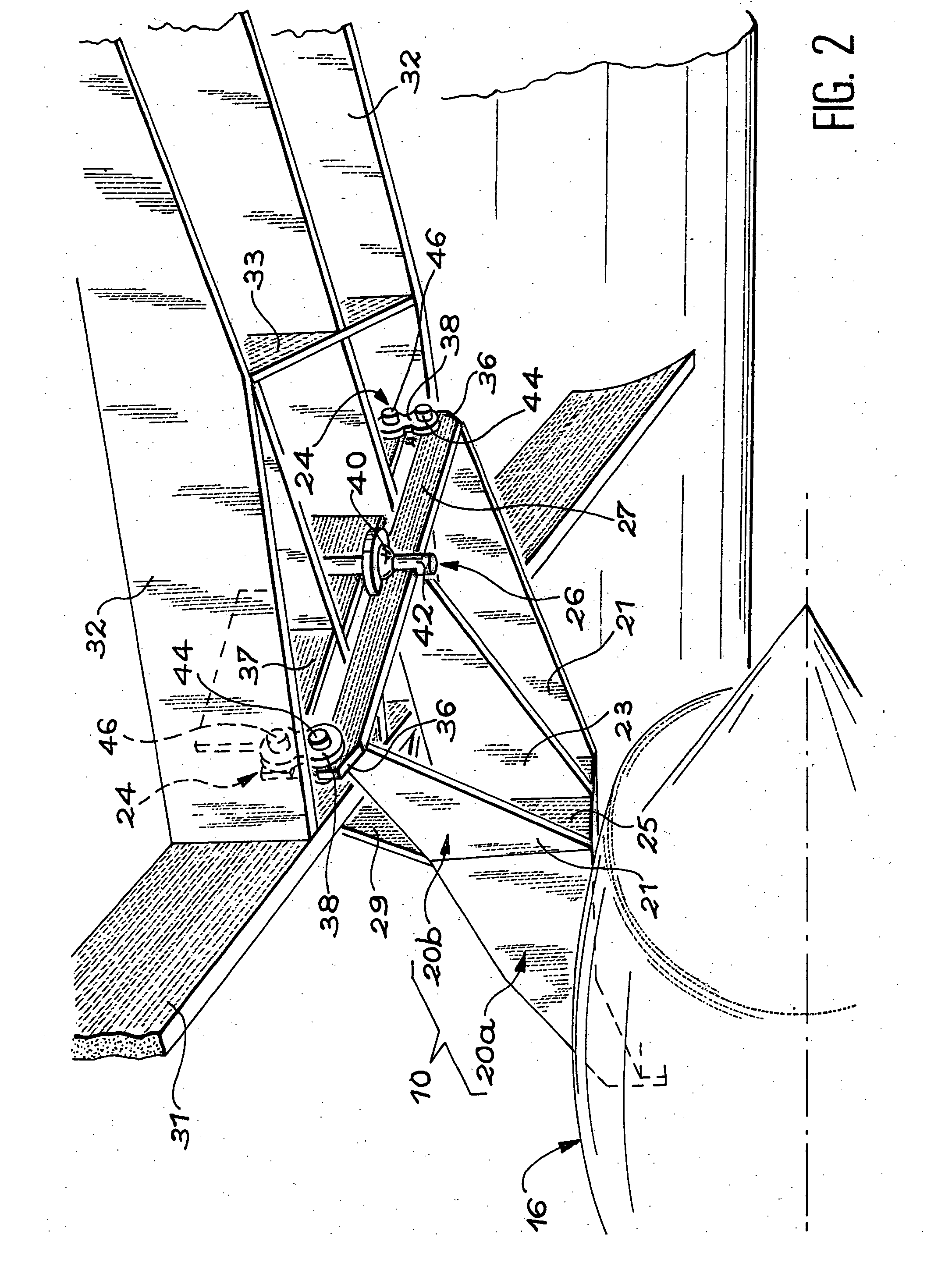

Engine pylon suspension attachment of an engine under an aircraft wing section

InactiveUS20040129832A1Reduce modificationIncrease distancePower plant constructionJet type power plantsMechanical engineeringRigid structure

A strut (10) for hooking an engine (16) under a wing body assembly (12) of an aircraft comprises a rigid structure as well as a mechanism for hooking this structure under the wing body assembly. This mechanism comprises a front fastener (22), a rear fastener (24) and a structure (26) for absorbing thrust. To install an engine (16) of greater diameter under the wing body assembly (12) of an existing plane, the rear part (20b) of the strut (10) is given a width which increases as it progresses to the rear. Furthermore, the rear fastener (24) comprises two braces which are fixed on both sides of the rigid structure and two shackles which connect each of the braces to an additional transverse rib integrated into the wing body assembly.

Owner:AIRBUS OPERATIONS (SAS)

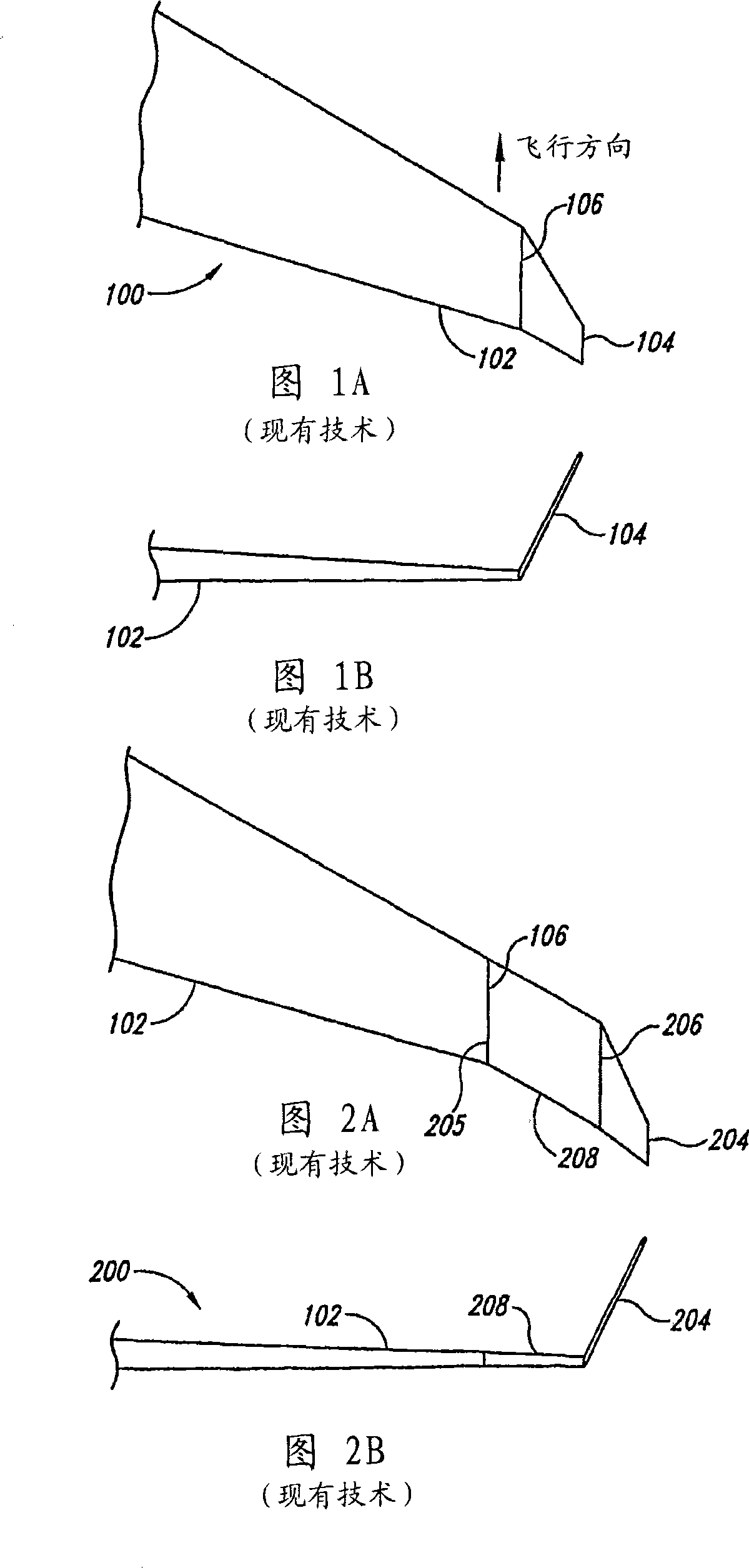

Integrated wingtip extensions for jet transport aircraft and other types of aircraft

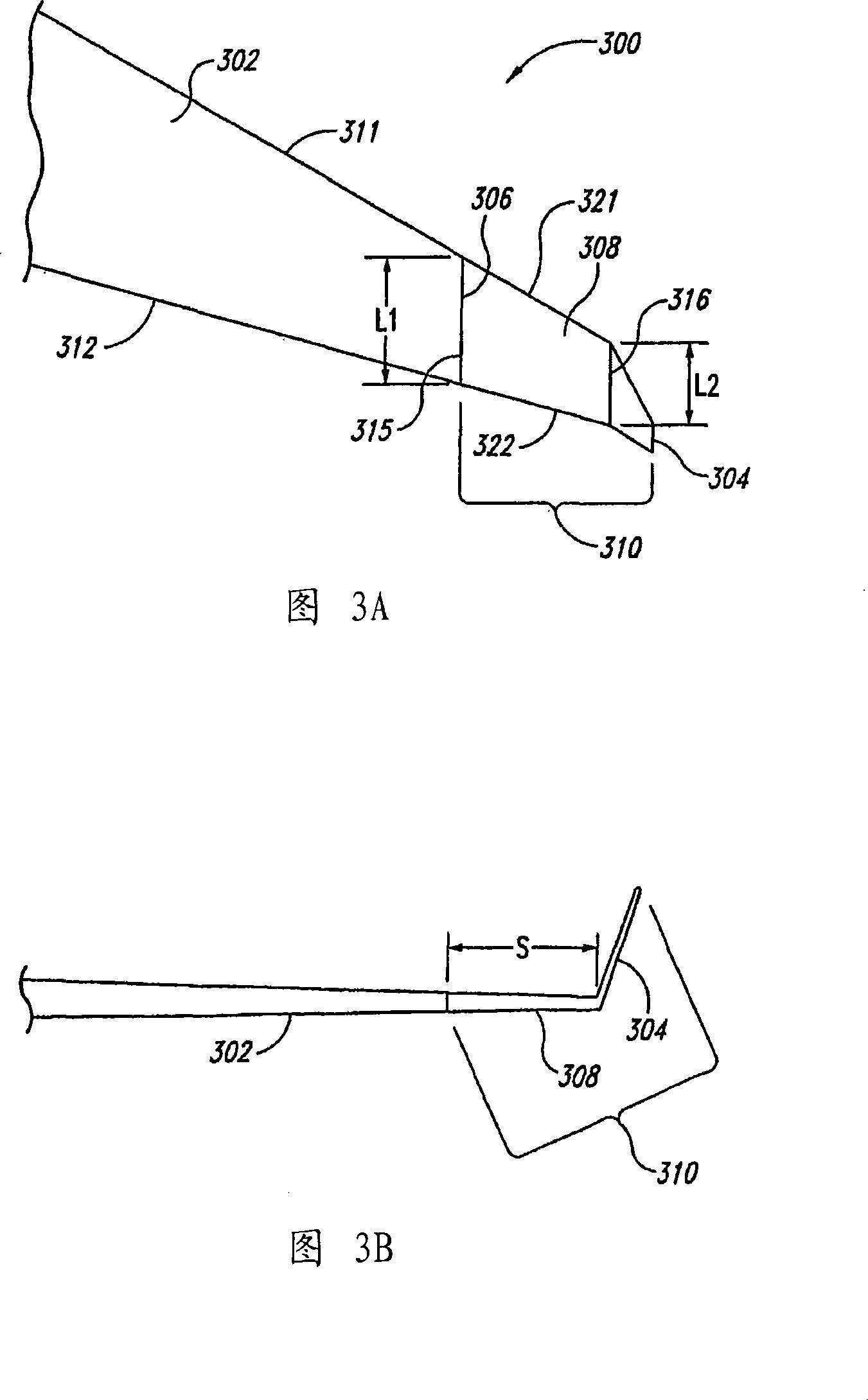

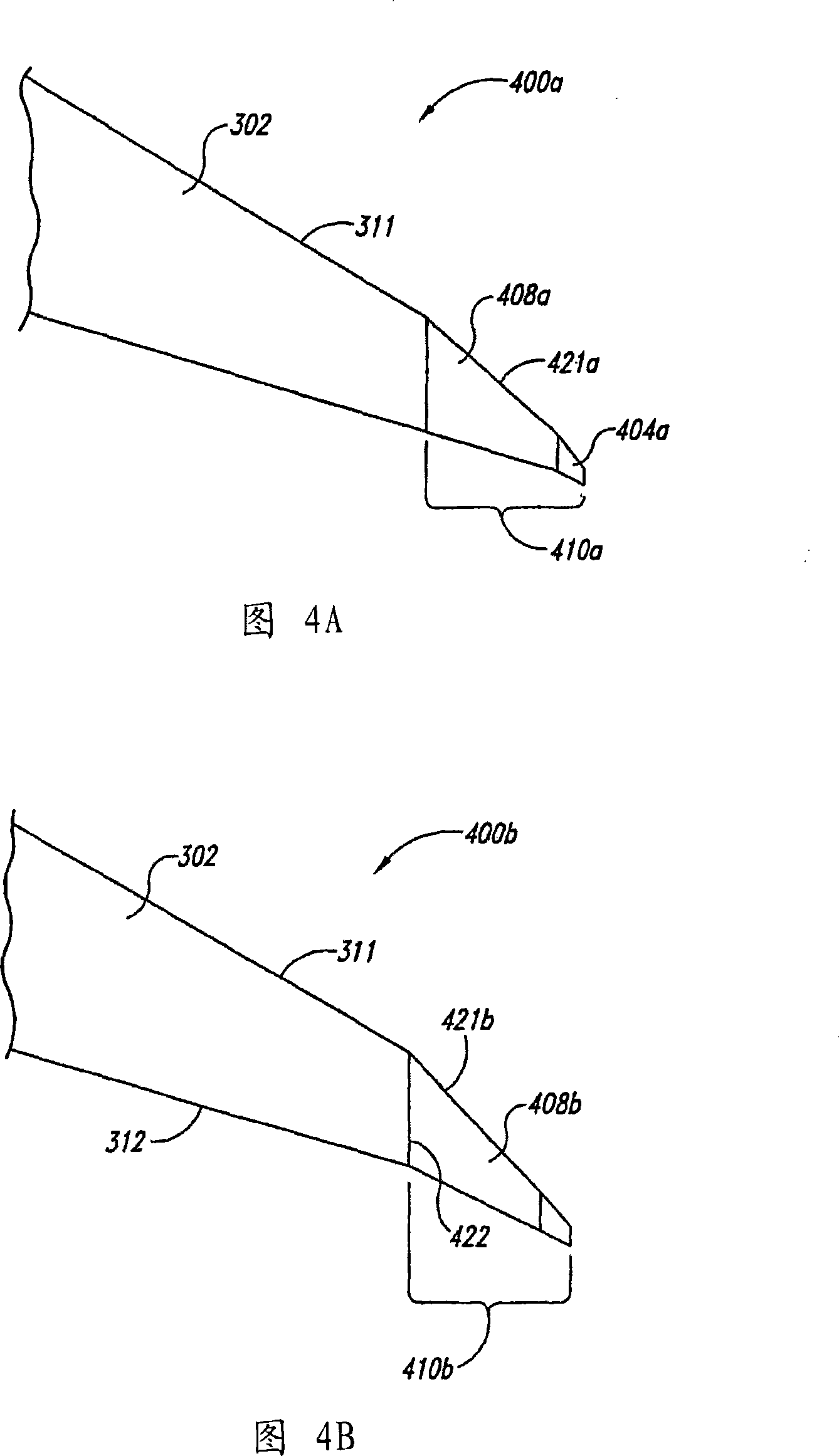

Methods and systems for efficiently increasing the wing area of an aircraft are disclosed herein. An integrated wingtip extension (310) configured in accordance with one embodiment of the invention includes a tapered wing section and a winglet (304). The tapered wing section (308) includes an inboard end portion (306) having a first chord length (L1) and an outboard end portion (306) having a second chord length (L2) that is less than the first chord length (L1). The winglet (304) is fixedly attached to the outboard end portion (316). The inboard end portion (306) is configured to be fixedly attached to a tip portion of an aircraft wing (302). In one embodiment, the tapered wing section (308) and the winglet (304) can be integrally formed from composite materials.

Owner:THE BOEING CO

Wind power generation device

InactiveUS7354245B2Increase wind speedEliminating flow of windWind motor controlPump componentsImpellerNacelle

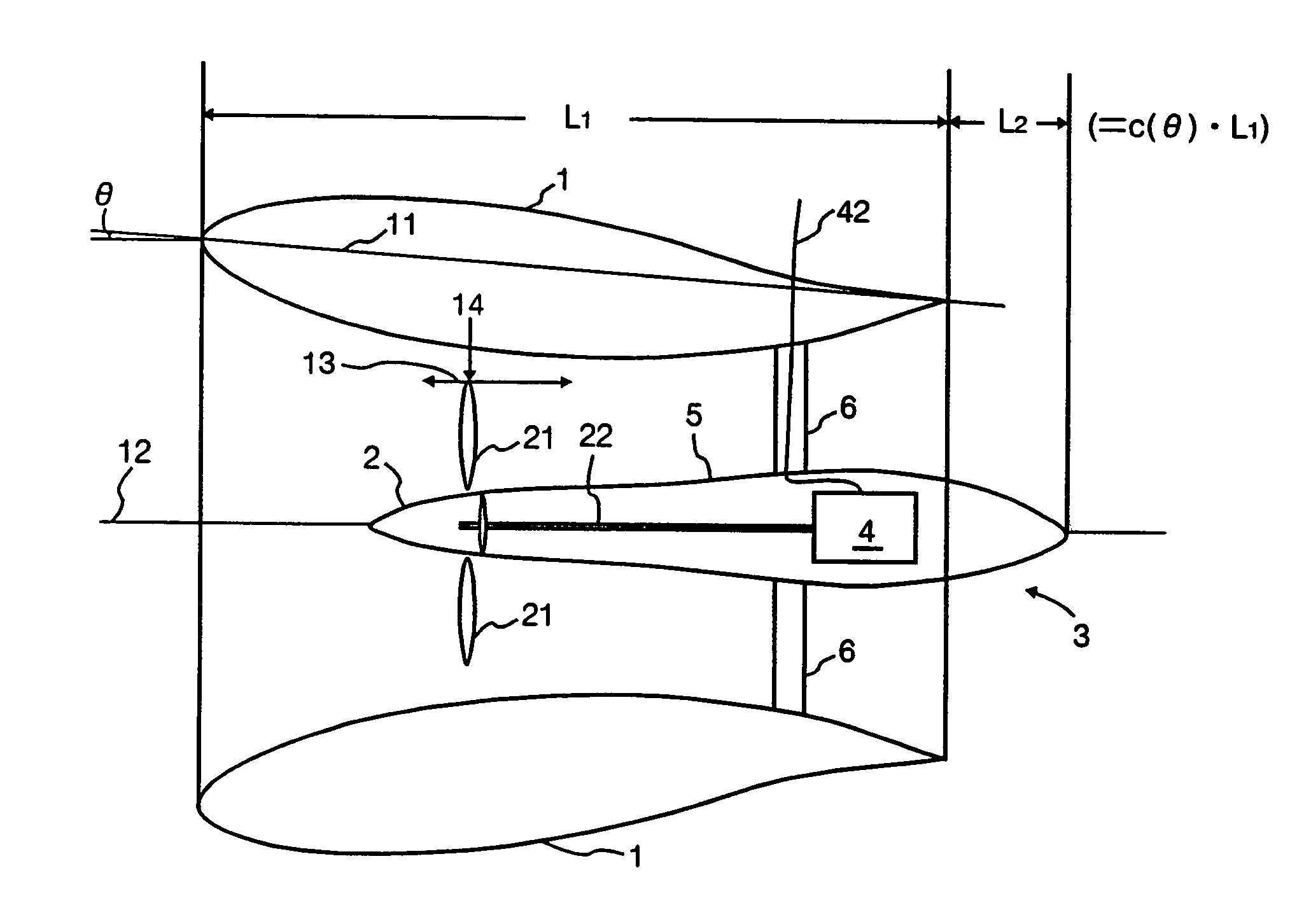

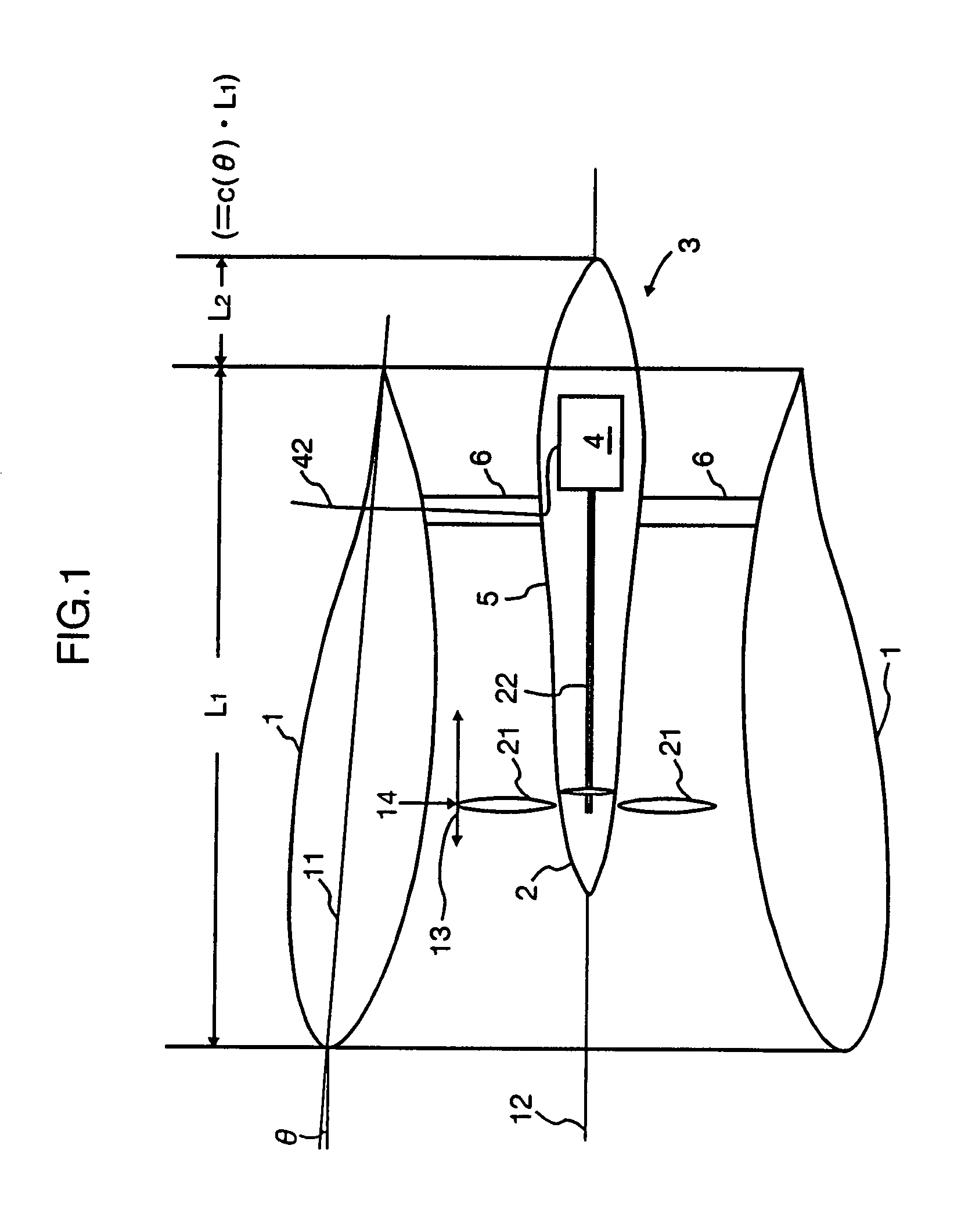

A wind power generation device capable of improving power generation efficiency is provided. The wind power generation device according to the present invention comprises: a substantially cylindrical duct 1 having a side wall with a substantially wing section; an impeller 2 rotatable around an axis of the duct 1; and a nacelle 5 that constitutes a streamlined pencil body 3 together with the impeller 2 and houses a generator 4 that uses torque of the impeller 2. The duct 1 has the side wall with the wing section so as to be able to produce a reduced pressure area at a rear of the duct and prevent generation of swirl at the rear of the duct 1. The pencil body 3 is provided so that a tip thereof is placed in the duct 1 and a rear end thereof protrudes from a rear end of the duct 1 so as to be close to a tip of the reduced pressure area produced at the rear of the duct 1. Blades 21 of the impeller 2 are provided in a maximum wind speed area 13 in the duct 1.

Owner:BABA TECHN LAB

Implement transport

InactiveUS7861795B2Reduce risk of damageImprove economySpadesAgricultural machinesActuatorWing section

Owner:DILLON PETER

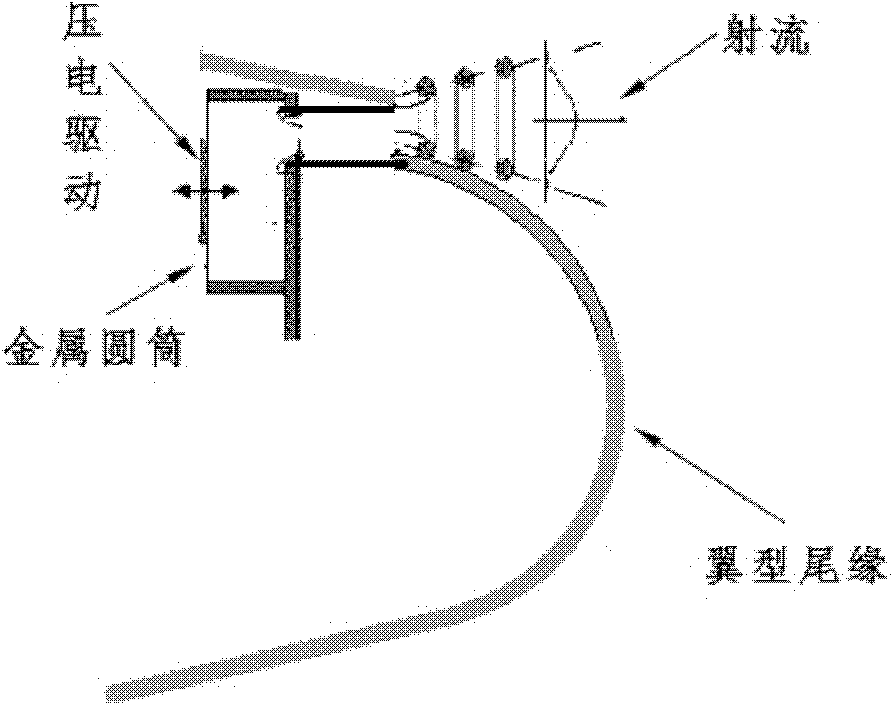

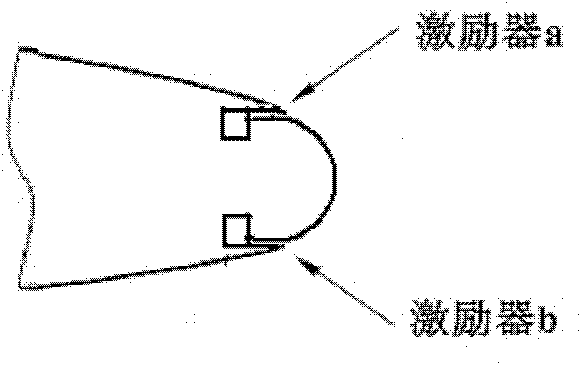

Synthetic jet circulation control method for increasing wing lifting force

The invention discloses a synthetic jet circulation control method for increasing wing lifting force, and the method provided by the invention comprises the following four steps: (1) selecting applicable synthetic jet exciters; (2) arranging a slit tangent to a wing section or a wing surface on a Coanda surface at the rear edge of the wing section or the wing surface; (3) on the Coanda surface at the rear edge of the wing section or the wing surface, arranging the synthetic jet exciters in various forms; and (4) according to different arrangement manners of the synthetic jet exciters, carrying out different controls on the wing section or an airplane, thus achieving the purposes of increasing or decreasing wing lifting force or realizing the airplane rolling control. In the invention, the synthetic jet is utilized to replace the traditional continuous jet, the method has the characteristic of external output momentum only and zero output quality, neither a gas source nor a pipeline system is required, and the defect that the traditional blowing type circulation control structure is complicated is solved. The method has better practical value and wide application prospect in the technical field of aviation flow control.

Owner:BEIHANG UNIV

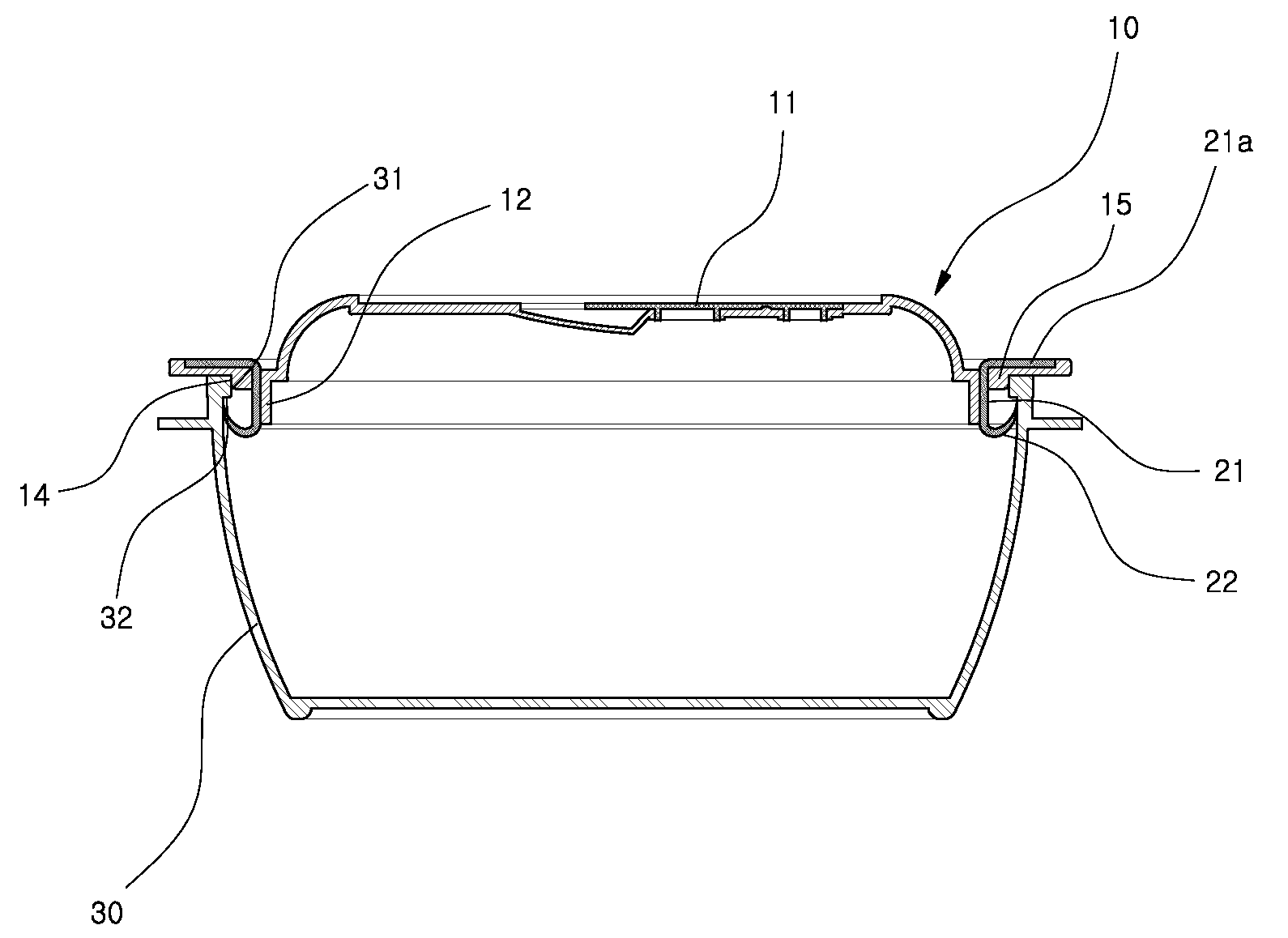

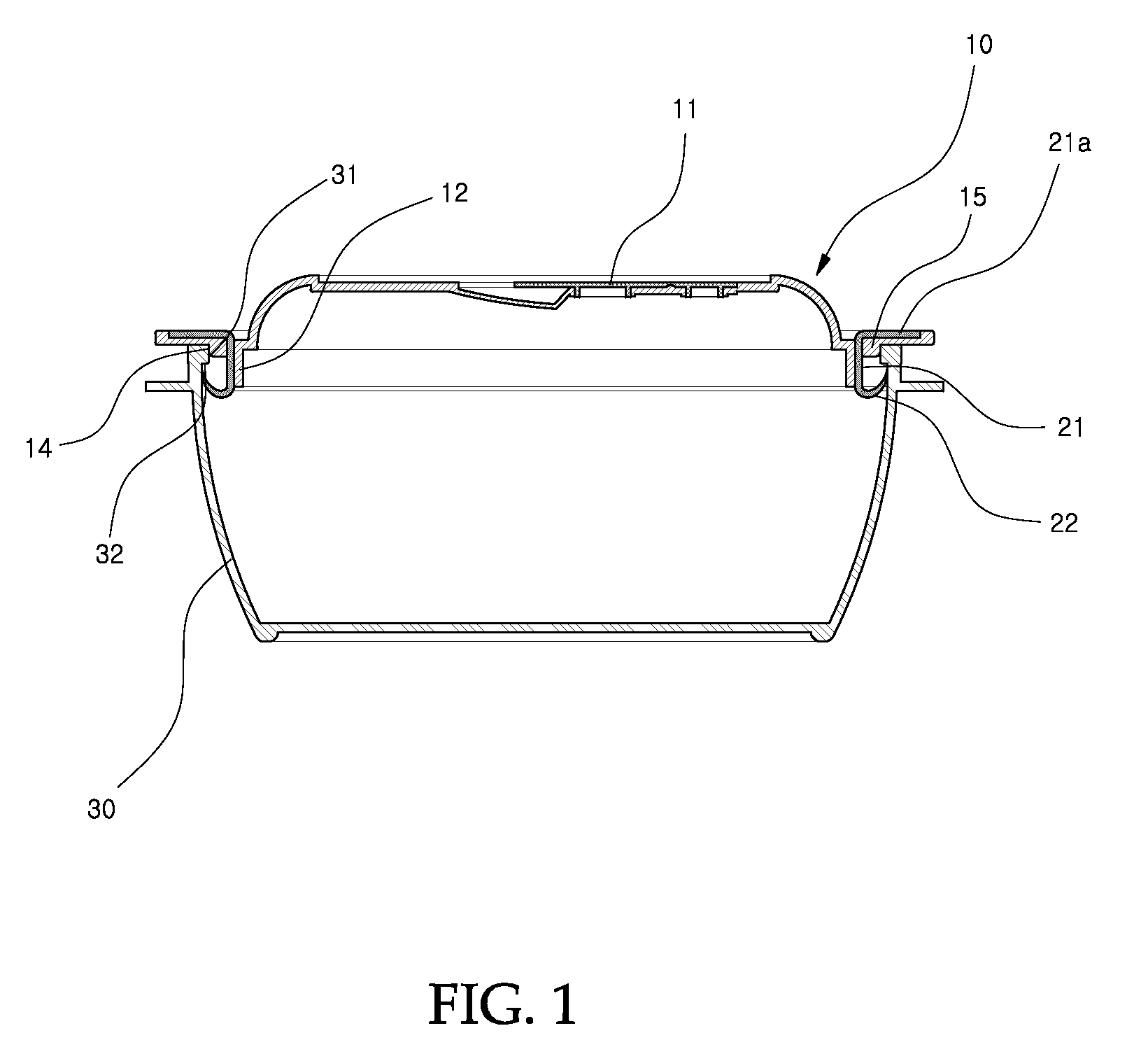

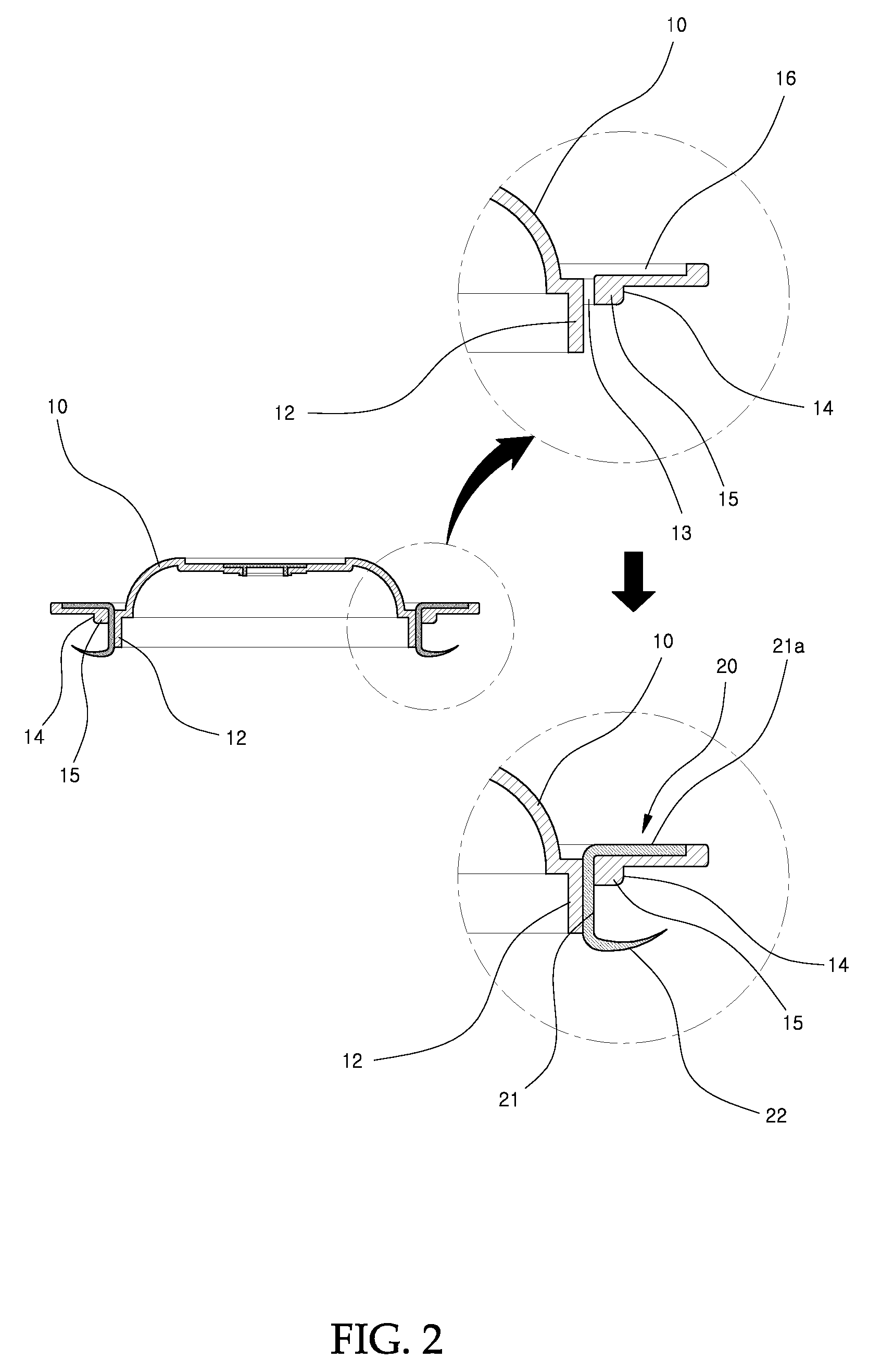

Receptacle with lid integrally formed with packing having wing section

InactiveUS20090026205A1Avoid separationImprove sealingRemovable lids/coversSealingInternal pressureProduction rate

Disclosed is a receptacle with a lid. When the lid is press-fitted into a receptacle body, the packing that which protrudes outward from a rim section of the lid moves down along an inner wall of a receptacle body while varying internal pressure of the receptacle, thereby preventing the lid from being unintentionally separated from the receptacle body. The packing installed at the rim of the lid is integrally formed with the lid through an insert molding process. In a conventional lid structure, a packing having a wing section protrudes from a rim of the lid in a state in which the wing section is spaced apart from the lid, so that an additional coupling device is necessary to couple the packing to the lid. Due to the coupling device, productivity is lowered and quality of the product deteriorates. To solve this problem, a support wall is provided at a lower portion of the lid and a fixing member of a packing is fabricated through an insert molding process such that the fixing member closely adheres to the support wall. A wing section protrudes from the fixing member while being integrally formed with the fixing member, so that the packing is installed in the lid without using an additional coupling device.

Owner:MYOUNG MOON L C

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com