Patents

Literature

106results about How to "High maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

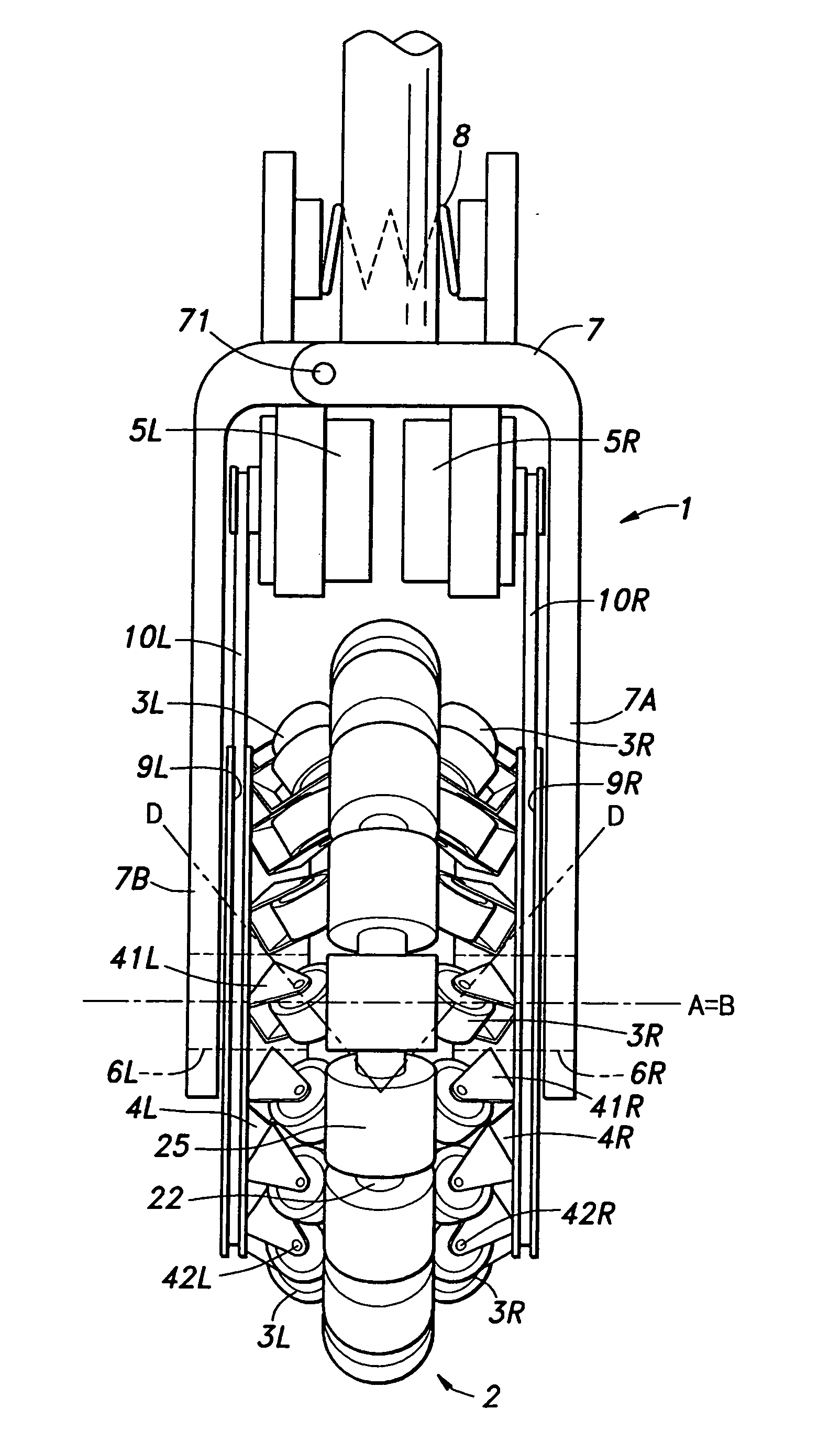

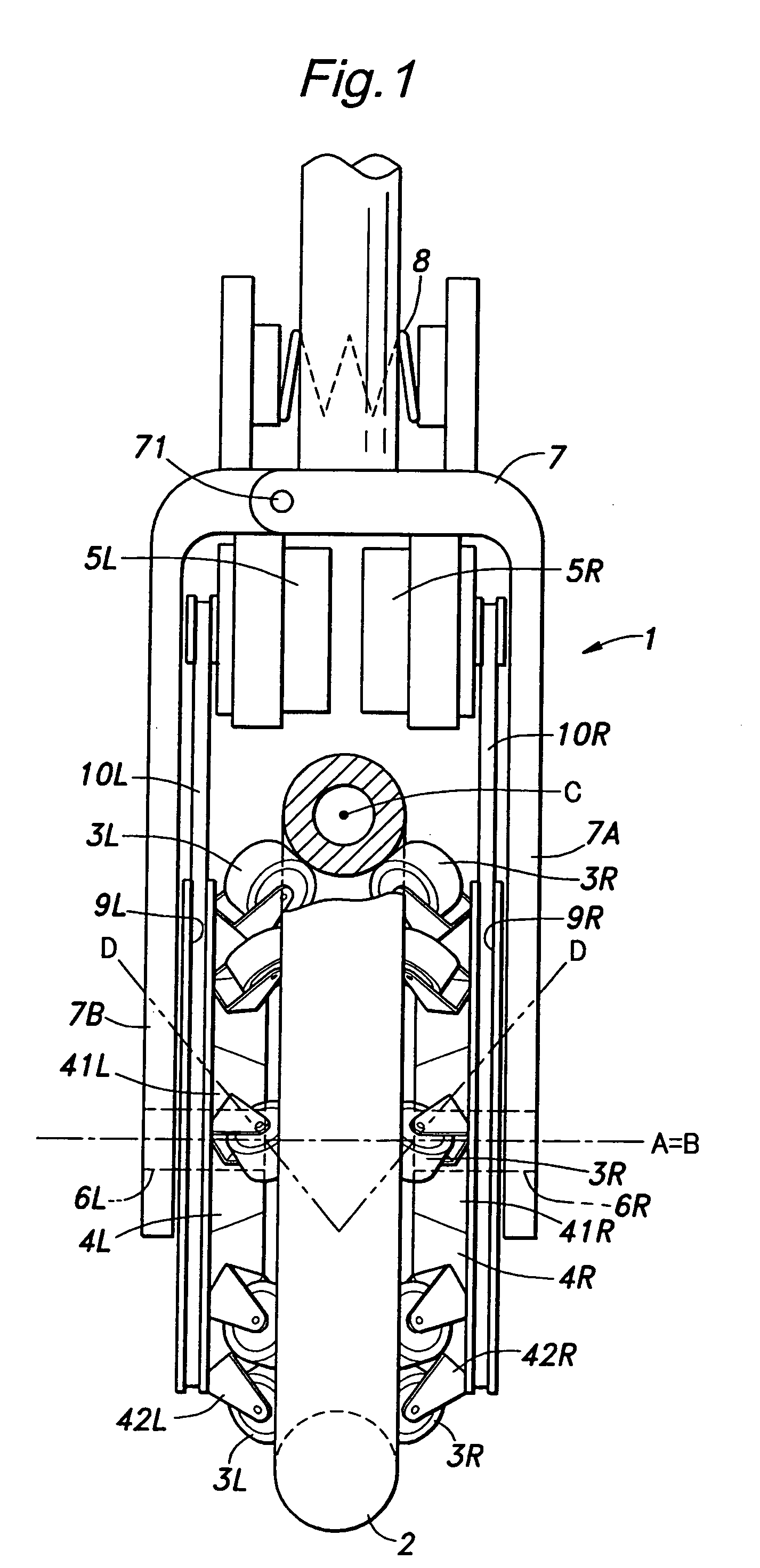

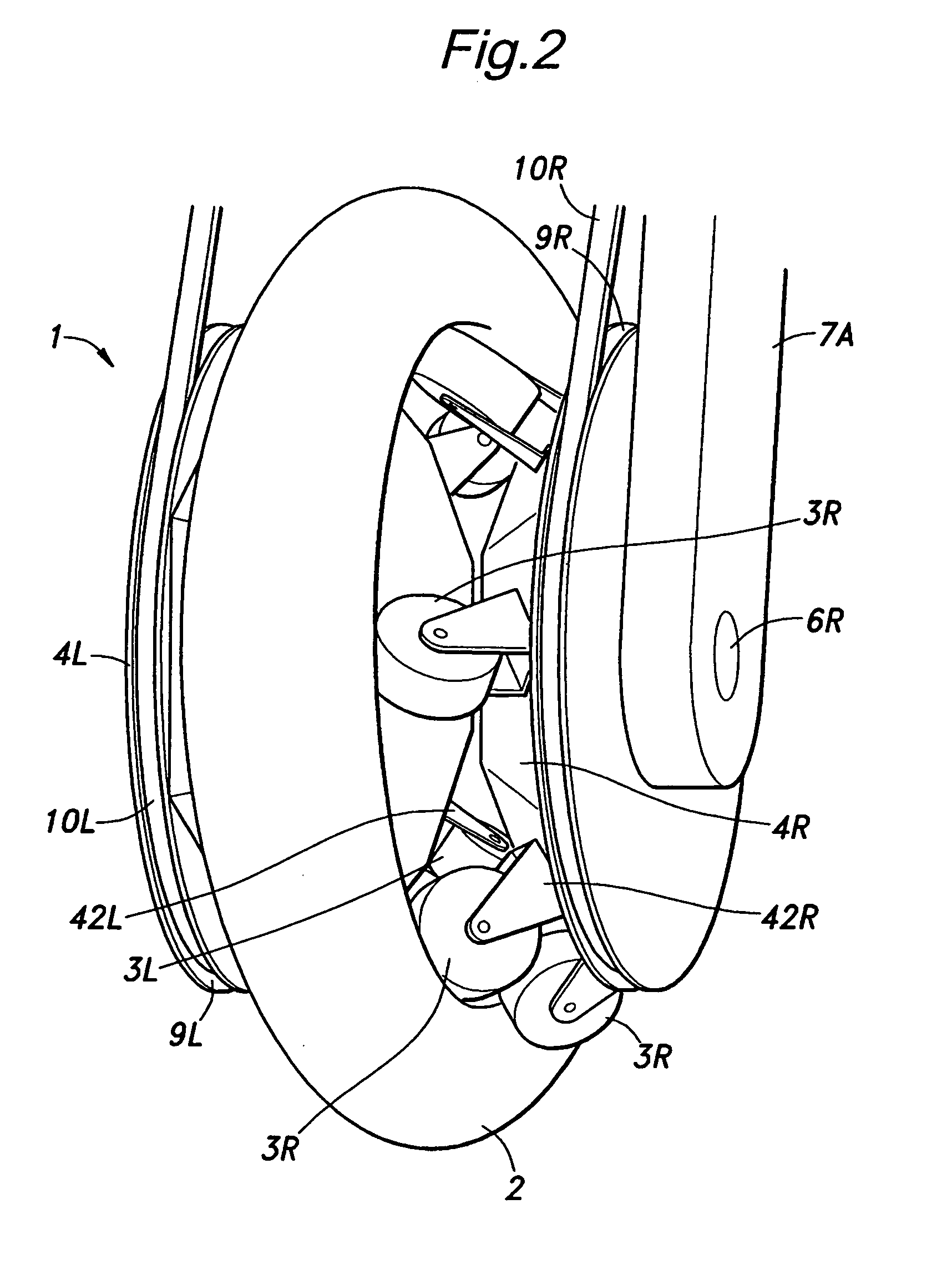

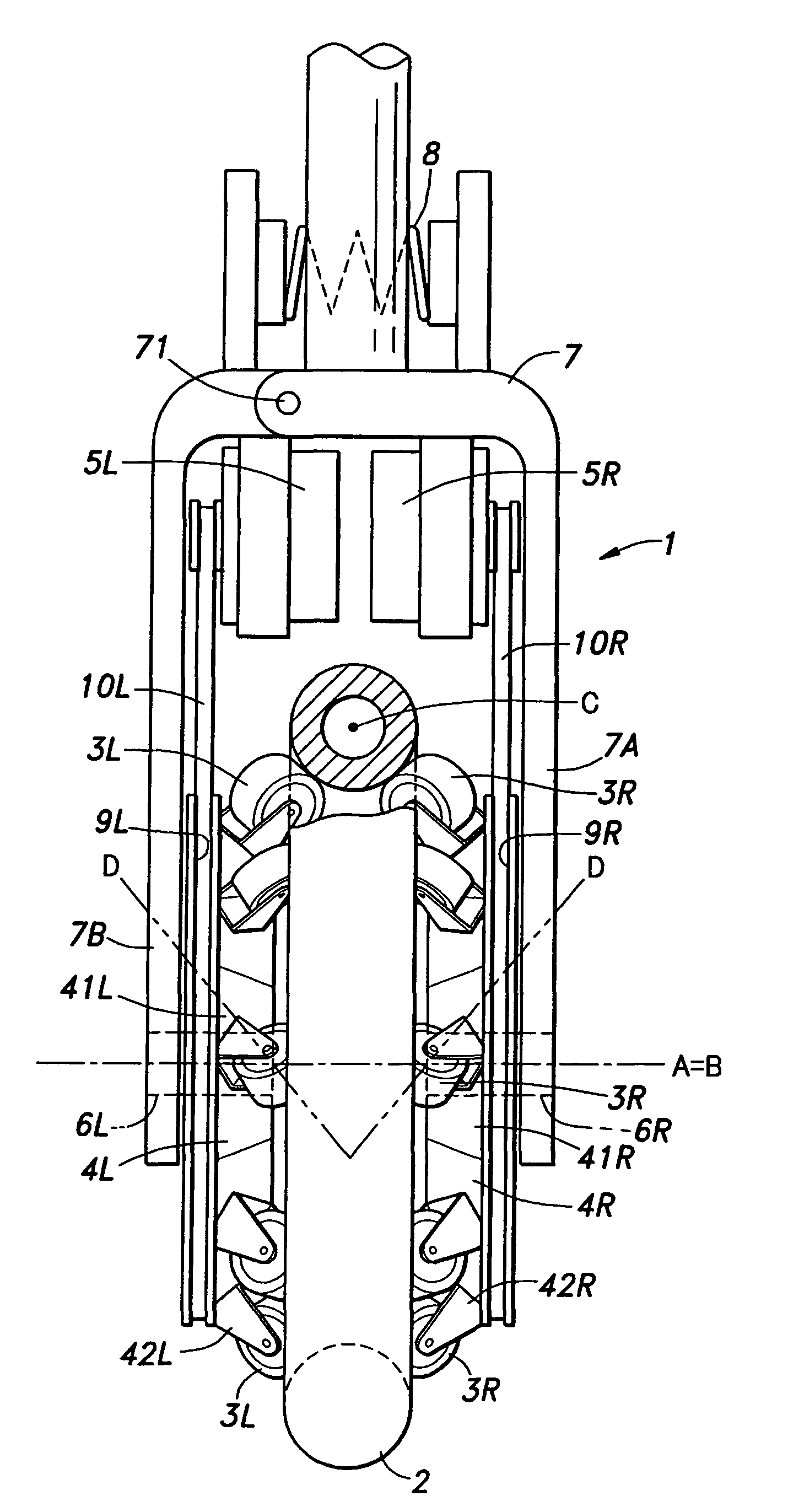

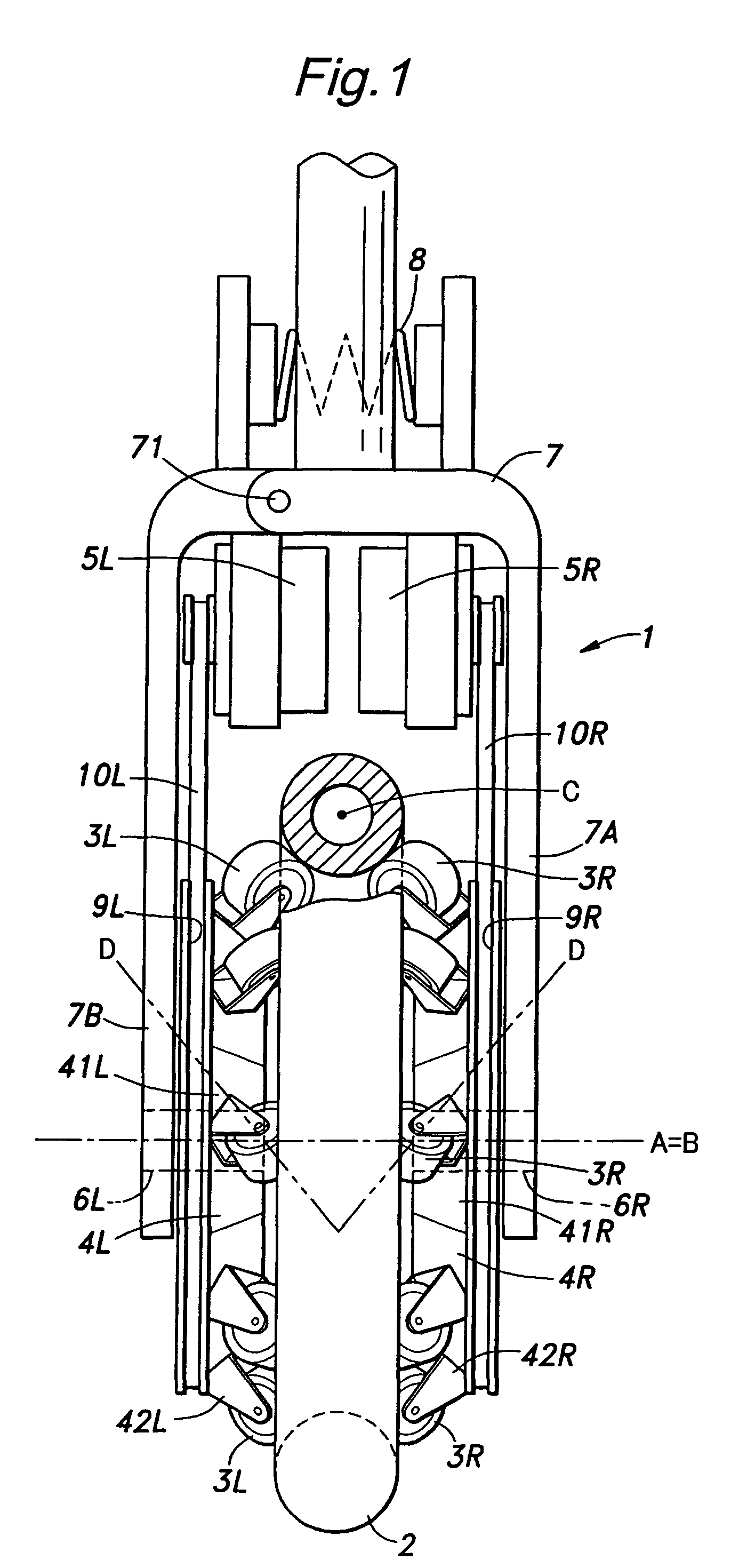

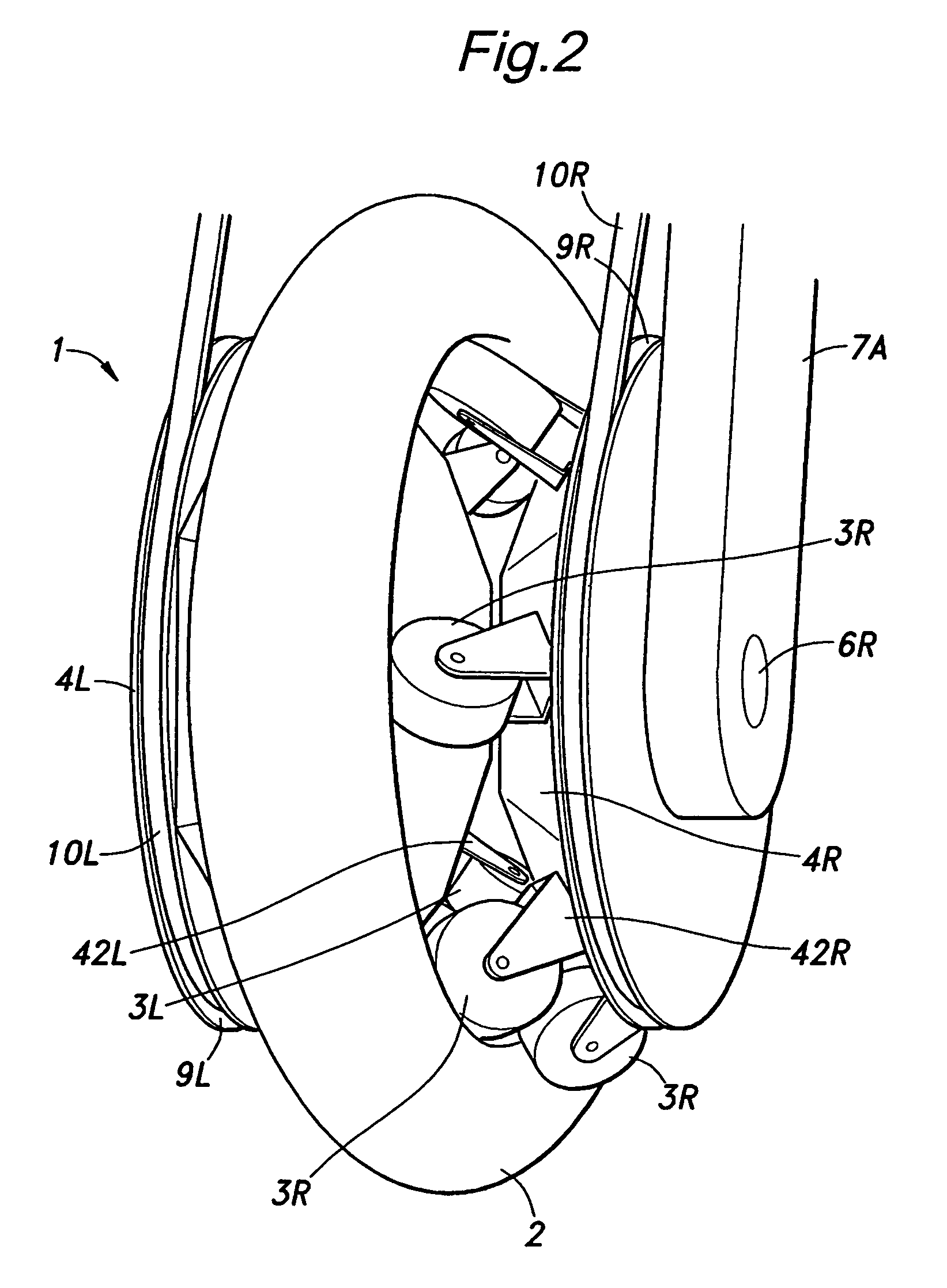

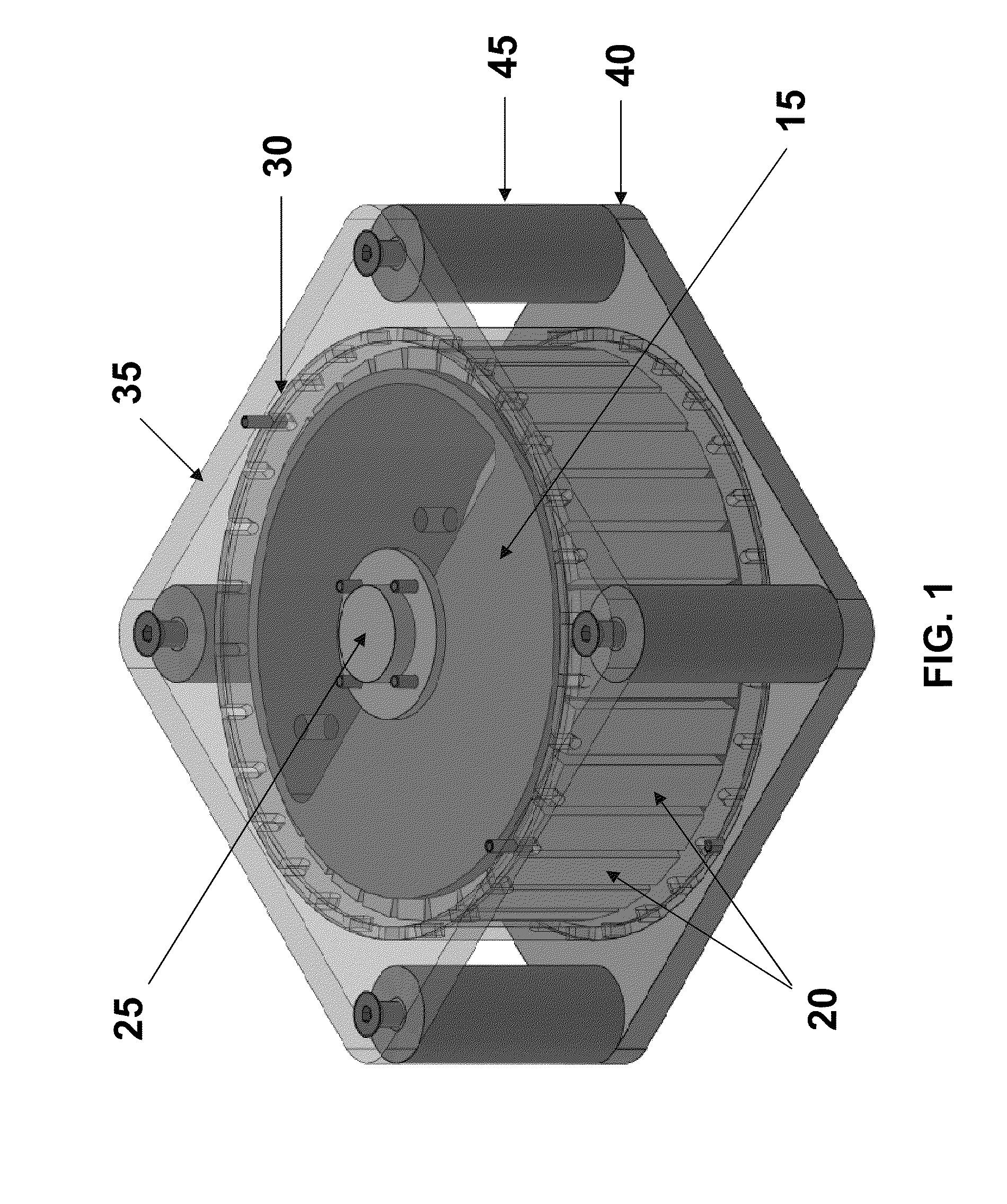

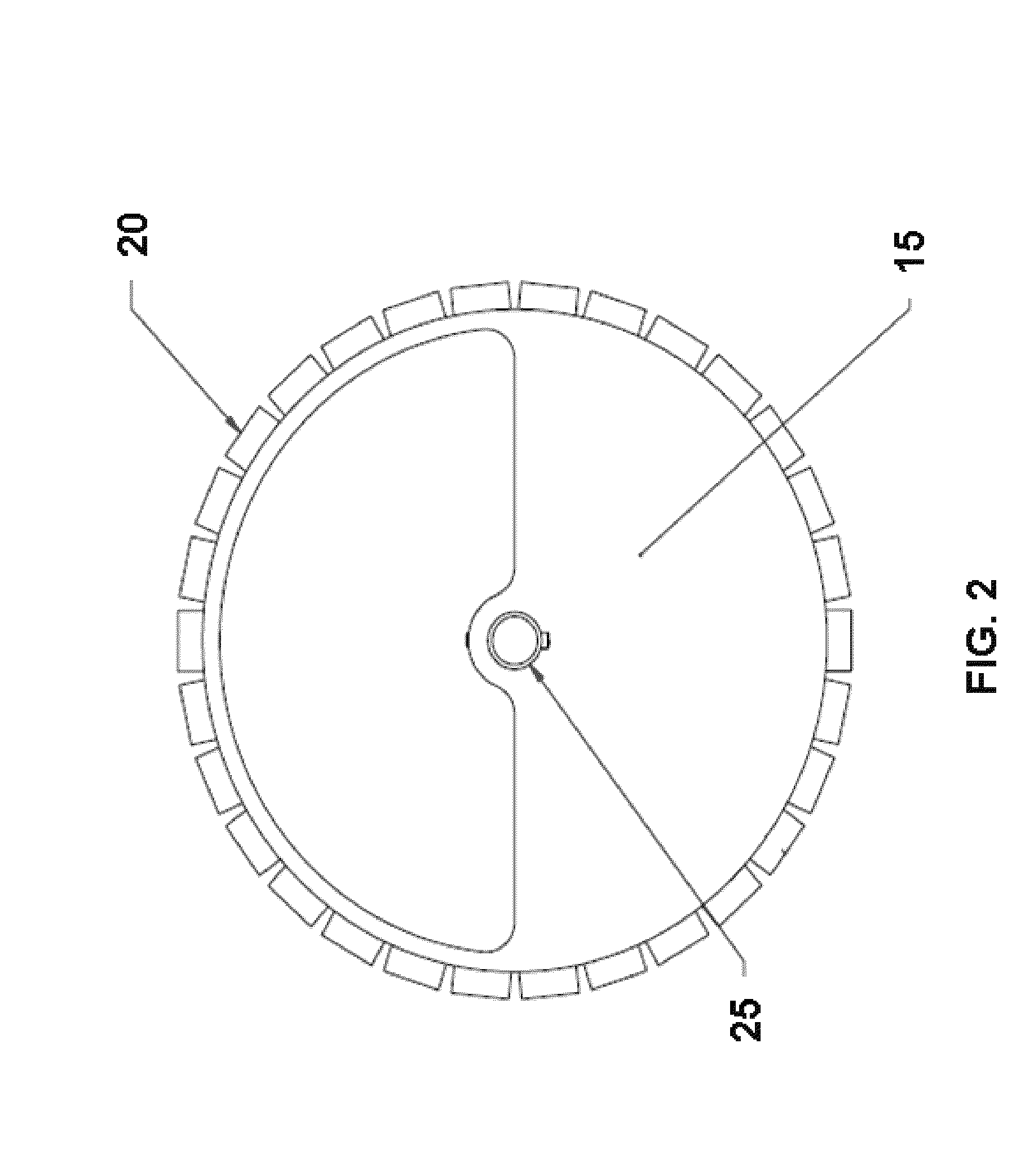

Omni-directional drive device and omni-directional vehicle using the same

ActiveUS20100096905A1Increased durabilityHigh ease of maintenanceUnicyclesHubsEngineeringOmni directional

Owner:HONDA MOTOR CO LTD

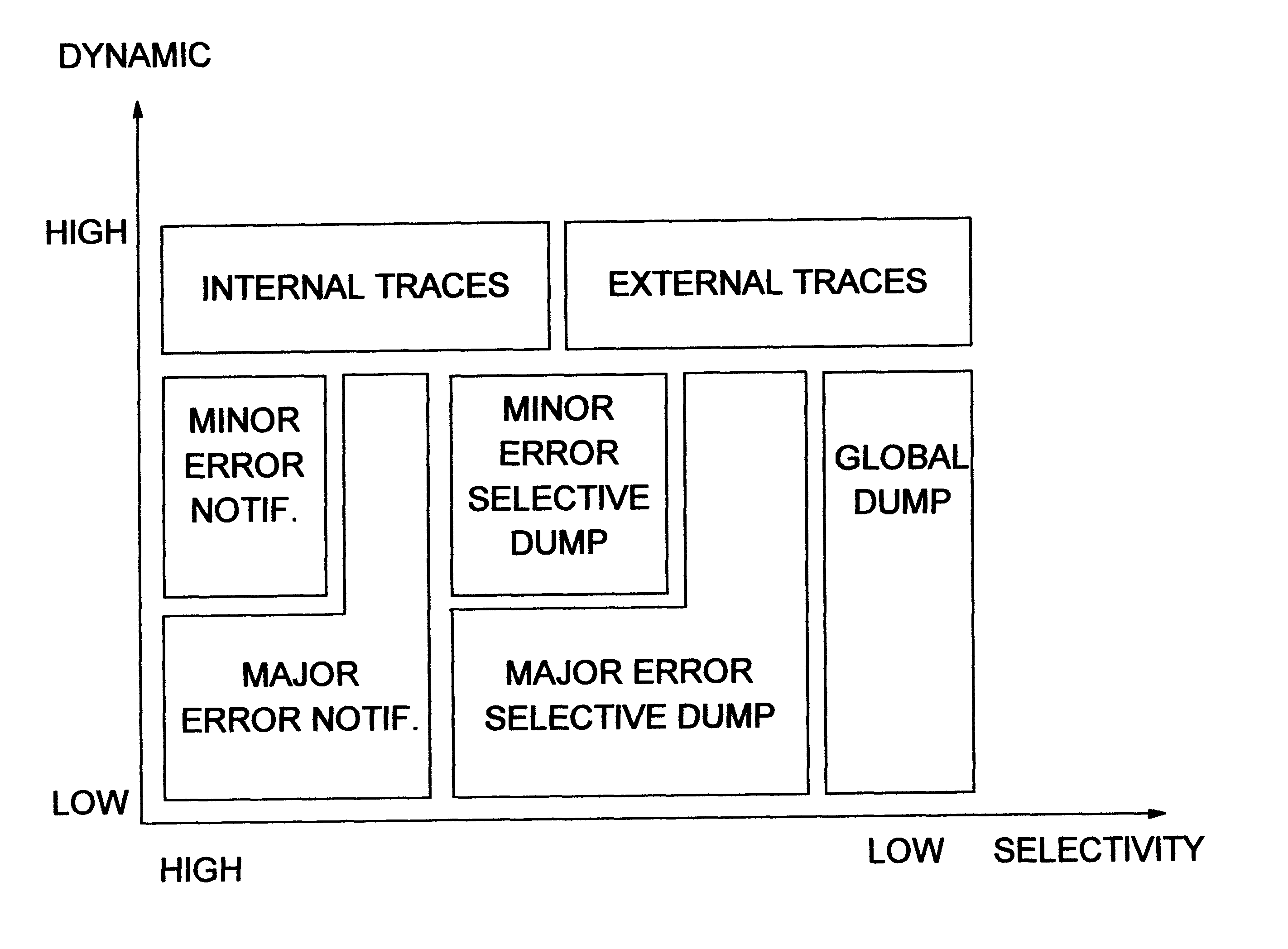

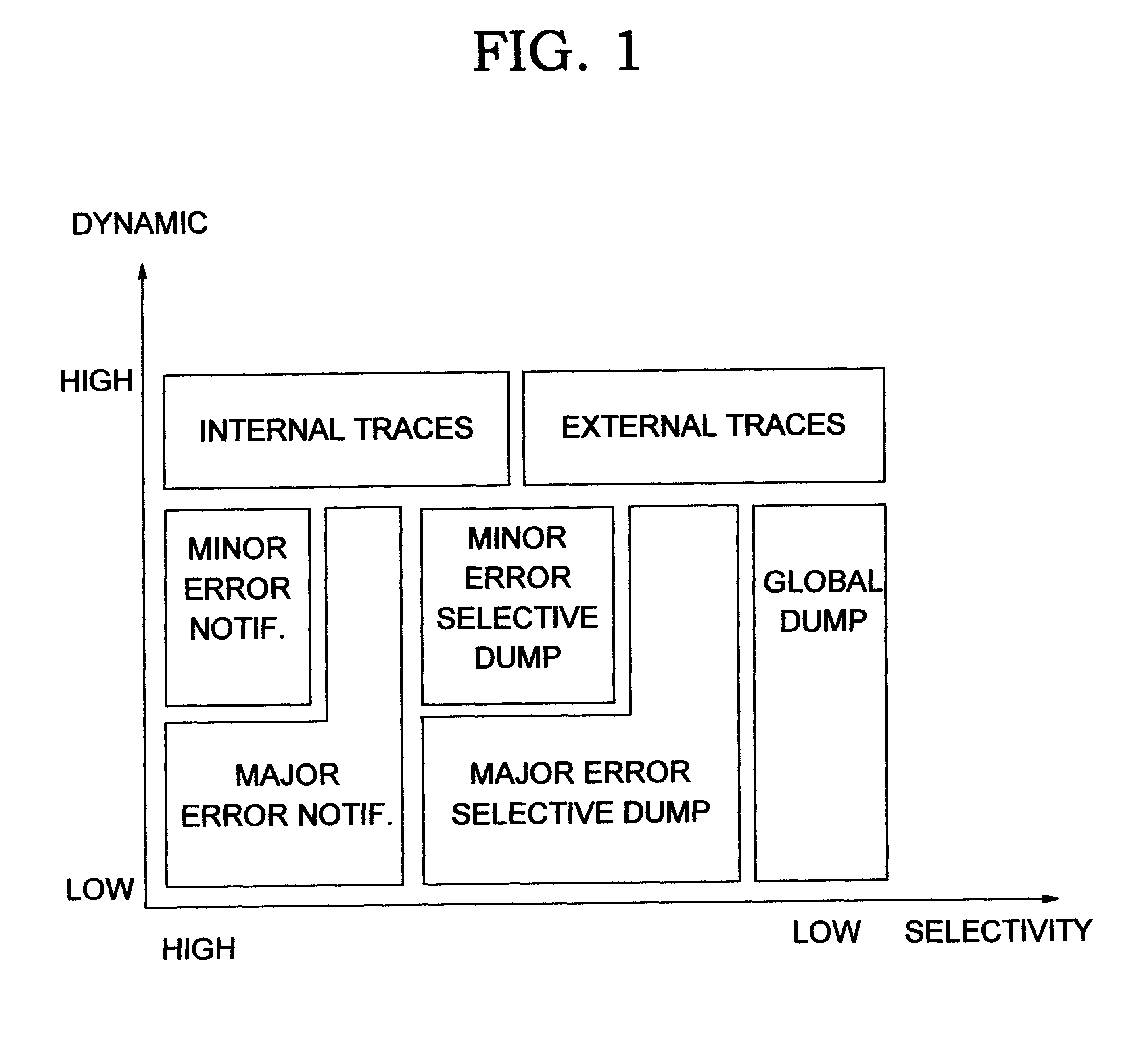

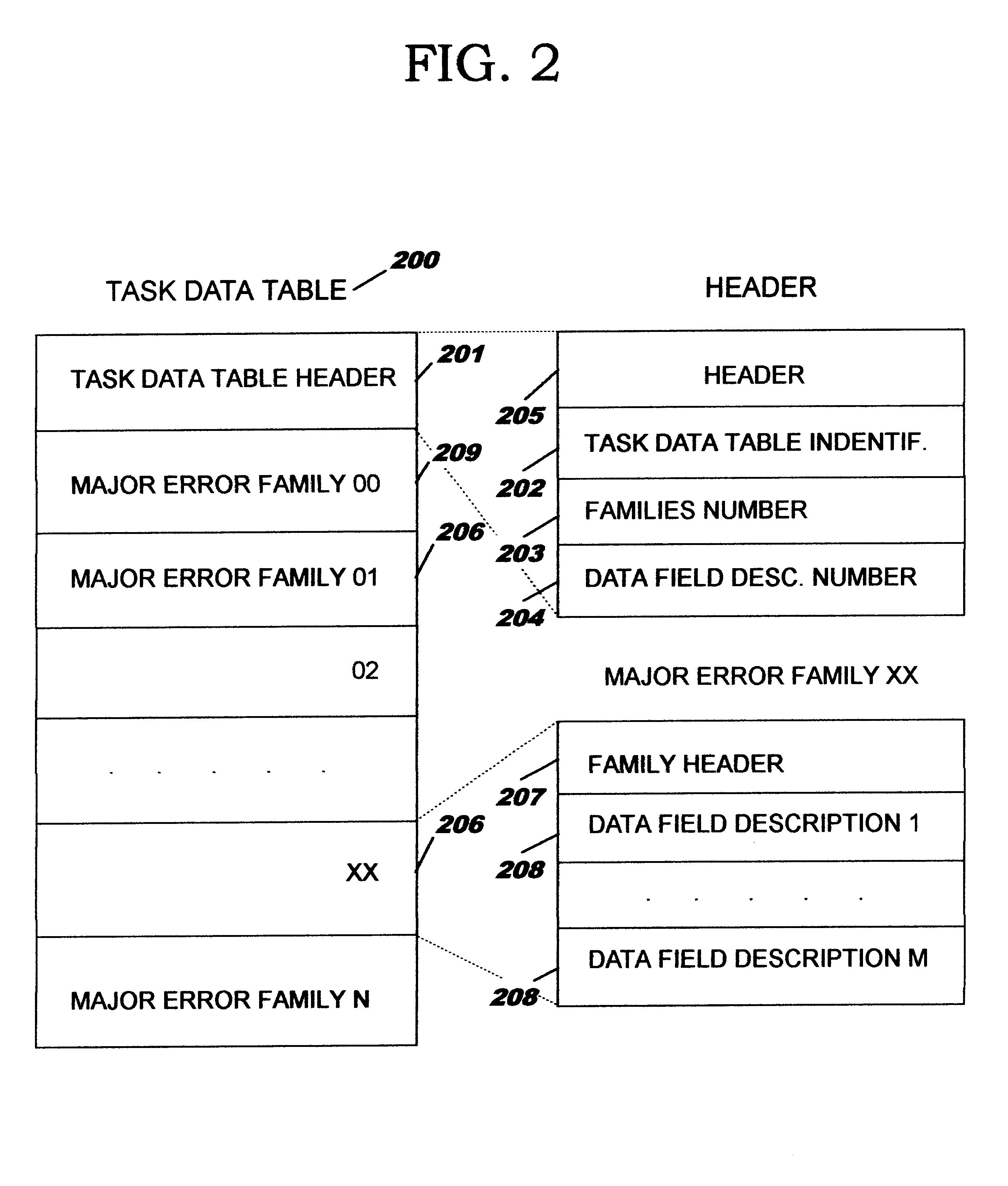

Selective data capture for software exception conditions

InactiveUS6182243B1Improve integrityQuality improvementProgram initiation/switchingHardware monitoringData processing systemData set

A selective data capture method for software exception conditions in the operation of a data processing system includes steps for describing the pertinent data to collect before loss of control of the faulty program occurs. First the program preventively declares in a table all the data to capture in case of error (501). In a second stage, at the key points of the code, the pertinent sets of data in the table are activated (502). On the occurrence of an error (503), only the data previously declared and activated are collected (504) by the external code in charge of managing the error reporting to a maintenance subsystem (505). The invention is attached to the global data capture strategy, particularly to the Error Notification and Selective Dump processes.

Owner:IBM CORP

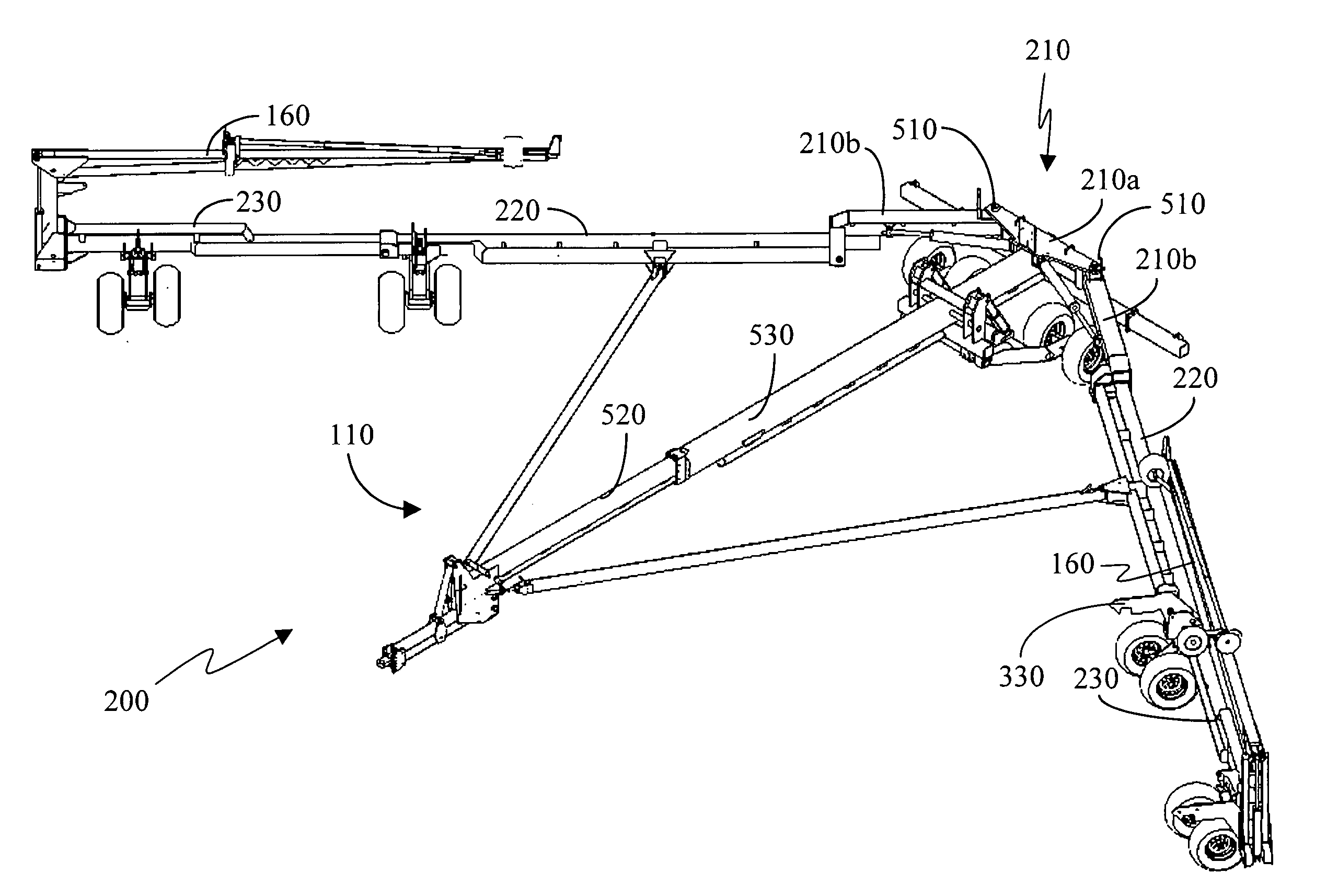

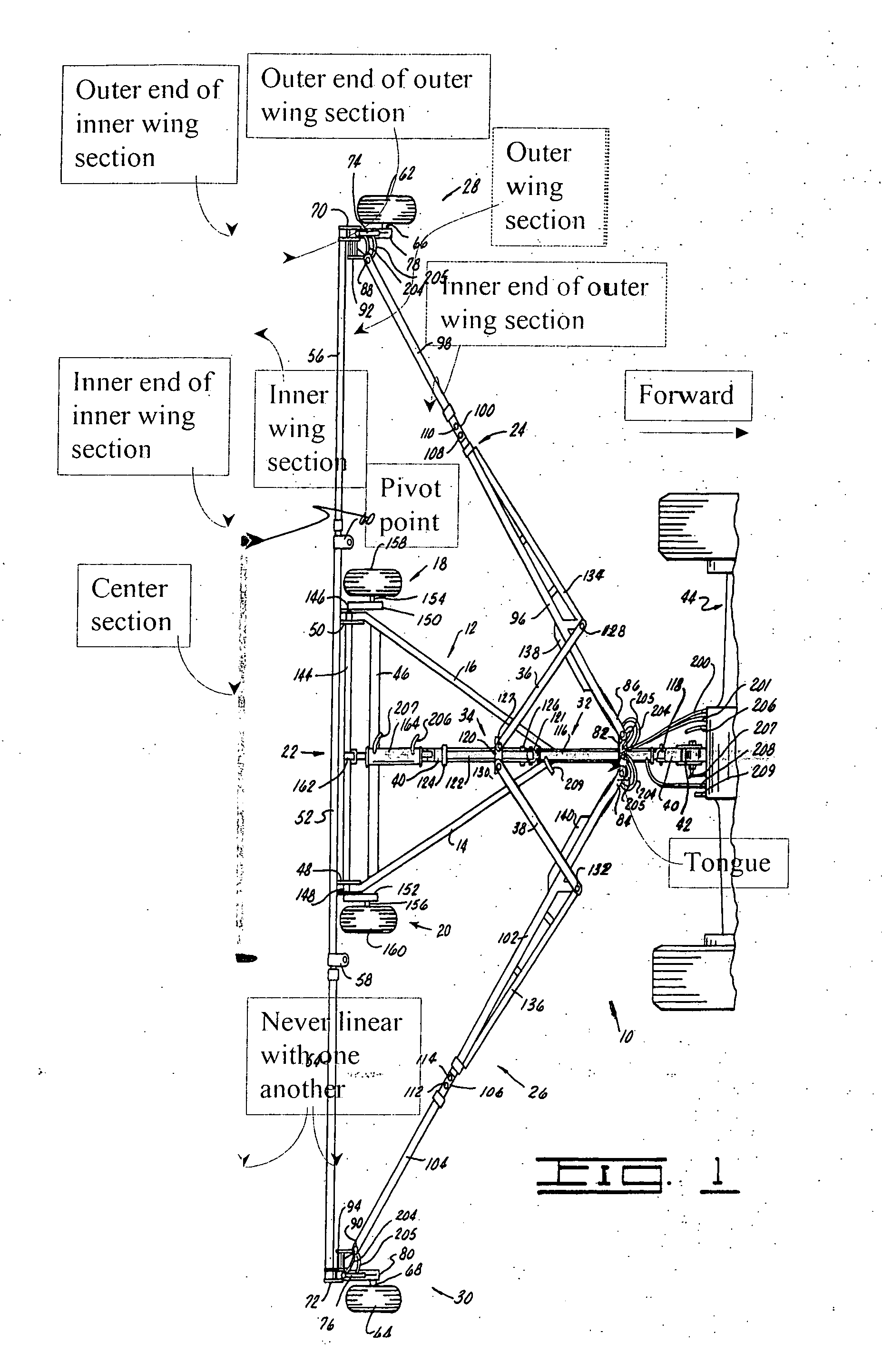

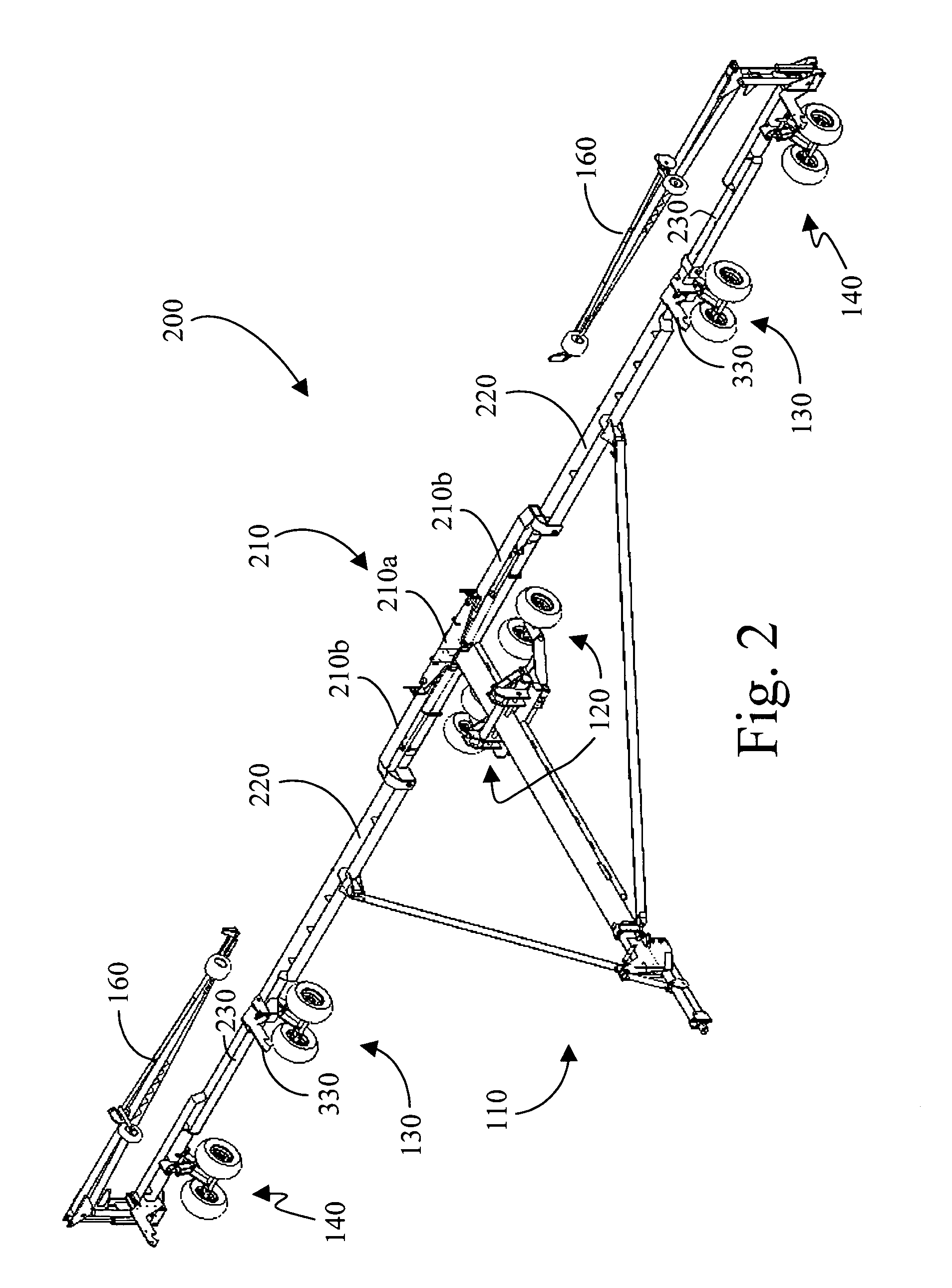

Sectional toolbar for a planter

InactiveUS20050087350A1High maintenanceImprove reliabilitySpadesAgricultural machinesSeederGround contact

Implement toolbars as used for planters have become very long in recent years. In order to assure good ground contact, the long toolbar of the present invention is divided up into more than three sections, including a center section and wing sections. The wing sections fold forward for transport on public roads, over field accesses, and through gates. The resulting planter can be longer than prior art planters while providing sound ground contact and a compact transport mode.

Owner:BAUER VAUGHN L

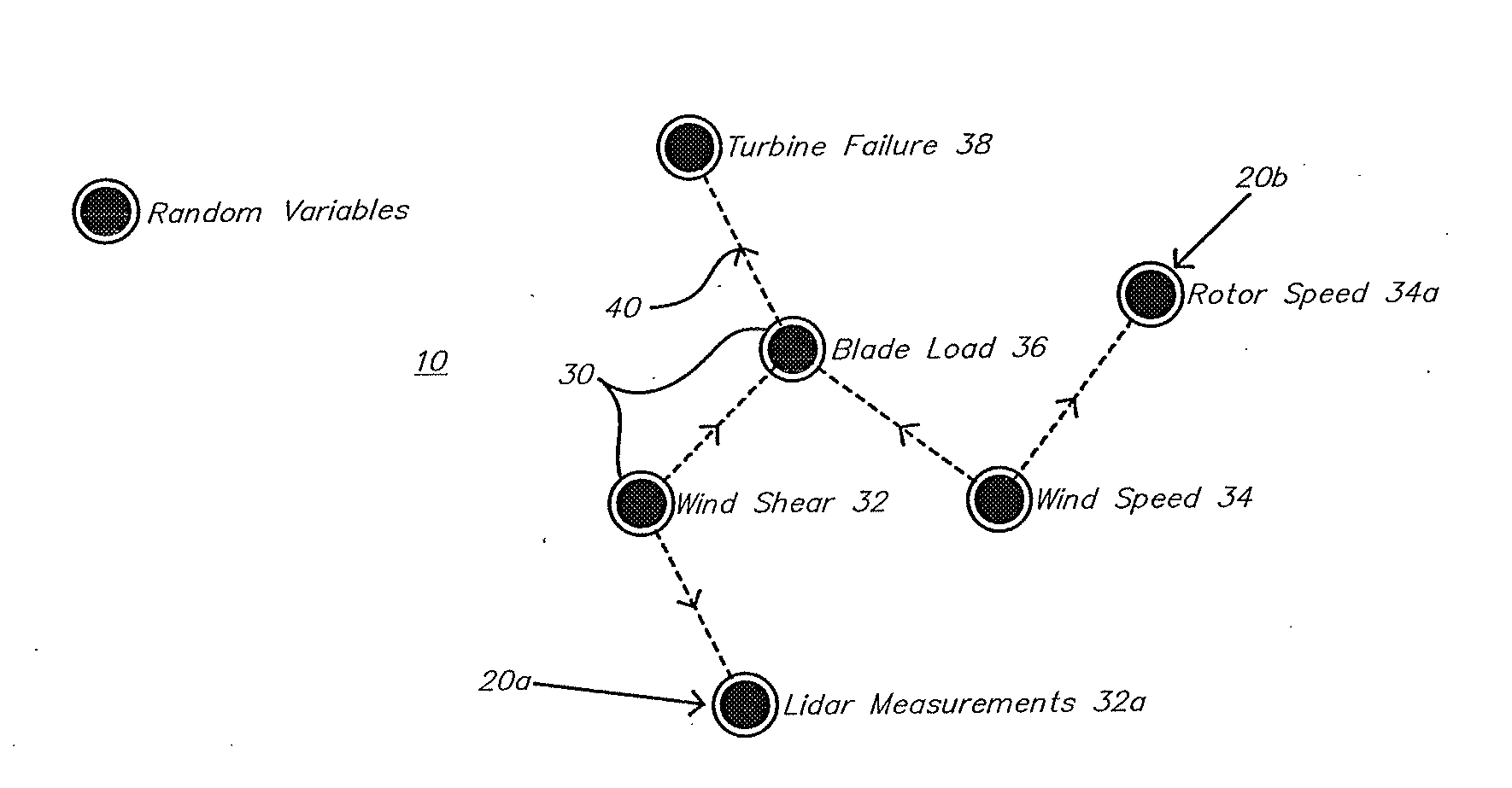

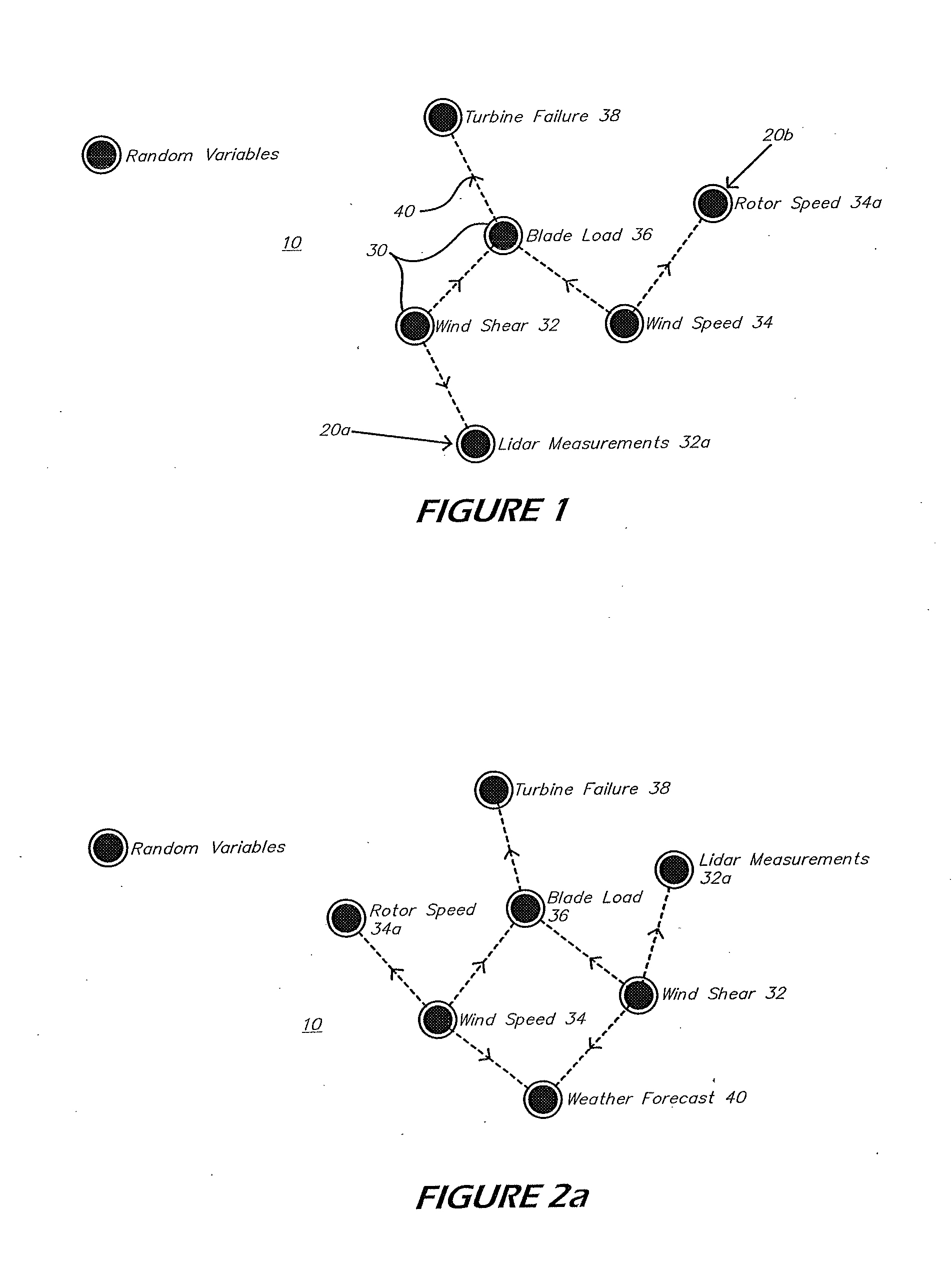

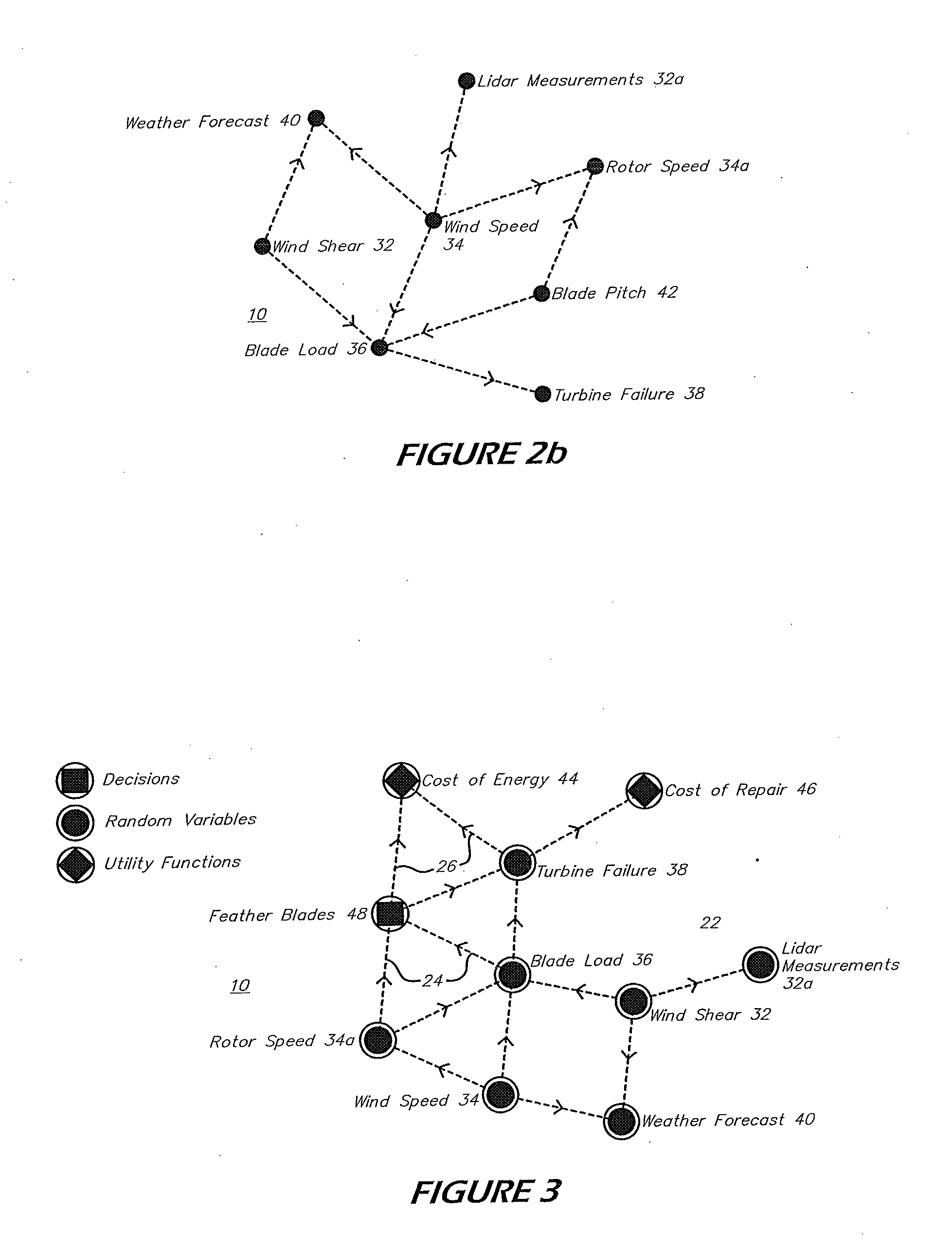

Resource optimization using environmental and condition-based monitoring

InactiveUS20130184838A1Increase in sizeIncreased susceptibilityWind motor controlMachines/enginesProbit modelAnalysis data

In a method for dynamically optimizing resource utilization in a system over time according to one or more objectives, data including information indicative of current environmental conditions, upcoming environmental conditions, a current state of a system configuration, and current system operating conditions is dynamically updated. Automatic analysis of the data using a probabilistic model based on conditional relationships is performed periodically. For each periodically generated set of possible system control actions, a probabilistic model is used to automatically analyze each possible system control action and an optimal system control action is selected based on a set of current utility functions. For each periodically generated set of possible system control actions, control of the system according to the optimal system control action selected from the possible system control actions. Resource optimization couples condition-based and environmental monitoring with automated reasoning and decision making technologies, to develop real time optimal control and decision strategies.

Owner:MICHIGAN AEROSPACE

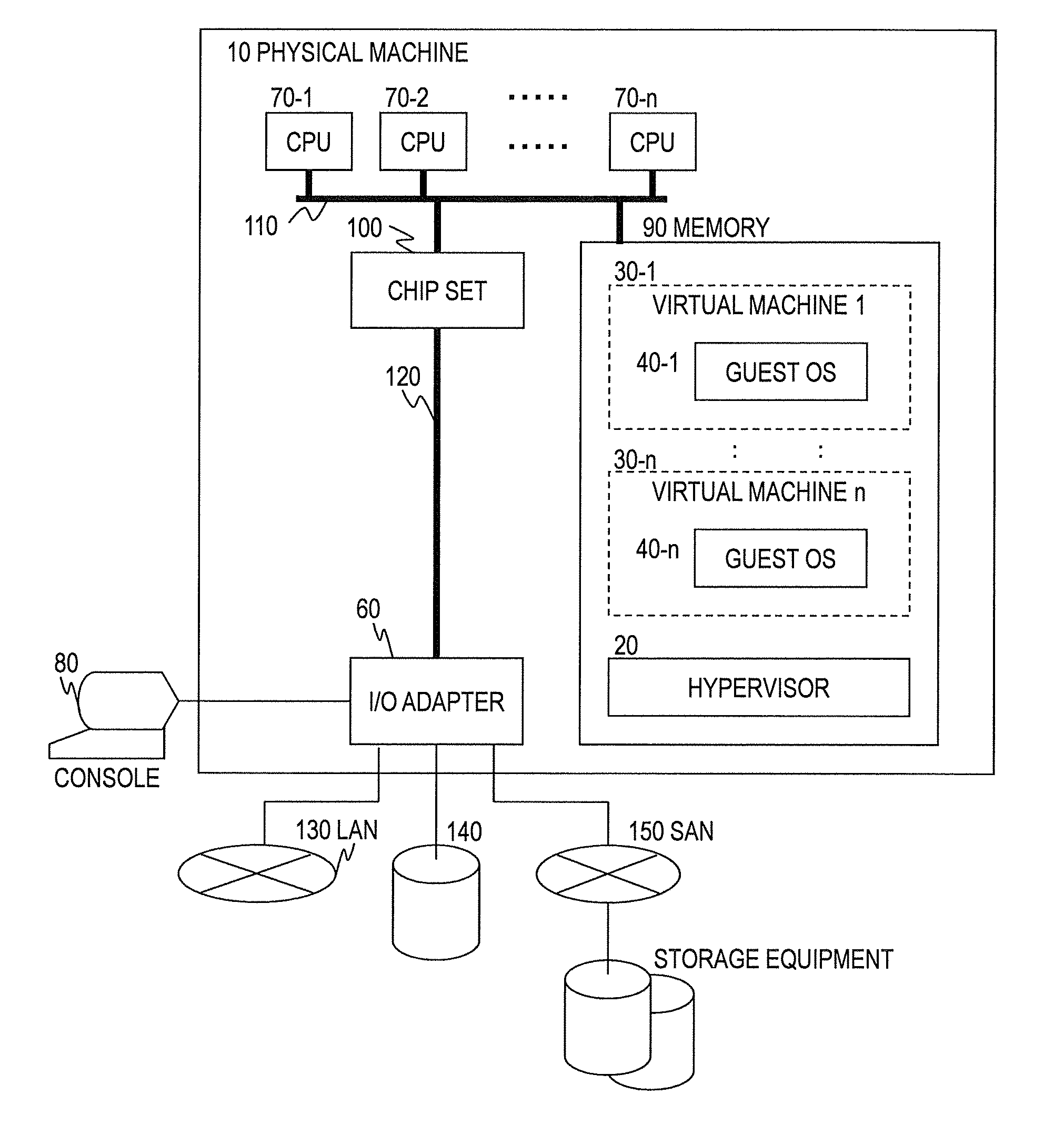

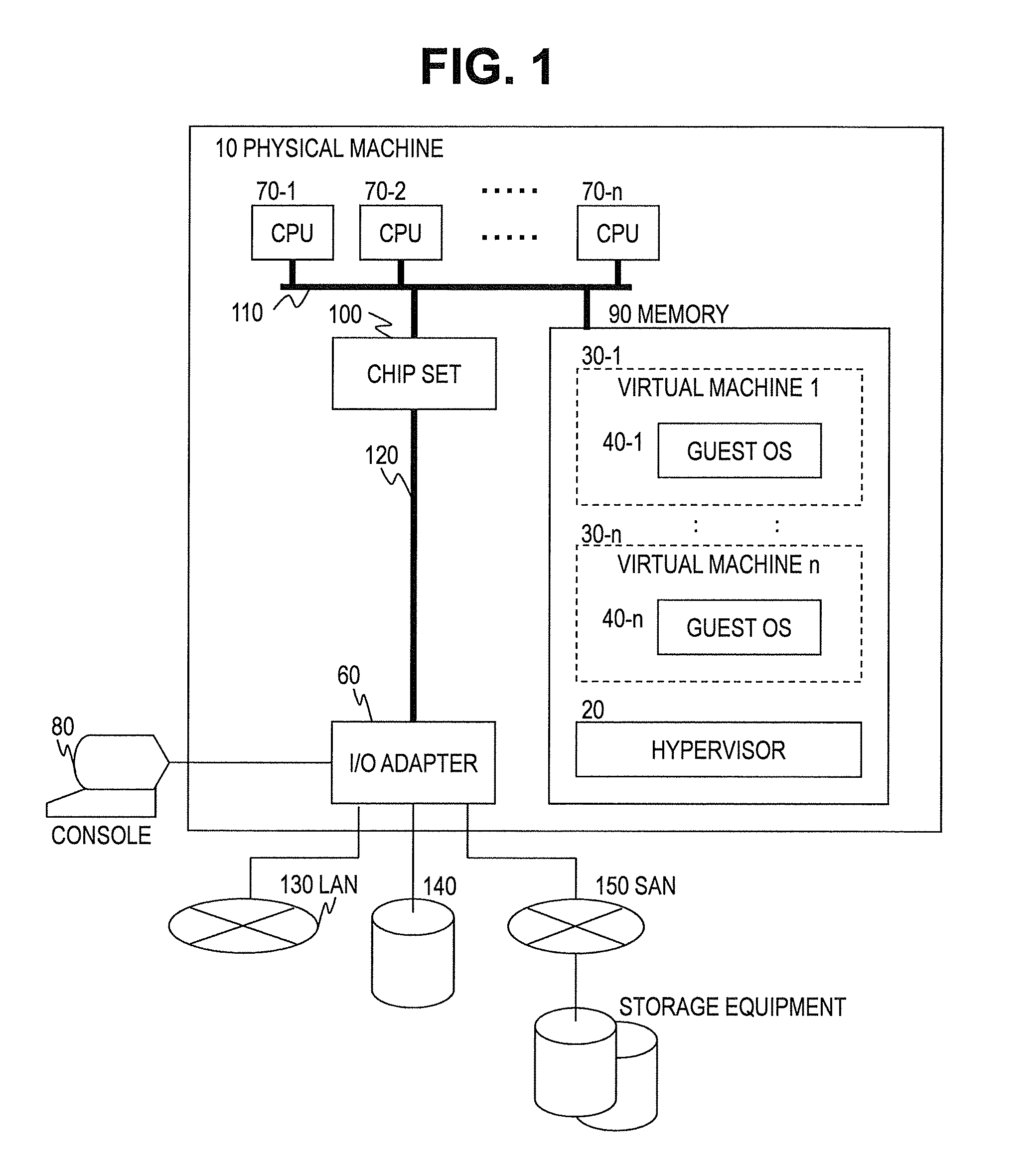

Virtual computer system and controlling method of virtual computer

InactiveUS20120246644A1Improve performanceImprove reliabilitySoftware simulation/interpretation/emulationMemory systemsComputer resourcesVirtualization

A method of controlling a virtual machine of a computer, the computer comprising: a physical machine comprising an I / O adapter having a physical function that creates a virtual function; a virtualization unit that provides computer resources of the physical machine to the virtual machine; and an OS that is executed on the virtual machine, the virtualization unit creating a virtual machine to which the virtual function is assigned, the virtual machine running the OS thereon, the method comprising: a first step of detecting, by the virtualization unit, a state change of the I / O adapter; a second step of identifying, by the virtualization unit, when a state of the I / O adapter becomes a predetermined state, the virtual machine to which the virtual function is assigned; and a third step of notifying, by the virtualization unit, the OS running on the identified virtual machine of the state of the I / O adapter.

Owner:HITACHI LTD

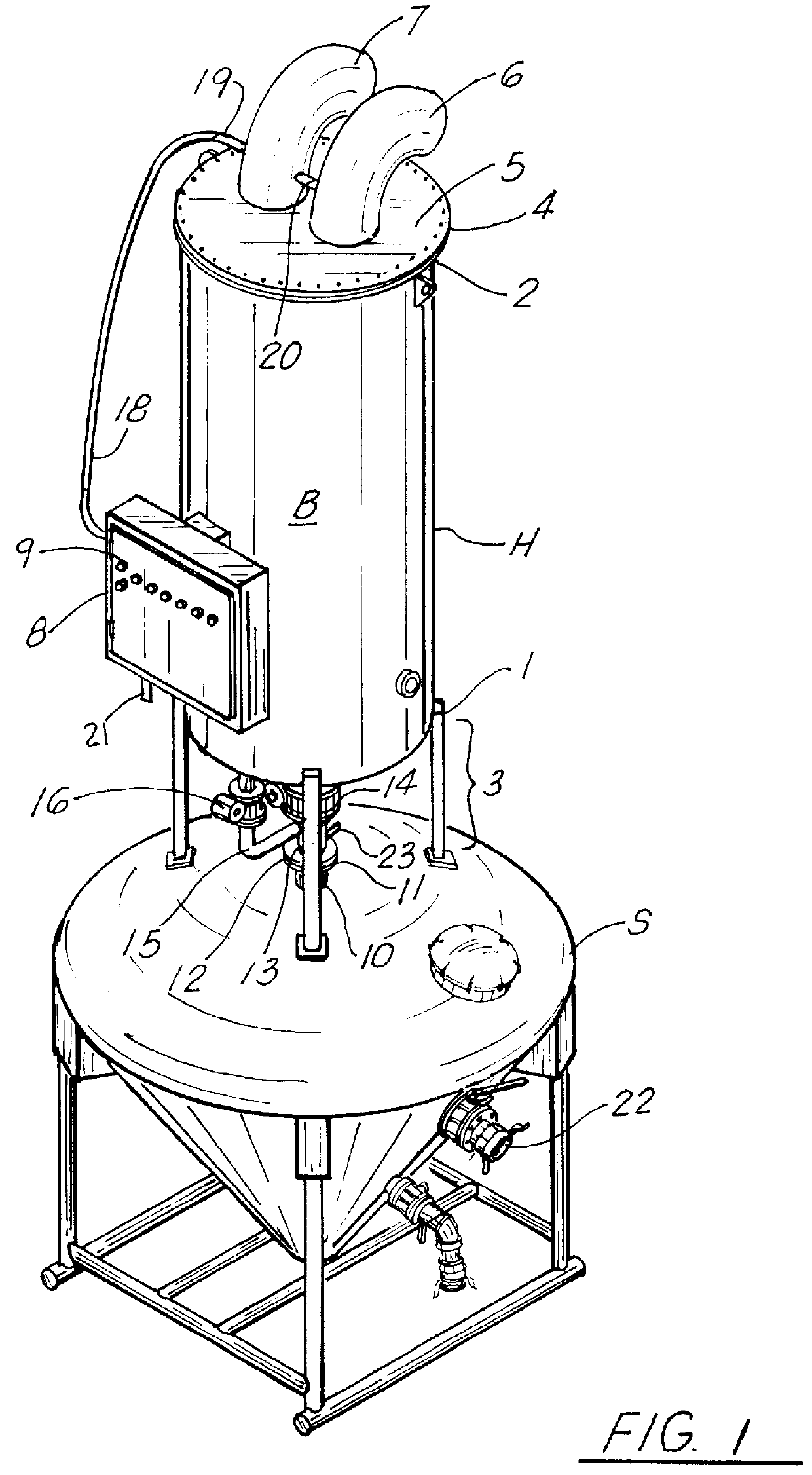

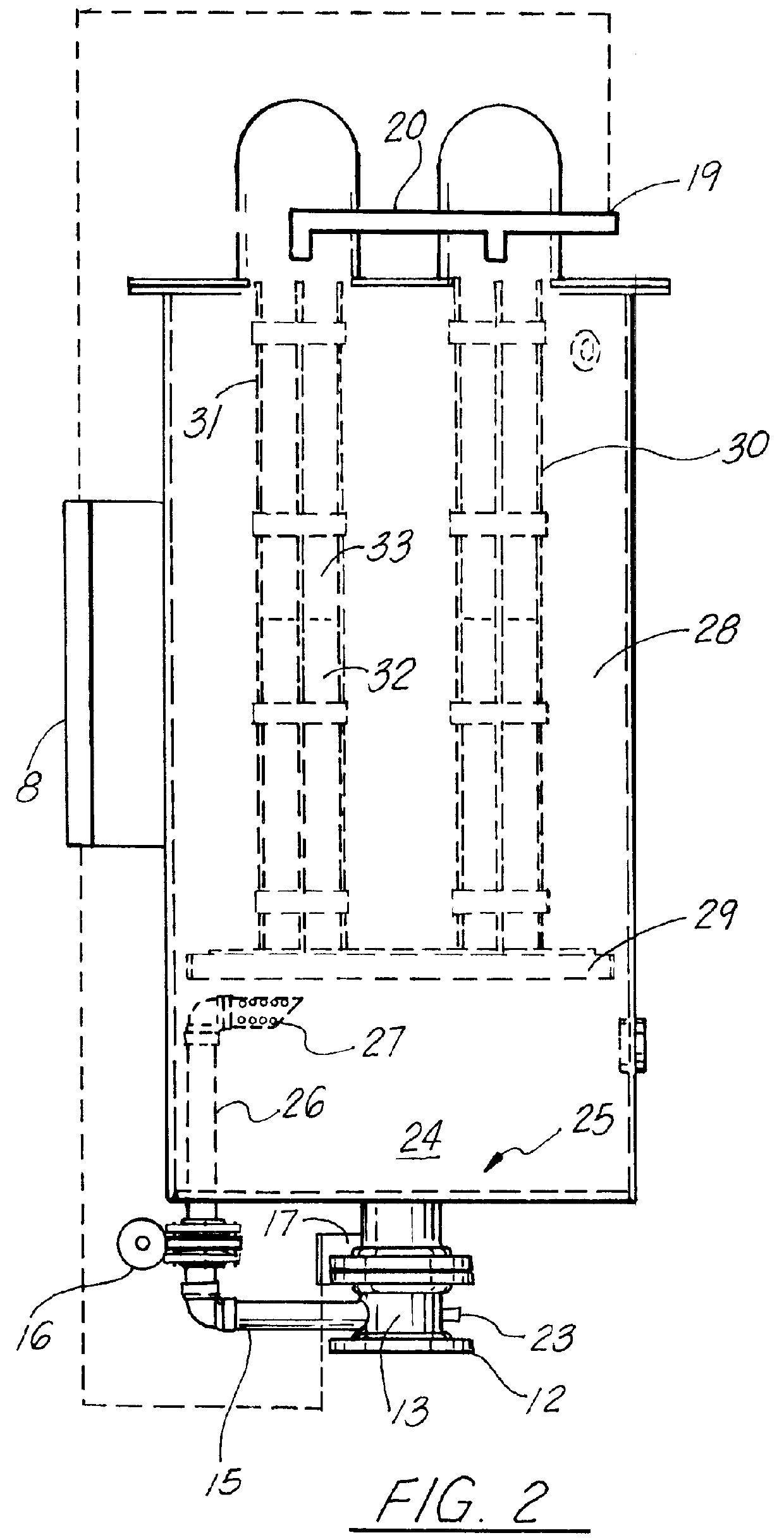

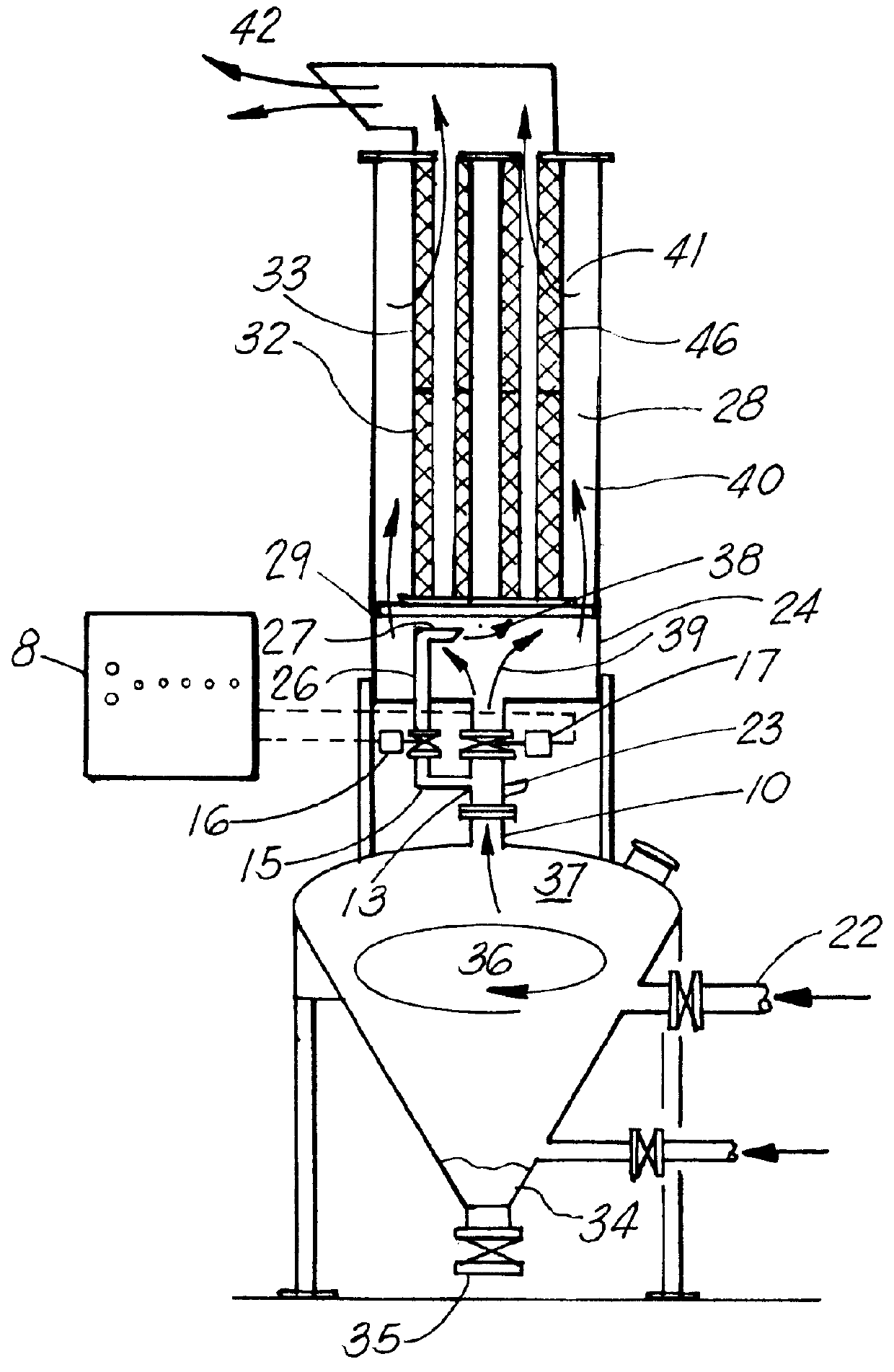

System for depressurizing, filtering, and noise suppression of high pressure pneumatic vessels

InactiveUS6036751AEfficient and safe and reliable and cost-effectiveIncrease pressureCombination devicesAuxillary pretreatmentParticulatesAtmospheric air

A pressure vessel venting, dust collecting, and noise silencing system for continuous venting of dry process air during the filling and depressurization of pressure vessels configured to contain, for example, barite or the like, by filtering of vented air through a filter media, with the air discharge being controlled by a pressure sensor actuating a depressurizing regulator valve, located between the vessel and the filter. The present system contemplated a filter which may be cleaned by reverse pulse pressurization or backwash, thereby providing low maintenance filtration while preventing particle emissions into the atmosphere. The present system utilizes a high capacity, stacked filtration medium, which provides a greater filtration, with a surface contact area far in excess of the present systems on the market, which primarily rely upon bag house filtration. The present system thereby provides a low maintenance, efficient, and relatively cost effective system of controlled, filtered, and silenced venting on a process which would otherwise emit particulates into the air, while generating a significant amount of noise in the process.

Owner:RIBARDI HARRIS J +1

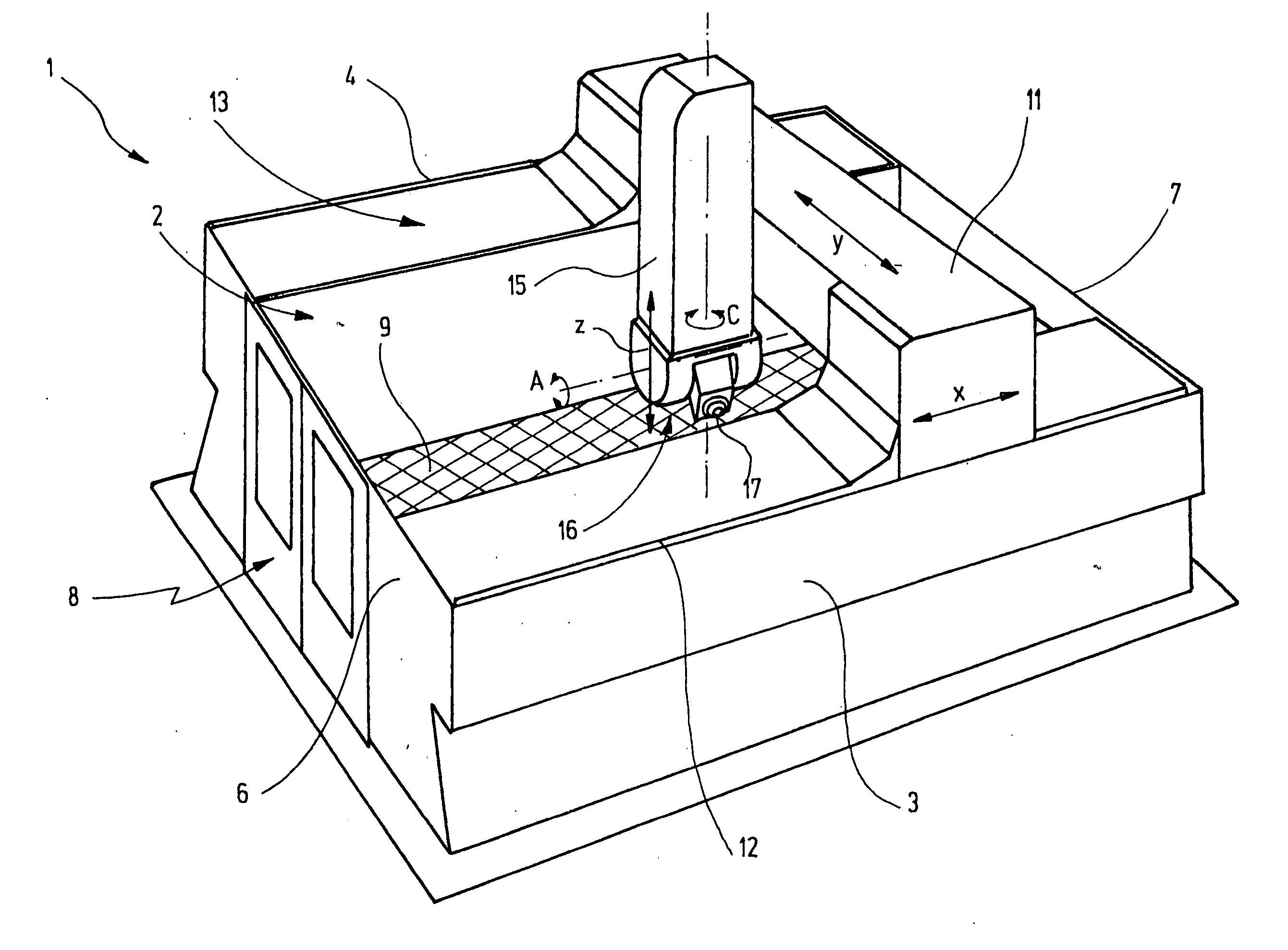

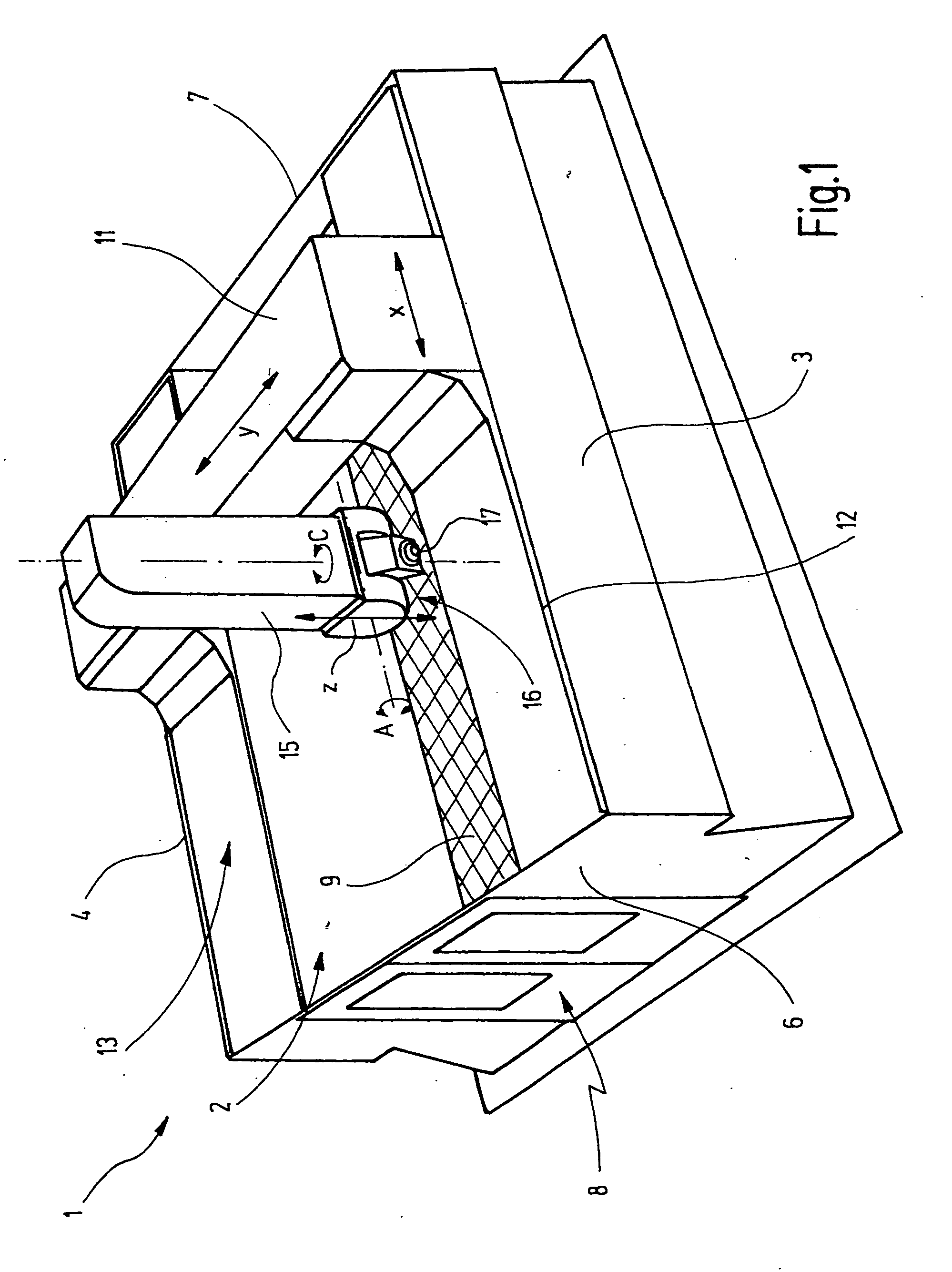

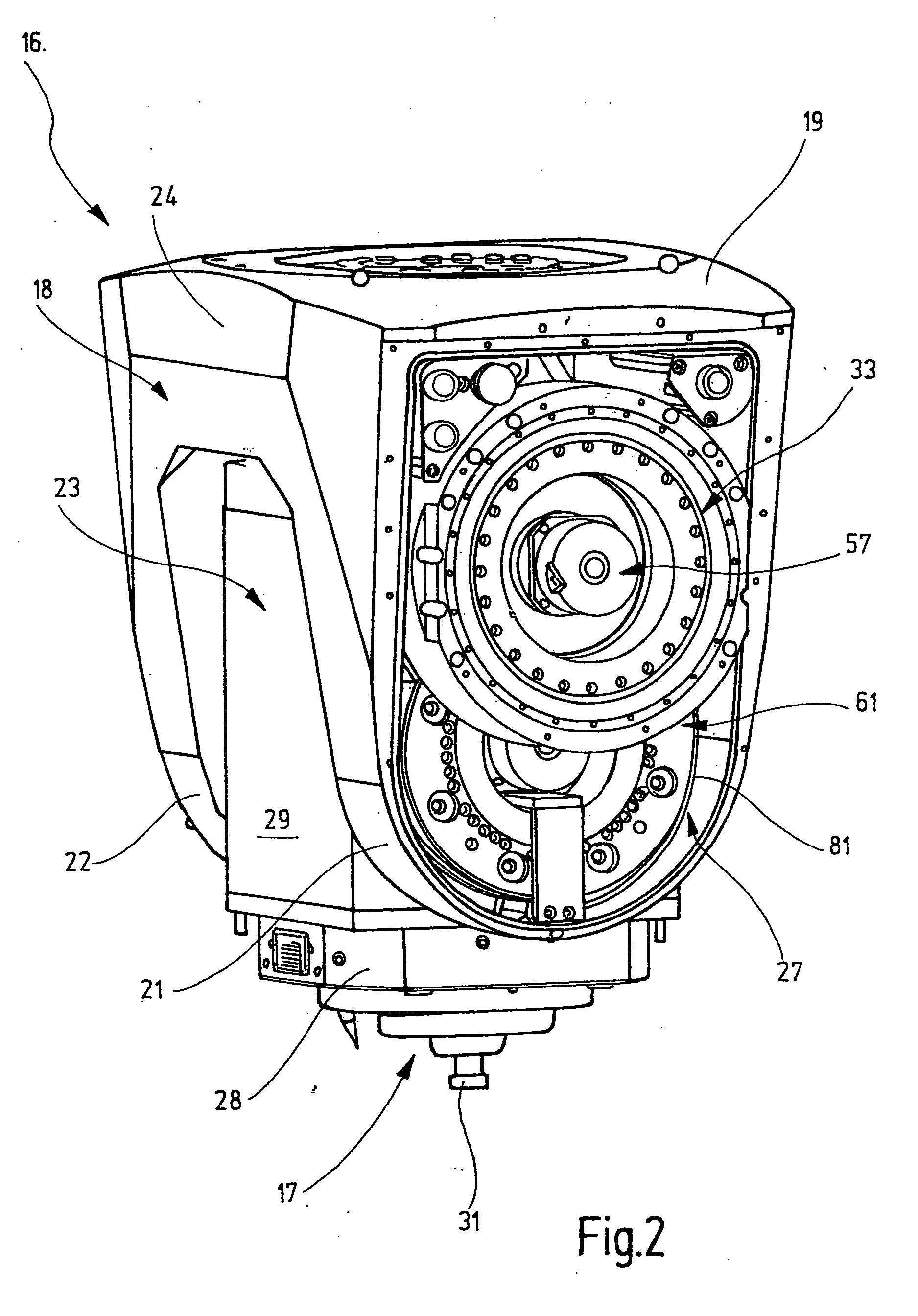

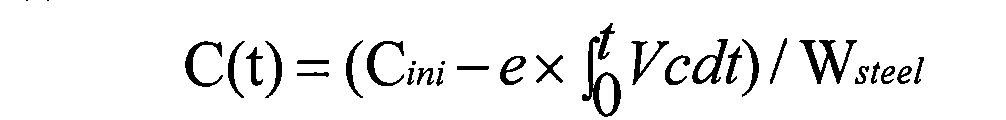

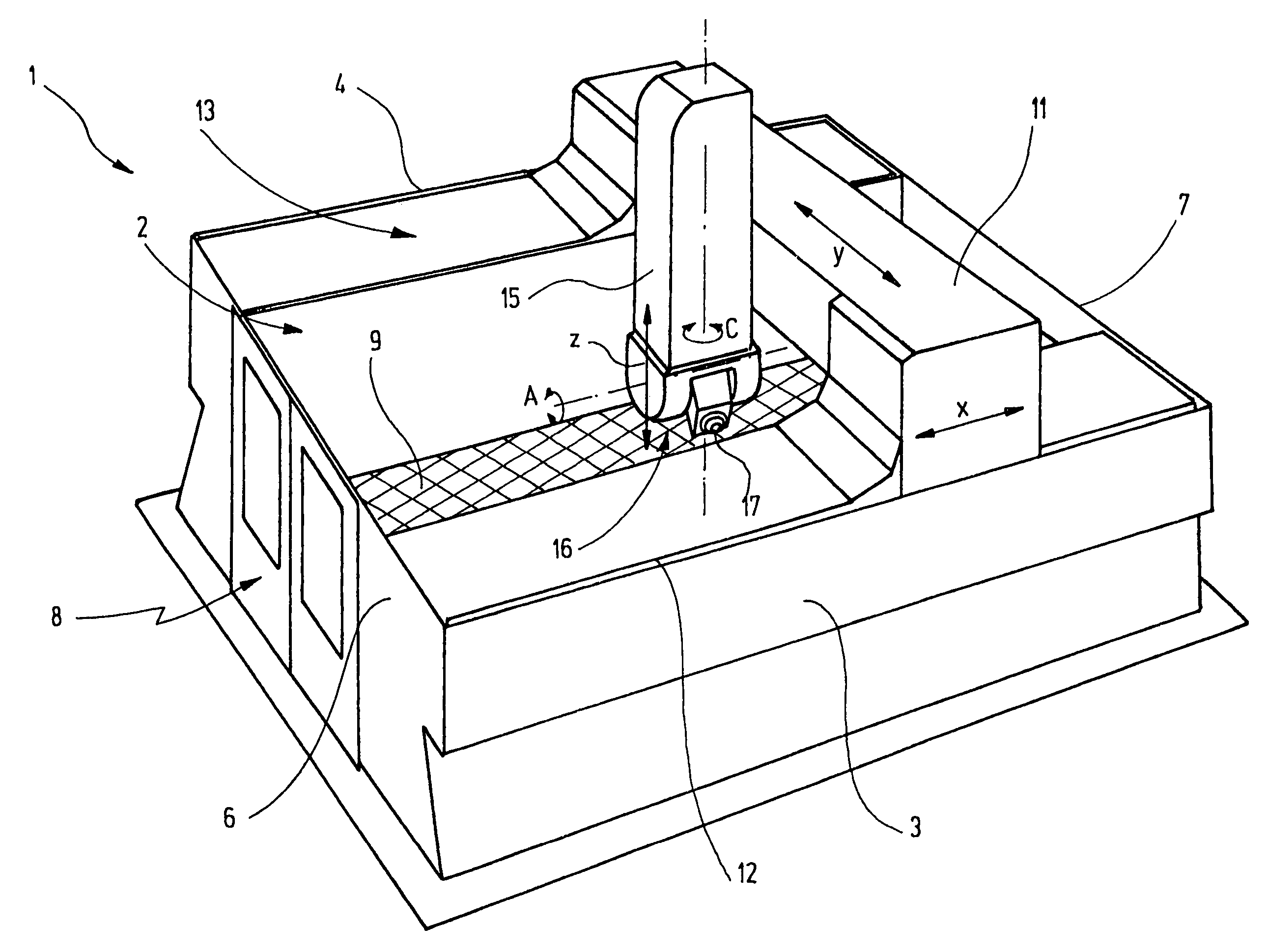

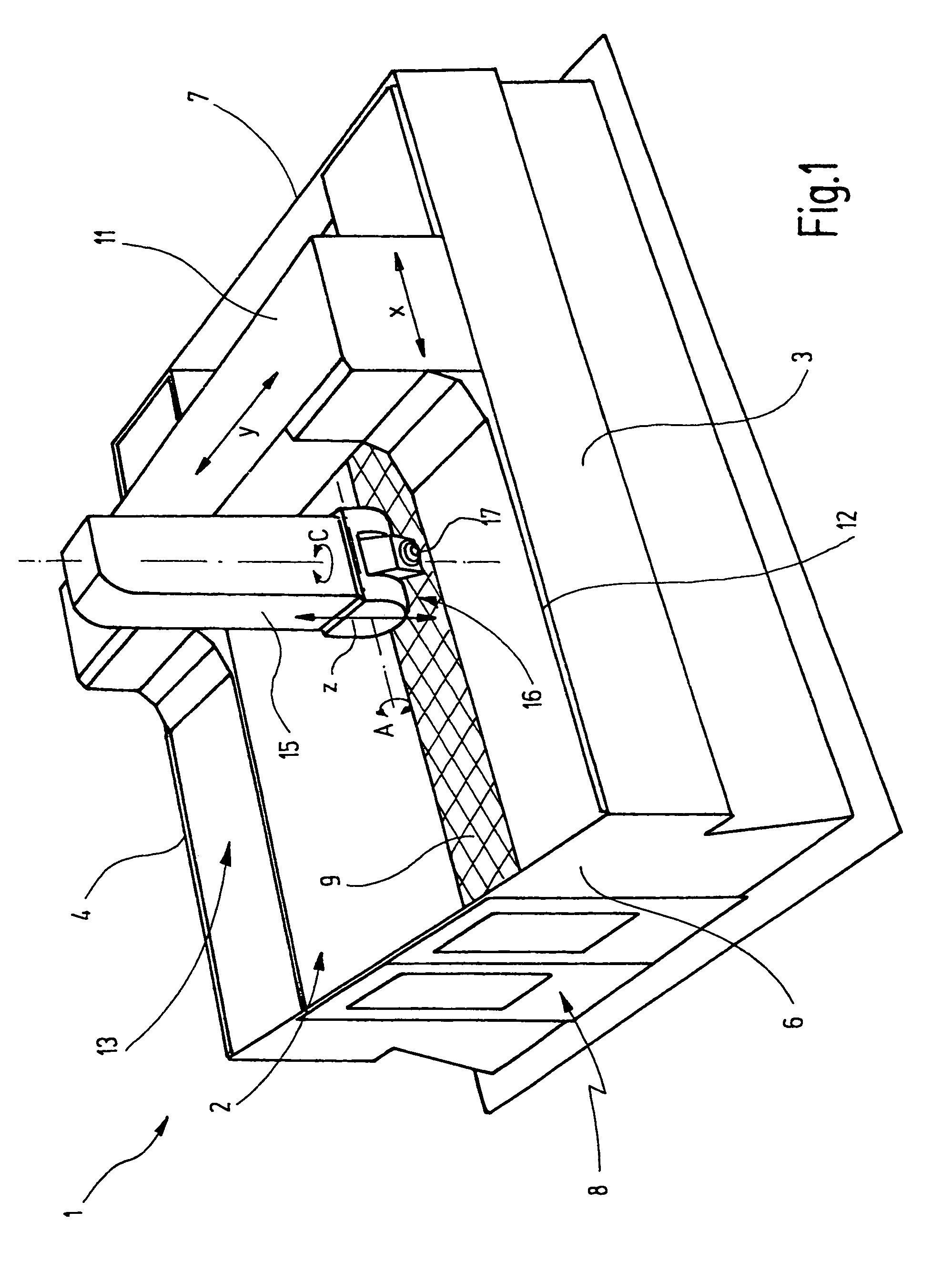

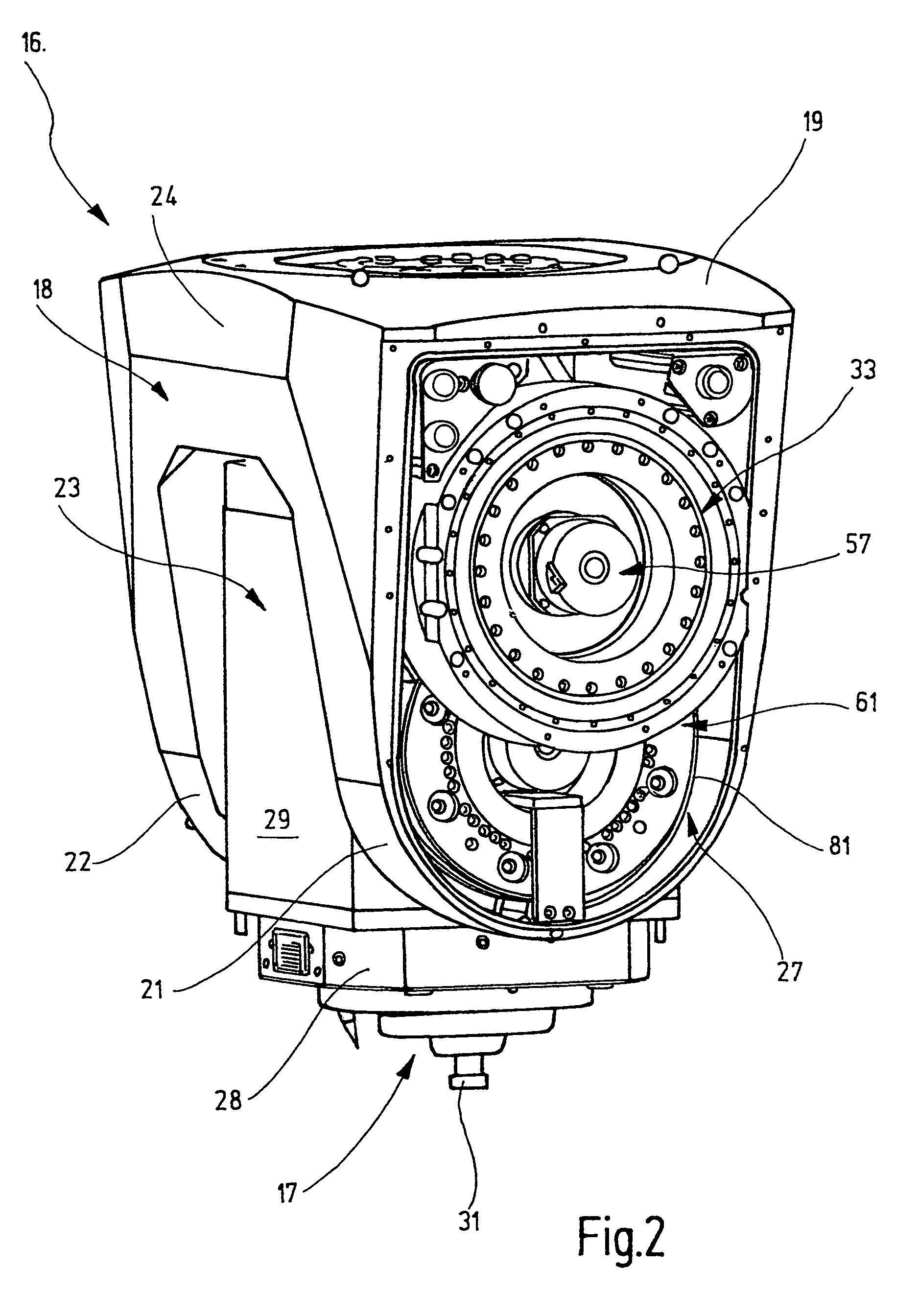

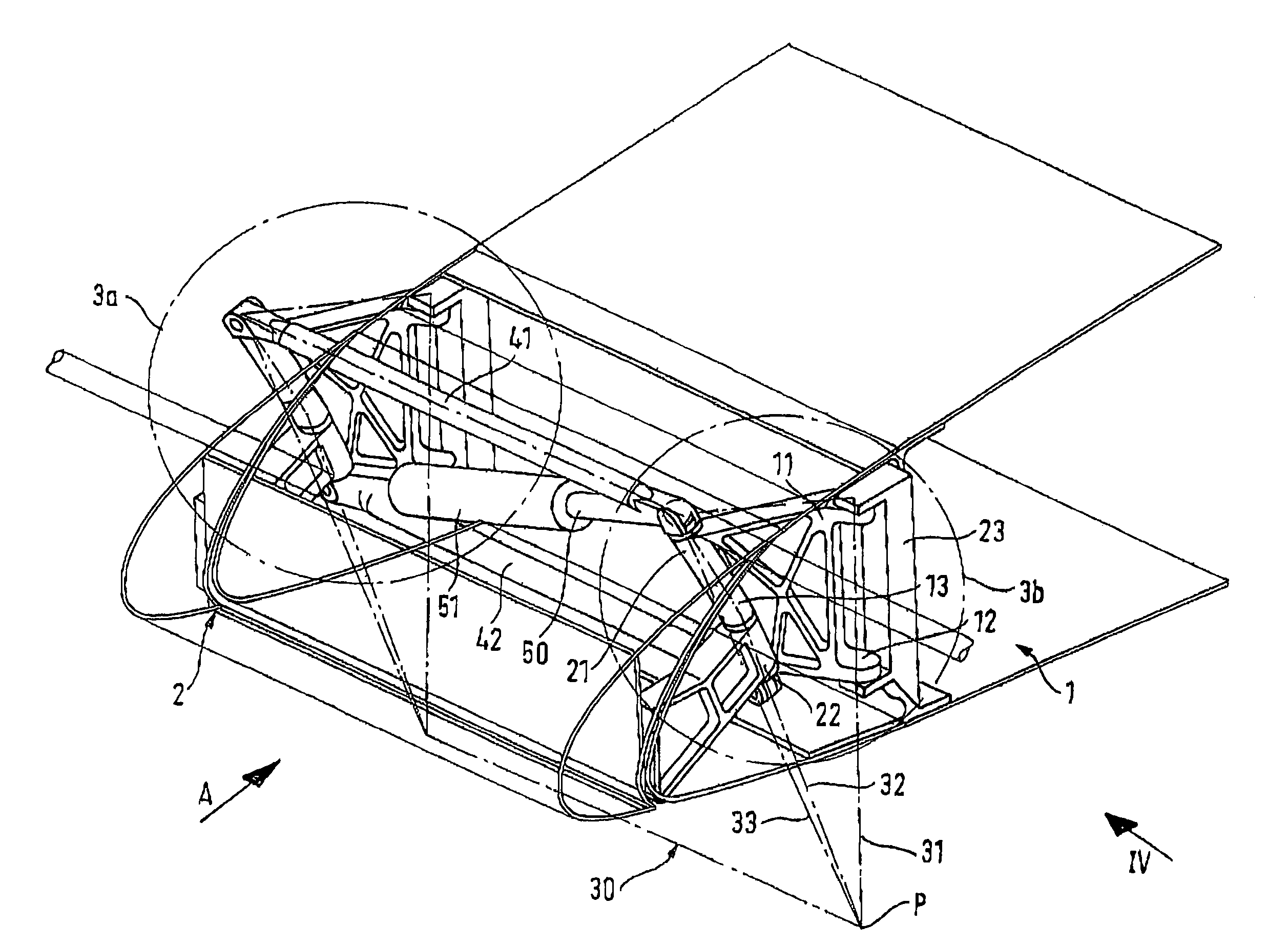

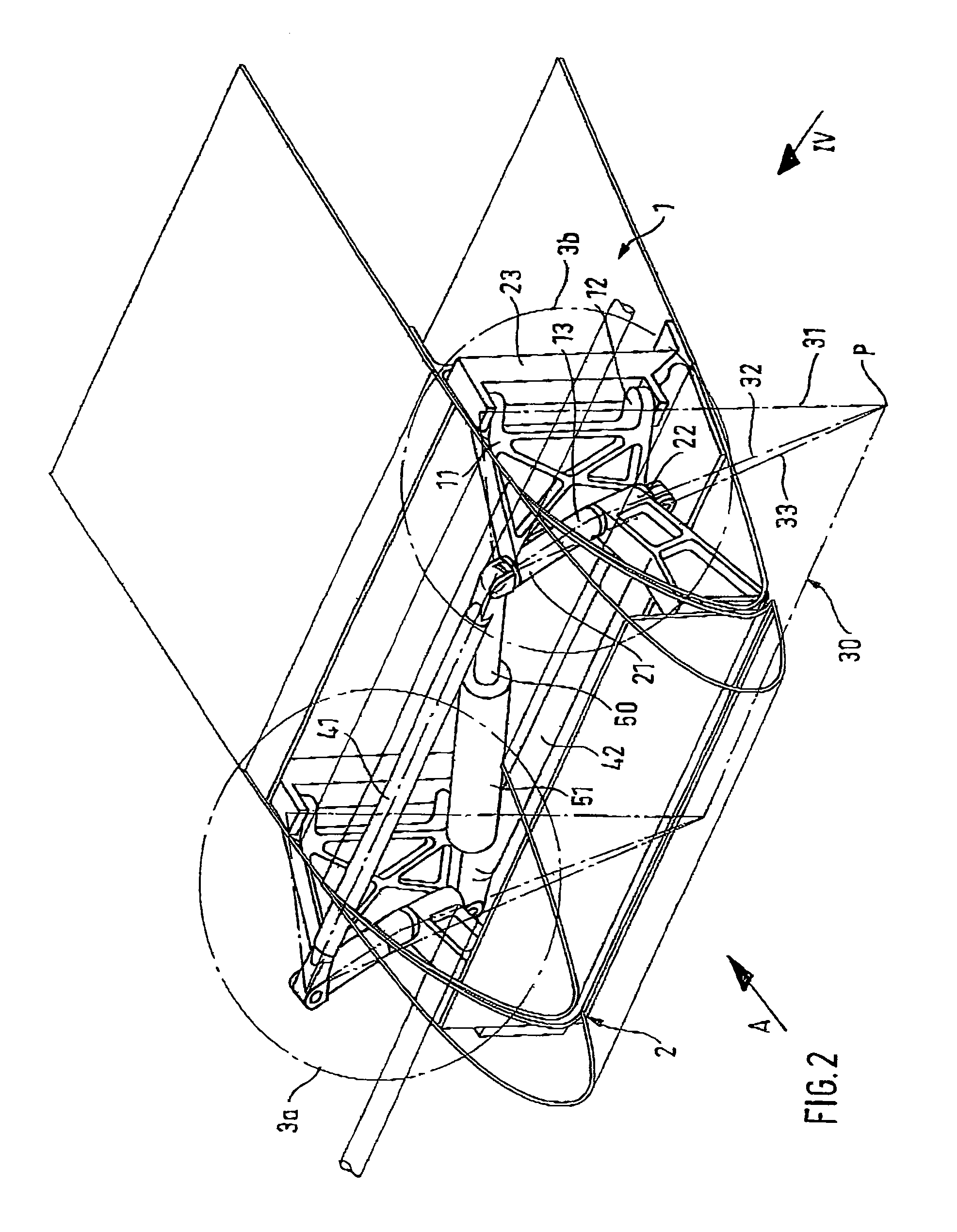

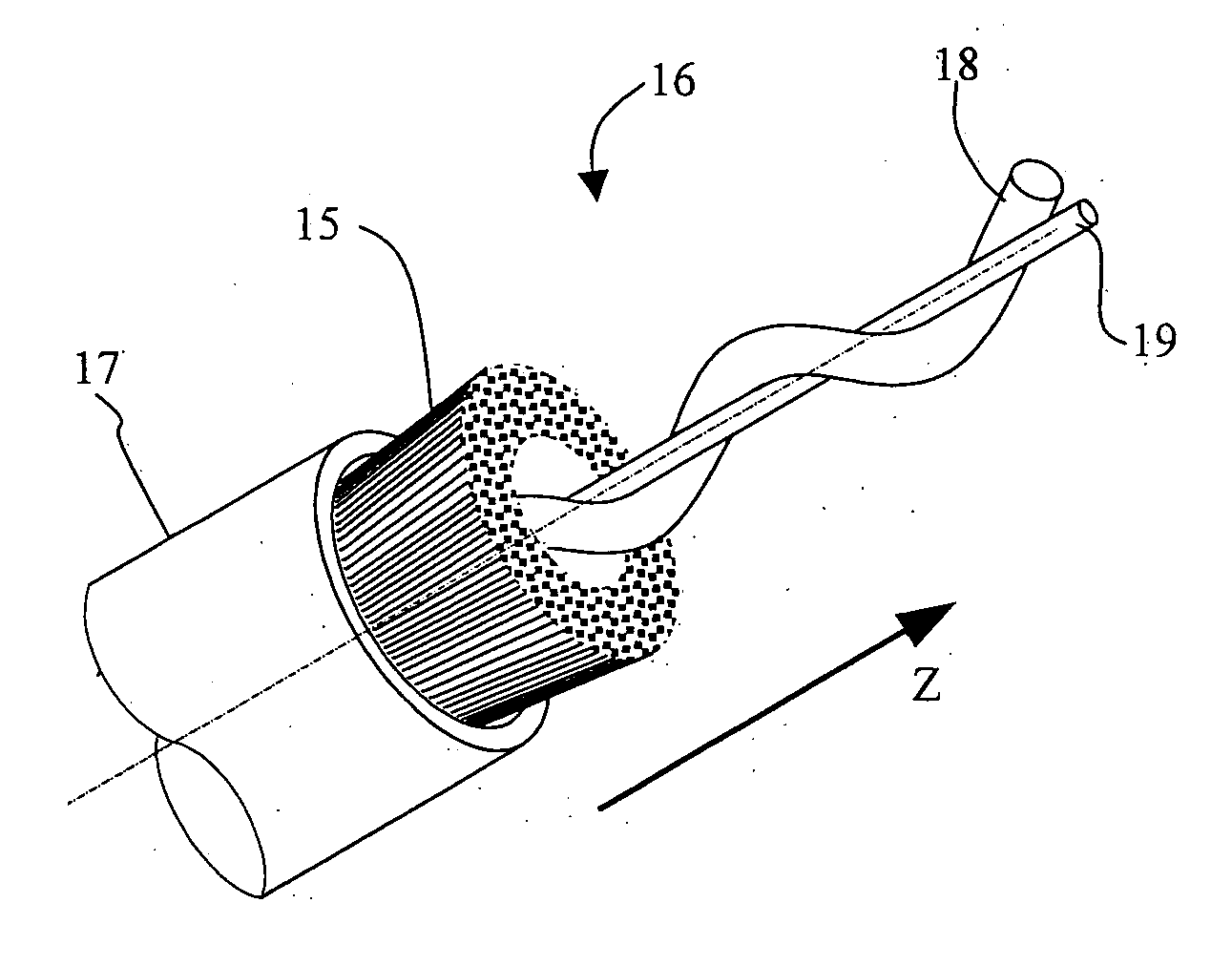

Mobile milling head with torque motor drive

InactiveUS20070059116A1Improve surface qualityPrecise positioningMachine tool componentsWorkpiecesDynamic stiffnessGear drive

A milling head (16) for a milling machine (1) arranged for machining large-size workpieces comprises a fork 18, which is rotatably arranged around a first axis (C) and demonstrates a pair of fork arms (21, 22), which are separated from one another, a spindle device (23), which is arranged between the fork arms and rotatable around a second axis A, a first torque motor (42), which is coupled to the fork 18 for directly driving and controlling of the rotation of the fork around the first axis (C), and a second torque motor (57) for driving and controlling the rotation of the spindle around the second axis (A), said second torque motor being coupled to the spindle device (23) by means of a one-stage toothed gearing (61), which is mechanically clamped free of backlash. The configuration according to the invention is arranged to achieve high torque with high dynamic stiffness and small interference contour of the milling head (16).

Owner:FA F ZIMMERMANN

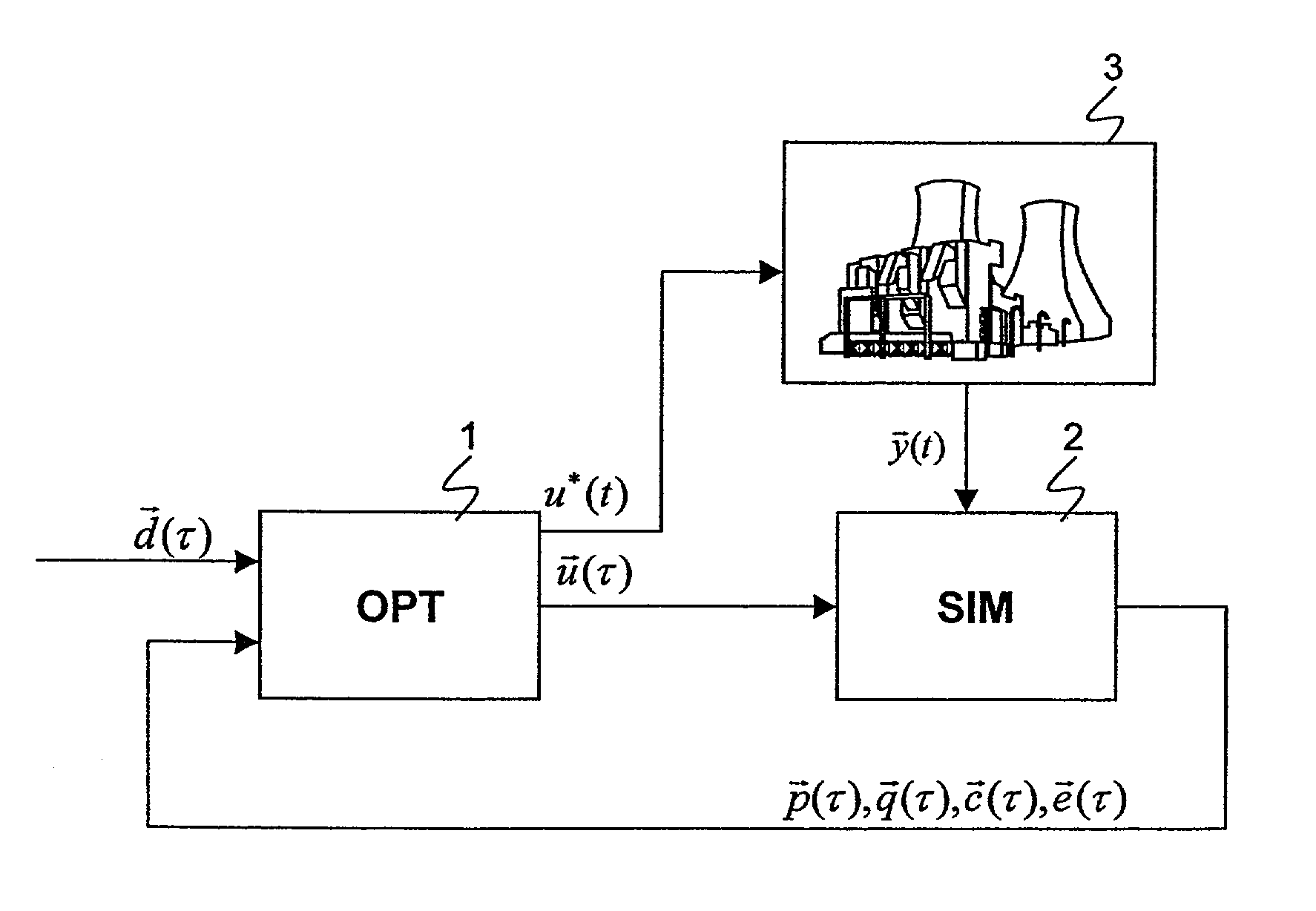

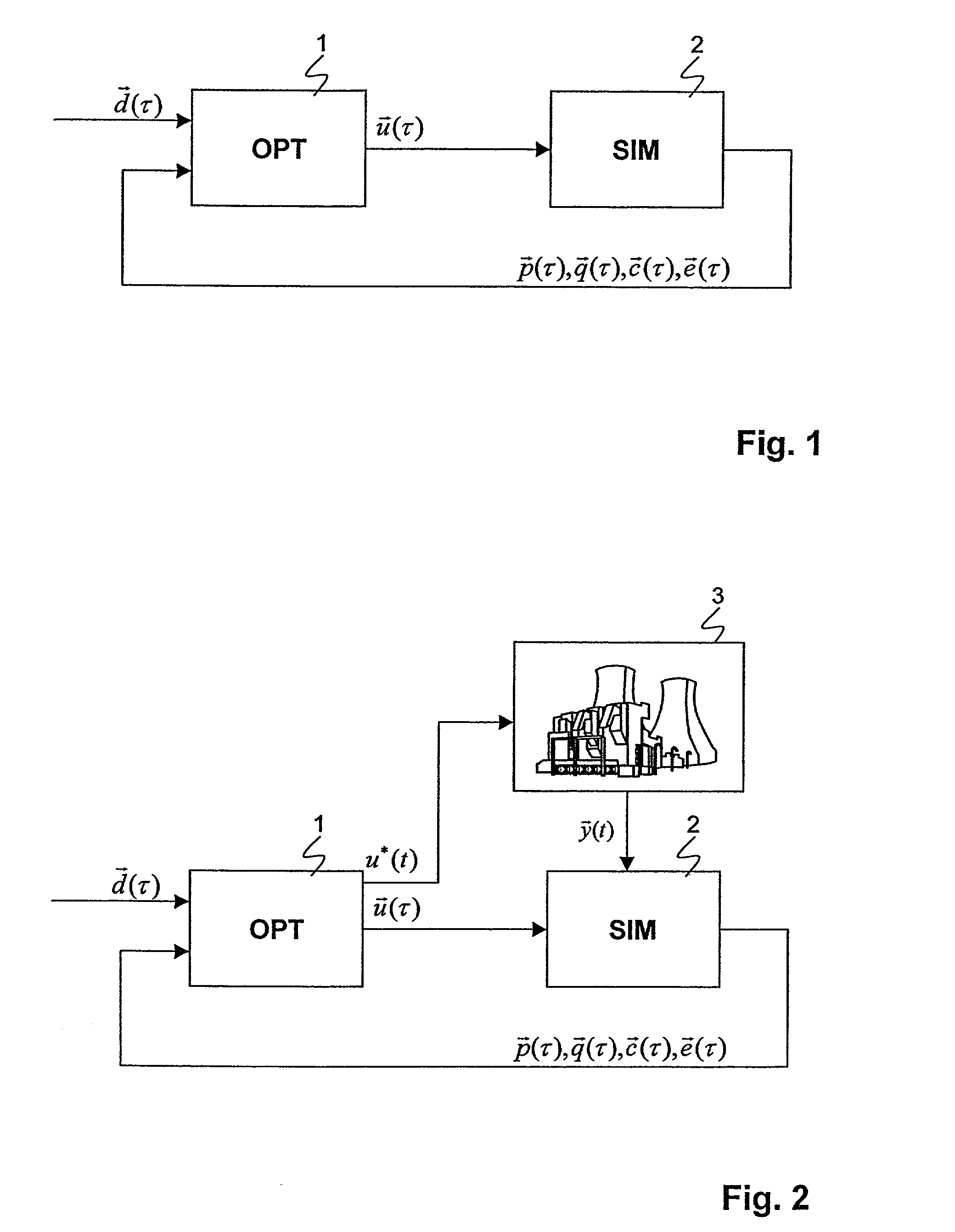

Optimizing plant control values of a power plant

InactiveUS7058552B2High maintenance and replacement costHigh maintenanceComputation using non-denominational number representationAdaptive controlProcess engineeringPower station

In a method and computer program product for optimizing power plant control values and a power plant optimizing system an optimization module (1) minimizes total plant operation costs while achieving predetermined required output values for produced power and process steam. This is done by, at a given time, determining future values of control values and simulating, in a simulation module (2), the behavior of the plant up to a given future time. Corresponding fuel costs and generated power are determined in the simulation, and incorporated in an objective function. The optimization module (1) minimizes the objective function by varying the control values. According to the invention, a rate of ageing of plant components is determined when simulating the future behavior of the plant, and the objective function to be minimized comprises said rate of ageing.

Owner:ABB RES LTD

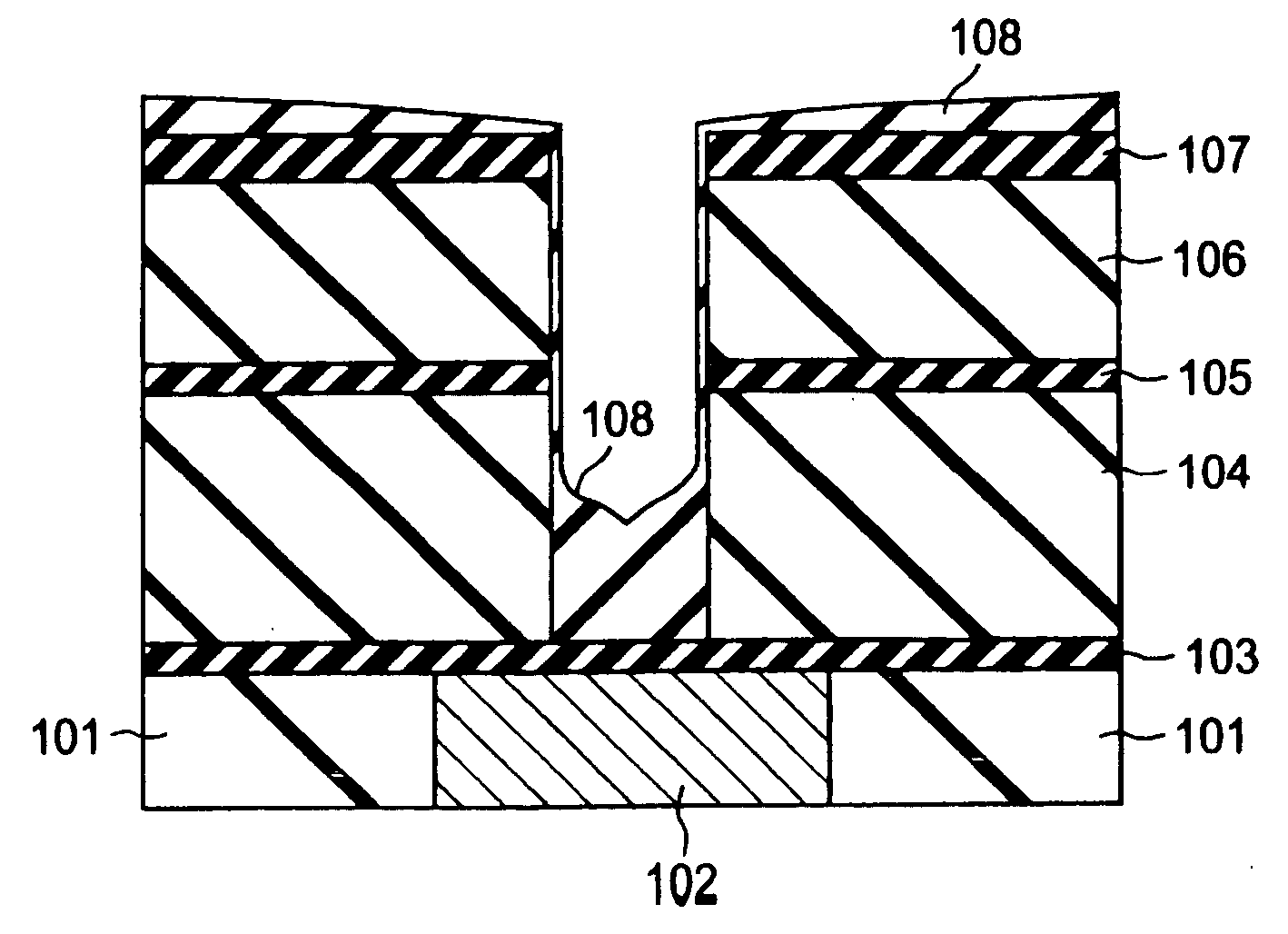

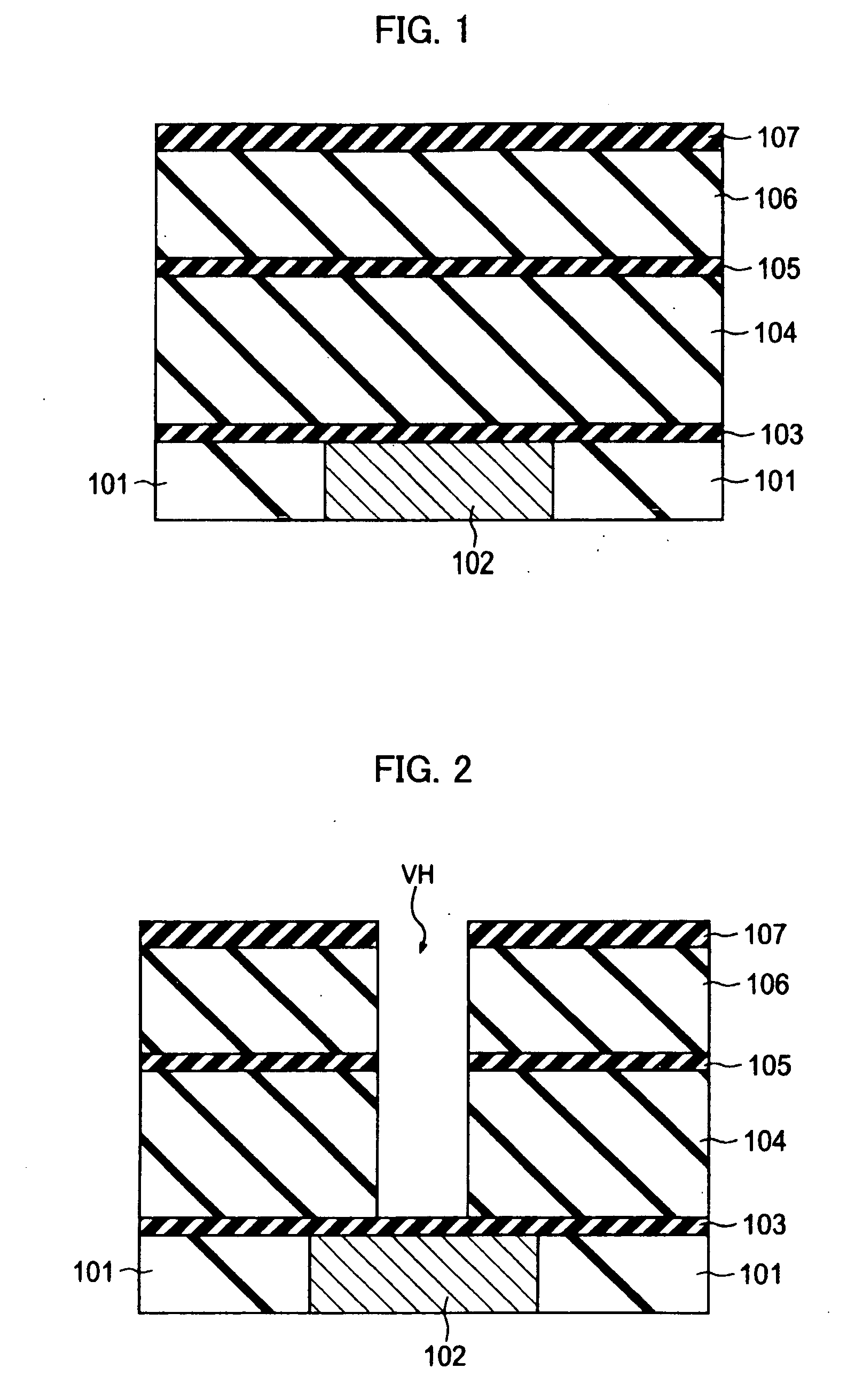

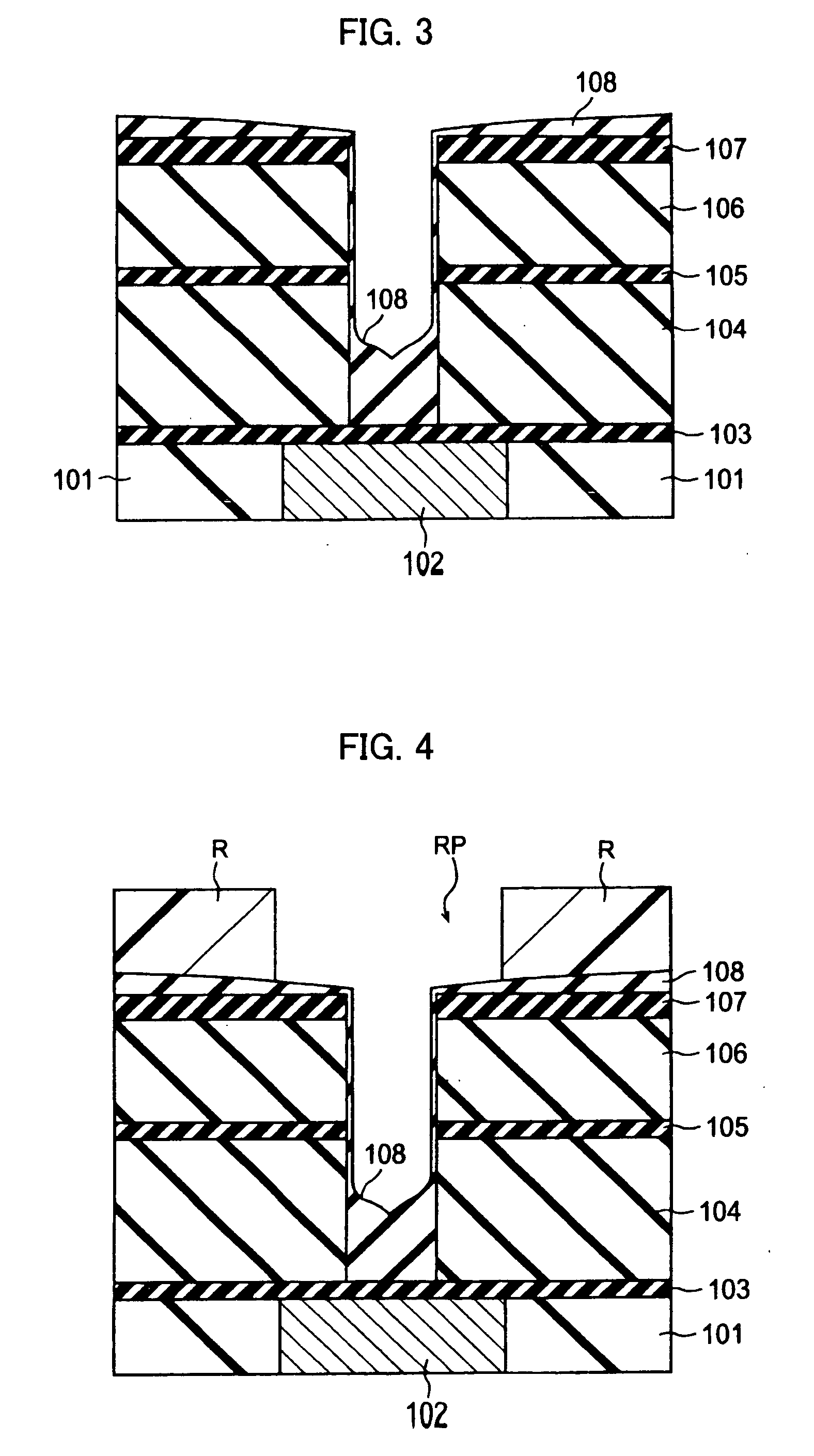

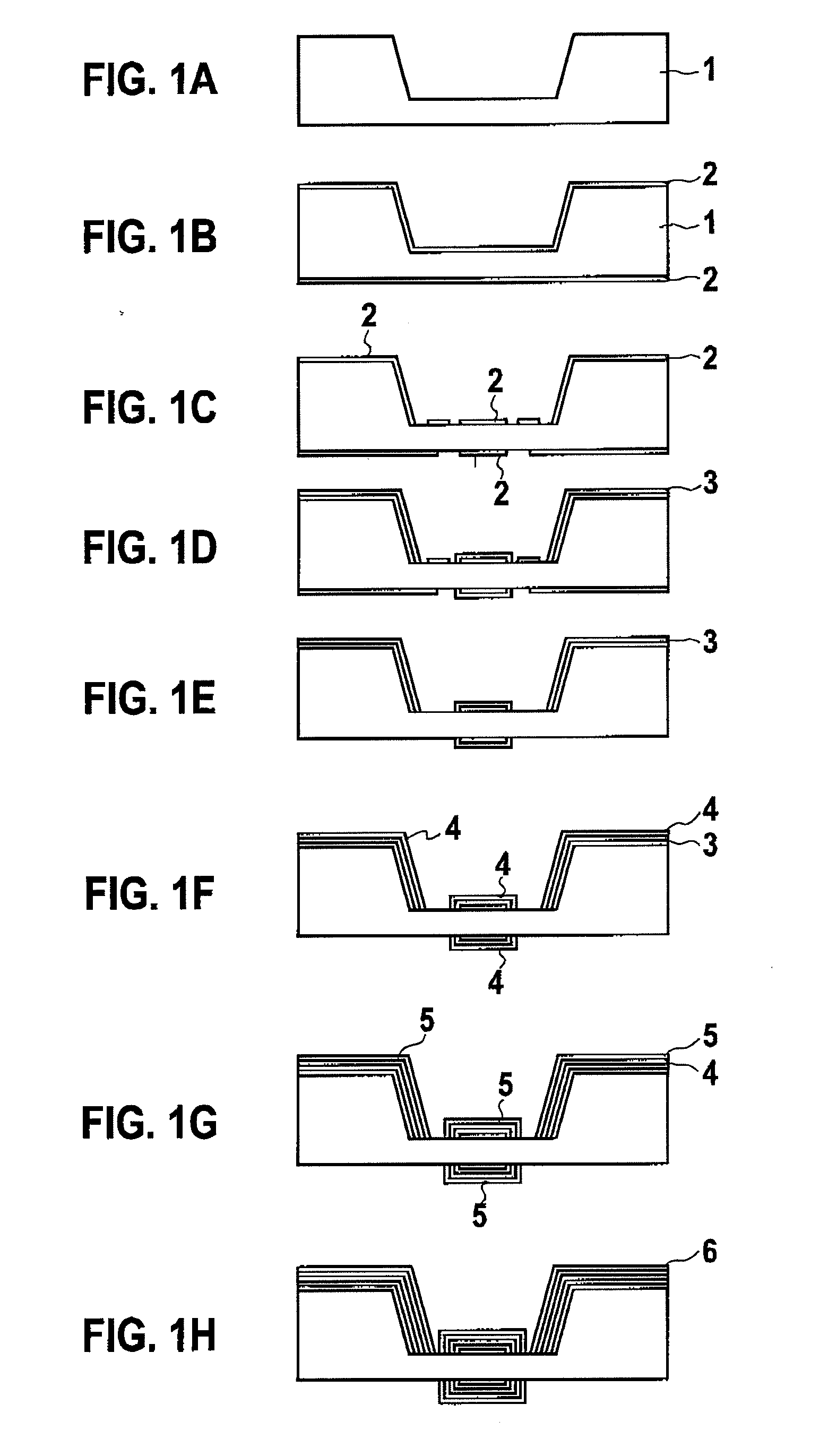

Process for producing semiconductor device and semiconductor device

InactiveUS20050079705A1High maintenanceLower power consumptionSemiconductor/solid-state device manufacturingOrganic baseEngineering

A method of producing a semiconductor device wherein an already formed opening portion inner wall of an organic based interlayer insulation film is prevented from changing in quality or corroding when performing etching on other organic material. The production method includes a step of depositing organic based interlayer insulation films (4, 6), a step of forming an opening on the organic based interlayer insulation films (4, 6), and a step of silylating a wall surface portion of the organic based interlayer insulation films (4, 6) exposed in the opening portion for reforming (forming reformed layers (4a, 6a) by silylation). A more preferable production method further includes a step of forming protective layers (4b, 6b) including an inorganic based insulation material on a surface of the silylated opening portion wall surface.

Owner:SONY CORP

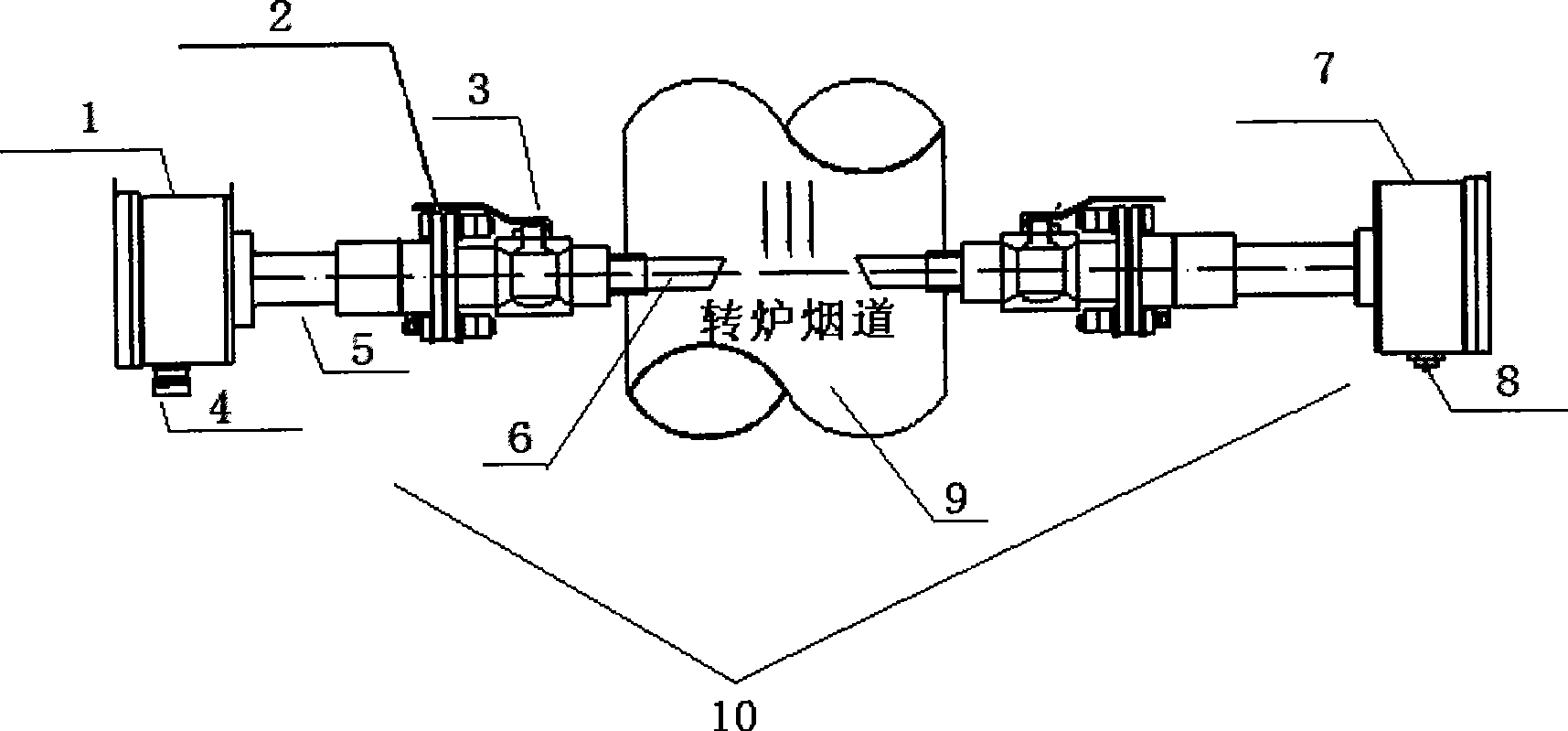

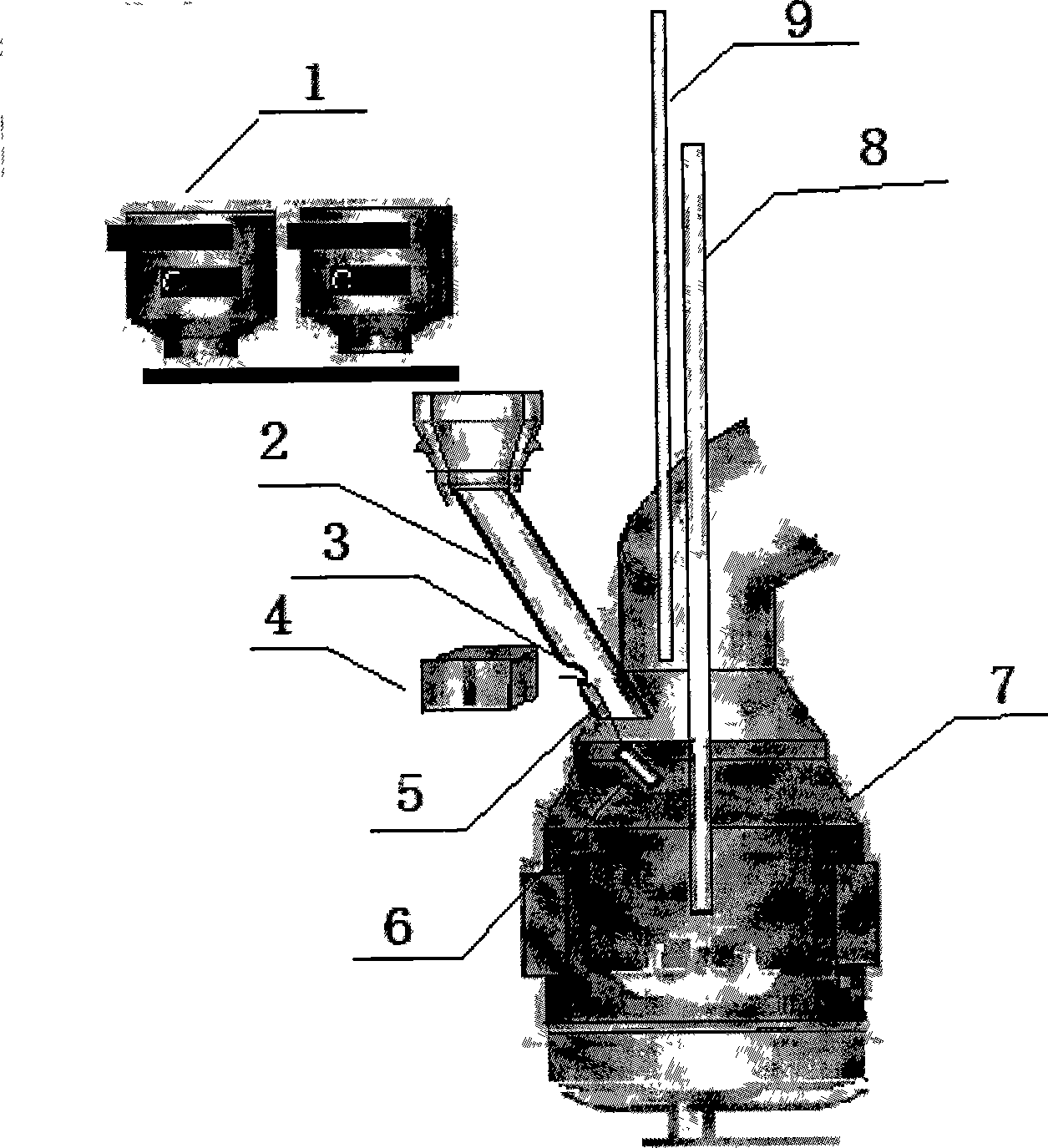

Whole process dynamic monitoring method for converter steel melting

ActiveCN101476014AHigh precisionQuality improvementProgramme controlComputer controlSteelmakingProcess dynamics

The invention pertaining to the field of metallurgy and steel-making technology provides a convertor steelmaking whole-course dynamic monitoring method. The whole-course dynamic control of the convertor steelmaking can be realized by adopting a laser gas analyzer and a stock bin port bombing technology, molten steel component and temperature are forecasted continuously and detected dynamically, and the convertor is assisted to perform the end point judgment. The method comprises steps of using a network of computer to monitor the information of charging, jetting and the like; using the laser gas analyzer as the gas signal acquiring and analyzing device in the convertor smelting process; using the bombing device installed at the stock bin port to performing head ejecting to detect information of molten steel component, temperature and the like; acquired parameters are all transferred through the network of computer; the computer continuously forecasts the parameters of molten steel component, temperature and the like by utilizing the above parameters and a built-in control model, and displays the parameters and provides guidance on the user interface.The invention has advantages that the whole-course feedback signals can be obtained, a whole-course dynamic control of the convertor smelting can be realized, variation of temperature and molten steel component can be forecasted continuously, the size of the convertor capability is not limited, and the convertor has characteristics of simple structure, convenient maintenance, small investment and low rate of fault.

Owner:北京北科麦思科自动化工程技术有限公司

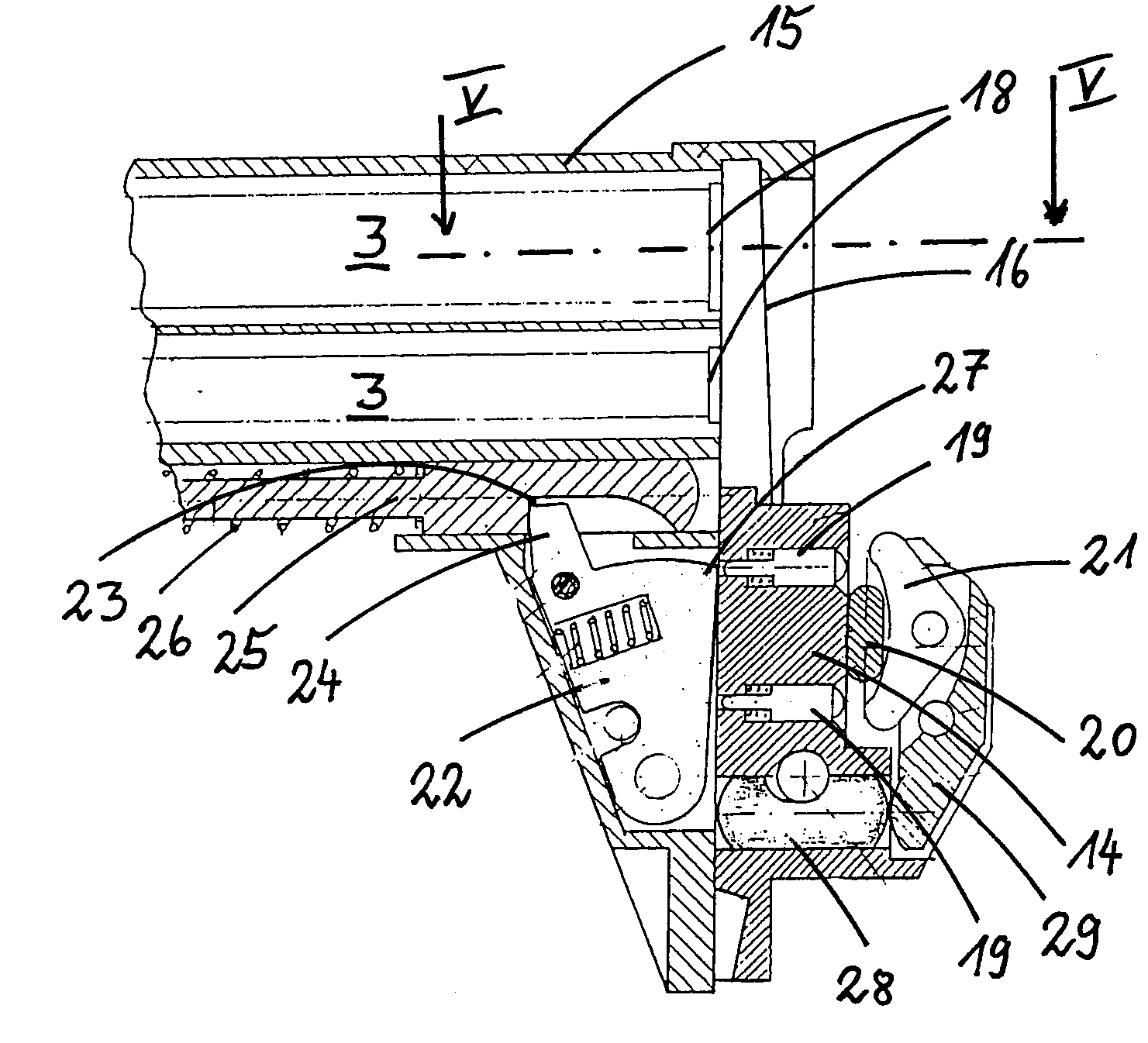

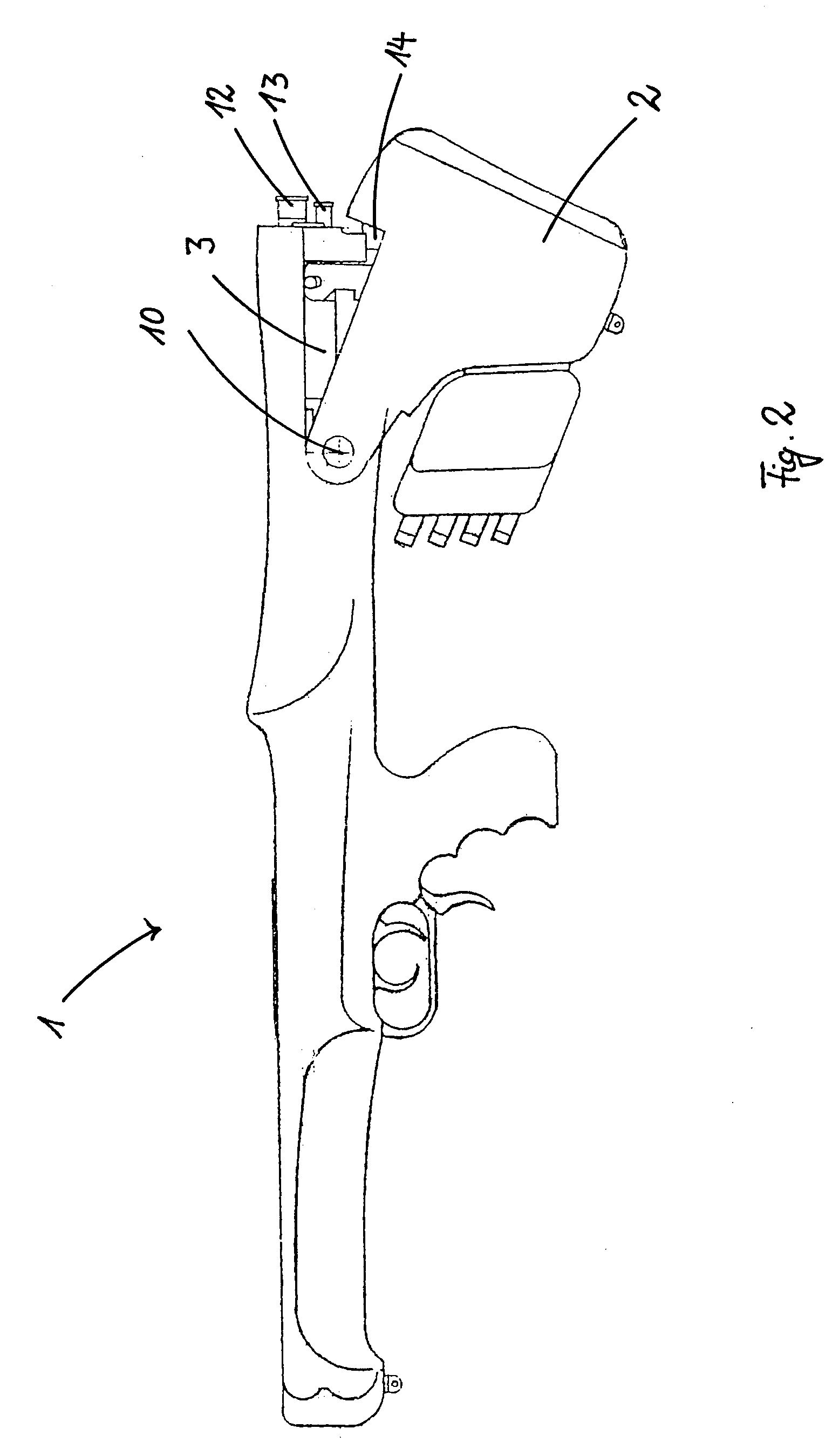

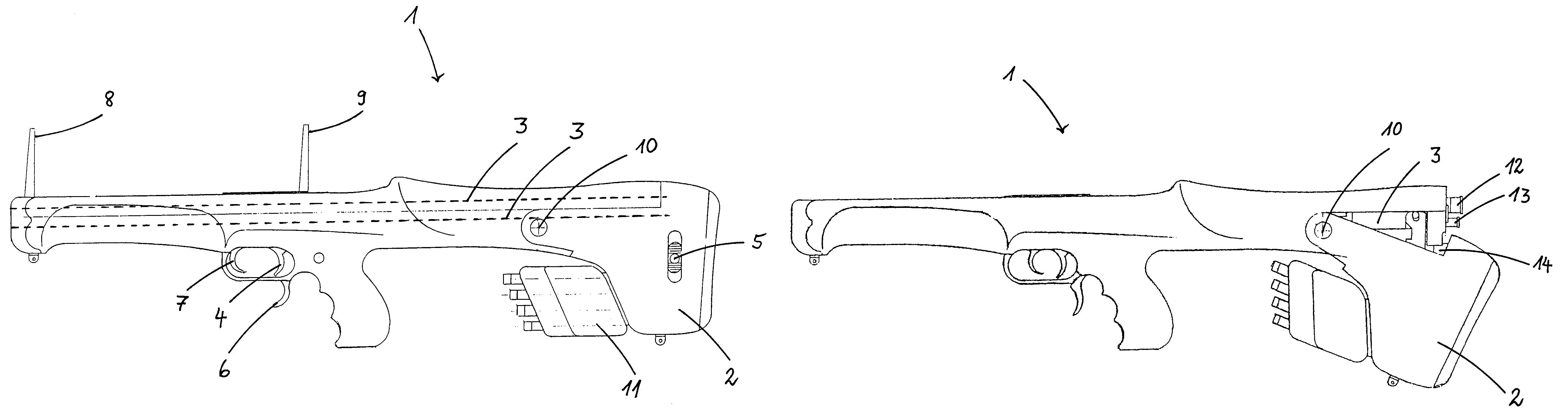

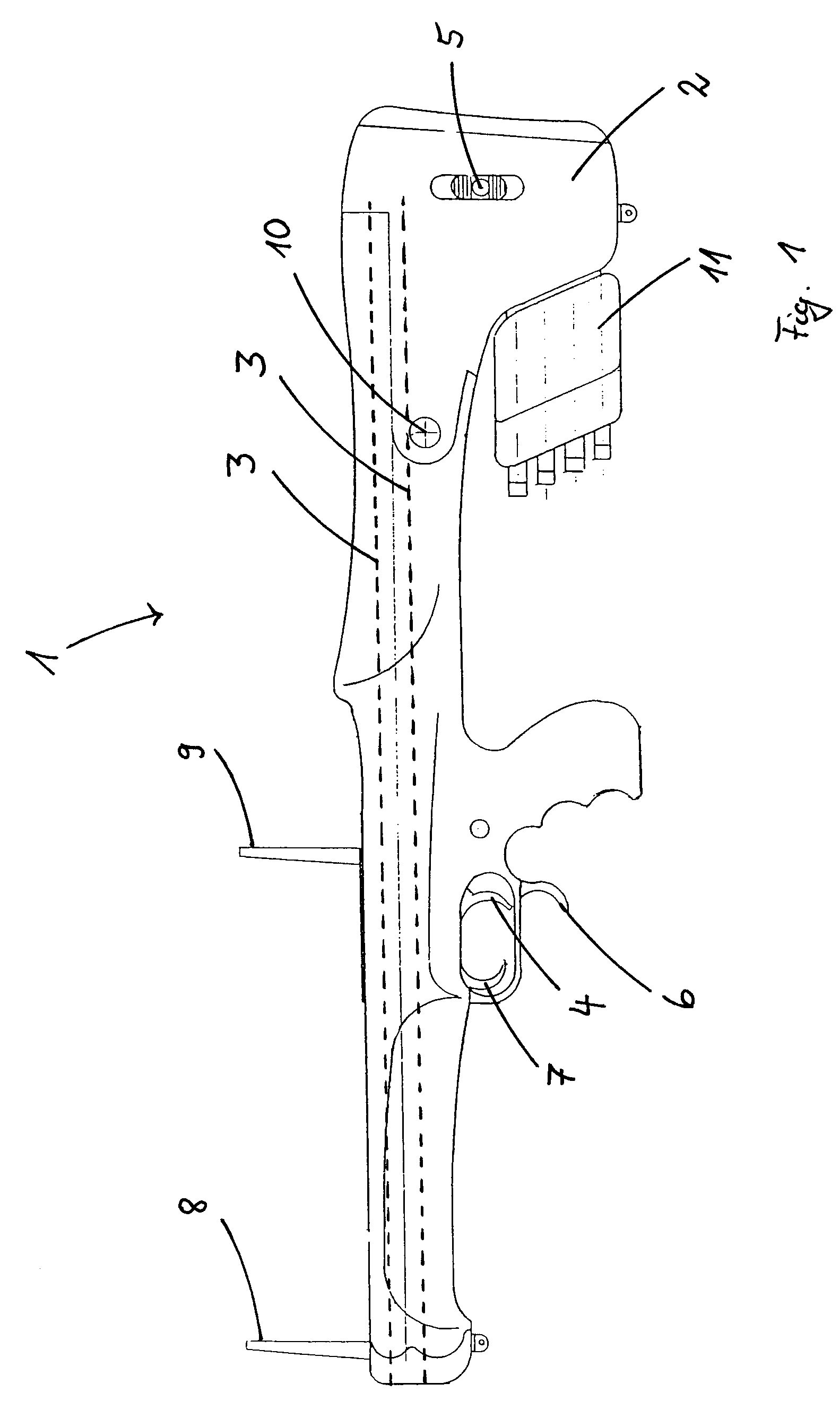

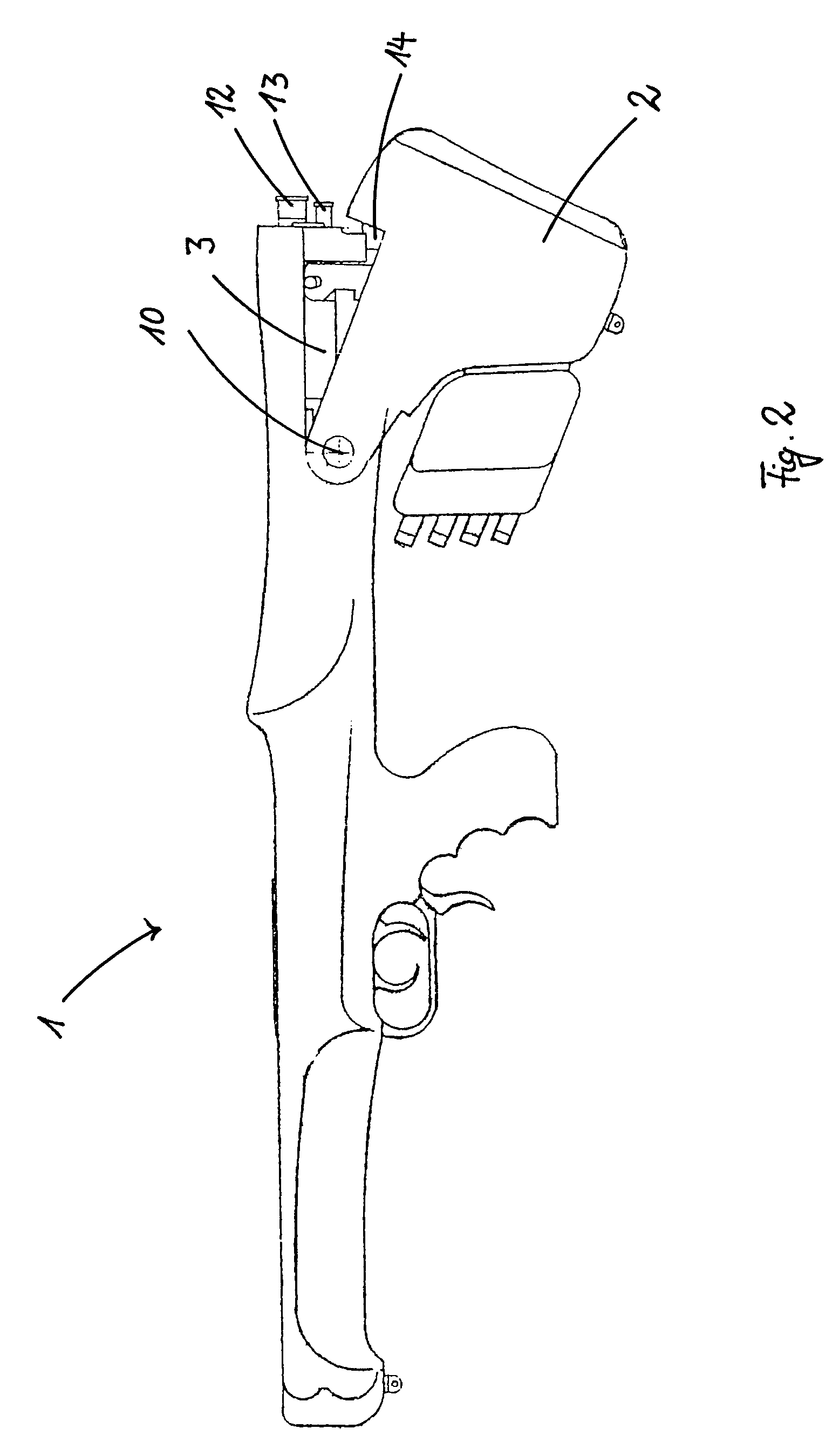

Rifle with Shoulder Support

InactiveUS20080005951A1Easy to startMinimal weightFiring/trigger mechanismsBreech mechanismsEngineeringShoulder Support

A rifle has a shoulder support and at least one barrel connected to the shoulder support. A trigger is provided and a chamber is arranged behind the trigger when looking in a direction from a front end of the barrel toward the shoulder support. A movable breechblock has a closed position in which the chamber is closed off. At least one firing pin for firing a cartridge inserted into the chamber when the trigger is triggered is provided. A coupling mechanism connects the shoulder support or a swivel arm to the breechblock. The breechblock is movable by a pivot movement of the shoulder support or the swivel arm transmitted by the coupling mechanism. An axis of rotation of the shoulder support or the swivel arm is arranged within a space delimited by the breechblock and the trigger viewed across a length of the rifle.

Owner:STEINKAMP MASCHENBAU

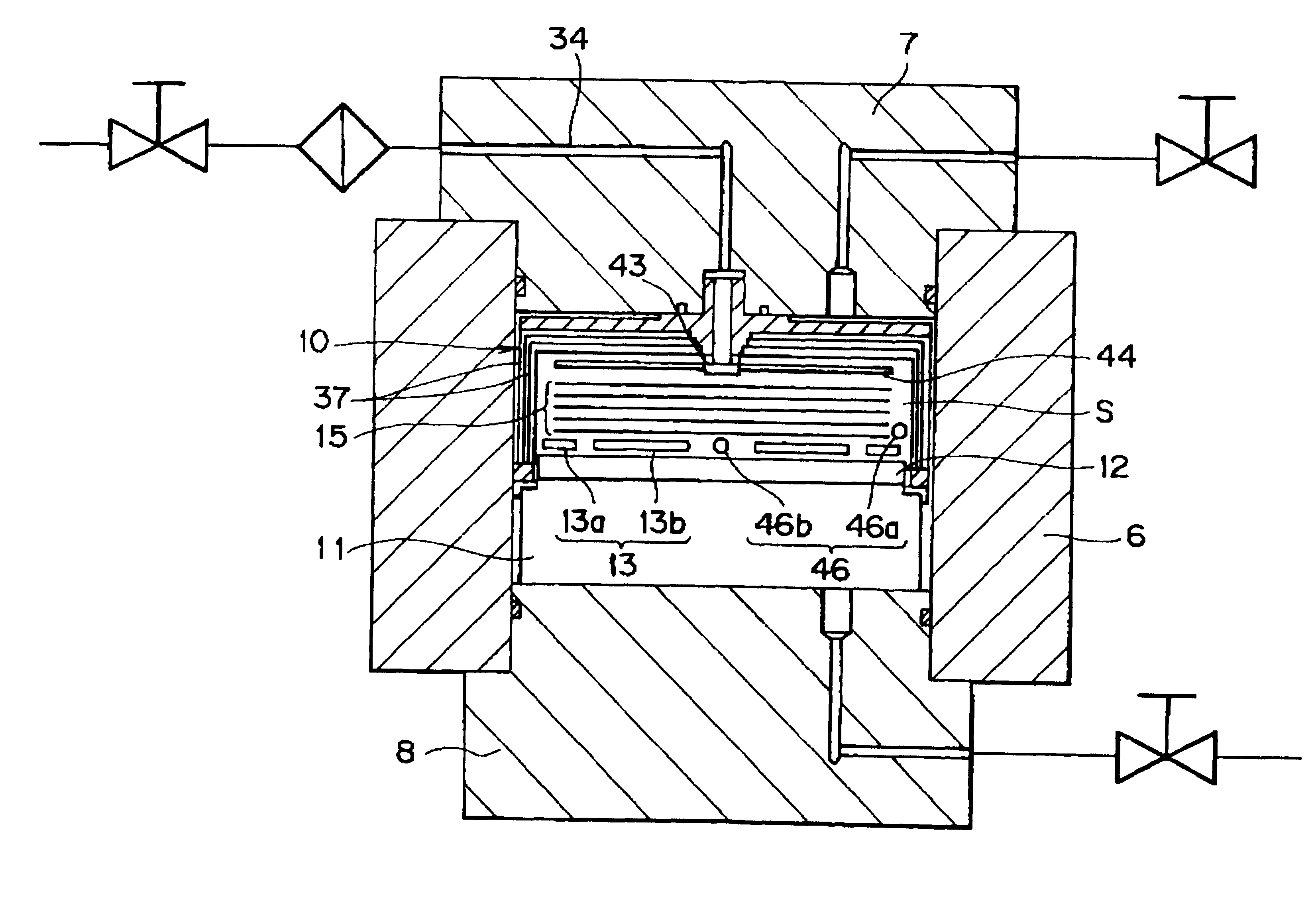

Method and device for high-temperature, high-pressure treatment of semiconductor wafer

InactiveUS6285010B1Improve productivityShort-time treatmentMuffle furnacesBaking ovenElectrical resistance and conductanceSemiconductor materials

In a high-temperature, high-pressure treatment method for semiconductor wafer for charging a wafer-like semiconductor material in a pressure vessel, forcing and pressurizing an inert gas such as argon thereto, and raising the temperature by heating by use of an electric resistance type heater, wafers are vertically stacked in the treatment chamber, and the heater is arranged within the treatment chamber to perform the treatment while supplying a heating power by DC to the heater, whereby generation of particles from the heater is suppressed.

Owner:KOBE STEEL LTD

Silver layer formed by electrosilvering substrate material

InactiveUS20080006911A1Effective reflectionInhibited DiffusionSemiconductor/solid-state device detailsSolid-state devicesSilver plateSilver coating

Owner:MATSUSHITA ELECTRIC WORKS LTD

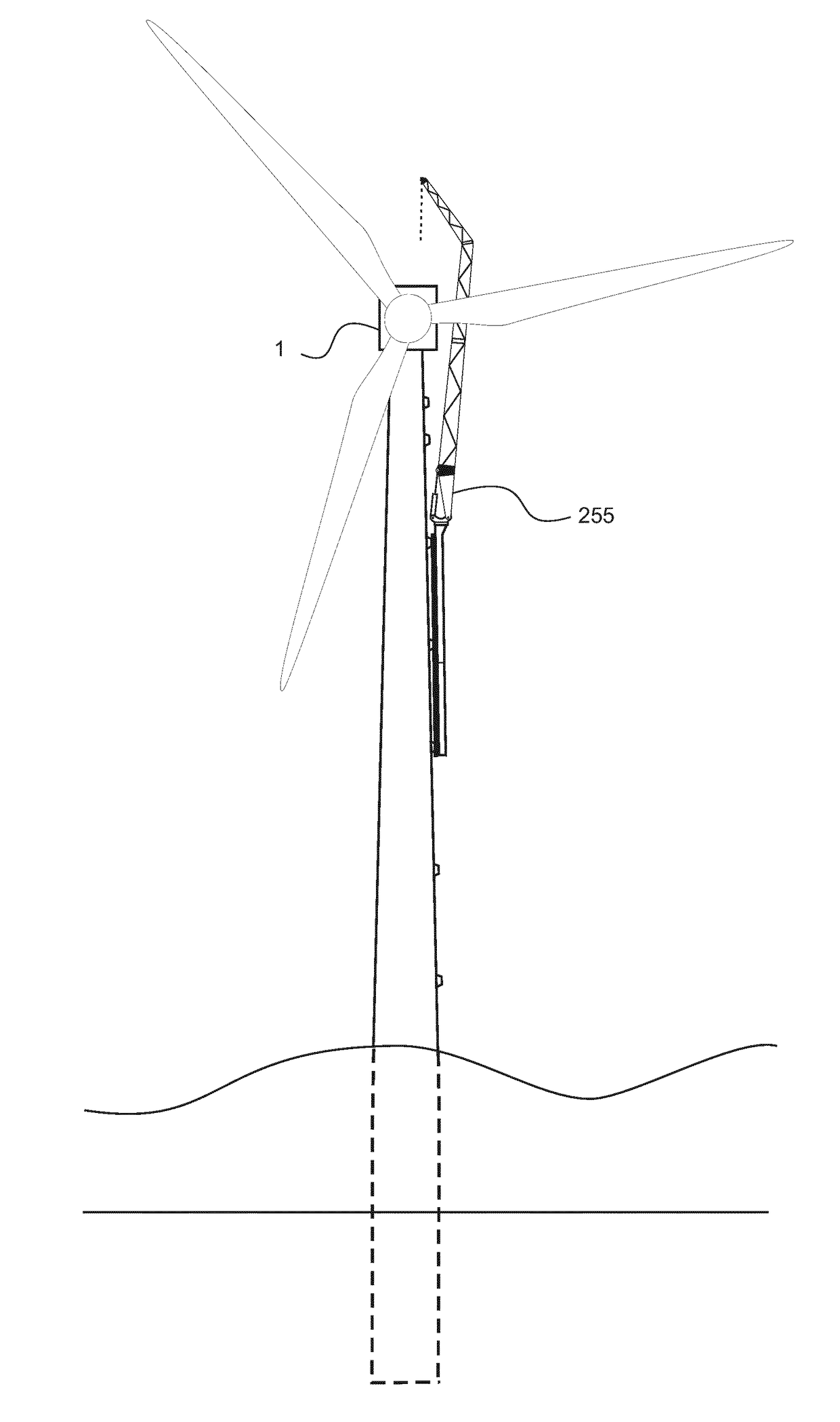

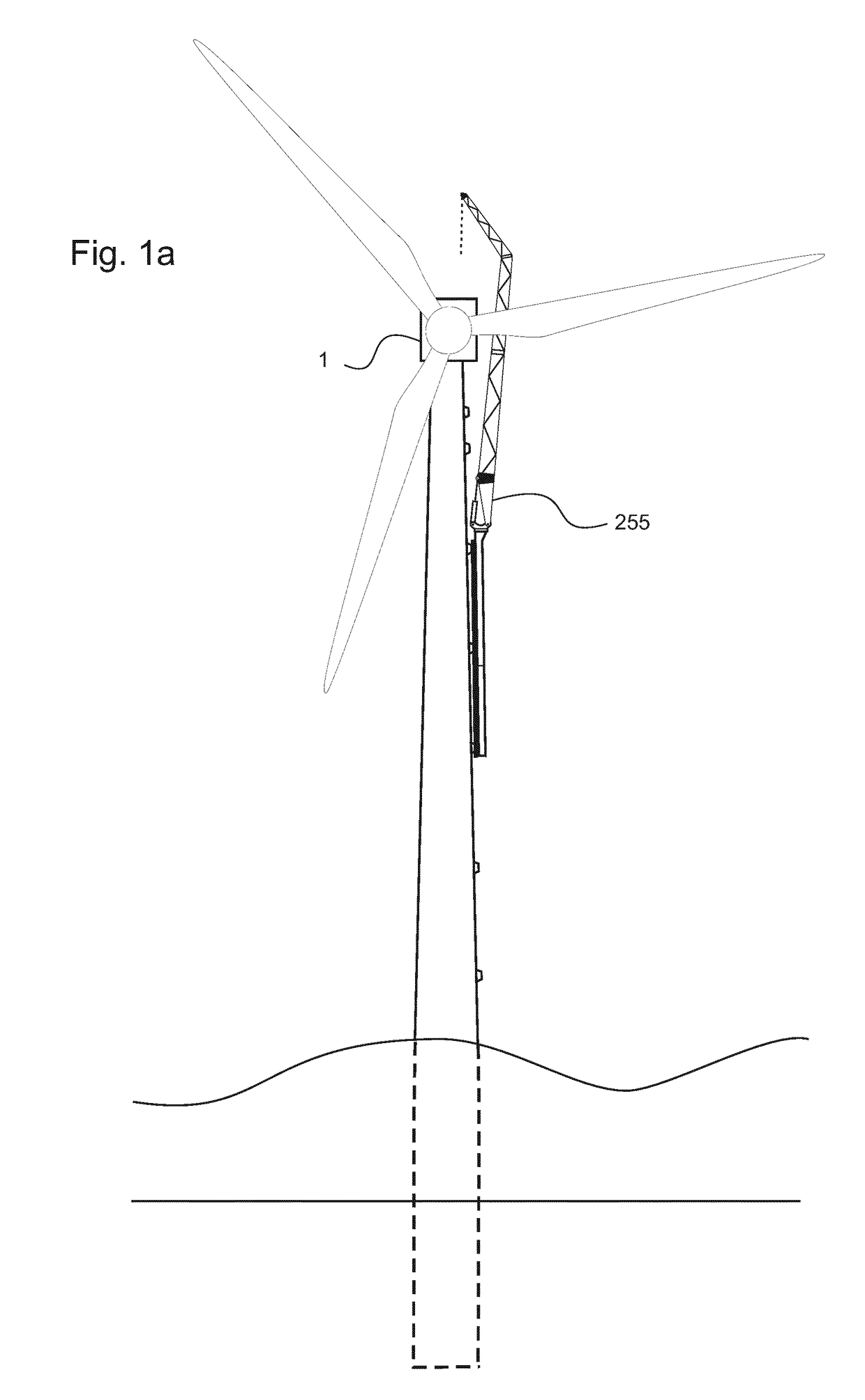

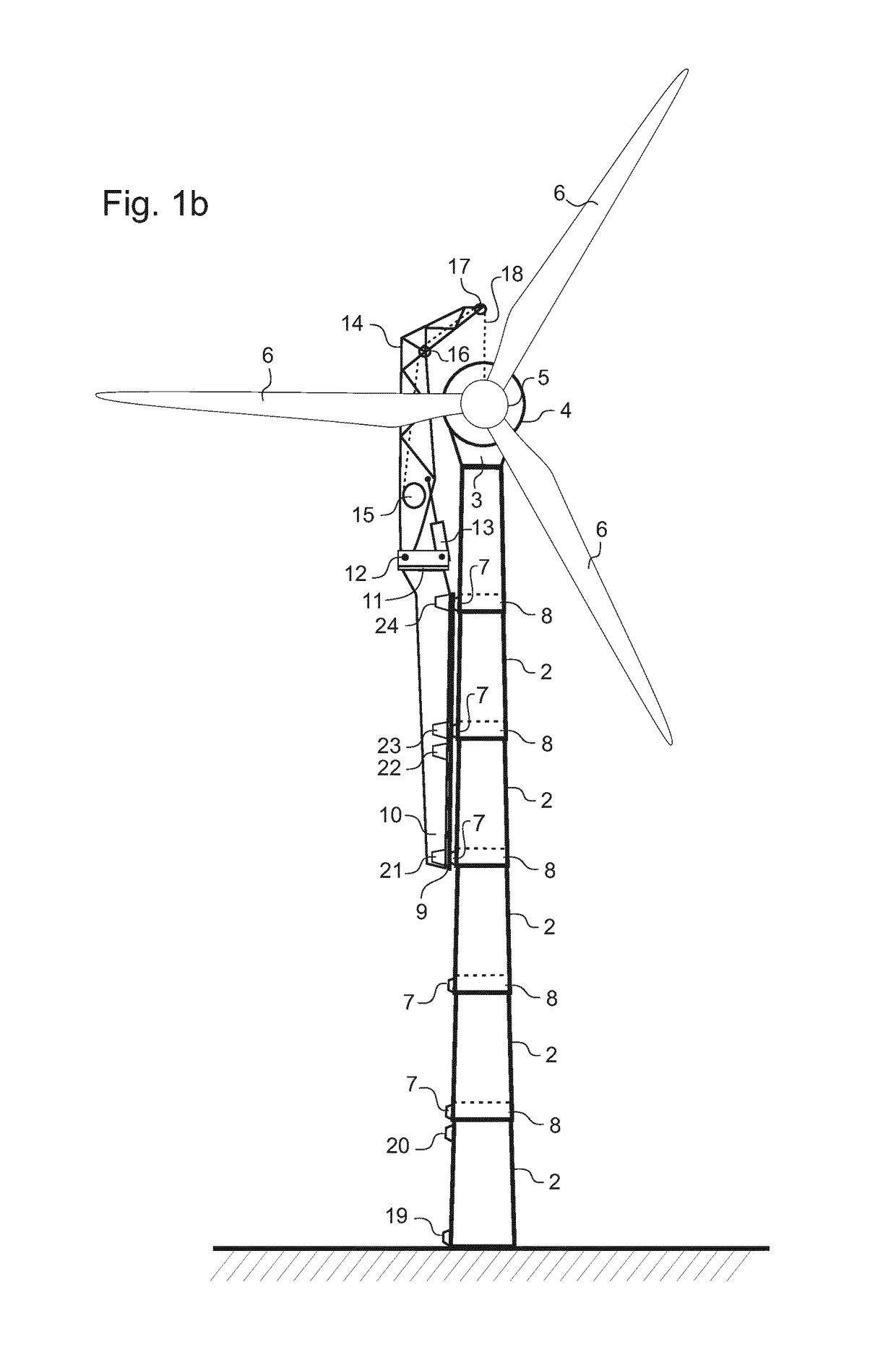

Hoisting system for installing a wind turbine

ActiveUS20180282134A1Cancellation costSmall and lightArtificial islandsEngine manufactureNacelleEngineering

A hoisting system for the installation of a wind turbine wherein said hoisting system comprises measures to achieve a load bearing connection to the tower of the wind turbine and comprises measures to move the hoisting system up and down along the tower wherein the hoisting system, when it is fixed to an already installed part of the wind turbine tower with said load bearing connection, is arranged to install or remove any of a tower segment, a nacelle, a generator, a hub, and a blade in one or more combined hoists or in a single hoist.

Owner:LAGERWEY WIND BV

Mobile milling head with torque motor drive

InactiveUS7470095B2Rapid corrective movementReduce stiffnessMachine tool componentsWorkpiecesDynamic stiffnessGear drive

A milling head (16) for a milling machine (1) arranged for machining large-size workpieces comprises a fork 18, which is rotatably arranged around a first axis (C) and demonstrates a pair of fork arms (21, 22), which are separated from one another, a spindle device (23), which is arranged between the fork arms and rotatable around a second axis A, a first torque motor (42), which is coupled to the fork 18 for directly driving and controlling of the rotation of the fork around the first axis (C), and a second torque motor (57) for driving and controlling the rotation of the spindle around the second axis (A), said second torque motor being coupled to the spindle device (23) by means of a one-stage toothed gearing (61), which is mechanically clamped free of backlash. The configuration according to the invention is arranged to achieve high torque with high dynamic stiffness and small interference contour of the milling head (16).

Owner:F ZIMMERMAN GMBH & CO KG

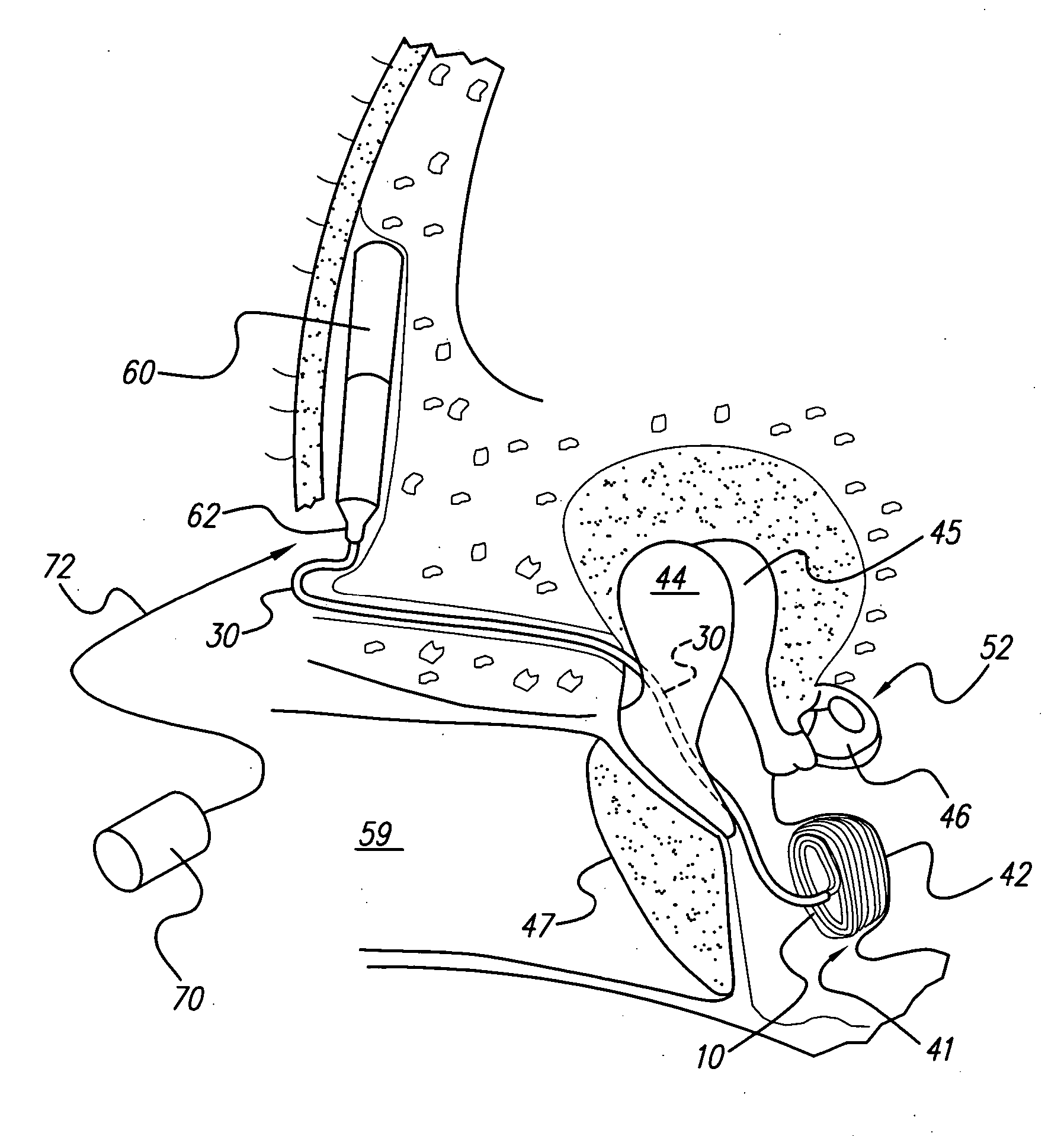

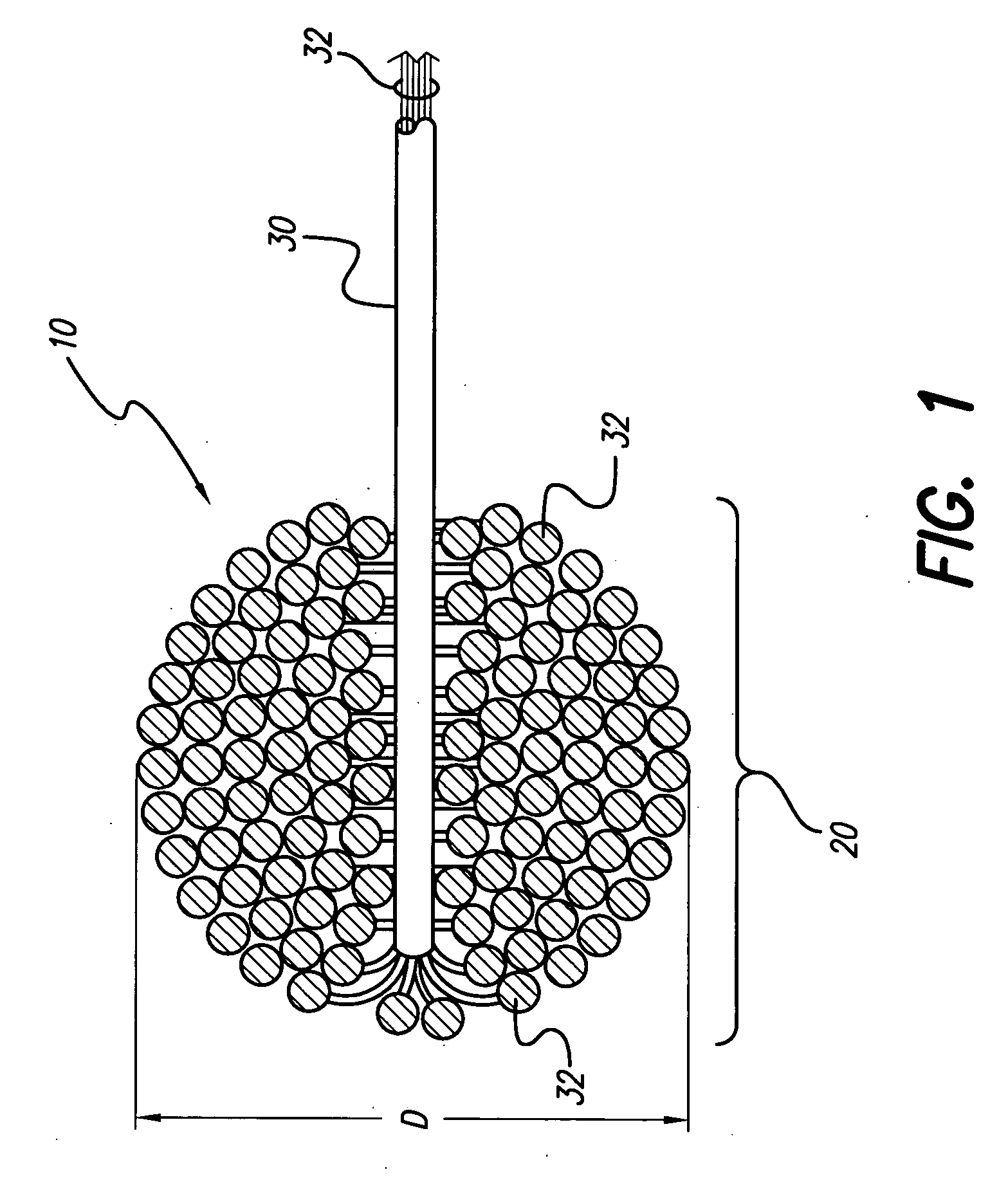

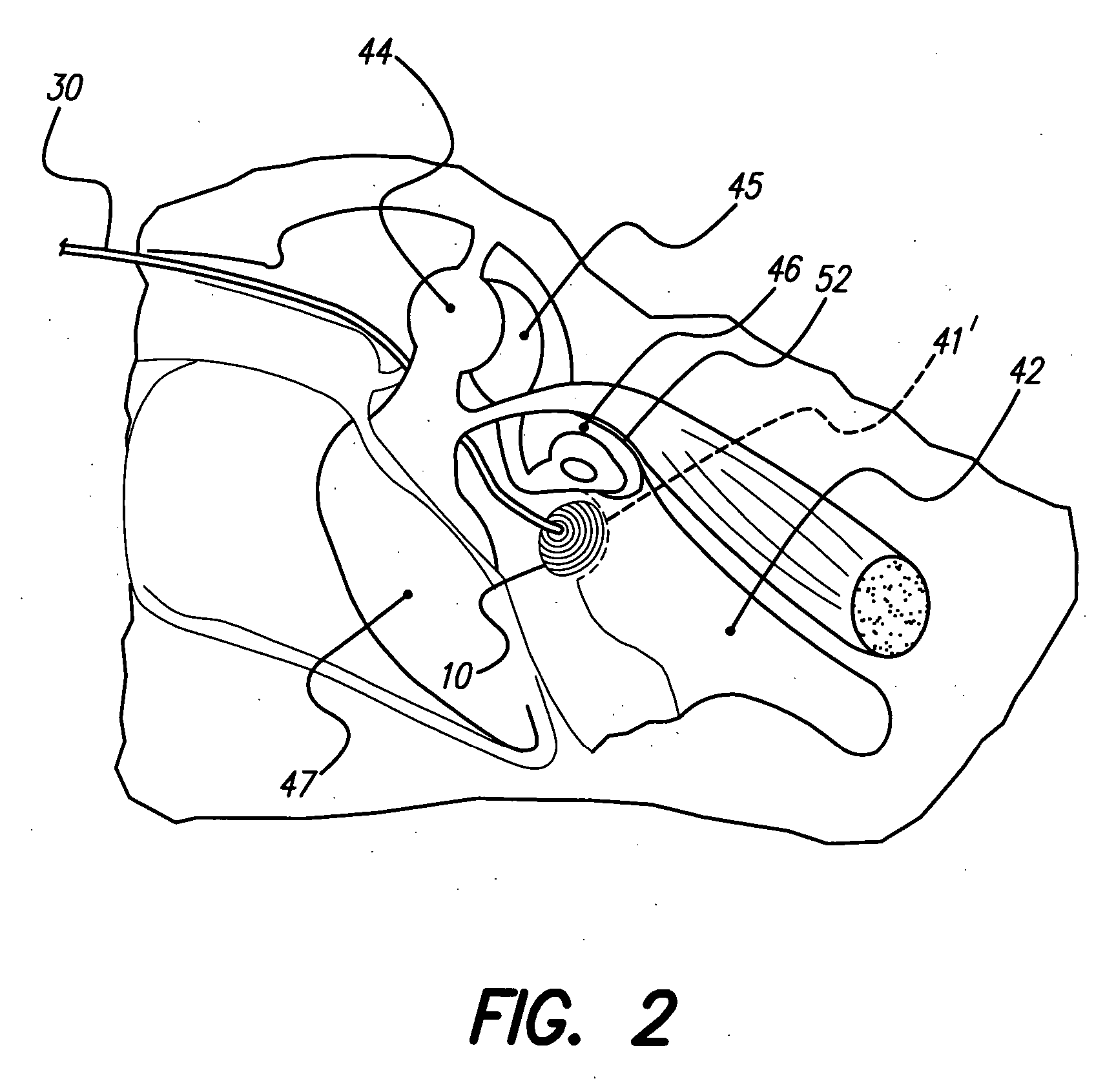

System and method of contra-lateral ear stimulation for preserving neuronal survival and plasticity of the auditory system prior to permanent intra-cochlear implantation

InactiveUS20070282396A1Preserving neuronal survivalPreserving plasticityElectrotherapyArtificial respirationAuditory pathwaysAuditory system

An implantable microstimulator, or equivalent neural stimulator, generates a relatively simple signal containing temporally challenging information and delivers such signal to the middle or outer portion of the ear contra-lateral to an ear having a cochlear implant of a bilaterally deafened patient. Such stimulation delivered to the contra lateral ear advantageously increases the survival rate of neurons therein, and further helps maintain or extend the plasticity of the higher auditory pathways of the contra-lateral ear, thereby allowing a cochlear implant to be more effectively used in such ear at a later date. The stimulation provided by the microstimulator, or equivalent simple neural stimulator, need not be continuous, but may be provided only during limited periods of time each day, or only on selected days. Further, such stimulation preserves whatever residual hearing may be left in the contra lateral ear.

Owner:BOSTON SCI NEUROMODULATION CORP

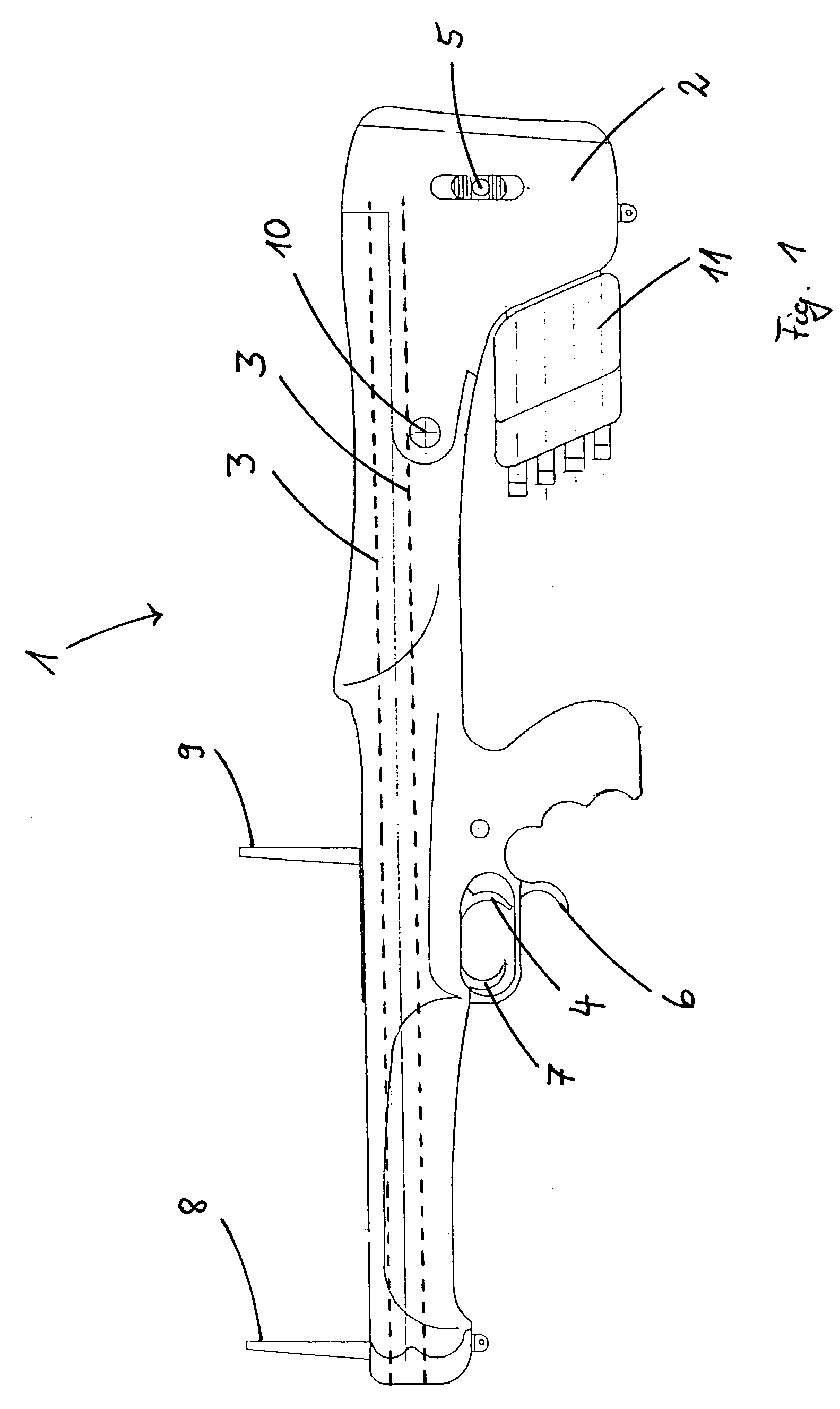

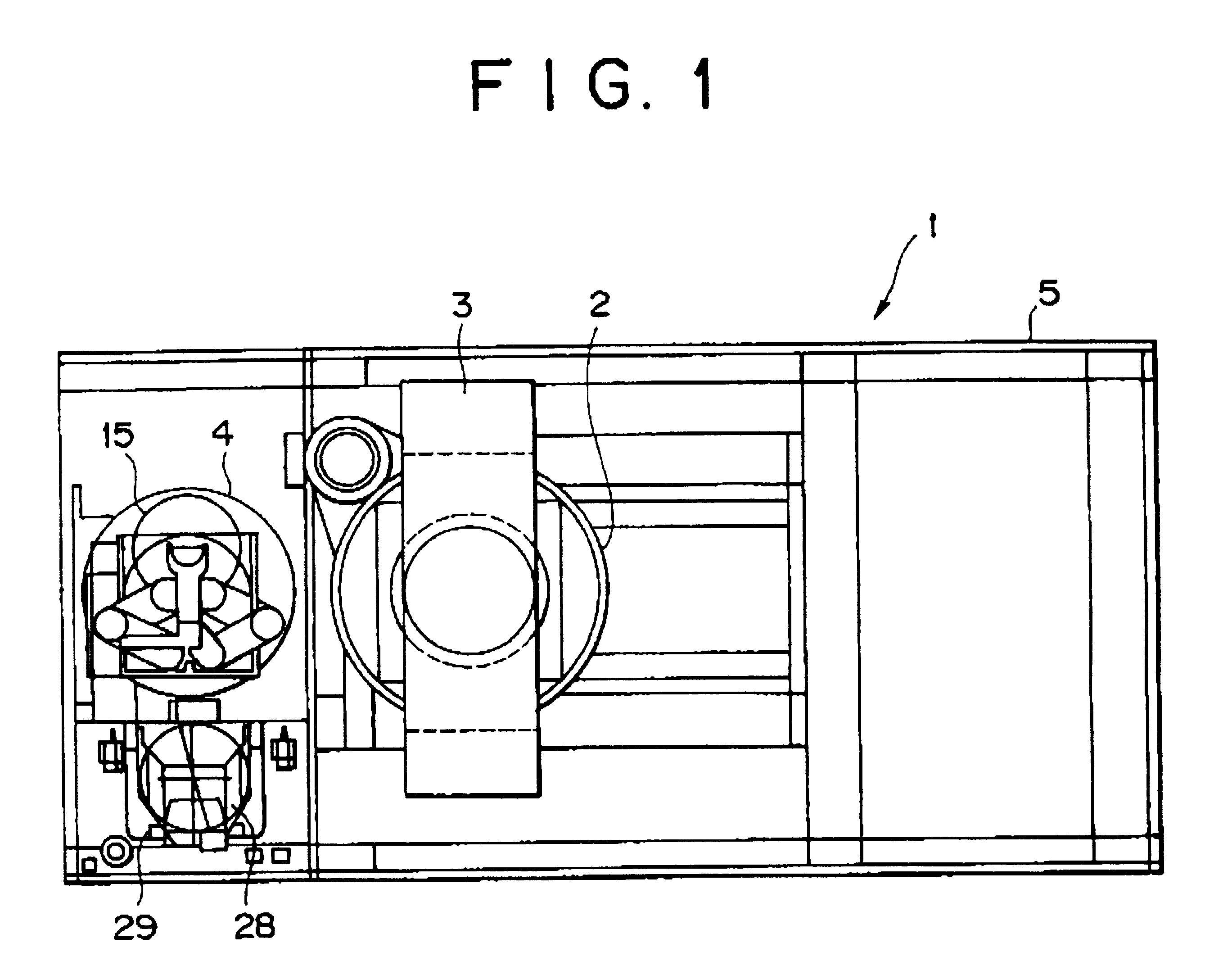

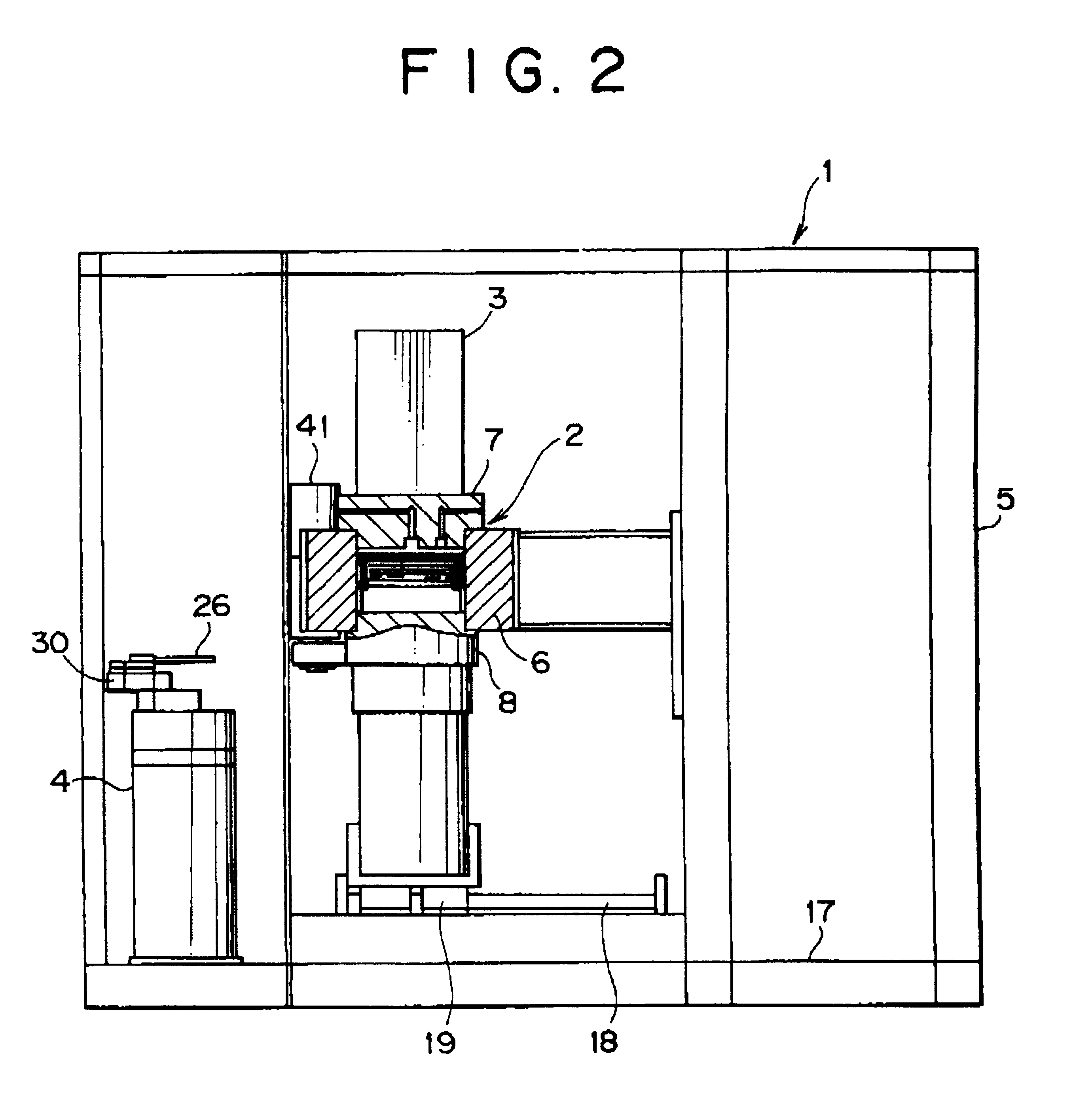

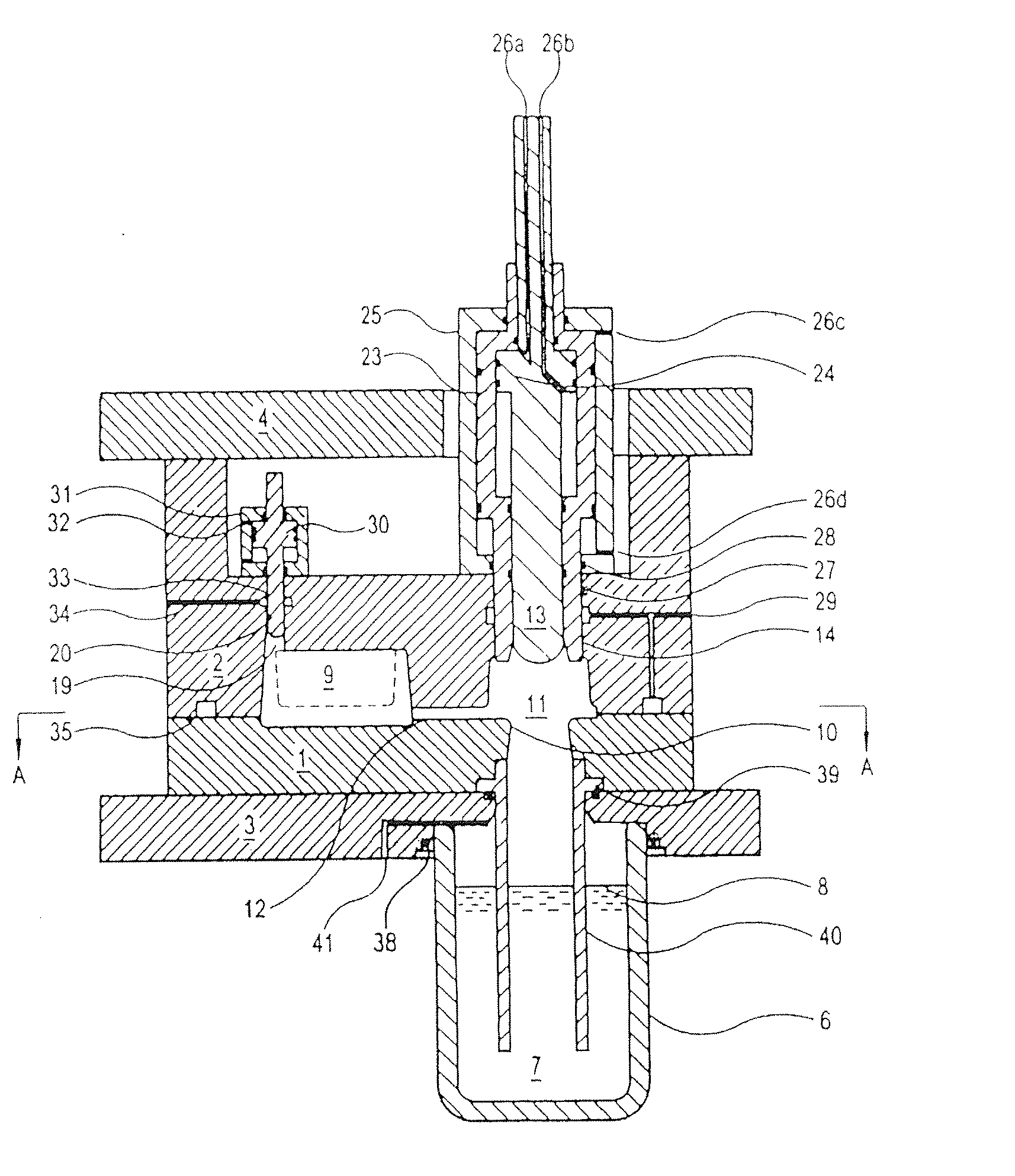

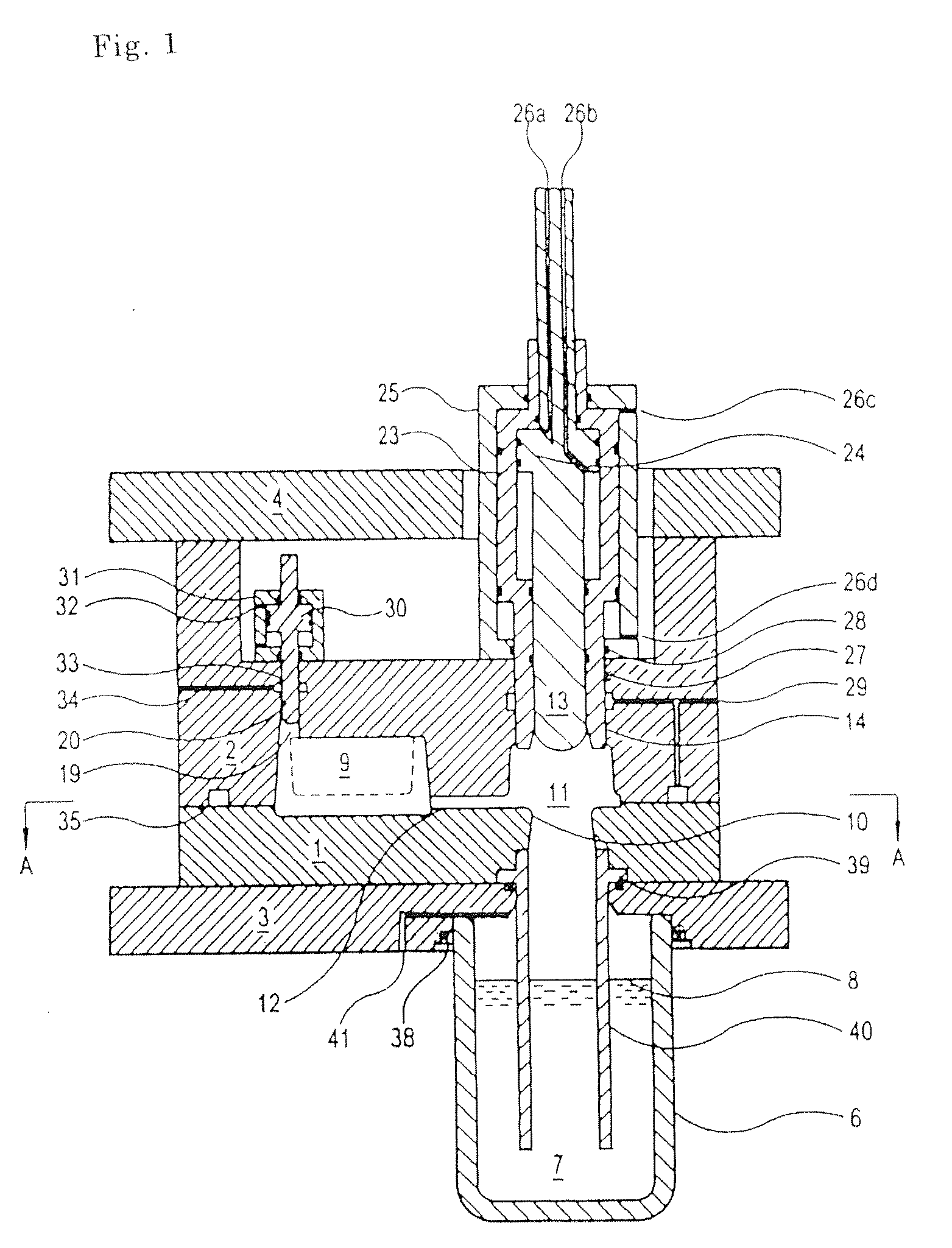

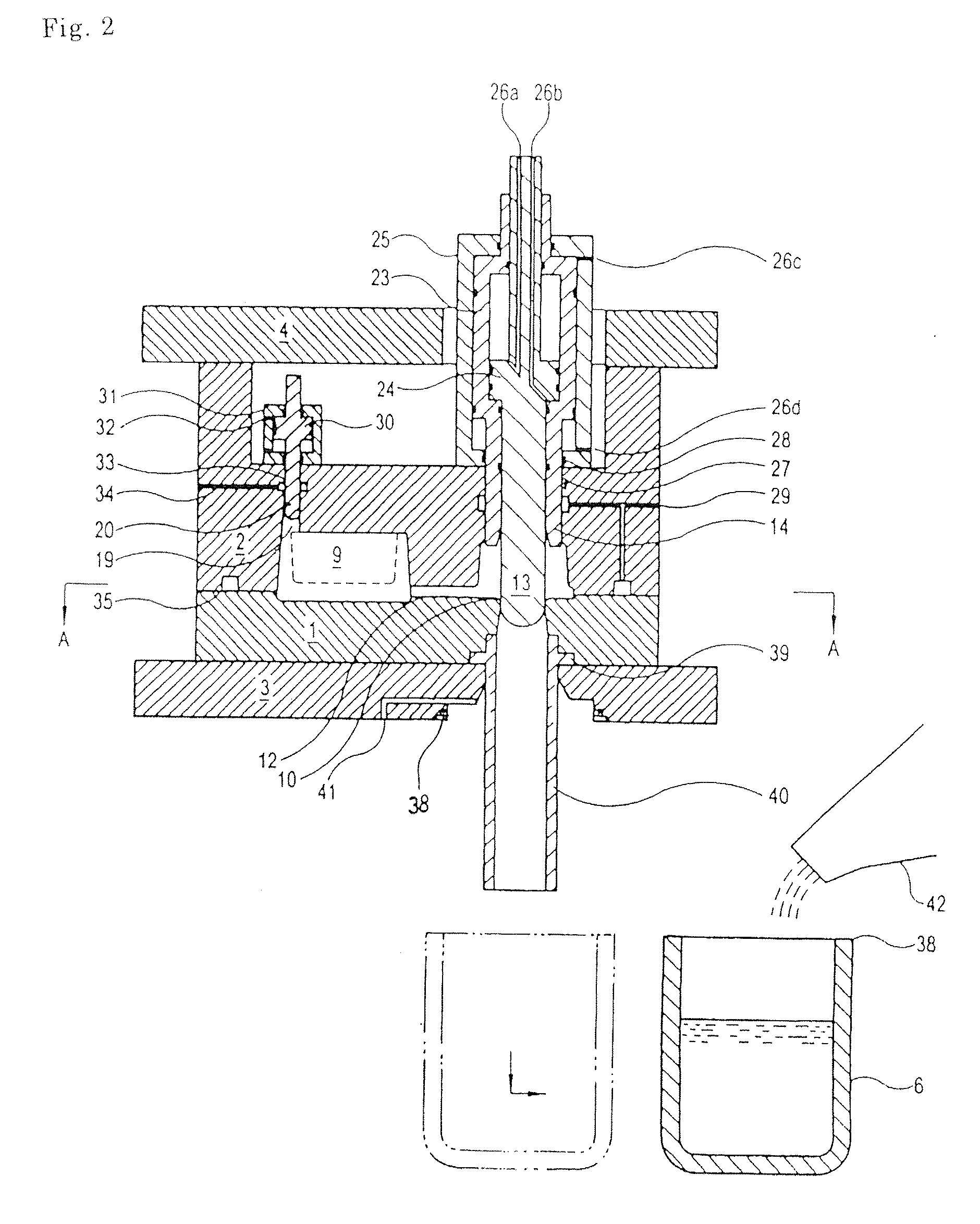

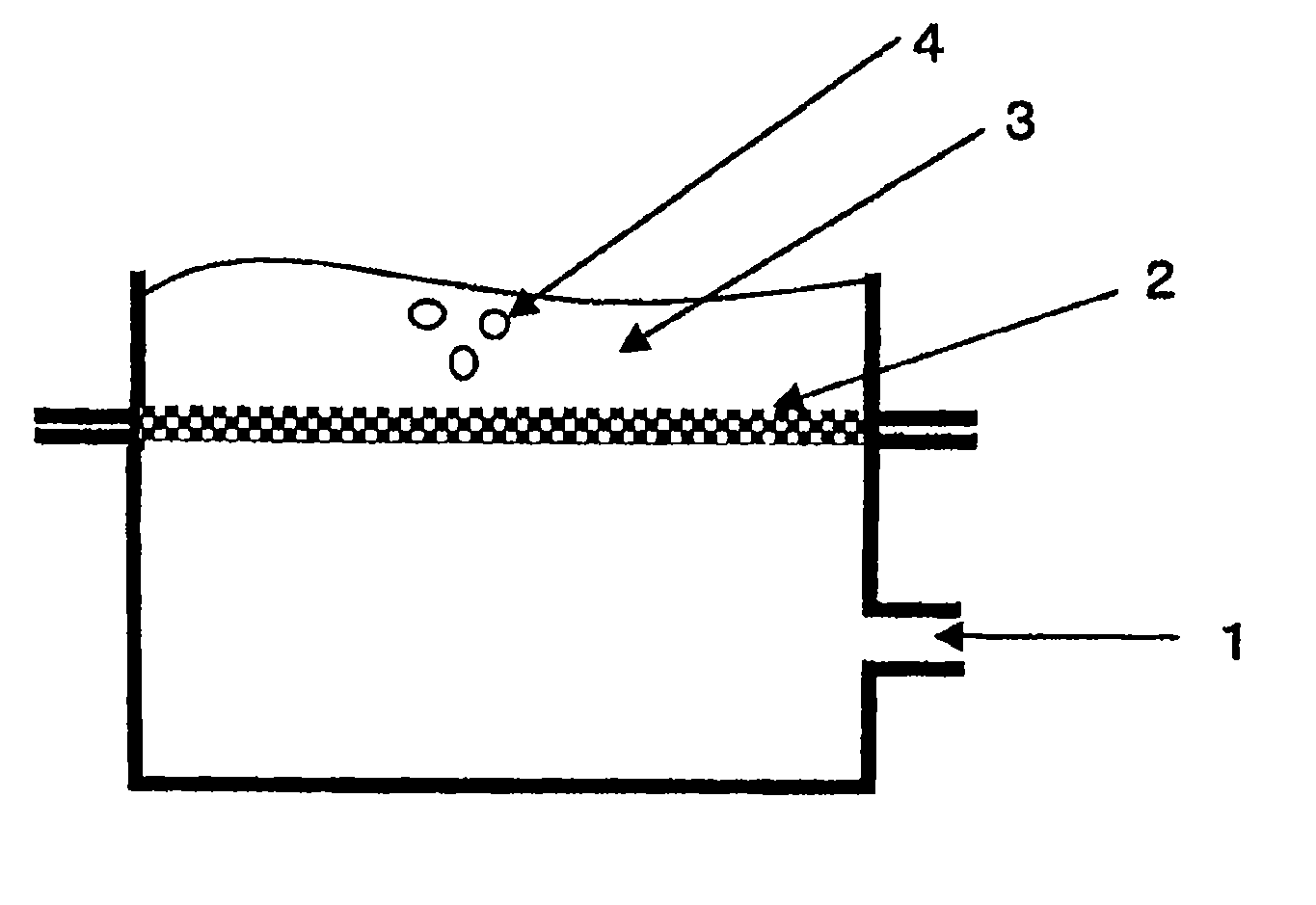

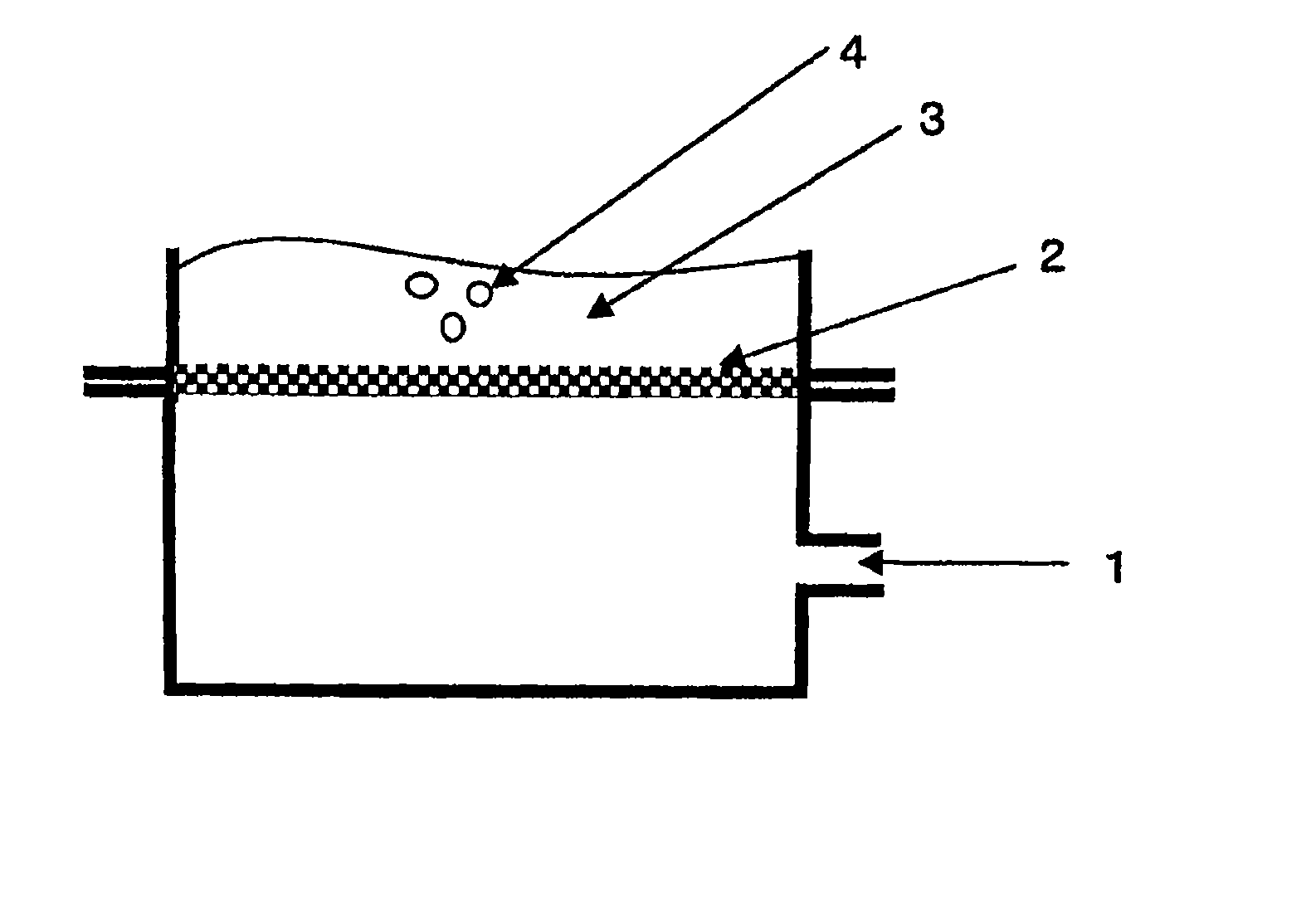

Vertical Casting Apparatus and Vertical Casting Method

The present invention is to provide a vertical casting apparatus capable of easily manufacturing castings without causing shrinkage cavities and entrainment of gas, by filling a molten metal into a mold cavity at a high speed and by effectively pressurizing the molten metal in the closed cavity, which has high work efficiency, ease of maintenance, and a low cost of equipment, and a vertical casting method using the vertical casting apparatus. The vertical casting apparatus is provided with an apparatus body comprising a fixed mold 1 on the lower side and a movable mold 2 on the upper side, a closing means 13 for closing a molten metal in-flow gate 10 formed in the fixed mold 1, and a pressurizing means 20 for pressurizing the molten metal in the closed mold cavity, and a casting means for supplying and filling the molten metal into the mold cavity from the underside. The casting means has a gas-pressurized molten metal pouring ladle 6 attachable to and detachable from the apparatus body.

Owner:KOSEI ALUMINUM

Rifle with shoulder support

InactiveUS7493718B2Easy to startMinimal weightFiring/trigger mechanismsBreech mechanismsEngineeringShoulder Support

A rifle has a shoulder support and at least one barrel connected to the shoulder support. A trigger is provided and a chamber is arranged behind the trigger when looking in a direction from a front end of the barrel toward the shoulder support. A movable breechblock has a closed position in which the chamber is closed off. At least one firing pin for firing a cartridge inserted into the chamber when the trigger is triggered is provided. A coupling mechanism connects the shoulder support or a swivel arm to the breechblock. The breechblock is movable by a pivot movement of the shoulder support or the swivel arm transmitted by the coupling mechanism. An axis of rotation of the shoulder support or the swivel arm is arranged within a space delimited by the breechblock and the trigger viewed across a length of the rifle.

Owner:STEINKAMP MASCHENBAU

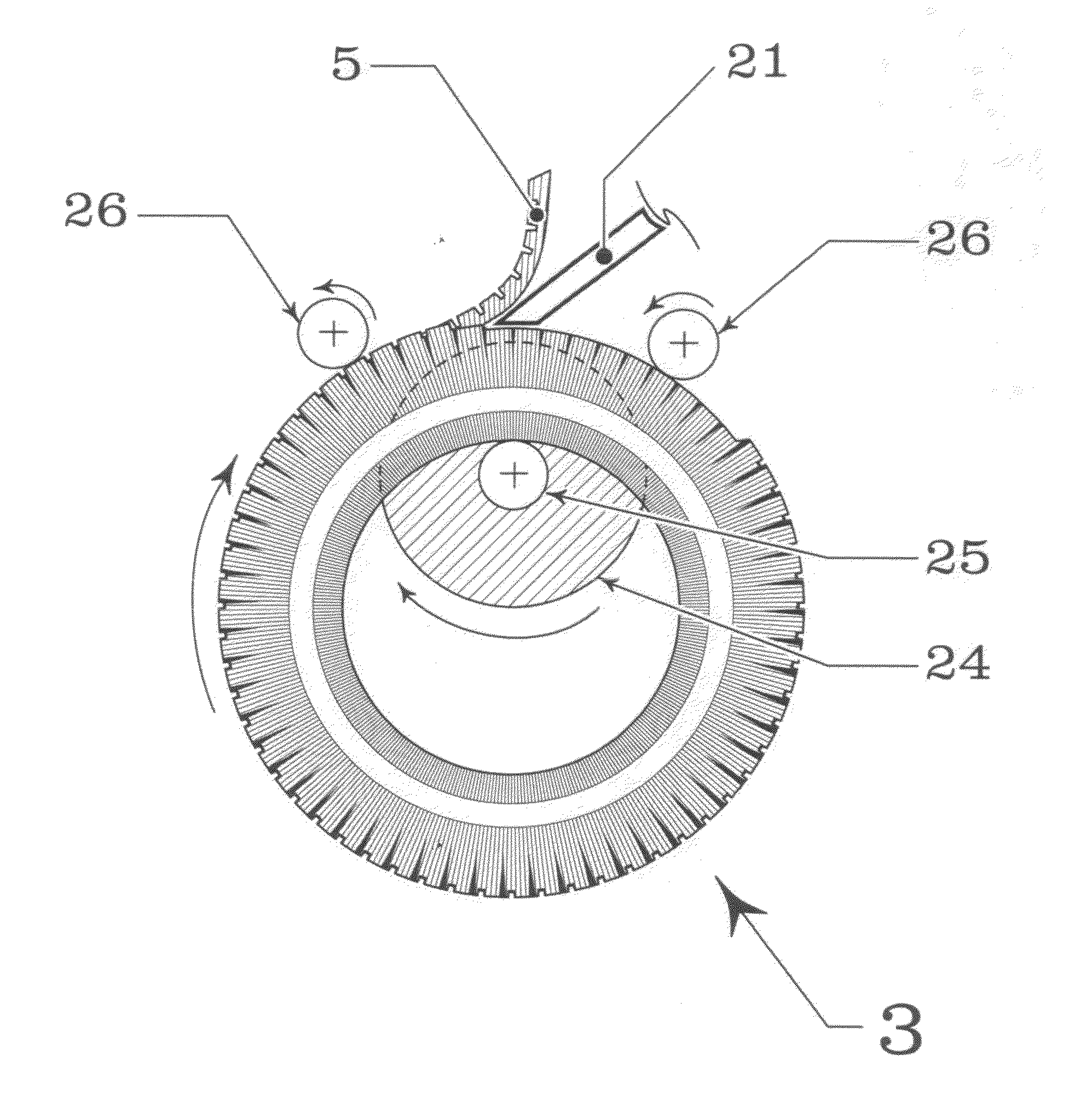

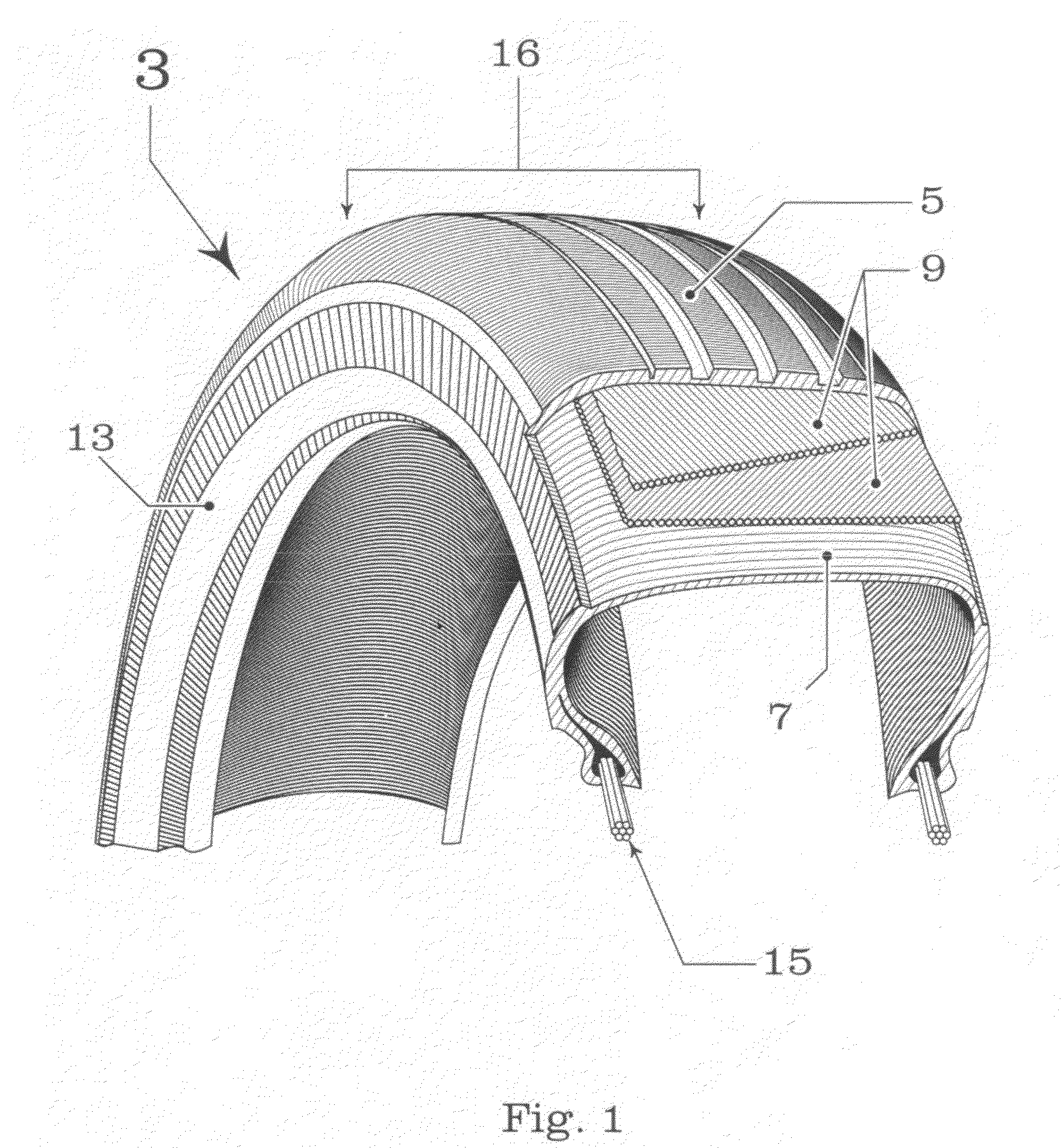

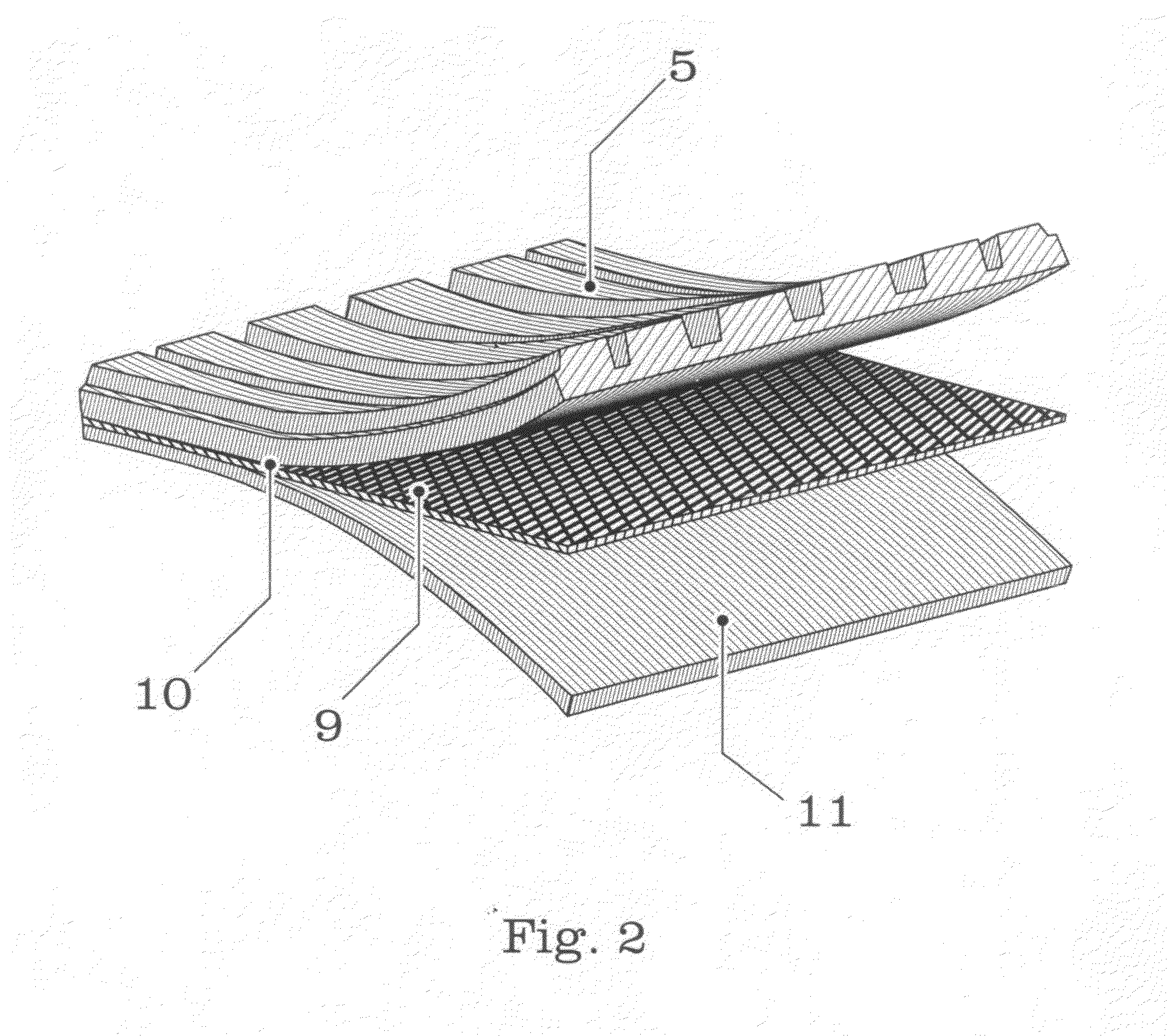

Recovery of high value rubber from tires

InactiveUS20110023668A1Less costReduces energy and maintenance requirementLamination ancillary operationsPaper/cardboard articlesEnvironmental resistanceSteel belt

A process for recovering rubber from a tire, the tire including a rubber tread block, a reinforced portion below the tread block portion, typically known as steel belting, and an inner liner that serves to hold the air pressure in the tire. The bead and sidewall are removed from the tire leaving a loop of tread material. Next, the loop is placed on several rollers of a rubber-separating machine to hold the loop in place. One or more cutting blades, preferably chisels, are positioned at the tread portion of the tire. The cutting blades are lowered into position. Access to the steel belting can be accomplished by making an initial cut through tread block to expose the steel belting. Once the blades are in place, the tread loop is placed in motion around the rollers. As the blades contact the steel belts, the cutting blades separate the tread rubber from the reinforced rubber at the interface between the tread rubber and the steel belts. The inner layer may also be removed in a similar fashion with blades positioned within the loop rather than above it.The ultimate goal of the present invention is to provide an environmentally and economically beneficial process that disposes of all the parts of the tire. Using the cutting blades or chisel(s) to separate the rubber in a tire's tread area from the embedded steel results in the following tire parts: 1) high value metal free rubber from the tread area; 2) the steel belt / thin layer of rubber / steel belt (with or without the inner liner); 3) the inner liner with polyester or similar fiber; 4) the metal free sidewall with polyester or similar fiber; and 5) the tire bead surrounded with rubber and polyester or similar fiber.

Owner:RUBBER RECOVERY SOLUTIONS

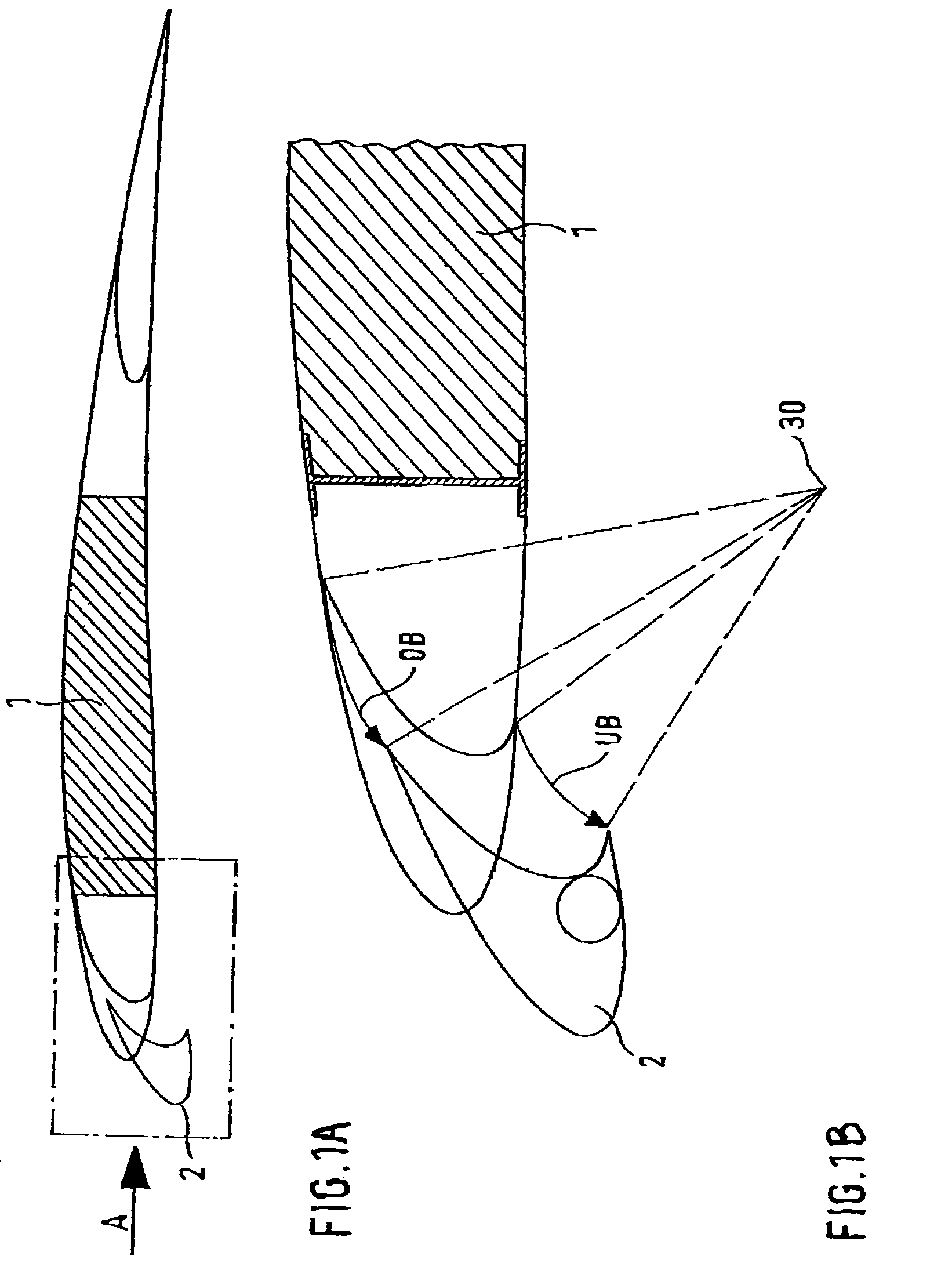

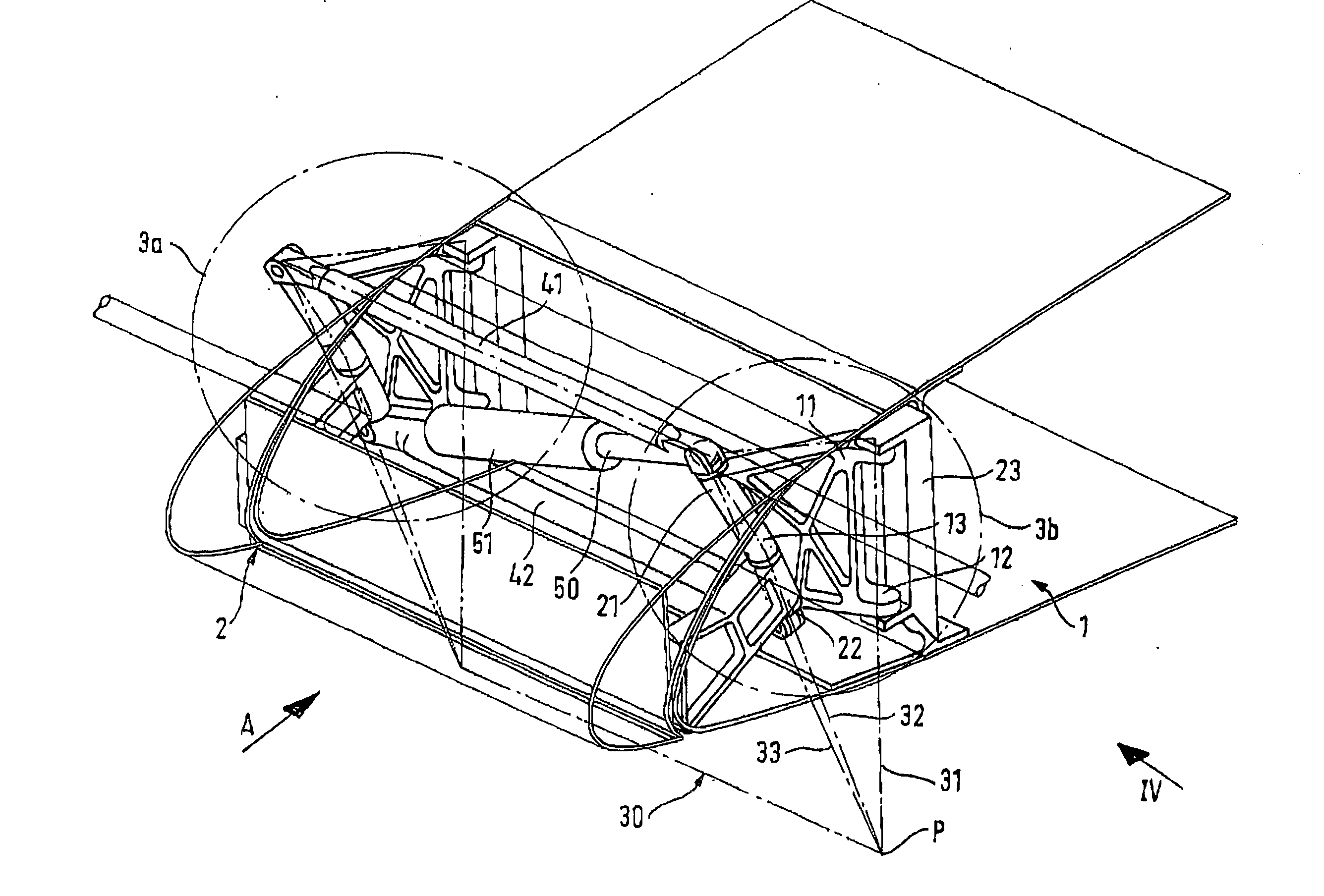

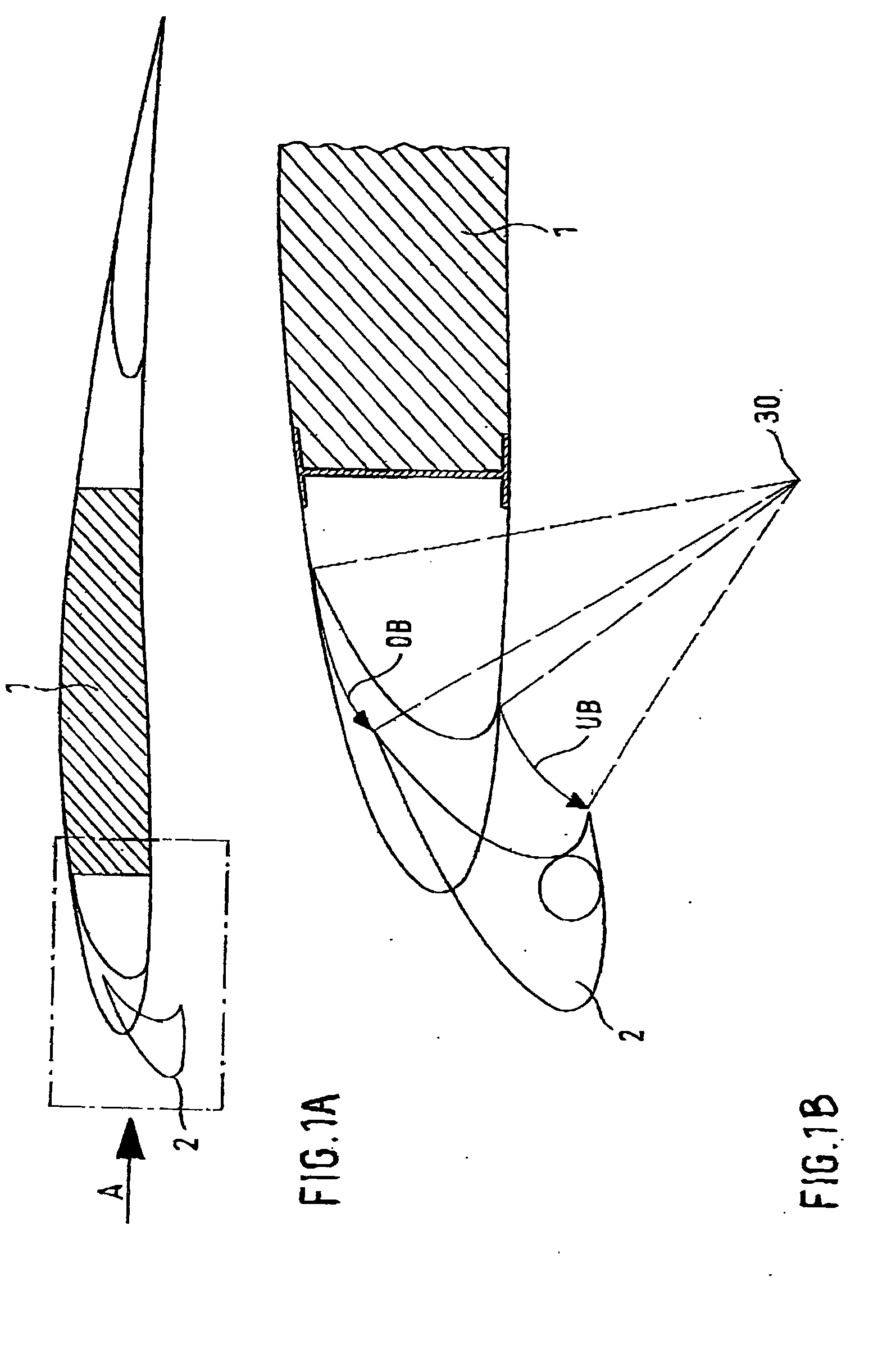

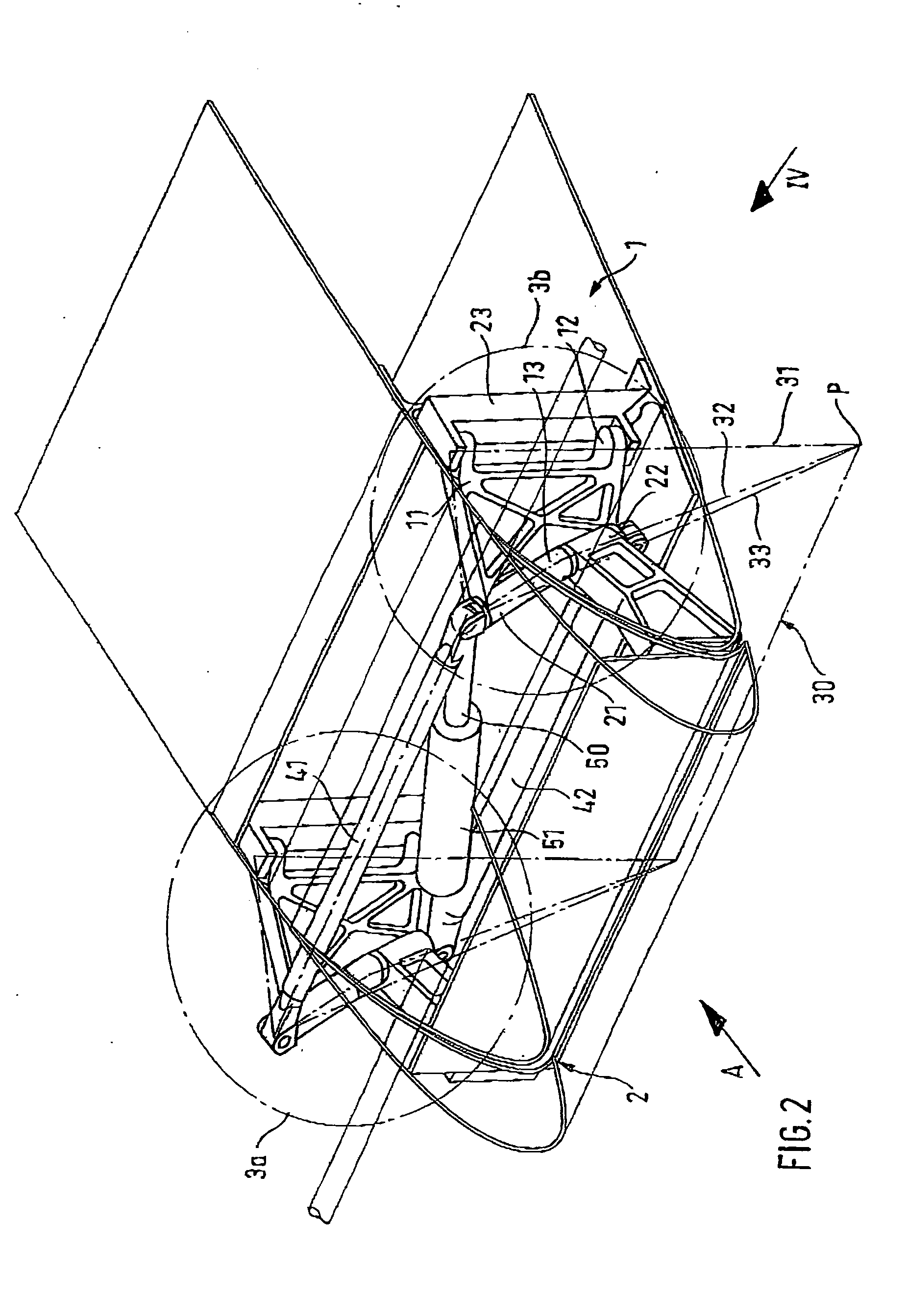

Aircraft wing with extendible nose flap

ActiveUS7484694B2Easy maintenanceIncrease variabilityAir braking surfacesWeight reductionNoseAircraft landing

An aircraft wing including a wing box and a nose flap moveably connected to the wing box by first and second folding hinges. A first transverse link is pivotally connected to first portions of the first and second folding hinges. A second transverse link is pivotally connected to second portions of the first and second folding hinges. An actuator is connected diagonally between the first and second transverse links for moving the nose flap between a retracted position and an extended position. The instant abstract is neither intended to define the invention disclosed in the specification nor intended to limit the scope of the invention in any way.

Owner:AIRBUS DEFENCE & SPACE

Aircraft wing with extendible nose flap

ActiveUS20090001224A1Easy maintenanceIncrease variabilityAir braking surfacesWeight reductionNoseAircraft landing

An aircraft wing including a wing box and a nose flap moveably connected to the wing box by first and second folding hinges. A first transverse link is pivotally connected to first portions of the first and second folding hinges. A second transverse link is pivotally connected to second portions of the first and second folding hinges. An actuator is connected diagonally between the first and second transverse links for moving the nose flap between a retracted position and an extended position. The instant abstract is neither intended to define the invention disclosed in the specification nor intended to limit the scope of the invention in any way.

Owner:AIRBUS DEFENCE & SPACE

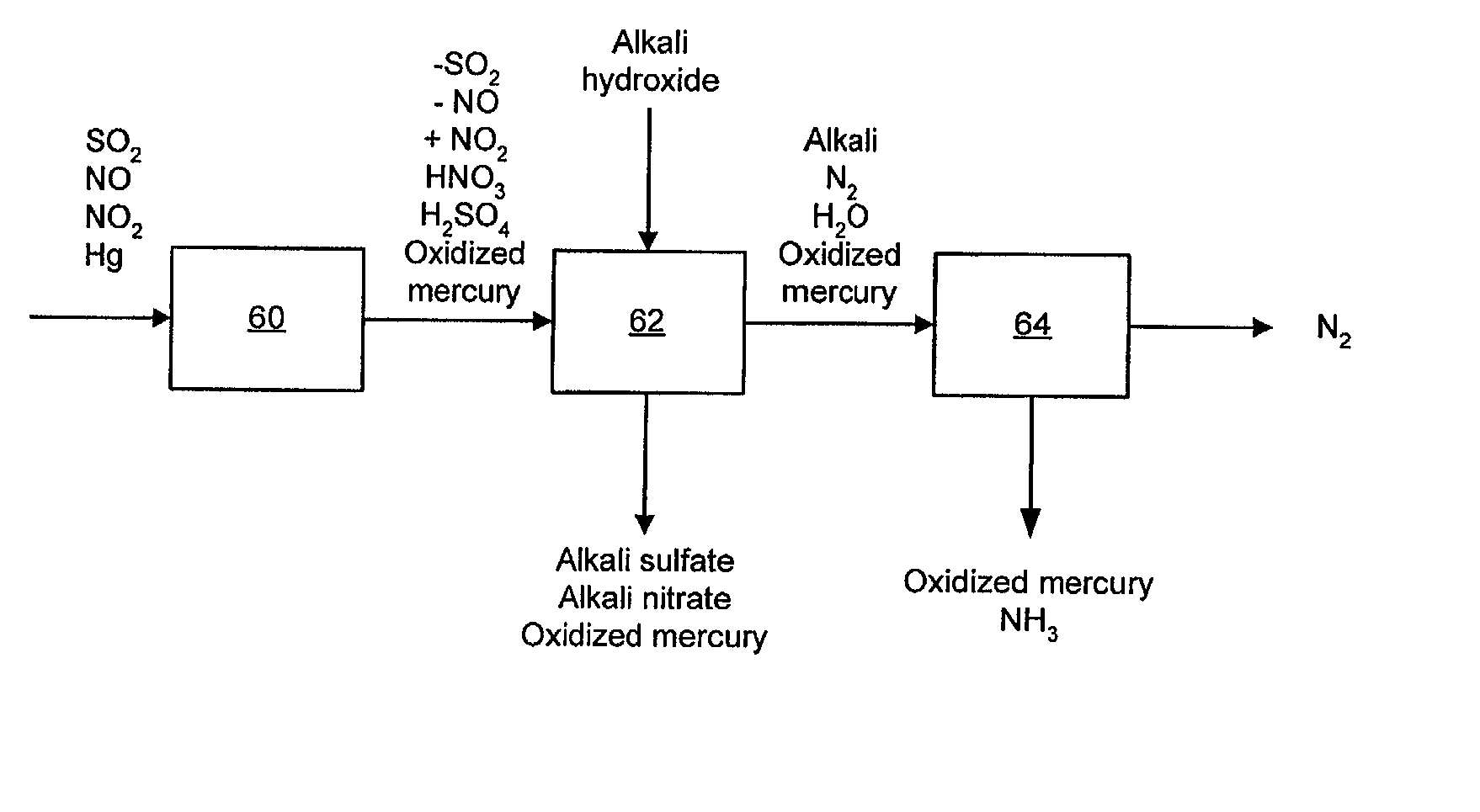

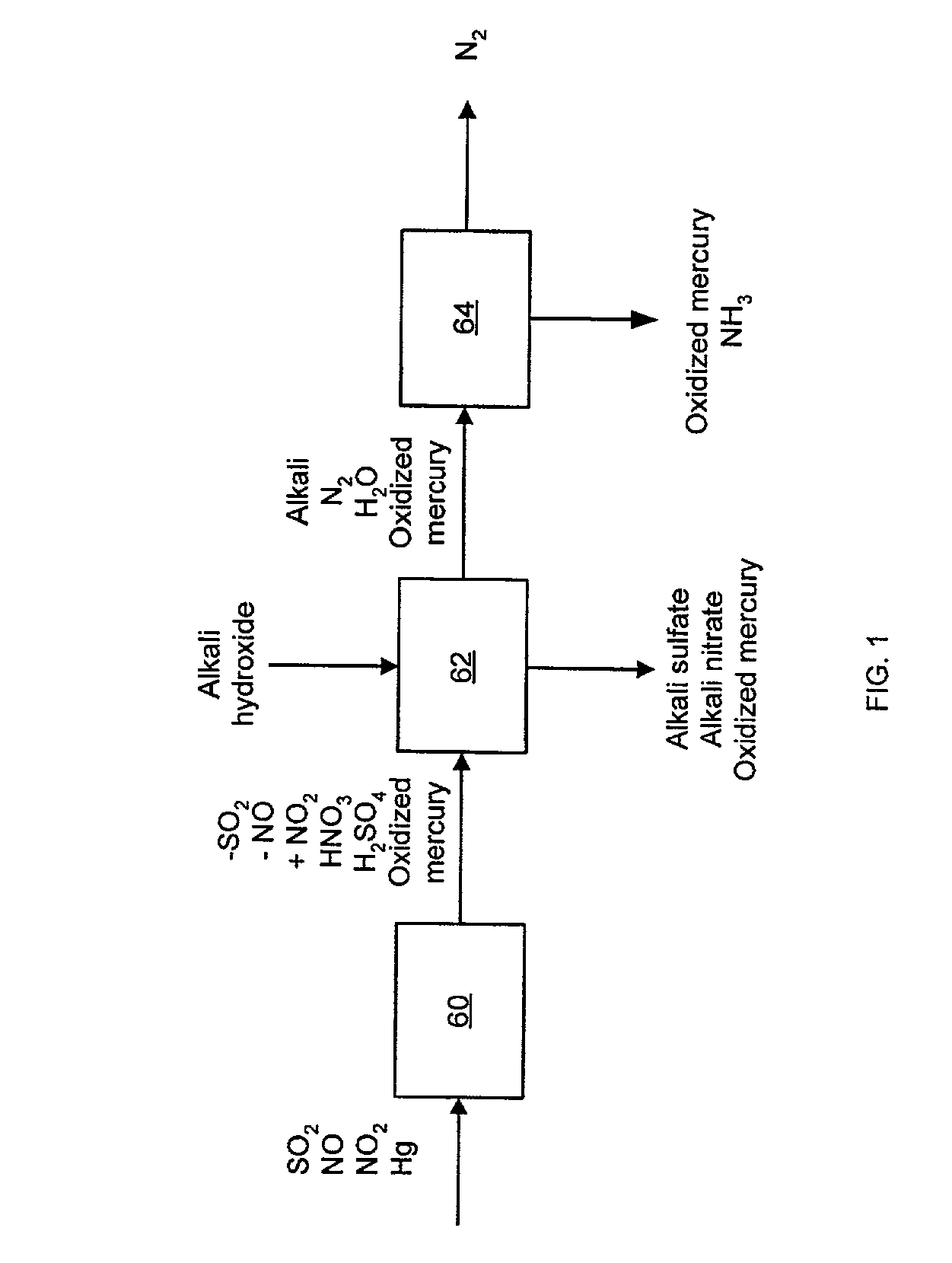

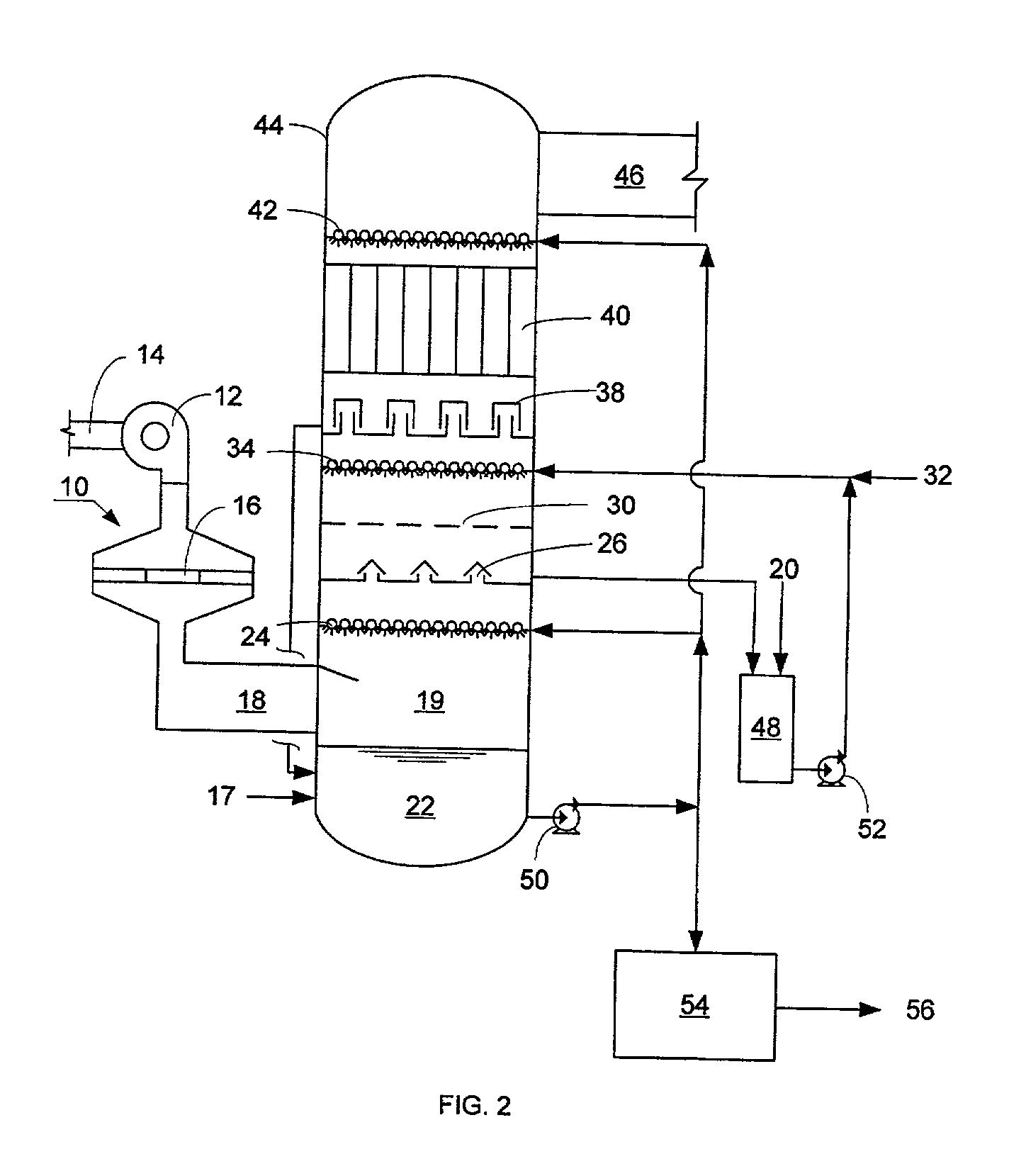

NOx, Hg, and SO2 removal using alkali hydroxide

A process and apparatus for removing SO2, NO, and NO2 from a gas stream having the steps of oxidizing a portion of the NO in the flue gas stream to NO2, scrubbing the SO2, NO, and NO2 with an alkali scrubbing solution, and removing any alkali aerosols generated by the scrubbing in a wet electrostatic precipitator. The process can also remove Hg by oxidizing it to oxidized mercury and removing it in the scrubbing solution and wet electrostatic precipitator. Alkali sulfates, which are valuable fertilizers, can be withdrawn from the rubbing solution.

Owner:POWERSPAN CORP

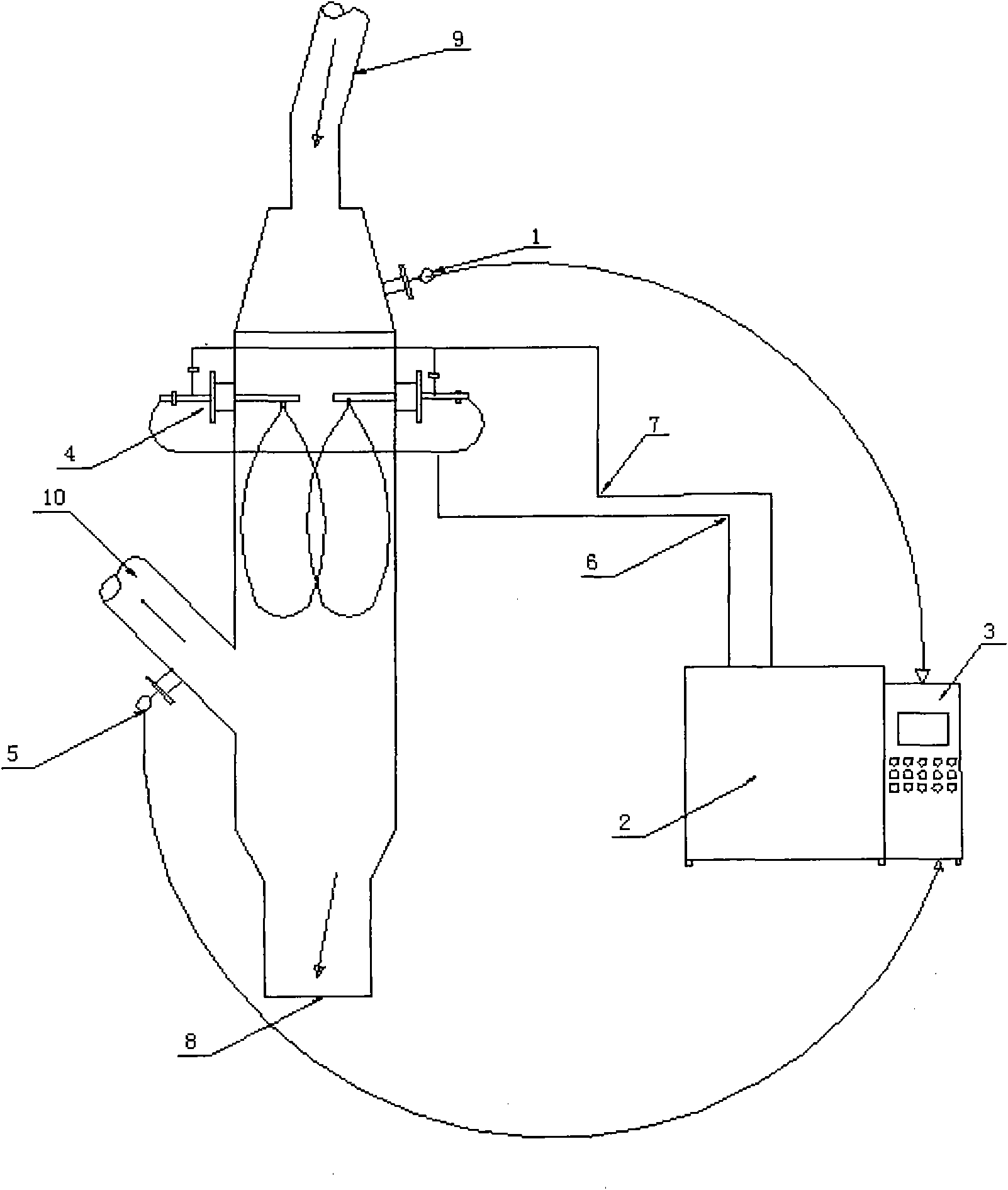

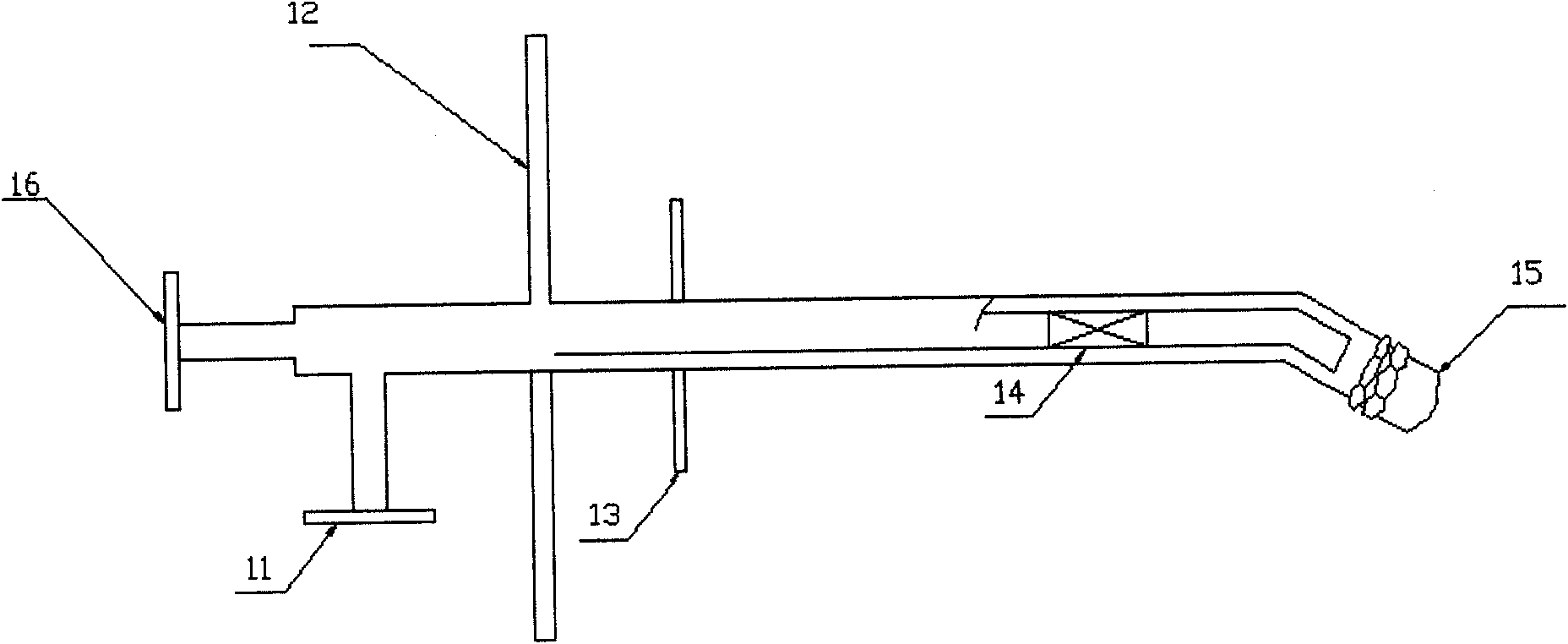

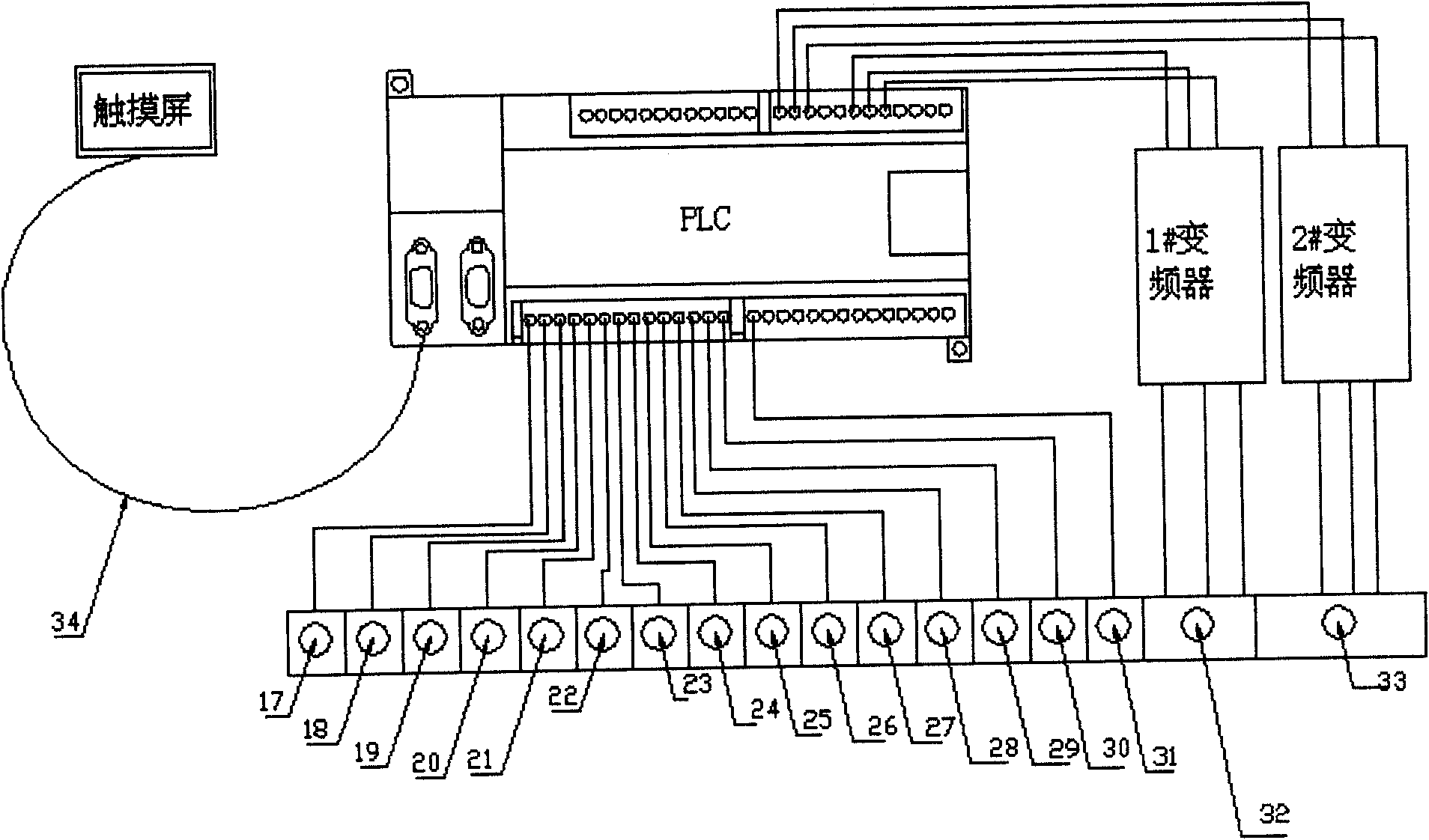

Quenching and tempering device for cooling high-temperature fume

InactiveCN101596389AEmission reductionReduce energy consumptionAuxillary pretreatmentEfficient regulation technologiesFrequency changerAir pump

The invention discloses a quenching and tempering device for cooling high-temperature fume, comprising a two-fluid electrical appliance controller, a water path and an air path arranged between a high-temperature fume inlet and a high-temperature fume outlet. The device of the invention is characterized in that a low pressure pump is arranged in the air path, a low pressure air path is combined into a water pipeline before a spray gun, two transducers are arranged to adjust the pressure and flow of a water pump and an air pump, the nozzle bore diameter is phi 6-7mm, and the spray particle diameter is smaller than 300 micrometers; a temperature sensor is respectively arranged at a wetting tower inlet and the fume outlet, and the outlet temperature is controller to 130-150 DEG C; an operation program is controlled to calculate the temperature difference of the fume inlet temperature and the fume outlet temperature, tower volume and spray fall height; two transducers are used for controlling the water pump and the air pump to automatically adjust operation power when low air pressure is 0.4-0.6MPa, and air flow quantity and water flow quantity are 5-25T / H. the particle diameter of sprayed water spray is small and even, which can better realize precise control to temperature and reduces atomization particle residence time and wet bottom danger. The dust removal device designed by the invention increases fume density and volume, lowers speed and improves dust removal function. In particular, the spray granularity is small, which can obviously control temperature and humidity, lower discharge Dioxin and furan mixed in dust and reduce environment protection cost.

Owner:SHENYANG XINCHENG TECH

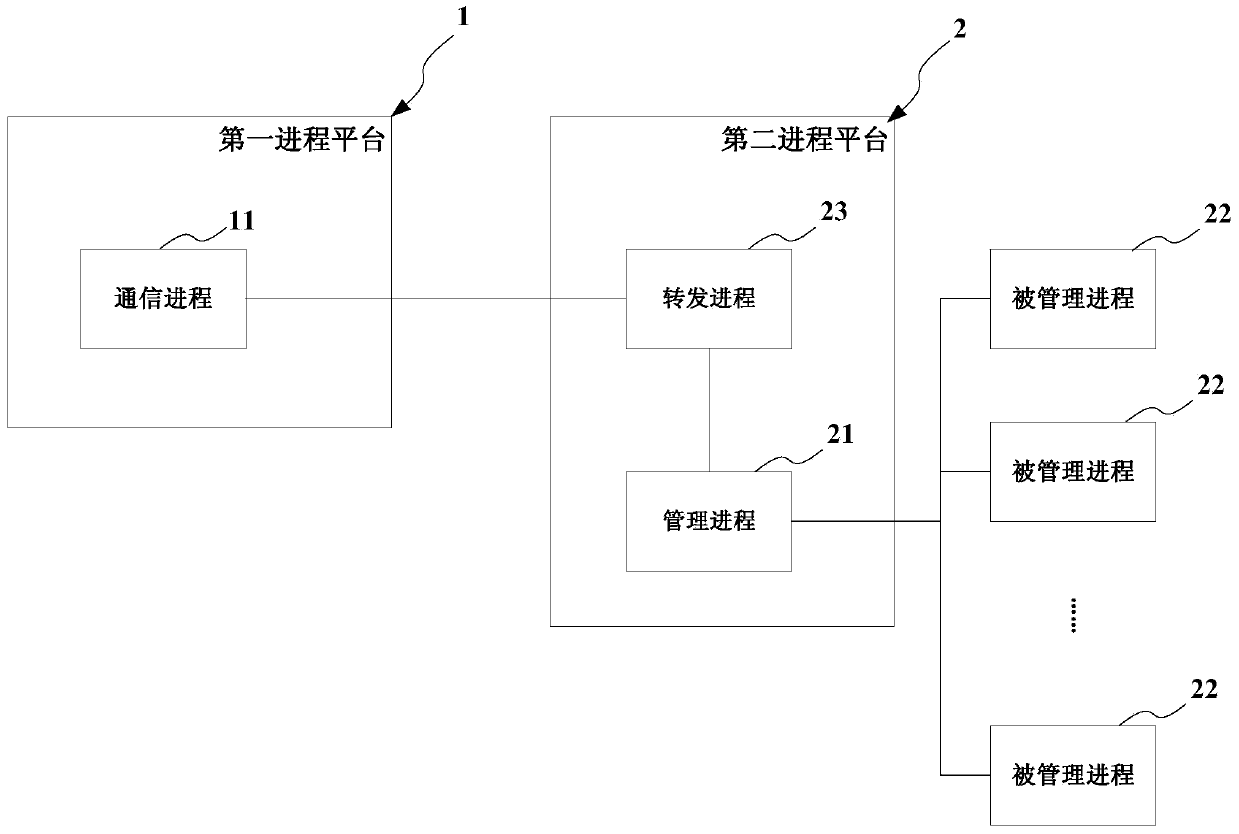

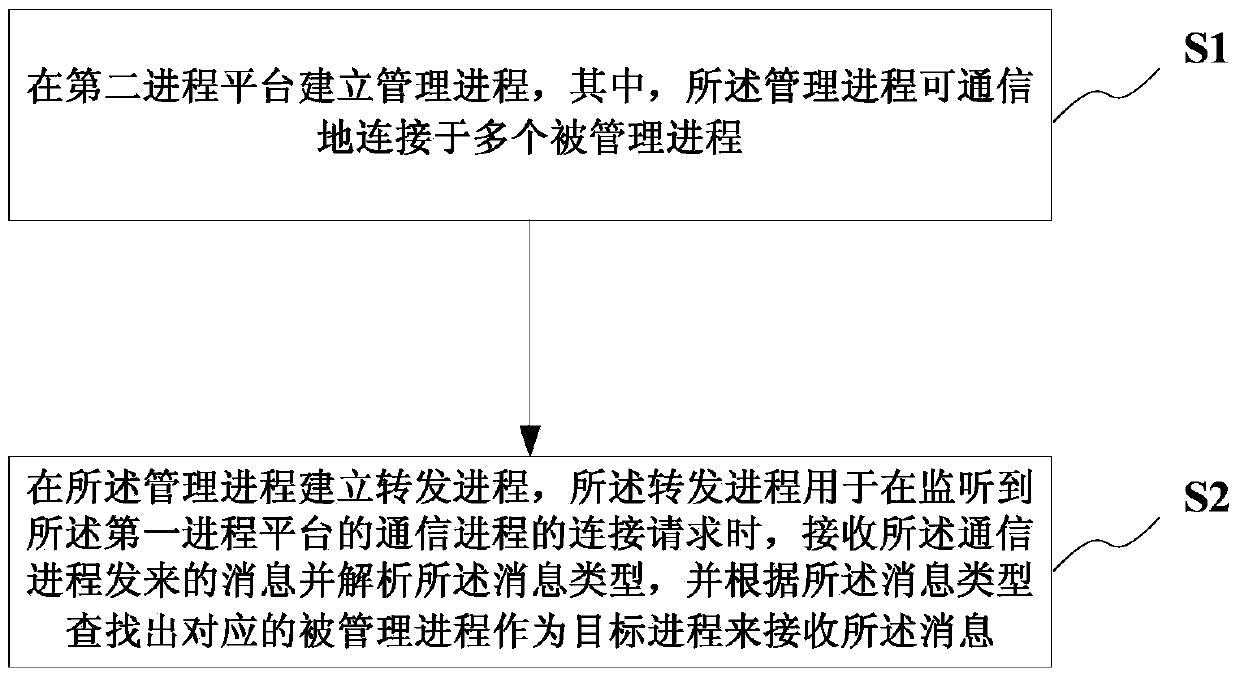

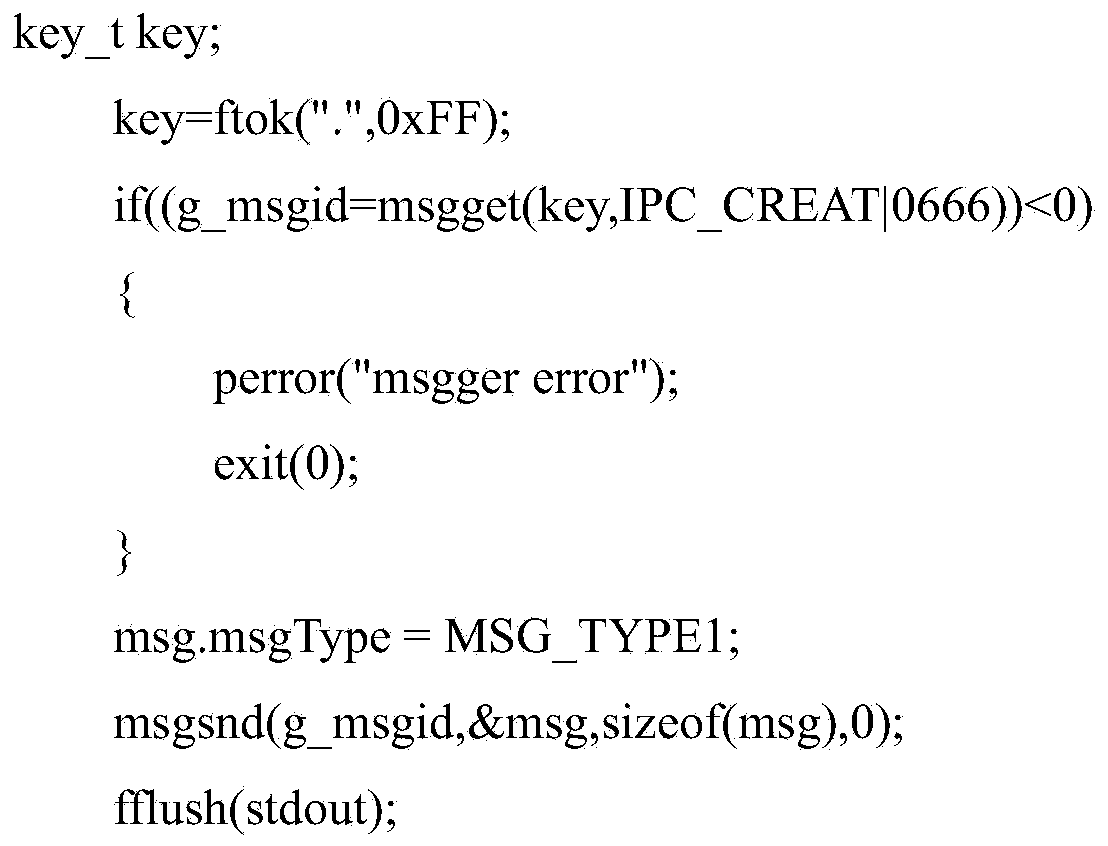

Cross-platform communication system and method

ActiveCN103995751AHigh maintenanceImprove general performanceInterprogram communicationInformation typeCommunications system

The invention provides a cross-platform communication system and method. A forwarding process is set up in the management process of a second process platform and used for receiving information sent by a communication process and analyzing the information type when the connecting request of the communication process of a first process platform is monitored, and a corresponding managed process is discovered according to the information type and serves as a target process to receive the information; communication between two cross-platform processes is achieved by setting up the intermediate forwarding process, and the universality is high. The cross-platform communication system and method can be used for process communication of a communication process, a management process and a managed process, any other processes do not need to be set up, the degree of code maintenance is greatly increased, and the method of the forwarding process can protect the cross-platform process structure against changes.

Owner:湖州帷幄知识产权运营有限公司

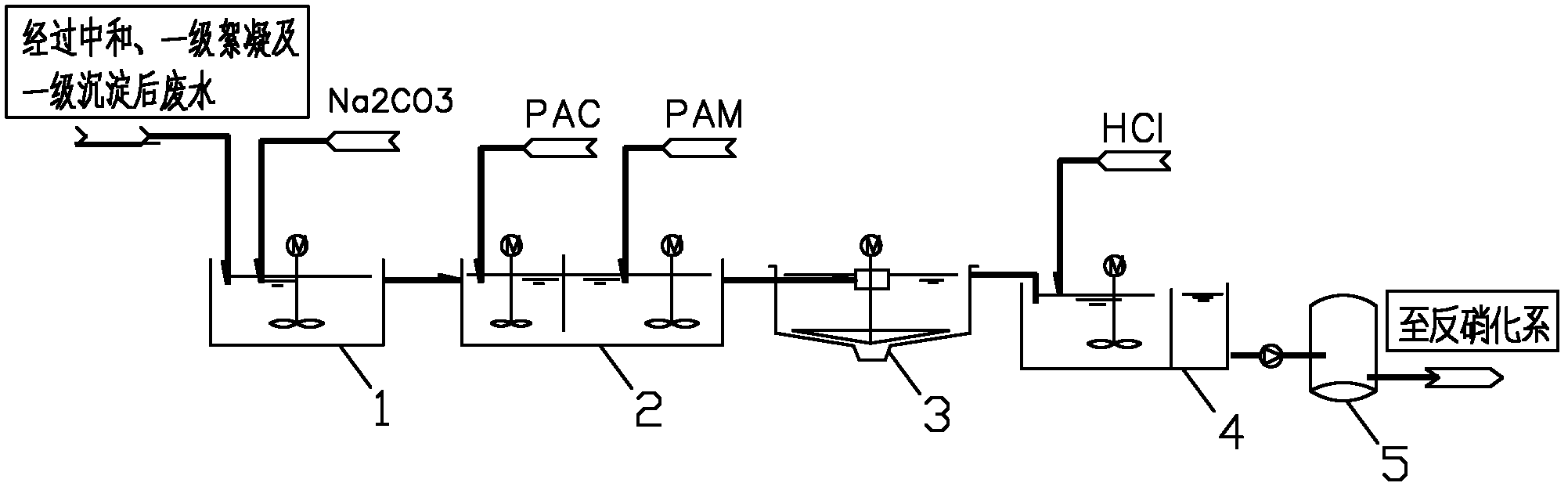

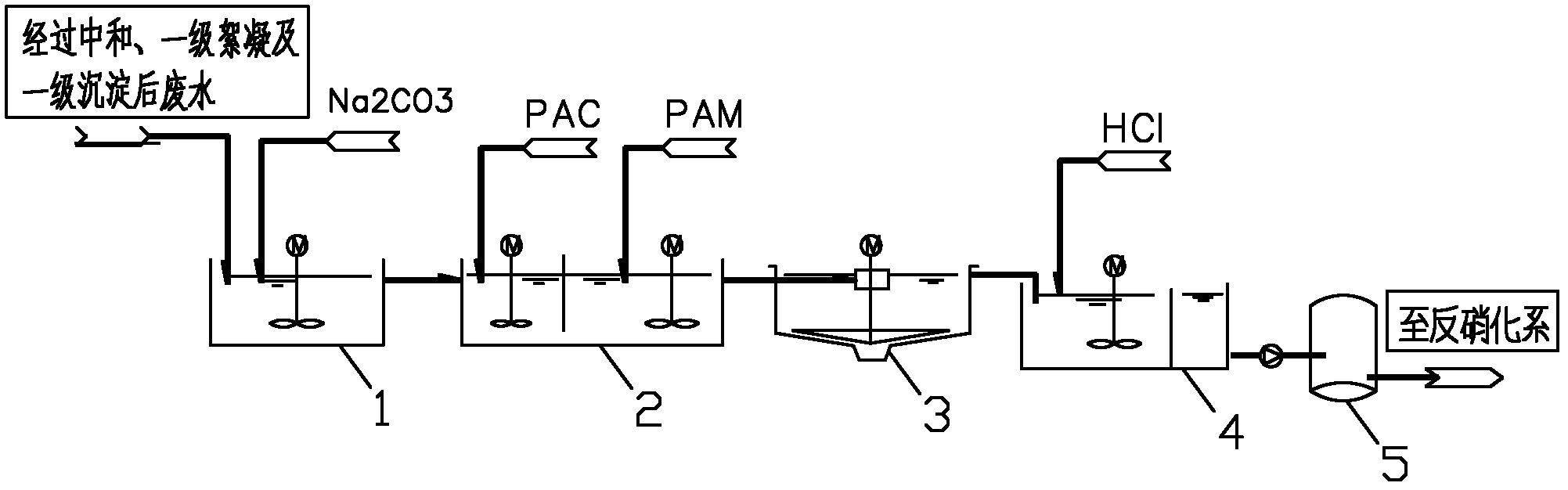

Anti-scaling treatment method for stainless steel acid waste water subsequent treatment

ActiveCN102351348AGood for the environmentReduce manual labor intensityMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationSand filterEnvironmental chemistry

The invention relates to an anti-scaling treatment method for stainless steel acid waste water subsequent treatment. The method comprises the following steps: (1) residual Ca<2+> in acid waste water which is subjected to lime neutralization, flocculation and precipitation is formed into precipitate of Ca<2+>; (2) flocculation is carried out, wherein the precipitate of Ca<2+> and other sludge formlarge alumen ustum; (3) precipitation is carried out; (4) pH value is regulated, wherein precipitated effluent flows into a final pH regulating pondage, the pH of water quality in the final pH regulating pondage is between 6 and 7 by adding hydrochloric acid; (5) filter is carried out, wherein after the performed steps, the Ca<2+> content in the water in the final pH regulating pondage is less than 150mg / l, SS content is 20mg / l, the effluent can meet the requirement of denitrification and subsequent treatment by utilizing filter of a sand filter, and the effluent is delivered to a denitrification facility for treatment. According to the method, the problems causing scaling and blockage of denitrification system pump and pipeline can be solved, so that the production and environmental-friendliness are facilitated, and the labor intensity of workers is reduced.

Owner:中国冶金科工股份有限公司

Omni-directional drive device and omni-directional vehicle using the same

Owner:HONDA MOTOR CO LTD

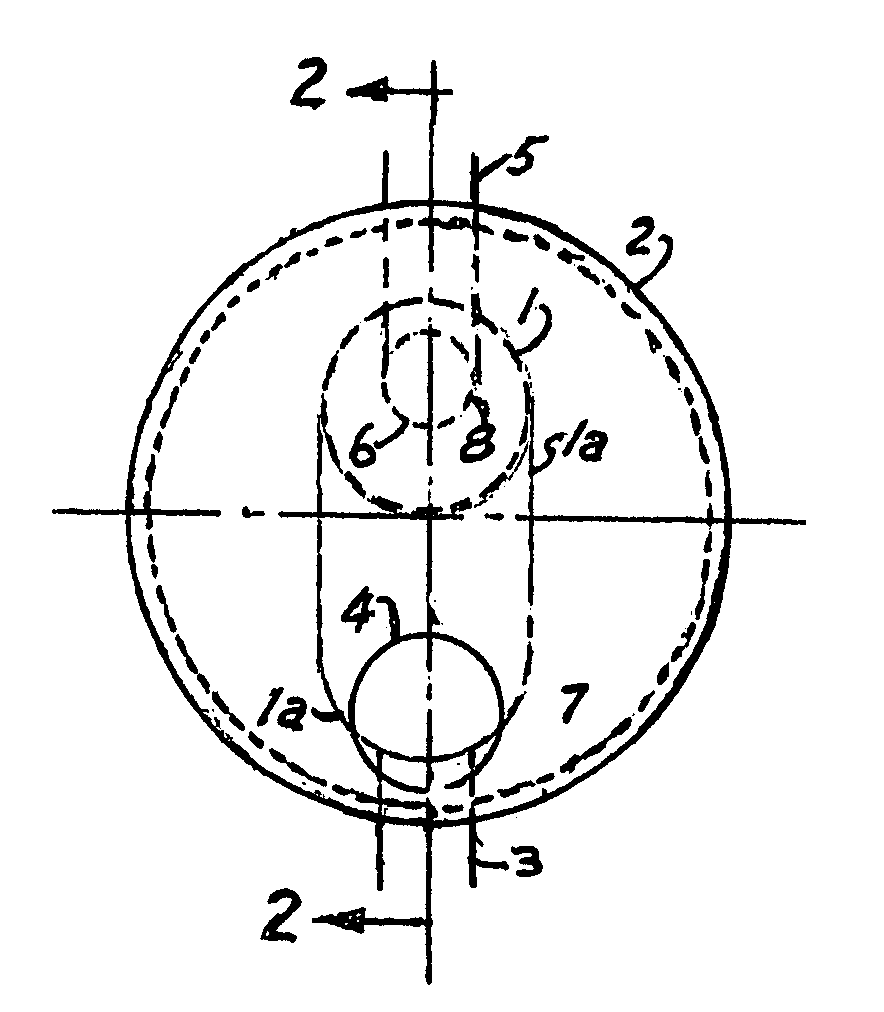

Energy efficient pyrolytic processing oven

InactiveUS7032525B1Improve energy efficiencyEasy maintenanceSolid fuel combustionIncinerator apparatusFree fallingProcess engineering

A method and apparatus of converting waste materials into combustible vapor and char utilizing an energy efficient pyrolytic processing oven that eliminates the complex mechanisms usually associated with these systems for heating and transporting the waste material through the oven. The oven of this system has a unique configuration that permits the pyrolized material to free fall through the unit.

Owner:EDMONDSON JERRY M

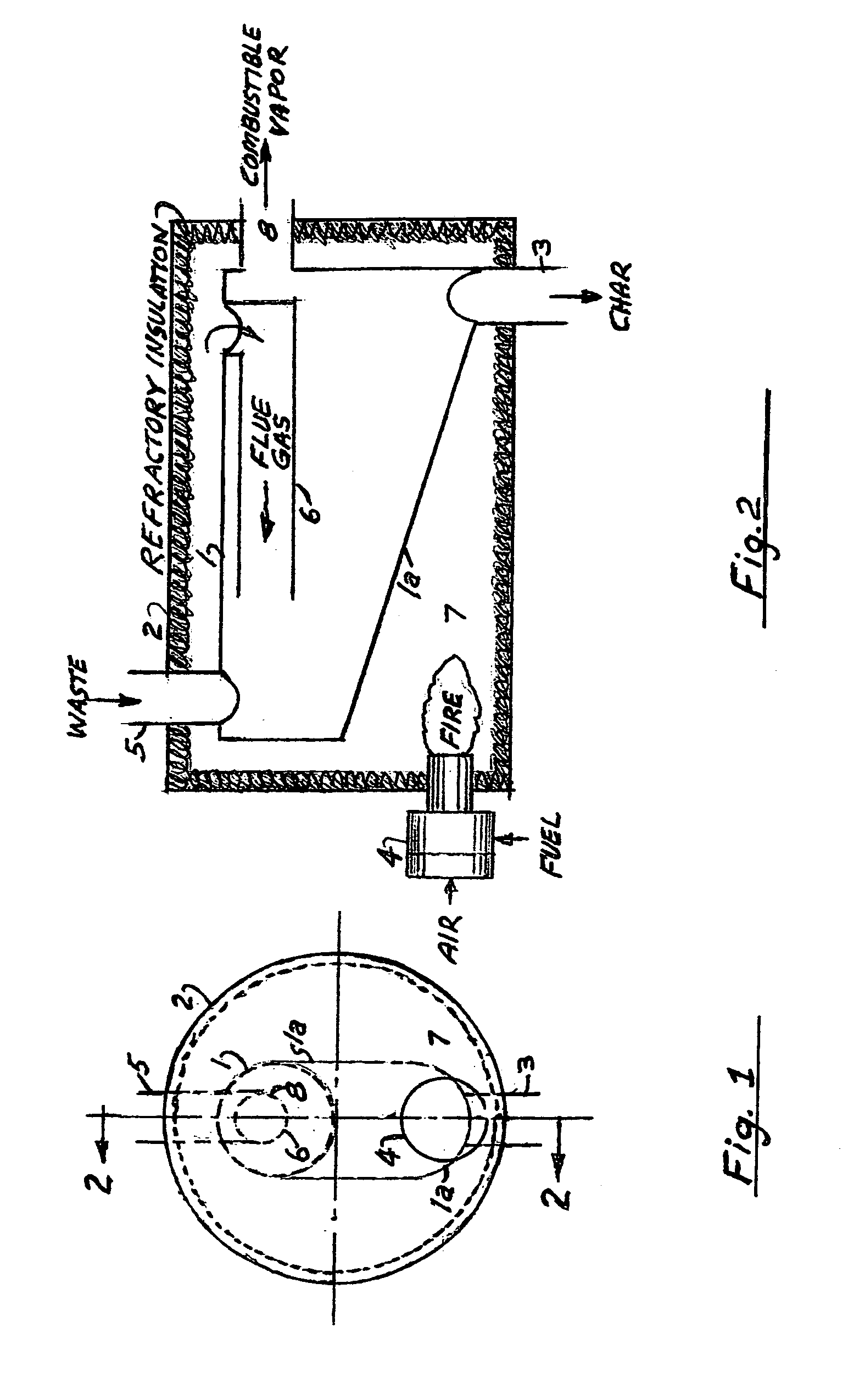

Radial flux permanent magnet alternator with dielectric stator block

ActiveUS20110278847A1High maintenanceHigh operating requirementsAsynchronous induction motorsMachines/enginesEnvironmental energyAlternator

An energy conversion system is described and includes a cylindrical rotor having a mass and multiple magnets affixed on an outer face thereof; a cylindrical stator including a dielectric cylinder wound with copper wire in a predetermined configuration, the cylindrical rotor being placed within the cylindrical stator; and a rotatable shaft for rotating the rotor, the rotatable shaft being placed in the center of the cylindrical rotor. The system harvests environmental energy for lower power generation and accounts for non-mechanical sources of rotational resistance within the generator.

Owner:LEIDOS

Process for producing microfiber assembly

InactiveUS20100001438A1Easy maintenanceReduce intermolecular forcesElectric discharge heatingNon-woven fabricsMetallic materialsEngineering

A process for producing a fiber assembly or agglomerate requiring micropores, such as for a battery separator or any of various filters, which is performed by electrostatic spinning and provides high productivity and ease of maintenance, is provided. The process for producing a microfiber assembly or agglomerate by electrostatic spinning includes continuously forming bubbles on a polymer solution or a polymer melt and applying high voltage to the formed bubbles. The bubbles can be formed by passing compressed air through porous material of one or a combination of two or more of plastic, ceramic and metal materials, or capillaries.

Owner:KANKYOKIKI CORP

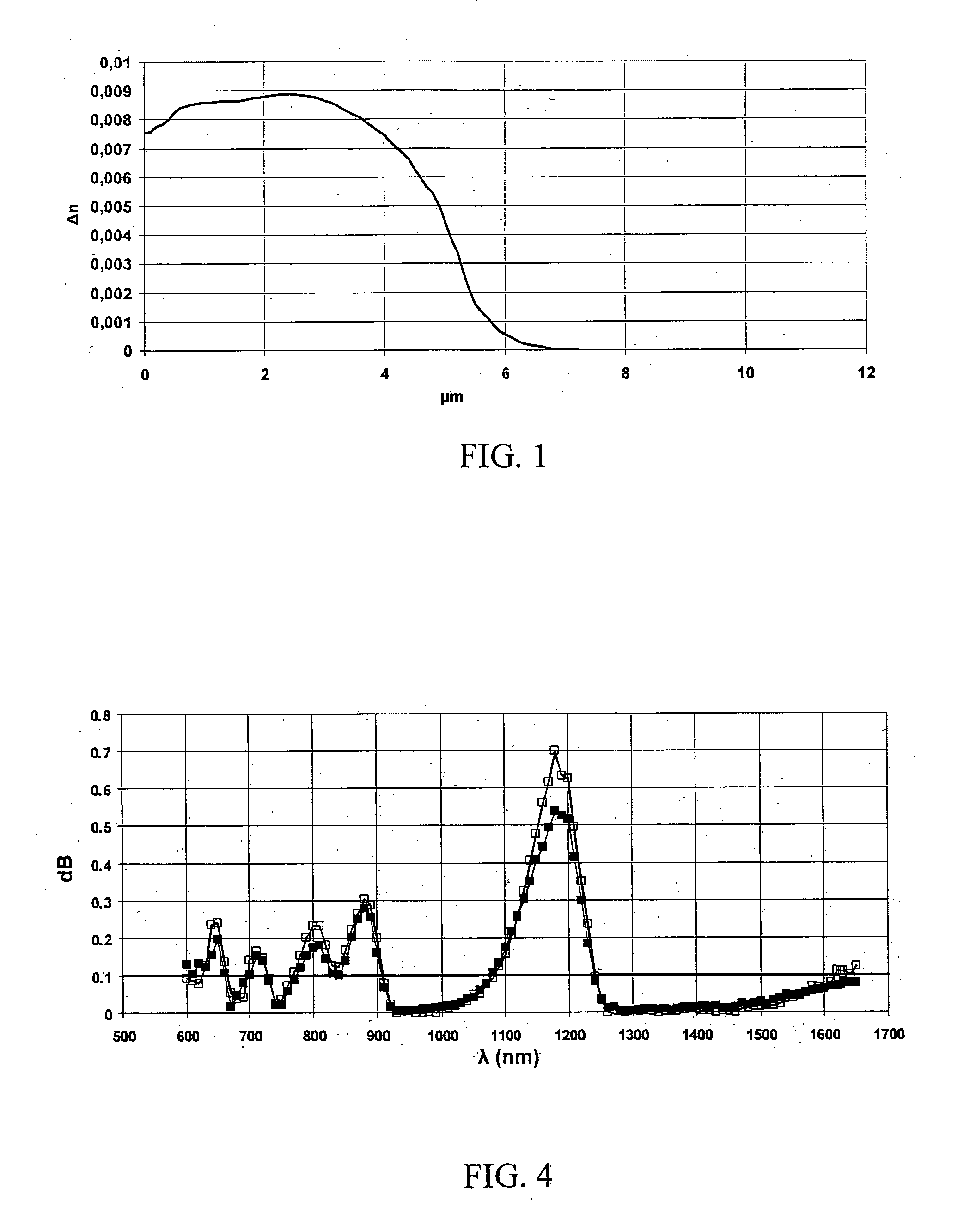

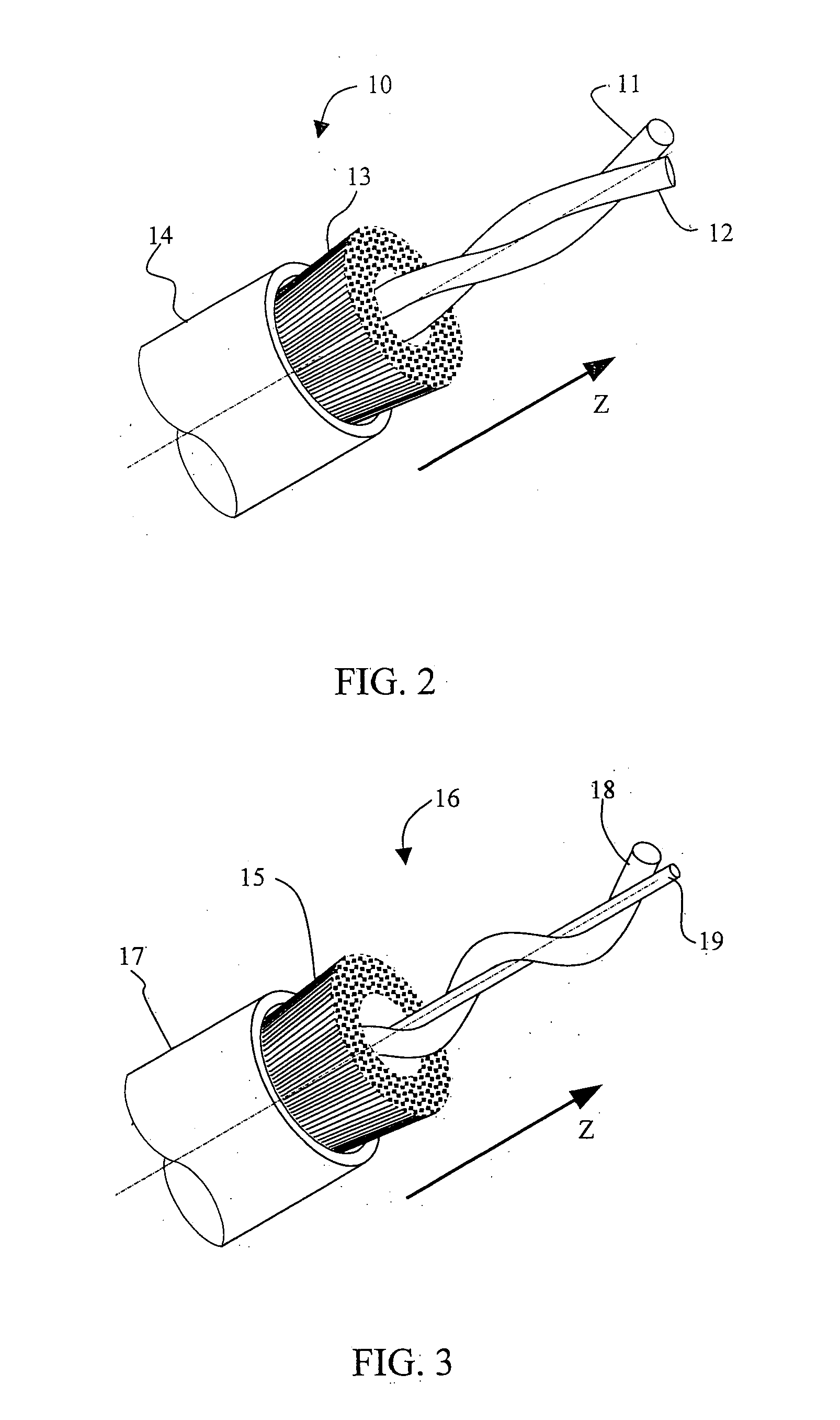

Method for checking the correct installation of a bend-insensitive optical cable and optical cable suitable for the method thereof

ActiveUS20130142491A1Cost-effectiveHigh maintenanceMaterial analysis by optical meansOptical fibre/cable installationUltrasound attenuationEngineering

A method for detecting faulty laying down of an optical cable exhibiting a measured cut-off wavelength includes providing an optical cable for transmitting optical signals including at least one single-mode optical fibre having an attenuation equal to or larger than a first threshold value as measured when wound for one turn around a bending radius equal to or smaller than 5 mm at at least one predetermined test wavelength, the test wavelength being smaller than the measured cut-off wavelength, and an attenuation smaller than a second threshold value as measured when wound for one turn around a bending radius equal to at least a minimum bending radius at an operative wavelength equal to or larger than the measured cut-off wavelength; laying the optical cable; and measuring the attenuation in the at least one optical fibre at the predetermined test wavelength. An optical cable includes at least one optical fibre that is bend sensitive at a predetermined test wavelength not larger than the measured cut-off wavelength and is bend insensitive at an operative wavelength larger than the measured cut-off wavelength, where the cable operates in single-mode regime.

Owner:PRYSMIAN SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com