Patents

Literature

1879 results about "Tire bead" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tire bead is the term for the edge of a tire that sits on the wheel. Wheels for automobiles, bicycles, etc. are made with a small slot or groove into which the tire bead sits. When the tire is properly inflated, the air pressure within the tire keeps the bead in this groove.

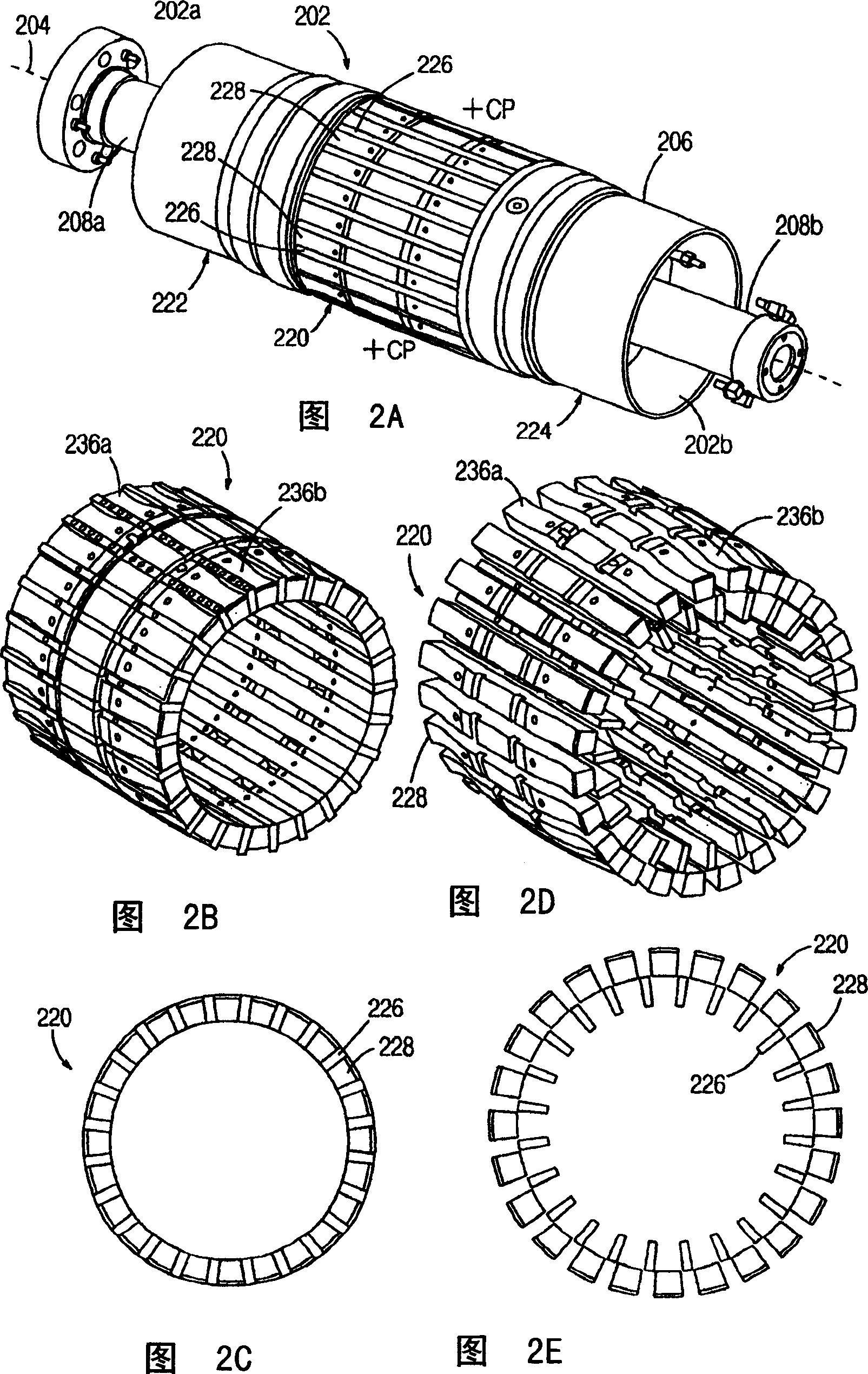

Pneumatic automobile tire with integrated sensors and traction control system

InactiveUS6339956B1Complicates of longitudinal forceReduce brake pressureForce measurement using piezo-electric devicesTyre beadsTire beadTraction control system

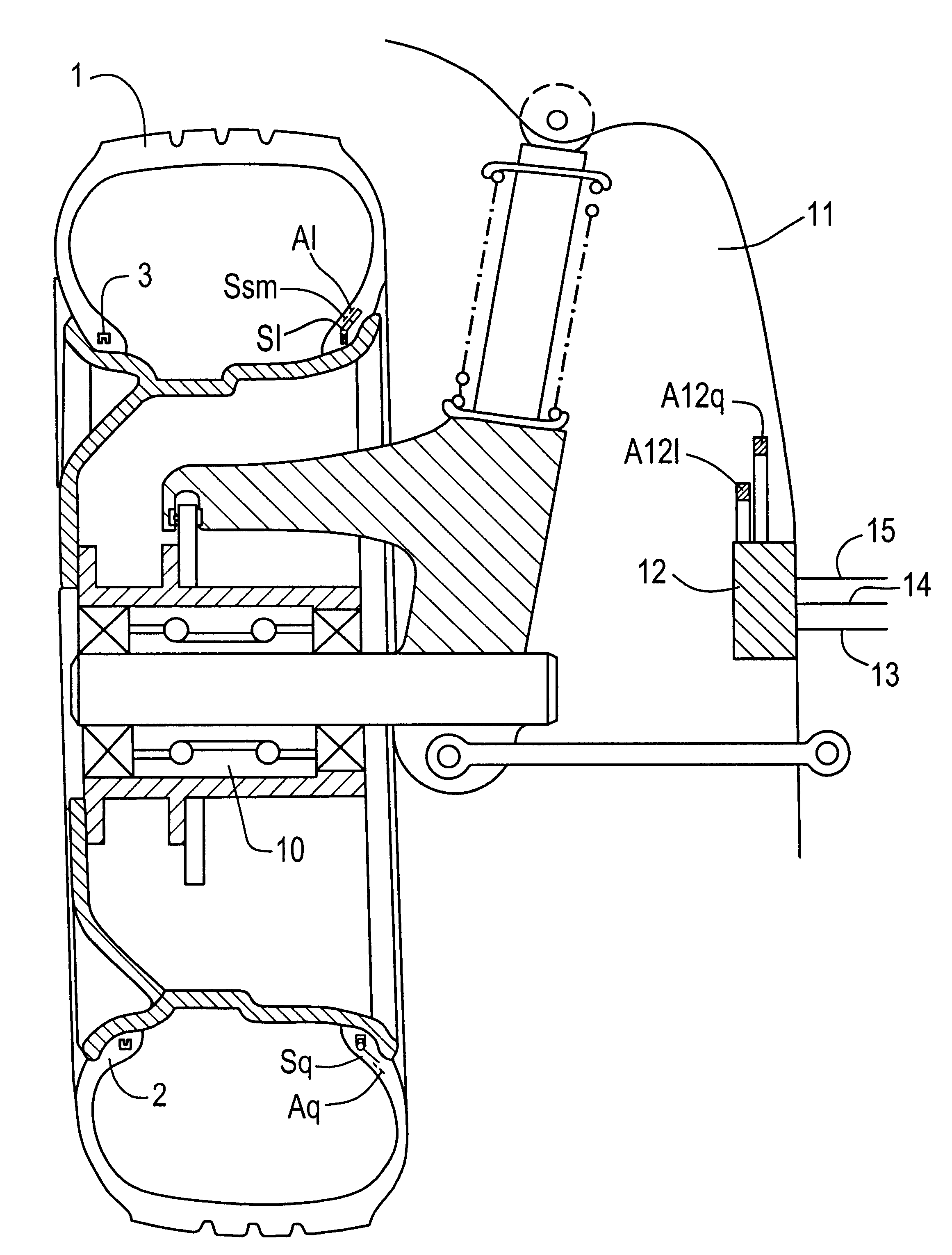

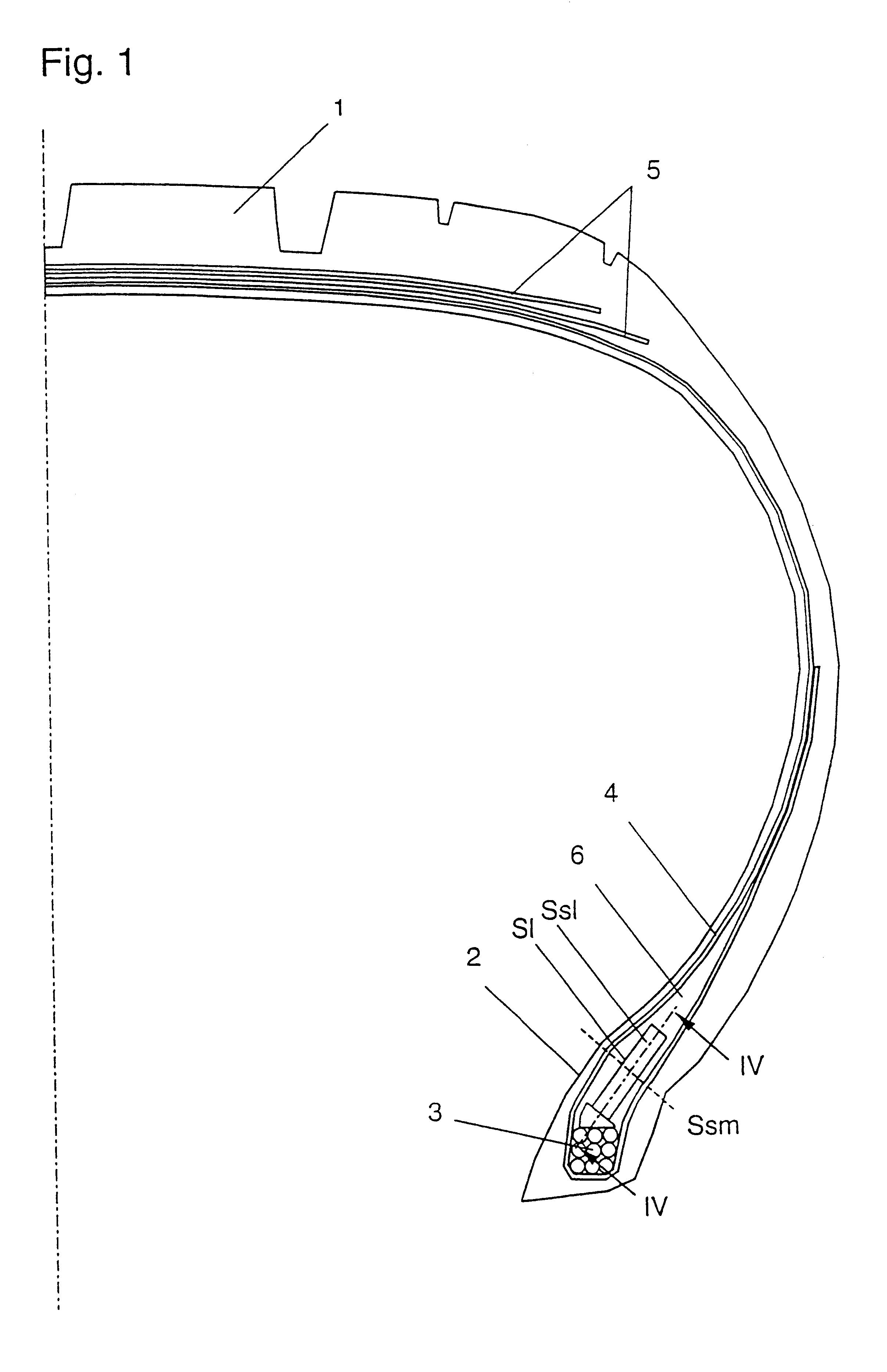

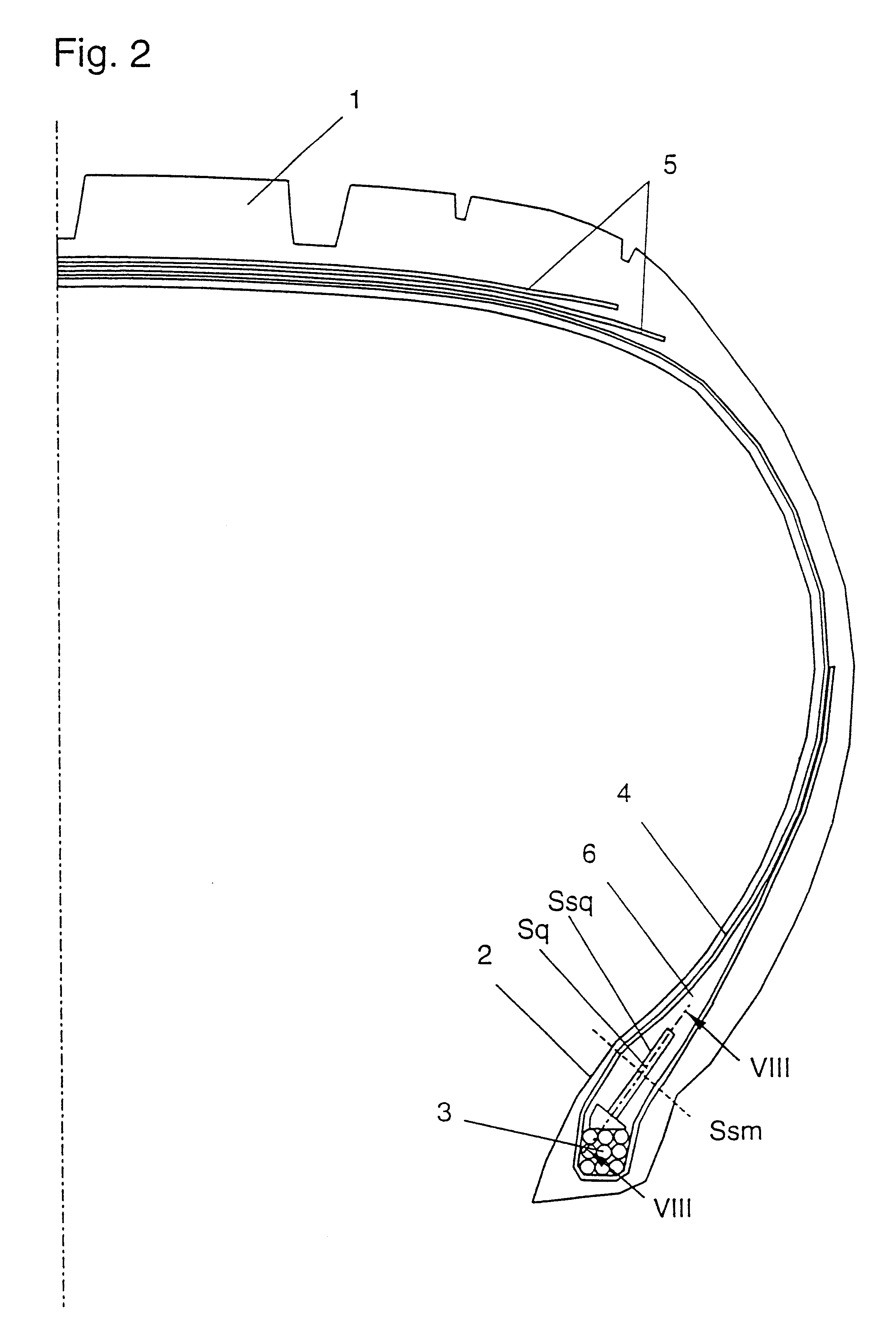

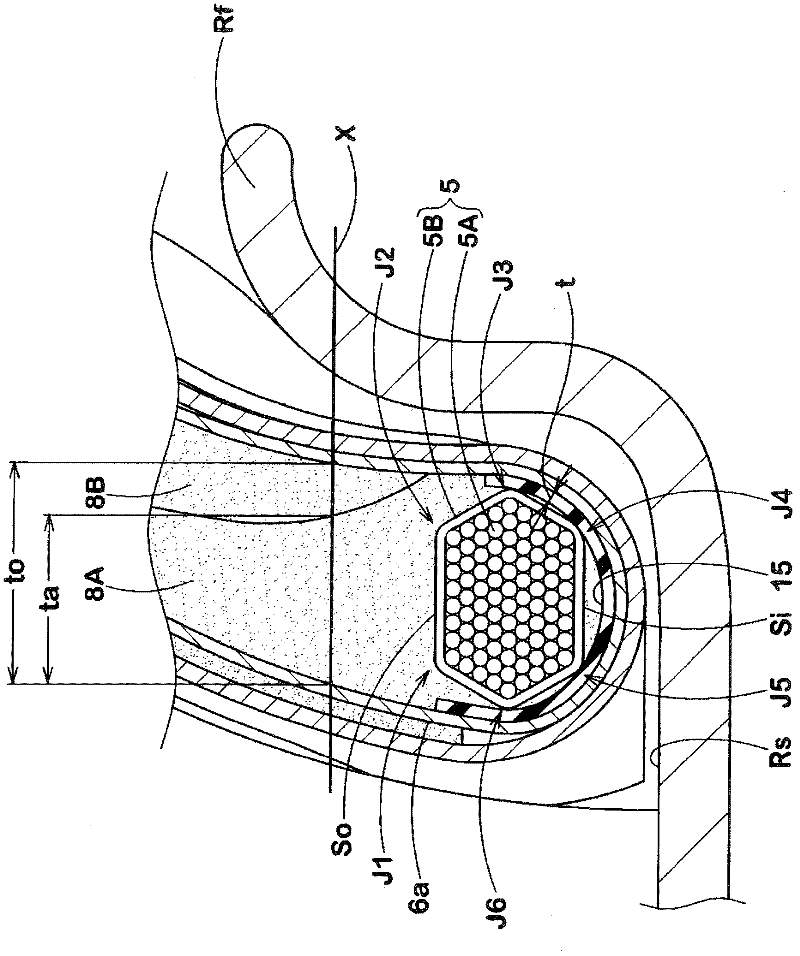

A pneumatic vehicle tire includes a carcass, a bead with a bead core arranged in the bead, and a first sensor located within the bead. The first sensor delivers signals which are correlated to frictional forces transmitted by the pneumatic vehicle tire during operation. This sensor has a first end and a second end, wherein the first end includes a heel attached to the bead core and the second end extends radially outward from the bead core within the tire. A plurality of such sensors can be included in each tire, some for measuring longitudinal forces in a circumferential direction of the tire and others for measuring lateral forces in an axial direction of the tire.

Owner:CONTINENTAL AG

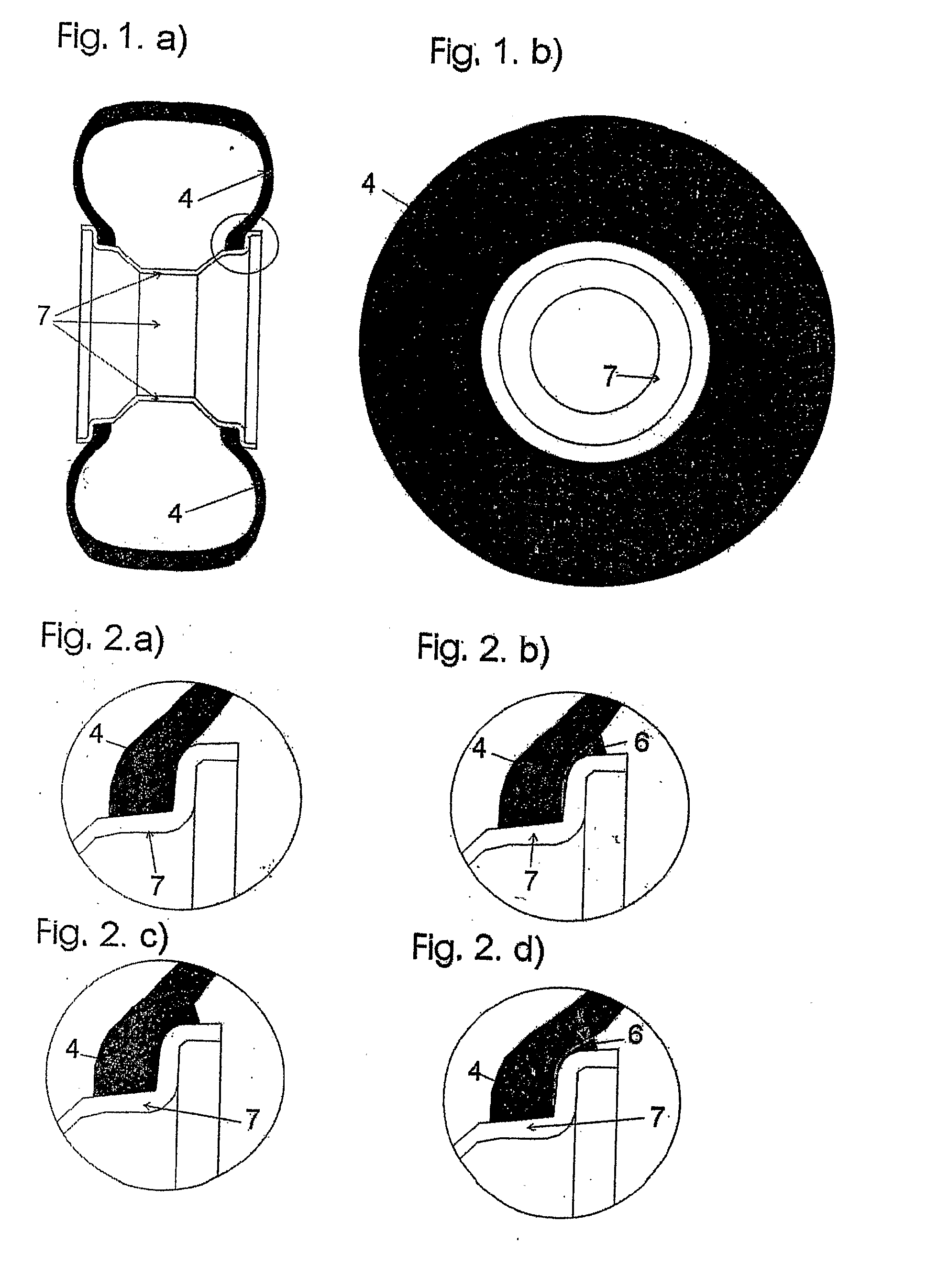

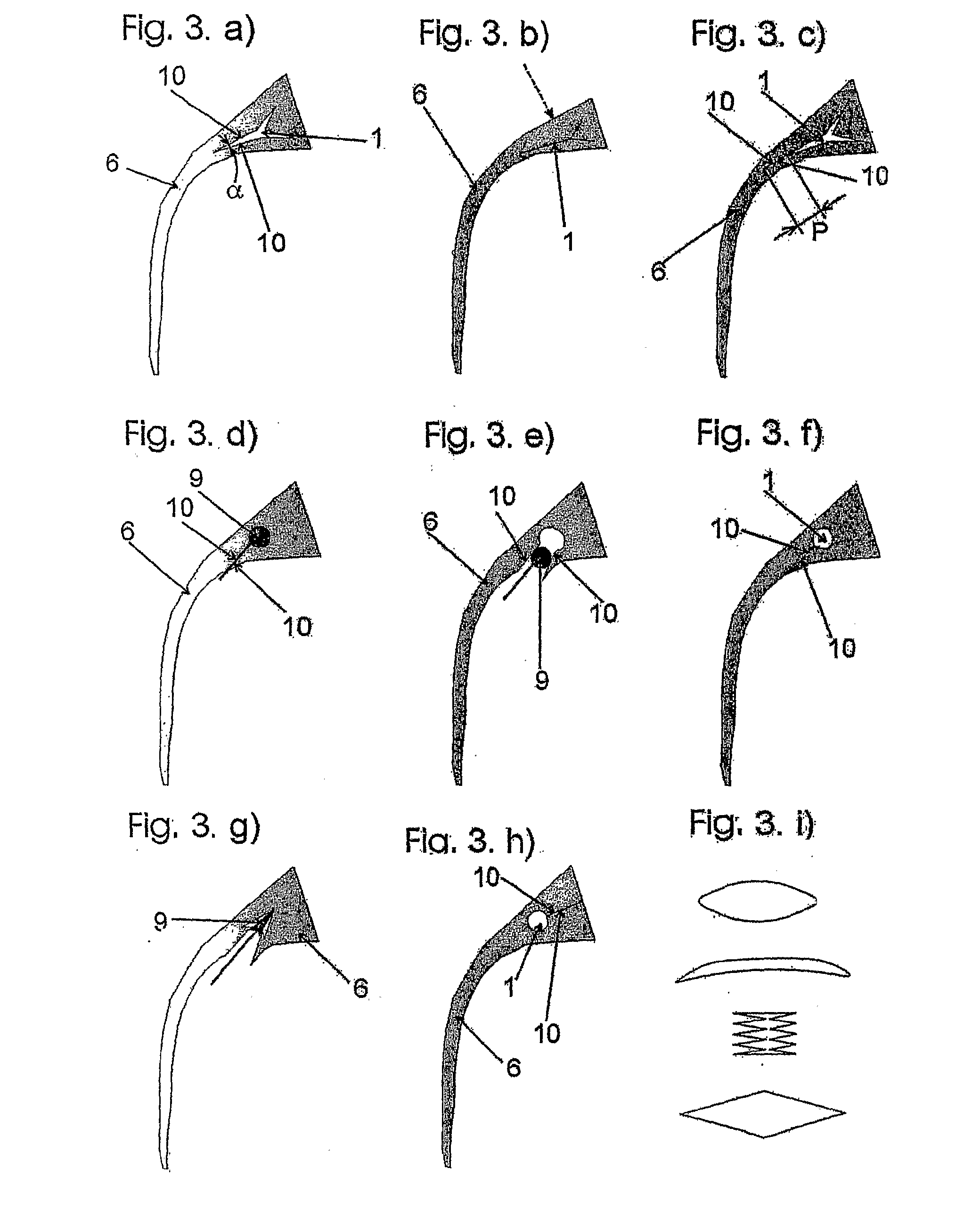

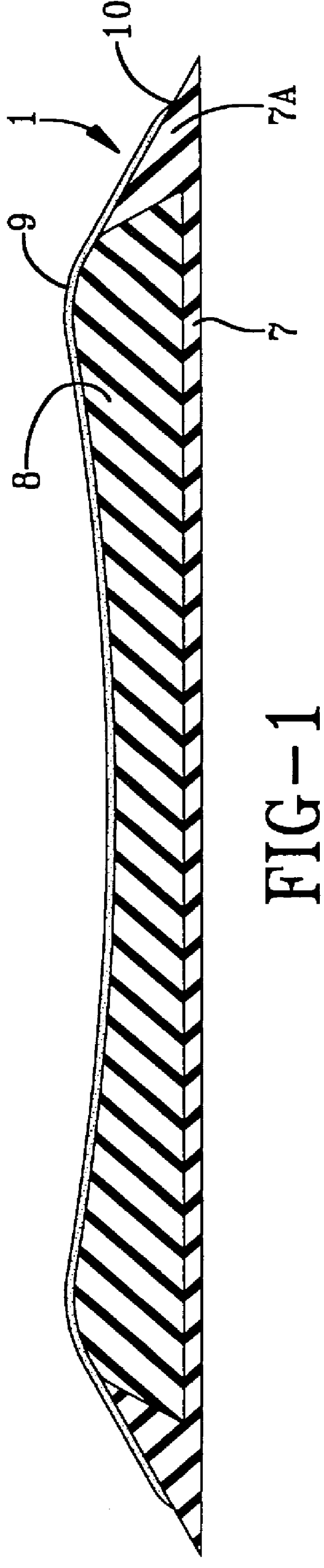

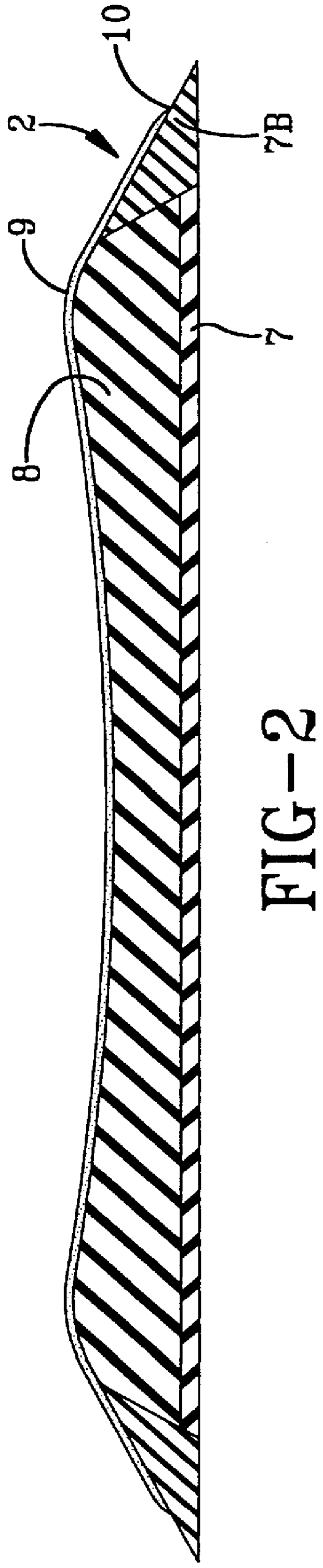

Chamber of a peristaltic pump for tire pressure adjustment

InactiveUS20090294006A1Effective shapingReduced service lifeTyresTyre beadsTire beadPeristaltic pump

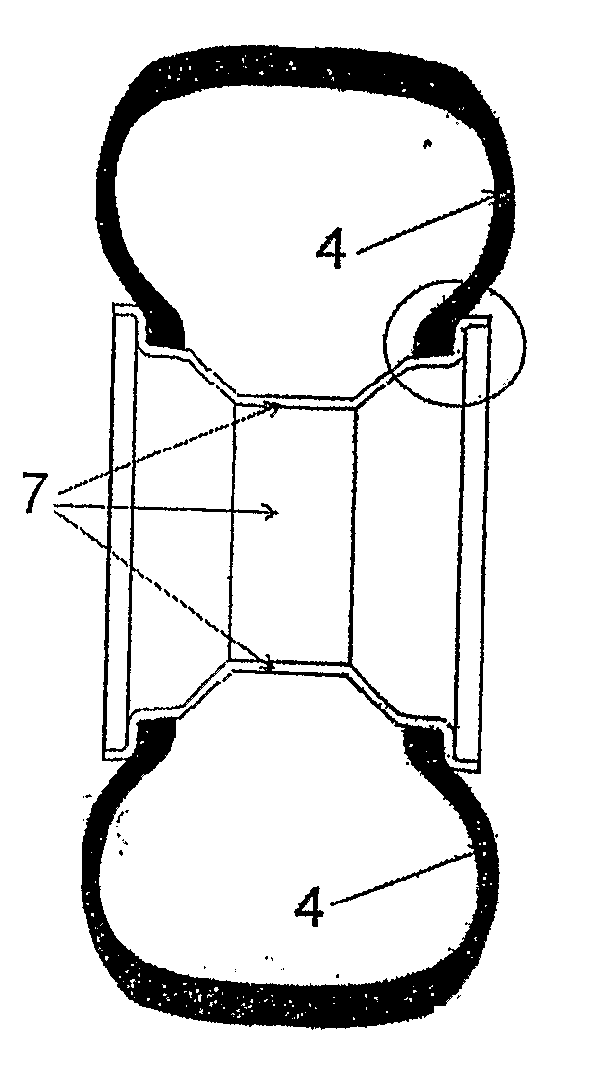

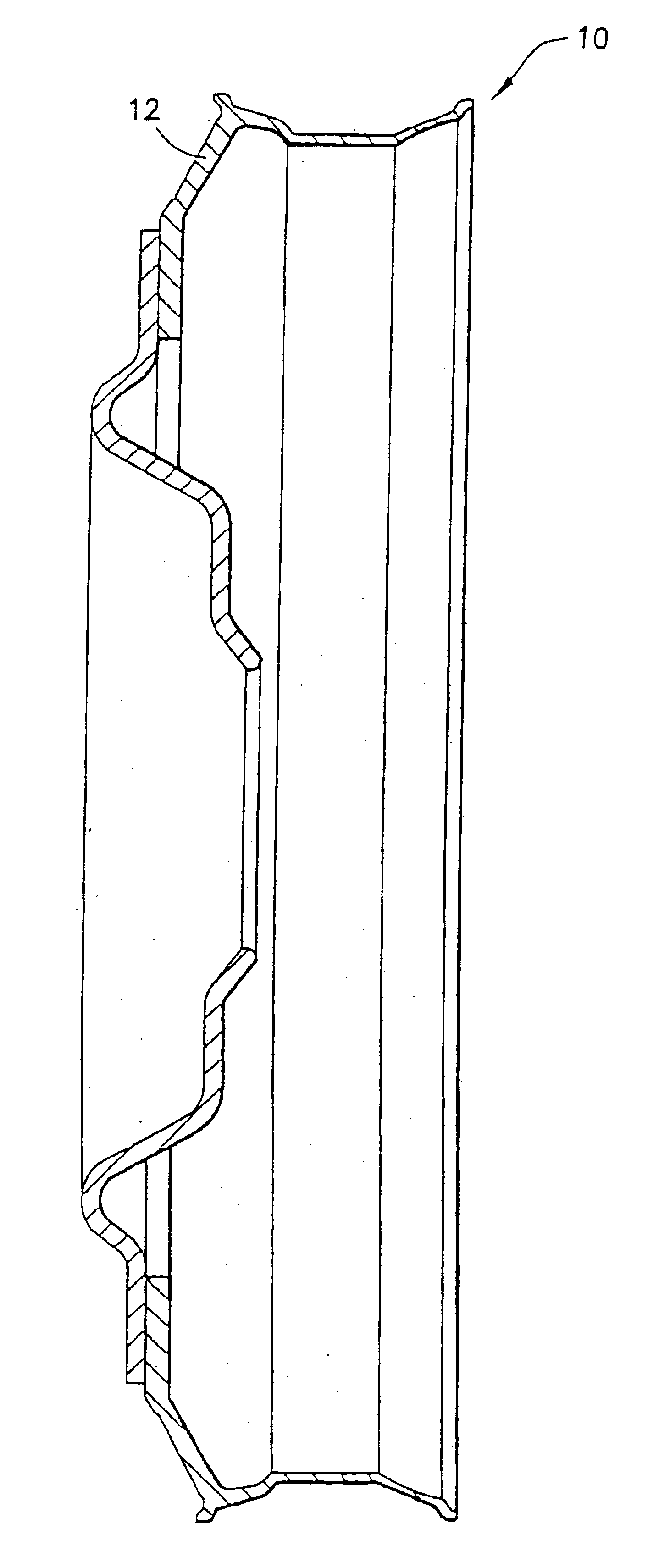

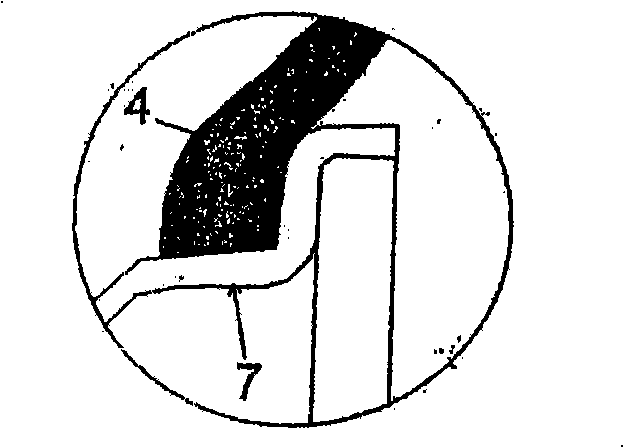

A chamber (1) that works as a peristaltic pump for the pressure correction in the tire (4), which is a part of the tire (4) or of an ancillary structure (6) placed between the rim (7) and the tire bead (4) and is connected with the tire (4) internal space at one end and with the external environment at the other end. The chamber (1) is in the shape of a curved hollow channel, where at least one enclosing wall is at least partially formed by at least a pair of surfaces (10) coplanar with the longitudinal direction of the chamber (1). When the tire is mounted on the rim, the pair of surfaces (10) are pressed together thus hermetically closing the chamber (1). When the chamber (1) is closed during rotation of the wheel, the surfaces (10) can slightly slide on one another taking internal wall tensions onto themselves thus decreasing the possibility of wall damage through ripping. A method of producing the chamber (1) is also disclosed.

Owner:CODA INNOVATIONS SRO

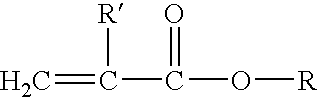

Rubber composition containing resinous nanoparticle

InactiveUS7347237B2Deteriorate controllabilityDeteriorate stabilitySpecial tyresInflatable tyresElastomerEngineering

Owner:THE GOODYEAR TIRE & RUBBER CO

Tire having silica reinforced rubber tread with outer cap containing carbon black

InactiveUS6044882AImprove propertiesAdvantageously producedSpecial tyresTyresTire beadPolymer science

The invention relates to a rubber tire composed of carbon black reinforced rubber carcass and having a rubber tread which is quantitatively reinforced with silica and which, in turn, has a thin, integral, rubber outer cap on its outer surface which contains a quantitative amount of carbon black. In one aspect, said outer cap, sometimes referred to herein as an outer top cap, extends across the outer surface of the tread which is normally intended to be ground contacting and in an alternative aspect, the outer top cap extends only over the outer portion, namely the peripheral edges, of said tread surface intended to be ground contacting. The outer, carbon black reinforced, rubber tread top cap connects with at least one other carbon black reinforced rubber component of the tire in a manner to provide a path of reduced electrical resistance from said outer tread top cap to the bead portion of the tire carcass and, therefore, such a path from the vehicle to the road surface.

Owner:THE GOODYEAR TIRE & RUBBER CO

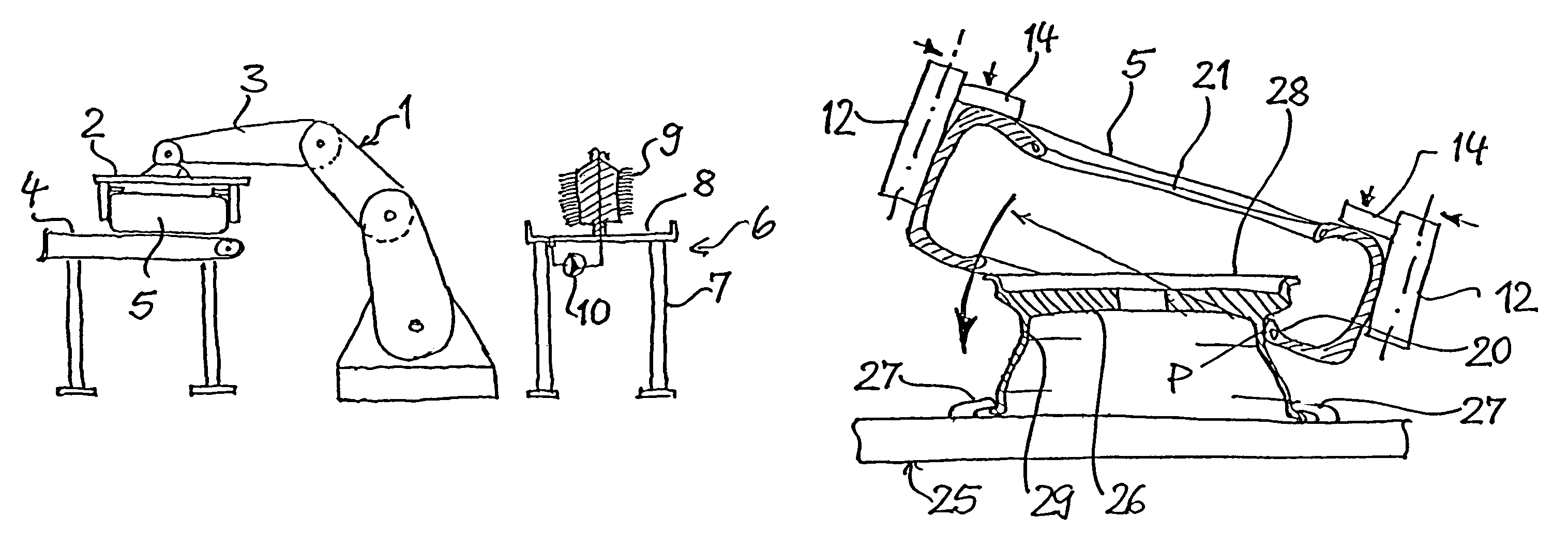

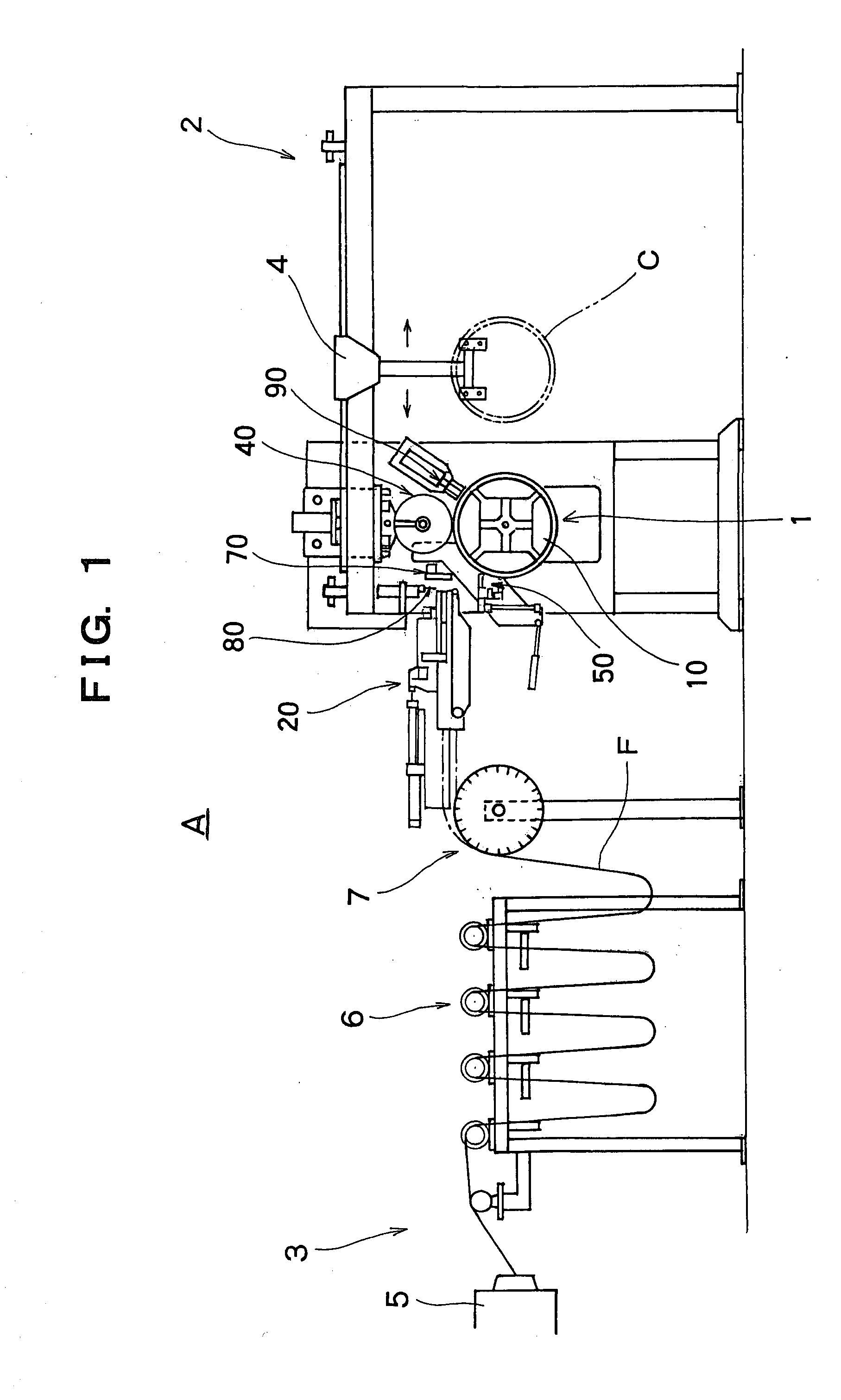

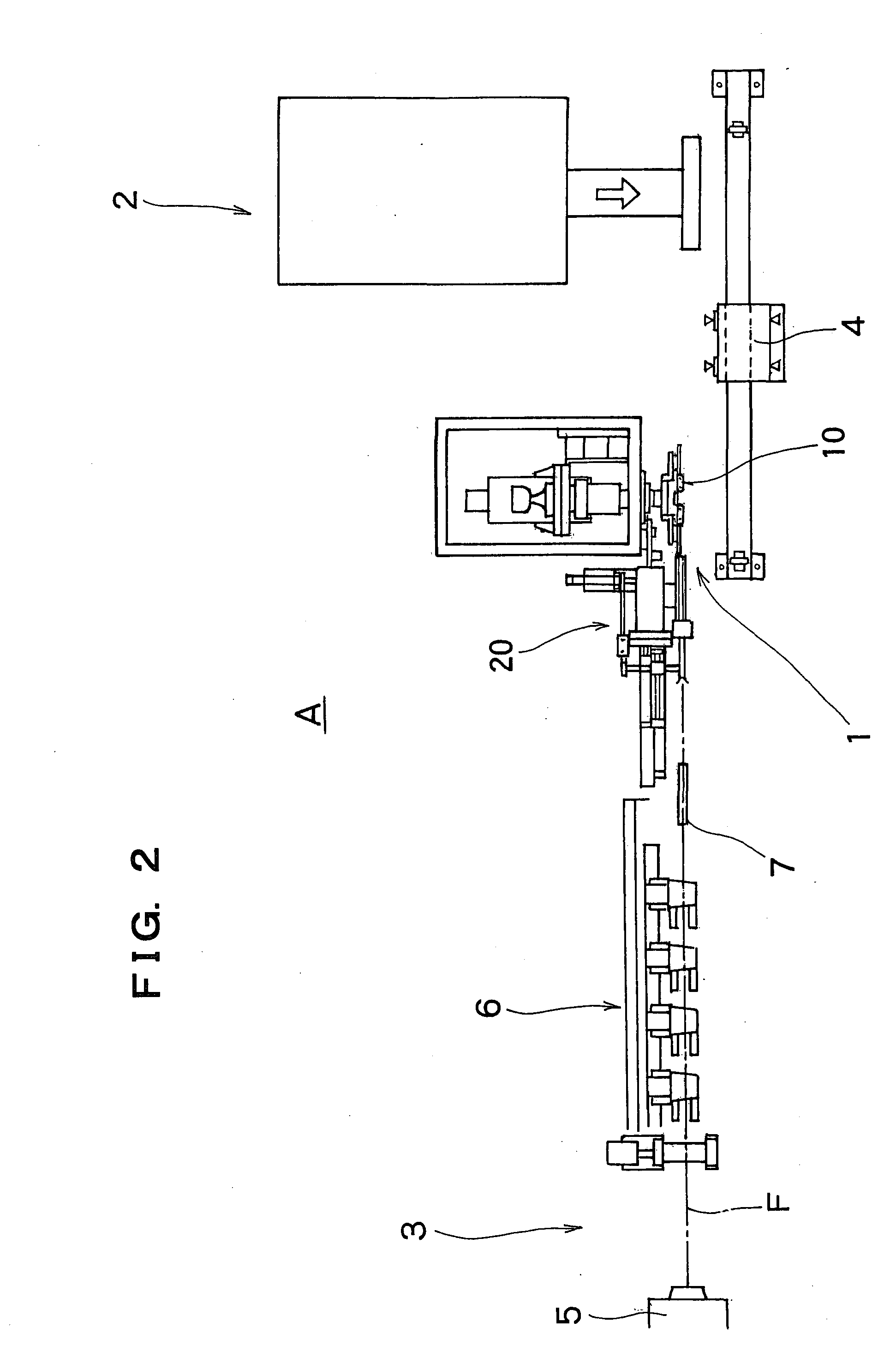

Method and apparatus for mounting a pneumatic tire

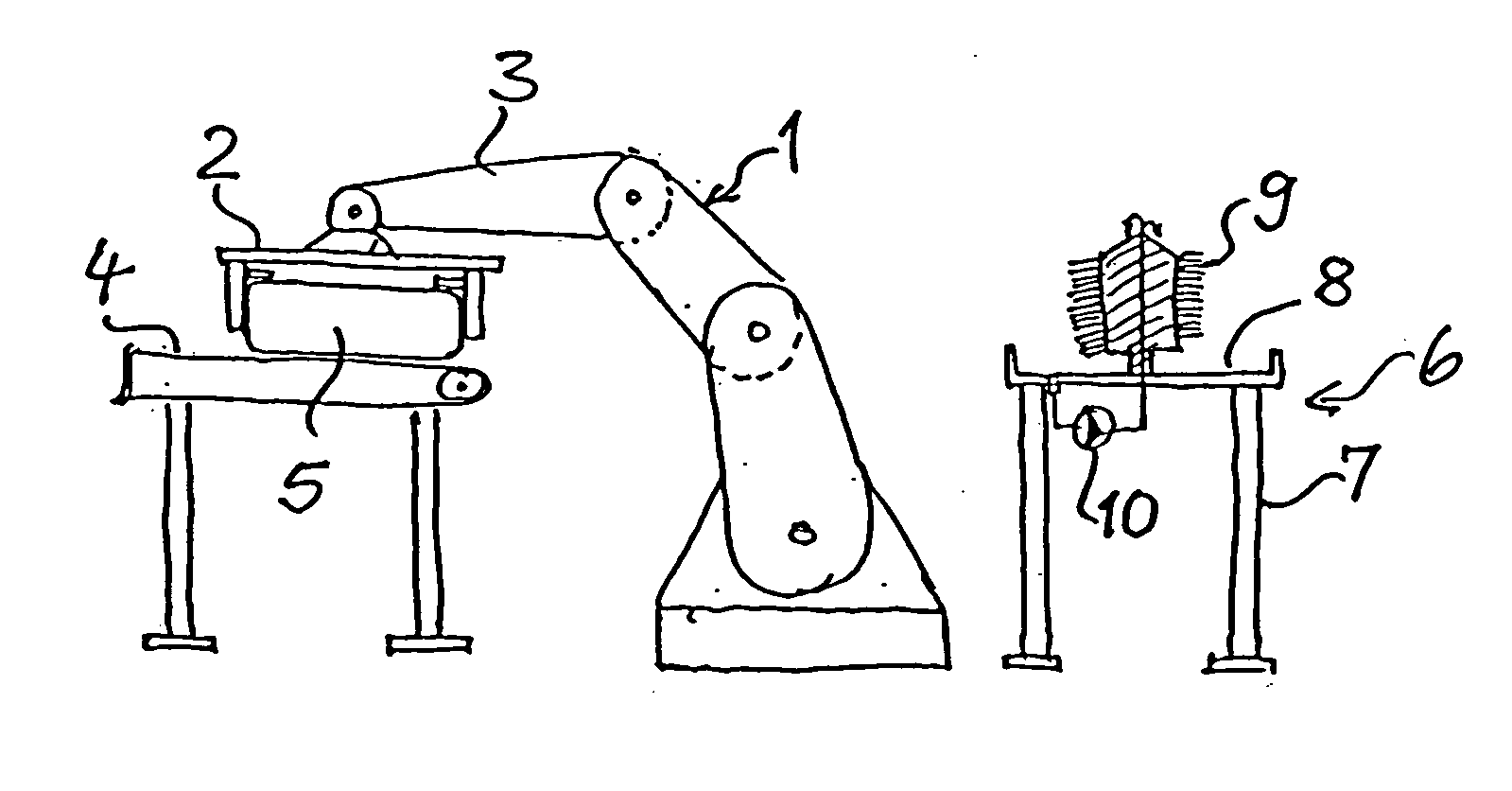

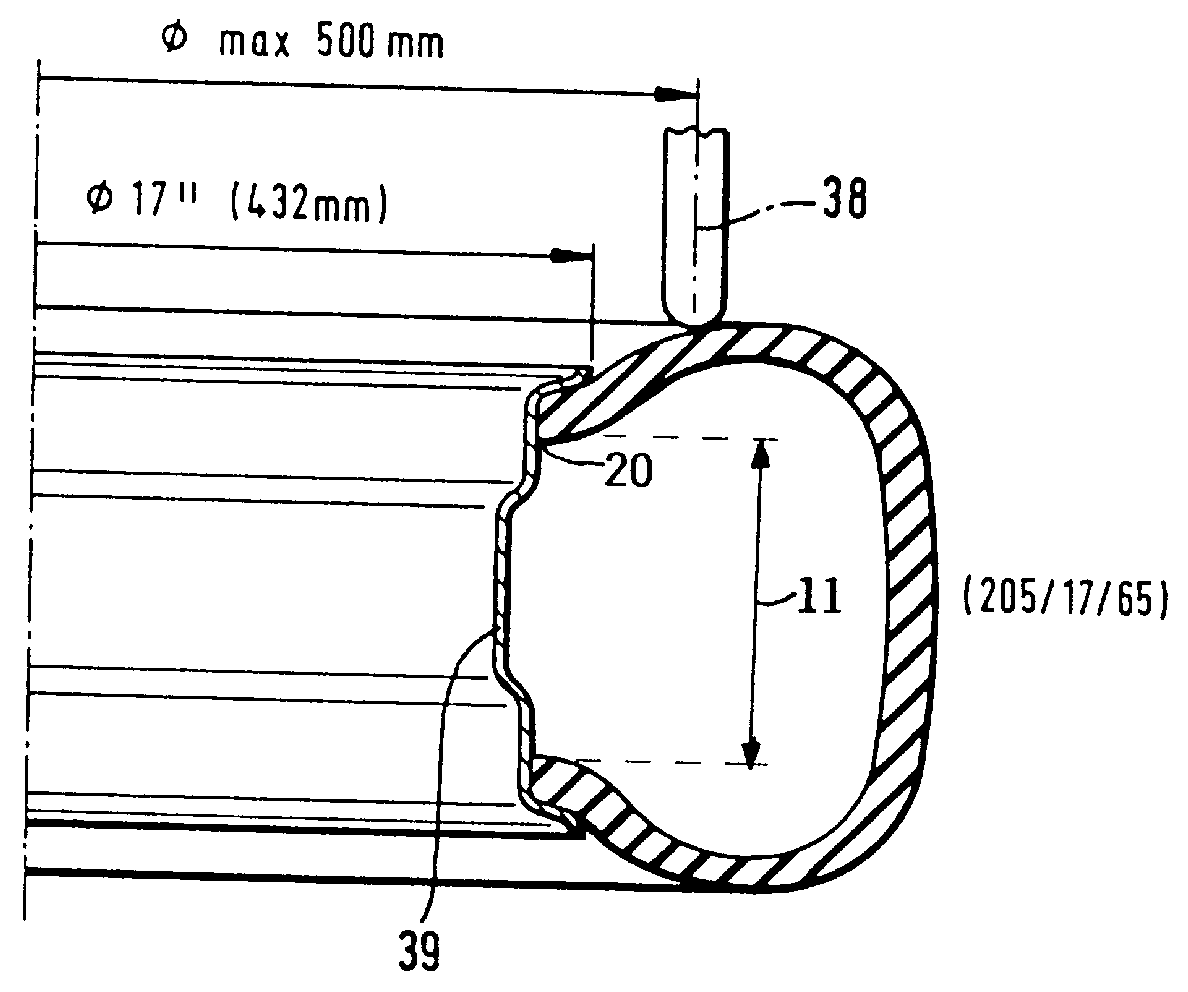

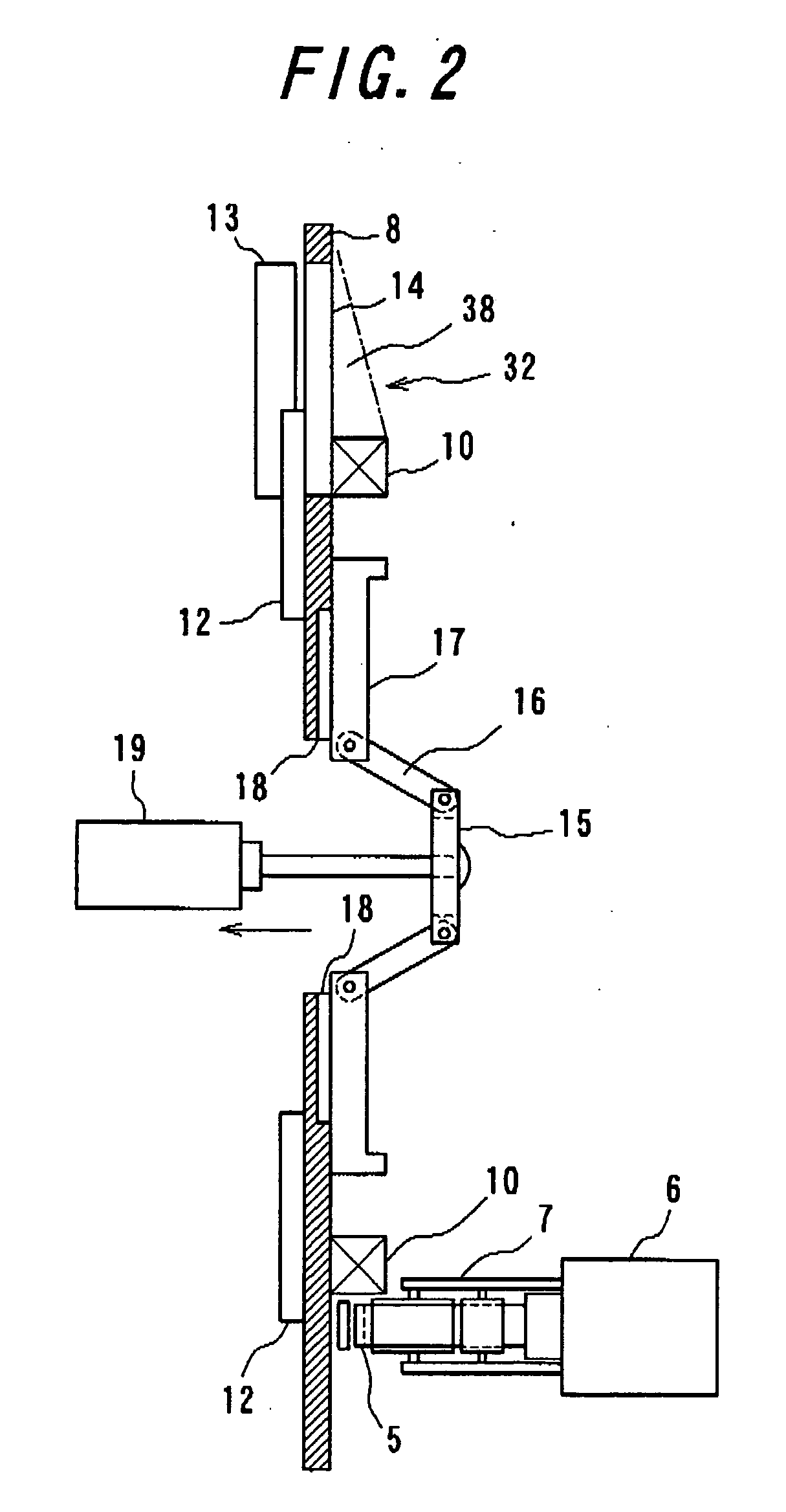

Method and apparatus for mounting a pneumatic tire Method for mounting a pneumatic tire (5) on a well base rim (26) of a motor vehicle wheel, in which the pneumatic tire (5) is grasped by means of a manipulator (1), brought up to a rim (26) held in a clamping device (27) and slipped with at least the one tire bead (20) facing the rim over a rim flange (28) by controlled movement of the manipulator (1). The apparatus suitable for this purpose comprises a manipulator (1) with an articulated arm (3) movable in three directions, which bears at its free end a gripper (2) for gripping and holding pneumatic tires (5), and a first mounting station (25) with clamping means (27) for releasably holding a rim (26), wherein the mounting station (25) is arranged within the working range of the manipulator (1).

Owner:SCHENCK ROTEC GMBH

Coated vehicle wheel and method

InactiveUS6872425B2Improve wear conditionsIncrease resistanceMolten spray coatingRimsTire beadThermal spraying

A method of coating a vehicle wheel to increase wear and corrosion resistance of the vehicle wheel, includes the steps of providing a vehicle wheel and applying a wear and corrosion resistant coating onto a surface of the vehicle wheel. The coating is applied to at least a tire bead retaining flange of the vehicle wheel. The coating is of particular use with vehicle wheels made of forged aluminum. The coating is selected from tungsten carbide, optionally including cobalt or chrome, a nickel-based superalloy, aluminum and silicon carbide, or stainless steel.The coating is typically applied to a thickness of about 0.004-0.01 inch. The surface of the vehicle wheel may be prepared by mechanically abrading the surface or chemically etching the surface of the vehicle wheel. The coating may be applied by cold spraying, thermal spraying, or triboelectric discharge kinetic spraying and other similar processes.

Owner:ARCONIC INC

Tire with sidewall rubber insert

InactiveUS6202726B1Improve propertyHigh modulusPaper coatingSpecial tyresUltra-high-molecular-weight polyethyleneMechanical engineering

A pneumatic tire has a sidewall rubber insert axially inward of at least one carcass ply. Such insert may, for example, be an apex extending radially outward from the bead core region of the tire into the tire sidewall. Alternatively, it may be positioned higher in the sidewall portion of the tire and away from the bead core. Such insert is a rubber composition containing a dispersion of an ultra high molecular weight polyethylene and a dispersion of a starch composite.

Owner:THE GOODYEAR TIRE & RUBBER CO

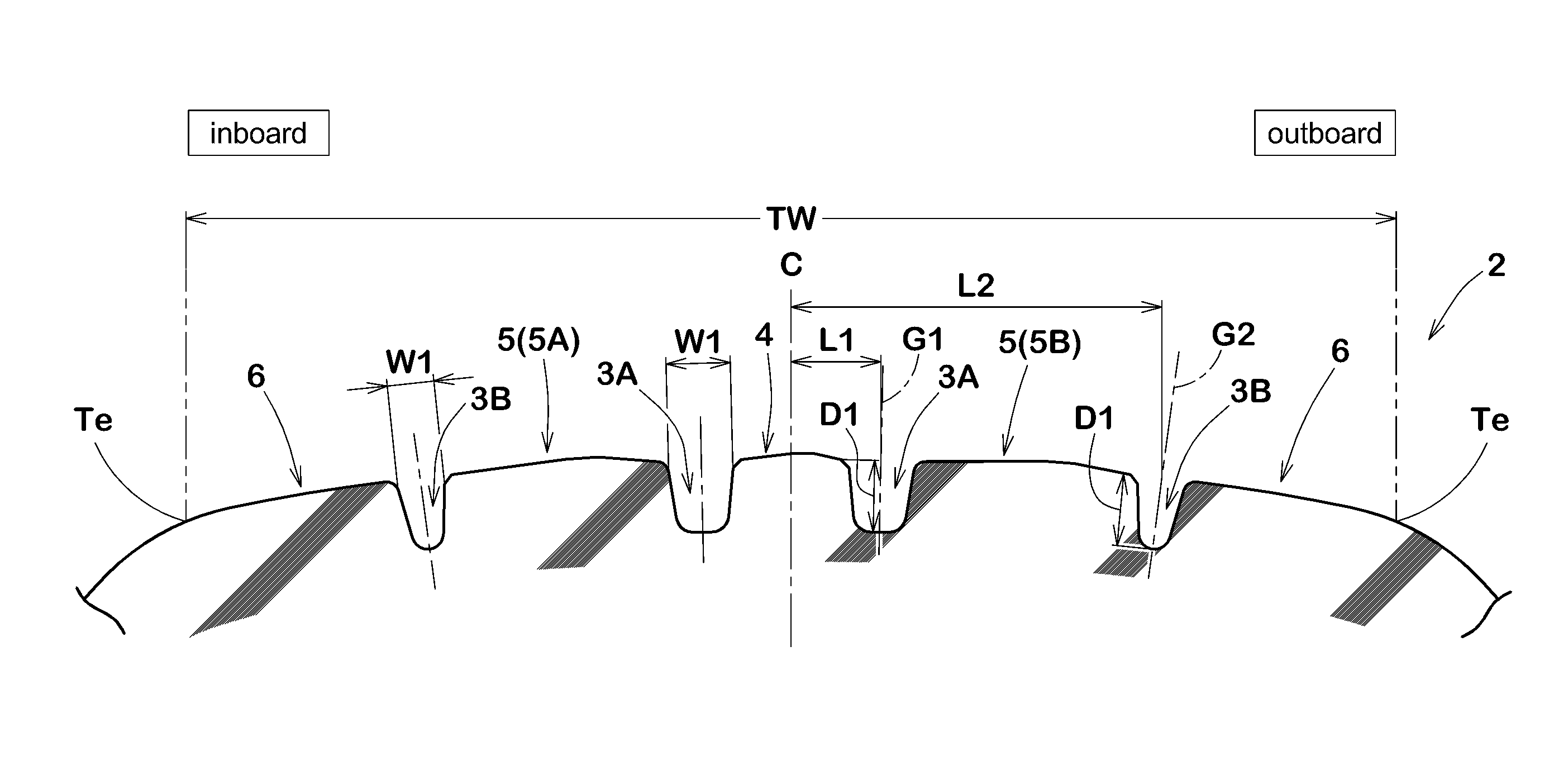

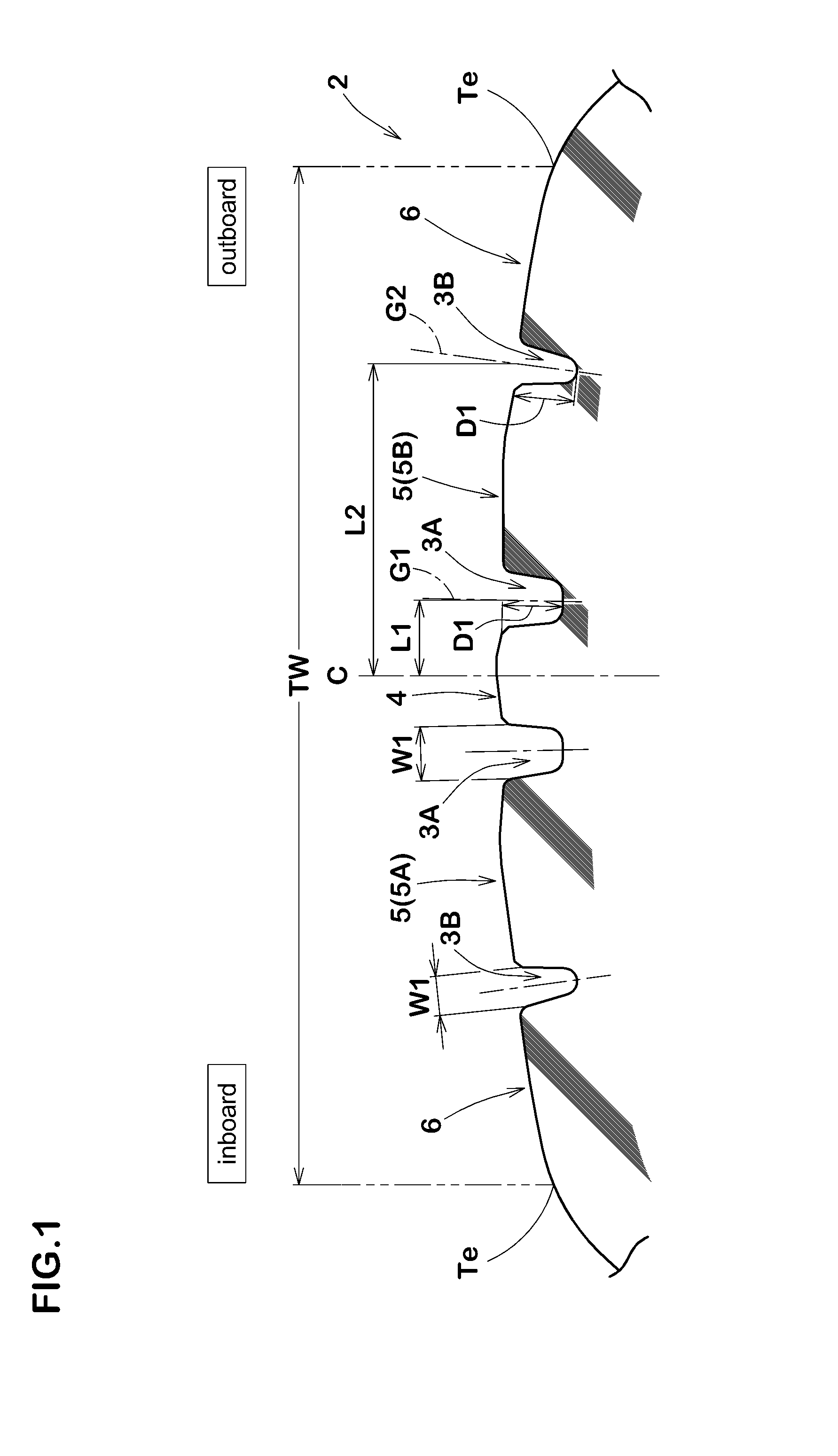

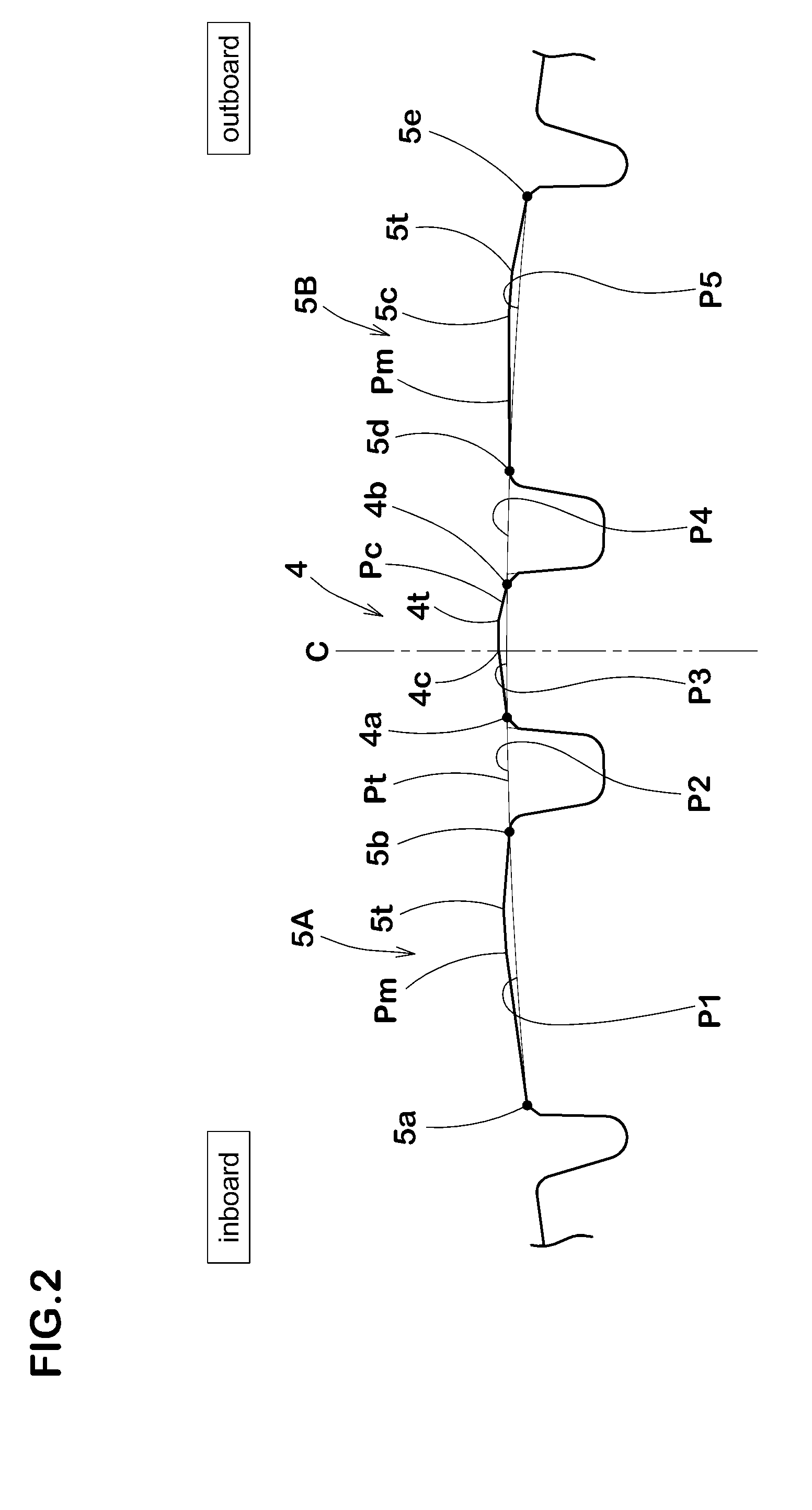

Pneumatic tire

ActiveUS20140166169A1Improve uneven wear resistanceTyre tread bands/patternsNon-skid devicesTire beadEngineering

Owner:SUMITOMO RUBBER IND LTD

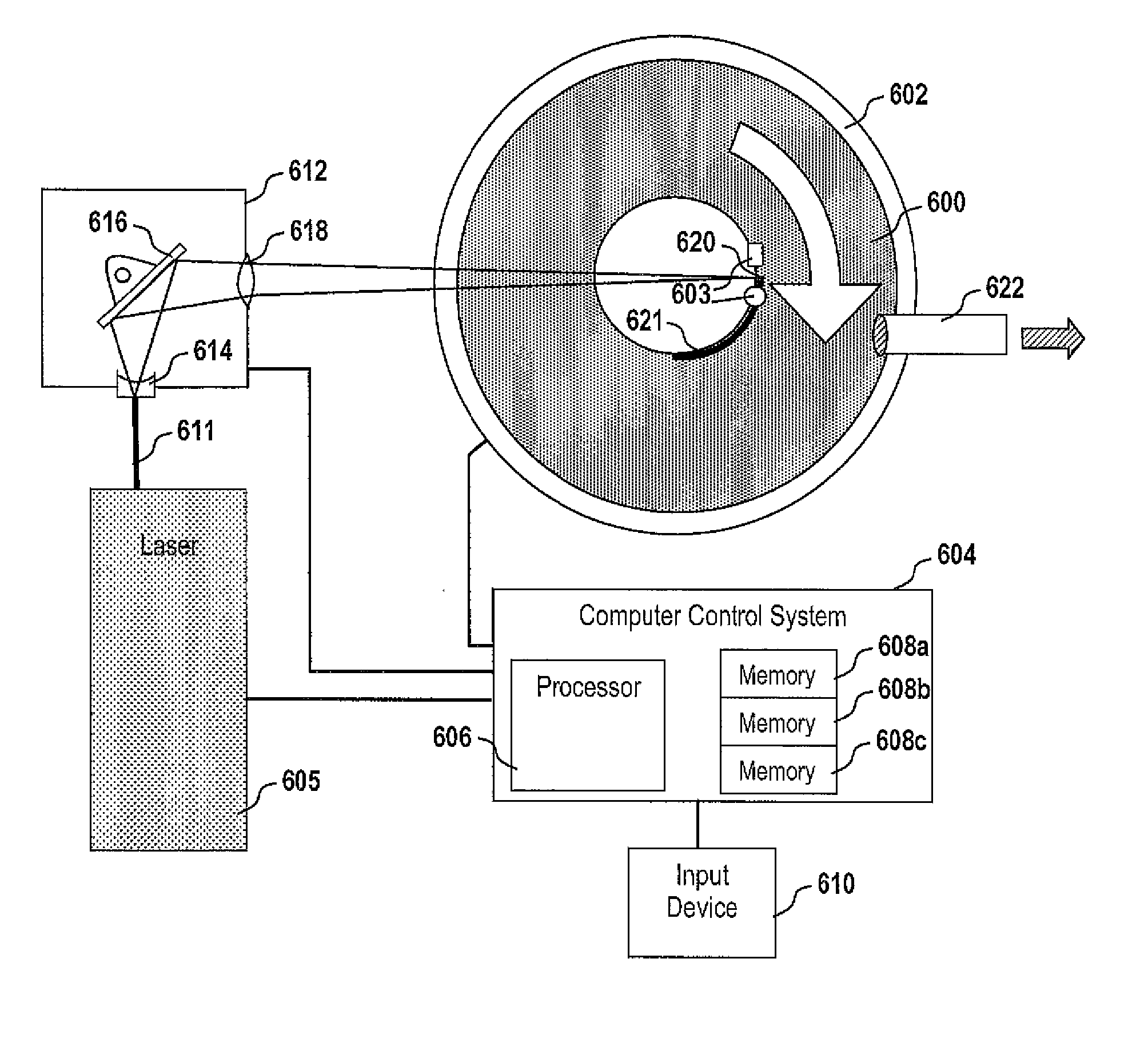

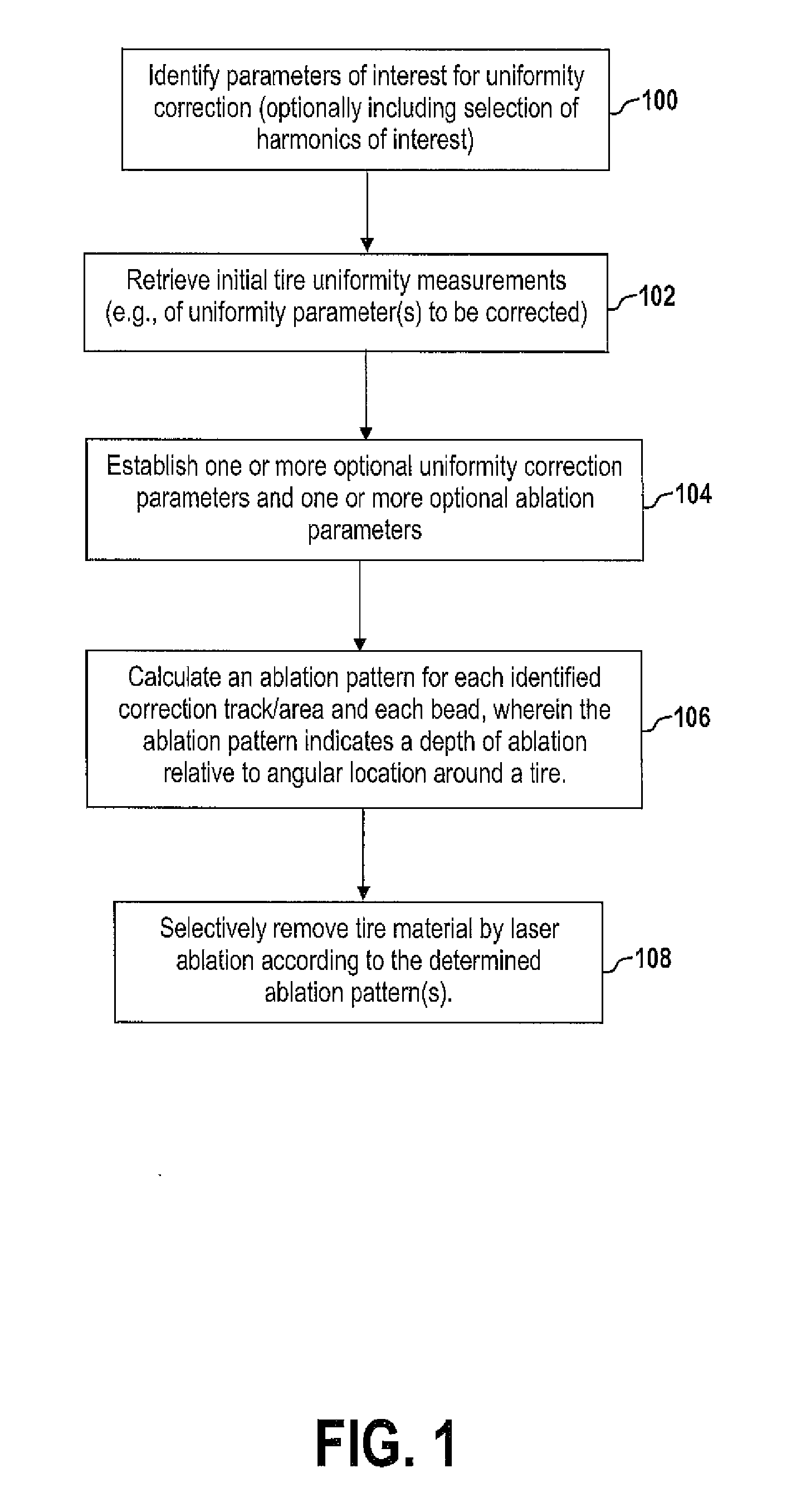

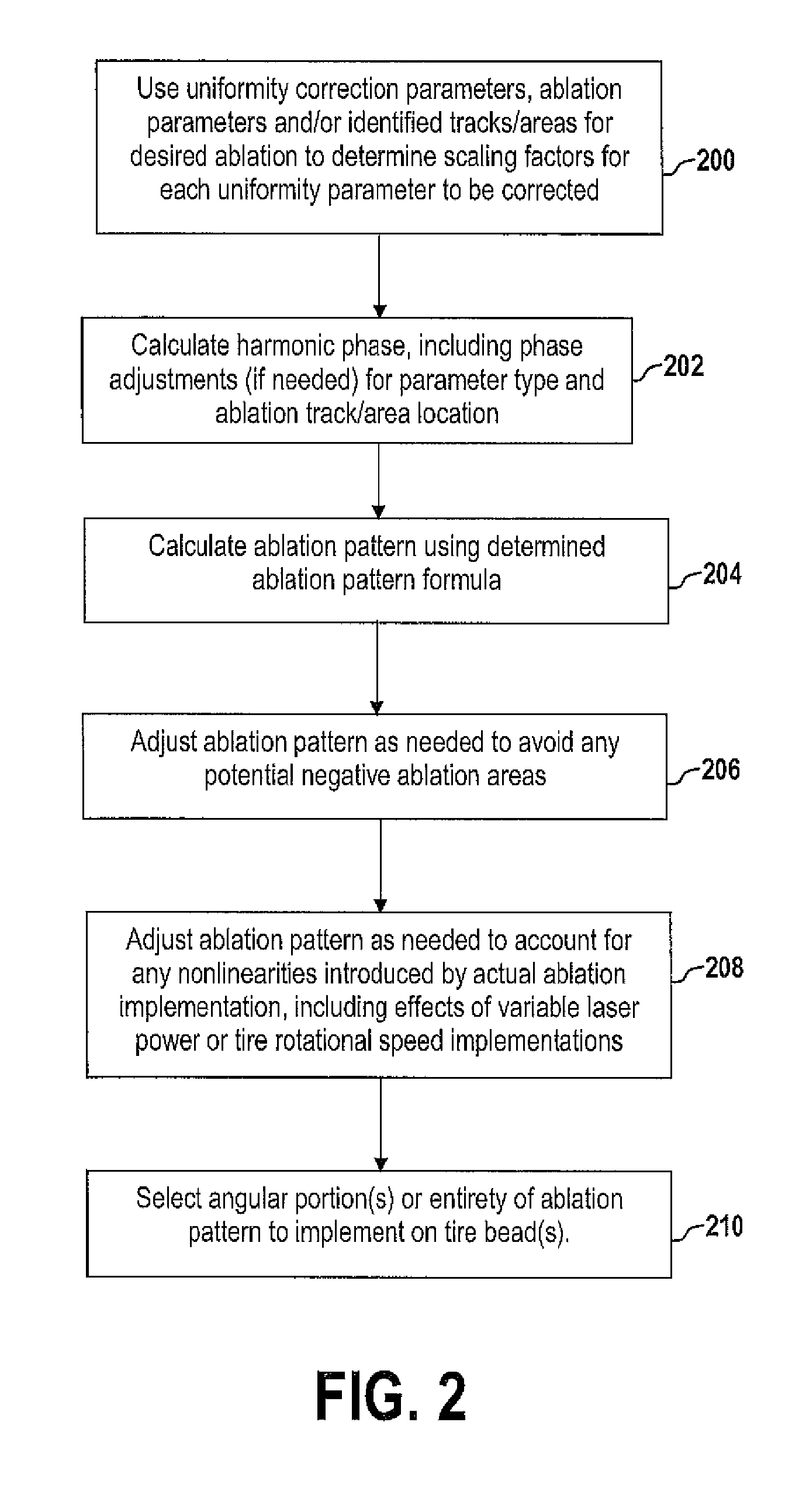

Uniformity correction by ablation at different track locations along a tire bead

A system and method for reducing the magnitude of one or more harmonics of one or more uniformity parameters in a cured tire involves selective removal of tire material at one or more track / area locations along first and second bead profiles. Selective removal may occur via ablation at the bead seat, low flange and / or high flange zones to correct for a selected number of harmonics of such parameters as radial, lateral and tangential force variation. Ablation patterns are calculated and implemented on first and second tire beads to achieve desired levels of force reduction at selected angular locations (within the expanse from 0-360 degrees along each tire bead). Ablation patterns may be calculated for implementation at fixed or varied tire rotational speeds and / or fixed or varied levels of laser power.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Rubber composition and pneumatic tire using the same

InactiveUS20070167555A1Reduce fuel consumptionReduce consumptionSpecial tyresTyre beadsSilicon dioxidePolybutadiene

A rubber composition containing (i) a conjugated diene-based rubber gel having a toluene swelling index of 16 to 70, (ii) a diene-based rubber such as natural rubber, polyisoprene rubber, aromatic vinyl-conjugated diene copolymer rubber and / or polybutadiene rubber, and (iii) an optional carbon black and / or silica and (a) a pneumatic tire using this composition as a high hardness reinforcing layer extending from a bead along a tire sidewalls, in which the fluidity and dimensional stability at the time of extrusion are improved, while maintaining a sufficient hardness of a high hardness reinforced rubber, (b) a pneumatic tire using this composition as two ends of a tire tread extrudate, maintaining a flex fatigue of the two ends of the tread, in which the extrudability and extrusion dimensional stability are improved and (c) a pneumatic tire using the composition as a 1.5 mm to 6 mm thick undertread, in which a high elasticity and relatively thick gauge undertread, and excellent processability and steering stability are provided.

Owner:THE YOKOHAMA RUBBER CO LTD +1

Tire apex composition for improving bond system and its preparation method and application

The invention relates to the tire manufacture field, especially to a tire apex composition for improving a bond system and its preparation method and application. The tire apex composition for improving the bond system is formed by the mixing of the following ingredients of: by weight, 70-100 parts of natural rubber, 0-30 parts of styrene-butadiene rubber, 55-75 parts of carbon black, 1.0-4.0 parts of resorcinol, 0.2-3.0 parts of cobalt decanoate, 3-8 parts of a methylene donator adhesive, 0-20 parts of white carbon black, 3-8 parts of a vulcanizing agent and a sulfuration promoter and other processing auxiliary agents. The tire apex composition for improving a bond system obviously raises modulus and binding property, decreases heat generation, minimizes modulus loss at high temperature,and simultaneously reduces formula cost. By employing BTR tires under the precondition of unchanged structure, the hard apex strength and hardness can be guaranteed not to be decreased, the modulus is substantially increased, the bond performance between the apex and steel wires / steel wire cords is remarkably improved, and the anti-destroy performance of tire bead positions is raised.

Owner:ZHONGCE RUBBER GRP CO LTD

Heavy duty tire

InactiveUS20050045260A1Improve bead durabilityEffectively restrict occurrenceHeavy duty tyresHeavy duty vehicleTire beadHeavy duty

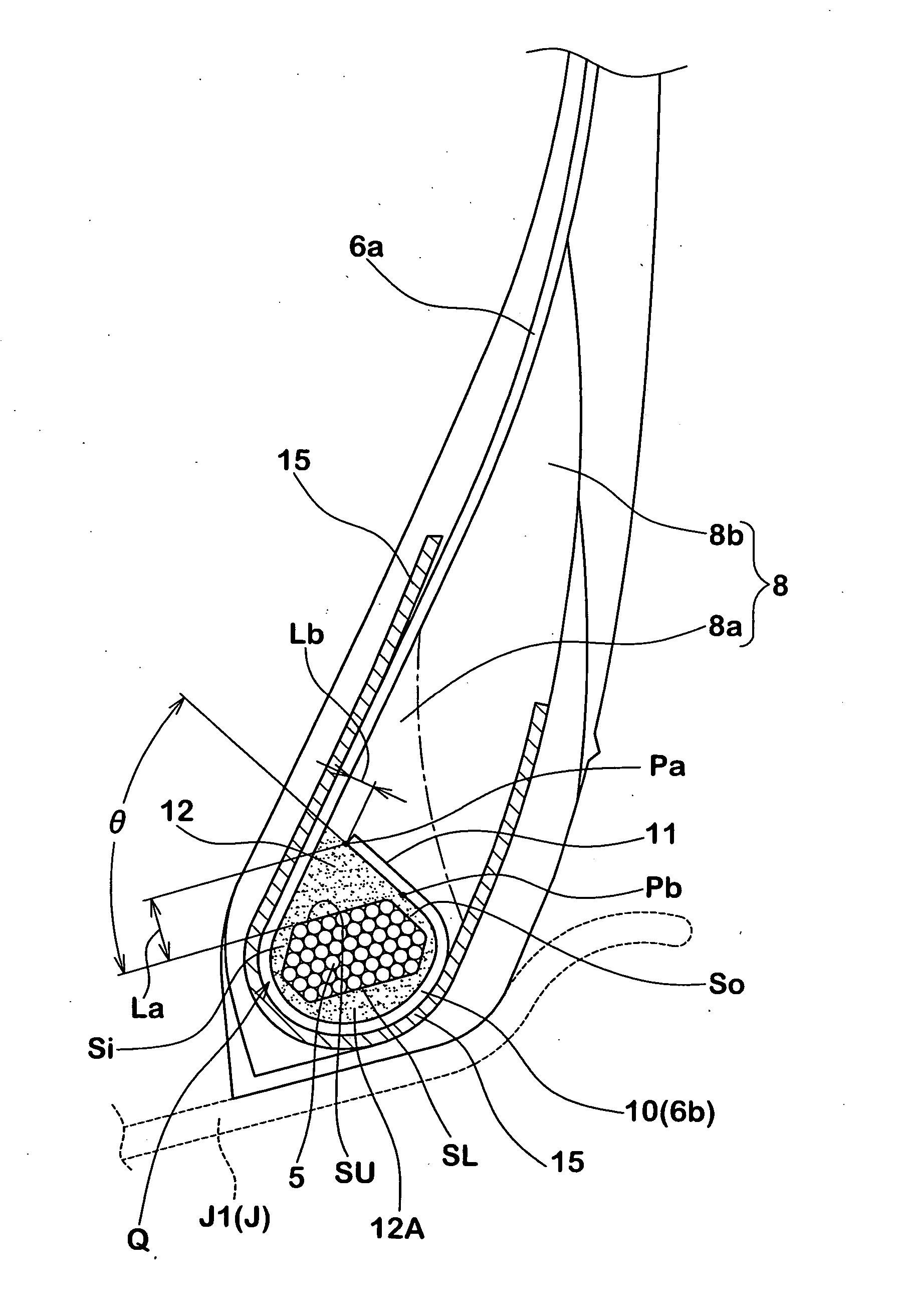

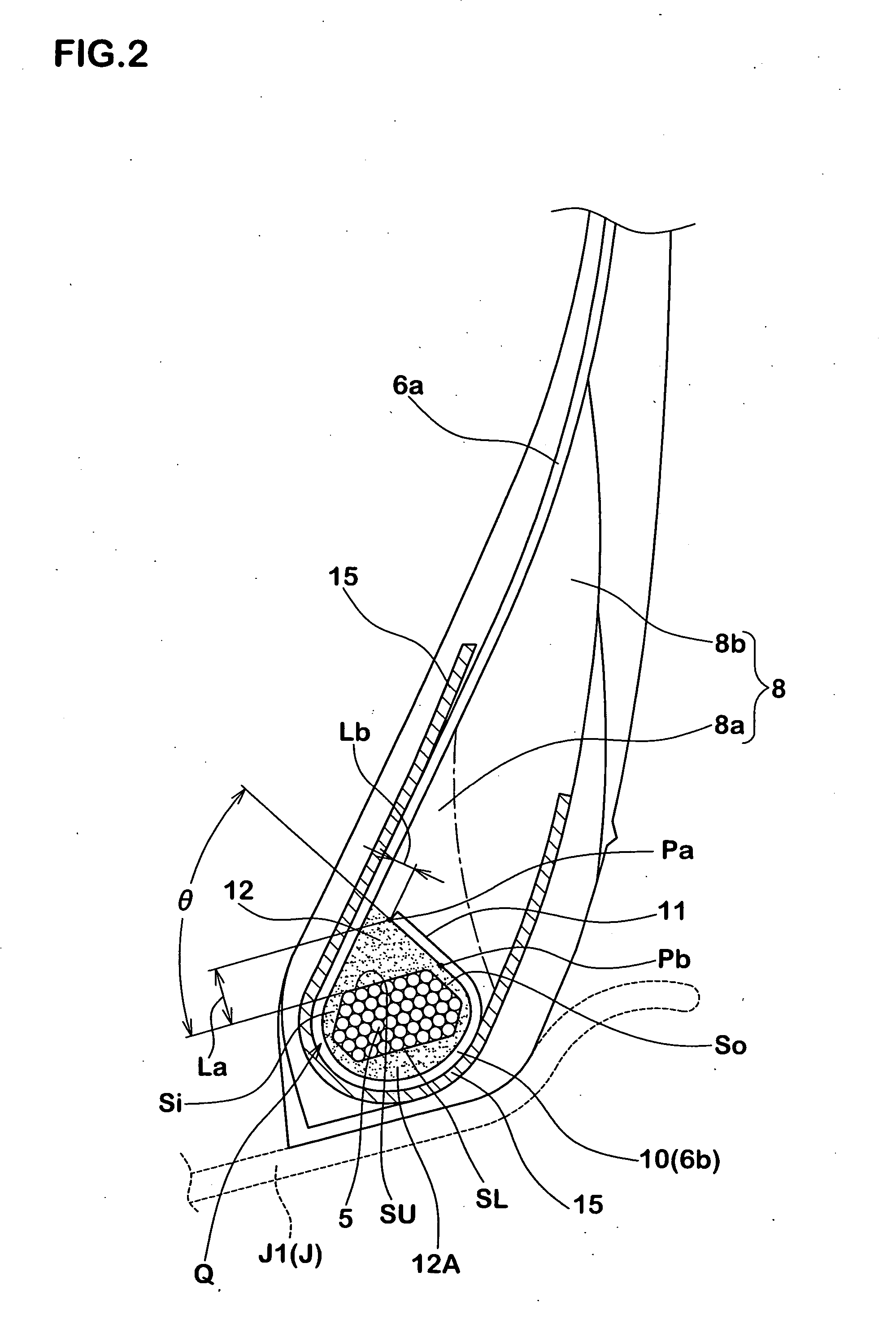

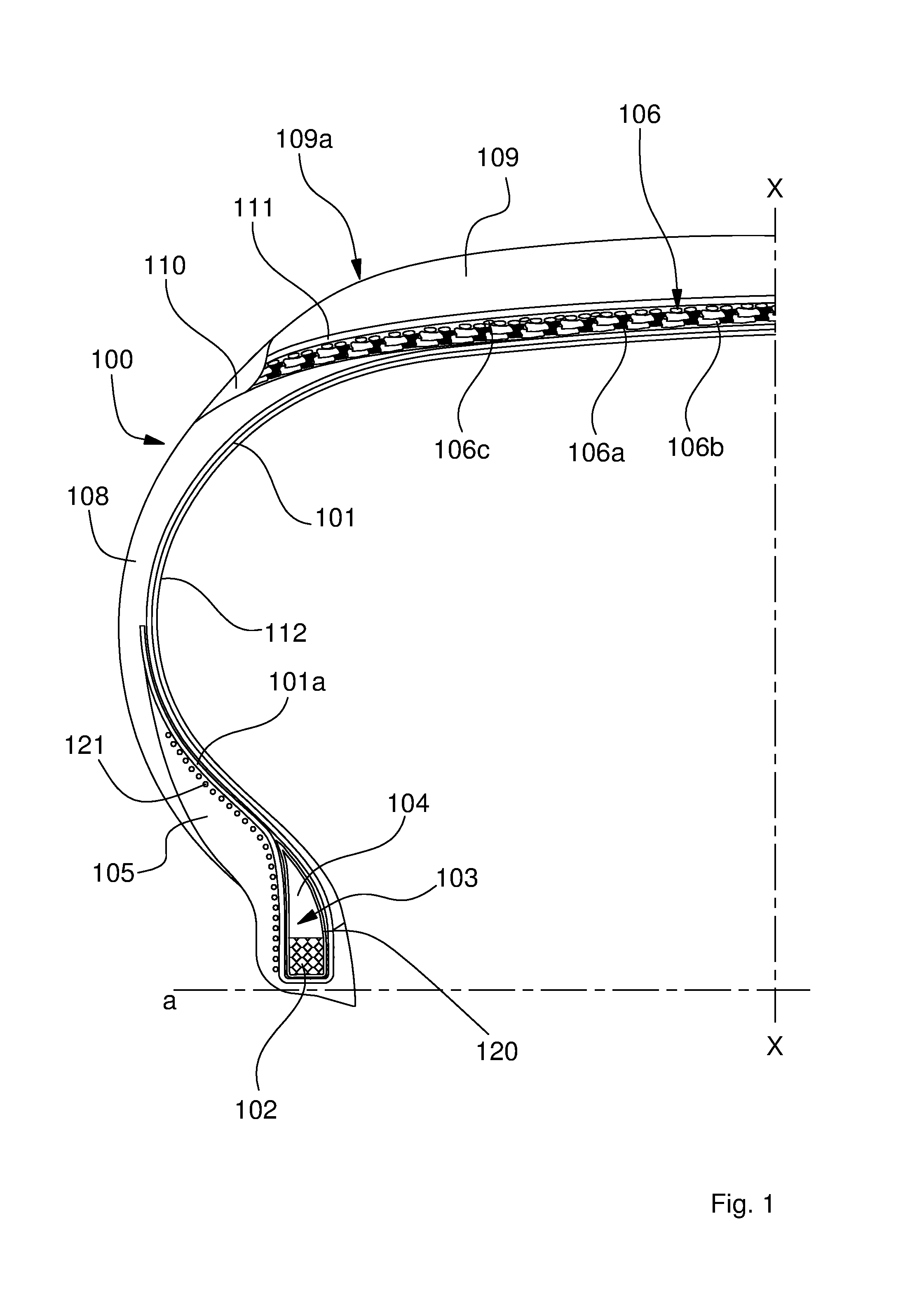

It is a subject to restrict occurrence of deficient moldings and to improve the bead durability without harming the advantages provided through a bead wind structure, and for this purpose, a ply turn-up portion of a carcass comprises a winding portion, which continues from a main portion that is bent along a bead core, which extends while being spaced from the bead core, and which inclines at an angle θ that is smaller than 90°. A height of a tip end of the winding portion from an outer surface of the bead core is 3 to 15 mm. A cushion rubber having a complex elastic modulus E1* at 70° C. of 2 to 25 MPa is disposed in a region surrounded by a ply main body portion of the carcass, the bead core and the winding portion.

Owner:SUMITOMO RUBBER IND LTD

Method for mounting a pneumatic tire

ActiveUS7699087B2Low structure complexitySimply set up and optimizedTyre repairingTire beadManipulator

Method for mounting a pneumatic tire on a well base rim of a motor vehicle wheel, in which the pneumatic tire is grasped by means of a manipulator, brought up to a rim held in a clamping device and slipped with at least the one tire bead facing the rim over a rim flange by controlled movement of the manipulator.

Owner:SCHENCK ROTEC GMBH

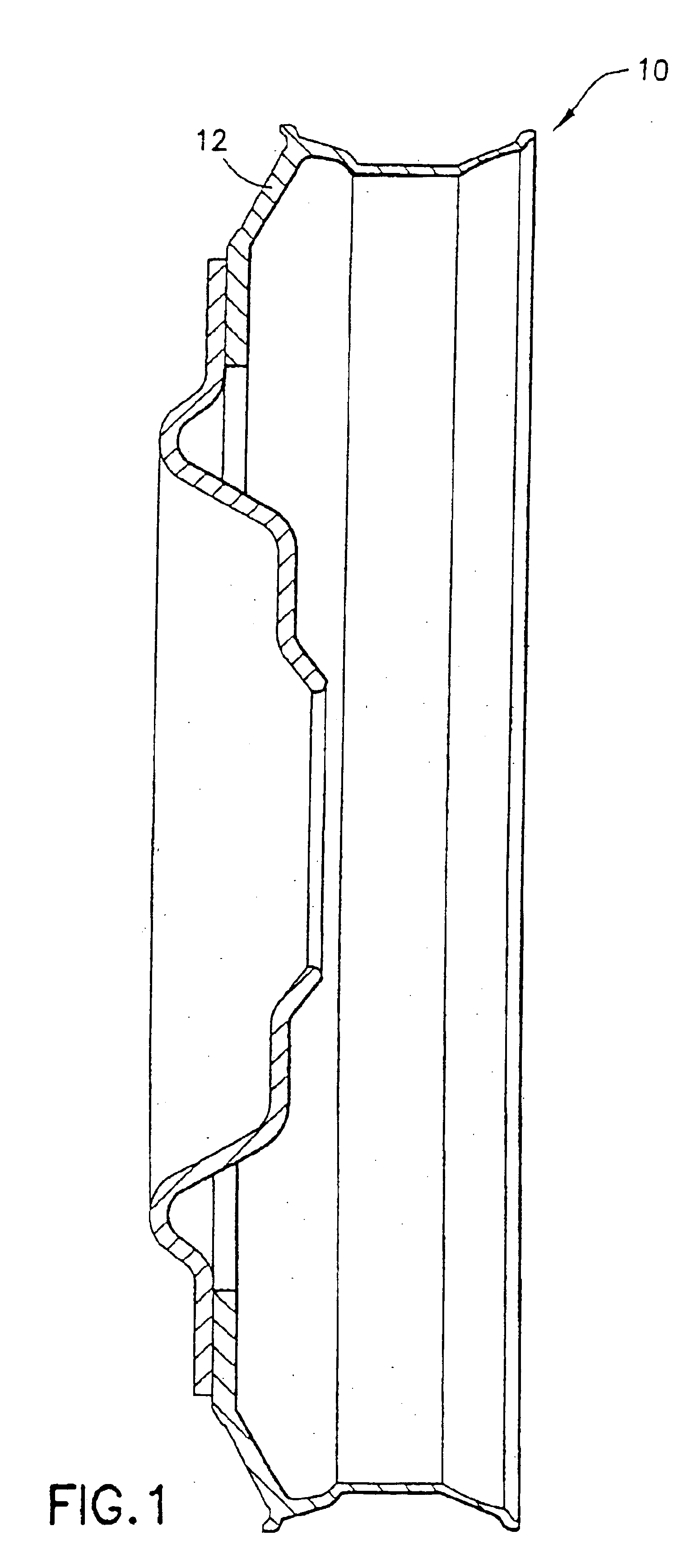

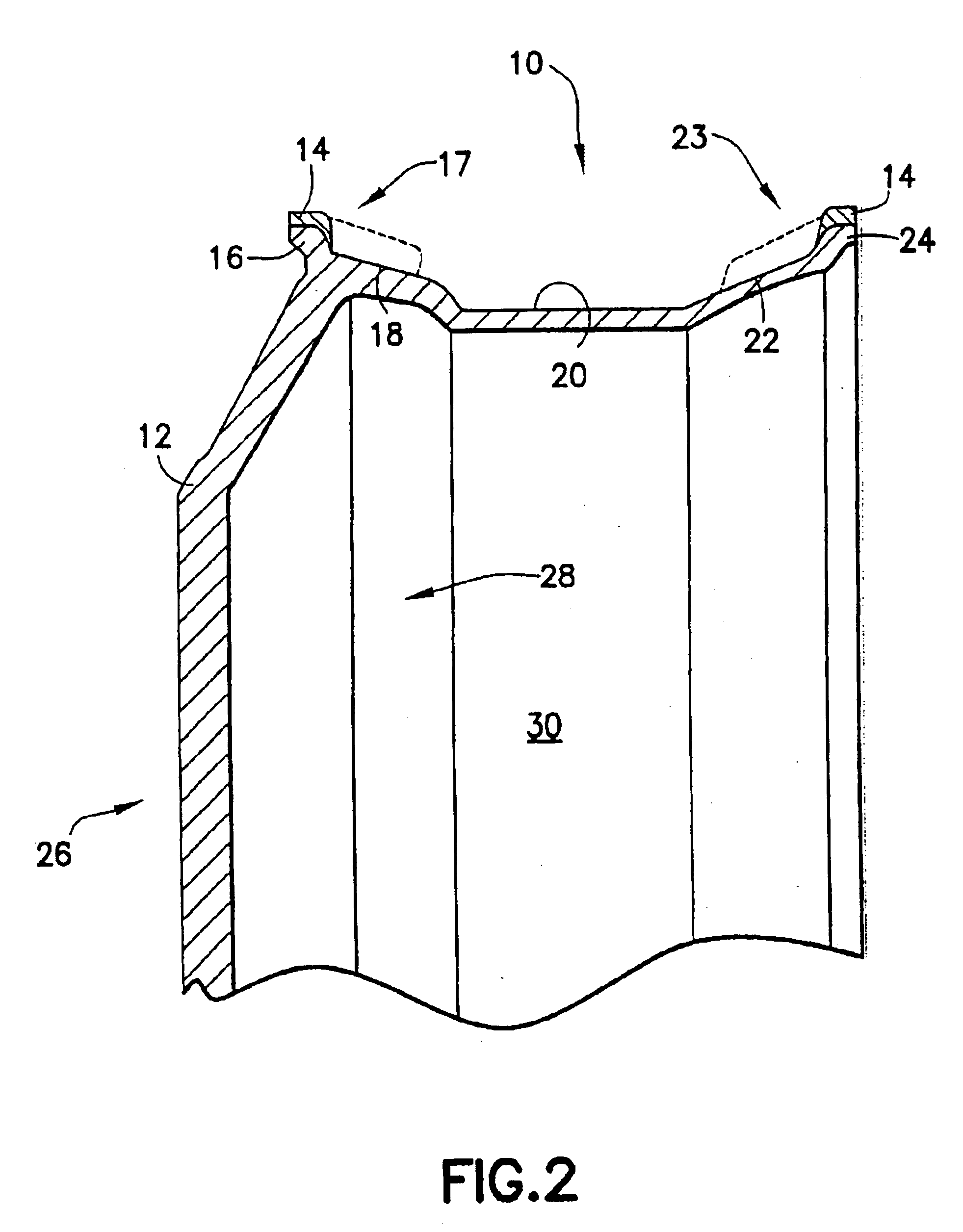

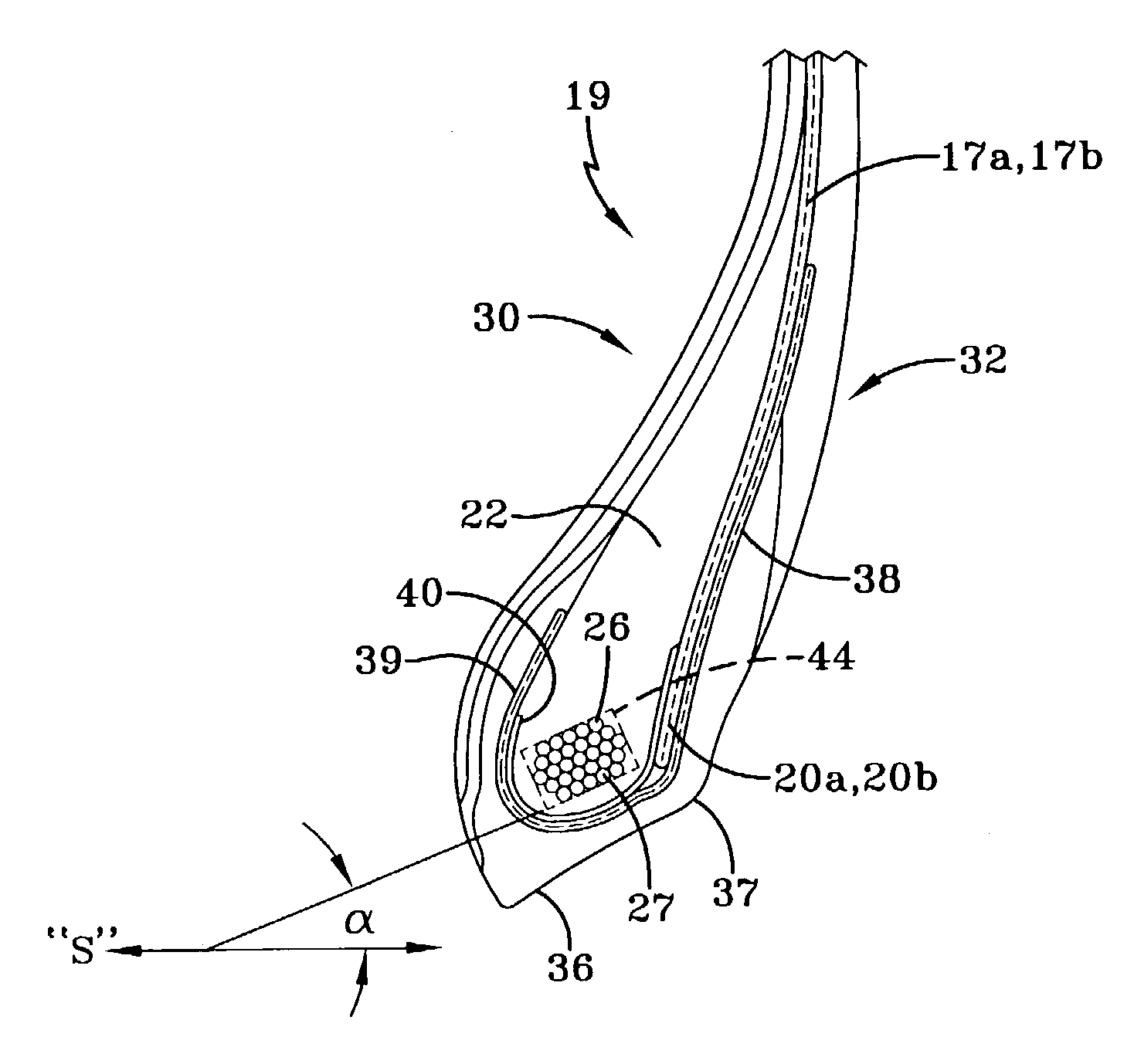

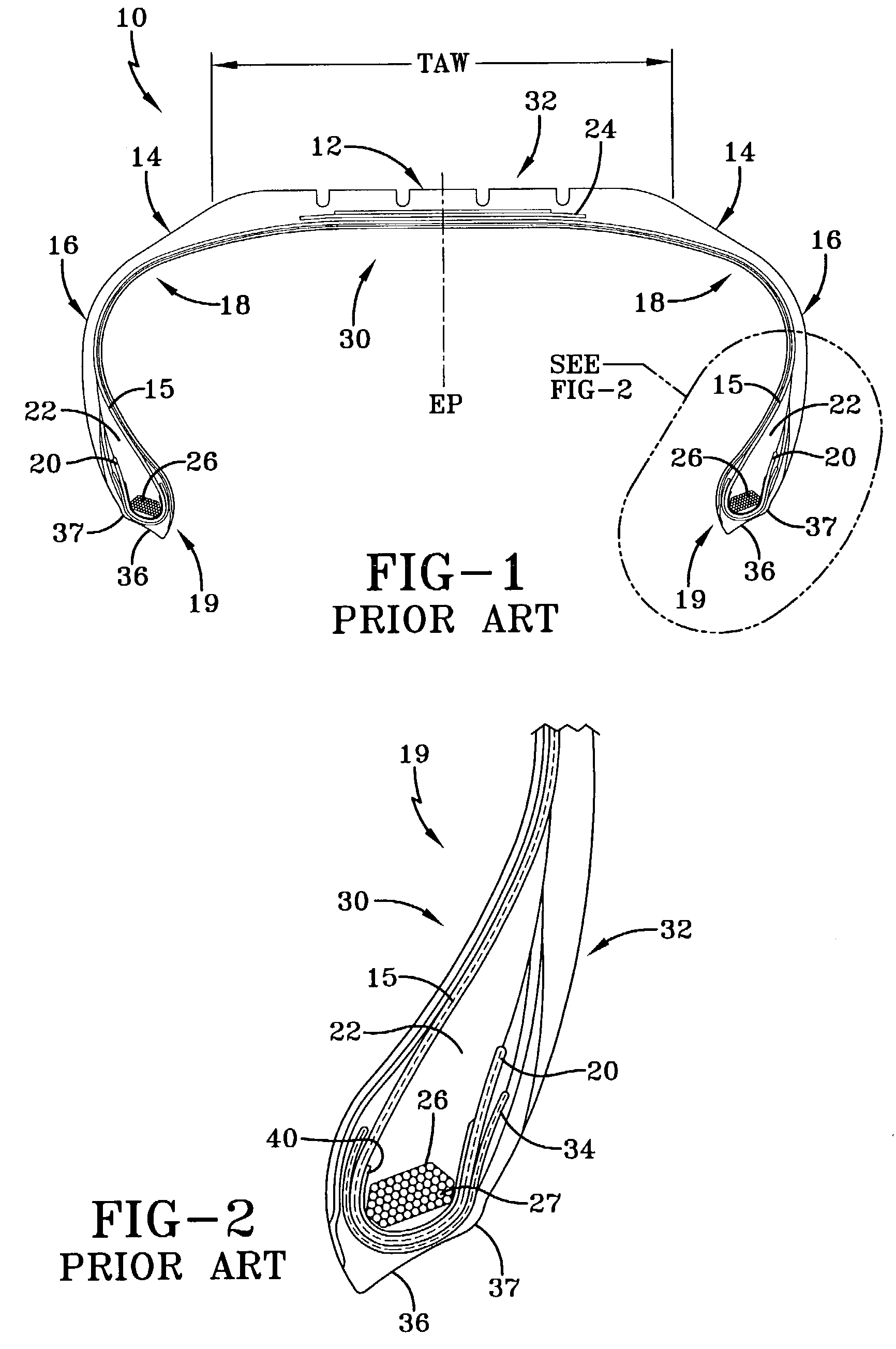

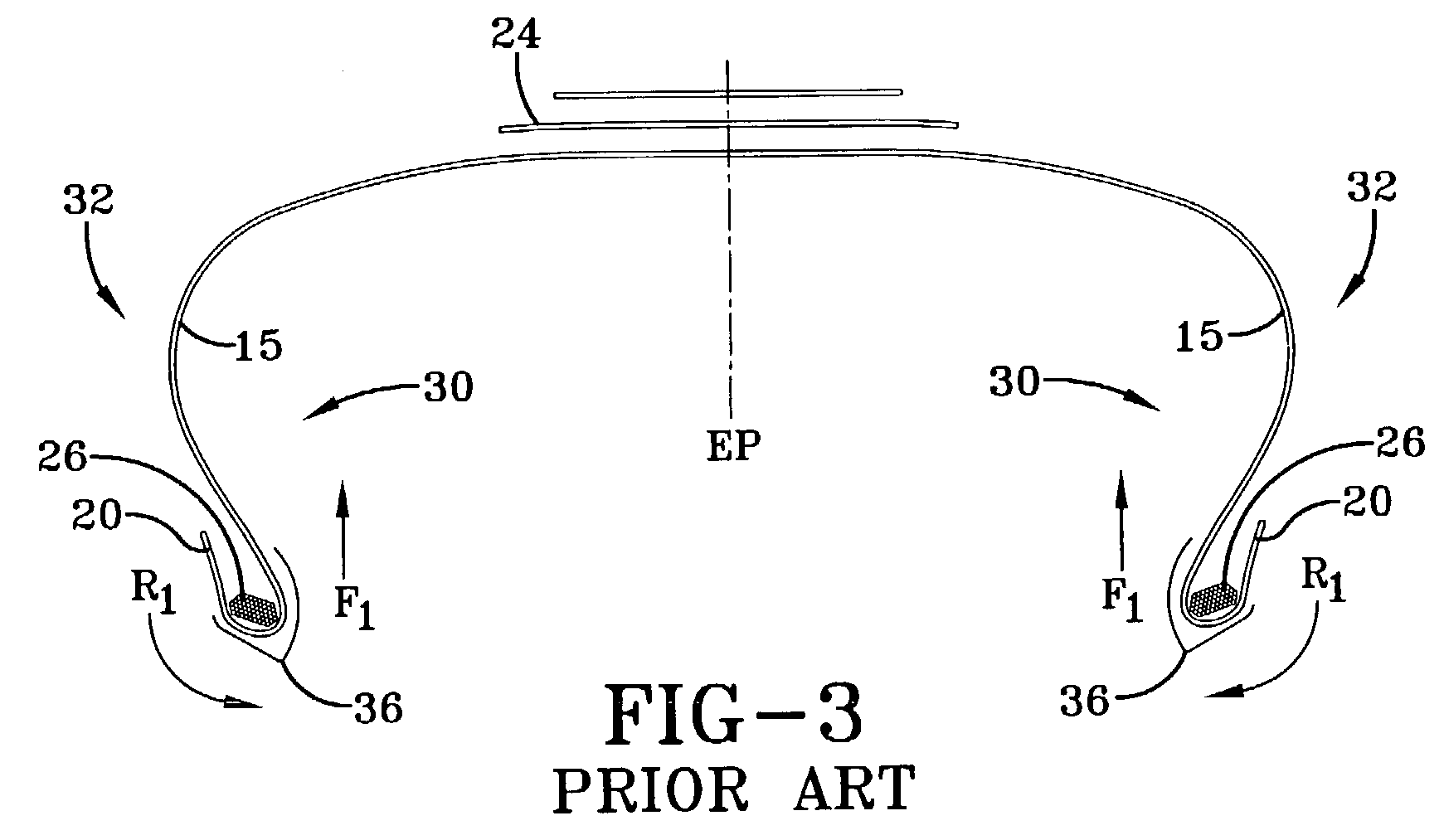

Tire with outside-in ply construction

Owner:THE GOODYEAR TIRE & RUBBER CO

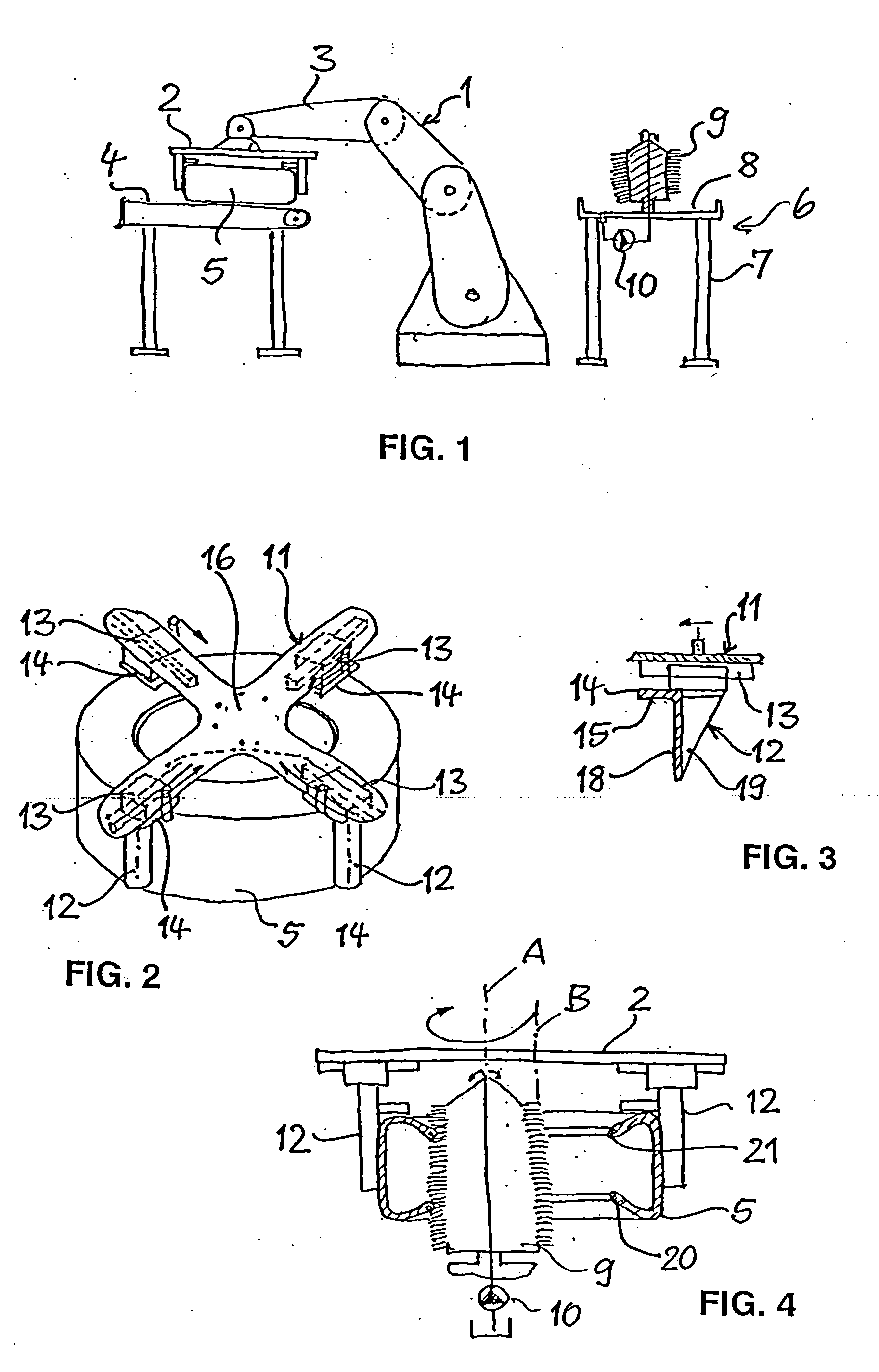

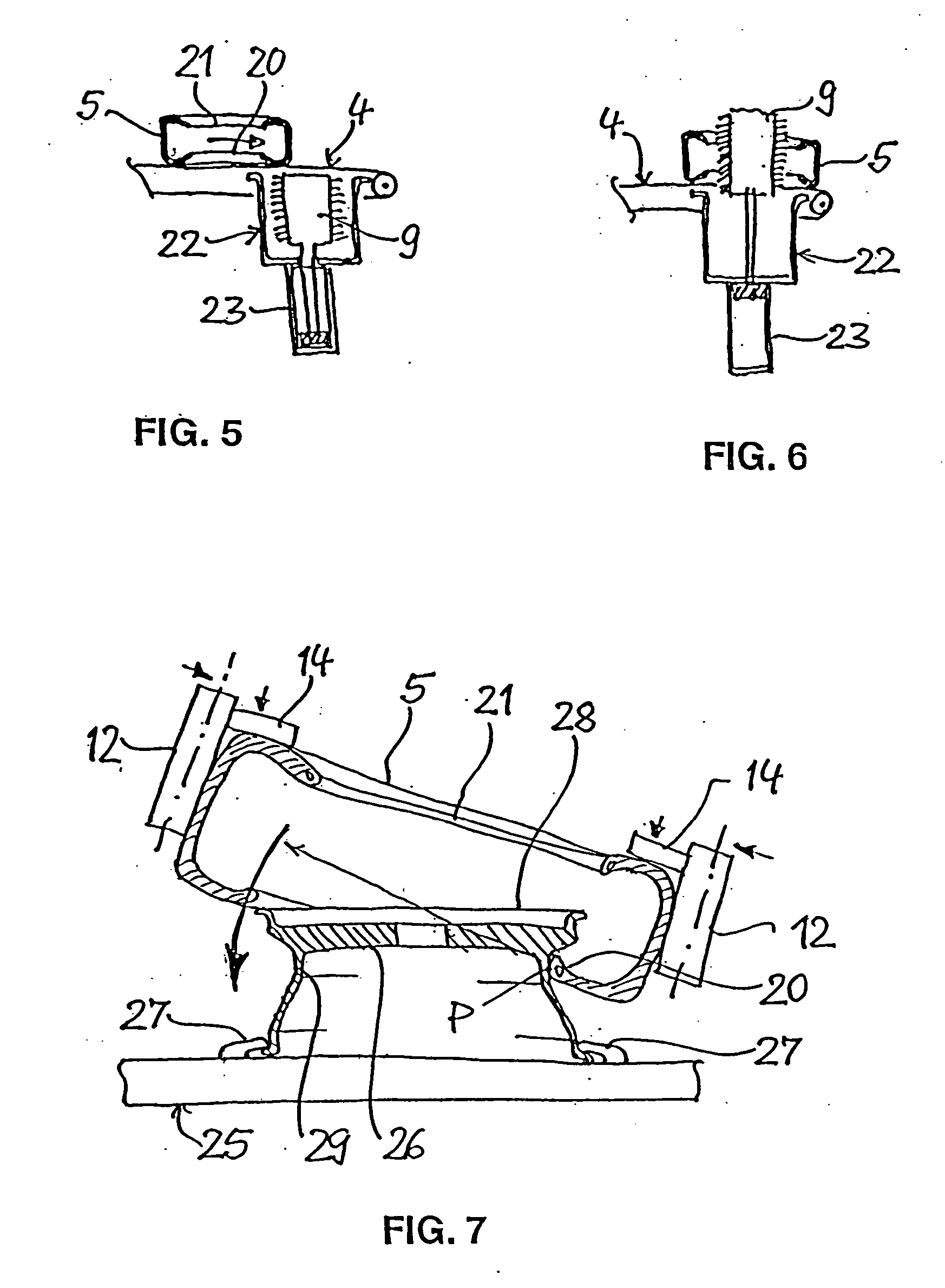

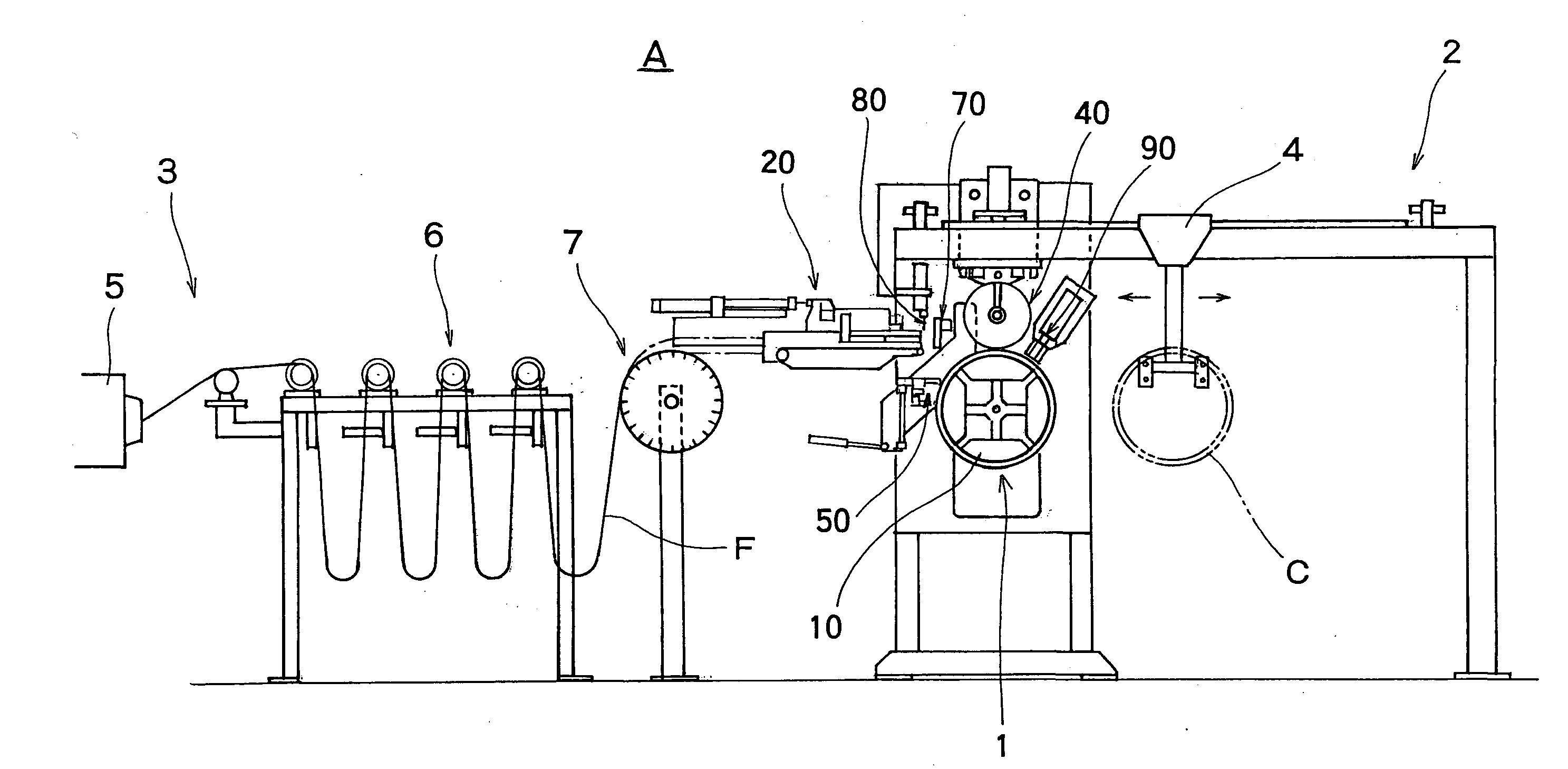

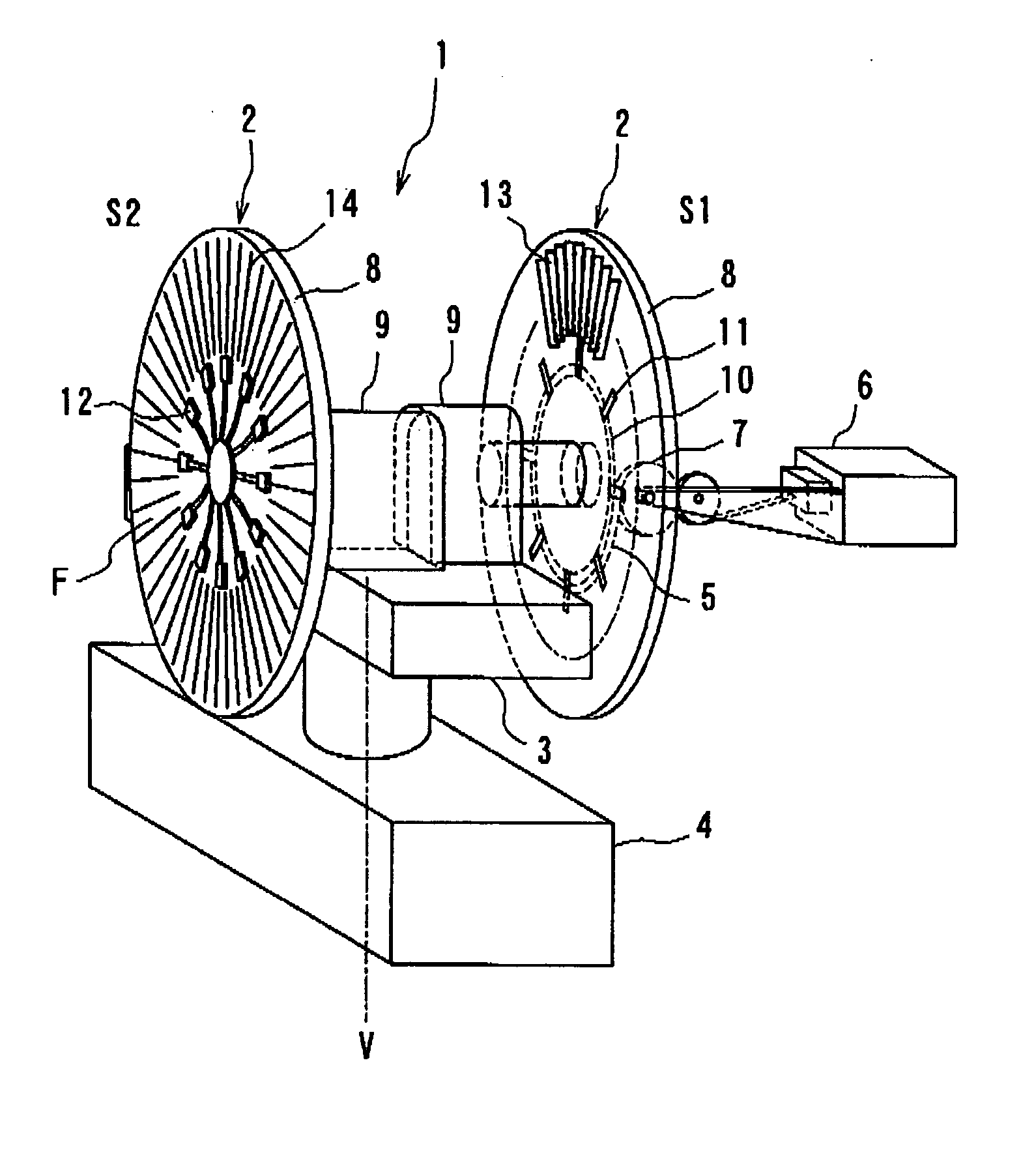

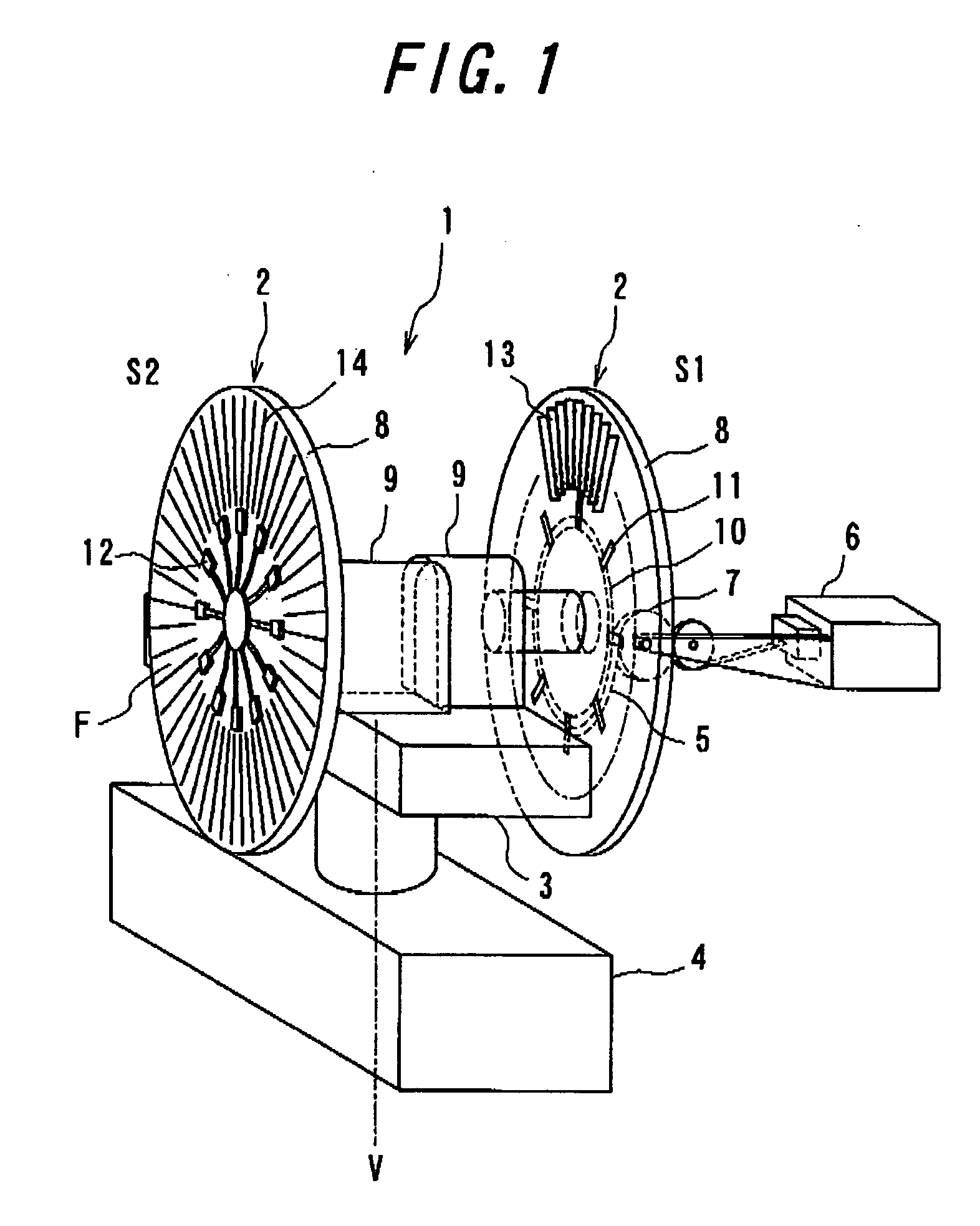

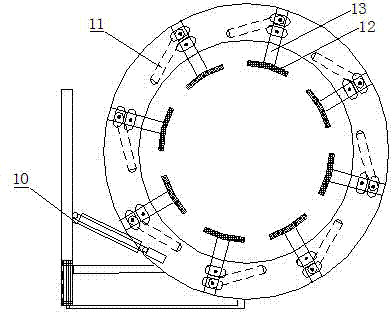

Method of and apparatus for manufacturing a tire bead

A filler rubber being triangular-shaped in cross section can be held in an upright posture to be stuck to an outer peripheral surface of a bead core and a leading end and a trailing end can be butted against each other to be joined without the generation of crack. A filler rubber (F) is held in an upright posture to be wound around an outer peripheral surface of a bead core (C) supported by a rotary support body (10), and in joining a leading end (F1) and a trailing end (F2) of the filler rubber cut to a predetermined length, the neighborhood of the leading end and the neighborhood of the trailing end, respectively, are interposed by first and second interposing means (50), (70), and one (50) of the interposing means is displaced toward the other from a state, in which the leading end (F1) and the trailing end (F2) are opposed to each other whereby end surfaces of the leading end (F1) and the trailing end (F2) are butted against each other.

Owner:TOYO TIRE & RUBBER CO LTD

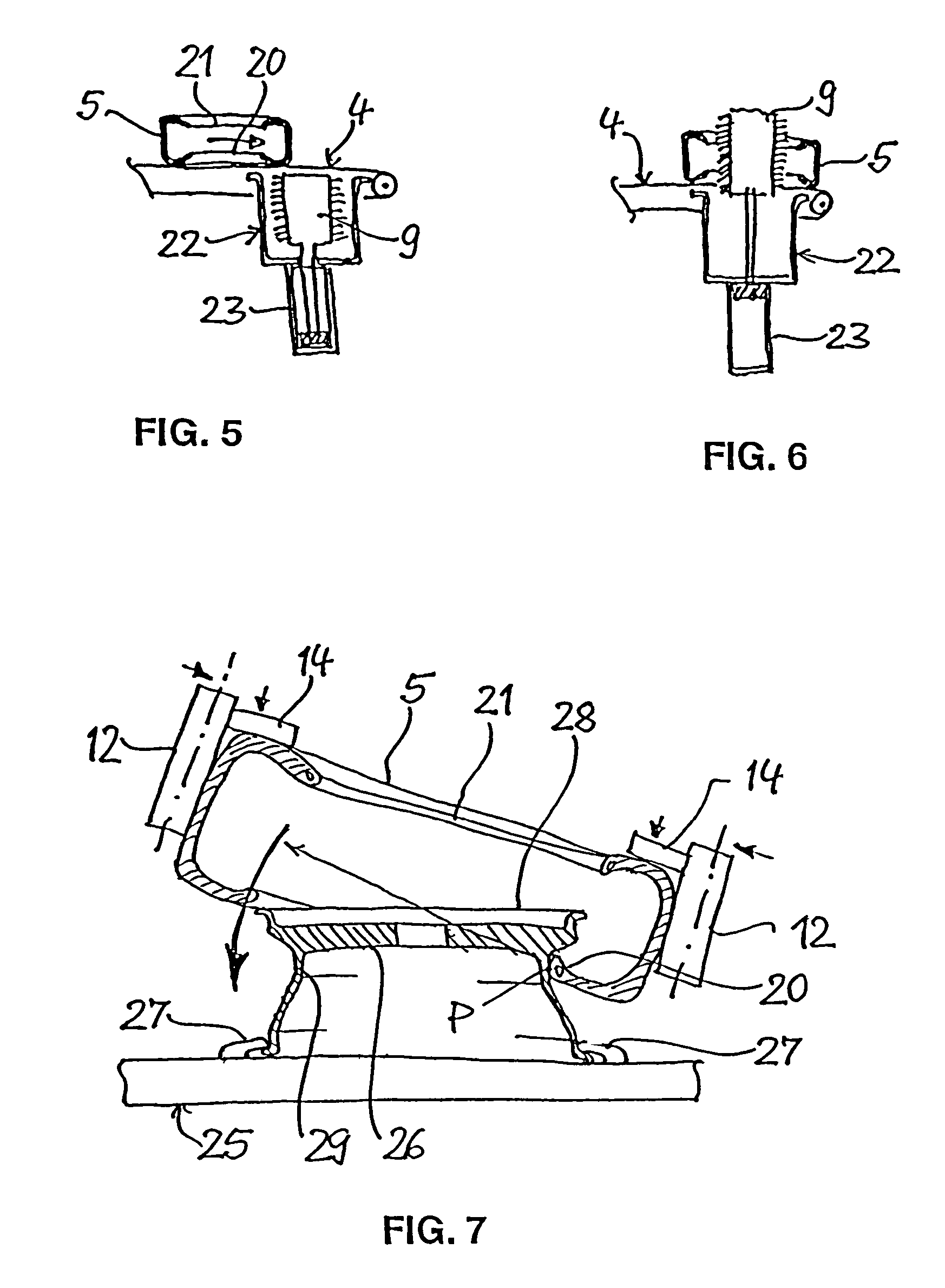

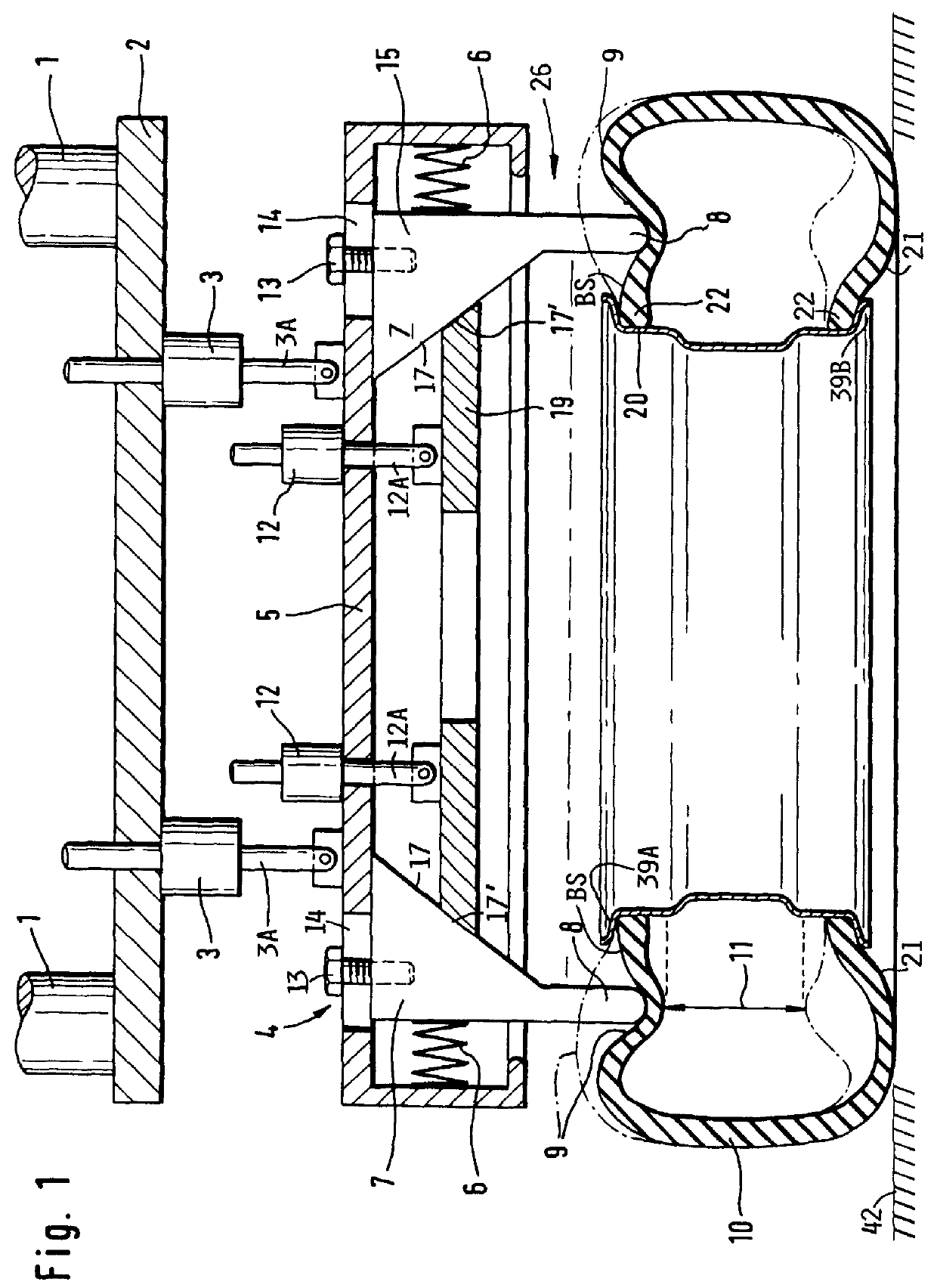

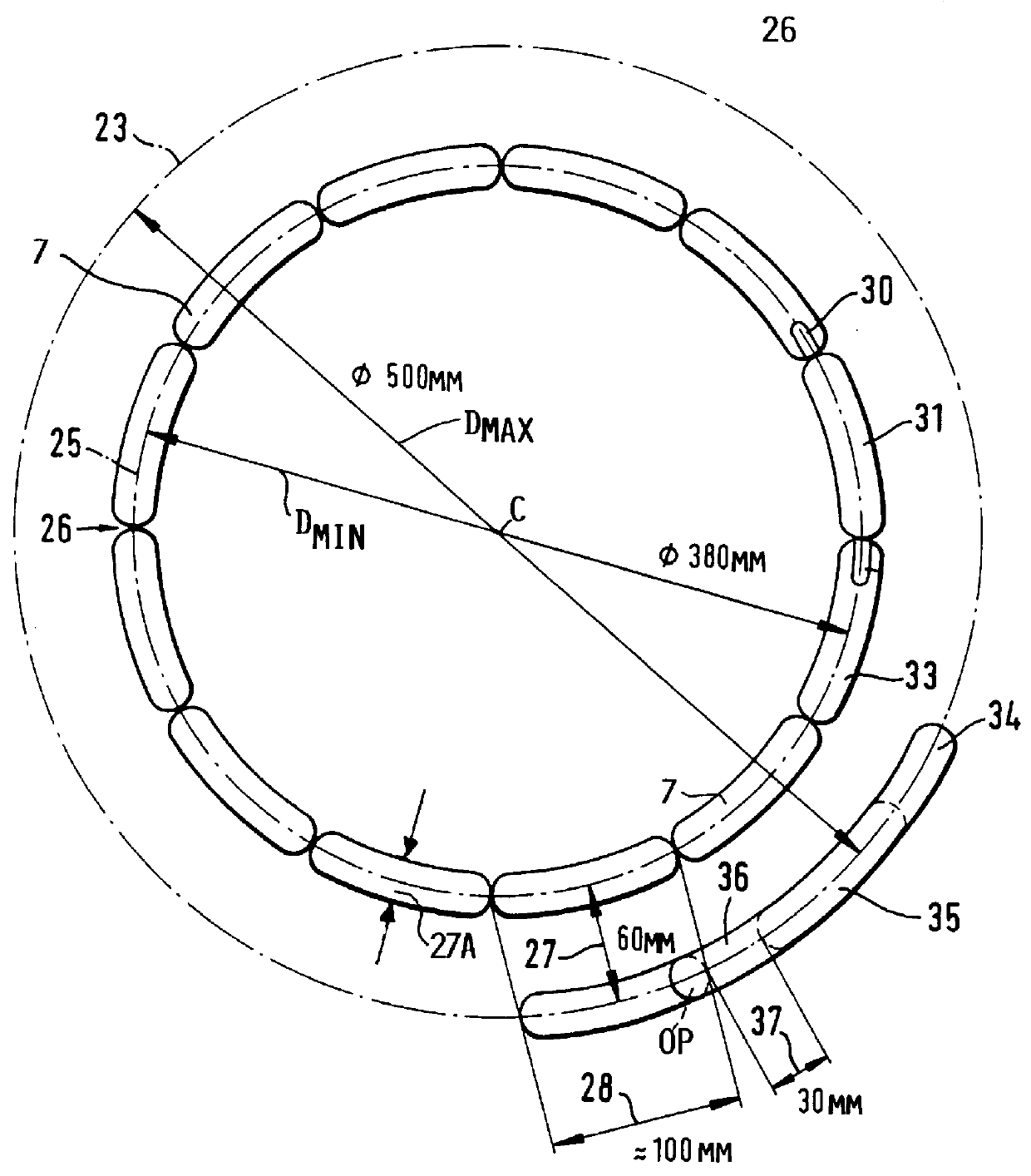

Apparatus for improving the running quality of air tire vehicle wheels

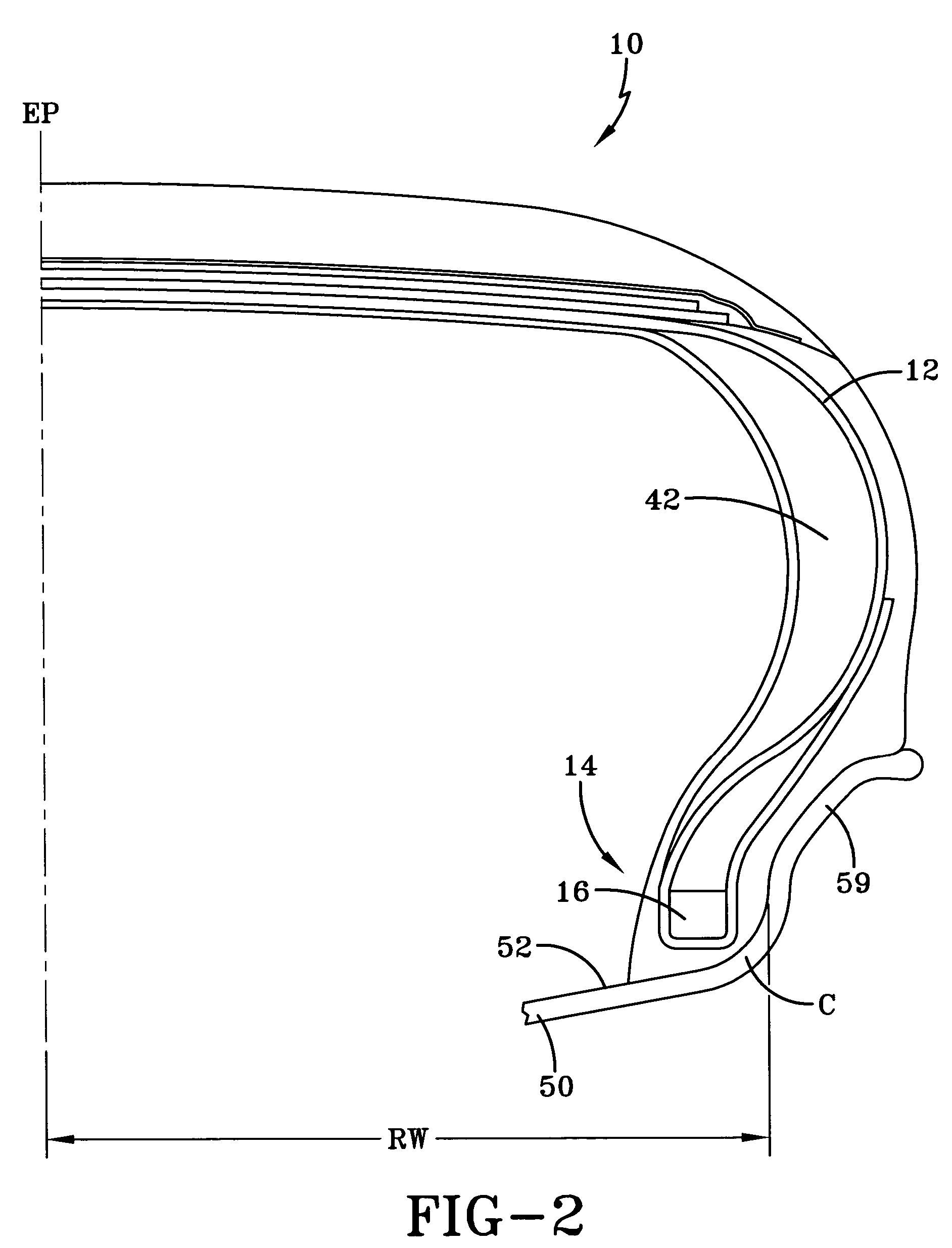

InactiveUS6076586AEasily integrated into manufacturing sequenceAdd seatsTyre repairingTire beadAxial pressure

The running characteristics of a vehicle wheel with a tire are improved by applying axial pressure with a pressure application ring (26) which temporarily compresses the flanks of a tire (10) to such an extent that a portion of the axially outwardly facing surface of the respective tire bead lifts off from the respective rim flange. This permits the tire bead to press itself, in response to the air pressure in the tire, into the corner formed between a cylindrical portion of the rim and the flange portion of the rim. The ring-shaped pressure application ring (26) comprises a plurality of circumferentially arranged ring sectors (7). These sectors can be adjusted in their radially inwardly or outwardly to thereby adapt the diameter of the pressure application ring for use in connection with a wide range of tire diameters.

Owner:SCHENCK ROTEC GMBH

Pneumatic tire

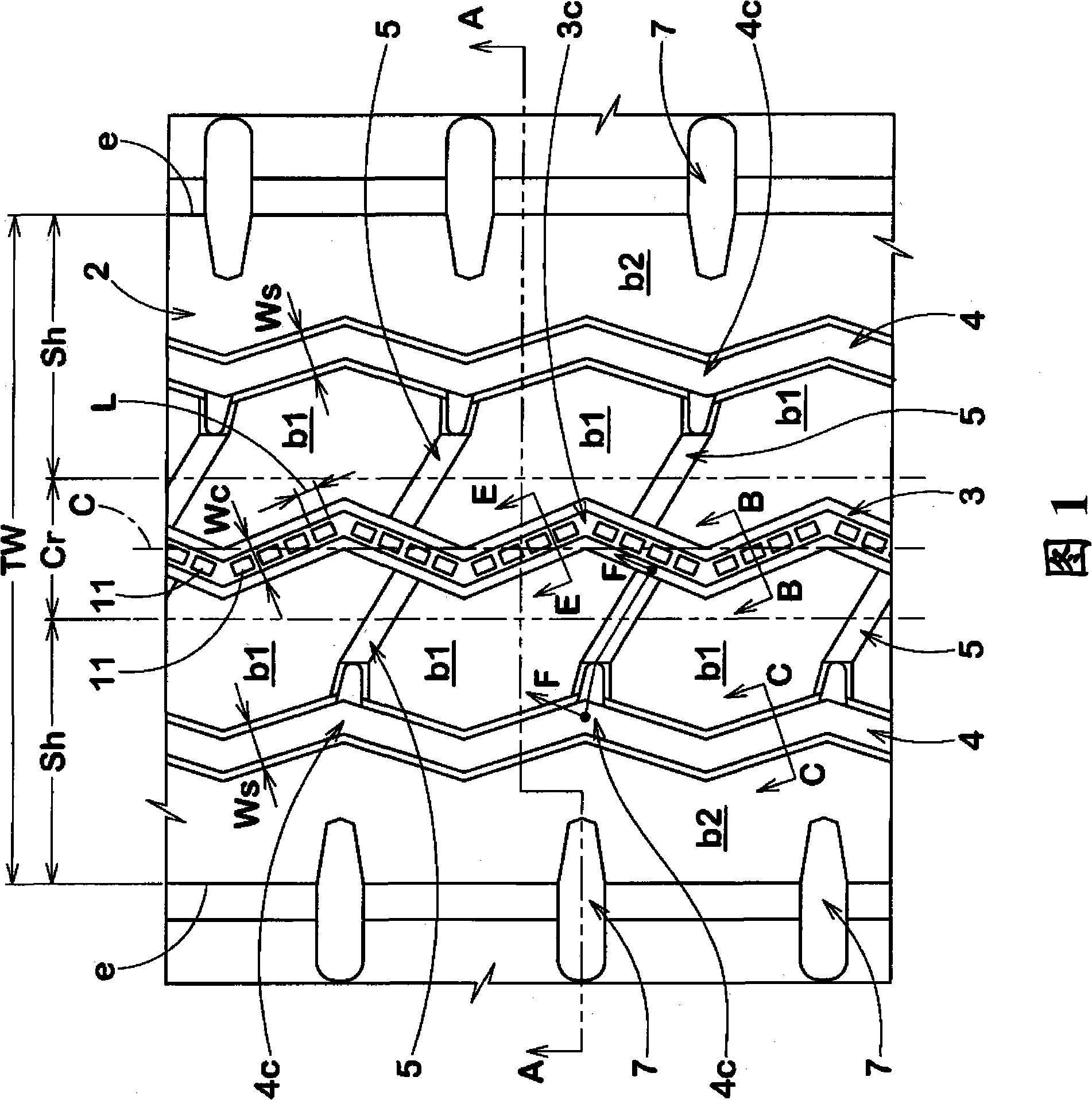

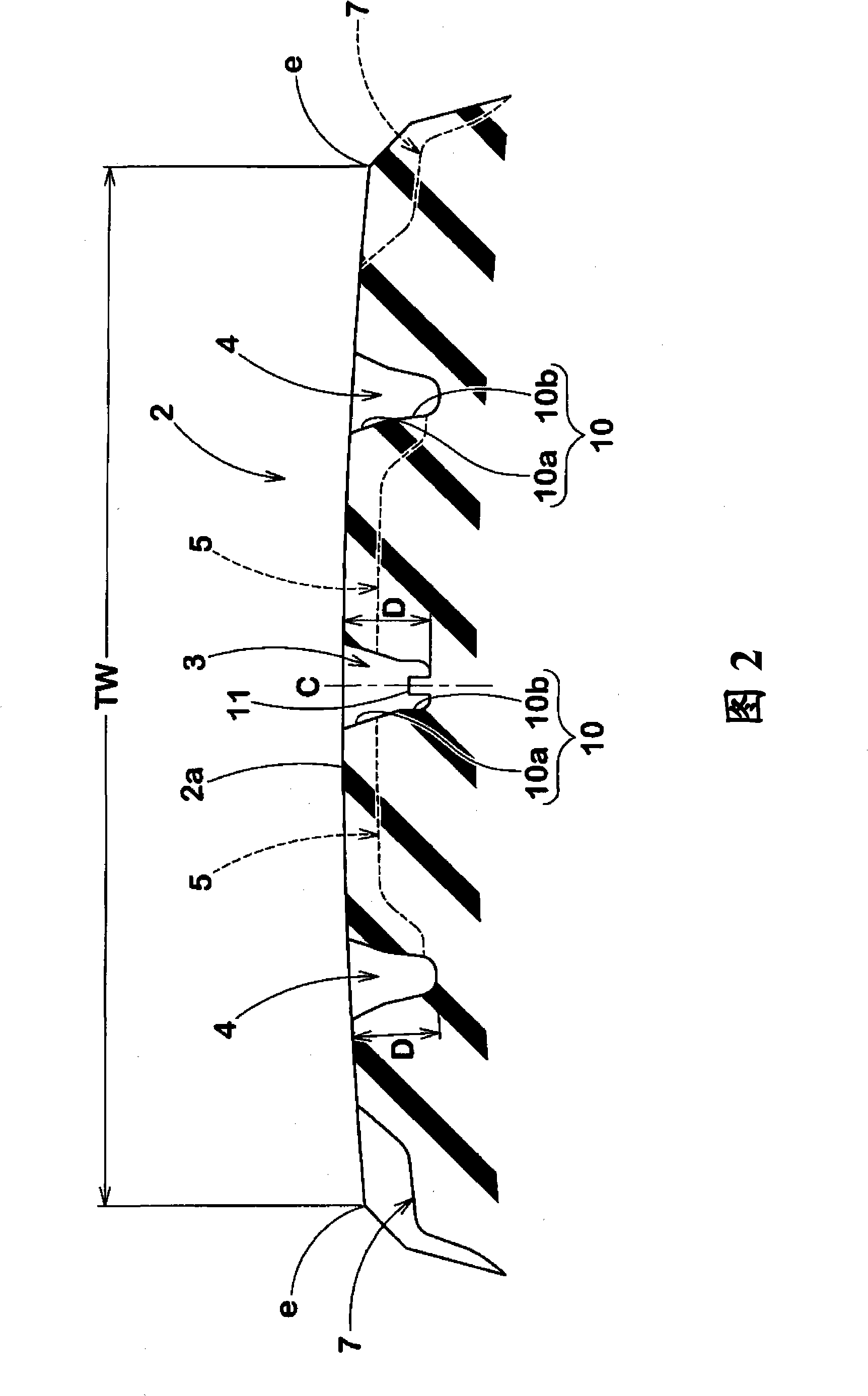

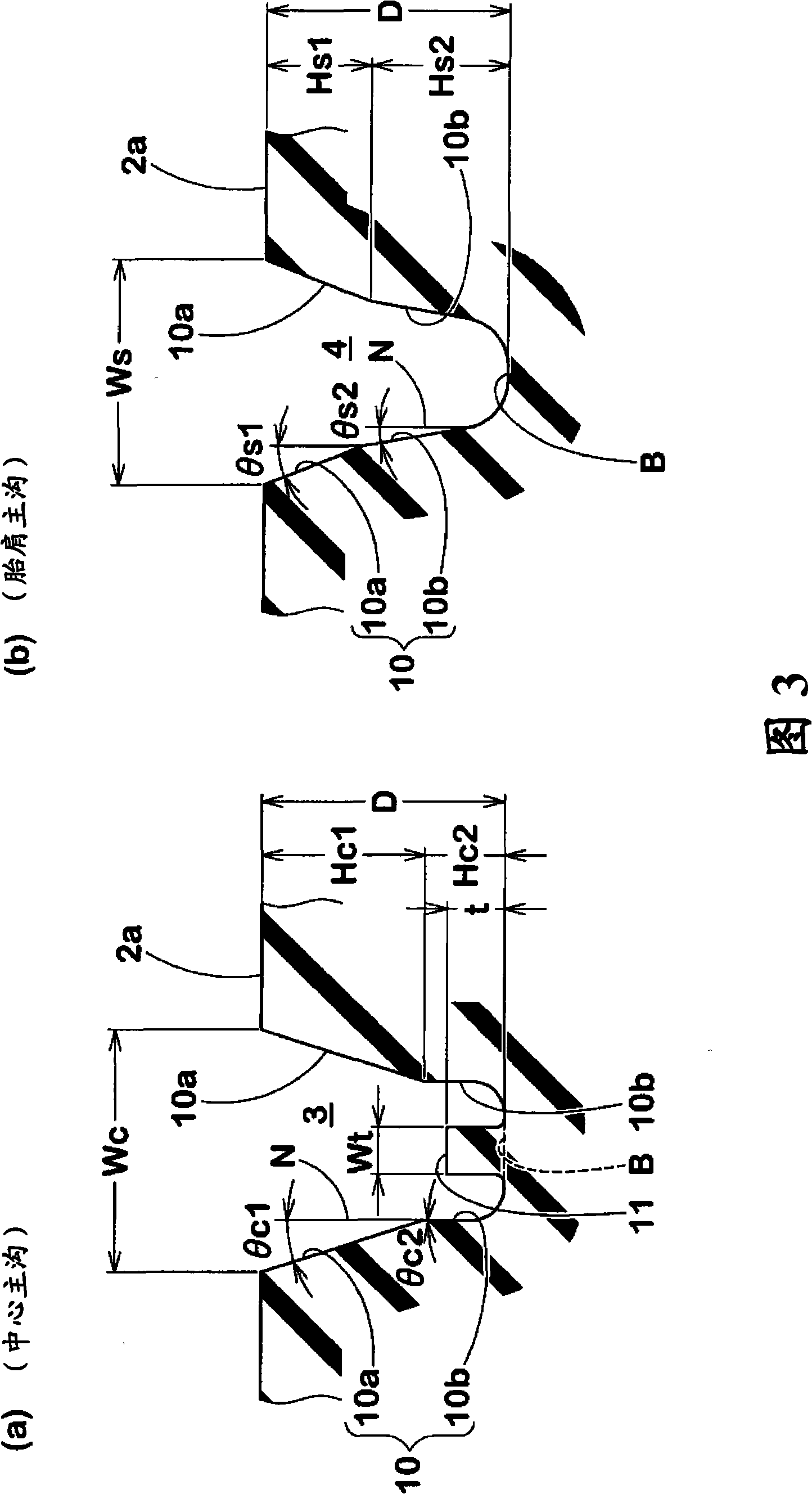

The invention provides a pneumatic tire which can reduce dunn bass of a main channel, the pneumatic tire is provided with at a tire surface section: a central main channel (3) and a tire shoulder main channel (4). For the central main channel (3) and the tire shoulder main channel (4), a channel wall surface (10) in a channel section which is at a right angle to the length direction of the channel comprises; a base (10b) which extends from channel bottom (B) to one side vertical to a tire tread (2a) or in a direction of enlarging width of the channel; and a gentle slope section (10a) which extends from an upper end of the base (10b) to the tire tread (2a) in such a manner of being more gentle than the base (10b). The height (Hc1) in tire radius direction of the gentle slope section (10a) of the central main channel (3) is larger than the height (Hs1) in tire radius direction of the gentle slope section (10a) of the tire shoulder main channel (4), and projections (11), which are used for prevention of dunn bass, are provided at the channel bottom (B) of the central main channel (3) and at a position away from the channel wall surface (10) at interval in the length direction of the tire.

Owner:SUMITOMO RUBBER IND LTD

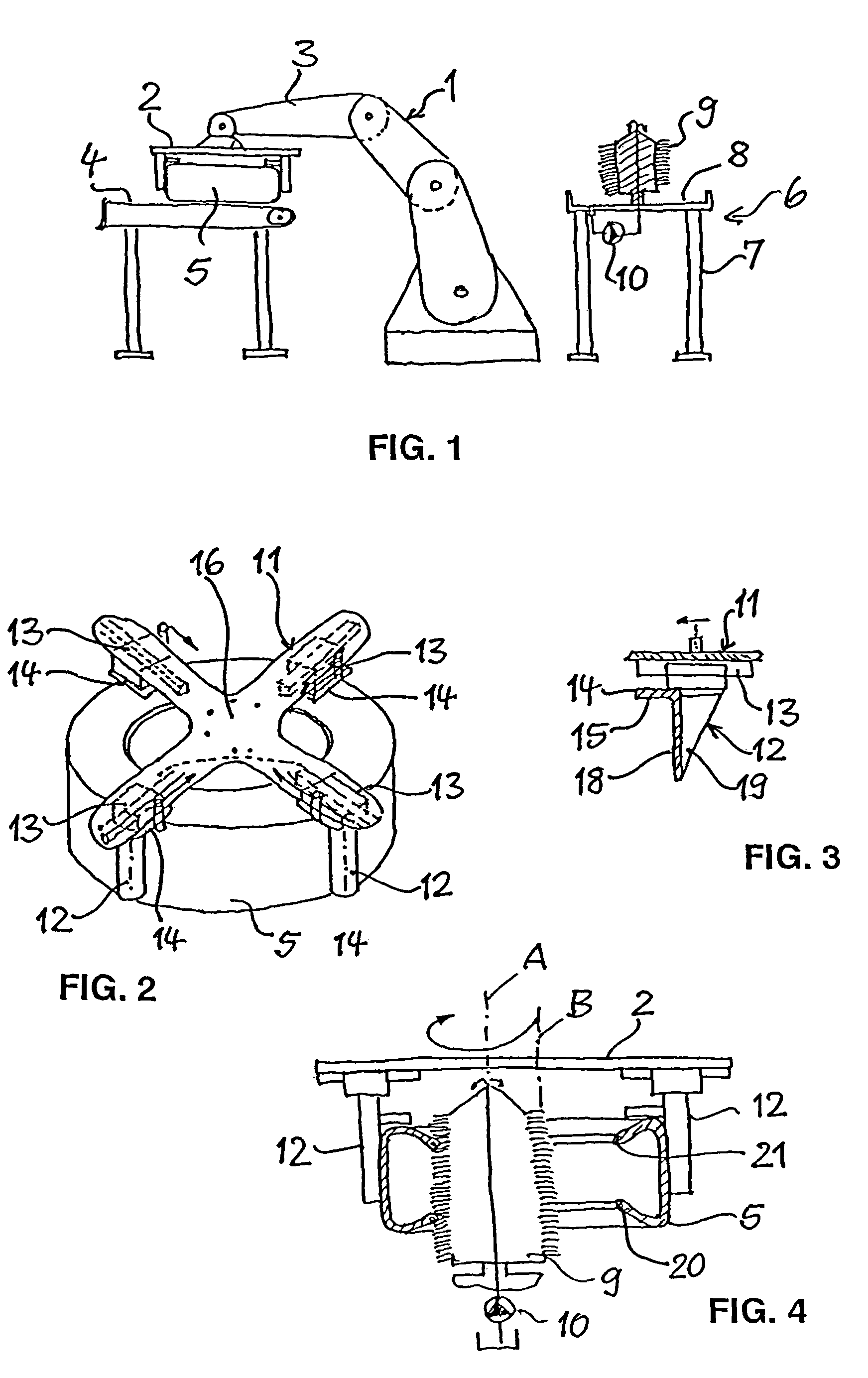

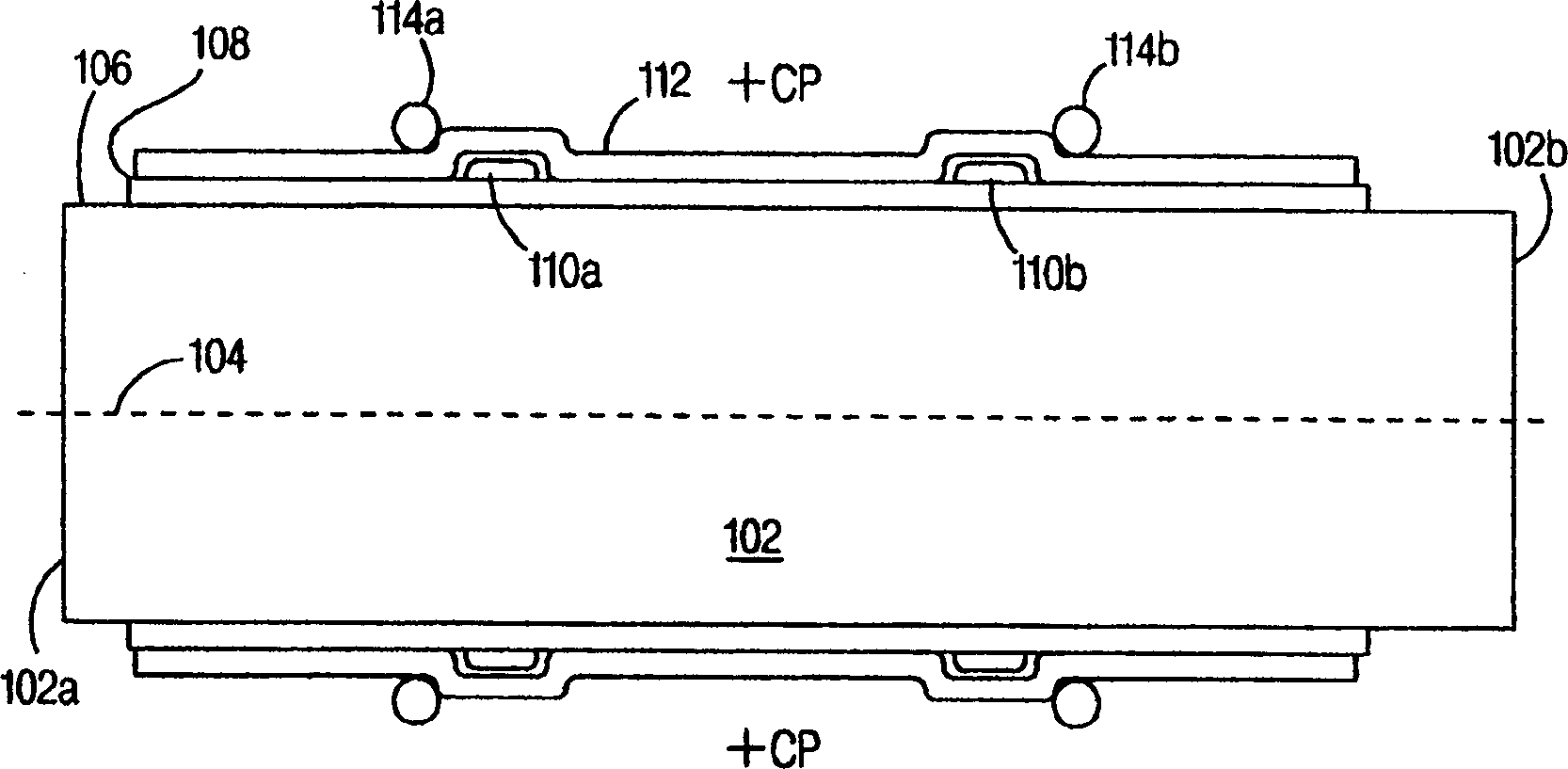

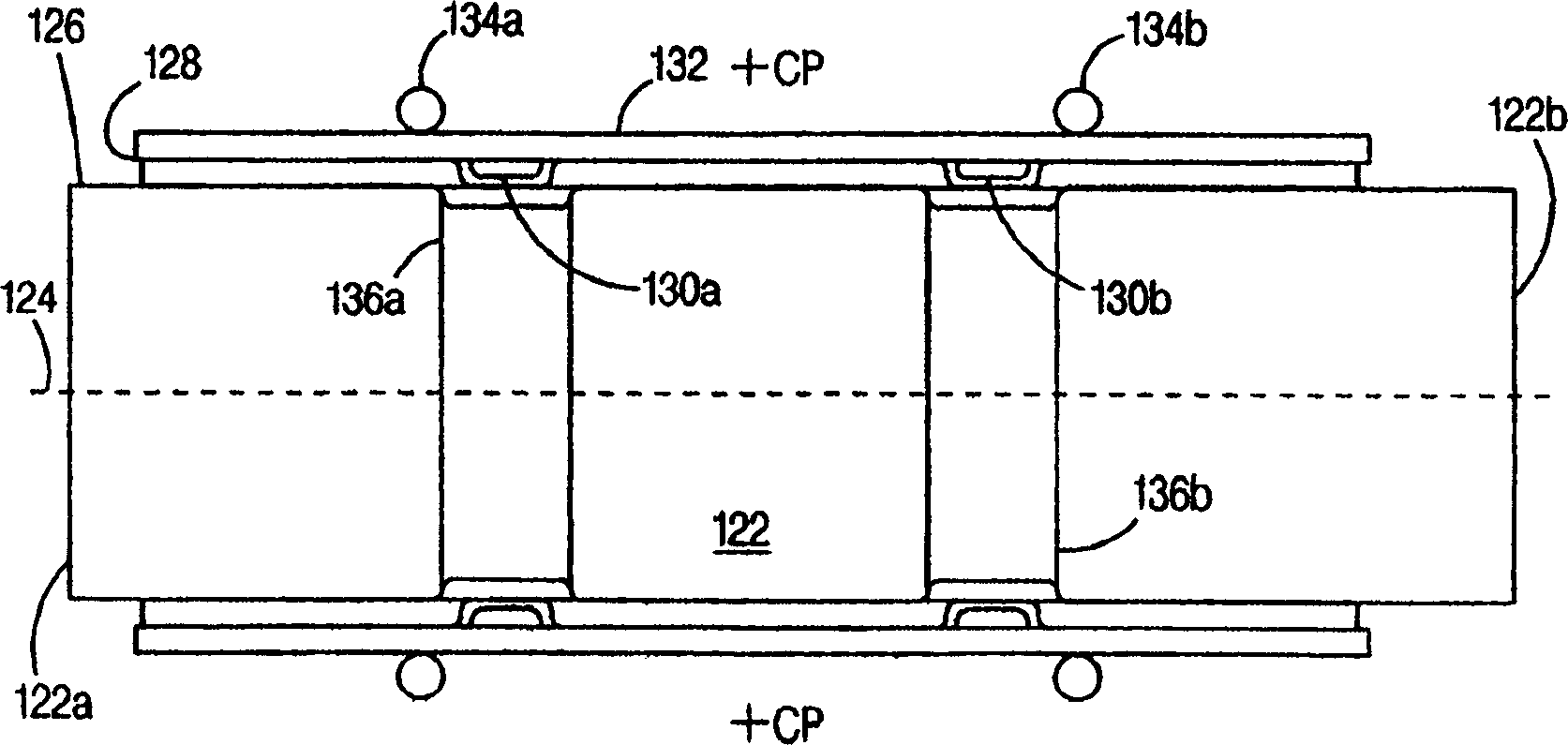

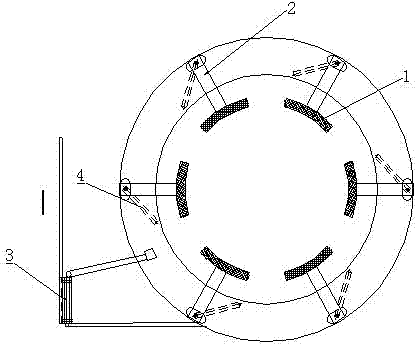

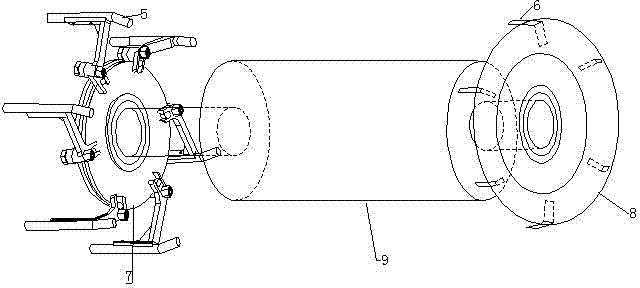

Tyre forming drum with expansible centre and independent expansible tyre rim locking assembly in its end

A tire building drum has a center section and two end sections. Each end section is provided with an expandable bead lock assembly. The center section is preferably expandable. The expandable bead lock assembly comprises a carrier ring and a plurality of elongate links extending between the carrier ring an d a plurality of radially- expandable segments. When the carrier ring moves inward (towards the center section), the radially-expandable segments move radially outward, urging a plurality o f axially extending, circumferentially spaced-apart finger segments outward from a collapsed position to an expanded position, and at least one position therebetween. In an embodiment of the invention, the bead lock assembly comprises a cylinder and two pistons disposed within the cylinder. The pistons are free to move axially within the cylinder, in response to pneumatic pressure. The first piston is constrained from moving axially inward by rods. The second piston is connected by rods to the carrier ring. Pressurized air supplied through hoses and passageways in the cylinder control the movement of the pistons so that the beach lock assembly can be partially-expanded, fully-expanded, and retracted, unexpanded position.

Owner:THE GOODYEAR TIRE & RUBBER CO

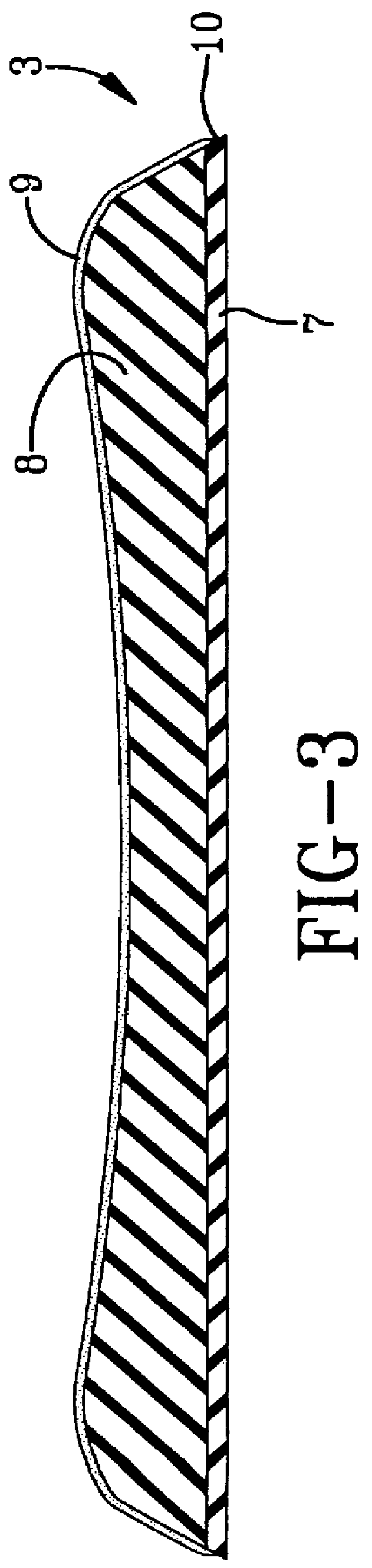

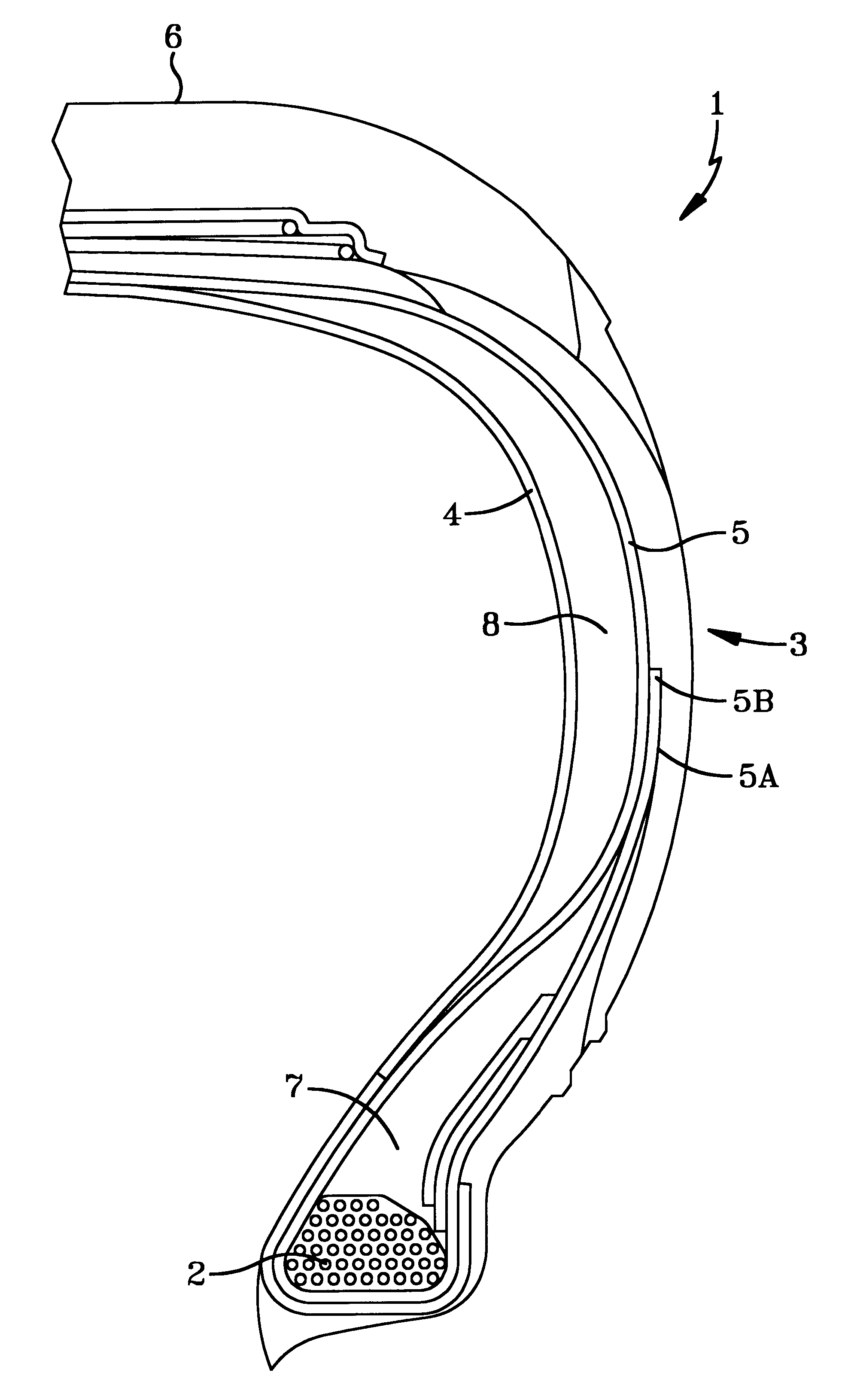

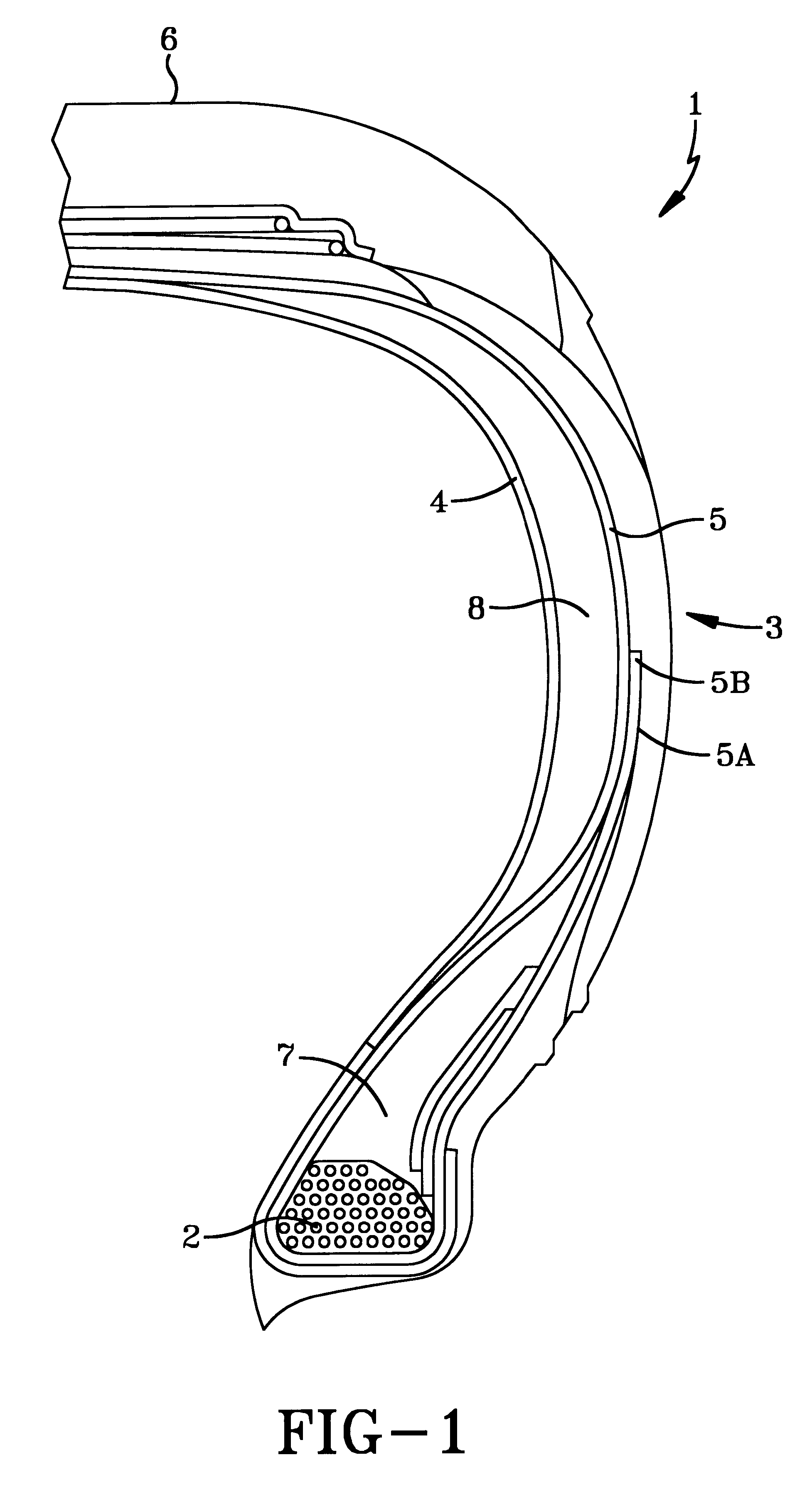

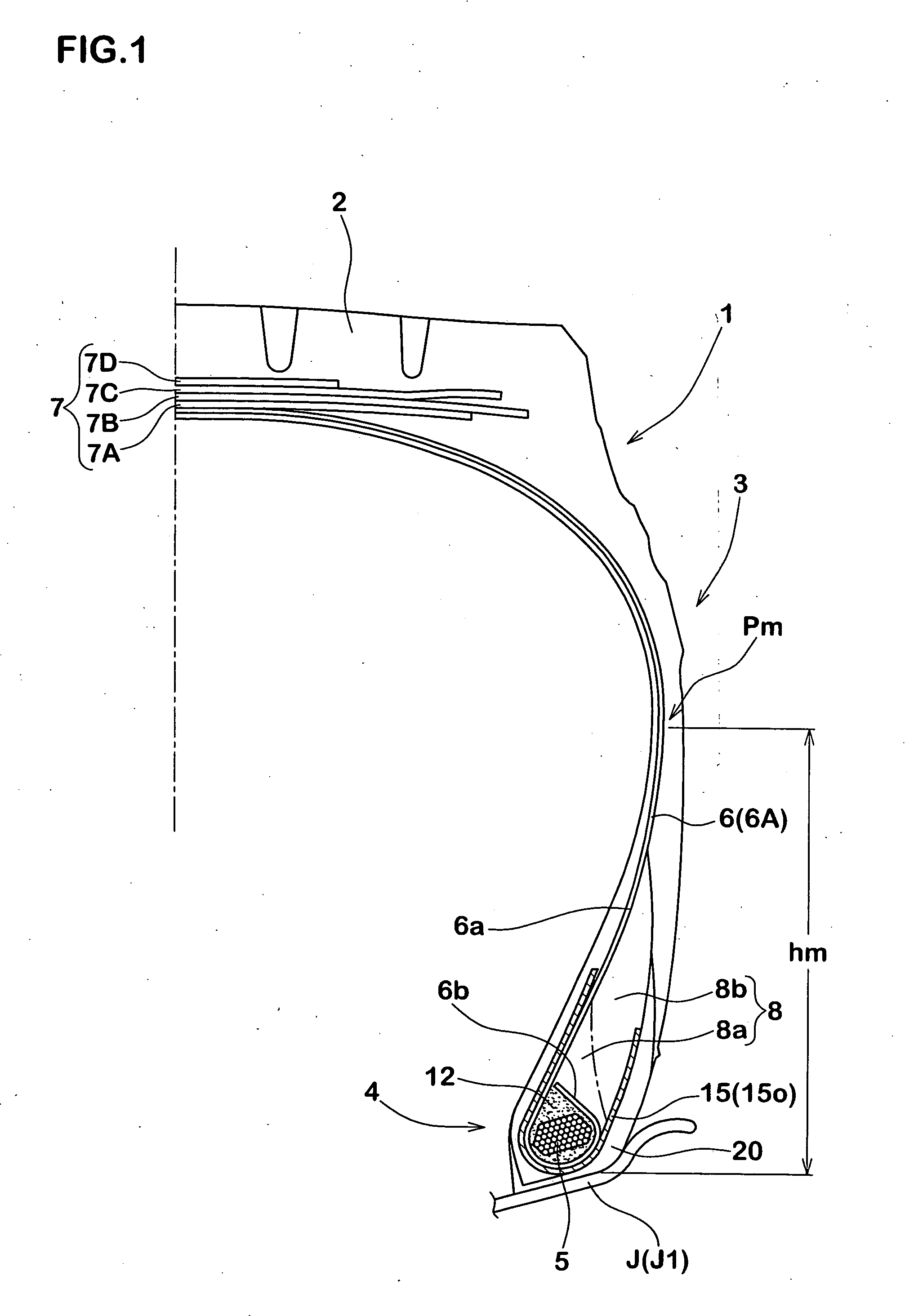

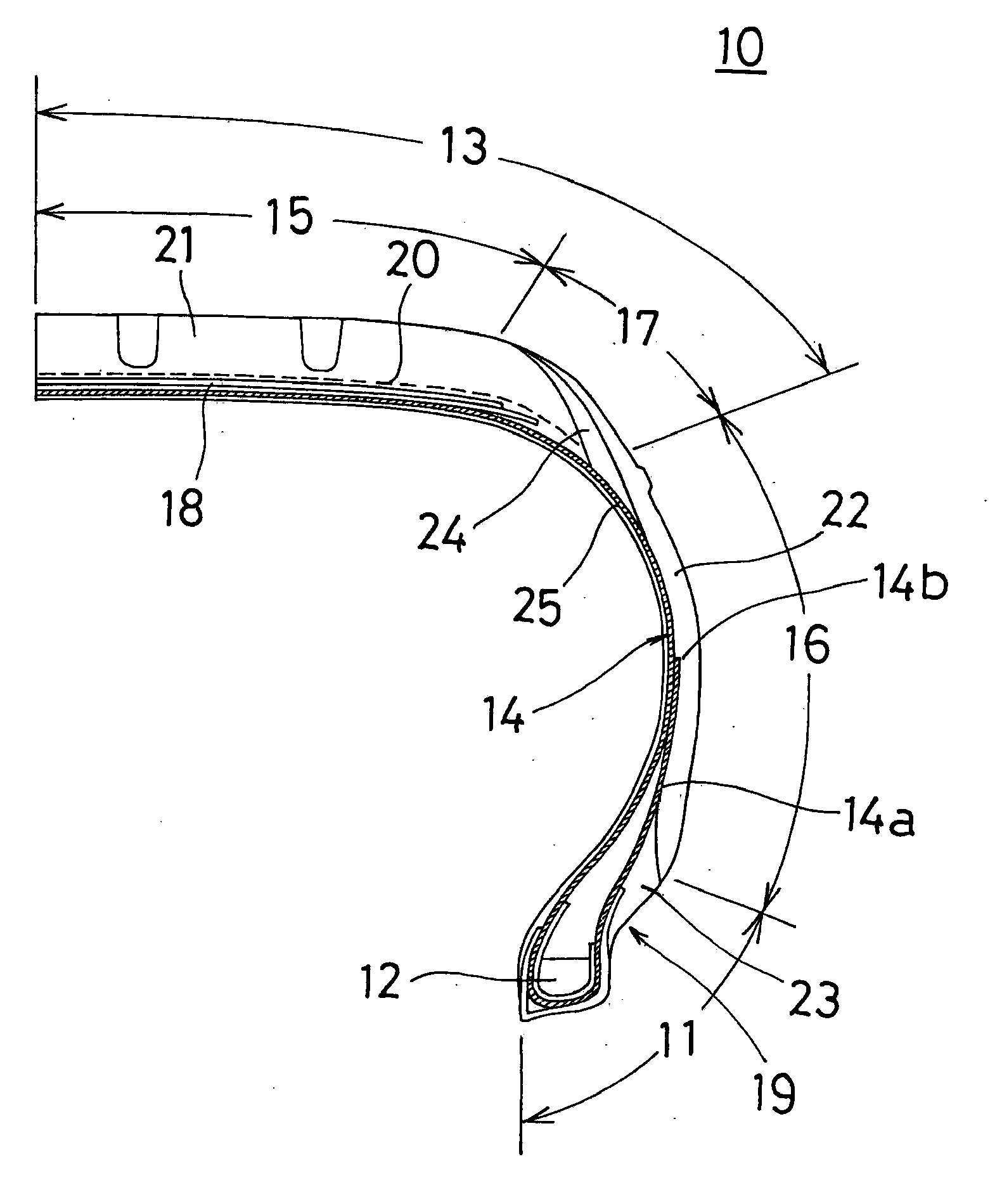

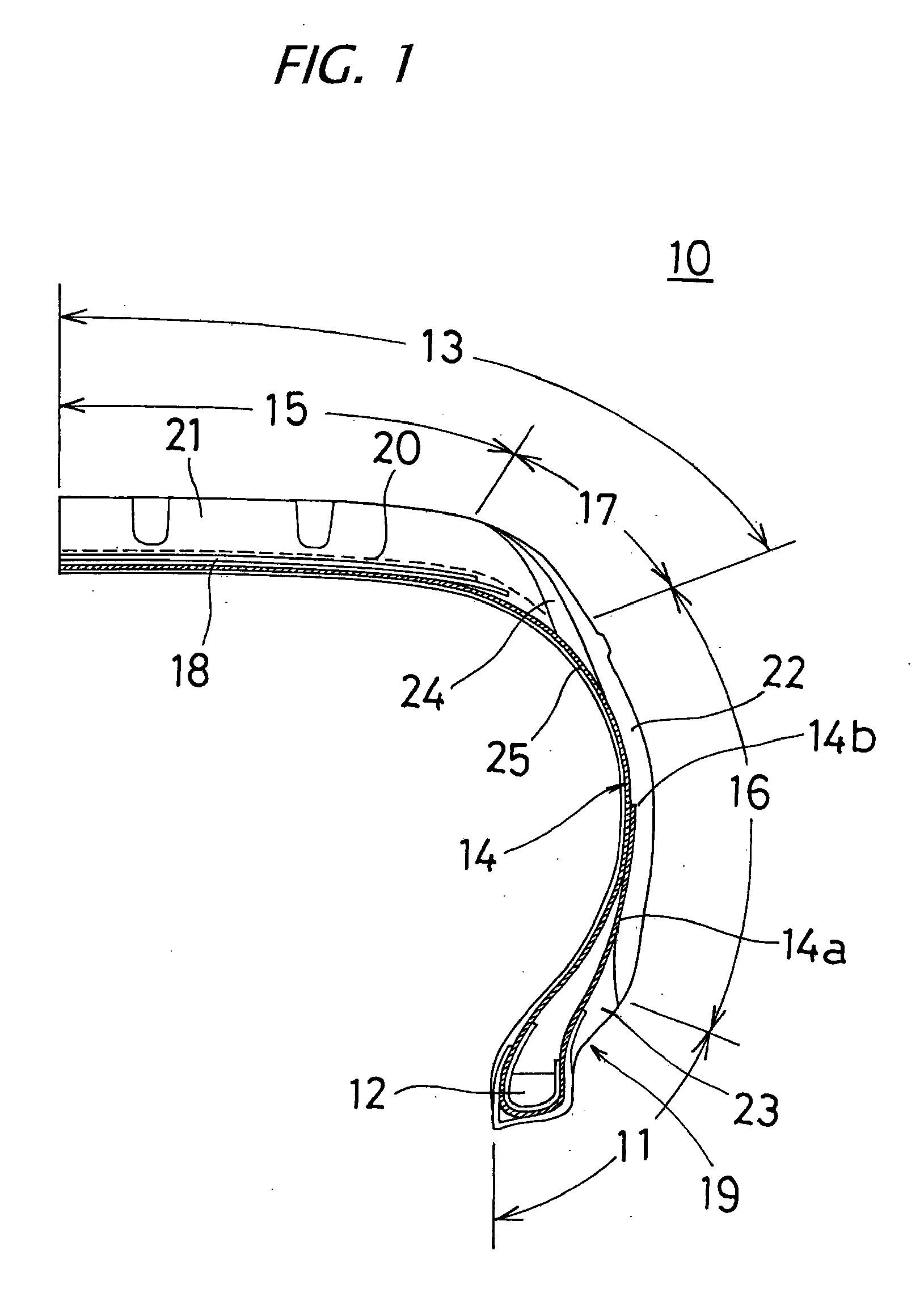

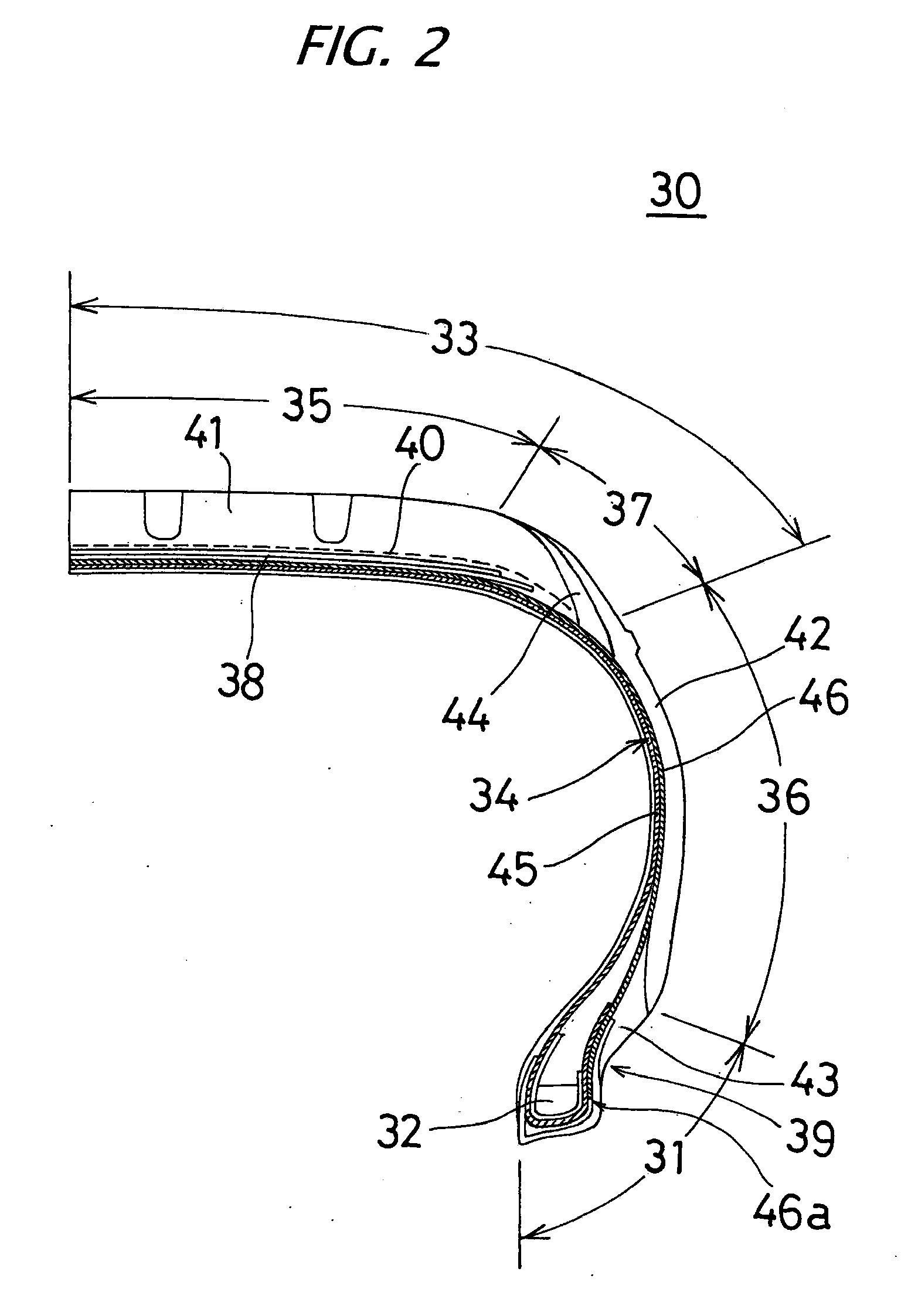

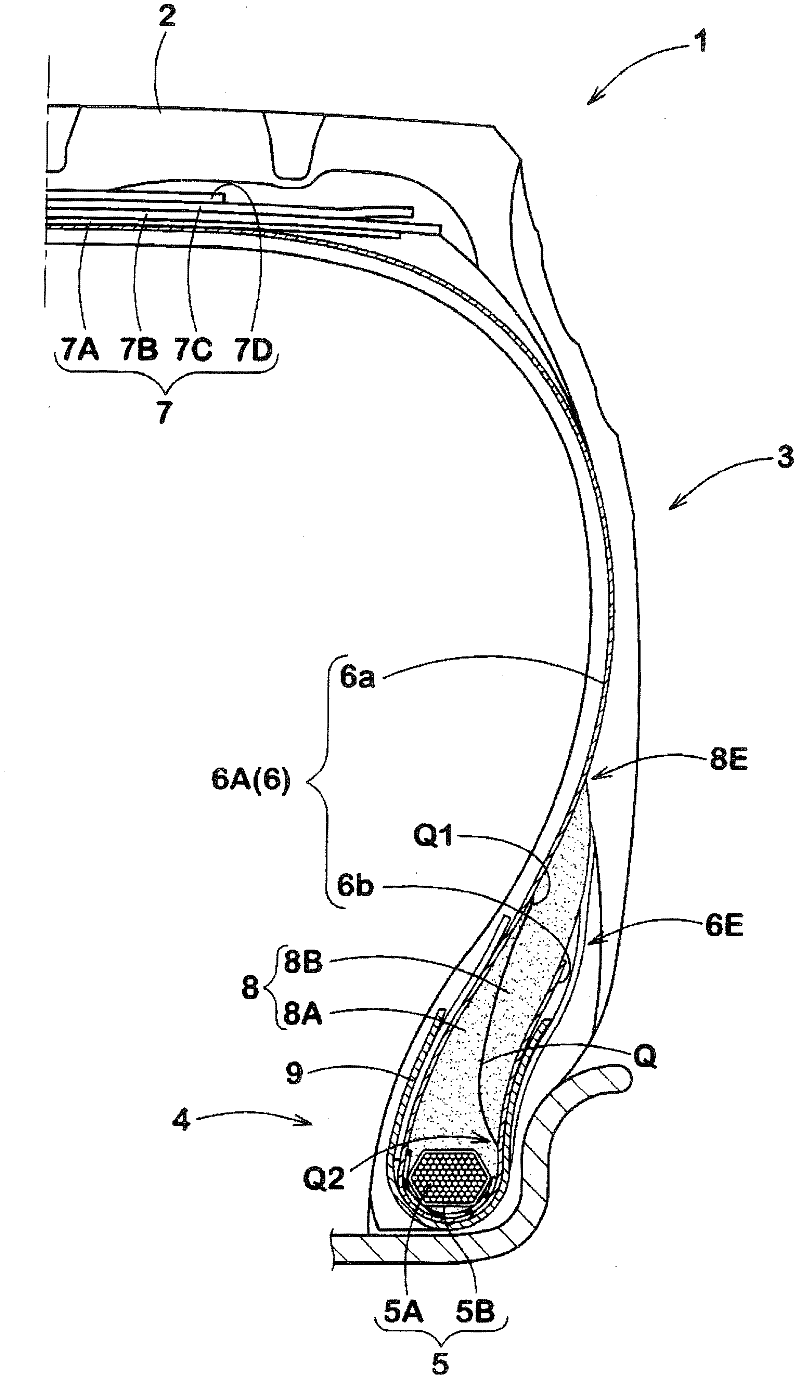

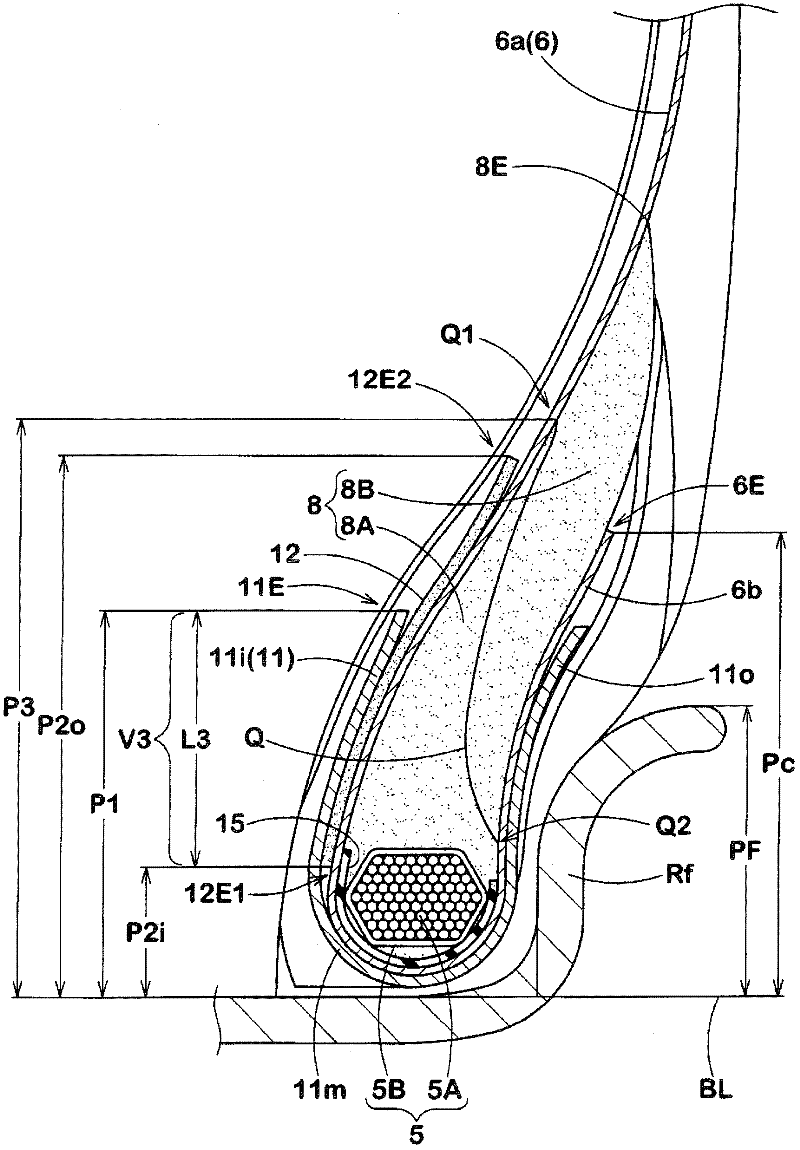

Pneumatic Tire

ActiveUS20100078103A1Improve rolling resistanceGood wetting propertiesSpecial tyresTyre beadsGround contactRubber material

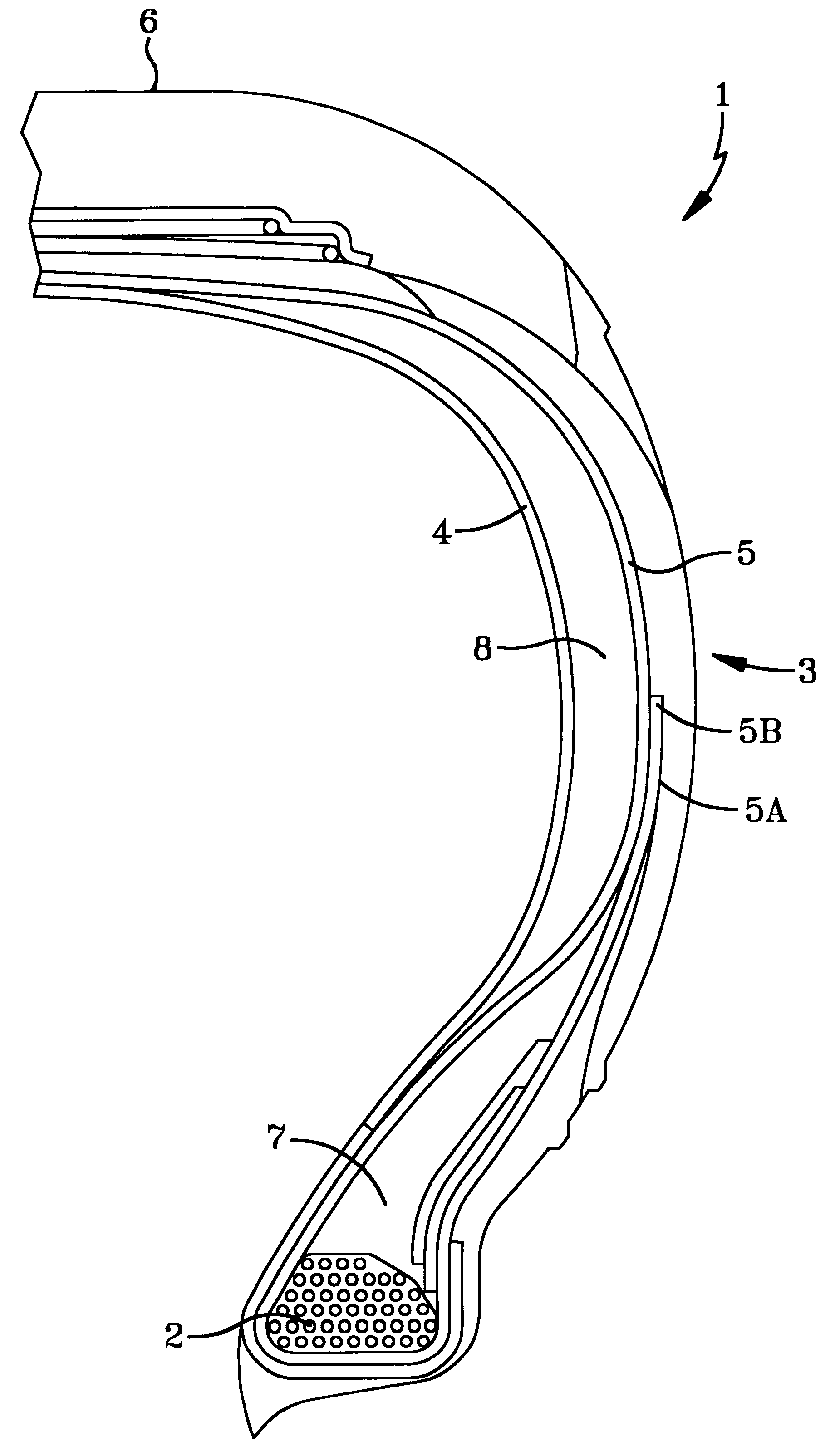

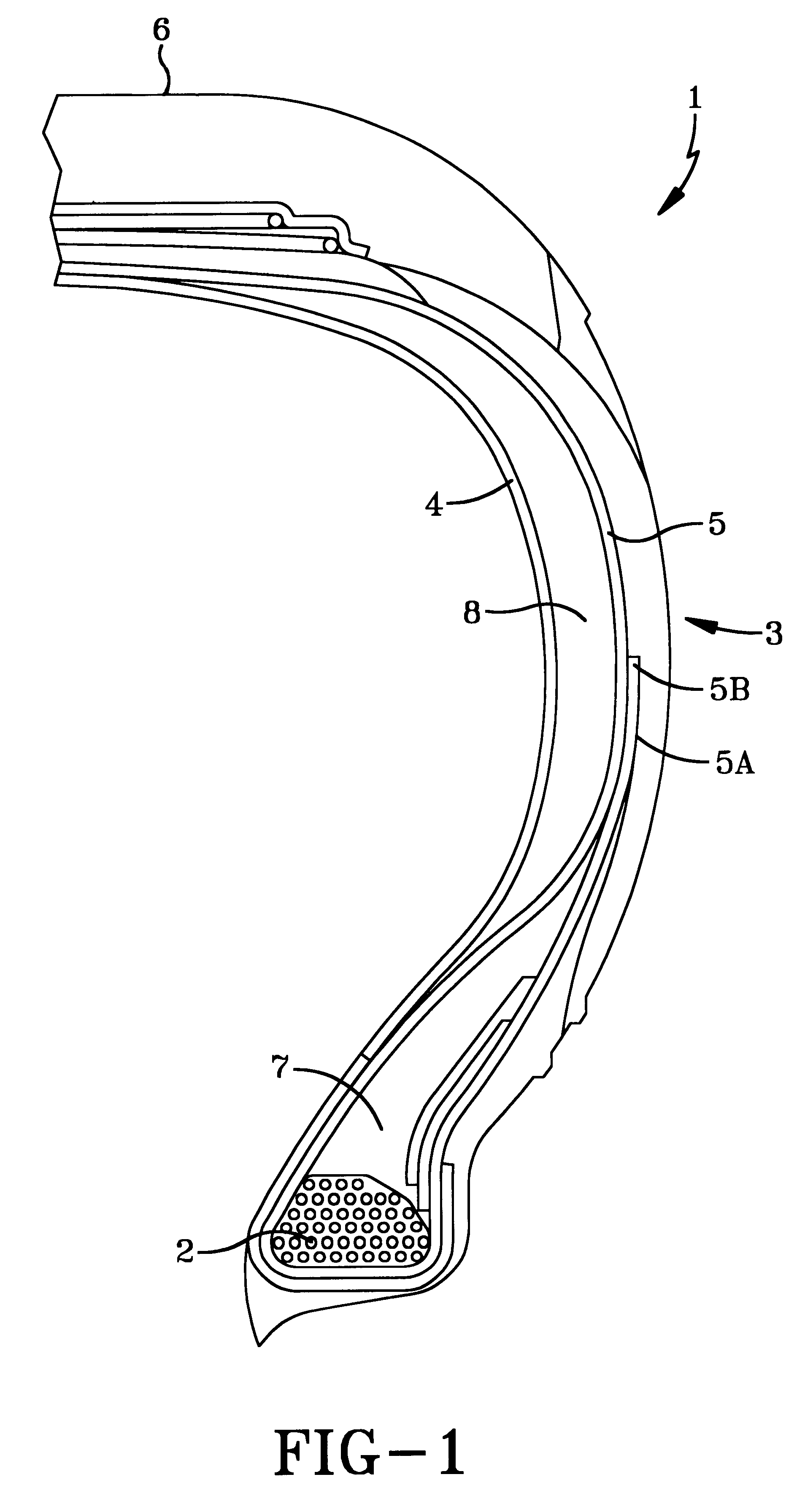

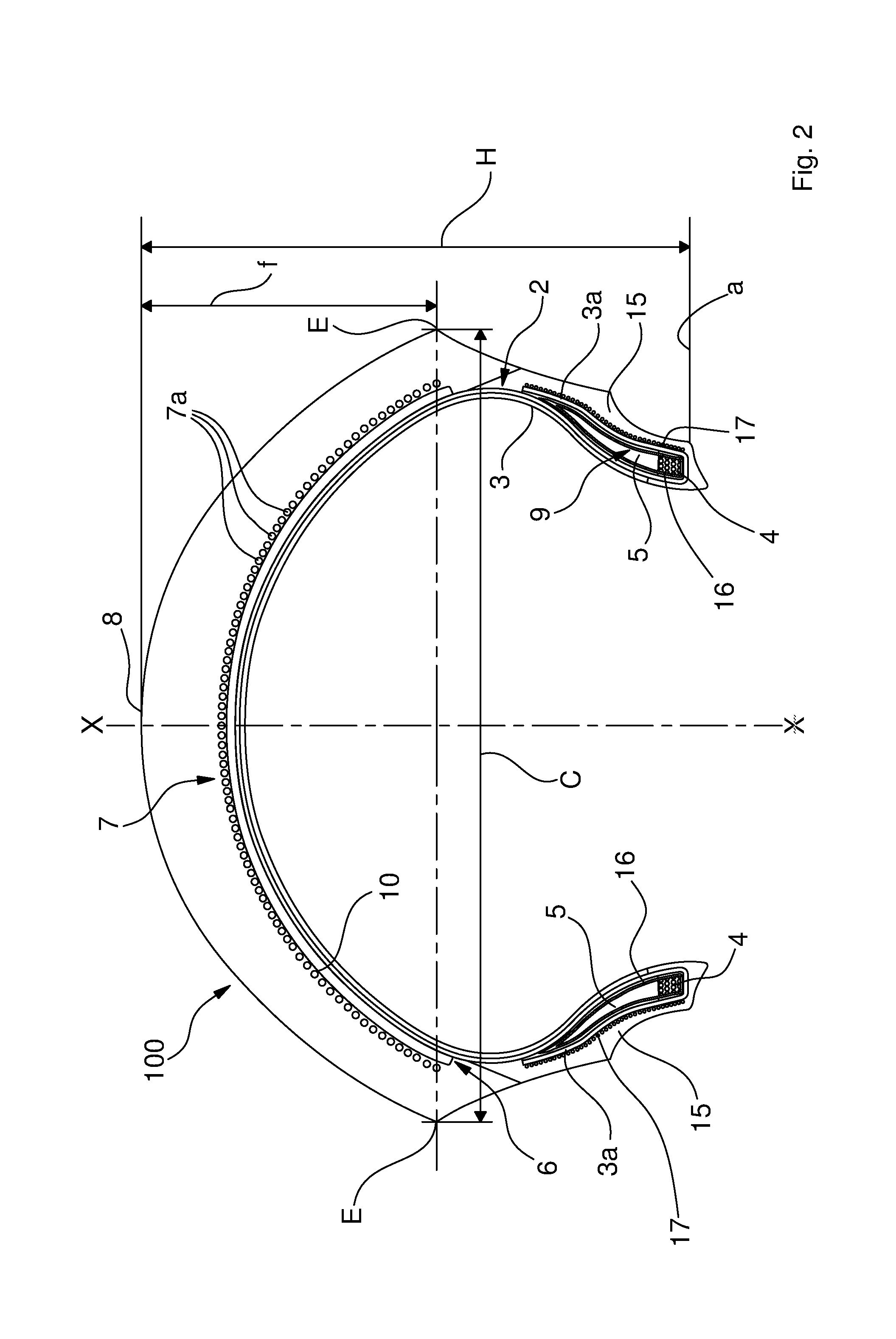

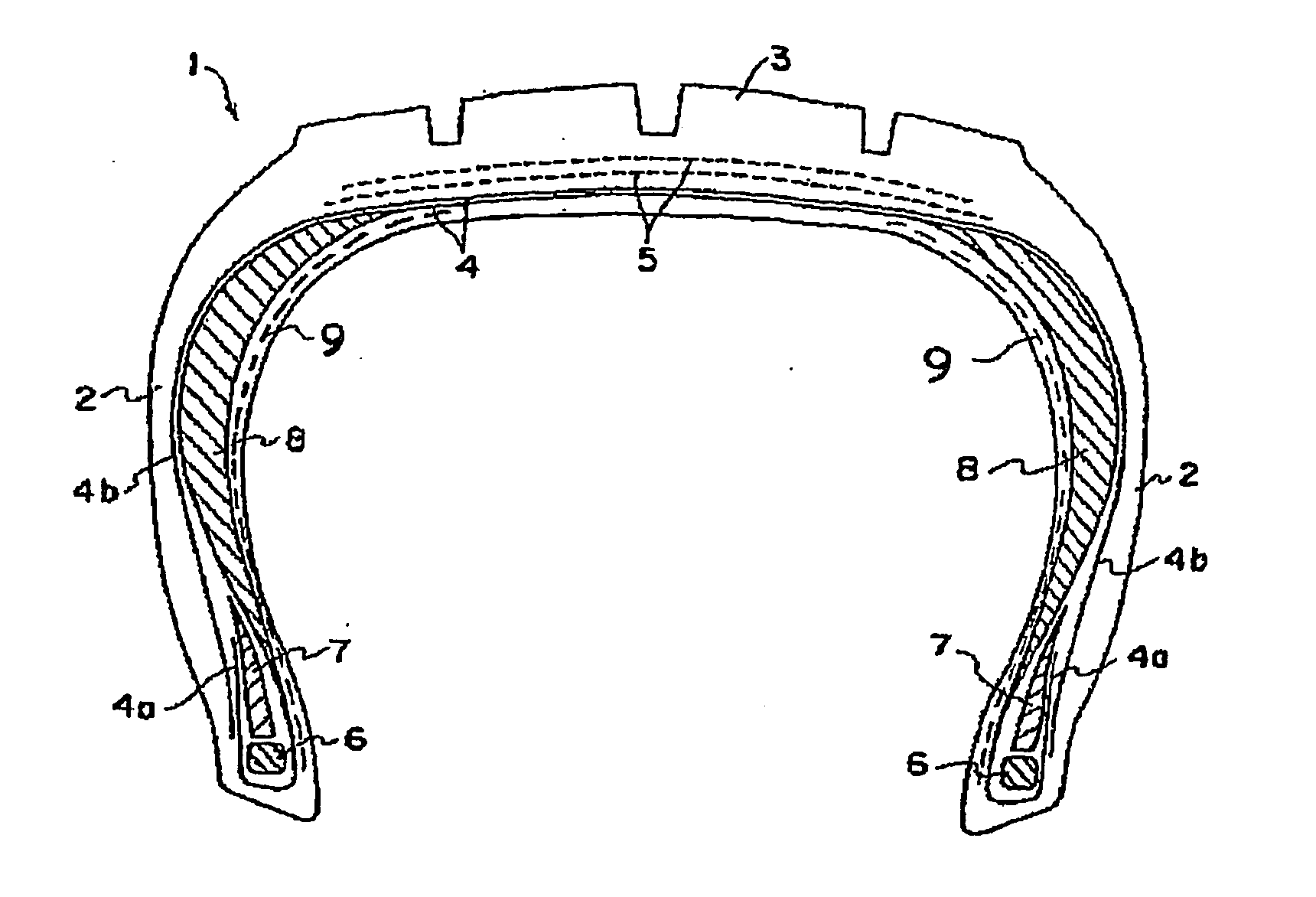

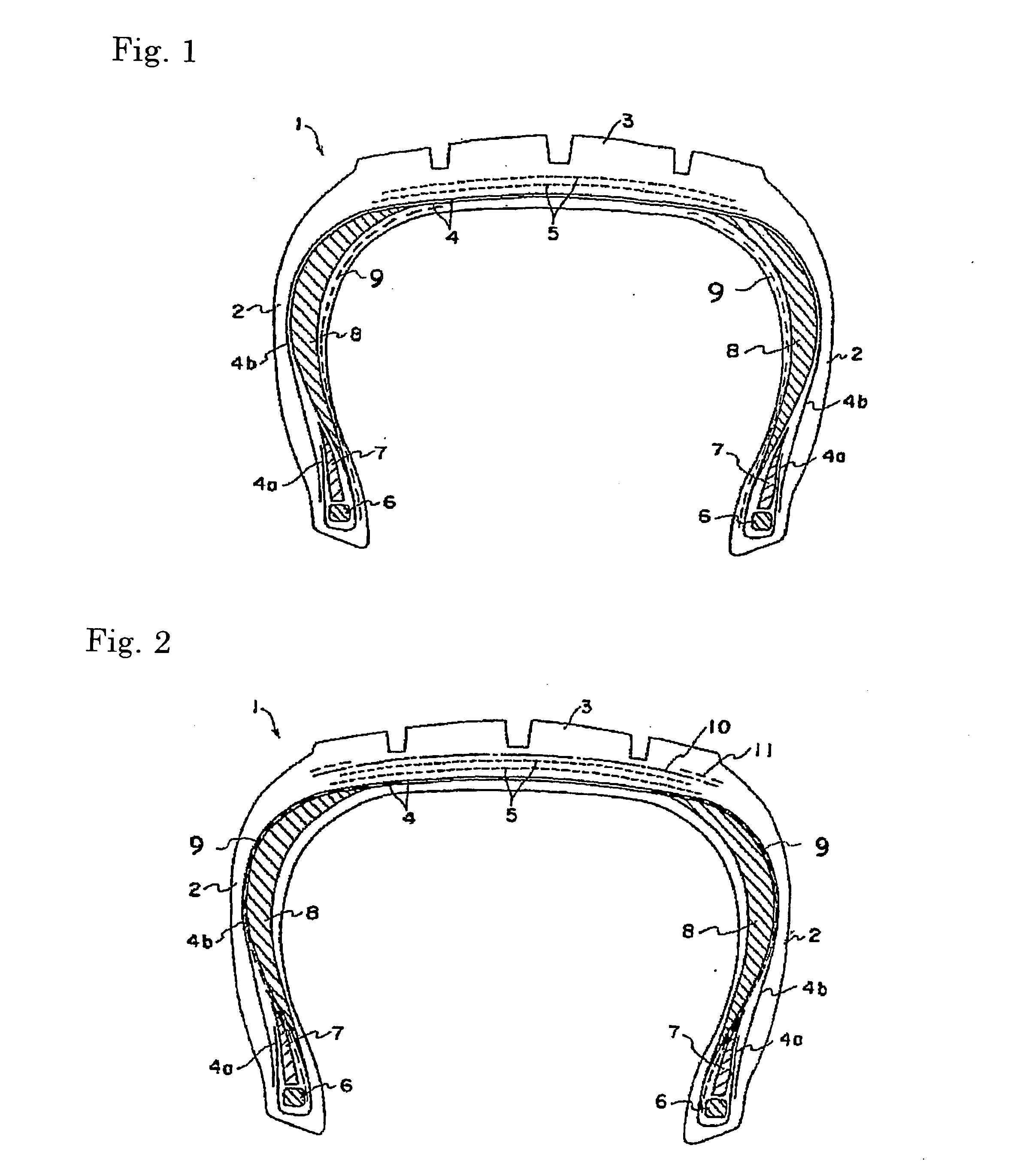

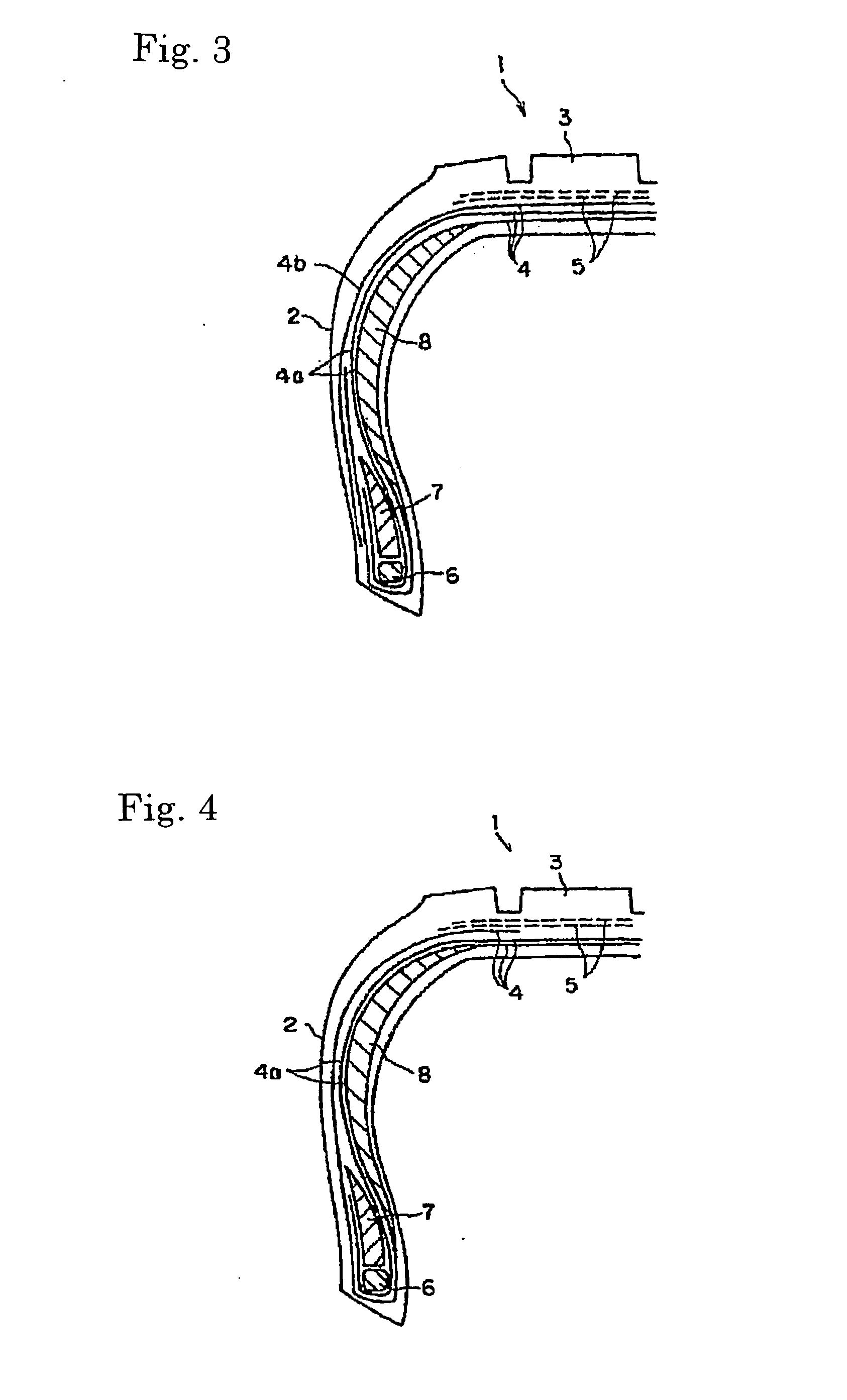

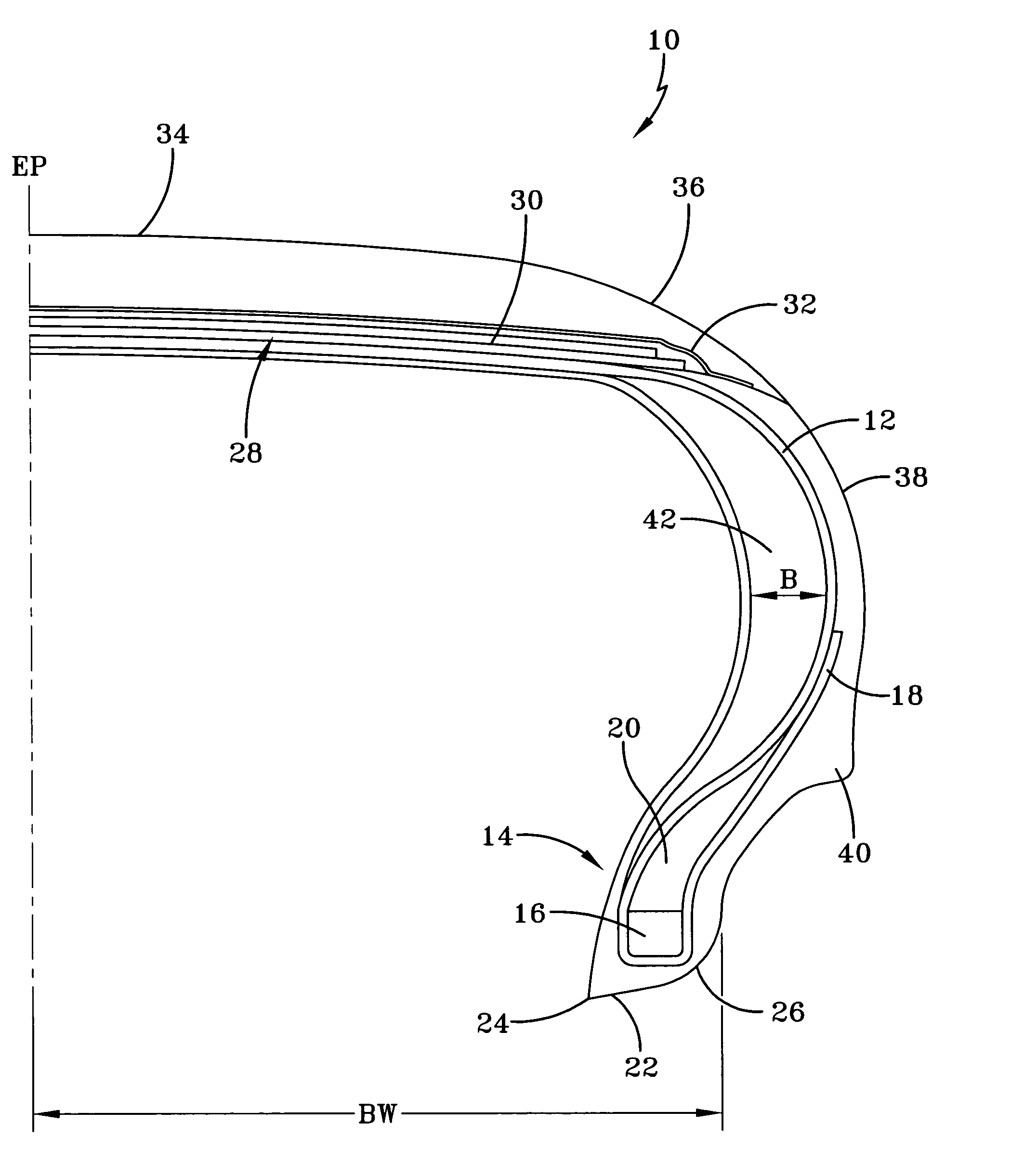

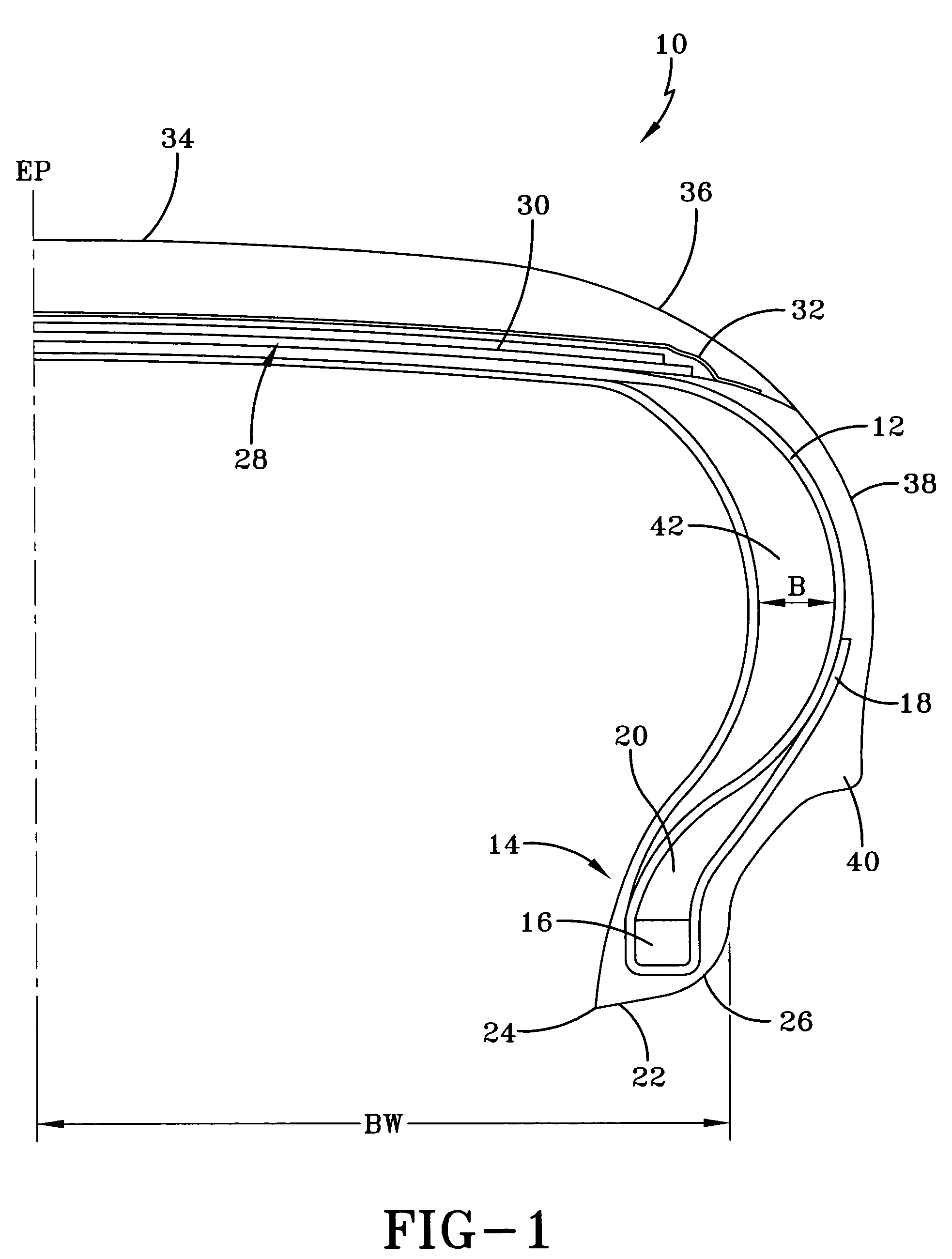

A pneumatic tire that can be manufactured according to the conventional method without requiring special tire manufacturing steps and without needing addition of material members and production steps, and having excellent rolling resistance and wet properties, and having conductivity is to be provided. A pneumatic tire 10 comprises a carcass 14 having a ply which is turned back and locked around a bead core 12, a rim strip 19 provided in a bead part 11, and a wing 24 in which one edge thereof is contacted with the carcass 14 and the other edge is exposed to the surface of a ground contact edge region of a tread part 13, wherein a covering rubber of a carcass ply 25, the rim strip 19 and the wing 24 are formed into a continuous conductive path by a conductive rubber material, only the conductive path is used as a conducting path of the tire 10, and members other than the conducting path are selected and used from a conductive rubber material or a nonconductive rubber material.

Owner:TOYO TIRE & RUBBER CO LTD

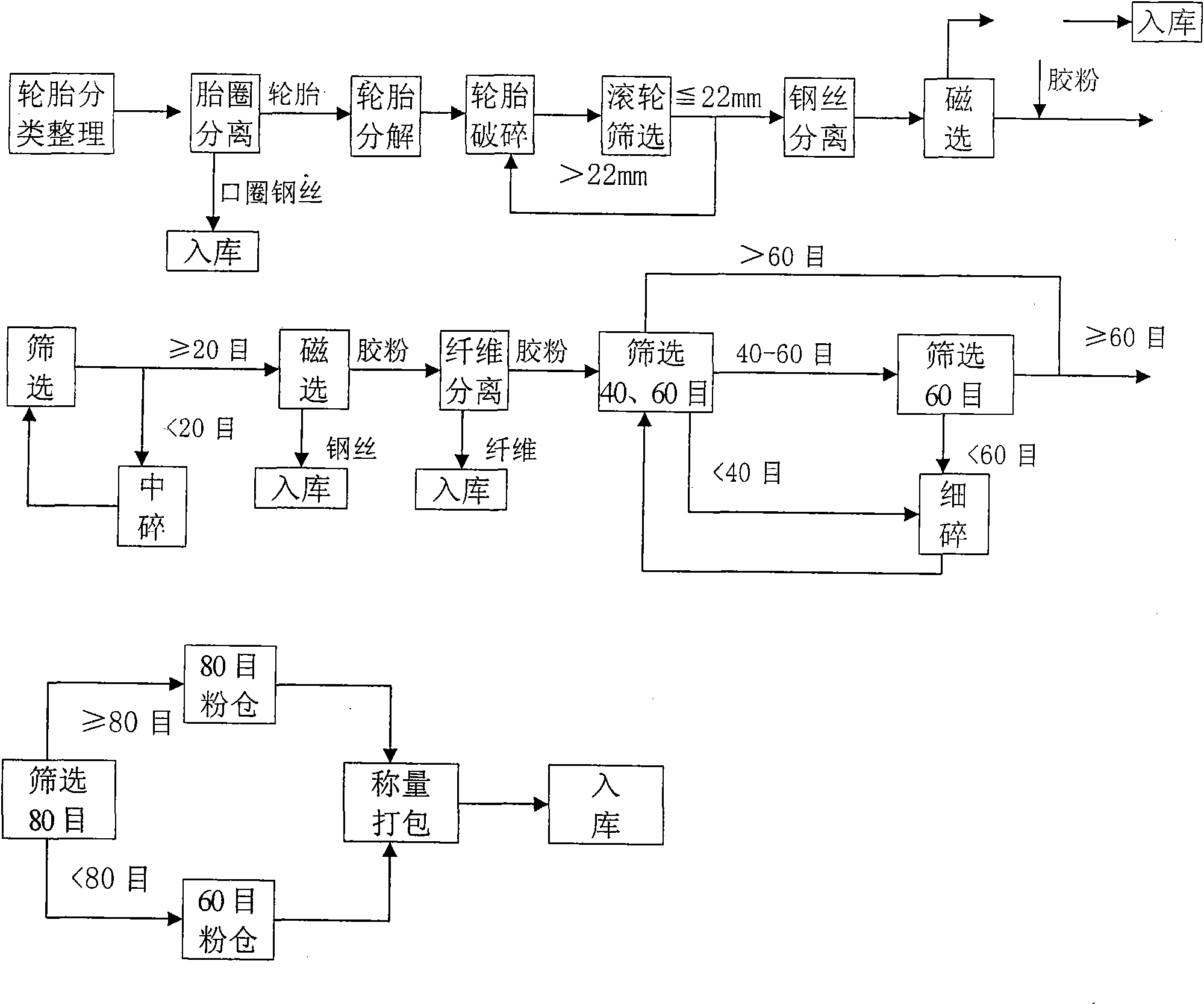

Method for producing gelatine powder under normal temperature by using waste tires

InactiveCN101670625ALow investment costLow production costSolid waste disposalPlastic recyclingTire beadRoom temperature

The invention discloses a method for producing gelatine powder under normal temperature by using waste tires, which relates to the technical field of producing gelatine powder under normal temperatureby using waste rubber products, and comprises the detailed steps of: a. separating a tire bead; b. crashing the tire; c. separating steel wires; d. magnetically separating for the first time; e. screening for the first time; f. magnetically separating for the second time; g. screening for the second time; and h. screening for the third time. The method has simple technique, is convenient for large-scale industrial production, and has lower investment and production cost; the grain diameter quality of the produced gelatine powder is stable; moreover, the method can produce the gelatine powderwith different grain diameter specifications, thus meeting the demands of different users.

Owner:SICHUAN LESHAN YALIAN MACHINE

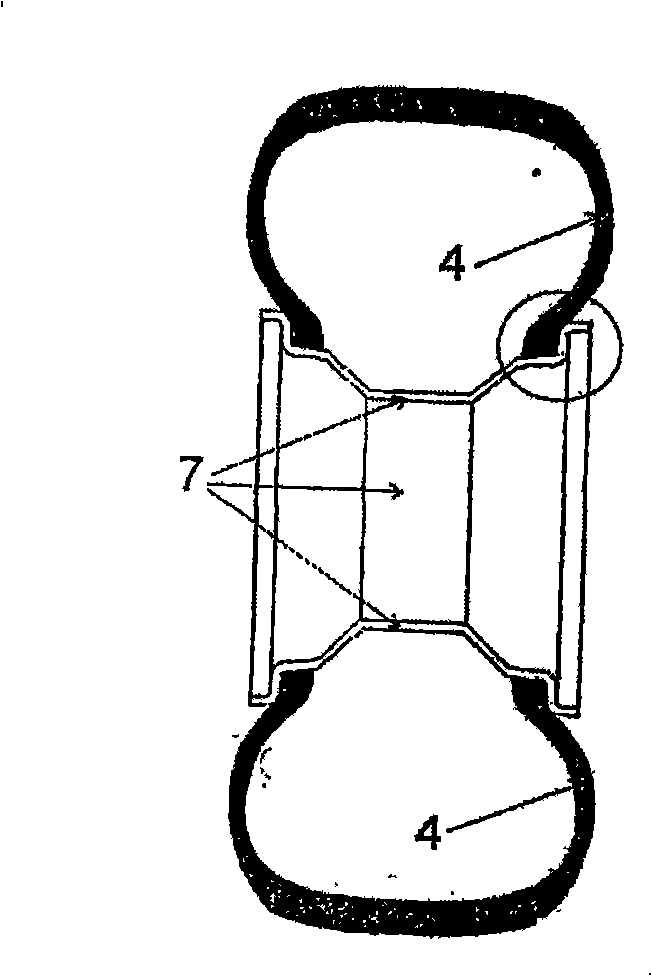

A chamber of a peristaltic pump for tire pressure adjustment

InactiveCN101495331AEasy to modifyComplete structureTyre beadsTyre measurementsPeristaltic pumpTire bead

A chamber (1) that works as a peristaltic pump for the pressure correction in the tire (4), which is a part of the tire (4) or of an ancillary structure (6) placed between the rim (7) and the tire bead (4) and is connected with the tire (4) internal space at one end and with the external environment at the other end. The chamber (1) is in the shape of a curved hollow channel, where at least one enclosing wall is at least partially formed by at least a pair of surfaces (10) coplanar with the longitudinal direction of the chamber (1). When the tire is mounted on the rim, the pair of surfaces (10) are pressed together thus hermetically closing the chamber (1). When the chamber (1) is closed during rotation of the wheel, the surfaces (10) can slightly slide on one another taking internal wall tensions onto themselves thus decreasing the possibility of wall damage through ripping. A method of producing the chamber (1) is also disclosed.

Owner:哥达发展公司

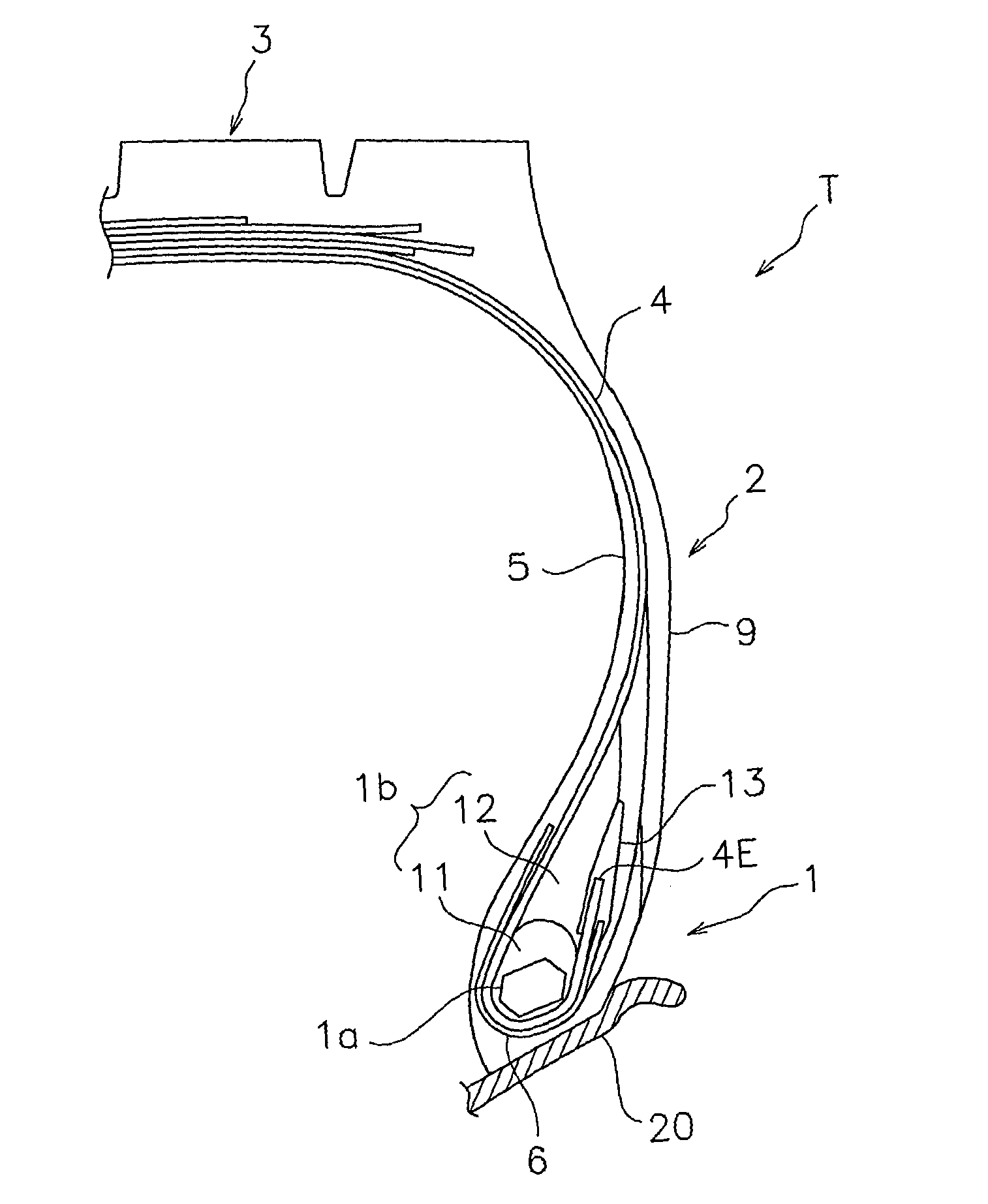

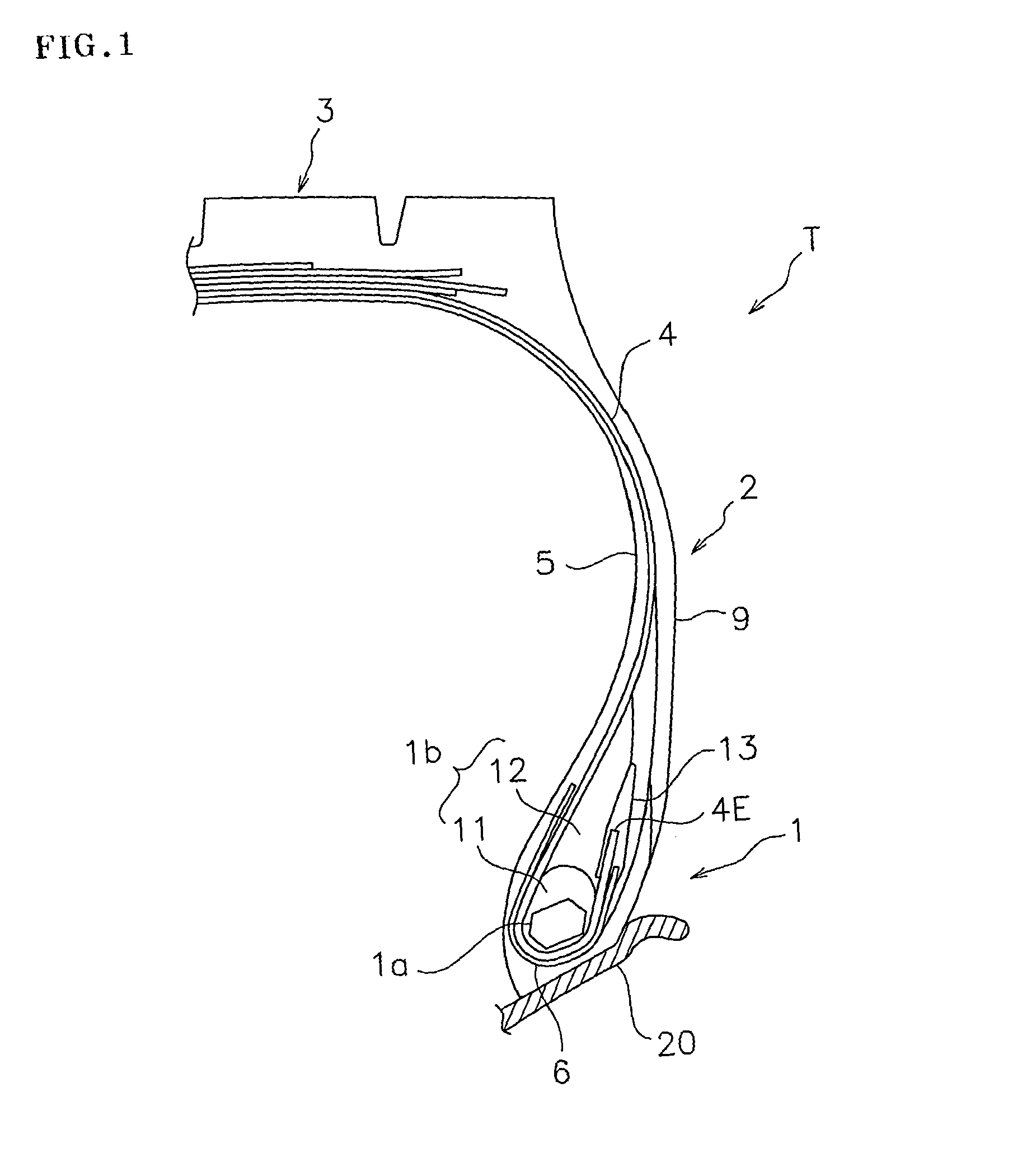

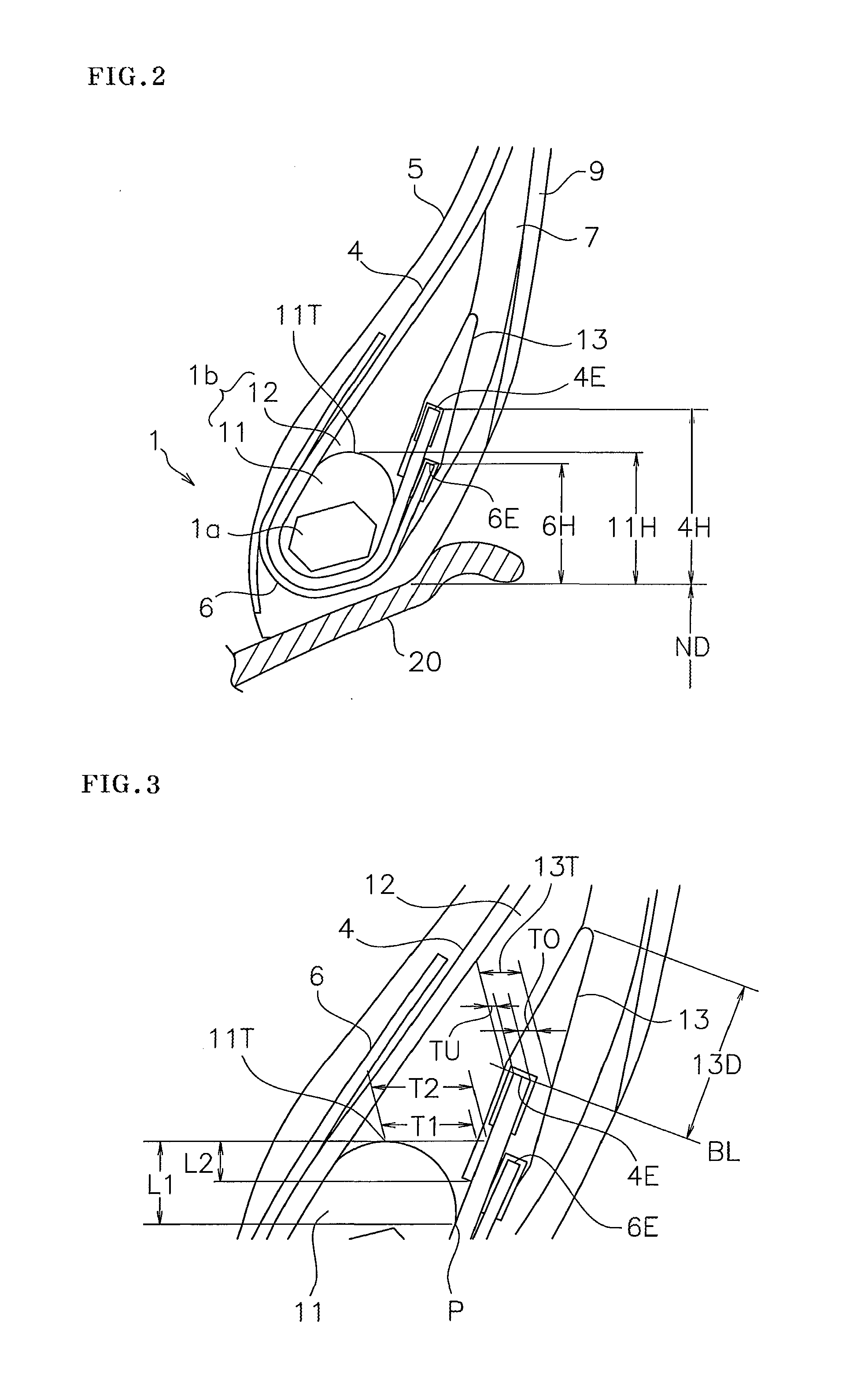

Tire Manufacturing Method, Preset Bead Molding Apparatus, and Preset Bead Molding

There is provided a method of tire manufacturing a tire in which preset-beads each preformed by mounting a bead filler on a bead core are disposed radially outward of a carcass band and both side portions of the carcass band are turned around the preset beads to build the tire. The method eliminates a need to bold the considerable intermediate stocks and does not deteriorate the tire uniformity due to the unevenness of the preset bead in the circumference direction. There are also provided an apparatus of forming a preset bead used therefore and a system of forming a preset bead. In the method of manufacturing a tire in which preset-beads each preformed by mounting a bead filler on a bead core are disposed radially outward of a carcass band and both side portions of the carcass band are turned around the preset beads to build the tire, the preset bead is formed by winding and laminating a ribbon-shaped filler rubber 5 radially outward of the bead core 10 over several laps.

Owner:BRIDGESTONE CORP

Tire with sidewall rubber insert

InactiveUS6539996B1High modulusEnhanced interactionPaper coatingSpecial tyresTire beadPolymer science

A pneumatic tire has a sidewall rubber insert axially inward of at least one carcass ply. Such insert may, for example, be an apex extending radially outward from the bead core region of the tire into the sidewall. Alternatively, it may be positioned higher in the sidewall portion of the tire and away from the bead core. Such insert is a rubber composition containg a dispersion of an ultra high molecular weight polyethylene and a dispersion of a starch composite.

Owner:THE GOODYEAR TIRE & RUBBER CO

Tyre for vehicle wheels

ActiveUS20150314644A1Low toxicityCosmetic preparationsWithout separate inflatable insertsElastomerTire bead

Tyres for vehicle wheels having reduced environmental impact and the components thereof, in particular reinforcing structural elements such as carcass structures, belt structures, flippers and chafers, include elongated reinforcing elements treated with resorcinol and formaldehyde-free cross-linkable adhesive compositions. The adhesive compositions include at least a) a rubber latex, at least b) an epoxide and at least c) a polyamine with molecular weight higher than 190 Daltons, including at least two amino groups selected from primary —NH2 and secondary —NH— amino groups. In the structural element, these compositions confer an adhesion between cords and compounds that is comparable to, if not better than, the traditional RFL system in use in this sector. Furthermore, by suitably modifying the compound compositions in the reinforced structural elements and, possibly, also in the other elastomeric components of the tyre, it is possible to manufacture tyres while avoiding the use of toxic chemicals, such, as resorcinol and formaldehyde.

Owner:PIRELLI TYRE SPA

Inflatable tire

InactiveCN104002618AInhibition of soakingAvoid wear and tearWithout separate inflatable insertsPneumatic tyre reinforcementsTire beadRubber sheet

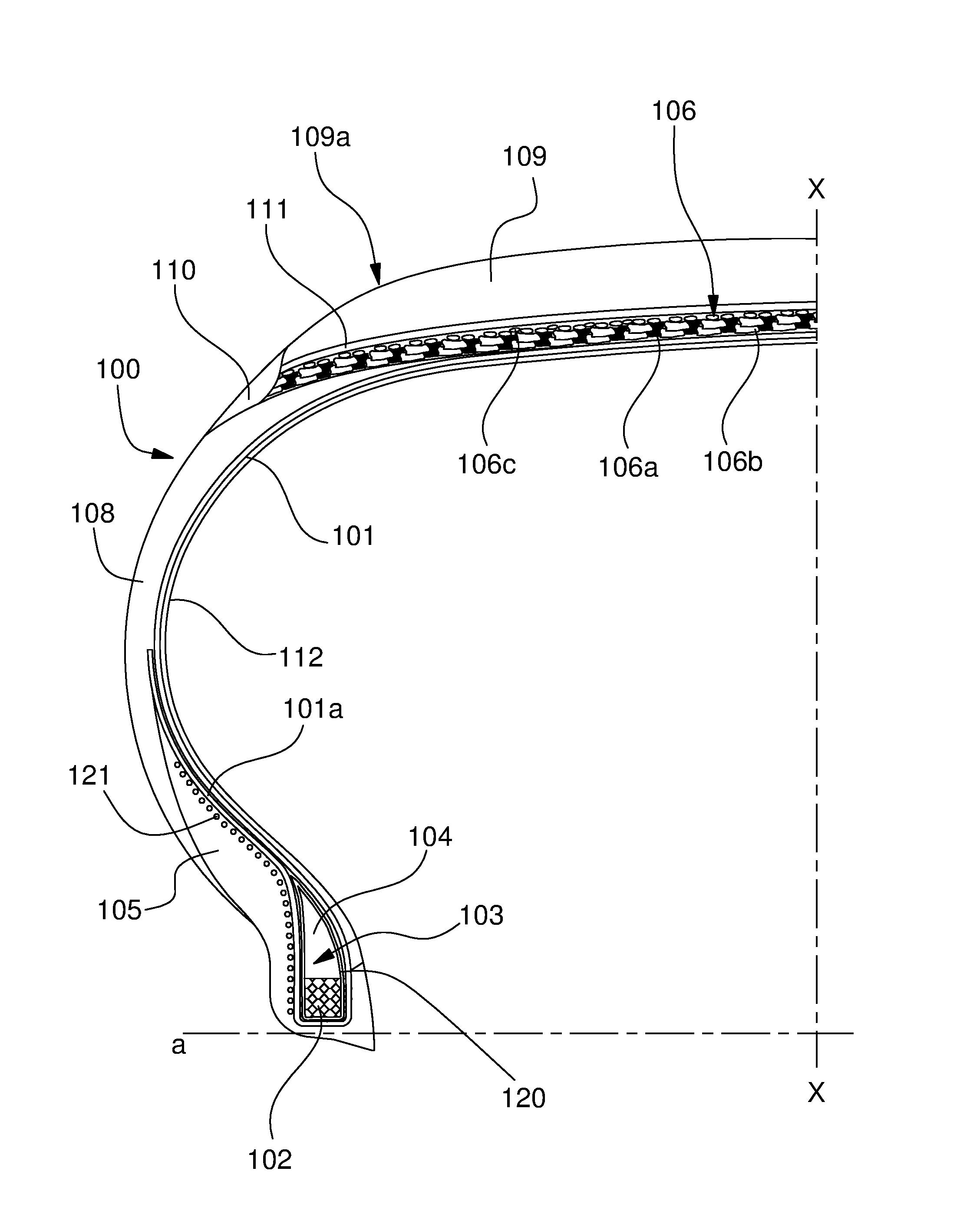

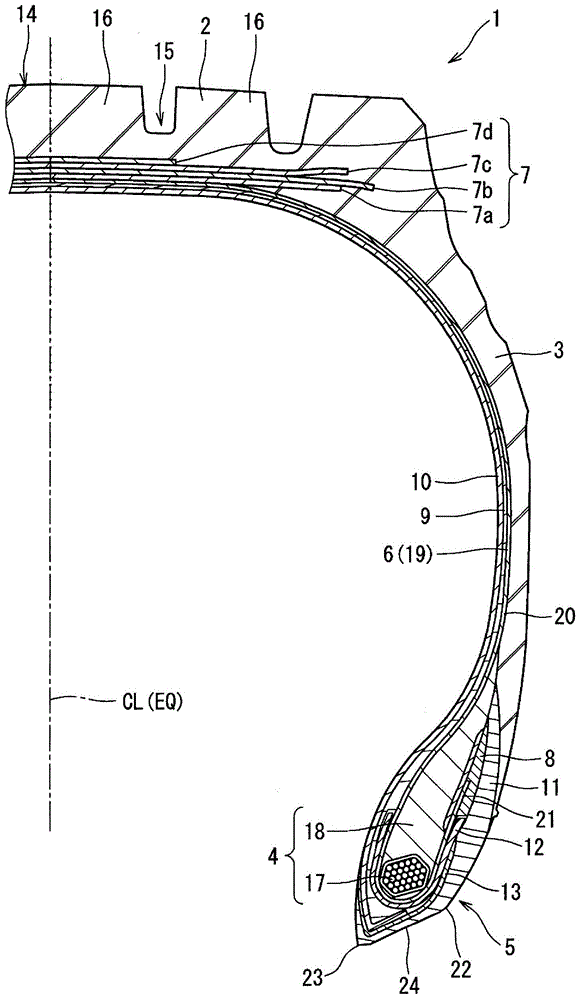

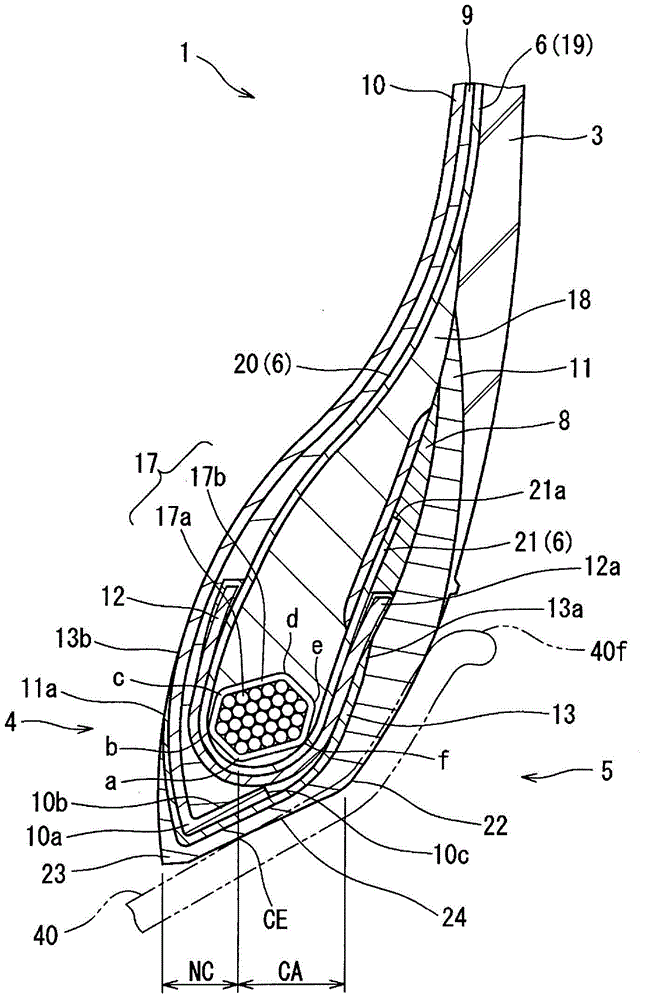

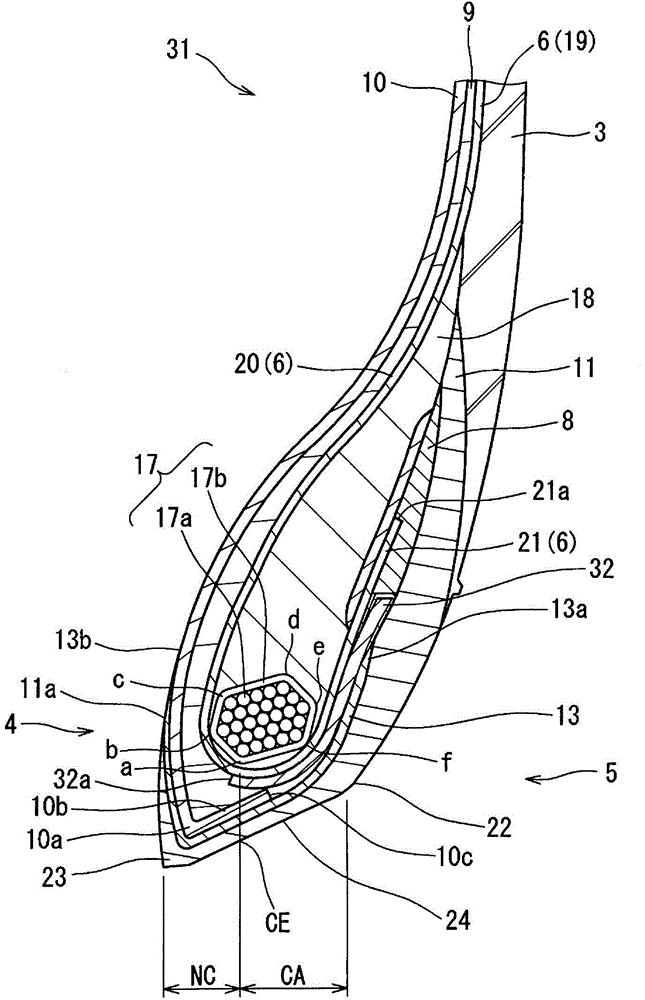

The invention provides an inflatable tire which can suppress water entering a tire bead core. The inflatable tire (1) comprises a tire bead part (4) provided with the annular tire bead core (17) along the circumference of the tire. The inflatable tire further comprises an inner lining (10), a tire bead wrapping rubber (11), a tire bead basal part (24) and a rubber sheet (13) clamped between the inner lining (10) and the tire bead wrapping rubber (11). In a tire (1) cross section including a central shaft plane, the end part (10c) of the inner lining (10) is located on a position closer to the tire axial outer side than the end part position (CE) of an embedding area (CP). The embedding area (CP) is in close connection with a tire rim (40) of the tire bead basal part (24). The thickness of the inner lining (10) at least on the embedding area is over 1.0mm.

Owner:SUMITOMO RUBBER IND LTD

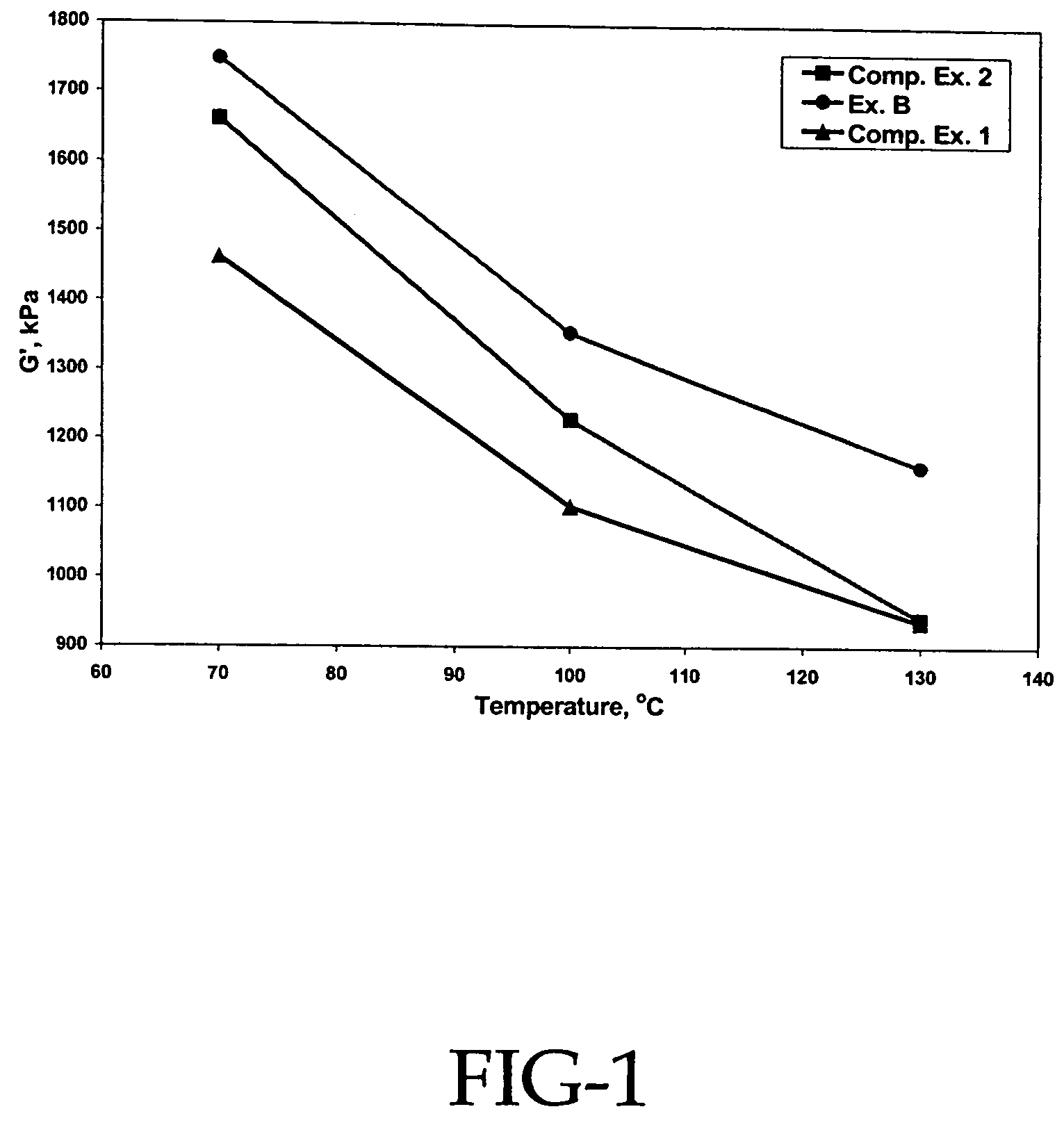

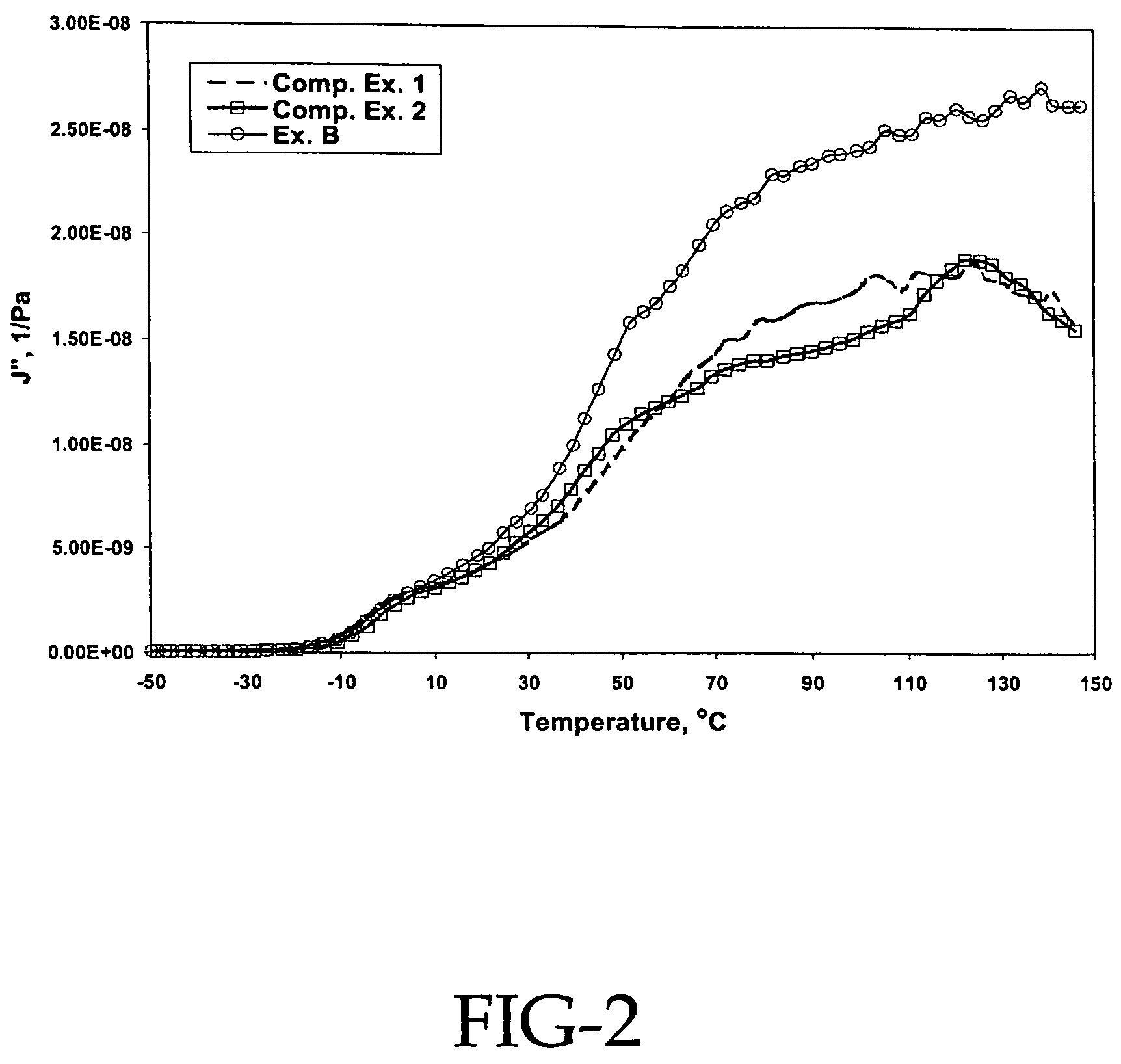

Pneumatic tire

InactiveUS20060272760A1Increased durabilitySacrificing rolling resistance and ride comfortSpecial tyresPneumatic tyre reinforcementsDynamic storageMeridional direction

A pneumatic tire which comprises a pair of right and left bead portions, a carcass layer disposed extending between the bead portions, a tread portion arranged at an outside of the carcass layer in a radial direction of the tire, a pair of side wall portions arranged at right and left sides of the tread portion and at least one pair of rubber members selected from a pair of rubber members constituted with a rigid rubber and arranged in the bead portions and a pair of rubber members disposed in the side wall portions, wherein at least one pair of rubber members selected from a pair of rubber members arranged in the bead portions and a pair of rubber members disposed in the side wall portions are constituted with rubber composition having a minimum value of a dynamic storage modulus within a temperature range of 200 to 250° C. which is 75% of a dynamic storage modulus at 50° C. or more.

Owner:BRIDGESTONE CORP

Pneumatic radial tire

InactiveUS20120318427A1Increased durabilityAvoid separationHeavy duty tyresHeavy duty vehicleTire beadPolymer science

A pneumatic radial tire has a rubber filler includes a lower filler and an upper filler. The lower filler surrounds a bead core and has a round cross sectional shape. The upper filler has a lower rubber hardness than the lower filler. A chafer is wound up around the bead core outside of a carcass ply and includes a metal cord. A wound-up end of the carcass ply is arranged radially outside of an upper end of the lower filler and a wound-up end of the chafer. A rubber pad has a higher rubber hardness than the upper filler and sandwiches the wound-up end of the carcass ply. The rubber pad extends to radially inside of the upper end of the lower filler and contacts with an inside of a wound-up portion of the carcass ply.

Owner:TOYO TIRE & RUBBER CO LTD

Three-drum forming method of full steel wire loading radial tire via one-time method

ActiveCN102371696AAchieve precise positioningIncrease the level of automationTyresTire beadMechanical engineering

The invention relates to a three-drum forming method of a full steel wire loading radial tire via a one-time method, belonging to the manufacturing technical field of a tire. A tire bead is located by a magnet absorption ring, a tire cord joint adopts an automatic seaming type joint, an inclined angle between an lining layer / a tire-side composite component joint and a tire cord is more than or equal to 6 degrees, the joint adopts automatic lamination, and weighing control of each tire blank is implemented by adopting a device which repairs the tire in the front and dismounts the tire at the back for a material feeding frame. In such a forming process, an automatic level and production efficiency of the forming are improved, a labor intensity of operators and a quality defect caused by human factors are reduced, a forming storage space and a transportation line are optimized, and the quality and the cost control level of products are improved.

Owner:TRIANGLE TIRE

Truck tire

The truck tire of the invention allows the endurance of an ordianry tire not to be damaged and helps to improve the wearing resistance. A tire bead is provided with a first tire bead reinforcing cord layer, a second tire bead reinforcing cord layer and an anti-wearing rubber layer. The first tire bead reinforcing cord layer is U-shaped for connecting an internal portion and an external portion via a bottom portion, wherein the internal portion is arranged along the internal side of the cord main body of a tire body, and the external portion is arranged along the external side of the cord returning portion of the tire body. From an internal end clamped between the internal portion and the cord main body, the second tire bead reinforcing cord layer extends toward an radial external side beyond the internal portion along the cord main body. The anti-wearing rubber layer comprises a rubber sheet which is 0.5-1.5mm in thickness, has a complex modulus of 6.0-10.0MPa, and is arranged between a tire body cord and a tire bead core along the tire body cord. The difference between the height of the external end of the second tire bead reinforcing cord layer and the height of the external end of the cord returning portion is 5-25mm. The difference between the height of the external end of the internal portion and the height of the internal end of the second tire bead reinforcing cord layer is 10-40mm.

Owner:SUMITOMO RUBBER IND LTD

Self-supporting pneumatic tire

InactiveUS7093633B2Ride comfort is improvedIncreased durabilityWithout separate inflatable insertsRimsStrain energyEngineering

A self-supporting pneumatic tire is molded in such a manner that ride comfort is improved, durability is increased, and a greater run-flat capability can be achieved. The self-supporting run-flat tire is molded such that the molded bead base width is equal or less than the rim width of the intended rim upon which the tire is to be mounted. By molding the tire with a bead width less than or equal to the rim width, the sidewall inserts are not subjected to additional stress during and after inflation of the tire and the strain energy is more evenly distributed through the sidewall pillar construction.

Owner:THE GOODYEAR TIRE & RUBBER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com