A chamber of a peristaltic pump for tire pressure adjustment

A tire and memory technology, applied in the field of shape memory cavity, can solve the problems that cannot be basically corrected, cannot be manufactured, and the components of a single cavity are difficult to combine with each other, and achieve the effect of cheap technical modification and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

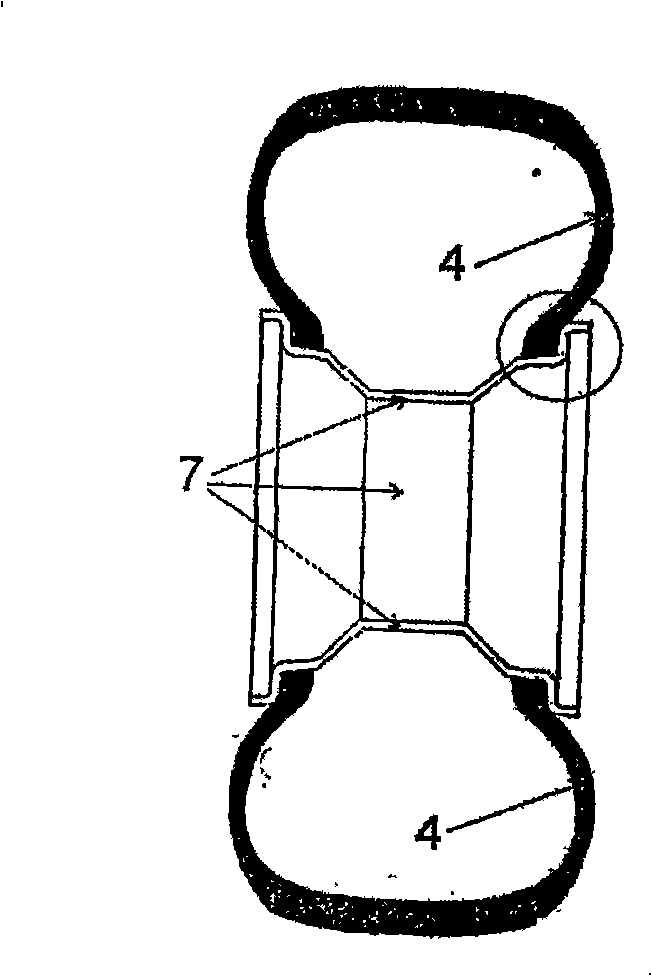

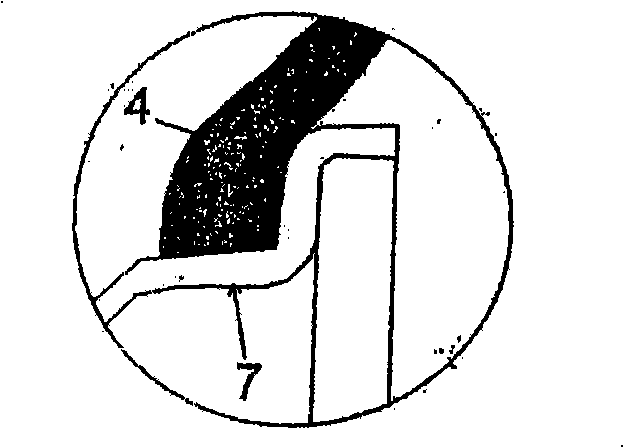

[0046] The shape memory cavity 1 for adjusting the pressure inside the tire is a part of the tire or is arranged near the outer wall of the tire. One end of the cavity is connected to the inner cavity of the tire, and the other end is connected to the outside. Its shape is a curved hollow pipe, and its outer wall The part consists of a pair of surfaces 10 coplanar with the chamber 1 (pipe) longitudinally and at an angle α = 2 to 15°. The included angle α>0° is located on the side where these surfaces 10 intersect, and is set on the side farther from the center of the cross-section of the cavity 1 . The cavity 1 is located in the region of the tire sidewall 4 of the bead of the tire.

[0047] When manufacturing the chamber 1, a flat substrate 9, which has a protrusion and is 0.8 mm wide and 0.22 mm thick, is inserted between the layers of glue constituting the sidewall 4 of the tire before vulcanization, after which the inserted substrate 9 is taken out as a whole in the direc...

Embodiment 2

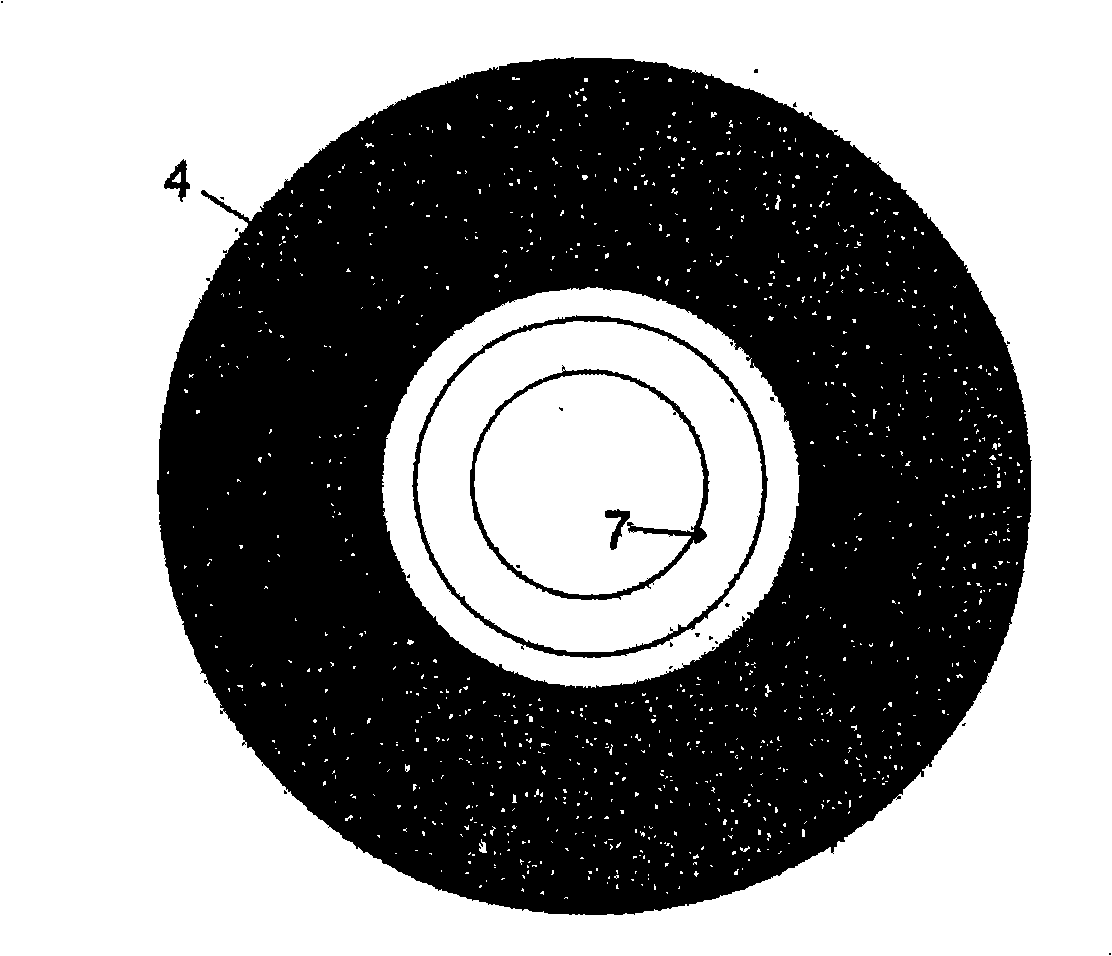

[0056] Figure 3a An auxiliary structure 6 is shown containing a cavity 1 with a three-pointed star shape in cross-section. This part of the cavity 1 is located on the outer sidewall of the tire 4 above the bead of the tire 4 and the hub 7 . The tire 4 is not shown here, the chamber 1 is shown in an unloaded state. There is an acute angle α on the surface 10 of the outer wall forming one of the corners. This acute angle will ensure the airtightness of the outer walls constituting the cavity 1 when the cavity 1 is deformed, the side walls are subject to minimal bending and tension, which will reduce the combined tension and material pressure on the outer walls of the cavity 1 . Figure 3b The cross-section through the chamber 1 is shown in the loaded state, and the outer walls of the chamber 1 are pressed against each other at the load point, so that the chamber 1 disappears and assumes a state of zero cross-sectional area. The direction of deformation caused by compression ...

Embodiment 3

[0062] The base body 9 is pressed between the outer walls of the cavity 1, and then the base body 9 is taken out, so that the cavity 1 is processed. The surfaces 10 extend themselves out of the cavity 1 with zero angle between the surfaces 10 so that the base body 9 can be easily removed when the cavity 1 is being processed.

[0063] Figure 3d The manufacture of a circular cavity 1 is shown. The part-circular base body 9 is pressed into the material of the future chamber 1 ; it extends beyond the circular cross-section of the chamber 1 and leads out of the auxiliary structure 6 . After compaction, this extension will extend the parallel surface 10 through the outer wall of the cavity 1 all the way to the outside of the auxiliary structure 6 . This creates a channel for removing the pressed-in base body 9 . The removal of the matrix 9 is done in Figure 3e shown in .

[0064] After mounting the auxiliary structure 6 and the tire 4 on the hub 7, these extended surfaces 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com