Patents

Literature

2442results about "Tyre beads" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

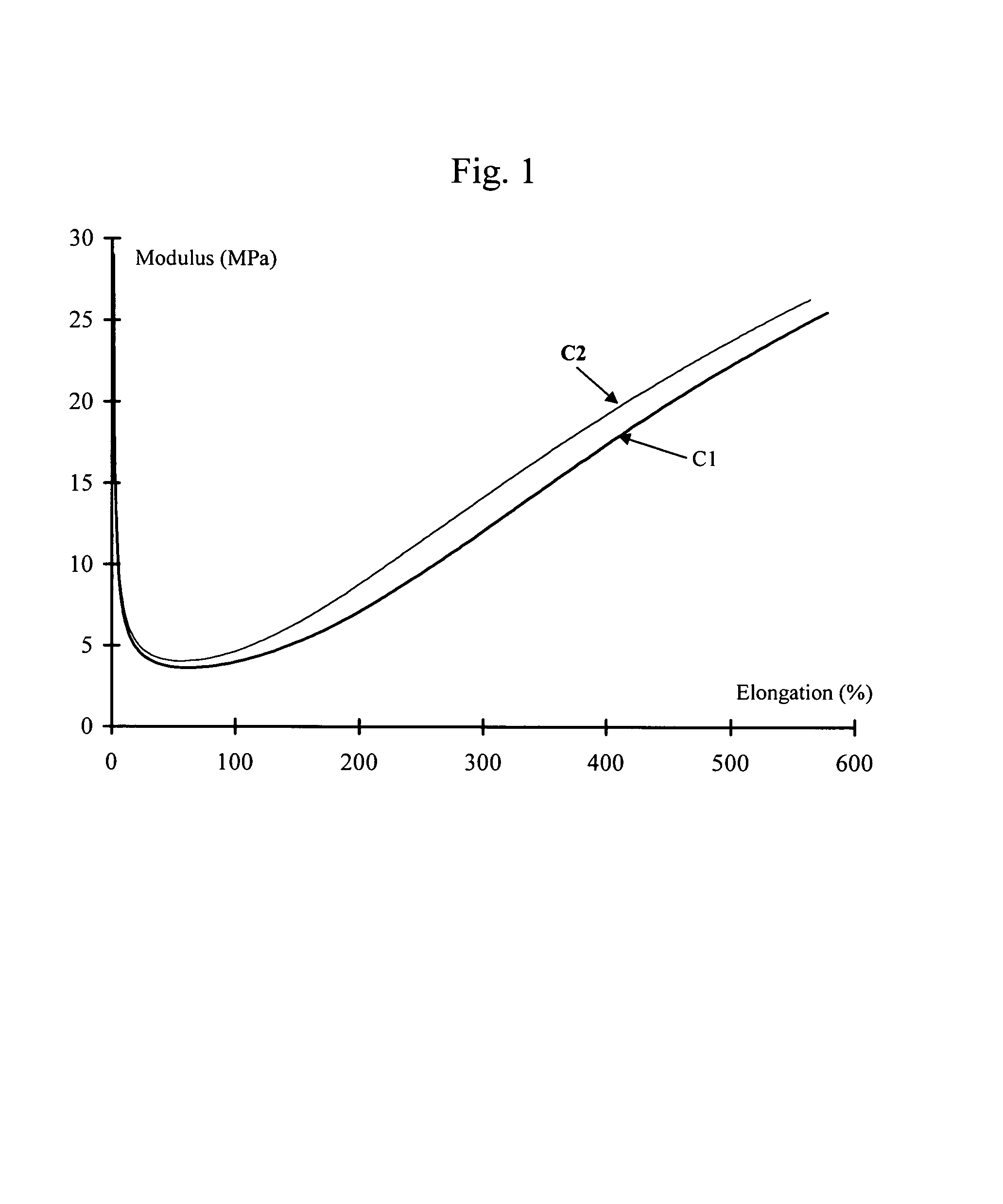

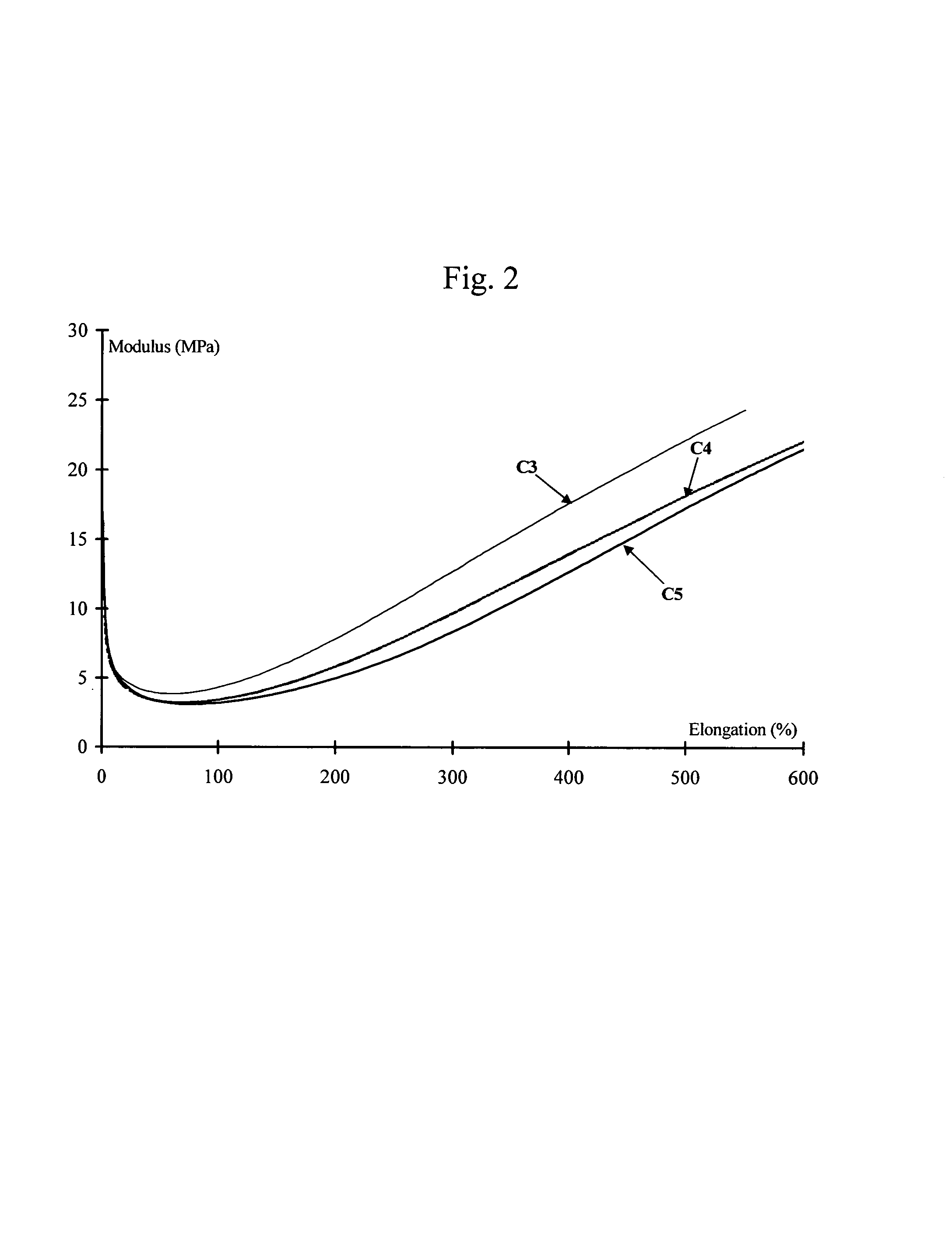

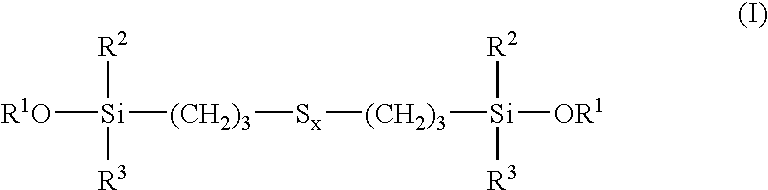

Tire and tread comprising a bis-alkoxysilane tetrasulfide as coupling agent

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

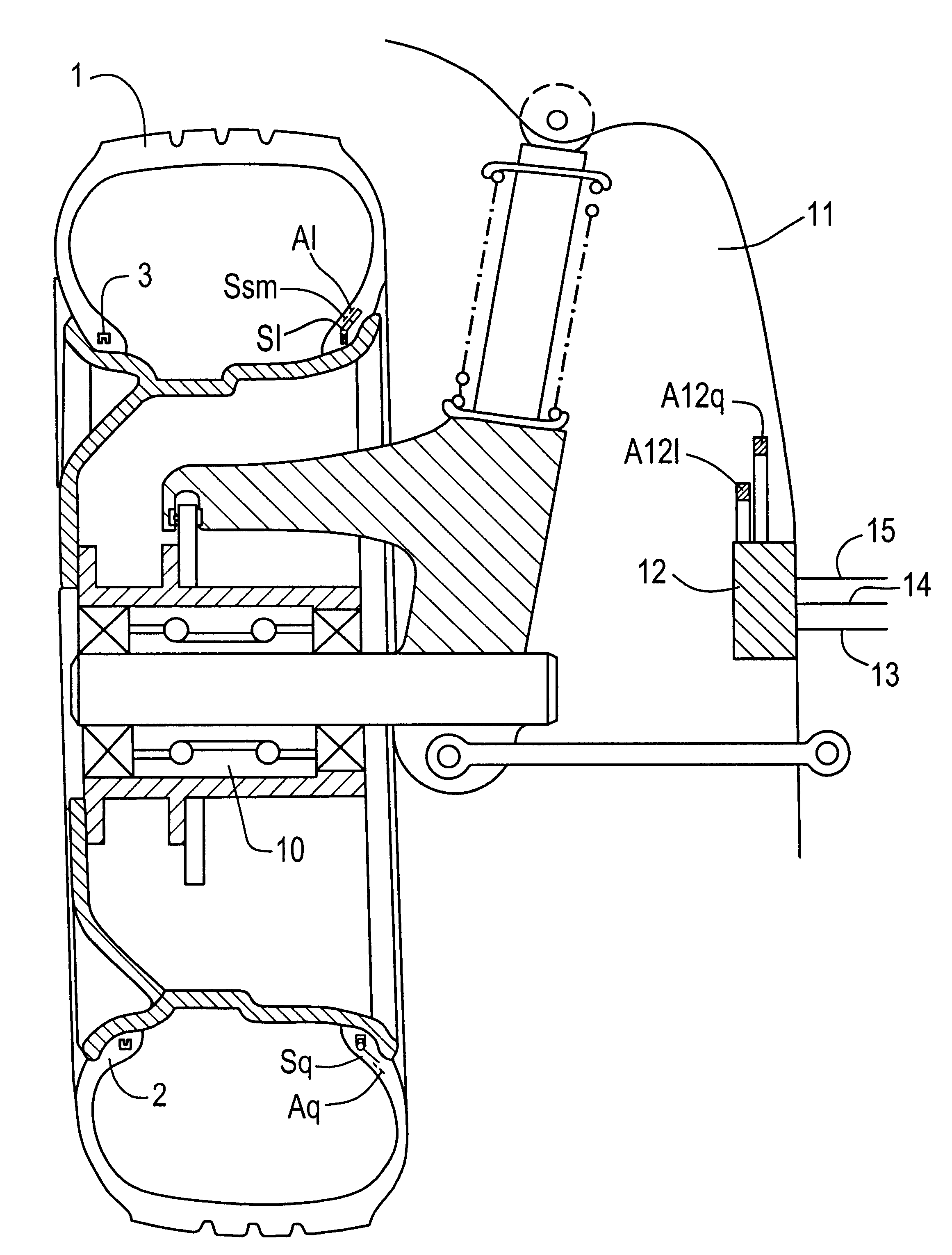

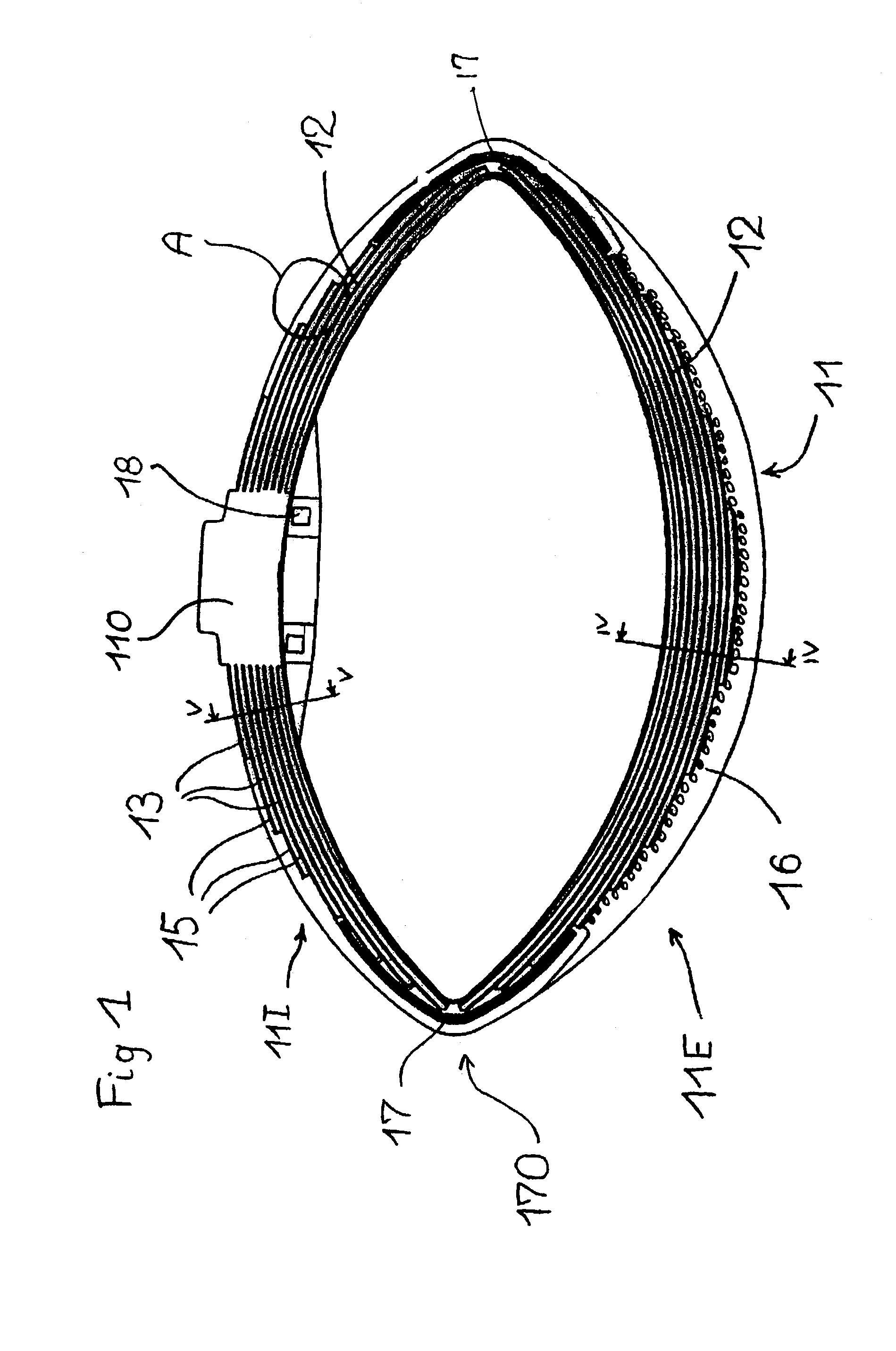

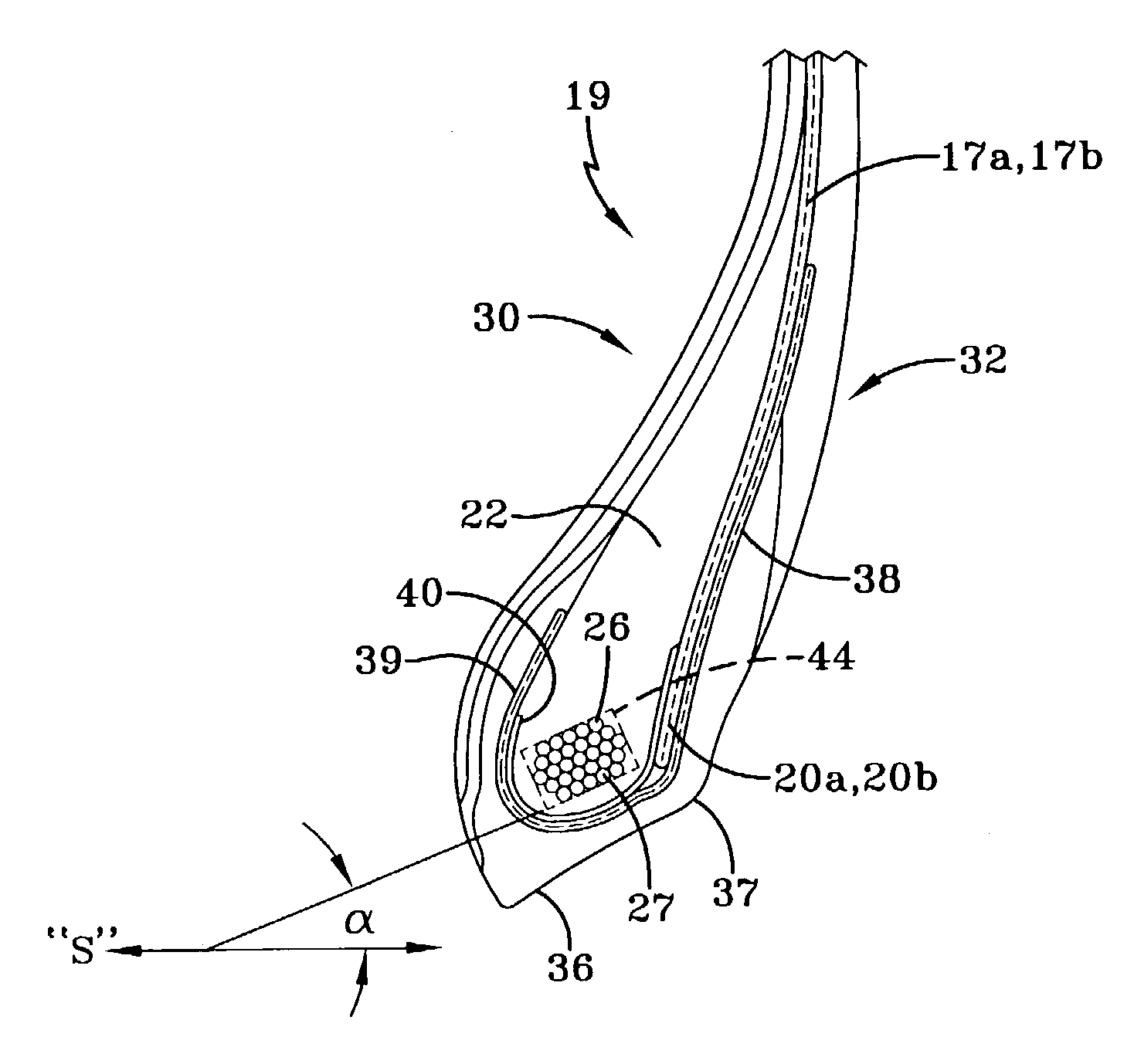

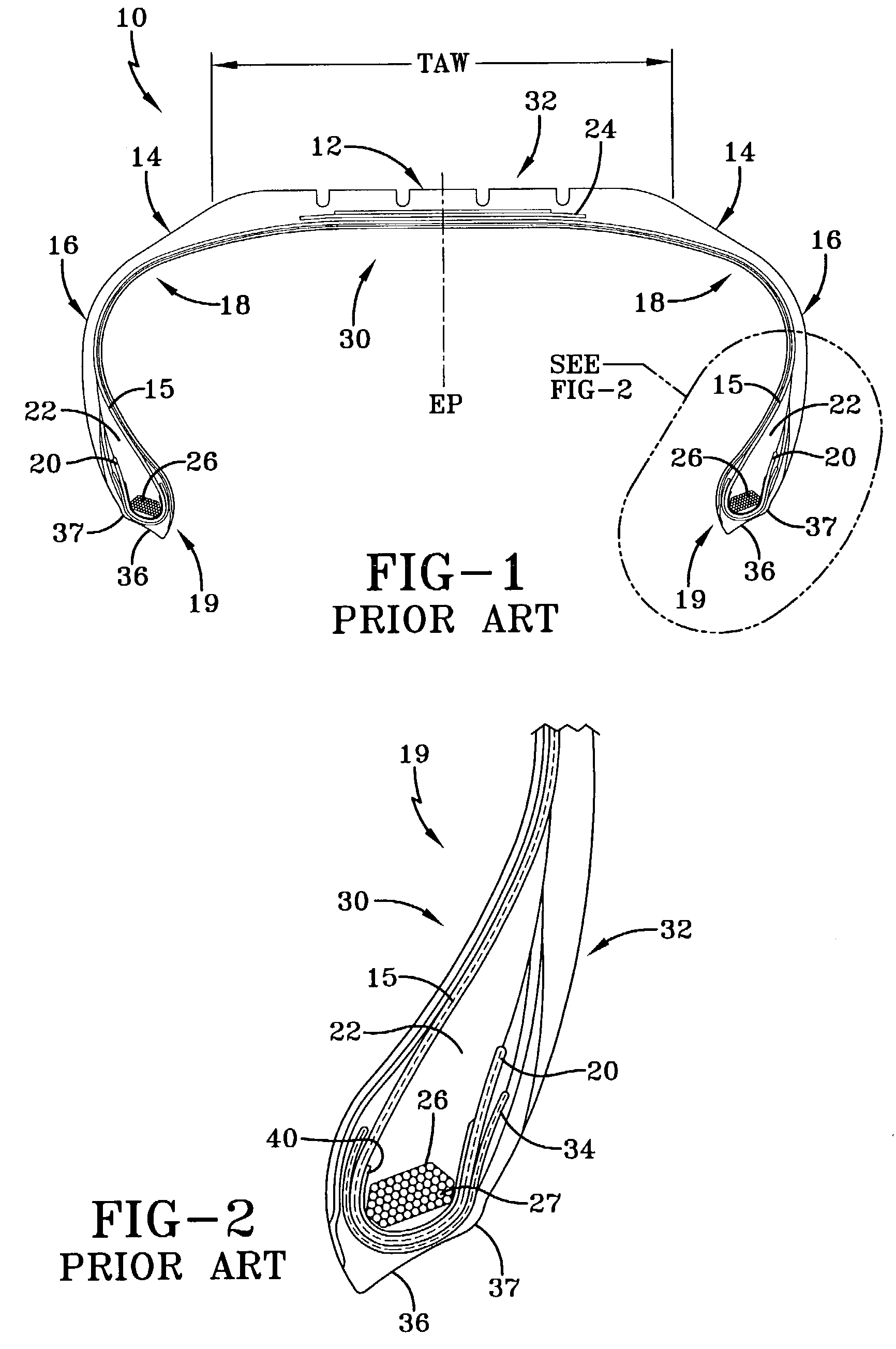

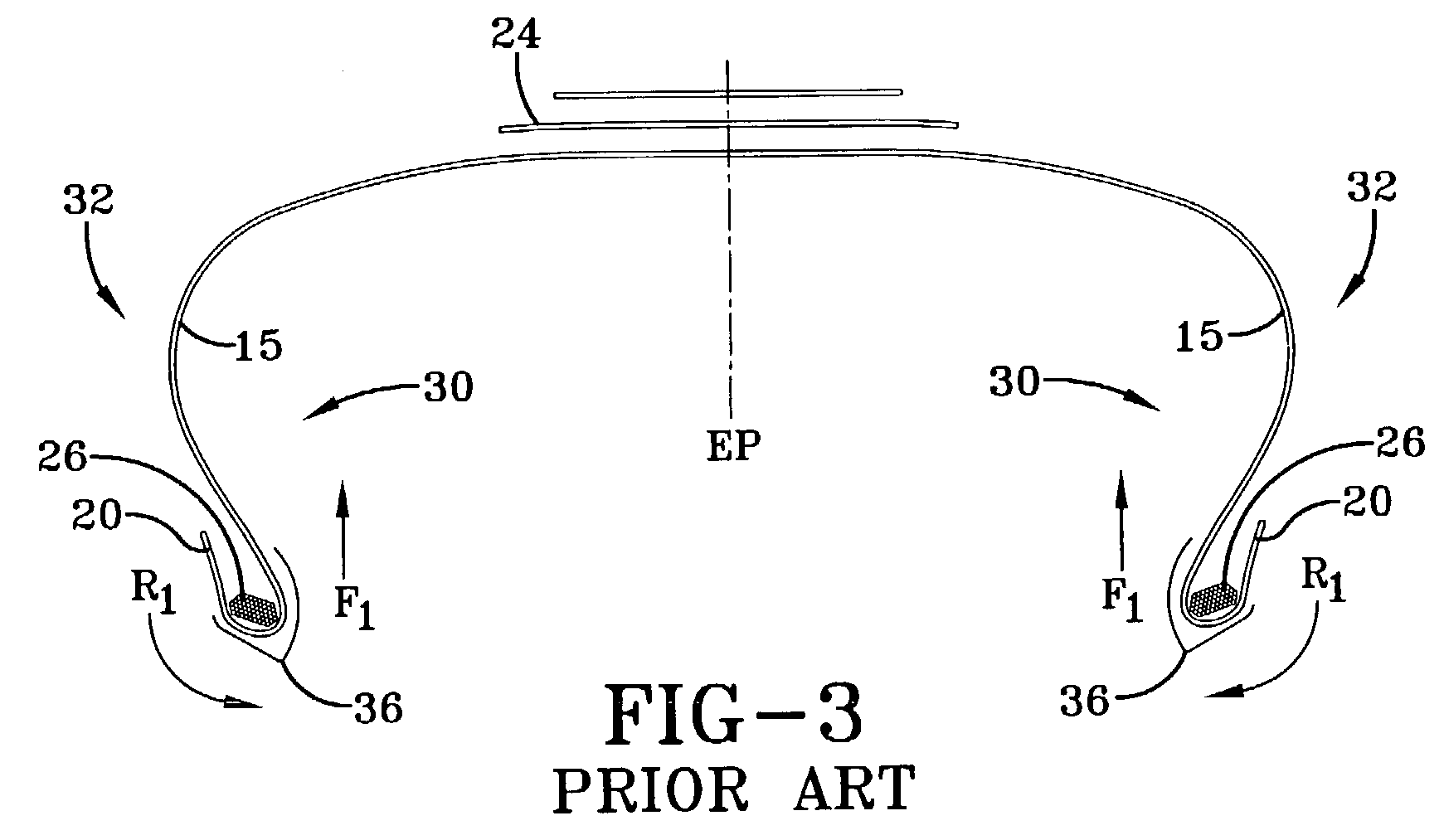

Pneumatic automobile tire with integrated sensors and traction control system

InactiveUS6339956B1Complicates of longitudinal forceReduce brake pressureForce measurement using piezo-electric devicesTyre beadsTire beadTraction control system

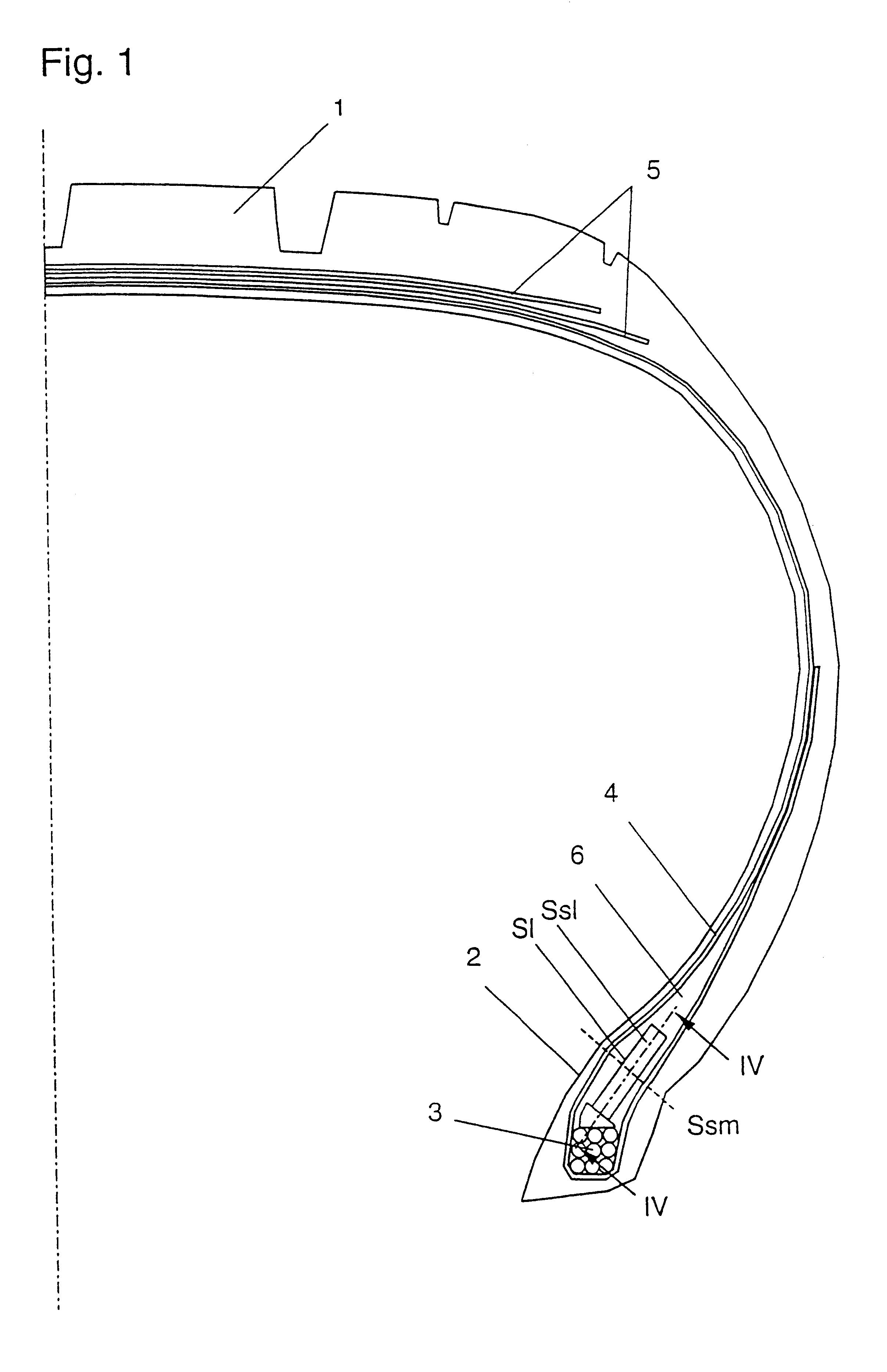

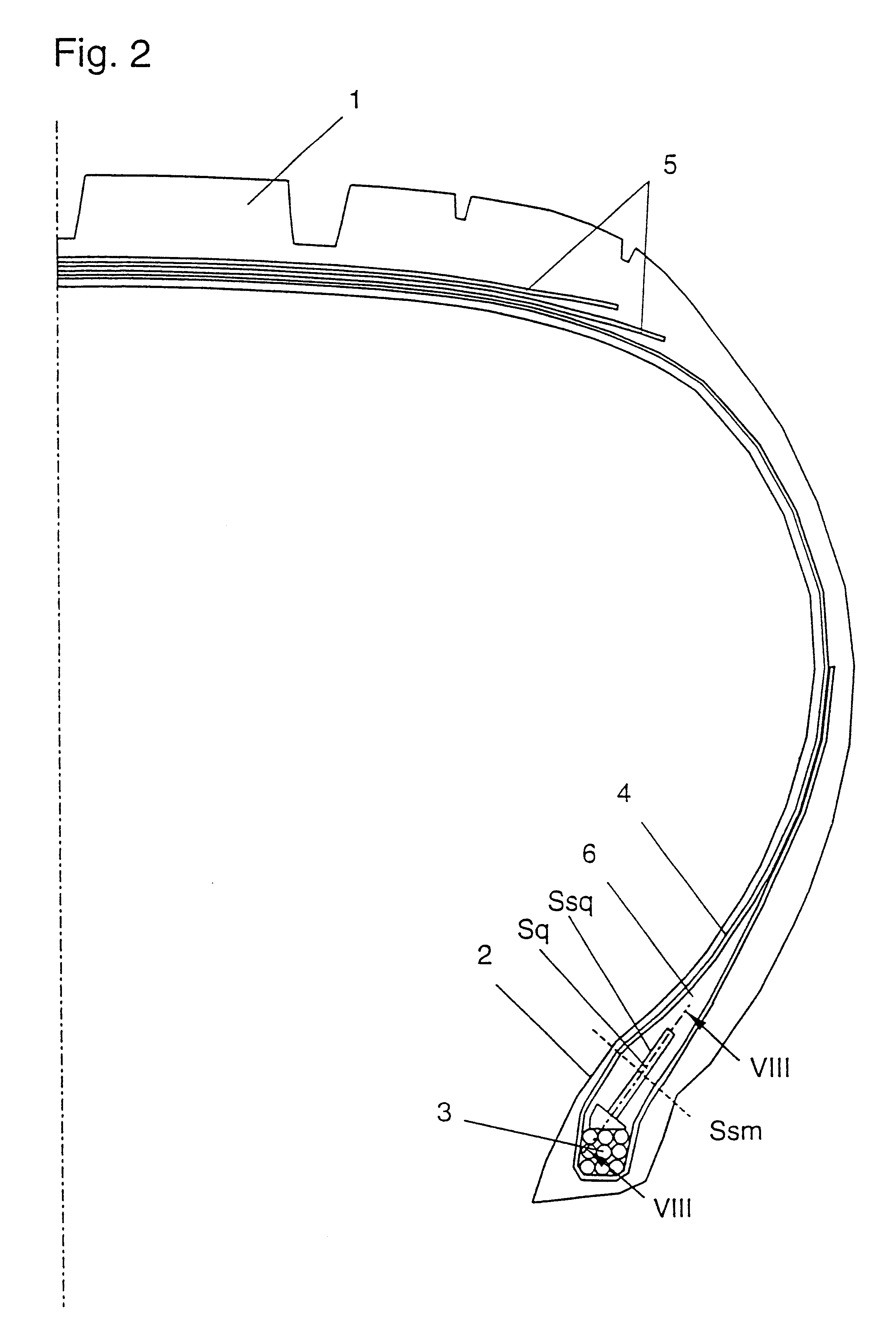

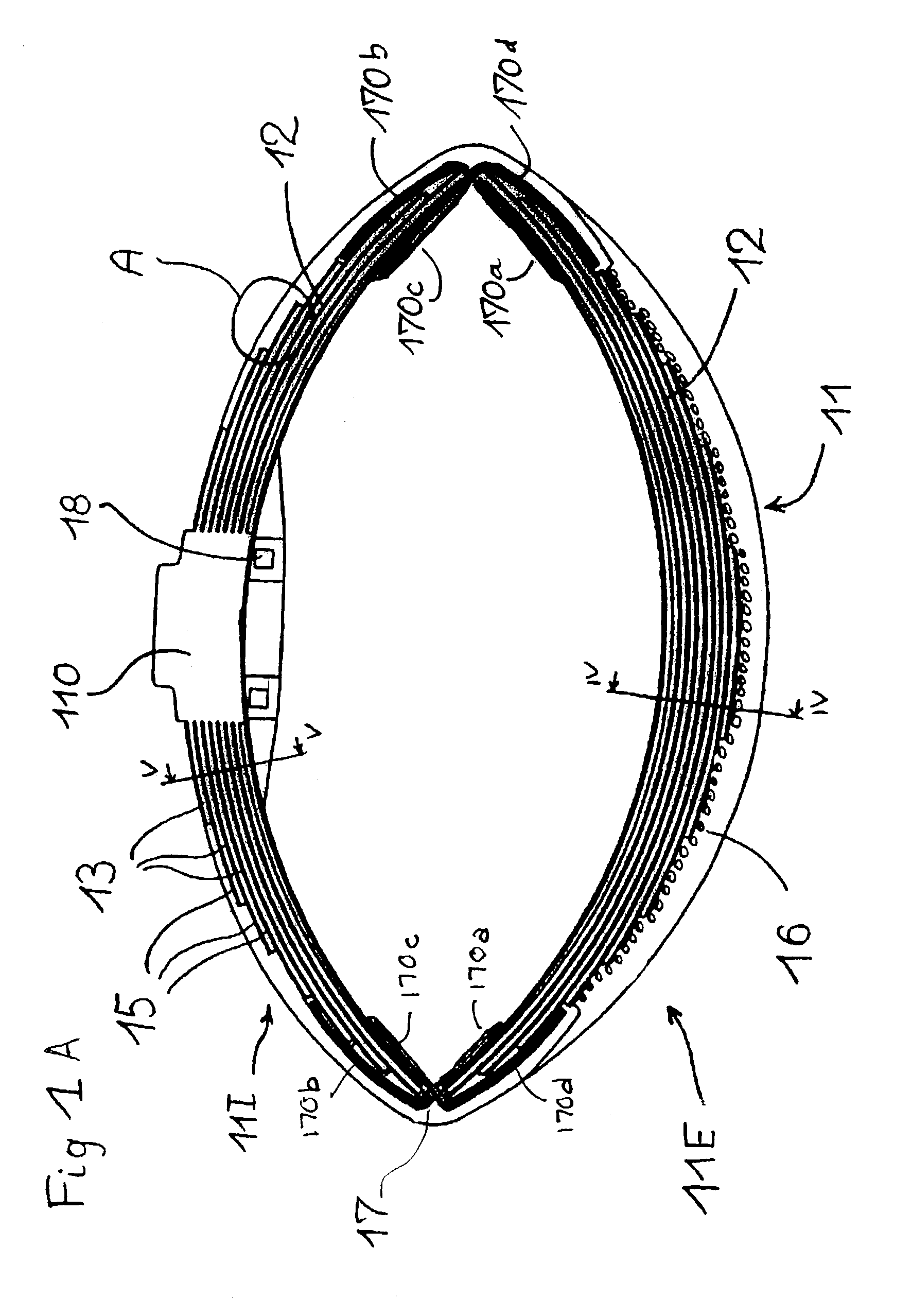

A pneumatic vehicle tire includes a carcass, a bead with a bead core arranged in the bead, and a first sensor located within the bead. The first sensor delivers signals which are correlated to frictional forces transmitted by the pneumatic vehicle tire during operation. This sensor has a first end and a second end, wherein the first end includes a heel attached to the bead core and the second end extends radially outward from the bead core within the tire. A plurality of such sensors can be included in each tire, some for measuring longitudinal forces in a circumferential direction of the tire and others for measuring lateral forces in an axial direction of the tire.

Owner:CONTINENTAL AG

Rubber composition based on diene elastomer and a reinforcing silicon carbide

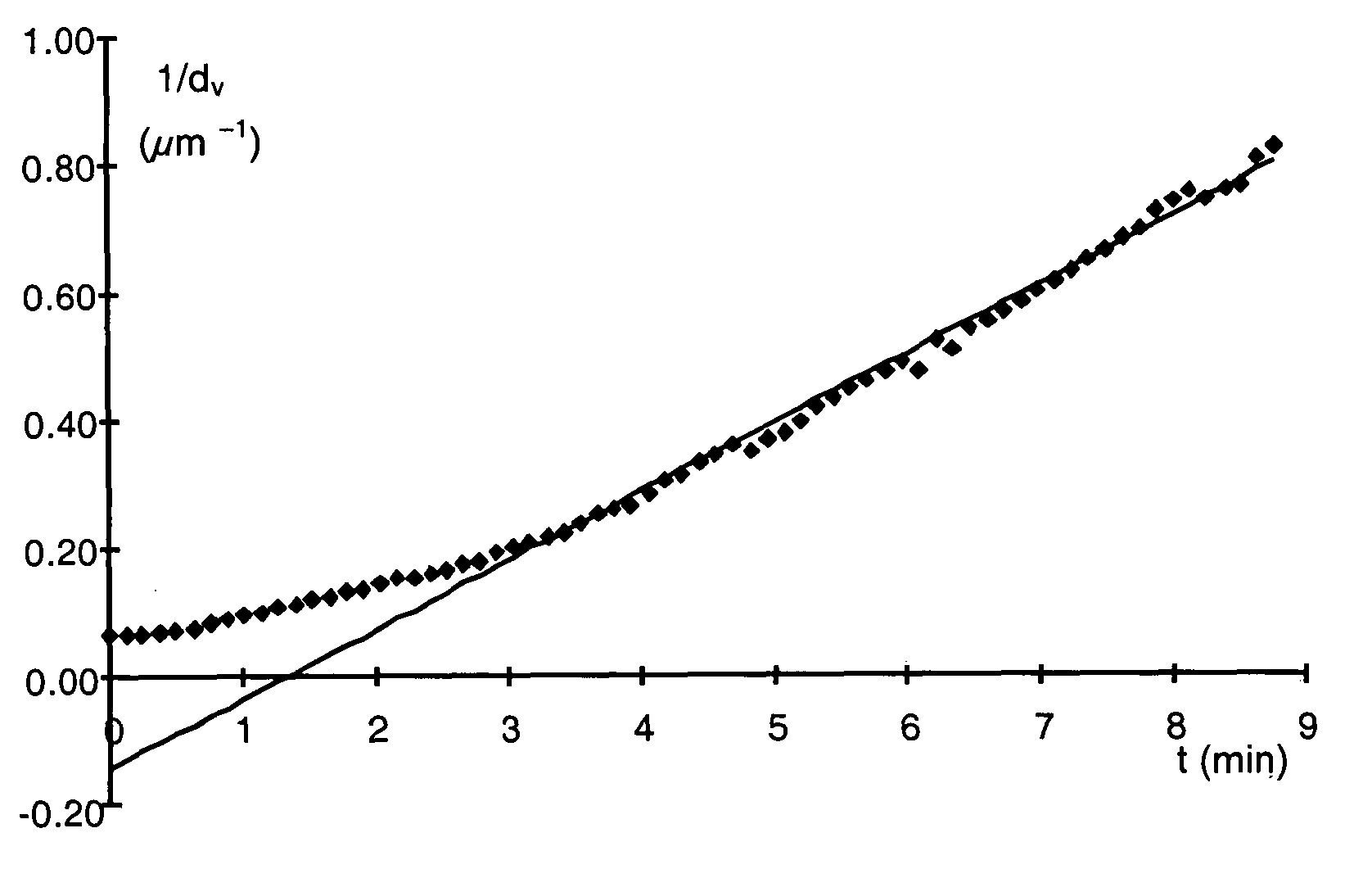

InactiveUS20040030017A1Improve homogeneityReduce consumptionSpecial tyresTyre beadsElastomerPolymer science

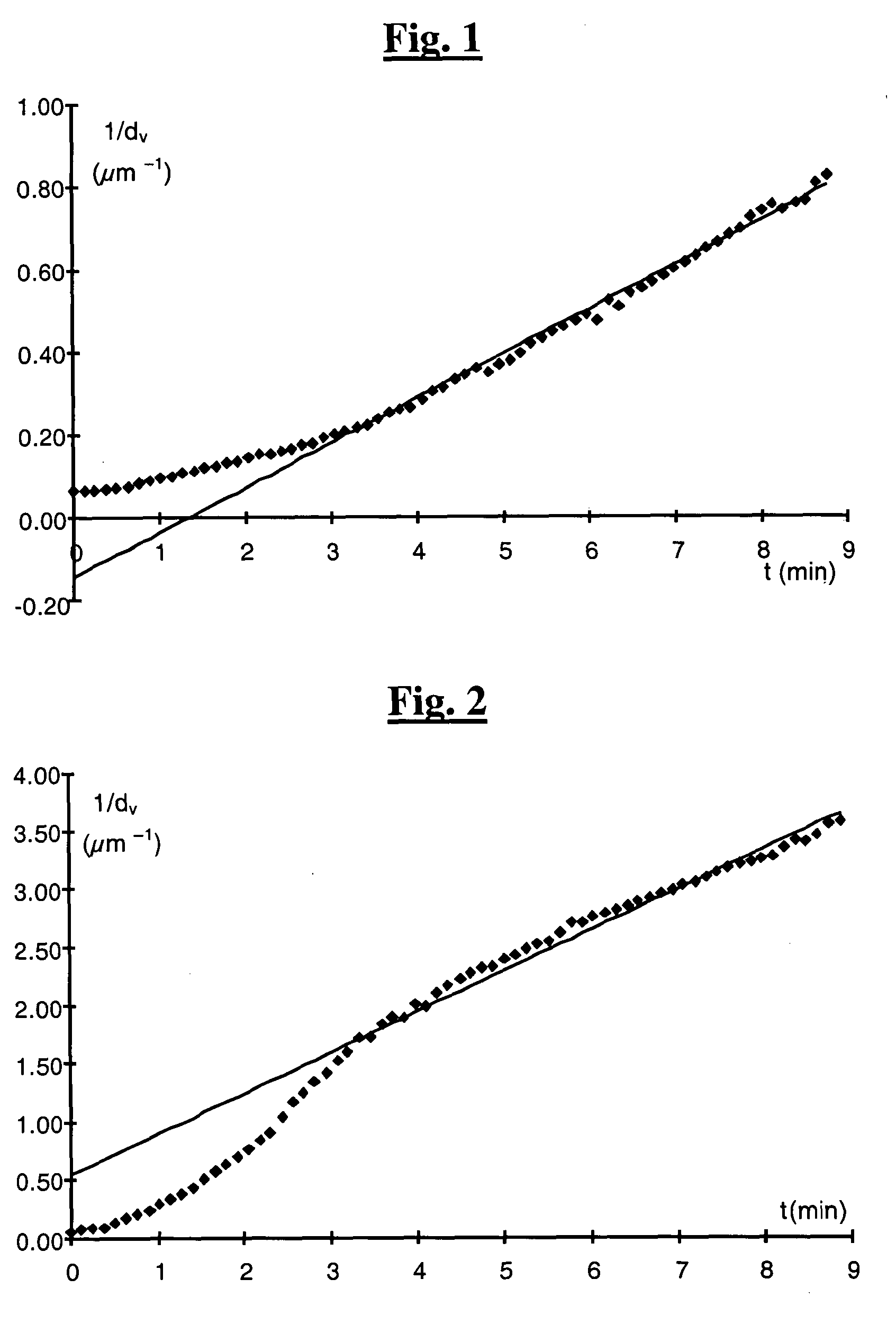

A rubber composition usable for the manufacture of tires, based on at least one diene elastomer, a reinforcing inorganic filler and a coupling agent providing the bond between the inorganic filler and the elastomer, wherein said inorganic filler comprises a silicon carbide having the following characteristics: (a) a BET specific surface area of between 20 and 200 m<2> / g; (b) an average particle size (by mass), dw, of between 10 and 350 nm. Tires or semi-finished products for tires such as treads comprising said rubber composition.

Owner:MICHELIN RECH & TECH SA

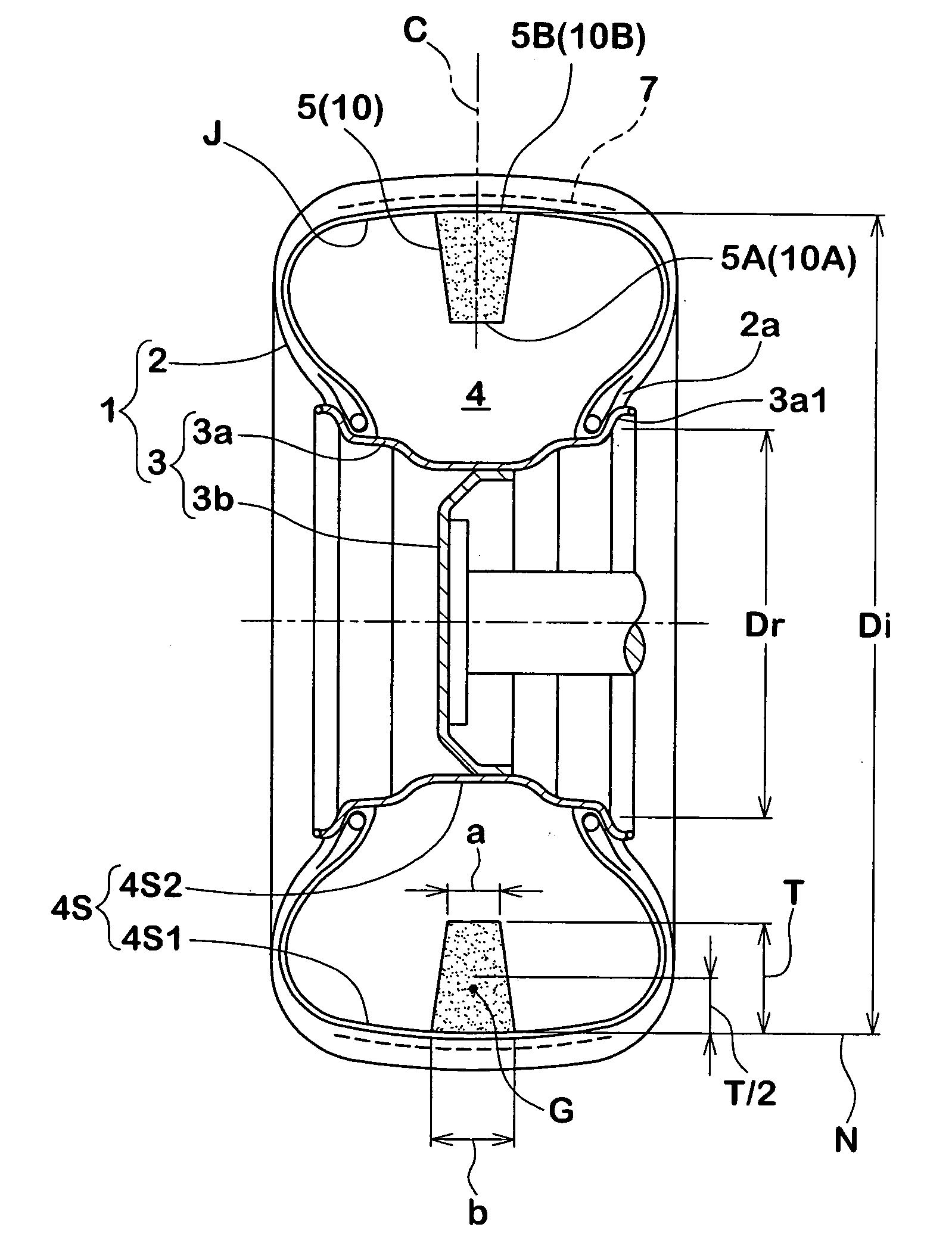

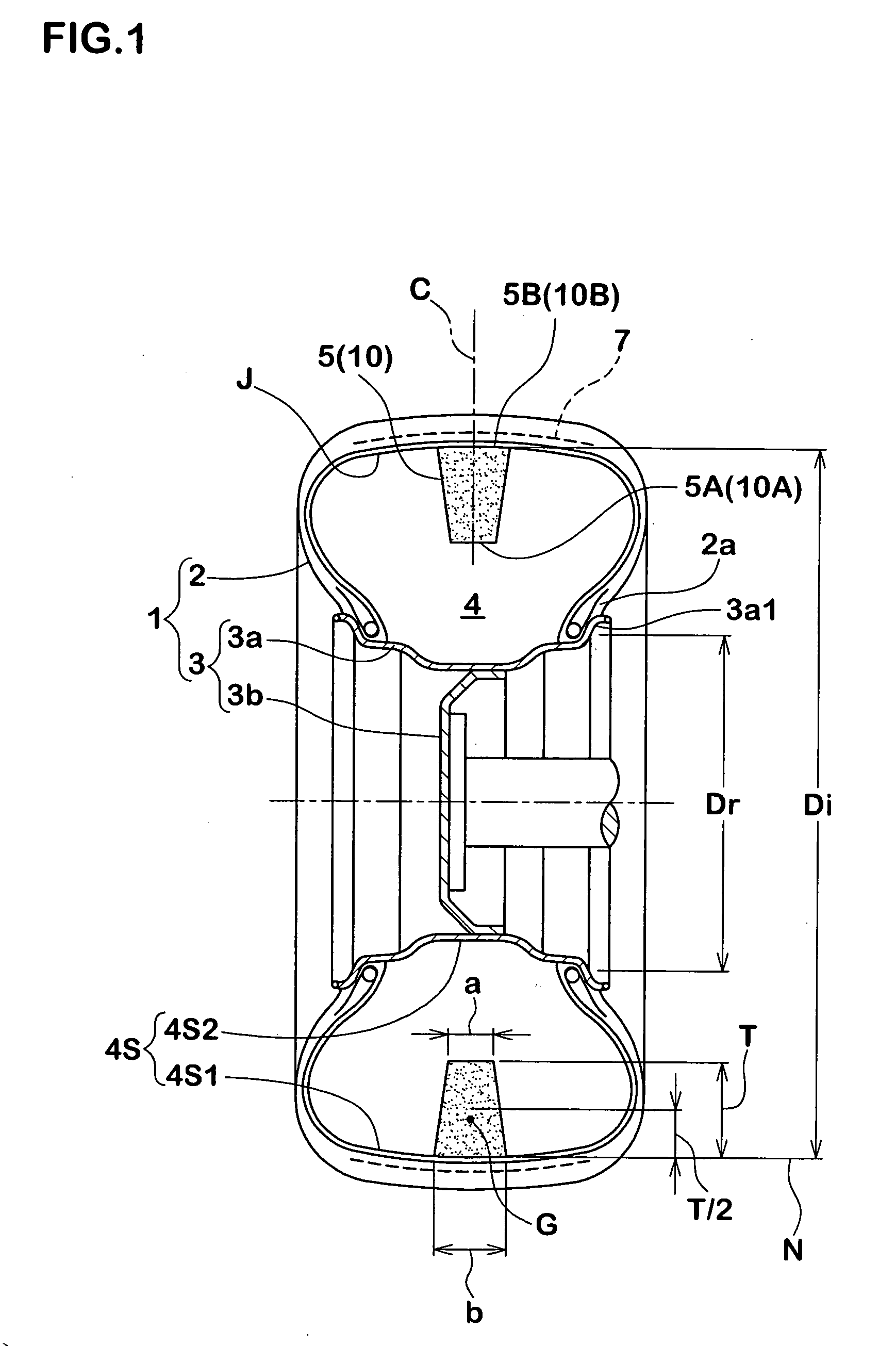

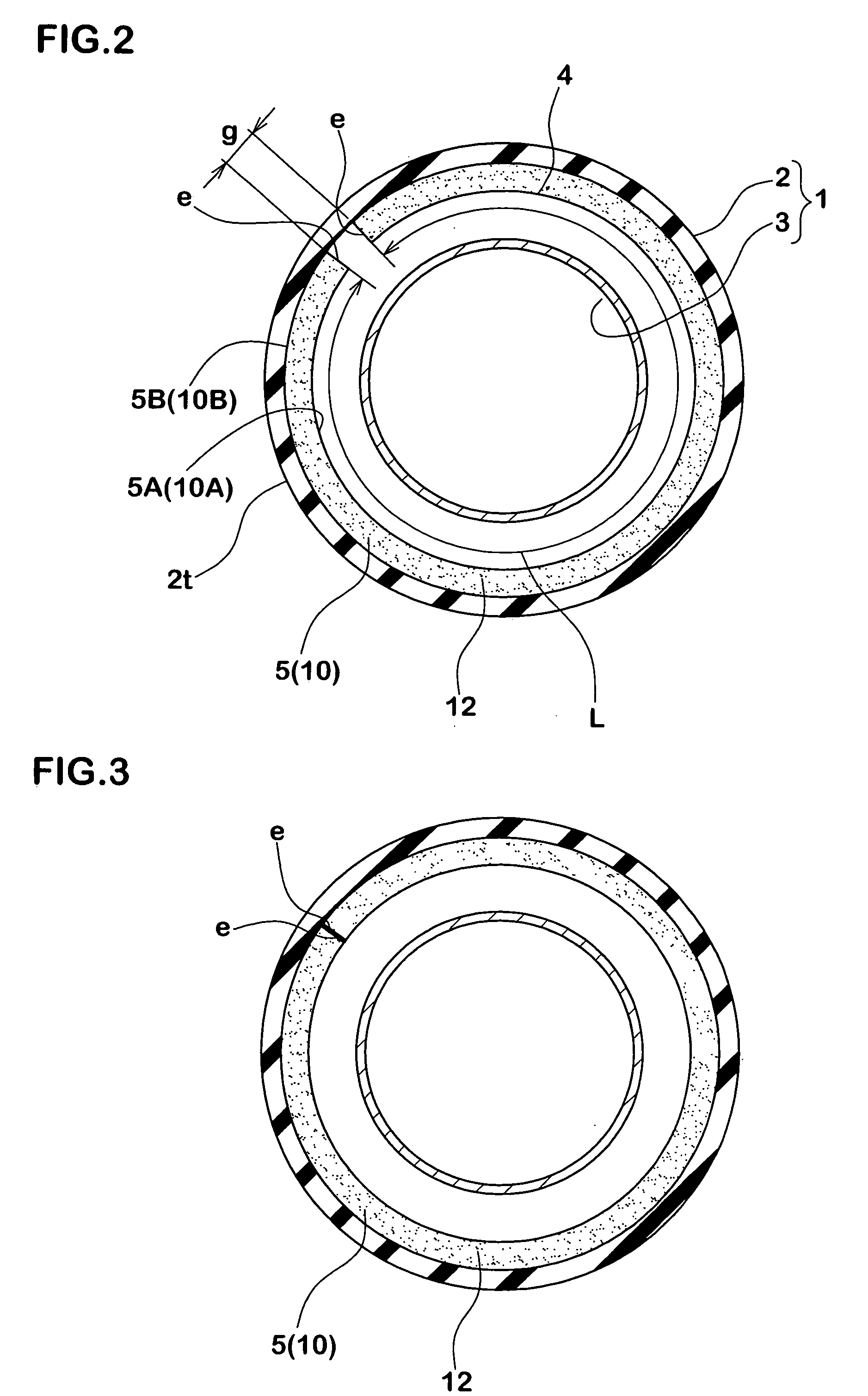

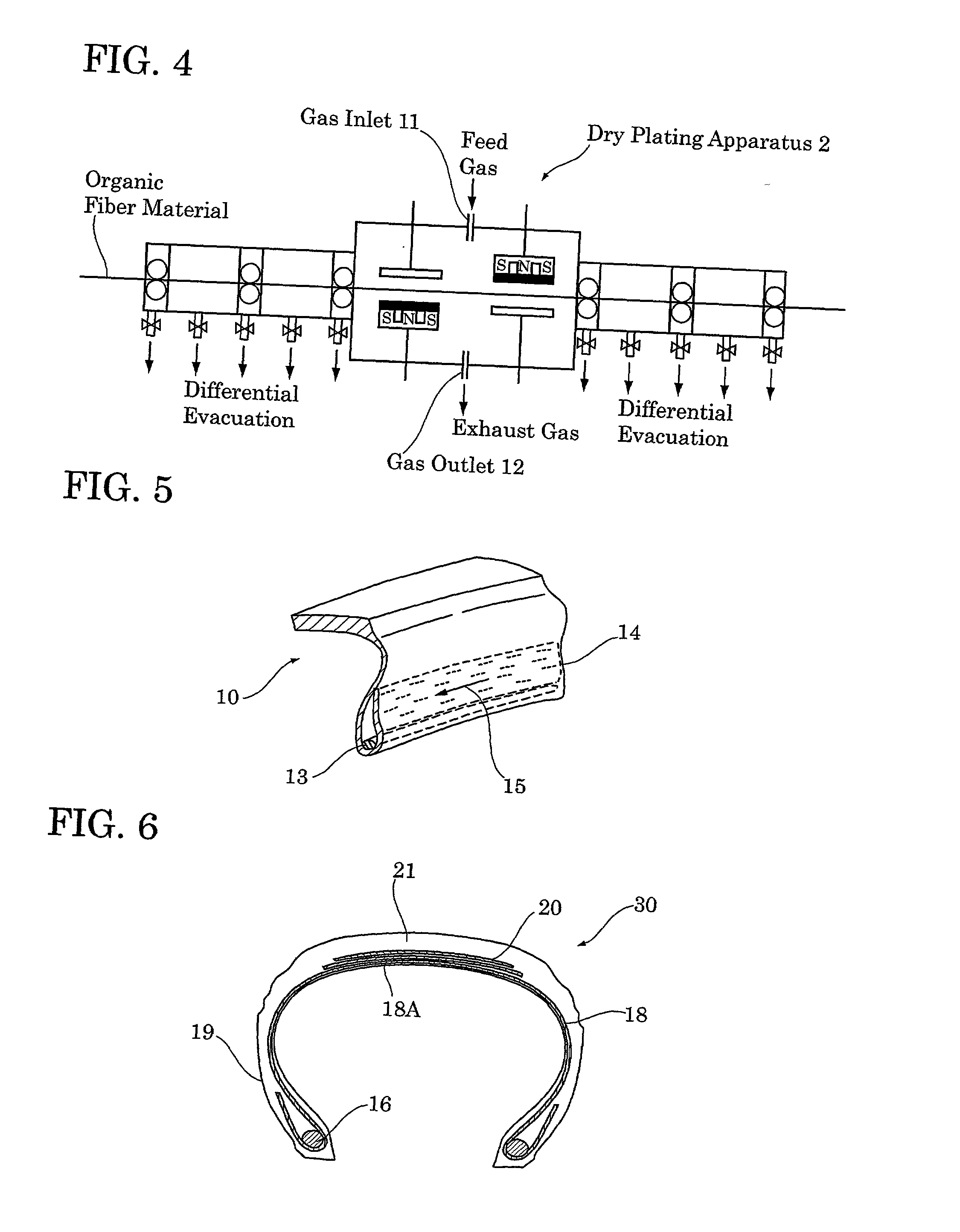

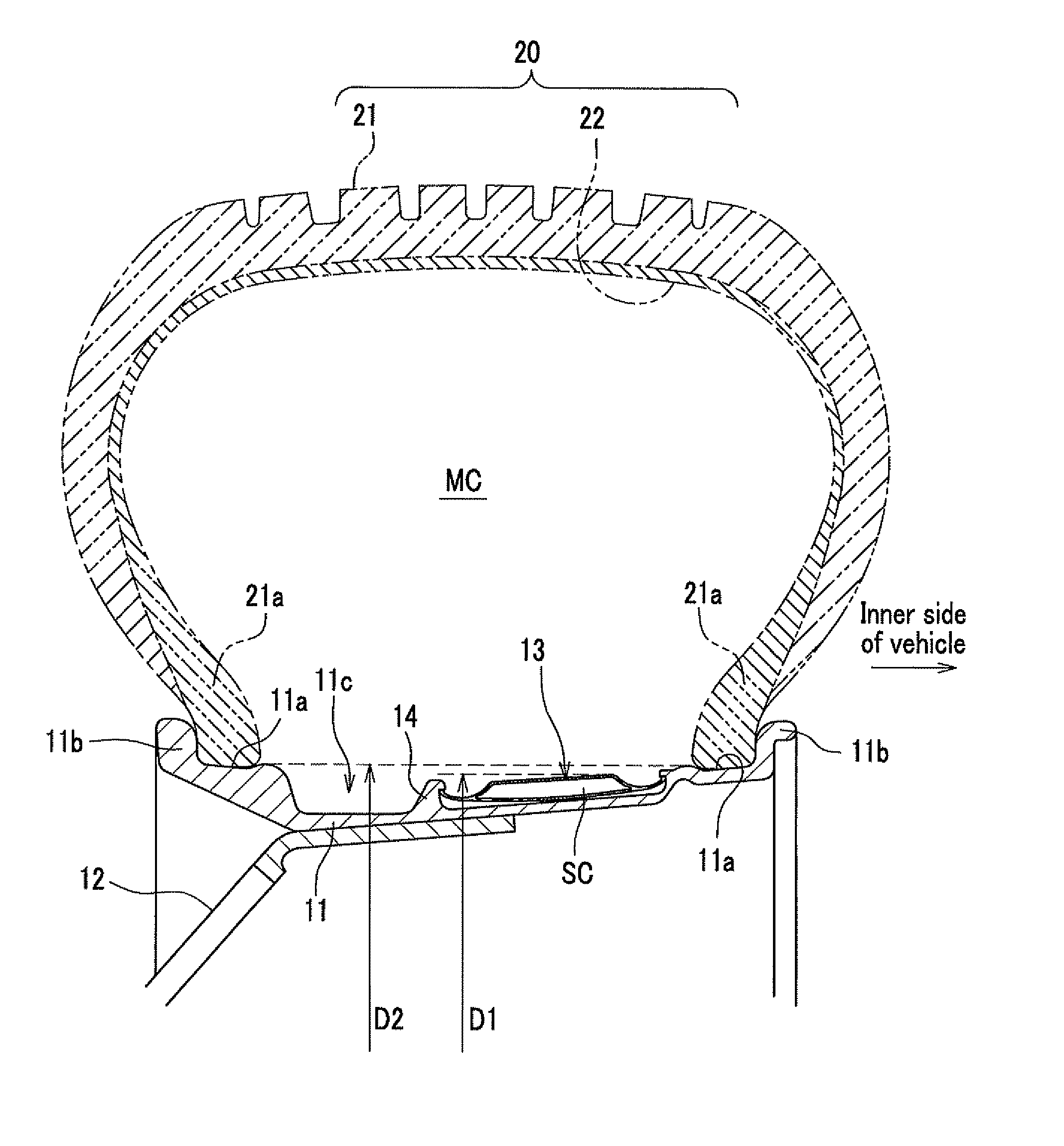

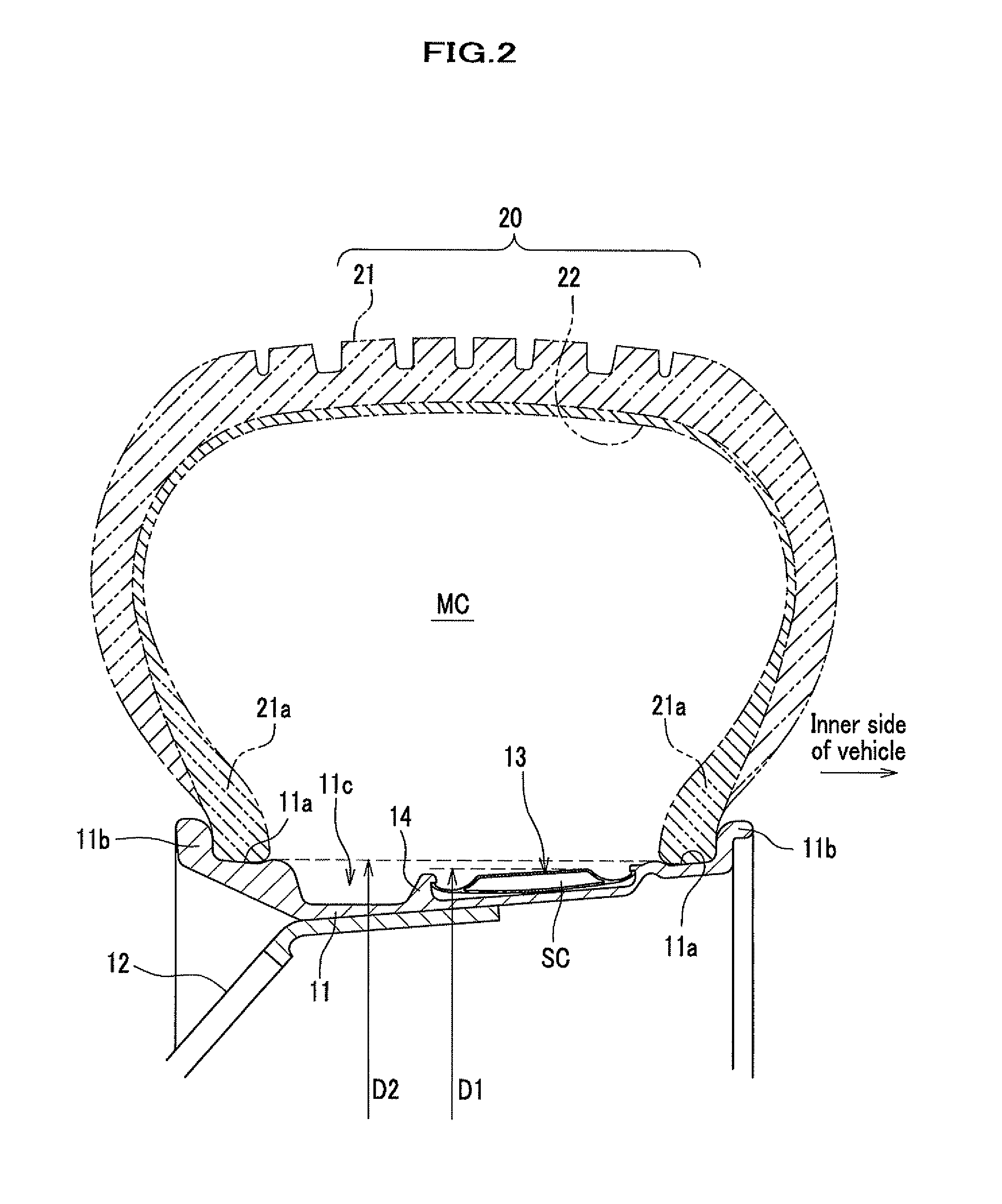

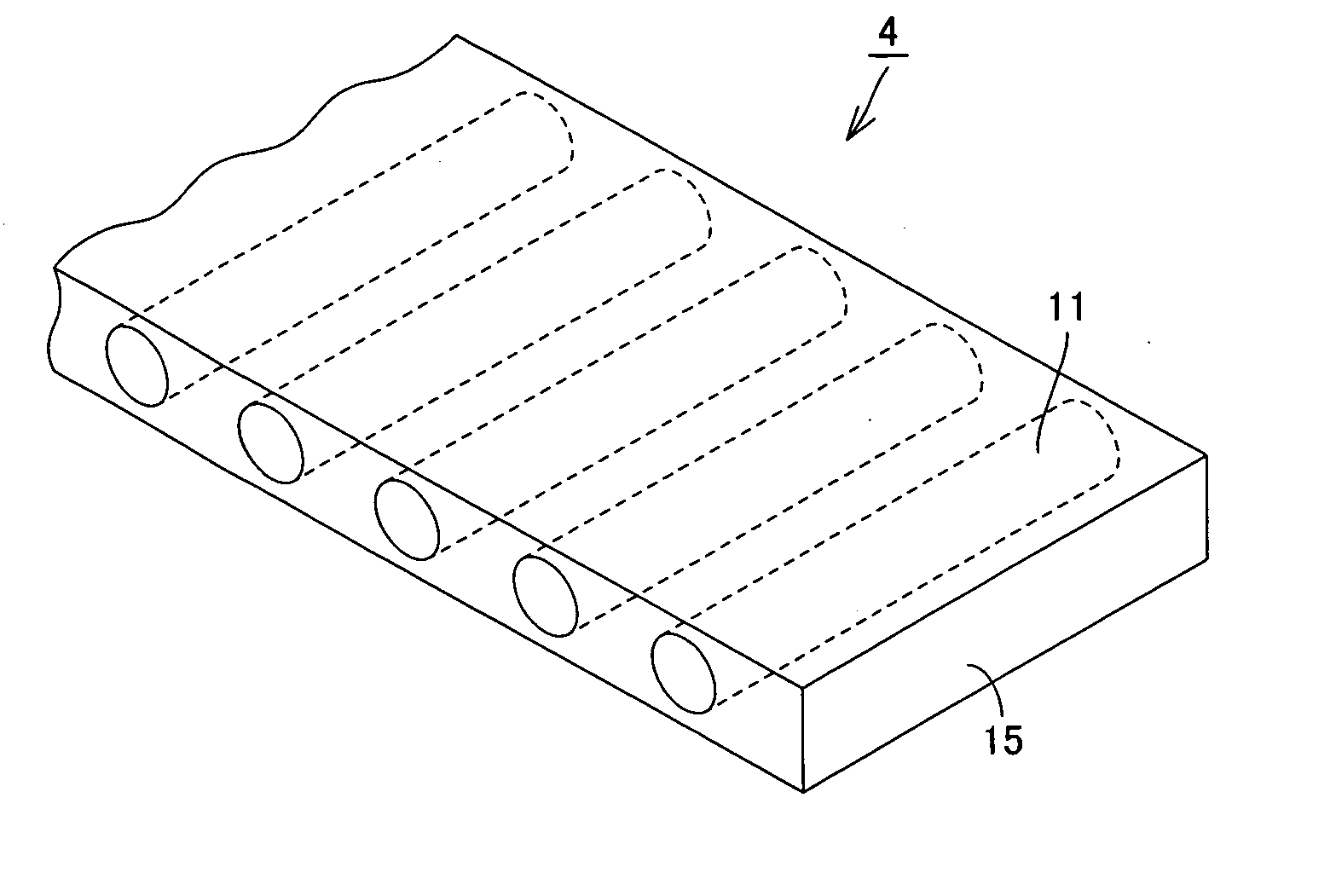

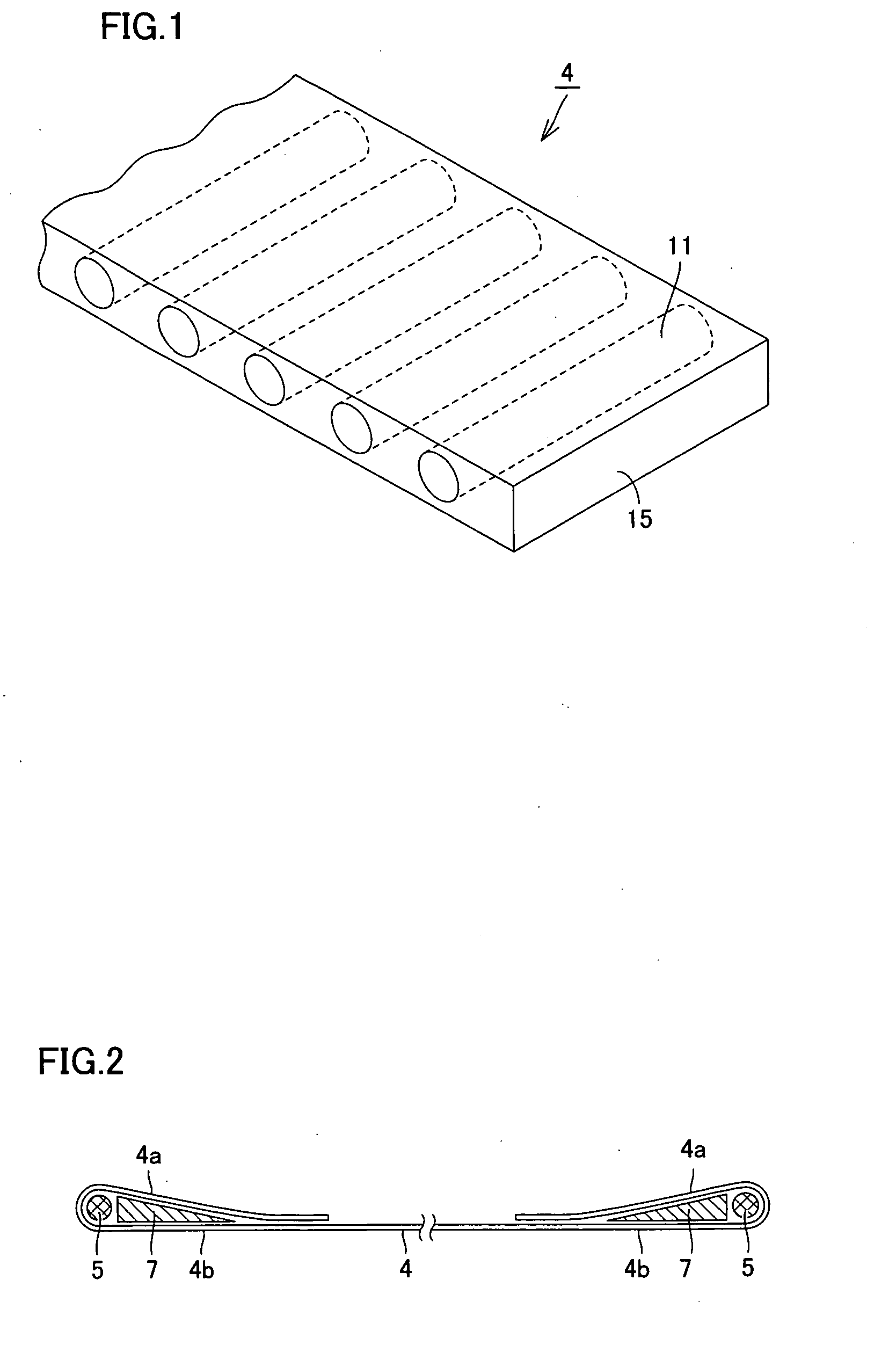

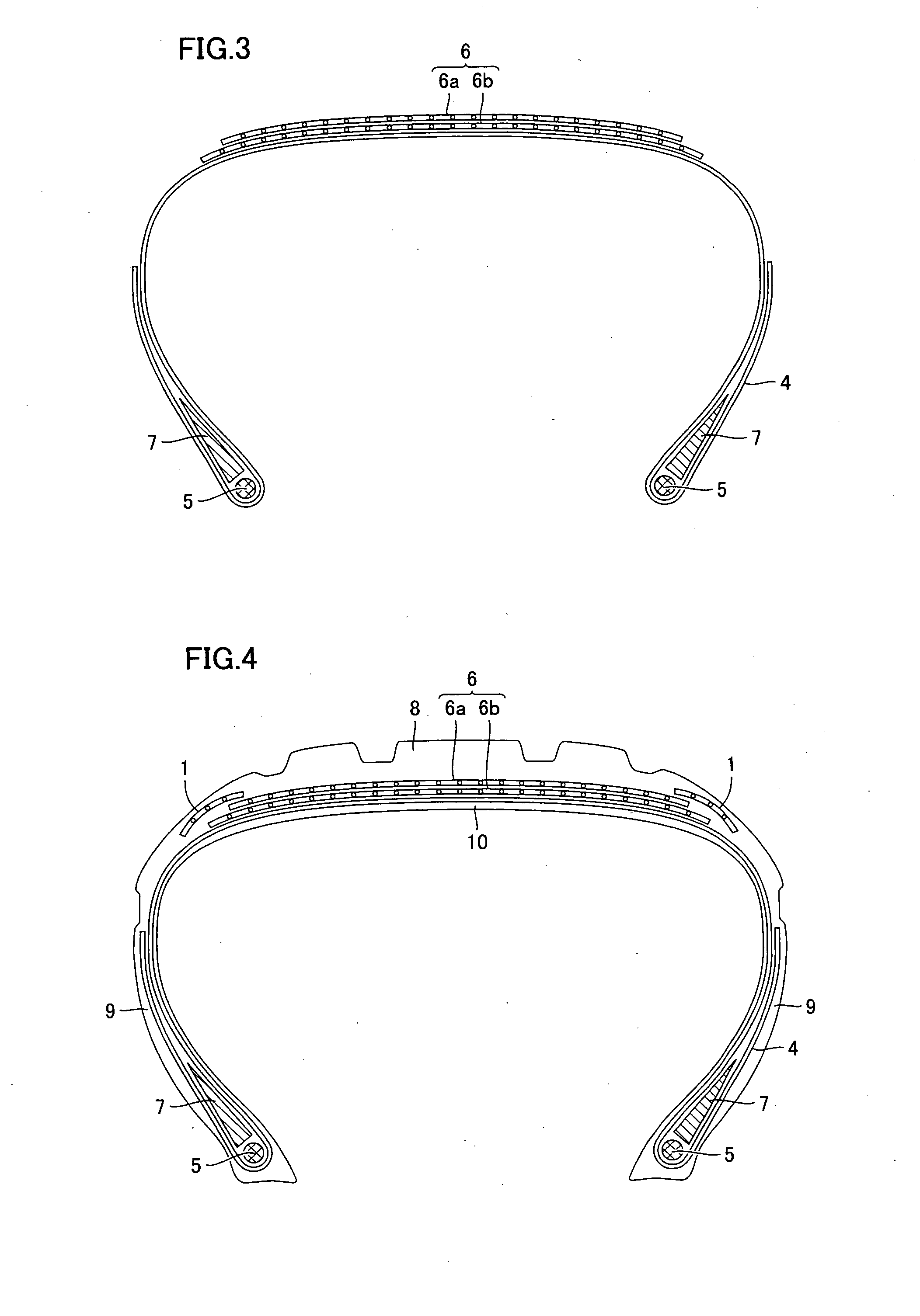

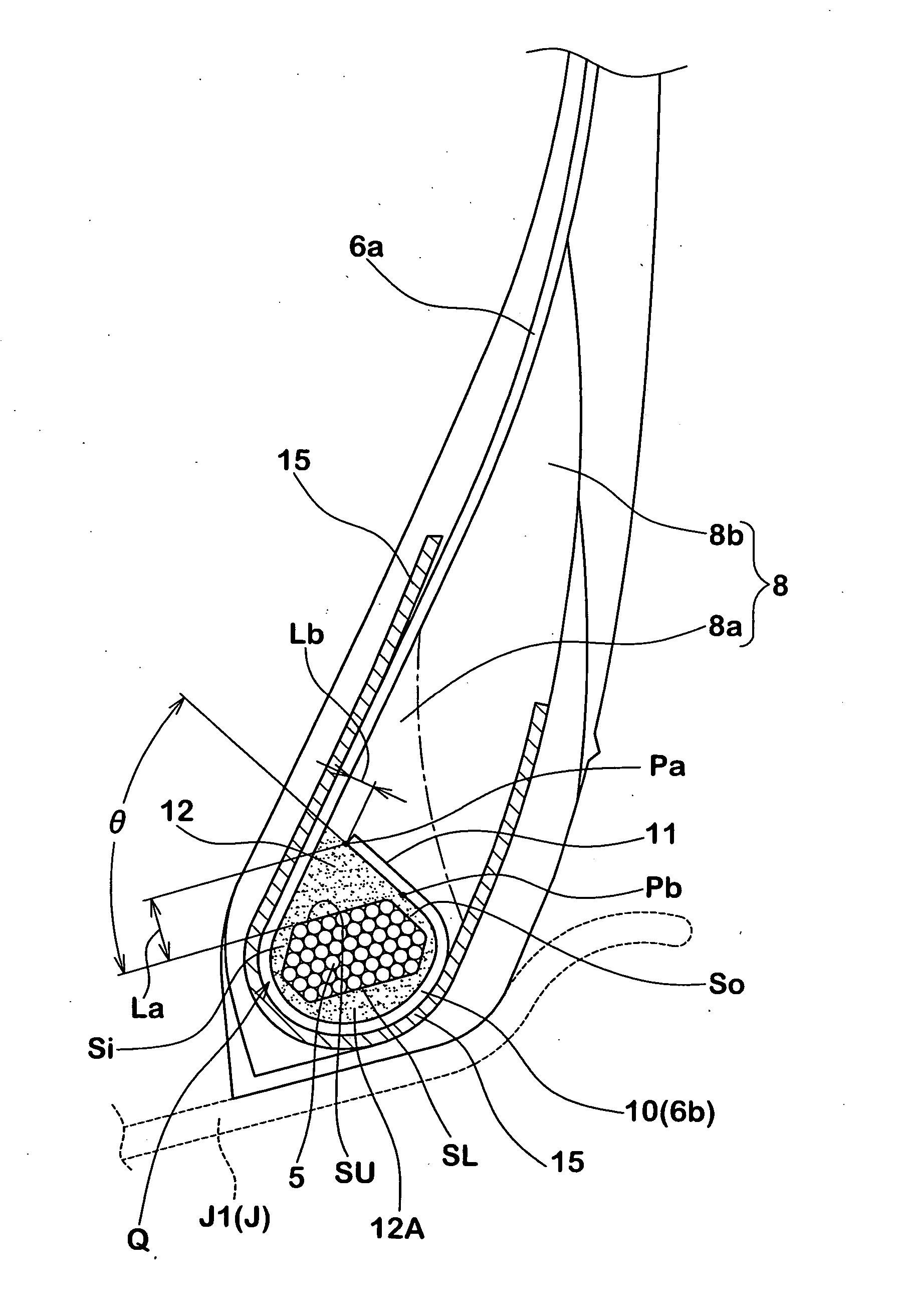

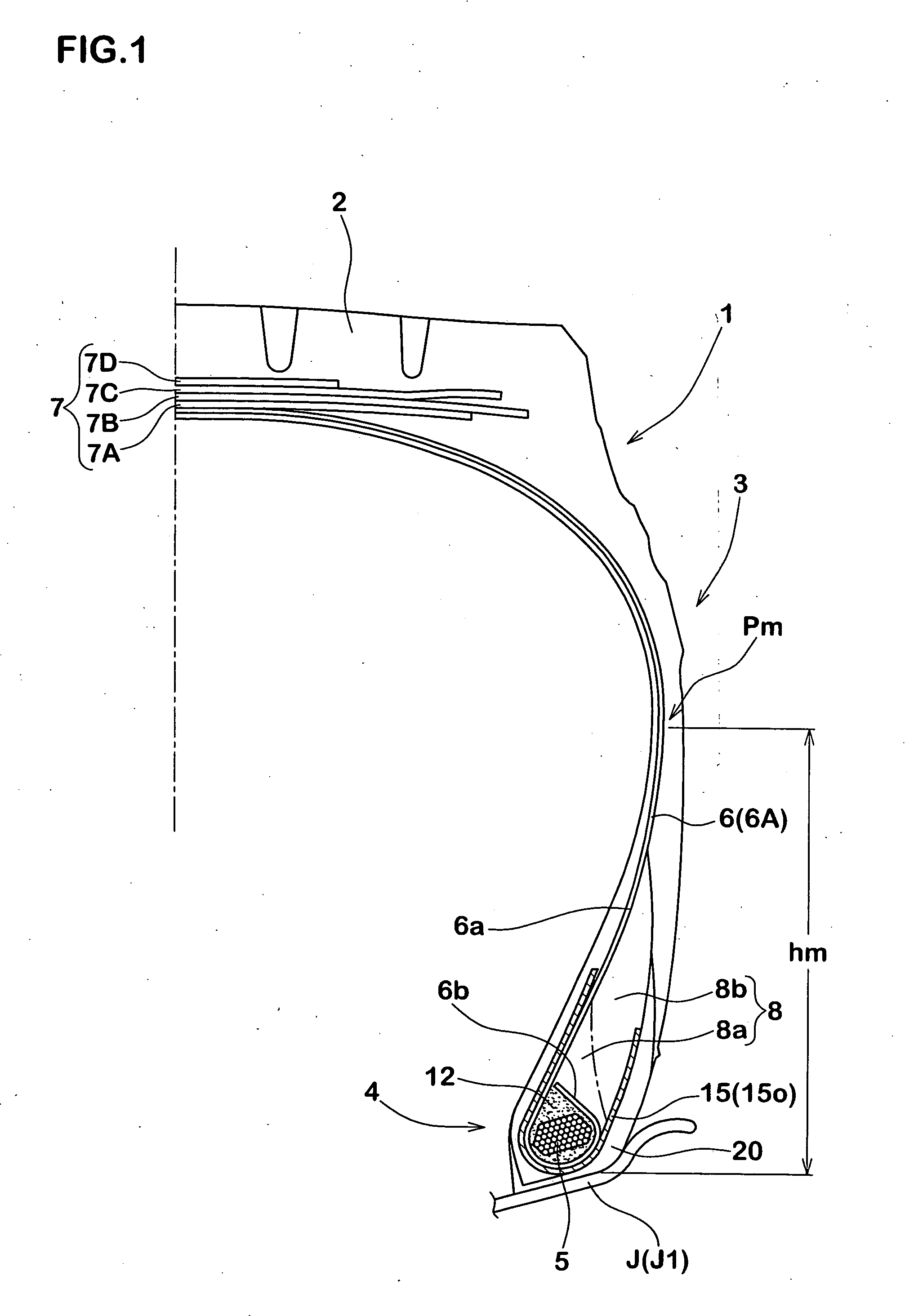

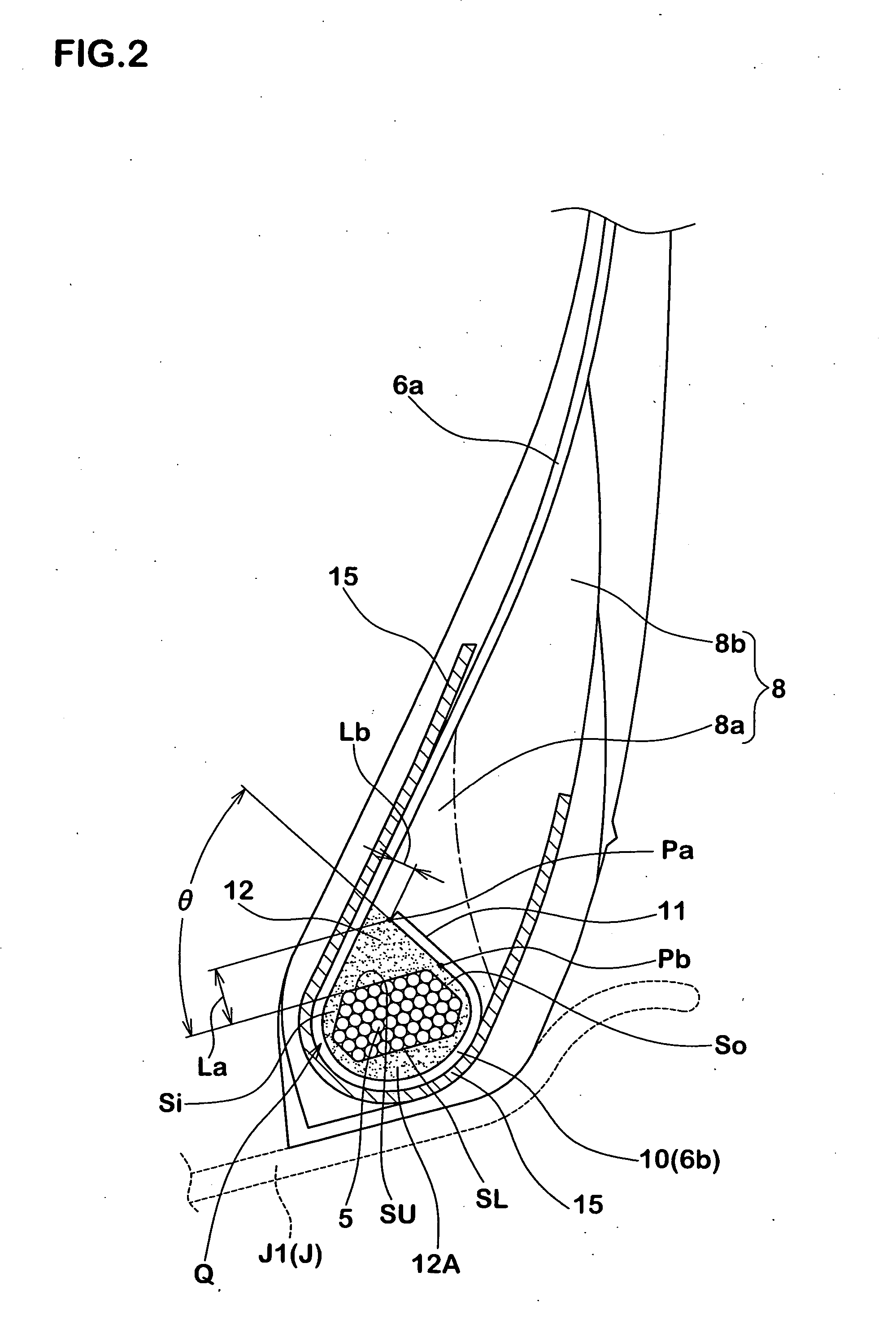

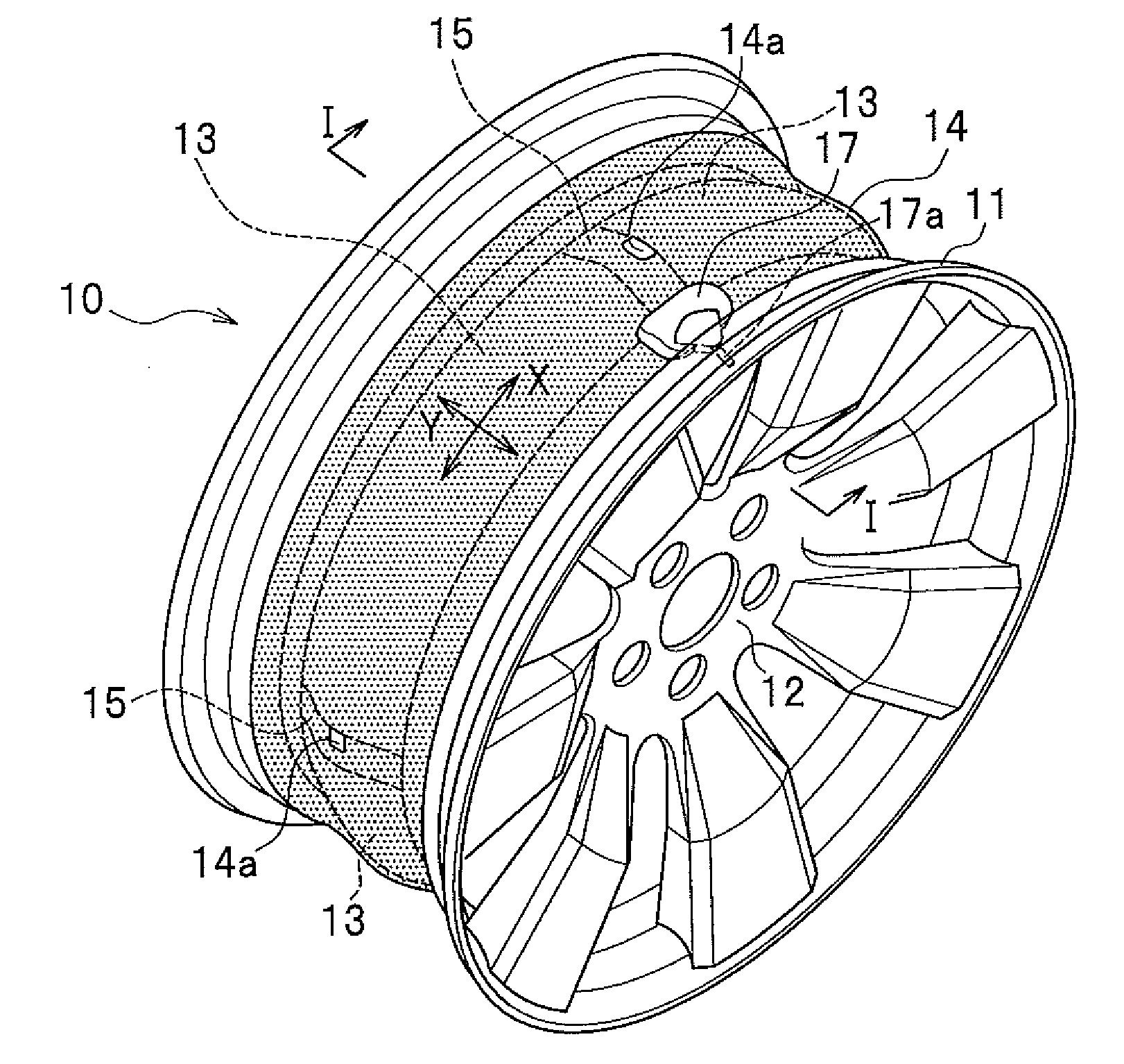

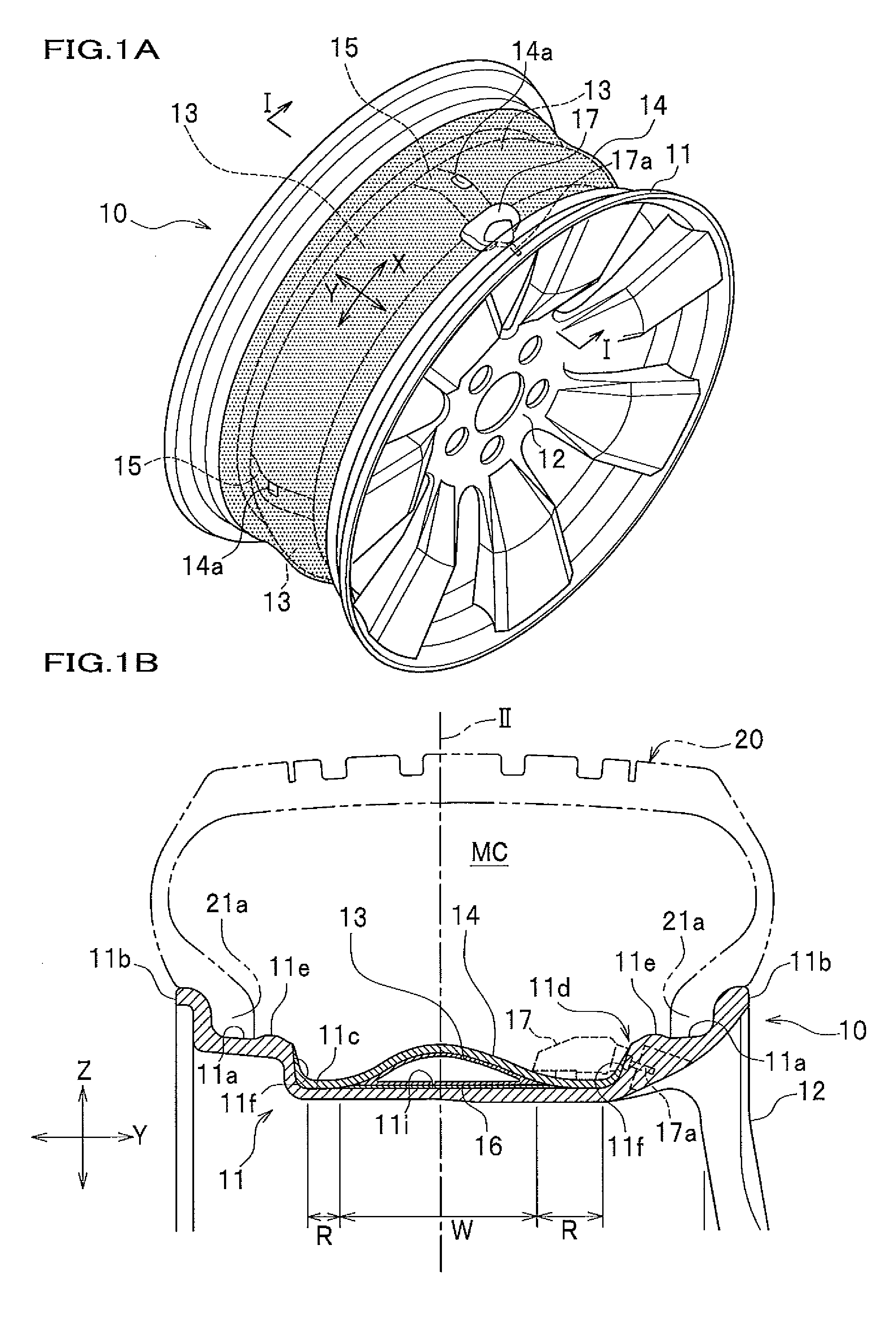

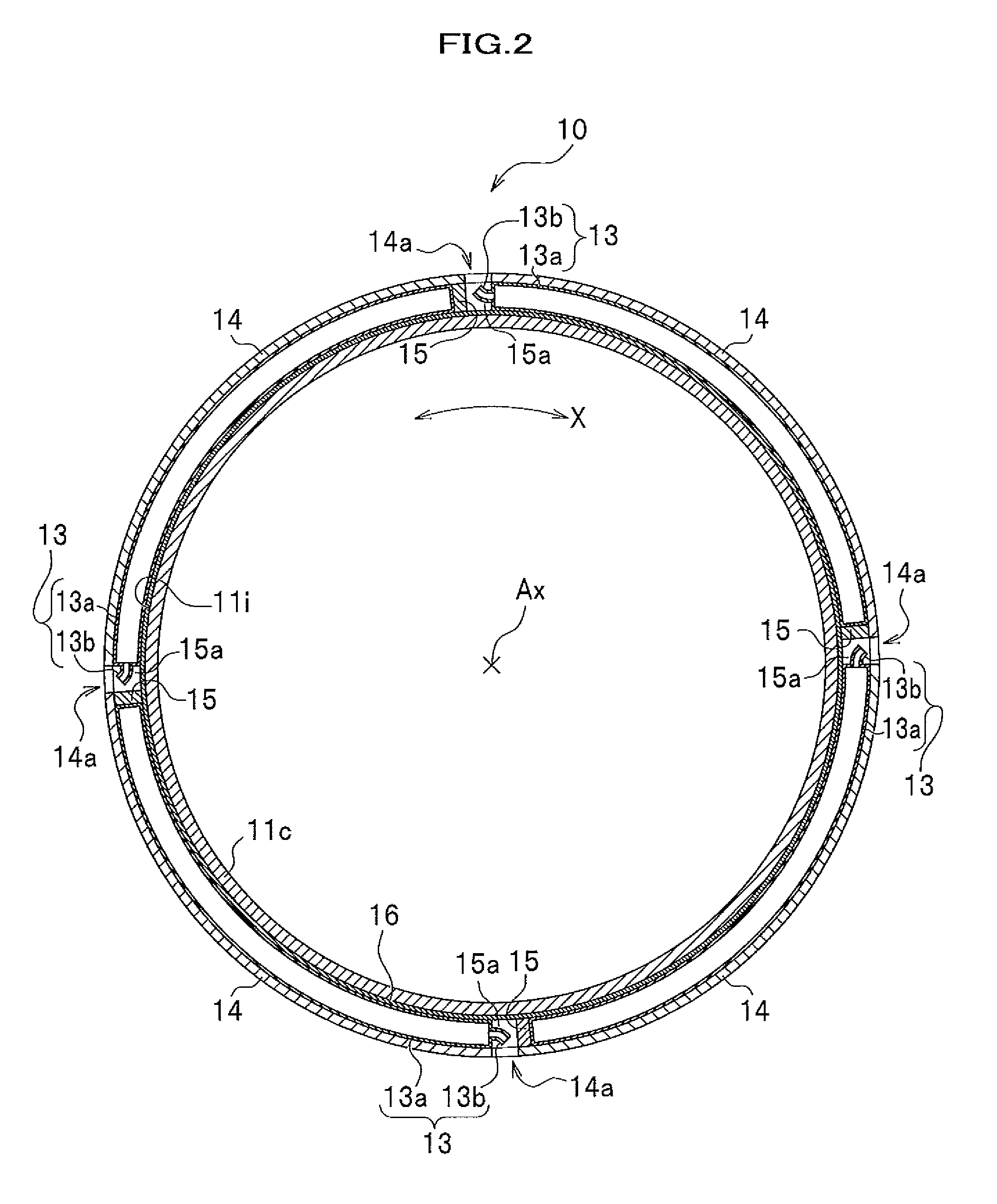

Assembly of pneumatic tire and rim, sound suppressing body used for the assembly and pneumatic tire storage method

An Assembly of a pneumatic tire and a rim and a sound suppressing body used for the assembly, the assembly wherein the sound suppressing body having a volume (V2) of 0.4 to 20% of the total volume (V1) of a tire inside hollow and formed of a sponge material extending in circumferential direction is installed in the tire inside hollow formed by the tire and the rim; the sound suppressing body comprising a tire side sound suppressing body having a bottom face fixed to the tire or a rim side sound suppressing body having a bottom face fixed to the rim, wherein the area gravity of the tire side sound suppressing body main part exceeding the bead base line of the rim side sound suppressing body is positioned in an area ranging form the middle point of a height form a reference plane to the trip of the sound suppressing body to the reference plane.

Owner:SUMITOMO RUBBER IND LTD

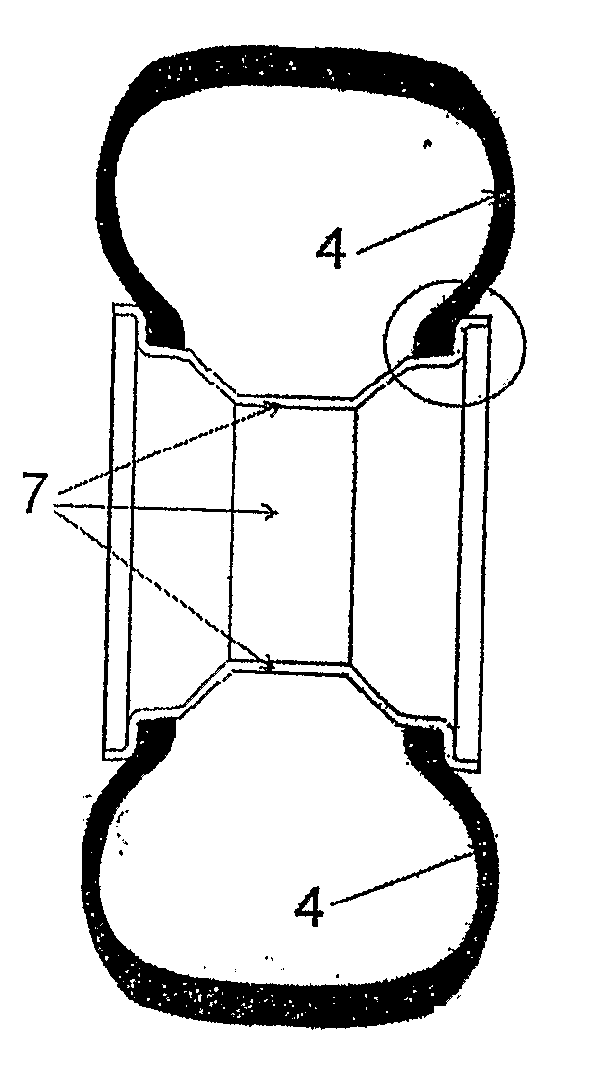

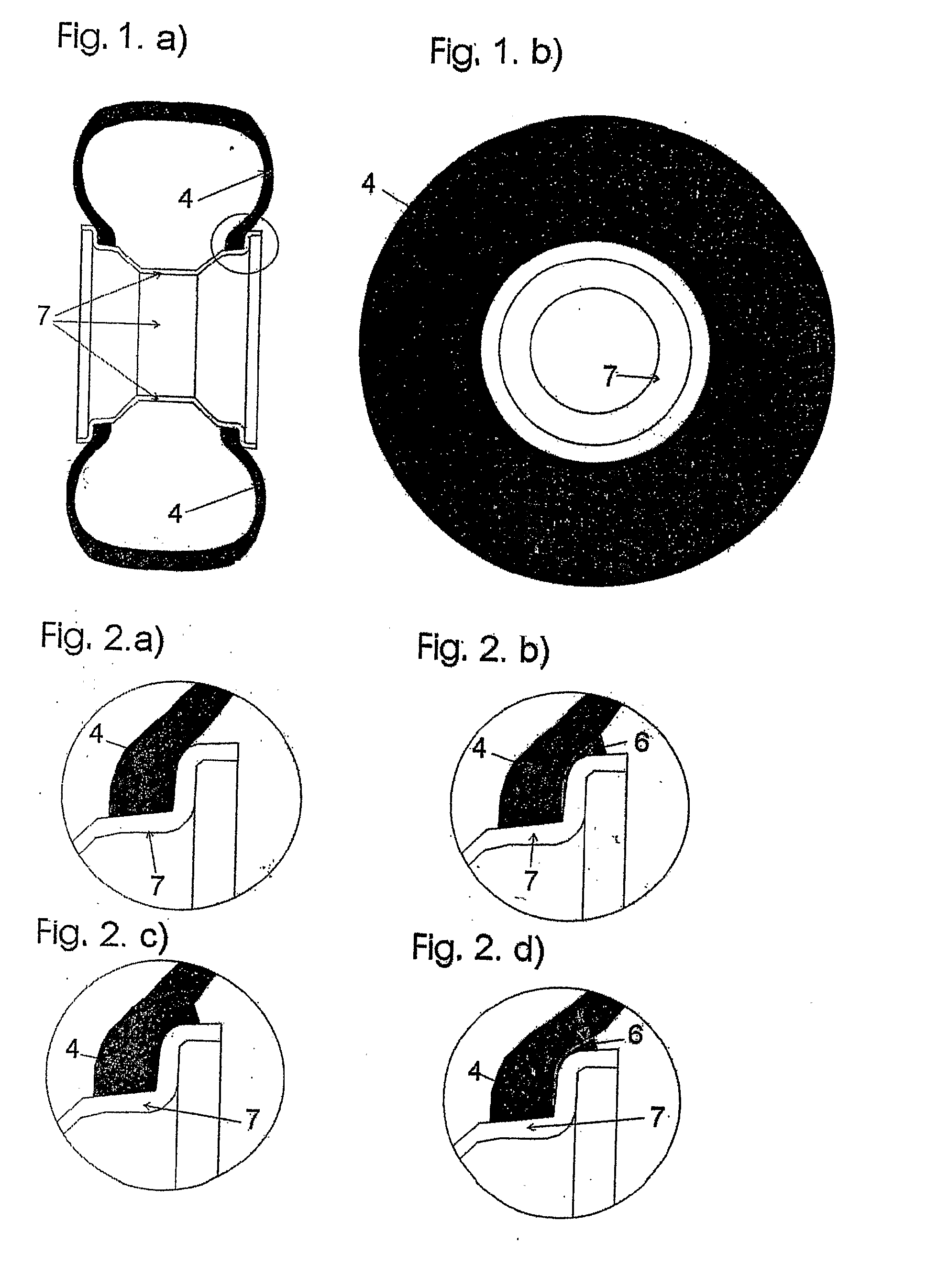

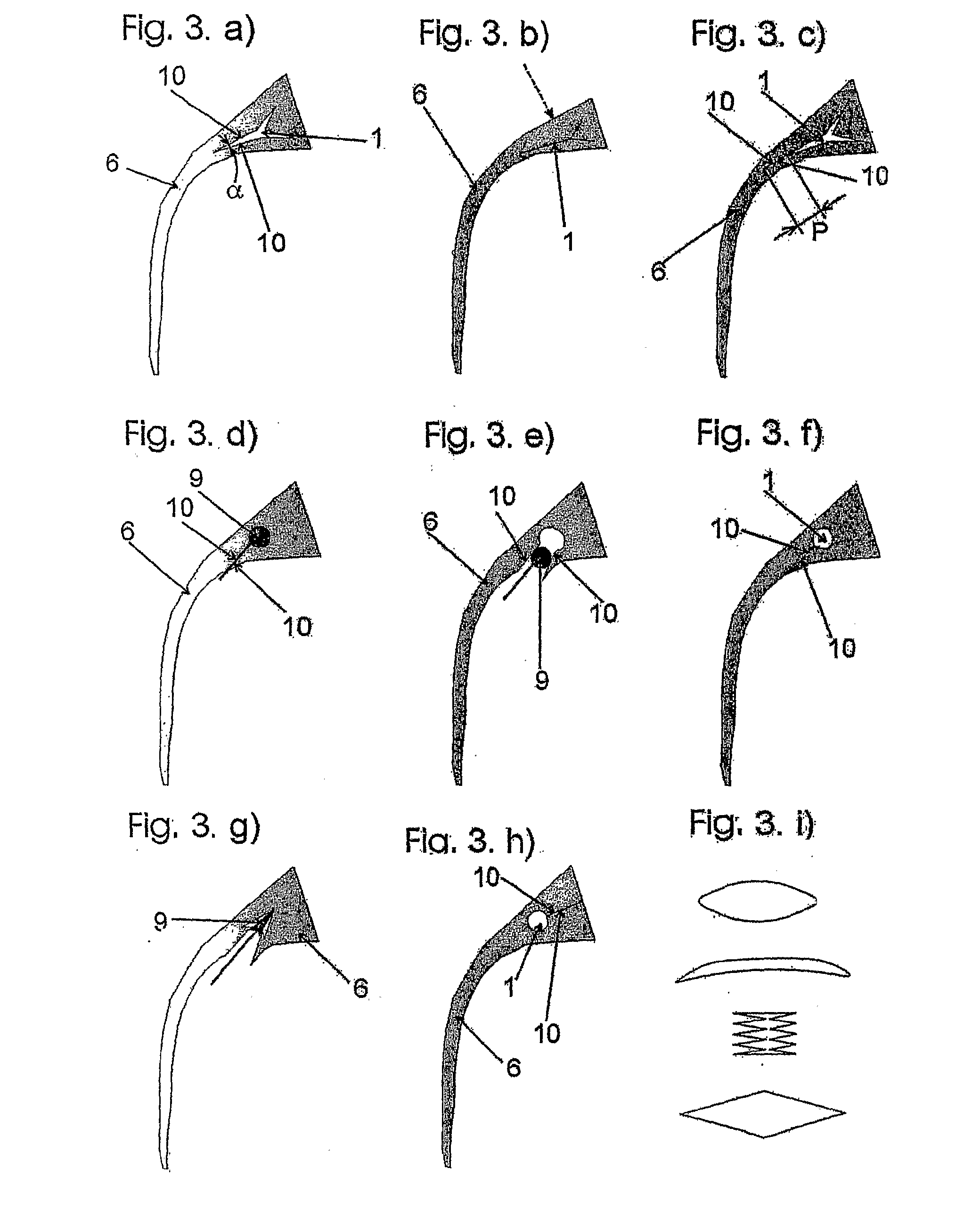

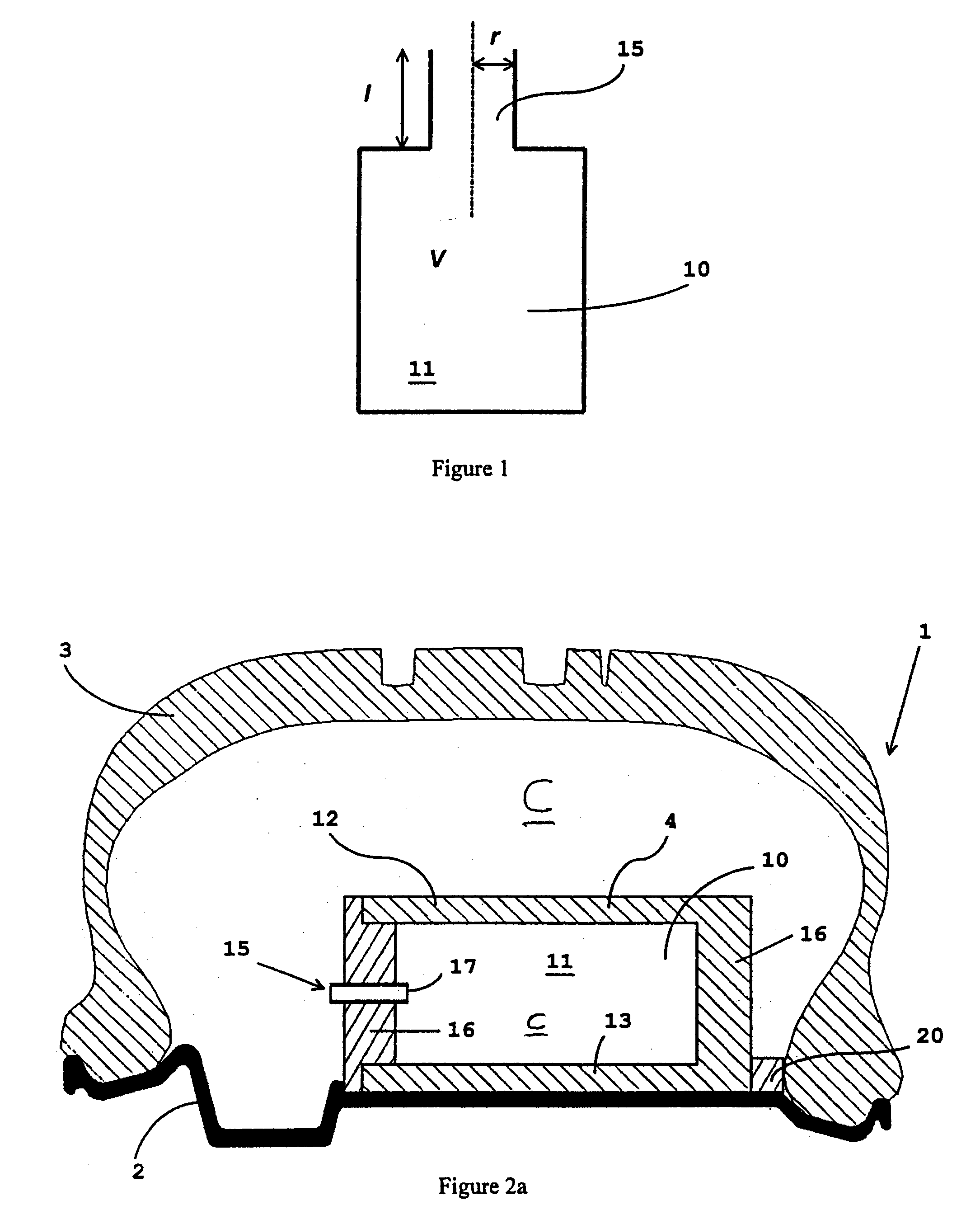

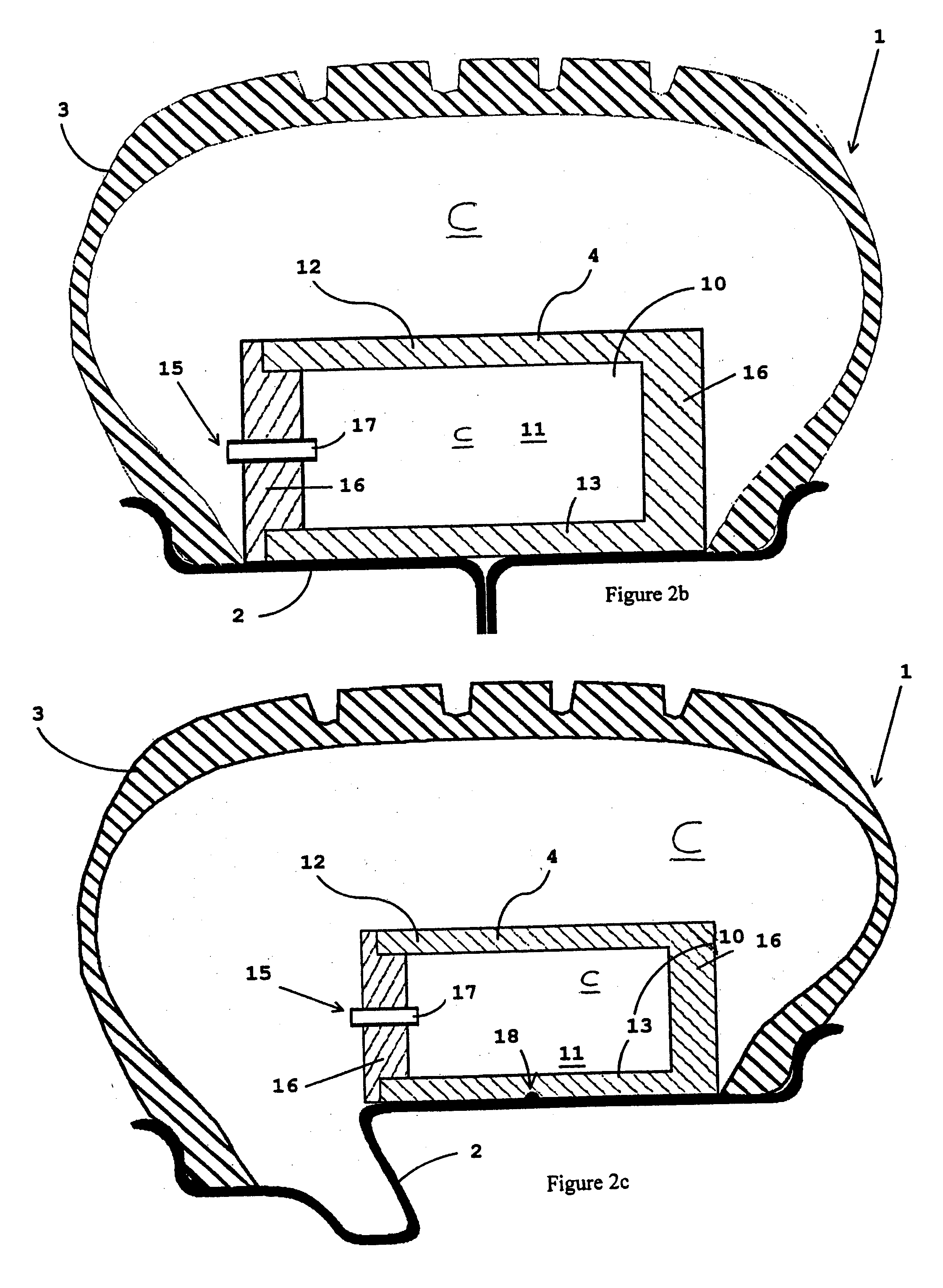

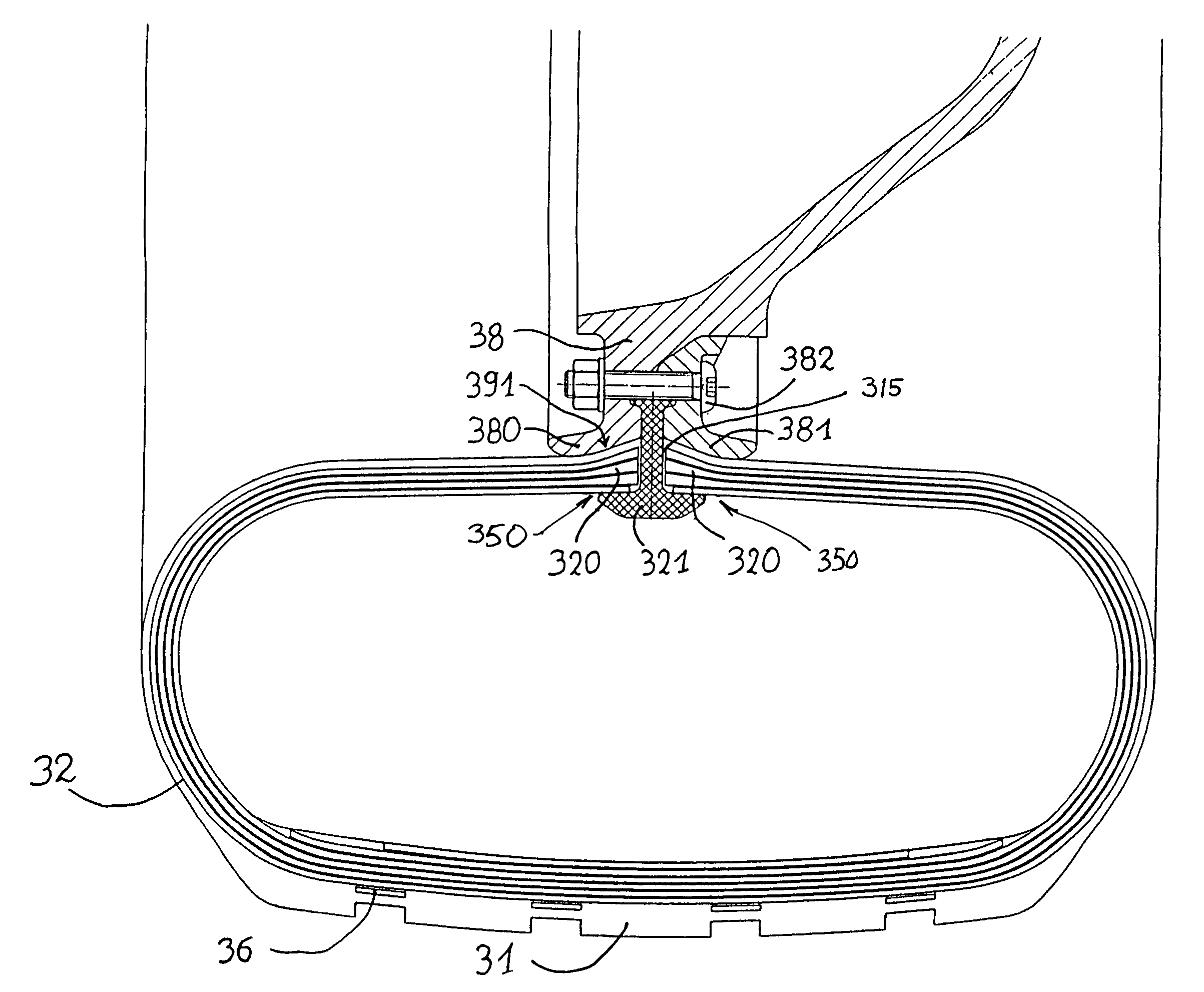

Chamber of a peristaltic pump for tire pressure adjustment

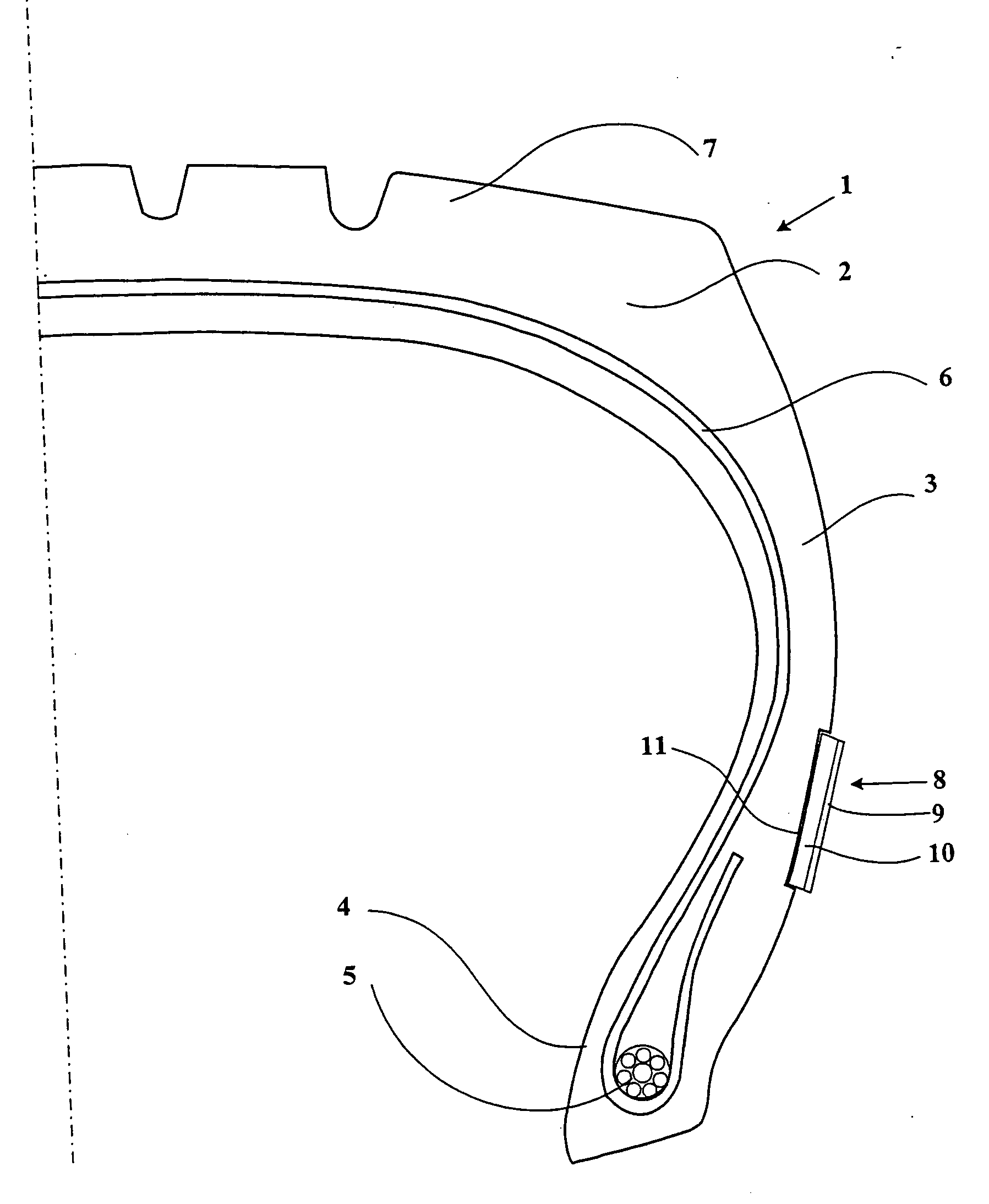

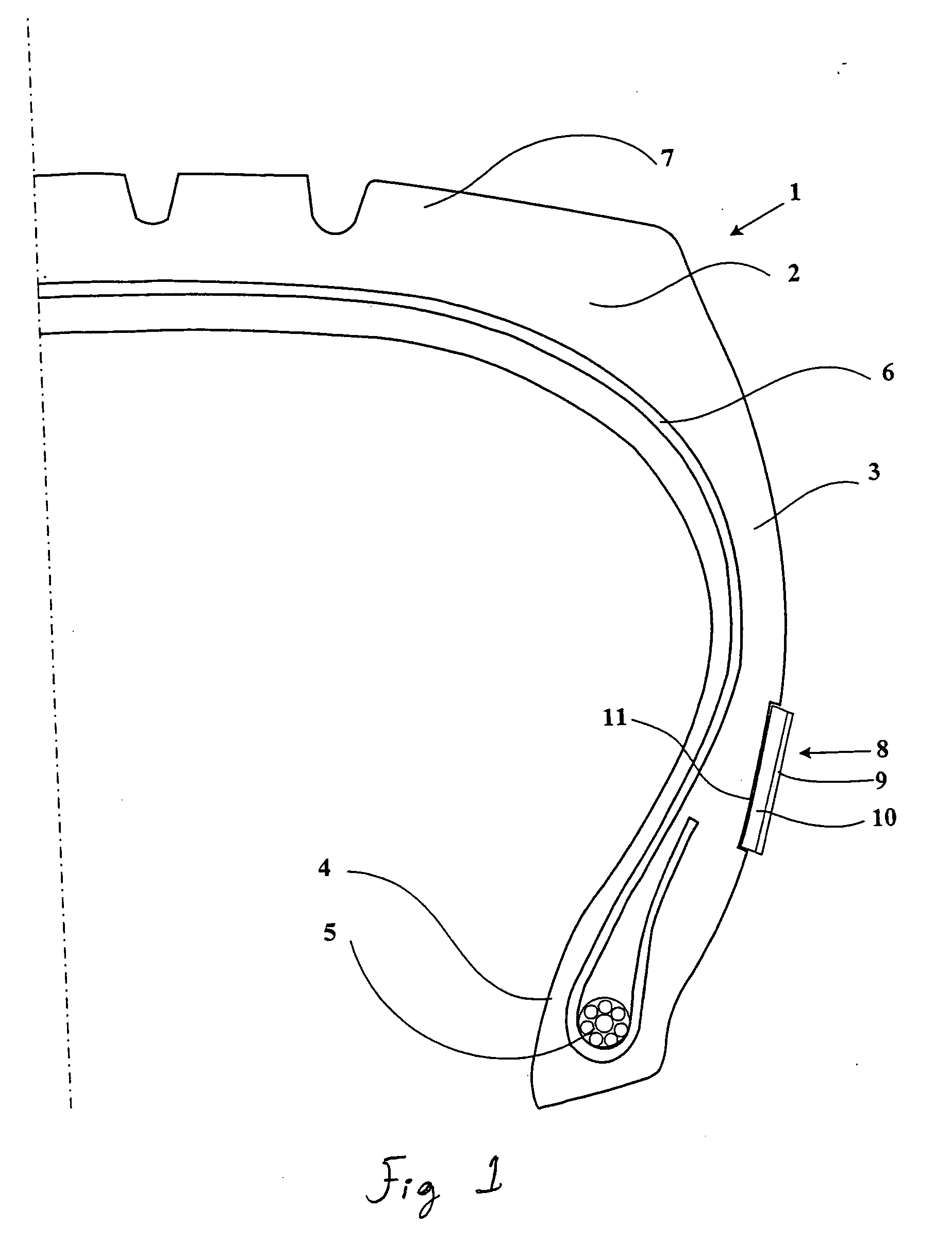

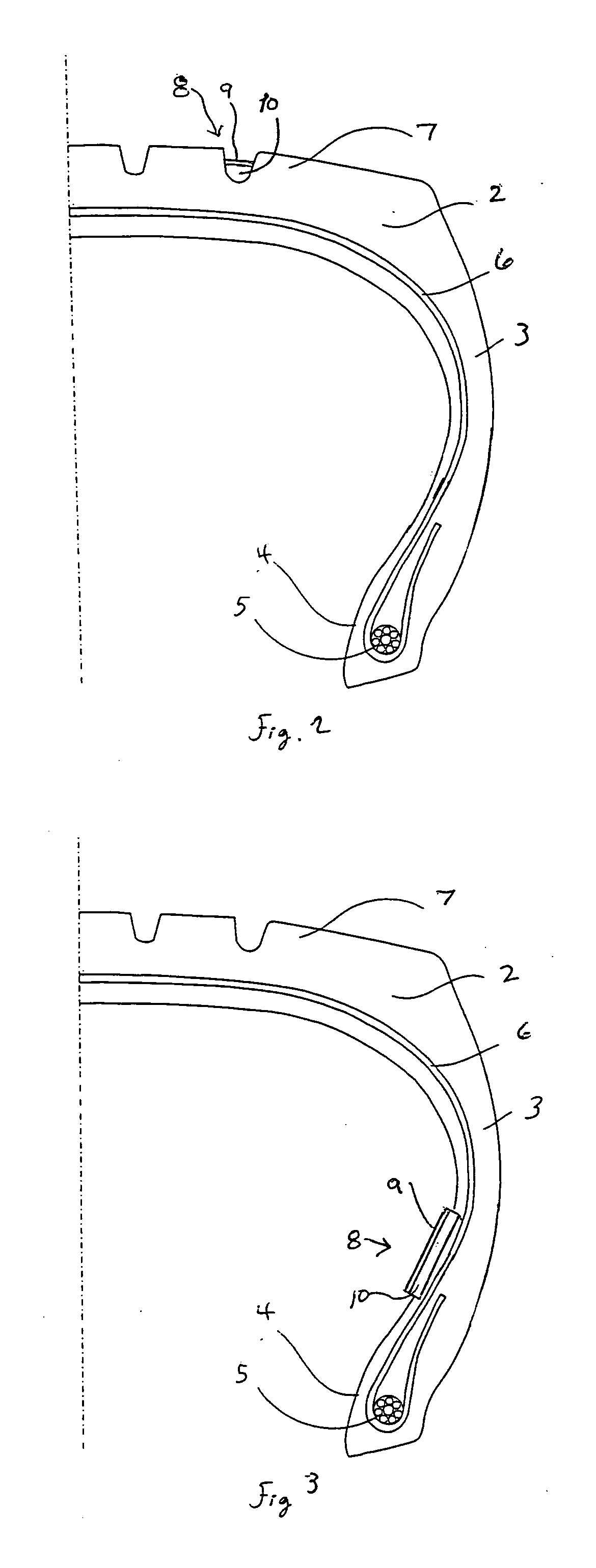

InactiveUS20090294006A1Effective shapingReduced service lifeTyresTyre beadsTire beadPeristaltic pump

A chamber (1) that works as a peristaltic pump for the pressure correction in the tire (4), which is a part of the tire (4) or of an ancillary structure (6) placed between the rim (7) and the tire bead (4) and is connected with the tire (4) internal space at one end and with the external environment at the other end. The chamber (1) is in the shape of a curved hollow channel, where at least one enclosing wall is at least partially formed by at least a pair of surfaces (10) coplanar with the longitudinal direction of the chamber (1). When the tire is mounted on the rim, the pair of surfaces (10) are pressed together thus hermetically closing the chamber (1). When the chamber (1) is closed during rotation of the wheel, the surfaces (10) can slightly slide on one another taking internal wall tensions onto themselves thus decreasing the possibility of wall damage through ripping. A method of producing the chamber (1) is also disclosed.

Owner:CODA INNOVATIONS SRO

Rubber containing starch reinforcement and tire having component thereof

InactiveUS6269858B1Enhance tire rolling resistanceImprove lagPaper coatingSpecial tyresPlasticizerTread

The present invention relates to a rubber composition containing a combination of starch, modified starch and / or starch / plasticizer composite together with selected methylene donor and / or methylene acceptor compounds. The invention also relates to tires having at least one component comprised of such rubber composition. Such tire component can be, for example, its circumferential tread or other component of the tire.

Owner:THE GOODYEAR TIRE & RUBBER CO

Safety support with a noise attenuator for a vehicle wheel

InactiveUS6516849B2Permit dissipation of vibrational energyMinimize eliminate transferWithout separate inflatable insertsRimsTreadResonator

Owner:MICHELIN RECH & TECH SA

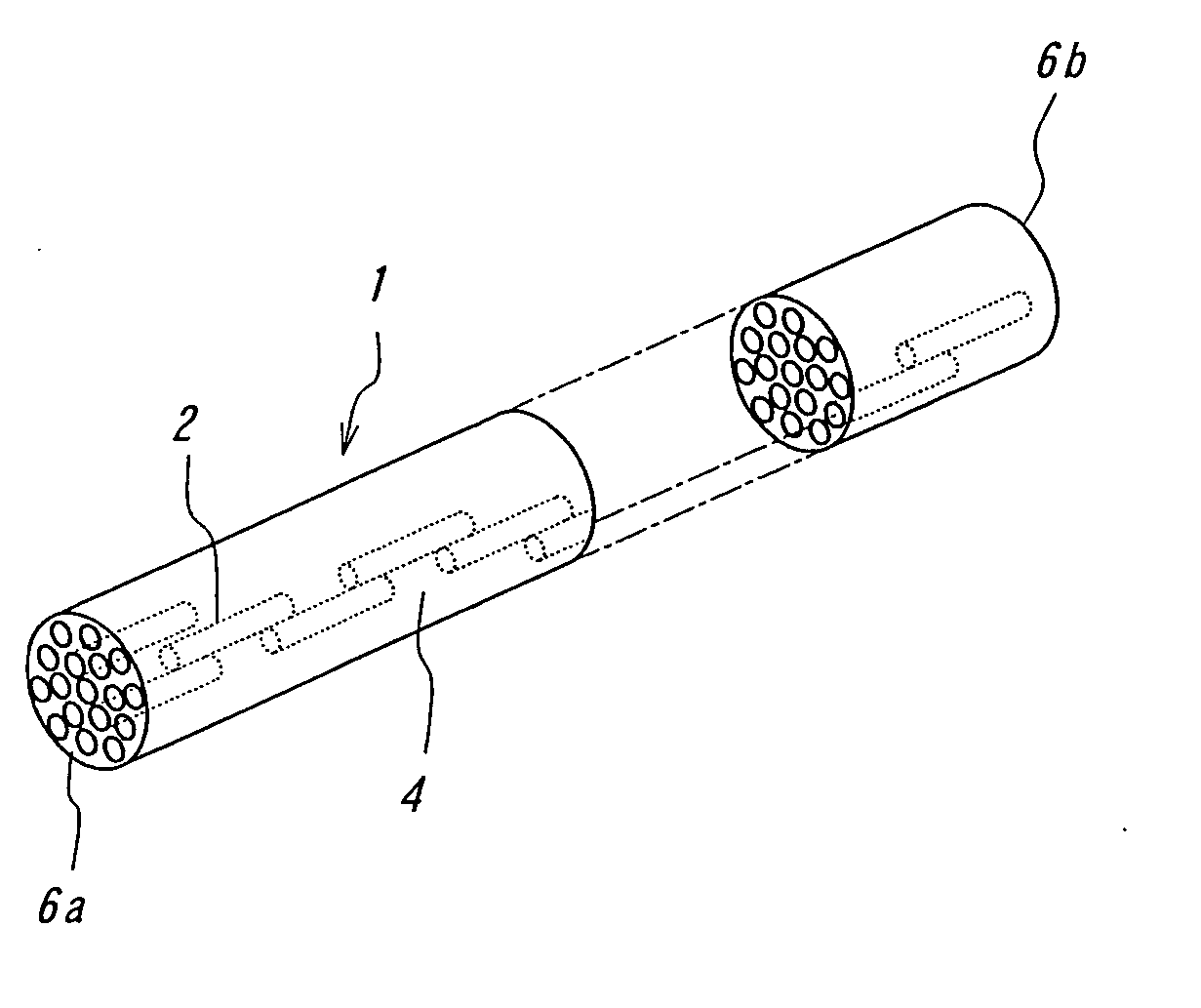

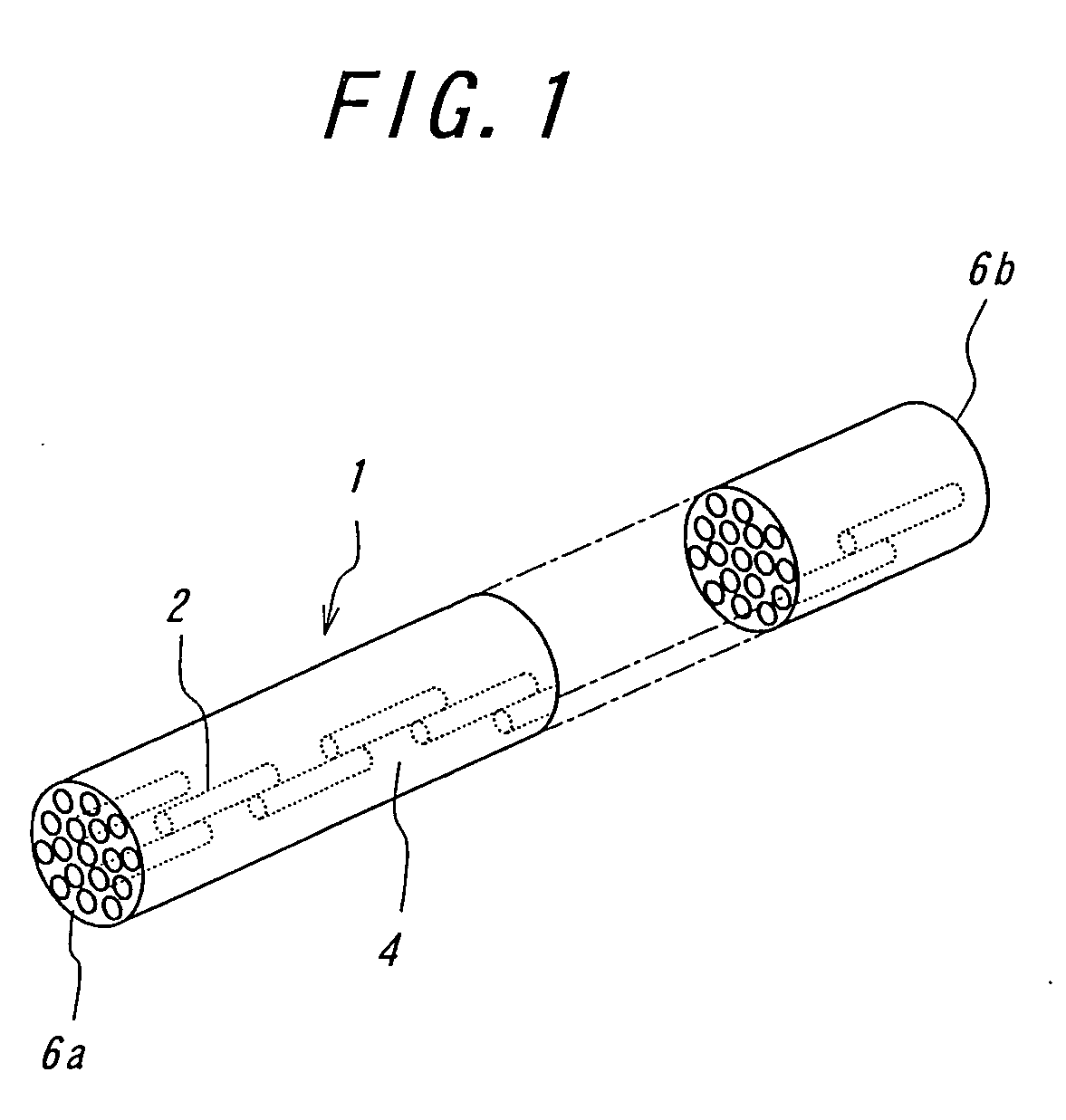

Orientated carbon nanotube composite, process for producing orientated carbon nanotube, and, produced using orientated carbon nanotube composite, pneumatic tire, wheel for vehicle, tire wheel assembly and disk brake

InactiveUS20060061011A1Improve efficiencyImprove conductivityMaterial nanotechnologyBraking discsRubber materialCarbon nanotube

A carbon nanotube orientated composite formed by orientating carbon nanotubes in a given direction in a matrix having a heat conductivity lower than that of carbon nanotube, in which at least a part of carbon nanotubes are contacted with each other to be continuous from one end to the other end between both ends in the orientated direction, is provided as a material having a heat conductivity considerably higher than that of copper, aluminum or the like or a material to be disposed in rubber material having a low heat releasing characteristic to considerably improve the heat conduction, and also there are provided a method of producing the same as well as a pneumatic tire, a wheel for a vehicle, a tire-wheel assembly and a disc brake using this material.

Owner:BRIDGESTONE CORP

Partially vulcanized shaped rubber composition and preparation of an article, including tires, having a component thereof

InactiveUS6426378B1Improve responseIncrease stiffnessOther chemical processesSpecial tyresElastomerPolymer science

The invention relates to the preparation of a partially vulcanized, pre-shaped rubber composition and use thereof as a component of an article of manufacture. In practice, the partially vulcanized rubber composition is adhered to an unvulcanized rubber substrate to form a composite thereof and the resulting composite vulcanized to create an article of manufacture. Such pre-vulcanized rubber composition is a composite comprised of at least one diene-based elastomer, amorphous silica, coupling agent and liquid diene-based polymer. Such partially vulcanized, pre-shaped rubber composition may be a component of a tire such as, for example, an apex, sidewall insert or tread. It may also be a component of an industrial rubber product such as, for example, a component of a conveyor belt, power transmission belt or a hose.

Owner:THE GOODYEAR TIRE & RUBBER CO

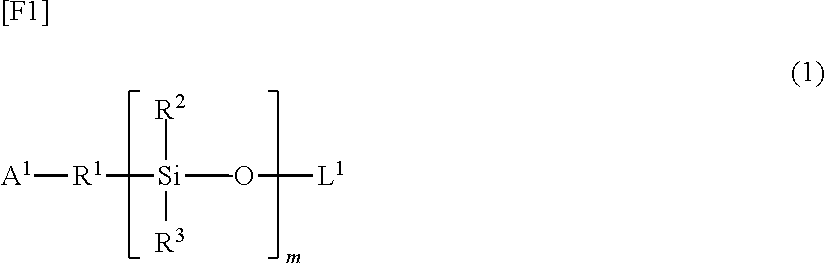

Method for producing modified conjugated diene polymer/copolymer, modified conjugated diene polymer/copolymer, and rubber composition and tier using the same

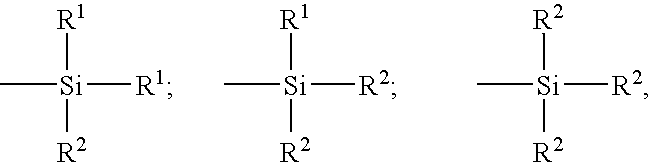

ActiveUS20110146877A1Increased durabilityImprove rolling resistanceSpecial tyresPneumatic tyre reinforcementsSilane compoundsPolymer science

The invention provides a method for producing a modified conjugated diene (co)polymer, the method including comprising: a modification reaction step including causing an organic silane compound to react with a conjugated diene (co)polymer having an active site at the active site, the organic silane compound having a characteristic group for forming a silanol group through hydrolysis and, in the vicinity of the characteristic group, (i) a functional group which binds the organic silane compound to the conjugated diene (co)polymer via addition to or substitution at the active site and which promotes reaction between the silanol group and a reinforcing filler after the addition or substitution reaction, or (ii) a functional group which promotes reaction between the silanol group and a reinforcing filler, and a hydrolyzation step performed after the modification reaction step; a modified conjugated diene (co)polymer having, at a molecular end of the conjugated diene (co)polymer, a silanol group, and a functional group in the vicinity of the silanol group, the functional group accelerating reaction between the silanol group and the reinforcing filler; a rubber composition containing the (co)polymer and carbon black having specific characteristics; and a tire formed from the rubber composition.

Owner:BRIDGESTONE CORP

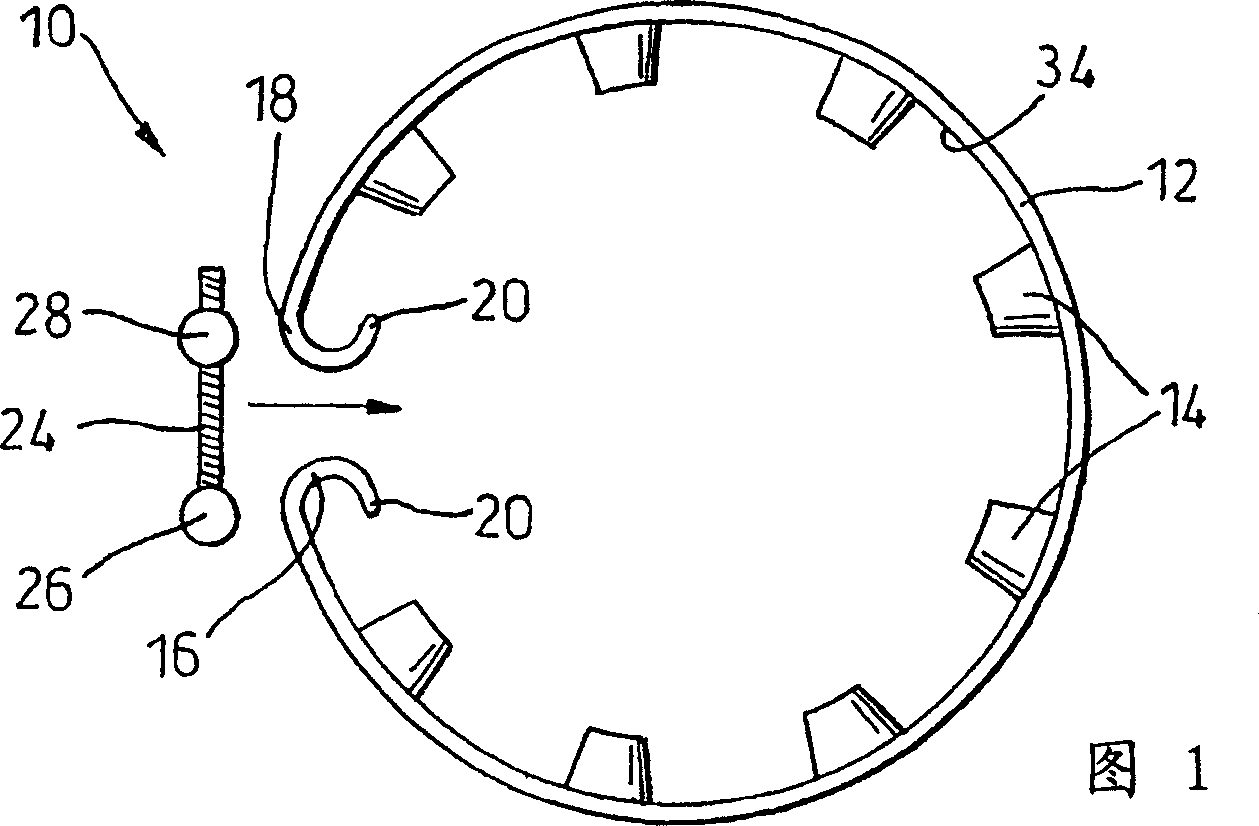

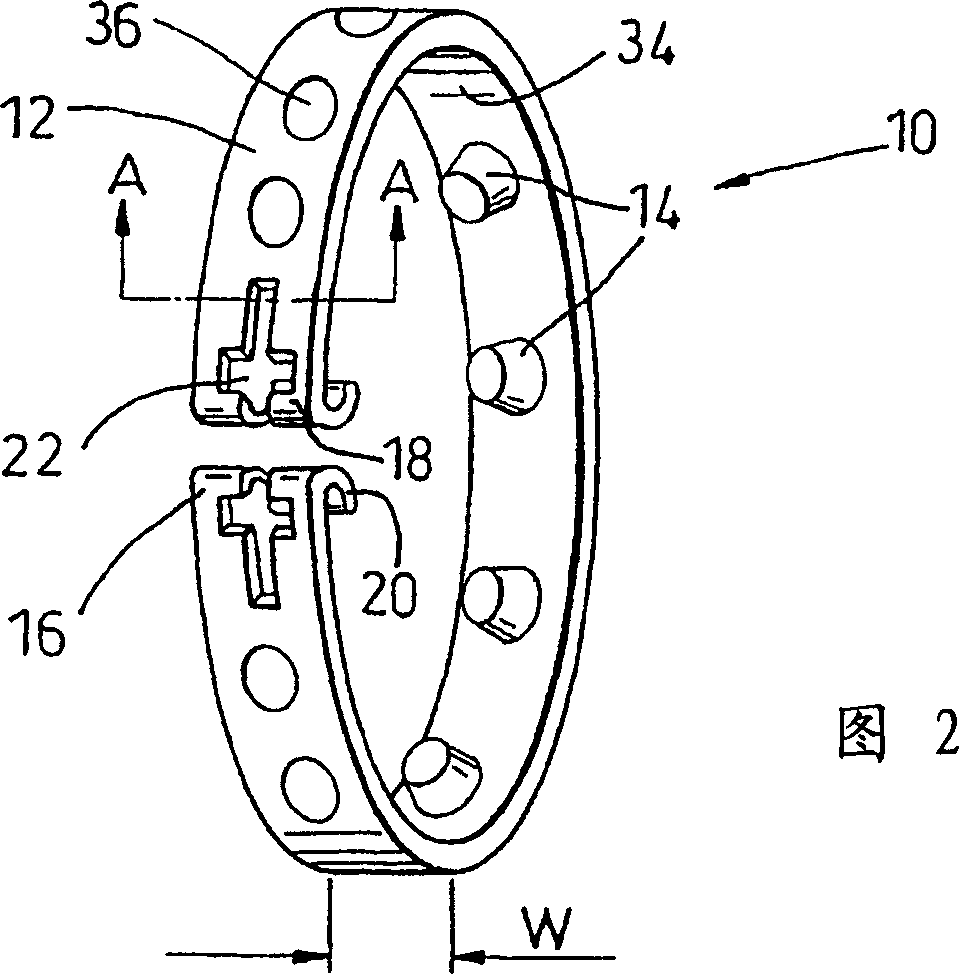

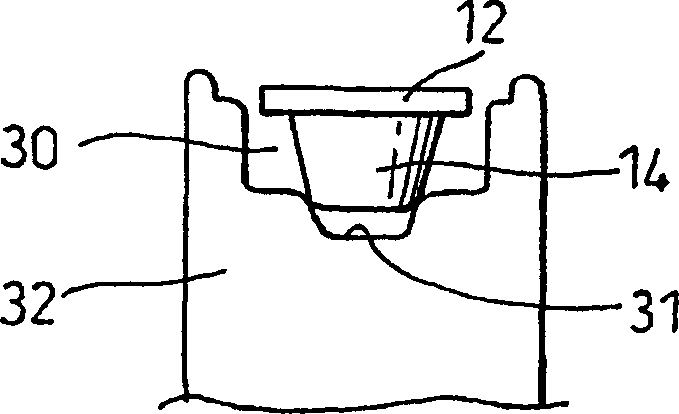

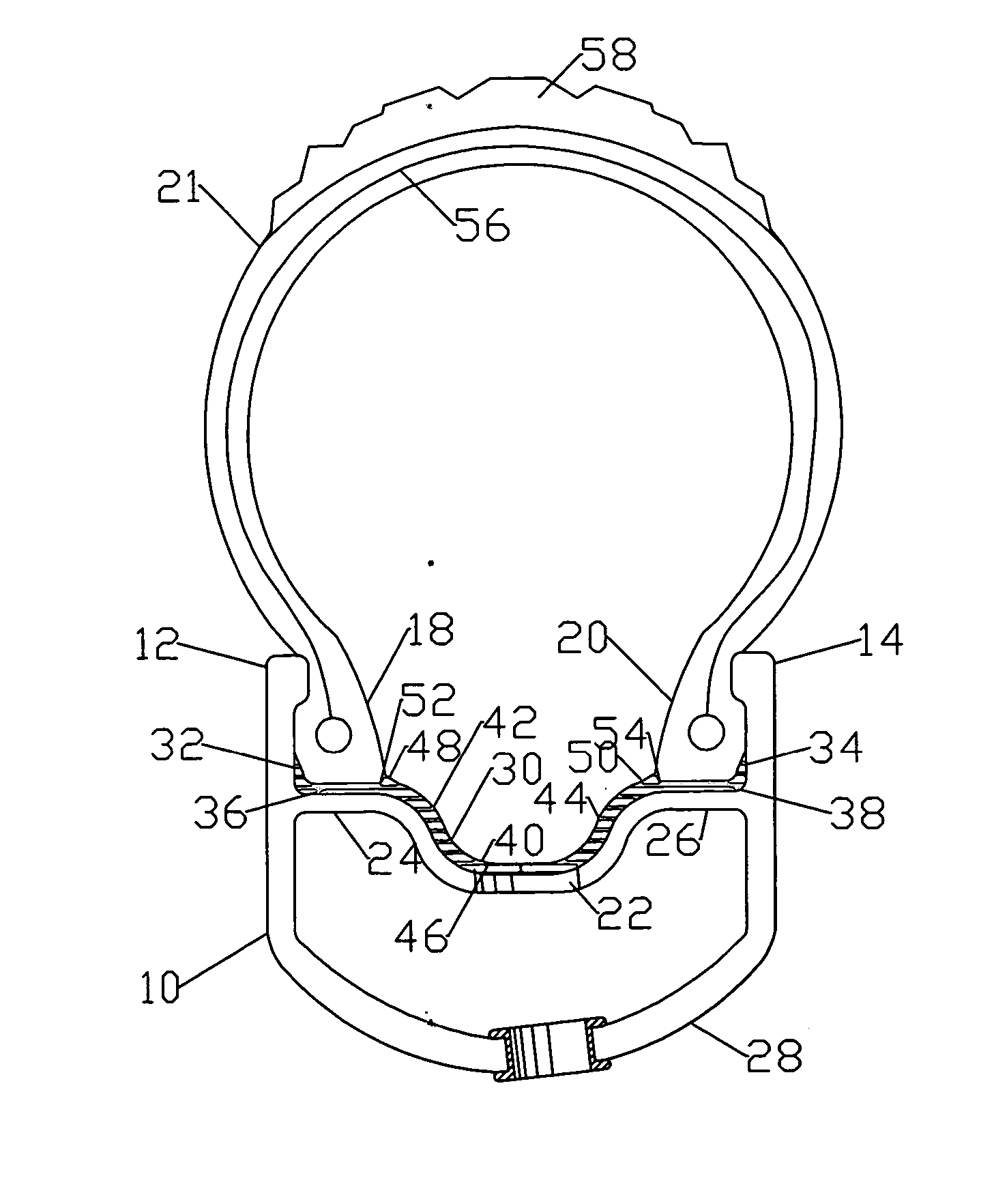

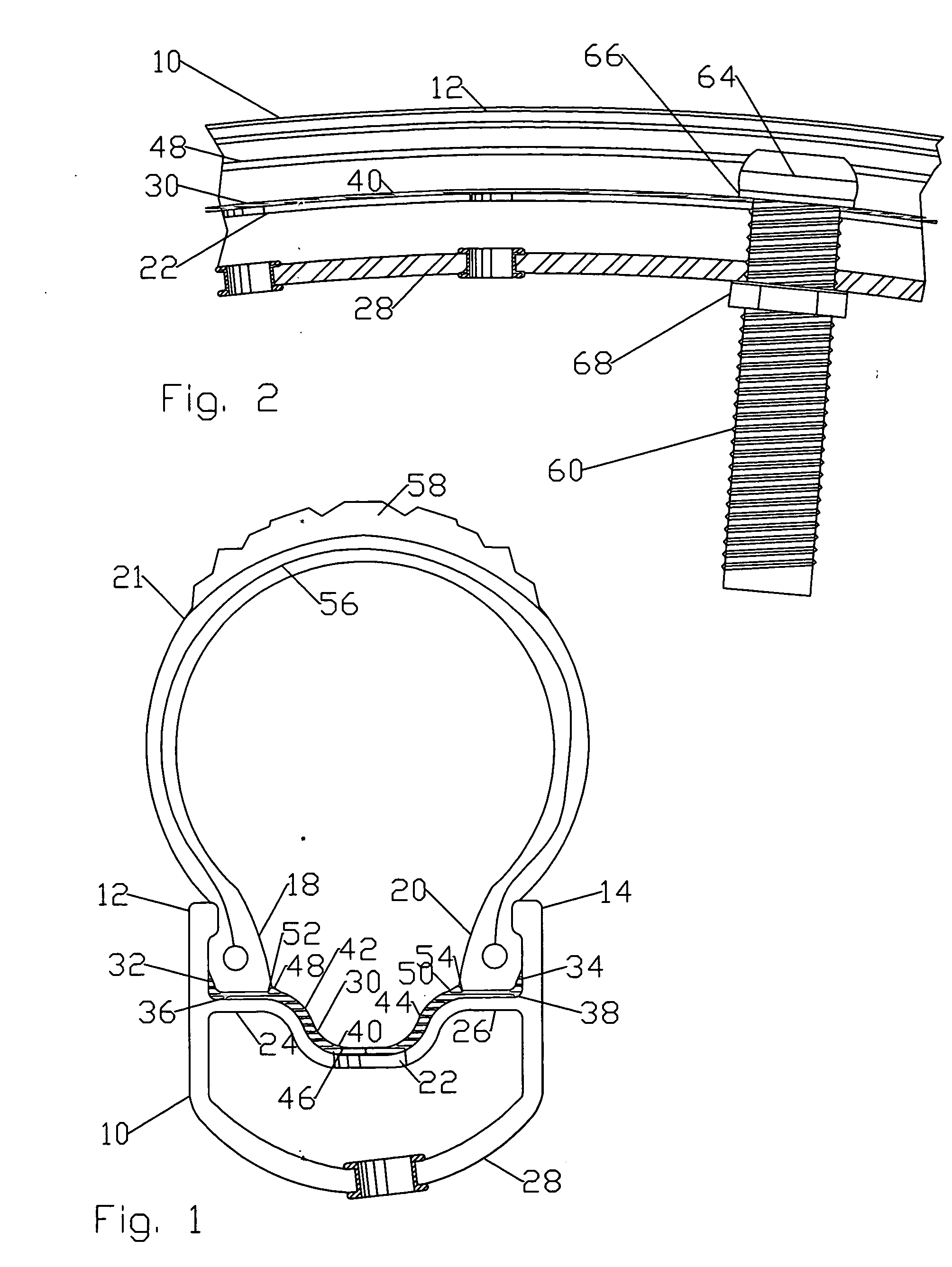

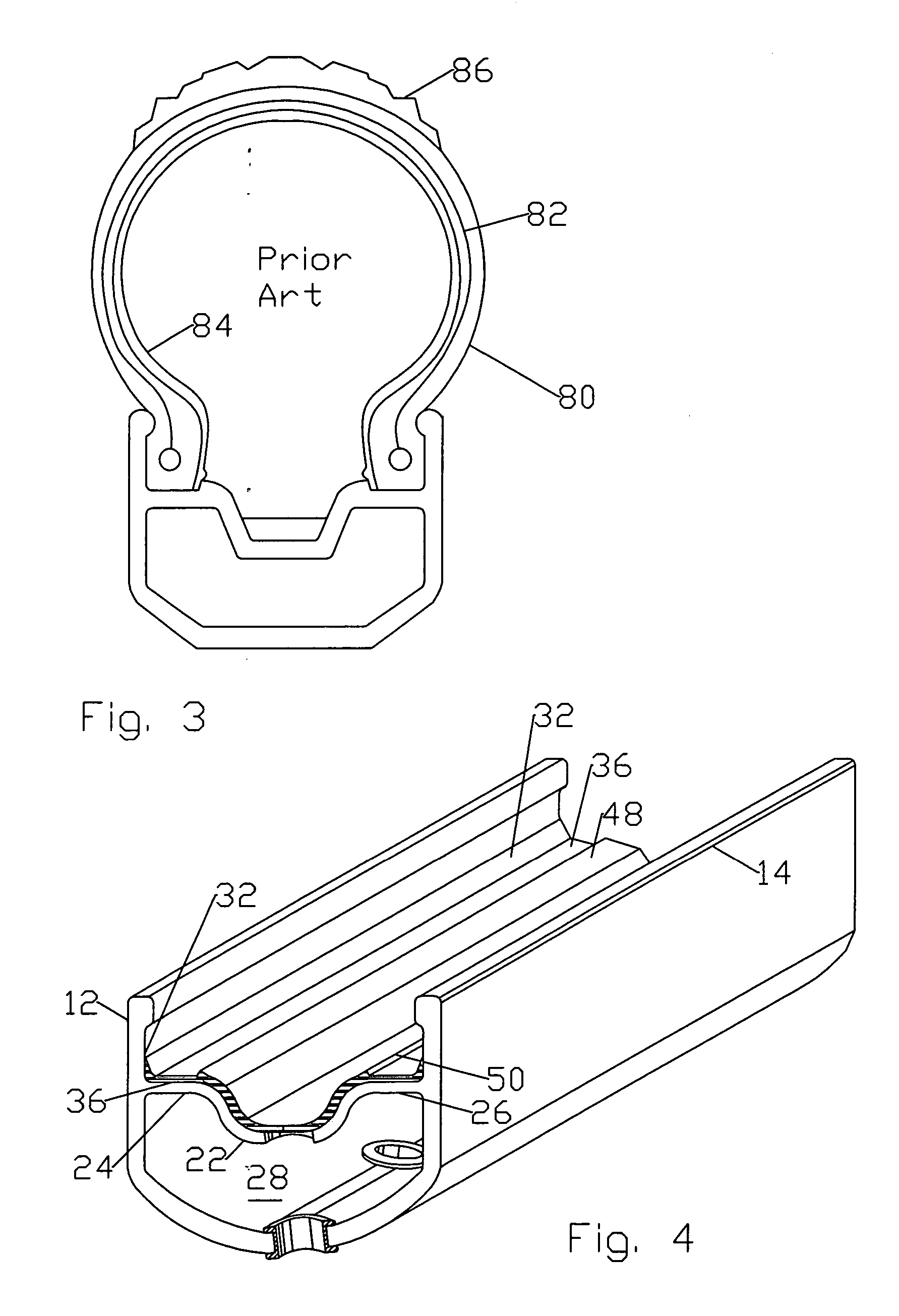

Band device for a wheel rim

An assembly ( 10 ) for location around a wheel rim ( 32 ) includes an annular support band ( 12 ) being formed of a relatively inextensible material. The support band ( 12 ) is split at at least one circumferential location to define a pair of opposed ends ( 16, 18 ). Adjustment bolt ( 24 ) is operably connected to the opposed ends ( 16, 18 ) for enabling adjustment of the diameter of the support band ( 12 ), and feet ( 14 ) depend from the radially inner face ( 34 ) of the support band ( 12 ). The feet ( 14 ) are formed from a relatively non-compressible material and, in use, are seated upon the wheel rim ( 32 ) to maintain the support band ( 12 ) in a spaced apart relationship with the wheel rim ( 32 ). The assembly may be adapted for use as a runflat assembly or as a beadlock assembly.

Owner:蒂龙爆胎保护有限公司

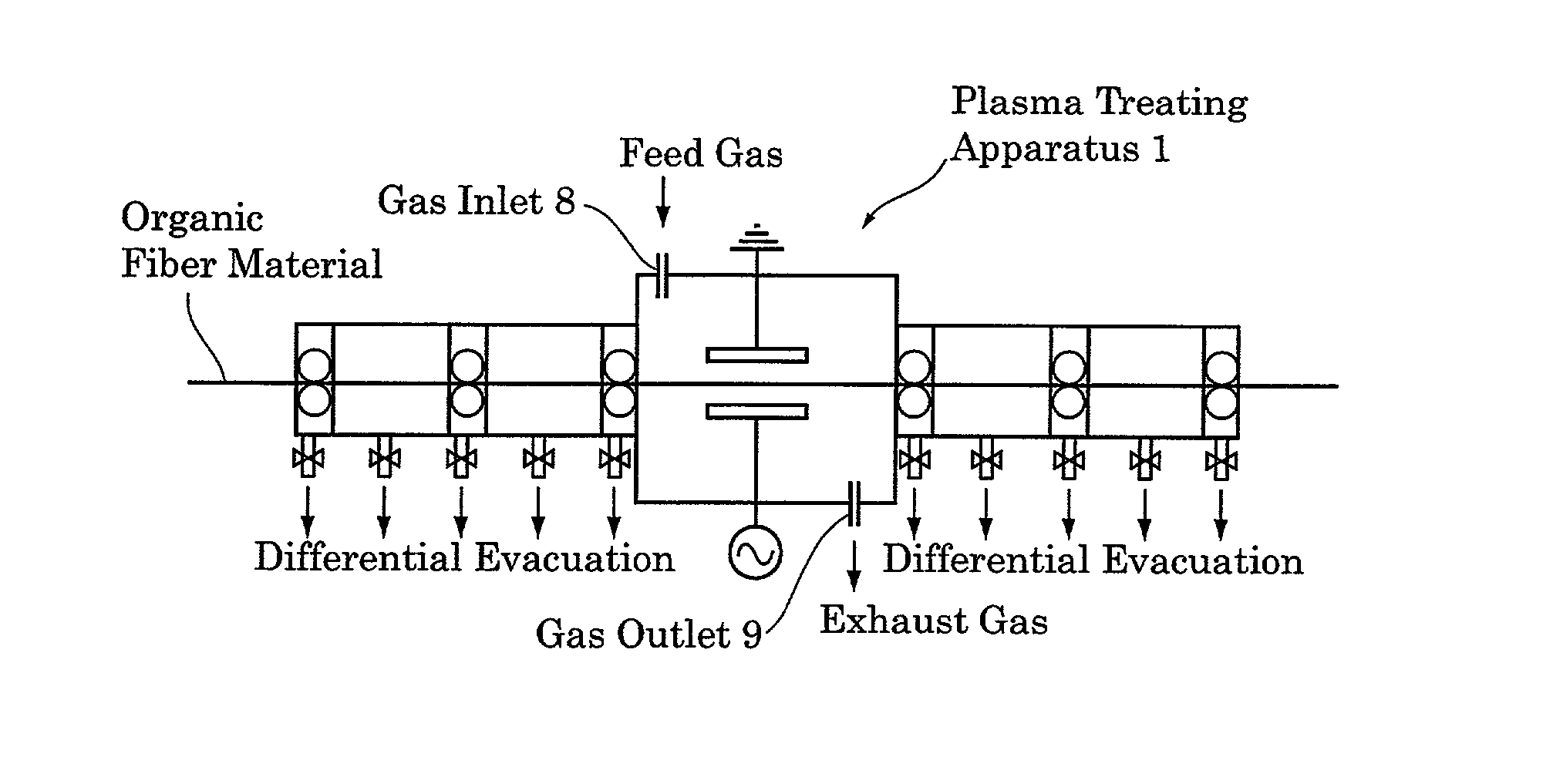

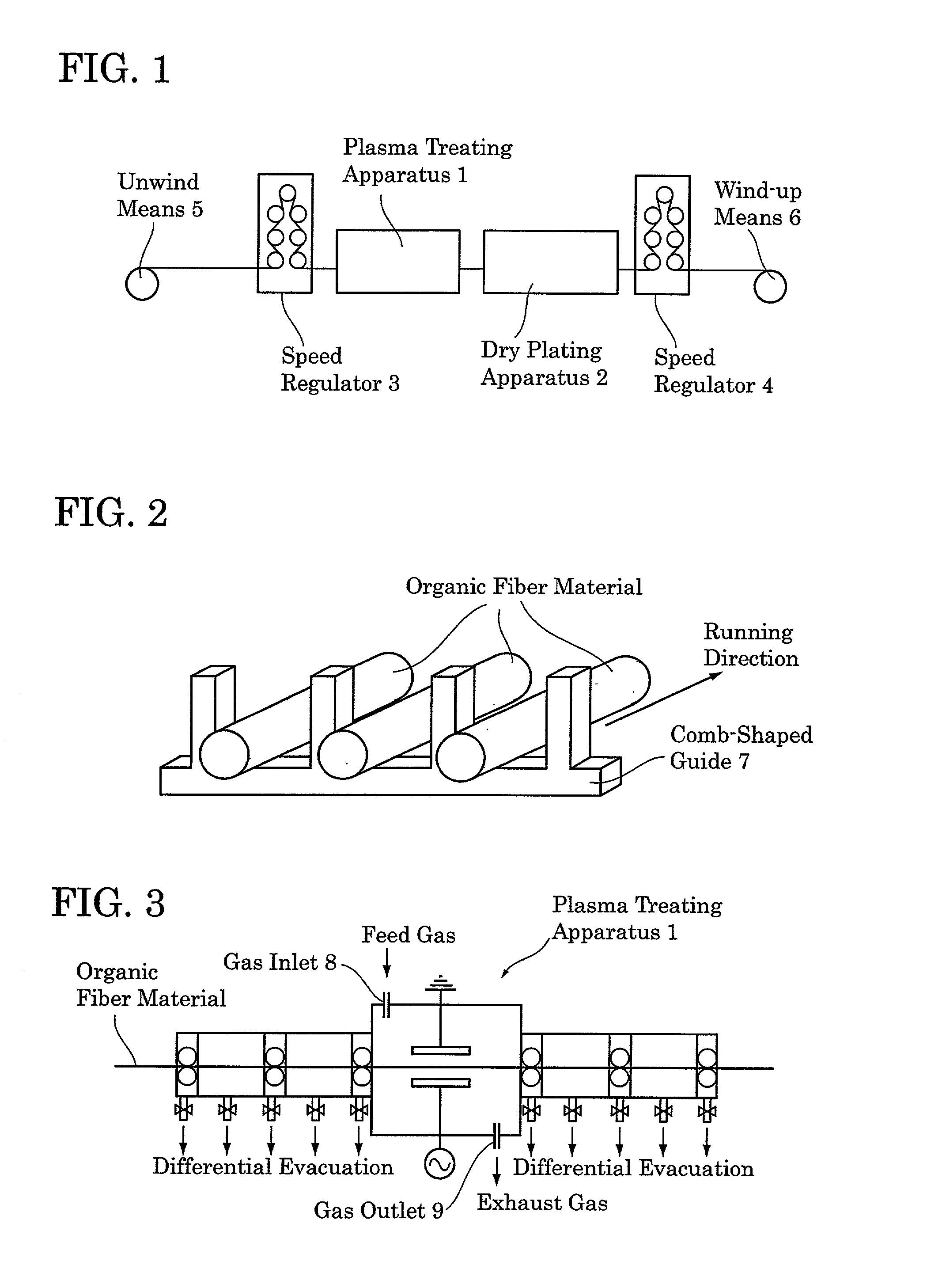

Rubber-reinforcing fiber, process for producing the same, and rubber product and pneumatic tire each made with the same

InactiveUS20030000619A1Sufficient fatigue resistanceSolve the lack of resistanceLiquid surface applicatorsTyresFiberTitanium

The rubber-reinforcing fiber of the present invention is provided with a coating layer of a thickness of 10 Å to 40 mum. The coating layer is formed by dry plating and contains at least one metal and / or metal compound selected from the group consisting of cobalt, zinc, copper, titanium, silver, nickel and compounds of the aforesaid metals. With such a coating layer, the rubber-reinforcing fiber of the present invention forms a firm adhesion to a rubber component and drastically improves the fatigue resistance and durability of a rubber article, particularly, a pneumatic tire.

Owner:BRIDGESTONE CORP

Non-pneumatic resilient tire

InactiveUS7032634B2Improve comfortImprove adhesionNon-inflatable tyresSpecial tyresEngineeringMechanical engineering

Owner:CONCEPTION & DEV MICHELIN SA

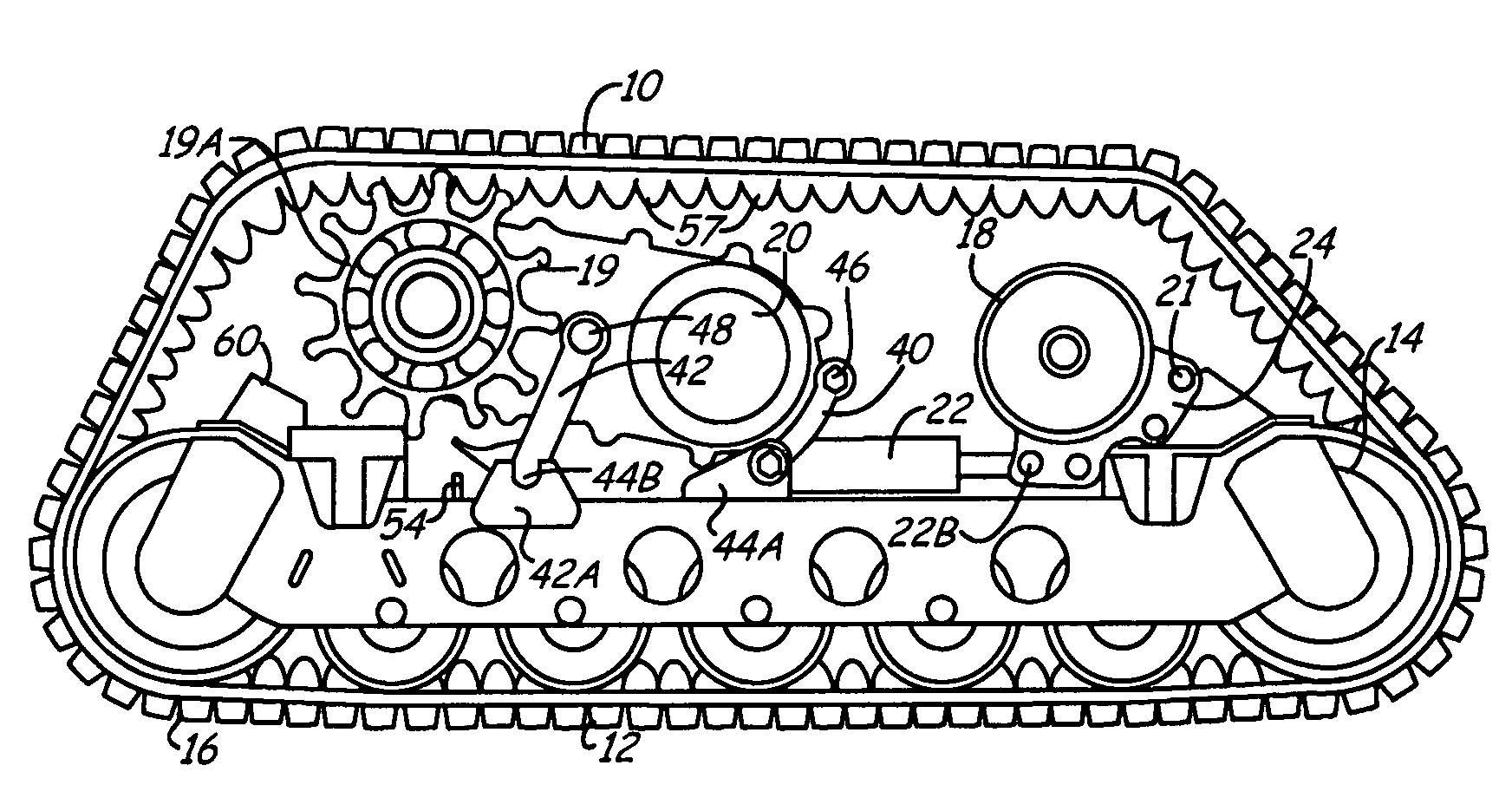

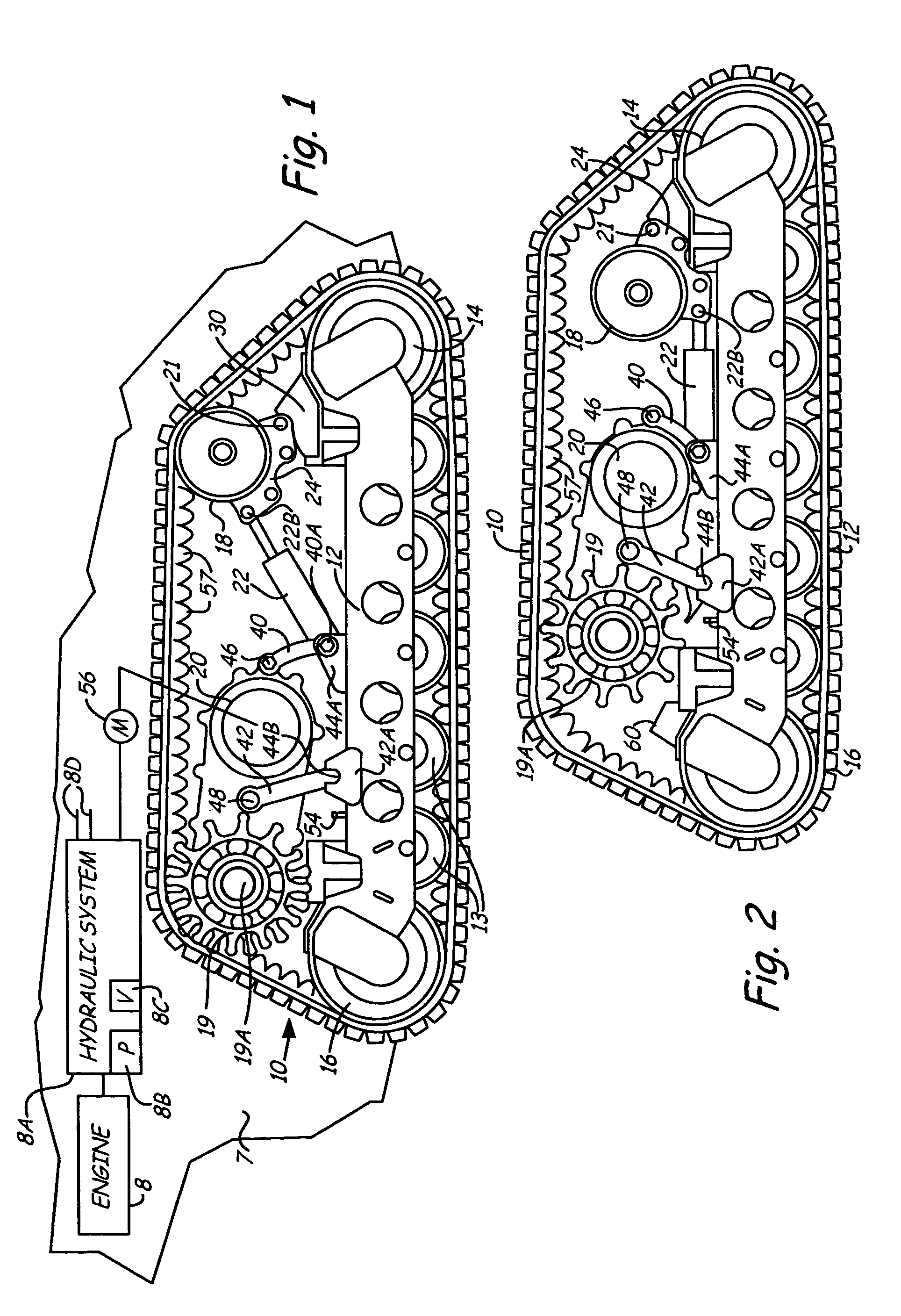

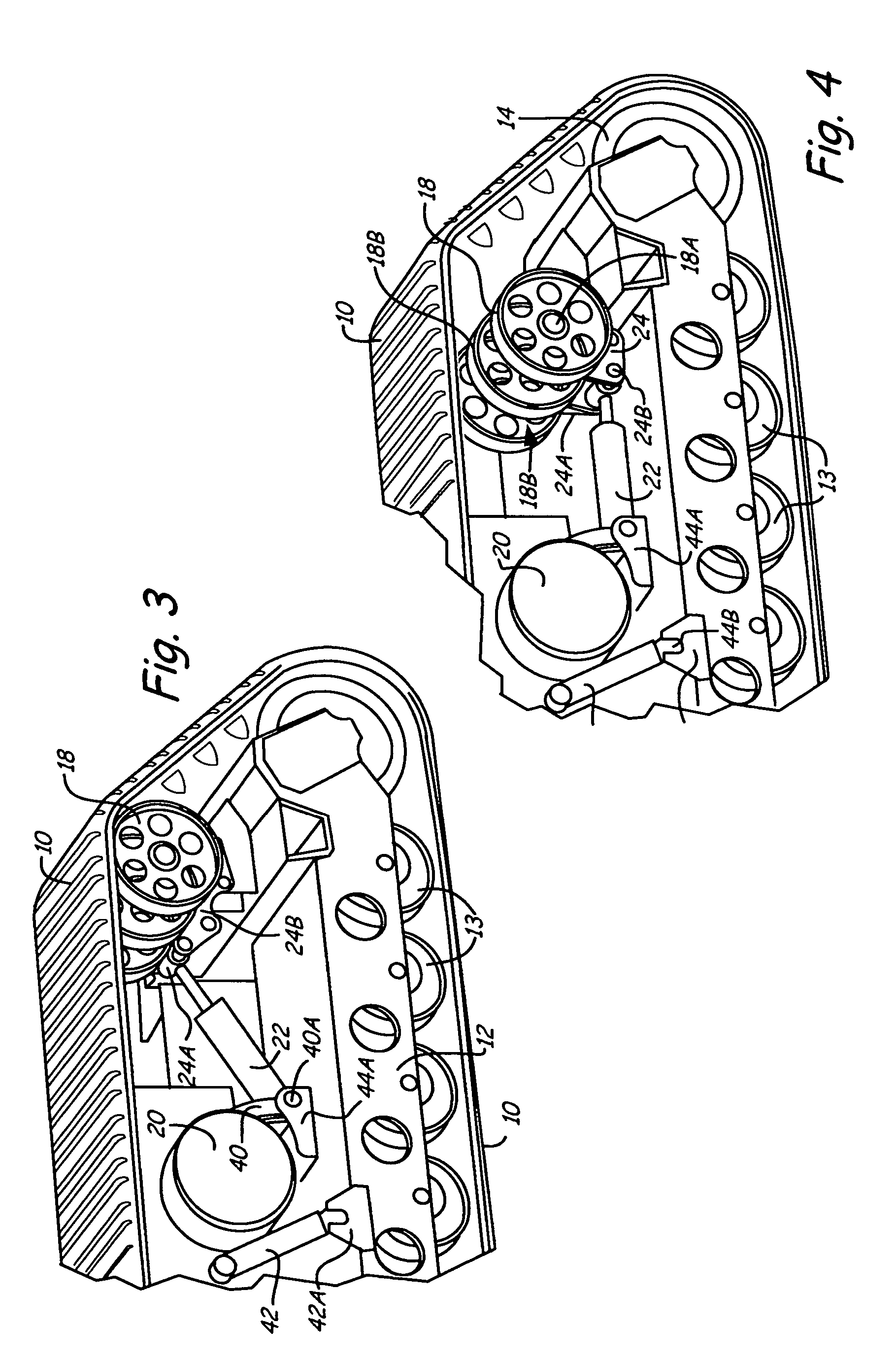

Collapsible track undercarriage for installation and tensioning

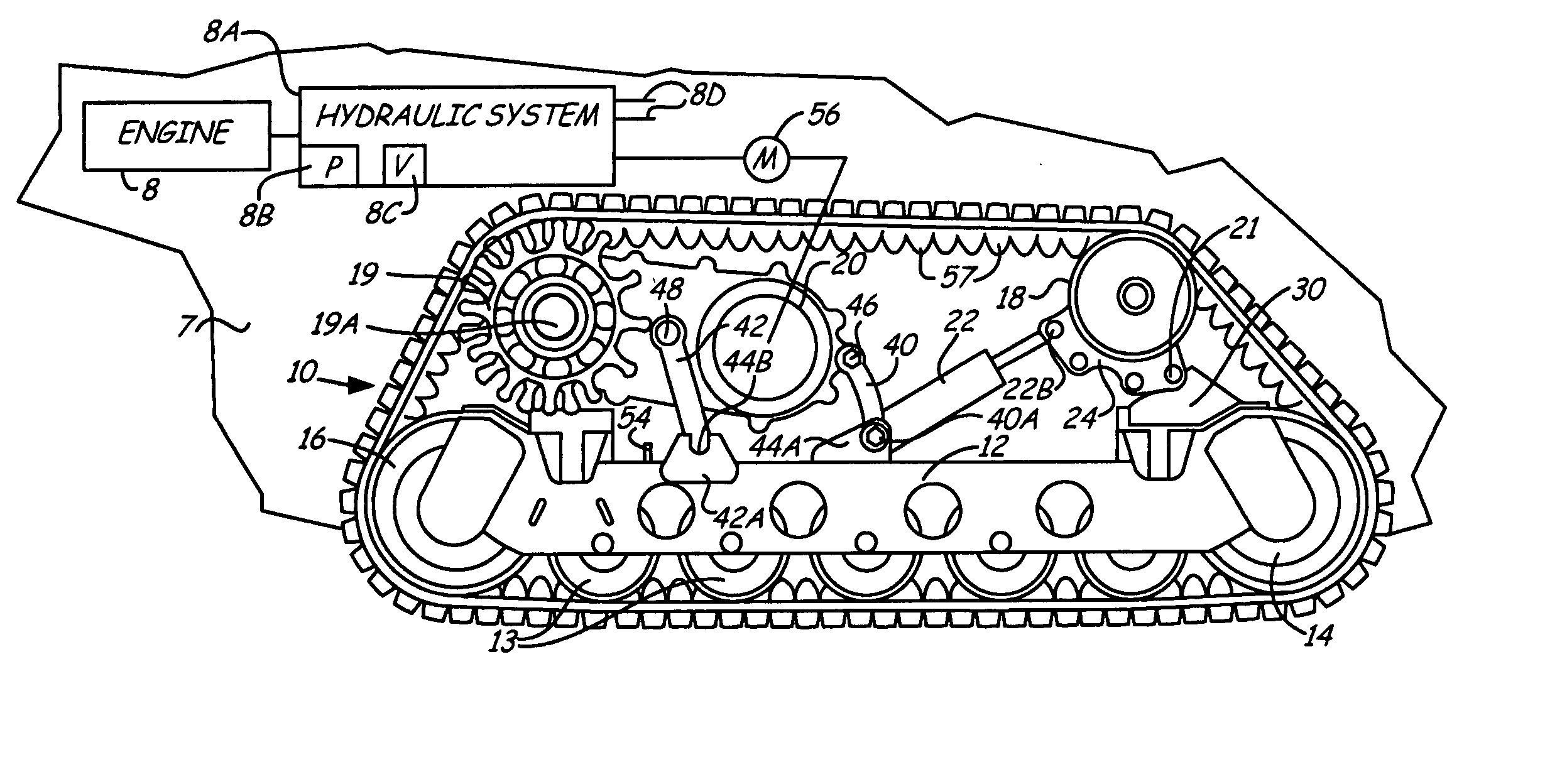

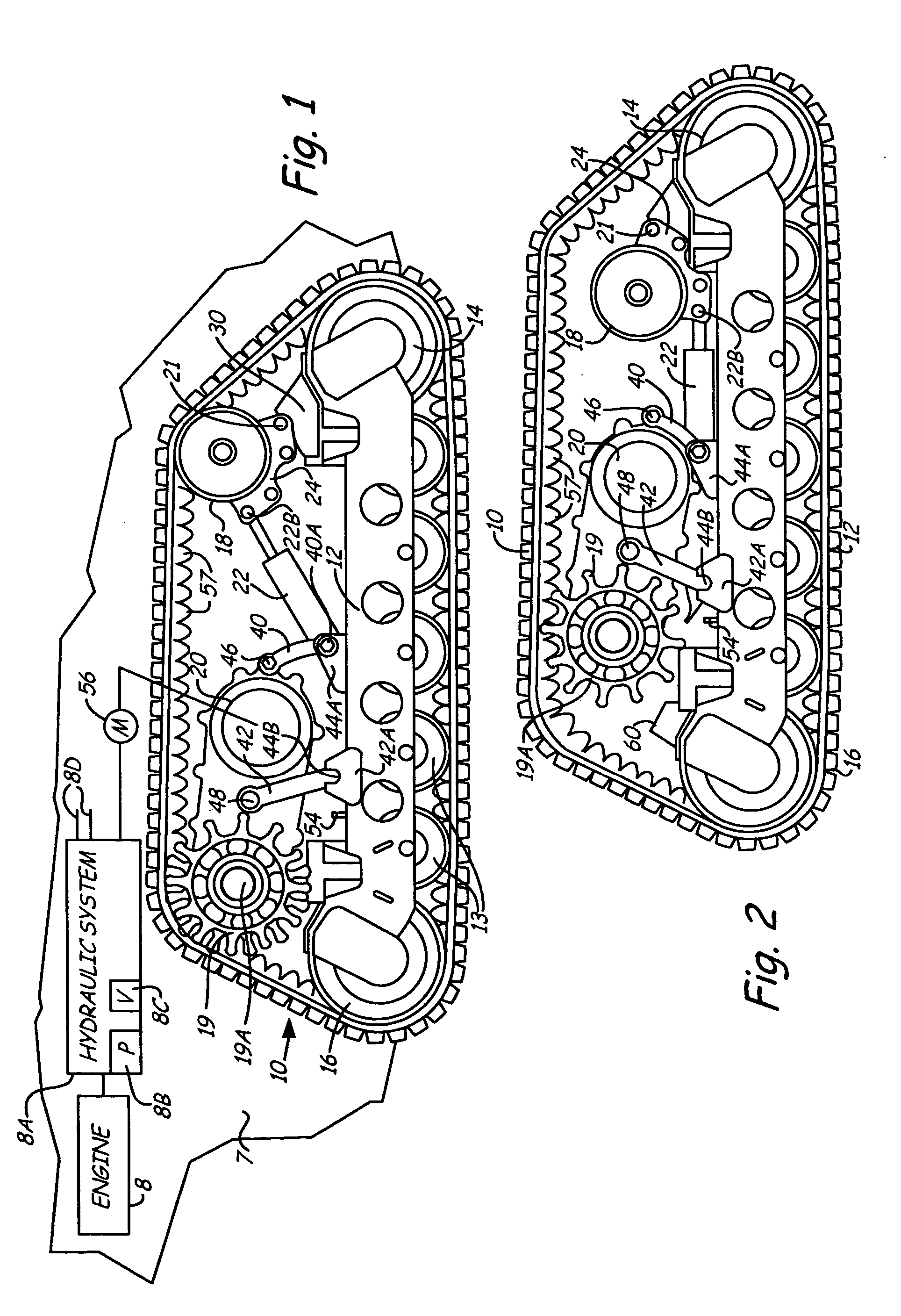

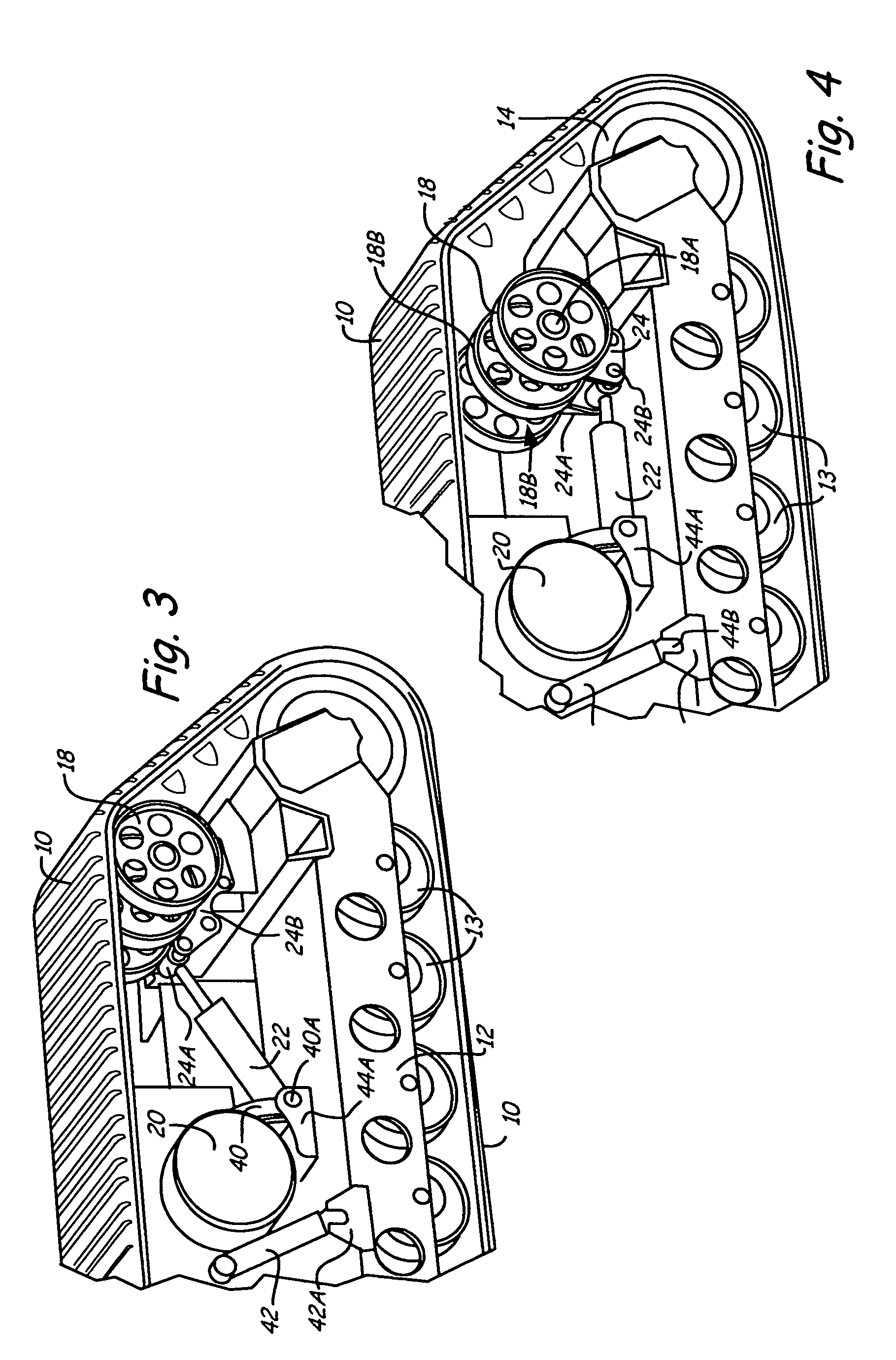

A track frame or undercarriage is made to support a rubber track on suitable guide rollers. A tensioning roller is provided as one of the guide rollers on the interior of the track and is mounted on a pivoting bracket. The pivoting bracket moves the tensioning roller to a working position for creating tension in the track. An actuator provides a known force on the pivoting bracket to move the tensioning roller to its working position, using a controlled pressure applied to the actuator. Drive sprockets for the track are mounted onto a drive case that is mounted to the frame through pivoting linkages such that the drive case and the drive sprocket can be held in a working position and retracted away from the track. The position of the tensioning roller is maintained within set limits of retractions during use, by providing a stop to limit the amount that the tensioning roller can retract.

Owner:CLARK EQUIP CO INC

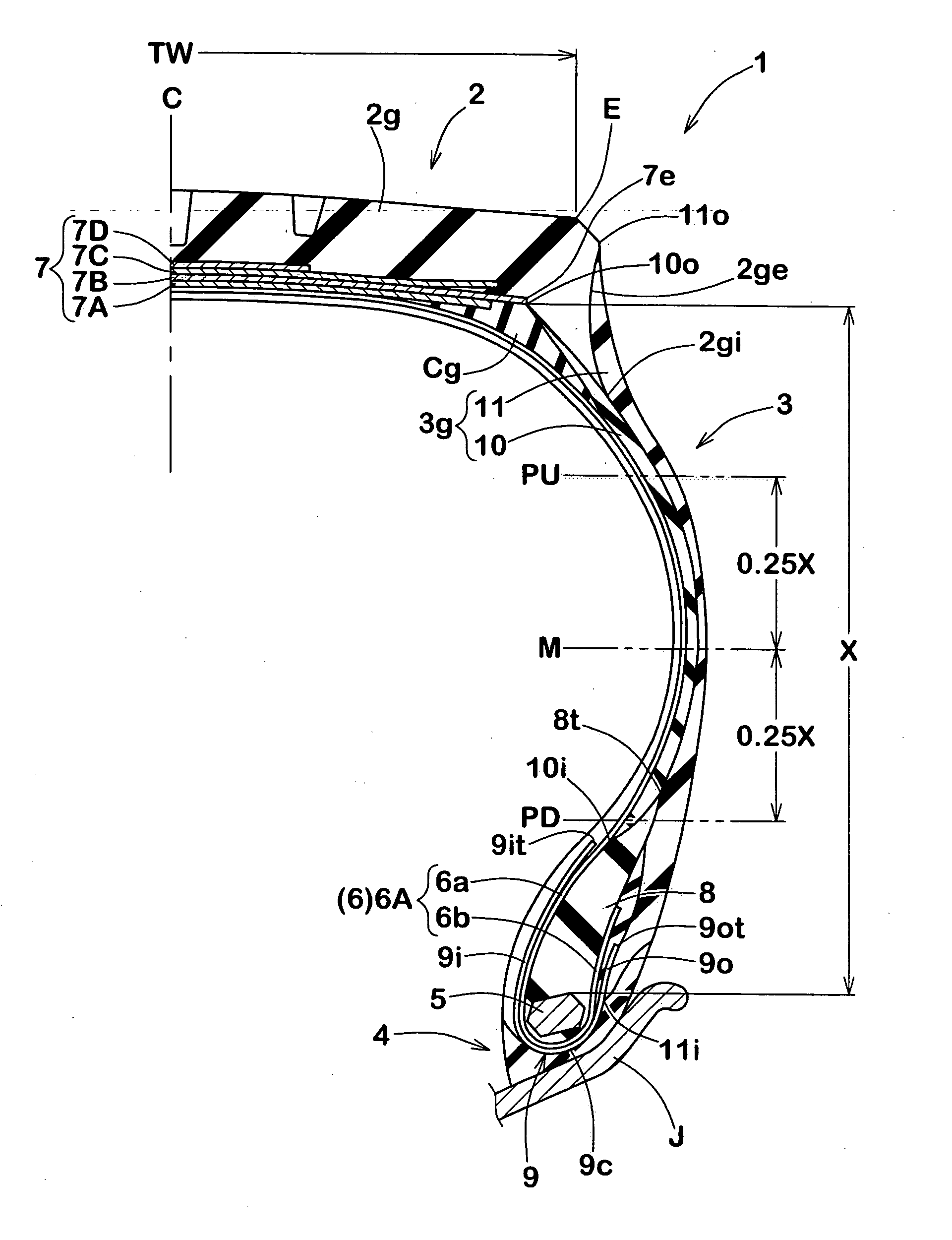

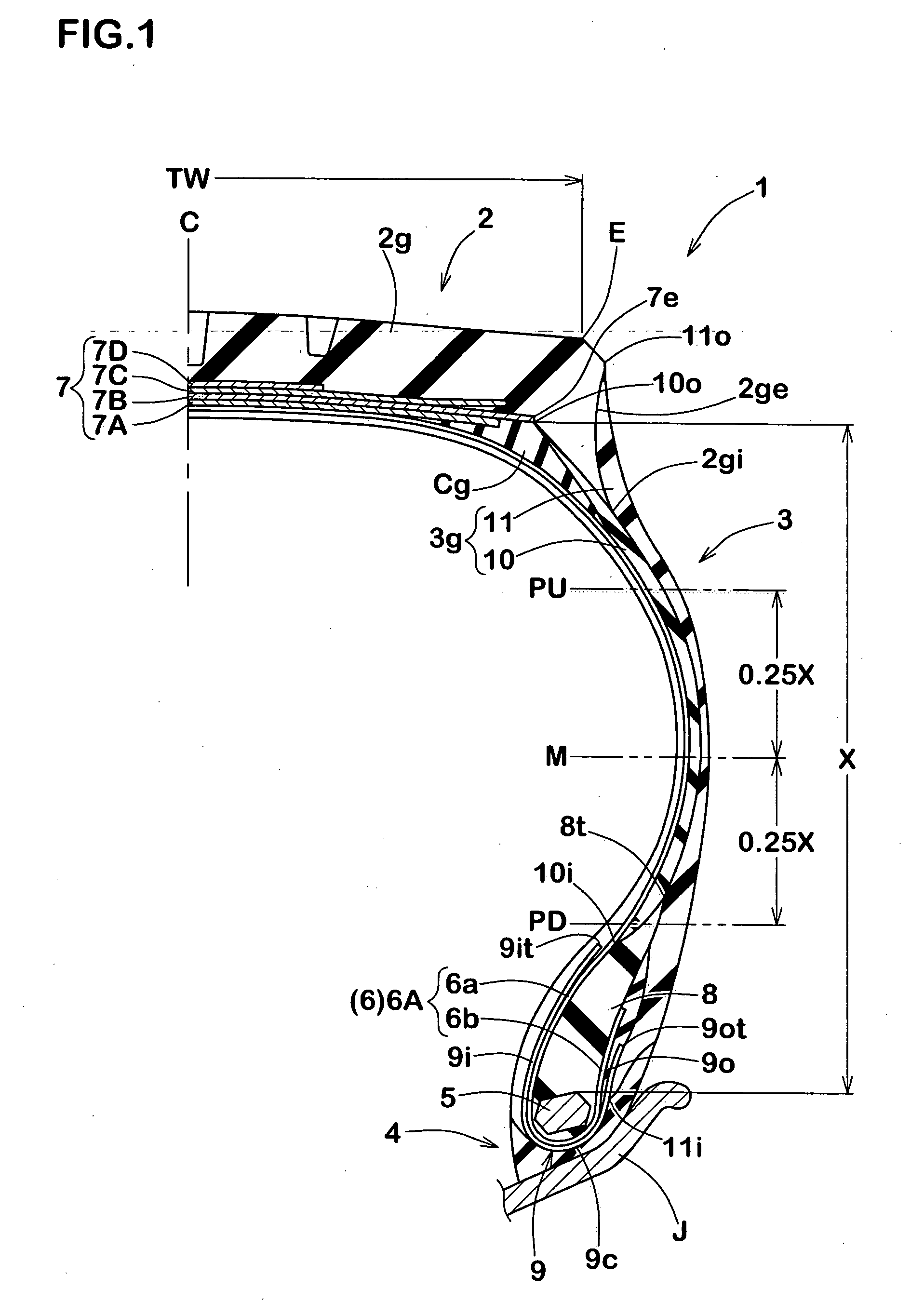

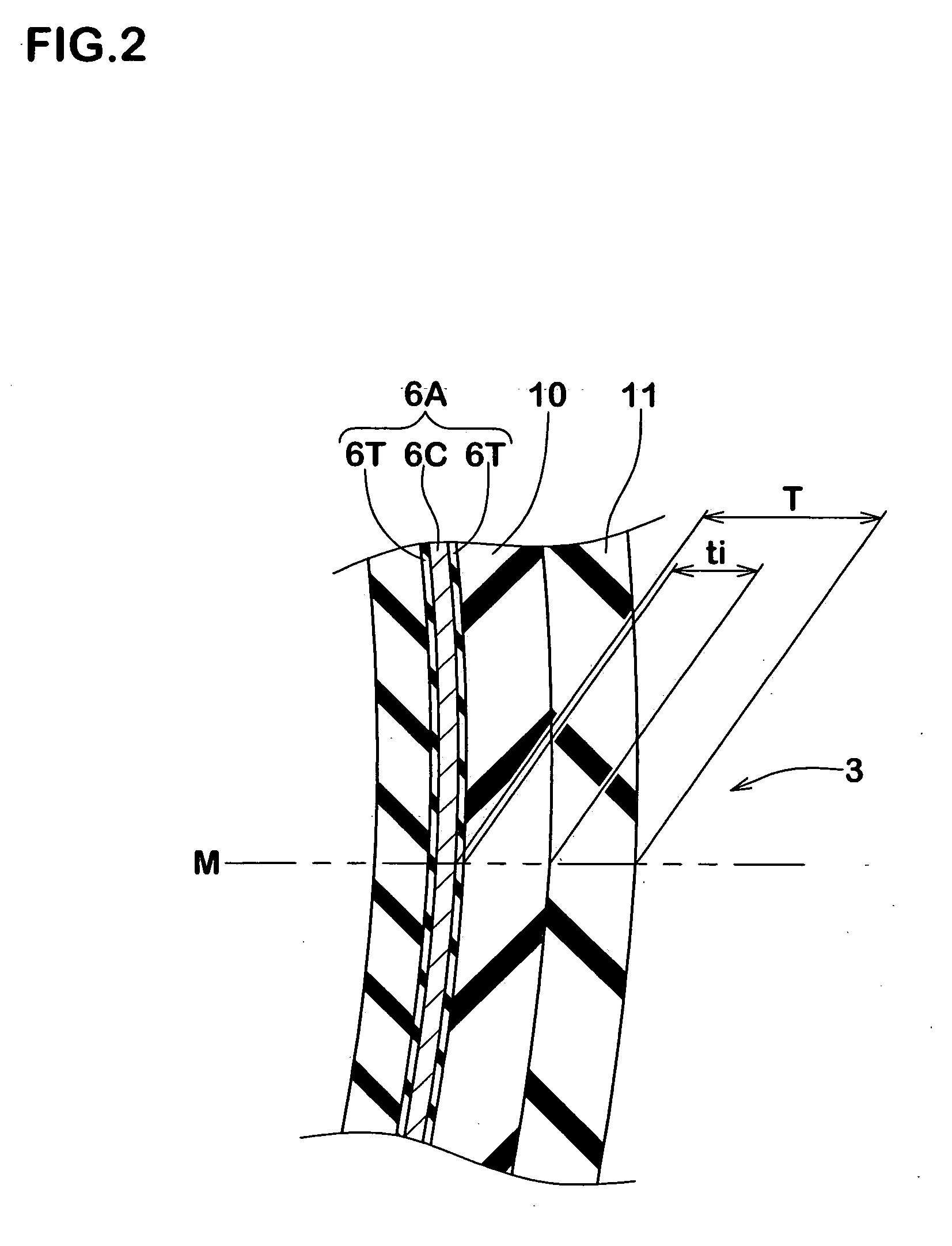

Heavy duty tire

InactiveUS20070151649A1Reduce rolling resistanceDurability can be prevented being deterioratedSpecial tyresPneumatic tyre reinforcementsRolling resistanceEngineering

Owner:SUMITOMO RUBBER IND LTD

Collapsible track undercarriage for installation and tensioning

Owner:DOOSAN BOBCAT NORTH AMERICA INC

Rubber composition and pneumatic tire using the same

InactiveUS20070167555A1Reduce fuel consumptionReduce consumptionSpecial tyresTyre beadsSilicon dioxidePolybutadiene

A rubber composition containing (i) a conjugated diene-based rubber gel having a toluene swelling index of 16 to 70, (ii) a diene-based rubber such as natural rubber, polyisoprene rubber, aromatic vinyl-conjugated diene copolymer rubber and / or polybutadiene rubber, and (iii) an optional carbon black and / or silica and (a) a pneumatic tire using this composition as a high hardness reinforcing layer extending from a bead along a tire sidewalls, in which the fluidity and dimensional stability at the time of extrusion are improved, while maintaining a sufficient hardness of a high hardness reinforced rubber, (b) a pneumatic tire using this composition as two ends of a tire tread extrudate, maintaining a flex fatigue of the two ends of the tread, in which the extrudability and extrusion dimensional stability are improved and (c) a pneumatic tire using the composition as a 1.5 mm to 6 mm thick undertread, in which a high elasticity and relatively thick gauge undertread, and excellent processability and steering stability are provided.

Owner:THE YOKOHAMA RUBBER CO LTD +1

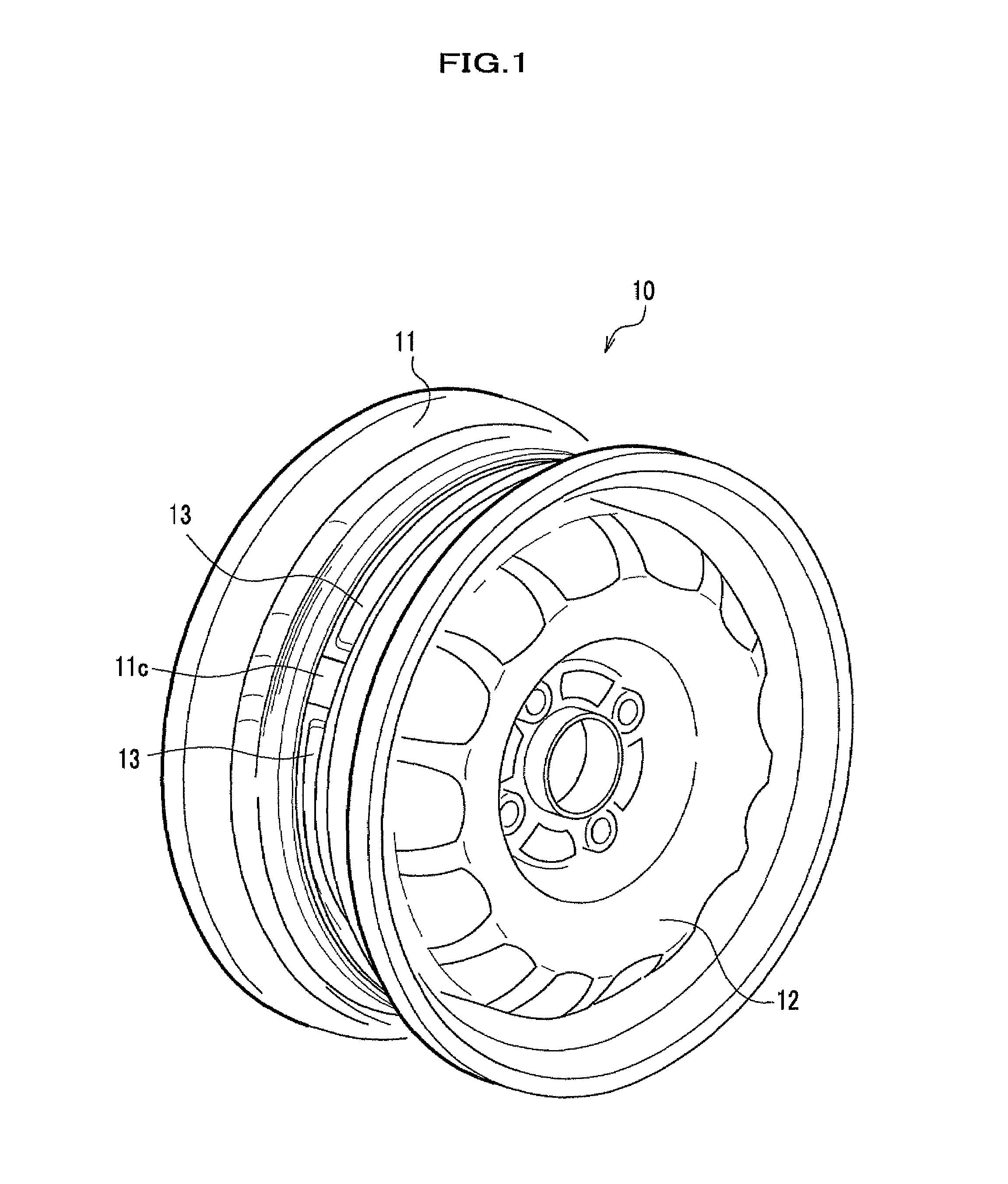

Vehicle wheel

A vehicle wheel in which an additional air chamber member in a tire air chamber is fixed on an outer circumferential surface of a well portion, includes: a first vertical wall surface rising outward in a radial direction from the outer circumferential surface of the well portion and extending in a circumferential direction of the outer circumferential surface; and a second vertical wall surface formed in the well portion facing the first vertical wall surface. The additional air chamber member has an additional air chamber and a communication hole formed therein. The communication hole provides communication between the additional air chamber and the tire air chamber. The additional air chamber member is fitted between the first and second vertical wall surfaces. Side end portions of the additional air chamber member in a width direction of the vehicle wheel are secured between the first and second vertical wall surfaces.

Owner:HONDA MOTOR CO LTD

Sealed tubeless tire bicycle wheel

InactiveUS20050210675A1Good handling characteristicsImprove featuresWithout separate inflatable insertsWith separate inflatable insertsTubeless tireAutomotive engineering

Pneumatic tires adapted to use on bicycles have a number of criteria that need to be evaluated. For high performance bicycle riding, such as in mountain bike races, it is advantageous to optimize performance. Standard tires with tubes have ease of repair in the replacement of a punctured tube, have the ability to maintain pressure for long periods, and do not require special adaptation of the rim for sealing.

Owner:PRICE CHAD NATHANIEL +1

Diene rubber, process for producing the rubber and rubber composition containing the same

InactiveUS6147178AReduce heat buildupReduce rolling resistanceOrganic-compounds/hydrides/coordination-complexes catalystsSpecial tyresRolling resistancePolymer science

PCT No. PCT / JP97 / 00519 Sec. 371 Date Aug. 24, 1998 Sec. 102(e) Date Aug. 24, 1998 PCT Filed Feb. 24, 1997 PCT Pub. No. WO97 / 31028 PCT Pub. Date Aug. 28, 1997A diene rubber comprised of a conjugated diene homopolymer or a conjugated diene / aromatic vinyl copolymer; the homopolymer or copolymer having on at least one end of its polymer chain a quaternary ammonium group to which four carbon atoms have been bound; at least 10% of the bound conjugated diene units being a vinyl bond; and the homopolymer or copolymer further having a weight average molecular weight (Mw) of 100,000 to 2,000,000. This rubber exhibits well reduced heat build-up, which is an index of a well reduced rolling resistance, and having tensile strength and abrasion resistance.

Owner:ZEON CORP

Rubber composition for tire, tire member and tire

A rubber composition for a tire comprising a rubber component containing at least one of a natural rubber and an epoxidized natural rubber, not less than 15 parts by mass of silica based on 100 parts by mass of the rubber component, and not less than 0.5 part by mass of calcium stearate based on 100 parts by mass of the rubber component, a tire member made using the rubber composition for a tire, and a tire made using the tire member.

Owner:SUMITOMO RUBBER IND LTD

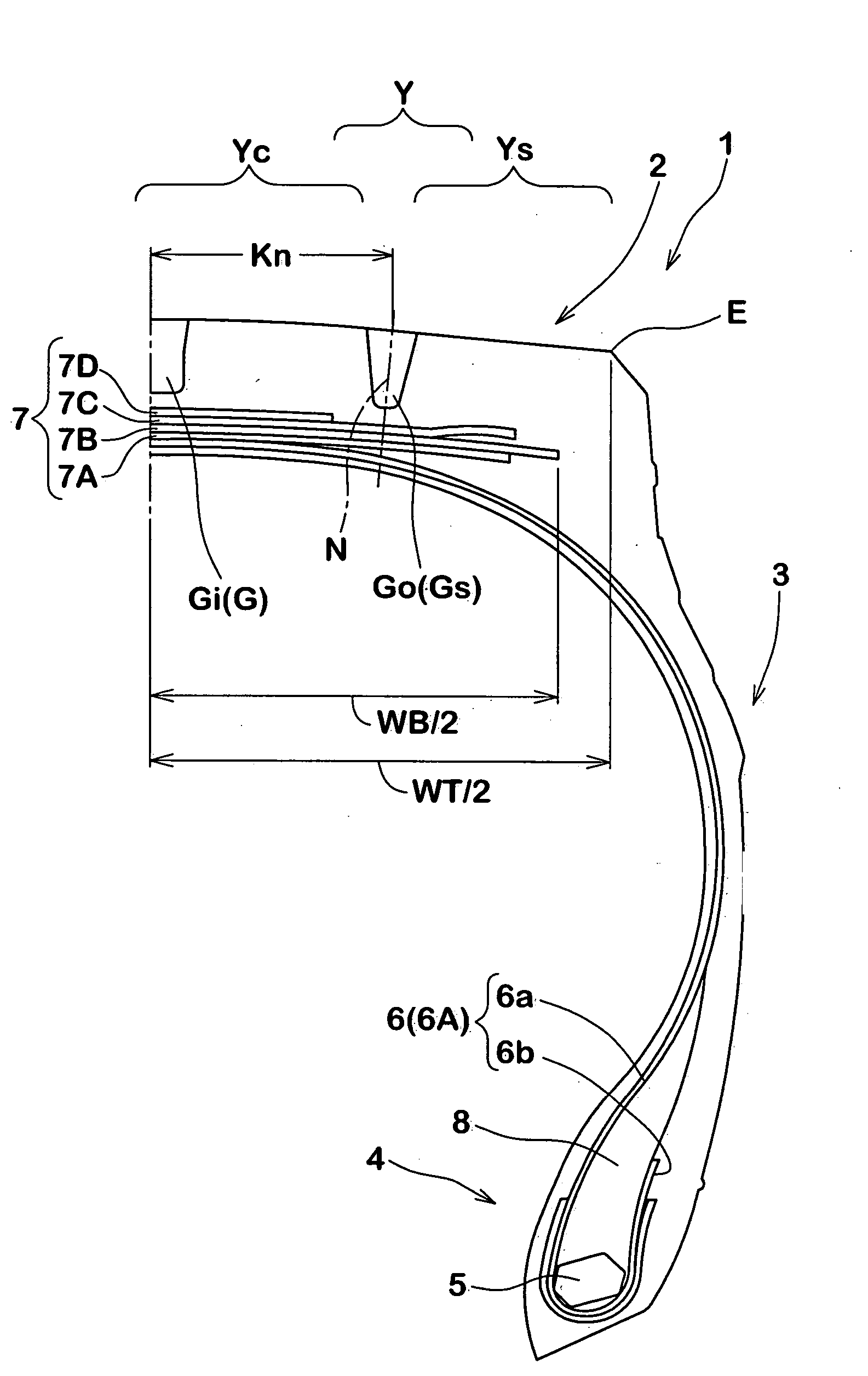

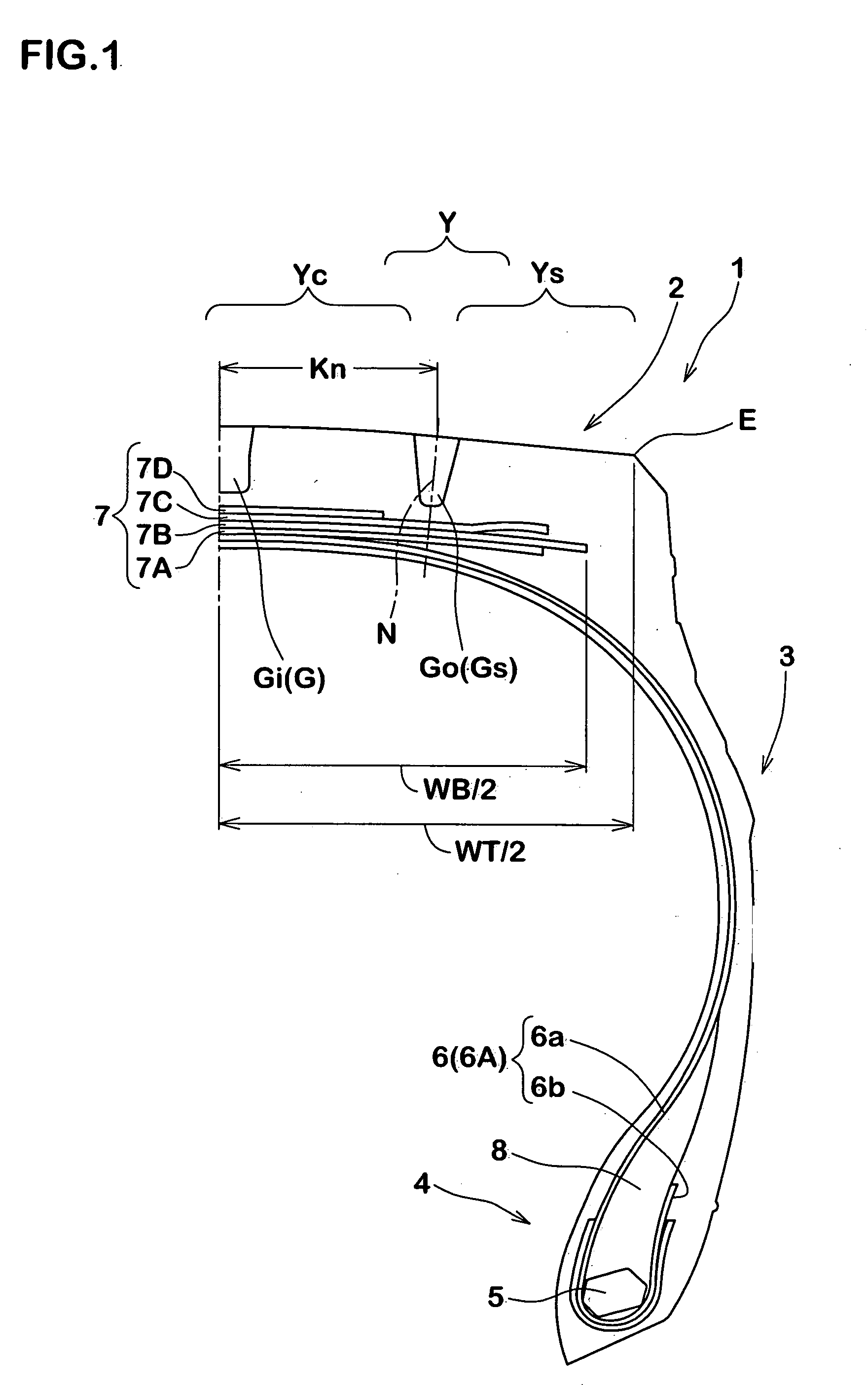

Heavy duty tire

InactiveUS20050045260A1Improve bead durabilityEffectively restrict occurrenceHeavy duty tyresHeavy duty vehicleTire beadHeavy duty

It is a subject to restrict occurrence of deficient moldings and to improve the bead durability without harming the advantages provided through a bead wind structure, and for this purpose, a ply turn-up portion of a carcass comprises a winding portion, which continues from a main portion that is bent along a bead core, which extends while being spaced from the bead core, and which inclines at an angle θ that is smaller than 90°. A height of a tip end of the winding portion from an outer surface of the bead core is 3 to 15 mm. A cushion rubber having a complex elastic modulus E1* at 70° C. of 2 to 25 MPa is disposed in a region surrounded by a ply main body portion of the carcass, the bead core and the winding portion.

Owner:SUMITOMO RUBBER IND LTD

Heavy-duty tire

InactiveUS20050016656A1High level of equalizationInhibits uneven wearPneumatic tyre reinforcementsTyre beadsGround contactEngineering

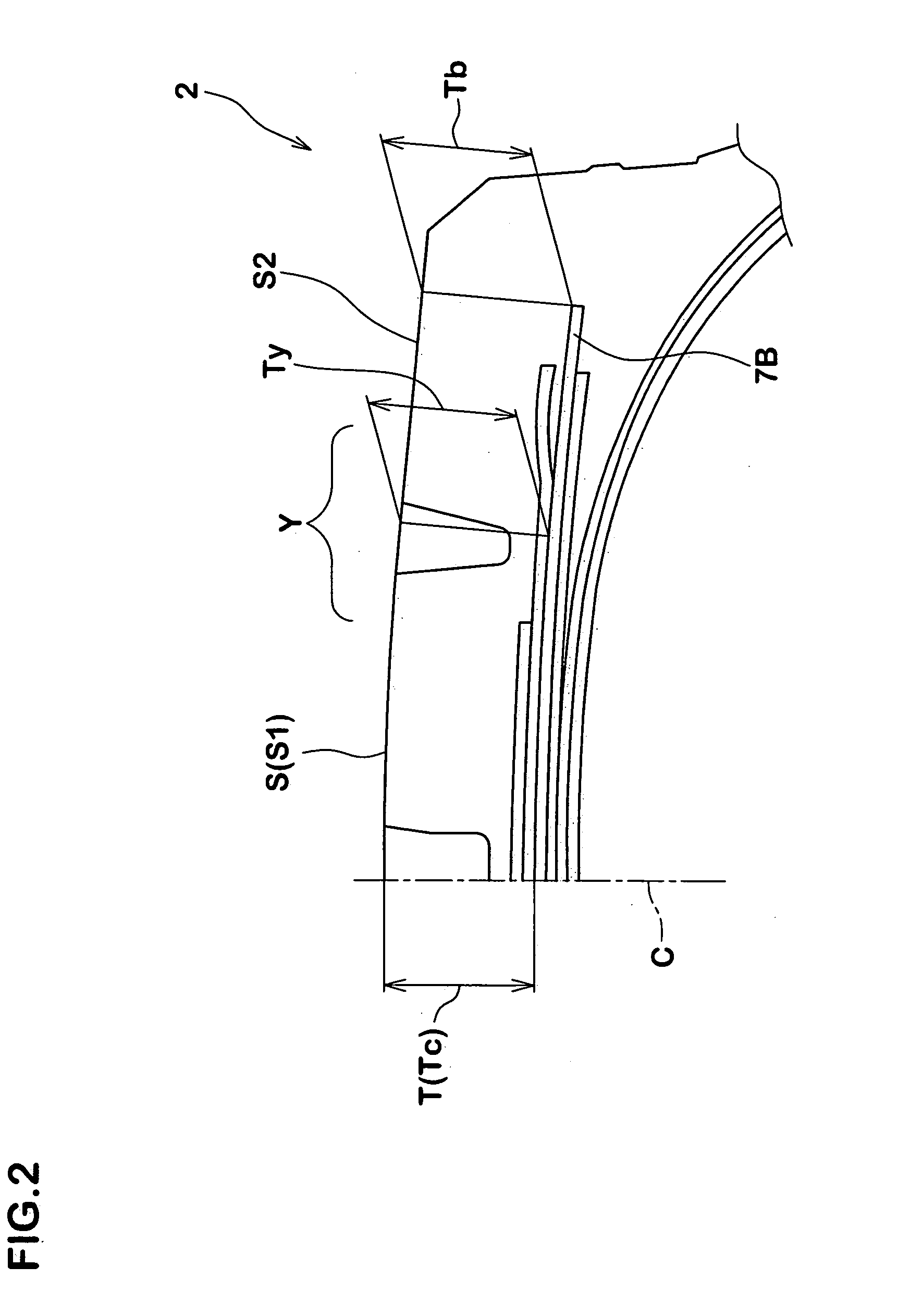

In a ground-contact surface shape of a tire, when a tangent angle formed between an axial direction of the tire and a tangent X at each point P on a profile line of the tire is defined as θ, a tangent angle θ1 in a ground-contact end point Pd is 25° or smaller. When a minimum value of the tangent angle θ in a region Y which is separated away from a tire equator C by a distance in a range of not less than 0.4 times but not more than 0.7 times a half of the ground-contact width of the tread is defined as θ2, and a tangent angle at a 0.9 times point Pq which is separated away from the tire equator C by a distance of 0.9 times the half of the ground-contact width of the tread is defined as θ3, a difference (θ3−θ2) is set in a range of not less than −10° but not more than +10°.

Owner:SUMITOMO RUBBER IND LTD

Vehicle wheel

There is provided a vehicle wheel that can suppress any detachment of a sub air chamber from a well portion when a fixing member between the sub air chamber and the well portion becomes defective by any possibility. A vehicle wheel comprises a sub-air-chamber member which reduces any air column resonance of a tire and which is disposed on an outer circumference surface of a well portion of a rim. The sub-air-chamber member is fixed on the well-portion outer circumference surface, the sub-air-chamber member is covered by a cover made of a rubber from an external side, and the cover is fixed on an outer circumference surface of the rim at both sides of the sub-air-chamber member in a rim width direction.

Owner:HONDA MOTOR CO LTD

Tire with outside-in ply construction

Owner:THE GOODYEAR TIRE & RUBBER CO

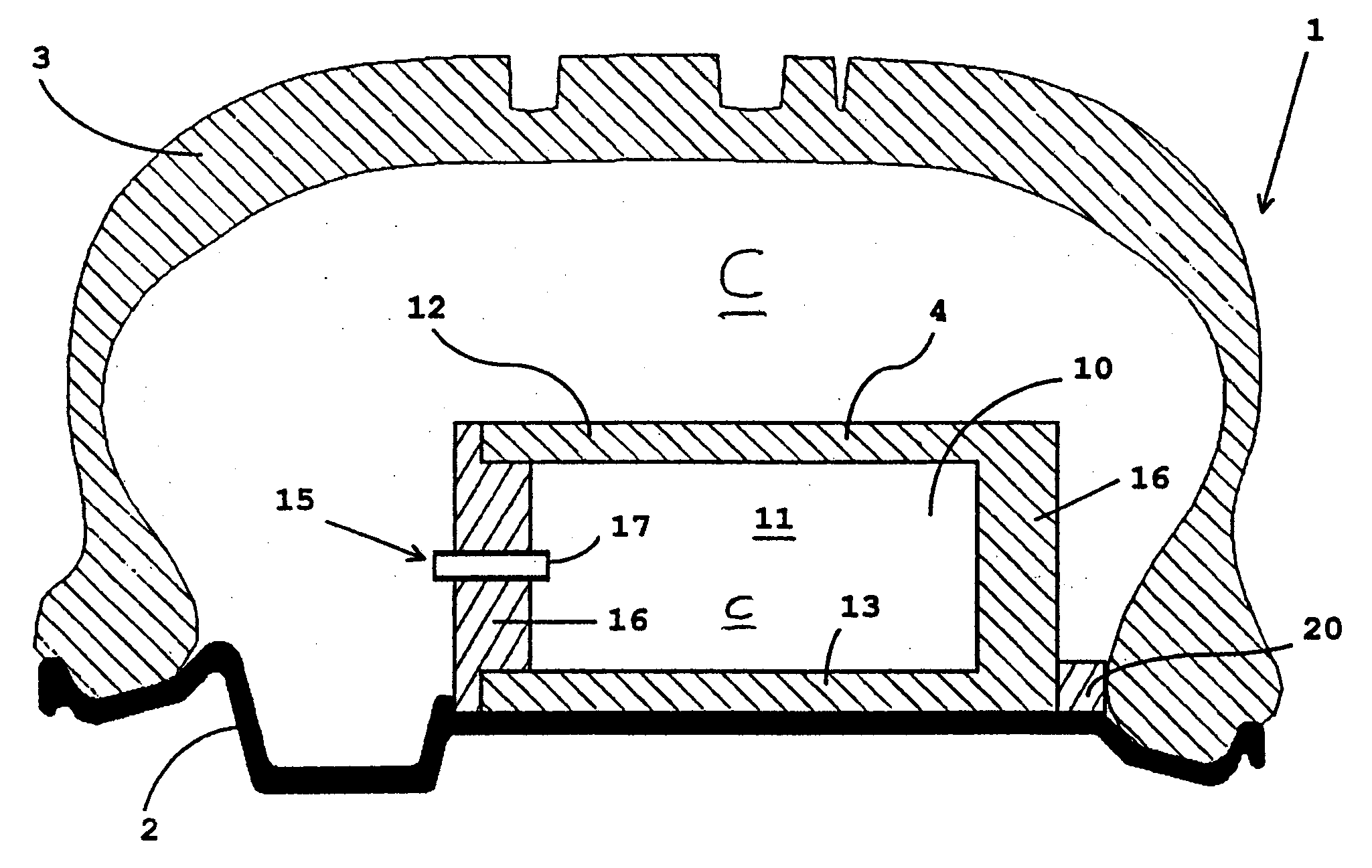

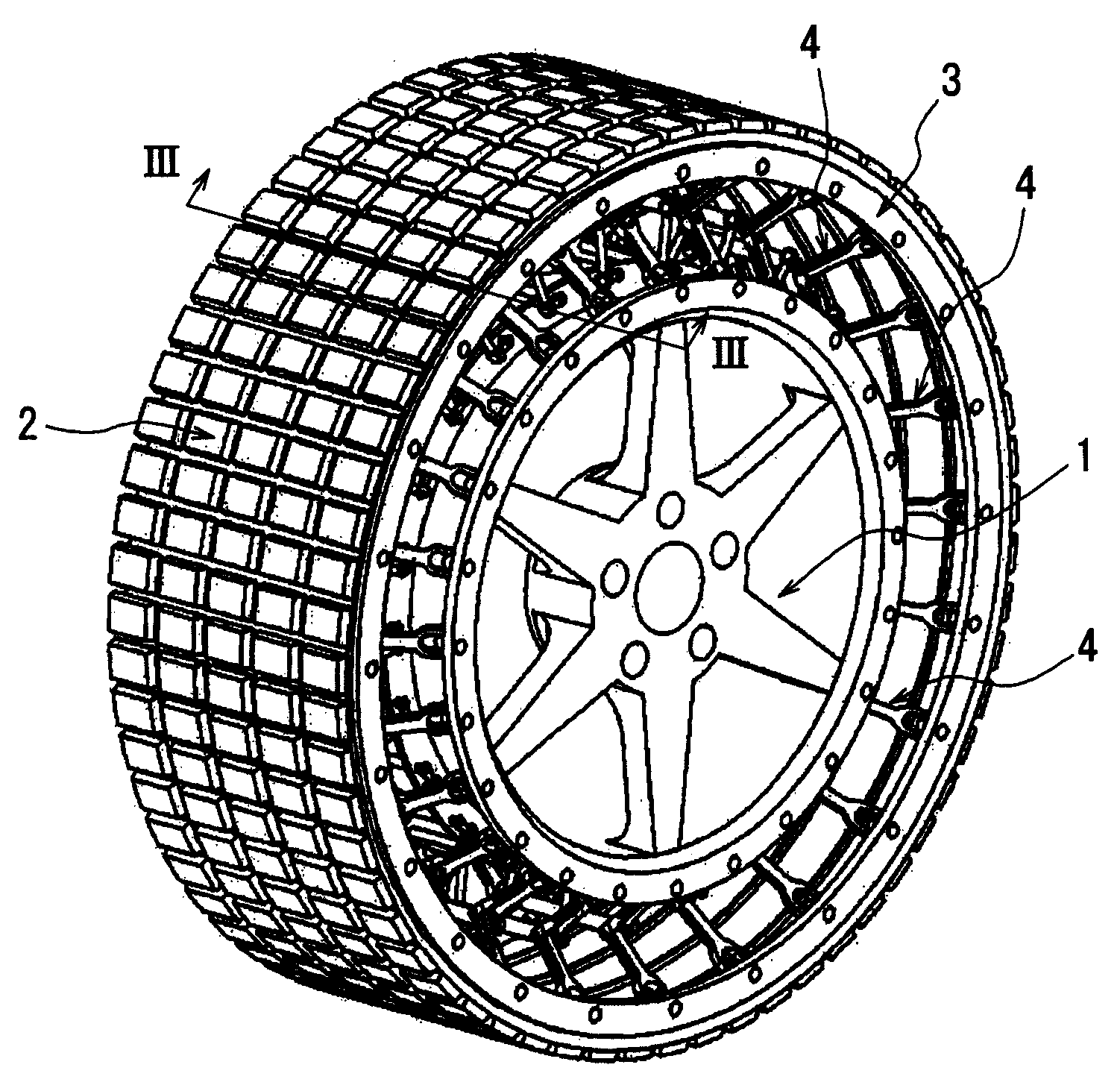

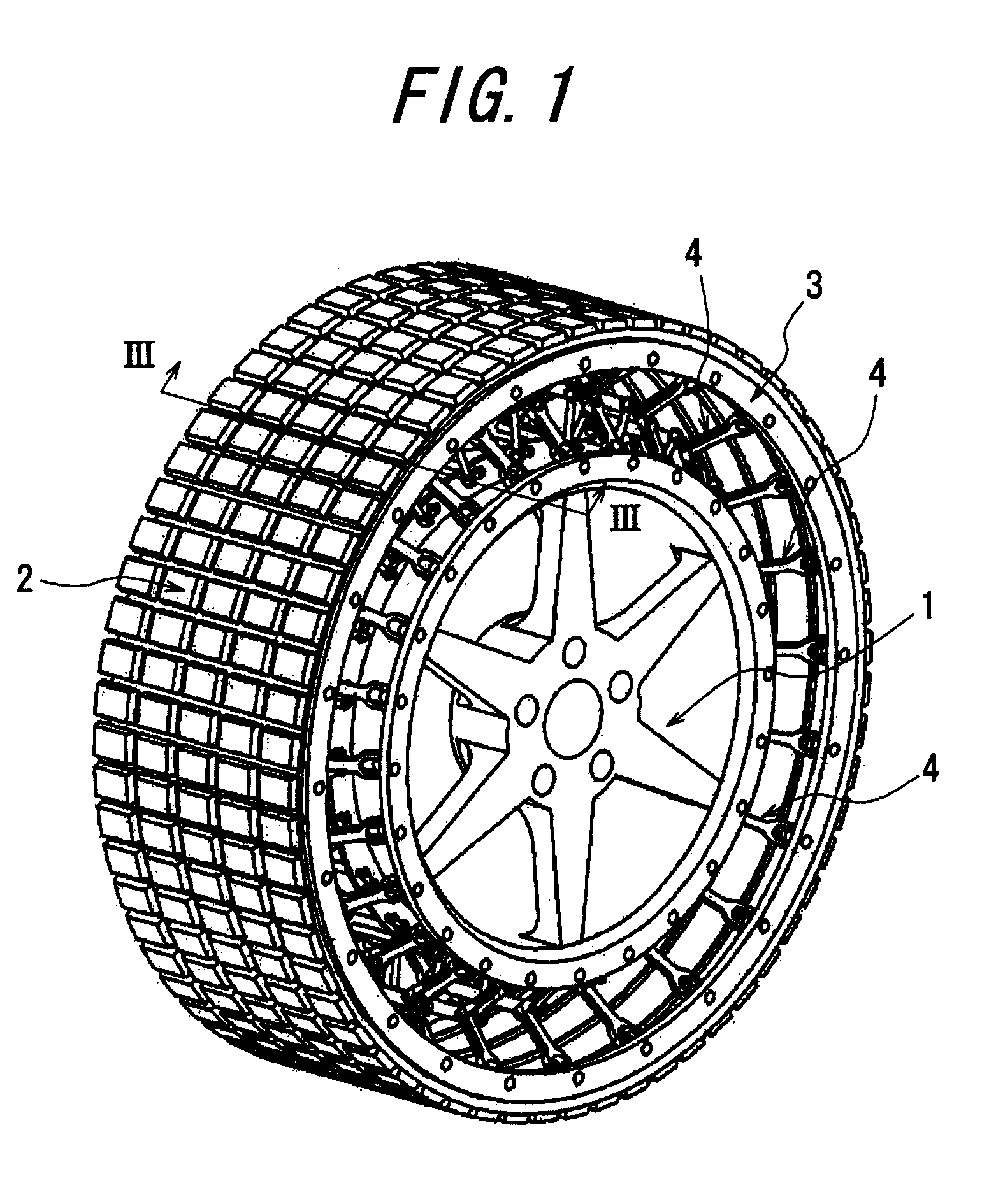

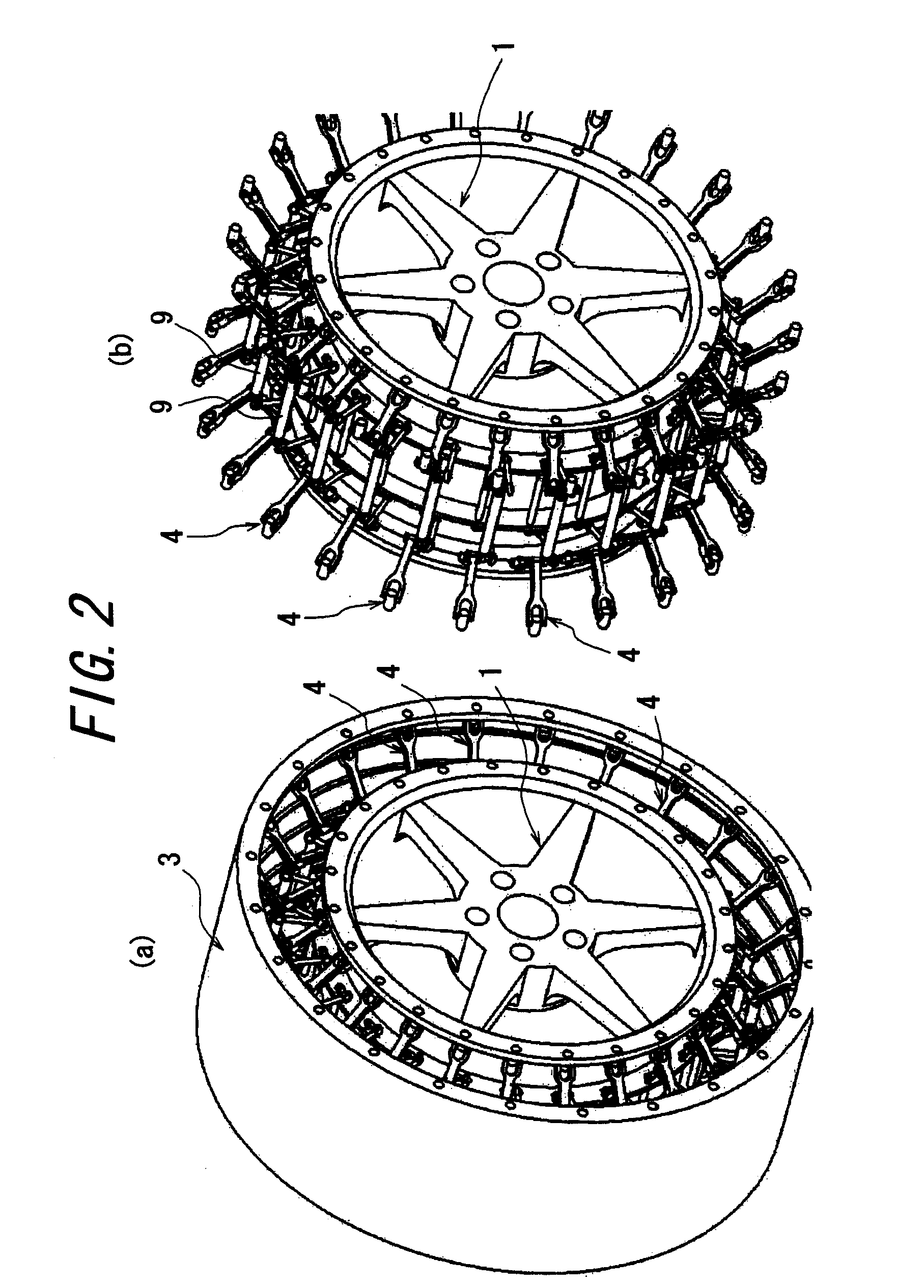

Non-pneumatic tire

InactiveUS20080073014A1Easy to provideReduce necessityRimsMetal-working apparatusRelative displacementInternal pressure

There is provided a non-pneumatic tire which can eliminate a necessity of filling a pressurized air or other gases to obviate a possibility of decrease or loss of the internal pressure of the tire and which can easily provide desired vertical, longitudinal and lateral stiffnesses in a mutually independent state.The non-pneumatic tire has a rim member 1, a ring member 3 disposed at an outer circumferential side of the rim member 1 and provided with a tread 2 on a circumferential face, and a plurality of link mechanisms 4 coupling the rim member with the ring member. Each of the link mechanisms 4 consists of a pair of link members 7a, 7b consisting of a link 5a, 5b which is connected at a first end with a side portion of the rim member 1 and which is swingable in the circumferential and meridian directions and another link 6a, 6b which is connected at a first end with a side portion of the ring member and 3 which is swingable in the circumferential and meridian directions with second ends of the links being hingedly connected one another to make the links swingable in the meridian direction. A spring member 9 imparting a stiffness against relative displacements in the radian, circumferential and width directions with respect to the rim and ring members 1, 3 is provided on the link mechanisms 4.

Owner:BRIDGESTONE CORP

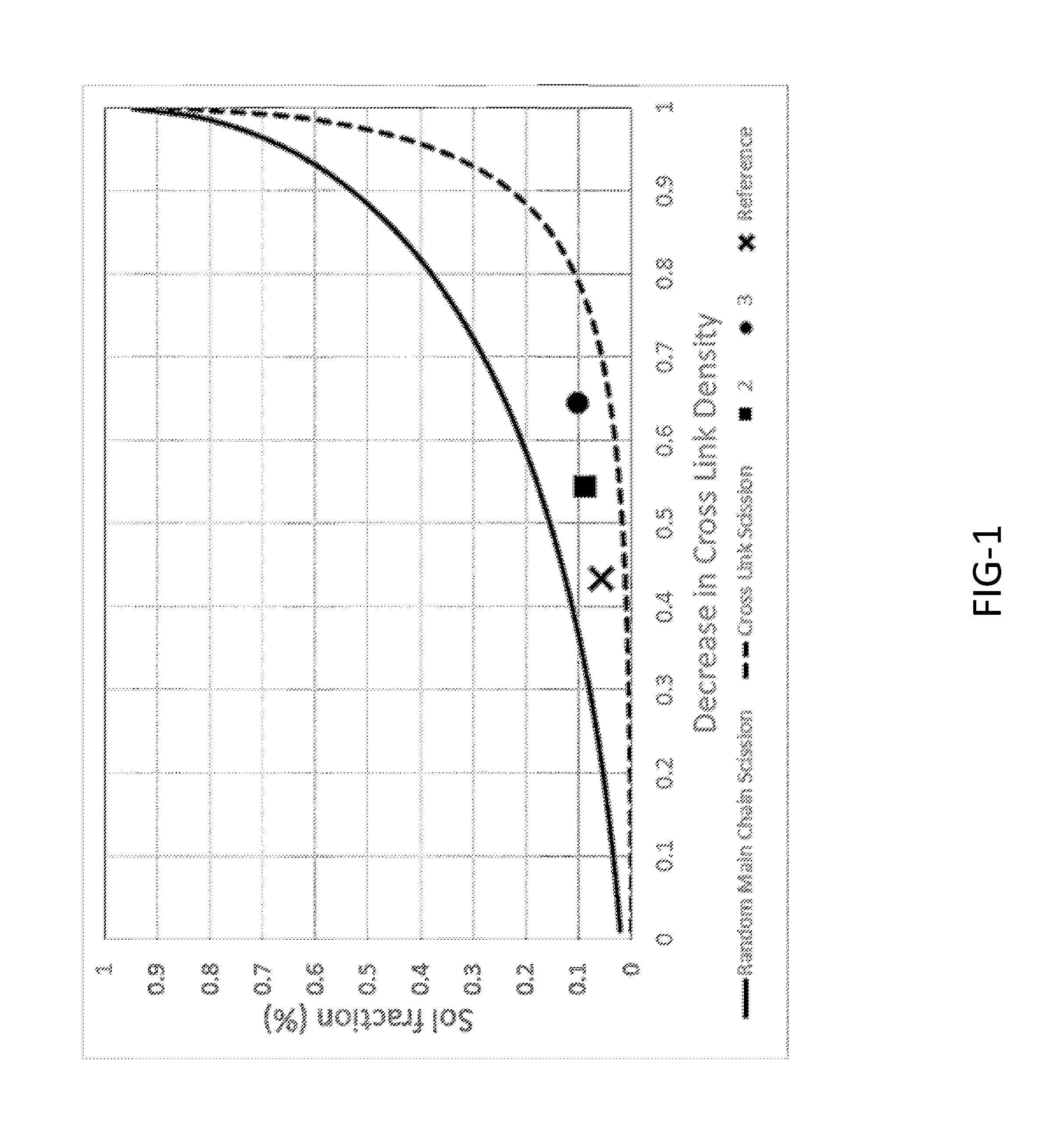

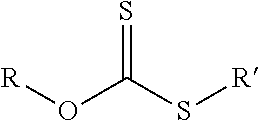

Chemically functionalized renewed rubber composition

ActiveUS20160152805A1Low hysteretic propertyImprove energy consumption efficiencySpecial tyresPneumatic tyre reinforcementsSolubilityElastomer

This invention relates to certain rubber formulations which exhibit a low level of hysteresis which are comprised of a chemically functionalized renewed rubber and virgin solution styrene-butadiene rubber. These rubber formulations are loaded with a reinforcing silica. The rubber formulations of this invention can be utilized in making rubber products such as, tires, tracks, and conveyor belts which will promote energy savings by virtue of their low hysteretic properties. The present invention more specifically discloses a rubber composition which is comprised of (1) a solution styrene-butadiene rubber; (2) a functionalized renewed rubber composition which is comprised of an elastomeric polymer and a stabilizer; wherein the rubber composition has a crosslink density which is within the range of 0.05 to 2.0×10−5 mole / g, and wherein the rubber composition has a solubility fraction of less than 90 percent; and (3) a reinforcing filler including reinforcing silica.

Owner:LEHIGH TECH INC

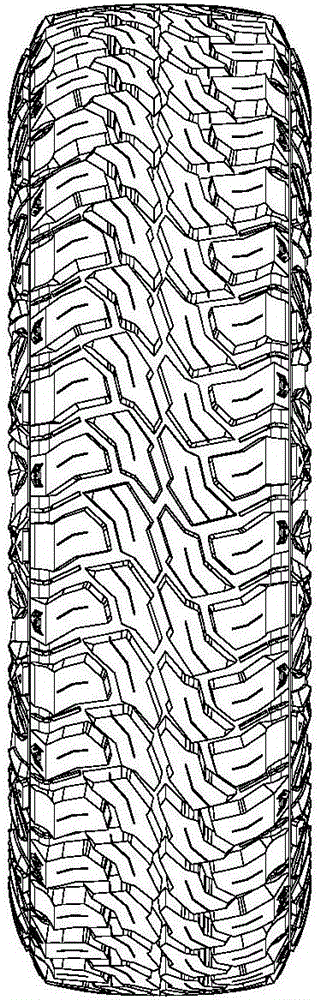

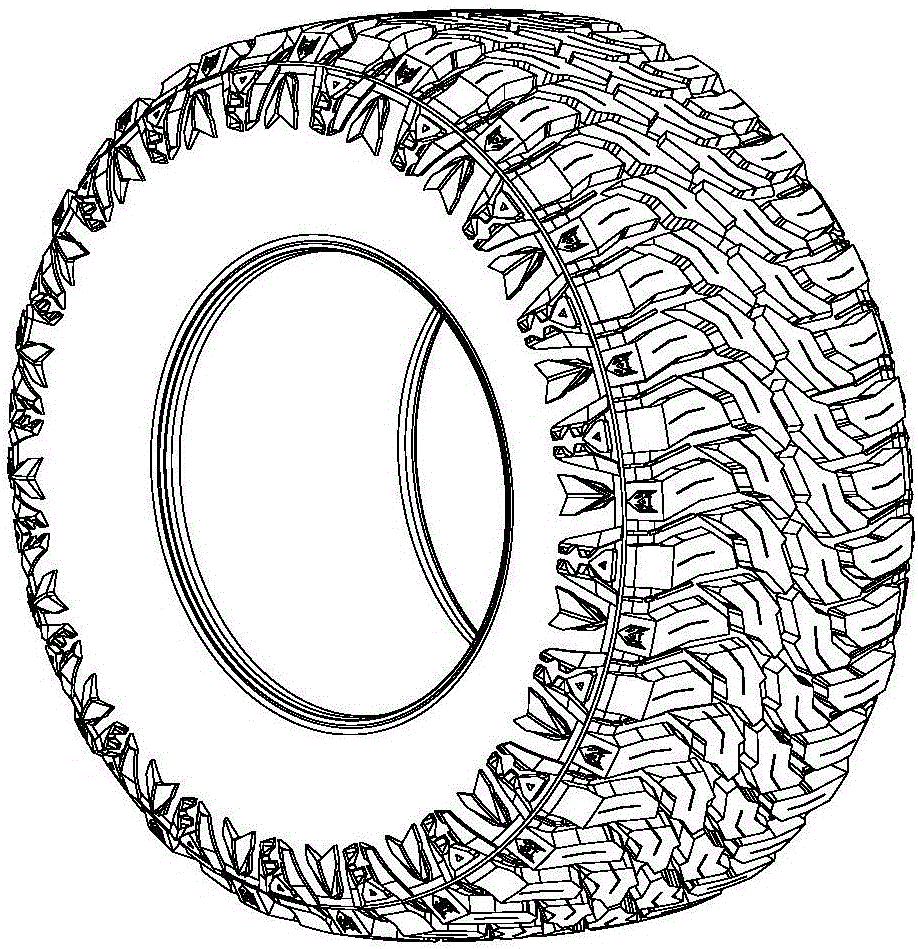

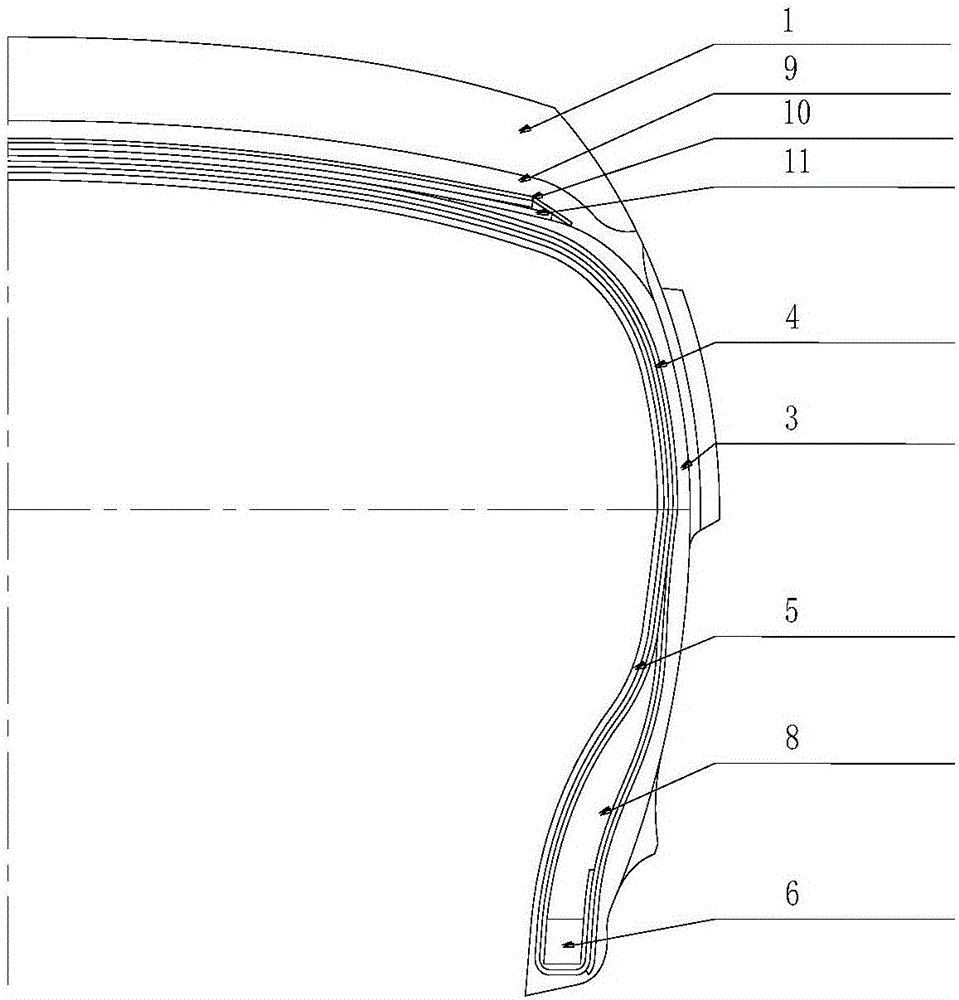

All-steel mud-field tire

InactiveCN106394128AHigh strengthImprove securityOff-road vehicle tyresPneumatic tyre reinforcementsUltimate tensile strengthTire iron

The invention provides a novel all-steel mud-field tire, and belongs to the field of tires. Through the adoption of the novel all-steel mud-field tire disclosed by the invention, improving tire strength is facilitated, impact resistance and durability of the tire are improved, and the service life of the tire is prolonged. A longitudinal section of the all-steel mud-field tire comprises a tire crown (1), a tire shoulder (2), a tire sidewall (3), a tire bead (6), and a tire body (4), wherein the tire crown (1) is located on the outer side of the upper part of the longitudinal section; the tire shoulder (2) is connected with the tire crown (1); the tire sidewall (3) is connected with the tire shoulder (2); the tire bead (6) connected with a wheel rim is arranged at the lower part of the tire sidewall (3); the tire body (4) is located on the inner side of the section of the tire; a tire shoulder pad (21) is arranged on the tire shoulder (2); a convex rib (31) is circumferentially and annularly arranged on the outer part of the tire sidewall (3); and the tire body (4) is a layer of all-steel tire body.

Owner:QINGDAO DOUBLESTAR TIRE IND CO LTD

Tire having an element or covering attached to a surface thereof

ActiveUS20060016534A1Reduce and even eliminate of and brightnessMarking is durableTyresInflatable tyresVoid ratioEngineering

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Pneumatic tire

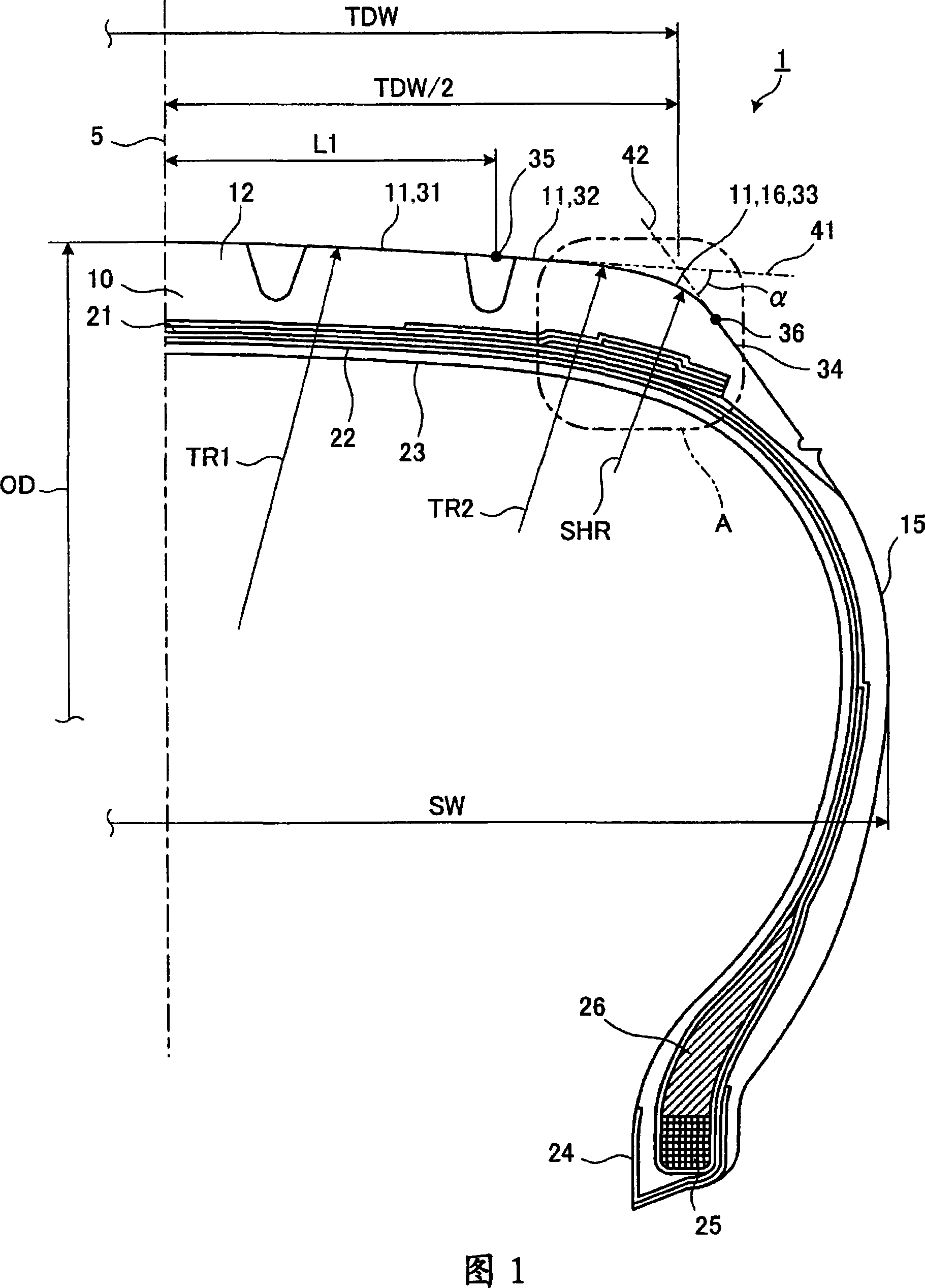

ActiveCN101111397AMaintainable handling stabilityImprove overturning characteristicsSpecial tyresPneumatic tyre reinforcementsRolloverEngineering

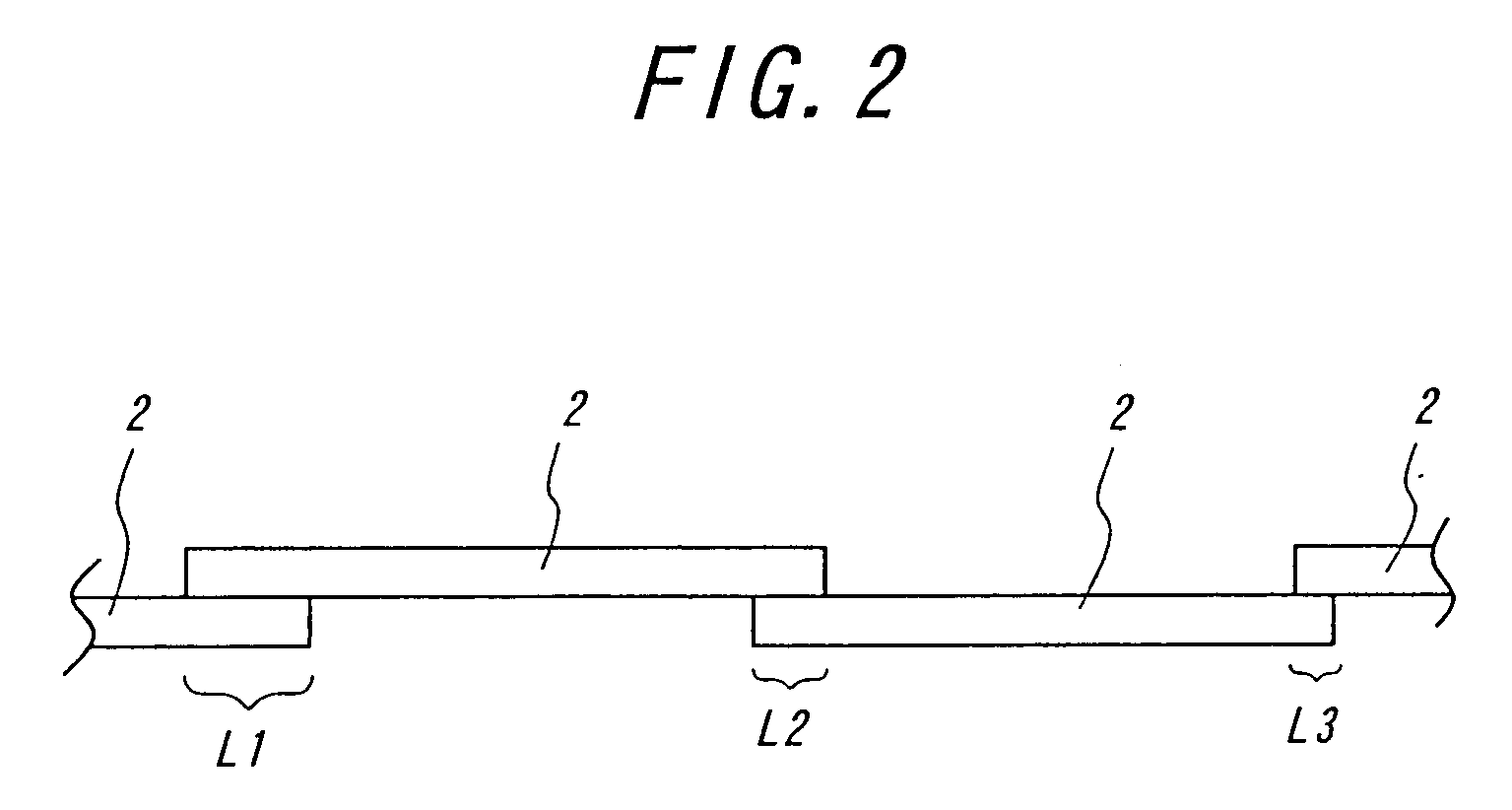

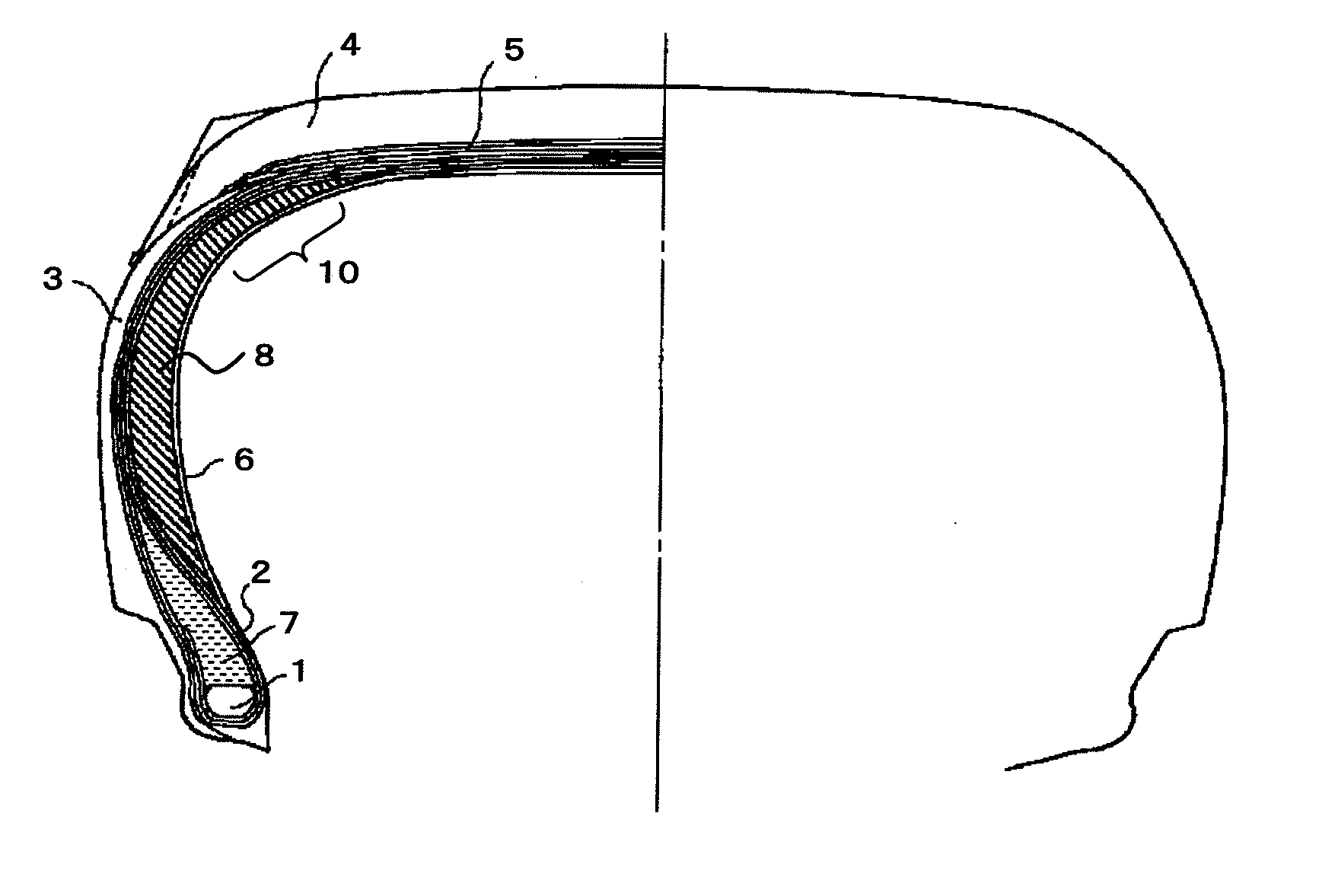

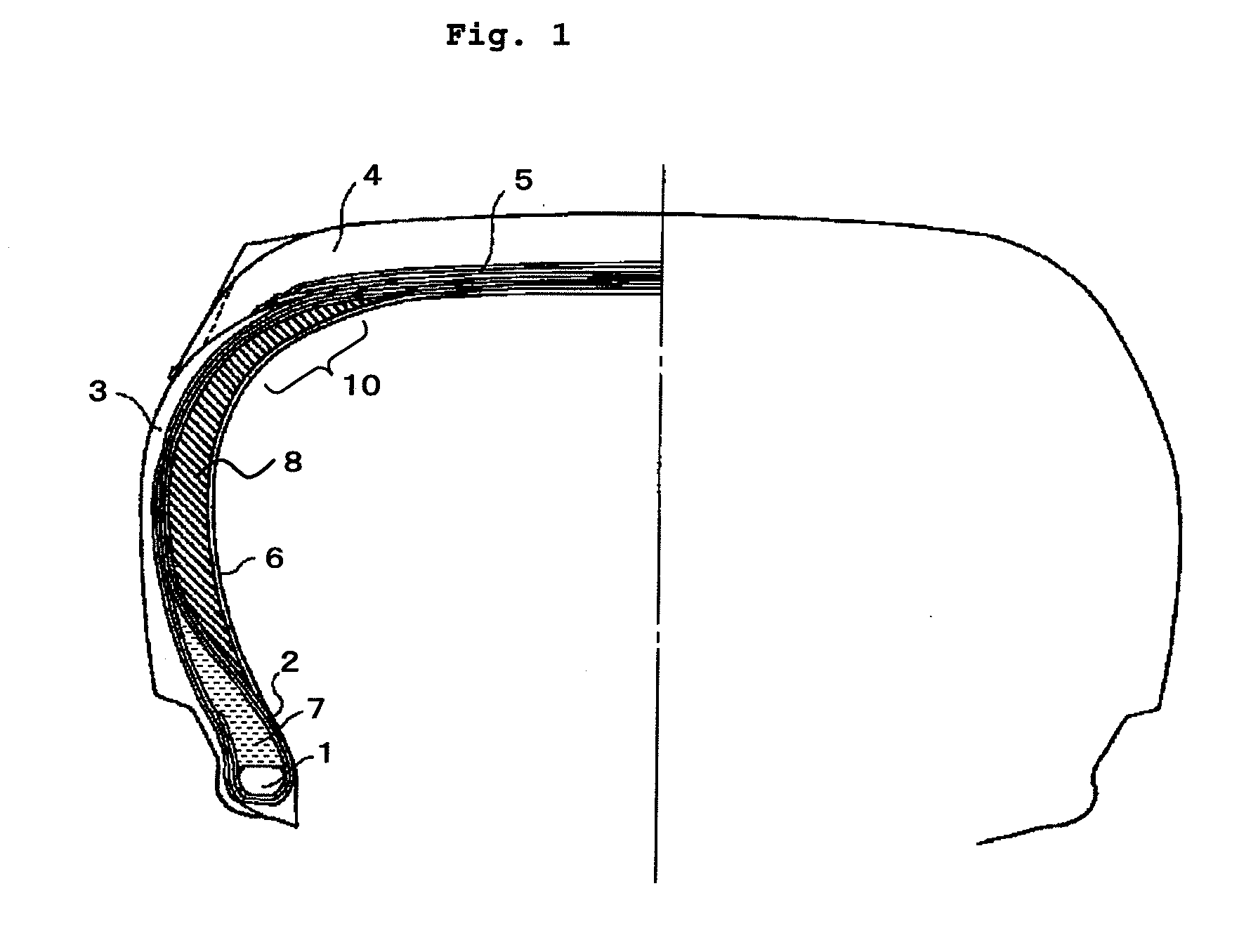

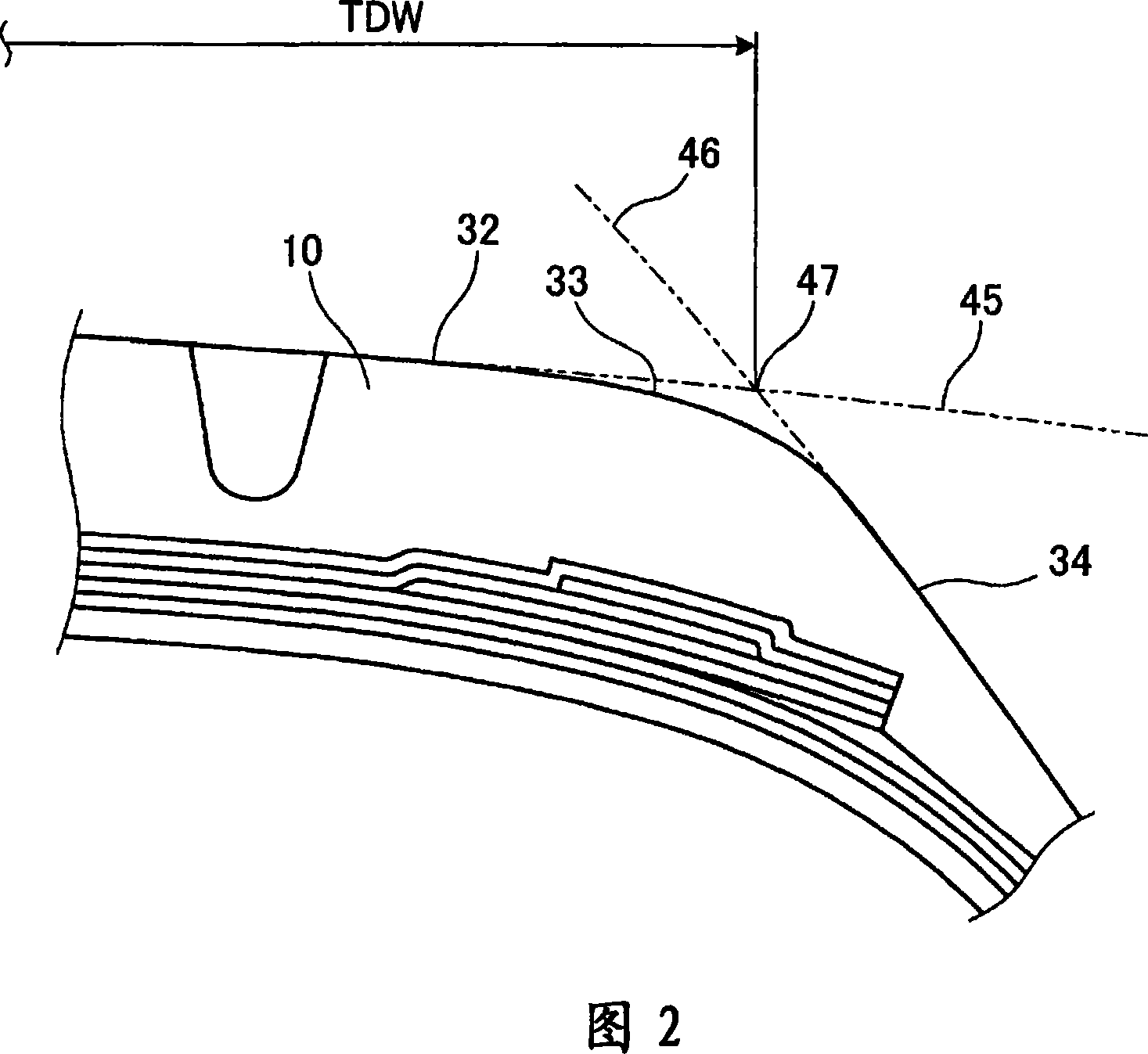

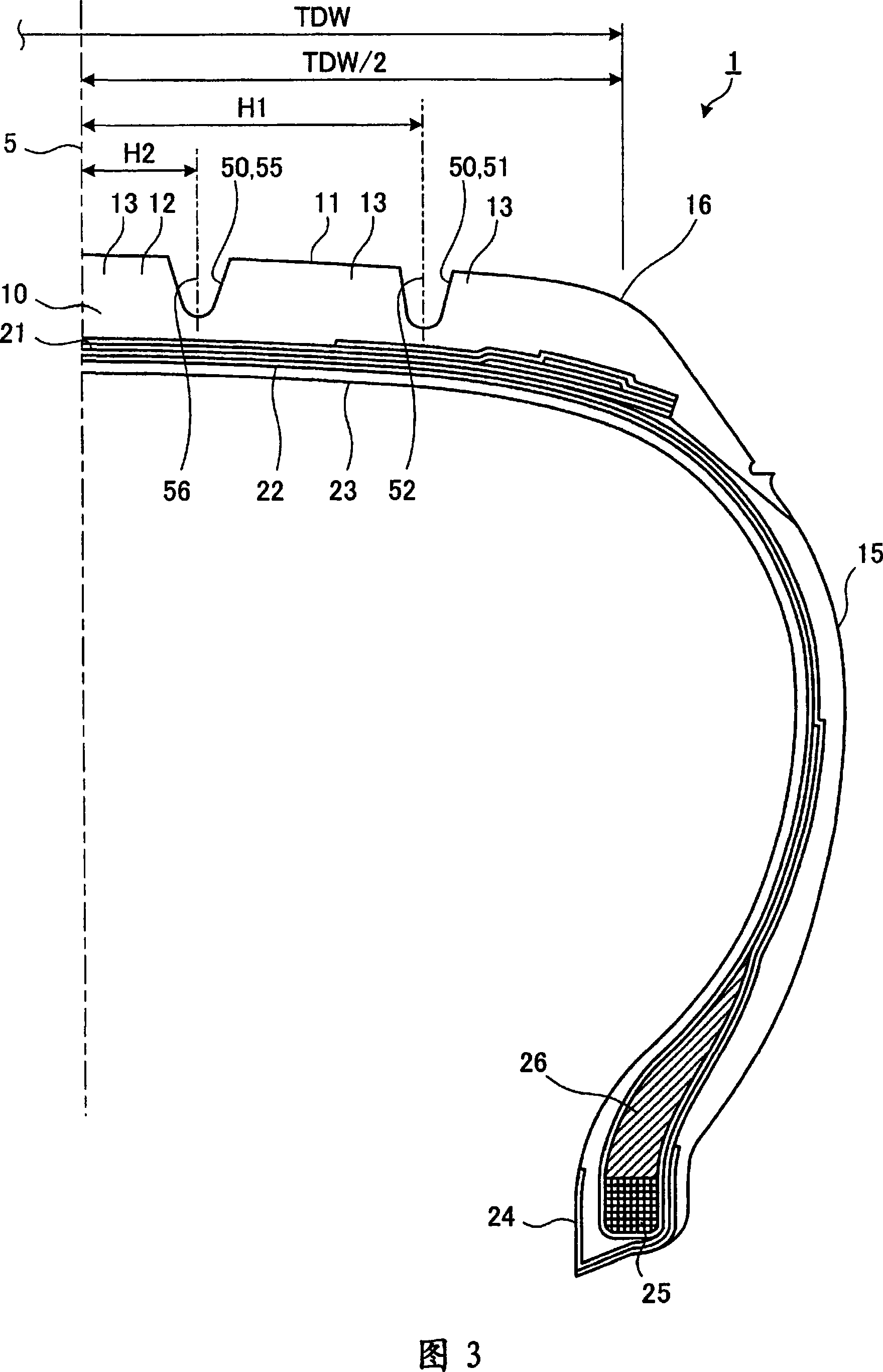

To provide a pneumatic tire that can improve a rollover resistance while retaining a driving stability, a tread surface 11 is formed from a center arc 31, a shoulder-side arc 32, and a shoulder arc 33. Moreover, the tread surface 11 is formed in such a manner that a value obtained from a relation K1=L1 / (TDW×0.5) satisfies 0.6‰ K1‰ 0.8, where K1 is a relation between an outline area L1 that is a width from an equatorial plane 5 to the end of the center arc 31 and a tread development width TDW, and a ratio K2 satisfies 0.9‰ K1‰ 2.0, where K2=TR1 / OD, and K2 is a ratio of a curvature radius TR1 of the center arc 31 to a tire outside diameter OD. Furthermore, the tread surface 11 is formed in such a manner that a value obtained from a relation K3=(²×TDW) / (100×SW) satisfies 0.40‰ 3‰ 0.48, where k3 is a relation between an aspect ratio ², the tread development width TDW, and a total width SW. As a result, the rollover resistance can be improved while retaining the driving stability.

Owner:THE YOKOHAMA RUBBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com