Pneumatic tire

A technology of pneumatic tires and tires, which is applied to pneumatic tires, reinforcement layers of pneumatic tires, special tires, etc., can solve problems such as partial wear, and achieve the effects of improving overturn resistance, maintaining handling stability, and increasing maximum steering force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

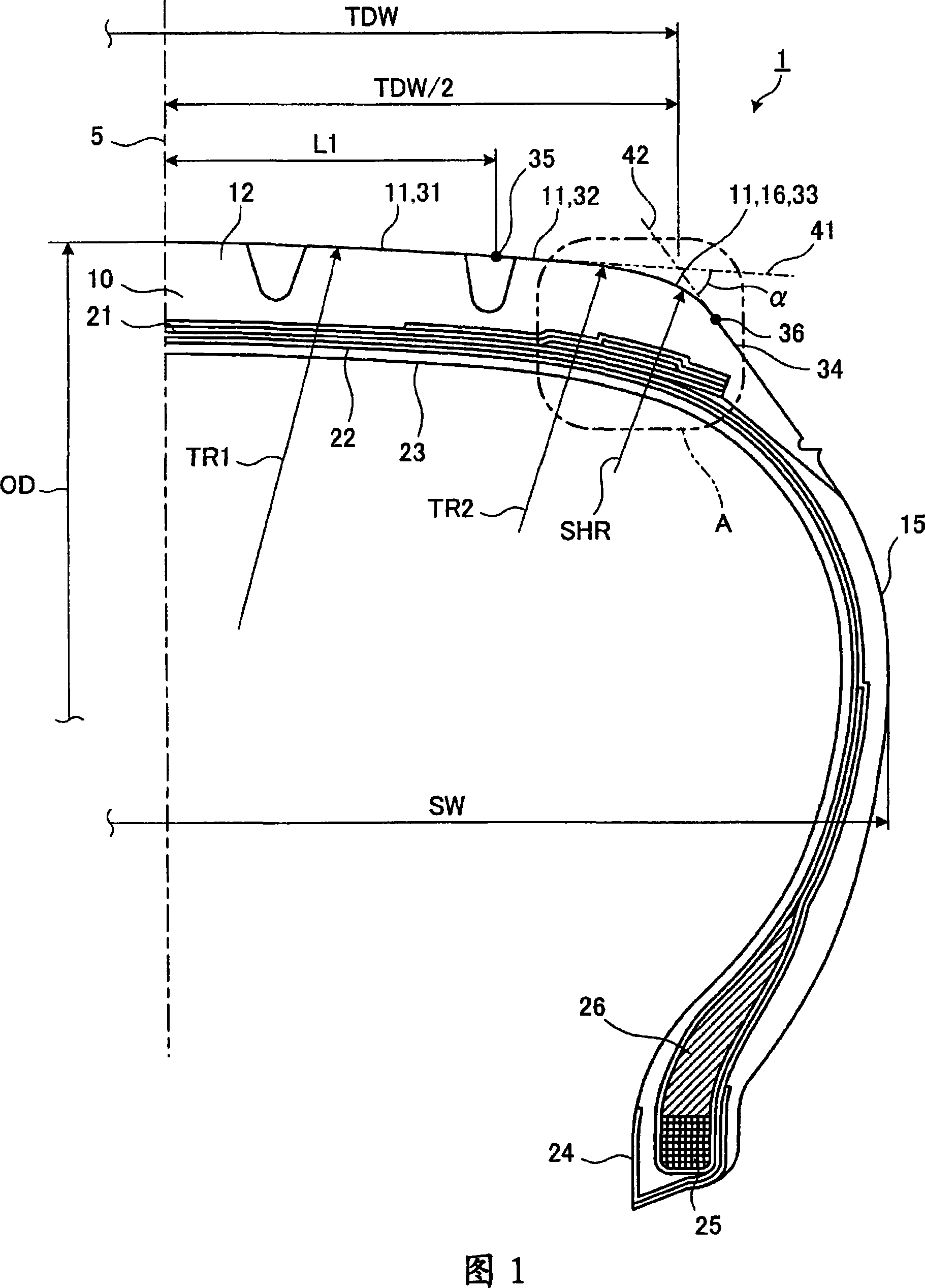

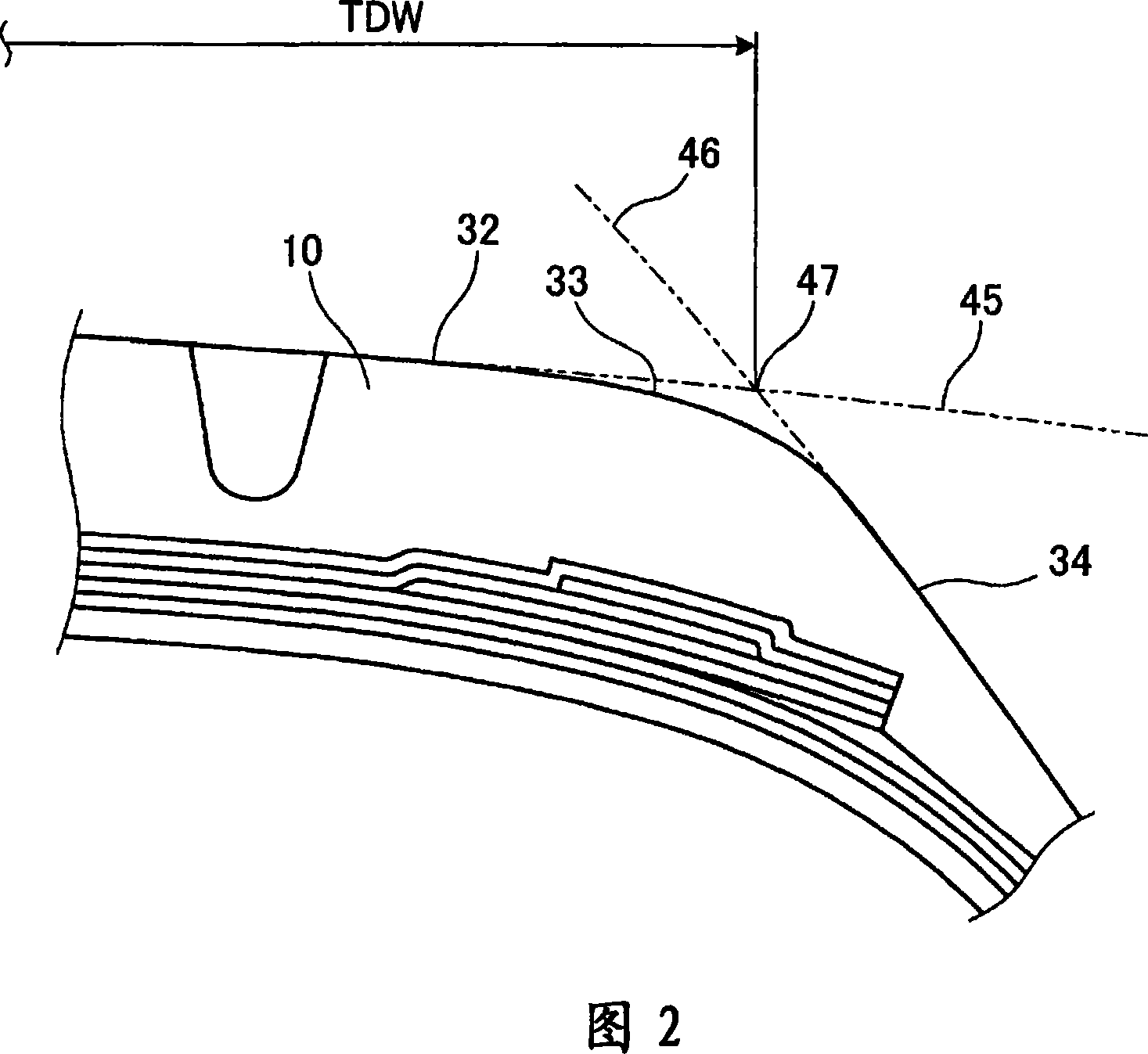

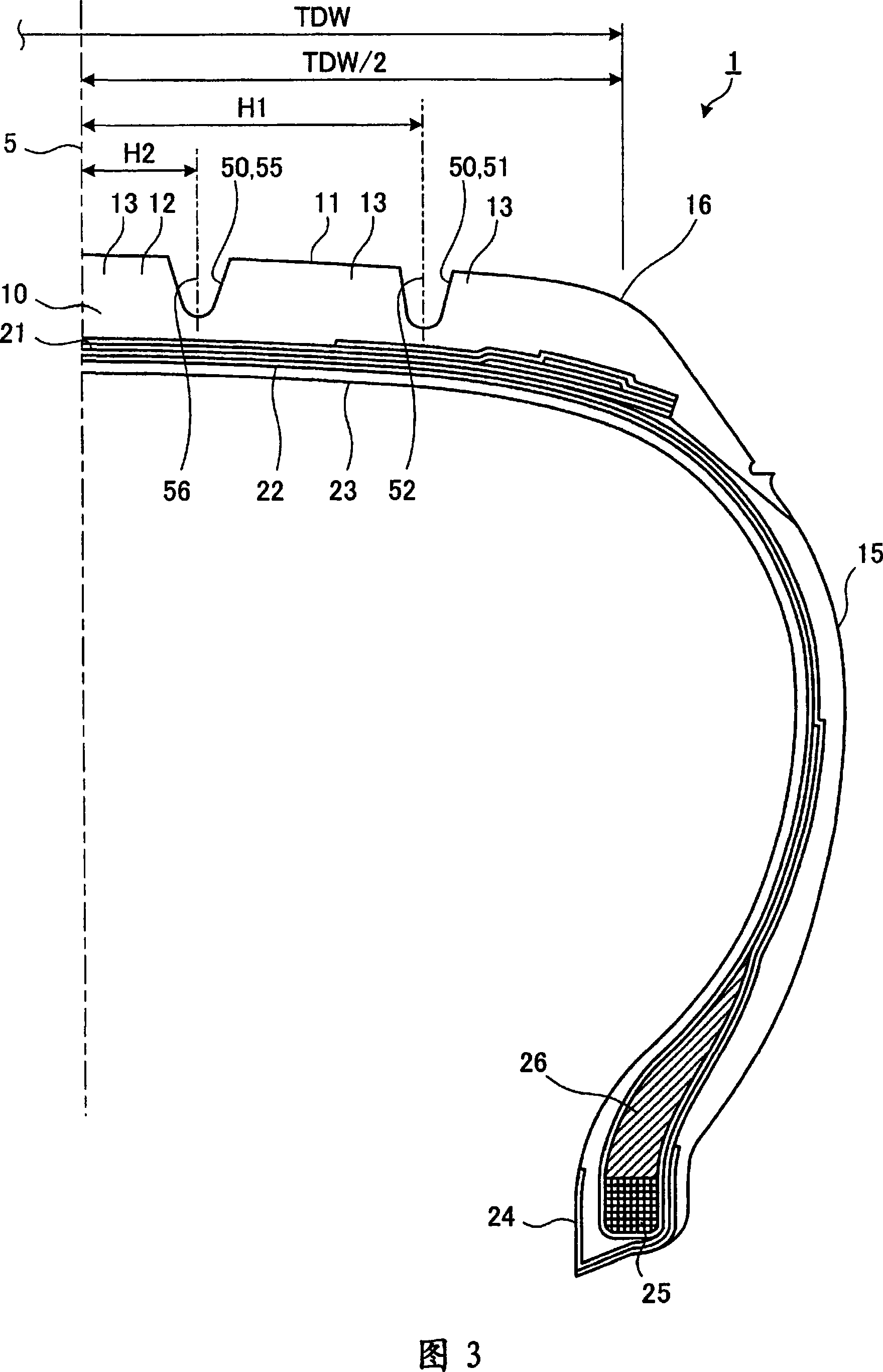

[0121] In the following description, the tire width direction refers to the direction parallel to the rotation axis of the pneumatic tire, the tire width direction inner direction refers to the direction toward the equatorial plane in the tire width direction, and the tire width direction outer direction refers to the direction in the tire width direction. in the opposite direction to the direction towards the equatorial plane. In addition, the tire radial direction refers to a direction perpendicular to the aforementioned rotary shaft, and the tire circumferential direction refers to a direction in which the aforementioned rotary shaft is turned as a center axis of rotation. Fig. 1 is a meridian cross-sectional view showing main parts of a pneumatic tire of the present invention. The pneumatic tire 1 shown in the figure is provided with a tread portion 10 at the outermost portion in the tire radial direction when viewed from a meridian cross section. In addition, a side wall...

Embodiment

[0206] Hereinafter, with regard to the aforementioned pneumatic tire 1 , performance evaluation tests performed on a conventional pneumatic tire and the pneumatic tire 1 of the present invention will be described. Seven types of performance evaluation tests were performed, of which two types of performance evaluation tests were performed only by double-track change tests, and the other five types of performance evaluation tests were performed by double-track change tests and driving real vehicles on the test field.

[0207] Among the seven performance evaluation tests, the first test method is conducted by assembling a pneumatic tire 1 of size 225 / 65R17 on a rim, and mounting the pneumatic tire 1 on an SUV vehicle with a displacement of 1800cc for test driving. . The evaluation method of the performance evaluation test is to conduct a two-lane change test (Eric test) specified in ISO3888-2 with the aforementioned vehicle, and determine the overturning characteristics by whethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com