Orientated carbon nanotube composite, process for producing orientated carbon nanotube, and, produced using orientated carbon nanotube composite, pneumatic tire, wheel for vehicle, tire wheel assembly and disk brake

a carbon nanotube and composite technology, applied in the direction of brake discs, tire wheel assemblies, mechanical equipment, etc., can solve the problems of non-uniform dispersion of fillers and lowering dynamic properties, and achieve simple cooling and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0121] The carbon nanotube orientated composite of the second embodiment and the pneumatic tire using the same are explained in detail with reference to the following examples but the invention is not limited to these examples.

examples 1-15

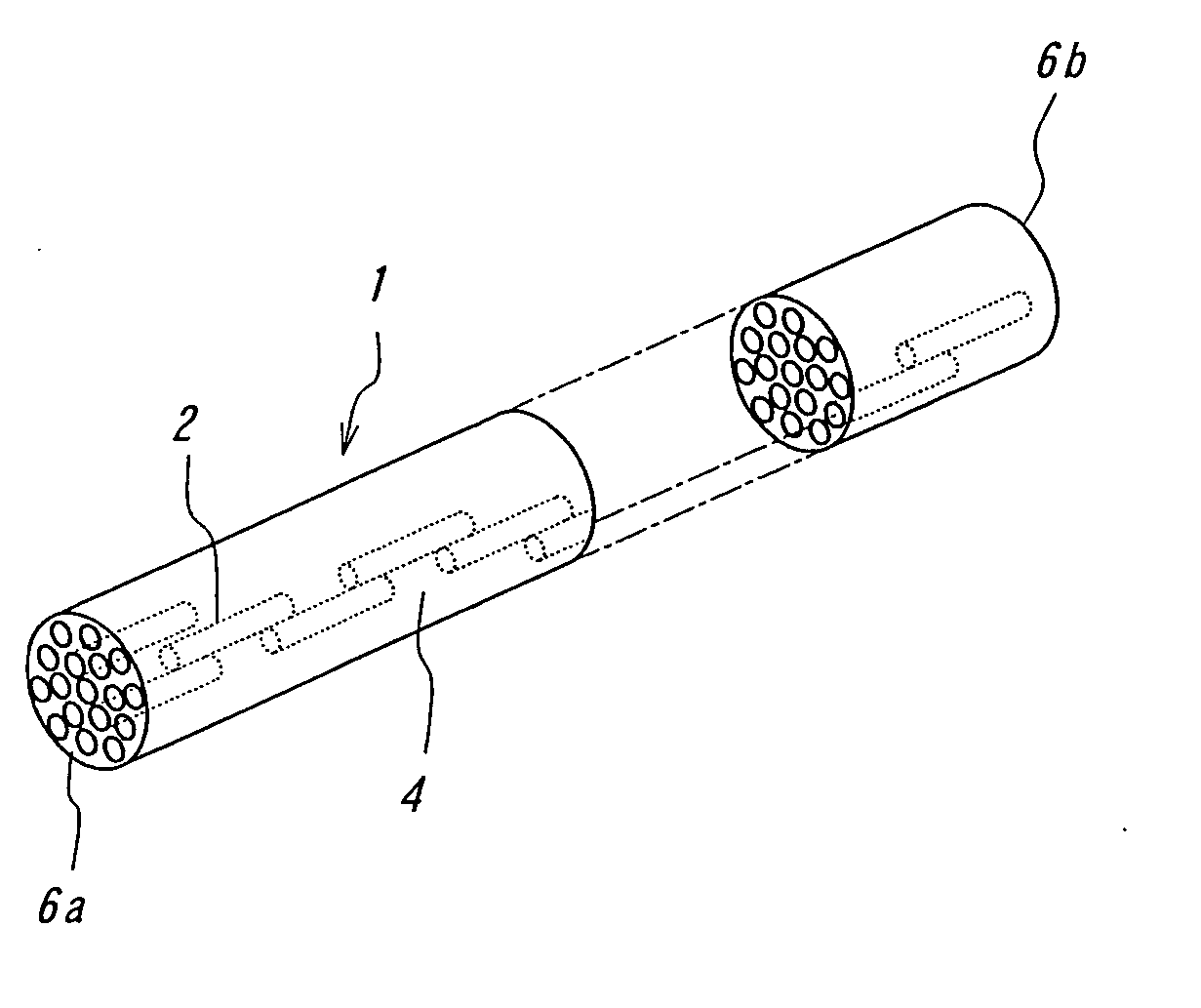

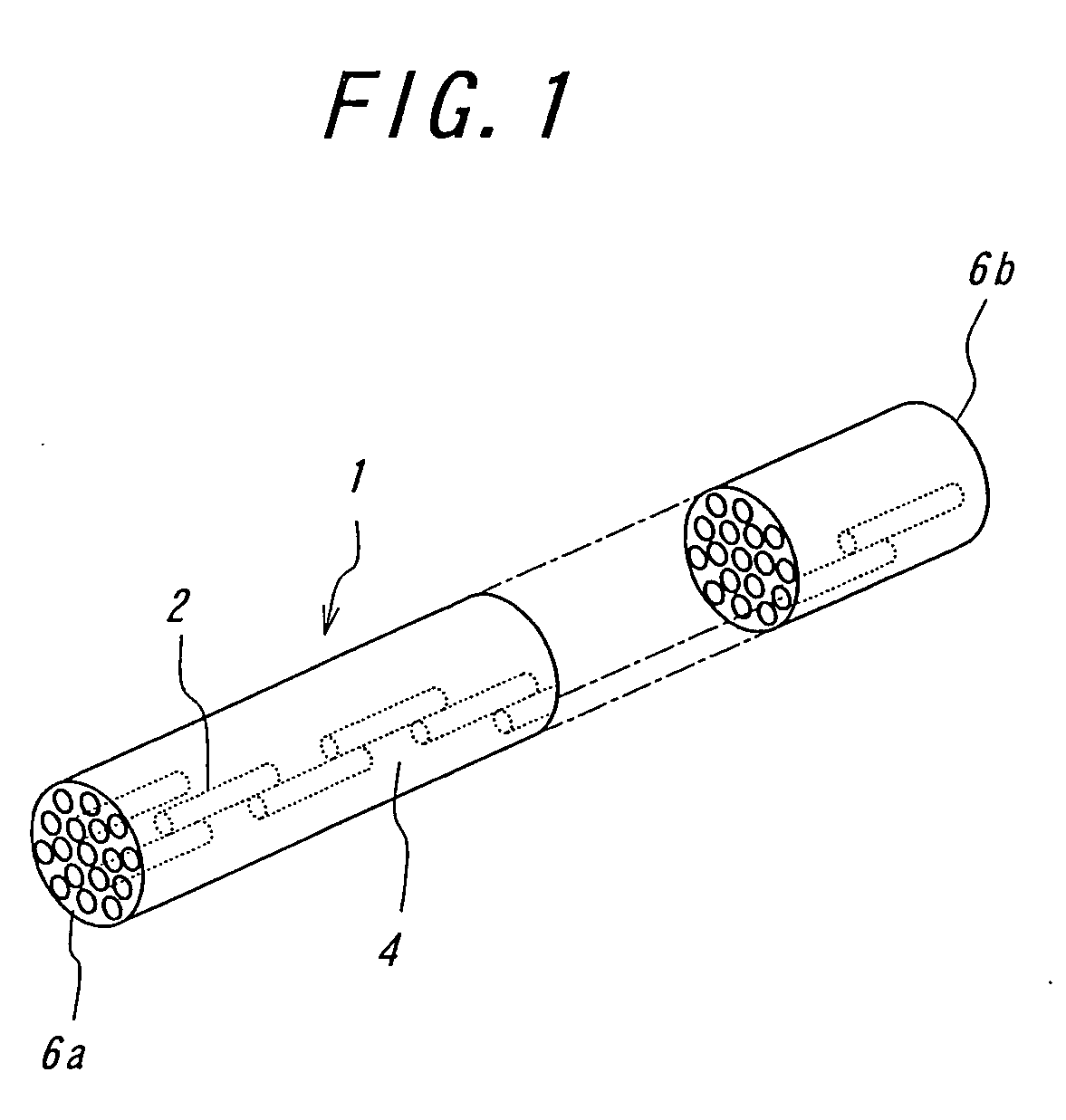

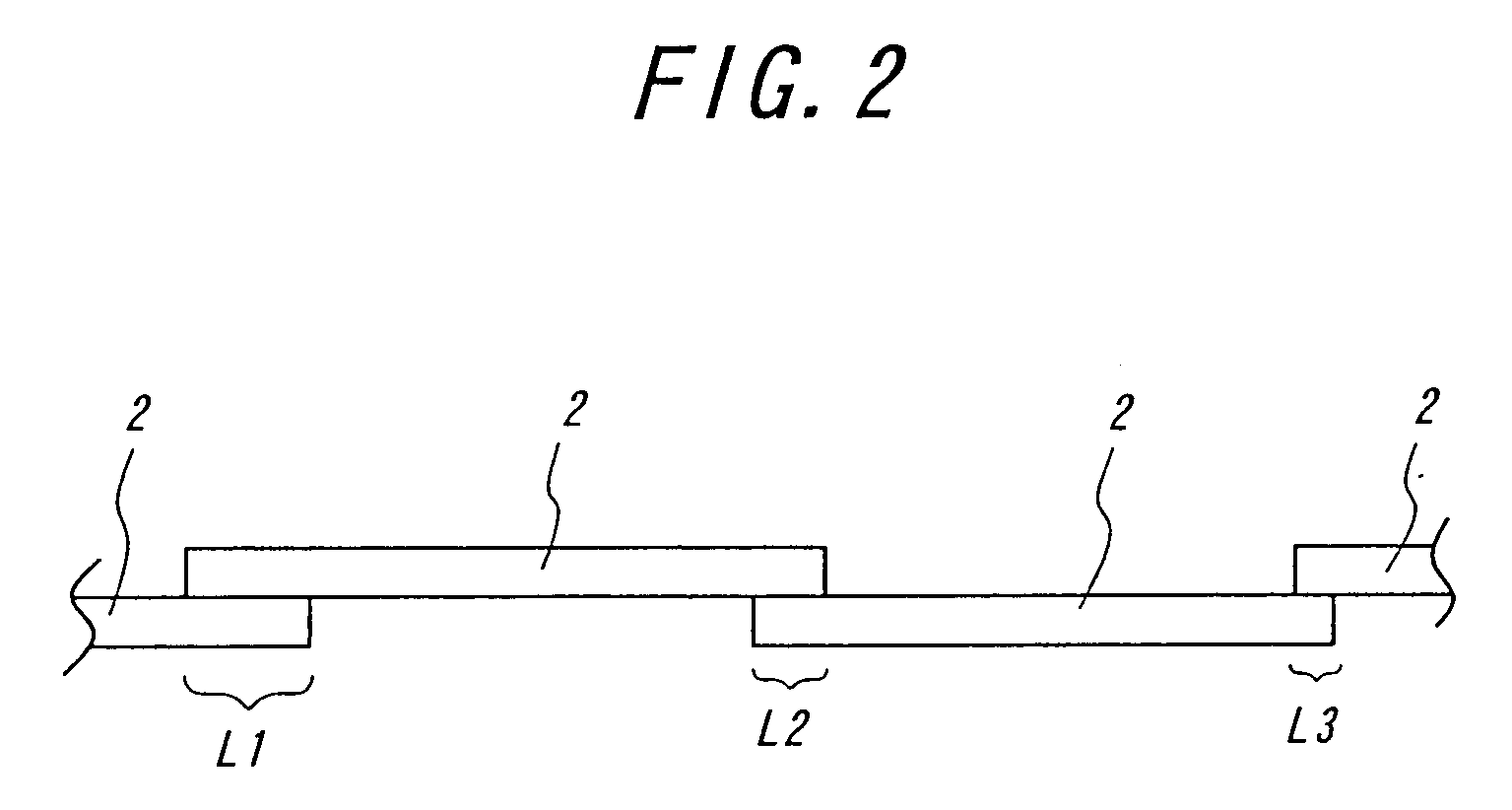

[0122] There are prepared various rubber compositions having a compounding recipe shown in Table 1. Then, each of these rubber composition after the kneading is extruded through an extruder at an extrusion rate of 10 m / min and drawn at a drawing rate of 15 m / min under a tension of 0-200 N / mm2 and vulcanized to prepare a rod-shaped carbon nanotube orientated composite having a diameter of 1 mm in which carbon nanotubes are orientated therein.

examples 1-3

Conventional Examples 1-3

[0123] A rubber composition is kneaded in the same manner as in Example 3, 8 or 12 except that carbon nanotubes are not compounded, and extruded without applying tension and vulcanized to prepare a thread-shaped vulcanized rubber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com