Patents

Literature

665results about "With separate inflatable inserts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

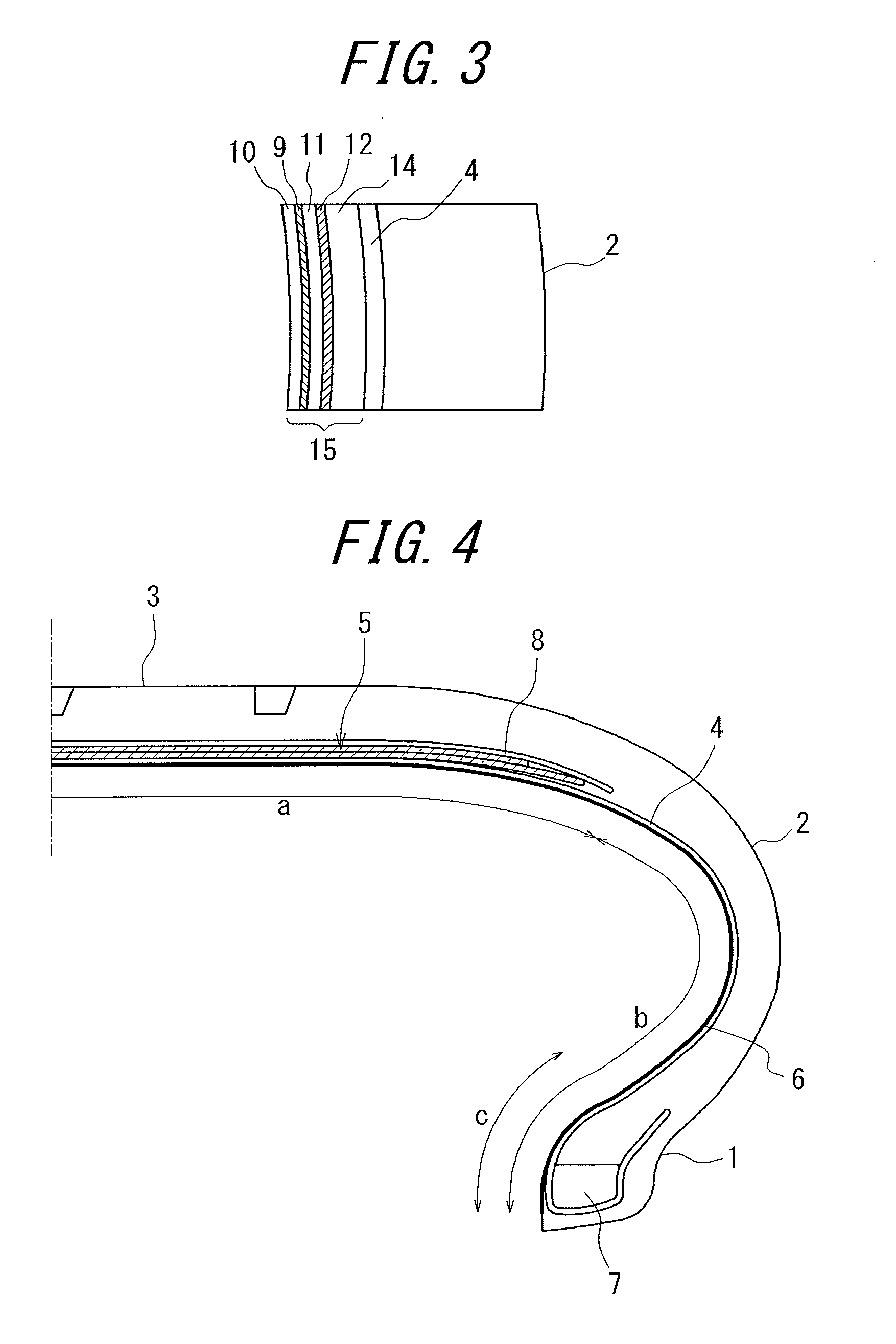

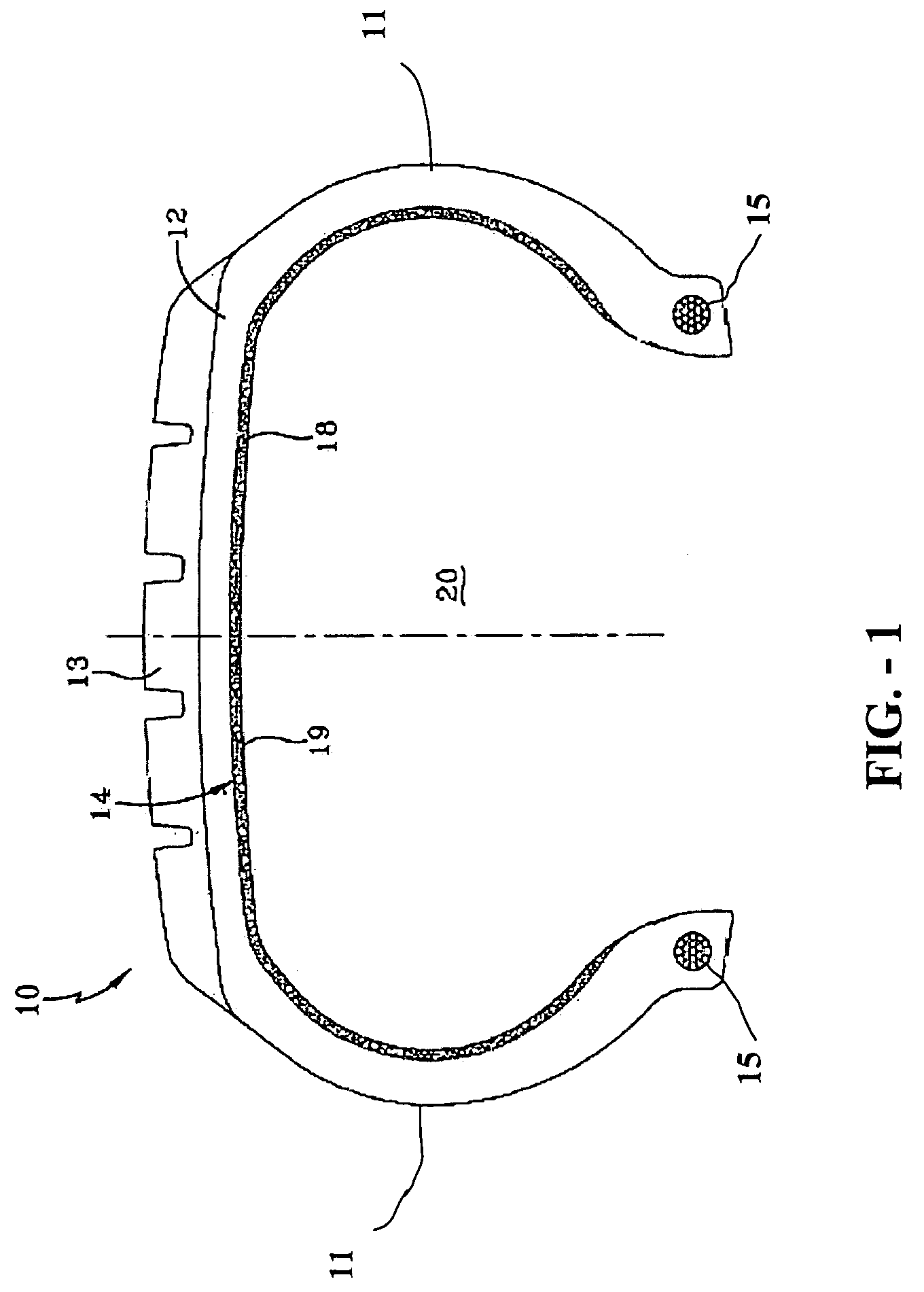

Pneumatic tire made by using lowly permeable thermoplastic elastomer composition in gas-barrier layer and thermoplastic elastomer composition for use therein

InactiveUS6062283AHigh elastomer ratioAbundant flexibilityWithout separate inflatable insertsWith separate inflatable insertsElastomerThermoplastic elastomer

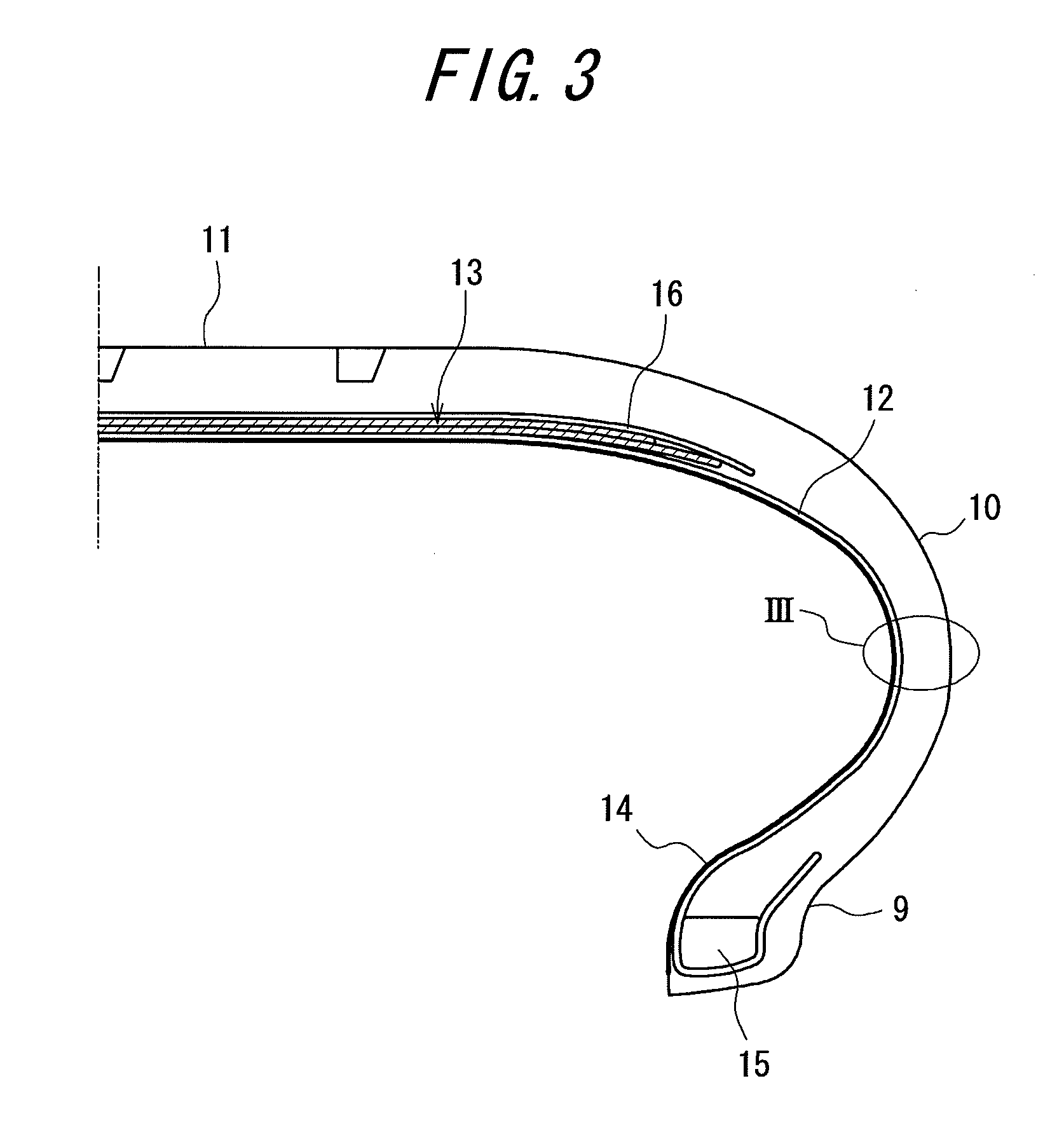

PCT No. PCT / JP97 / 01514 Sec. 371 Date Jan. 28, 1998 Sec. 102(e) Date Jan. 28, 1998 PCT Filed May 2, 1997 PCT Pub. No. WO97 / 45489 PCT Pub. Date Dec. 4, 1997A pneumatic tire having an air permeation preventive layer comprising a low permeability thermoplastic elastomer composition comprising a thermoplastic elastomer having a thermoplastic resin composition as a continuous phase and a rubber composition as a dispersed phase, in which a barrier resin composition is contained, which low permeability thermoplastic elastomer composition has a phase structure in which the barrier resin composition is dispersed in the form of a flat state in the thermoplastic elastomer, is abundant in flexibility, is superior in gas permeation preventive property, and enables the tire to be reduced in weight.

Owner:YOKOHAMA RUBBER CO LTD

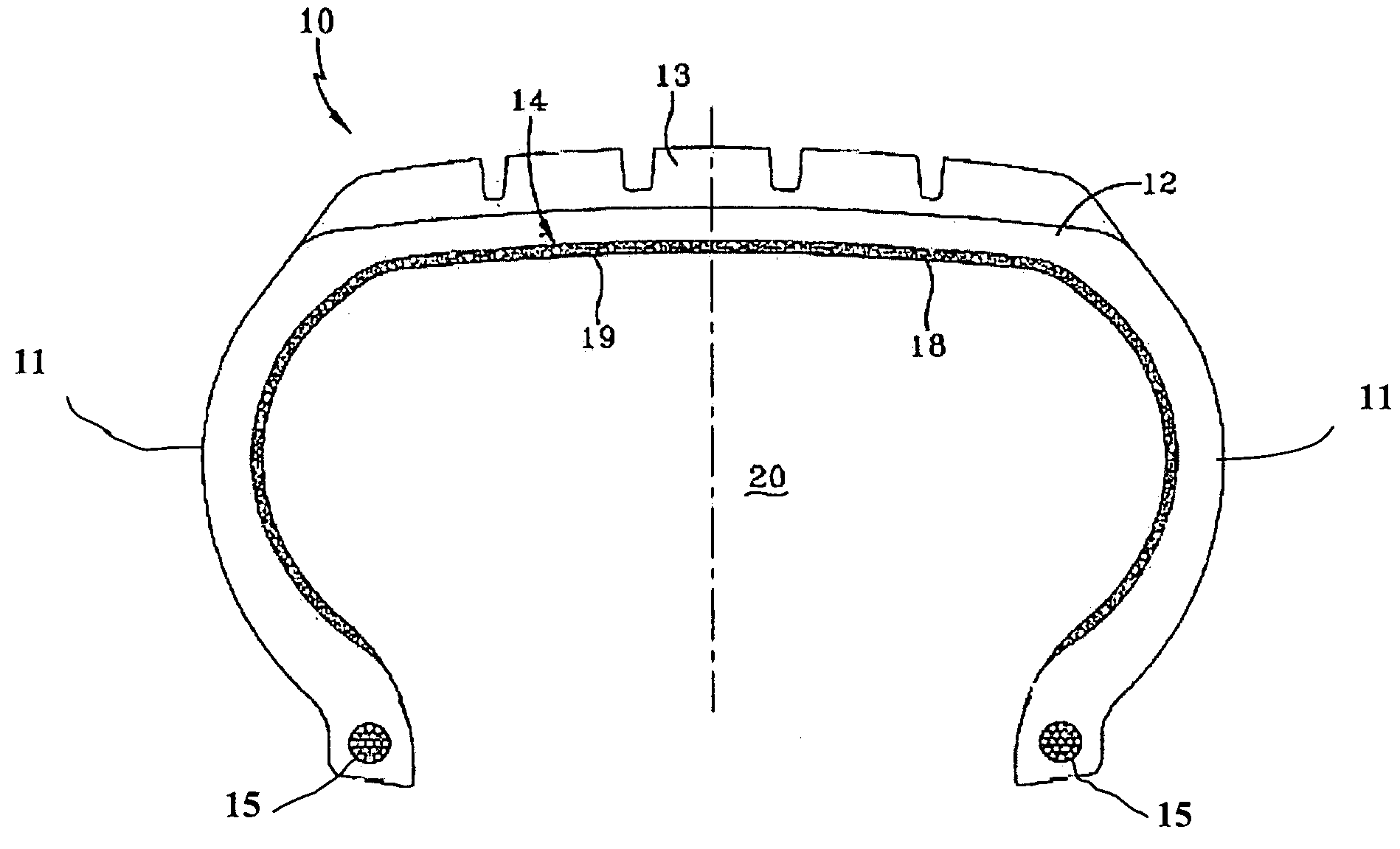

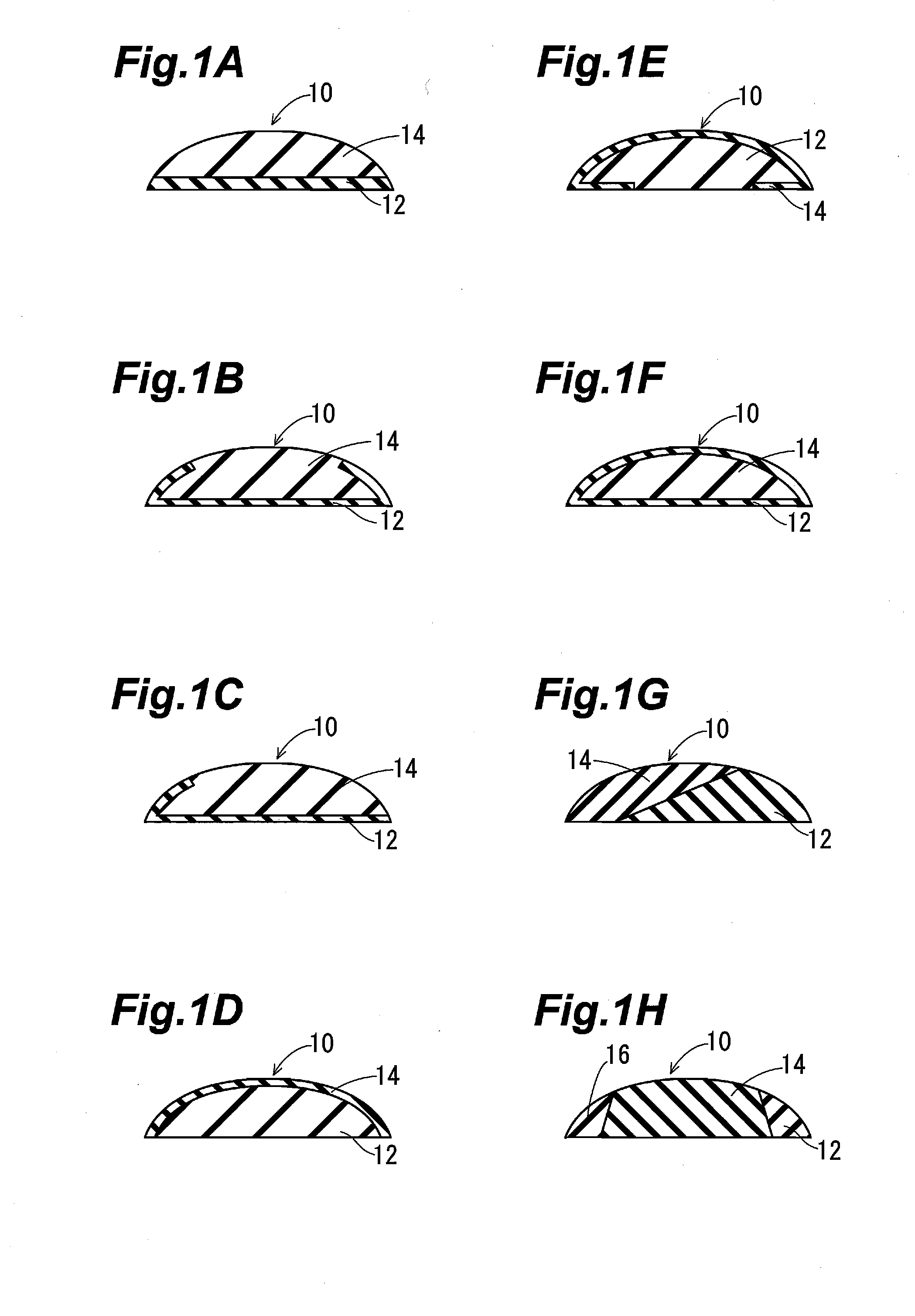

Pneumatic tire with colored thermoplastic elastomer layer adjacent a black-concealing layer

InactiveUS6397912B1Raise the ratioAbundant flexibilityWithout separate inflatable insertsWith separate inflatable insertsElastomerThermoplastic elastomer

A pneumatic tire having an air permeation preventive layer comprising a low permeability thermoplastic elastomer composition comprising a thermoplastic elastomer having a thermoplastic resin composition as a continuous phase and a rubber composition as a dispersed phase, in which a barrier resin composition is contained, which low permeability thermoplastic elastomer composition has a phase structure in which the barrier resin composition is dispersed in the form of a flat state in the thermoplastic elastomer, is abundant in flexibility, is superior in gas permeation preventive property, and enables the tire to be reduced in weight.

Owner:THE YOKOHAMA RUBBER CO LTD

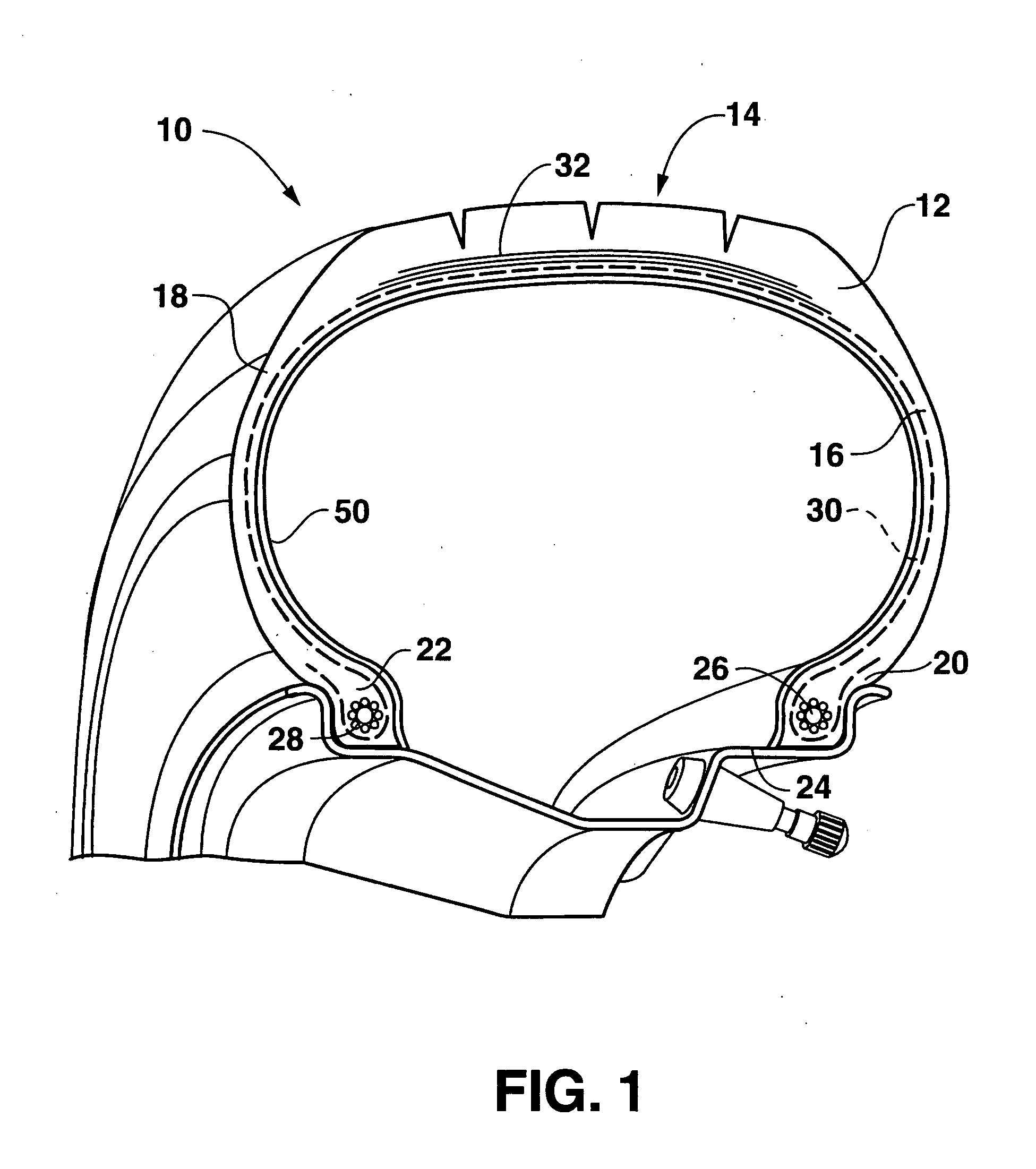

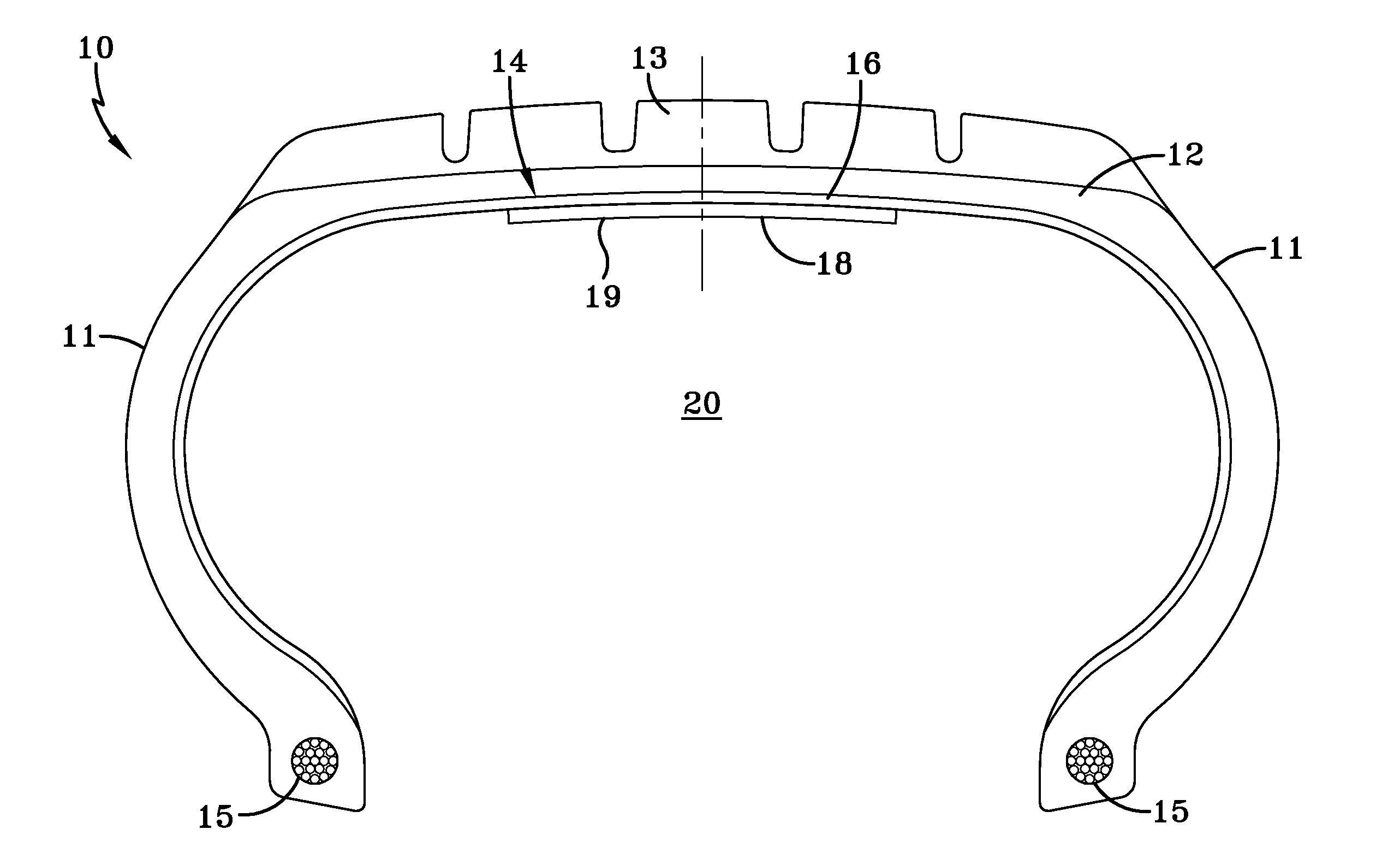

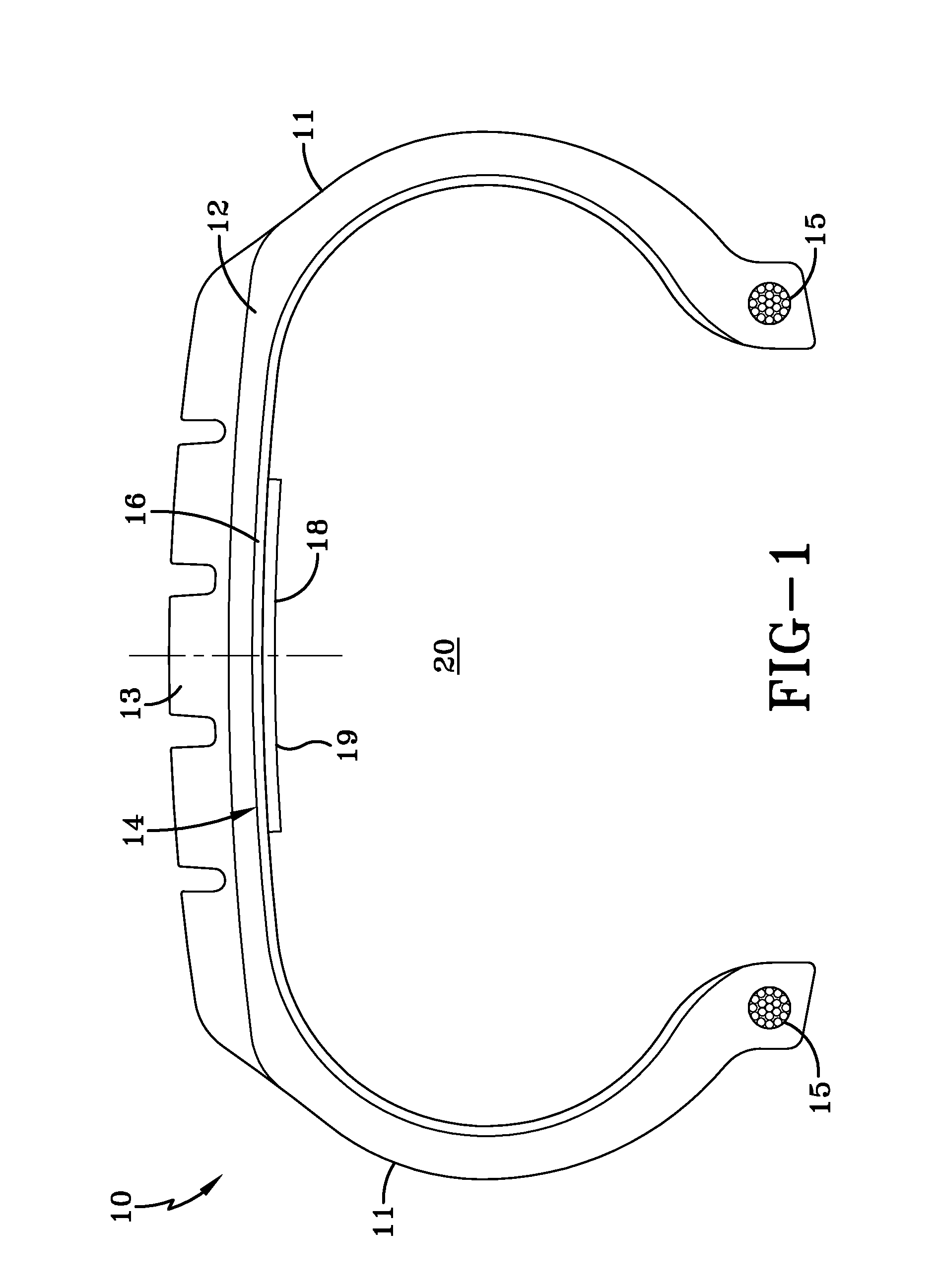

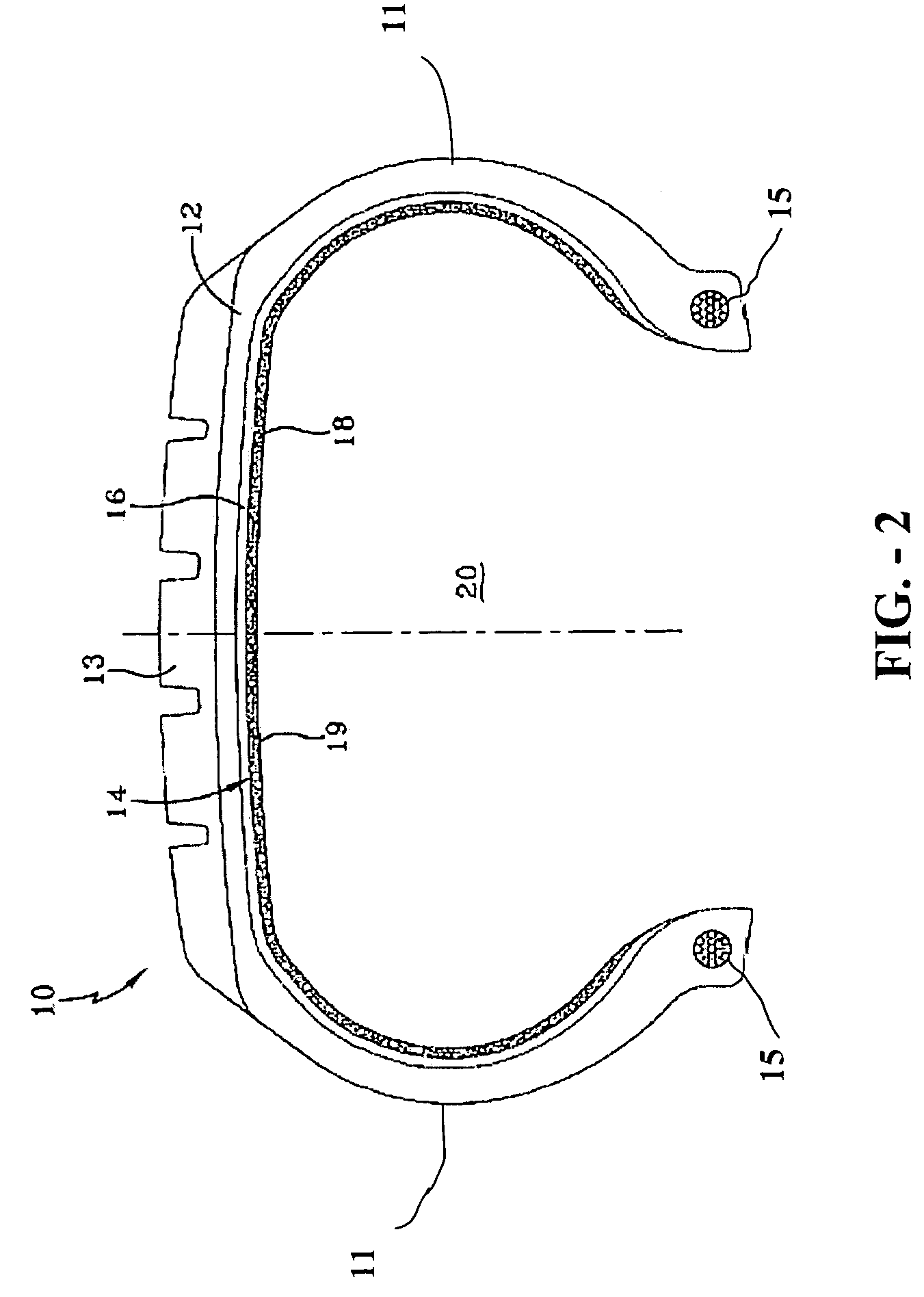

Pneumatic tire having run flat capability

InactiveUS20040031550A1Reduce tire weightSuppressing heat buildupWithout separate inflatable insertsWith separate inflatable insertsElastomerThermoplastic elastomer

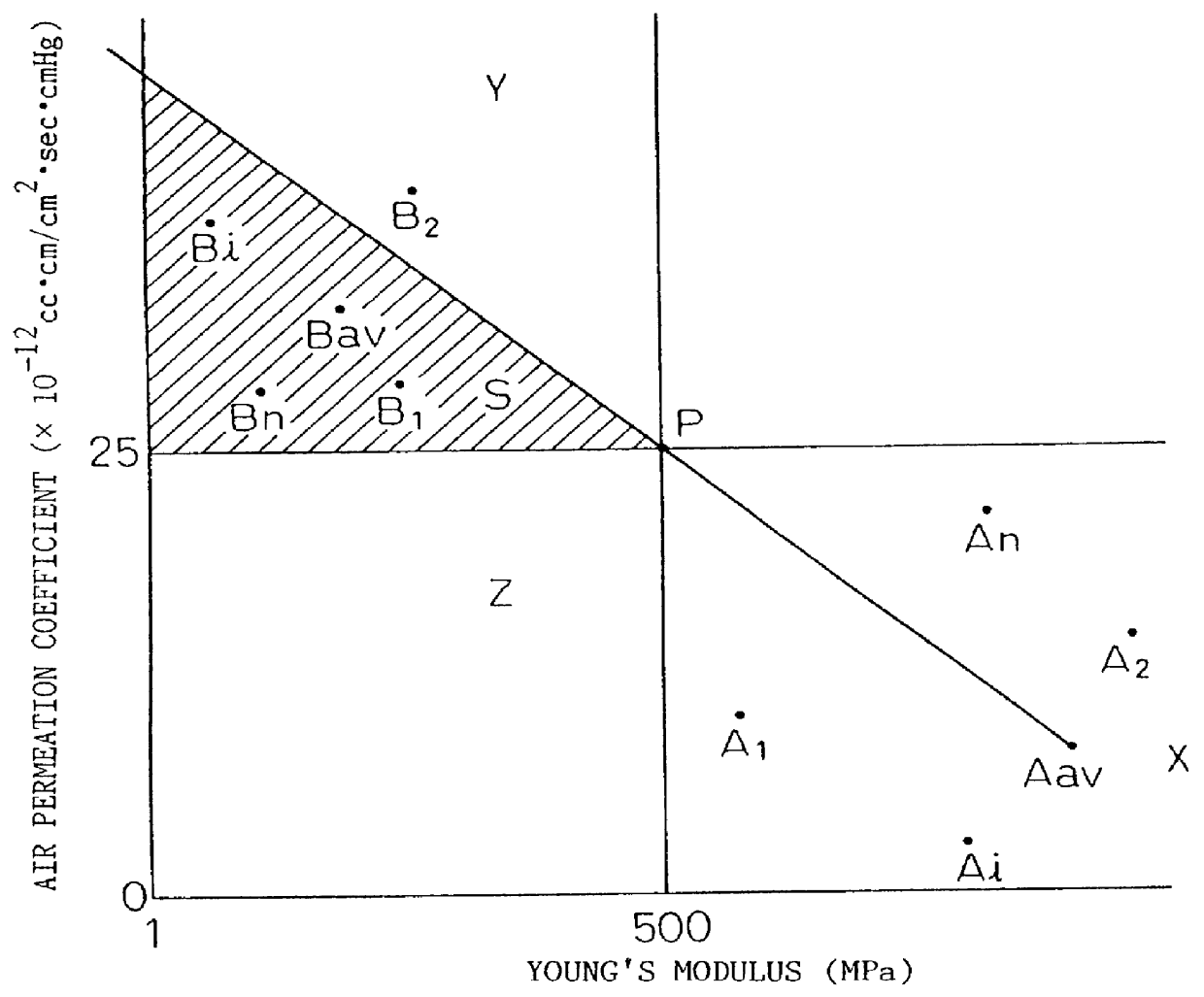

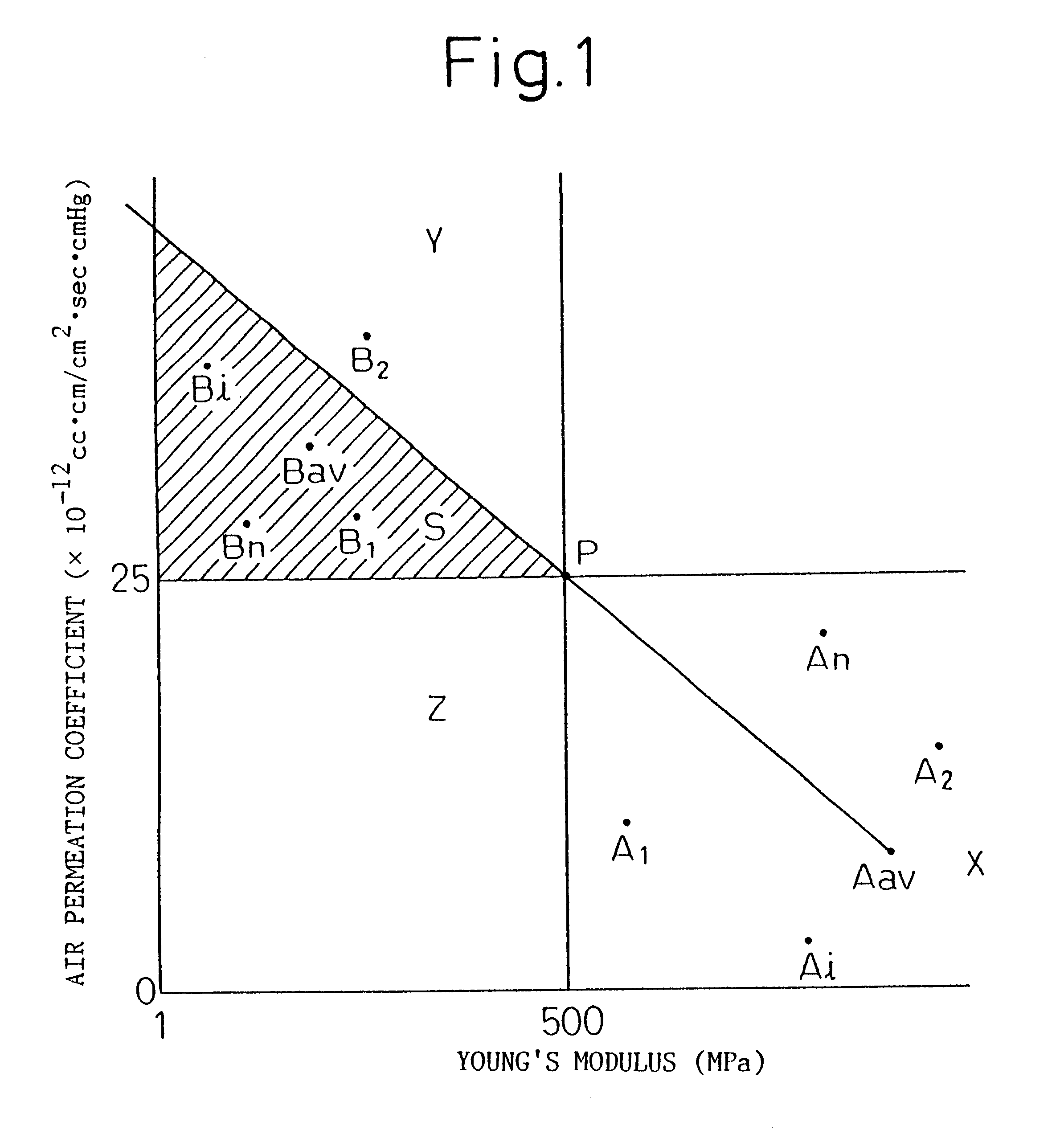

A pneumatic tire having a runflat capability provided with a crescent shaped reinforcing rubber layer at the side part thereof, wherein an inner layer is composed of a thermoplastic elastomer composition containing (A) at least one thermoplastic resin having an air permeation coefficient of 100x10<-12 >cc.cm / cm<2>.sec.cmHg or less and a Young's modulus of more than 500 MPa and (B) at least one elastomer ingredient having an air permeation coefficient of 50x10<-12 >cc.cm / cm<2>.sec.cmHg or more and a Young's modulus of 500 MPa or less in amounts of at least 30% by weight based upon the total polymer ingredients and having an air permeation coefficient of 100x10<-12 >cc.cm / cm<2>.sec.cmHg or less.

Owner:YOKOHAMA RUBBER CO LTD

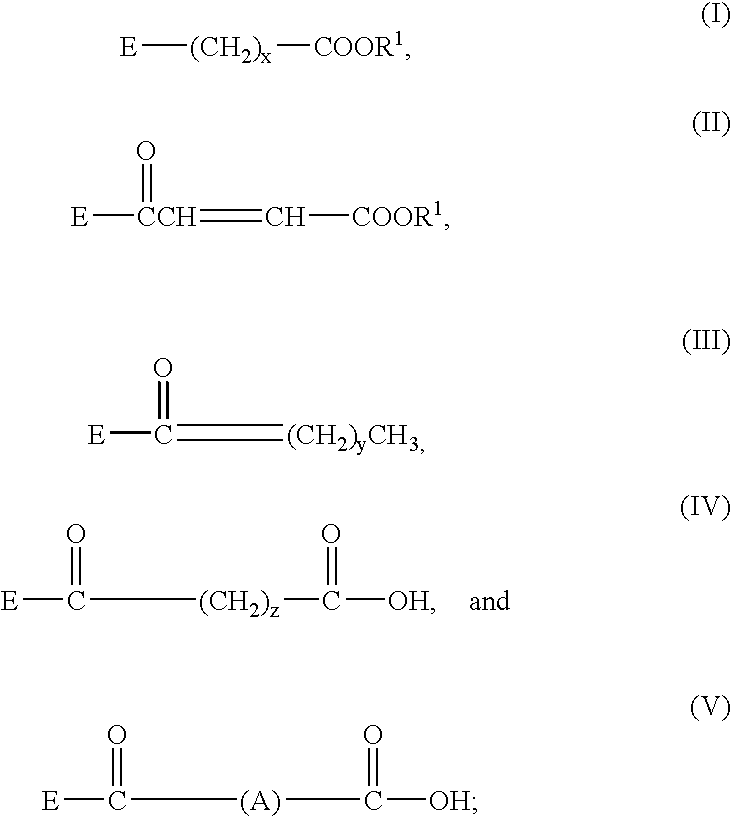

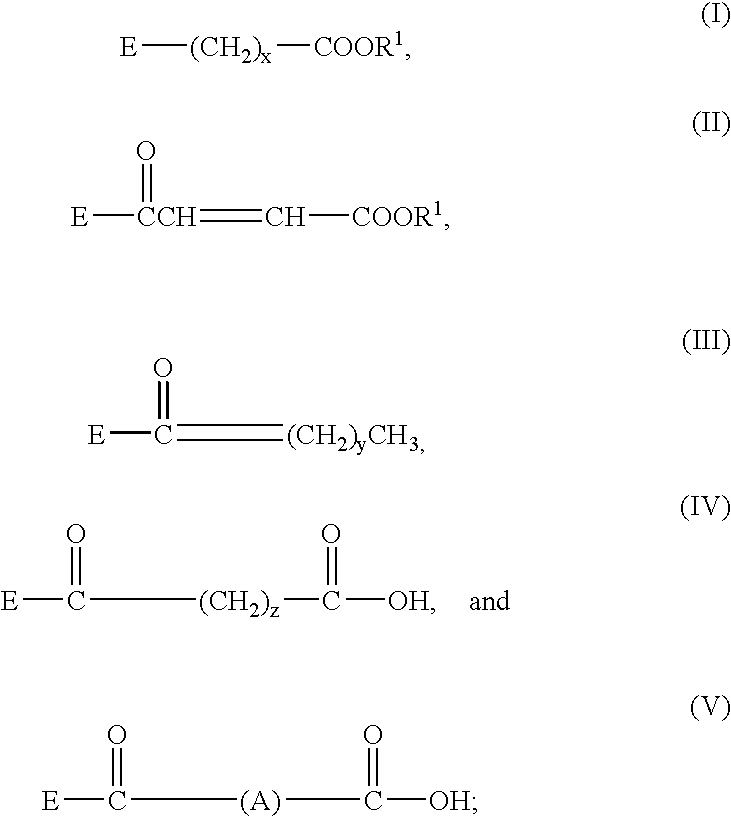

Barrier layer for elastomeric articles

InactiveUS20070161735A1Improve performanceAvoid flowWithout separate inflatable insertsWith separate inflatable insertsVitrificationElastomer

A composition well suited to forming gas barrier layers in elastomeric articles is described. The barrier layer may be incorporated into, for instance, inflatable articles that are intended to contain a gas, such as air, under pressure. For example, in one embodiment, the barrier layer may be incorporated into a tire for preventing oxygen or other gaseous components from migrating through the tire. In general, the barrier layer is made from an elastomer that is combined with permeability reducing particles, such as a silicate, and a terpene hydrocarbon resin having a relatively high glass transition temperature. The terpene hydrocarbon resin can improve the processability of the composition and, in one embodiment, can even serve to improve the permeability characteristics of the barrier layer.

Owner:MICHELIN RECH & TECH SA +1

Construction Comprising Tie Layer

ActiveUS20080314491A1Without separate inflatable insertsWith separate inflatable insertsElastomerTackifier

This disclosure relates to a vulcanizable layered composition comprising at least two layers and at least one tie layer. The first of the two layers comprises a fluid permeation prevention layer and the second comprises at least one high diene rubber. The tie layer comprises, a mixture, in parts by weight relative to 100 weight parts of rubber of: (1) 10 to 70 parts by weight of epoxidized natural rubber; (2) 30 to 90 parts by weight of at least one high diene elastomer; (3) 20 to 90 parts by weight of at least one filler; (4) 1 to 20 parts by weight of at least one tackifier, —and (5) at least 0.2 to 15 parts by weight of curing system for the elastomers and rubbers; The fluid permeation prevention layer comprises: (A) at least one thermoplastic engineering resin component; and (B) at least one elastomer component, wherein (B) is dispersed in a vulcanized or partially vulcanized state, as a discontinuous phase, in a matrix of component (A).

Owner:YOKOHAMA RUBBER CO LTD +1

Low moisture permeability laminate construction

ActiveUS20100024941A1Improve bindingImproved vulcanizable layered constructionRecord information storageMagnetic recordingElastomerResin matrix

An article having a fluid permeation prevention layer, such as a pneumatic tire or hose. A tire for example includes an outer tread layer, intermediate sidewall and carcass layers and an innermost air permeation prevention layer: (i) the air permeation prevention (APP) layer having an upper and a lower surface, the layer having a polymer composition exhibiting an air permeation coefficient (APC) of about 25×1O′12 cc cm / cm2 sec cmHg (at 30* C) or less and a Young's modulus of about 1 MPa to about 500 MPa, the polymer composition comprising: (A) at least 10 wt % of at least one. thermoplastic resin component having an APC of about 25×1O″12 cc cm / cm2 sec cmHg (at 30° C.) or less and a Young's modulus of more than 500 MPa, which is preferably a polyamide resin or mixture, and (B) at least 10 wt % of at least one elastomer component having an APC of more than about 25×10″12 cc cm / cm2 sec cmHg (at 30° C.) and a Young's modulus of not more than 500 MPa, which elastomer component is preferably a halogen-containing rubber or mixture, the total amount (A)+(B) being not less than about 30 wt %, and the elastomer component is a dispersed vulcanized, discontinuous phase in the thermoplastic resin matrix; and (ii) at least one thermoplastic laminate layer bonded to at least said lower surface of the APP layer, the thermoplastic layer comprising a film-forming, semi-crystalline, substantially hydrophobic carbon chain polymer having a glass transition temperature, Tg, of less than about −200 C.

Owner:EXXONMOBIL CHEM PAT INC +1

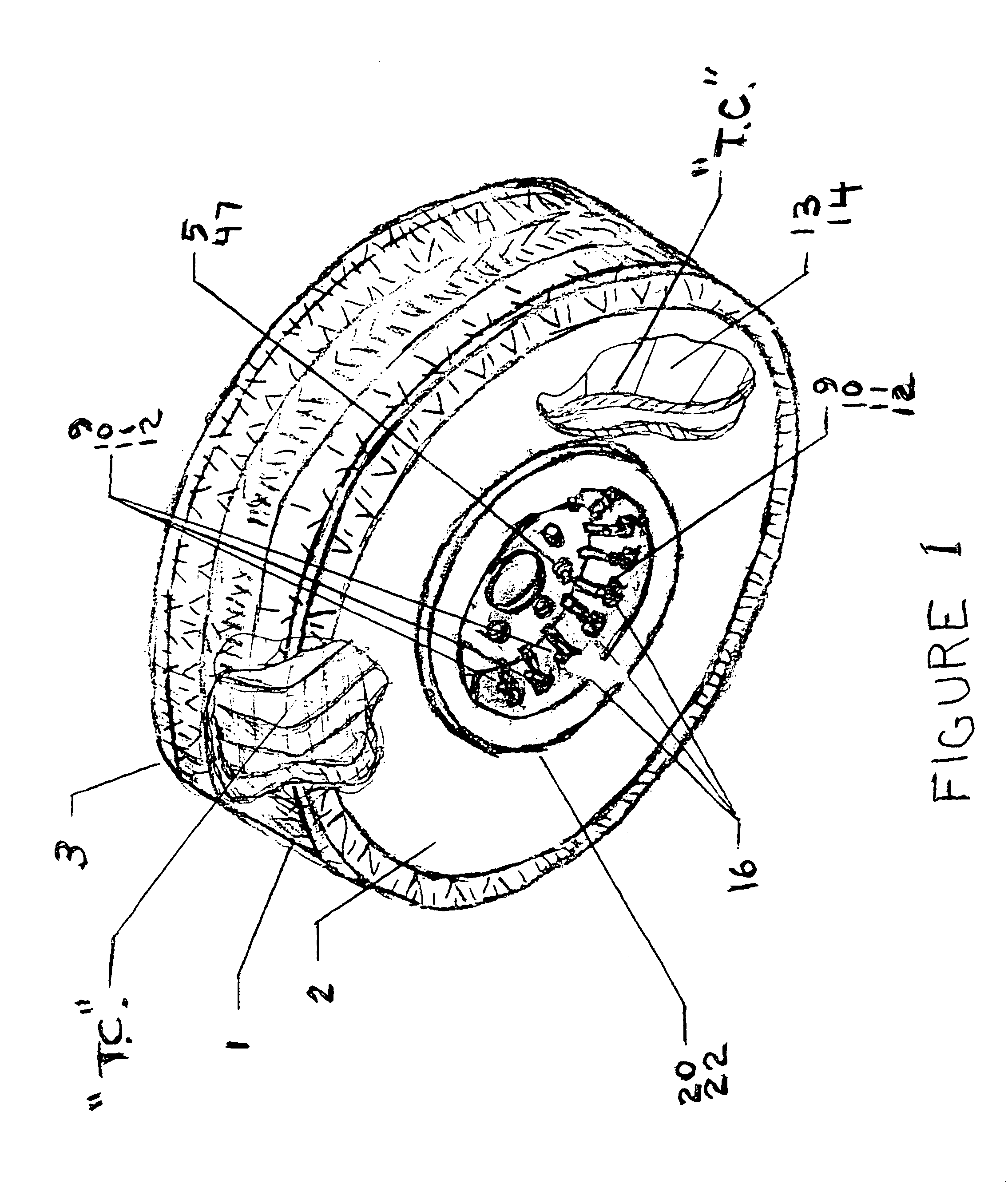

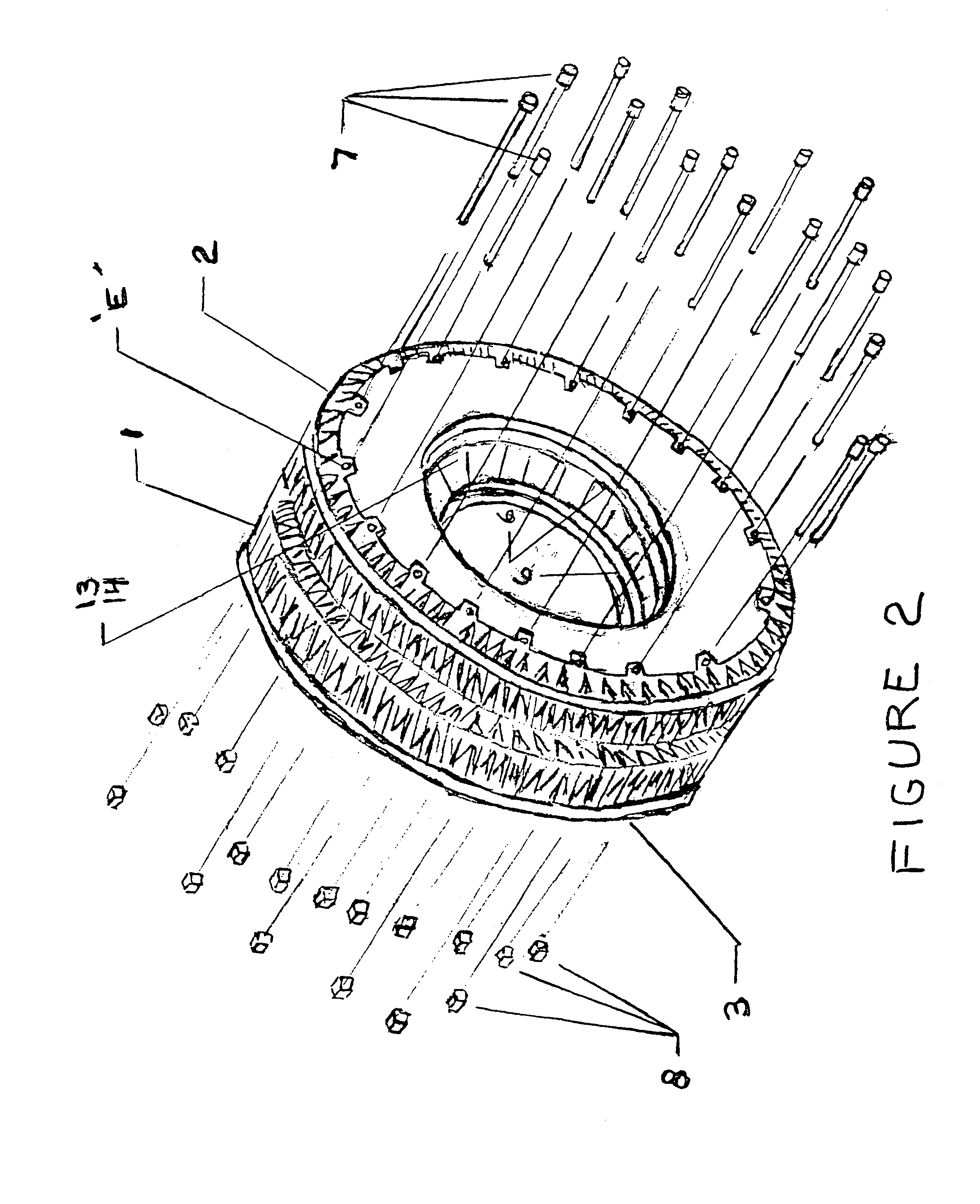

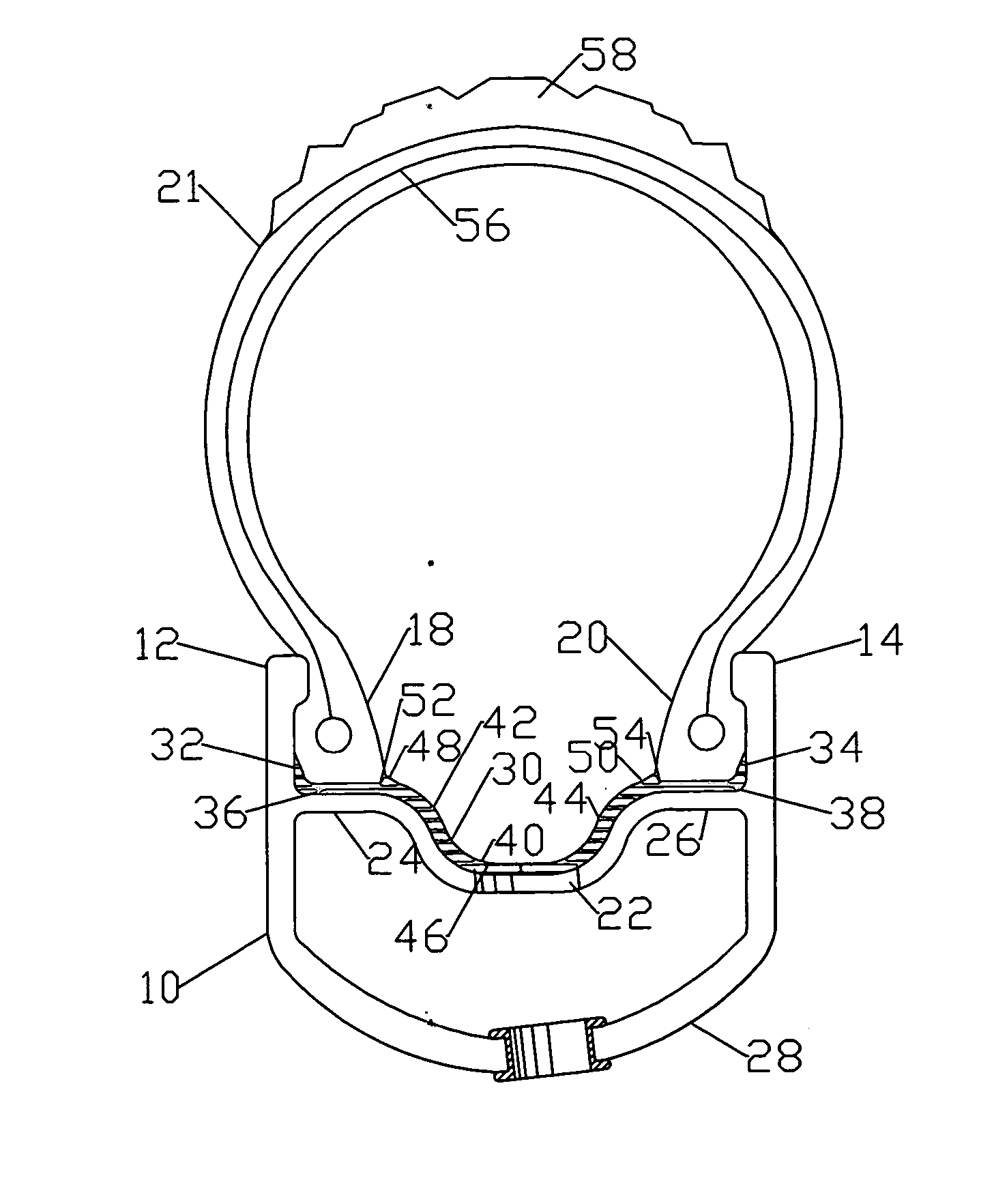

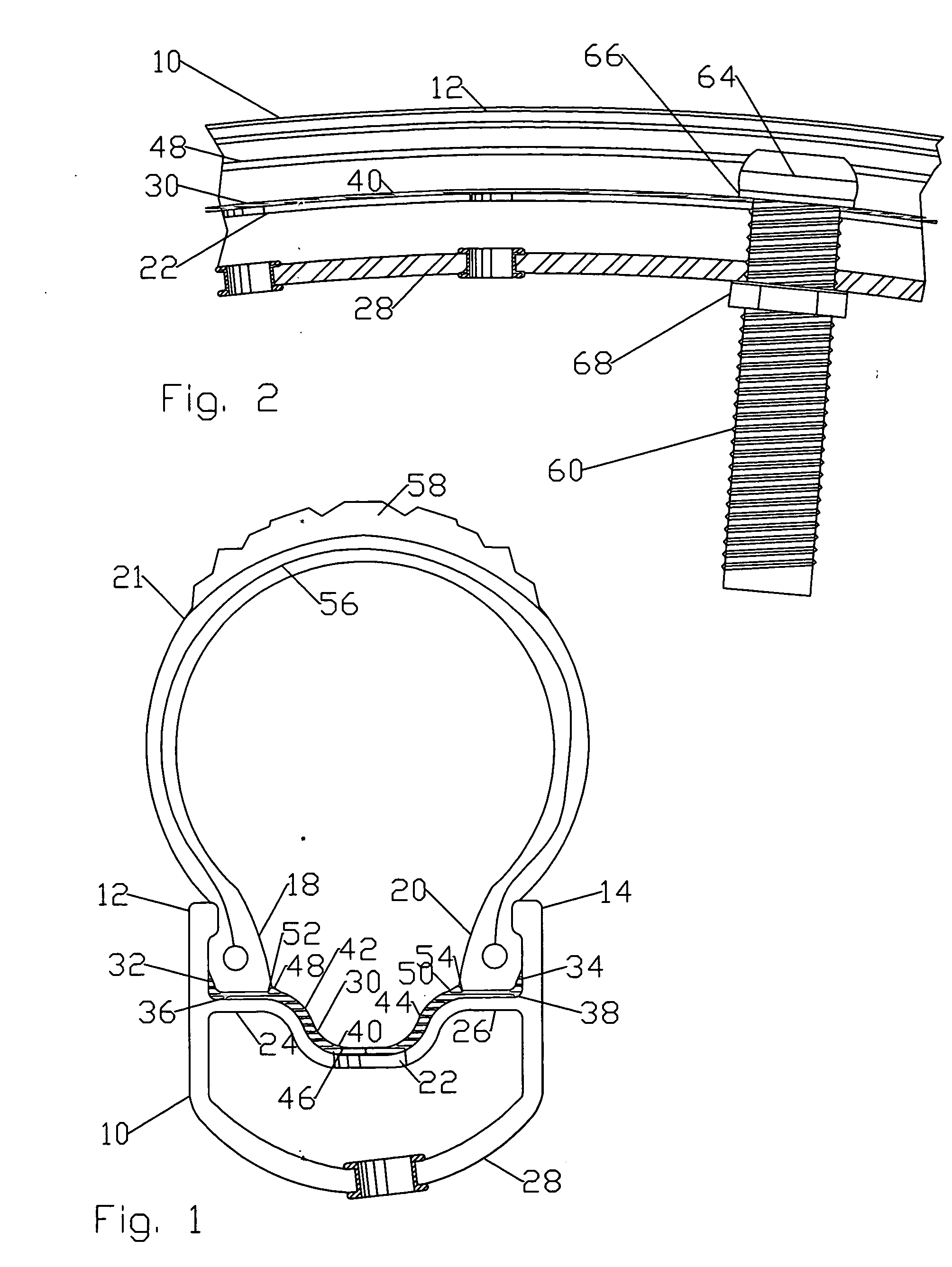

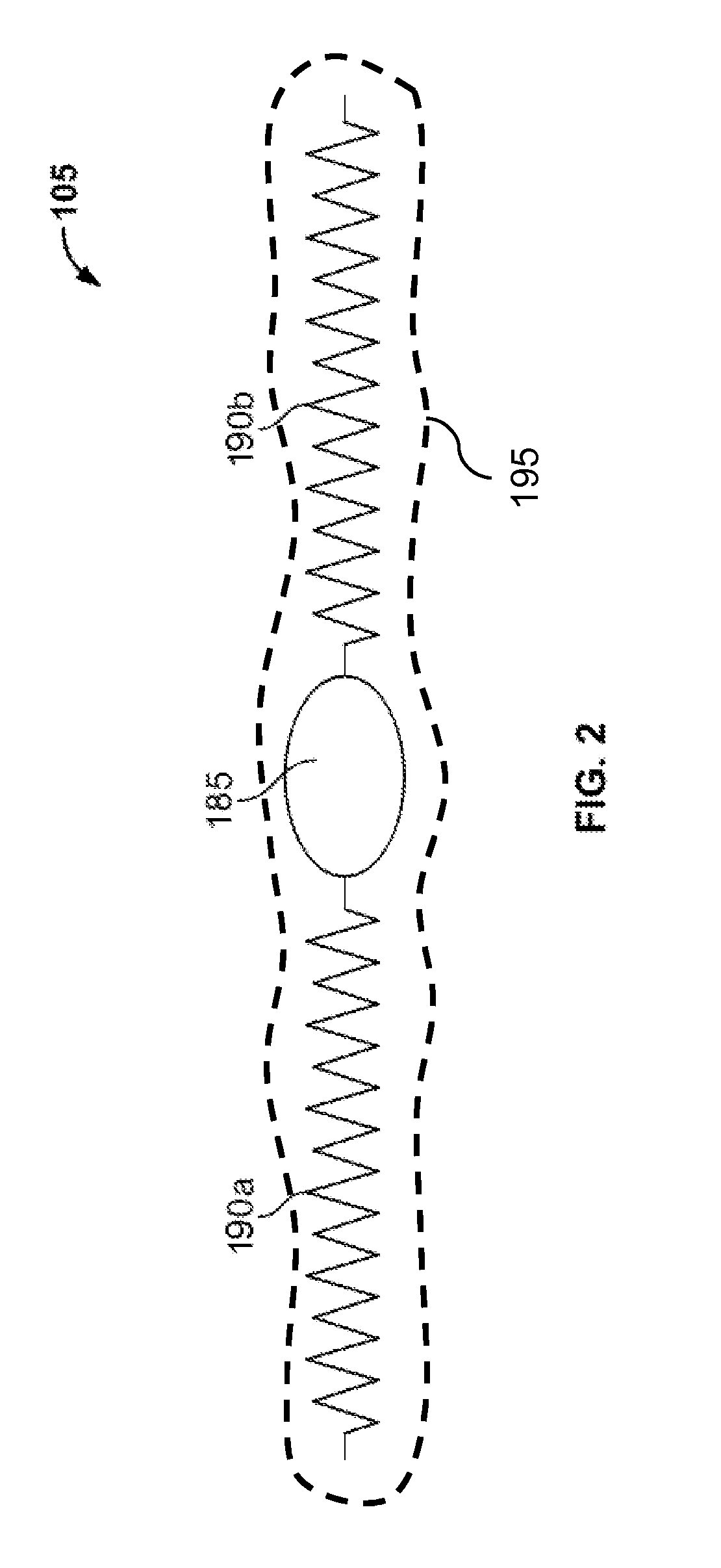

Modular tire

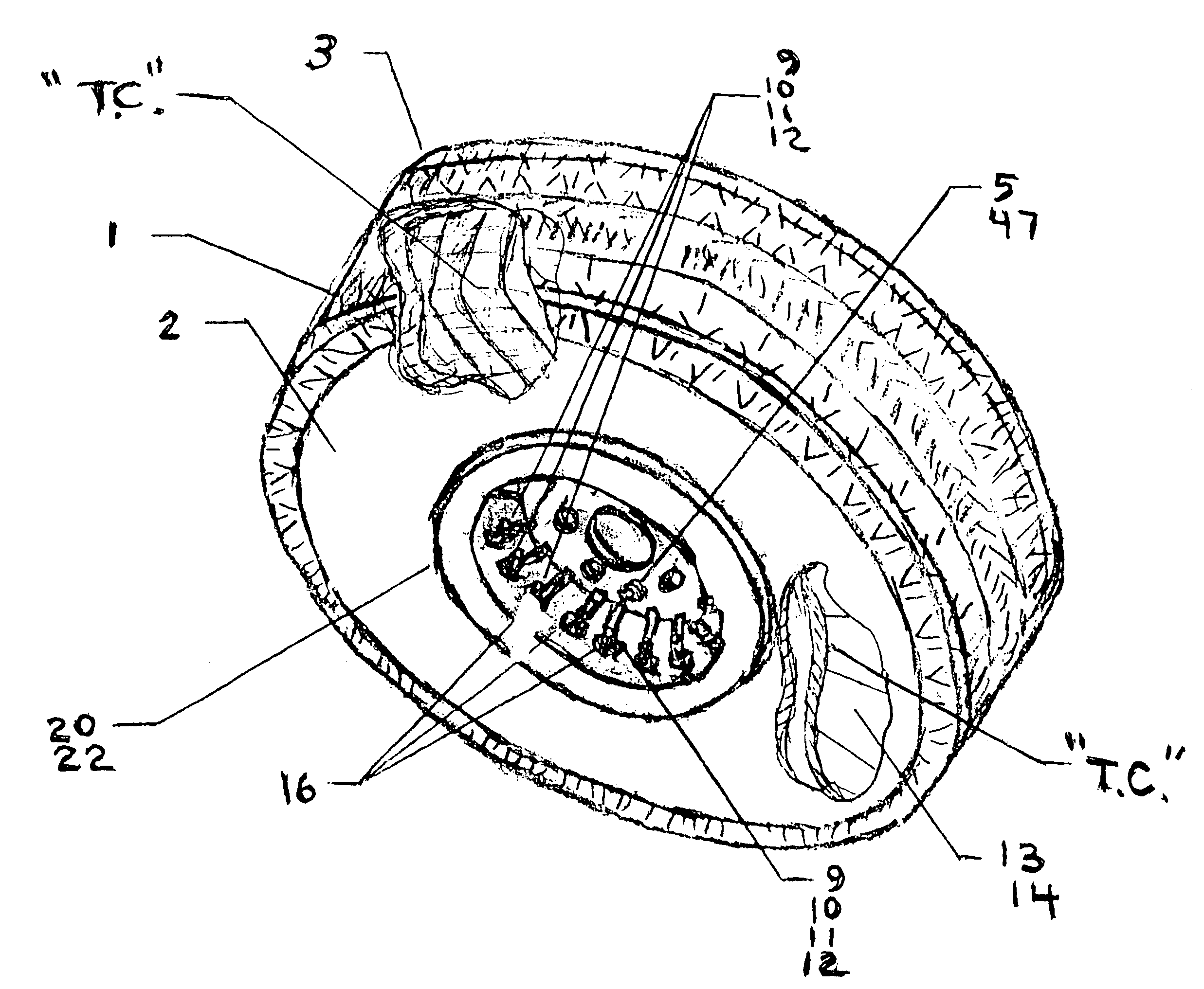

InactiveUS7316252B1Less expensiveWith separate inflatable insertsWith multiple inflatable chambersModularityFlat tire

A device for serving as a wheel for motor vehicles, where the wheel has its tire tread replaceable when it is worn out via unique rims and molded tire features. An alternate internal structure prevents the tire from “going flat” or “blowing out” when it is punctured or cut. In one variation the tire can be used with existing rims and can be retro-fitted into existing tire by mating the tires with this invention's “Non-Flat Tire” internal element and special rim. A variation of the “Non-Flat Tire” system uses spring-like materials for its tire core that is shaped similar to a tire's inner tube, and functions like an “air-filled” tire, but the absence of the use of air in this unique configuration gives it the “Flat Tire Prevention” effect.

Owner:HEARD NATHANIEL

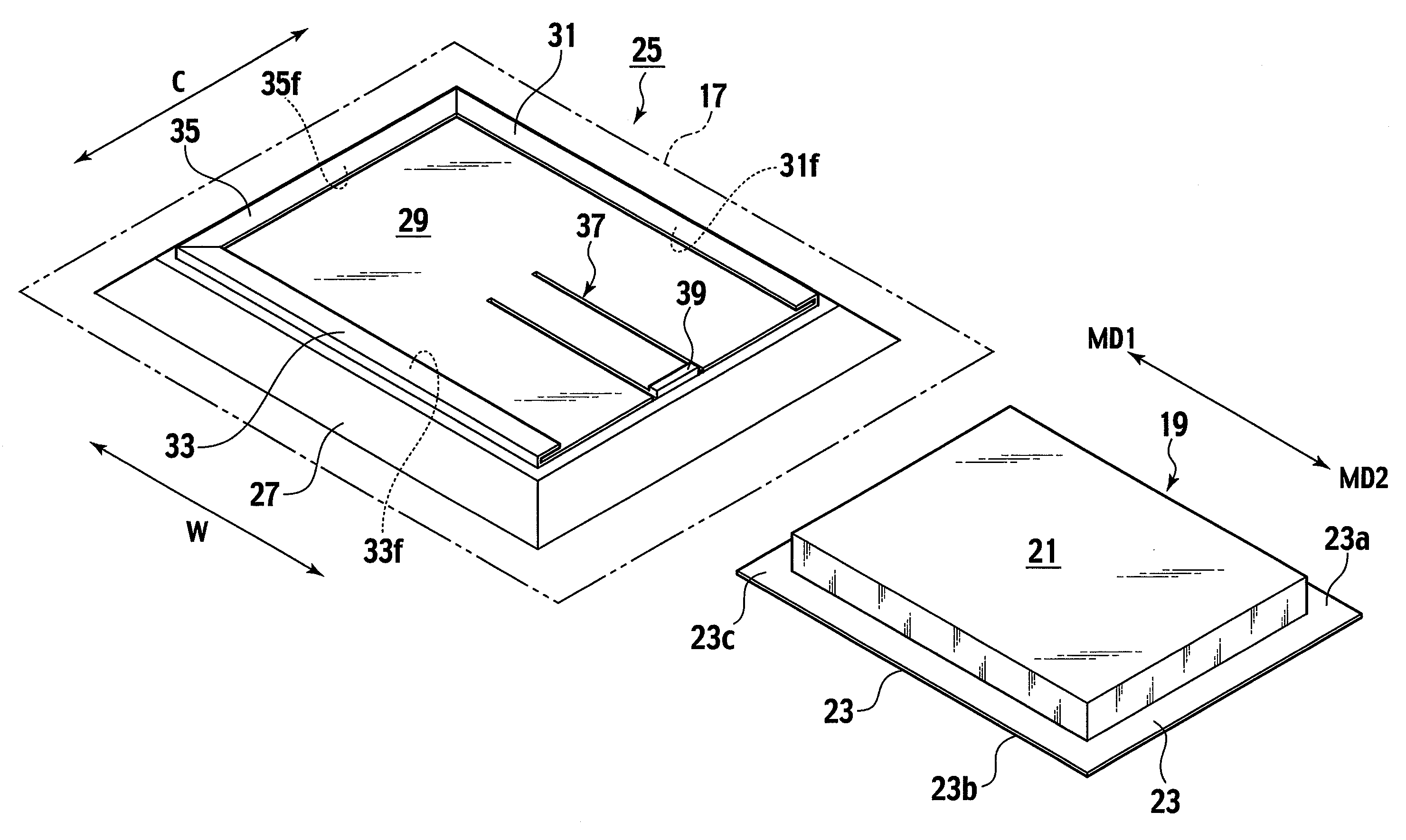

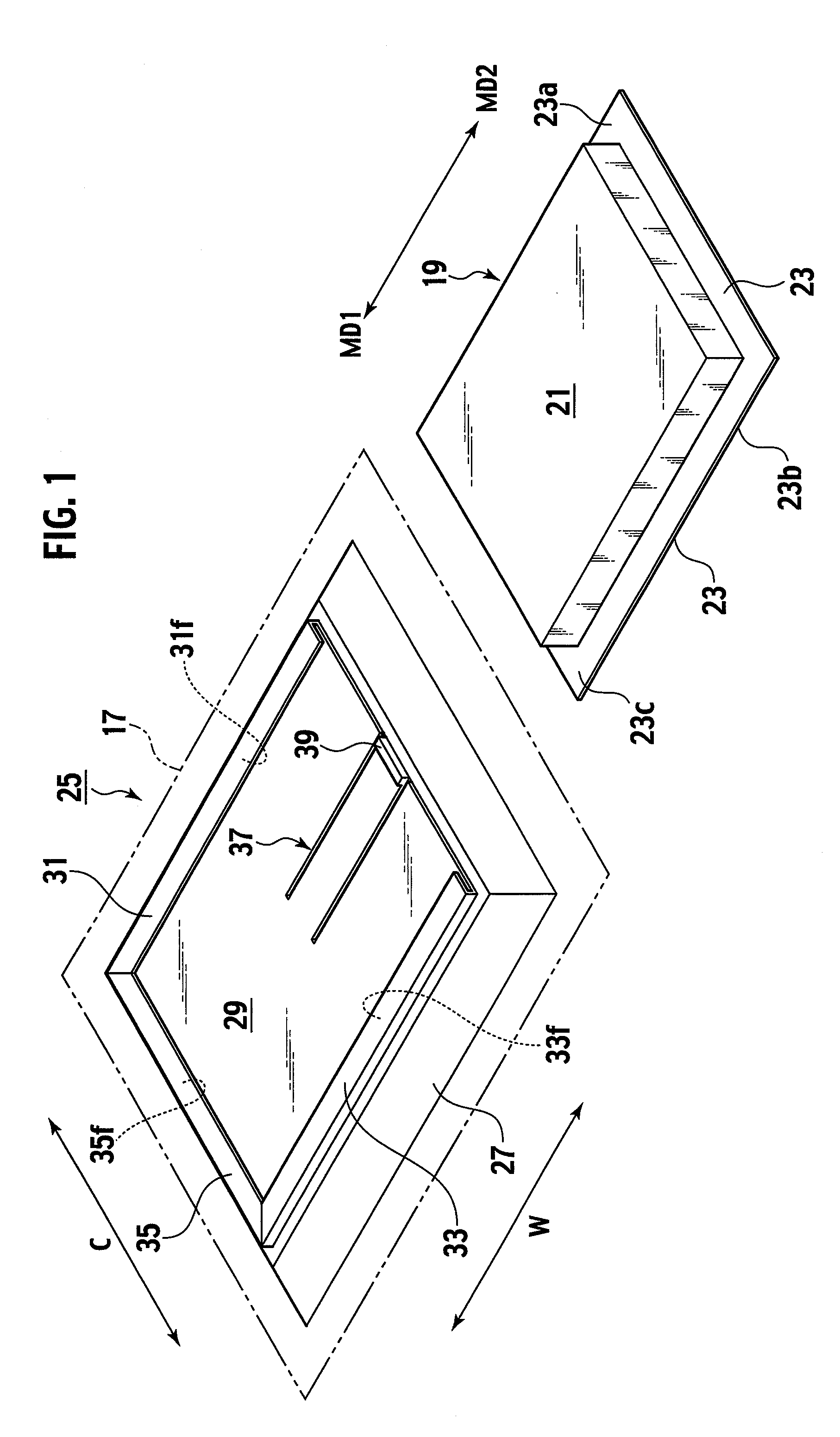

Film, inner liner for tire, and tire using the same

InactiveUS20110024015A1Excellent gas barrier propertiesImprove bending resistanceWithout separate inflatable insertsWith separate inflatable insertsInternal pressureEngineering

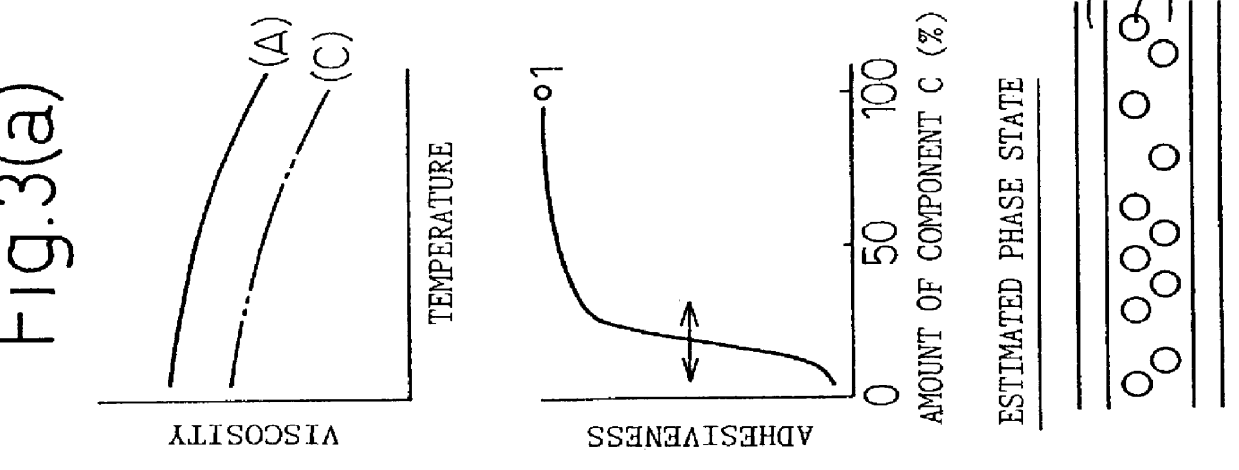

An object of the present invention is to provide: a film which is applicable to a tire, has excellent gas barrier properties and bending resistance, allows weight of a tire to be reduced with improving internal pressure retainability of the tire at both the brand-new stage and the used stage thereof, and is capable of demonstrating good gas barrier properties without breaking especially in a running condition at a relatively low temperature in winter time or the like; an inner liner for tire, using the film; and a tire provided with the inner liner for tire. The film of the present invention comprises at least a layer composed of resin composition (D) produced by dispersing viscoelastic substance (C) in a resin containing modified ethylene-vinyl alcohol copolymer (B) obtained by subjecting ethylene-vinyl alcohol copolymer (A) to a reaction, wherein 100% modulus at −30° C. of the viscoelastic substance (C) is smaller than 6 MPa. The inner liner for tire, and the tire, of the present invention are an inner liner for tire, using said film, and a tire provided with said inner liner for tire, respectively.

Owner:BRIDGESTONE CORP +1

Sealed tubeless tire bicycle wheel

InactiveUS20050210675A1Good handling characteristicsImprove featuresWithout separate inflatable insertsWith separate inflatable insertsTubeless tireAutomotive engineering

Pneumatic tires adapted to use on bicycles have a number of criteria that need to be evaluated. For high performance bicycle riding, such as in mountain bike races, it is advantageous to optimize performance. Standard tires with tubes have ease of repair in the replacement of a punctured tube, have the ability to maintain pressure for long periods, and do not require special adaptation of the rim for sealing.

Owner:PRICE CHAD NATHANIEL +1

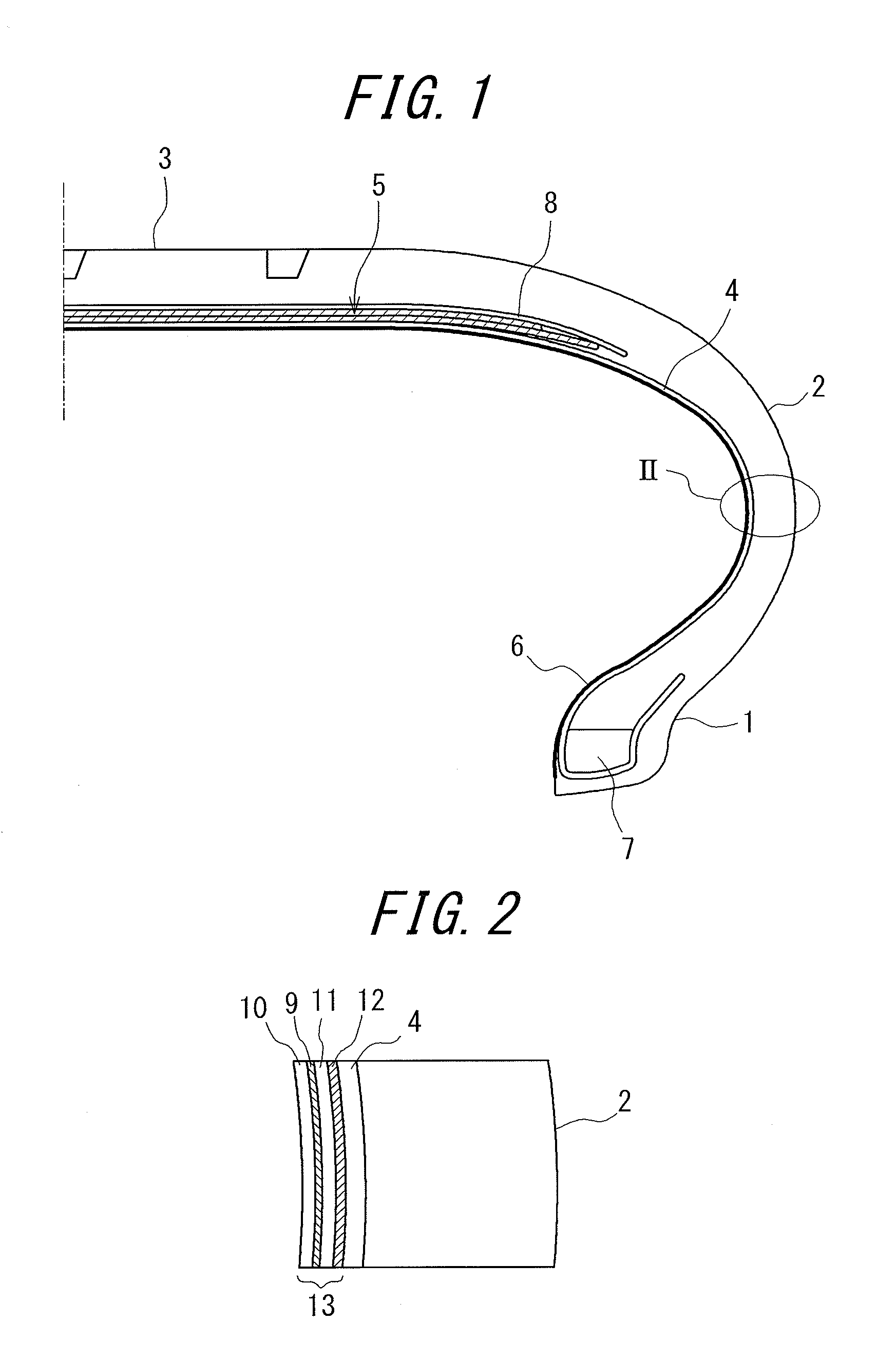

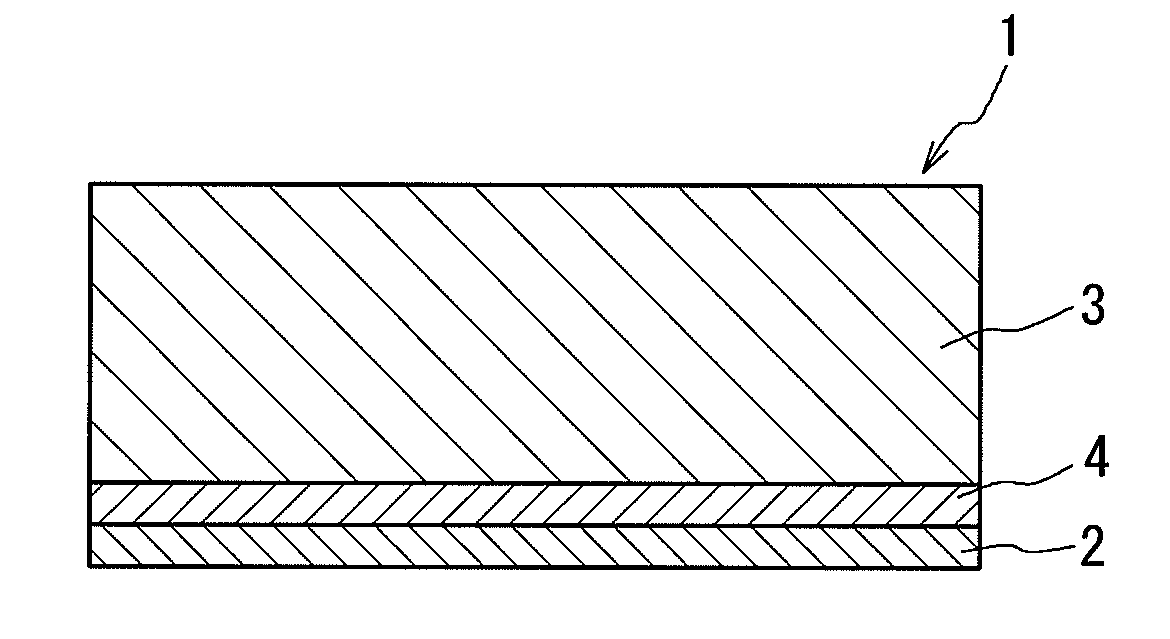

Pneumatic tire

ActiveUS20090242094A1High peel strengthIncrease flexibilityWithout separate inflatable insertsWith separate inflatable insertsPliabilityRoom temperature

A pneumatic tire in which the average peel strength between the surface of (A) a layer of a single-layered or multi-layered film of a thermoplastic resin and (B) a rubbery elastic layer, which are used as the inner liner layer, is 6 kN / m or greater at −20° C., i.e., a pneumatic tire exhibiting excellent average peel strength between the surface of layer (A) and layer (B), which are used in combination as the inner liner layer exhibiting excellent gas barrier property and flexibility, at a low temperature and at the room temperature, is provided.

Owner:BRIDGESTONE CORP

Inner Liner of Pneumatic Tire

InactiveUS20080047646A1Avoid stickingEasy to packWithout separate inflatable insertsWith separate inflatable insertsElastomerRoom temperature

The present invention provides an inner liner of pneumatic tires that is formed from a non-drawn film of a polymer composition including 60 to 90 wt. % of a thermoplastic resin and 10 to 40 wt. % of an elastomer to have an oxygen permeation rate of less than 15×10−3 ccm / m2 24 hratm, and a fracture elongation of more than 200% at the room temperature. The tire thus manufacture has no fracture under a severe deformation during the tire shaping process, facilitating the tire manufacture, and exhibits an air permeation preventive property as an excellent air permeation preventive layer.

Owner:KOLON IND INC

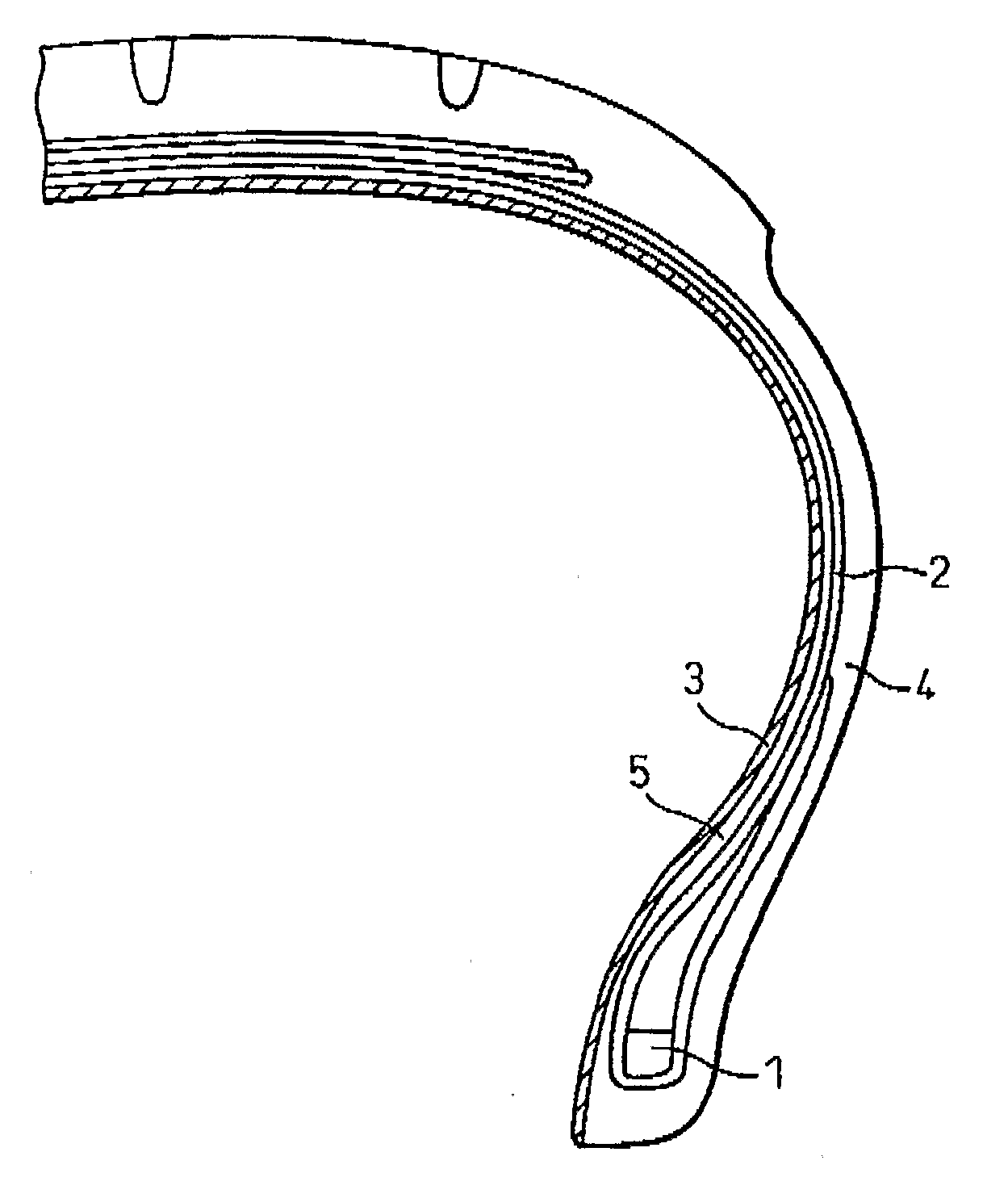

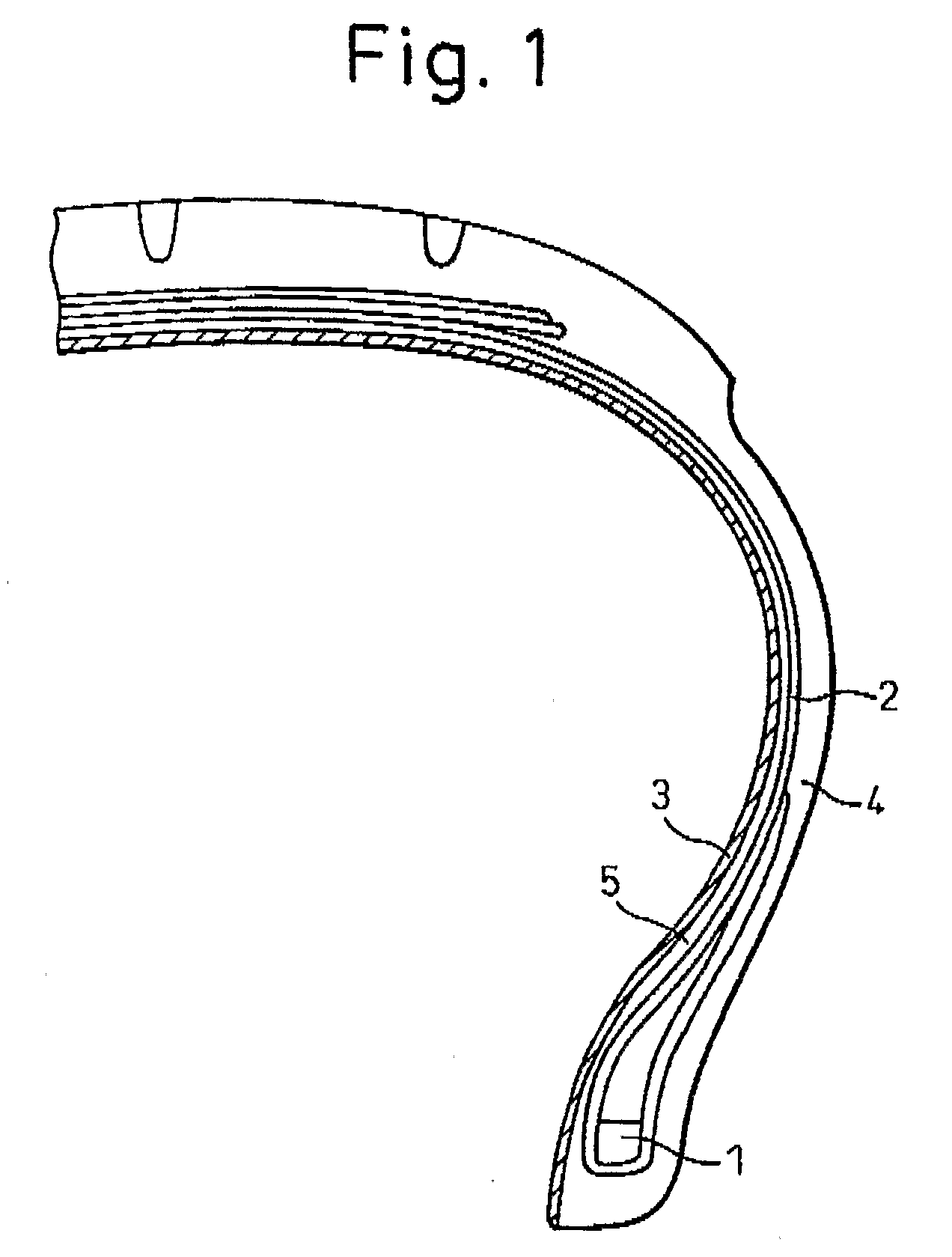

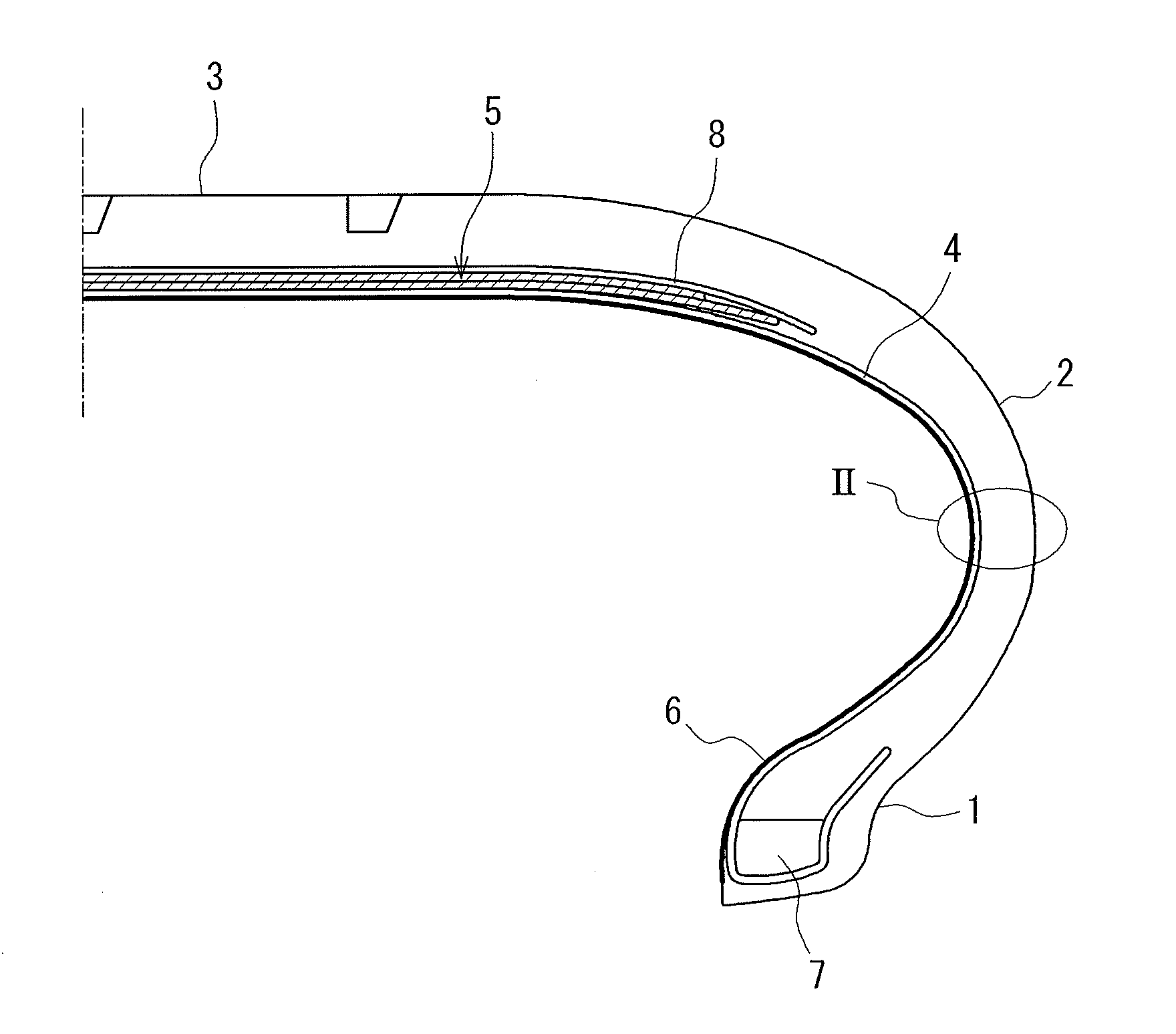

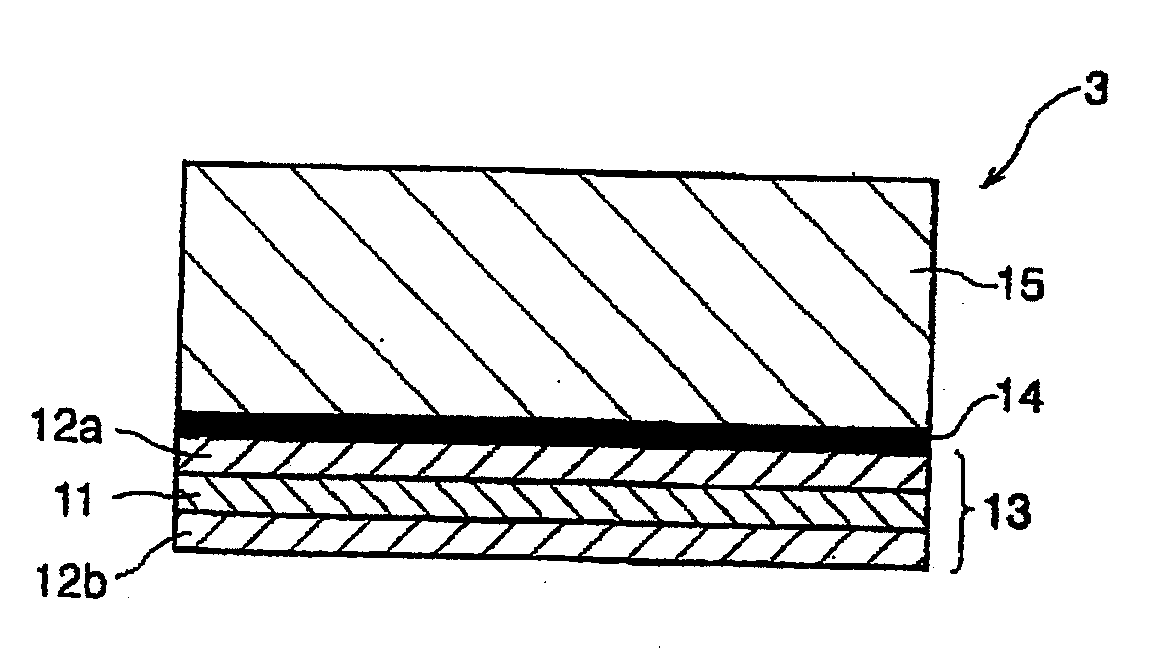

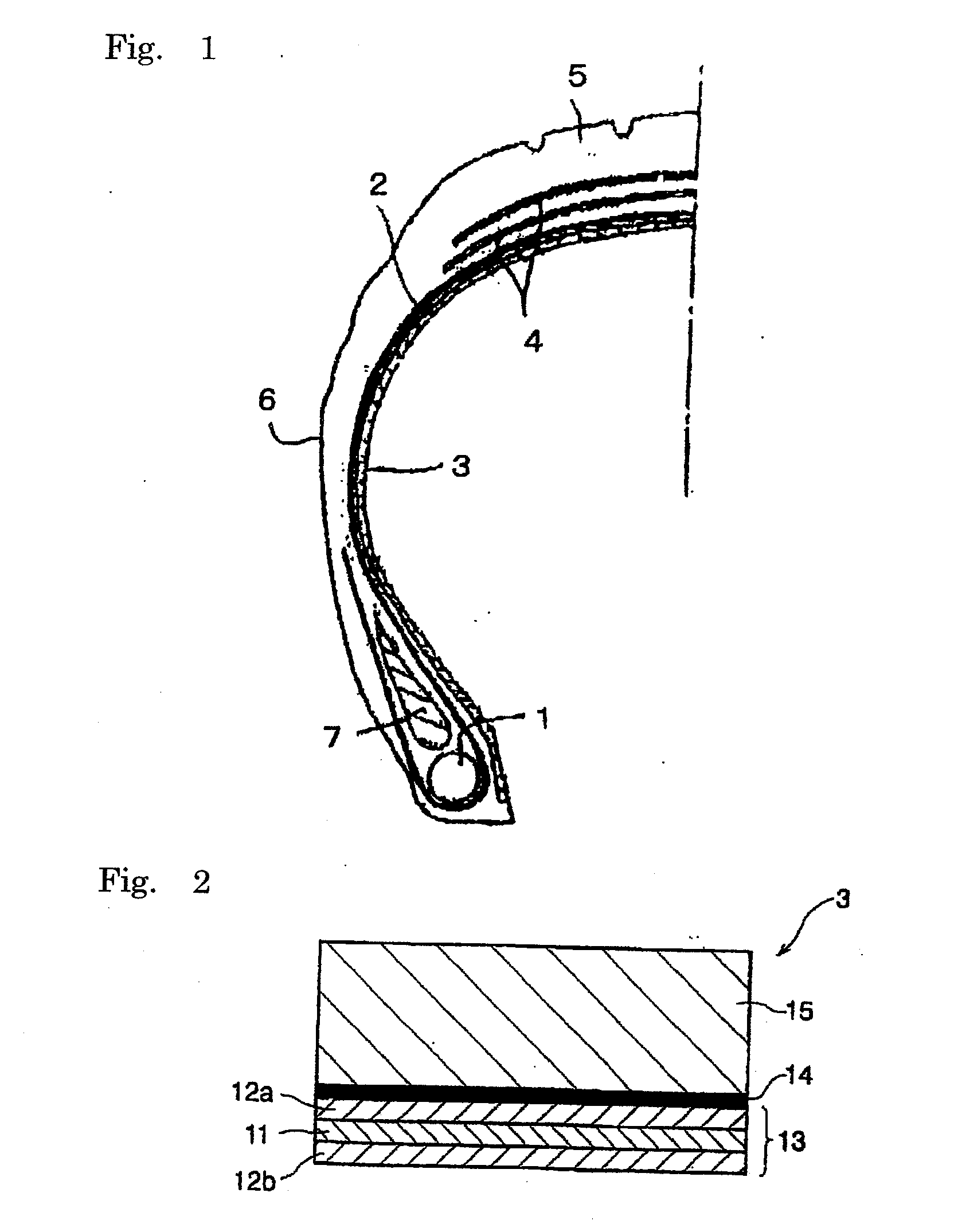

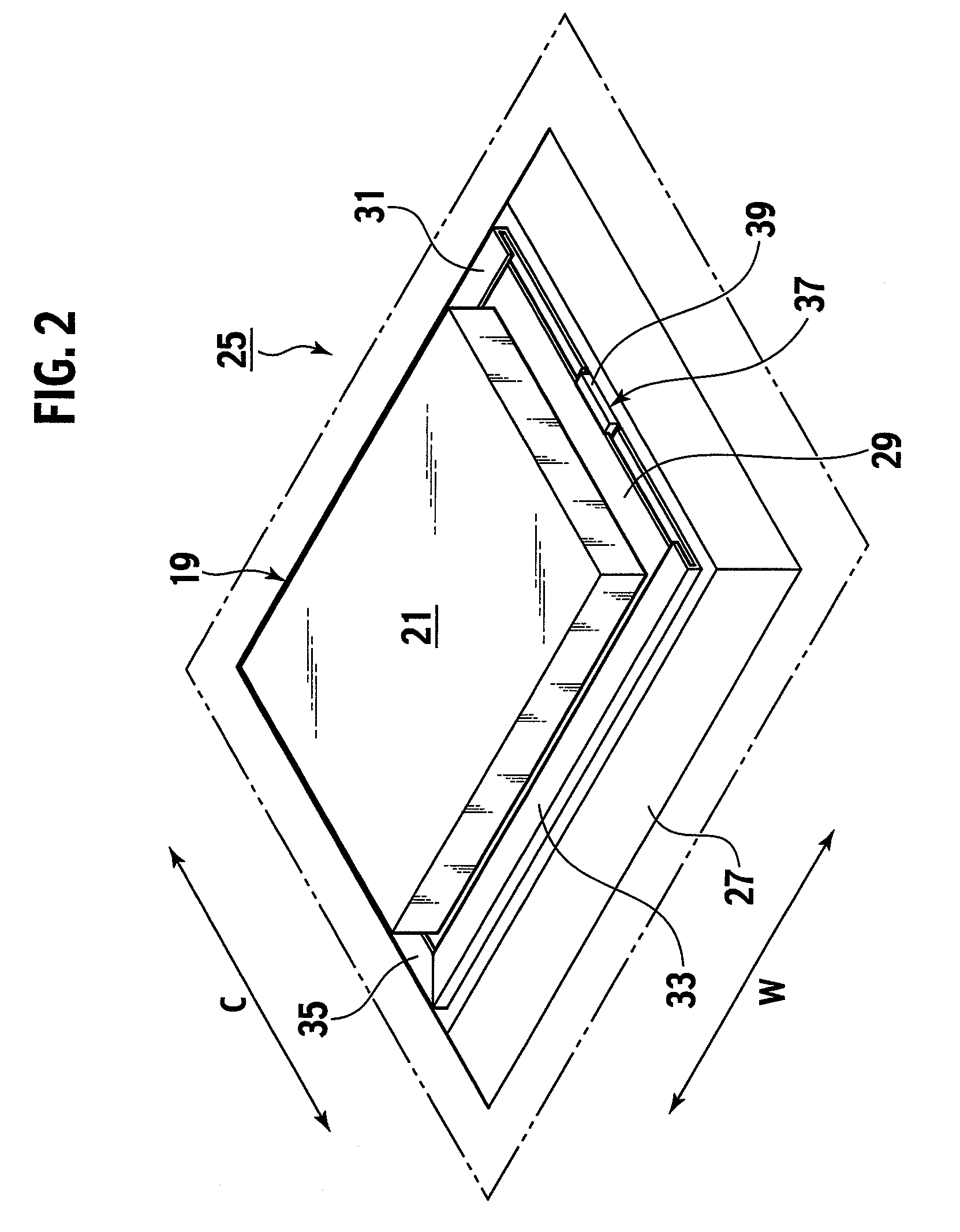

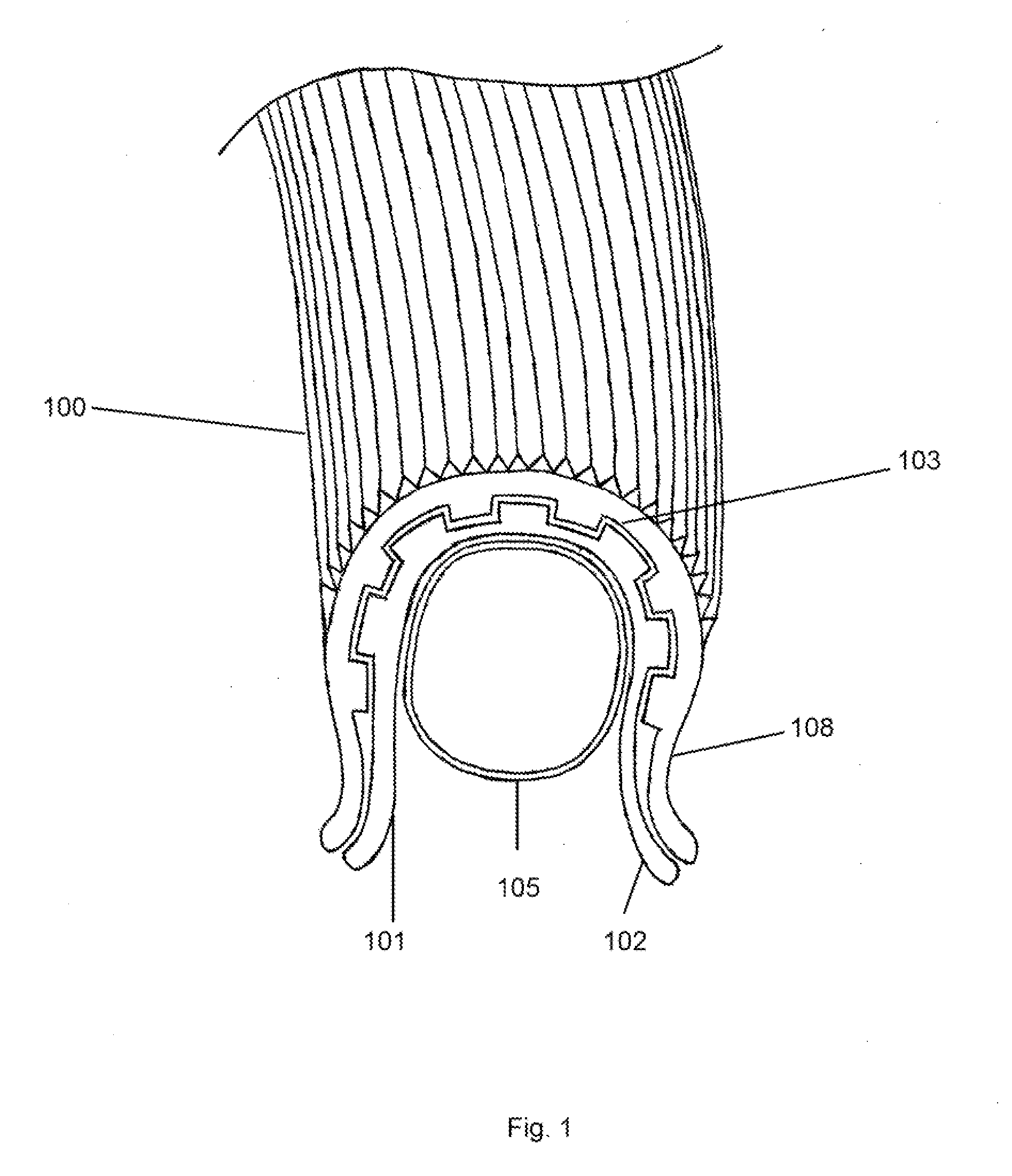

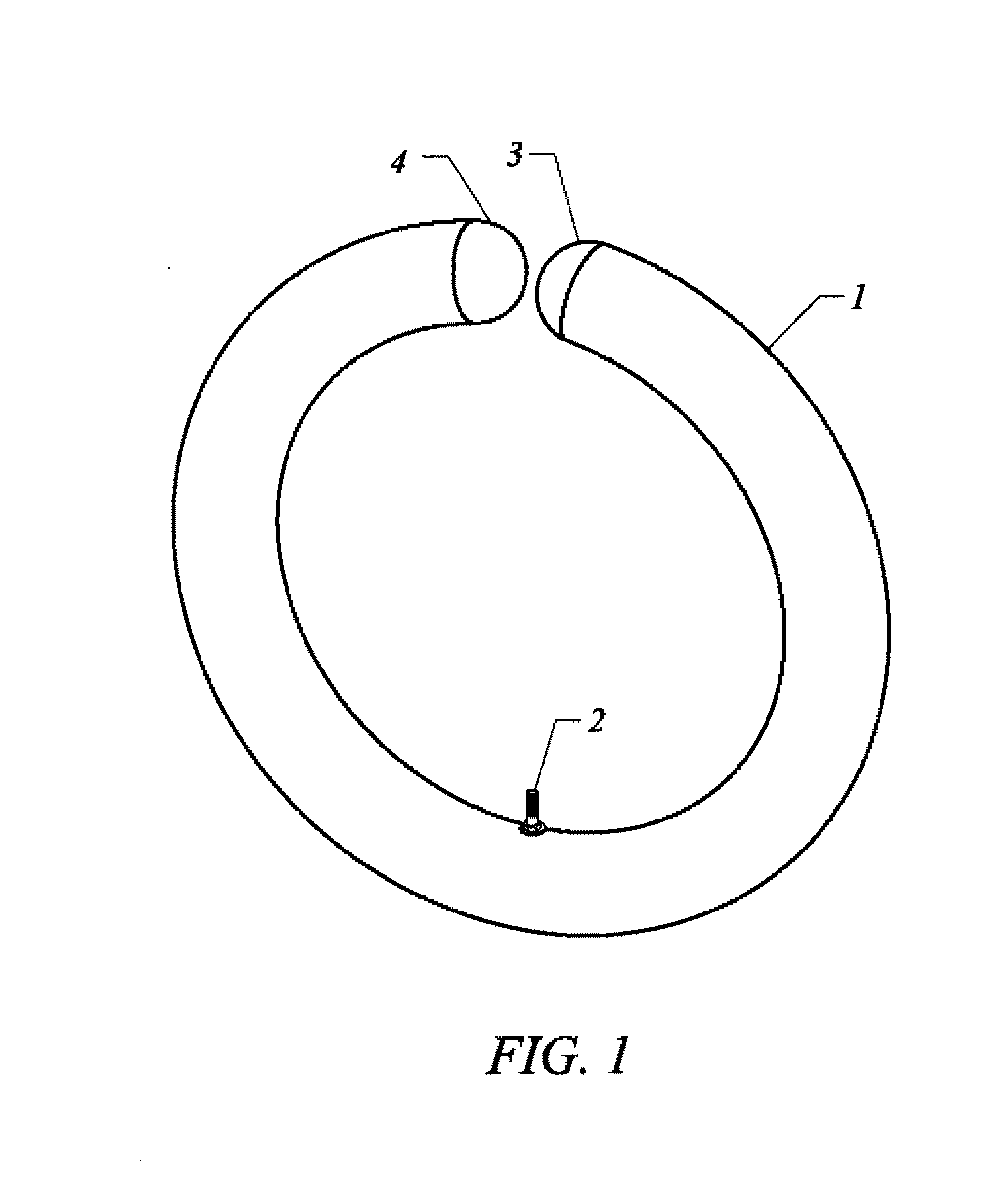

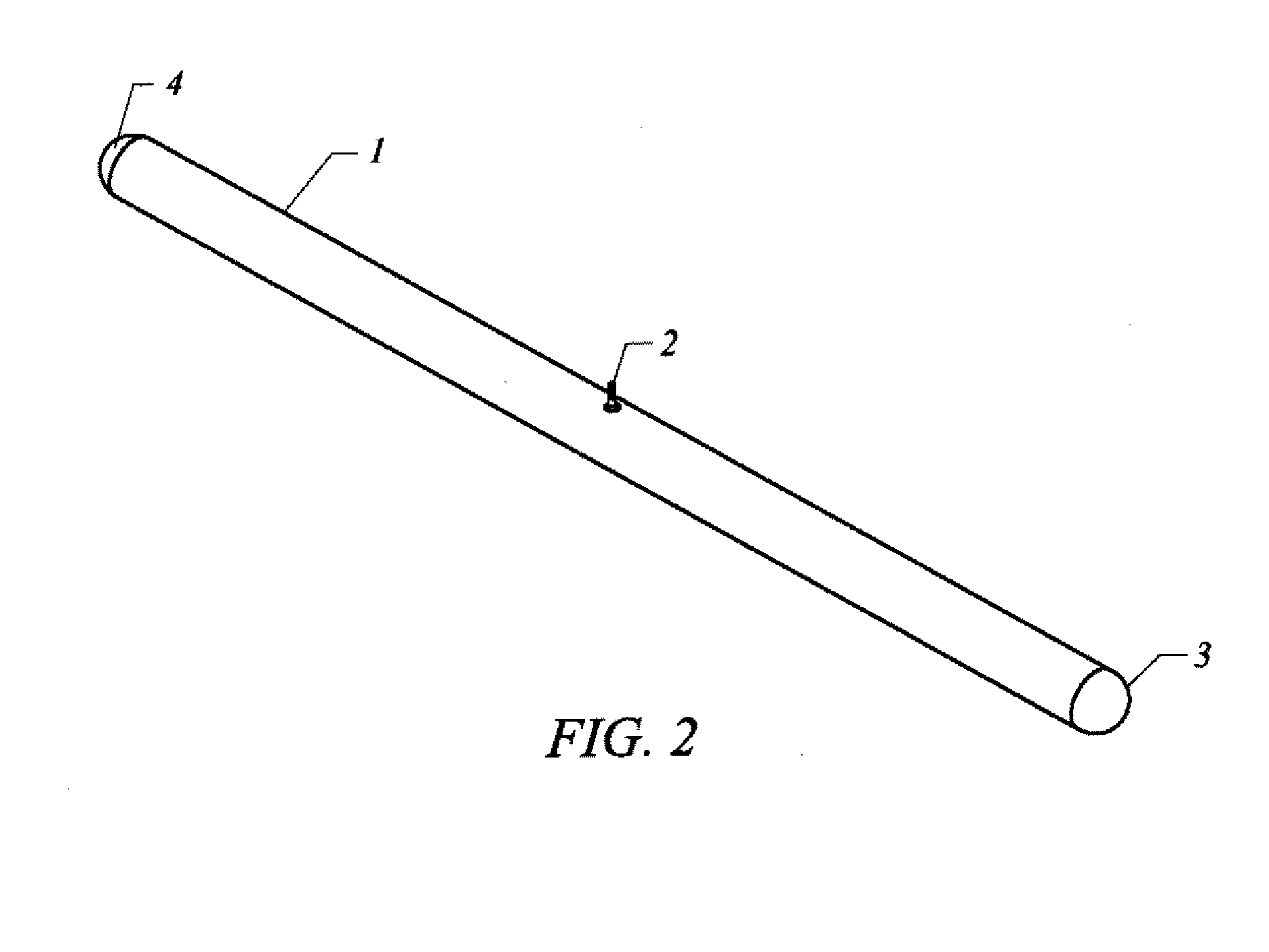

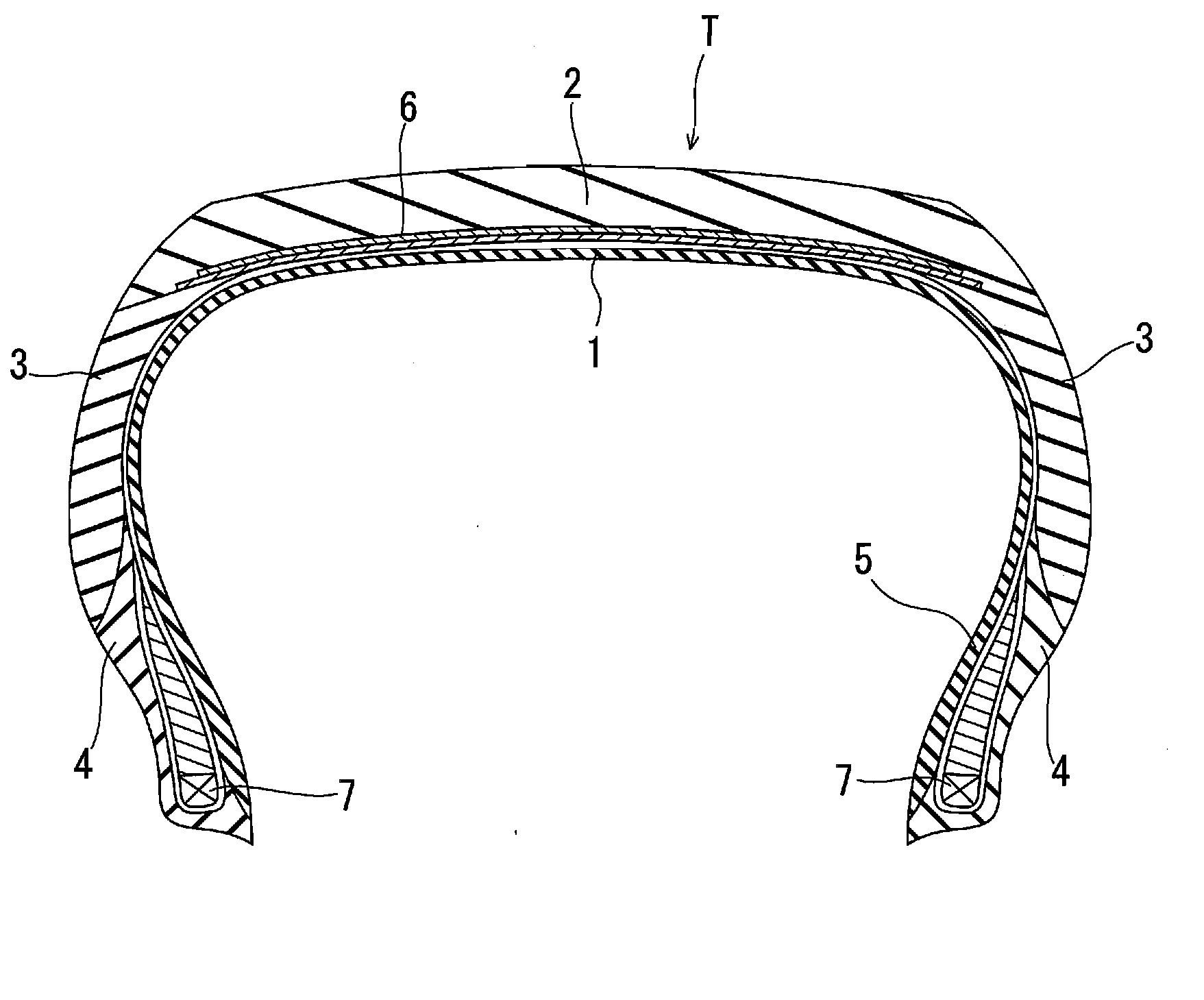

Laminated body and method of producing the same as well as innerliner for pneumatic tire and pneumatic tire

InactiveUS20090308517A1Improve machinabilityImprove anti-stripping performanceCoatingsWheelsElastomerYoung's modulus

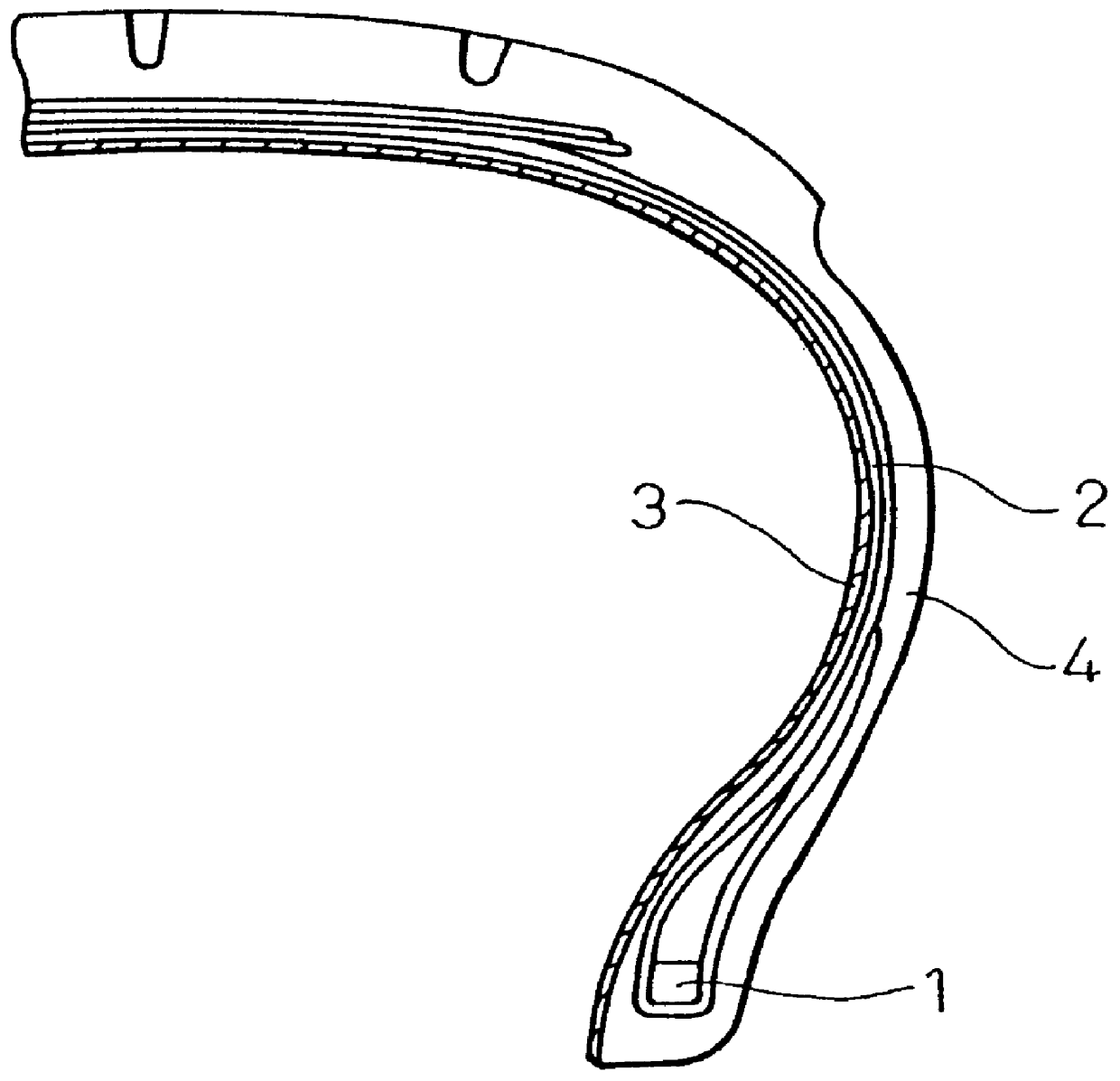

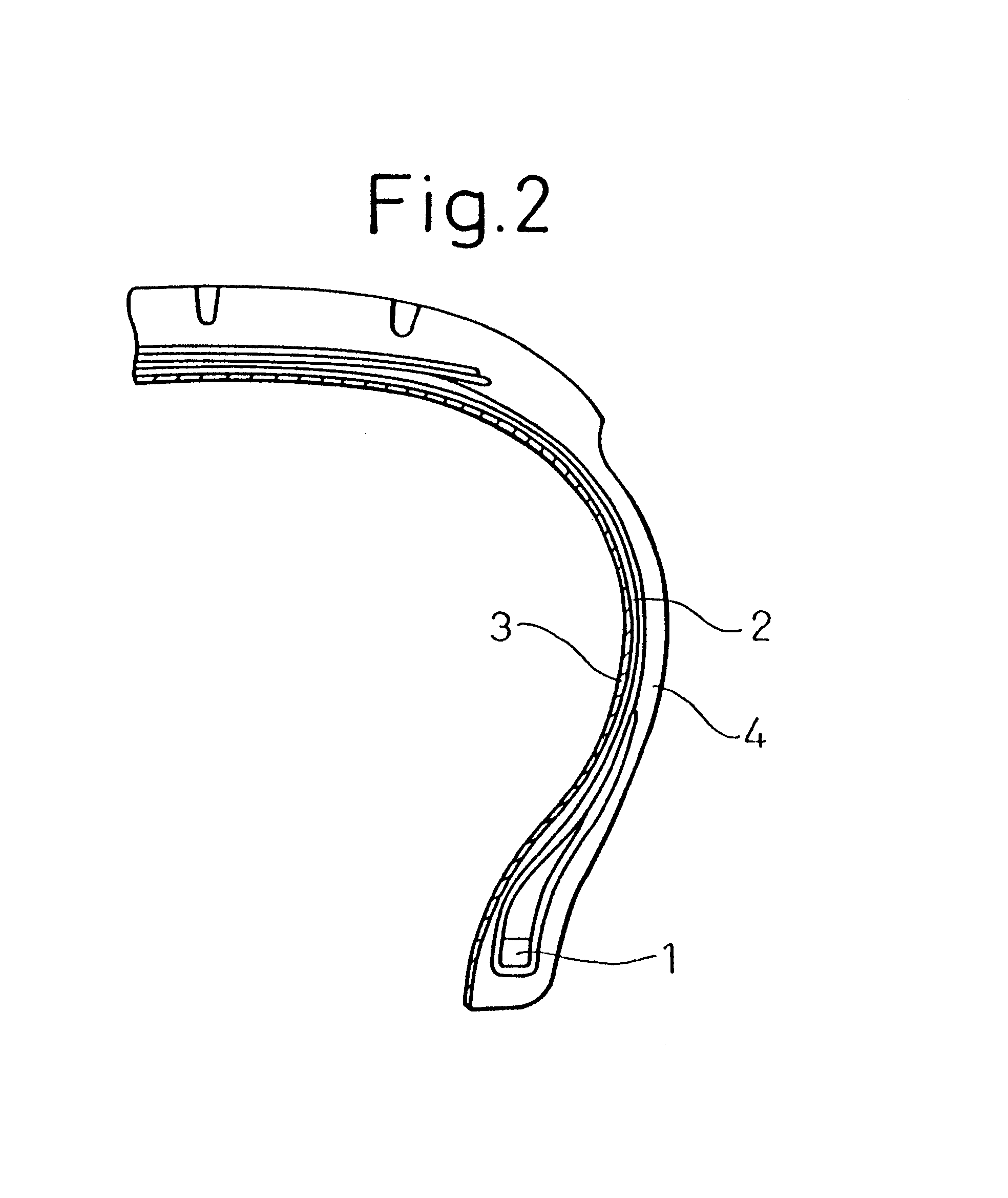

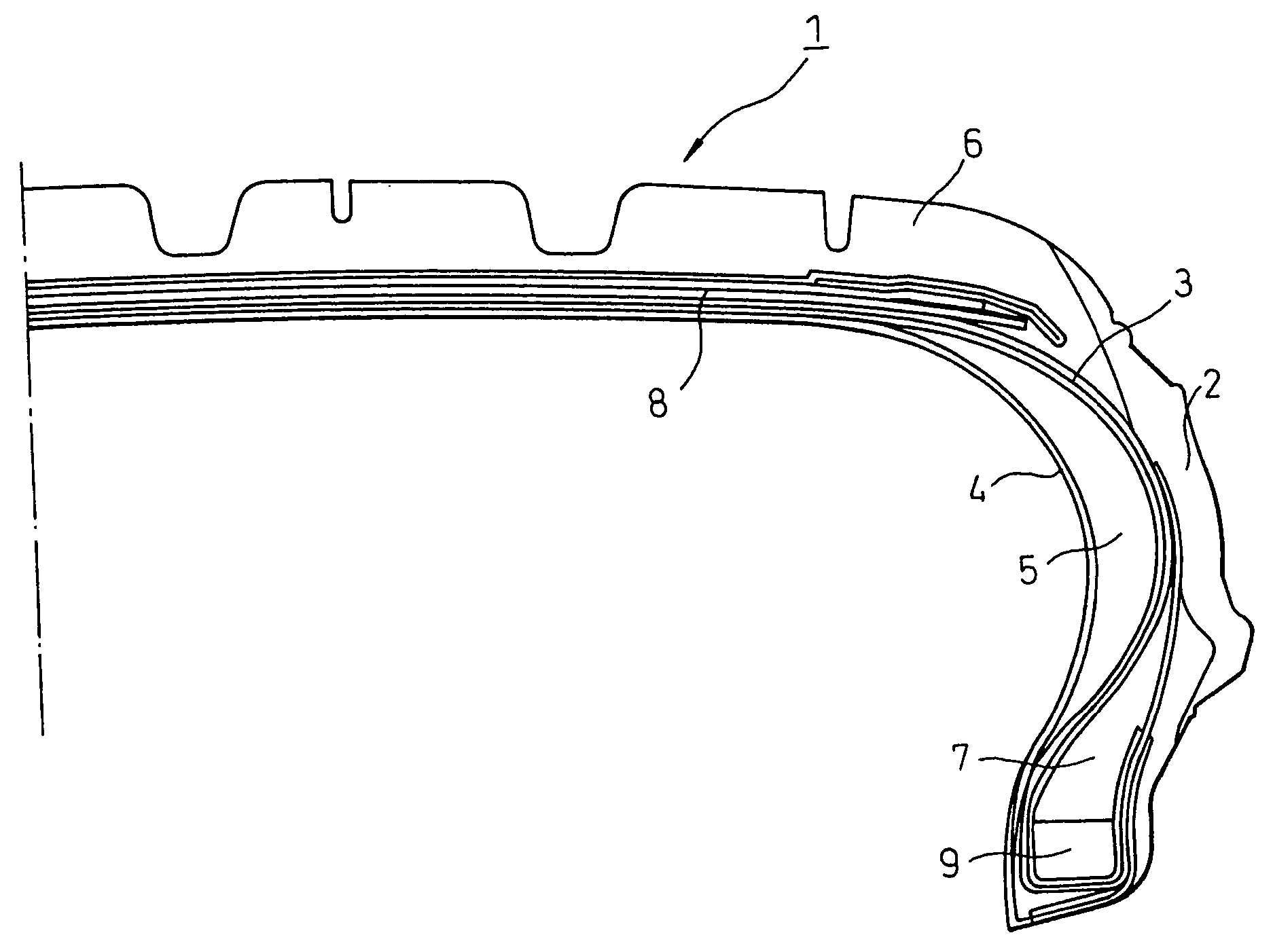

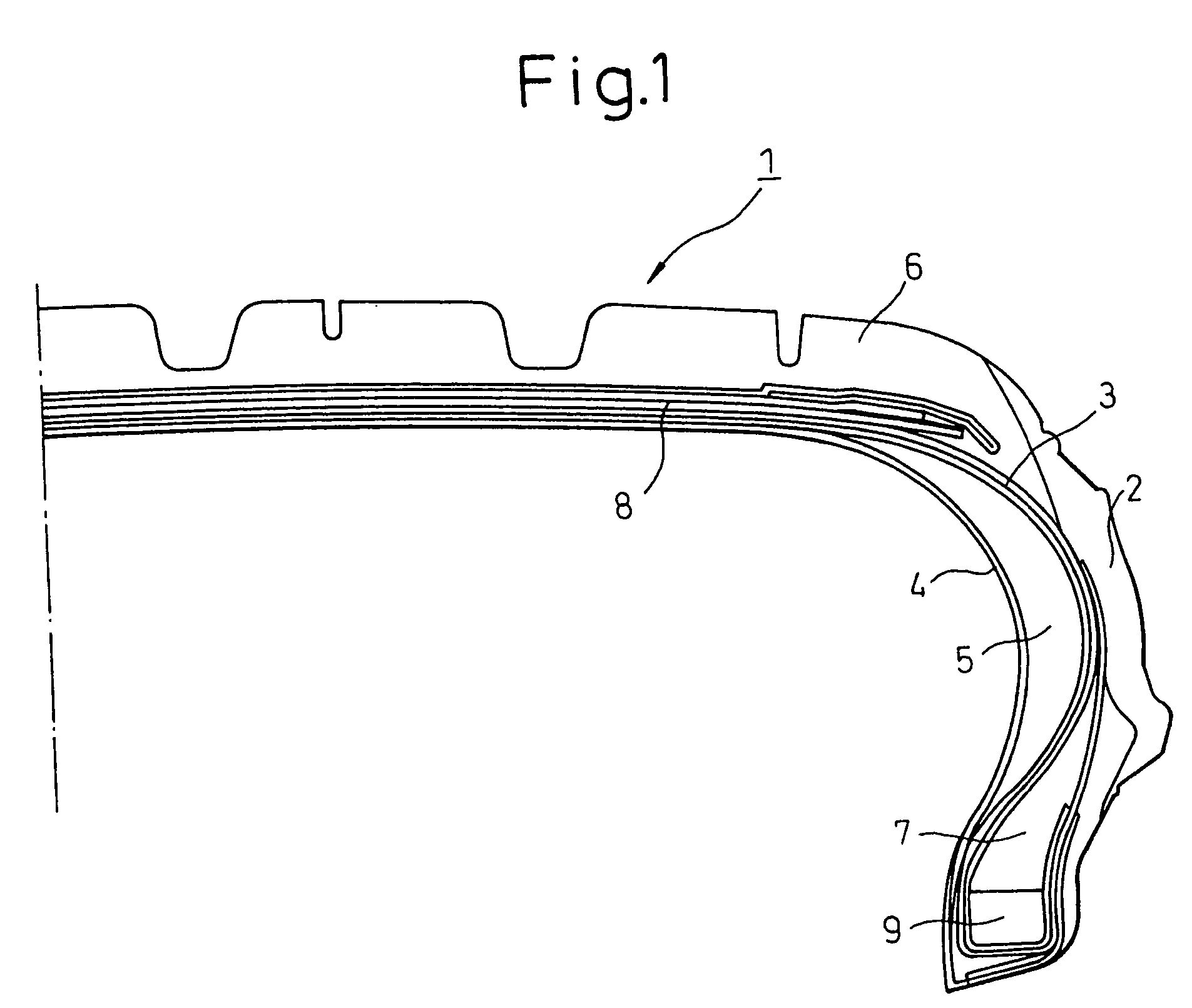

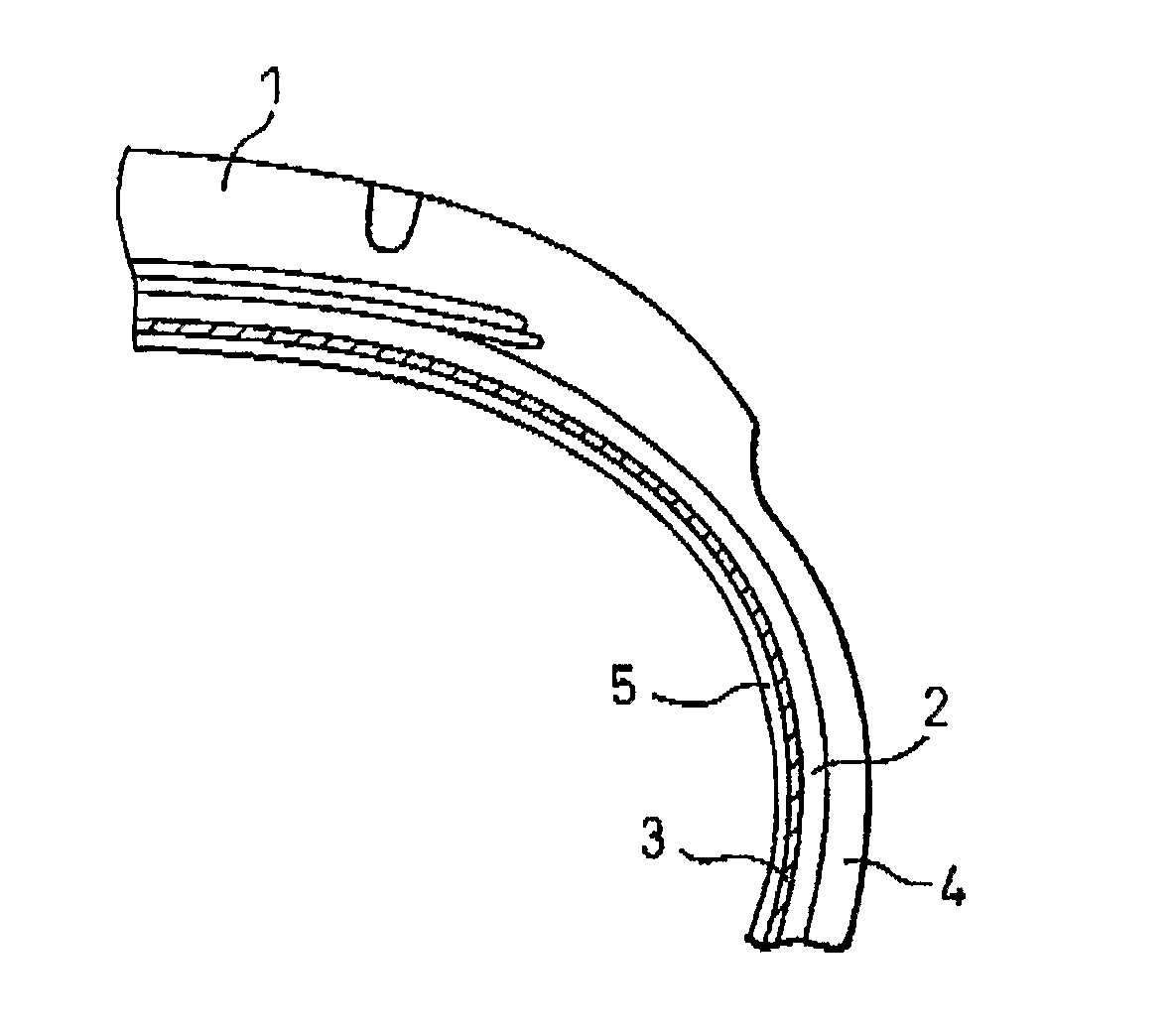

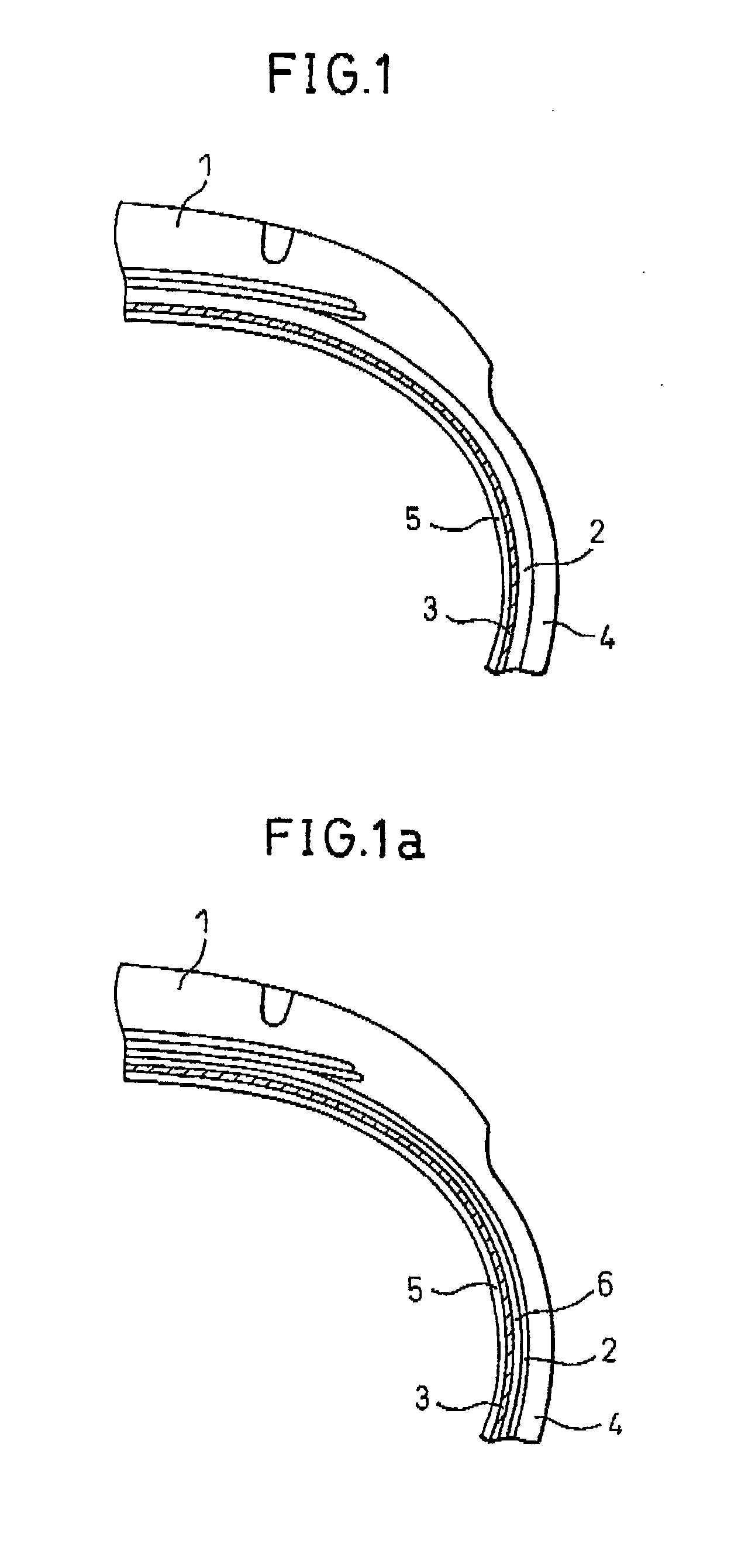

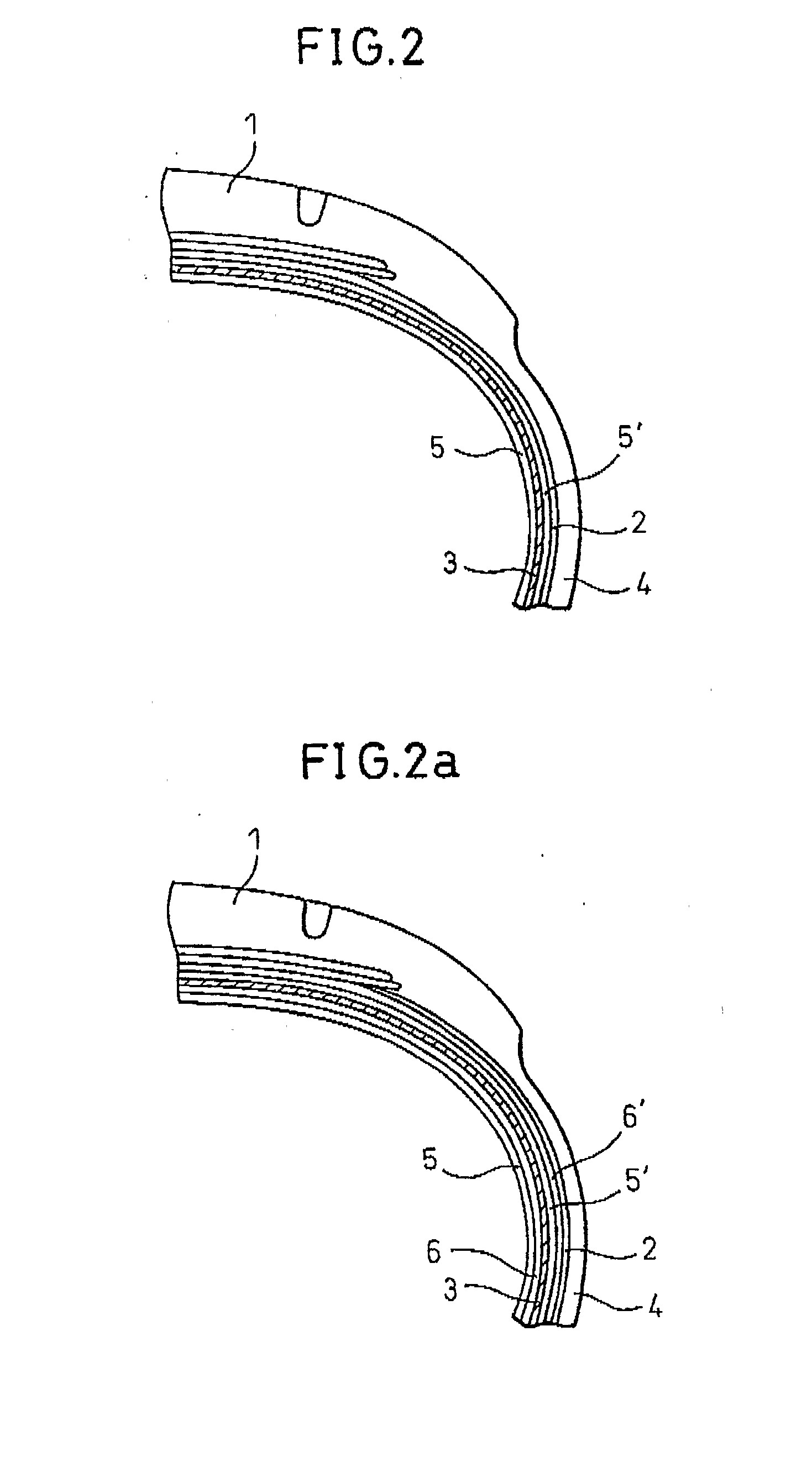

The invention provides a laminated body (1) having a good workability during the production and an excellent peeling resistance, which is formed by joining a resin film layer (D) (2) comprising at least a layer composed of a resin composition (C) in which a soft resin (B) having a Young's modulus at 23° C. lower than that of a thermoplastic resin (A) is dispersed in a matrix made from the thermoplastic resin (A) and a rubbery elastomer layer (E) (3) through an adhesive layer (F) (4), wherein an adhesive composition (I) formed by compounding not less than 0.1 part by mass of at least one of a maleimide derivative (H) having not less than two reaction sites in a molecule thereof and poly-p-dinitrosobenzene based on 100 parts by mass of a rubber component (G) is applied to the adhesive layer (F) (4).

Owner:KURARAY CO LTD +1

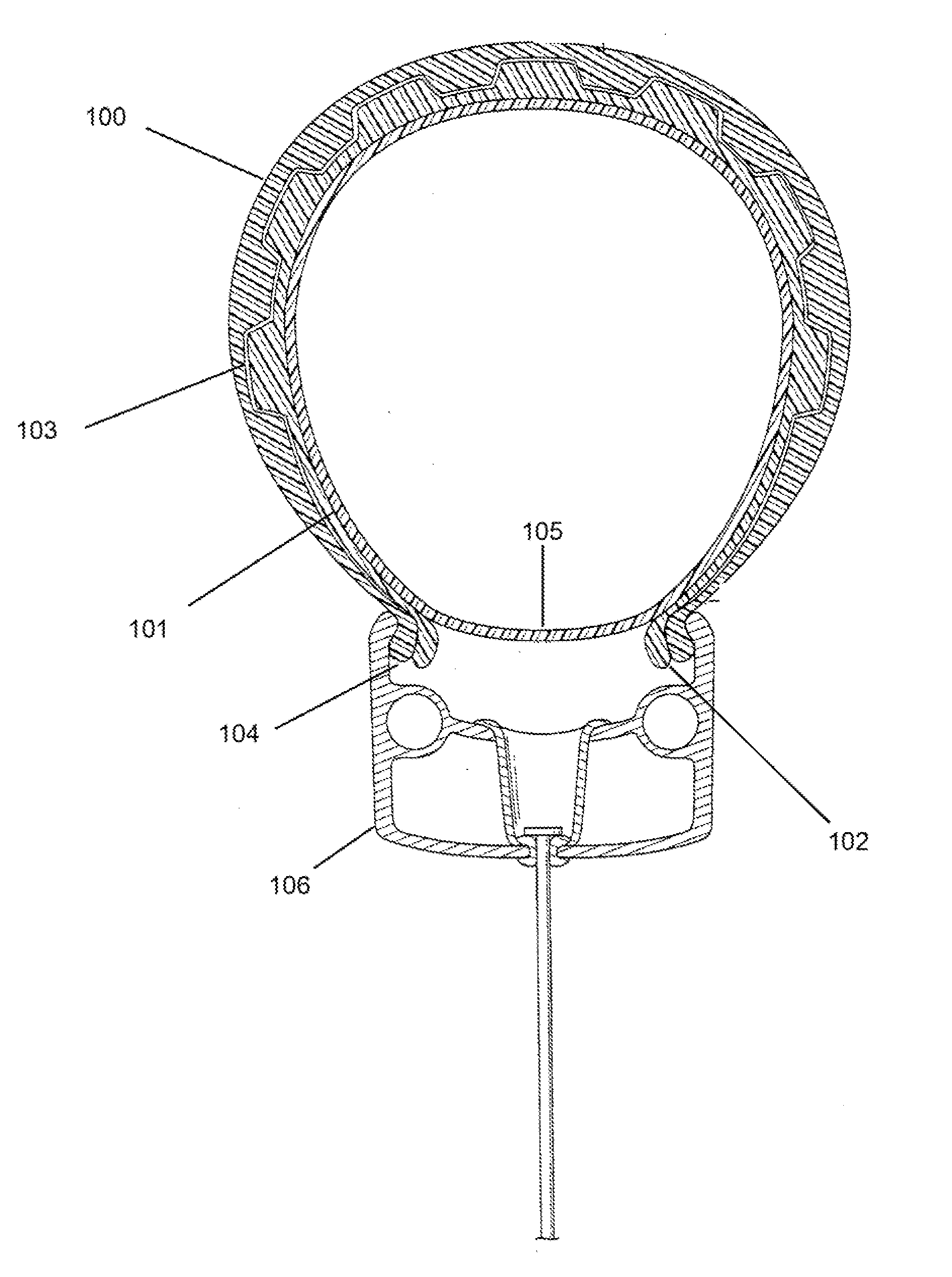

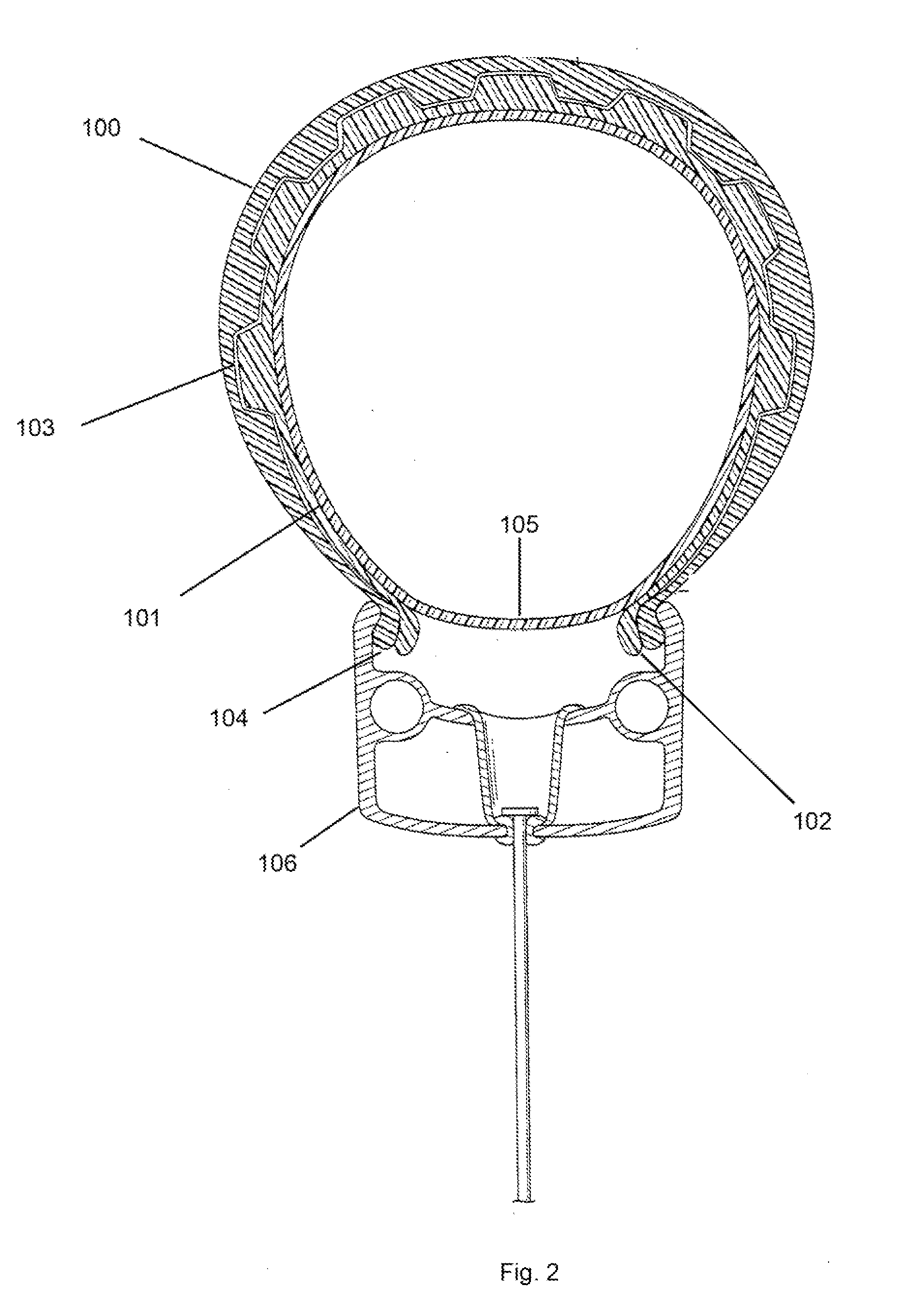

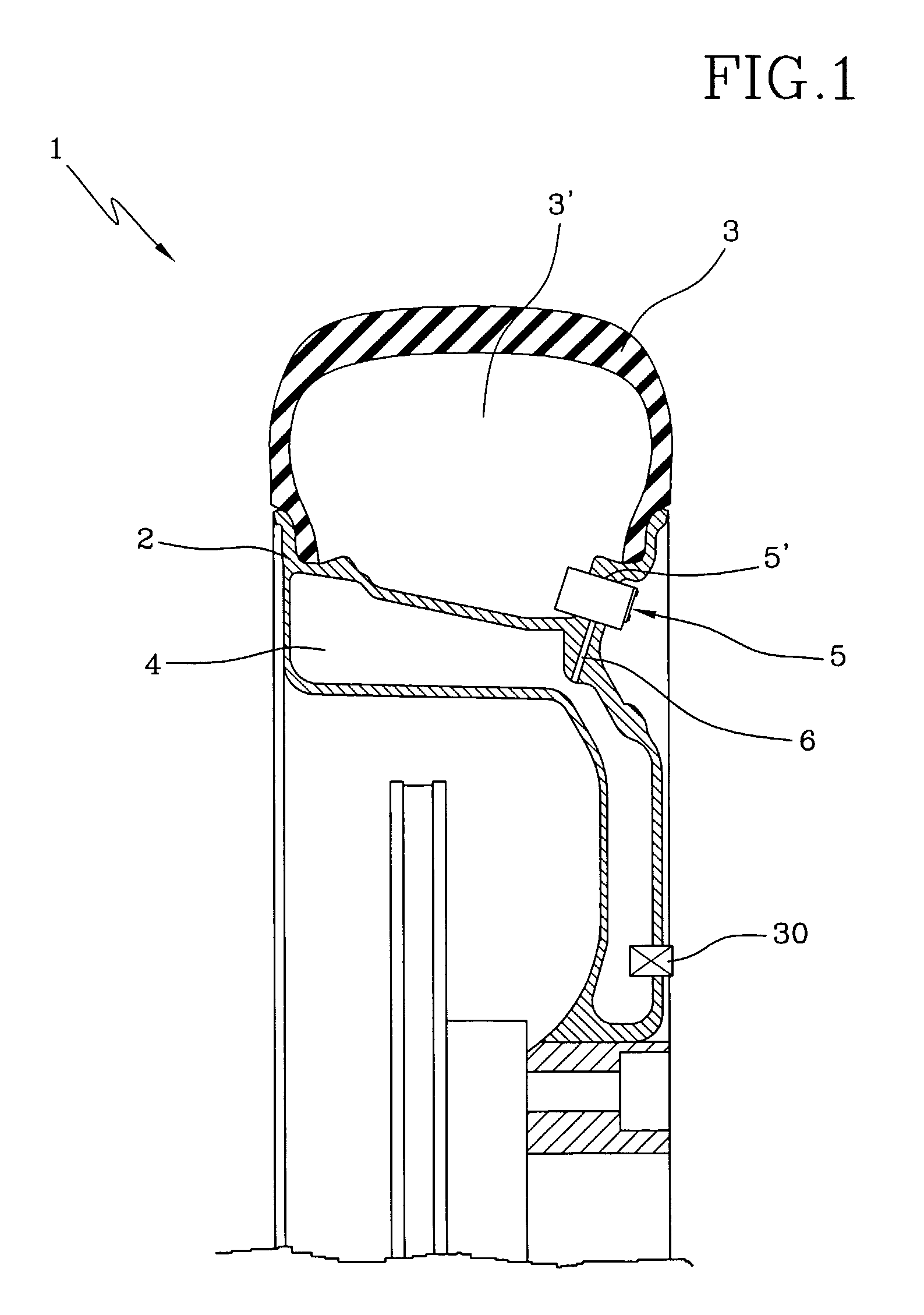

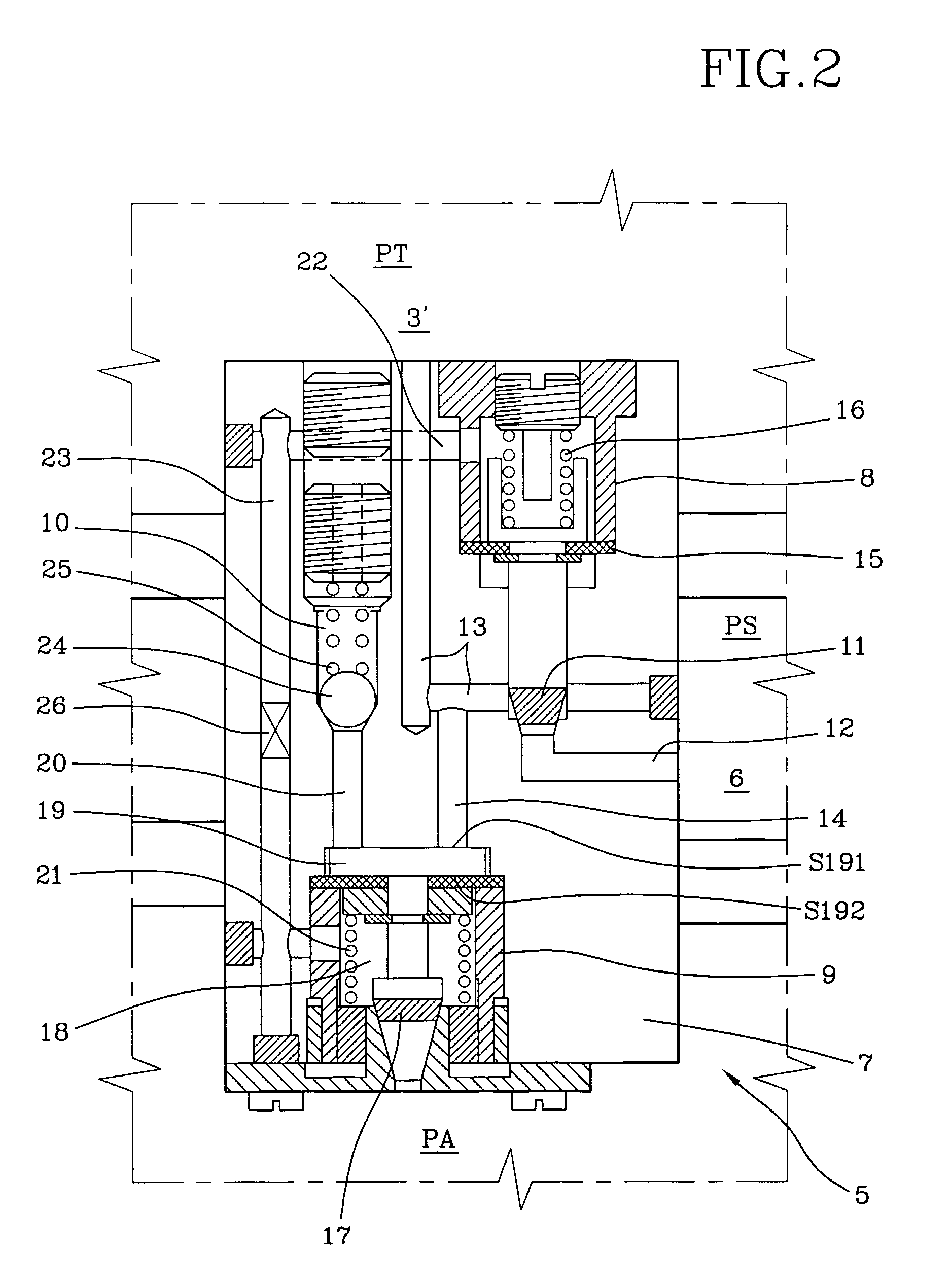

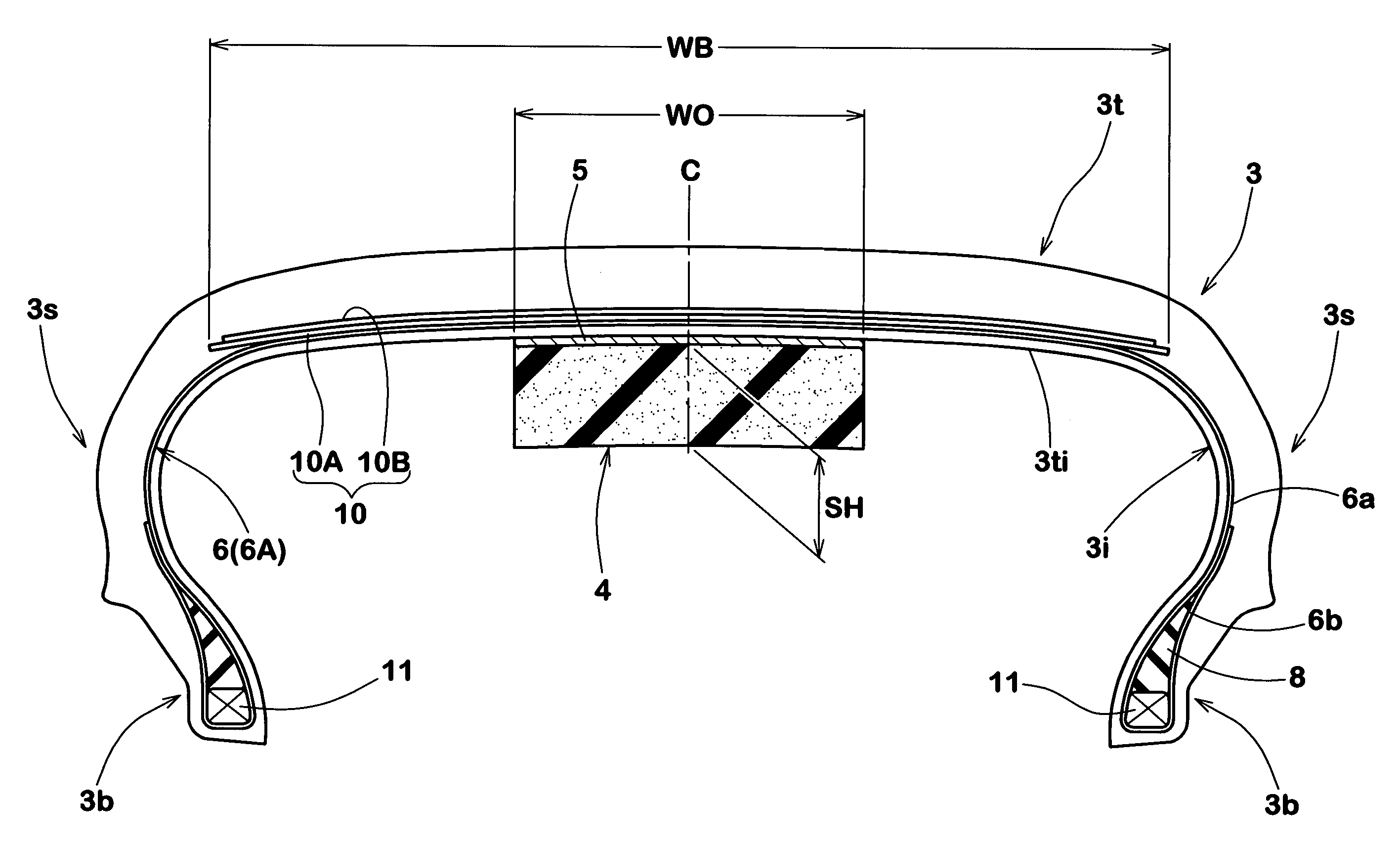

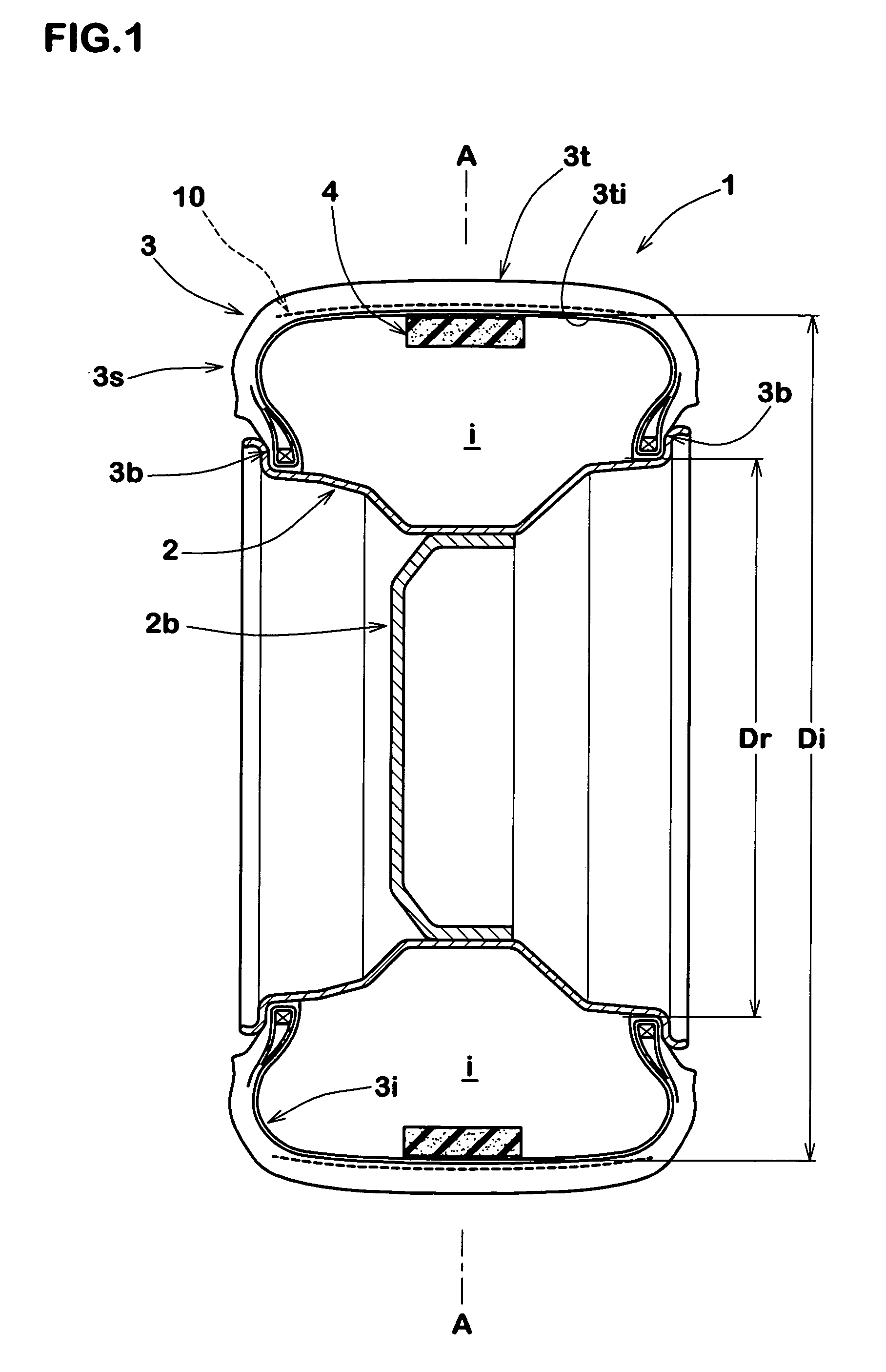

Mounting structure of electronic device and pneumatic tire

InactiveUS20090173422A1Prevent rattlingWithout separate inflatable insertsWith separate inflatable insertsDevice PlateEngineering

A electronic device is mounted on a circumferential surface of an inner liner by tucking first, second and third edges of a device plate between a first holding plane of a first guide tab and a surface of a holder plate, between a second holding plane of a second guide tab and the surface of the holder plate, and between a third holding plane of a third guide tab and the surface of the holder plate. The electronic device can be stably-mounted over the long term without difficulty and can be removed from the circumferential surface of the inner liner without difficulty.

Owner:BRIDGESTONE CORP

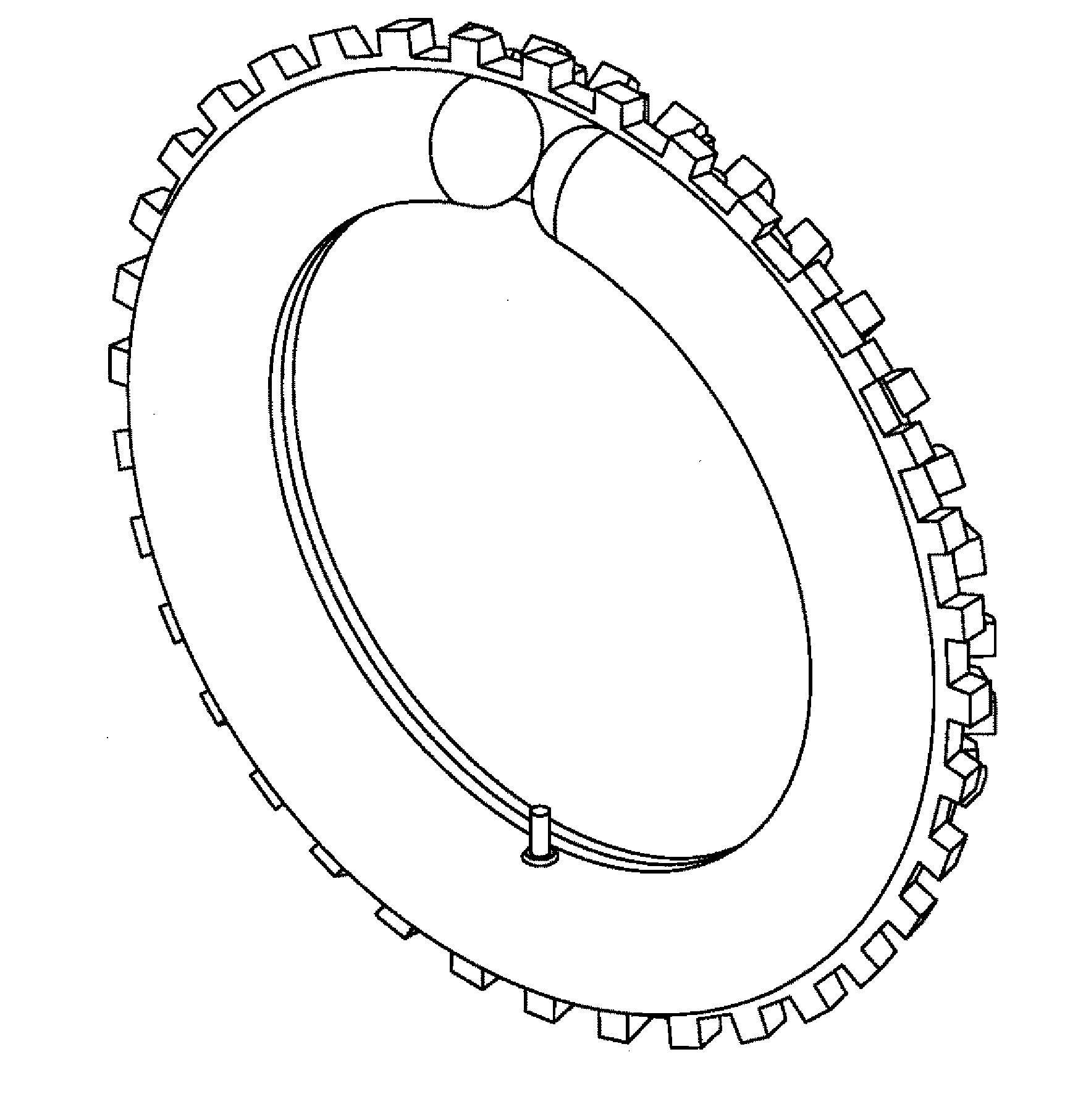

Modular Tire with Variable Tread Surfaces

InactiveUS20100200136A1Knob becomes largeBicycle tyresWith separate inflatable insertsMechanical engineeringTread

A new kind of tire utilizes a replaceable tread surface to enable variable tread characteristics determined by a removable riding surface. The tire body defines a slot that extends circumferentially around the tire and receives the removable riding surface. The removable riding surface is attached within the slot by attachment mechanisms. In other embodiments, the variable tread is accomplished via a removable sleeve that fits over the existing tire.

Owner:HAMILTON BRIAN H

Wheel having a controlled pressure and a pressure reservoir

InactiveUS7911332B2Reduce pressureExtended operating timeWith separate inflatable insertsWith multiple inflatable chambersInternal pressureExhaust valve

A wheel having a controlled pressure includes a rim associated with a tank adapted to be filled with a fluid to a first pressure; a tire mounted on the rim and having an inner volume inflated to an operating pressure at a reference temperature, the operating pressure being lower than the first pressure; and at least one valve assembly adapted to establish a communication between the tank, the inner volume of the tire and the external environment. The valve assembly includes a command valve, an exhaust valve and a compensation valve operatively associated with each other. The command valve controls communication between the tank and the inner volume of the tire. The exhaust valve is connected to the external environment, to the inner volume, to the command valve and to the compensation valve. The compensation valve is connected to the exhaust valve and the command valve. The command valve includes an inner chamber connected with the exhaust valve and the compensation valve in such a manner that the command valve is operated by the exhaust valve and the compensation valve through a pressure variation of the inner chamber in response to a variation of the inner pressure of the tire.

Owner:PIRELLI TYRE SPA

Tire having embedded electronic device affixed with adhesive

InactiveUS20160107490A1Without separate inflatable insertsWith separate inflatable insertsAdhesiveEngineering

A tire includes a circumferential tread, a pair of sidewalls, and a pair of bead portions. Each bead portion includes a bead and a bead filler. The tire further includes at least one body ply extending from bead portion to bead portion. The body ply includes a pair of turn up portions radially outside of a respective bead portion. An electronic device is embedded in the tire. The electronic device is encapsulated in a curable adhesive including at least one of natural rubber, styrene butadiene rubber, and butadiene rubber.

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

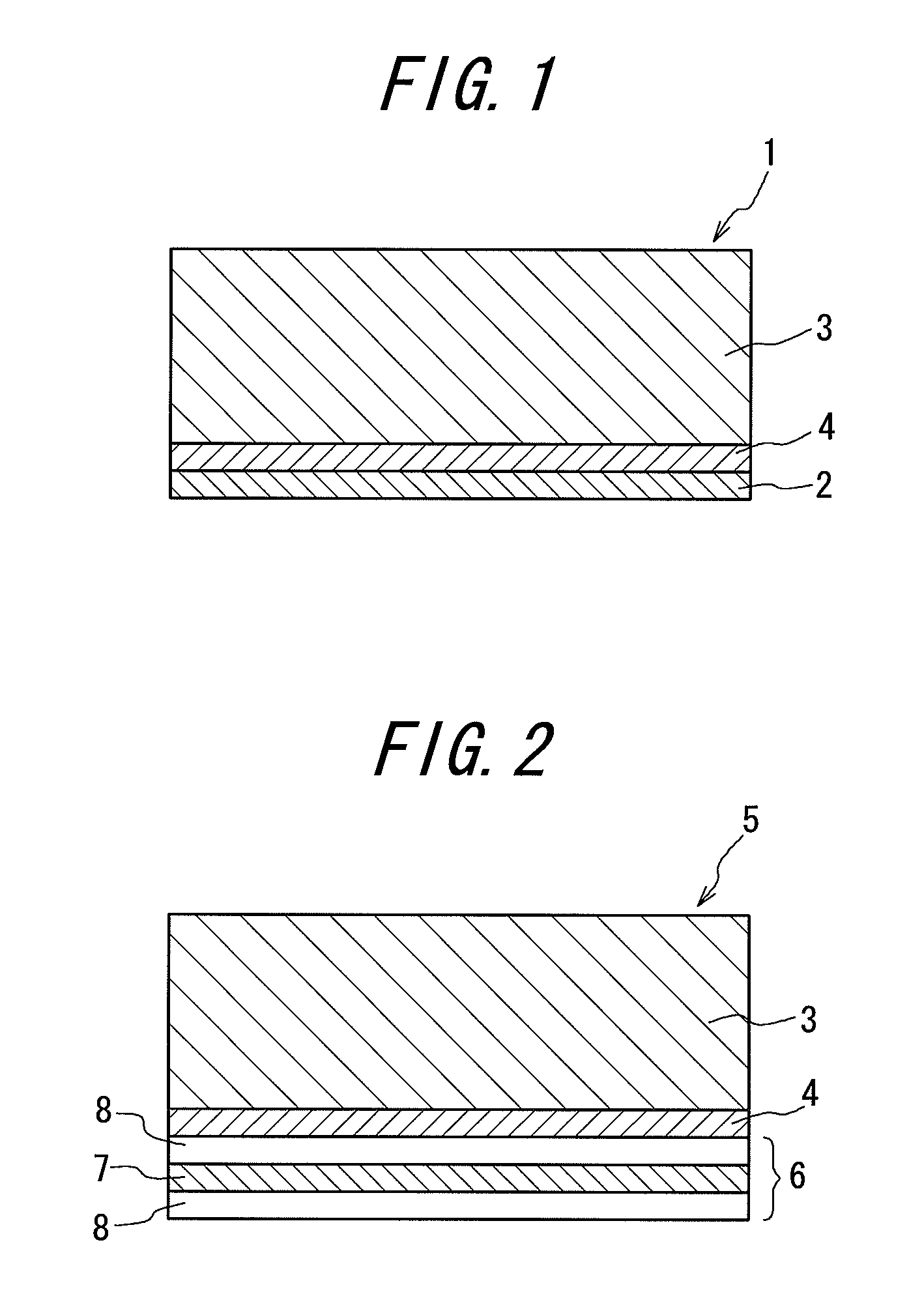

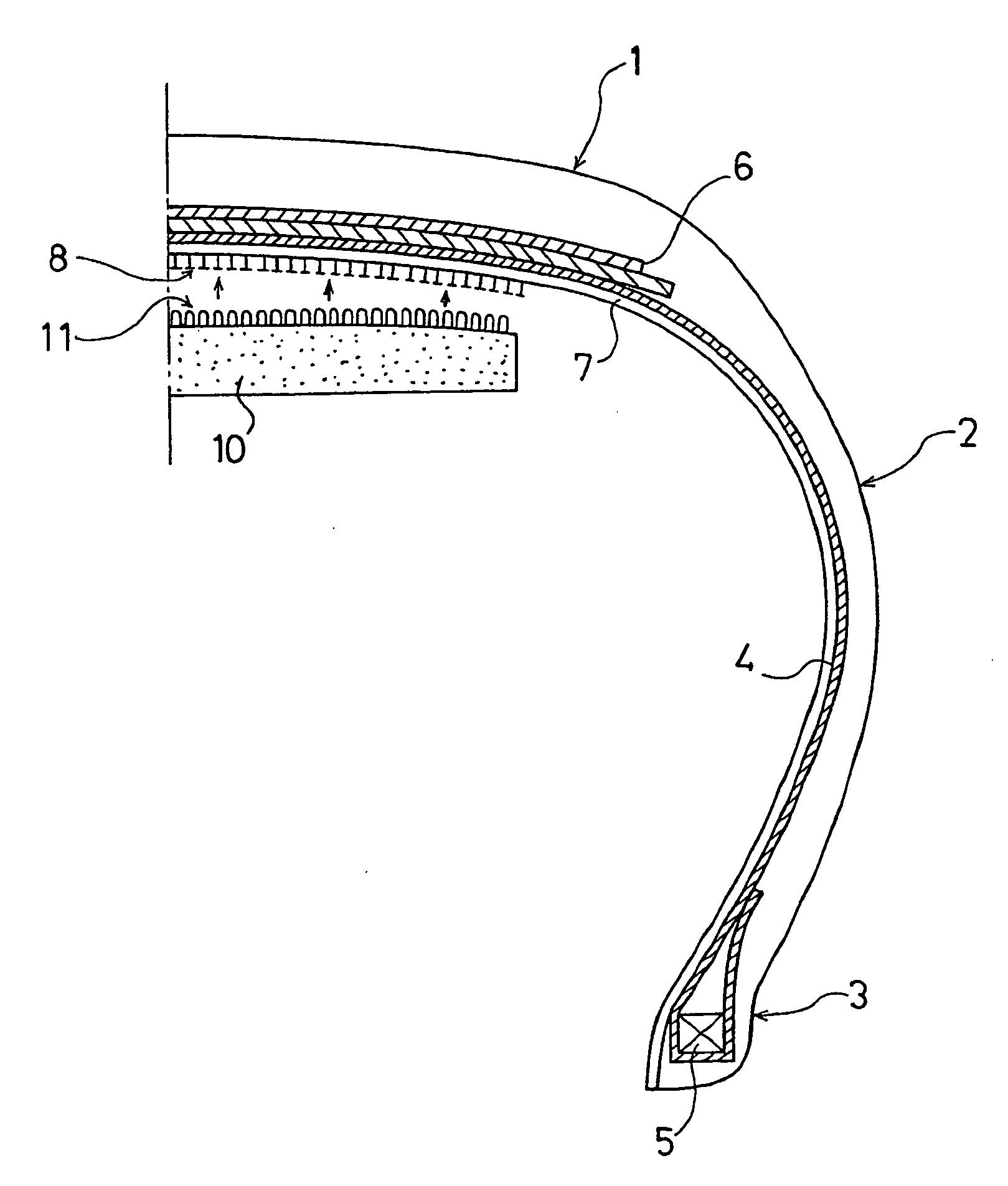

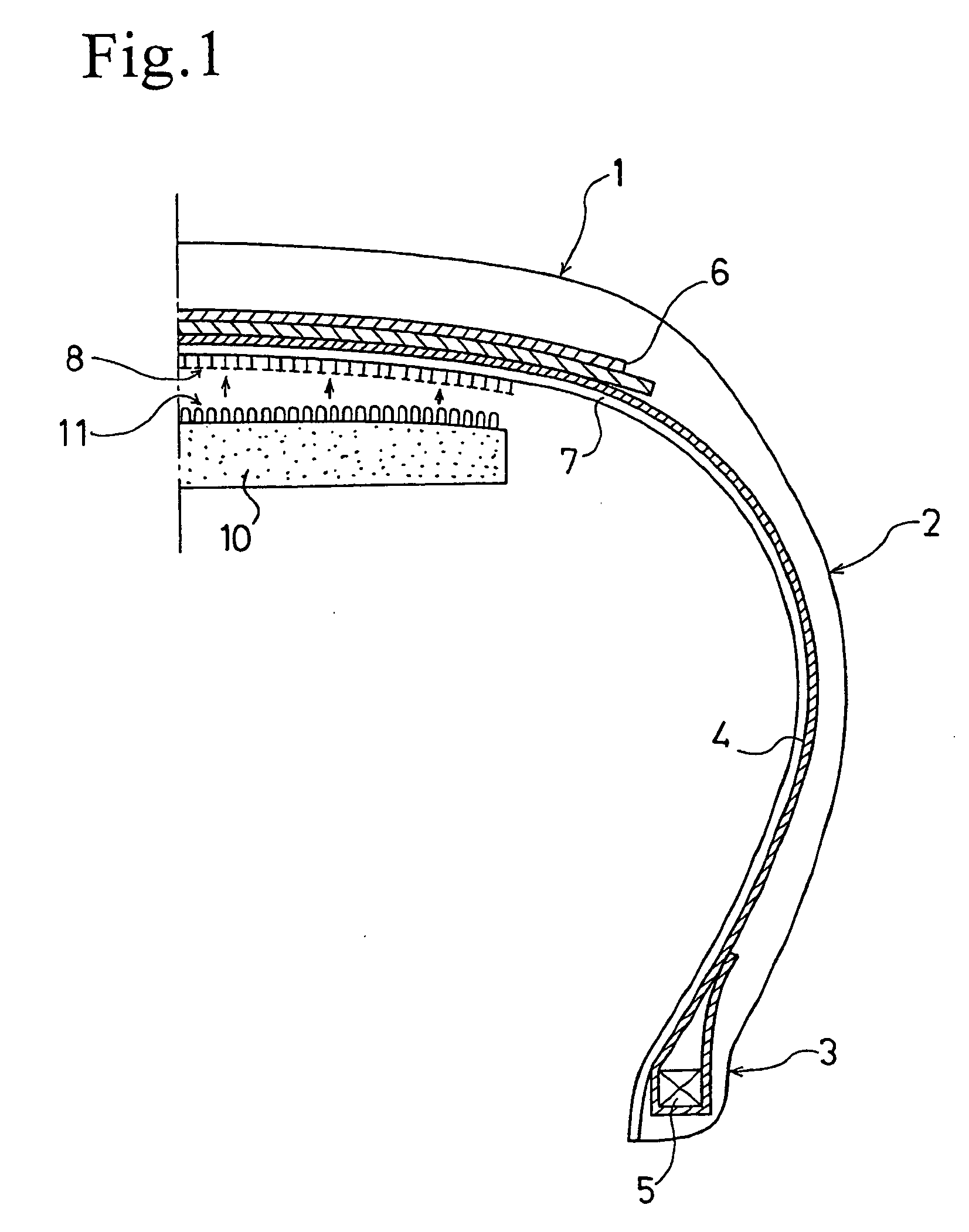

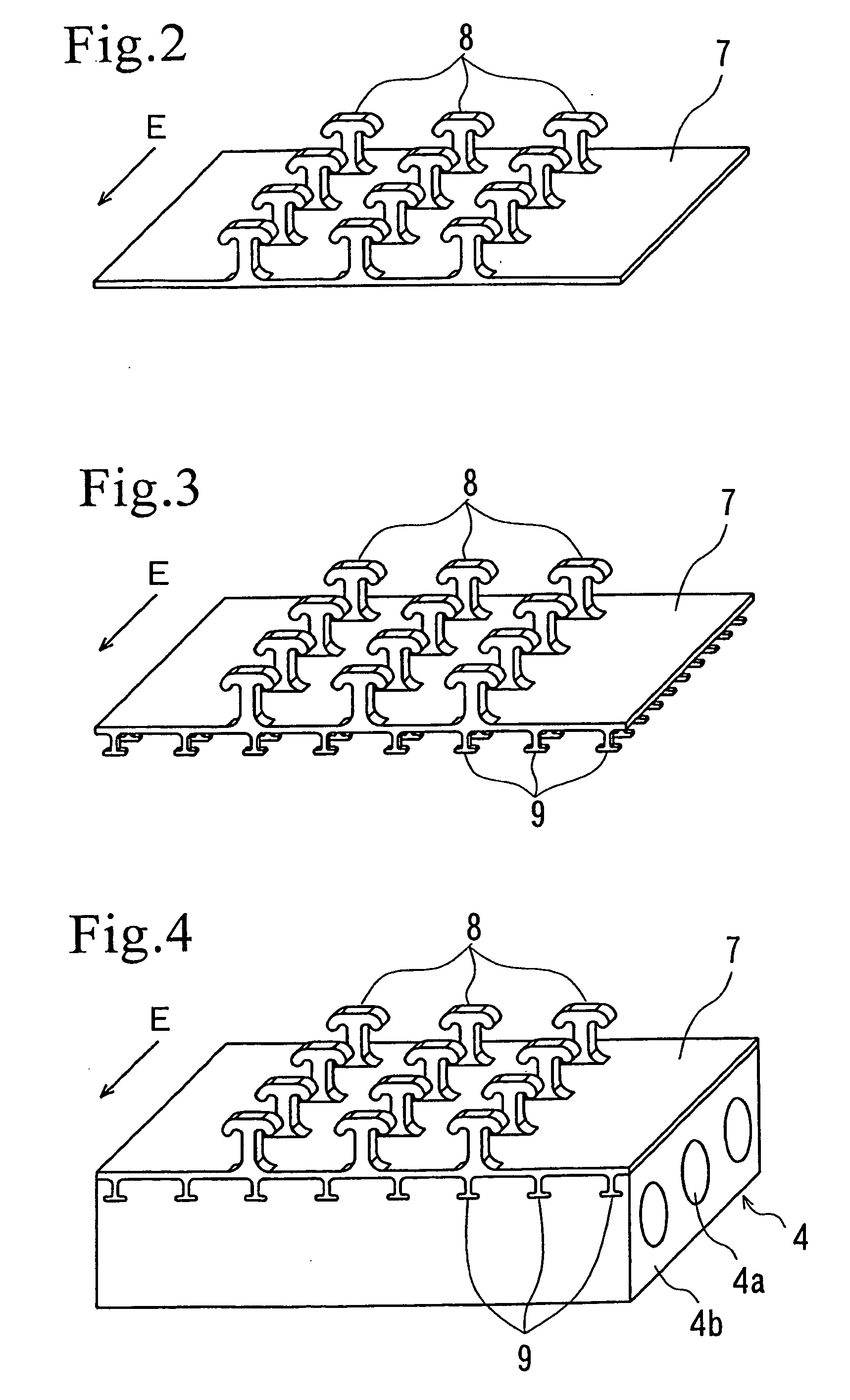

Pneumatic tire

InactiveUS20100018622A1Free from damageEasily elongatedWithout separate inflatable insertsWith separate inflatable insertsElastomerThermoplastic elastomer

A pneumatic tire designed so that when a hook and loop fastener is fitted to the tire internal face of a pneumatic tire furnished with an inner liner layer consisting of a thermoplastic elastomer composition of a blend of thermoplastic resin and elastomer, or a thermoplastic resin, the hook and loop fastener can easily follow the elongation of the inner liner layer and is free from damaging of the inner liner layer. There is disclosed a pneumatic tire furnished on its internal face with an inner liner layer (7) consisting of a thermoplastic elastomer composition composed of thermoplastic resin and elastomer, or a thermoplastic resin, characterized in that integral forming of a multiplicity of interlocking elements (8) protruding on the hollow side of the tire is effected on the surface of the inner layer (7).

Owner:YOKOHAMA RUBBER CO LTD

Tire with foamed noise damper

InactiveUS20120125507A1Without separate inflatable insertsWith separate inflatable insertsEngineering

The present invention is directed to a method for making a tire having a foam noise damper, comprising the steps of: obtaining a tire having an innerliner, the innerliner having a surface facing an interior cavity of the tire; applying a foamable liquid to the surface; and foaming the foamable liquid to form a solid foam noise damper secured to the tire innerliner.

Owner:BORMANN RENE LOUIS +2

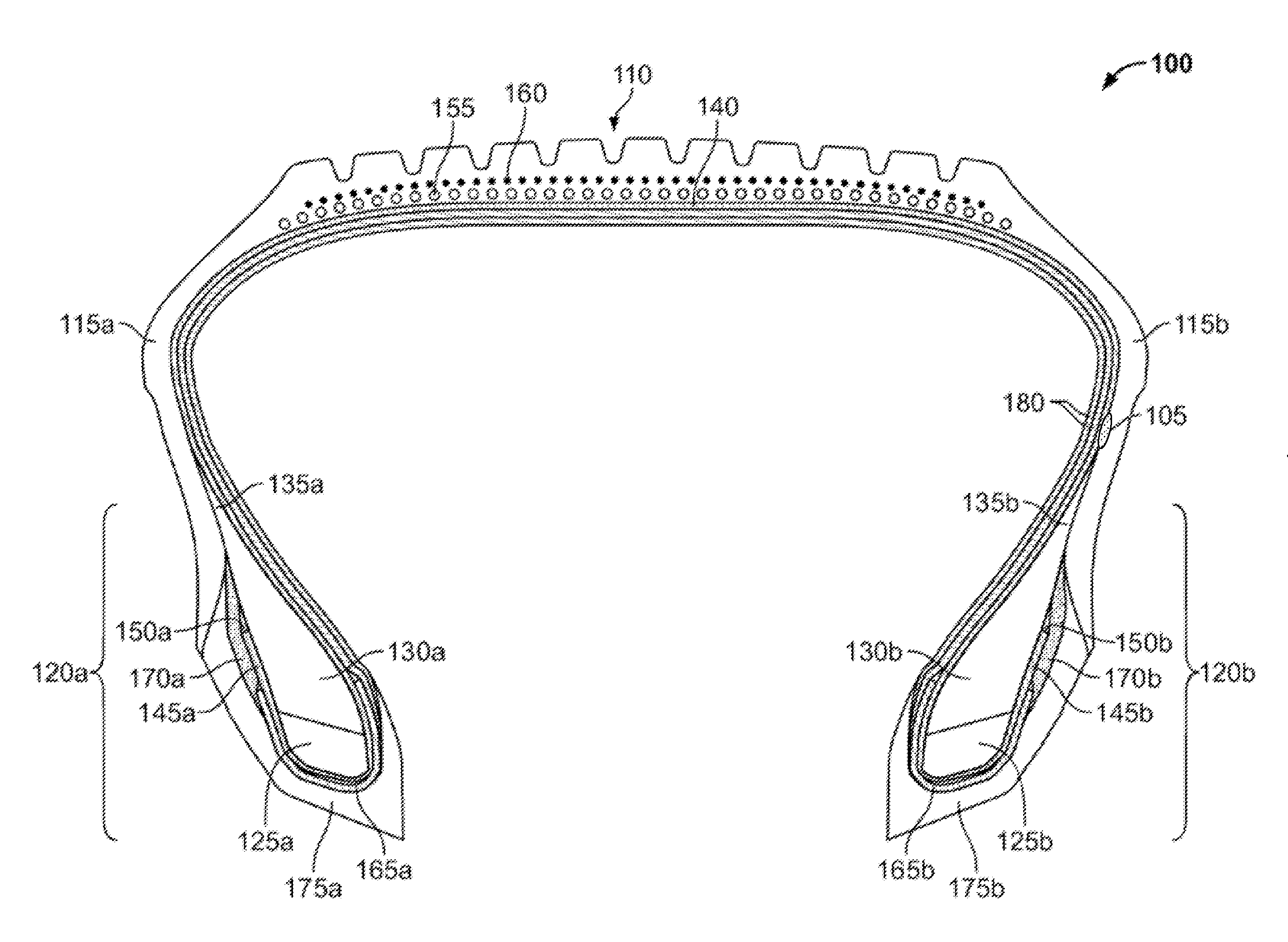

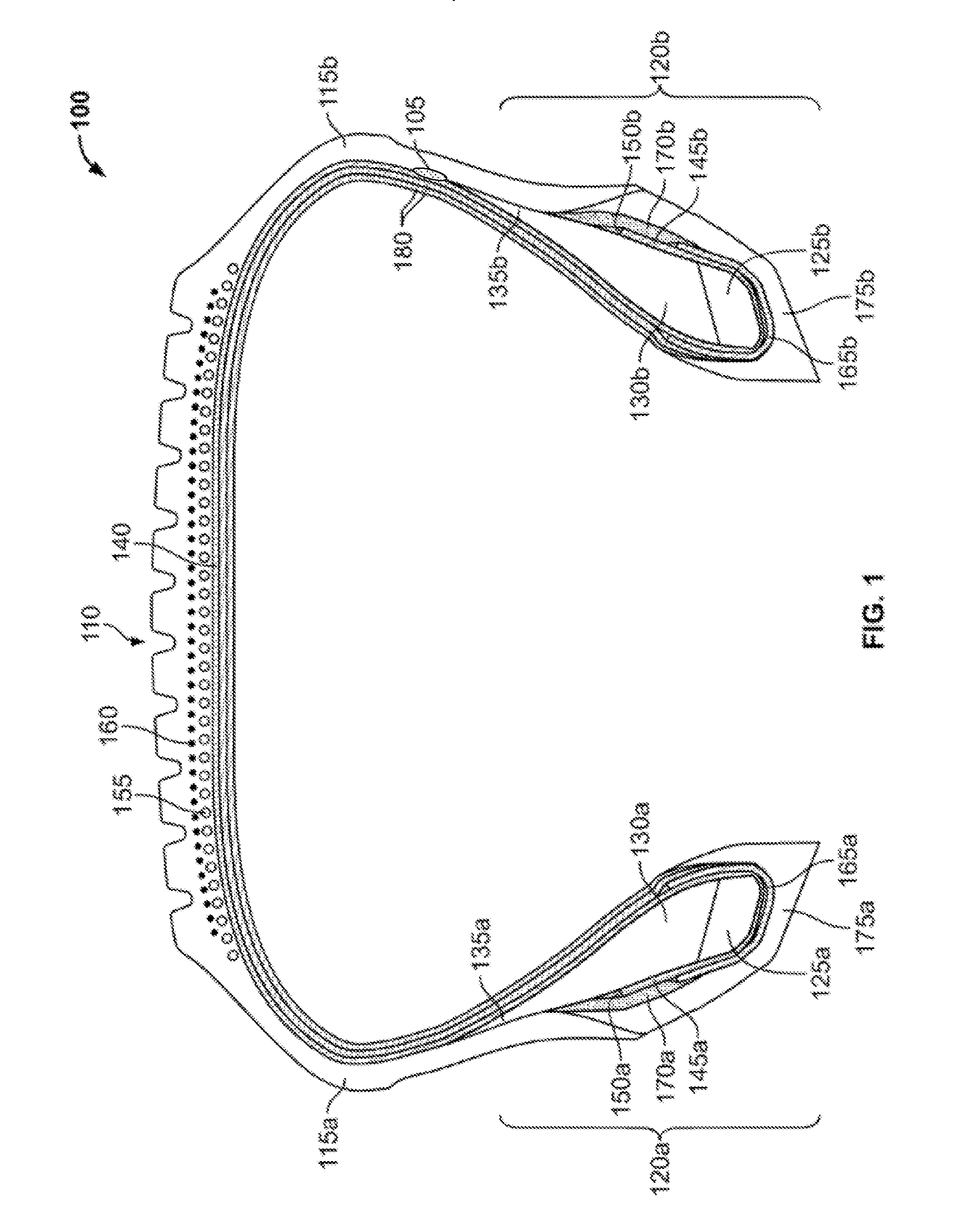

Laminate and pneumatic tires made by using the same

A laminate of an air permeation preventive layer an adhesive layer provided with an air permeation preventive layer comprising a thermoplastic elastomer composition containing a thermoplastic resin as a continuous phase and a rubber composition dispersed therein as a dispersed phase and arranged on one surface of the air permeation preventive layer, an adhesive composition layer having a thickness of 100 μm or less, a self tack of less than 5N and a tack to an unvulcanized diene-based rubber or 5N or more, containing 100 parts by weight of a thermoplastic elastomer containing 50 parts by weight or more of an epoxy-modified styrene-butadiene-based block copolymer so that a total of 30 to 200 parts by weight of a terpene resin and an aromatically modified terpene resin having a weight average molecular weight Mw of 1000 or less and a softening point of 60 to 120° C., 0.1 to 3 parts by weight of an internal mold release agent and 0.1 to 2 parts by weight of an organic peroxide.

Owner:YOKOHAMA RUBBER CO LTD

Tire Inner Tube

InactiveUS20080223497A1Reduce in quantityUnnecessary removalWith separate inflatable insertsSpecial tyresEngineeringInflatable

The present invention is an inner tube apparatus, and article of manufacture, that comprises an inflatable compartment capable of surrounding a wheel. The tube comprises a first and second end that allows the user to replace the inner tube without removing the wheel, or other elements of the vehicle, for repair.

Owner:BALZOWSKI JOHN

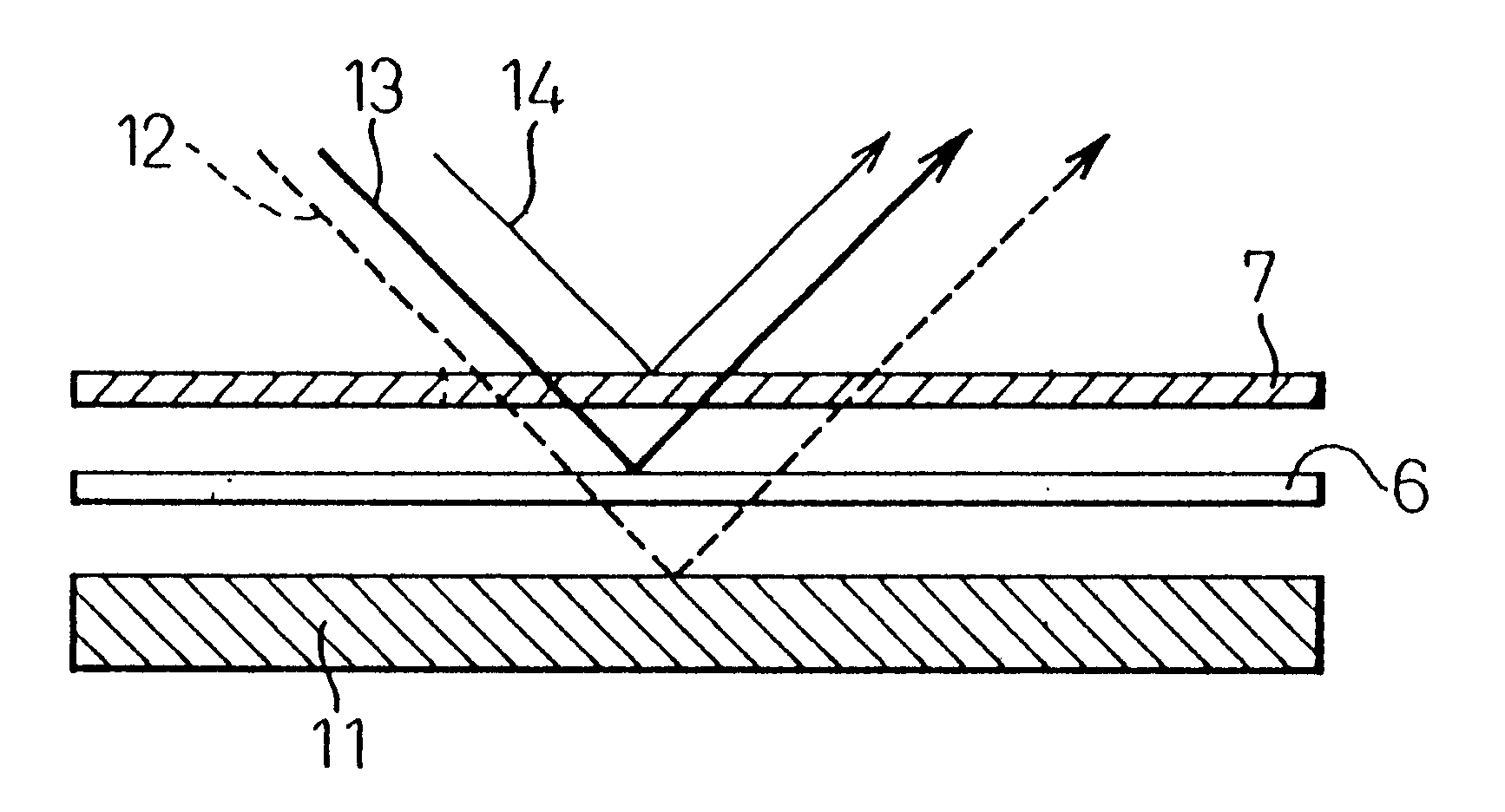

Laminate or thermoplastic polymer composition having low air permeability and pneumatic tire using same as inner liner

ActiveUS20090038729A1Without separate inflatable insertsWith separate inflatable insertsOsmotic coefficientRoom temperature

A laminate (C) of a thermoplastic polymer composition comprising: a thermoplastic resin composition (A) having an permeation coefficient of 10×10−12 cc·cm / cm2·sec·cmHg or less, laminated with a thermoplastic polymer composition (B) having a melt viscosity of 500-2000 Pa·s and a Young's modulus at a room temperature of 1-400 MPa, wherein the thickness of a layer of the thermoplastic resin composition (A) is 0.05-10 μm and the air permeation coefficient of the laminate (C) of 20×10−12 cc·cm / cm2·sec·cmHg or less, and a pneumatic tire using the above laminate (C) as an inner liner.

Owner:YOKOHAMA RUBBER CO LTD +1

Method for manufacturing low noise pneumatic tire

ActiveUS7669628B2Easy to fixLamination ancillary operationsWithout separate inflatable insertsLow noiseHeat resistance

Owner:SUMITOMO RUBBER IND LTD

Tire with integral foamed noise damper

InactiveUS20070137752A1Without separate inflatable insertsWith separate inflatable insertsGround contactMechanical engineering

The present invention is directed to a pneumatic tire having two spaced inextensible beads; a ground contacting tread portion; a pair of individual sidewalls extending radially inward from the axial outer edges of said tread portion to join the respective beads, the axial outer edges of the tread portion defining a tread width; a supporting carcass for the tread portion and sidewalls; and at least one foamed structure disposed radially inwardly of the carcass and exposed to the inner cavity of the tire, the foamed structure including a co-vulcanized foamed rubber composition having a density ranging from 0.1 to 1 g / cm3.

Owner:THE GOODYEAR TIRE & RUBBER CO

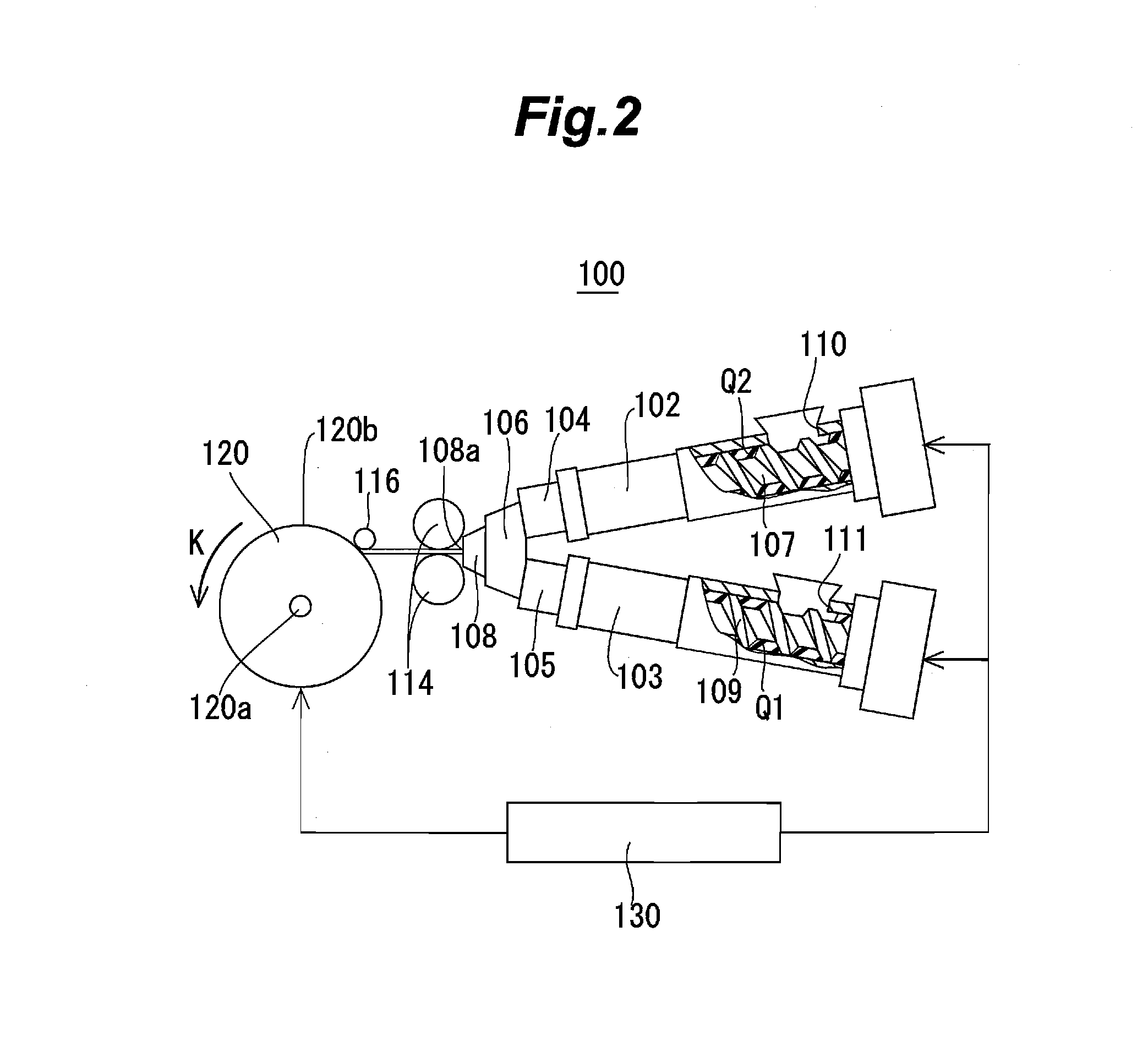

Rubber strip material

ActiveUS20090320985A1Reduced number of time of windingFabrication can be reducedWithout separate inflatable insertsWith separate inflatable insertsBand shapeEngineering

When forming a rubber member which is made up of a combination of a plurality of rubber compounds by winding spirally a ribbon-shaped unvulcanized rubber strip material in an overlapping fashion, the number of times of winding is reduced so as to shorten a fabrication cycle time of the rubber member to thereby increase the productivity thereof. As a means therefore, a rubber strip material whose cross section is divided into two or more regions which are made up of different rubber compounds is wound spirally on to a drum in an overlapping fashion so as to build a green tire or a tire rubber member.

Owner:TOYO TIRE & RUBBER CO LTD

Pneumatic tire having a flexible mold releasable protective layer

InactiveUS20090114329A1Prevent appearanceAvoid areaWithout separate inflatable insertsWith separate inflatable insertsElastomerShell molding

An inorganic powder mold release agent at the surface of an air permeation preventive layer is prevented from falling off, using a thermoplastic resin or thermoplastic elastomer composition.A pneumatic tire comprising a layer of a thermoplastic resin, or a layer of a thermoplastic elastomer composition comprising a thermoplastic resin containing an elastomer component is dispersed therein, as an air permeation preventive layer arranged at an inside surface of a tire cavity, further arranging a mold releasable protective layer containing an inorganic powder and a polymer component further arranged on the surface of the layer of thermoplastic resin or the layer of the thermoplastic elastomer composition, wherein the resultant assembly vulcanized and molded.

Owner:YOKOHAMA RUBBER CO LTD

Functionalized elastomer nanocomposite

InactiveUS20050277723A1Improve air tightnessWithout separate inflatable insertsWith separate inflatable insertsElastomerGeneral purpose

An embodiment of the present invention is a nanocomposite comprising a clay and an elastomer comprising at least C2 to C10 olefin derived units; wherein the elastomer also comprises functionalized monomer units pendant to the elastomer. Desirable embodiments of the elastomer include poly(isobutylene-co-p-alkylstyrene) elastomers and poly(isobutylene-co-isoprene) elastomers, which are functionalized via Friedel-Crafts reaction with a Lewis acid and a functionalizing agent such as acid anhydrides and / or acylhalides. The clay is exfoliated in one embodiment by the addition of exfoliating agents such as alkyl amines and silanes to the clay. The composition can include secondary rubbers such as general purpose rubbers, and curatives, fillers, and the like. The nanocomposites of the invention have improved air barrier properties such as are useful for tire innerliners and innertubes.

Owner:EXXONMOBIL CHEM PAT INC

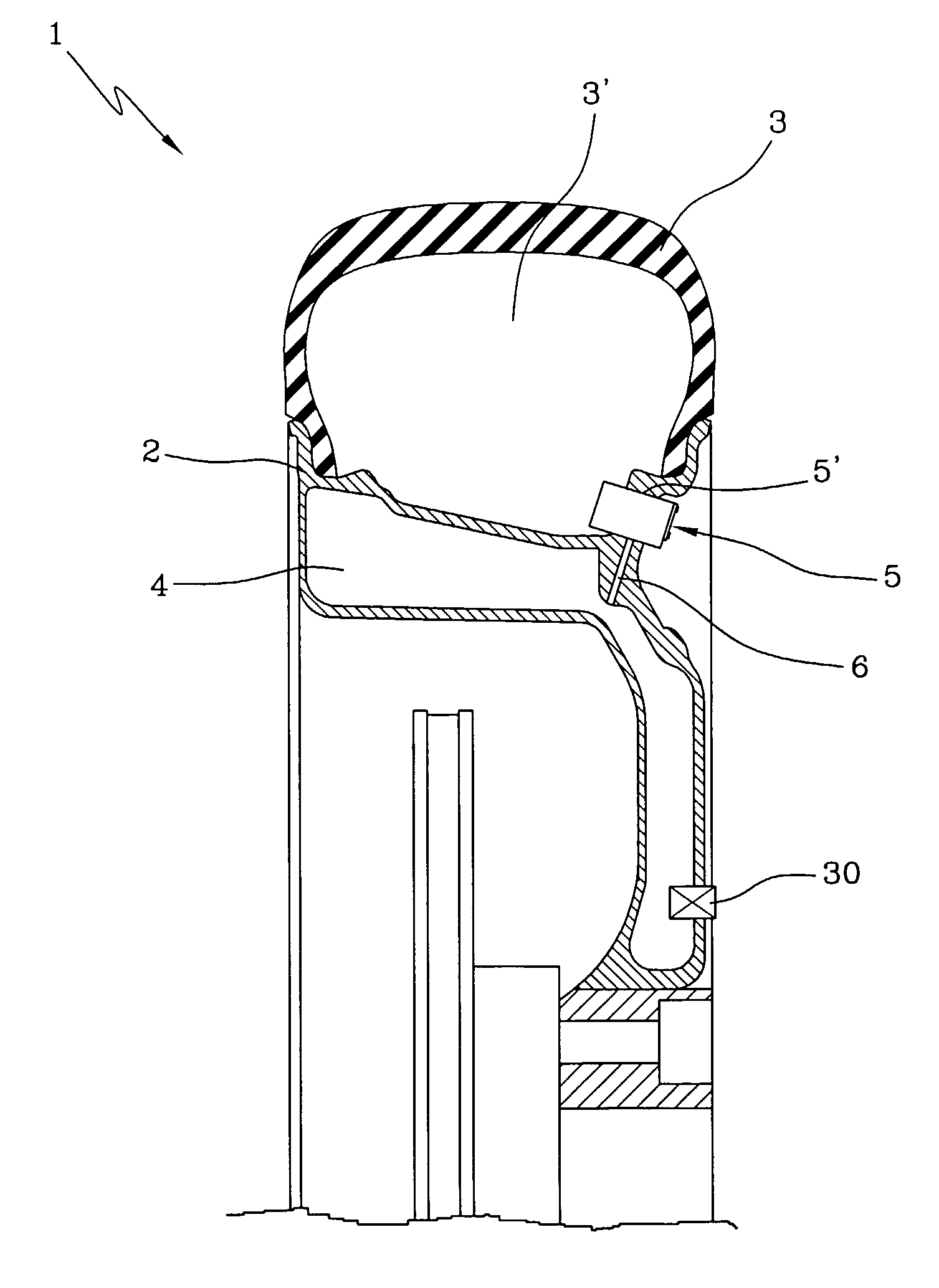

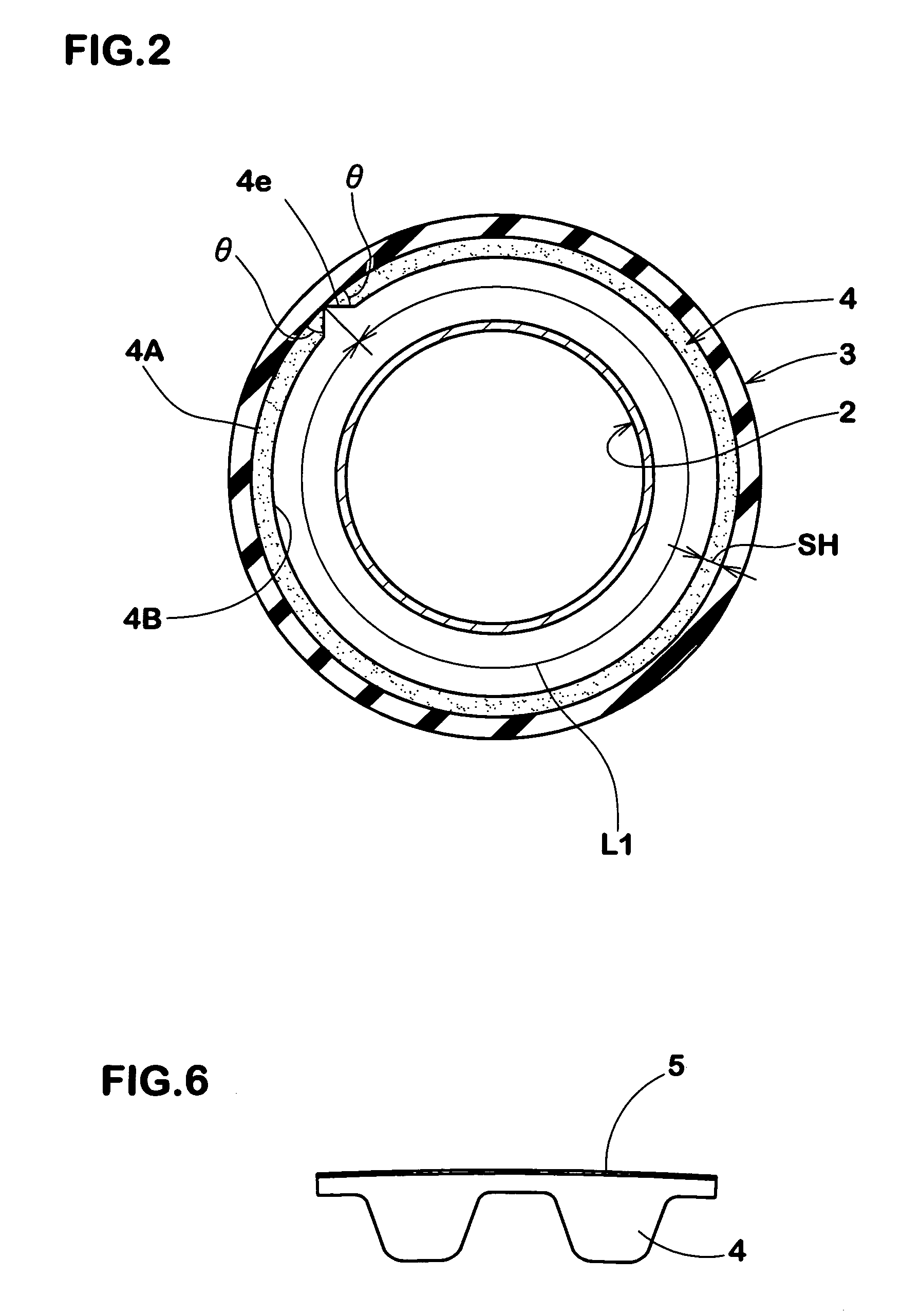

Flexible polyurethane foam for tires, noise reducing device and tire

InactiveUS20090053492A1Damage suppressionLight weightWith separate inflatable insertsLayered productsVolumetric Mass DensityEngineering

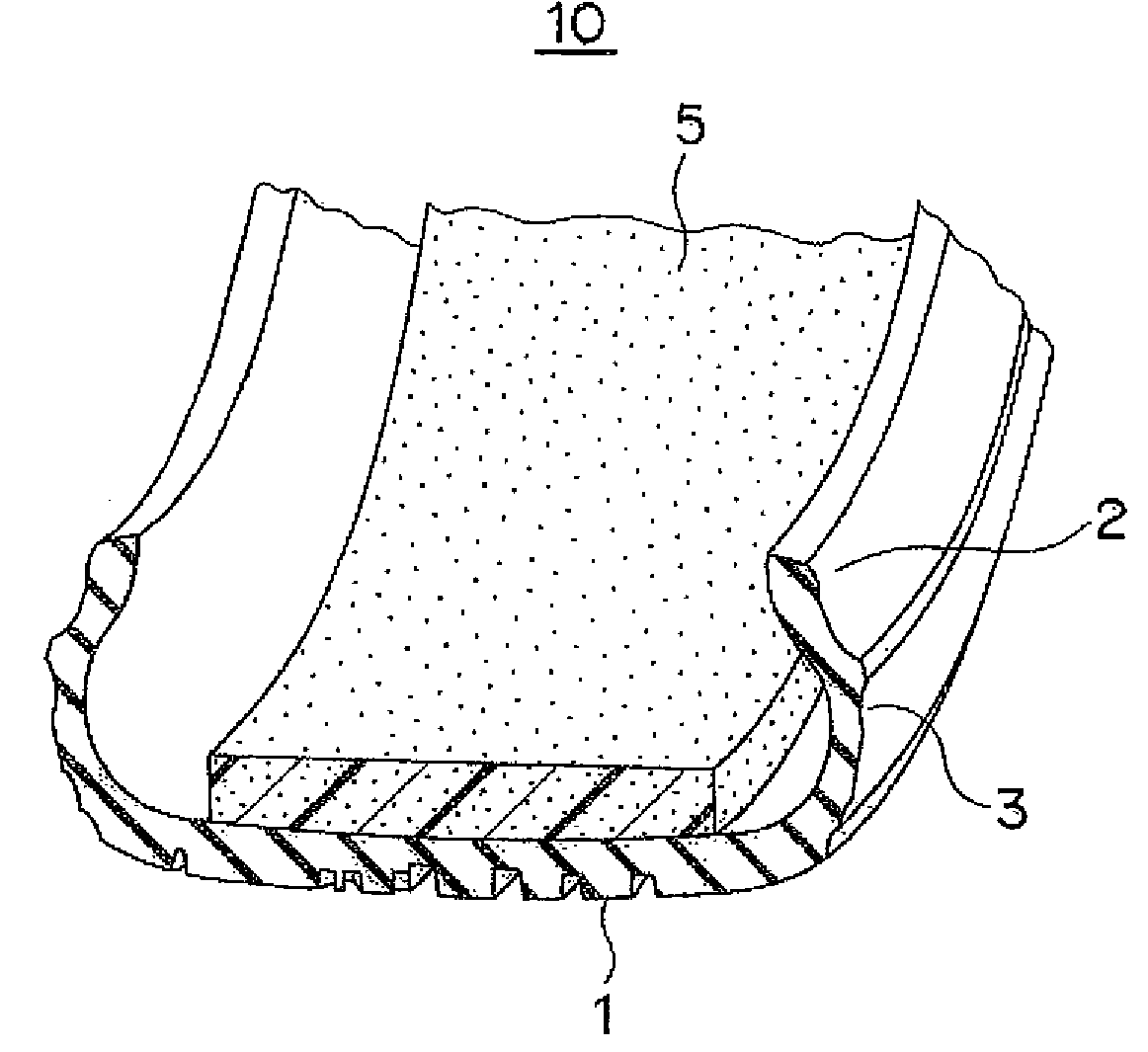

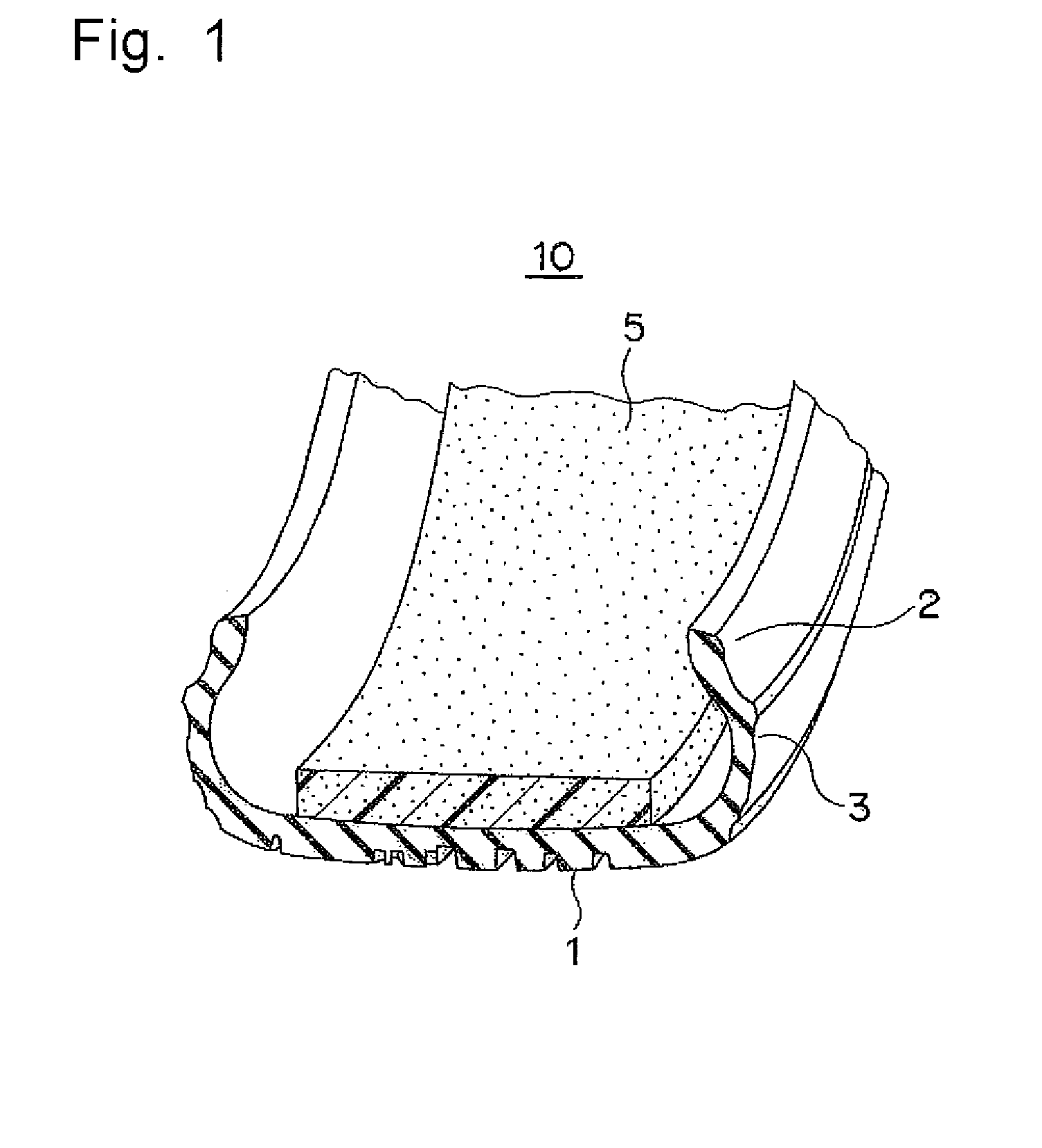

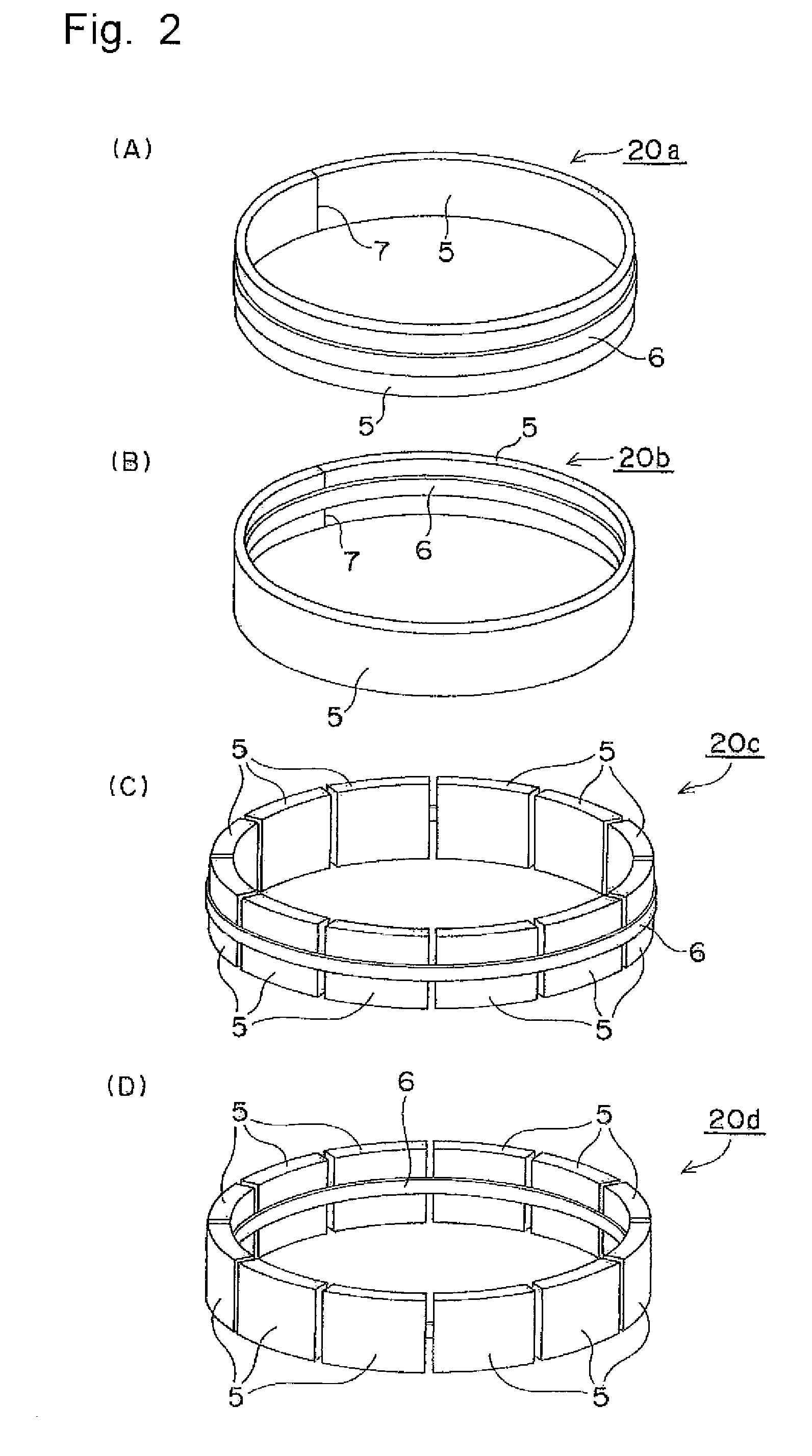

The present invention is to provide a flexible polyurethane foam for tires that can effectively suppress damages, such as chips and cracks, and deformation, such as compression (permanent set in fatigue), even when attached to an inner face of a tire by using a band member.A flexible polyurethane foam for tires 5 which is attached to a gap between a tire and a wheel rim, wherein a density is in the range from 7 to 40 kg / m3 and a tear strength (N / cm) per unit density (kg / m3) is 0.30 or more, a noise reducing device with the flexible polyurethane foam for tires 5 fixed to a ring-shaped band member, and a tire 10 with the noise reducing device attached thereto.

Owner:THE YOKOHAMA RUBBER CO LTD +1

Air Barrier Composition For Innerliners

InactiveUS20090050251A1Reduce air permeabilityImprove at least oneWithout separate inflatable insertsWith separate inflatable insertsProcessing aidFood science

According to the invention, a processing aid is used to improve processing in a green (uncured) rubber composition, such as in downstream in-plant processing of an innerliner compound, and maintaining, or more preferably, reducing the air permeability of the cured composition, e.g., innerliner compound. In embodiments, another of the advantages of the present invention is that the processing aid according to the invention can be used in very low levels relative to the other processing aids and oils.

Owner:EXXONMOBIL CHEM PAT INC

Alloy blends of polyurethane and rubber

InactiveUS20050267245A1Improve barrier propertiesImprove balanceHollow inflatable ballsWith separate inflatable insertsPolymer scienceAlloy

The present invention relates to a rubber formulation suitable for making barrier articles, such as inflatable sports balls or bicycle tubes, that resist the passage of gases, such as air, particularly as applicable to tennis balls, and more particularly to the rubber formulation which contains substantially amorphous, millable polyurethane alloyed with natural and / or synthetic rubbers.

Owner:SANDUSKY DONALD ALLAN +1

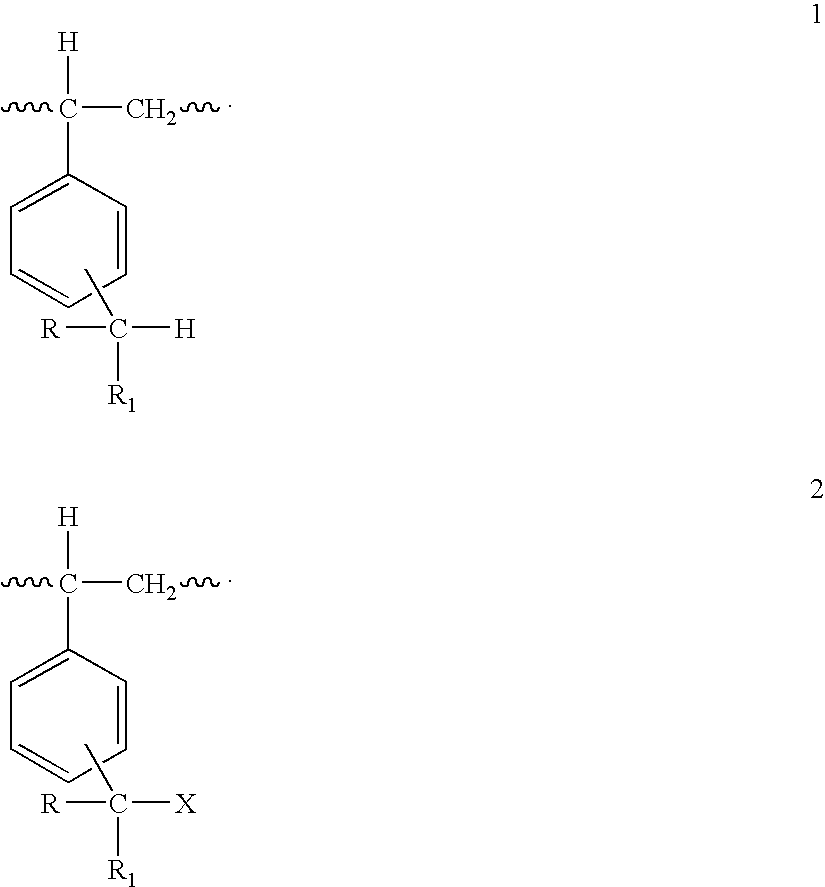

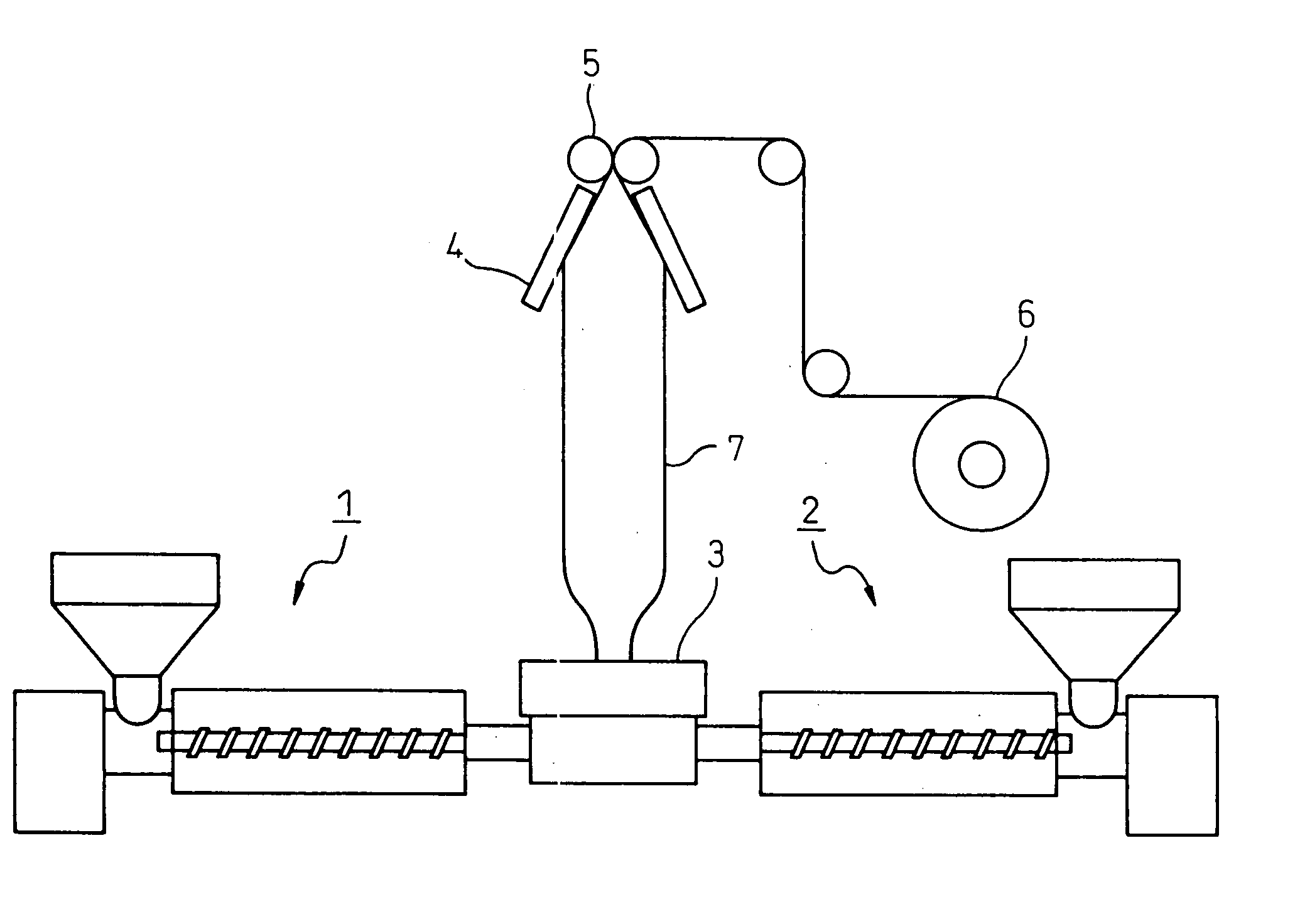

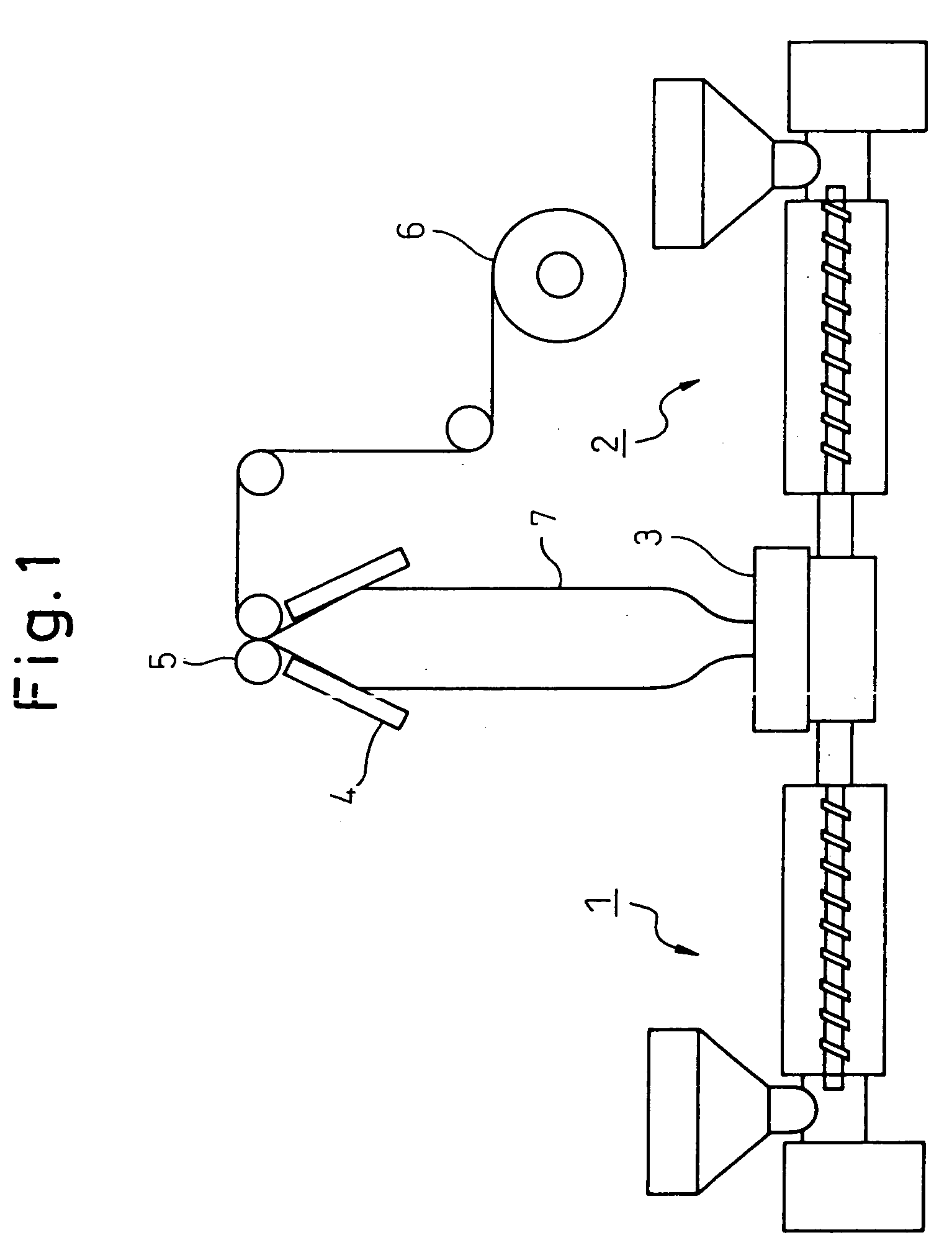

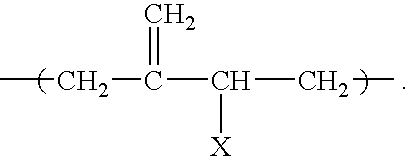

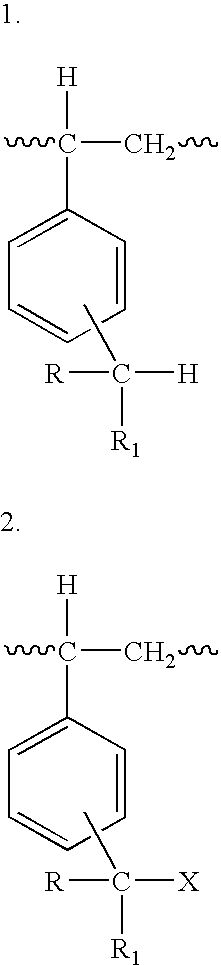

Elastomer Composition, Method for Producing Same, and Pneumatic Tire Using Same

InactiveUS20080314493A1Reduced durabilityWithout separate inflatable insertsWith separate inflatable insertsElastomerChemistry

An elastomer composition, having an excellent flexibility and low temperature durability, a method for producing the same and a pneumatic tire using the same are provided.An elastomer composition (C) comprising a matrix of a thermoplastic resin (A), in which a dispersed phase of an elastomer component (B) is finely dispersed to form an island-in-sea structure, wherein volume ratios of the thermoplastic resin (A) and the elastomer component (B) satisfy the following formula (I):Φd / Φm>ηd / ηm (I)wherein Φd and ηd, respectively, indicate a volume ratio and a melt viscosity of the elastomer component (B), and Φm and ηm, respectively, indicate a volume ratio and a melt viscosity of the thermoplastic resin (A)), a method for producing the same and a pneumatic tire using the same.

Owner:THE YOKOHAMA RUBBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com