Flexible polyurethane foam for tires, noise reducing device and tire

a technology tires, which is applied in the field of flexible polyurethane foam for tires, can solve the problems of cavity resonance, damage such as chips and cracks in the urethane foam, and it is not desirable to attach a member having a high density, so as to reduce damage, reduce noise, and reduce nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0054]Commercially available polyurethane foam (“Kuralafoam 281”, made by Kurabo Industries Ltd.) was used. The flexible polyurethane foam was cut into 12 pieces so that twelve board-shaped polyurethane foams having a size of 150 mm in width×20 mm in thickness×140 mm in length were prepared.

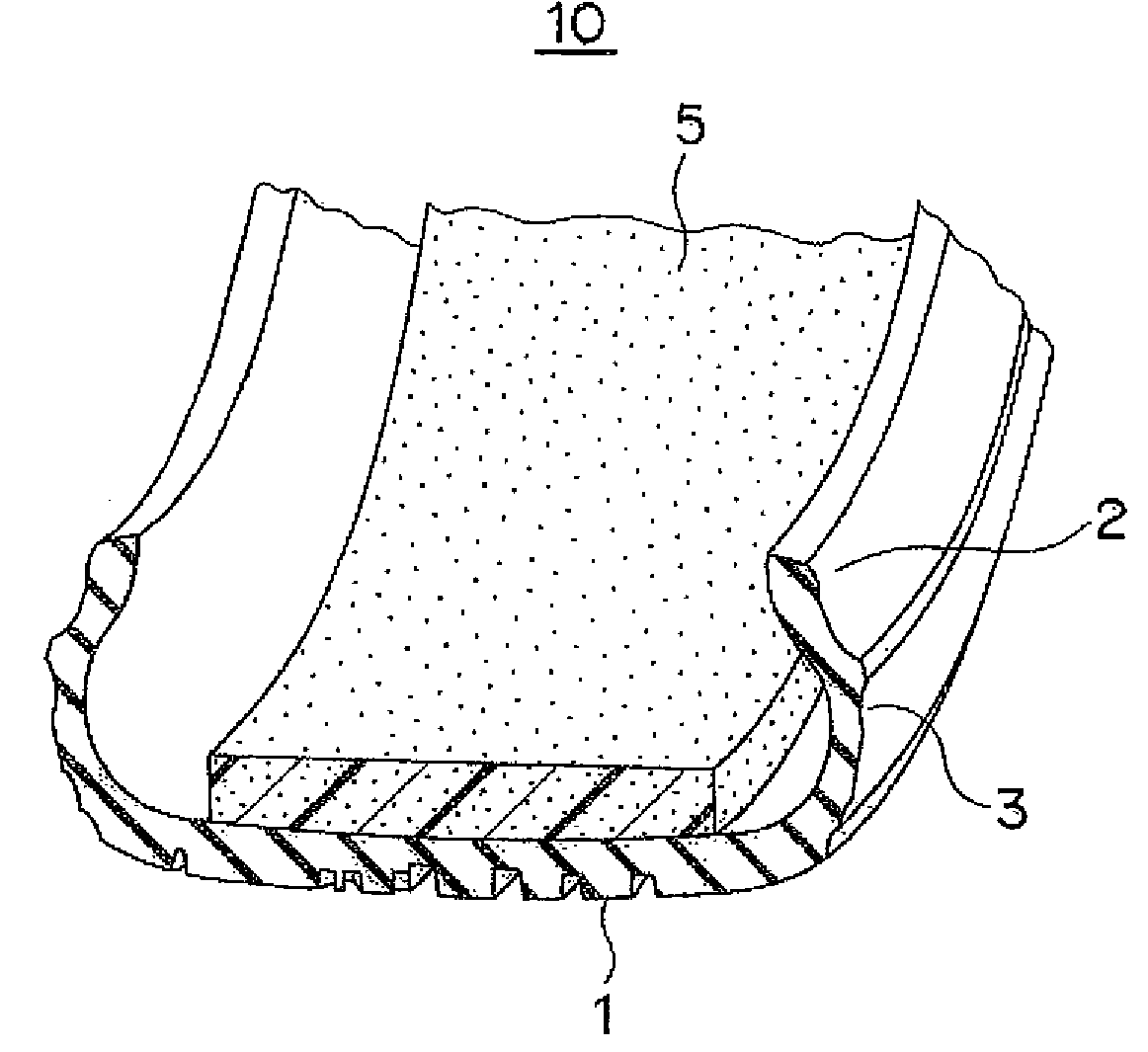

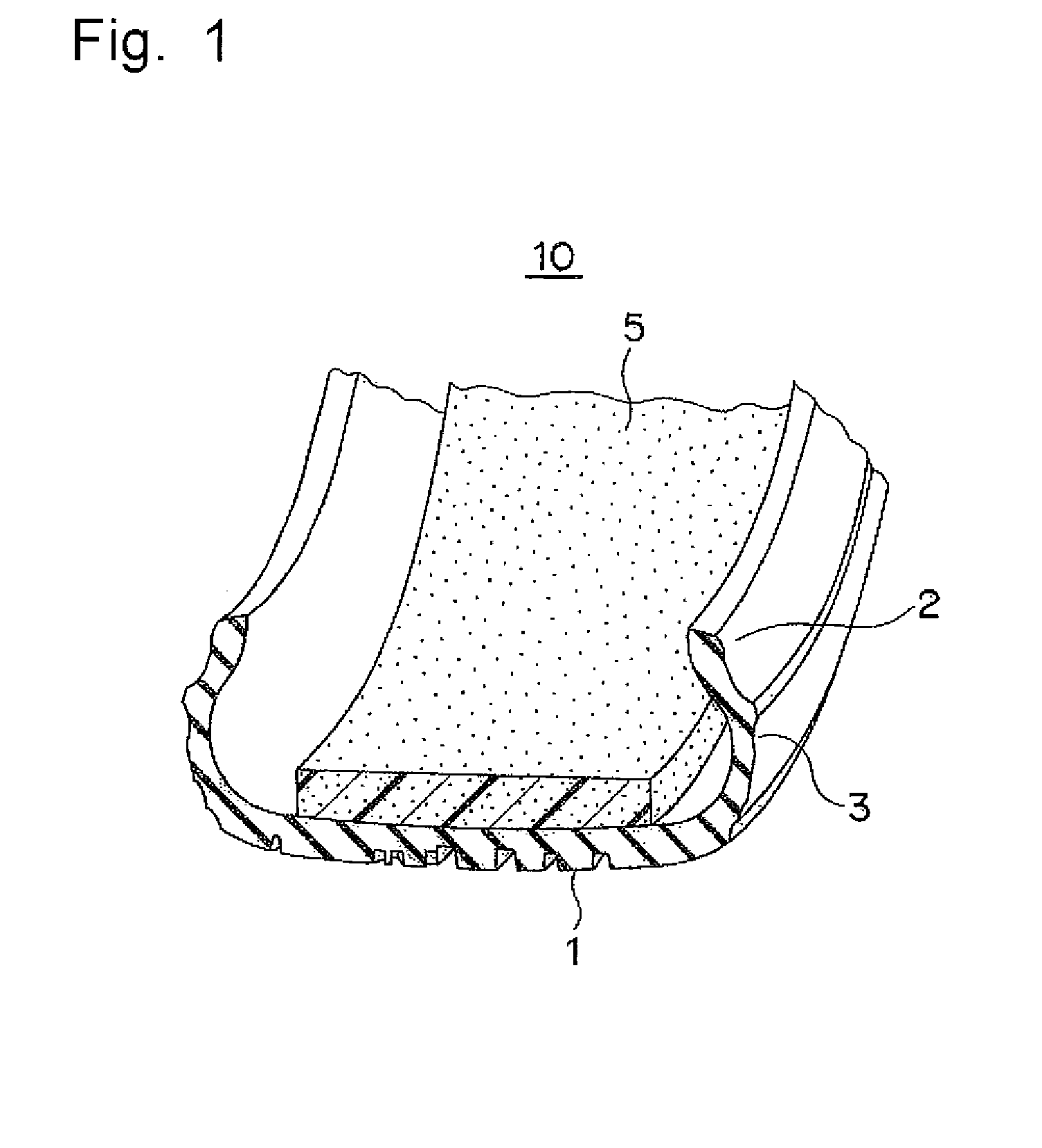

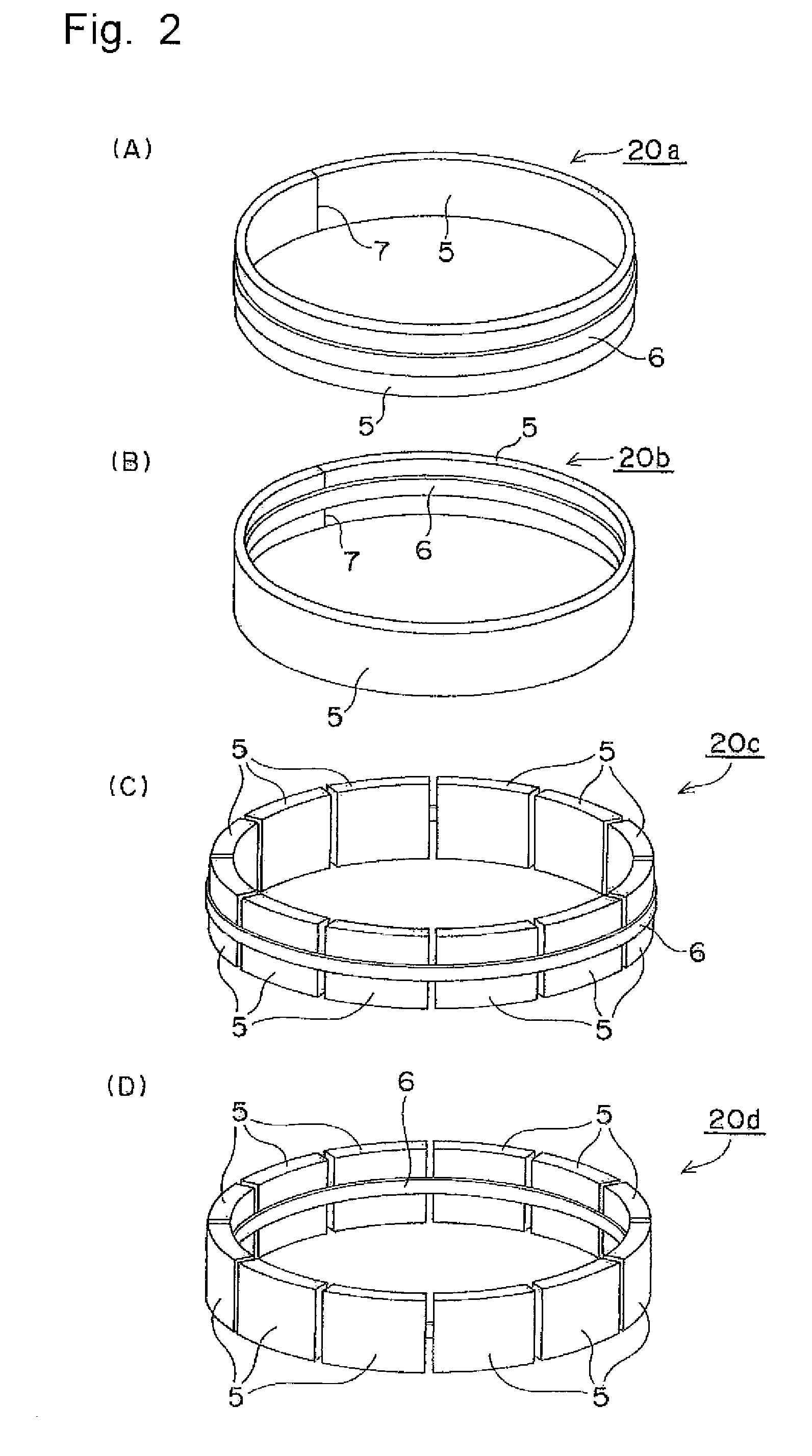

[0055]Next, a noise reducing device of a type shown in FIG. 2(C) was manufactured. Specifically, twelve board-shaped polyurethane foam members are placed at predetermined positions of a string-shaped band member (20 mm in width×2 mm in thickness×Tire inner circumferential length) made from polypropylene, with equal intervals, and fixed thereto by using a bonding agent (Super X: made by Cemedine Co., Ltd.), and the two ends of the string-shaped band member were connected to each other through fusion splicing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com