Patents

Literature

100results about How to "Stable travel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

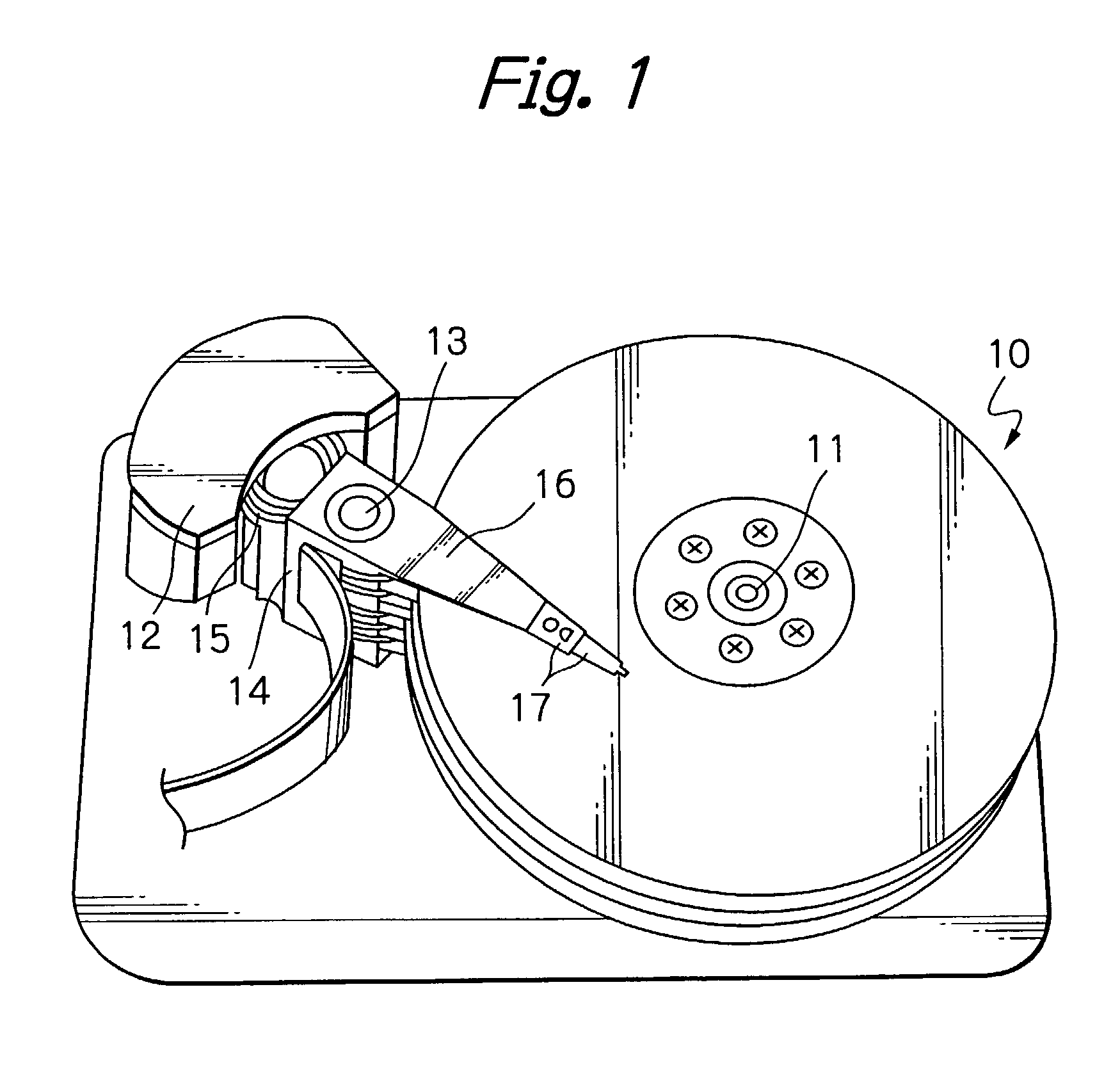

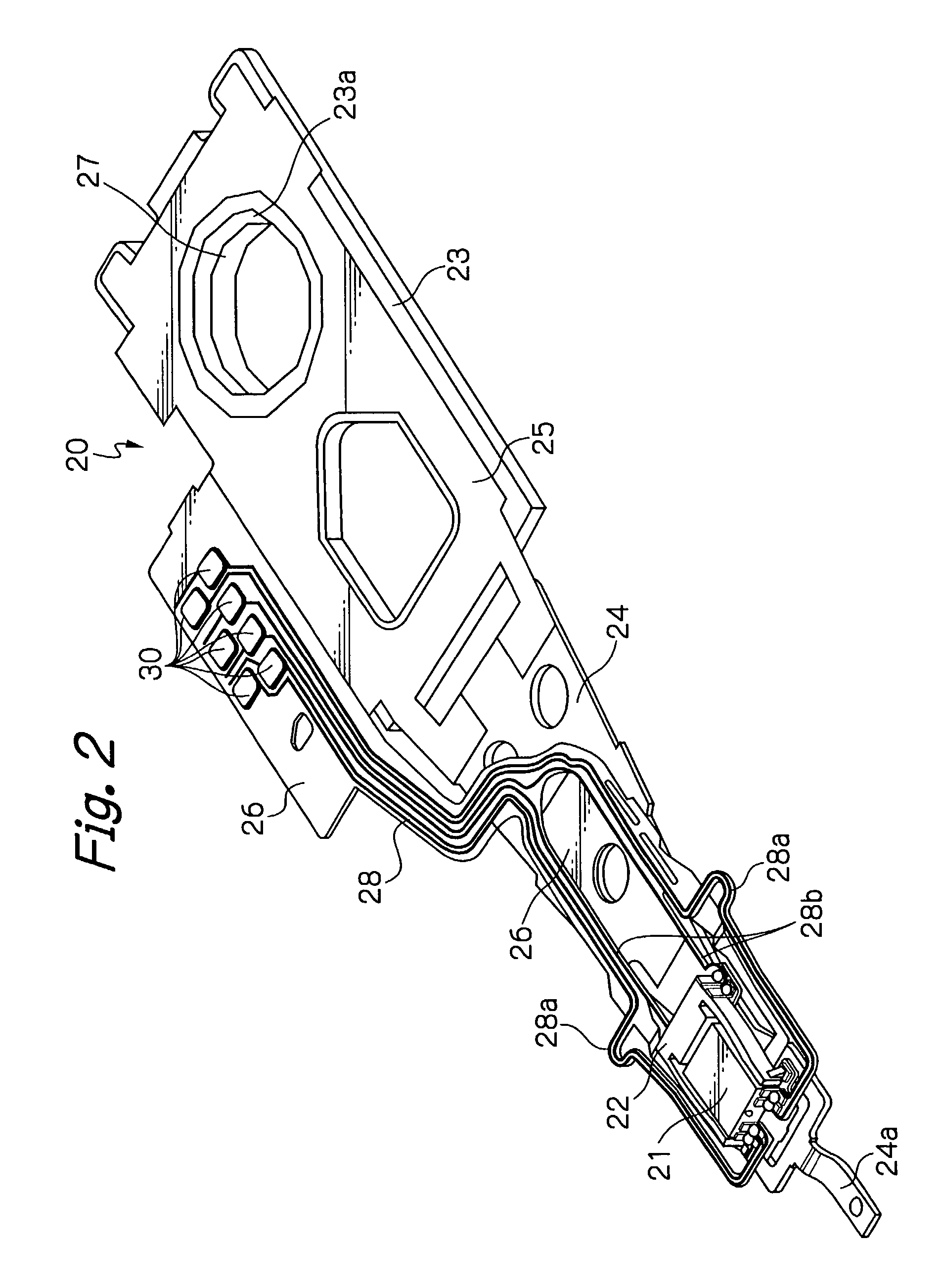

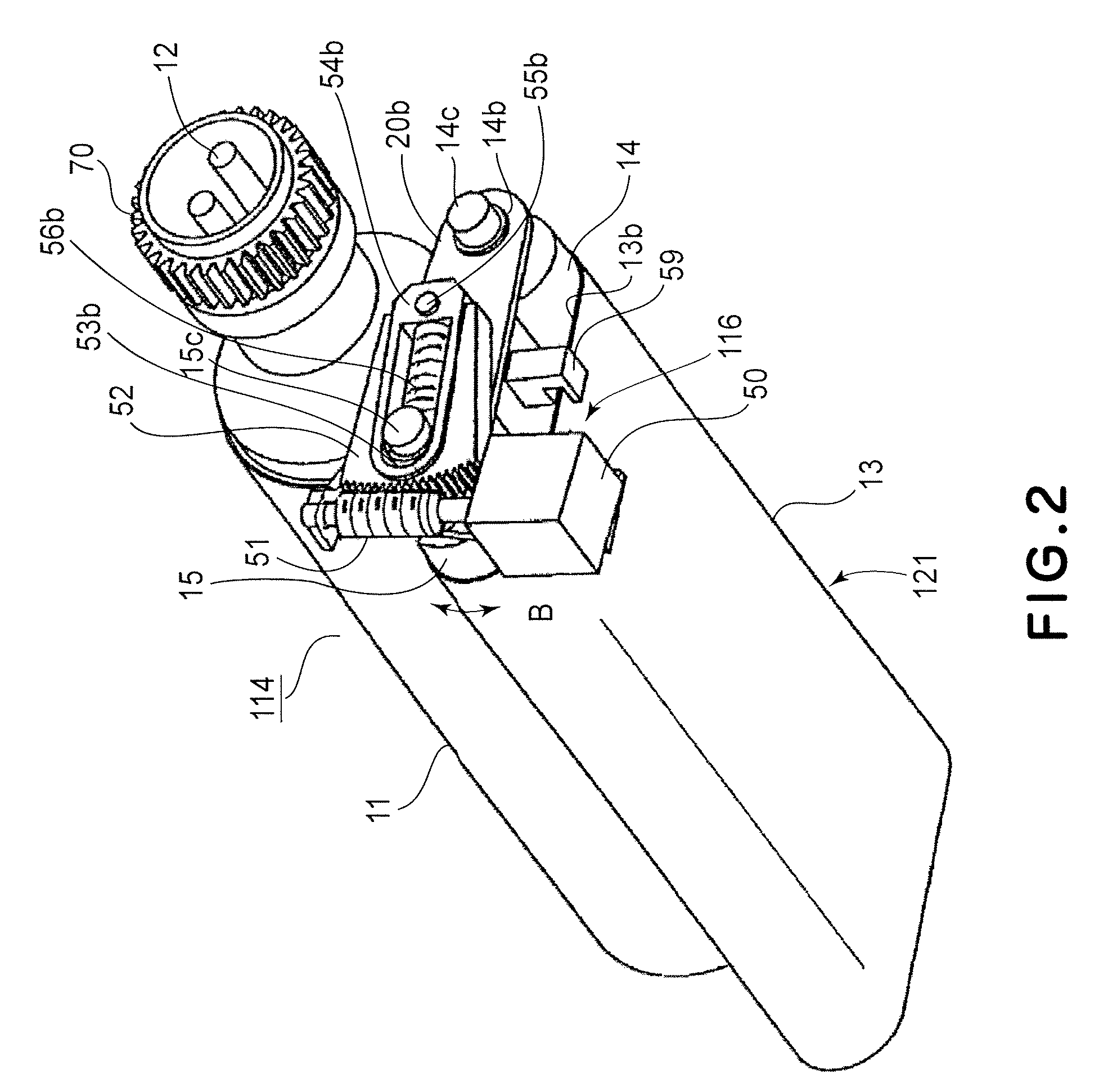

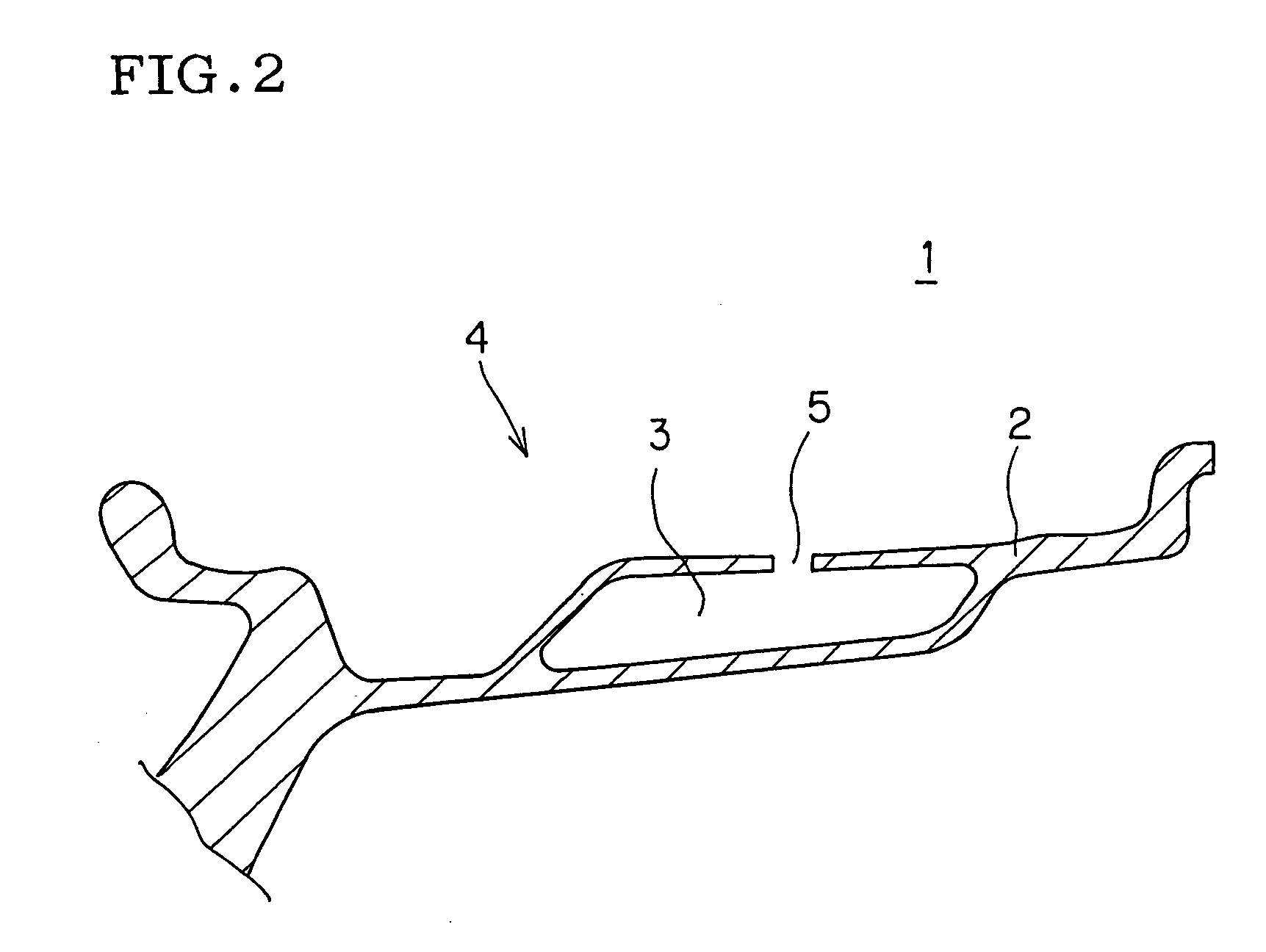

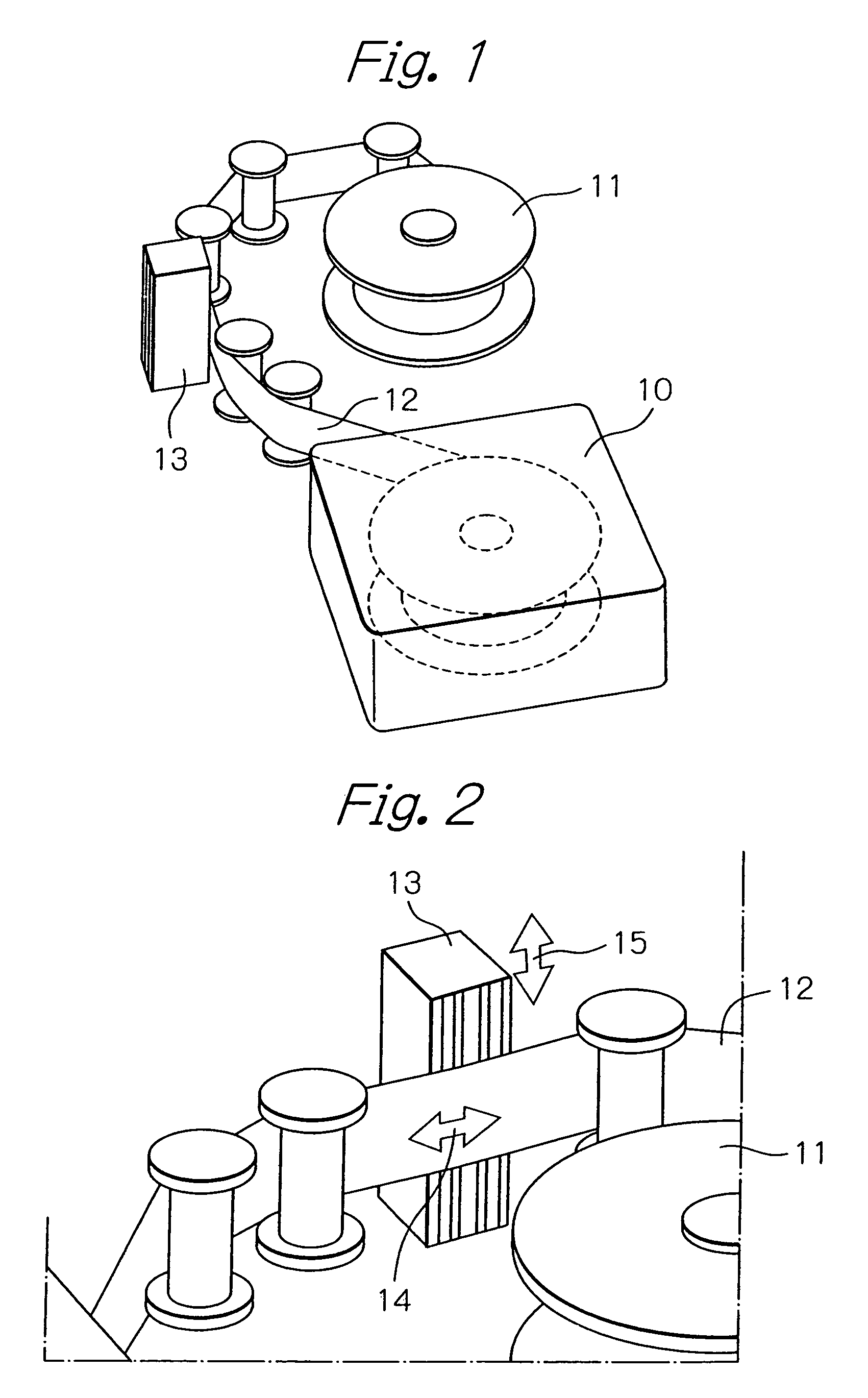

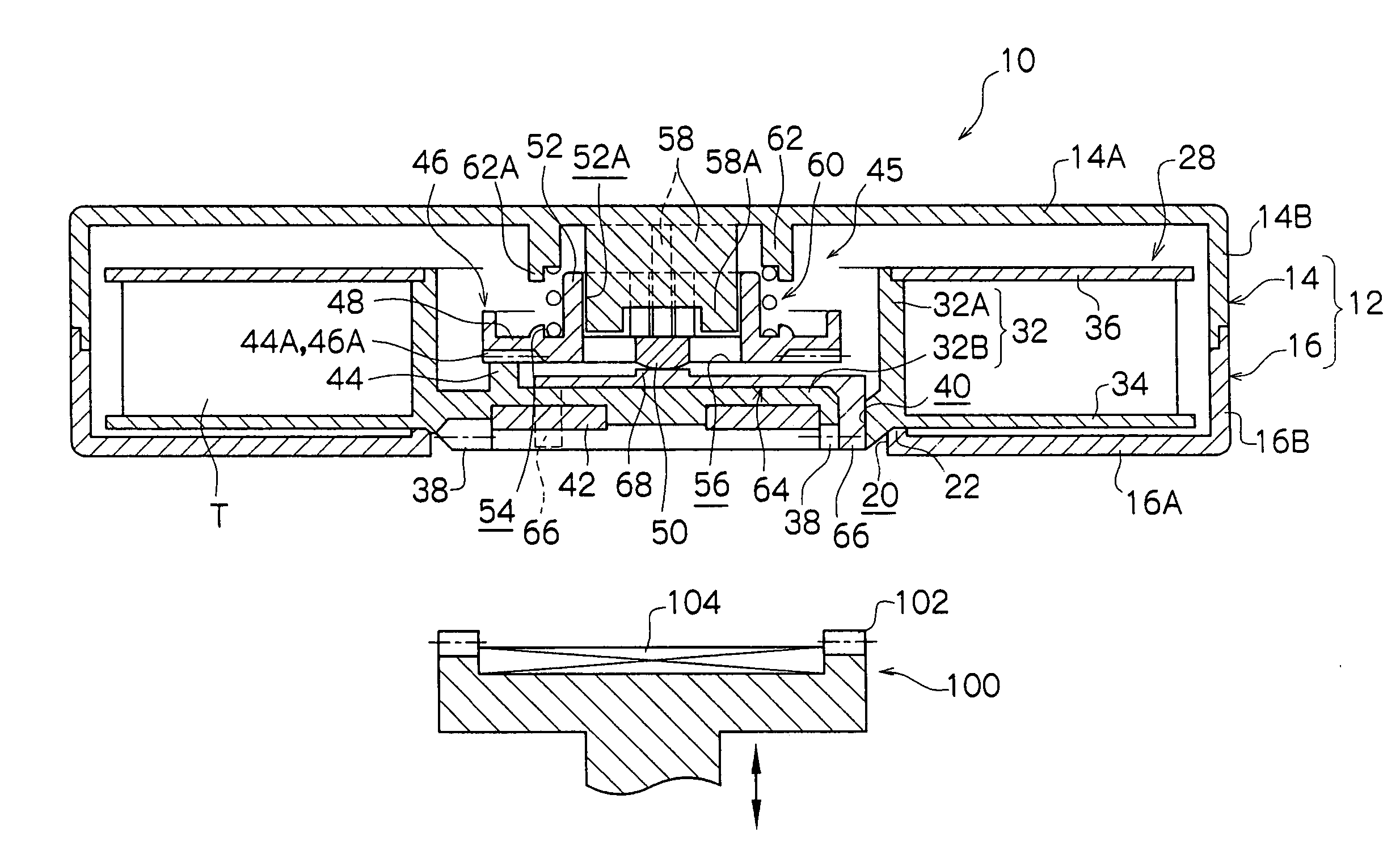

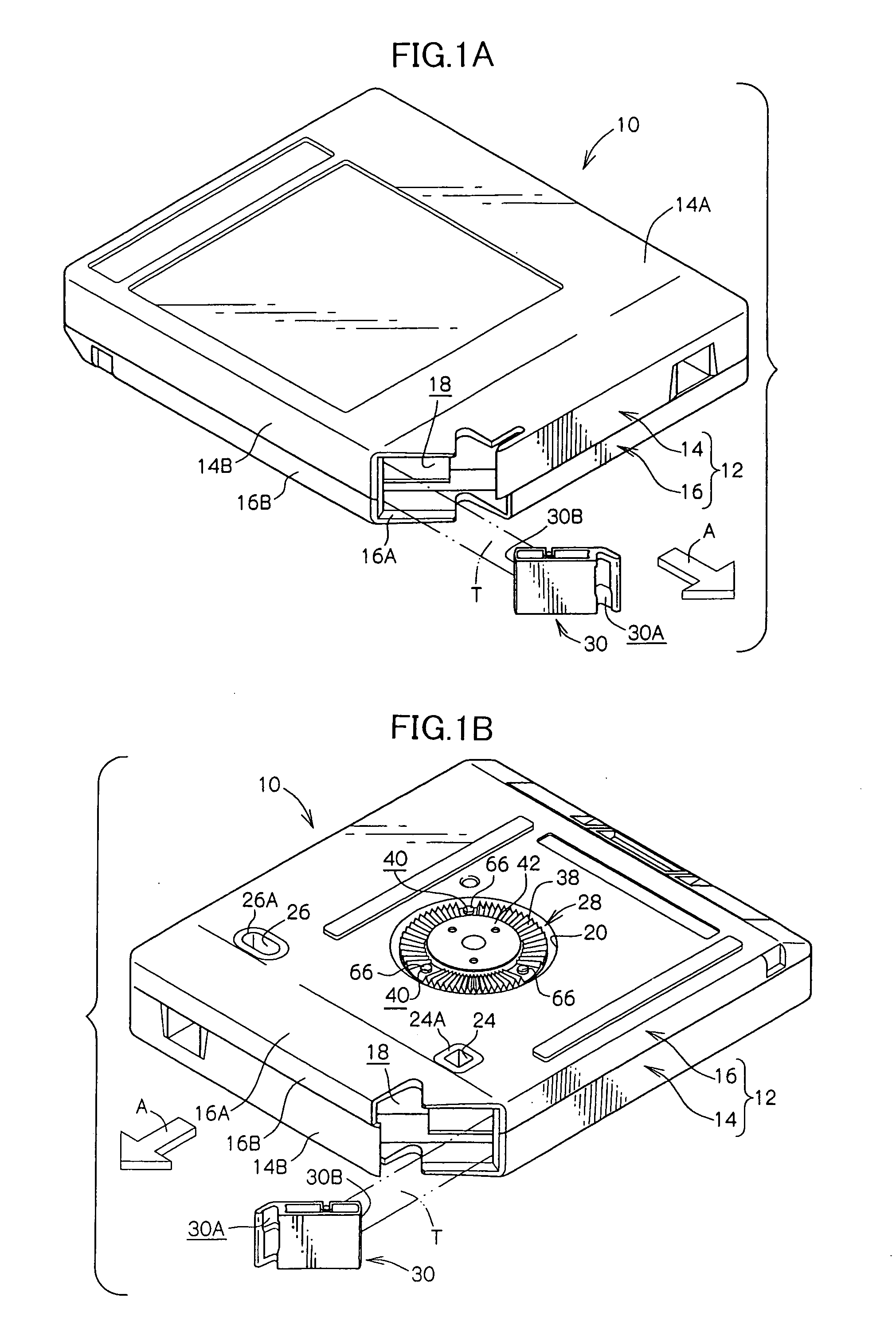

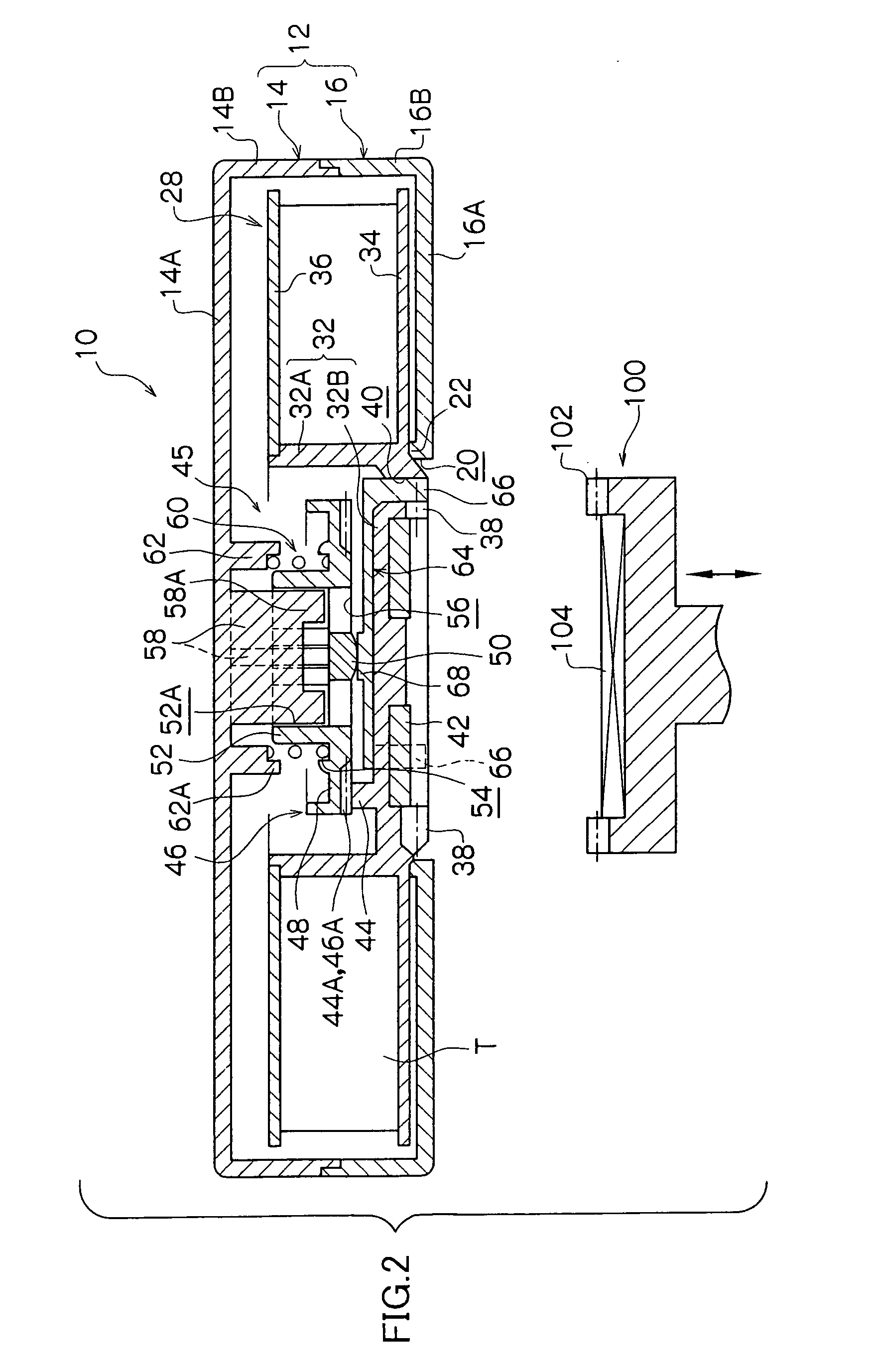

Head gimbal assembly with precise positioning actuator for head element, disk drive apparatus with the head gimbal assembly, and manufacturing method of the head gimbal assembly

InactiveUS7099115B2Shorten assembly timeStable travelTrack finding/aligningElectrical connection between head and armGimbalActuator

An HGA includes a head slider with at least one head element, a precise positioning actuator fixed to the head slider for precisely positioning the at least one head element, and a support for supporting the actuator. The actuator has a pair of movable arms capable of displacing in response to a drive signal applied to the actuator. The head slider is mounted between the pair of movable arms. The head slider and the actuator are adhered by at least one adhesive film.

Owner:SAE MAGNETICS (HK) LTD

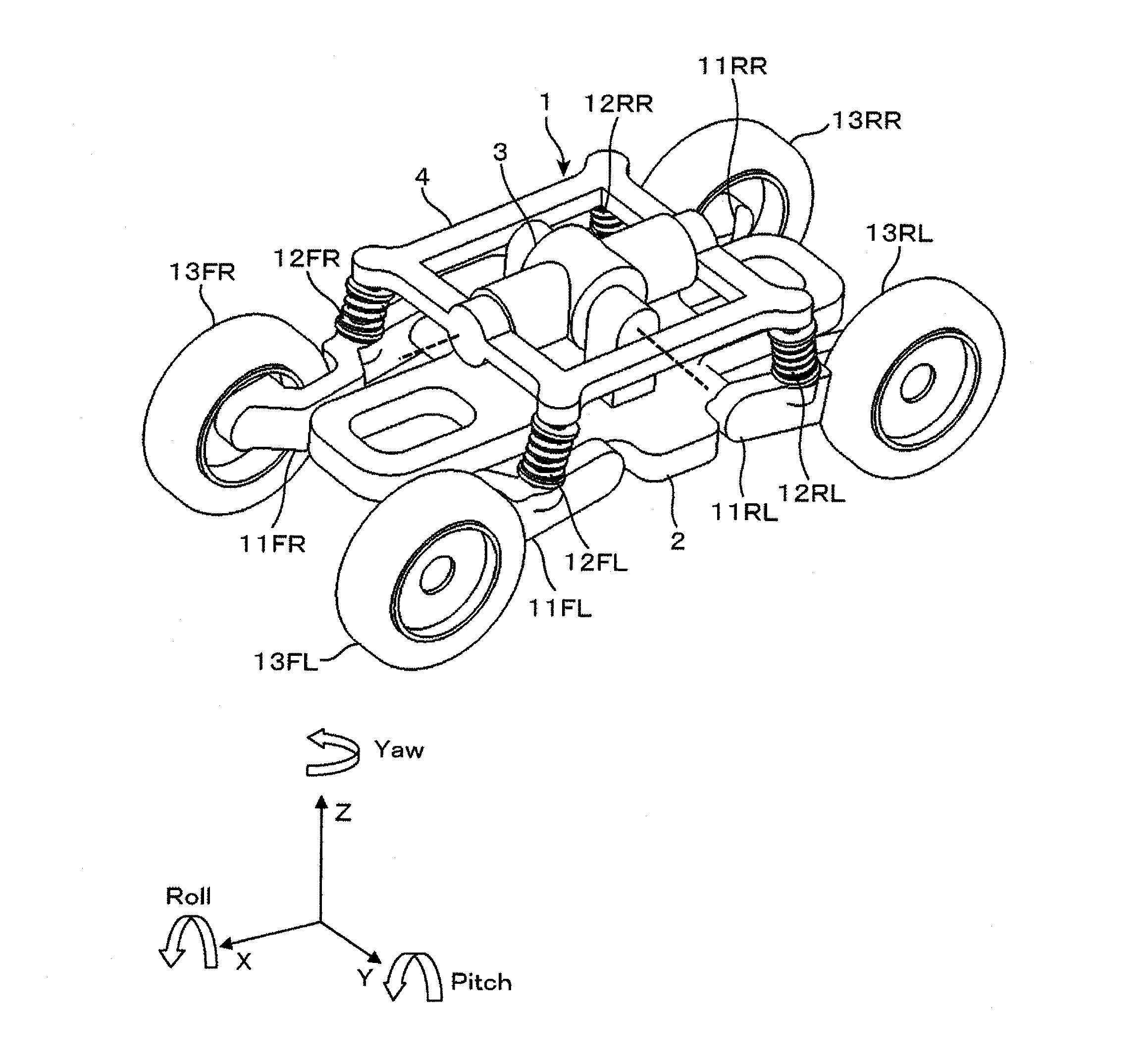

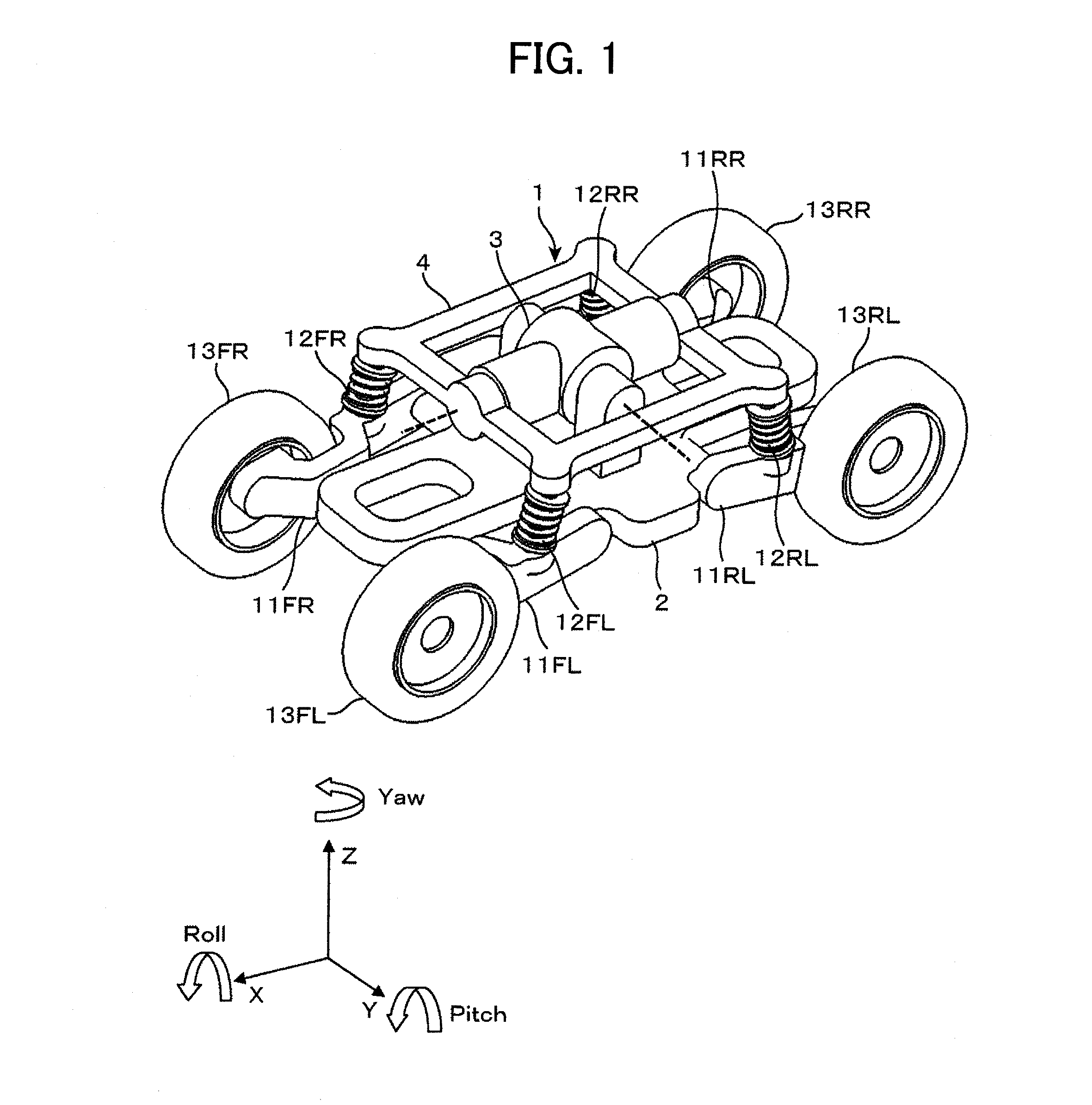

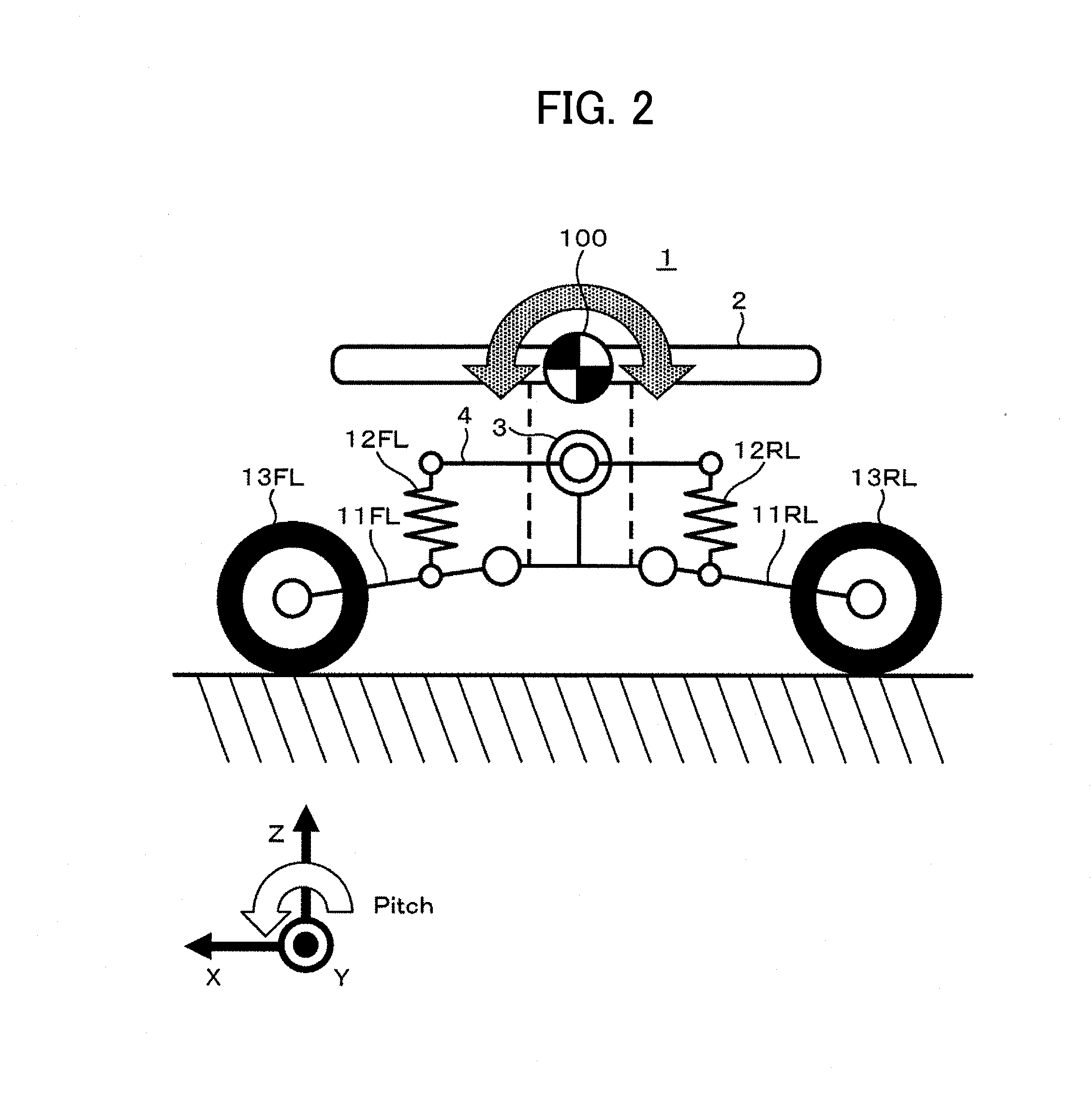

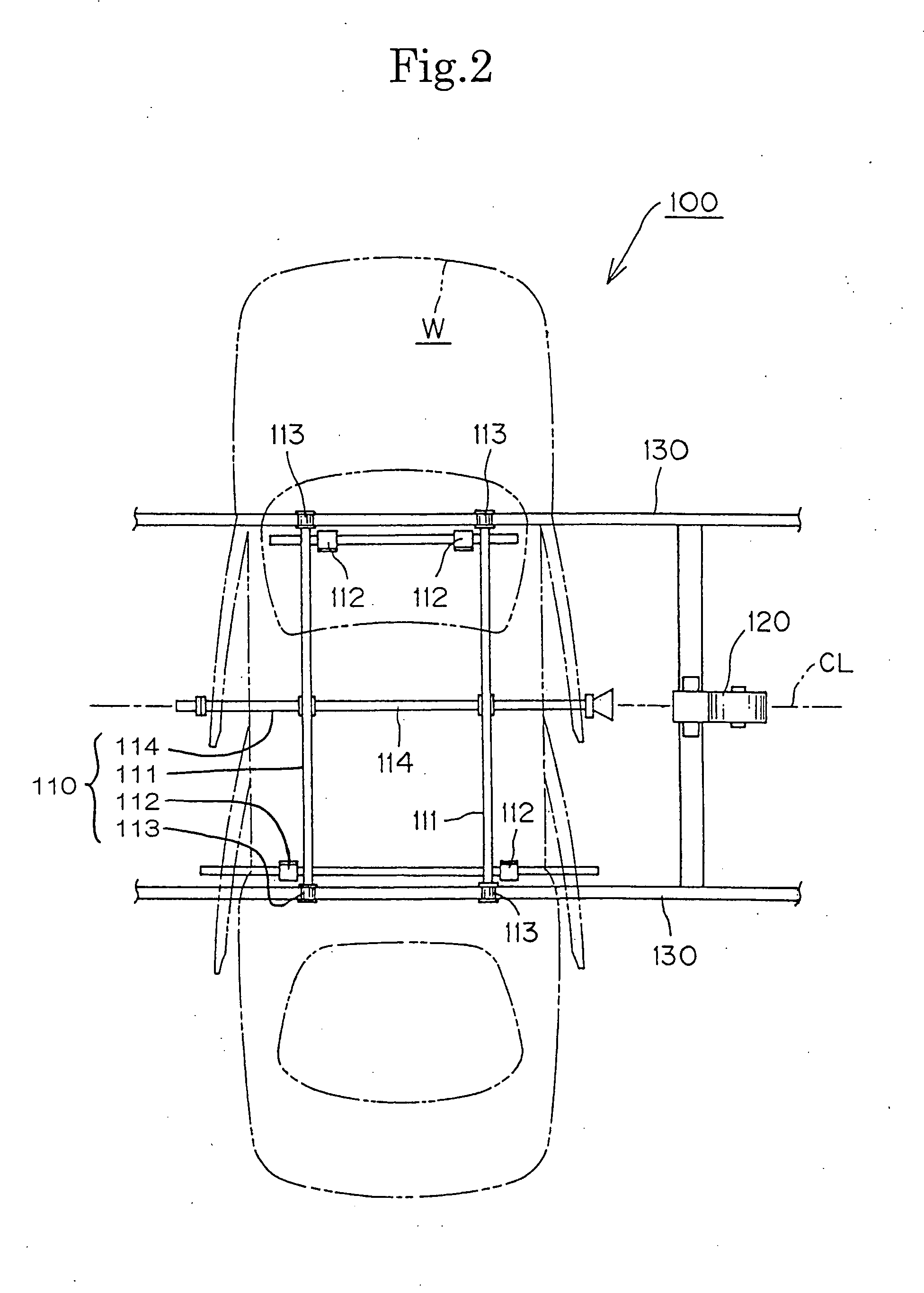

Moving mechanism

InactiveUS20120053788A1Stable travelDigital data processing detailsAnimal undercarriagesVehicle frameEngineering

A moving mechanism for running stably, with keeping a car frame horizontal even on a road surface inclined, while absorbing disturbances from unevenness on the road surface, comprises a car frame attached with wheels for running, wherein each of the wheels is attached to a car body through a swing arm, and an appropriate control is made on an inclination of a table rotatable in pitch / roll directions, to which coil springs for supporting the swing arms, respectively, are suspended; thereby achieving the moving mechanism for running stably, with keeping the car frame horizontal.

Owner:HITACHI LTD

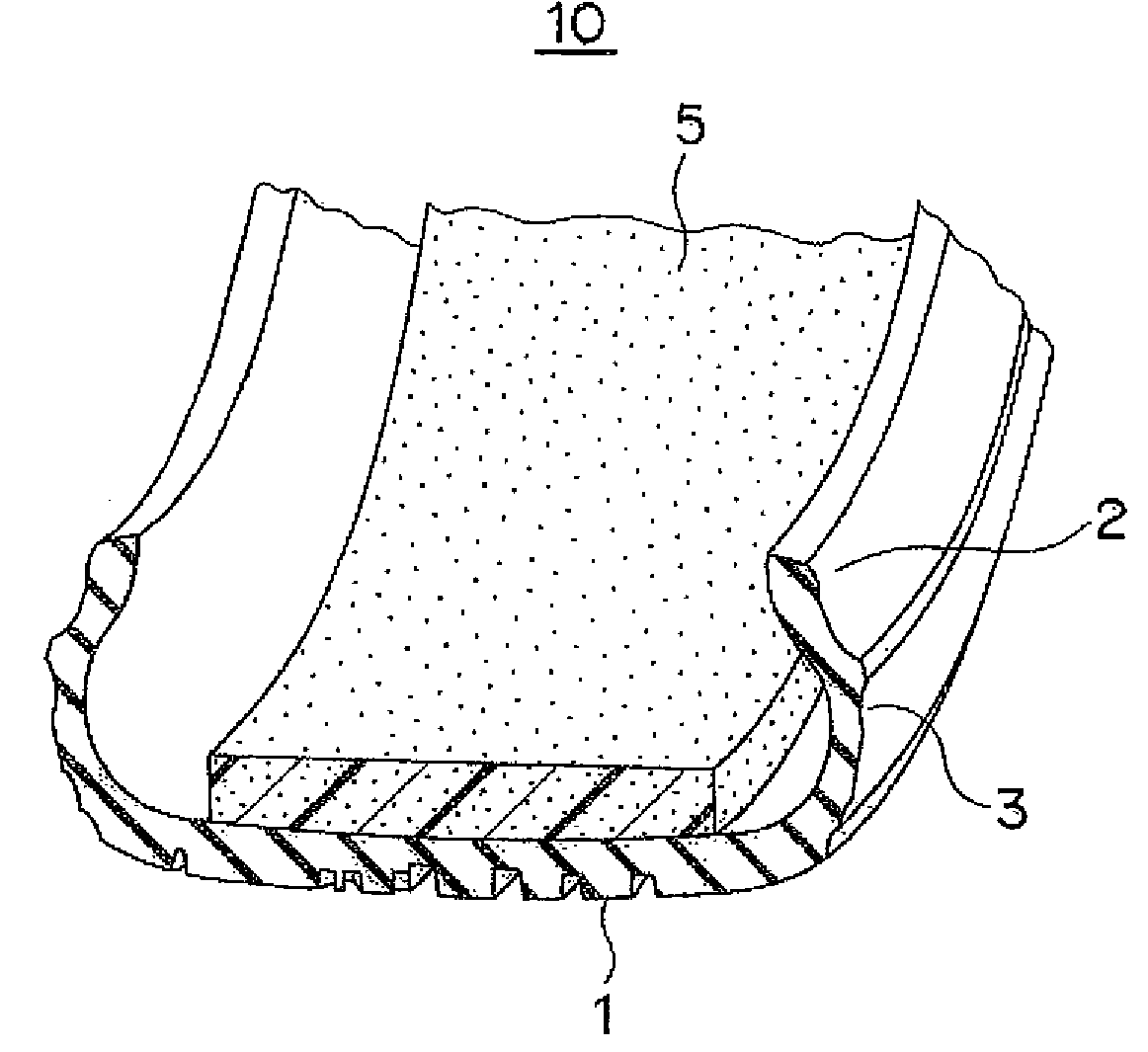

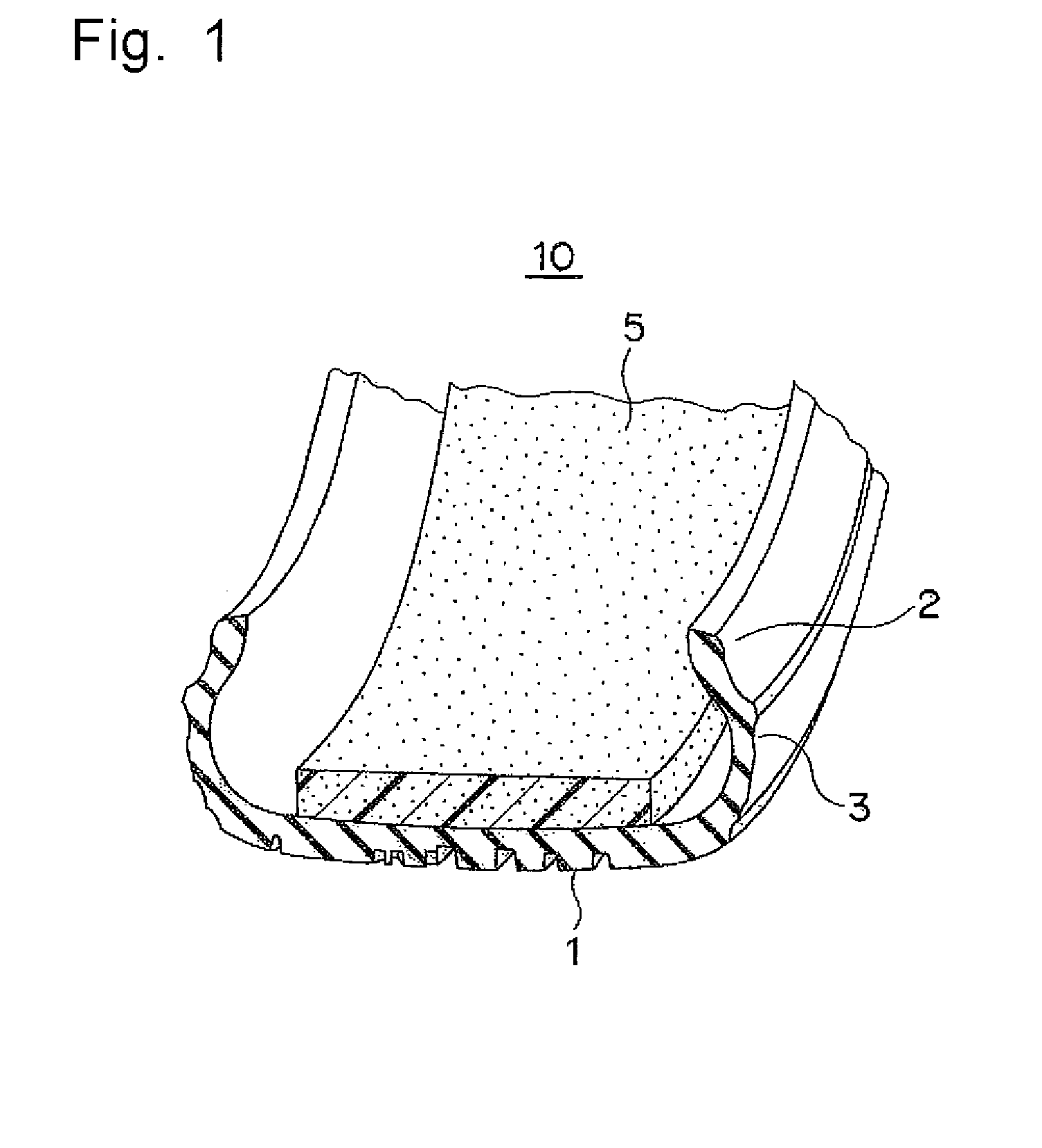

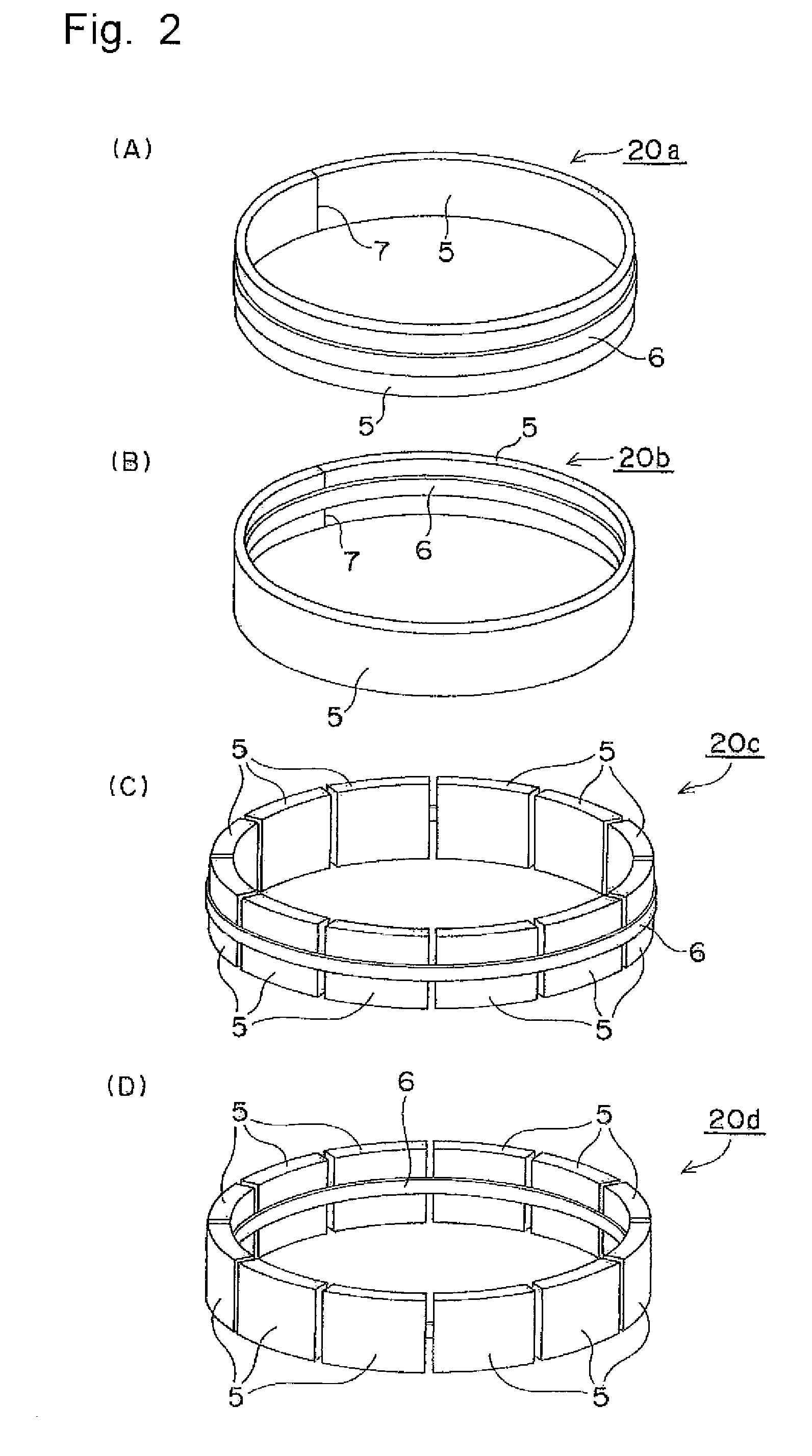

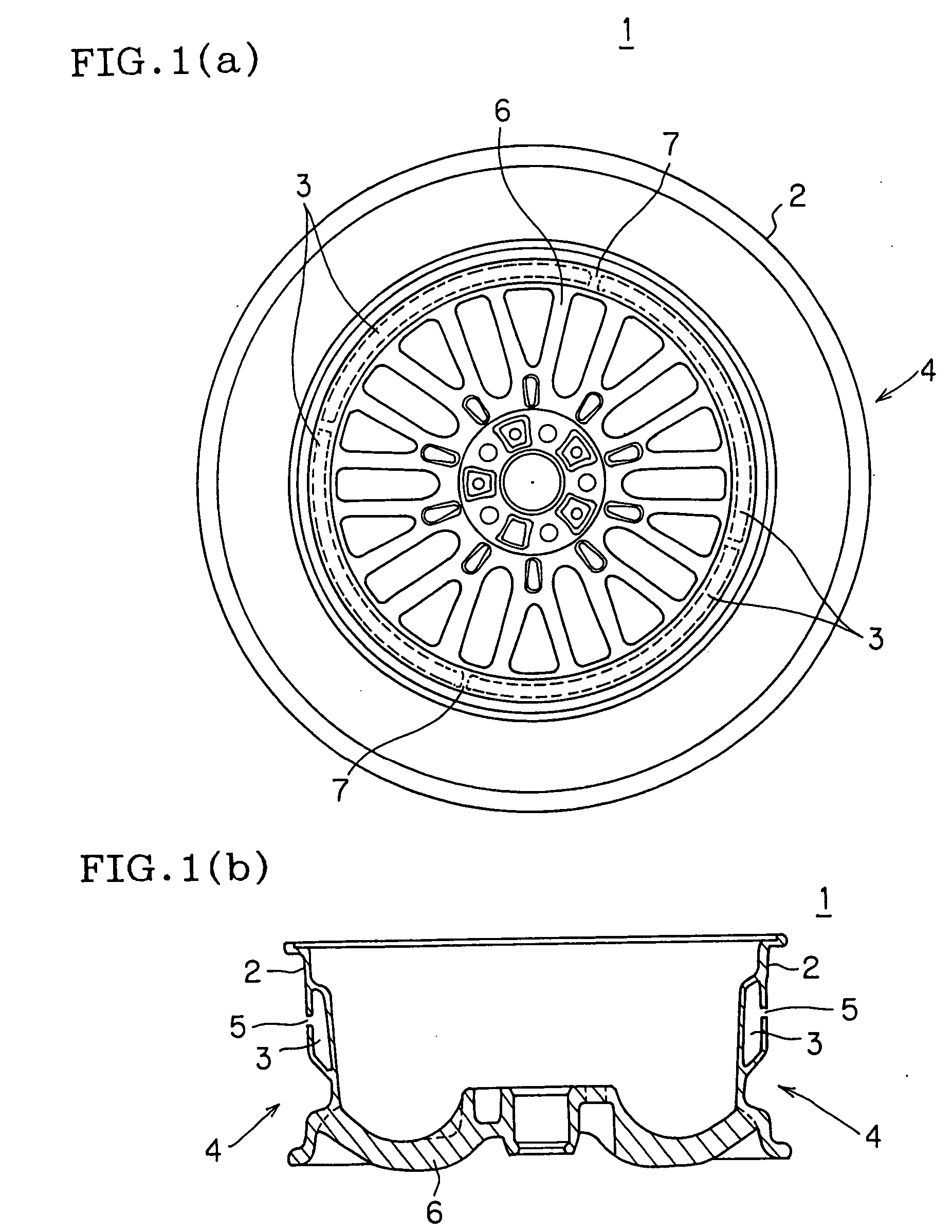

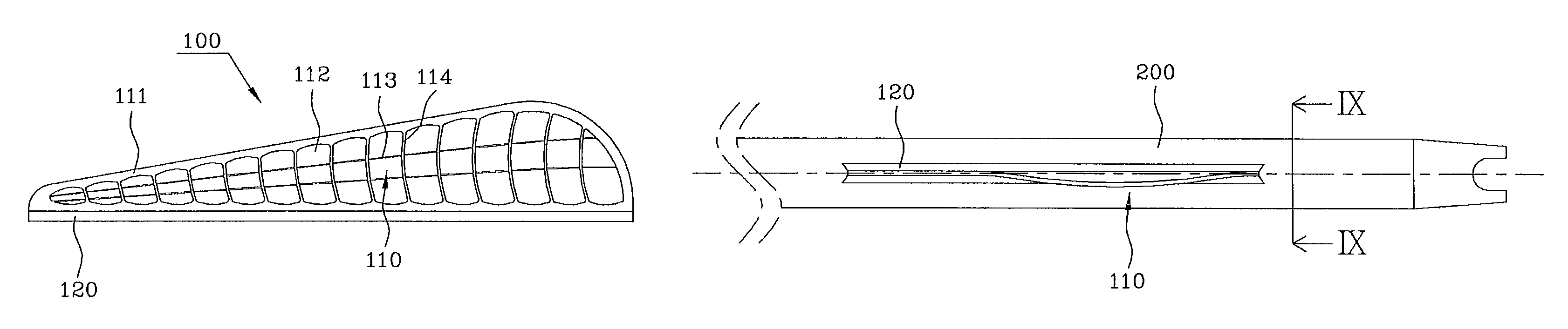

Flexible polyurethane foam for tires, noise reducing device and tire

InactiveUS20090053492A1Damage suppressionLight weightWith separate inflatable insertsLayered productsVolumetric Mass DensityEngineering

The present invention is to provide a flexible polyurethane foam for tires that can effectively suppress damages, such as chips and cracks, and deformation, such as compression (permanent set in fatigue), even when attached to an inner face of a tire by using a band member.A flexible polyurethane foam for tires 5 which is attached to a gap between a tire and a wheel rim, wherein a density is in the range from 7 to 40 kg / m3 and a tear strength (N / cm) per unit density (kg / m3) is 0.30 or more, a noise reducing device with the flexible polyurethane foam for tires 5 fixed to a ring-shaped band member, and a tire 10 with the noise reducing device attached thereto.

Owner:THE YOKOHAMA RUBBER CO LTD +1

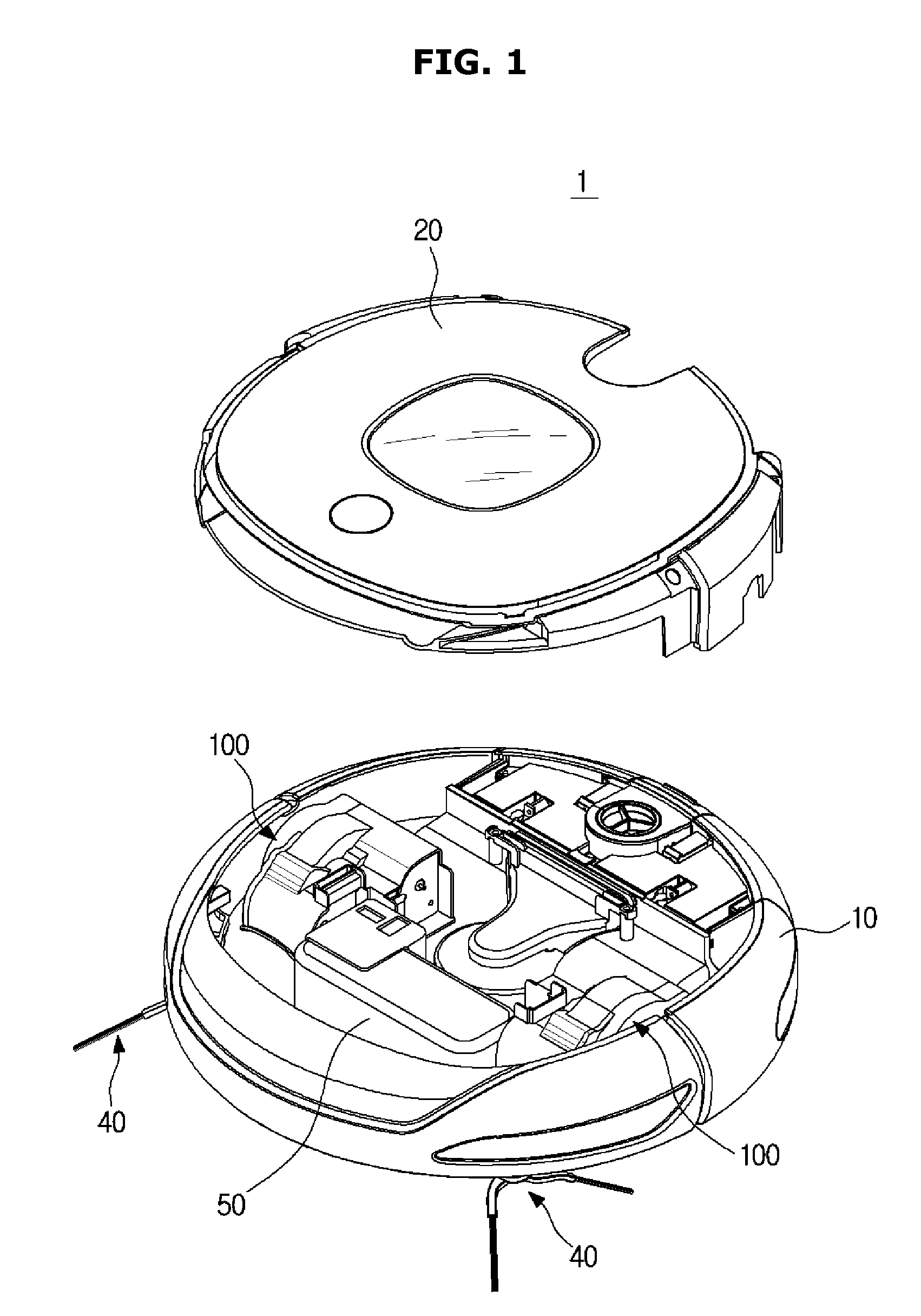

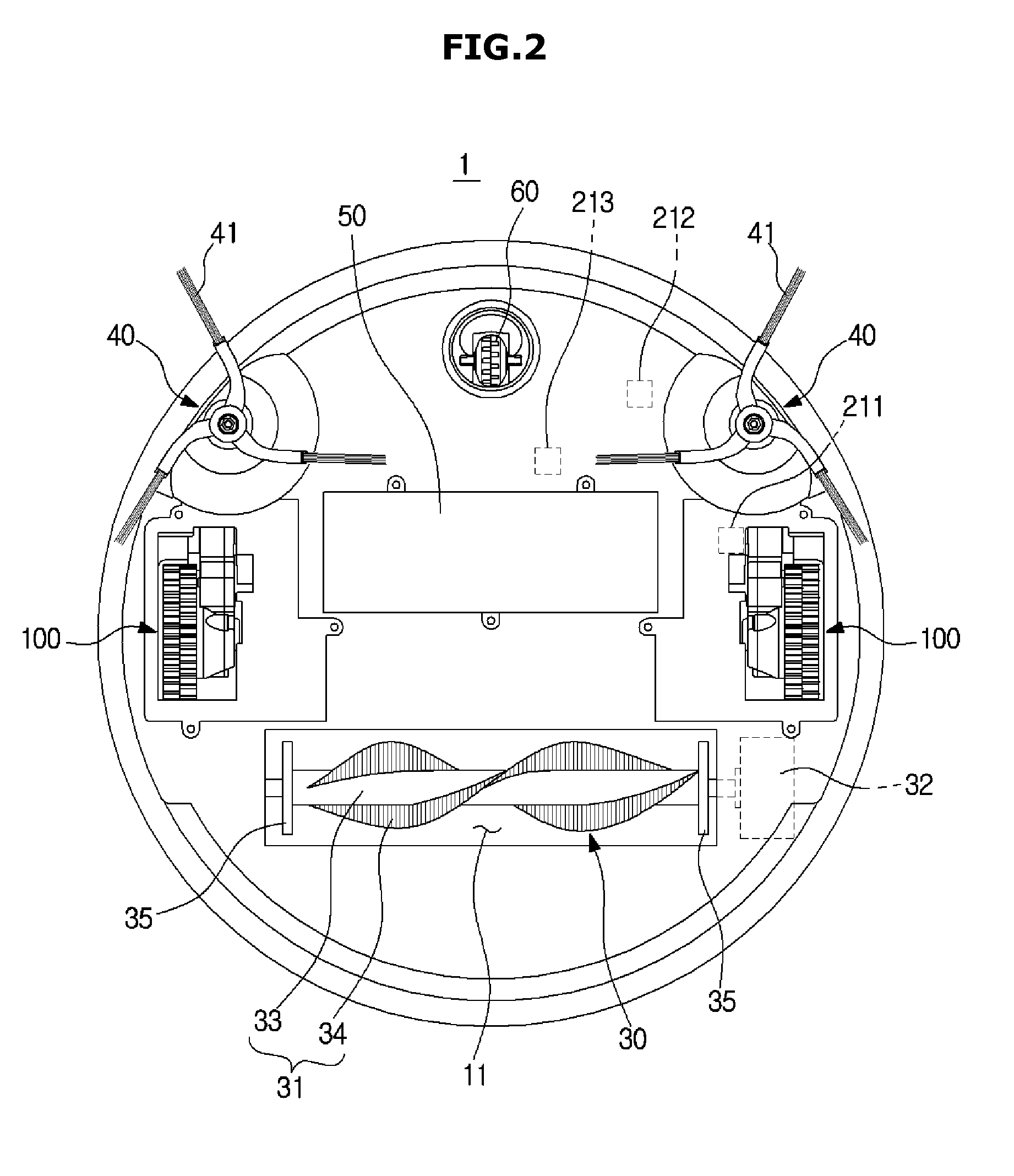

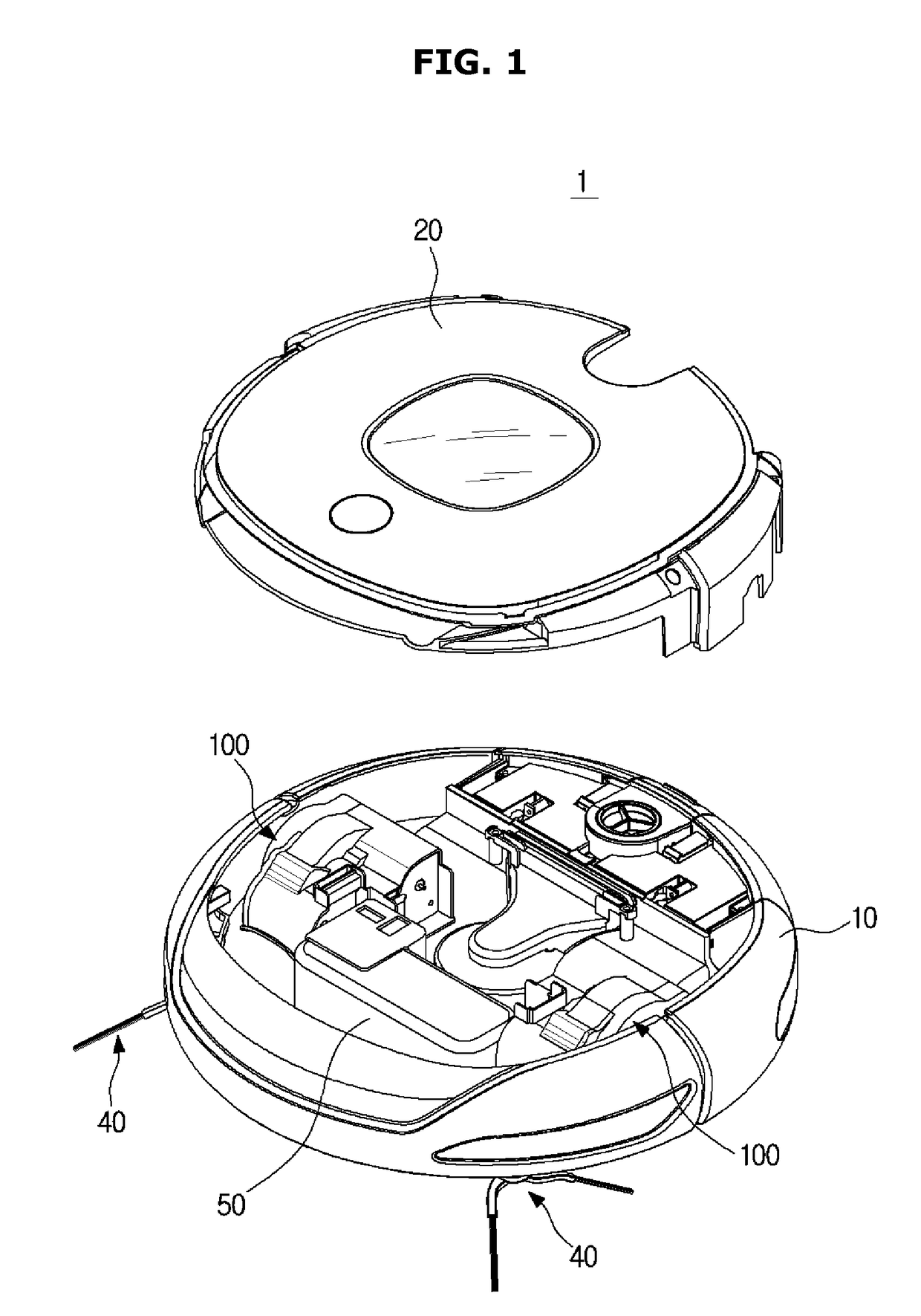

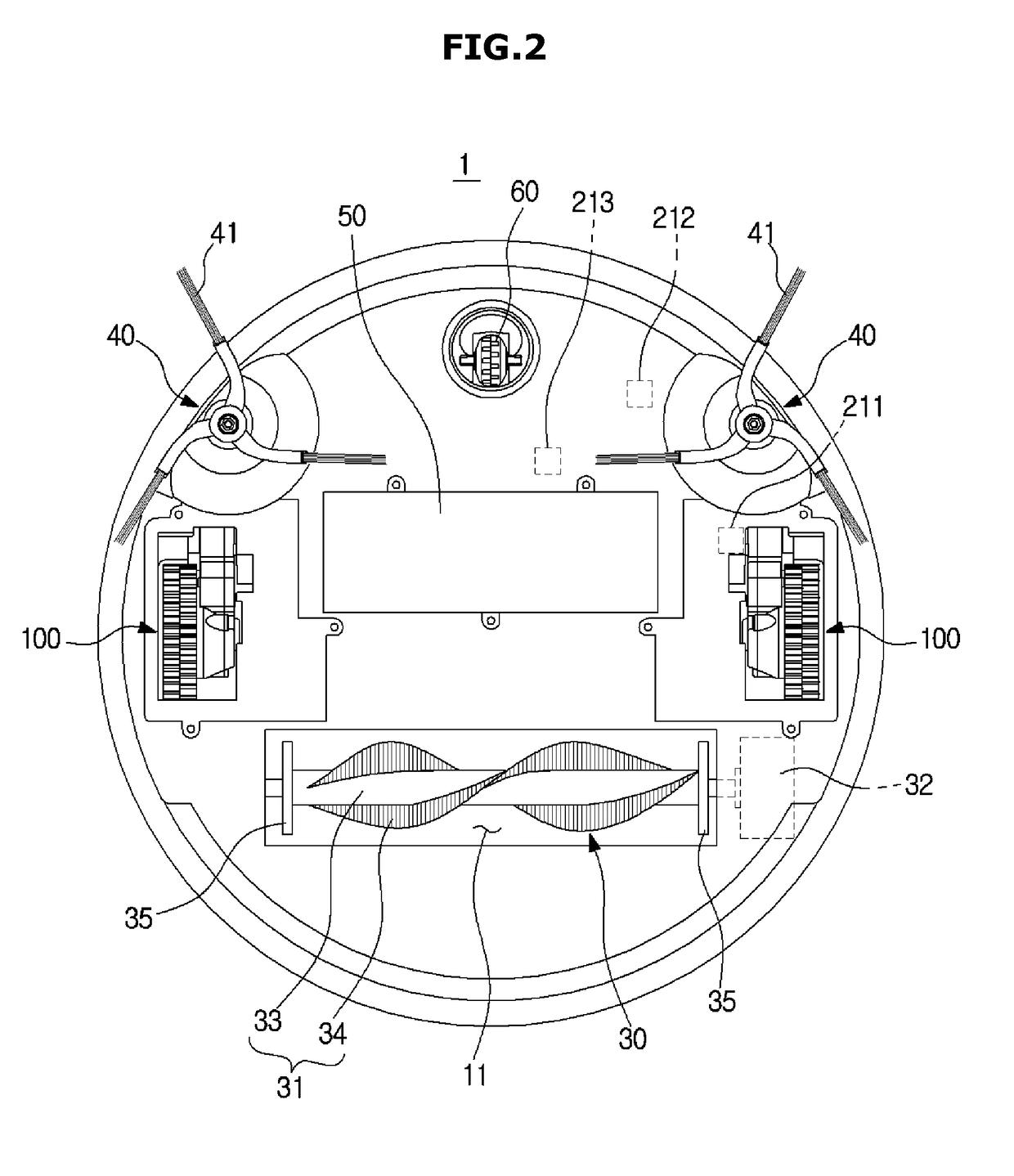

Robot cleaner and control method thereof

ActiveUS20160259336A1Simple structureStable travelSpeed controllerAutonomous decision making processDrive wheelNormal mode

Proposed are a robot cleaner having an improved wheel structure to escape from being stuck in various travel conditions, and a control method thereof. The robot cleaner may smoothly escape from a door sill or an obstacle to stably travel irrespective of a state of a floor by providing an optimal frictional force of the floor through the control of an electric current of a motor when the robot cleaner escapes from being stuck. Also, the robot cleaner may stably travel without shaking by controlling an electric current flowing through the motor after the robot cleaner escapes from being stuck and before the driving wheel returns to a normal mode. Furthermore, it is possible to prevent a wheel mechanism such as a gear from being damaged by an external shock (e.g., which is caused by a pet or an object drop) or a shock caused by autonomous vibration when the robot cleaner crosses over an obstacle.

Owner:SAMSUNG ELECTRONICS CO LTD

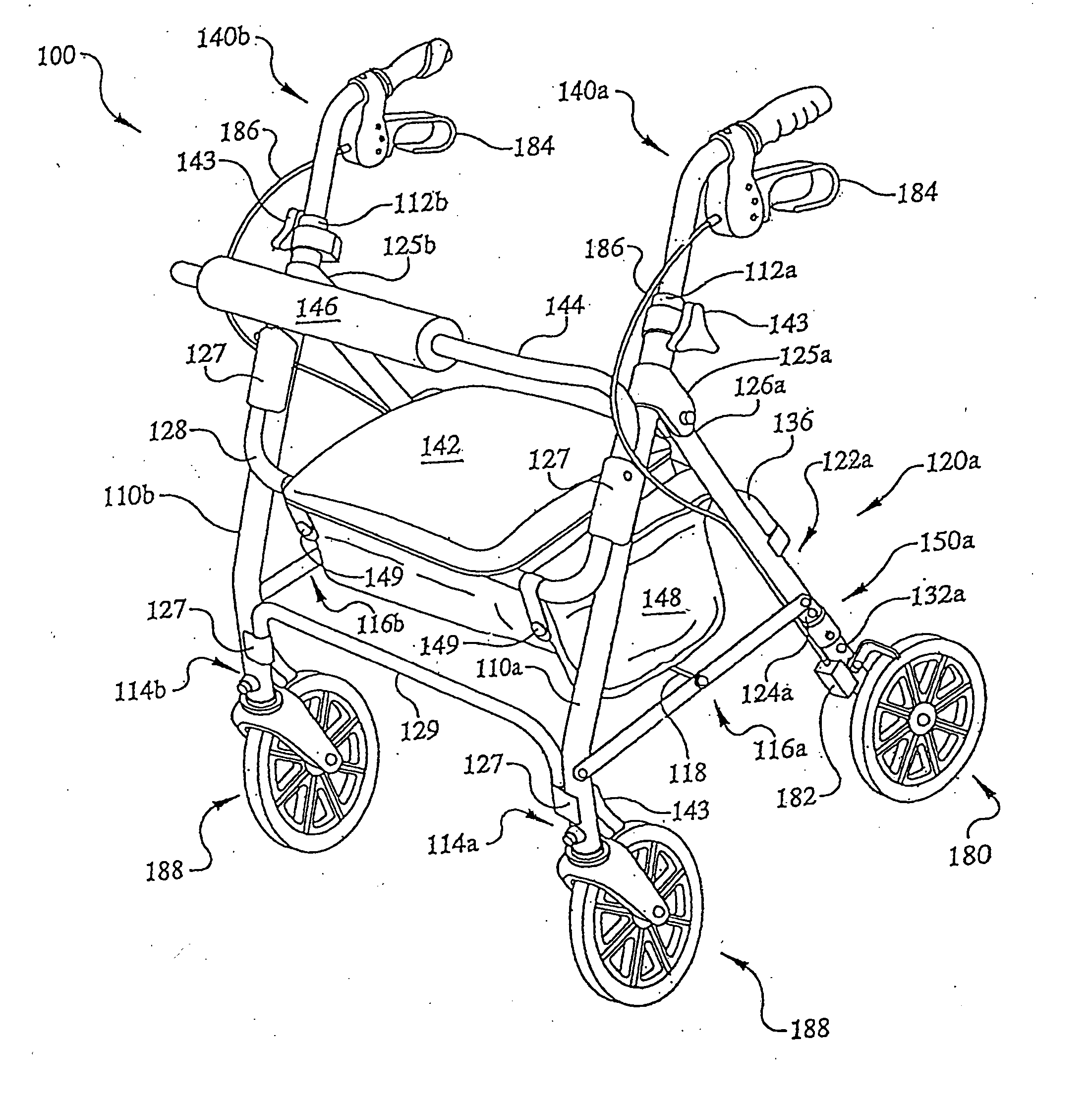

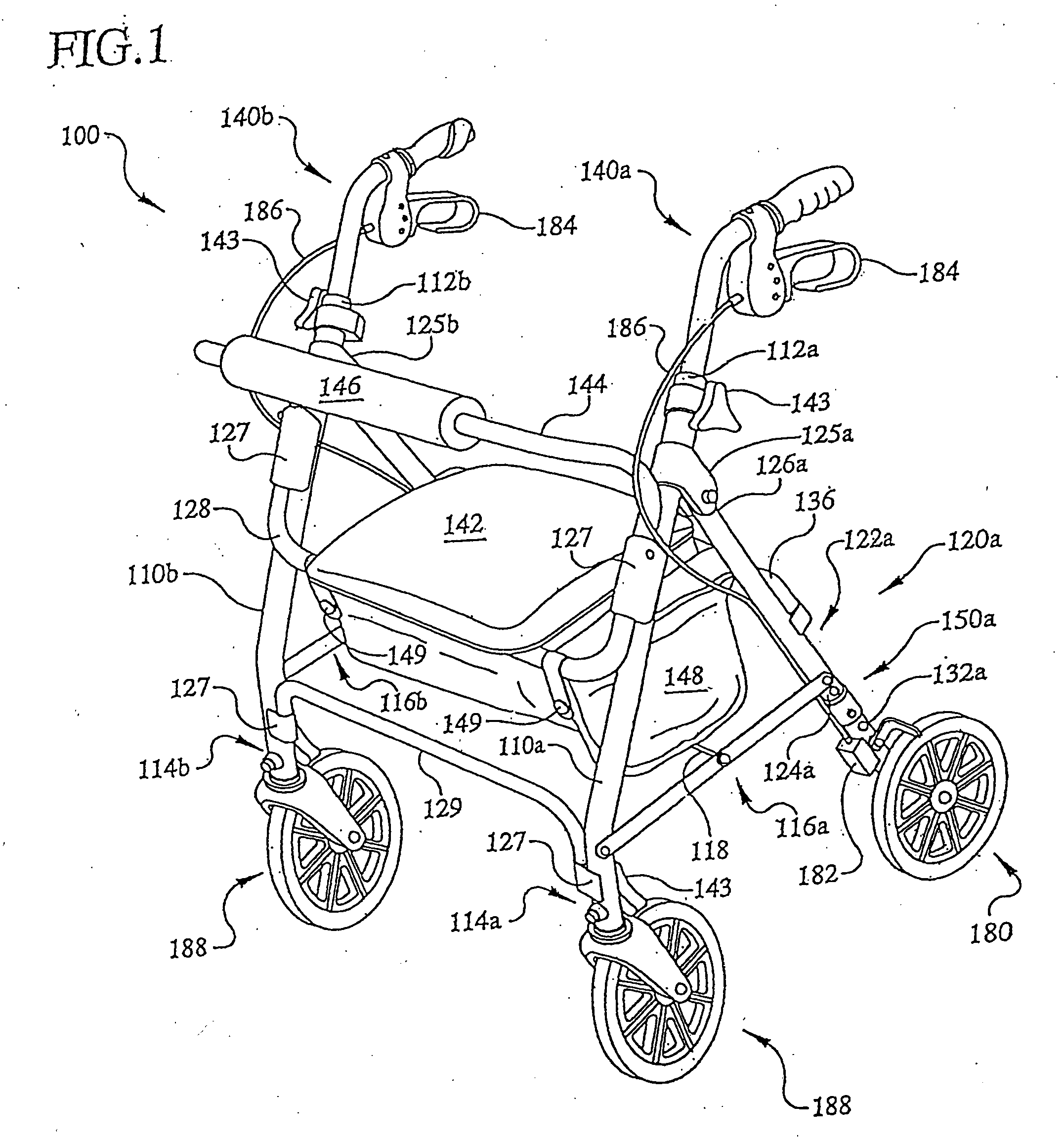

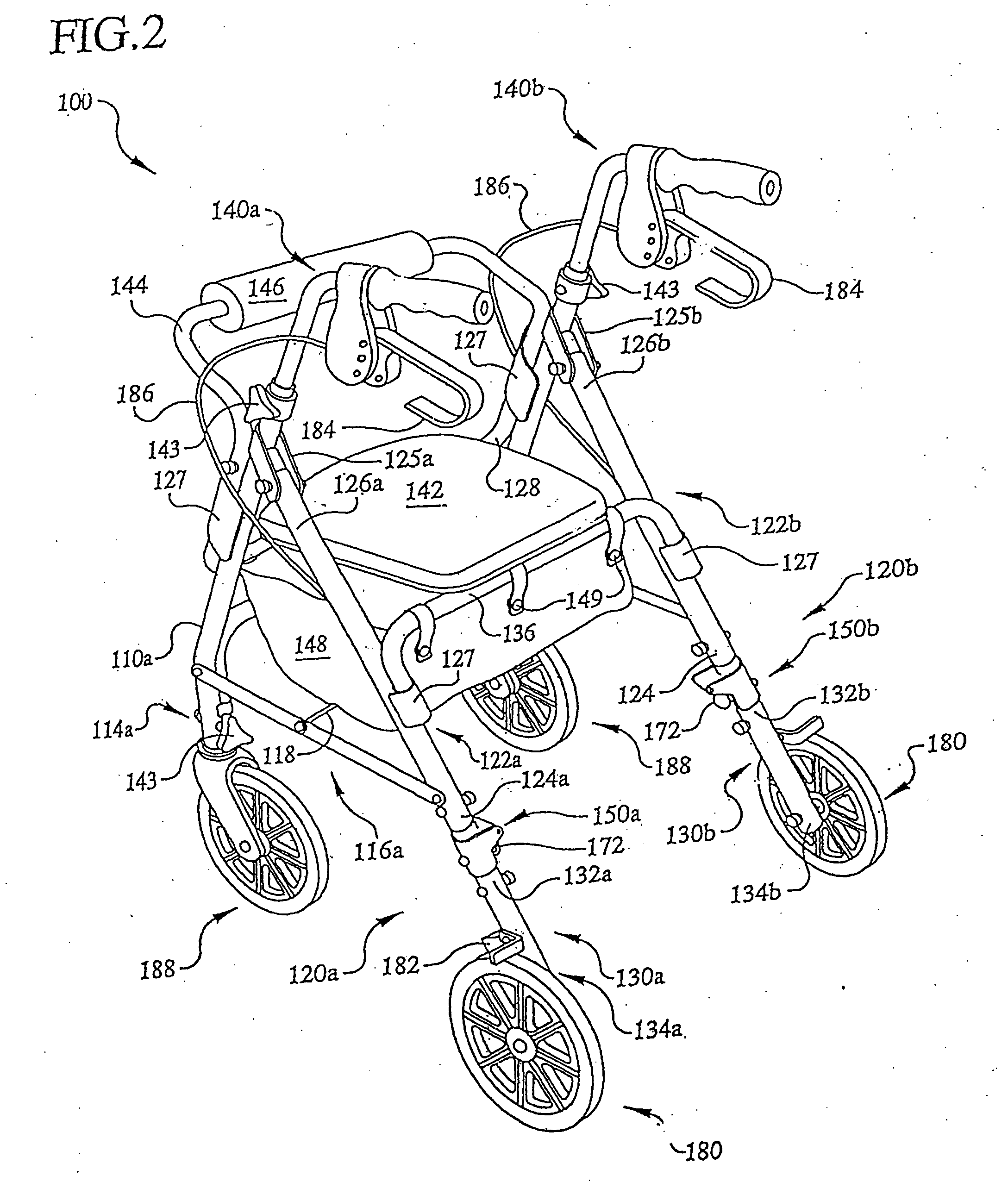

Mobile support assembly

InactiveUS20070096436A1Easy accessImprove versatilityCarriage/perambulator accessoriesWalking aidsEngineering

Owner:DRIVE MEDICAL CANADA INC

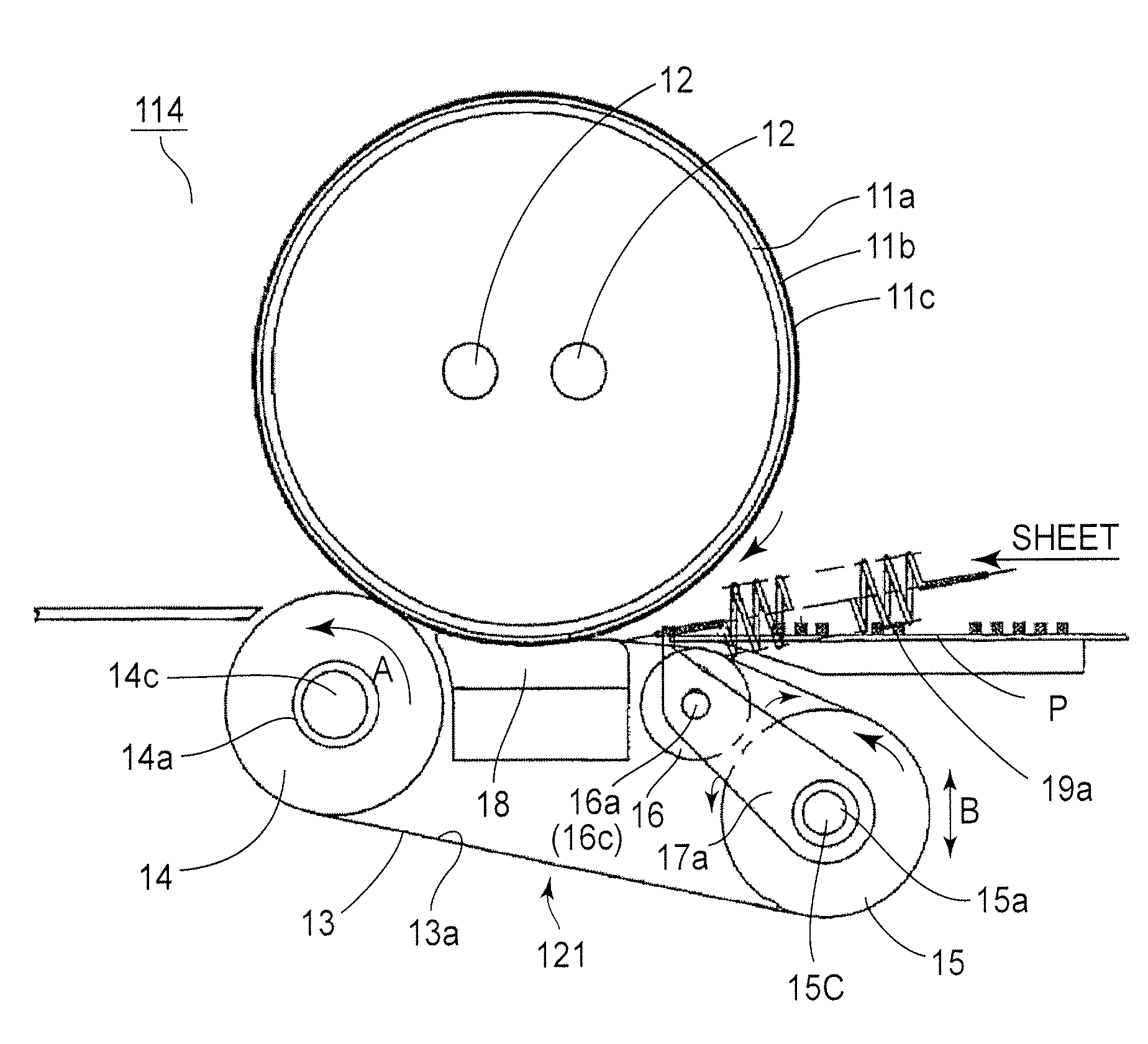

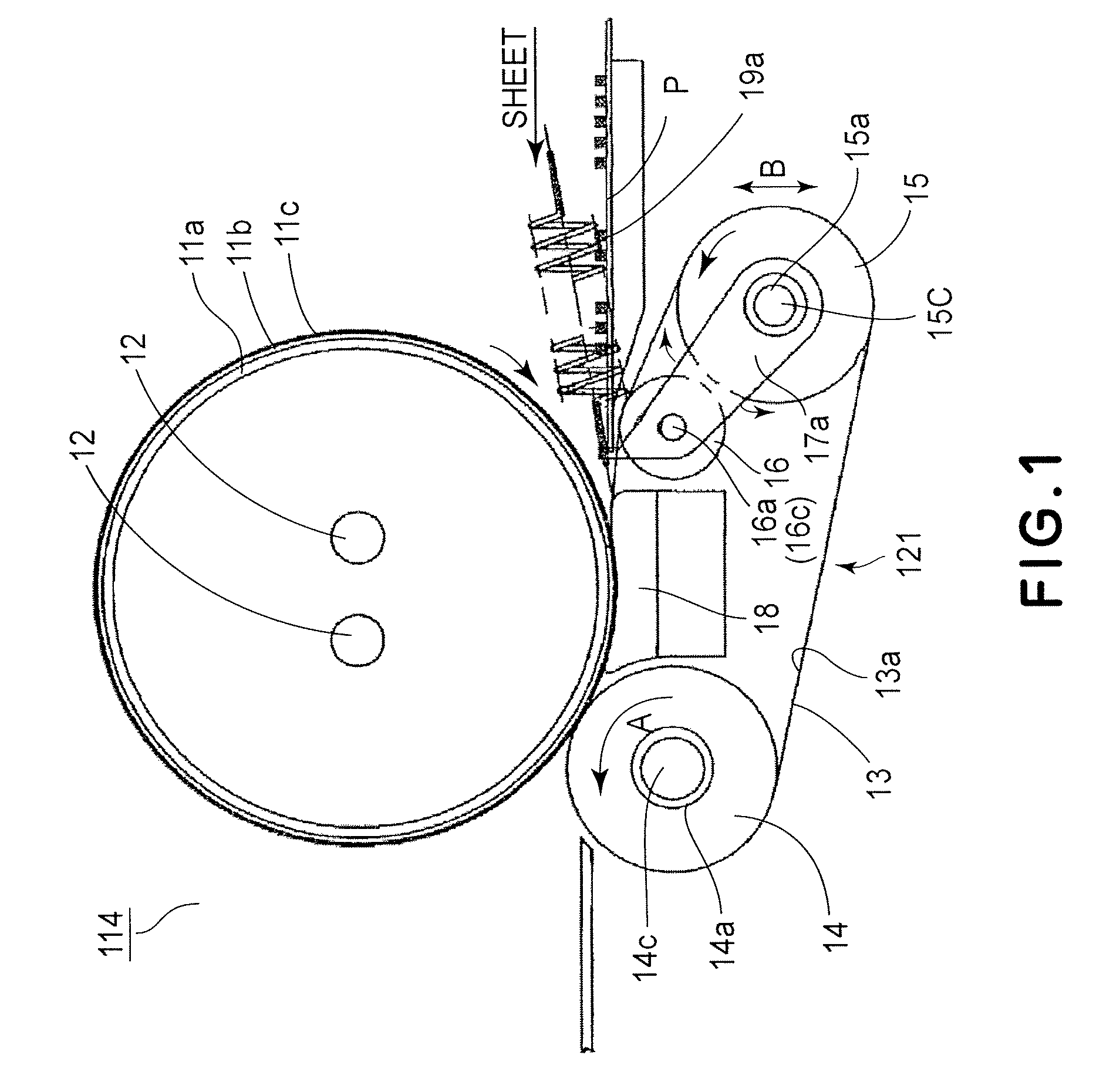

Image heating apparatus and image forming apparatus with displacing members for displacing other members of the apparatuses

ActiveUS7546078B2Stable travelPrecise applicationElectrographic process apparatusEngineeringLubricant

An image heating apparatus includes an endless belt for heating an image on a recording material at a nip; a pressing pad for pressing the belt at the nip; a supporting member for supporting the belt at an inner surface thereof, the supporting member being displaceable to move the belt in a widthwise direction of the belt; a lubricant application member for applying lubricant onto the inner surface of the belt; and displacing means for displacing the lubricant application member in accordance with a displacement of the supporting member.

Owner:CANON KK

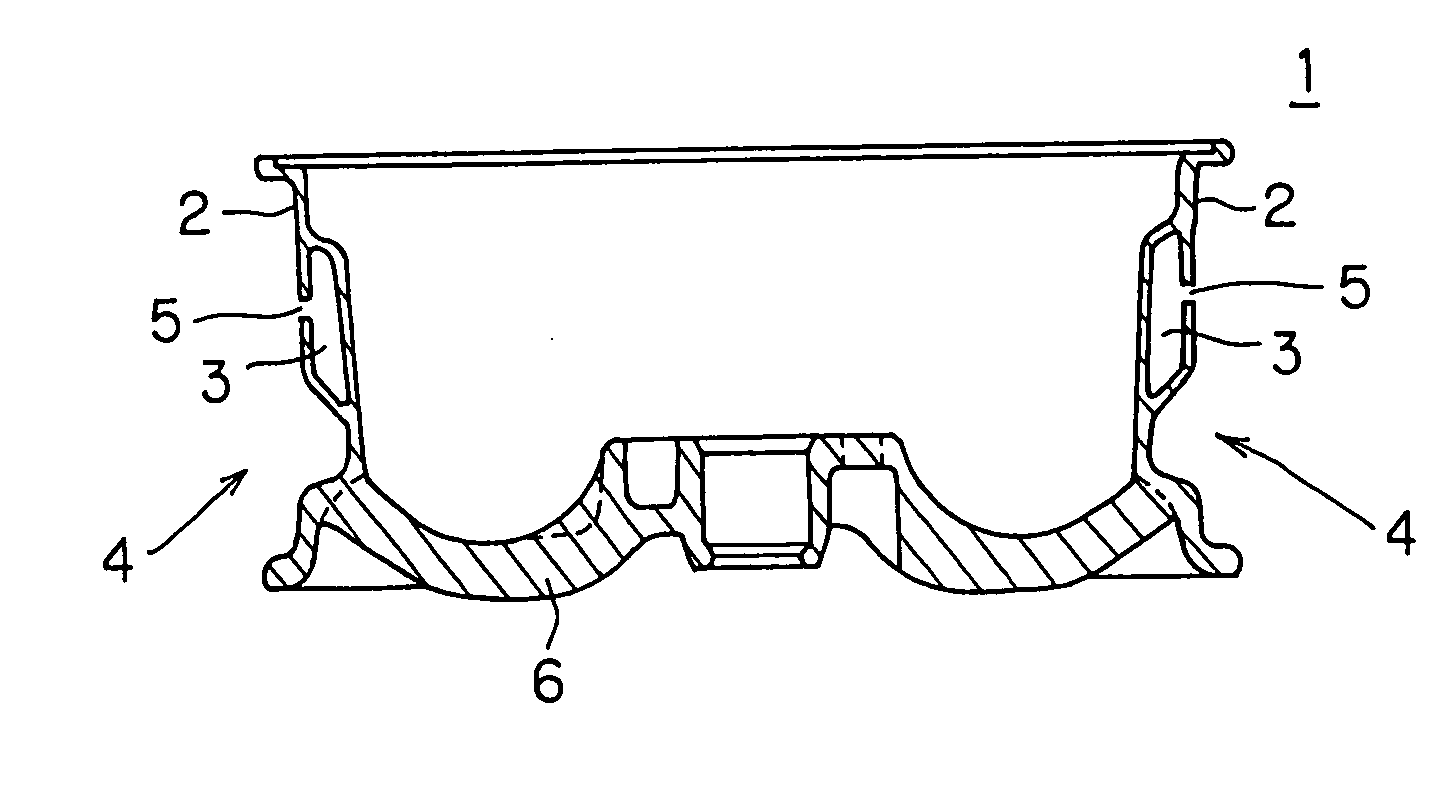

Vehicle wheel and manufacturing method of the same

InactiveUS20050212350A1High mechanical strengthSmooth rideRimsFoundry mouldsEngineeringAutomotive engineering

A vehicle wheel includes a rim for mounting a tire thereon and at least one hollow air chamber provided inside the rim, and the rim having the air chamber is integrally cast so as to have the vehicle wheel having the rim with an excellent mechanical strength and achieving stable traveling.

Owner:ASAHI TEC CORP +1

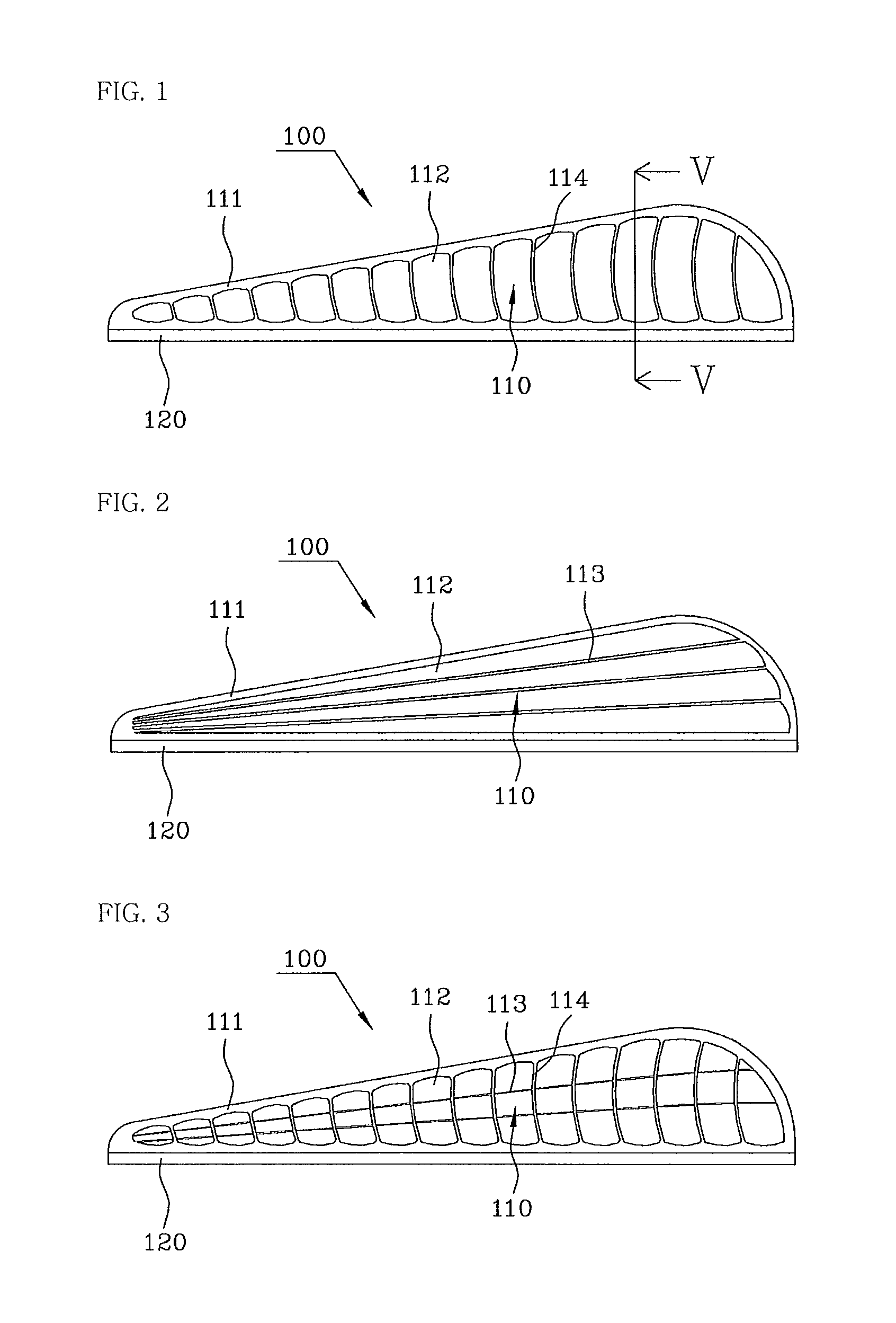

Fletching for arrow

Disclosed herein is fletching for an arrow, which is light and displays sufficient air resistance, thus ensuring the linear travel and stability of the flight of the arrow, being easy to attach to a shaft, and reliably maintaining the shape of the fletching. The fletching includes a wing part and an adhesive part. The wing part includes a frame formed such that an inside portion of an outer edge thereof is open and defining an overall structure, a plurality of vertical ribs connecting upper and lower portions of the frame to each other and arranged to be spaced apart from each other in a longitudinal direction of the frame, and a thin film provided in an empty space defined by the frame and each of the vertical ribs. The adhesive part is provided on the lower end of the wing part and attached to a shaft.

Owner:SONG JIN HEE

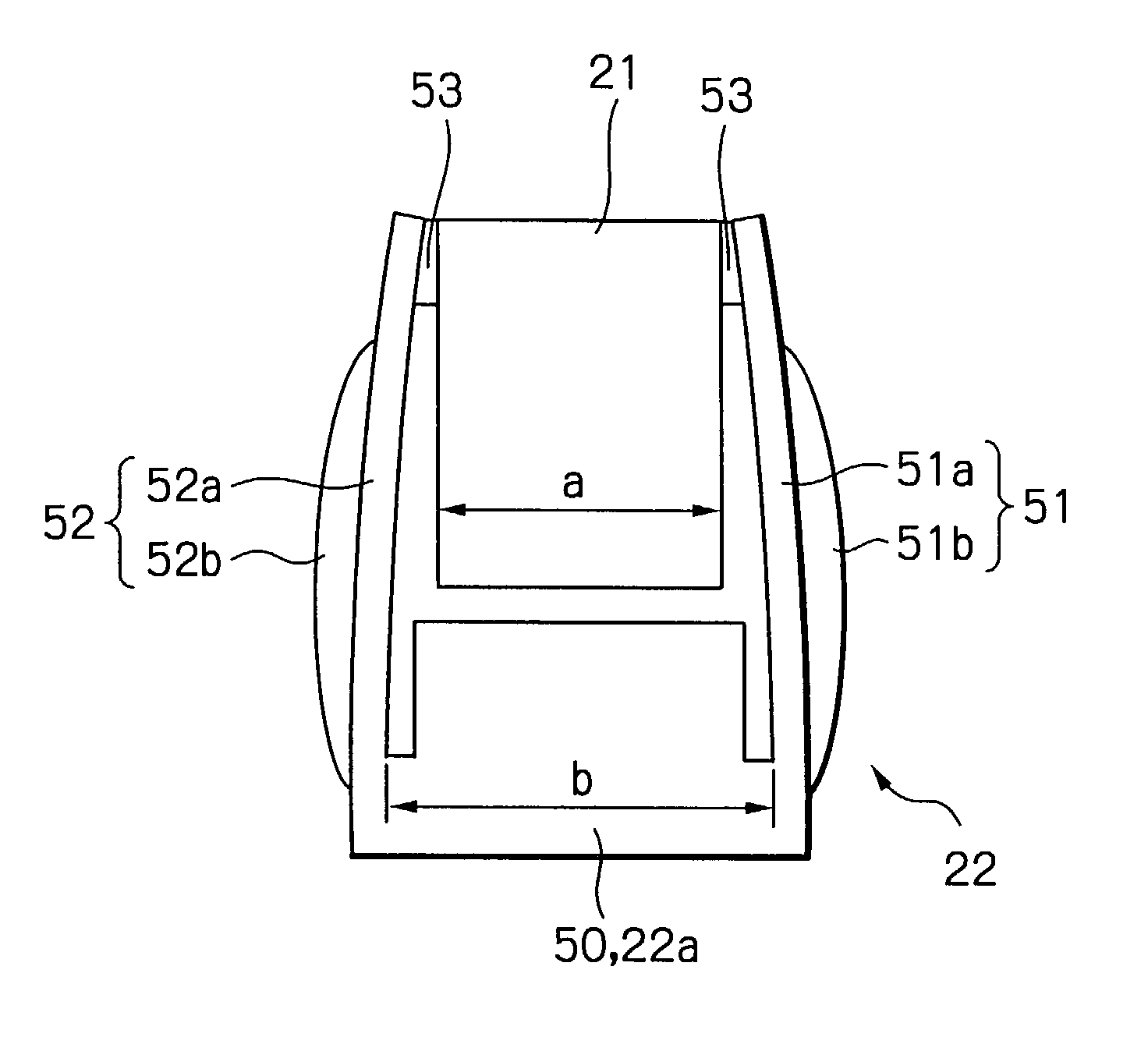

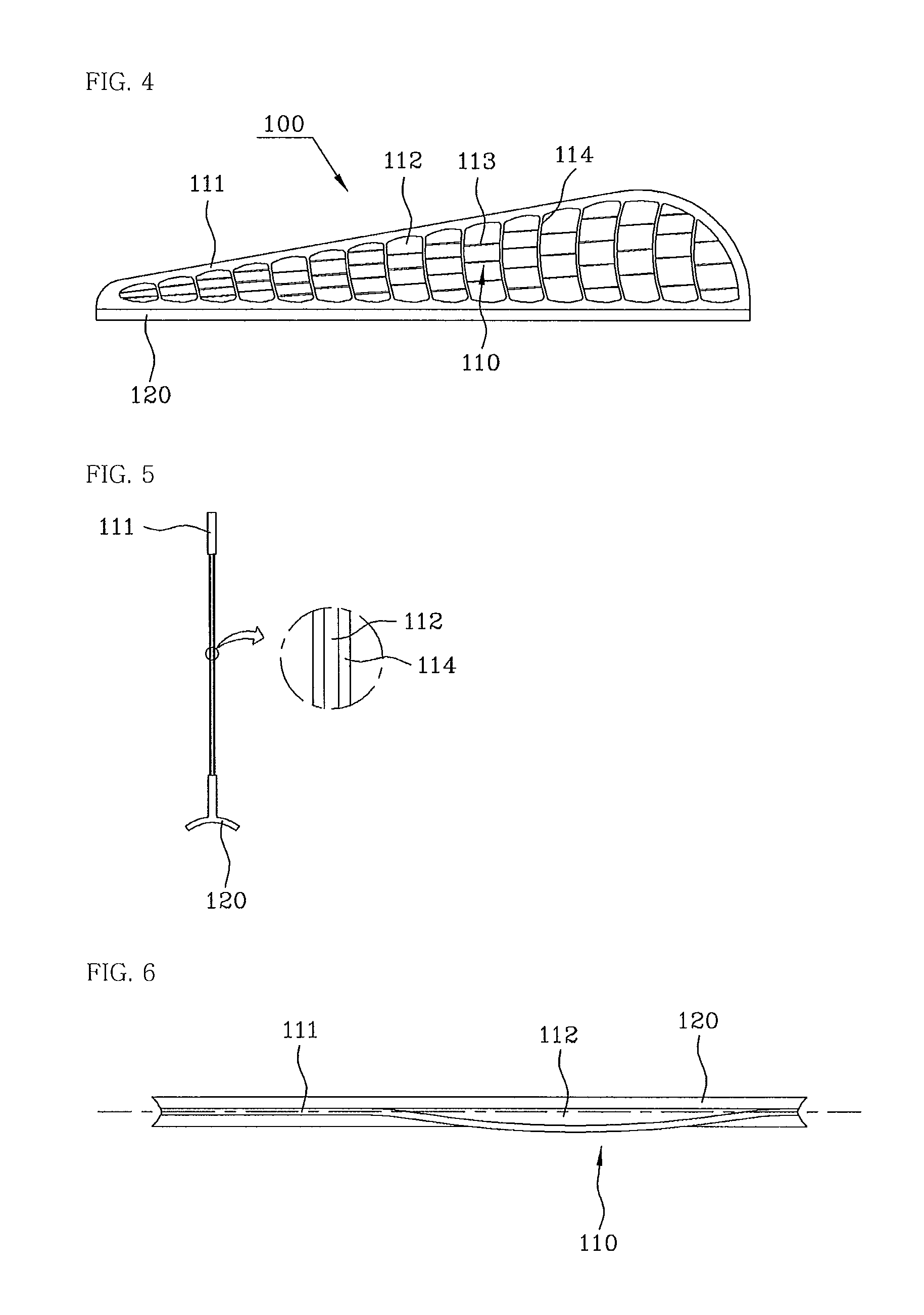

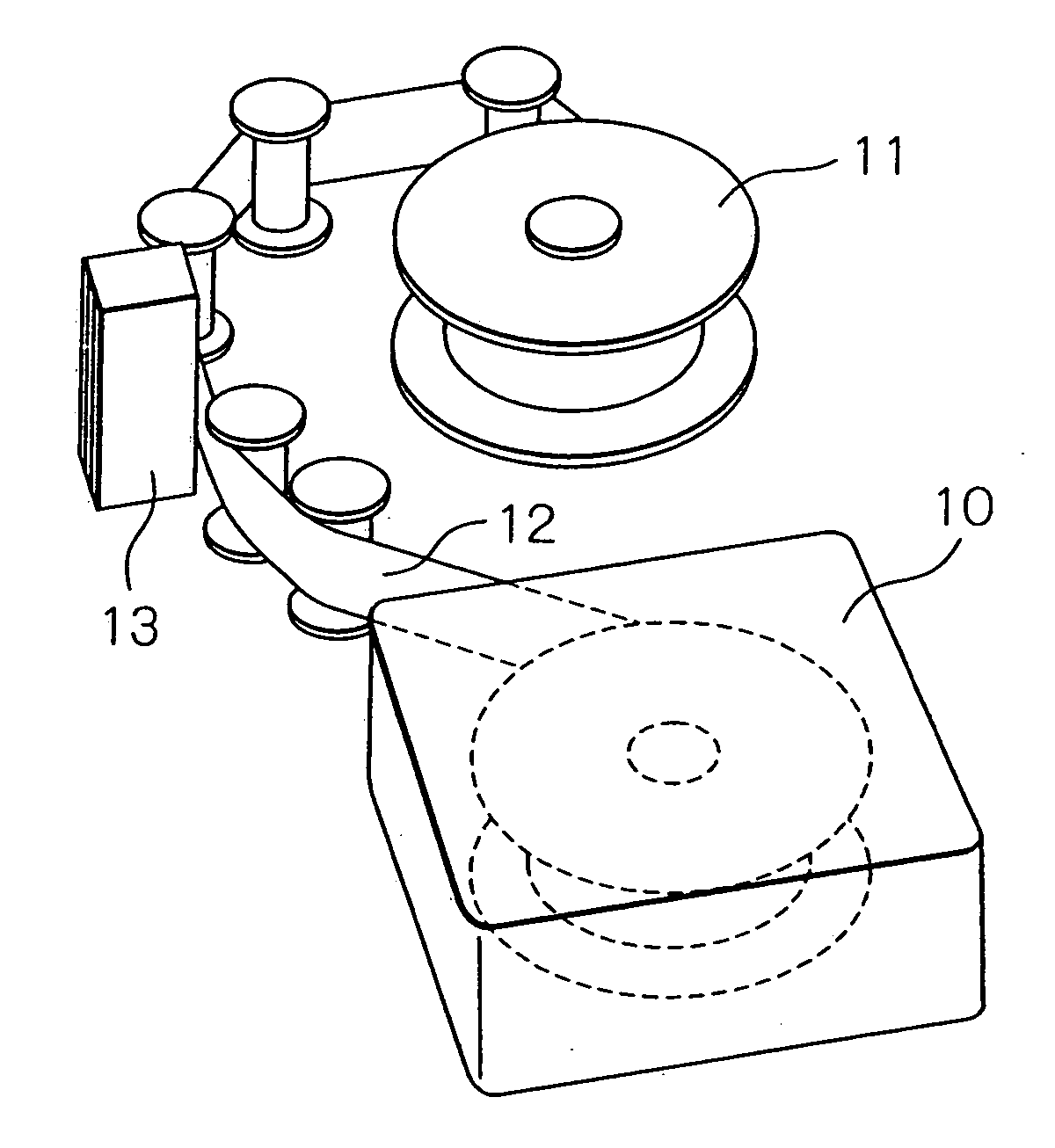

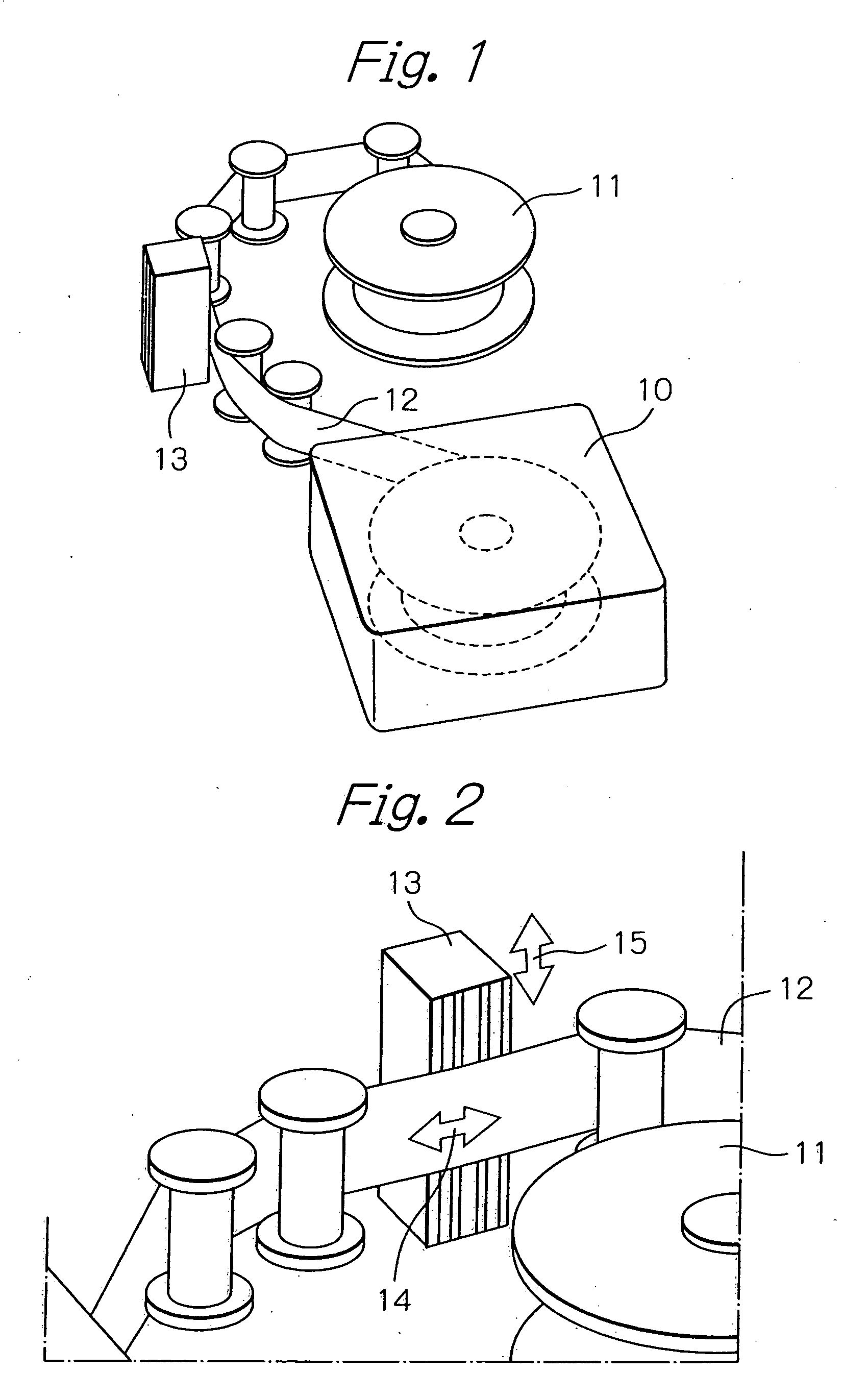

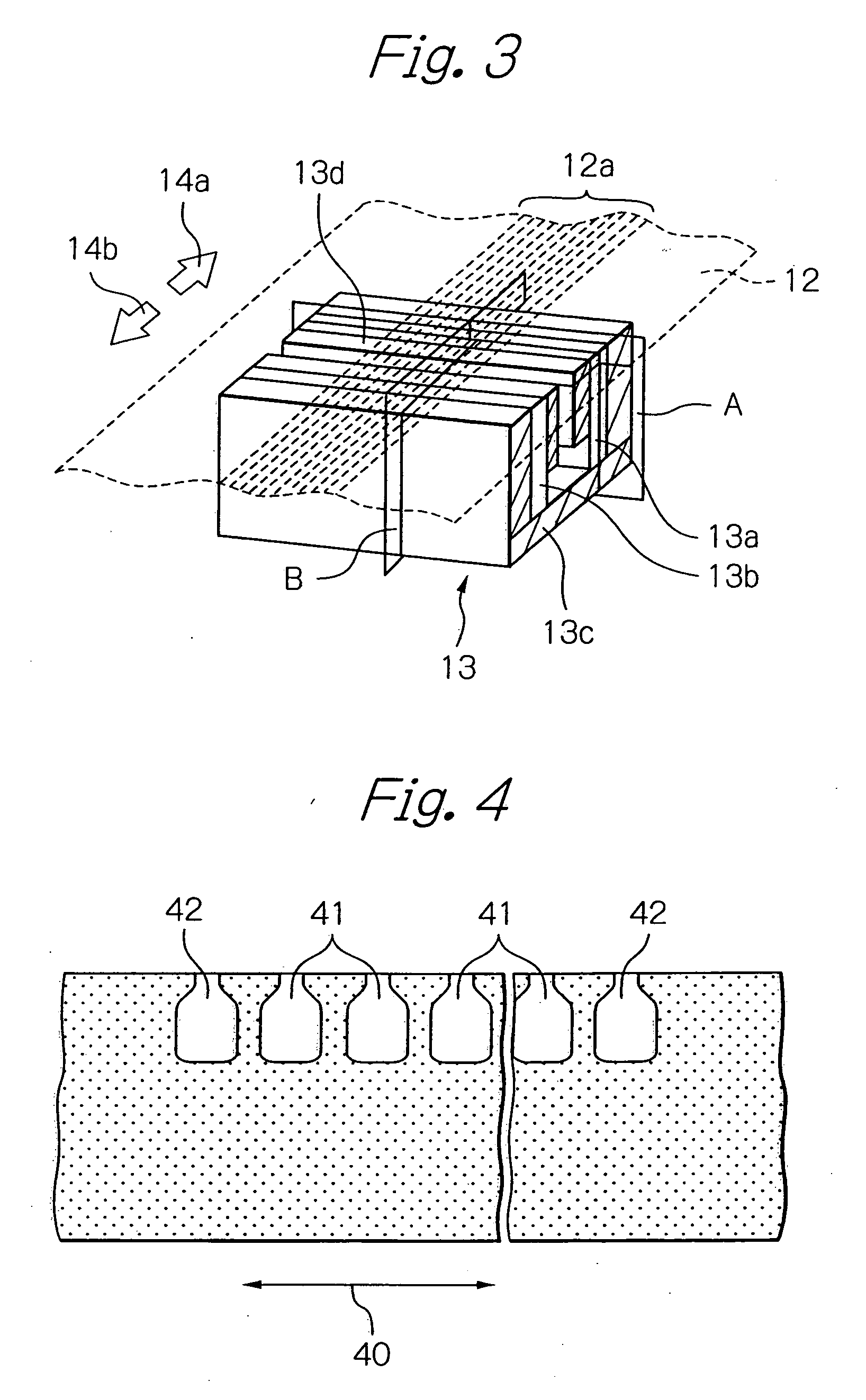

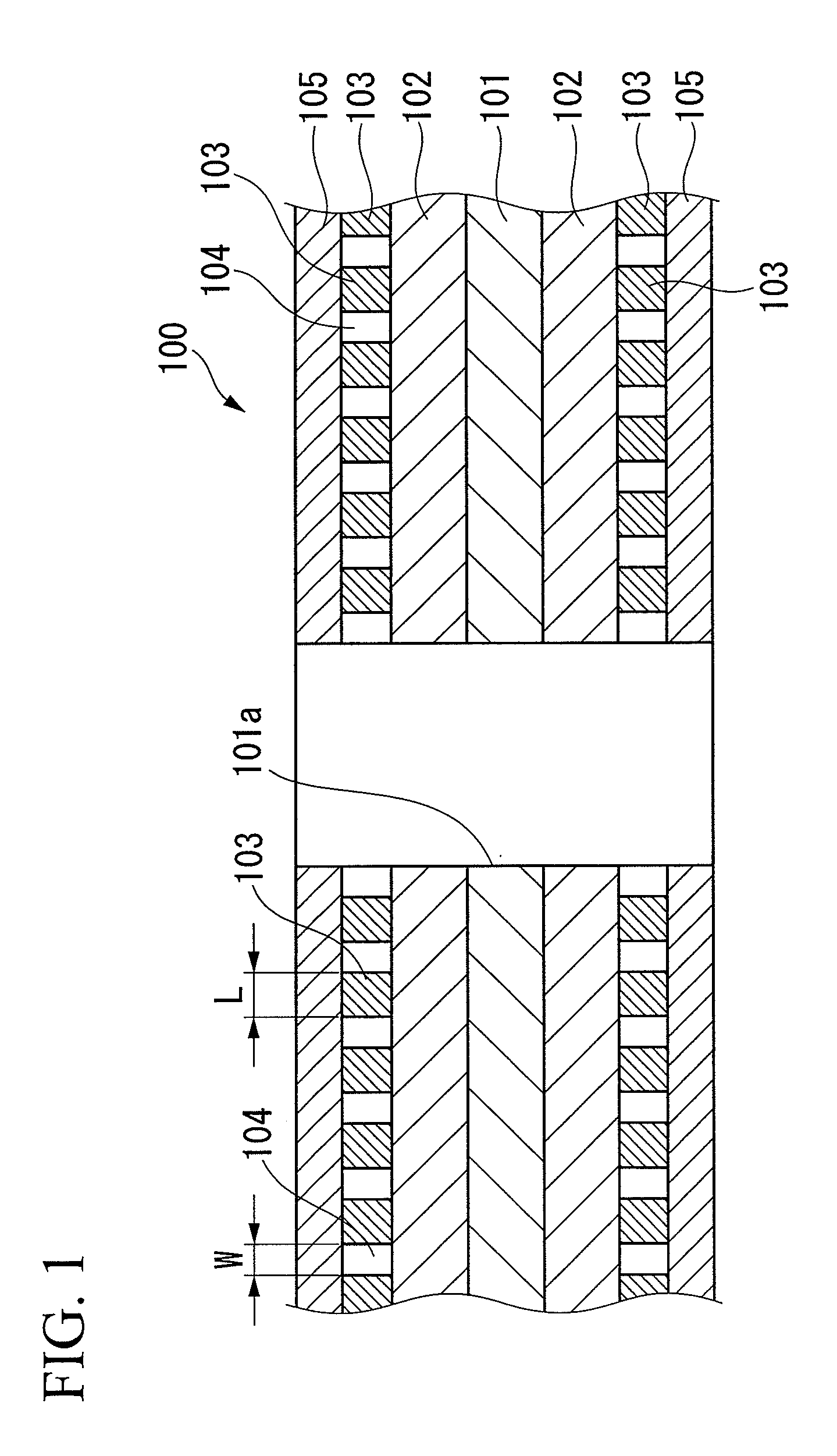

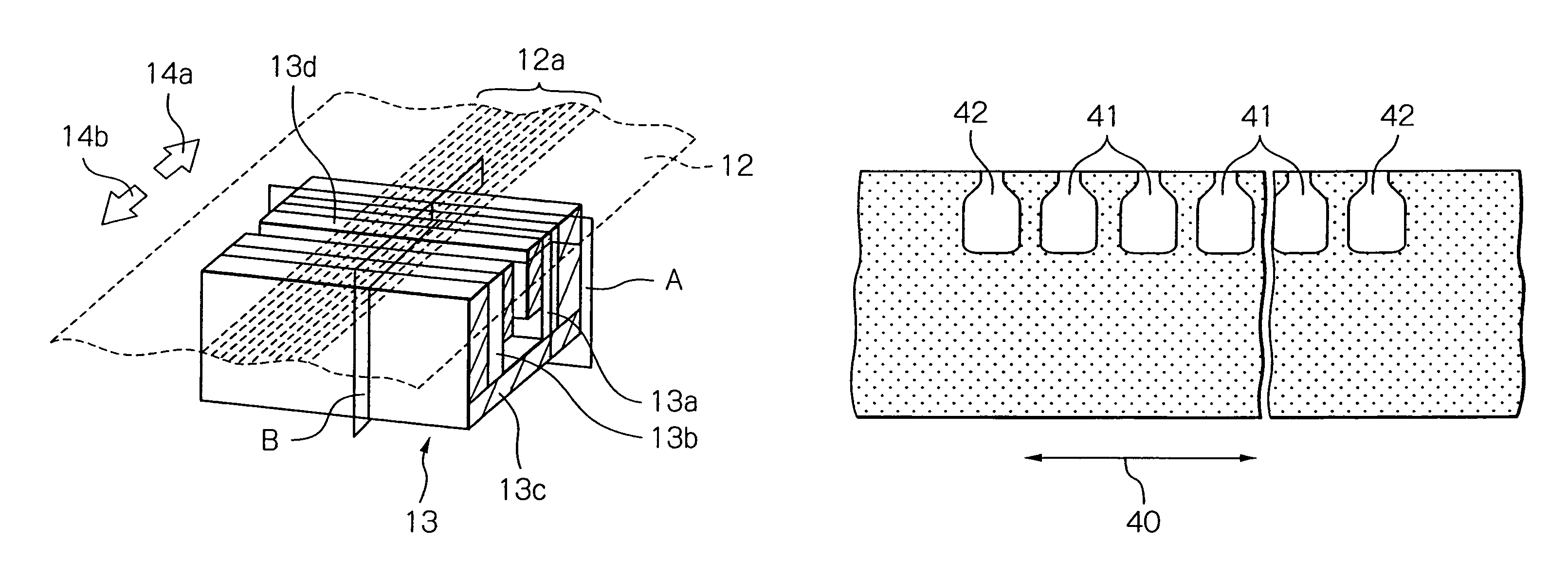

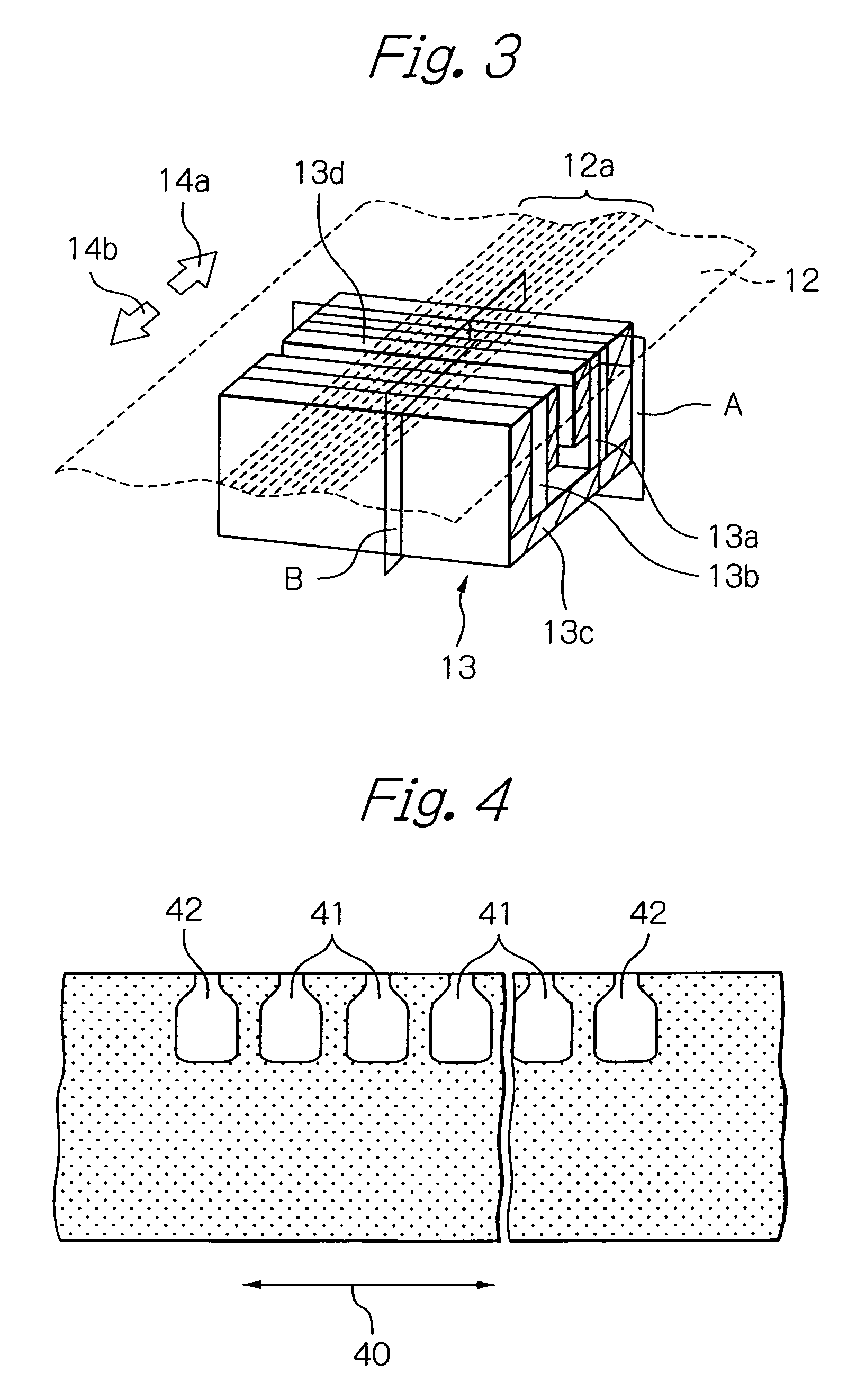

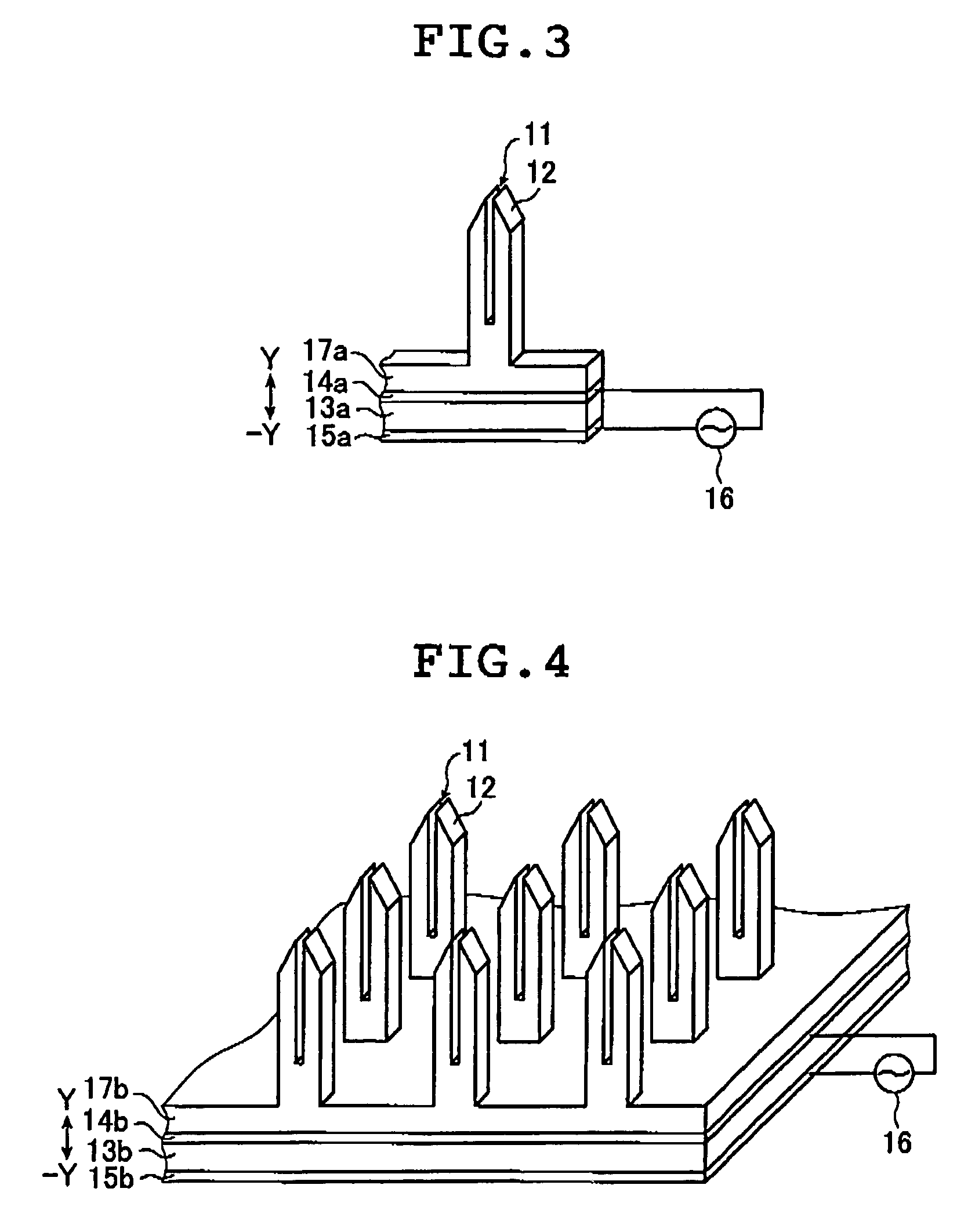

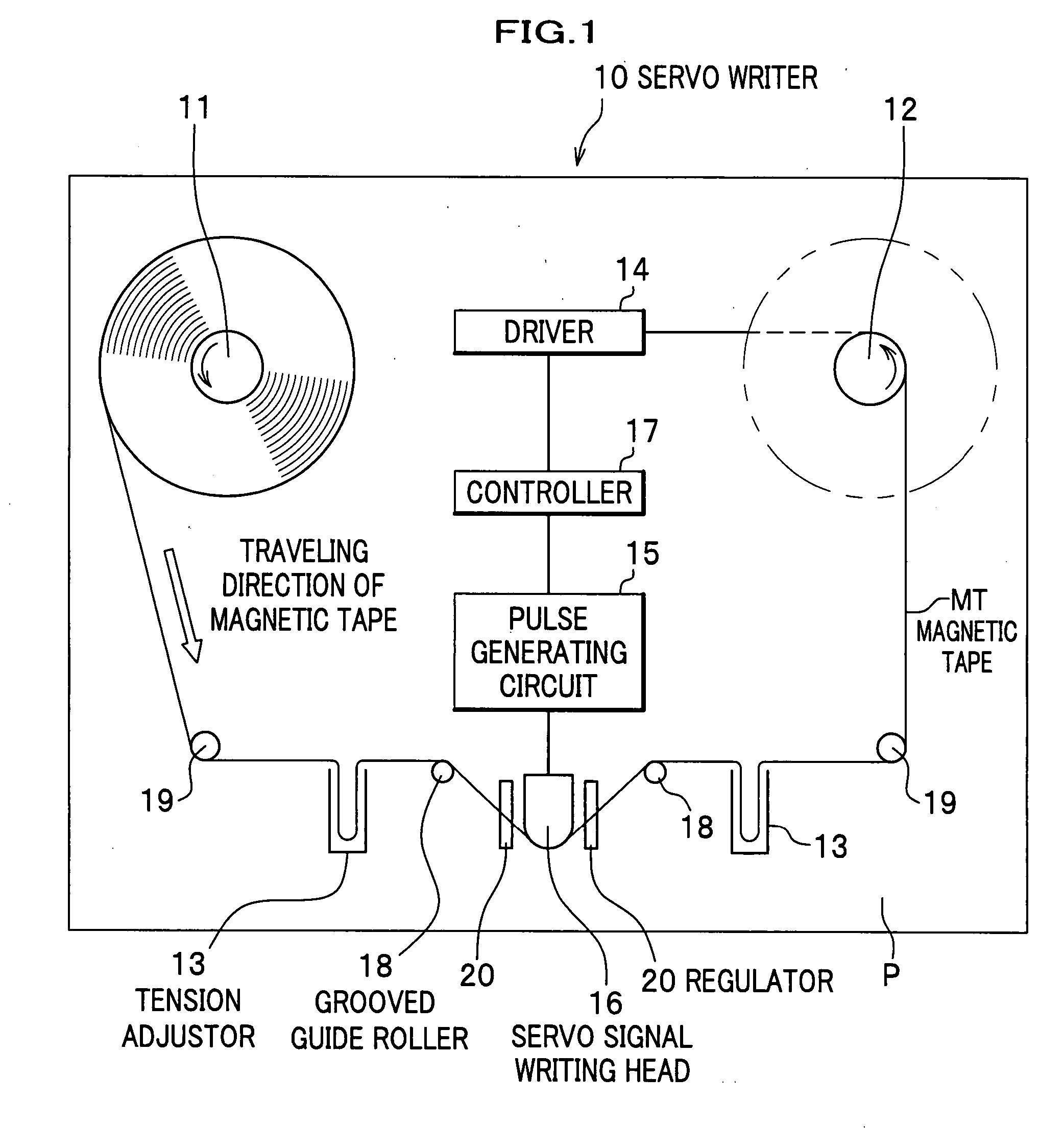

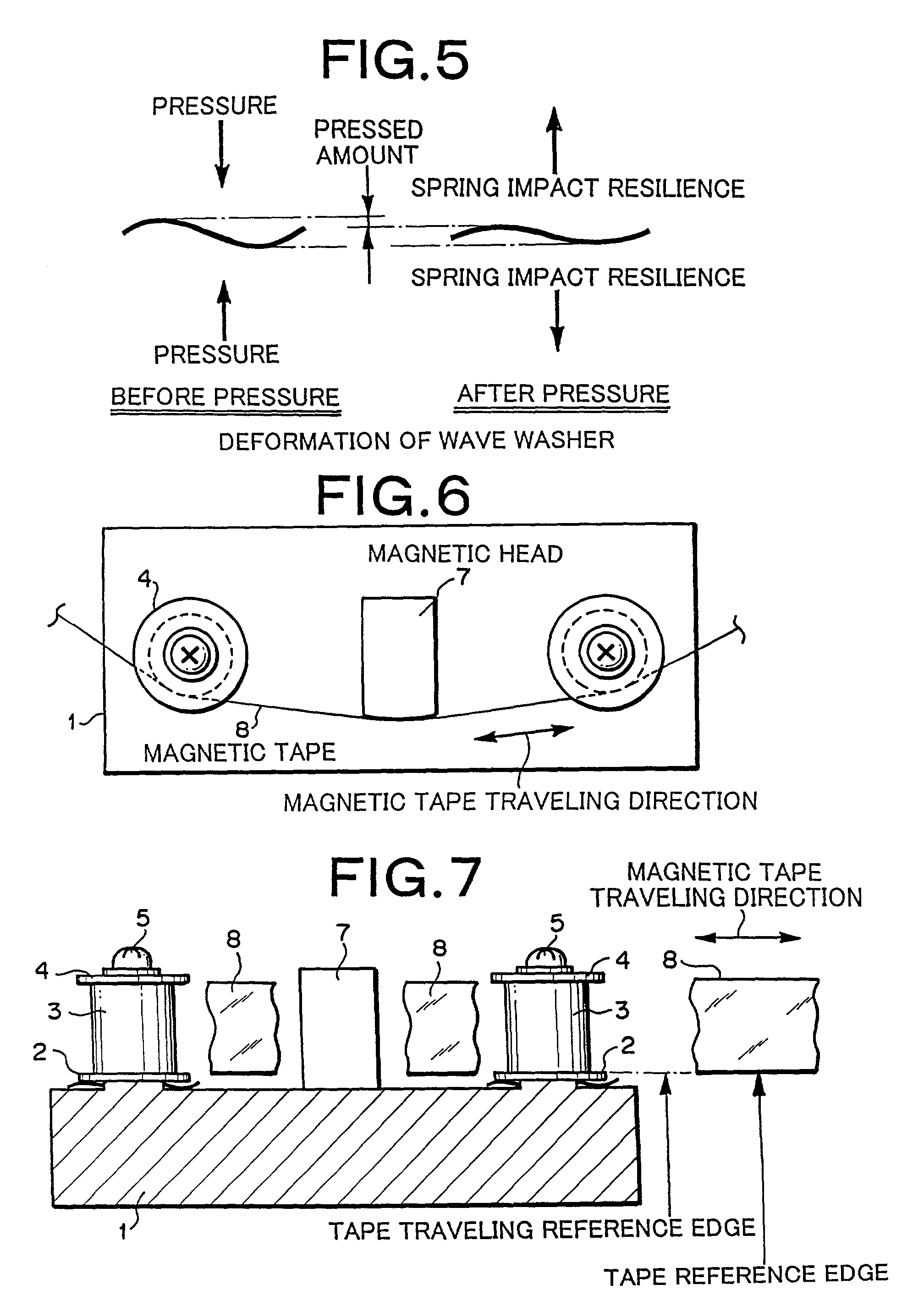

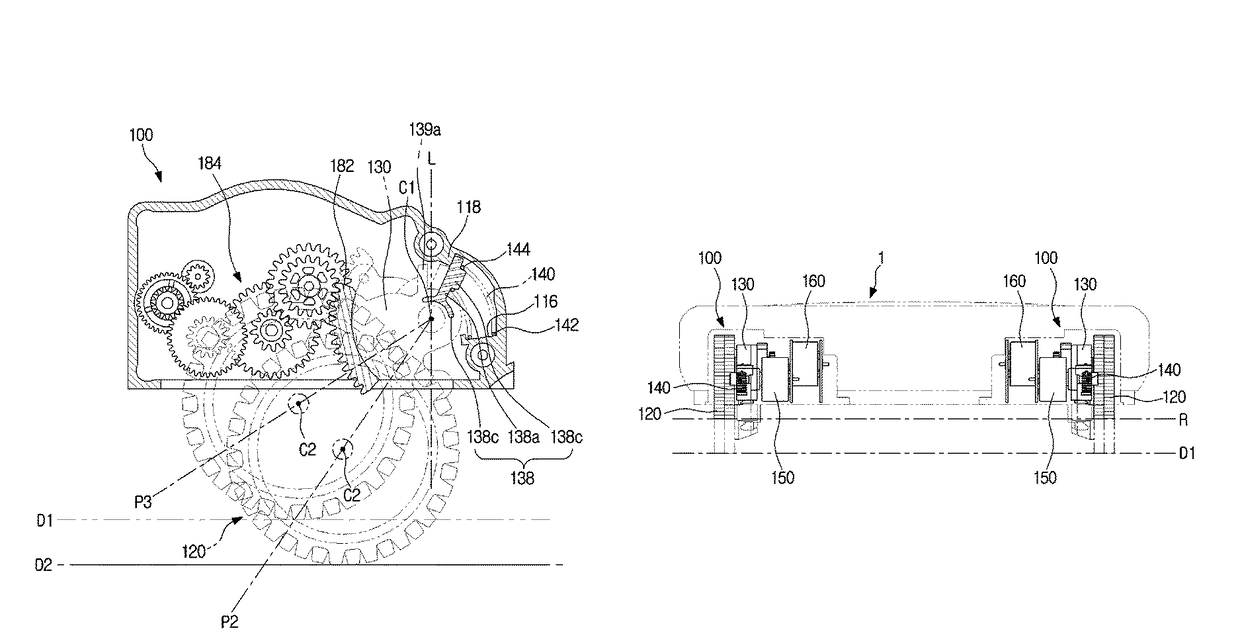

Multi-channel thin-film magnetic head, magnetic tape drive apparatus with the multi-channel thin-film magnetic head and manufacturing method of multi-channel thin-film magnetic head

InactiveUS20100149685A1Smooth rideStable travelManufacturing heads with multiple gapsDecorative surface effectsTectorial membraneMagnetic tape

Owner:TDK CORPARATION

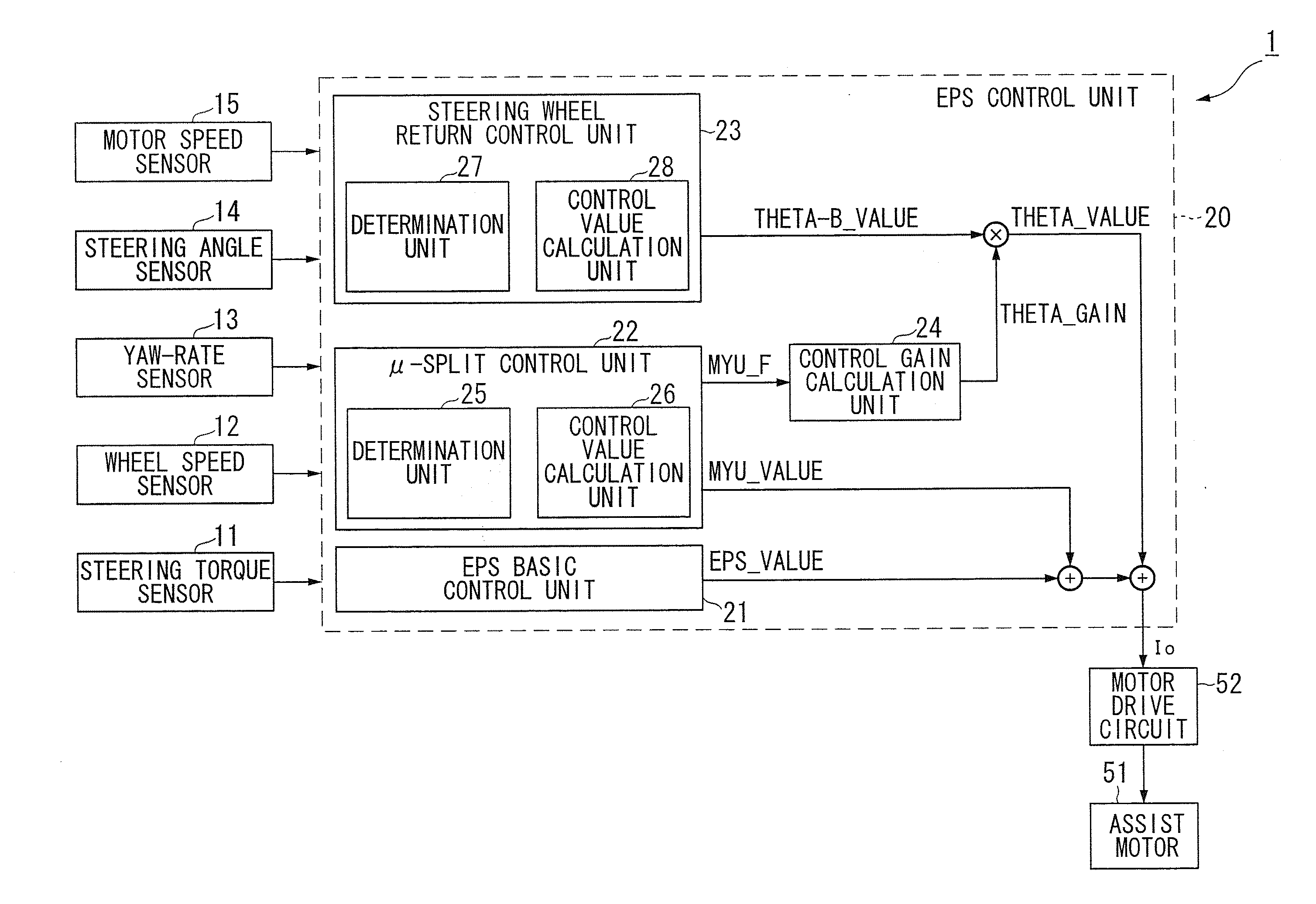

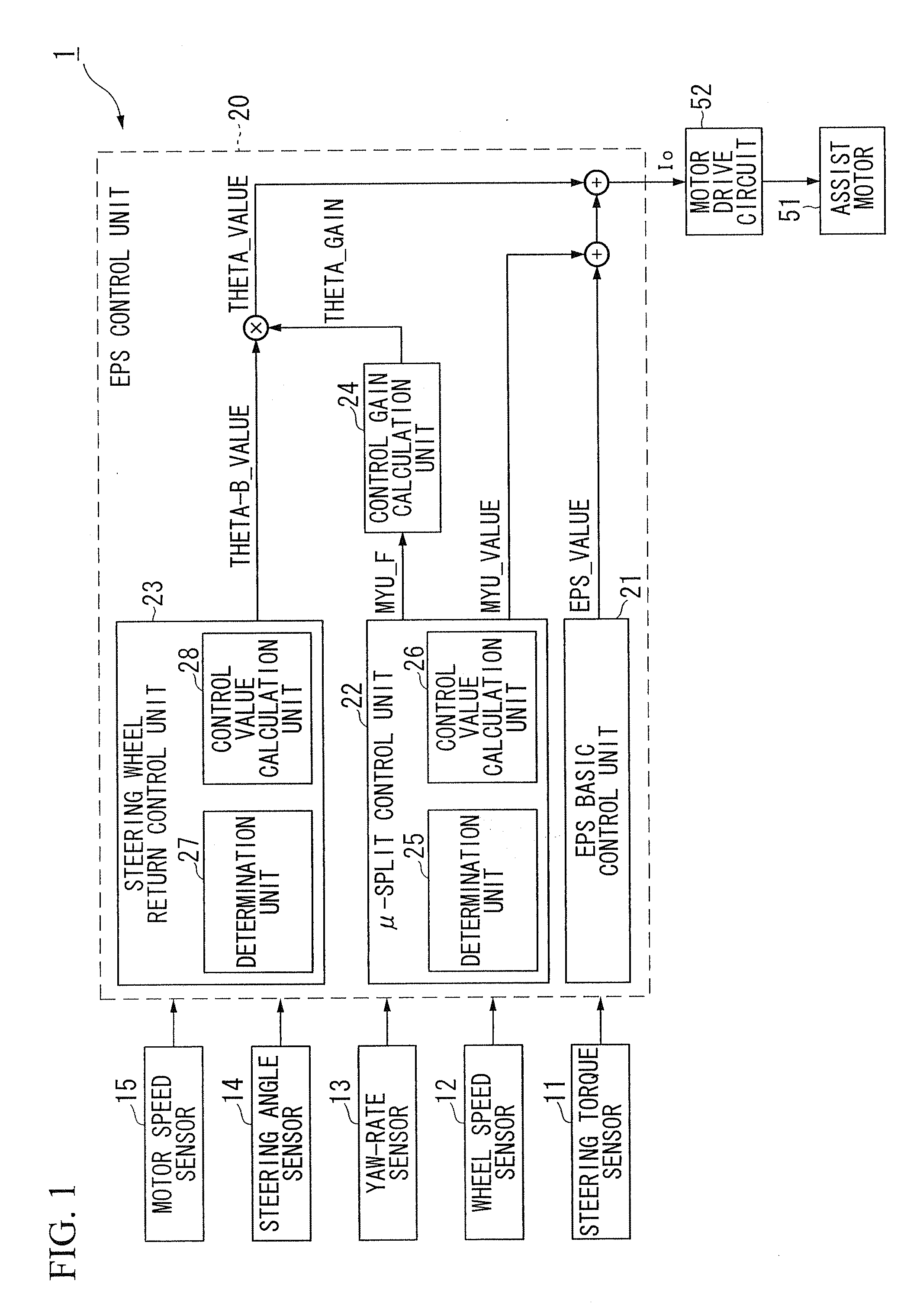

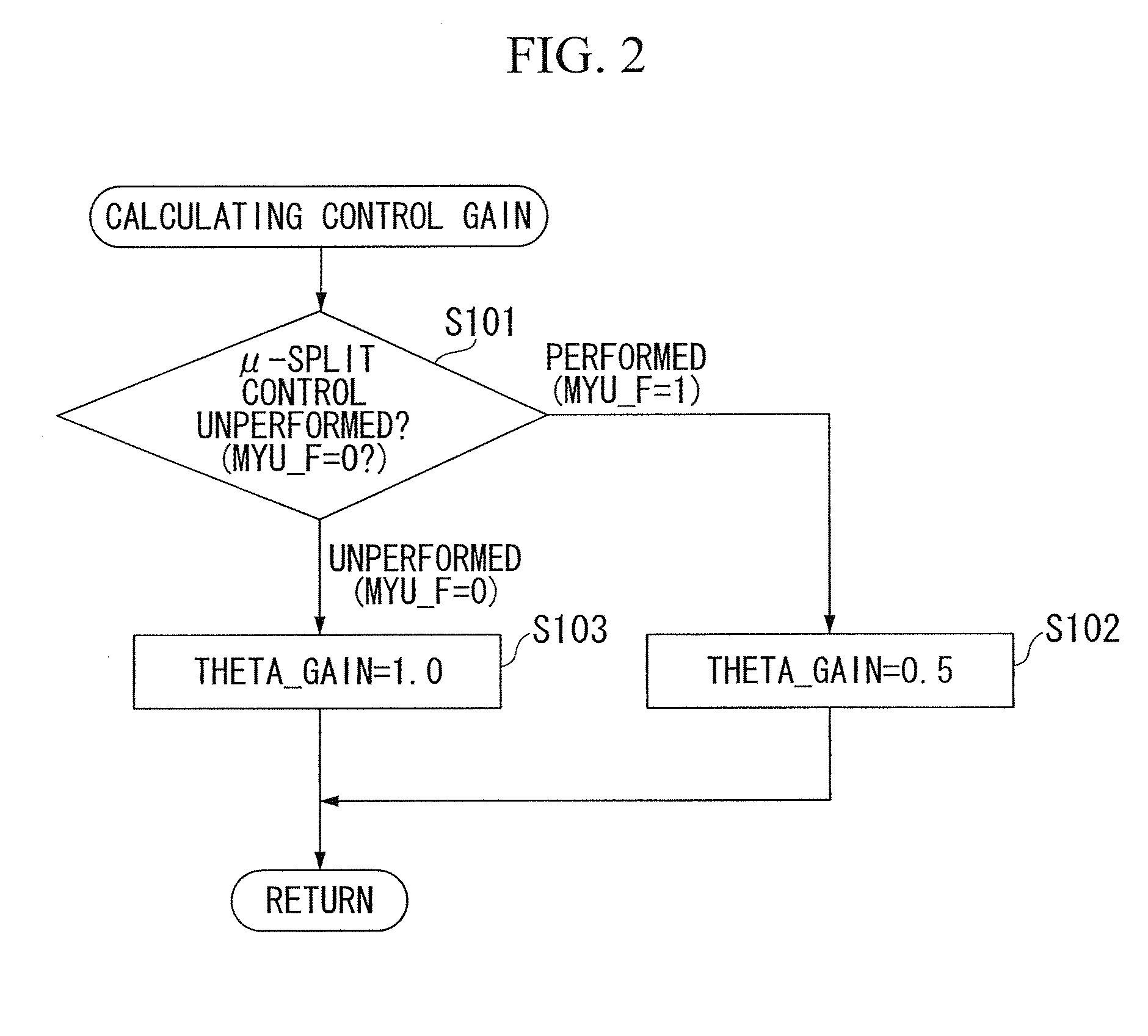

Electric power steering device

InactiveUS20100087989A1Improve stabilityStable travelBrake system interactionsSteering initiationsElectric power steeringSteering wheel

An electric power steering device for a vehicle includes: a steering wheel return control unit that performs a steering wheel return control when a direction of a steering angle and a direction of a steering angular velocity is different; and a μ-split control unit that performs a μ-split control in order to suppress a behavior of the vehicle traveling on a μ-split road; wherein when the μ-split control unit performs the μ-split control, a value of a steering wheel return control gain in the steering wheel return control unit is set to be lower than a value which is used when the μ-split control is not performed.

Owner:HONDA MOTOR CO LTD

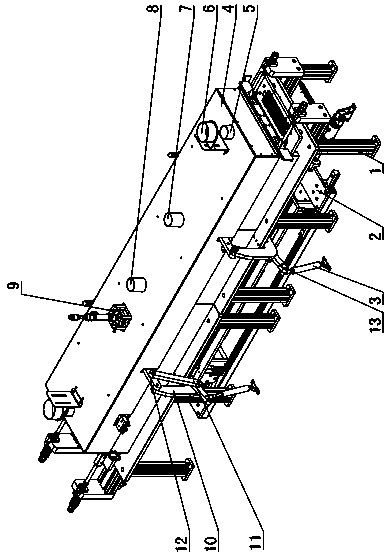

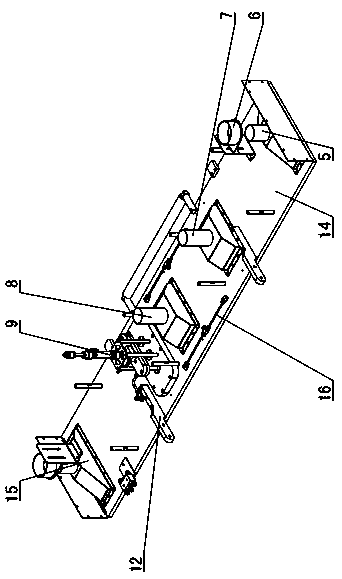

Vacuum welding furnace and welding technology

ActiveCN107931768AReduce the temperaturePrevent oxidationHeating appliancesMetal working apparatusEngineeringOxygen

The invention provides a vacuum welding furnace and a welding technology, and belongs to the technical field of vacuum welding. The vacuum welding furnace is characterized in that one end, close to the feeding end, of a welding platform (20) is used as a heating area; one side, close to the discharging end, of the welding platform (20) is used as a cooling area; a negative pressure pumping module(9) is arranged at the upper side of one end, close to the cooling area, of the heating area, and the negative pressure pumping module (9) is mounted on a furnace cover (4) by lifting; the bottom partof the negative pressure pumping module (9) and the heating area encircles a closed negative pressure chamber; a protecting gas inlet pipe is arranged on a welding chamber (18) or the furnace cover (4). According to the vacuum welding furnace, material sheets can be heated through the heating area, so that the material sheets can be quickly welded in the negative pressure chamber; protecting gasis charged, so that the material sheets are prevented from reacting with oxygen during being heated; the material sheets can be cooled and prevented from being oxidized through the cooling area. According to the welding technology, the welding time is decreased; the welding is accelerated; with the adoption of the cooling area, the material sheet can be completely cooled and is prevented from deformation caused by excessively quick cooling.

Owner:SHANDONG CAIJU ELECTRONICS TECH CO LTD

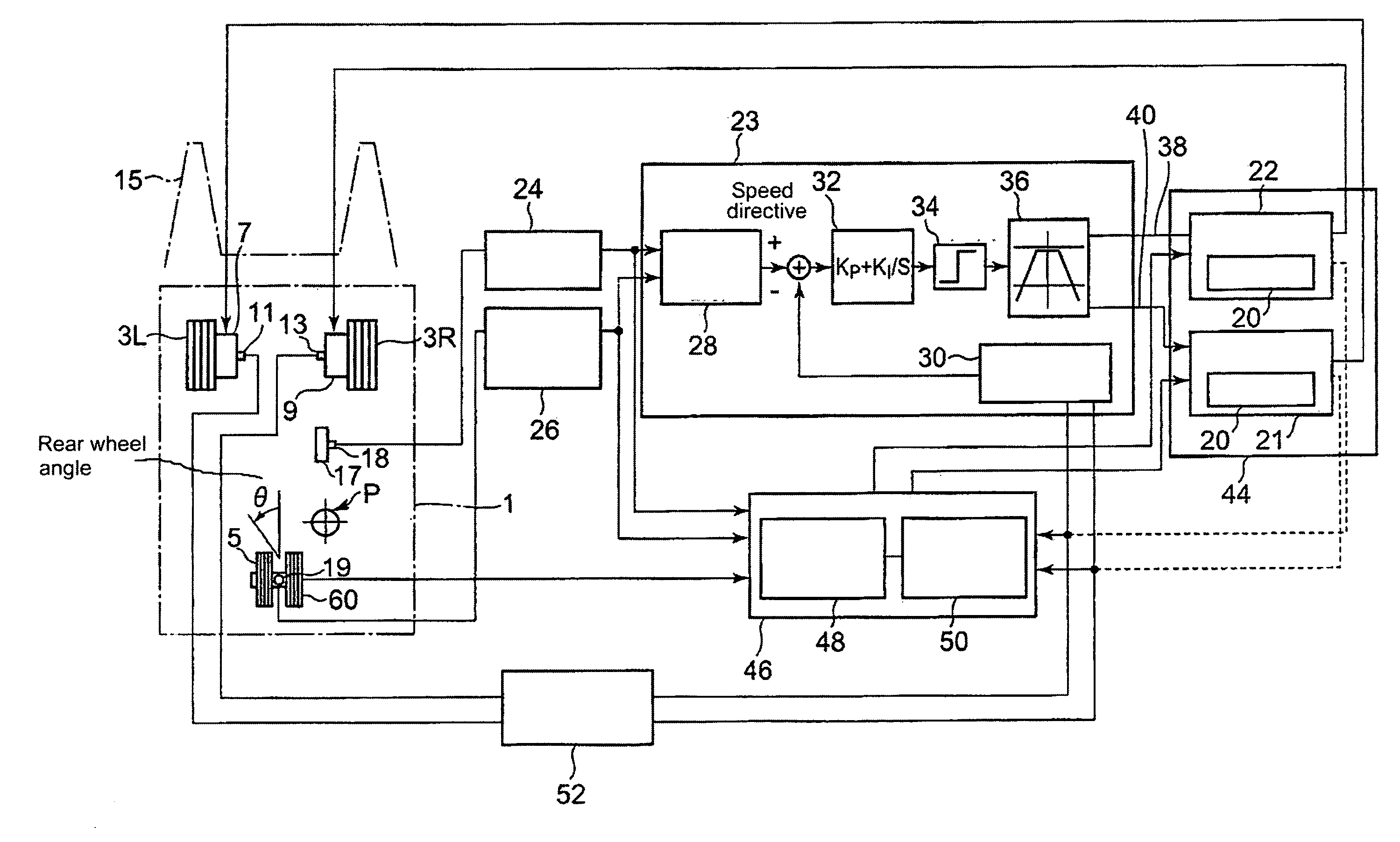

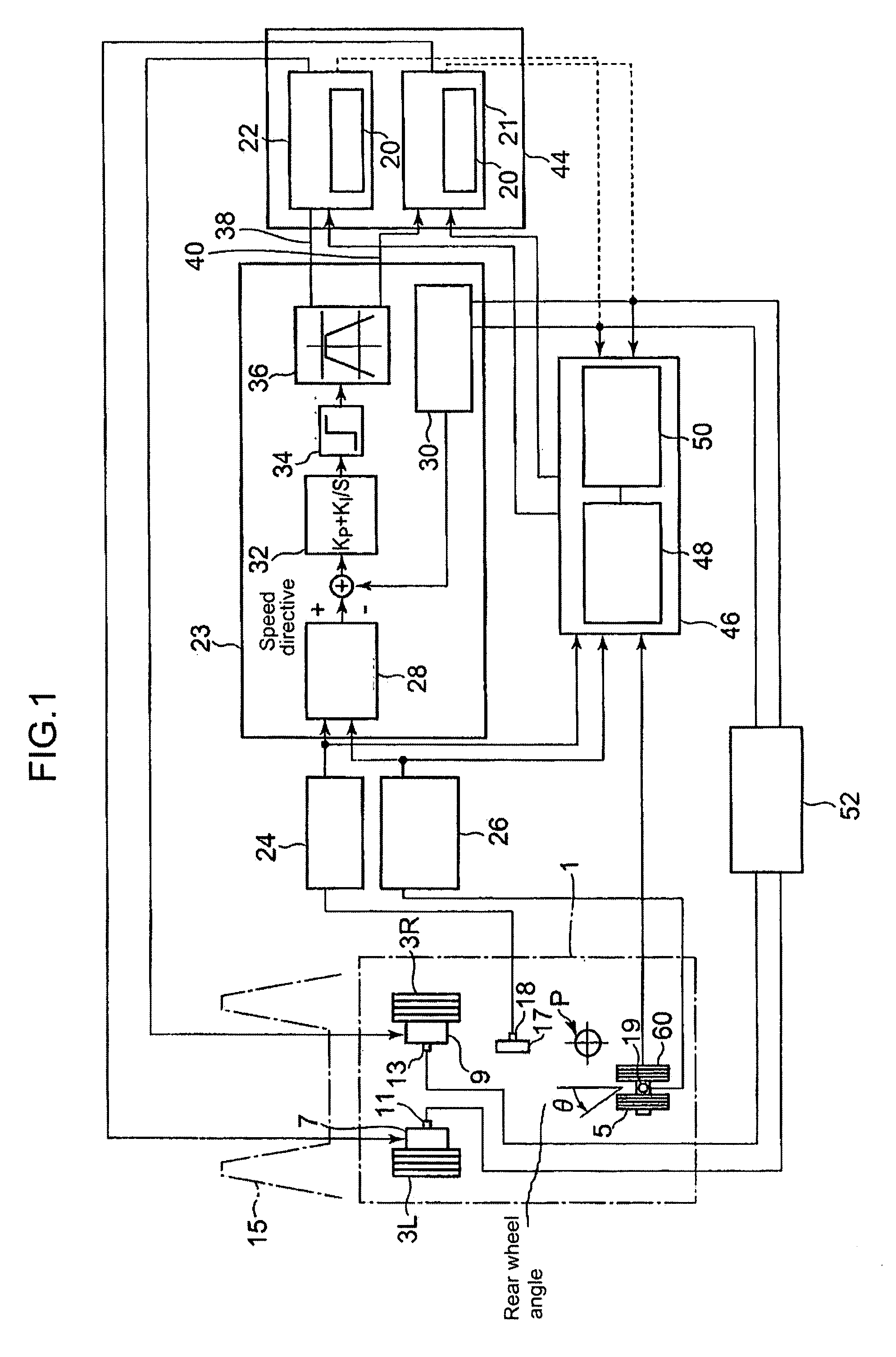

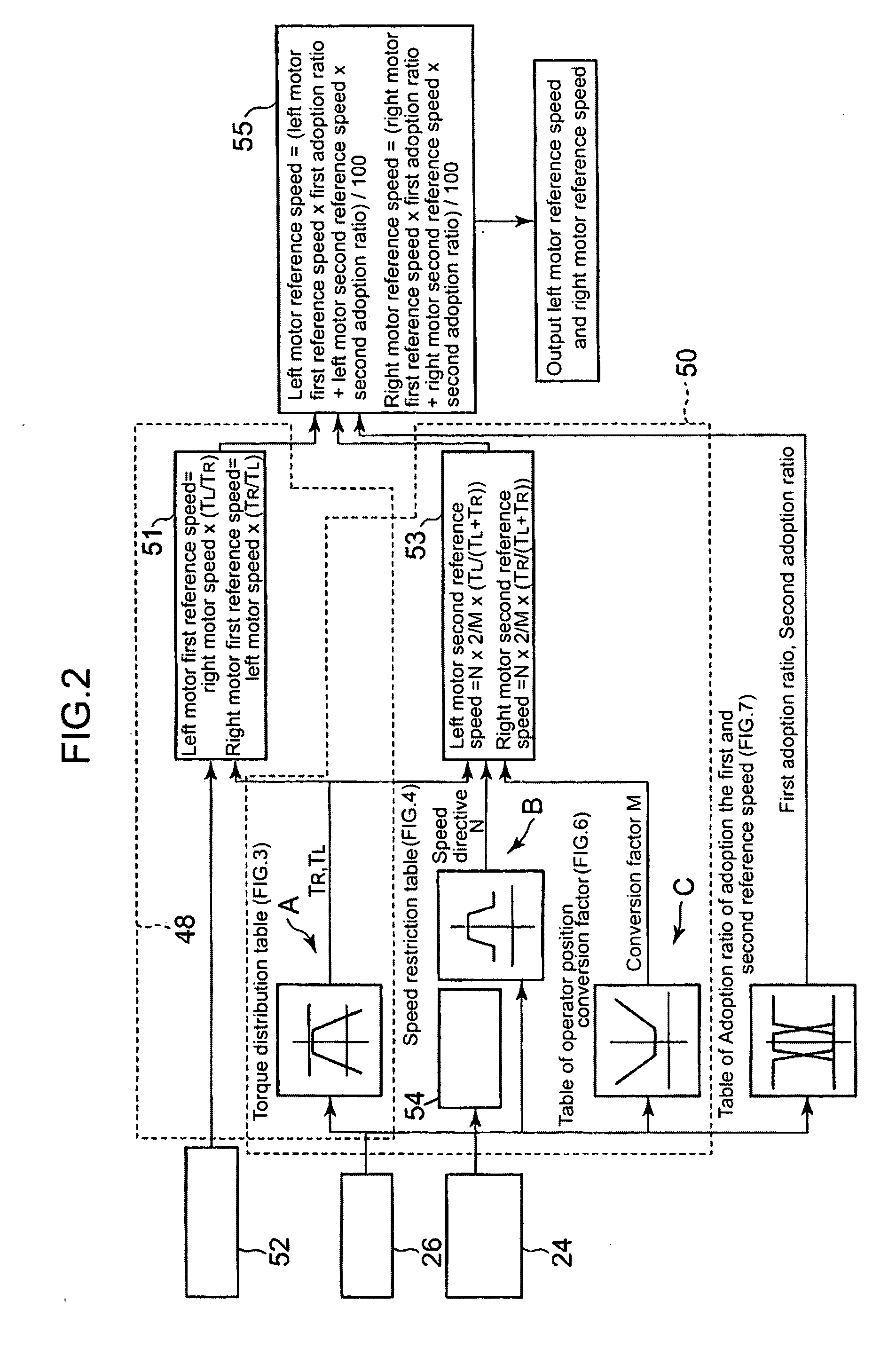

Electric vehicle, and device and method of controlling slip thereof

ActiveUS20090026984A1Good road holdingStable travelDC motor speed/torque controlMultiple dynamo-motor startersSteering angleRoad surface

A slip control device, a slip control method, and a vehicle provided with such a slip control device are provided, with which the vehicle can travel stably even on a slippery road surface maintaining good road holding. The device is provided with a torque directive control means (23) for calculating torque directives for the motors respectively based on acceleration pedal depressions (24) and steering angles (26) and outputting them to each of motor control sections (21, 22) of the motors, a first reference speed calculation means (48) for calculating first reference speed of one of the pair of left and right motors to be controlled based on rotation speed of the other motor of the pair of motors, and a restriction putting means (20) for putting restriction to each of the torque directives sent from the torque directive control means (23) based on a permissible speed range determined for each of the motors by putting prescribed permissible speed deviation to each of the calculated reference speeds.

Owner:NIPPON YUSOKI

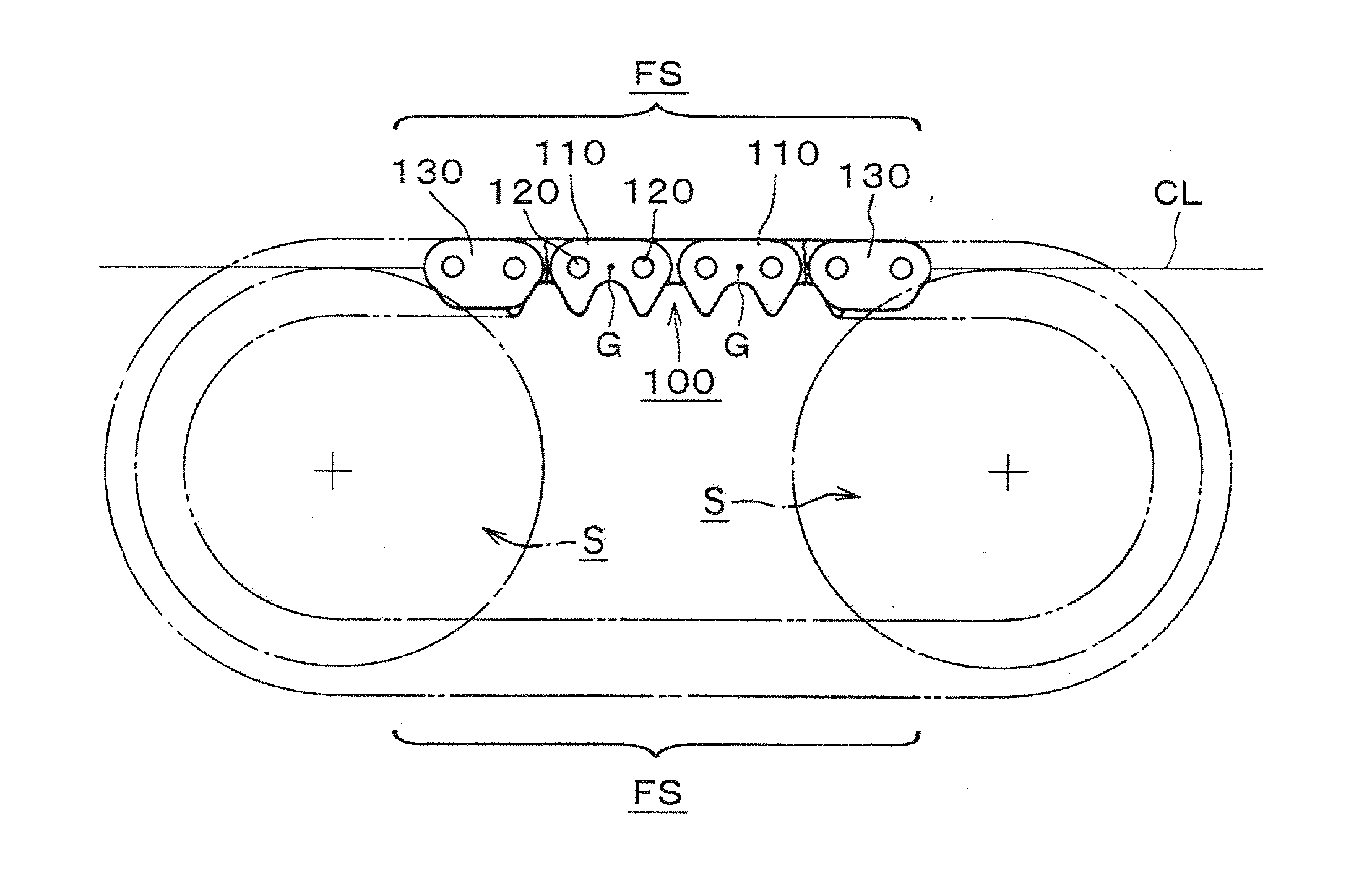

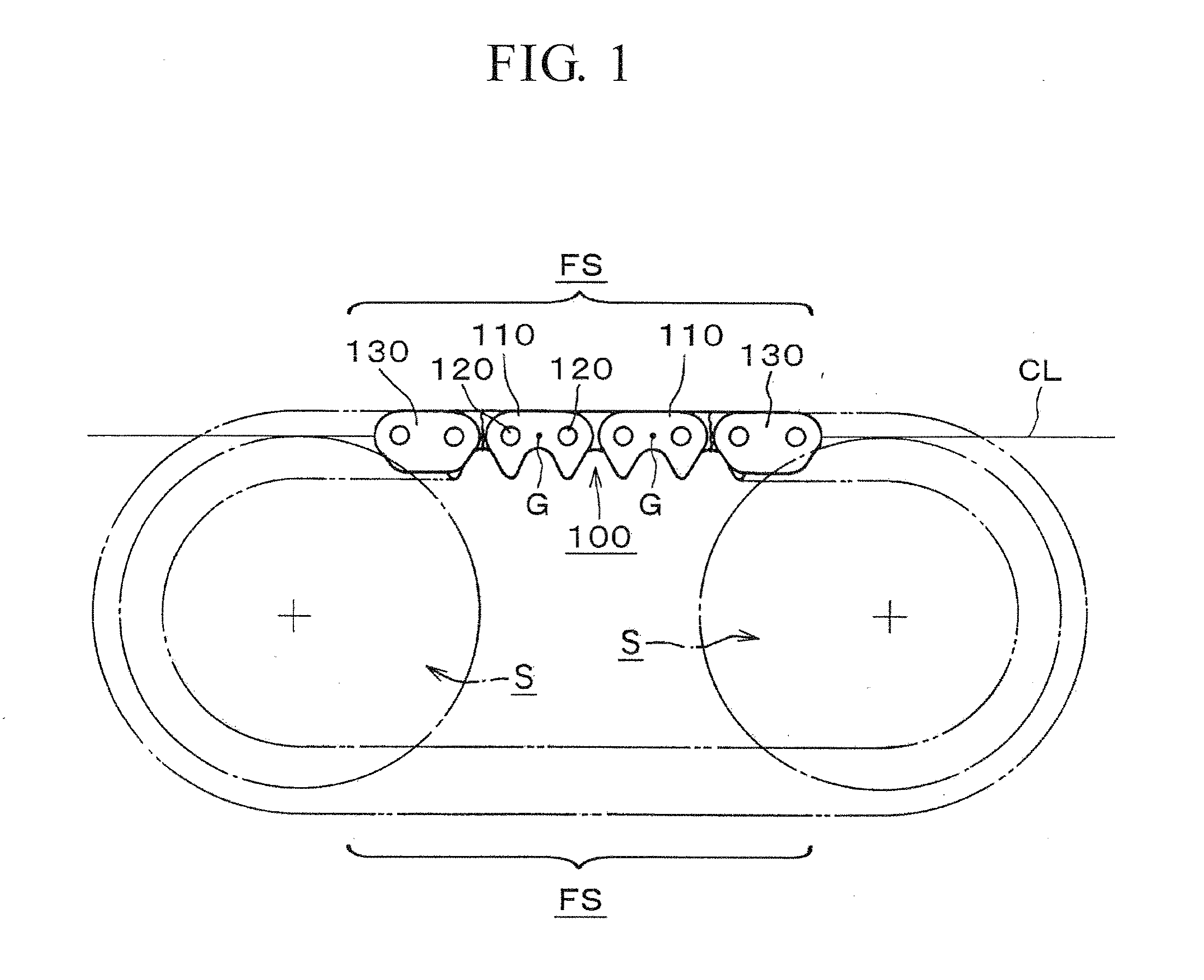

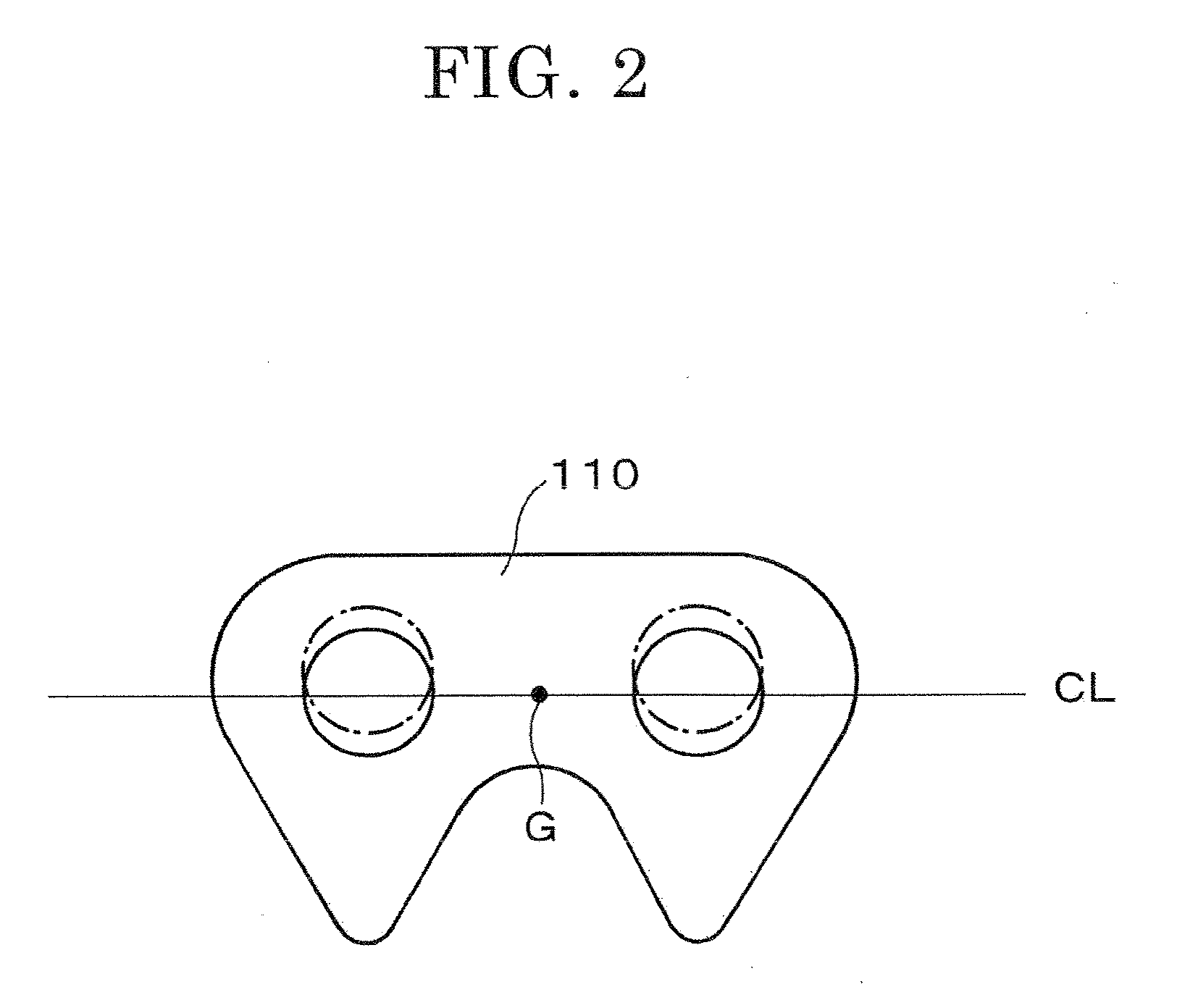

Vibration-proof silent chain

InactiveUS20100304911A1Less vibration noiseStable chain travelDriving chainsLine of actionEngineering

In a silent chain, the toothed link plates are configured so that their centers of gravity are aligned with the line of action of chain tension in a free span of the chain, when the free span is straight and under tension. The positions of the centers of gravity are aligned with the centers of the pin holes in the case of a chain incorporating round connecting pins and are aligned with the points of contact of the rocker pins and joint pins in the case of a chain having rocker joint connecting pins. Positioning of the centers of gravity can be effected by thickening the backs of the link plates or by providing weight-reducing holes in the vicinity of the teeth of the link plates.

Owner:TSUBAKIMOTO CHAIN CO

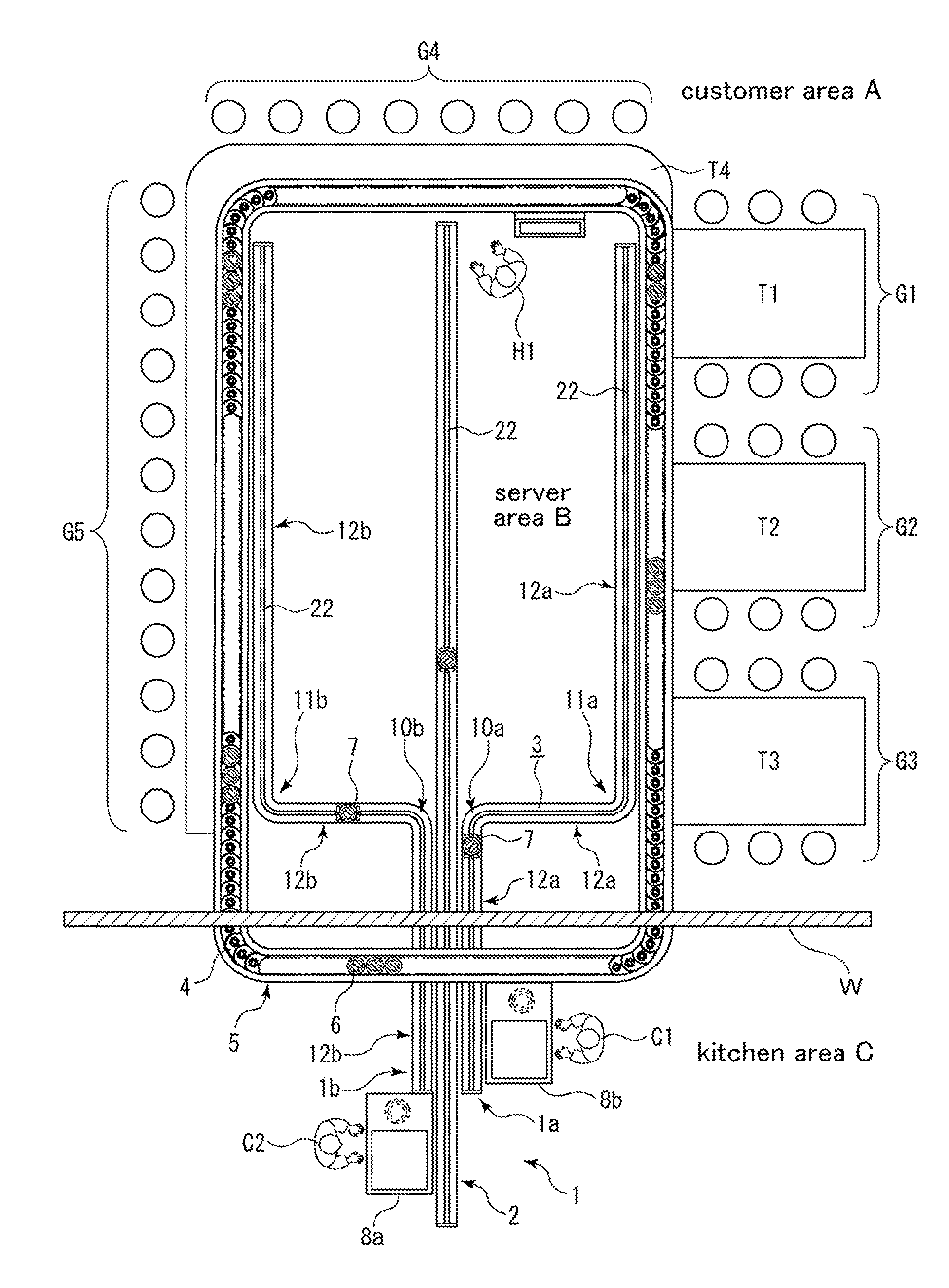

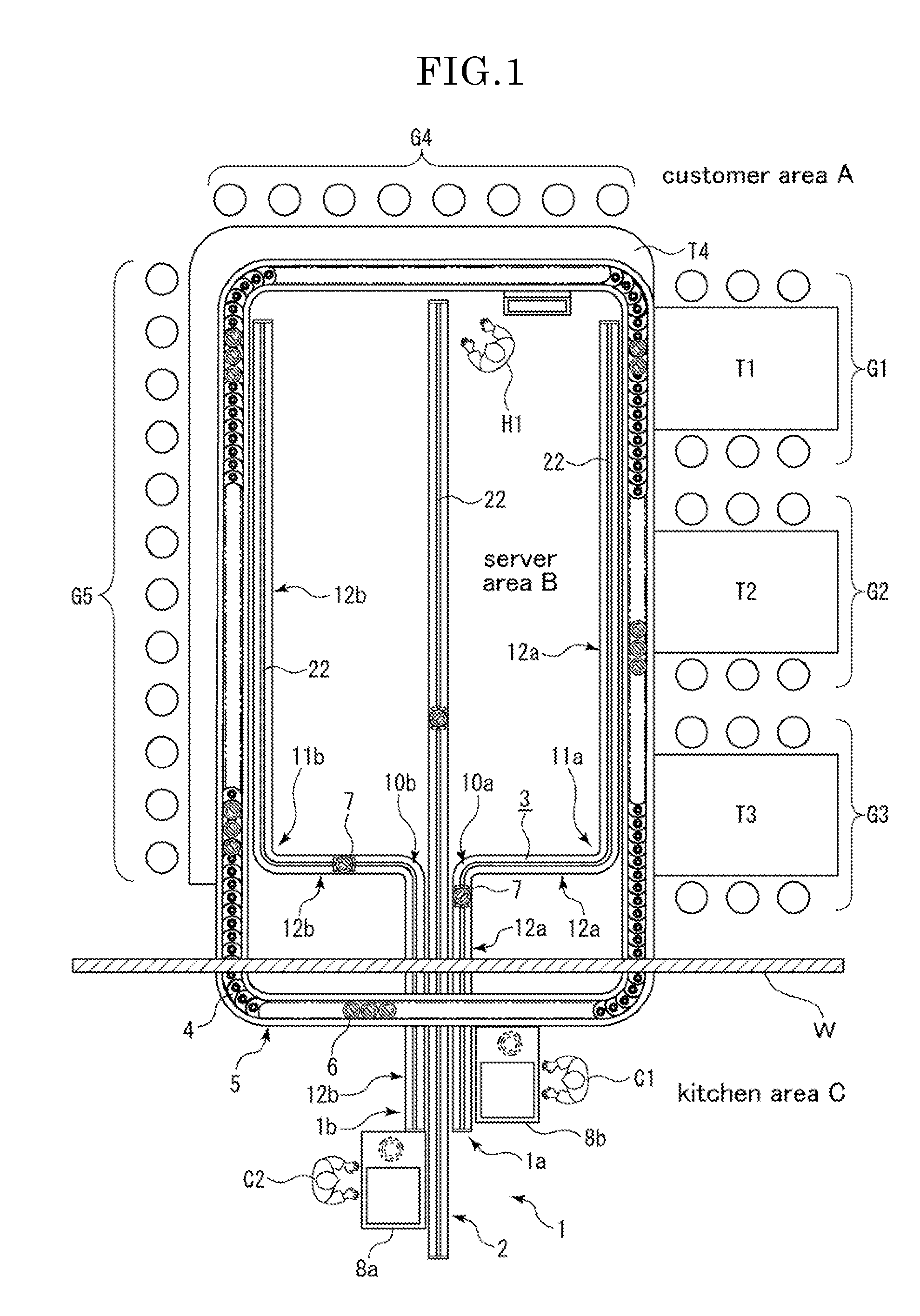

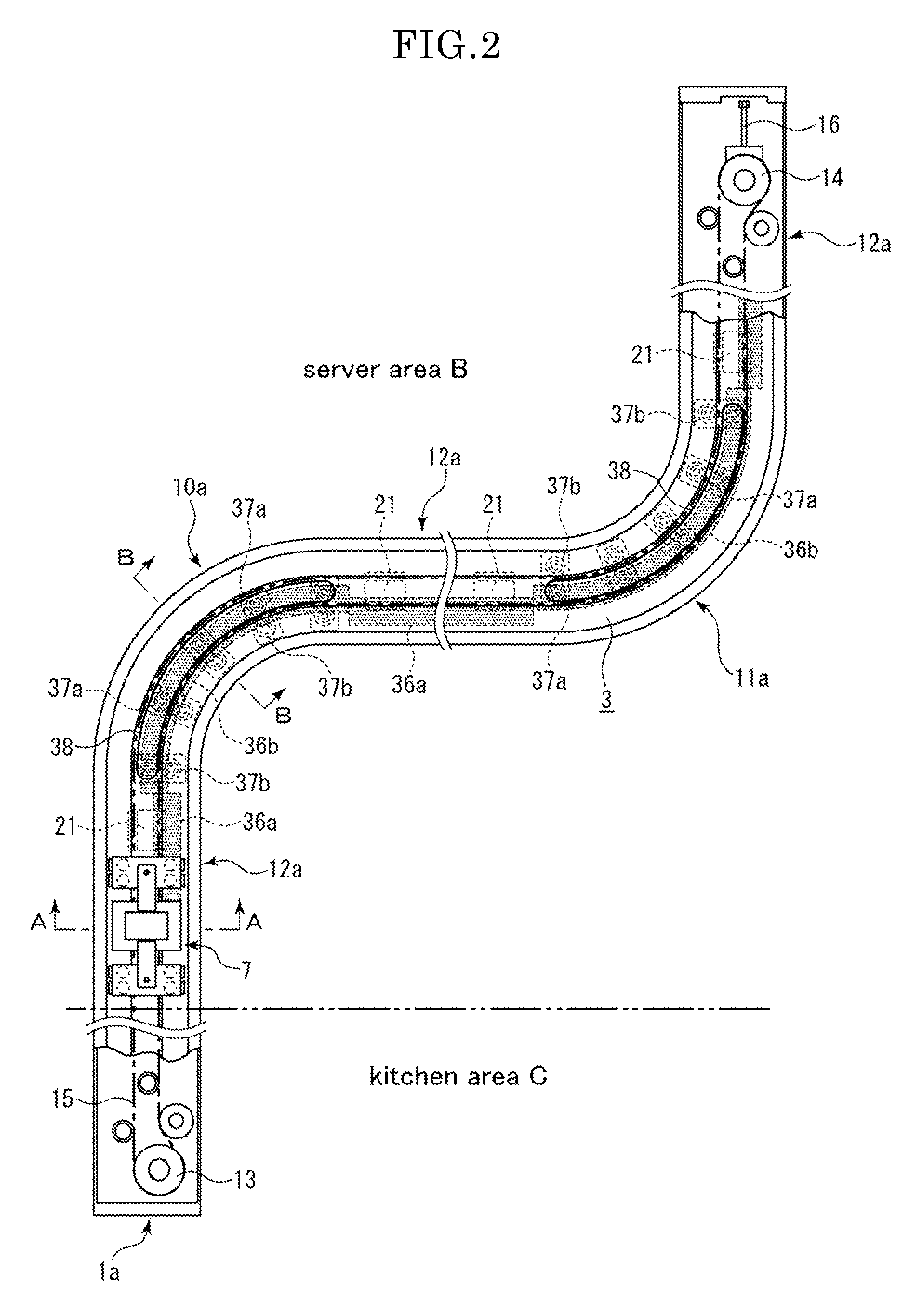

Food and Drink Conveying Device

ActiveUS20120186950A1Stable stateStable travelService system furnitureNon-mechanical conveyorsEngineeringElectrical conductor

Owner:ISHINO SEISAKUSHOKK

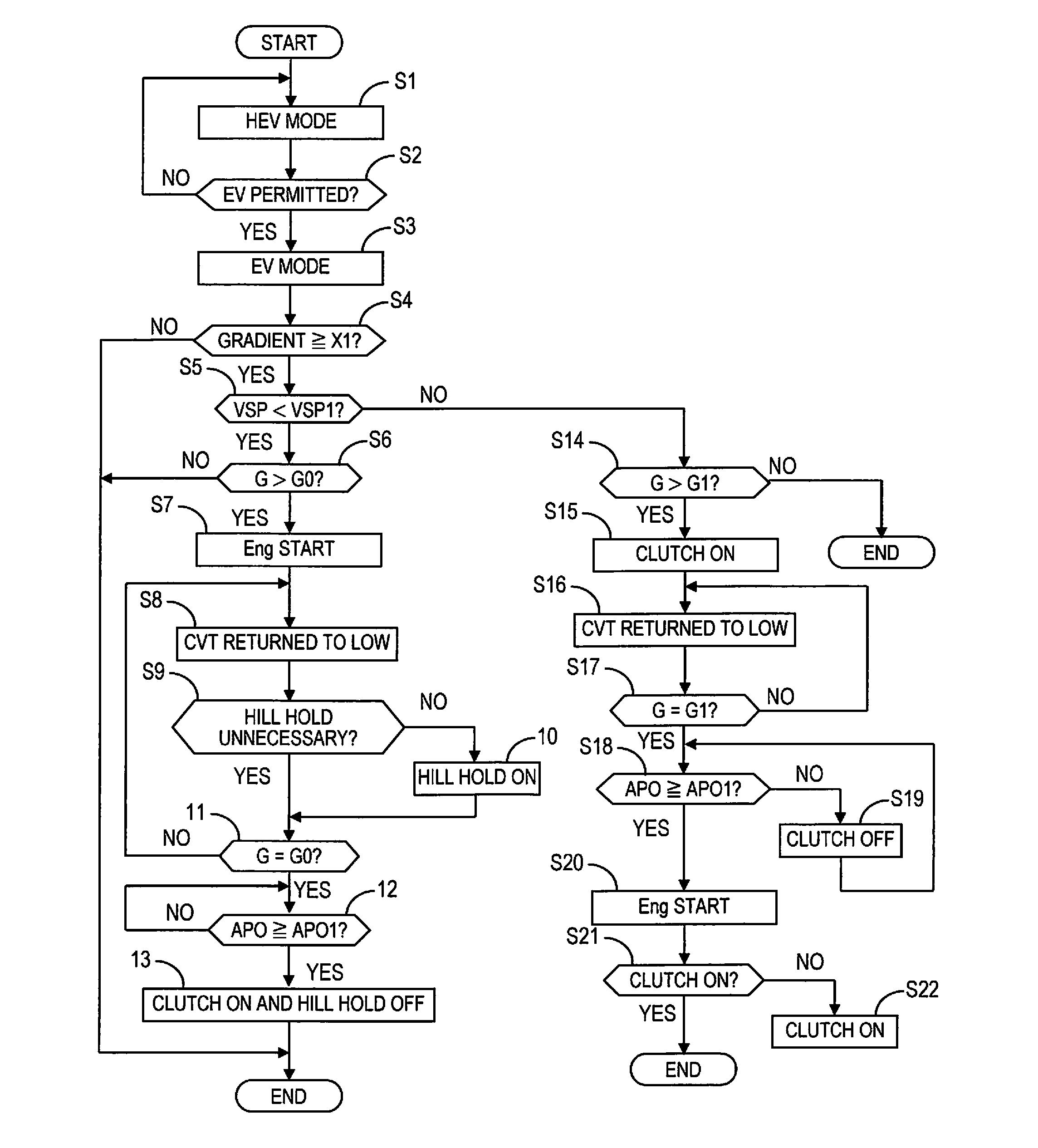

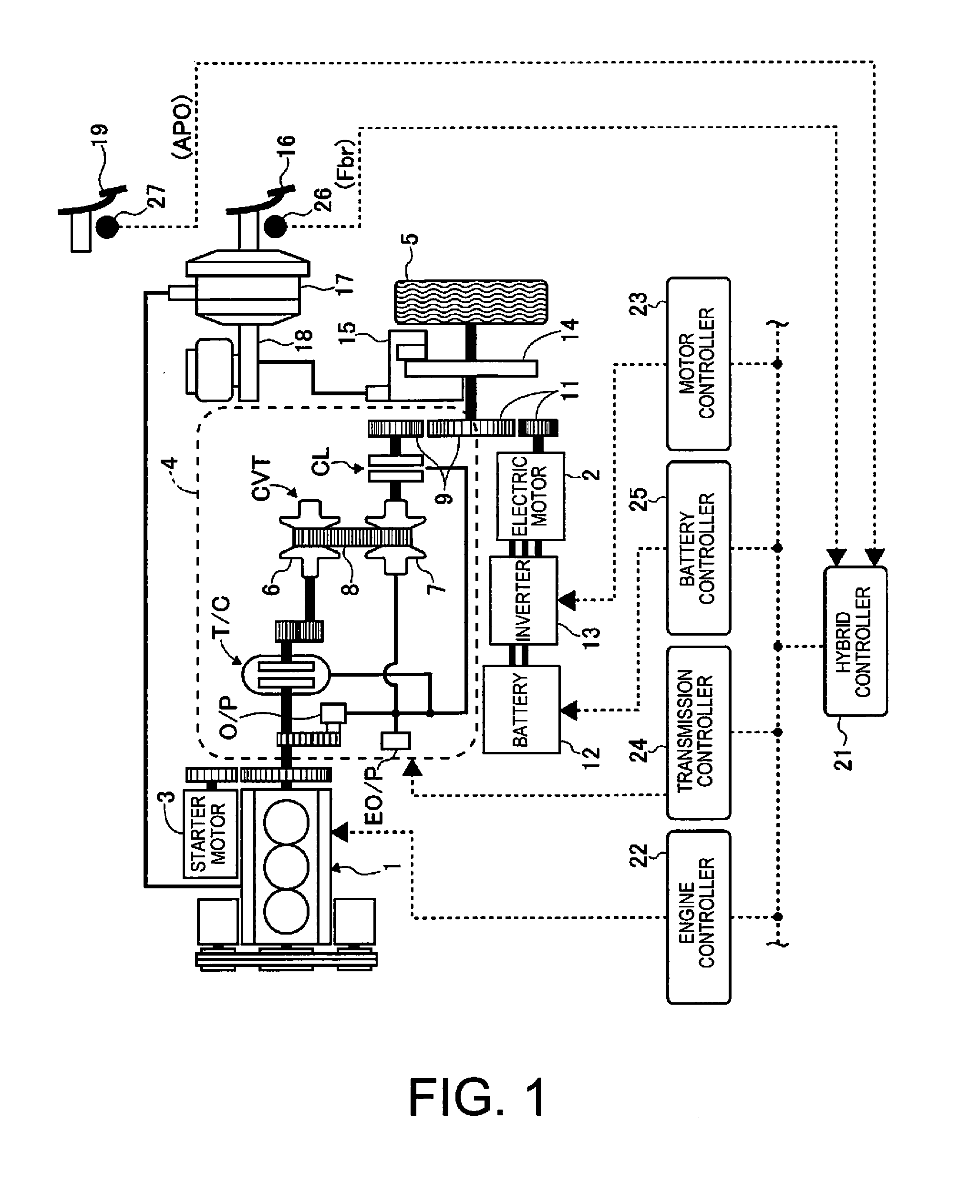

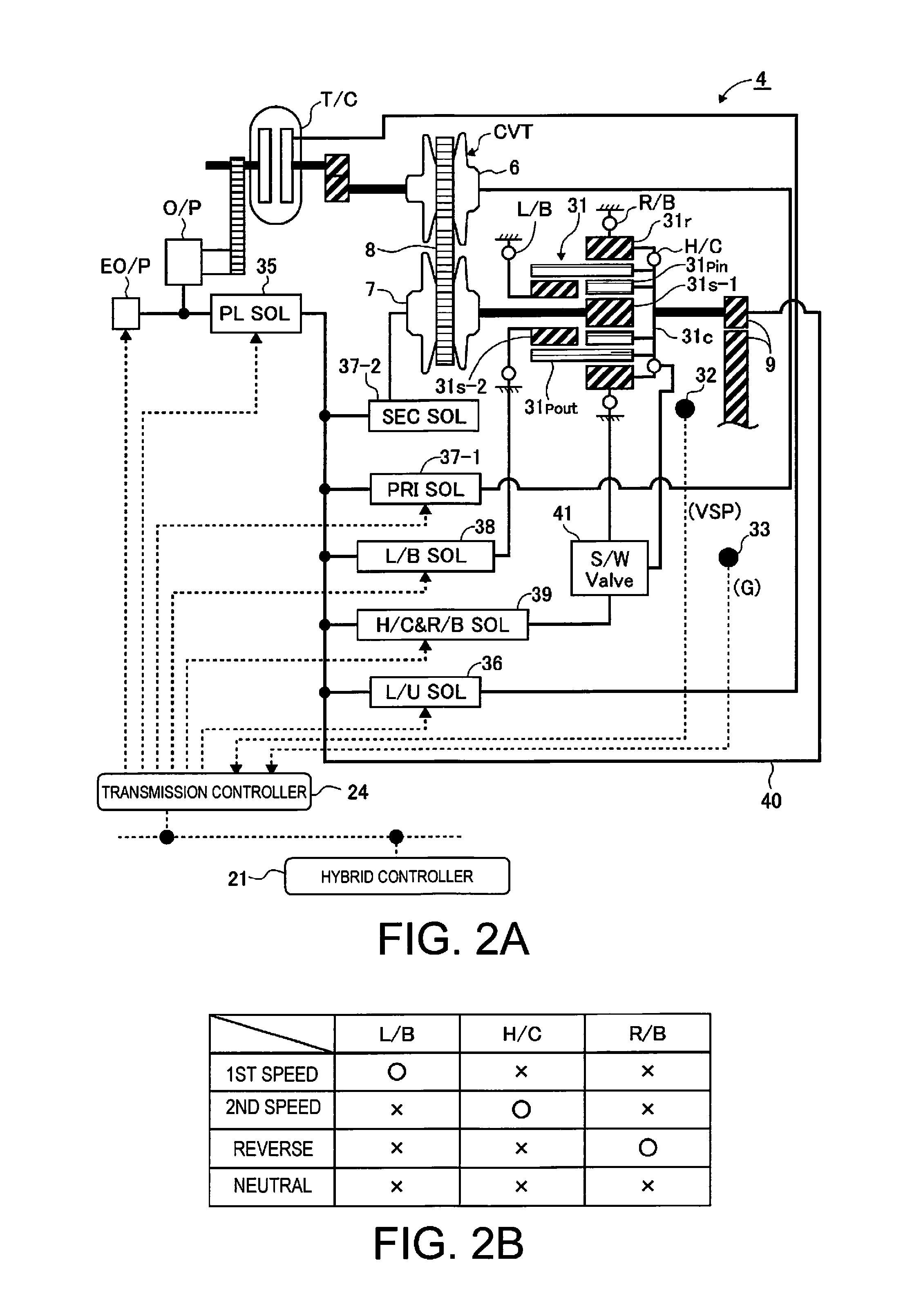

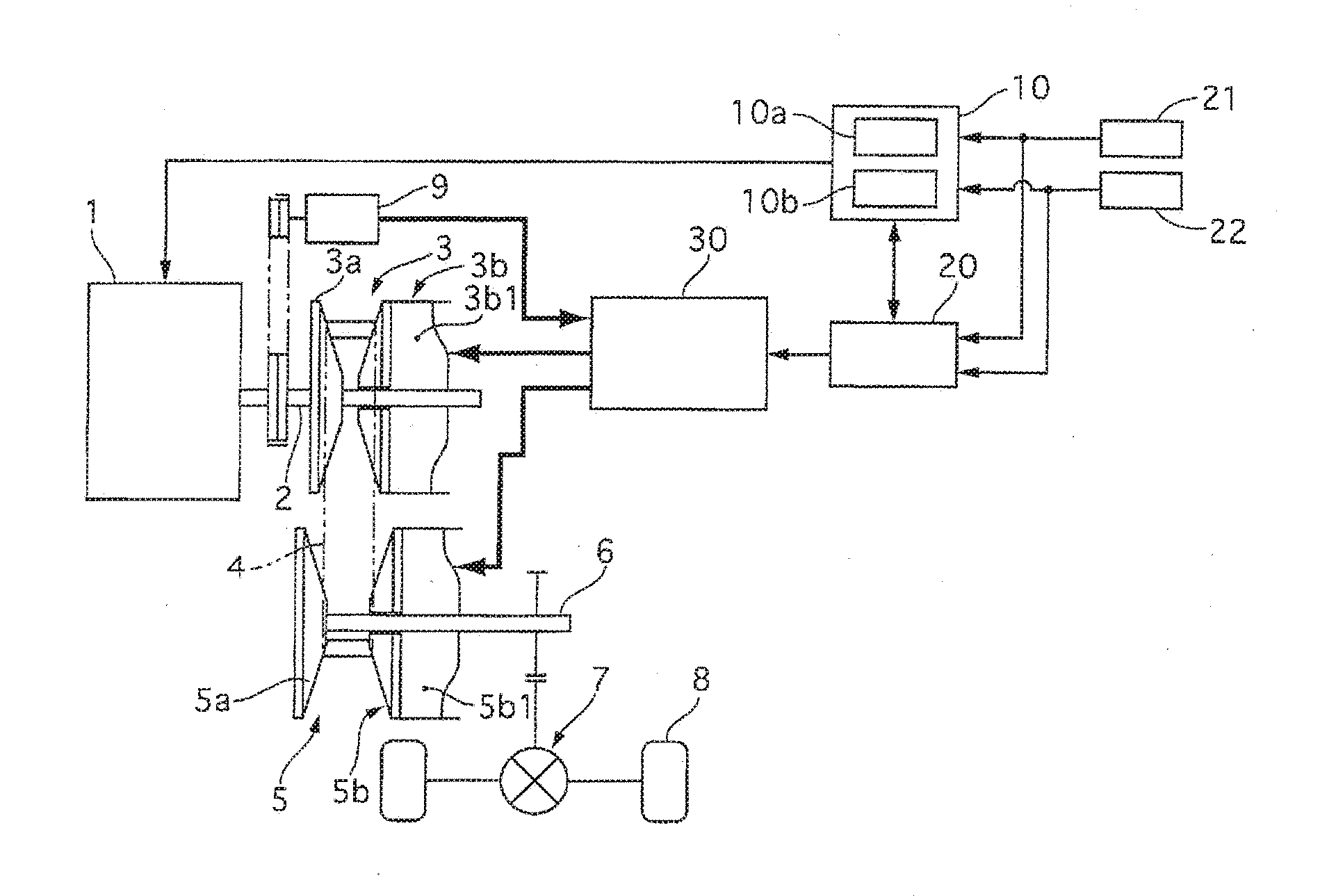

Hybrid vehicle control device

Owner:NISSAN MOTOR CO LTD

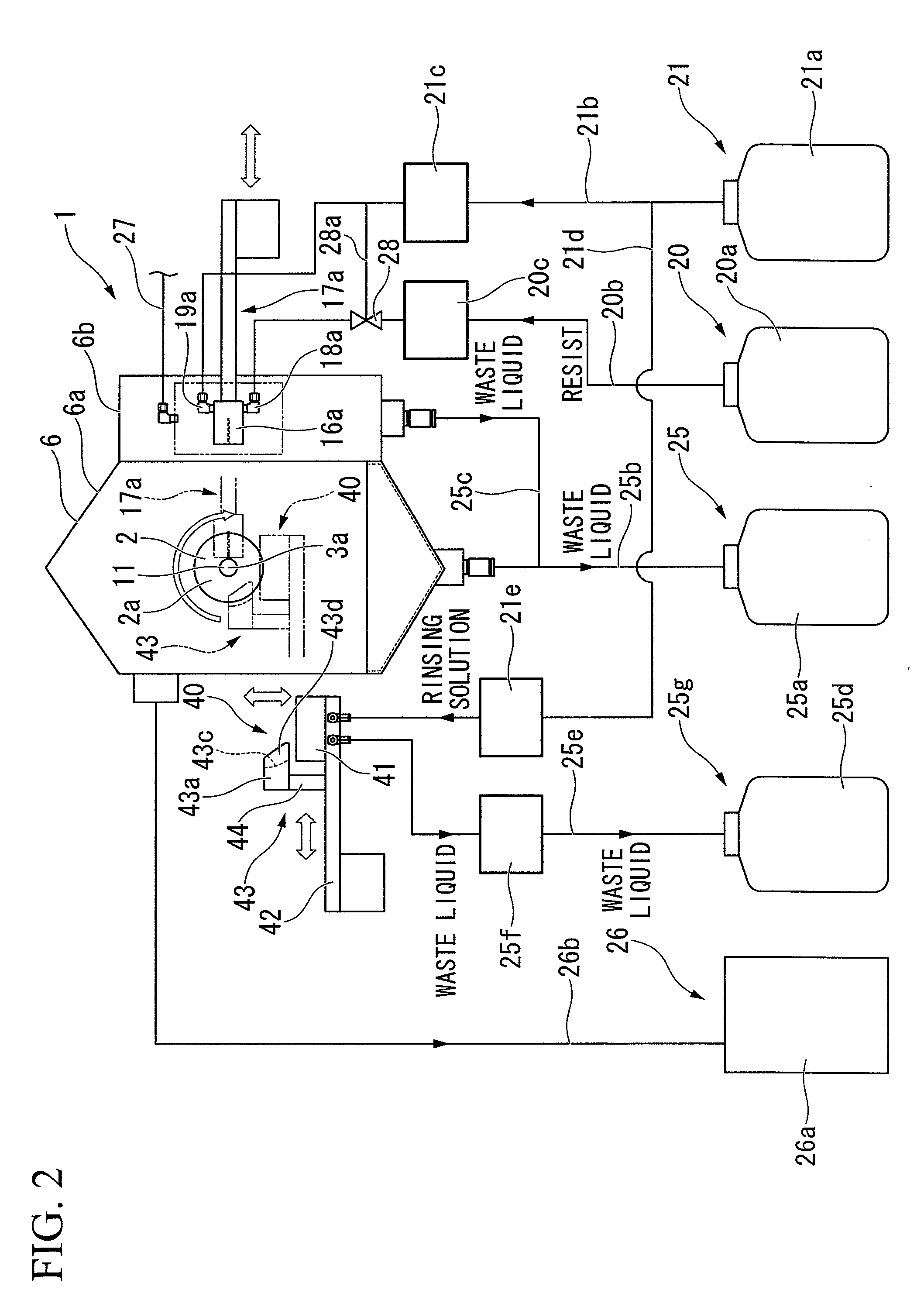

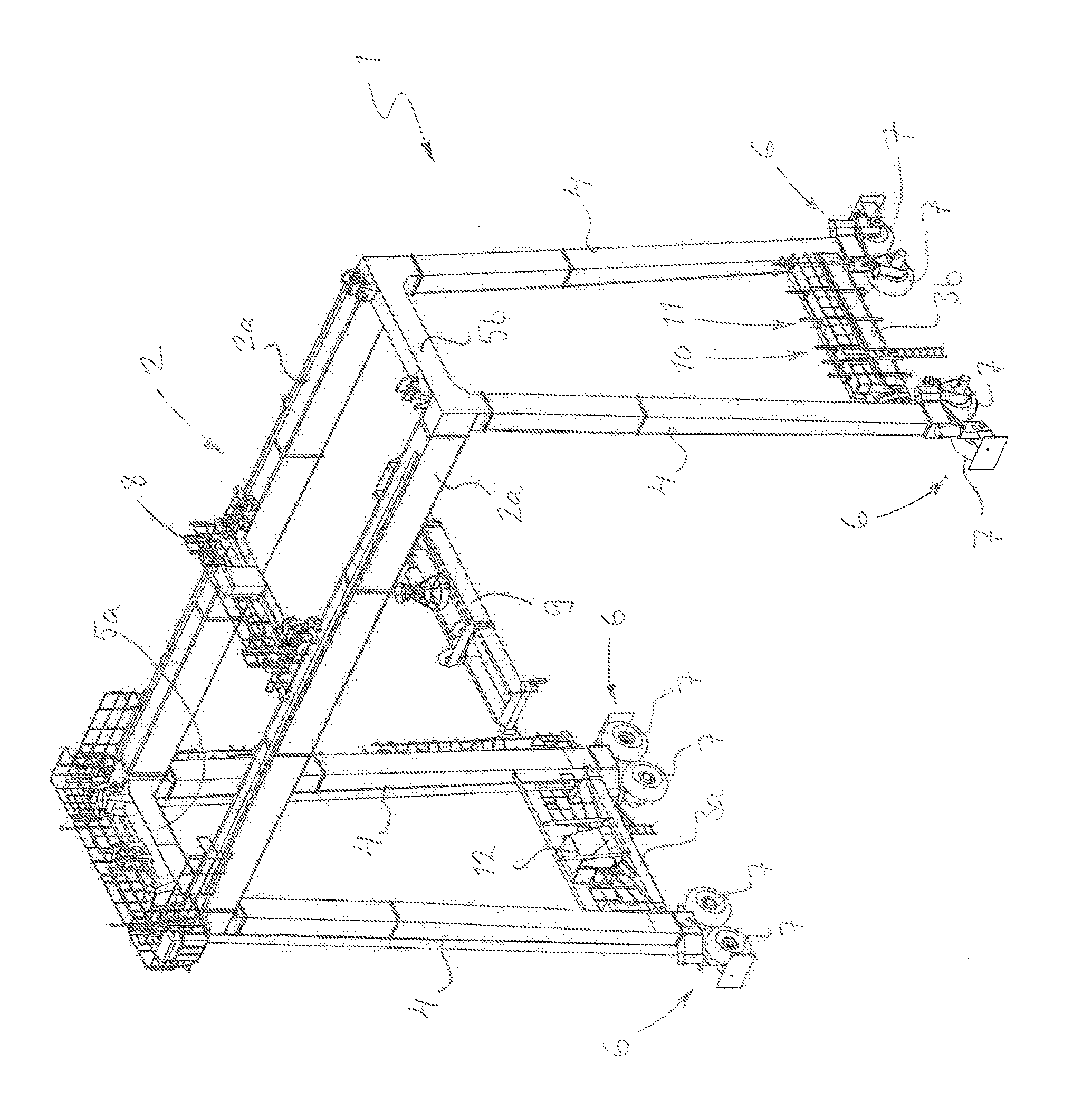

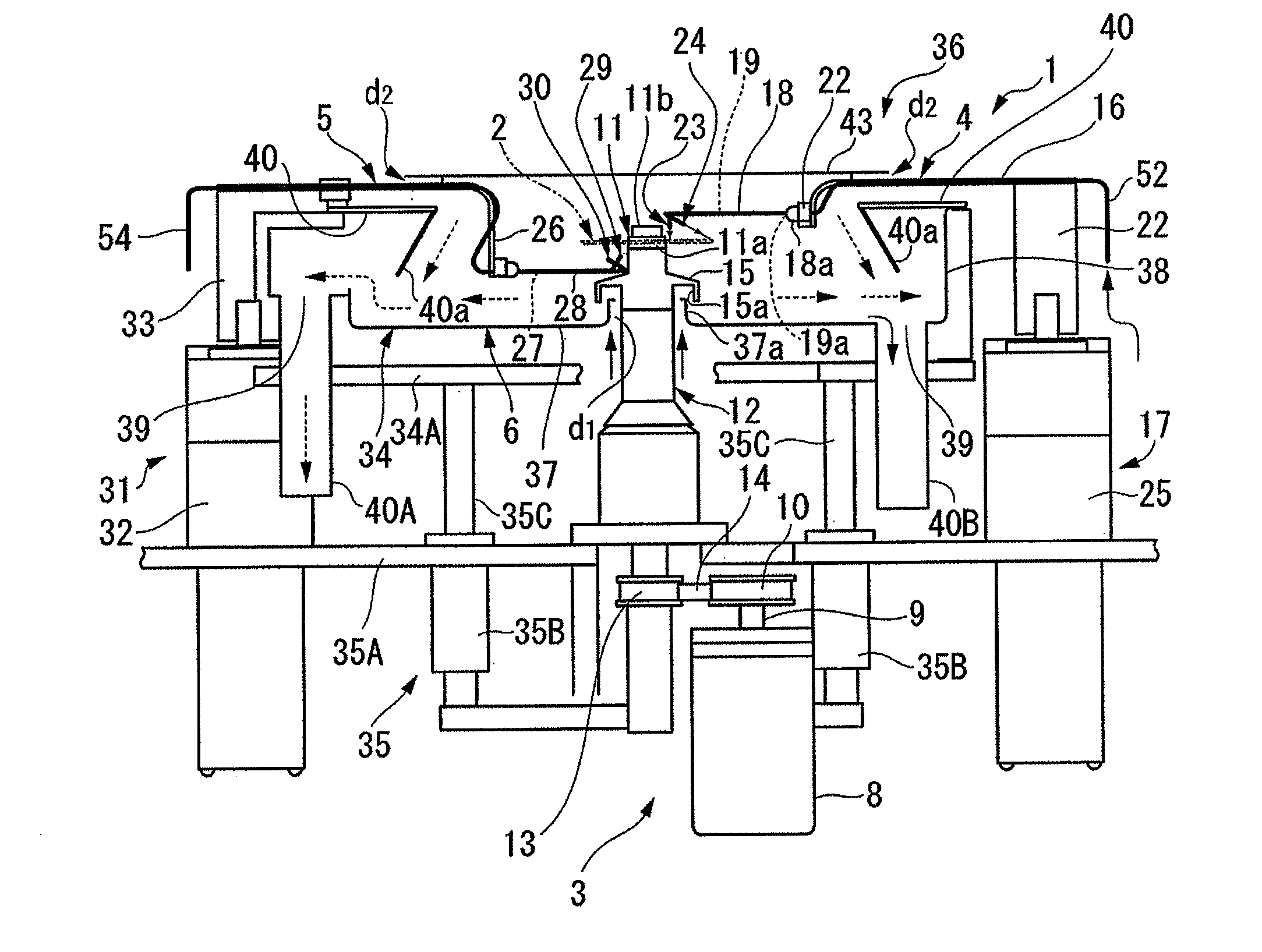

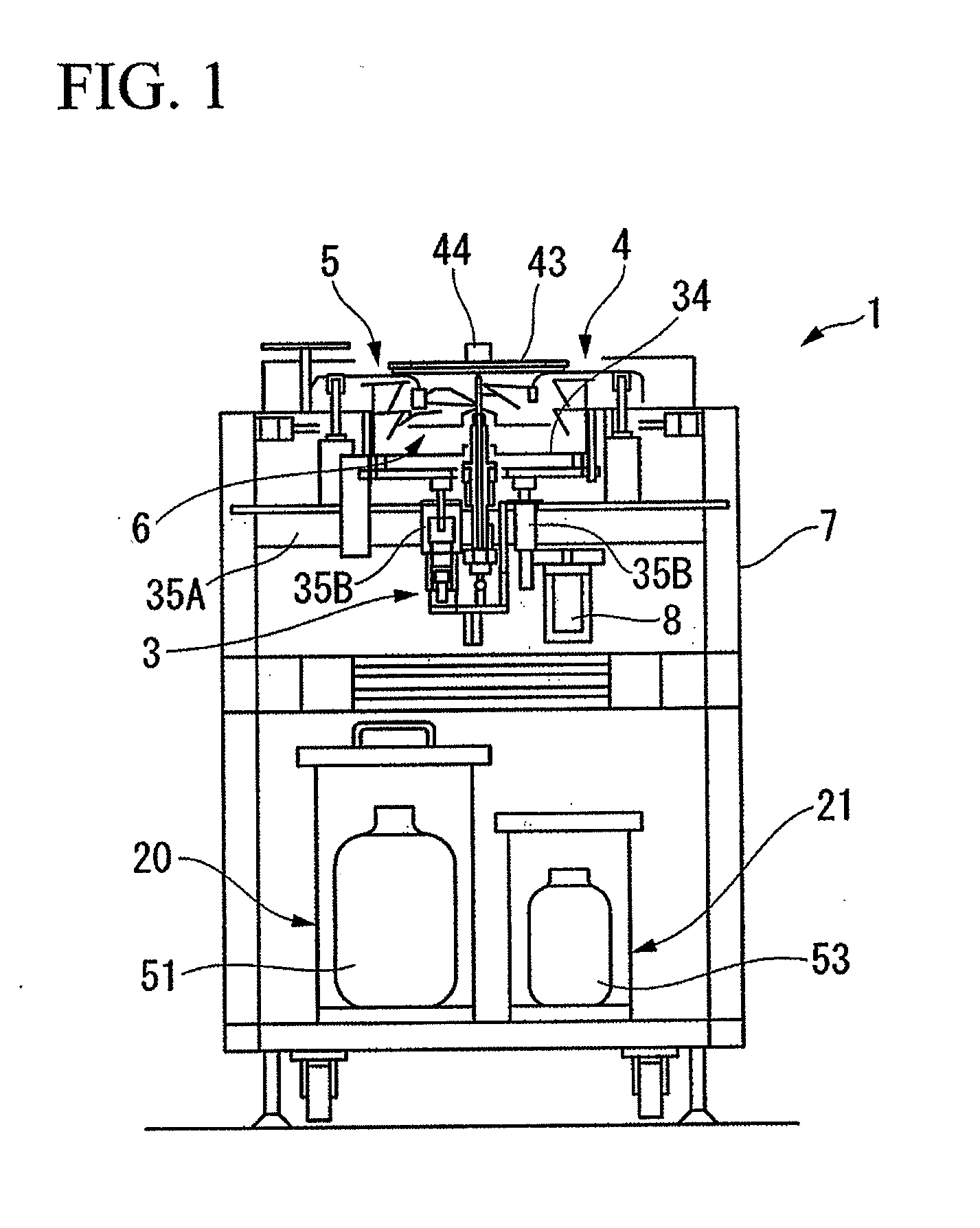

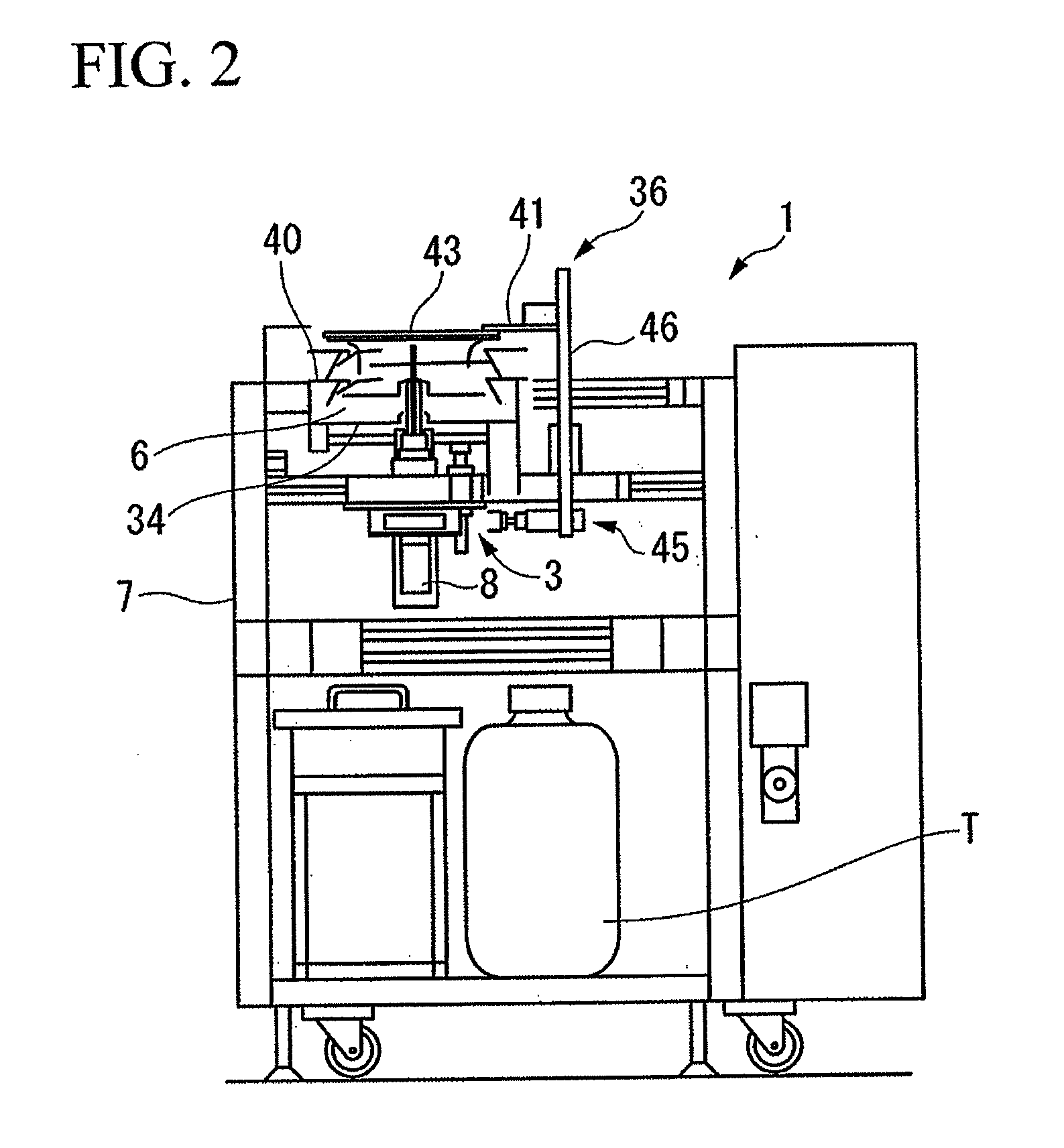

Double-side coating apparatus, method for coating double sides with coating solution, edge rinsing apparatus, and edge rinsing method

InactiveUS20110027478A1Avoid pollutionStable travelPretreated surfacesCleaning using toolsEngineeringCoating

Provided is a double-side coating apparatus which can uniformly coat both surfaces of a substrate to be processed with a coating solution and form uniform coating films on both the surfaces of the substrate to be processed. A double-side coating apparatus (1) includes a holding mechanism (3a) which holds a substrate (2) to be processed so that the thickness direction of the substrate (2) to be processed is a horizontal direction; a rotational driving mechanism which rotates the substrate (2) to be processed in a circumferential direction; a first coating solution nozzle (18a) which jets a coating solution onto one main surface (2a) of the substrate (2) to be processed; and a second coating solution nozzle which jets the coating solution onto the other main surface (2b) of the substrate (2) to be processed. The first coating solution nozzle (18a) and the second coating solution nozzle are symmetrically arranged with respect to a thickness center surface of the substrate (2) to be processed. Provided is an edge rinsing apparatus which can accurately and stably rinse only a fixed width of an outer peripheral portion of the substrate and can easily control the width of the outer peripheral portion to be rinsed even if the width of the outer peripheral portion to be rinsed is small.

Owner:SHOWA DENKO KK

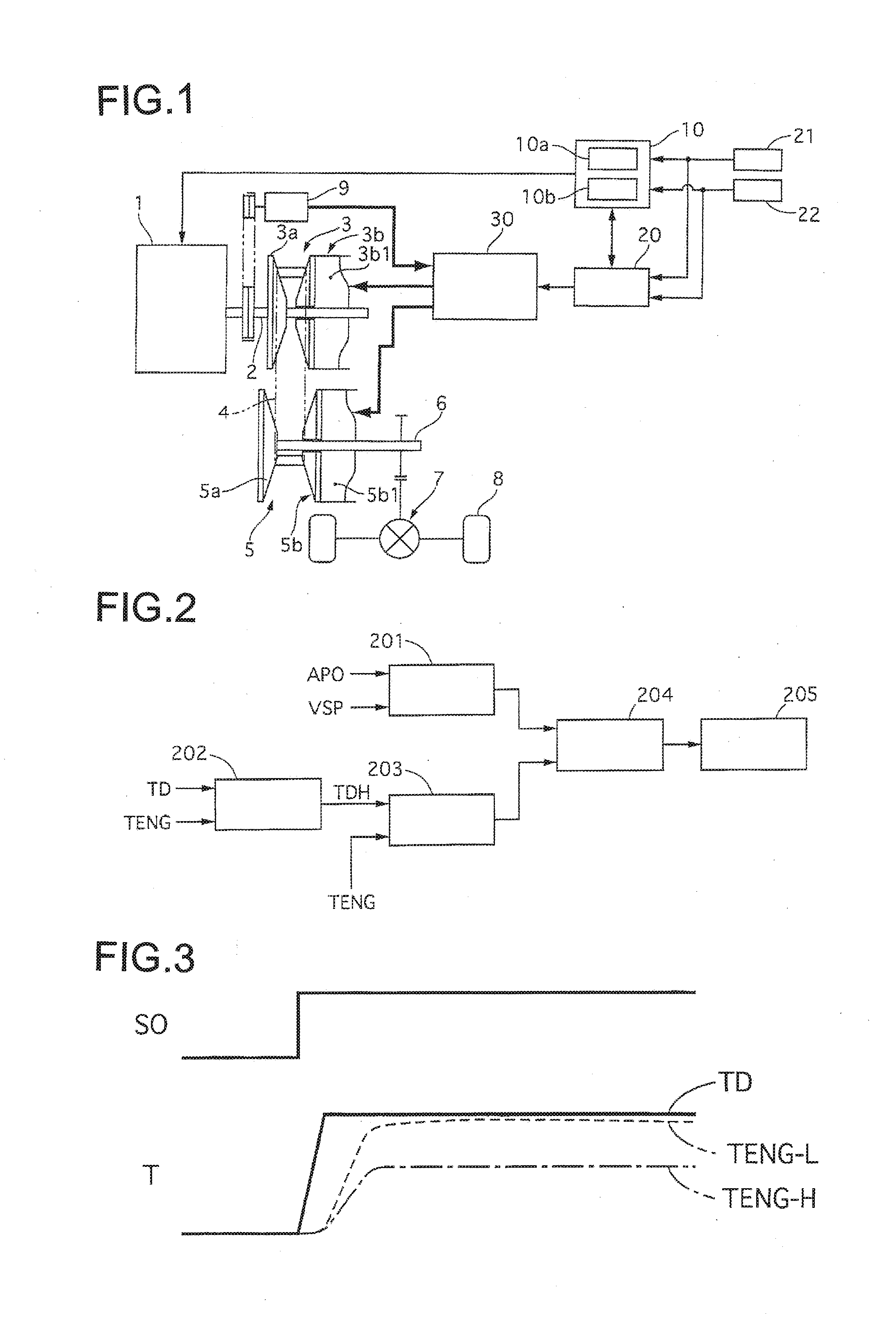

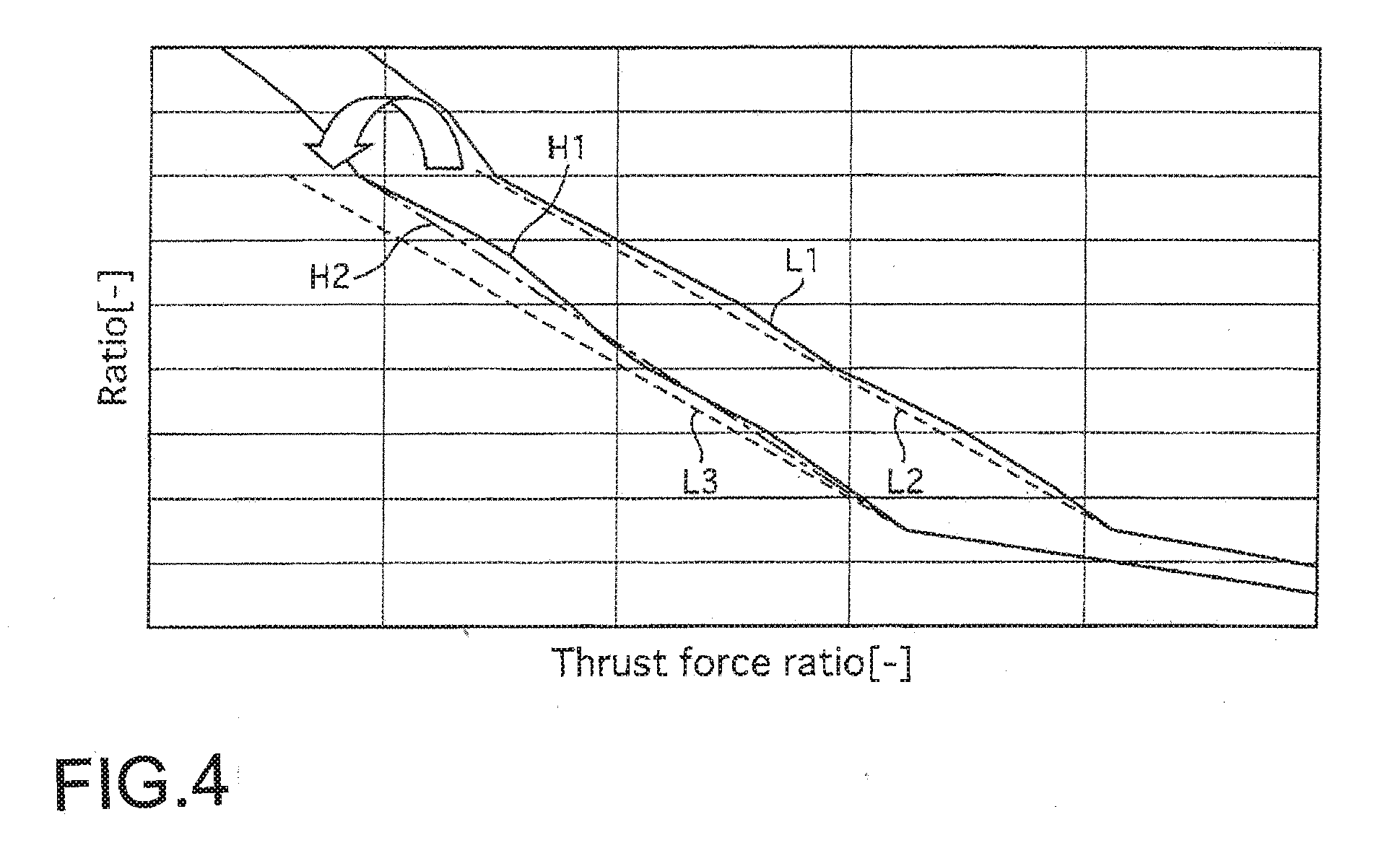

Oil pressure control device for belt-type continuously variable transmission

ActiveUS20160223078A1Excessive oil pressure can be preventedReducing the request torqueGearing controlEngineeringControl theory

There is provided an oil pressure control device for a belt-type continuously variable transmission which includes two pulleys and a belt, wherein each of the two pulleys has a movable sheave which moves by oil pressure supplied to a hydraulic chamber, wherein the oil pressure control device calculates a request torque according to a running state, wherein when calculating the oil pressure which is supplied to the hydraulic chamber of the movable sheave on the basis of the request torque, the oil pressure control device reduces the request torque if the request torque is greater by a predetermined value or more than an actual input torque which is inputted to the belt-type continuously variable transmission. Accordingly, it is possible to provide an oil pressure control device for a belt-type continuously variable transmission with which undesirable vibration can be avoided by means of stable speed-ratio control.

Owner:JATCO LTD +1

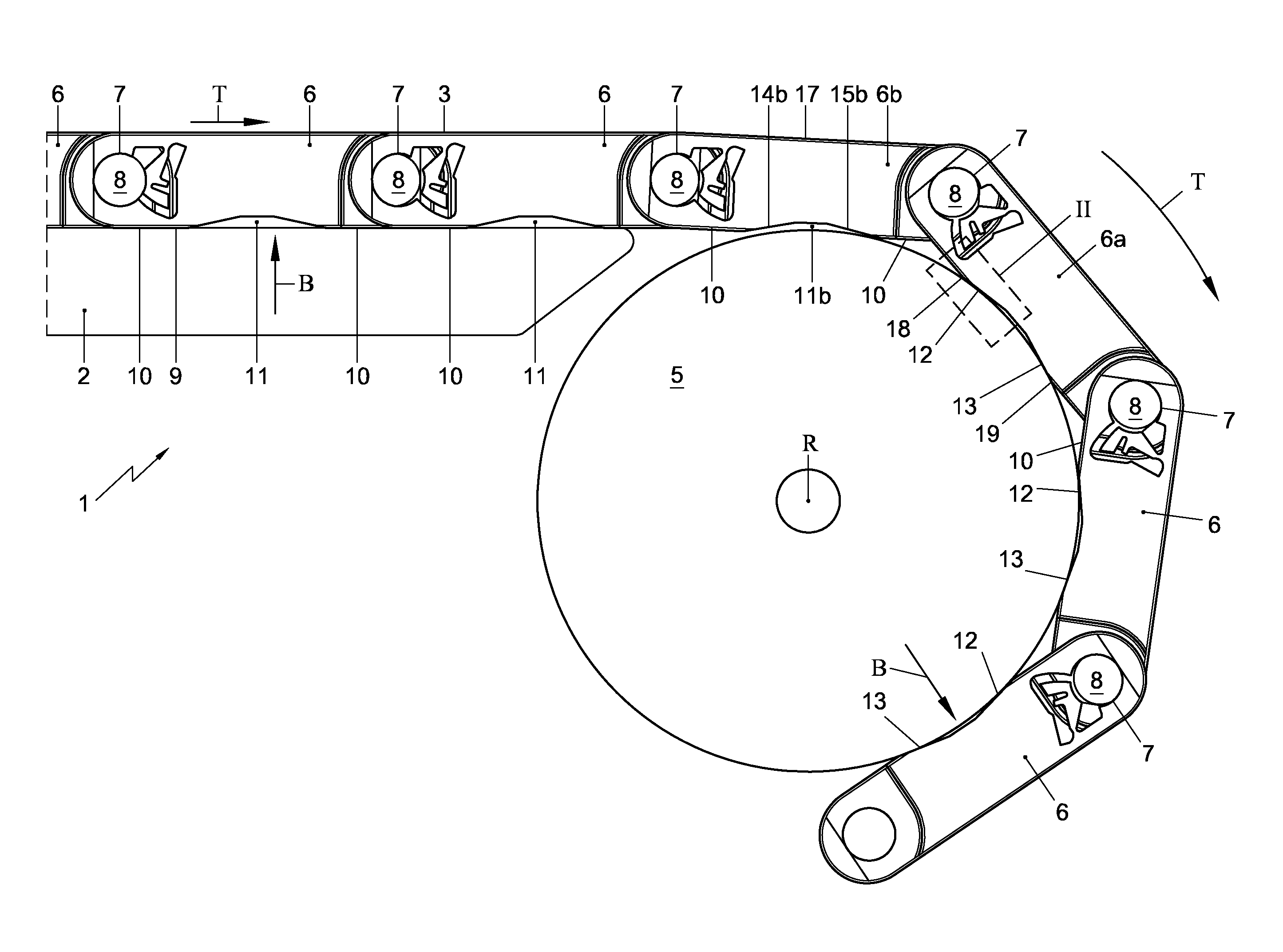

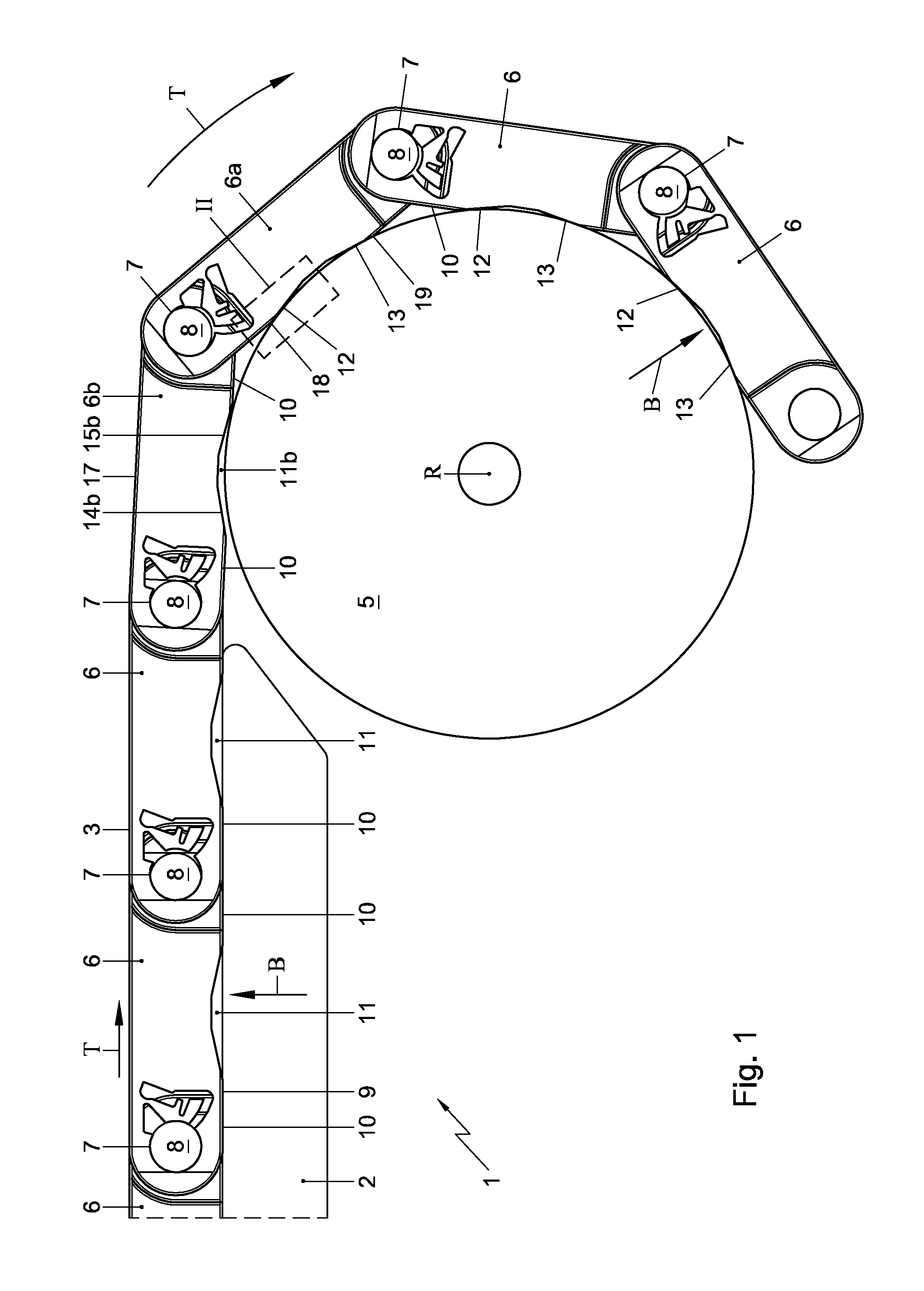

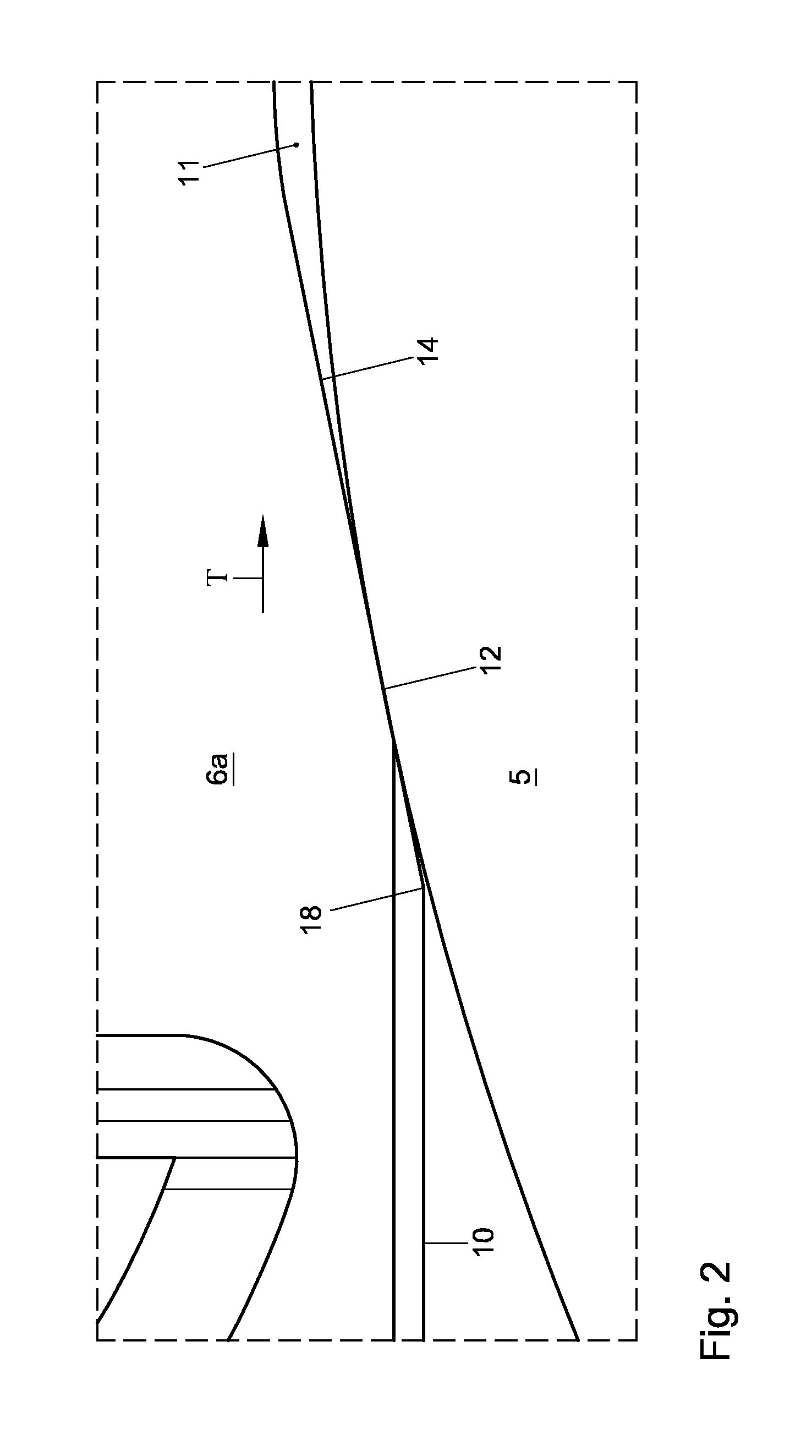

Conveying system, and use of a chamber extending inwardly with respect to a plastic module in a conveying system

The invention relates to a conveying system. The conveying system comprises a conveying track, an endless conveyor mat for conveying products in a conveying direction, a drive for driving the conveyor mat, and a return guide provided at the conveying track for guiding the conveyor mat upon circulation. The return guide extends substantially transversely to the conveying direction. The conveyor mat comprises a number of plastic modules, which are provided at their bottom side with a track guide surface, while at least a part of the plastic modules at the location of the respective track guide surface comprise at least one chamber extending inwardly with respect to the module for being in a contact with the return guide during circulation of the module around the return guide. The chamber is formed such that the contact upon circulation consists of a first line contact and a second line contact.

Owner:REXNORD FLATTOP EURO BV

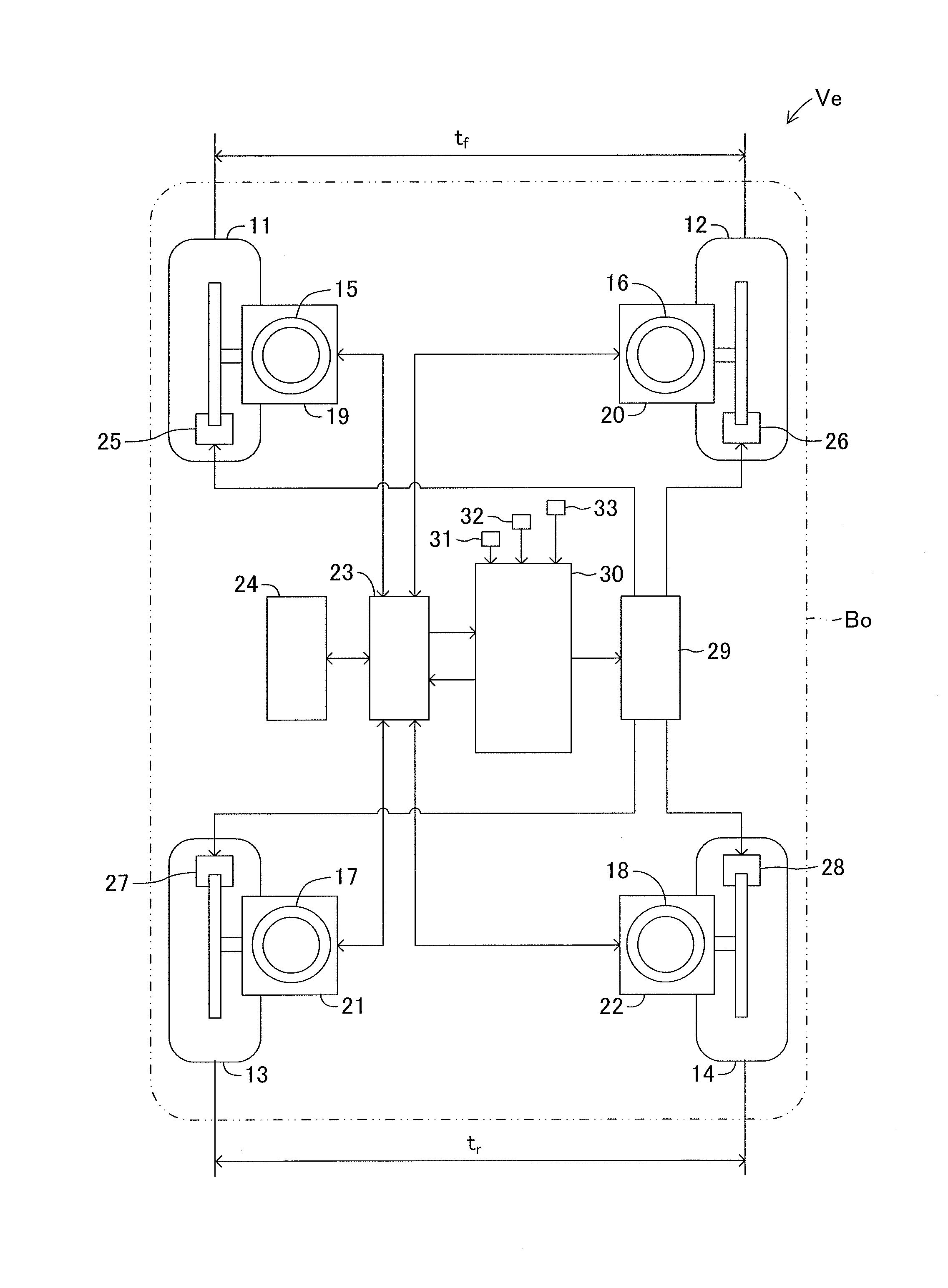

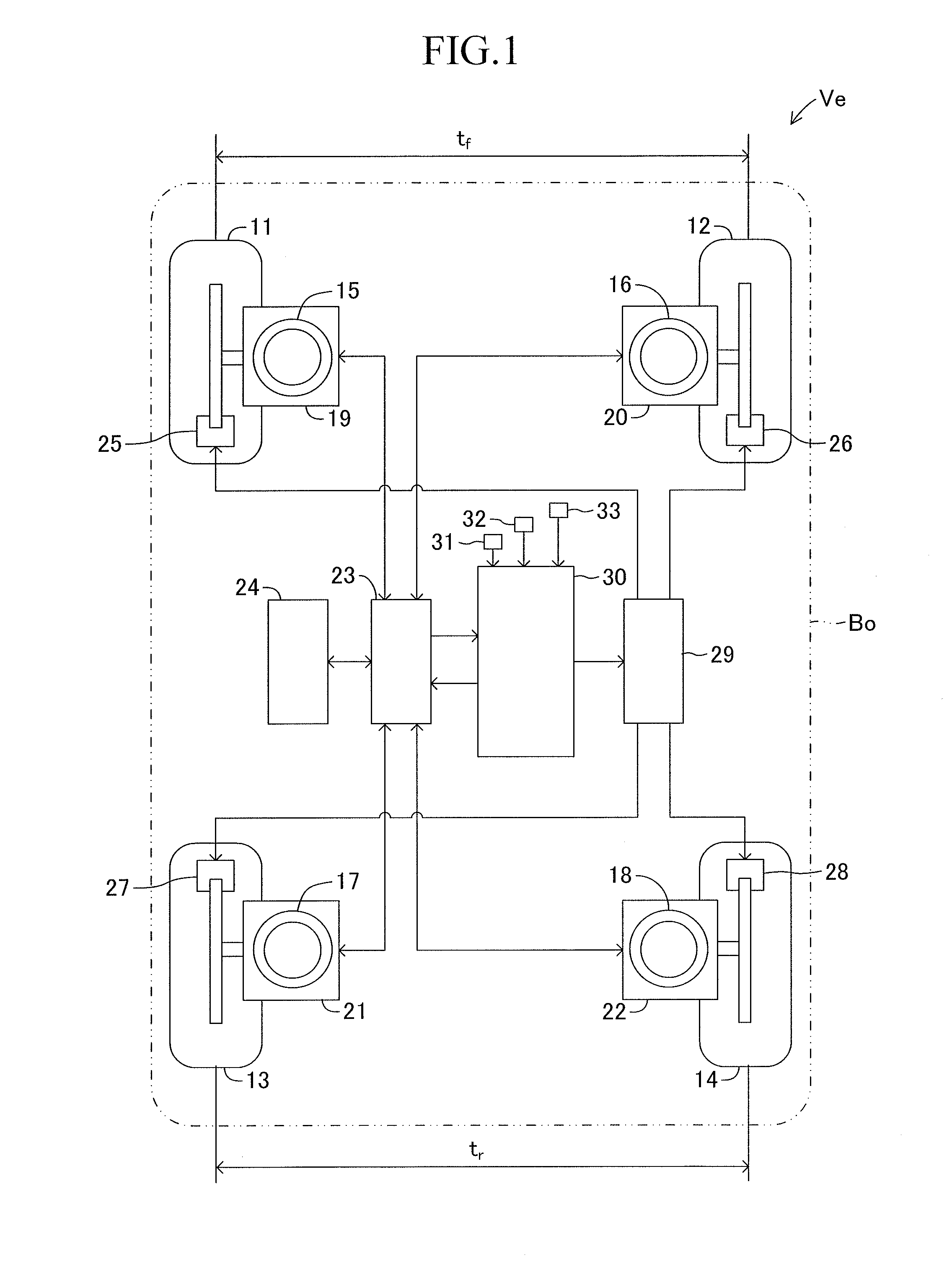

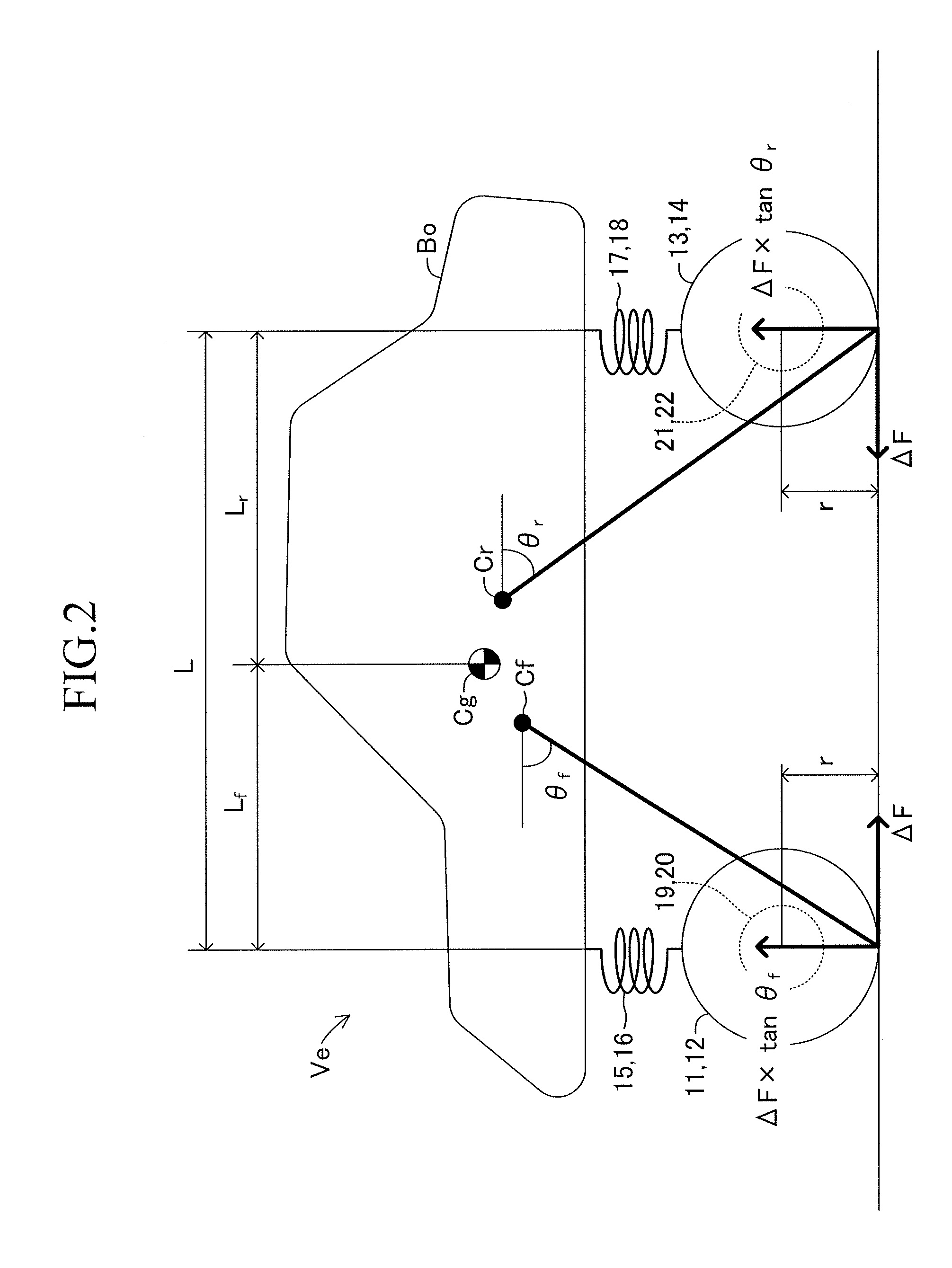

Vehicle braking/driving force control apparatus

ActiveUS20150100205A1Excellently secure stability steeringExcellently secure travel stabilitySpeed controllerElectric devicesIn vehicleRoll moment

Provided is a vehicle braking / driving force control apparatus for securing travel stability of a vehicle by priority when a slip occurs on a wheel for generating a braking / driving force while a plurality of motions are controlled. An electronic control unit identifies a slipping wheel having the maximum slip ratio (Si (i=fl, fr, rl, rr)) among wheels. The unit determines to increase or decrease a target roll moment (KmxMx) and a target pitch moment (KmyMy) for controlling a roll motion and a pitch motion, which are motions on the body in the vehicle vertical direction, so that the driving force on the slipping wheel has a direction to eliminate the slip state. The unit executes driving force distribution control so that a target longitudinal driving force (Fx) and a target yaw moment (Mz) for respectively controlling a longitudinal motion of a vehicle (Ve) and a yaw motion of a body (Bo), which are motions in vehicle longitudinal and lateral directions, and the increased / decreased moments (KmxMx, KmyMy) so as to simultaneous realize those factors.

Owner:TOYOTA JIDOSHA KK

Multi-channel thin-film magnetic head, magnetic tape drive apparatus with the multi-channel thin-film magnetic head and manufacturing method of multi-channel thin-film magnetic head

InactiveUS8035919B2Stable travelReduce areaManufacturing heads with multiple gapsDecorative surface effectsTectorial membraneMagnetic tape

Owner:TDK CORPARATION

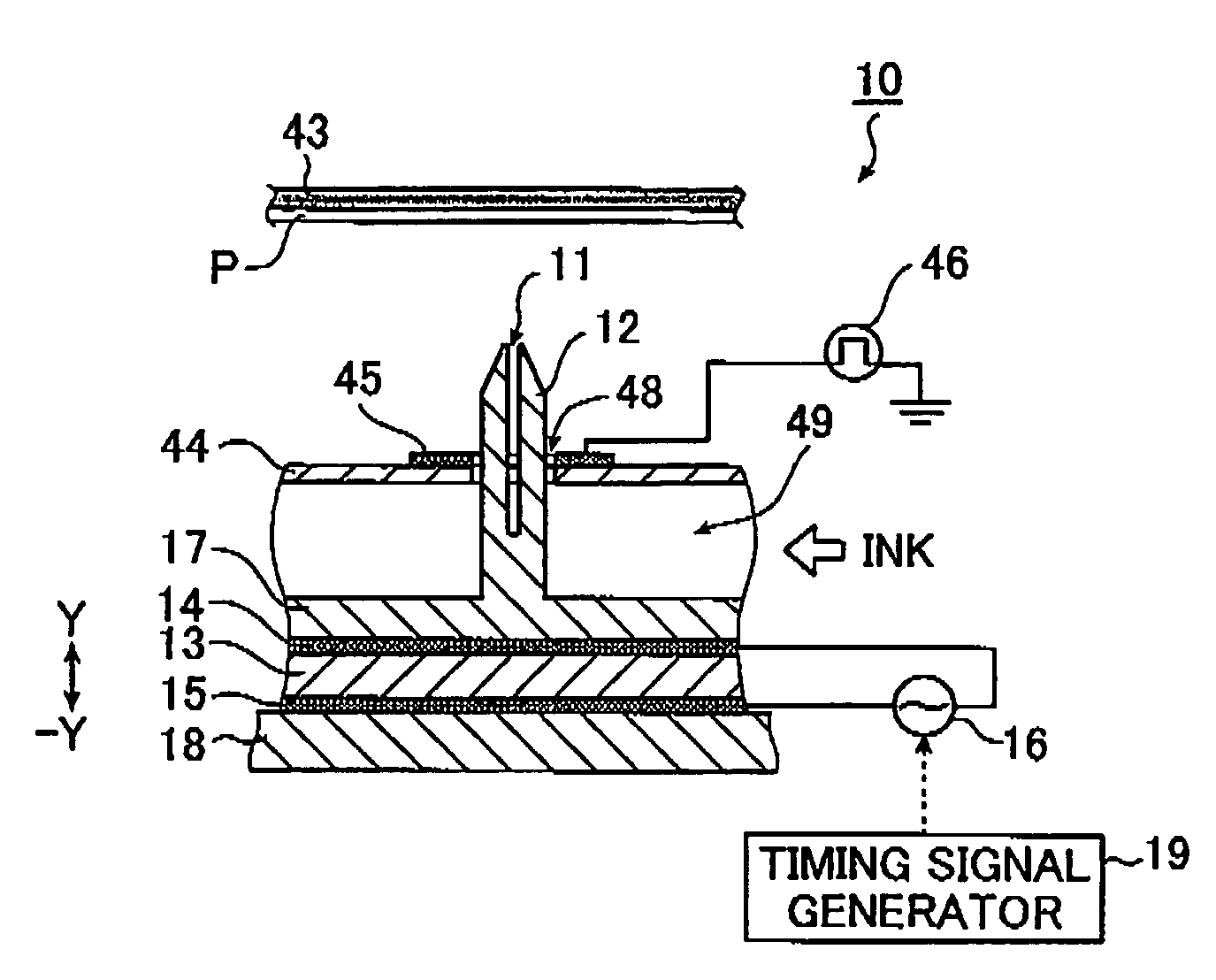

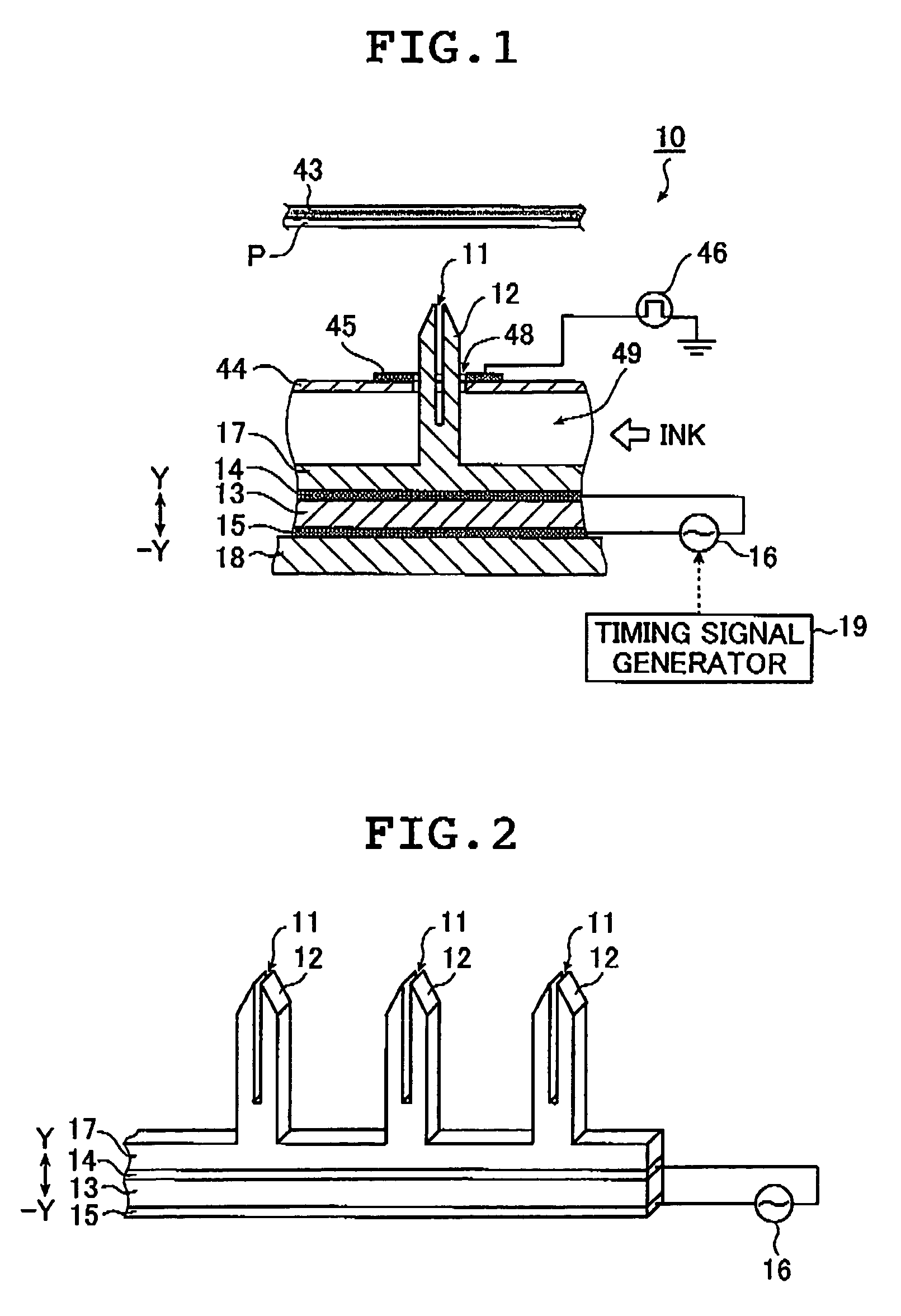

Ink-jet recording unit, ink-jet recording method and recording head cleaning method for ink-jet recording unit

The ink-jet recording unit and method apply a voltage identical in polarity with charged colorant particles agglomerated at a tip of each of ink guides to an ejecting electrode, eject ink from the tip and shake the colorant particles at the tip to agglomerate the colorant particles at the tip in preparation for a subsequent ejection of the ink. The recording head cleaning method for the ink-jet recording unit fills the ink channel with a cleaning solution and shakes the cleaning solution to clean the ink guides.

Owner:FUJIFILM HLDG CORP +1

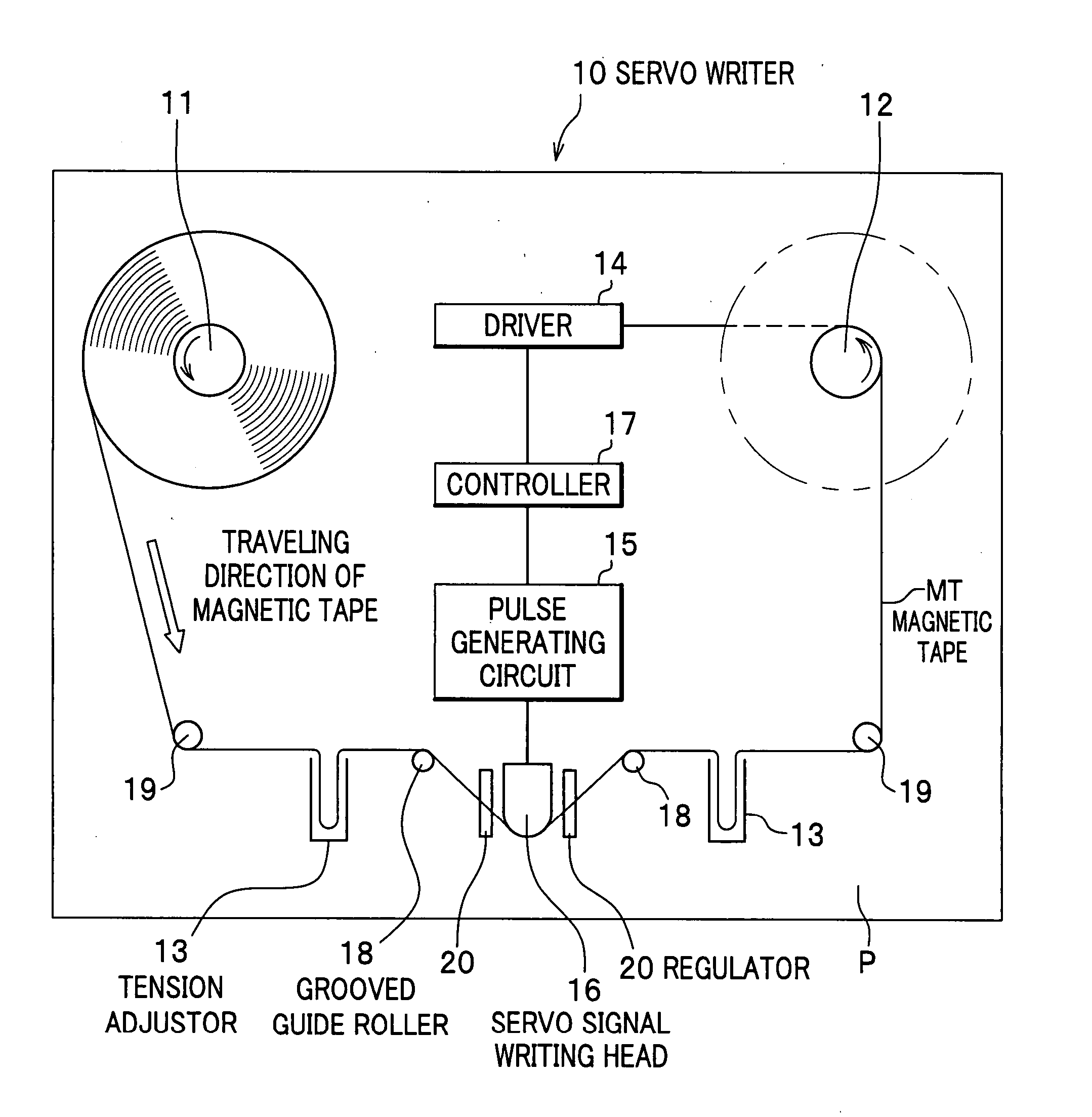

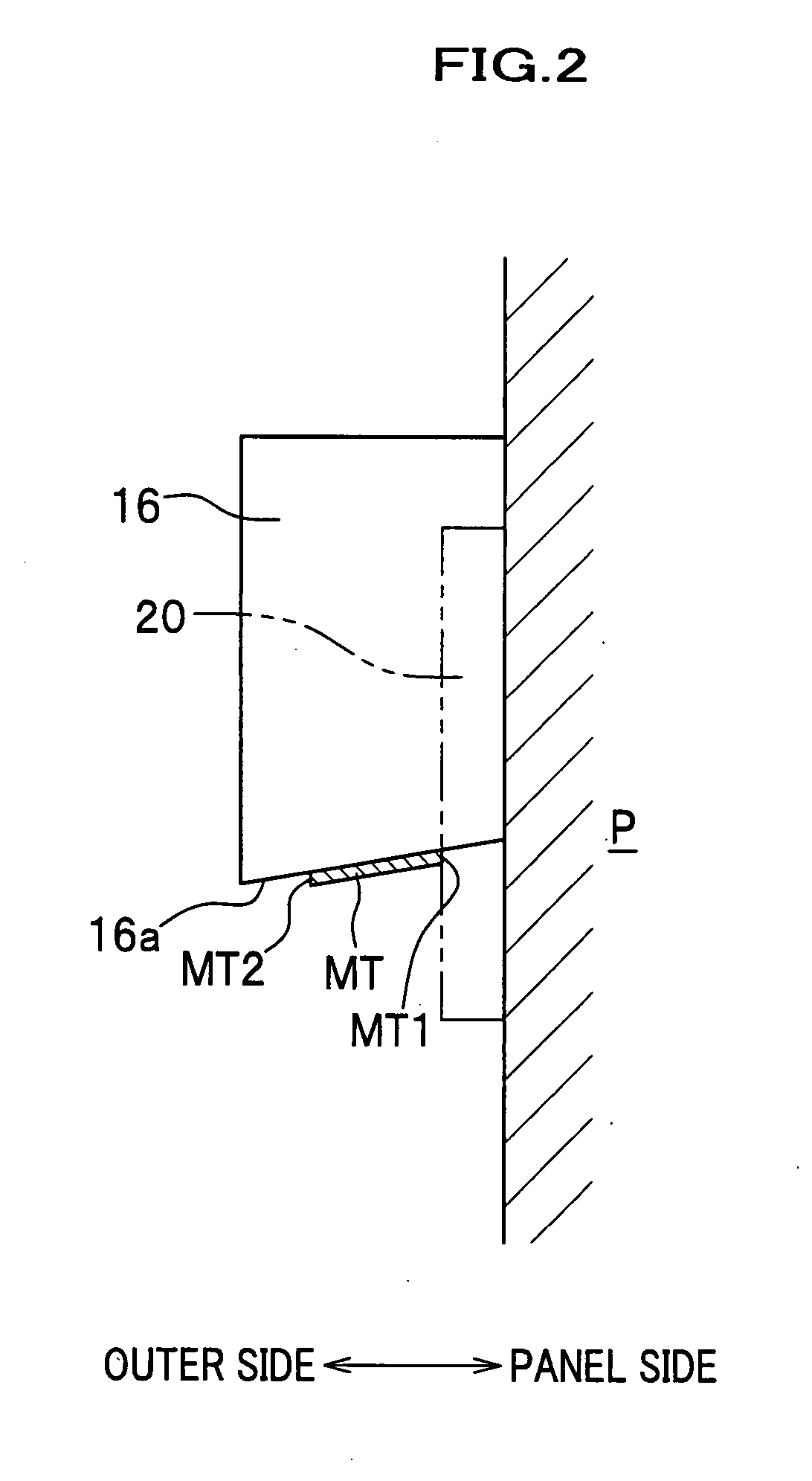

Tape guiding mechanism, magnetic tape apparatus, and method for manufacturing magnetic tape

ActiveUS20070285840A1Hinders its propagationStable travelAlignment for track following on tapesTape carriersMagnetic tapeEngineering

A tape guiding mechanism for guiding a traveling tape is provided including a guide roller for guiding the traveling tape and a regulator which rubs against at least one edge of the traveling tape in its width direction, in which the guide roller includes a circumferential surface with which the tape is in contact, a spiral groove is formed on the circumferential surface around an axis of the guide roller, and the traveling tape shifts to one side in a width direction on the circumferential surface of the guide roller.

Owner:FUJIFILM CORP

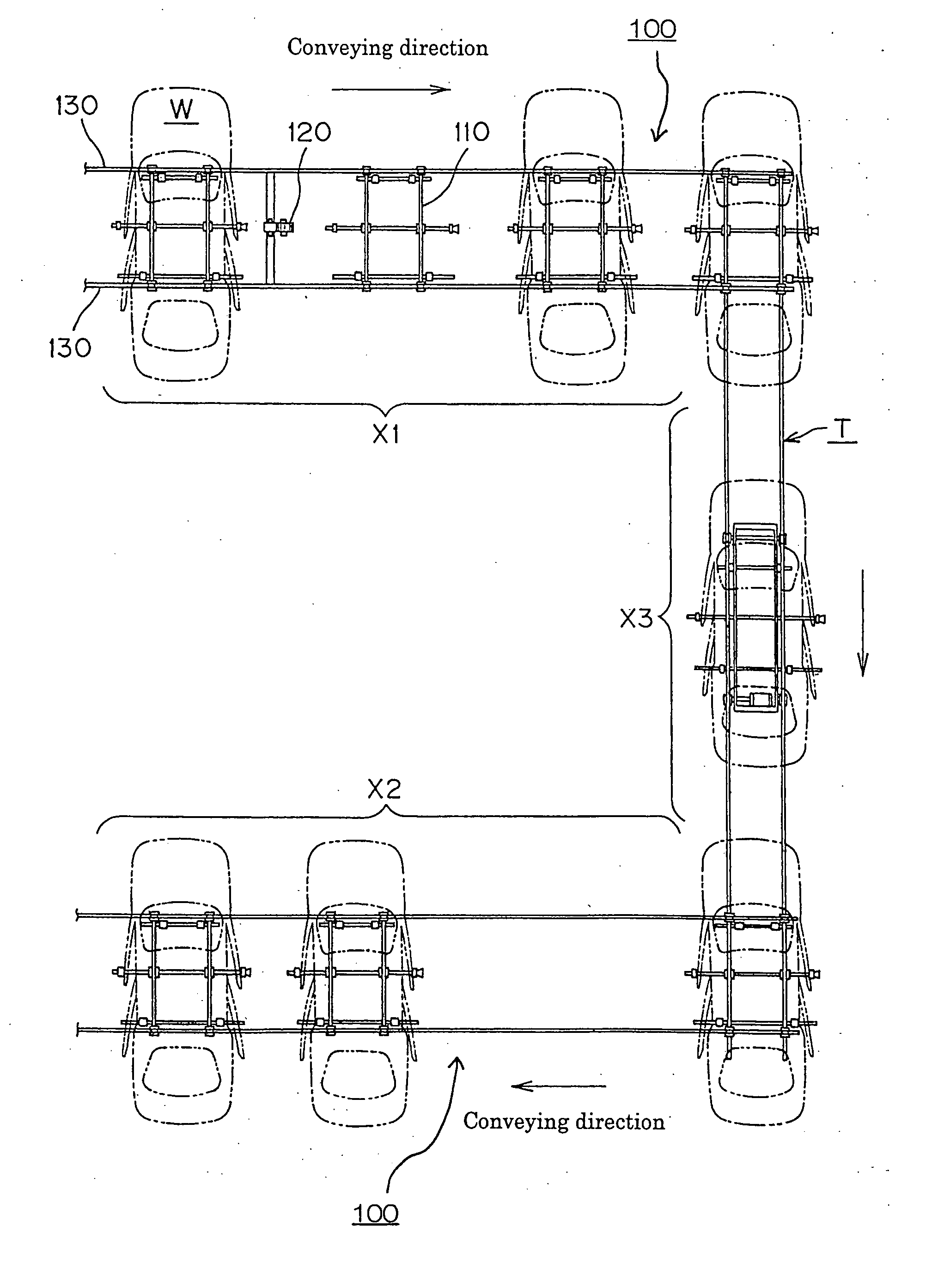

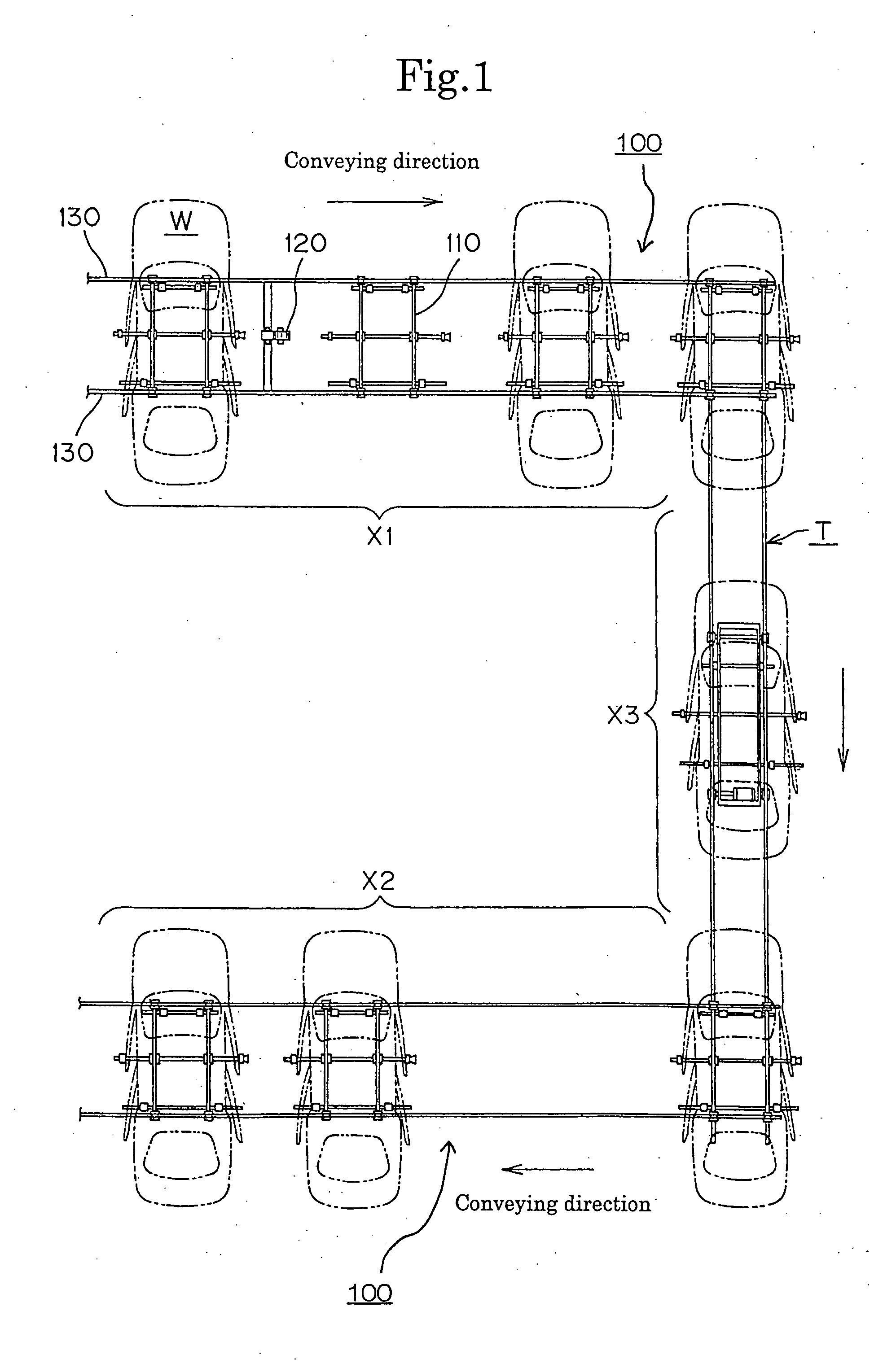

Transverse car body conveying system

InactiveUS20070245922A1Improve storage efficiencySmall sizeRailway componentsTramway railsEngineeringMechanical engineering

Owner:TSUBAKIMOTO CHAIN CO

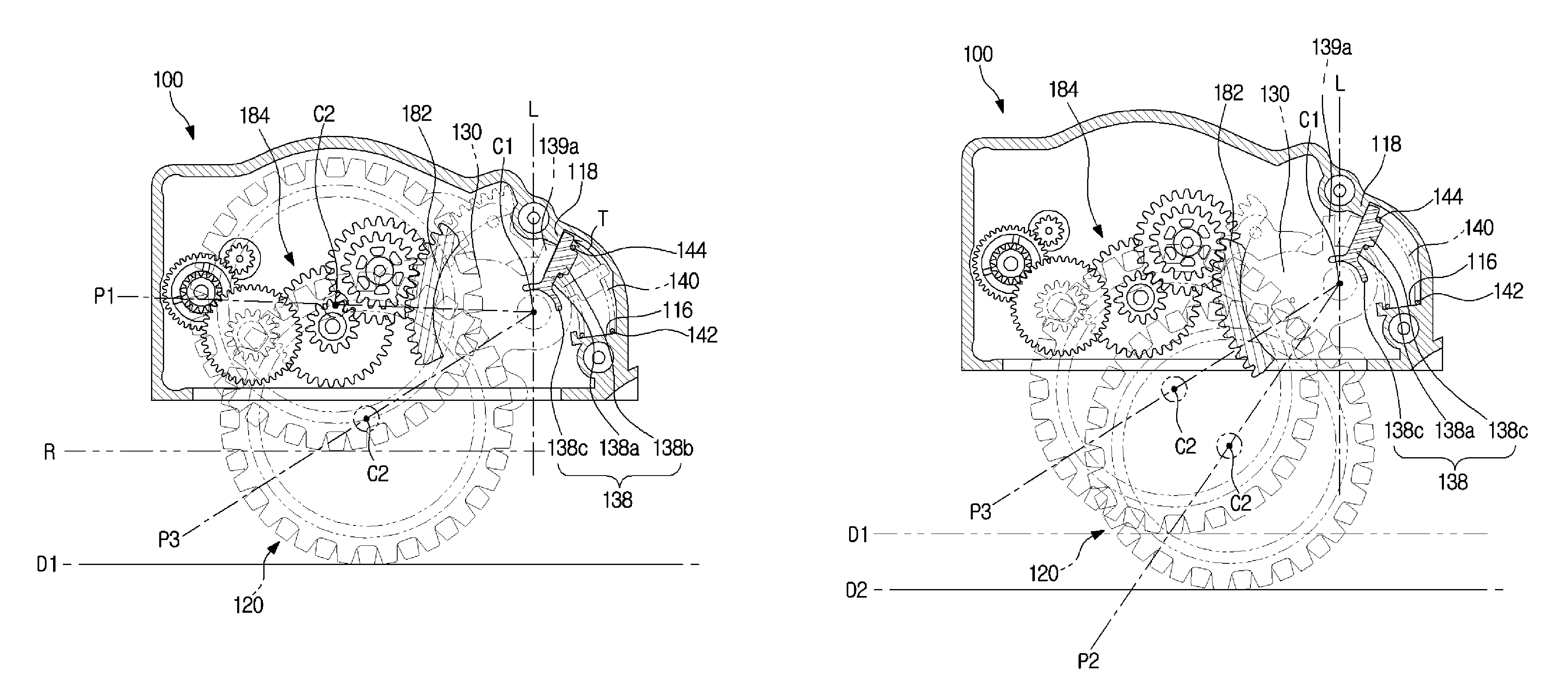

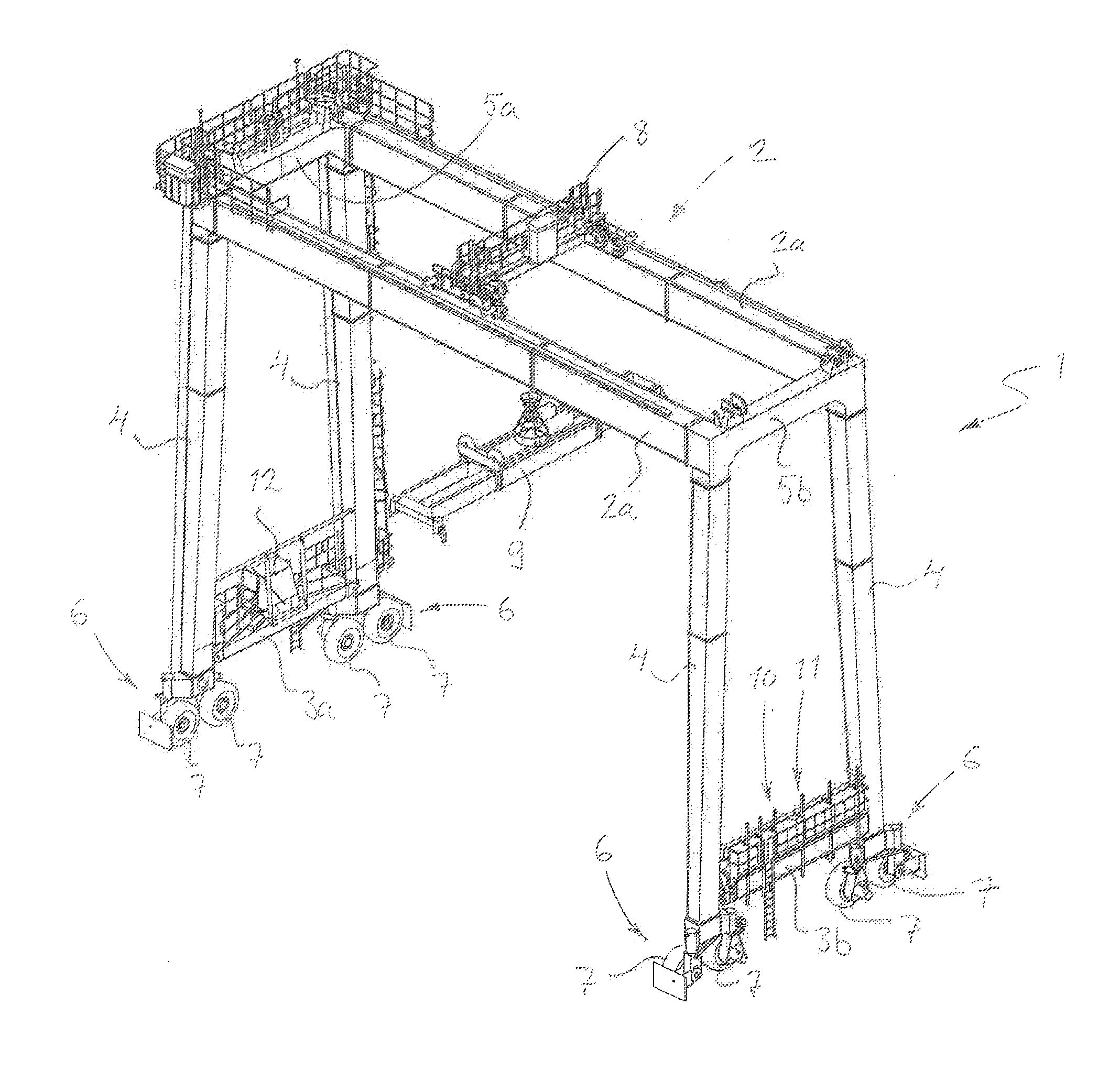

Moving crane

InactiveUS20170015532A1Cheap constructionImproved weight distributionTrolley cranesLoad-engaging elementsEngineering

Owner:KONECRANES GLOBAL

Recording tape cartridge

InactiveUS20050127224A1Reduce vibrationReduce the amplitudePicture changing apparatusRecord information storageCoil springSliding contact

A recording tape cartridge is disclosed wherein when in non-use, a reel accommodated in a case and having a recording tape wound thereon is prevented from rotating by being meshed with a braking member which is non-rotatble with reference to the case; and when in use, in response to the braking member being pushed up by a release pad or a clutch member, the reel is released from the meshed state and allowed to rotate together with the release pad or the clutch member. With the rotation of the reel, the braking member has its pivot portion disposed in sliding contact with a sliding contact portion formed at a portion corresponding to an axial center of the release pad or the clutch member while being pressed against the sliding contact portion by a biasing force of a compression coil spring. The recording tape cartridge is designed such that a relation μ×L≦0.4 holds between a length L (mm) of the compression coil spring along the axis line of the reel when the reel rotates together with the release pad or the clutch member and a coefficient of dynamic friction μ between the pivot portion of the braking member and the sliding contact portion of the release pad or the clutch member.

Owner:FUJIFILM CORP +1

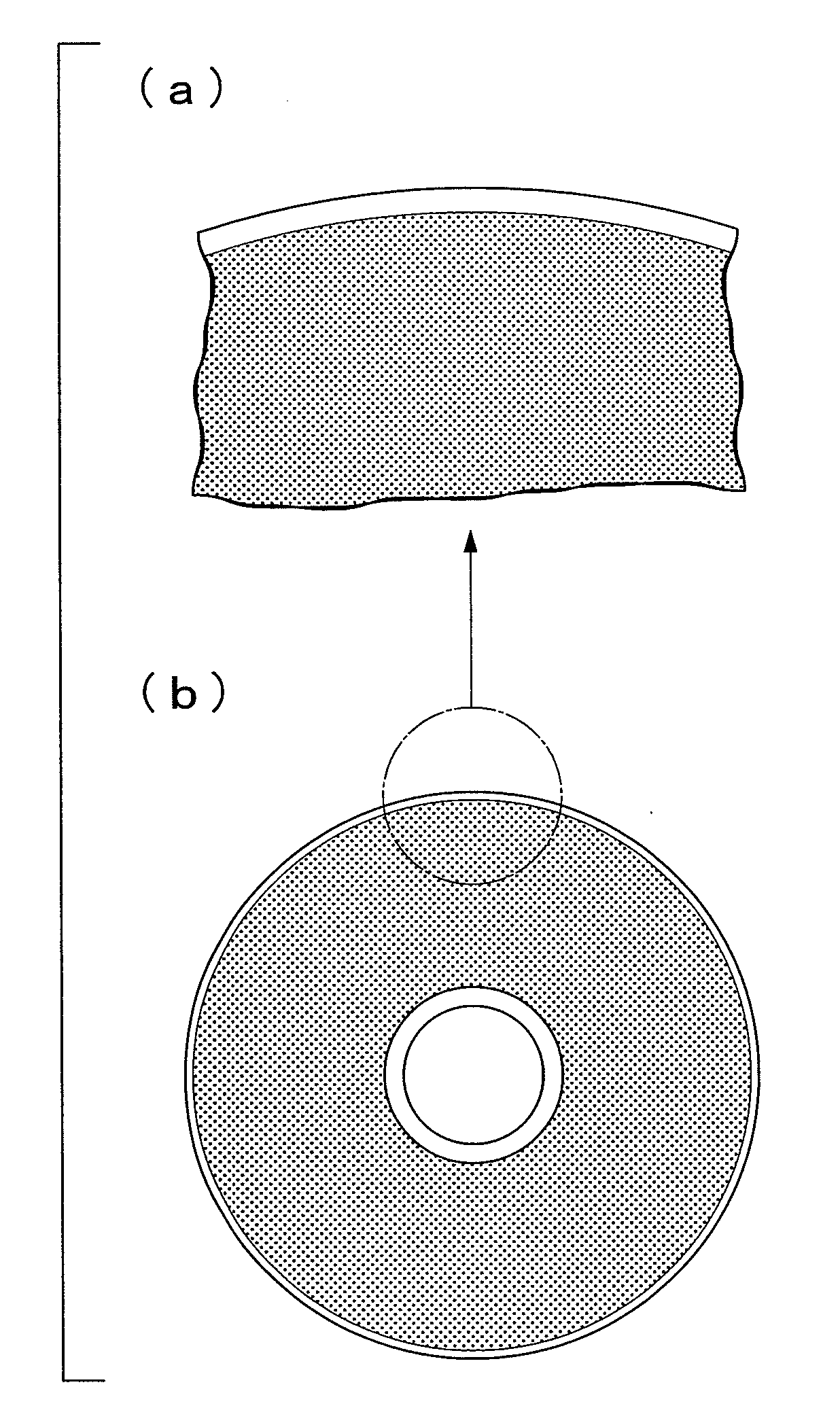

Double-sided coating apparatus and method for double-sided coating with coating solution

InactiveUS20100196596A1Avoid confictStable travelCoating by liquid dispersionSpecial surfacesNozzleMaterials science

Provided are a double-sided coating apparatus and a method for double-sided coating with a coating solution configured to uniformly apply a coating solution to both surfaces of a substrate having a central opening in a simple process while preventing ingress of the coating solution to the central opening. A coating apparatus 1 according to the invention applies a coating solution to both main surfaces of a substrate 2 having a central opening 2a. The coating apparatus 1 includes: a rotation driving mechanism 3 with a chuck 11 which holds the substrate 2 by blocking the central opening 2a; a first coating solution nozzle 18 which ejects a coating solution to a first main surface of the substrate 2; a first pivot driving mechanism 17 which operates the first coating solution nozzle 18 to move to scan the first main surface of the substrate 2; a second coating solution nozzle 28 which ejects the coating solution to a second main surface of the substrate 2; a second pivot driving mechanism 31 which operates the second coating solution nozzle 28 to move to scan the second main surface of the substrate 3, and a device to independently control an ejection amount of the coating solution from the first coating solution ejection port 23 and an ejection amount of the coating solution from the second coating solution ejection port 29.

Owner:SHOWA DENKO KK

Power Paddle

InactiveUS20070224894A1Easy to moveStable travelOutboard propulsion unitsMuscle power acting propulsive elementsWater wheelPower tool

This invention relates to a paddle for a water vehicle that is powered by a power tool. The paddle is suitable for use alone for manual movement of a water vehicle but can be attached to a power tool for mechanical movement across water.

Owner:PRODUCT DEVELOPMENT TECHNOLOGIES

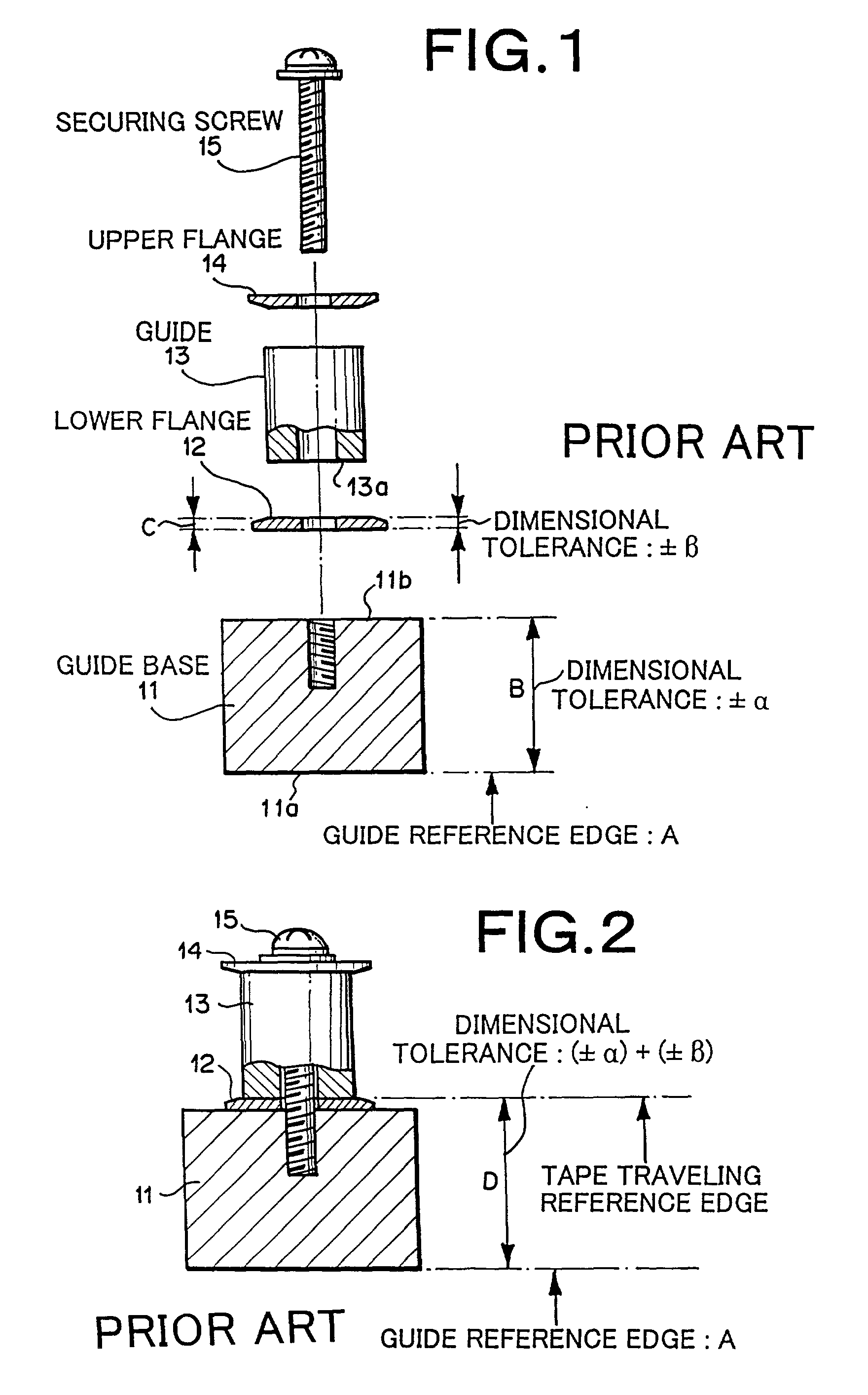

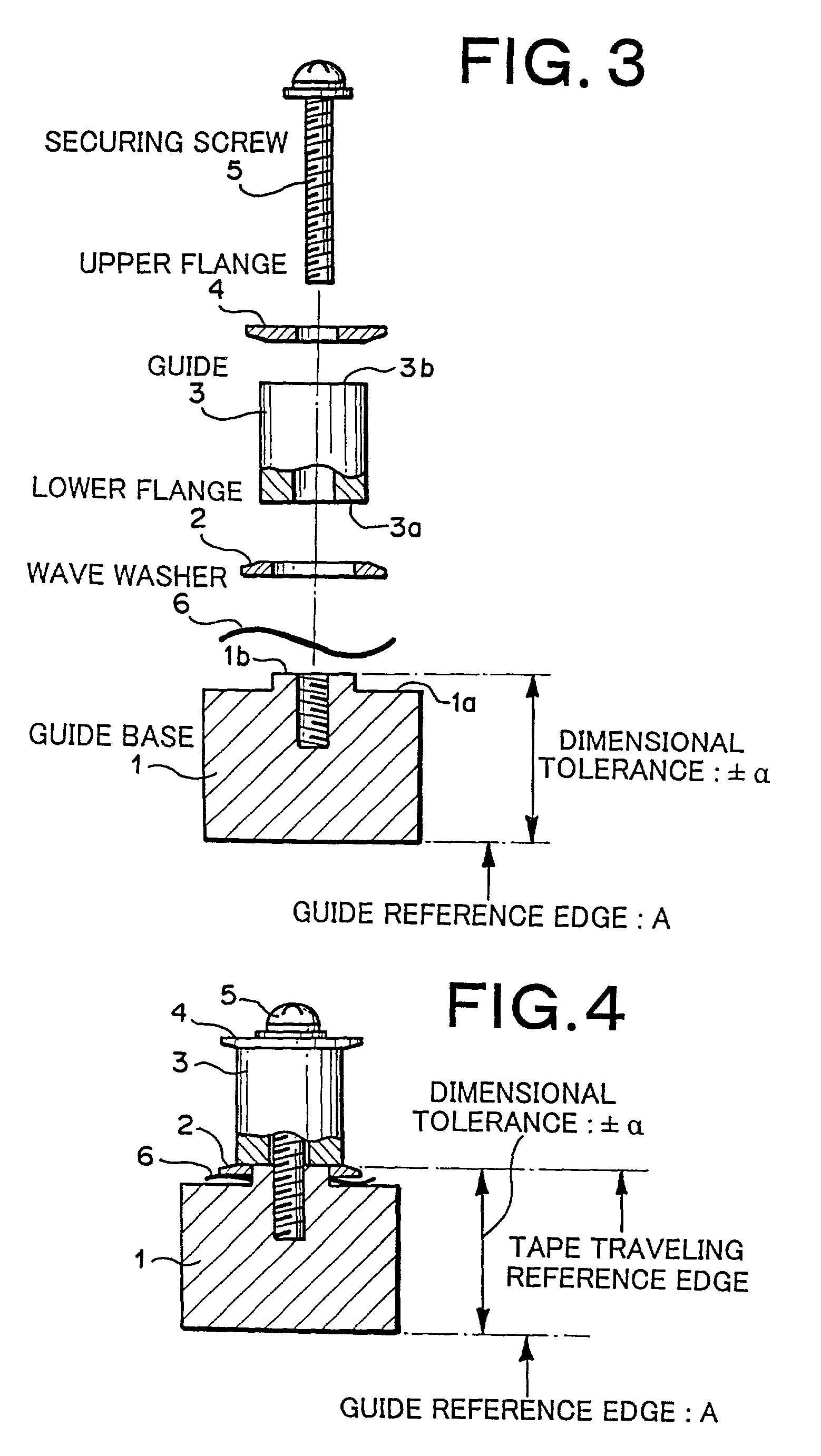

Mechanism for restricting lateral position of tape traveling in longitudinal direction

InactiveUS20010020633A1Stable travelLow costProjector film strip handlingFilament handlingEngineeringFront edge

A mechanism for restricting a lateral position of a tape traveling in a longitudinal direction is disclosed, that comprises a base having a convex portion, a guide directly disposed on the convex portion, a lower flange having an opening through which the convex portion passes, the lateral position of said lower flange against said base being movable between the front edge of said base and the bottom edge of said guide, and a member for pressing said lower flange to the bottom edge of said guide.

Owner:NEC CORP

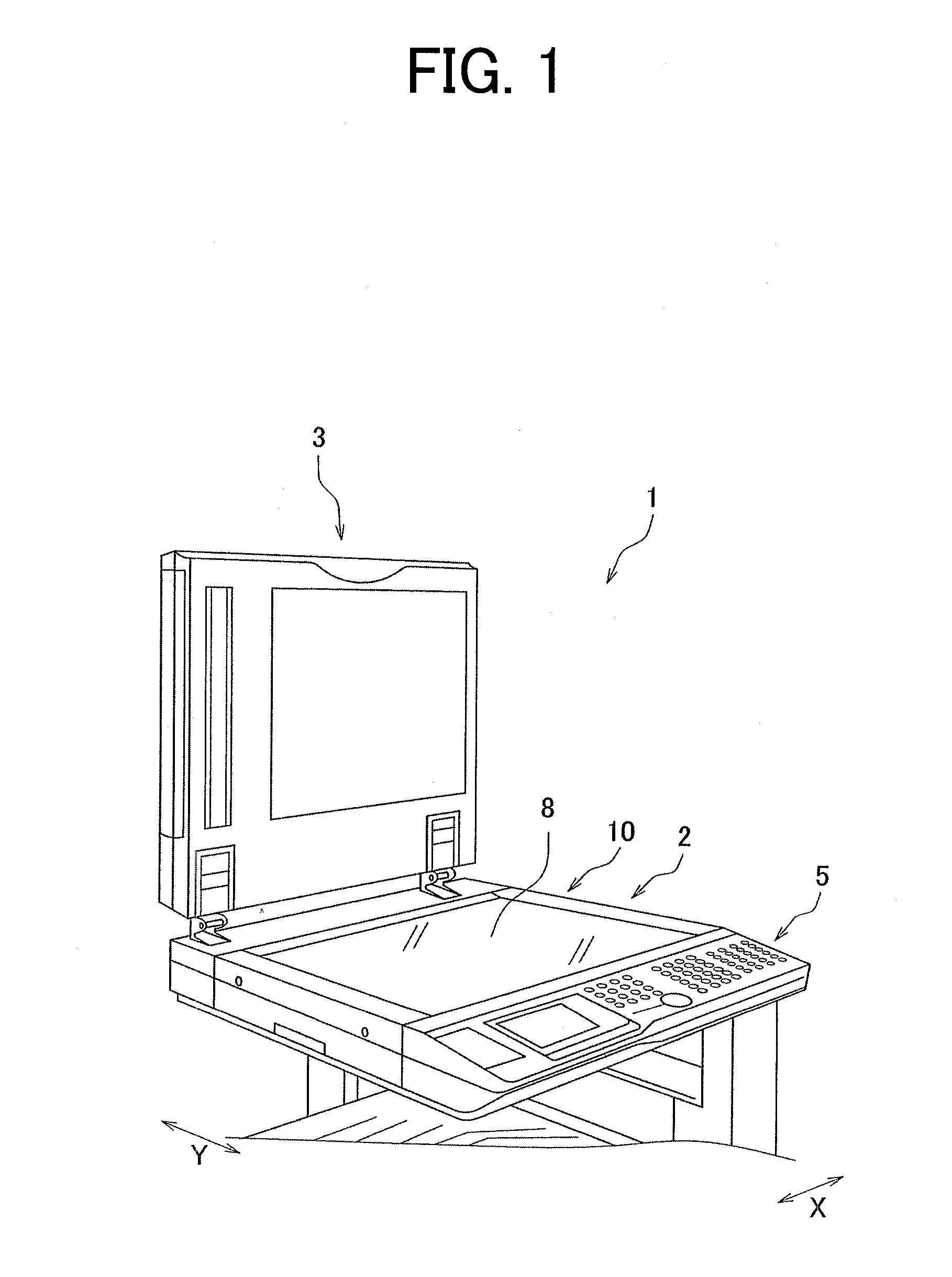

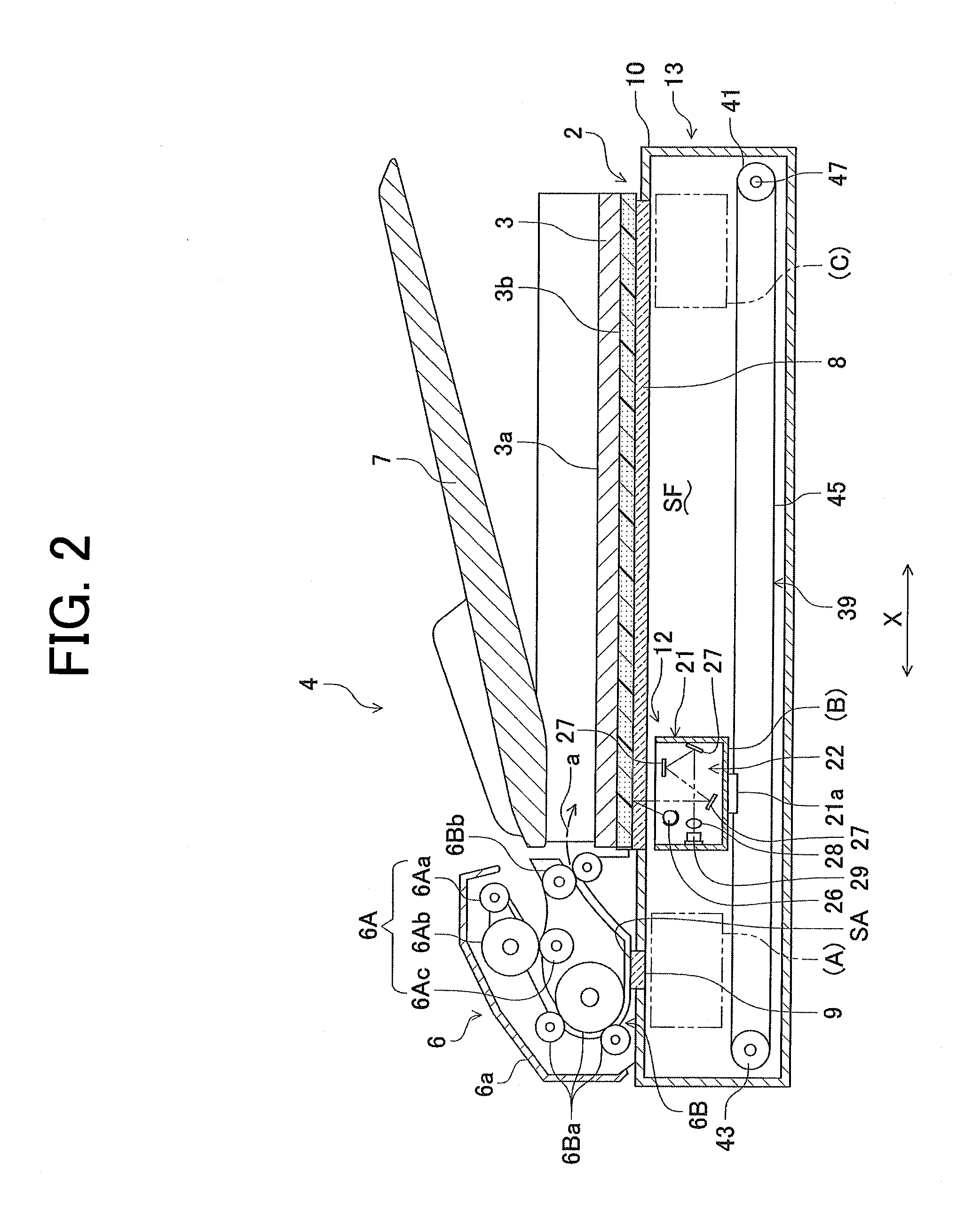

Image scanning device

InactiveUS20110176182A1Reduce component countSimple configurationPictoral communicationEngineeringChassis

An image scanning device includes a housing, a scanning carriage, and a first guide groove and a second guide groove. The housing includes a bottom chassis and a side wall member, and defines a document tray. A scanning carriage is movably arranged in the housing. The first guide groove and the second guide groove are arranged at the side wall members of the housing, and guide the scanning carriage in a scanning direction.

Owner:MURATA MASCH LTD

Robot cleaner and control method thereof

Proposed are a robot cleaner having an improved wheel structure to escape from being stuck in various travel conditions, and a control method thereof. The robot cleaner may smoothly escape from a door sill or an obstacle to stably travel irrespective of a state of a floor by providing an optimal frictional force of the floor through the control of an electric current of a motor when the robot cleaner escapes from being stuck. Also, the robot cleaner may stably travel without shaking by controlling an electric current flowing through the motor after the robot cleaner escapes from being stuck and before the driving wheel returns to a normal mode. Furthermore, it is possible to prevent a wheel mechanism such as a gear from being damaged by an external shock (e.g., which is caused by a pet or an object drop) or a shock caused by autonomous vibration when the robot cleaner crosses over an obstacle.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com