Vacuum welding furnace and welding technology

A vacuum welding furnace and welding chamber technology, which is applied in welding equipment, manufacturing tools, metal processing, etc., can solve the problems of low welding efficiency, slow cooling speed, downward bending, etc., and achieve reduced energy consumption, rapid heating and temperature Effect of cooling and avoiding sheet deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

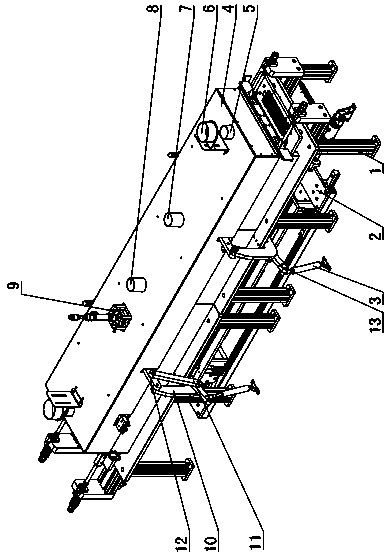

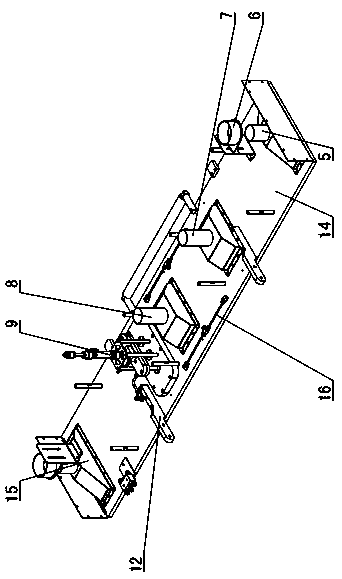

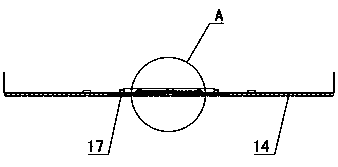

[0069] Figure 1~18 It is the best embodiment of the present invention, below in conjunction with the attached Figure 1~18 The present invention will be further described.

[0070] A vacuum welding furnace, comprising a welding chamber 18, a furnace cover 4 and a transport mechanism 2, the furnace cover 4 is covered on the upper side of the welding chamber 18, and a welding cavity is formed between the welding chamber 18 and the furnace cover 4, and the lower part of the welding chamber 18 A welding station 20 is provided, the side of the welding station 20 close to the feed end is a heating zone, the side of the welding platform 20 close to the discharge end is a cooling zone, and the upper side of the heating zone close to the cooling zone is provided with a negative pressure module 9 for pumping The negative pressure module 9 can be lifted and installed on the furnace cover 4. The bottom of the negative pressure module 9 and the heating zone are enclosed to form a closed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com