Patents

Literature

400 results about "Fixed width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fixed width. Fixed width is the width of a website element that does not change depending on the size of the used viewport and specifics of the used browser. If a website element has a fixed width, this width will change under no circumstances.

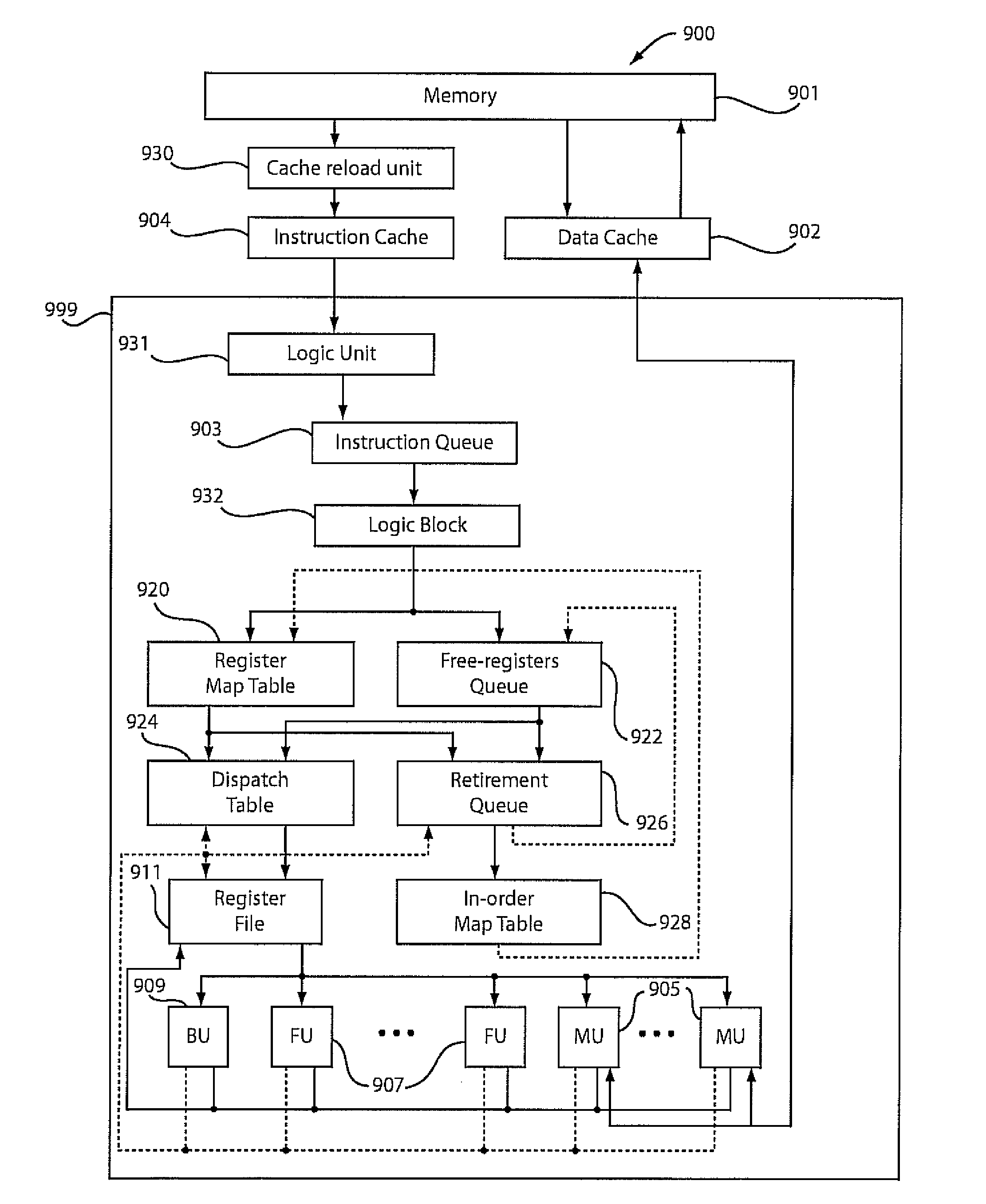

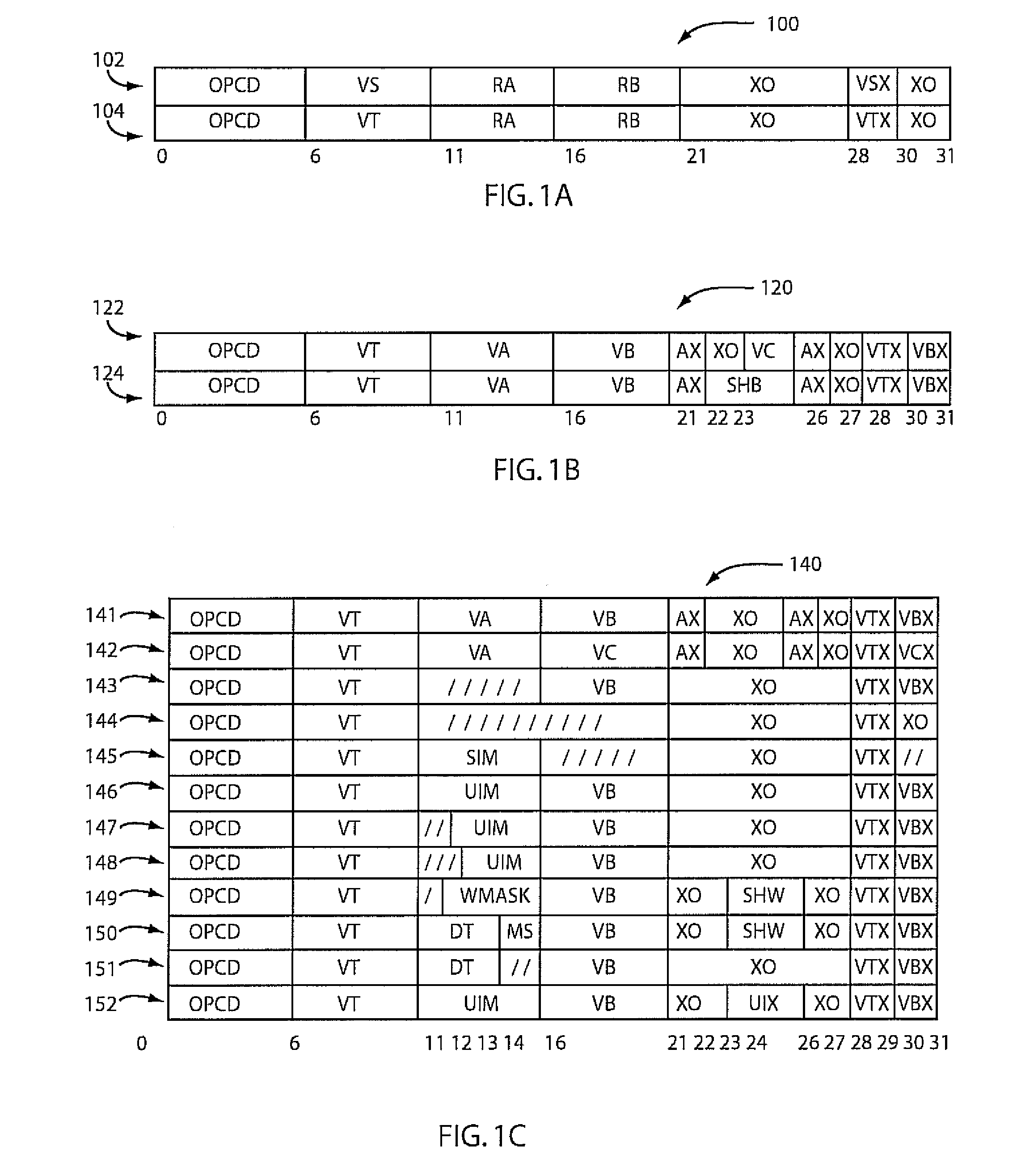

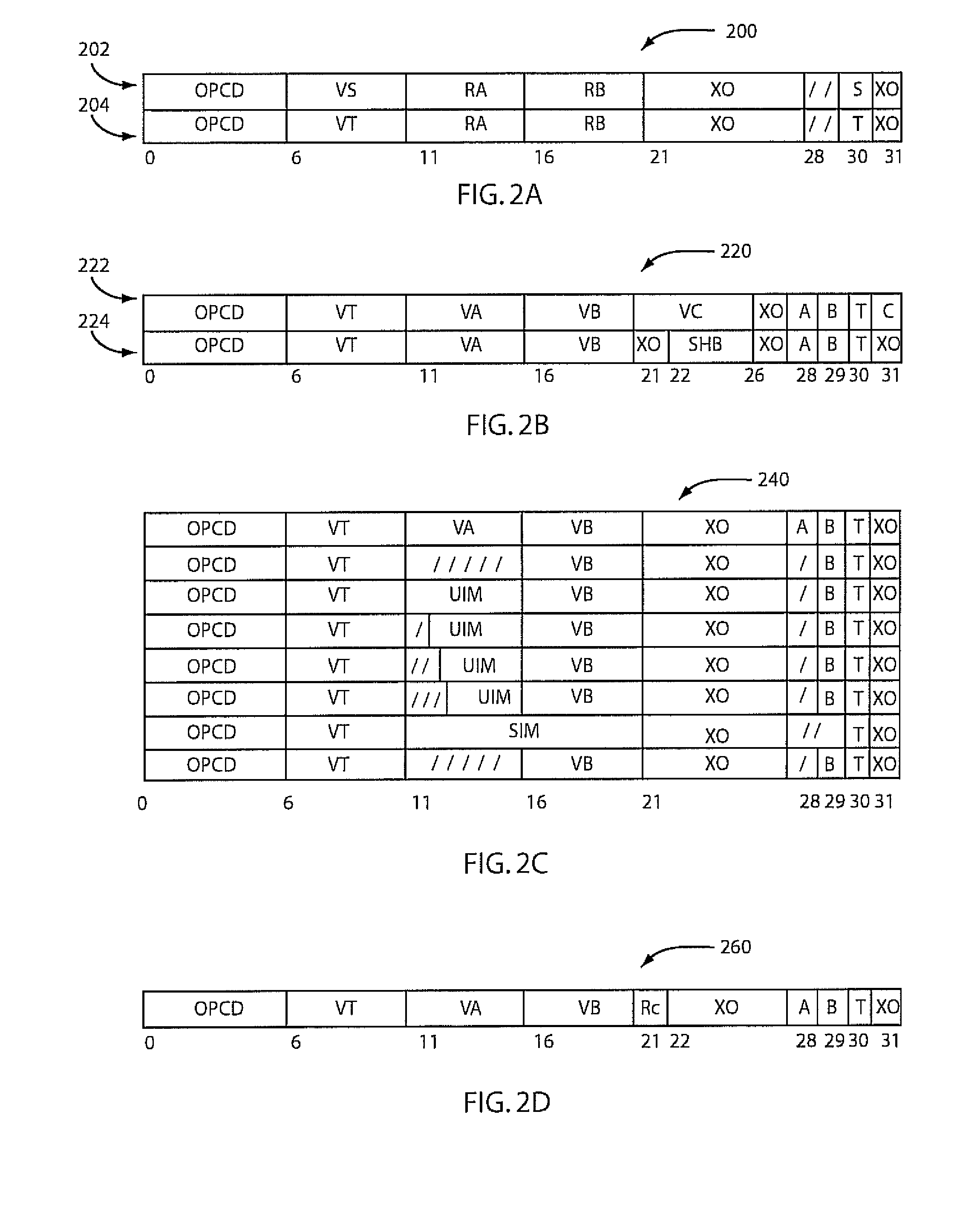

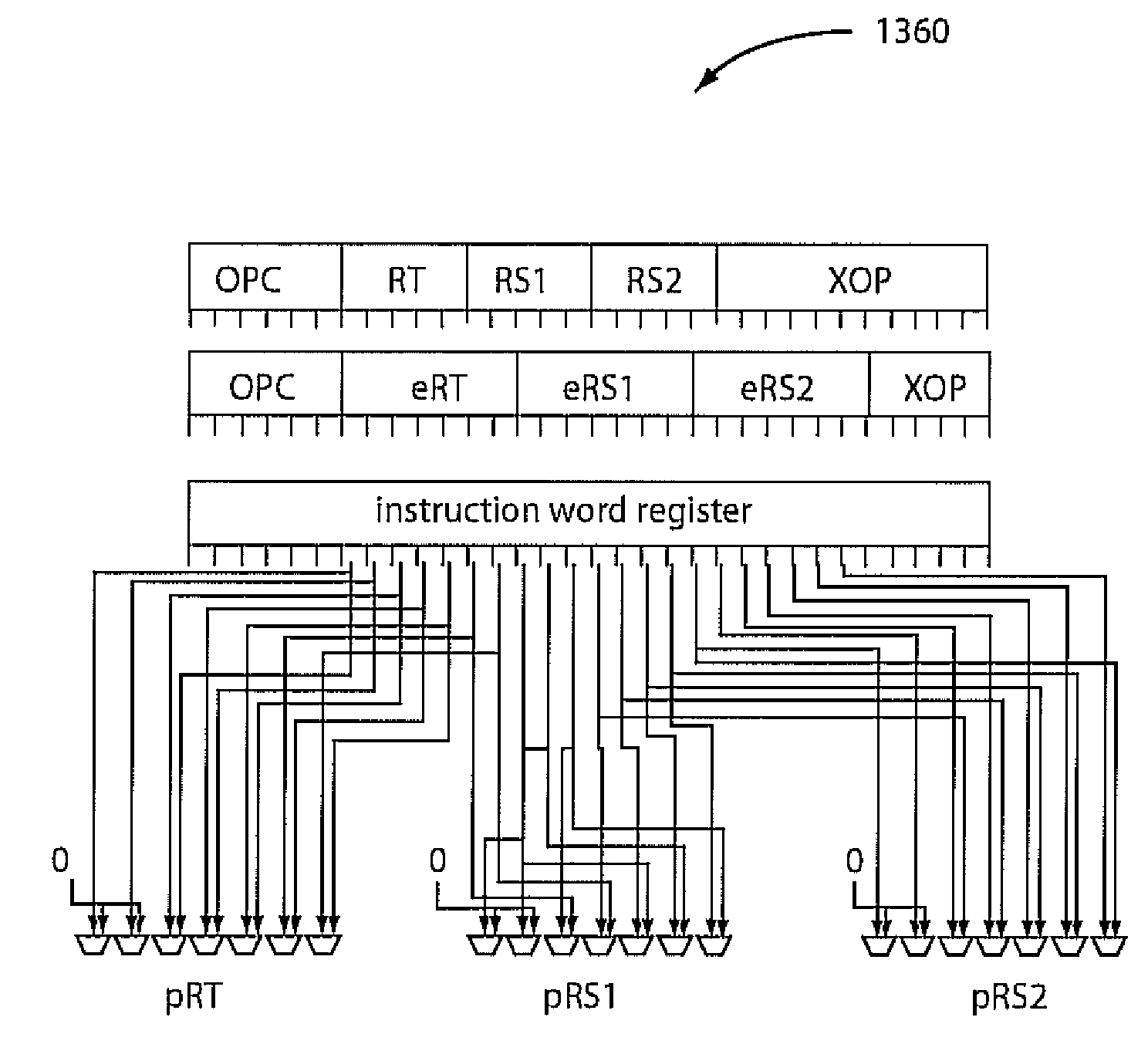

Implementing instruction set architectures with non-contiguous register file specifiers

ActiveUS20080189519A1Register arrangementsInstruction analysisProcessing InstructionProcessor register

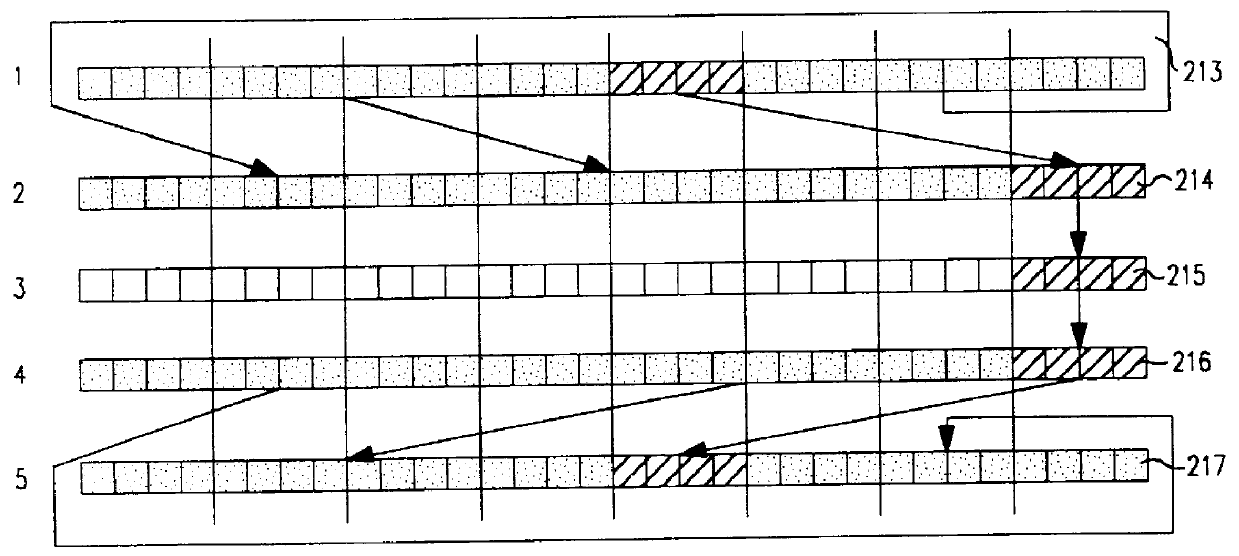

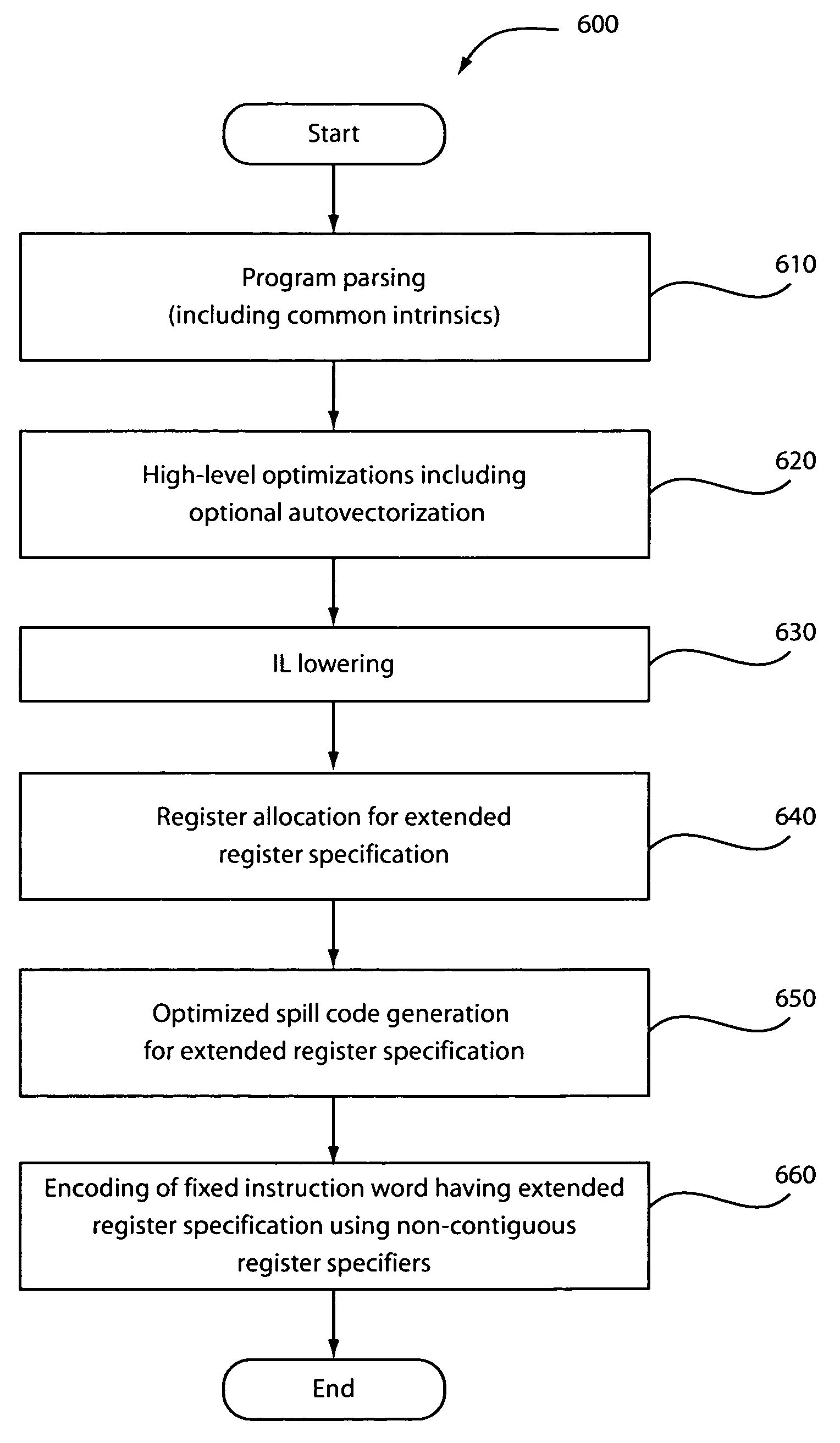

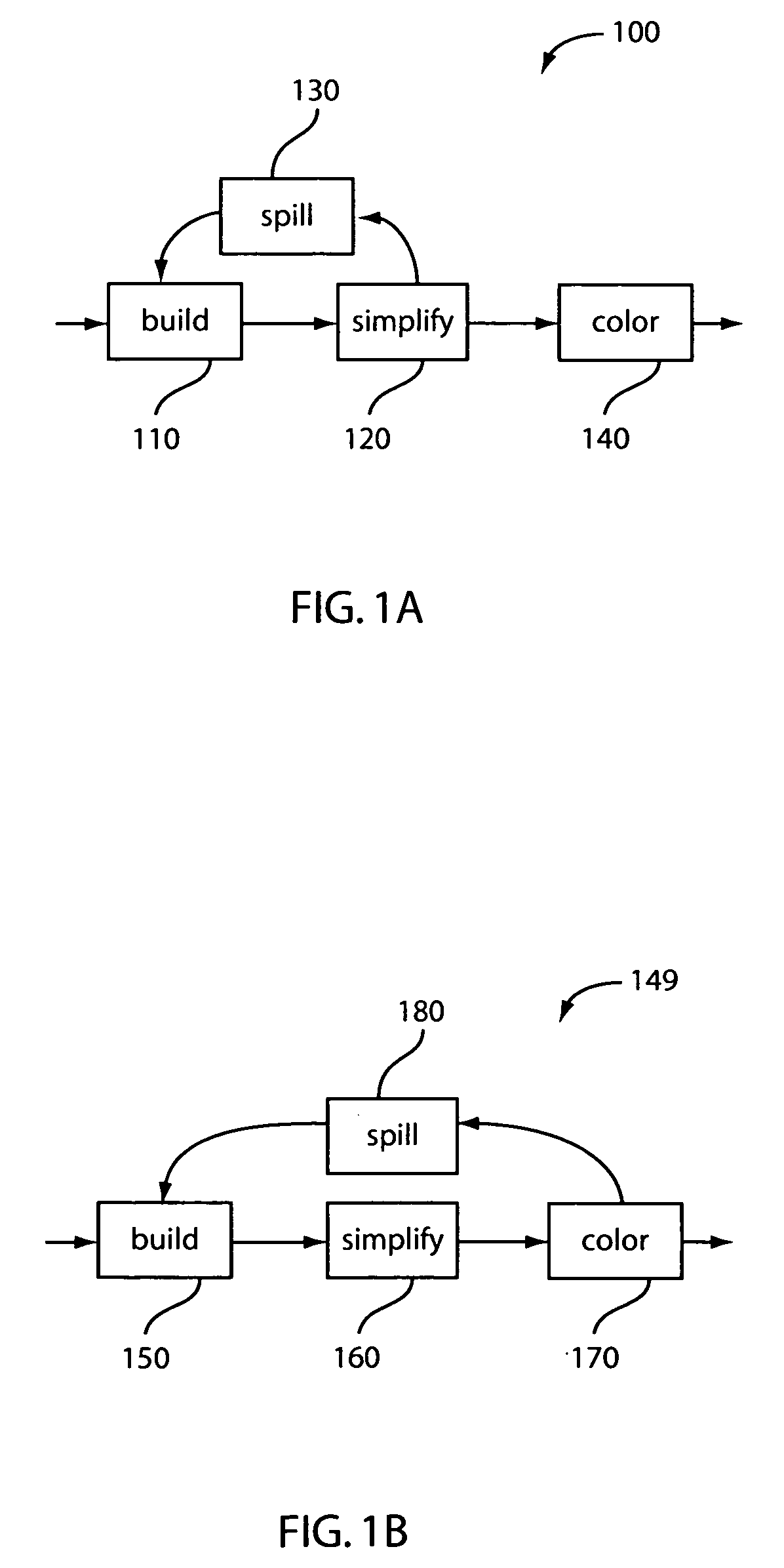

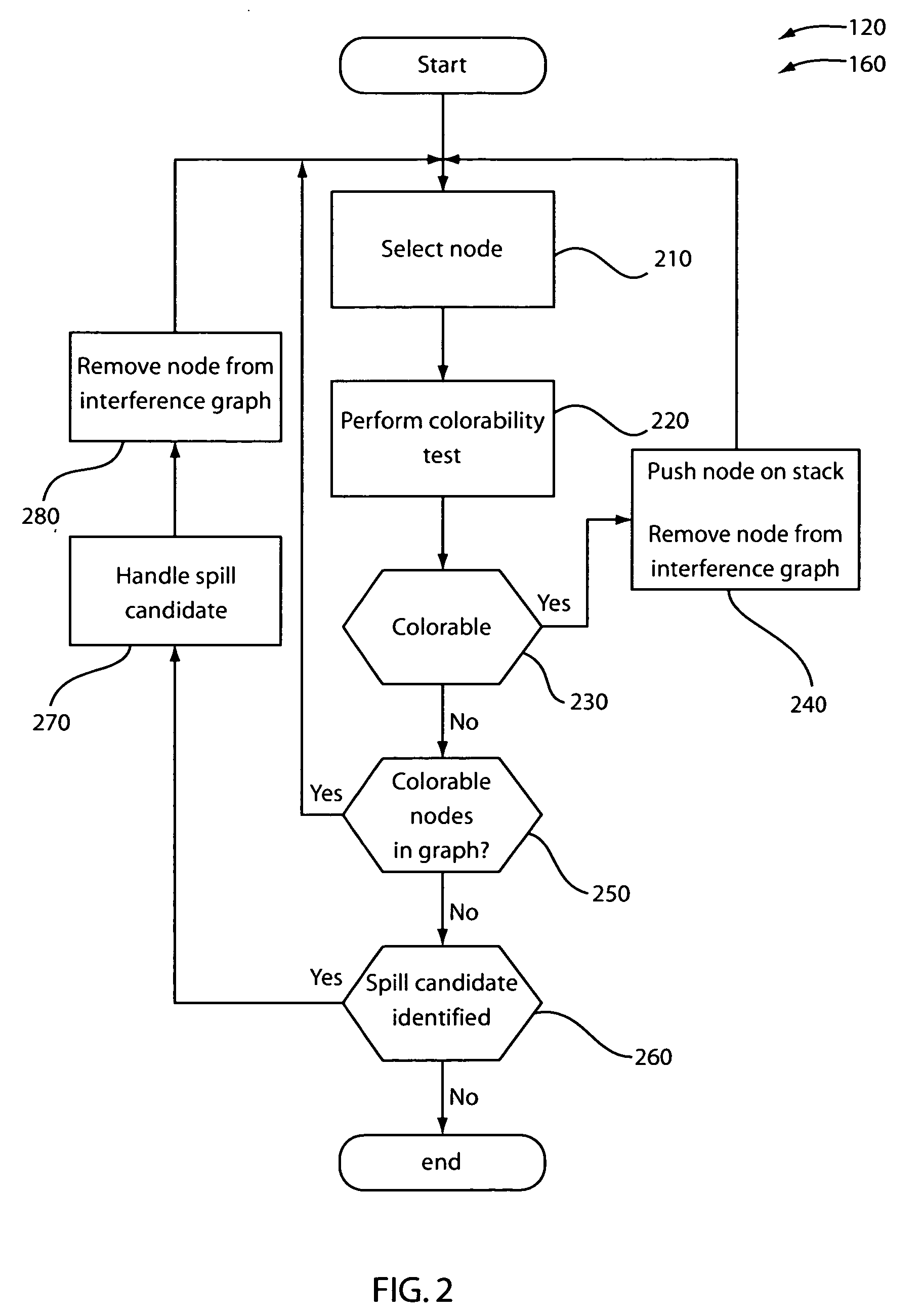

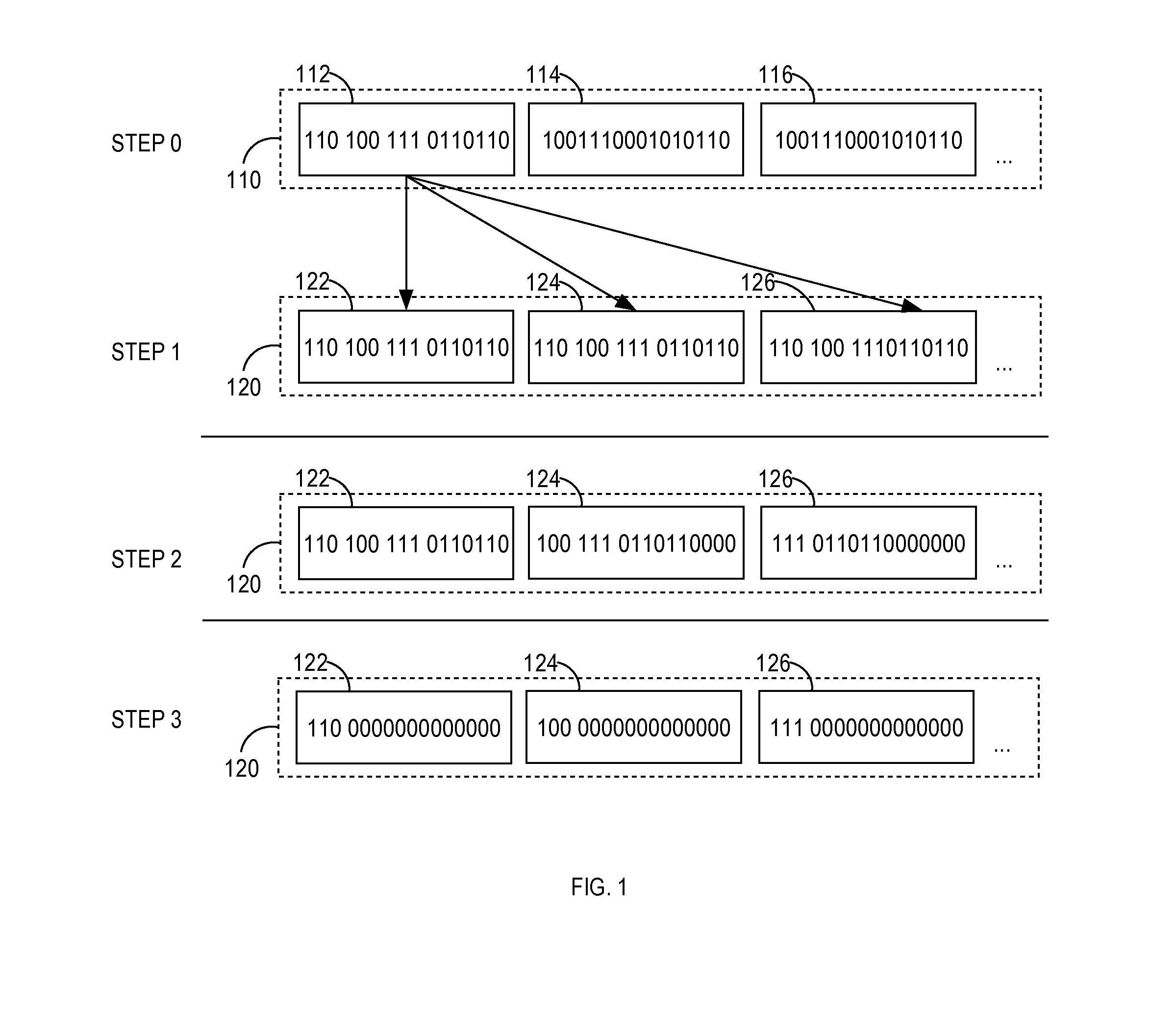

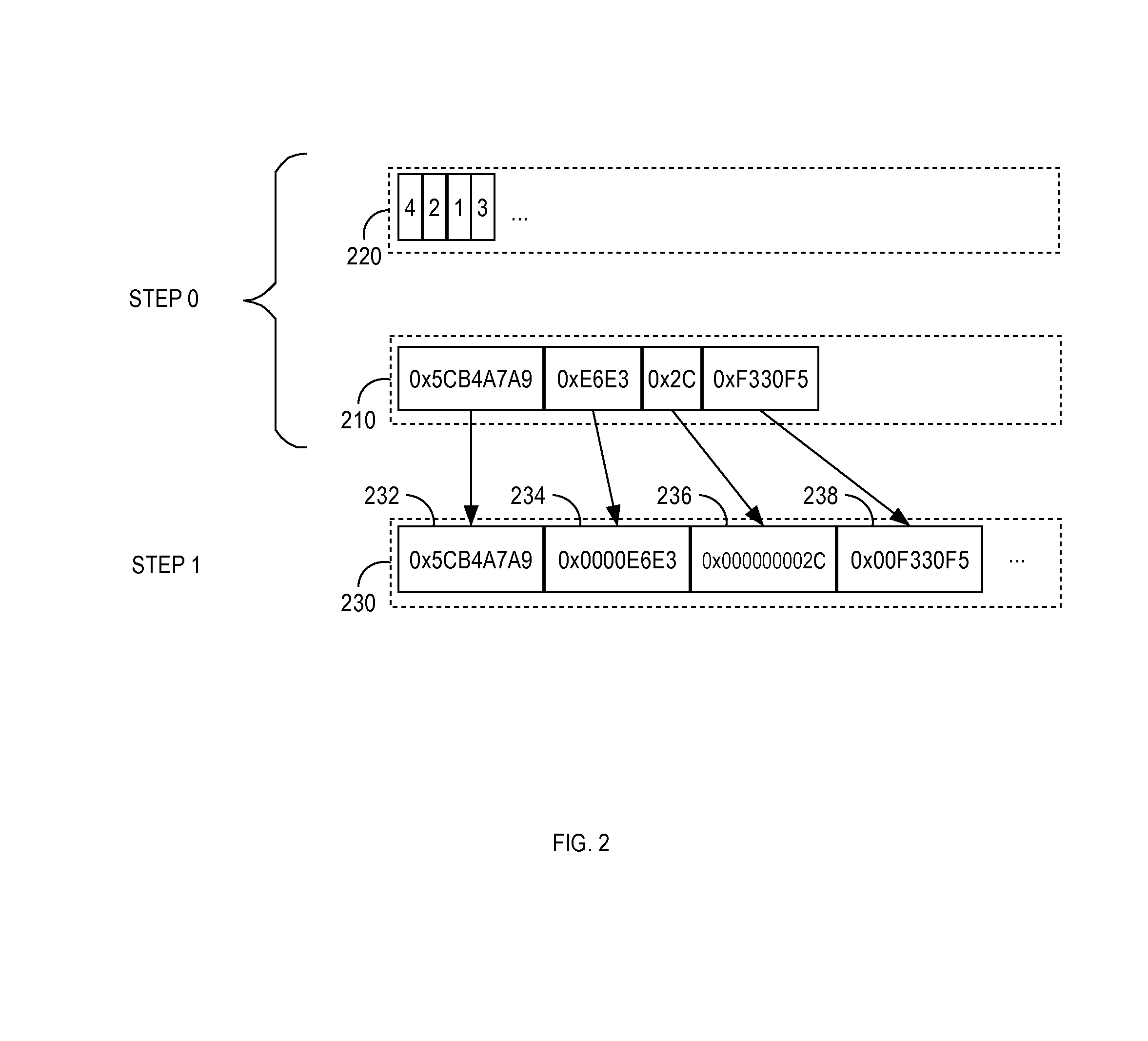

There are provided methods and computer program products for implementing instruction set architectures with non-contiguous register file specifiers. A method for processing instruction code includes processing a fixed-width instruction of a fixed-width instruction set using a non-contiguous register specifier of a non-contiguous register specification. The fixed-width instruction includes the non-contiguous register specifier.

Owner:INT BUSINESS MASCH CORP

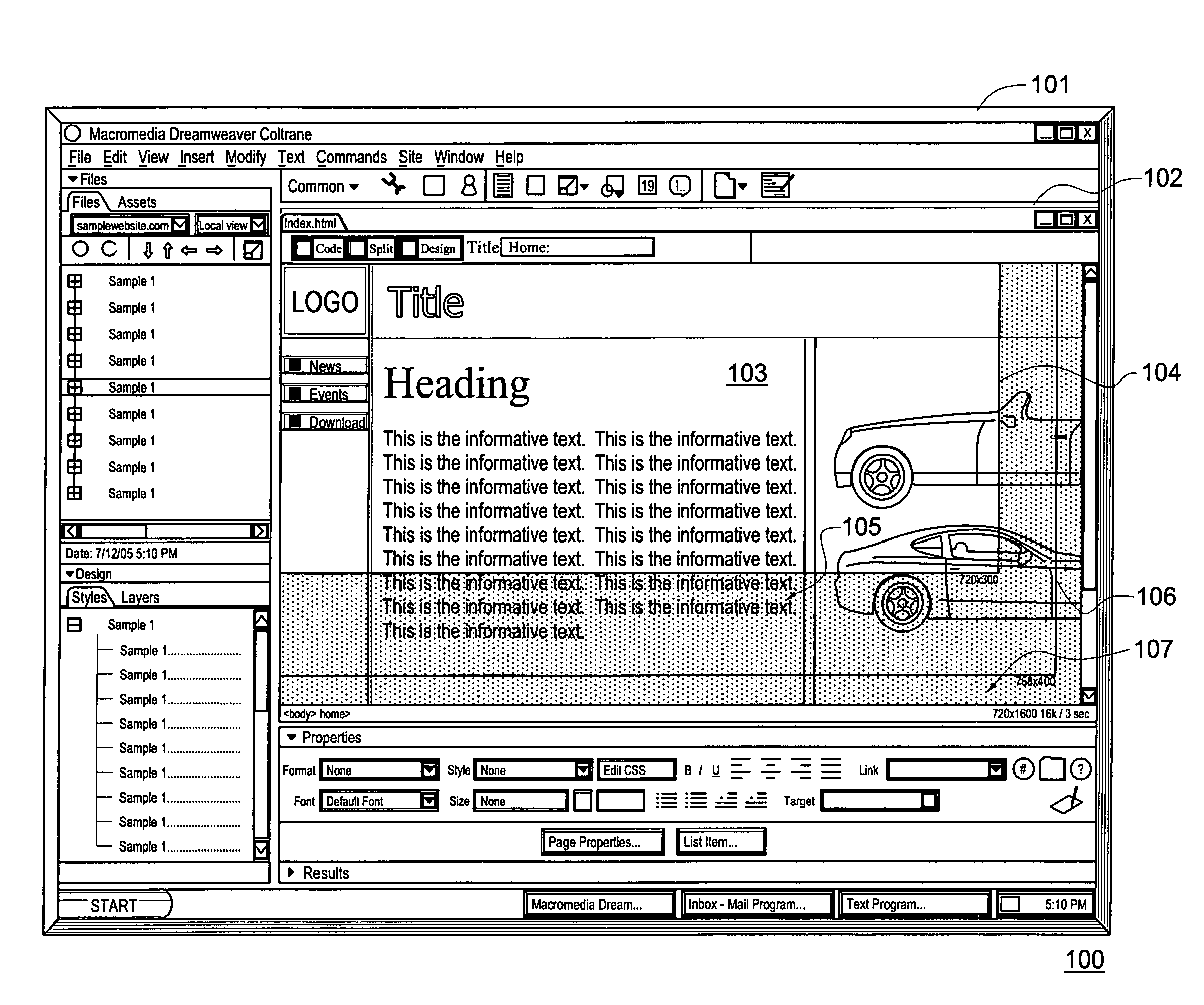

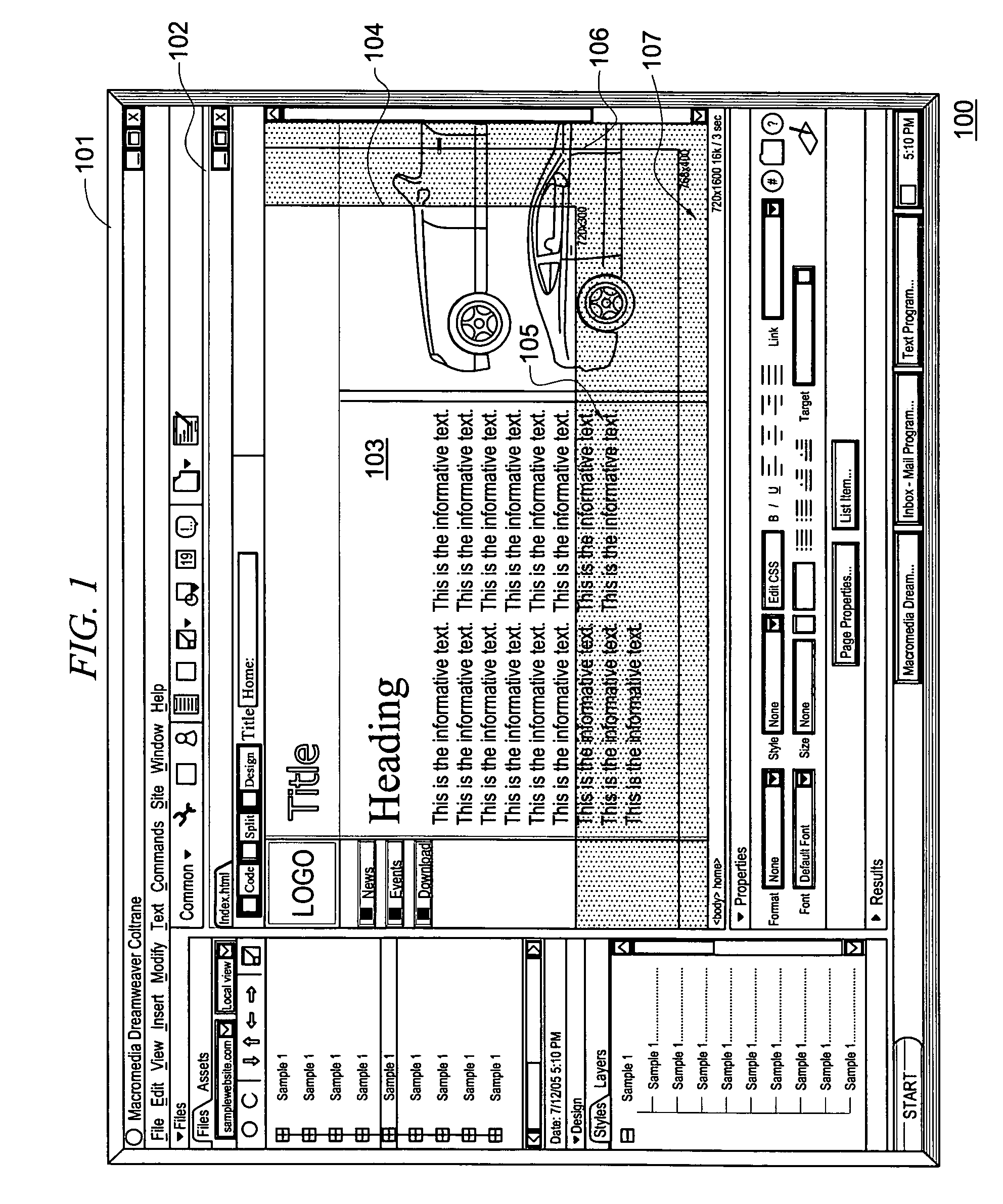

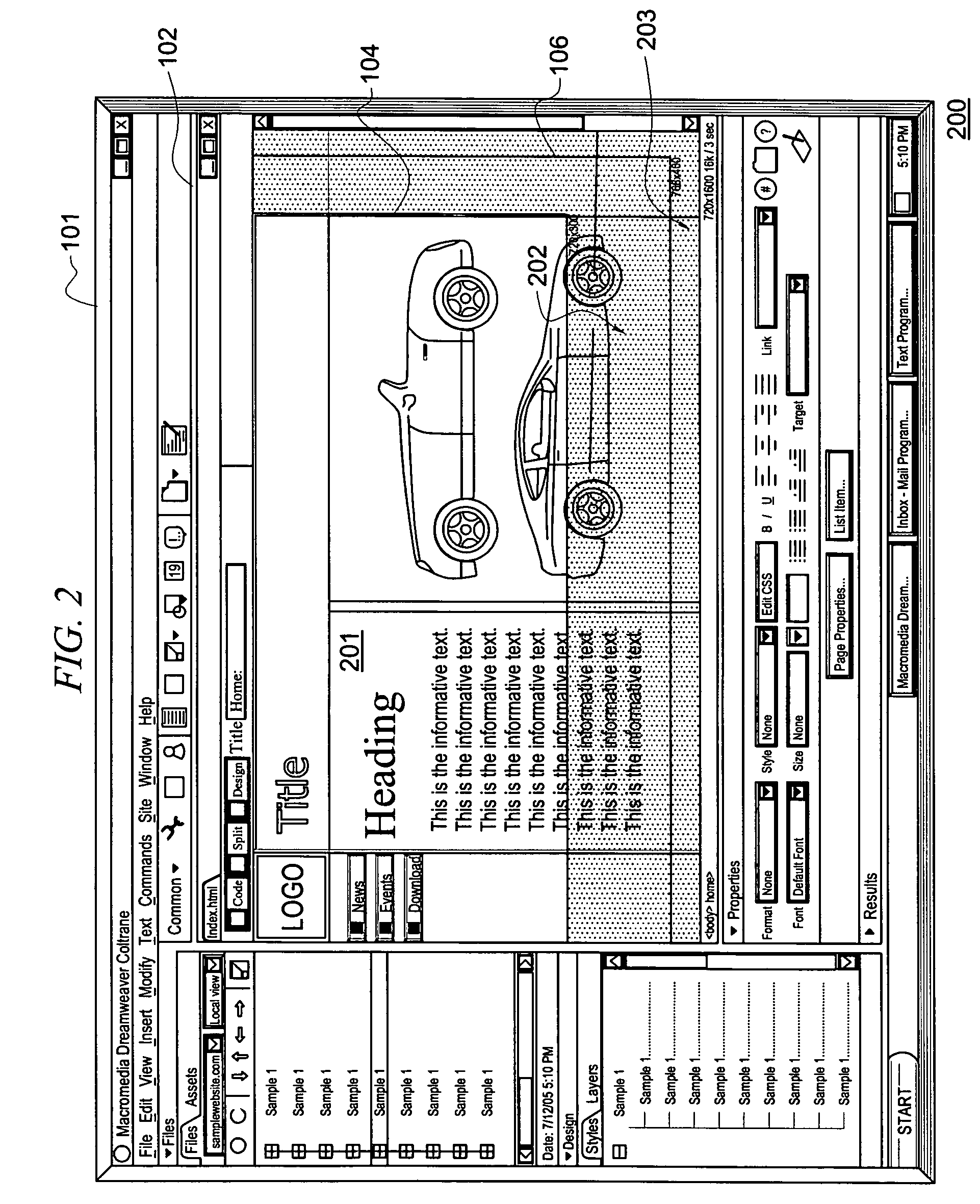

Systems and methods for a fold preview

ActiveUS7890881B1Accurate fitNatural language data processingSpecial data processing applicationsImage resolutionWeb design

The invention comprises systems and methods for a fold preview. Various embodiments of the present invention provide a fold preview of a web page, including fixed-width and flexible-width web page designs. Other embodiments of the present invention provide a fold preview of any software application interface. In one exemplary embodiment, a method for providing a fold preview comprises calculating a cut-off region for one or more display resolutions, rendering one or more fold indicators, and continuing to display an area of a page falling within the cut-off region.

Owner:ADOBE INC

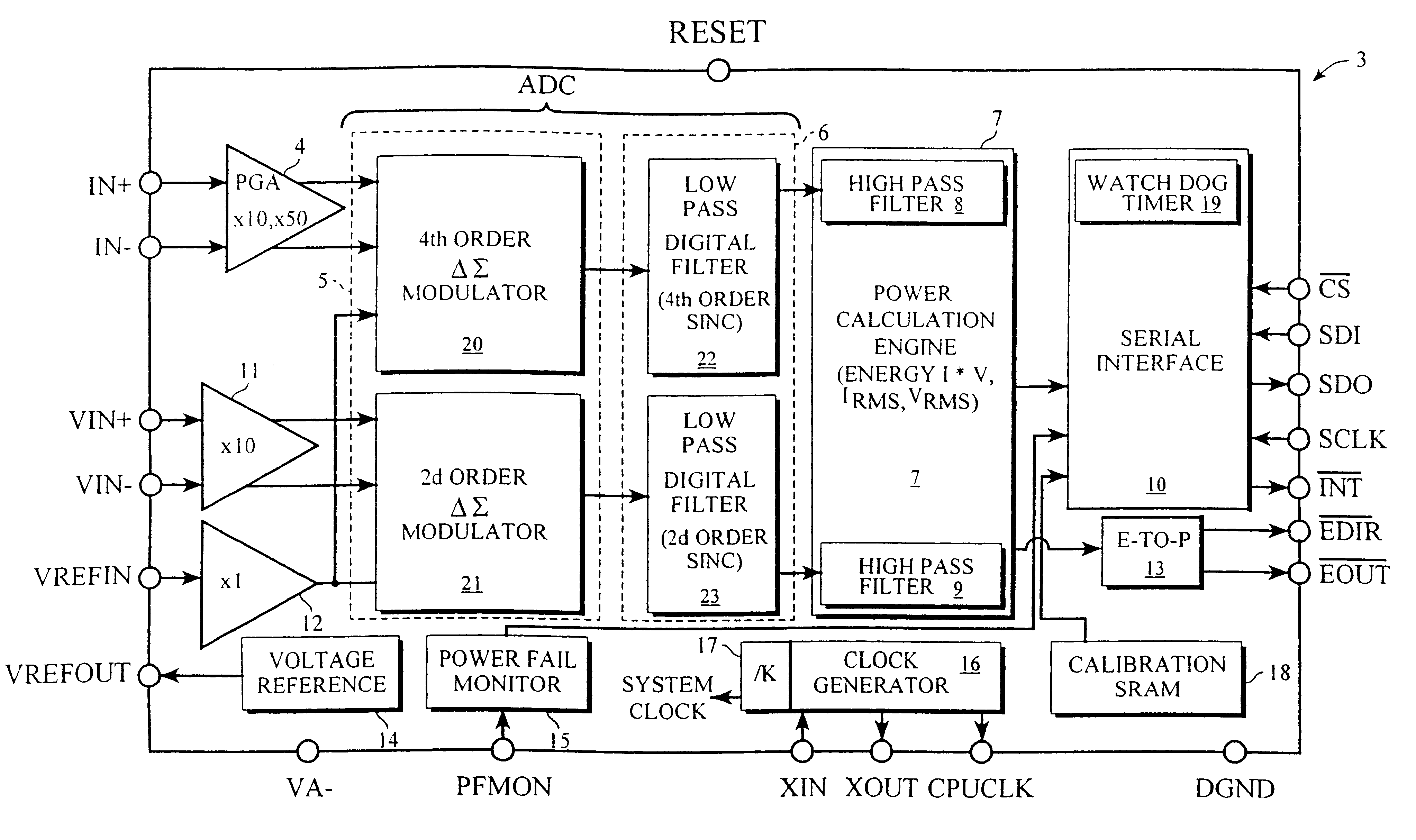

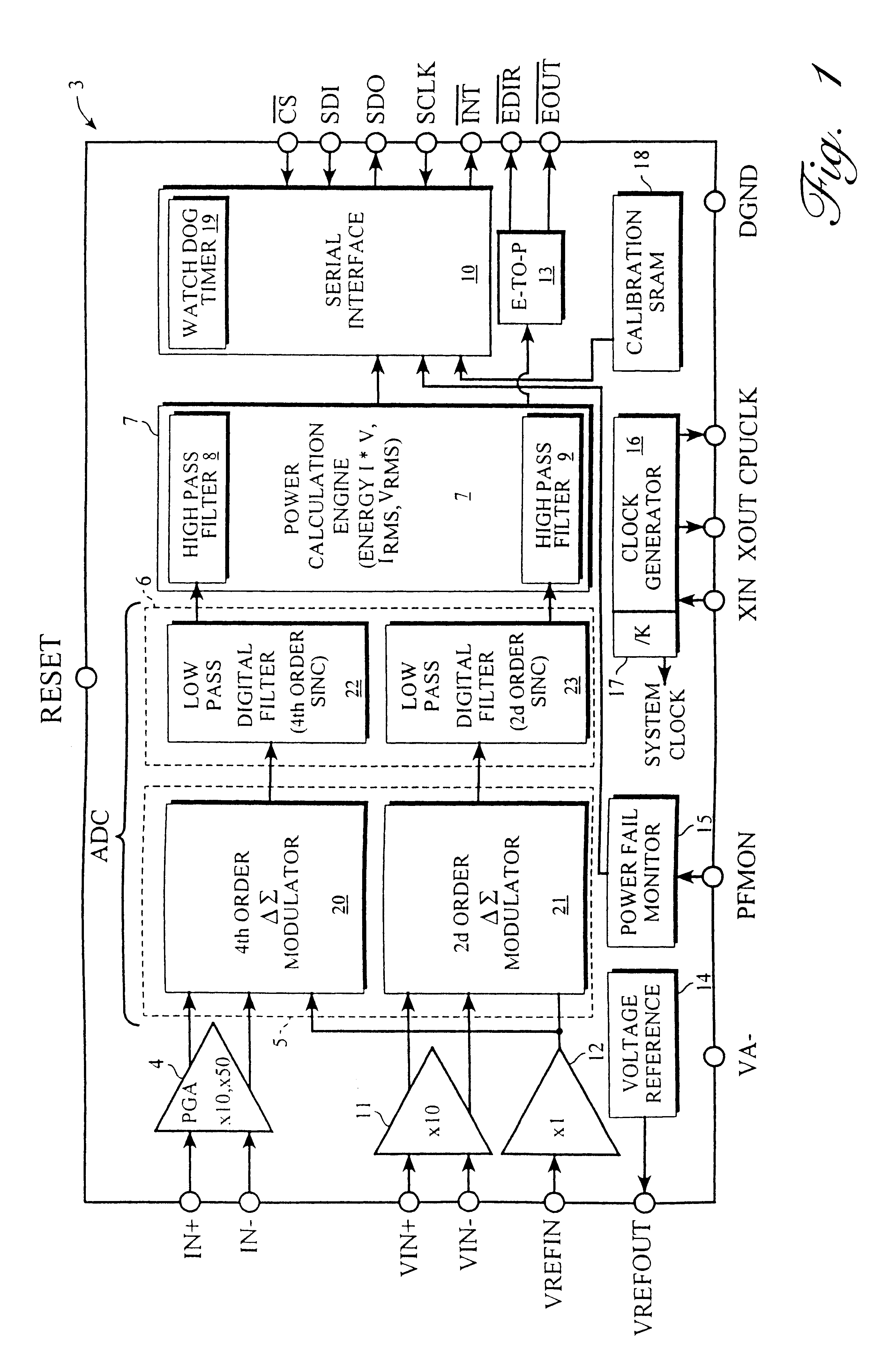

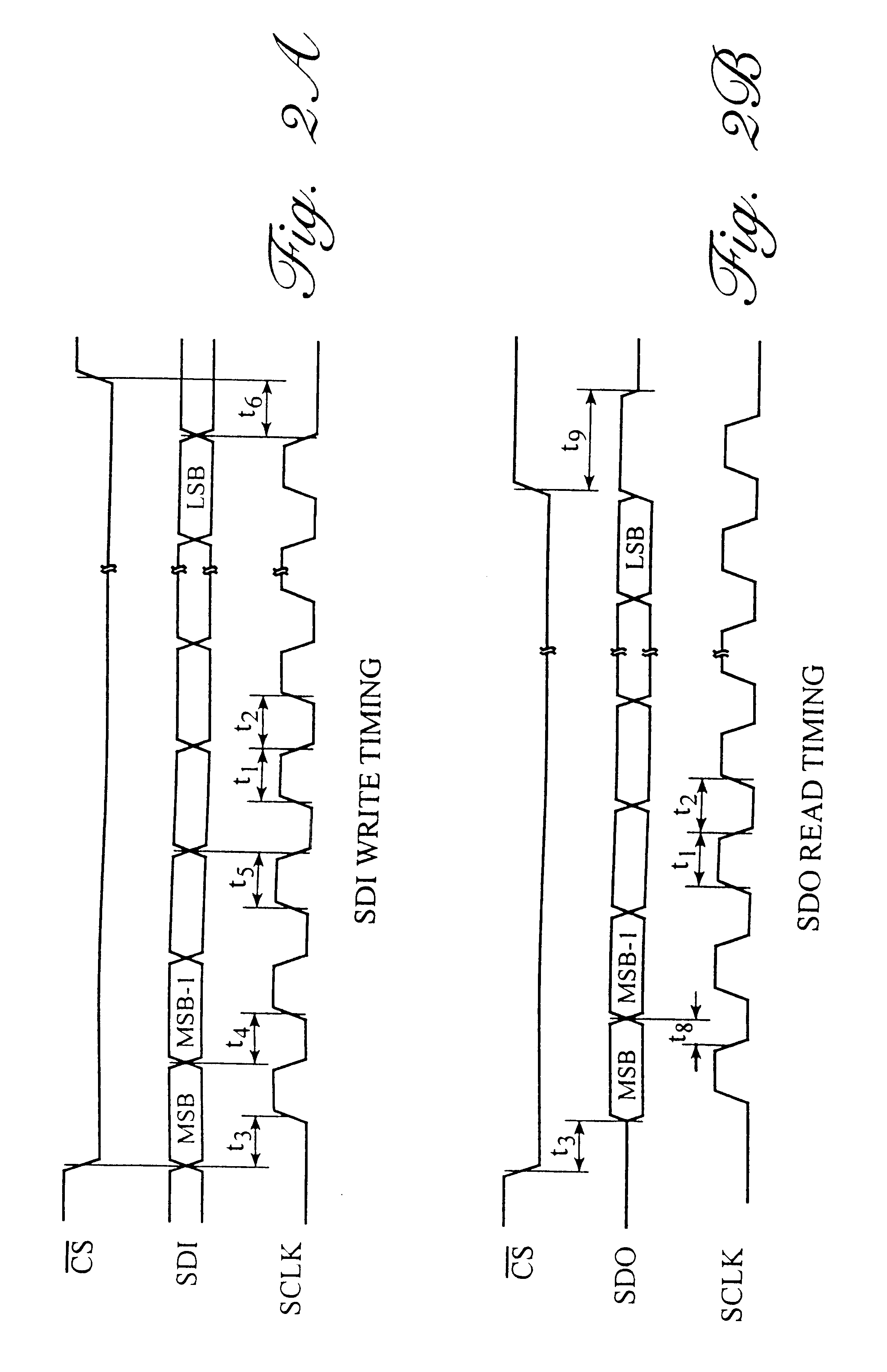

Single phase bi-directional electrical measurement systems and methods using ADCs

An analog to digital converter system includes first and second delta sigma converters, a calculation engine, and a serial interface on a single chip. The calculation engine is configured to calculate energy, power, rms current and voltage for single phase 2 or 3 wire power meters. Voltage and current are measured with a shunt or transformer, and a divider or transformer, respectively. The serial interface is bidirectional for communication with a microprocessor or controller, and provides a fixed width programmable frequency output proportional to energy. The digital converter system is user system calibratible.

Owner:CIRRUS LOGIC INC

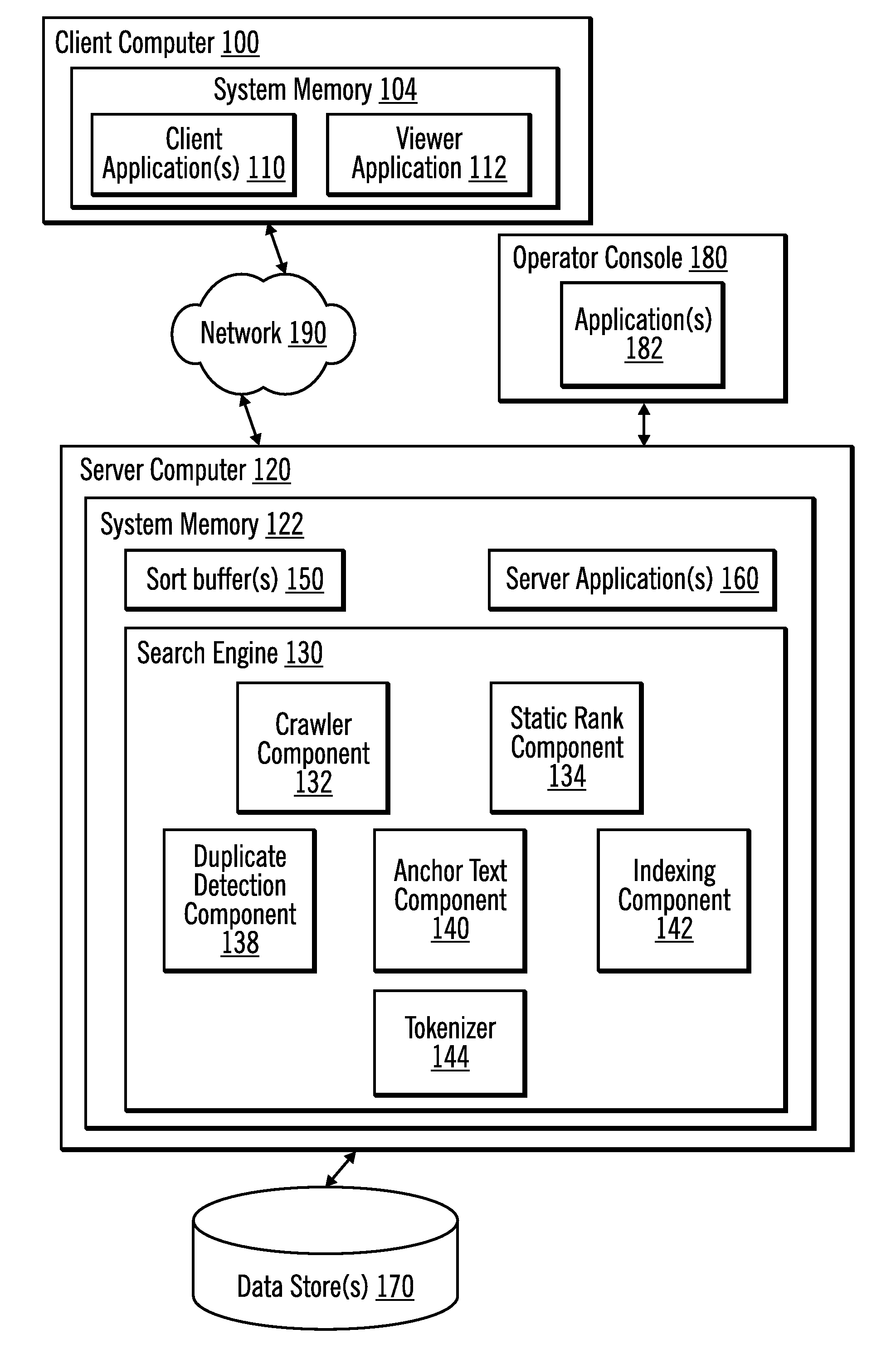

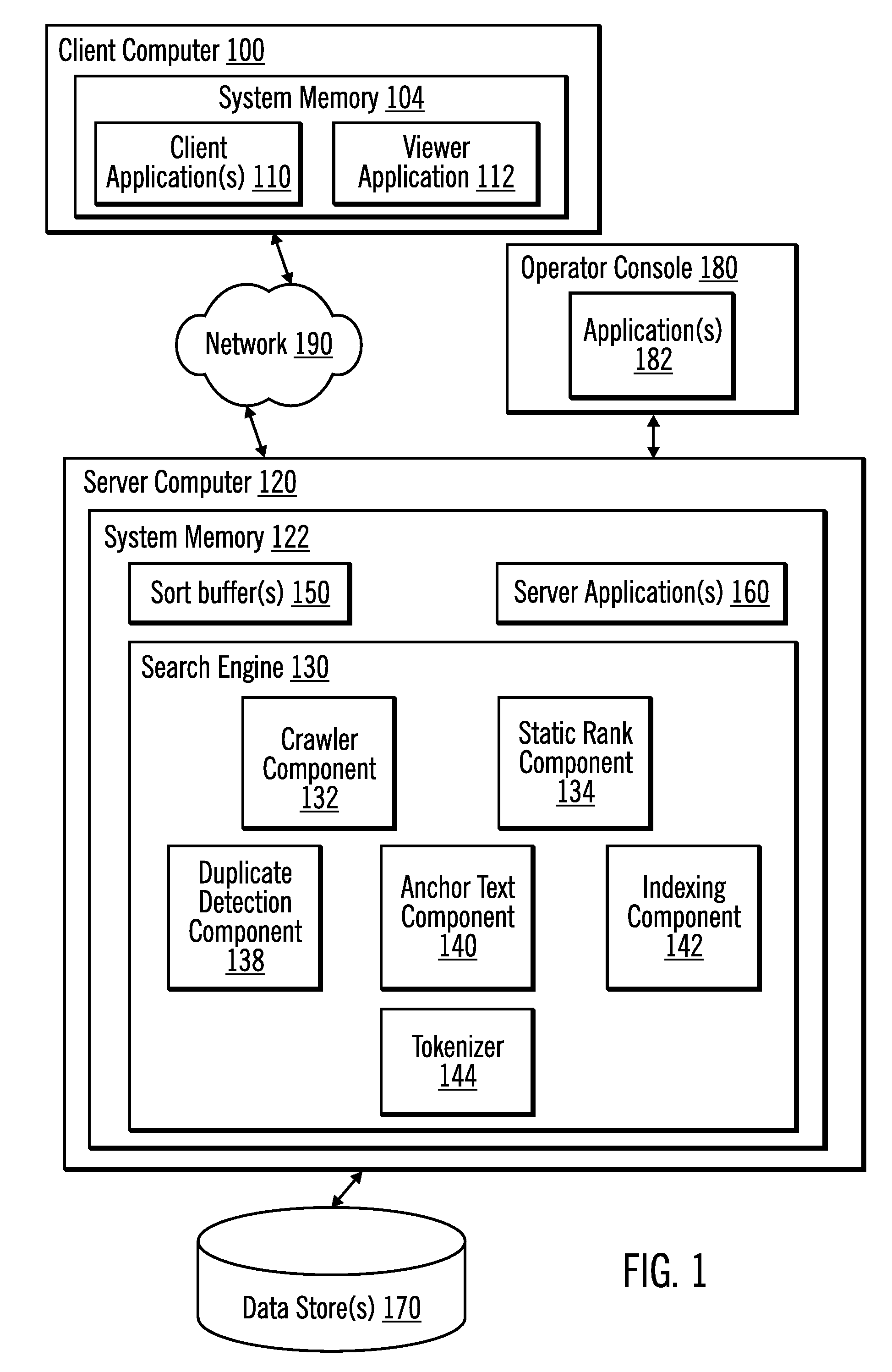

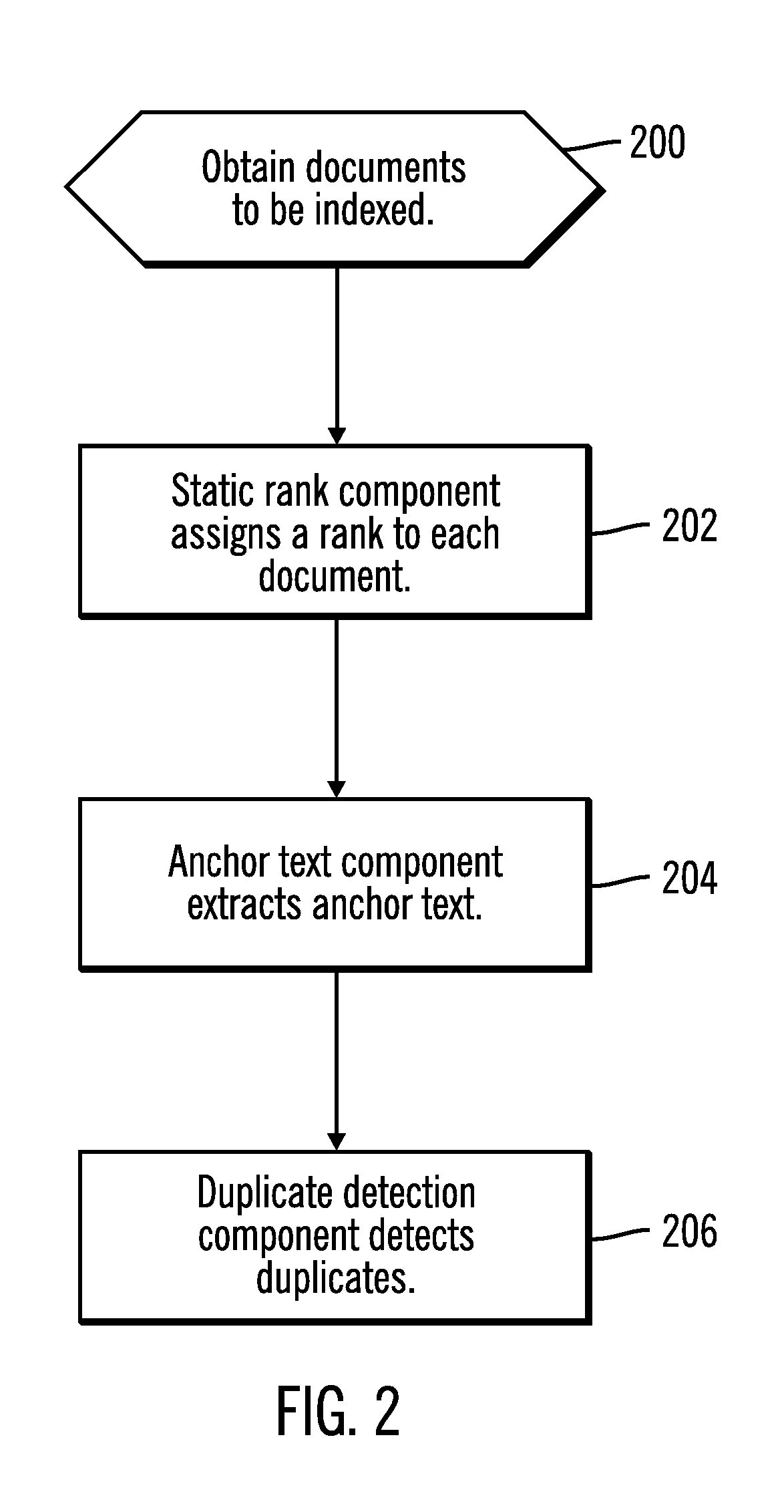

Architecture for an indexer

Disclosed is a technique for indexing data. For each token in a set of documents, a sort key is generated that includes a document identifier that indicates whether a section of a document associated with the sort key is an anchor text section or a context section, wherein the anchor text section and the context text section have a same document identifier; it is determined whether a data field associated with the token is a fixed width; when the data field is a fixed width, the token is designated as one for which fixed width sort is to be performed; and, when the data field is a variable length, the token is designated as one for which a variable width sort is to be performed. The fixed width sort and the variable width sort are performed. For each document, the sort keys are used to bring together the anchor text section and the context section of that document.

Owner:IBM CORP

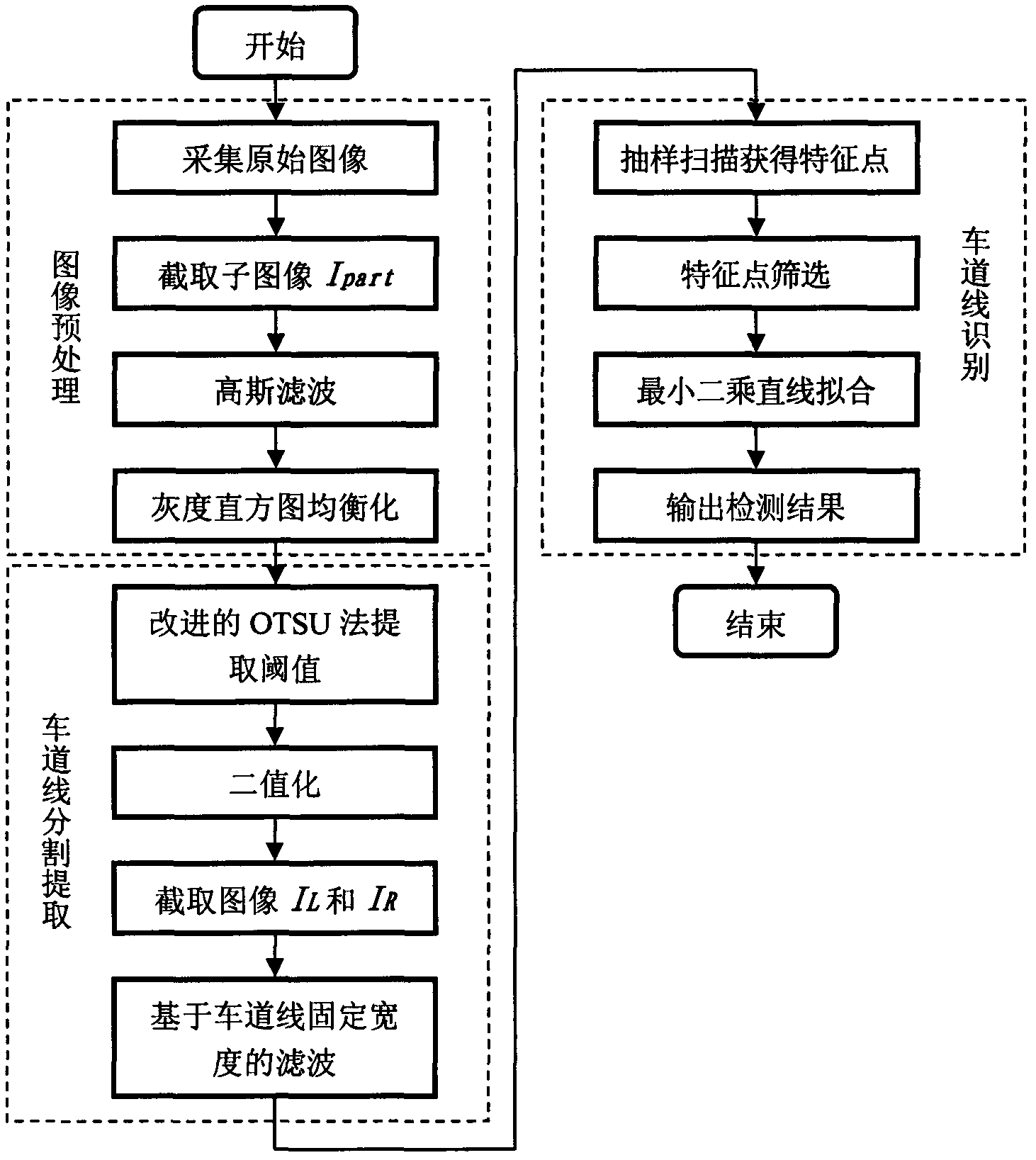

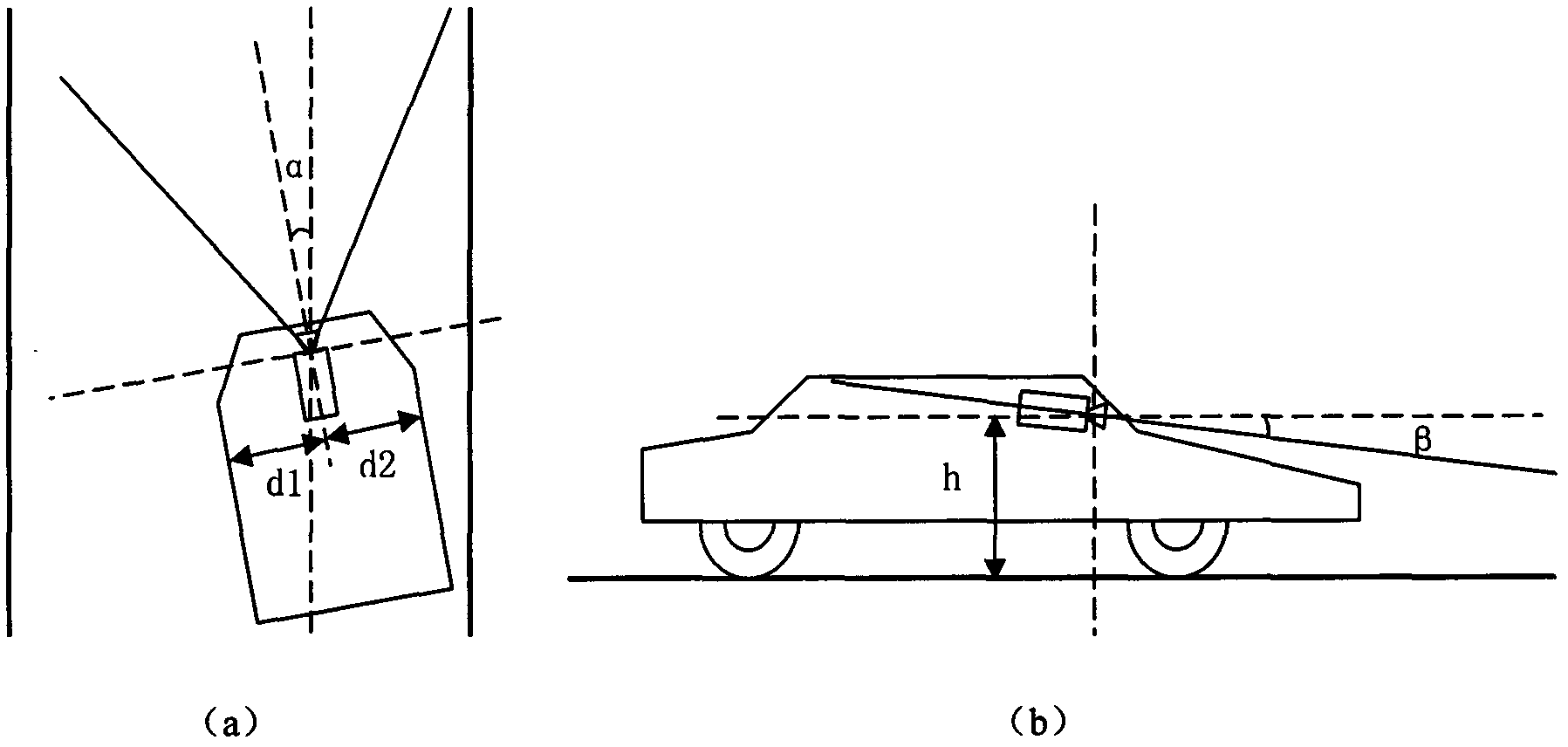

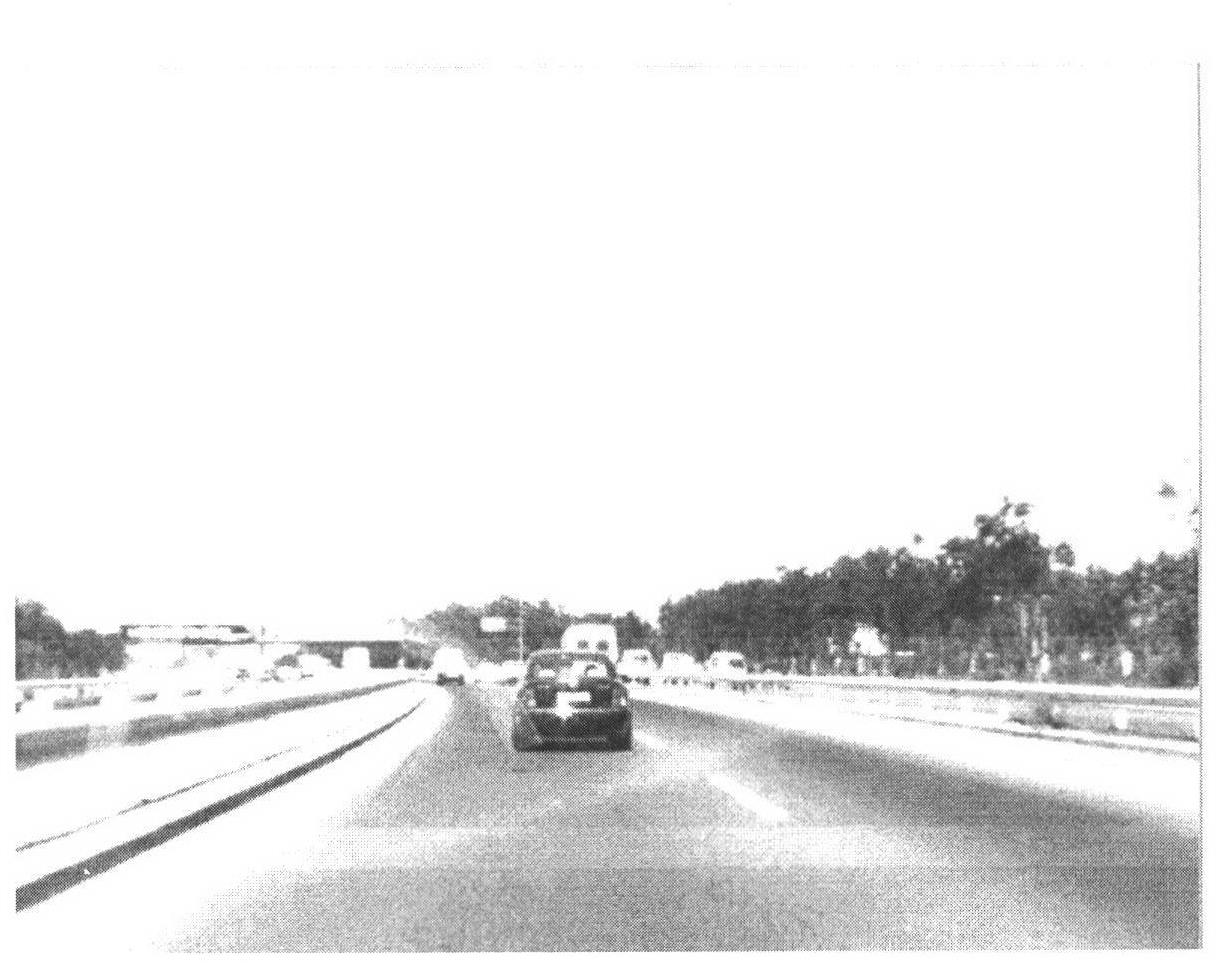

Lane line detection method based on monocular vision

InactiveCN102629326AGood split extractionSmall amount of calculationCharacter and pattern recognitionActive safetyPattern recognition

The invention belongs to the technical field of vehicle active safety and relates to a lane line detection method based on monocular vision. The lane line detection method comprises the following steps: acquiring an original image of a road condition in front of a vehicle; intercepting subimages of boundary regions at the two sides, wherein the subimages include the original image; removing the high-frequency noise of the subimages and carrying out grey level histogram equalization and binaryzation; intercepting left and right lane line detection region images; filtering based on the fixed width range of a lane line according to the features of low grey value pavements at the two sides of the lane line; preliminarily determining feature points of the lane line in a sampling line scanning manner and screening; and carrying out lane detection. The lane line detection method has the characteristics of good real time and high reliability.

Owner:TIANJIN POLYTECHNIC UNIV

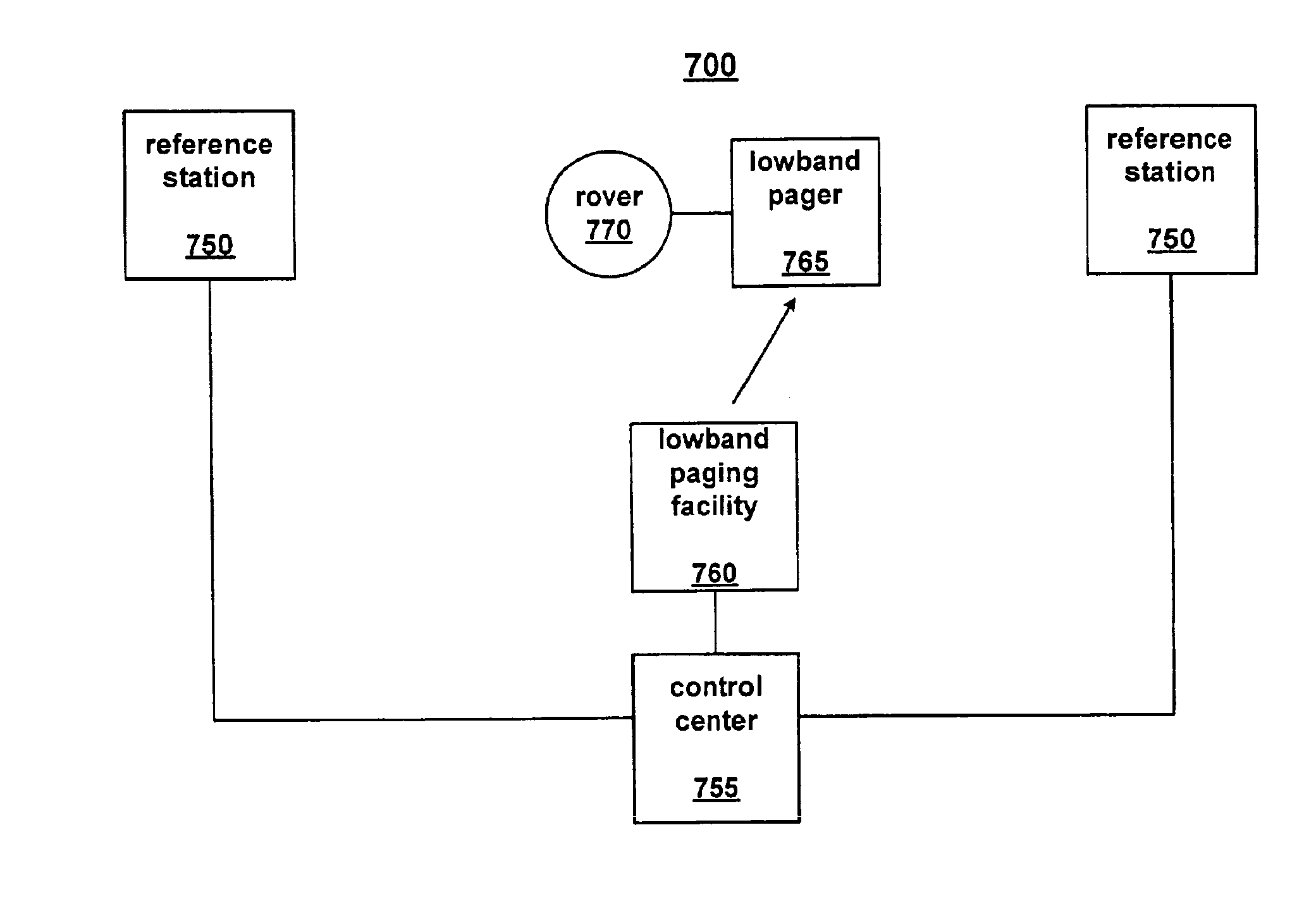

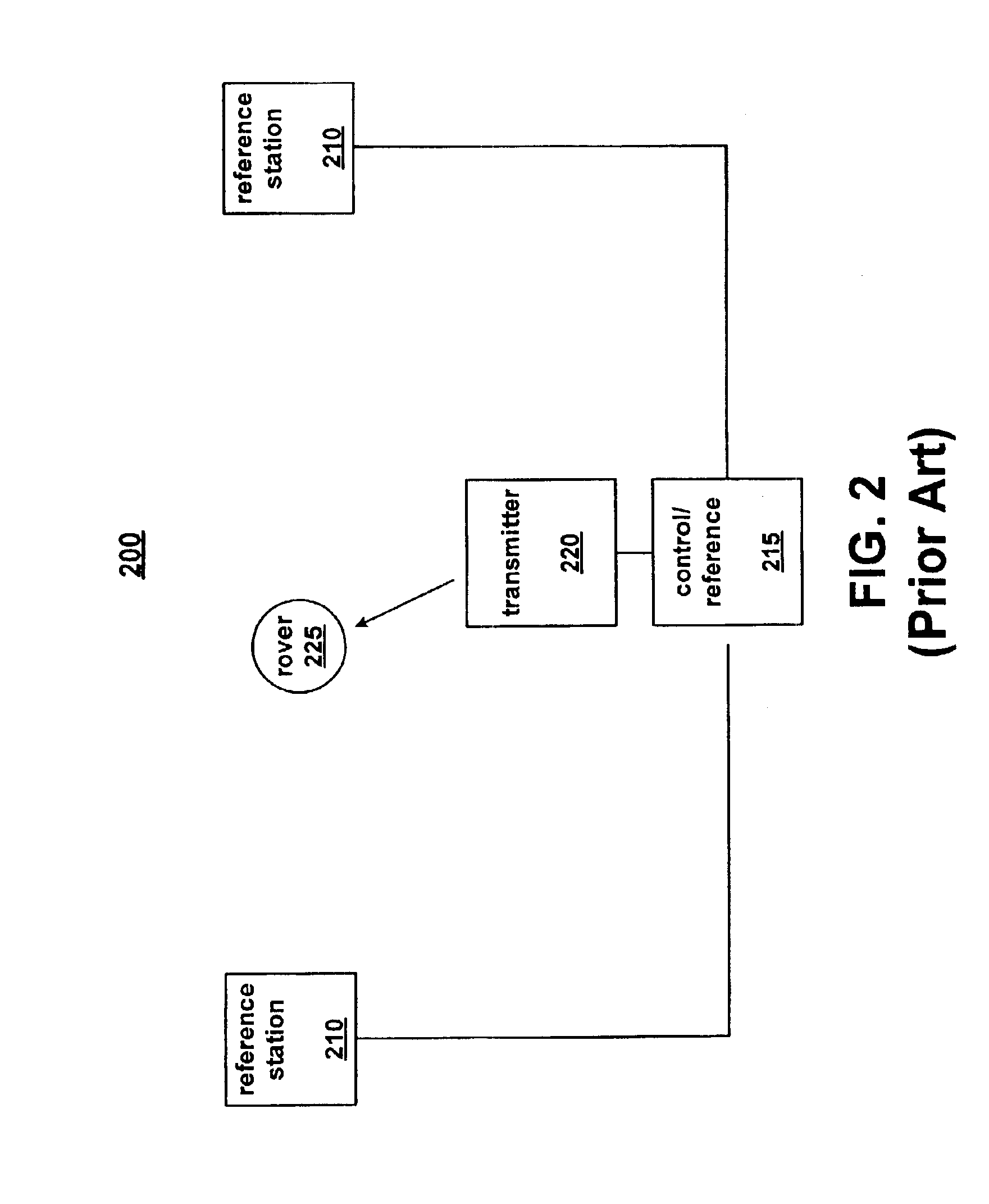

Method and system for transmission of real-time kinematic satellite positioning system data

InactiveUS6879283B1Precise positioningPosition fixationRadio transmission for post communicationReal Time KinematicData transmission

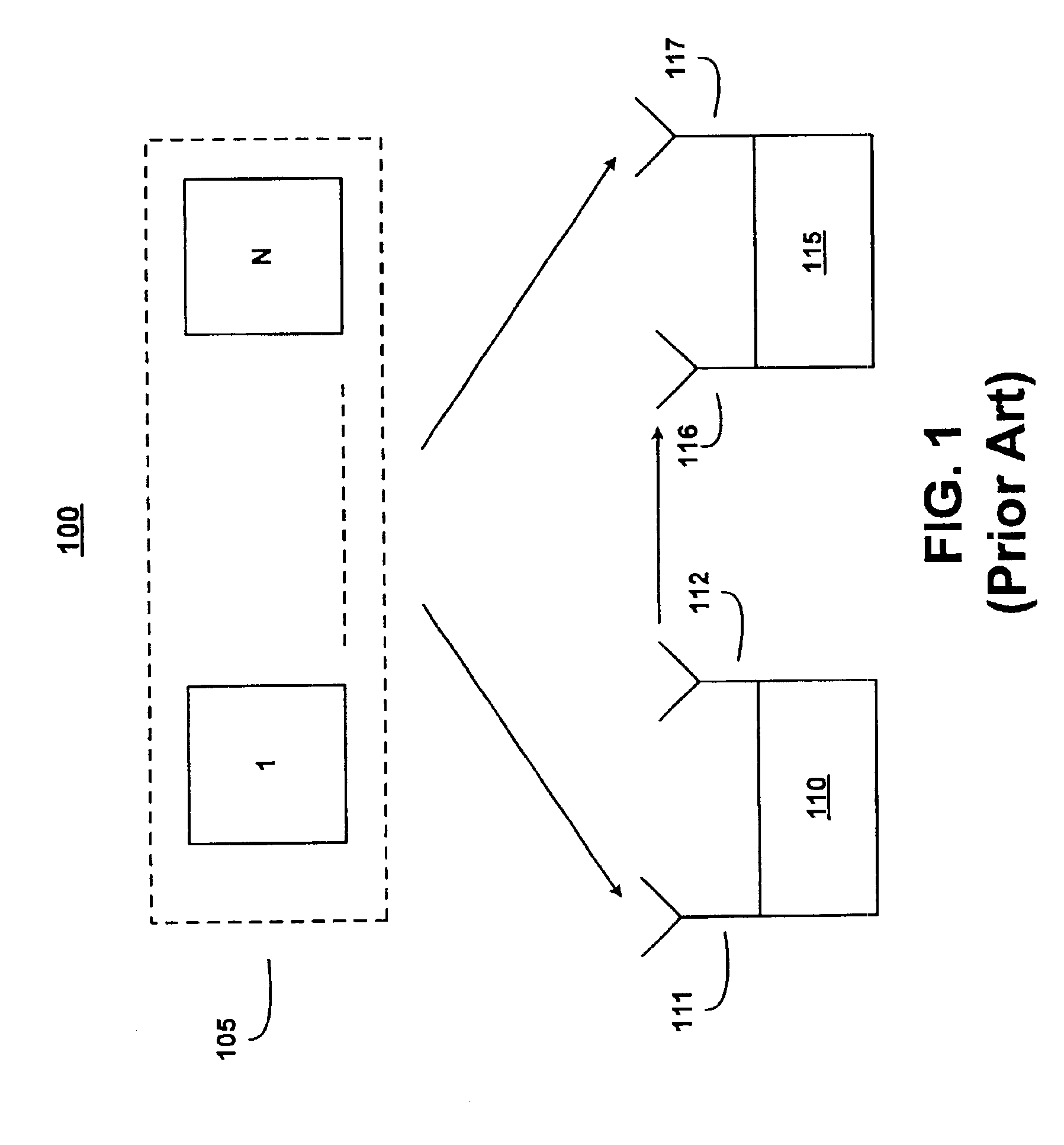

A method and system for communication in a real-time kinematic (RTK) positioning system by paging. An RTK positioning system having a reference station and a rover utilizes a paging system for data transfer. A single satellite positioning system (SATPS) reference station may be coupled to the paging system to provide RTK correction data, or multiple networked reference stations may be coupled to the paging system to provide data. Paging systems using allocated paging bands having fixed width channels (e.g. 20 kHz) such as those between 35 MHz and 36 MHz or 43 MHz and 44 MHz may be used.

Owner:TRIMBLE NAVIGATION LTD

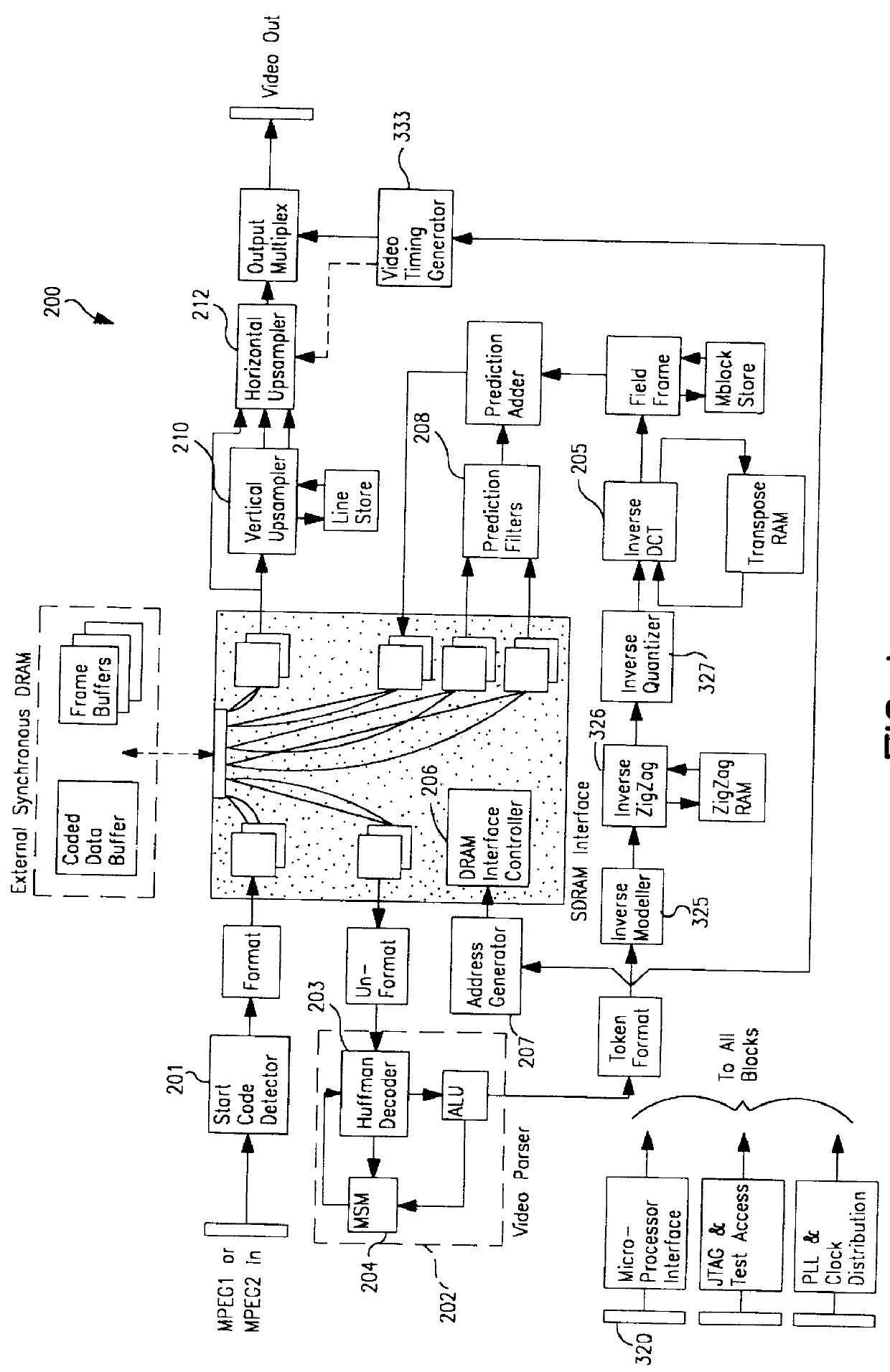

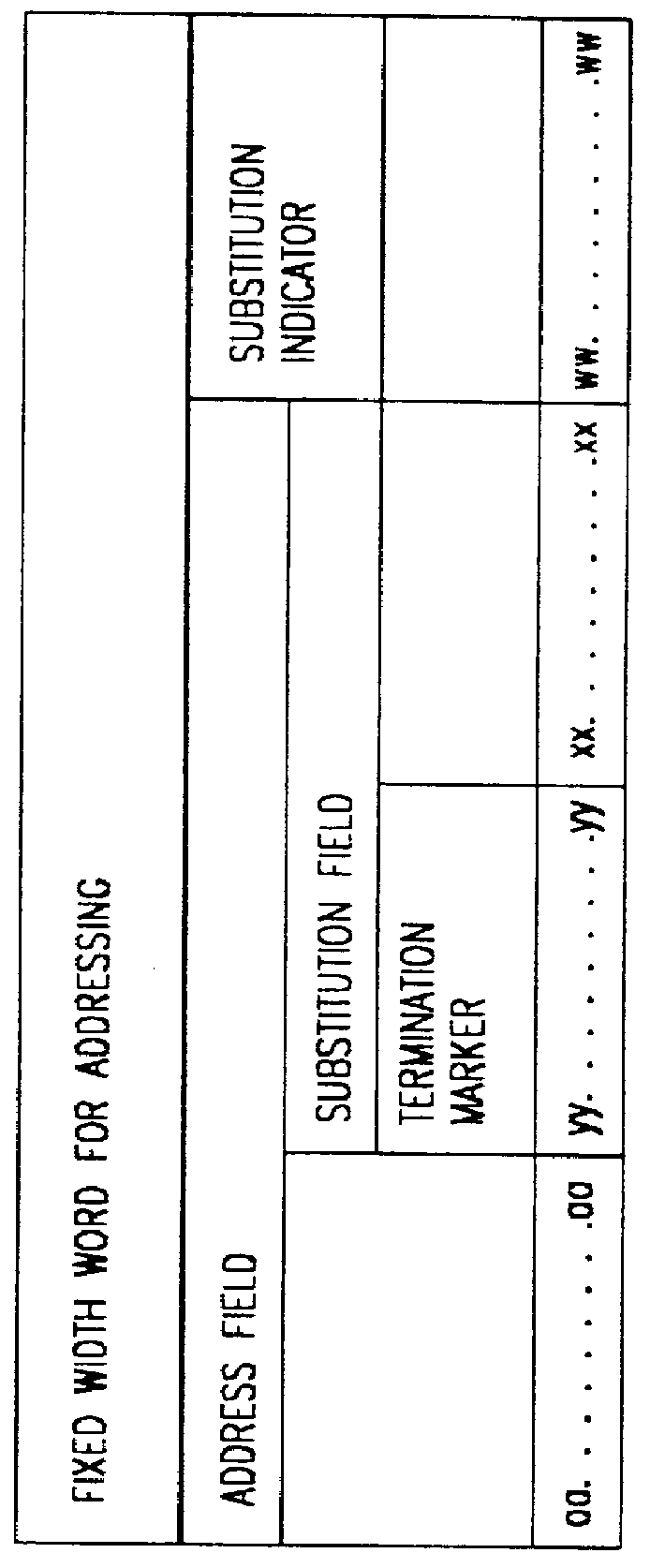

Method for addressing data having variable data width using a fixed number of bits for address and width defining fields

InactiveUS6119213AFacilitate decodingPulse modulation television signal transmissionMemory adressing/allocation/relocationOperating systemFixed width

In a method and apparatus for addressing memory there is a procedure for providing a word with fixed width, having a fixed number of bits to be used for addressing variable width data, and having a width defining field and address field, is disclosed. In addition, a procedure for addressing memory with a fixed width word, having a fixed number of bits, to be used for addressing data and having a substitution field and an address field, is discussed.

Owner:TALON RES

Methods for generating code for an architecture encoding an extended register specification

There are provided methods and computer program products for generating code for an architecture encoding an extended register specification. A method for generating code for a fixed-width instruction set includes identifying a non-contiguous register specifier. The method further includes generating a fixed-width instruction word that includes the non-contiguous register specifier.

Owner:IBM CORP

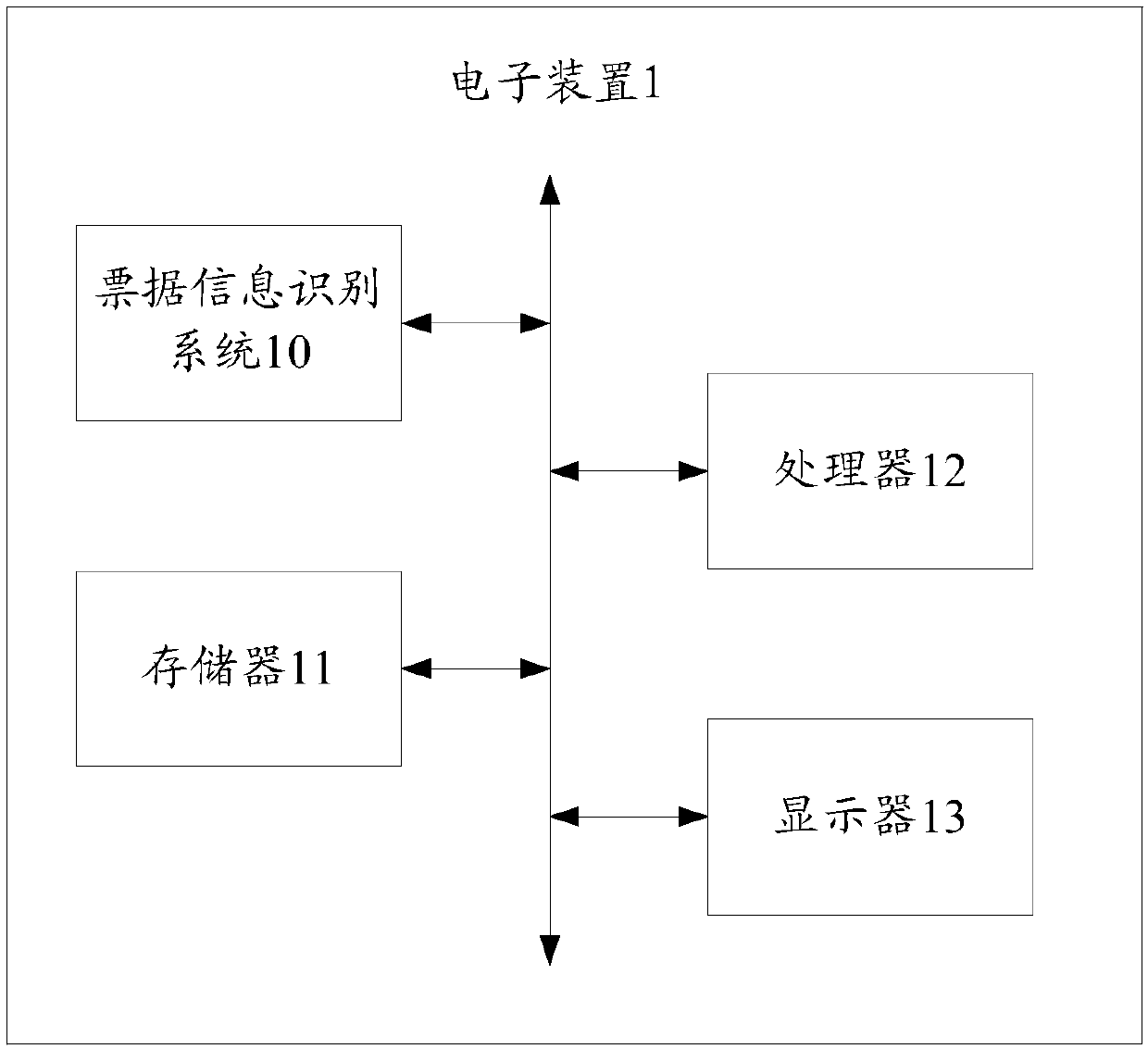

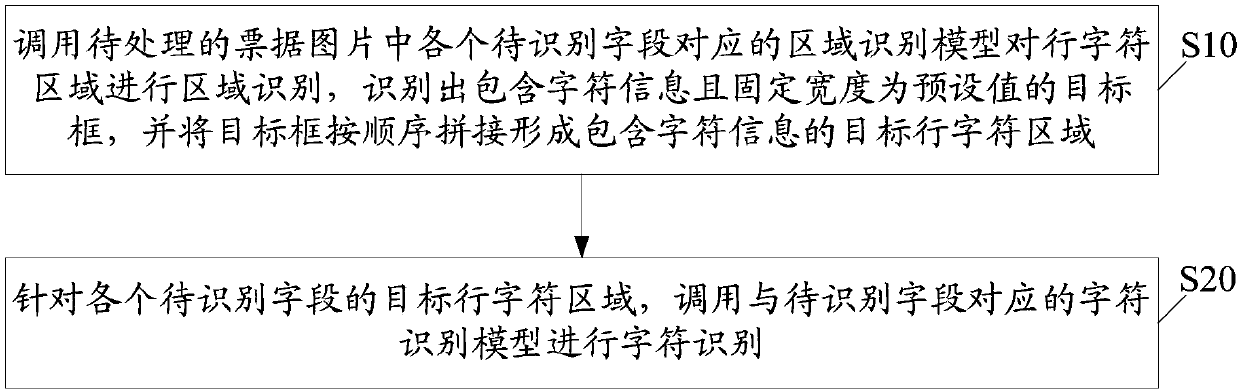

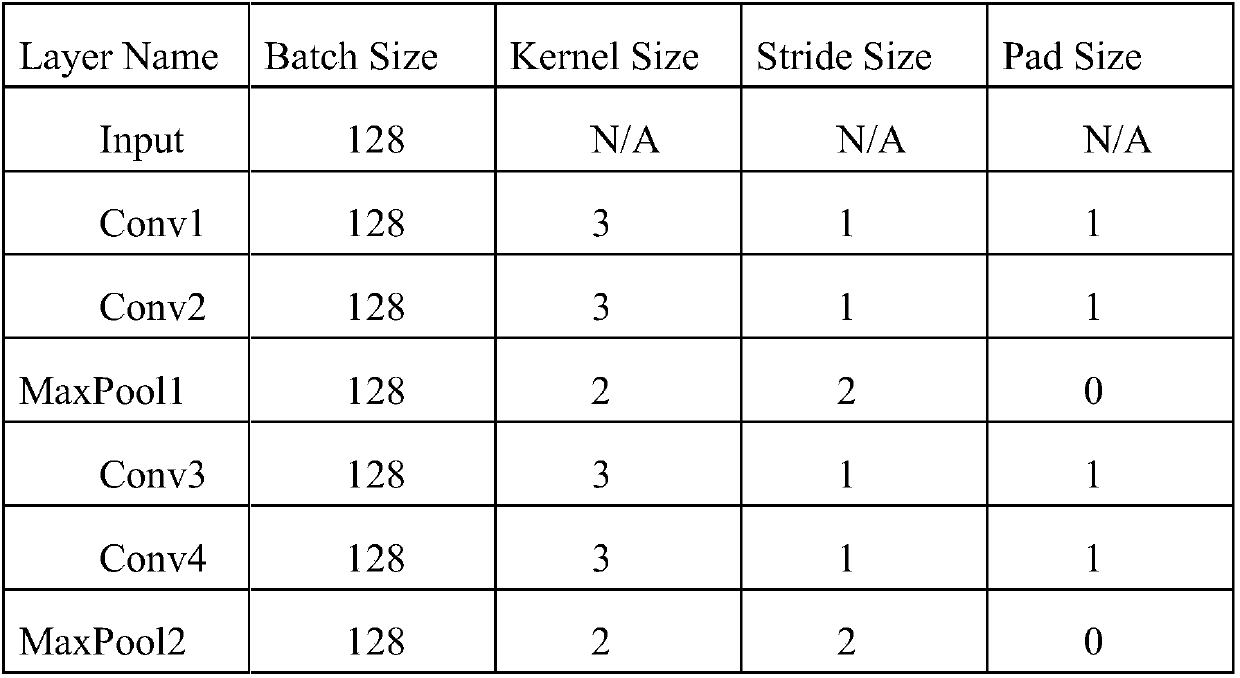

Bill information identification method, electronic device and readable storage medium

ActiveCN107798299AReduce error rateLess distracting factorsCharacter recognitionCharacter recognitionFixed width

The invention relates to a bill information identification method, an electronic device and a readable storage medium. The method includes: determining a region identification model, which correspondsto each to-be-identified field in a bill picture, according to a predetermined mapping relationship of the to-be-identified field and the region identification model, invoking the corresponding region identification models for region identification on row character regions of the bill picture, identifying target frames, which contain character information and have a fixed width which is a presetvalue, on the bill picture, and splicing the target frames, which contain the character information in the same rows, together according to successive orders of identification to form target row character regions containing the character information; and determining a character identification model, which corresponds to each to-be-identified field, according to a predetermined mapping relationshipof the to-be-identified field and the character identification model, and invoking the corresponding character identification model for the target row character regions of each to-be-recognized fieldfor character identification. The method can decrease an error rate of bill information identification.

Owner:PING AN TECH (SHENZHEN) CO LTD

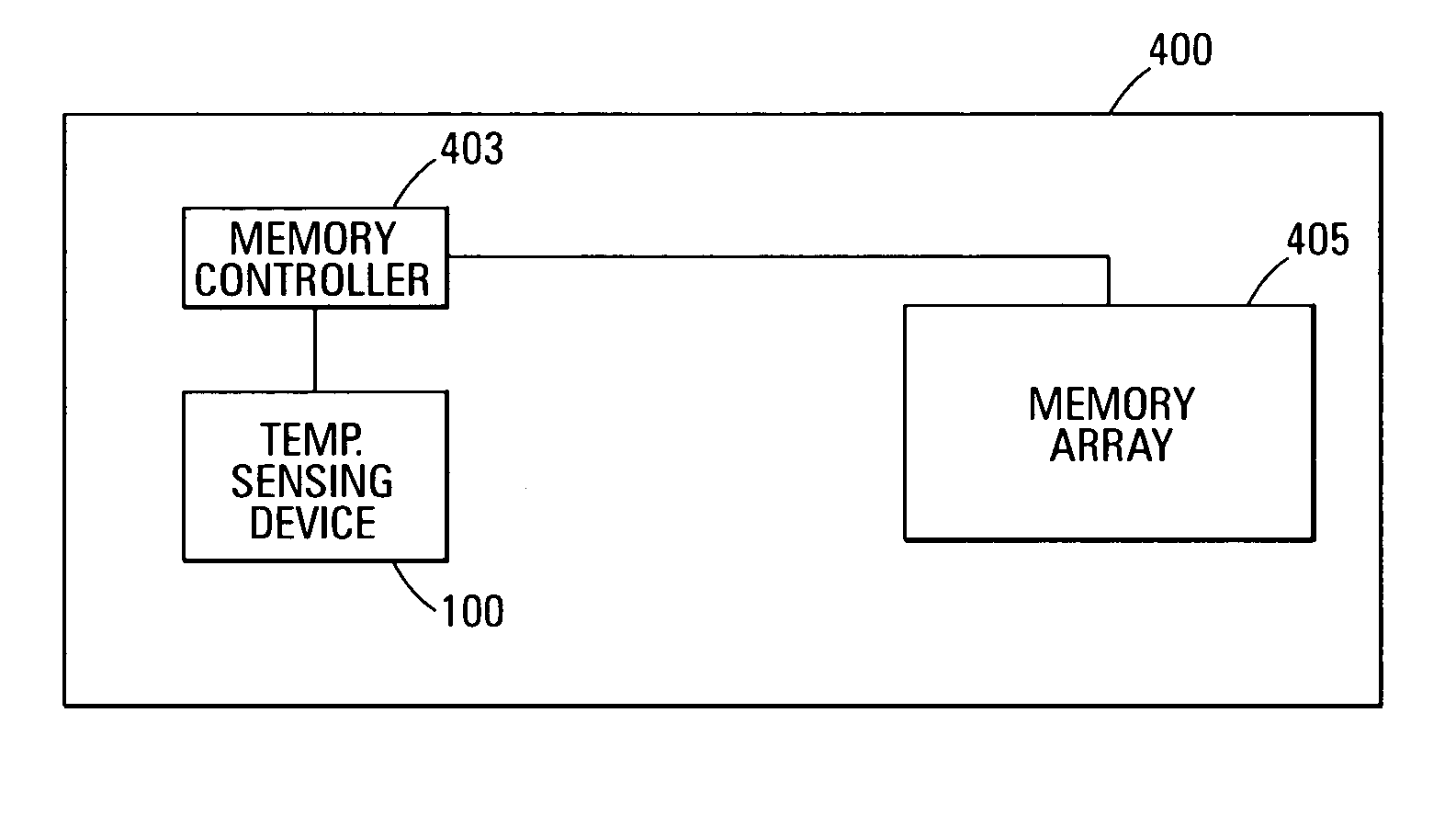

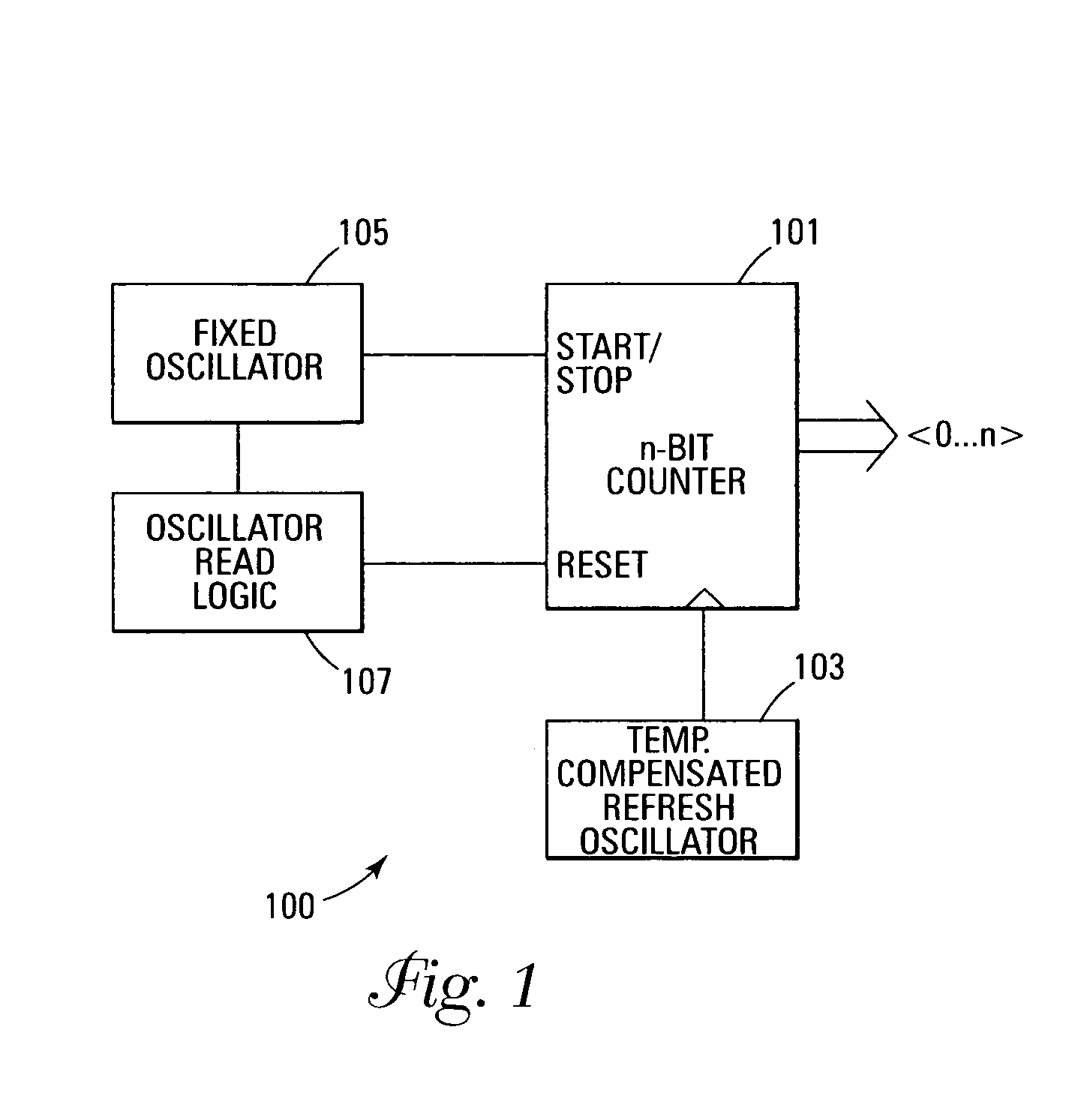

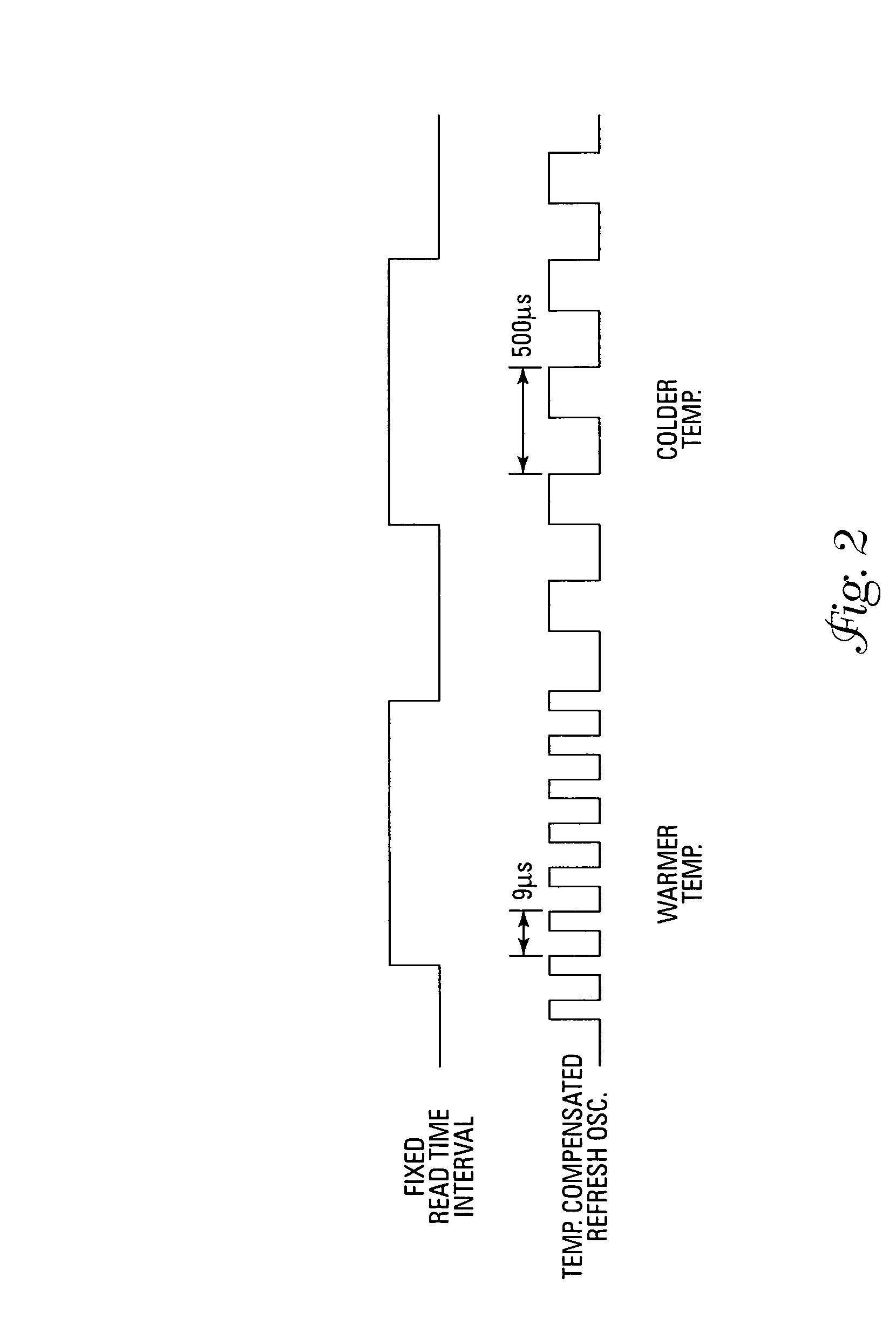

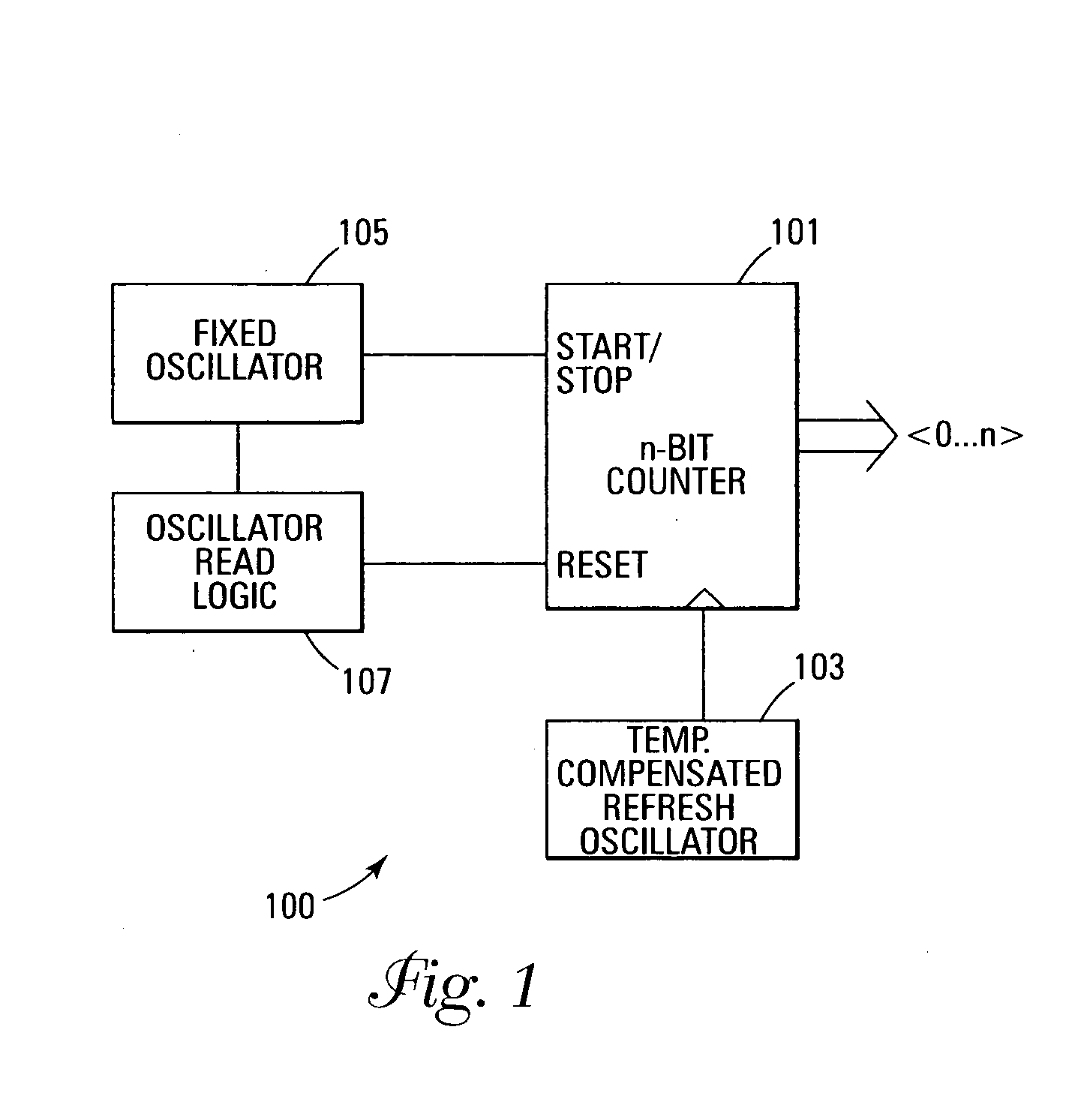

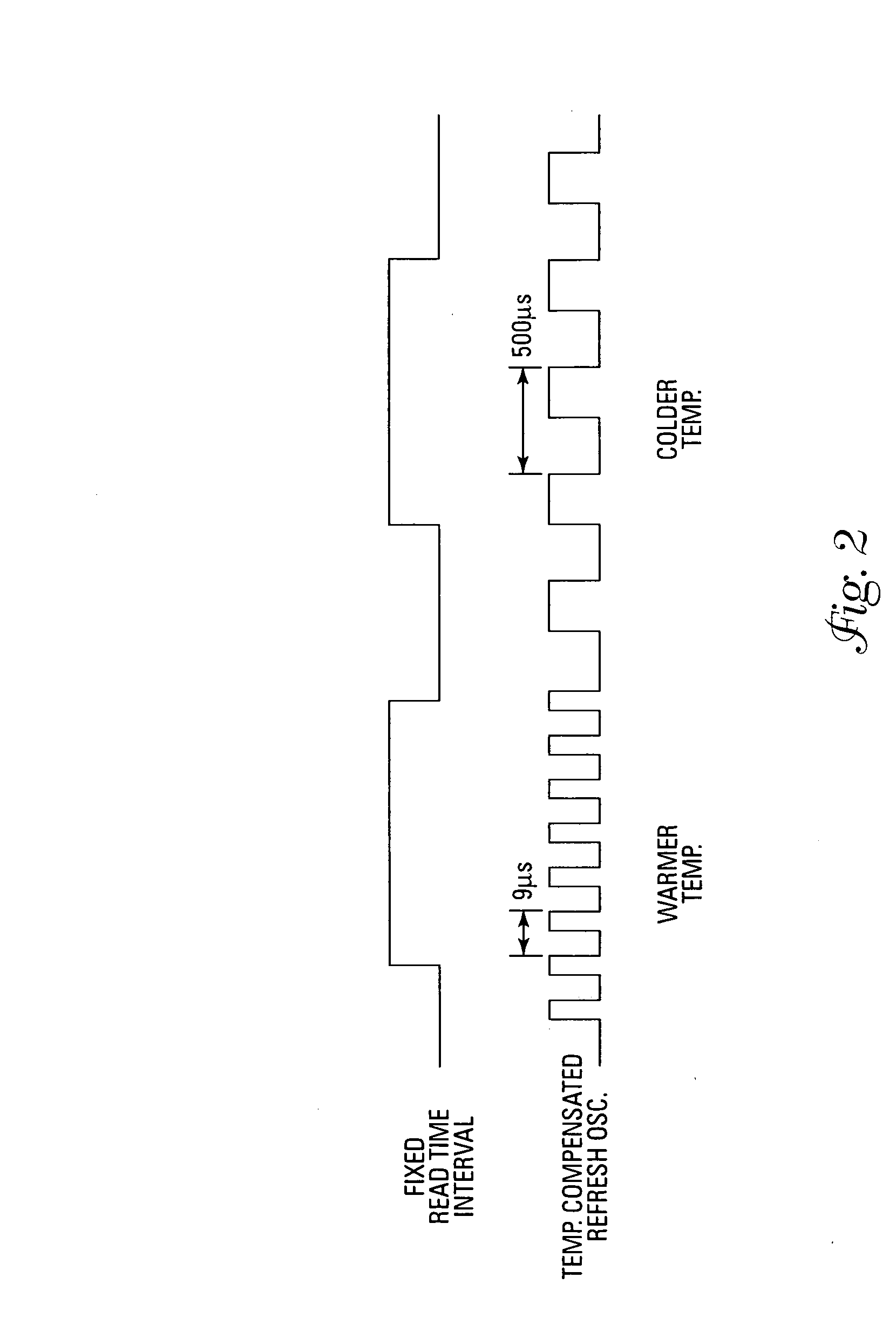

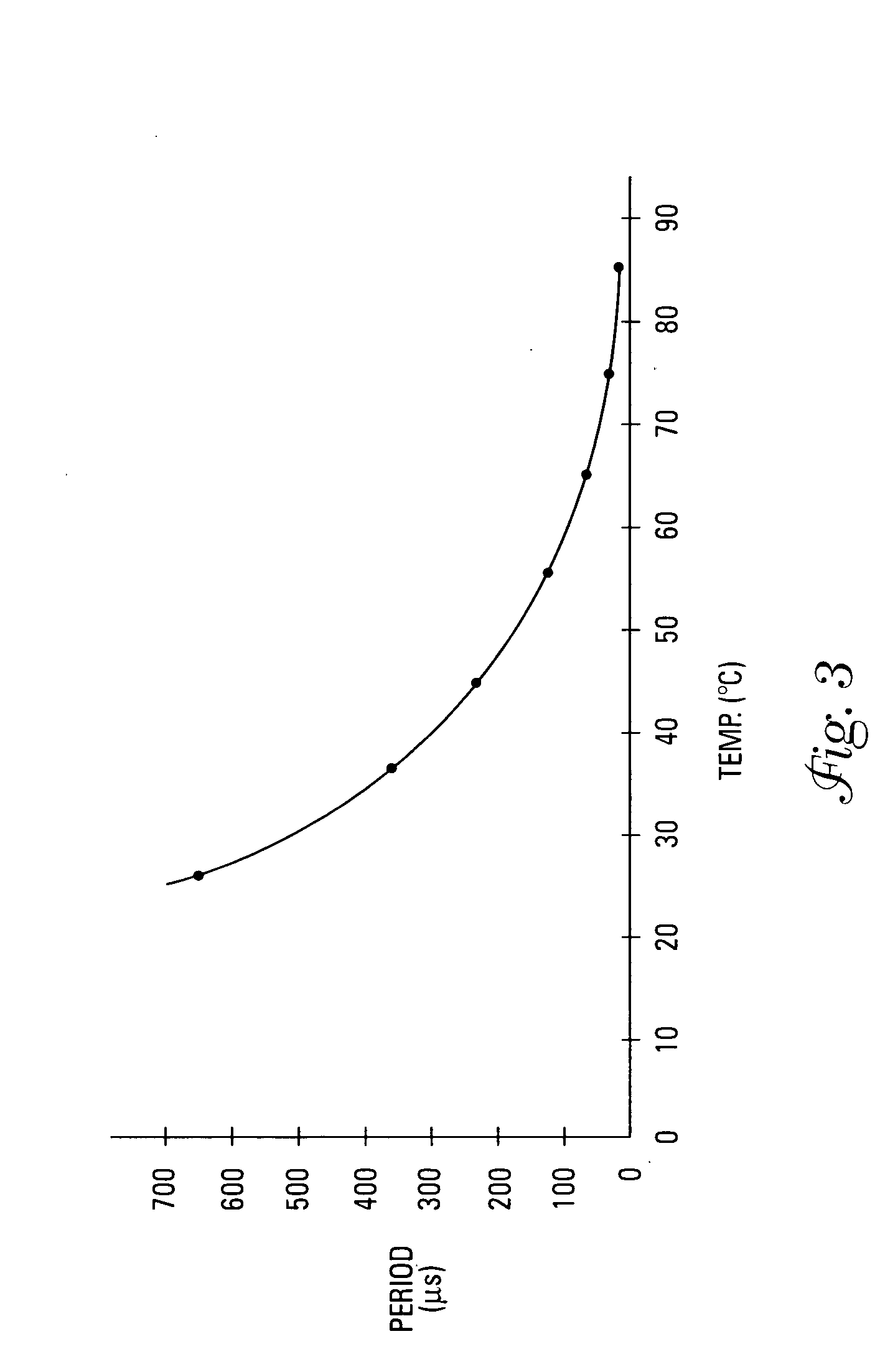

Temperature sensing device in an integrated circuit

InactiveUS7034507B2Thermometer detailsSecondary cells charging/dischargingMemory circuitsIntegrated circuit

A temperature sensing device can be embedded in a memory circuit in order to sense the temperature of the memory circuit. One oscillator generates a temperature variable signal that increases frequency as the temperature of the oscillator increases and decreases frequency when the temperature of the oscillator decreases. A temperature invariant oscillator generates a fixed width signal that is controlled by an oscillator read logic and indicates a temperature sense cycle. An n-bit counter is clocked by the temperature variable signal while the fixed width signal enables / inhibits the counter. The faster the counter counts, the larger the count value at the end of the sense cycle indicated by the fixed width signal. A larger count value indicates a warmer temperature. A smaller count value indicates a colder temperature.

Owner:ROUND ROCK RES LLC

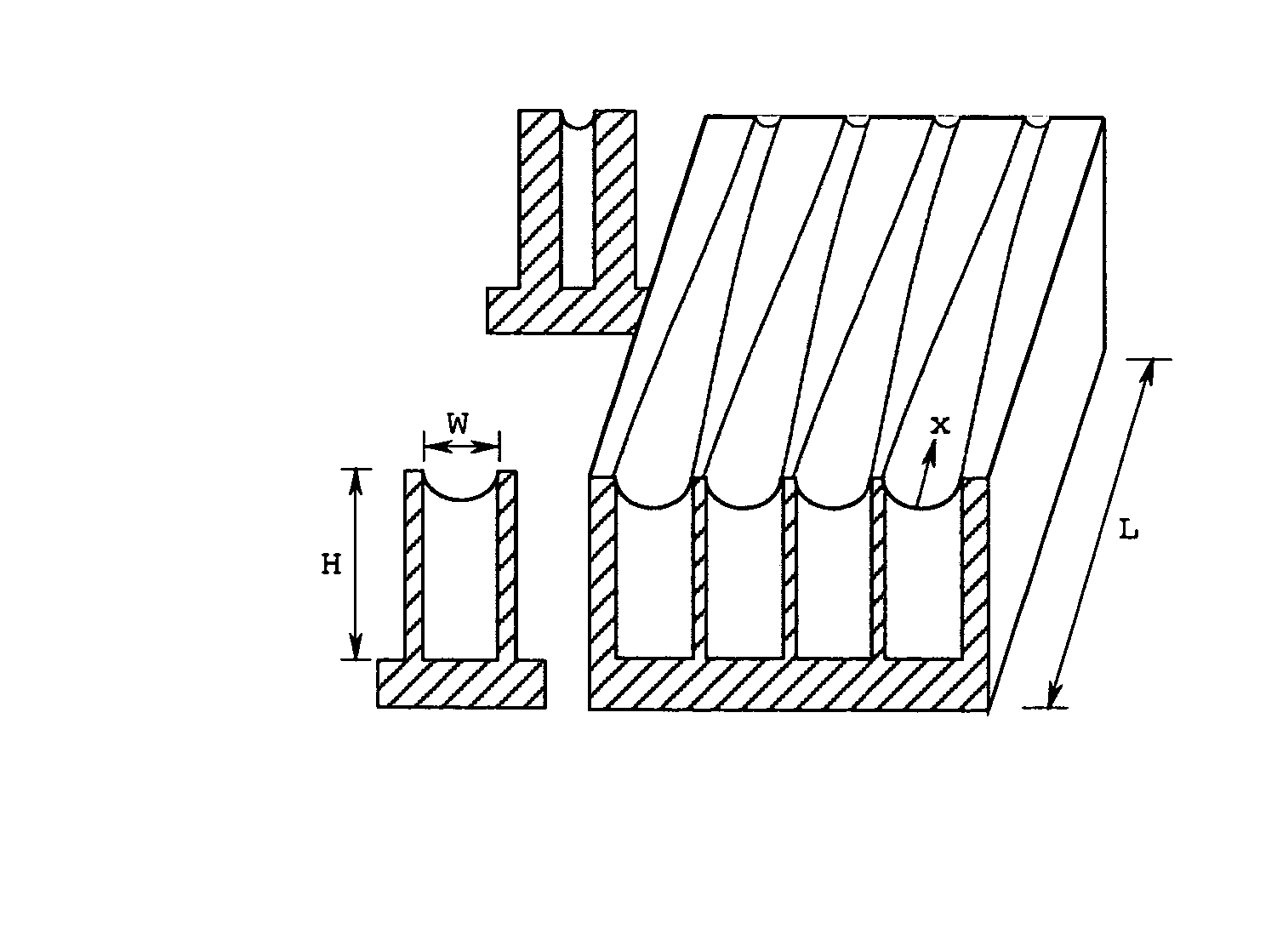

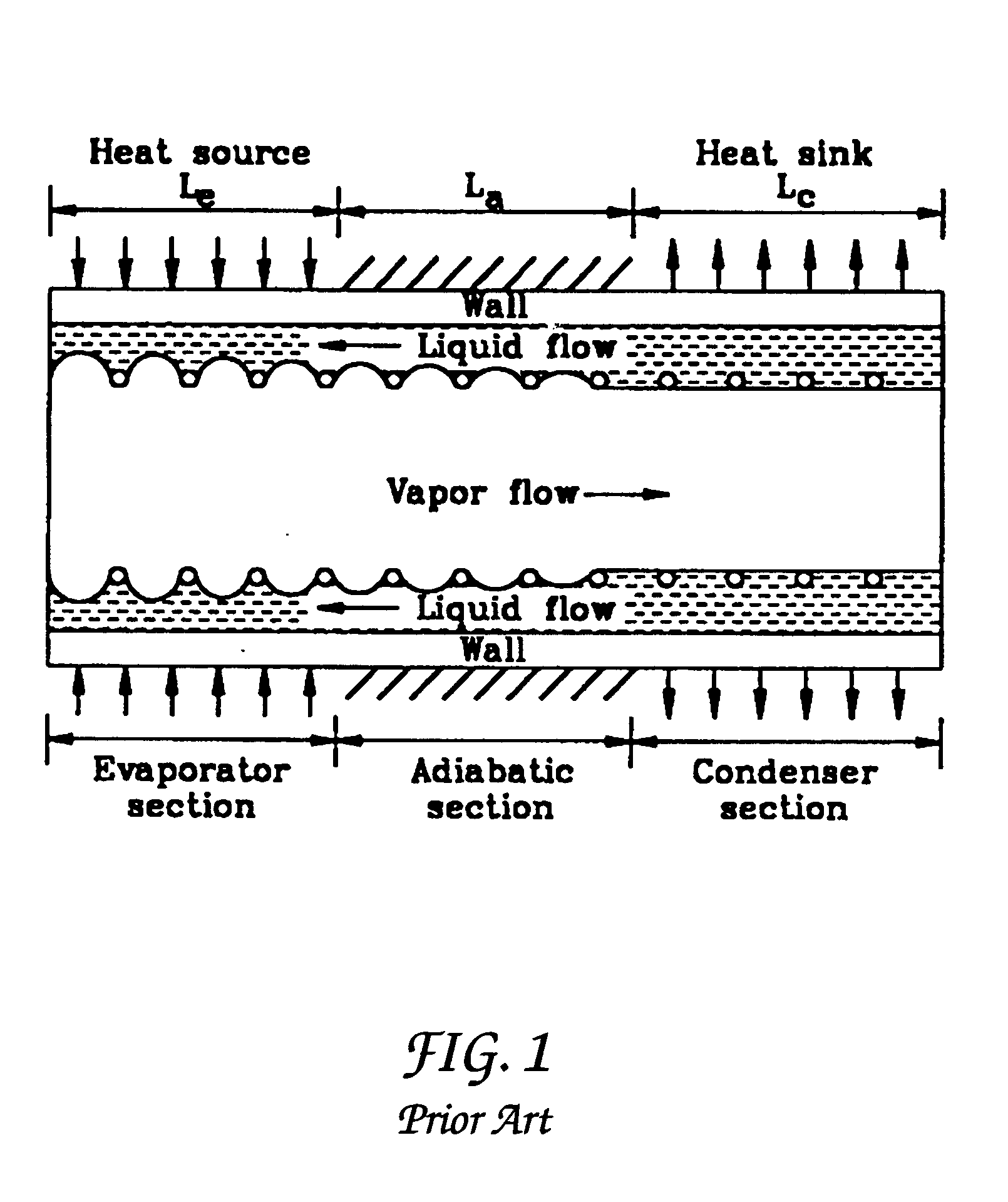

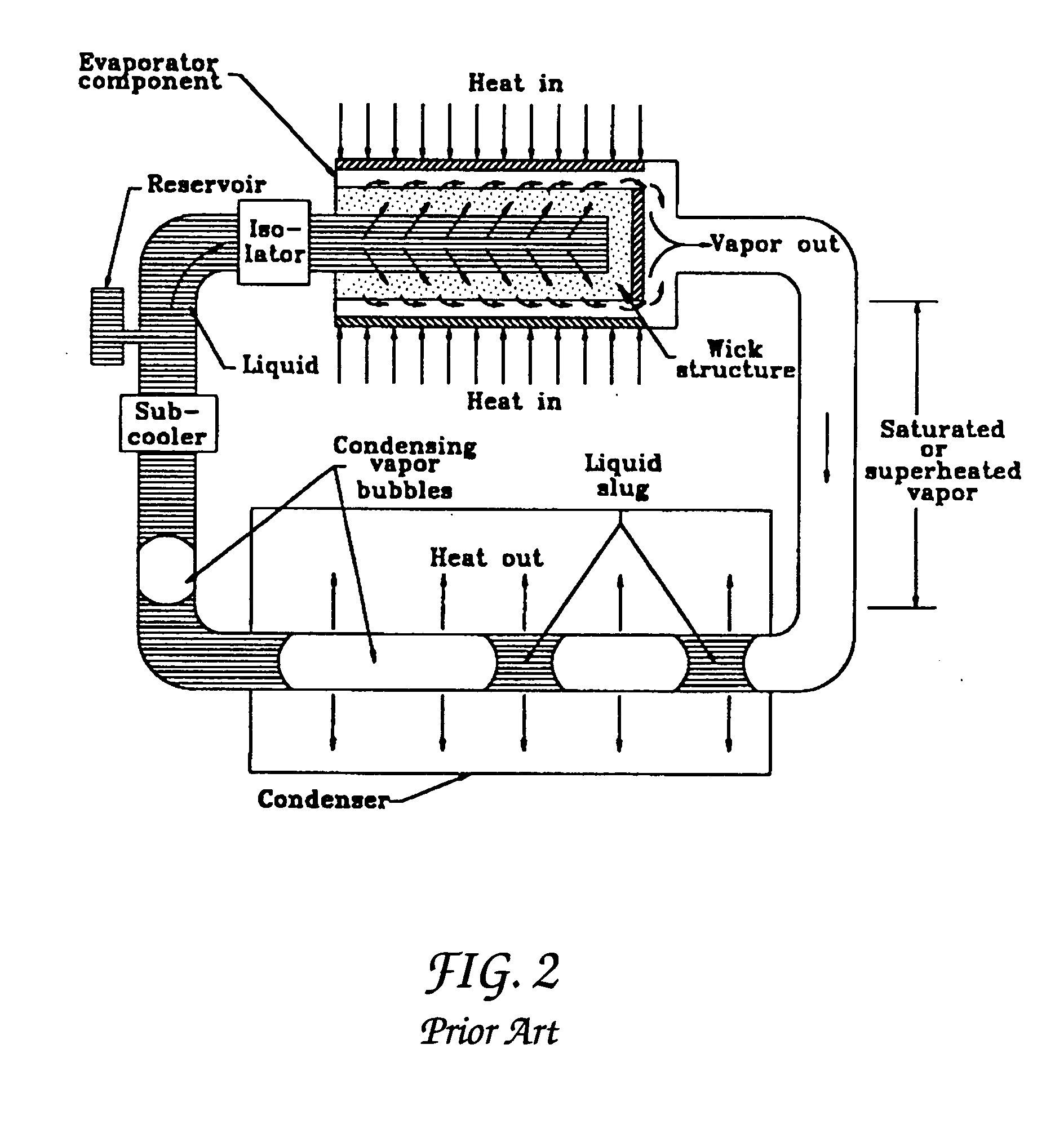

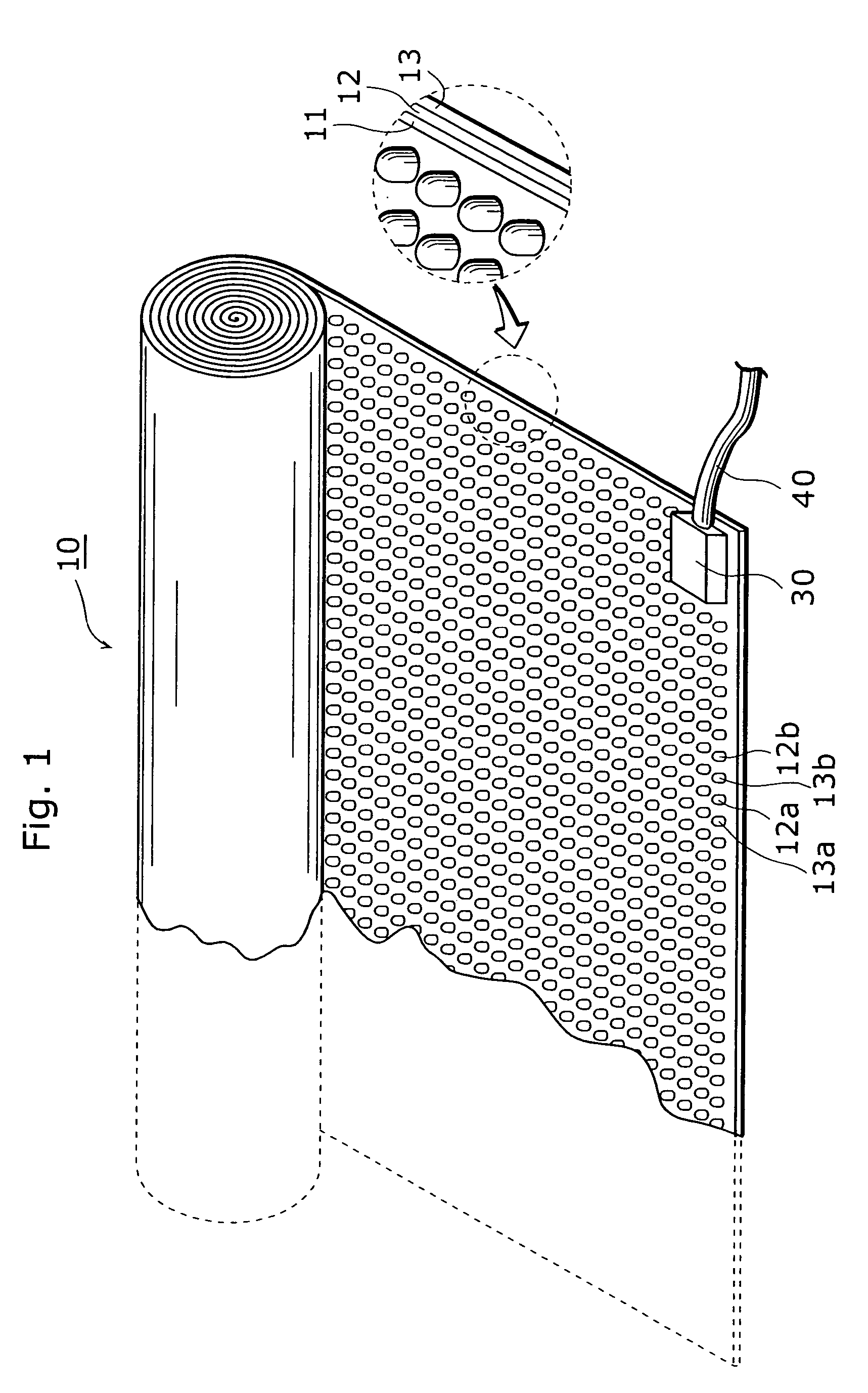

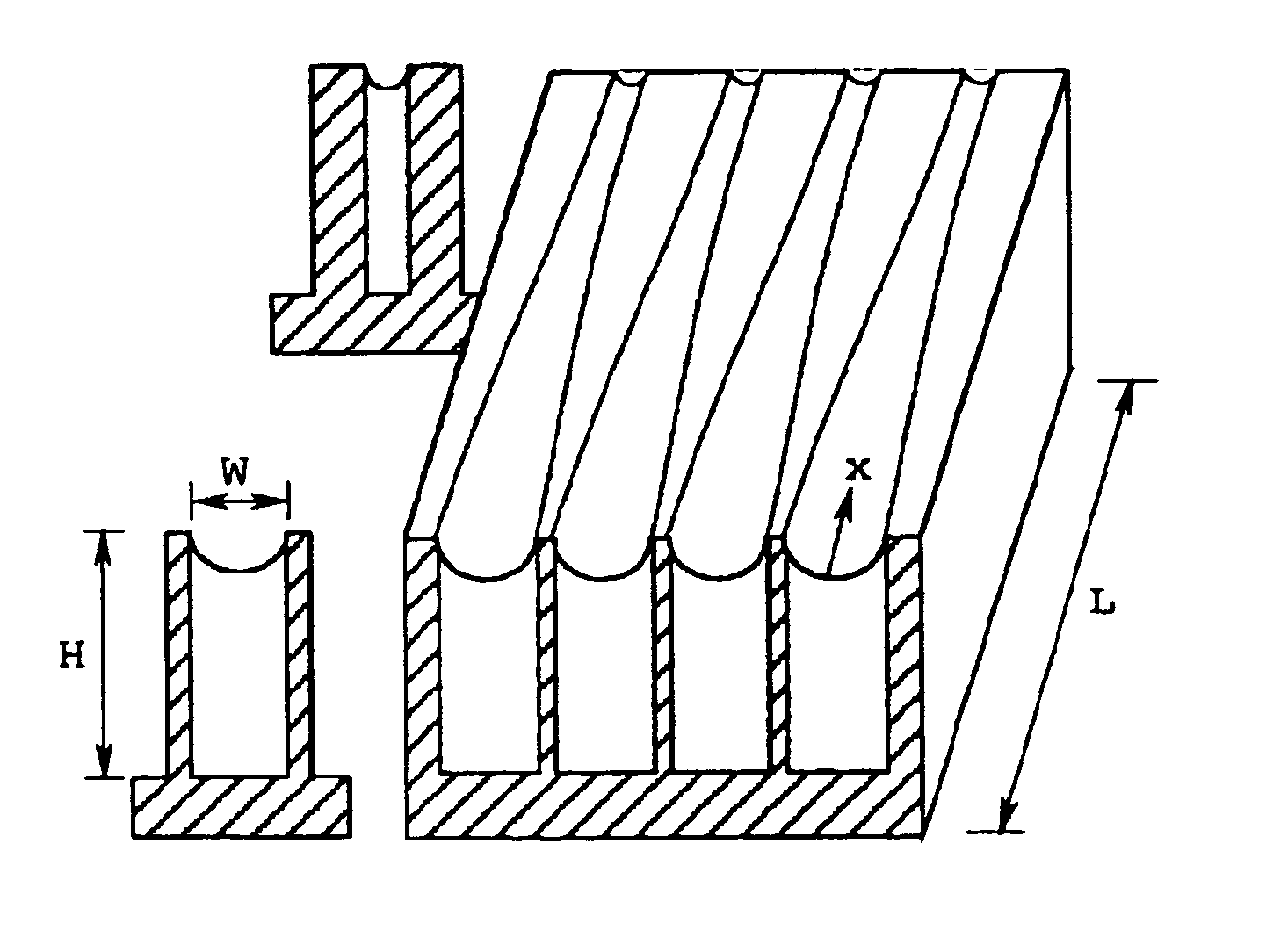

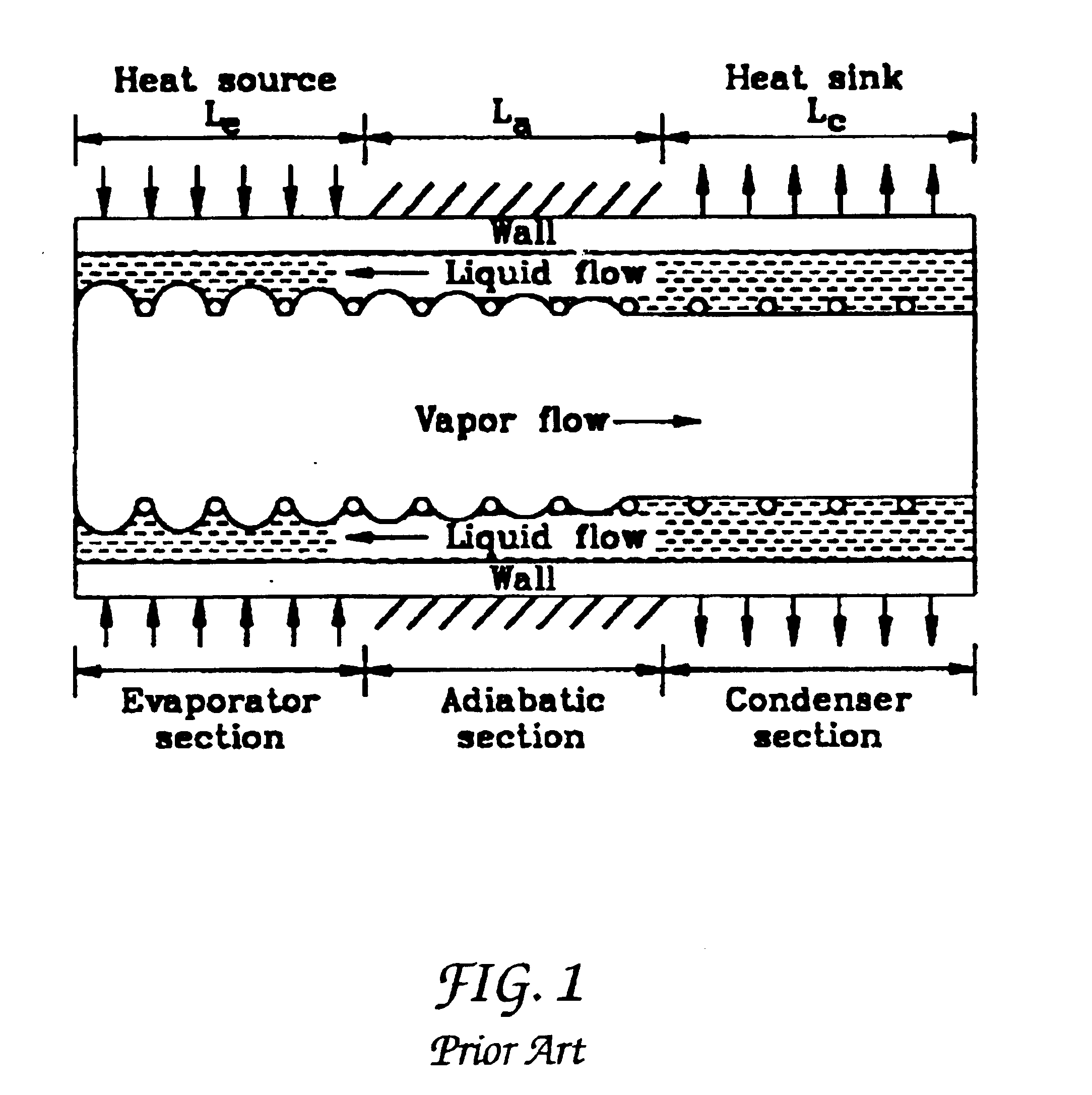

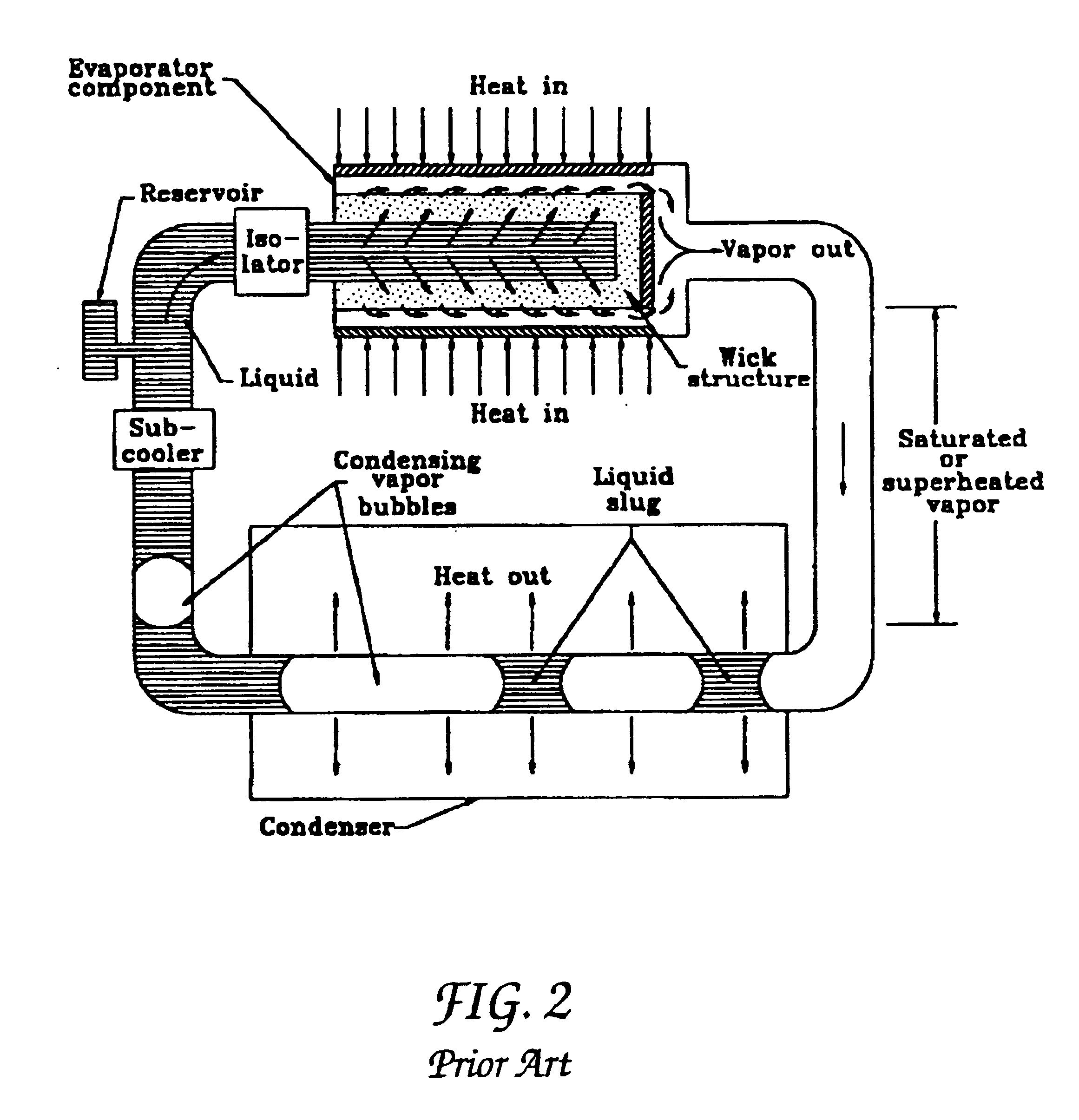

Axially tapered and bilayer microchannels for evaporative coolling devices

The invention consists of an evaporative cooling device comprising one or more microchannels whose cross section is axially reduced to control the maximum capillary pressure differential between liquid and vapor phases. In one embodiment, the evaporation channels have a rectangular cross section that is reduced in width along a flow path. In another embodiment, channels of fixed width are patterned with an array of microfabricated post-like features such that the feature size and spacing are gradually reduced along the flow path. Other embodiments incorporate bilayer channels consisting of an upper cover plate having a pattern of slots or holes of axially decreasing size and a lower fluid flow layer having channel widths substantially greater than the characteristic microscale dimensions of the patterned cover plate. The small dimensions of the cover plate holes afford large capillary pressure differentials while the larger dimensions of the lower region reduce viscous flow resistance.

Owner:SANDIA NAT LAB

Efficient hardware instructions for single instruction multiple data processors

ActiveUS20140013078A1General purpose stored program computerConcurrent instruction executionVariable lengthByte

A method and apparatus for efficiently processing data in various formats in a single instruction multiple data (“SIMD”) architecture is presented. Specifically, a method to unpack a fixed-width bit values in a bit stream to a fixed width byte stream in a SIMD architecture is presented. A method to unpack variable-length byte packed values in a byte stream in a SIMD architecture is presented. A method to decompress a run length encoded compressed bit-vector in a SIMD architecture is presented. A method to return the offset of each bit set to one in a bit-vector in a SIMD architecture is presented. A method to fetch bits from a bit-vector at specified offsets relative to a base in a SIMD architecture is presented. A method to compare values stored in two SIMD registers is presented.

Owner:ORACLE INT CORP

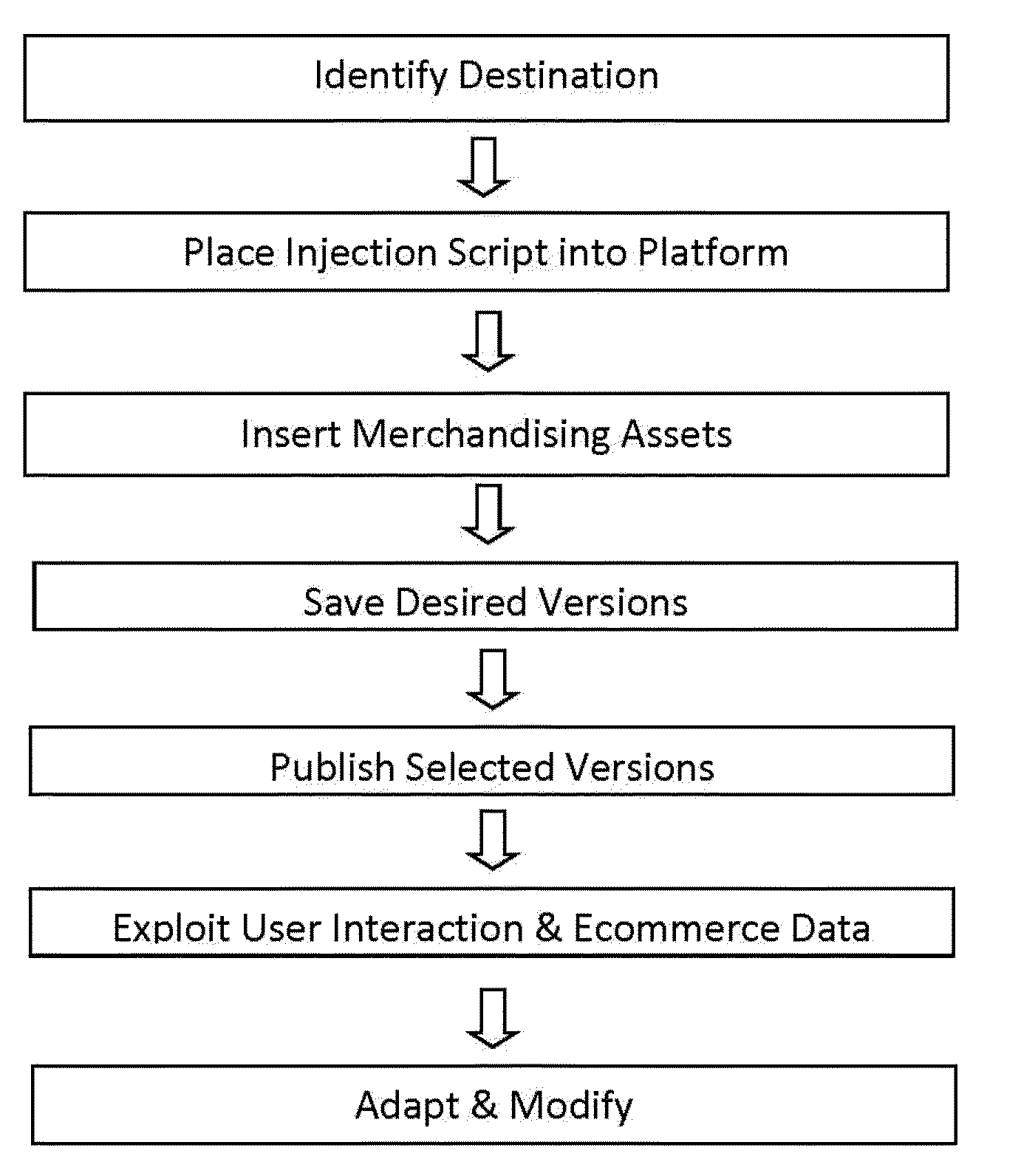

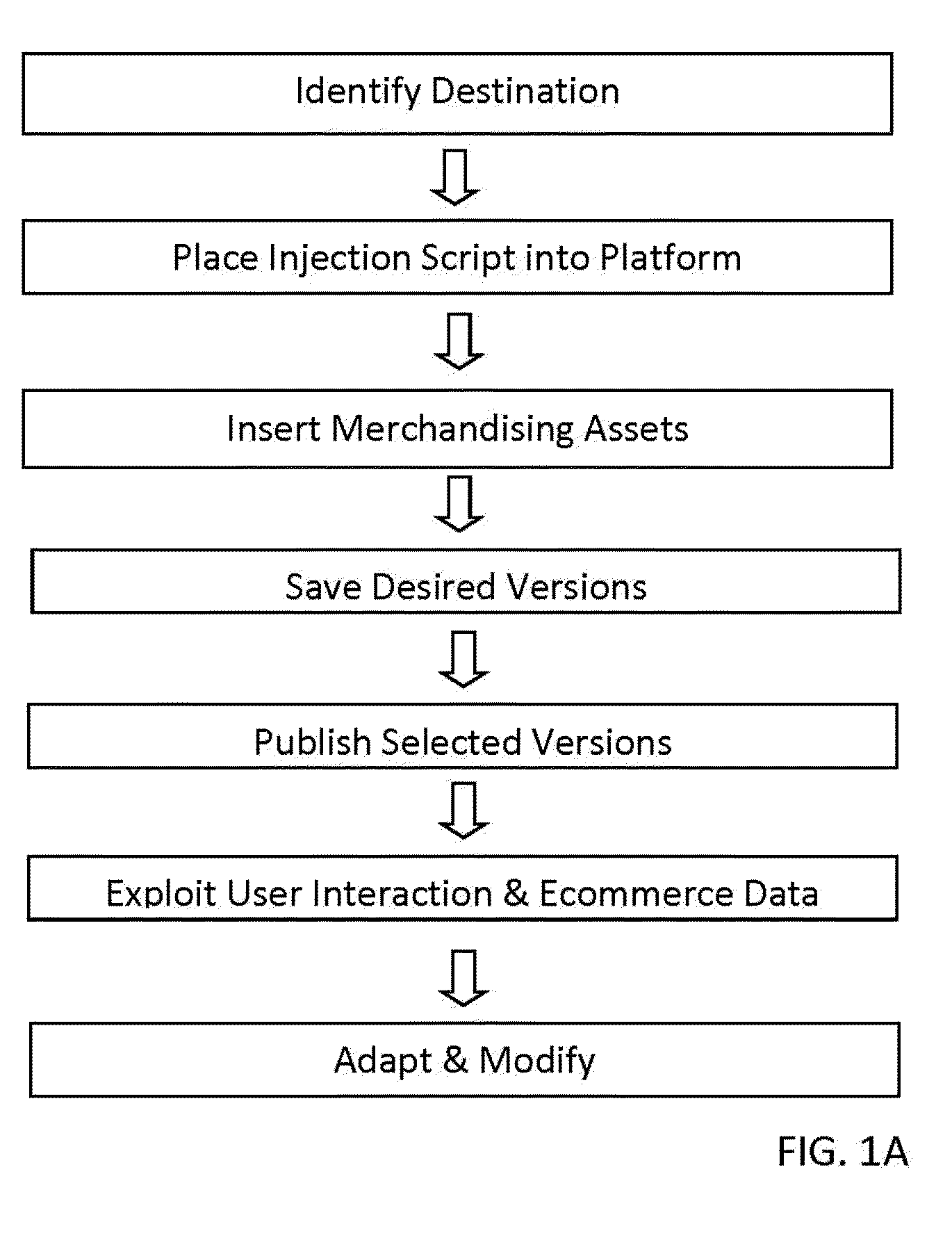

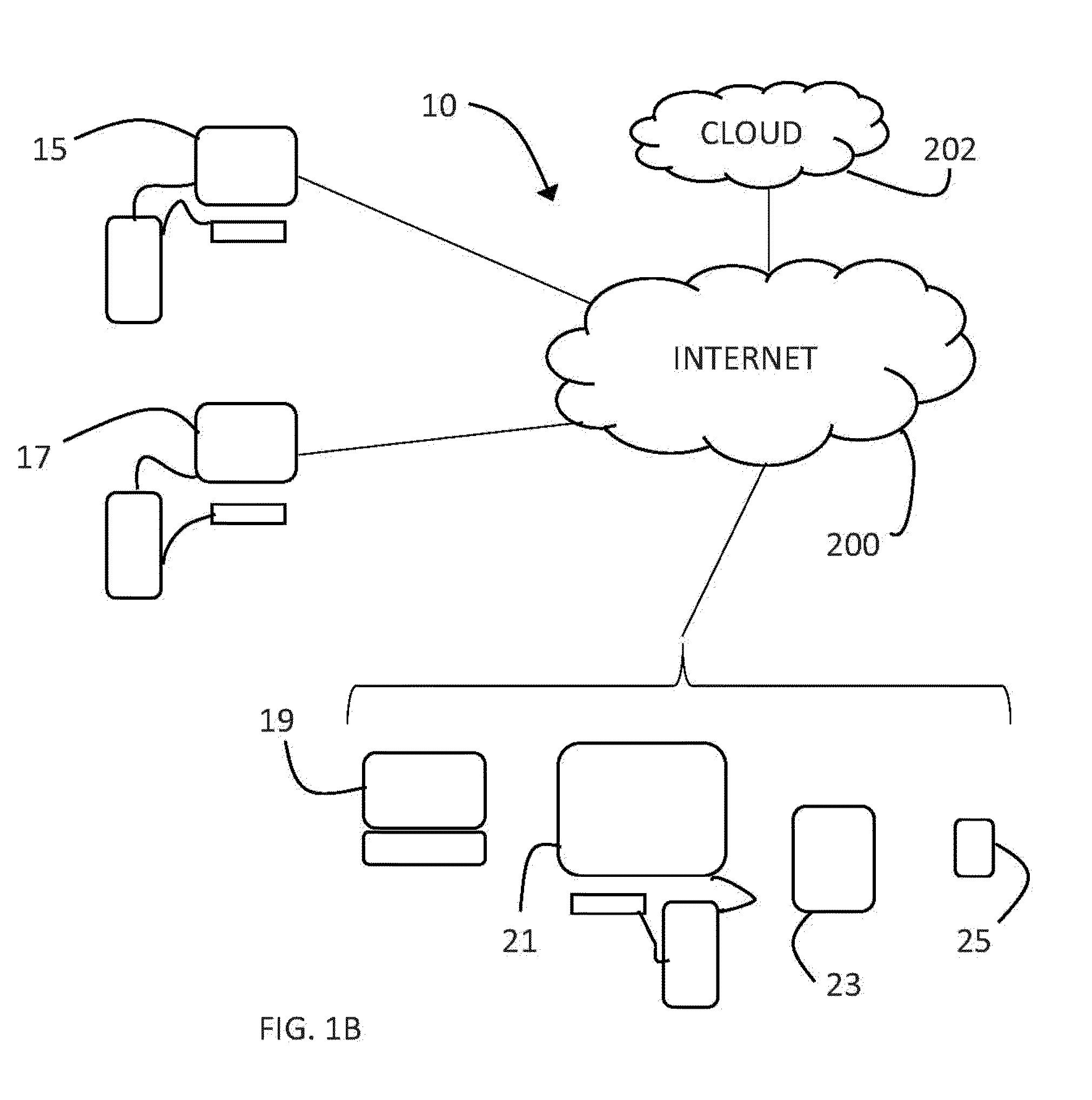

Dynamic Website Campaign Builder for Merchandising

InactiveUS20140222553A1Enhanced customer engagementImprove consistencyAdvertisementsWeb siteApplication programming interface

Dynamic website Campaign builder software for enabling merchandising via the Internet. The Campaign builder software has an application programming interface for display on programming computing devices with display screens to permit building a Campaign. Plural Campaign templates are retained in electronic memory, and an insertion mechanism, such as a Destination Script or an iFrame, permits insertion of assets into the Campaign template to create Campaigns. A saving mechanism permits selective saving of Campaigns, and a publishing mechanism permits selective publication of Campaigns, including with fixed width and responsive design templates. A recipient user interface is operative on recipient computing devices with display screens to permit viewing and usage of published Campaigns. Campaigns are saved to content delivery network (CDN) Media Cloud Server storage for rapid CDN publishing. A linking mechanism permits a linking of Campaigns to an Analytic program for harvesting and analysis of user interaction and Ecommerce data.

Owner:BOWMAN WILLIAM

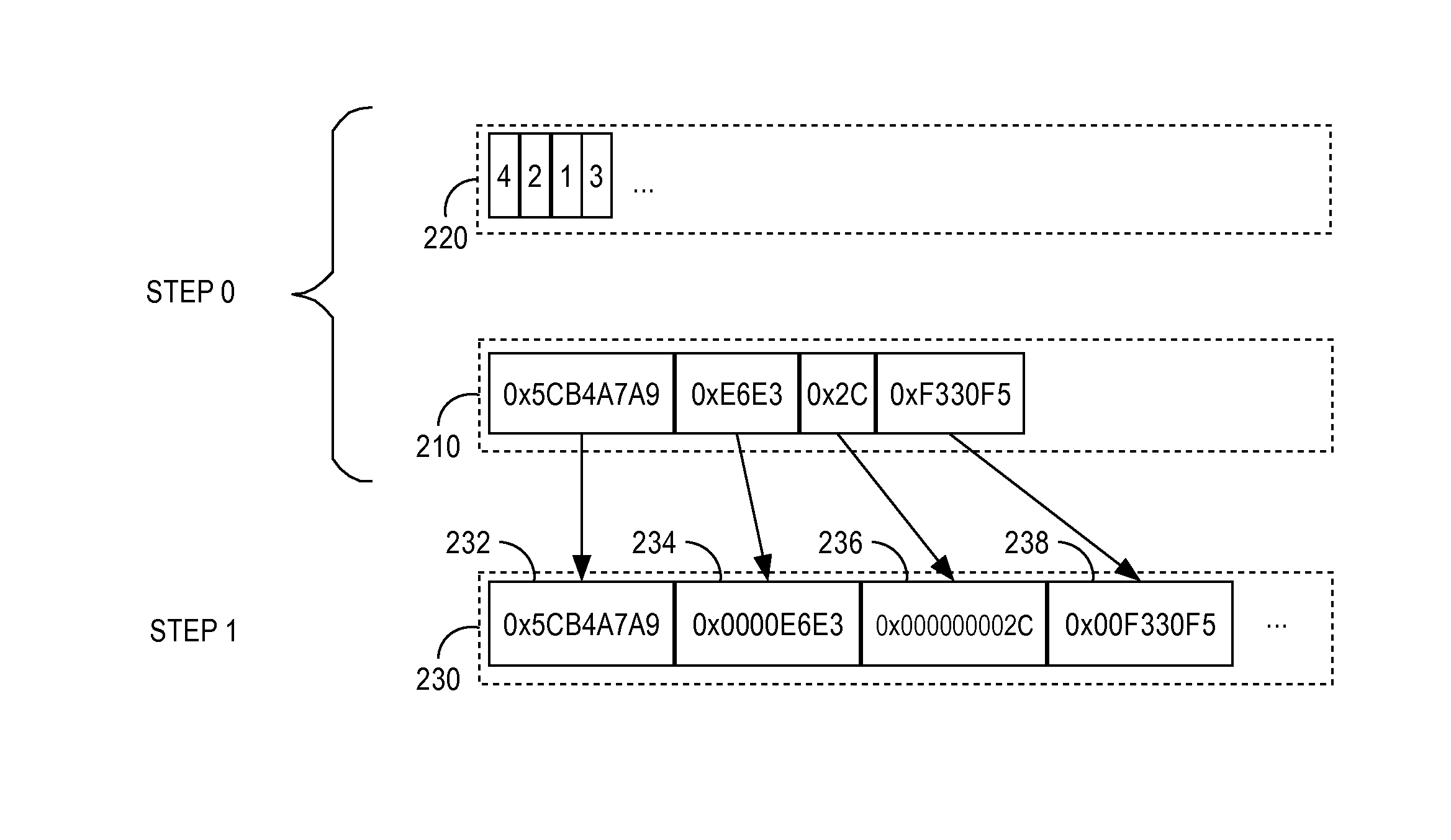

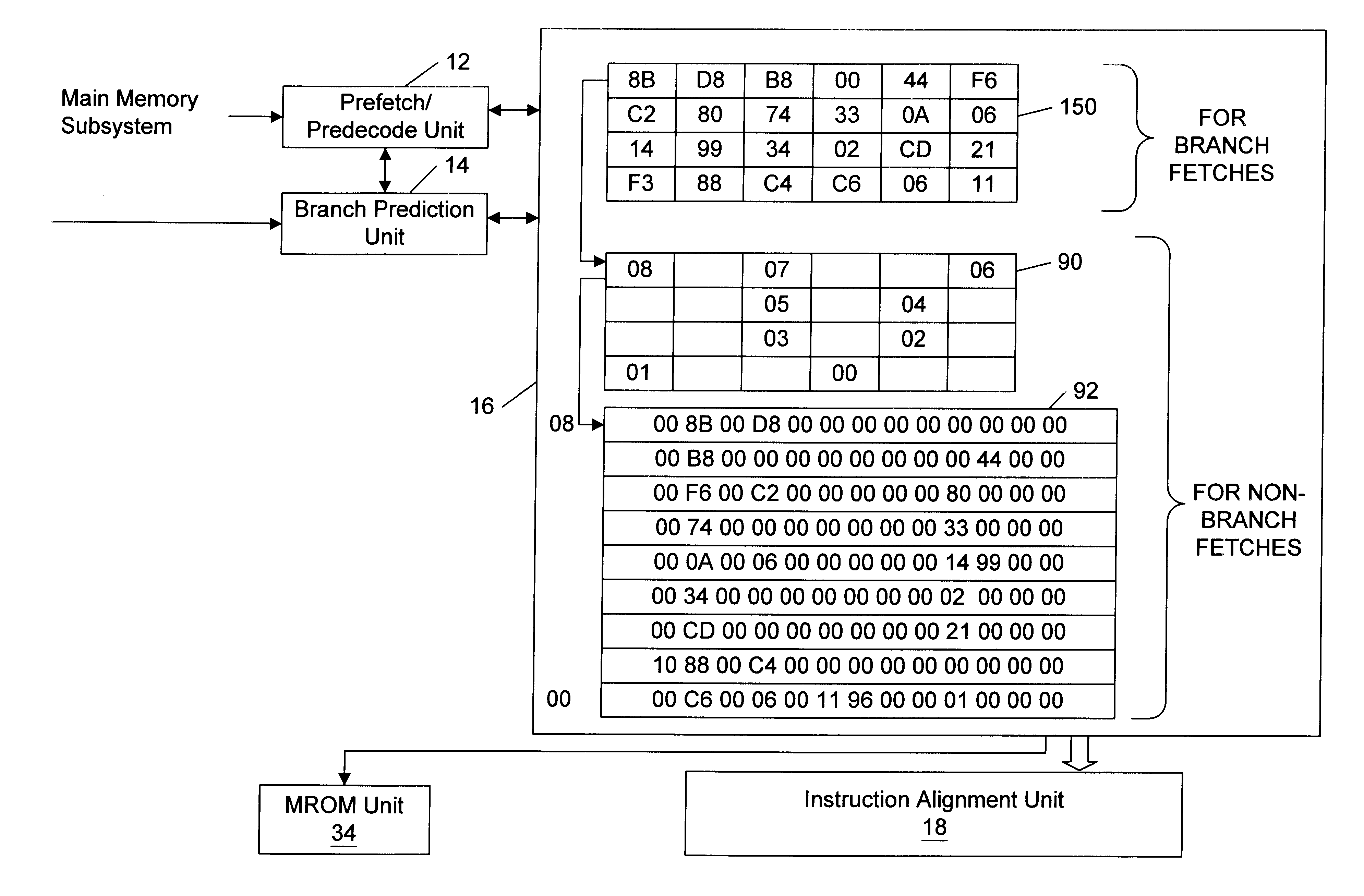

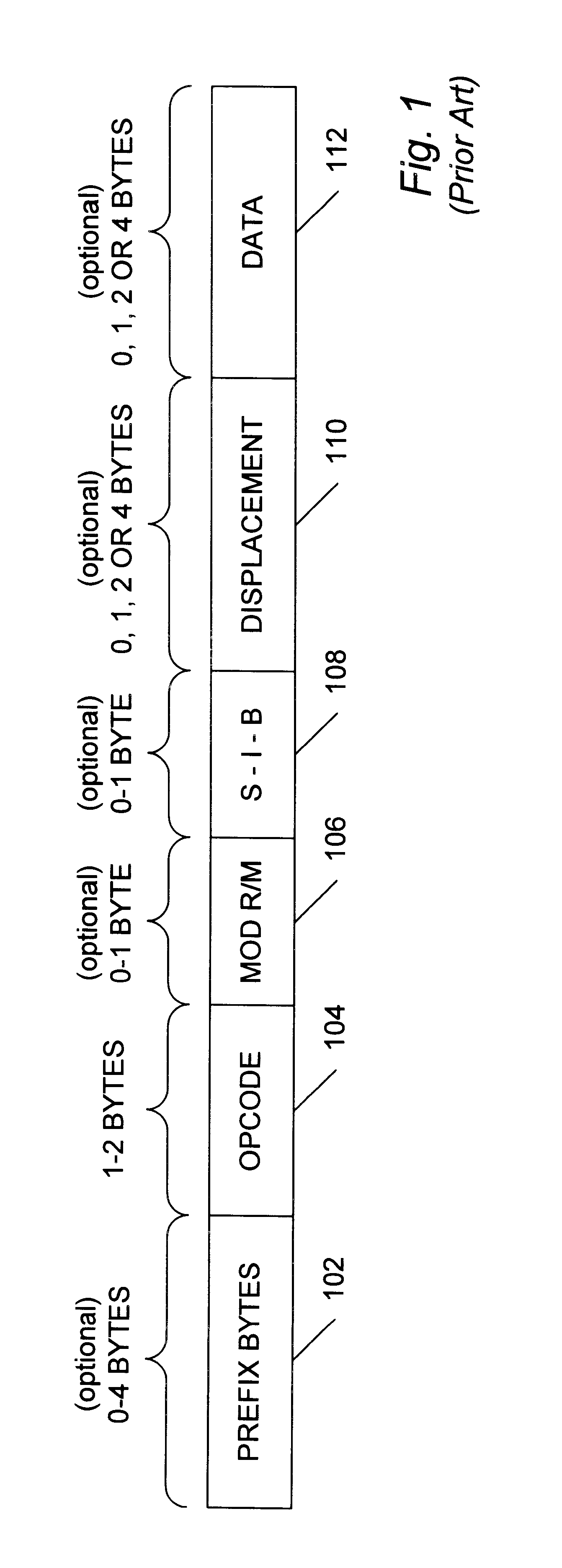

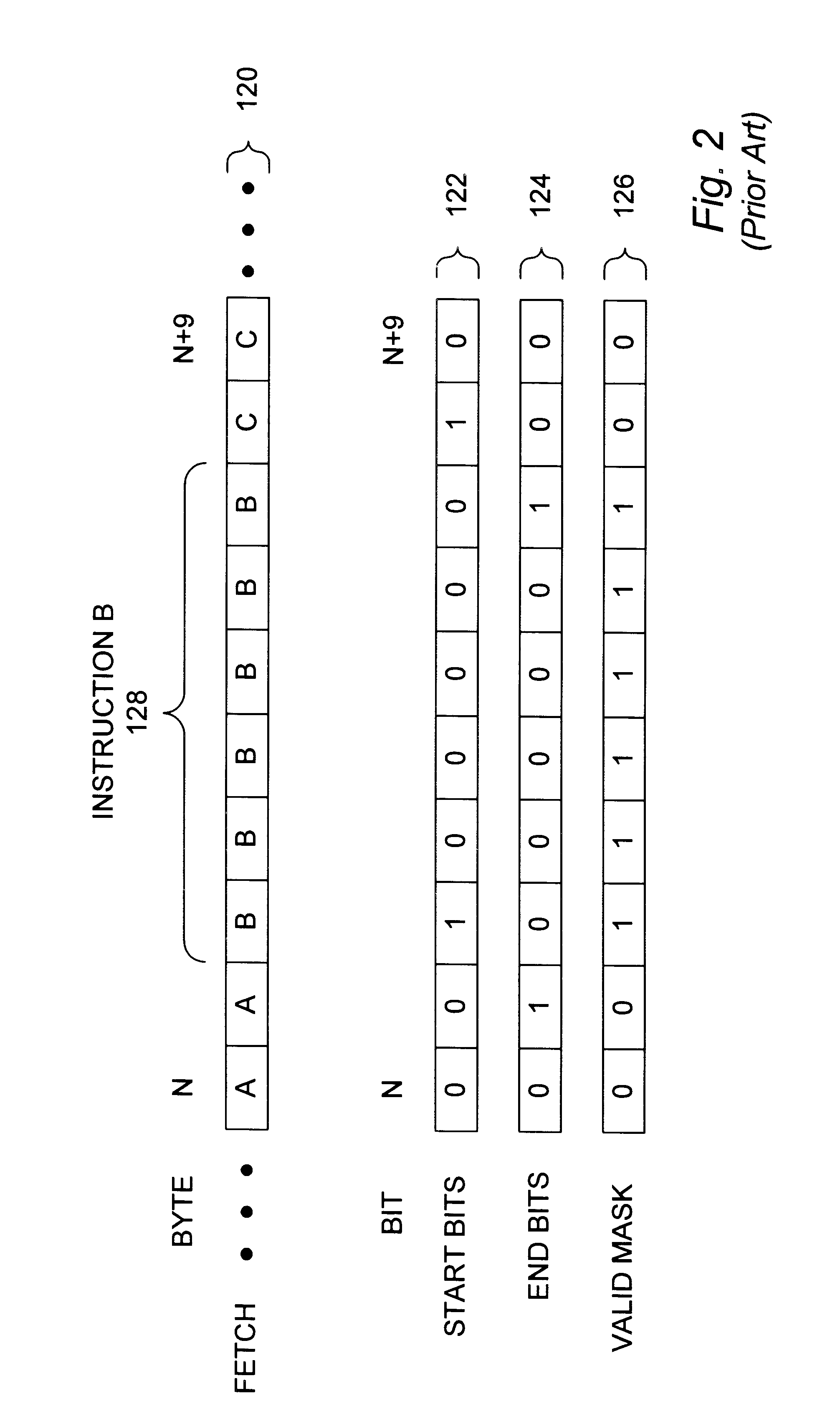

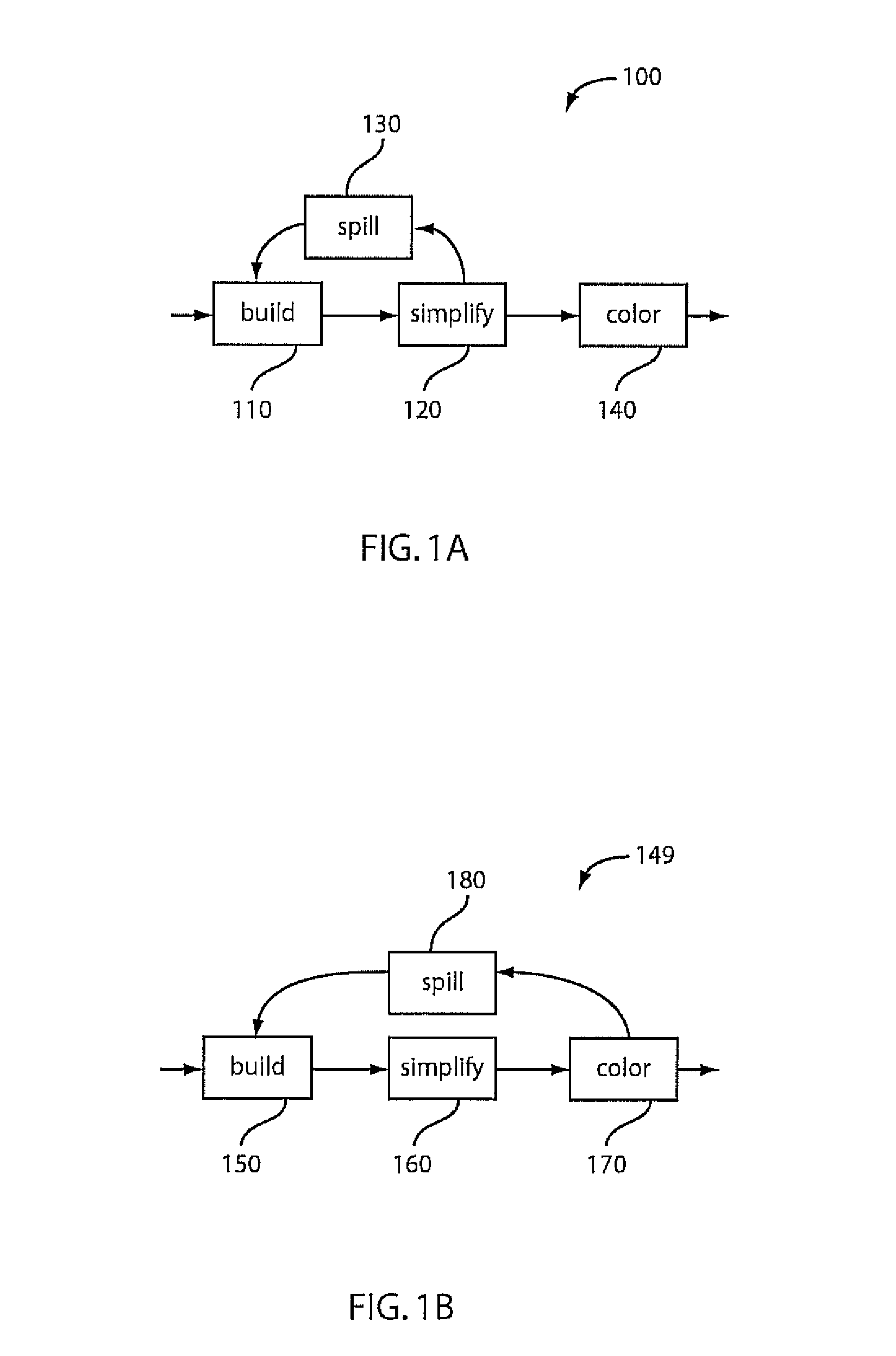

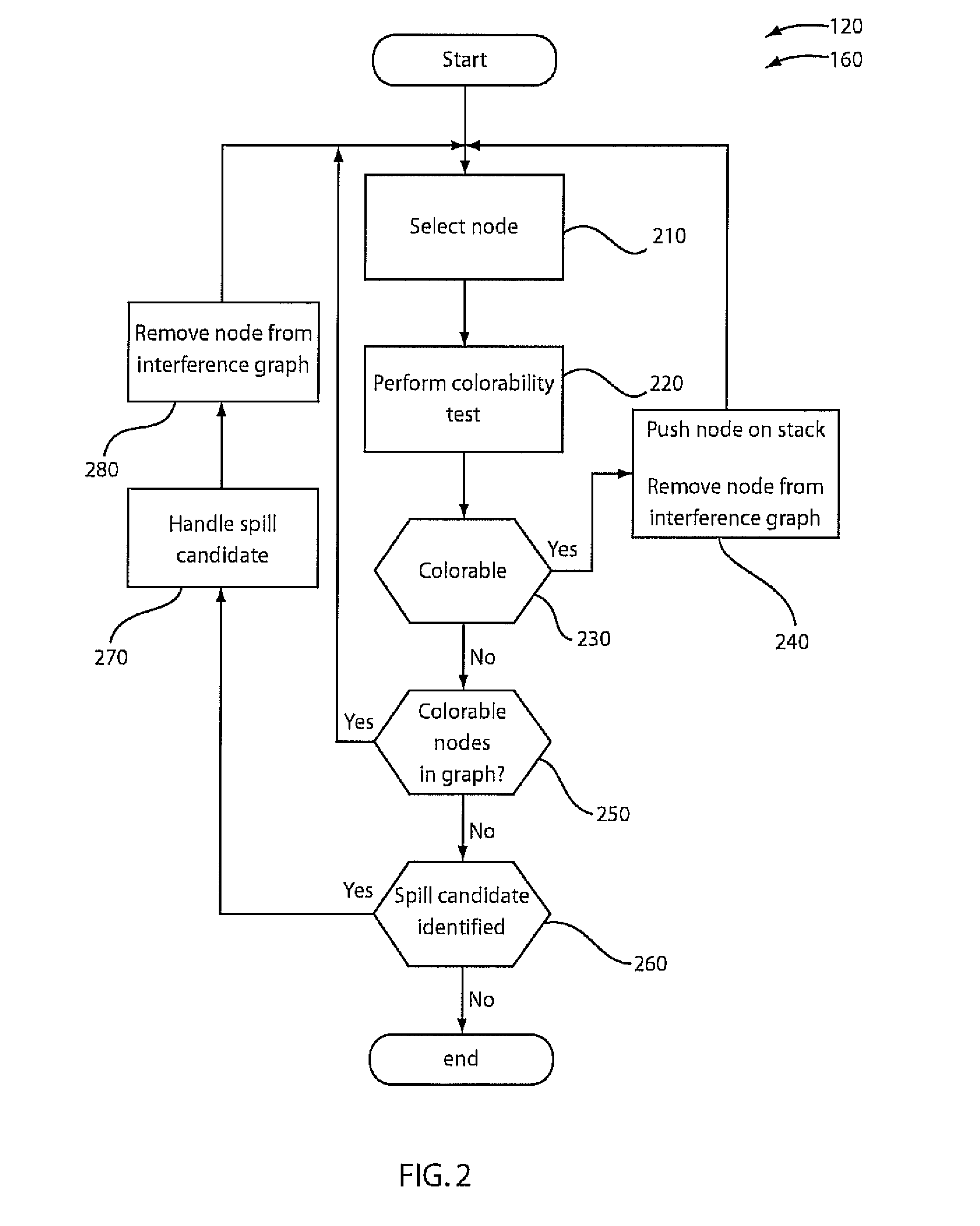

Forcing regularity into a CISC instruction set by padding instructions

InactiveUS6253309B1Instruction analysisGeneral purpose stored program computerArray data structureVariable length

A microprocessor configured to rapidly decode variable-length instructions is disclosed. The microprocessor is configured with a predecoder and an instruction cache. The predecoder is configured to expand variable-length instructions to create fixed-length instructions by padding instruction fields within each variable-length instruction with constants until each field reaches a predetermined maximum width. The fixed-width instructions are then stored within the instruction cache and output for execution when a corresponding requested address is received. The instruction cache may store both variable- and fixed-width instructions, or just fixed-width instructions. An array of pointers may be used to access particular fixed-length instructions. The fixed-length instructions may be configured to all have the same fields and the same lengths, or they may be divided into groups, wherein instructions within each group have the same fields and the same lengths. A software program configured to generate fixed-length instructions from variable-length instructions is also disclosed. A method for predecoding variable-length instructions is also disclosed.

Owner:GLOBALFOUNDRIES INC

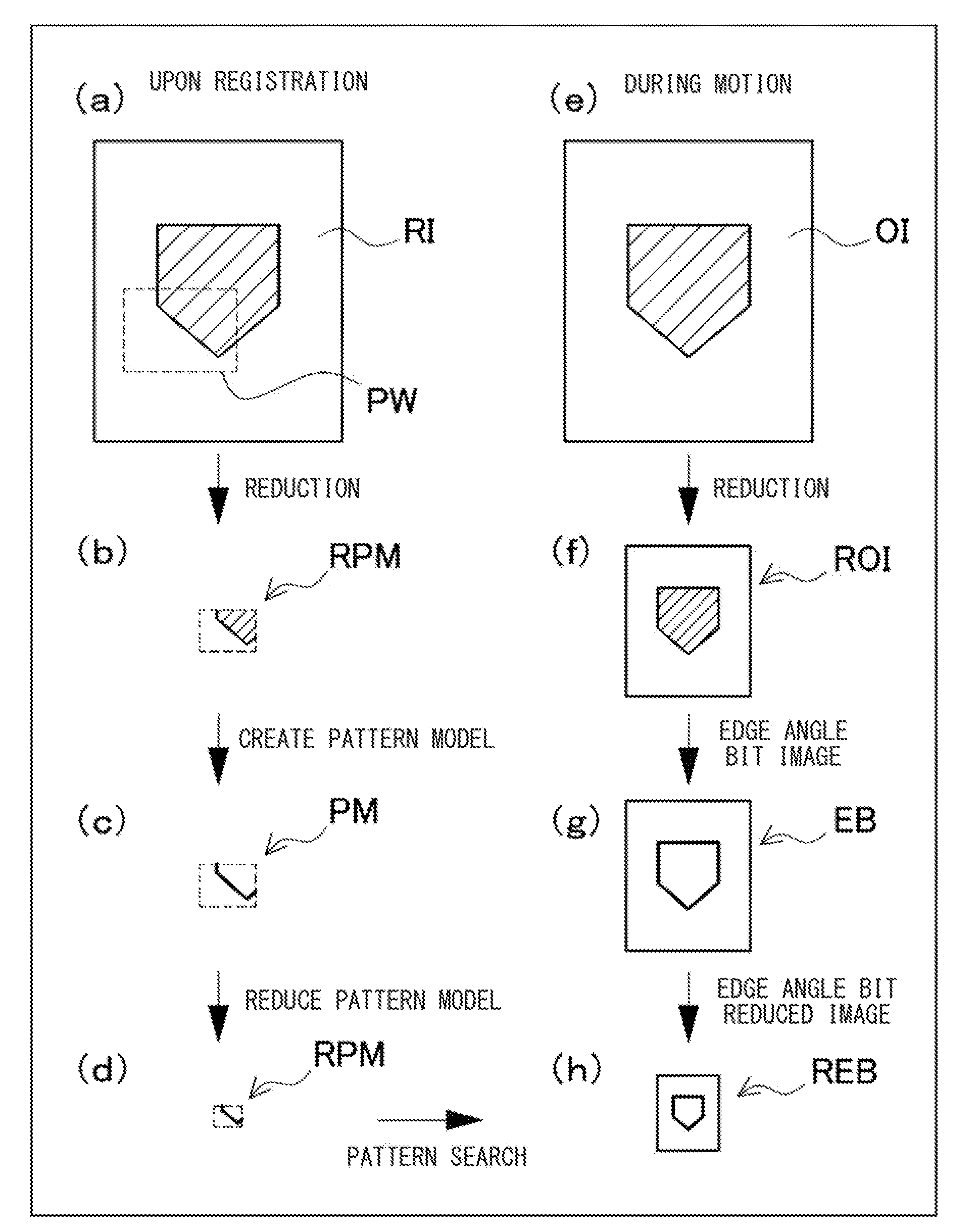

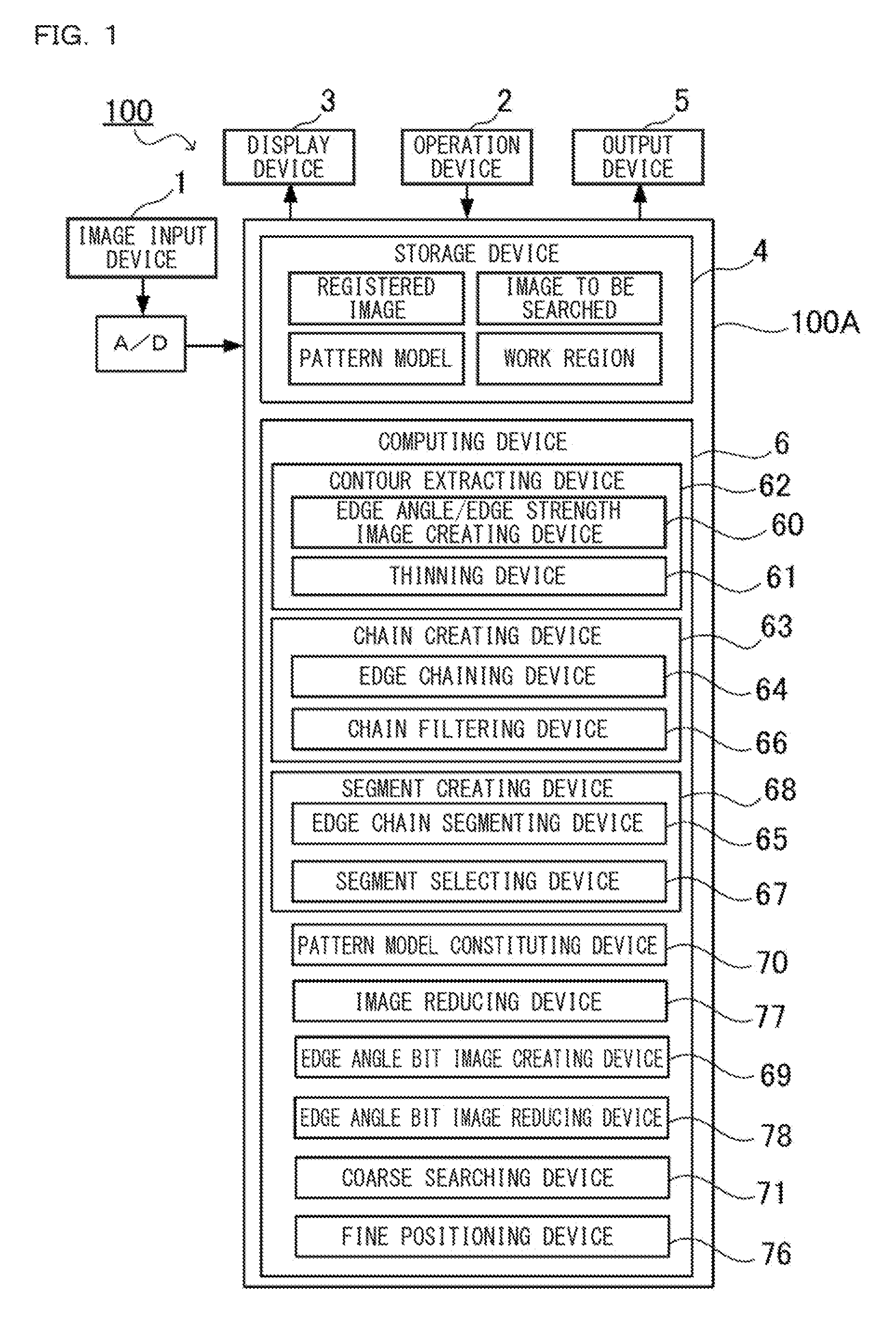

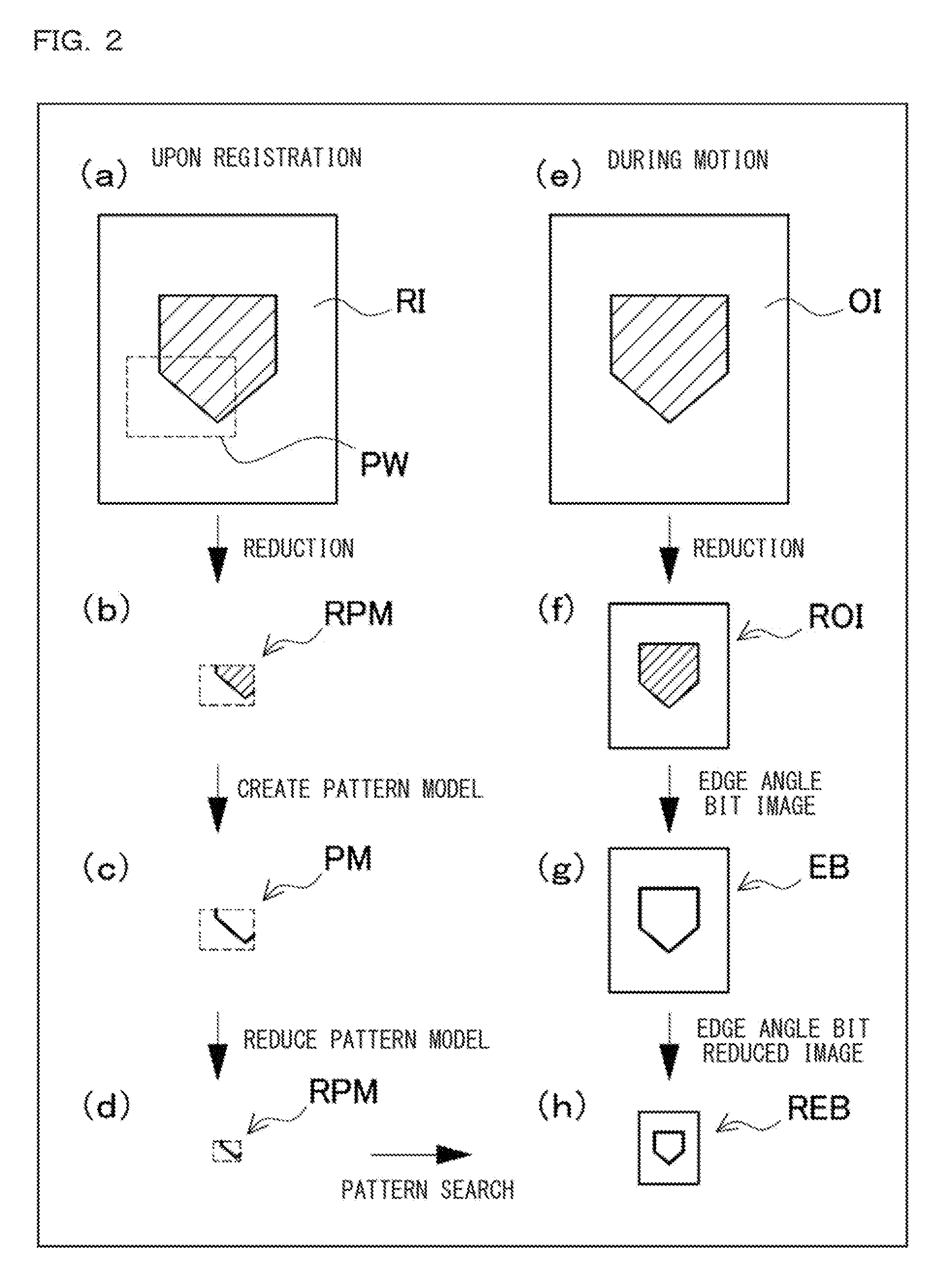

Image Data Compression Method, Pattern Model Positioning Method in Image Processing, Image Processing Apparatus, Image Processing Program, and Computer Readable Recording Medium

InactiveUS20100034476A1Accurately perform adjustmentPrecise positioningCharacter and pattern recognitionData compressionImaging processing

There is provided a data compression method for increasing a reduction ratio, while keeping a sufficient characteristic amount, to seek speeding up of processing, the method being for compressing image data in pattern model positioning in image processing of searching out of an image to be searched and positioning a pattern model corresponding to a pre-registered image. The method includes the steps of computing an edge strength image having edge strength information and an edge angle image having edge angle information with respect to each pixel constituting an image; transforming the edge angle image of each pixel into an edge angle bit image expressed by an edge angle bit indicating an angle with a pre-defined fixed width; and compressing the edge angle bit image to create an edge angle bit reduced image by taking a sum with respect to each edge angle bit.

Owner:KEYENCE

Methods for generating code for an architecture encoding an extended register specification

InactiveUS20080215856A1Software engineeringDigital computer detailsProcessor registerInstruction set

There are provided methods and computer program products for generating code for an architecture encoding an extended register specification. A method for generating code for a fixed-width instruction set includes identifying a non-contiguous register specifier. The method further includes generating a fixed-width instruction word that includes the non-contiguous register specifier.

Owner:INT BUSINESS MASCH CORP

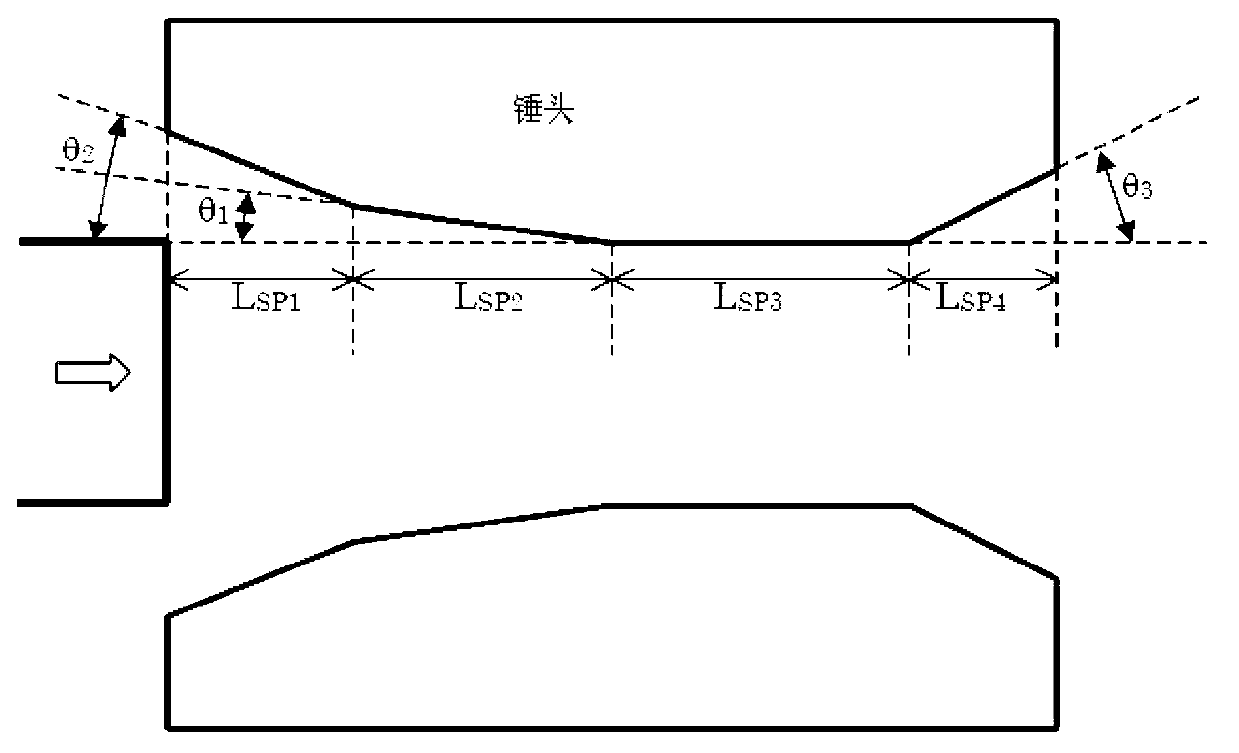

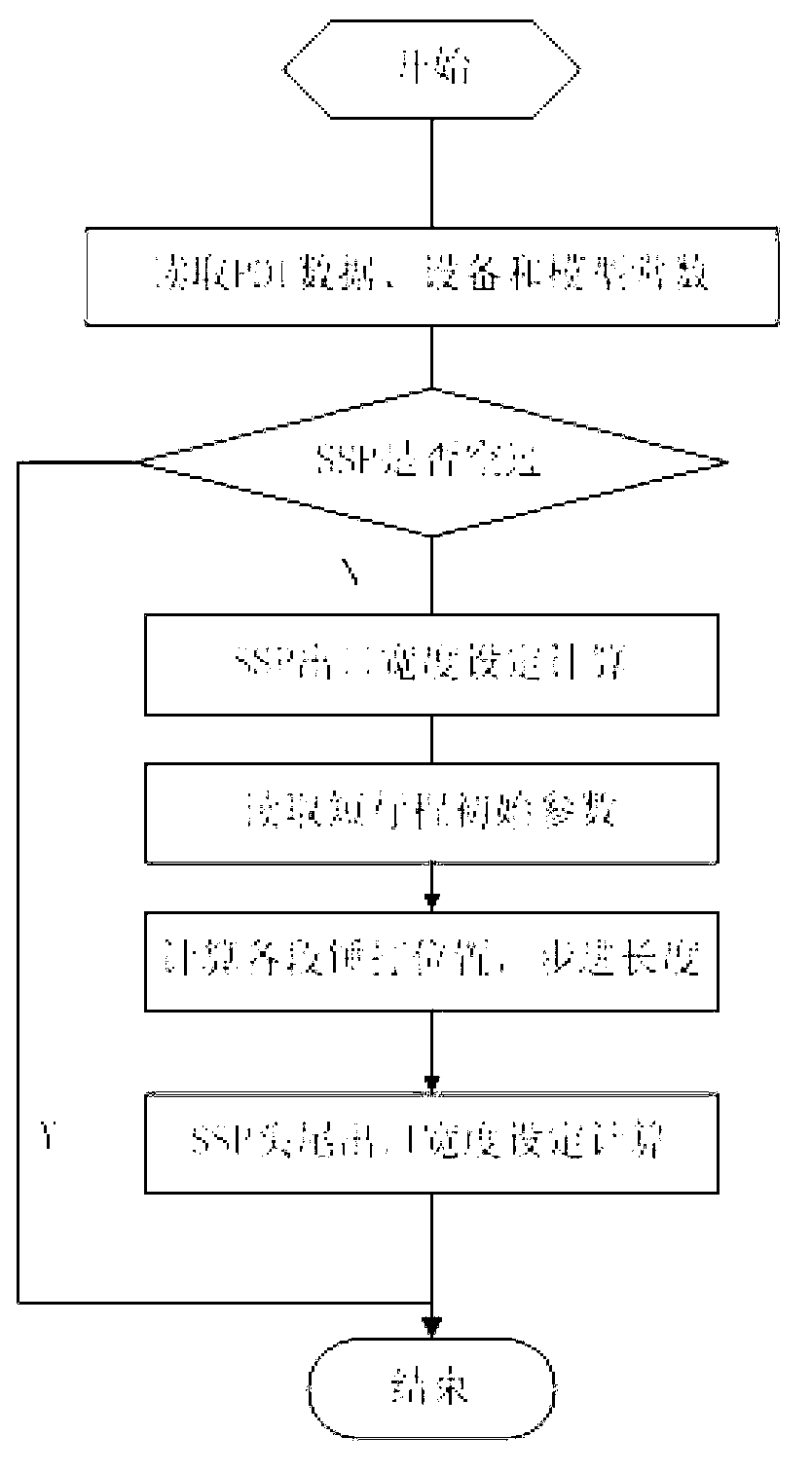

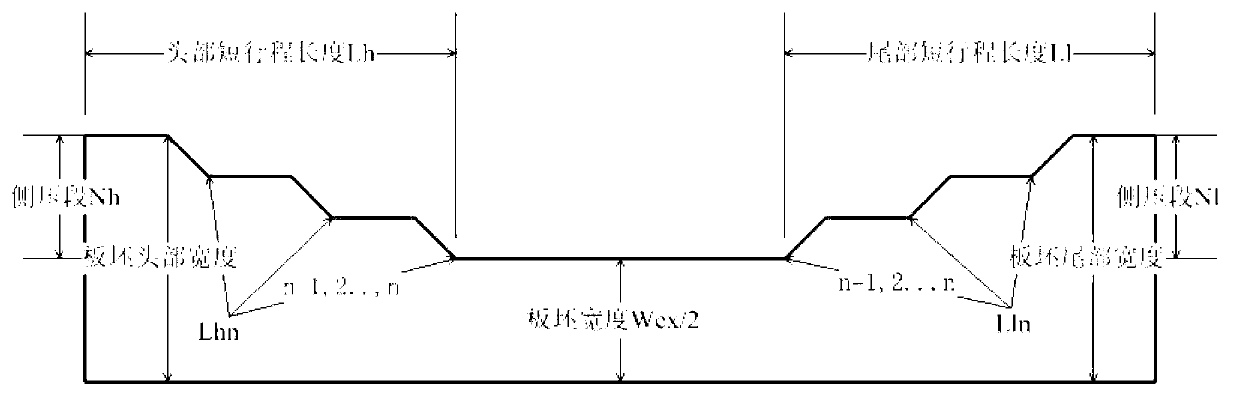

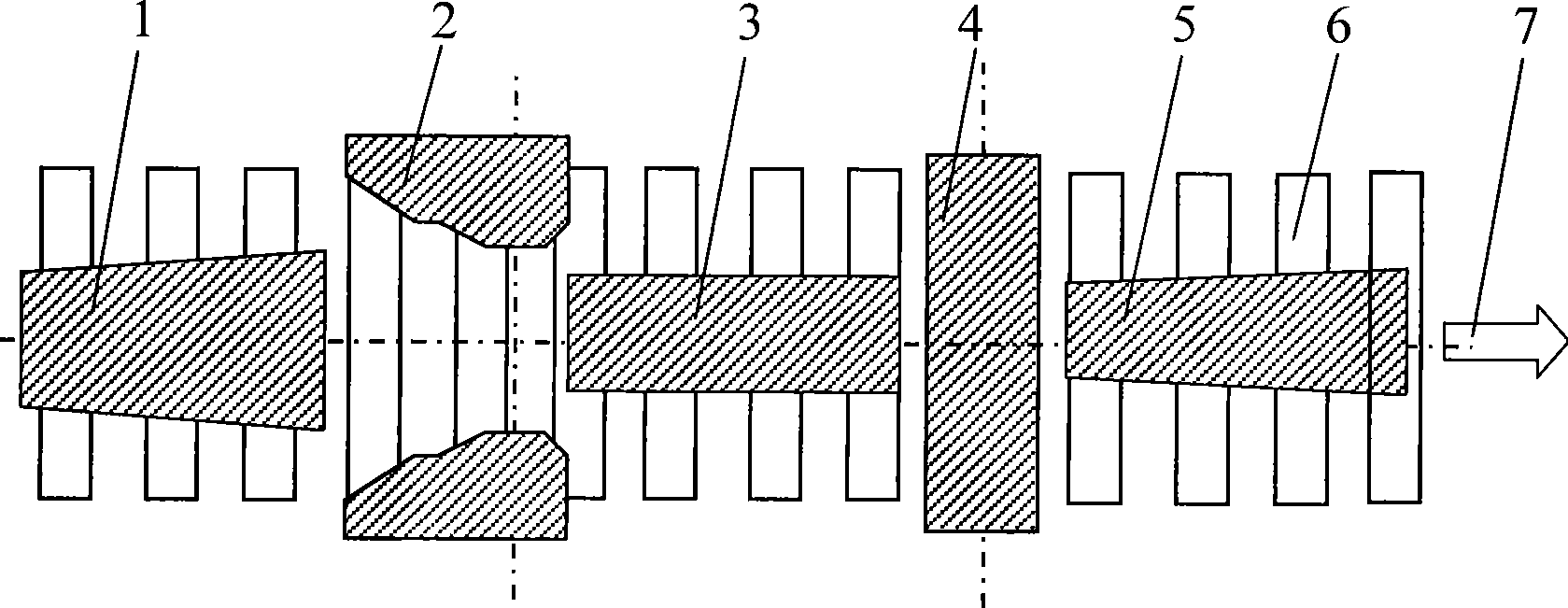

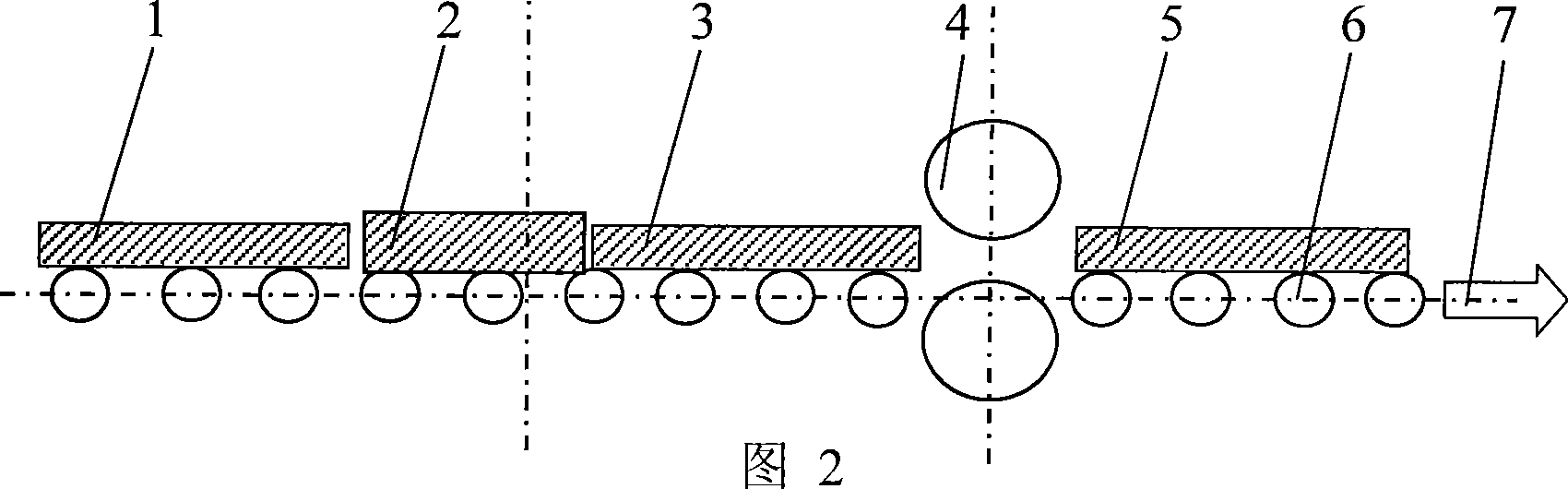

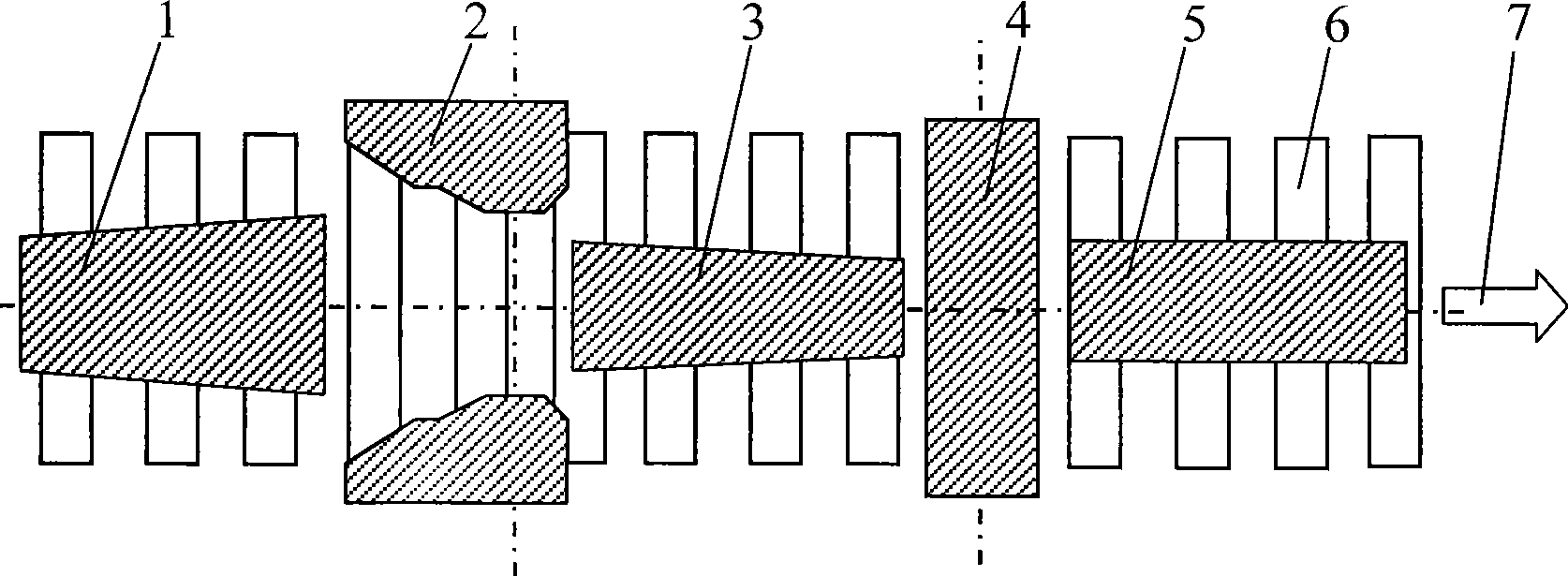

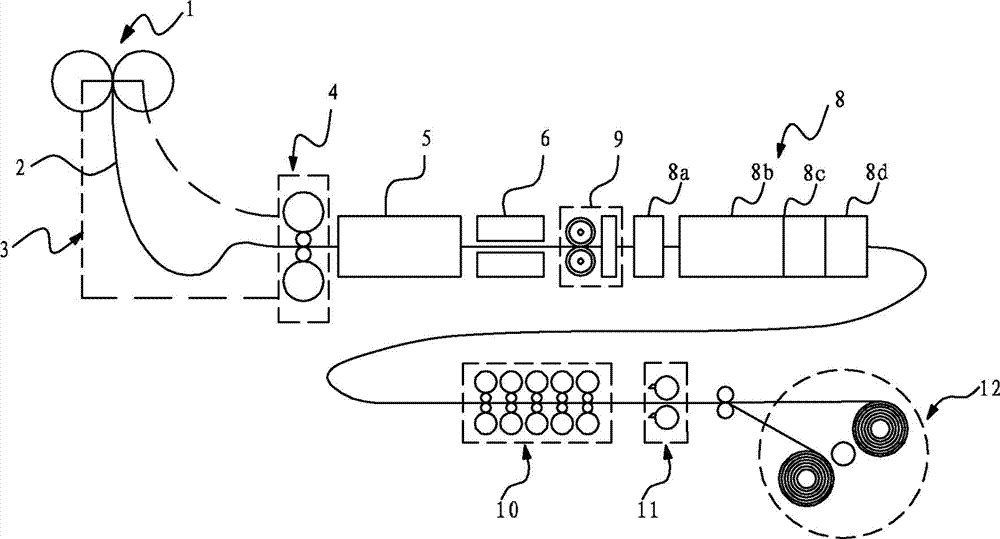

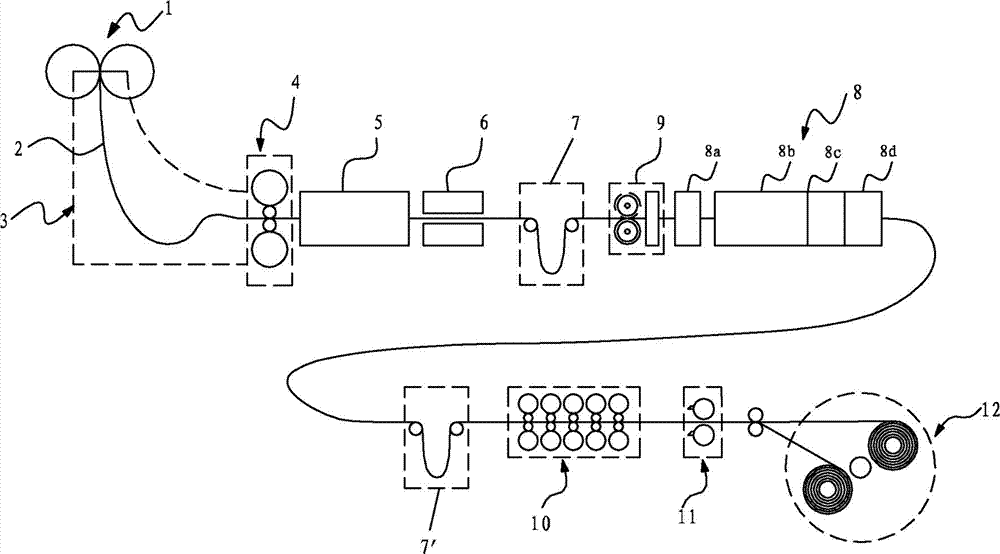

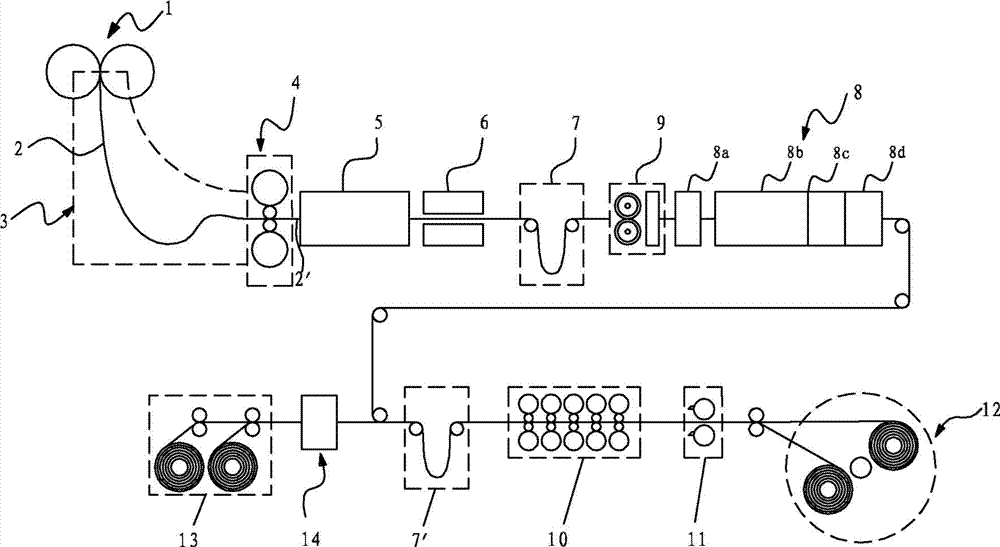

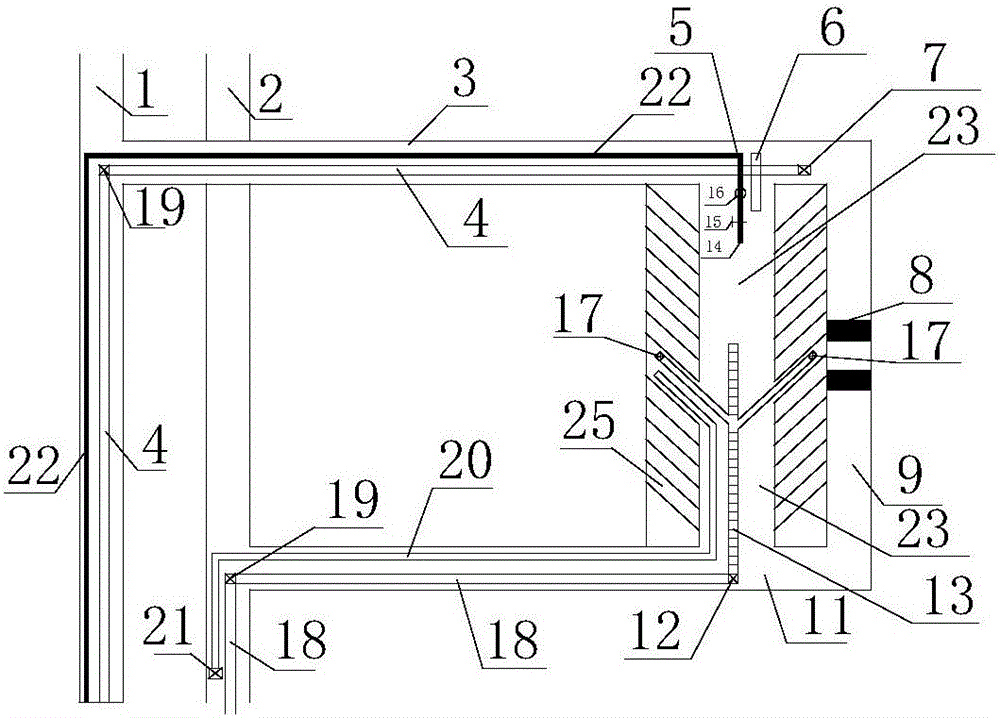

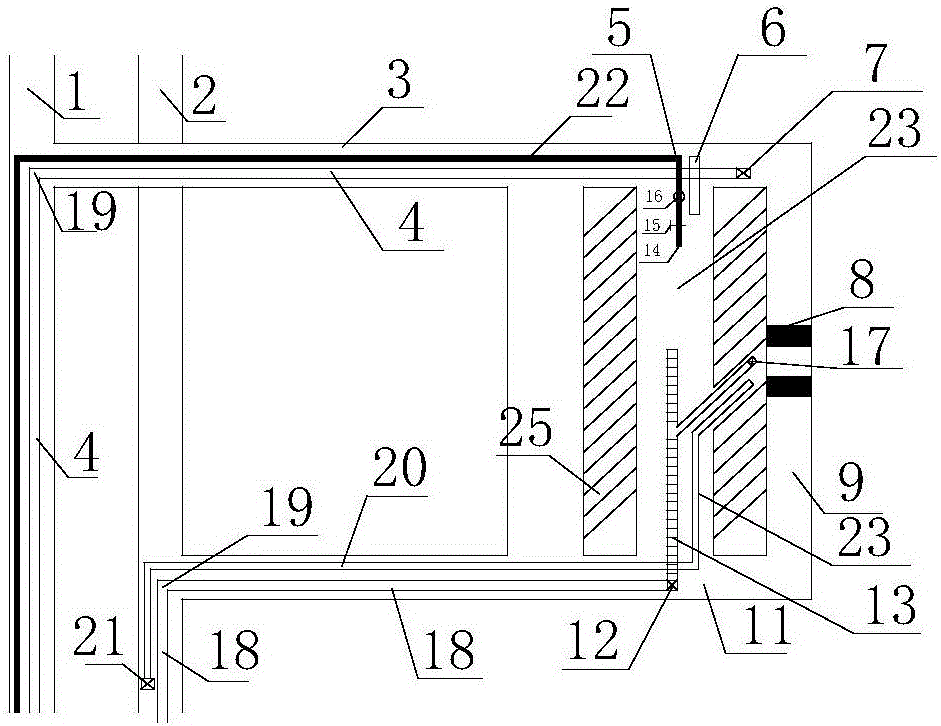

Fixed-width press plate blank width control method

ActiveCN102989784APrecise calculation of adaptive positionImplement width control methodMetal rolling stand detailsAutomatic controlEngineering

The invention discloses a fixed-width press plate blank width control method, and belongs to the technical field of steel rolling automatic control. During the process of laterally rolling the head and the tail of a plate blank by a fixed-width press, the head part and the tail part of the plate blank are in plane stress states; according to the metal flow principle of the head part and the tail part of the plate blank, and tongue and fishtail phenomena can be generated. In order to improve the condition, the widths of the head and the tail of the plate blank are controlled in short stroke by adopting the fixed-width press; under the working condition that stripe steel rolling temperature and rolling cycle are ensured, the severe width failure of the head and the tail of the stripe steel can be improved, and the final rolling target width index is ensured effectively; a pass band guarantees the width index deviation range to be 0-8mm, the yield is improved, and the production cost is saved; and when the plate blank is pressed greatly, similar to the small lateral pressing amount, the outlet width is obtained through pressing one time, the rolling temperature of the stripe steel is ensured, and the rolling cycle is improved.

Owner:BEIJING ARITIME INTELLIGENT CONTROL +1

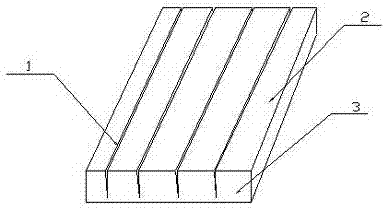

Original bamboo inner-dissecting outer-linked softening unfolding recombining technology

ActiveCN102225564AFew slicesHigh yieldWood compressionWood treatment detailsSingle plateCarbonization

The invention discloses original bamboo inner-dissecting outer-linked softening unfolding recombining technology. The technology comprises the following steps: sawing an original bamboo into bamboo tubes with a specified length, dissecting the bamboo tubes into several arc shaped bamboo sheets, removing inner bamboo joints, performing high-temperature softening and plasticizing treatment of the bamboo sheets, performing inner-dissecting outer-linked unfolding of the arc shaped bamboo sheets by a bamboo filament-linked unfolding milling machine, removing the inner of the bamboo with a fixed width and milling, performing boiling or carbonization, drying, dipping, drying, prepressing into single plates, drying, cutting core layers, dipping, performing blank assembling and plate alignment, performing hot pressing and stratification, trimming, and finally performing hot pressing and recombination according to the purposes. The invention overcomes the disadvantages of existing excessive processing procedures for bamboo, large equipment investment, high labor expense consumption, low raw material utilization rate, and high processing cost, and the prepared bamboo sheet material is applicable to industry such as architecture, decoration, furniture, etc.

Owner:HUNAN ACAD OF FORESTRY

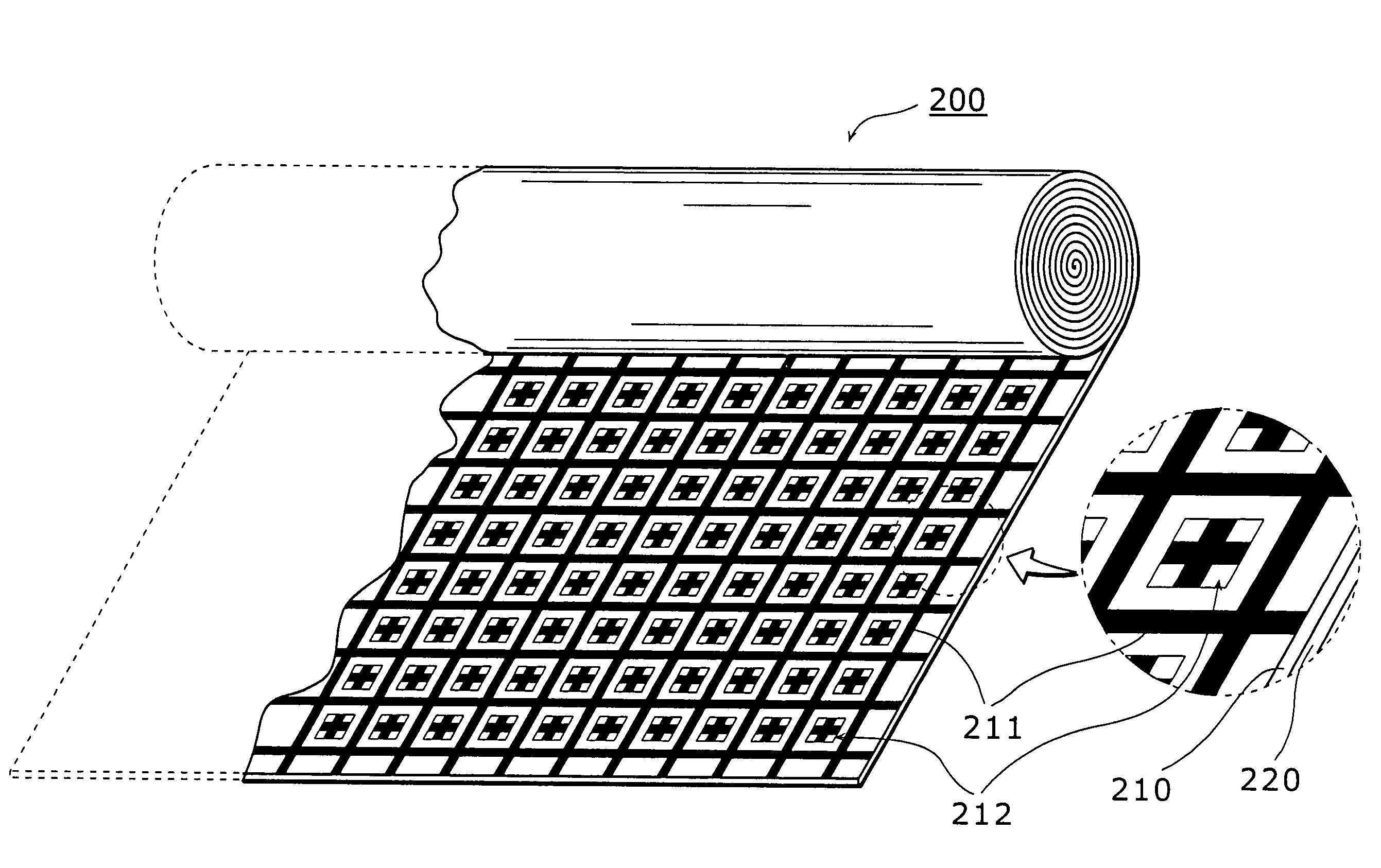

Rat exterminating electroshock sheet, and method of expelling harmful birds and animals

InactiveUS6993867B2Increase probabilityReducing extermination effectElectric shock equipmentsSynthetic resin layered productsCopper foilEngineering

A sheet for exterminating rats by electric shock includes two plastic sheets in the form of upper and lower layered sheets. A grid-type copper foil pattern of straight lines with a fixed width, intersecting at right angles, is formed as first electrodes on the upper surface of the upper sheet, and windows are opened through rectangular areas surrounded by the copper foil pattern. A copper foil pattern is formed as second electrodes on the upper surface of the lower sheet, and has the same pattern as the copper foil pattern formed on the upper surface of the upper sheet. The upper sheet and the lower sheet are layered on each other so that the intersecting points in the copper foil pattern formed on the upper surface of the lower sheet are placed at the centers of the windows.

Owner:TOYOTA JUNZO

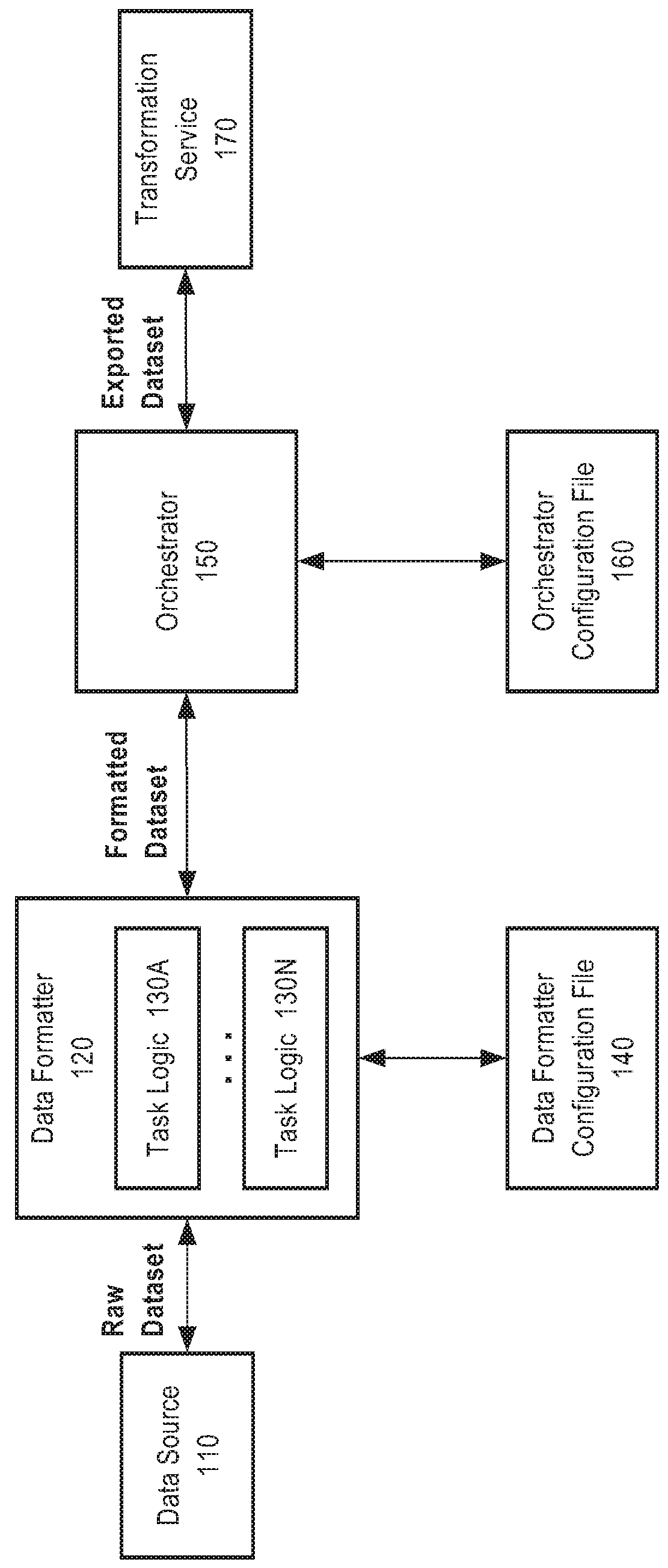

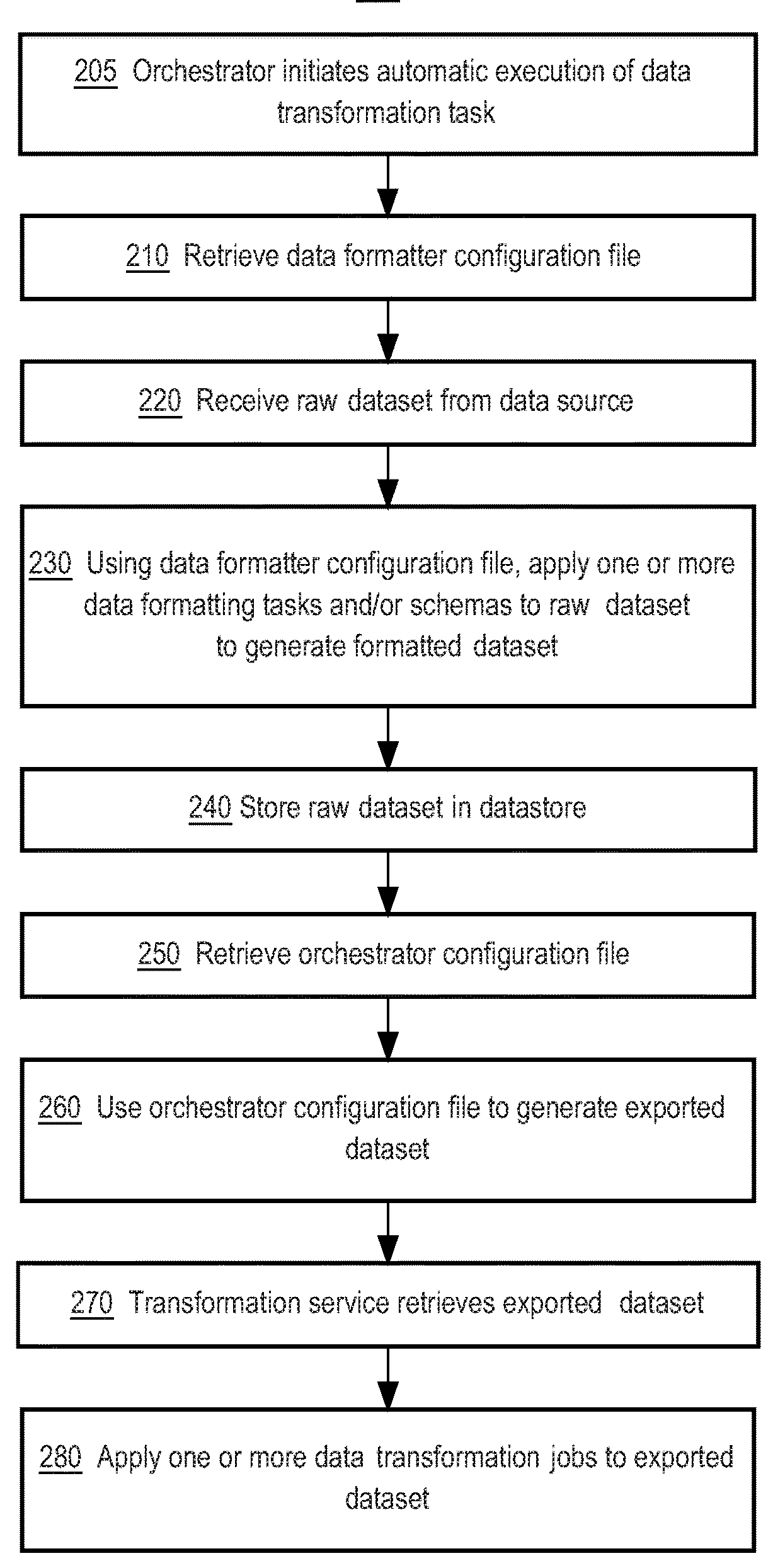

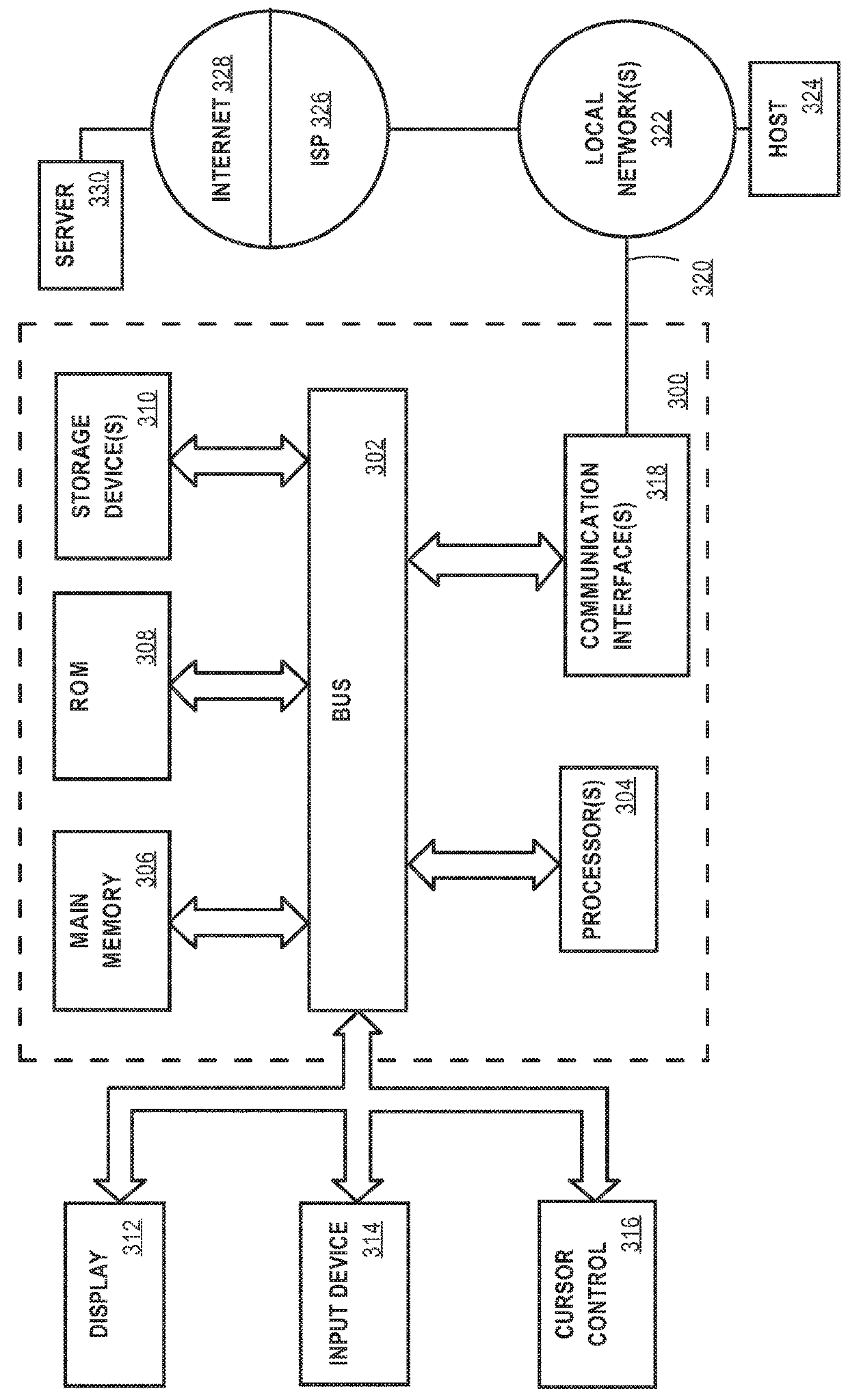

Automatically executing tasks and configuring access control lists in a data transformation system

A computer-implemented system or process is programmed or configured to use a configuration file to specify one or more tasks to apply to raw ingested data. A task may be a sequence of instructions programmed or configured to format raw ingested data into a dataset in a CSV format. Examples of tasks may include: a parser to parse Cobol data into a CSV, a parser to parse XML into a CSV, a parser to parse text using fixed-width fields to a CSV, a parser to parse files in a zip archive into a CSV, a regular expression search / replace function, or formatting logic to remove lines or blank lines from raw ingested data. In one embodiment, the configuration file may specify a schema definition for a task to use for generating a dataset. In one embodiment, the configuration file may also include one or more access control list (ACL) definitions for the generated dataset. In one embodiment, the building of datasets using the configuration file is automated, for example, on a nightly basis.

Owner:PALANTIR TECHNOLOGIES

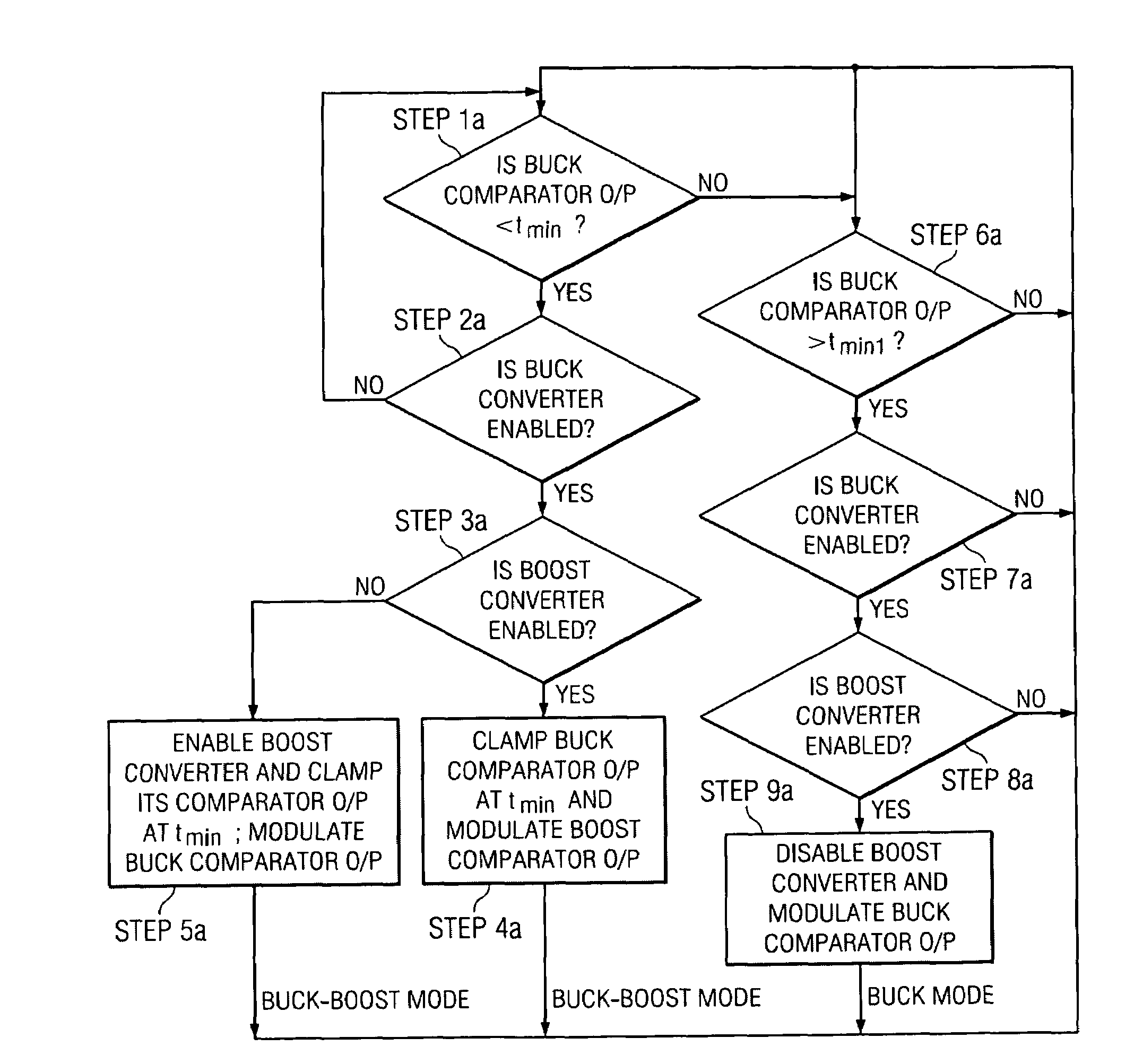

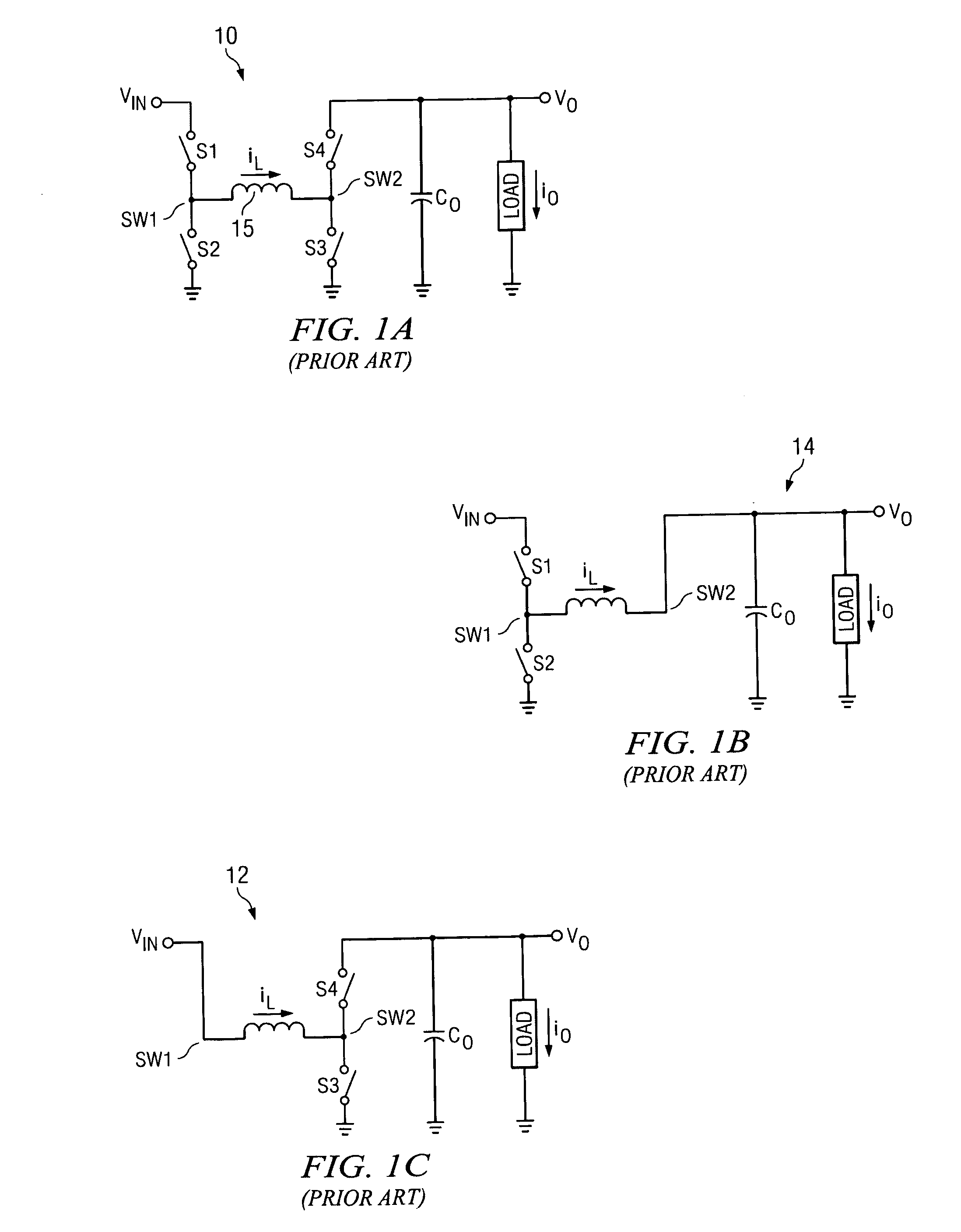

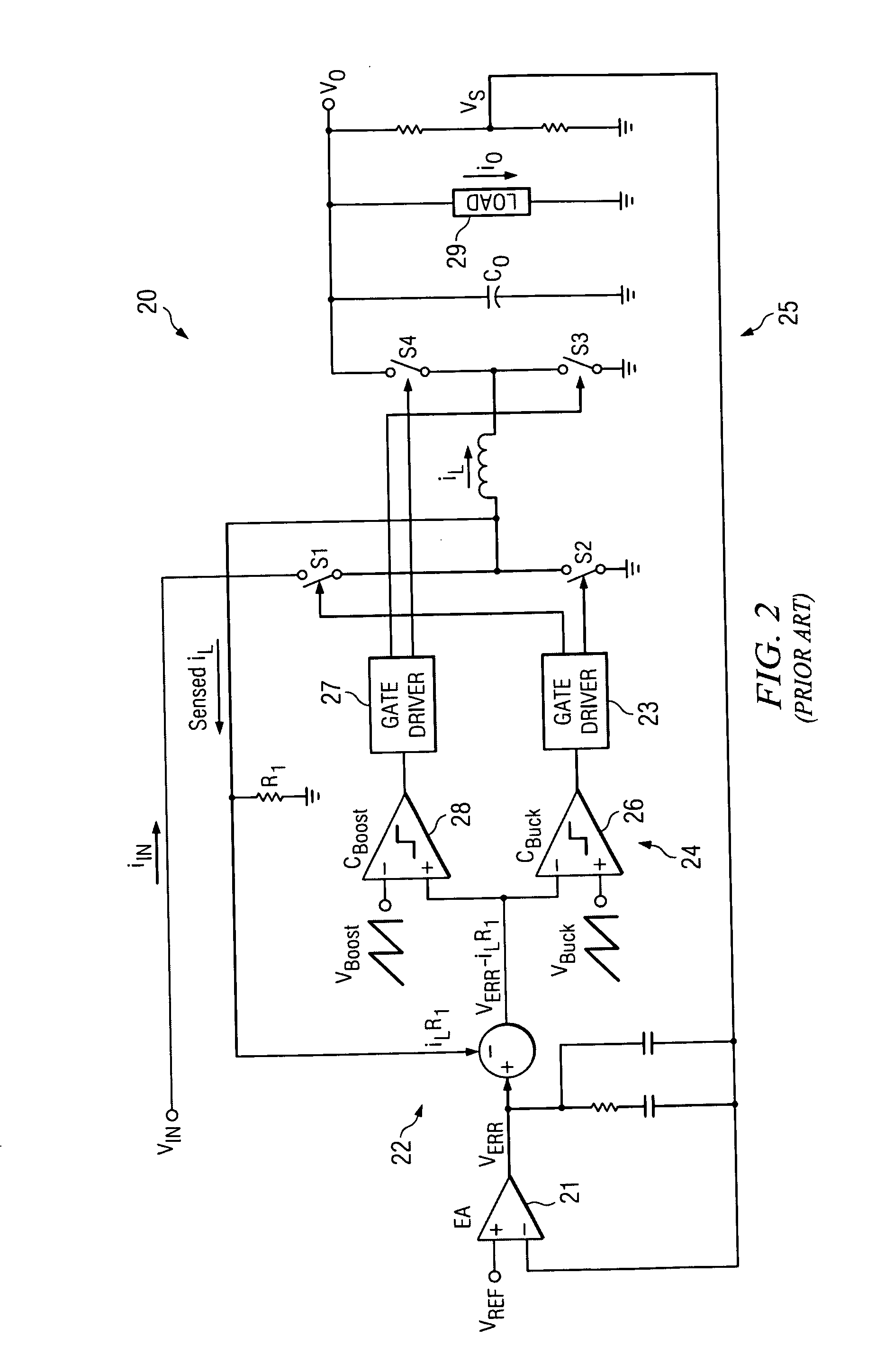

Multiple switch node power converter control scheme that avoids switching sub-harmonics

ActiveUS20100019745A1Eliminates switchingGenerate energyDc-dc conversionElectronic switchingOperating pointTransverter

A method of and system for modulating buck and boost modulation ramps of a multiple switch node power converter without overlap. As the pulse width or duty cycle of the signal to a modulated complementary switching pair approaches a pre-established reference pulse width or duty cycle, plural fixed-width or fixed duty cycle pulses are generated and introduced to a nonmodulated complementary switching pair. A controller detects proximity to the pulse width or duty cycle limit and, correspondingly, initiates prematurely a pseudo-buck-boost mode in the power converter by generating fixed-width or fixed duty cycle pulses to the nonmodulated complementary switching pair while the duty cycles or pulse widths to the modulated complementary switching pair are still controlled by the appropriate modulation ramp. The net effect is that the power converter reaches its optimal operating point without overlap and eliminates any sub-harmonic switching.

Owner:TEXAS INSTR INC

Control method for producing conical plate blank using side compression machine of fixed width plate blank

ActiveCN101376139AEfficient Control Integrated Automation Control MethodOvercoming the disadvantages of producing conical billetsMetal rolling stand detailsStrip steelCanis lupus familiaris

The invention relates to a control method for producing hot rolling strip steel, particularly to an effective control method that a tapered plate blank (a transitional blank of continuous casting) is rolled to form a near rectangular plate blank through a horizontal rolling mill after being subjected to side compression through reasonably changing the openness of a side press machine with a fixed width, thereby improving the width control precision of the tapered plate blank produced by a hot rolling machine and reducing the width quality loss. In the invention, through the accurate description and the definition to the shape of the tapered blank, a dog-bone formed by the different amount of side compression at each point of the tapered blank and the width stretching quantity of the dog-bone after being horizontally rolled accurately calculated; a changeable amount of side compression exerted on the tapered plate blank is calculated by adopting rapid iteration and taking the rectangular width of an outlet plate blank of the horizontal rolling mill as an objective function, thereby achieving the control method for effectively controlling the tapered blank and overcoming the disadvantage of producing the tapered blank in the traditional control method.

Owner:BAOSHAN IRON & STEEL CO LTD

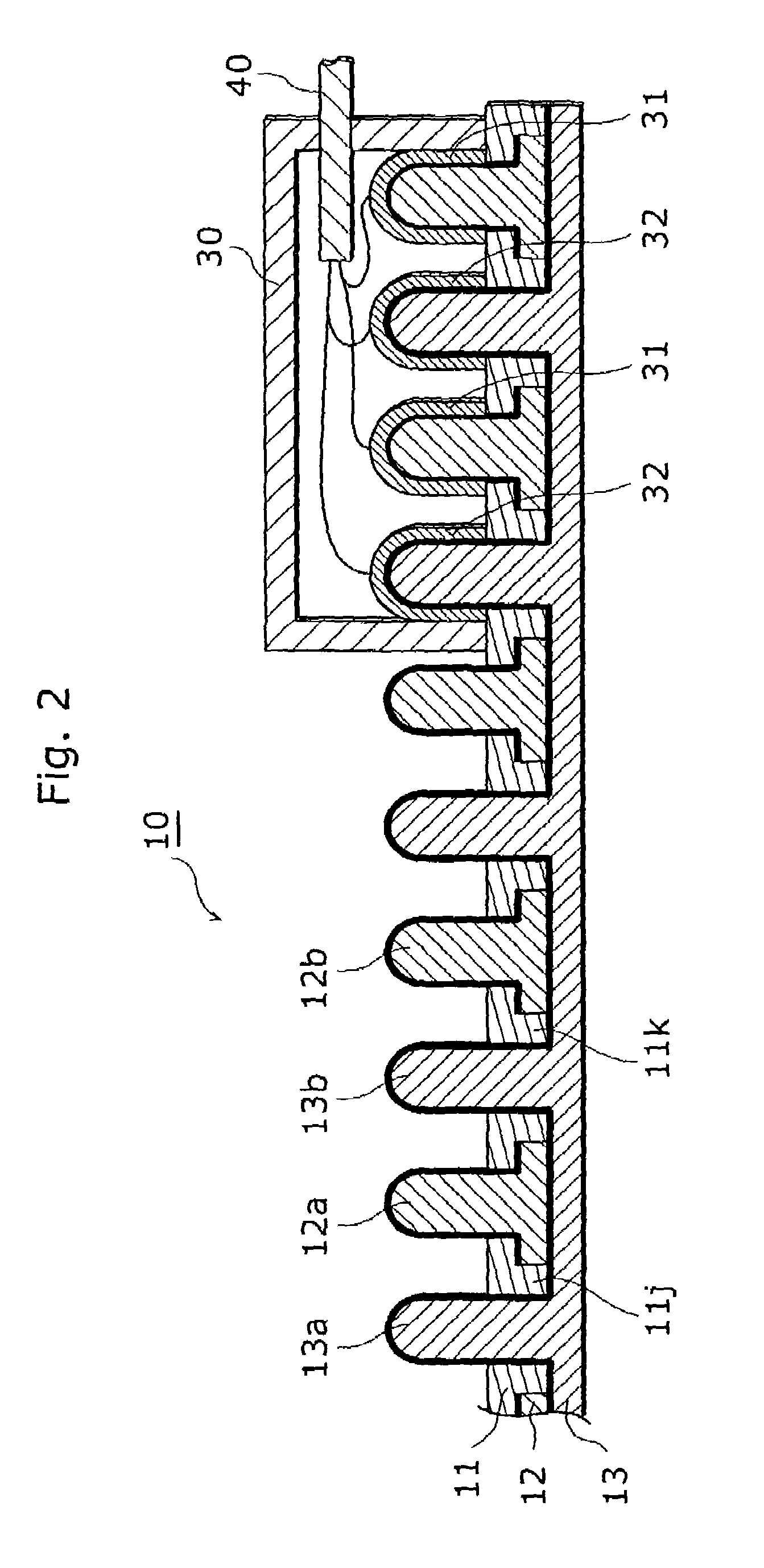

Axially tapered and bilayer microchannels for evaporative coolling devices

The invention consists of an evaporative cooling device comprising one or more microchannels whose cross section is axially reduced to control the maximum capillary pressure differential between liquid and vapor phases. In one embodiment, the evaporation channels have a rectangular cross section that is reduced in width along a flow path. In another embodiment, channels of fixed width are patterned with an array of microfabricated post-like features such that the feature size and spacing are gradually reduced along the flow path. Other embodiments incorporate bilayer channels consisting of an upper cover plate having a pattern of slots or holes of axially decreasing size and a lower fluid flow layer having channel widths substantially greater than the characteristic microscale dimensions of the patterned cover plate. The small dimensions of the cover plate holes afford large capillary pressure differentials while the larger dimensions of the lower region reduce viscous flow resistance.

Owner:SANDIA NAT LAB

Temperature sensing device in an integrated circuit

InactiveUS20050001596A1Maximum countThermometer detailsElectric powerMemory circuitsIntegrated circuit

A temperature sensing device can be embedded in a memory circuit in order to sense the temperature of the memory circuit. One oscillator generates a temperature variable signal that increases frequency as the temperature of the oscillator increases and decreases frequency when the temperature of the oscillator decreases. A temperature invariant oscillator generates a fixed width signal that is controlled by an oscillator read logic and indicates a temperature sense cycle. An n-bit counter is clocked by the temperature variable signal while the fixed width signal enables / inhibits the counter. The faster the counter counts, the larger the count value at the end of the sense cycle indicated by the fixed width signal. A larger count value indicates a warmer temperature. A smaller count value indicates a colder temperature.

Owner:ROUND ROCK RES LLC

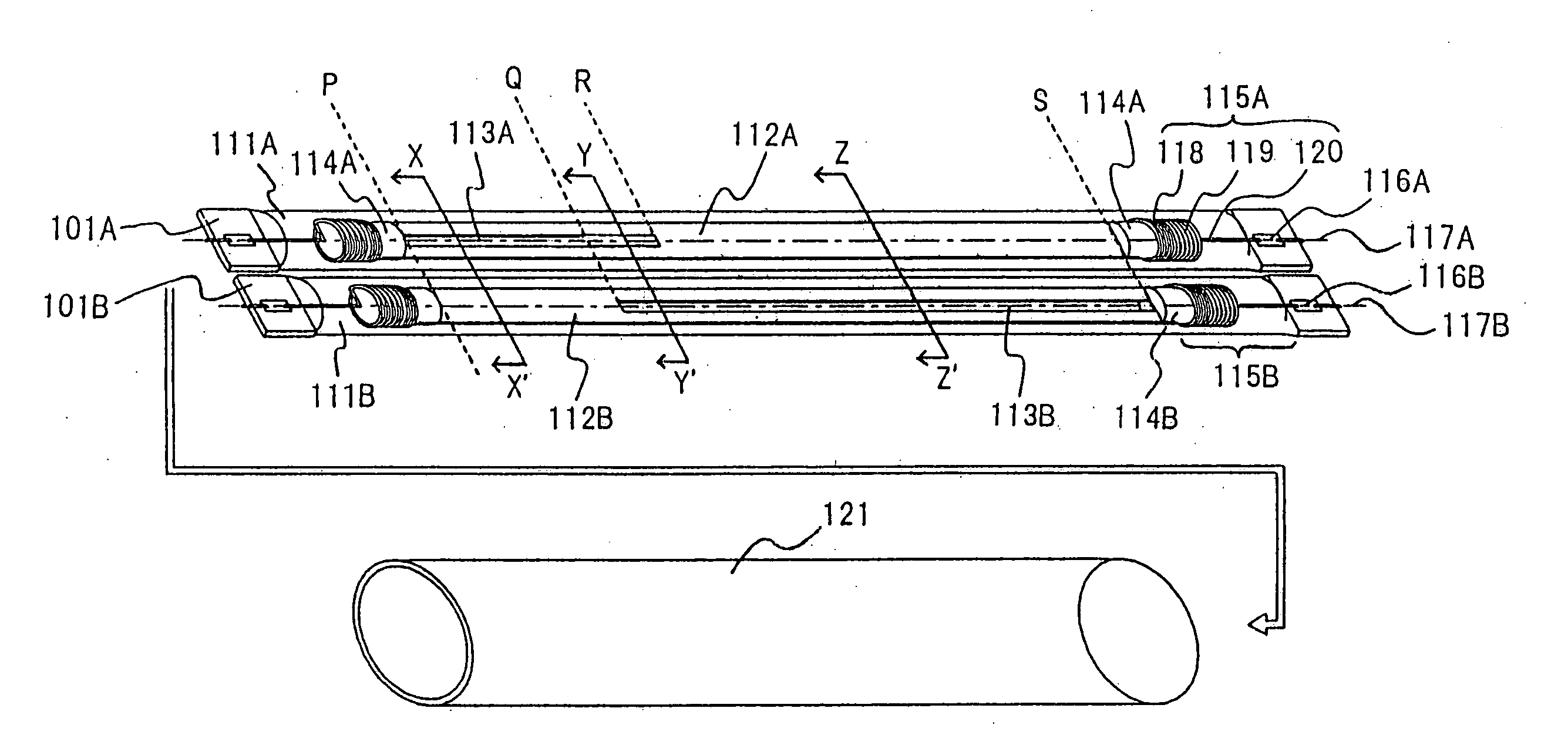

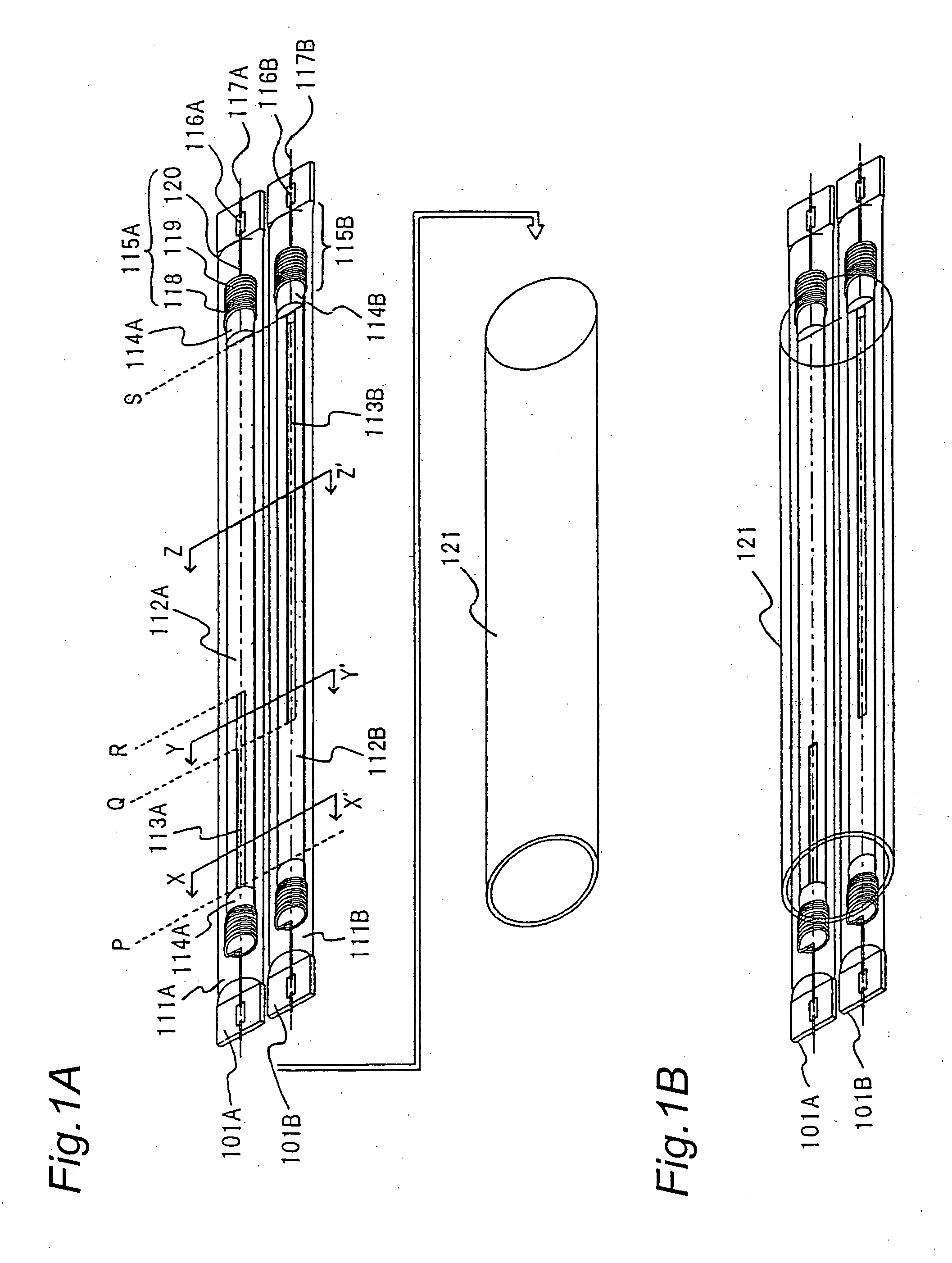

Infrared ray lamp, heating devices and electronic device

InactiveUS20060289418A1Improve reliabilityImprove heating efficiencyDrying solid materials with heatOhmic-resistance waterproof/air-tight sealsInfrared lampEffect light

The invention provides a heating apparatus which has a high heating efficiency, can locally heat a part to be heated, can achieve a rated temperature for an extremely short time after starting the heating, reduces a large rush current and flicker at a time of lighting, has a long service life, and can correspond to a plurality of modes having different heating widths, an infrared ray lamp suitable for the heating apparatus, and a high reliable electronic apparatus having the above-mentioned heating apparatus. The infrared ray lamp in accordance with the invention seals one or a plurality of heat generating elements in a glass tube, the heat generating elements having a shape extending in a longitudinal direction at a fixed width and an opening part extending substantially in a longitudinal direction provided only in a part in the longitudinal direction.

Owner:PANASONIC CORP

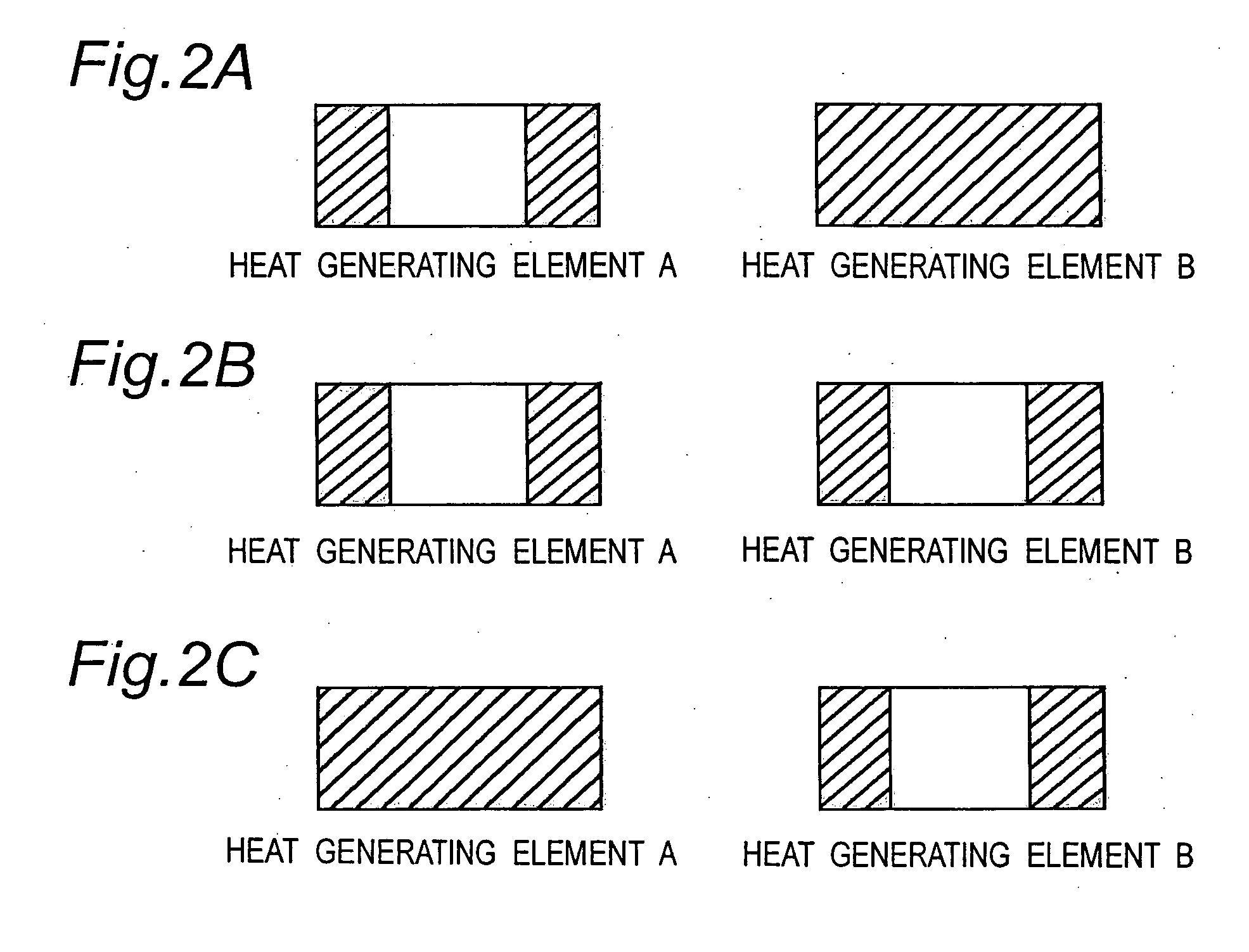

Bitstream generation for VLC encoded data

ActiveUS7439883B1Picture reproducers using cathode ray tubesCode conversionData streamVariable length

A bitstream generator is described, for placing variable length coding (VLC) data into a fixed width data stream. The bitstream generator includes an input for receiving VLC data; the VLC data may be separated into a value component, and a length component. The bitstream generator also includes an output buffer, a memory module, for storing the VLC data before sending. The bitstream generator also incorporates a backup buffer, which is used to store any overflow data which does not fit in the output buffer. A comparator is used, to determine how much of the VLC data will fit in the output buffer. Any portion of the VLC data which does not fit in the output buffer is stored in the backup buffer.

Owner:NVIDIA CORP

Continuous rolling production process and process arrangement

InactiveCN104722577AReduce the temperatureSatisfy the protective effectWork cooling devicesMetal rolling arrangementsBand shapeLiquid metal

The invention discloses a continuous rolling production process and process arrangement. The continuous rolling production process includes the steps: 1) adopting liquid metal for casting of hot strip billet materials according to a thin-strip continuous casting and rolling process, subjecting the cast strip billets to hot rolling, and subjecting the strip billets to stipulated-curve heat treatment including heating and cooling after casting and hot rolling of the strip billets are finished; 2) enabling the cold hot-rolled strip billets to enter a side cutting unit to realize fixed-width cutting of side materials of the cold hot-rolled strip billets; 3) subjecting the cold strip billets to scale removal by means of jet mixing flow; 4) subjecting metal strips to continuous rolling in a cold-state continuous rolling unit; 5) enabling the metal strips to enter a shearing unit and a rolling unit sequentially. The continuous rolling production process and process arrangement have the advantages that intensified metallurgical production process arrangement is realized, one-time investment cost is remarkably reduced while the technical process is greatly simplified, carbon emission and acid liquid pollution are remarkably reduced, and processing cost of metal strip products is directly reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Technique for performing arbitrary width integer arithmetic operations using fixed width elements

ActiveUS20150081753A1Improve abilitiesSave overheadComputation using denominational number representationOperandFloating point

One embodiment of the present invention includes a method for performing arithmetic operations on arbitrary width integers using fixed width elements. The method includes receiving a plurality of input operands, segmenting each input operand into multiple sectors, performing a plurality of multiply-add operations based on the multiple sectors to generate a plurality of multiply-add operation results, and combining the multiply-add operation results to generate a final result. One advantage of the disclosed embodiments is that, by using a common fused floating point multiply-add unit to perform arithmetic operations on integers of arbitrary width, the method avoids the area and power penalty of having additional dedicated integer units.

Owner:NVIDIA CORP

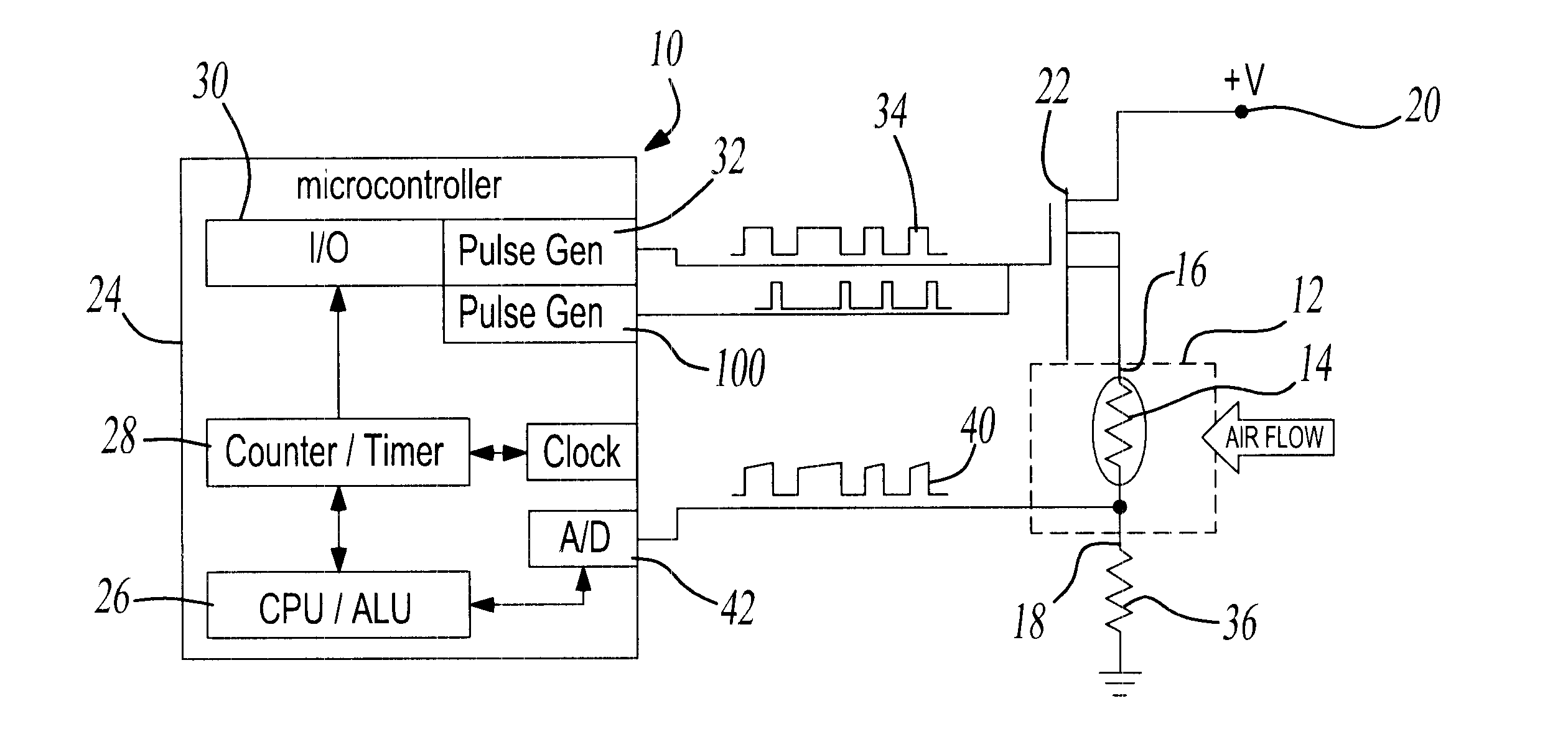

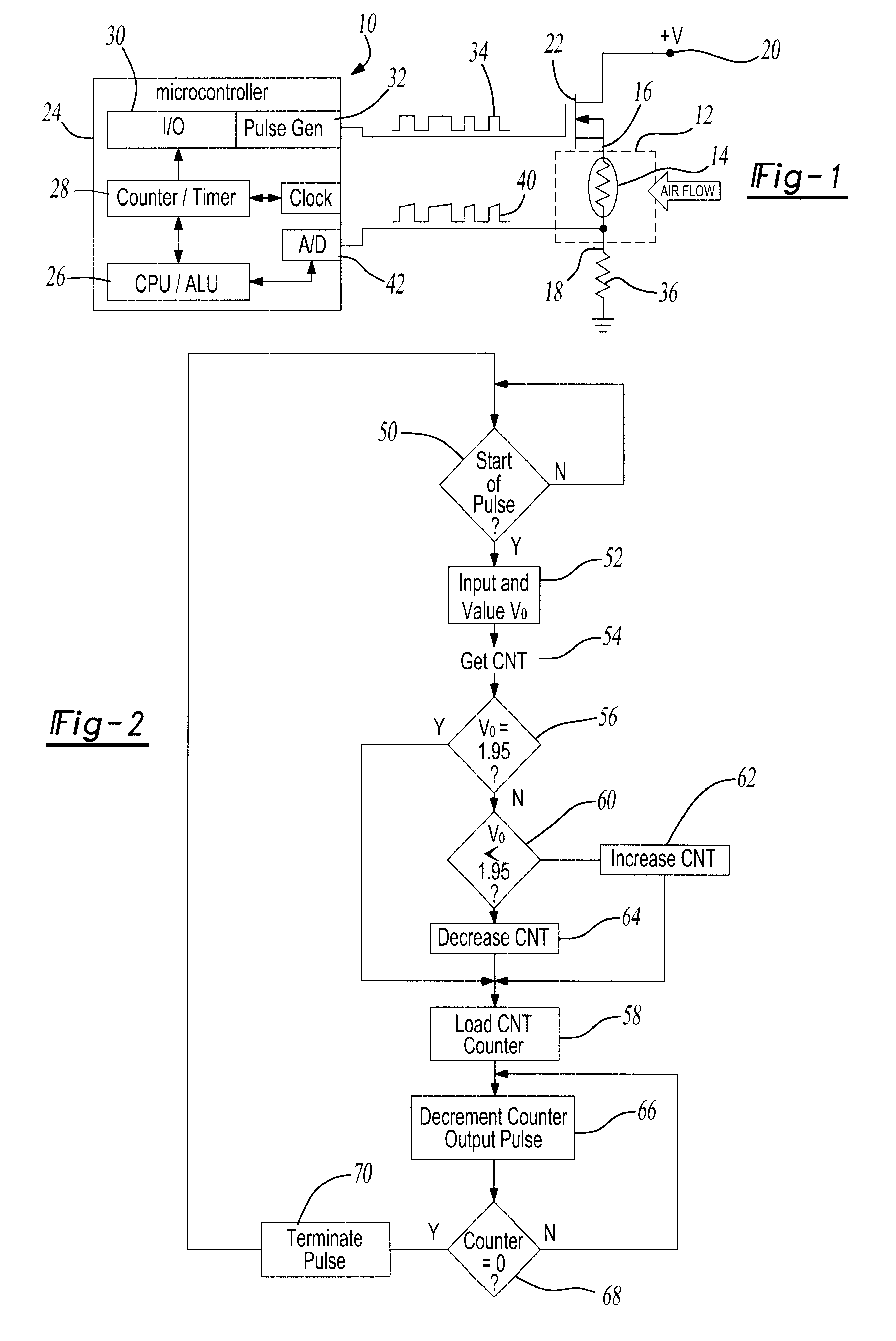

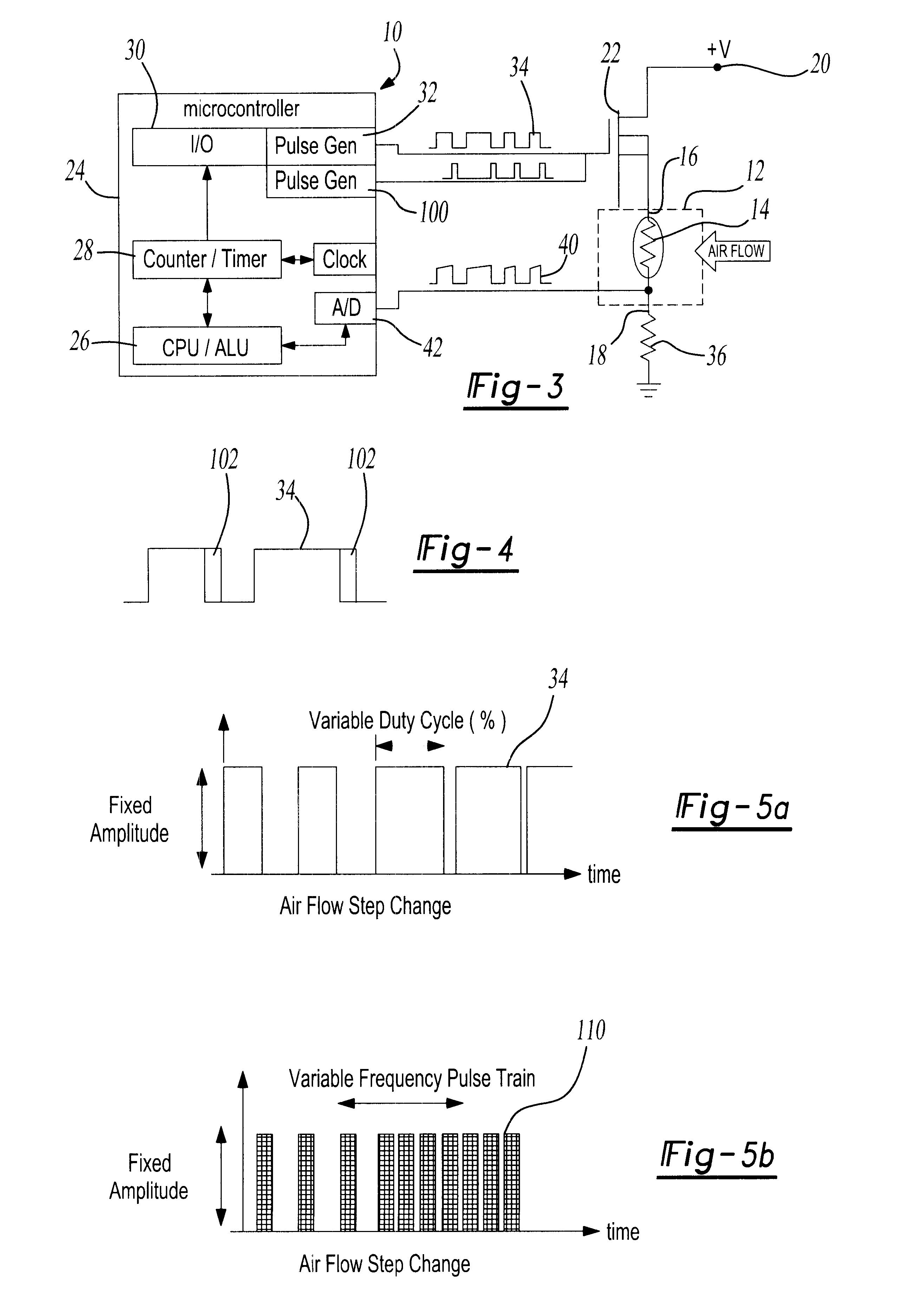

Time domain measurement and control system for a hot wire air flow sensor

InactiveUS6453739B1Constant amplitudeVolume/mass flow by thermal effectsEngine controllersVoltage amplitudeEngineering

A time domain measurement and control system for a hot wire air flow sensor is disclosed in which the air flow sensor is of the type having a resistive heating element with an input end and an output end. The control system includes a fixed frequency variable width pulse generator which generates a pulse train through the heating element. This pulse train, furthermore, has a first predetermined voltage amplitude. The output voltage amplitude of the pulse train is determined at the outlet end of the heating element while a control circuit varies the duty cycle of the pulse train to maintain the output voltage amplitude at a second predetermined voltage level. The duty cycle of the pulse train is proportional to the air flow rate through the air flow sensor. In a modification of the invention, a fixed width variable frequency pulse train is generated through the resistive heating element and the frequency of the pulse train is varied to maintain the output voltage amplitude of the pulse train at the outlet end of the resistive heating element at a second predetermined voltage level. In this modification, the frequency of the pulse train is proportional to the air flow rate through the air flow sensor.

Owner:HITACHI AMERICA

Short-wall waste rock gluing continuous mining and continuous filling mining method

InactiveCN106522948AControlled sinkingReduce distortionUnderground miningSurface miningCement slurryCoal pillar

The invention discloses a short-wall waste rock gluing continuous mining and continuous filling mining method and belongs to the technical field of coal mine filling and mining. The problem that in the prior art, due to the fact that an overlying strata above a goaf directly collapses, surface deformation is severe is solved. The method comprises the steps that a coal seam is divided into a plurality of strip coal pillars according to the fixed width in the direction parallel to open-off cut, then the strip coal pillars are mined sequentially at intervals through a continuous mining machine, the strip coal pillars are filled sequentially at intervals after a roof is stabilized, specifically, cement slurry and waste rock reach a working face through a grouting system and a waste rock delivery system correspondingly, are mixed and are injected for filling a branch roadway, and the filling and mining process is completed. The short-wall waste rock gluing continuous mining and continuous filling mining method is adopted for filling and mining, the roof does not sink, only bending deformation happens, and the defects of wall type caving mining are overcome effectively; and meanwhile, surface deformation is small, surface buildings can be effectively protected, and a new idea is provided for three-underground mining.

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com