Fixed-width press plate blank width control method

A fixed-width press, width control technology, applied in the direction of metal rolling stand, metal rolling mill stand, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

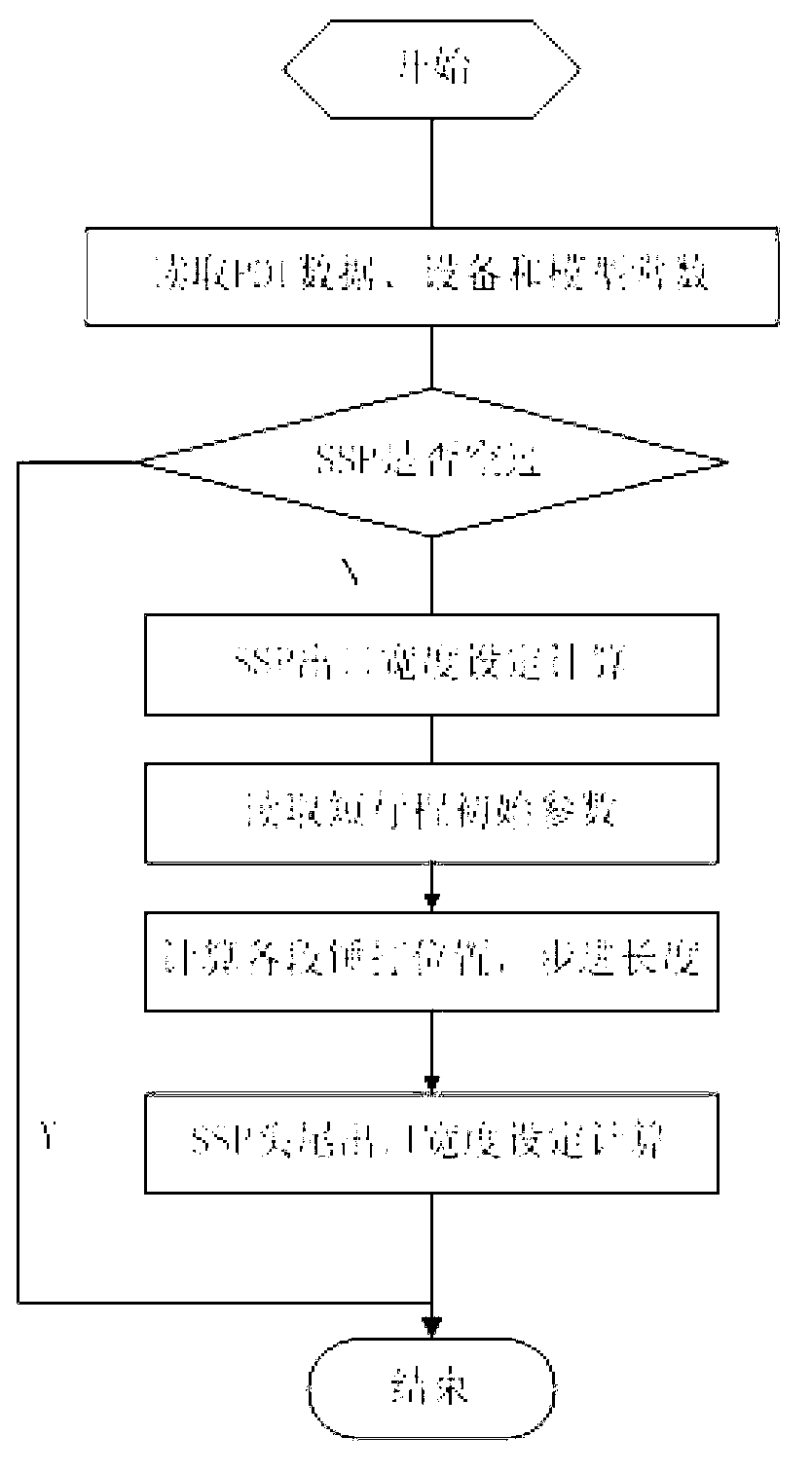

Method used

Image

Examples

Embodiment

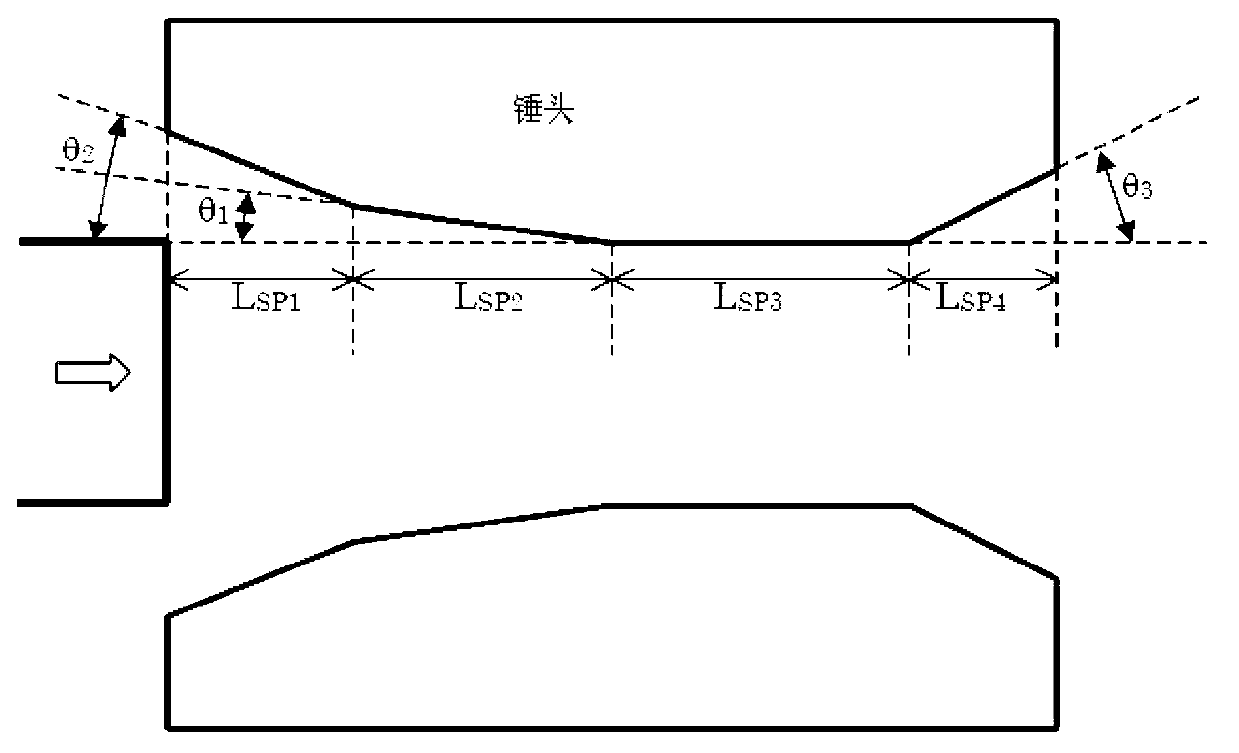

[0093] The present invention takes a slab as an example in combination with the attached Figure 5 To be explained as follows:

[0094] 1. Read the slab PDI data, slab number 122E058794041, steel type SPHC, slab specification 237*1400*11900mm, target width 1280mm, read equipment constants and width model related parameters, when the slab arrives at the width measuring instrument before the machine The measured entrance width is 1442.10mm, and the measured value of the entrance pyrometer is 1176.23°C;

[0095] 2. Calculate the outlet width Wex of the fixed width machine during normal rolling to be 1293.10mm;

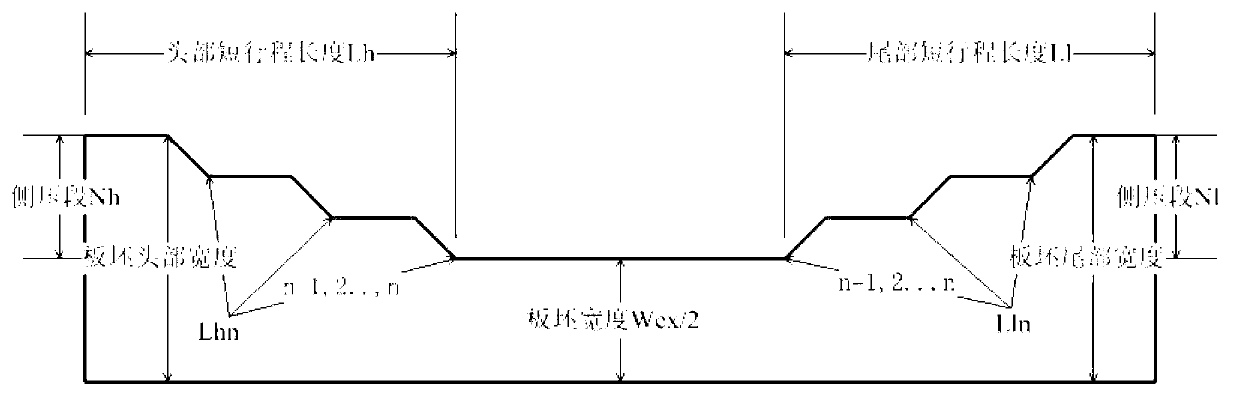

[0096] 3. Determine the short stroke length Lh of the head and tail of the slab as 1035mm, Ll as 800mm, the number of side pressure sections Nh as 2 and Nl as 2;

[0097] 4. Calculate the hammering position Lh1=1124.00mm, Lh2=869.00mm, Lh1=9427.25mm, Ll2=9057.25mm in each section of the slab head and tail, and the hammering step length L_feed is 370mm;

[0098] 5. Calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com