Rough rolling short stroke control and self-learning method

A technology of short-stroke control and self-learning method, applied in the field of rough rolling short-stroke control and self-learning, can solve the problems that the control effect cannot fully meet the actual production requirements, and the short-stroke control cannot be adjusted in real time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

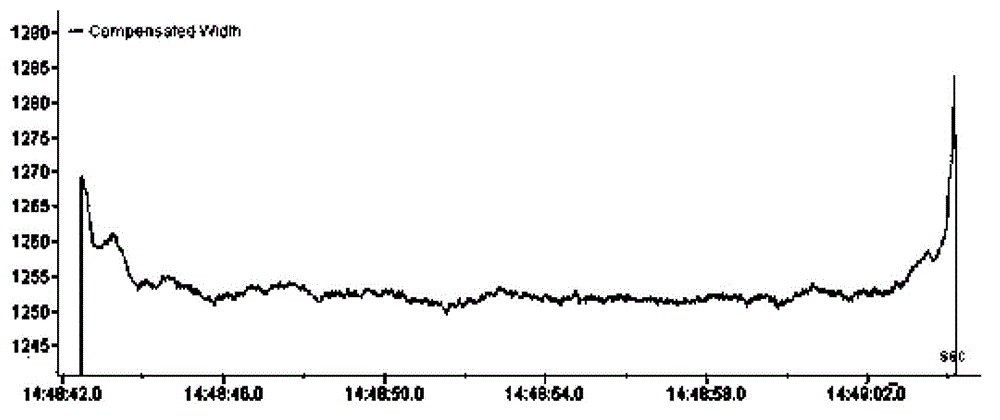

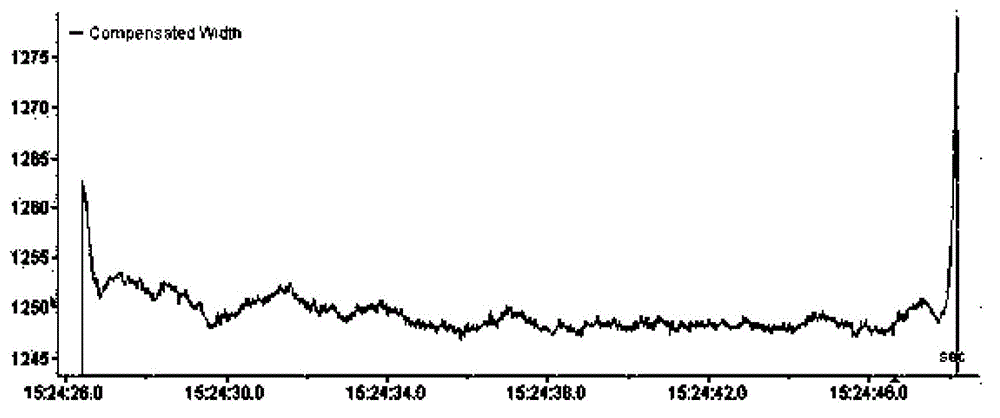

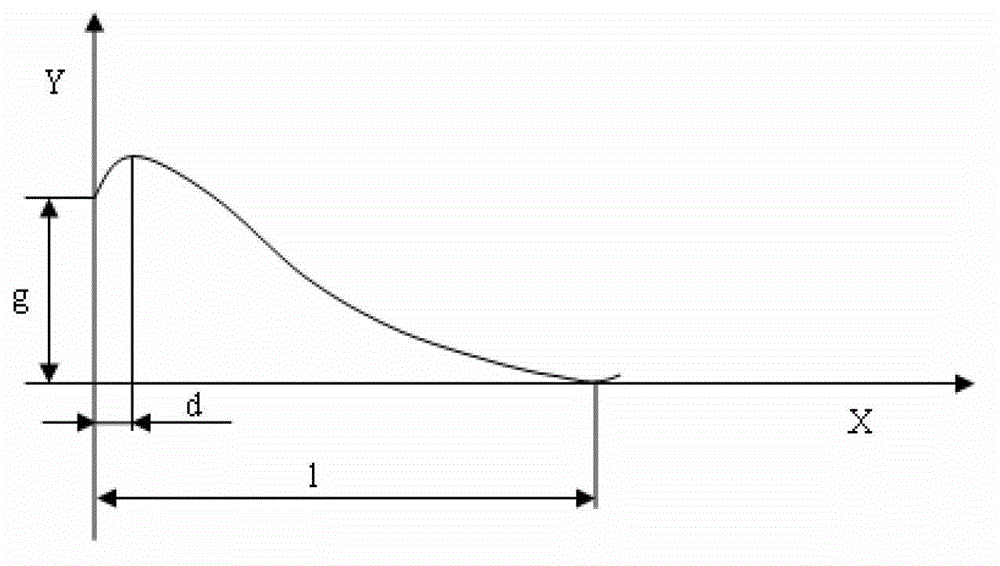

[0096] The present invention will be further described below according to the embodiments and corresponding drawings. A control and self-learning method of a rough rolling short stroke of the present invention comprises the following steps:

[0097] 1) Read slab PDI data (slab width, thickness, steel type, intermediate billet thickness, finished product width, etc.), equipment parameters (roll diameter, rolling mill maximum rolling force, torque, etc.), when the slab reaches the roughing mill The measured value is extracted from the width measuring instrument, and data preparation is made for the self-learning of the short-stroke model. Among them, the equipment parameters are used to check the rolling mill after the calculation is completed.

[0098] 2) According to the slab data (slab width, thickness, steel type, intermediate billet thickness, finished product width, etc.), read the short-stroke model parameters layer by layer to read the short-stroke model parameters, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com