Short-wall waste rock gluing continuous mining and continuous filling mining method

A wall gangue and cementation technology, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of surface water level drop, gangue pile accumulation, and large subsidence, so as to achieve small equipment investment, reduce surface deformation, and control The effect of roof sinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

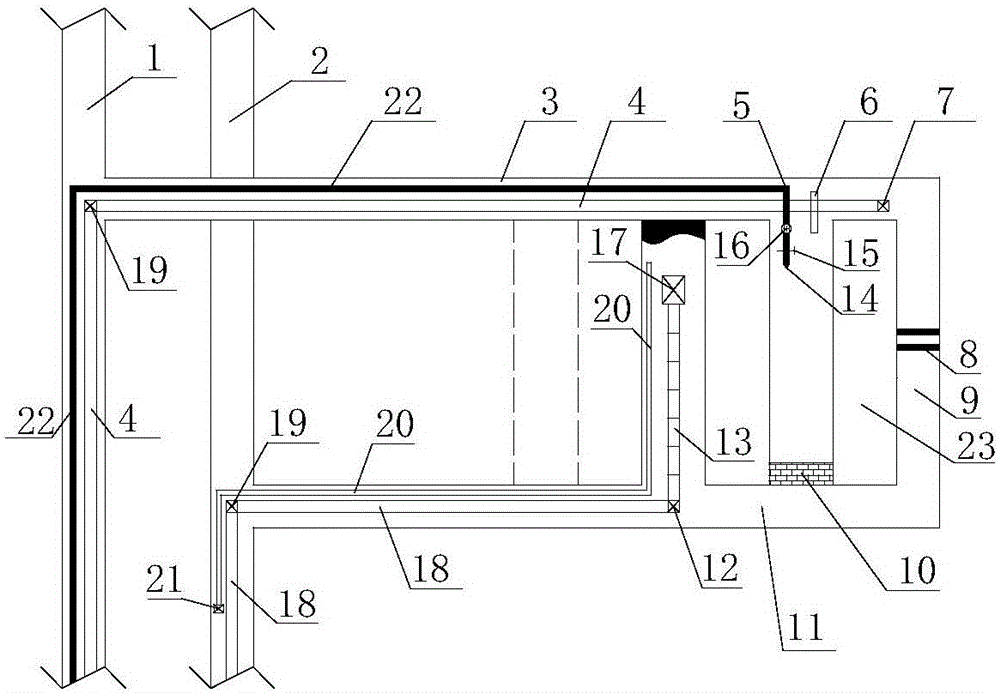

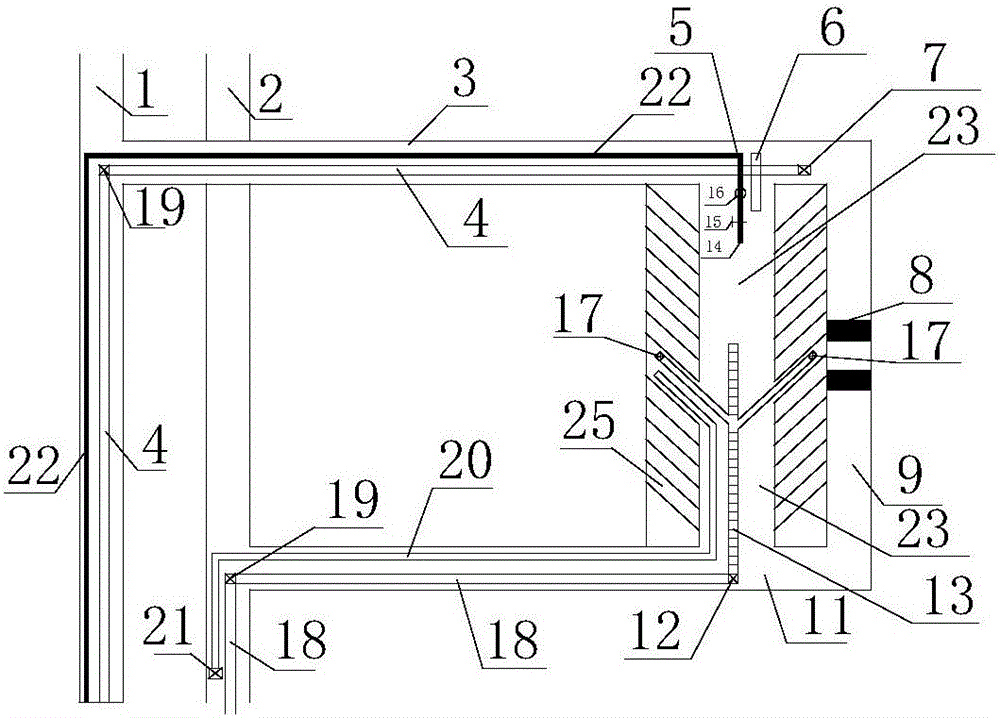

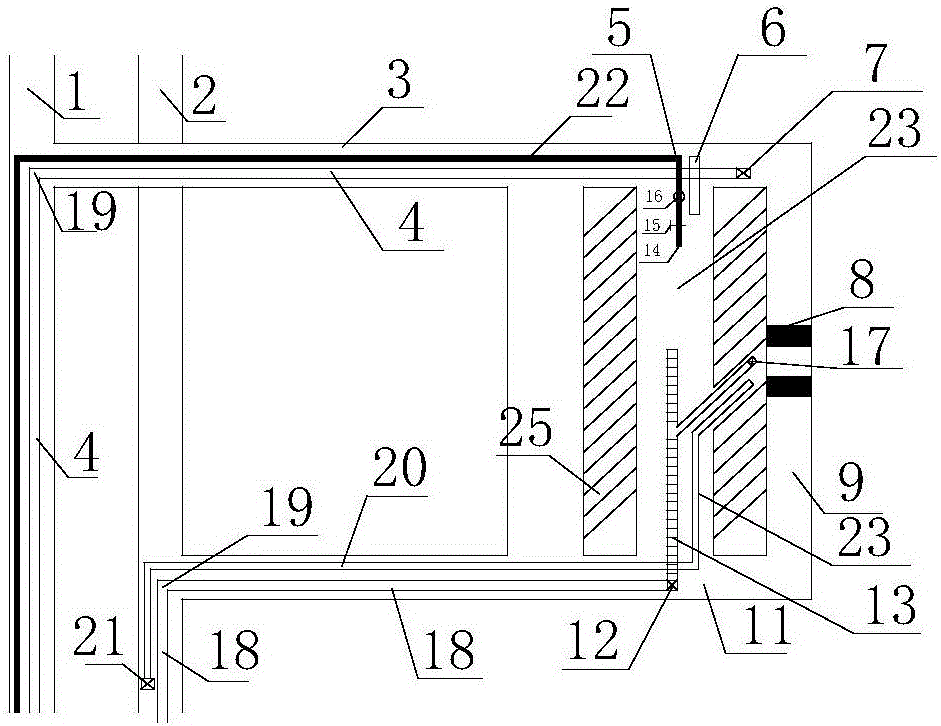

[0043] The present invention proposes a short-wall gangue cemented continuous mining and continuous filling coal mining method. In order to make the advantages and technical solutions of the present invention clearer and clearer, the present invention will be described in detail below in conjunction with specific examples.

[0044] 1. Material ratio design

[0045] The filling material of the grouting system involved in the present invention is ordinary 32.5 cement, fly ash, calcium carbide 1:3:1, and the mass concentration is 50%. 4:6 mixture, the mass concentration of the finished filling material is 75-78%, and the design 28-day filling body strength is not less than 2MPa.

[0046] 2. Length design along the groove

[0047] The length of the trough mainly considers the transportation of coal and gangue, and the belt conveyor is used for continuous transportation. The width of the belt is preferably 1.0-1.4m, and 1.1m is used. According to the transportation cost and ventil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com