Original bamboo inner-dissecting outer-linked softening unfolding recombining technology

A technology for cutting yellow and combining green and process, which is applied in the field of softening and recombining process of original bamboo cutting and combining with green, can solve the problems of low utilization rate of raw materials, loss of bamboo materials, and many processing procedures, and achieves high equipment work efficiency, reduced personnel, and reduced procedures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

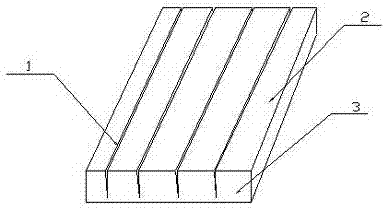

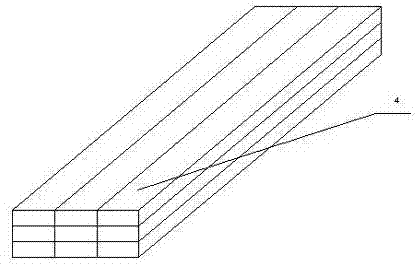

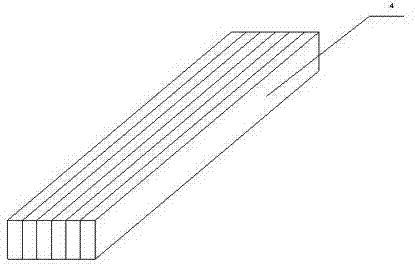

[0030] refer to Figure 4 , the process flow of the present invention is as follows: after sawing the original bamboo into bamboo tubes of standard length, the bamboo tubes are cut into several pieces of arc-shaped bamboo slices with a longitudinal sawing machine or a collider, and the inner nodes are removed, and high-temperature soft plastic treatment is carried out; The combined wire milling machine cuts the bamboo yellow surface into longitudinal cracks with a spacing of 5~6mm. The depth of the bamboo yellow surface is 2~3mm away from the bamboo green surface, forming some small bamboo strips evenly dissected longitudinally on the bamboo yellow surface, and the bamboo green surface The bamboo layer is not dissected and it is a complete body. The small bamboo yellow bamboo strips are retained on the bamboo green layer to form the original bamboo bamboo yellow layer. The green bamboo layer forms an unfolded bamboo unit, the structure diagram of which is shown in figure 1 In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com