Patents

Literature

918results about "Wood charring/burning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing charred wood by heat treatment

InactiveCN101069972AGuaranteed drying qualityShorten the timeWood treatment detailsWood charring/burningStrength lossMoisture

The invention relates to a preparation method of heat-treatment charred wood. It aims at providing the charred wood with short treatment cycle, small wood strength loss, industrialized and high maneuverability. It contains stages of preparing, preheating, heating, insulation and cooling. In the heating stage, heat the medium in the stove to 95-105 C degree with the speed of 10-18 C degree / h. Then, heat the materials to 120-130 C degree with the speed of 3-8 / C degree h for high temperature drying and reduce the inner moisture content of the woods to nearly 0. Finally, heat them to 185-220 C degree with the speed of 12-20 C degree / h. The intermittent steam-jet method is adopted to complete steam-jet treatment during the heating.

Owner:ZHEJIANG FORESTRY UNIVERSITY

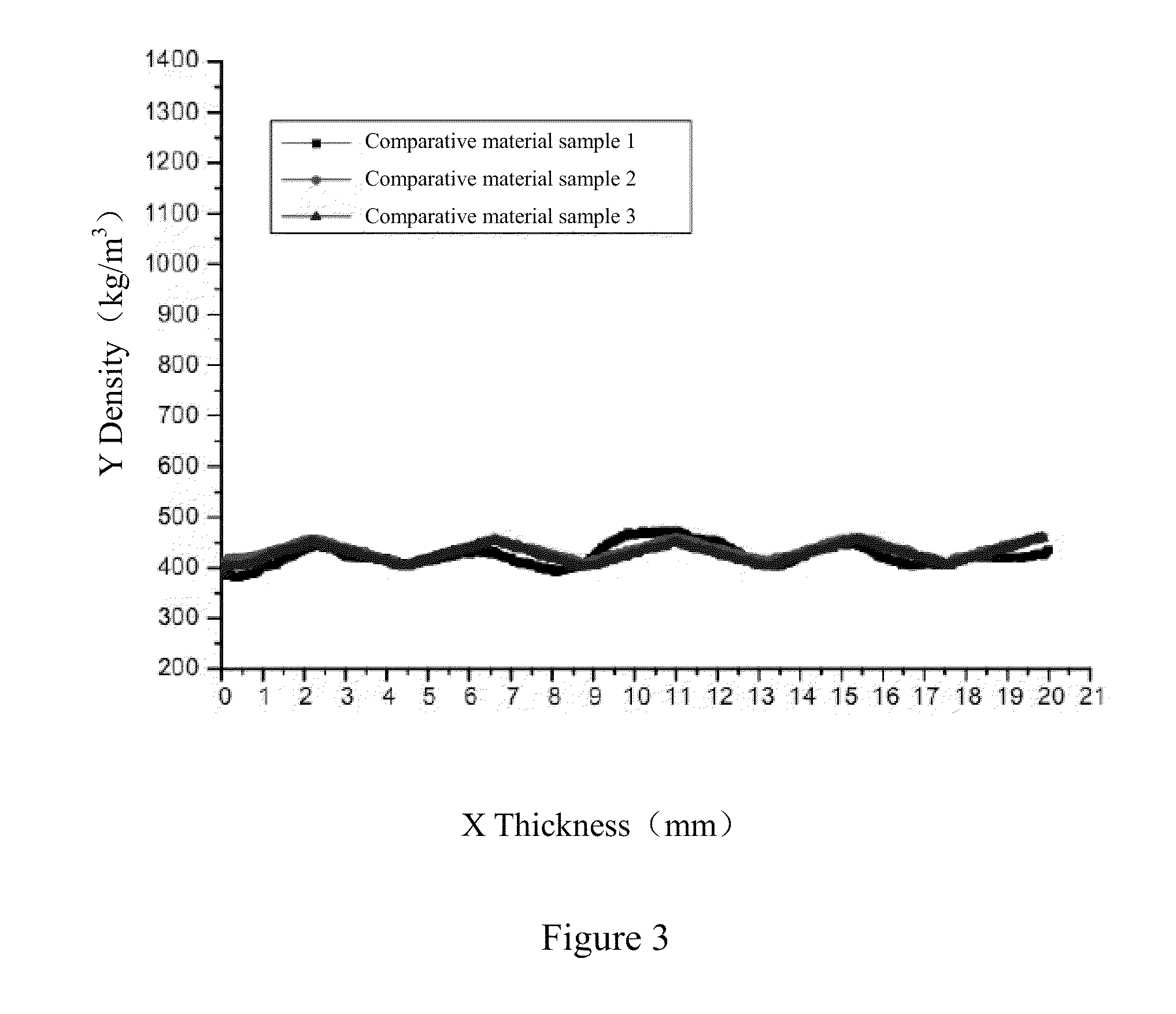

Timber wood hot pressing charing intensification method

ActiveCN101214675AUnlimited thicknessGood dimensional stabilityDrying using combination processesWood compressionCarbonizationVolumetric Mass Density

The present invention discloses a hot-pressing carbonization strengthening method of timbers, which includes drying, planing, hot-pressing carbonization, cooling and other steps. The present invention applies a hot press as a timber-carbonizing device, and the timbers under the state of compression are processed by hot-pressing carbonization. The present invention is characterized in that the investment on carbonization devices is less, the carbonization process is simple, the production is safe, the production efficiency is high, the consumption of heat energy is little, and the production cost is low; moreover, the thickness of the carbonized timbers is not limited, the defects of the timbers, such as deformation, cracking, stiker stain, color difference, knot fall-off, etc., do not occur in the process of production, so the quality of products is high; not only is the size stability and noncorrodibility of the carbonized timbers improved, but also the density and mechanical property of the timbers is increased.

Owner:广州豪沃仕家具有限公司

Method and apparatus for separating sheet glass

InactiveUS20060191970A1Heating evenlyQuality improvementWood compressionGlass severing apparatusFlat glassInitiation point

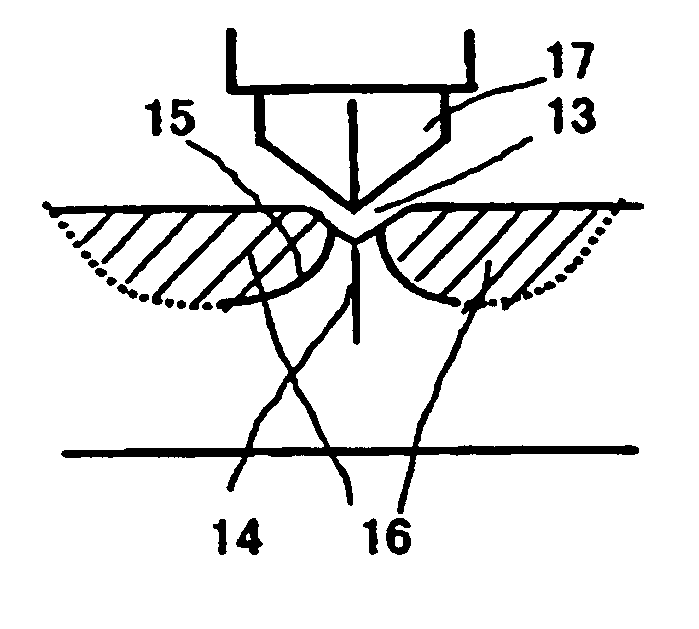

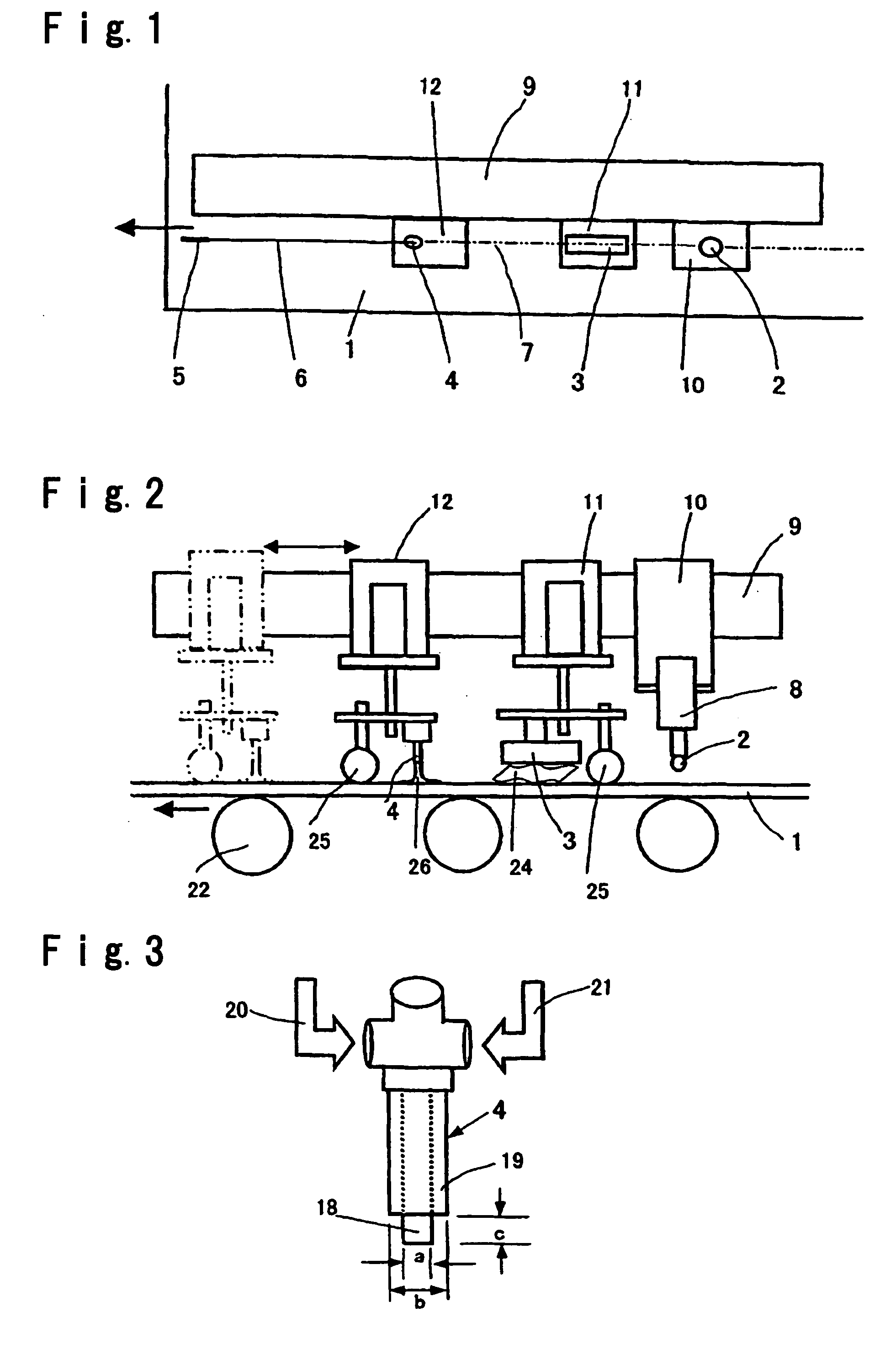

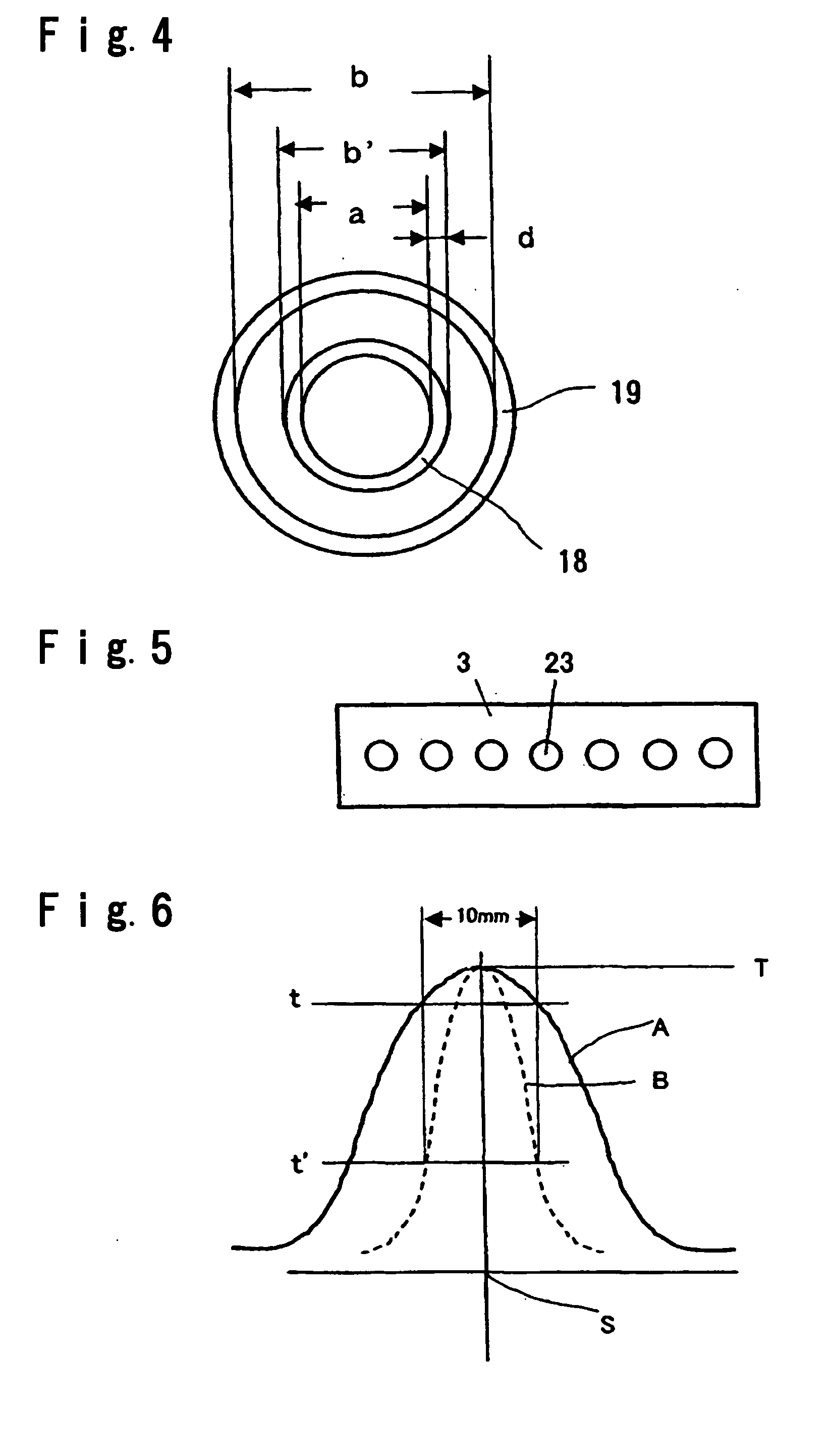

In separation of sheet glass by making use of thermal strain, separated surfaces can be obtained to avoid the occurrence of glass chips and to have excellent linearity even in relatively thick sheet glass. After a score, which serves as a crack initiation point is engraved at a separation initiation point in sheet glass, the sheet glass is heated along an imaginary line of by a heating burner; the heated portion of the sheet glass with the imaginary line of separation set therein is locally cooled by a mist, which is produced by a cooling nozzle comprising a liquid-ejecting port disposed at a central portion thereof and a gas-ejecting port disposed around an outer periphery of the liquid-ejecting port, the liquid-ejecting port projecting farther than the gas-ejecting port; and a minute crack of the score is caused to propagate along the imaginary line of separation to form a crack required for separation of the sheet glass.

Owner:ASAHI GLASS CO LTD

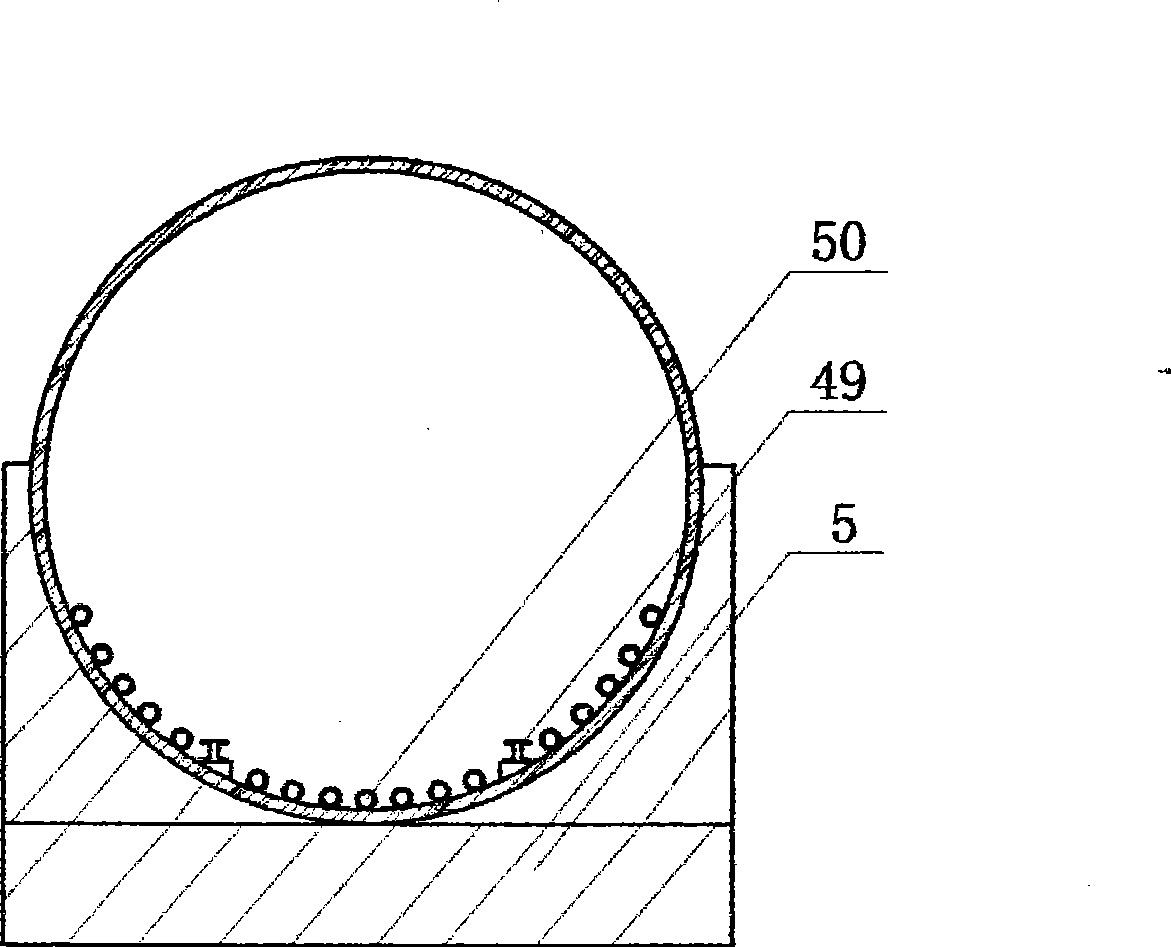

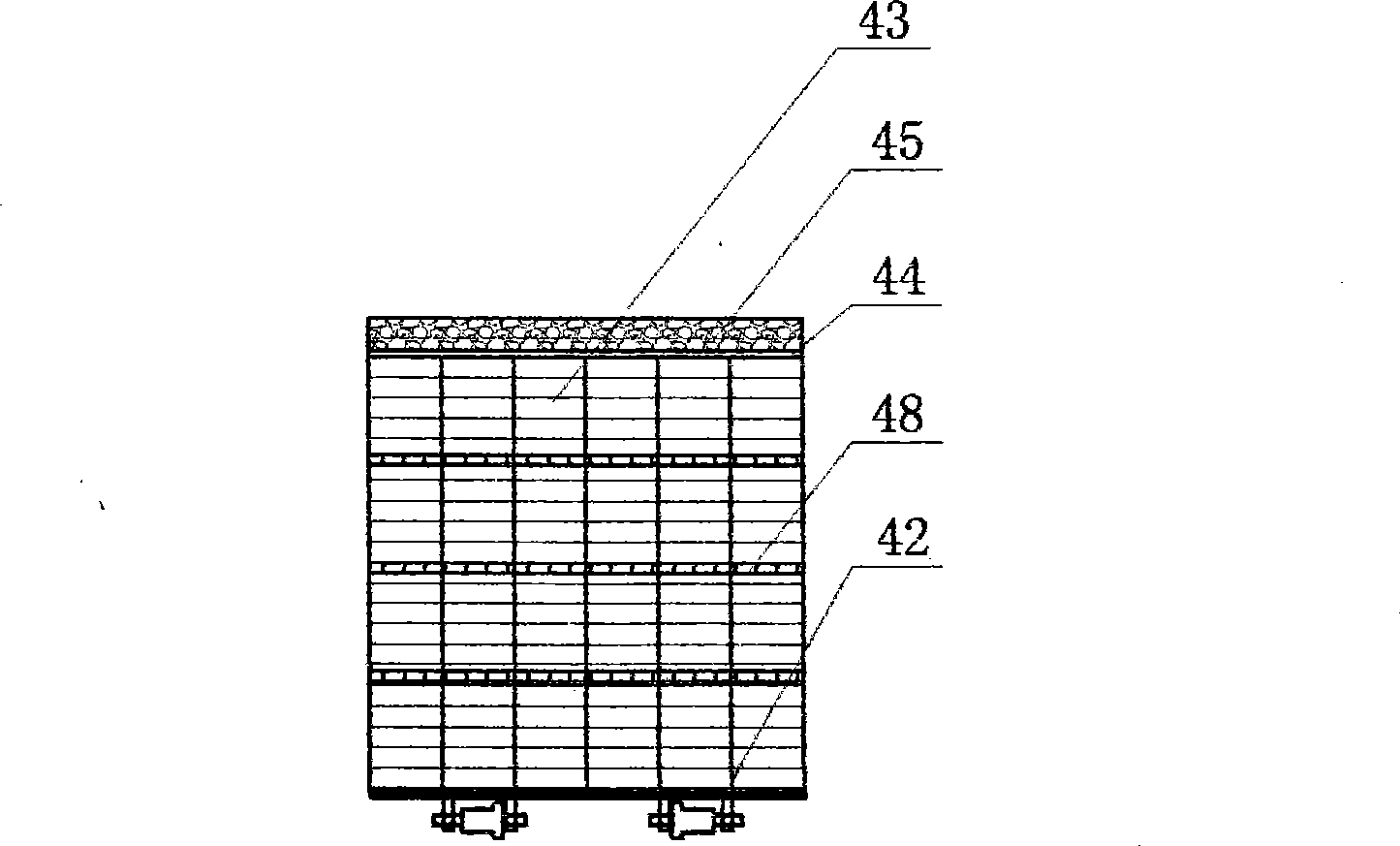

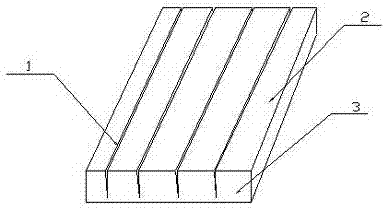

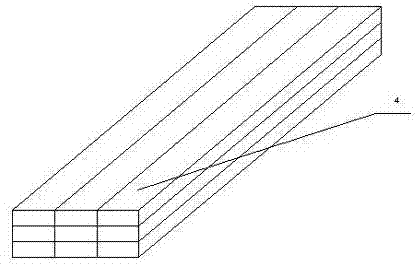

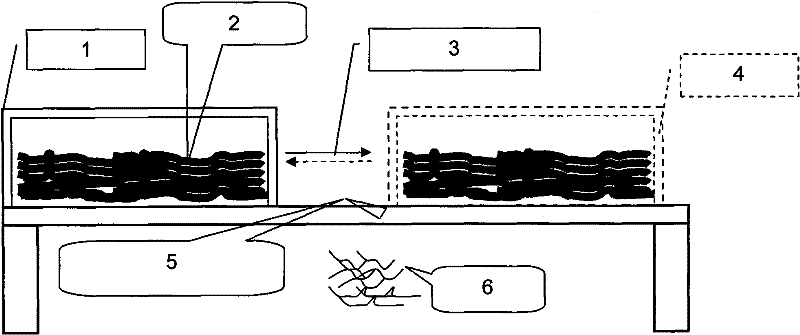

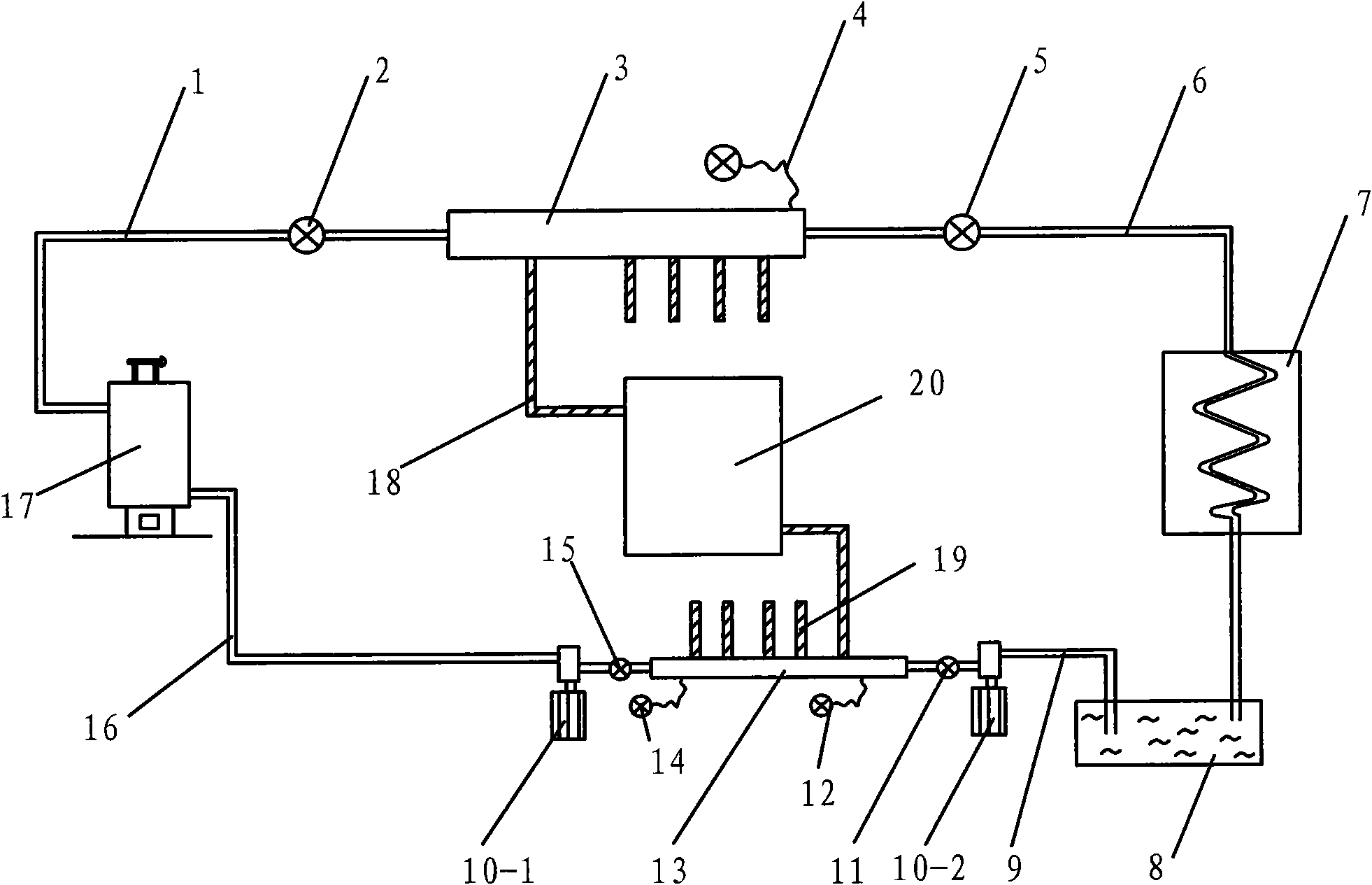

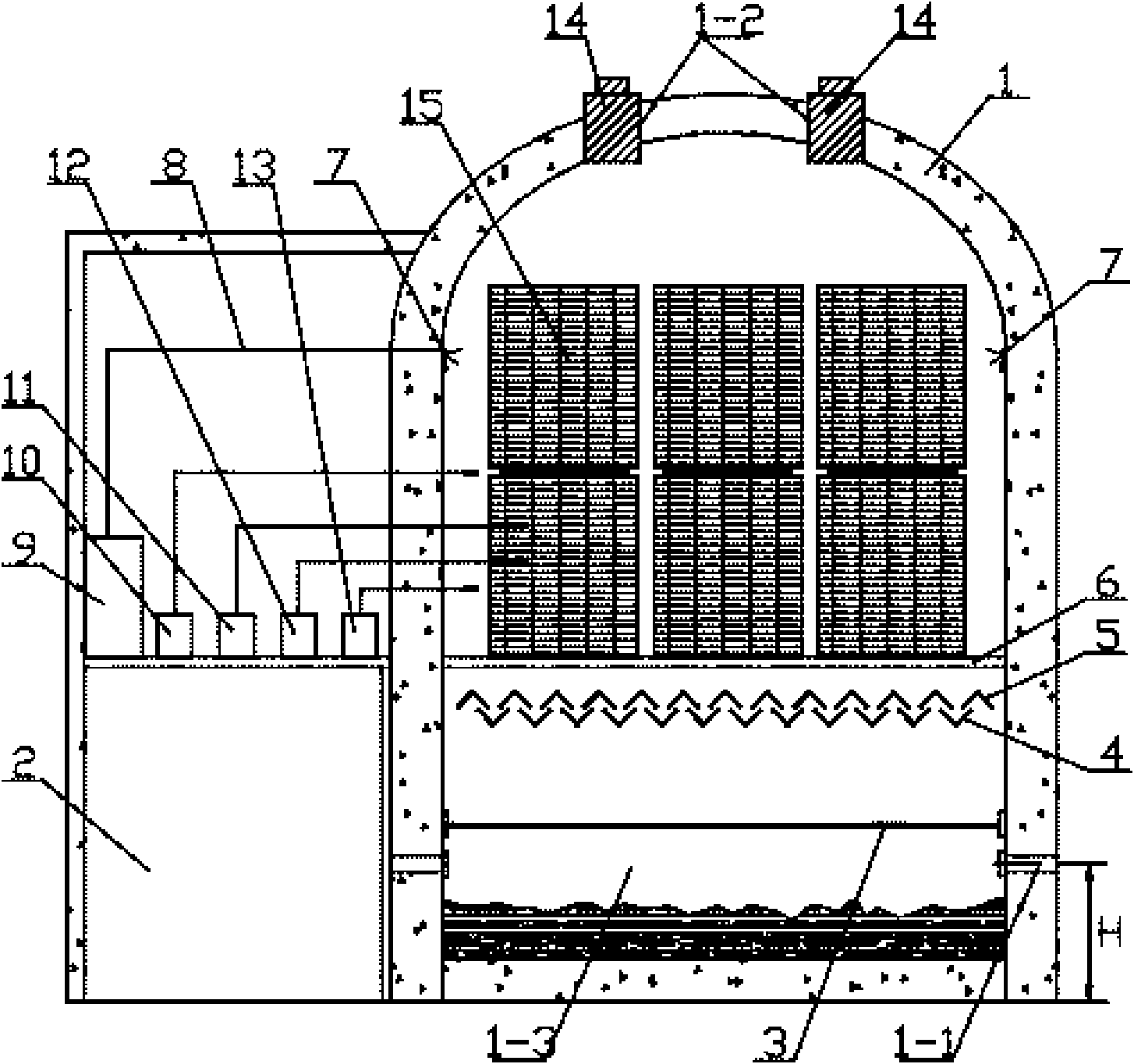

Microwave vacuum device for drying and charring lumber

ActiveCN101439529AConsistent heating inside and outsideDry evenlyWood treatment detailsWood dampingAir cycleFurnace temperature

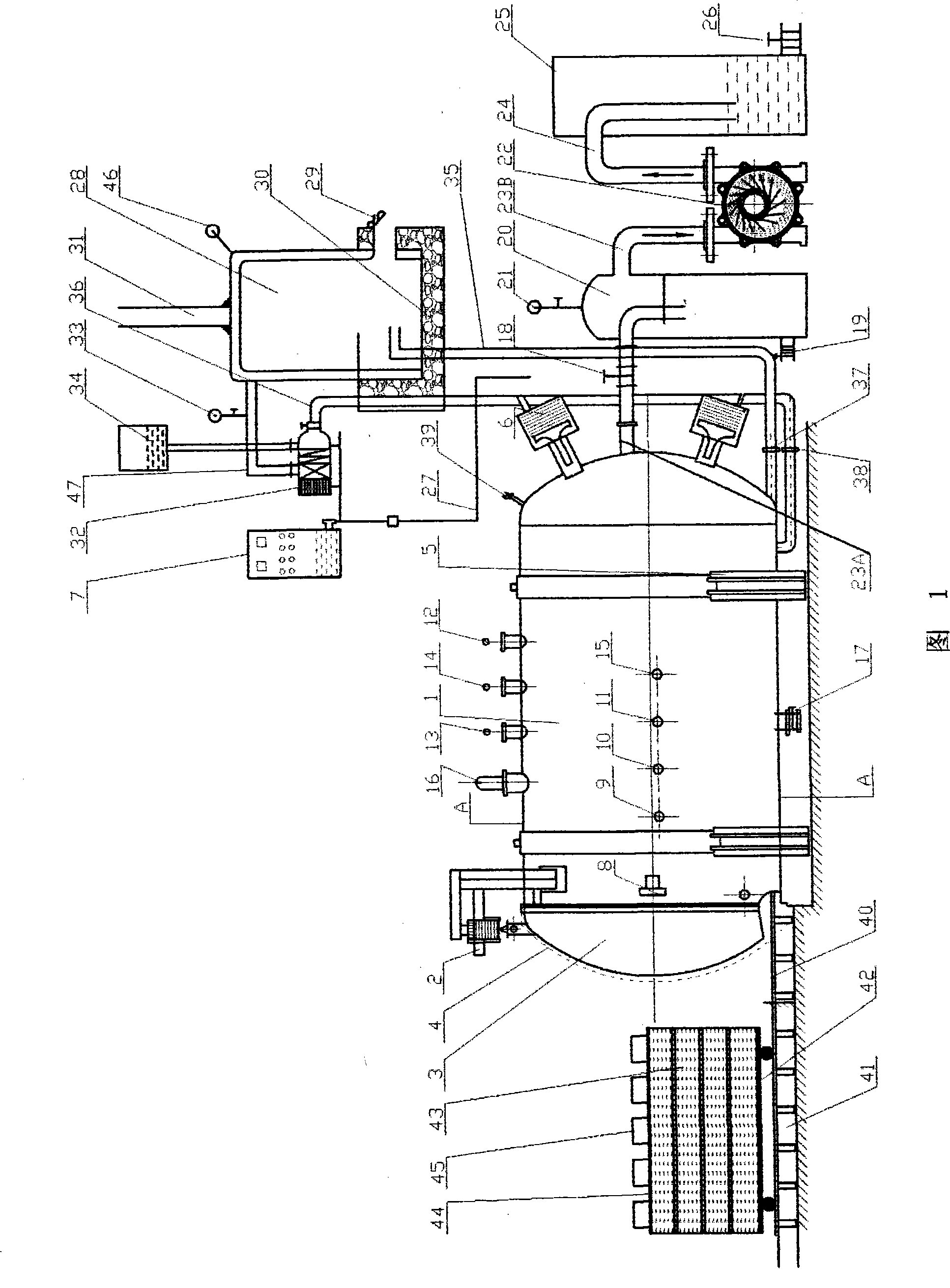

The invention relates to a wood microwave vacuum drying and charring device and a drying and charring method thereof. The device comprises one charring tank (box) with a tank door (3), a tank door opener (2) and a charring chamber (1), a vacuum system, and one or more microwave sources (6) generating the microwave, a heat-conducting oil furnace system and a material preparation and feed system. The drying and charring method comprises the following steps: A. rising the temperature inside the tank to 30-50 DEG C, and then to 80-130 DEG C at the rate of 2-8 DEG C / h; B. preserving the temperature for 2-100 hours; C. vacuumizing the tank for 4-100 hours; D. starting a hot recycle pump to control the oil furnace temperature, the oil flow rate and the pressure inside the tank for 4-100 hours: E. turning off the microwave source and a heat source, opening an intake and exhaust valve (39) to discharge the pressure inside the tank to 0 and lower the temperature to 70-130 DEG C, and then closing the intake and exhaust valve (39); and F. starting a vacuum pump (22) to lower the temperature inside of the tank by air circulation and removing the wood from the tank when the temperature decreases to 30-70 DEG C. The device and the method help char the wood evenly, shorten the production cycle by 60% compared with the conventional method, and lower the energy consumption by 70%, thus greatly reducing the production cost.

Owner:罗玉成

Carbonization heat treatment process for wood

Disclosed is carbonization heat treatment process for wood. The technical scheme includes that the wood is loaded in a carbonization kiln, saturated steam is used as a protector, a fain is used for realizing airflow circulation, the inside of the kiln is slowly heated by a hot oil or electric heating system, a high-temperature environment is formed, pressure generated in the kiln is released by a pressure release system so as to form a constant pressure environment, generated flue gas is treated by a water film dust removal system to meet requirements of environmental protection, and steps of the process include a temperature rising and drying stage, a carbonization temperature rising stage, a carbonization stage and a cooling stage. Carbonization colors of the inside of the carbonized wood and carbonization colors of the surface of the carbonized wood are even and uniform, color difference of the surface of the carbonized wood is avoided, the surface of the carbonized wood is bright, and SB / T10508-2008 standards are met. In addition, an integral carbonization process is easy to control, and the carbonization heat treatment process is applicable to wood of various trees. Besides, the carbonization heat treatment process has high technical content, and is low in production cost and favorable for large-scale production.

Owner:开原圣意达木材干燥设备有限公司

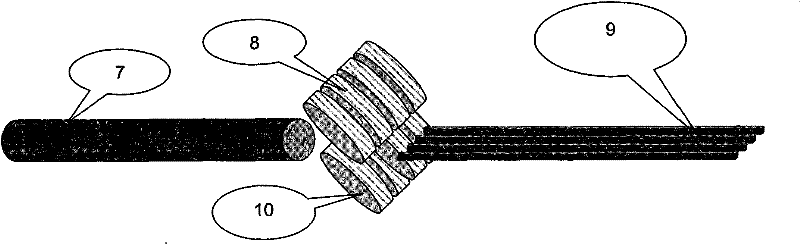

Original bamboo inner-dissecting outer-linked softening unfolding recombining technology

ActiveCN102225564AFew slicesHigh yieldWood compressionWood treatment detailsSingle plateCarbonization

The invention discloses original bamboo inner-dissecting outer-linked softening unfolding recombining technology. The technology comprises the following steps: sawing an original bamboo into bamboo tubes with a specified length, dissecting the bamboo tubes into several arc shaped bamboo sheets, removing inner bamboo joints, performing high-temperature softening and plasticizing treatment of the bamboo sheets, performing inner-dissecting outer-linked unfolding of the arc shaped bamboo sheets by a bamboo filament-linked unfolding milling machine, removing the inner of the bamboo with a fixed width and milling, performing boiling or carbonization, drying, dipping, drying, prepressing into single plates, drying, cutting core layers, dipping, performing blank assembling and plate alignment, performing hot pressing and stratification, trimming, and finally performing hot pressing and recombination according to the purposes. The invention overcomes the disadvantages of existing excessive processing procedures for bamboo, large equipment investment, high labor expense consumption, low raw material utilization rate, and high processing cost, and the prepared bamboo sheet material is applicable to industry such as architecture, decoration, furniture, etc.

Owner:HUNAN ACAD OF FORESTRY

Environment-friendly craft furniture processing method

ActiveCN103204029AAchieve softeningImprove anti-agingDecorative surface effectsWood treatment detailsCarbonizationProcess engineering

The invention discloses an environment-friendly craft furniture processing method. By processing trunks, branches and roots with conditioning fluid, softening, disinfecting and sterilizing of raw materials are realized and anti-ageing and physical performances of the raw materials are improved. By the processing method, utilization rate of the raw materials can be increased by 8-12%, and by high-temperature carbonization, disinfection and prevention of molding and being damaged by worms can be further realized.

Owner:六安皖智知识产权运营有限公司

Flame-retardant anti-corrosive fiber bamboo base material and preparation technology thereof

ActiveCN102794801AIncrease profitCarbonization pyrolysis effect is remarkableWood compressionLayered productsFiberCarbonization

The invention discloses a flame-retardant anti-corrosive fiber bamboo base material and a preparation technology thereof. The method comprises the following steps of: 1) cutting raw bamboo into bamboo filament; 2) flame-retardant treatment: soaking the bamboo filament prepared in the step 1) in a flame retardant aqueous solution; 3) drying: after the flame-retardant treatment, drying the bamboo filament at 55-65 DEG C until the absolute water content does not exceed 12%; 4) carbonization pyrolysis: feeding the dried bamboo filament into a carbonization pyrolysis kiln, and performing high-temperature treatment according to the pyrolysis gradient; and 5) sequentially performing gumming, post-gumming drying, pressing, curing, maintaining and splitting to obtain the bamboo base material. The bamboo base material has strong stability, the product surface does not crack, the corrosion resistance is enhanced, good flame retardance is realized, and the bamboo base material can be used in various weathers and environments.

Owner:WUXI BODA BAMBOO & WOOD INDAL

Efficient carbonization and crack-free treatment method of bamboo pipes

ActiveCN105643750AGood dimensional stabilityAntisepticWood treatment detailsWood charring/burningCrack freeCarbonization

The invention provides an efficient carbonization and crack-free treatment method of bamboo pipes. The method comprises the following process steps that 1, the fresh bamboo pipes are drilled; 2, the bamboo pipes are stacked and enter a high-pressure tank; 3, the round bamboo pipes are softened and carbonized at a high temperature in the high-pressure tank; and 4, the round bamboo pipes are dried. The fresh round bamboo pipes are placed into a high-temperature saturated steam tank with the temperature ranging from 140 DEG C to 190 DEG C, high-temperature steam is utilized for fast heating, softening points of lignin, cellulose and hemicellulose can be reached fast, meanwhile, the hemicellulose is hydrolyzed fast at such a high temperature and humidity, and therefore the purpose of efficient carbonizing within a short time is achieved. Water in the bamboo pipes is drained by means of dry hot steam, the bamboo pipes are dried and shrunk and cannot cause cracking, thus, fast carbonization treatment and softening treatment are achieved, and the crack-free carbonized round bamboo pipes manufactured through the method are better in size stability and suitable for manufacturing artware, furniture, bamboo buildings and outdoor landscape, and have anticorrosion and anti-moth performance. The better processing method is provided for the bamboo industry.

Owner:贵州新锦竹木制品有限公司

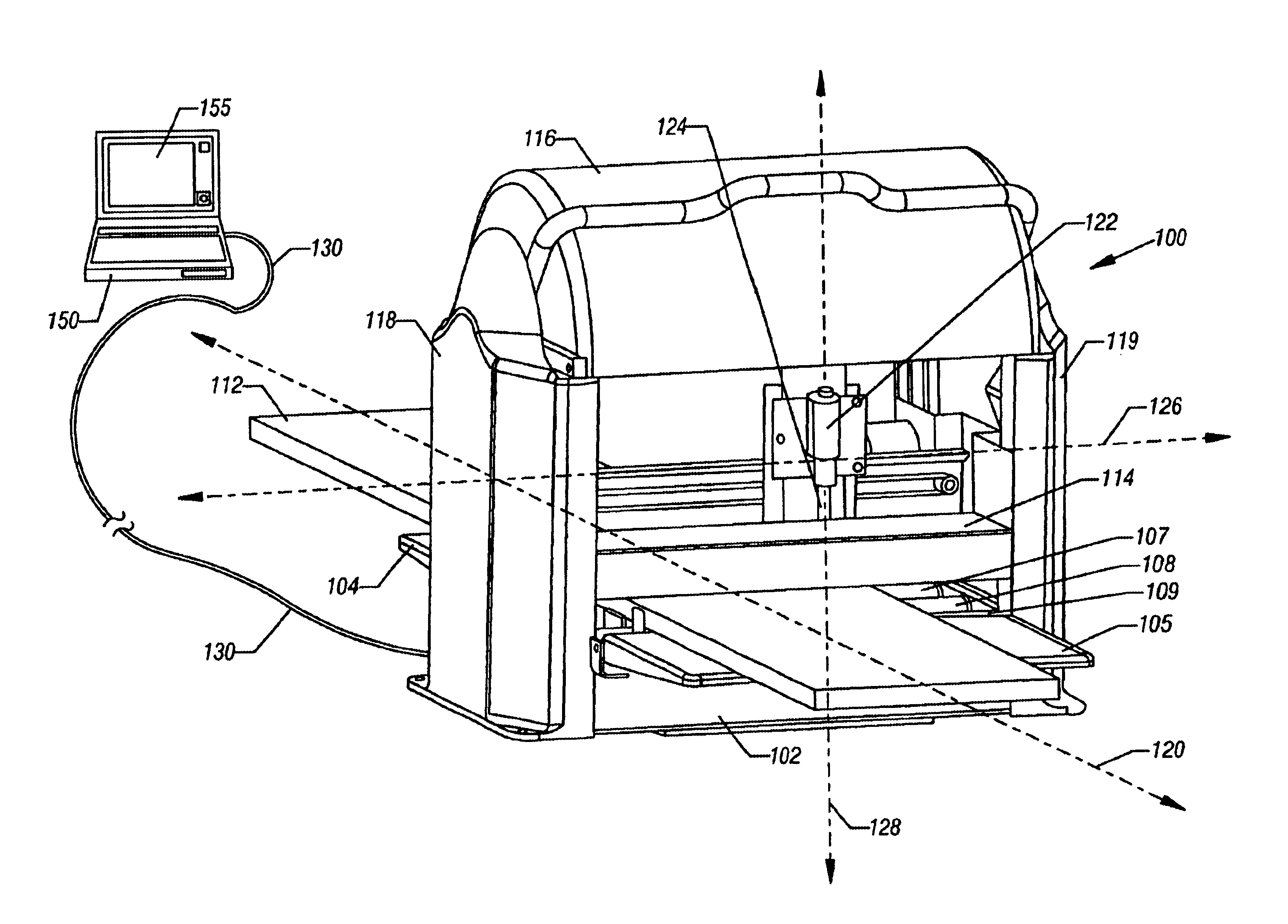

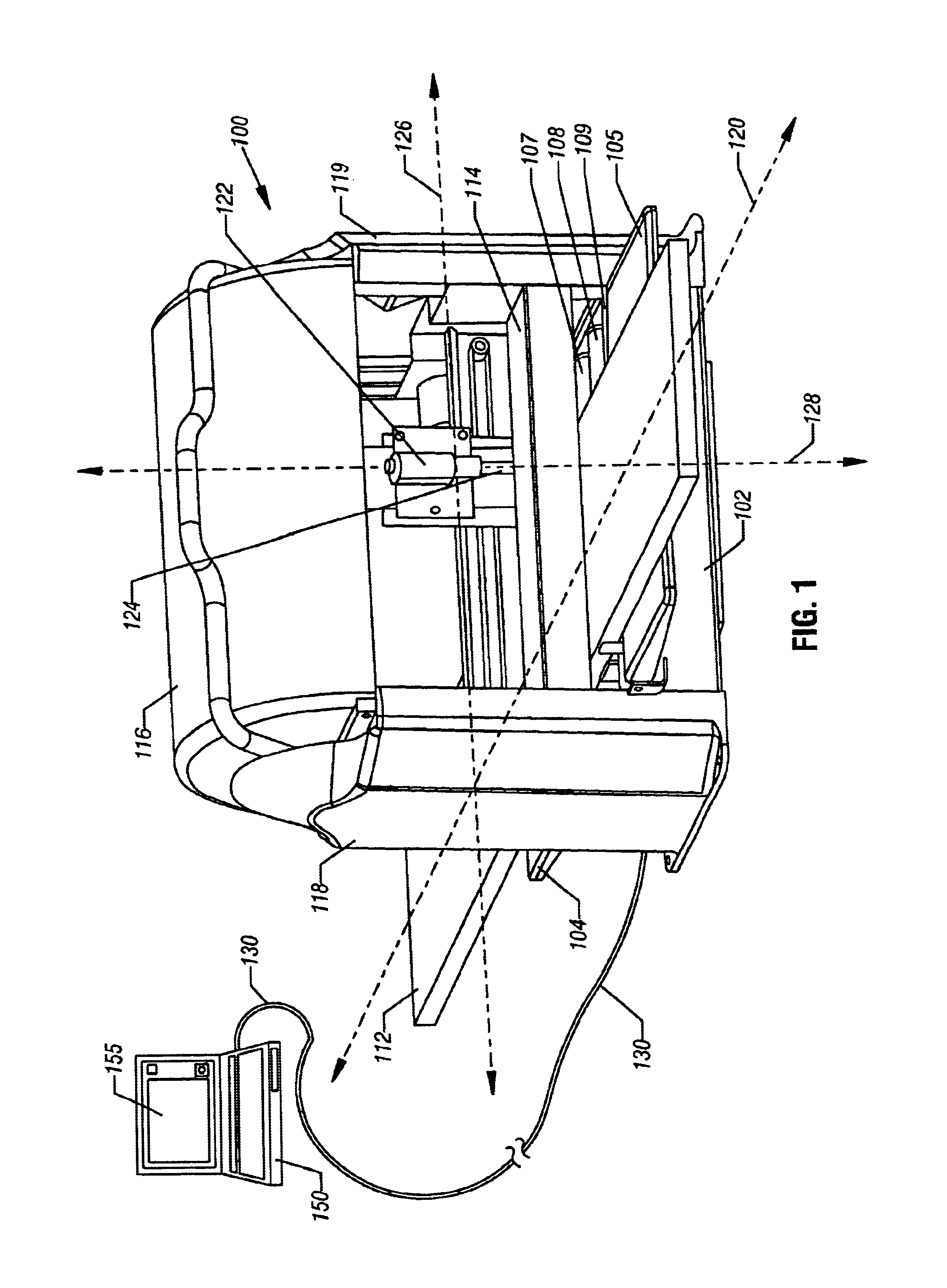

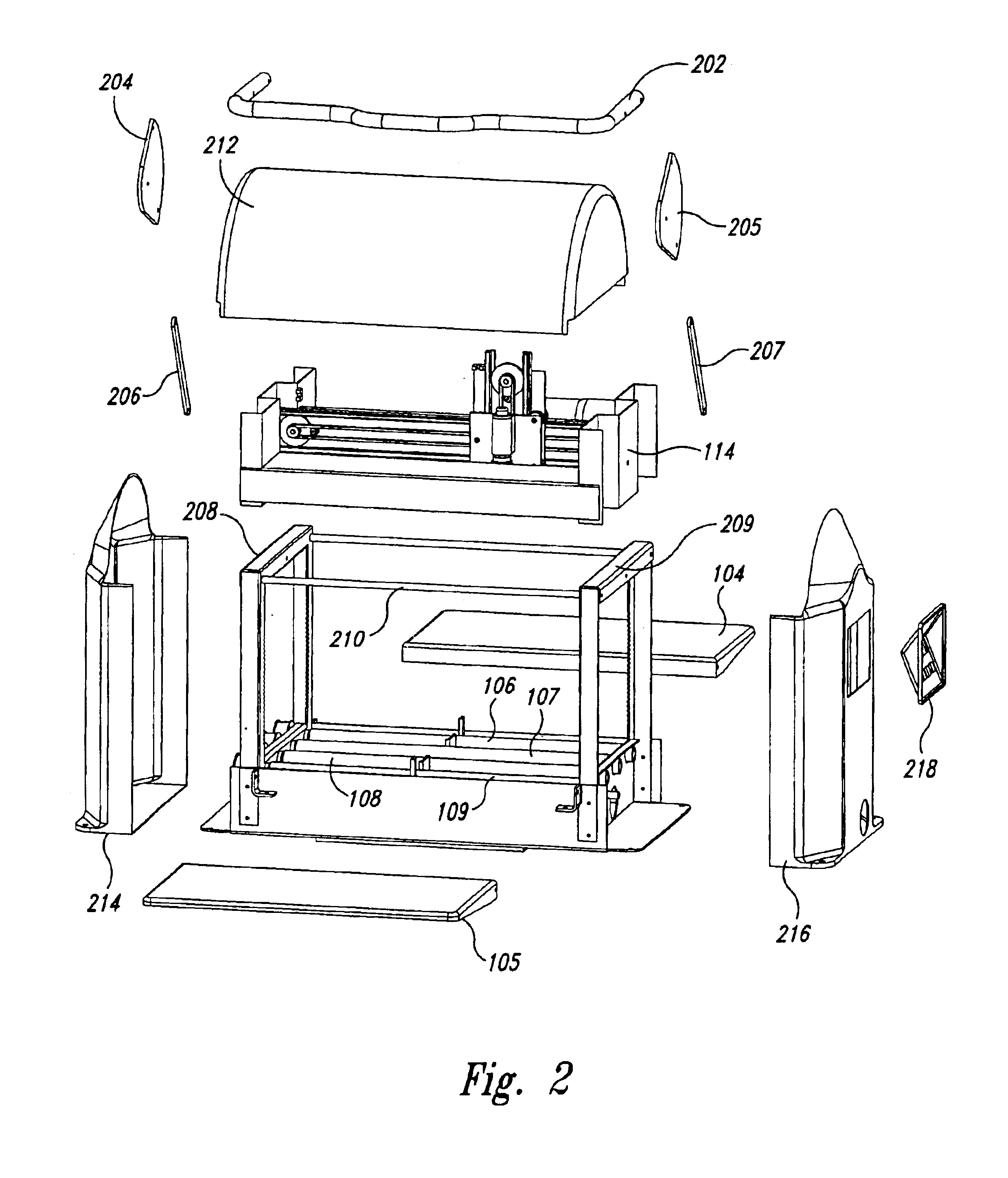

Processor-controlled carving and multi-purpose shaping device

InactiveUS6859988B2Easy to operateFineness is limitedSawing apparatusGearingComputer printingEngineering

Owner:LHR TECH

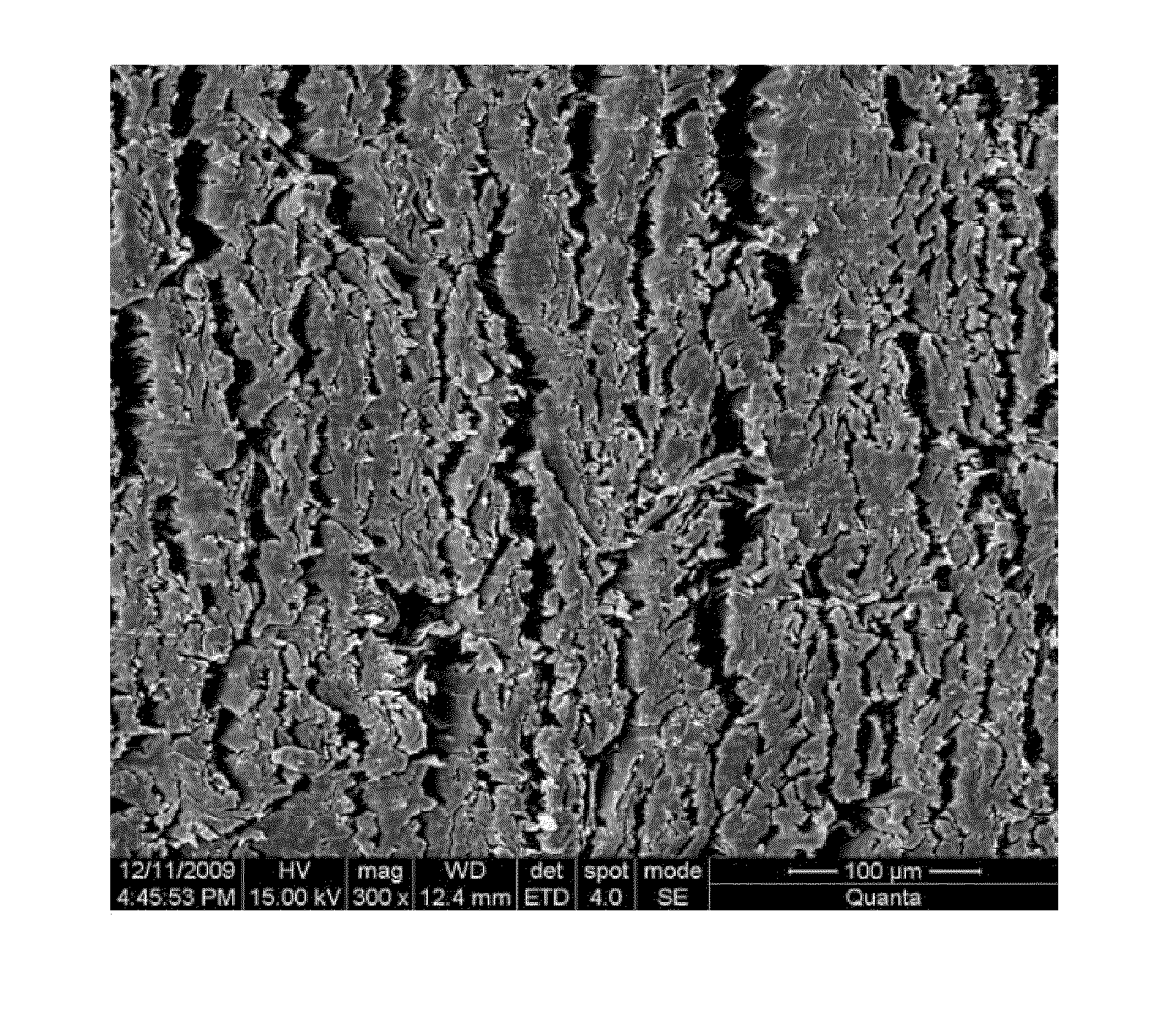

Method for producing high-density recombined wood

InactiveCN102172940AHigh static bending strengthHigh surface hardnessWood compressionVeneer manufactureHigh densityEngineering

The invention relates to a method for producing high-density recombined wood, which is used for manufacturing plates and recombined module timber by the following steps of planning, processing by high-temperature steam, drying, dipping glue, draining glue, drying after draining glue, tidying or weaving, balancing for nourishing, pressing to shape, solidifying at a high temperature and the like. The density of the high-density recombined wood can reach 0.7-1.2kg / cm<3>; the high-density recombined wood has the characteristics of peculiar texture, fine grain, excellent performance, small possibility of cracking and deforming and the like, does not need to prevent insects, prevent mildew, prevent corrosion, prevent from cracking and the like, and can be directly used for the fields of floor, furniture, building and the like. The method disclosed by the invention has simple working procedures, and abandoned secondarily secondary small fuel wood and secondary small wood are utilized to produce plates and module wood, thereby changing waste materials into things of value, and greatly saving forest resource. The wood is an ideal log substitute.

Owner:浙江仕强竹业有限公司

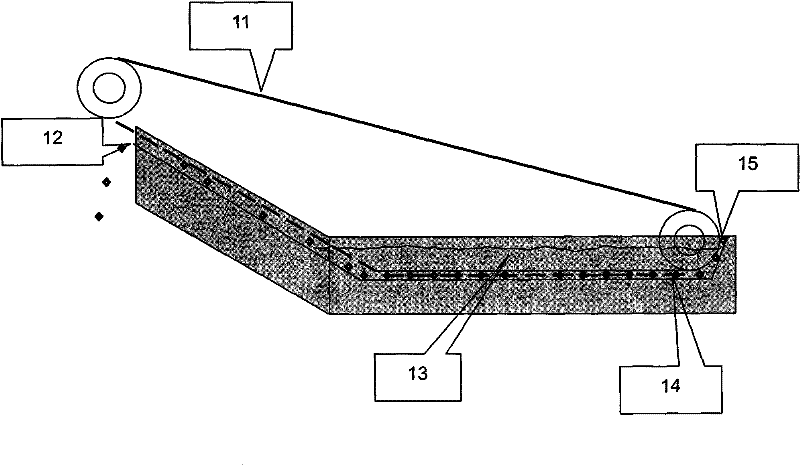

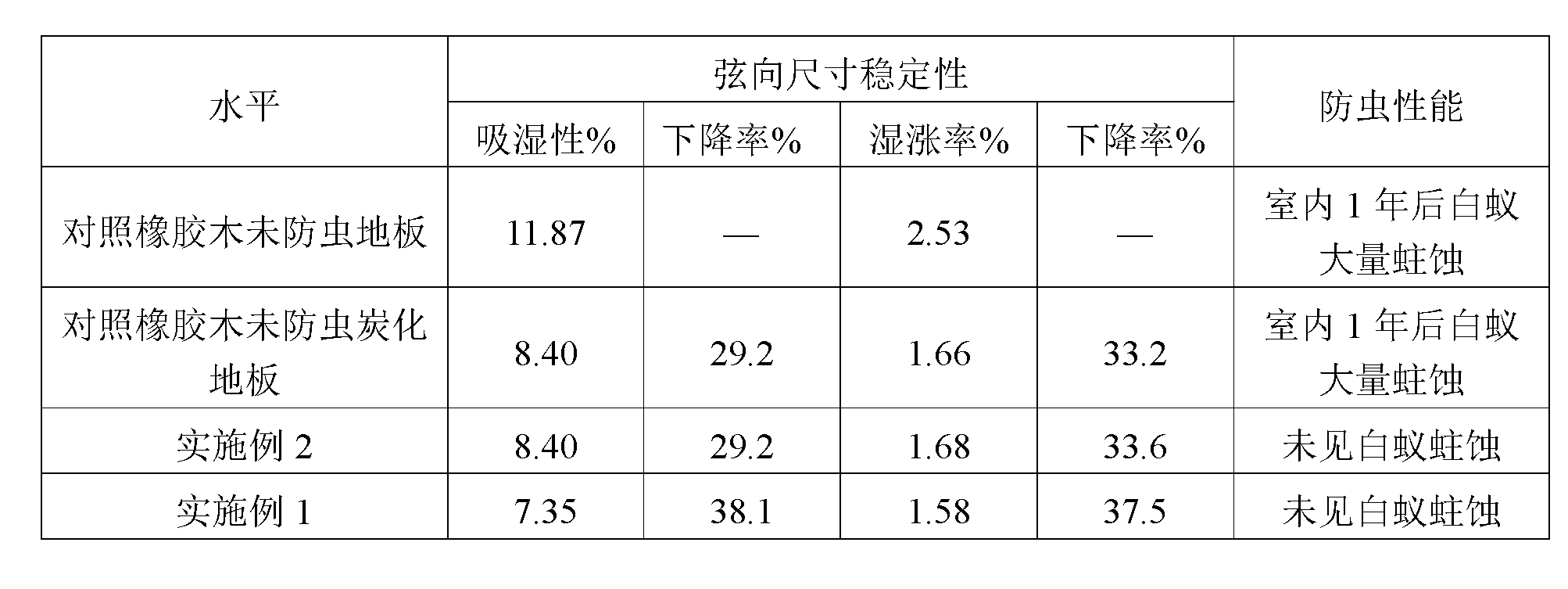

Production method of high-temperature heating modified rubber wood floor

InactiveCN103072165AReduce direct dryingReduce routine drying process timeWood treatment detailsPressure impregnationSolid woodCarbonization

The invention relates to a production method of a high-temperature heating modified rubber wood floor, wherein rubber wood is sawn into wood beams or billets, the wood beams or billets are subjected to insect and termite prevention treatment, drying, carbonization and wood conditioning, the stress and the water content are balanced, and subsequent processing is conducted to obtain the rubber wood floor. The rubber wood is subjected to high temperature heating modified treatment and termite prevention treatment, the manufactured carbonized rubber wood floor is stable in size and excellent in stability and can resist corrosion by moths and termites, the produced carbonized rubber wood solid floor can be used indoors in both the humid south and the dry north, the problem that the solid floor is not easily made in a large width from the rubber wood is solved, and the additional value of the rubber wood is increased. Meanwhile, due to the adoption of the process of subdividing a sheet after carbonizing the wood beams, the problems of large the bending deflection, large reserved allowance in the thickness direction and large loss, resulting from the fact of direct drying and carbonizing of the sheet, can be solved, and the outturn percentage is increased.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI +1

A kind of manufacture method of carbonized bamboo chopsticks

InactiveCN102267151AConsistent colorImprove appearance qualityWood treatment detailsWood charring/burningFiberBrick

The invention discloses a method for manufacturing carbonized bamboo chopsticks, which comprises the steps of: sawing bamboo into sections, splitting pieces to make bamboo strips; processing the bamboo strips into bamboo chopsticks with a chopstick forming machine; placing the processed bamboo chopsticks on a mass The percentage concentration is 1~2% Na2S2O5 solution for 24~30 hours; take it out and soak it in clean water for 4~5 times; dry the bamboo chopsticks at 60~120°C to make the moisture content below 10%; The bamboo chopsticks are stacked neatly, placed in the carbonization furnace, and water vapor is introduced, the pressure of the carbonization furnace is controlled at 0.18~0.2MPa, the temperature is 128~135°C, and carbonization takes 1.5~3 hours; take out the bamboo chopsticks and dry them. Carbonizing bamboo chopsticks under high temperature and high pressure can carbonize all nutrients such as insect eggs, fat, sugar, and protein in the bamboo material, fundamentally eliminate the living space of insects and bacteria, and make the material lighter. Arranged in the shape of "hollow bricks", the tensile and compressive strength and waterproof performance are greatly improved. The bamboo chopsticks prepared by using the invention have properties such as anti-corrosion, insect-proof, mildew-proof and moisture-proof, and the bamboo chopsticks have beautiful and consistent colors.

Owner:ZHEJIANG SHUANGQIANG BAMBOO & WOOD CO LTD

Production method for manufacturing sliced veneer by bamboo split recombined bamboo wood

ActiveCN103878839AIncrease color varietiesIncrease added valueOther plywood/veneer working apparatusWood treatment detailsPulp and paper industryChemistry

The invention relates to a production method for manufacturing sliced veneer by bamboo split recombined bamboo wood and aims to realize that firstly, bamboo splits can be used for manufacturing bamboo veneer decorating materials and bamboo wood utilization rate is increased; secondly, natural-color, carbonized and dyed bamboo splits can be used for manufacturing bamboo veneers and colors of the bamboo veneers are enriched; thirdly, the technical problem of humidifying square timber of the bamboo splits is omitted and procedures are saved. The production method includes steps of 1) manufacturing the bamboo splits; 2) subjecting the bamboo splits to natural-color, carbonized or dyed treatment; 3) drying the bamboo splits; 4) shaping the square timber of the bamboo splits; 5) conditioning the square timber of the bamboo splits; 6) softening the square timber of the bamboo splits; 7) slicing the square timber of the bamboo splits; 8) post processing.

Owner:NANJING FORESTRY UNIV

Manufacturing method of carbonization heat treatment-modified solid wood flooring

ActiveCN102922580AAvoid influenceQuality impactWood treatment detailsWood charring/burningSolid woodCarbonization

The invention relates to a functional improvement method of woods, in particular to a manufacturing method of a carbonization heat treatment-modified solid wood flooring, belonging to the technical field of functional modification of the woods and wood product processing. The technical solution for the manufacturing method comprises the following steps: (1) a solid wood flooring blank manufacturing step; (2) a drying step; (3) a carbonization heat-treatment improving step; and (4) a solid wood flooring manufacturing step. Due to the technical solution for the manufacturing method of a carbonization heat treatment-modified solid wood flooring, a production method of a solid wood flooring designed special for fast-growing woods while the existing technical problems are solved. Compared with the prior art, the manufacturing method has the advantages of simple production process, short production cycle, low energy consumption, low production cost and the like, and technical indexes of obtained solid wood flooring made of fast-growing woods achieve the national standard quality requirement.

Owner:福建秦朝木业科技有限公司

Method for preparing charing bamboo chopsticks

InactiveCN101434082AEliminate living spacePrevent deformationWood charring/burningWater vaporSelf purification

The invention relates to a method for preparing carbonized bamboo chopsticks by utilizing carbonized bamboo chips with uniform shallowness, which is characterized in that the method comprises the process steps: 1. the pretreatment of a bamboo material, in which the bamboo material is transversely sawn at intervals along the length direction of the bamboo material, and each section of sawn bamboo material is chopped into four pieces; 2. bamboo material carbonization with uniform shallowness, in which the large bamboo materials are placed into a carbonization furnace, water vapor is introduced as shielding gas, the carbonization is performed for 2 to 3 hours at a temperature increase rate of between 5 and 10 DEG C / h, and finally the carbonization temperature reaches between 160 to 180 DEG C, 180 to 200 DEG C, 200 to 220 DEG C, and 220 to 40 DEG C respectively; and 3. the preparation of the carbonized bamboo chopsticks, in which joints of the obtained carbonized bamboo chips are subjected to grinding processing to be prepared into flat boards, and then a chopstick forming machine is utilized for processing to be formed. The method has the advantages that the carbonized bamboo chopsticks are not added with any chemical agent during the production, has no pollution and simple treatment process, and has the advantages of good durability, dimensional stability, moisture protection, mold prevention, moth prevention, sterilization, powerful self-purification function and so on.

Owner:张东升 +1

Method for processing bamboo sectional material

InactiveCN101708618AStress reliefImprove anti-corrosion performanceWood treatment detailsCane mechanical workingCarbonizationHigh pressure

The invention discloses a processing method, which can form a bamboo sectional material having rich texture, sufficiently eliminates the internal stress of bamboo chips, enhances the antiseptic property of the bamboo chips and can adjust the colour of the bamboo chip through a carbonization process at 150 to 180 DEG C. The processing method comprises the following steps: after twisting retiform bamboo chips into twist strip-shaped bamboo cables, weaving the bamboo cables into a bamboo braid; immersing the bamboo braid into a glue; and thermo-curing the bamboo braid under a high pressure to obtain a texture as a precious wood can be obtained. The number of strands and weaving methods are different, so the texture of the sectional material changes correspondingly; the original form of the bamboo is changed radically through the high pressure treatment of the process; bamboo fires are recombined into a novel bamboo sectional material; and various physical performance indexes exceeding that of the wood are obtained. The method for processing the bamboo sectional material performs precompression on the bamboo braid before thermo-curing the bamboo braid under the high pressure, which reduces the stroke of an oil cylinder of a mould press, reduces the height of equipment, saves the cost of the equipment, and improves the production efficiency. The bamboo sectional material prepared by the process method can replace the precious wood facing depletion, can be used for houses, floor boards, doors and windows and building materials, and has good market prospect.

Owner:周东华

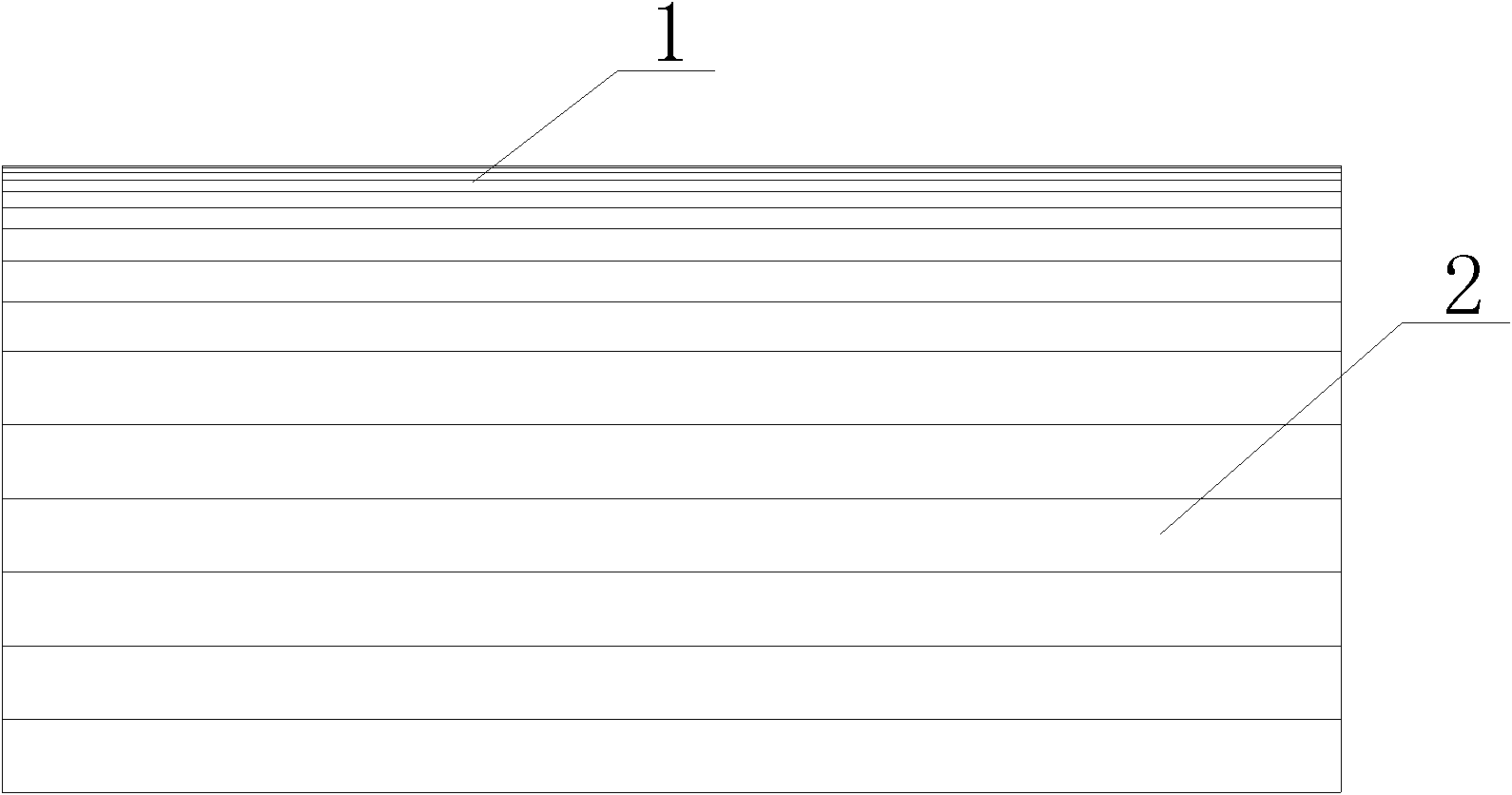

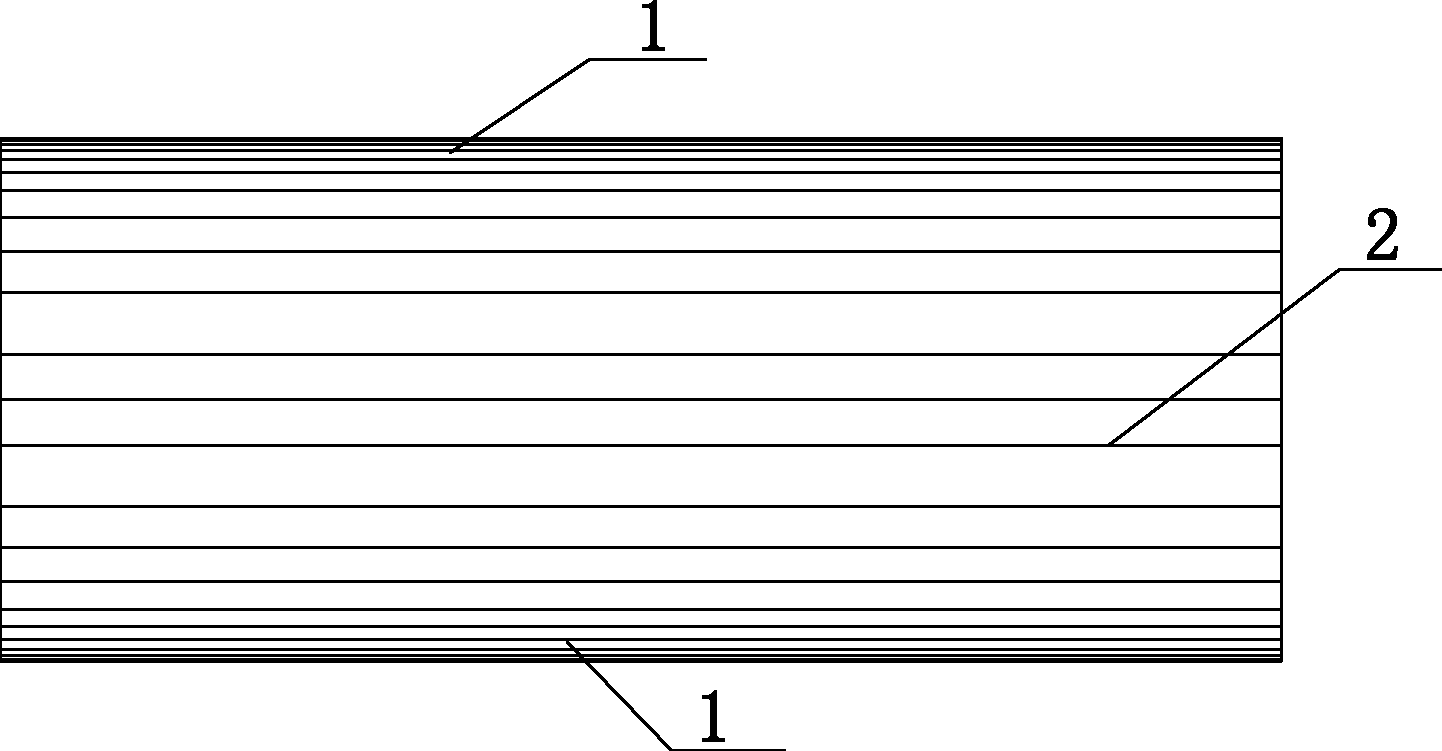

Manufacturing method of laminated veneer lumber

ActiveCN102554980AColor deepeningImprove flatnessWood treatment detailsWood veneer joiningMaterials preparationUltimate tensile strength

The invention discloses a manufacturing method of a laminated veneer lumber, which comprises the following steps of: 1) material preparation; 2) carbonization; 3) maintaining; 4) gluing and laying up; 5) cold pressing; 6) hot pressing; 7) edging and sawing; 8) and sanding and packaging. The manufacturing method of the laminated veneer lumber is simple, and the manufactured laminated veneer lumber has good size stability and high structural strength and is not easily deformed.

Owner:ZHEJIANG SHIYOU TIMBER

Bamboo floor preparation process

ActiveCN104085031AGuarantee processing qualityHigh strengthWood veneer joiningWood charring/burningMaterials preparationCarbonization

The invention discloses a bamboo floor preparation process. The bamboo floor preparation process includes the following steps of firstly, material preparation, secondly, rough milling, thirdly, cooking and carbonization, fourthly, drying, fifthly, manual selection, sixthly, finish milling, seventhly, splicing and pressing, eighthly, planing, tenthly, end-face tenoning, eleventhly, polishing and twelfthly, paint spraying. In the material preparation step, purchased raw bamboo is truncated and sliced into bamboo slices of the same specification and the same size; in the rough milling step, bamboo joints are planished, and part of bamboo outer skin and tabasheer of the bamboo slices are milled and removed; in the cooking and carbonization step, sugar and fat in the bamboo slices are removed; in the drying step, the bamboo slices are dried with the moisture content smaller than 7%; in the manual selection step, the bamboo slices meeting the splicing condition are selected; in the finish milling step, the bamboo outer skin and the tabasheer of the dried bamboo slices are completely milled and removed; in the splicing and pressing step, the bamboo slices are glued in a hot-press mode through a hot press, and then a bamboo blank is formed; in the planing step, the bamboo blank is planed, so that the surface of the bamboo blank is smooth; in the polishing step, a crude bamboo floor is polished through a polishing machine; in the paint spraying step, paint is sprayed to rabbets of the crude bamboo floor, then three times of priming paint coating, photocuring and priming paint polishing are sequentially and respectively conducted on the surface of the crude bamboo floor, and a finished bamboo floor is acquired. The bamboo floor prepared through the process has enough strength and rigidity, and is not prone to getting mildew and further capable of effectively resisting moths.

Owner:贵州新锦竹木制品有限公司

Fast-growing wood surface reinforcing manufacturing method and sections manufactured thereby

ActiveCN102626941AImprove permeabilityNo burstDrying using combination processesWood compressionPulp and paper industryMoisture

The invention relates to a fast-growing wood surface reinforcing manufacturing method and sections manufactured thereby, belonging to the field of functional improvement on wood and wood processing. The technical scheme comprises the following steps of (1) drying step: drying fast-growing wood till a moisture content of 5-12%; (2) carbonizing step: carbonizing the fast-growing wood; (3) surface reinforcing step: compacting and reinforcing the surface of the fast-growing wood; and (4) thermally processing and fixing step: thermally processing and fixing the fast-growing wood at the temperature of 180-220 DEG C. The problems are solved that in the conventional technical scheme, the production process is complicated, the production cost is high, the wood yield is low, obtained sections are poor in texture and color and luster and poor in product stability, and the like; compared with the prior art, the fast-growing wood surface reinforcing manufacturing method has the advantages of simple process, no addition of any chemical in the production process, environment-friendly production, high production efficiency, capability of realizing large-scale flow-line production, low wood loss, high wood yield, low production cost and the like; and the obtained fast-growing wood surface-reinforced sections have the advantages of hard surfaces and soft middle parts or bottoms, high size stability, high corrosion resistance, clear texture, plump color and luster, good decorative effect and the like.

Owner:福建秦朝木业科技有限公司

Method for manufacturing compressed carbonized poplar board

InactiveCN101733805AReduce stressGood dimensional stabilityWood compressionWood charring/burningCarbonizationHardness

The invention relates to a method for manufacturing fast-growing wood sheet, in particular to a manufacturing method for modifying a fast-growing poplar board, belonging to the technical field of sheet manufacture. The invention has the advantages of small internal stress of a compressed carbonized poplar board manufactured by the method and good stability of the size of the board, thereby ensuring the quality of a compressed carbonized wood. The invention overcomes the defects of a fast-growing poplar sheet, such as low density, low hardness, low strength, easy corrosion, difficult direct use and the like, improves the density of the sheet by carrying out compression and densification for the poplar sheet, carries out carbonization on the compressed poplar sheet on the condition of pressurization, and eliminates the compression stress inside the sheet so as to prevent springback of the sheet and improve the size stability, density and strength. The poplar board manufactured by the method can be directly used as a sheet. The compressed carbonized poplar board can be partially or entirely used to replace high-quality precious wood, thereby relieving the contradiction between continuously reduced precious wood resources and increasing demand for wood.

Owner:NANJING FORESTRY UNIV

Wood floor carbonizing processing method

InactiveCN101570031AEasy to operateQuality improvementWood compressionWood charring/burningEngineeringWood plank

The invention refers to the field of wood floor processing, in particular to a wood floor carbonizing processing method. The method comprises the following steps: (1) pretreatment: cutting wood into the shape of floor to obtain floor planks; (2) heat pressing carbonizing: putting the floor plank into a heat pressing machine for high temperature carbonizing to obtain carbonized wood planks; (3) cooling: putting the carbonized wood planks into the heat pressing machine to be cooled to lower than 160 DEG. C by the cold oil device of the heat pressing machine; (4) finish product producing: withdrawing the cooled carbonized wood plank from the heat pressing machine and executing post-treatment to obtained finished carbonized wood floor product. This method finishes carbonizing and cooling directly in the same heat pressing machine, thus causing the operation to be simple and convenient and the whole carbonizing process to be safe and controllable with higher yielding rate and higher quality of the finished floor product.

Owner:周发荣

Flame-retardant decorative plate, preparation method thereof and flame-retardant material comprising flame-retardant decorative plate

ActiveCN102756404AImprove flame retardant performanceGood gluing propertiesFilm/foil adhesivesAldehyde/ketone condensation polymer adhesivesAdhesivePyrophosphate

The invention provides a flame-retardant decorative plate and a preparation method thereof. The flame-retardant decorative plate comprises a plate component and a flame-retardant adhesive layer which is at least attached on at least one side surface of the plate component in the thickness direction and formed by an adhesive containing a flame-retardant adhesive, the plate component at least comprises a layer of wood veneer, the flame-retardant adhesive contains water-soluble amine resin, a dehydration catalyst, a char forming agent and auxiliaries, and the flame-retardant adhesive contains water or does not contain the water; the dehydration catalyst is selected from one or more of ammonium polyphosphate, melamine orthophosphate and melamine pyrophosphate; and the degree of polymerization of the ammonium polyphosphate is above 20. The invention further provides a flame-retardant material. The gluing performance of the flame-retardant decorative plate prepared by the method disclosed by the invention can meet the requirements of national standard and the flame retardance can be given to a base material; furthermore, the mechanical properties of the base material can not be affected, the formaldehyde release amount is also above E1 grade, and the flame-retardant decorative plate is safe and environment-friendly; and simultaneously, the natural texture of wood is kept and the decorative effect is good.

Owner:固安盛辉阻燃材料有限公司

Bamboo chip secondary carbonization process

ActiveCN104085028AGuarantee processing qualityConsistent colorWood treatment detailsWood charring/burningTemperature controlHigh humidity

The invention discloses a bamboo chip secondary carbonization process. The bamboo chip secondary carbonization process includes the following steps that firstly, bamboo chips obtained after slicing are placed in a carbonized oven for primary carbonization at the temperature controlled to range from 120 DEG C to 140 DEG C for 2 hours to 3 hours; secondly, after the bamboo chips obtained after primary carbonization are completely cooled, secondary carbonization is conducted, in the secondary carbonization process, the bamboo chips are carbonized at the high temperature ranging from 110 DEG C to 125 DEG C for 2 hours to 2.5 hours, and then the bamboo chips are carbonized at the temperature ranging from 130 DEG C to 135 DEG C for 1 hour to 1.5 hours. By the adoption of the secondary carbonization process, organic matter such as sugar, starch and protein in bamboo wood is decomposed in a high-temperature and high-humidity environment, fungi and other insects lose nutrient sources, eggs and fungi attached to the bamboo wood are killed, and therefore machining quality of the bamboo chips is guaranteed and the service life of products is prolonged; in addition, due to the adoption of secondary carbonization, colors of the bamboo chips with different ages and in different positions tend to be consistent, the color difference is reduced, and attractiveness of floors is improved.

Owner:贵州新锦竹木制品有限公司

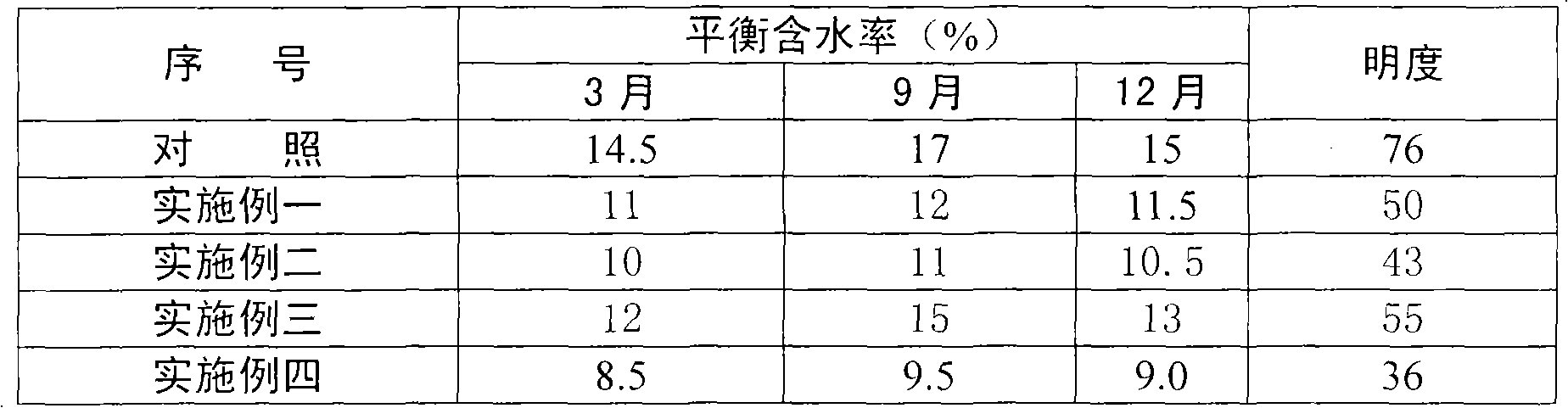

Production method for indoor integrated carbonized rubberwood

InactiveCN102581902AGood dimensional stabilityIncreased durabilityPressure impregnationWood charring/burningCarbonizationEquilibrium moisture content

The invention relates to a production method for indoor integrated carbonized rubberwood, which includes: sawing rubberwood log into specified wood, and subjecting the specified wood to termite proofing treatment, stacking, air drying and carbonizing; and subjecting the carbonized specified wood to tenoning, finger jointing, polishing, paneling and sanding to obtain the indoor integrated carbonized rubberwood. By means of combination of high-temperature carbonization and termite proofing treatment, the strength, moth and termite resistance, durability and mould proofing performance of the integrated rubberwood can be effectively improved, the integrated carbonized rubberwood has the coffee appearance, has the advantages of low variation of equilibrium moisture content, stable size, high corrosion resistance and the like, and is widely applicable to indoor furniture, floors, stair boards, decoration, fitment and the like.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

Wood-plastic profiles and manufacturing method therefor

ActiveCN101181789APromote environmental protectionReduce releaseWood treatment detailsWood veneer joiningEnvironmental resistanceVolumetric Mass Density

The invention provides a wood-plastic sectional material that is synthesized by fast-growing wood veneer, corner offal of artificial boards that take the fast-growing wood as raw material and water-soluble phenol aldehyde resin adhesive and produced through production procedures of material selection-treatment-drying-gumming-gelatin-mould pressing-solidifying-post solidify. The density of the sectional material is 900-1300kg / m<3>, the hardness is 55-120MPa, the scale length is 500-5000mm, the width is 100-1300mm, the thickness is 15-200mm, 24-hour absorbing water thickness expansion rate is 0.6-3 percent and the formaldehyde release quantity is less than 1.5MG / L. The invention enhances the utilization of the fast-growing wood and the wood-plastic sectional material produced has high density and is a high quality material with the advantages of waterproof, heatproof, oil proof, age resistant, fungus resistant, chemical mediator resistant and better security, thereby being applicable to being used for making furniture, floor, decoration material, building moulding board, structure parts, motherboard of containers, track ties, and so on. The invention can also promote the utilization of the fast-growing wood and virtuous circle of the utilization of the wood, thereby having great environmental protection value.

Owner:SHANGHAI XINGJIA NUOHUA MATERIALS TECH

Production method of carbonized wood

InactiveCN101664947AGood dimensional stabilityIncreased durabilityWood charring/burningWater contentBiomass

The invention discloses a production method of carbonized wood, relating to a production method of wood and solving the problems that the existing production of the carbonized wood has high cost due to adoption of nitrogen as protective gas, exhausts CO2 and is not environment-friendly when in burning due to adoption of coal as fuel. The method comprises the following steps: (1) the wood is stacked on a support steel beam in a carbonization treating kiln from down to up; (2) a kiln door is closed and a gas inlet and a gas outlet are opened; (3) a biomass material is ignited; (4) the temperature-rising speed is 15 to 20 DEG C / h, and intermittent steam-spraying is carried out to the wood; (5) when the temperature in the kiln rises to 180 to 230 DEG C, mixed gas of carbon dioxide and nitrogenin the kiln forms a flame-retardant oxygen-separation layer between the wood and a combustion chamber; (6) the temperature of the wood is kept for 3.5 to 4.5 hours; (7) the gas inlet and the gas outlet are opened, and the water content of the wood is 4 to 8 percent; and (8) when the temperature in the kiln is reduced to 40 to 60 DEG C, the wood is taken out, namely, a carbonized wood finished product. The production method of carbonized wood uses biomass as fuel, and does not add chemical medicament, and the produced carbonized wood has no pollution and is beneficial to environment protection.

Owner:NORTHEAST FORESTRY UNIVERSITY

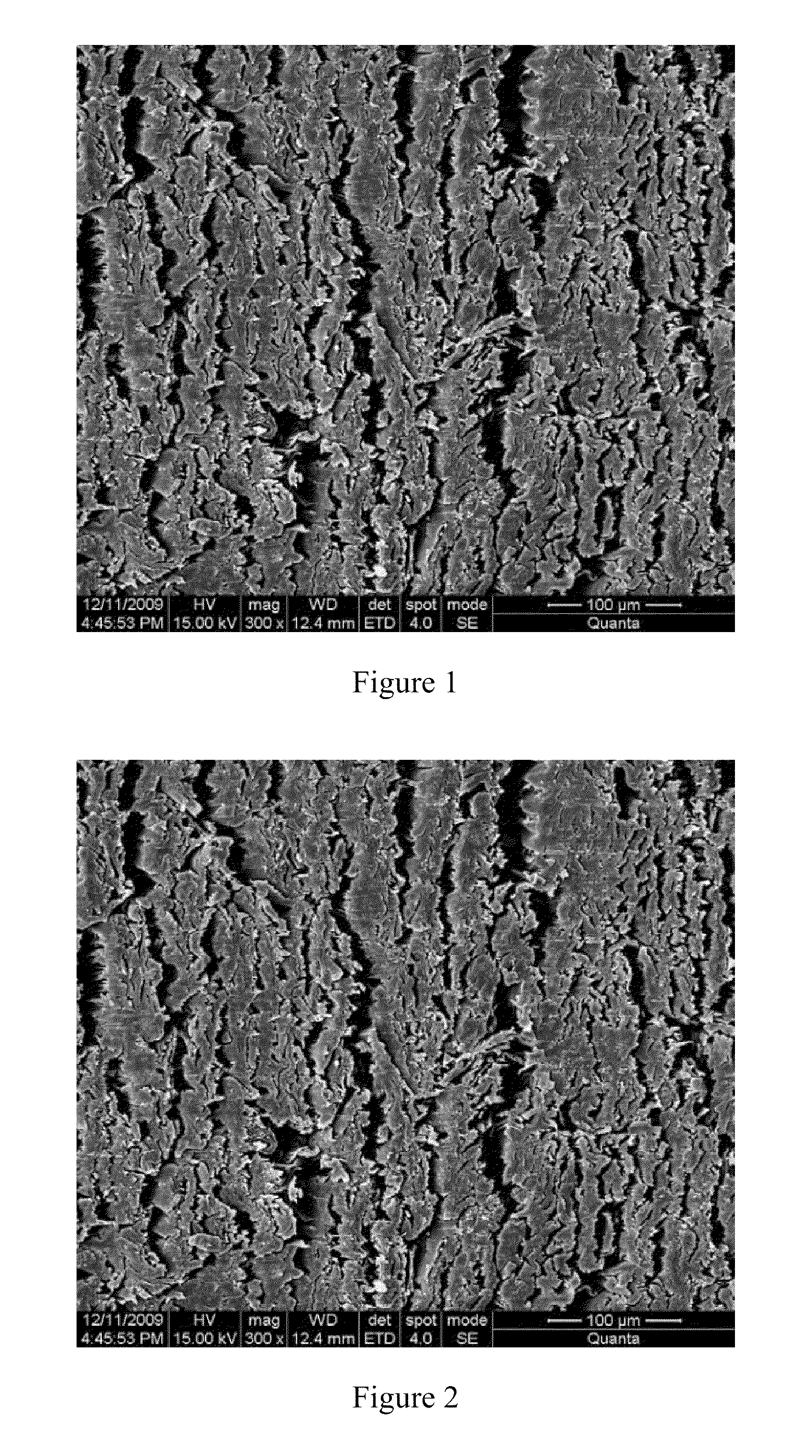

Type of wood section material and its manufacturing method

ActiveUS20110262727A1Easy to useLow densityThermal wood treatmentWood layered productsWood machiningCarbonization

The present invention relates to a type of wood section material manufacturing method, especially with respect to soft wood section material and its manufacturing method. It belongs to wood processing field. This invention is achieved by the following technical plans: a type of wood section material manufacturing method includes the following steps: (1) wood preparation; (2) drying; (3) Polishing; (4) Hot pressing, which is to use two hot pressing boards with 140-200° C. to firmly press two surfaces of panel blank material; (5) Pre-carbonization, which pre-carbonize the panel blank material under 160° C. and 200° C.; (6) Carbonization, which carbonize the panel blank material between 200° C. and 225° C.; (7) Cooling; and (8) Moisture content control. This invention is particularly suitable to make wooden floor boards and office furniture.

Owner:TU DENGYUN +1

Method for processing black bamboo

InactiveCN101234499ALow mechanical strengthNo side effectsWood treatment detailsWood charring/burningWater vaporCarbonization

The invention discloses a processing method of a black bamboo, which comprises the following processing steps: (1) the bamboo is soaked in a solution, wherein, the soaking process is carried out in a temperature of 0-100 DEG C; the volume ratio between the bamboo and the solution is (0.01-10): (2-200); after soaking for 1-7 days, the bamboo is taken out to derive soaking bamboo; (2) the soaking bamboo is carbonized in the temperature of 100-200 DEG C for 0.5-10h with hot water vapor as a medium, thus acquiring the carbonization bamboo; (3) a drying method is adopted to reduce the moisture content of the carbonization bamboo to 4-14 to derive the black bamboo. The black bamboo processed by the method has a mechanical strength less than 10 percent, takes on black, grey or dark grey and is provided with faint scent of the bamboo; furthermore, the black bamboo is also mildewproof, free from brightness reversion in 10 years and toxic and side effects, which is an ideal material of black bamboo products. The processing method of black bamboo has the advantages of simple process, good controllability, low cost, no expensive equipment and industrialization facilitating, thereby having a broad application prospect.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

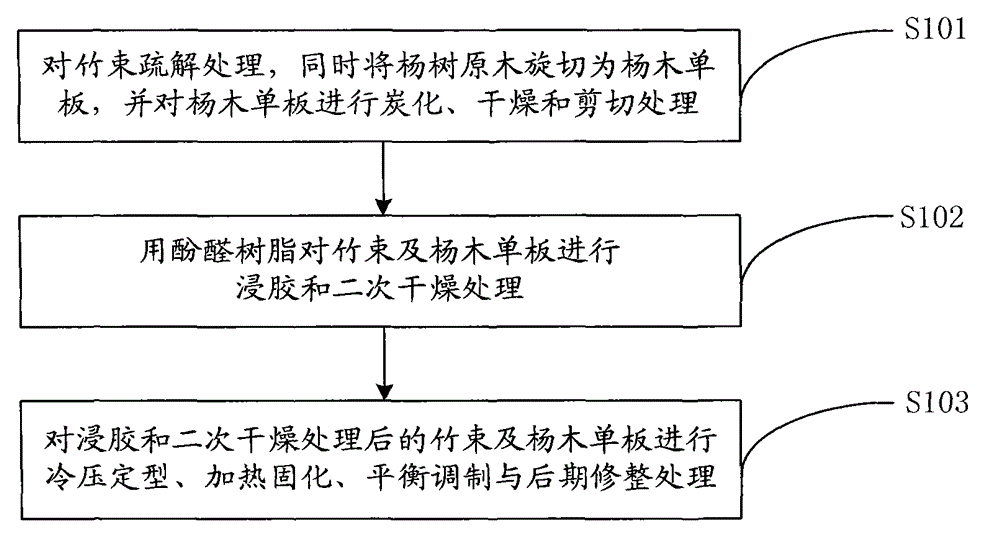

Method for manufacturing recombined bamboo decorative material

InactiveCN102941612AGood dimensional stabilityHigh transverse bonding strengthWood dampingFlat articlesVolumetric Mass DensityLow density

The invention discloses a method for manufacturing recombined bamboo decorative material, firstly bamboo beams are processed by a defibering treatment, a poplar log is rotary-cut into veneers, poplar veneers are carbonized, dried and sheared, then the bamboo beams and the poplar veneers are dipped with phenolic resin and are processed by second drying treatment, and finally the treatments of cold-pressing, heat curing, balanced modulation and post trimming are carried out, a novel recombined bamboo decorative material with stripe decorative effect, lower density, good dimensional stability and high horizontal bonding strength can be manufactured, during the manufacturing process of the recombined bamboo decorative material, the carbonized poplar veneer strips and the original bamboo beams are evenly mixed, the recombined bamboo decorative material manufactured with the method can be widely applied in the manufacture of floors, interior and exterior decoration materials and engineering structural materials, is practical, and is high in promotion and application value.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com