Production method for indoor integrated carbonized rubberwood

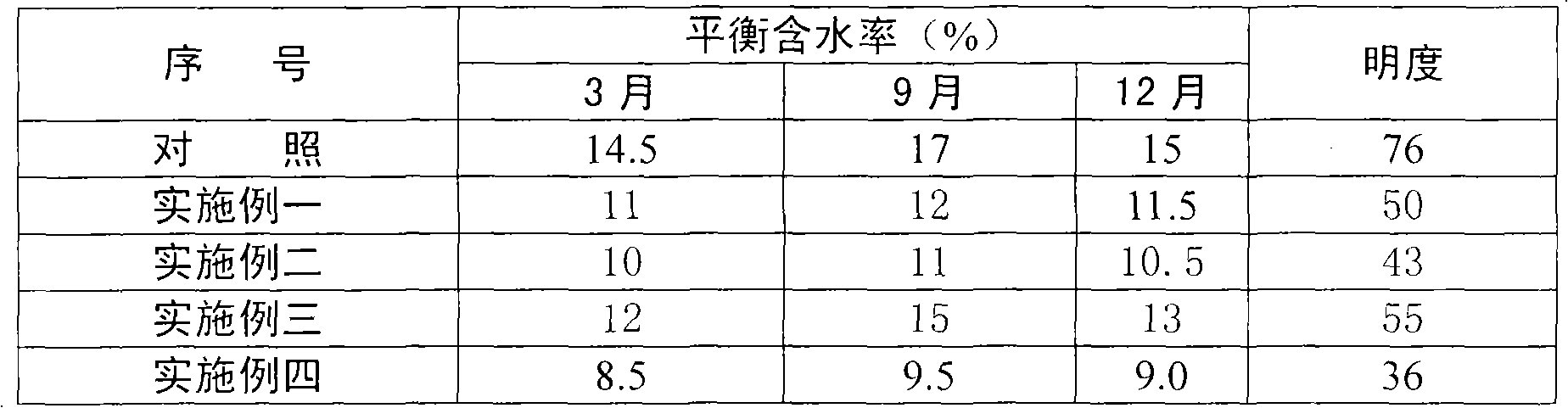

A production method and technology of rubber wood, applied in impregnated wood, wood impregnation, wood processing equipment, etc., can solve the problems of no improvement in termite prevention performance, vulnerability to termite erosion, termite hidden dangers, etc., achieve dimensional stability and improve dimensional stability , the effect of small changes in equilibrium moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. The small rubber wood logs with a diameter of 6cm or more are sawn into specifications with multiple saws. The thickness specifications are 2.5cm, the width is 7.5cm, 6.5cm, 5.5cm, 4.5cm, and the length is more than 30cm;

[0024] 2. Put the rubber wood specification material stack into a vacuum treatment tank, and use 2.5% sodium octaborate aqueous solution as the treatment liquid for vacuum pressure infusion (for insect and termite treatment);

[0025] 3. The stacks of rubber wood specifications are air-dried and dried to a moisture content of 12% in a conventional manner, then discharged from the kiln;

[0026] 4. Put the specification material into the carbonization processing equipment, first quickly raise the temperature to 100°C, dry at high temperature for 3 hours, then raise the temperature to 130°C within 6 hours and dry for 2 hours, and then heat up to 185°C in 6 hours, and pass the steam intermittently during the carbonization process , Keep the wet bulb tempera...

Embodiment 2

[0029] 1. The small logs of rubber wood with a diameter of more than 6cm are sawn into specifications with multiple saws. The thickness specifications are 1.8cm, the width is 7.5cm, 6.5cm, 5.5cm, 4.5cm, and the length is more than 30cm;

[0030] 2. Put the rubber wood specification material stack into a vacuum treatment tank, and use 1.5% boric acid and 2.0% sodium tetraborate aqueous solution as the treatment liquid to vacuum and pressurize and impregnate it to prevent insects and termites;

[0031] 3. The stacks of rubber wood specifications are air-dried, and dried to 15% moisture content in a conventional manner, and then discharged from the kiln;

[0032] 4. Put the specification material into the carbonization treatment equipment, first quickly raise the temperature to 100°C, dry at a high temperature for 2 hours, then heat up to 130°C within 5 hours and dry for 1.5 hours, then heat up to 200°C within 7 hours and carbonize for 1 hour, stop heating , And then continue to pass in...

Embodiment 3

[0036] The carbonization temperature is 170°C, the length of the tenon is 12cm, and the other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com