Patents

Literature

3299 results about "Vacuum pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vacuum pressure is measured relative to ambient atmospheric pressure. It is referred to as pounds per square inch (vacuum) or PSIV. The electrical output of a vacuum pressure transducer is 0 VDC at 0 PSIV (14.7 PSIA) and full scale output (typically 5 VDC) at full scale vacuum, 14.7 (0 PSIA).

Method for sterilizing medical appliance

InactiveCN1634601AAvoid influenceImprove sterilization effectDiagnosticsSurgeryVacuum pressureMicrowave

A medical instrument sterilization method is disclosed, which characterizes in following process: pending medical instrument for sterilization treatment being placed in a closed container, then being vacuum pumped, the vacuum pressure of the container being controlled between 1 Pa to 1500 Pa, air and / or oxygen and / or inert gases are charged to closed container and the vacuum pressure being between 1 Pa to 1500 Pa, microwave is fed, the favorable power of which should make the gas charged into the container to generate ionization, the microwave be cut after the sterilization, then air being charged to release vacuum to finish the whole process.

Owner:吉林省中立实业有限公司

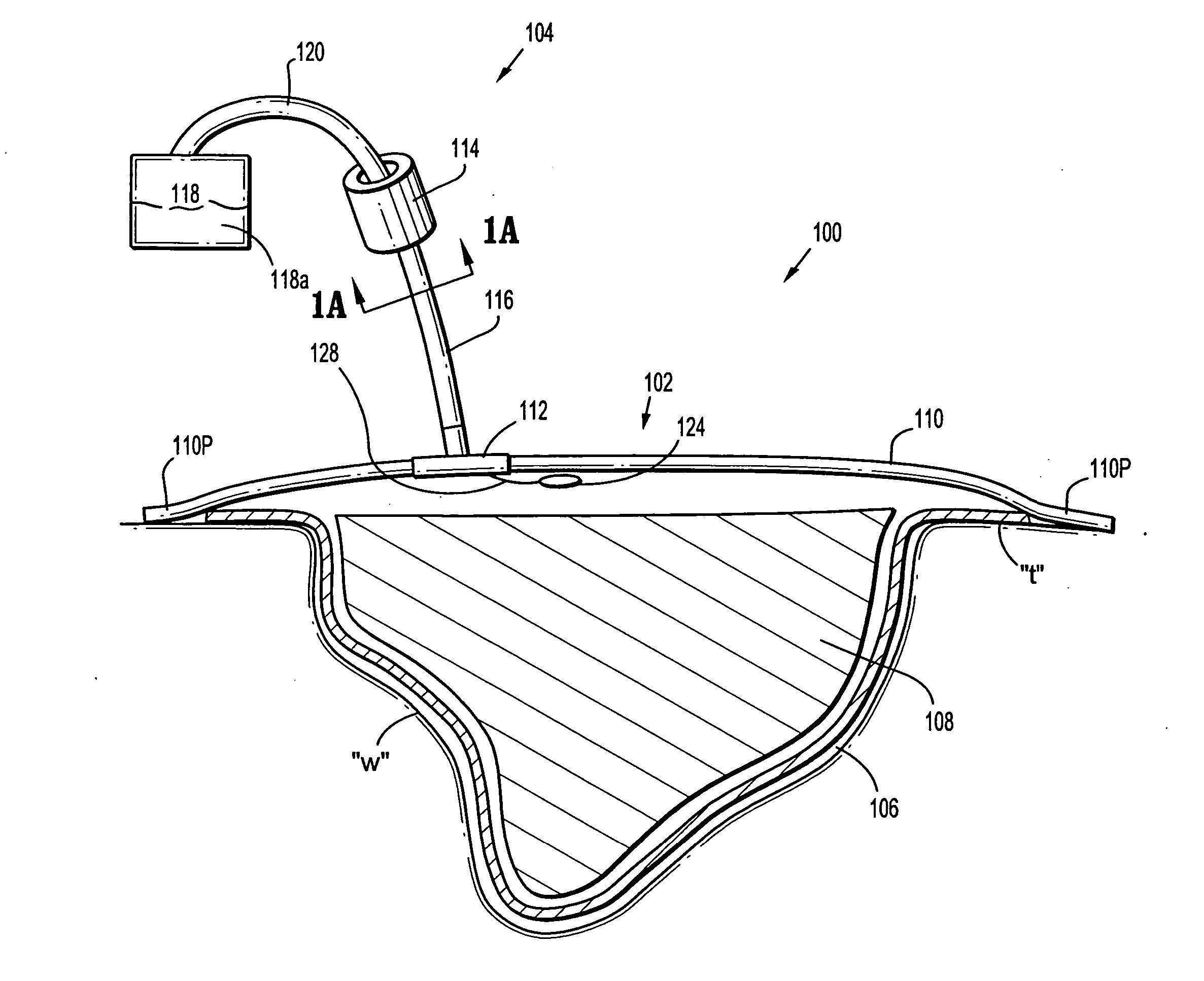

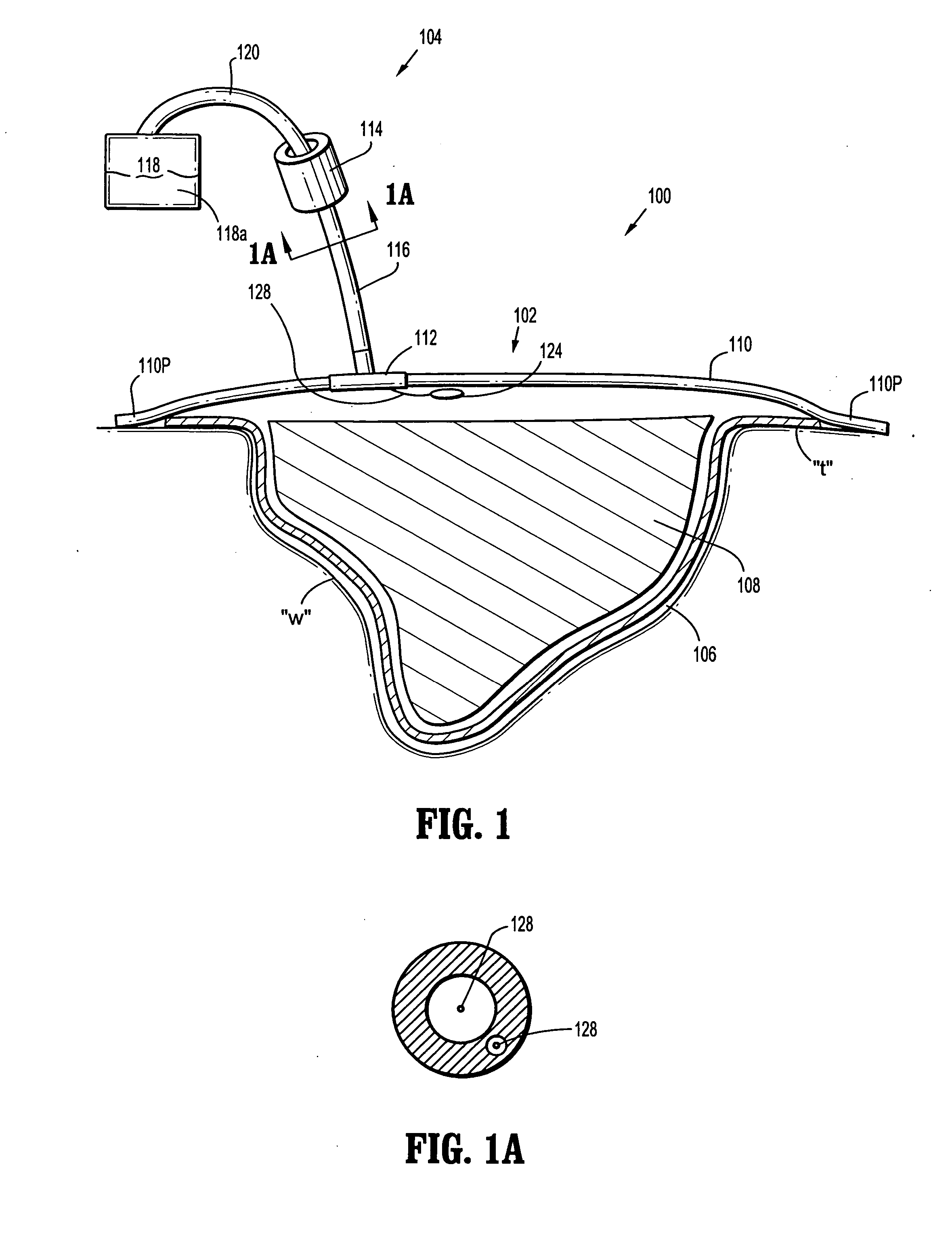

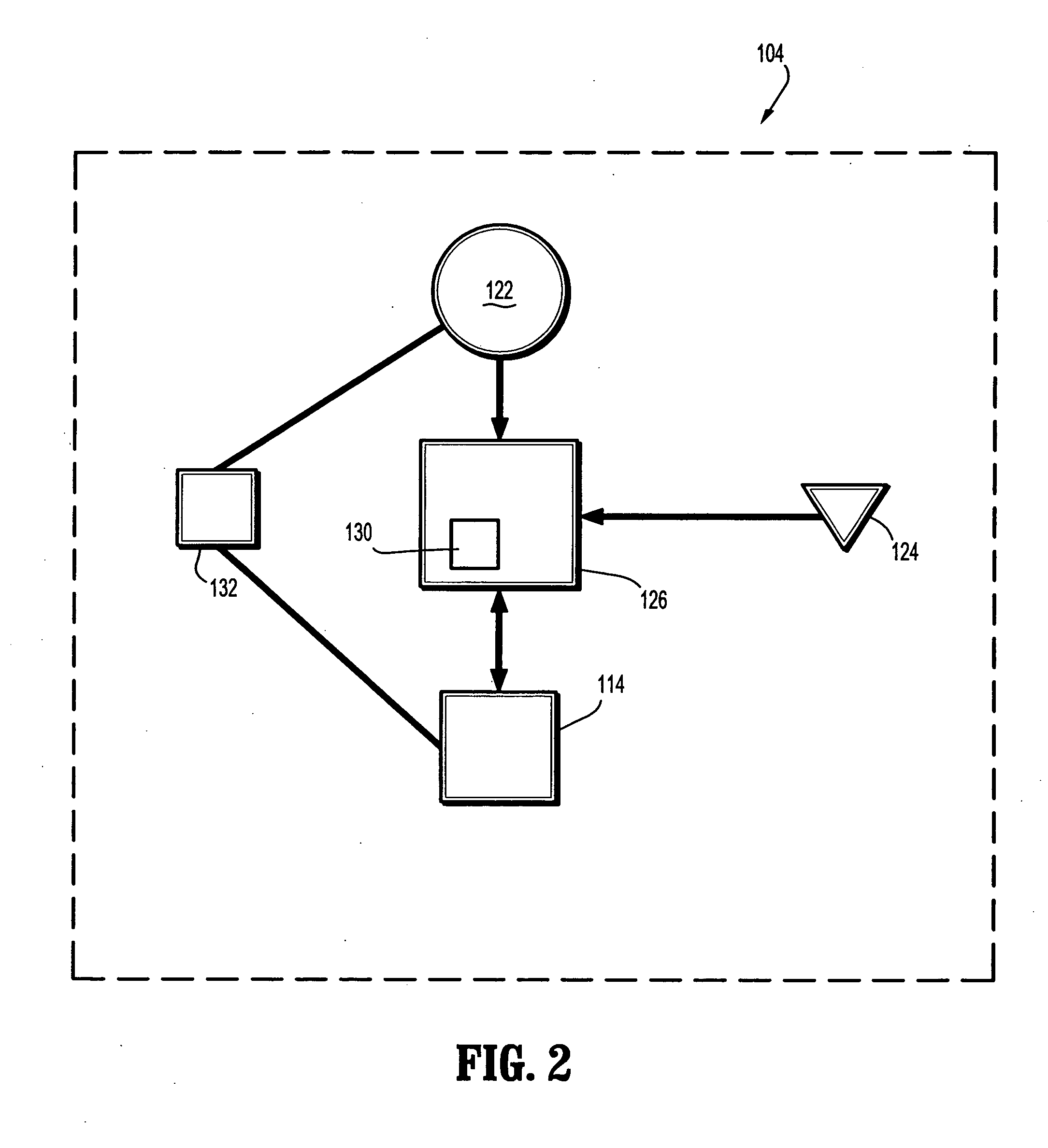

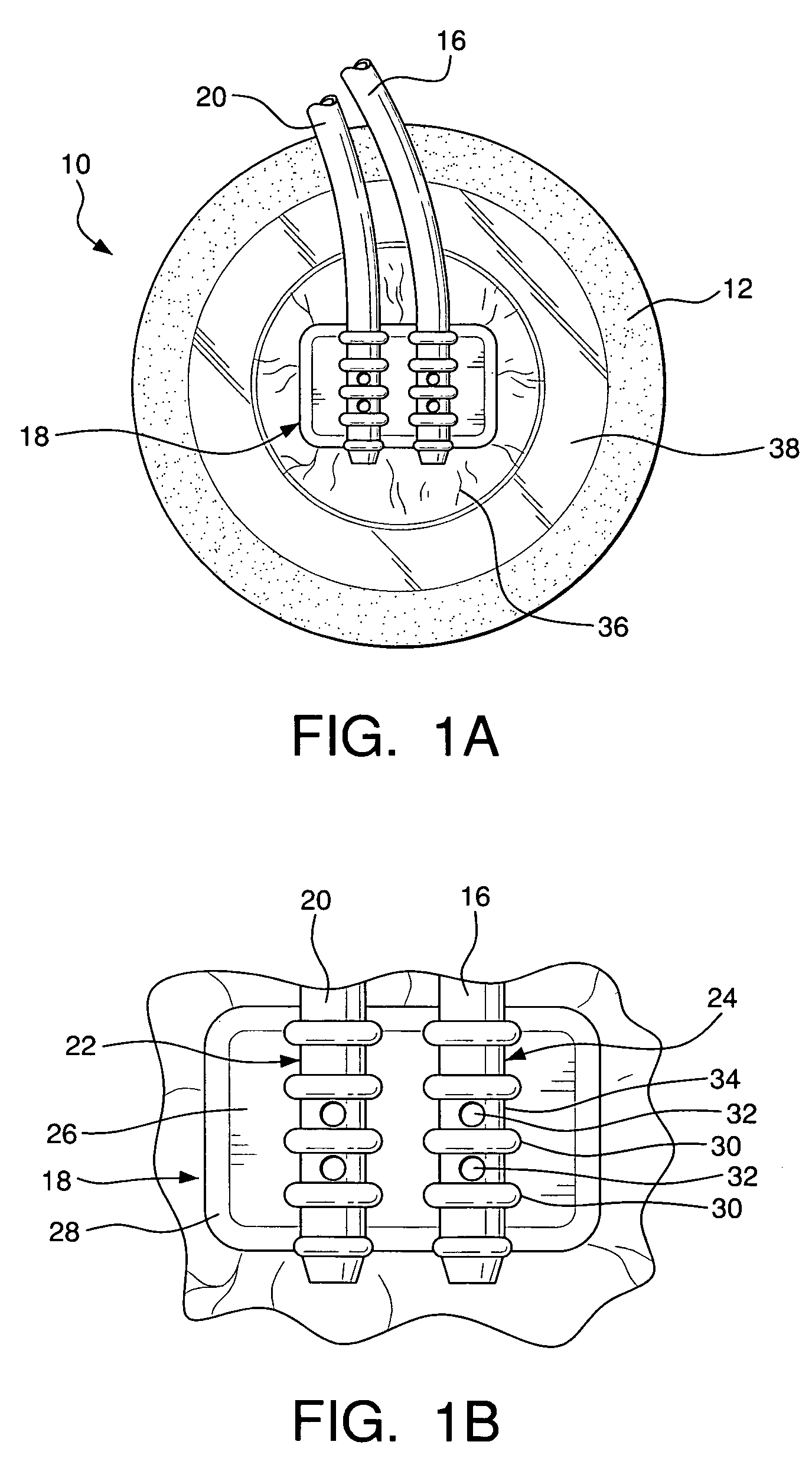

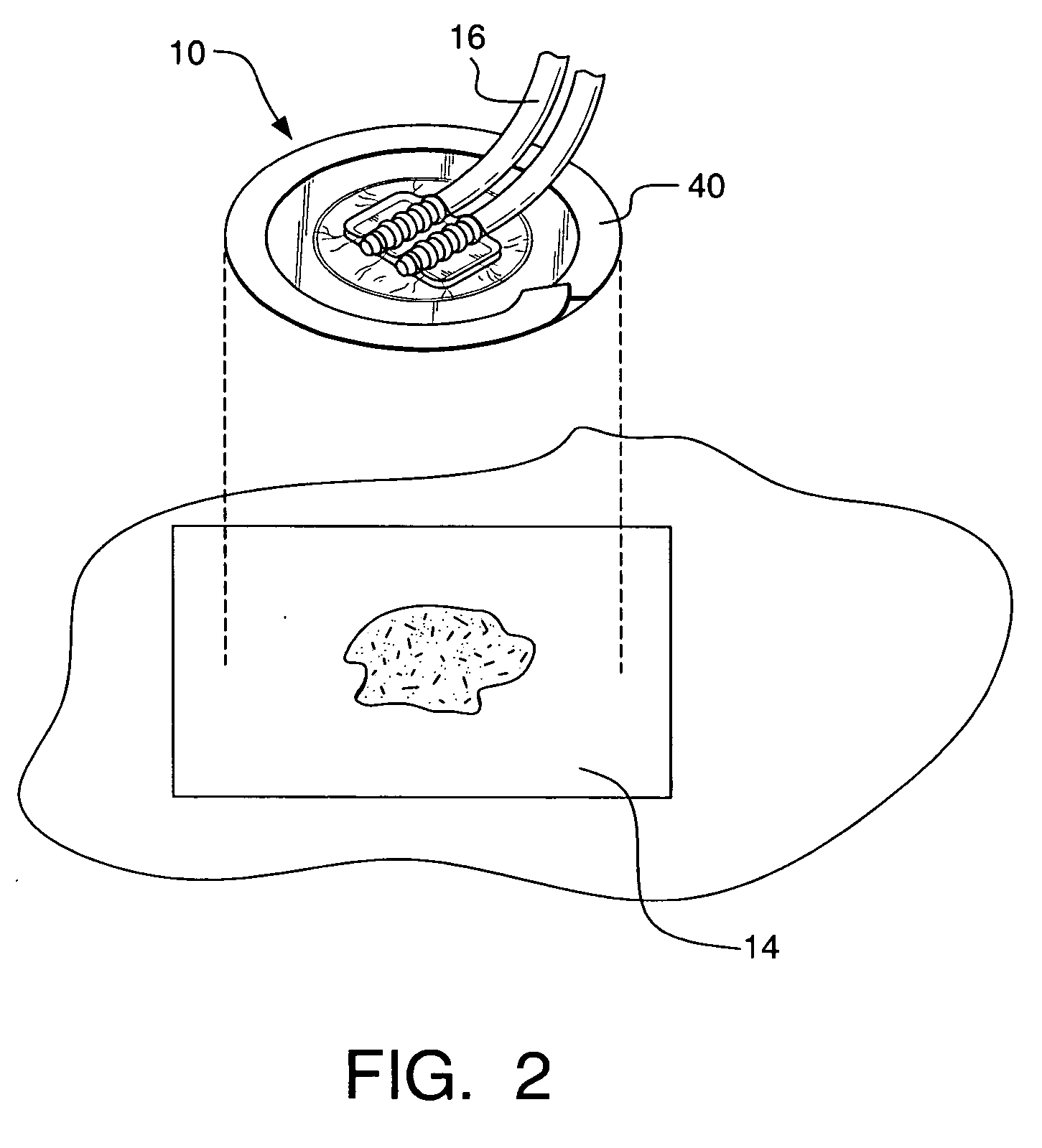

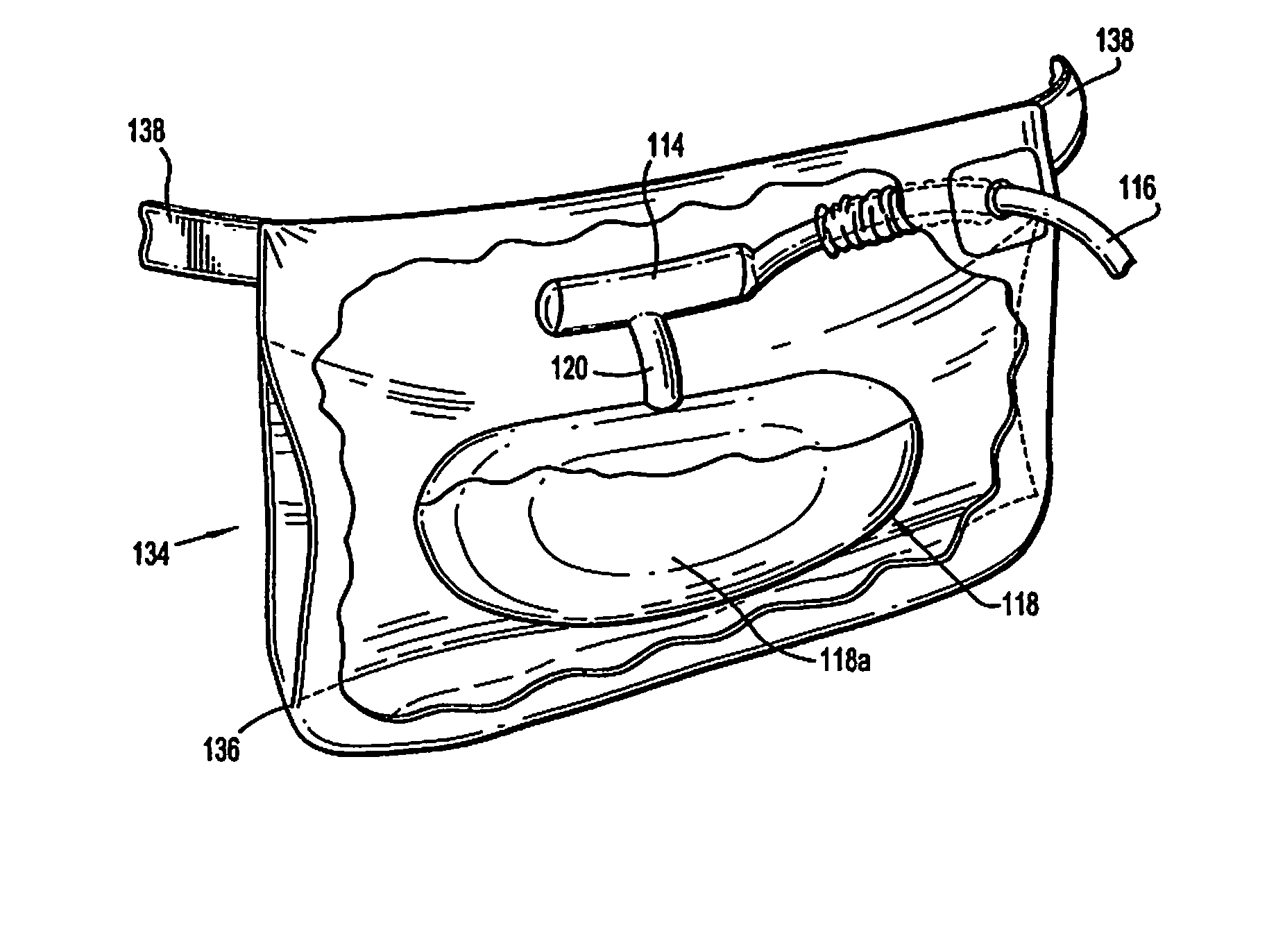

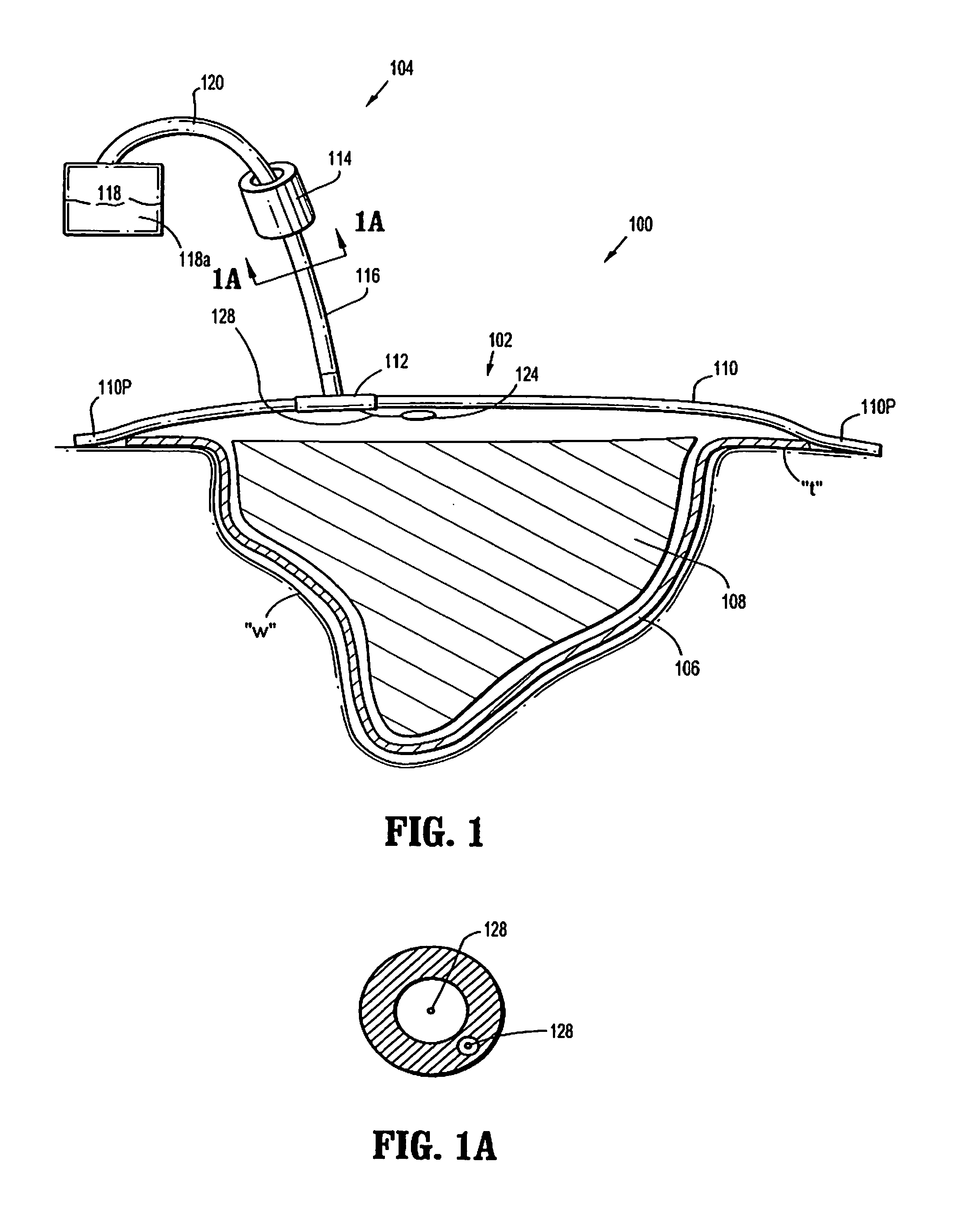

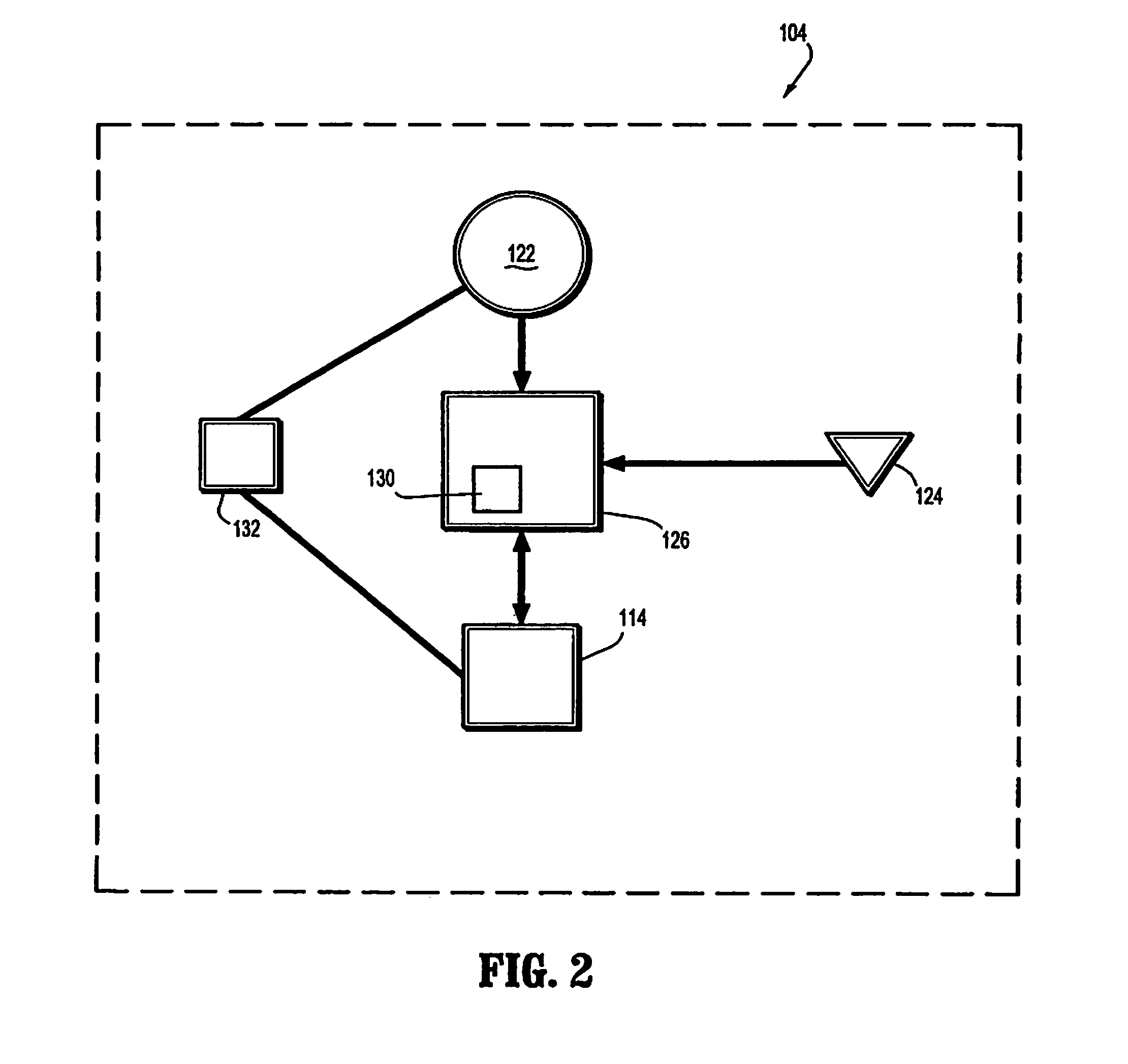

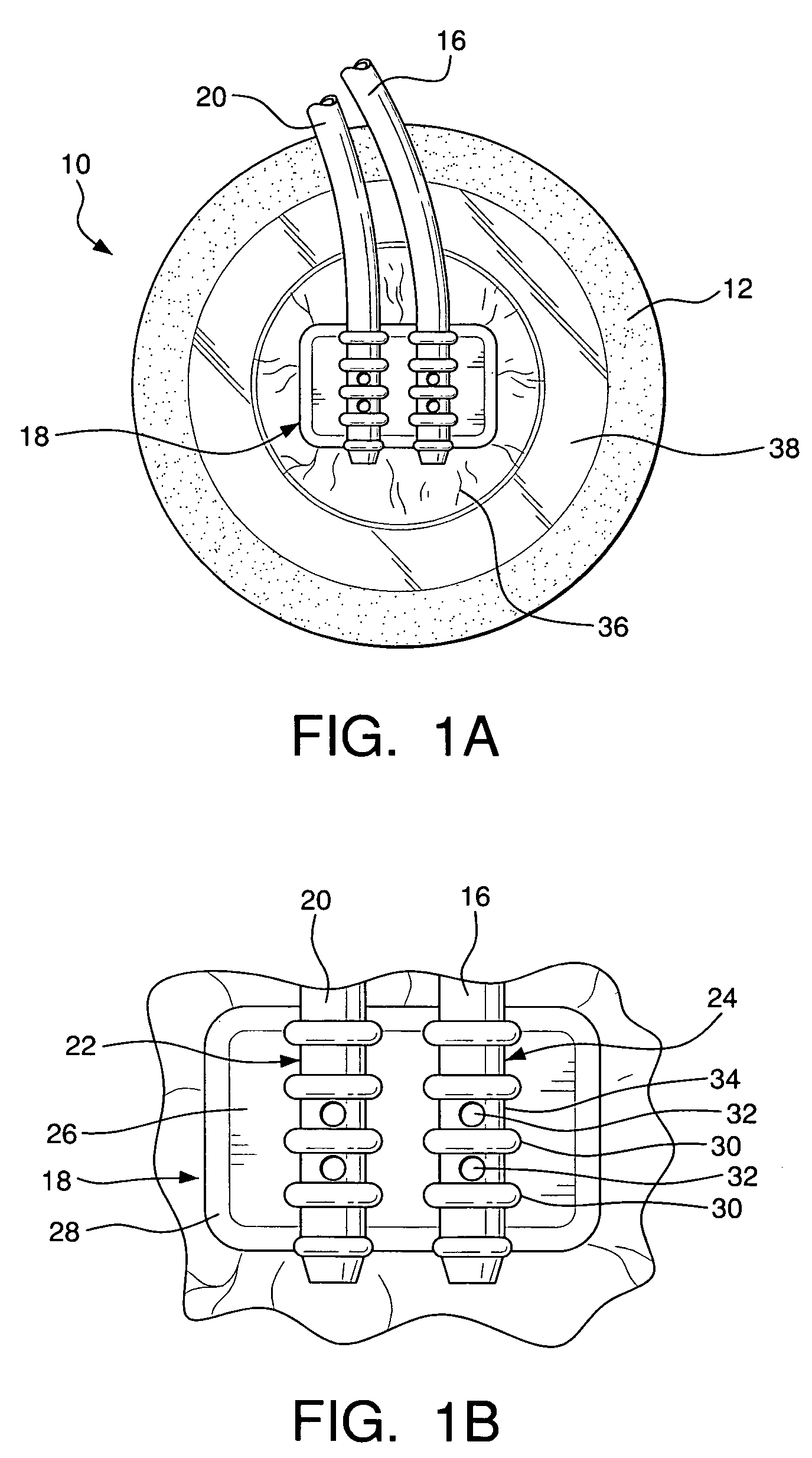

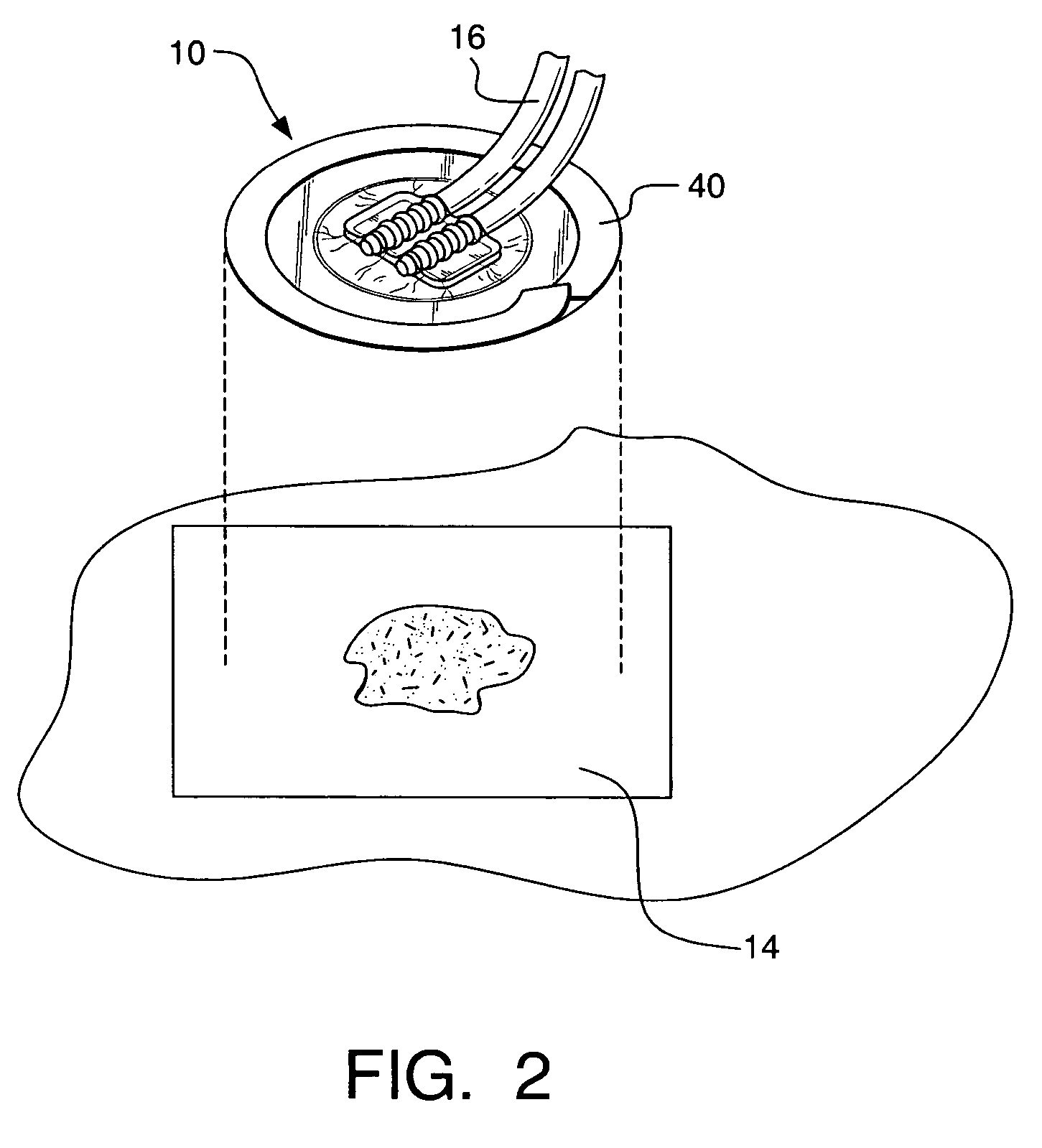

Self contained wound dressing apparatus

InactiveUS20070055209A1Easy to disassemblePromote healingAntibacterial agentsSurgical needlesPeristaltic pumpVacuum pressure

The composite wound dressing apparatus promotes healing of a wound via the use of an external peristaltic vacuum pump. The external peristaltic pump applies a vacuum pressure to the wound to effectively draw wound fluid or exudate away from the wound bed. The external peristaltic pump is tethered to the wound dressing and is portable, preferably, carried by the patient in a support bag, which permits patient mobility. Moreover, the patient does not need to be constrained for any period of time while exudate is being removed from the wound.

Owner:TYCO HEALTHCARE GRP LP

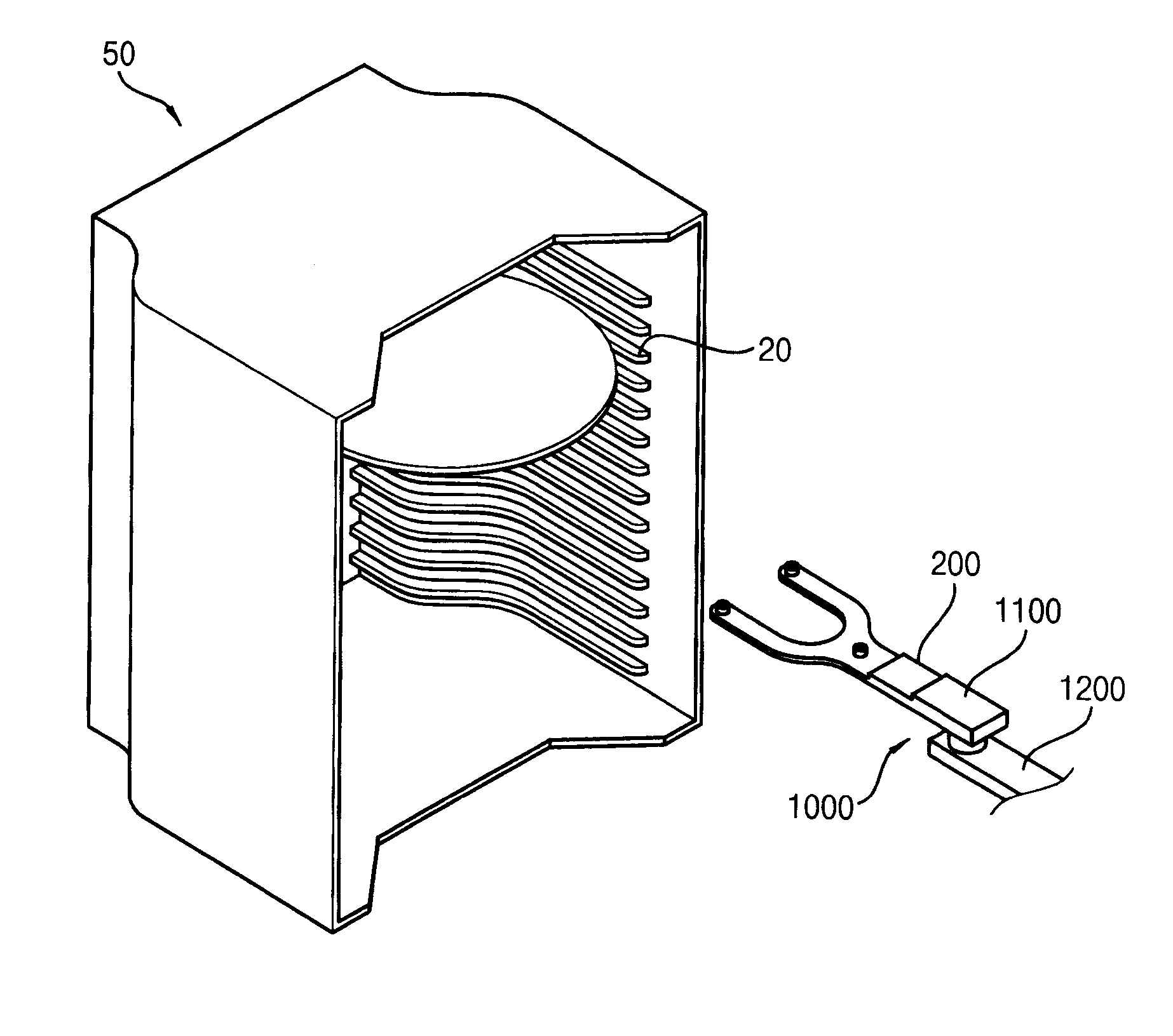

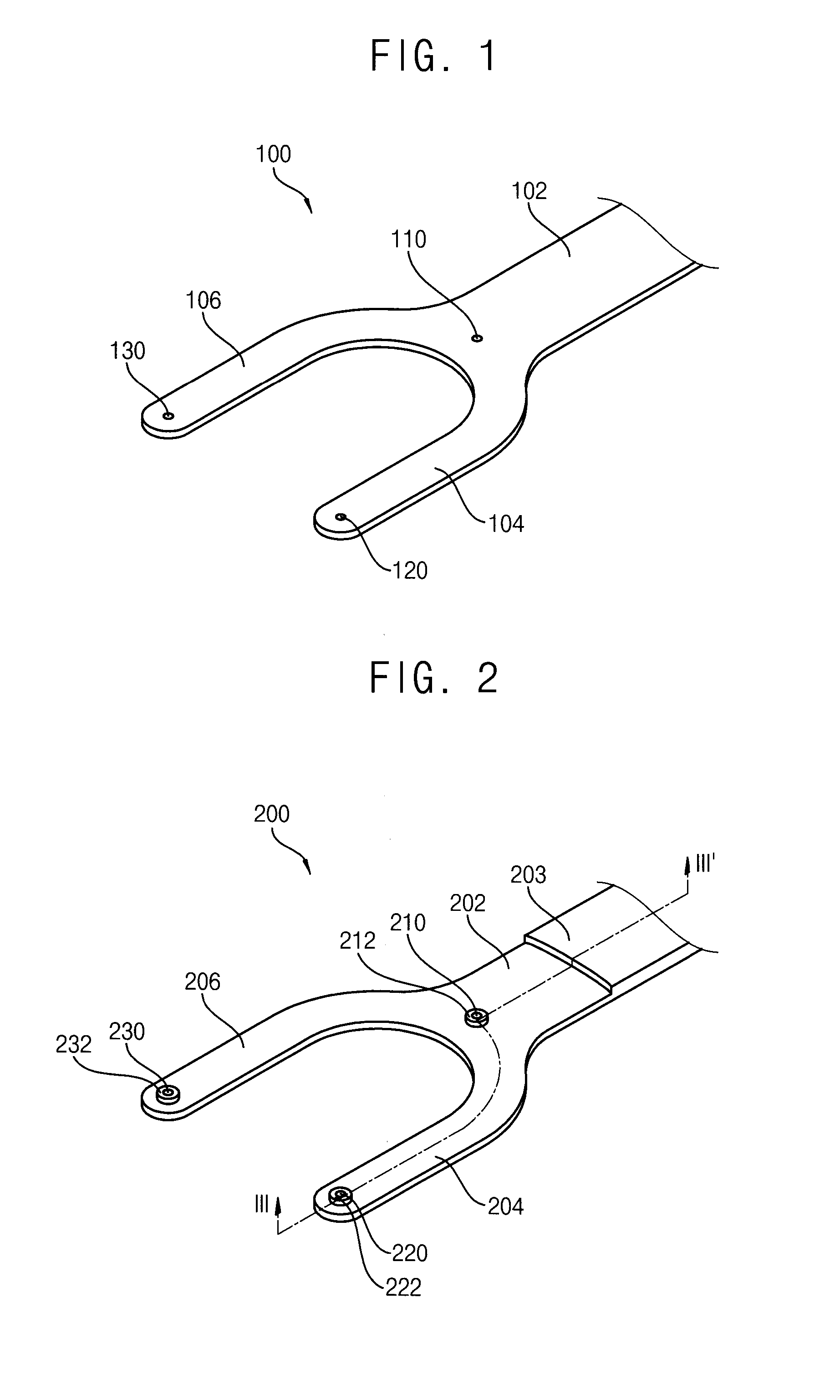

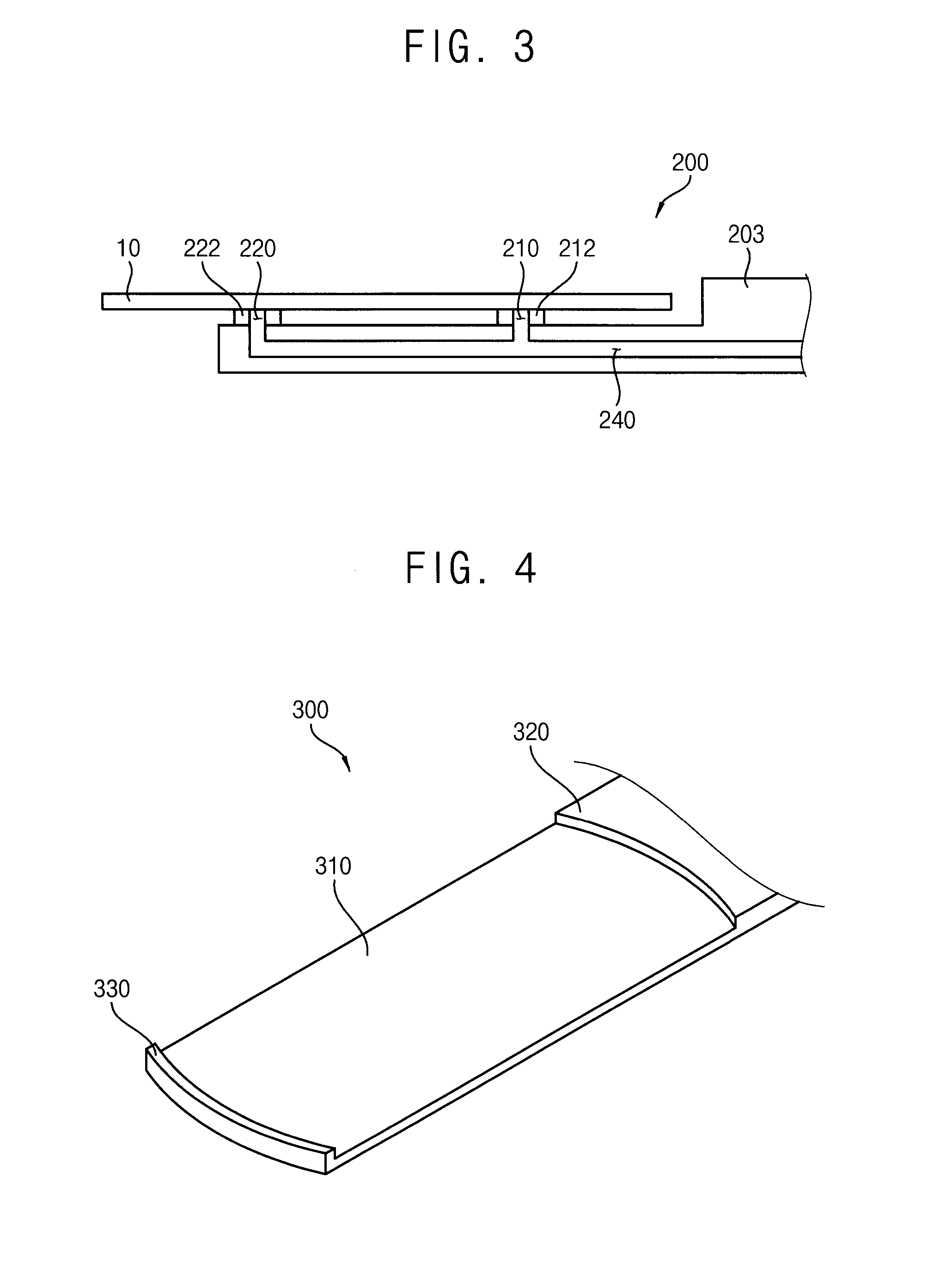

Wafer transfer blade and wafer transfer apparatus having the same

InactiveUS20140227072A1Damage is prevented and mitigatedDamage can be prevented and mitigatedGripping headsSemiconductor/solid-state device manufacturingVacuum pressureEngineering

A wafer transfer blade including a body including metal oxide and configured to support a wafer, and an adsorbing part on the body, the adsorbing part having at least one therein and configured to apply vacuum pressure to attach the wafer on the body may be provided. The body may include metal oxide to prevent static electricity.

Owner:SAMSUNG ELECTRONICS CO LTD

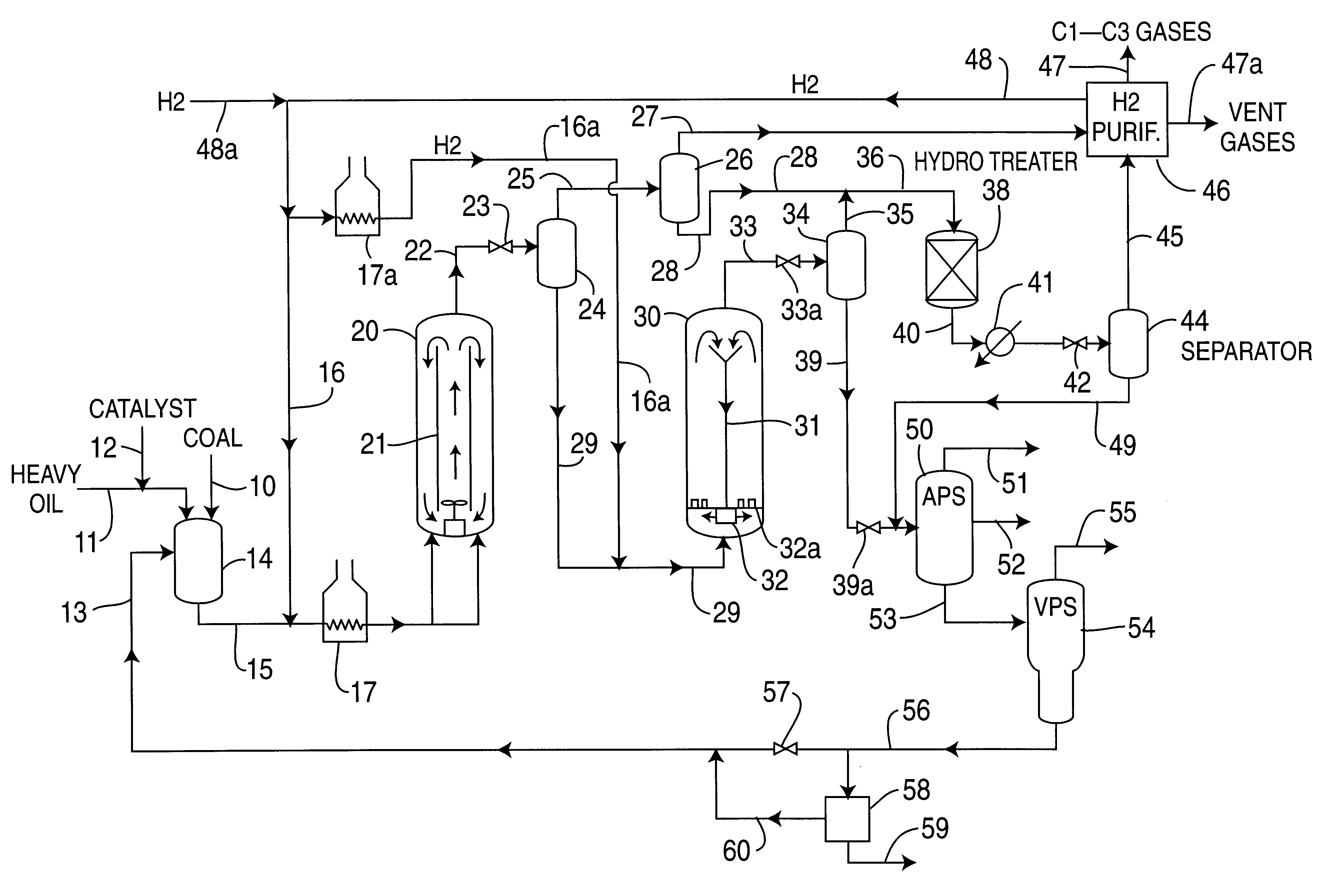

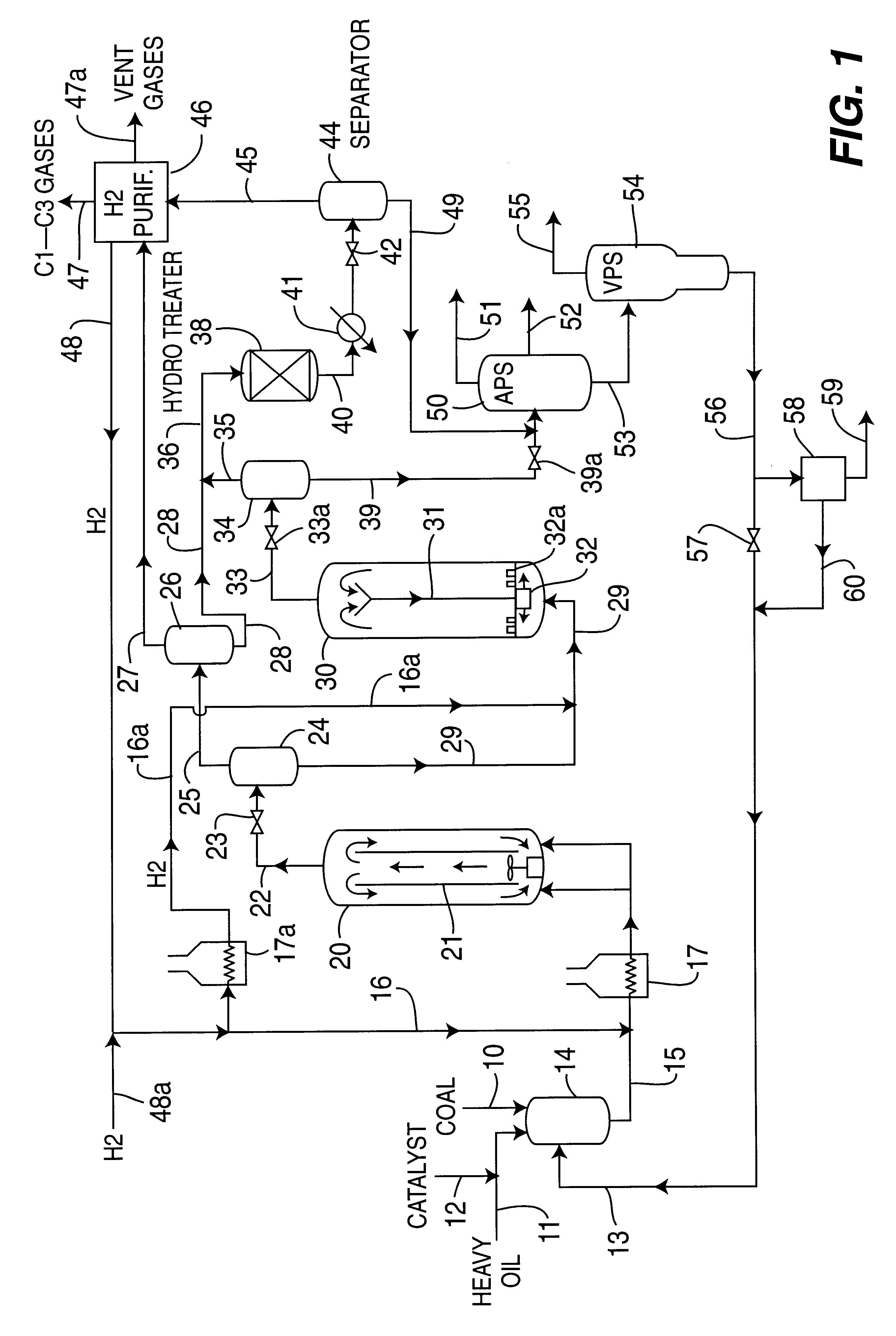

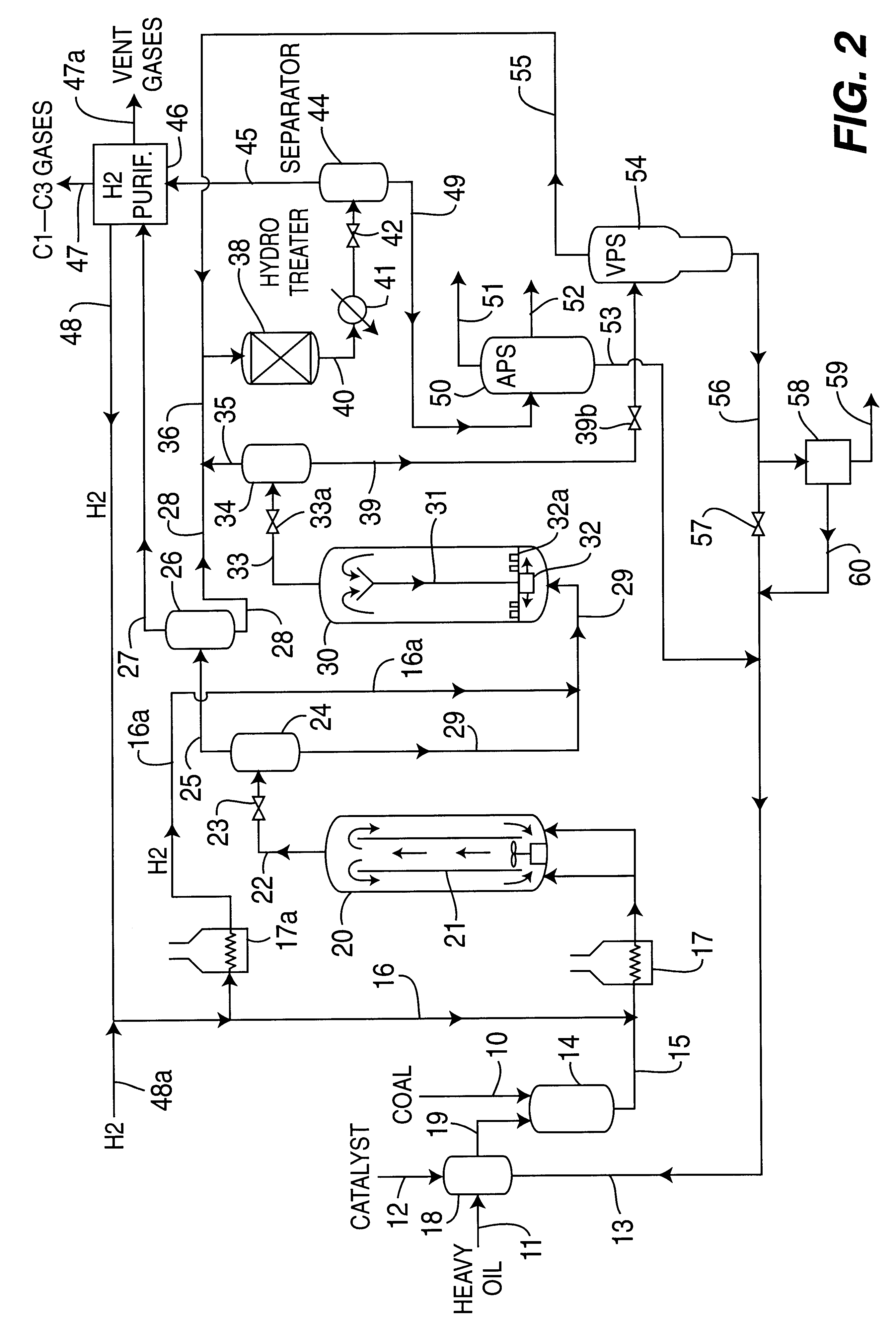

Catalytic multi-stage process for hydroconversion and refining hydrocarbon feeds

InactiveUS6190542B1Improve distillation yieldQuality improvementCatalyst activation/preparationLiquid hydrocarbon mixture productionLiquid productDistillates petroleum

A multi-stage catalytic hydrogenation and hydroconversion process for heavy hydrocarbon feed materials such as coal, heavy petroleum fractions, and plastic waste materials. In the process, the feedstock is reacted in a first-stage, back-mixed catalytic reactor with a highly dispersed iron-based catalyst having a powder, gel or liquid form. The reactor effluent is pressure-reduced, vapors and light distillate fractions are removed overhead, and the heavier liquid fraction is fed to a second stage back-mixed catalytic reactor. The first and second stage catalytic reactors are operated at 700-850.degree. F. temperature, 1000-3500 psig hydrogen partial pressure and 20-80 lb. / hr per ft.sup.3 reactor space velocity. The vapor and light distillates liquid fractions removed from both the first and second stage reactor effluent streams are combined and passed to an in-line, fixed-bed catalytic hydrotreater for heteroatom removal and for producing high quality naphtha and mid-distillate or a full-range distillate product. The remaining separator bottoms liquid fractions are distilled at successive atmospheric and vacuum pressures, low and intermediate-boiling hydrocarbon liquid products are withdrawn, and heavier distillate fractions are recycled and further upgraded to provide additional low-boiling hydrocarbon liquid products. This catalytic multistage hydrogenation process provides improved flexibility for hydroprocessing the various carbonaceous feedstocks and adjusting to desired product structures and for improved economy of operations.

Owner:HEADWATERS CTL

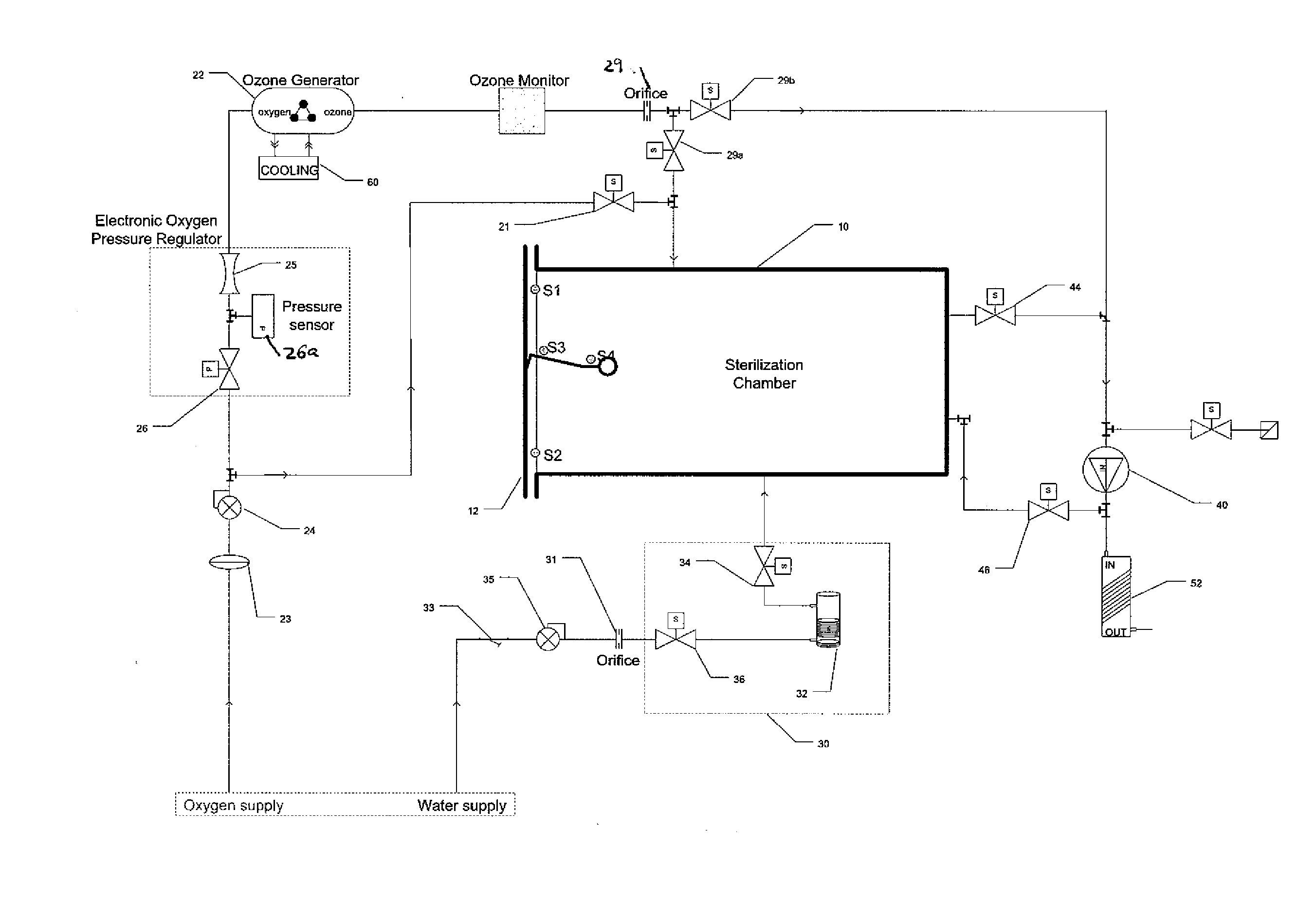

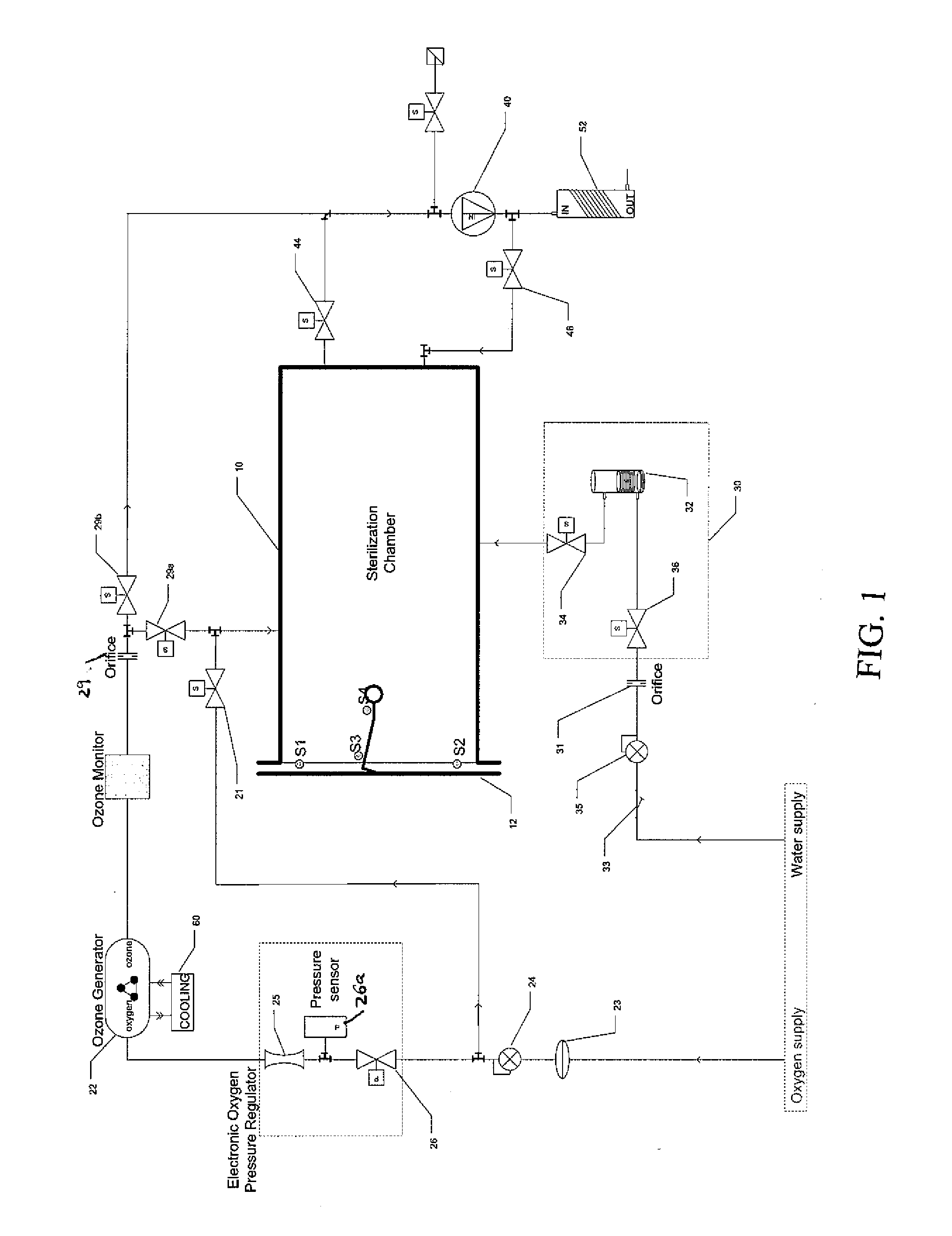

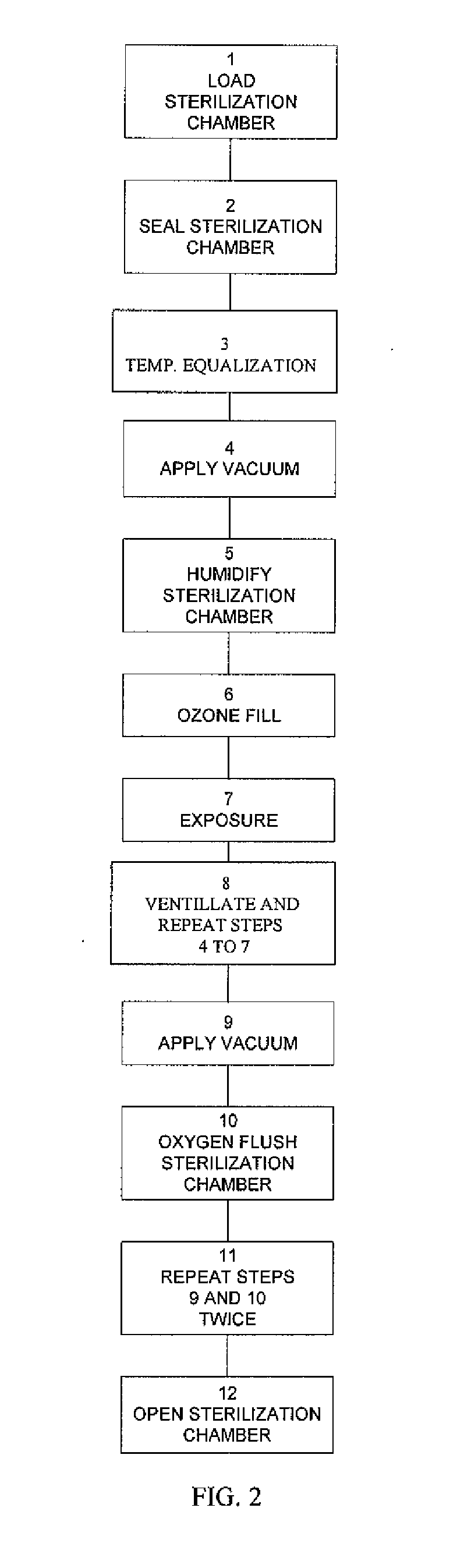

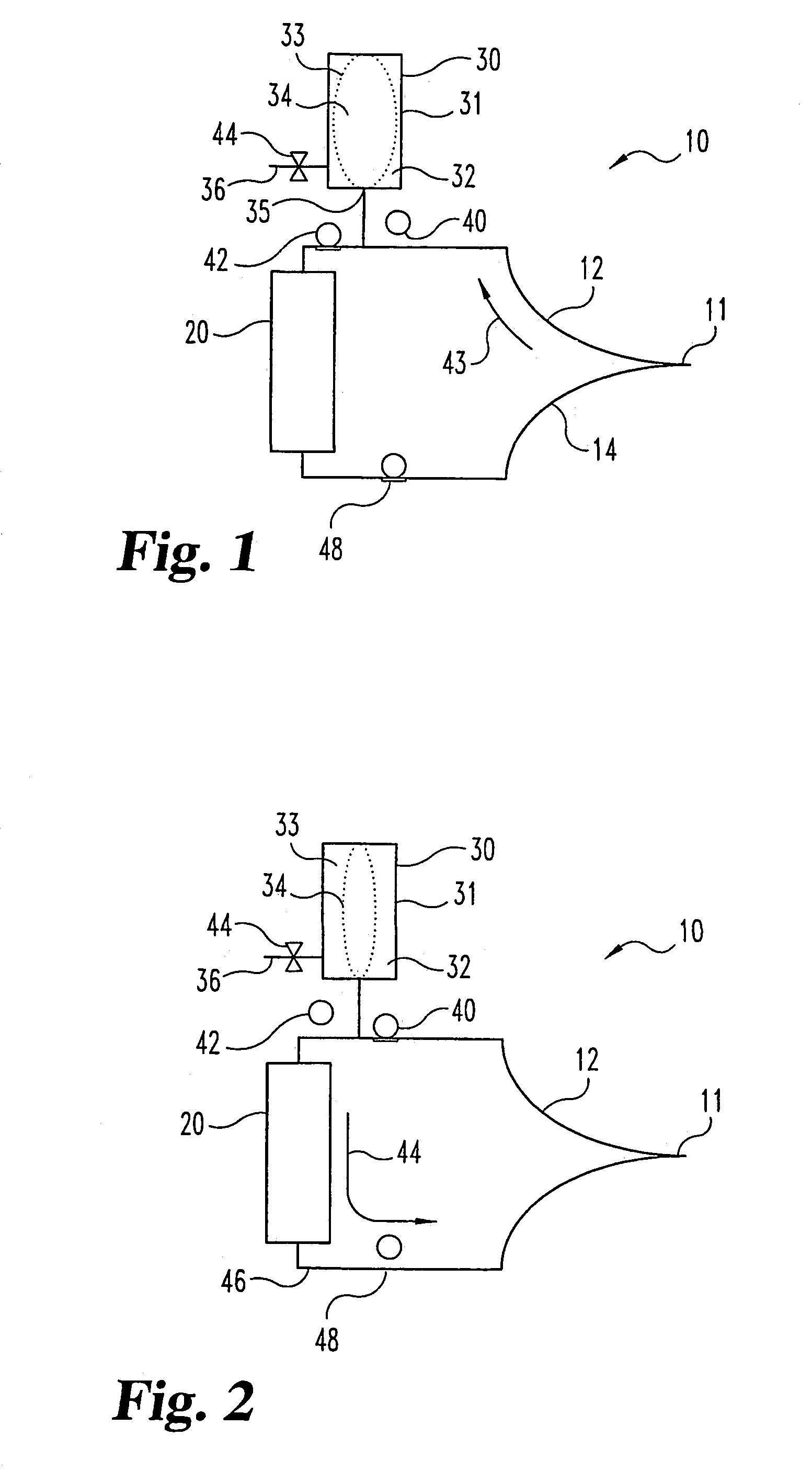

Method and apparatus for ozone sterilization

InactiveUS20070258855A1Avoid condensationPrevent water condensationElectrolysis componentsExhaust apparatusVacuum pressureWater vapor

The present invention provides a method and apparatus for sterilizing articles using an ozone-containing gas, where condensation of water from the sterilization atmosphere during the sterilization process is substantially prevented. The inventive sterilization method includes providing a sterilization chamber and placing an article into the sterilization chamber. The sterilization chamber is sealed prior to equalizing the temperature of the article and the atmosphere in the sterilization chamber. A vacuum is applied to achieve a preselected vacuum pressure in the sterilization chamber. Once the vacuum pressure is set, water vapour is supplied to the sterilization chamber. Ozone-containing gas is then supplied to the sterilization chamber and the sterilization chamber remains sealed for a preselected treatment period, where the sterilization chamber remains sealed throughout the whole process. Finally, vacuum in the sterilization chamber is released.

Owner:STRYKER CORP

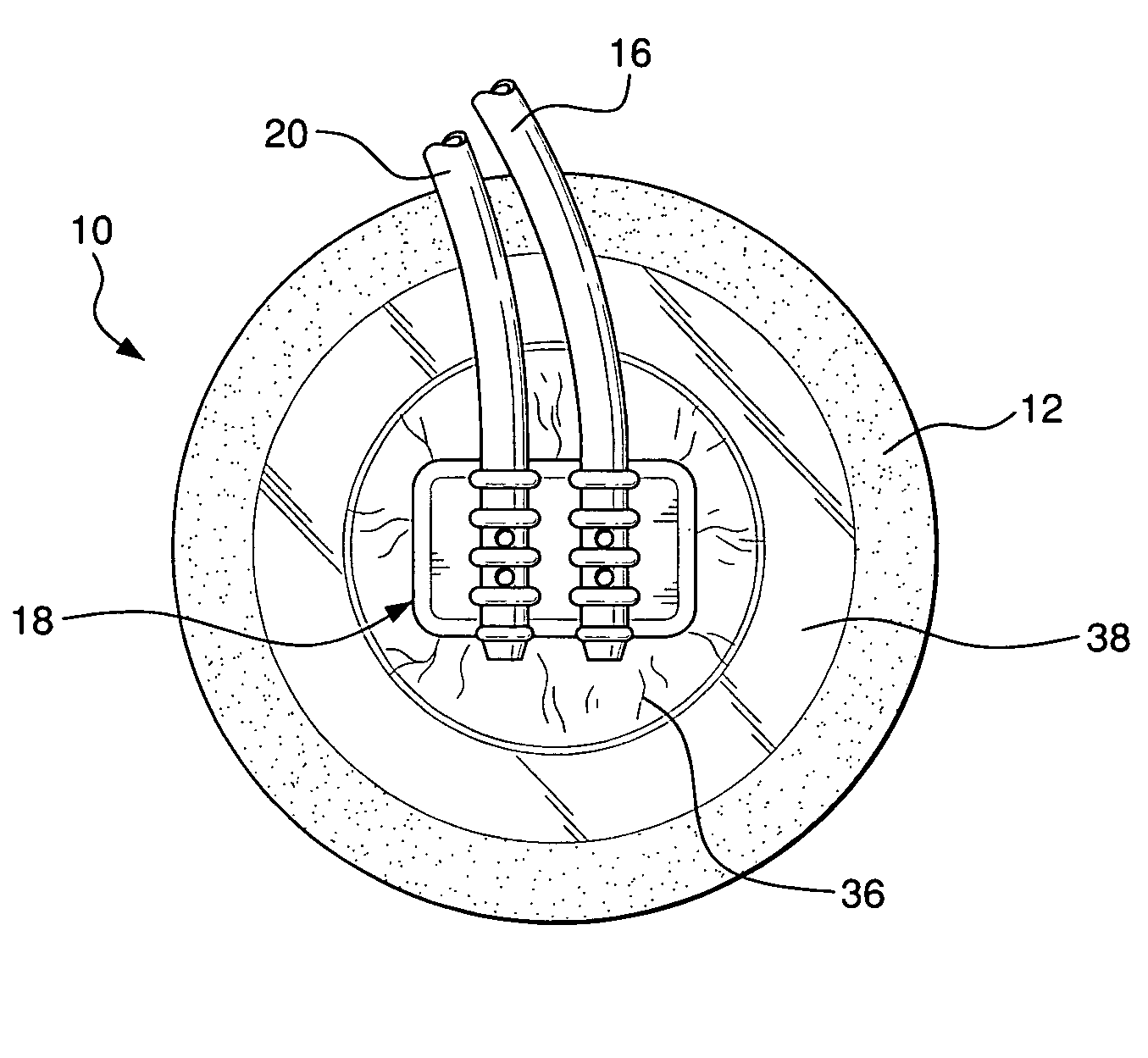

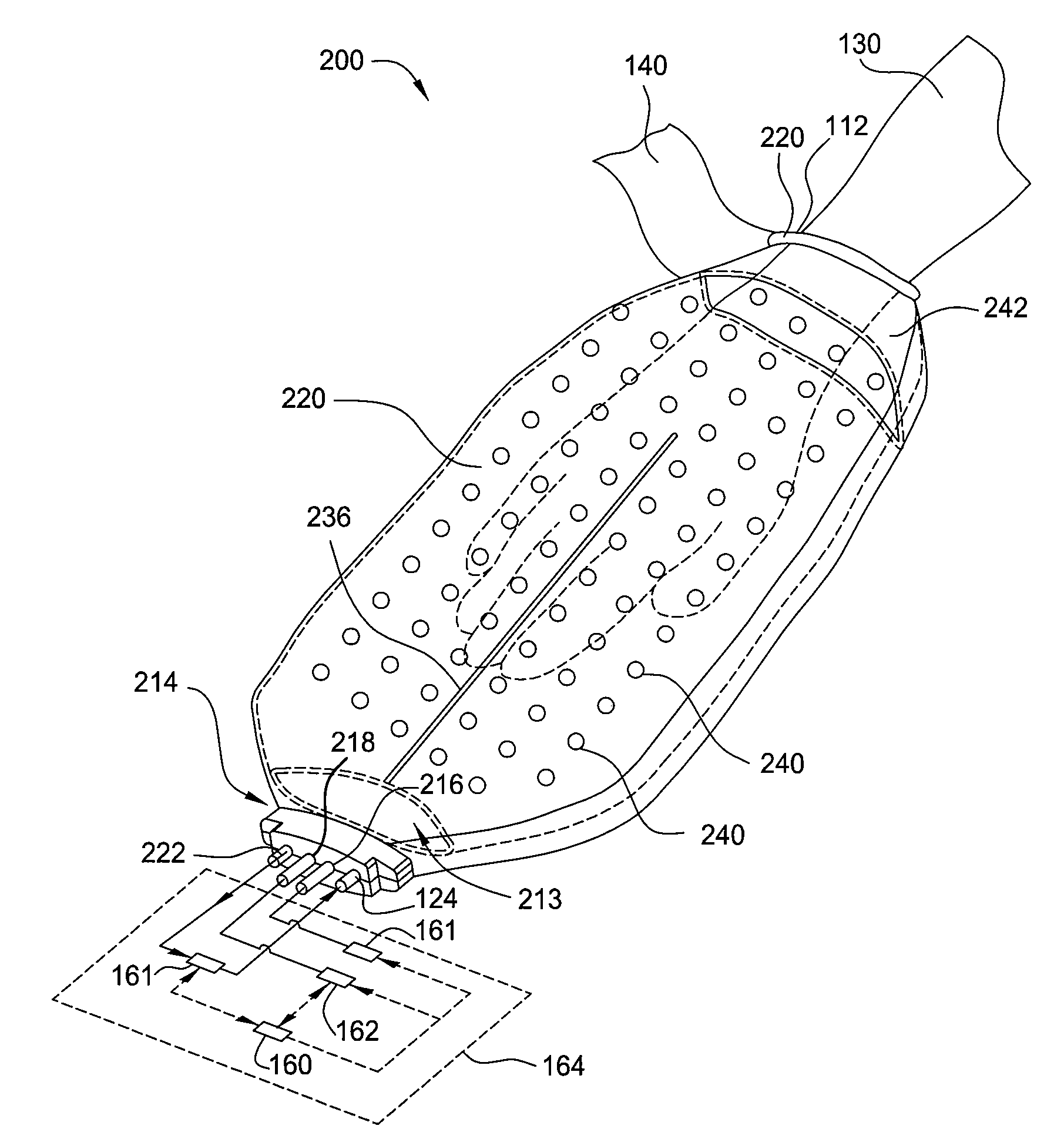

Wound healing device

ActiveUS20080275409A1Promote growthPromote woundWound drainsVaccination/ovulation diagnosticsMicron scaleVacuum pressure

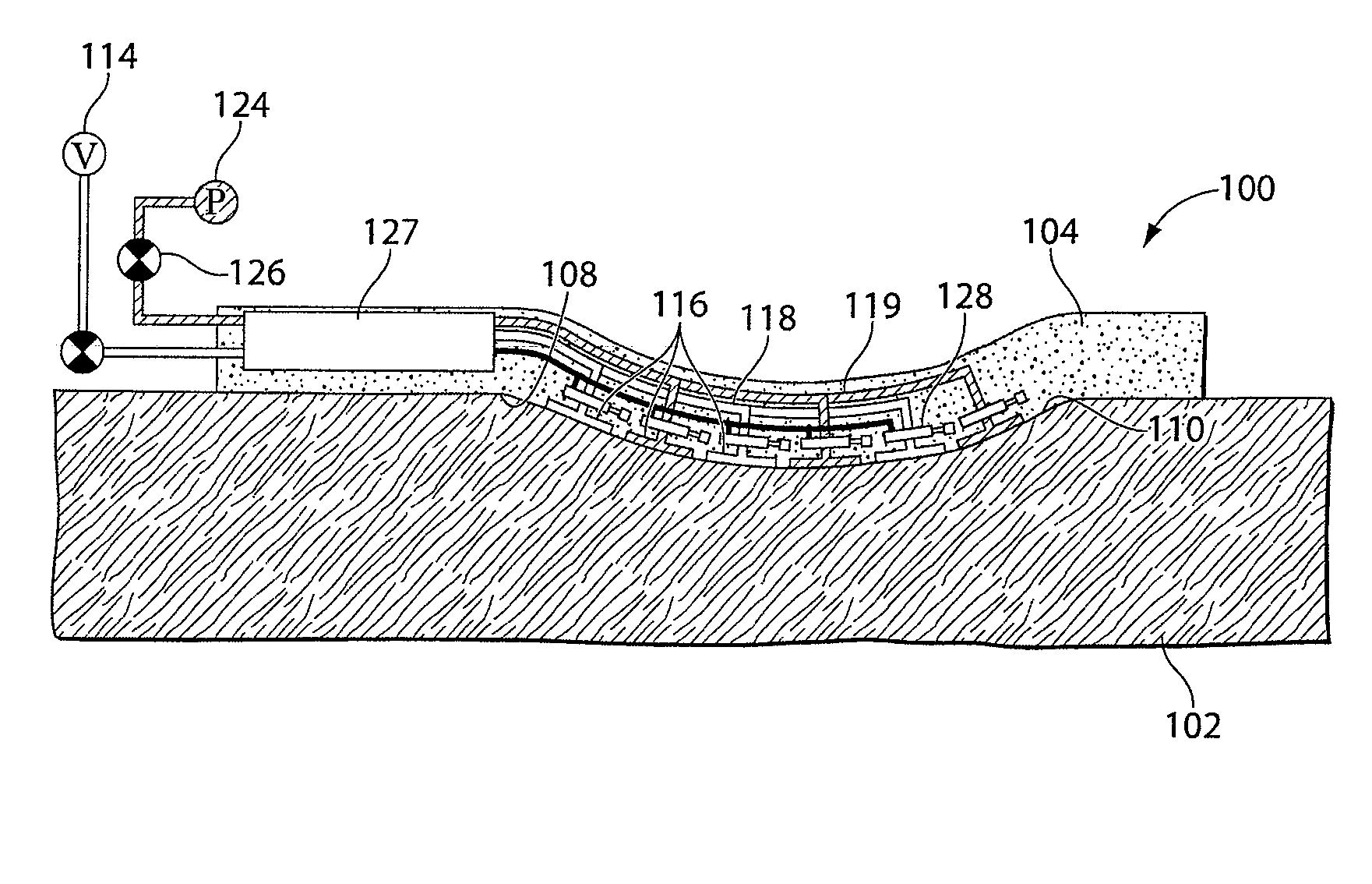

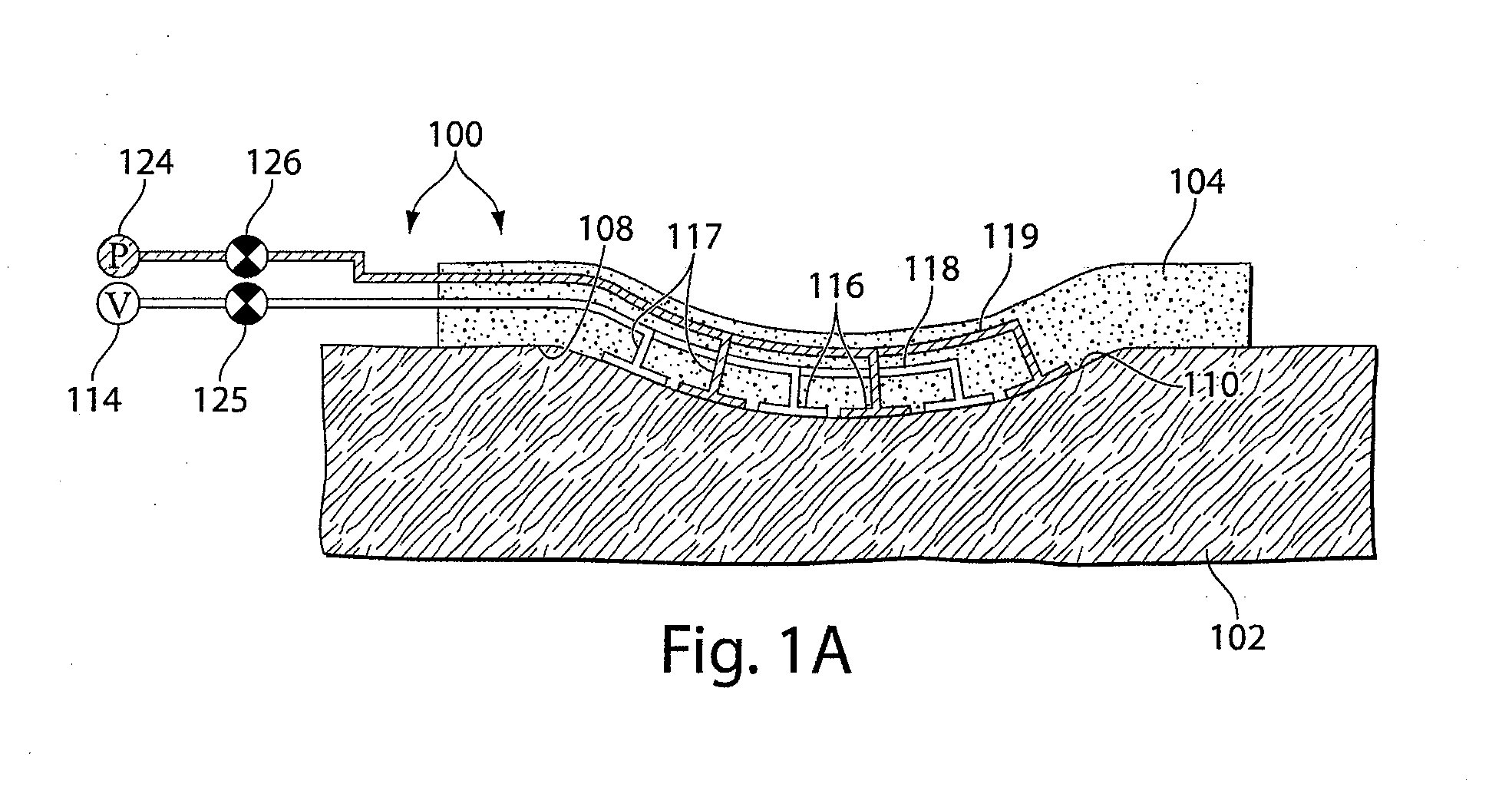

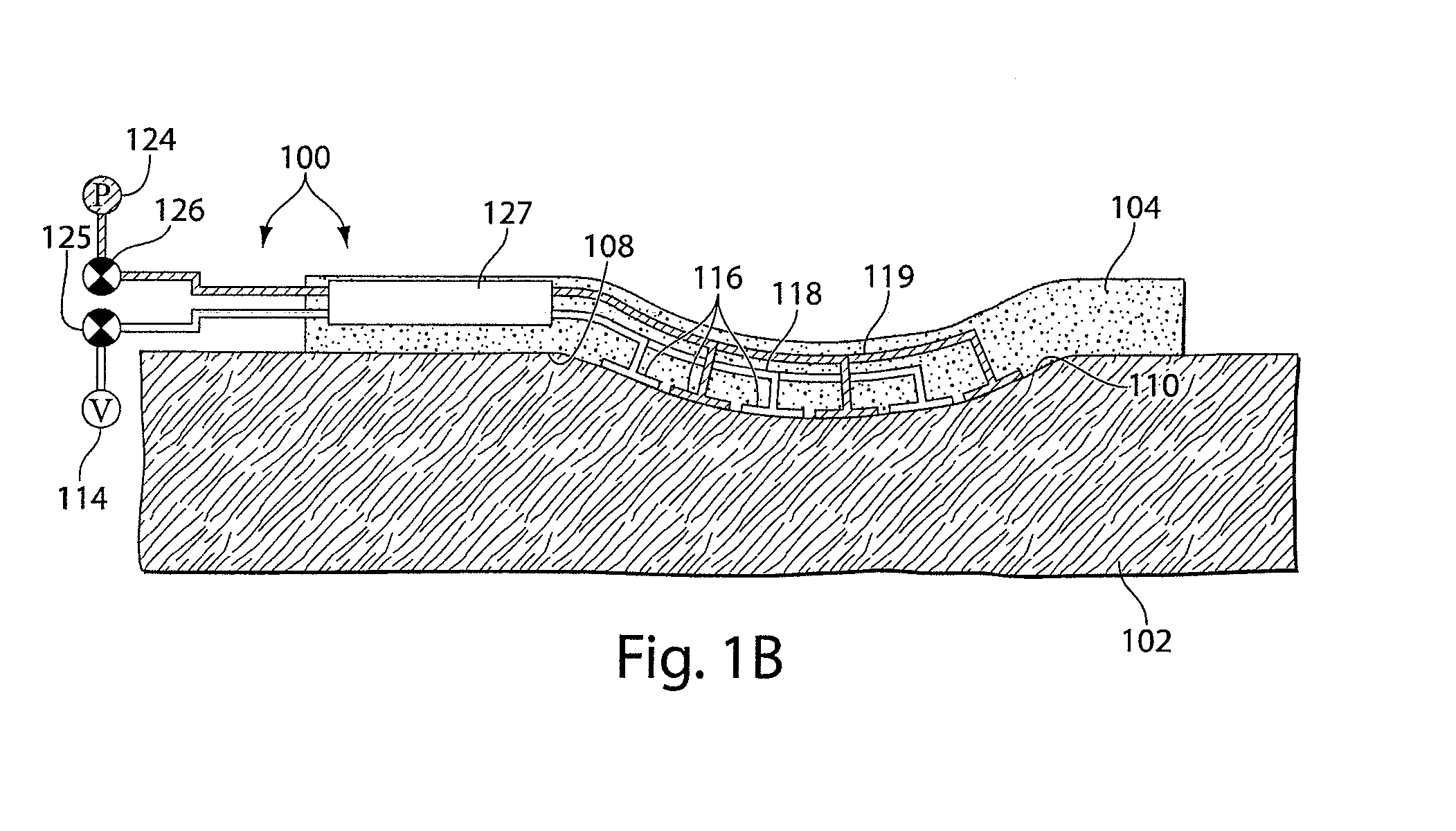

Methods and devices transmit micromechanical forces locally on the millimeter to micron scale for promoting wound healing. Micromechanical forces can selectively be applied directly to tissue, in some embodiments, by using microchambers fluidically connected to microchannels. Each chamber, or in some cases, group of chambers, may be associated with a valve to control vacuum pressure, positive pressure, liquid delivery, and / or liquid removal from each chamber or group of chambers. Application of embodiments of the invention may shorten wound-healing time, reduce costs of therapy, enable restoration of functional tissue, and reduce the need for more invasive therapies, including surgery.

Owner:THE BRIGHAM & WOMEN S HOSPITAL INC

Tube attachment device for wound treatment

The invention provides a vacuum tube attachment device for vacuum assisted wound dressings. The device is in the form of a patch that can be attached to the primary wound cover. The patch forms a substantially air-tight seal to the primary wound cover, and a vacuum tube is fixed to the patch such that the patch can be oriented on the wound cover to locate the tube near an opening in the cover to allow vacuum pressure to be communicated to the wound. The patch has an adhesive area around its perimeter for attaching the patch in a substantially air-tight seal to the wound cover at any convenient location on the cover. Several embodiments of the patch are described.

Owner:PAUL HARTMANN AG

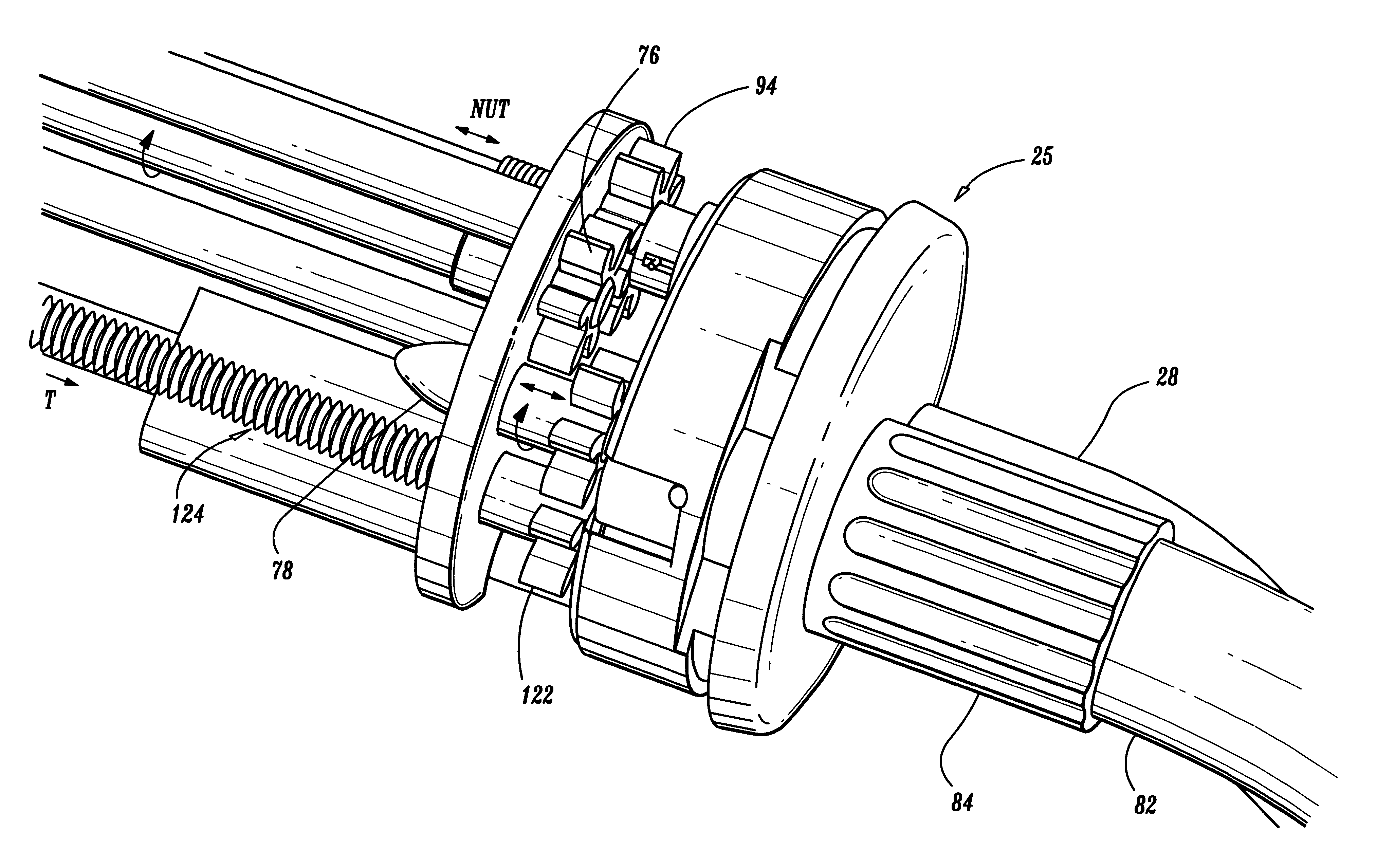

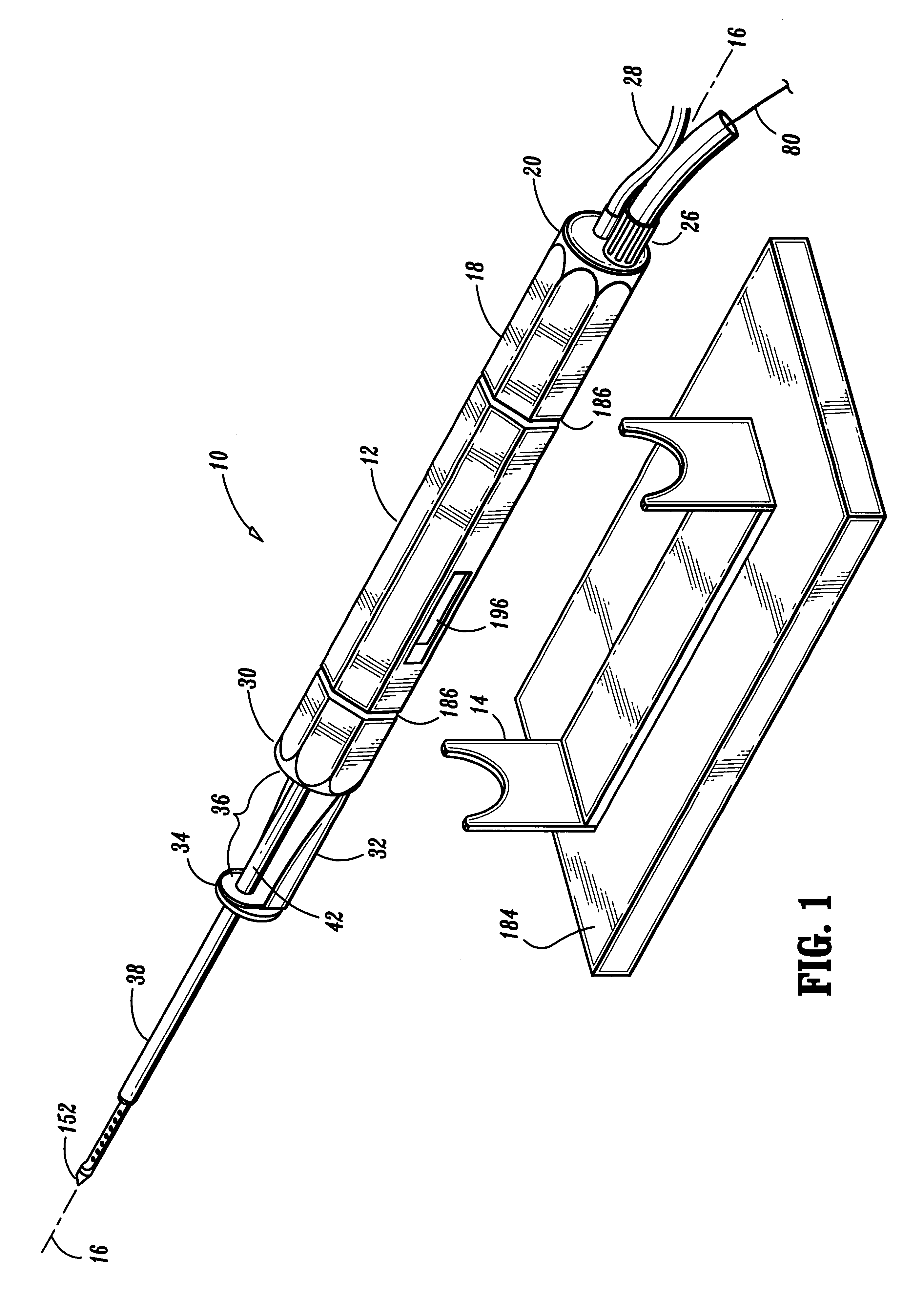

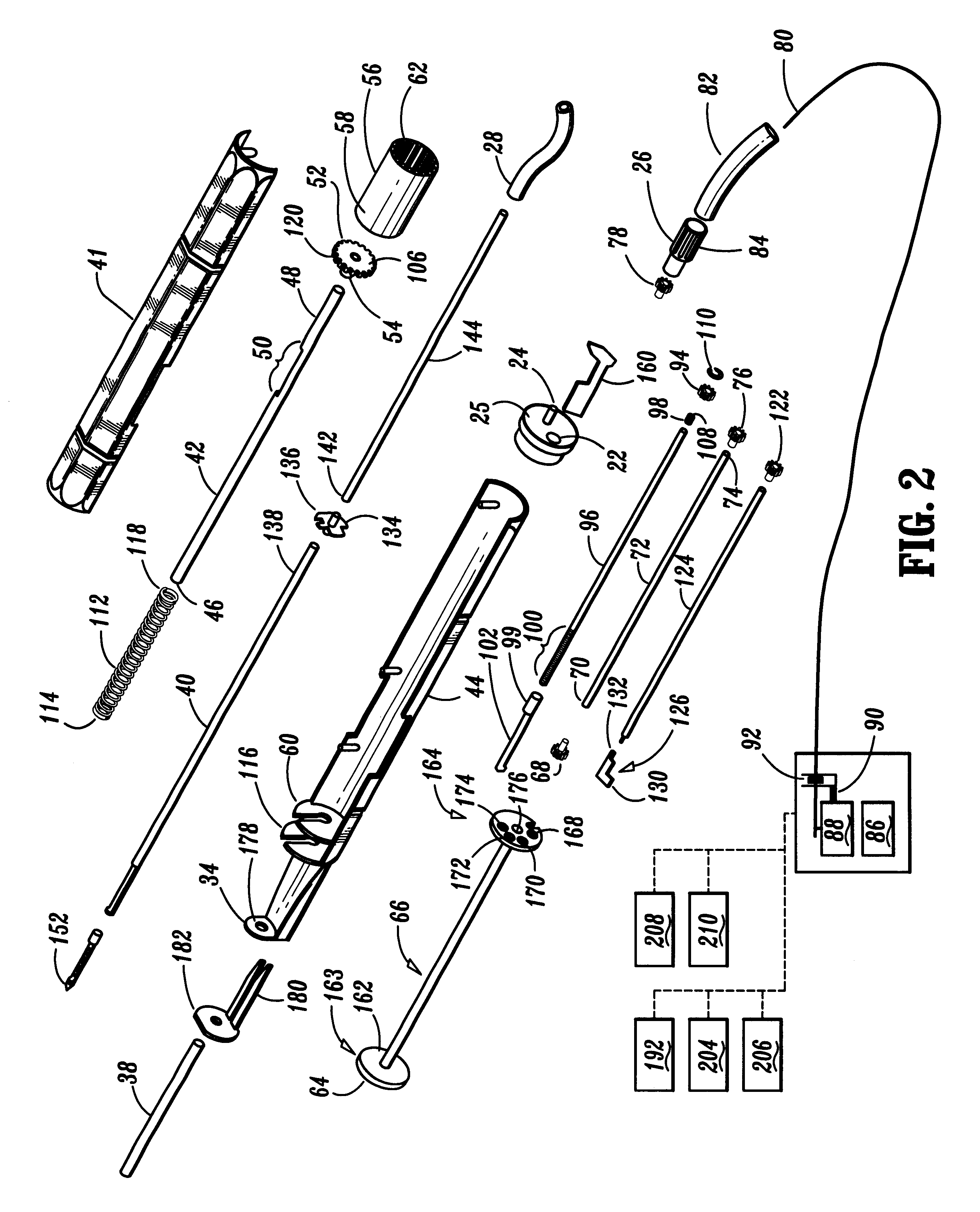

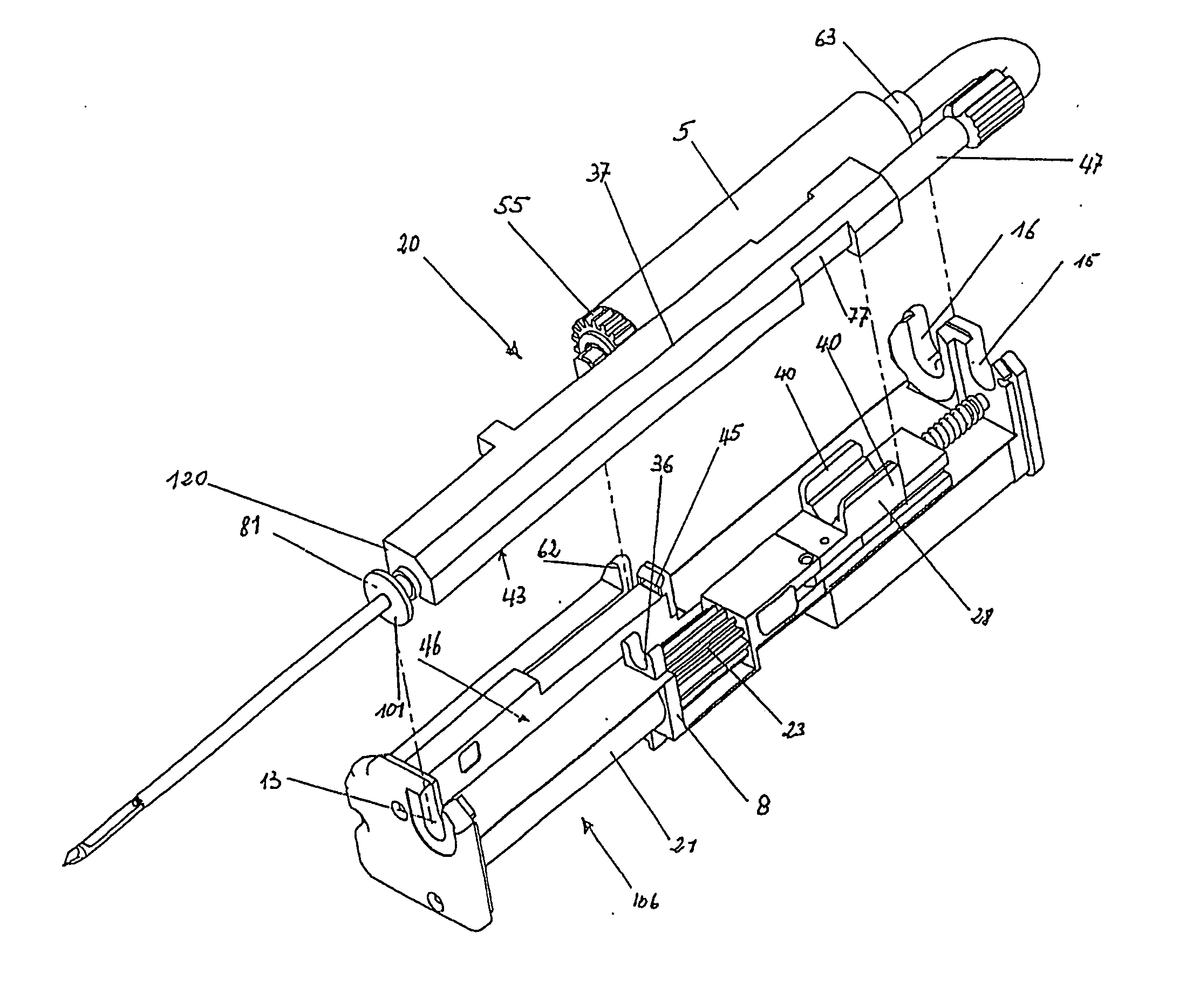

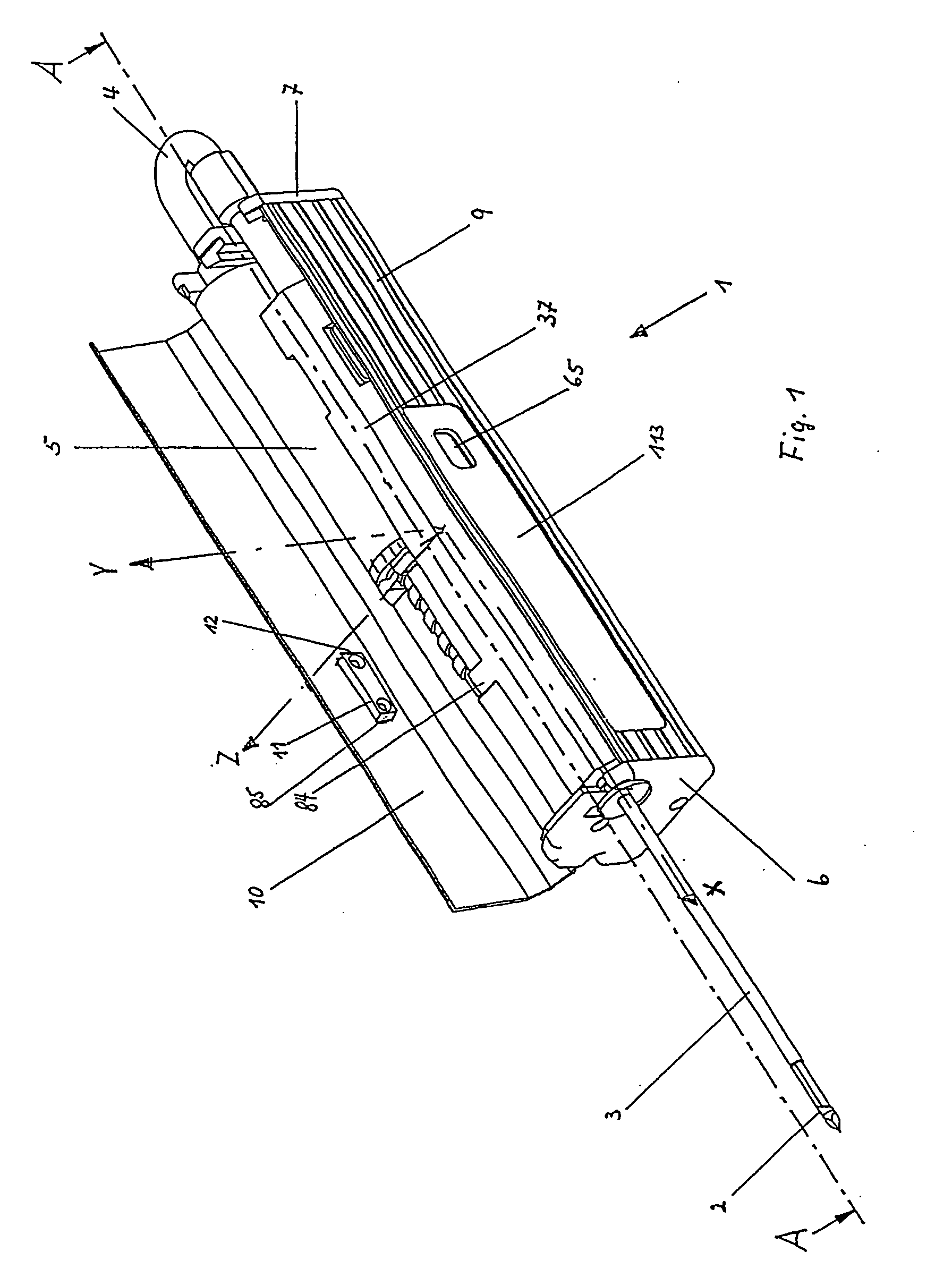

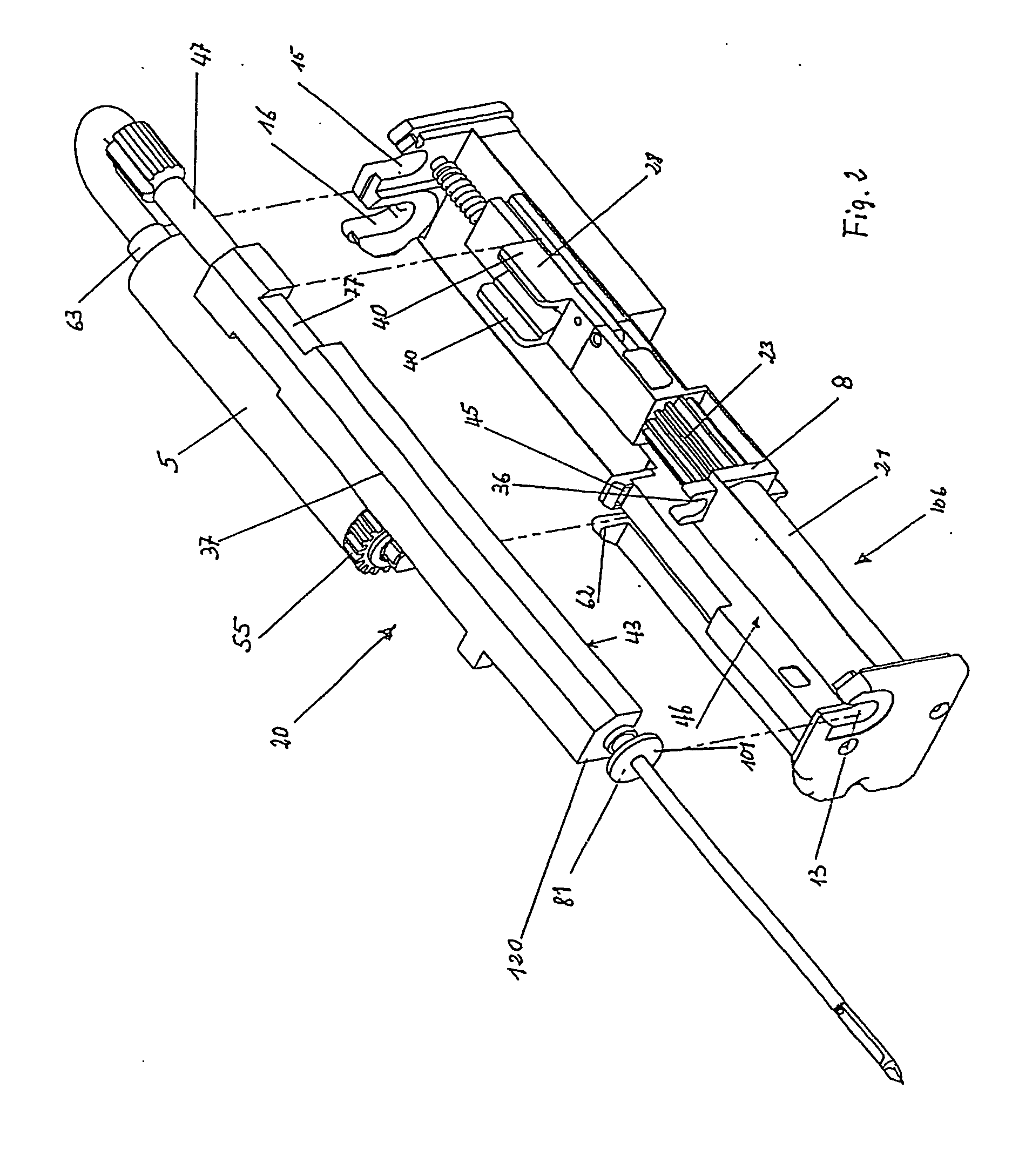

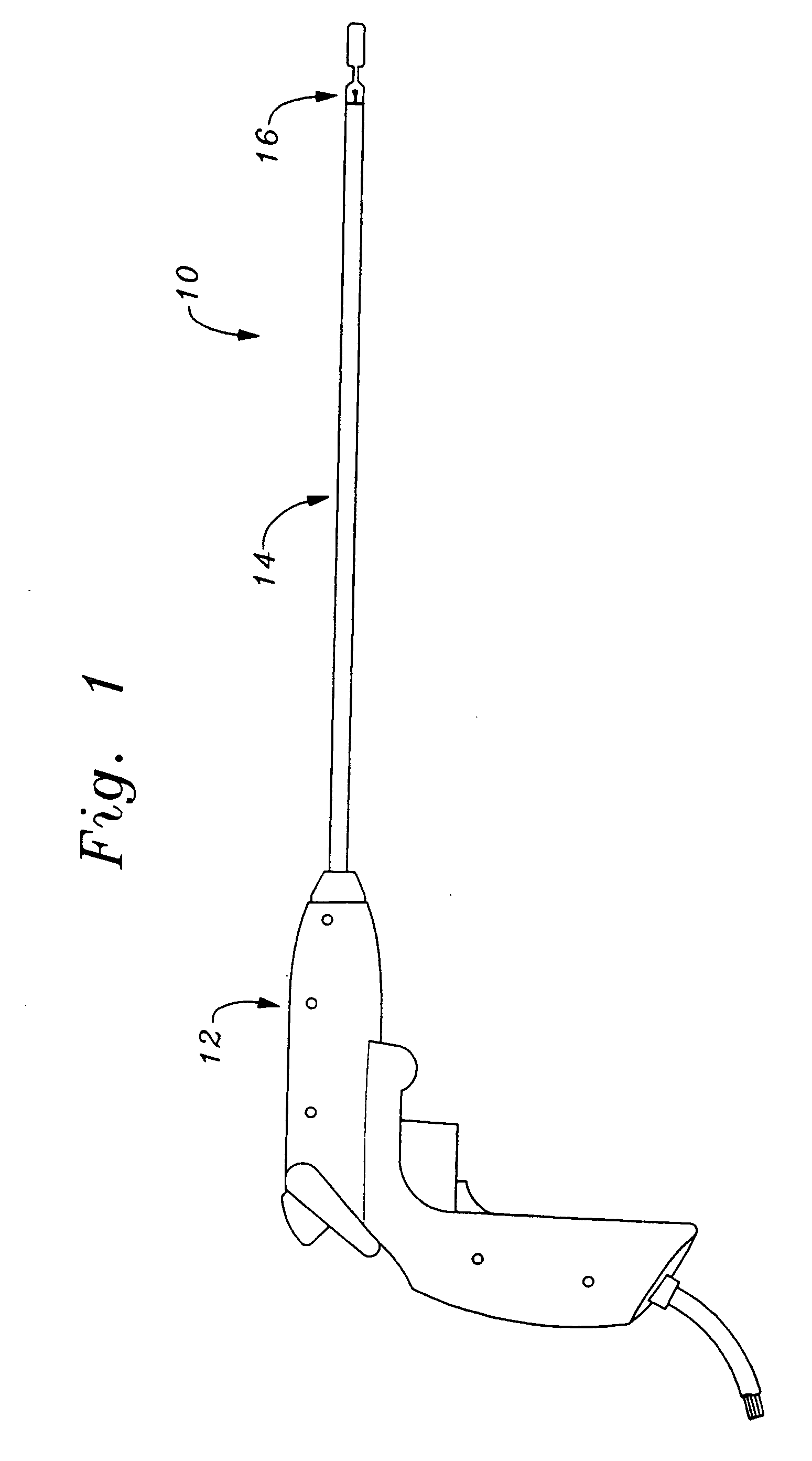

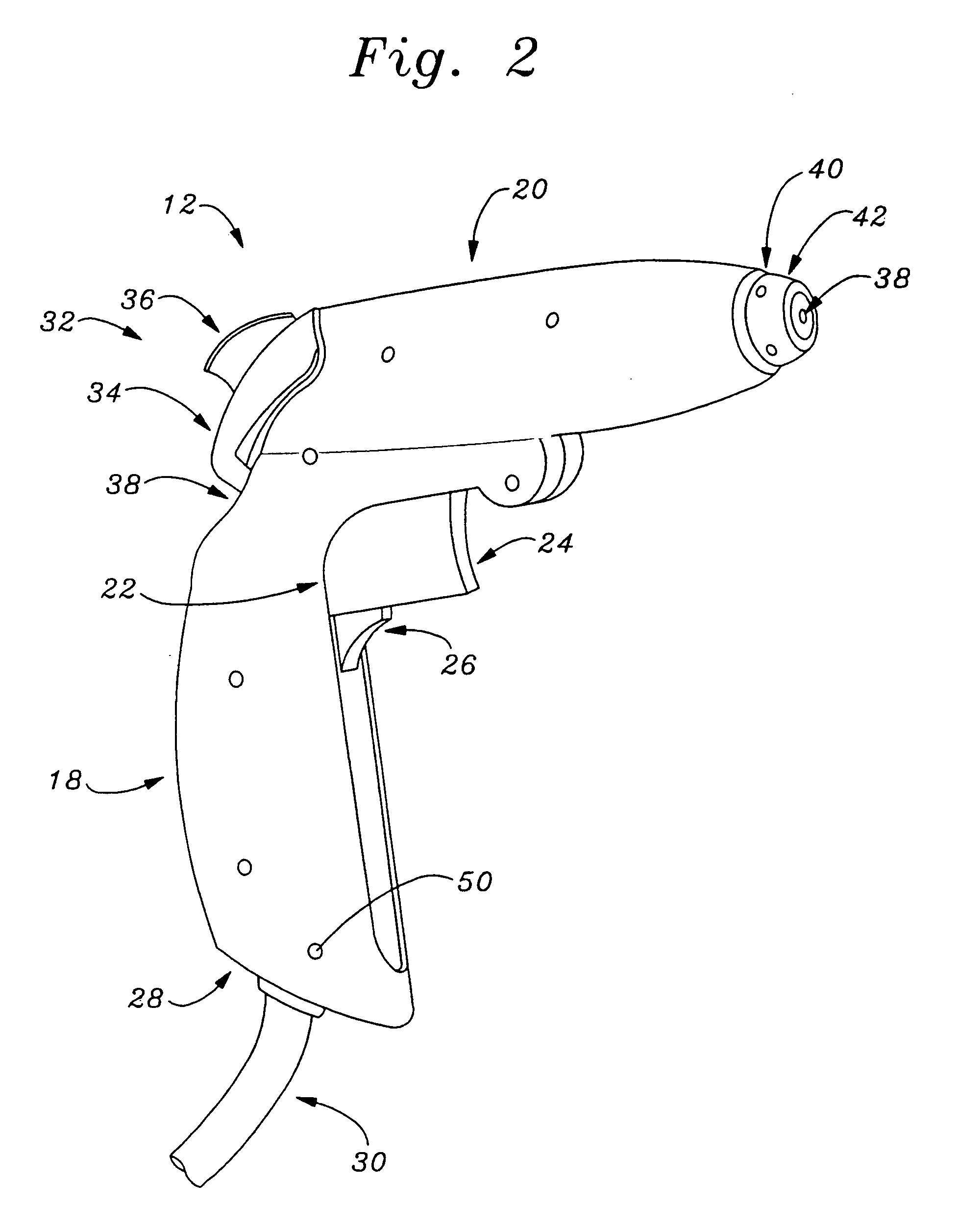

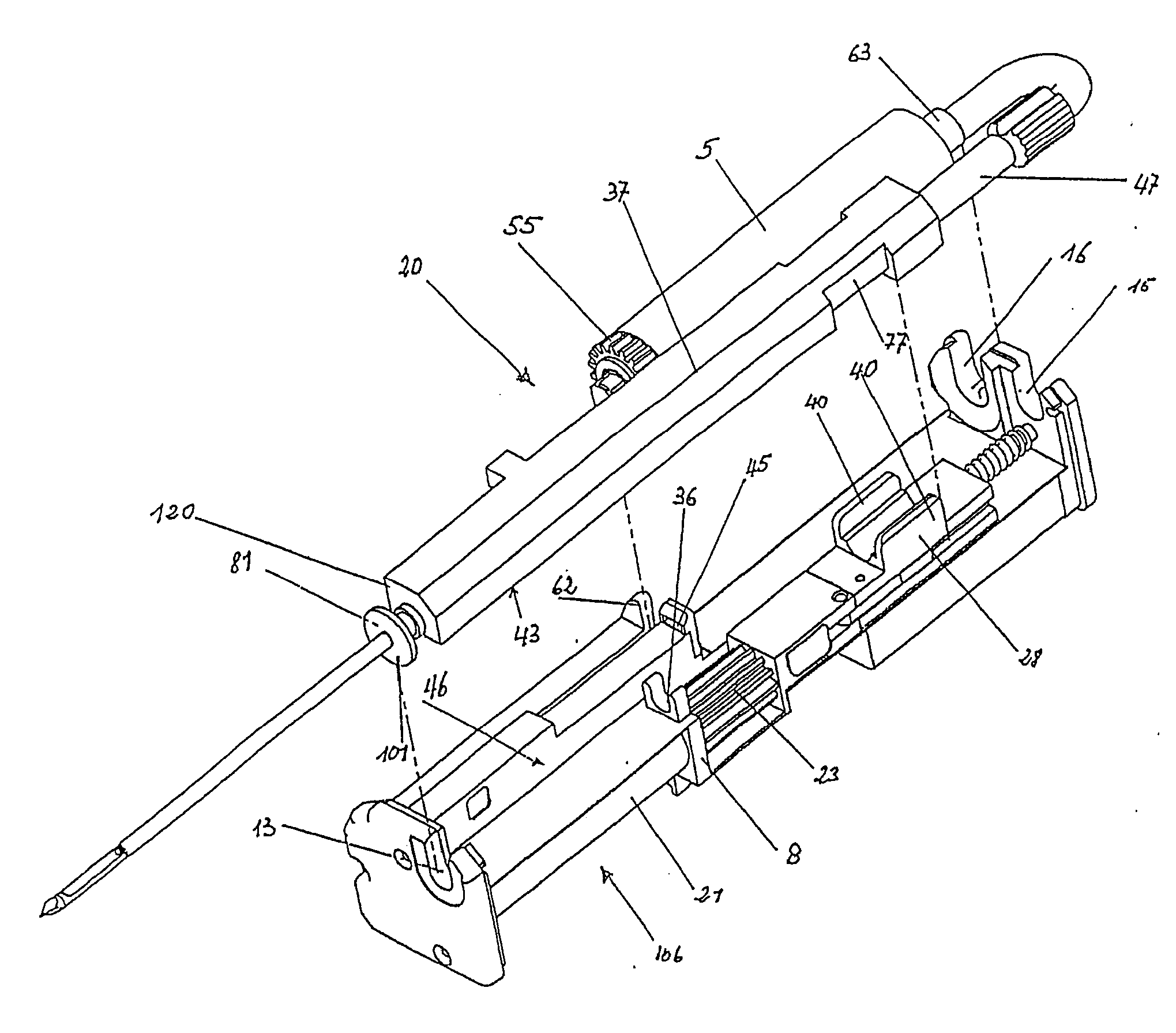

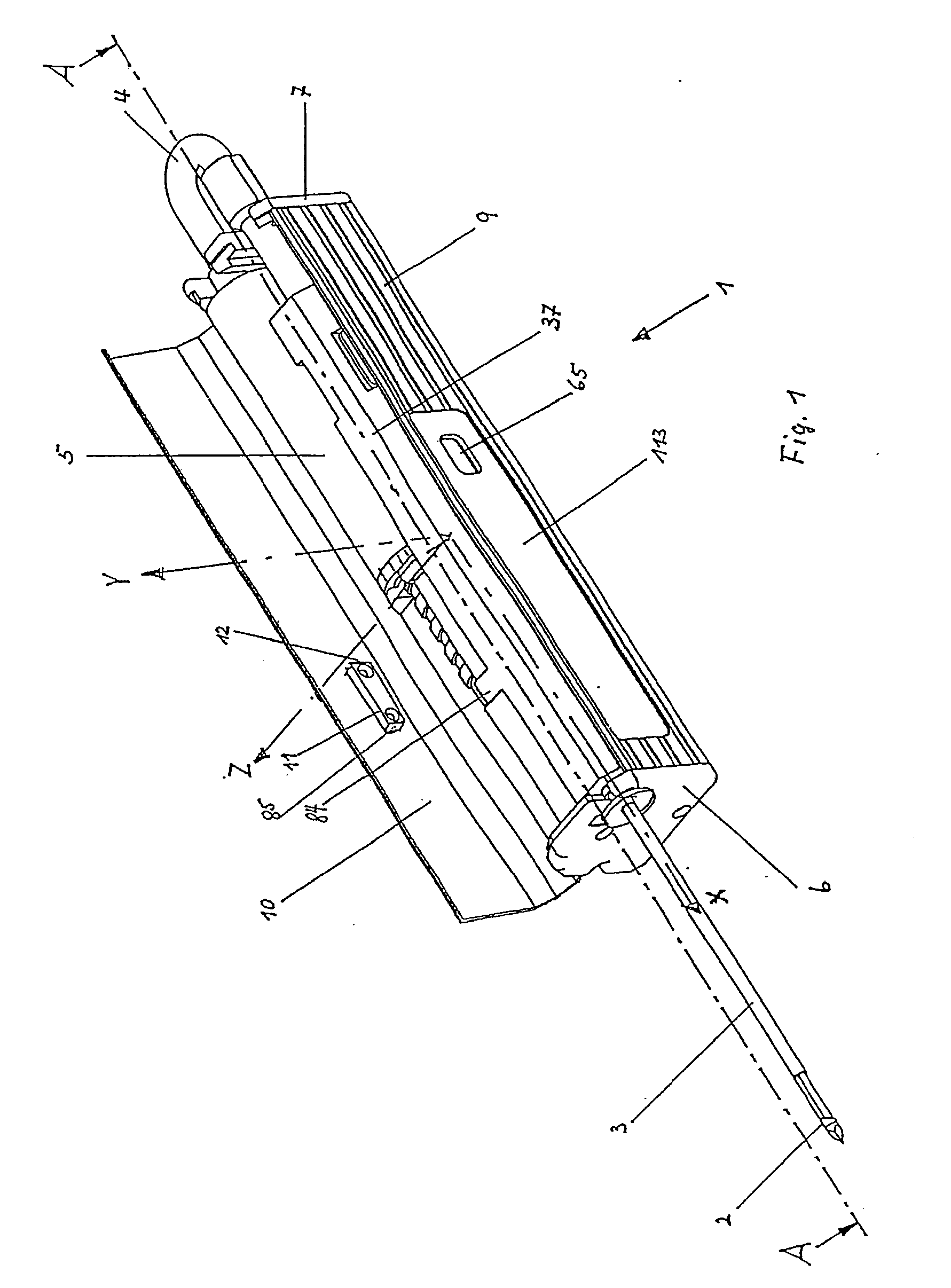

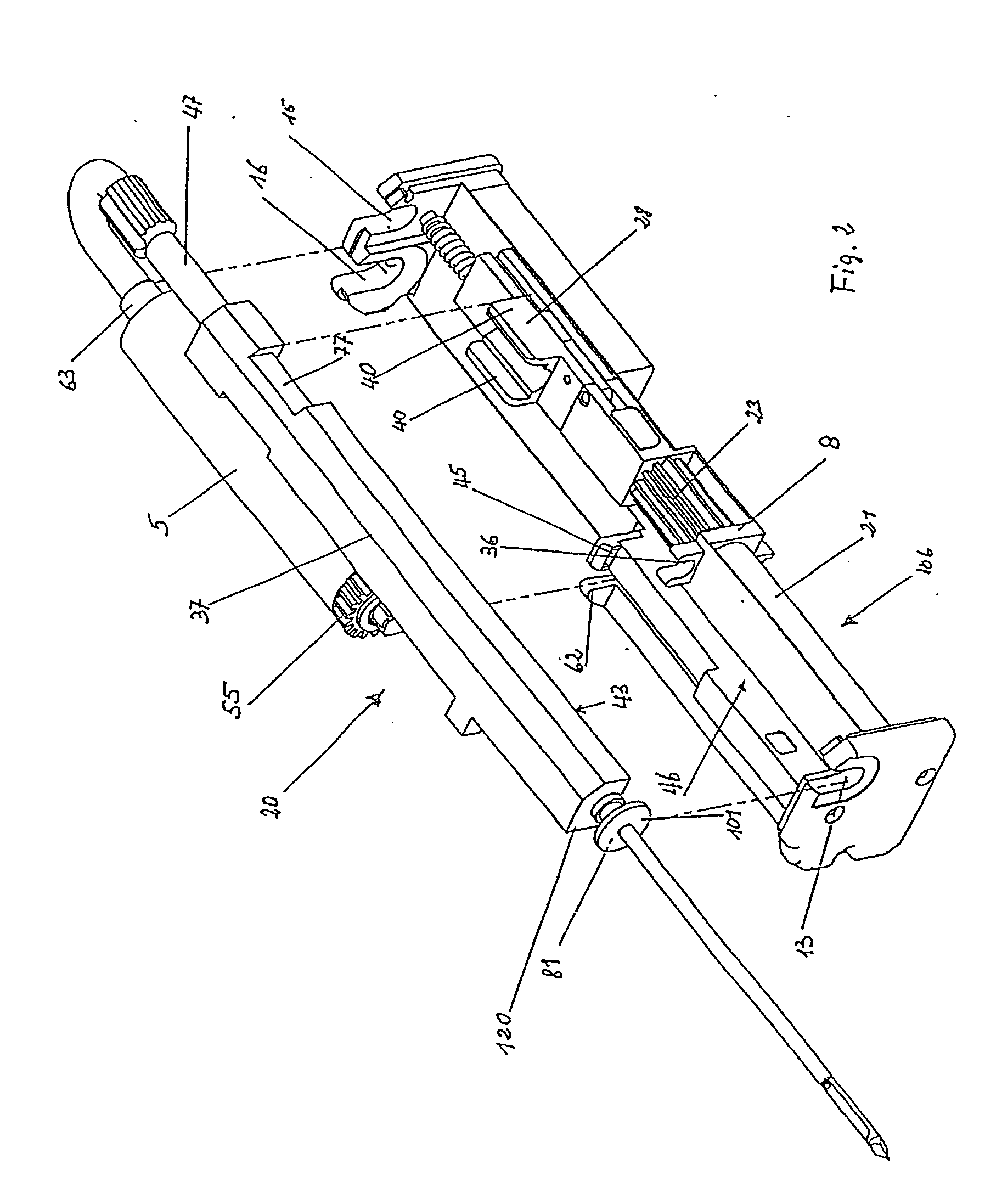

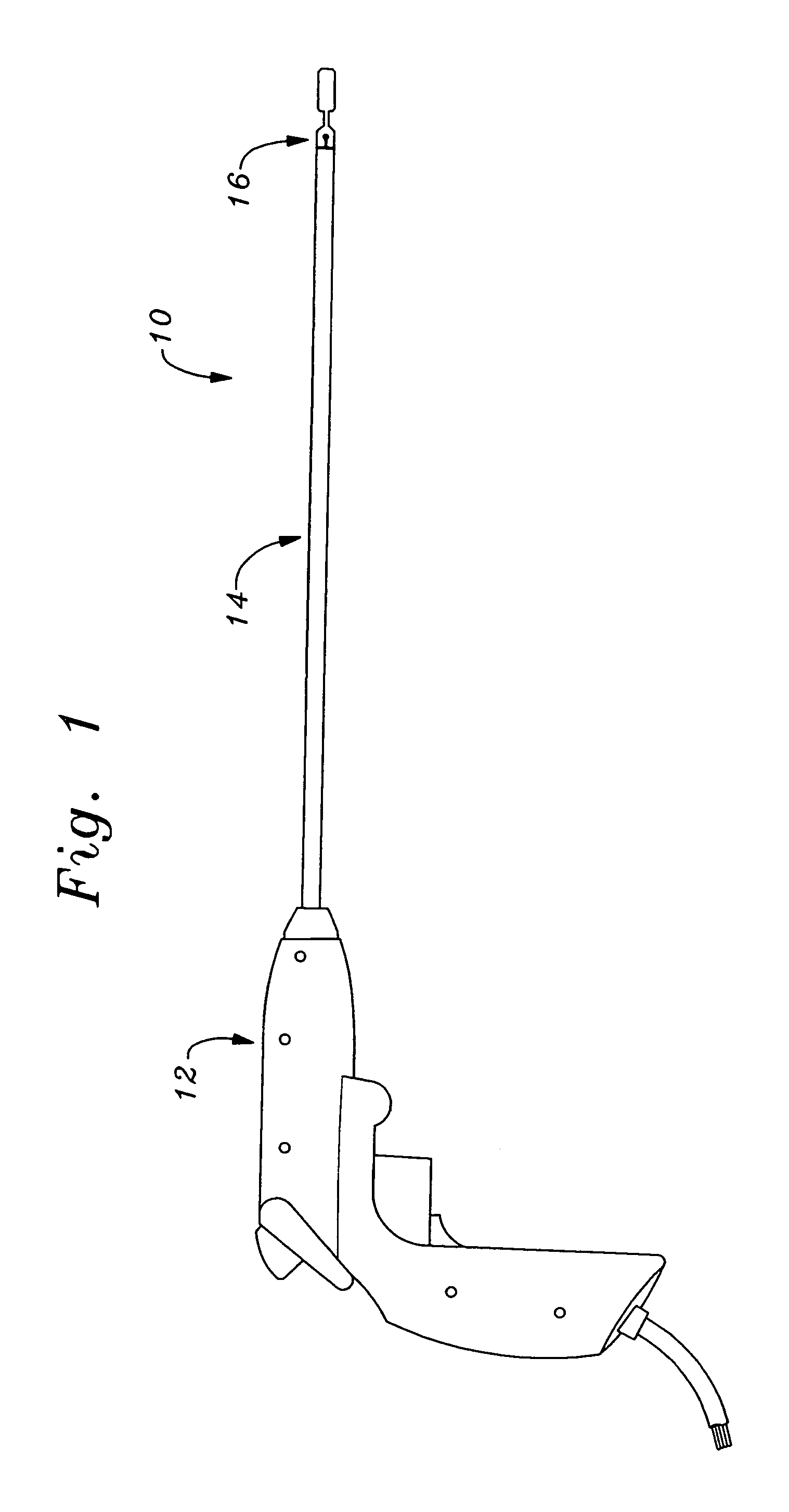

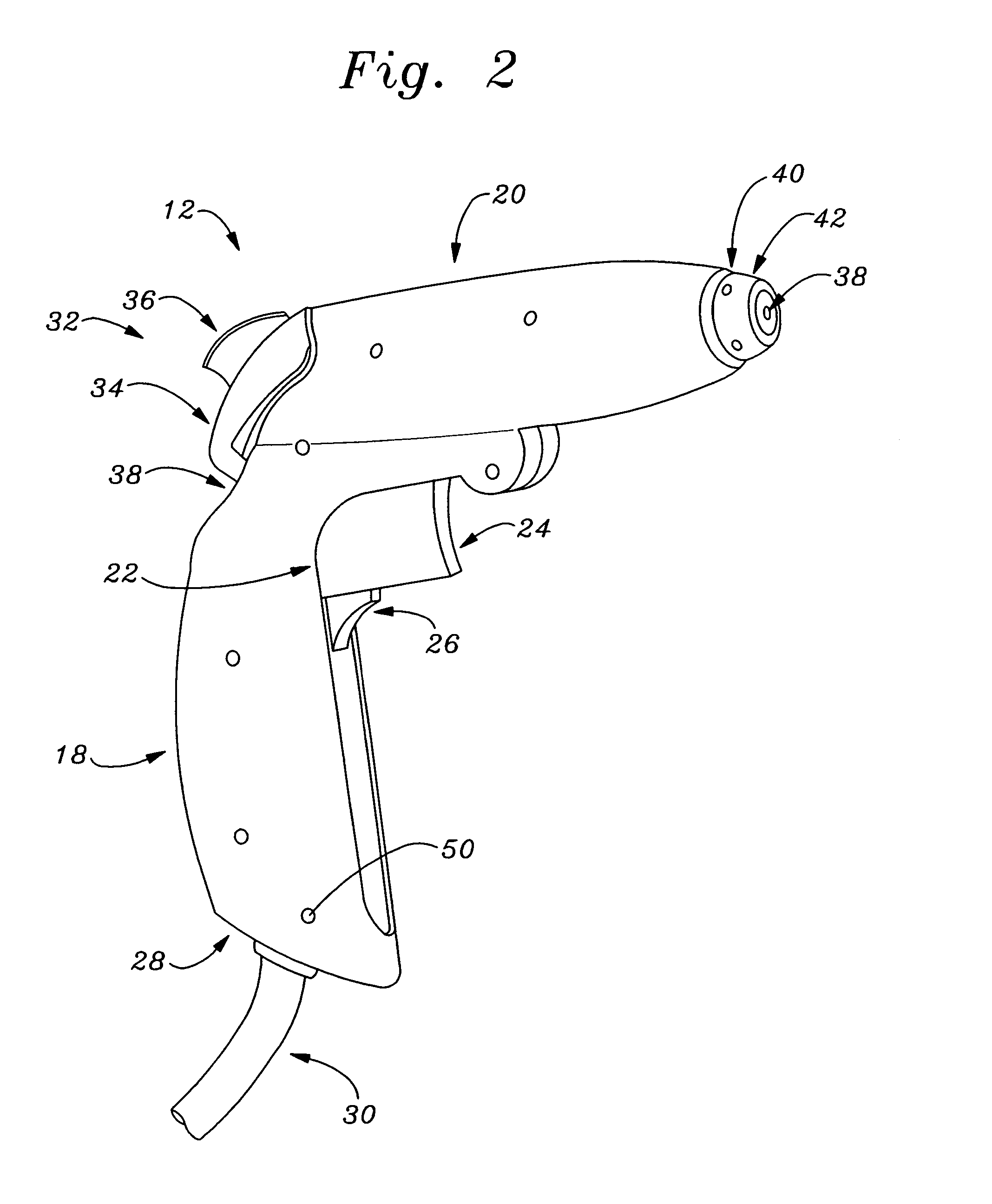

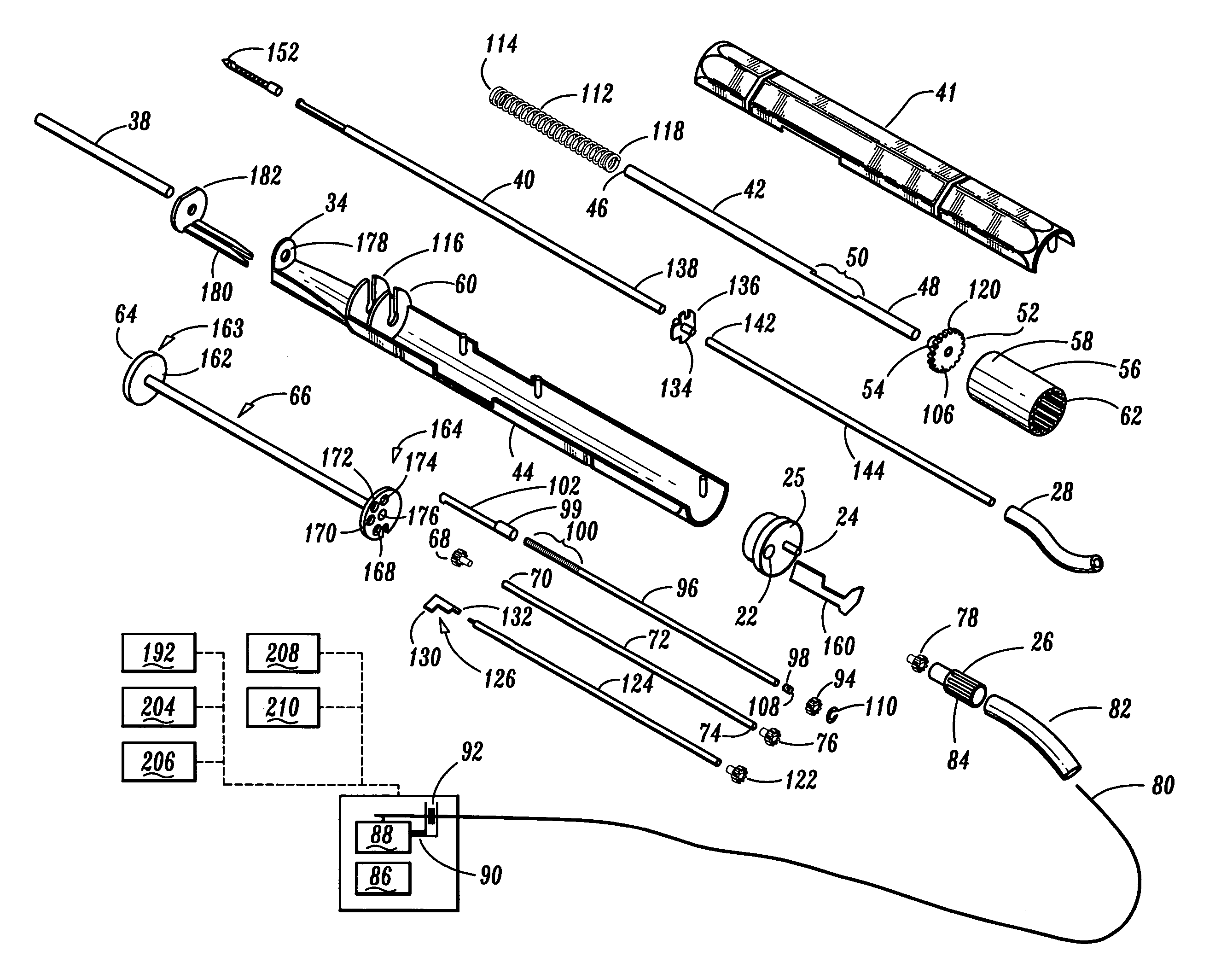

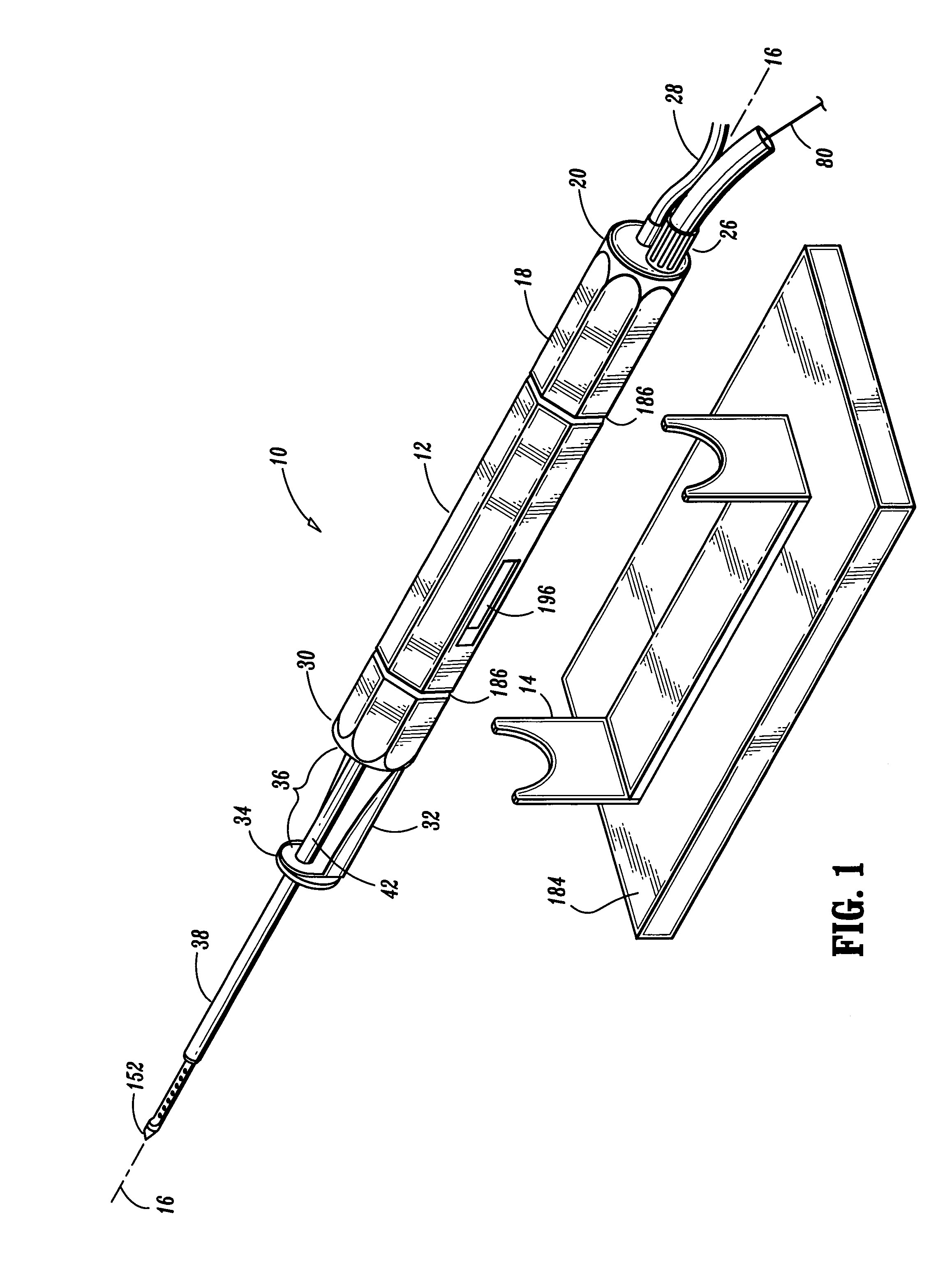

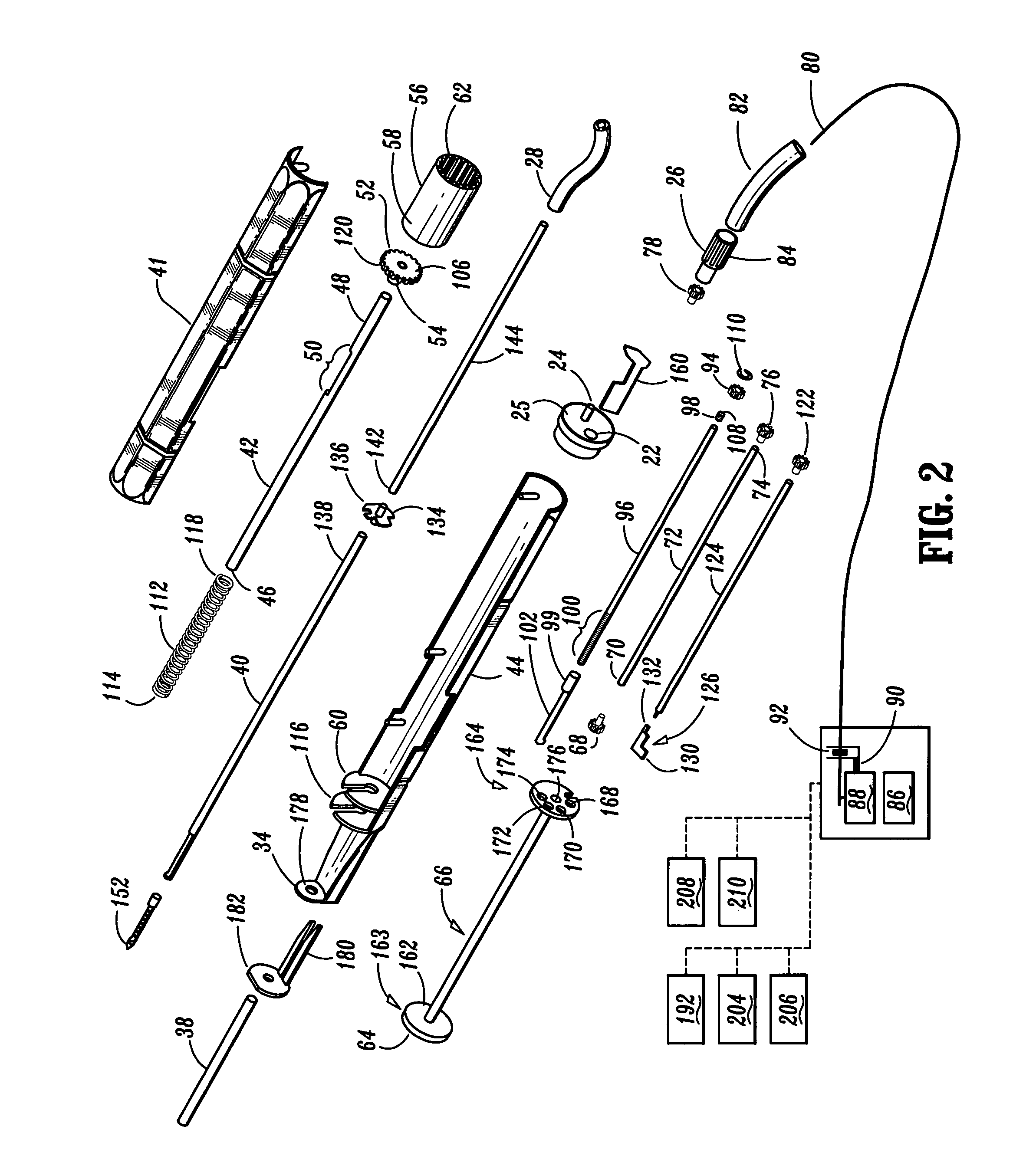

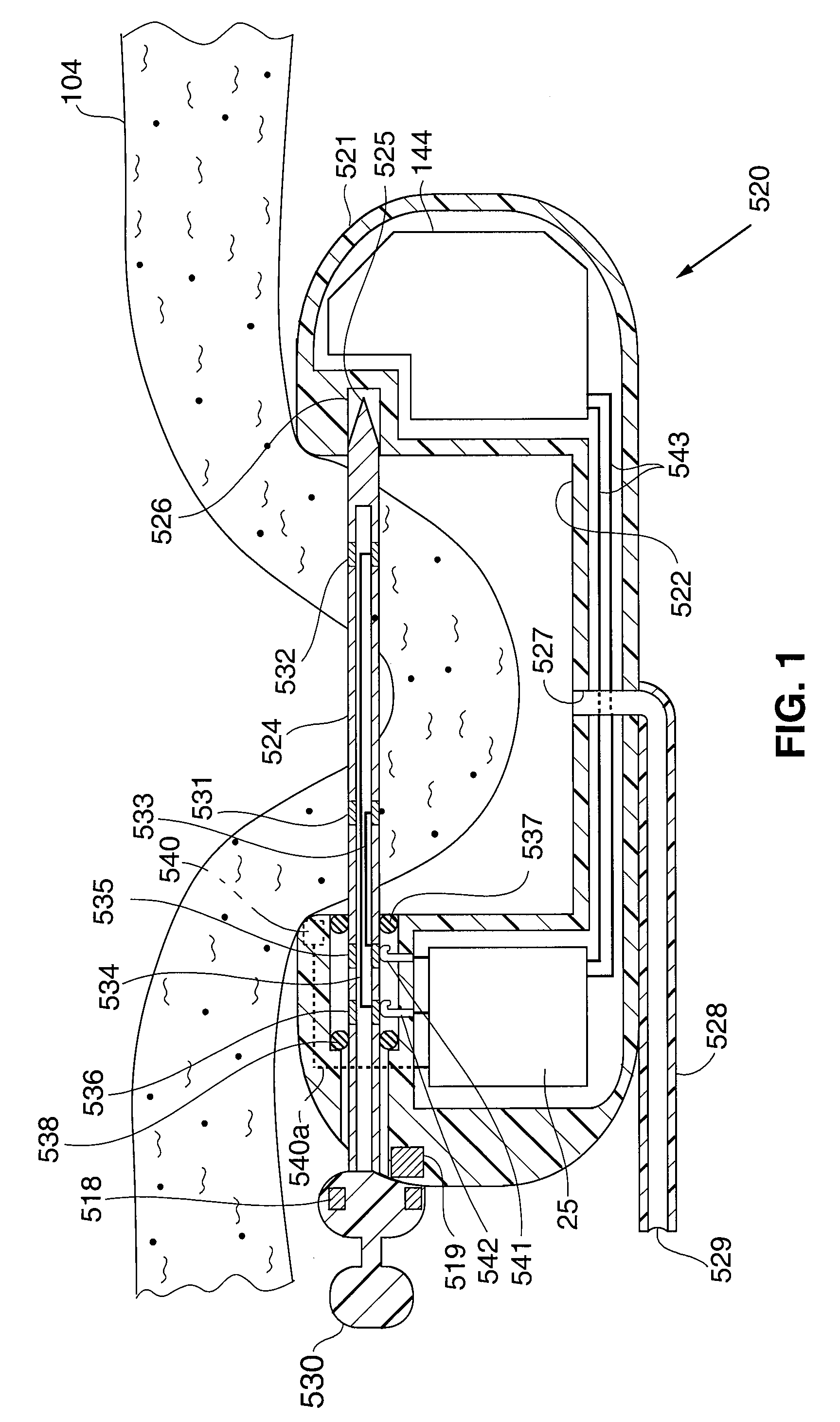

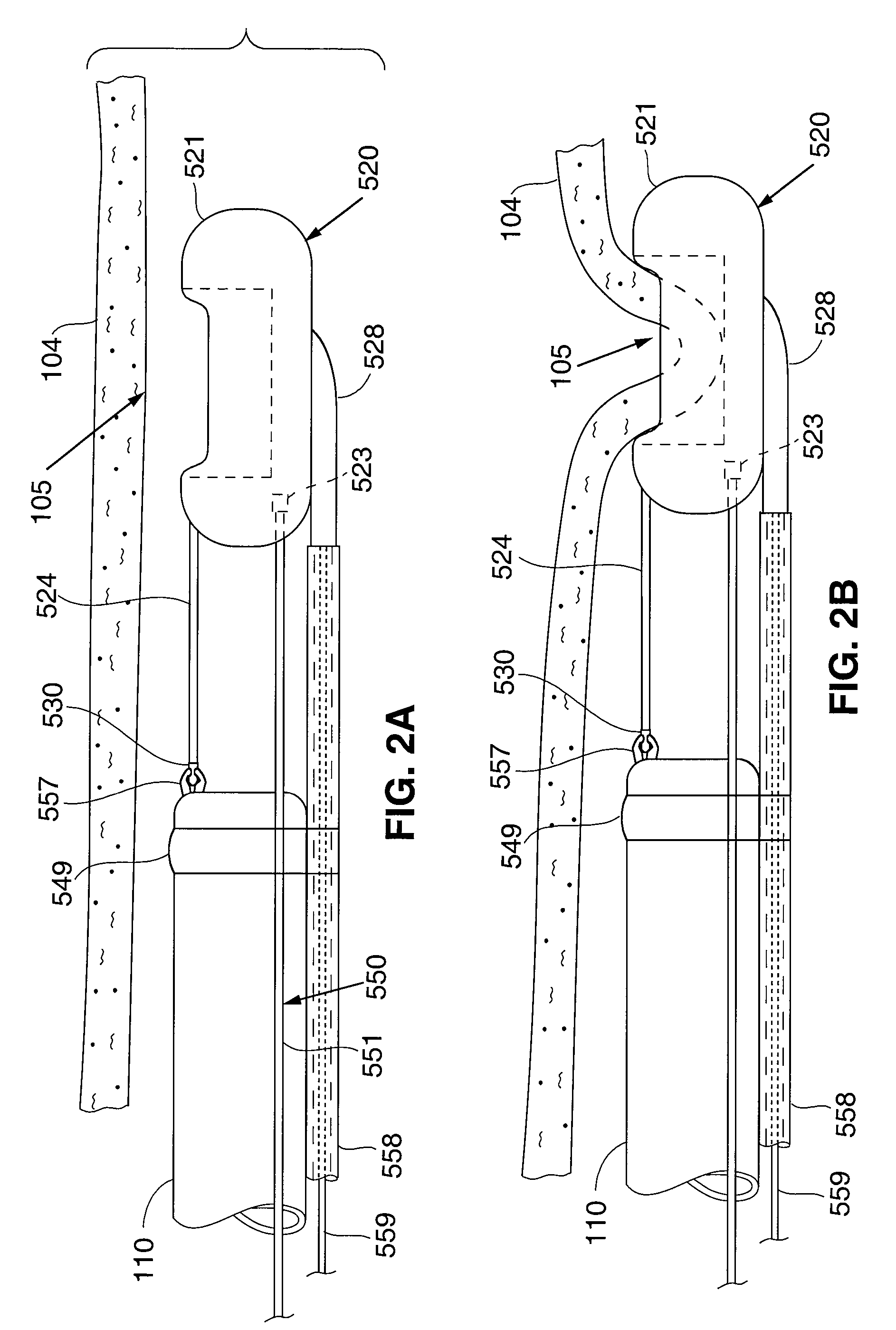

Tissue sampling and removal apparatus and method

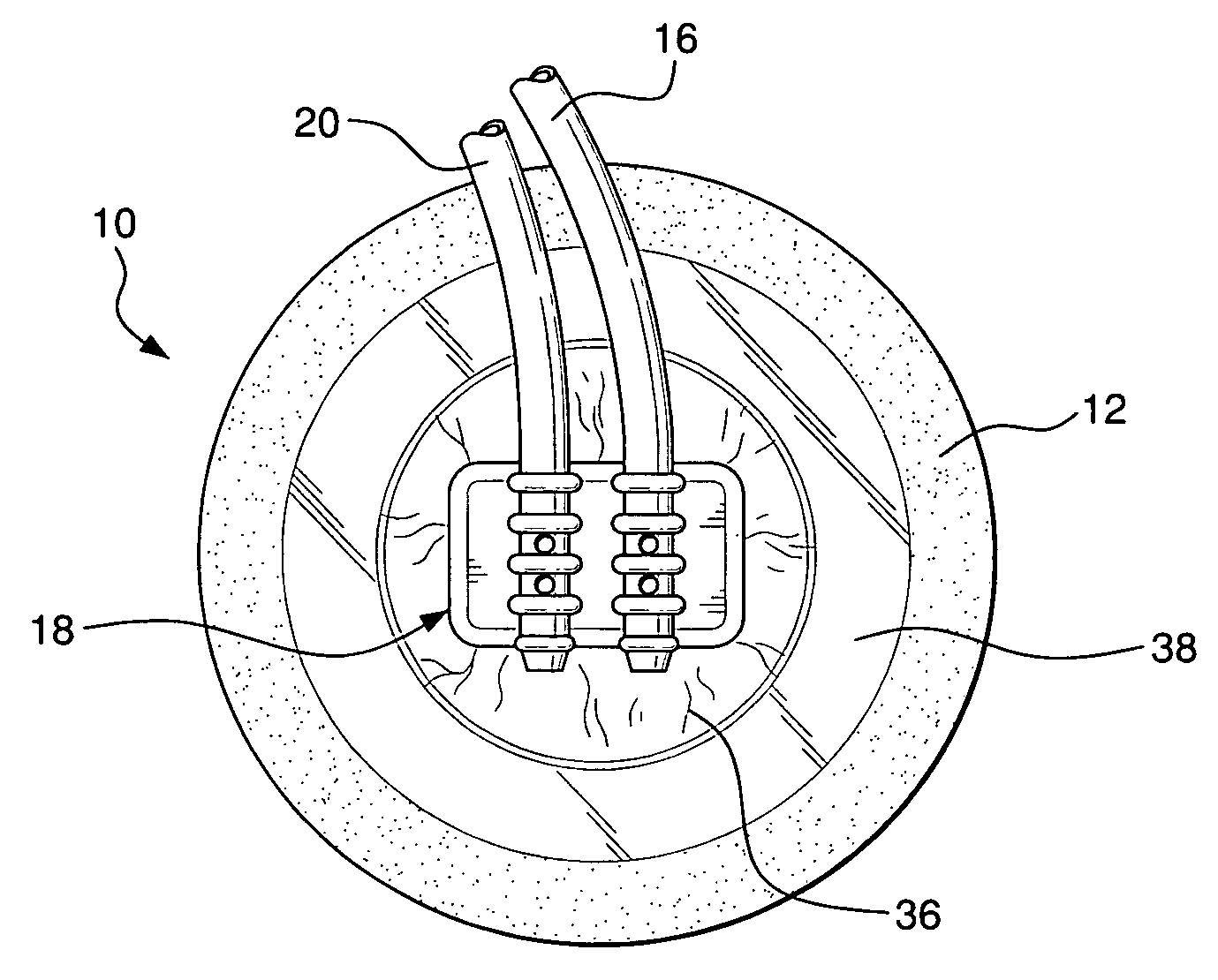

InactiveUS6860860B2Improve cutting effectAbility to retrieve multiple samplesSurgical needlesVaccination/ovulation diagnosticsVacuum pressureTissue sample

A tissue sampling device (10) for retrieving one or more tissue samples from a patient is either handheld or mounted to a moveable carriage (184) and advanced so that the needle tip (152) is introduced into the patient. The needle tip (152) is advanced until the tissue receiving basket (154) reaches the tissue sample target zone (190). Vacuum pressure is supplied to the basket (154) via a vacuum tube (144) so that tissue to be sampled is drawn into the basket (154). The cutter (42) is rotated and advanced linearly to cut a tissue sample (212) which is then retrieved by retracting the needle (40).

Owner:TYCO HEALTHCARE GRP LP

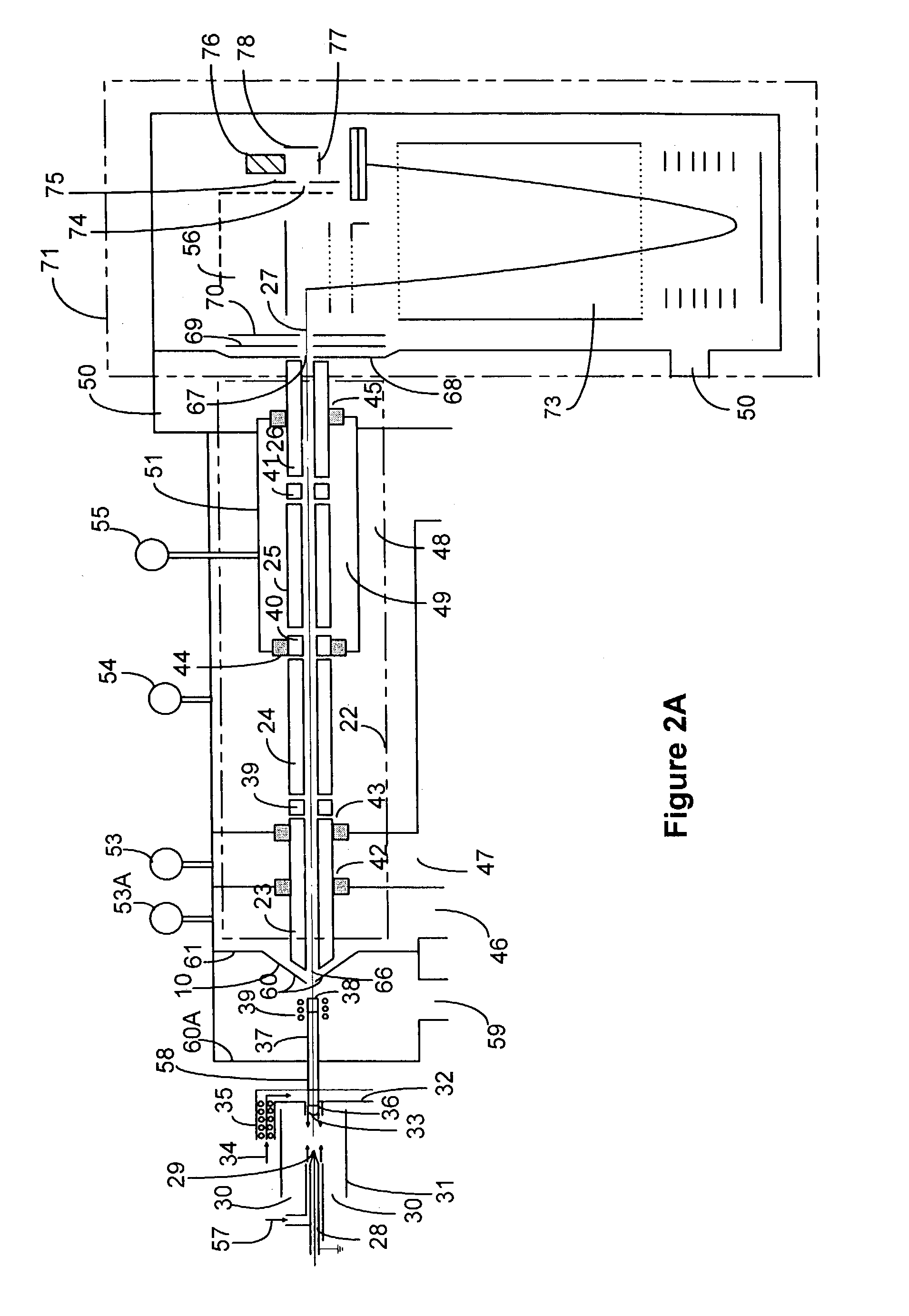

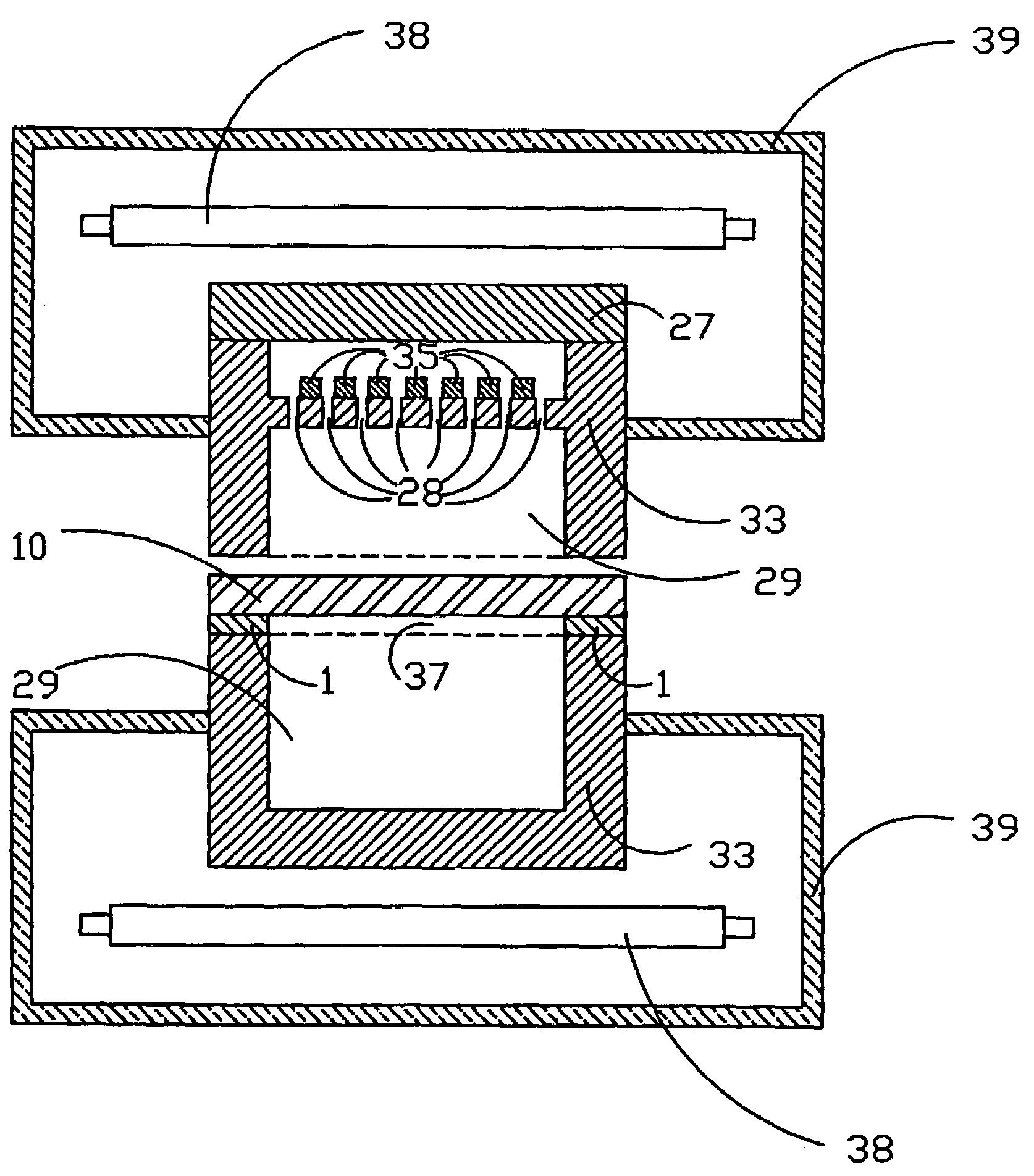

Mass spectrometry with segmented RF multiple ion guides in various pressure regions

InactiveUS7034292B1Reduce lossesEliminate and reduce numberIsotope separationSpectrometer combinationsFourier transform on finite groupsMass analyzer

A mass spectrometer is configured with individual multipole ion guides, configured in an assembly in alignment along a common centerline wherein at least a portion of at least one multipole ion guide mounted in the assembly resides in a vacuum region with higher background pressure, and the other portion resides in a vacuum region with lower background pressure. Said multipole ion guides are operated in mass to charge selection and ion fragmentation modes, in either a high or low pressure region, said region being selected according to the optimum pressure or pressure gradient for the function performed. The diameter, lengths and applied frequencies and phases on these contiguous ion guides may be the same or may differ. A variety of MS and MS / MSn analysis functions can be achieved using a series of contiguous multipole ion guides operating in either higher background vacuum pressures, or along pressure gradients in the region where the pressure drops from high to low pressure, or in low pressure regions. Individual sets of RF, + / −DC and resonant frequency waveform voltage supplies provide potentials to the rods of each multipole ion guide allowing the operation of ion transmission, ion trapping, mass to charge selection and ion fragmentation functions independently in each ion guide. The presence of background pressure maintained sufficiently high to cause ion to neutral gas collisions along a portion of each multiple ion guide linear assembly allows the conducting of Collisional Induced Dissociation (CID) fragmentation of ions by axially accelerating ions from one multipole ion guide into an adjacent ion guide. Alternatively ions can be fragmented in one or more multipole ion guides using resonant frequency excitation CID. A multiple multipole ion guide assembly can be configured as the primary mass analyzer in single or triple quadrupole mass analyzers with or without mass selective axial ejection. Alternatively, the multiple multipole ion guide linear assembly can be configured as part of a hybrid Time-Of-Flight, Magnetic Sector, Ion Trap or Fourier Transform mass analyzer.

Owner:PERKINELMER U S LLC

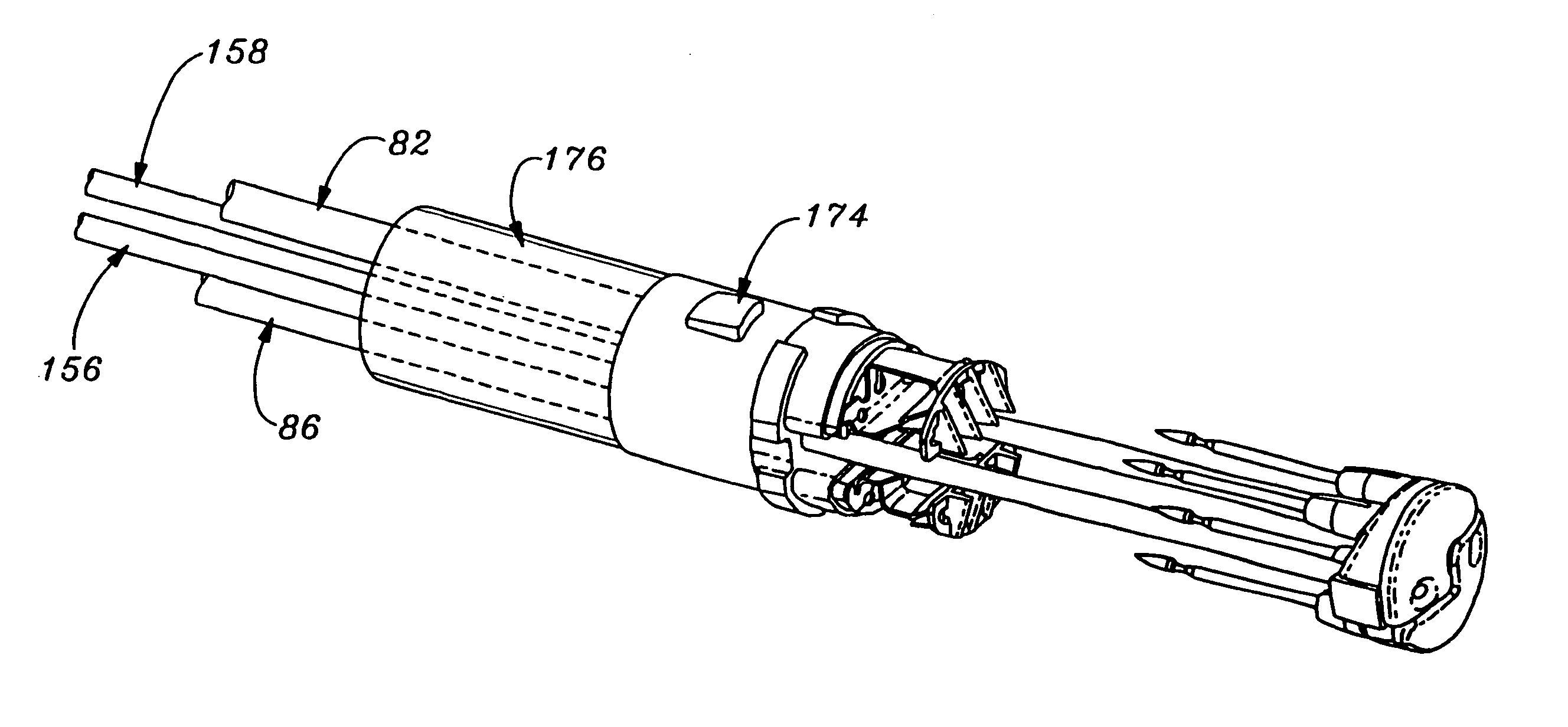

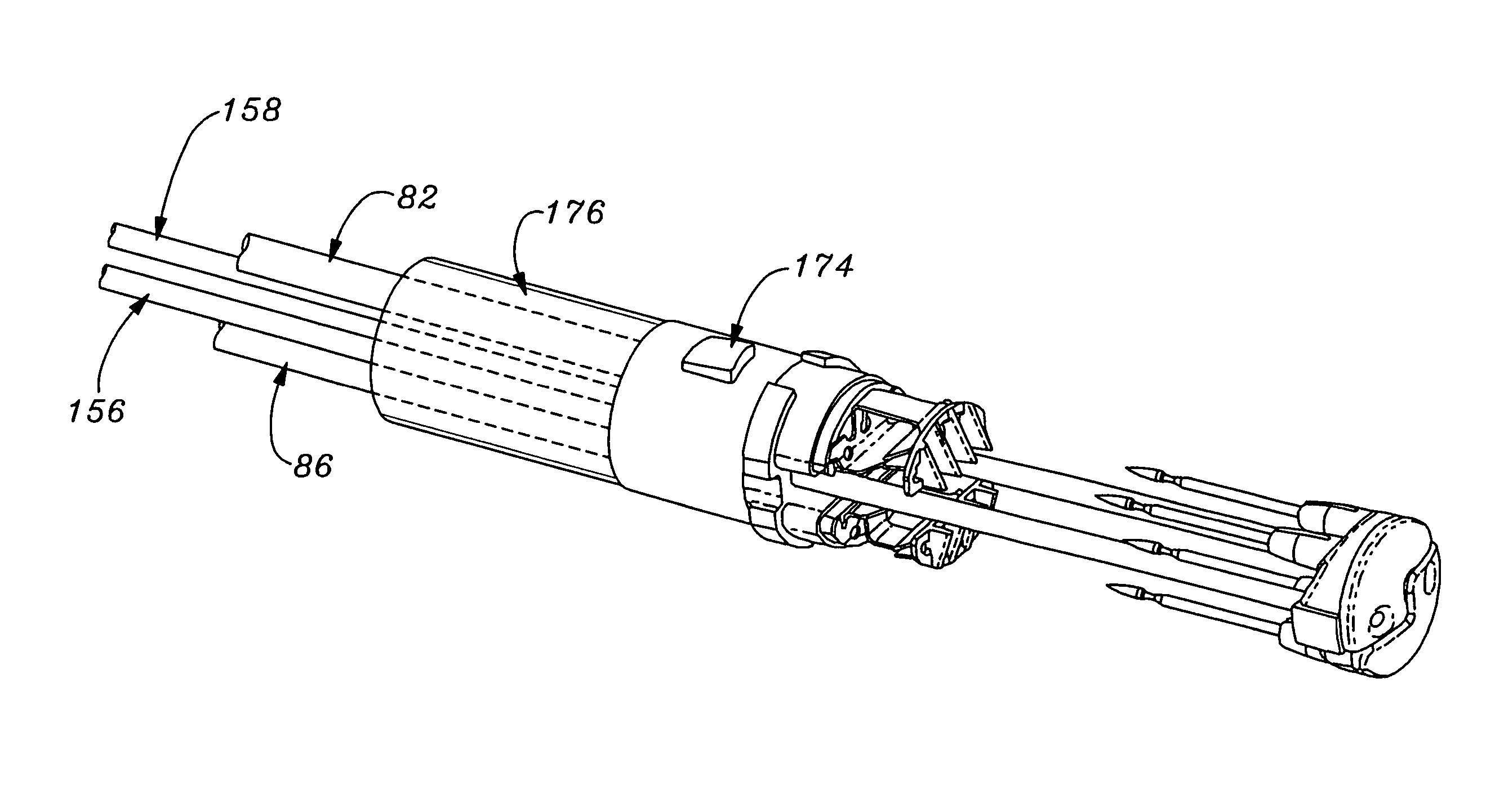

Vacuum biopsy device

ActiveUS20050203439A1Simple and reliable and uncomplicated in structureSufficient quantityGuide needlesCannulasVacuum pressureTissue sample

A biopsy device for taking tissue samples, includes a housing, a removable element and a control panel. The housing contains an electric power source and a tension slide connected to the power source. The tension slide may be brought into a cocked position against the action of a spring by the power source. The removable element is configured for insertion into the housing and includes a biopsy needle unit, a vacuum pressure-generating device and a control panel. The removable element may be provided as a sterile package unit. The biopsy needle unit can be arranged on the tension slide and includes a hollow biopsy needle with a sample removal chamber and a cutting sheath. The biopsy device can be held in one hand and is fully integrated with all components required to perform a vacuum biopsy such that no cables or lines are required to other external units.

Owner:CR BARD INC

Sequential heart valve leaflet repair device and method of use

InactiveUS20060030866A1Effective and stableReduce distanceSuture equipmentsHeart valvesVacuum pressureTissue repair

A heart valve and tissue repair device for independently, selectively and sequentially grasping heart valve leaflets and independently, selectively and sequentially applying one or more fasteners thereto is disclosed. The device includes a leaflet engaging tip having one or more graspers capable of individually and sequentially grasping leaflets, and one or more deployable fasteners capable of fastening the leaflets. An actuation system for the device individually and selectively controls the graspers and deploys the one or more fasteners. Vacuum pressure from an external vacuum source can be used to grasp the leaflets via a selector system that controls the actuation system so as to individually and sequentially apply vacuum force to the graspers.

Owner:SCHRECK STEFAN

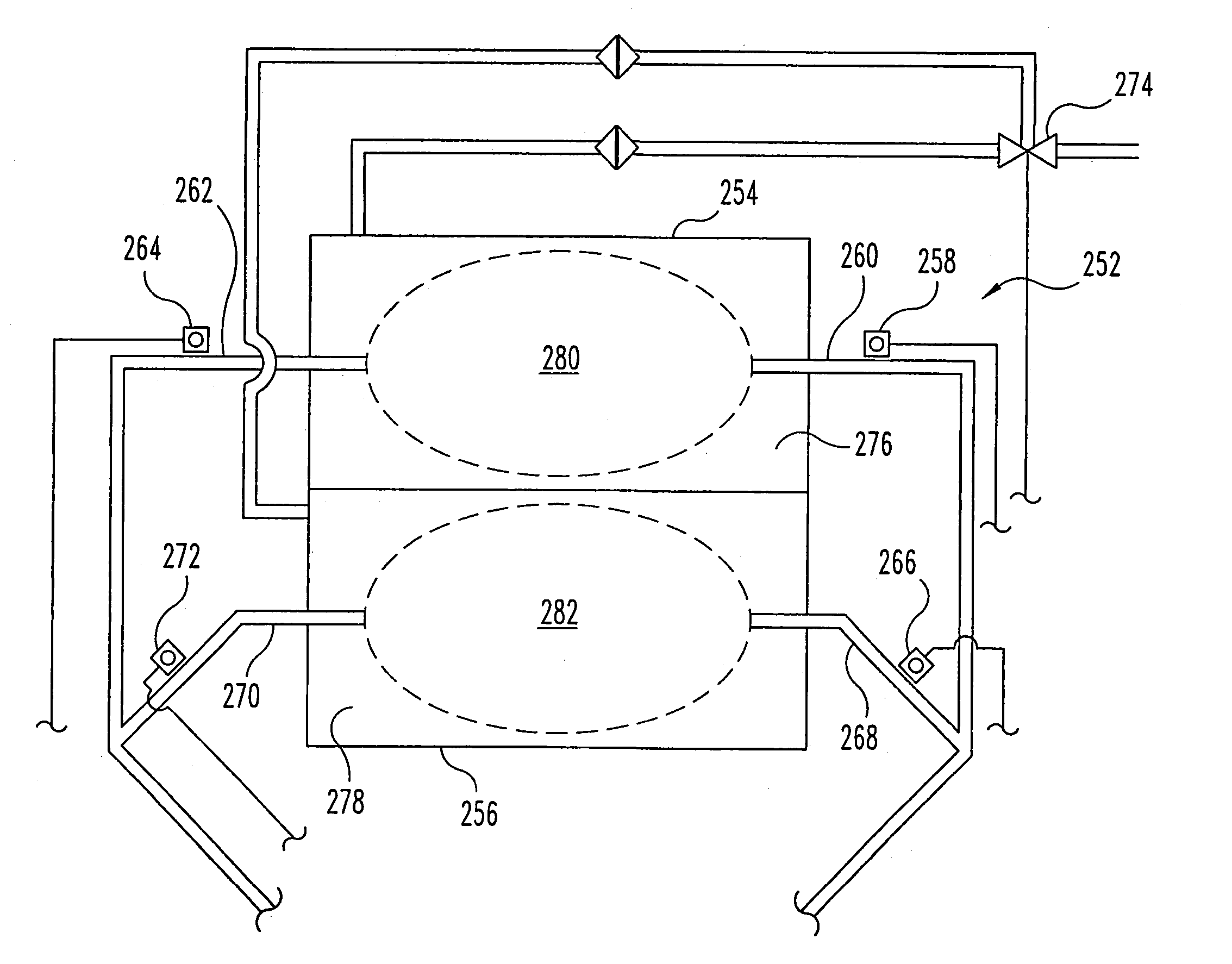

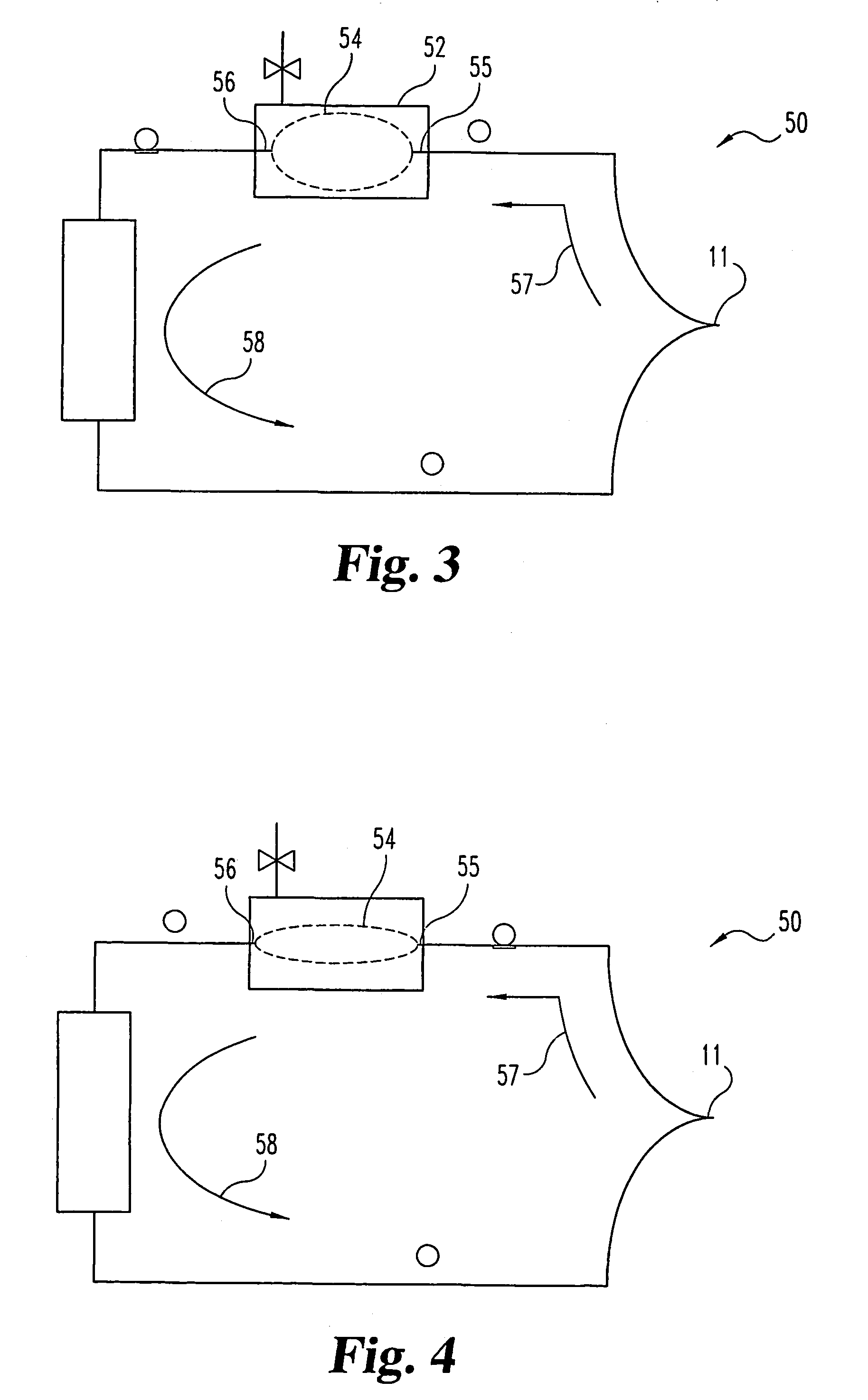

Device and methods for body fluid flow control in extracorporeal fluid treatments

Disclosed are devices and methods for the control of body fluid flow in the extracorporeal treatment of body fluid. Body fluid flow through on of a body fluid flow circuit (10, 50, 60, 100 or 250) is controlled by alternating applying vacuum pressure and positive pressure to the circuit through a pumping chamber (30, 51, 66, 102, or 200) coordinated with flow control valves (40, 42, 44, 62, 114, 116, 118, and 120) to effect a net downstream flow of body fluid through the circuit.

Owner:RENAL SOLUTIONS

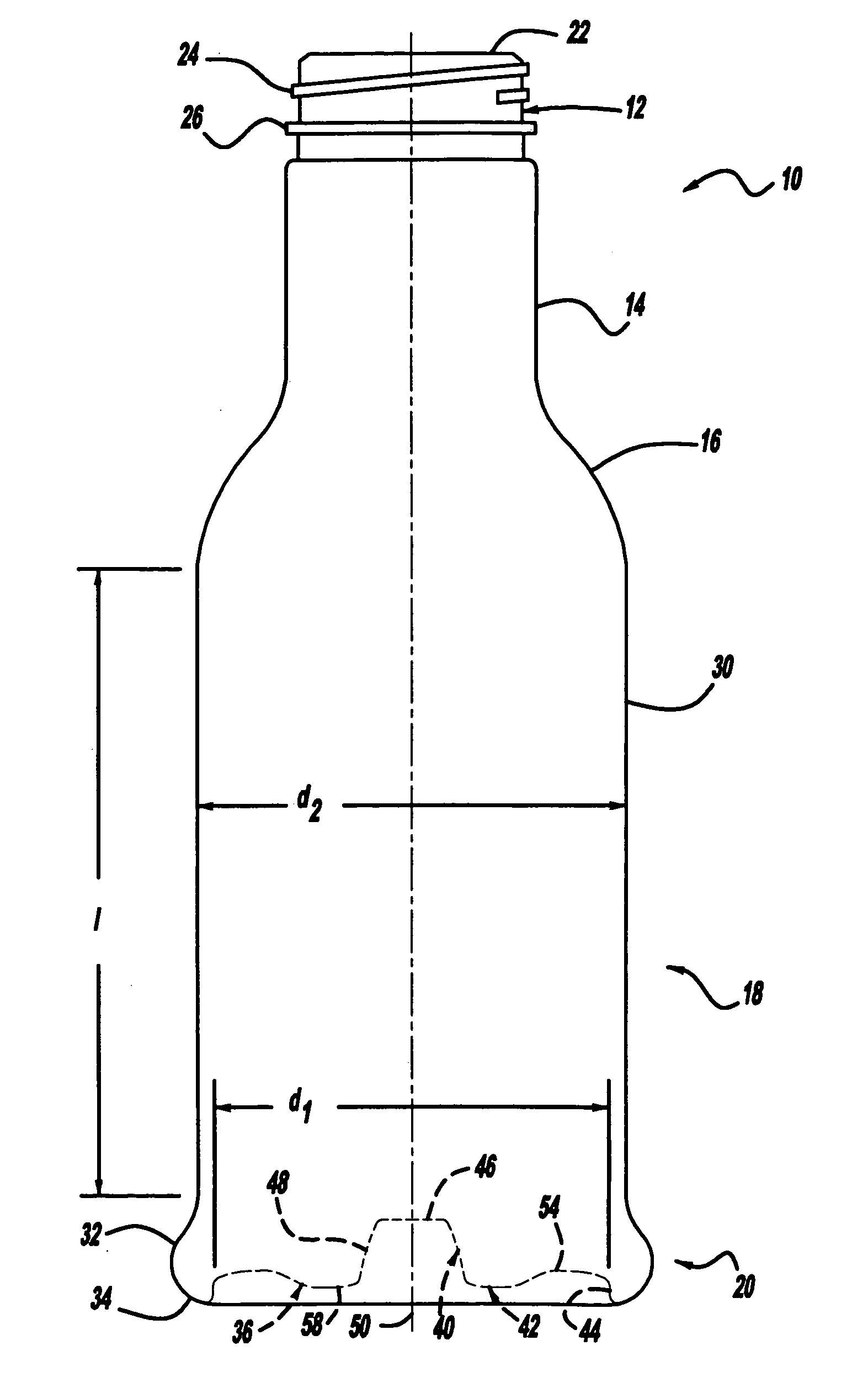

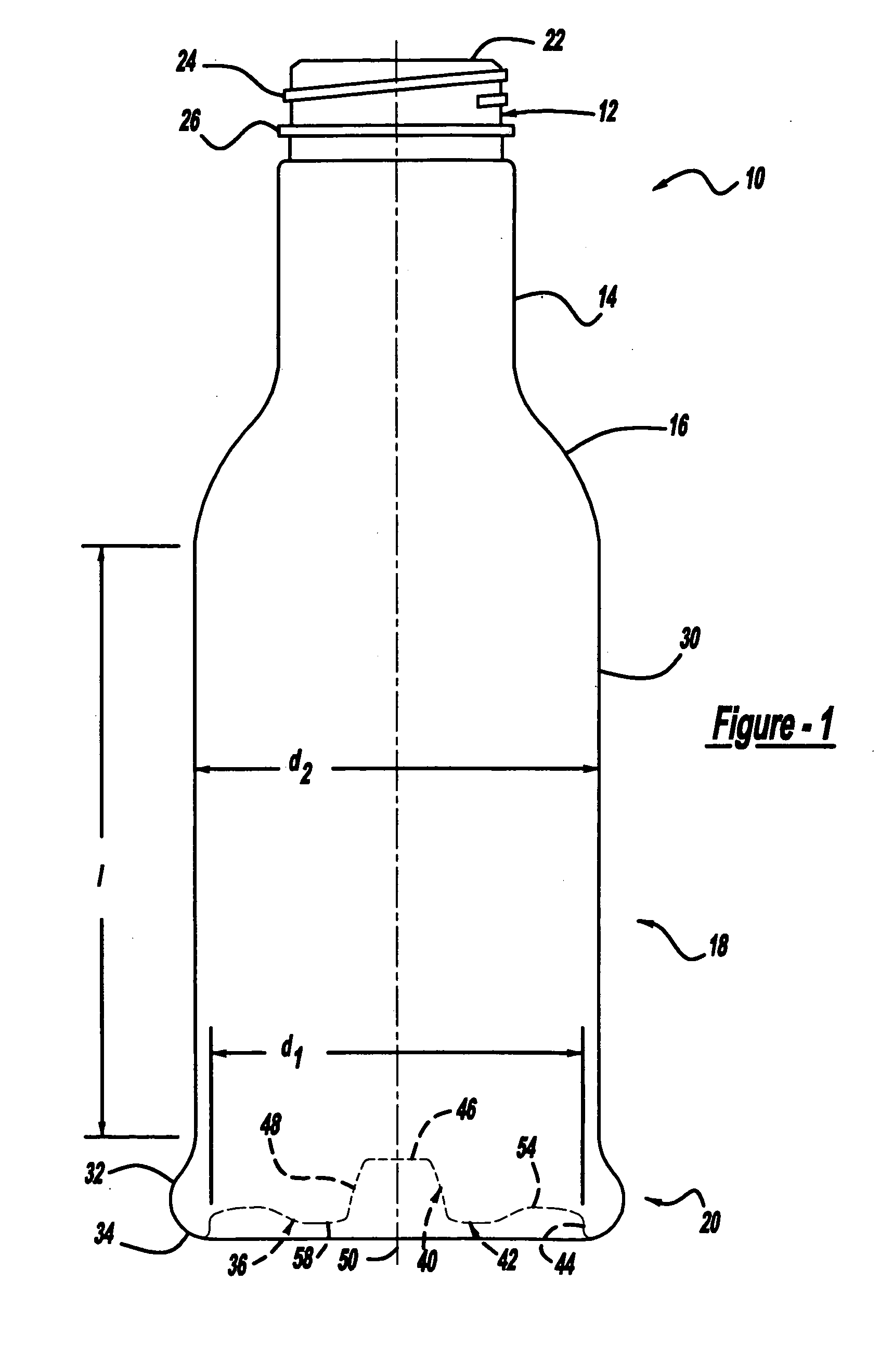

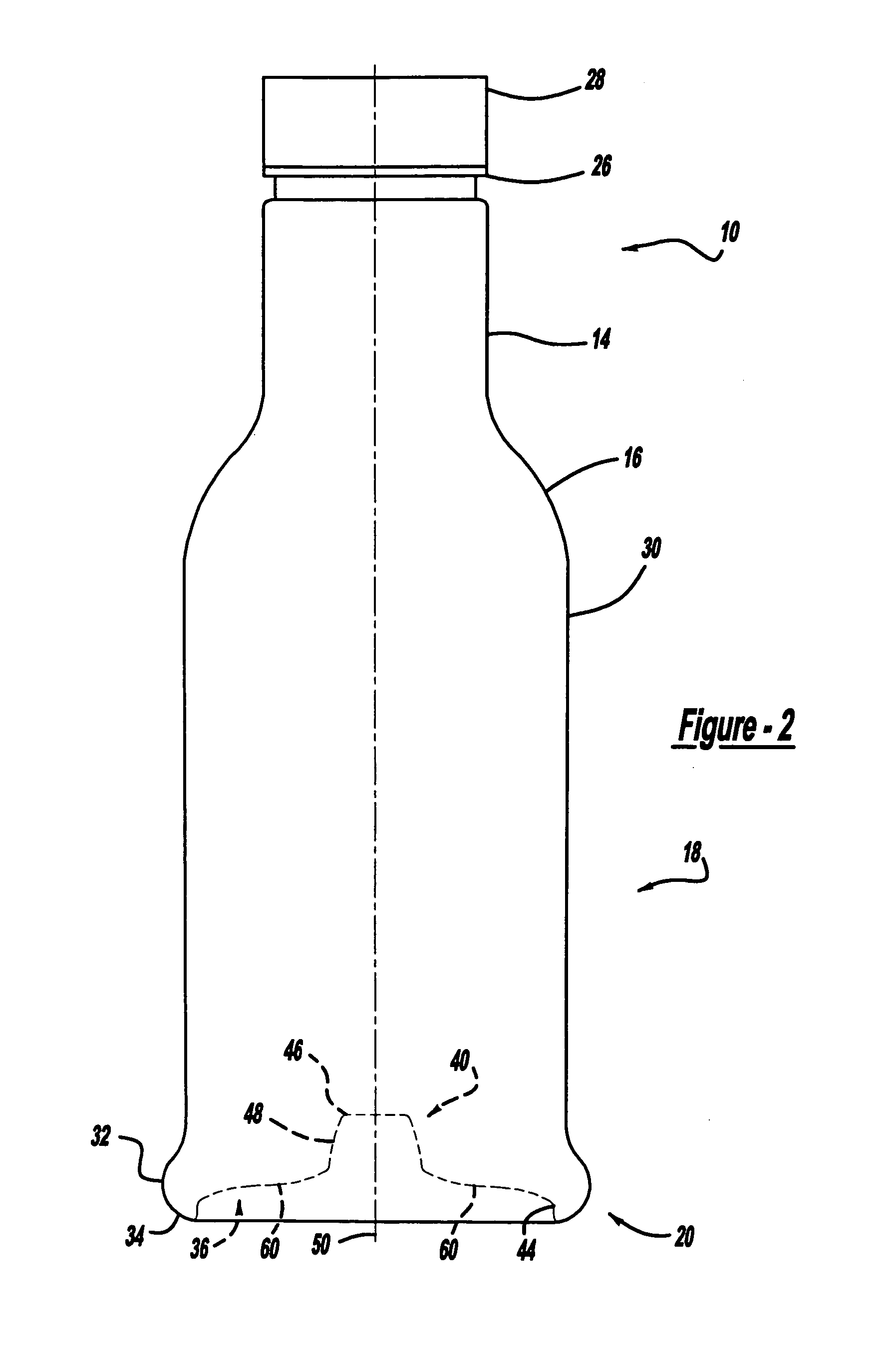

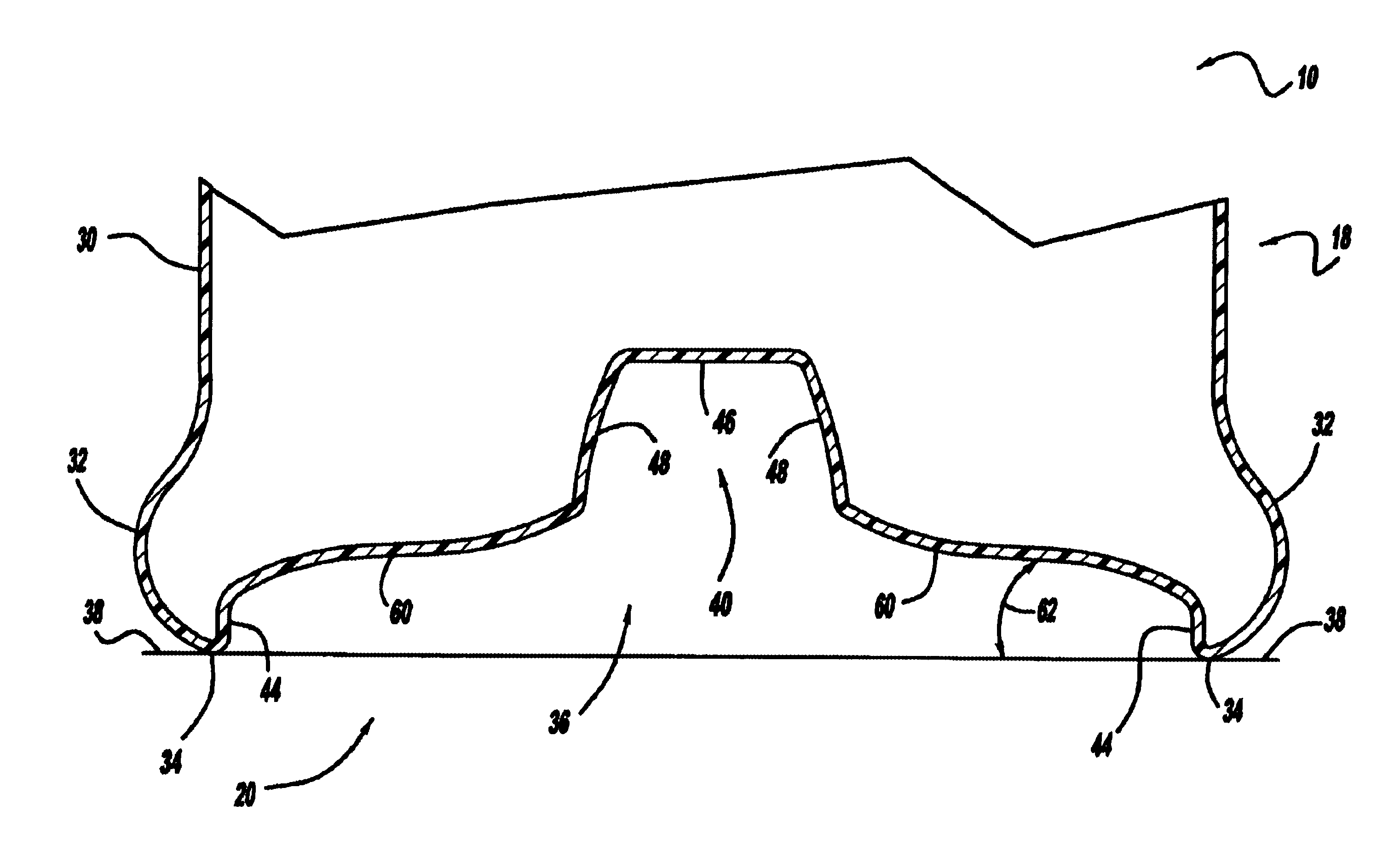

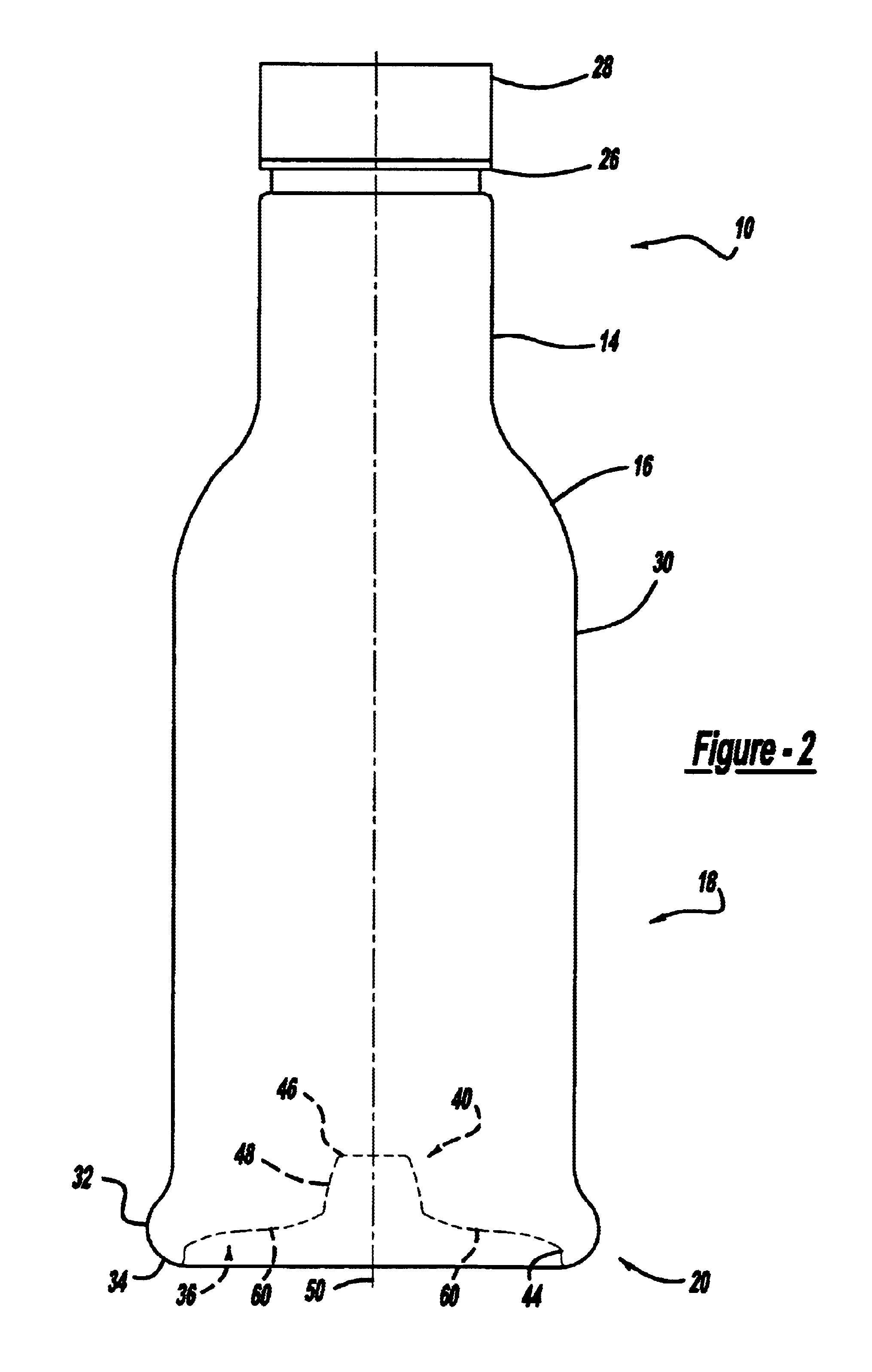

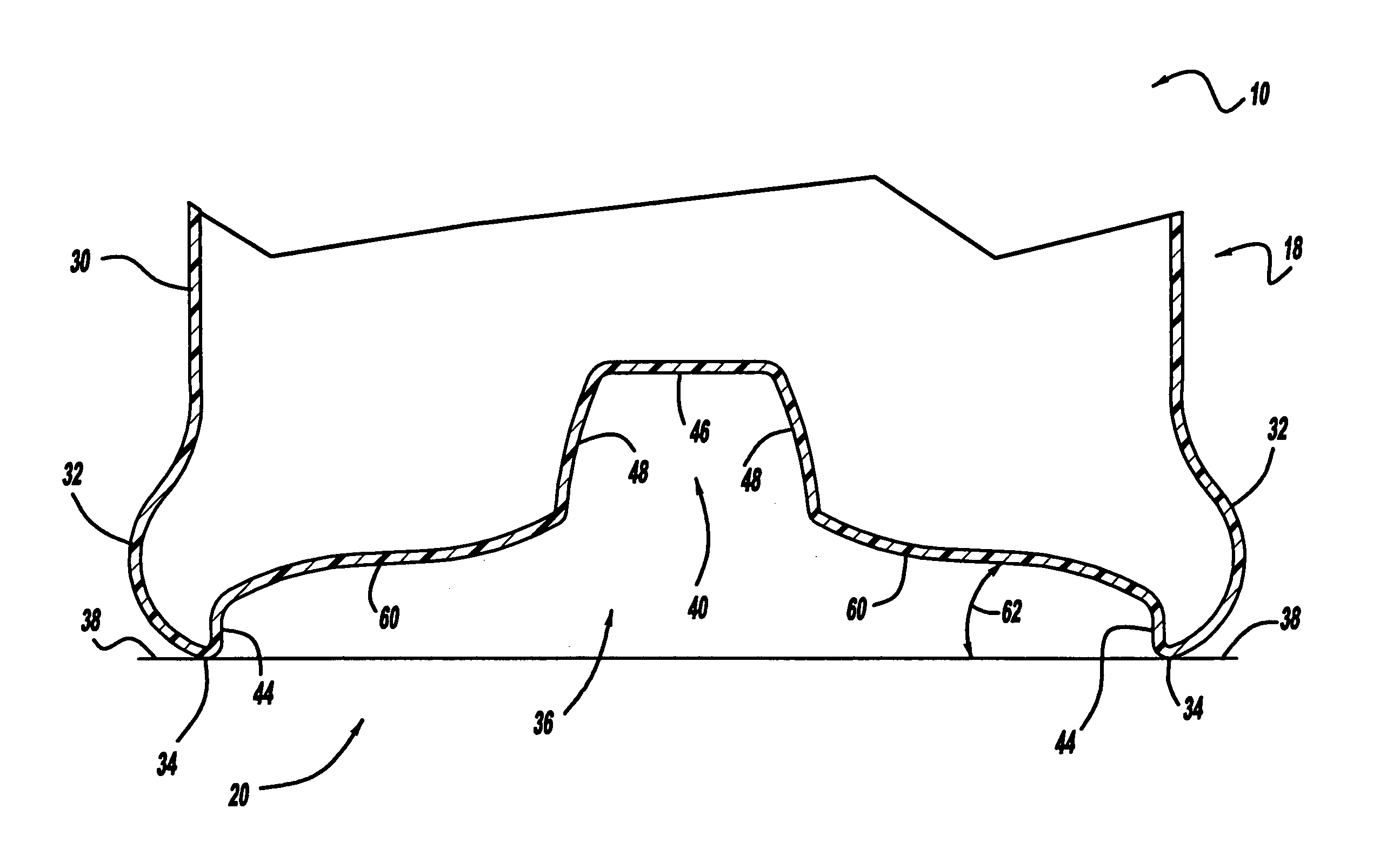

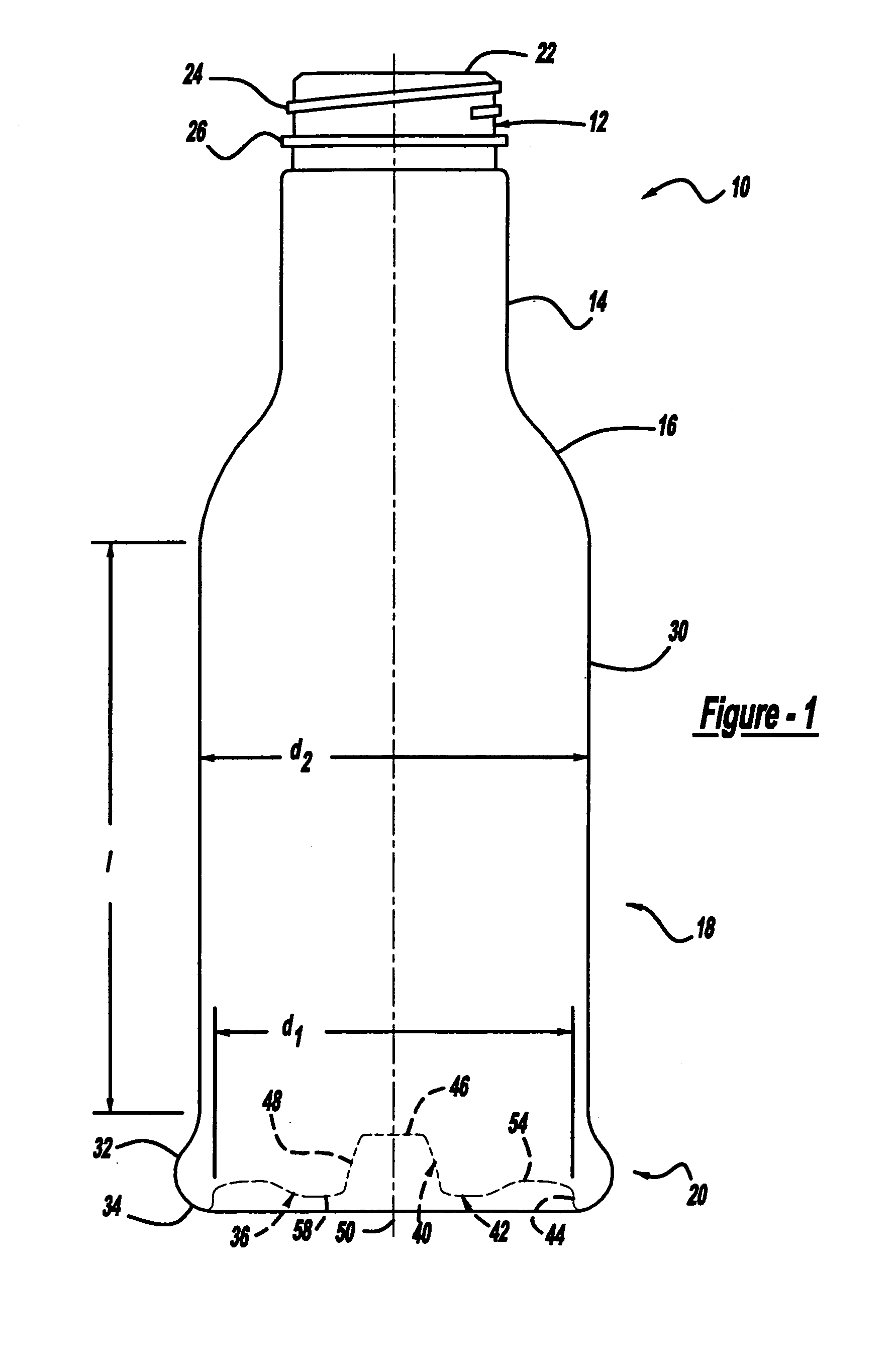

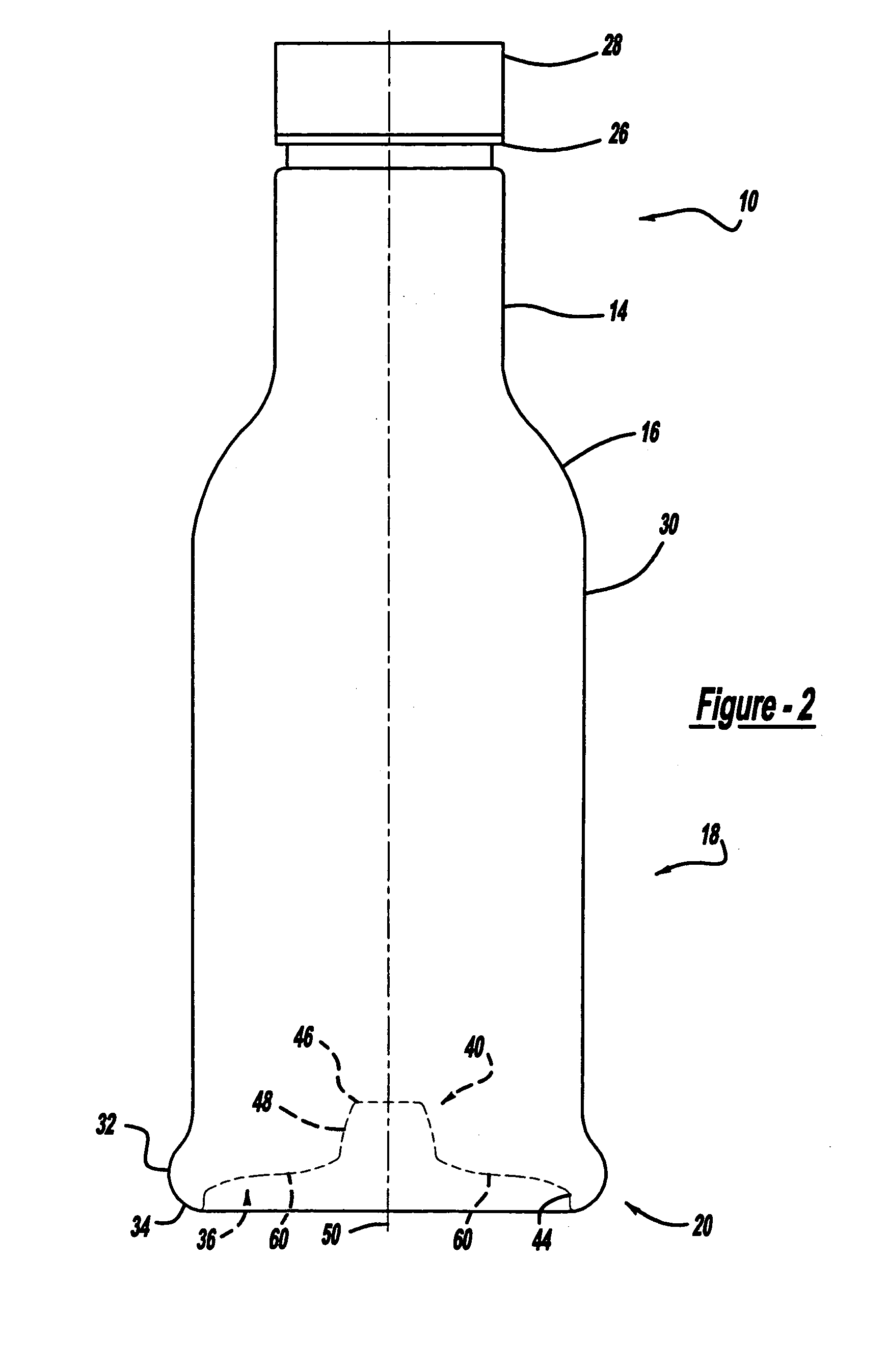

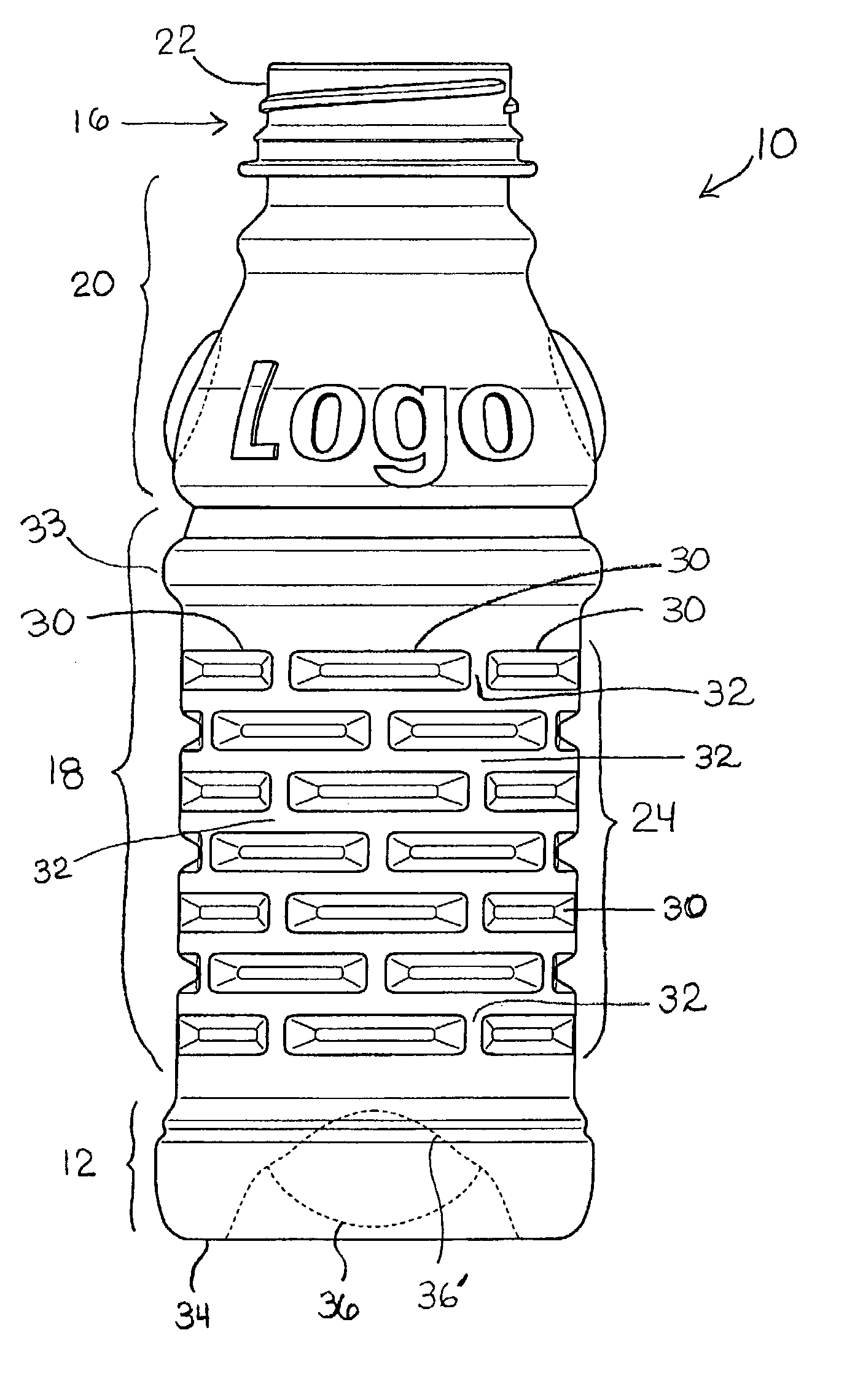

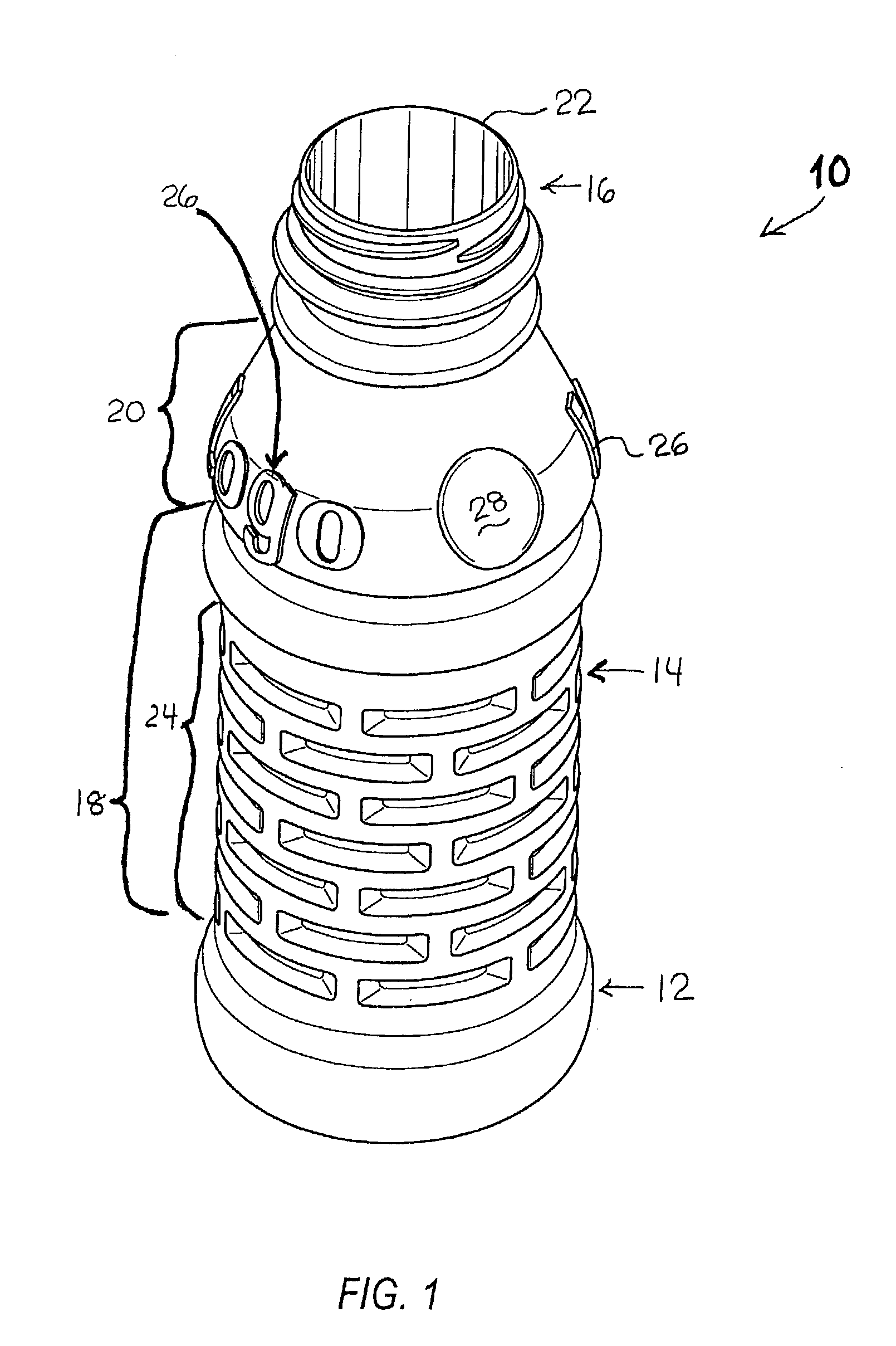

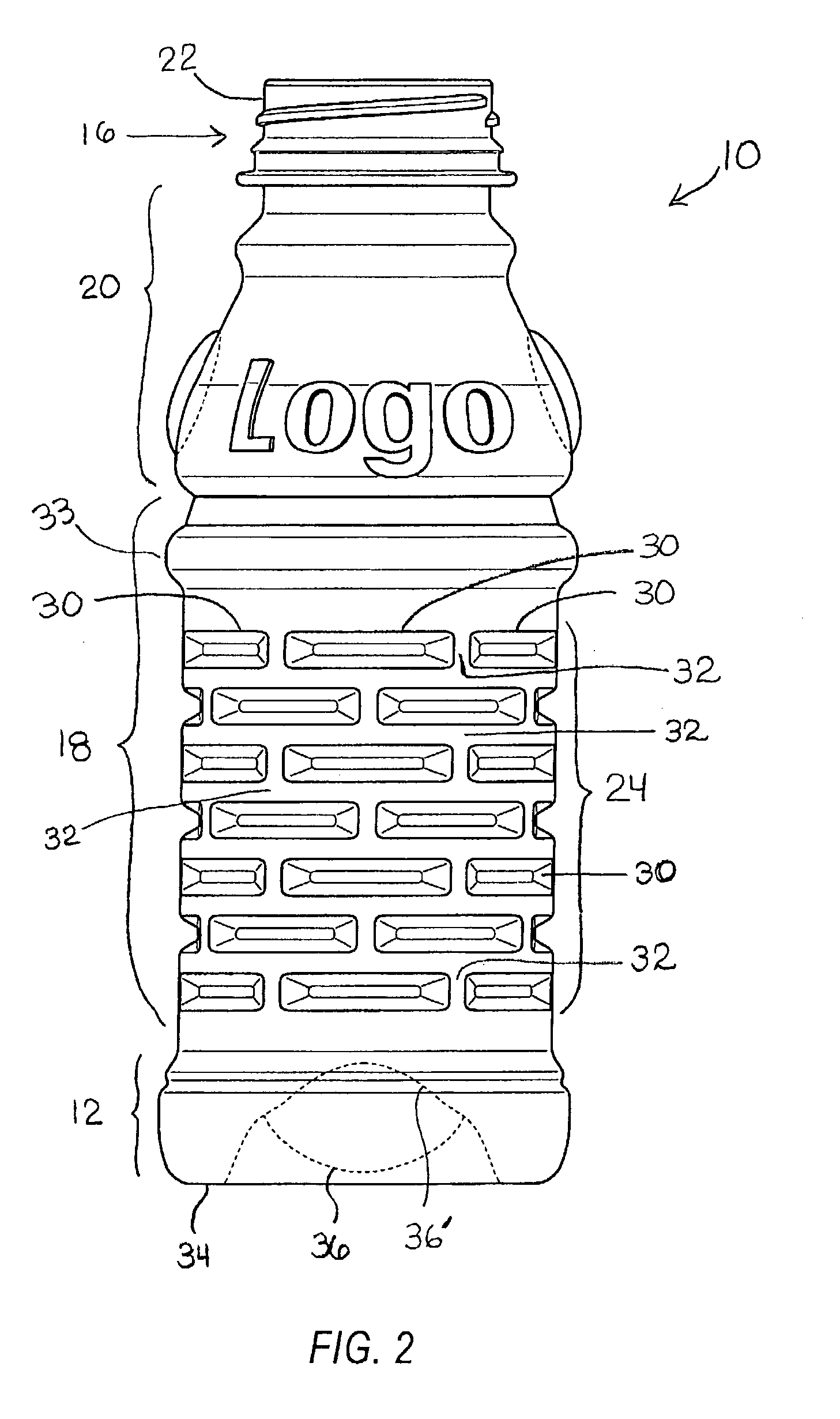

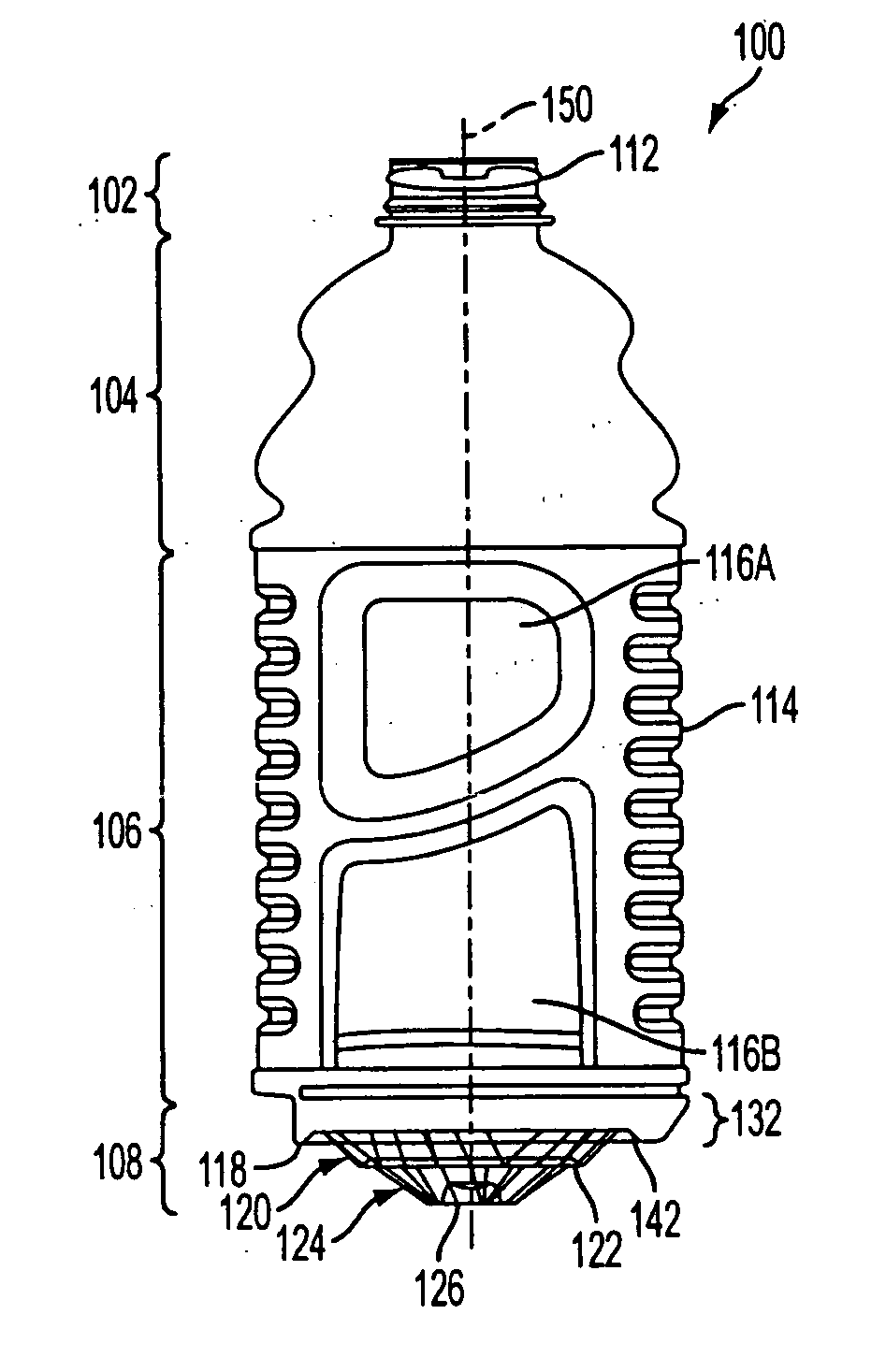

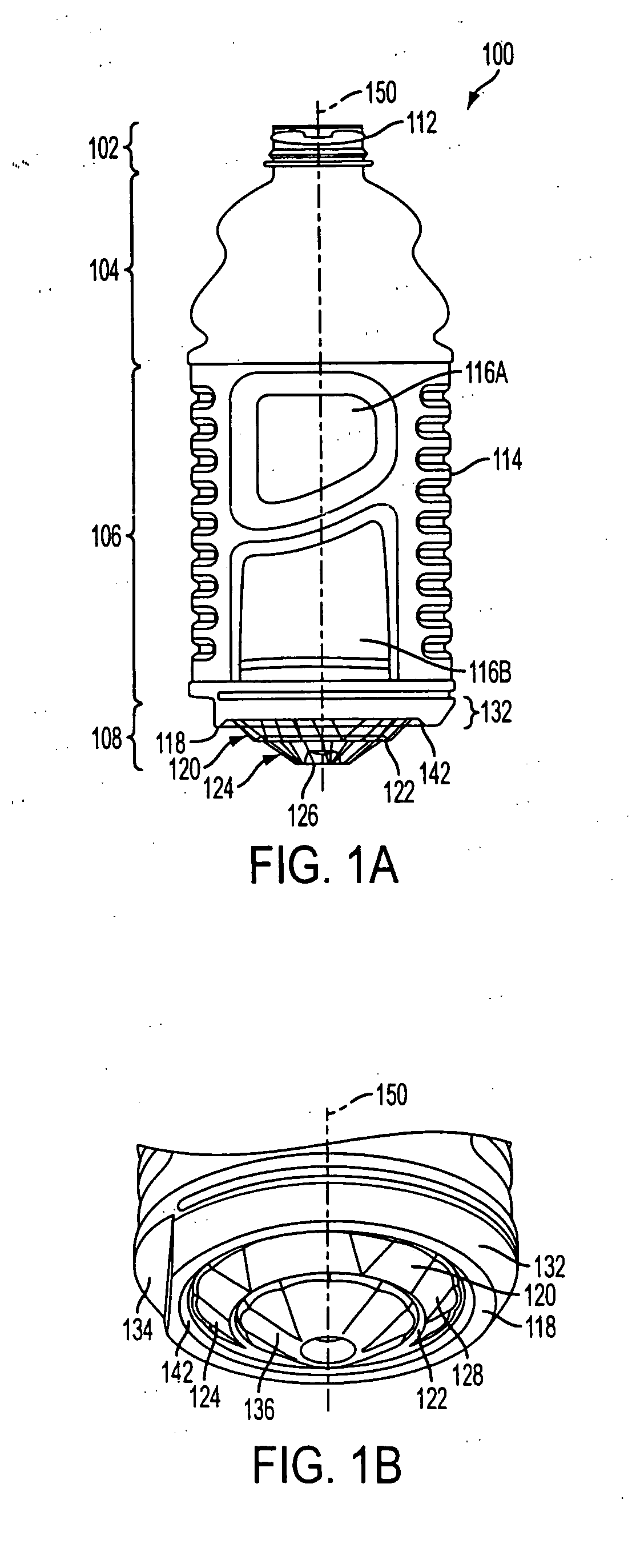

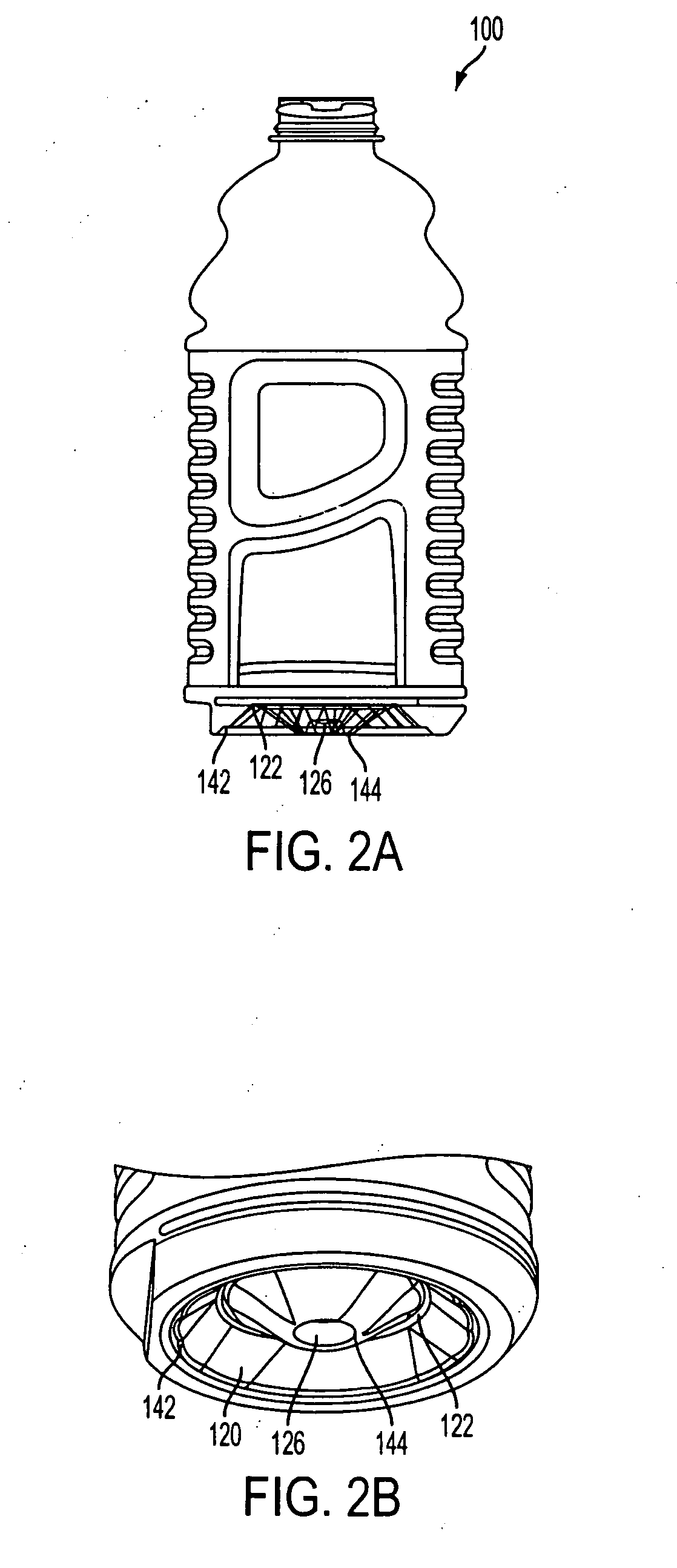

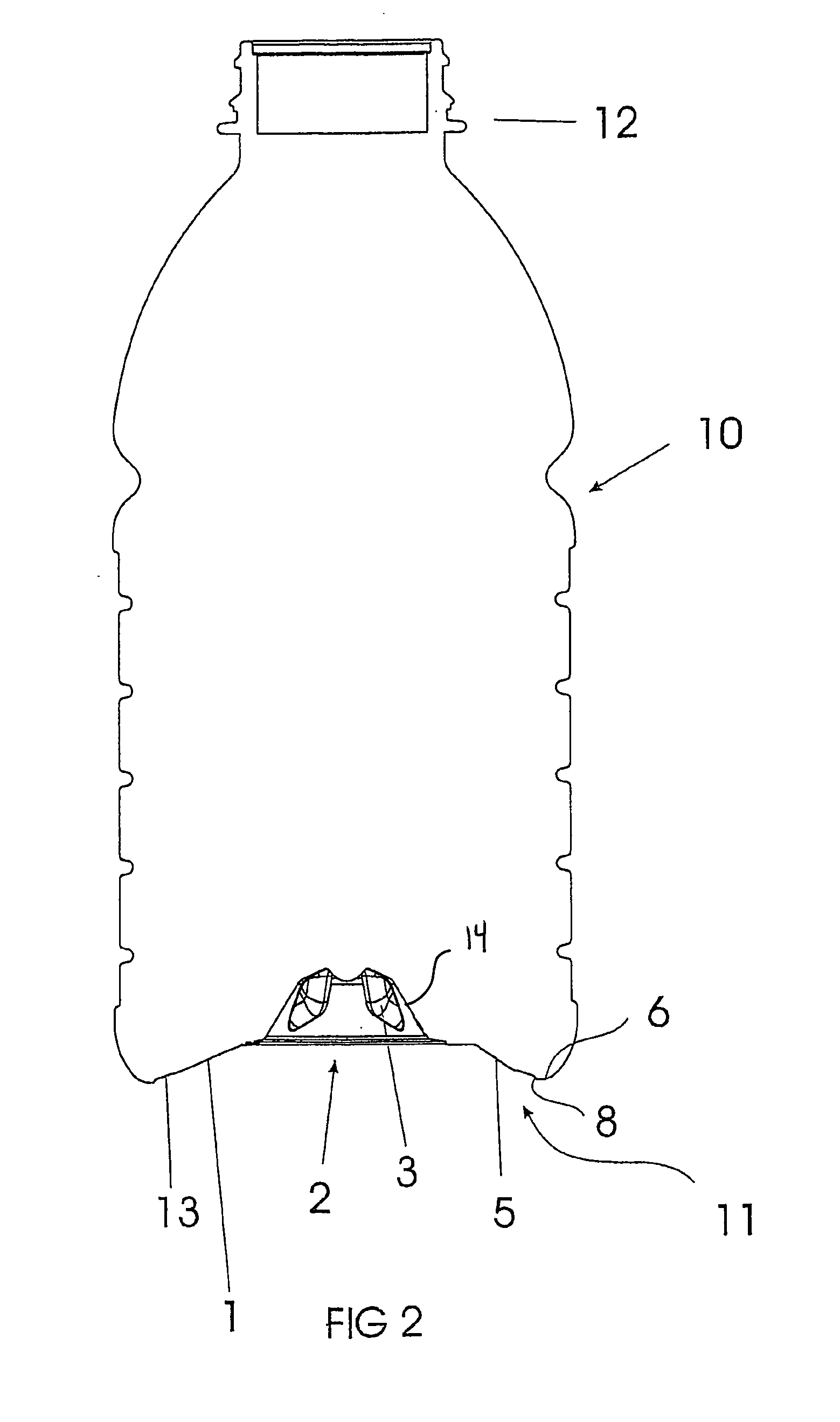

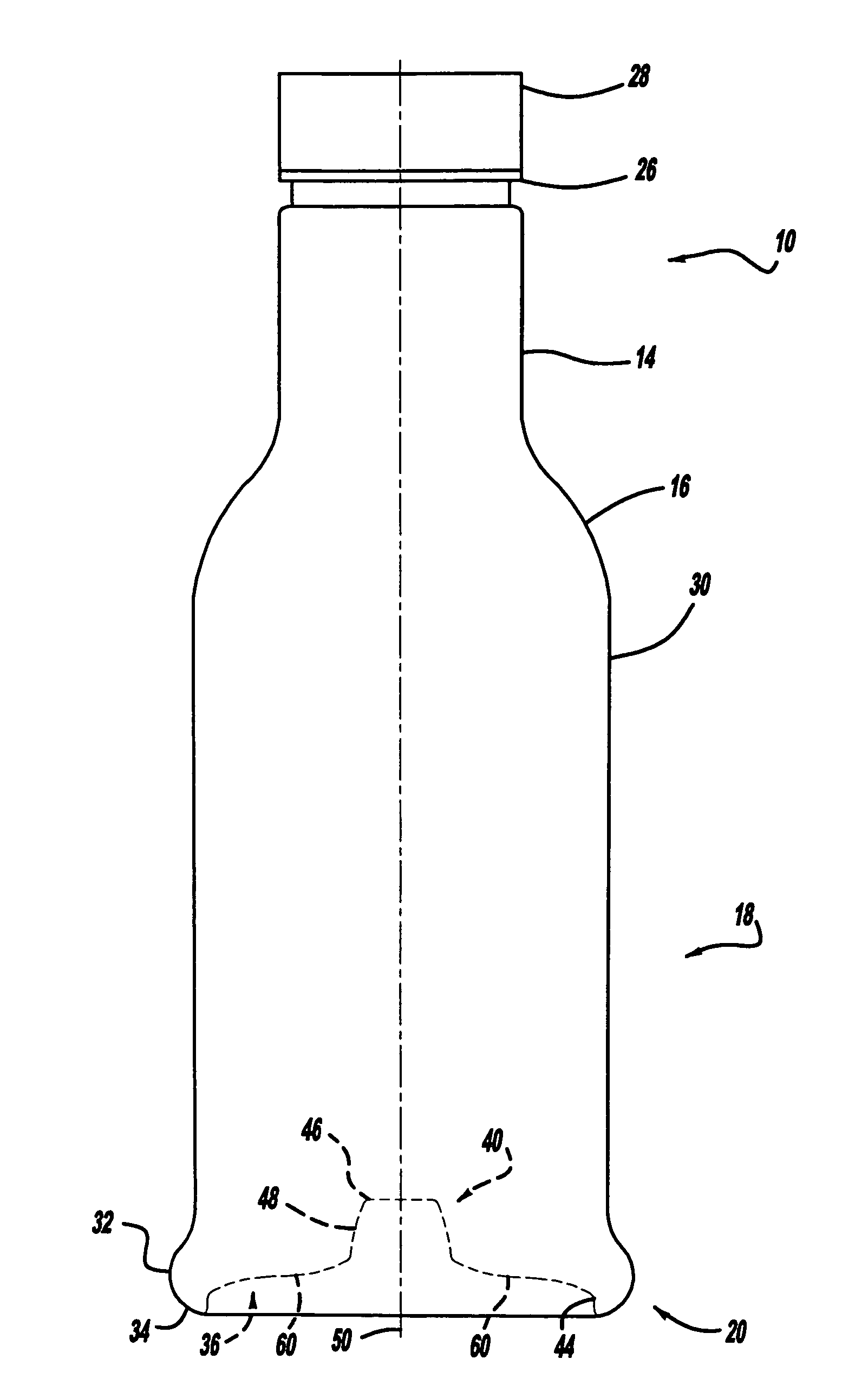

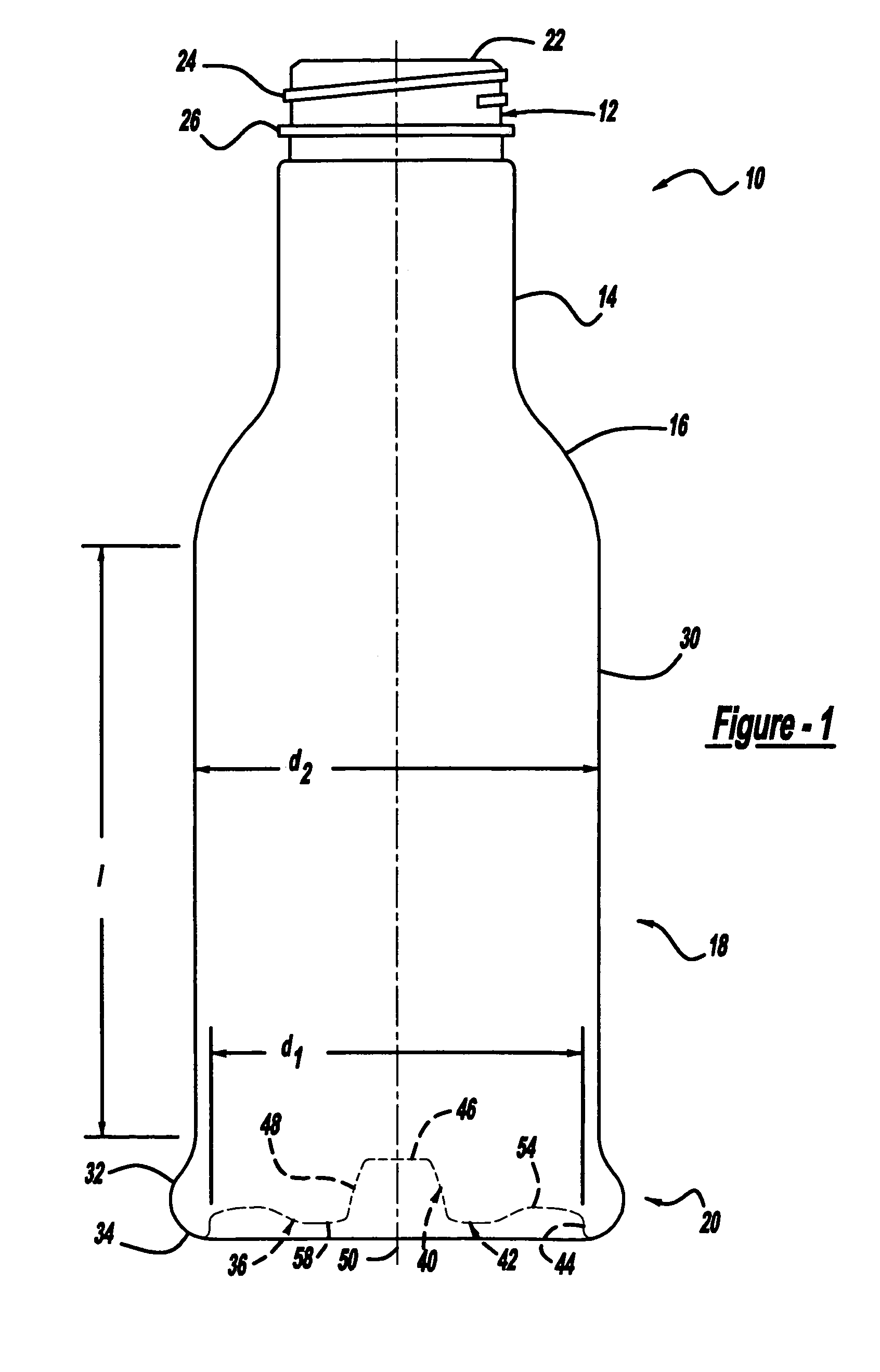

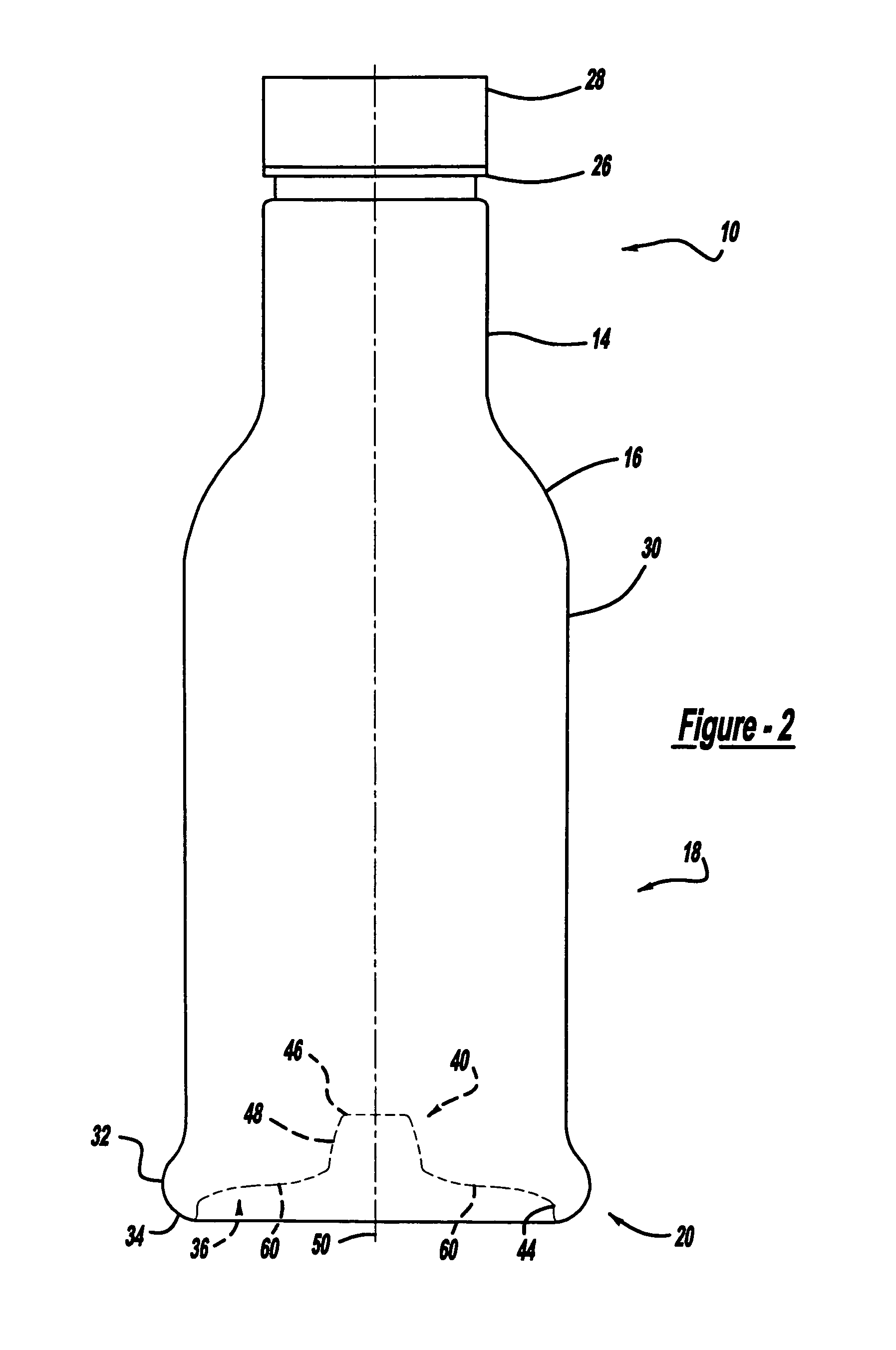

Container base structure responsive to vacuum related forces

A plastic container having a base portion adapted for vacuum pressure absorption. The base portion including a contact ring that supports the container, an upstanding wall, and a central portion. The upstanding wall being adjacent to and generally circumscribing the contact ring. The central portion defined in at least part by a pushup and an inversion ring that generally circumscribes the pushup. The pushup and the inversion ring being moveable to accommodate vacuum related forces generated within the container.

Owner:AMCOR RIGID PLASICS USA LLC

Self contained wound dressing apparatus

The composite wound dressing apparatus promotes healing of a wound via the use of a vacuum pump. The vacuum pump applies a vacuum pressure to the wound to effectively draw wound fluid or exudate away from the wound bed. The vacuum pump is tethered to the wound dressing and is portable, preferably, carried by the patient in a support bag, which permits patient mobility. Moreover, the patient does not need to be constrained for any period of time while exudate is being removed from the wound.

Owner:SMITH & NEPHEW INC

Tube attachment device for wound treatment

The invention provides a vacuum tube attachment device for vacuum assisted wound dressings. The device is in the form of a patch that can be attached to the primary wound cover. The patch forms a substantially air-tight seal to the primary wound cover, and a vacuum tube is fixed to the patch such that the patch can be oriented on the wound cover to locate the tube near an opening in the cover to allow vacuum pressure to be communicated to the wound. The patch has an adhesive area around its perimeter for attaching the patch in a substantially air-tight seal to the wound cover at any convenient location on the cover. Several embodiments of the patch are described.

Owner:PAUL HARTMANN AG

Container base structure responsive to vacuum related forces

A plastic container having a base portion adapted for vacuum pressure absorption. The base portion including a contact ring upon which the container is supported, an upstanding wall and a central portion. The upstanding wall being adjacent to and generally circumscribing the contact ring. The central portion being defined in at least part by a central pushup and an inversion ring which generally circumscribes the central pushup. The central pushup and the inversion ring being moveable to accommodate vacuum forces generated within the container.

Owner:AMCOR RIGID PLASICS USA LLC

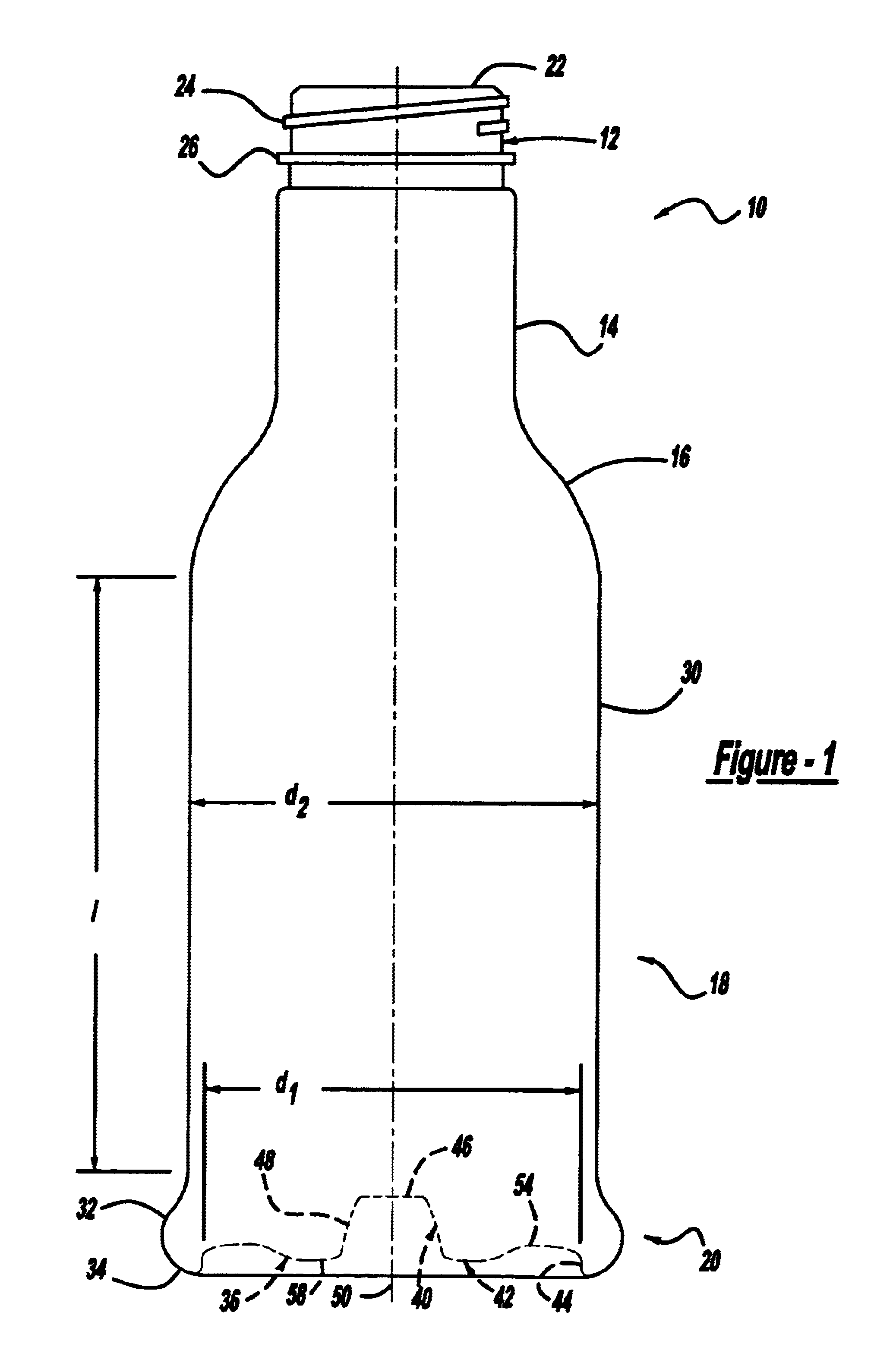

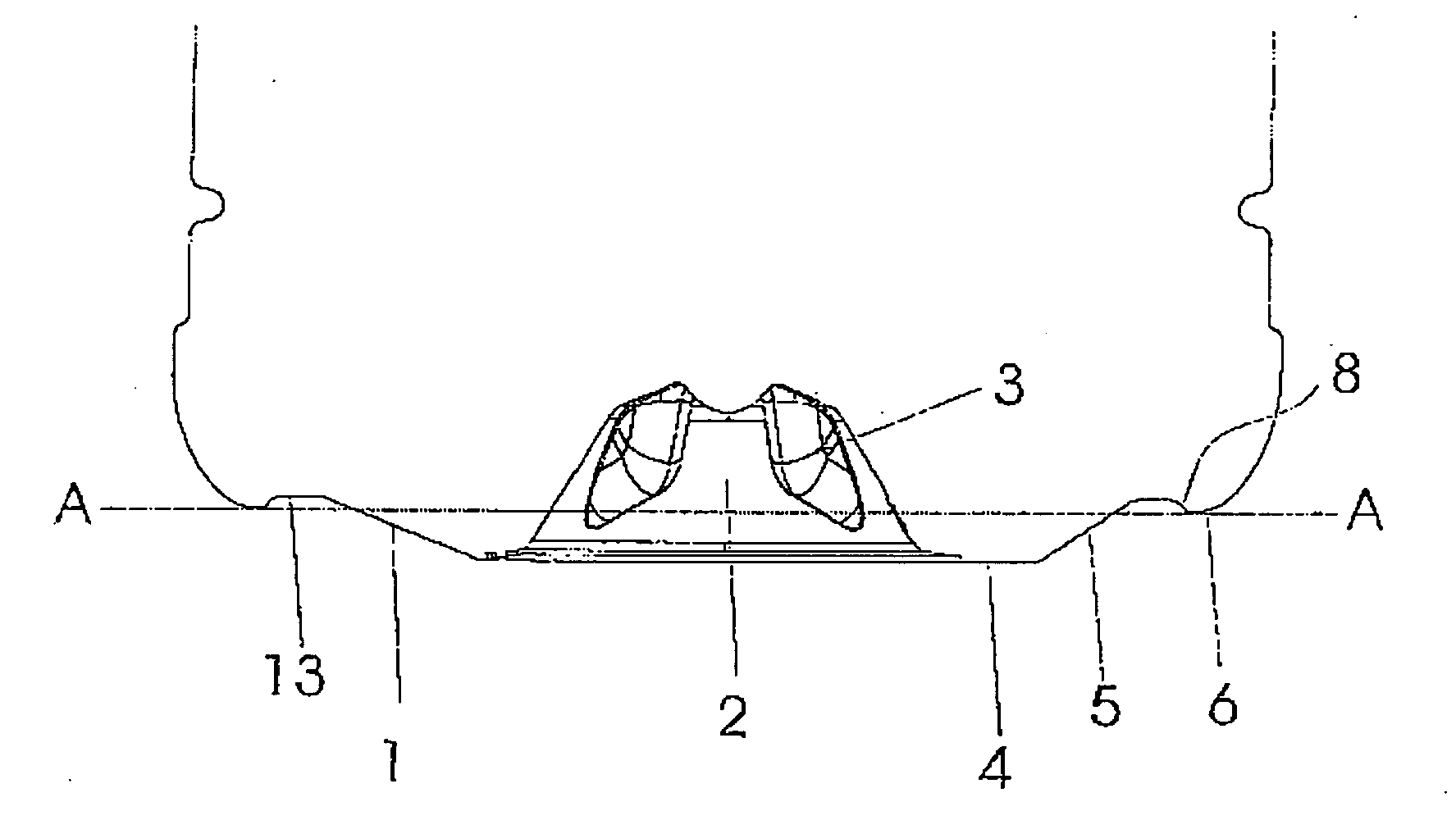

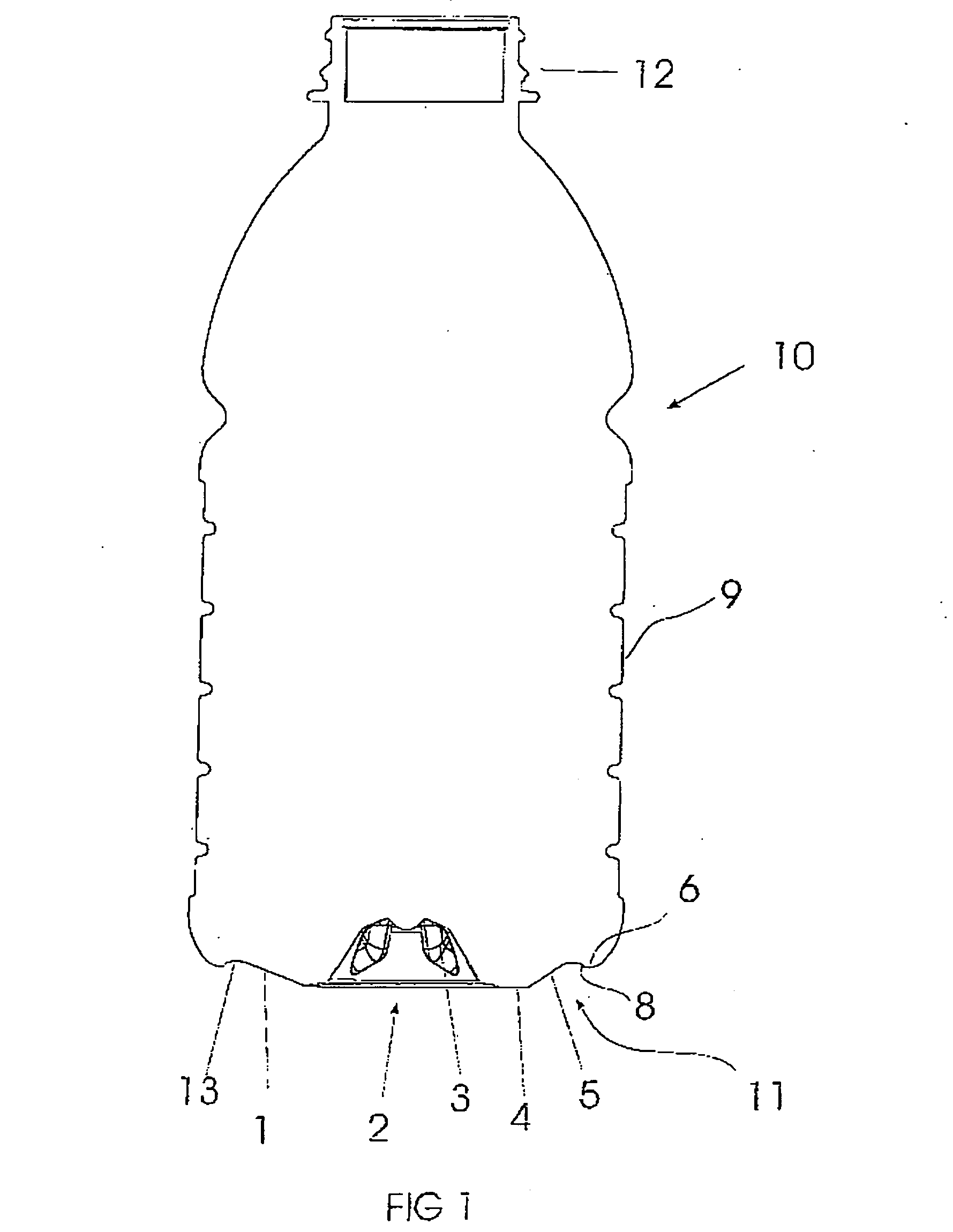

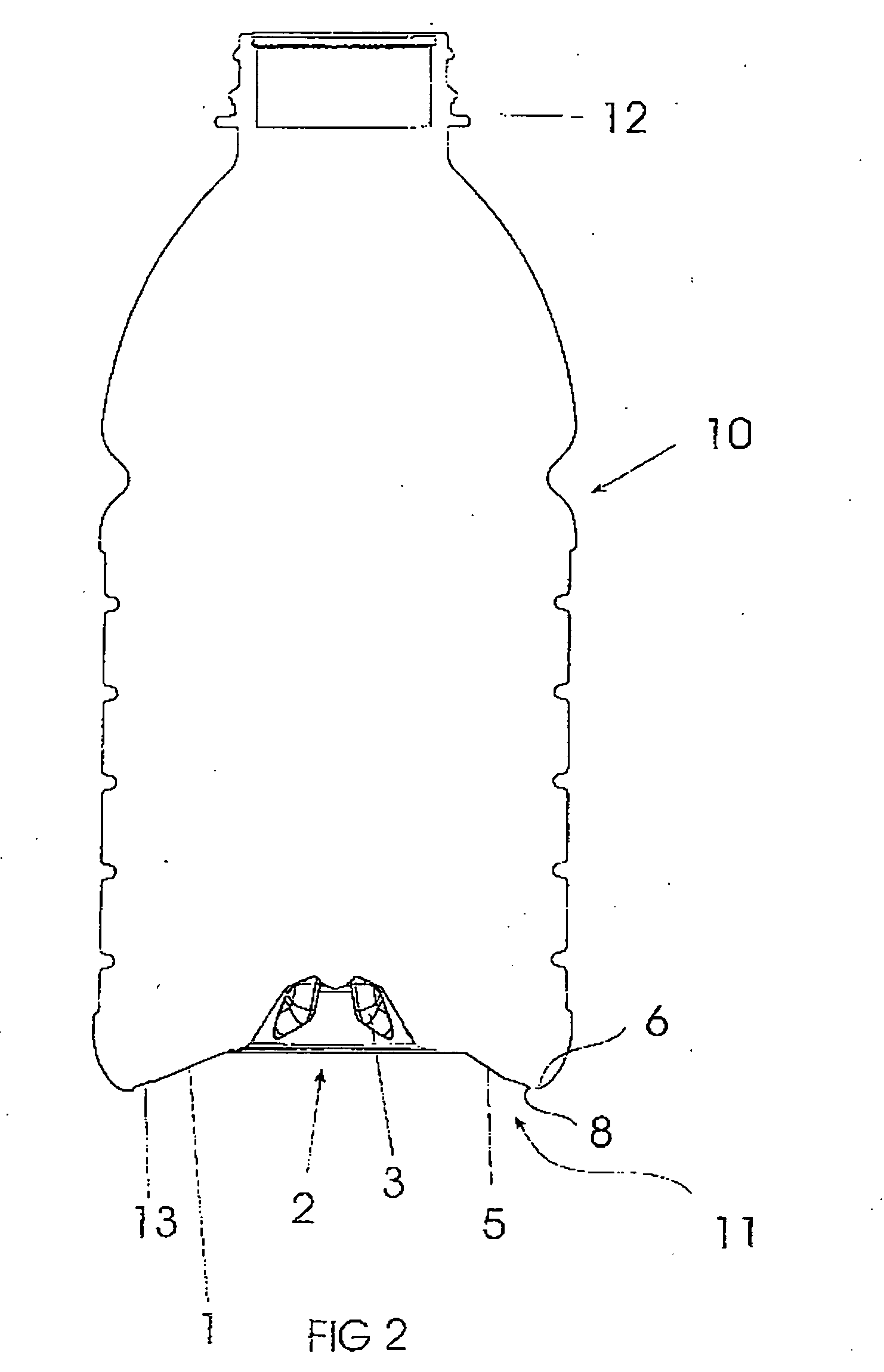

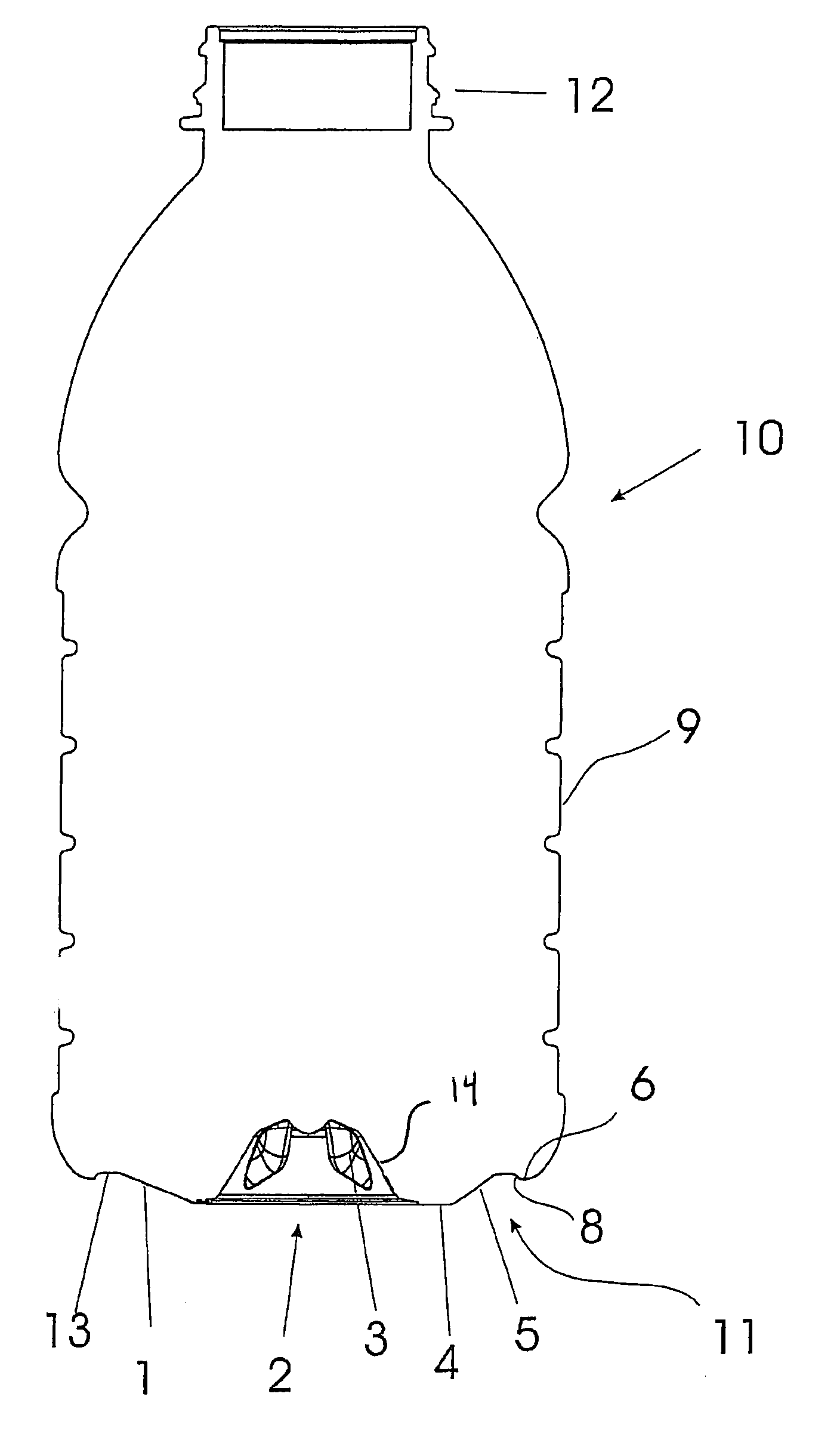

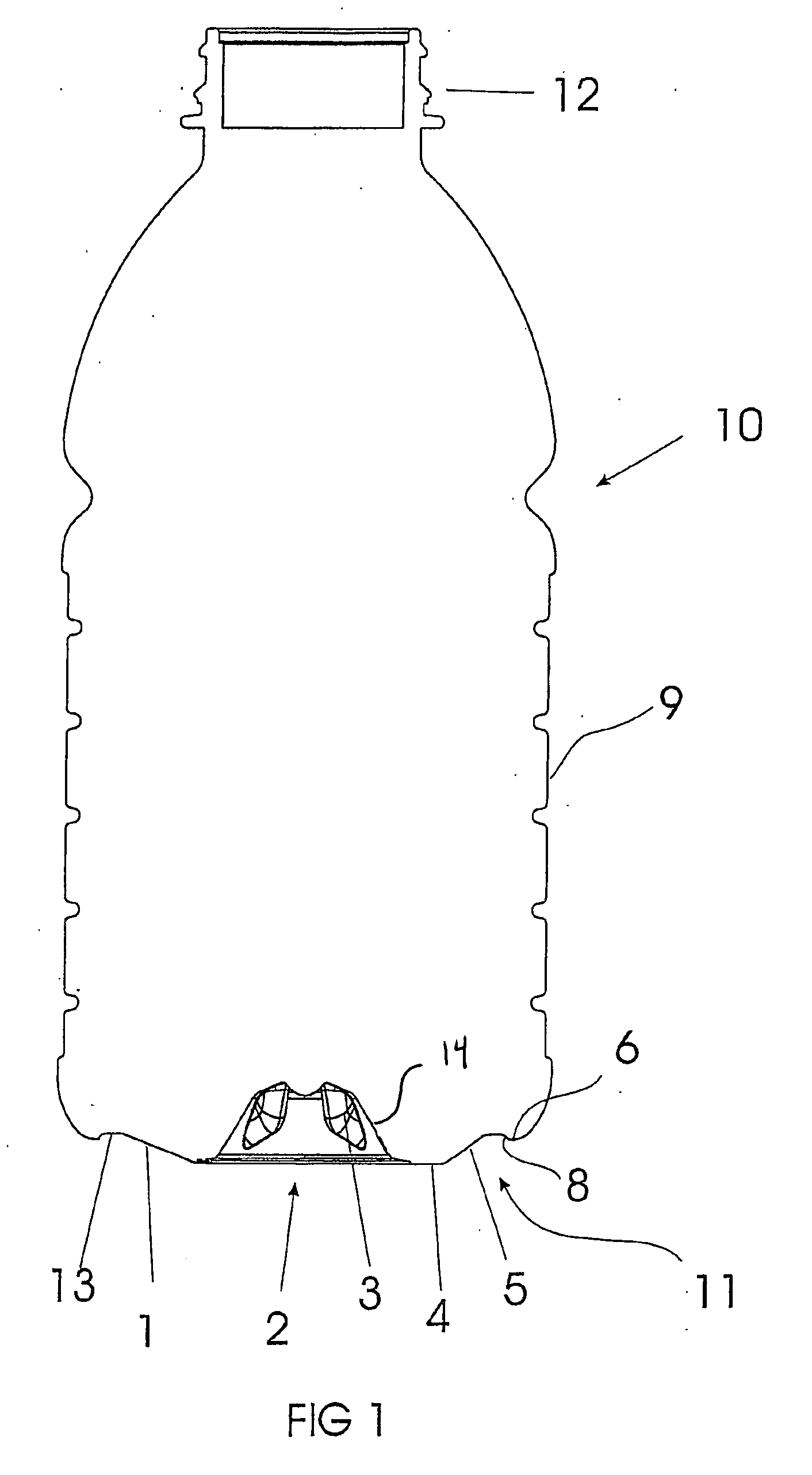

Container structure for removal of vacuum pressure

A hot-fill PET container or bottle (10) filling with a liquid at an elevated temperature has a side wall (9) extending to a lower portion including a pressure panel (11) and a base (21) in its unfolded or pre-fill position. The panel (11) is transversely oriented and has a decoupling or hinge structure (13), an initiator portion (1) and control portion (5) of a steeply angled inverting conical section between 30 and 45 degrees. The control portion enables the inversion of the panel (11) into the container (10) to compensate for vacuum or reduced pressure induced within the container as the liquid cools down. The base (2) can also have a plurality of reinforcing ribs (3).

Owner:CO2 PAC

Biopsy device for removing tissue specimens using a vacuum

InactiveUS20070149894A1Simple and reliable and uncomplicated in structureSufficient quantityGuide needlesCannulasVacuum pressureTissue sample

A biopsy device for taking tissue samples, includes a housing, a removable element and a control panel. The housing contains an electric power source and a tension slide connected to the power source. The tension slide may be brought into a cocked position against the action of a spring by the power source. The removable element is configured for insertion into the housing and includes a biopsy needle unit, a vacuum pressure-generating device and a control panel. The removable element may be provided as a sterile package unit. The biopsy needle unit can be arranged on the tension slide and includes a hollow biopsy needle with a sample removal chamber and a cutting sheath. The biopsy device can be held in one hand and is fully integrated with all components required to perform a vacuum biopsy such that no cables or lines are required to other external units.

Owner:CR BARD INC

Sequential heart valve leaflet repair device and method of use

InactiveUS7094244B2Effective and stableReduce distanceSuture equipmentsHeart valvesVacuum pressureTissue repair

A heart valve and tissue repair device for independently, selectively and sequentially grasping heart valve leaflets and independently, selectively and sequentially applying one or more fasteners thereto is disclosed. The device includes a leaflet engaging tip having one or more graspers capable of individually and sequentially grasping leaflets, and one or more deployable fasteners capable of fastening the leaflets. An actuation system for the device individually and selectively controls the graspers and deploys the one or more fasteners. Vacuum pressure from an external vacuum source can be used to grasp the leaflets via a selector system that controls the actuation system so as to individually and sequentially apply vacuum force to the graspers.

Owner:EDWARDS LIFESCIENCES CORP

Tissue sampling and removal apparatus and method

InactiveUS7513877B2Improve cutting effectAbility to retrieve multiple samplesSurgical needlesVaccination/ovulation diagnosticsVacuum pressureTissue sample

A tissue sampling device (10) for retrieving one or more tissue samples from a patient is either handheld or mounted to a moveable carriage (184) and advanced so that the needle tip (152) is introduced into the patient. The needle tip (152) is advanced until the tissue receiving basket (154) reaches the tissue sample target zone (190). Vacuum pressure is supplied to the basket (154) via a vacuum tube (144) so that tissue to be sampled is drawn into the basket (154). The cutter (42) is rotated and advanced linearly to cut a tissue sample (212) which is then retrieved by retracting the needle (40).

Owner:TYCO HEALTHCARE GRP LP

Container base structure responsive to vacuum related forces

Owner:AMCOR RIGID PLASICS USA LLC

Hot fillable container with flexible base portion

A plastic container comprised of a closed base, a body portion, and a neck portion with a dispensing opening. The closed base includes a substantially rigid support portion and a flexible portion. The body portion preferably includes a shoulder portion and a substantially rigid wall portion that includes a plurality of reinforcement formations. The container is configured so that the flexible portion of the base contracts upwardly about the support portion in response to vacuum pressures generated within the container, while the substantially rigid support portion of the sidewall remains substantially firm, for example, to accept or receive a label. If desired, the shoulder portion may include a logo and / or one or more pressure relief formations. A method for producing hot-filled, labeled containers is also disclosed.

Owner:PLASTIPAK PACKAGING

Container and method for blowmolding a base in a partial vacuum pressure reduction setup

ActiveUS20070215571A1Significant distortionPrevents substantial net distortionLarge containersDomestic articlesVacuum pressureEngineering

A base of a container may include a standing surface, a first wall, a second wall, a first hinge, and a second hinge. The first hinge may be positioned between the standing surface and the first wall, the first wall being rotateable about the first hinge relative to a longitudinal axis of the container. The second hinge may be positioned between the first wall and the second wall, the second wall being rotateable about the second hinge relative to the longitudinal axis of the container, where rigidity of the base prevents substantial net distortion of the base during rotation of the second wall.

Owner:CO2 PAC

Container structure for removal of vacuum pressure

Owner:CO2 PAC

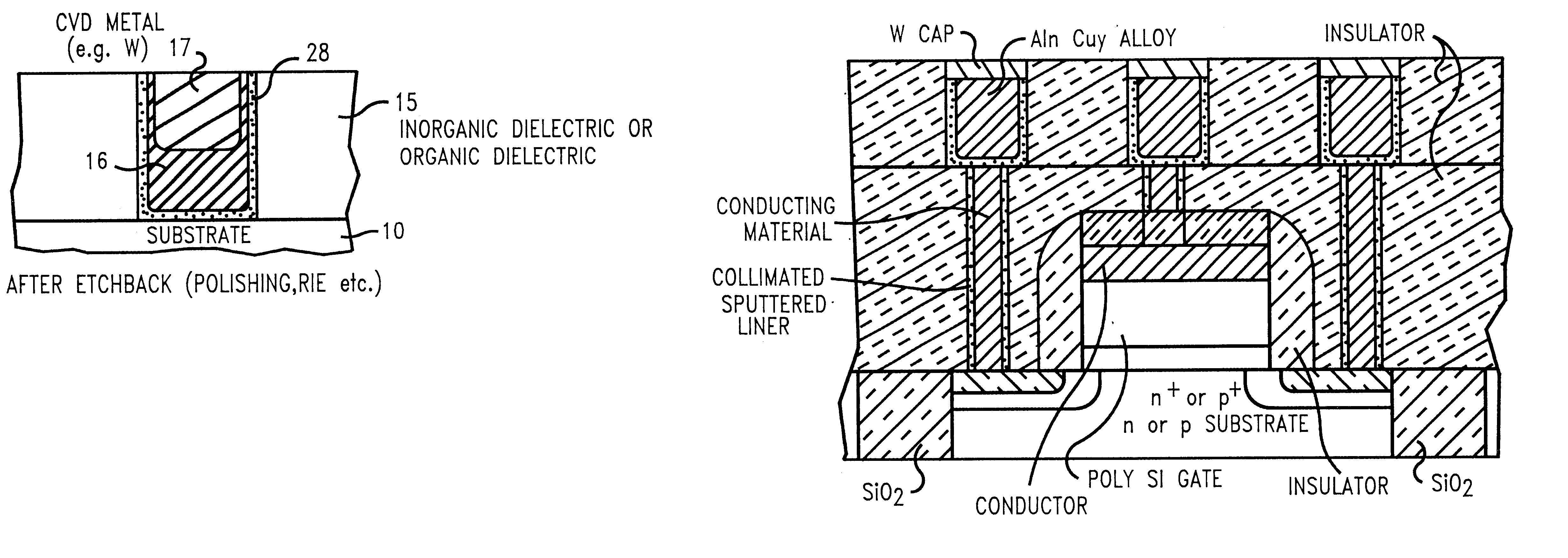

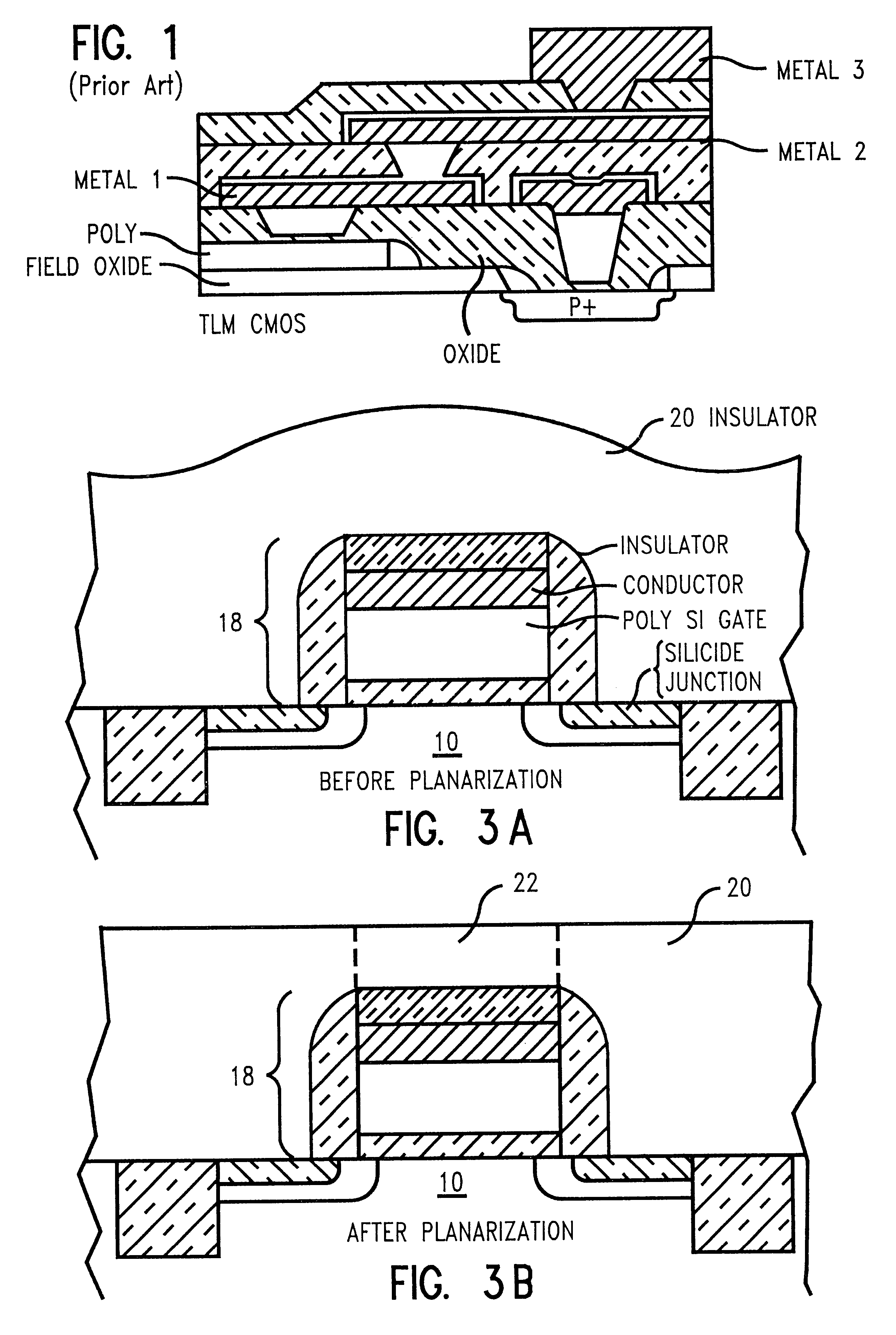

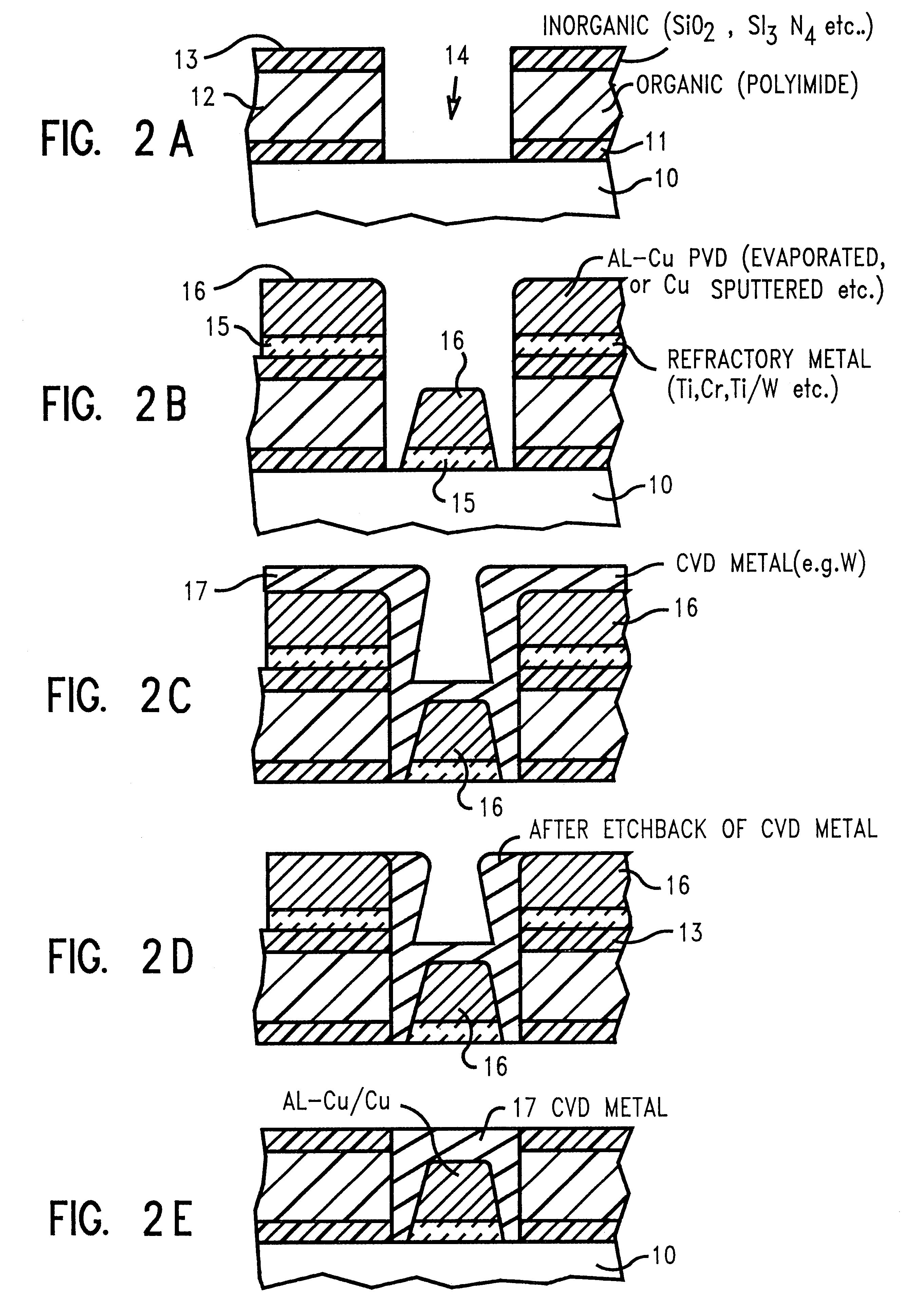

Refractory metal capped low resistivity metal conductor lines and vias formed using PVD and CVD

InactiveUS6323554B1High process yieldSemiconductor/solid-state device detailsSolid-state devicesDielectricGas phase

Capping a low resistivity metal conductor line or via with a refractory metal allows for effectively using chemical-mechanical polishing techniques because the hard, reduced wear, properties of the refractory metal do not scratch, corrode, or smear during chemical-mechanical polishing. Conductive lines and vias are created using a combination of both physical vapor deposition (e.g., evaporation or collimated sputtering) of a low resistivity metal or alloy followed by chemical vapor deposition (CVD) of a refractory metal and subsequent planarization. Altering a ratio of SiH4 to WF6 during application of the refractory metal cap by CVD allows for controlled incorporation of silicon into the tungsten capping layer. Collimated sputtering allows for creating a refractory metal liner in an opening in a dielectric which is suitable as a diffusion barrier to copper based metalizations as well as CVD tungsten. Ideally, for faster diffusing metals like copper, liners are created by a two step collimated sputtering process wherein a first layer is deposited under relatively low vacuum pressure where directional deposition dominates (e.g., below 1 mTorr) and a second layer is deposited under relatively high vacuum pressure where scattering deposition dominates (e.g., above 1 mTorr). For refractory metals like CVD tungsten, the liner can be created in one step using collimated sputtering at higher vacuum pressures.

Owner:GLOBALFOUNDRIES INC

Container base structure responsive to vacuum related forces

A plastic container having a base portion adapted for vacuum pressure absorption. The base portion including a contact ring that supports the container, an upstanding wall, and a central portion. The upstanding wall being adjacent to and generally circumscribing the contact ring. The central portion defined in at least part by a pushup and an inversion ring that generally circumscribes the pushup. The pushup having a generally truncated cone shape in cross section and the inversion ring having a generally S shaped geometry in cross section. The pushup and the inversion ring being moveable to accommodate vacuum related forces generated within the container.

Owner:AMCOR RIGID PLASICS USA LLC

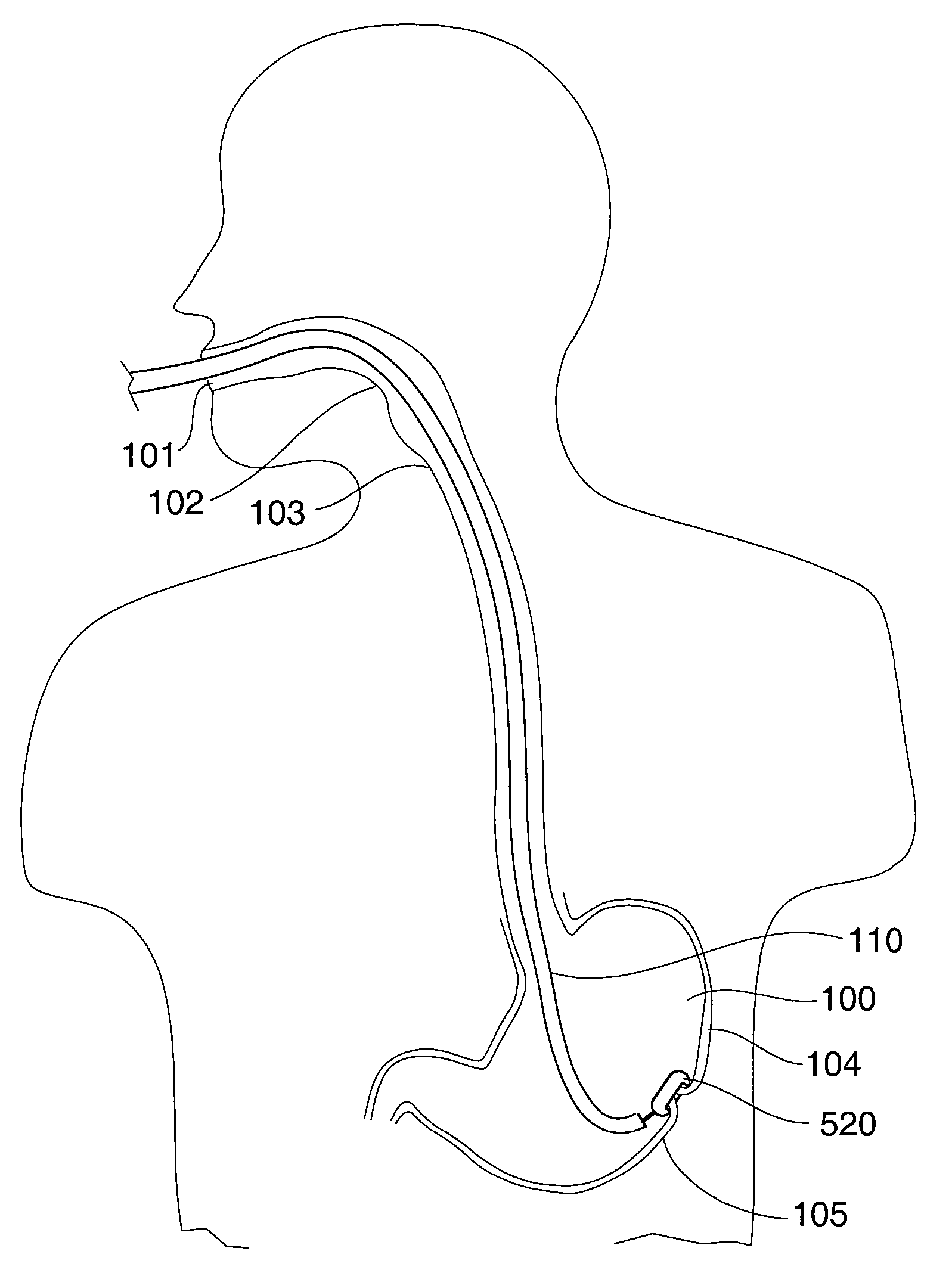

Endoscopic Instrument for Engaging a Device

A device, system and method for diagnosing and treating a patient is provided where a functional device is attached to a stomach wall. The device in one embodiment provides electrical stimulation of the stomach wall. The device may also have other functional aspects such as a sensor for sensing various parameters of the stomach or stomach environment, or a substance delivery device. The implant may be programmed to respond to sensed information or signals. The device may be modular with a portion of the device accessible for removal and replacement. In one embodiment, an endoscopic delivery system delivers the functional device through the esophagus and into the stomach where it is attached the stomach wall with the assistance of a suction used to stabilize the tissue of the stomach wall. The device includes a chamber for receiving tissue of the stomach wall for attachment where a vacuum pressure is applied through the chamber to draw the tissue into the chamber.

Owner:INTRAPACE

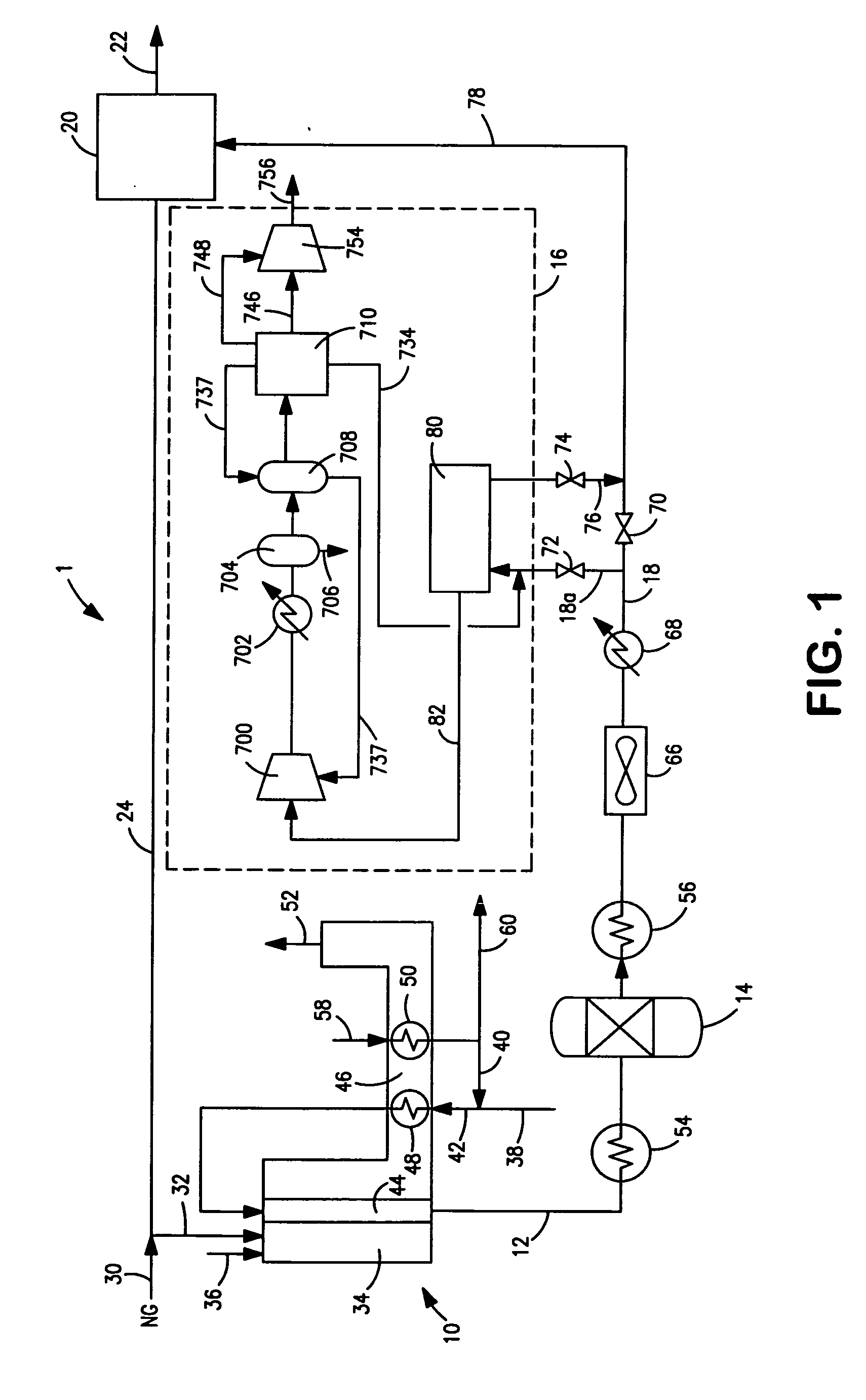

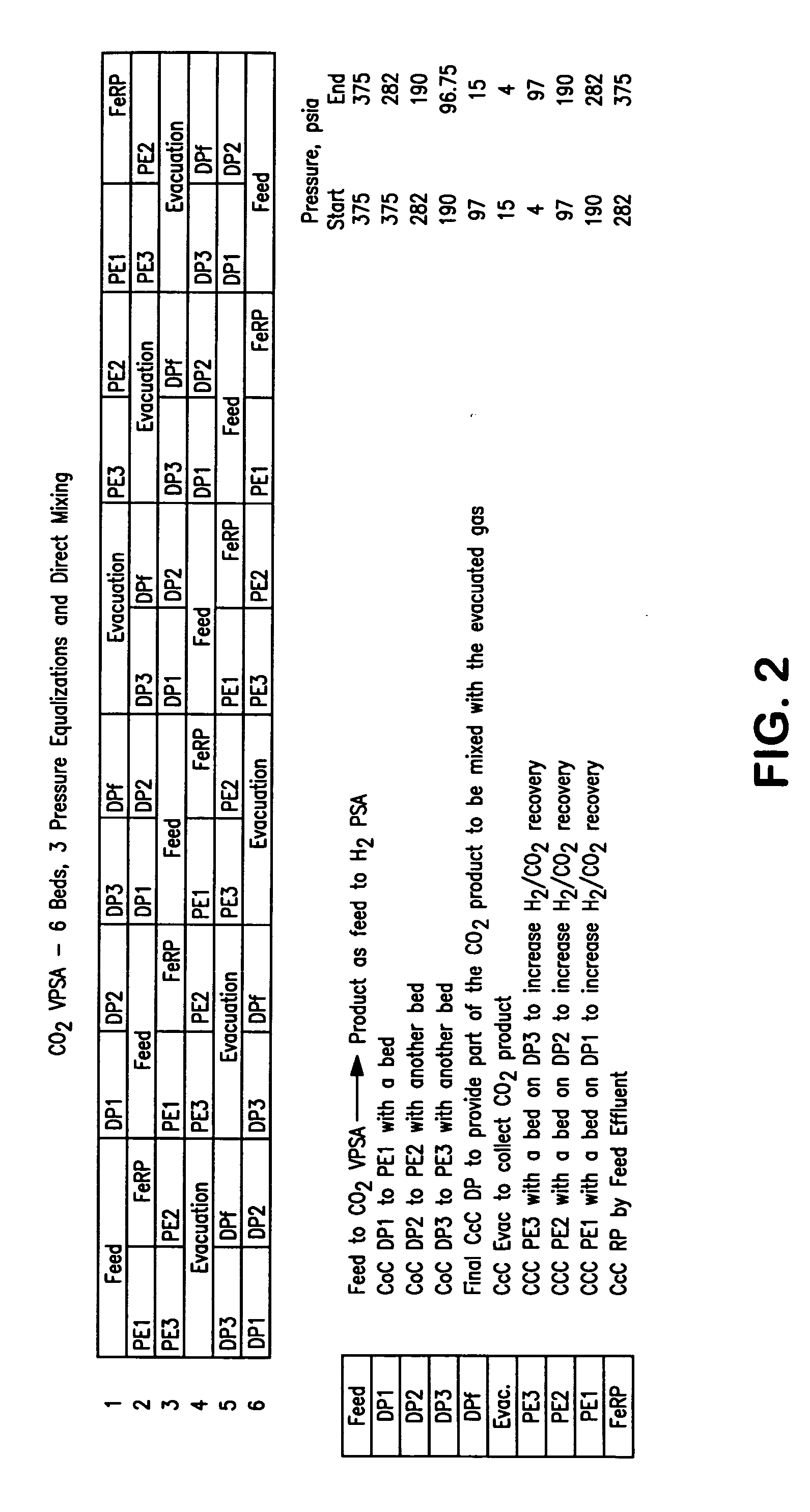

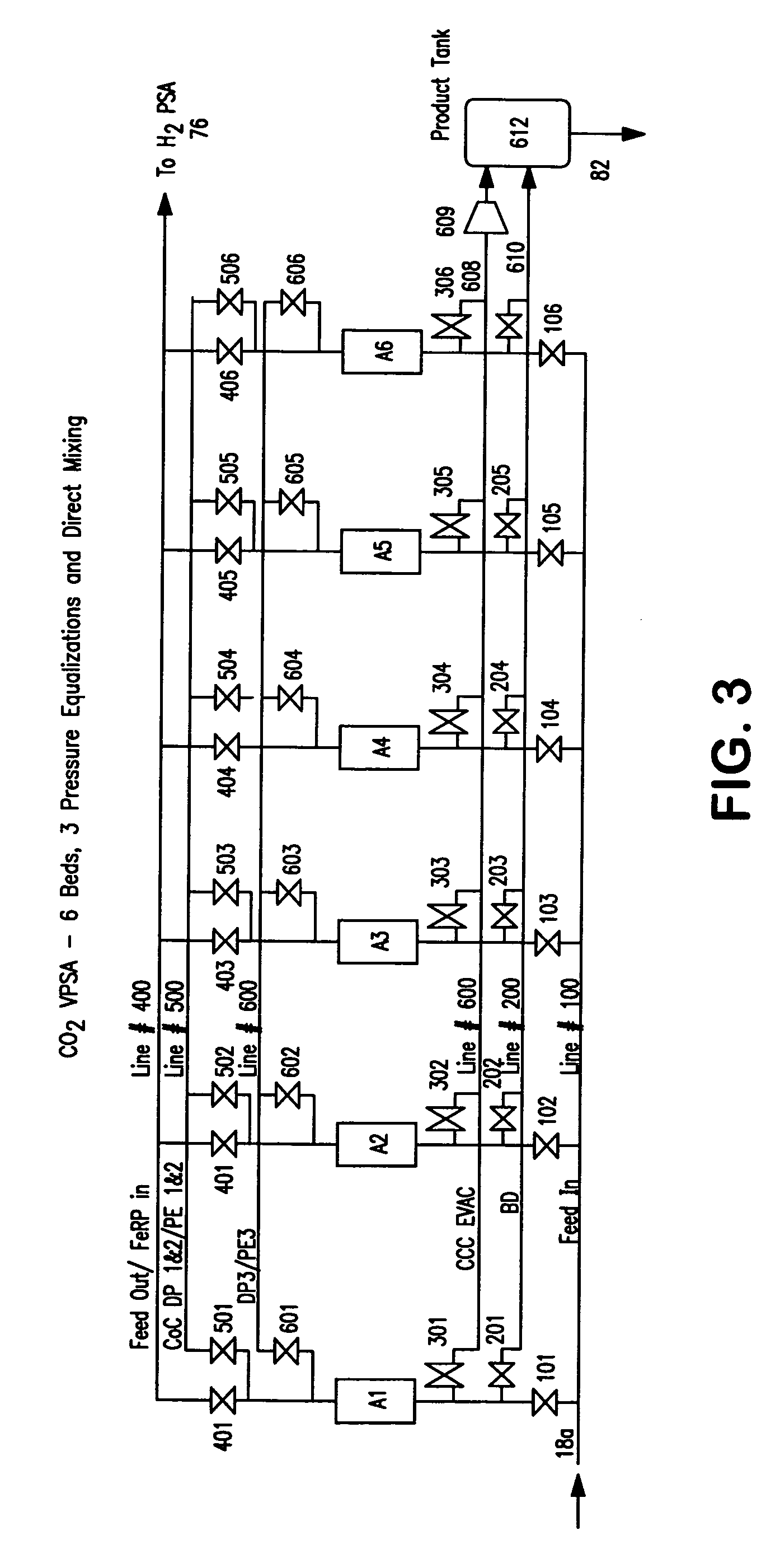

Carbon dioxide production method

ActiveUS20070232706A1Increased hydrogen recoveryPromote recoverySolidificationLiquefactionVacuum pressureCarbon dioxide production

A method of producing a carbon dioxide product stream from a synthesis gas stream formed within a hydrogen plant having a synthesis gas reactor, a water-gas shift reactor, located downstream of the synthesis gas reactor to form the synthesis gas stream and a hydrogen pressure swing adsorption unit to produce a hydrogen product recovered from the synthesis gas stream. In accordance with the method the carbon dioxide from the synthesis gas stream by separating the carbon dioxide from the synthesis gas stream in a vacuum pressure swing adsorption system, thereby to produce a hydrogen-rich synthesis gas stream and a crude carbon dioxide stream and then purifying the crude carbon dioxide stream by a sub-ambient temperature distillation process thereby to produce the carbon dioxide product. A hydrogen synthesis gas feed stream to the hydrogen pressure swing adsorption unit is formed at least in part from the hydrogen rich stream.

Owner:PRAXAIR TECH INC

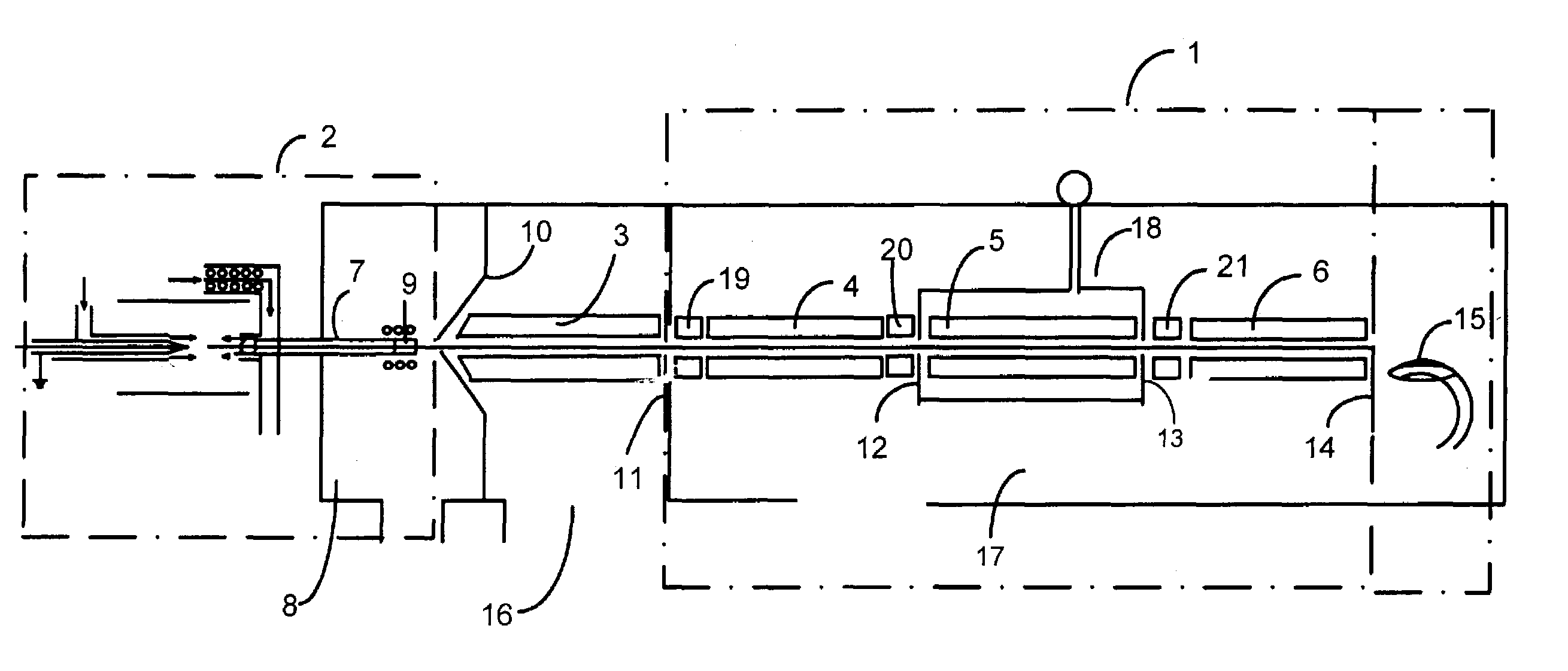

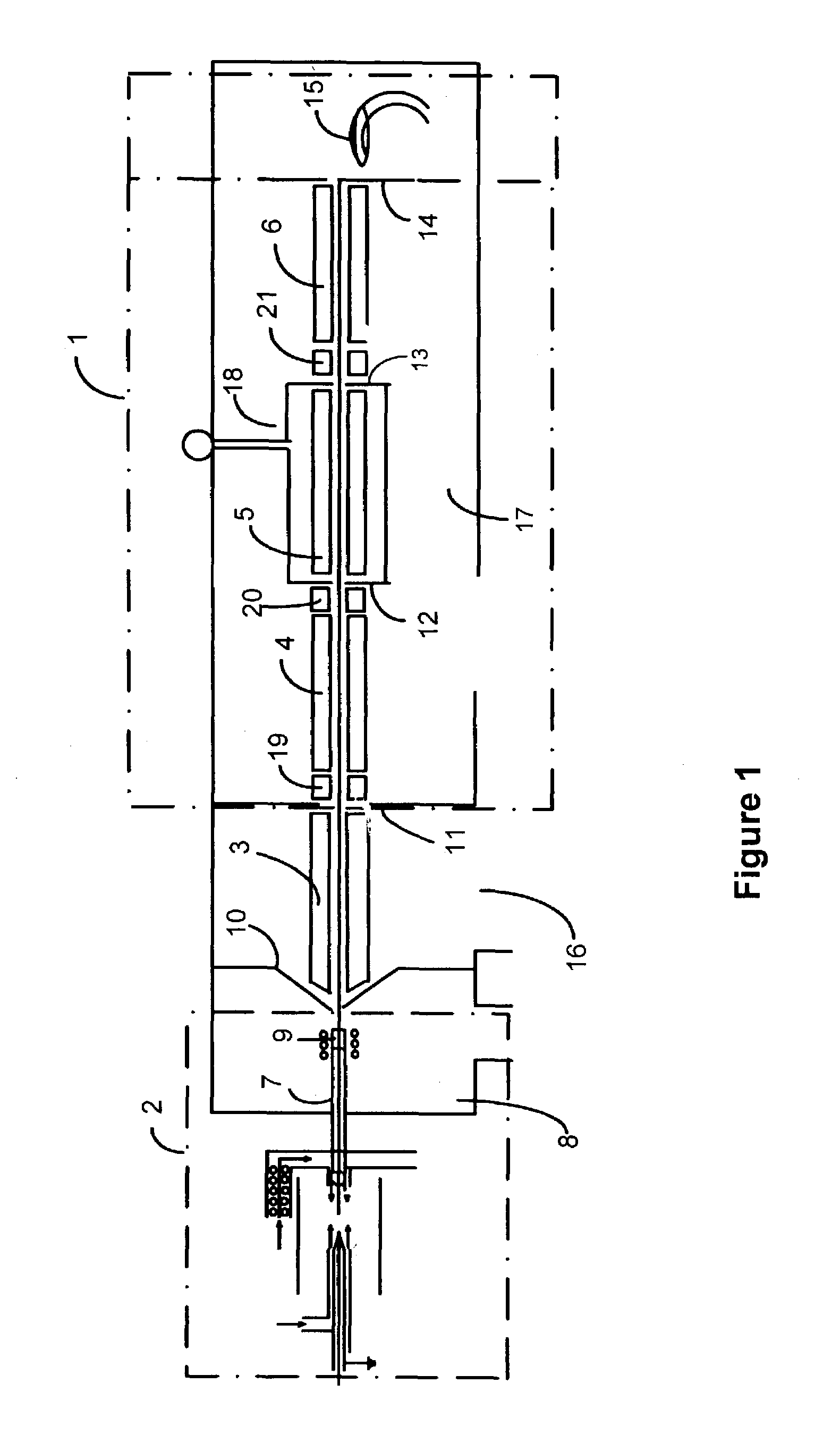

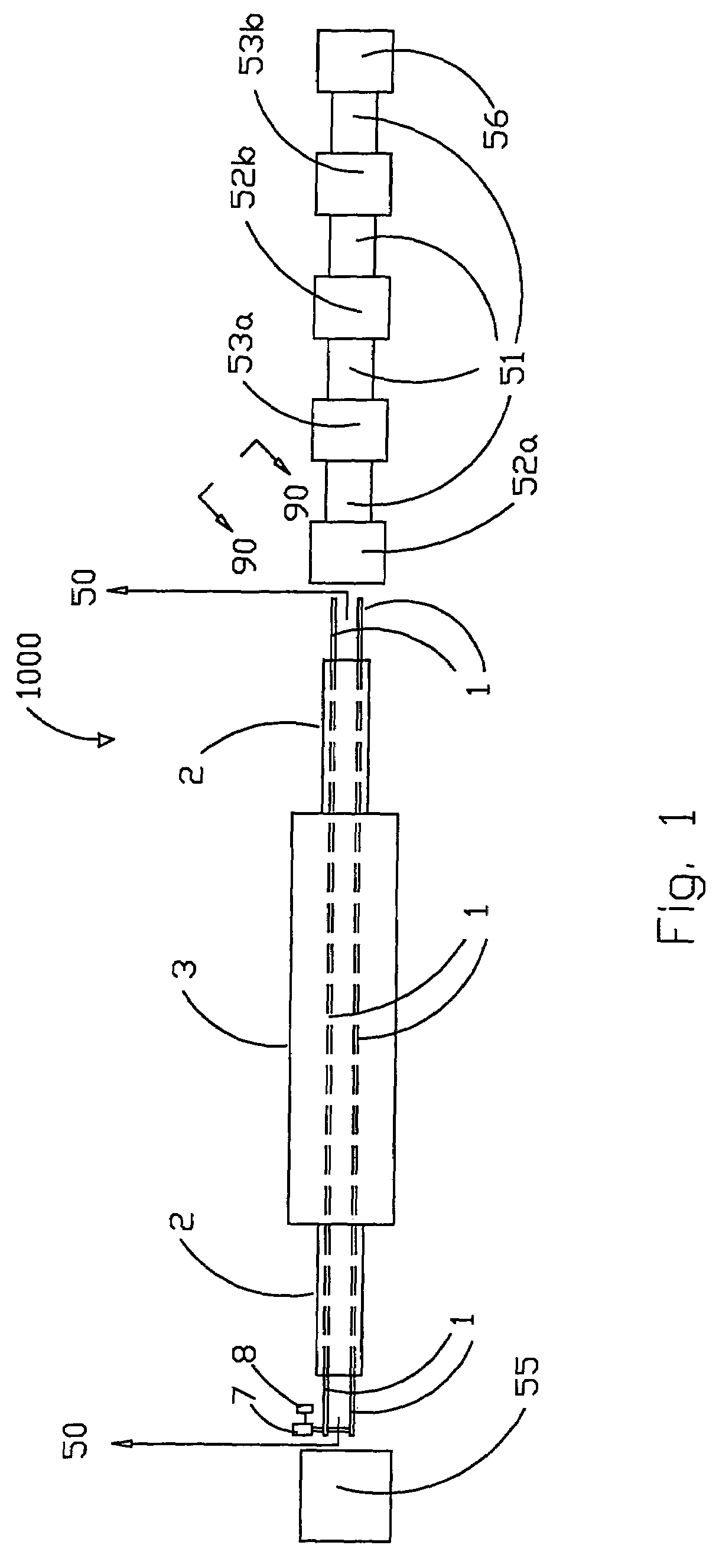

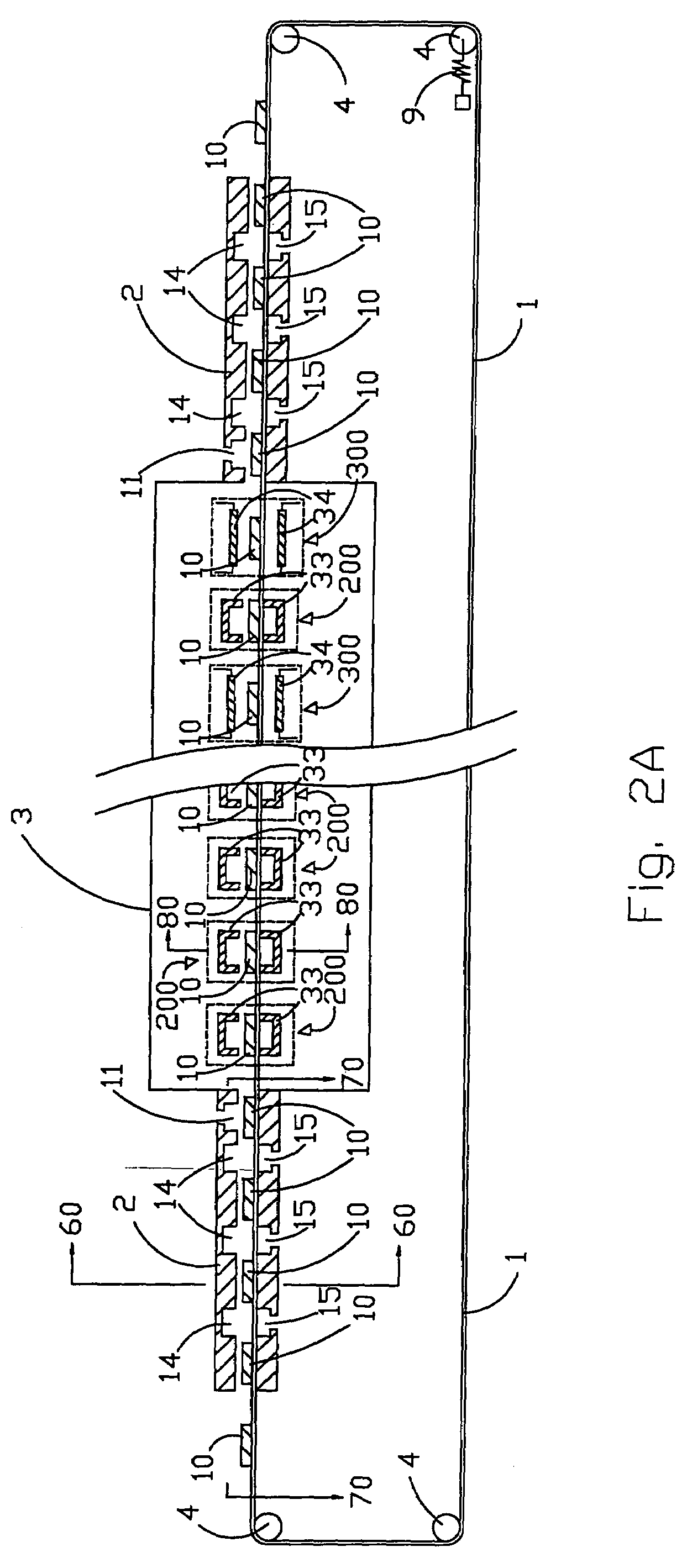

Apparatus and processes for the mass production of photovoltaic modules

InactiveUS7220321B2Inhibition formationLow costPolycrystalline material growthSemiconductor/solid-state device manufacturingAbrasive blastingVacuum pressure

An apparatus and processes for large scale inline manufacturing of CdTe photovoltaic modules in which all steps, including rapid substrate heating, deposition of CdS, deposition of CdTe, CdCl2 treatment, and ohmic contact formation, are performed within a single vacuum boundary at modest vacuum pressures. A p+ ohmic contact region is formed by subliming a metal salt onto the CdTe layer. A back electrode is formed by way of a low cost spray process, and module scribing is performed by means of abrasive blasting or mechanical brushing through a mask. The vacuum process apparatus facilitates selective heating of substrates and films, exposure of substrates and films to vapor with minimal vapor leakage, deposition of thin films onto a substrate, and stripping thin films from a substrate. A substrate transport apparatus permits the movement of substrates into and out of vacuum during the thin film deposition processes, while preventing the collection of coatings on the substrate transport apparatus itself.

Owner:COLORADO STATE UNIVERSITY

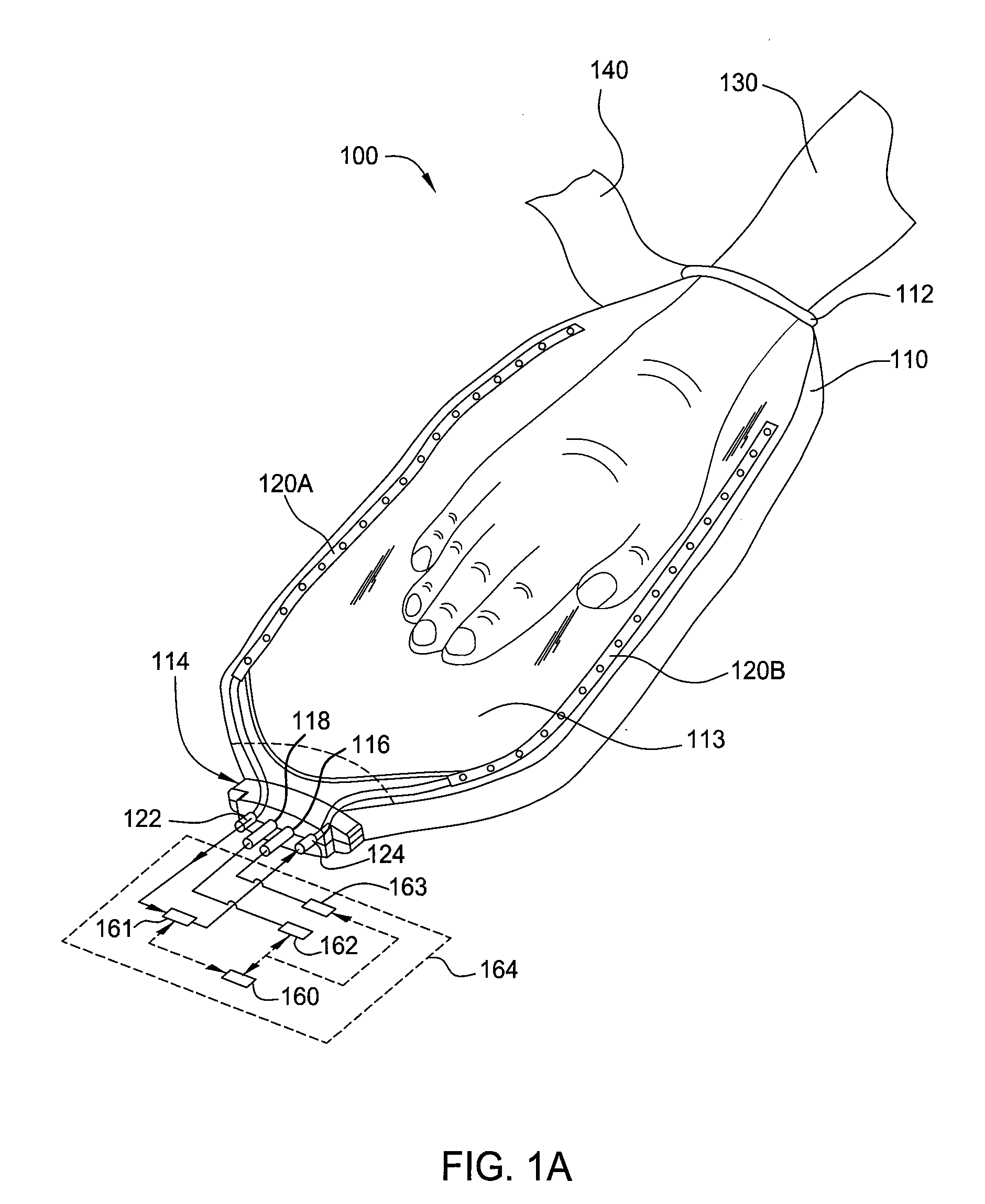

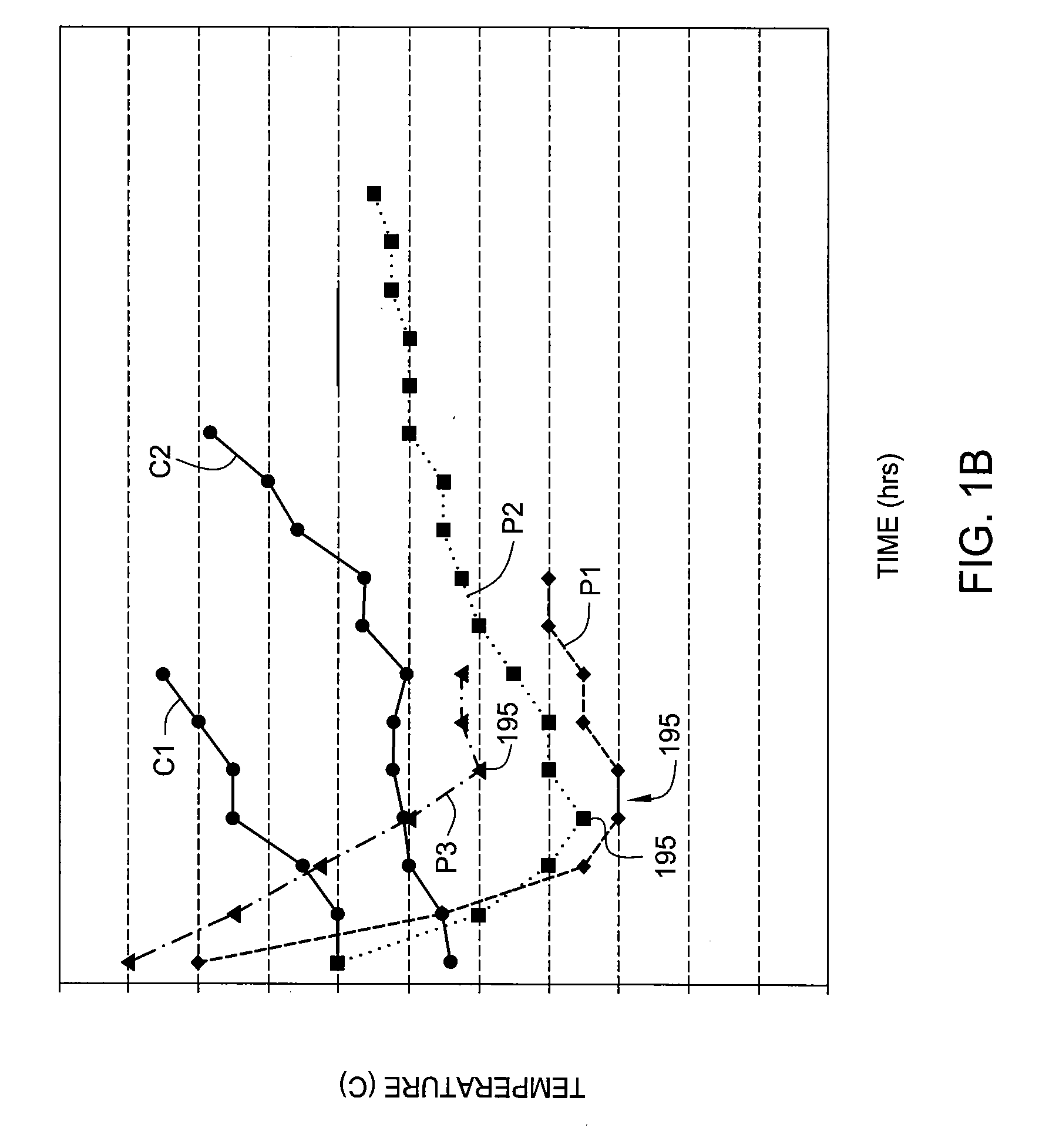

Method and apparatus for improving venous access

InactiveUS20090177184A1Improving venous accessBreathing protectionPneumatic massageVenous accessVein

Embodiments of the invention include a method and a device for increasing vasodilatation and / or controlling the temperature of a mammal by applying a desired vacuum pressure to the skin of the extremity of a mammal. In some cases it is also desirable to provide heat to regions of the extremity of the mammal to further dilate the veins or arteries in the patient. In some cases it is also desirable to apply a contact pressure to regions of the extremity of the mammal to improve perfusion of these regions. In one embodiment, the device includes a device that is adapted to rigidly enclose a portion of an extremity of the mammal therein so that a sub-atmospheric pressure can be applied to the mammal's extremity, which is further discussed below.

Owner:AVACORE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com