Patents

Literature

499 results about "Liquid fraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

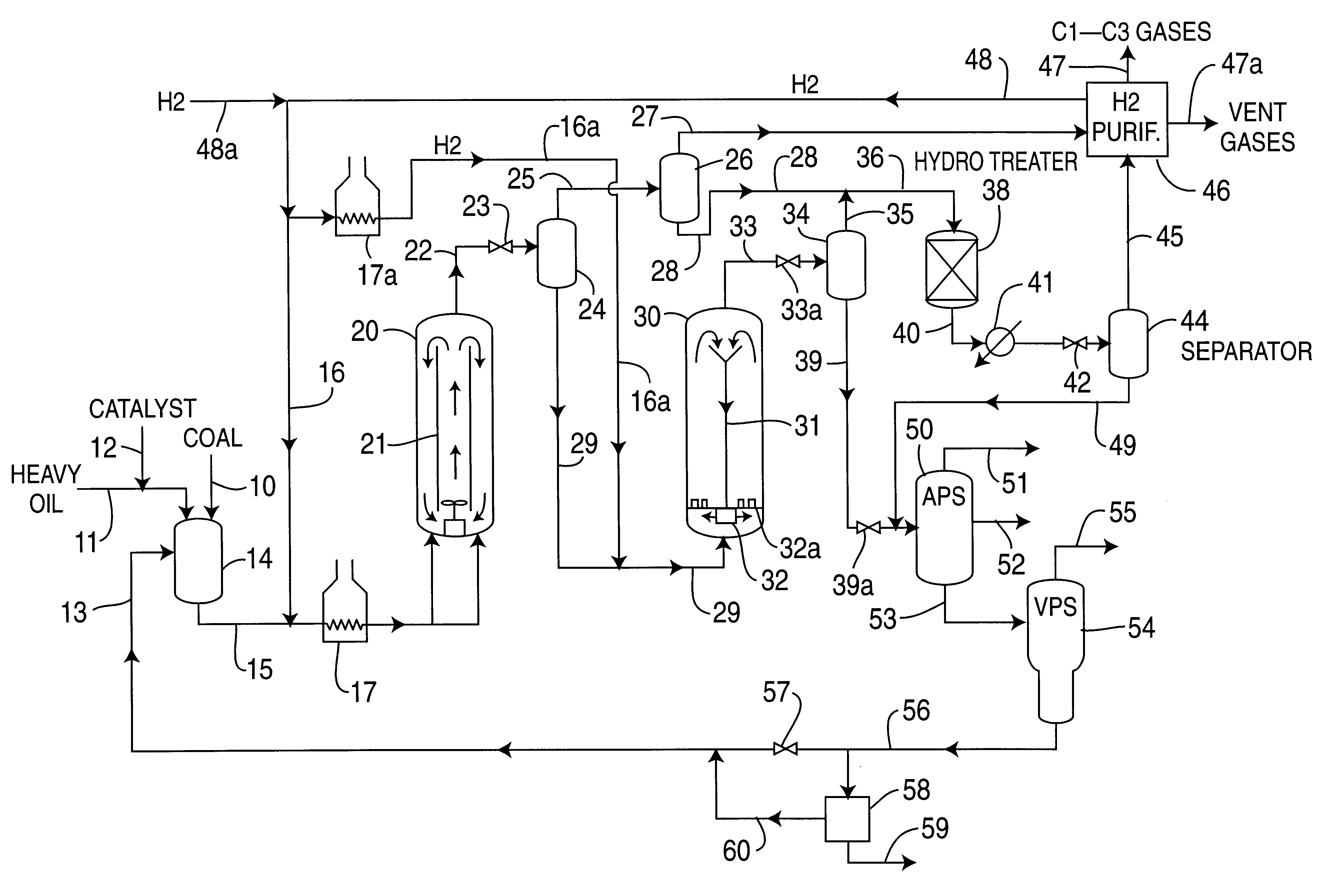

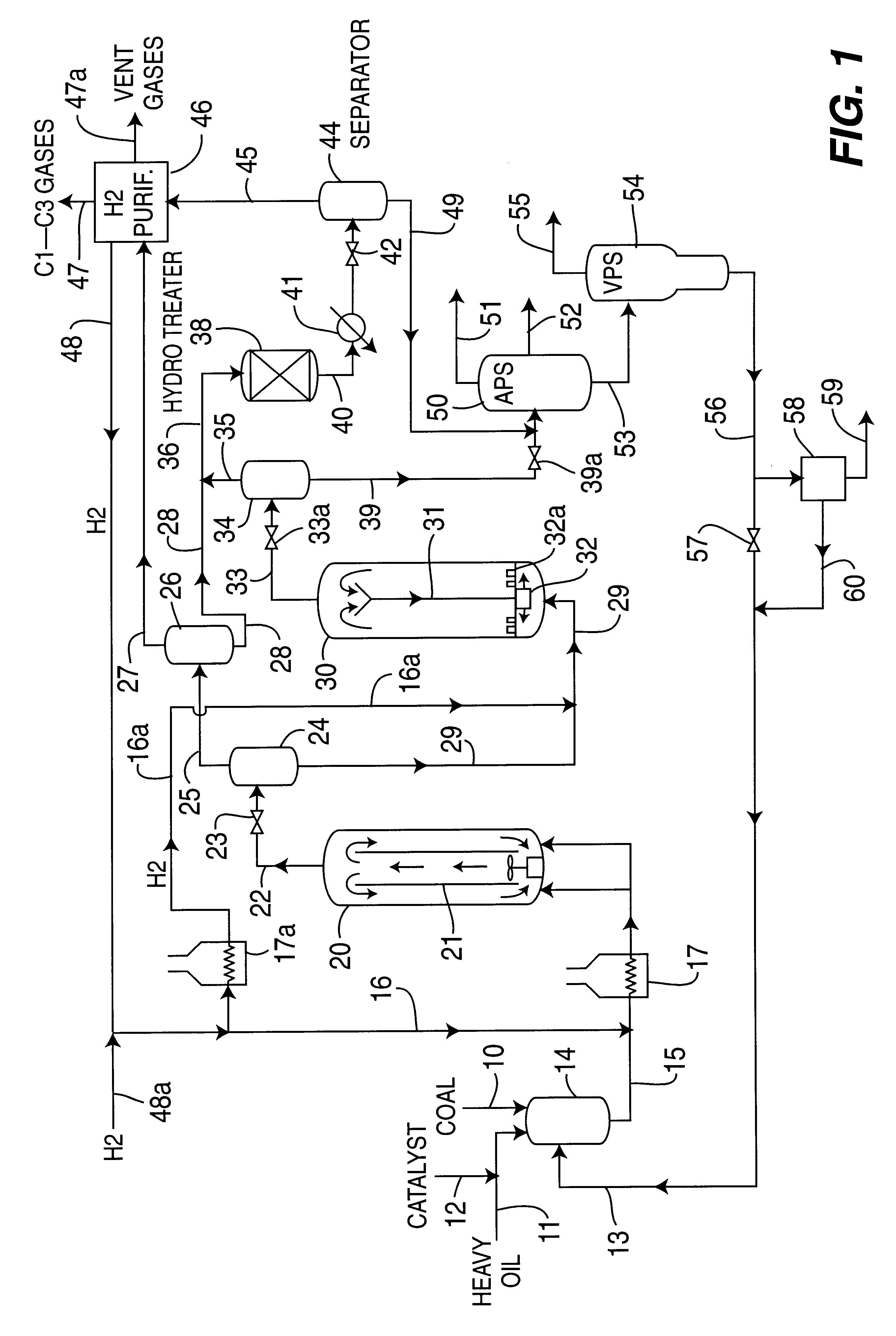

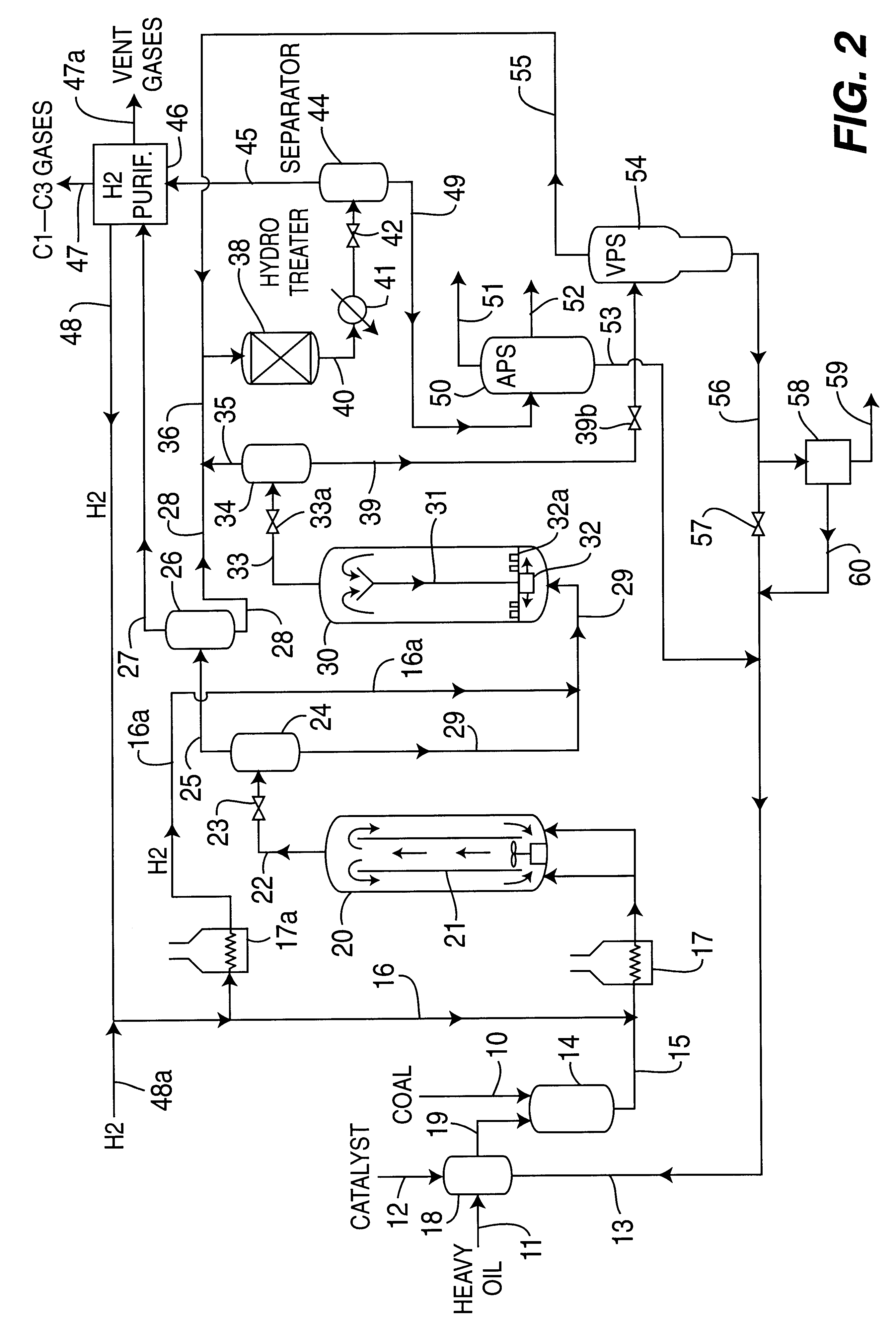

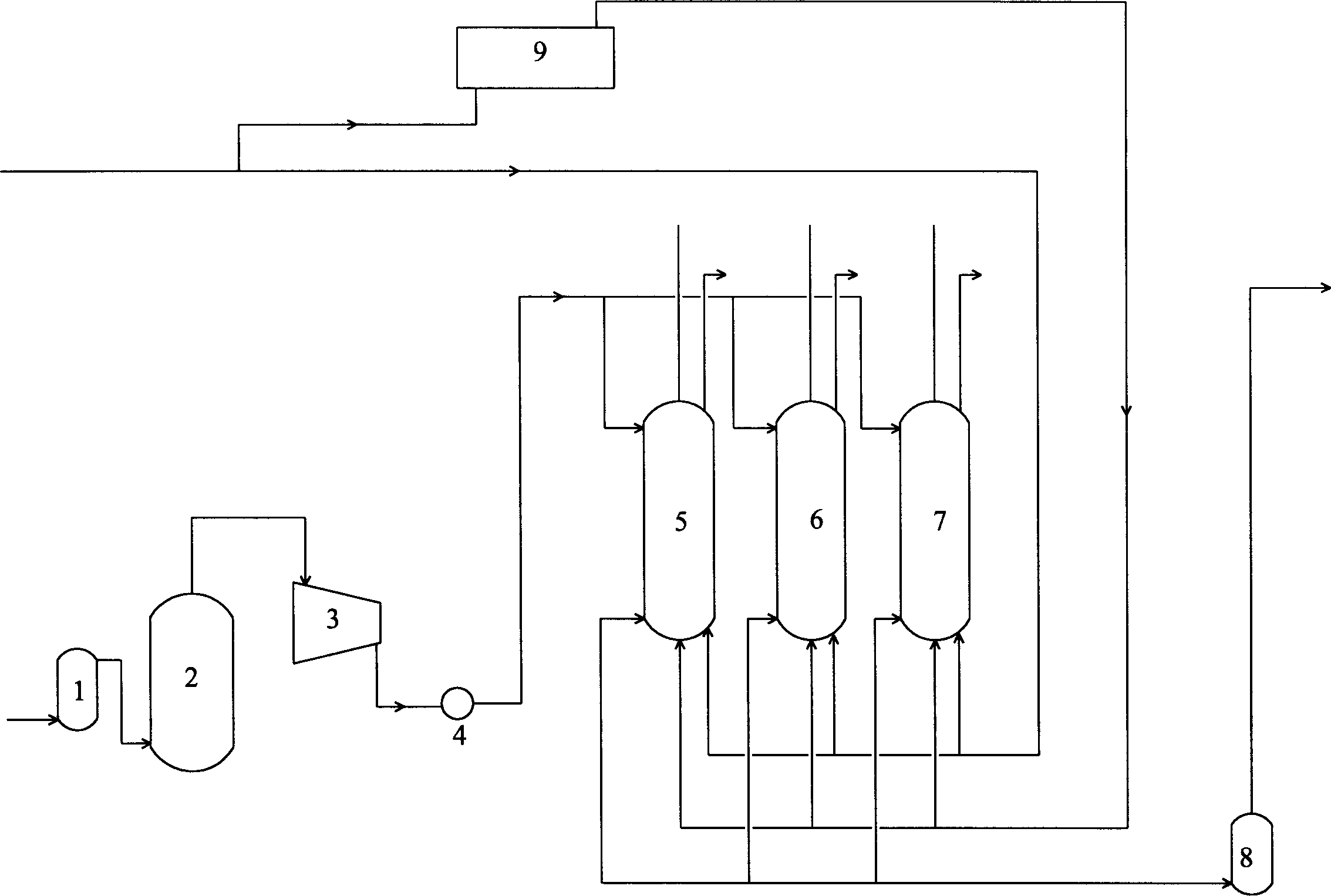

Catalytic multi-stage process for hydroconversion and refining hydrocarbon feeds

InactiveUS6190542B1Improve distillation yieldQuality improvementCatalyst activation/preparationLiquid hydrocarbon mixture productionLiquid productDistillates petroleum

A multi-stage catalytic hydrogenation and hydroconversion process for heavy hydrocarbon feed materials such as coal, heavy petroleum fractions, and plastic waste materials. In the process, the feedstock is reacted in a first-stage, back-mixed catalytic reactor with a highly dispersed iron-based catalyst having a powder, gel or liquid form. The reactor effluent is pressure-reduced, vapors and light distillate fractions are removed overhead, and the heavier liquid fraction is fed to a second stage back-mixed catalytic reactor. The first and second stage catalytic reactors are operated at 700-850.degree. F. temperature, 1000-3500 psig hydrogen partial pressure and 20-80 lb. / hr per ft.sup.3 reactor space velocity. The vapor and light distillates liquid fractions removed from both the first and second stage reactor effluent streams are combined and passed to an in-line, fixed-bed catalytic hydrotreater for heteroatom removal and for producing high quality naphtha and mid-distillate or a full-range distillate product. The remaining separator bottoms liquid fractions are distilled at successive atmospheric and vacuum pressures, low and intermediate-boiling hydrocarbon liquid products are withdrawn, and heavier distillate fractions are recycled and further upgraded to provide additional low-boiling hydrocarbon liquid products. This catalytic multistage hydrogenation process provides improved flexibility for hydroprocessing the various carbonaceous feedstocks and adjusting to desired product structures and for improved economy of operations.

Owner:HEADWATERS CTL

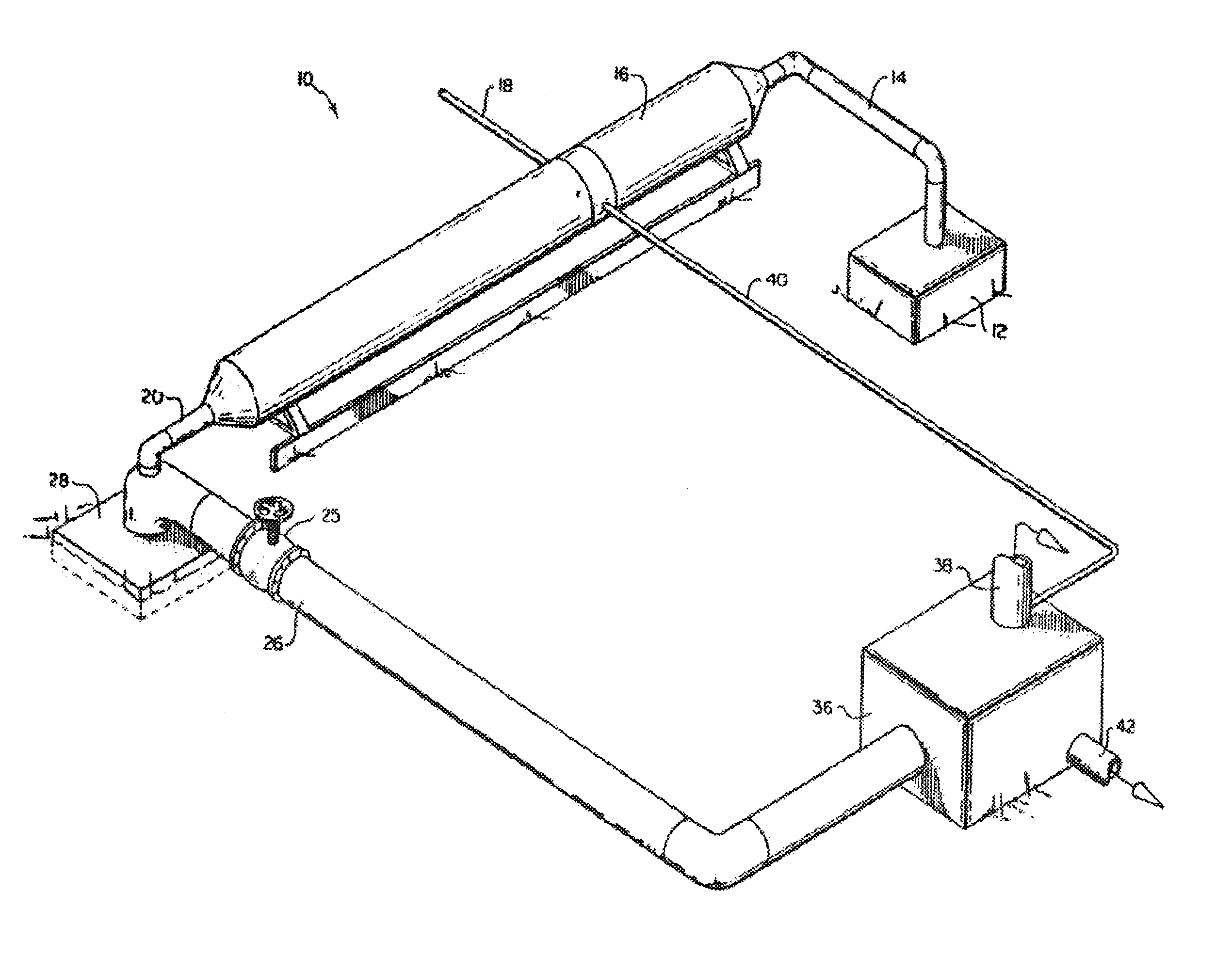

Recovery of products from oil shale

InactiveUS7048051B2Maximize recoveryProcedure is time-consume and expensiveFluid removalKerogenThermal energy

A process and system for recovering hydrocarbonaceous products from in situ oil shale formations. A hole is drilled in the oil shale formation and a processing gas inlet conduit is positioned within the hole. A processing gas is pressurized, heated, and introduced through the processing gas inlet conduit and into the hole. The processing gas creates a nonburning thermal energy front within the oil shale formation so as to convert kerogen in the oil shale to hydrocarbonaceous products. The products are withdrawn with the processing gas through an effluent gas conduit positioned around the opening of the hole, and are then transferred to a condenser wherein a liquid fraction of the products is formed and separated from a gaseous fraction.

Owner:GENERAL SYNFUELS INT

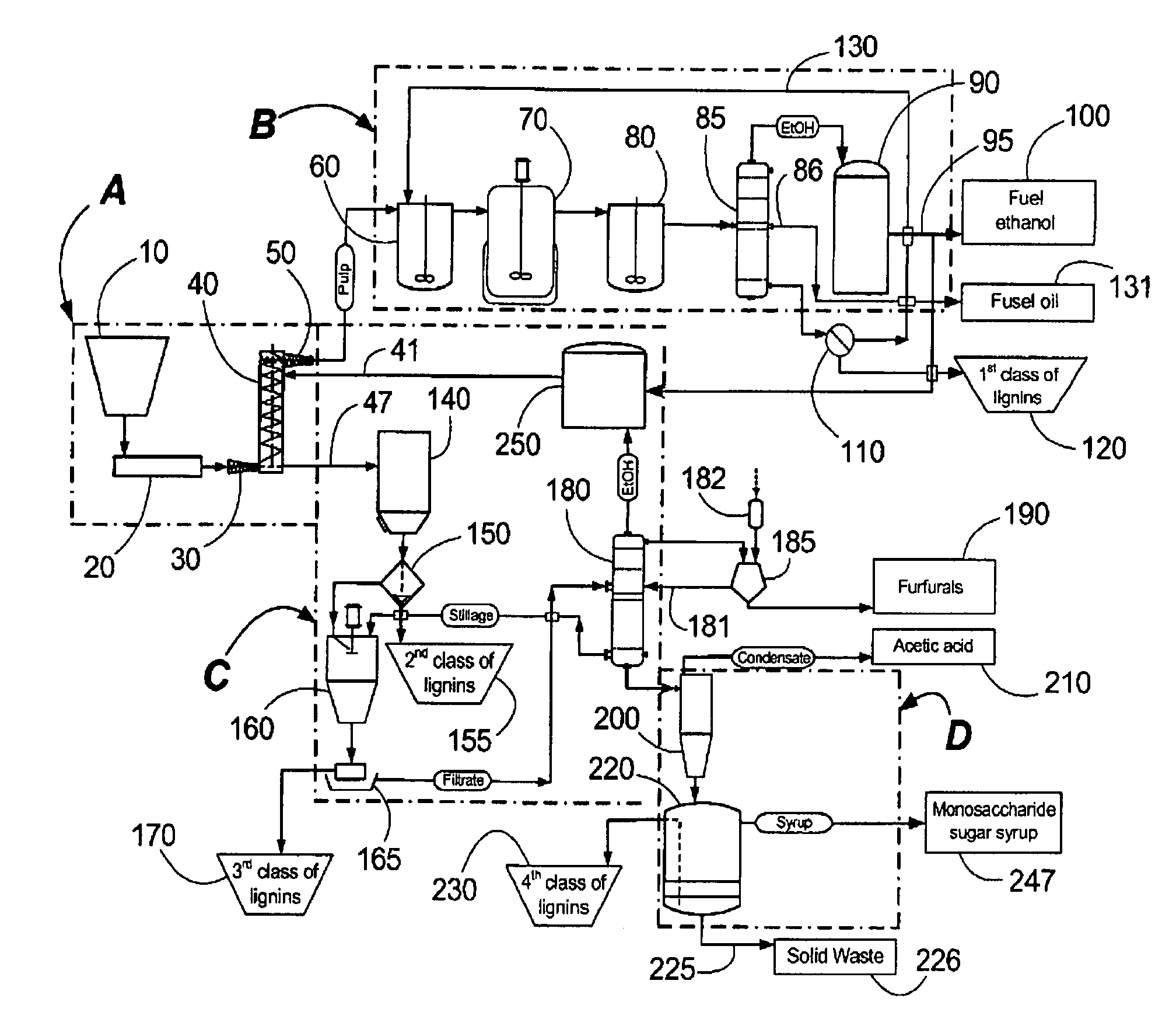

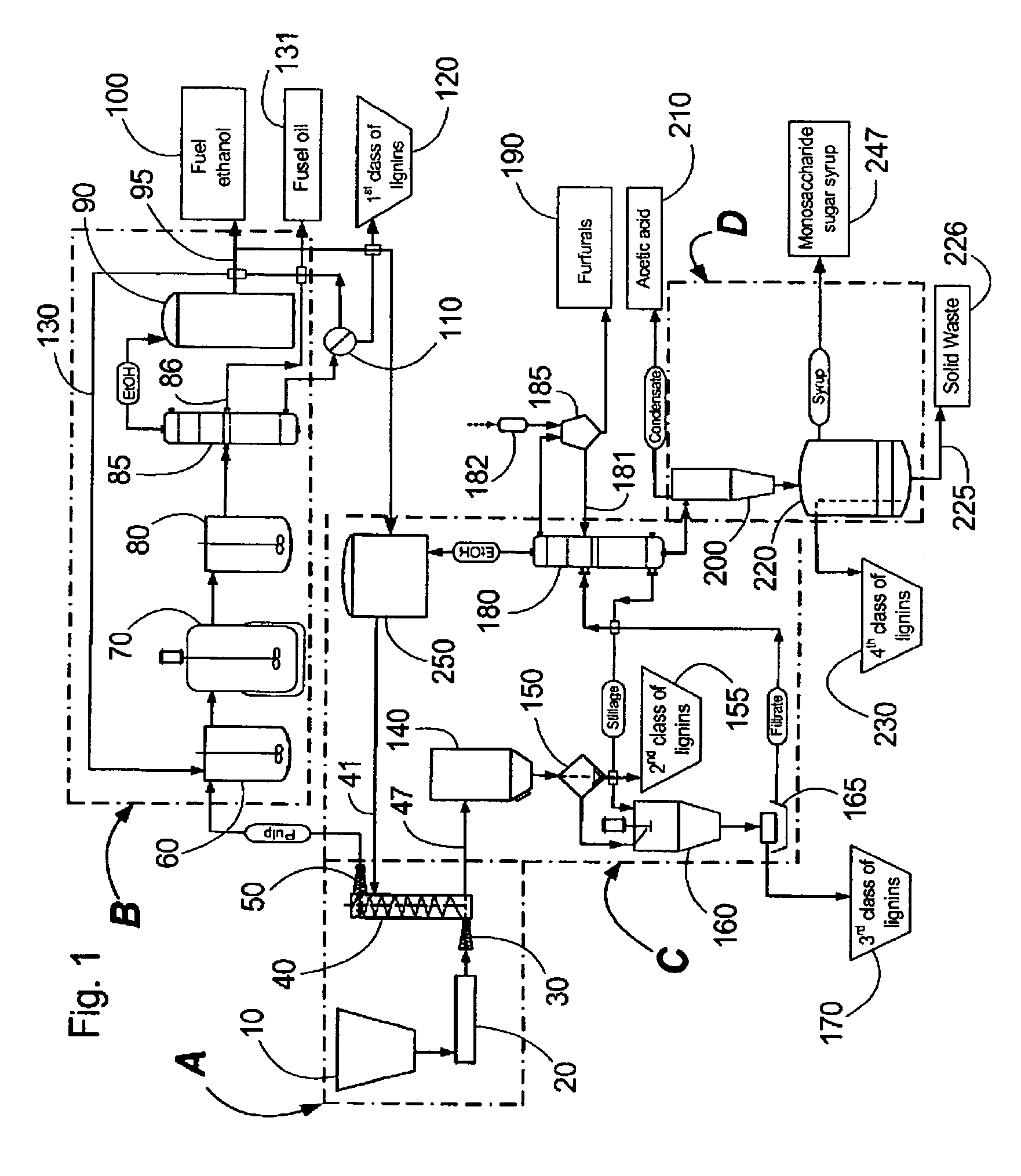

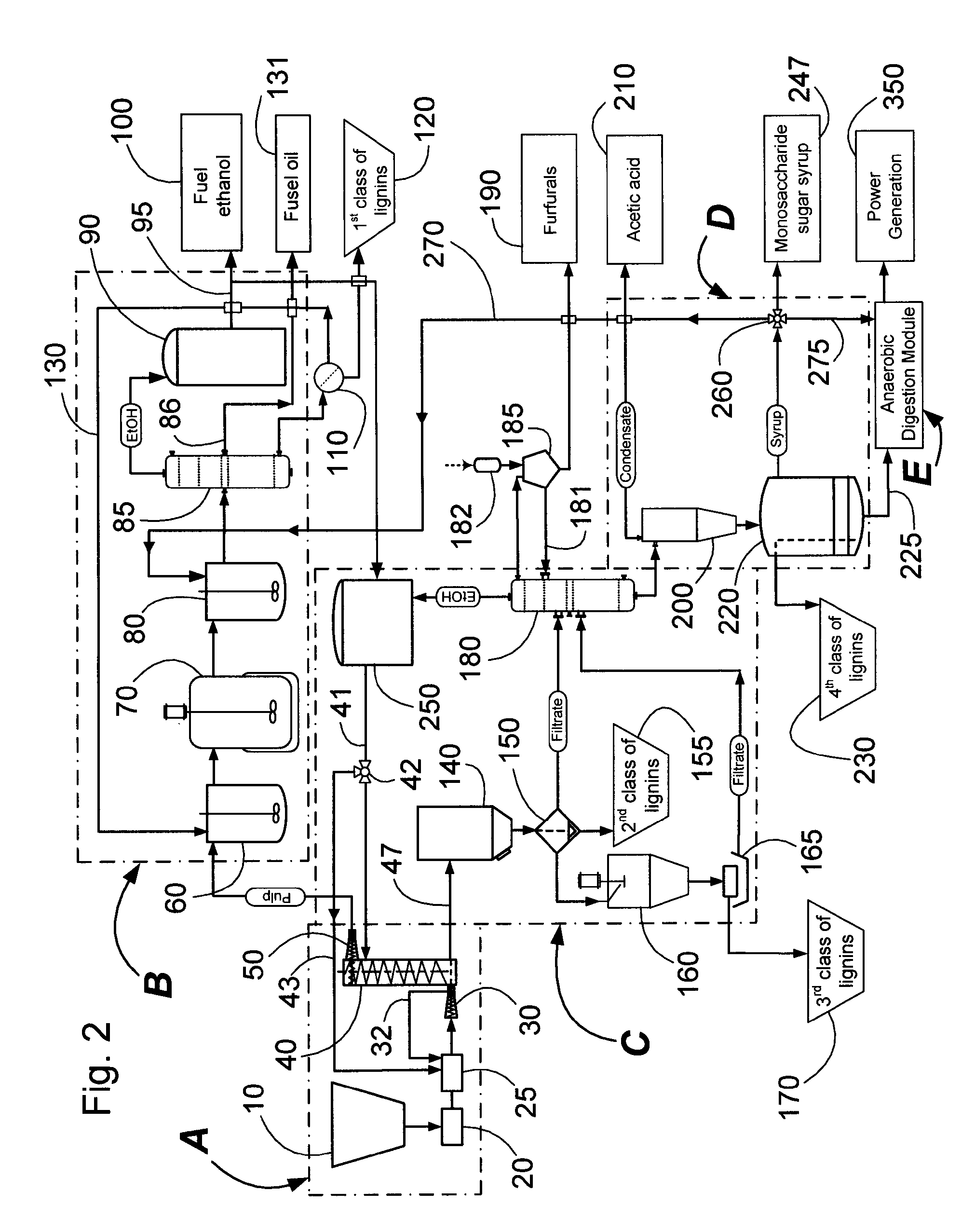

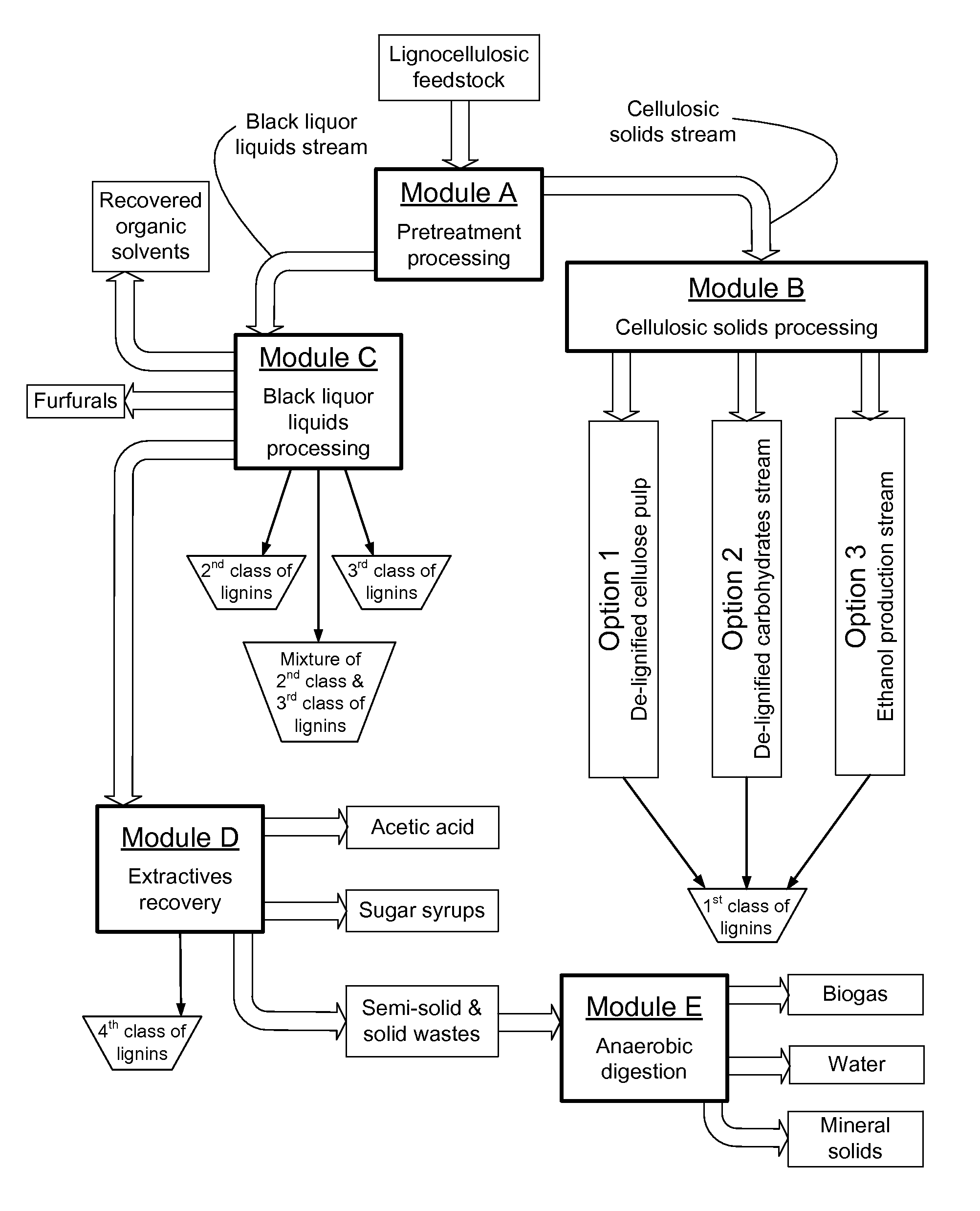

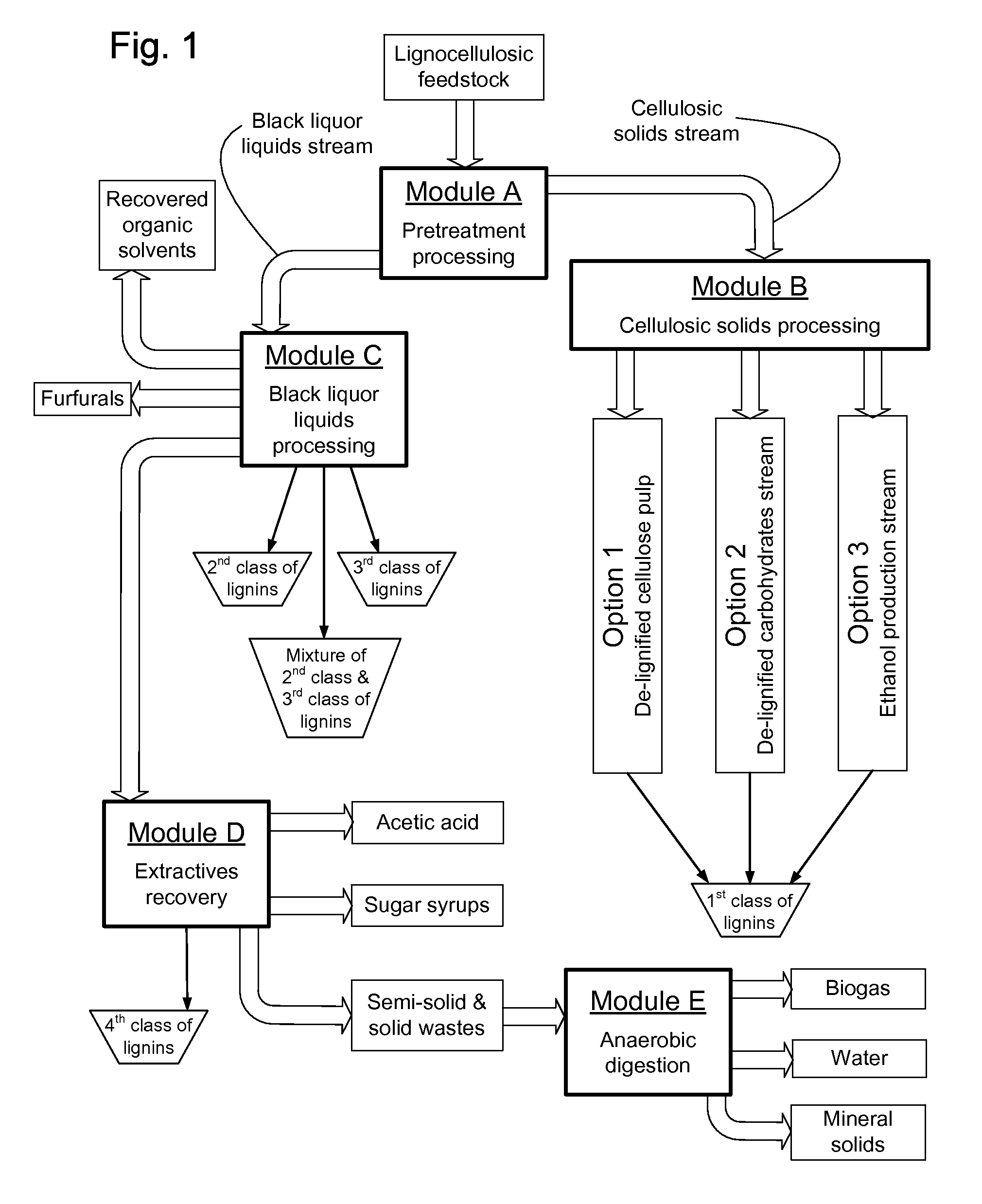

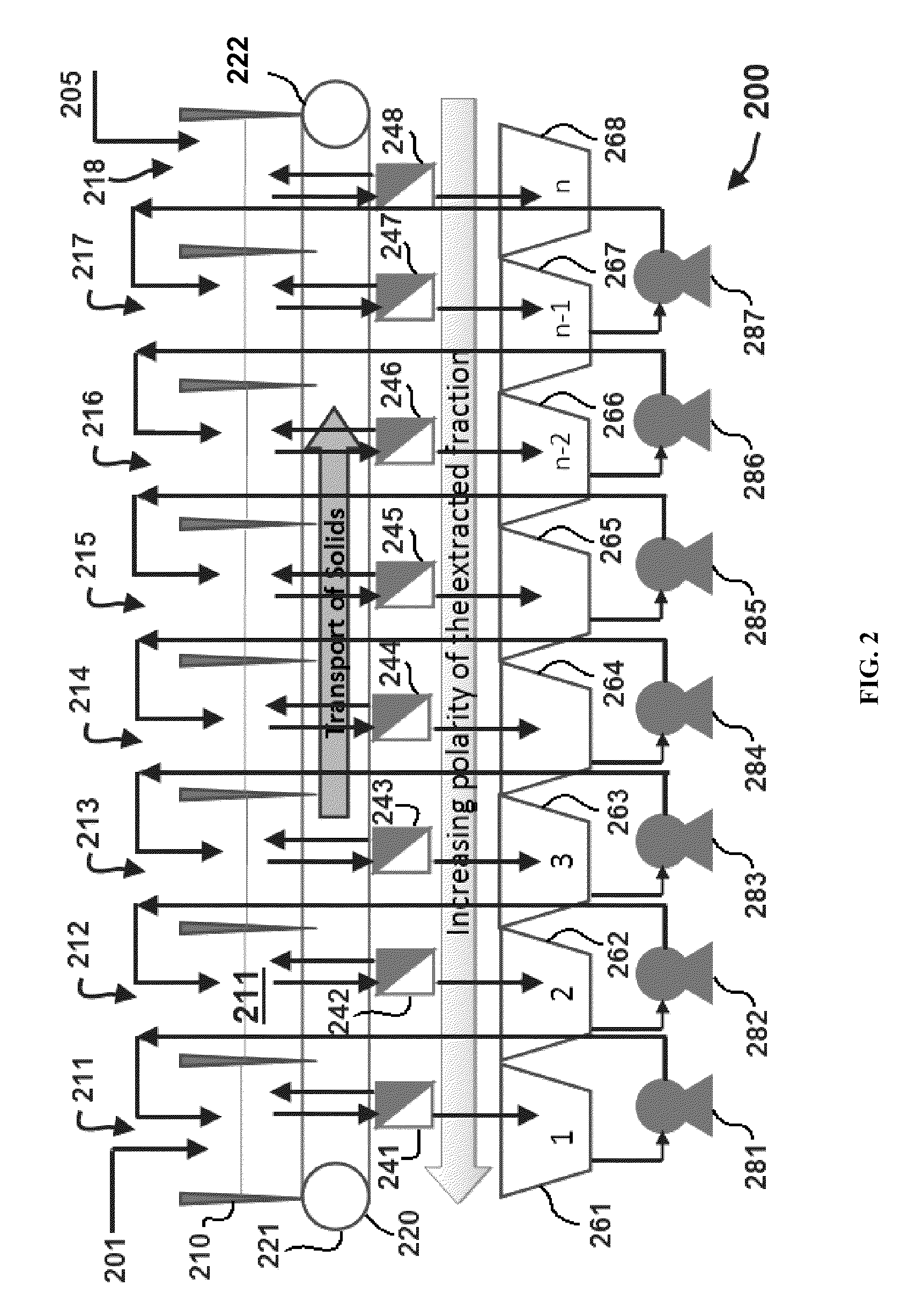

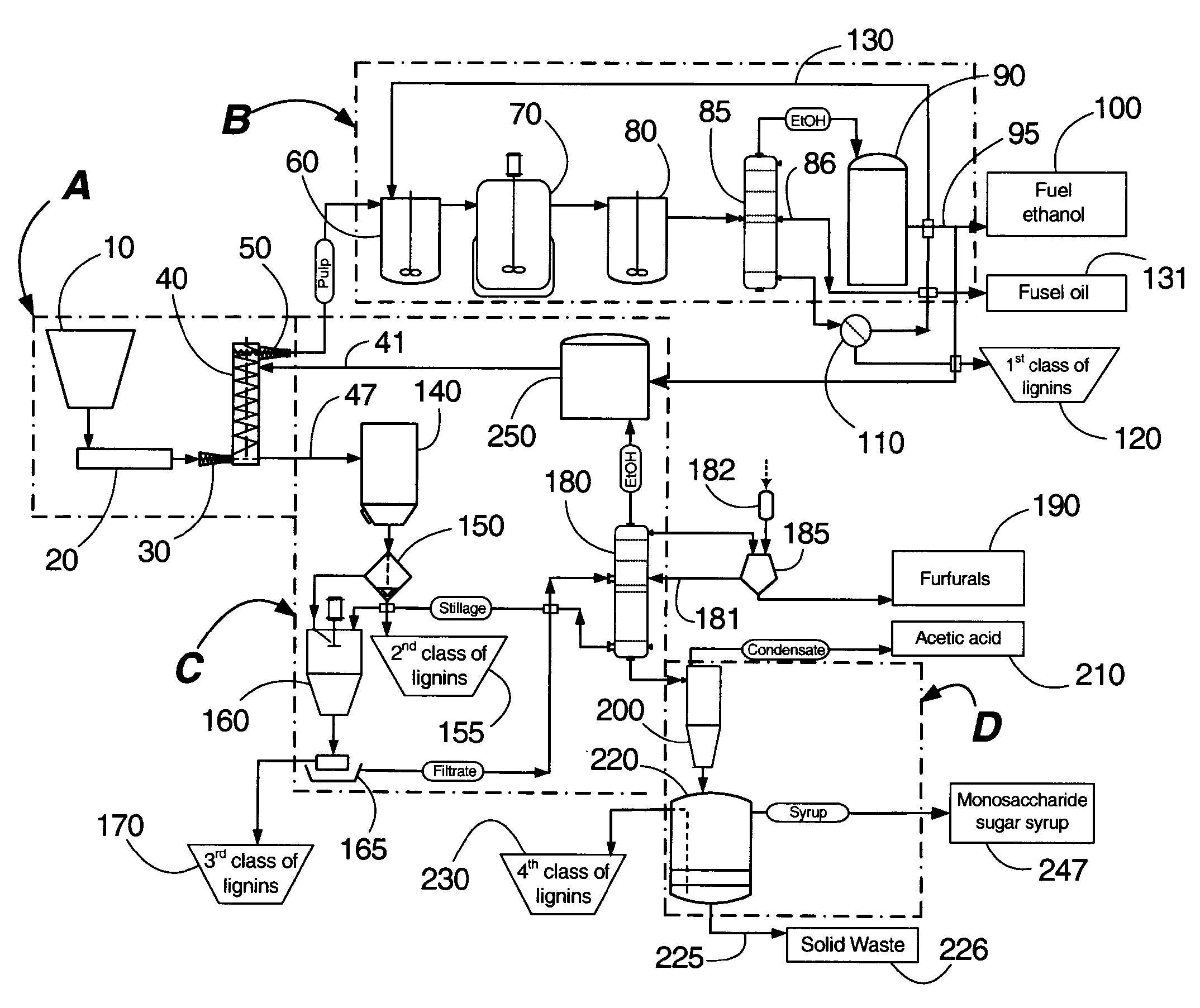

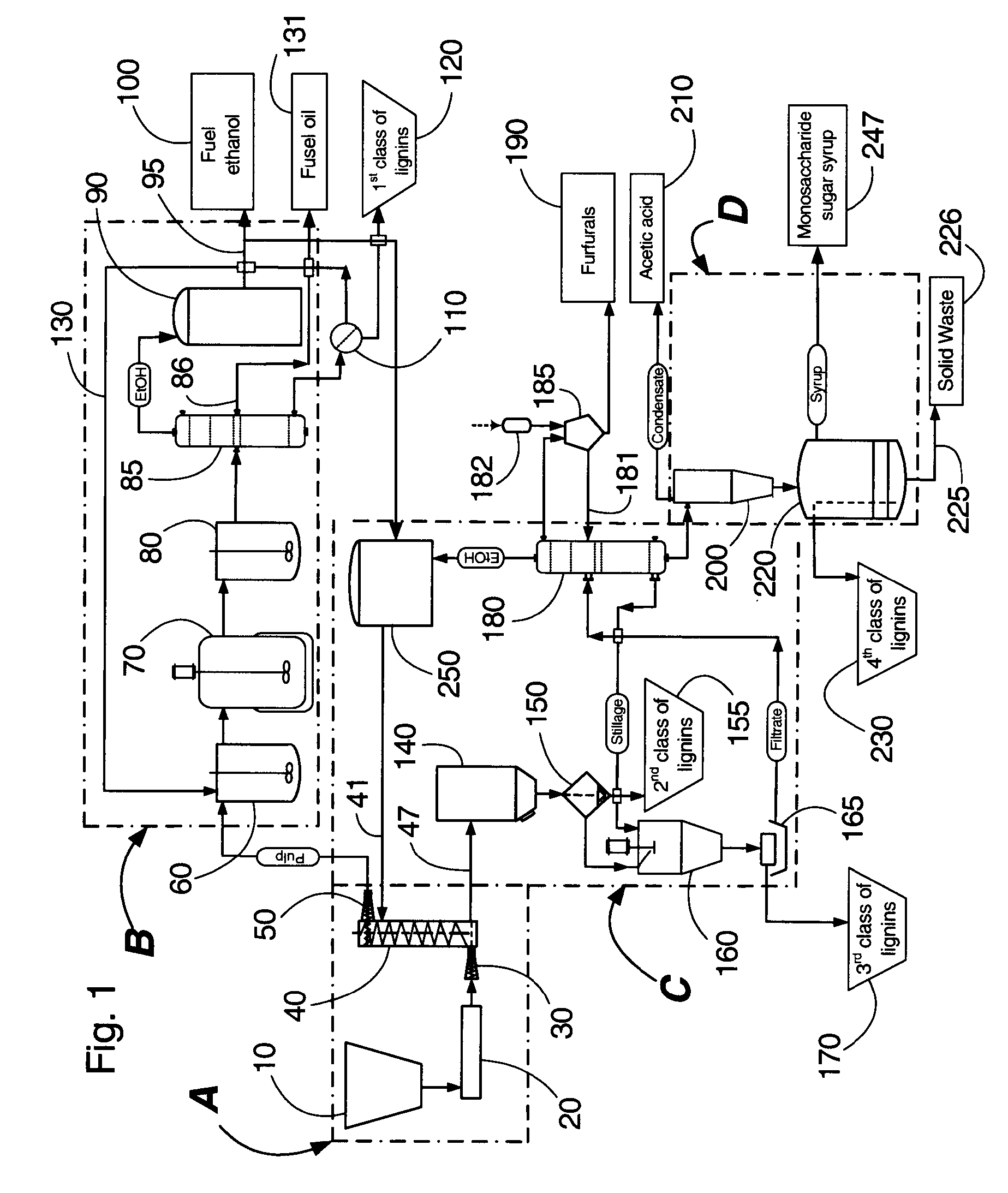

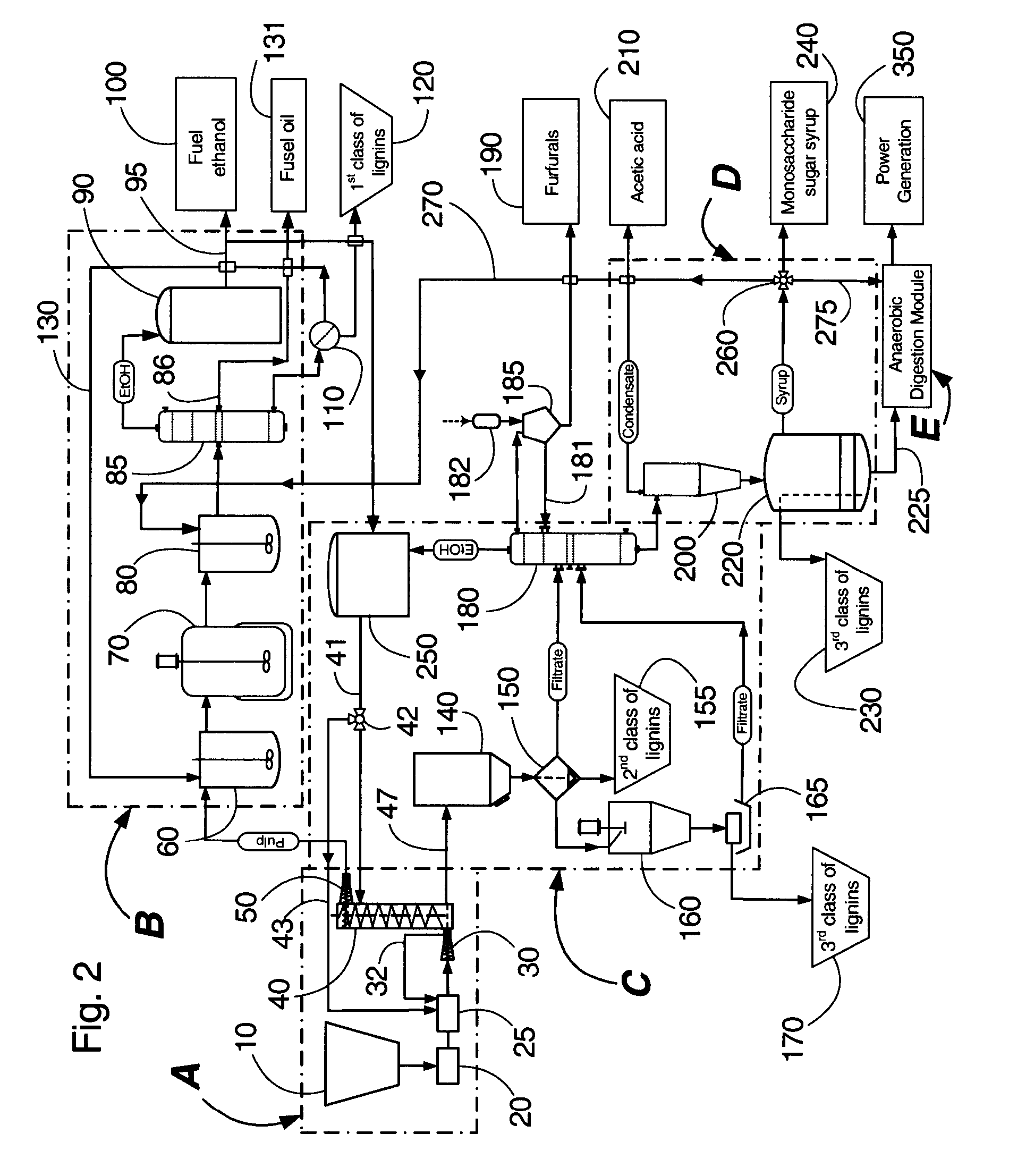

Continuous counter-current organosolv processing of lignocellulosic feedstocks

InactiveUS7465791B1Low viscosityNon-fibrous pulp additionBiological substance pretreatmentsFractionationOrganosolv

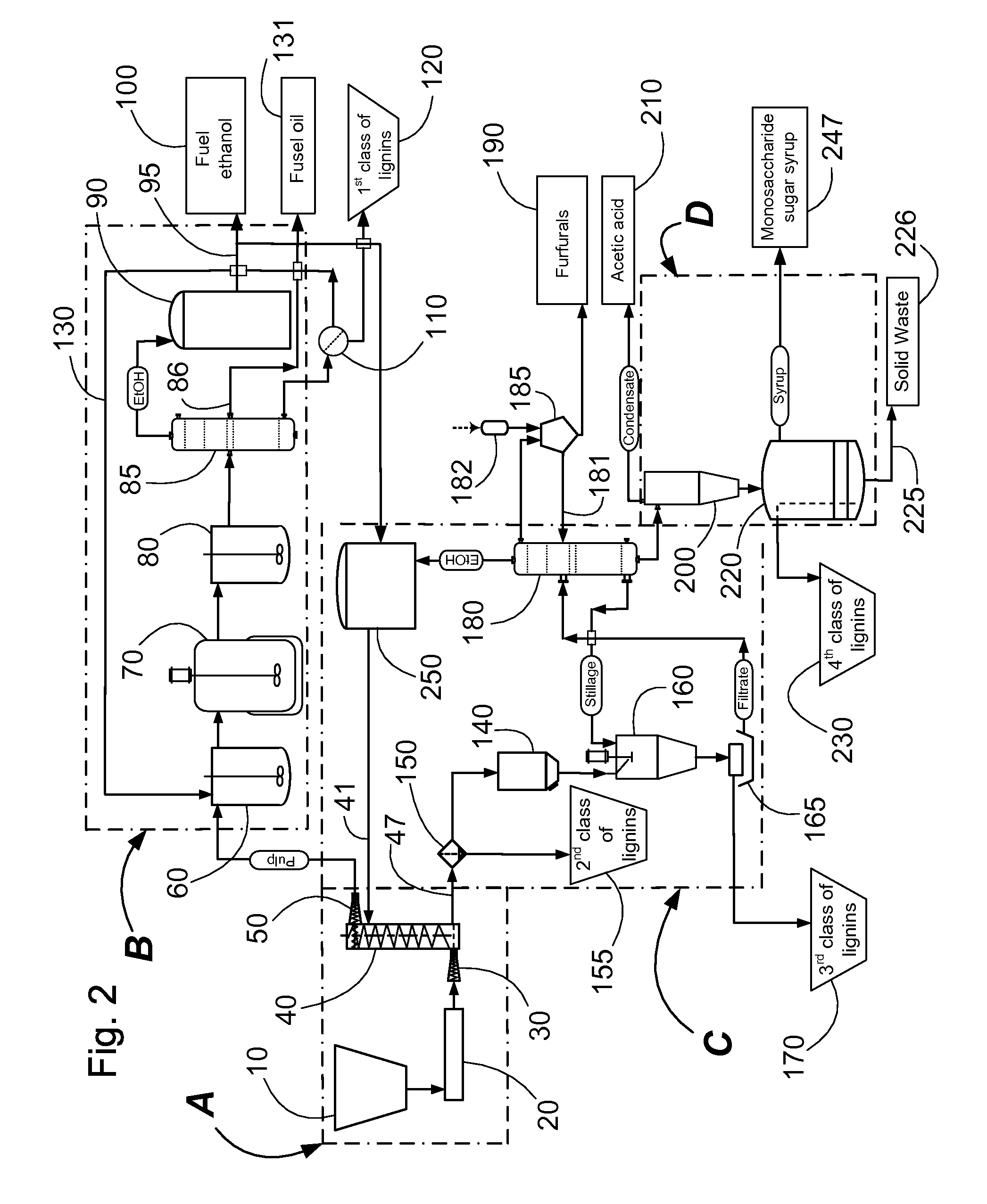

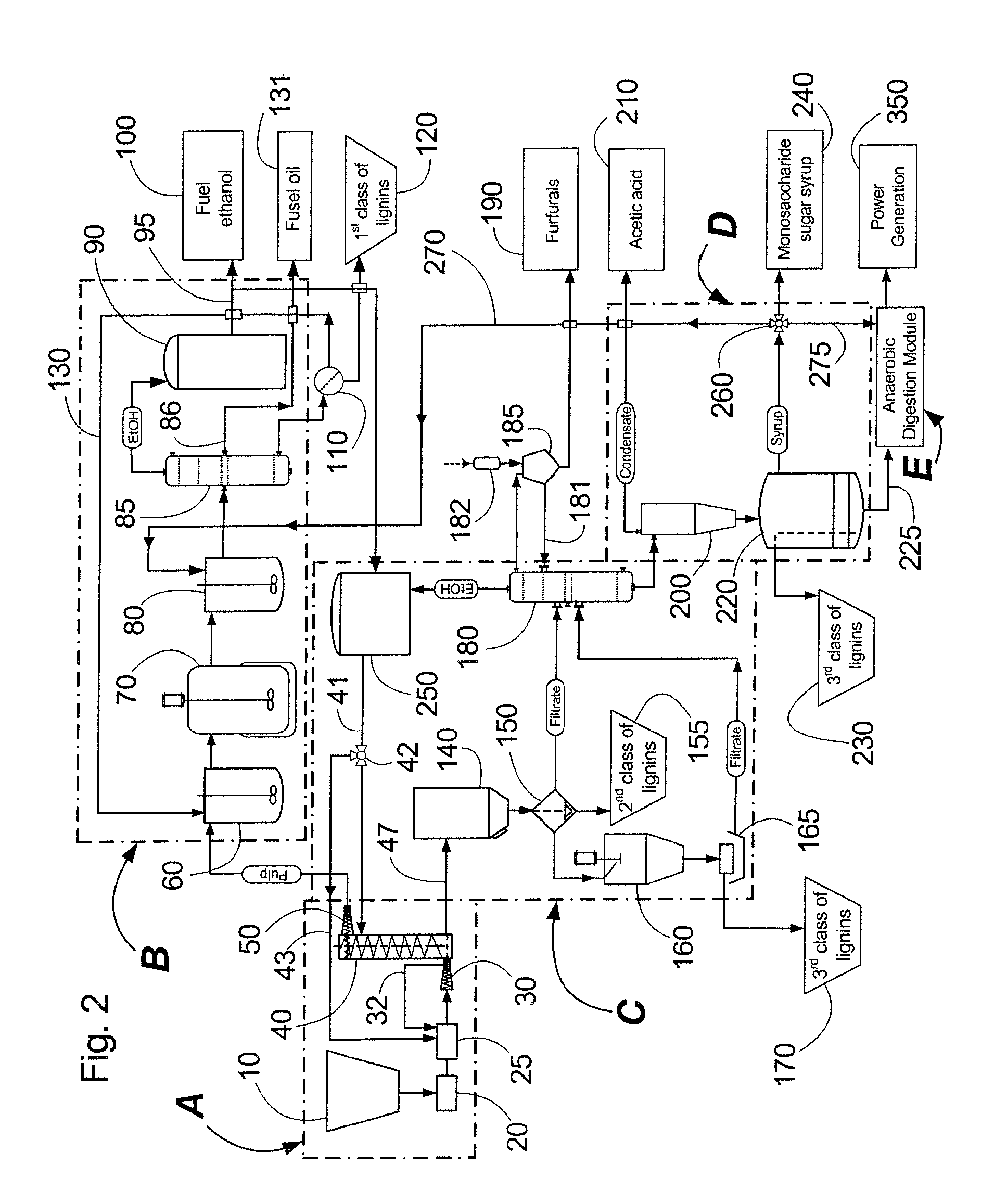

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into at least fuel-grade ethanol and four classes of lignin derivatives. The modular process comprises a first processing module configured for physico-chemically digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for producing at least a fuel-grade ethanol and a first class of novel lignin derivatives from the cellulosic solids fraction, a third processing module configured for separating a second class and a third class of lignin derivatives from the liquid fraction and further processing the liquid fraction to produce a distillate and a stillage, a fourth processing module configured for separating a fourth class of lignin derivatives from the stillage and further processing the stillage to produce a sugar syrup.

Owner:SUZANO CANADA INC

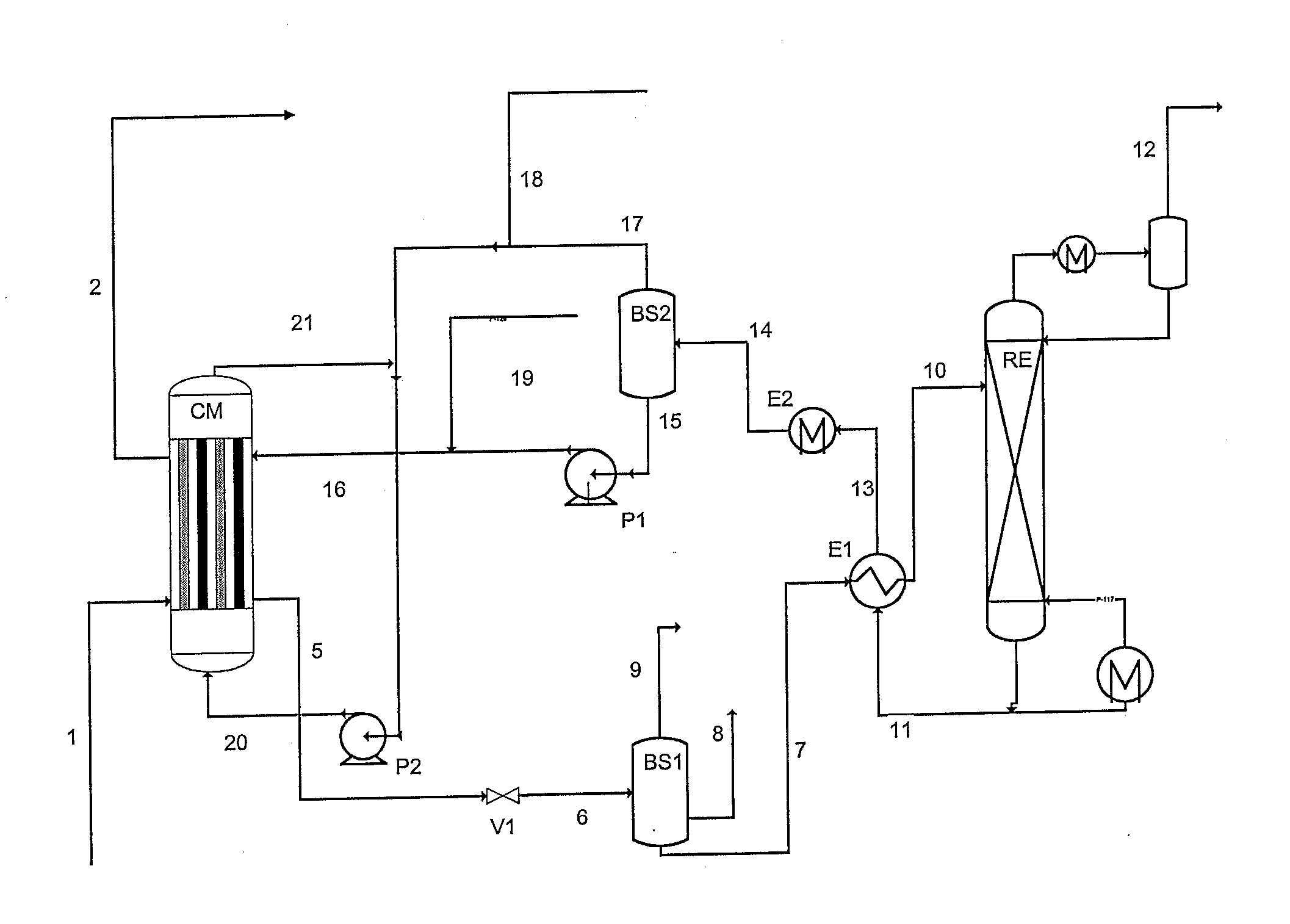

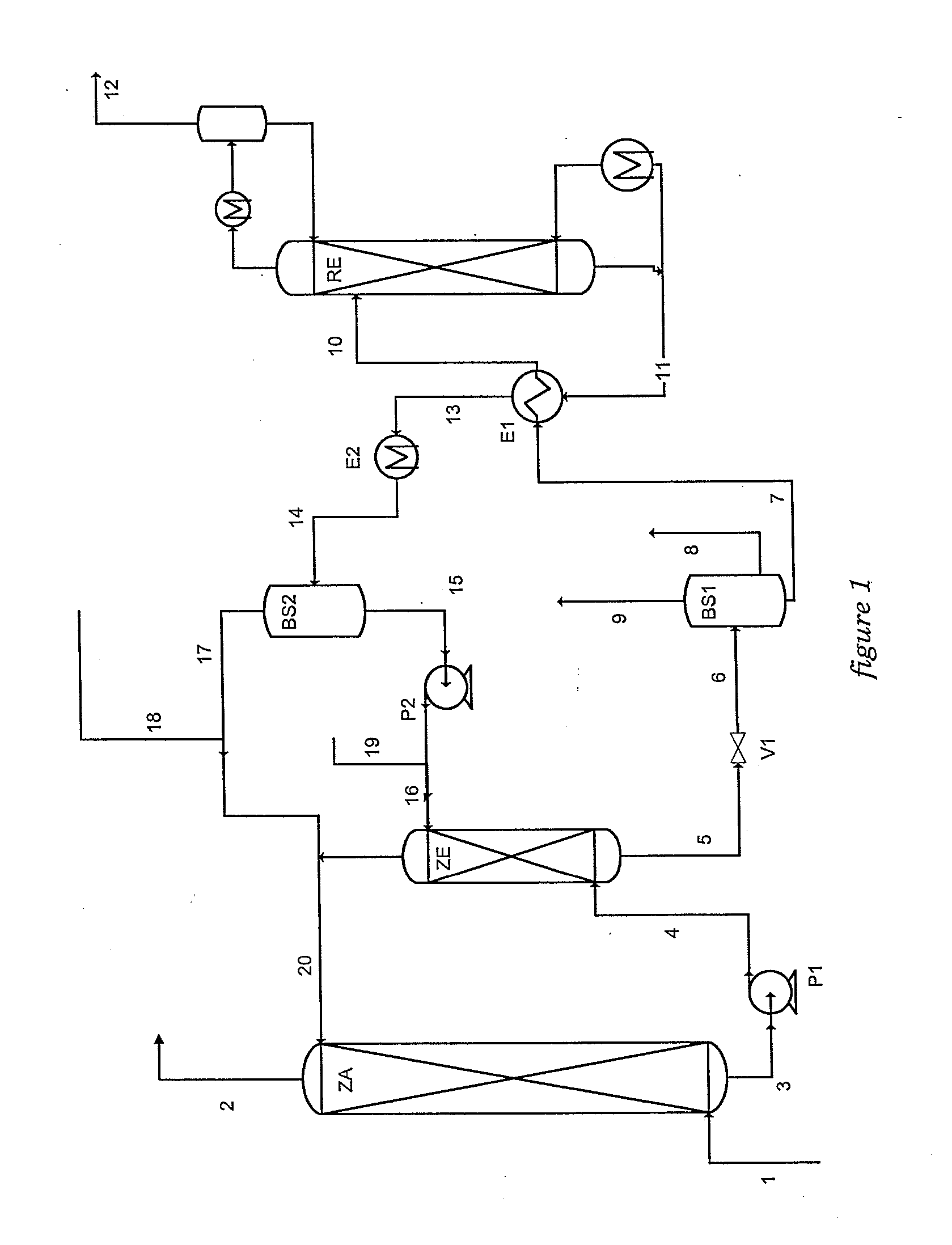

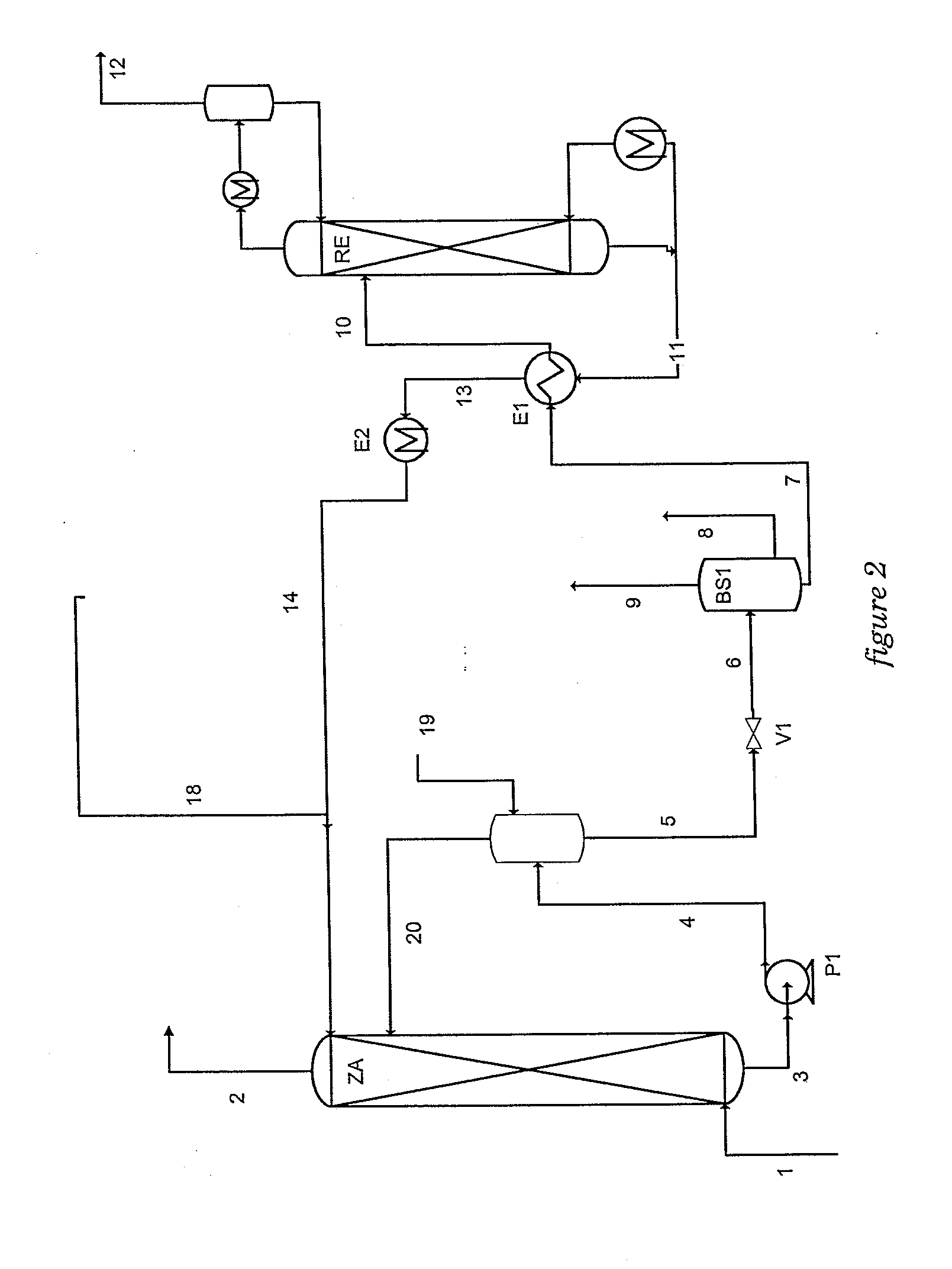

Method of deacidizing a gaseous effluent with extraction of the products to be regenerated

The present invention relates to a method of deacidizing a gaseous effluent comprising at least one of the acid compounds as follows: H2S, mercaptans, CO2, COS, SO2, CS2, wherein the following stages are carried out: a) contacting the acid compounds contained in said effluent with reactive compounds forming a liquid, so as to obtain a gaseous effluent depleted in acid compounds and a first liquid fraction comprising products formed by reaction of the reactive compounds with acid compounds, and reactive compounds that did not react with acid compounds, b) contacting said products contained in the first liquid fraction with extraction compounds forming a second liquid fraction so as to obtain a product-depleted first liquid fraction and a product-enriched second liquid fraction, c) recycling to stage a) the first liquid fraction obtained in stage b), said first liquid fraction obtained making up at least part of said liquid, d) regenerating the second liquid fraction obtained in stage b) so as to release acid compounds in gaseous form and to obtain a mixture of reactive compounds and of extraction compounds.

Owner:CARRETTE PIERRE LOUIS +6

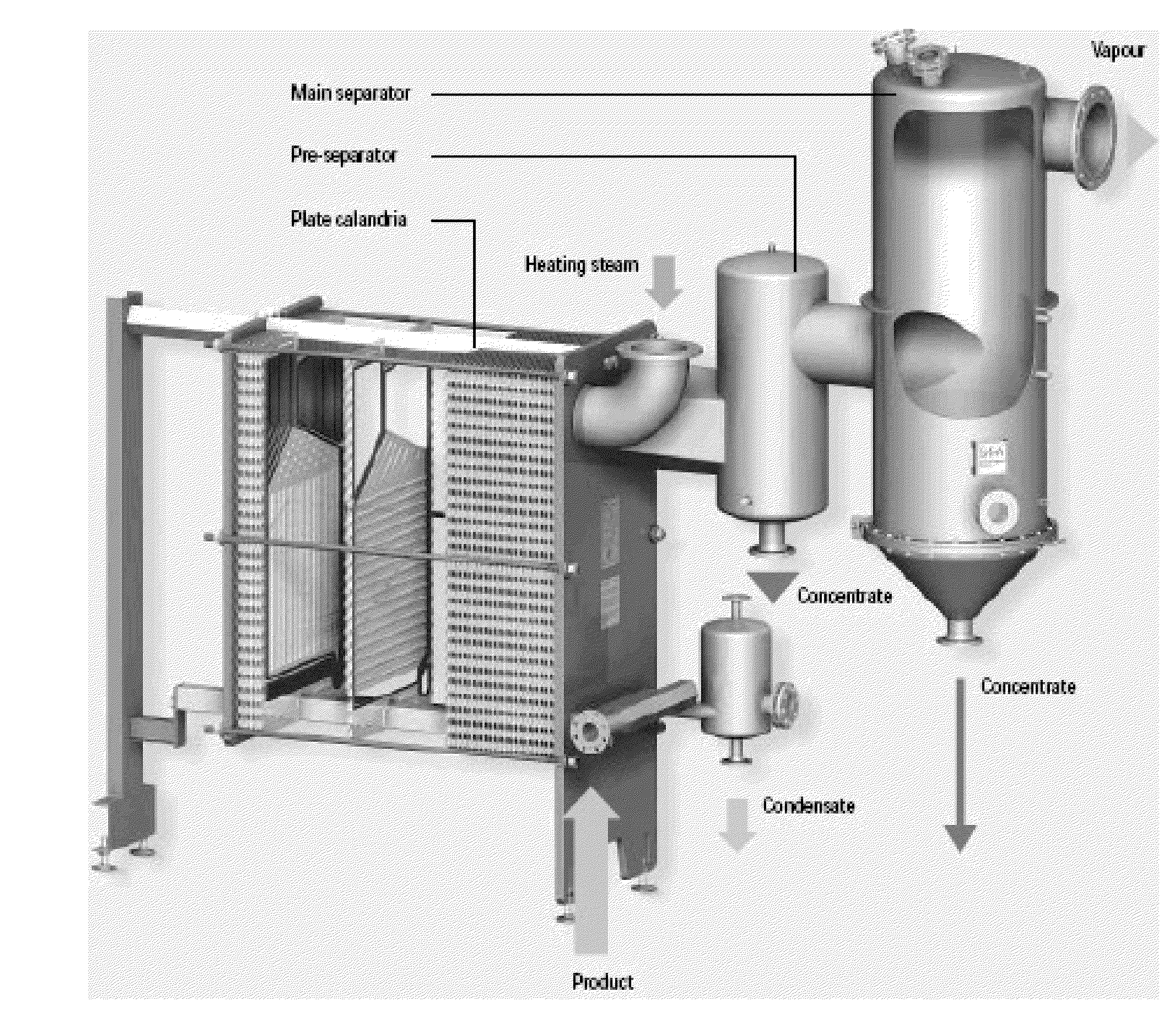

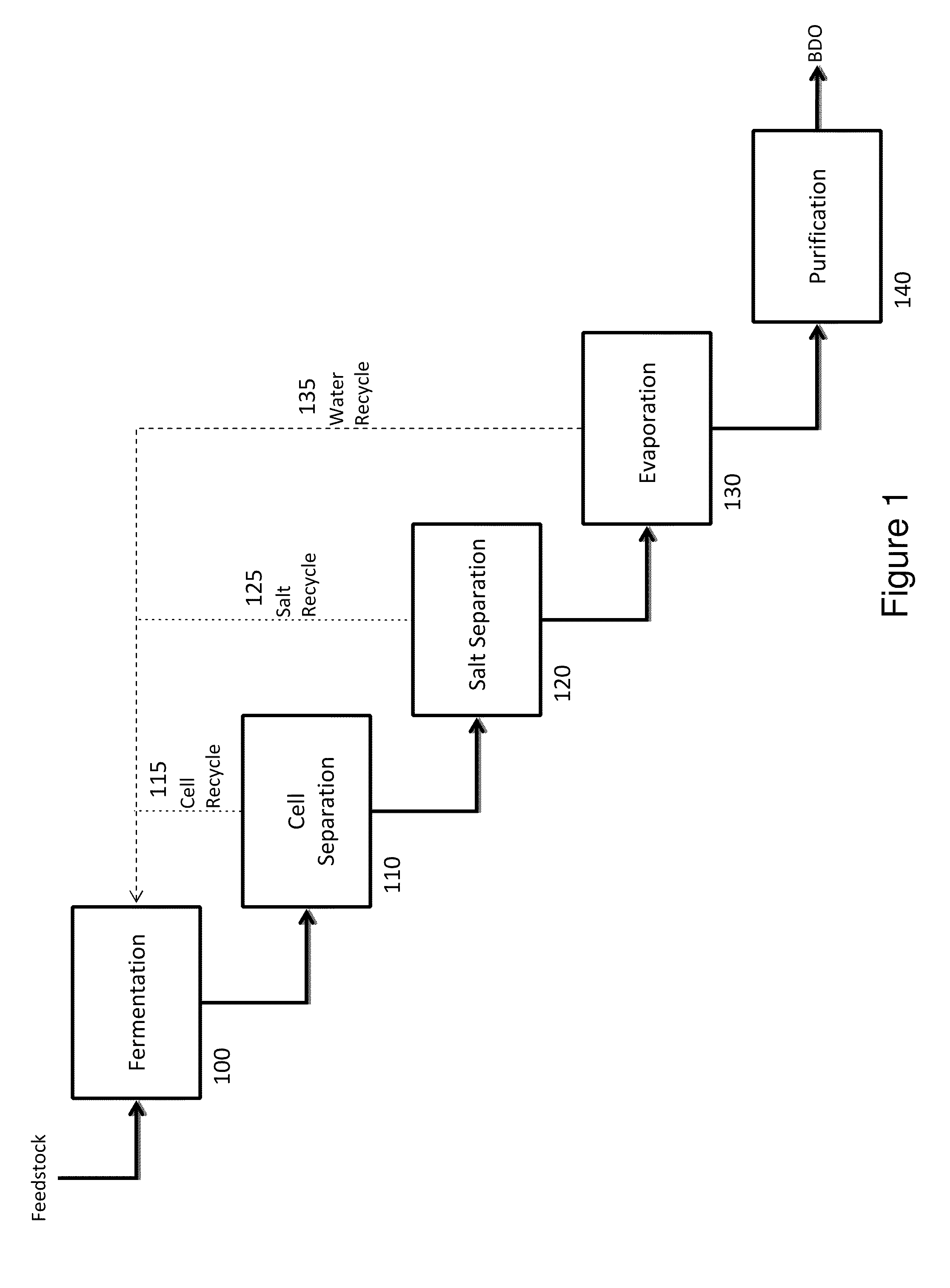

Process of separating components of a fermentation broth

ActiveUS20110003355A1Produce lotFermented solutions distillation/rectificationOrganic compound preparation1,4-ButanediolMicroorganism

A process of isolating 1,4-butanediol (1,4-BDO) from a fermentation broth includes separating a liquid fraction enriched in 1,4-BDO from a solid fraction comprising cells, removing water from said liquid fraction, removing salts from said liquid fraction, and purifying 1,4-BDO. A process for producing 1,4-BDO includes culturing a 1,4-BDO-producing microorganism in a fermentor for a sufficient period of time to produce 1,4-BDO. The 1,4-BDO-producing microorganism includes a microorganism having a 1,4-BDO pathway having one or more exogenous genes encoding a 1,4-BDO pathway enzyme and / or one or more gene disruptions. The process for producing 1,4-BDO further includes isolating 1,4-BDO.

Owner:GENOMATICA INC

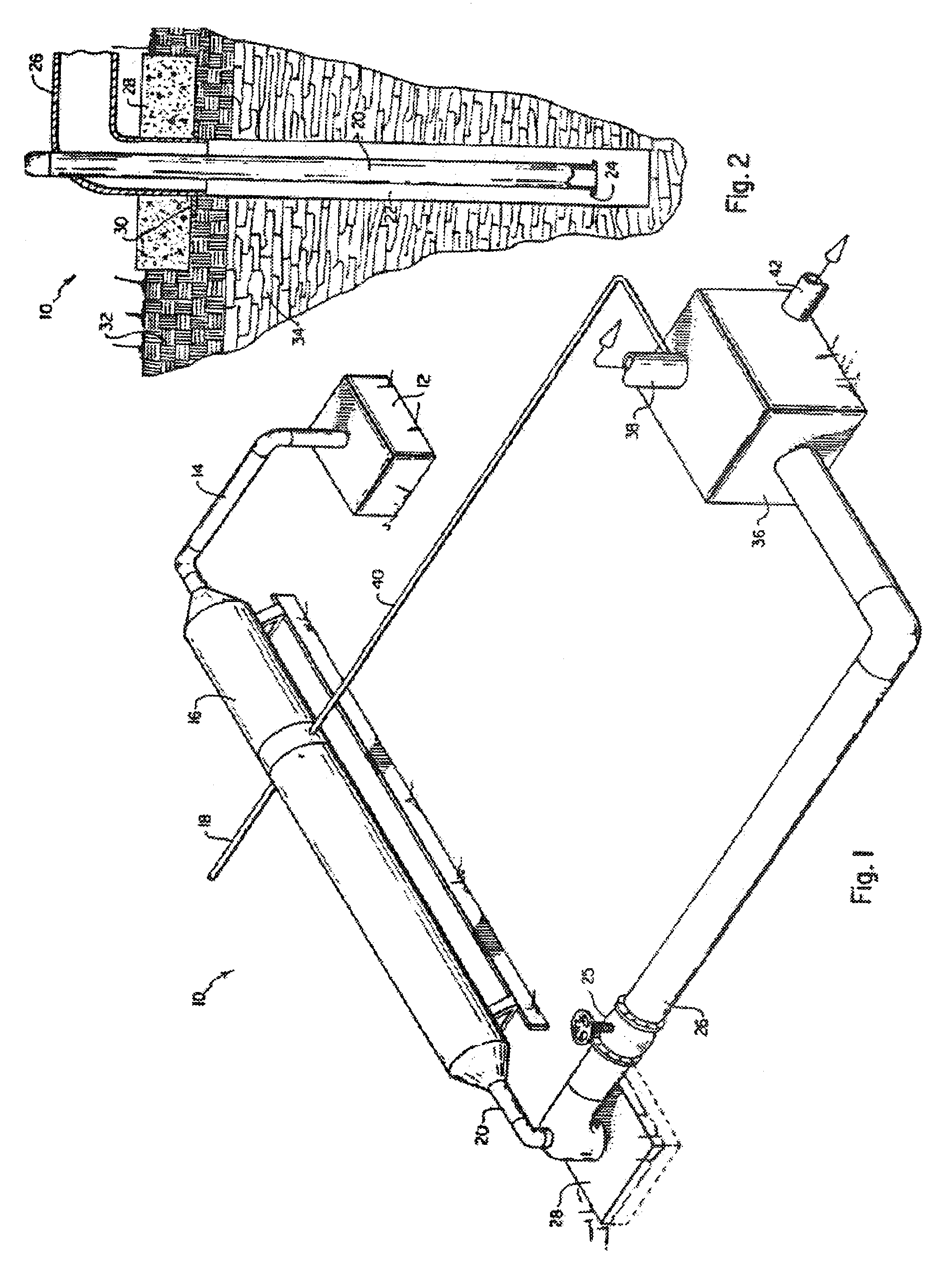

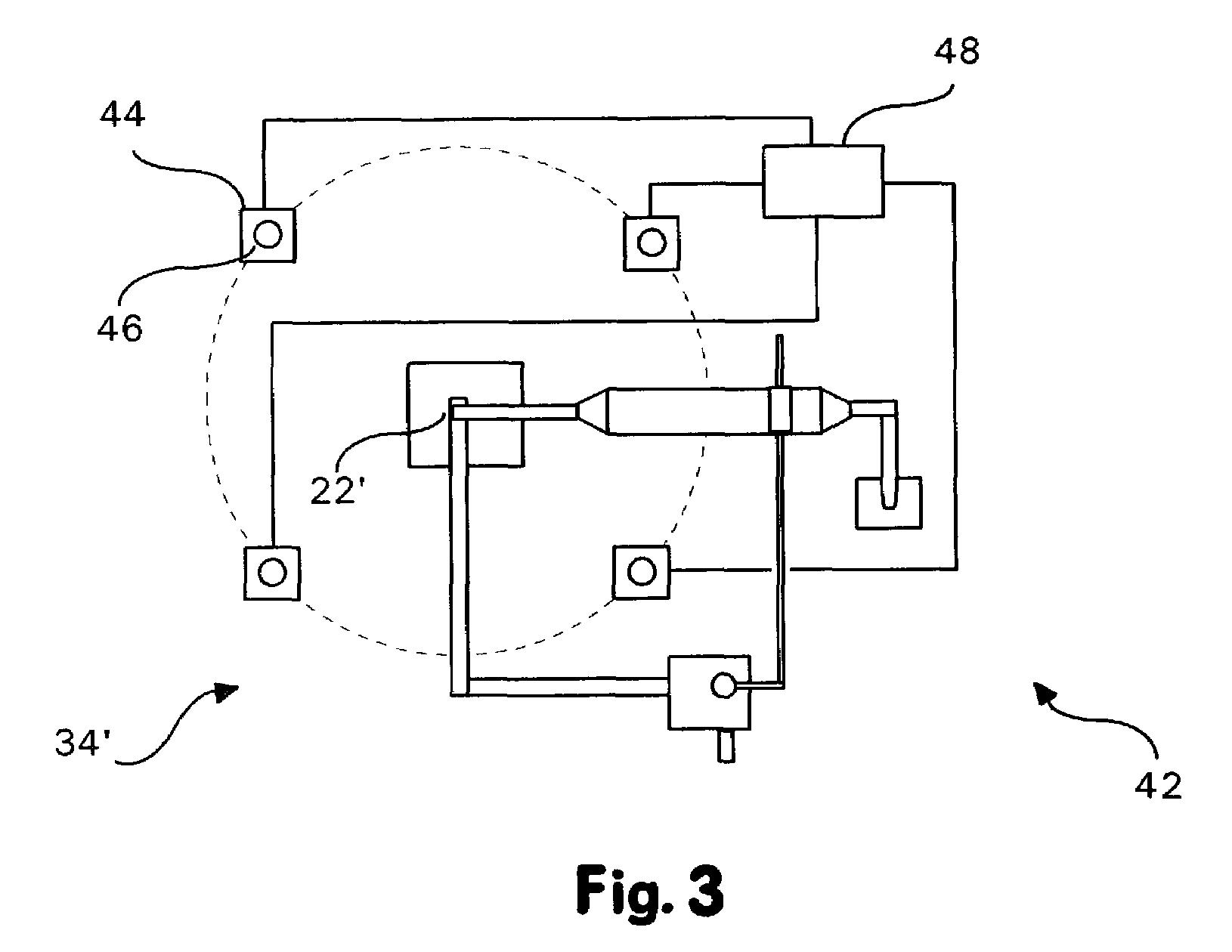

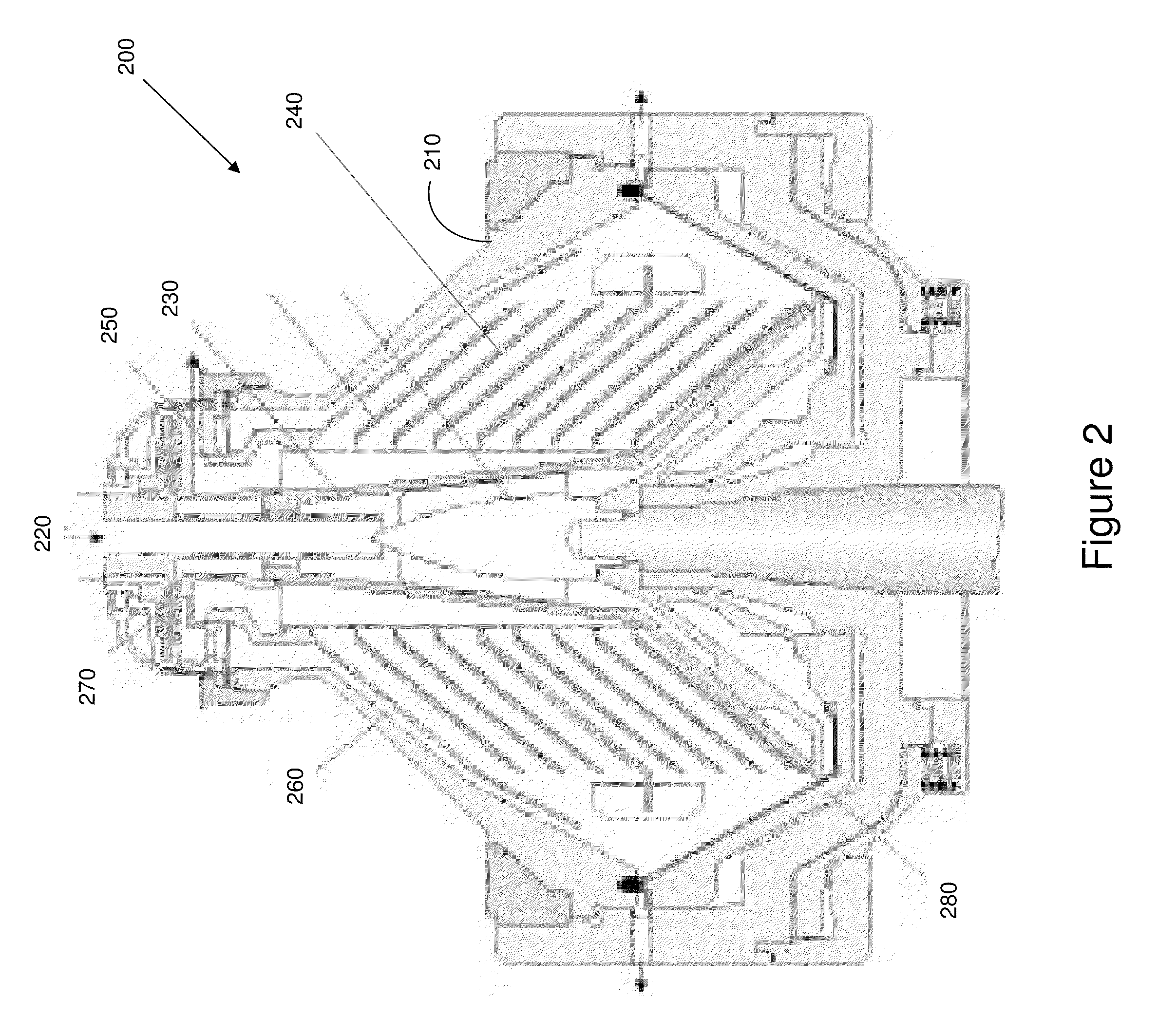

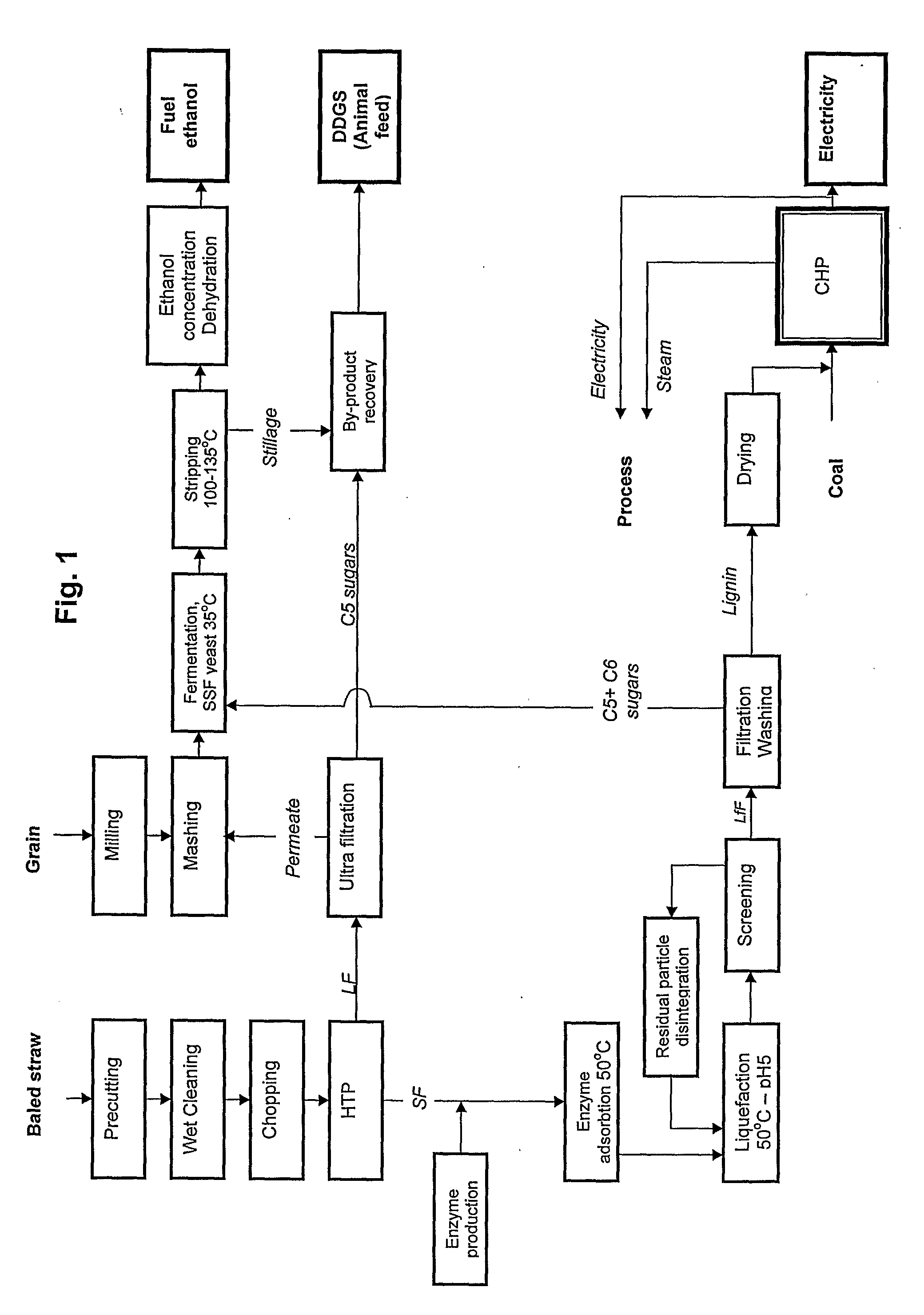

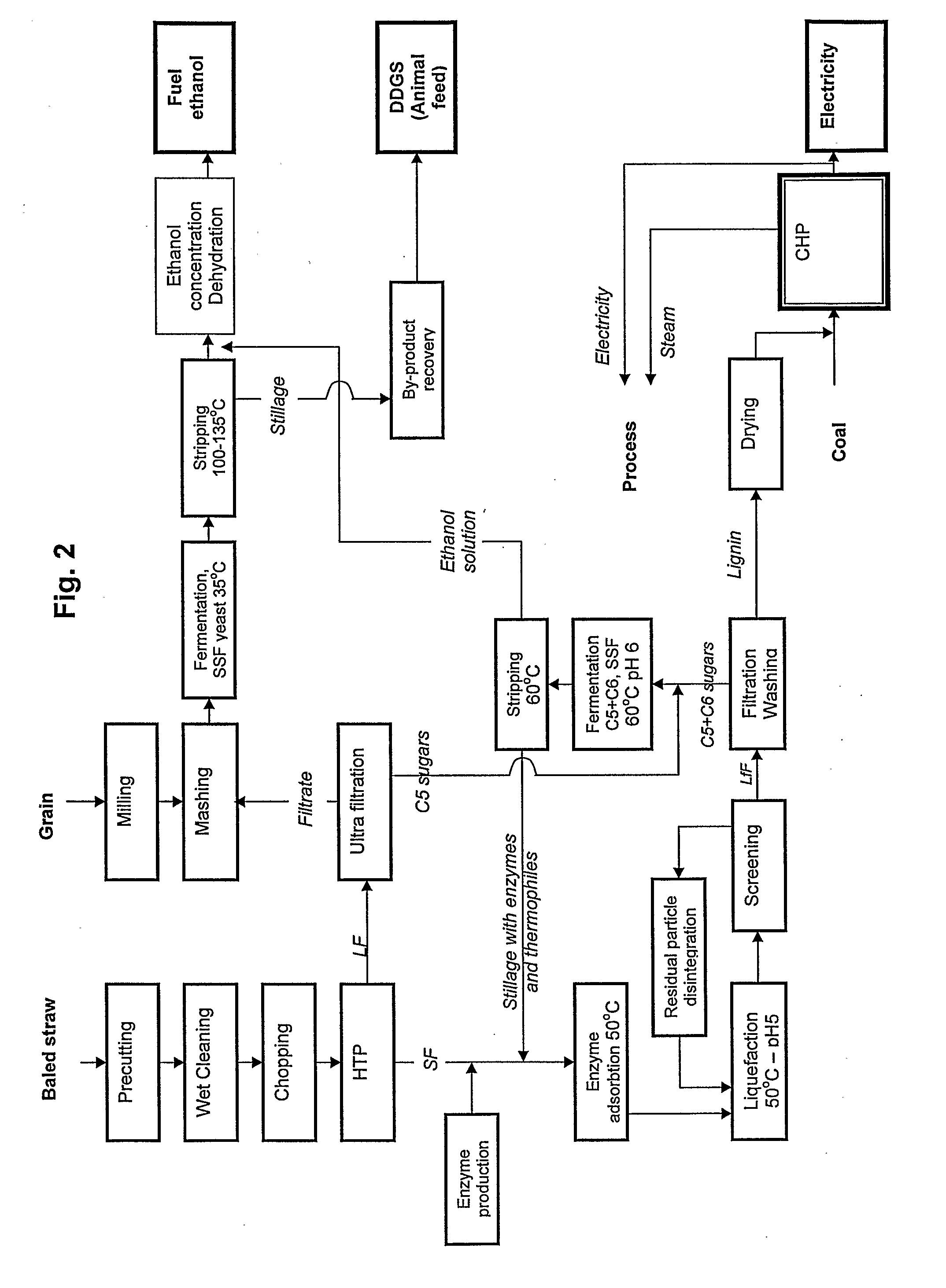

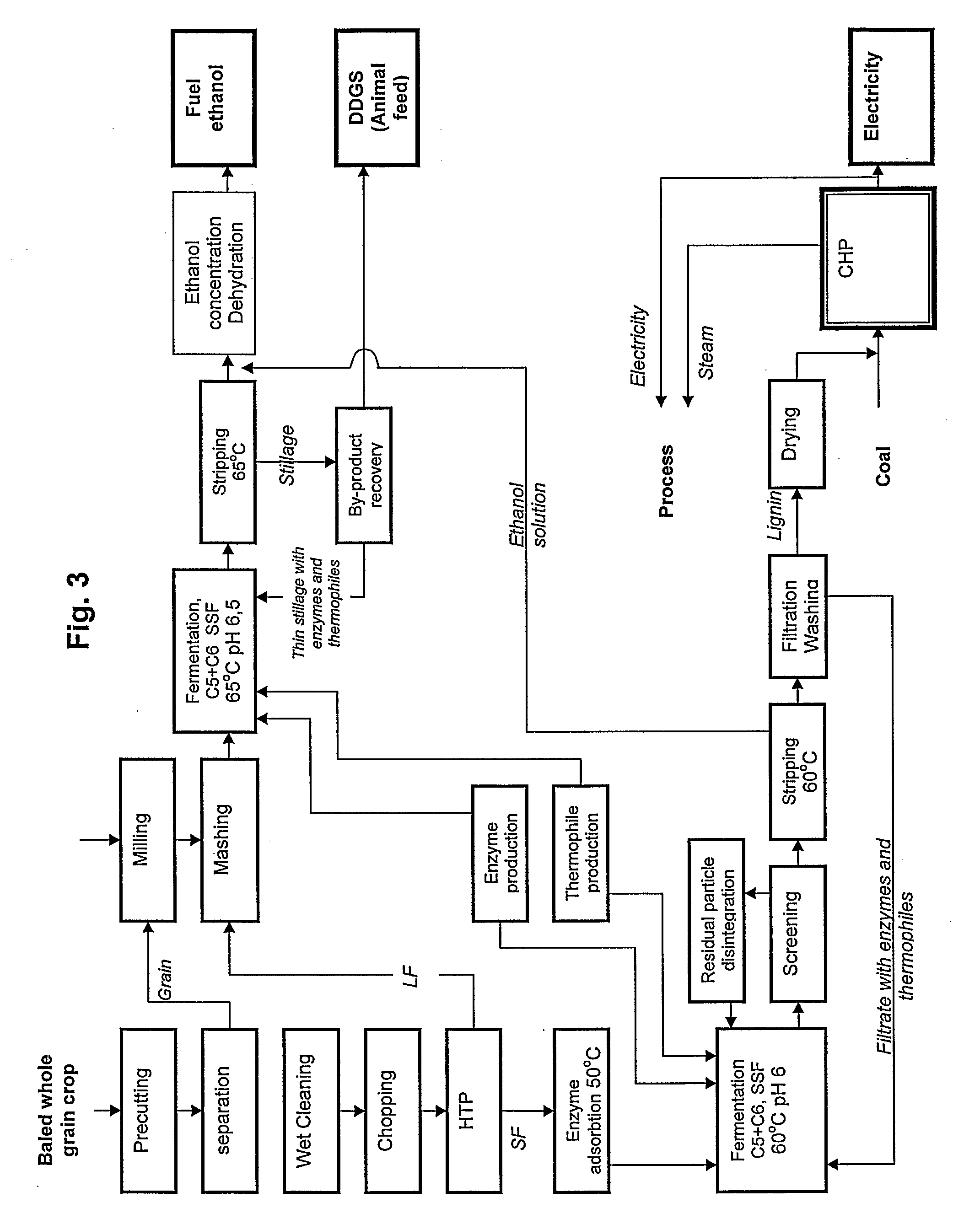

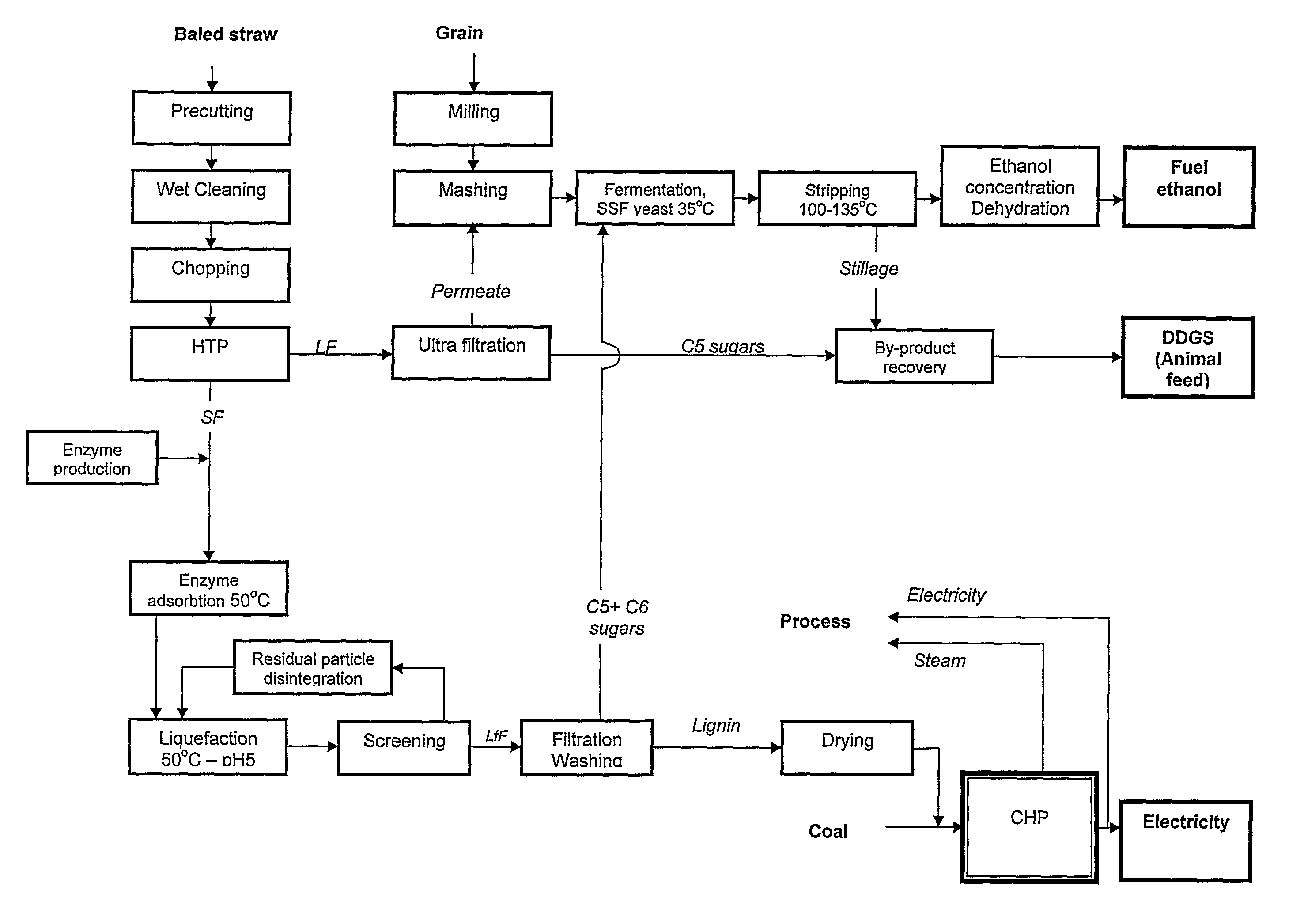

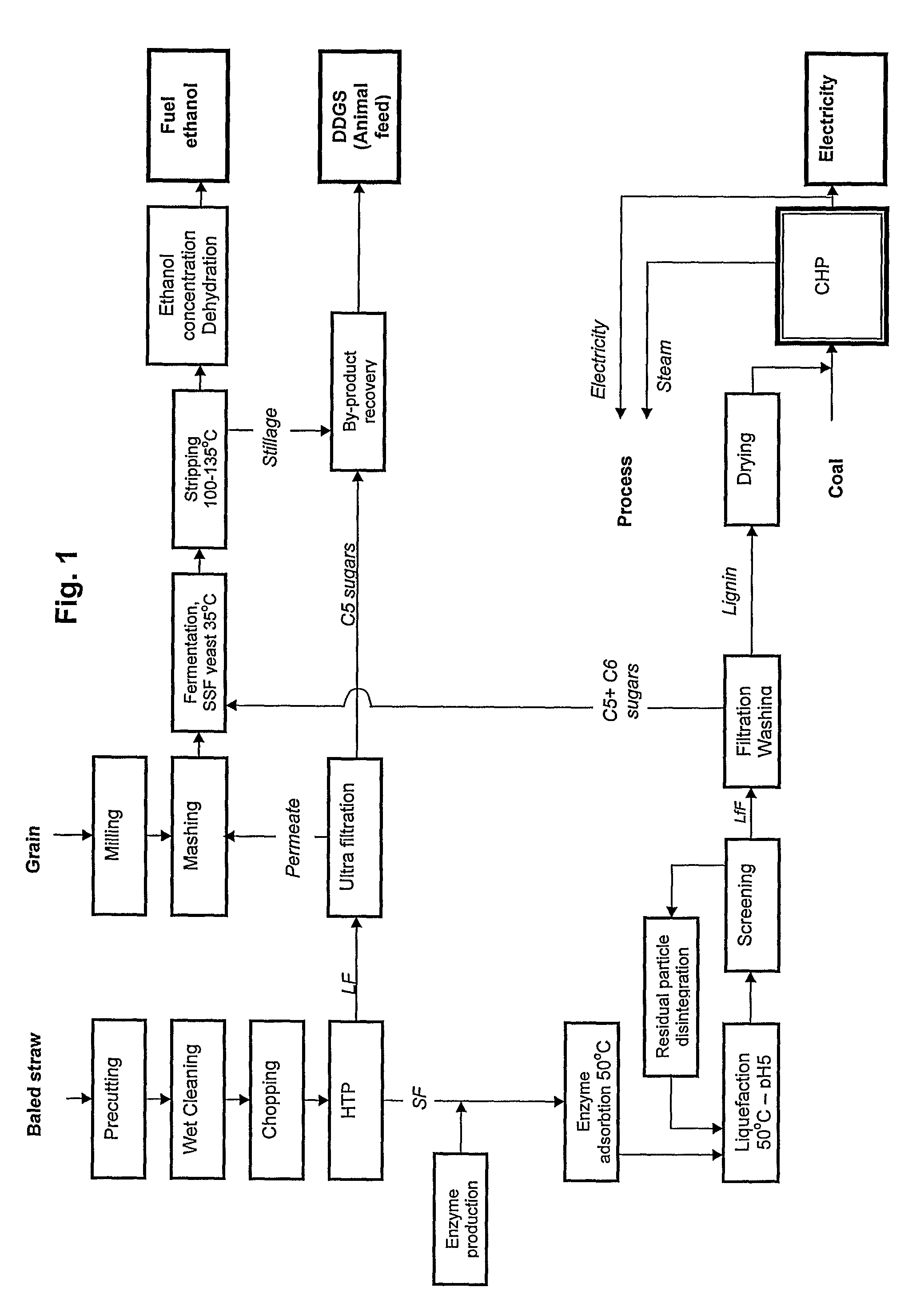

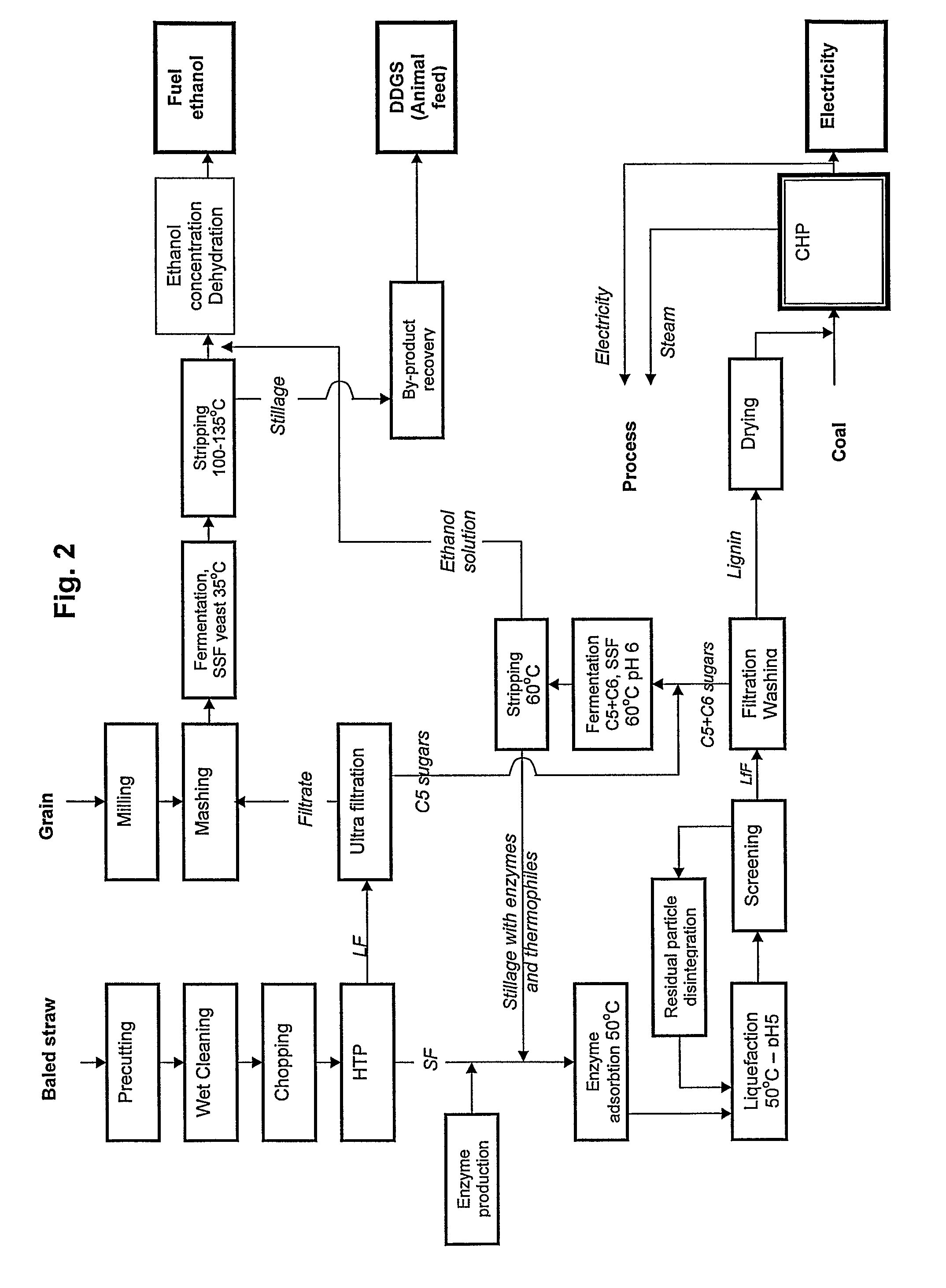

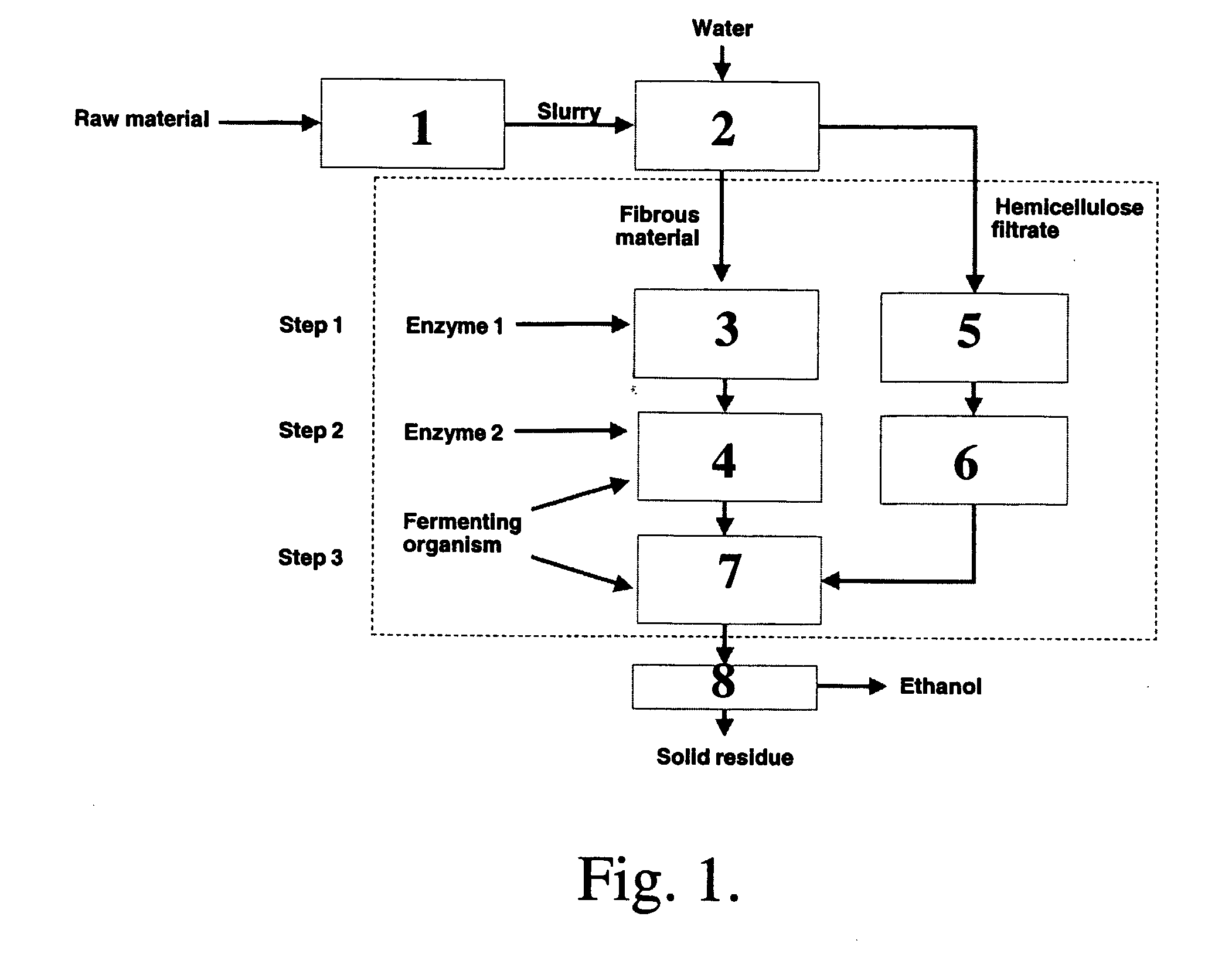

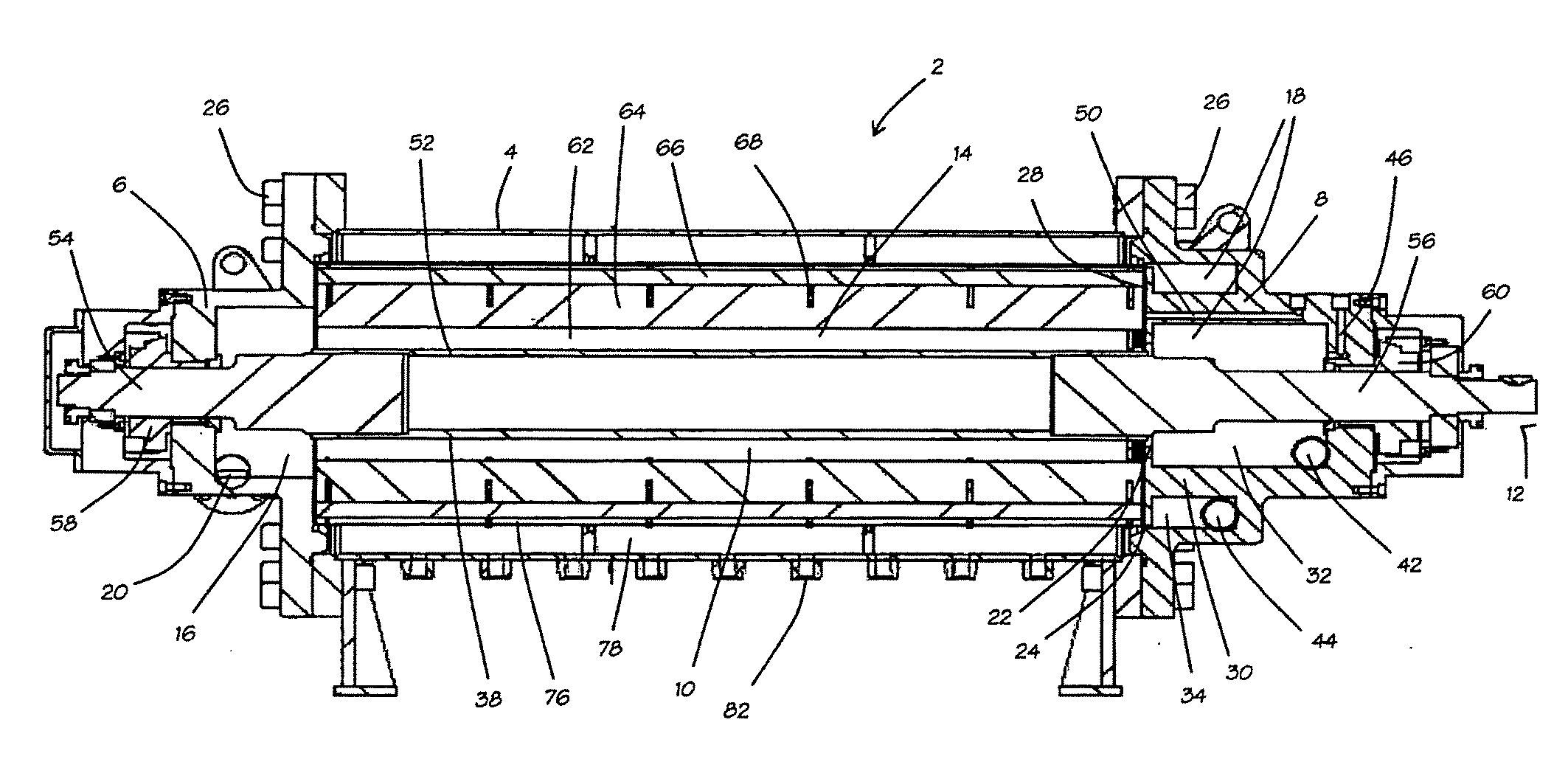

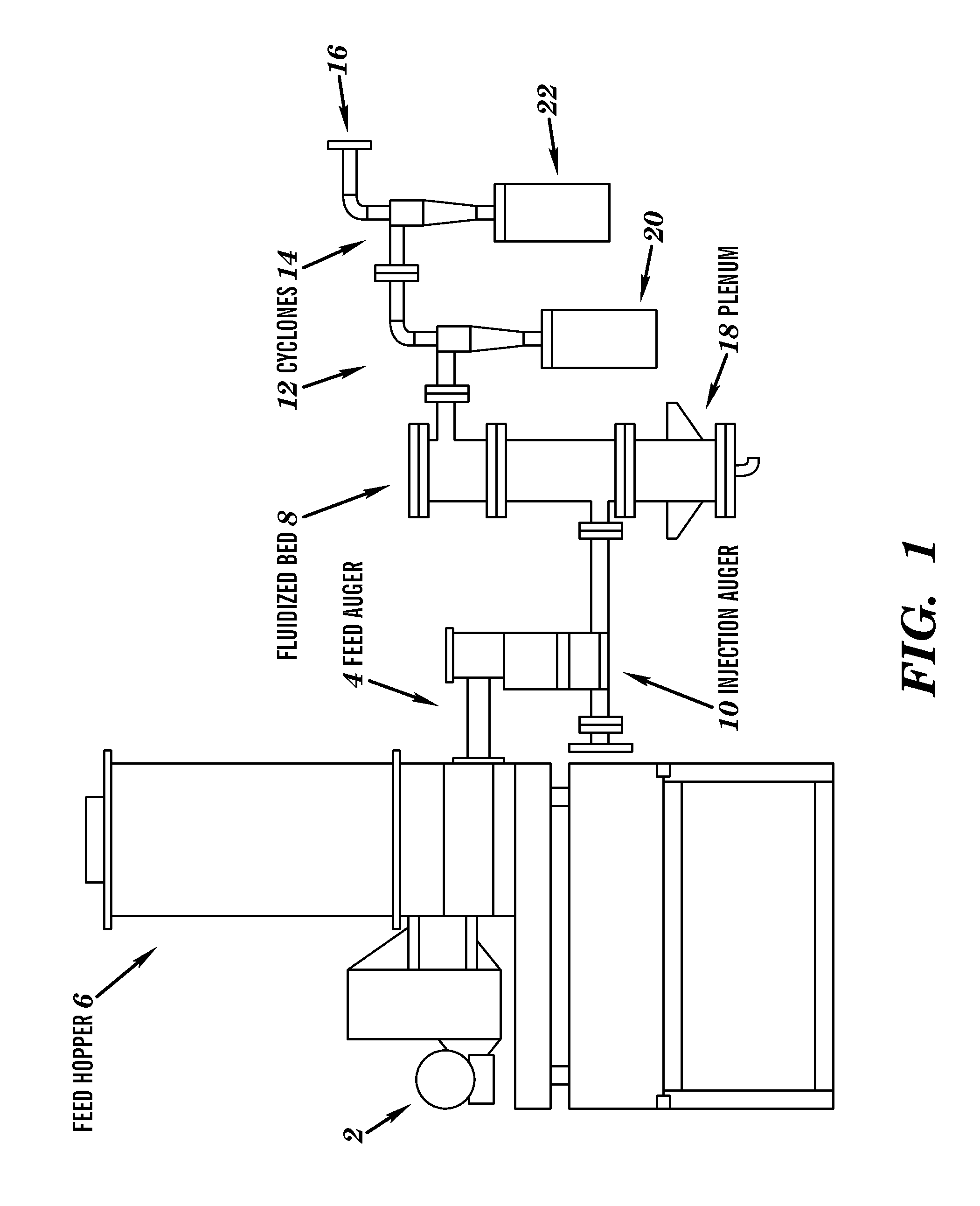

Method and apparatus for conversion of cellulosic material to ethanol

ActiveUS20100041119A1Low costDown rate of fermentationBiological substance pretreatmentsBiofuelsFiberCellulose

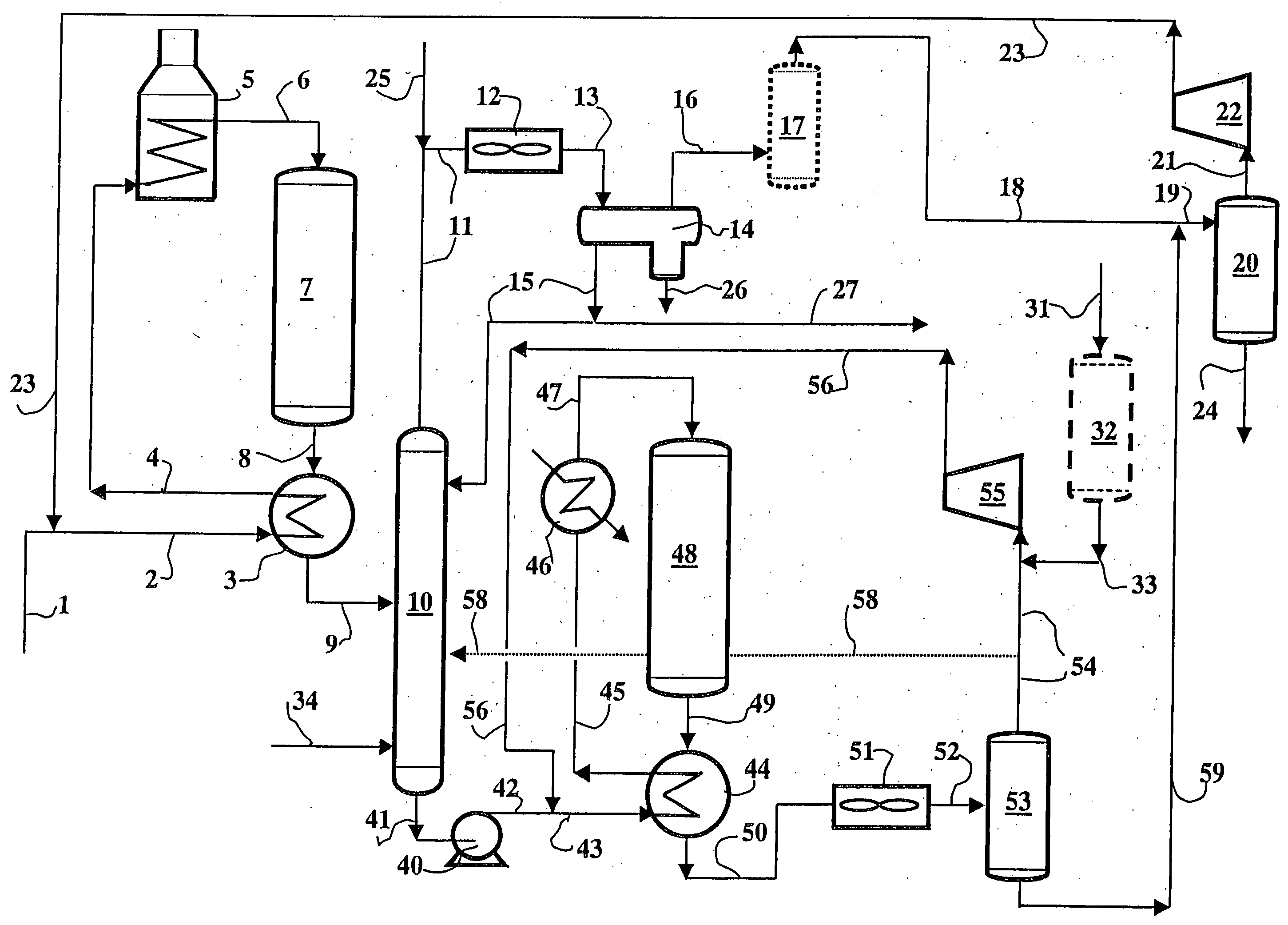

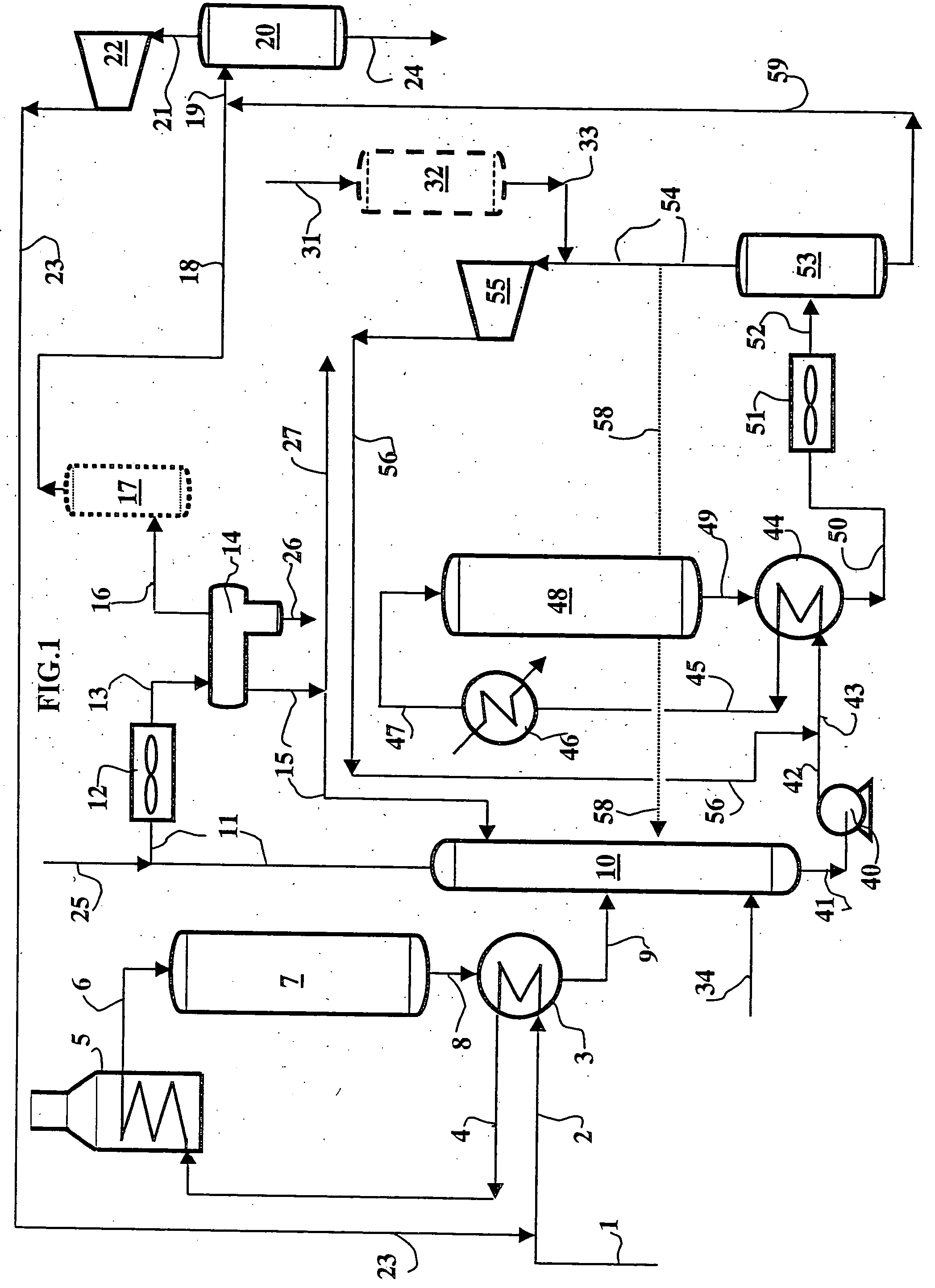

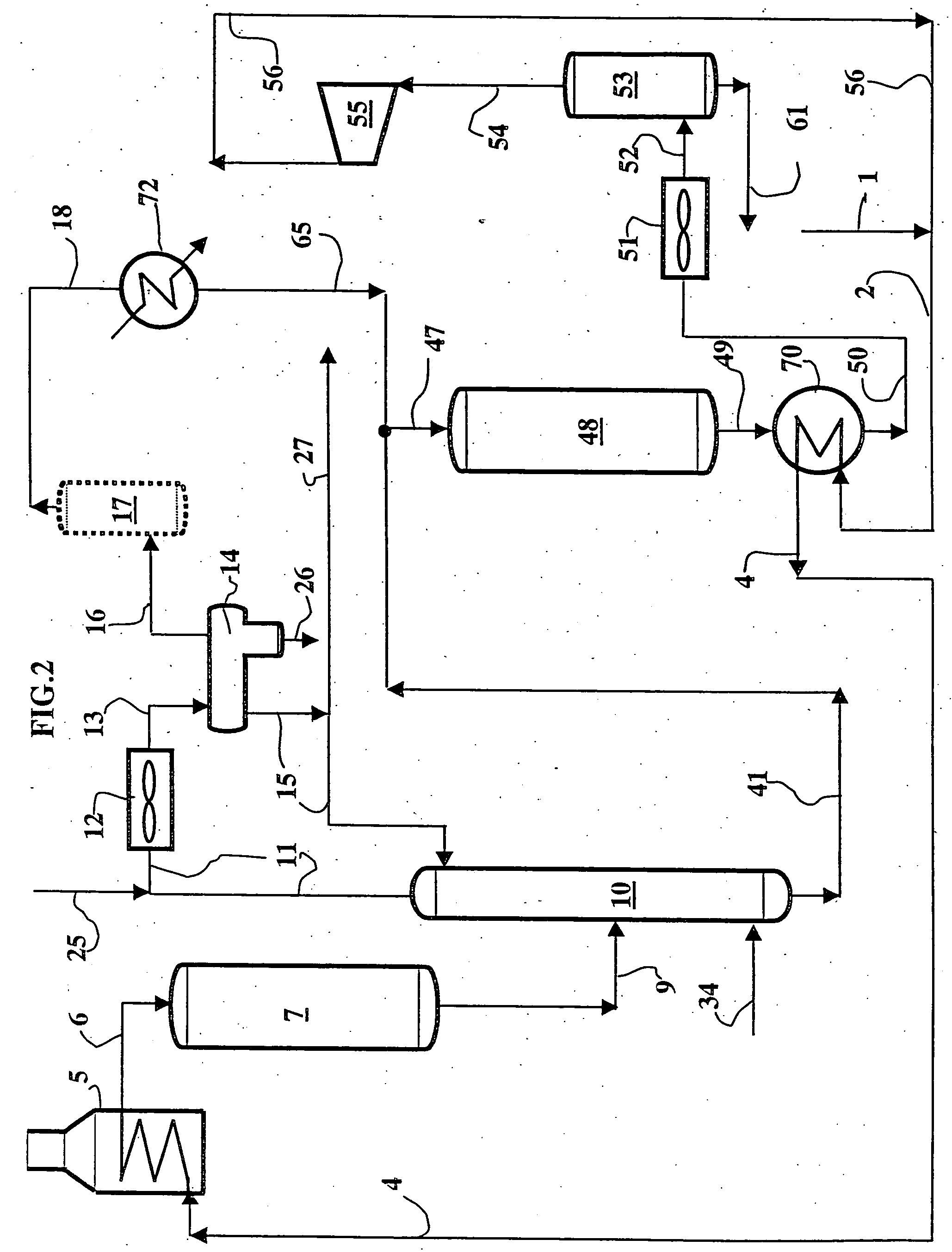

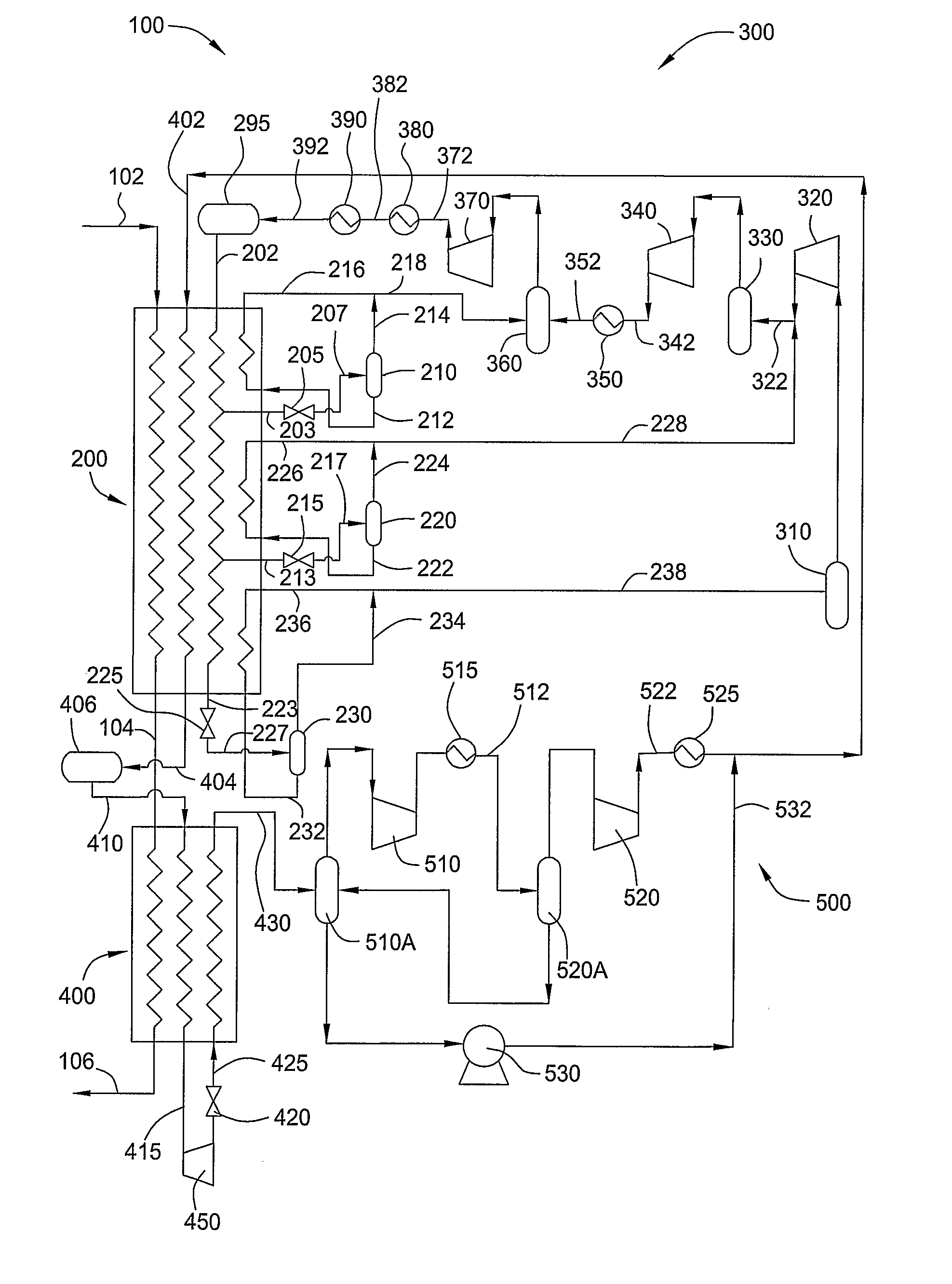

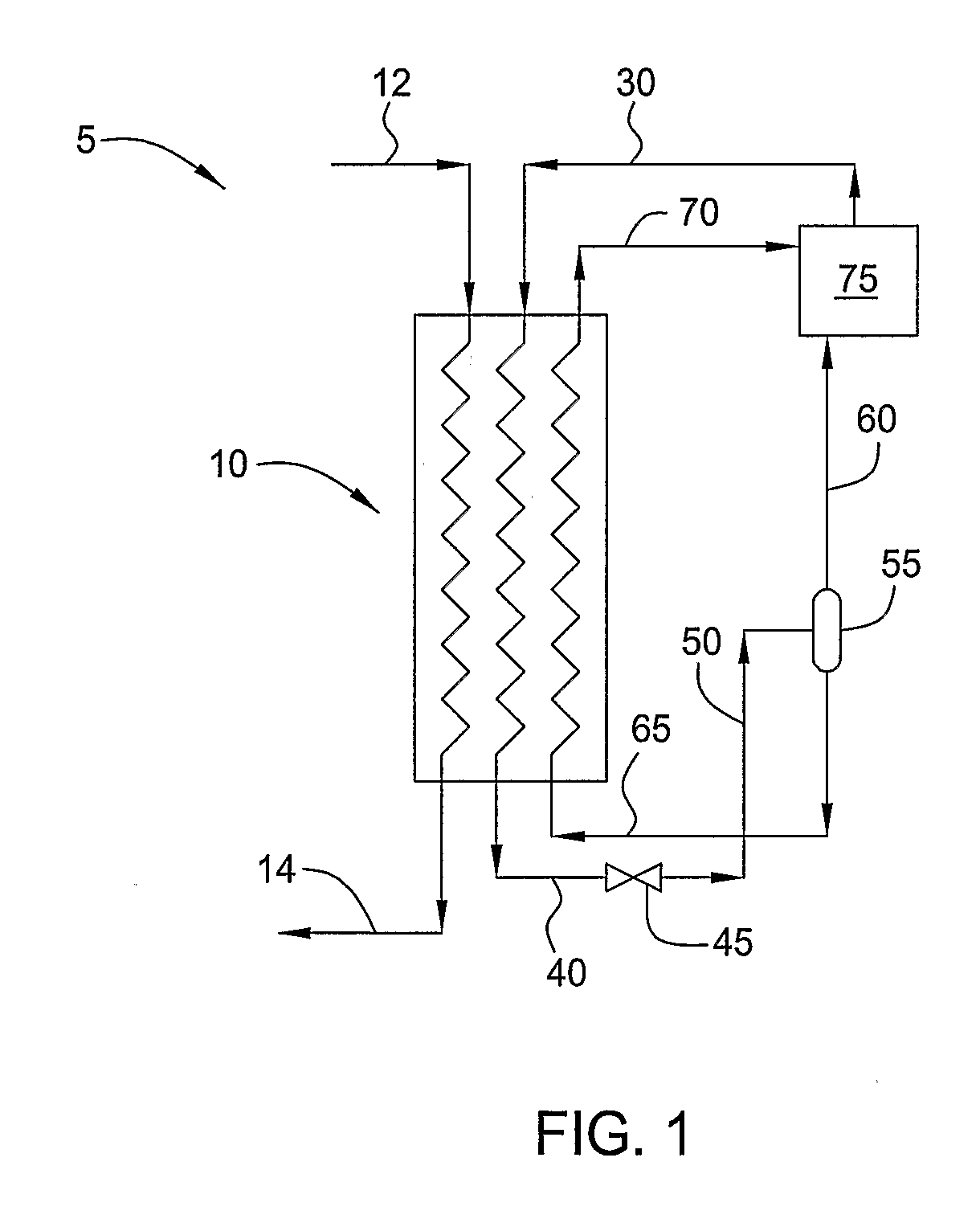

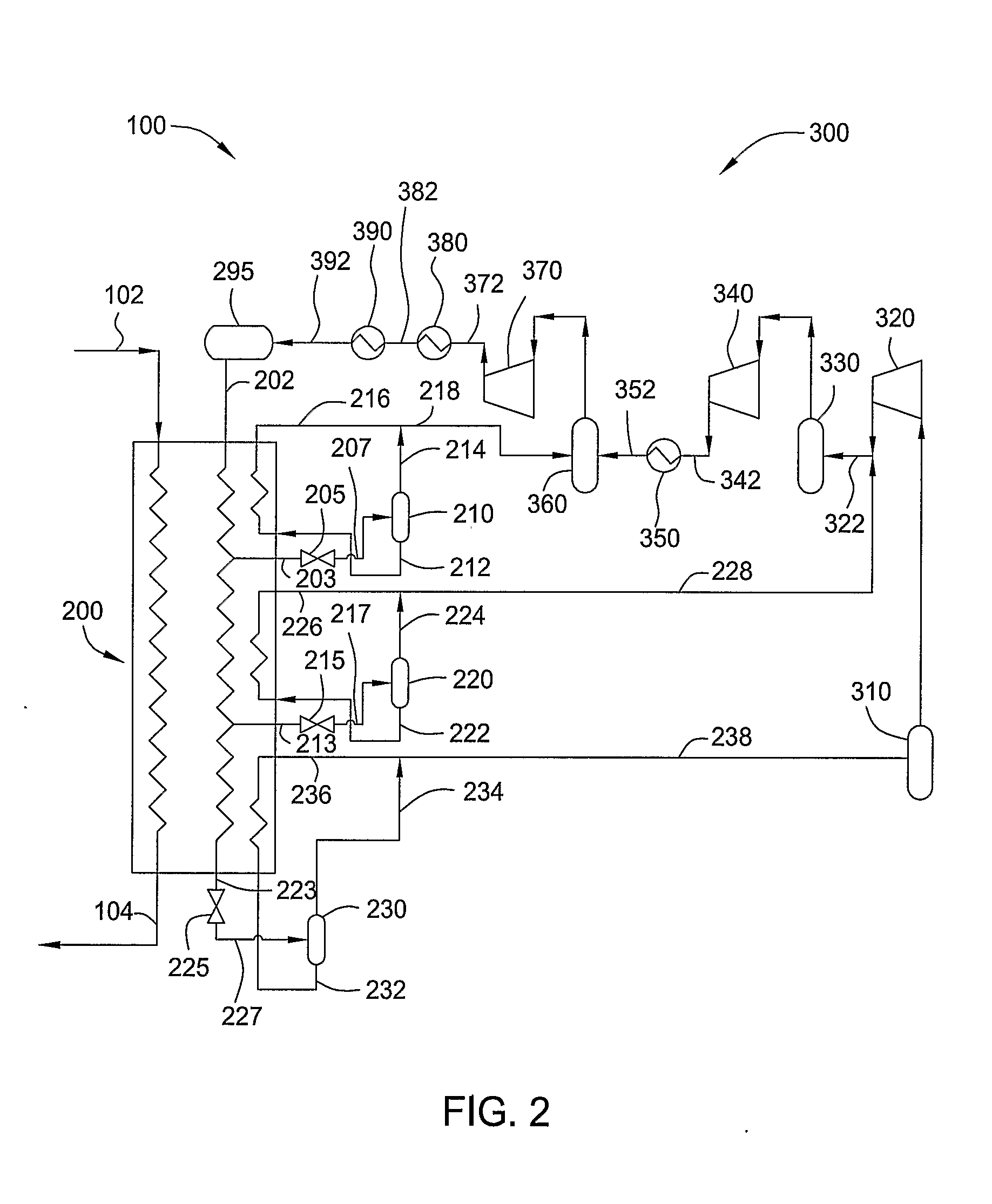

The present invention provides an apparatus and a method for conversion of cellulosic material, such as chopped straw and corn stover, and household waste, to ethanol and other products. The cellulosic material is subjected to continuous hydrothermal pre-treatment without addition of chemicals, and a liquid and a fibre fraction are produced. The fibre fraction is subjected to enzymatic liquefaction and saccharification. The method of the present invention comprises:performing the hydrothermal pre-treatment by subjecting the cellulosic material to at least one soaking operation, and conveying the cellulosic material through at least one pressurised reactor, and subjecting the cellulosic material to at least one pressing operation, creating a fibre fraction and a liquid fraction;selecting the temperature and residence time for the hydrothermal pretreatment, so that the fibrous structure of the feedstock is maintained and at least 80% of the lignin is maintained in the fibre fraction.

Owner:INBICON AS

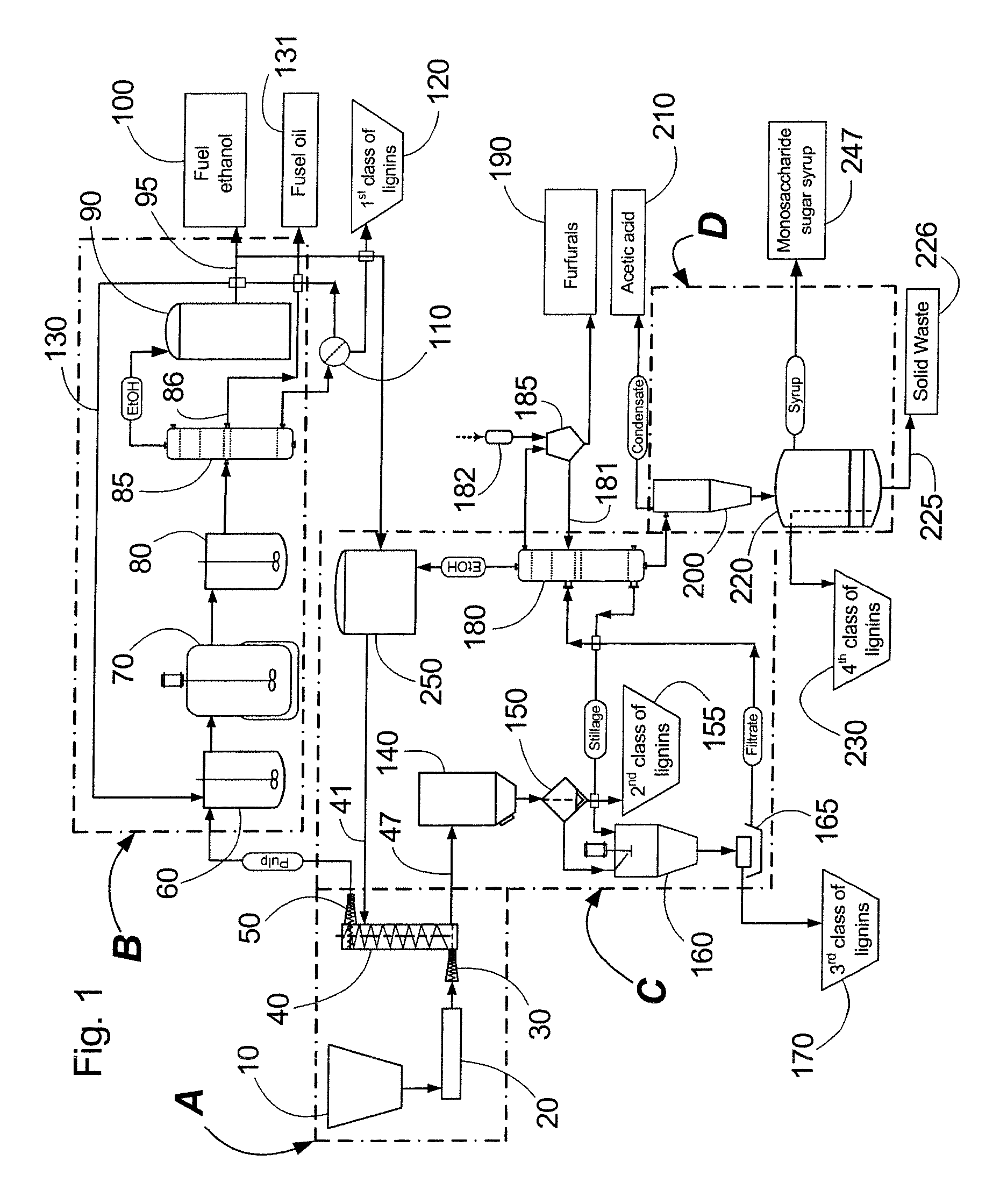

Continuous counter-current organosolv processing of lignocellulosic feedstocks

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into one or more of a de-lignified cellulose stream, a sugar stream, small-chain alcohol streams and four structurally distinct classes of lignin derivatives. The modular process comprises a first processing module configured for digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for recovering small-chain alcohols and optionally a first class of lignin derivatives from the cellulosic solids fraction, a third processing module configured for recovering from the liquid fraction at least one of a second class and a third class of lignin derivatives or mixtures thereof, and waste stream comprising a fourth class of lignin derivatives. The fourth processing module may optionally recover the fourth class of lignin derivatives.

Owner:SUZANO CANADA INC

Fractionation process

InactiveUS6552208B1Fatty oils/acids recovery from wasteCosmetic preparationsVegetable oilActive component

The invention refers to a process for fractionating a vegetable oil giving one or more solid fractions suitable for confectionary applications as well as a liquid fraction rich in unsaponifiable biologically active components. The liquid fractions of shea butter and rapeseed oil having a high content of phytosterols and tocoferols, respectively, are useful for cosmetical and pharmaceutical preparations.

Owner:KARLSHAMNS AB KARLSHAMN

Method and apparatus for conversion of cellulosic material to ethanol

ActiveUS8123864B2Low costDown rate of fermentationBiological substance pretreatmentsBiofuelsFiberCellulose

The present invention provides an apparatus and a method for conversion of cellulosic material, such as chopped straw and corn stover, and household waste, to ethanol and other products. The cellulosic material is subjected to continuous hydrothermal pre-treatment without addition of chemicals, and a liquid and a fiber fraction are produced. The fiber fraction is subjected to enzymatic liquefaction and saccharification. The method of the present invention comprises:performing the hydrothermal pre-treatment by subjecting the cellulosic material to at least one soaking operation, and conveying the cellulosic material through at least one pressurized reactor, and subjecting the cellulosic material to at least one pressing operation, creating a fiber fraction and a liquid fraction;selecting the temperature and residence time for the hydrothermal pretreatment, so that the fibrous structure of the feedstock is maintained and at least 80% of the lignin is maintained in the fiber fraction.

Owner:INBICON AS

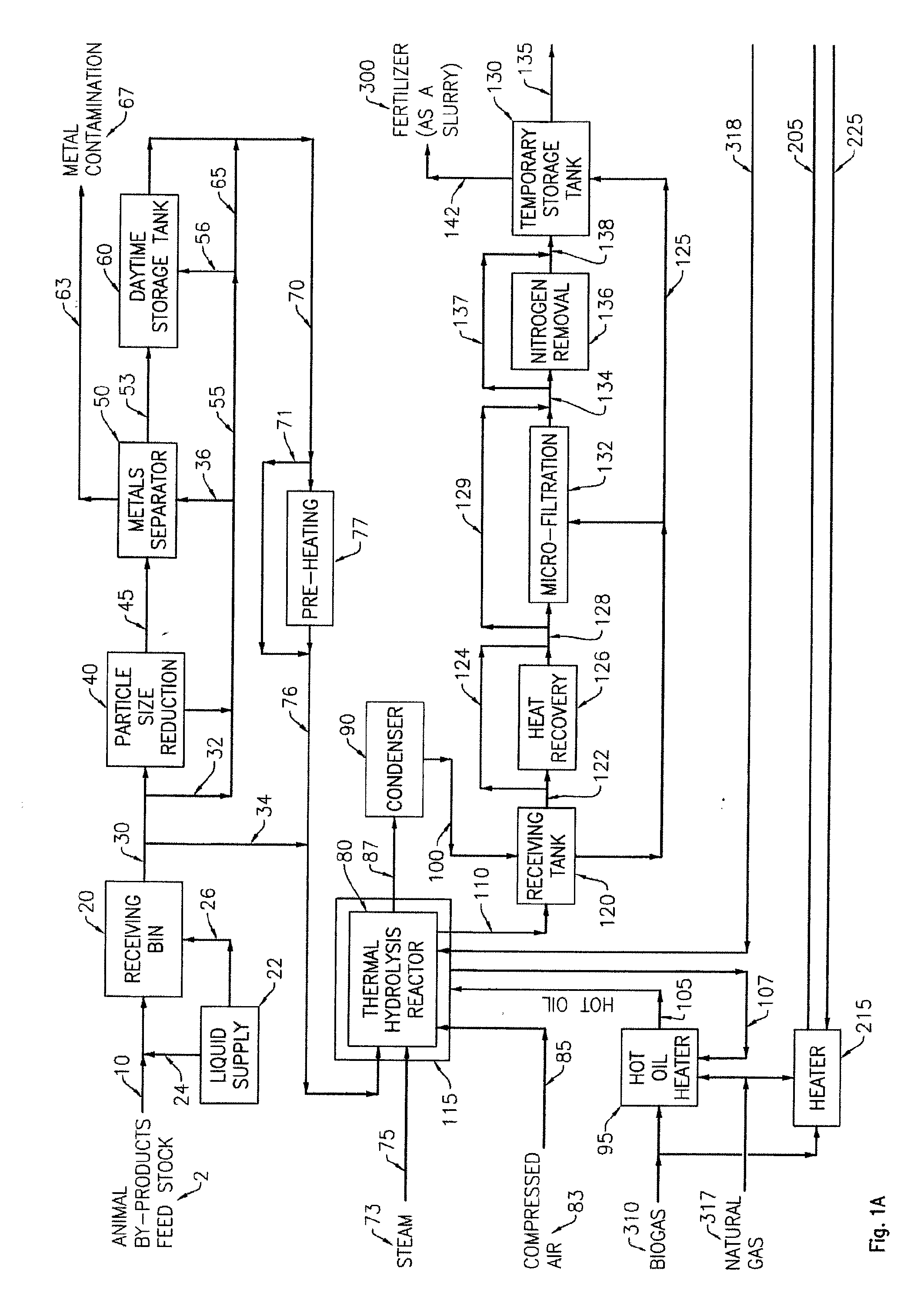

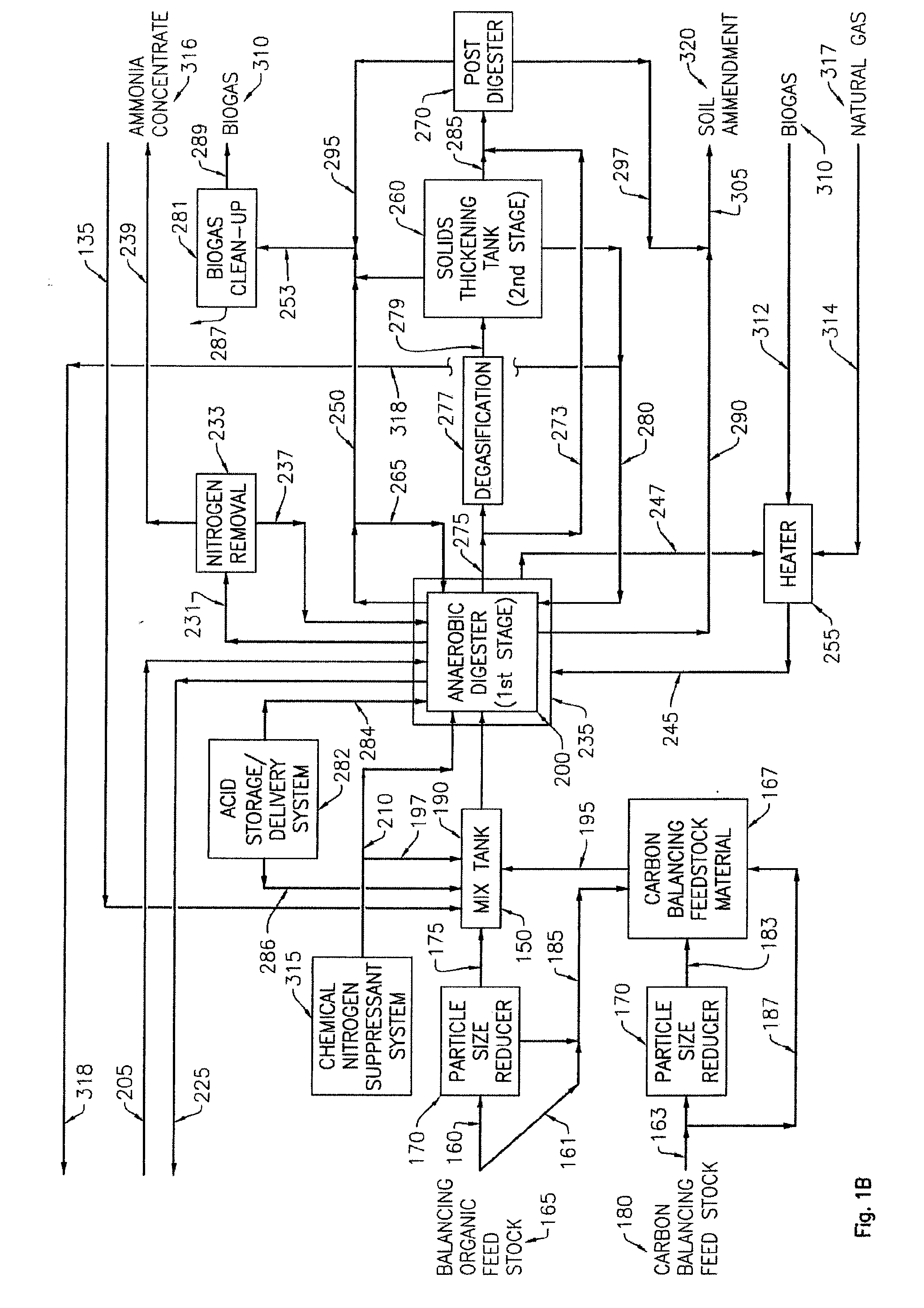

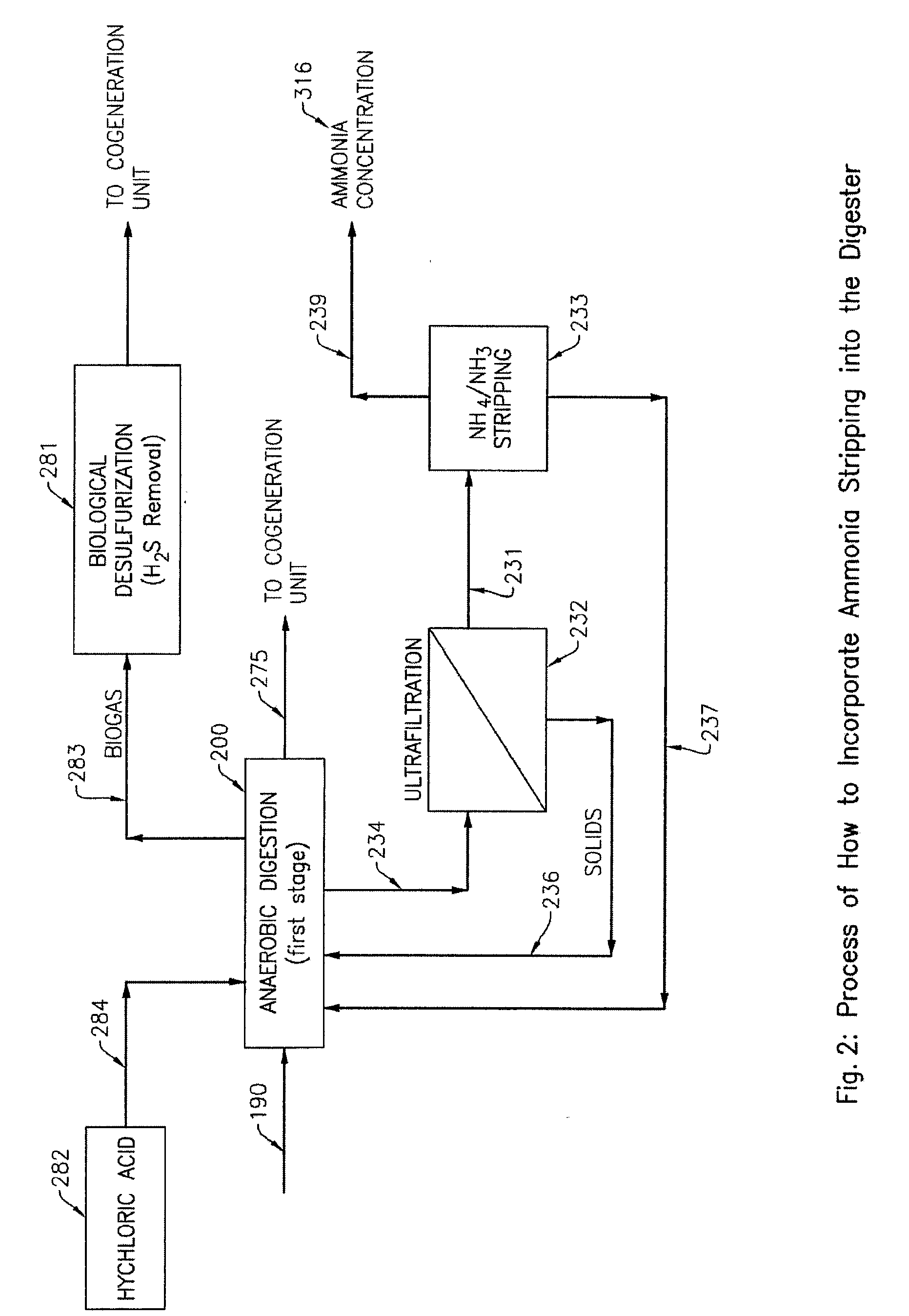

Apparatus and Process for Production of Biogas

ActiveUS20100021979A1Quick conversionDigesting retention timeBioreactor/fermenter combinationsBiological substance pretreatmentsHydrolysateSolid fraction

A process and an apparatus for the manufacture of biogas and a solids fraction from an organic waste feedstock is provided. The process involves thermal hydrolysis of the organic waste feedstock at a temperature from about 100 to about 220° C., a pressure from about 5 to about 20 bars, for a period of time from about 15 minutes to 4 hours, to produce a hydrolysate. The hydrolysate undergoes anaerobic digestion at a temperature from about 25 to 60° C., for a period of time from about 1 to 35 days to produce a biogas stream and a digestate. The digestate is separated into a solids fraction and a liquid fraction, and a portion of the solids fraction is recycled for further anaerobic digestion. The biogas stream, characterized as having a methane content from between 55 to 80% by volume, and the solids fraction, are recovered. The apparatus includes a receiving bin for receiving and supplying organic waste feedstock to a thermal hydrolysis reactor. The thermal hydrolysis reactor for processing the organic waste feedstock at a temperature from about 100 to about 220° C., a pressure from about 5 to about 20 bars, for a period of time from about 15 minutes to 4 hours to produce a hydrolysate. An anaerobic digester for processing the hydrolysate at a temperature from about 25 to 60° C., for a period of time from about 1 to 35 days to produce the biogas and a digestate, and a solids thickening tank for separating the digestate into the solid fraction, a liquid fraction and a secondary biogas fraction.

Owner:GEMINI CORP

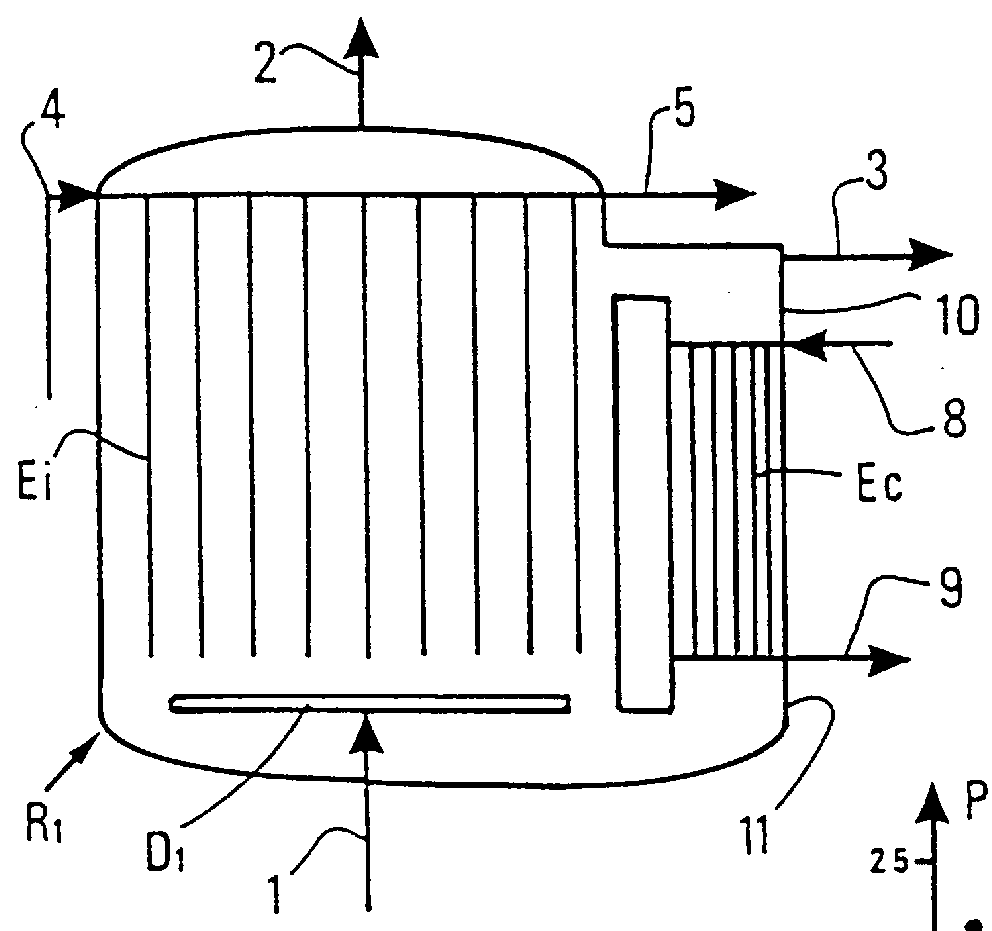

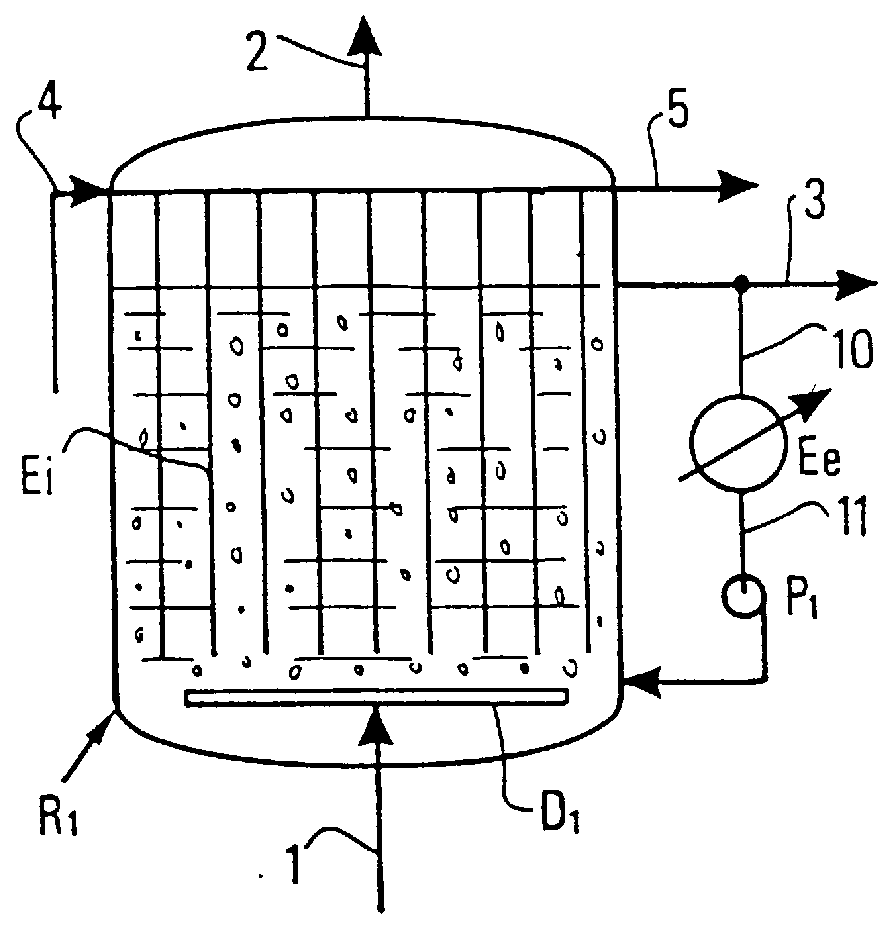

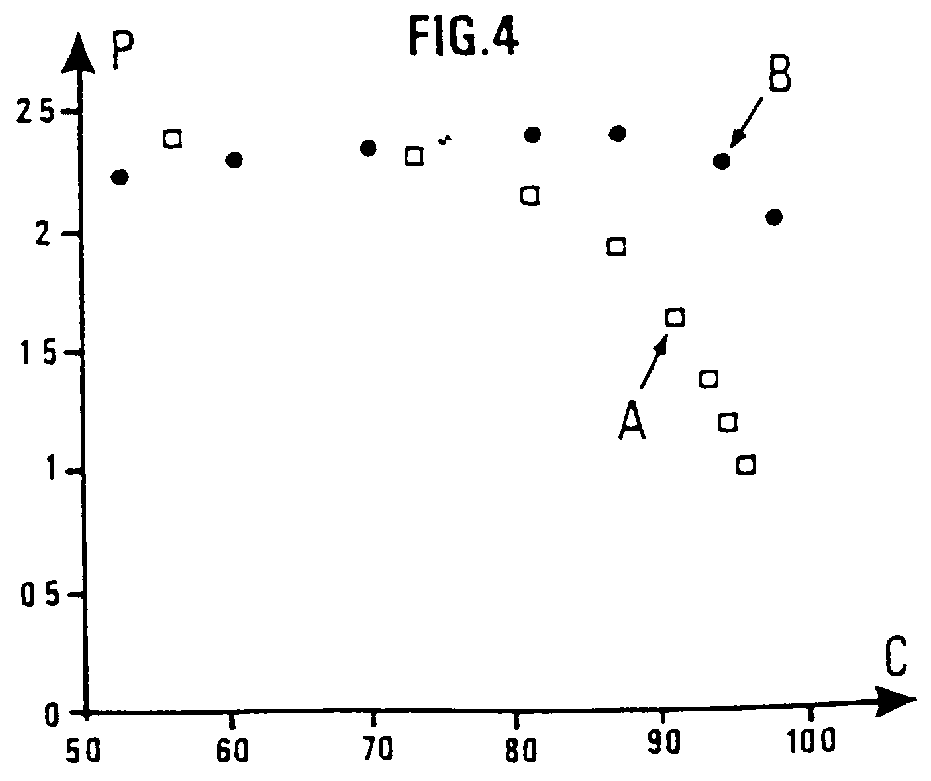

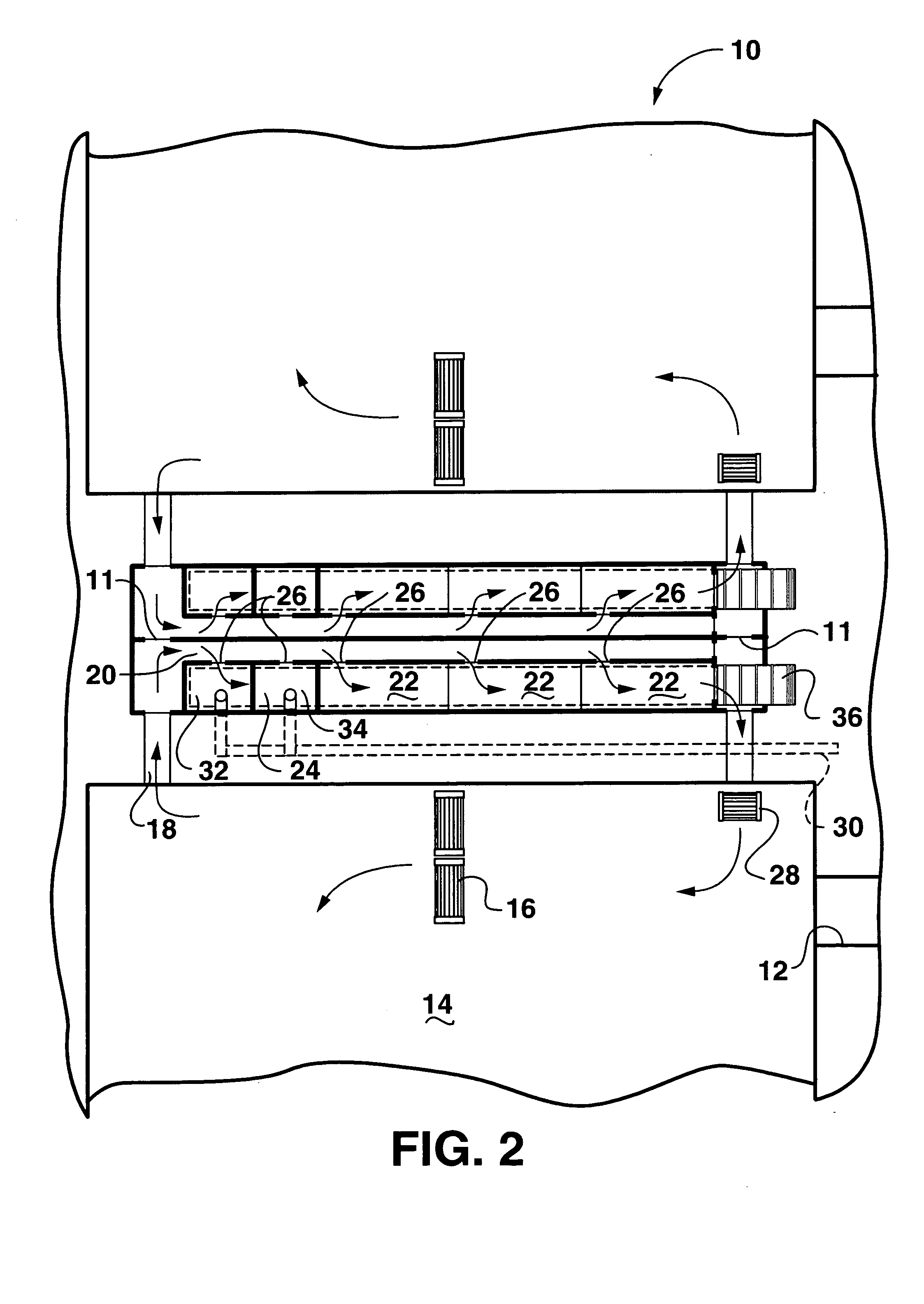

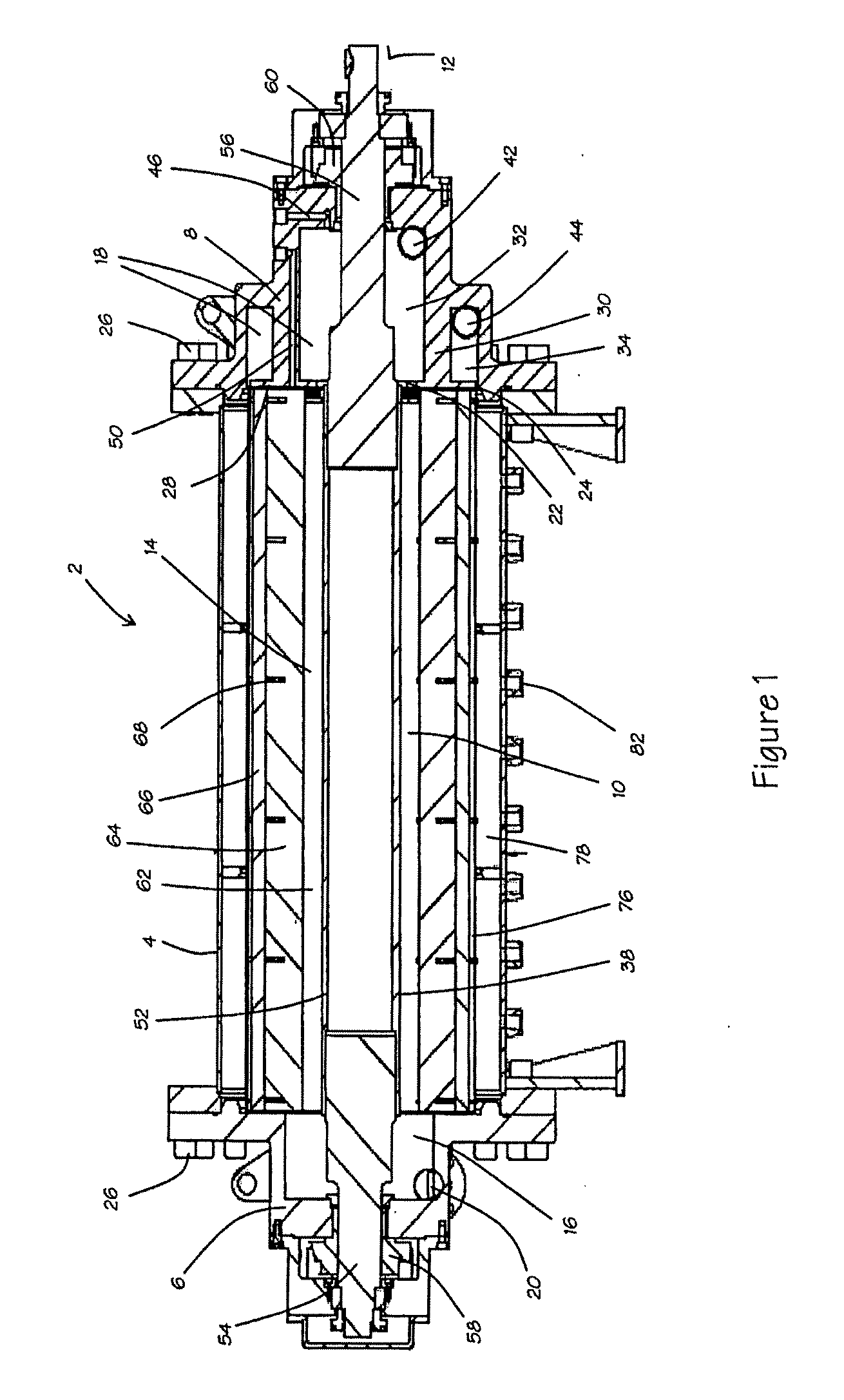

Process and apparatus for operation of a slurry bubble column with application to the fischer-tropsch synthesis

InactiveUS6060524AGuaranteed uptimeAvoid small quantitiesHydrocarbon from carbon oxidesOrganic compound preparationGas phaseBubble column

The invention concerns a process for optimal operation of a slurry bubble column containing a suspension of solid particles in a liquid, characterized in that a gas phase containing the reactant(s) required for the production of the desired products is injected in the form of bubbles close to the lower extremity of said reactor and at least a portion of the liquid fraction and optionally of the solid fraction of said suspension is recirculated, drawn off from close to one extremity of said reactor and reintroduced close to the other extremity of said reactor, with a liquid flow rate U1 in the reactor which is at least equal to and preferably greater than the sedimentation rate Us of the solid particles. The invention also concerns an apparatus for optimal operation of the process. Finally, the invention concerns the use of the process and apparatus in the Fischer-Tropsch synthesis.

Owner:INST FR DU PETROLE +1

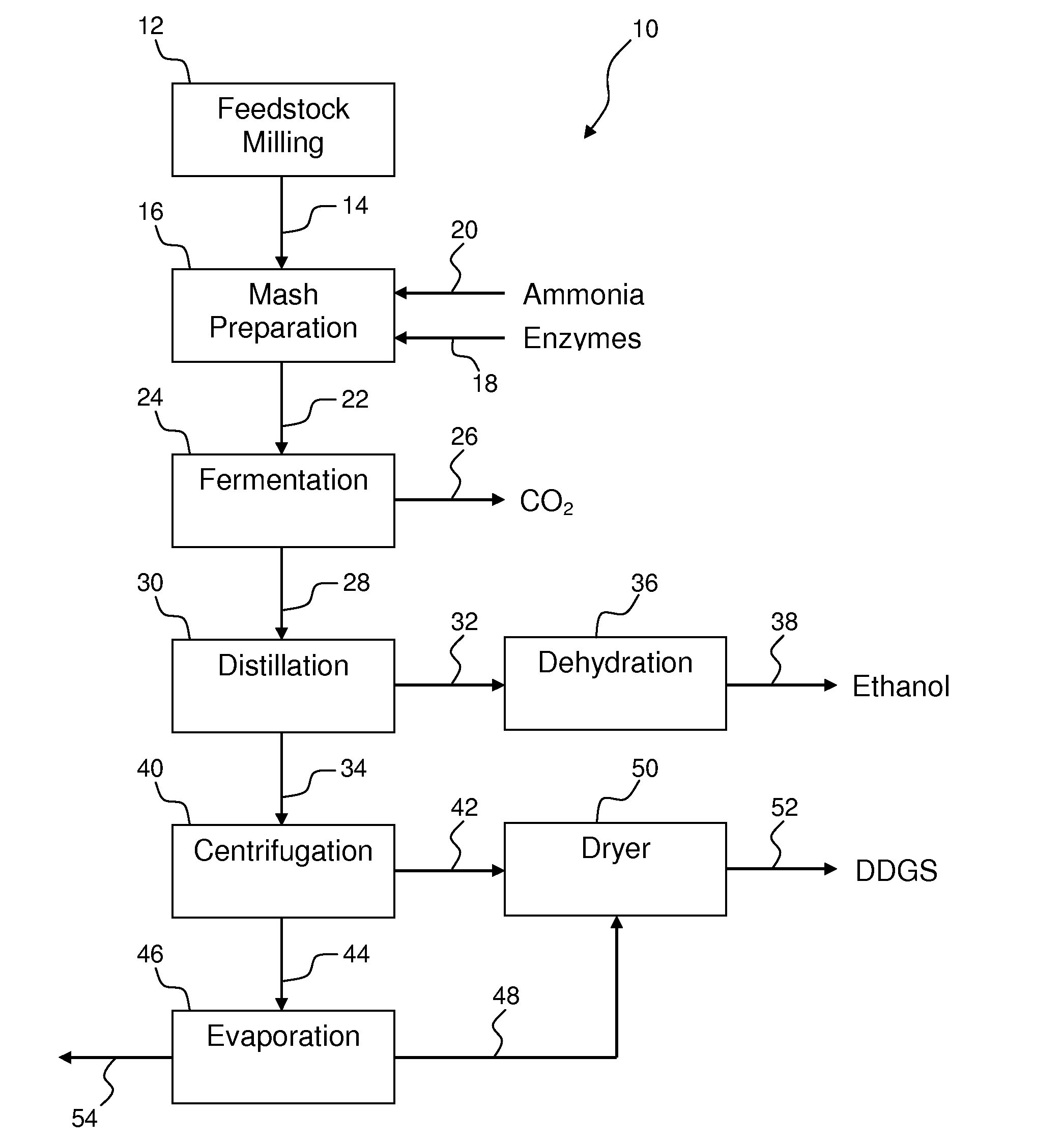

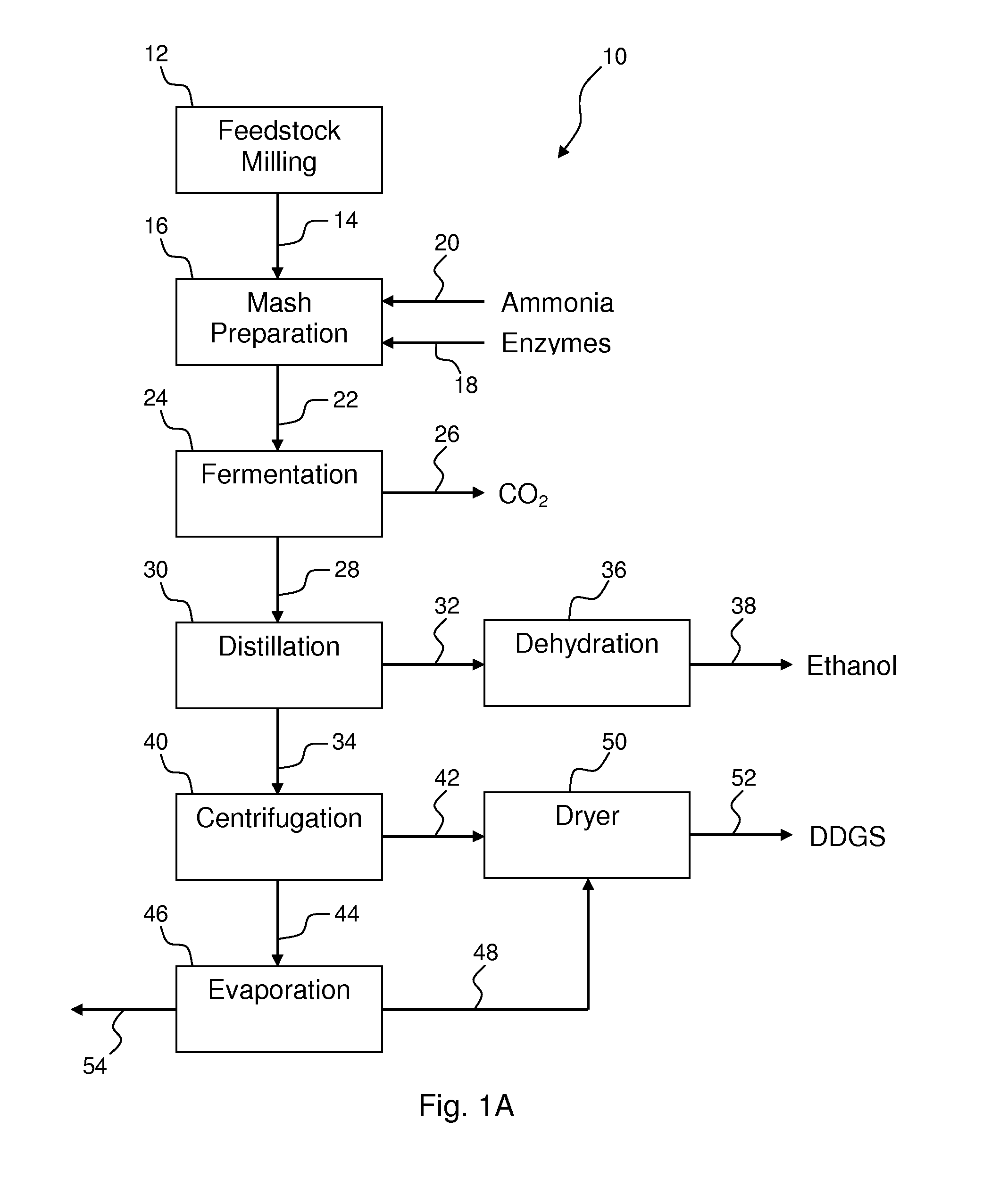

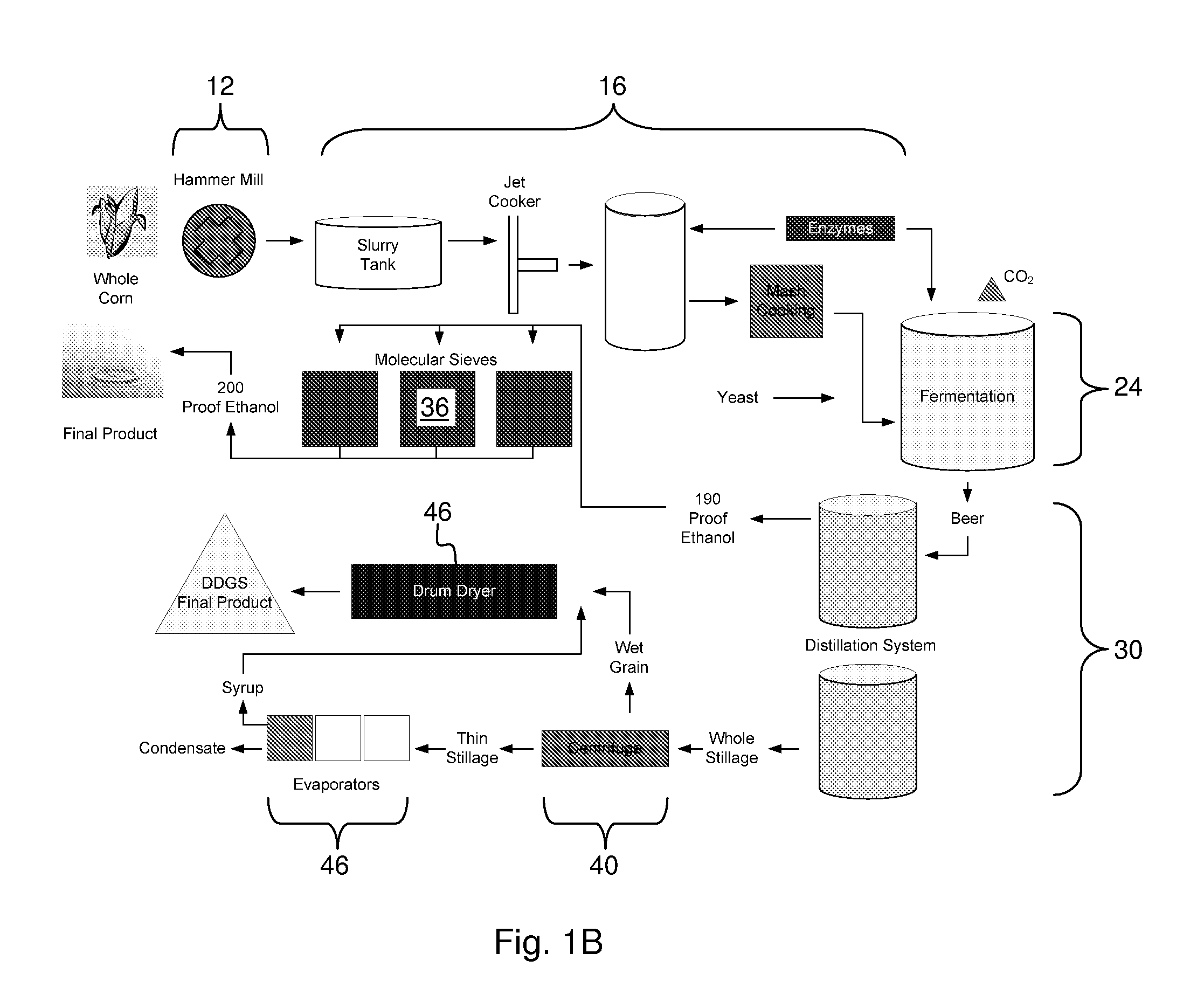

Process for improving the yield and efficiency of an ethanol fermentation plant

A process for improving the yield and efficiency of an ethanol fermentation plant that receives organic fermentable feedstock material, prepares the feedstock for fermentation, ferments the feedstock with yeast to produce ethanol, and produces stillage as a byproduct of ethanol fermentation. The process steps which can be operated independently or in combination, may include, but are not limited to, degrading fatty acids in the fermentable feedstock material prior to fermentation; degrading cellulose and hemicellulose present in the feedstock prior to fermentation; adding a surfactant to the fermentable feedstock; separating a liquid fraction from the stillage; recycling the liquid fraction to be combined with the fermentable feedstock; recovering a solid fraction from the stillage; and introducing at least a portion of the solid fraction to an anaerobic digester to produce methane.

Owner:WATER SOLUTIONS TECH LLC

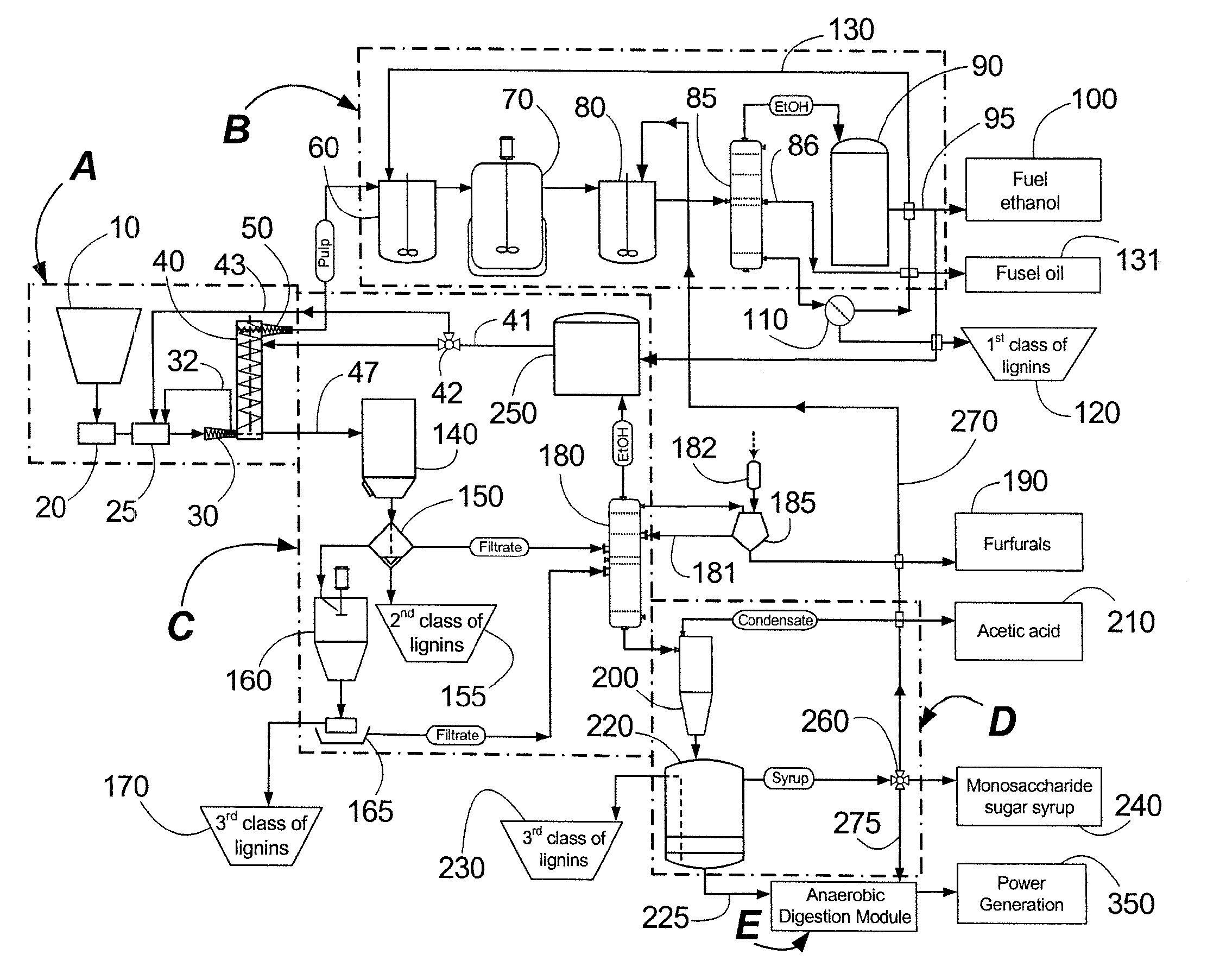

Continuous counter-current organosolv processing of lignocellulosic feedstocks

InactiveUS20080299628A1Facilitate and enhance of fermentation and efficiencyFacilitate and enhance rateBioreactor/fermenter combinationsPressurized chemical processFractionationOrganosolv

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into at least fuel-grade ethanol and four classes of lignin derivatives. The modular process comprises a first processing module configured for physico-chemically digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for producing at least a fuel-grade ethanol and a first class of novel lignin derivatives from the cellulosic solids fraction, a third processing module configured for separating a second class and a third class of lignin derivatives from the liquid fraction and further processing the liquid fraction to produce a distillate and a stillage, a fourth processing module configured for separating a fourth class of lignin derivatives from the stillage and further processing the stillage to produce a sugar syrup.

Owner:LIGNOL INNOVATIONS

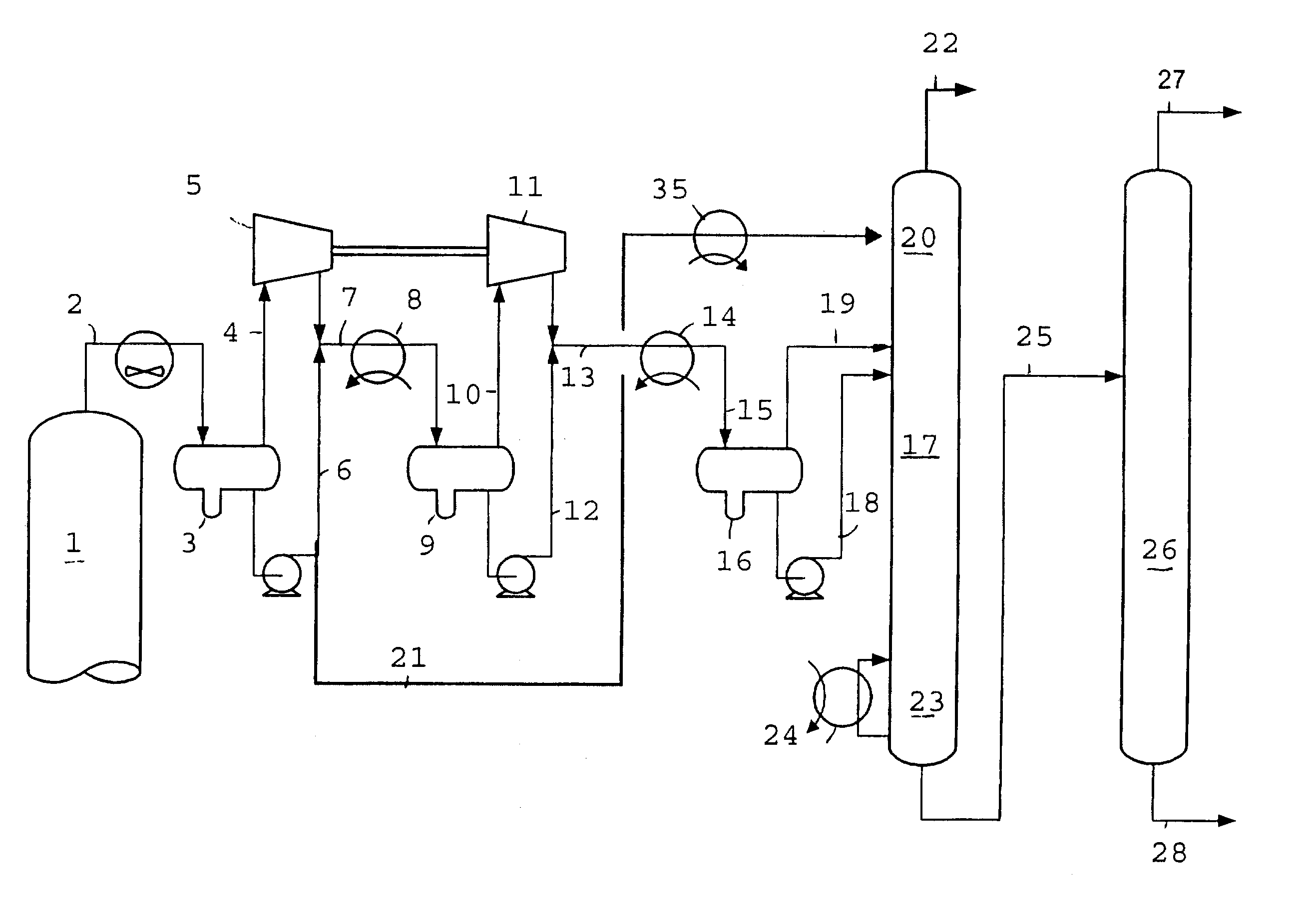

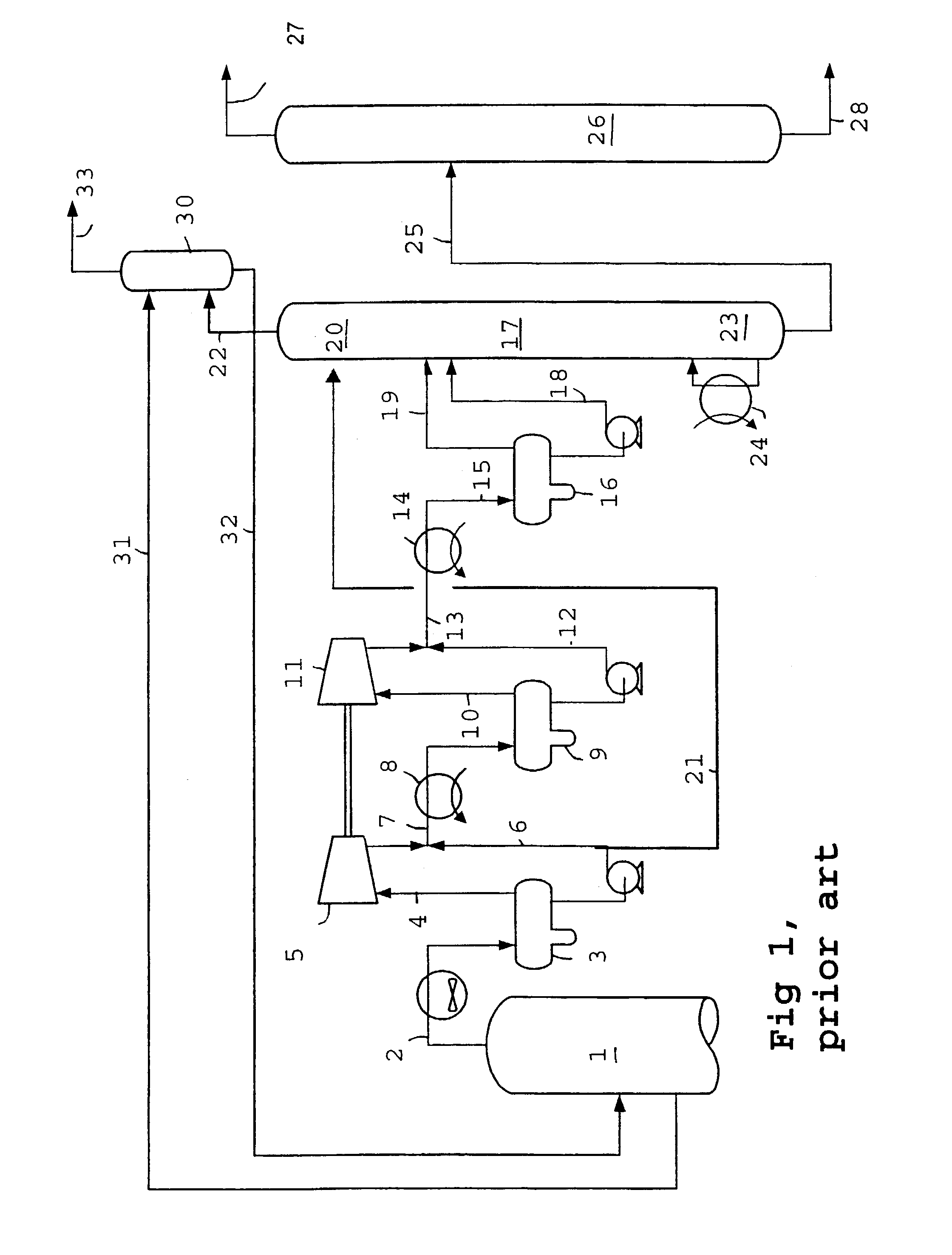

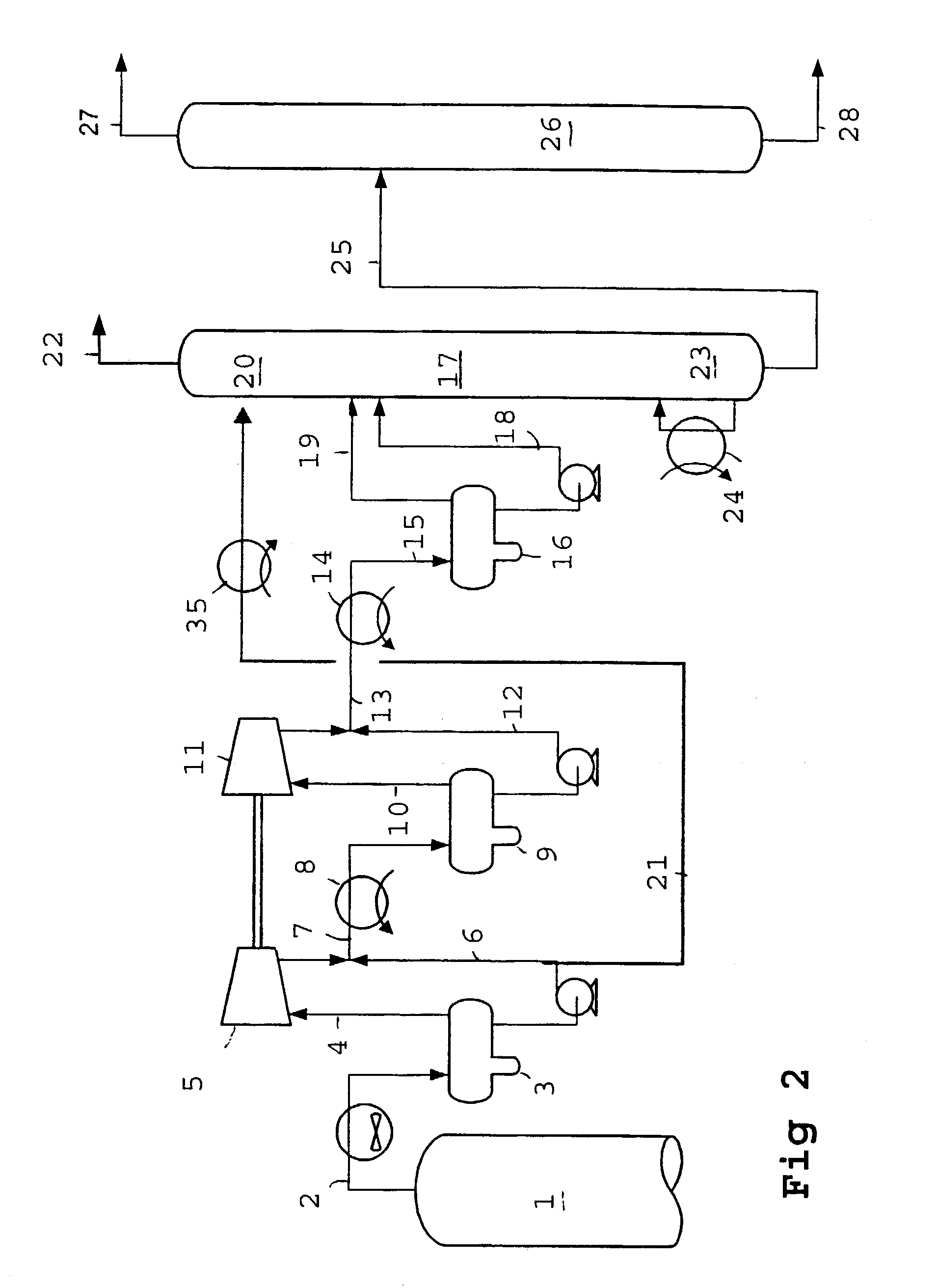

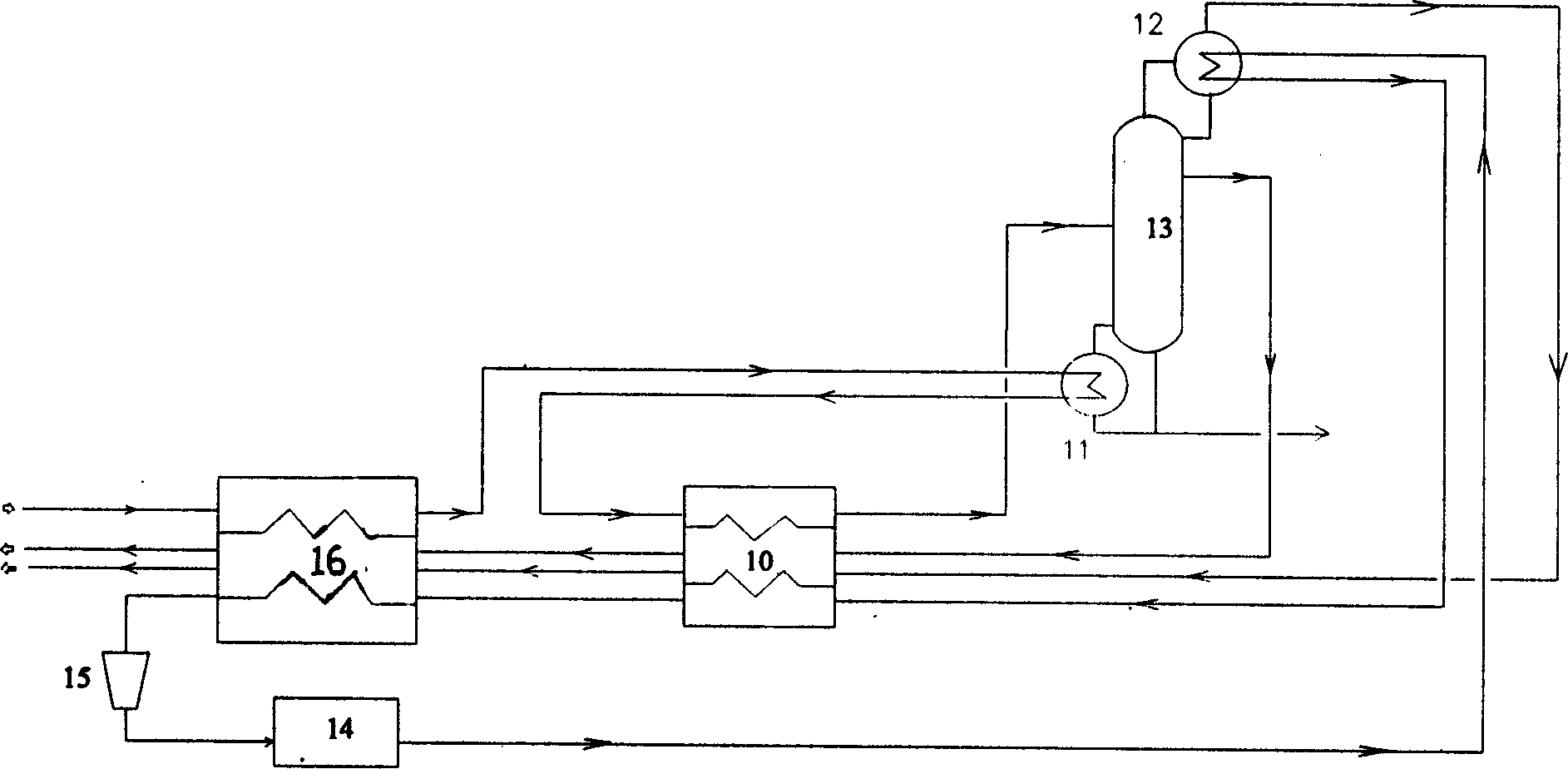

Two-step method for hydrotreating of a hydrocarbon feedstock comprising intermediate fractionation by rectification stripping

InactiveUS20060118466A1Reduce sulfur contentReduce nitrogen contentHydrocarbon distillation control/regulationTreatment with hydrotreatment processesPtru catalystPhysical chemistry

A process for hydrotreatment of a hydrocarbon feed comprises at least two reaction steps with intermediate fractionation of the effluent from the first step to eliminate unwanted impurities for the catalyst of the second step and to produce a desulphurized light liquid fraction. The intermediate fractionation comprises stripping the liquid effluent from the first step using low pressure hydrogen with rectification of the stripping vapours using a substantially desulphurized liquid reflux. The conditions for said fractionation and for the first hydrotreatment step can produce a substantially desulphurized light liquid fraction which is not supplied to the second step.

Owner:INST FR DU PETROLE

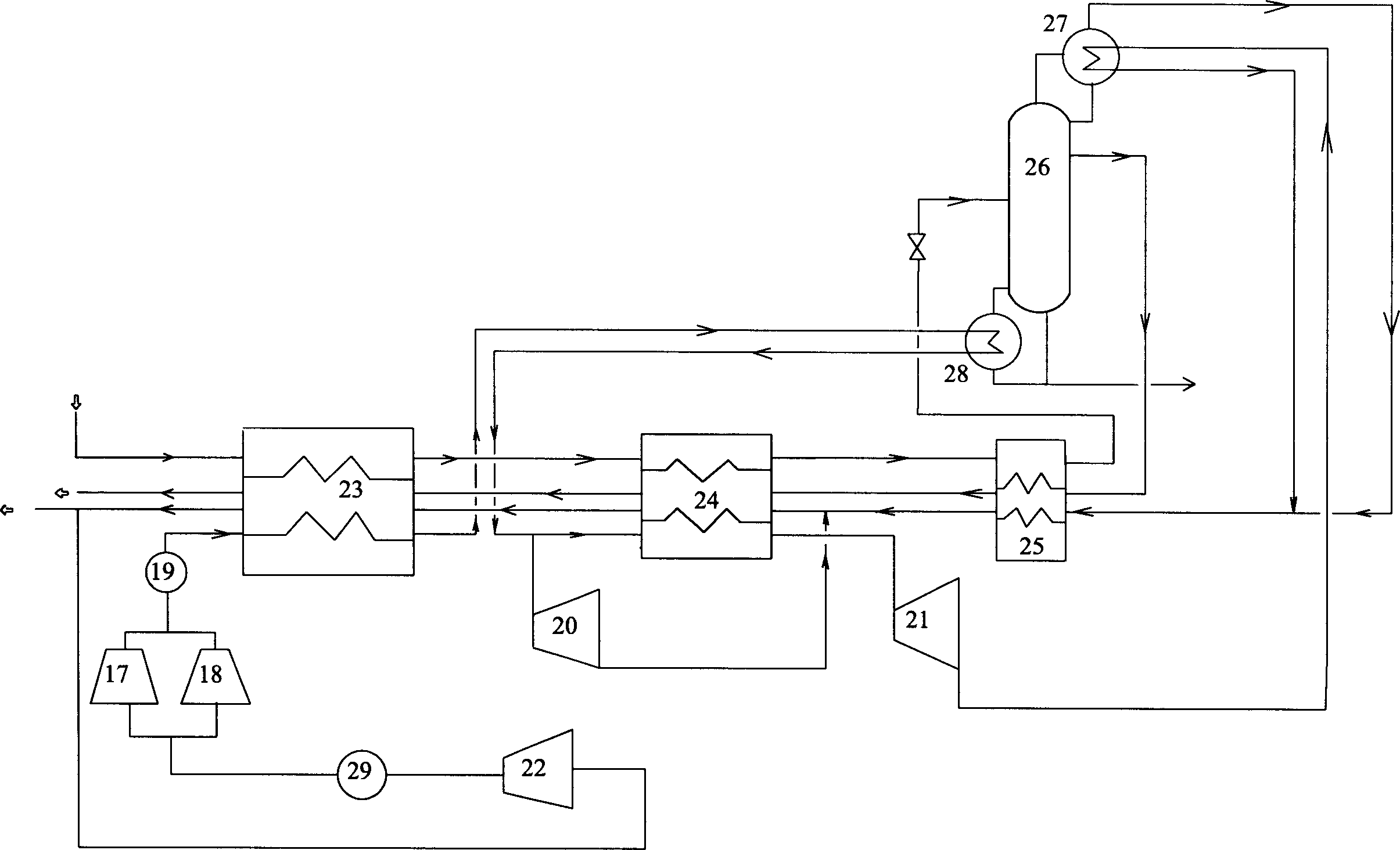

Mixed Refrigerant Liquefaction Process

A method for liquefying a natural gas stream is provided. In one embodiment, the method includes placing a mixed component refrigerant in a heat exchange area with a process stream; separating the mixed component refrigerant at one or more pressure levels to produce a refrigerant vapor and a refrigerant liquid; bypassing the refrigerant vapor around the heat exchange area to a compression unit; and passing the refrigerant liquid to the heat exchange area. In another embodiment, the method further includes partially evaporating the refrigerant liquid stream within the heat exchange area to retain a liquid fraction of at least 1% by weight.

Owner:STONE JOHN B +2

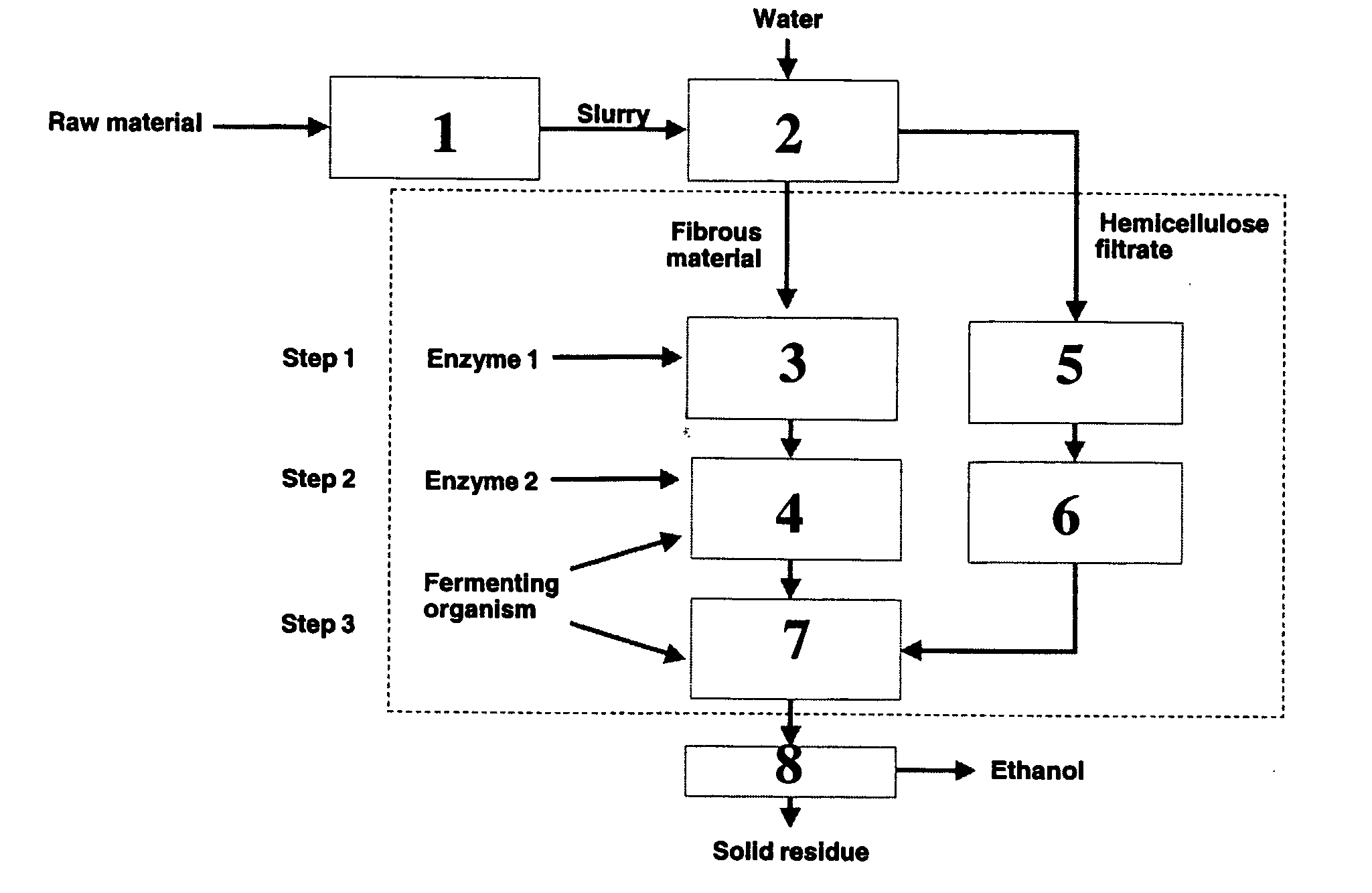

Process for Producing Ethanol

InactiveUS20080044877A1Improve efficiency and economyIncrease final ethanol concentrationBiofuelsAlcoholic beverage preparationFiberCellulose breakdown

A process for producing ethanol from a fibrous lignocellulosic raw material. After pre-treatment of the raw material, the fibrous fraction is first hydrolysed at high consistency and then the modified material is subjected simultaneously to continued hydrolysis with a cellulase and to ethanol fermentation in a fermentation mixture. Fermentation is continued to convert an essential portion of the available cellulose into ethanol, then a liquid fraction containing solubilized hemicelluloses is added to the fermentation mixture and fermentation continued. By means of the invention, high fermentation rates, high ethanol concentrations and low ethanol production costs can be attained.

Owner:VALTION TEKNILLINEN TUTKIMUSKESKUS

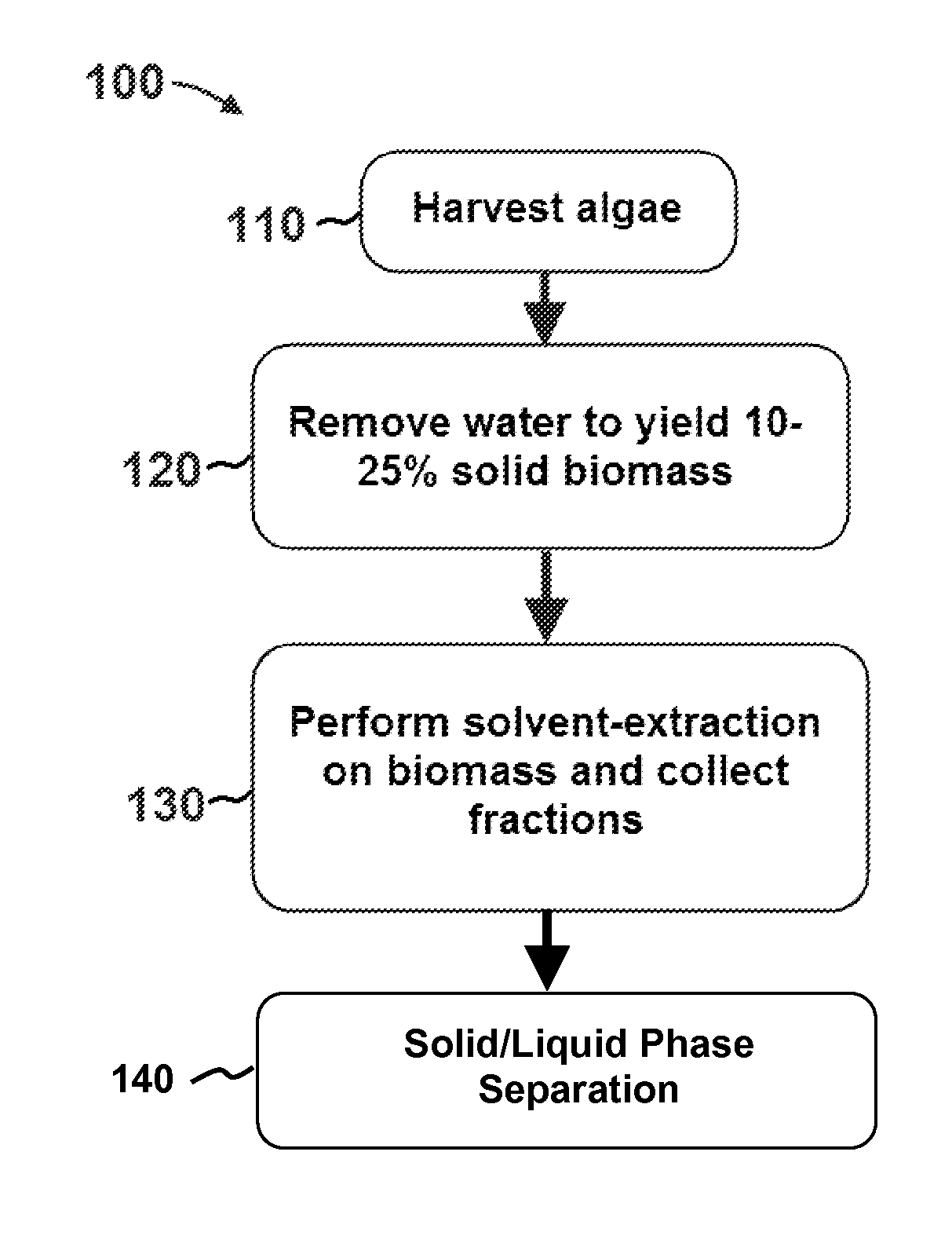

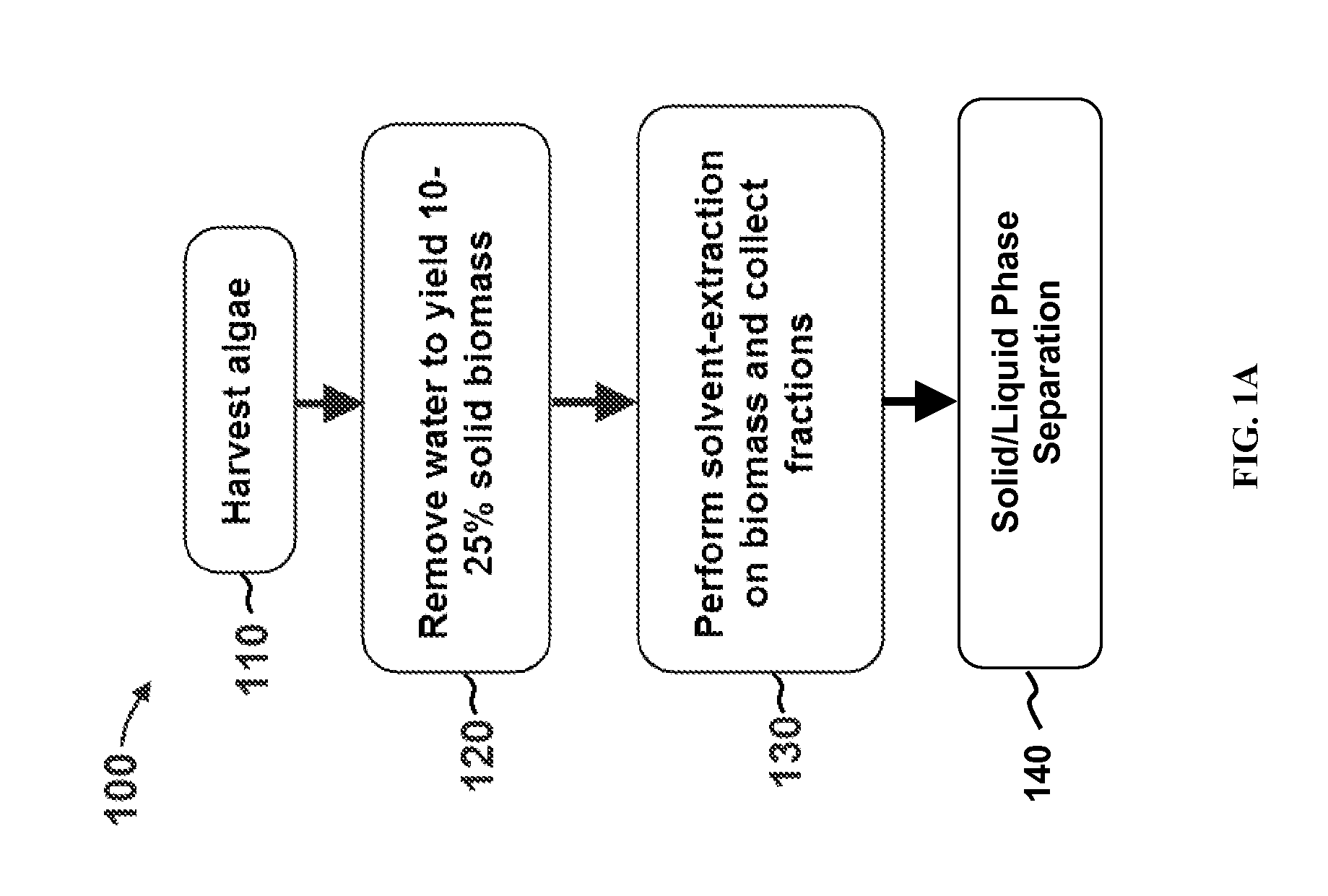

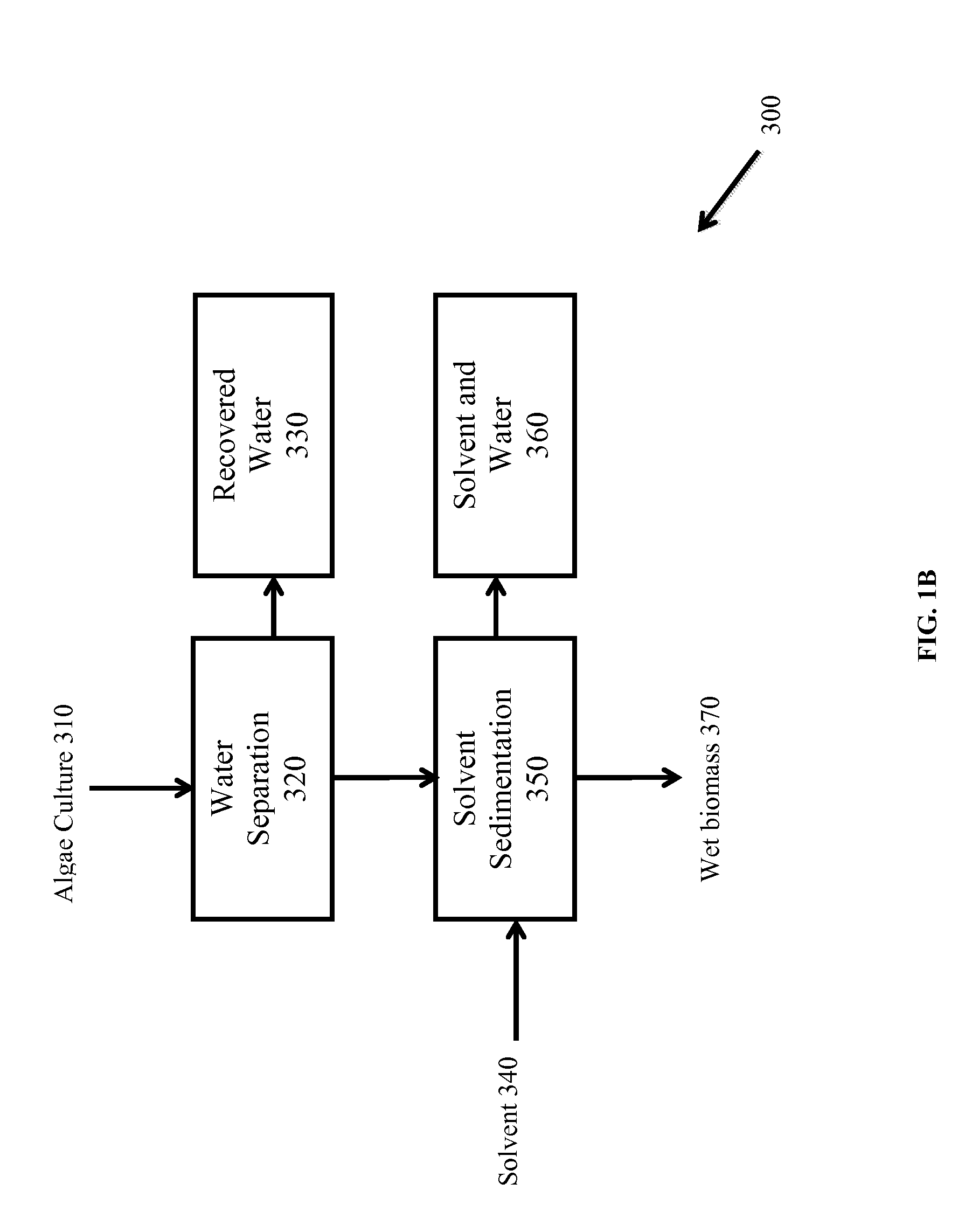

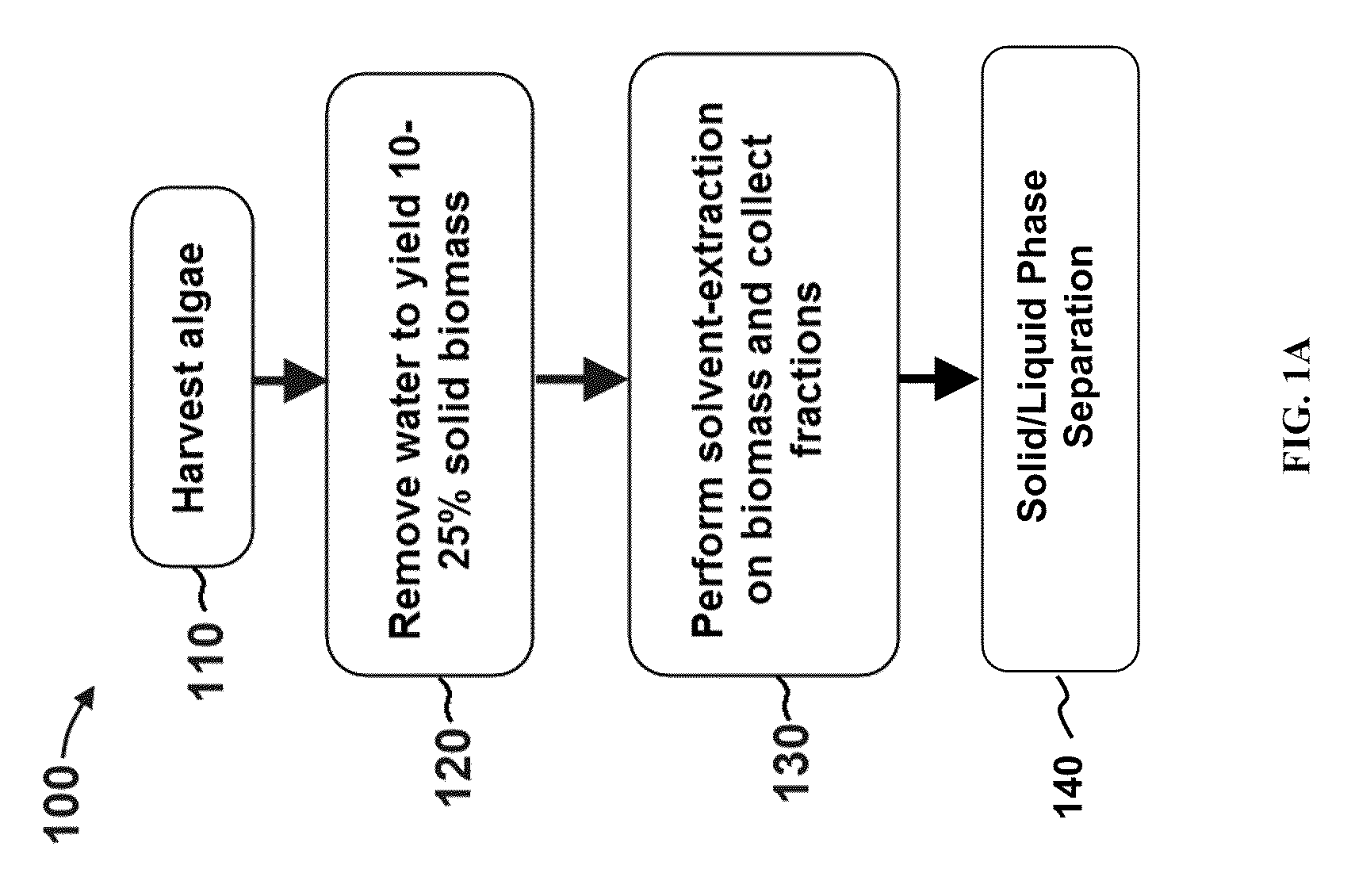

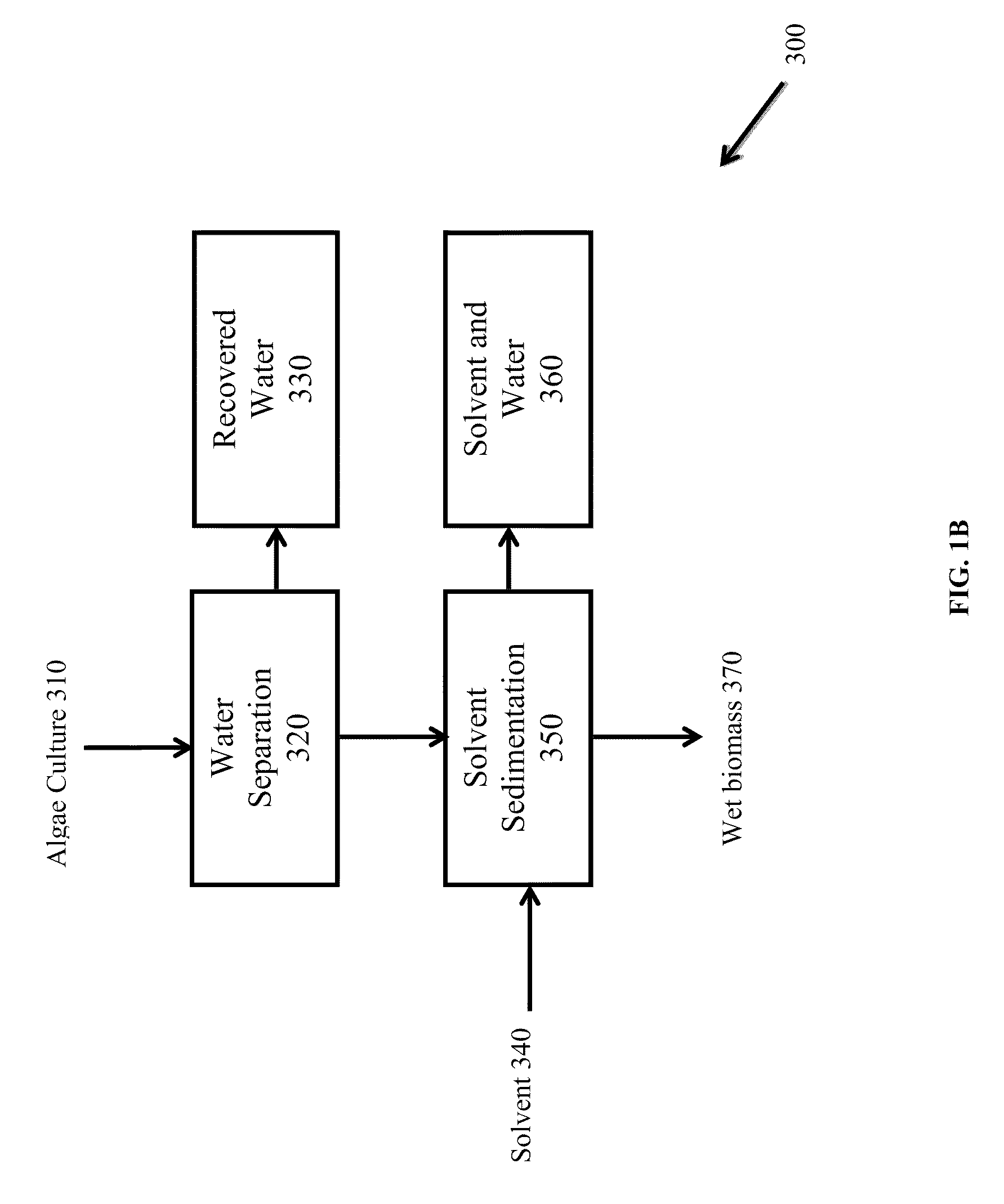

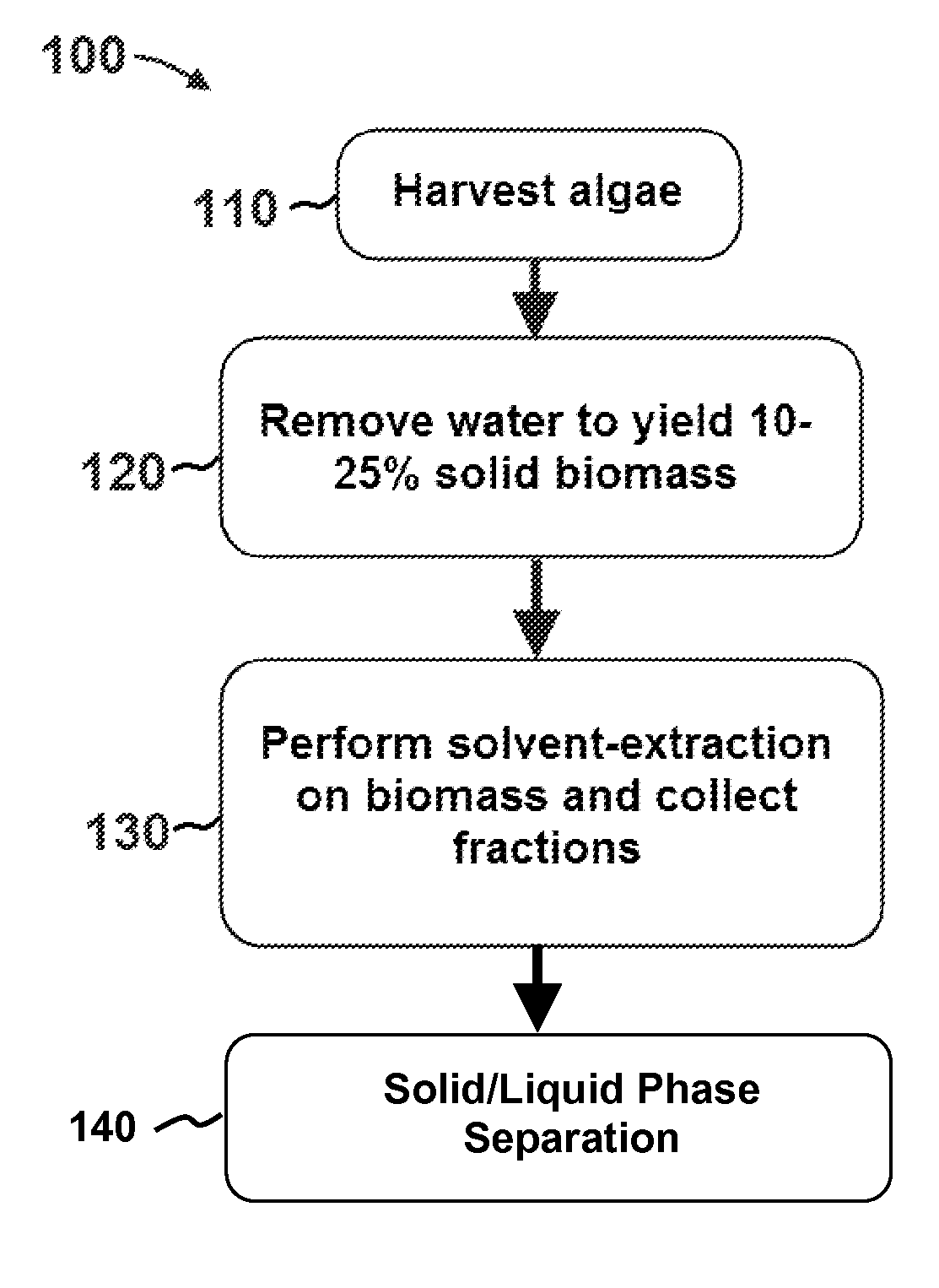

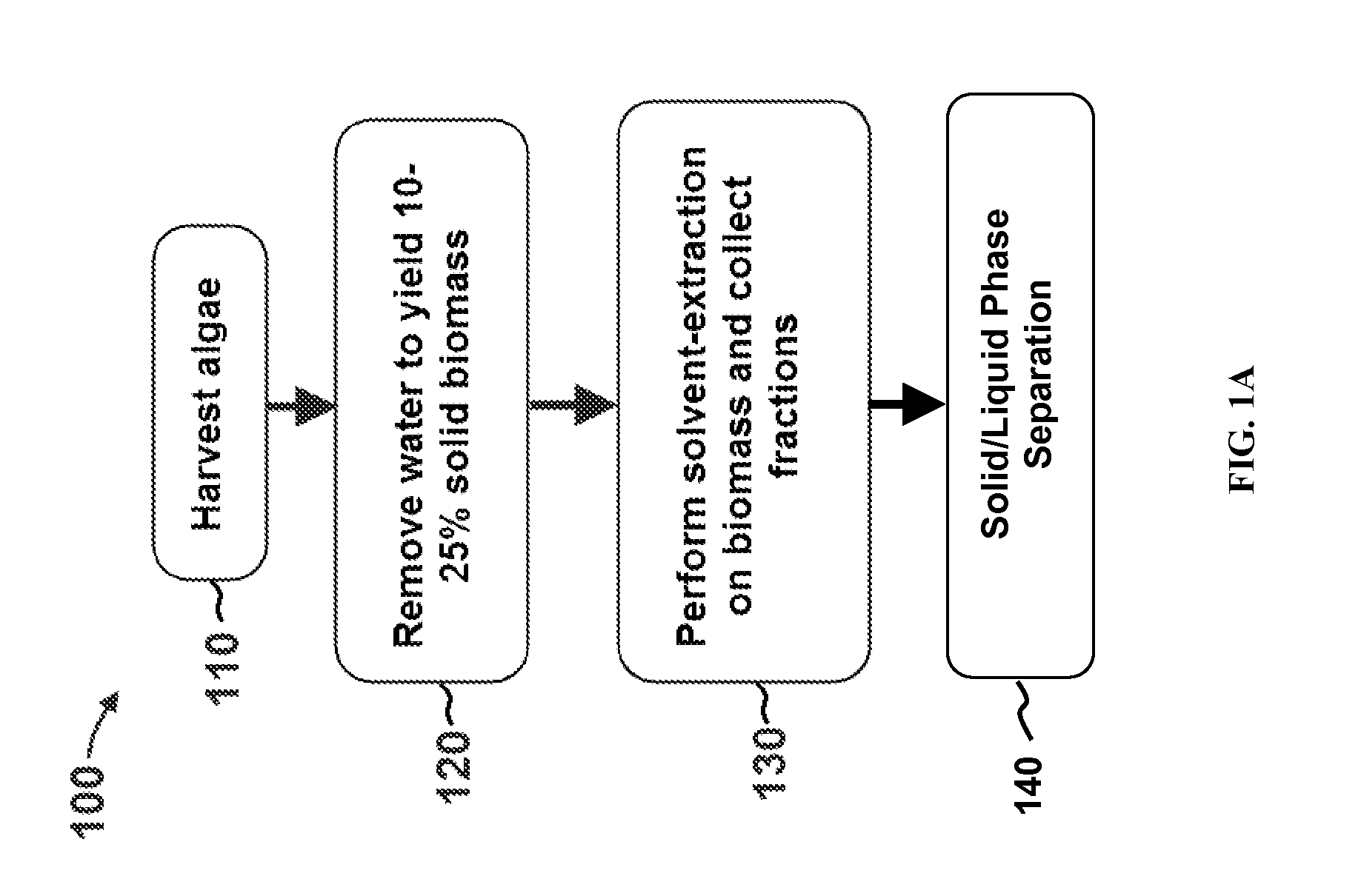

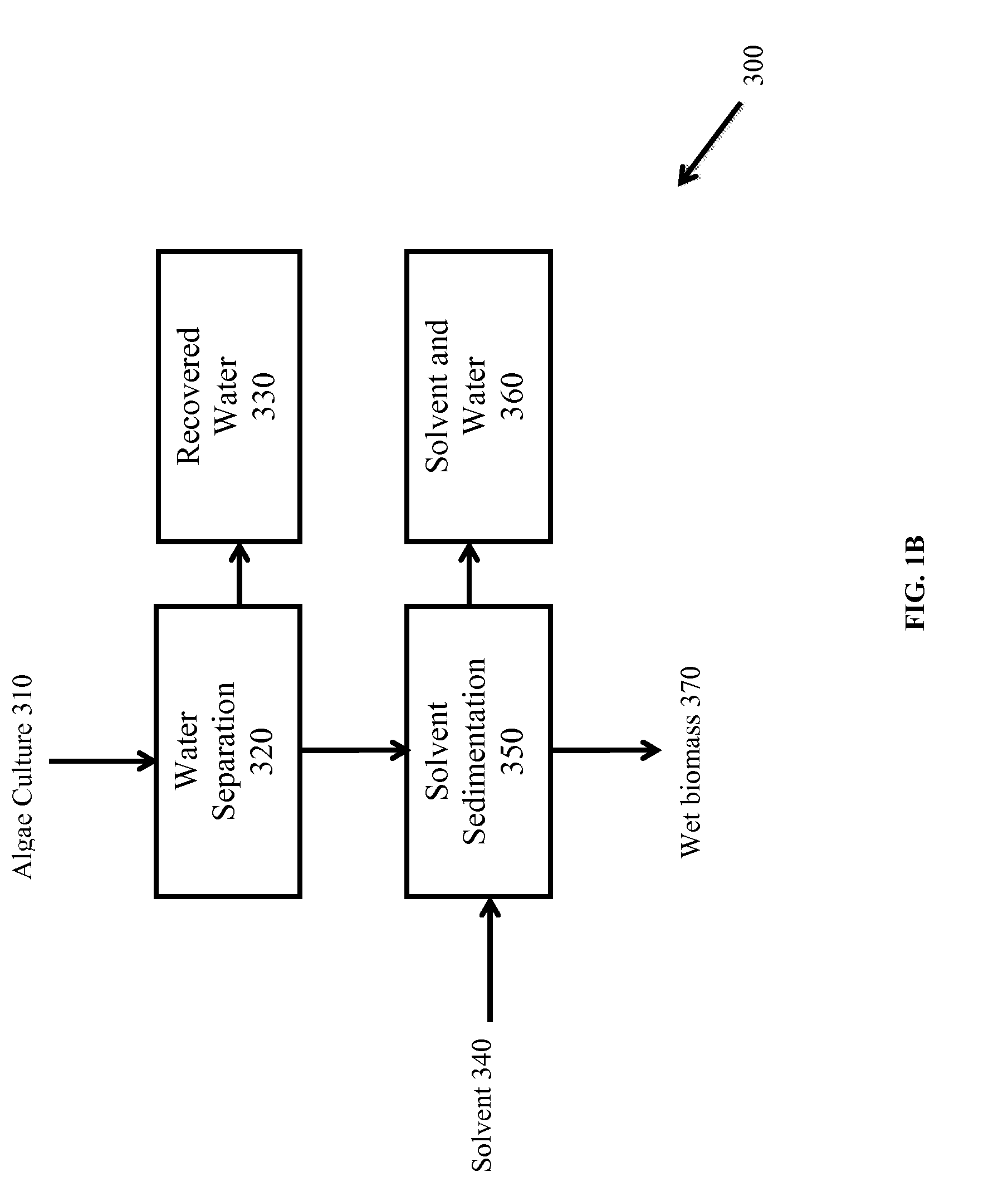

Methods of and Systems for Isolating Nutraceutical Products from Algae

A method of isolating nutraceuticals products from algae is provided. A method of isolating carotenoids and omega-3 rich oil from algae includes dewatering substantially intact algal cells to make an algal biomass and adding a first ethanol fraction to the algal biomass. The method also includes separating a first substantially solid biomass fraction from a first substantially liquid fraction comprising proteins and combining the first substantially solid biomass fraction with a second ethanol fraction. The method further includes separating a second substantially solid biomass fraction from a second substantially liquid fraction comprising polar lipids and combining the second substantially solid biomass fraction with a third ethanol solvent fraction. The method also includes separating a third substantially solid biomass fraction from a third substantially liquid fraction comprising neutral lipids, wherein the third substantially solid biomass fraction comprises carbohydrates and separating the neutral lipids into carotenoids and omega-3 rich oil.

Owner:HELIAE DEVMENT

Use of low pressure distillate as absorber oil in a FCC recovery section

InactiveUS7074323B2Less equipmentImprove throughputThermal non-catalytic crackingCatalytic crackingNaphthaDistillation

A process for the recovery of gaseous products from the product mixture obtained by contacting a hydrocarbon feed with a catalyst in a fluid catalytic cracking process, wherein the liquid, obtained by separating the top product of main fractionators into gaseous and liquid fraction, when supplied to the absorber has a temperature of between about 8–25 DEG C. This liquid may be pre-saturated with gaseous top product from absorber; or also a high boiling fraction (cat cracker naphtha / light cycle oil) may be first separated from this liquid by distillation.

Owner:SHELL OIL CO

Methods of and systems for isolating nutraceutical products from algae

A method of isolating nutraceuticals products from algae is provided. A method of isolating carotenoids and omega-3 rich oil from algae includes dewatering substantially intact algal cells to make an algal biomass and adding a first ethanol fraction to the algal biomass. The method also includes separating a first substantially solid biomass fraction from a first substantially liquid fraction comprising proteins and combining the first substantially solid biomass fraction with a second ethanol fraction. The method further includes separating a second substantially solid biomass fraction from a second substantially liquid fraction comprising polar lipids and combining the second substantially solid biomass fraction with a third ethanol solvent fraction. The method also includes separating a third substantially solid biomass fraction from a third substantially liquid fraction comprising neutral lipids, wherein the third substantially solid biomass fraction comprises carbohydrates and separating the neutral lipids into carotenoids and omega-3 rich oil.

Owner:HELIAE DEVMENT

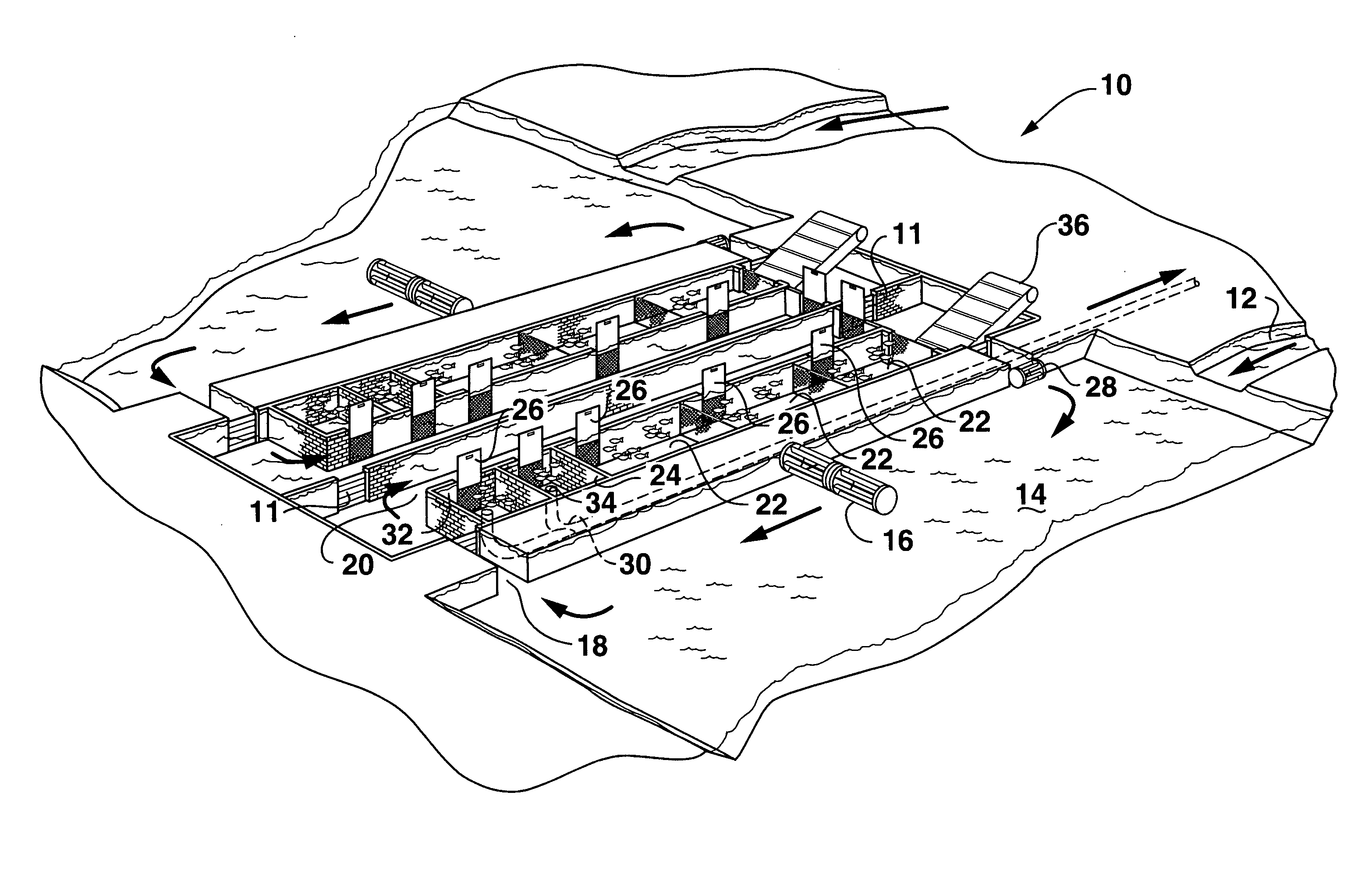

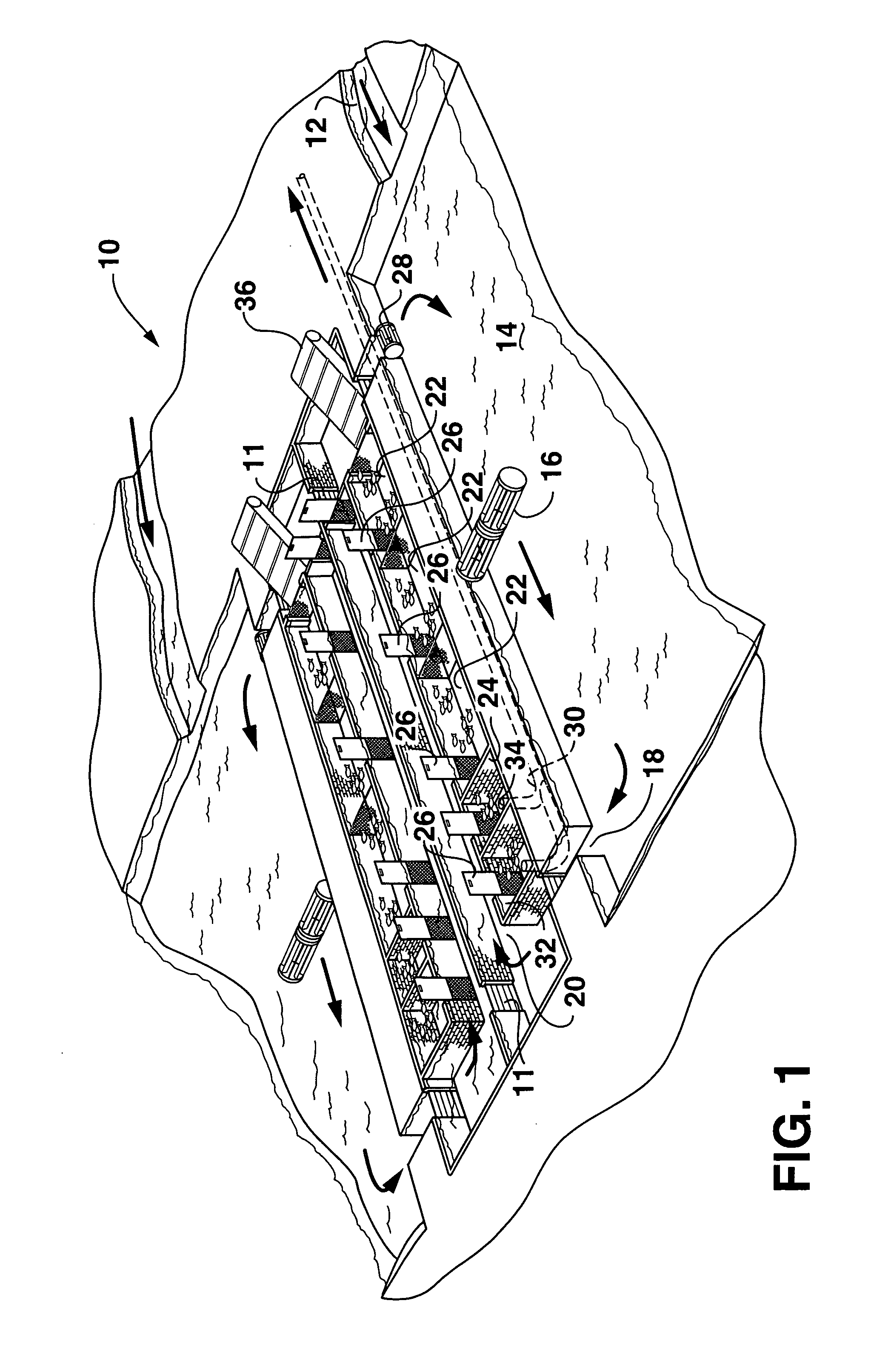

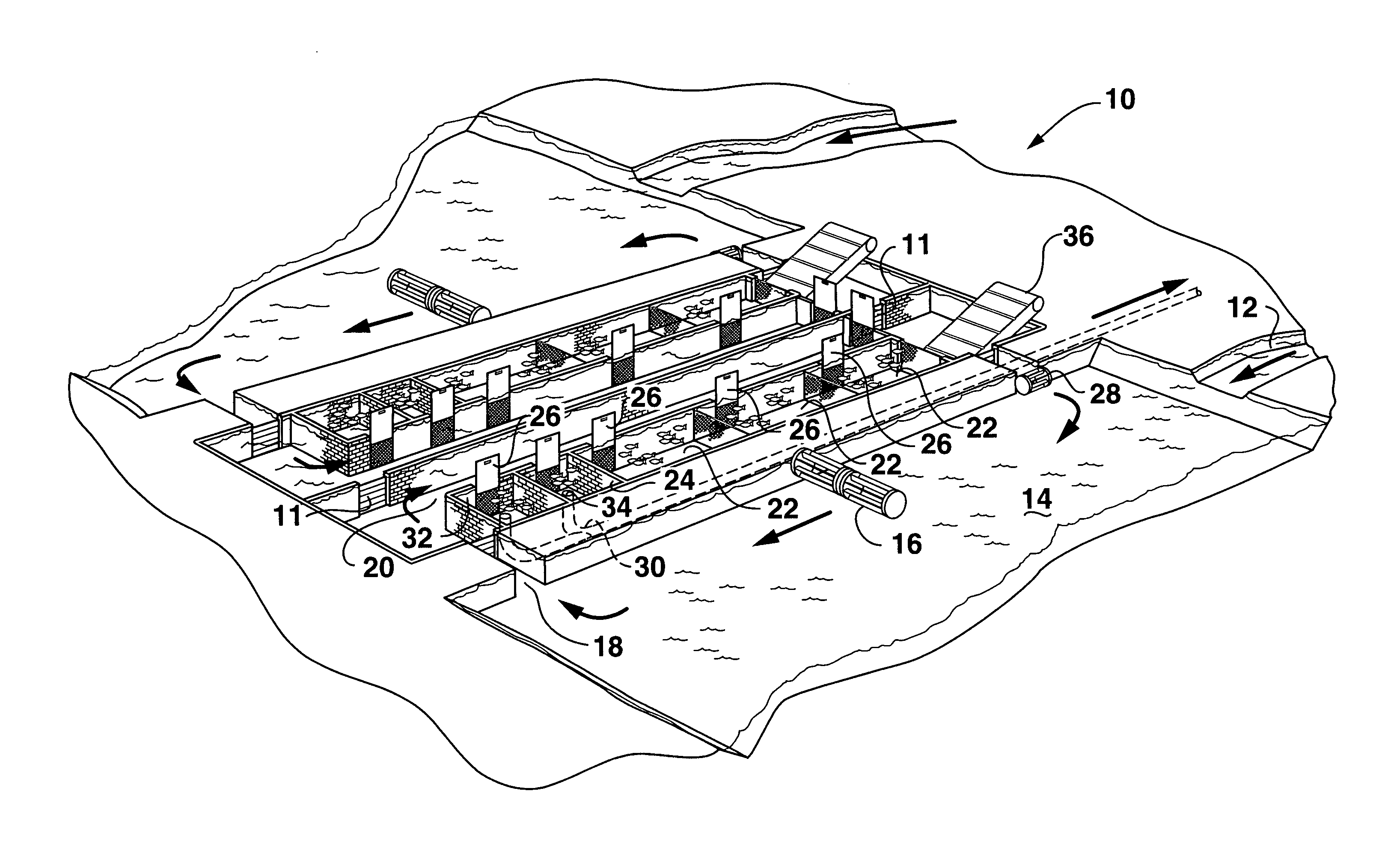

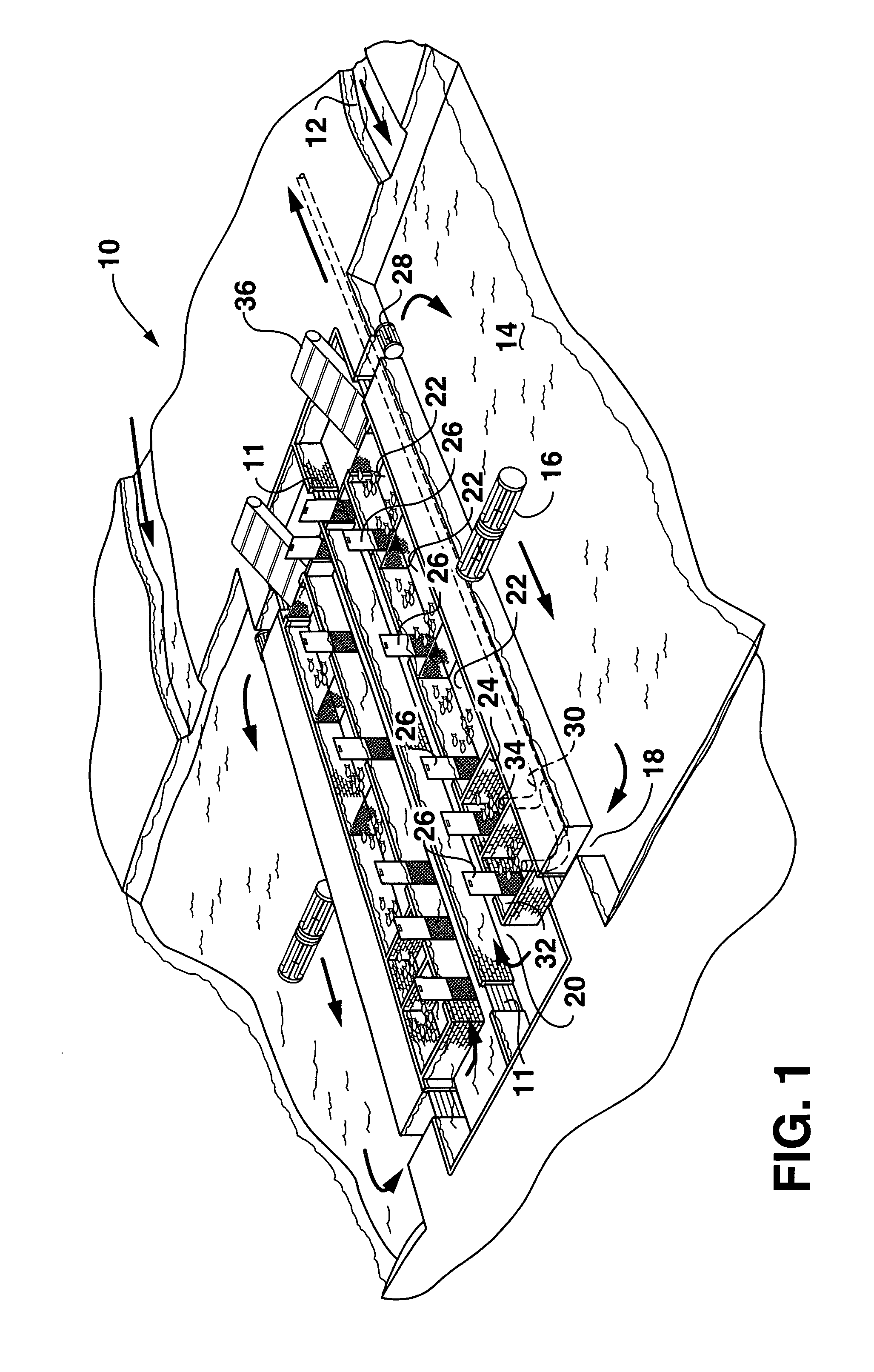

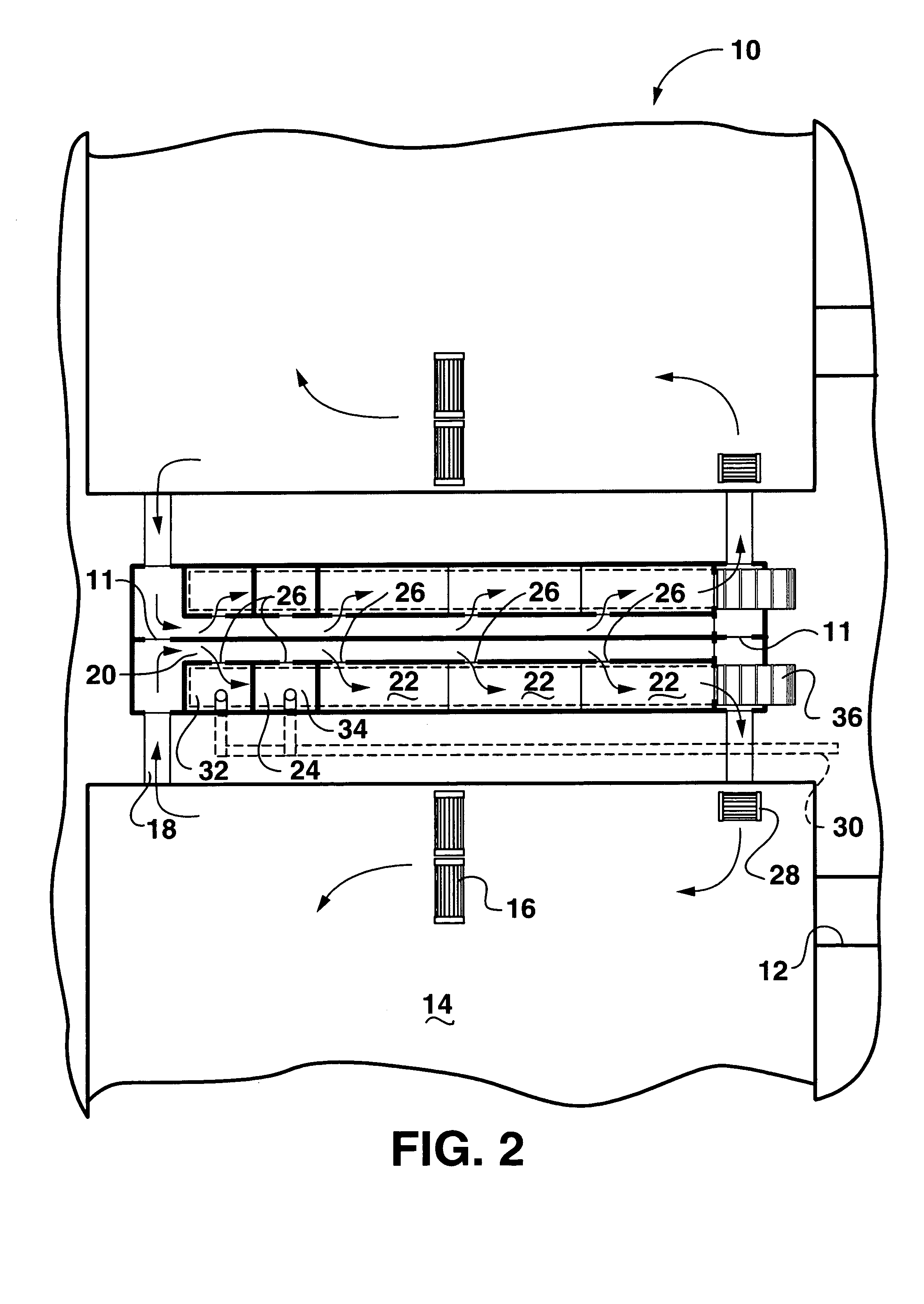

Controlled eutrophication system and process

InactiveUS20050115893A1Improve productivityReduce investmentWater cleaningTreatment using aerobic processesEutrophicationWater source

A controlled eutrophication system and process are disclosed. The system includes the combination of a partitioned aquaculture system in conjunction with an anaerobic digester. Wastewater containing pollutants, such as nitrogen and phosphorus, are fed to the partitioned aquaculture system. Algae within the system converts the pollutants into algal biomass. Fish populations, in turn, control the algal populations. The fish populations may then be periodically harvested for human or animal consumption. A polishing chamber is contained in the system in which aquatic organisms remove substantial amounts of the algae from batch fed additions of water. The water is then discharged to an external water source containing virtually no pollutants. In one embodiment, the biomass excreted by the aquatic organisms in the system are collected and fed to a digester. In the digester, the biomass is converted to a hydrocarbon gas and collected for its fuel value, while the liquid fraction is collected for its fertilizer value.

Owner:CLEMSON UNIV RES FOUND

Methods of and Systems for Producing Biofuels

A method for producing biofuels is provided. A method of making biofuels includes dewatering substantially intact algal cells to make an algal biomass, sequentially adding solvent sets to the algal biomass, and sequentially separating solid biomass fractions from liquid fractions to arrive at a liquid fraction comprising neutral lipids. The method also includes esterifying the neutral lipids, separating a water miscible fraction comprising glycerin from a water immiscible fraction comprising fuel esters, carotenoids, and omega-3 fatty acids. The method also includes obtaining a C16 or shorter fuel esters fraction, a C16 or longer fuel ester fraction, and a residue comprising carotenoids and omega-3 fatty acids. The method includes hydrogenating and deoxygenating at least one of (i) the C16 or shorter fuel esters to obtain a jet fuel blend stock and (ii) the C16 or longer fuel esters to obtain a diesel blend stock.

Owner:HELIAE DEVMENT

Air-contained coal gas gasification and separation process and equipment

The present invention relates to an air-contained coal gas gasification and separation process, which is chiefly to passing over the air-contained coalbed gas to the middle of the fractionating tower after cooling, through the evaporation of the evaporator in the bottom of the fractionating tower and the condensation of the top condenser, gas fraction inside the inner of the tower, the sufficient quality and heat exchange of the liquid fraction. The high purity nitrogen gas is obtained in the top of the fractionating tower and the high purity liquid natural gas is obtained in the bottom of the fractionating tower, wherein one part of pure air is induced to the heat exchanger at the entrance between the top of the fractionating tower and the air-contained coalbed gas. The invention also provides an equipment of the separation process. The air-contained coal gas gasification and separation process and equipment are separation liquefaction process specially designed for the air-contained coalbed gas, which adopts the single stage rectifying still simpler than the doublestage rectifying, and has convenient operation, low cost and easy to popularize in large scale.

Owner:BEIJING ZHONGKE RUIAO ENERGY TECH CO LTD

Continuous counter-current organosolv processing of lignocellulosic feedstocks

InactiveUS20080295980A1Facilitate and enhance of fermentation and efficiencyFacilitate and enhance rateNon-fibrous pulp additionBiological substance pretreatmentsFractionationOrganosolv

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into at least fuel-grade ethanol and four classes of lignin derivatives. The modular process comprises a first processing module configured for physico-chemically digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for producing at least a fuel-grade ethanol and a first class of novel lignin derivatives from the cellulosic solids fraction, a third processing module configured for separating a second class and a third class of lignin derivatives from the liquid fraction and further processing the liquid fraction to produce a distillate and a stillage, a fourth processing module configured for separating a fourth class of lignin derivatives from the stillage and further processing the stillage to produce a sugar syrup.

Owner:LIGNOL INNOVATIONS

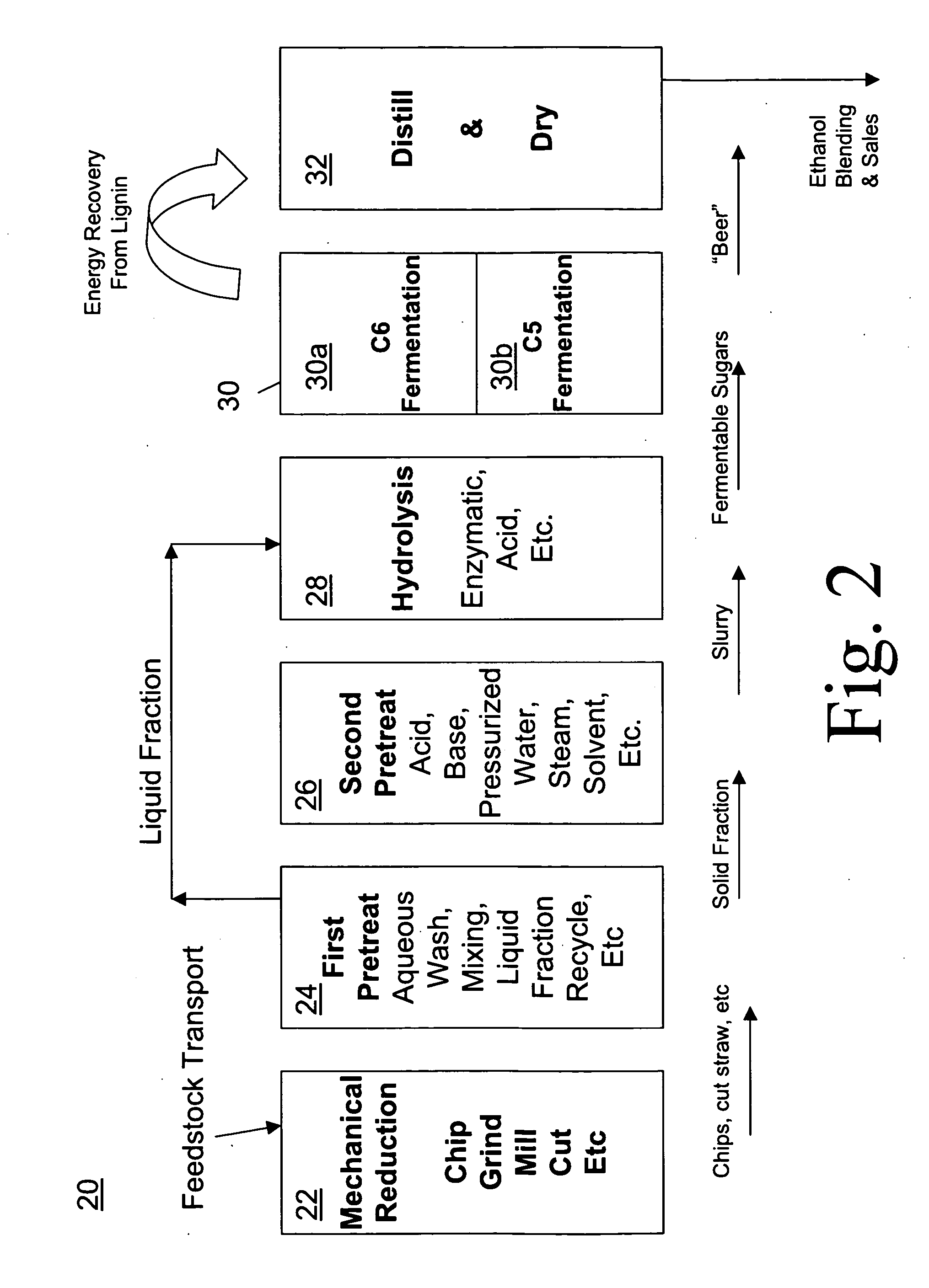

Treatment Systems and Processes for Lignocellulosic Substrates that Contain Soluble Carbohydrates

InactiveUS20090061495A1Lowering capital cost per unit of ethanol producedImprove throughputBiofuelsFermentationDistillationPolymer

A biorefining process used to convert lignocellulosic biomass into ethanol via a fermentation pathway. In a first pretreatment process step, the biomass is mixed with an aqueous wash solution to remove soluble carbohydrates from the biomass structure. Next, the solid fraction is separated from a liquid fraction. In a second pretreatment process, the solid fraction is pre-treated to make the fiber bundles and complex polysaccharides more amenable to enzymatic hydrolysis. Following the second pretreatment process, the pre-treated biomass is subjected to one or more enzymes in a hydrolysis process. The liquid fraction isolated from the first pretreatment process is diverted past the second pretreatment process and is recombined with the solid fraction in the hydrolysis process. The enzyme cocktail in the hydrolysis process breaks down the alpha- and hemicellulose polymers into fermentable sugars. Finally, a fermentation process produces a “beer” that is further processed in a distillation and dehydration process.

Owner:BEATTY CHRIS +2

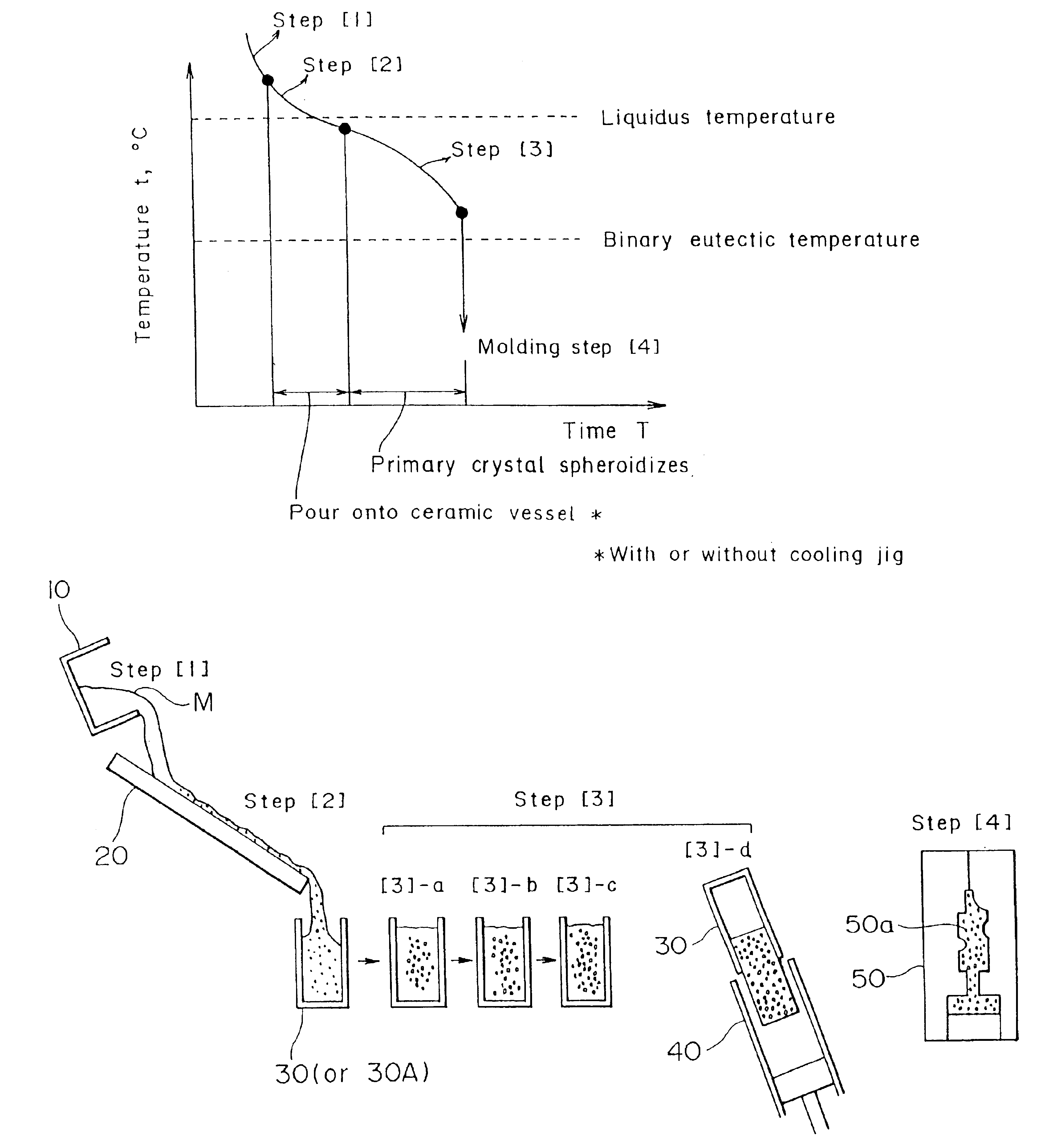

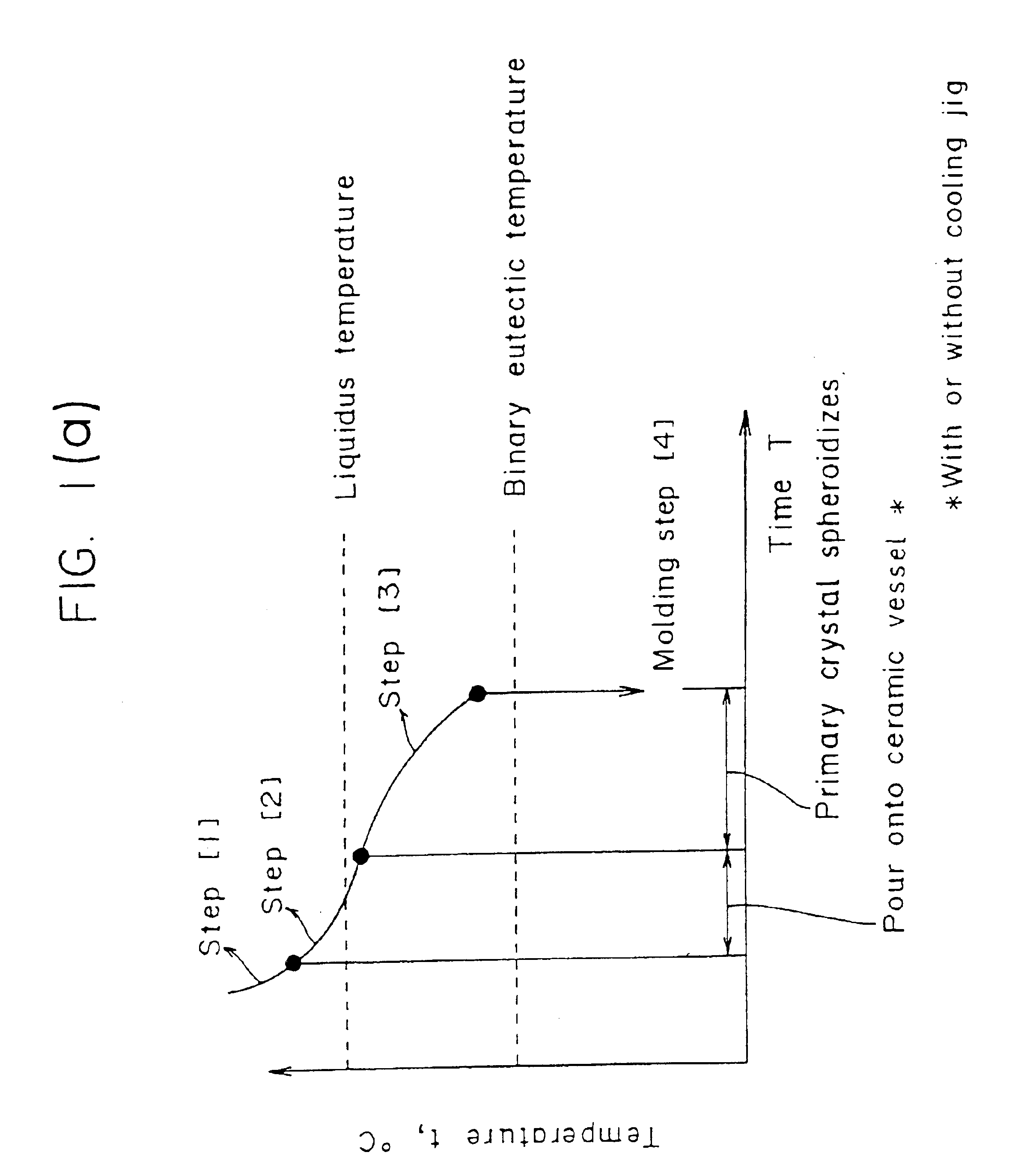

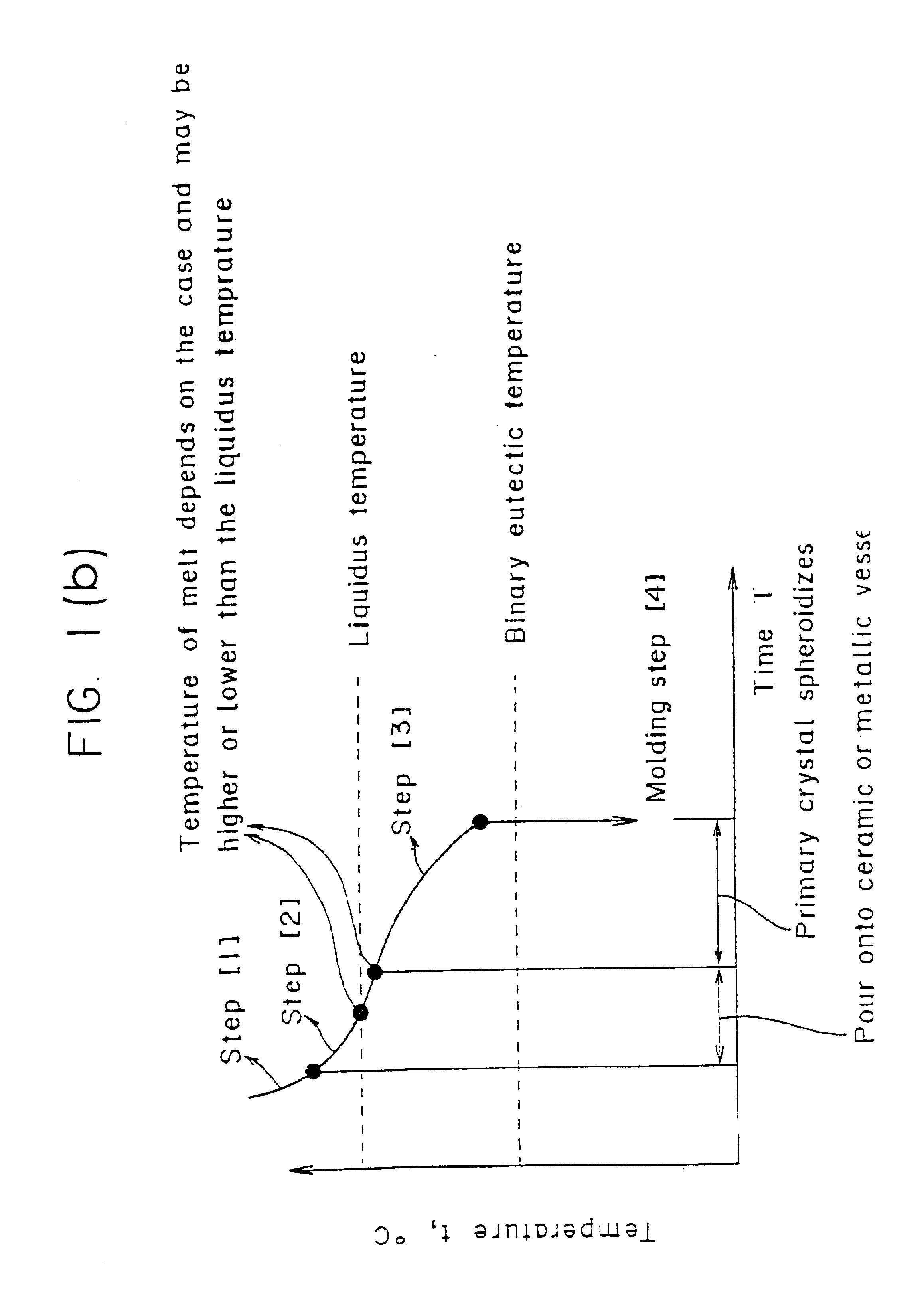

Method of shaping semisolid metals

A method and apparatus for the semisolid forming of alloys to enable shaped parts having a fine-grained, spherical thixotropic structure to be produced in a convenient, easy and inexpensive manner without relying upon the conventional mechanical or electromagnetic agitation. In the method, a molten alloy having crystal nuclei at a temperature not lower than the liquidus temperature or a partially solid, partially molten alloy having crystal nuclei at a temperature not lower than a molding temperature is fed into an insulated vessel and is maintained in the insulated vessel for 5 seconds to 60 minutes as it is cooled to the molding temperature where a specified liquid fraction is established, thereby crystallizing fine primary crystals in the alloy solution, and the alloy is fed into a forming mold, where it is shaped under pressure.

Owner:UBE IND LTD

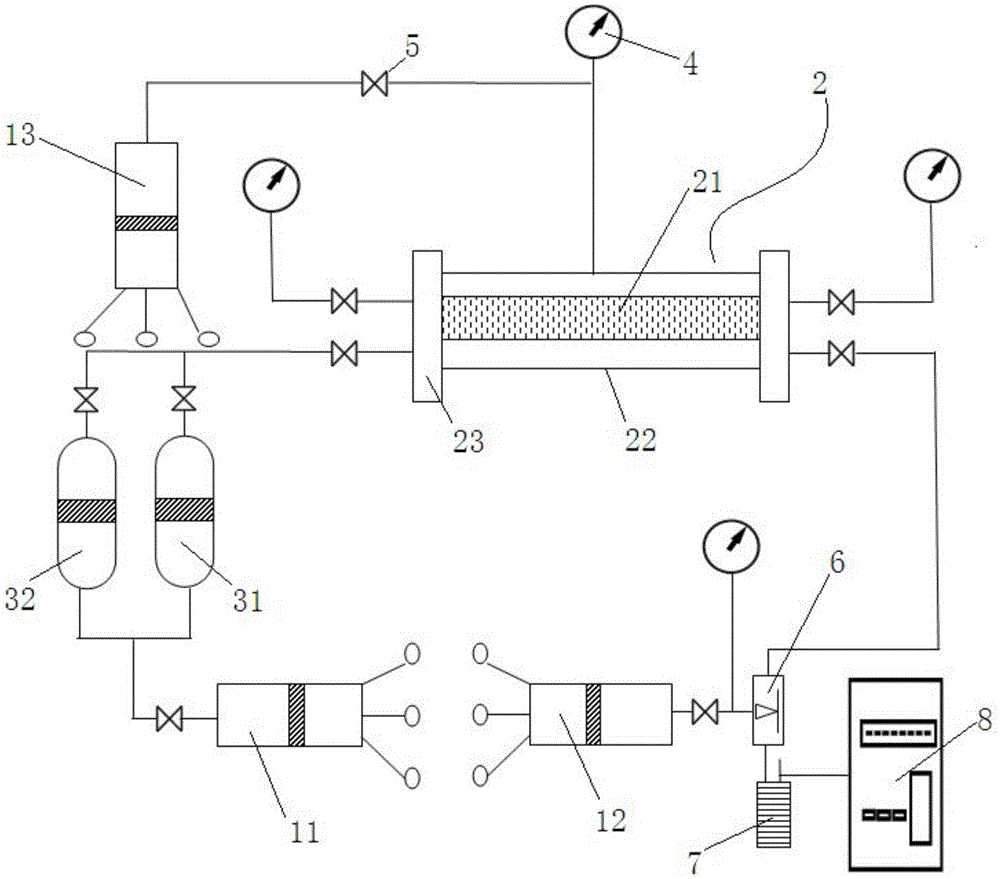

Testing device for competitive adsorption of supercritical CO2 and CH4 in shale and testing method of device

InactiveCN105628811ATrue restorationLarge volume of gas injectionComponent separationPermeability/surface area analysisInjection volumeDifferential pressure

The invention provides a testing device for competitive adsorption of supercritical CO2 and CH4 in shale and a testing method of the device. The device comprises an injection pump system, a long core holder, a back-pressure valve, a differential pressure gauge, a temperature control system, a liquid fraction collector, a gas meter and a gas chromatograph instrument. The testing method comprises an evaluation method of CH4 single component gas in a shale core and an evaluation method of CH4 gas, converted by the supercritical CO2, in the shale core. According to the device and method, the detection conditions of a laboratory test that the supercritical CO2 displaces CH4 adsorbed in the shale under the high temperature and high pressure conditions of a stratum are met through a multifunctional long core displacement method, and then the purpose of evaluating the efficiency that the supercritical CO2 displaces the adsorbed CH4 is achieved; by using the combined long core, the gas injection volume is large, the errors are decreased, and the formation condition is truly restored; the cracked long core can simulate the competitive adsorption process of the fractured supercritical CO2 and the CH4 under the true shale reservoir condition; the injected CO2 is in the supercritical state, and an experiment is performed in a step-by-step depressurizing mode, and the depletion exploitation process of a stratum can be truly simulated.

Owner:SOUTHWEST PETROLEUM UNIV

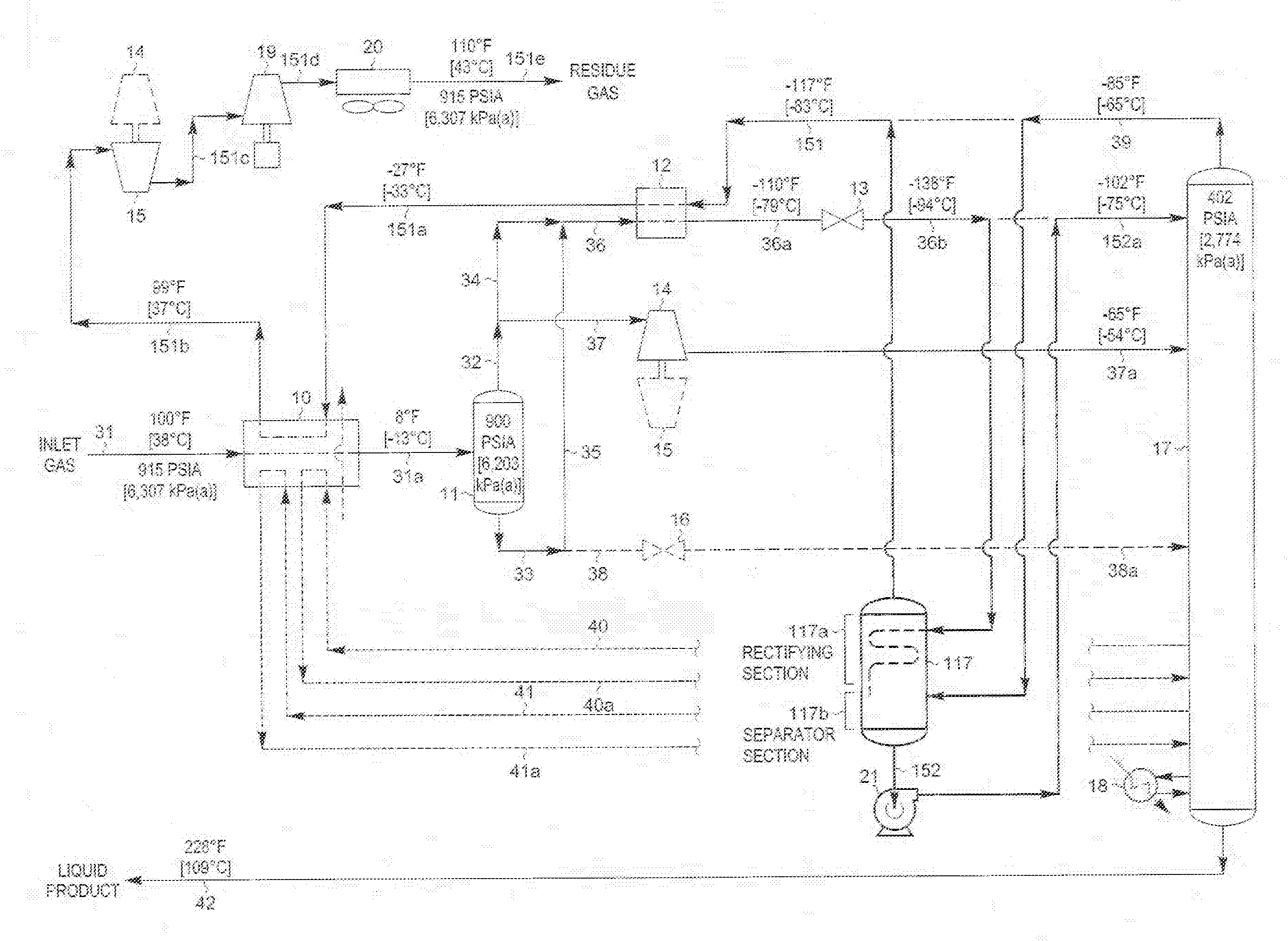

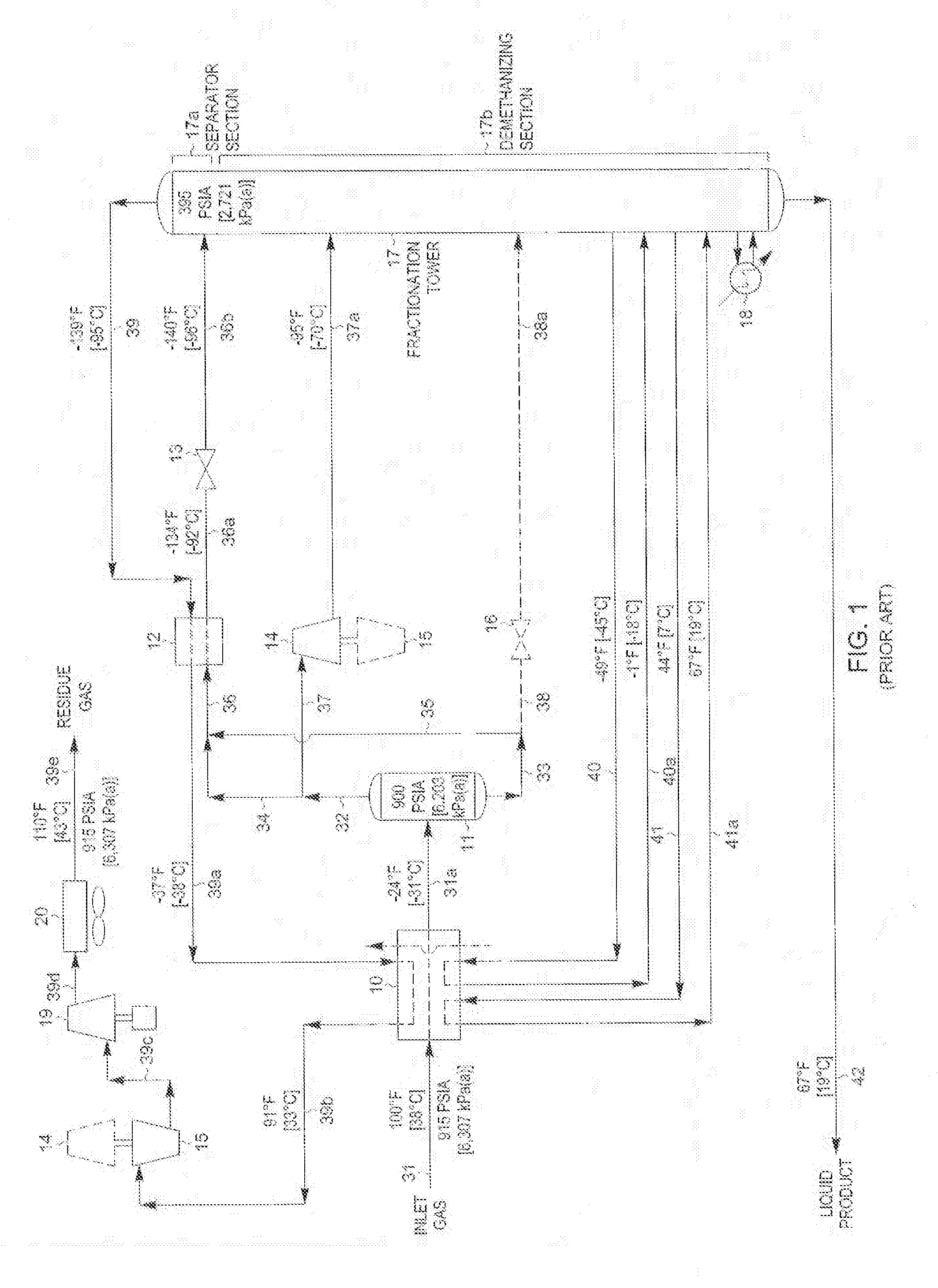

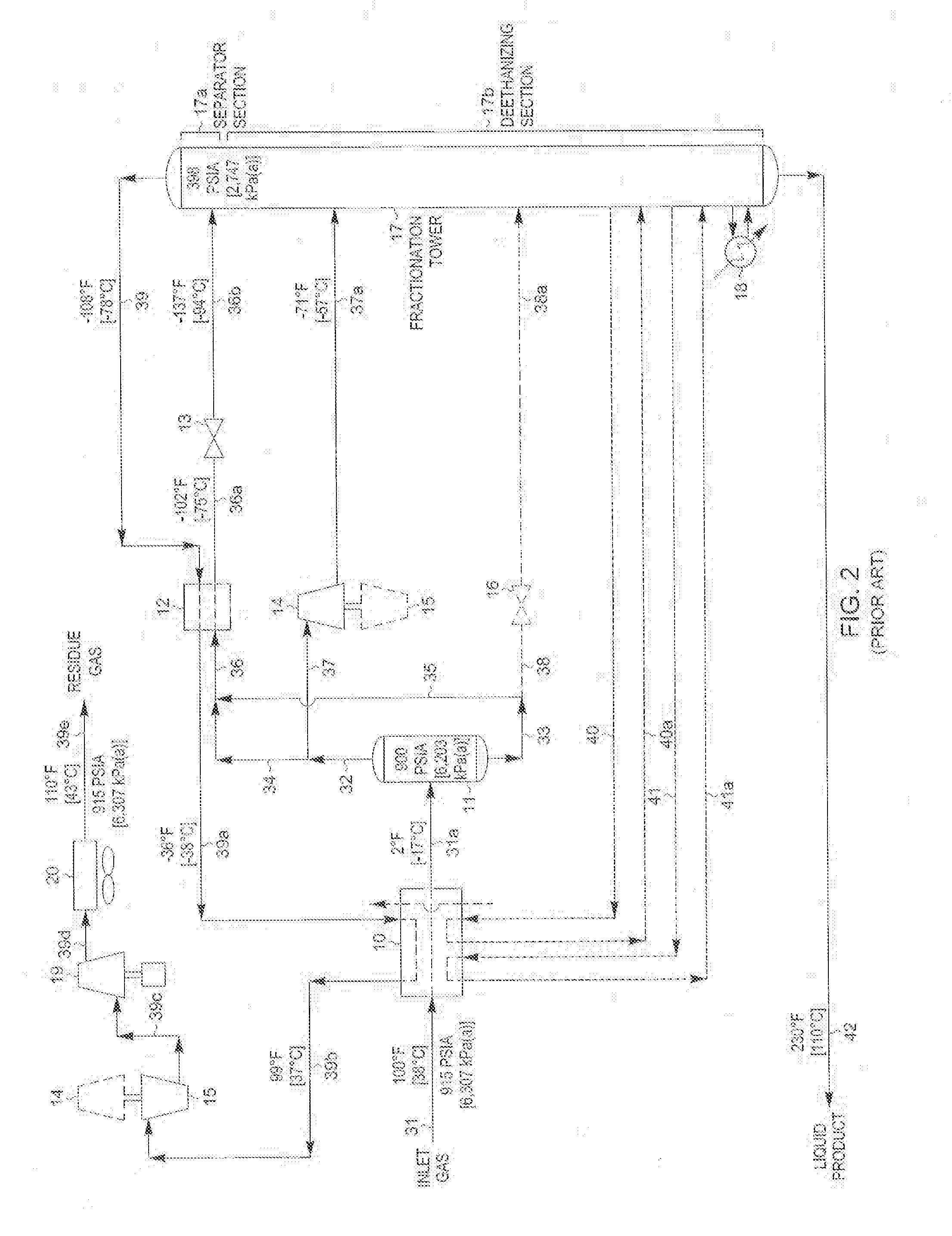

Hydrocarbon Gas Processing

ActiveUS20150073194A1Low costMeet cutting requirementsSolidificationLiquefactionFractionationProduct gas

A process and an apparatus are disclosed for a compact processing assembly to improve the recovery of C2 (or C3) and heavier hydrocarbon components from a hydrocarbon gas stream. The preferred method of separating a hydrocarbon gas stream generally includes producing at least a substantially condensed first stream and a cooled second stream, expanding both streams to lower pressure, and supplying the streams to a fractionation tower. In the process and apparatus disclosed, the expanded first stream is heated to form a vapor fraction and a liquid fraction. The vapor fraction is combined with the tower overhead vapor, directed to a heat and mass transfer means inside a processing assembly, and cooled and partially condensed by the expanded first stream to form a residual vapor stream and a condensed stream. The condensed stream is combined with the liquid fraction and supplied to the tower at its top feed point.

Owner:S M E PROD +1

Controlled eutrophication system and process

InactiveUS7258790B2Improve productivityIncrease productionWaste based fuelSeparation devicesEutrophicationWater source

Owner:CLEMSON UNIV RES FOUND

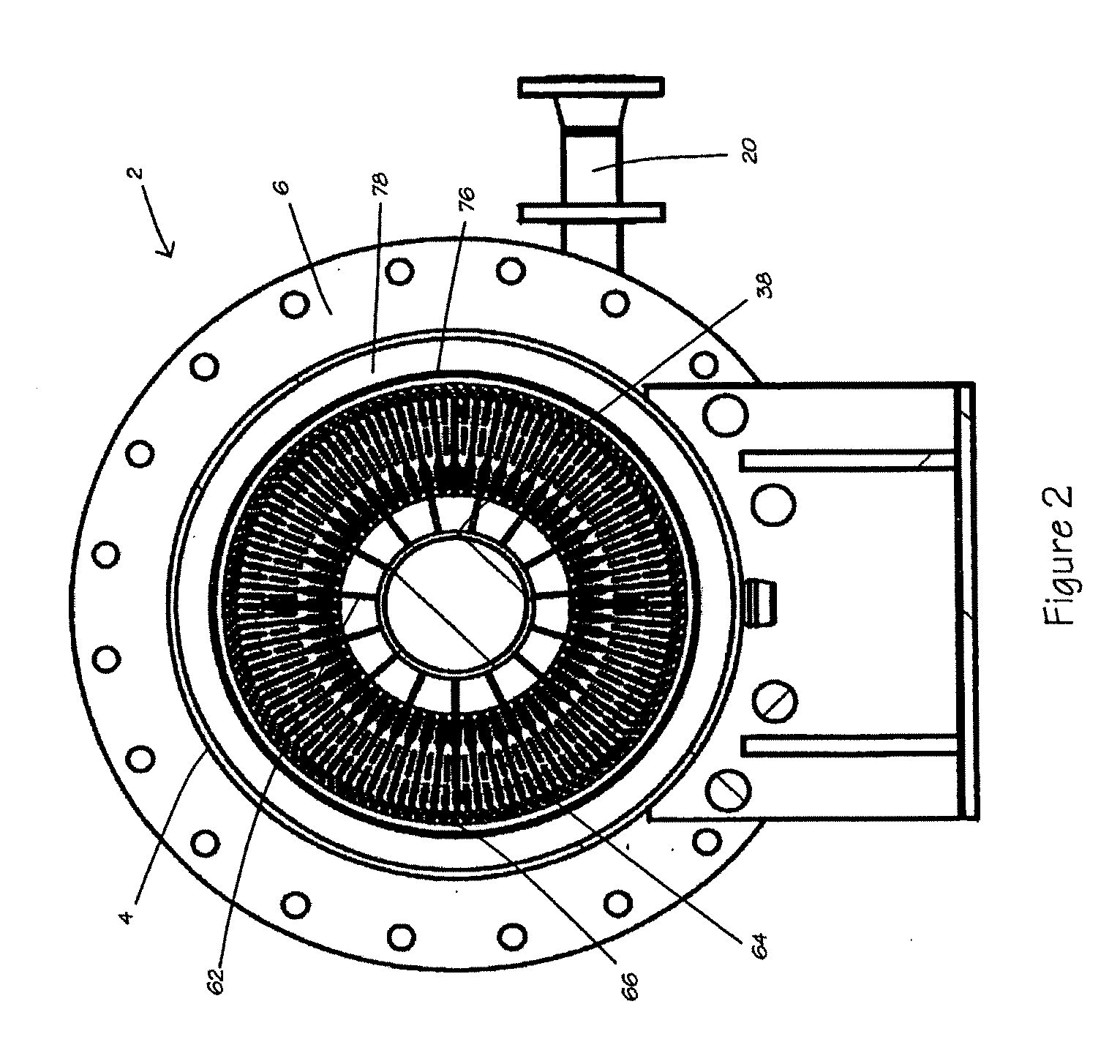

A separation device

A separator device comprises a cylindrical separation chamber within which a motor-driven rotor is situated. The rotor has vanes. In operation, an inflowing mixture enters through an inlet and is subjected to centrifugal force imposed by the rotation of the rotor. A lighter liquid fraction leaves through an annular outlet, and a heavier liquid fraction leaves through an annular outlet. Solids pass through a screen to a region where rotational flow is reduced or absent. The solids in the region are fluidized by liquid passing through the screen, and are extracted from outlets.Control means is provided to control operation of the device in response to changes in the incoming mixture.

Owner:SPECIALIST PROCESS TECH

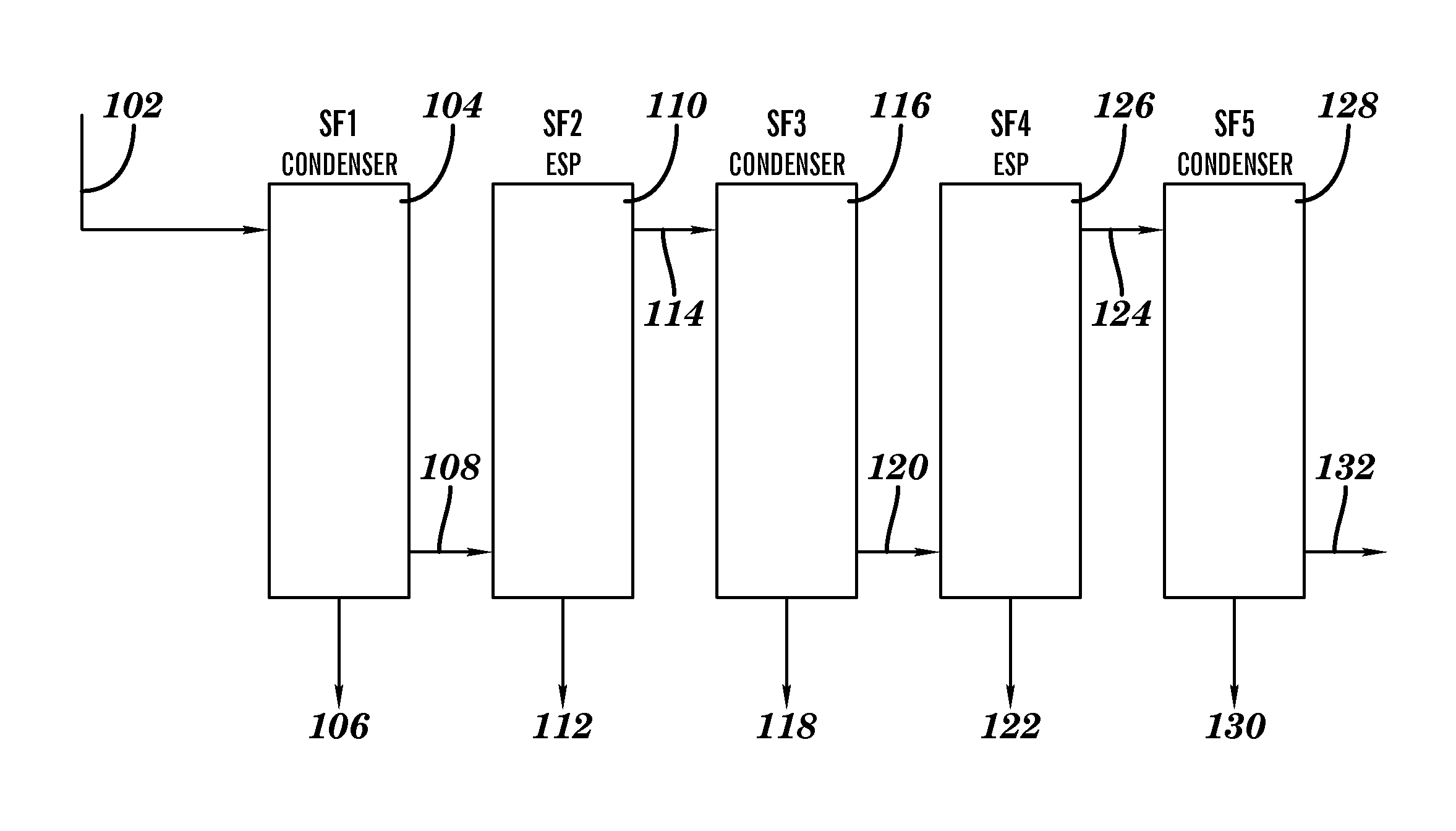

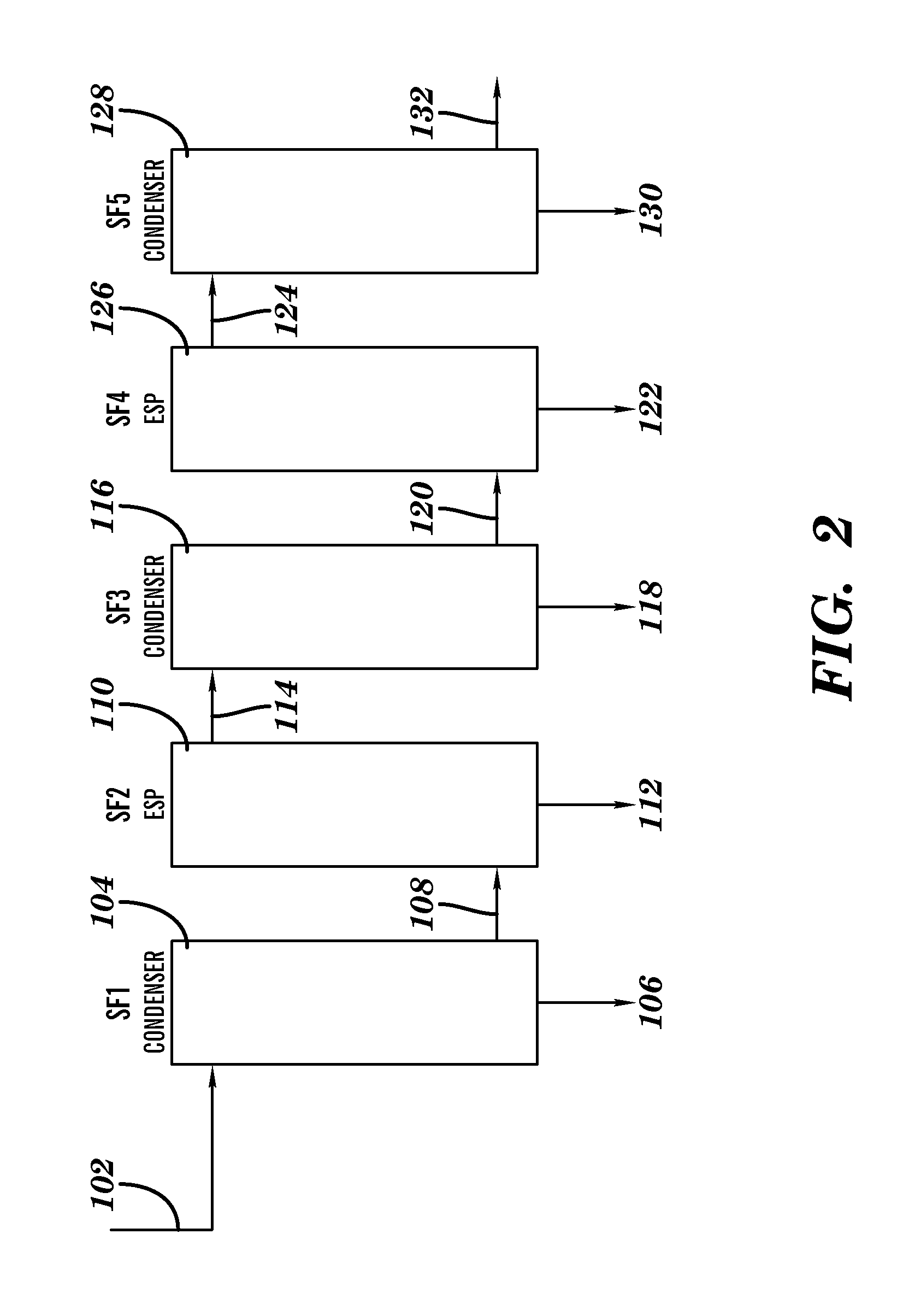

Bio-oil fractionation and condensation

ActiveUS8476480B1Reduced stabilityLower performance requirementsSolid waste disposalDirect heating destructive distillationHeat conductingFractionation

A method of fractionating bio-oil vapors which involves providing bio-oil vapors comprising bio-oil constituents is described. The bio-oil vapors are cooled in a first stage which comprises a condenser having passages for the bio-oil separated by a heat conducting wall from passages for a coolant. The coolant in the condenser of the first stage is maintained at a substantially constant temperature, set at a temperature in the range of 75 to 100° C., to condense a first liquid fraction of liquefied bio-oil constituents in the condenser of the first stage. The first liquid fraction of liquified bio-oil constituents from the condenser in the first stage is collected. Also described are steps for subsequently recovering further liquid fractions of liquefied bio-oil constituents. Particular compositions of bio-oil condensation products are also described.

Owner:IOWA STATE UNIV RES FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com