Patents

Literature

752results about How to "Reduce nitrogen content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aerogel metallic compositions

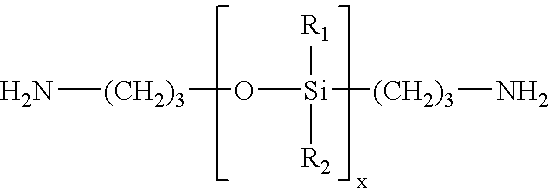

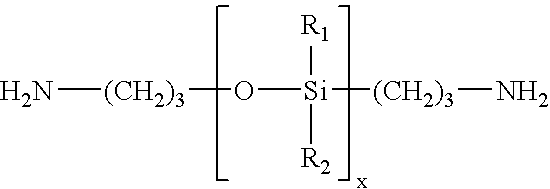

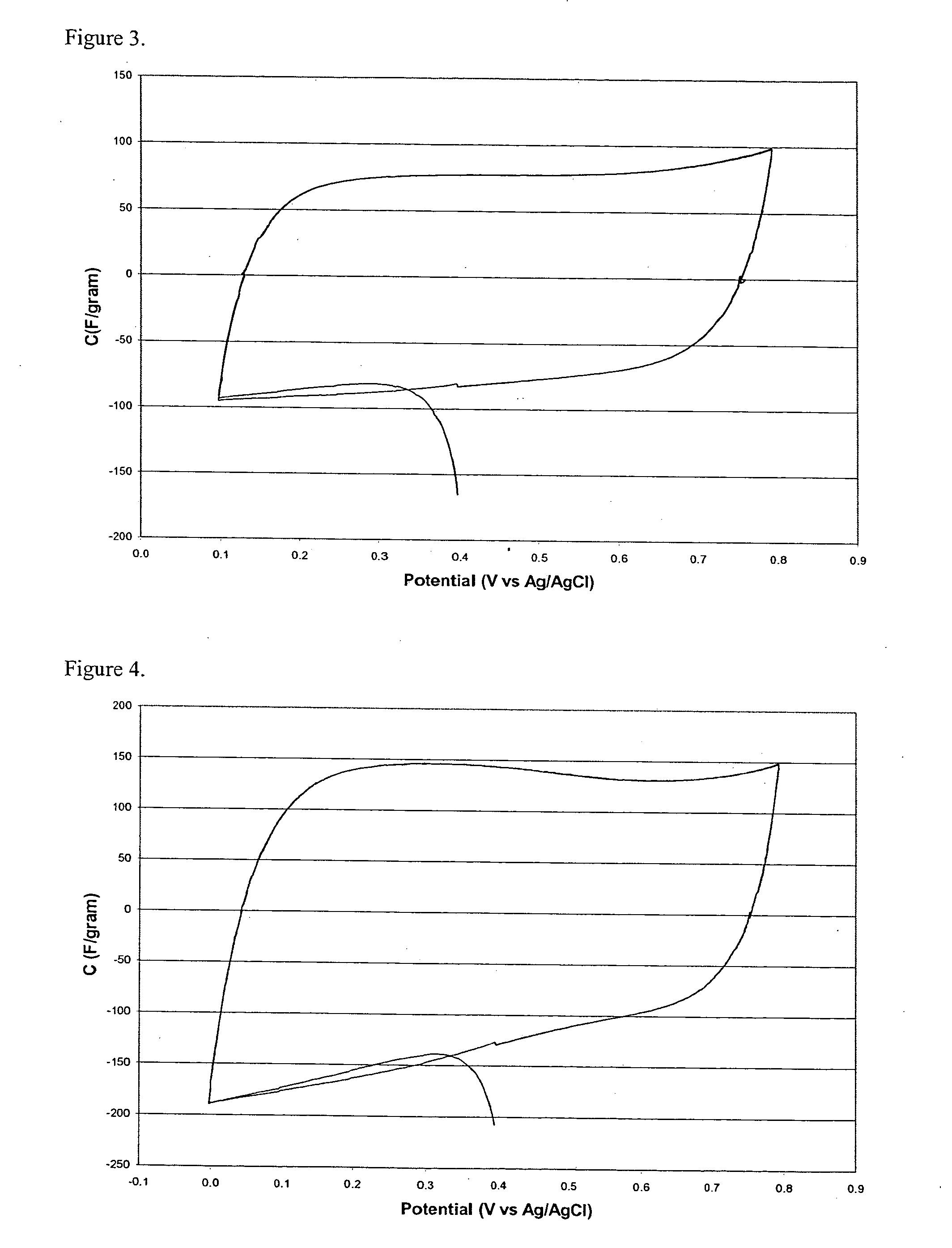

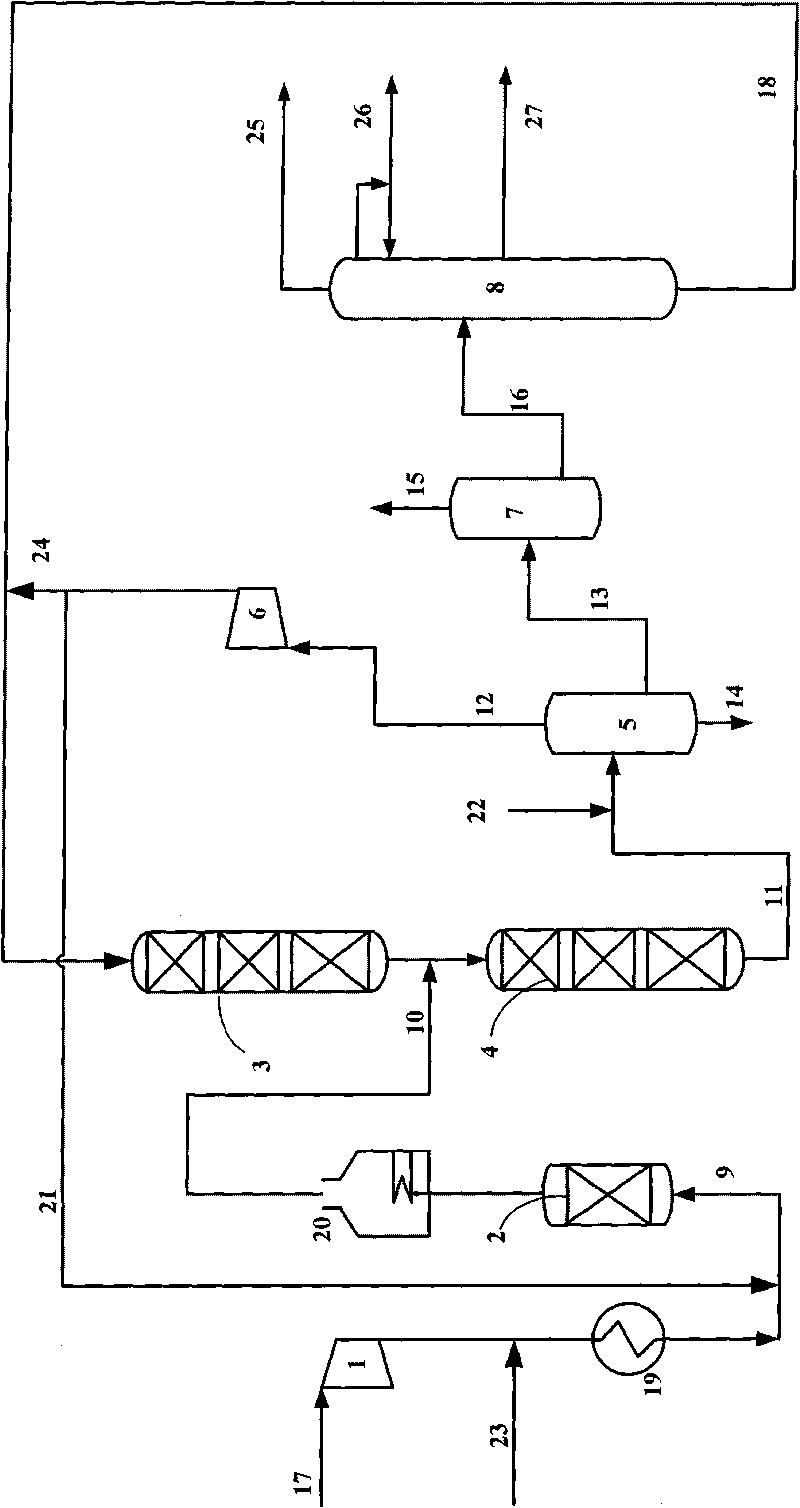

InactiveUS7071287B2Reduce nitrogen contentSuperior physical and electrical propertyMaterial nanotechnologyCell electrodesImidePolymer science

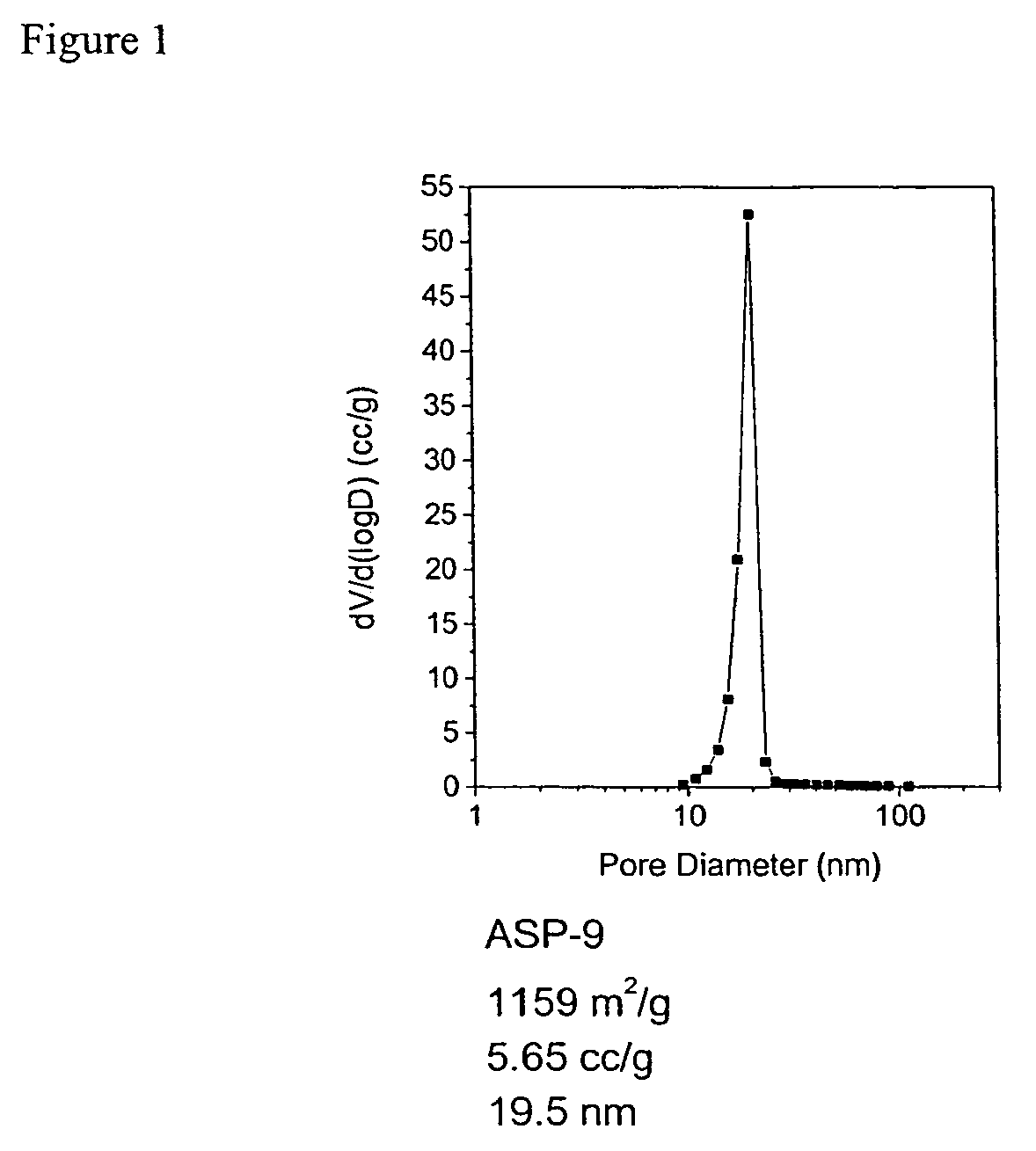

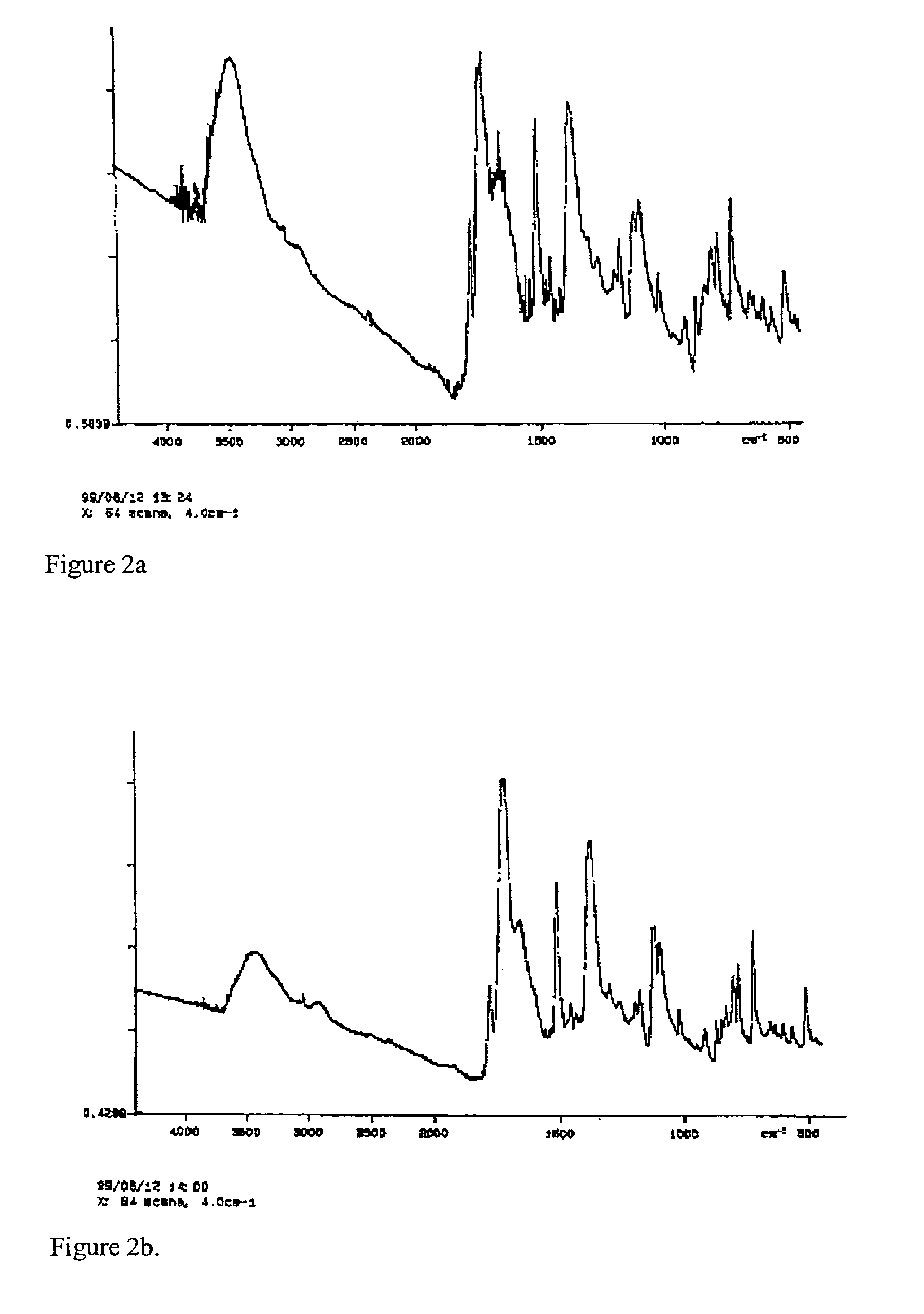

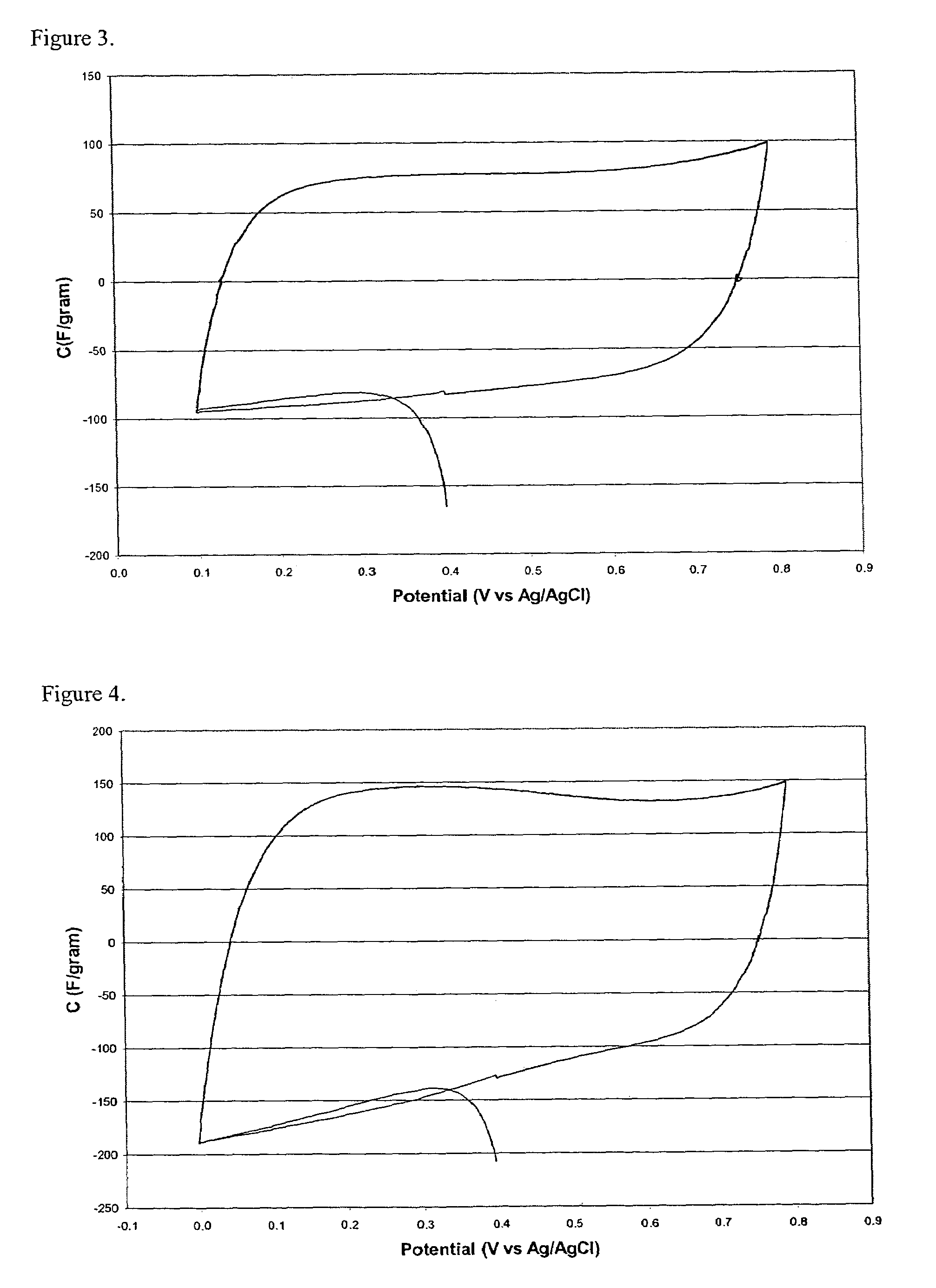

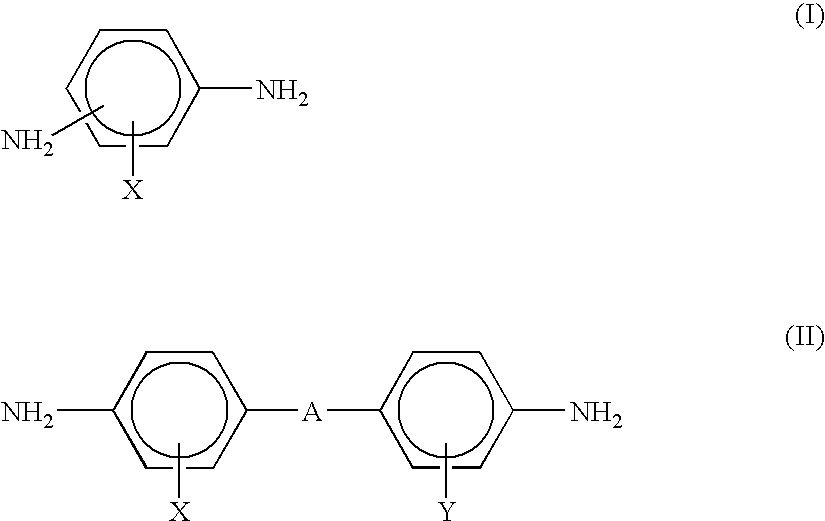

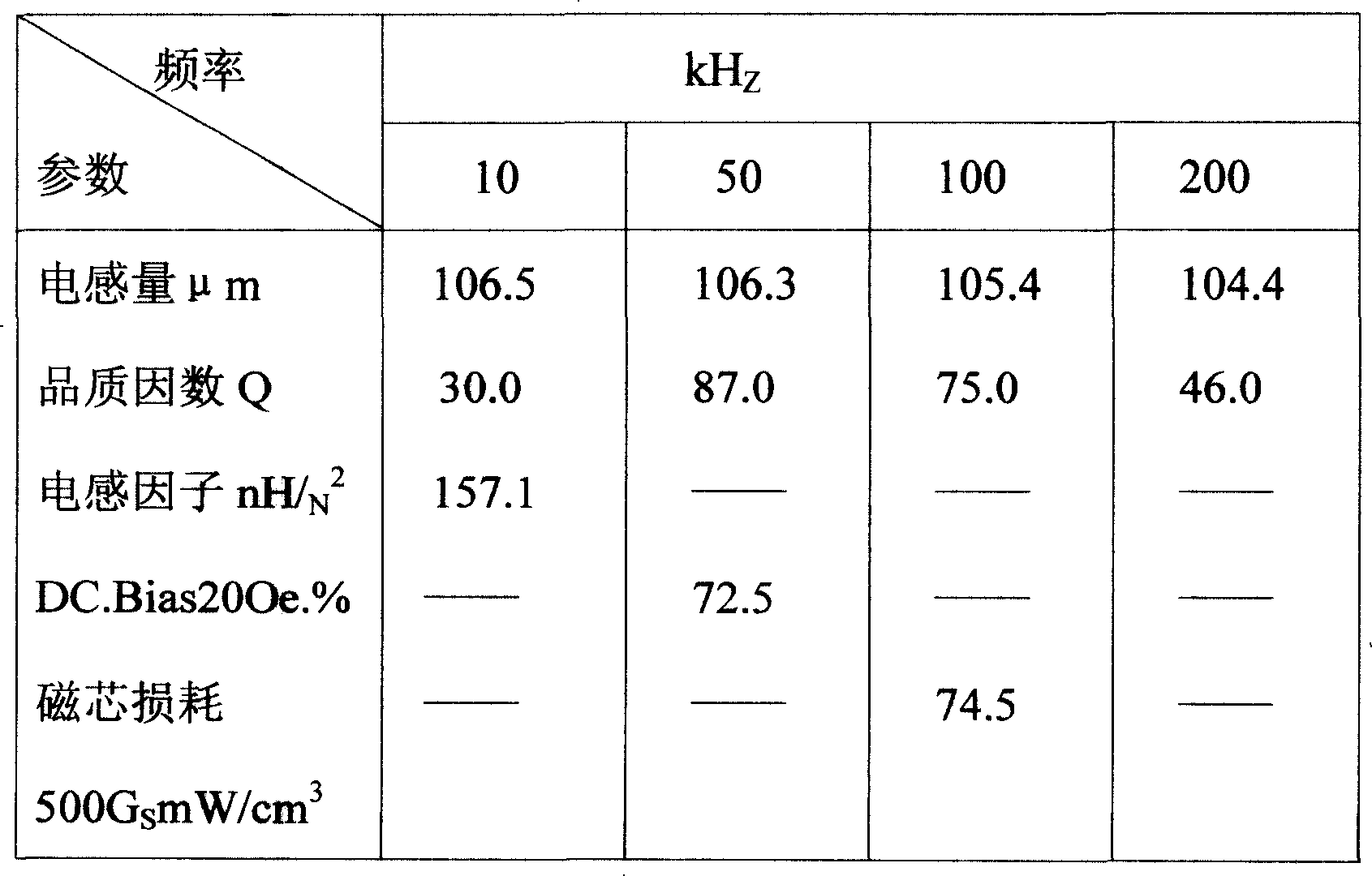

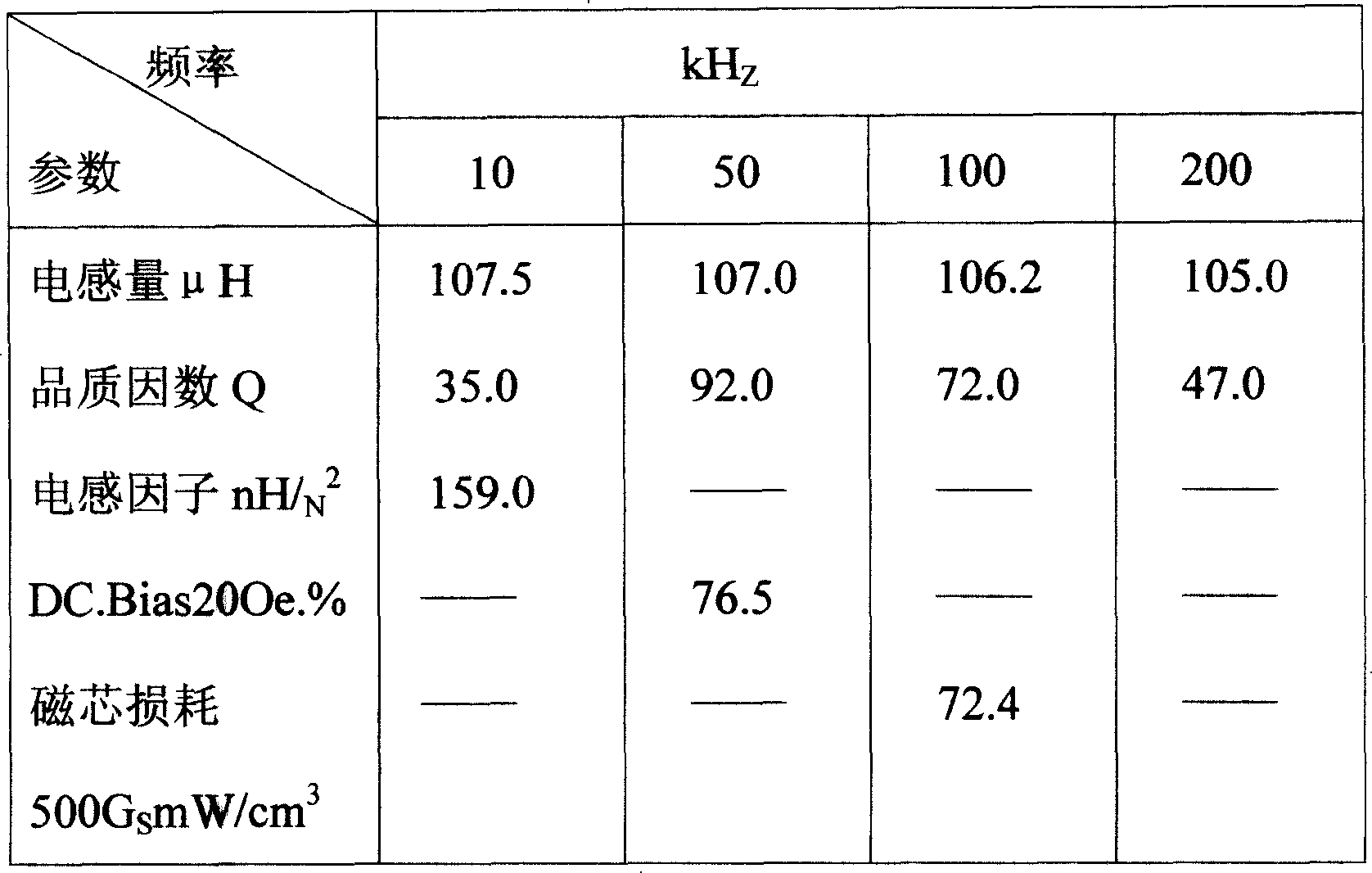

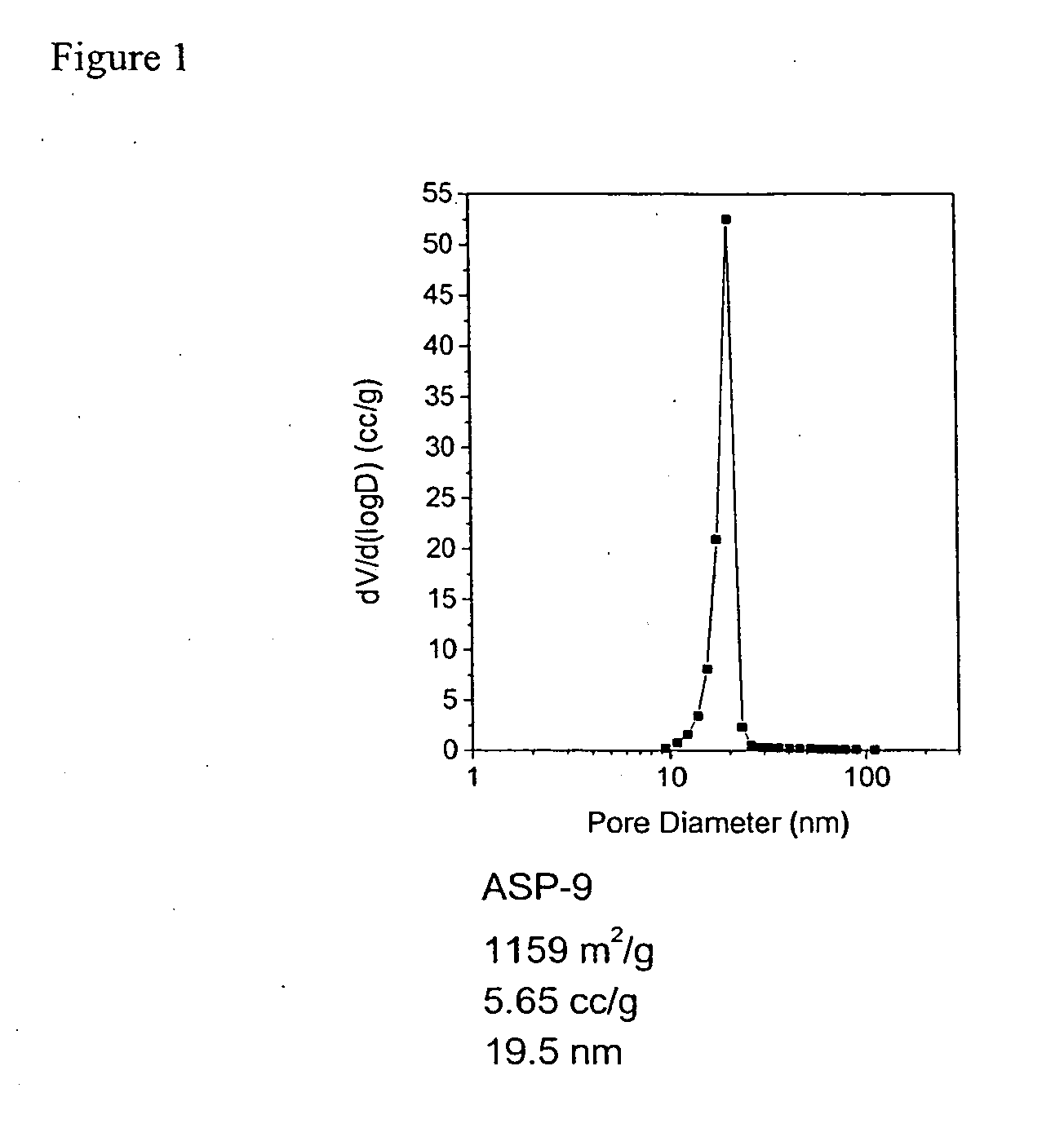

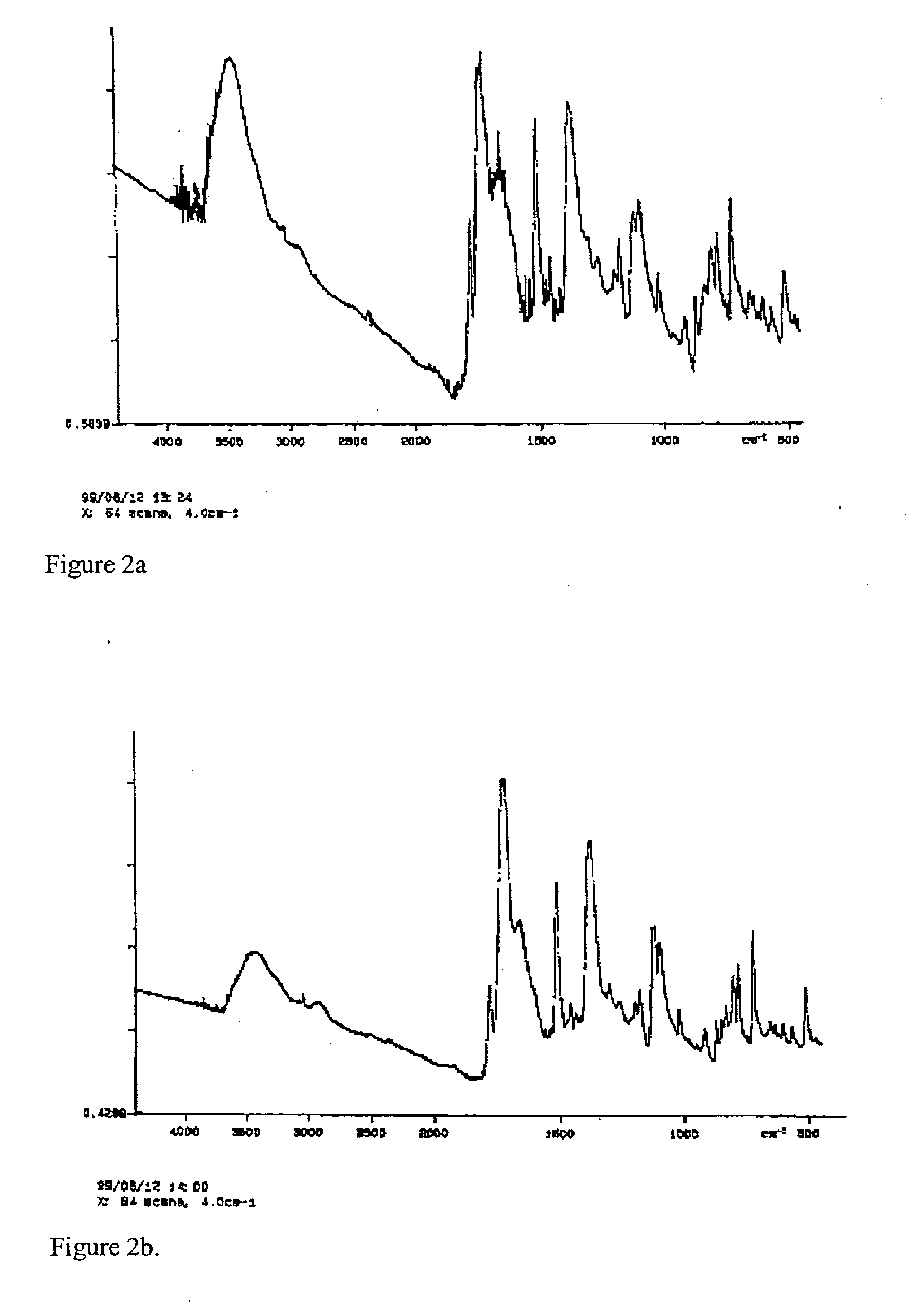

A preparation process of polyimide aerogels that composed of aromatic dianhydrides and aromatic diamines or a combined aromatic and aliphatic diamines is described. Also descried is a process to produce carbon aerogels derived from polyimide aerogel composed of a rigid aromatic diamine and an aromatic dianhydride. Finally, the processes to produce carbon aerogels or xerogel-aerogel hybrid, both of which impregnated with highly dispersed transition metal clusters, and metal carbide aerogels, deriving from the polyimide aerogels composed of a rigid aromatic diamine and an aromatic dianhydride, are described. The polyimide aerogels and the polyimide aerogel derivatives consist of interconnecting mesopores with average pore size at 10 to 30 nm and a mono-dispersed pore size distribution. The gel density could be as low as 0.008 g / cc and accessible surface area as high as 1300 m2 / g.

Owner:ASPEN AEROGELS INC

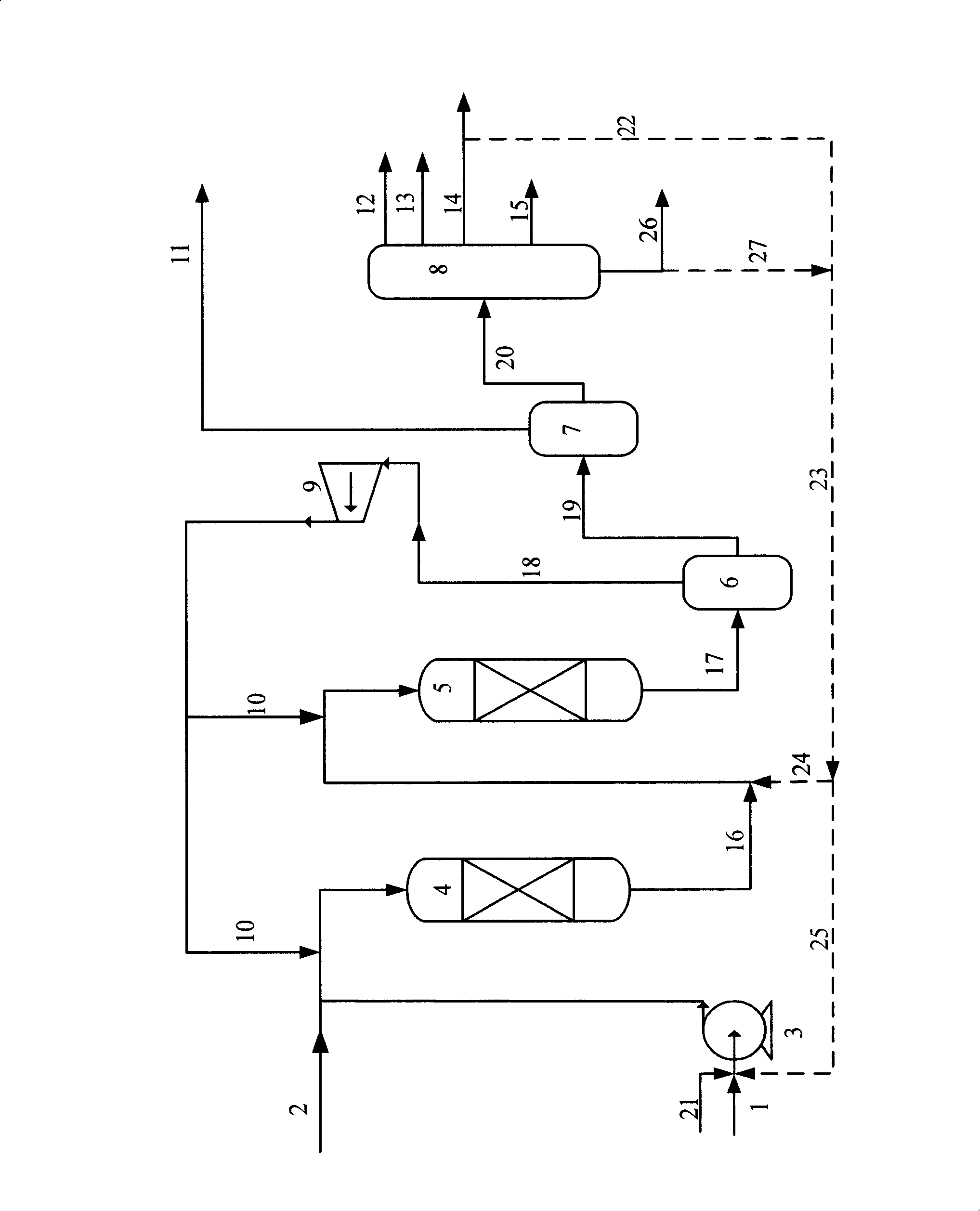

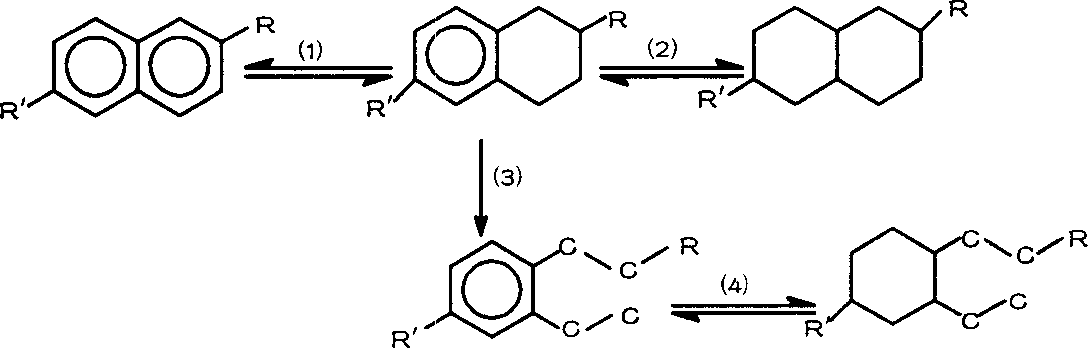

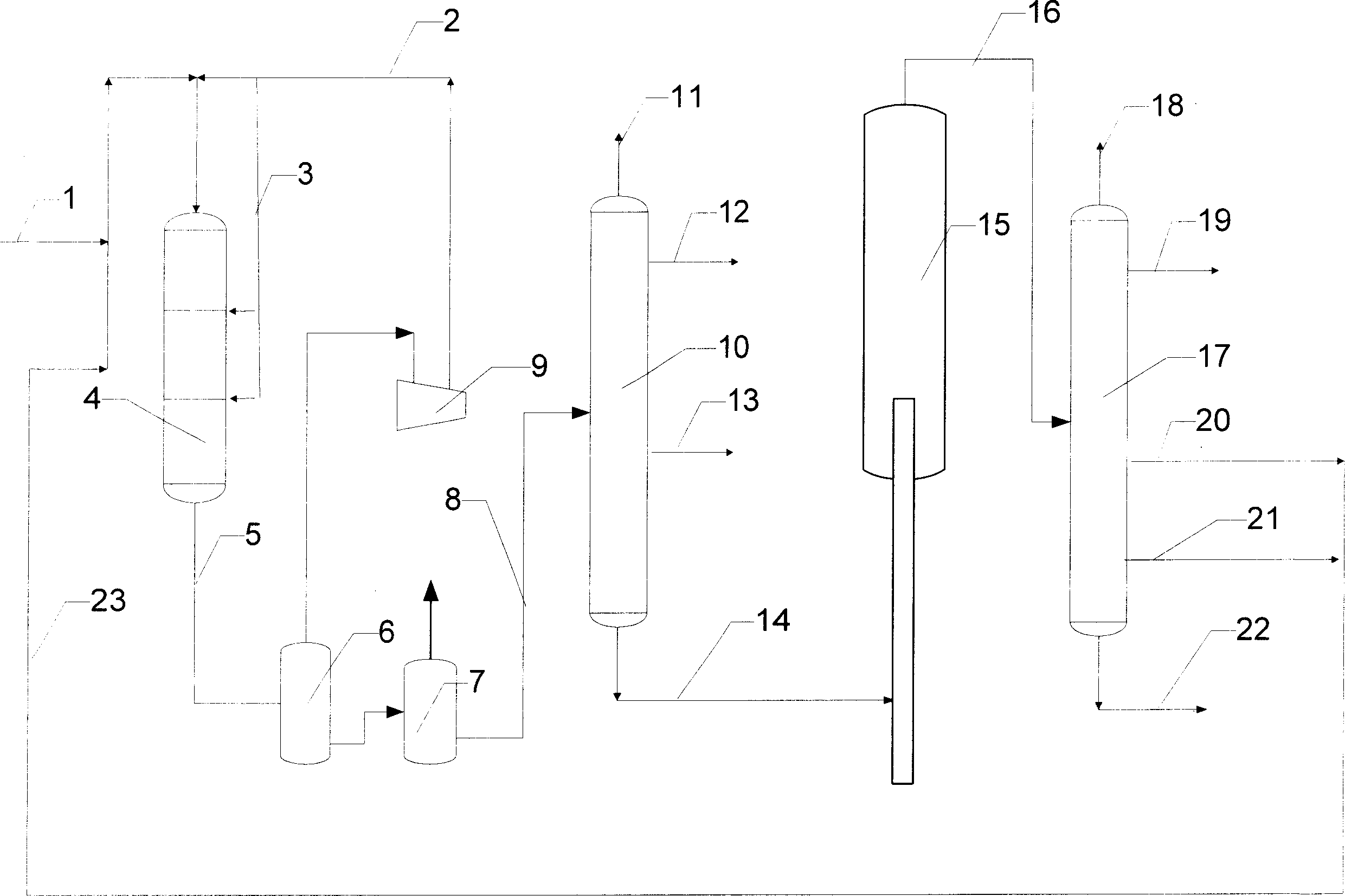

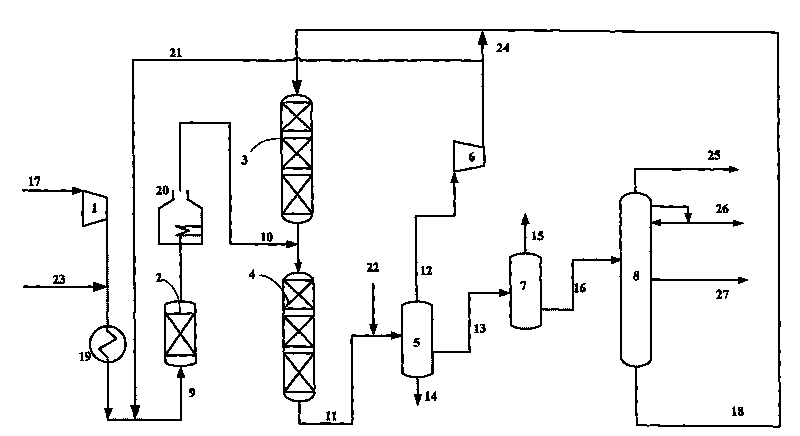

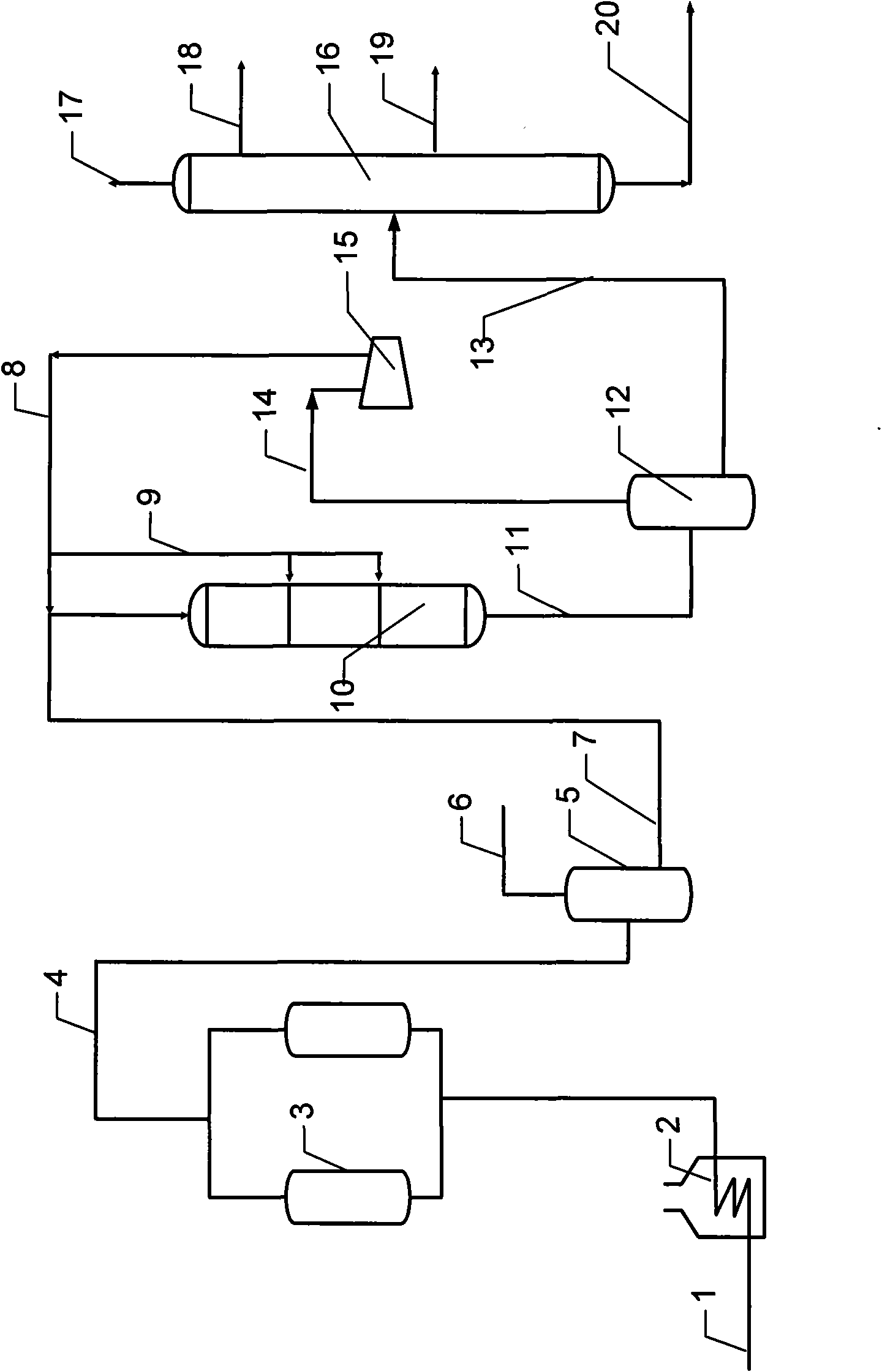

Method for preparing high-quality ethylene raw material with petroleum naphtha hydrogenation

ActiveCN101343557AImprove qualityIncrease productionOrganic chemistryBulk chemical productionVegetable oilPetroleum naphtha

The invention relates to a method for generating the high quality ethylene raw material through naphtha hydrogenation. The method takes naphtha fraction and animal and vegetable oil as the raw material oil, under the condition of hydrofining, the raw material oil and hydrogen are mixed and passed through a hydrofining reaction area, the hydrogen-rich gas recycling utilization can be acquired through separating the hydrofining generated oil, and low Sulfur, low hydrogen and low aromatic naphtha can be acquired through removing hydrogen sulfide of the separated liquid with an air stripping tower. Compared with the prior art, the method has the advantages that the oil is mixed in the naphtha hydrogenation raw material, the quality of the product as the ethylene cracking raw material, in particular to aromatic long chain hydrocarbon nC16 to 18 and propane acquired through the animal and vegetable oil hydrogenation, can be remarkably improved, the cracking furnace ethylene output can be increased and the cracking furnace life can be prolonged through adding the aromatic long chain hydrocarbon nC16 to 18 and propane in the ethylene cracking raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polyimide aerogels, carbon aerogels, and metal carbide aerogels and methods of making same

InactiveUS20040132845A1Reduce nitrogen contentSuperior physical and electrical propertyMaterial nanotechnologySiliconPolymer scienceCarbide

A preparation process of polyimide aerogels that composed of aromatic dianhydrides and aromatic diamines or a combined aromatic and aliphatic diamines is described. Also descried is a process to produce carbon aerogels derived from polyimide aerogel composed of a rigid aromatic diamine and an aromatic dianhydride. Finally, the processes to produce carbon aerogels or xerogel-aerogel hybrid, both of which impregnated with highly dispersed transition metal clusters, and metal carbide aerogels, deriving from the polyimide aerogels composed of a rigid aromatic diamine and an aromatic dianhydride, are described. The polyimide aerogels and the polyimide aerogel derivatives consist of interconnecting mesopores with average pore size at 10 to 30 nm and a mono-dispersed pore size distribution. The gel density could be as low as 0.008 g / cc and accessible surface area as high as 1300 m<2> / g.

Owner:ASPEN AEROGELS INC

Hydrogenation method for producing high grade diesel oil and high grade reforming raw material

ActiveCN101210198AHigh saturation activityImprove hydrodesulfurization activityHydrocarbon oil crackingTreatment with hydrotreatment processesWaxHydrogen

A hydrogenation method for producing high-quality diesel oil and high-quality reforming materials comprises the following steps of: mixing diesel oil and / or a light wax oil material with hydrogen gas, and sequentially contact-reacting with a hydrorefining catalyst and a hydrocracking catalyst without middle separation, cooling the reaction result, and separating to obtain a light naphtha fraction, a heavy naphtha fraction, a kerosene fraction, a diesel oil fraction and a tail oil fraction, wherein the kerosene fraction and / or the tail oil fraction can be directly extracted or partially or completely recycled back to the reaction system. By adopting single-stage once-through process and a non-noble metal catalyst, the invention can produce the reforming materials with high aromatic content and the diesel oil fraction with high cetane number, wherein the yield of the reforming material is larger than 20wt%, and the cetane number of the diesel oil fraction can be improved by more than 15 units. The method provided by the invention has high operation flexibility and can flexibly adjust the technical scheme according to different raw materials and different product scheme requirements.

Owner:CHINA PETROLEUM & CHEM CORP +1

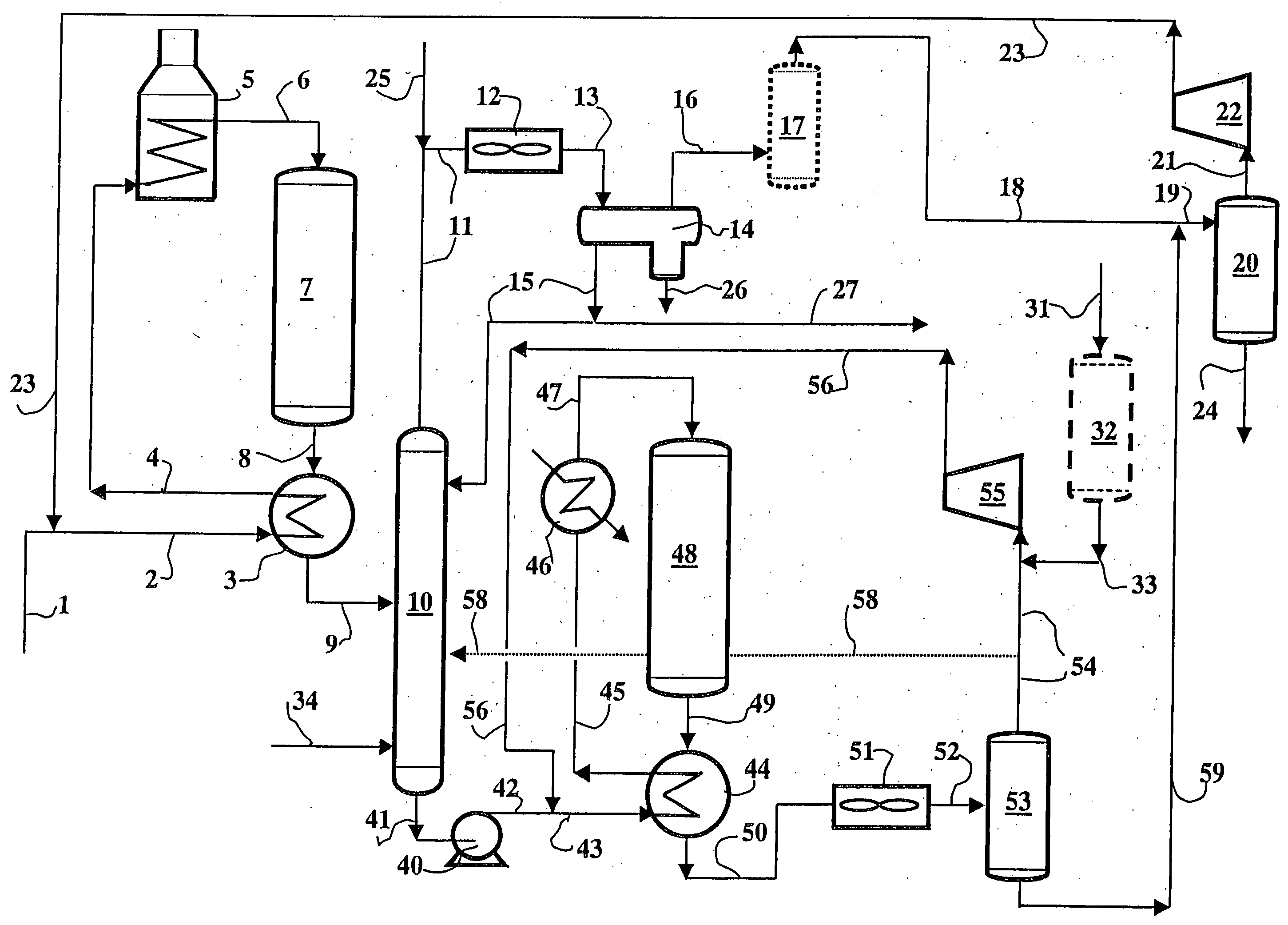

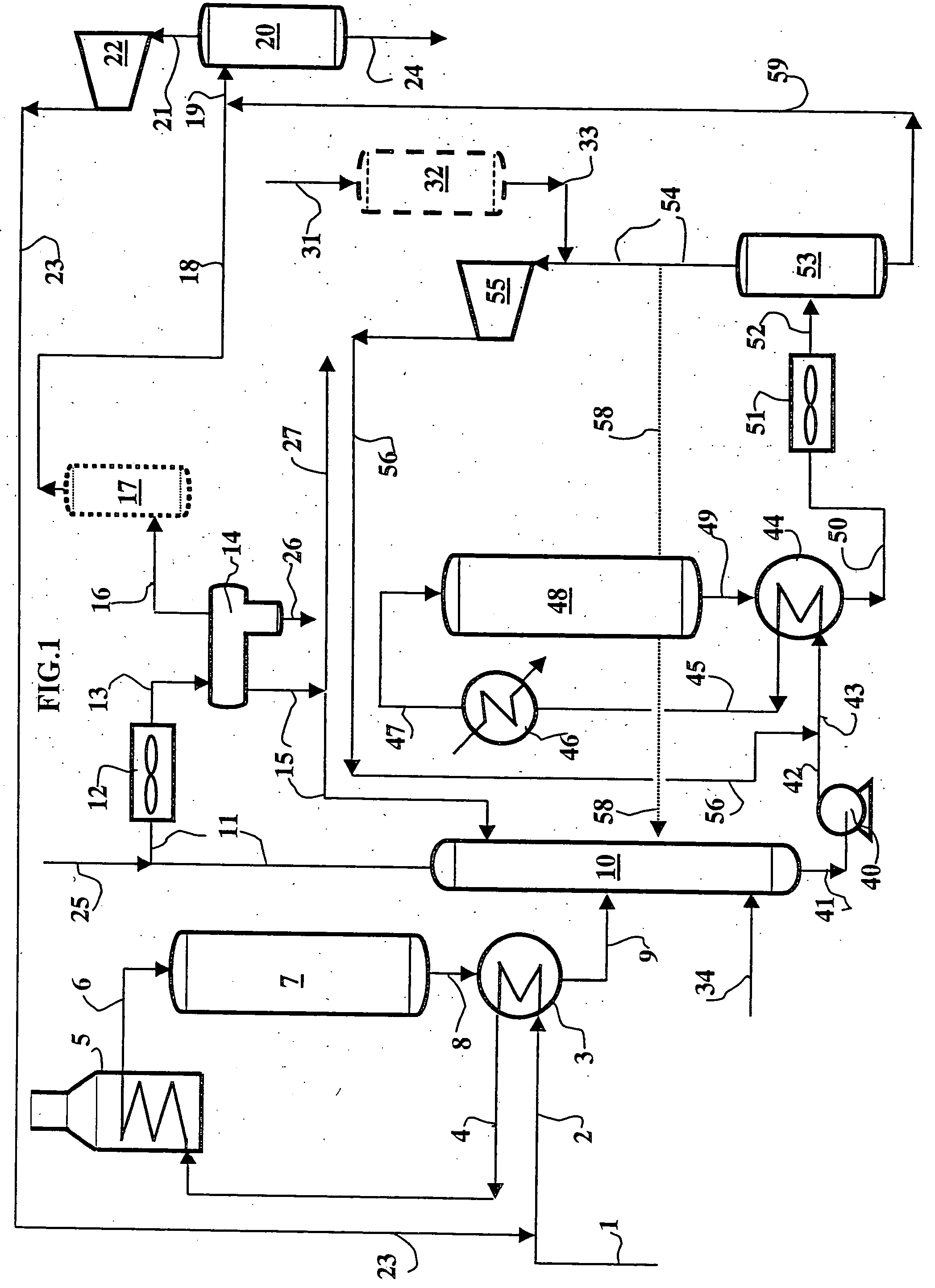

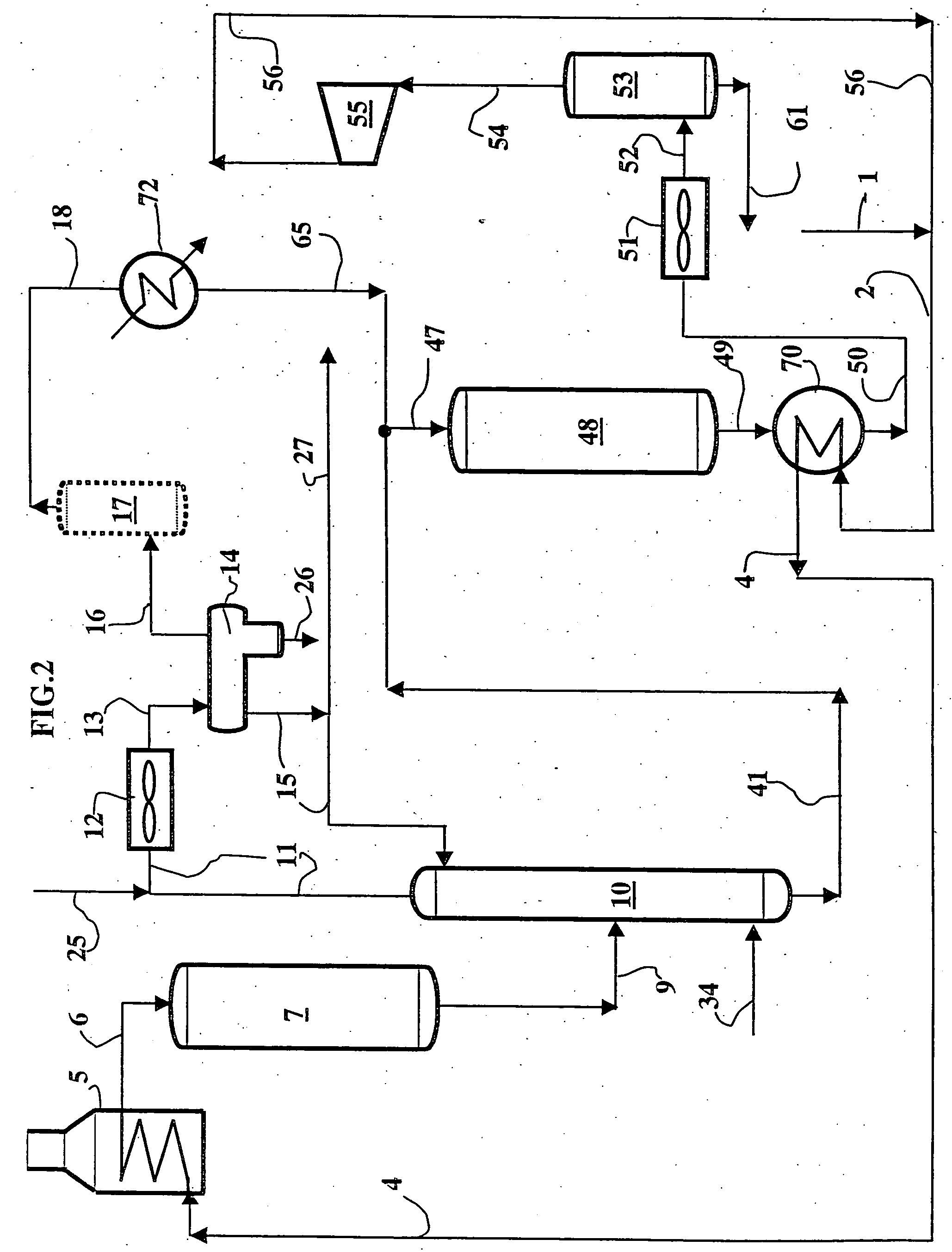

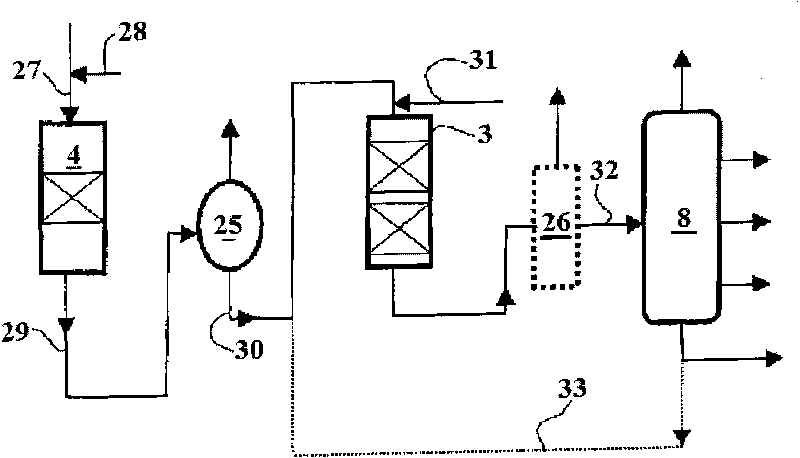

Two-step method for hydrotreating of a hydrocarbon feedstock comprising intermediate fractionation by rectification stripping

InactiveUS20060118466A1Reduce sulfur contentReduce nitrogen contentHydrocarbon distillation control/regulationTreatment with hydrotreatment processesPtru catalystPhysical chemistry

A process for hydrotreatment of a hydrocarbon feed comprises at least two reaction steps with intermediate fractionation of the effluent from the first step to eliminate unwanted impurities for the catalyst of the second step and to produce a desulphurized light liquid fraction. The intermediate fractionation comprises stripping the liquid effluent from the first step using low pressure hydrogen with rectification of the stripping vapours using a substantially desulphurized liquid reflux. The conditions for said fractionation and for the first hydrotreatment step can produce a substantially desulphurized light liquid fraction which is not supplied to the second step.

Owner:INST FR DU PETROLE

Two-way combined process of wax-oil hydrogenation treatment and catalytic cracking

A two-way combined process of wax oil hydro-process and catalytic crack is carried out by entering wax oil, catalytic cracking re-circulating oil and catalytic cracking diesel oil into hydro-processor, hydrogenation reacting under existence of hydrogen and hydrogenation catalyst, separating for reactant to obtain gas, hydrogenation naphtha oil, hydrogenation diesel oil and hydrogenation tail oil, entering hydrogenation tail oil into catalytic cracker, crack reacting under existence of catalytic cracking agent, separating to obtain dry gas, liquefied gas, catalytic cracking gasoline, catalytic cracking diesel oil and catalytic cracking re-circulating oil and oil slurry, and circulating for catalytic cracking diesel oil and catalytic cracking re-circulating oil to hydro-processor. It has higher recovery rate and cetyl value, less sulfur content, arene content and coke output.

Owner:CHINA PETROLEUM & CHEM CORP +1

Manufacturing method of Fe-6.5Si alloy powder and manufacturing method of magnetic powder core

The making of Fe-6.5Si alloy magnetic powder core comprises grain proportion, alloy powder inactivating, adding insulation agent to the metal powder, binder, lubricant and stripping agent, compression, heat treatment, solidification, surface coating, with the inactivating treatment getting phosphopyruvic acid with 5-15% phosphate chrome, the rest being acetone, adding alloy powder with 2-6% of mass percentage. Adding small quantity Ti nor Ni, it can reach the saturated alloy magnetic sensing strength BS value of 16000- 18000 Gaussian, coercitive force <=80A / m. It has better forming and compression feature. It reduces broken stress. The made magnetic powder core having magnetic conductivity of 125, with low metal core consumption.

Owner:武汉欣达磁性材料有限公司

Ni-base heat resistant alloy and welded joint thereof

InactiveUS20030005981A1Improve carburization resistanceImprove solubilityWelding/cutting media/materialsSoldering mediaUltimate tensile strengthEthylene

A Ni-base heat resistant alloy excellent in weldability and strength at elevated temperatures and suited for use in manufacturing cracking furnace tubes and reformer furnace tubes to be used in ethylene plants as well as a welded joint therefor is provided. The alloy of the invention is a Ni-base heat-resistant alloy, which comprises C: not more than 0.1%, Si: not more than 2%, Mn: not more than 2%, P: not more than 0.025%, S: not more than 0.005%, N: not more than 0.04%, Cr: 10 to 30%, Al: 2.1 to less than 4.5%, and Mo: 2.5 to 15% or W: 2.5 to 9% or Mo and W: 2.5 to 15% in total, and satisfies the relation (1) given below:<paragraph lvl="0"><in-line-formula>(104Si+1980P+1980S+9Al+15Ti+11Nb+1.8W+11600B)<={1.1(240-20000S-1900P-30Al-10Ti-9W+17000B) (1)< / in-line-formula>In the welded joint of the invention, both of the base metal and weld metal are made of the alloy having the above composition, and the ST value of the weld metal as calculated according to the following formula (2) or (3) is larger by not less than 3 than the ST value of the base metal:<paragraph lvl="0"><in-line-formula>in the case of Ti<=4C; ST-Mo+1.5W+100Ti (2)< / in-line-formula><paragraph lvl="0"><in-line-formula>in the case of Ti>4C; ST=Mo+1.5W+400C (3).< / in-line-formula>

Owner:NIPPON STEEL CORP

Aerogel metallic compositions

InactiveUS20050131163A1Reduce nitrogen contentSuperior physical and electrical propertyMaterial nanotechnologyCell electrodesCarbideAccessible surface area

A preparation process of polyimide aerogels that composed of aromatic dianhydrides and aromatic diamines or a combined aromatic and aliphatic diamines is described. Also descried is a process to produce carbon aerogels derived from polyimide aerogel composed of a rigid aromatic diamine and an aromatic dianhydride. Finally, the processes to produce carbon aerogels or xerogel-aerogel hybrid, both of which impregnated with highly dispersed transition metal clusters, and metal carbide aerogels, deriving from the polyimide aerogels composed of a rigid aromatic diamine and an aromatic dianhydride, are described. The polyimide aerogels and the polyimide aerogel derivatives consist of interconnecting mesopores with average pore size at 10 to 30 nm and a mono-dispersed pore size distribution. The gel density could be as low as 0.008 g / cc and accessible surface area as high as 1300 m2 / g.

Owner:ASPEN AEROGELS INC

High-temperature solid-phase synthesis method of high-purity silicon carbide powder

InactiveCN102701208AReduce intrinsic conductivityReduce nitrogen contentPolycrystalline material growthCarbon compoundsCrucibleNitrogen

The invention relates to a high-temperature solid-phase synthesis method of high-purity silicon carbide powder. The high-temperature solid-phase synthesis method comprises the following procedures of: material compounding: uniformly mixing high-purity Si powder and high-purity C powder according to the molar ratio of (1:1)-(1.5:1); high-vacuum heat treatment: placing high-purity Si and C powder into a crucible, placing the crucible in a heating furnace, vacuumizing a growth chamber of the heating furnace to be below 9*10<-4> Pa, increasing the temperature to 600-1300 DEG C and maintaining the temperature for more than 2 h; inert gas cleaning: charging a high-purity inert gas under first specified pressure into the growth chamber, maintaining for more than 1 h, vacuumizing the growth chamber to be below 9*10<-3> Pa once again, and repeating the procedure more than twice; and high-temperature synthesis: in the present of high-purity inert gas under a second specified pressure, reacting for more than 2 h at the reaction temperature of 1500-2500 DEG C, and cooling to room temperature to obtain the high-purity silicon carbide powder with nitrogen content below 15 ppm.

Owner:上海上硅中试基地科技有限公司 +1

Method for hydrocracking of coked wax oil

The invention provides a method for hydrocracking of coked wax oil, which comprises: contact reaction of raw materials, hydrogen and a hydrogenation protection catalyst under the condition for hydrogenation protection reaction, wherein oil in the raw materials is coked wax oil or mixed oil containing coked wax oil; contact reaction of products in the hydrogenation protection reaction, products ofhydrocracking reaction and a hydrogenation refining catalyst under the condition for hydrogenation refining reaction; separation of light distillates, intermediate distillates and heavy distillates with initial boiling points being 350-360 DEG C from products of the hydrogenation refining reaction; and contact reaction of the heavy distillates with the initial boiling points being 350-360 DEG C and a hydrocracking catalyst under the condition for hydrocracking reaction, thereby obtaining products of the hydrocracking reaction. The method of the invention prolongs the operating cycle of the device, the consumption of the hydrocracking catalyst is low, and the yield of the intermediate distillates in the products is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrorefining catalyst and preparation method thereof

ActiveCN106179380AHigh active site densityEvenly dispersedMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsNitrogenAluminium oxide

The invention discloses a hydrorefining catalyst and a preparation method thereof. The catalyst is a bulk phase hydrorefining catalyst, and comprises alumina and hydrogenation active metal components W, Ni and Mo. The surface phase of the catalyst has the characteristics of high content of active metals, large density of active sites, uniform dispersion of the active metals, good coordination and cooperation among the active metals, and high utilization rate of the active metals, and the catalyst has the characteristics of reasonable pore structure, high mechanical strength and high hydrodesulfurization and hydrodenitrogenation reaction performances, and is especially suitable for being applied to ultra deep hydrodesulfurization and nitrogen removal reaction of diesel oil fraction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Vacuum induction smelting method for nickel-based superalloy

The invention discloses a vacuum induction smelting method for nickel-based superalloy, comprising the steps of firstly, sequentially arranging raw materials from bottom to top in a crucible according to the order of Ni, Fe, C and Mo or Mo, Fe and Ni, melting and smelting; carrying out primary refining after completely melting the materials in a furnace and calming the surface of a melt; then, adding a strong nitride into the melt to form an element for secondary refining; and finally, adding a micro and easily-volatilized element, stirring until completely melting microalloy, and then, pouring to finish alloy smelting. The smelting method disclosed by the invention has an excellent denitrification effect; and compared with the existing method, the vacuum induction smelting method disclosed by the invention has the advantages that the nitrogen content of the nickel-based superalloy prepared by using the method is remarkably reduced, so that the application field of the nickel-based superalloy is greatly widened.

Owner:西部超导材料科技股份有限公司

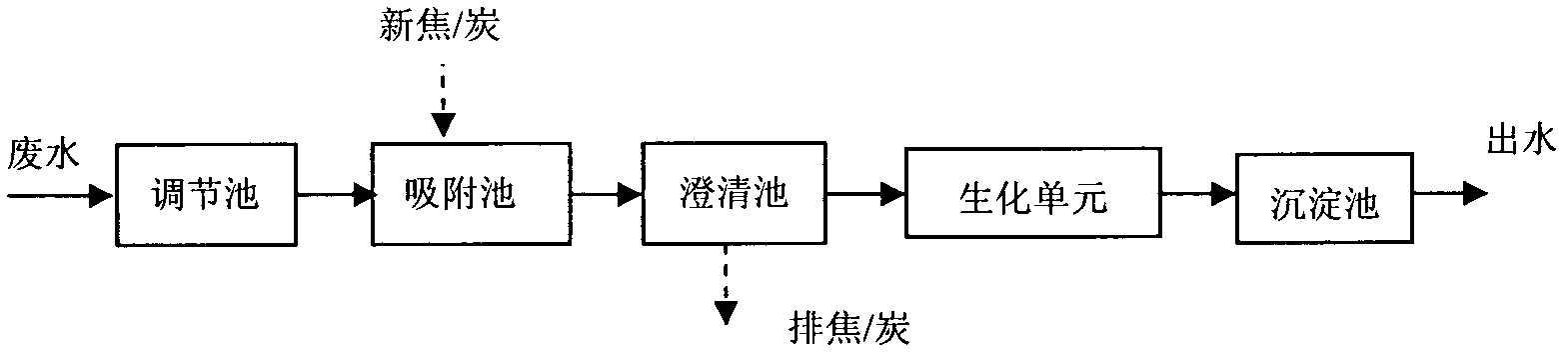

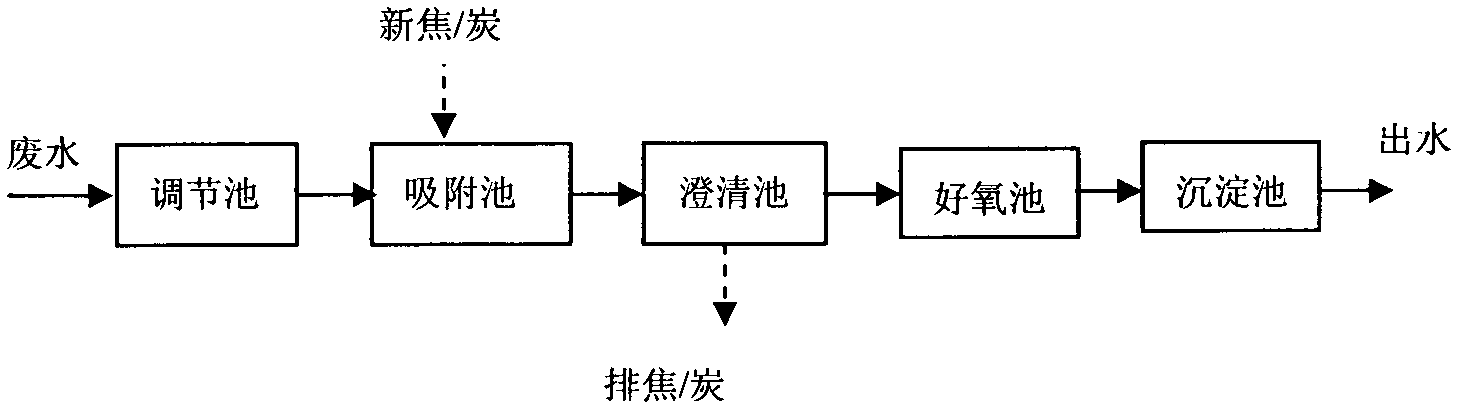

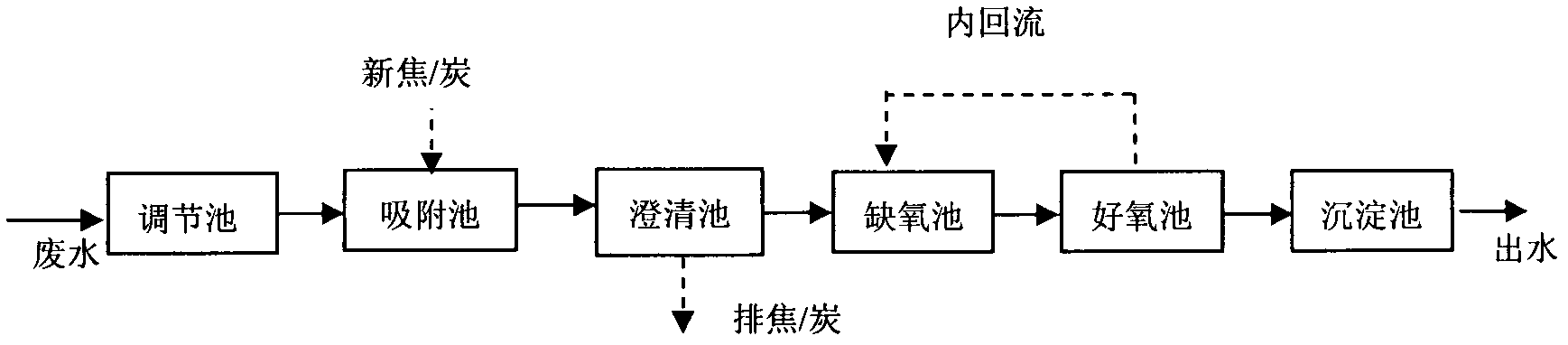

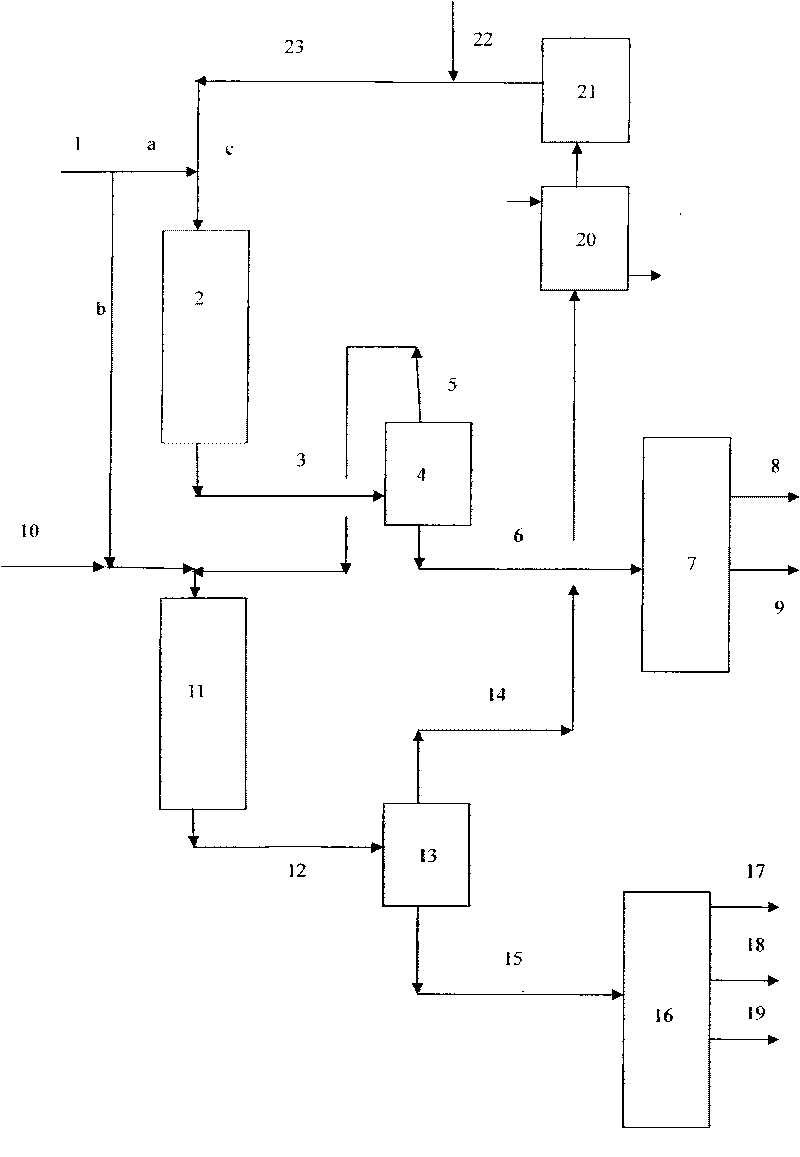

Process for treating coal chemical waste water

ActiveCN102001789AImprove biodegradabilityEasy to handleTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentActivated carbonActivated sludge

The invention relates to a process for treating coal chemical waste water, wherein a method combining active material adsorption and biochemical treatment is adopted. The method comprises the following steps of: firstly, introducing coal chemical waste water in a waste water regulating reservoir; secondly, introducing the waste water subjected to adsorption treatment by an adsorption tank into a clarification reservoir for sedimentation; then introducing the waste water subjected to the treatment of the clarification reservoir into a biochemical unit for biochemical treatment; and finally, introducing the waste water subjected to the biochemical treatment into a sedimentation reservoir for sedimentation treatment. In the technical scheme, macromolecular organic pollutants are removed through adsorption, therefore, the requirement of the subsequent biochemical treatment is met, and the problems of insufficient utilization of pores of activated carbon and incomplete exertion of the adsorbability of the activated carbon due to the influence of sludge when the activated carbon is added into an activated sludge aeration tank in the prior art are solved; and the process for treating coal chemical waste water has high efficiency and can sufficiently utilize the pores of the activated carbon and ensure the full exertion of the adsorbability of the activated carbon.

Owner:北京国能普华环保工程技术有限公司 +1

Coated low-nitrogen sand and its prepn

ActiveCN101088659AReduce usageReduce nitrogen contentFoundry mouldsFoundry coresLow nitrogenTetramine

The present invention discloses one kind of coated low-nitrogen sand and its preparation process. The coated low-nitrogen sand consists of phenolic resin 1.5-4.0 wt% of the material, hexamethylene tetramine in 0-6 wt% of the phenolic resin, lubricant in 3-7 wt% of the phenolic resin, and raw sand for the rest. It has greatly lowered hexamethylene tetramine consumption, low nitrogen content and capacity of ensuring the surface quality of the casting. During its heated formation, the thermosetting phenolic resin can speed the curing, raise the hardening rate and raising the hot strength of the sand mold.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

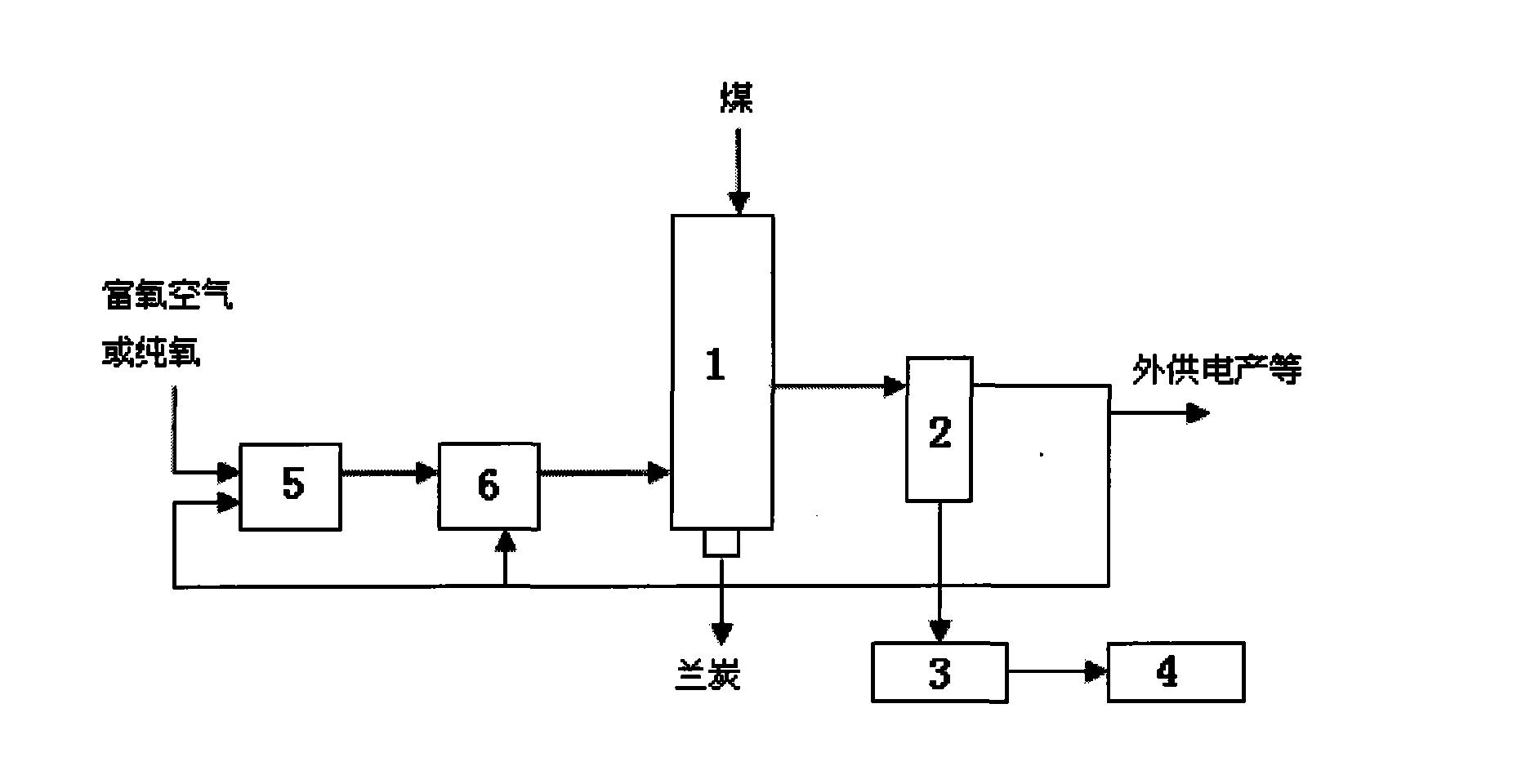

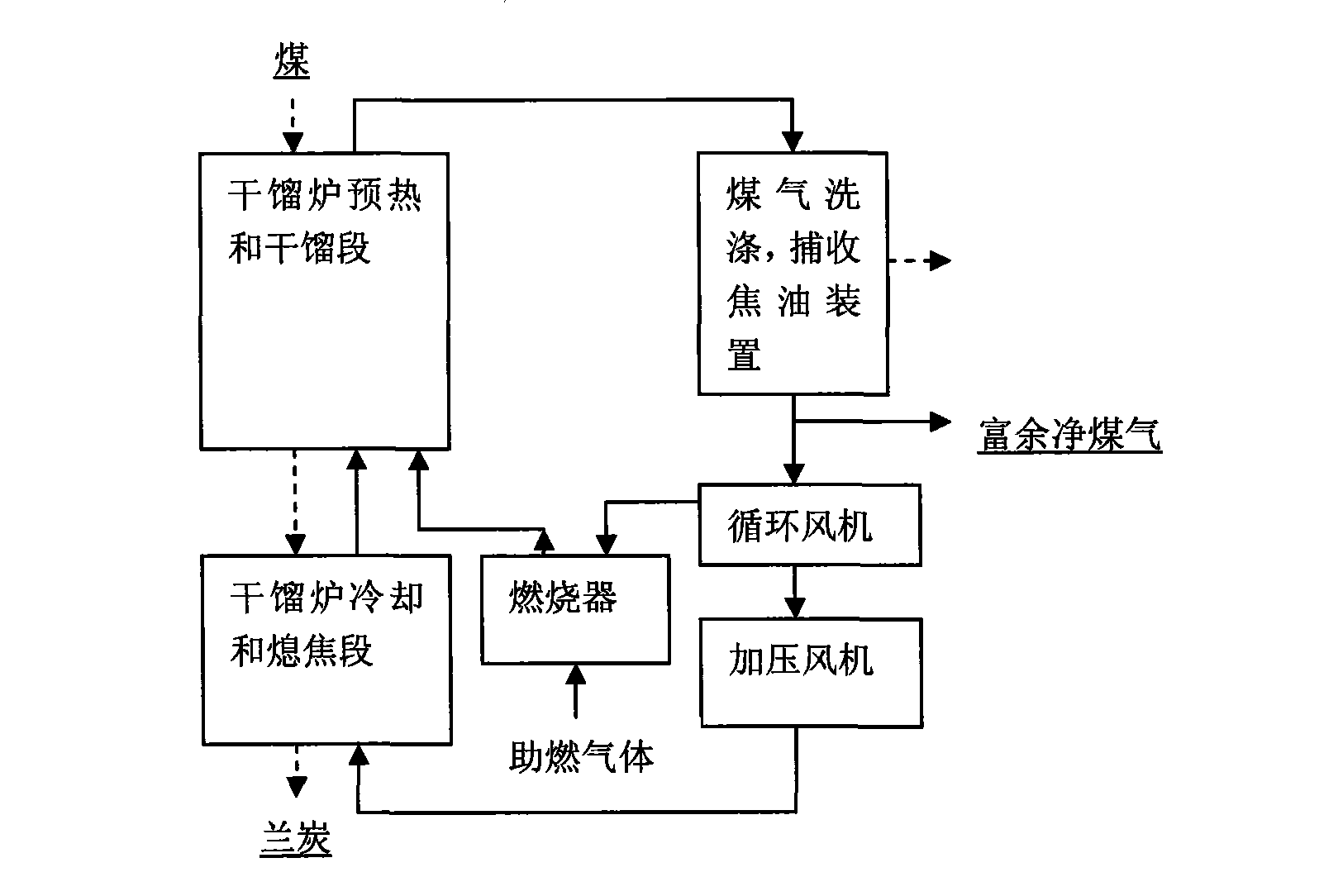

Method for coke dry quenching by coal internal heat smouldering

InactiveCN101514291ATake advantage ofImprove heat utilization efficiencyCoke quenchingIndirect heating destructive distillationCarbonizationQuenching

The invention discloses a method coke dry quenching by coal internal heat smouldering. In the method, high temperature carbonized coal gas produced by carbonized dry quenched coke is made into cool coal gas by washing and collecting tar; after the cool coal gas passes a circulating fan, part of the coal gas is introduced into a burner to be synthesized with high temperature waste gas into high temperature mixed gas satisfying the coal smouldering requirement; the high temperature mixed gas enters into a carbonization section of a coke oven to be used as a carbonization heat source; the other part of pure coal gas passing the circulating fan is introduced to a coke quenching and cooling section of a carbonization furnace by a booster fan to be used as an inertia medium of Ramsbottom coke and quenched coke; the cool coal gas passing the coke quenching and cooling section of the carbonization furnace absorbs the heat and then passes the carbonization section of the coke oven to carry out nonoxidation heating or weak-oxidation heating towards the coal together with the carbonization heat source to realize combustion-free circulation. The method simplifies the coke dry quenching technology, reduces the water content of the Ramsbottom coke, uses the heat of the Ramsbottom coke before coke quenching effectively, improves the utilization rate of the pure coal gas, reduces the use of combustion-supporting gas and accordingly reduces the energy consumption of the burner.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Delayed coking production method utilizing ethylene cracking tar as raw material

InactiveCN101608132AIncrease profitProcess operation impactThermal non-catalytic crackingKeroseneReaction temperature

The invention relates to a delayed coking production method utilizing ethylene cracking tar as a raw material. A delayed coking mixed raw material is formed by the ethylene cracking tar, vacuum residue and catalytic oil slurry according to the weight proportion of 1:1-100:0-10; a defoaming agent which accounts for 10 to 100 ppm of feeding weight is injected into the top of a coking tower; the feeding rate of a delayed coking device is between 1 and 10 kg / h; the temperature of a preheating section is between 360 and 380 DEG C; the reaction pressure of the top of the coking tower is between 0.1 and 0.3 MPa (meter); the reaction temperature is between 490 and 510 DEG C; and the recycle ratio is between 0.15 and 0.55. The method extends the source and variety of raw materials of delayed coking, ensures that the sulfur content and the nitrogen content of gasoline and kerosene produced by the delayed coking device are reduced, the sulfur content and the metal content of wax oil and coke are reduced, the yield is not affected, the yield of the coke is increased, and any adverse effect on the process operation of the delayed coking device cannot be produced.

Owner:PETROCHINA CO LTD

Method for producing tire cord steel wire by converter billet continuous casting process

ActiveCN102534094AGuaranteed surface qualityLow costManufacturing convertersMetal rolling arrangementsSlagSilicon alloy

The invention relates to a method for producing a tire cord steel wire according to a converter billet continuous casting process and belongs to the technical field of production of tire cord steel wires in the field of ferrous metallurgy. The method comprises the following process steps: desulfurizing by pre-treating molten iron, namely desulfurizing by spraying magnesium on a foundry ladle; smelting by using a converter, namely deoxidizing and alloying, modifying steel ladle slag, re-carburizing the molten iron and adding low-alkalinity pre-melted slag into the steel ladle after tapping; adding ferro-silicon alloy, manganese iron alloy and micronitrogen carburant in the tapping process and re-carburizing; and in the refining process and after the refining is finished, rolling the wire at high speed by adopting a two-stage steel ladle bottom blowing argon system and adopting billet continuous casting of 130mm*130mm or 160mm*160mm. The method has the advantages that: the production isreduced; the production efficiency is improved; and the method is particularly suitable for development and production of tire cord steel products in steel enterprises without big billet or rectangular billet continuous casting and without vacuum treatment equipment.

Owner:SHOUGANG CORPORATION

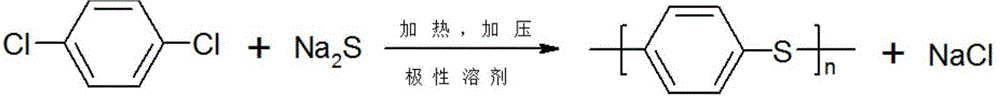

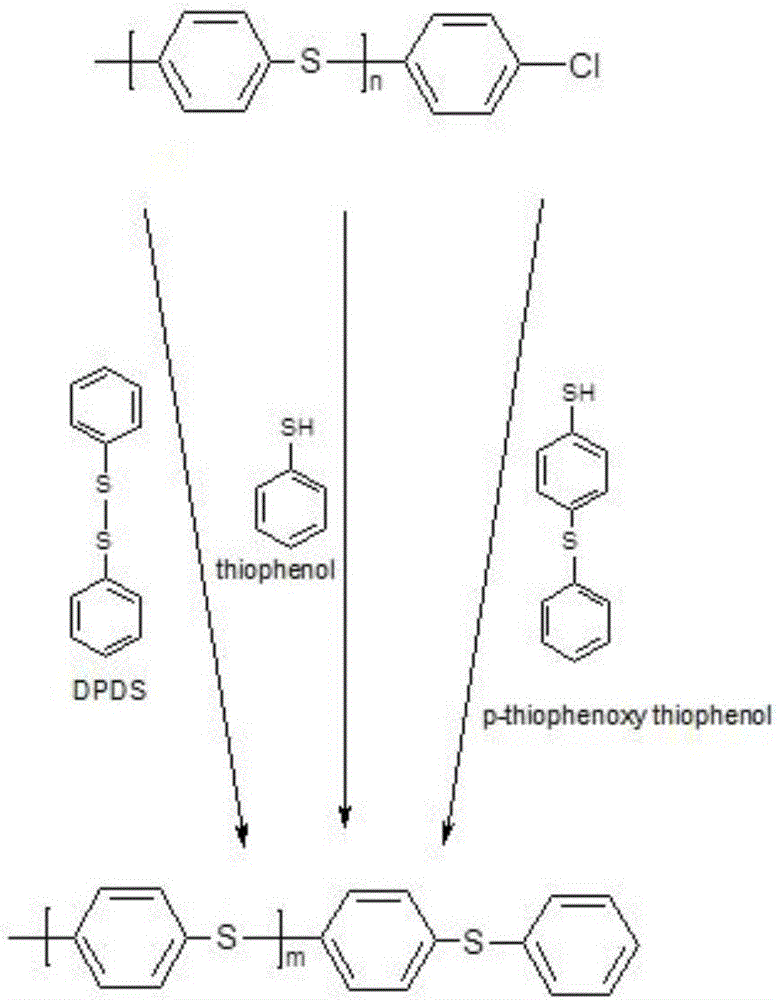

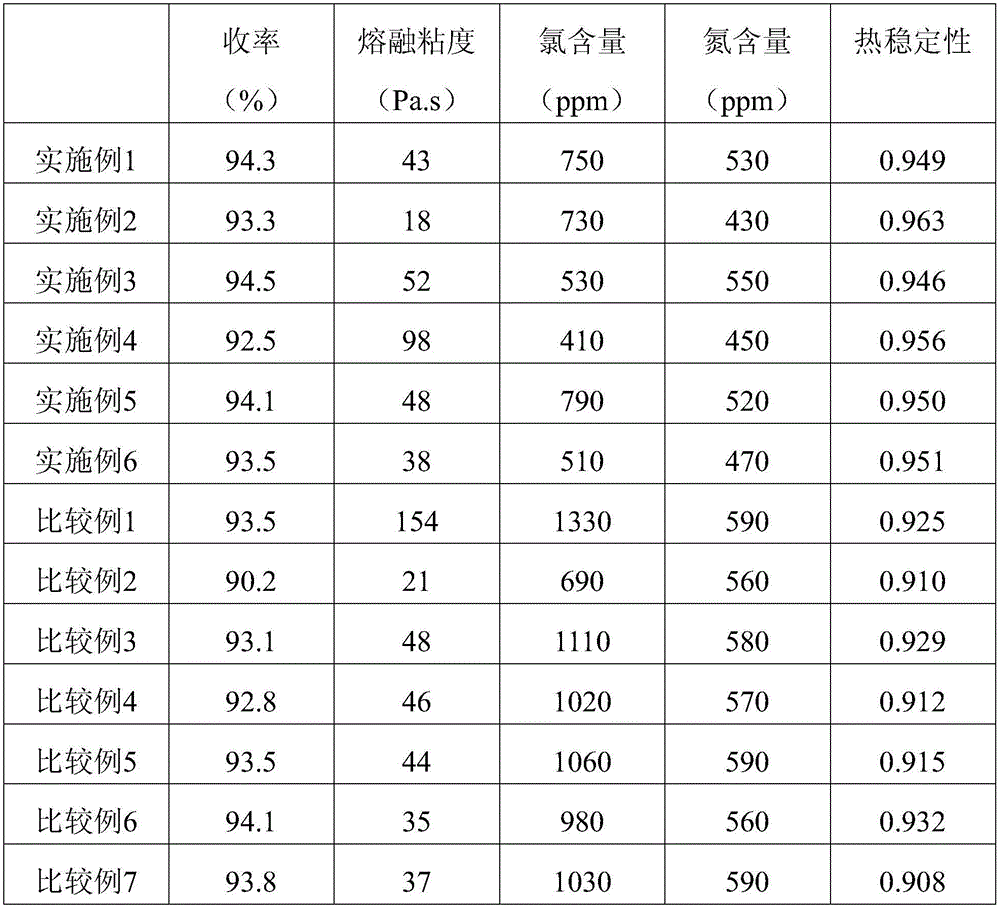

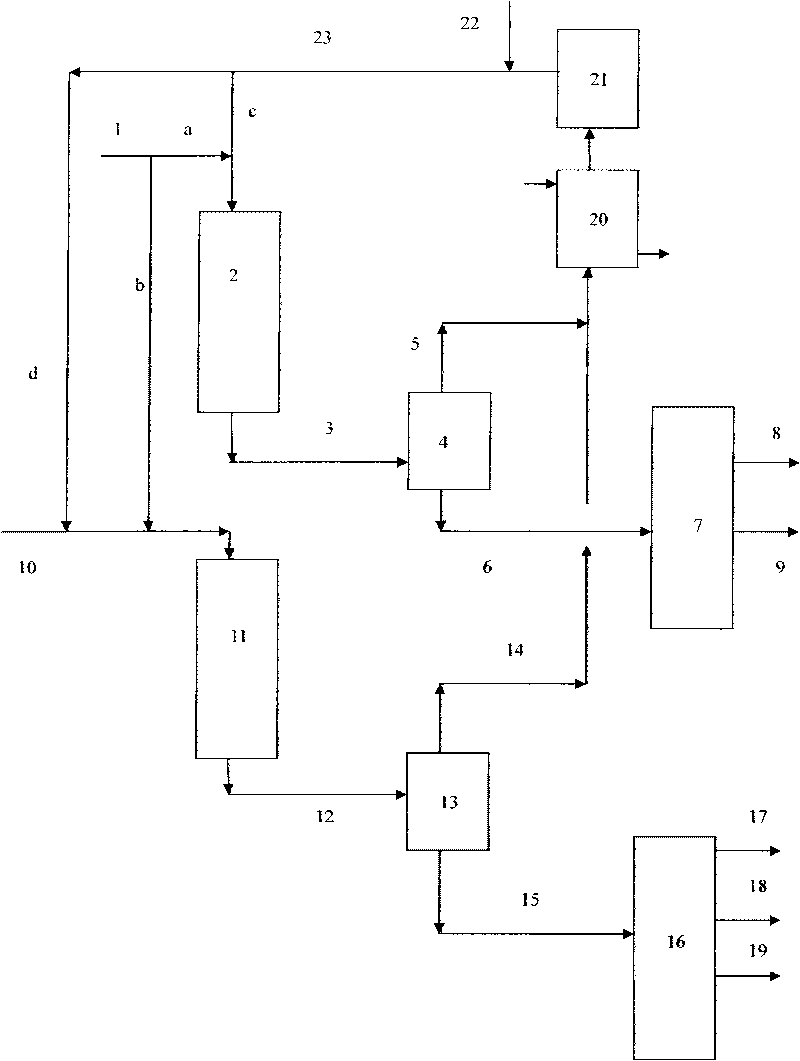

Polyphenylene sulfide with low chlorine content, preparation method of polyphenylene sulfide, resin composition and formed body

ActiveCN106633062AGood environmental friendlinessExcellent fluidity and thermal stabilitySulfur containingEthyl Chloride

The invention discloses polyphenylene sulfide with low chlorine content, a preparation method of the polyphenylene sulfide, a resin composition and a formed body. The polyphenylene sulfide with low chlorine content is prepared by performing end-capping 4-thiophenyl-benzenethiol. The method for preparing the polyphenylene sulfide disclosed by the invention comprises the following steps: taking a sulfur-containing compound, an alkaline matter and paradichlorobenzene as raw materials, taking fatty acids as polycondensation additives, taking 4-thiophenyl-benzenethiol (PTT) as an end group regulator, and carrying out a condensation polymerization reaction. The method disclosed by the invention is high in product yield and low in cost, the obtained polyphenylene sulfide product is low in chlorine content and has excellent fluidity and heat resistance. Therefore, the operating requirements of low chlorine and high fluidity in electronic enterprises can be met.

Owner:ZHEJIANG NHU SPECIAL MATERIALS +2

Hydrogenation combined method for diesel oil

ActiveCN101724457ADeep modificationReduce cokingTreatment with hydrotreatment processesHydrogenCombined method

The invention discloses a hydrogenation combined method for diesel oil, which comprises the following steps: dividing a straight-run diesel oil raw material and / or a coking diesel oil raw material into two parts of materials, performing hydro-upgrading reaction on one part of the material after being mixed with a catalytically cracked diesel oil raw material, and performing hydro-refining reaction on the other part of the material. The hydro-refining reaction and the hydro-upgrading reaction share a set of hydrogen recycling system. The combined method of the invention meets the requirement of products with different amounts and quality by flexibly adjusting raw oil ratio of two reaction zones, reduces operating severity of a hydro-upgrading reaction zone and prolongs the operation cycle at the same time. In addition, the method of the invention simplifies the process flow, can decrease equipment and reduces investment and operation cost. The method is suitable for hydro-processes of various inferior-quality distillate raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

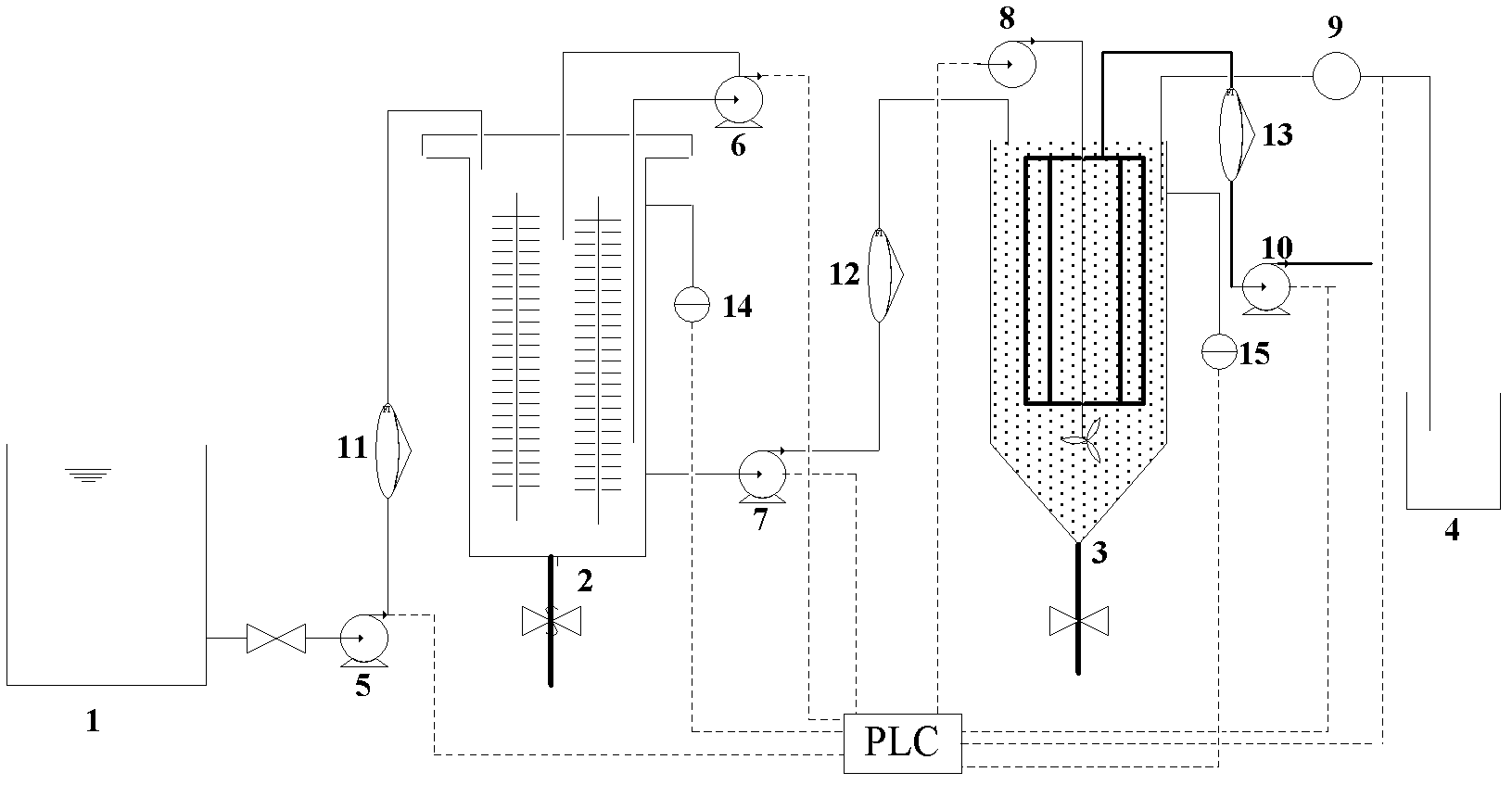

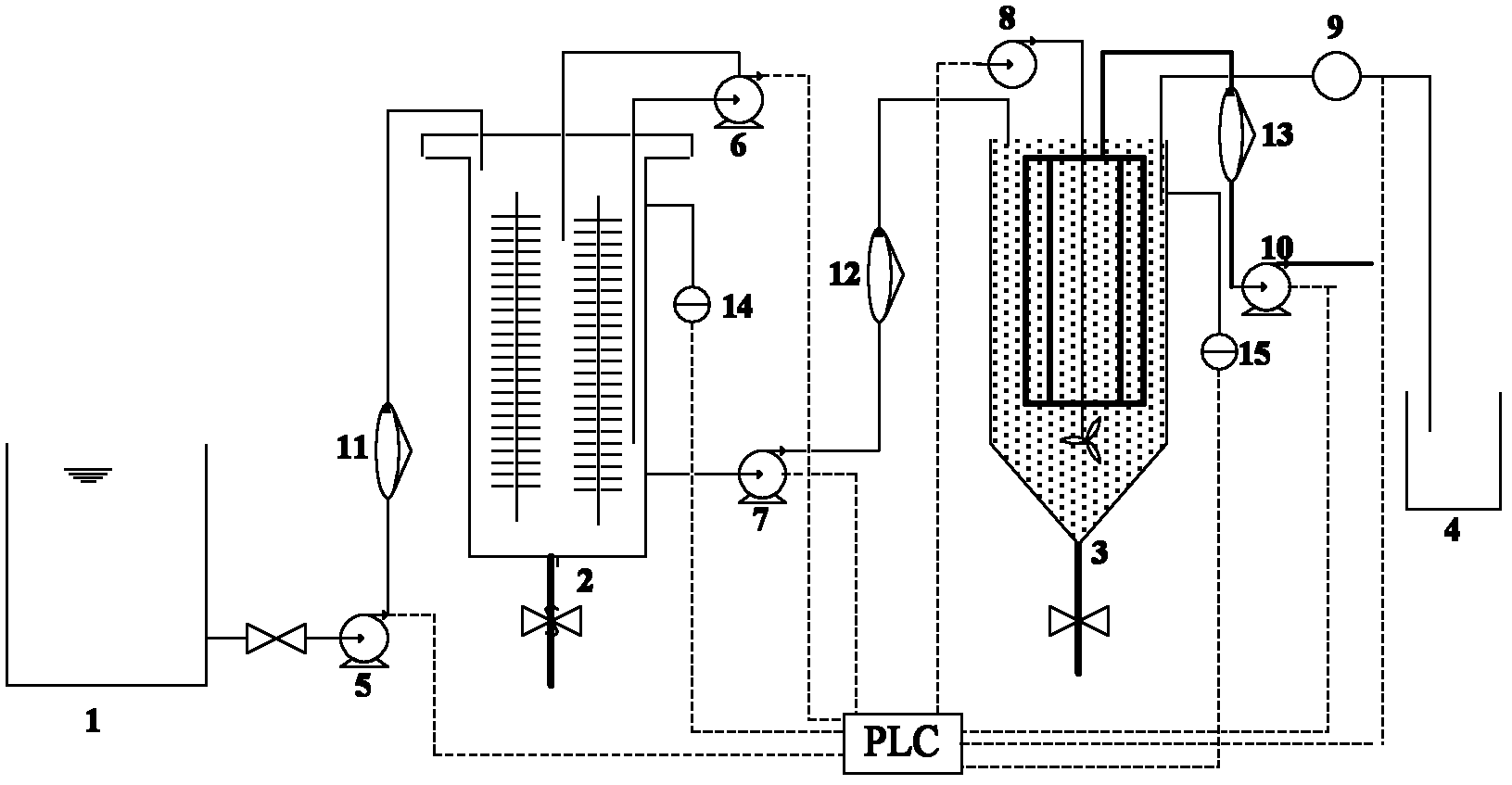

Method for treating organic nitrogen in sewage

ActiveCN102531300AInorganic nitrogen concentration decreasedReduce eutrophicationWater contaminantsWater/sewage treatment bu osmosis/dialysisFiberFiltration

The invention discloses a method for treating organic nitrogen in sewage. The method comprises the following steps of: treating sewage by using a sequencing batch biofilm reactor, decomposing macromolecular organic nitrogen into micromolecular organic nitrogen under the coexistence of anaerobic, anoxic and aerobic conditions, removing the micromolecular organic nitrogen by using the degradation of microbes, and simultaneously removing ammonia nitrogen and nitrate nitrogen through short-cut nitrification and denitrification and anaerobic ammonium oxidation; and treating by using a coagulation-microfiltration method, precipitating to remove bacteria, suspended solids (SS) and other nitrogen-containing substances by adding a coagulant, and removing refractory macromolecular organic nitrogen such as humic acid, fulvic acid and the like through filtration of a hollow fiber microfiltration membrane to reduce the total amount of the organic nitrogen in the sewage. The invention also discloses a device for implementing the treatment method.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

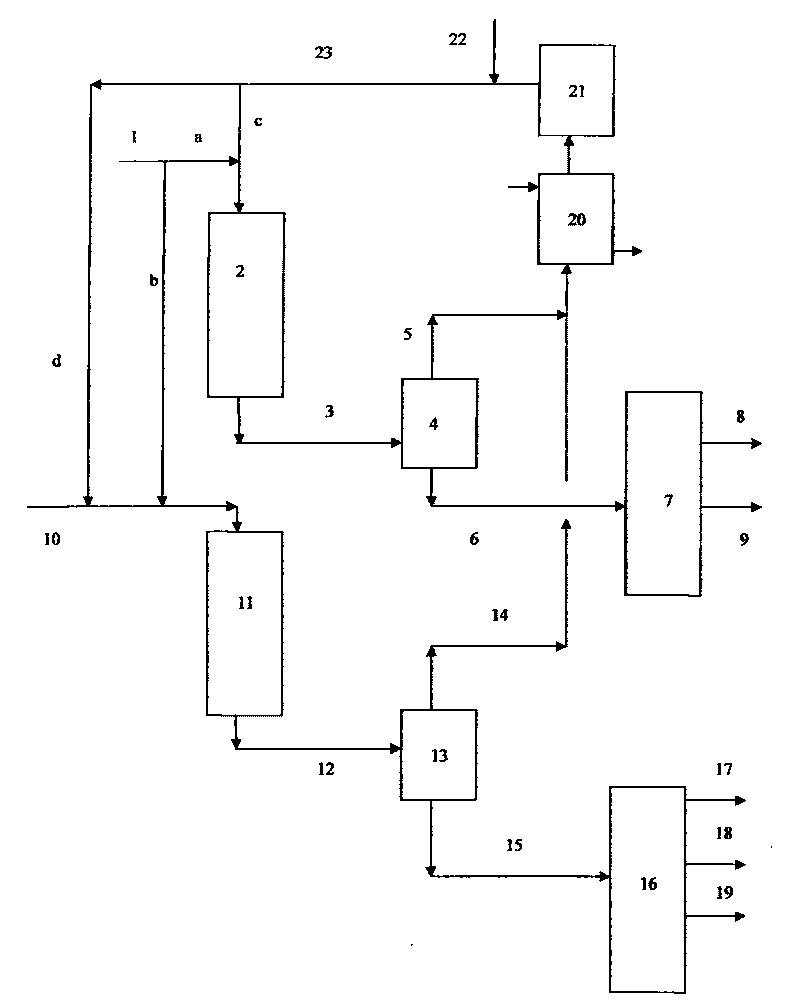

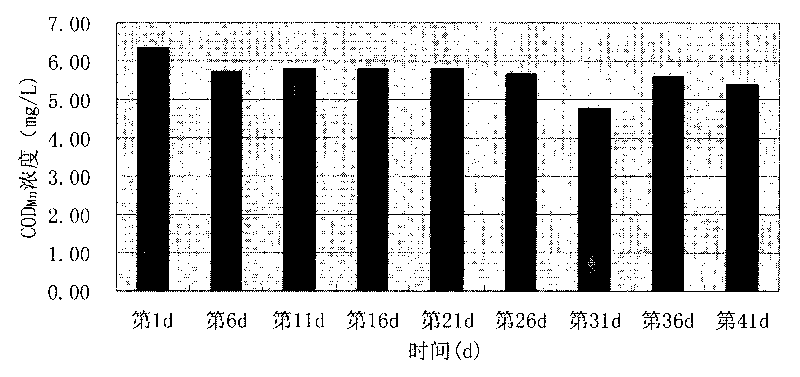

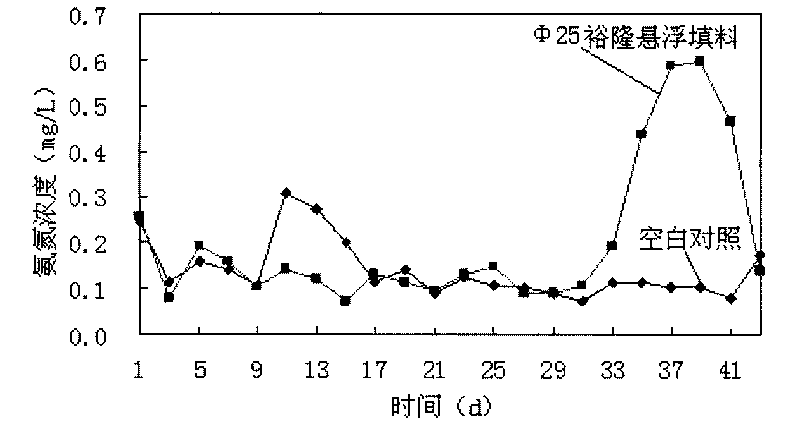

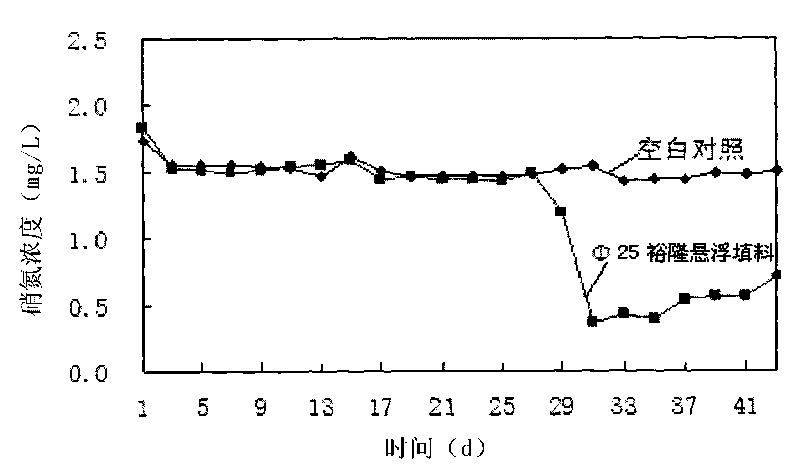

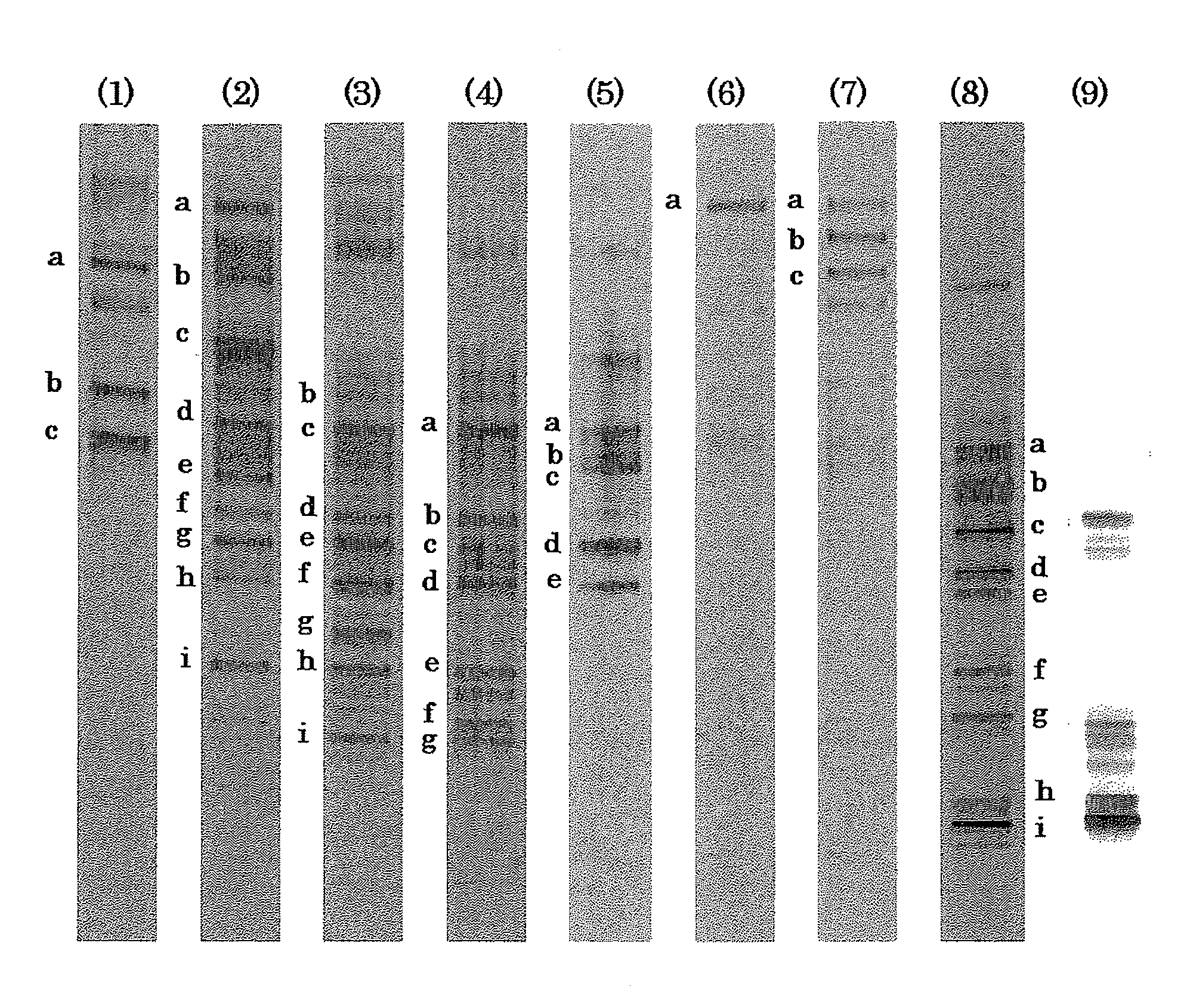

Method for restoring micro-scale polluted reservoir water by using situ bio-contact oxidation

ActiveCN101691547AReduce nitrogen contentRemoval of total nitrogen contentBacteriaMicroorganism based processesFiberEutrophication

The invention discloses a method for restoring micro-scale polluted reservoir water by using situ bio-contact oxidation. The method comprises the following steps: adopting fiber and sponge combined ball-type packings which are independently developed as carriers to perform screening, placing high effective strain which is obtained through screening in culture solution 'HS enrichment medium' to perform enrichment culture, then inoculating the strain which is through the enrichment culture in 'HSK culture medium' to perform expending cultivation and prepare biological microbial inoculum, placing packings in the microbial inoculum to perform biofilm formation and obtain biological immobilized packings; connecting the prepared biological immobilized packings with a string to fix the packings around the laboratory patented device water-lifting aerator of the invention and adopting water-lifting aeration-situ bio-contact oxidation to perform bioremediation to the micro-scale polluted reservoir water. The method of the invention can be used to effectively reduce the concentrations of COD, N, P and other pollutants in reservoir water and especially effectively lower the total nitrogen content of the micro-scale polluted reservoir water so as to fundamentally resolve the pollution problem of reservoir water, inhibit the growth of algae and control water eutrophication.

Owner:西安唯源环保科技有限公司

Method for controlling nitrogen content in steel by semi-steel smelting

InactiveCN102230051AReduce the amount of nitrogenReduce nitrogen contentManufacturing convertersFoaming agentLow nitrogen

The invention discloses a method for controlling nitrogen content in steel by semi-steel smelting. According to the invention, the method for controlling nitrogen content in steel by semi-steel smelting comprises the following steps of: performing oxygen top blowing by using a converter, performing slag-modifying treatment before tapping, and blocking the slag and tapping. In addition, according to the requirements steel on nitrogen content, different bottom-blowing modes are adopted in the oxygen top blowing process by converter, a foaming agent is added at the last stage of blowing, argon gas is blown to ladles 1 to 3 minutes before tapping, and the soft argon blowing operation is performed on ladles during the tapping step. By adoption of the method provided by the invention, the nitrogen content in steel at the converter end-point can be controlled to be within 11 ppm and the nitrogen increase can be controlled to be between 1ppm to 3 ppm during the tapping step. The method provided by the invention can effectively reduce the nitrogen content at the converter end-point and the nitrogen increase in the tapping step, thereby providing a technical support for the production of low-nitrogen steel and ultra-low nitrogen steel.

Owner:PANZHIHUA IRON AND STEEL +2

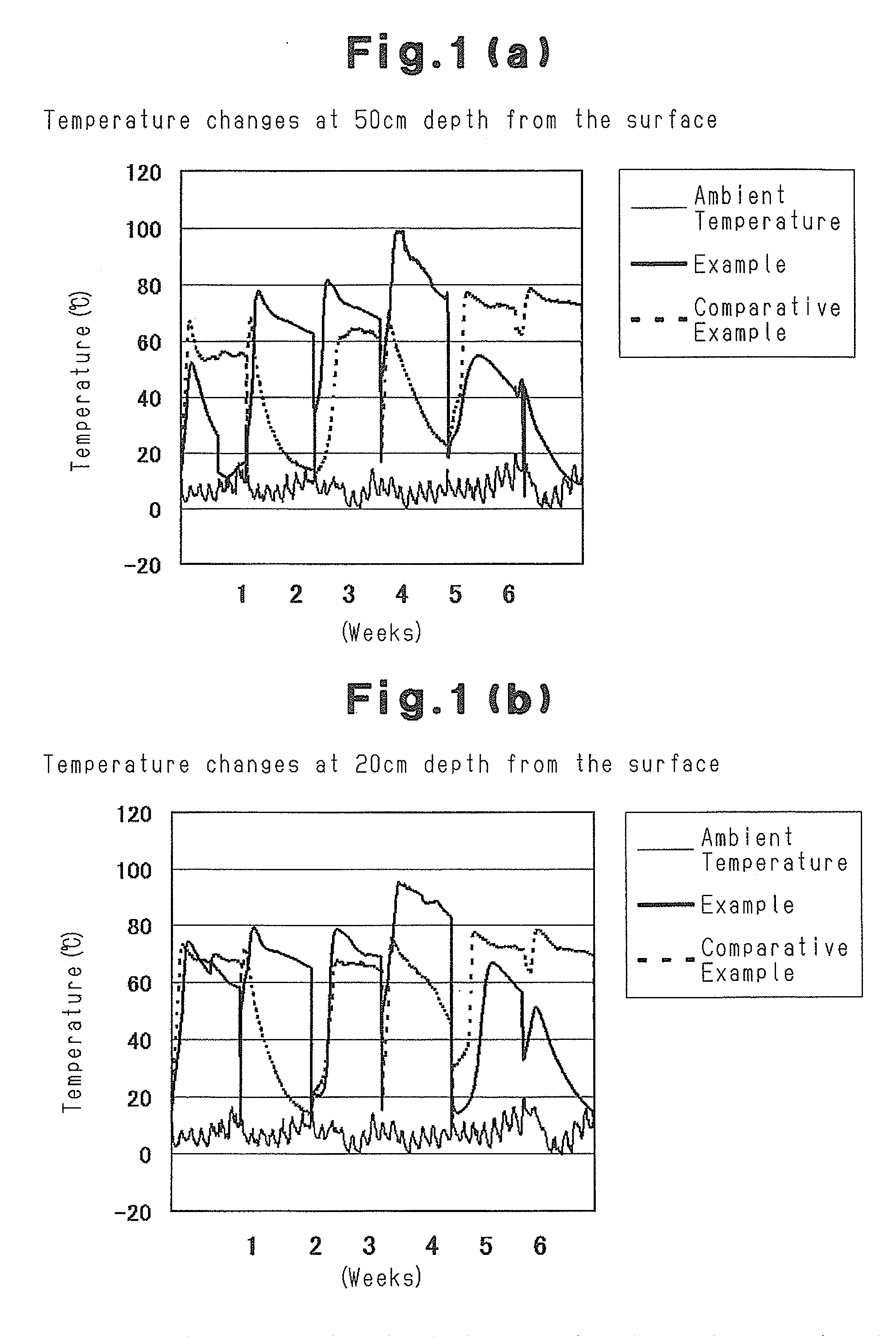

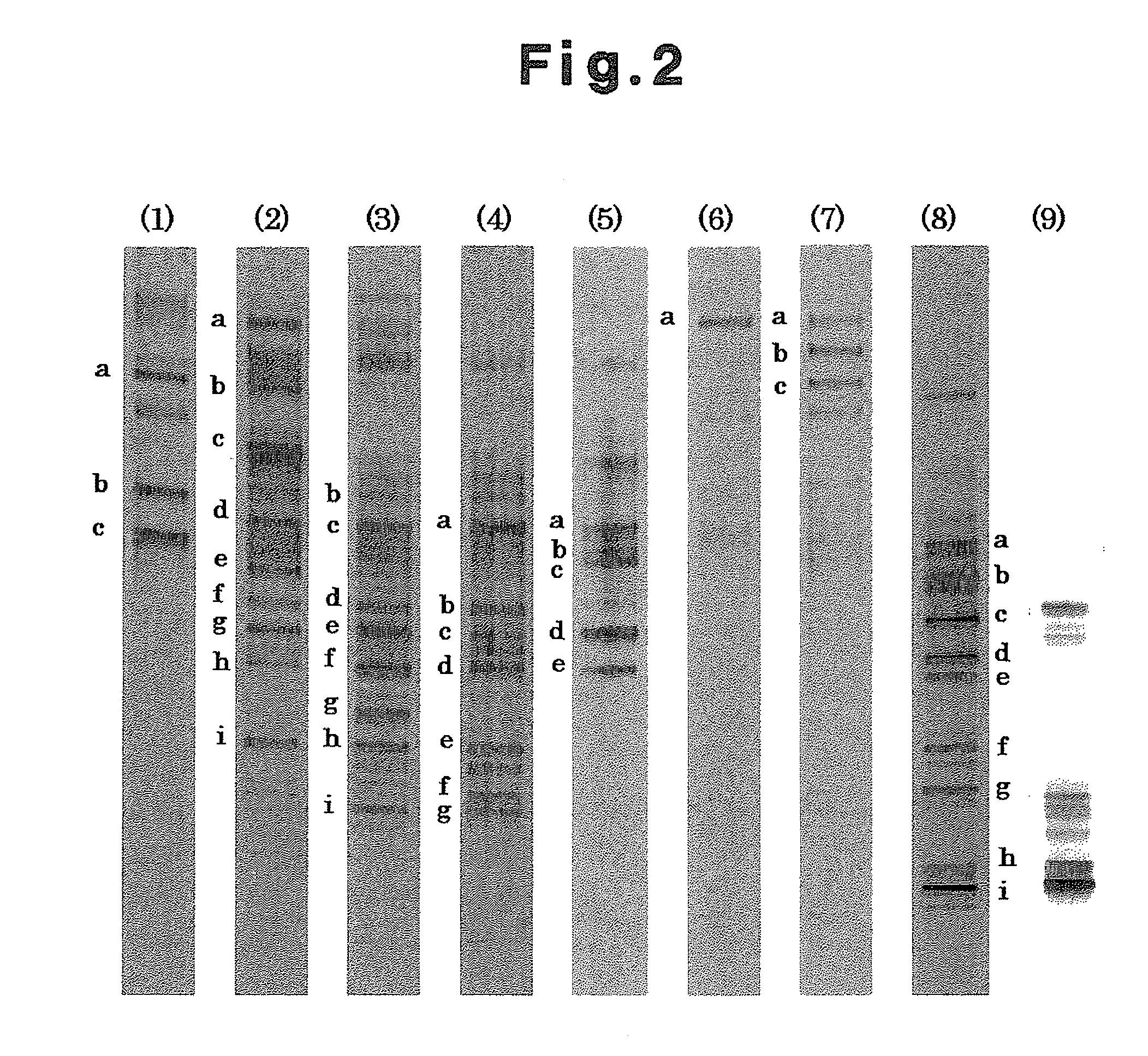

Method of treating biomass, compost, mulching material for livestock and agent for treating biomass

ActiveUS20090241623A1Inhibit productionReduce nitrogen contentBio-organic fraction processingBacteriaMicroorganismMedicine

The present invention provides a method of treating biomass that reduces water-polluting substances, suppresses the production of malodorous gases and greenhouse gases, decreases the nitrogen content in the compost or livestock bedding thus prepared, and furthermore, easily treats nitrogen-containing biomass in a short time at high temperature. The present invention also provides compost and livestock bedding produced by the method and a biomass treating agent. The method of treating biomass includes blending, with nitrogen-containing biomass, a Geobacillus microorganism having denitrification capability and a fermentation promoter that promotes the fermentation of the nitrogen-containing biomass by the Geobacillus microorganism.

Owner:TOYOTA JIDOSHA KK

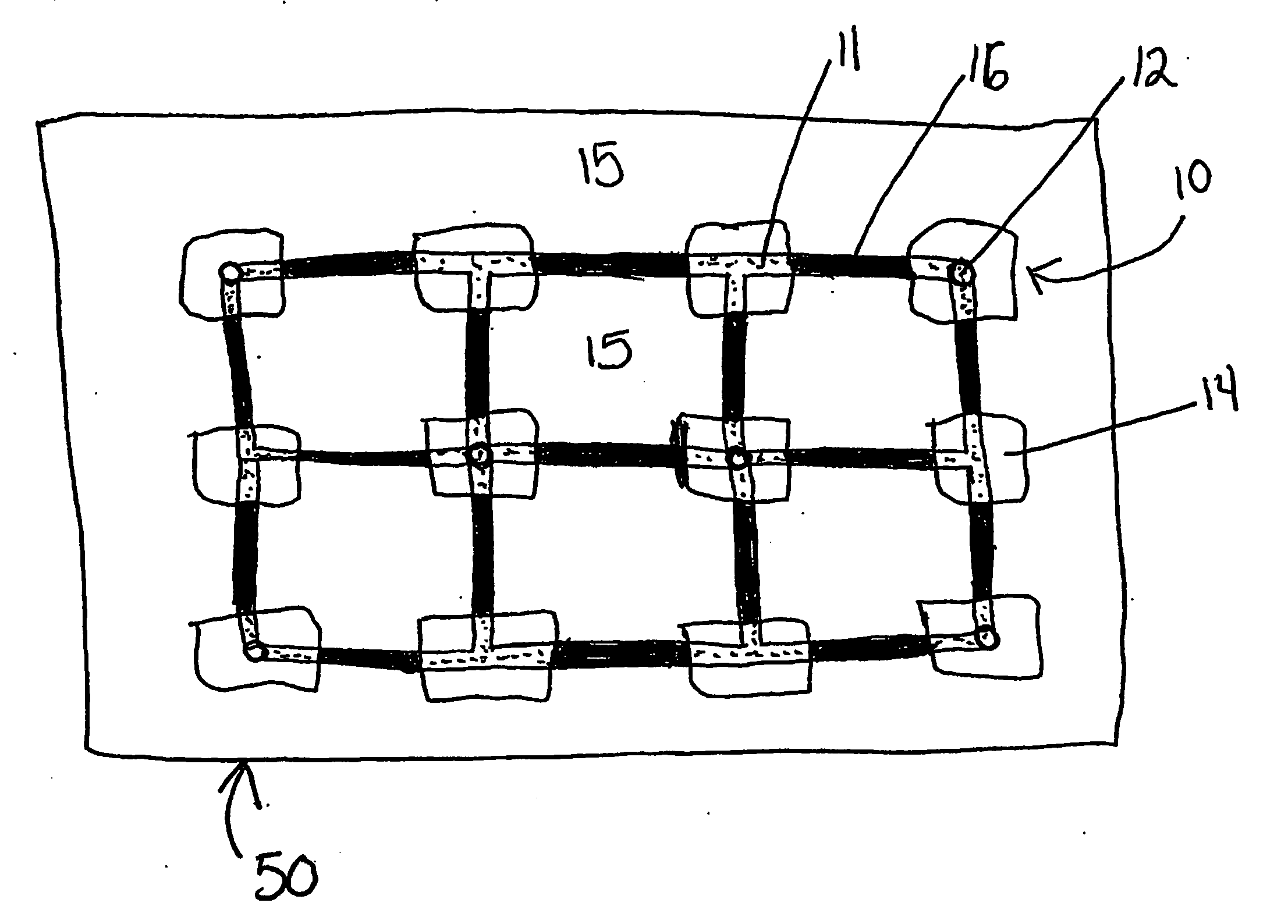

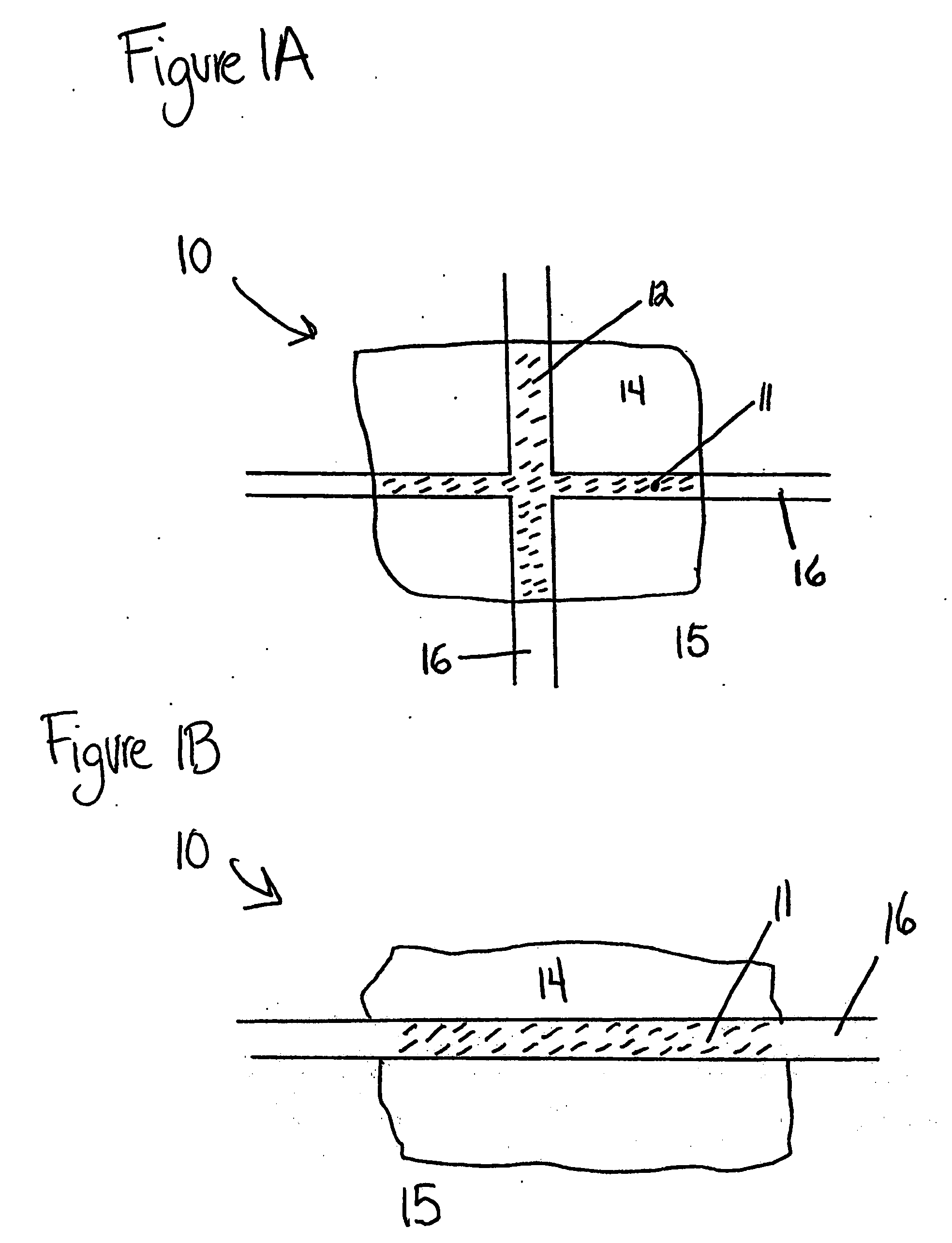

Aerobic and anaerobic waste management systems and methods for landfills

ActiveUS20060222464A1Promote degradationFast settlementSolid waste disposalContaminated soil reclamationDisposal wasteEnvironmental engineering

The invention provides systems and methods for creating, managing and staging aerobic and / or anaerobic landfills. The invention provides systems and methods for collecting liquids from and recirculating liquids into landfills and systems and methods for collecting gases from and introducing gases into landfills. The invention also provides a novel conduit for conveying liquids and gases which comprises a first pipe coaxially disposed within a second pipe.

Owner:CASELLA WASTE SYSTEMS

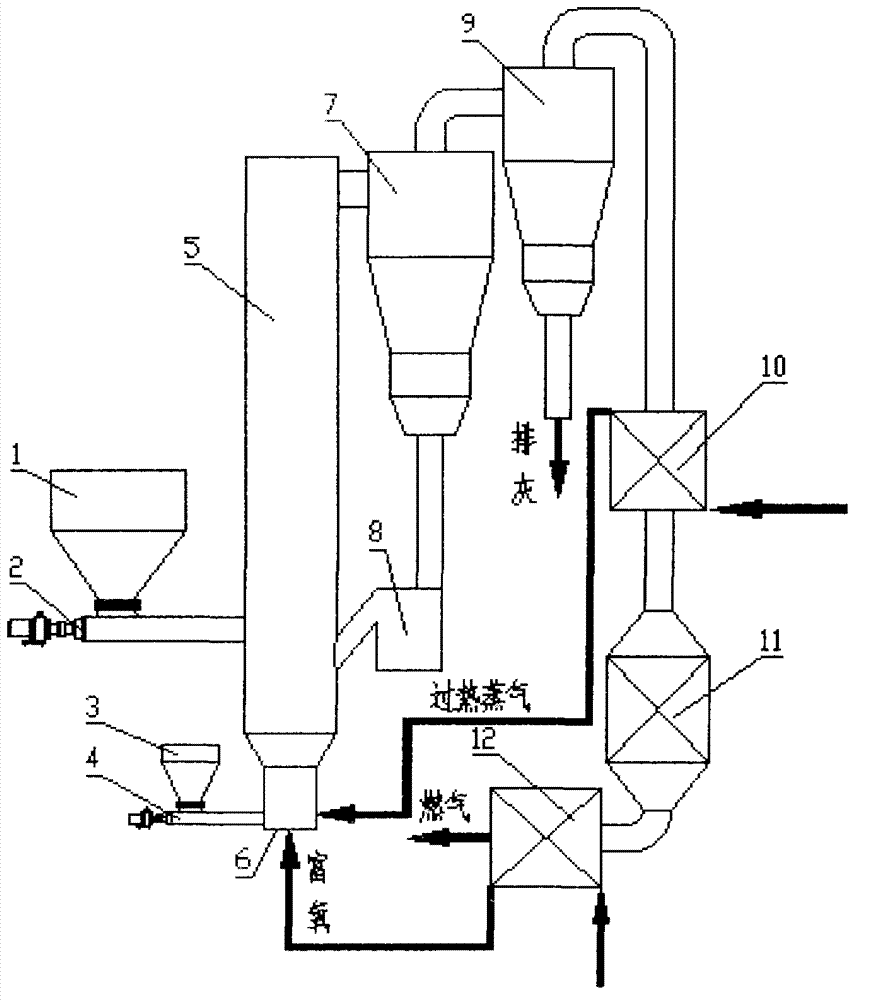

Gasification system of oxygen-enriched biomass circulating fluidized-bed

InactiveCN103205281AImprove stabilityImprove heat transfer performanceEnergy inputGranular/pulverulent flues gasificationSuperheaterCyclonic spray scrubber

The invention relates to a gasification system of an oxygen-enriched biomass circulating fluidized-bed. Biomass is fed from the middle-lower part of a gasification furnace, oxygen-enriched air preheated by a preheater and overheated water steam are fed from the bottom of the gasification furnace, the biomass is rapidly fluidized under the assistant action of a bed material to generate pyrolysis and gasification reactions, generated high-temperature fuel gas is subjected to gas-solid separation by using a cyclone separator, carbon residues in the fuel gas and the bed material are fed to the gasification furnace from the lower part of the gasification furnace by a material return device to continuously react, and the high-temperature fuel gas passes through a cyclone dust collector, a superheater, a waste heat boiler and the preheater in sequence and is then separated from the system. According to the gasification system, the volume fraction as well as the dust and tar concentration in the fuel gas can be effectively reduced, the heat value of the fuel gas is increased, and the high-quality clean fuel gas is obtained.

Owner:HEFEI DEBO BIOENERGY SCI & TECH

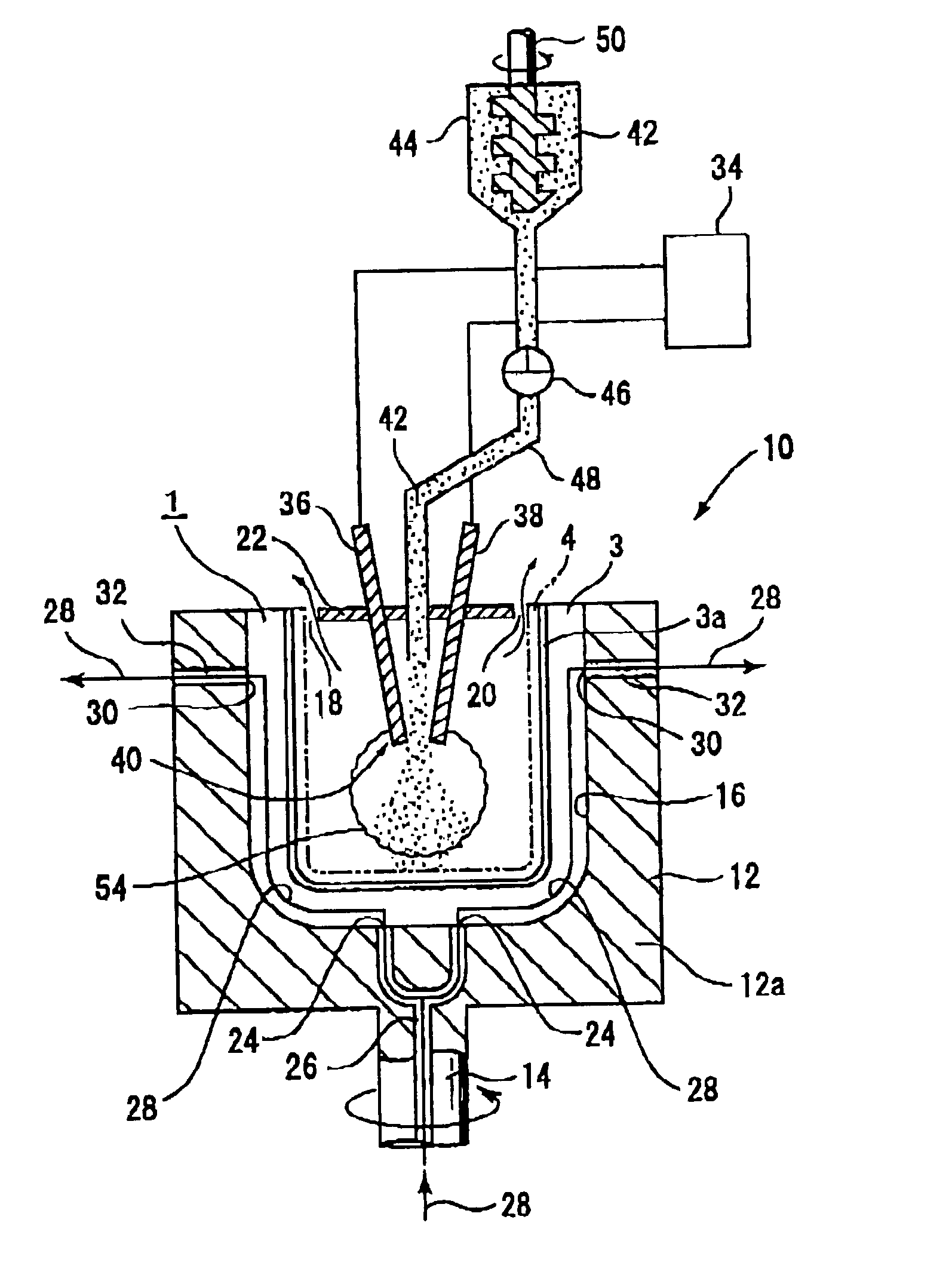

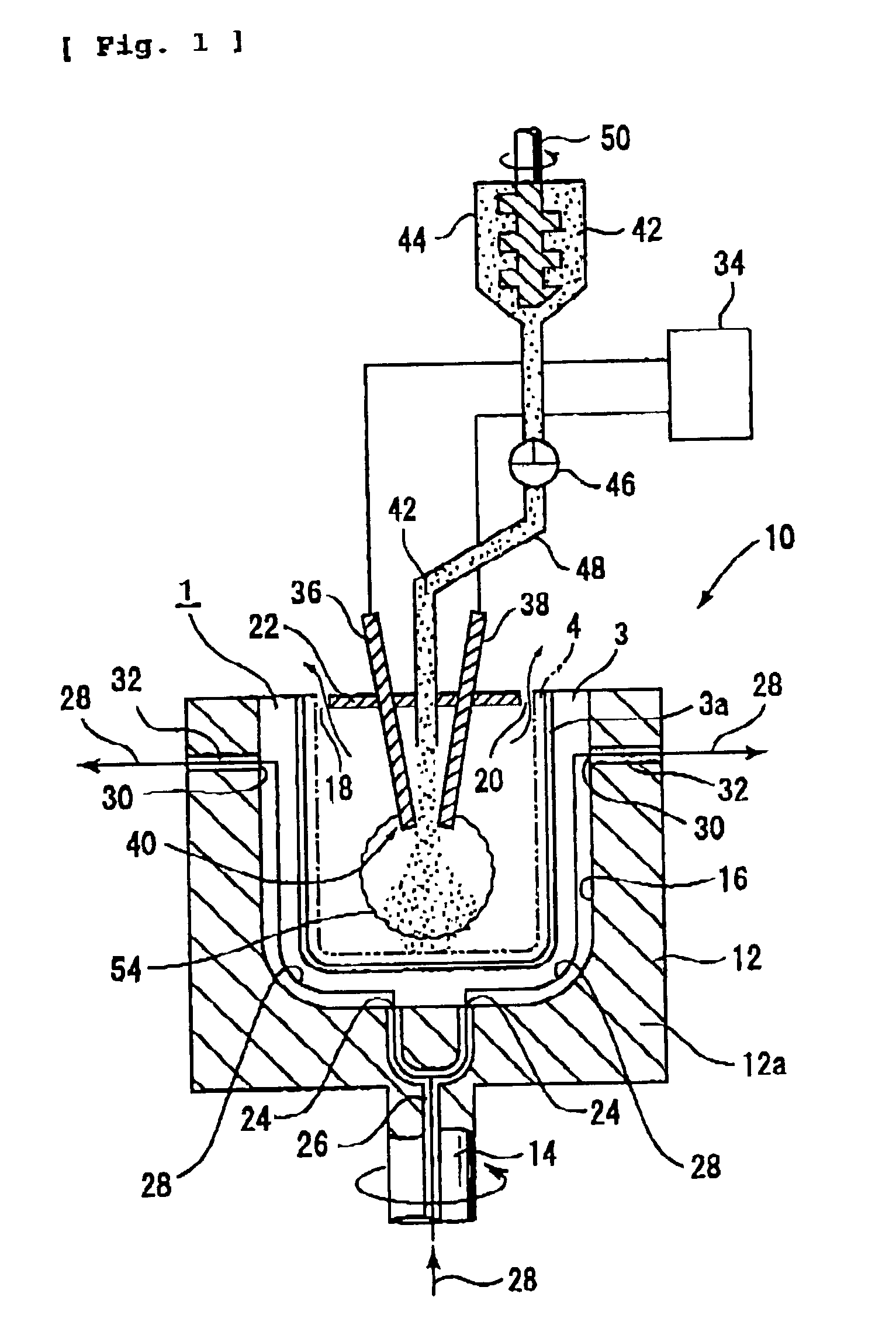

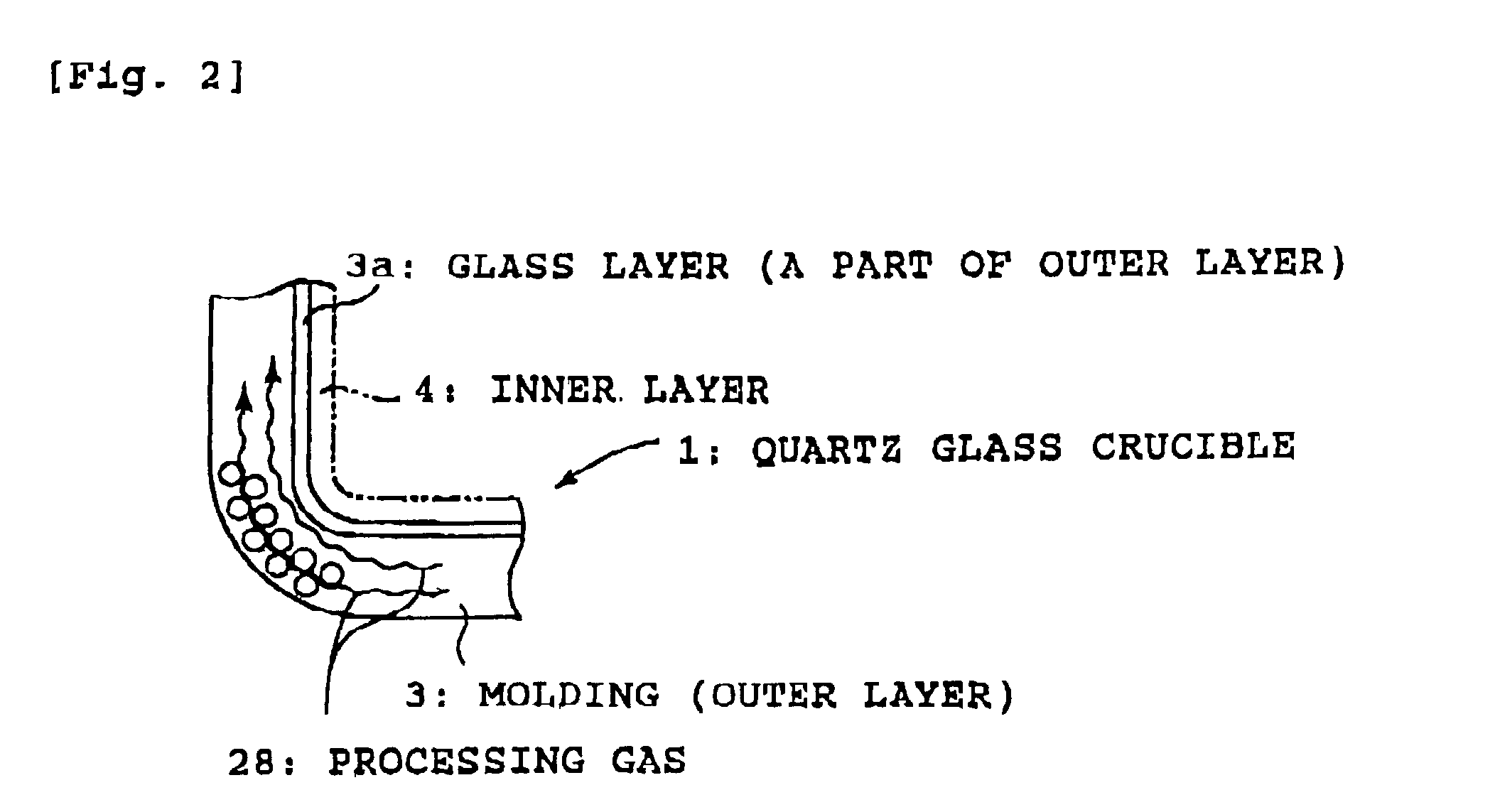

Method for producing a quartz glass crucible for pulling up silicon single crystal and apparatus

InactiveUS20030029195A1Reduce nitrogen contentLow oxygenPolycrystalline material growthBy pulling from meltCrucibleNitrogen

A method and an apparatus for producing a quartz glass crucible for pulling up a silicon single crystal capable of effectively reducing the content of bubbles by reducing the bubble diameters of the outer layer of the crucible are proposed. The method comprises the method step that during heat-melting of a porous outer molding a processing gas is supplied for flowing through the porous molding, whereby the processing gas preferably contains less nitrogen than air or less oxygen than air.

Owner:HERAEUS QUARZGLAS +1

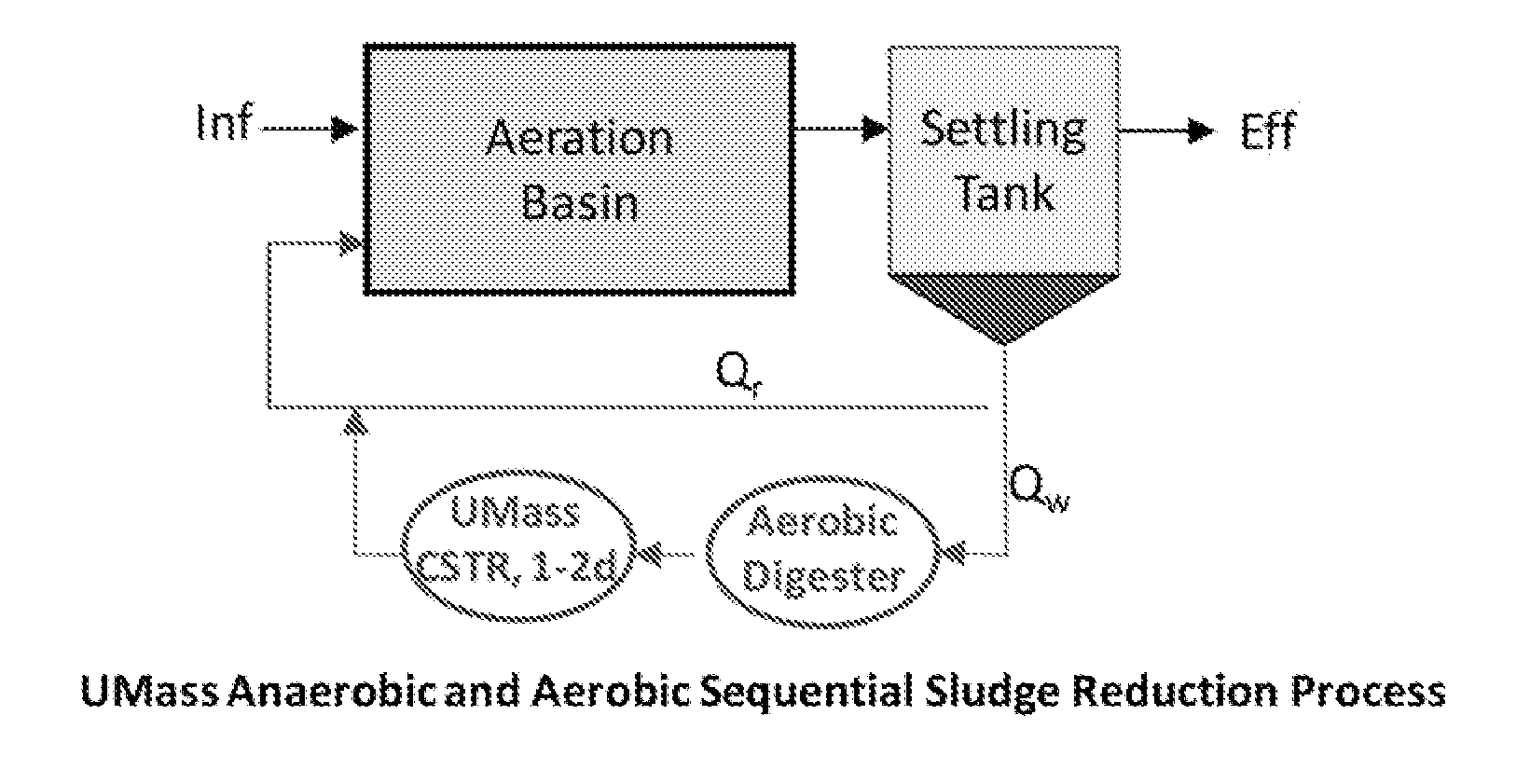

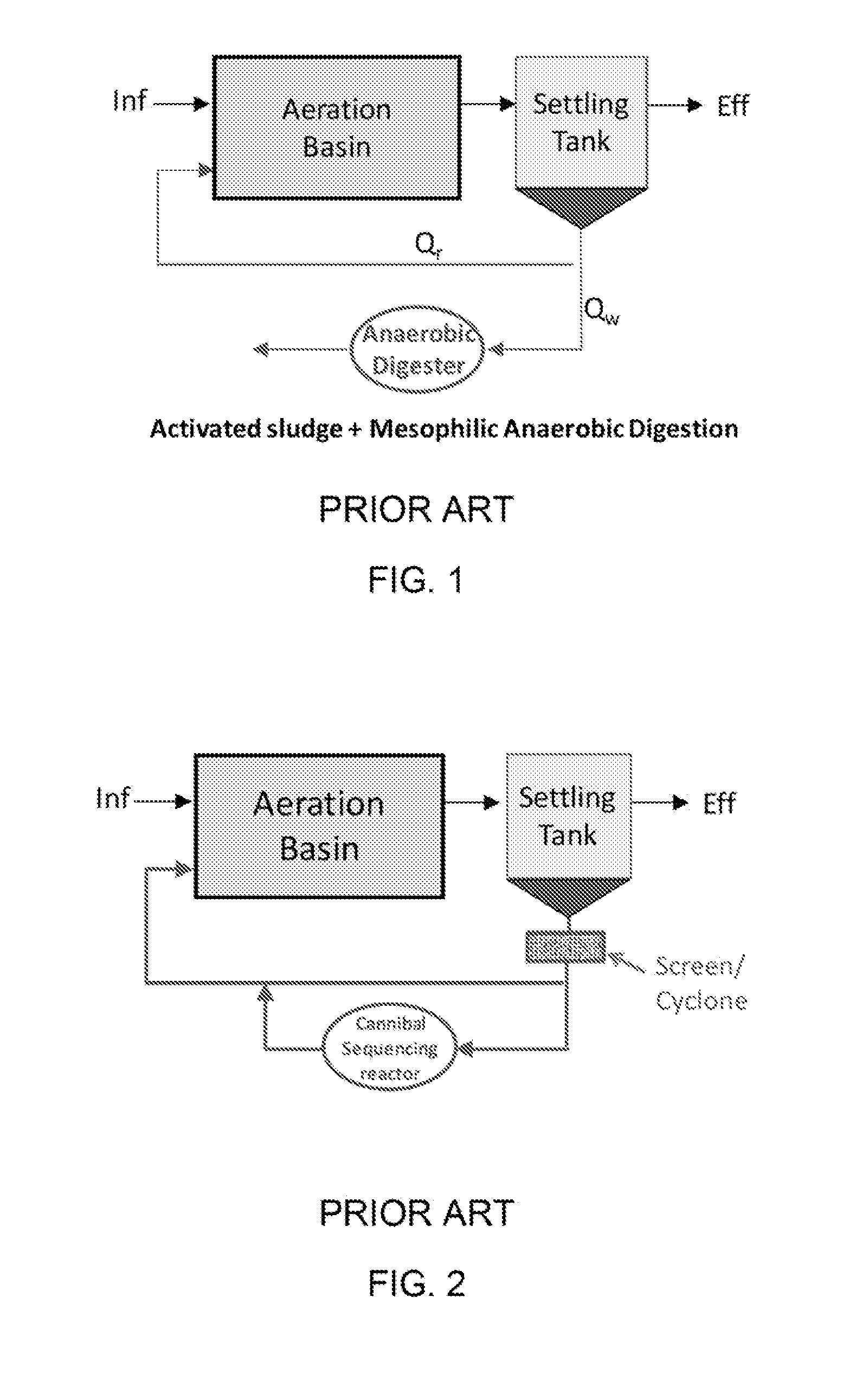

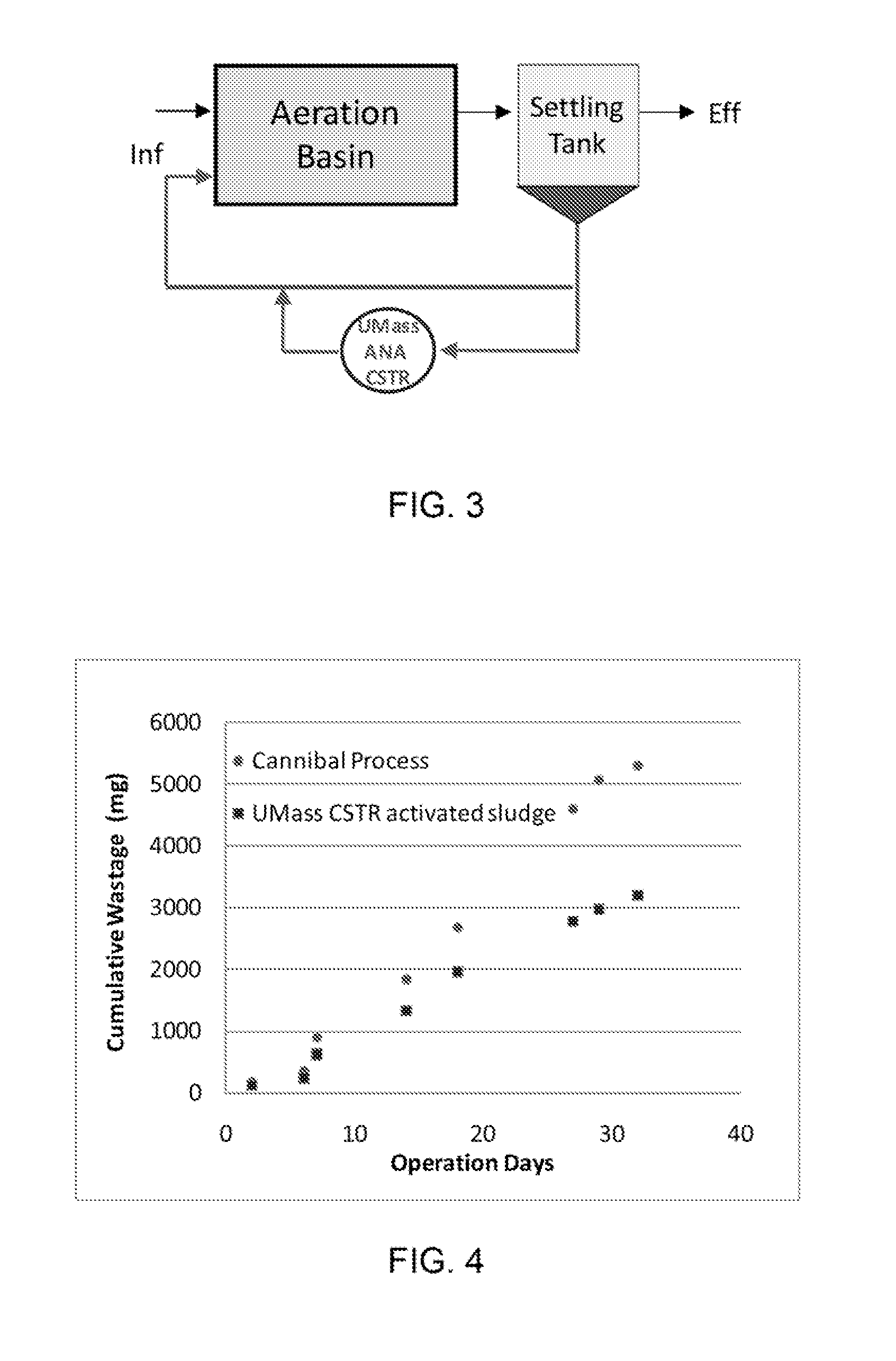

Method to reduce sludge generation in wastewater treatment systems

ActiveUS20120152812A1Reduce phosphorus contentReduce nitrogen contentSludge treatment by thermal conditioningWater/sewage treatment with mechanical oscillationsSludgeReactor design

The systems and methods described provide for reducing sludge generation, and thus sludge wasting and handling, by including an anaerobic completely stirred tank reactor (CSTR) as a bioreactor in a side-stream. The CSTR provides a significant simplification of side-stream treatment design, enhanced sludge minimization, and enhanced removal of nitrogen and phosphorous without the need to add organic carbon. The described systems and methods provide generation of biogas including both hydrogen and methane from the activated sludge system. The described systems and methods avoid complex reactor designs for nutrient removal.

Owner:UNIV OF MASSACHUSETTS

Hydrogenation catalyst carrier and production thereof

A carrier of hydrocatalyst for the hydrocracking of heavy oil, hydromodifying of poor diesel oil, etc is prepared from amorphour silicon aluminium, modified beta-molecular sieve and aluminium oxide. Its preparing process is also disclosed. Said catalyst has high catalytic activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Combined process for delayed coking and hydrotreating

ActiveCN101638588AOptimize processLess investmentTreatment with hydrotreatment processesWaxChemistry

The invention discloses a combined process for delayed coking and hydrotreating, which comprises the following steps that: a coking raw material is heated to enter a coking tower to react, oil gas escapes from the top of the coking tower, gas components and liquid components are separated, and the cycle ratio in a coking process is 0; and the liquid components are mixed with hydrogen to react in ahydrogenation reactor, then the obtained hydrogenated reaction effluent is distilled to obtain hydrogenated naphtha, hydrogenated diesel oil and hydrogenated wax oil, and the hydrogenated wax oil used as a high-quality raw material is fed into a catalytic cracking device or a hydrocracking device. By adopting the process flow of zero circulation of a coking device, the method provided by the invention furthest improves the yield of a liquid product, improves the processing depth of heavy oil, saves a coking fractionating tower, and achieves the aims of optimizing the flow and reducing the investment; and by adopting reasonable graduation of a hydrogenation catalyst, the method can furthest take account of the running period and the refining depth of each coking product fraction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com