Patents

Literature

50 results about "Paradichlorobenzene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A synthetic, white crystalline solid that is practically insoluble in water and soluble in ether, chloroform, carbon disulfide, benzene, alcohol and acetone. It is used primarily as a space deodorant in products such as room deodorizers, urinal and toilet bowl blocks, and as an insecticide fumigant for moth control. When 1,4-dichlorobenzene is heated to decomposition, toxic gases and vapors (such as hydrochloric acid and carbon monoxide) are released. The primary route of potential human exposure to this compound is inhalation. Acute inhalation exposure to 1,4-dichlorobenzene can result in coughing and breathing difficulties. Breathing high levels of this chemical can cause headaches, dizziness and liver damage. Contact with 1,4-dichlorobenzene can irritate the eyes, leading to burning and tearing. It is reasonably anticipated to be a human carcinogen. (NCI05)

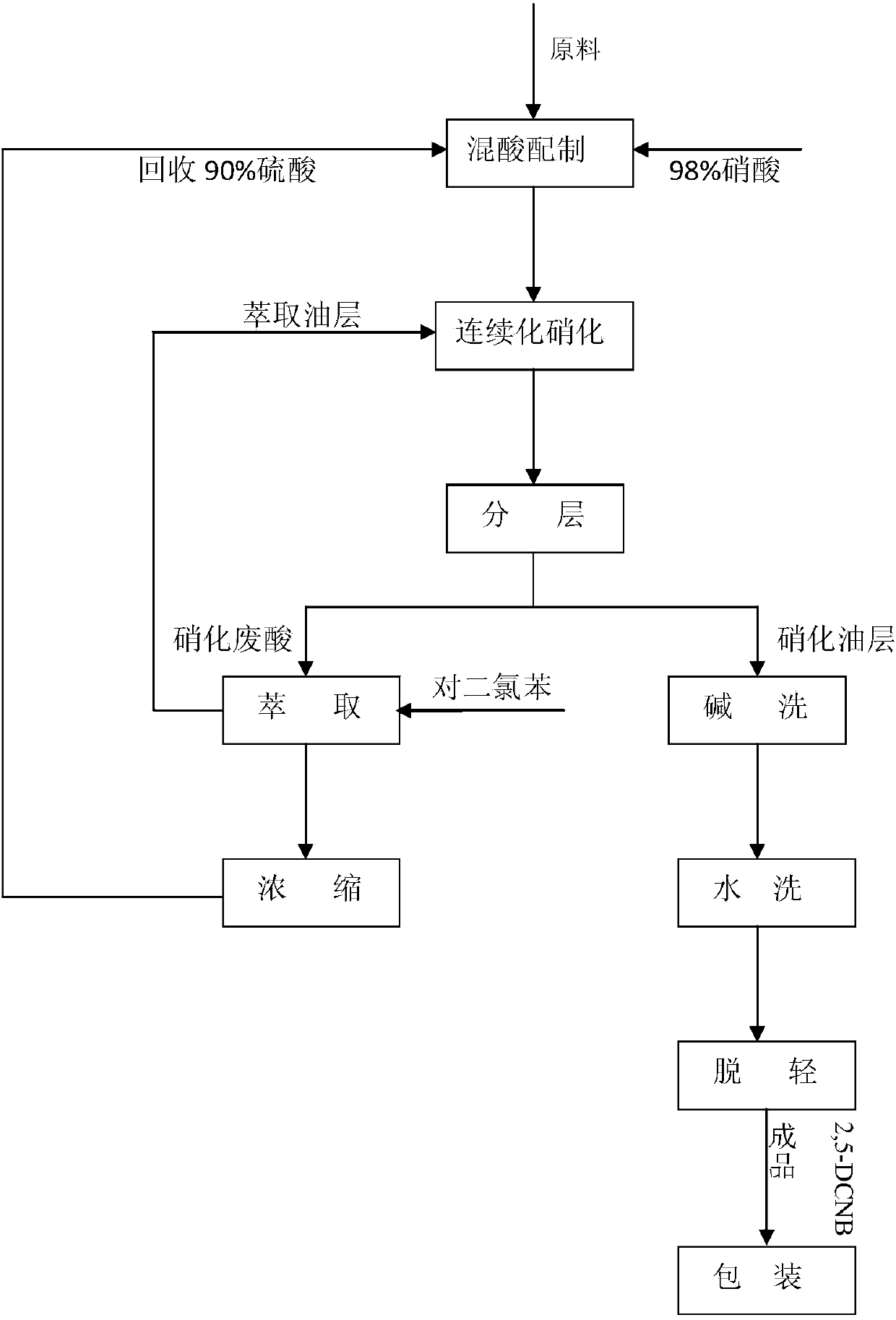

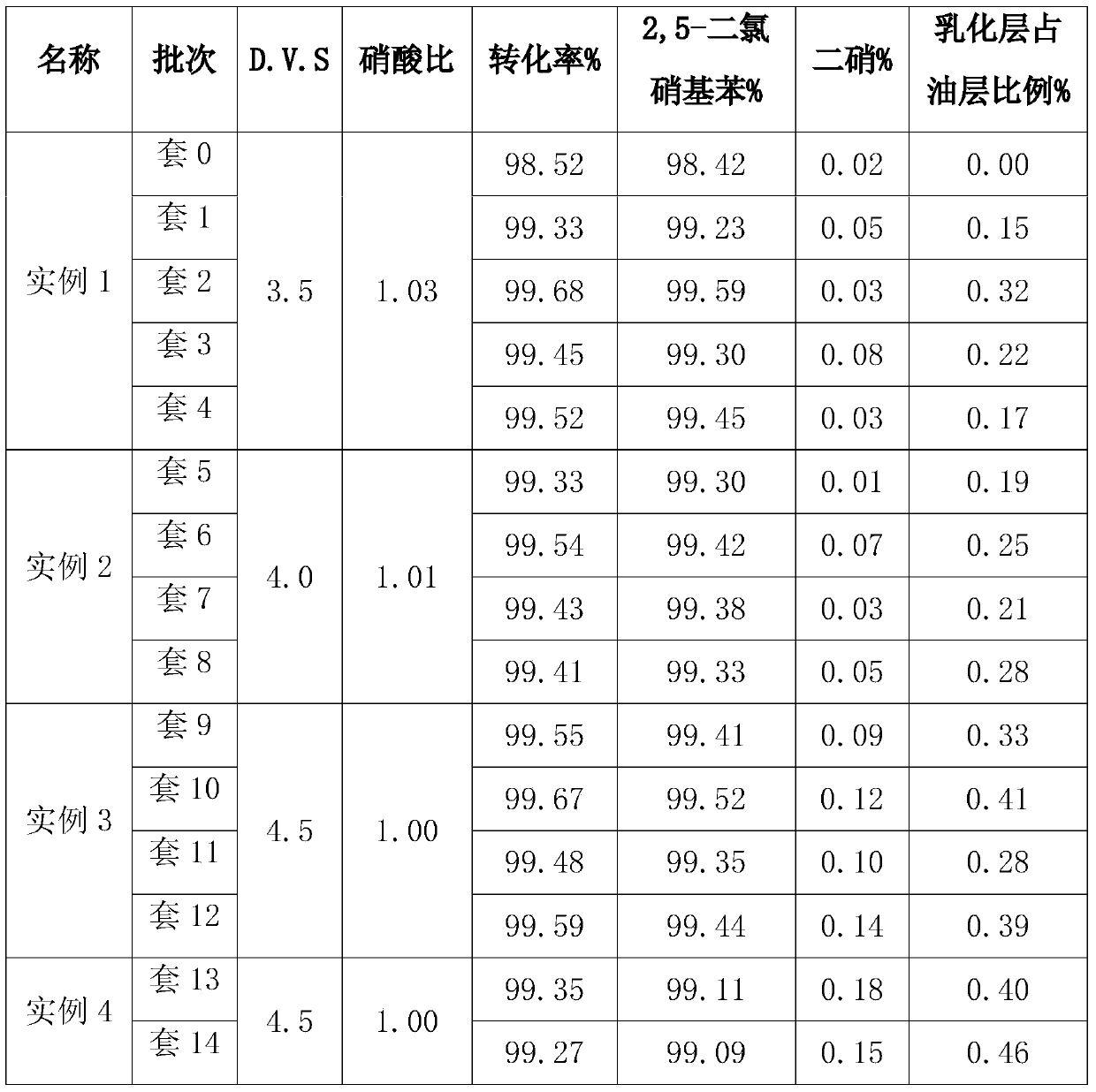

Method capable of recycling acids for preparing 2,5-dichloronitrobenzene (DCNB) through continuous nitration

ActiveCN104649910AReduce labor intensitySimple processNitro compound preparationContinuous reactorEmulsion

The invention relates to a production method for preparing 2,5-dichloronitrobenzene (DCNB) through continuous nitration, which particularly realizes the recycling of waste acids in the preparing process. The invention provides a technological program capable of recycling acids for preparing 2,5-dichloronitrobenzene (DCNB) through the continuous nitration, which is characterized in that sulfuric acid and nitric acid are prepared into a mixed acid, the mixed acid and paradichlorobenzene are simultaneously fed into a three-stages kettle (ring) type continuous reactor to carry out nitration reaction, a nitration reaction solution discharged form the third-stage kettle (ring) type continuous reactor is stood for layering so as to obtain a nitrifying oil layer and a nitrifying waste acid, and the nitrifying oil layer is subjected to alkali cleaning, water washing and light component removal so as to obtain a 2,5-DCNB finished product; paradichlorobenzene is added into the nitrifying waste acid to extract organic matters in the acid layer, residual HNO3 in the acid layer is consumed, after the extraction is completed, the obtained product is layered so as to obtain an extraction oil layer and an extracted residual waste acid, the extraction oil layer is used for next-batch nitrification, the extracted residual waste acid after being concentrated and nitric acid are prepared into the waste acid for next-batch nitrification, a small amount of emulsion layer is produced in the process of recycling, and the emulsion layer after being combined with the nitrifying oil layer is subjected to alkali cleaning and water washing.

Owner:JIANGSU YANGNONG CHEM GROUP +2

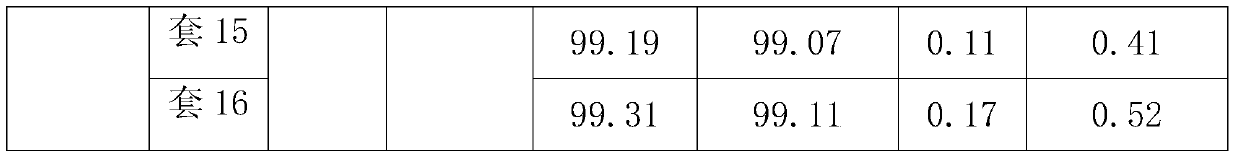

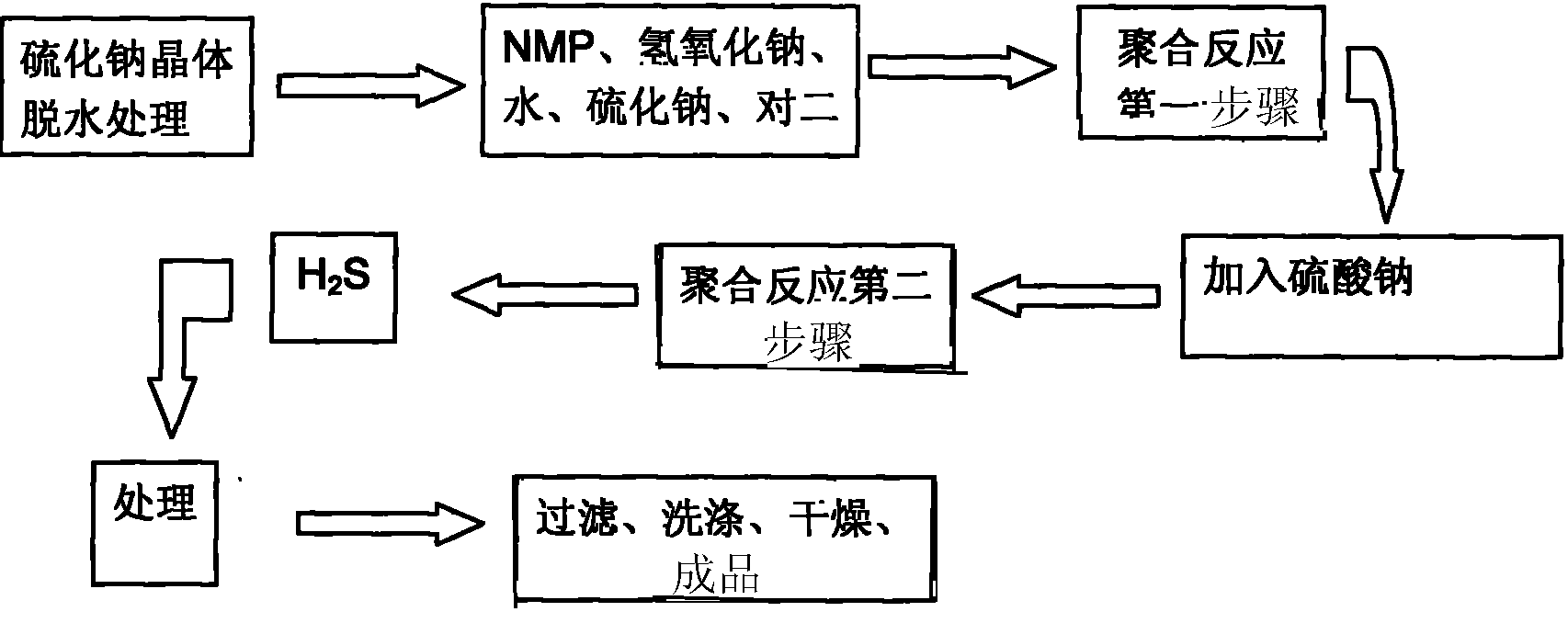

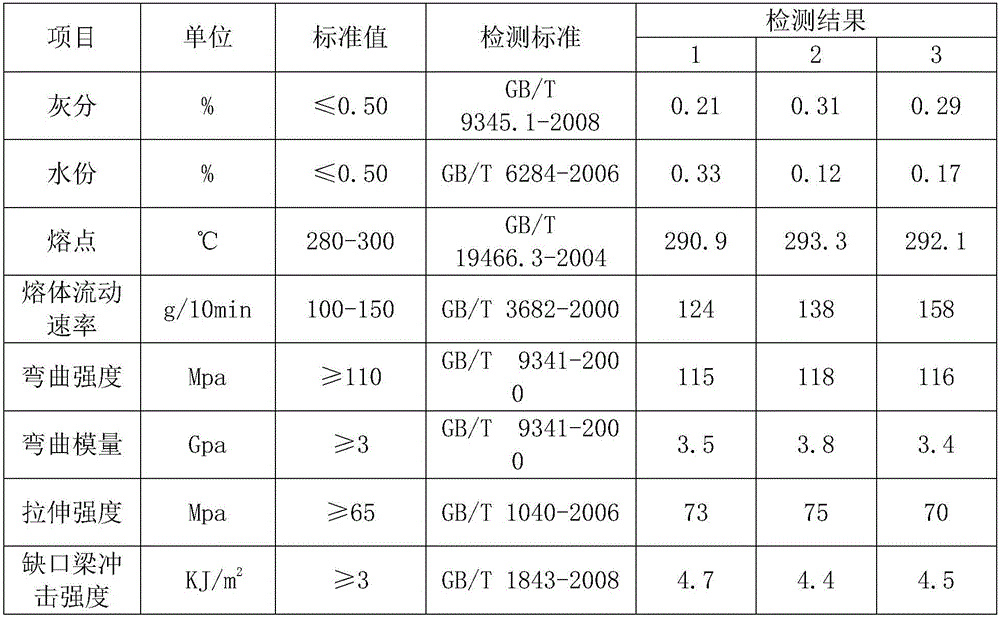

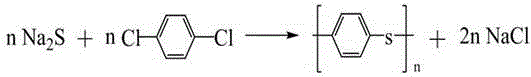

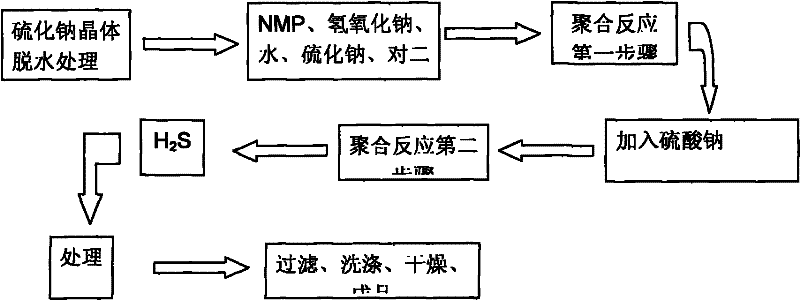

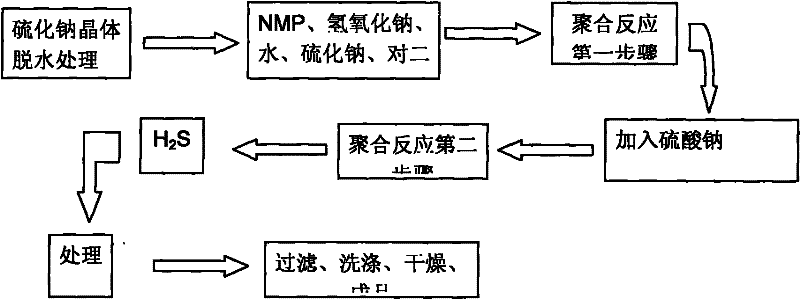

Process for synthesizing low-chlorine polyphenylene sulfide resin

The invention discloses a process for synthesizing low-chlorine polyphenylene sulfide resin. Sodium sulfide and paradichlorobenzene are used as raw materials, N-methyl-2-pyrrolidone is used as a solvent, and the molar ratio of the sodium sulfide to the paradichlorobenzene is 1:1. The synthesis process mainly comprises the following steps of: in a sodium sulfide dehydration treatment phase, carrying out sodium sulfide solution insulating and water sucking treatment by adopting three layers of 18cm water sucking column containing a 5 angstrom molecular sieve in each layer to form a sodium sulfide solution with the water content of 1.2-1.5mol / molNa2S and adding NaOH with the molar mass of 0.1-0.3mol / molNa2S; and in the polycondensation phase, adding Na2SO4 of 0.1-0.05mol / molNa2S and H2S gas of 0.01mol / molNa2S. The invention has lower halogen total content and polydispersion coefficient in the obtained product, narrow molecular weight distribution, high oxygen index and excellent electrical insulating property and can be used as a packaging material of an electronic device.

Owner:四川得阳特种新材料有限公司

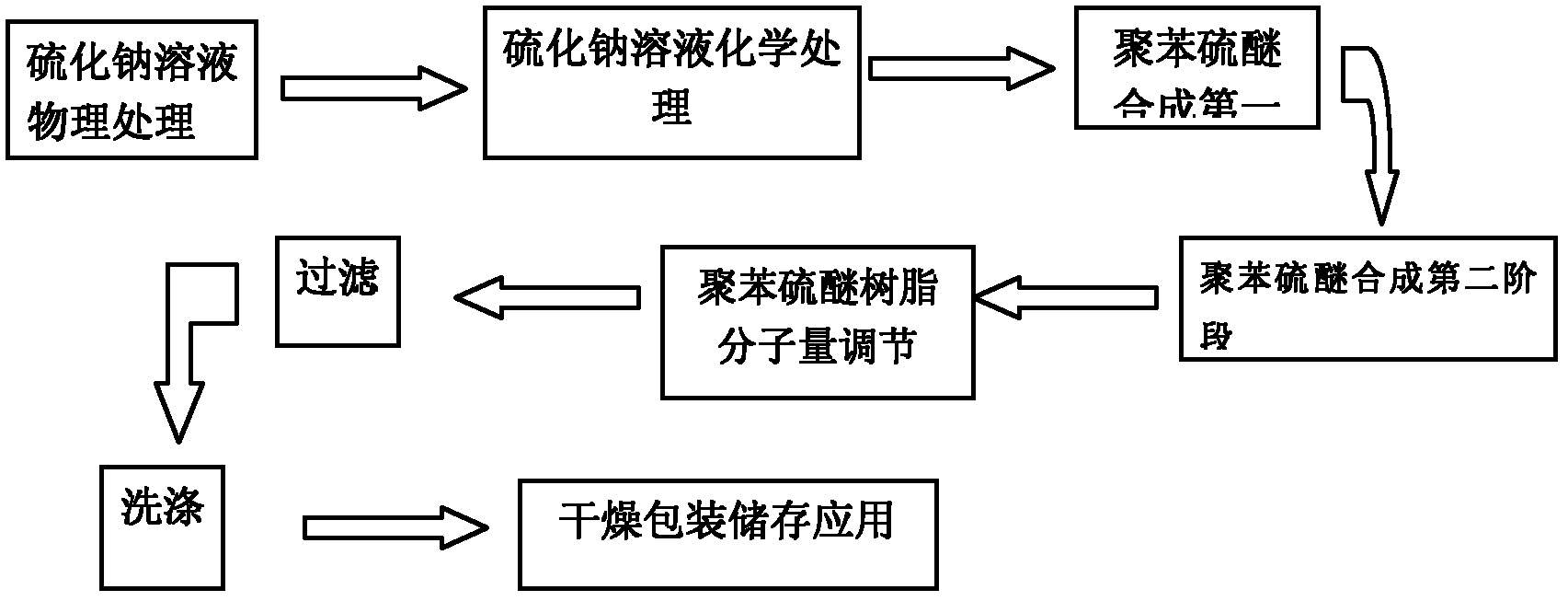

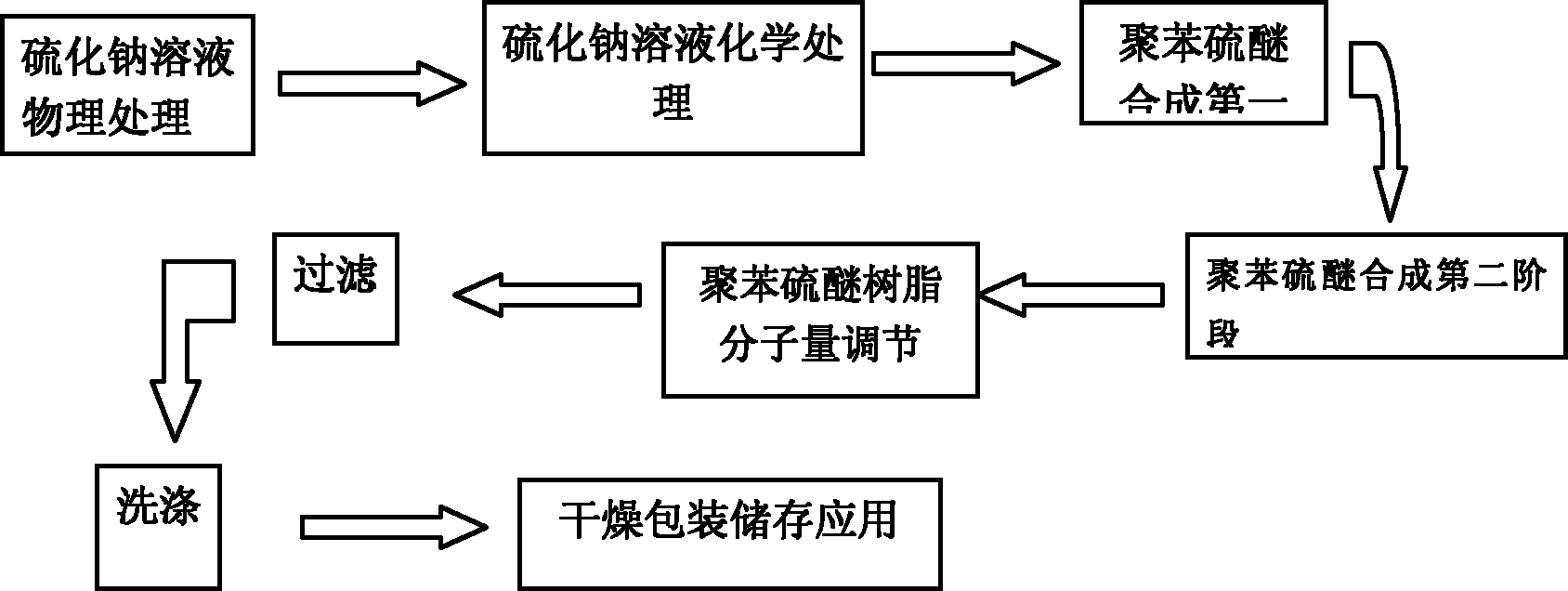

Synthesis process for polyphenylene sulfide resin

The invention discloses a synthesis process for a polyphenylene sulfide resin. In the synthesis process, sodium sulfide and paradichlorobenzene are used as raw materials, N-methyl-2pyrrolidone is used as a solvent, and the molar ratio of the sodium sulfide to the paradichlorobenzene is 1:1; under the conditions that an online infrared monitoring system is used for control and nitrogen is used forprotection, in a sodium sulfide dehydration treatment stage, 10%mol of NaOh and 50%mol of Na2CO3 relative to a prescription are added for chemically treating the sodium sulfide; and in a condensationstage, 50%mol of Na2CO3 and NaHs relative to the prescription are added for further performing molecular weight and molecular weight distribution ratio regulation on the synthesized polyphenylene sulfide resin and regulating the content of covalent chlorine to be 200-300ppm. According to the invention, halogens in an obtained product are lower in total content and a polydispersity index, and the obtained product has the advantages of narrow molecular weight distribution, high oxygen index and excellent electric insulating property, and can be used as a packaging material for electronic devices.

Owner:SHENZHEN POLYTECH SCI & TECH

Fragrant heterocycle-containing polyphenylene sulfide copolymer, preparing method, uses and products thereof

InactiveCN101402731AImprove structural strengthHigh strengthPlastic/resin/waxes insulatorsMonocomponent synthetic polymer artificial filamentFiberParadichlorobenzene

The invention discloses an aromatic heterocyclic polyphenylene sulfide copolymer and a preparation method, applications and products thereof. In the copolymer, -HAr-S- structure is embedded into -Ar-S molecular structure to form -Ar-S-HAr-S- structure; the preparation method thereof is that sodium sulfide, paradichlorobenzene and 2-(4-chloro-phenyl)-5-chloro-benzimadazole are taken as raw materials, N-methyl-2-pyrrolidone is taken as a solvent, condensation polymerization synthesis is carried out under the function of alkali metal assistant solvent to blend with polyphenylene sulfide so as to prepare various injection molding or plastic extruding products. The aromatic heterocyclic polyphenylene sulfide copolymer is particularly applicable to prepare membranes and fiber and can improve tenacity and intensity.

Owner:德阳科吉高新材料有限责任公司

Method for synthesizing polyphenylene sulfide copolymer containing heteroaromatics

The present invention discloses a synthetic method of heteroaromatics polyphenyl sulfur ether. The present invention adopts sodium sulfide and paradichlorobenzene and 2-(4-chlorine phenyl group)-5-chlorine phenyl benzimidazole as raw materials and N-methyl-2 pyrrolidone as solvent for condensation and polymerization under the role of alkali metal lacquer solvent, so as to produce the polyphenyl sulfur ether resin. The mol ratio between sodium sulfide and paradichlorobenzene and 2-(4-chlorine phenyl group)-5-chlorine phenyl benzimidazole is 1:0.6-0.9:0.4-0.1. The sequential process mainly includes: in the process of sodium sulfide dehydration stage, assistant lithium aluminum hydride is added; in the condensation and polymerization stage, 2-(4-chlorine phenyl group)-5-chlorine phenyl benzimidazole is added. The product provided by the present invention with excellent indexes of relatively low dispersion coefficient and narrow molecular weight distribution and oxygen index can be made into paint, injection mold, fiber and membrane and be widely applied to the fields of machinery, chemicals, oil, electronic apparatus, war industry and airspace.

Owner:四川中科兴业高新材料有限公司

Preparation method of low-cost polyphenylene sulfide

The invention discloses a preparation method of low-cost polyphenylene sulfide, and relates to the field of macromolecular materials. The preparation method is characterized by using sodium sulfide and paradichlorobenzene as raw materials, using sodium benzoate and caprolactone as catalysts, using N-methyl pyrrolidone as a solvent, and using sodium hydroxide as an additive, and a specific technological process in production sequentially comprises the following steps: feeding the sodium sulfide, feeding the paradichlorobenzene, dissolving the catalysts, pre-polymerizing, polymerizing again, filtering, washing, drying, and packaging, so as to obtain a polyphenylene sulfide product. The preparation method has the advantages that a lithium chloride catalyst in the existing domestic main technology is not used, and the low-cost sodium benzoate and caprolactone are used as the catalysts, so that the production cost is reduced; all raw materials are dripped by several times at normal temperature, so that the polymerization reaction is performed within a certain temperature range, so as to effectively prevent heat releasing implosion during the polymerization reaction, improve the polymerization degree and various mechanical properties of the polyphenylene sulfide, and thoroughly solve the problems of instability, low molecular weight and poor property in the traditional technology product.

Owner:四川中科兴业高新材料有限公司

In2O3@ZnIn2S4 nanosheet material and preparation method and application thereof

InactiveCN110624564AImprove targetingImprove degradation efficiencyPhysical/chemical process catalystsWater/sewage treatment by irradiationIndium TrichlorideChloride

The invention discloses an In2O3@ZnIn2S4 nanosheet material and a preparation method and application thereof. The method comprises the following steps: dissolving indium oxide in acidic water to obtain an indium oxide solution; and then adding zinc chloride, indium trichloride and thioacetamide into the indium oxide solution for a reaction; and carrying out washing and drying to obtain the In2O3@ZnIn2S4 nanosheet material, wherein a molar mass ratio of indium oxide to zinc chloride to indium trichloride to thioacetamide is 1: 2: 2: 5. The preparation method for the In2O3@ZnIn2S4 nanosheet material in the invention is simple and convenient in operation and low in cost; the prepared photocatalyst material, i.e., the In2O3@ZnIn2S4 nanosheet material, has extremely high targeting properties and degradation efficiency, and the degradation rate of 2,4-dichlorophenol in surface water can reach 93.2%; and the photocatalyst material can be recycled and still has high degradation rate after being used multiple times, so the treatment cost of 2,4-dichlorophenol is greatly reduced. Treatment with the photocatalyst material is efficient and energy-saving, and can meet national detection requirements on 2,4-dichlorophenol in surface water in China.

Owner:河北地质大学

Hair conditioner easy to clean

InactiveCN108078837AGood dispersionAvoid residueCosmetic preparationsHair cosmeticsPolyethylene glycolParadichlorobenzene

The invention provides a hair conditioner easy to clean, and belongs to the technical field of daily chemical products. The hair conditioner easy to clean is prepared from mustard, sesame oil, emulsion, vegetable protein, enzymolysis chitosan liquid, a compound enzyme, dimethyl siloxane, preservative, water and essence, wherein the emulsion is formed by mixing (N-amidino)dodecyl-acrylamide and polyethylene glycol derivative, and adding paradichlorobenzene and ferrocene for a stirring reaction, the enzymolysis chitosan liquid is obtained by mixing and swelling chitosan and water, and adding chitosanase for constant-temperature stirring and anzymolysis and enzyme deactivation, the compound enzyme is formed by compounding pancreatic lipase and ceratinase, and the hair conditioner easy to clean is obtained after adding the mustard, the sesame oil, the emulsion, vegetation protein, the enzymolysis chitosan liquid, compound enzyme, dimethyl siloxane, the preservative, the water and the essence into a blender mixer to be mixed. After being utilized, the hair conditioner is easy to clean and has an excellent hair care effect.

Owner:仇颖超

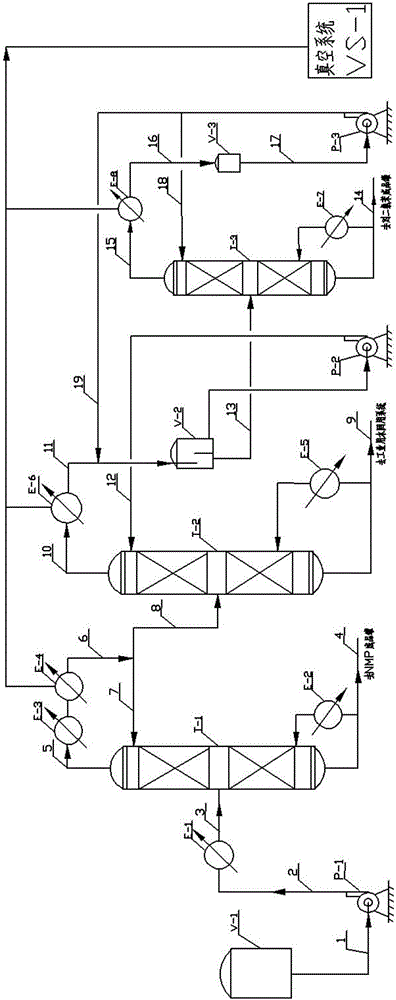

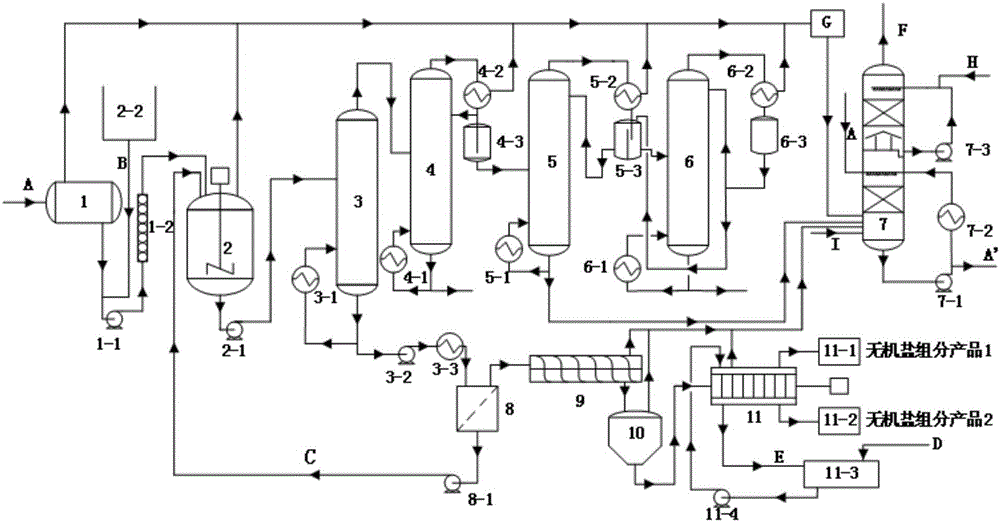

Ultra-high purity separating and refining technology of wastewater containing NMP (N-Methyl Pyrrolidone) and paradichlorobenzene

ActiveCN106478481ASolve the blockageReduce difficultyWater/sewage treatment by heatingHalogenated hydrocarbon preparationWastewaterParadichlorobenzene

The invention relates to an ultra-high purity separating and refining technology of wastewater containing NMP (N-Methyl Pyrrolidone) and paradichlorobenzene, and aims to provide a technical method for carrying out ultra-high purity recycling on all useful chemical components (including water) in industrial wastewater. The ultra-high purity separating and refining technology comprises the following step: respectively separating and recycling the wastewater containing NMP and paradichlorobenzene by adopting a decompression and rectification system which is of a three-tower serial-connection structure, thus obtaining a product of which the purity is higher than 99.99 wt percent and which contains NMP, water and paradichlorobenzene. The recycling rate of the whole process is up to 99.99 percent or above.

Owner:NANJING UNIV

Process for producing m-dichlorobenzene by using chloridized aromatic hydrocarbon waste as raw materials

InactiveCN102675039AIncrease contentHalogenated hydrocarbon preparationHigh concentrationSeparation technology

The invention discloses a process for producing m-dichlorobenzene by using chloridized aromatic hydrocarbon waste as raw materials. The process mainly comprises the following steps of: rectifying the chloridized aromatic hydrocarbon waste to obtain high-concentration paradichlorobenzene; preparing high-content paradichlorobenzene by a crystallization technology by using a paradichlorobenzene solution; inverting the high-content paradichlorobenzene into low-concentration paradichlorobenzene by a normal pressure inversion technology; washing with water; and crystallizing and purifying. According to the process, the chloridized aromatic hydrocarbon waste is used as the raw materials, the high-content paradichlorobenzene is separated by a separation technology, the high-concentration paradichlorobenzene is prepared by normal-pressure acylation reaction, and the high-content m-dichlorobenzene is extracted by the crystallization technology.

Owner:JIANGSU LONGCHANG CHEM

Kettle type crystallization process of paradichlorobenzene in solid waste benzene chloride tar

ActiveCN101580456AReduce energy consumptionHigh yieldSolution crystallizationHalogenated hydrocarbon preparationBenzeneMagma

The invention discloses a kettle type crystallization process of paradichlorobenzene in solid waste benzene chloride tar, which comprises the following steps of: conveying mixed dichlorobenzene raw materials to a crystallization kettle through vacuum or a pump; simultaneously starting a cooling system, and using cooling brine to reduce the temperature of the raw materials; stirring the raw materials, thus leading the raw materials to form qualified crystal nucleuses which grow; obtaining qualified magma after the crystal nucleuses grow up; discharging the qualified magma from the bottom of the crystallization kettle; and obtaining finished product through separation by a centrifuger. The process has the advantages that the raw material is crystallized by regulating circulating refrigerant and controlling temperature change, temperature of solution and stirring rate in the kettle type crystallization process; the energy consumption is low; the yield is high; and the operation is simple.

Owner:JIANGSU LONGCHANG CHEM

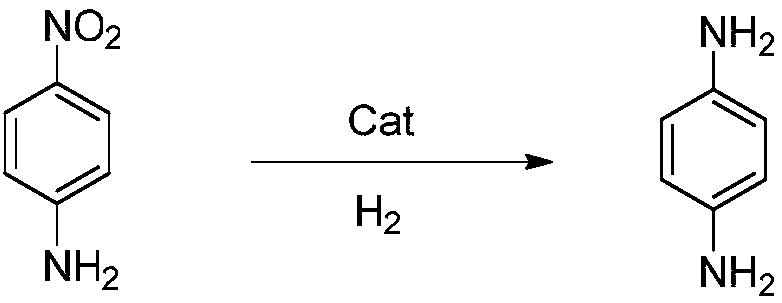

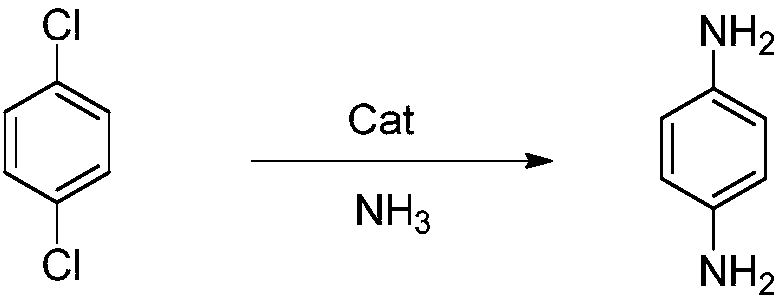

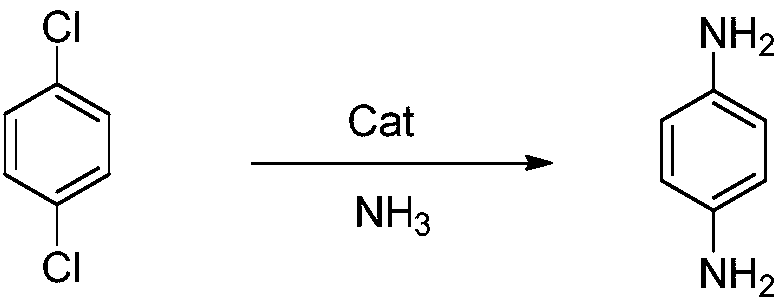

Preparation method of p-phenylenediamine

ActiveCN109336769AMild reaction conditionsGood choiceOrganic compound preparationAmino compound preparationDistillationIodide

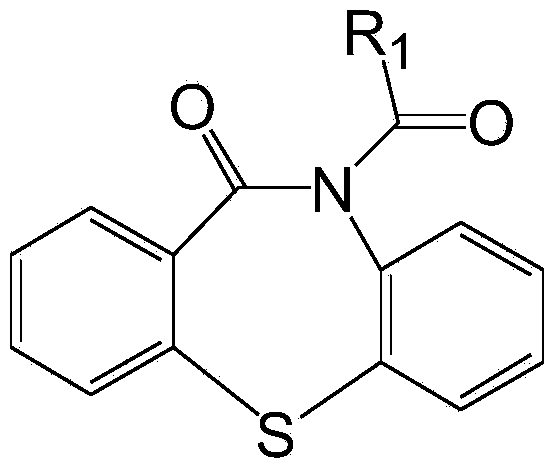

The invention discloses a preparation method of p-phenylenediamine. The preparation method comprises the following steps: adding paradichlorobenzene, ammonia water, the concentration of which is 35-45%, a catalyst and a Mannich alkaline ligand into a high pressure kettle; heating the mixture to 130-150 DEG C; stirring the mixture at a rotating speed of 600 rpm, wherein the reaction pressure is 2.0-4.5 MPa, carrying out an insulating reaction for 6-24 hours; after the reaction, reducing the temperature and relieving the pressure to recover ammonia; and carrying out desolventization and negativepressure distillation on kettle materials to obtain p-phenylenediamine, wherein the molar ratio of paradichlorobenzene and ammonia water is 1: 10 to 1: 20; the molar ratio of the catalyst and paradichlorobenzene is 0.005: 1 to 0.1: 1; the molar ratio of the Mannich alkaline ligand and the catalyst is 1: 1 to 3: 1; the catalyst is one of cuprous iodide, cuprous chloride, cuprous bromide, cuprous oxide, copper sulfate, copper chloride, cupric acetate and copper trifluoroacetate; the Mannich ligand structure is as shown in a formula, in which R is t-Bu or Cl or CH3. The preparation method is mild in reaction condition, efficient, good in selectivity, high in yield and suitable for industrial production of p-phenylenediamine on a large scale.

Owner:JIANGSU YANGNONG CHEM GROUP +2

Method for synthesizing high-molecular weight polyphenylene sulfide by controlling water content

ActiveCN110294844AControl reaction processEasy to separatePolymer scienceSynthetic Polymeric Macromolecules

The invention discloses a method for synthesizing high-molecular weight polyphenylene sulfide by controlling water content, and relates to the technical field of synthesizing of polyphenylene sulfide,which solves the problem of failure in controlling of physical property of the obtained polyphenylene sulfide in the polymerizing process of the existing polyphenylene sulfide synthesizing technologyand the problems of higher content of impurities and difficulty in separation of products in the reaction kettle. The method comprises the following steps of using sodium sulfide, sodium hydroxide, paradichlorobenzene and water as the raw materials, and condensing to synthesize high-molecular weight polyphenylene sulfide resin in an N-methyl pyrrolidone solvent; sending the dissolved paradichlorobenzene solution into the reaction kettle in the pre-polymerizing process; feeding nitrogen gas for protecting, stirring, and maintaining the system temperature at 150 to 240 DEG C; when the temperature of the reaction kettle is constant, uniformly and slowly adding distilled water into the reaction kettle, closing a valve of a high-pressure dripping device after the adding of the distilled wateris finished, reacting for 1 to 6h, and re-polymerizing after the pre-polymerizing is finished. The method has the advantage that the different amounts of water are added in the pre-polymerizing and polymerizing stages, so as to controllably synthesize the polyphenylene sulfide products with different molecular weights.

Owner:四川中科兴业高新材料有限公司

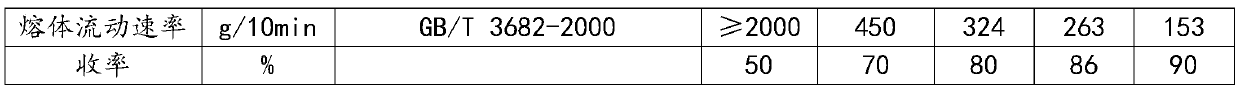

Degradable mulching film

InactiveCN108219330AImprove mechanical propertiesImprove insulation effectCarrageenanPolymer science

The invention discloses a degradable mulching film, which belongs to the technical field of high polymer materials. The degradable mulching film is prepared through the steps of mixing (N-amidino) dodecyl acrylamide and a polyethylene glycol derivative according to the mass ratio of 1:1 to 2:1, adding paradichlorobenzene with the mass being 0.1 to 0.2 time of the mass of the polyethylene glycol derivative and ferrocene with the mass being 0.07 to 0.10 time of the mass of the polyethylene glycol derivative, stirring and mixing to obtain a modified swelling agent; putting a modified additive, polyvinyl alcohol liquid, an Arabic gum liquid, carrageenan liquid, modified corn cob powder, phospholipid and shii-takemushroom waste mushroom dreg fermentation liquor into a blender mixer, stirring and mixing at highspeedfor 30 to 50min under the condition of the rotation speed of 1000 to 1200r / min, and obtaining a mixed slurry; flow-casting the mixed slurry to the surface of a clean glass plate,then putting the clean glass plate flow-cast with the mixed slurry into a drying oven, drying and curing for 2 to 3h at the temperature of 100 to 120 DEG C, scraping a film through a scraper, and obtaining the degradable mulching film. The degradable mulching film prepared through the invention has the characteristics of excellent mechanical property, heat insulation property and degradation property.

Owner:姜向军

High-purity recycling process system of complex chemical waste liquid

ActiveCN106366030ADispersed particle separationHalogenated hydrocarbon separation/purificationProcess systemsLiquid waste

The invention discloses a high-purity recycling process system of complex chemical waste liquid. The high-purity recycling process system consists of six units such as a decomplexing unit, an evaporation separating unit, an inorganic salt drying unit, an inorganic salt compound separation recycling unit, an organic matter and water comprehensive separation unit and a tail gas purification unit. The invention aims to provide a recycling process technical method for solving the complex chemical waste liquid generated in the production process of polyphenylene sulfide. According to the method, useful chemical substances (including water) in the complex chemical waste liquid consisting of paradichlorobenzene, catalyst LiCl, chemical solvent nitrogen methyl pyrrolidone, NaCl, water and minimal quantity lubrication high-boiling-point impurities are separated and refined one by one, and then 99.9% or not less than 99.99% of high-purity or ultra-pure chemical product is prepared for recycling, so that the recycling recovery rate reaches up to not less than 99%, the pollution problem of the complex chemical waste liquid is thoroughly solved, the system has the characteristics of high product quality, low energy consumption, high reliability and the like, and the system has a wide industrial application prospect.

Owner:NANJING UNIV

Process for extracting high-purity paradichlorobenzene by using solvent extraction method

InactiveCN101580454ASolve stickinessSolve the coercion problemHalogenated hydrocarbon separation/purificationCentrifugationParadichlorobenzene

The invention discloses a process for extracting high-purity paradichlorobenzene by using a solvent extraction method, which comprises the following steps of: introducing paradichlorobenzene containing o-dichlorohenzene in an ethanol solvent, separating out o-dichlorohenzene crystal, conducting centrifugation by a centrifuger, separating dichlorobenzene crystal from mother solution, and obtaining paradichlorobenzene with the content higher than 99.5 percent. The process has the advantage that by using ethanol as solvent, integrating the processes of extraction, crystallization, washing, filtration and the like, utilizing the functions of ethanol solvent of selective extraction on o-dichlorohenzene and washing on crystal, and using the centrifuger to conduct centrifugal filtration on solid-liquid mixture, the problem that o-dichlorohenzene is adhered to and wrapped in the paradichlorobenzene crystal is effectively solved, and the purity and yield of the product are guaranteed.

Owner:JIANGSU LONGCHANG CHEM

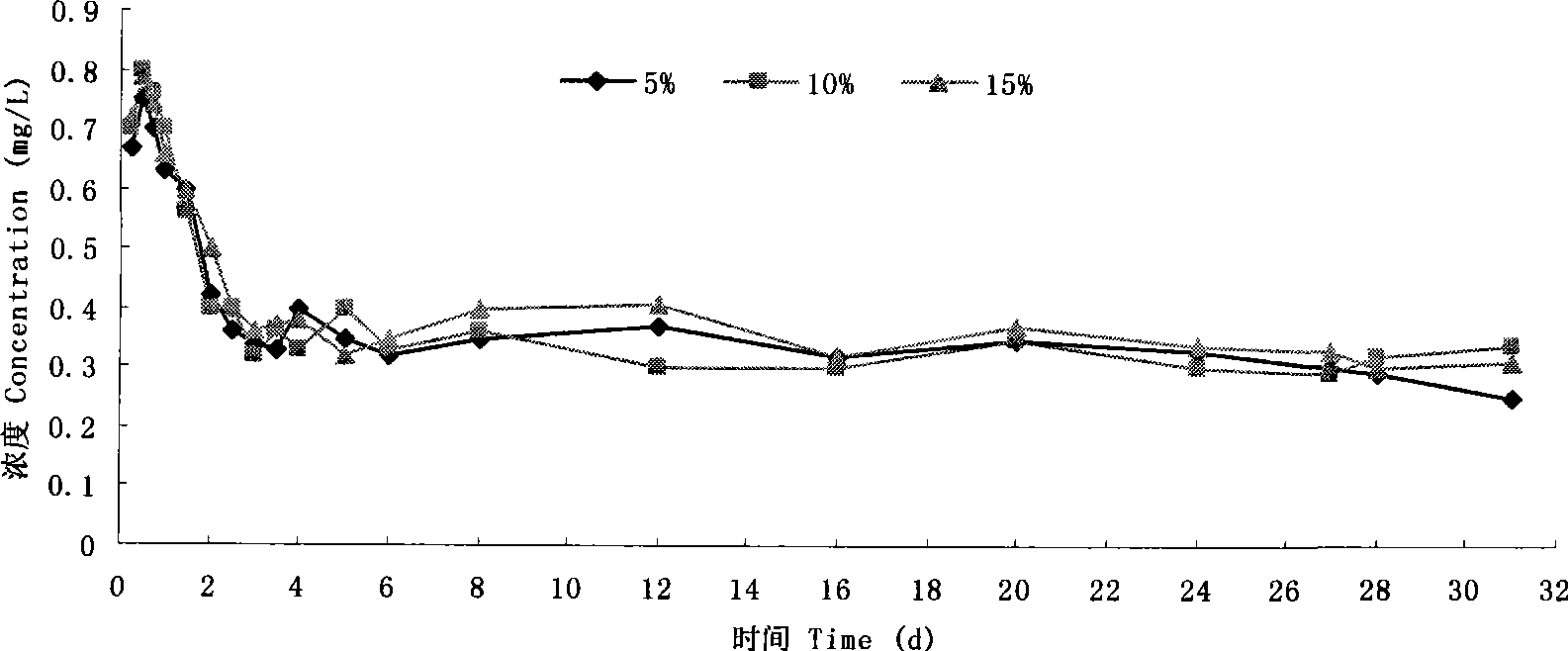

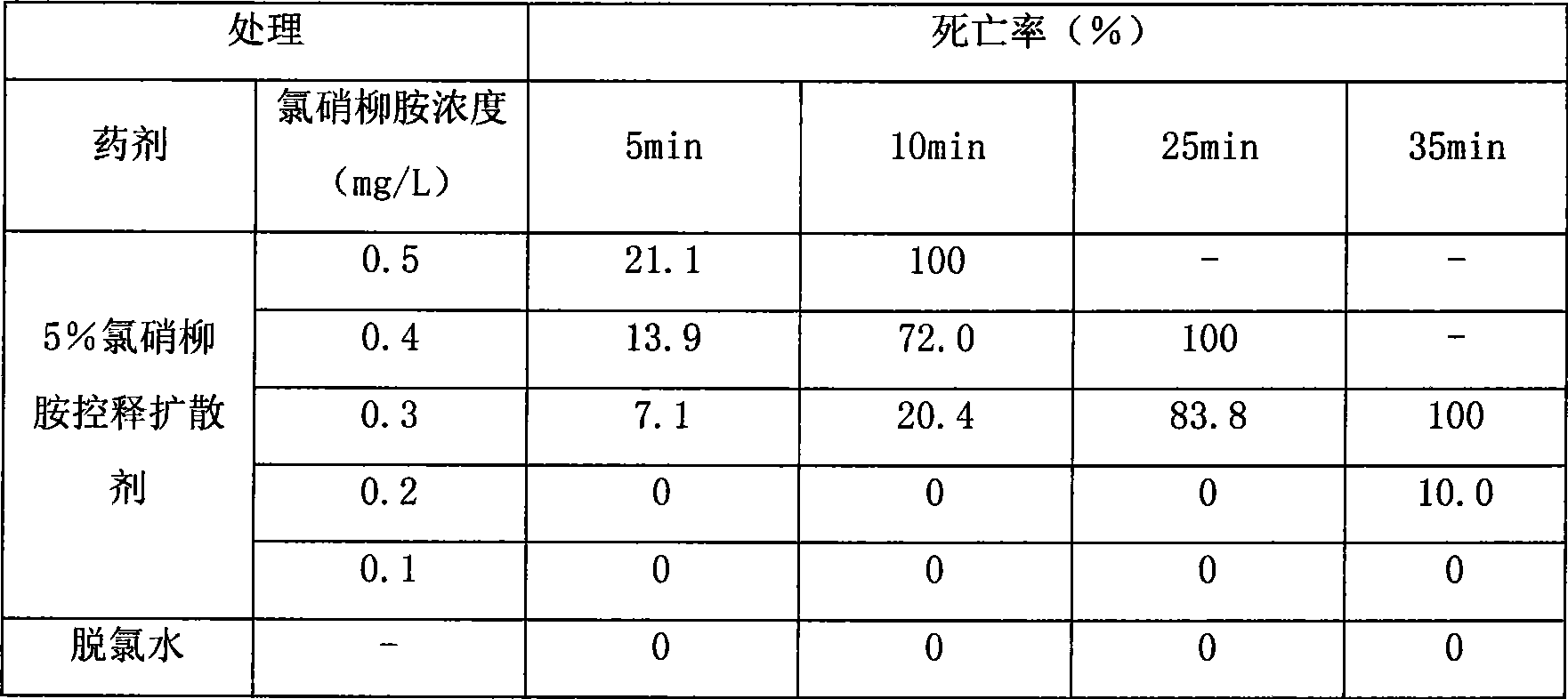

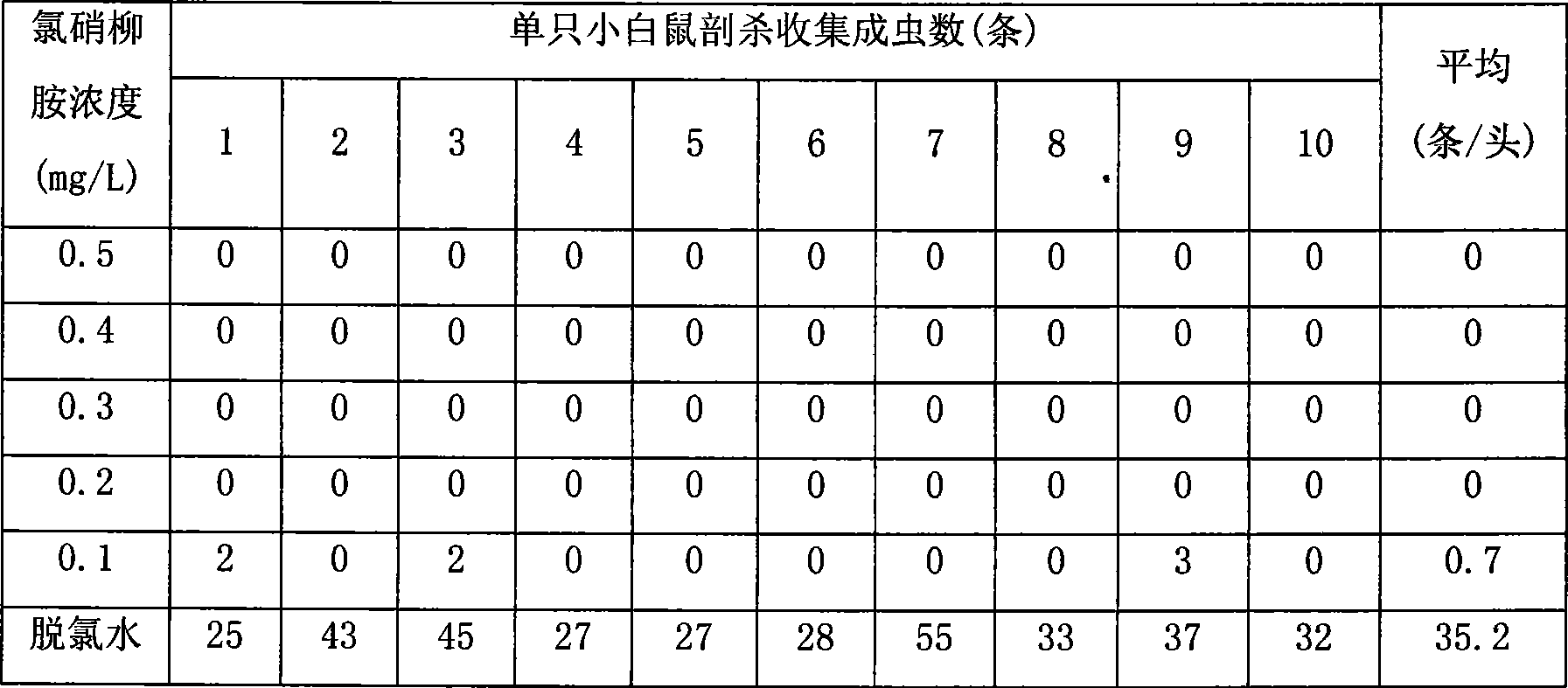

Niclosamide controlled release dispersing agent for killing blood fluke cercaria and preparation method thereof

InactiveCN101366376AEffective in killing Schistosoma cercariaeEfficient killingBiocideArthropodicidesParadichlorobenzeneMaterials processing

The invention discloses a niclosamide controlled-release dispersing agent for killing schistosoma japonicum cercaria and a preparation method thereof. The niclosamide controlled-release dispersing agent for killing the schistosoma japonicum cercaria is characterized in that the compositions of the niclosamide controlled-release dispersing agent are niclosamide, paradichlorobenzene, floating carriers and a dispersing agent and the main compositions of the niclosamide controlled-release dispersing agent are the niclosamide and the paradichlorobenzene, wherein the weight ratio of the niclosamide to the paradichlorobenzene is between 10 and 30 to between 90 and 70. The niclosamide controlled-release dispersing agent and the preparation method have scientific and reasonable formula and ratio, advanced and simple technique and good effect of killing the schistosoma japonicum cercaria. The controlled-release dispersing agent for killing the schistosoma japonicum cercaria, which is prepared by processing the niclosamide, the paradichlorobenzene, corncob particles and so on as materials, is applied to a pathogen generation water area, releases the niclosamide at a fixed quantity in virtue of sublimation of the paradichlorobenzene, freely diffuses in virtue of the molecular tension and the function of the dispersing agent, reaches the predicted concentration in a water body, has long lasting period, effectively kills the schistosoma japonicum cercaria, and prevents the schistosoma japonicum cercaria from infecting human beings and livestock; and the death rate of the schistosoma japonicum cercaria reaches 100 percent.

Owner:扬州绿源生物化工有限公司 +3

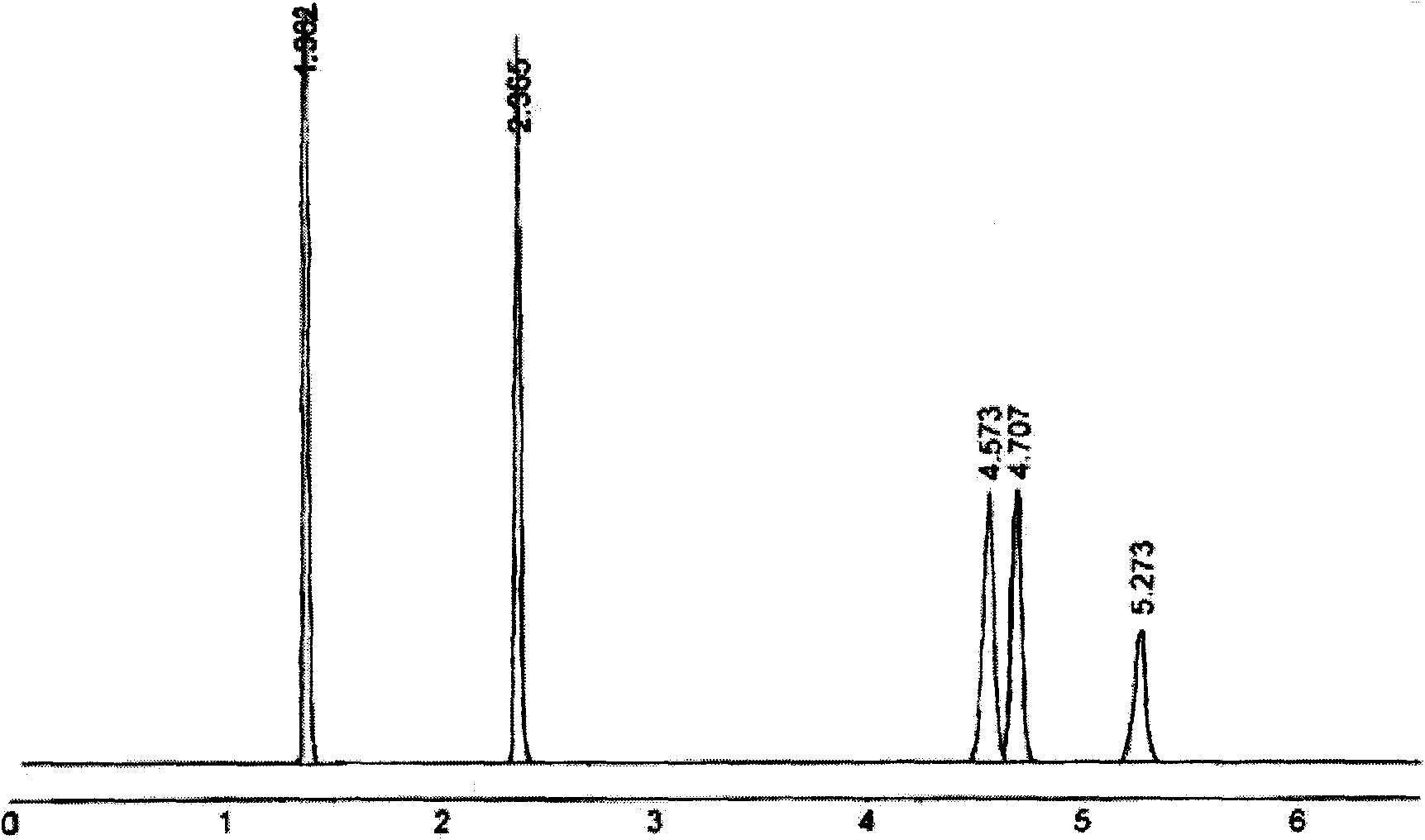

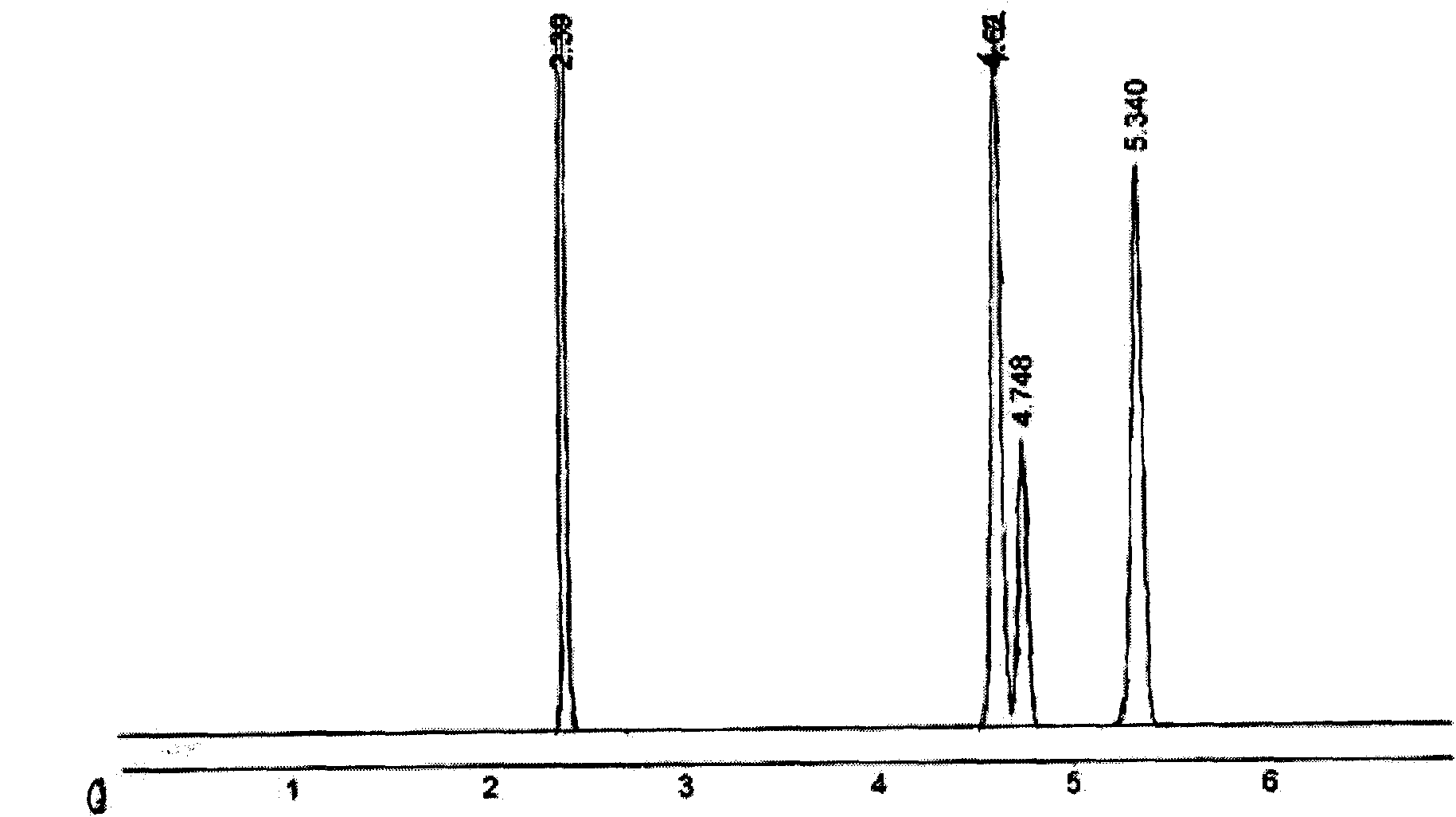

Capillary chromatography detection process of mixed benzene

The invention discloses a capillary chromatography detection process of mixed benzene. The mixed benzene mainly comprises chlorobenzene, paradichlorobenzene, meta-dichlorobenzene, ortho-dichlorobenzene and little trichlorobenzene. The mixed benzene is placed into a gas chromatograph to be detected with a capillary column, and finally the detection result is obtained from the standard deviation value through multiple detection comparison. The invention is characterized in that the capillary column for detection is the cross linked SE-54 high efficiency capillary column, and in the experiment, specific conditions are designed for the capillary column, thus the chlorobenzene, paradichlorobenzene, meta dichlorobenzene, ortho-dichlorobenzene and little trichlorobenzene with similar structures and close boiling points can be effectively detected. The method has the characteristics of simple and rapid operation, high degree of accuracy and high precision and has certain instructive significance to process production.

Owner:JIANGSU LONGCHANG CHEM

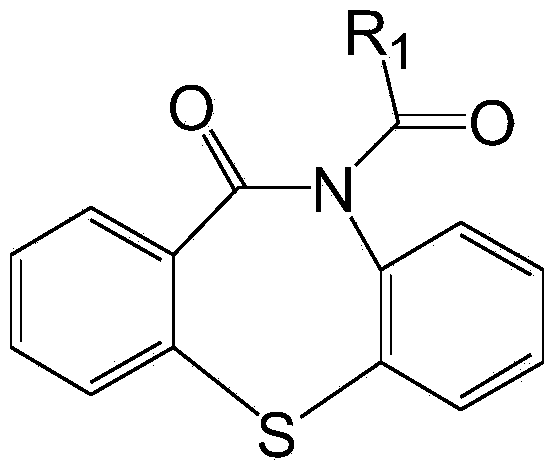

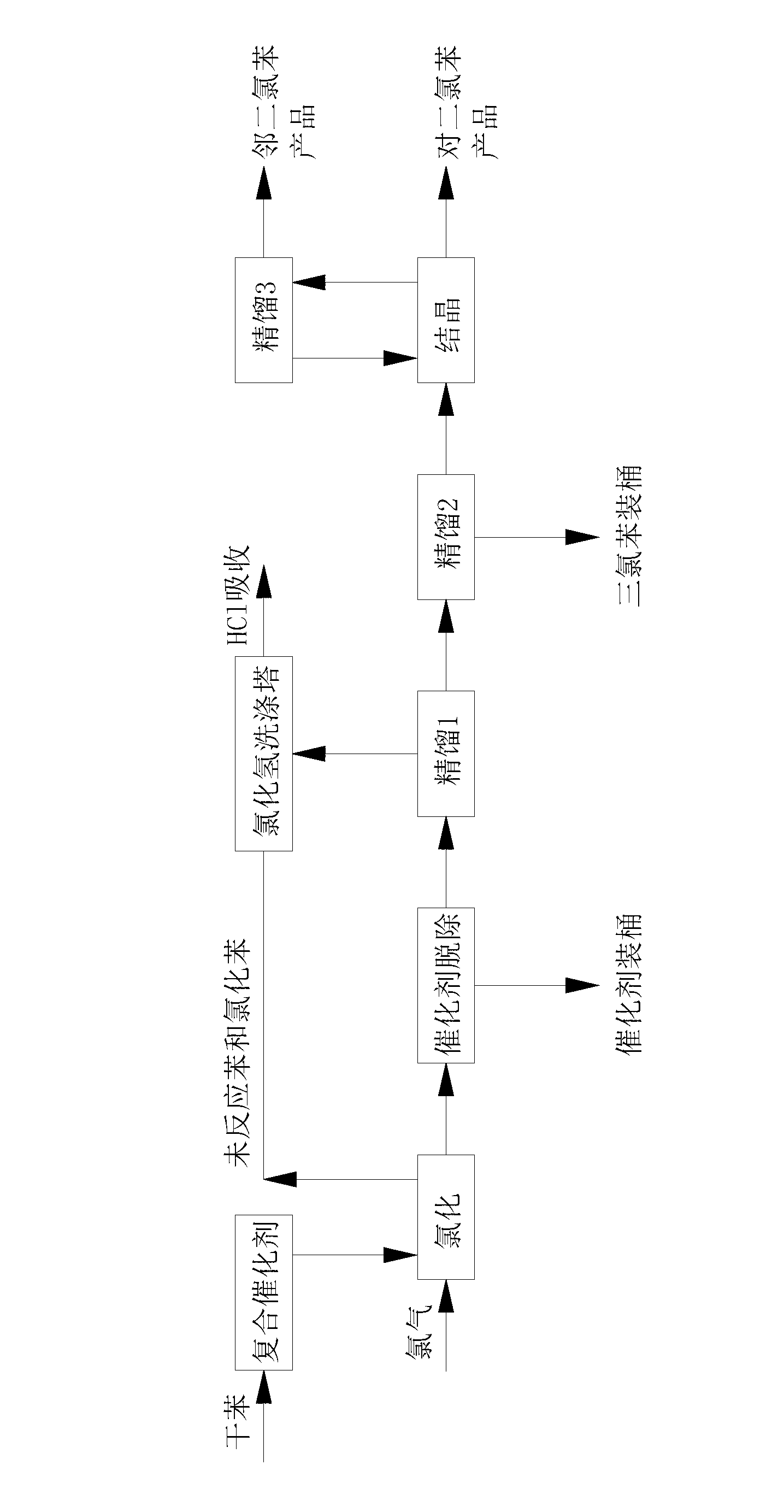

Method for increasing proportion of paradichlorobenzene in benzene chlorination product

InactiveCN103739441ARaise the ratioOrganic-compounds/hydrides/coordination-complexes catalystsHalogenated hydrocarbon preparationBenzeneChlorobenzene

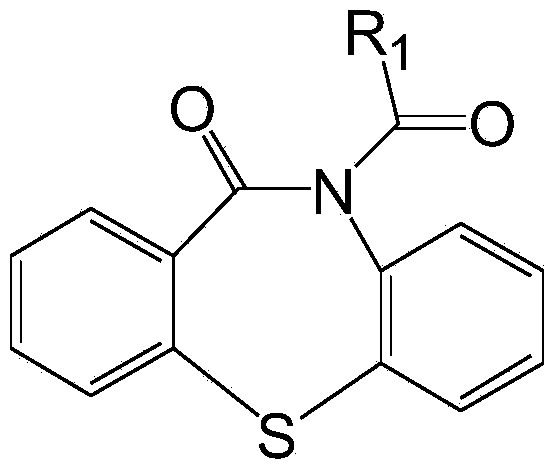

The invention discloses a method for increasing a proportion of paradichlorobenzene in a benzene chlorination product. The method comprises the steps: adding a combined catalyst in benzene, introducing chlorine under a stirring condition, to obtain the chlorination product with high paradichlorobenzene content, wherein the temperature of the whole process is controlled to be 50-80 DEG C, and the amount of the introduced chlorine is controlled to ensure that the conversion rate of the benzene is more than 99 percent and the conversion rate of chlorobenzene is more than 93 percent, and in addition, the combined catalyst comprises a main catalyst and a co-catalyst, the main catalyst is one of iron powder, ferric trichloride, aluminum trichloride, antimony trichloride, antimony pentachloride or tin tetrachloride, the co-catalyst is a dibenzo thiazepine organic matter, and the weight ratio of the main catalyst to the co-catalyst is 1:1. According to the method, the proportion of the paradichlorobenzene in the product is effectively increased, the ratio of the paradichlorobenzene to orthodichlorobenzene can reach 4.8, the content of the orthodichlorobenzene is less than 0.4 percent, and the content of phenyl polychloride is less than 1 percent.

Owner:SOUTHEAST UNIV

Catalyst used in preparation of paradichlorobenzene and method for preparing paradichlorobenzene by using such catalyst

InactiveCN102836731AHigh yieldReduce pollutionPhysical/chemical process catalystsHalogenated hydrocarbon preparationDisulfur dichlorideParadichlorobenzene

The invention discloses a catalyst used in preparation of paradichlorobenzene and a method for preparing the paradichlorobenzene by using such catalyst, wherein iron trichloride and disulfur dichloride are mixed according to a mass ratio of 5:3-12:7. The catalyst and the method have the advantages that the paradichlorobenzene is prepared by using the composite catalyst of the iron trichloride and the disulfur dichloride, the disulfur dichloride has an orientation effect, the productivity of the paradichlorobenzene is improved, the production of trichlorobenzene is inhibited, the conversion and the selectivity of the reaction are improved, the productivity of the paradichlorobenzene in chlorinated liquid is obviously improved, the purity of the prepared paradichlorobenzene product reaches up to 99.95 percent, washing and alkaline washing are not required during preparation, and the environmental pollution is reduced.

Owner:江苏省格林艾普化工股份有限公司

Air deodorization refreshener

The invention relates to an air deodorization refreshener and belongs to the technical field of cleaning and disinfection products. The air deodorization refreshener is prepared from the following raw materials in parts by weight: 30-38 parts of benzyl trichloroacetate, 2-9 parts of beewax, 12-19 parts of essence, 20-28 parts of oxalaldehyde, 5-12 parts of zinc ricinoleate, 10-21 parts of paradichlorobenzene, 25-36 parts of sodium tripolyphosphate and 5-15 parts of sodium tetraborate. The air deodorization refreshener provided by the invention can be applied to an environment or toilet stored with garbage; on the basis of the effect of masking peculiar smell, the air deodorization refreshenerthe can be used for initiatively removing peculiar smell and odour in the air due to a special raw material formula, matching ratio and combination.

Owner:CHENGDU SHUNFA DISINFECTANT & WASHING TECH

Anti-aging back film used for solar photovoltaic panel

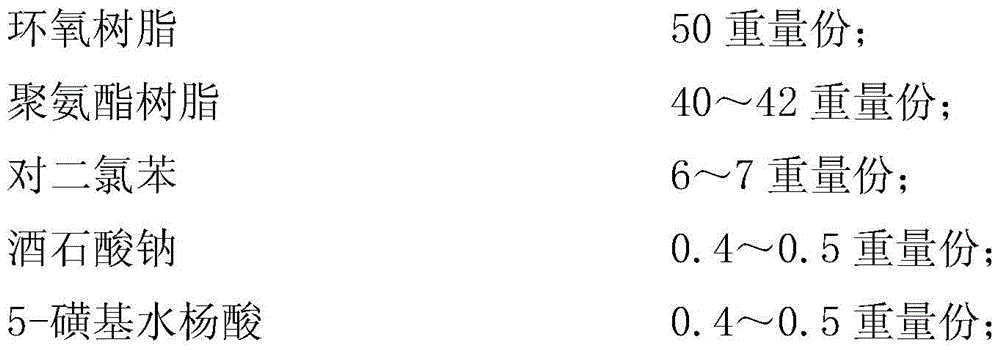

InactiveCN105679865AHigh bonding strengthImprove structural strengthPhotovoltaic energy generationSemiconductor devicesSulfosalicylic acidEngineering

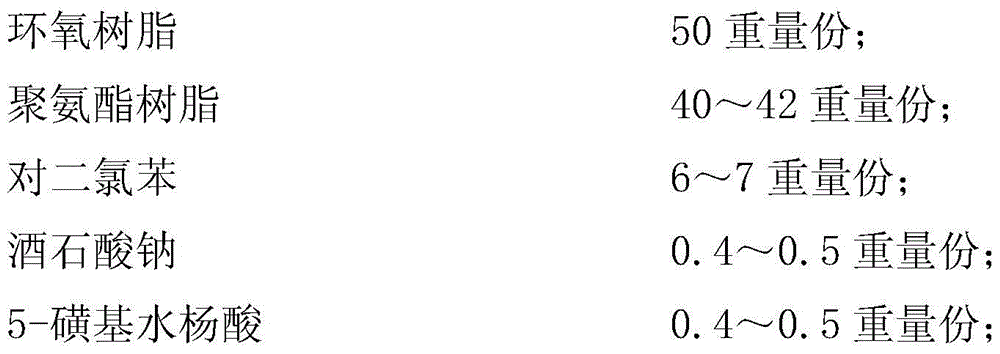

The invention discloses an anti-aging back film used for a solar photovoltaic panel. The anti-aging back film comprises a weather-proof layer, an adhesive layer and a carrion-resistant layer from upper to lower in sequence, wherein the weather-proof layer comprises the following components in parts by weight: 50 parts of epoxy resin, 40-42 parts of polyurethane resin, 6-7 parts of paradichlorobenzene, 0.4-0.5 parts of sodium tartrate and 0.4-0.5 parts of 5-sulfosalicylic acid; and the adhesive layer comprises the following components in parts by weight: 50 parts of polymethyl methacrylate, 22-23 parts of propylene-octyl methacrylate copolymer and 2-3 parts of ammonium acetate. According to the scheme, the anti-aging back film is obtained based on improvement on the structure and formula of the conventional back film structure, so that the binding strength between layers is improved; meanwhile, the structural strength, the corrosion resistance, the weather resistance and the anti-aging performance of the single layer body are reinforced; and therefore, the anti-aging back film is relatively long in service life, low in manufacturing cost and easy to popularize and apply.

Owner:SUZHOU JIAYIDA ELECTRICAL APPLIANCES

Method for recycling paradichlorobenzene in polyphenylene sulphide production mother liquor

InactiveCN105037082AImprove biodegradabilityReduce processing difficultyHalogenated hydrocarbon separation/purificationLiquid stateWastewater

The invention discloses a method for recycling paradichlorobenzene in polyphenylene sulphide production mother liquor. The method comprises the following steps: (1) firstly filtering the polyphenylene sulphide production mother liquor and removing impurities; (2) distilling the filtered polyphenylene sulphide production mother liquor at the temperature of 150-200 DEG C, so that an NMP solvent and paradichlorobenzene waste water are obtained; (3) then settling the paradichlorobenzene waste water for 6-18 hours at the temperature of 0-30 DEG C; (4) centrifuging and separating settled paradichlorobenzene to obtain crude paradichlorobenzene crystals; (5) melting the crude paradichlorobenzene crystals at the temperature of 50-80 DEG C, so that liquid-state crude paradichlorobenzene is obtained; (6) filtering liquid-state crude paradichlorobenzene, and removing insoluble substances in liquid-state crude paradichlorobenzene; and (7) settling liquid-state paradichlorobenzene with the insoluble substances removed for 1-2 hours at the temperature of 0-20 DEG C, so that refined paradichlorobenzene crystals are obtained. The method disclosed by the invention has the advantage that paradichlorobenzene in the polyphenylene sulphide production mother liquor can be recycled.

Owner:ZHANGJIAGANG XINSHENG NEW MATERIAL

Charging method used in polyphenylene sulfide production

The invention discloses a feeding method in the process of production of polyphenylene sulfide, which guarantees the mixture ratio of materials and simultaneously can reduce energy consumption, shorten the feeding time and guarantee smooth operation of subsequent reaction. The feeding method is characterized in that: firstly, the addition of a solvent is 30 to 40 percent of the total weight of the solvent when the solvent is added into a reaction kettle for the first time; secondly, the residual solvent is added into the reaction kettle after the procedure of temperature rise and dehydration is over, and added until the temperature in the reaction kettle is reduced to be suitable for addition of paradichlorobenzene; and thirdly, the paradichlorobenzene and all the residual solvent are added into the reaction kettle, and the feeding process is over. The feeding method can be widely applied to the process of production of the polyphenylene sulfide.

Owner:江苏新任环保科技有限公司

Boric oxide fibre moisture-proof coating material and method of manufacturing the same

The invention relates to a boric oxide fiber damp-proof coating material and the production method thereof, and belongs to the technical field of special ceramic. The invention comprises the steps as follows: liquid paraffin and paradichlorobenzene are mixed in the ratio of 100ml: (5 to 30) g. The liquid paraffin is mixed with the paradichlorobenzene to be heated and mixed by a magnetism mixing device with the heating temperature of 40 to 80 DEG C till the paradichlorobenzene unfreezes completely and the solution is cooled to the room temperature, then the damp-proof coating material for the boric oxide fiber is obtained. The coating material of the invention has the functions of drawing lubrication, and preventing the boric oxide fiber from pulverization. The material is coated at the surface of the front boric oxide fiber and can form a layer of thick protective films at the boric oxide fiber surface, and separates the corrosion of water to the boric oxide fiber, improves the intensity of the boric oxide fiber obviously, thereby improving the integrative performance of the boric oxide fiber and having good basis for research of the fiber reinforcing ceramics composite material. The invention which has simple and reasonable production method is convenient and practical.

Owner:ZHONGCAI HIGH NEW MATERIAL +1

Surface insulating paint for wind power generation

InactiveCN108441082AGood compatibilityImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyCalcium bicarbonate

Owner:FOSHAN JIUBAI TECH INFORMATION CONSULTATION CO LTD

Disincrustant with deodorizing function for toilet and preparation method thereof

InactiveCN109517669AFast descalingStrong pungent smellInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPhosphatePolyvinyl alcohol

The invention relates to a cleaning agent, in particular to a disincrustant for a toilet and a preparation method thereof. The disincrustant for the toilet is prepared from the following raw materialsin parts by weight: 40-60 parts of polyvinyl alcohol, 5-10 parts of fatty alcohol-polyoxyethylene ether, 6-8 parts of dodecyl trimethyl ammonium chloride, 10-12 parts of citric acid, 16-20 parts of mirabilite, 3-5 parts of stearic acid, 2-4 parts of polyacrylamide, 4-8 parts of paradichlorobenzene, 10-12 parts of phosphate, 10-20 parts of essence and 0.5-1.5 parts of a surfactant. The disincrustant can form a protecting film on the surface of a closestool to effect scaling effectively. The disincrustant is high in anti-scaling ability, prolongs the cleaning period of the closestool and can prevent bacteria breeding. The preparation method is simple and feasible.

Owner:任纪伟

Coating-grade polyphenylene sulfide (PPS) resin and preparation method thereof

InactiveCN104861164AReduce crystallinityImprove brittlenessCoatingsReaction temperatureParadichlorobenzene

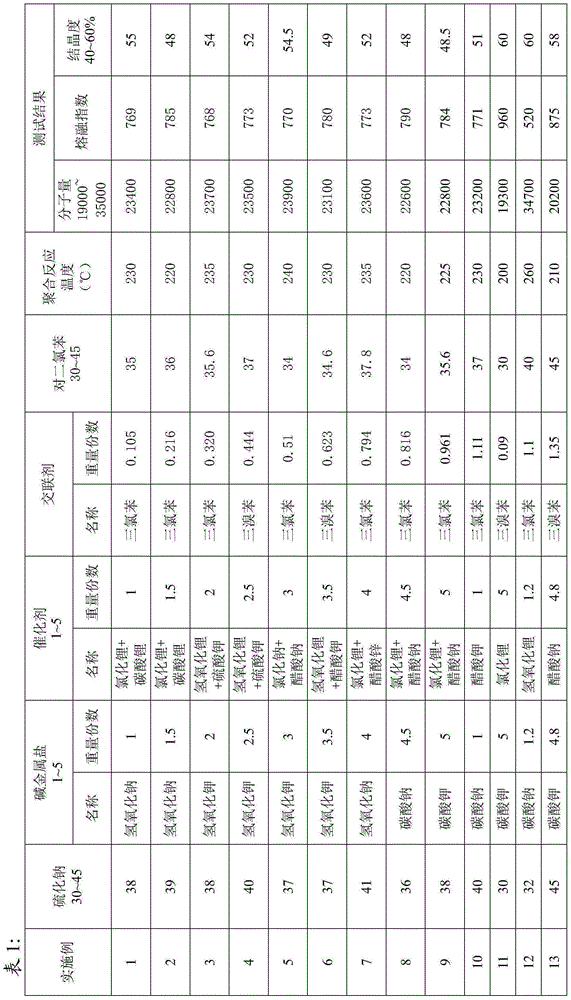

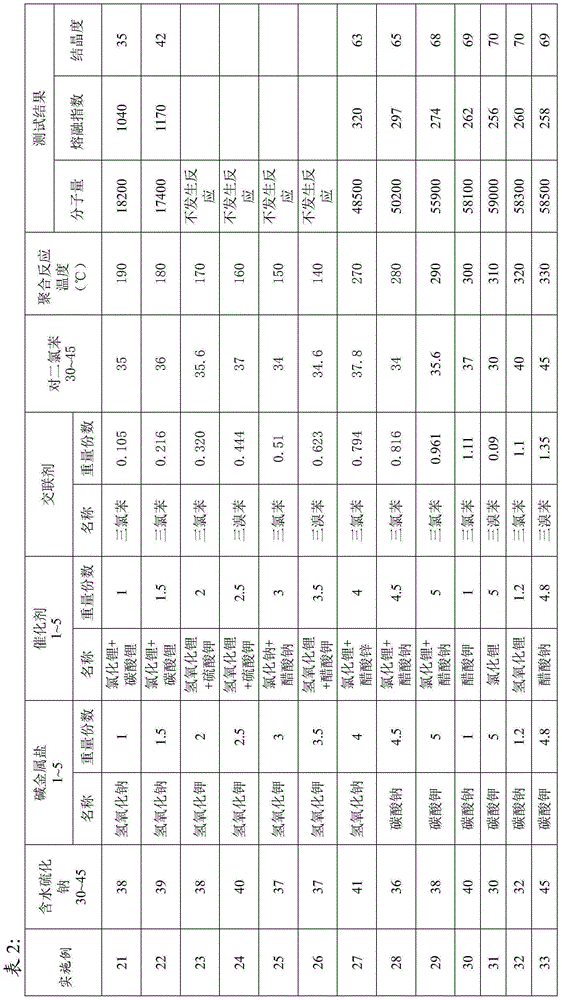

The invention discloses coating-grade polyphenylene sulfide (PPS) resin which is mainly prepared by enabling sodium sulfide, alkali metal salts, a crosslinking agent, a catalyst and paradichlorobenzene to react for 3-6 hours at 200-260 DEG C, wherein the crosslinking agent is trichlorobenzene or tribromobenzene. The invention further provides a preparation method of the coating-grade PPS resin. The preparation method comprises the following steps: (1) stirring and dispersing sodium sulfide and the alkali metal salts in a solvent NMP (N-methyl pyrrolidone), and dehydrating, thereby obtaining a mixture; (2) adding the solvent NMP, the catalyst, the crosslinking agent and paradichlorobenzene into the mixture, and heating to be 200-260 DEG C for polymerization reaction for 3-6 hours, thereby obtaining the coating-grade PPS resin. When the coating-grade PPS resin is synthesized, as a proper amount of the crosslinking agent is added, and the reaction temperature and the reaction time are controlled, the requested flowability of a coating can be met, the rigidity of PPS resin can be alleviated, the toughness and the adhesion strength can be improved, and thus the coating-grade PPS resin is applicable to insulation or anti-corrosion coatings on inner and outer surfaces of metals.

Owner:GUANGZHOU GAOBAER PLASTIC

Moth-resistant PP (Polypropylene) foaming board with paradichlorobenzene and preparation method thereof

The invention discloses a moth-resistant PP (Polypropylene) foaming board with paradichlorobenzene and a preparation method thereof. The moth-resistant PP foaming board is prepared from the following raw materials in parts by weight: 88-104 parts of polypropylene resin, 5-10 parts of phenoxyethanol, 7-12 parts of carnauba wax, 14-22 parts of epoxy rice bran oleic acid butyl ester, 16-24 parts of light calcium powder, 4-8 parts of permethrin, 10-15 parts of eucalyptus essential oil, 25-40 parts of sulfur-fixing ash residue, 1-3 parts of azodicarbonamide, 19-36 parts of bauxite tailing, 2-4 parts of lead cyanurate, 13-27 parts of alumina-chrome slag, 15-20 parts of paradichlorobenzene, 14-22 parts of aluminium oxide, 3-6 parts of sodium bicarbonate and 18-34 parts of calcined flint clay tailing. Due to the added materials such as the phenoxyethanol, the permethrin, the eucalyptus essential oil and the aluminium oxide, the moth resistance of the material can be obviously improved. The moth-resistant PP foaming board disclosed by the invention has the advantages of good heat insulation property, good sound-proof effect, good moth-resistant effect, excellent ageing resistance and long service life and the like.

Owner:郭云鹏

Process for synthesizing low-chlorine polyphenylene sulfide resin

The invention discloses a process for synthesizing low-chlorine polyphenylene sulfide resin. Sodium sulfide and paradichlorobenzene are used as raw materials, N-methyl-2-pyrrolidone is used as a solvent, and the molar ratio of the sodium sulfide to the paradichlorobenzene is 1:1. The synthesis process mainly comprises the following steps of: in a sodium sulfide dehydration treatment phase, carrying out sodium sulfide solution insulating and water sucking treatment by adopting three layers of 18cm water sucking column containing a 5 angstrom molecular sieve in each layer to form a sodium sulfide solution with the water content of 1.2-1.5mol / molNa2S and adding NaOH with the molar mass of 0.1-0.3mol / molNa2S; and in the polycondensation phase, adding Na2SO4 of 0.1-0.05mol / molNa2S and H2S gas of 0.01mol / molNa2S. The invention has lower halogen total content and polydispersion coefficient in the obtained product, narrow molecular weight distribution, high oxygen index and excellent electrical insulating property and can be used as a packaging material of an electronic device.

Owner:四川得阳特种新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com