Patents

Literature

97results about How to "Control reaction process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemically excited combustion process for synthesizing Si3N4/SiC composite powder

The present invention belongs to the field of inorganic material technology, and is especially chemically excited combustion process for synthesizing Si3N4 / SiC composite powder. The Si3N4 / SiC composite powder is prepared with silica powder in 40-70 weight portions, carbon black in 20-50 weight portions, and chemical energizer in 0.5-20 weight portions, and through mg to obtain mixture, grinding and activating the mixture, loading in a high pressure reaction kettle in the bulk density of 0.3-1.0 g / cu cm, vacuum pumping and filling N2 or Ar in the pressure of 1-3 MPa, and inducing the mixture to produce self-spreading combustion synthesis reaction to prepare Si3N4 / SiC composite powder. The process of the present invention has the advantages of simple steps, short production period, low power consumption and low cost.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

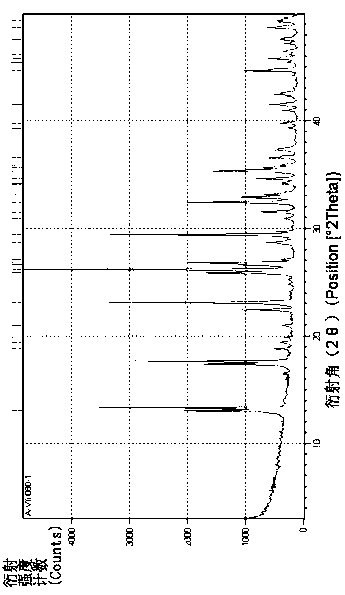

Silicon carbide powder and preparation method thereof

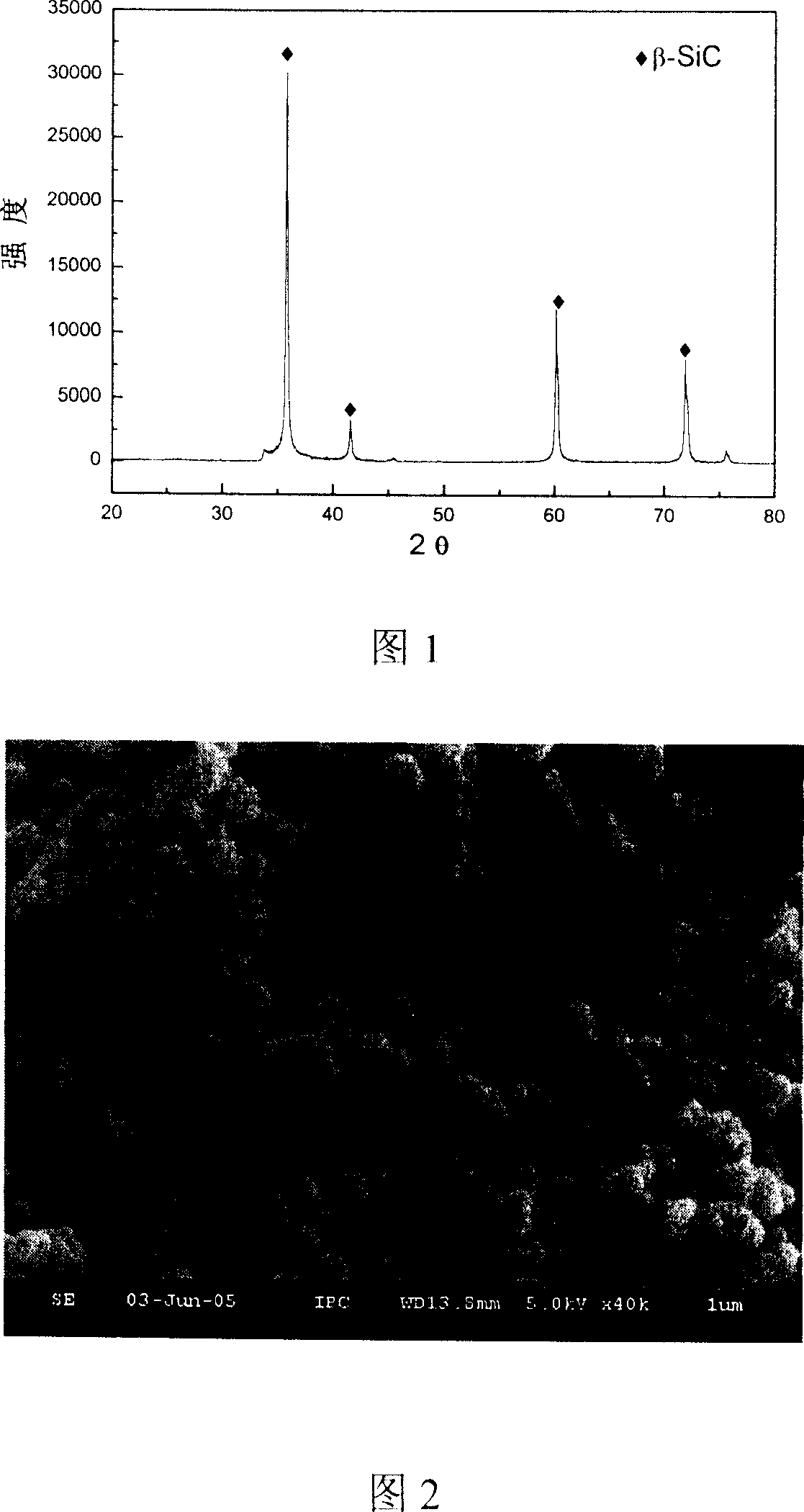

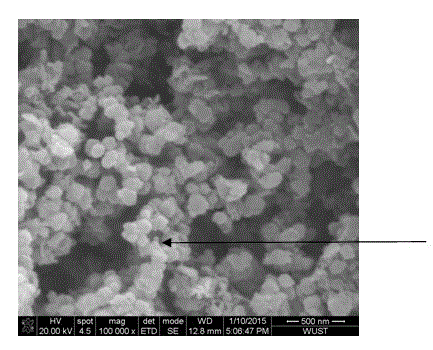

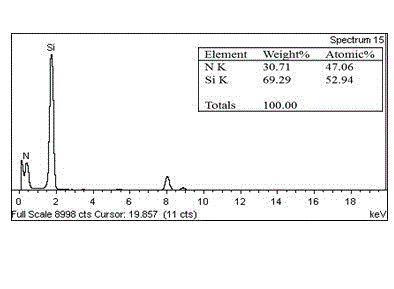

InactiveCN102491333AControl reaction processLow reaction temperatureNanotechnologySilicon carbideCarbide siliconReaction temperature

The invention specifically relates to silicon carbide powder and a preparation method thereof. According to a technical scheme, the preparation method comprises the following steps of: uniformly mixing 5-20 percent by weight of nano-silicon dioxide or silica micro-powder, 0.5-2.5 percent by weight of carbon black or amorphous graphite powder, 70-88 percent by weight of an alkali metal chloride and 5-15 percent by weight of aluminum powder serving as raw materials; putting the uniformly-mixed raw materials into a tubular electric furnace, raising the temperature to 800-1,000 DEG C at the temperature raising rate of 4-10 DEG C per minute under the atmosphere of argon, and preserving heat for 2-10 hours; and putting an obtained product into nitric acid of which the concentration is 2-5 mol / L for soaking for 3-8 hours, filtering, cleaning with deionized water till the pH value of a cleaning solution is 7.0, and drying at the temperature of 110 DEG C for 8-24 hours to obtain silicon carbide powder. The method has the characteristics of low reaction temperature, simple process, controllable synthesis process, low production cost, and the like; and the prepared silicon carbide powder has the characteristics of high crystallization, high product purity, freeness from an impure phase and powder particle size of 50-200 nanometers.

Owner:WUHAN UNIV OF SCI & TECH

Casting mixture for epoxy casting transformer and preparation method thereof

The invention discloses a casting mixture for an epoxy casting transformer, which comprises the following raw materials in part by weight: 1 part of epoxy resin, 2.5 to 3.1 parts of silicon micropowder, 0.1 to 0.2 part of toughening agent, 0 to 0.02 part of color paste, 0.6 to 0.7 part of curing agent, and 0.001 to 0.003 part of accelerating agent. The preparation method for the casting mixture comprises the following steps: melting the materials; adding the silicon micropowder, the toughening agent, the color paste, the curing agent, and the accelerating agent in the melted epoxy resin in turn under the conditions of heating and stirring; and then performing vacuum defoamation. Due to the adoption of mixed glue prepared from the components of the casting mixture by the preparation method thereof, the crack ratio of a cast casting body can be reduced, and the quality of the product can be improved.

Owner:PINGGAO GRP +2

Preparation method for iron-based super conductor

ActiveCN102522154AHigh purityReduce generationSuperconductors/hyperconductorsSuperconductor devicesMaterials scienceIron based

Owner:深创超导(深圳)科技有限公司

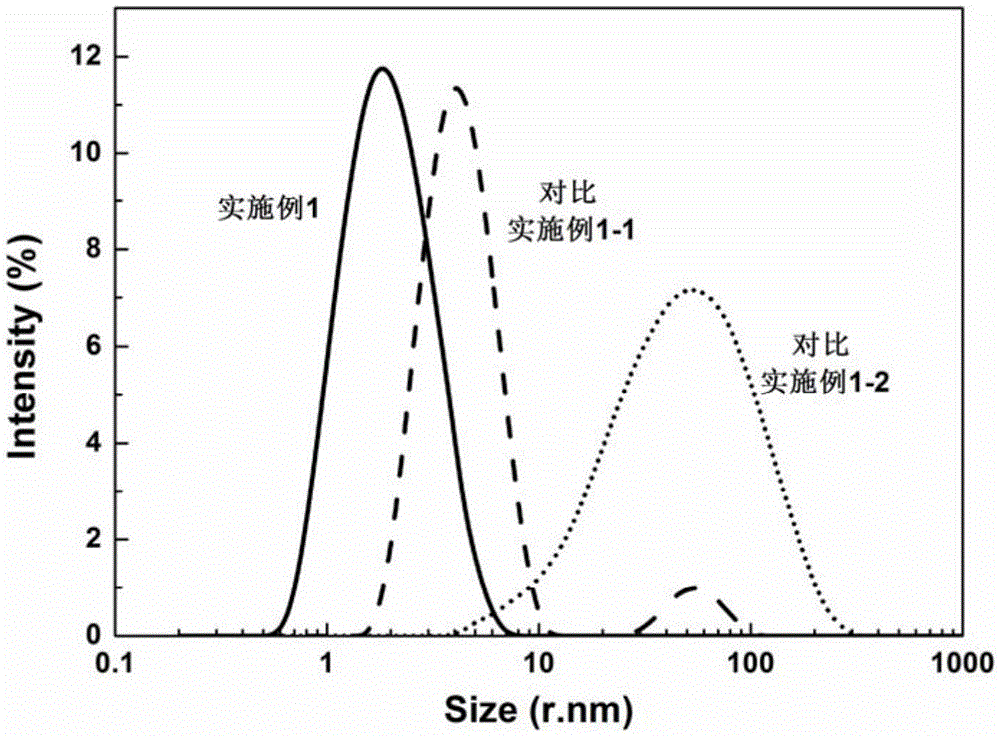

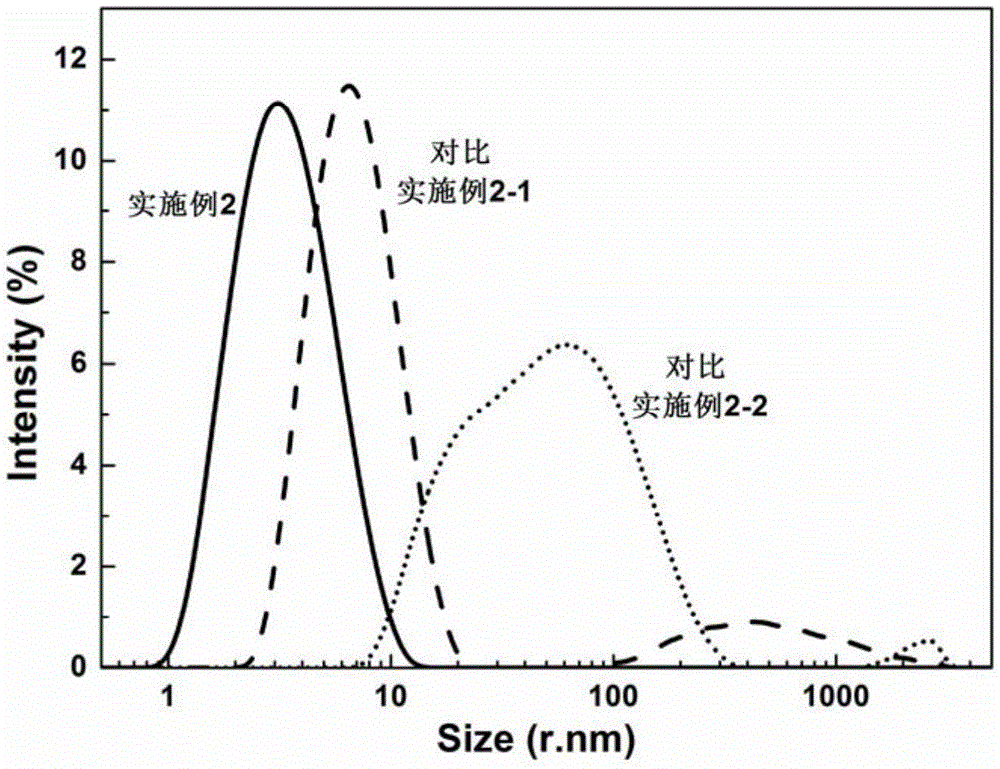

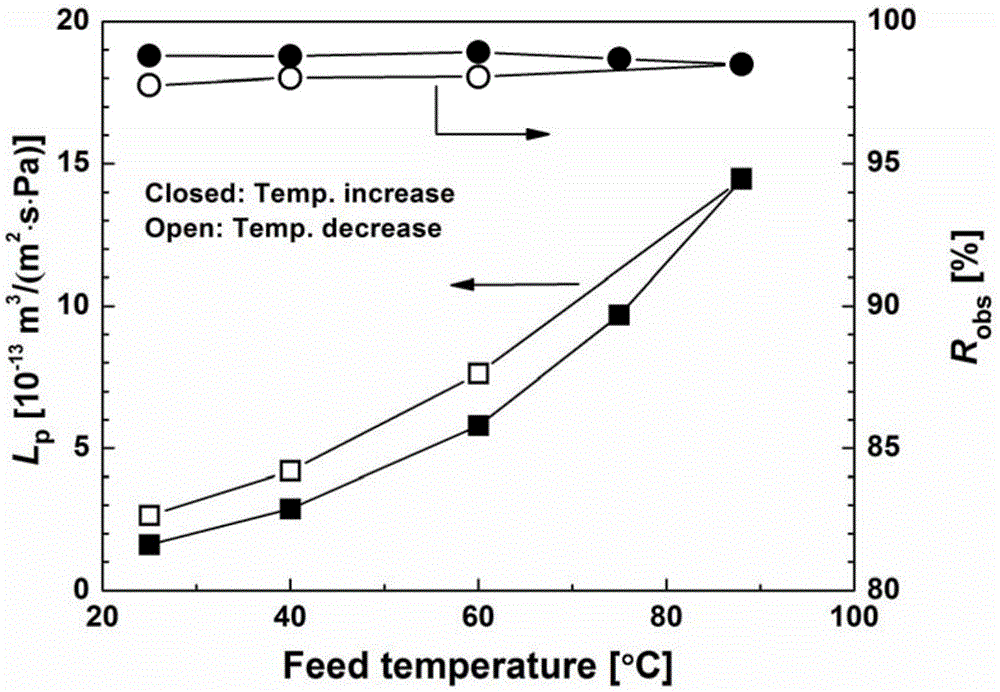

Preparation method and application of organosilicone sol based on pH swing

ActiveCN105597561AEnhanced network structureLarge particle sizeMembranesSemi-permeable membranesWater bathsAlcohol

The invention belongs to the field of preparation of inorganic membrane materials, in particular to a preparation method and application of an organosilicone sol based on pH swing. The preparation method comprises the following steps of adding an organosilicone source precursor into absolute ethyl alcohol; after stirring in water bath, adding deionized water; on the premise of continuous stirring in the water bath, adjusting the pH of the system to acidity by using acid and reacting for one hour; adjusting the pH of the system to weak acidity or neutrality, and reacting for one hour to prepare the organosilicone sol of which particle size distribution is extremely-narrow and stable; gelatinizing the sol into a membrane for reverse osmosis desalination. The organosilicone reverse osmosis membrane shows excellent hydrothermal stability and salt rejection rate.

Owner:CHANGZHOU UNIV

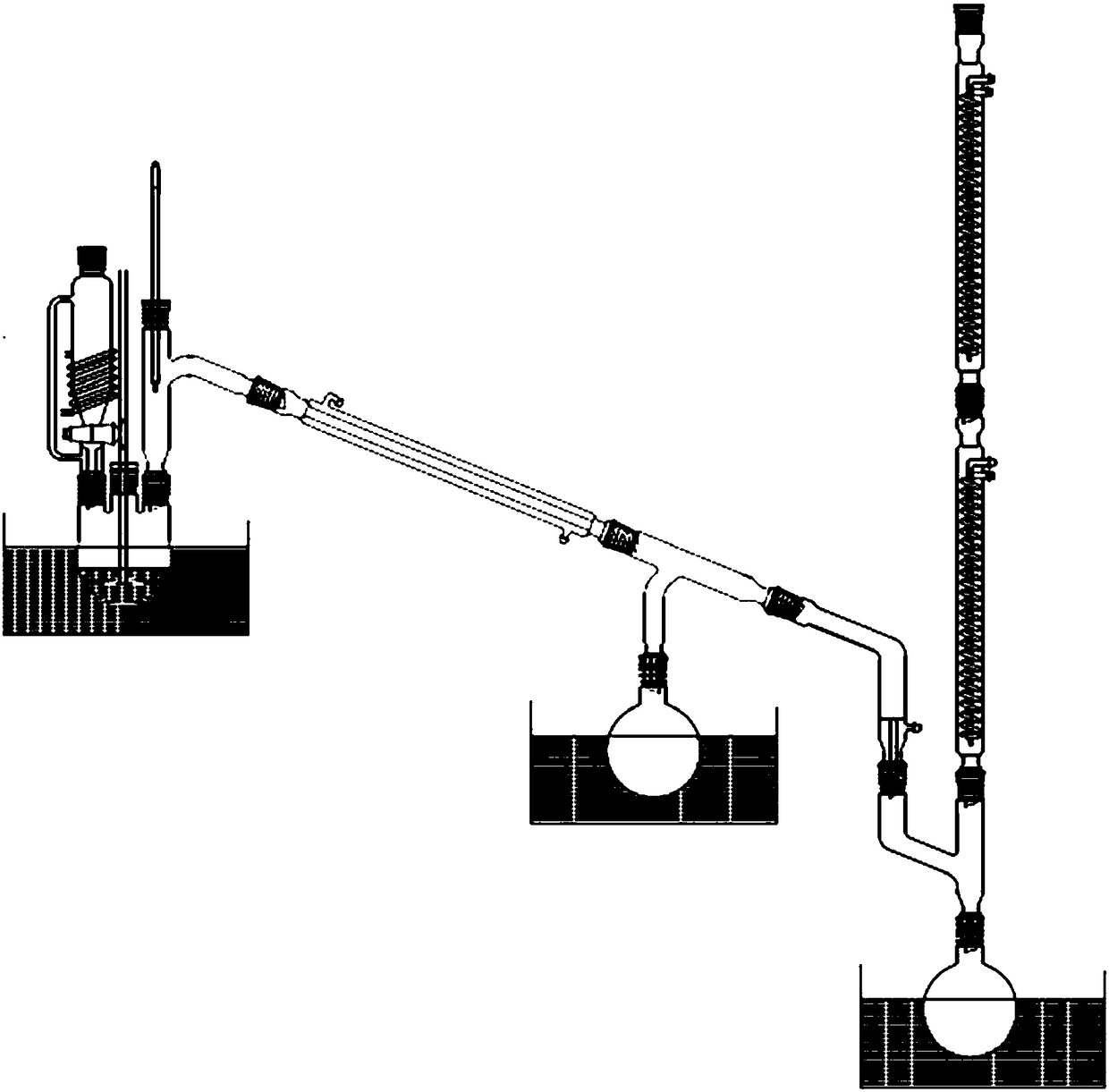

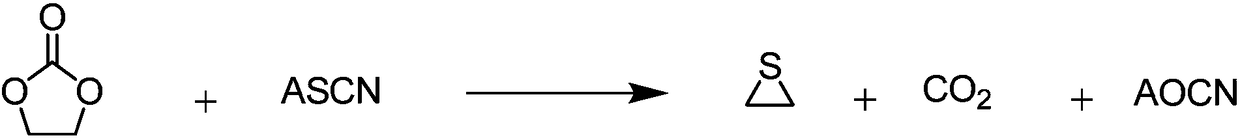

Method for preparing diethylaminoethanethiol

ActiveCN109134322AReduce generationLower requirementThiol preparationVapor–liquid separatorGas phase

The invention provides a method for preparing diethylaminoethanethiol. The method comprises the steps that 1, a part of pre-heated and liquefied ethylene carbonate with the amount being 0.2-0.7 time of the total feeding amount of ethylene carbonate is added and stirred, the temperature is controlled to be 40-70 DEG C, then thiocyanate is added, the temperature is quickly increased to 75-105 DEG C,thiirane generated by reactioni s collected through a condensation system and a gas-liquid separator, meanwhile, remaining ethylene carbonate with the temperature of 45-85 DEG C starts to be added dropwise, the temperature is controlled to be 80-110 DEG C in the dropwise adding process, the temperature continues to be increased to 130-140 DEG C after dropwise addition, and the reaction is finished until fractions cannot be evaporated; 2, thiirane and diethylamine are subjected to closed reaction and are gradually heated to 110-130 DEG C, the pressure of 0.3-0.7 MPa is kept for 0.5-1.5 h, andthe reaction is finished. The method avoids the outrush risk is avoided, the reaction time is short, the quantity of generated impurities is small, the yield of the obtained product, namely diethylaminoethanethiol, reaches 98% or above, and the gas-phase detection purity of the product is 99% or above.

Owner:保定加合精细化工有限公司

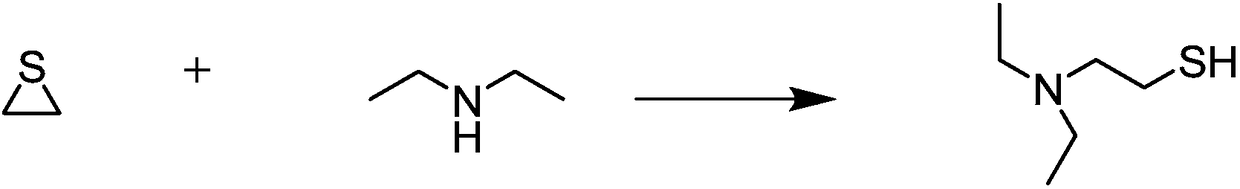

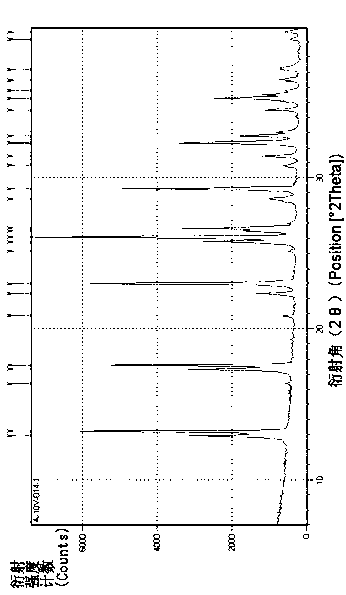

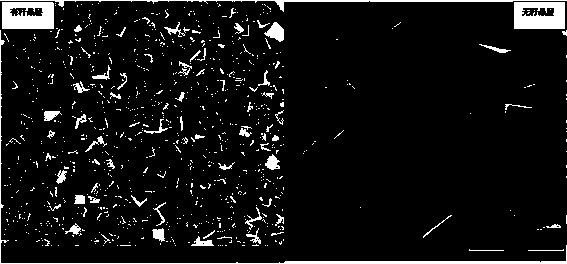

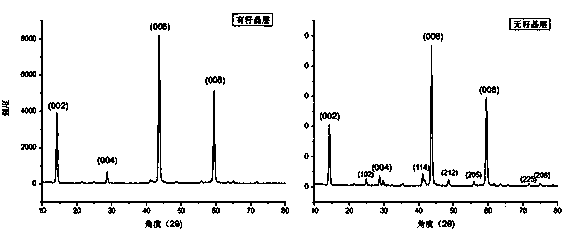

Single-phase alpha-Si3N4 micropowder and preparation method thereof

The invention relates to a single-phase alpha-Si3N4 micropowder and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps: uniformly mixing 5-30 wt% of simple substance silicon powder, 15-45 wt% of solid nitrogen source and 40-80 wt% of halide powder to prepare a mixture; putting the mixture into an electric tube furnace, heating to 1000-1300 DEG C at the heating rate of 2-10 DEG C / minute in a nitrogen atmosphere, and keeping the temperature for 2-6 hours; repeatedly washing the product with deionized water until no white precipitate appears when respectively titrating with AgNO3 and Ca(NO3)2 solutions; and finally, drying at 110 DEG C for 10-24 hours to obtain the single-phase alpha-Si3N4 micropowder. The preparation method has the characteristics of low reaction temperature, low cost, simple synthesis technique, controllable process, high yield and wide industrialization prospects. The particle size of the prepared single-phase alpha-Si3N4 micropowder is 100-500nm; and the single-phase alpha-Si3N4 micropowder has the advantages of no impurity phase, high activity, small particle aggregation and uniform particle size distribution.

Owner:WUHAN UNIV OF SCI & TECH

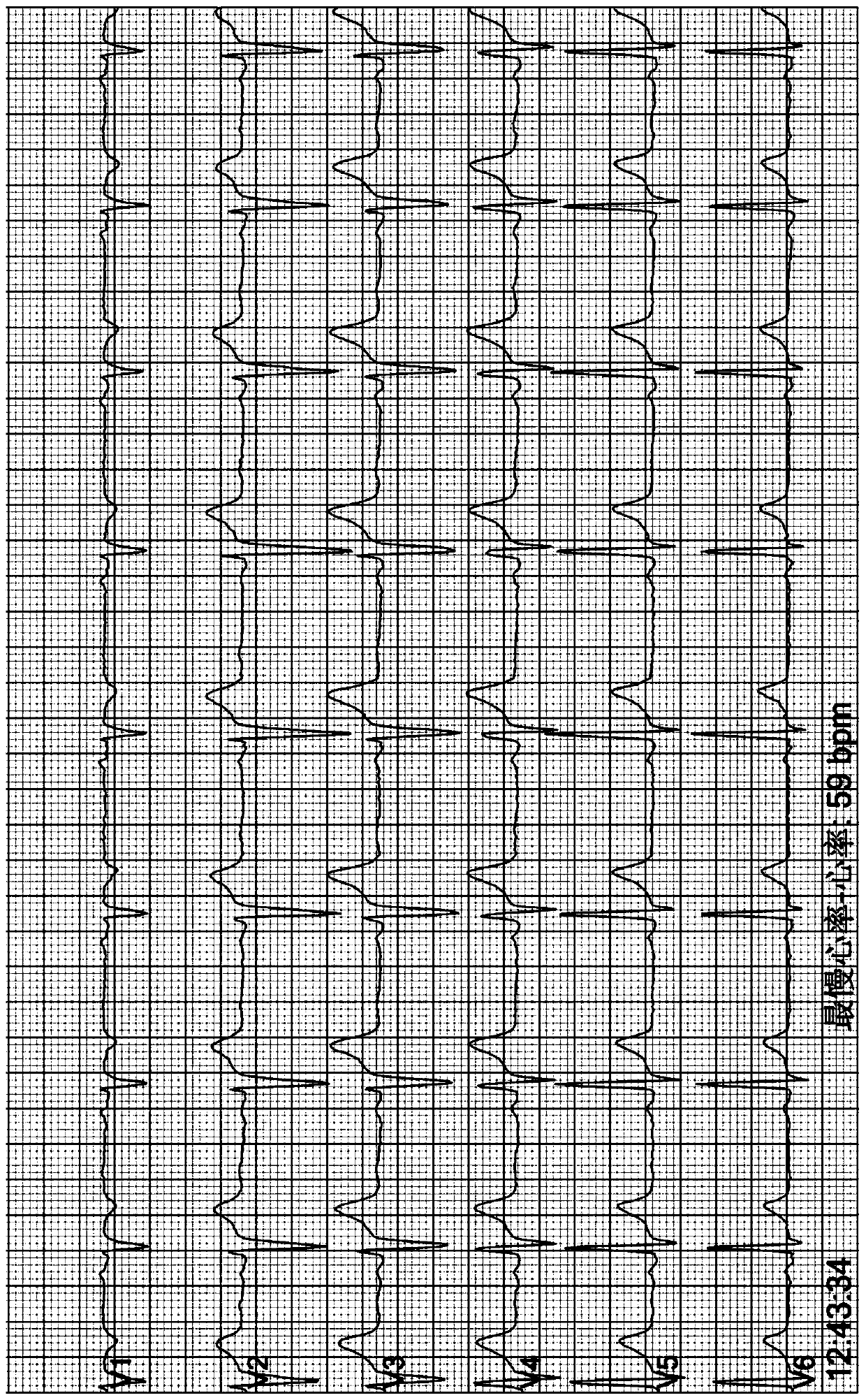

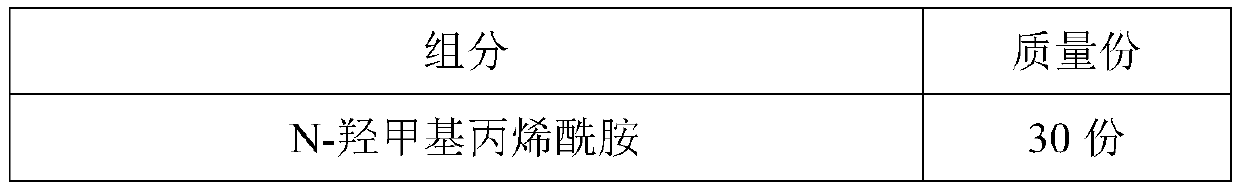

Light-cured cross-linked conductive hydrogel as well as preparation method and application thereof

ActiveCN111057186AAvoid it happening againWell mixedDiagnostic recording/measuringSensorsPolymer scienceCross linker

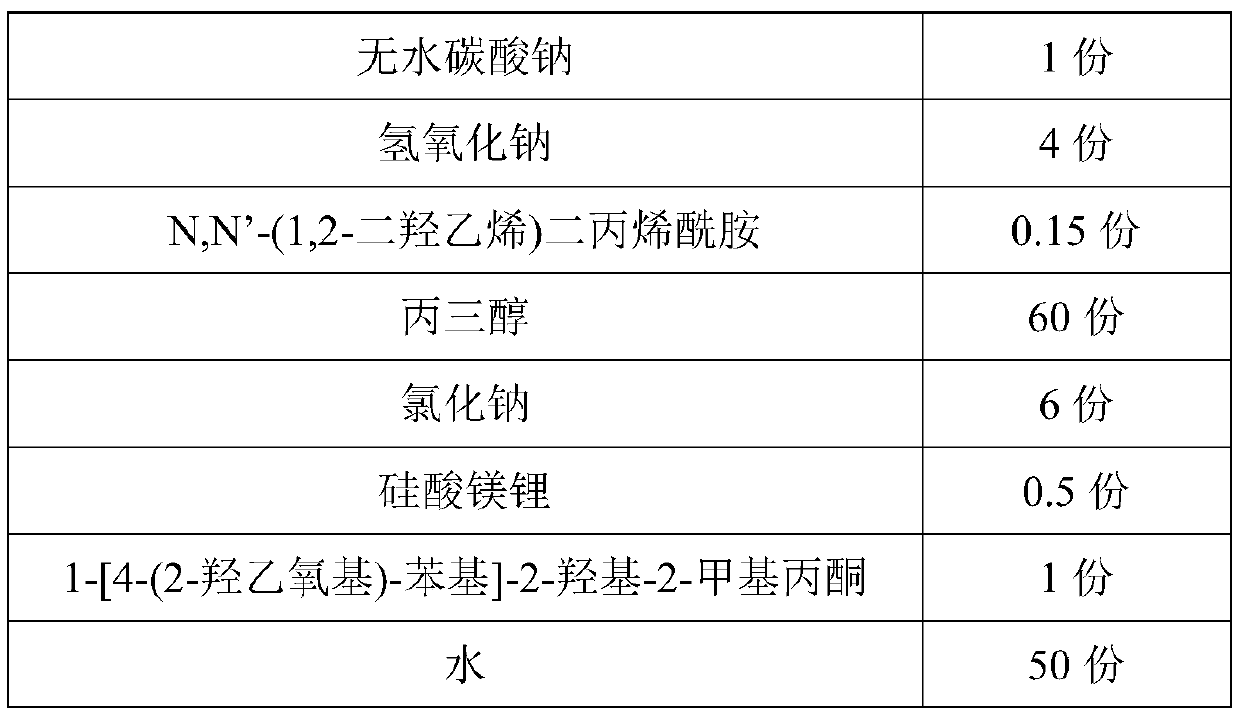

The invention discloses light-cured cross-linked conductive hydrogel as well as a preparation method and application thereof. The light-cured cross-linked conductive hydrogel is prepared from the following components in parts by mass: 12 to 40 parts of a monomer, 3 to 9 parts of a neutralizer, 0.07 to 0.3 part of a cross-linking agent, 20 to 65 parts of a humectant, 4 to 10 parts of a conductive agent, 0.3 to 5 parts of a thickening agent, 0.2 to 1.2 parts of a photoinitiator and 20 to 70 parts of water, wherein the monomer is an acrylamide monomer. The invention also discloses a preparation method of the light-cured cross-linked conductive hydrogel, and an application of the light-cured cross-linked conductive hydrogel in preparation of an electrocardio-electrode patch. The light-cured cross-linked conductive hydrogel has the characteristics of strong conductivity, good biocompatibility and the like. The disposable electrocardio-electrode patch prepared from the gel can keep good contact with the skin for a long time without dryness and is non-irritant to the skin, and the obtained electrocardio-signals are stable in potential, clear in waveform and convenient to operate.

Owner:GUANGDONG PROV MEDICAL INSTR INST

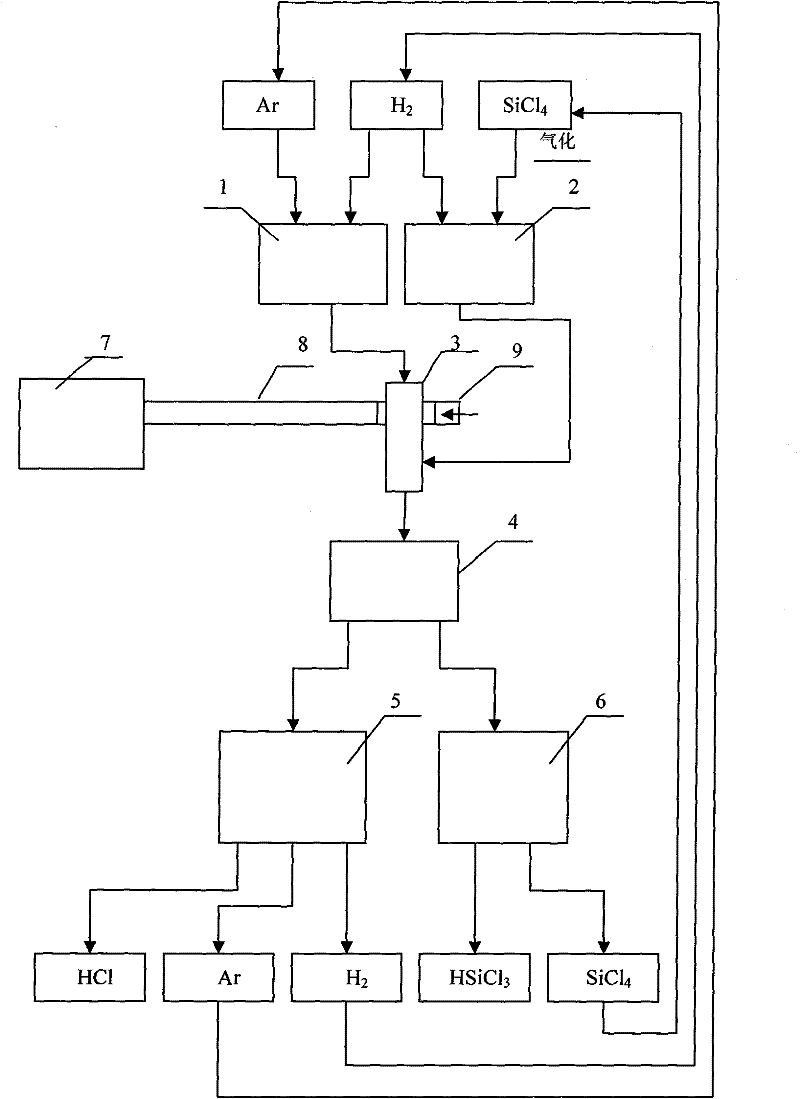

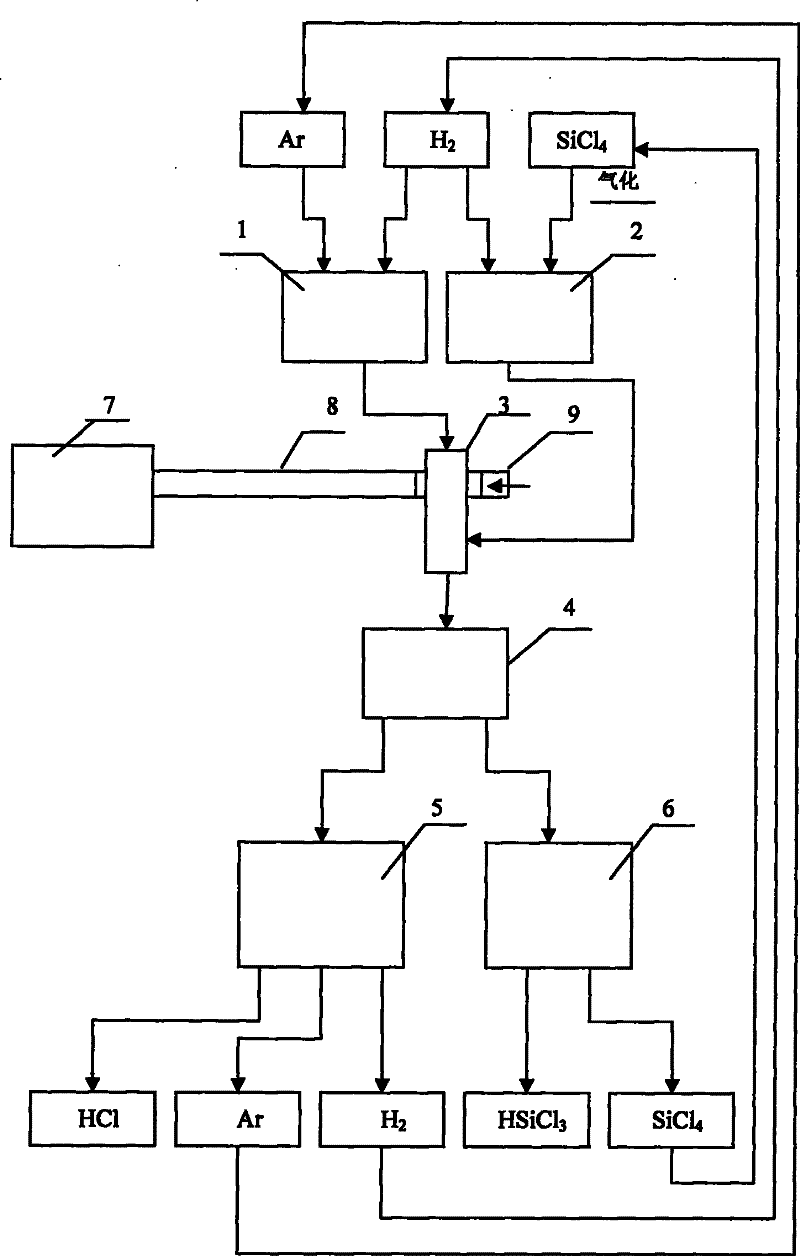

Method for preparing trichlorosilane and dichlorosilane by hydrogenating silicon tetrachloride through microwave plasma

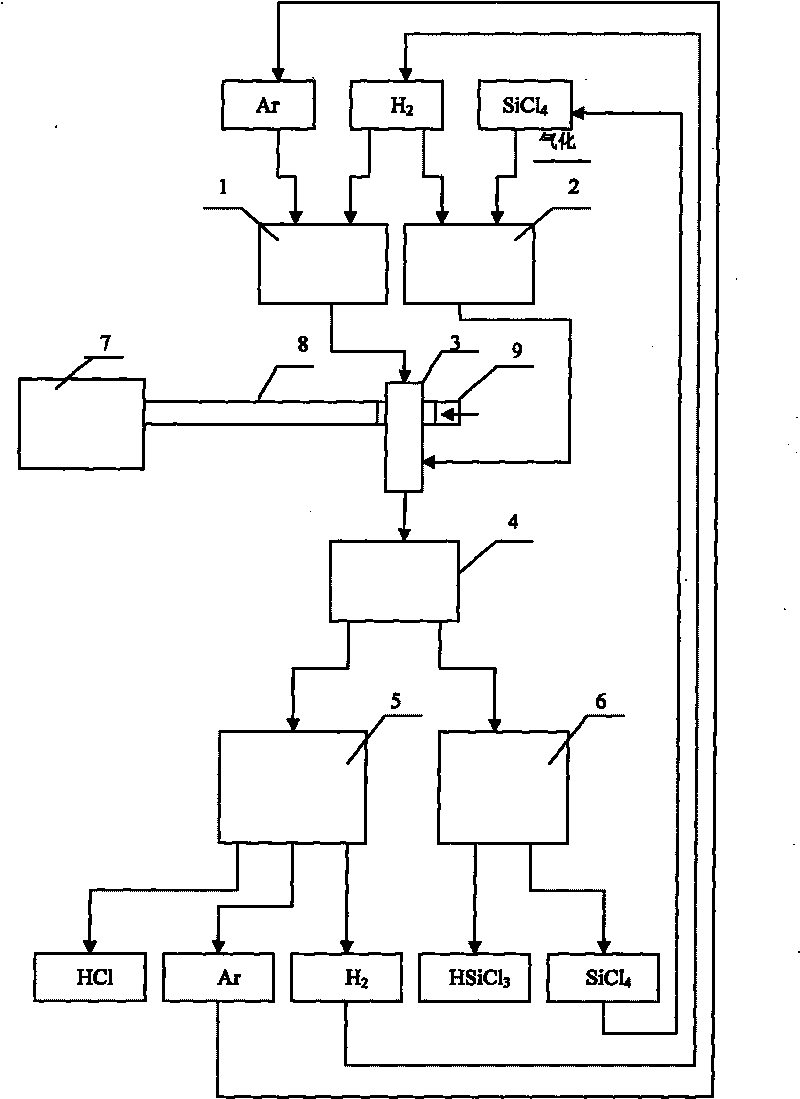

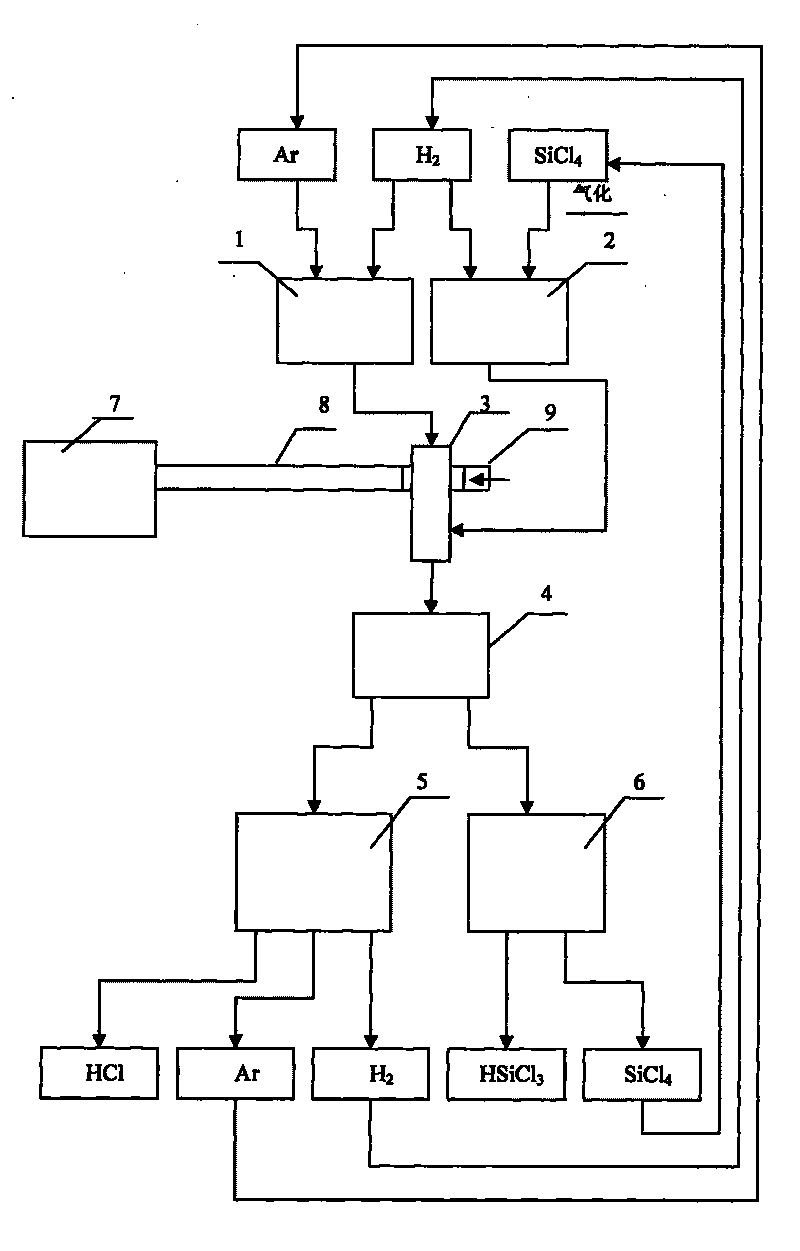

The invention provides a method for preparing trichlorosilane and dichlorosilane by hydrogenating silicon tetrachloride through microwave plasma, which aims to solve the problems of high energy consumption, low single-pass conversion rate and high equipment investment in the catalytic hydrogenation of the silicon tetrachloride by a Siemens method and problems of high energy consumption and material consumption and difficult industrialization in hydrogenating the silicon tetrachloride by a conventional thermal plasma method and a radio-frequency induction plasma method in the conventional polysilicon industry. The method comprises the following steps: forming a stable cold plasma through arced hydrogen, argon or a mixture of the two under excitation of microwaves; forming a plasma jet flow by a plasma torch under the condition of the flow of the arced gas; and ejecting feed gas into a specific area of the plasma jet flow to form an active particle consumption zone in which the silicon tetrachloride is hydrogenated into trichlorosilane. The single-pass conversion rate of the silicon tetrachloride of the method reaches about 60 percent; and the method has the advantages of simple subsequent treatment of a product, low requirement on equipment and operation control, and easy realization of industrialization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

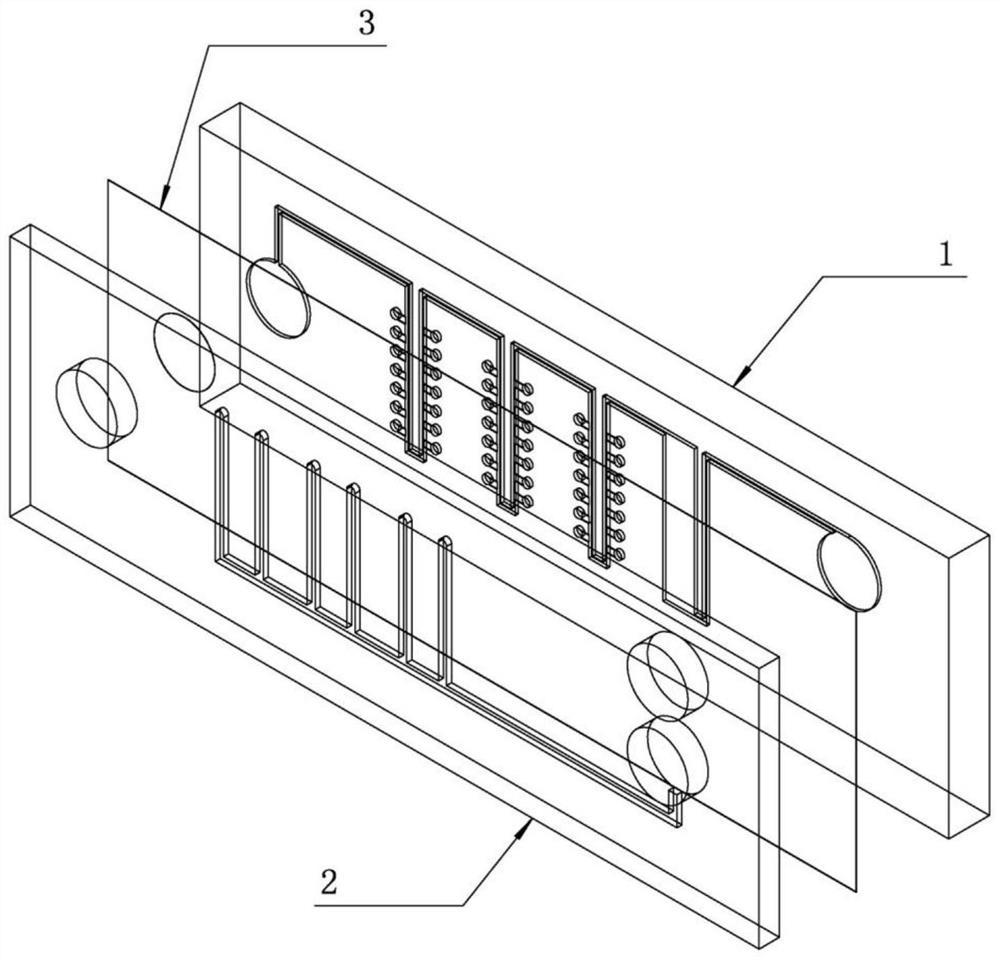

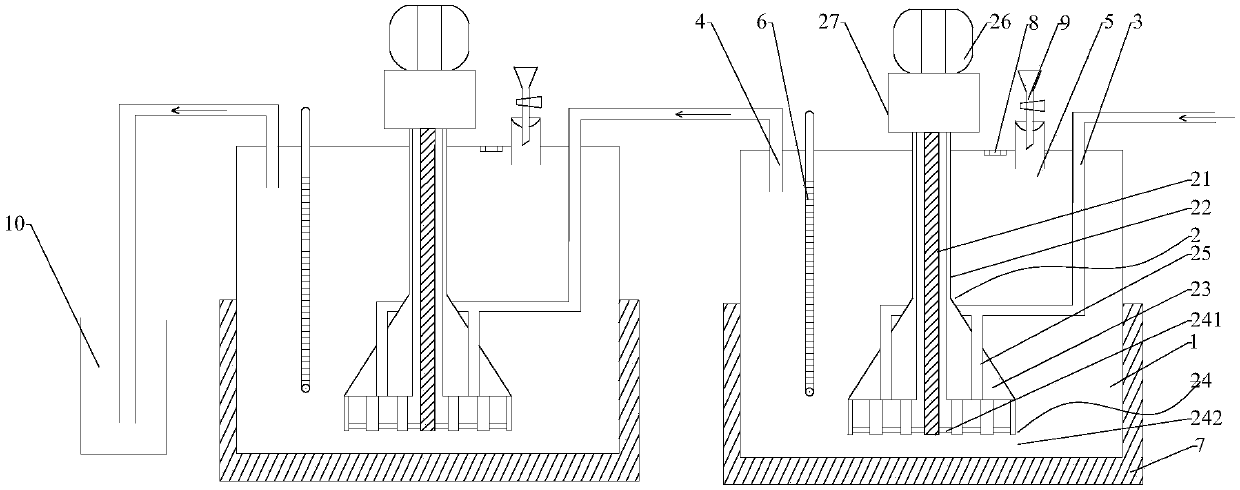

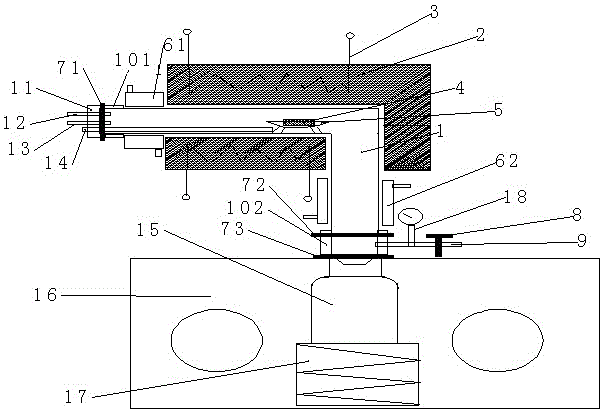

Gas-solid phase continuous reaction device with heat transfer enhancing function

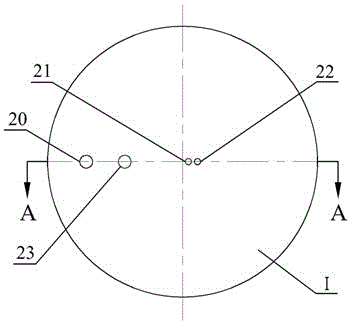

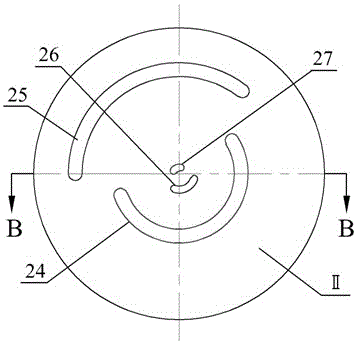

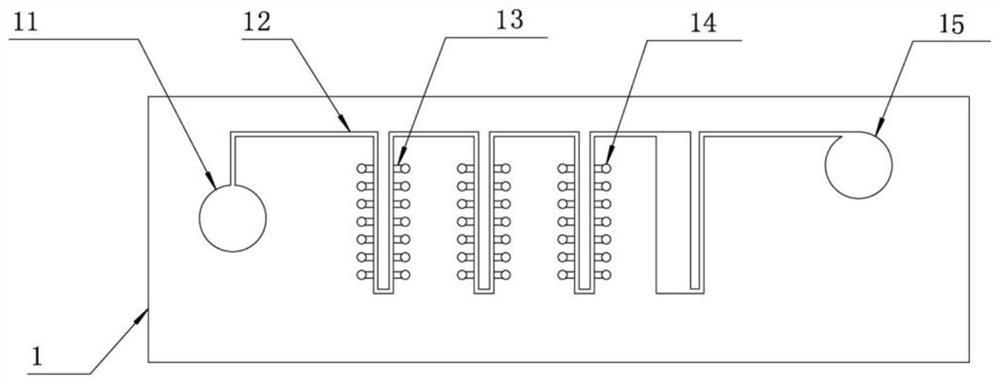

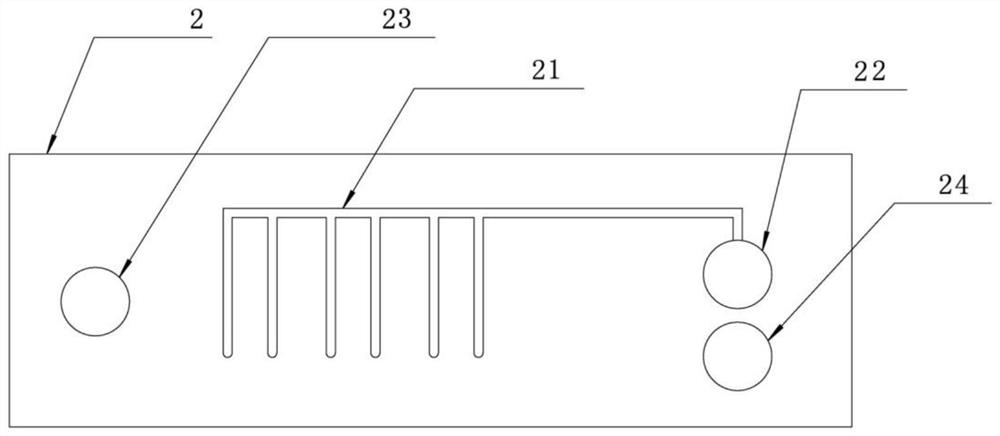

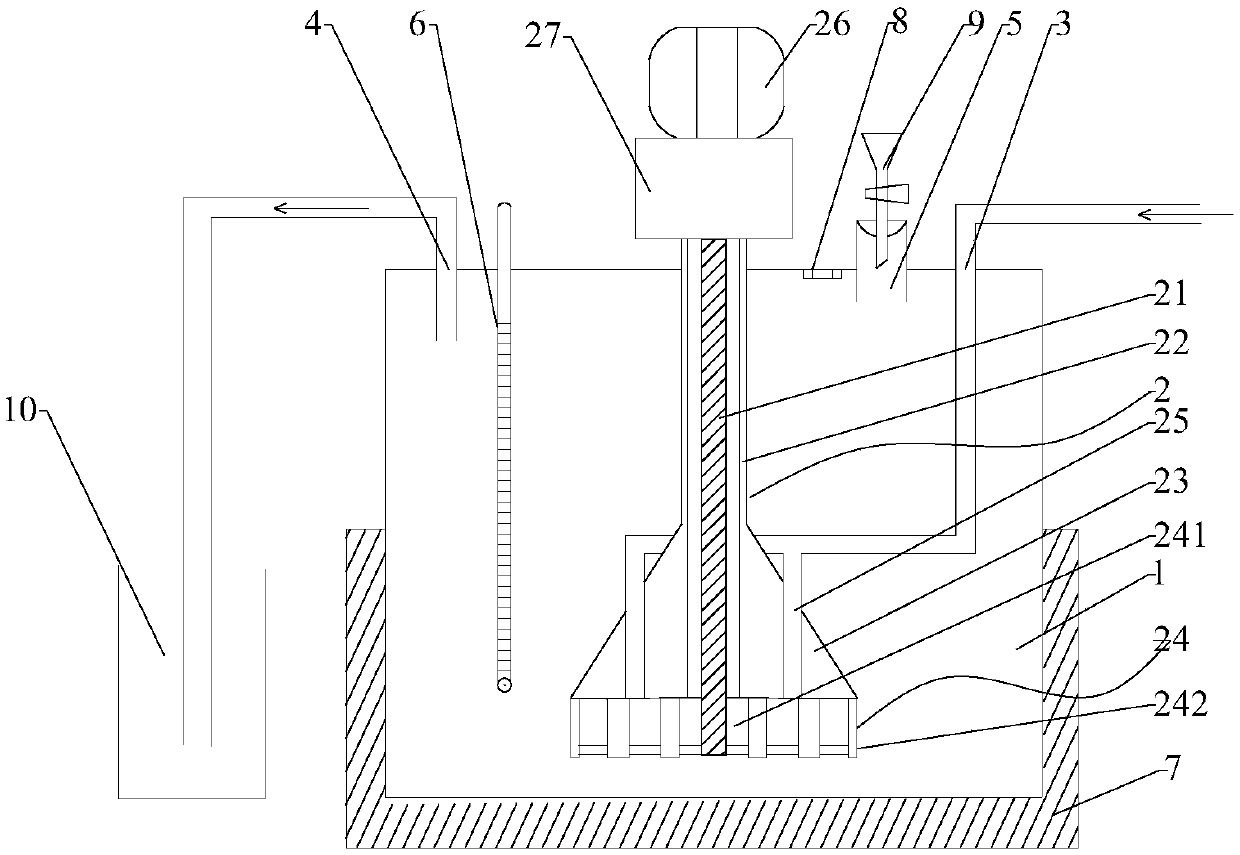

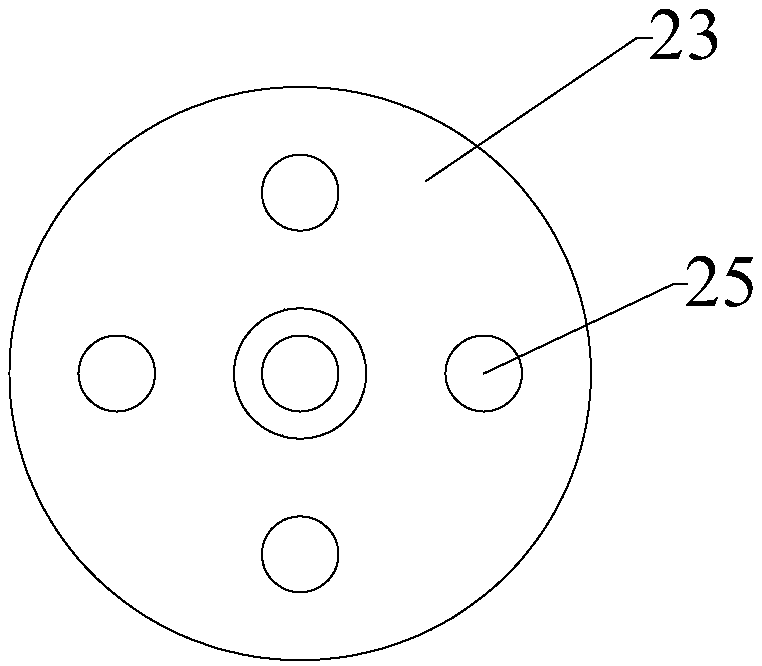

ActiveCN106179167AControl reaction timeControl reaction processChemical/physical/physico-chemical stationary reactorsFeed devicesGas solidGas phase

The invention discloses a gas-solid phase continuous reaction device with a heat transfer enhancing function. The gas-solid phase continuous reaction device comprises a rotating disc (I), a fixed disc (II) and a reactor (III), wherein a gas phase inlet, a gas phase outlet, a cold fluid inlet and a hot fluid inlet are distributed in the rotating disc along the radial distribution; a gas phase inlet groove, a gas phase outlet groove, a cold fluid inlet groove and a hot fluid inlet groove are distributed in the fixed disc; distances between the grooves and the center of the rotating disc are equal to distances between corresponding holes of the rotating disc and the center of the rotating disc, the width of each groove is equal to the diameter of a corresponding hole, and a central angle of each groove (namely groove length) depends on reaction time period required to be controlled by a user. The gas-solid phase continuous reaction device has the characteristics of continuous operation, controllable reaction time, high equipment utilization rate, stable technological parameters, convenience in operation, guarantee of production safety, simple structure, low cost and the like.

Owner:NORTHWEST UNIV(CN)

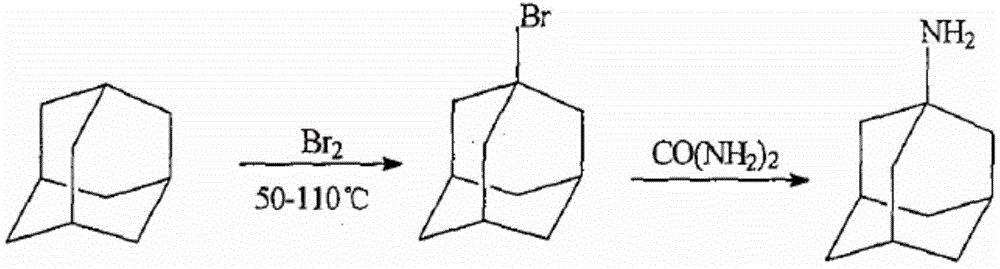

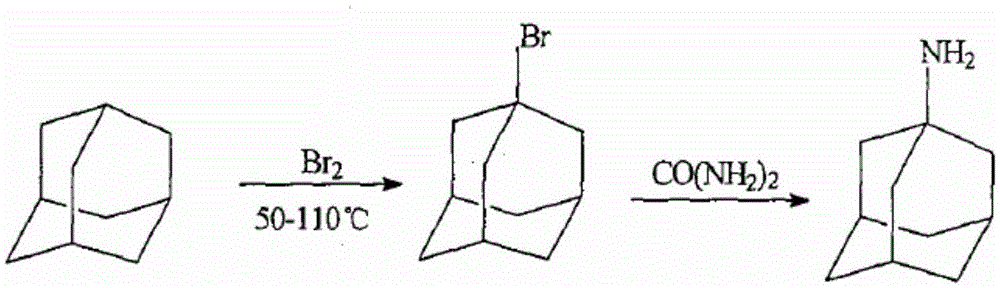

Process for high-yield preparation of amantadine hydrochloride

InactiveCN105523942AReduce harmEnvironment-friendlyOrganic compound preparationCarboxylic acid amides preparationTwo stepAmmonia

The invention discloses a process for high-yield preparation of amantadine hydrochloride; the process includes two steps of (1) preparation of 1-acetamidodamantane and (2) preparation of amantadine hydrochloride. Amantadine hydrochloride can be prepared in one reaction kettle, so the operation steps are simplified; in addition, by using a phase transfer catalyst, the reaction effect is promoted; with a selected solvent system after screening, the reaction conversion rate and yield are increased, and costs, energy consumption and environmental pollution are reduced.

Owner:天津民祥生物医药股份有限公司

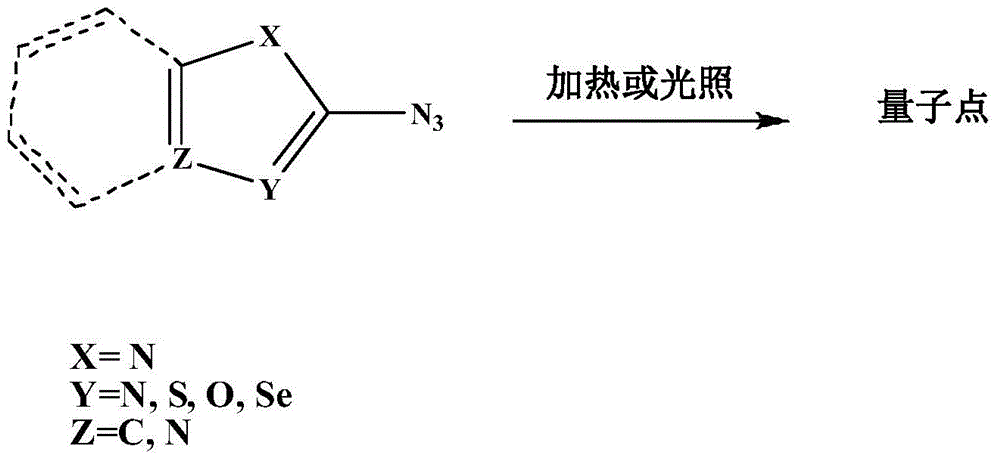

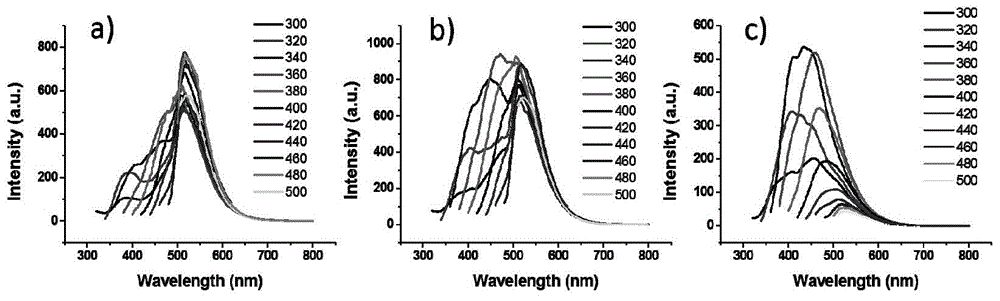

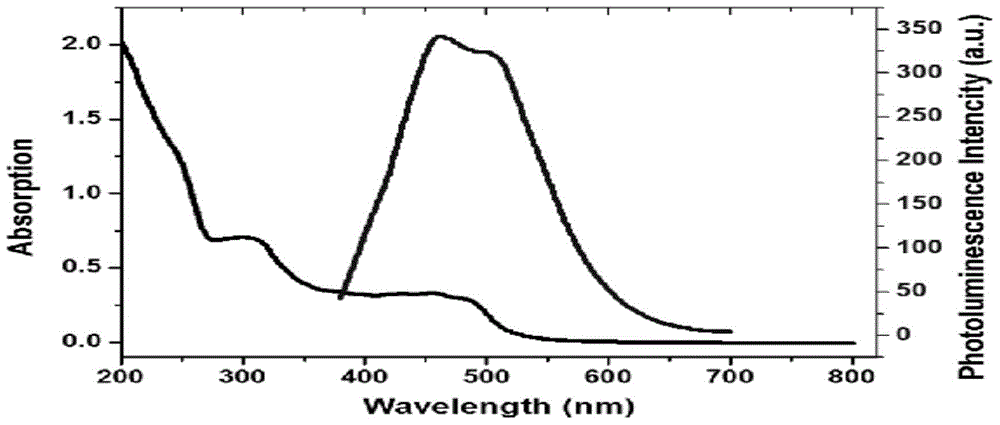

Preparation method of fluorescent nitrogen-enriched quantum dots as well as products and application of quantum dots

InactiveCN104694120AExcellent fluorescence propertiesFluorescent properties can be controlled and adjustedInksDyeing processOptical propertyFluorescence

The invention discloses a preparation method of fluorescent nitrogen-enriched quantum dots (N-dots) as well as products and an application of the quantum dots. The preparation method comprises the steps: (1) dissolving a compound as shown in a formula I in a solvent such as methanol or water to carry out heating reaction or illumination reaction; and (2) removing the solvent in a reaction product, and drying; removing a reaction raw material in a drying product, drying again, and dispersing again by adding water to obtain an aqueous solution; filtering the aqueous solution by using a filtering membrane, and drying a filtrate to obtain crude nitrogen-enriched quantum dots; and separating three types of nitrogen-enriched quantum dots different in optical properties from the crude nitrogen-enriched quantum dots by using an exclusion chromatography. The highest nitrogen content of the nitrogen-enriched quantum dots can be up to 34.48%, the particle sizes of the nitrogen-enriched quantum dots are less than 10nm, and the nitrogen-enriched quantum dots are good in fluorescence and water solubility and can be processed into fluorescent ink or biocompatible dye so as to be applied in various research fields. According to the preparation method, the nitrogen-enriched quantum dots with good fluorescent property are prepared by using single small molecules as initialing materials under mild conditions. The preparation method is good in repeatability, the reaction process can be artificially controlled, and the quantum efficiency is high.

Owner:PEKING UNIV

Process for preparing amantadine hydrochloride with high yield

InactiveCN105348111AReduce harmEnvironment-friendlyOrganic compound preparationCarboxylic acid amides preparationAmmoniaPhase-transfer catalyst

The invention discloses a process for preparing amantadine hydrochloride with high yield. The process comprises the steps of (1) preparing 1-acetamidoadamantane; and (2) preparing amantadine hydrochloride. By using the process, amantadine hydrochloride is prepared in one reaction kettle, so that the operation step is simplified; in addition, the reaction effect is promoted due to the adoption of a phase-transfer catalyst, the conversion rate and yield of the reaction can be increased due to the adoption of a solvent system selected after screening, and the cost, energy consumption and environment pollution are reduced.

Owner:天津民祥生物医药股份有限公司

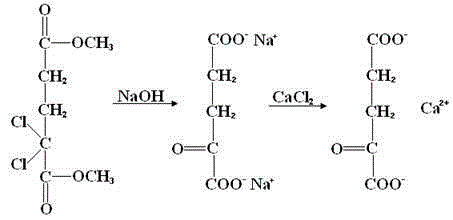

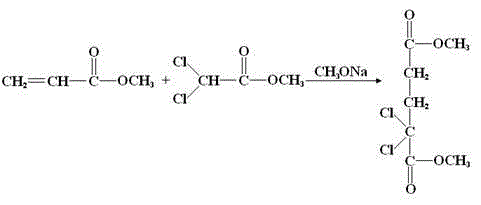

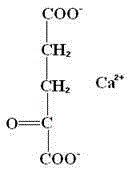

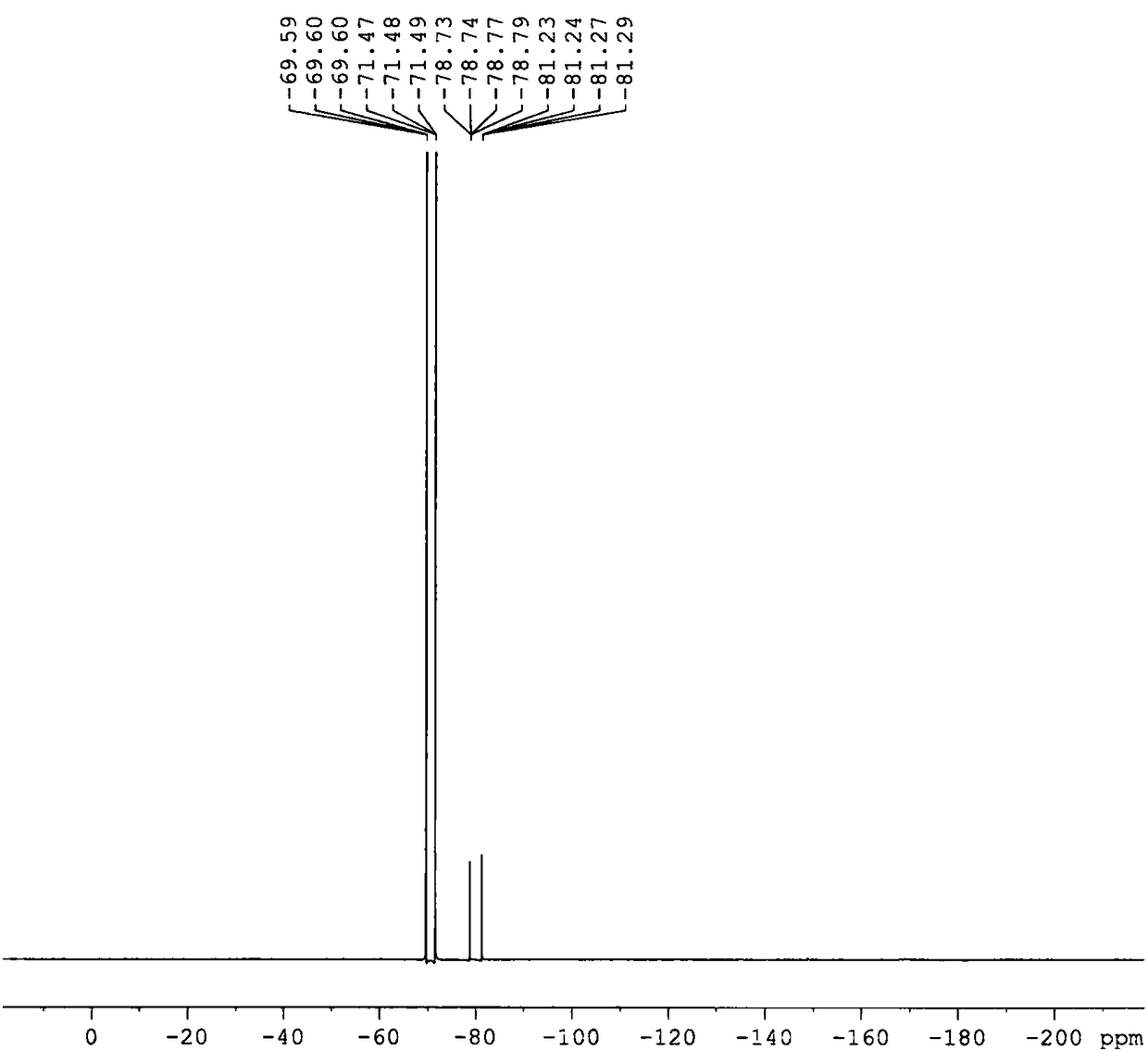

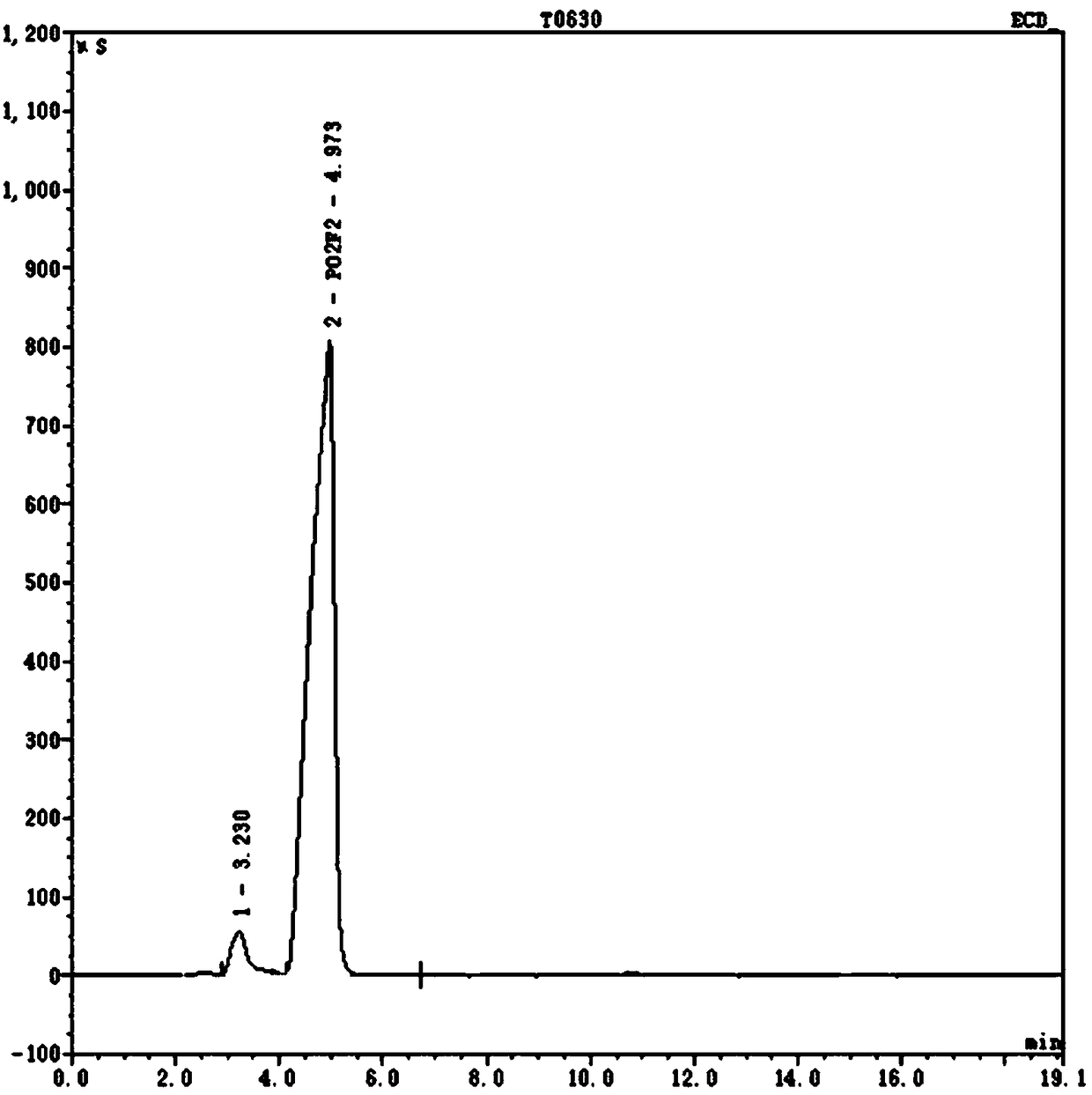

Preparation method of calcium alpha-ketoglutarate

InactiveCN102976927AEvenly distributedHigh yieldCarboxylic acid salt preparationSodium methoxideHydrolysis

The invention provides a preparation method of calcium alpha-ketoglutarate, which comprises the following steps: a) adding sodium methoxide into methyl dichloroacetate, and dropwisely adding methyl acrylate to carry out reaction; b) washing the mixed solution in the step a) with water, separating the water phase from the organic phase, and carrying out vacuum distillation on the organic phase to obtain dimethyl 2,2-dichloroglutarate; c) adding NaOH into the dimethyl 2,2-dichloroglutarate, and reacting at 60 DEG C to generate sodium alpha-ketoglutarate; and d) adding calcium chloride into the product in the step c), and stirring to obtain the calcium alpha-ketoglutarate. By changing the addition mode of the catalyst, the catalyst is uniformly distributed in the reaction system; and as the other product is added gradually, the concentration of the catalyst becomes lower, thereby effectively controlling the reaction process between the methyl dichloroacetate and methyl acrylate and enhancing the product yield. The intermediate product can be prepared into the sodium alpha-ketoglutarate by hydrolysis once, thereby shortening the procedure and enhancing the yield.

Owner:TIANJIN TIANCHENG PHARMA

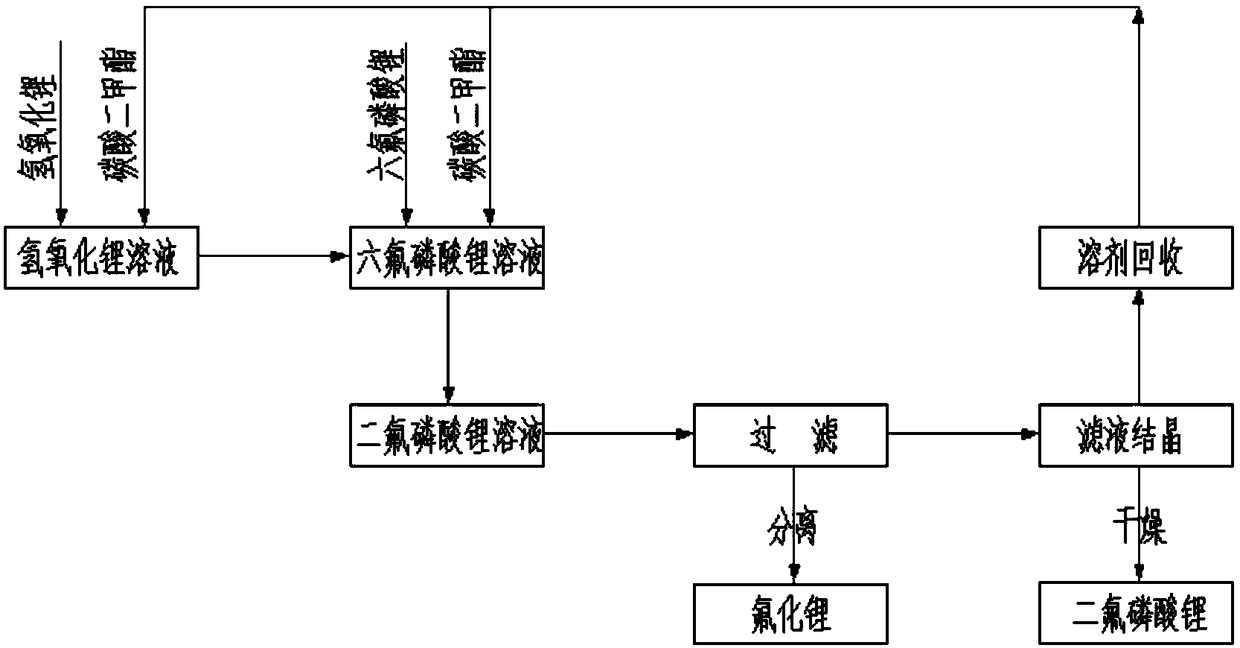

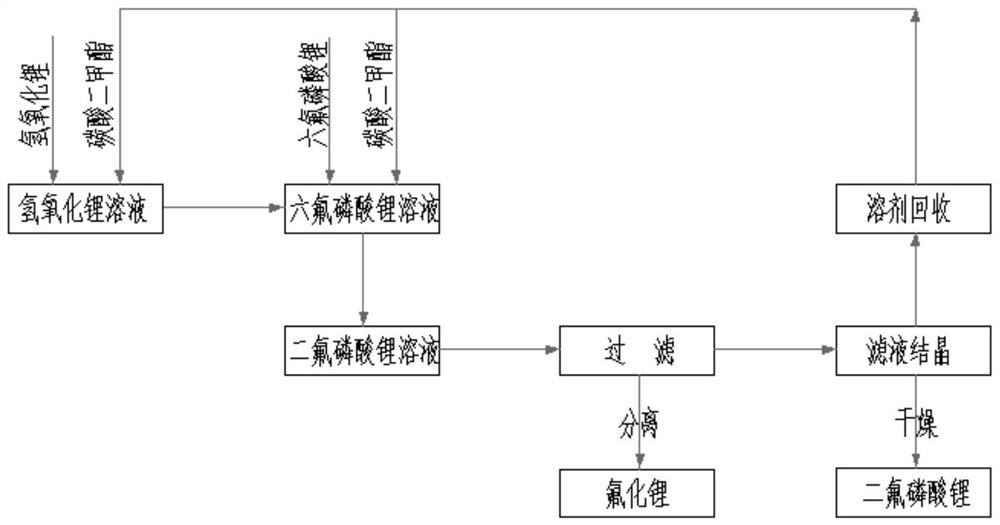

Preparation method of alkali metal difluorophosphate

The invention relates to a preparation method of alkali metal difluorophosphate. The preparation process is as follows: evenly mixing alkali metal hexafluorophosphate with corresponding dihydrogen phosphate and monohydrogen phosphate, carrying out a reaction, after the solid phase reaction is completed, performing extraction on the reaction mixture by a non-aqueous solvent for a period of time, carrying out filtration to obtain a clarified extract, after a solvent reaction is completed, carrying out filtration, and performing concentration, crystallization and drying on the obtained extract toobtain an alkali metal difluorophosphate solid. The method can also be as follows: uniformly mixing the alkali metal hexafluorophosphate with the corresponding dihydrogen phosphate and monohydrogen phosphate, carrying out a reaction in a non-aqueous solvent, after the reaction is finished, carrying out filtration, and performing concentration, crystallization and drying on the obtained filtrate to obtain the alkali metal difluorophosphate solid. The preparation method of the invention greatly reduces the cost of raw materials, improves the process safety, and has good industrial prospects.

Owner:TIANJIN JINNIU POWER SOURCES MATERIAL

Method of implementing short course nitration in aeration biological filter chamber using inhibitor

InactiveCN1911833ALower requirementAchieve short-cut nitrificationTreatment using aerobic processesSustainable biological treatmentReaction rateBiological filter

The present invention is short range nitrifying method realized with inhibitor in aerating biofilter and belongs to the field of sewage treating technology in environment protecting engineering. By using NaClO3 as inhibitor, partial nitrosomonas is preserved while inhibiting nitromonas so as to form short range nitrifying; active sludge is then inoculated into the aerating biofilter and aerated for 3-5 days and water with ammonia nitrogen controlled in 30-80 mg / L is fed and stayed for 1.5-2.5 hr in the air / water volume ratio of 4 to 1 for whole range nitrification; and NaClO3 is added into water to reach 10-20 mmol / L and run for 7-14 days or more time to form short range nitrifying. The present invention realizes short range nitrifying chemically rather by means of strict environment conditions, and has aerating biofilter as reaction carrier and raised short range nitrifying reaction rate.

Owner:TSINGHUA UNIV

Preparation method of acrylic ester emulsion

ActiveCN101693753AThe average degree of polymerization is largeGood lookingOxidation reductionEmulsion

The invention discloses a preparation method of acrylic ester emulsion, which is realized by the following steps: 1. adding quantitative water, a monomer, an emulsifier and a crosslinker into a reactor and stirring; 2. adding an oxidant and stirring; 3. adding a reducing agent and a stabilizer and continuously stirring, controlling temperature to rise, self-warming through monomer polymerizing heat releasing, and starting heat preservation; and 4. adding hydrogen peroxide and tert-butyl hydroperoxide, keeping heat preservation, reducing the temperature below 45 DEG C, neutralizing to lead the pH to be 6.8-7 by ammonia water, and filtering and discharging, thus obtaining the acrylic ester emulsion. Compared with the prior art, the method adopts an one-off feeding technological scheme, improves the work efficiency and product stability, saves energy and reduces environmental pollution by adopting low-temperature oxidation reduction reaction, can obtain higher molecular weight through low-temperature reaction, and improves the product quality and environmental performance.

Owner:JINJIANG NANXING PRINTING & DYEING MATERIAL

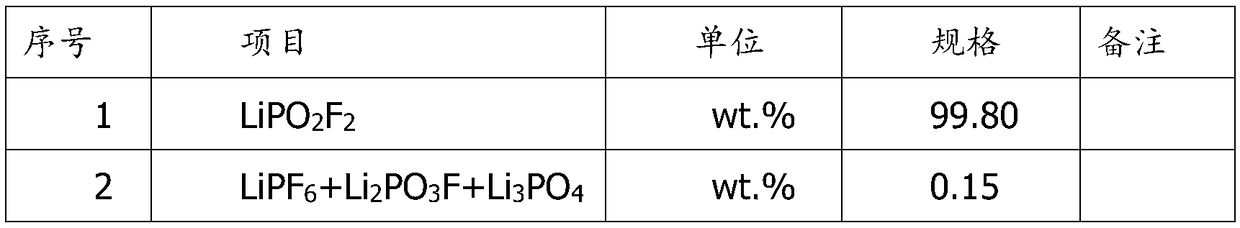

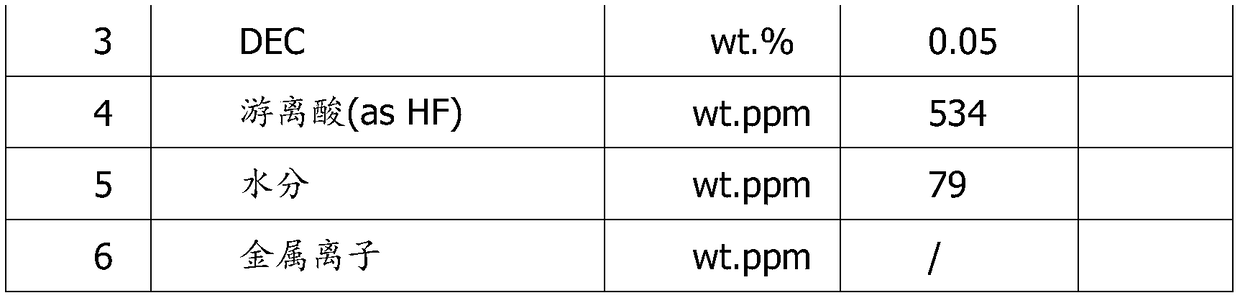

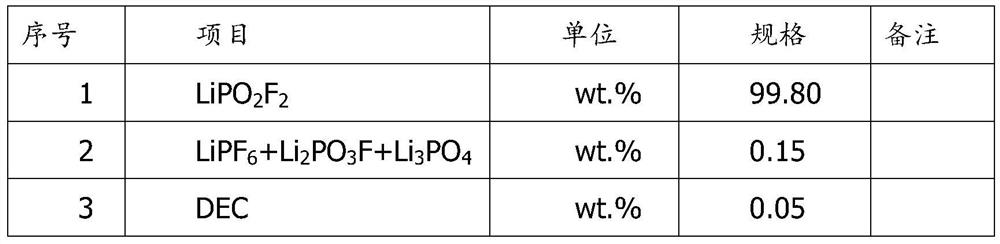

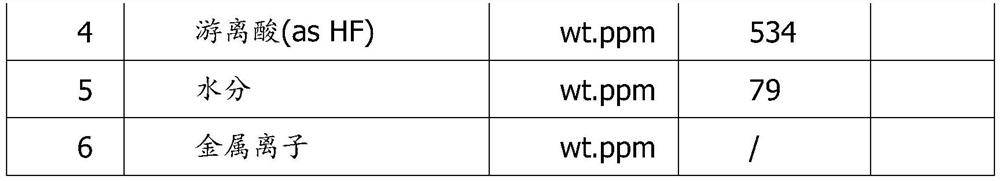

Preparation method of lithium difluorophosphate

ActiveCN108910857AImprove conversion rateRealize full angle contactLithium halidesPhosphorus compoundsOrganic solventLithium hydroxide

The invention provides a preparation method of lithium difluorophosphate, wherein the preparation method comprises the following steps: 1) dissolving lithium hexafluorophosphate in an organic solventto obtain a first solution, and adjusting the temperature of the first solution to 20-30 DEG C; 2) dissolving lithium hydroxide in an organic solvent to obtain a second solution, and adjusting the temperature of the second solution to 15-30 DEG C; 3) dropwise adding the second solution to the first solution, and carrying out a reaction to obtain a reactant; 4) carrying out solid-liquid separationof the reactant to obtain a lithium difluorophosphate solution; and 5) filtering the lithium difluorophosphate solution, then crystallizing to obtain lithium difluorophosphate crystals, and drying toobtain the finished product. The preparation method has the advantages of high conversion rate of raw materials, fewer by-products, stable reaction and easy control, and can realize industrialized production.

Owner:SHENZHEN YANYI NEW MATERIALS CO LTD

Preparation device and preparation method of high-purity electronic-grade diiodosilane

The invention provides a preparation device and a preparation method of high-purity electronic-grade diiodosilane, and relates to the technical field of diiodosilane purification. The preparation device comprises a first reactor, a second reactor and a vacuum rectification purifier. The first reactor is divided into a fluidized bed section, an oil phase section and a hydrogen iodide section; the lower ends of the oil phase section and the hydrogen iodide section are connected to the second reactor. The preparation method of the high-purity electronic-grade diiodosilane comprises the following steps: nitrogen replacement; initiating reaction by adopting phenylsilane, an oxygen-containing compound catalyst and an aromatic organic solvent to generate a phenylsilane layer, a monoiodobenzene silane layer and a hydrogen iodide layer; continuously introducing phenylsilane, adjusting the flow of the discharge port and the flow of the phenylsilane, and controlling the interface of the monoiodobenzene silane layer and the hydrogen iodide layer to be on the interface of the oil phase section and the hydrogen iodide section; and rectifying under reduced pressure. According to the preparation device and the preparation method, side reactions are reduced by isolating the contact between phenylsilane and HI, and the purity of the product and the conversion rate of raw materials are improved.

Owner:福建福豆新材料有限公司

Phosphine and sodium trimetaphosphate preparation method

The invention discloses a phosphine and sodium trimetaphosphate preparation method, wherein a mixture of a sodium salt of trivalent phosphate and a sodium salt of pentavalent phosphate is heated to a temperature of 300-400 DEG C to be subjected to a disproportionation and condensation reaction under nitrogen protection so as to obtain phosphine and sodium trimetaphosphate, wherein a sodium-phosphorus ratio of the mixture is 0.93-0.99, and a ratio (P<III> / P<V>) of trivalent phosphorus atoms to pentavalent phosphorus atoms of the mixture is 1-1.34. With the method, decomposition and oxidation of an intermediate product phosphine produced from the reaction are avoided, the important chemical industry material phosphine is collected, the condensation reaction for sodium trimetaphosphate production is promoted in the presence of the phosphine, the high purity sodium trimetaphosphate is obtained, long chain high molecule weight substance production is avoided, the sodium trimetaphosphate process is shortened, environmental pollution is reduced, production energy consumption is reduced, production cost is reduced, the whole production process and the final product meet food industry requirements, and comprehensive utilization is achieved.

Owner:江苏先锋生物基技术研究中心有限公司

Driving method for liquid flow of micro-fluidic chip

PendingCN112916062ARapid mass productionReduce the difficulty of productionLaboratory glasswaresFluid controllersPhysicsMicrofluidic chip

The invention relates to a driving method for liquid flow of a micro-fluidic chip, the driving method is characterized in that in the process that liquid dispersedly flows from the main flow channel of a main chip to branches, the positions of branch wells are communicated with a negative pressure flow channel through isolating membranes, and the negative pressure flow channel is communicated with all or part of the branch wells through isolating membranes according to needs, different negative pressures are applied to the negative pressure flow channel or thrust is generated in the main flow channel according to needs so that the speed of the main flow channel entering the flow channel branch and the branch well is controlled.

Owner:HARBIN MEDICAL UNIVERSITY +1

Process and device for preparing ferric chloride

The invention belongs to the technical field of waste liquid treatment, and provides a device for preparing ferric chloride. The device comprises a reaction groove, wherein the reaction groove comprises a reaction groove body, a stirring mechanism, an air inlet, an air outlet and a catalyst inlet; the air inlet and the air outlet are both formed in the upper part of the reaction groove body; the stirring mechanism extends into the reaction groove body; the stirring mechanism comprises a transmission shaft, a hollow shaft sleeve and an impeller; the hollow shaft sleeve is sleeved on the transmission shaft; the impeller is arranged below the hollow shaft sleeve; an air inlet pipeline is connected to the air inlet; and the air inlet pipeline is connected with the impeller. The invention further provides a process for preparing ferric chloride by adopting the device for preparing ferric chloride. The process includes taking a pickling waste liquid as a raw material; adopting NH4Cl, NH4NO3,MnCl2 or HNO3 as cocatalysts, and cooperating with a main catalyst NaNO2 to jointly catalyze an oxidation reaction of ferrous chloride, hydrogen chloride and oxygen or air under normal pressure. Thedevice and the process solve the problems of high danger and high cost of adopting high-temperature high-pressure oxidation pickling waste liquid in the preparation of ferric chloride in the prior art.

Owner:唐山达润达危废处理有限公司 +1

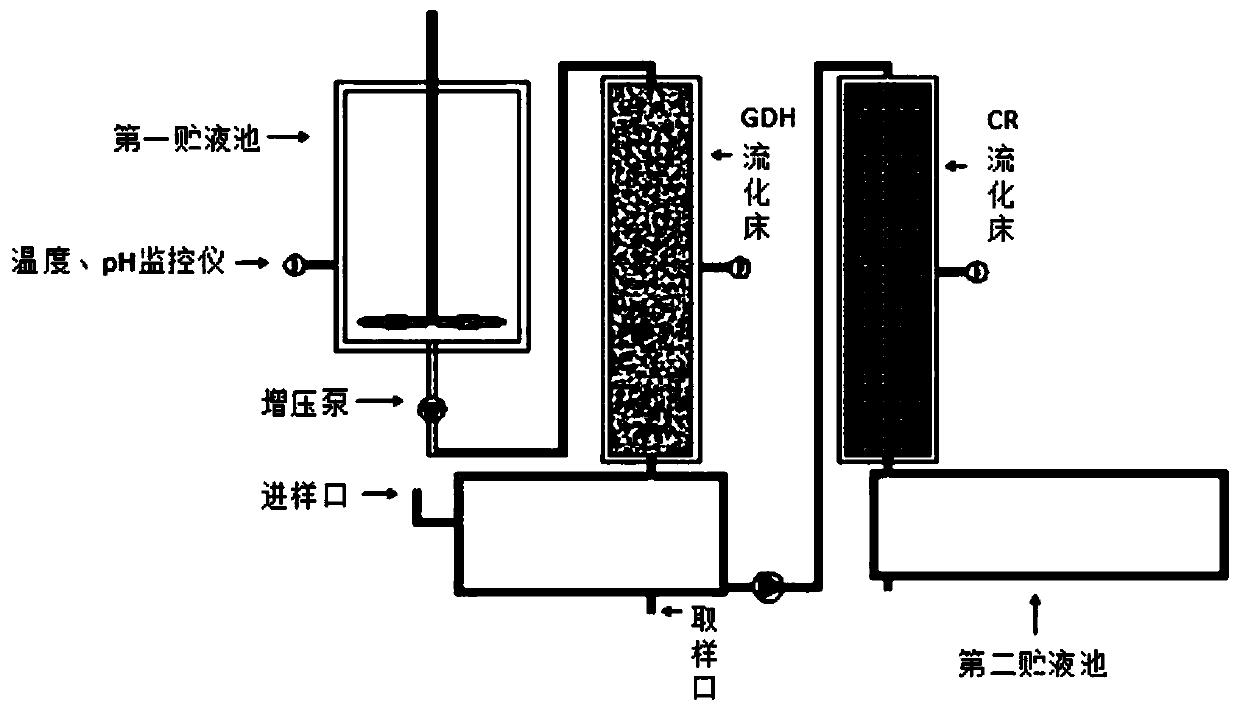

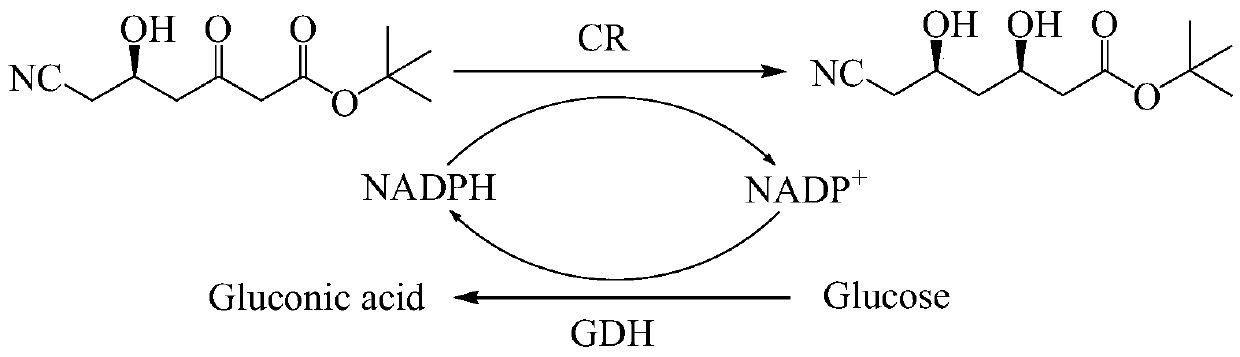

Method for continuously catalyzing and synthesizing ATS-7 by immobilized enzyme fluidization bed

PendingCN109913514AHigh catalytic efficiencyIncrease profitFermentationChemical industryEnzyme catalyzed

The invention belongs to the field of pharmaceutical and chemical industry, and particularly relates to a method for continuously catalyzing and synthesizing ATS-7 by an immobilized enzyme fluidization bed. Mixed liquid of glucose and a nicotinamide adenine dinucleotide phosphate (NADP+) generates reduced nicotinamide adenine dinucleotide phosphate (NADPH) through a GDH (glutamate dehydrogenase) bed, and mixed solution of ATS-6 and generated NADPH is implemented through a CR fluidized bed, so that the ATS-7 is continuously catalyzed and synthesized by the immobilized enzyme fluidization bed. By the continuous reaction catalysis method of the immobilized enzyme fluidization bed, enzyme catalyzing efficiency is improved; enzyme utilization rate is increased, the catalytic efficiency of the immobilized enzyme is improved by 3.1-4.2 times as compared with that of traditional free enzyme, reaction processes can be controlled by independently adjusting different sample feeding flow speed, the immobilized enzyme cannot easily fall off, continuously catalyzing reaction can be achieved, the immobilized enzyme and a product are conveniently separated, the yield of the product is improved, and purification steps are simplified, and industrialization is more facilitated.

Owner:JIANGSU UNIV OF TECH

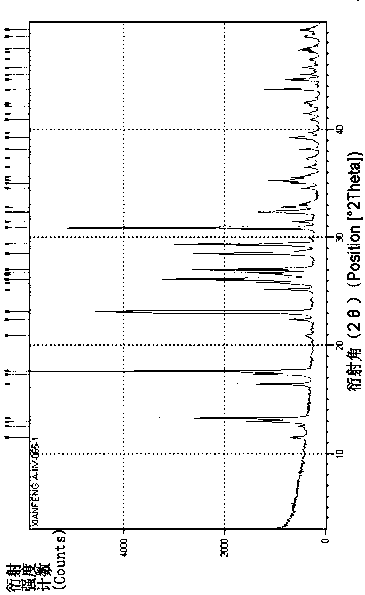

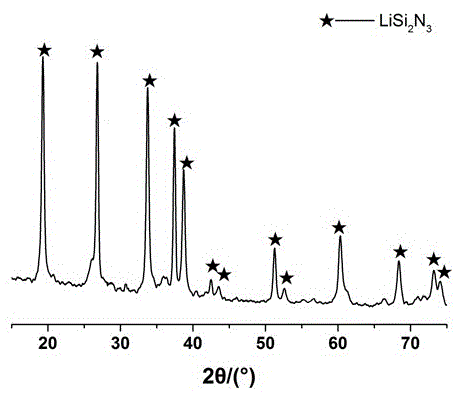

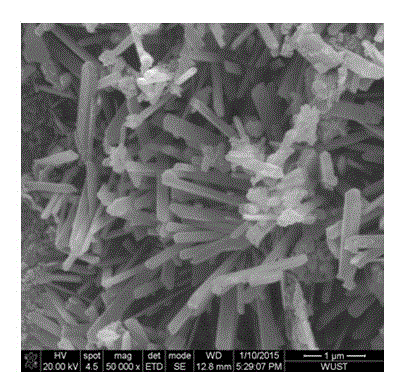

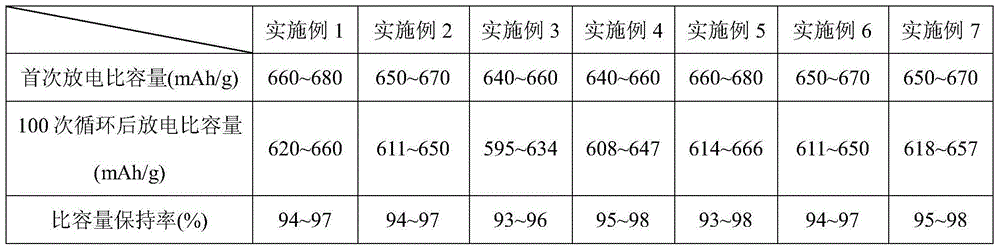

Lithium ion battery anode material LiSi2N3 and method for preparing material

ActiveCN104638250AImprove liquidityIncreased diffusion rateCell electrodesLithiumReaction temperature

The invention relates to a lithium ion battery anode material LiSi2N3 and a method for preparing the material. The technical scheme is as follows: the method comprises the following steps that 10-30wt% of elementary-substance silicon powder, 25-45wt% of trimeric cyanamide, 35-55wt% of a lithium precursor and 0.5-15wt% of halide powder are uniformly mixed to prepare a mixture; the mixture is placed in a tubular electric furnace, and heated up to 900-1200 DEG C at the heating rate of 2-10 DEG C / min under nitrogen atmosphere, and the temperature is kept for 2-6 hours; the prepared product is repeatedly washed by de-ionized water and titrated by respectively using AgNO3 and Ca(NO3)2 solutions until no white precipitates appear; and finally the prepared product is dried for 10-24 hours at 110 DEG C and thus the lithium ion battery anode material LiSi2N3 is prepared. The preparation method is low in reacting temperature and cost, easy to control, high in productivity, and applied to industrial production; the prepared lithium ion battery anode material LiSi2N3 is high in activity, large in specific surface area, high in purity and specific capacity, and steady in performance.

Owner:SUZHOU ZIGUANG WEIYE LASER TECH CO LTD

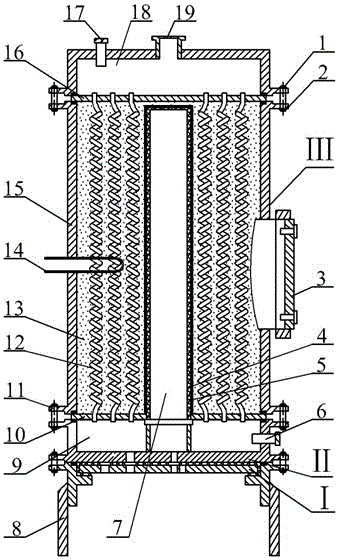

High-temperature corrosion-resistant vacuum synthesizing furnace and process method thereof

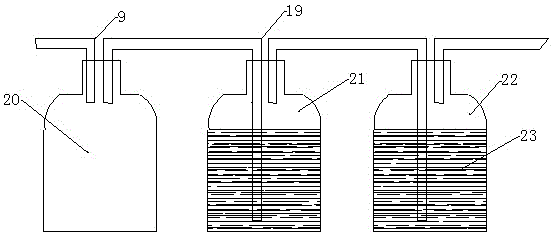

ActiveCN106766910APrevent leakageSafety qualityFurnace typesSub-atmospheric pressure processesMetallurgyBottle

The invention provides a high-temperature corrosion-resistant vacuum synthesizing furnace and a process method thereof. The high-temperature corrosion-resistant vacuum synthesizing furnace comprise a tubular high-temperature furnace, a glove box and a gas washing device, wherein the tubular high-temperature furnace comprises a furnace body and a furnace tube, an electric heating device is arranged on the inner wall of the furnace body, the furnace tube comprises a transverse furnace tube and a vertical furnace tube, an inlet sealing flange and an inlet cooling sleeve are arranged at the left end of the transverse furnace tube, a reaction boat is arranged in the transverse furnace tube, the vertical furnace tube is provided with an outlet cooling sleeve and an outlet sealing flange, and the lower end of the outlet sealing flange is connected with a collecting bottle in a sealed manner. The high-temperature corrosion-resistant vacuum synthesizing furnace has the advantages that vacuum heating can be effectively performed on reactants, the synthesized products of reaction can be collected conveniently, and reaction conditions can be observed at any time.

Owner:ZHUZHOU SMELTER GRP

Preparation method for polycrystalline mercury iodide film seed crystal layer

InactiveCN103820851ASolve the removal problemAvoid pollutionPolycrystalline material growthSingle crystal growth detailsVapour phase epitaxyMercury(II) iodide

The invention belongs to the field of chemical liquid phase deposition, particularly relates to a preparation method for a polycrystalline mercury iodide film seed crystal layer and solves the problems that the pollution of solvent and reaction by-products are difficult to remove during solution precipitation in the prior art. According to the preparation method for the polycrystalline mercury iodide film seed crystal layer, provided by the invention, yellow mercury oxide (HgO) and hydroiodic acid (HI) are used as basic materials, and the reaction rate between the HgO and (HI) is controlled by adjusting the concentration of the HI added into a system, so that fine mercury iodide particles are generated. The generated fine mercury iodide particles deposit on a substrate (electrode) material to form a layer of homogeneous film, so that directional crystal nucleuses are provided for gas phase epitaxial growth, thereby increasing one-way growth probability of the film.

Owner:XIAN TECHNOLOGICAL UNIV

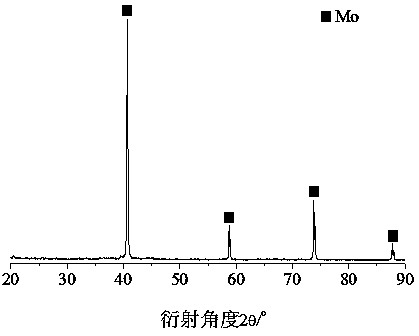

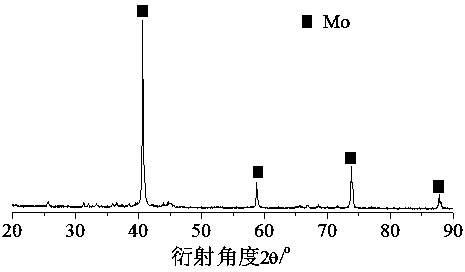

Molybdenum superfine powder and preparation method thereof

InactiveCN104190947AImprove liquidityIncreased diffusion rateMaterial nanotechnologyFiltrationReaction temperature

The invention relates to a molybdenum superfine powder and a preparation method thereof. The preparation method comprises the following steps: 19.4-40wt % of a sodium molybdate powder, 5-11.3wt % of a metal aluminum powder and 50-75wt % of a halide powder are uniformly mixed; the mixture of the sodium molybdate powder, the metal aluminum powder and the halide powder is placed into a box type electric furnace; under the condition of argon gas atmosphere and the temperature increment rate of 2-8 DEG C / min, the mixture of the sodium molybdate powder, the metal aluminum powder and the halide powder is heated to 600-850 DEG C; the heat preservation is kept for 2-5 hours, so as to prepare A pretreatment powder; the pretreatment powder is placed into a nitric acid solution with the concentration of 2-4 mol / L for 3-8 hours of soaking; after filtration, a filtered compound is prepared; deionized water is adopted to repeatedly clean and filter the filtered compound until a cleaning solution becomes neutral; then, drying is conducted for 6-12 hours at 110 DEG C; the molybdenum superfine powder is obtained. The preparation method of the molybdenum superfine powder has the characteristics of simple and easily controlled synthesis process, low reaction temperature, high productivity, low cost, broad industrialization prospect and small environmental pollution. The molybdenum superfine powder prepared by the method has high activity, small particle aggregation and high purity.

Owner:WUHAN UNIV OF SCI & TECH

A kind of modified ptfe suspension resin with high weldability and preparation method thereof

The invention relates to a modified PTFE (Polytetrafluoroethylene) suspension resin which comprises the following components in parts by weight: 3500-6000 parts of tetrafluoroethylene, 0.2-1.5 parts of oxidizing agent, 0.1-0.5 part of dispersion agent, 1-8 parts of buffer salt, 0.02-0.15 parts of reducing agent, and 30-70 parts of perfluor propyl vinyl ether. By regulating the adding steps of polymerization monomers, the reaction process is effectively controlled, the obtained polymer is compact in structure and low in porosity, and the welding property and the electrical property of the polymer are improved.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Method for preparing trichlorosilane and dichlorosilane by hydrogenating silicon tetrachloride through microwave plasma

InactiveCN101734666BIncrease ion densityThe alternating electric field is more uniform and stable than the induced electric fieldHalogenated silanesPlasma jetHigh energy

The invention provides a method for preparing trichlorosilane and dichlorosilane by hydrogenating silicon tetrachloride through microwave plasma, which aims to solve the problems of high energy consumption, low single-pass conversion rate and high equipment investment in the catalytic hydrogenation of the silicon tetrachloride by a Siemens method and problems of high energy consumption and material consumption and difficult industrialization in hydrogenating the silicon tetrachloride by a conventional thermal plasma method and a radio-frequency induction plasma method in the conventional polysilicon industry. The method comprises the following steps: forming a stable cold plasma through arced hydrogen, argon or a mixture of the two under excitation of microwaves; forming a plasma jet flowby a plasma torch under the condition of the flow of the arced gas; and ejecting feed gas into a specific area of the plasma jet flow to form an active particle consumption zone in which the silicon tetrachloride is hydrogenated into trichlorosilane. The single-pass conversion rate of the silicon tetrachloride of the method reaches about 60 percent; and the method has the advantages of simple subsequent treatment of a product, low requirement on equipment and operation control, and easy realization of industrialization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A kind of preparation method of lithium difluorophosphate

ActiveCN108910857BImprove conversion rateRealize full angle contactLithium halidesPhosphorus compoundsOrganic solventLithium hydroxide

Owner:SHENZHEN YANYI NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com