Method for preparing diethylaminoethanethiol

A technology of ethylaminoethanethiol and thiocyanate, which is applied in the preparation of mercaptans, organic chemistry, etc., can solve the problems that thiol is difficult to effectively condense and recover, is prone to safety accidents, and has a long reaction time, so as to avoid The risk of flushing, good product quality, and the effect of increasing the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

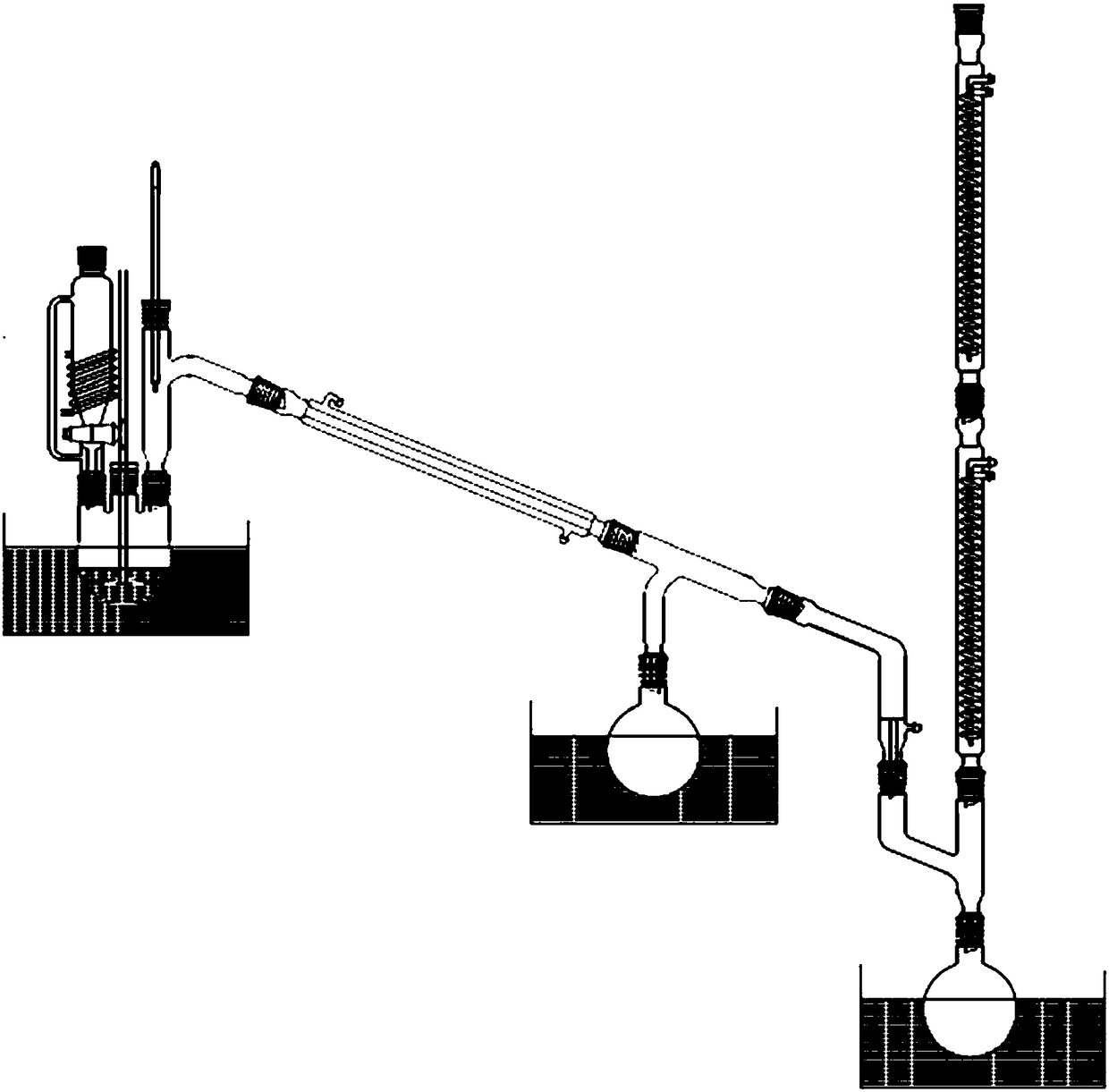

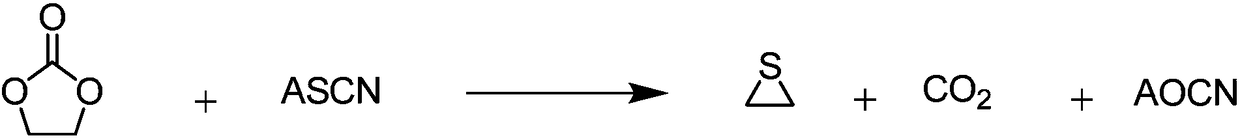

Method used

Image

Examples

Embodiment 1

[0030] Add 220 kg of ethylene carbonate (0.52 times the total amount of ethylene carbonate) in the reaction tank, heat to 55 ° C to melt, stir, add 375 kg of sodium thiocyanate, directly turn on the steam and heat up to 85 ° C, after the distillate, through The coil heat exchanger and the cyclone gas-liquid separator were used to separate and collect fractions. At the same time, the remaining 200 kg of ethylene carbonate at a temperature of 75° C. was started to be added dropwise, and the temperature was controlled at 100° C. during the dropping process. Continue to heat up to 138°C after the addition of sulfide, and stop the reaction until no distillate is evaporated. The chemical reaction and operation of this step were stable, and it took 2 hours to obtain 270.8 kg of ethylene sulfide, the gas phase detection purity was 99.6%, and the yield was 97.5%.

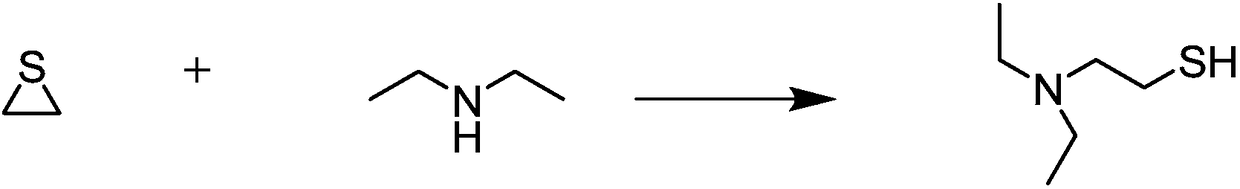

[0031] Transfer 270.8kg of the ethylene sulfide fraction to a 1000L autoclave, add 330kg of diethylamine, seal it and stir...

Embodiment 2

[0034] This embodiment is a small test carried out in the laboratory, the main purpose is to test the technical effect of the two-step feeding.

[0035]Add 200g of ethylene carbonate (0.49 times the total amount of ethylene carbonate) into the four-neck bottle, heat to 50°C to melt, stir, add 375g of sodium thiocyanate, heat the oil bath to 95°C, start to drop after the distillate The remaining temperature is 208g of ethylene carbonate at 65°C, and the dropwise addition process controls the temperature at 110°C. Continue to heat up to 136°C after the addition of sulfide, and stop the reaction until no distillate is evaporated. The reaction lasted for 1 hour, and 270.1 g of ethylene sulfide was obtained, the gas phase detection purity was 99.3%, and the yield was 97.2%.

[0036] Transfer 270 g of the ethylene sulfide fraction to a 1-liter autoclave, add 329 g of diethylamine, and stir in an airtight manner, heat up to 128° C., and keep the pressure at 0.4 MPa for 1 hour to com...

Embodiment 3

[0038] This embodiment is a small test carried out in the laboratory, the main purpose is to verify the reliability of the technical effect of the two-step feeding.

[0039] Add 260g of ethylene carbonate to the four-necked bottle, heat to 55°C to melt, stir, add 443g of potassium thiocyanate, heat up the oil bath to 100°C, and start to drop the remaining 160g of ethylene carbonate at 75°C after the distillate , The dropping process controlled the temperature at 105°C. Continue to heat up to 129°C after the addition of sulfide, and stop the reaction until no fraction can be evaporated. The reaction took 1.2 hours to obtain 267.2 g of sulfide, the gas phase detection purity was 99.2%, and the yield was 97.5%.

[0040] Transfer 267.1 g of the ethylene sulfide fraction to a 1-liter autoclave, add 325 g of diethylamine, and stir in an airtight manner, raise the temperature to 120° C., and keep the pressure at 0.5 MPa for 1 hour to complete the reaction to obtain diethylaminoethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com