Patents

Literature

1105results about "Thiol preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

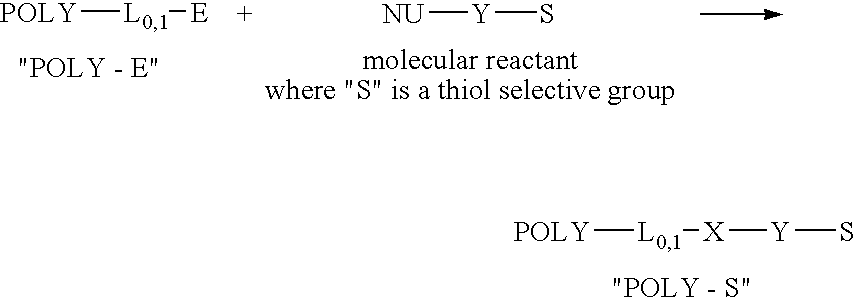

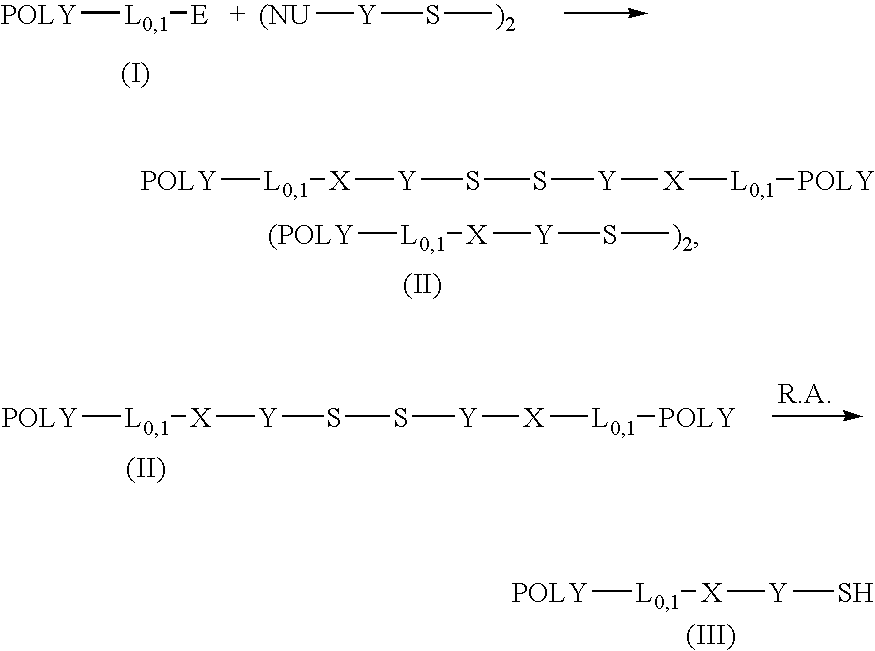

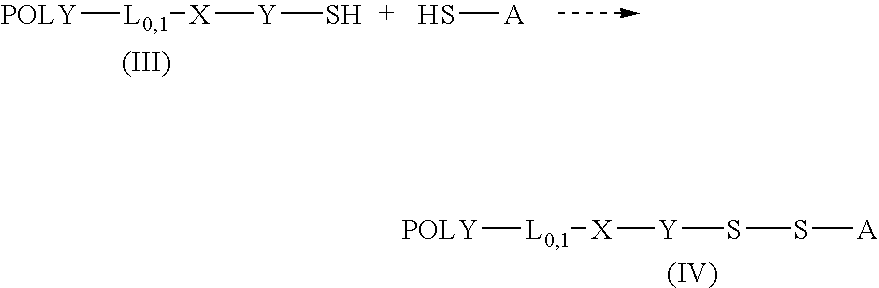

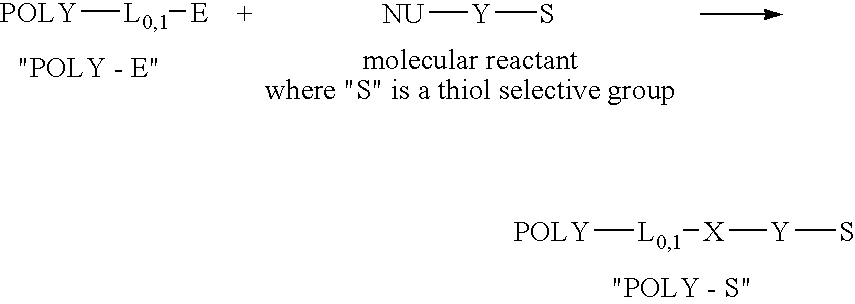

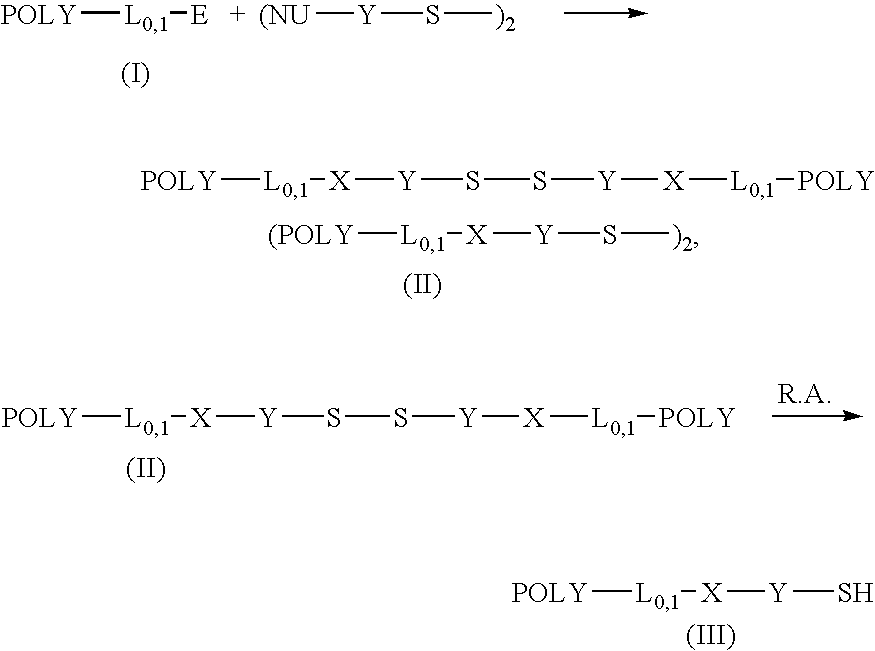

Thiol selective water soluble polymer derivatives

ActiveUS20050014903A1Improve responseThiol preparationPharmaceutical non-active ingredientsCouplingWater soluble

Owner:NEKTAR THERAPEUTICS INC

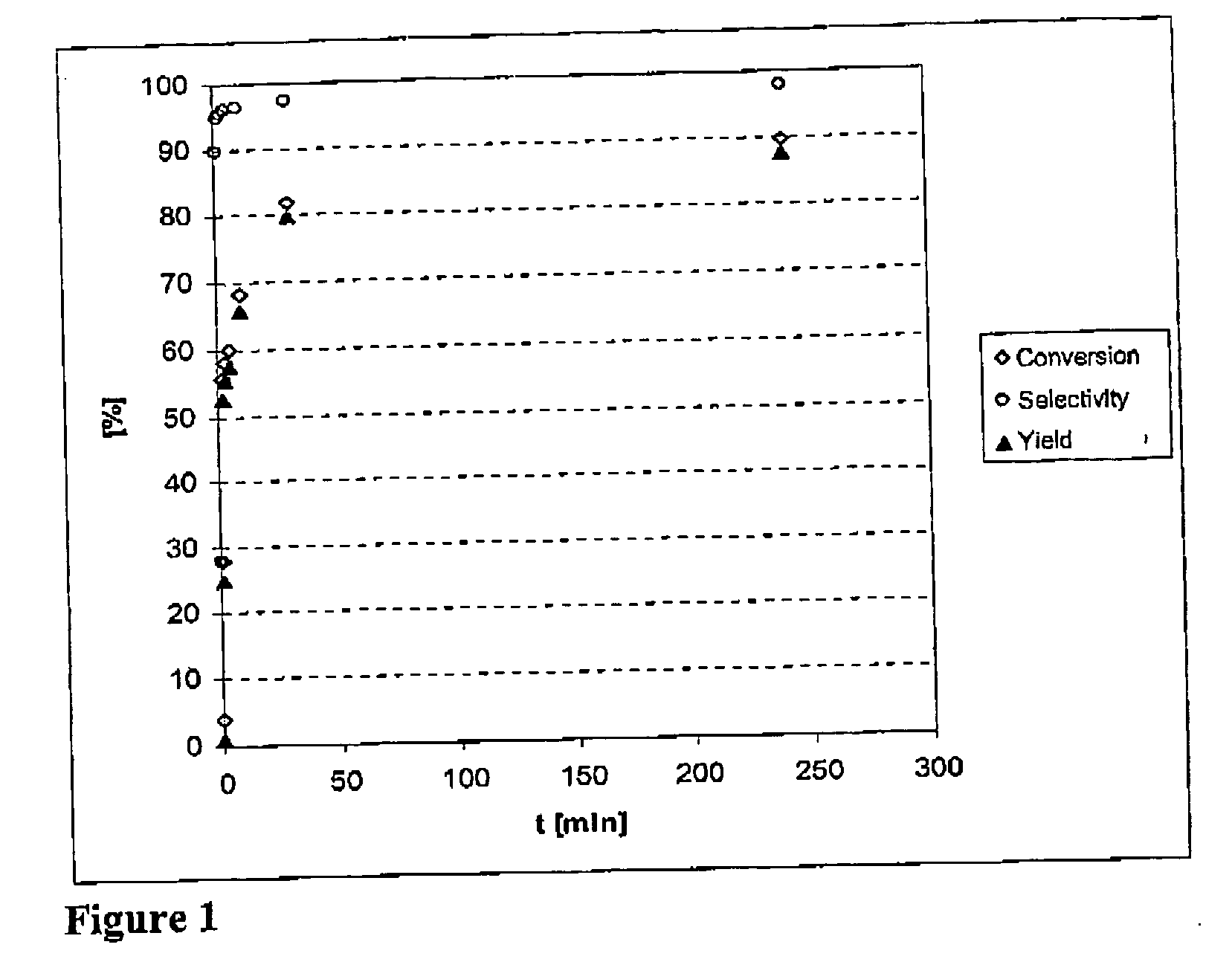

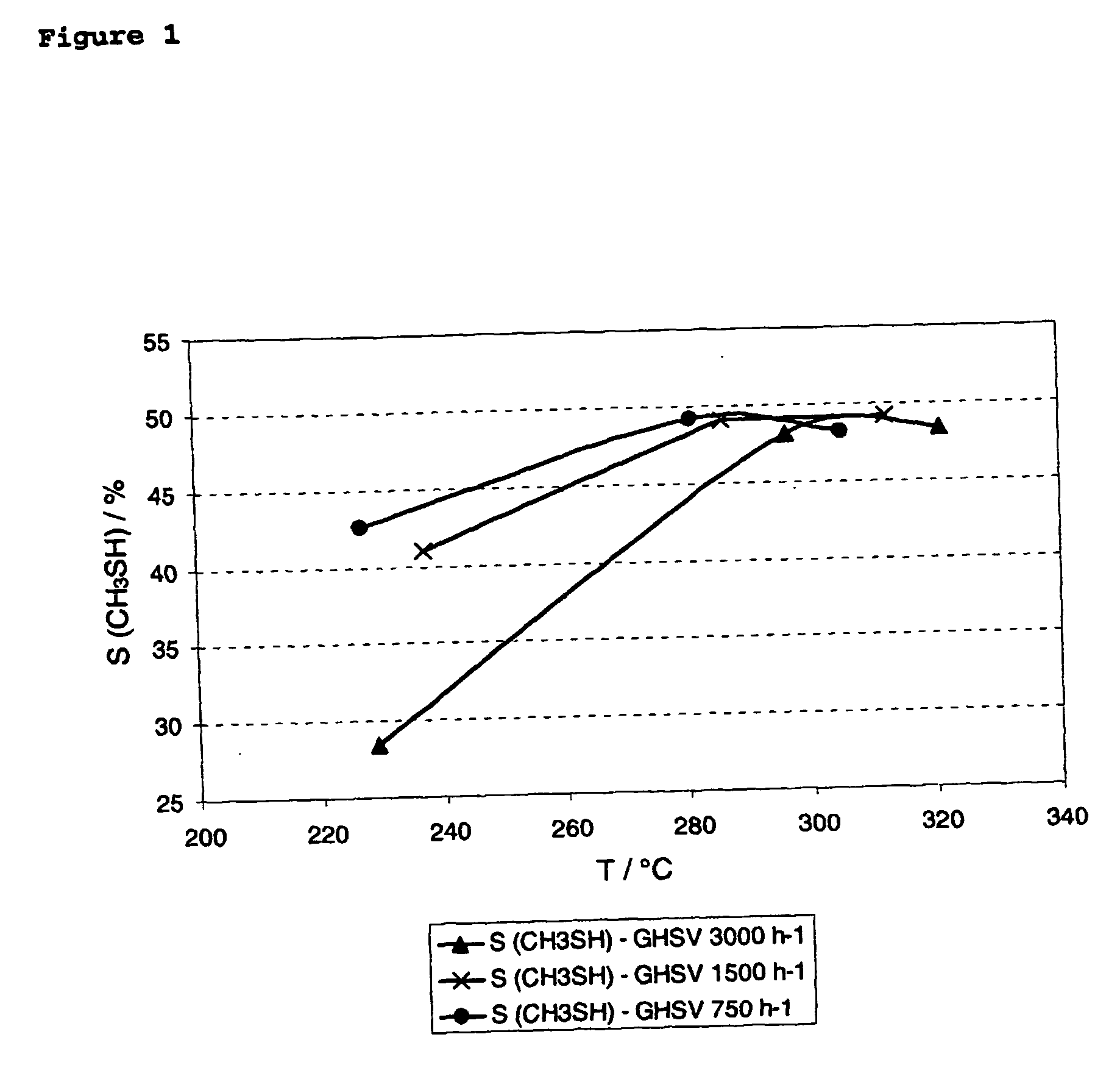

Process for the manufacture of methymercaptan

InactiveUS20070213564A1High selectivityHigh yieldOrganic compound preparationThiol preparationSpace velocityOrganic chemistry

The present invention refers to a continuous process for the manufacture of methyl mercaptan using Mo-O—K-based catalysts. It is further described that the total selectivity of methylmercaptan can be increased by at least 1% by lowering the total gas hourly space velocity. The invention further refers to a process for the preparation of a solid, preformed catalyst system.

Owner:EVONIK DEGUSSA GMBH

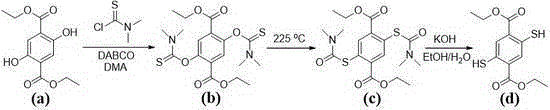

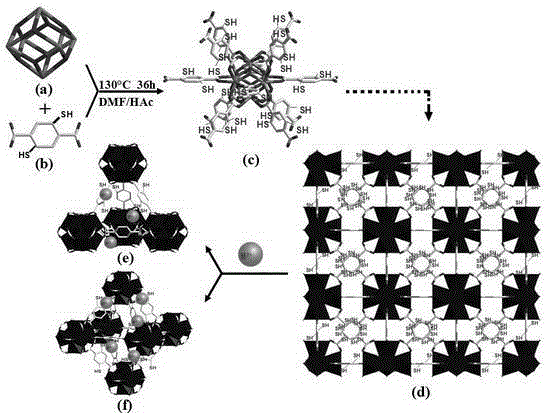

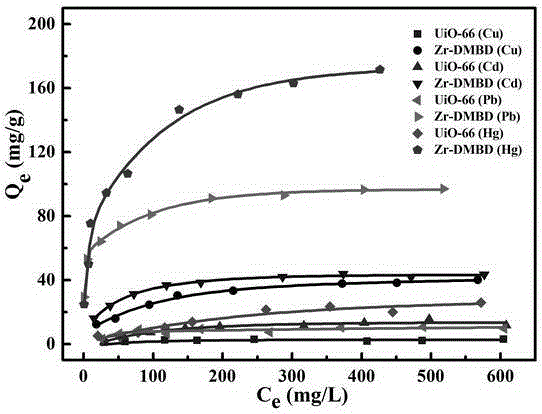

Preparation for thiol-functionalization MOFs material and application thereof in adsorption and removal of heavy metal ions in water

The invention relates to a preparation method for a thiol-functionalization MOFs material and application thereof in adsorption and removal of heavy metal ions in water. The thiol-functionalization MOFs (UiO-66-SH) material can effectively adsorb and remove the ions of heavy metal such as copper, cadmium, lead, mercury in the water. The method comprises the steps that 1, thiol-modified terephthalic acid organic ligands are synthesized; 2, the thiol-functionalization MOFs material (UiO-66-SH) is synthesized through a solvothermal method; 3, the thiol-functionalization MOFs material (UiO-66-SH) serves as an adsorbing agent to be applied to adsorption and removal for the heavy metal ions such as copper, cadmium, lead, mercury in the water. The thiol-functionalization MOFs material can efficiently adsorb and remove the ions of heavy metal such as copper, cadmium, lead, mercury in the water, and compared with ordinary UiO-66, the adsorption property of the material is significantly improved; in addition, the material can selectively adsorb and remove mercury ions on the high-concentration condition, and novel application of the material is widened.

Owner:江西智汇环境技术有限公司

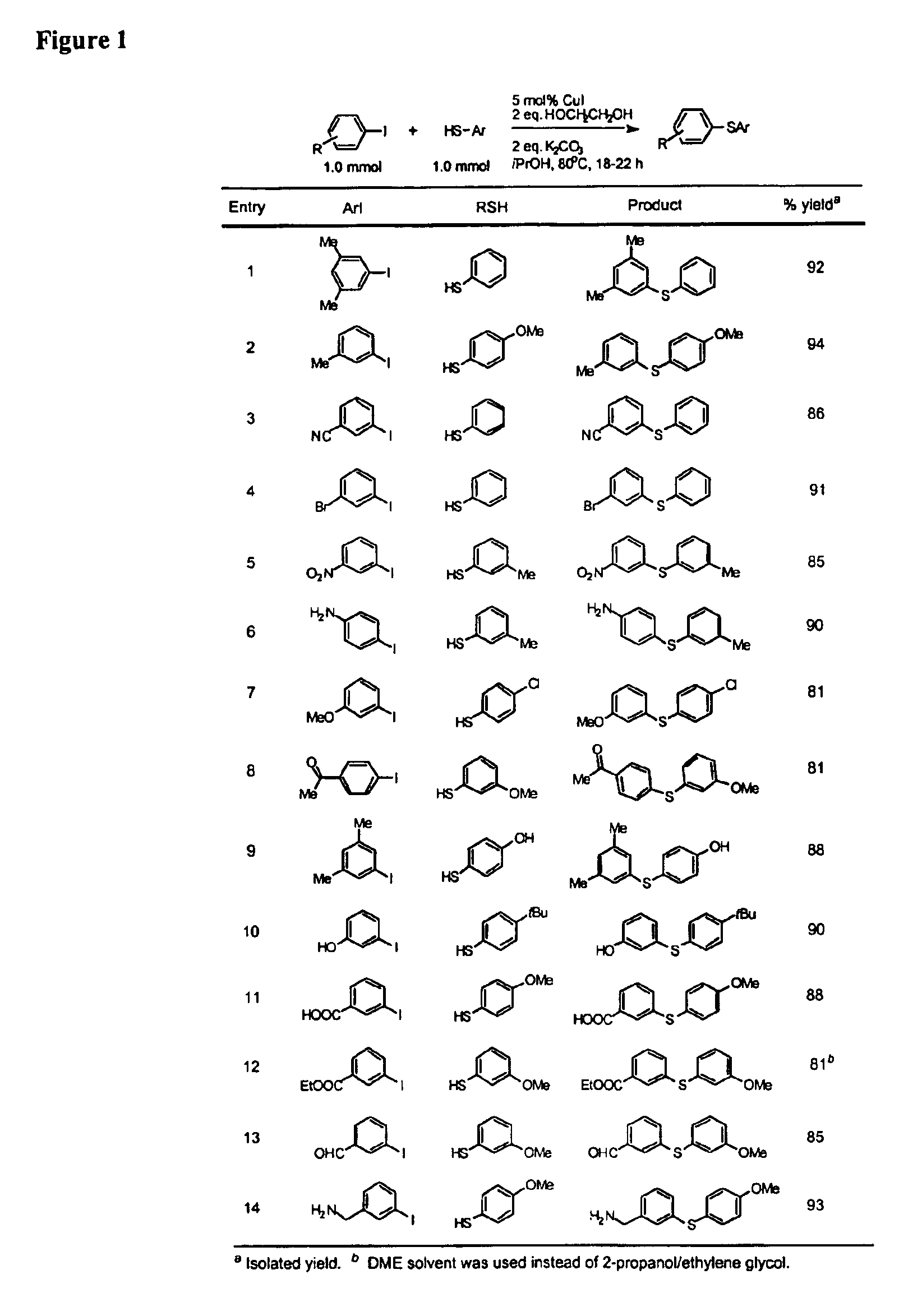

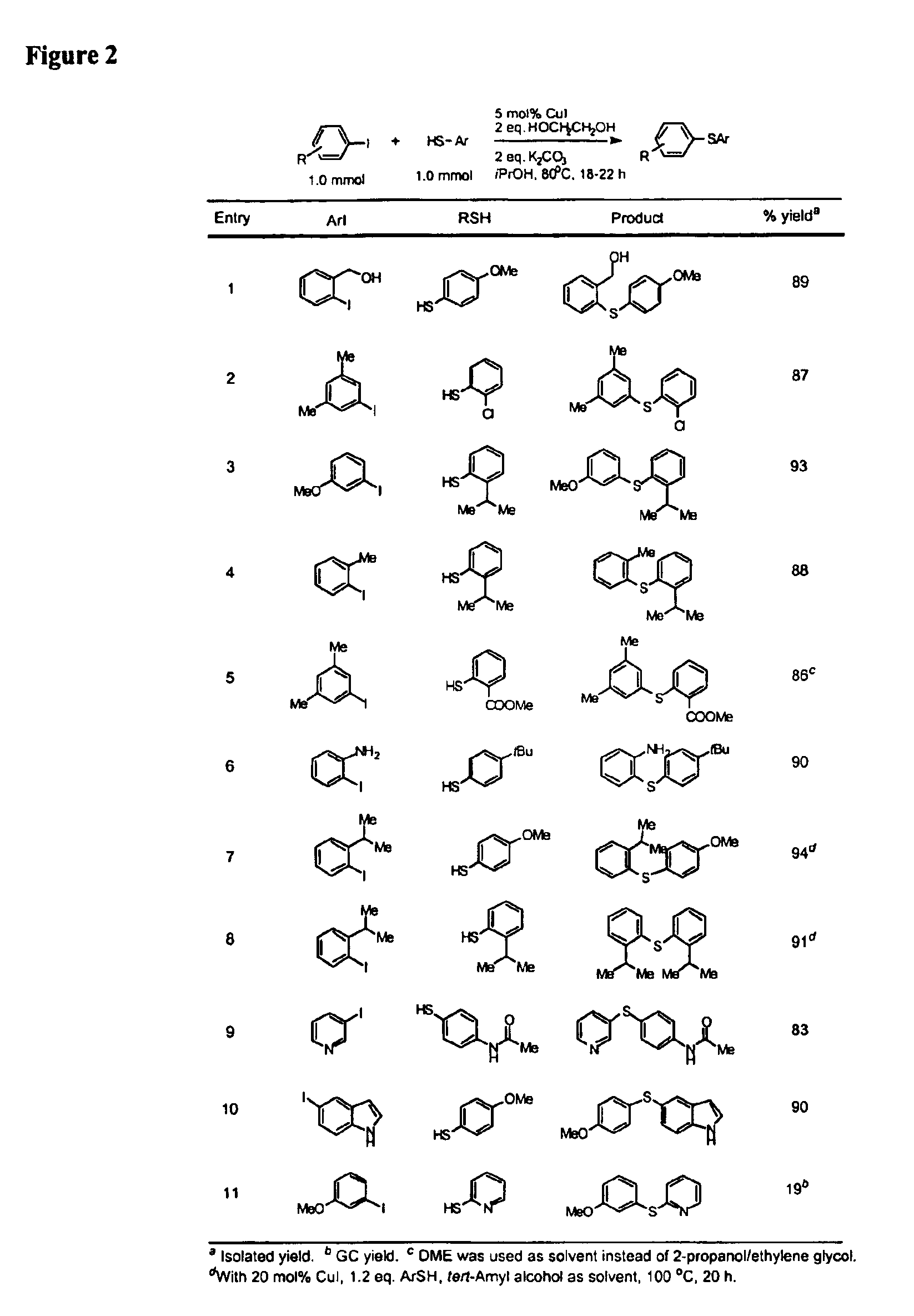

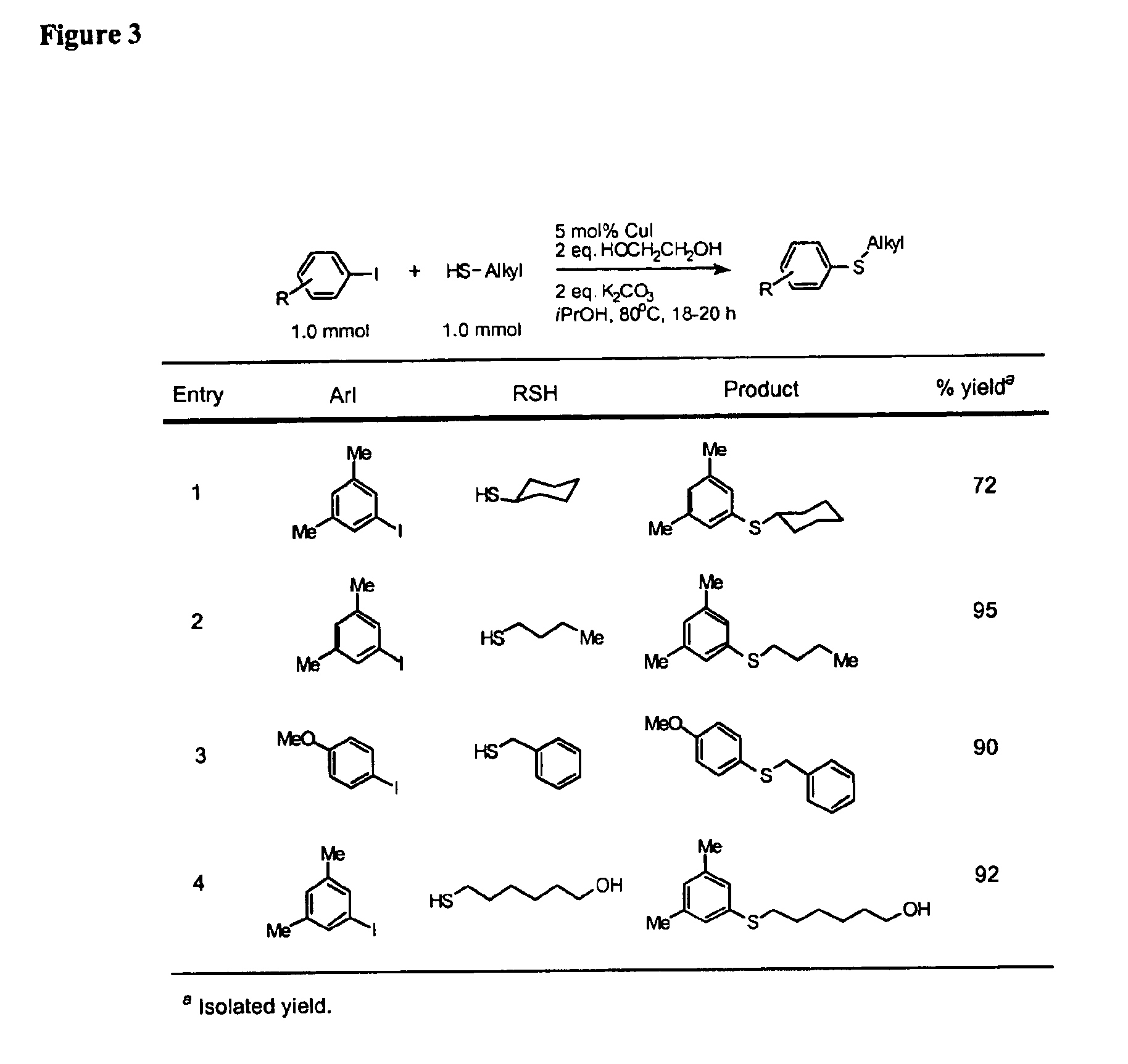

Copper-catalyzed formation of carbon-heteroatom and carbon-carbon bonds

InactiveUS6888032B2Cheap and practicalLow costOrganic compound preparationThiol preparationCarbon–carbon bondSulfide

One aspect of the present invention relates to copper-catalyzed carbon-heteroatom and carbon-carbon bond-forming methods. In certain embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-sulfur bond between the sulfur atom of a thiol moiety and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In other embodiments, the present invention relates to copper(II)-catalyzed methods of forming a carbon-nitrogen bond between the nitrogen atom of an amide and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In certain embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-carbon bond between the carbon atom of cyanide ion and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In another embodiment, the present invention relates to a copper-catalyzed method of transforming an aryl, heteroaryl, or vinyl chloride or bromide into the corresponding aryl, heteroaryl, or vinyl iodide. Yet another embodient of the present invention relates to a tandem method, which may be practiced in a single reaction vessel, wherein the first step of the method involves the copper-catalyzed formation of an aryl, heteroaryl, or vinyl iodide from the corresponding aryl, heteroaryl, or vinyl chloride or bromide; and the second step of the method involves the copper-catalyzed formation of an aryl, heteroaryl, or vinyl nitrile, amide or sulfide from the aryl, heteroaryl, or vinyl iodide formed in the first step.

Owner:MASSACHUSETTS INST OF TECH

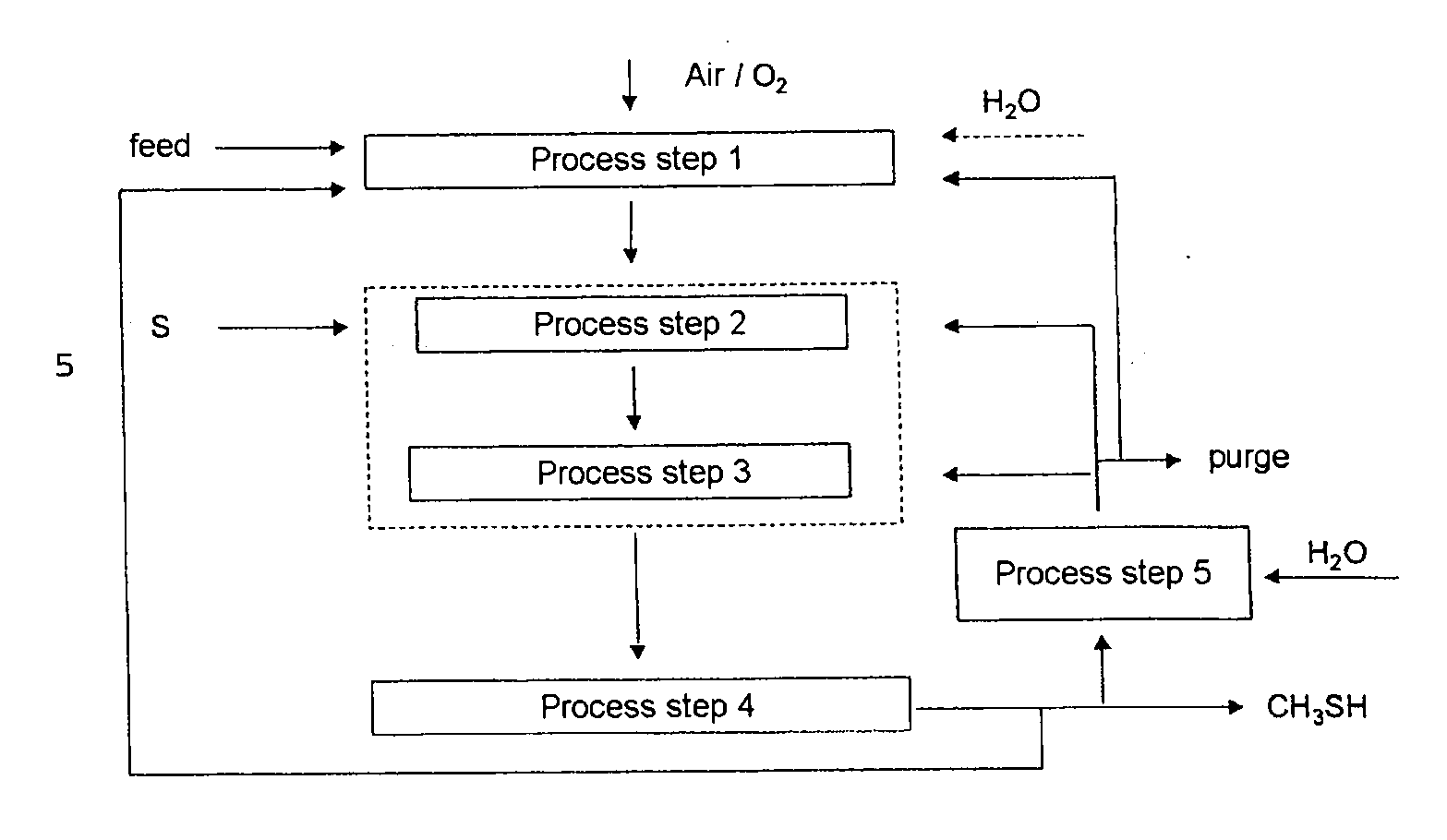

Process for continuously preparing methyl mercaptan from carbon- and hydrogen-containing compounds

ActiveUS20080293974A1Improve economyCost advantageOrganic compound preparationThiol preparationHydrogenSulfur

Owner:EVONIK DEGUSSA GMBH

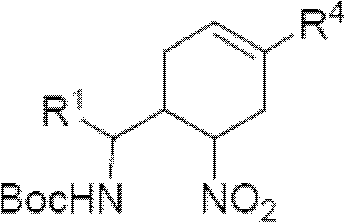

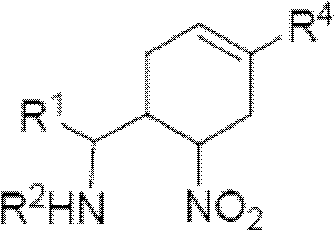

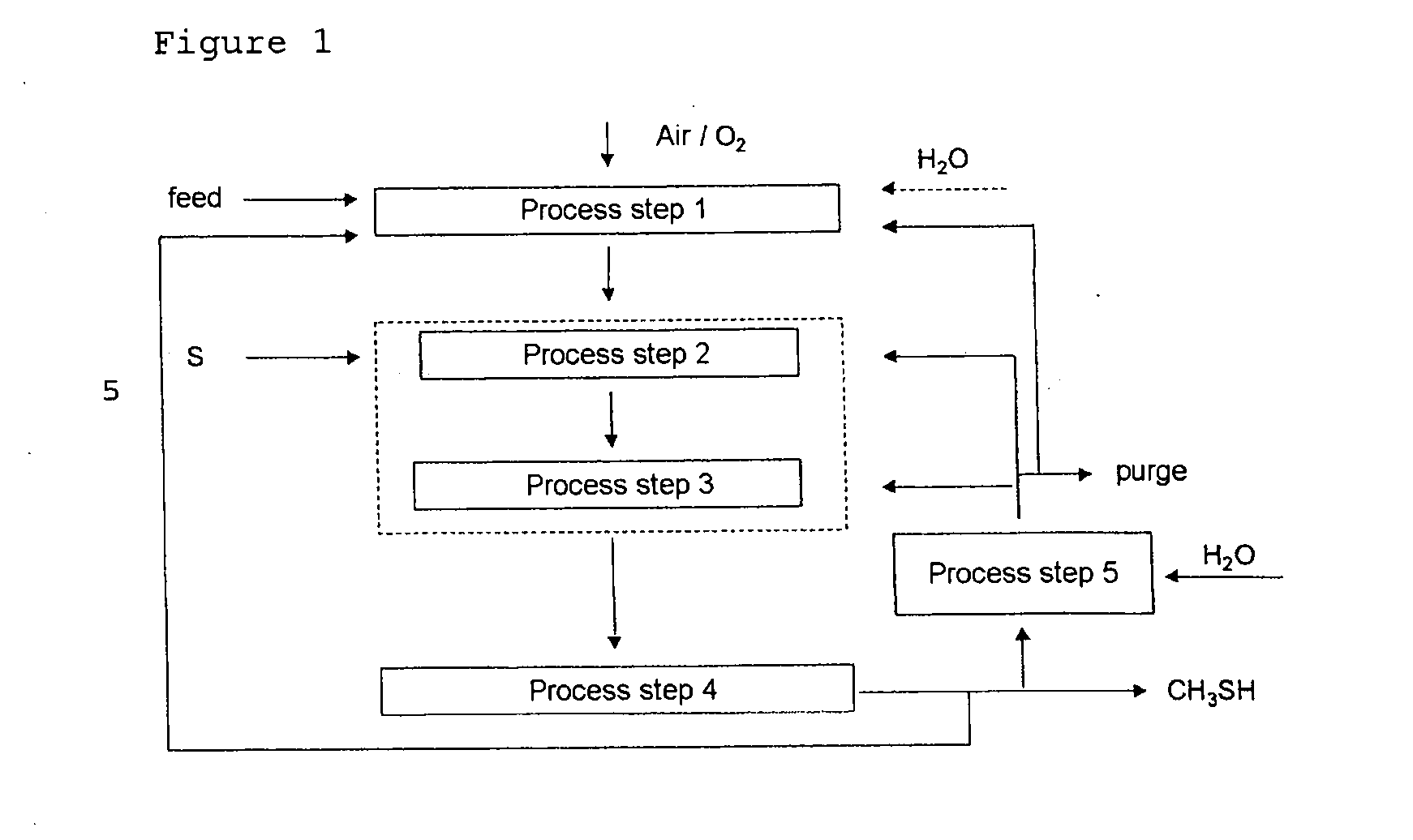

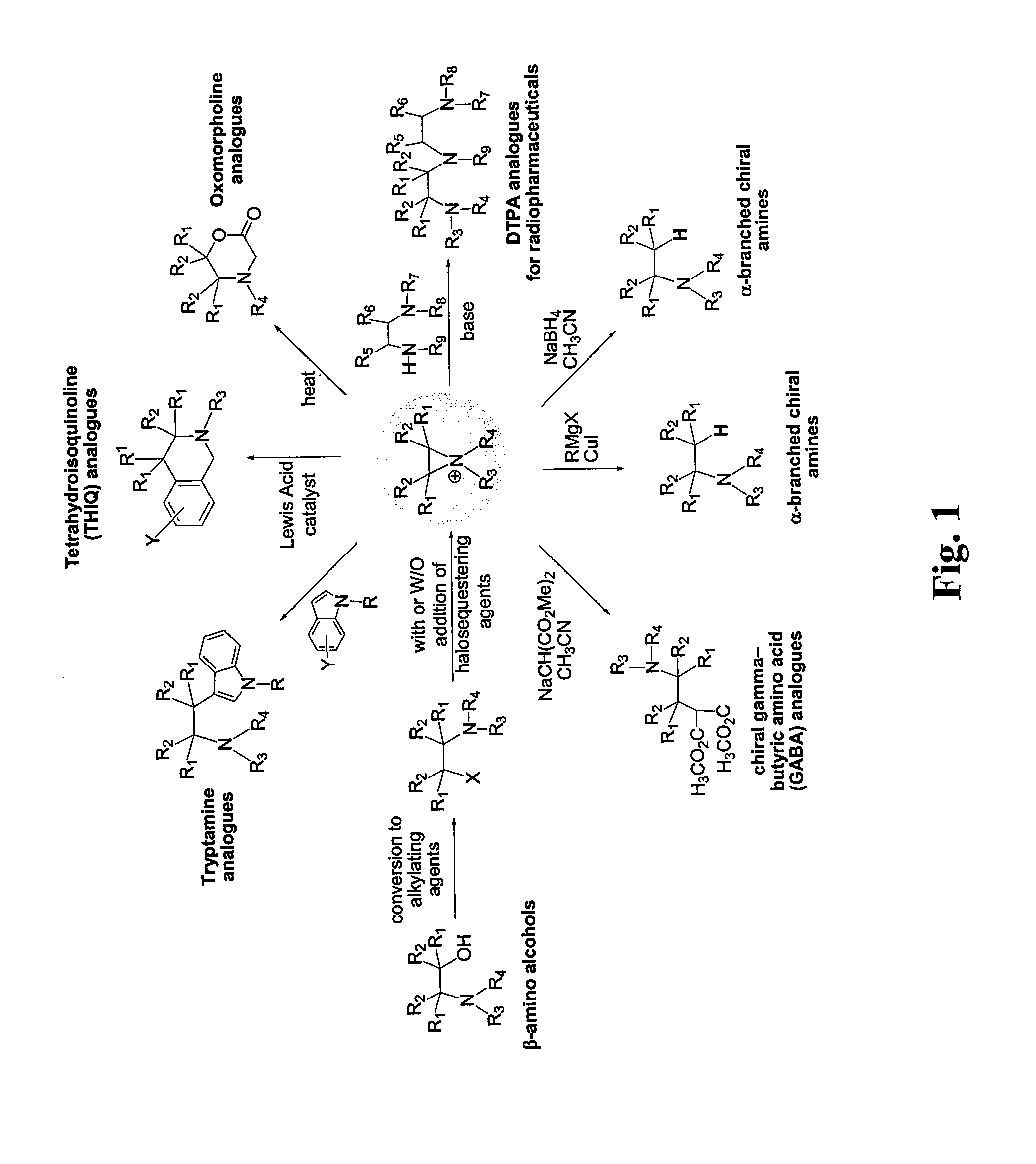

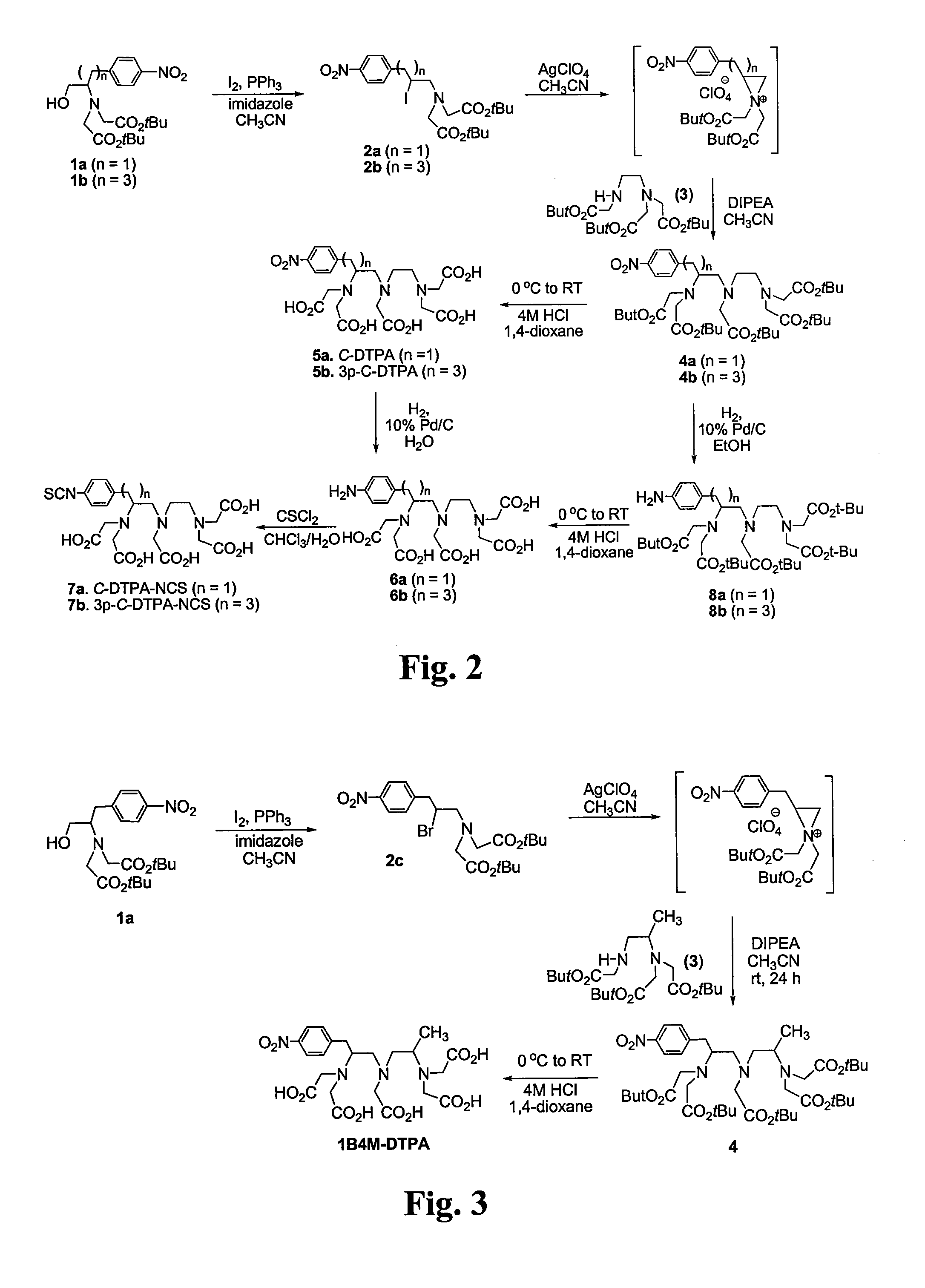

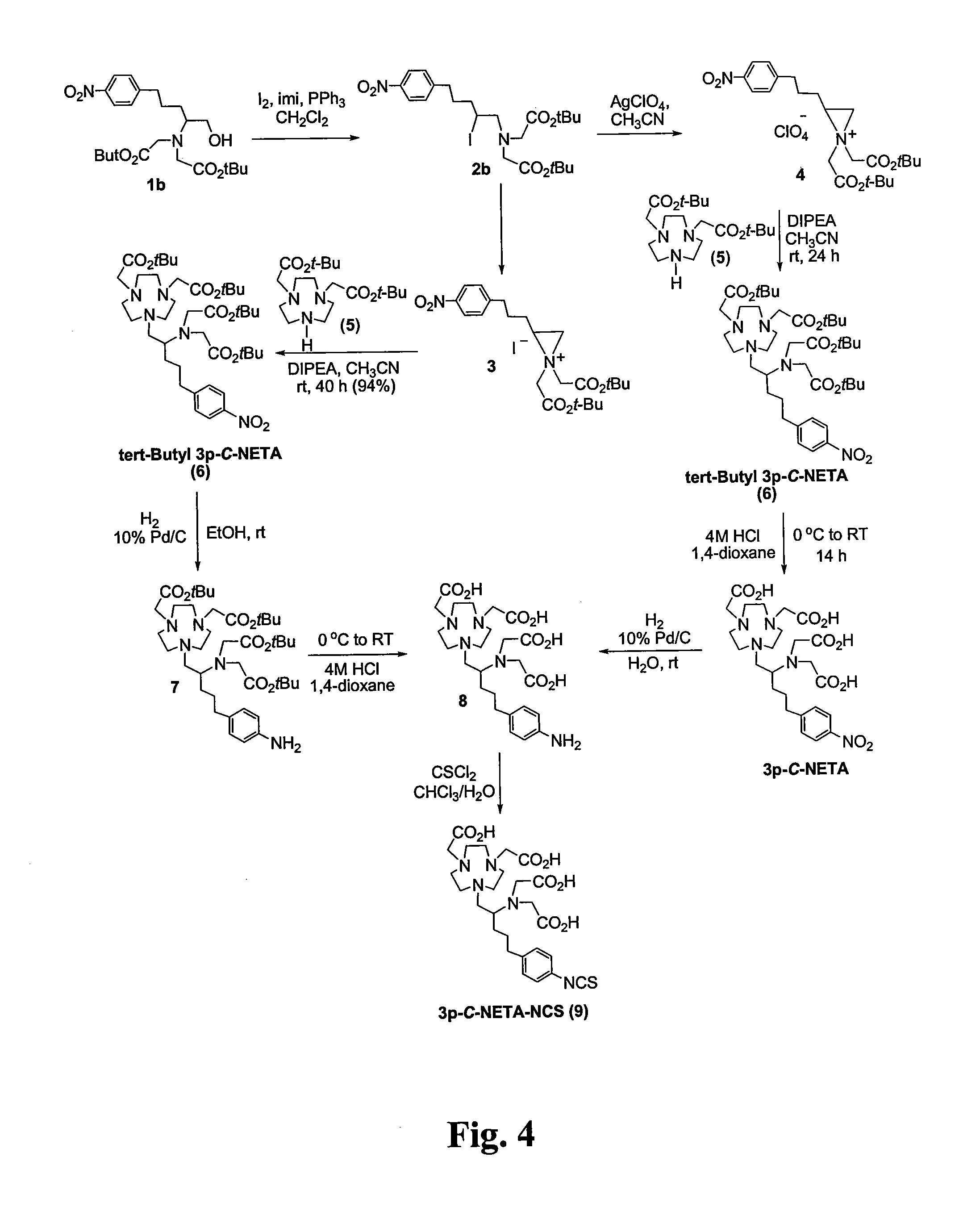

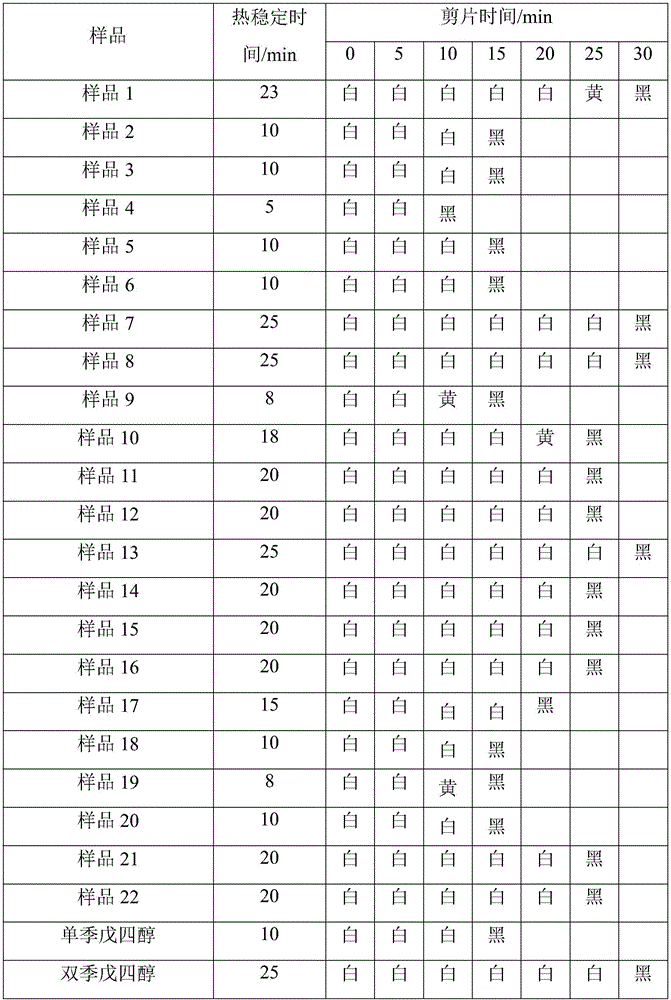

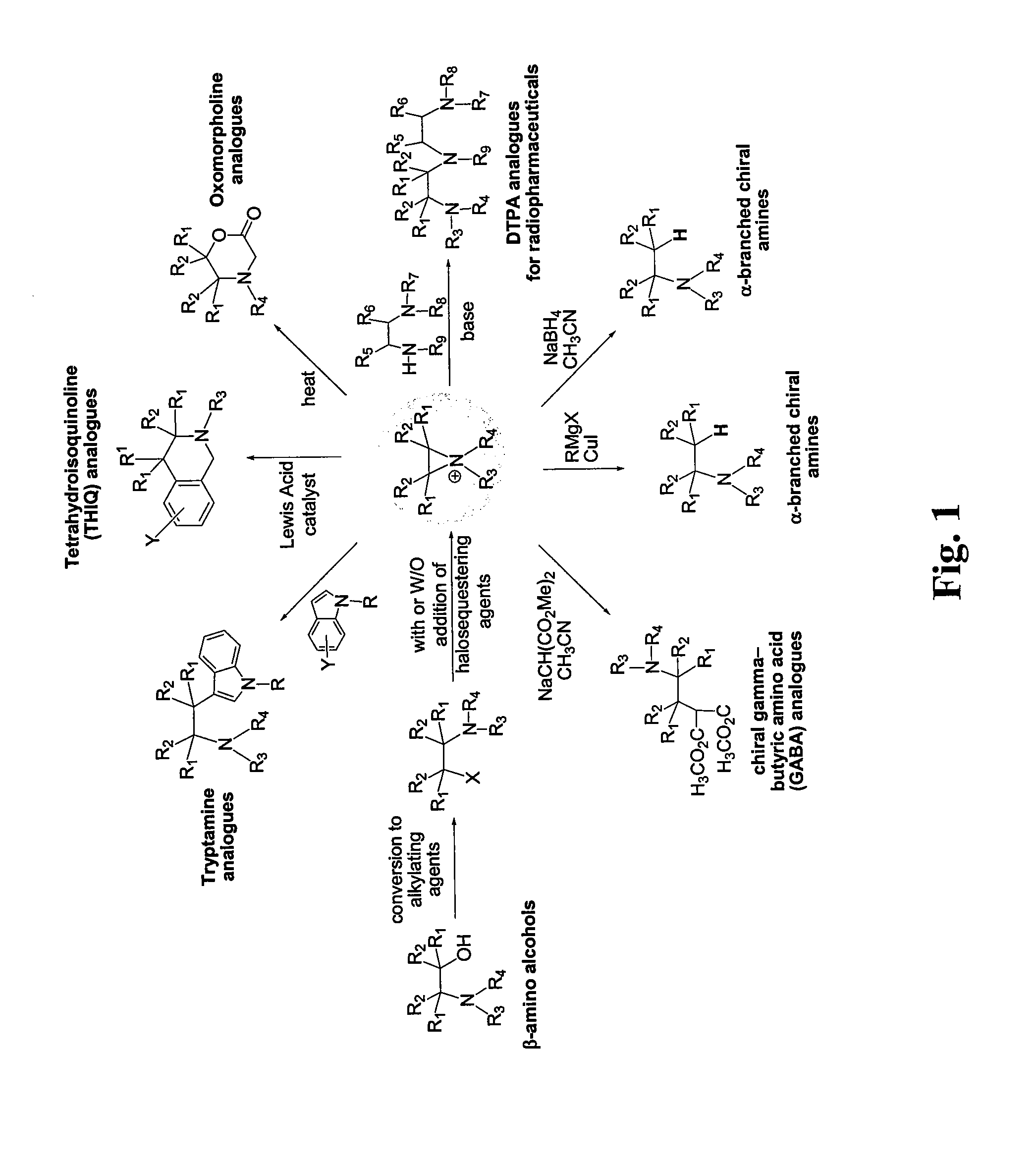

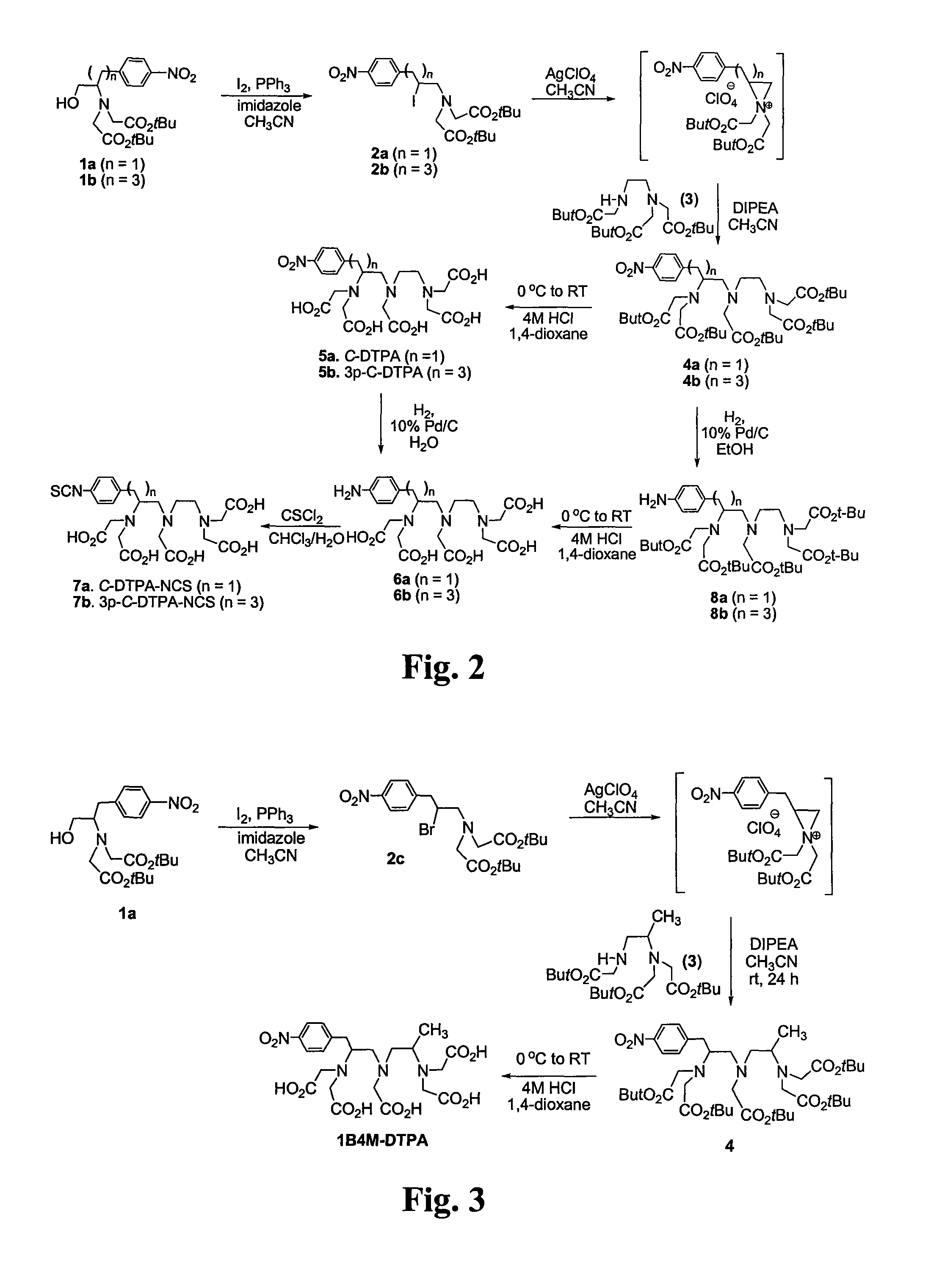

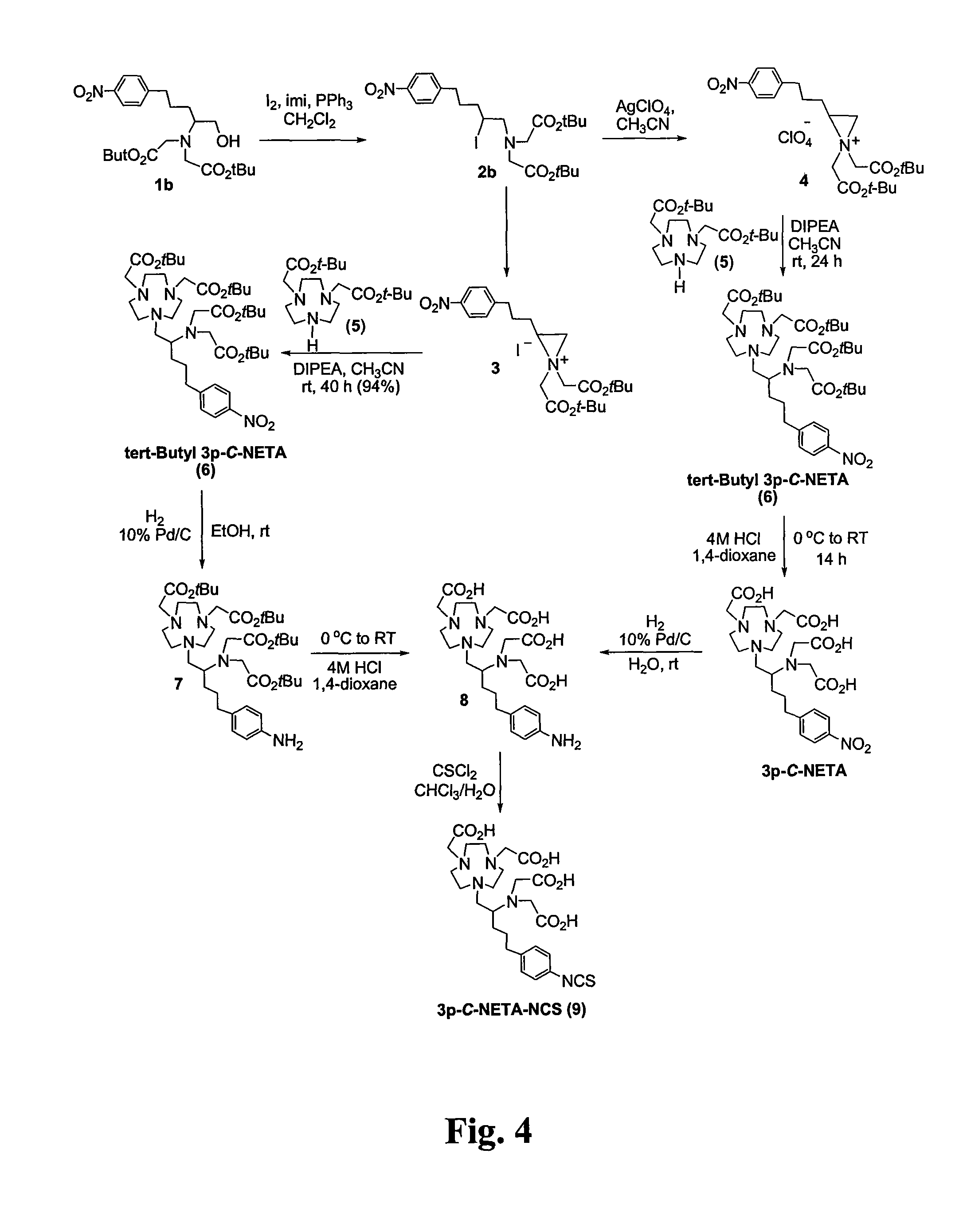

Synthesis of therapeutic and diagnostic drugs centered on regioselective and stereoselective ring opening of aziridinium ions

ActiveUS20130310555A1Short reaction stepsHigh yieldOrganic compound preparationThiol preparationRegioselectivityStereoselectivity

Owner:ILLINOIS INSTITUTE OF TECHNOLOGY

Composition for treating bacterial, viral, fungal diseases, inflammation and pain

The present invention is directed to compositions and methods of treating bacterial, viral, fungal diseases; inflammation or inflammatory-related disorders; pain; and skin conditions. The composition comprises an organic solvent extract, which is prepared by the method comprising the steps of: (a) mixing methionine with water, (b) adding an aqueous hypochlorite solution to the methionine solution and mixing, (c) adding a water-immiscible organic solvent to (b) and mixing, and (d) separating the organic solvent phase from the water phase to obtain the organic solvent extract.

Owner:OLATEC THERAPEUTICS

Thiol-selective water-soluble polymer derivatives

ActiveUS7910661B2Thiol preparationPharmaceutical non-active ingredientsPolymer sciencePerylene derivatives

Owner:NEKTAR THERAPEUTICS INC

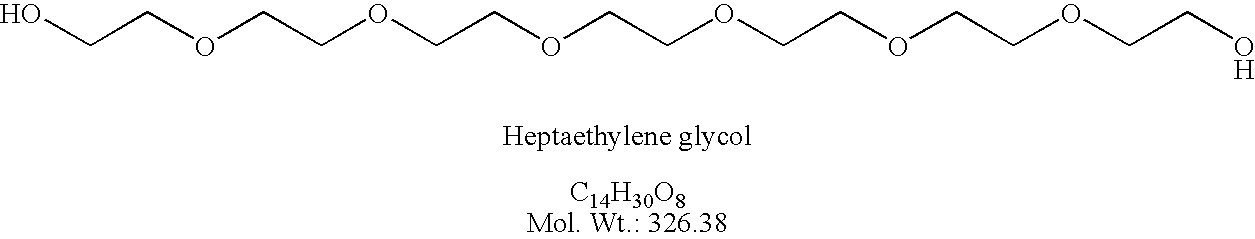

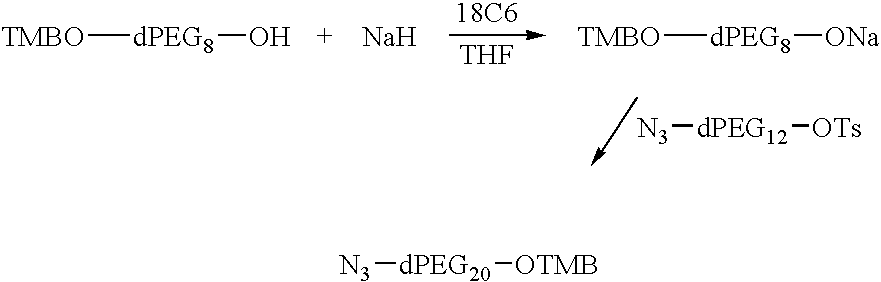

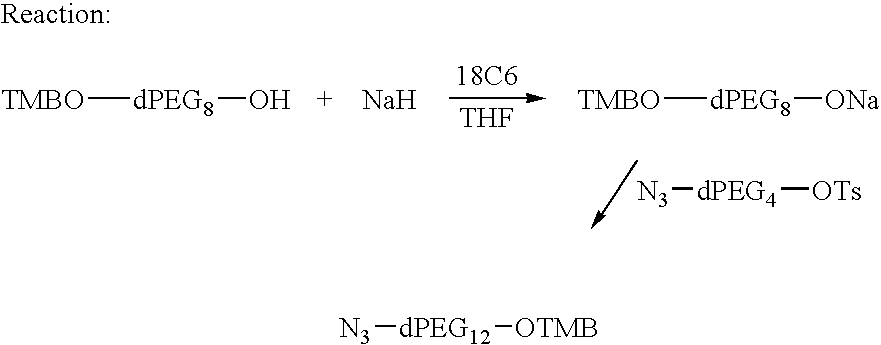

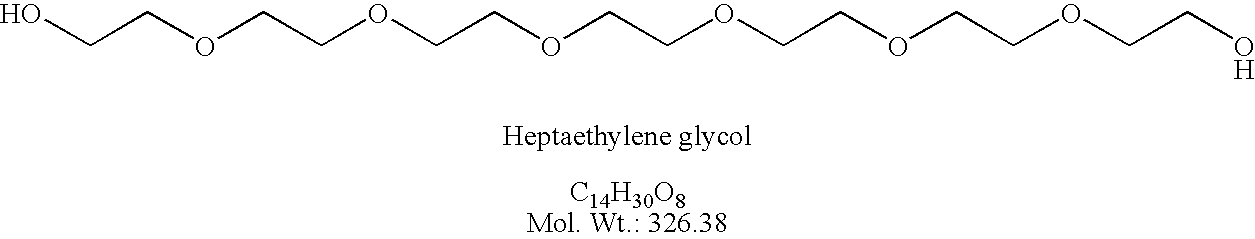

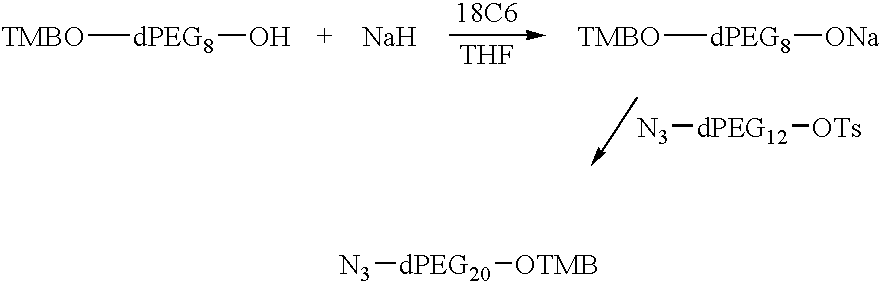

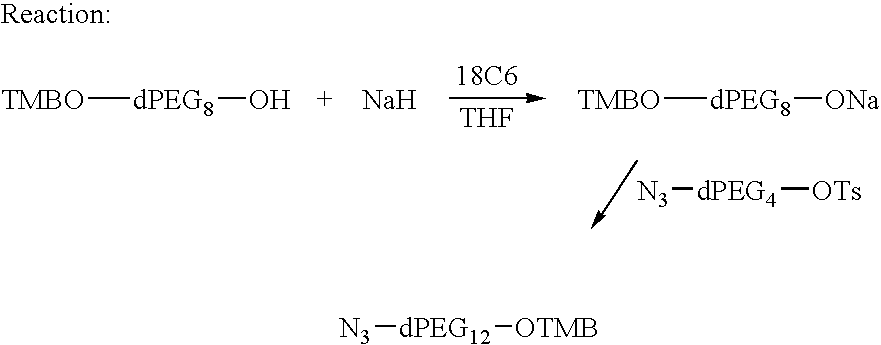

Selective and specific preparation of discrete peg compounds

ActiveUS20060020134A1Improve abilitiesWide range of utilityOrganic compound preparationThiol preparationState of artEthylene oxide

Aspects of the present invention are directed to novel methods for making discrete polyethylene compounds selectively and specifically to a predetermined number of ethylene oxide units. Methods which can be used to build up larger dPEG compounds (a) containing a wider range of utility to make useful homo- and heterofunctional and branched species, and (b) under reaction configurations and conditions that are milder, more efficient, more diverse in terms of incorporating useful functionality, more controllable, and more versatile then any conventional method reported in the art to date. In addition, the embodiments of the invention allow for processes that allow for significantly improving the ability to purify the intermediates or final product mixtures, making these methods useful for commerial manufacturing dPEGs. Protecting groups and functional groups can be designed to make purification at large scale a practical reality. The novel dPEG products form the compositional and material basis for making other novel compounds of valuable application in the fields of diagnostics and therapeutics, amongst others.

Owner:QUANTA BIODESIGN

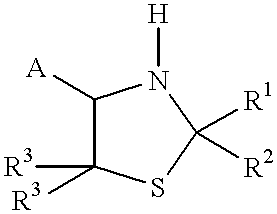

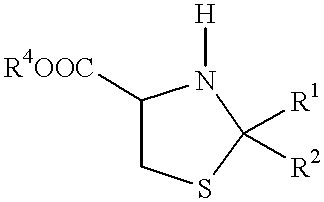

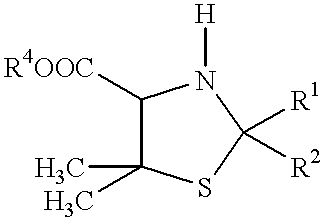

Process for ring cleavage of thiazolidine derivatives

InactiveUS6372912B1High yieldHigh purityThiol preparationOrganic compound preparationIon exchangeAqueous solution

Process for the hydrolytic ring cleavage of thiazolidine derivatives to give 2-aminomercaptan derivatives and carbonyl compounds, which comprisesbringing an aqueous solution of the thiazolidine derivative into contact with an acidic cation exchanger in the H+ form, giving a solution L1 which contains the carbonyl compound andeluting the cation exchanger with a suitable eluent, giving a solution L2 which contains the 2-aminomercaptan derivative.

Owner:CONSORTIUM FUR ELEKTROCHEM

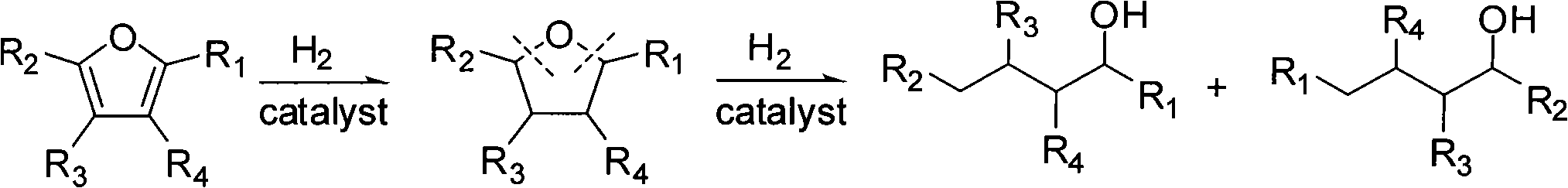

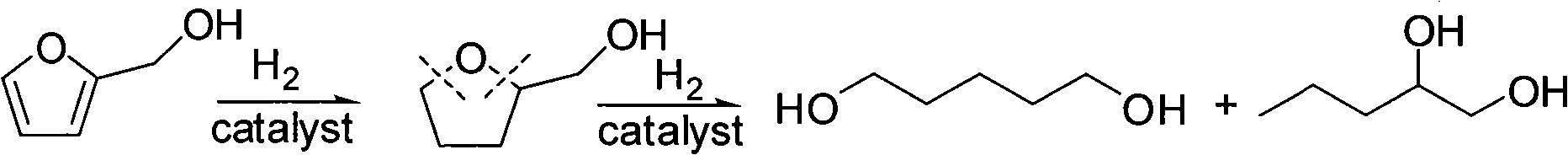

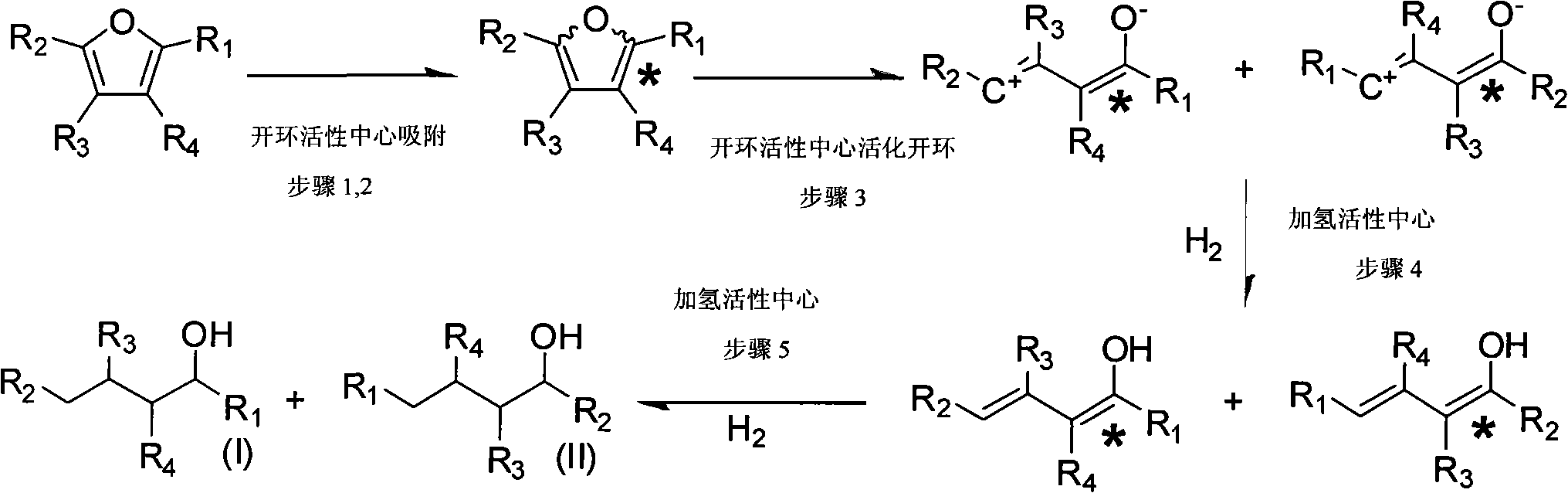

New loop opening hydrogenation reaction method for furan derivant

InactiveCN102134180ALower activation energyLow reaction pressureOrganic compound preparationThiol preparationFuranHydrogenation reaction

The invention aims at providing a new loop opening hydrogenation reaction method for furan derivant, which changes a reaction way by changing the traditional mechanism of catalytic reaction, realizes transformation from the traditional way of hydrogenation first and ring opening secondly to the way of ring opening first and hydrogenation secondly, and reduces the activation energy of reaction, thus greatly reducing reaction pressure and cost, alleviating operation difficulty, and have good industrial application prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

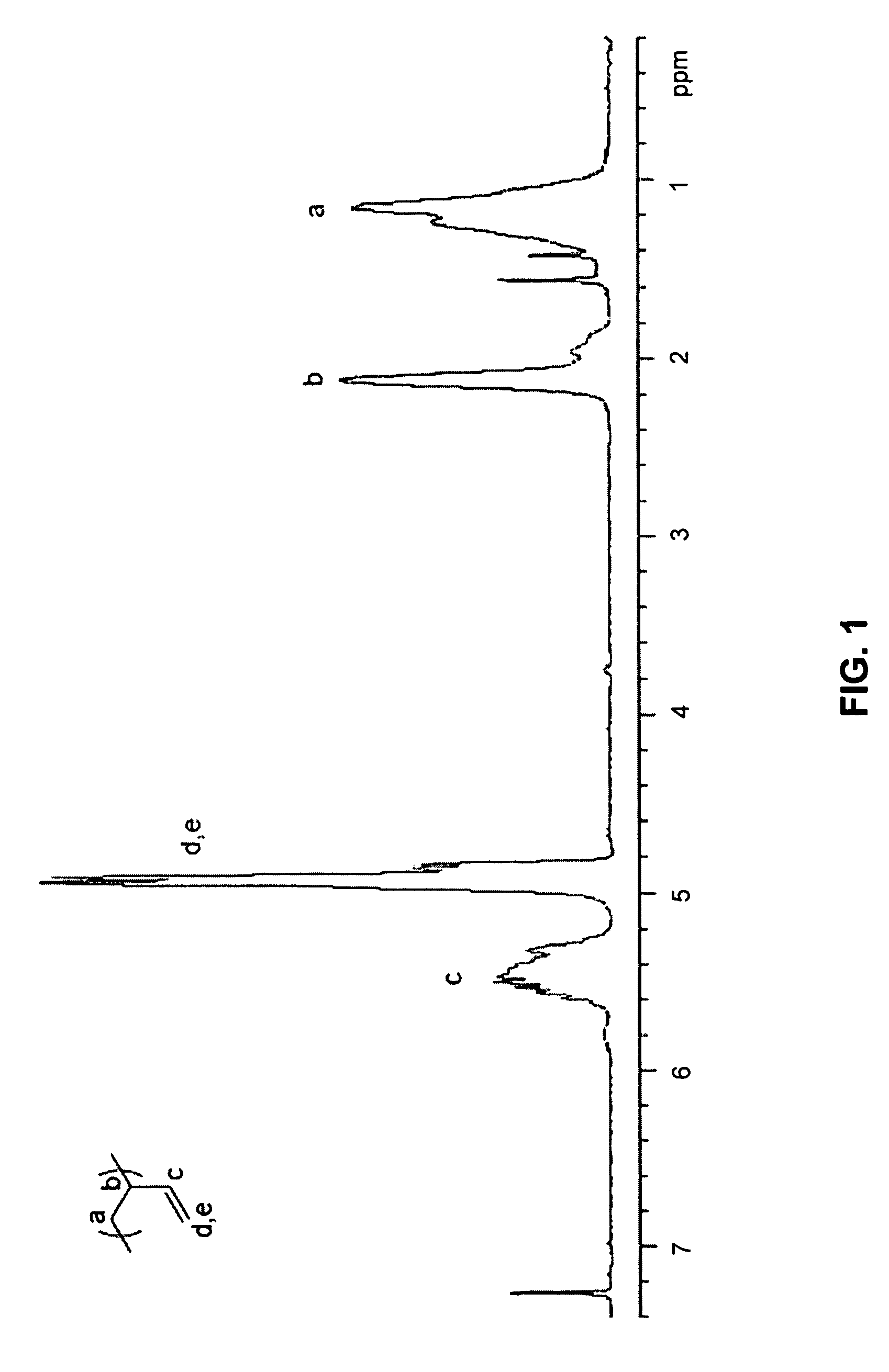

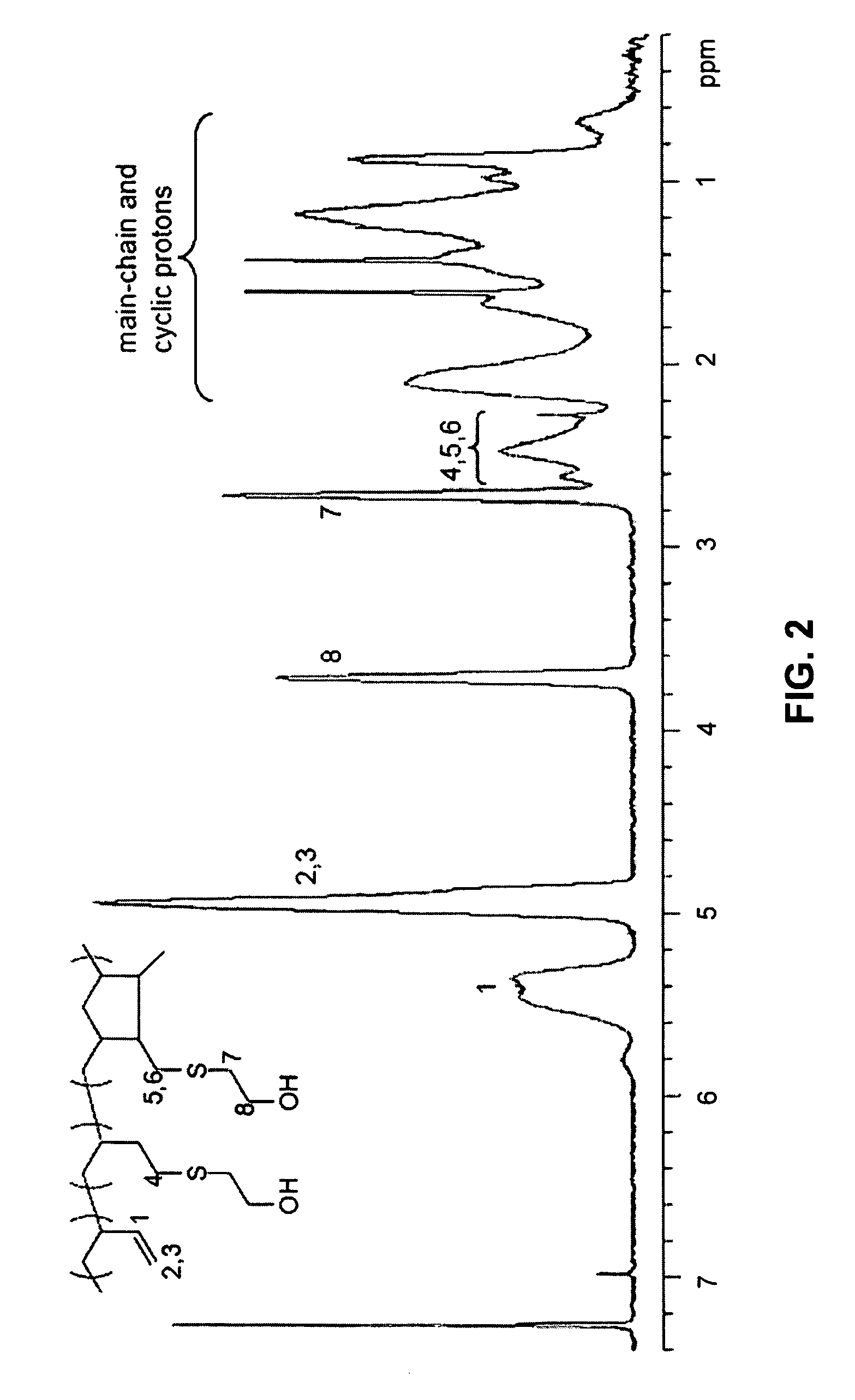

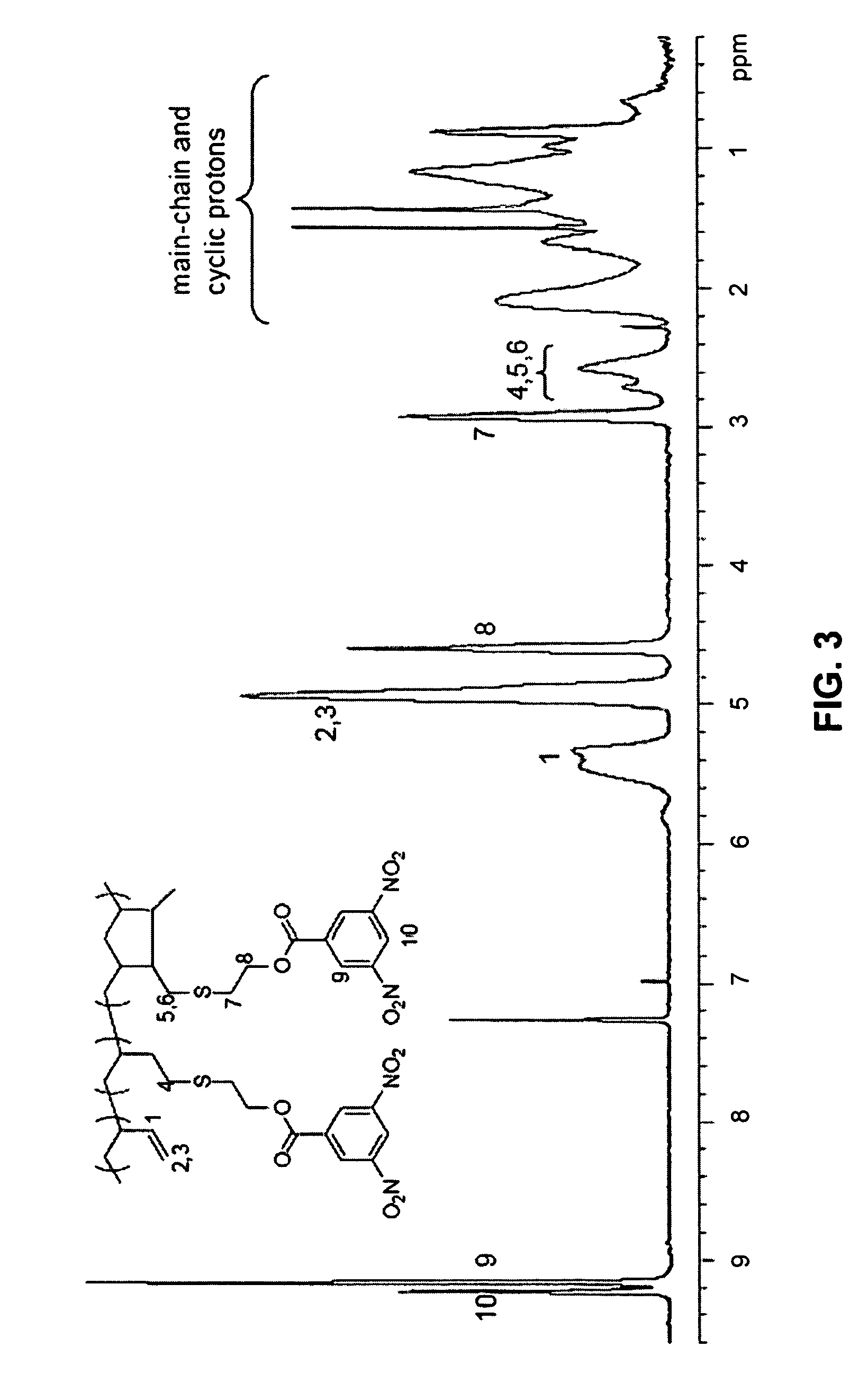

Functionalized polymers using protected thiols

InactiveUS7847019B2Conveniently addedThiol preparationPharmaceutical non-active ingredientsThioester synthesisAcyl group

Owner:CALIFORNIA INST OF TECH

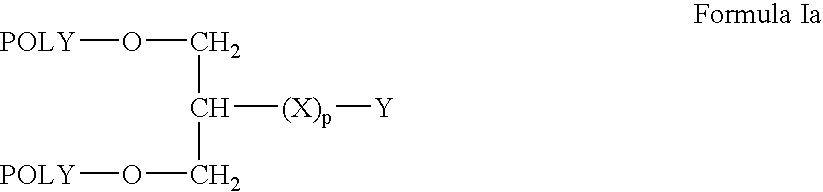

Branched polymers and their conjugates

InactiveUS20060178475A1Avoid a significant reduction in the biological activity of the moleculePreparationThiol preparationOrganic compound preparationArylActive agent

The present invention is directed to branched reactive water-soluble polymers comprising at least two polymer arms, such as poly(ethylene glycol), attached to a central aliphatic hydrocarbon core molecule through heteroatom linkages. The branched polymers bear at least one functional group for reacting with a biologically active agent to form a biologically active conjugate. The functional group of the branched polymer can be directly attached to the aliphatic hydrocarbon core or via an intervening linkage, such as a heteroatom, -alkylene-, —O-alkylene-O—, -alkylene-O-alkylene-, -aryl-O—, —O— aryl-, (—O-alkylene-)m, or (-alkylene-O—)m linkage, wherein m is 1-10.

Owner:NEKTAR THERAPEUTICS INC

Method for preparing multi-sulfhydryl carboxylic ester

InactiveCN102603583AHigh purityGood colorThiol preparationOrganic compound preparationAlcoholIndustrial effluent

The invention discloses a method for preparing multi-sulfhydryl carboxylic ester. The method comprises the steps of carrying out an esterification reaction on sulfydryl carboxylic acid and polyatomic alcohol under catalysis of an acid catalyst to obtain a crude product of the multi-sulfhydryl carboxylic ester; meanwhile, distilling and bringing out water generated in the esterification reaction through adding an azeotropic water-carrying agent; extracting excessive raw material sulfydryl carboxylic acid and the catalyst in the multi-sulfhydryl carboxylic ester crude product generated through the esterification reaction by using an alcohol extracting agent, purifying to obtain the multi-sulfhydryl carboxylic ester; and recycling the residual sulfydryl carboxylic acid and catalyst after distilling and recovering the extracting agent. The multi-sulfhydryl carboxylic ester prepared by adopting the method disclosed by the invention is high in purity, good in color, weak in odour or odorless, simple in process, green and environment-friendly and has the advantages that the generated industrial effluent is little, the catalyst and the excessive sulfydryl carboxylic acid can be recycled and better economic value is achieved.

Owner:XIANGTAN UNIV

Novel catalysts and process for dehydrating glycerol

InactiveUS20080183019A1Low carbonization tendencyPromote regenerationMolecular sieve catalystsThiol preparationAcroleinGlycerol

Owner:EVONIK DEGUSSA GMBH

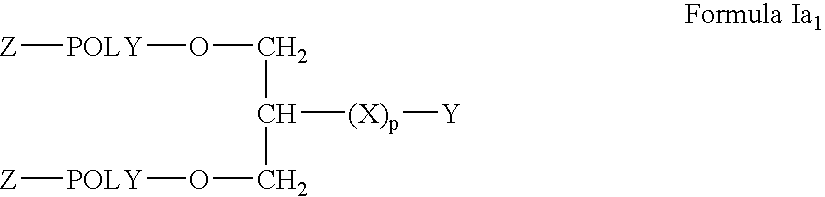

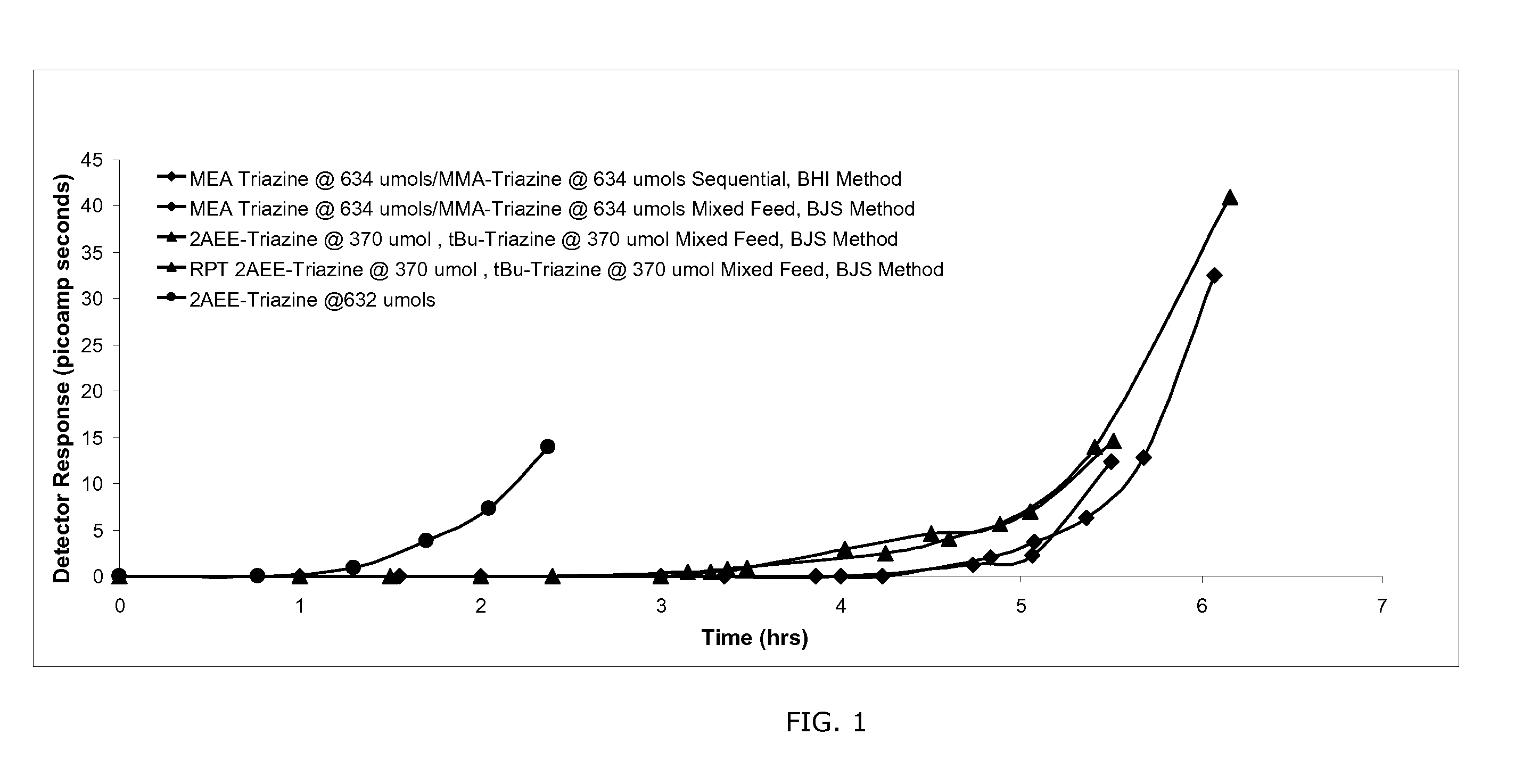

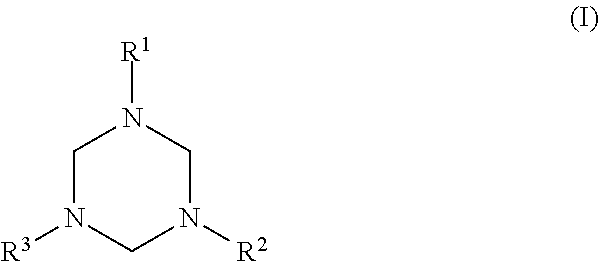

Method of Scavenging Hydrogen Sulfide and/or Mercaptans Using Triazines

Sulfhydryl compounds, including hydrogen sulfide and mercaptans, may be removed from a fluid or gaseous stream or substrate by reacting the hydrogen sulfide and mercaptans in the stream with a scavenger of the structural formula:wherein R1, R2 and R3 are each independently selected from the group consisting of R4 and R5, R4 is a C1-C20 straight or branched chain alkyl group, R5 is —[(CH)m—NH]p—(CH2)nOH, n and m are independently an integer from 2 to about 6, p is from 1 to about 6; and wherein at least one of R1, R2 and R3 is R4 and at least one of R1, R2 and R3 is R5.

Owner:BAKER HUGHES INC

Process for producing (POLY)thiol compound for use as optical material, and polymerizable composition containing the compound

InactiveUS20090264613A1Coloring is suppressedOrganic compound preparationThiol preparationAlcoholHalogen

Owner:MITSUI CHEM INC

Selective and specific preparation of discrete PEG compounds

ActiveUS7888536B2Improve abilitiesRapidity of resultingOrganic compound preparationThiol preparationEthylene oxideChemical compound

Aspects of the present invention are directed to novel methods for making discrete polyethylene compounds selectively and specifically to a predetermined number of ethylene oxide units. Methods which can be used to build up larger dPEG compounds (a) containing a wider range of utility to make useful homo- and heterofunctional and branched species, and (b) under reaction configurations and conditions that are milder, more efficient, more diverse in terms of incorporating useful functionality, more controllable, and more versatile then any conventional method reported in the art to date. In addition, the embodiments of the invention allow for processes that allow for significantly improving the ability to purify the intermediates or final product mixtures, making these methods useful for commerial manufacturing dPEGs. Protecting groups and functional groups can be designed to make purification at large scale a practical reality. The novel dPEG products form the compositional and material basis for making other novel compounds of valuable application in the fields of diagnostics and therapeutics, amongst others.

Owner:QUANTA BIODESIGN LLC

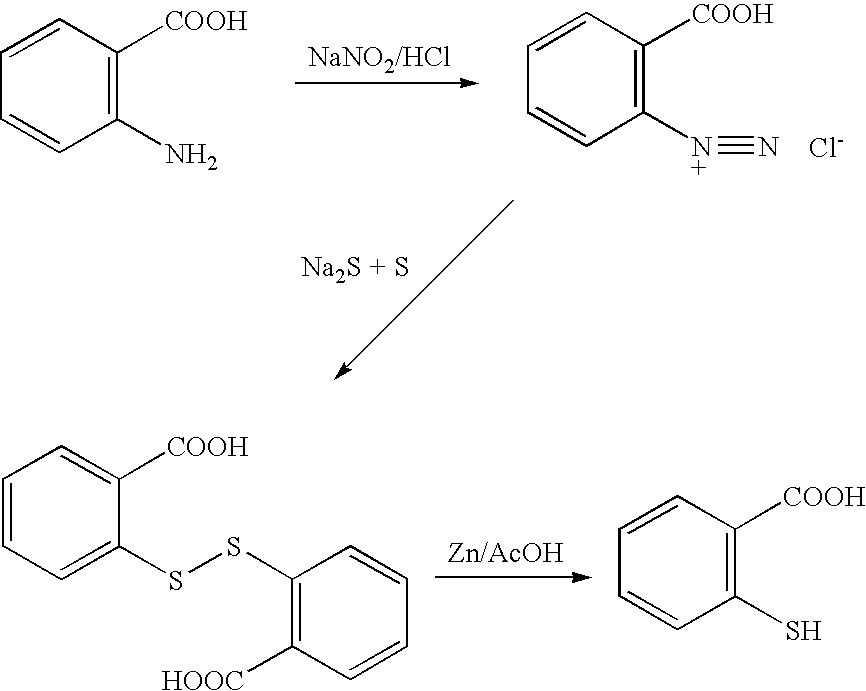

Method for producing thiosalicylic acid

InactiveUS20040116734A1Reduce production efficiencyLow yieldThiol preparationOrganic compound preparationSulfurAnthranilic acid

The present invention relates to a method for causing sodium sulfide or a mixture of sodium sulfide and sulfur to react with diazonium salt formed by diazotizing anthranilic acid, wherein the Na / S atomic ratio as calculated on the basis of the employed sodium sulfide and sulfur is adjusted to within the range of 1.33 to 2.0 during the reaction. Thus is made practicable the manufacture of thiosalicylic acid in a high yield without going through the individual route of isolating and reducing dithiosalicylic acid.

Owner:AIR WATER INC

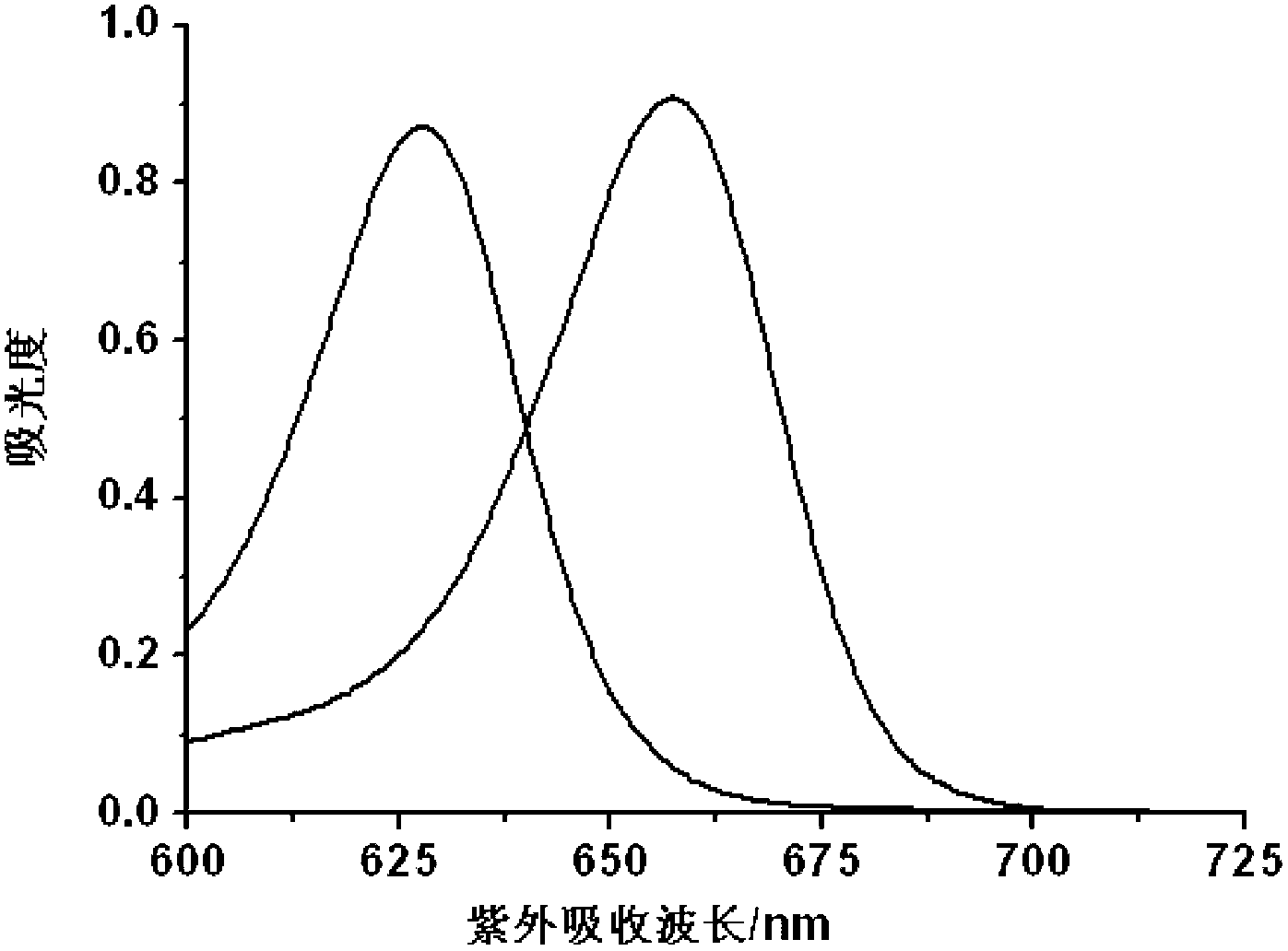

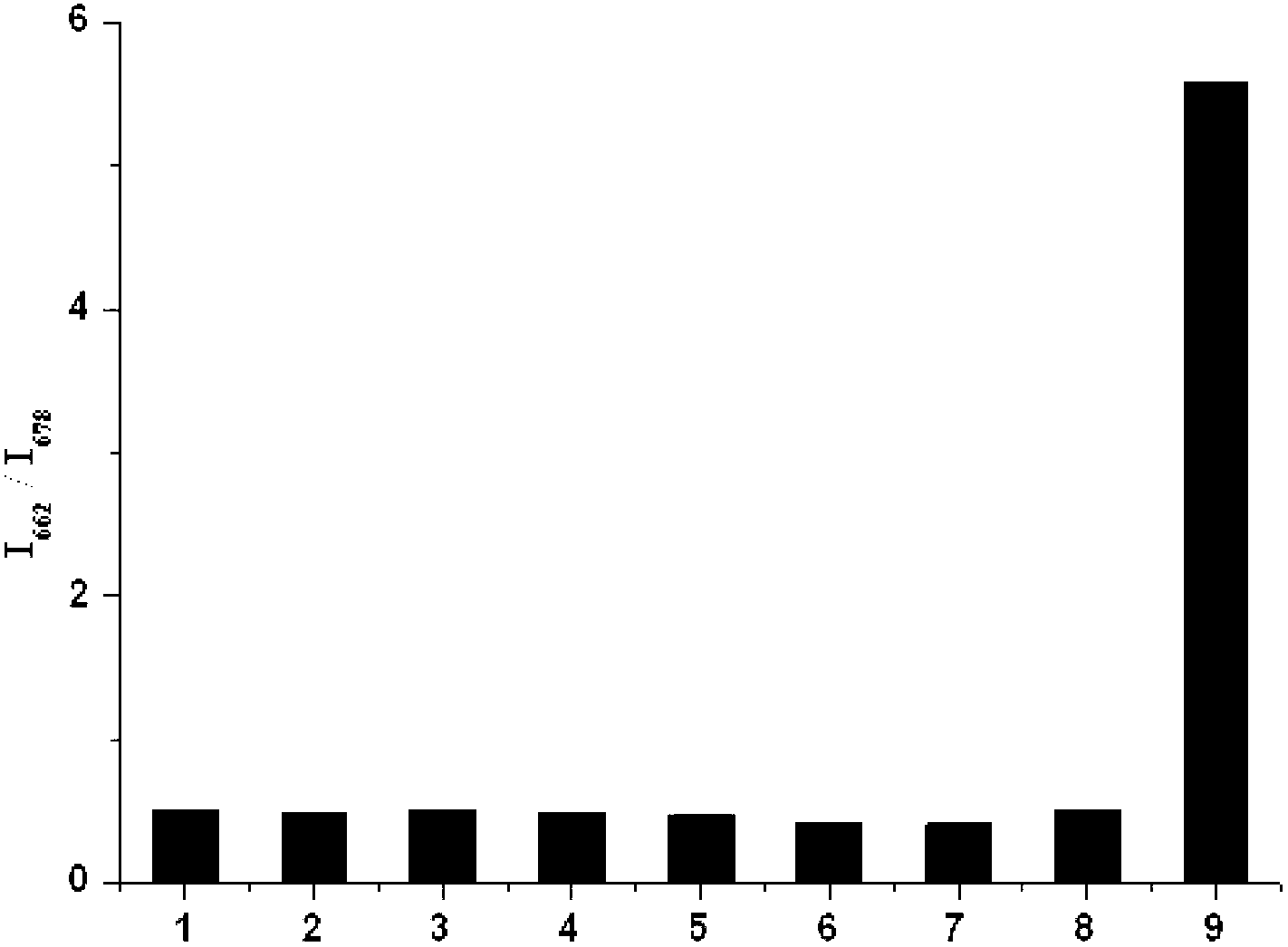

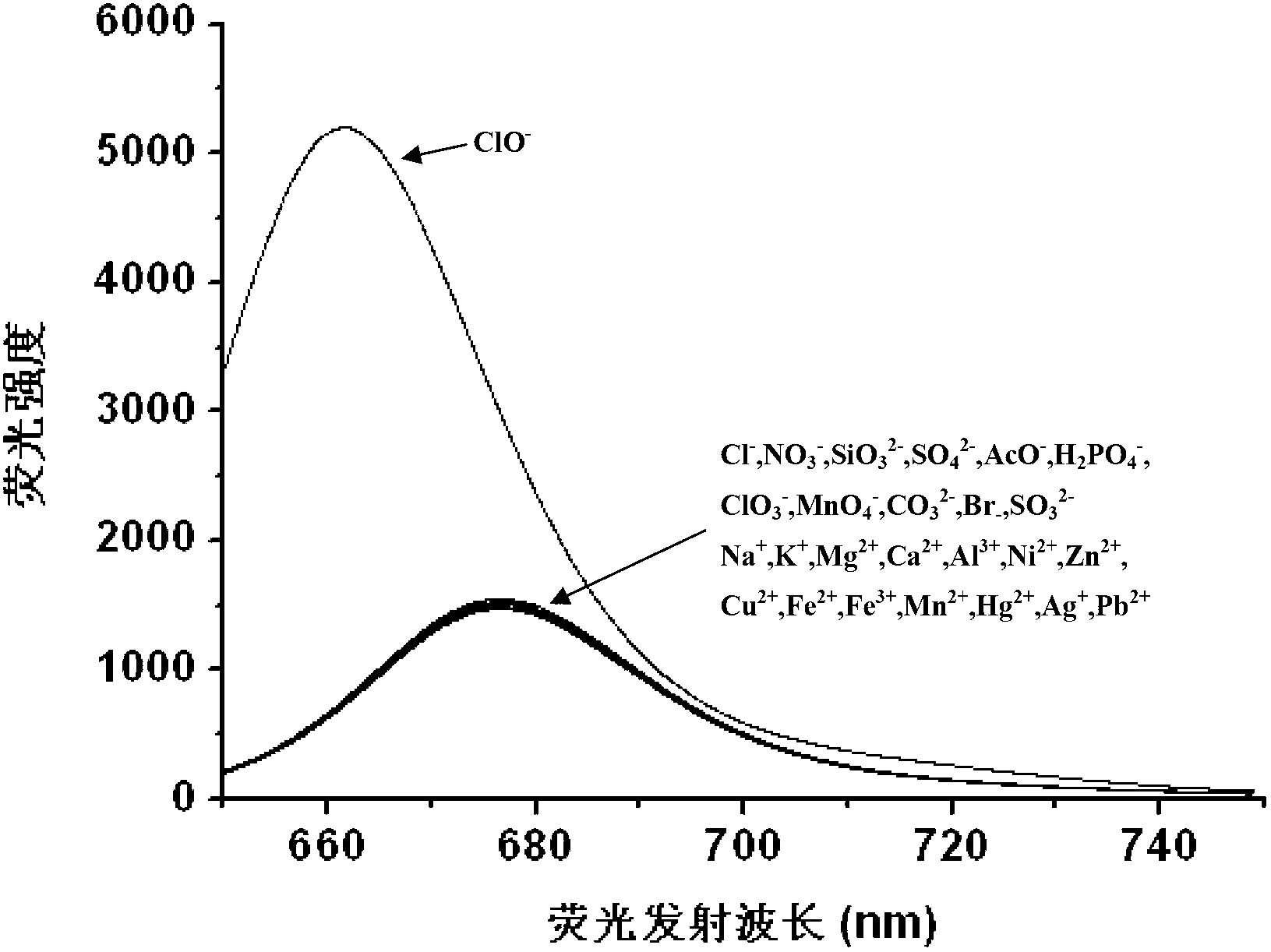

Hypochlorite ion fluorescence probe, and synthetic method and application thereof

InactiveCN103173213AGood choiceLow detection limitThiol preparationFluorescence/phosphorescenceHypochloriteDistillation

The invention discloses a hypochlorite ion fluorescence probe, and a synthetic method and an application thereof. The synthetic method comprises the following steps: 1, adding 3,4-dihydroxy-3-cyclobutene-1,2-dione (squaric acid) and 3-N,N-diethylamino phenol to a solvent which is a mixed solution comprising toluene and n-butanol, carrying out a heating reflux reaction for 8-12h, filtering, washing the obtained reaction precipitate with methanol, and drying to obtain an intermediate squaric acid dye, wherein the molar ratio of 3,4-dihydroxy-3-cyclobutene-1,2-dione (squaric acid) to 3-N,N-diethylamino phenol is 1:1.8-2.2; and 2, carrying out the heating reflux reaction of the squaric acid dye and a Lawesson reagent in a solvent toluene under the protection of nitrogen for 6-24h, carrying out reduced pressure distillation to remove the solvent, and carrying out silica gel column chromatography to obtain the fluorescence probe. The probe has a simple synthetic process, has a very high selectivity and a very high sensitivity to hypochlorite ions, and has a good application prospect.

Owner:CENT SOUTH UNIV

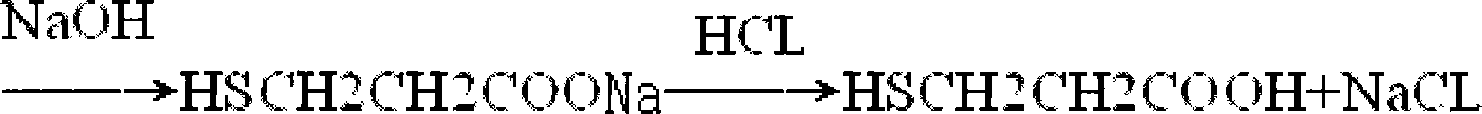

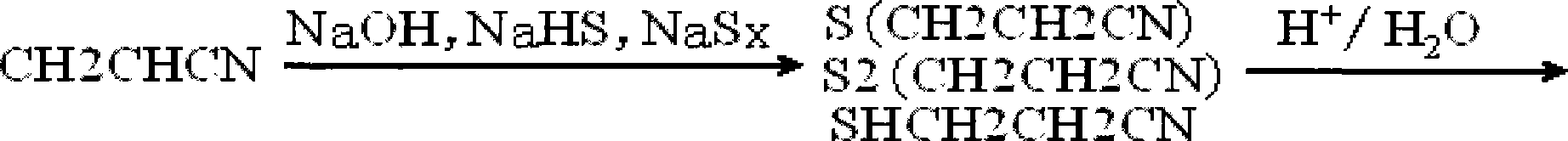

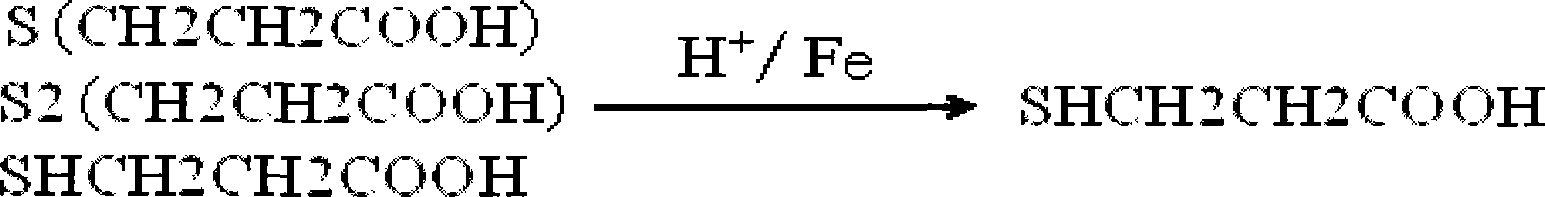

Method for preparing 3-mercaptopropionic acid

The invention relates to a preparation method of 3-mercaptopropionic acid. Sodium hydroxide solution, sodium hydrosulfide and sodium polysulfide (as catalyst) are mixed, then acrylonitrile is dripped into the mixture at the temperature of 20-70 DEG C to produce under insulated temperature the mixed solution of a plurality of intermediates, then hydrochloric acid is added for acidification and iron powder is added for deoxidization, thus acquiring the solution of 3-mercaptopropionic acid. The raw material sodium hydrosulfide selected in the reaction is cheap, reducing the production cost; hydrogen sulfide gas that is produced after the hydrochloric acid is added can be recycled to produce hydrogen sulfide nano, the production cost is further reduced; the final waste liquid mainly contains surplus hydrochloric acid and ammonia chloride, which is easy to be disposed; pollution is hardly caused during the whole reaction process.

Owner:顾建荣

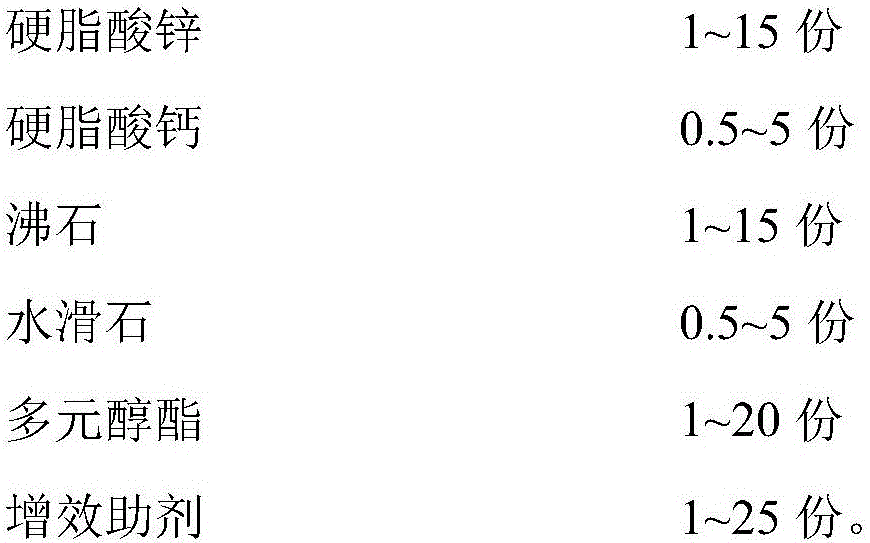

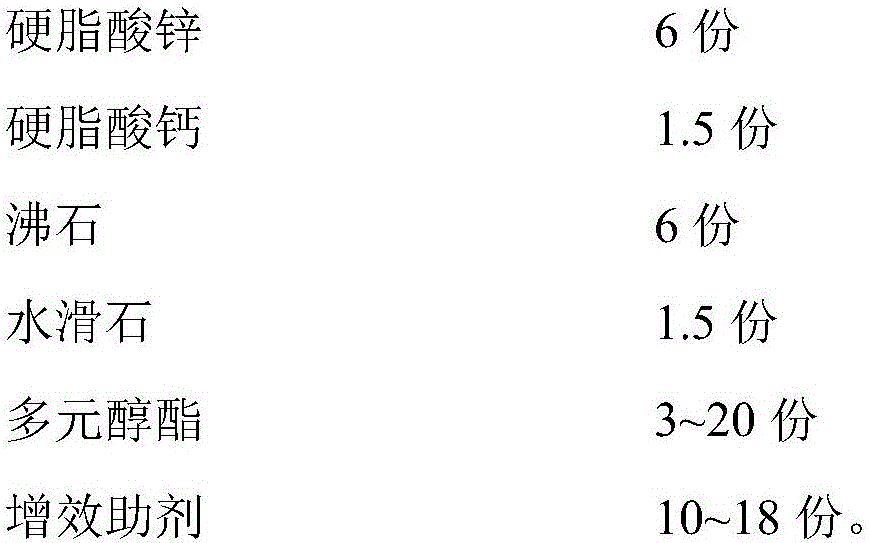

Polyol ester and application of same to processing of halogenated vinyl polymer

ActiveCN106631779AImprove hot workabilityLong thermal stability timeOrganic compound preparationThiol preparationPolyolPolymer science

The invention discloses polyol ester and application of the same to processing of a halogenated vinyl polymer. The polyol ester is prepared by subjecting one of polyols and one selected from a group consisting of carboxylic acid and acid anhydrides to esterification or subjecting one of polyols and one of the esters of carboxylic acid to transesterification. The polyol ester provided by the invention has good compatibility with the halogenated vinyl polymer and can improve the hot-working performance of the halogenated vinyl polymer when cooperated with a heat stabilizer; in particular, the polyol ester can inhibit or alleviate the phenomenon of zinc burning of a zinc-containing heat stabilizer in the later phase of hot-working when cooperated with the zinc-containing heat stabilizer; so the whiteness of a halogenated vinyl polymer product is improved, later zinc burning is effectively inhibited, the thermostabilization time, particularly medium-and-long-term heat stability, of the halogenated vinyl polymer (especially PVC) is substantially prolonged, and the defect of poor stability in the later phase of the zinc-containing heat stabilizer is compensated for. The polyol ester has good application prospects in the field of processing of the halogenated vinyl polymer, especially PVC.

Owner:济南金昌树新材料科技有限公司

Synthesis of therapeutic and diagnostic drugs centered on regioselective and stereoselective ring opening of aziridinium ions

ActiveUS9446995B2Short reaction stepsHigh yieldThiol preparationOrganic compound preparationRegioselectivityStereoselectivity

Owner:ILLINOIS INSTITUTE OF TECHNOLOGY

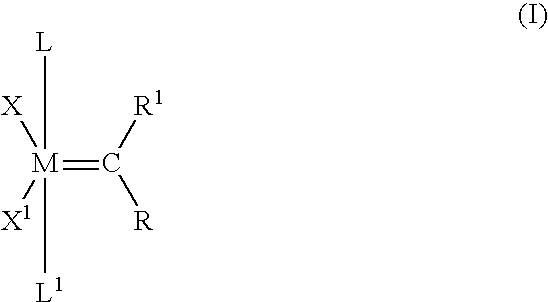

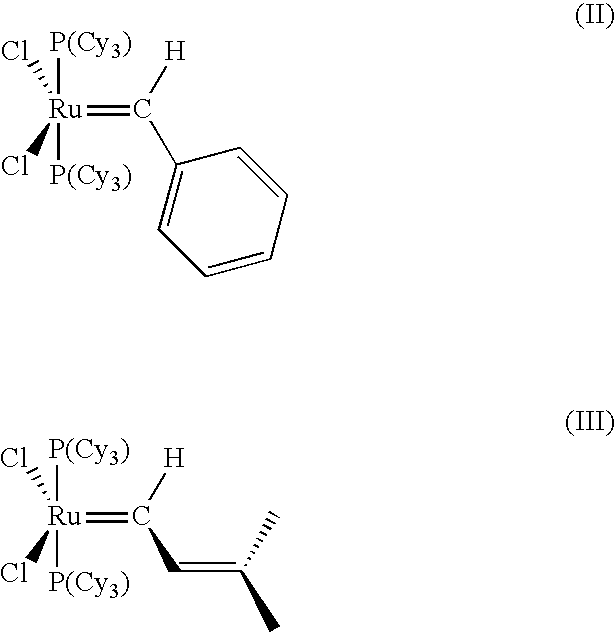

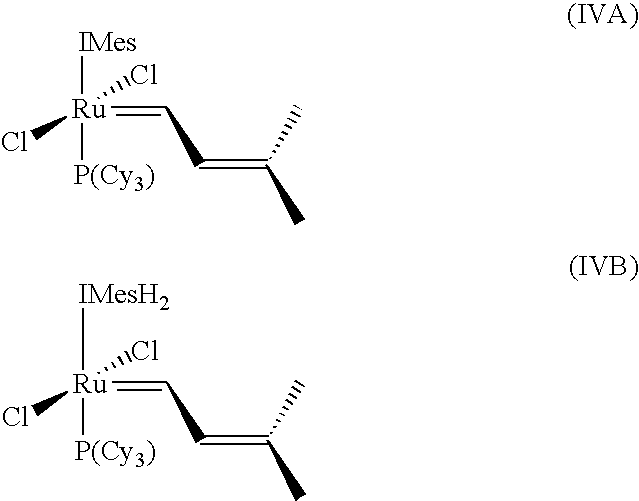

Cross-metathesis reaction of functionalized and substituted olefins using group 8 transition metal carbene complexes as metathesis catalysts

InactiveUS20070155975A1Carboxylic acid esters preparationHydroxy compound preparationFunctional diversityAlkene

The invention pertains to the use of Group 8 transition metal carbene complexes as catalysts for olefin cross-metathesis reactions. In particular, ruthenium and osmium alkylidene complexes substituted with an N-heterocyclic carbene ligand are used to catalyze cross-metathesis reactions to provide a variety of substituted and functionalized olefins, including phosphonate-substituted olefins, directly halogenated olefins, 1,1,2-trisubstituted olefins, and quaternary allylic olefins. The invention further provides a method for creating functional diversity using the aforementioned complexes to catalyze cross-metathesis reactions of a first olefinic reactant, which may or may not be substituted with a functional group, with each of a plurality of different olefinic reactants, which may or may not be substituted with functional groups, to give a plurality of structurally distinct olefinic products. The methodology of the invention is also useful in facilitating the stereoselective synthesis of 1,2-disubstituted olefins in the cis configuration.

Owner:CALIFORNIA INST OF TECH

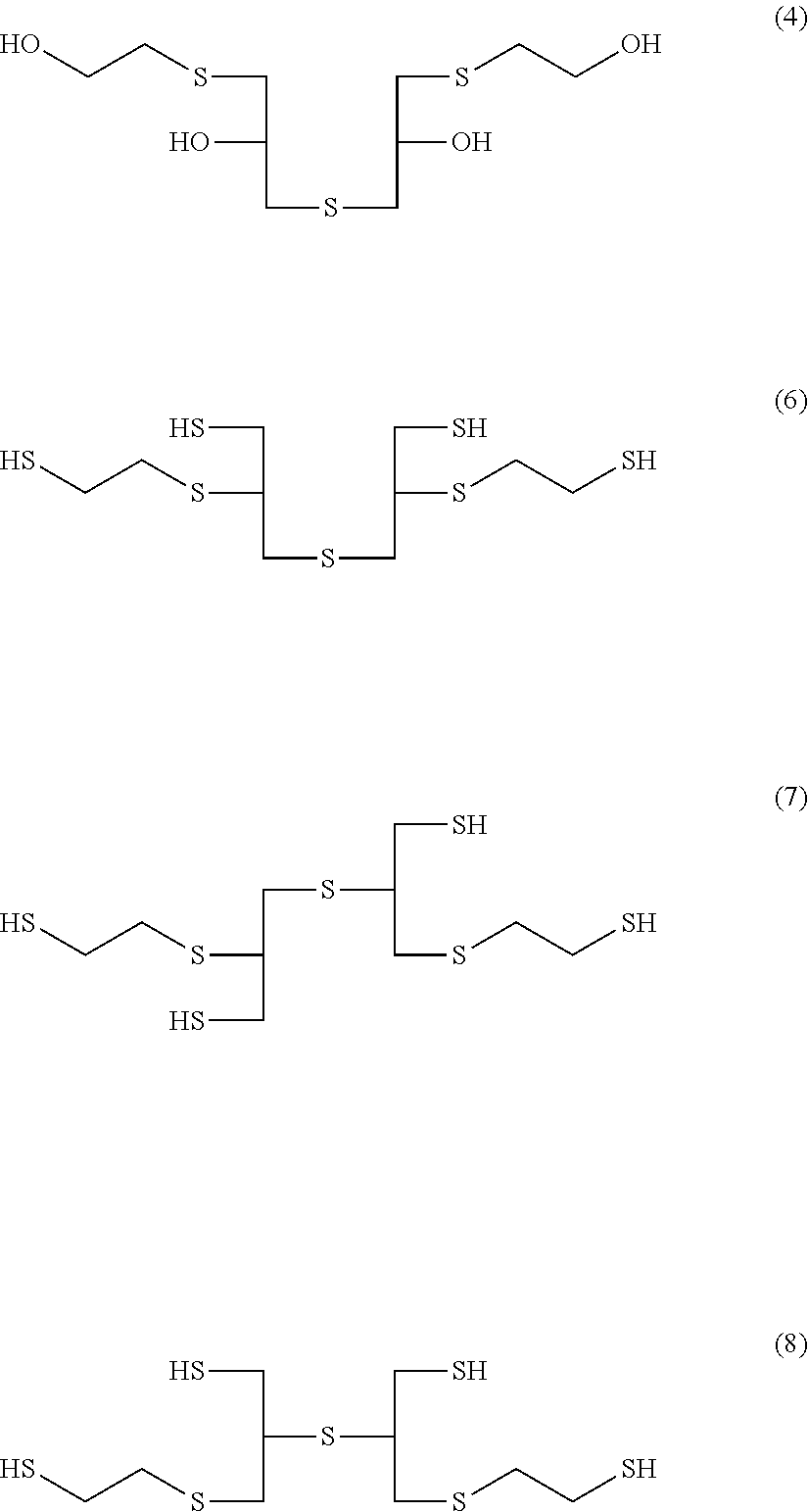

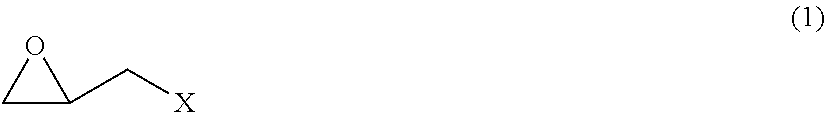

Method for producing polythiol compound, polymerizable composition for optical material, and uses thereof

ActiveUS20150126781A1Quality improvementGet stableOrganic compound preparationThiol preparationPolyolAmmonia

Provided is a method for producing a polythiol compound, comprising: a step for reacting a polyalcohol compound represented by the following formula (4) with thiourea in the presence of hydrogen chloride to obtain an isothiuronium salt; a step for adding, while maintaining a reaction solution containing the isothiuronium salt thus obtained at a temperature of 20° C. to 60° C., aqueous ammonia to the reaction solution within 80 minutes, thereby hydrolyzing the isothiuronium salt to obtain a polythiol compound containing, as a main component, one kind or two or more kinds selected from the group consisting of compounds represented by the following formulae (6) to (8); and a step for adding hydrochloric acid which is a concentration of 30% to 36% to the solution containing the polythiol compound thus obtained, washing the solution at a temperature of 30° C. to 55° C. to purify the polythiol compound.

Owner:MITSUI CHEM INC

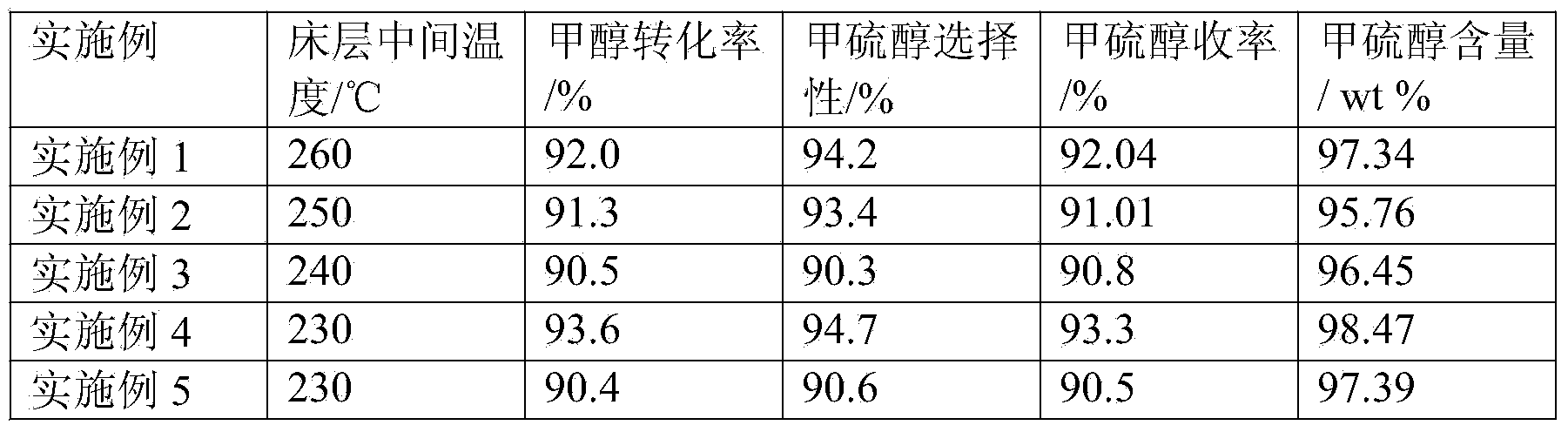

Catalyst for synthesizing methyl mercaptan and preparation method of catalyst

ActiveCN103506130AGood choiceLow activation temperatureThiol preparationMetal/metal-oxides/metal-hydroxide catalystsAlkali metal oxideReaction temperature

The invention discloses a catalyst for synthesizing methyl mercaptan and a preparation method of the catalyst. The catalyst comprises a carrier, an active component and an assistant, wherein the carrier is gamma-Al2O3, the active component is one or more of Fe2O3, MoO3, ZnO and NiO, and the assistant is alkali metal oxide or alkaline earth metal oxide. The catalyst is prepared as follows: impregnating a precursor of the assistant on the carrier by using a secondary equivalent-volume impregnation method, loading the precursor containing the active component by using the impregnation method again after roasting for one time, and obtaining a target product namely the catalyst for synthesizing the methyl mercaptan after the secondary roasting. According to the catalyst provided by the invention, methyl alcohol and sulfuretted hydrogen are used as raw materials to synthesize the methyl mercaptan, the selectivity of the catalyst is good, the active temperature of the catalyst is lower than that of the prior art, the reaction temperature is between 230-260 DEG C, the yield of the methyl mercaptan is more than 90%, in addition, no dimethyl sulfide is produced in the target product, so that subsequent separation is not needed.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

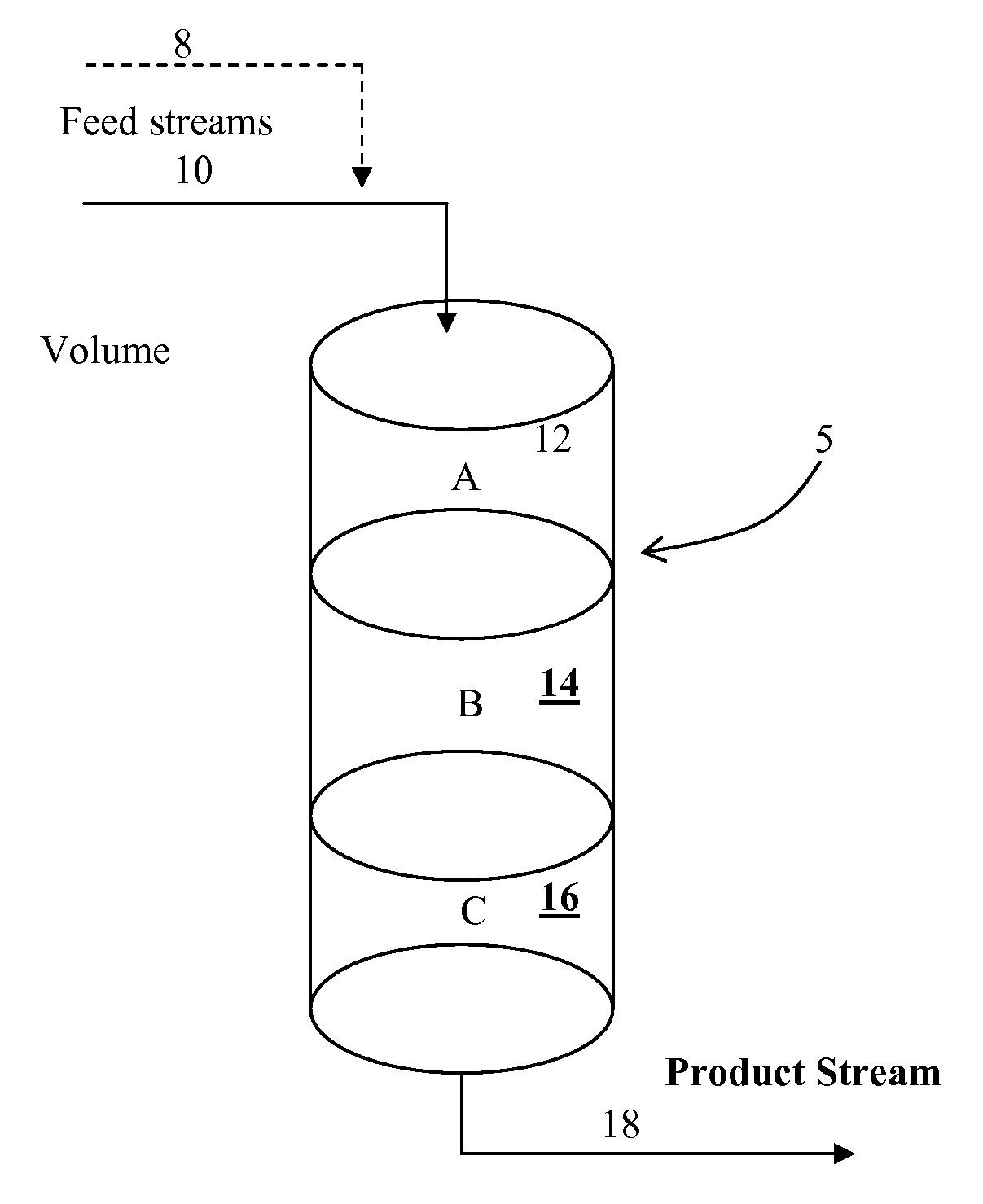

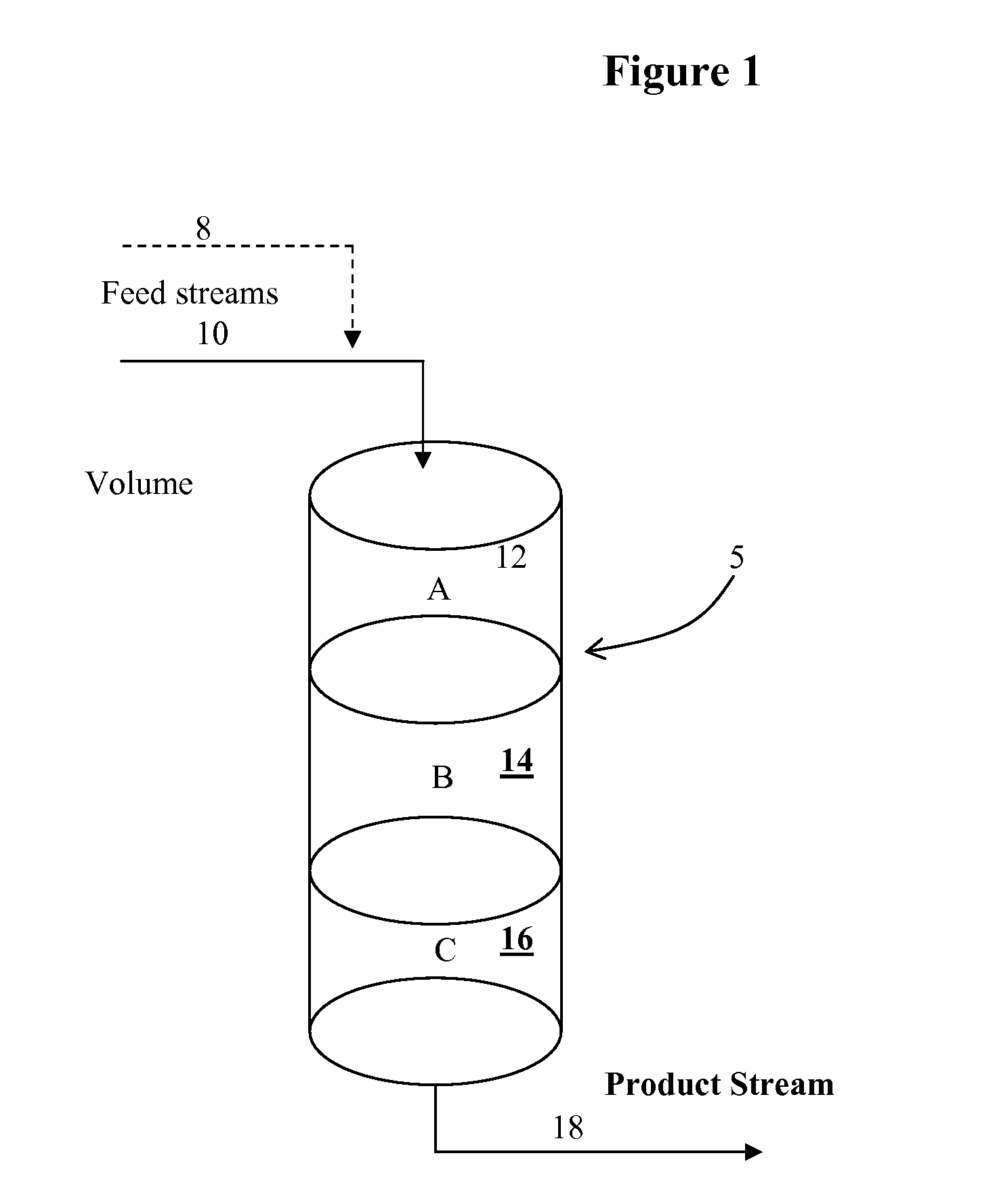

Graded catalyst bed for methyl mercaptan synthesis

A process and graded catalyst bed for selectively producing methyl mercaptan from methanol. The methanol is reacted with hydrogen sulfide, in the presence of a graded catalyst bed containing at least three types of nickel or cobalt molybdenum alumina catalysts to convert the methanol to methyl mercaptan in one-pass. At least one of the hydrotreating catalysts can contain aluminium phosphate. Use of the graded catalyst bed prevents the formation of a hot spot within the graded catalyst bed. The methyl mercaptan having less than about 30 wt. % unreacted methanol contained therein.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Process for Producing 2-Amino-2-[2-[4-(3-Benzyloxyphenylthio)-2-Chlorophenyl]Ethyl]-1,3-Propanediol Hydrochloride and Hydrates Thereof, and Intermediates in the Production Thereof

A process for the industrial production of 2-amino-2-[2-[4-(3-benzyloxyphenylthio)-2-chlorophenyl]ethyl]-1,3-propanediol hydrochloride (Compound I), an effective immunosuppressant.The process for producing 2-amino-2-[2-[4-(3-benzyloxyphenylthio)-2-chlorophenyl]ethyl]-1,3-propanediol hydrochloride or a hydrate thereof includes the steps of reacting 4-(3-benzyloxyphenylthio)-2-chlorobenzaldehyde with ethyl diethylphosphonoacetate in a solvent in the presence of a base to form ethyl 3-[4-(3-benzyloxyphenylthio)-2-chlorophenyl]acrylate; reducing the resulting ethyl 3-[4-(3-benzyloxyphenylthio)-2-chlorophenyl]acrylate, followed by mesylation, iodination and nitration, to form 1-benzyloxy-3-[3-chloro-4-(3-nitropropyl)phenylthio]benzene; forming 2-[2-[4-(3-benzyloxyphenylthio)-2-chlorophenyl]ethyl]-2-nitro-1,3-propanediol using a formaldehyde solution; and reducing the resulting 2-[2-[4-(3-benzyloxyphenylthio)-2-chlorophenyl]ethyl]-2-nitro-1,3-propanediol to form the desired product.

Owner:KYORIN PHARMA CO LTD

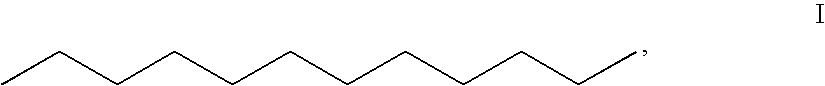

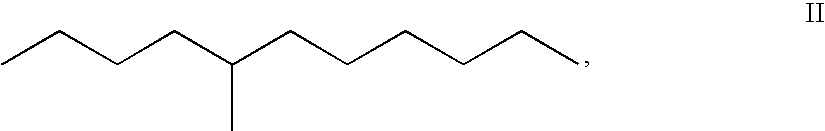

Preparation of thiols

InactiveUS20060173218A1Avoid disadvantagesOrganic compound preparationThiol preparationDouble bondHydrogen sulfide

The present invention relates to a process for preparing alkyl thiols by adding hydrogen sulfide to double bonds of C6-C20 olefins at a temperature of from 20 to 150° C. and a pressure of from 1 to 40 bar, wherein the reaction is carried out in the presence of at least one organic, liquid acid, and to the use of organic, liquid acids as a catalyst for increasing the selectivity and / or reaction rate in the addition of hydrogen sulfide to double bonds of C6-C20 olefins to prepare alkyl thiols.

Owner:BASF AG

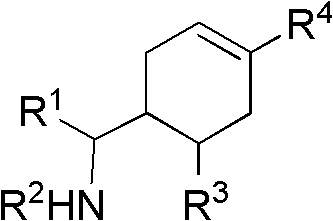

Cyclohexene compound having influenza virus neuraminidase inhibition activity, preparation method and application

InactiveCN102964267AHas neuraminidase inhibitory activityOvercoming drug resistanceCarbamic acid derivatives preparationCarboxylic acid nitrile preparationCyclohexeneEnantiomer

The invention provides a compound expressed by a general formula I, or its pharmaceutically acceptable salt, and an analyzed enantiomer and a purified diastereomer, wherein R<1>is H or C1-12 alkyl groups; R<2> is H, -C(O)R<1a>, -C(O)OR<1a> or -S(O)2R<1b>, wherein R<1a> is H or C1-6 alkyl groups, R<1b> is selected from H or C1-6 alkyl groups halogenated hydrocarbon, phenyl or aryl group; R<3> is selected from C1-4 alkyl groups substituted amino, halogen, hydroxyl, sulfydryl, guanidyl, nitryl or cyano group; and R<4> is -(CH2)nCO2H, -(CH2)nP(O)(OH)2, -(CH2)nCO2R<1a> and -(CH2)nP(O)(OR<1a>)2, wherein R<1a> is H or C1-6 alkyl groups, n is an integer between 0 and 4, or a salt of the above groups. The invention also provides a preparation method of the cyclohexene compound expressed by the general formula I, and an application of the cyclohexene compound taken as an influenza virus neuraminidase inhibitor for preparing the medicines to prevent or treat the influenza diseases.

Owner:SUN YAT SEN UNIV

Popular searches

Organic-compounds/hydrides/coordination-complexes catalysts Catalyst activation/preparation Chemical recycling Other chemical processes Water contaminants Water/sewage treatment by sorption Preparation by halogen replacement Preparation by cyanide reaction Carboxylic acid amides preparation Sulfonic acid amide preparation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Process for Producing 2-Amino-2-[2-[4-(3-Benzyloxyphenylthio)-2-Chlorophenyl]Ethyl]-1,3-Propanediol Hydrochloride and Hydrates Thereof, and Intermediates in the Production Thereof Process for Producing 2-Amino-2-[2-[4-(3-Benzyloxyphenylthio)-2-Chlorophenyl]Ethyl]-1,3-Propanediol Hydrochloride and Hydrates Thereof, and Intermediates in the Production Thereof](https://images-eureka.patsnap.com/patent_img/b72066a5-1ba6-491b-b000-f4fc89f3c7ce/US20080207941A1-20080828-C00001.png)

![Process for Producing 2-Amino-2-[2-[4-(3-Benzyloxyphenylthio)-2-Chlorophenyl]Ethyl]-1,3-Propanediol Hydrochloride and Hydrates Thereof, and Intermediates in the Production Thereof Process for Producing 2-Amino-2-[2-[4-(3-Benzyloxyphenylthio)-2-Chlorophenyl]Ethyl]-1,3-Propanediol Hydrochloride and Hydrates Thereof, and Intermediates in the Production Thereof](https://images-eureka.patsnap.com/patent_img/b72066a5-1ba6-491b-b000-f4fc89f3c7ce/US20080207941A1-20080828-C00002.png)

![Process for Producing 2-Amino-2-[2-[4-(3-Benzyloxyphenylthio)-2-Chlorophenyl]Ethyl]-1,3-Propanediol Hydrochloride and Hydrates Thereof, and Intermediates in the Production Thereof Process for Producing 2-Amino-2-[2-[4-(3-Benzyloxyphenylthio)-2-Chlorophenyl]Ethyl]-1,3-Propanediol Hydrochloride and Hydrates Thereof, and Intermediates in the Production Thereof](https://images-eureka.patsnap.com/patent_img/b72066a5-1ba6-491b-b000-f4fc89f3c7ce/US20080207941A1-20080828-C00003.png)