Polyol ester and application of same to processing of halogenated vinyl polymer

A polyol ester and vinyl halide technology, applied in the field of polyol ester, can solve problems such as high price of dipentaerythritol, influence on product transparency, strong water solubility of polyol, etc., achieve good compatibility, prolong thermal stability time, The effect of prolonging the zinc burn phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

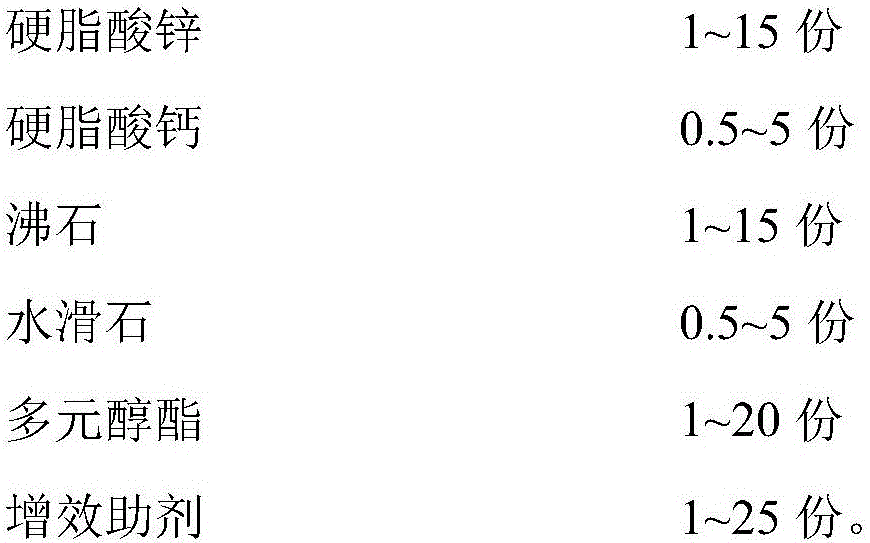

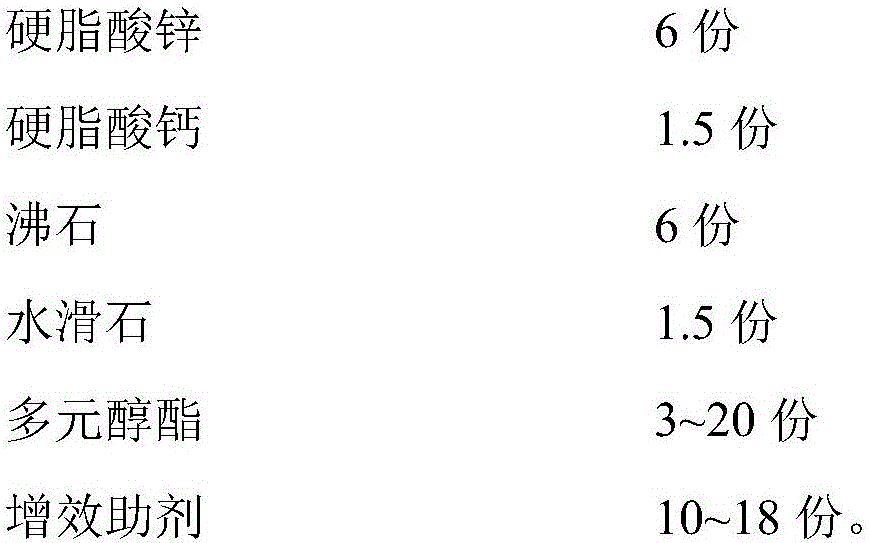

Method used

Image

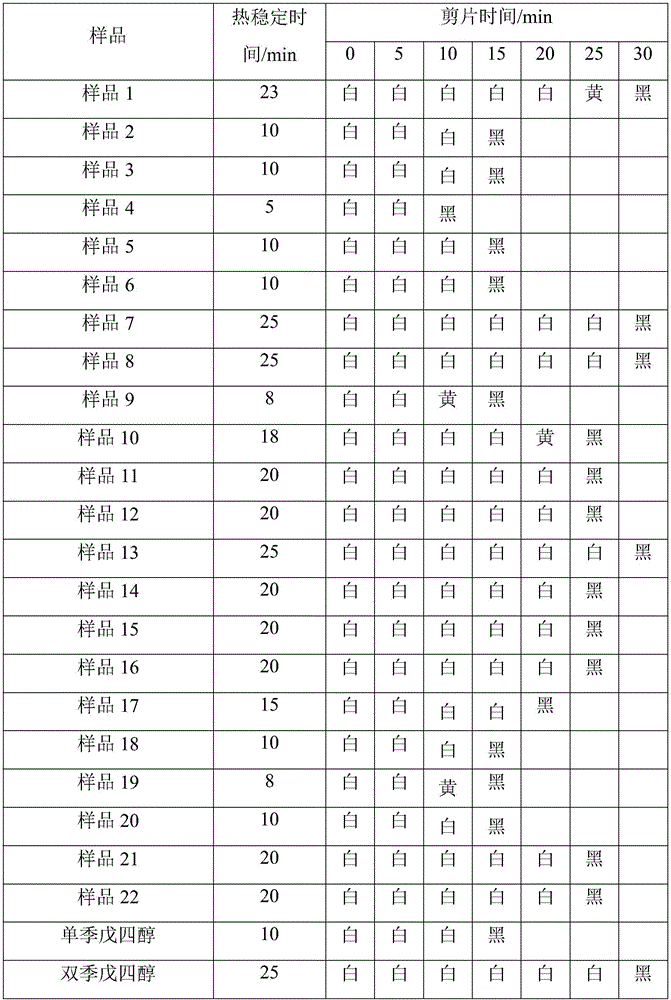

Examples

Embodiment 1

[0045] Add terephthalic acid and dipentaerythritol into the reaction flask at a molar ratio of 1:2, control the temperature at 170°C until no water vapor overflows, and add 0.75% of the total mass of terephthalic acid as a tetrabutyl titanate catalyst , continue to react until anhydrous, draw negative pressure for 30 minutes, pour out and cool to obtain sample 1, the product is dipentaerythritol terephthalate.

Embodiment 2

[0047] Add phthalic anhydride and monopentaerythritol into the reaction flask at a molar ratio of 1:2, control the temperature at 190°C until no water vapor escapes, add 0.5% tetrabutyl titanate of the total mass of phthalic anhydride Ester catalyst, continue to react until there is no water, pump negative pressure for 30 minutes, pour out and cool to obtain sample 2, and the product is monopentaerythritol phthalate.

Embodiment 3

[0049] Add dipentaerythritol and adipic acid into a four-necked flask at a molar ratio of 2:1, and react at 160°C under temperature control until no water vapor overflows, add 0.75% tetrabutyl titanate catalyst based on the mass of adipic acid, and continue the reaction To anhydrous, negative pressure was pumped for 30 minutes, poured out and cooled to obtain sample 3, the product was dipentaerythritol adipate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com