Patents

Literature

37results about How to "Long thermal stability time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

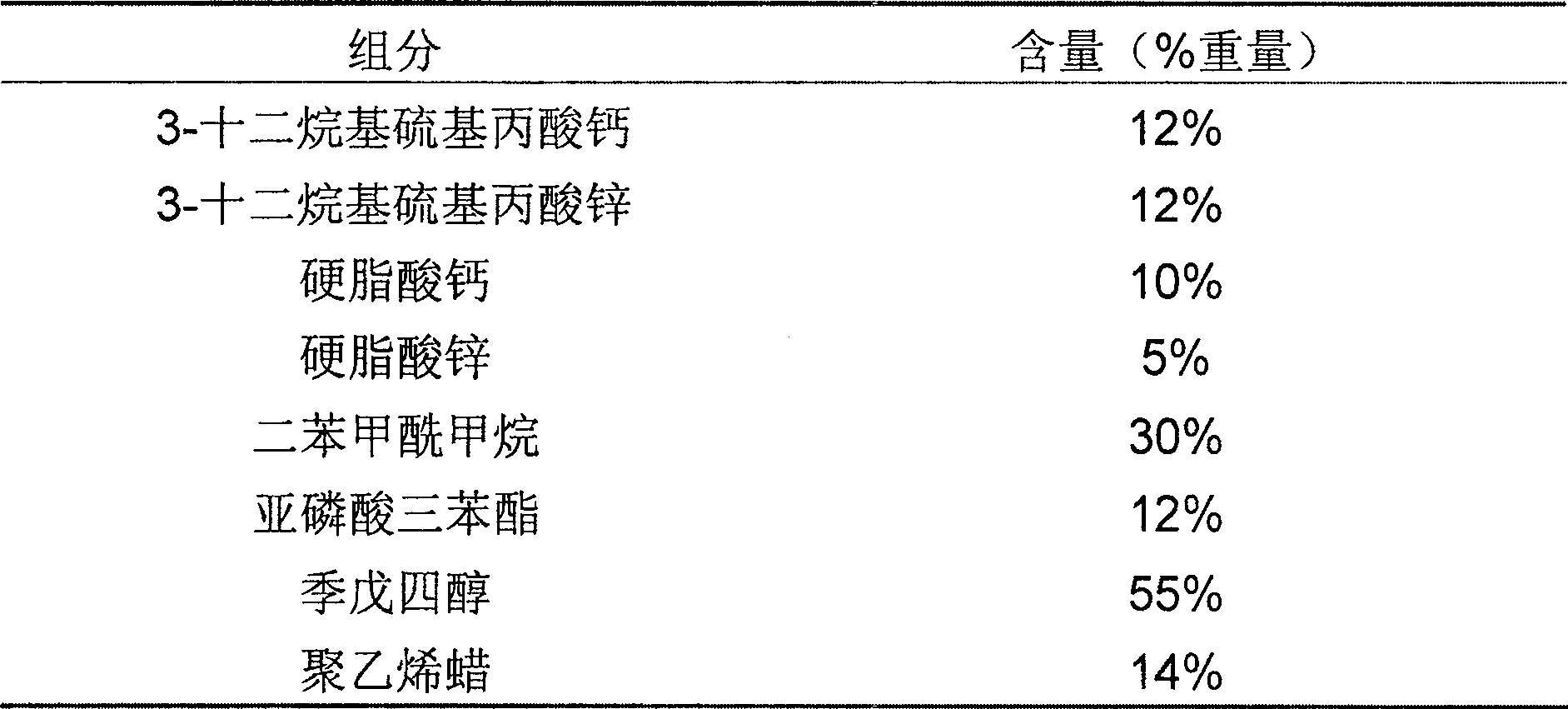

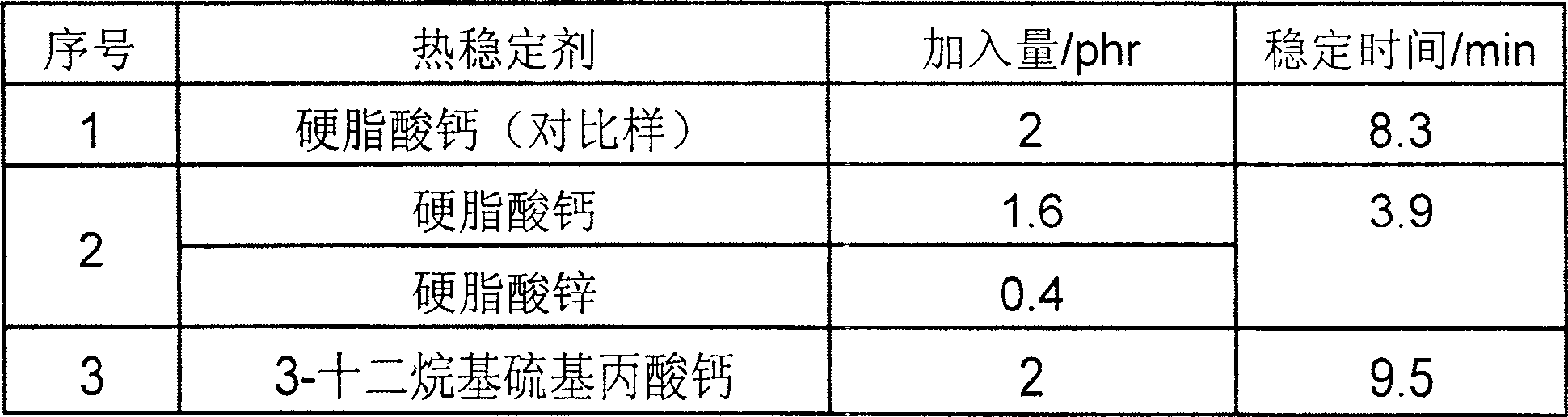

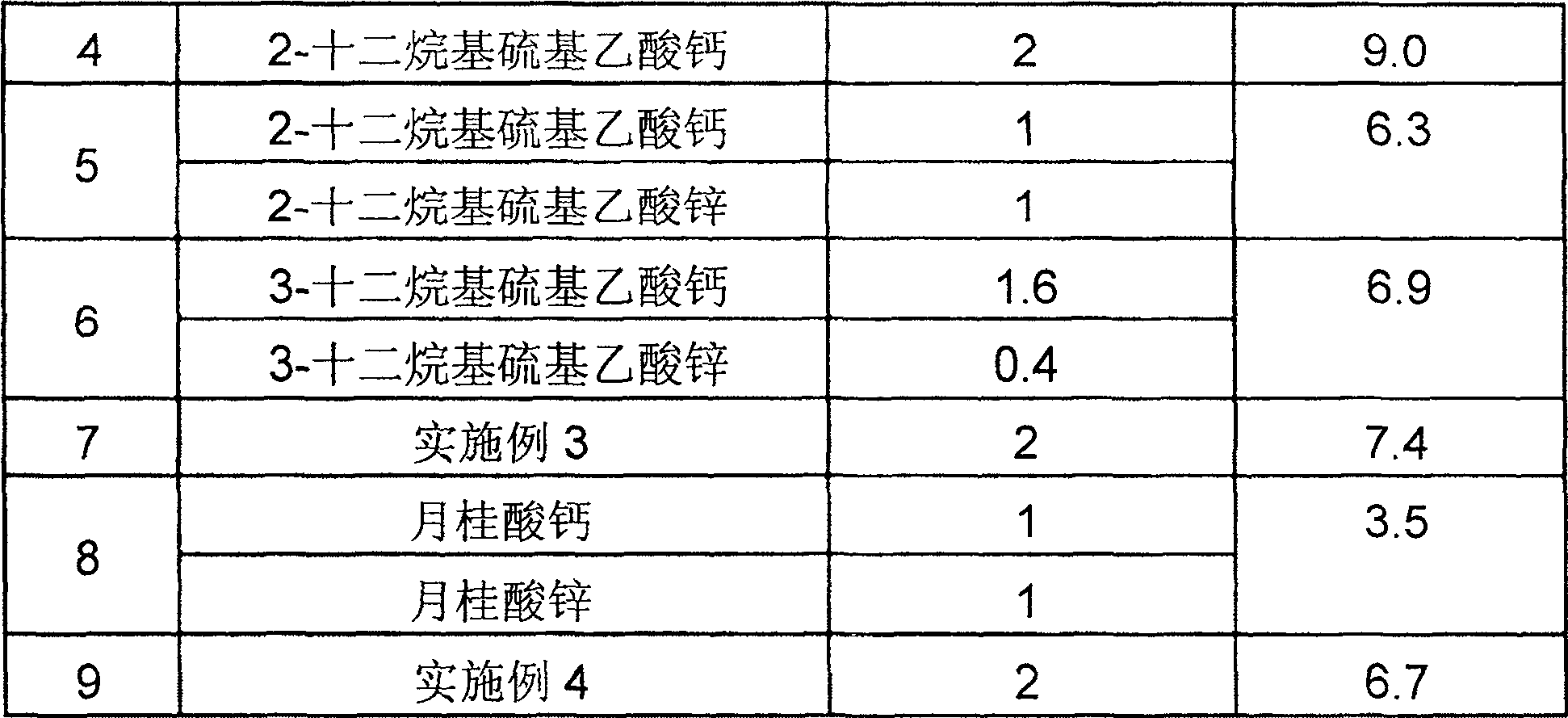

Composite stabilizer of metal salt of organic carboxylic acid containing sulfur in use for polymer containing halogen, and application

This invention discloses a sulfur-containing metal carboxylate composite stabilizer and its application. The sulfur-containing metal carboxylate composite stabilizer comprises: sulfur-containing metal carboxylate, metal salt stabilizer, organic metal stabilizer, lubricant, and organic auxiliary stabilizer. The sulfur-containing metal carboxylate composite stabilizer can be used in halogen-containing polymers to increase their processing stability. The sulfur-containing metal carboxylate composite stabilizer has such advantages as long thermal stabilization period, low early coloration, and low toxicity.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

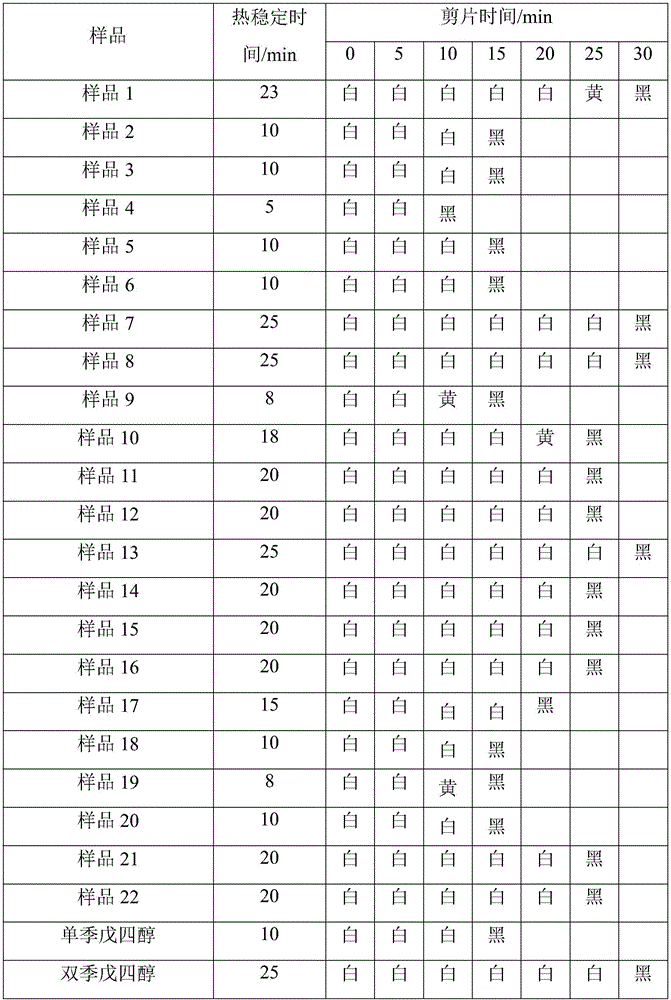

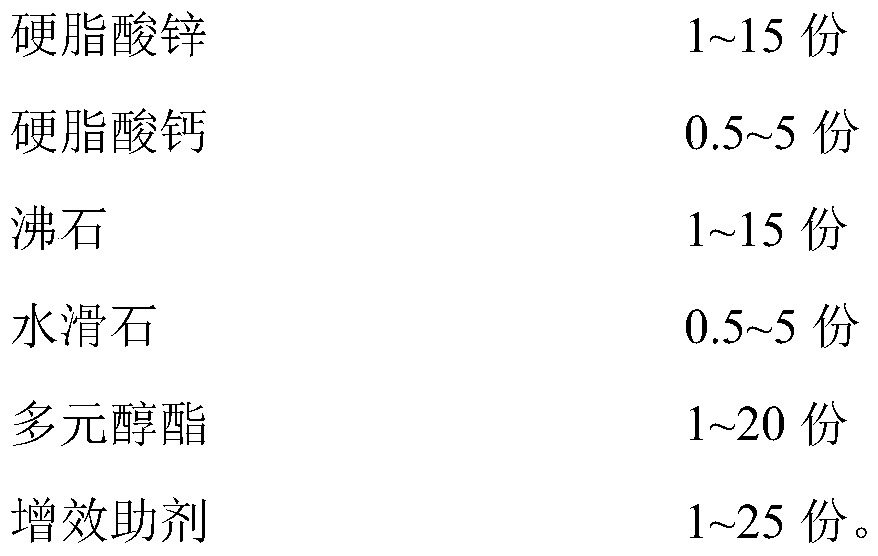

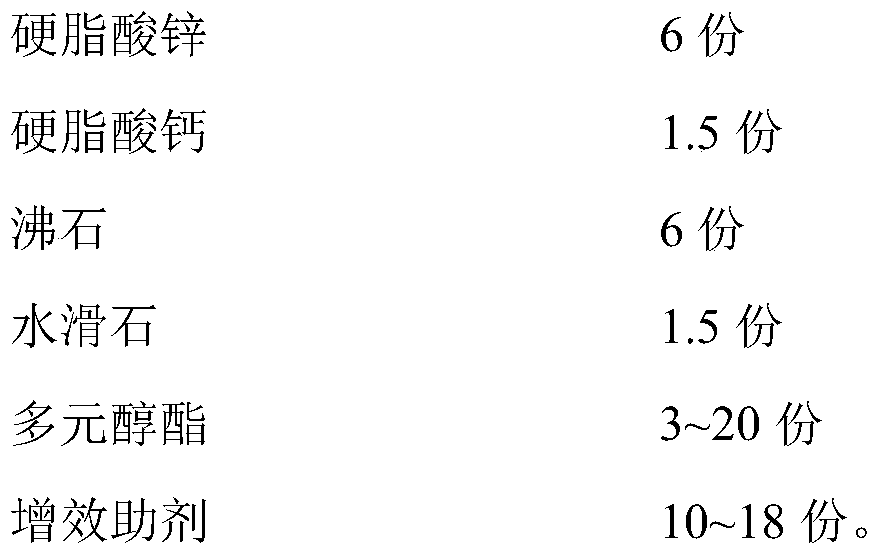

Polyol ester and application of same to processing of halogenated vinyl polymer

ActiveCN106631779AImprove hot workabilityLong thermal stability timeOrganic compound preparationThiol preparationPolyolPolymer science

The invention discloses polyol ester and application of the same to processing of a halogenated vinyl polymer. The polyol ester is prepared by subjecting one of polyols and one selected from a group consisting of carboxylic acid and acid anhydrides to esterification or subjecting one of polyols and one of the esters of carboxylic acid to transesterification. The polyol ester provided by the invention has good compatibility with the halogenated vinyl polymer and can improve the hot-working performance of the halogenated vinyl polymer when cooperated with a heat stabilizer; in particular, the polyol ester can inhibit or alleviate the phenomenon of zinc burning of a zinc-containing heat stabilizer in the later phase of hot-working when cooperated with the zinc-containing heat stabilizer; so the whiteness of a halogenated vinyl polymer product is improved, later zinc burning is effectively inhibited, the thermostabilization time, particularly medium-and-long-term heat stability, of the halogenated vinyl polymer (especially PVC) is substantially prolonged, and the defect of poor stability in the later phase of the zinc-containing heat stabilizer is compensated for. The polyol ester has good application prospects in the field of processing of the halogenated vinyl polymer, especially PVC.

Owner:济南金昌树新材料科技有限公司

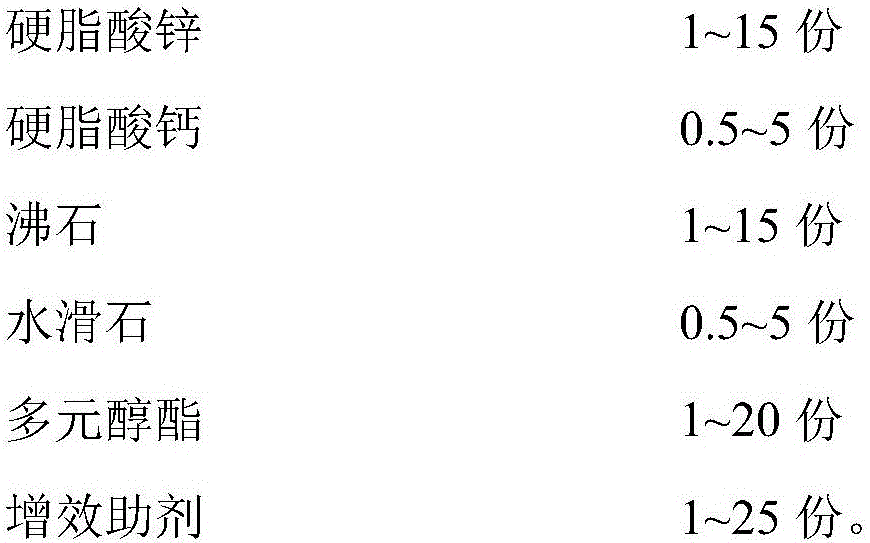

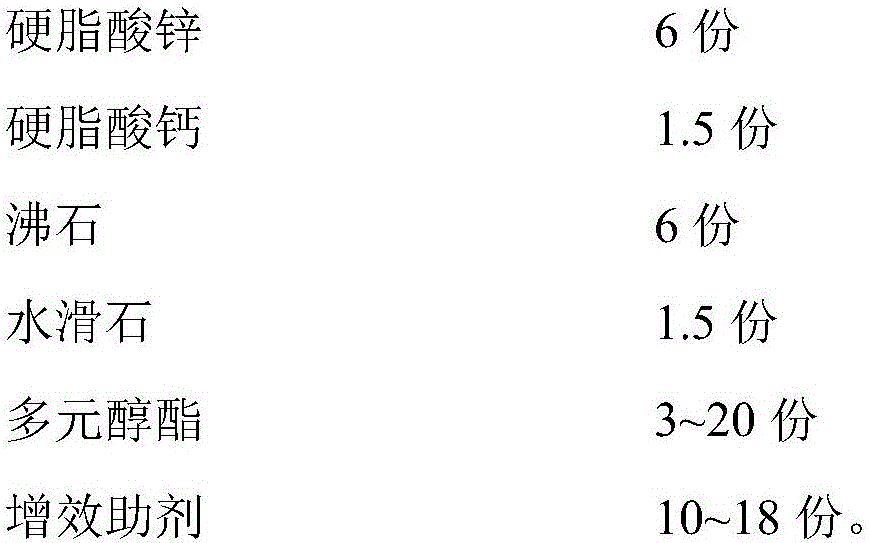

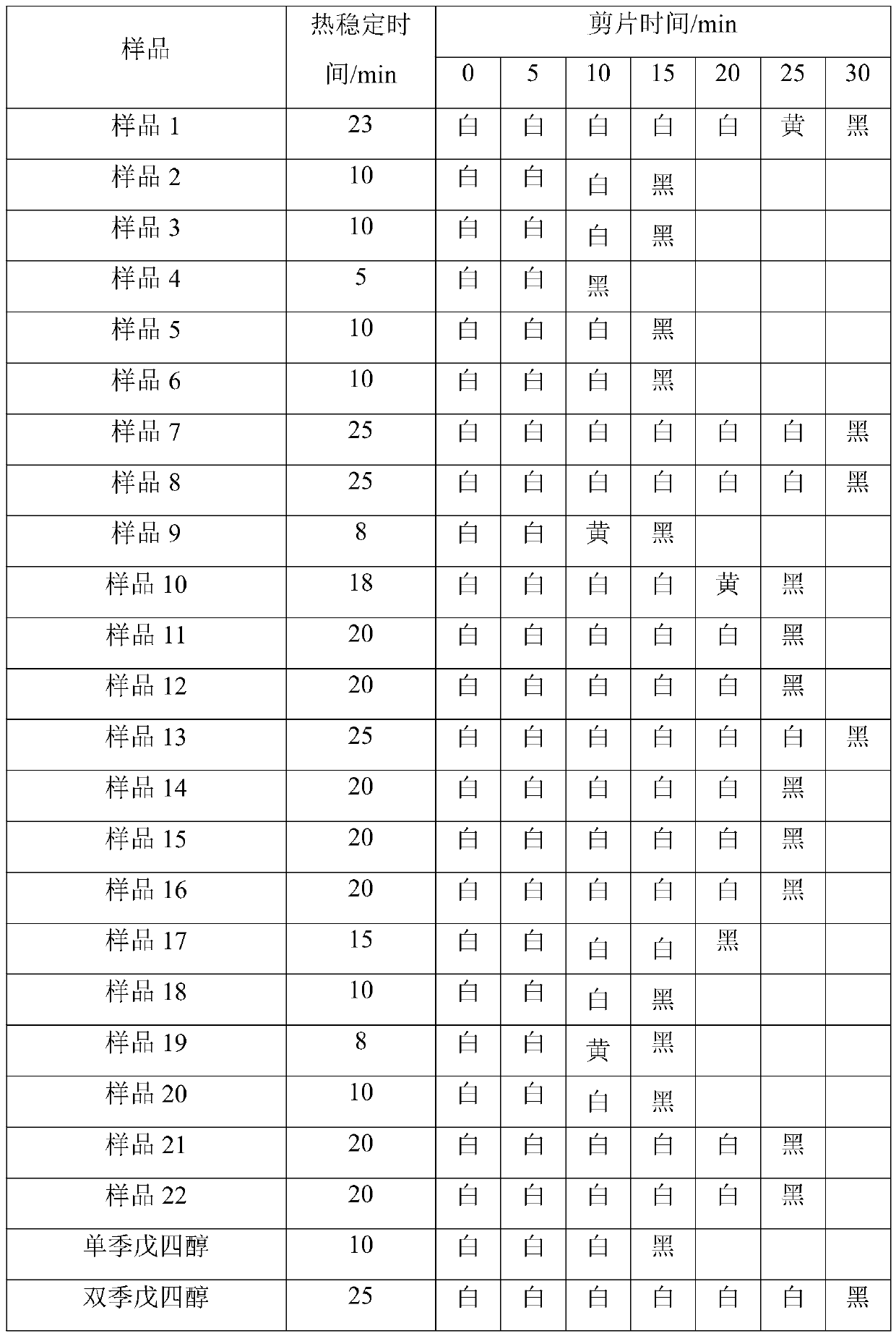

PVC (Polyvinyl Chloride) heat stabilizer with long heat stability time

InactiveCN103540048ALong thermal stability timeExcellent discoloration resistanceAntioxidantPolyvinyl chloride

The invention discloses a PVC (Polyvinyl Chloride) heat stabilizer with long heat stability time. The PVC heat stabilizer is applied to PVC products having high requirement on heat stability time and good color changing resistance. According to the PVC heat stabilizer, talcum, hydroxide and zeolite are used as main modifiers and a special antioxidant is added. The phenomena of relatively short heat stability time and poor color change resistance are solved. The PVC heat stabilizer has excellent properties, is environmentally-friendly and wins the competitive power for Chinese enterprises in European and American markets.

Owner:SUZHOU LANGCHUANG CHEM

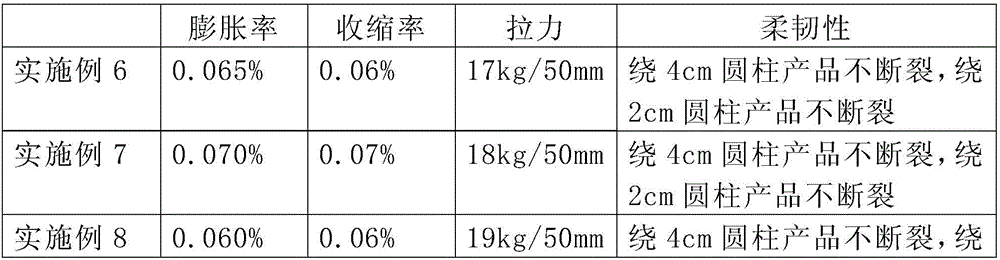

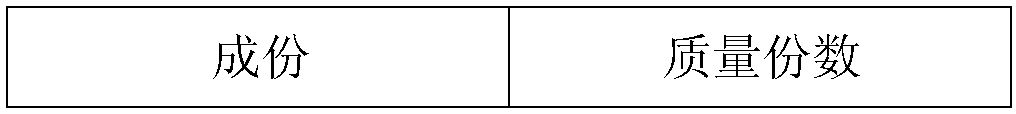

Middle material layer of plastic floor and plastic floor obtained by the same

The invention provides a middle material layer of a plastic floor and the plastic floor obtained by the same. The middle material layer of the plastic floor is prepared from the following raw materials in parts by weight: 90-95 parts of polyvinyl chloride, 28-33 parts of a plasticizer, 2.1-3 parts of a stabilizer, 0.2-0.5 part of carbon black, 455-465 parts of calcium carbonate and 6.2-10.5 parts of chlorinated polyethylene. A certain amount of chlorinated polyethylene is added into the formula of the middle material layer, the chlorinated polyethylene and the polyvinyl chloride have good compatibility, so that the toughness of the polyvinyl chloride is improved, the flexibility and the tensile force of the plastic floor product are improved, and the expansion rate and the shrinkage rate of the plastic floor are reduced; the weather resistance of the plastic floor is improved by using the high weather resistance of the chlorinated polyethylene, and thus the physical performance of the plastic floor is more excellent. In addition, the plasticizer adopts dioctyl terephthalate and is environment-friendly and non-toxic and long in thermal stable time, the plasticizer is prepared from natural oil, has the characteristics of fire resistance, no toxicity and environmental protection.

Owner:ZHEJIANG KINGDOM NEW MATERIAL GRP CO LTD

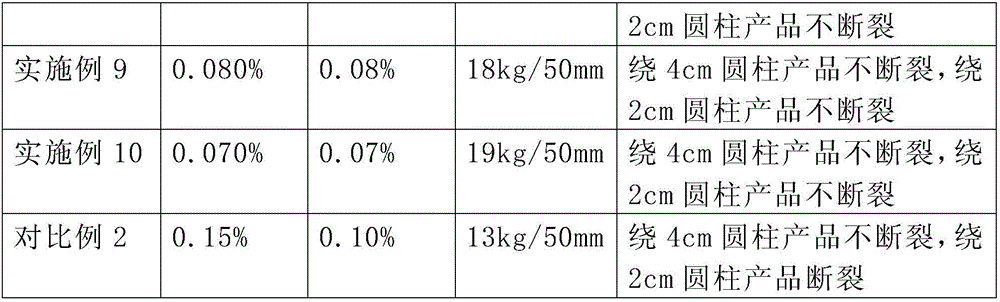

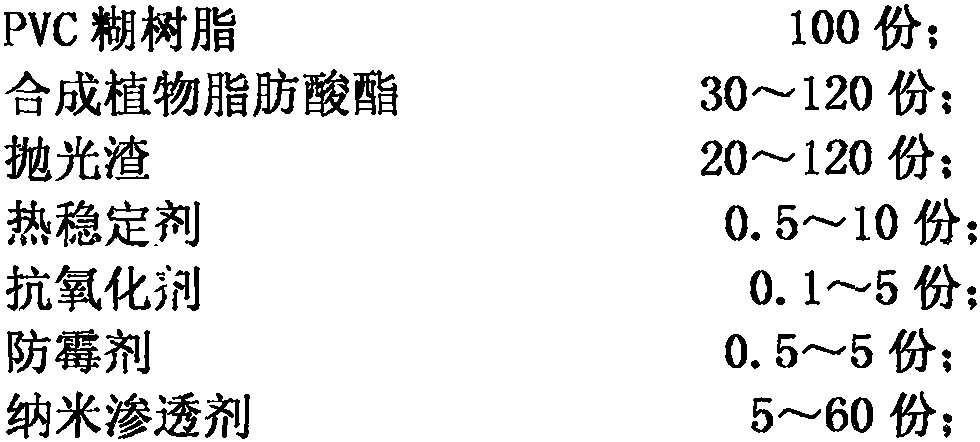

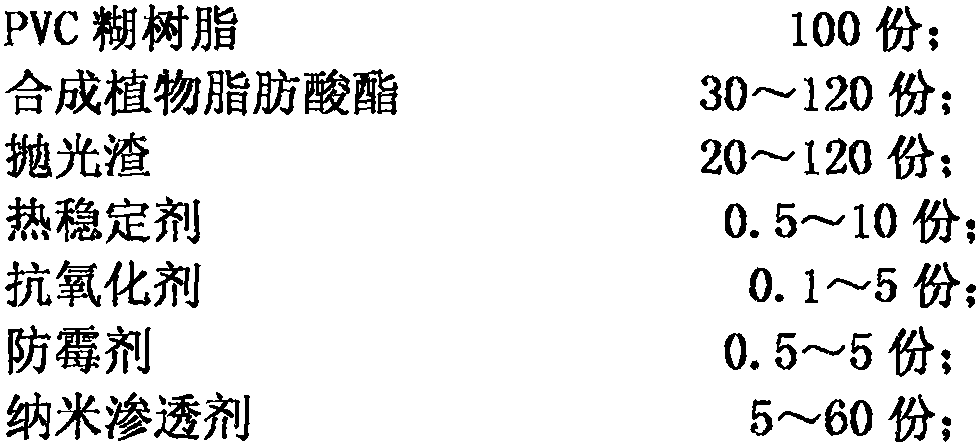

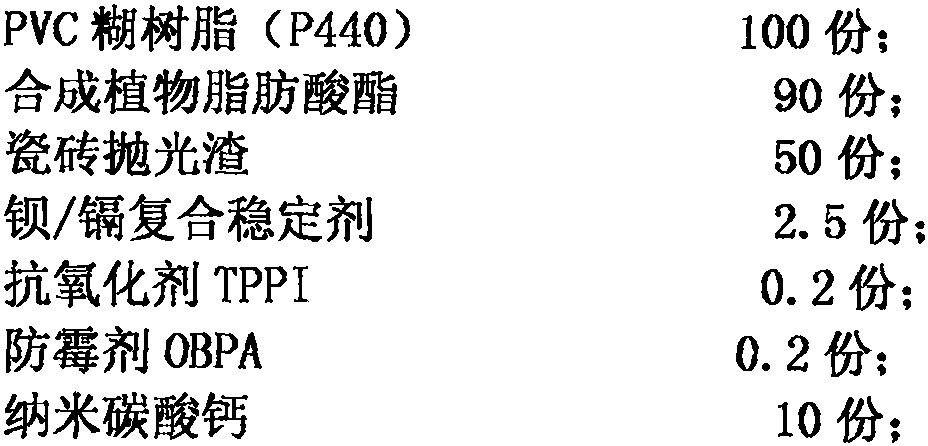

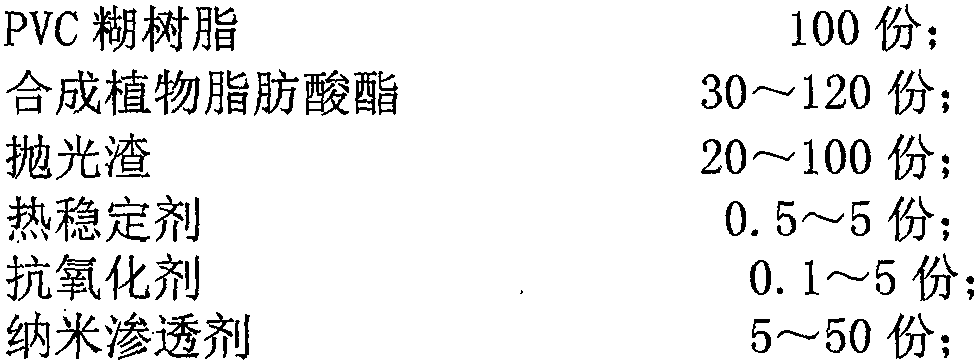

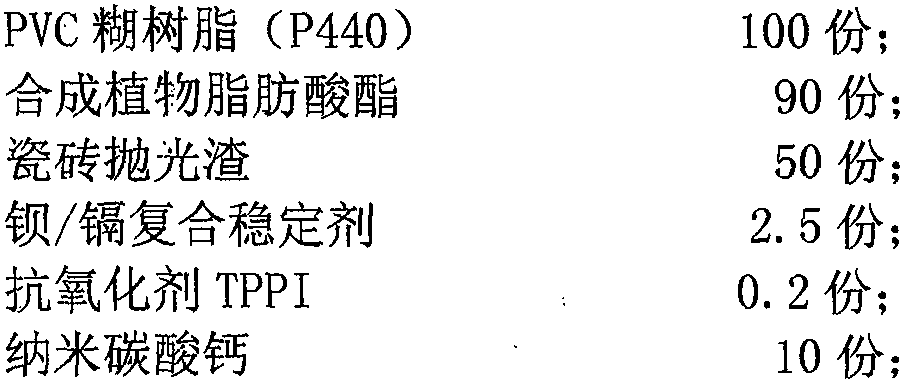

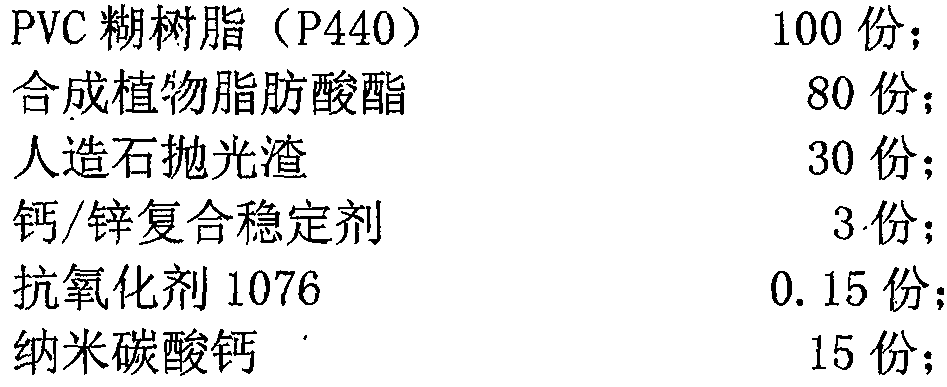

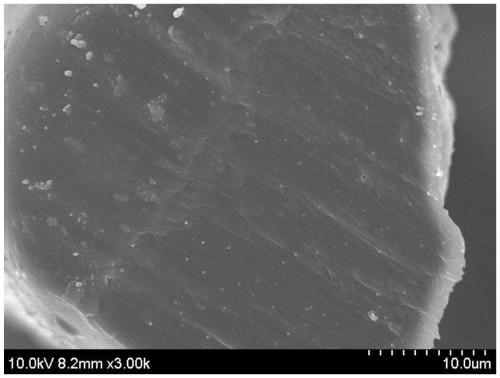

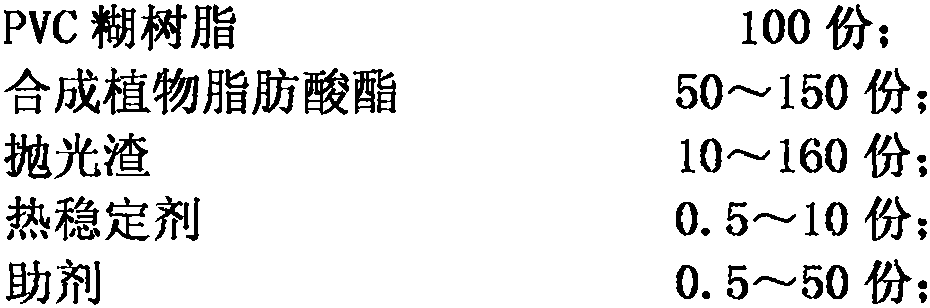

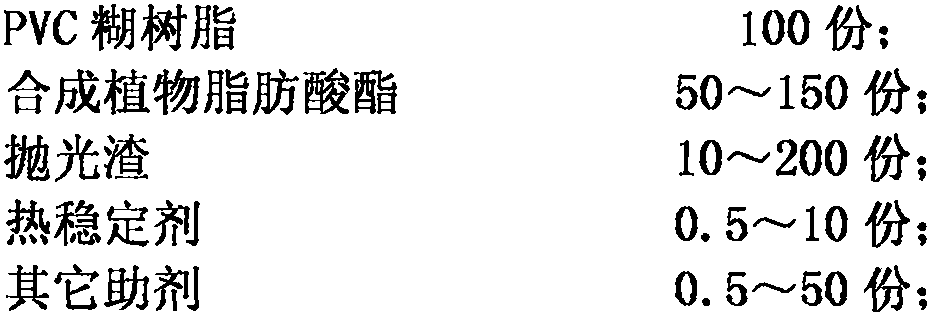

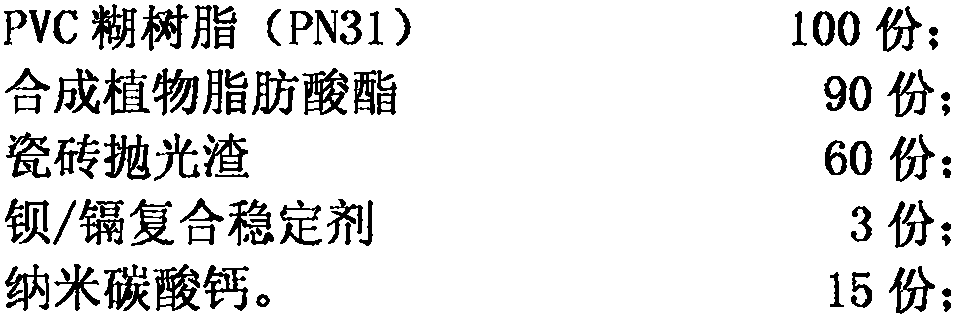

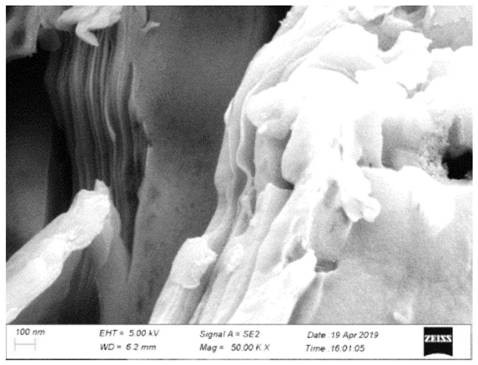

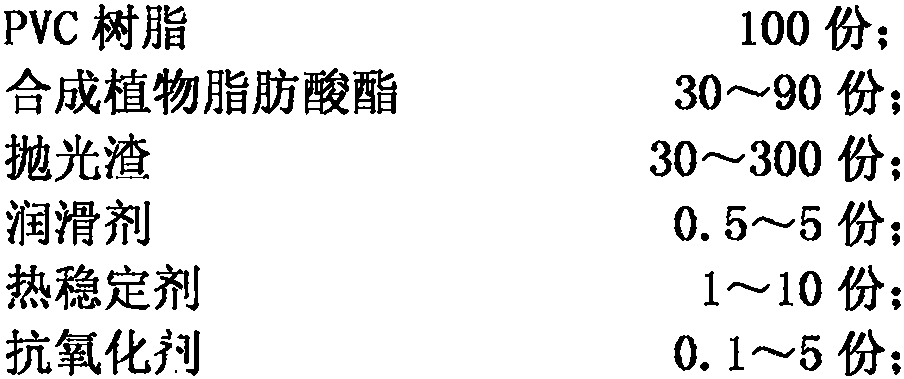

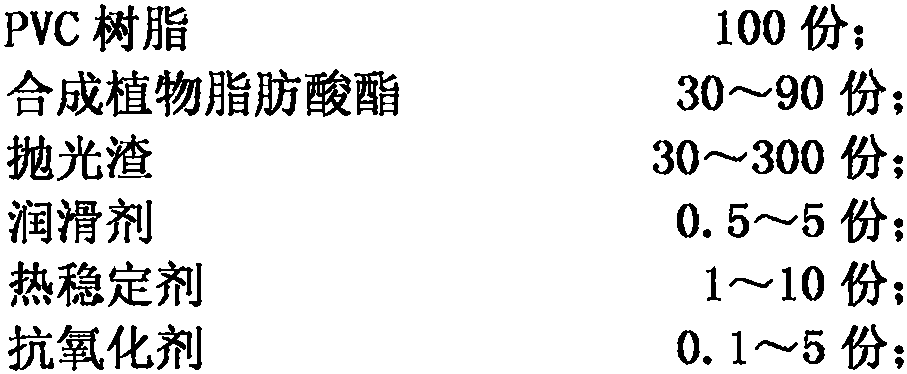

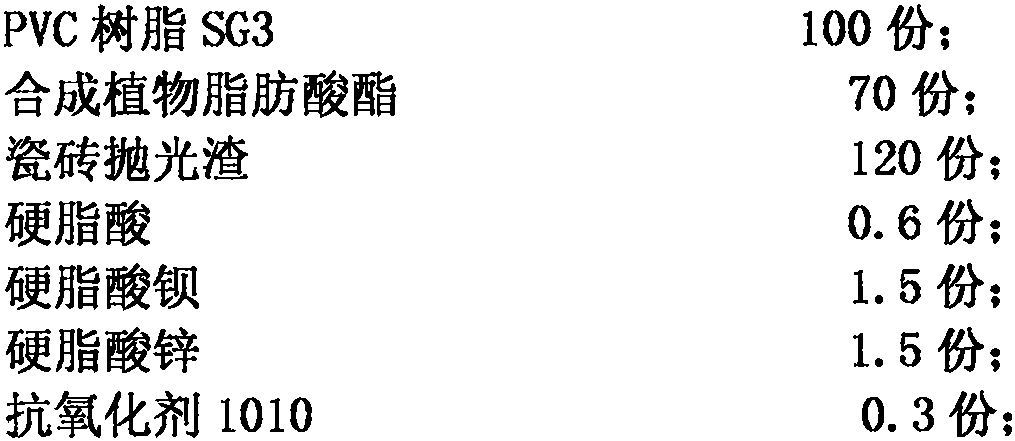

Nano PVC flame-retardant waterproof tarpaulin and preparation method thereof

InactiveCN110965341AImproved resistance to water penetrationSolve the problem of reduced flame retardancyTextiles and paperPolymer sciencePlasticizer

The invention discloses nano PVC flame-retardant waterproof tarpaulin and a preparation method thereof. The nano PVC flame-retardant waterproof tarpaulin is prepared by the steps that a synthetic fiber base cloth is dipped with PVC nano flame-retardant plasticizing paste, particles with very small nano-penetrant penetrate completely into the fiber gaps of the base cloth, and then the base cloth isflattened by a flattening machine and is heated and plasticized by a drying oven to prepare into a covering film with smooth two sides, so that the tarpaulin is quite high in water permeability resistance. The problems that in the prior art, the tarpaulin covering film is easy to fall off and skin is broken are solved. According to the formula, synthetic plant fatty acid ester with the flame retardant property, and polishing slag with flame retardant and smoke suppression performance are added, so that the problem that the flame retardant performance is reduced due to the addition of a largenumber of small molecule plasticizers in the prior art is solved. The polishing slag is added in a large amount as inorganic filler, so that the production cost is reduced, the flame-retardant and smoke suppression performance of the PVC flame-retardant waterproof tarpaulin is improved, and the problem of environmental pollution caused by waste landfill due to difficult recycling of stone, ceramictiles and artificial stone polishing residues is solved.

Owner:林铭昭

Nano flame-retardant antistatic air duct cloth and preparation method thereof

InactiveCN111320828ASolve sheddingSolve the problem of air leakage caused by broken skinPolymer sciencePlasticizer

The invention discloses a nano flame-retardant antistatic air duct cloth and a preparation method thereof. The nano flame-retardant antistatic air duct cloth is prepared by dipping synthetic fibrous base cloth into PVC flame-retardant antistatic plasticizing paste containing a nano penetrating agent, flattening the synthetic fibrous base cloth by a flattening machine, heating and plasticizing thesynthetic fibrous base cloth in a drying oven to prepare a covering film with a flat and smooth surface, and cooling the covering film to obtain the nano flame-retardant antistatic air duct cloth. Theplasticizing paste completely permeates into the synthetic fibers, and the problem of air leakage of an air duct caused by easy falling and skin breaking of a covering film in the prior art is solved. Synthetic vegetable fatty acid ester with flame-retardant and antistatic properties and stone, ceramic tiles and artificial stone polishing slag with flame-retardant and smoke-suppressing propertiesare added into the formula, so that the problem that the flame-retardant property is weakened due to the addition of a large amount of a small molecular plasticizer in the prior art is solved. A large amount of polishing slag taken as an inorganic filler is added, the production cost is reduced, the flame retardant property and smoke suppressing performance of the product are improved, the problems that the polishing slag is difficult to recycle and environmental pollution is caused by waste landfill are solved, and waste is turned into resources.

Owner:林铭昭

Graphene reinforced polyketone fiber and preparation method thereof

InactiveCN111411417AReduce forceHigh crystallinityArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentPolymer sciencePolyketone

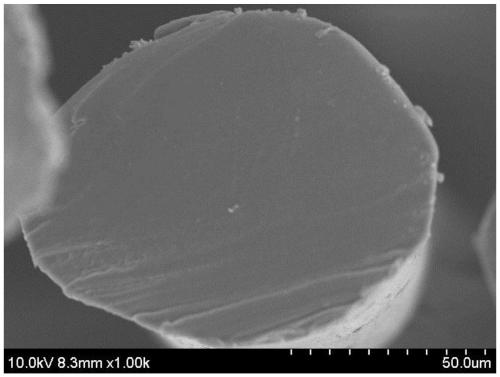

The invention discloses a preparation method of graphene reinforced polyketone fibers. The preparation method comprises the following steps of firstly, uniformly mixing graphene with a surface treating agent; adding polyketone granules, and continuously melting and uniformly mixing to obtain a graphene / polyketone mixture; carrying out melt spinning on the graphene / polyketone mixture to prepare fused filaments; and finally, cooling the fused filaments through an air channel, and carrying out hot roller drafting and heat setting to prepare the graphene reinforced polyketone fibers. The grapheneis adopted as a reinforcing modification material of the polyketone, and is evenly dispersed in polyketone to play roles in an obstructing effect, a high heat conduction effect and a reinforcing effect. And the barrier property of graphene is utilized to weaken the acting force between ketone groups. A rate of transferring heat from the equipment to a polymer molecular chain is increased, and thetime required for the polyketone to form a crystal-nucleus-free melt is shortened. In the drafting process, the graphene is oriented in the axial direction of the fiber, polyketone molecular chains are induced to regularly grow and be arranged on the surface of the graphene, a string-shaped crystalline structure is formed, and the ultrahigh-strength polyketone fiber is obtained.

Owner:TIANJIN POLYTECHNIC UNIV +1

Method for preparing thermal stabilizer/lubricant for polyvinyl chloride profiles

The invention discloses a method for preparing thermal stabilizer / lubricant for polyvinyl chloride profiles. The method comprises the following steps: firstly reacting part of stearic acid, part of salicylic acid and part of diglycol in a reactor to prepare an auxiliary agent 1; reacting another part of stearic acid, the rest of salicylic acid and the rest of diglycol in the reactor to prepare an auxiliary agent 2; heating part of yellow lead, the rest of stearic acid and paraffins to react in another reactor to prepare an intermediate; reacting the rest of yellow lead, glacial acetic acid and cyanuric acid in the reactor and grinding to prepare a synthetic material; reacting part of the prepared intermediate, the synthetic material and part of the auxiliary agent 1 to prepare a composite; heating and reacting the composite, the rest of intermediate, the rest of auxiliary agent 1, the auxiliary agent 2, bisphenol A and a brightening agent in a kneading machine; and carrying out extrusion molding.

Owner:蒋马小

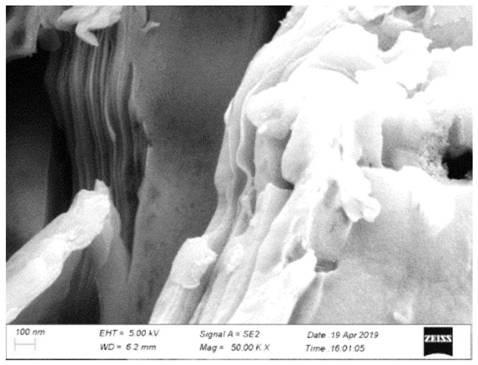

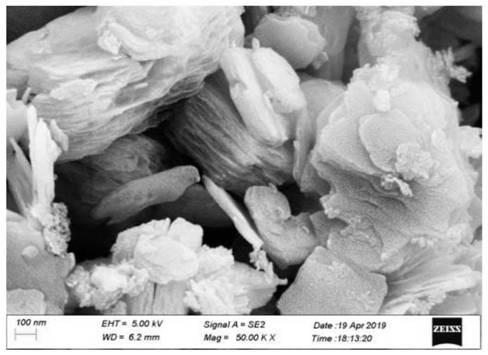

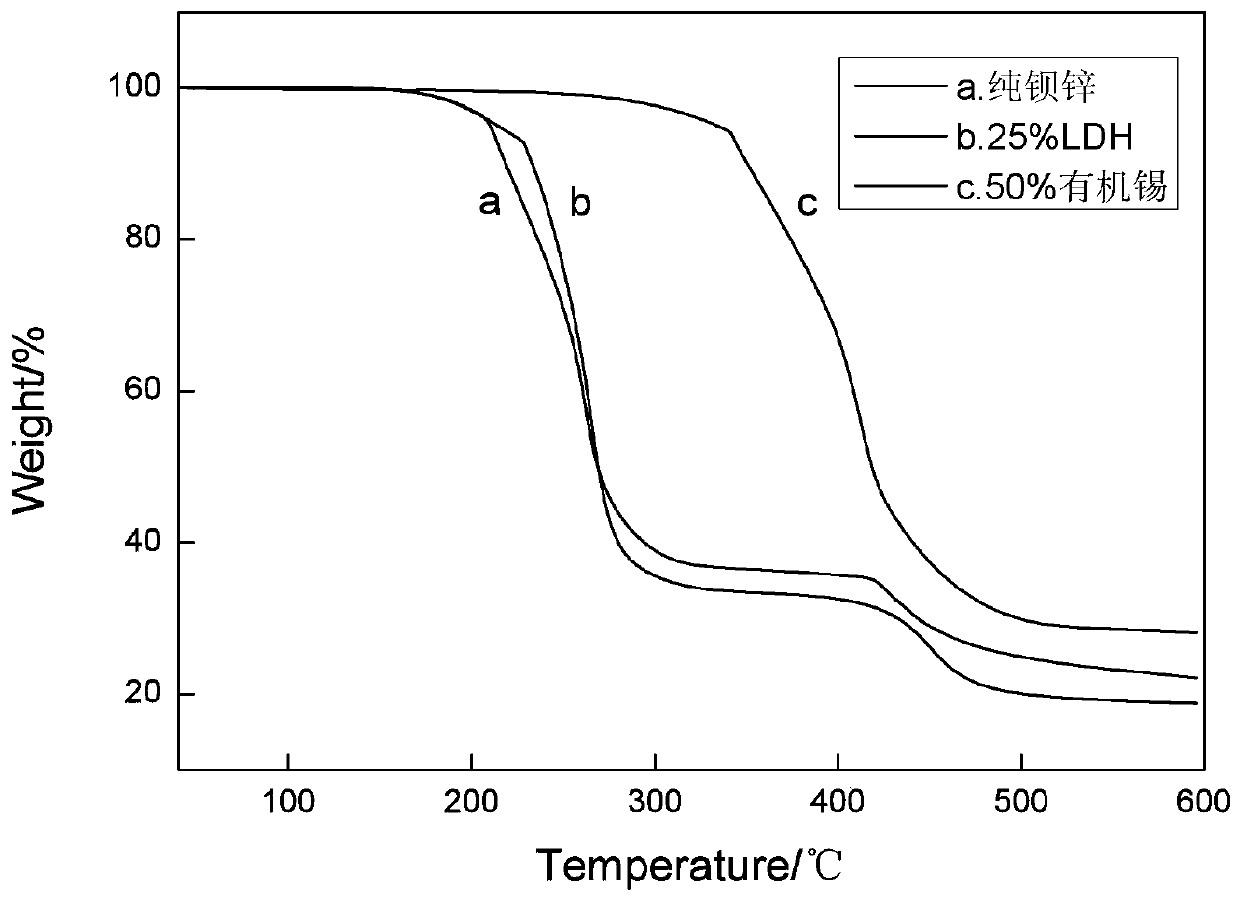

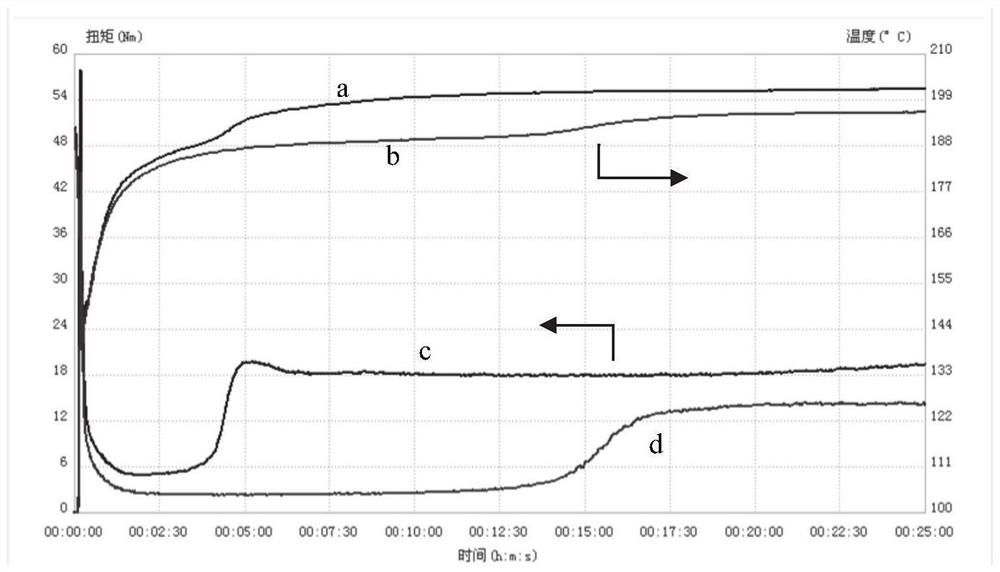

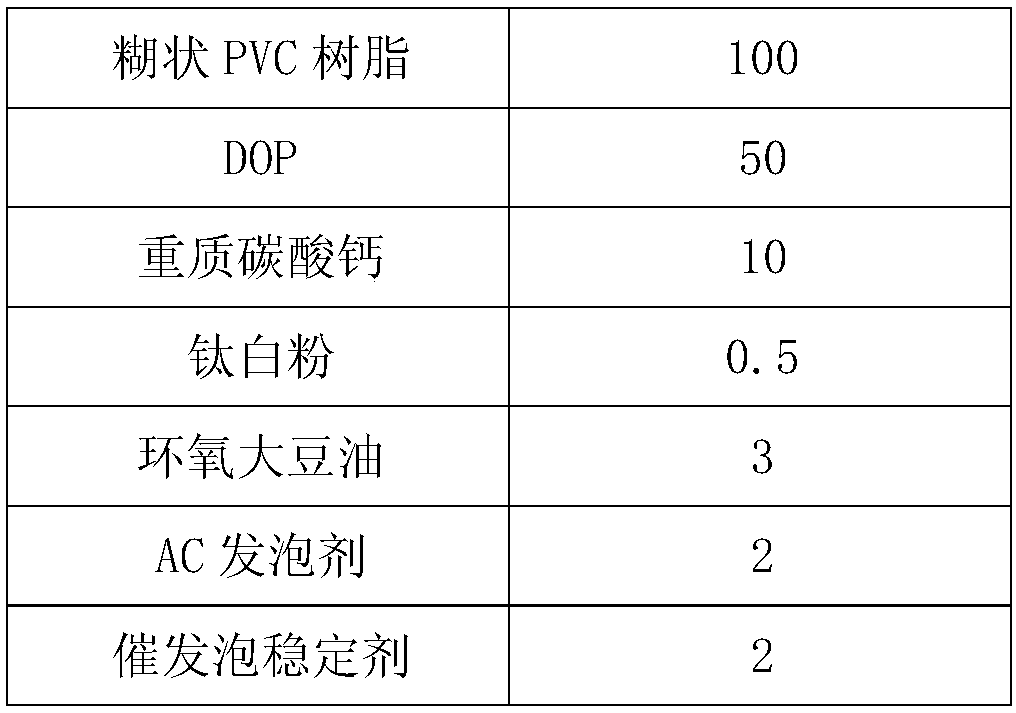

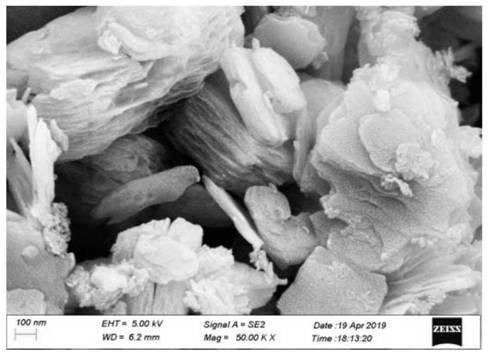

Organic stannic acid intercalated calcium/zinc-aluminum rare earth hydrotalcite complex heat stabilizer for rigid PVC and preparation method thereof

The invention provides an organic stannic acid intercalated calcium / zinc-aluminum rare earth hydrotalcite complex heat stabilizer for rigid PVC and a preparation method thereof. The organic stannic acid intercalated calcium / zinc-aluminum rare earth hydrotalcite complex heat stabilizer for rigid PVC comprises the following components in parts by mass: 30-90 parts of organic stannic acid intercalated calcium-aluminum rare earth hydrotalcite and 10-50 parts of organic stannic acid intercalated zinc-aluminum rare earth hydrotalcite. The preparation method comprises the following steps: (1) dissolving a calcium salt, an aluminum salt and a rare earth salt in deionized water to obtain a solution, dissolving sodium hydroxide and organic stannic acid in a mixed solution of deionized water and ethanol; (2) adding the two solutions dropwise, and carrying out reflux, precipitation, suction filtration and washing; and carrying out drying and grinding to obtain the organic stannic acid intercalatedcalcium-aluminum rare earth hydrotalcite; (3) replacing the calcium salt with a zinc salt, and repeating the steps (1) and (2) to obtain the organic stannic acid intercalated zinc-aluminum rare earthhydrotalcite; and (4) mixing the two hydrotalcites according to the parts by mass. When used for rigid PVC, the organic stannic acid intercalated calcium / zinc-aluminum rare earth hydrotalcite complexheat stabilizer can effectively improve the thermal stability of the rigid PVC.

Owner:TANGSHAN NORMAL UNIV

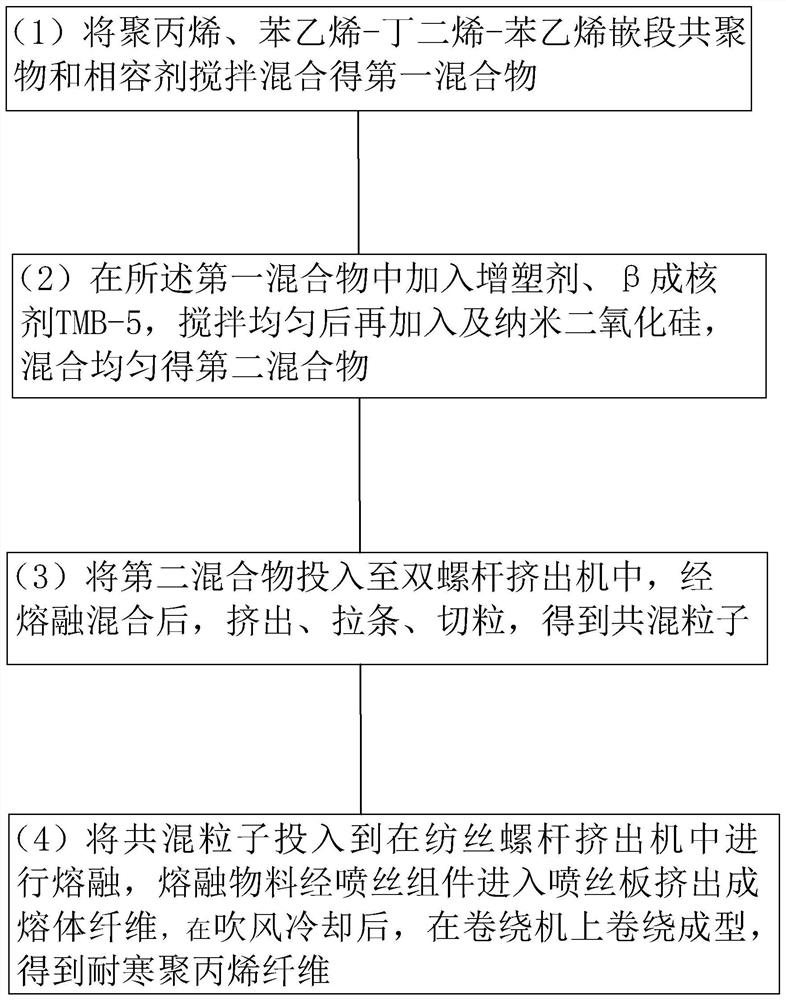

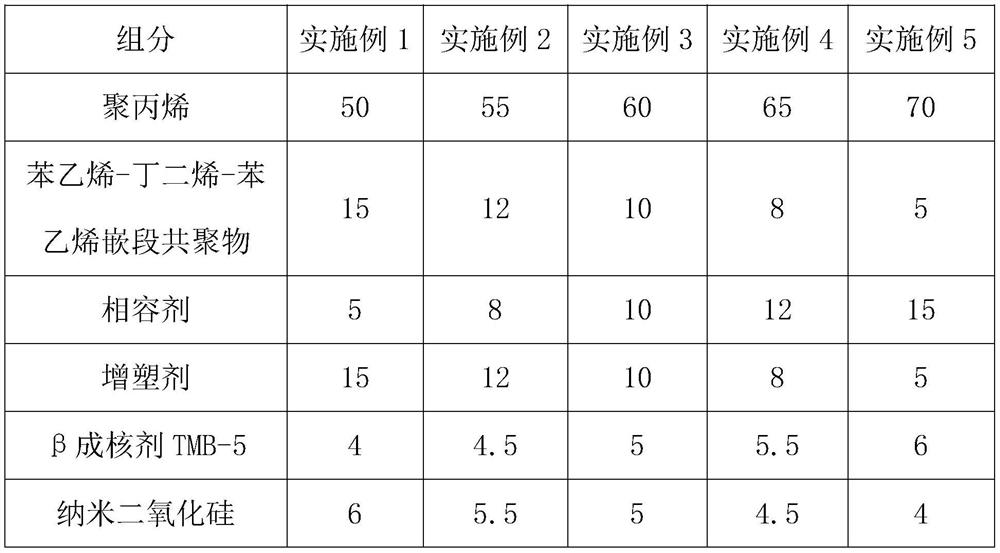

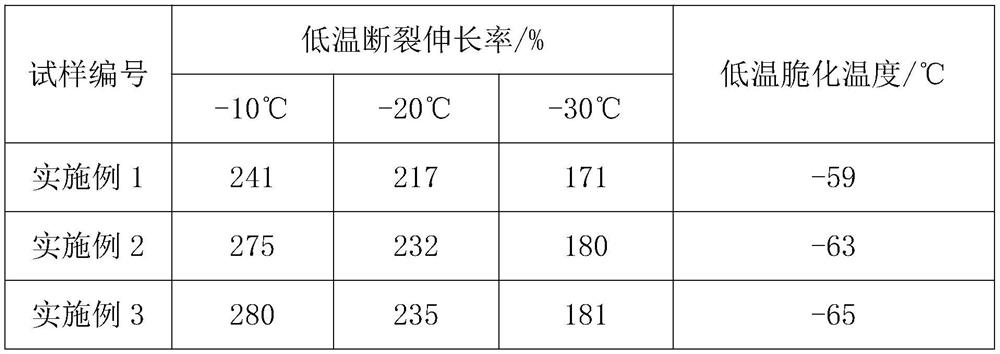

Cold-resistant polypropylene and preparation method thereof

The invention relates to the field of polypropylene fibers, and particularly discloses cold-resistant polypropylene and a preparation method thereof. The cold-resistant polypropylene is prepared fromthe following raw materials in parts by weight: 50-70 parts of polypropylene, 5-15 parts of a styrene-butadiene-styrene block copolymer, 5-15 parts of a compatilizer and 5-16 parts of a plasticizer. The cold-resistant polypropylene disclosed by the invention can be used in a low-temperature environment and has the advantage of prolonging the service life of polypropylene at a low temperature.

Owner:慈溪金轮复合纤维有限公司

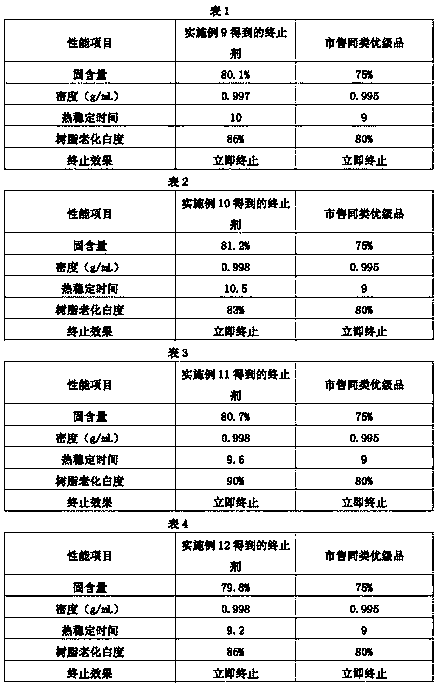

PVC resin oil-soluble terminator and preparation method thereof

The invention relates to the technical field PVC resin auxiliaries, in particular to a PVC resin oil-soluble terminator and a preparation method thereof.The PVC resin oil-soluble terminator is prepared from, by weight, 5-50 parts of epoxidized soybean oil, 10-30 parts of an antioxidant, 10-40 parts of bisphenol A, 1-20 parts of a solid terminator, 5-40 parts of a stabilizer, 1-40 parts of a plasticizer, 5-45 parts of styrene, 5-25 parts of solvent oil and 5-40 parts of a methanol solution.The obtained PVC resin oil-soluble terminator is good in termination effect and long in heat stabilization time; solid materials are added into a reaction kettle at a time in the preparation process, reaction time is greatly shortened, the reaction temperature is low, energy consumption is reduced, and the productivity of a production device is improved; no wastewater is generated in the whole production process, the production technology is environmentally friendly, and the equipment requirement of the technology is low; a production system is safe and stable in operation and has good economic benefits.

Owner:乌鲁木齐市华泰隆化学助剂有限公司

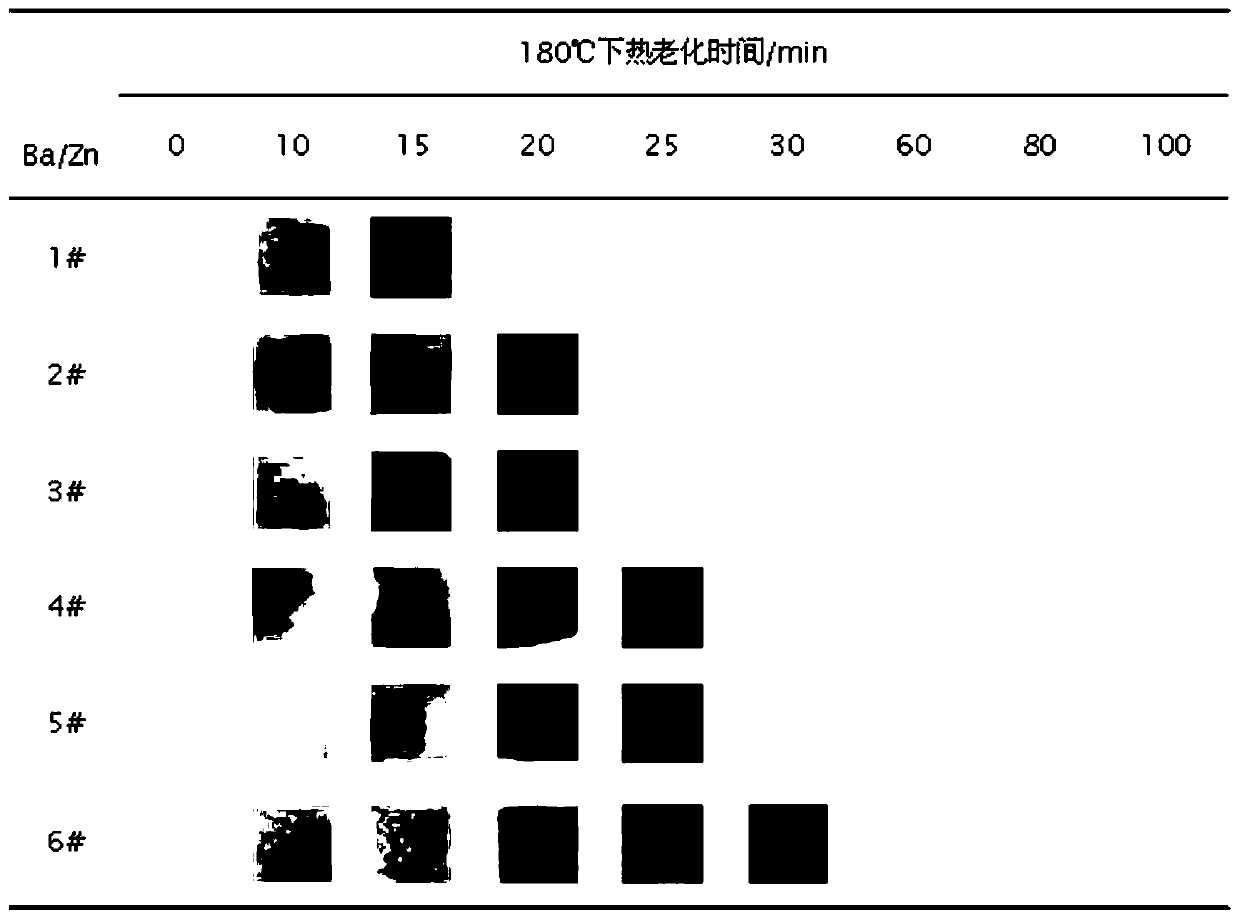

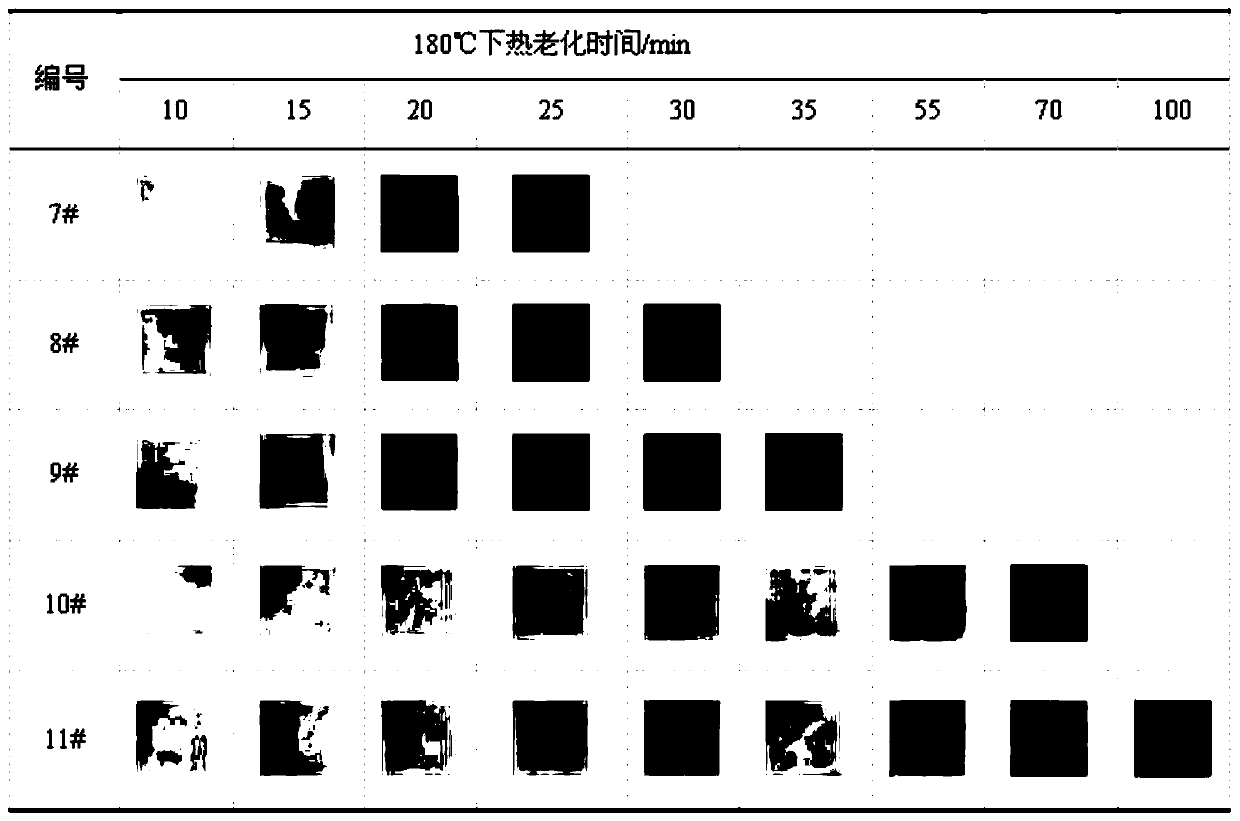

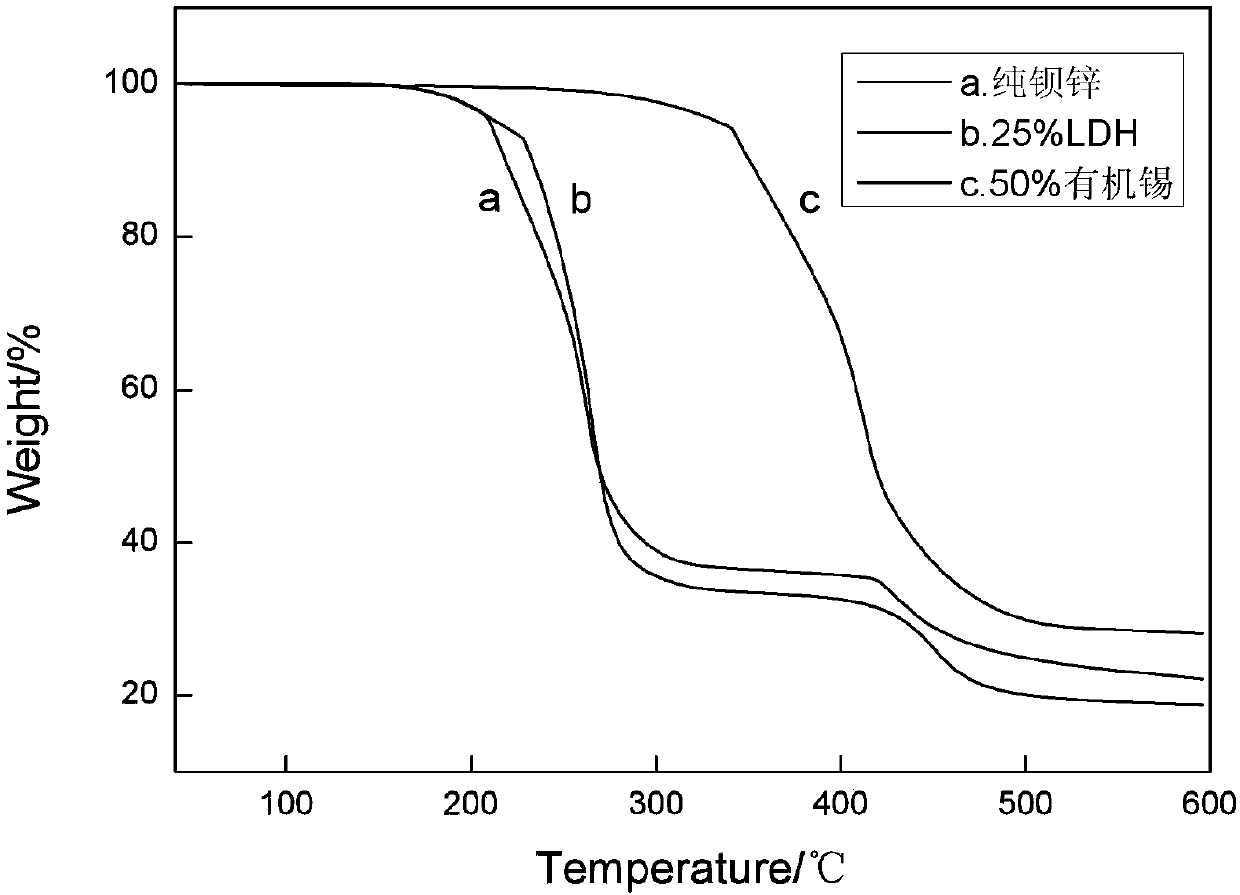

A liquid barium/zinc transparent composite heat stabilizer for pvc

The invention relates to a liquid barium / zinc transparent composite heat stabilizer for PVC (Polyvinyl Chloride). The liquid barium / zinc transparent composite heat stabilizer is prepared from a main stabilizer and an auxiliary heat stabilizer, wherein the main stabilizer is a composite heat stabilizer prepared from barium isotanoate and zinc isoocatanoate according to a certain proportion; the auxiliary heat stabilizer is hydrotalcite or organic tin. The barium / zinc composite heat stabilizer is creatively selected as a main stabilizer of a PVC material, and a best synergistic effect is achieved by limiting the proportion of the barium isotanoate to the zinc isoocatanoate at 3 / 1; compared with the prior art, the liquid barium / zinc transparent composite heat stabilizer has the advantages of prolonged heat stabilizing time, better aging-resisting effect, higher transparence and better effect than other schemes in the prior art.

Owner:TIANJIN UNIV OF SCI & TECH

Calcium-zinc stabilizer and application thereof in SPC floor base material production

The invention relates to the technical field of SPC floors, in particular to a calcium-zinc stabilizer and application thereof in SPC floor base material production. The raw materials comprise, by mass, 60-80 parts of stearic acid, 5-8 parts of nano zinc oxide, 2-5 parts of calcium stearate, 2-4 parts of hydrotalcite, 5-10 parts of monoglyceride, 5-10 parts of polyethylene wax, 2-5 parts of pentaerythritol, and 5-10 parts of light calcium carbonate. The calcium-zinc stabilizer provided by the invention has the advantages of high lubricating property, high plasticizing speed and the like, the use amount of processing aids is greatly reduced, and meanwhile, the calcium-zinc stabilizer is efficient and stable in the SPC floor base material processing process, energy-saving and consumption-reducing, and the productivity is improved.

Owner:青岛佳百特新材料科技有限公司

Degradable offset printing ink

The invention discloses degradable offset printing ink, and relates to the technical field of degradable ink. The offset printing ink provided by the invention is prepared from the following raw materials in parts by weight: 40 to 60 parts of PU (Polyurethane)-6011 waterborne polyurethane, 15 to 30 parts of polylactic acid, 10 to 20 parts of colorant, 8 to 15 parts of linseed oil, 6 to 12 parts ofrosin, 3 to 6 parts of PPC, 1 to 4 parts of 4010 wetting dispersant, 2 to 6 parts of RQT-P-1 plasticizer, 8 to 16 parts of additive and 25 to 38 parts of organic solvent. The degradable offset printing ink provided by the invention is reasonable in componential proportion, has the advantages of being quick in drying rate, good in impact strength and high in degradation rate, and can be used for the printing of a book, a bag, a newspaper, a sheet material and the like.

Owner:天长市天翔包装有限公司

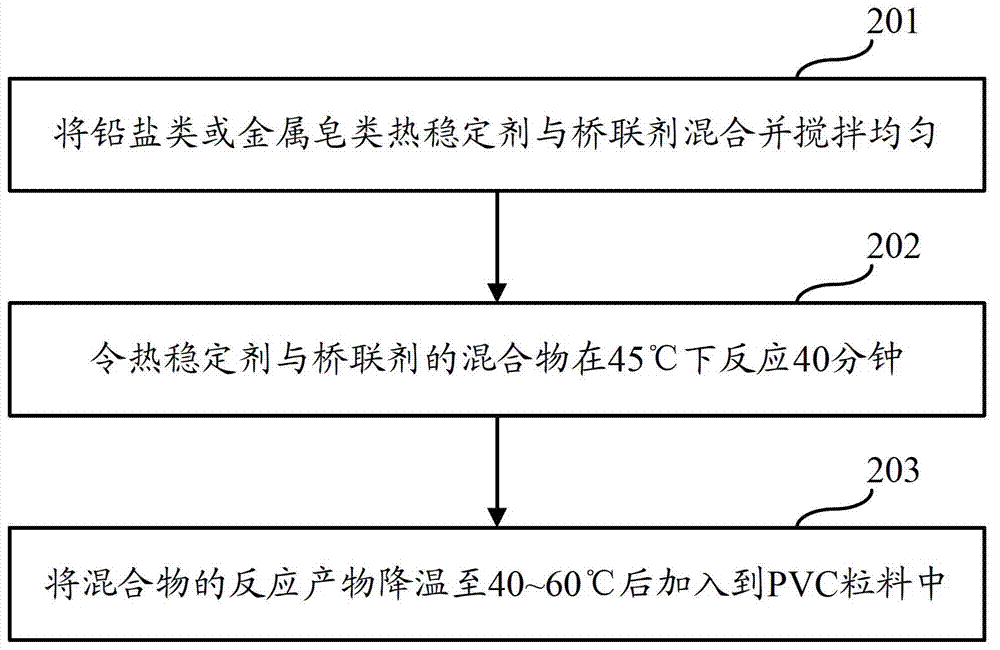

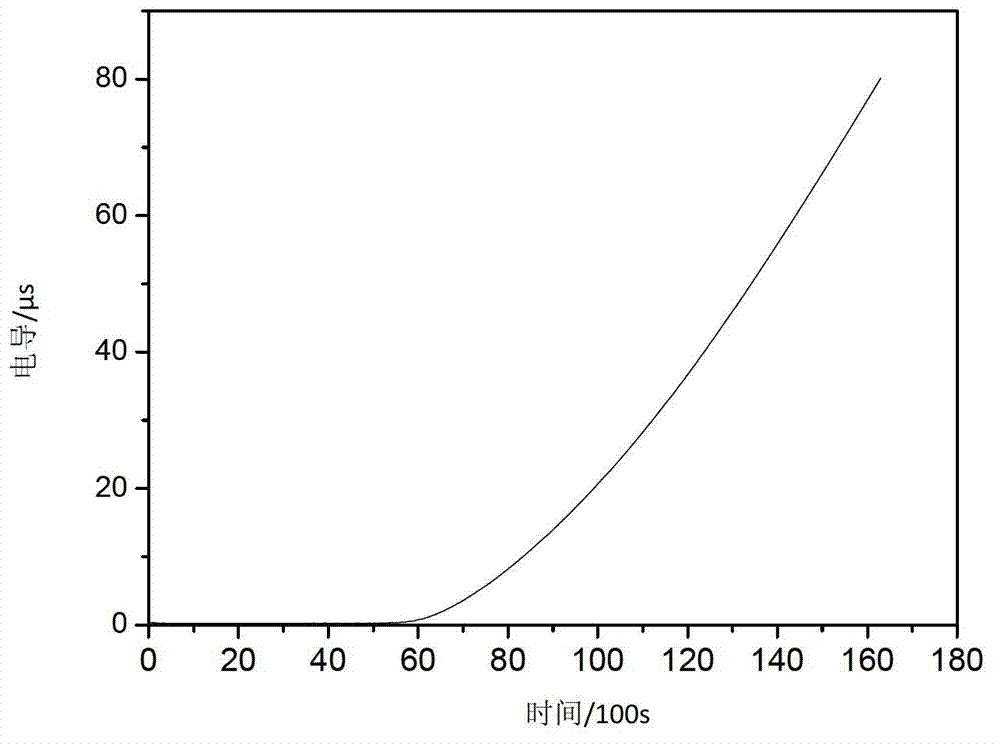

Manufacture method of PVC (Poly Vinyl Chloride) product

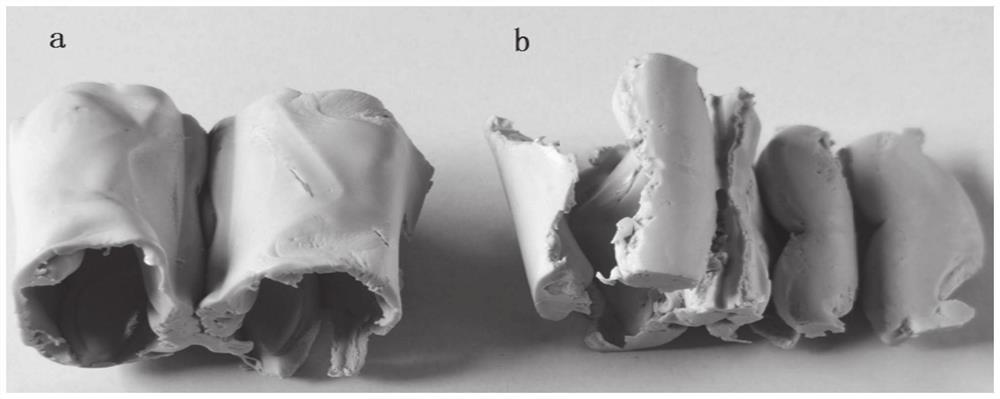

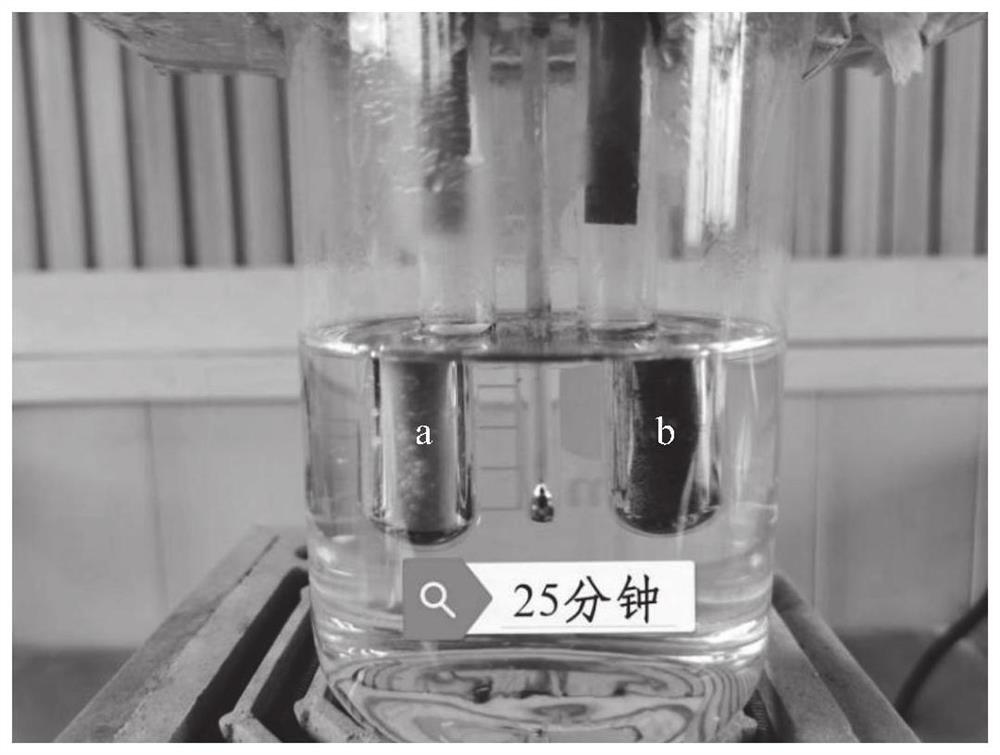

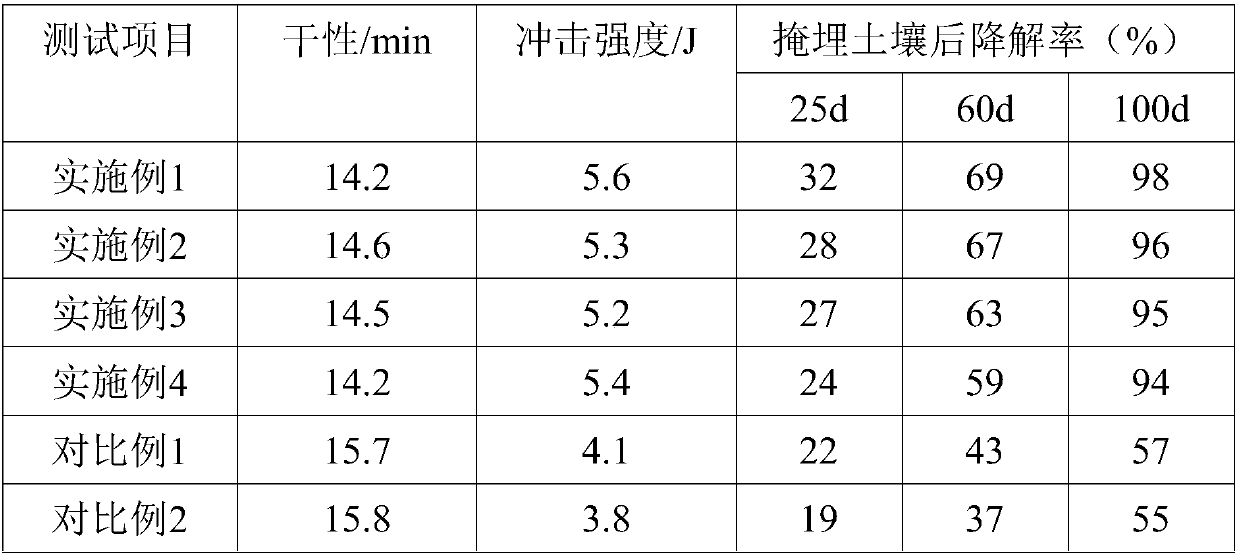

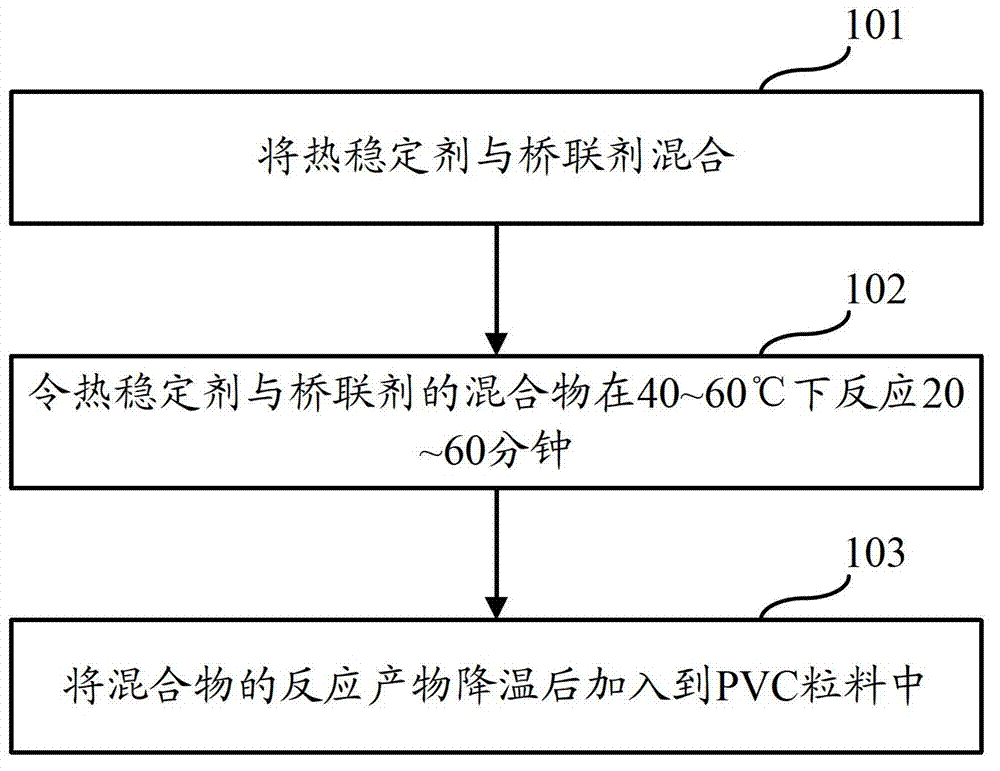

The invention discloses a manufacture method of a poly vinyl chloride PVC product. The method comprises the step of adding a bridge linking agent to a heat stabilizer required to be added to PVC particles, wherein the bridge linking agent is a substance containing a hydrophilic group and a lipophilic group in the molecular structure. The method is to fully mix the PVC molecule and the heat stabilizer under a bridging effect of the bridge linking agent, so as to achieve the purpose of fully performing the effect of the heat stabilizer and reducing the amount of the used heat stabilizer. The heat stabilizing time of the PVC product can be prolonged under the condition that the same quantity of heat stabilizer is added; and the quantity of added heat stabilizer can be correspondingly reduced with the same heat stabilizing time, therefore, the cost for manufacturing the PVC product can be reduced, and the toxicity of the PVC product also can be reduced; the benefit is brought to the health of a manufacturer and a user of the PVC product; and a more environment-friendly effect is achieved.

Owner:XIHUA UNIV

Composite stabilizer of metal salt of organic carboxylic acid containing sulfur in use for polymer containing halogen, and application thereof

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Polyol Esters and Their Application in Processing of Halovinyl Polymers

ActiveCN106631779BImprove hot workabilityLong thermal stability timeThiol preparationOrganic compound preparationTrans esterificationPolymer science

The invention discloses polyol ester and application of the same to processing of a halogenated vinyl polymer. The polyol ester is prepared by subjecting one of polyols and one selected from a group consisting of carboxylic acid and acid anhydrides to esterification or subjecting one of polyols and one of the esters of carboxylic acid to transesterification. The polyol ester provided by the invention has good compatibility with the halogenated vinyl polymer and can improve the hot-working performance of the halogenated vinyl polymer when cooperated with a heat stabilizer; in particular, the polyol ester can inhibit or alleviate the phenomenon of zinc burning of a zinc-containing heat stabilizer in the later phase of hot-working when cooperated with the zinc-containing heat stabilizer; so the whiteness of a halogenated vinyl polymer product is improved, later zinc burning is effectively inhibited, the thermostabilization time, particularly medium-and-long-term heat stability, of the halogenated vinyl polymer (especially PVC) is substantially prolonged, and the defect of poor stability in the later phase of the zinc-containing heat stabilizer is compensated for. The polyol ester has good application prospects in the field of processing of the halogenated vinyl polymer, especially PVC.

Owner:济南金昌树新材料科技有限公司

A kind of urea grease/biuret-based liquid potassium zinc foaming stabilizer for PVC and preparation method thereof

The invention discloses a urea grease / biuret-based liquid zinc potassium sparkle stabilizer for PVC (Polyvinyl Chloride) and a preparation method thereof. A currently main used environmentally-friendly liquid zinc potassium foaming agent mostly contains a lot of solvent, and most of the used organic acids are from petroleum resources. The stabilizer provided by the invention is prepared from the following components: 30 to 50 percent of urea grease / biuret-based emulsion, 40 to 50 percent of potassium salt / zinc salt solution, 0 to 5 percent of antioxidant, 0 to 5 percent of beta-diketone, and 0 to 10 percent of phosphite ester; the urea grease / biuret-based emulsion is prepared from the following components: 20 to 30 percent of urea, 5 to 20 percent of isocaprylic acid, 10 to 40 percent of oleic acid, 1 to 5 percent of catalyst, and 30 to 50 percent of solvent; and the potassium salt / zinc salt solution is prepared from the following components: 0 to 15 percent of potassium hydroxide, 15 to 25 percent of zinc compound, 25 to 60 percent of isocaprylic acid, 5 to 10 percent of oleic acid, and 10 to 40 percent of solvent. The stabilizer provided by the invention has the characteristic of enabling a PVC product to be excellent in heat stability, high in foaming ratio and delicate and compact in foaming holes.

Owner:ZHEJIANG TRANSFAR WHYYON CHEM

Liquid barium/zinc transparent composite heat stabilizer for PVC (Polyvinyl Chloride)

The invention relates to a liquid barium / zinc transparent composite heat stabilizer for PVC (Polyvinyl Chloride). The liquid barium / zinc transparent composite heat stabilizer is prepared from a main stabilizer and an auxiliary heat stabilizer, wherein the main stabilizer is a composite heat stabilizer prepared from barium isotanoate and zinc isoocatanoate according to a certain proportion; the auxiliary heat stabilizer is hydrotalcite or organic tin. The barium / zinc composite heat stabilizer is creatively selected as a main stabilizer of a PVC material, and a best synergistic effect is achieved by limiting the proportion of the barium isotanoate to the zinc isoocatanoate at 3 / 1; compared with the prior art, the liquid barium / zinc transparent composite heat stabilizer has the advantages of prolonged heat stabilizing time, better aging-resisting effect, higher transparence and better effect than other schemes in the prior art.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

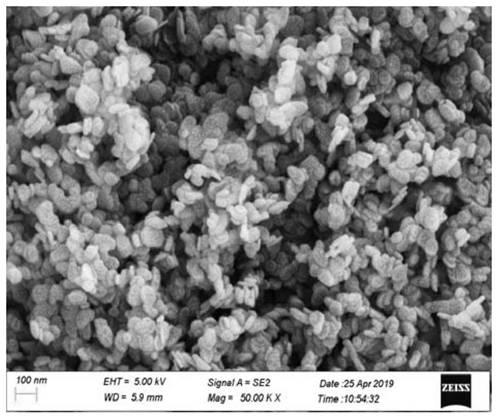

Mg-Ca-Zn-Al four-component hydrotalcite heat stabilizer

InactiveCN101284953BImprove performanceNo pollution in the processInorganic pigment treatmentHazardous substancePhysical chemistry

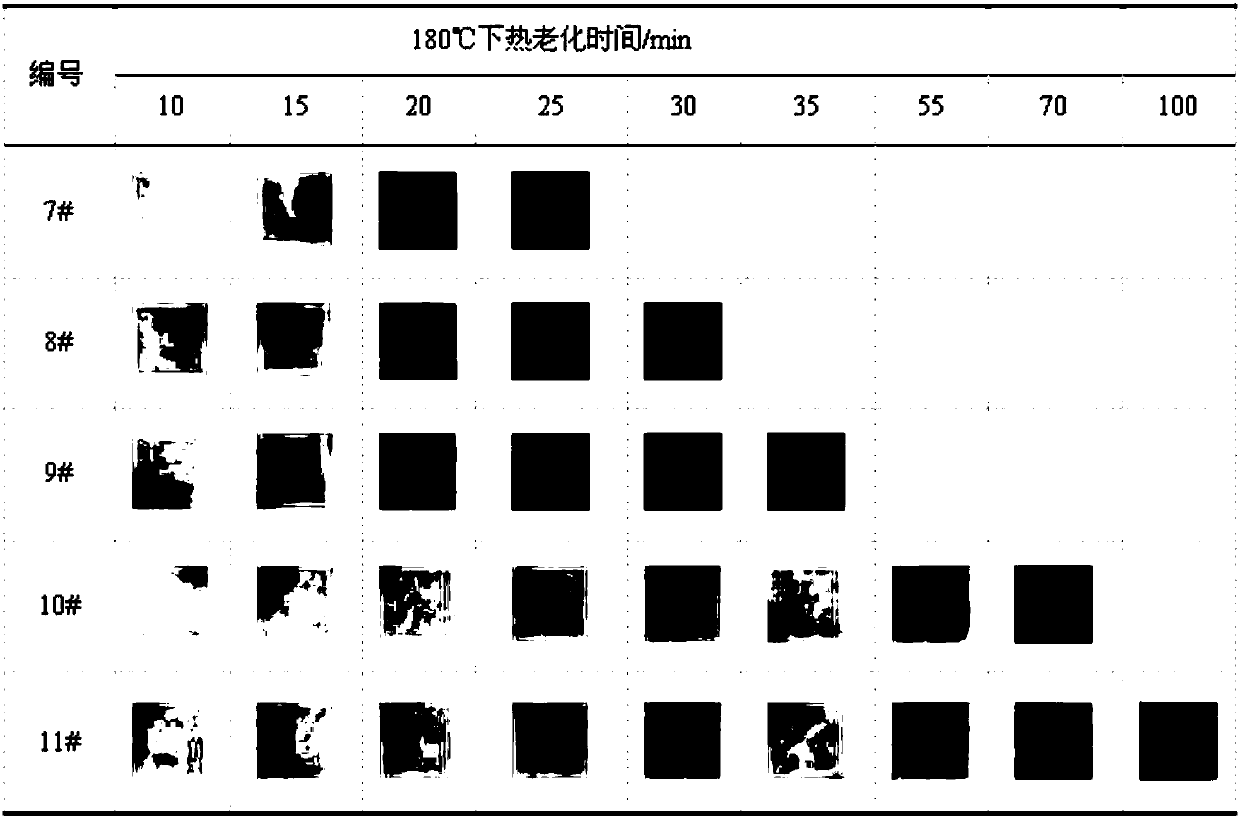

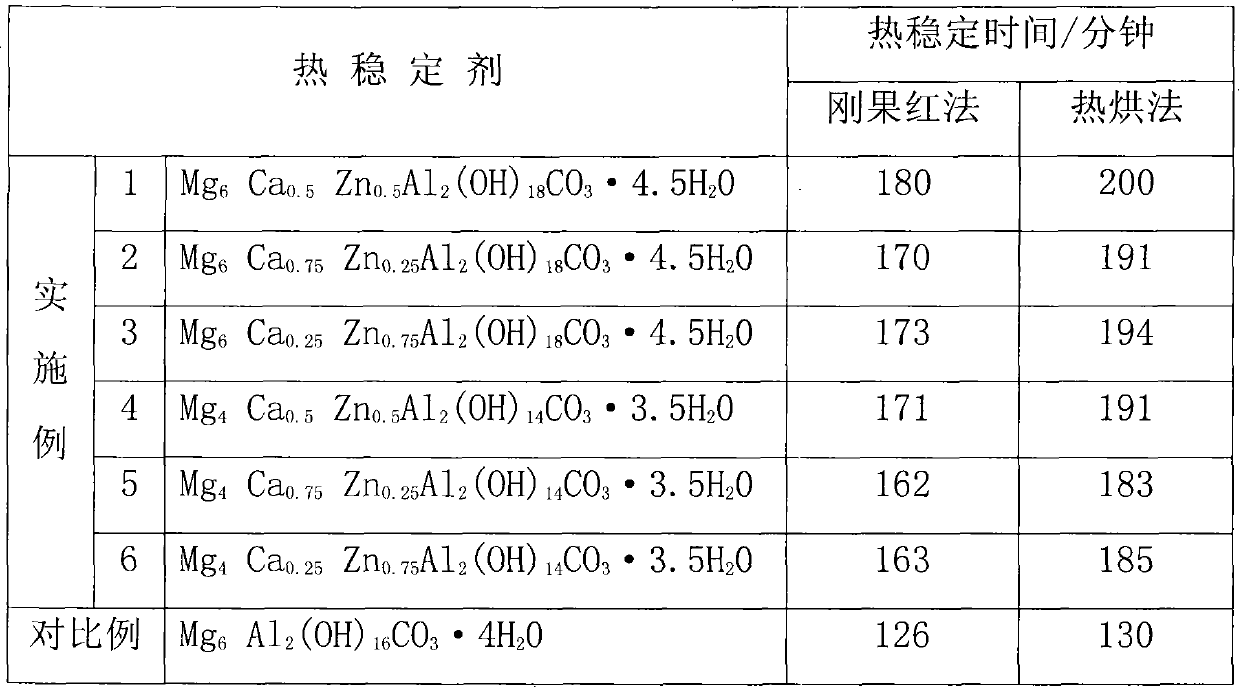

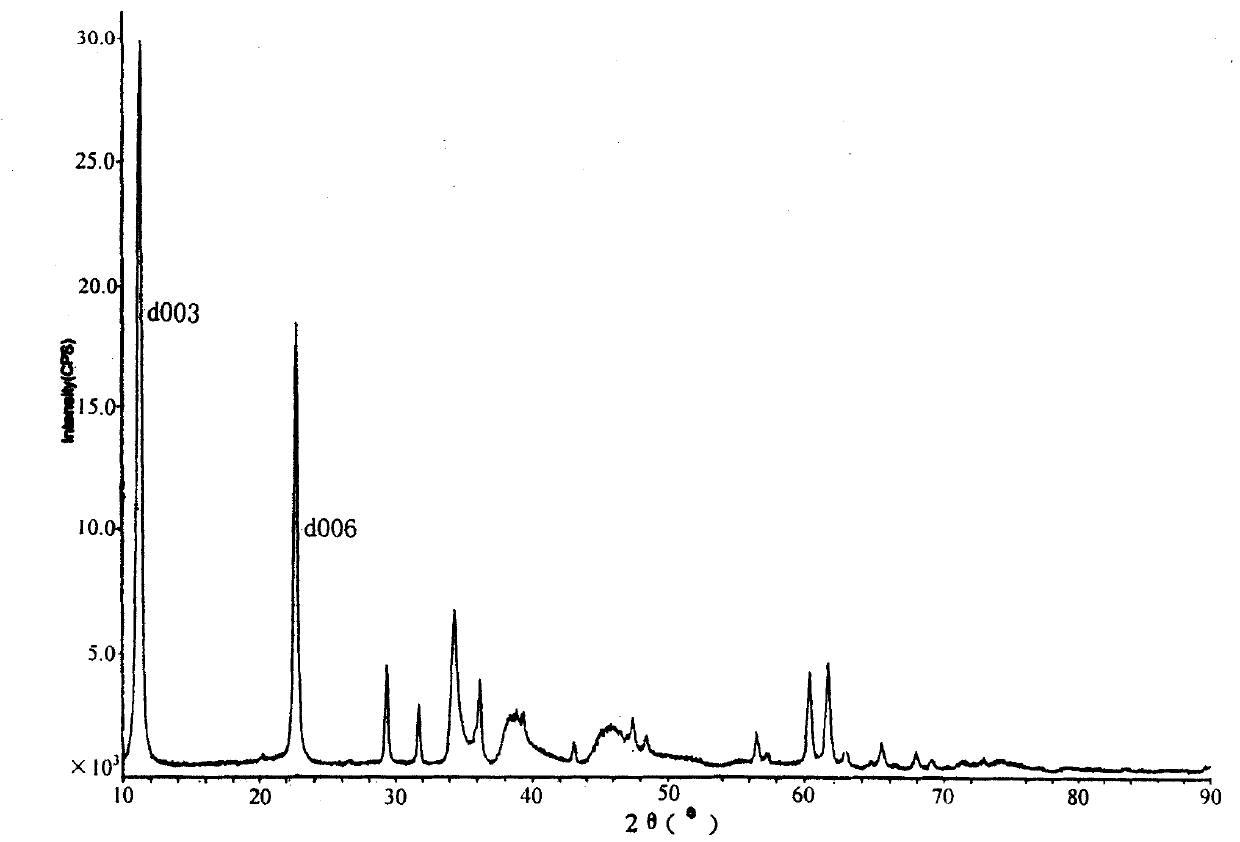

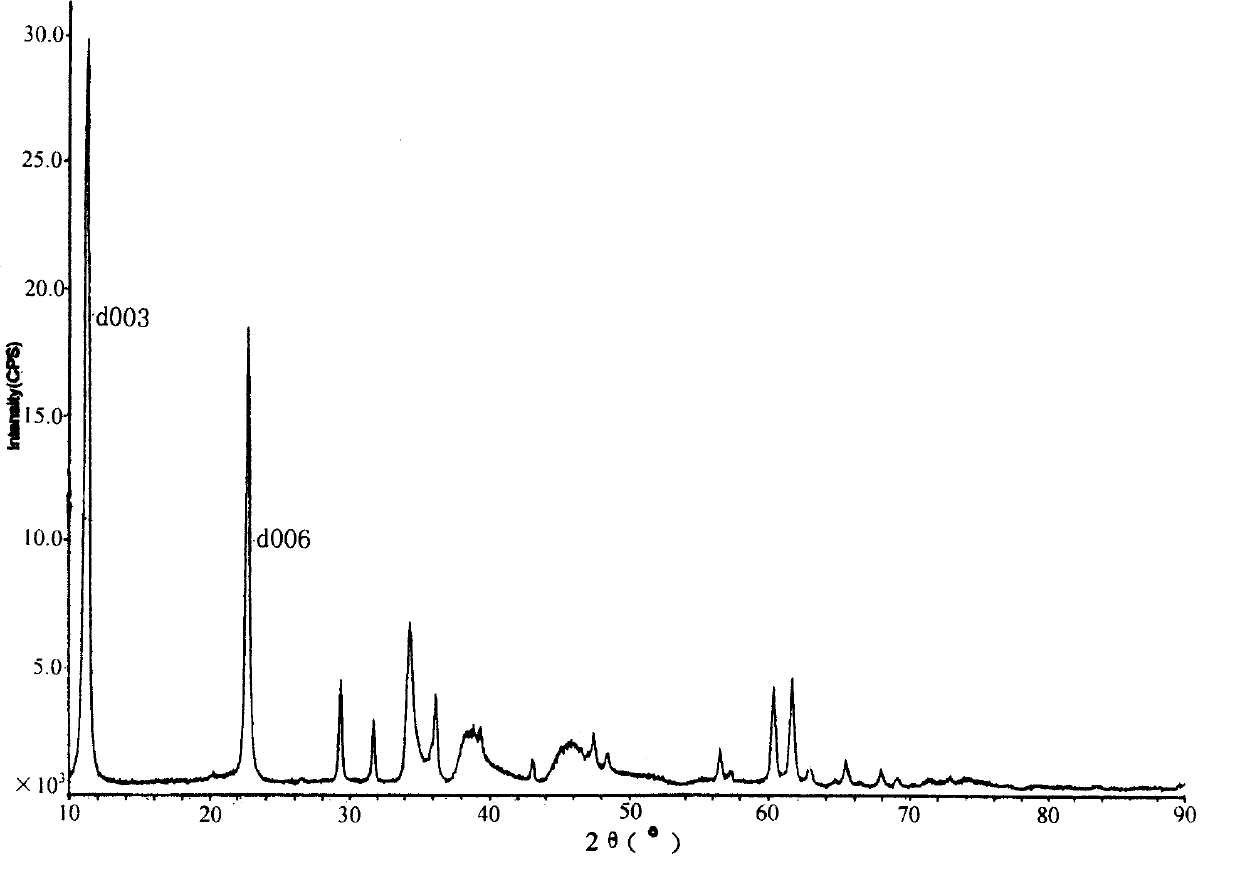

The invention provides Mg-Ca-Zn-Al quadribasic hydrotalcite heat stabilizer, wherein, three divalent metal ions contained are Mg<2+>, Ca<2+> and Zn<2+>; trivalent metal ions are Al<3+>, and anions are CO3<2->. The invention also provides a method for preparing the heat stabilizer, comprising the following steps of: a) preparation of salt-mixture solution; b) preparation of calcium salt solution; c) preparation of mixed alkali solution; d) normal-atmosphere reaction; e) pressurizing and aging; f) post treatment, during which Mg-Ca-Zn-Al quadribasic hydrotalcite powder is obtained. The heat stabilizer and the preparation method have the advantages that: the performance of the Mg-Ca-Zn-Al quadribasic hydrotalcite heat stabilizer is better than that of binary hydrotalcite; the preparation method is simple in technique, low in investment and low in cost; hazardous substances are not involved in the production process and no environmental pollution occurs. The congo red method and the heating method are used for testing the effect of the quadribasic hydrotalcite in improving the thermal stability of PVC; compared with the binary Mg-Al hydrotalcite, the thermal stabilization time of the quadribasic hydrotalcite at a temperature of 180+-1 DEG C is prolonged 29 to 54 percent.

Owner:TIANJIN HAOHUA CHEM INDAL

Polishing slag modified flame-retardant PVC plasticizing paste and preparation method thereof

InactiveCN111253695ASolve the problem of reduced flame retardancySolve pollutionSpecial paperPaper coatingCarbonizationMagnesium chloride hexahydrate

The invention discloses a polishing slag modified flame-retardant PVC plasticizing paste and a preparation method thereof. According to the polishing slag modified flame-retardant PVC plasticizing paste, synthetic vegetable fatty acid ester with flame retardance and stone, ceramic tiles and artificial stone polishing slag with flame retardance and smoke suppression are added into a formula to generate a synergistic flame-retardant effect through the matching of the two components; the synthetic vegetable fatty acid ester can absorb a large amount of oxygen, and be oxidized and decomposed intoCO2 and H2O after being heated, the CO2 isolates the oxygen, and the H2O takes away heat, so that the flame retardance is achieved; the abrasive dust in the polishing slag contains magnesium oxide, magnesium hydroxide, magnesium chloride hexahydrate and other materials, and is a composite flame retardant with multiple flame retardant mechanisms; and the SiO2 powder in the polishing slag is non-flammable and resistant to high-temperature decomposition, is used as a filling agent to be filled into a paste resin product in quantity, and can form a carbonization layer on the surface of the productduring combustion, so that heat and oxygen are prevented from entering, and the flame retardant mechanism of dehydration, dilution, heat absorption and cooling of the flame retardant can play a greatrole in flame retardance and smoke suppression.

Owner:林铭昭

Composite lead salt thermally-stable anti-degradation auxiliary agent as well as preparation method and application thereof

The invention belongs to the technical field of plastic processing, in particular relates to a composite lead salt thermally-stable anti-degradation auxiliary agent as well as a preparation method andapplication thereof. The composite lead salt thermally-stable anti-degradation auxiliary agent provided by the invention comprises the following raw material components by mass percentage: 35-60% ofbasic lead salt, 0-10% of an acid binding agent, 10-20% of a lubricant, 0-2% of titanium dioxide, 5-18% of fly ash and 10-40% of calcium carbonate. Results of embodiments show that the composite leadsalt thermally-stable anti-degradation auxiliary agent provided by the invention has outstanding thermal stability performance, can effectively improve the degradation temperature of polyvinyl chloride, and has high initial whiteness and good long-term stability.

Owner:内蒙古佳运通智能环保新材料有限公司

Organic stannic acid intercalation calcium/zinc-aluminum rare earth hydrotalcite composite heat stabilizer for hard PVC and preparation method thereof

The invention provides an organic stannic acid intercalation calcium / zinc-aluminum rare earth hydrotalcite composite heat stabilizer for rigid PVC and a preparation method thereof. The organic stannoic acid intercalated calcium / zinc-aluminum rare earth hydrotalcite composite heat stabilizer for rigid PVC is composed of: in parts by mass, organic stannic acid intercalated calcium aluminum rare earth hydrotalcite is 30 to 90 parts; organic tin The amount of acid-intercalated zinc-aluminum rare earth hydrotalcite is 10-50 parts. The preparation method includes: (1) dissolving calcium salt, aluminum salt and rare earth salt in deionized water to obtain a solution, dissolving sodium hydroxide and organic stannic acid in a mixed solution of deionized water and ethanol; (2) mixing the two The solution is added dropwise, refluxed, precipitated, suction filtered, washed; dried and ground to obtain organic stannic acid intercalated calcium aluminum rare earth hydrotalcite; (3) zinc salt instead of calcium salt, repeating steps (1) and (2), Obtain organic stannic acid intercalated zinc-aluminum rare-earth hydrotalcite; (4) mix according to the above-mentioned parts by mass. When used in rigid PVC, it can effectively improve the thermal stability of rigid PVC.

Owner:TANGSHAN NORMAL UNIV

A kind of high-impact polyvinyl chloride water supply pipe and its preparation method

The invention discloses a high-impact resistance polyvinyl chloride water supply tube and a production method thereof, and belongs to the technical fields of processing and application of polymer materials. The tube comprises 100 parts of PVC resin, 0.8-1.5 parts of an organic tin stabilizer, 5-6 parts of an impact modifier, 2-5 parts of a processing assistant, 1.5-2 parts of a lubricant, 0.4-0.8part of an antioxidant, 0.1-0.2 part of a colorant and 1-5 parts of a filler; and the processing assistant is modified hyperbranched polyester. The modified hyperbranched polyester is obtained by modifying the branched terminal group of hyperbranched polyester with formyl chloride, and the retention rate of final branched terminal hydroxyl groups is 40-50%. The high-impact resistance polyvinyl chloride water supply tube has the advantages of good impact resistance, good processing performances, good fluidity of a mixture in the processing process, and easiness in processing and molding. The production method of the high-impact resistance polyvinyl chloride water supply tube has the advantages of simplicity, easiness in implementation, and high processing efficiency.

Owner:CHINA PETROLEUM & CHEM CORP

Preparation method of pvc heat stabilizer

The invention relates to a PVC heat stabilizer and a preparing method thereof. The preparing method comprises the following steps of mixing a tartaric acid solution and a sodium hydroxide solution, then heating the mixed solution to 50-80 DEG C, conducting heat preservation for 0.5-2 h, and then adjusting the temperature of the mixed solution to 60-90 DEG C; taking a rare earth salt solution, dropwise adding the rare earth salt solution into the mixed solution, till the pH value of the solution is 6.5-7.5, stopping dropwise adding, then continuing a stirring reaction, and then conducting suction filtration, washing and drying in sequence to obtain the PVC heat stabilizer. The preparing method of the PVC heat stabilizer is simple, feasible, mild in reaction condition in the whole process and easy to operate. The prepared PVC heat stabilizer prepared through the preparing method is nontoxic and efficient, contains basic groups, and is high in rare earth content and excellent in performance; compared with other organic acid rare earth, the PVC heat stabilizer can drastically prolong the heat stabilizing time of PVC when in single use, and has a good synergistic effect when in joint use with stabilizers of other varieties.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

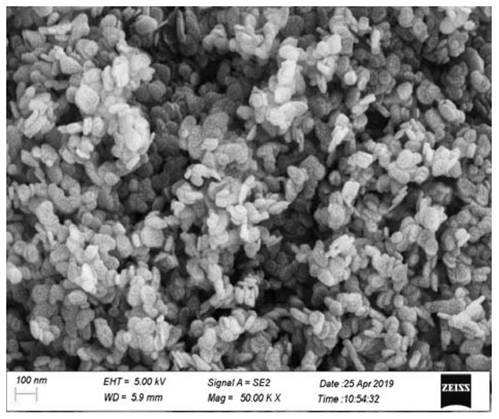

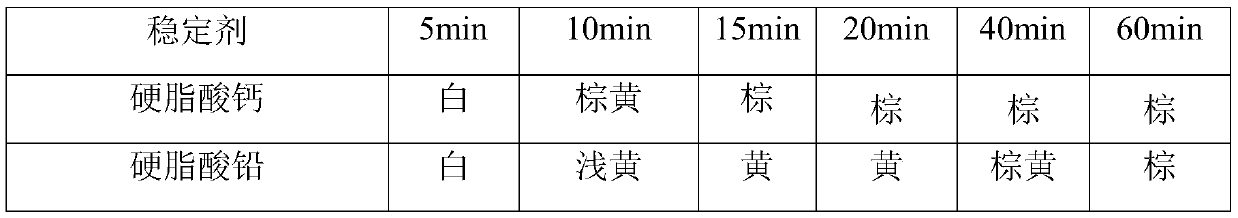

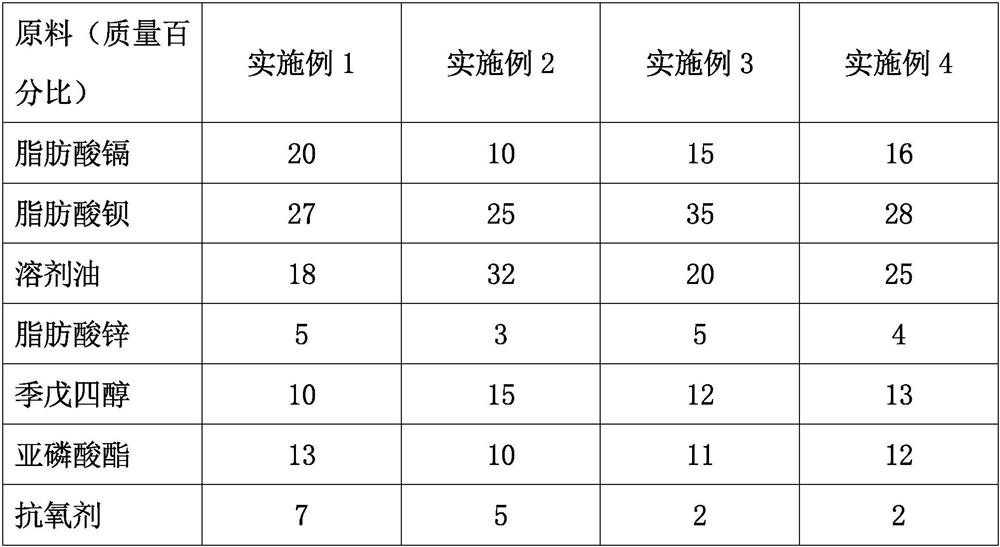

Barium-cadmium-zinc composite stabilizer and preparation method thereof

The invention discloses a barium-cadmium-zinc composite stabilizer and a preparation method thereof. The barium-cadmium-zinc composite stabilizer is prepared from fatty acid cadmium, fatty acid barium, solvent oil, fatty acid zinc, pentaerythritol, phosphite ester and an antioxidant. The barium-cadmium-zinc composite stabilizer has the beneficial effects that the barium-cadmium-zinc composite stabilizer provided by the invention has the advantages of good compatibility with PVC resin, long thermal stability time, high transparency, no dust pollution and the like, and plays a role in thermal stability during polyvinyl chloride processing. The invention also provides the preparation method of the barium-cadmium-zinc composite stabilizer, so as to obtain the barium-cadmium-zinc composite stabilizer.

Owner:广州百沙塑胶新材料有限公司

Polishing slag modified PVC flame-retardant electric insulation rubber mat

The invention discloses a polishing slag modified PVC flame-retardant electric insulation rubber mat. According to the polishing slag modified PVC flame-retardant electric insulation rubber mat disclosed by the invention, the synthetic vegetable fatty acid ester with flame retardance and polishing slag with flame retardance and smoke suppression are added into the formula, and the synthetic vegetable fatty acid ester and the polishing slag are synergistically used to generate better flame retardance and smoke suppression effects. The polishing slag modified PVC flame-retardant electric insulation rubber mat is prepared by mixing, extruding and cutting. The problems that the chlorine content of a PVC elastomer flame-retardant material is reduced and the flame-retardant property is reduced due to the addition of a large amount of small molecular plasticizers in the prior art are solved. A large amount of polishing slag is added as an inorganic flame-retardant filler, so that the production cost of the PVC flame-retardant electric insulation rubber mat is reduced, the flame retardance and smoke suppression performance of the product are improved, the problems that stone, ceramic tilesand artificial stone polishing slag is difficult to recycle and environmental pollution is caused by waste landfill are solved, and waste is turned into wealth.

Owner:林铭昭

A kind of composite lead salt heat-stable anti-degradation additive and its preparation method and application

The invention belongs to the technical field of plastic processing, and in particular relates to a composite lead salt heat-stable anti-degradation additive and its preparation method and application. The composite lead salt heat-stable anti-degradation aid provided by the invention comprises the following raw material components in mass percent: 35-60% of basic lead salt, 0-10% of acid-binding agent, 10-20% of lubricant, and 0% of titanium dioxide. ~2%, fly ash 5~18%, calcium carbonate 10~40%. The results of the examples show that the composite lead salt heat-stable anti-degradation additive provided by the present invention has outstanding performance in heat stability, can effectively increase the degradation temperature of polyvinyl chloride, and has high initial whiteness and good long-term stability.

Owner:内蒙古佳运通智能环保新材料有限公司

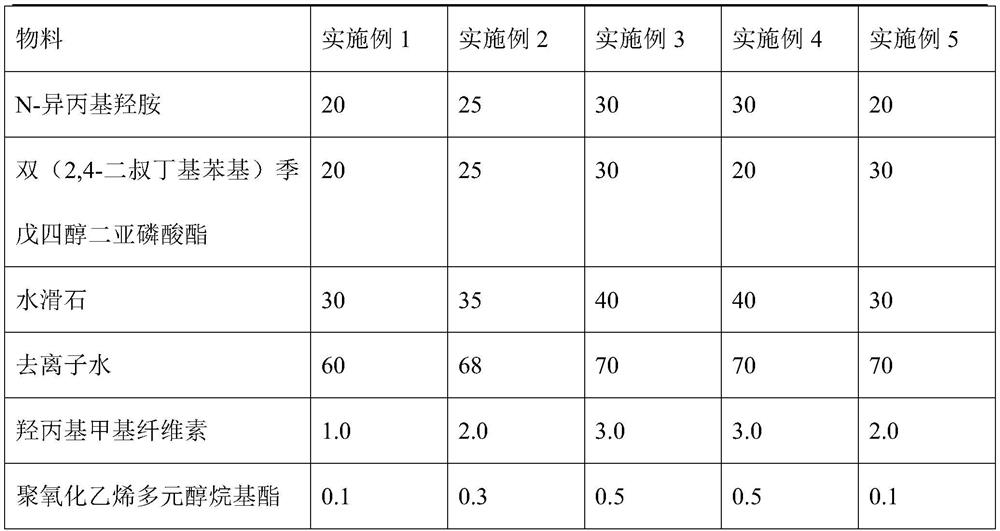

Thermally stable vinyl chloride polymerization terminator, its preparation method and application

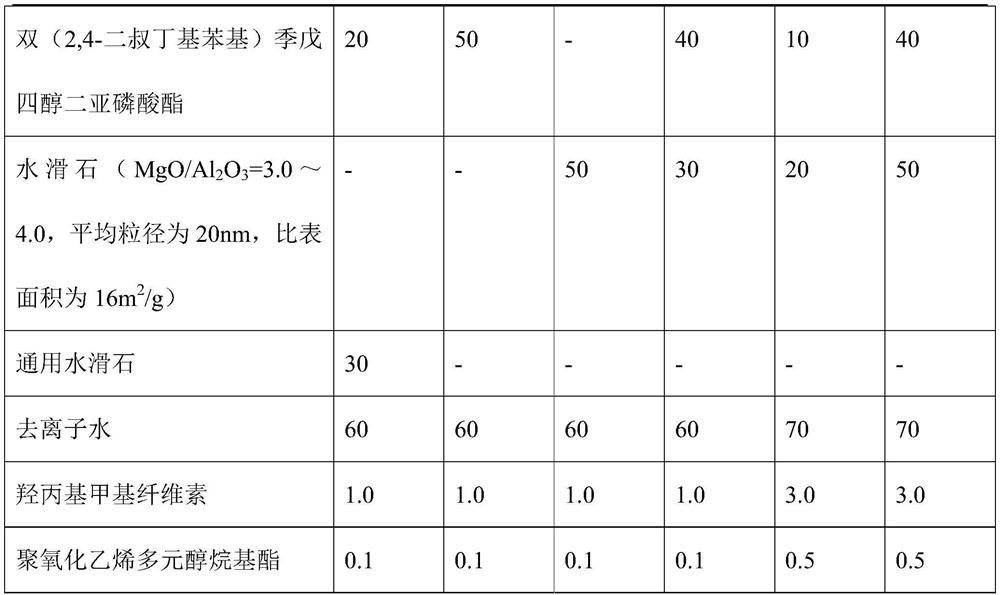

The invention belongs to the field of resin synthesis, and in particular relates to a heat-stable vinyl chloride polymerization terminator, its preparation method and application. Including the following raw materials: N-isopropyl hydroxylamine, hydrotalcite, bis(2,4-di-tert-butylphenyl) pentaerythritol diphosphite, deionized water, dispersant and emulsifier; wherein: hydrotalcite is: MgO / Al 2 o 3 =3.0~4.0, the average particle size is 10~20nm, and the specific surface area is 15~20m 2 / g. The terminator of the present invention has good vinyl chloride polymerization termination effect, effectively reduces the damage of residual initiator to the thermal stability of PVC resin, can improve the thermal stability of PVC resin, prolong the thermal stability time of resin, and does not affect the transparency of PVC products properties, the present invention also provides its preparation method and application.

Owner:CHINA PETROLEUM & CHEM CORP

Rare-earth heat stabilizer for PVC (Polyvinyl Chloride) and preparation method thereof

InactiveCN103087445BLow toxicityHas an aromatic smellCarboxylic acid salt preparationOrganic acidAlcohol

The invention discloses a rare-earth heat stabilizer for PVC (Polyvinyl Chloride) and a preparation method thereof. The main component of the rare-earth heat stabilizer is aromatic organic acid rare earth. The mass of the rare earth accounts for 25%-55% of the total mass of a stabilizer. A main raw material for preparing the stabilizer is coumarin or derivatives of the coumarin and rare-earth salts; and the preparation method of the rare-earth heat stabilizer comprises the steps of: firstly carrying out ring-opening on the coumarin or the derivatives of the coumarin to generate phenolic acid salts, adjusting pH, adding a rare-earth salt solution for reaction, then leaching, washing in alcohol, washing in water and drying to obtain the product. According to the rare-earth heat stabilizer, the coumarin or derivatives of the coumarin with low cost is / are taken as raw materials, reaction conditions are mild, and the finished product is yellow green powder and has very good long-term thermal stability for the PVC, aromatic odor, low toxicity and a very good application prospect.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com