Patents

Literature

67results about How to "Improve flame retardant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly dyeing and finishing technology of cotton cellulose fabric

InactiveCN105002720AHigh whitenessAvoid damagePhysical treatmentBiochemical fibre treatmentEpoxyCellulose

The invention discloses an environment-friendly dyeing and finishing technology of a cotton cellulose fabric. The technology comprises the following steps: pretreatment; preshaping; modification treatment; dyeing; mordant removing; soaping; color fixing; post-treatment; drying; shaping; calendaring; rolling. According to the technology, pretreatment is carried out through the adoption of helicase and alpha-amylase, and acetic acid aqueous solution of chitosan, hydrogen peroxide and epoxy chloropropane is adopted, so that the property of the cotton cellulose fabric is fundamentally modified, and the dye-uptake of the fabric is increased; during the dyeing procedure, large quantities of alkaline substances and inorganic salt are not used, and a levelling agent and a dispersing agent are added, so that the dye uniformity is improved; natural dye is used, so that environmental pollution is avoided, and the demand of environmental protection is met; modification treatment and fire retardant treatment are carried out on the fabric through the adoption of montmorillonite, so that the fire resistance of the fabric is high; self-cleaning treatment is added in post-treatment, so that the self-cleaning capacity, wrinkle resistance and water washable firmness of the fabric are improved; the whole technology is environment-friendly and free of pollution.

Owner:TAICANG CHENGLE CHEM FIBER

Environment protection type polyurethane elastomer/laminated nano composition and its preparing process

InactiveCN1376748AImprove mechanical propertiesImprove flame retardantGround pavingsPolyurea/polyurethane coatingsChemistryPlasticizer

An environment protection type composite polyurethane elastomer / nano laminated material is prepared through vacuum heating of dihydroxy polyoxyacrylether, dewatering, adding the mixture (MDI-50) of 4,4'-and 2,4'-diphenylmethane diisocyanate, reacting to obtain component A, compounding organic laminated nano material with trihydroxy or dihydroxy polyoxyacrylether, mixing with metaphenyldiamine pigment, filler and plasticizer to obtain component B, proportionally mixing components A with B, and laminating polymerization reaction under catalysis of zinc naphthenate. Its advantages are no pollution on preparing and using it, high mechanical performance, and excellent flame-retarding and anti-mildew performance.

Owner:孔克健

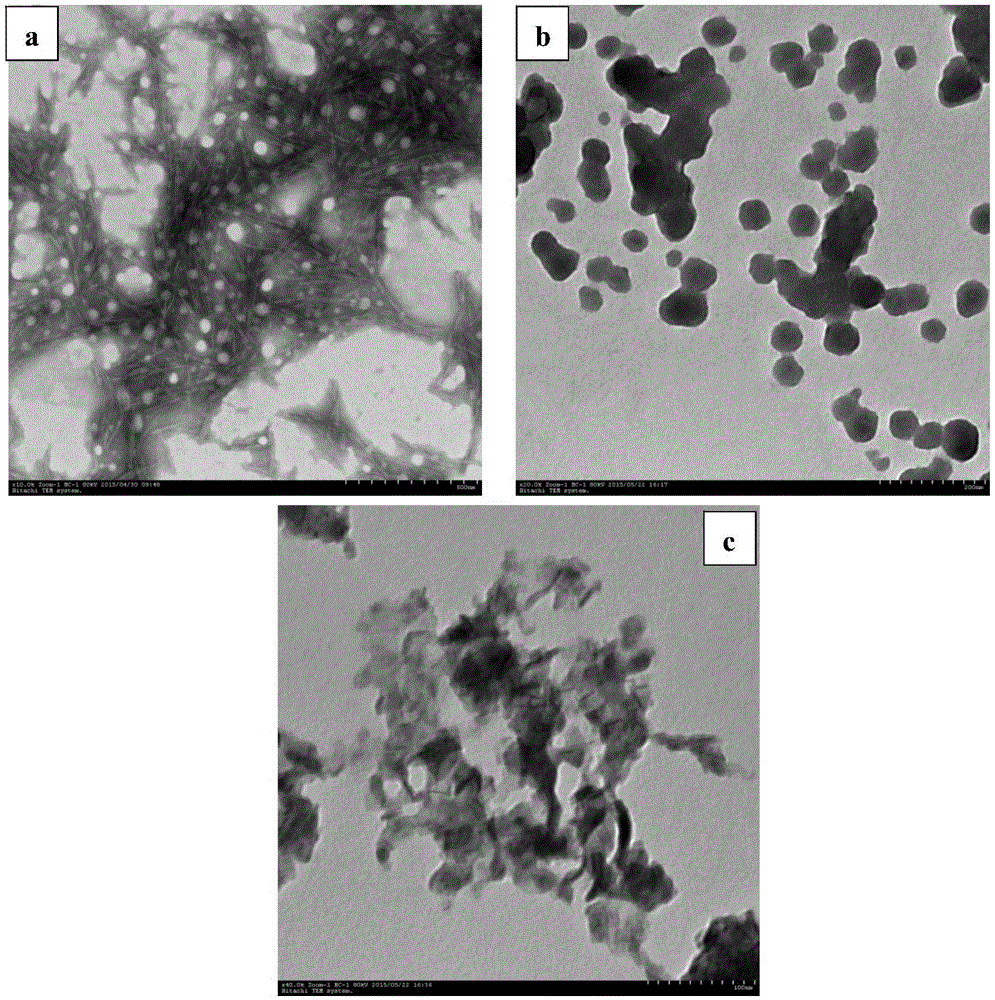

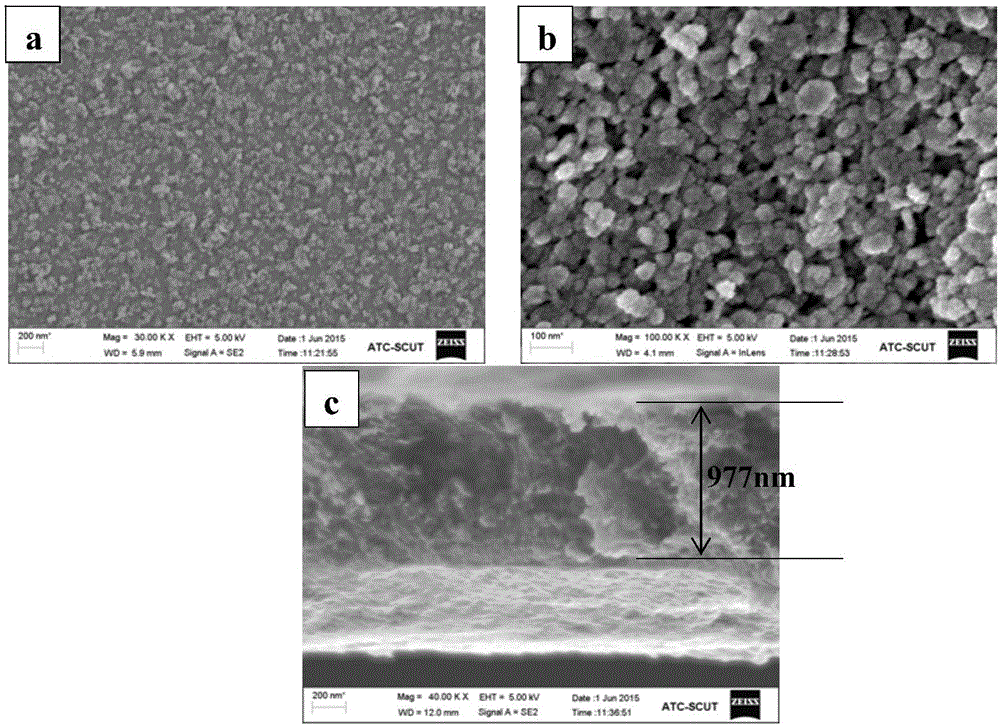

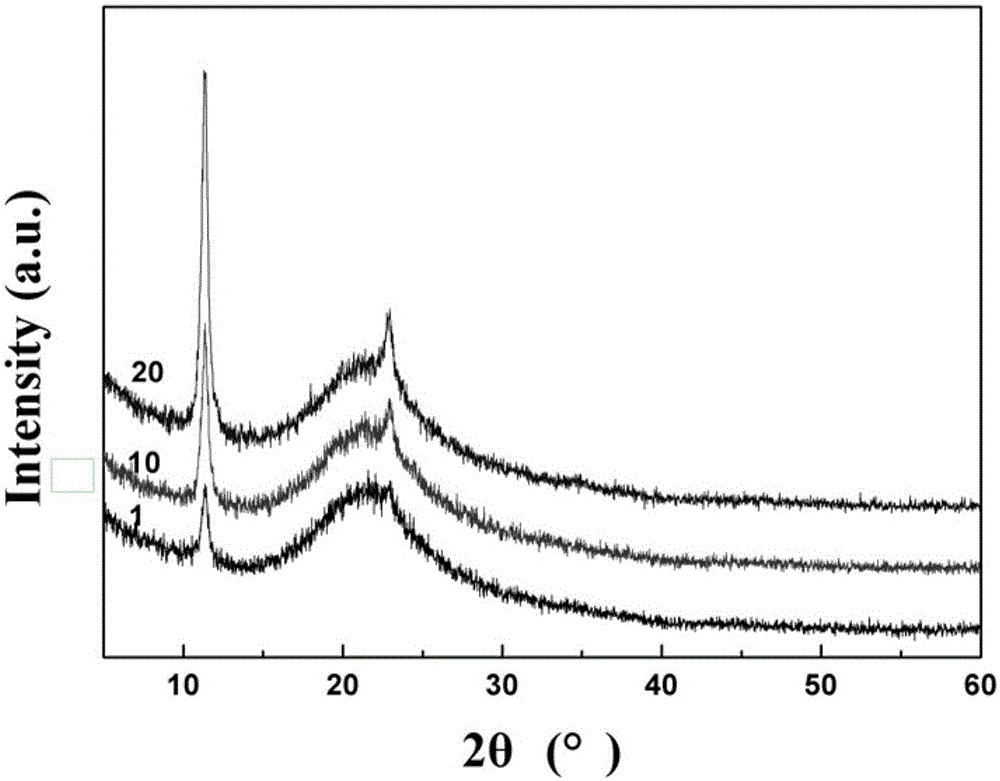

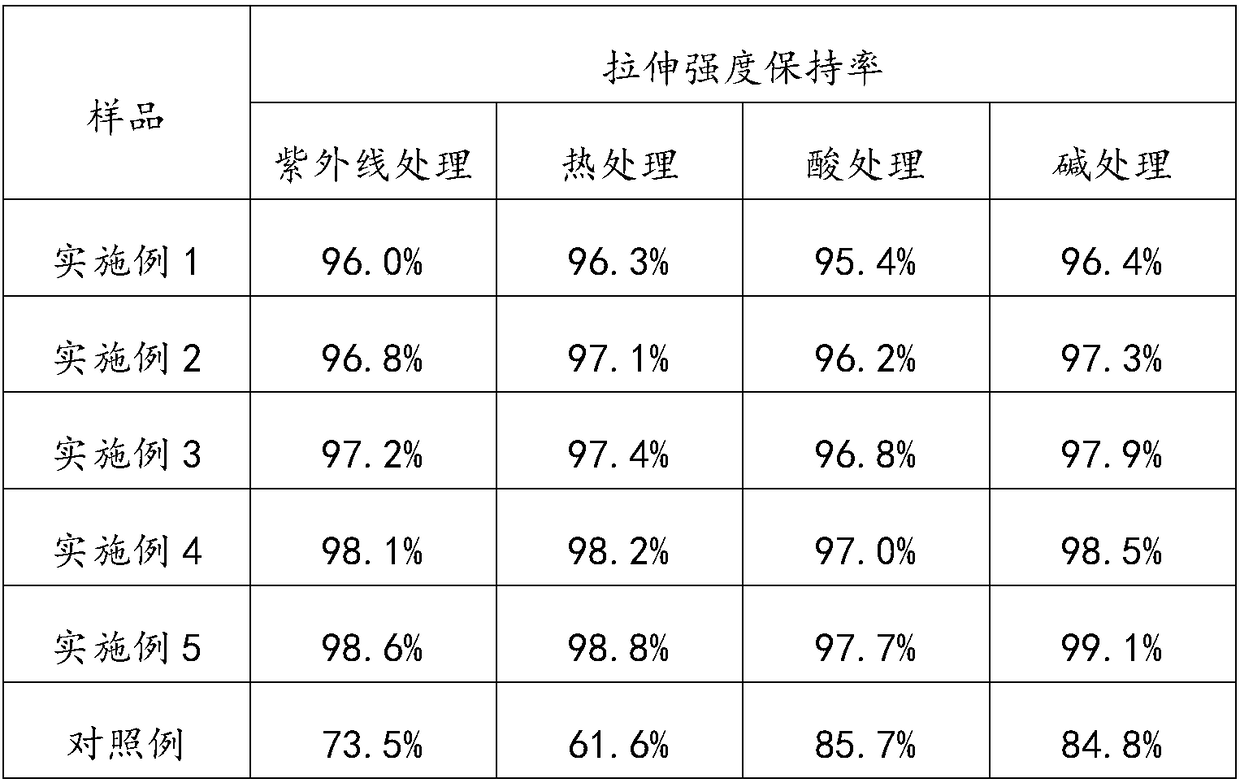

Nano-crystalline cellulose/layered double hydroxide composite membrane and preparation method

ActiveCN105058913AControl performanceImprove barrier propertiesLaminationLamination apparatusElectricityUltraviolet protection

The invention discloses a nano-crystalline cellulose / layered double hydroxide composite membrane and a preparation method. The method comprises the following steps: (1) preparing nano-crystalline cellulose (NCC) dispersion liquid with the surface provided with negative electricity; (2) preparing stripped layered double hydroxide (LDH) with positive electricity; and (3) preparing a layered NCC / LDH ultrathin composite membrane through a layer-by-layer (LBL) technology. The method is simple and low in cost and can be performed on the conditions of normal temperature, the prepared NCC / LDH composite membrane is normalized and uniform, and the structure, thickness and performance of the composite membrane are controllable. Due to the fact that the LDH layered structure is well stored in the prepared NCC / LDH composite membrane, the performances of the NCC, such as blockage, flame retardance, antibacterium and ultraviolet protection, can be improved.

Owner:SOUTH CHINA UNIV OF TECH

Light-resistant antibacterial water-based polyurethane coating and preparation method thereof

ActiveCN108384428AGood dispersionImprove stabilityFireproof paintsAntifouling/underwater paintsWater basedPolyol

The invention relates to light-resistant antibacterial water-based polyurethane coating and a preparation method thereof. The light-resistant antibacterial water-based polyurethane coating is preparedfrom the following raw materials of light-resistant antibacterial compounds, oligomeric polyols, polyisocyanates, catalysts, chain expanding agents, crosslinking agents and neutralizers, wherein thelight-resistant antibacterial compounds are oxidized graphene-cyclodextrin-antibacterial agent compounds and are obtained by modifying oxidized graphene by antibacterial agent coated cyclodextrin. Thecyclodextrin molecules are used for modifying the oxidized graphene; meanwhile, the antibacterial agents are contained in an inner cavity of the cyclodextrin molecules; the oxidized graphene-cyclodextrin-antibacterial agent light-resistant antibacterial compounds are obtained; the light-resistant antibacterial compounds are added into the water-based polyurethane coating, so that the water-basedpolyurethane coating has excellent ultraviolet light resistant performance, high-temperature-resistant performance, anti-aging performance, acid-alkali-resistant performance, antibacterial performanceand the like.

Owner:唐山德生科技有限公司

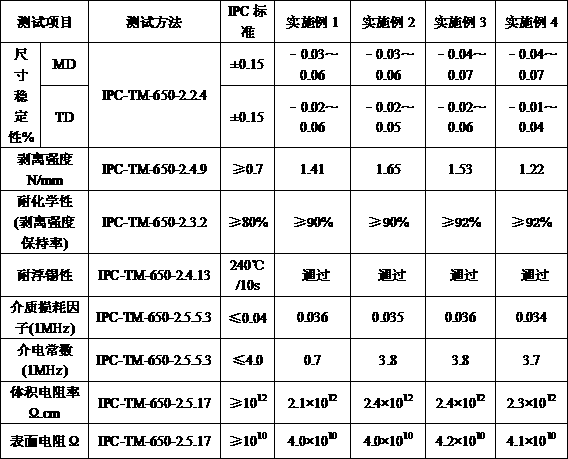

Preparation and application of polyester adhesive for PET flexible copper clad laminate

InactiveCN107779154AHigh peel strengthImprove flame retardantSynthetic resin layered productsLaminationSolventChemistry

The invention discloses preparation and application of a polyester adhesive for a PET flexible copper clad laminate. The polyester adhesive for the PET flexible copper clad laminate is prepared through mixing a main body, i.e., saturated polyester resin and a curing agent, i.e., amino resin, adding a proper amount of epoxy resin into the mixture for blended modification, and mixing a certain amount of catalyst, a certain amount of flame retardant, a certain amount of antifoamer, a certain amount of dispersant, a certain amount of organic solvent and the like. The polyester adhesive is preparedfrom the following ingredients in parts by weight: 20-70 parts of saturated polyester resin, 5-20 parts of amino resin, 10-30 parts of epoxy resin, 0.1-1.0 part of catalyst, 10-30 parts of flame retardant, 0.1-1.0 part of antifoamer, 0.1-2.0 parts of dispersant and 50-150 parts of organic solvent. The polyester adhesive for the PET flexible copper clad laminate has the advantages of high peelingstrength, high flame retardance, high flexural strength, low shrinkage ratio, good heat resistance and chemical solvent resistance, yellowing resistance, reliable performance and reasonable cost.

Owner:广东圣帕新材料股份有限公司

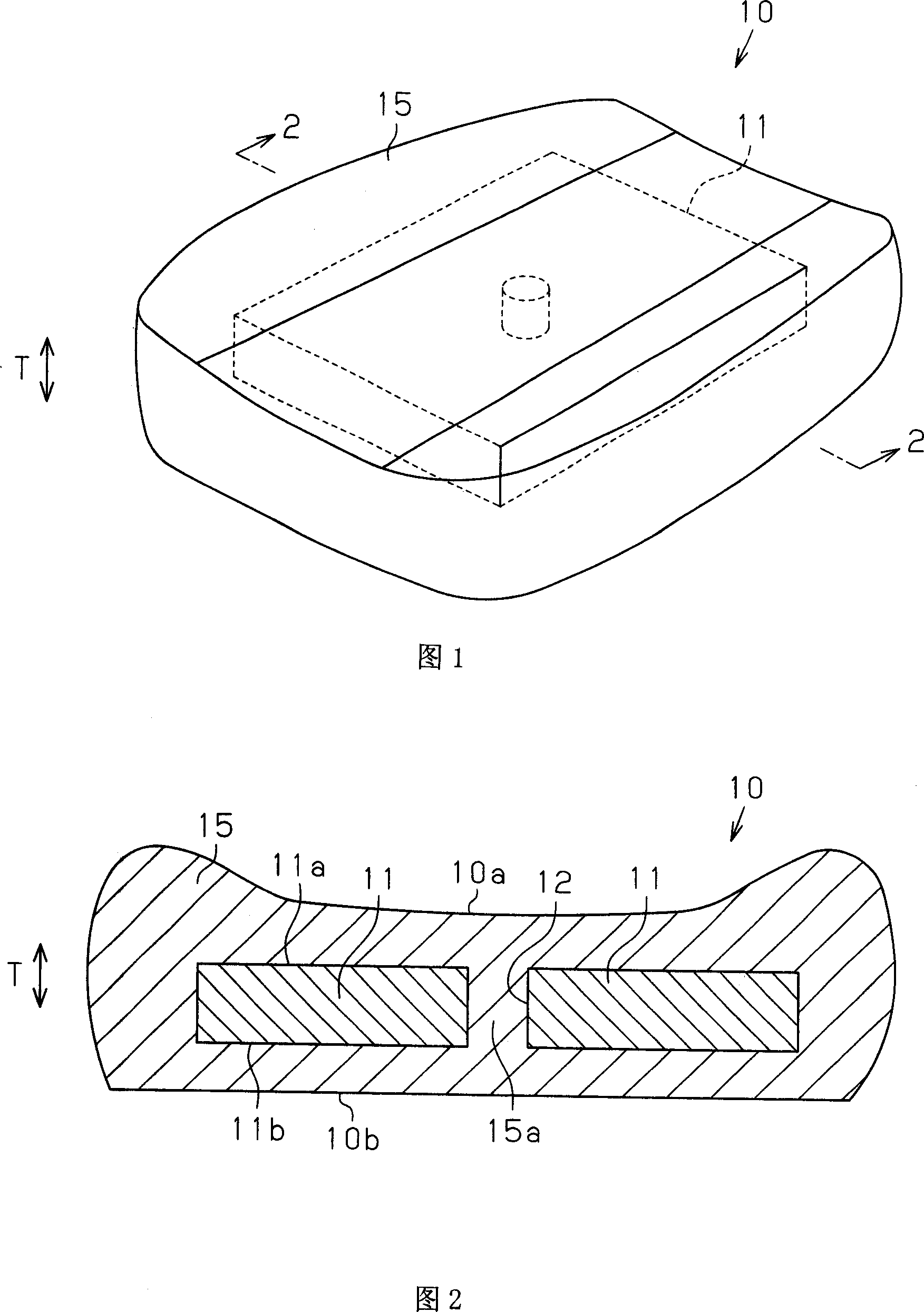

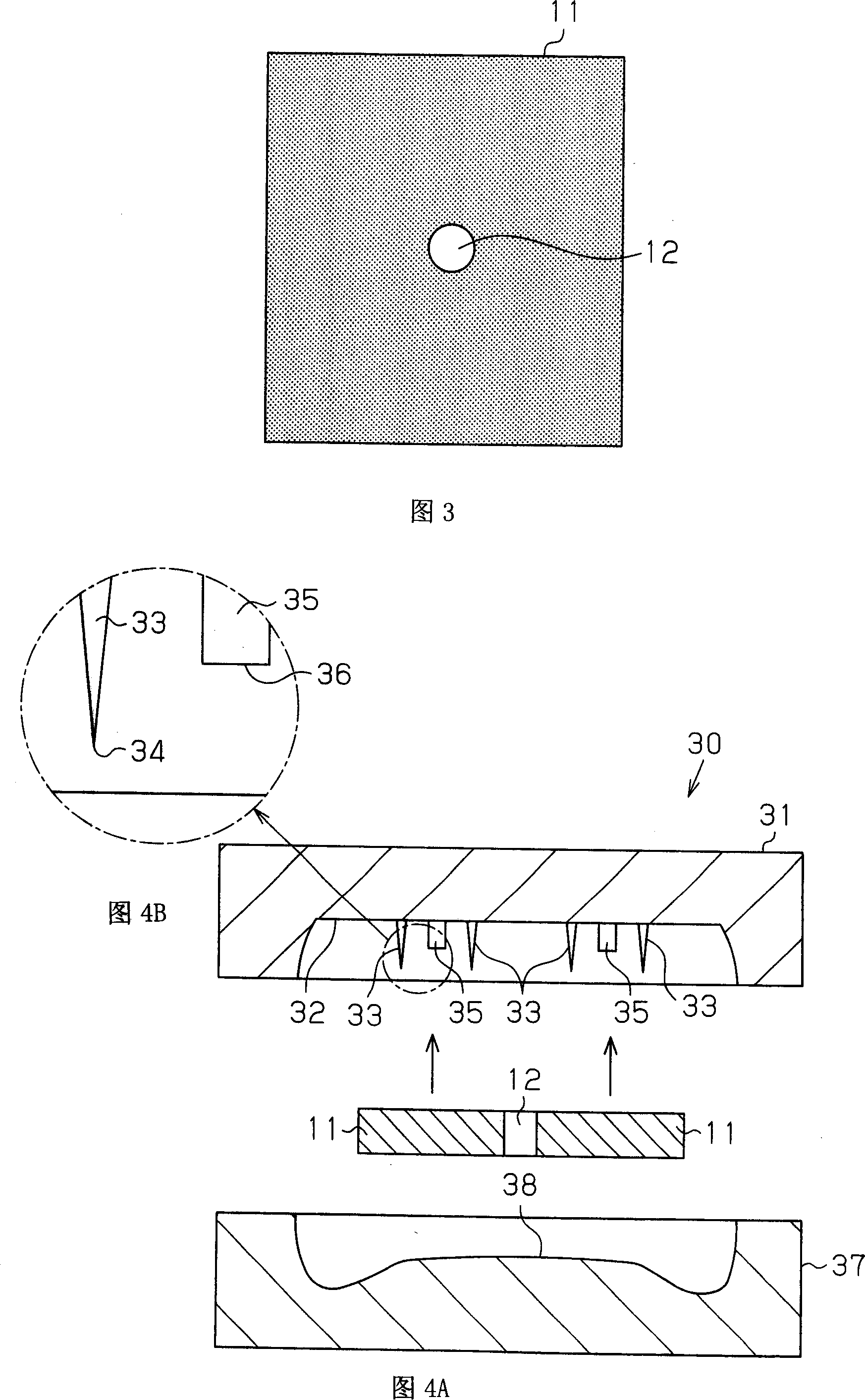

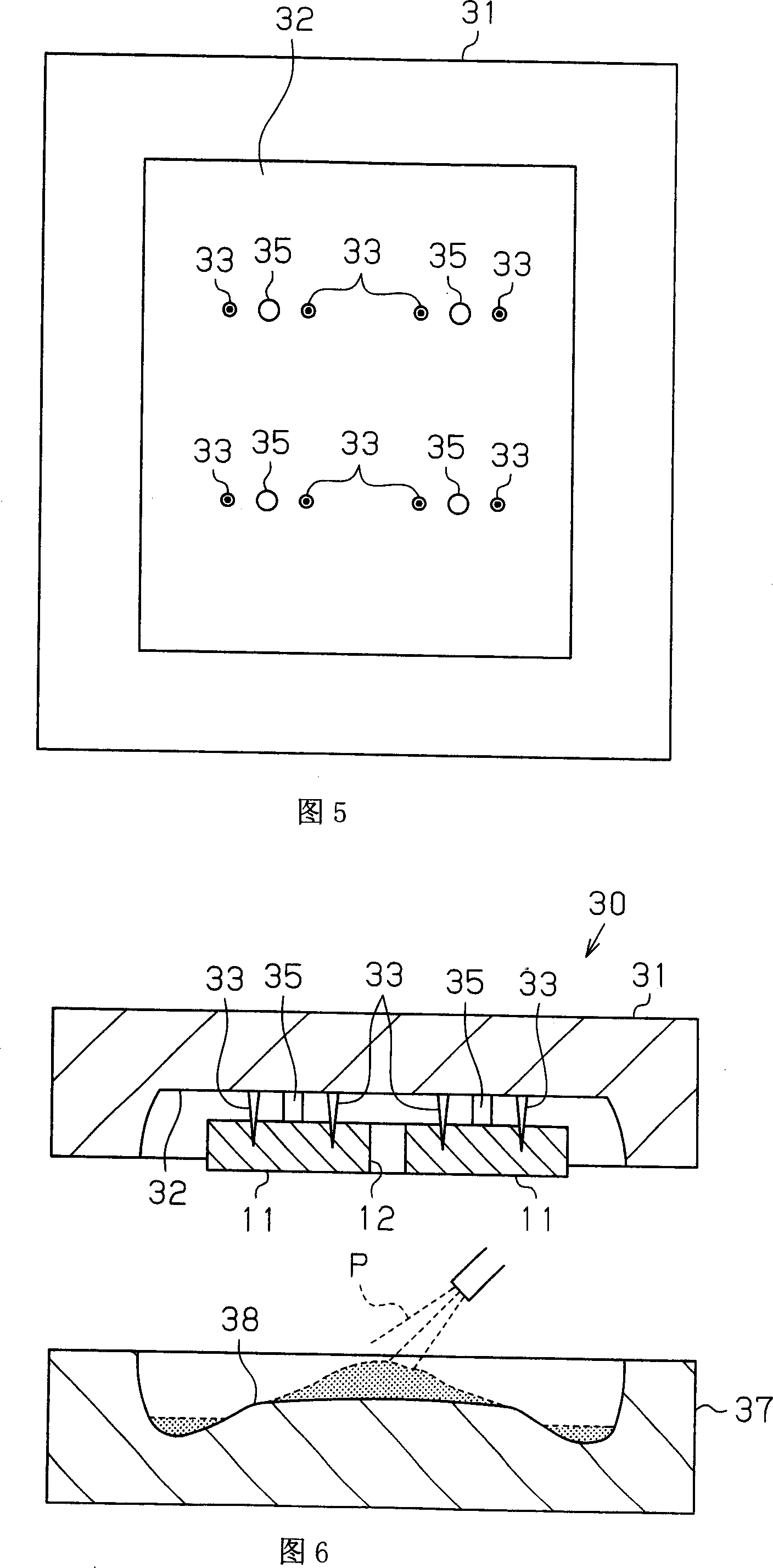

Cushion body and manufacturing method for a cushion body

InactiveCN101088435AImprove flame retardantImprove buffering effectUpholstery manufactureStuffed mattressesMelamine resinCushion

A cushion body is provided with a core material formed by a melamine resin foam body, and a surface layer material formed by a polyurethane resin foam body in which an expandable graphite is dispersed, and covering a periphery of the core material. A through hole extending along a thickness direction of the cushion body is formed at a predetermined position of the core material. The surface layer material fills the through hole, and the core material and the surface layer material are integrally formed. The cushion body increases a lightweight property of the cushion body by the core material formed by the melamine resin foam body, increases a fire retardant property of the cushion body by the expandable graphite, and increases cushioning and durability properties of the cushion body by the polyurethane resin foam body.

Owner:INOAC CORP

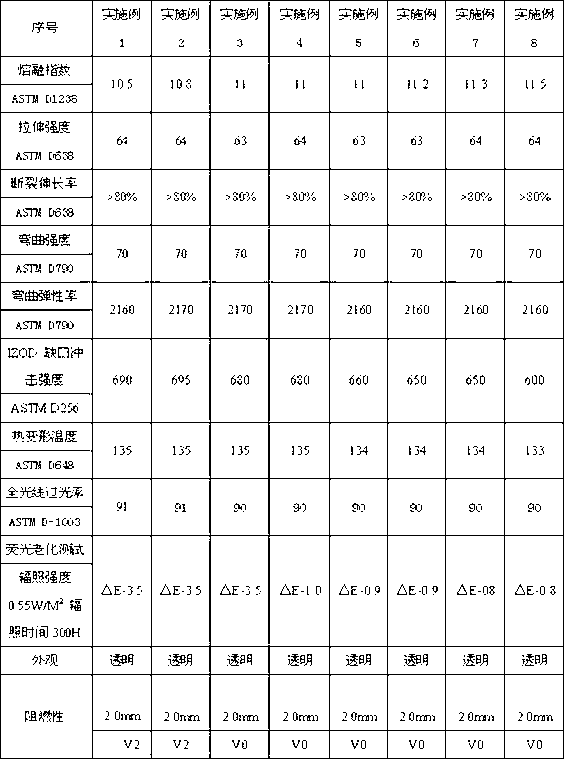

High light-transmittance and high flame-retardant polycarbonate material and preparation method of polycarbonate material

ActiveCN102702716AHigh light transmittanceImprove flame retardantGlobesOxidation resistantFire retardant

The invention relates to the technical field of polycarbonate material, particularly to high light-transmittance and high flame-retardant polycarbonate material. The polycarbonate material contains the following constituents and materials by weight: 94.8-99.5% of polycarbonate, 0.1-0.3% of fire retardant A, 0.1-3.5% of fire retardant B, 0.1-0.3% of antioxidant A, 0.1-0.3% of antioxidant B, 0.1-0.2% of a lubricating agent and 0-0.6% of light stabilizer, and the sum of the weight percentages of the constituents is 100%. The preparation method comprises the steps of putting the constituents except for the polycarbonate into a high-speed mixer to uniformly agitate, putting the polycarbonate and uniformly mixed material into the high-speed mixer to carry out three-segment agitation, and putting the material into a double-screw extruder to extrude and pelletize. The polycarbonate material disclosed by the invention has the advantages of high light transmittance and high fire resistance and the like, can meet the requirements of a lampshade for outdoor illumination, and is simple in process and beneficial for generalization and application.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

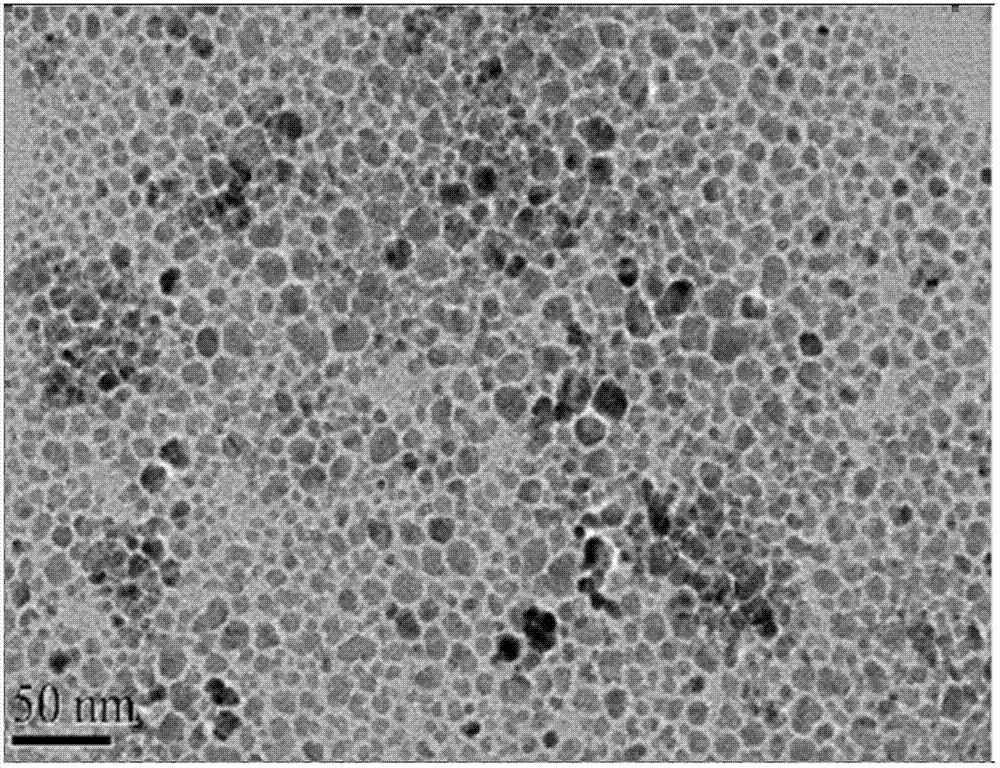

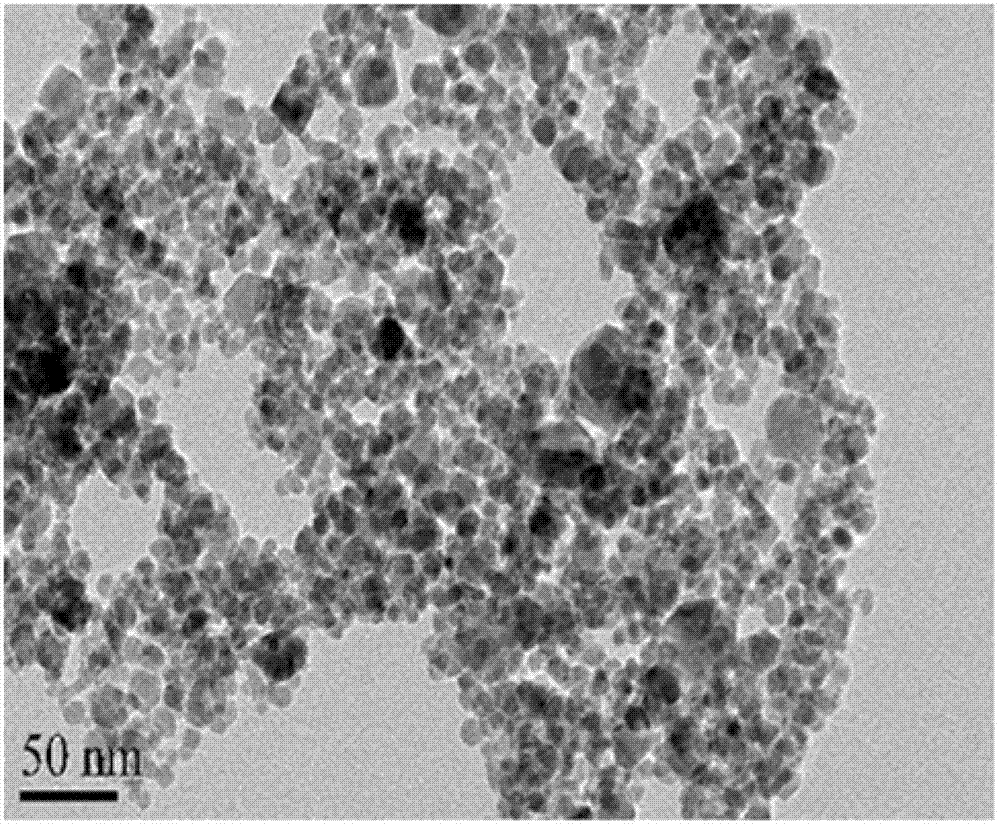

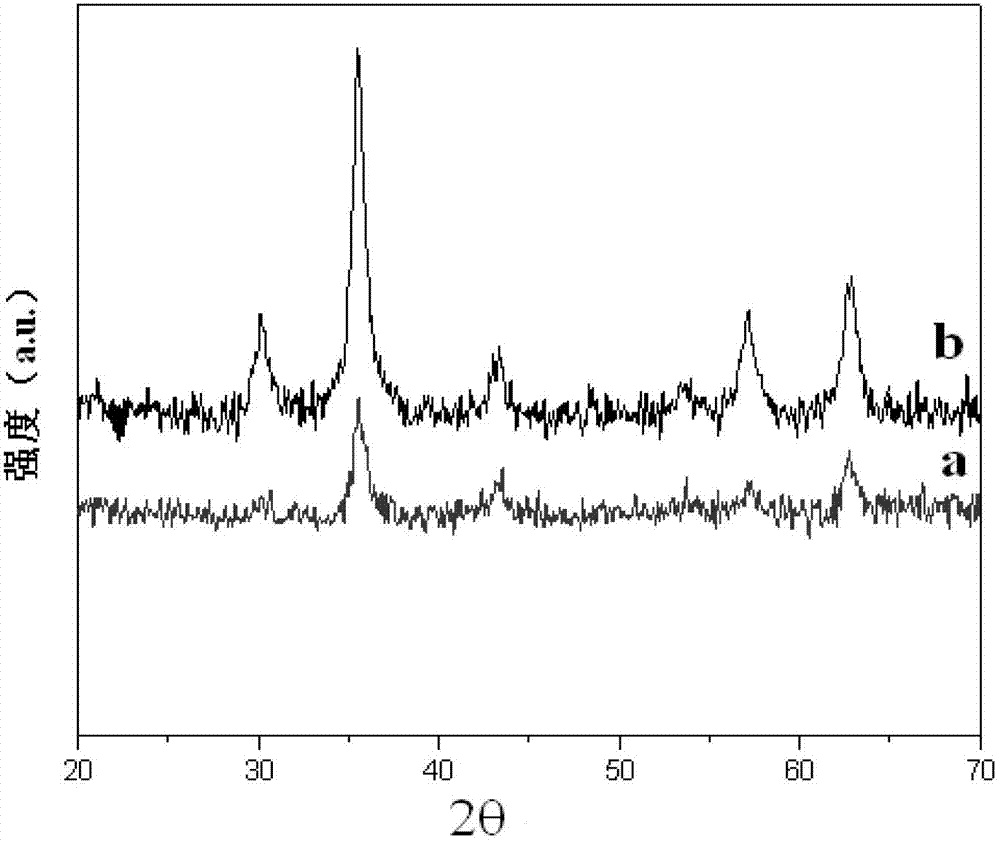

Preparation method of nano Fe3O4 powder for preparation of nano dielectric medium through compounding with polyethylene

InactiveCN103112904AGood compatibilityExcellent dielectric propertiesMaterial nanotechnologyFerroso-ferric oxidesDielectricFe3o4 magnetic nanoparticles

The invention provides a preparation method of nano Fe3O4 powder for preparation of a nano dielectric medium through compounding with polyethylene, relates to a preparation method of nano Fe3O4 powder, and aims to solve the problems that Fe3O4 magnetic nano particles are poor in compatibility and prone to aggregation before surface treatment is performed and can not be prepared into a nano dielectric medium through compounding with polyethylene at present. The method comprises the following steps: 1, weighing; 2, preparing a mixed solution; 3, preparing a nano Fe3O4 preform; and 4, preparing the nano Fe3O4 powder. The invention accurately controls the particle size of the prepared nano Fe3O4 powder and selects an appropriate surface modifier for the surface modification of the nano Fe3O4 powder, so that the surface of the nano Fe3O4 powder is coated with special functional groups having favorable compatibility with polyethylene; and meanwhile, the surface modifier can also achieve the effects of inhibiting the aggregation of the nano Fe3O4 powder and accurately controlling the particle size of the nano Fe3O4 powder. The invention is used for preparing the nano Fe3O4 powder for preparation of a nano dielectric medium through compounding with polyethylene.

Owner:HARBIN UNIV OF SCI & TECH

High-flame-retardancy high-flowability flaky molding compound and preparation method thereof

The invention relates to a high-flame-retardancy high-flowability flaky molding compound and a preparation method thereof, belonging to the field of chemical raw materials. The molding compound comprises the following substances in parts by mass: 15-30 parts of unsaturated polyester resin, 10-40 parts of glass fiber, 5-15 parts of low shrinkage agent, 30-60 parts of flame-retardant filler, 0.2-1 part of initiator, 0.02-0.1 part of para-benzoquinone, 0.2-1 part of thickener, 2-10 parts of styrene, 1-5 parts of internal molding lubricant and 0.1-0.5 part of viscosity breaking aid. The high-impact-resistance low shrinkage agent is adopted to make up for the loss of mechanical properties caused by the addition of the flame-retardant filler; the flame-retardant filler with different particle sizes performs the synergic filling functions to enhance the flame-retardant effect; and the viscosity breaking aid is utilized to lower the viscosity of the resin, thereby forming the high-flame-retardancy high-flowability flaky molding compound. The invention also provides a preparation method of the high-flame-retardancy high-flowability flaky molding compound.

Owner:陈小华

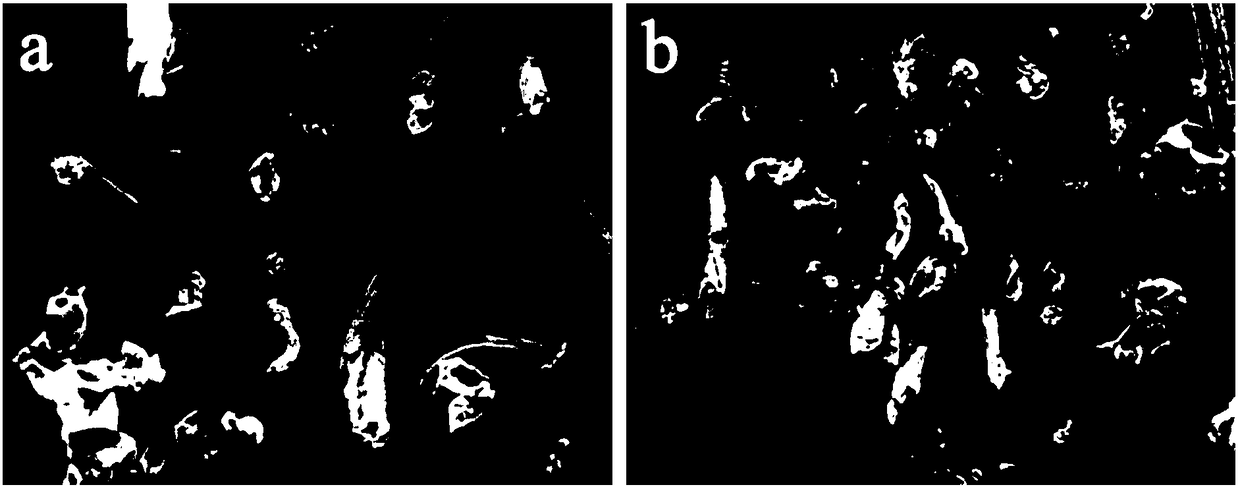

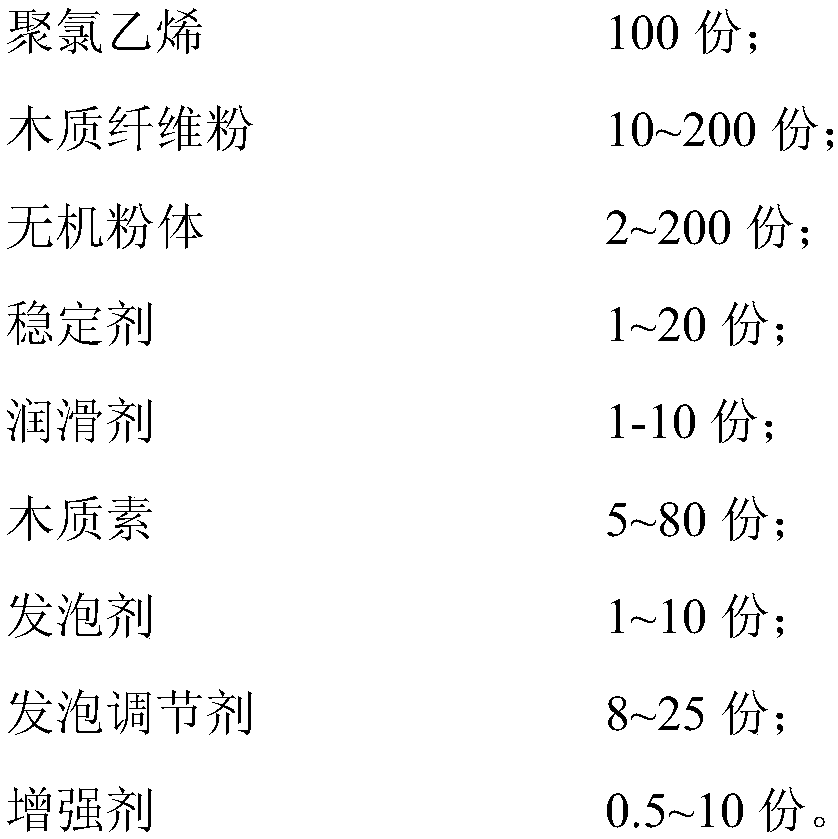

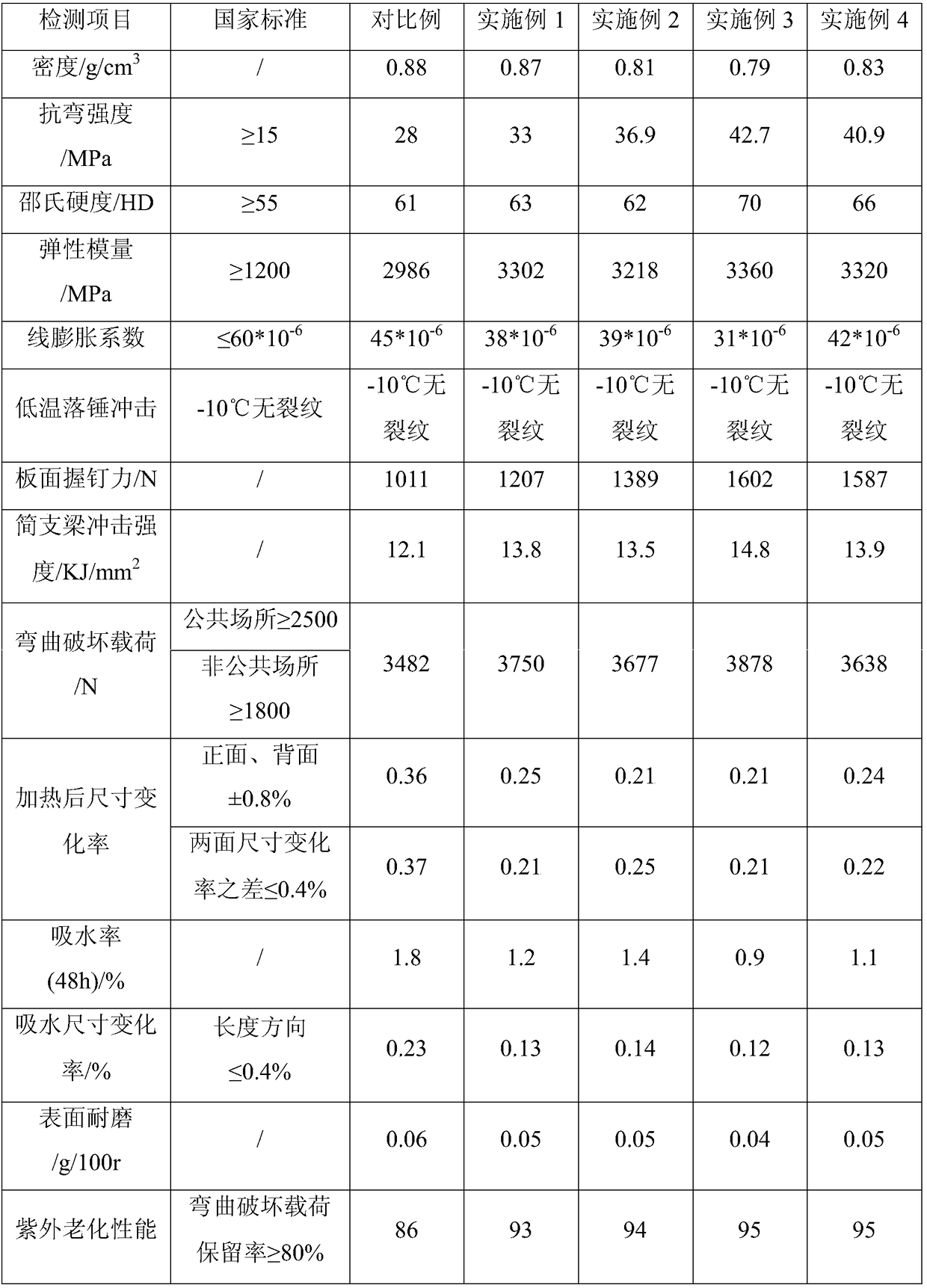

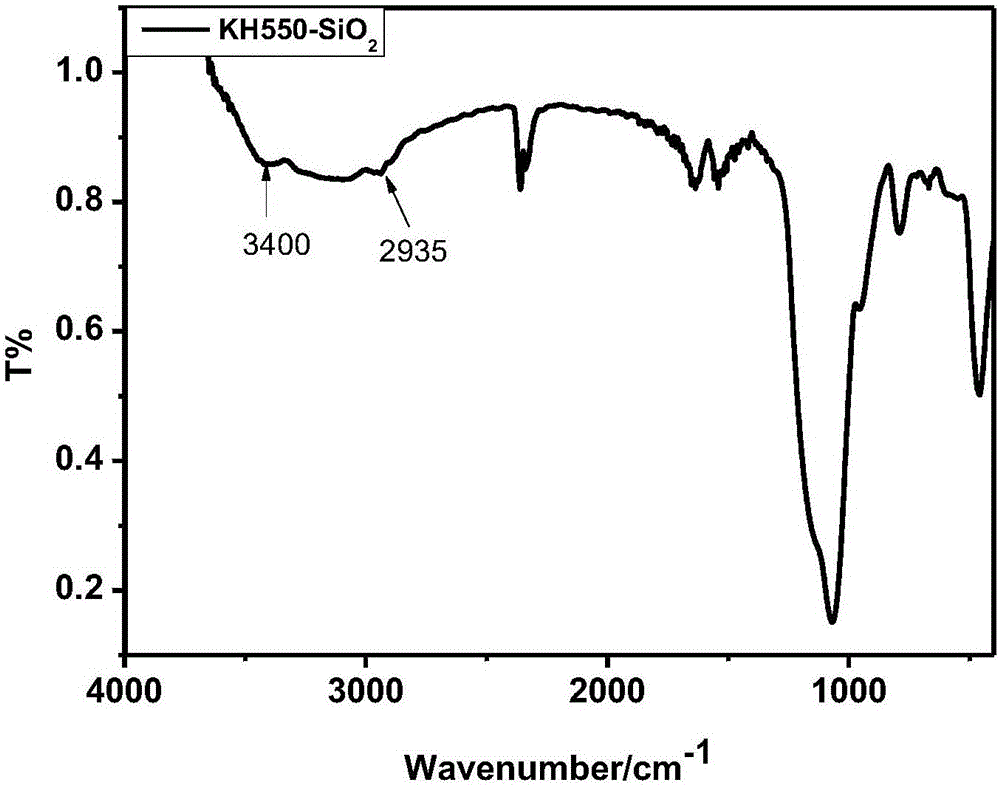

Lignin enhanced polyvinyl chloride wood plastic foam composite material, and preparation method thereof

The invention discloses a lignin enhanced polyvinyl chloride wood plastic foam composite material, and a preparation method thereof. The lignin enhanced polyvinyl chloride wood plastic foam compositematerial is composed of, by weight, 100 parts of polyvinyl chloride, 10 to 200 parts of wood fiber powder, 2 to 200 parts of an inorganic powder, 1 to 20 parts of a stabilizing agent, 1 to 10 parts ofa lubricant, 5 to 80 parts of lignin, 1 to 8 parts of a compatilizer, 1 to 10 parts of a foaming agent, 8 to 25 parts of a foaming conditioning agent, and 0.5 to 10 parts of a reinforcing agent. Compared with the prior art, the preparation method comprises following advantages: lignin enhancing technology is combined with micropore foaming technology, so that material lightweighting is ensured, and the plasticizing performance, the flame resistance, the ultraviolet resistance, the aging resistance, the biological resistance, the radiation resistance, and rheological performance, the screw extrusion performance, and the heat resistance of the lignin enhanced polyvinyl chloride wood plastic foam composite material are improved obviously, product surface gloss is improved, product water absorption performance is reduced, and the high performance lignin enhanced polyvinyl chloride wood plastic foam composite material with lightweighting characteristics is obtained.

Owner:NANJING UNIV OF TECH

Method for preparing light resistant and antiflaming aqueous acrylate resin coating

The invention relates to a method for preparing a light resistant and antiflaming aqueous acrylate resin coating. The method is characterized by comprising the steps of heating up water, an emulgator, tea polyphenol lipidosome and methacrylic acid to be 55DEG C, stirring for 90 minutes, adding polyaniline, nano zirconia, monomer A, an antiflaming material and estradiol benzoate, emulsifying for 40-60 minutes, heating up to 80DEG C, keeping warm for 1 hour, dropwise adding an initiator, then reacting for 2 hours so as to obtain nuclear layer emulsion; and dropwise adding monomer B and an initiator into the nuclear layer emulsion simultaneously, keeping warm and reacting for 2 hours, adding a fermenting material C, keeping warm at 75-85DEG C and reacting for 1-3 hours, adding metal salt, regulating pH to be 4.0, keeping warm at 75-85DEG C and reacting for 1-2 hours, cooling to be 50DEG C, adding a crosslinking agent, reacting for 30 minutes, adding ammonia water to regulate pH value to be 5, adding bronopol, regulating the temperature to be 75-85DEG C, reacting for 30 minutes, so as to obtain the light resistant and antiflaming aqueous acrylate resin coating. The obtained acrylate resin coating has good light resistance and fire resistance, and has environment-friendly production technology.

Owner:HUNAN HENGHAN HIGH TECH CO LTD

White carbon black with dyeing groups on surface and preparation method of white carbon black

InactiveCN106566290AAffinity plusImprove performanceAnthracene dyesPigment treatment with macromolecular organic compoundsPolymer sciencePolyolefin

The invention relates to white carbon black with dyeing groups on the surface and a preparation method of the white carbon black. In a formula I, R represents reactive groups of a silane coupling agent, and Dye represents the dyeing groups. The dye modified white carbon black prepared with the method has wide raw material sources and is lower in cost, part of monomers is the industrialized raw material, and a reaction method is mature. Compared with non-modified white carbon black, the dye modified white carbon black prepared with the method has high hydrophobic and lipophilic properties, and can improve combining property with reinforced rubber and improve reinforcement effect; meanwhile, the white carbon black has different colors and can endow the reinforced rubber with different colors, and besides, transference resistance of the dye is better; an obtained copolymer has broad application prospect in the aspect of improvement of flame retardancy and bonding flame retardancy of polyolefin.

Owner:QINGDAO UNIV OF SCI & TECH +1

Refractory wall plate material and production method thereof

The invention provides a refractory wall plate material and a production method thereof. The refractory wall plate material comprises component A, component B and component C, wherein the component A is a mixed solution of magnesium chloride, bamboo root water, ferrous sulfate and thickening agent, the component B is magnesium oxide, and the component C is a mixed material of plant straws, pulverized coal ash, cinder and foam particles; the component A, the component B and the component C are mixed in a ratio of 1:(1-1.5):(1-2.0), and bamboo stickers are added to produce the material; and thebamboo stickers are soaked with insect-proofing mould-proofing liquid, the radial size of each bamboo sticker is between 6 and 10mm, the length of each bamboo sticker is the same as that of the plate, and the bamboo stickers are arranged in the plate at an interval of between 8 and 12cm. The refractory wall plate material and the wall plate have good fire-proofing, water-proofing and anti-corrosion performance, no anti-brine phenomenon, safety and environmental friendliness, no toxic or odor, can be mixed with conventional decoration materials, has high integration degree, good compatibility and lower cost.

Owner:吴涛

Green multifunctional composite aid for wood plastic composite material and preparation method thereof

ActiveCN102391660AImprove securityImprove flame retardantPigment treatment with non-polymer organic compoundsPyridiniumPhosphonium salt

The invention discloses a green multifunctional composite aid for a wood plastic composite material and a preparation method thereof. The preparation method comprises the following steps of preparing high-stability organic cationic (quaternary phosphonium salt, pyridinium, imide salt and high-stability quaternary ammonium salt) modified clay; mixing a halogen-free flame retardant (zinc borate, ammonium polyphosphate and pentaerythritol), a mouldproof anticorrosive antibacterial agent (organic mouldproof antibacterial agents such as thiazolyl benzimidazole, isothiazolinone and the like) and natural mouse and ant dispelling agent microcapsules uniformly at a high speed under the heating condition; and adsorbing the mixture to the organic cationic modified clay to obtain the green multifunctional composite aid for the wood plastic composite material. The multifunctional composite aid for the wood plastic composite material has the characteristics of high safety, high durability, simple preparation process, low cost and the like. After the multifunctional composite aid is added into the wood plastic composite material, the flame retardance, the antimicrobial property and the mouse and anti preventing performance are improved, and mechanical properties of the wood plastic composite material are not influenced.

Owner:广东迪美生物技术有限公司

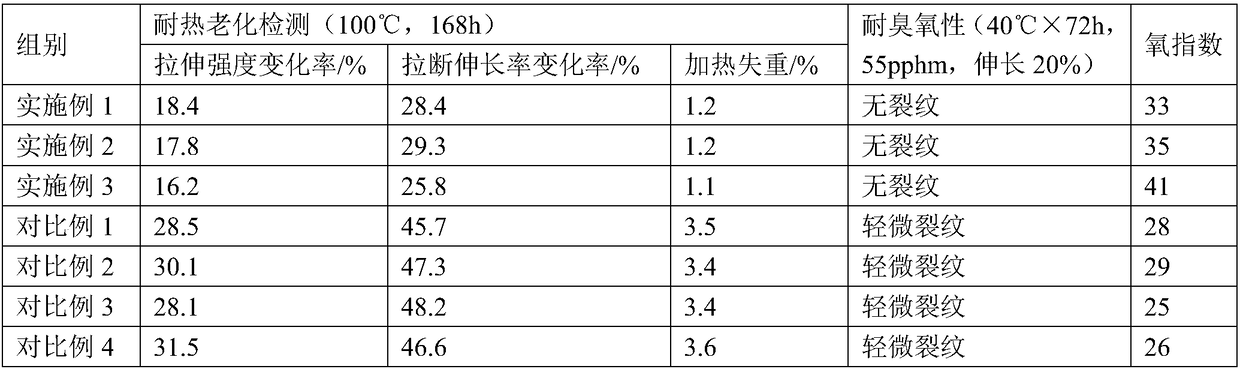

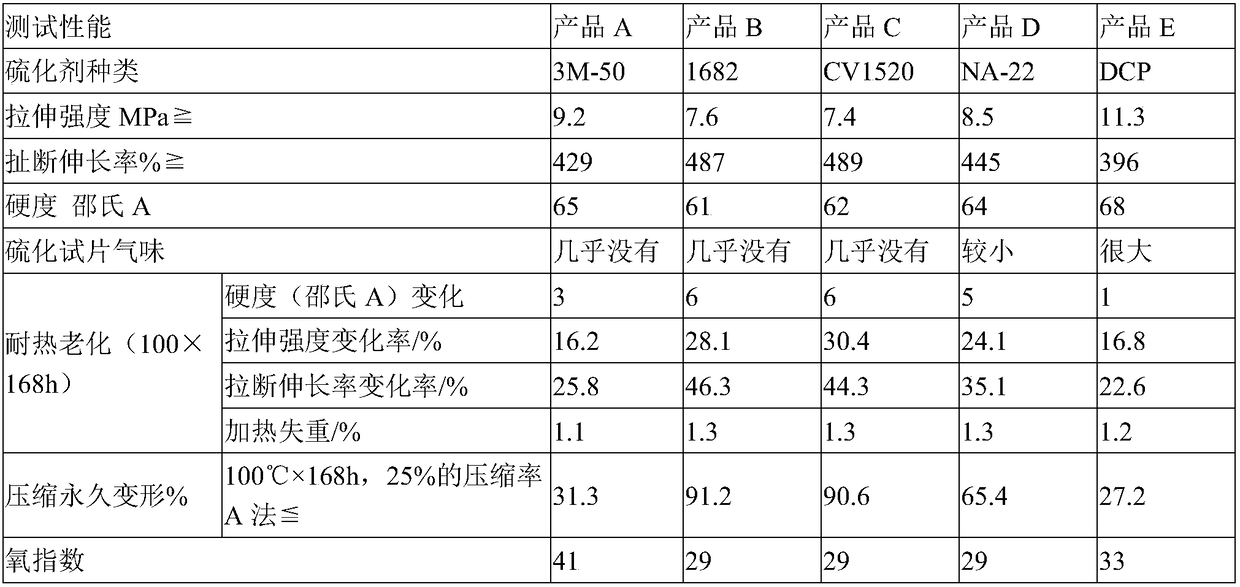

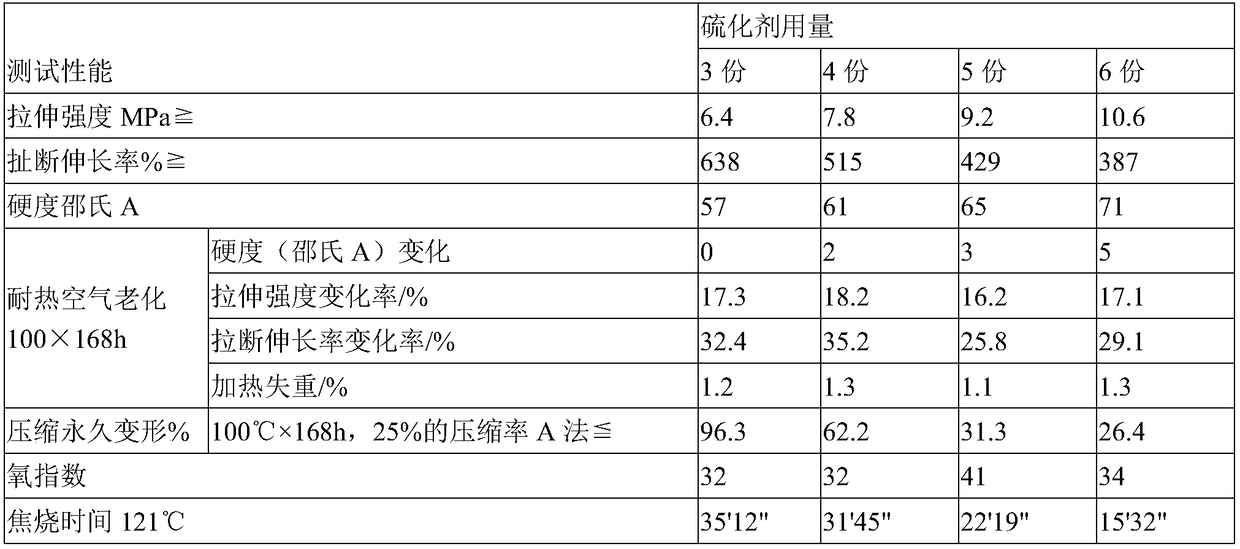

Novel chlorinated polyethylene rubber compound material and method for preparing same

The invention relates to a novel chlorinated polyethylene rubber compound material, in particular to a novel chlorinated polyethylene rubber compound material for preparing sealing strips and a methodfor preparing the novel chlorinated polyethylene rubber compound material. The novel chlorinated polyethylene rubber compound material comprises, by weight, 100 parts of rubber-based chlorinated polyethylene, 7-10 parts of magnesium hydroxide, 35-40 parts of semi-reinforced 774 carbon black, 60-70 parts of 990 carbon black, 0.5-1 part of stearic acid, 2-3 parts of calcium stearate, 15-20 parts ofkaolin E2, 25-32 parts of dioctyl terephthalate, 4-6 parts of antimony trioxide, 0.5-1 part of protection wax and 4.5-5.5 parts of vulcanizing agents ECHOS 808 3M-50. The novel chlorinated polyethylene rubber compound material and the method have the advantage that the novel chlorinated polyethylene rubber compound material is excellent in ageing resistance, ozone resistance, flame retardance andmechanical property and low in cost and can be used for preparing the flame-retardant building sealing strips. The invention further provides a method for preparing the sealing strips.

Owner:HANGZHOU KELI CHEM CO LTD

Antimony-based compounding flame retardant masterbatch for PVC and preparation method thereof

The present invention discloses an antimony-based compounding flame retardant masterbatch for PVC and a preparation method thereof, and belongs to the technical field of flame retardant materials. The masterbatch includes the following raw materials by weight: 25-40 parts of antimony trioxide, 13-25 parts of molybdenum trioxide, 8-13 parts of montmorillonite, 3-8 parts of organic tin, 3-6 parts of a coupling agent, and 20 to 35 parts of a carrier PVC resin. The flame retardant masterbatch is prepared from the steps of antimony trioxide surface modification, raw material mixing and granulation. The present invention employs antimony trioxide, molybdenum trioxide and montmorillonite and other environmentally friendly halogen-free flame retardants as a compounding flame retardant system, integrates the advantages of the system in synergistic flame retardant, and smoke suppression performance, improves the flame retardancy and smoke suppression of the compounding complex retardant masterbatch. Addition of the flame retardant masterbatch can greatly improve the limiting oxygen index of the PVC composite material and reduce the amount of smoke, and the flame retardant masterbatch has the characteristics of high flame retardancy, strong smoke suppression, no additive migration, easiness to use, and easy dispersion.

Owner:广西华锑科技有限公司

Flame retardation and antibiosis fabric

InactiveCN106009857AExcellent flame retardantGood acid and alkali resistanceFireproof paintsAntifouling/underwater paintsDiethylene glycol diethyl etherPolymer science

The invention relates to a flame retardation and antibiosis fabric. A gunny cloth fabric is bonded with a protection coating layer, and the coating layer comprises a-olefin elastomer, polymethyl methacrylate, isoprene rubber, tall oil fatty acid, butyl acetate, allyl sulfide, diethylene glycol diethyl ether, diethylene glycol butyl ether, propiconazole, sodium monofluorophosphate, dodecyl ethoxy sulfobetaine, dimethyl fumarate, cuprous chloride, metatitanic acid, silicon carbide fibers, phenyltriethoxysilane, chromium oxide green, chromium chloride, barium chromate powder, sodium cellulosate, trimethyl phosphate, polyacrylonitrile fibers, dibasic lead stearate, tris(butoxyethyl)phosphate, starch ether, vinyltris(beta-methoxyethoxy)silane, ethylamine, diethylenetriamine, alkylphenol polyoxyethylene and divinyl benzene. The flame retardation and antibiosis fabric has superior flame, acid-alkali, mildew and bacterium resistance, and improved performances.

Owner:李红玉

Composite modified aqueous acrylic resin emulsion coating-containing pearlescent flame retardation wallpaper

InactiveCN105295626AStable performanceImprove breathabilityCovering/liningsFlame-proof filament manufactureEmulsionFire retardant

The invention discloses a composite modified aqueous acrylic resin emulsion coating-containing pearlescent flame retardation wallpaper. A resin adhesive adopted in a coating slurry used by the wallpaper is a cellulose acetate copolymer modified aqueous acrylic resin emulsion, the emulsion has stable performances and contains no formaldehyde or other chronic volatile toxic compounds, a coating formed by the emulsion is smooth and elastic and has water resistance, antifouling and antibiosis functions, pearl powder-polylactic acid porous fibers added to the slurry have a uniform porous structure, and a flame retardation agent is uniformly dispersed in the resin emulsion, has coating permeability and flame retardation improvement efficacy, endows the coating with multi-angle pearlescent color, and increases the ornamental effect.

Owner:ANHUI SOYA DECORATIVE MATERIALS

Soft porcelain and preparation method thereof

The invention relates to soft porcelain comprising, by weight, 10-30% of polymethacrylic resin, 0.5-10% of organic silicon, 10-60% of a flame retardant, 10-40% of ore sand, 10-60% of quartz sand, 0-10% of an additive, and 5-20% of water. The soft porcelain has excellent flame-retarding, waterproof, anti-aging performances and mechanical property.

Owner:上海嘉宝莉建筑节能科技有限公司

Environment-friendly flame-retardant acid- and alkali-resistant treating coating for building materials

InactiveCN106349865AExcellent flame retardantExcellent flame retardant acid and alkali resistanceFireproof paintsAnti-corrosive paintsPhosphateAntibacterial property

The invention relates to environment-friendly flame-retardant acid- and alkali-resistant treating coating for building materials, made from methylated amino resin, heat-vulcanized silicone rubber, brominated bisphenol A epoxy resin, wintergreen oil, walnut oil, tangerine oil, rose essential oil, lemon oil, stearamidopropyl pyrrolidonylmethyl dimethyl ammonium chloride, nano sliver, penicillin, chitosan, lead difluoride powder, titanium dioxide powder, flyash, aluminum fluoride powder, corundum powder, zirconite powder, wollastonite powder, zirconium silicate powder, nano zinc oxide, tris(butoxyethyl)phosphate, hexabromo-benzene, sodium stannate, triallyl cyanurate, triethyl citrate, glutathione, Upsilon-mercaptopropyltriethoxysilane, hydroxyethyl methacrylate phosphate, and p-chlorophenol. The environment-friendly flame-retardant acid- and alkali-resistant treating coating for building materials has excellent flame retardance, acid and alkali resistance, and mildew-proof and antibacterial properties, and the properties of the coating are improved.

Owner:袁华

Method for preparing high-temperature-resistant, weather-resistant and flame-retardant cable sheaths

InactiveCN107674347AImprove flame retardancyImprove flame retardantPlastic/resin/waxes insulatorsWeather resistanceCarbon black

The invention discloses a method for preparing high-temperature-resistant, weather-resistant and flame-retardant cable sheaths. The method includes steps of 1, weighing raw materials according to theweights; 2, smashing basalt fibers, glass fibers and carbon fibers and sieving the basalt fibers, the glass fibers and the carbon fibers by 80-mesh filter sieves to obtain mixed fibers; 3, adding polyvinyl chloride, brominated polystyrene, pottery clay, titanium dioxide, carbon black and the mixed fibers obtained at the step 2 into a milling machine and milling the polyvinyl chloride, the brominated polystyrene, the pottery clay, the titanium dioxide, the carbon black and the mixed fibers for 18 min to obtain mixtures; 4, adding the mixtures obtained at the step 3, antioxidants, ultraviolet absorbents, softening agents, heat stabilizers, vulcanizing agents and coupling agents into a twin-screw extruder, extruding and granulating the mixtures, the antioxidants, the ultraviolet absorbents, the softening agents, the heat stabilizers, the vulcanizing agents and the coupling agents and then carrying out drying to obtain the high-temperature-resistant, weather-resistant and flame-retardant cable sheaths. The method has the advantage that the high-temperature-resistant, weather-resistant and flame-retardant cable sheaths prepared by the aid of the method are good in strength, high-temperature resistance, weather resistance, heat resistance and ageing resistance.

Owner:湖州荣吴索道运输服务有限公司

Lubricating oil flame-retardant antibacterial additive

InactiveCN106590844AExcellent flame retardantGood acid and alkali resistanceAdditivesPhosphatePolychlorinated biphenyl

The invention relates to a lubricating oil flame-retardant antibacterial additive which is composed of poly-4-methyl-1-pentene, pentaerythritol phosphate, urea formaldehyde resin, methyl acetate, ethylene oxide, dimethyl hydroxyl silicon oil, tetraethyl silicate, modified hydrogenated castor oil, polyhexamethylene biguanidine hydrochloride, didecyl dimethyl ammonium chloride, carbolic acid, calcium borate, aluminum carbonate powder, lead carbonate powder, potassium ferricyanate, bismuth tungstate powder, zinc oxide powder, rock wool, aluminum oxide powder, praseodymium oxide powder, polychlorinated biphenyl, decabrominated diphenyl ethane, sodium antimonite powder, polyacrylonitrile fiber, polyaryl ether nitrile, amino silicon oil, polyamide imide, methyl acetate, N-hydroxymethyl acrylamide and zinc palmitate soap. The lubricating oil flame-retardant antibacterial additive has excellent flame retardance, resistance to acid and alkali and anti-mildew antibacterial performance, and product performance is improved.

Owner:FOSHAN TIANSHUN TECH CO LTD

Fire hose material with flame-retardant and acid-base-resistant functions

InactiveCN106084365AExcellent flame retardantExcellent flame retardant acid and alkali resistancePolychlorinated biphenylPolyhexamethylene guanidine

The invention relates to a fire hose material with flame-retardant and acid-base-resistant functions. The fire hose material is prepared from components as follows: neoprene, hydrogenated rosin, melamino-formaldehyde resin, cellulose acetate butyrate, polychlorinated biphenyl, ammonium polyphosphate, pyromellitic dianhydride, piperine, sulfonic acid, chitin, polyhexamethylene guanidine, polyhexamethylene biguanidine hydrochloride, alunite powder, wood pulp, calcium lignosulphonate, nano aluminum nitride powder, nano aluminum powder, nano-zirconia powder, nano nickel oxide, a polyacrylate emulsifier solution, polypropylene glycol, polyglycerine, polylactic acid, polyepoxysuccinic acid, polyetheretherketone fibers, a polycarboxylate water reducing agent, polyoxypropylene oxyethylene glycol ether, polyethylene glycol, polyvinyl formal acetal and capsaicin. The fire hose material has relatively excellent flame retardance, acid-base resistance, mildewing prevention and antibacterial properties, and the product performance is improved.

Owner:余志娟

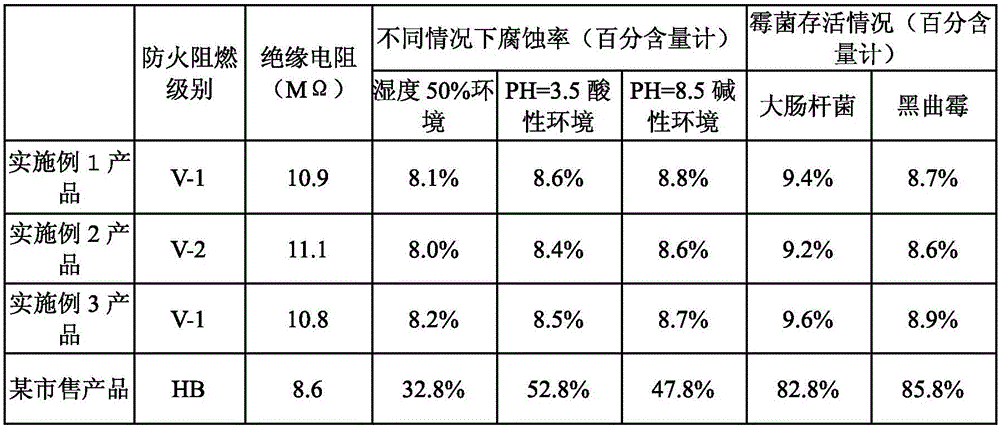

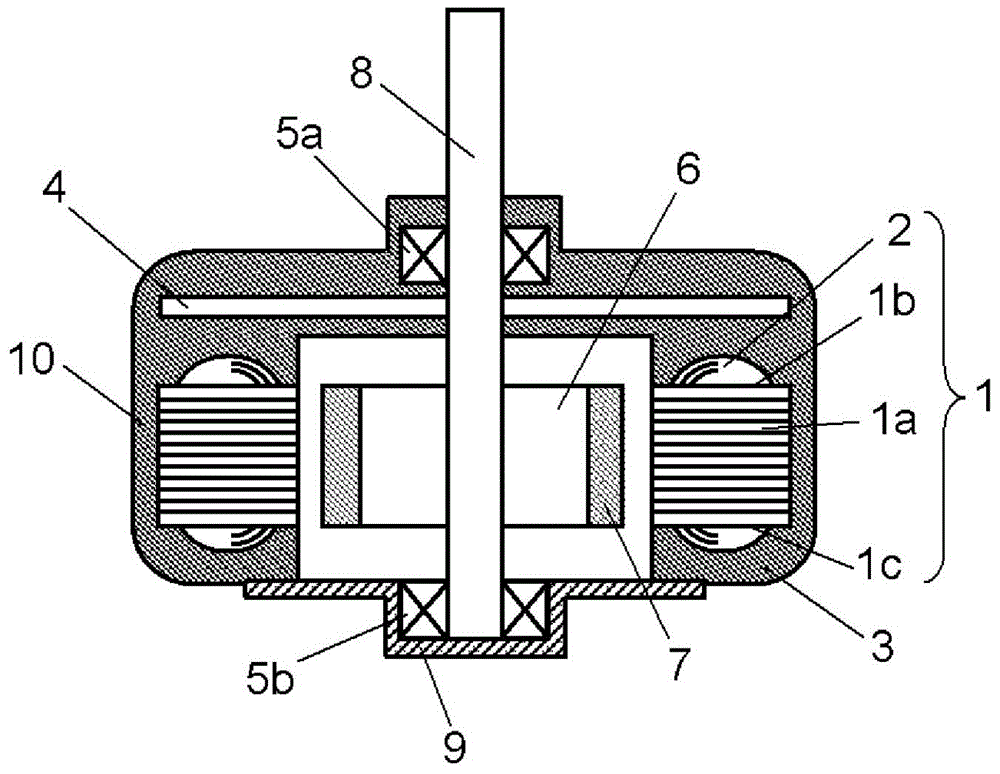

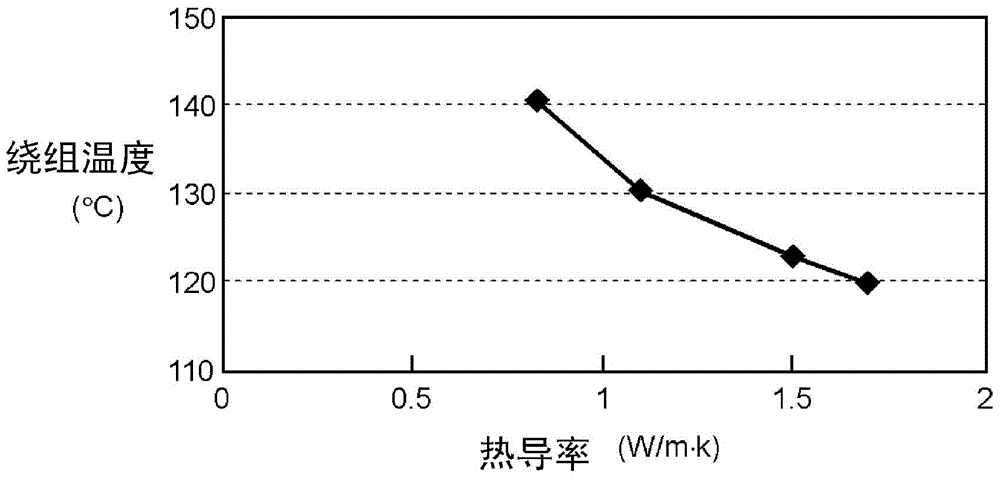

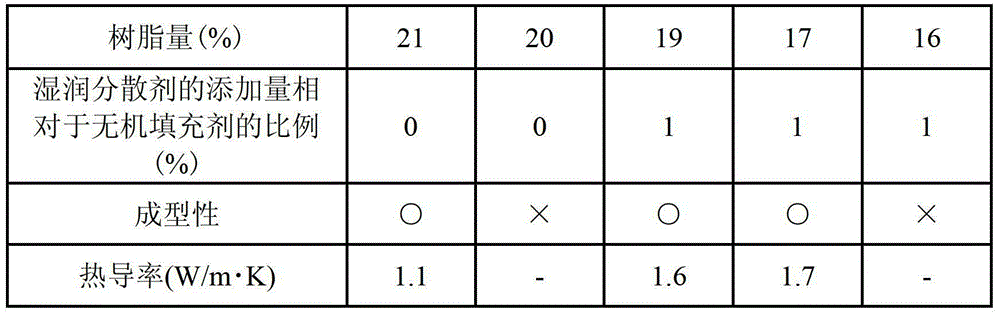

Mold structure and motor

InactiveCN103339205AGood dispersionImprove liquidityWindings insulation materialDomestic articlesMetalInorganic filler

This mold structure is composed of a mold resin comprising at least: a thermosetting resin; an inorganic filler having electrical insulating properties and containing at least a metal hydrate; and a dispersant. Thus, dispersibility of the inorganic filler in the mold resin is improved, enabling high filling and high fluidizing of the inorganic filler. As a result, a mold structure having high heat dissipation can be achieved by a mold resin which has high thermal conductivity and excellent moldability.

Owner:PANASONIC CORP

Packaging thin film material for electronic commerce logistics transportation

InactiveCN105907075AExcellent flame retardantGood acid and alkali resistanceBenzoic acidDecabromobiphenyl ether

The invention relates to a packaging thin film material for electronic commerce logistics transportation. The packaging thin film material is prepared from the following components: epichlorohydrin rubber, chloroprene rubber adhesive, neoprene, deca-brominated diphenyl ether, titanium tetrabutoxide, sodium stannate, barium stearate, parachlormetaxylenol, garlic extract, beta-bromo-beta-nitrotrimethyleneglycol, 2-mercaptobenzothiazole, garlic oil, sodium dihydrogen phosphate, lead oxide powder, lead iodate powder, vermiculite powder, camellia pollen, modified attapulgite powder, pearl powder, amyl acetate, sesame oil, methyl isobutyl carbinol, trimethyl borate, N-nitro sodimethylamine, arabinogalactan, amino propyl trimethoxy silane, a barium-zinc stabilizer, benzotriazole, benzoic acid and ricinoleic acid polyoxyethylene allyl ester. The packaging thin film material has relatively excellent flame resistance, acid and alkali resistance and mildew and mold resistance; and the product performance is improved.

Owner:王根夫

Flame-retardant corrosion-resistant paint for power equipment

InactiveCN106189644AExcellent flame retardantGood acid and alkali resistanceFireproof paintsAntifouling/underwater paintsSandalwood oilPolyester

The invention relates to a flame-retardant corrosion-resistant paint for power equipment. The paint is composed of an SEBS (styrene-ethylene-butadiene-styrene) thermoplastic elastomer, a polyester urethane resin, halogenated butyl rubber, dipropylene glycol monomethyl ether, peanut oil, polyglycerol, coal tar, sandalwood oil, cylindrin, silver sulfadiazine, oxydol, aluminum phosphide, tourmaline powder, lead difluoride powder, silicon dioxide powder, titanium dioxide powder, fly ash, calcium fluoride powder, modified attapulgite powder, alundum powder, triglycol diisooctoate, polyacrylonitrile fibers, aluminum stearate, nano zinc oxide, oxalic acid, m-phthalic acid, ethylamine, diethylenetriamine, lanolin and sterin. The product has the advantages of excellent flame retardancy, excellent acid / alkali resistance and excellent mildewing resistance, and thus, the product performance is improved.

Owner:孟根森

Flame-retardant and anti-corrosive coating for power equipment

InactiveCN105949935AExcellent flame retardantGood acid and alkali resistanceFireproof paintsAntifouling/underwater paintsPolychlorinated biphenylSodium phosphates

The invention relates to a flame-retardant and anti-corrosive coating for power equipment. The flame-retardant and anti-corrosive coating consists of the following components of melamine copolymer resin, styrene-maleic anhydride copolymer, nitrile rubber powder, polychlorinated biphenyl, ammonium polyphosphate, triphenyl phosphate, zinc hydroxystannate, diazolidinyl urea, propiconazole, calcium hypochlorite, sulfadiazine silver, limonene, sodium phosphate, crystalline graphite powder, diaminodiphenylmethane, calcium sulphate dehydrate, zinc fluoride, zirconite powder, aluminum phosphate powder, zinc sulfate, bowlder powder, glass fiber powder, transformer oil, propylene glycol methyl ether acetate, amyl propionate, aminopropyltriethoxysilane, amino silicone oil, amino acid, aminoethylpiperazine, and alkylolamide. The flame-retardant and anti-corrosive coating has the advantages that the flame-retardant, acid and alkali-resistant, mildew-proof and anti-bacterial properties are excellent; the product property is improved.

Owner:王根夫

Fabric with good flame resistance and weather resistance

InactiveCN106280772AExcellent flame retardantGood acid and alkali resistanceFireproof paintsRubber derivative coatingsFatty acidFerric Pyrophosphate

The invention relates to a fabric with good flame resistance and weather resistance. A protective coating is adhered to a burlap fabric, and the coating consists of the following components of fluoroether rubber, chlorosulphonated polyethylene resin, hydrogenated nitrile rubber, diethylene glycol monoethyl ether, a pure acrylic emulsion, tall oil fatty acids, terpineol, amyl propionate, arbutin, a garlic extract, propiconazole, sodium monofluorophosphate, sodium ferric pyrophosphate, sodium alginate, SiC micro powder, sodium tetraborate decahydrate, zinc stearate, guanidine phosphate powder, phenyltriethoxysilane, zinc chromate, hexahydrophthalic anhydride, tetrabutyl titanate, zinc borate, nano zinc oxide, aluminum distearate, wool grease, sodium dodecylbenzenesulfonate, isooctanoic acid, glyceryl monostearate and dibutyl phthalate. The fabric disclosed by the invention has good properties of flame retardance, acid-base resistance, mildew prevention and bacteria resistance, and product quality is improved.

Owner:李红玉

Composite insulation paper containing tencel fiber used for transformer

InactiveCN105355269AEvenly distributedImprove insulation performancePlastic/resin/waxes insulatorsTransformers/inductances coils/windings/connectionsFiberTransformer

The invention discloses composite insulation paper containing tencel fibers used for a transformer. The composite insulation paper is prepared from the following raw materials in parts by weight: 13-15 parts of nano-titanium dioxide, 2-3 parts of phenolic resin, 500-550 parts of pulp boards, 1-1.3 parts of sodium carboxymethylcellulose, 2-3 parts of carbon nano tube, 3-4 parts of tencel fibers, 1.3-1.5 parts of aluminum metaphosphate, 0.3-0.4 part of dimethyl sulfoxide, 0.4-0.5 part of barium stearate, 0.6-0.8 part of cristobalite powder, and a proper amount of deionized water. The composite insulation paper is simple in preparation method, low in cost, good in product stability and long in service life, has excellent performance of all aspects, can serve as insulating materials of transformers, motors and the like, and has good application prospect.

Owner:TONGLING SANJIA TRANSFORMER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com