Preparation method of nano Fe3O4 powder for preparation of nano dielectric medium through compounding with polyethylene

A polyethylene and dielectric technology, applied in the field of nano-Fe3O4 powder preparation, can solve the problems of poor compatibility, easy agglomeration, composite preparation of nano-dielectrics, etc., and achieve the effect of improving the heat of LDPE matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

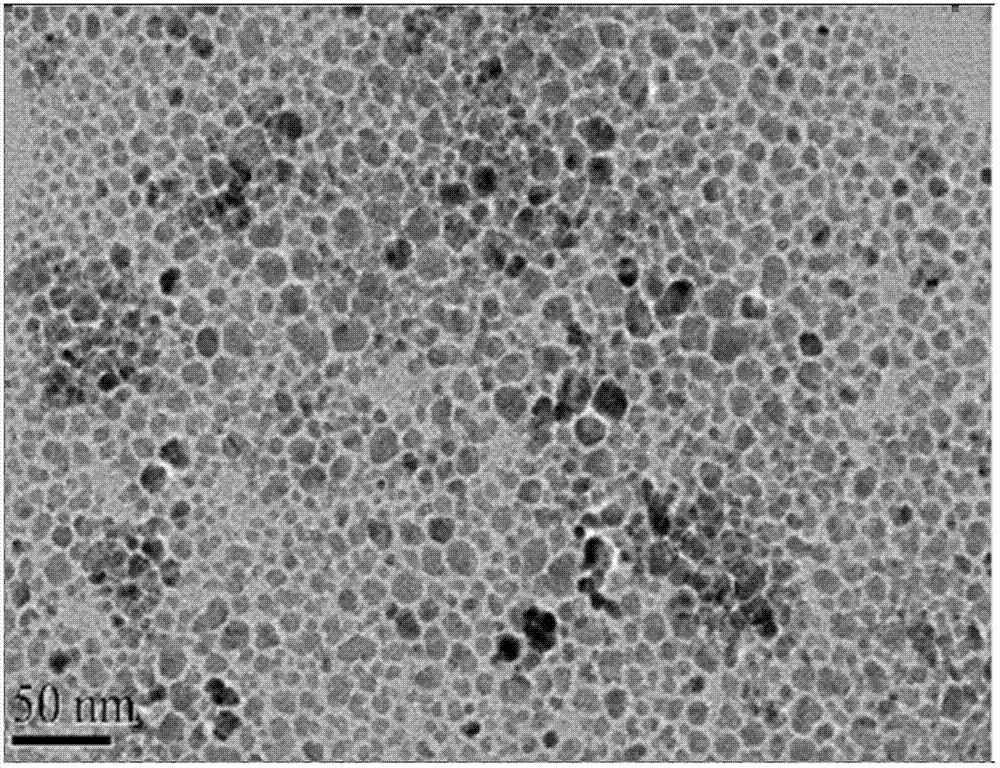

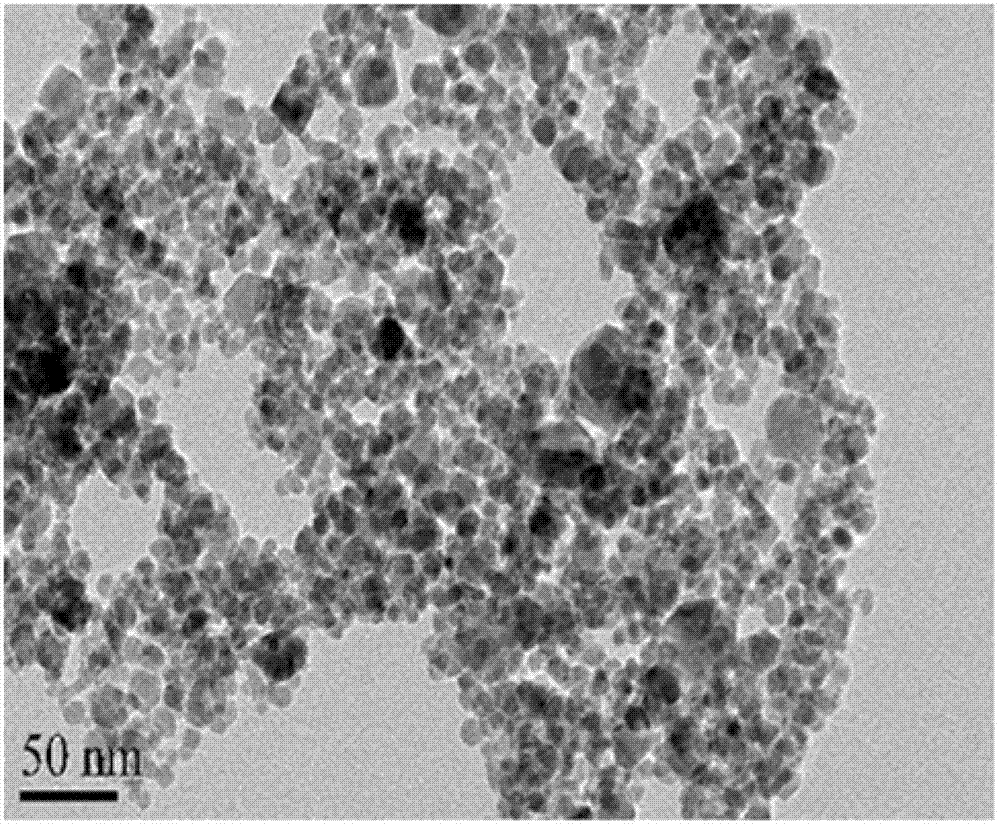

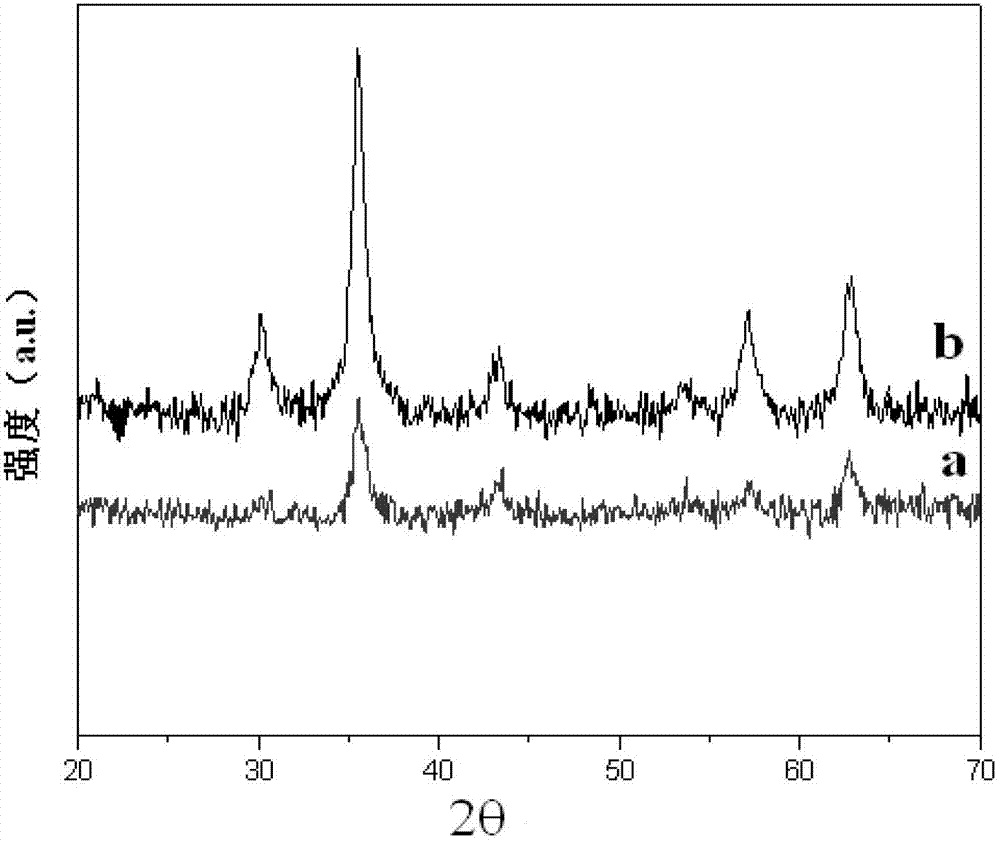

[0023] Specific implementation mode 1: In this implementation mode, a nano-Fe that can be combined with polyethylene to prepare nano-dielectrics 3 o 4 The preparation method of powder is specifically prepared according to the following steps:

[0024] 1. Weigh 9~11 parts of FeSO by weight 4 , 10 to 25 parts of FeCl 3 , 1-3 parts of surface modifier and 25-40 parts of saturated ammonia water;

[0025] 2. The FeSO4 taken in step 1 4 Dissolved in distilled water to obtain FeSO 4 solution, FeCl 3 Dissolved in distilled water to obtain FeCl 3 solution, where FeSO 4 FeSO in solution 4 The weight ratio with distilled water is 1:1~3, FeCl 3 FeCl in solution 3 The weight ratio with distilled water is 1:1~3, and then FeSO 4 solution with FeCl 3 The solution is mixed evenly to obtain a mixed solution;

[0026] 3. Under stirring conditions, add the mixed solution obtained in step 2 into the saturated ammonia water weighed in step 1, then heat up to 60°C~80°C, then add the sur...

specific Embodiment approach 2

[0029] Embodiment 2: This embodiment is different from Embodiment 1 in that: in step 1, the surface modifier is nonylphenol polyoxyethylene ether. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the stirring speed in Step 3 is 200r / min~500r / min. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com