Preparation and application of polyester adhesive for PET flexible copper clad laminate

A flexible copper clad laminate and adhesive technology, used in adhesives, lamination, layered products, etc., can solve the problems of copper clad laminates that cannot be fully cured, curled, deformed, etc., and achieves reliable performance, long service life, and high flame retardant effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

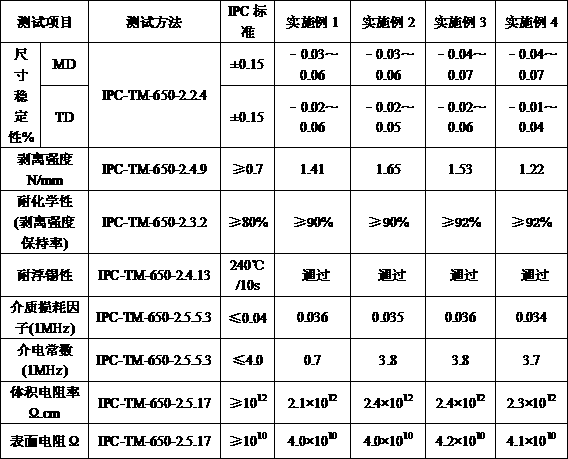

Examples

Embodiment 1

[0032] Step 1: Weigh 32.38 parts of solid saturated polyester resin Vylon670 and 23.15 parts of solid saturated polyester resin Vylon673 into different clean stainless steel constant pressure reaction vessels, and then add butanone to the stainless steel constant pressure reaction vessel while stirring 101.70 parts and 46.95 parts of toluene were dissolved, and after all the solvents were added, the temperature of the two stainless steel constant pressure reaction vessels was raised to 80°C, and the constant temperature continued to stir for 5 hours. The pressure of the stainless steel constant pressure reaction vessel was 3kg / cm 2 ;

[0033] Step 2: turn off the heat source, and continue to stir for 3 hours while making the saturated polyester resin solution cool naturally;

[0034] Step 3: After stopping stirring, filter with a screen, and store the filtered saturated polyester resin solution in a stainless steel bucket;

[0035] Step 4: Add the saturated polyester resin so...

Embodiment 2

[0038] Step 1: Weigh 32.38 parts of solid saturated polyester resin Vylon670 and 23.15 parts of solid saturated polyester resin ES210 into different clean stainless steel constant pressure reaction vessels, and then add 101.70 parts of Ding Dissolve the ketone and 46.95 parts of toluene. After all the solvents are added, raise the temperature of two stainless steel constant pressure reaction vessels to 90°C, and continue stirring at constant temperature for 4 hours. The pressure of the vessels is 3kg / cm 2 ;

[0039] Step 2: turn off the heat source, and continue to stir for 3 hours while making the saturated polyester resin solution cool naturally;

[0040] Step 3: After stopping stirring, filter with a screen, and store the filtered saturated polyester resin solution in a stainless steel bucket;

[0041] Step 4: Add the saturated polyester resin solution dissolved and filtered in the above step 1 into the mixing tank, and then add 12.50 parts of bisphenol A epoxy resin, 28.0...

Embodiment 3

[0044] Step 1: Weigh 26.5 parts of solid saturated polyester resin Vylon673 and 25.8 parts of solid saturated polyester resin ES210 into different clean stainless steel constant pressure reaction vessels, and then add 150 parts of Ding Ketone, after all the solvents are added, the temperature of the two stainless steel constant pressure reaction vessels is raised to 80°C, and the stirring is continued for 4 hours, and the pressure of the vessels is 4kg / cm 2 ;

[0045] Step 2: turn off the heat source, and continue stirring for 2 hours while the saturated polyester resin solution is cooled naturally;

[0046] Step 3: After stopping stirring, filter with a sieve, and store the filtered saturated polyester resin solution in a stainless steel barrel;

[0047] Step 4: Add the saturated polyester resin solution dissolved and filtered in the above step 1 into a stainless steel mixing tank, and then add 12.50 parts of bisphenol A epoxy resin, 28.00 parts of P series halogen-free flam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com