Halogen-free fire-retardant high heat conducting insulating resin composition and heat dissipation metal-base copper clad plate

A technology of insulating resin and high thermal conductivity, which is applied in the direction of epoxy resin glue, metal layered products, synthetic resin layered products, etc., which can solve the problems of poor thermal conductivity, difficult production, and lack of electrical insulation performance Effect of heat resistance and high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

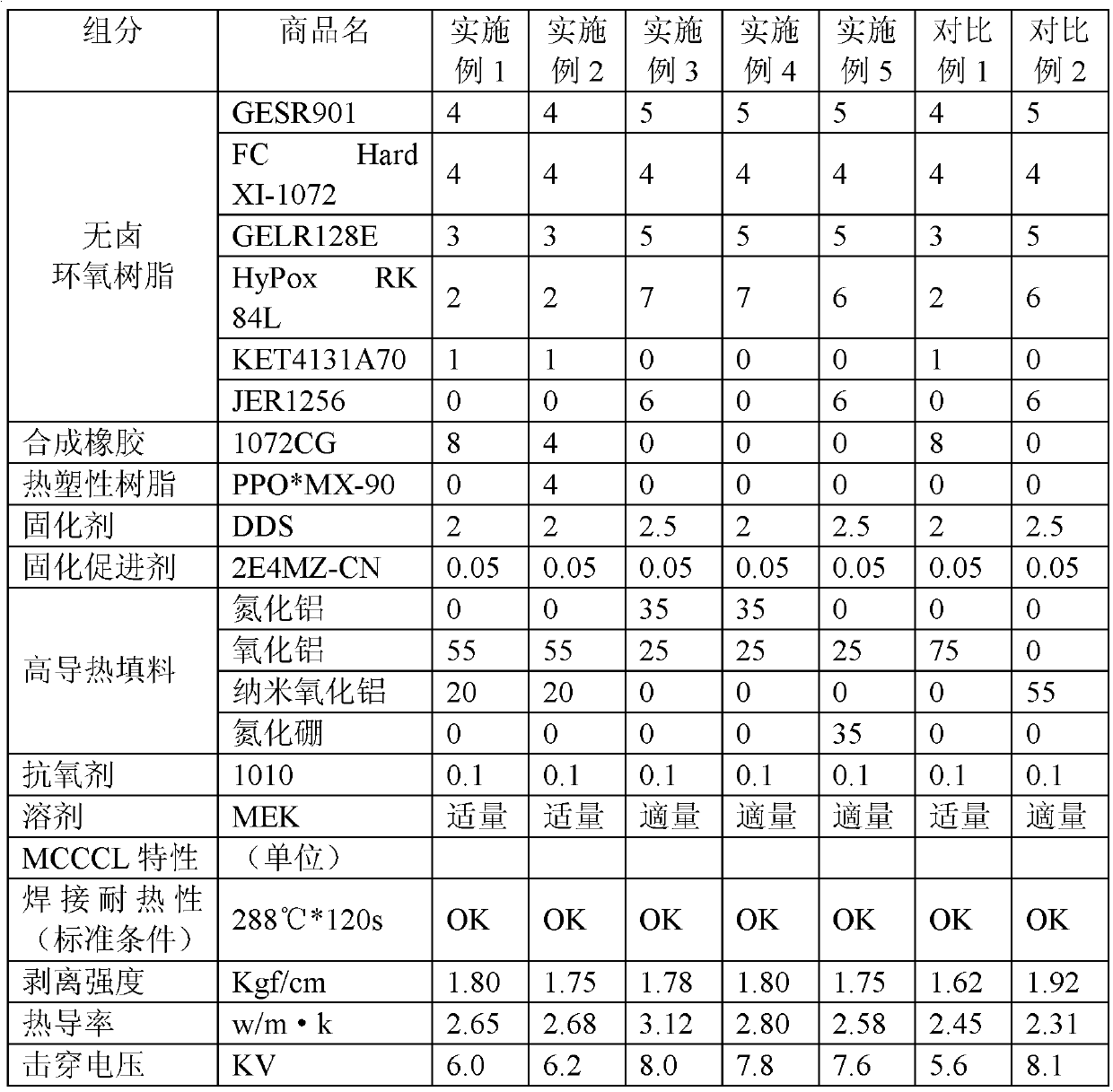

Examples

Embodiment 1

[0063] Halogen-free epoxy resin GESR901 (Hongchang Electronic Materials Co., Ltd., epoxy equivalent: 475g / eq) 4 parts by weight, FC Hard XI-1072 (Resinous Kasei Co., Ltd. epoxy equivalent: 253g / eq) 4 parts by weight , GELR128E (Hongchang Electronic Materials Co., Ltd., epoxy equivalent: 185g / eq) 3 parts by weight; HyPox RK 84L (CVC ThermosetSpecialties, elastomer content 32 mass%, epoxy equivalent: 1350g / eq) 2 parts by weight; KET4131A70 ( KOLON, epoxy equivalent: 215.5g / eq) 1 weight part; Synthetic rubber 1072CG (Nantex Industry Co., Ltd. acrylonitrile content 27 mass %) 8 weight parts; Diaminodiphenyl sulfone 2 weight parts; 0.05 parts by weight of base-2-ethyl-4-methylimidazole (2E4MZ-CN); 55 parts by weight of aluminum oxide (average particle diameter 2-3 μm, purity more than 99%), nano-alumina (average particle diameter 30nm, purity 99.99%) 20 parts by weight; antioxidant 1010 (CIBAGEIGY Co., Ltd.) 0.1 parts by weight. Put the above components in a sand mill, add methyl ...

Embodiment 2

[0066] Halogen-free epoxy resin GESR901 (Hongchang Electronic Materials Co., Ltd., epoxy equivalent: 475g / eq) 4 parts by weight, FC Hard XI-1072 (Resinous Kasei Co., Ltd. epoxy equivalent: 253g / eq) 4 parts by weight , GELR128E (Hongchang Electronic Materials Co., Ltd., epoxy equivalent: 185g / eq) 3 parts by weight; HyPox RK 84L (CVC Thermoset Specialties, elastomer content 32 mass%, epoxy equivalent: 1350g / eq) 2 parts by weight, synthetic rubber 4 parts by weight of 1072CG (Nantex Industry Co., Ltd. acrylonitrile content 27 mass %), 4 parts by weight of PPO*MX-90 (phenoxy resin, SABIC INNOVATIVE PLASTICS); 2 parts by weight of diaminodiphenyl sulfone; 1- 0.05 parts by weight of cyanoethyl-2-ethyl-4-methylimidazole (2E4MZ-CN); 55 parts by weight of aluminum oxide (average particle diameter 2-3 μm, purity more than 99%), nano-alumina (average particle diameter 30nm , purity 99.99%) 20 parts by weight; antioxidant 1010 (CIBA GEIGY Co., Ltd.) 0.1 parts by weight. Put the above com...

Embodiment 3

[0069] Halogen-free epoxy resin GESR901 (Hongchang Electronic Materials Co., Ltd., epoxy equivalent: 475g / eq) 5 parts by weight, FC Hard XI-1072 (Resinous Kasei Co., Ltd. epoxy equivalent: 253g / eq) 4 parts by weight , GELR128E (Hongchang Electronic Materials Co., Ltd., epoxy equivalent: 185g / eq) 5 parts by weight; HyPox RK 84L (CVC ThermosetSpecialties, elastomer content 32 mass%, epoxy equivalent: 1350g / eq) 7 parts by weight, JER1256 ( Mitsubishi Chemical Corporation, epoxy equivalent: 9052g / eq) 6 parts by weight; diaminodiphenylsulfone 2.5 parts by weight; 1-cyanoethyl-2-ethyl-4-methylimidazole (2E4MZ-CN) 0.05 parts by weight 35 parts by weight of aluminum nitride (average particle diameter 2-3 μm, purity more than 99%), 25 parts by weight of aluminum oxide (average particle diameter 2-3 μm, purity more than 99%); Antioxidant 1010 (CIBA GEIGY Co., Ltd.) 0.1 parts by weight. Put the above components in a sand mill, add methyl ethyl ketone solvent, adjust the solid content of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com