Solvent-based reticulated pressure-sensitive adhesive for polyethylene protective film and preparation method thereof

A polyethylene protective film, solvent-based technology, applied in the direction of adhesive types, ester copolymer adhesives, film/sheet adhesives, etc. , easy to form bubbles and other problems, to achieve the effect of good peel strength and cohesion, less glue, and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

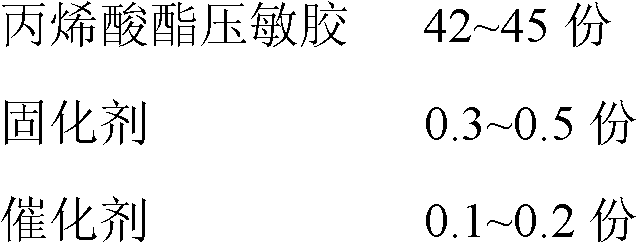

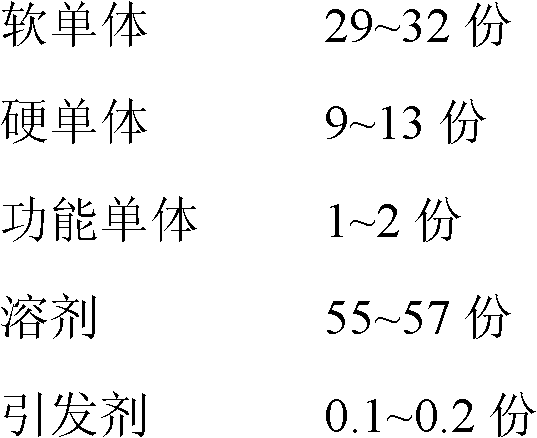

Method used

Image

Examples

Embodiment 1

[0032] Mix 86.4g isooctyl acrylate, 27g ethyl acrylate, 75.6g butyl acrylate, 54g methyl methacrylate, 10.8g hydroxyethyl acrylate, 1.4g acrylic acid and 0.95g benzoyl peroxide; 240g of ethyl acetate and 60g of toluene were added to the reactor, and 67.5g of the above mixture was added when the temperature rose to 80°C; after 45 minutes of polymerization, the remaining amount of the above mixture was slowly added dropwise under reflux for about 3 hours Dropwise; After the dropwise addition, continue reflux reaction for 60 minutes, add 0.14g benzoyl peroxide (dissolved in 15g ethyl acetate); continue reflux reaction for 60 minutes, add 0.14g benzoyl peroxide ( dissolved in 15 g of ethyl acetate); the reaction was continued for 2 hours, the reaction was stopped, and the acrylate pressure-sensitive adhesive was obtained after cooling.

[0033] Stir 50g of acrylate pressure-sensitive adhesive, 60g of ethyl acetate, 0.5g of toluene diisocyanate and 0.08g of dibutyltin dilaurate at ...

Embodiment 2

[0046]73.7g isooctyl acrylate, 31.6g ethyl acrylate, 67.5g butyl acrylate, 72.9g methyl acrylate, 6.2g hydroxypropyl acrylate, 0.81g glycidyl methacrylate and 0.81g azobisisobutyronitrile Mix evenly; add 200g of ethyl acetate and 100g of toluene into a nitrogen-protected reactor, and add 54g of the above mixture when the temperature rises to 82°C; after 45 minutes of polymerization, slowly add the remaining amount of the above mixture dropwise under reflux , dripped in about 3.5 hours; after the dropwise addition, continue to reflux for 60 minutes, add 0.14g of azobisisobutyronitrile (dissolved in 15g of ethyl acetate); continue to reflux for 60 minutes, add 0.14g Azobisisobutyronitrile (dissolved in 15 g of ethyl acetate); continue to react for 2 hours, stop the reaction, and obtain an acrylate pressure-sensitive adhesive after cooling.

[0047] Stir 45g of acrylate pressure-sensitive adhesive, 30g of ethyl acetate, 30g of toluene, 0.5g of methyl etherified high methylene mel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com