Patents

Literature

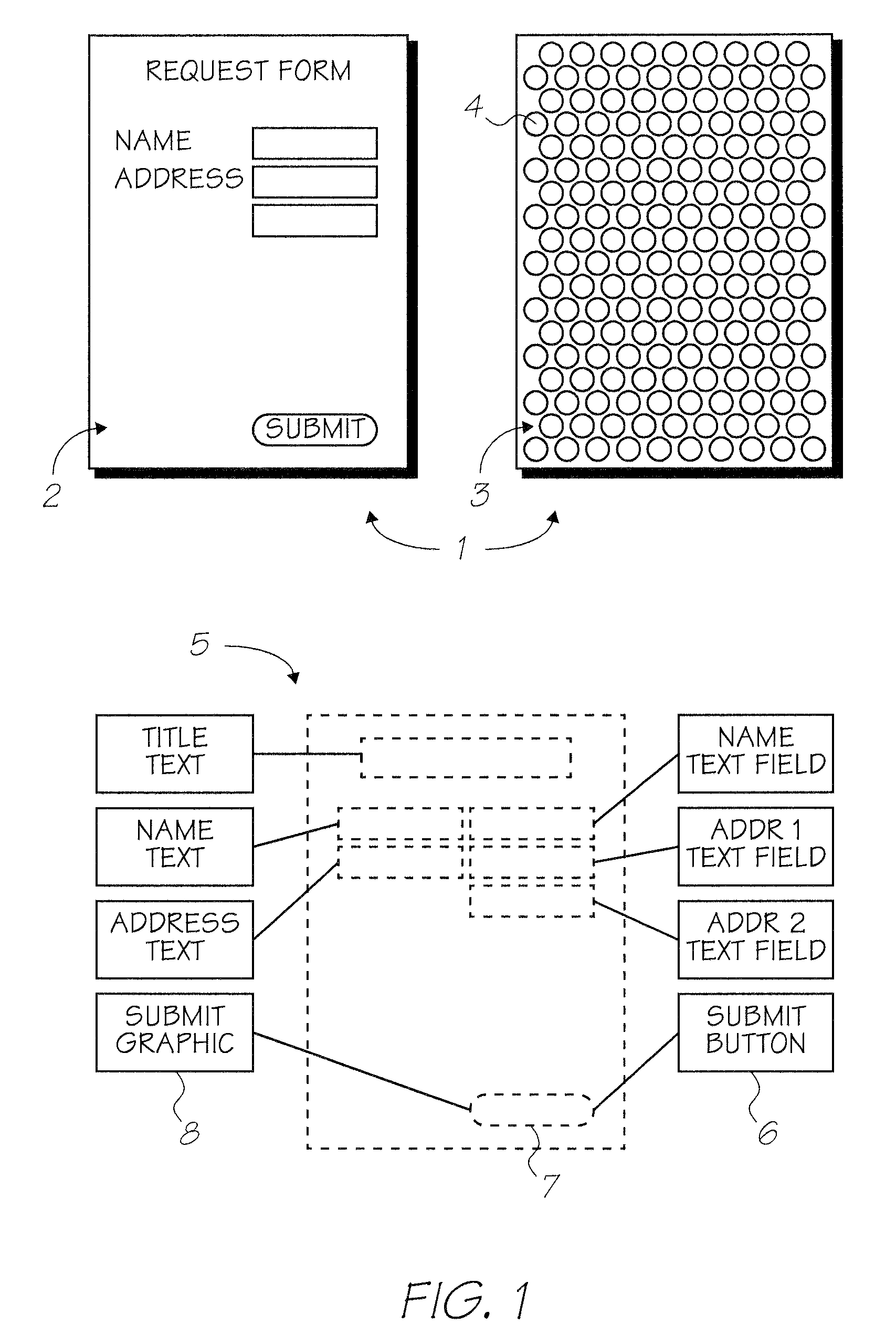

2576 results about "Solvent based" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solvent-based coatings. Solvent-based paints are made up of liquefying agents that are meant to evaporate via a chemical reaction with oxygen. Typically, moving air surrounding a solvent-based coating will help to speed up the reaction, reducing drying times. These coatings have one major advantage over water-based coatings.

Reactive oligomers for isocyanate coatings

InactiveUS6221494B1Extended shelf lifeHigh glossAluminium compoundsSynthetic resin layered productsEpoxyOligomer

The invention is directed to a two-pack solvent-based ambient curable coating composition comprising a binder of a hydroxyl and crosslinking components. The hydroxyl component includes a linear or branched cycloaliphatic moiety-containing reactive oligomer or blend of oligomers with a weight average molecular weight not exceeding 3,000, a polydispersity not exceeding about 1.7 with at least 2 hydroxyl groups, at least 1, on average, being a primary hydroxyl group. The reactive oligomer is formed by the reaction of an oligomeric acid with monofunctional epoxy. The crosslinking component includes one or more of an oligomeric crosslinker containing at least 2 isocyanate groups. The coating composition of the invention is particularly suited in automotive refinish coatings.

Owner:AXALTA COATING SYST IP CO LLC

Waterborne conductive ink and preparation method thereof

The invention relates to waterborne conductive ink which comprises the following components in percentage by weight: 1-40 percent of polymer emulsion or dispersion liquid, 0.1-0.7 percent of dispersant, 0.1-0.3 percent of wetting agent, 0.2-1.8 percent of defoaming agent, 30-70 percent of conductive material, 0.5-3 percent of film-forming addition agent and 5-60 percent of water. The waterborne conductive ink disclosed by the invention has the advantages of no toxicity or odor, safety, environment friendliness, convenience in use, resource economization, favorable film forming performance and printing performance of ink, strong adhesive force and good weather resistance; the defects of toxicity, harm, inflammability and explosiveness of solvent ink are overcome; and water replaces organic solvent, so that a volatile organic compound (VOC) is reduced, and the production cost is also reduced.

Owner:SUZHOU NIUJIAN NEW MATERIAL

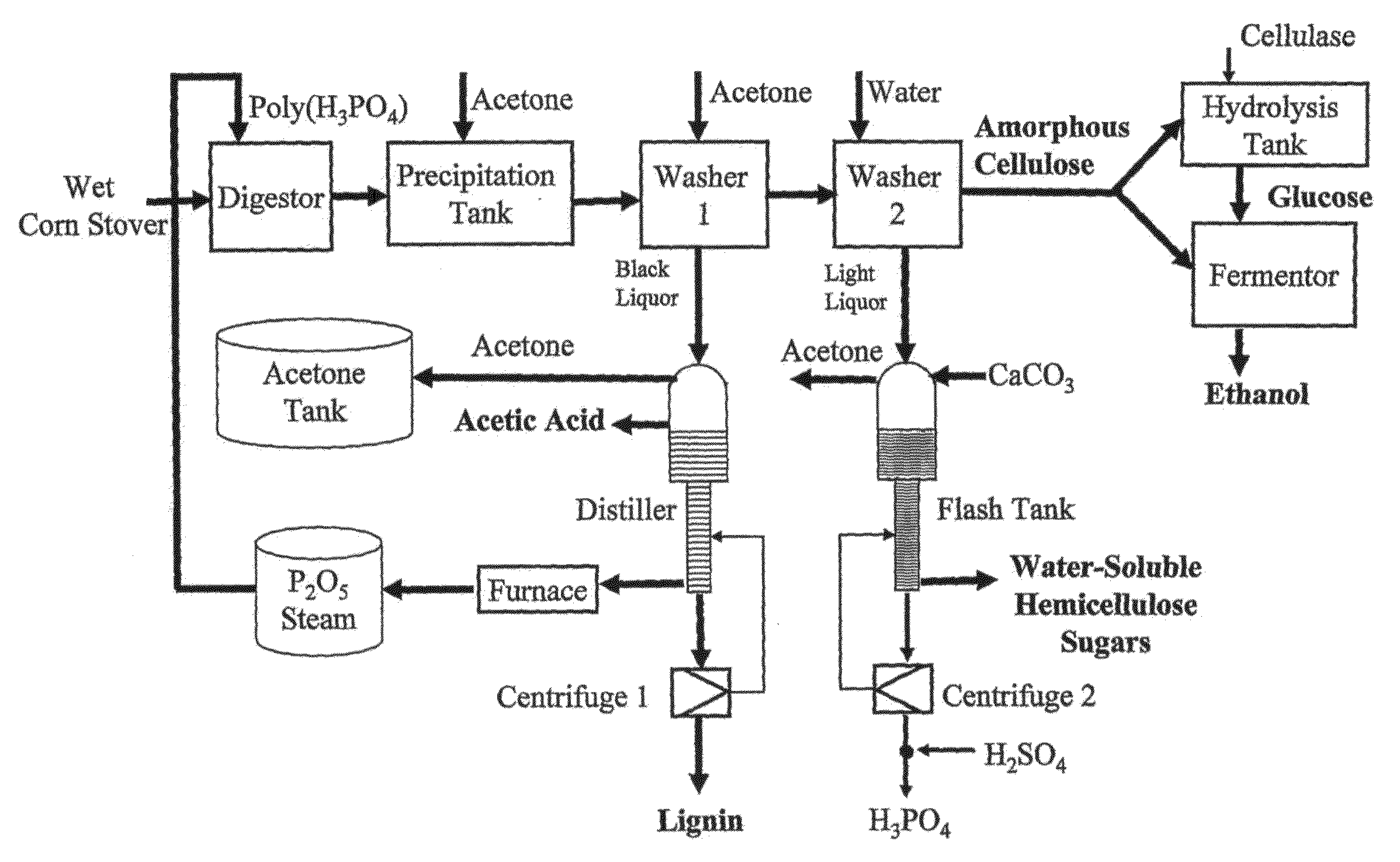

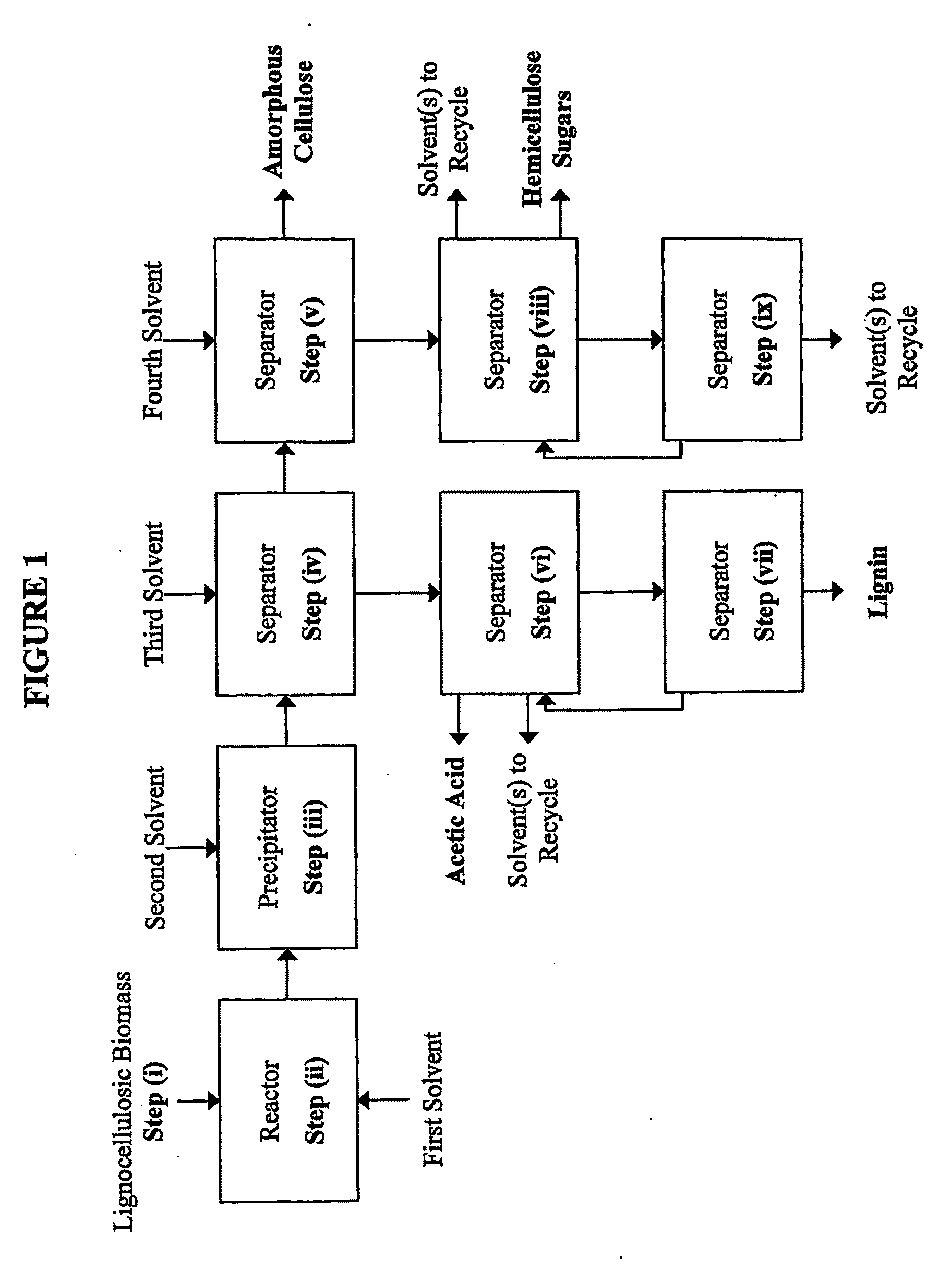

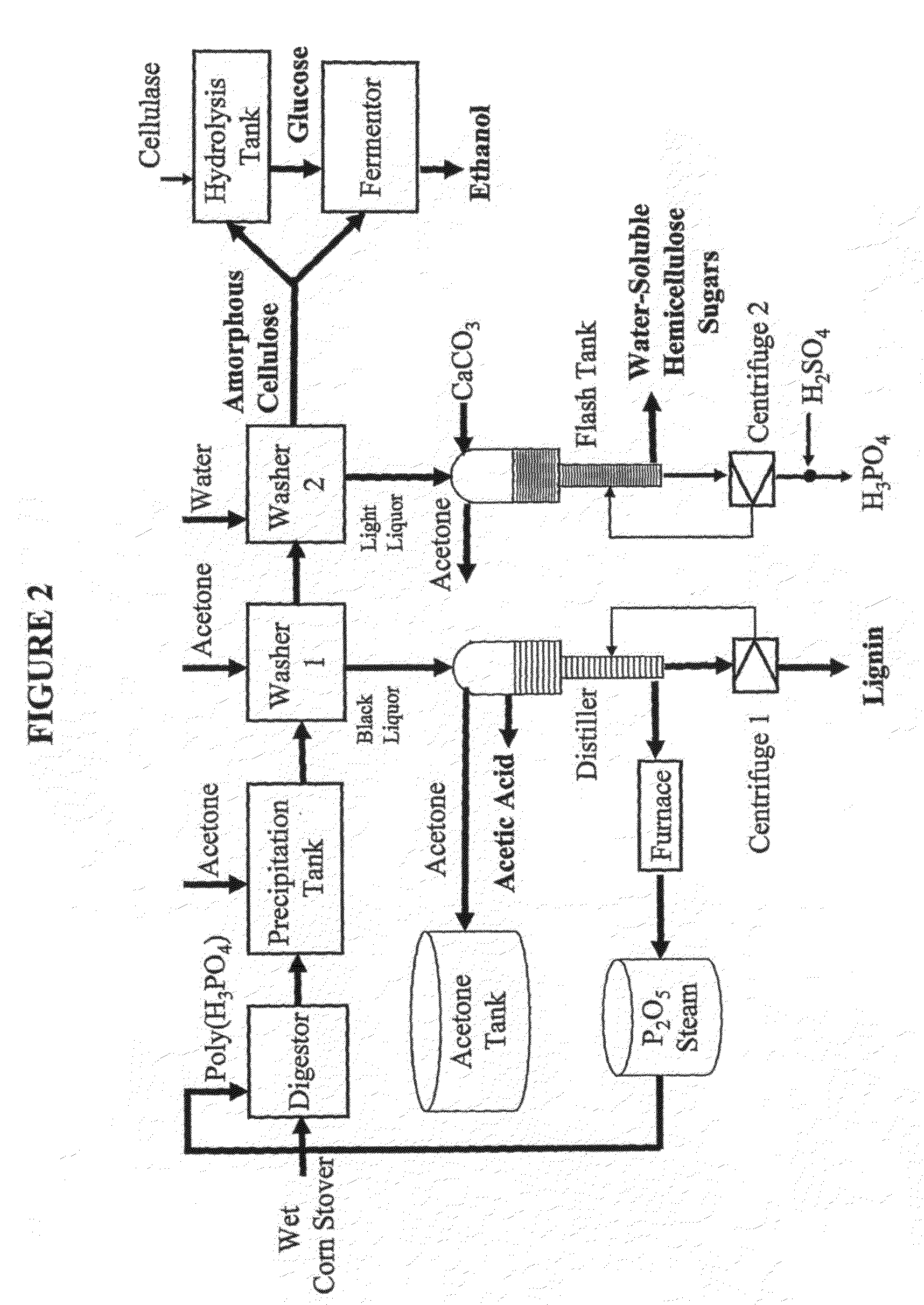

Cellulose-solvent-based lignocellulose fractionation with modest reaction conditions and reagent cycling

InactiveUS20100170504A1Lower cost of capitalReduce operating costsBiofuelsChemical recyclingFractionationProcessing cost

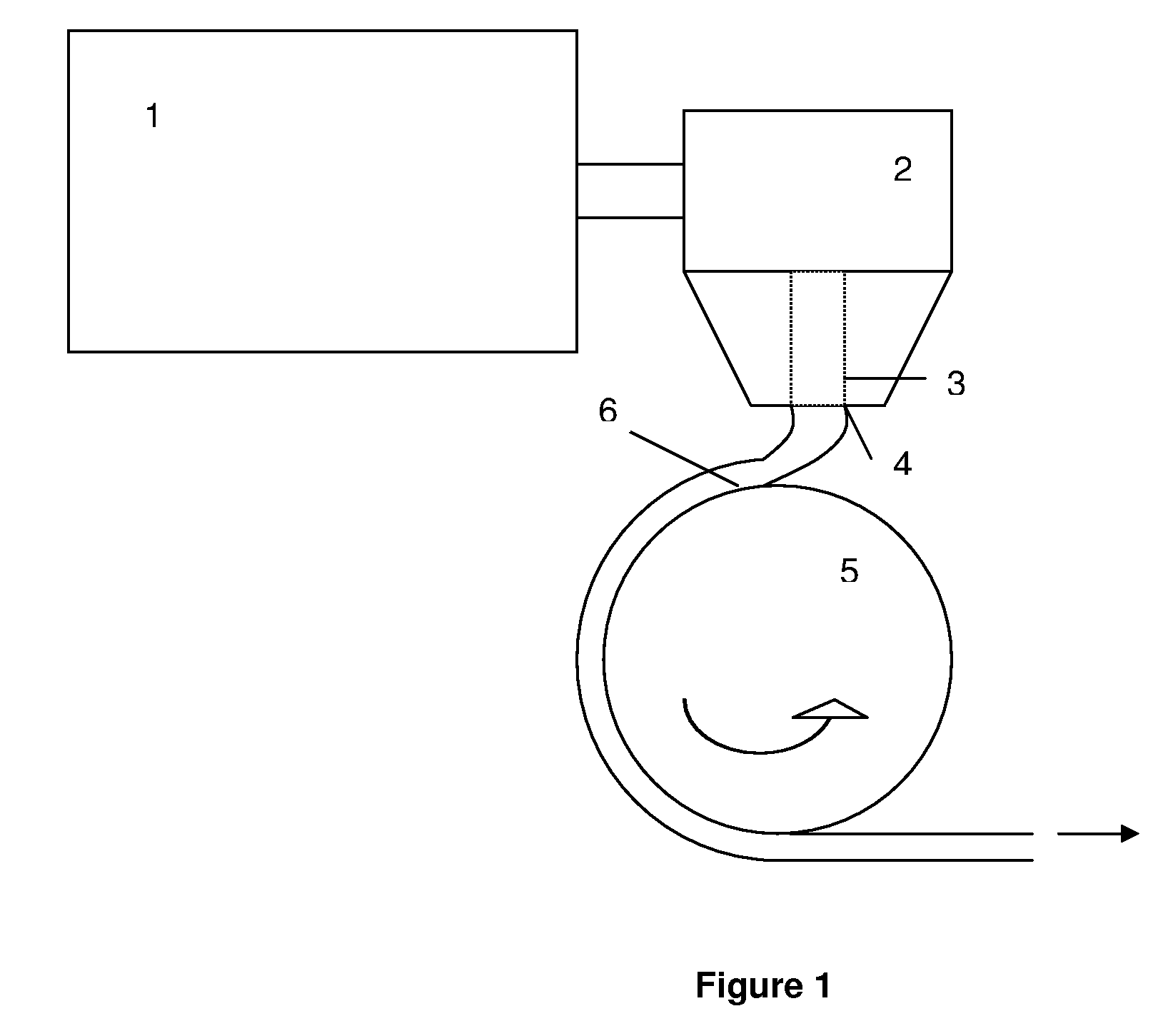

Embodiments of the present invention overcome the well-known recalcitrance of lignocellulosic biomass in an economically viable manner. A process and system are provided for the efficient fractionation of lignocellulosic biomass into cellulose, hemicellulose sugars, lignin, and acetic acid. The cellulose thus obtained is highly amorphous and can be readily converted into glucose using known methods. Fermentable hemicellulose sugars, low-molecular—weight lignin, and purified acetic acid are also major products of the process and system. The modest process conditions and low solvent / solid ratios of some embodiments of the invention imply relatively low capital and processing costs.

Owner:VIRGINIA TECH INTPROP INC

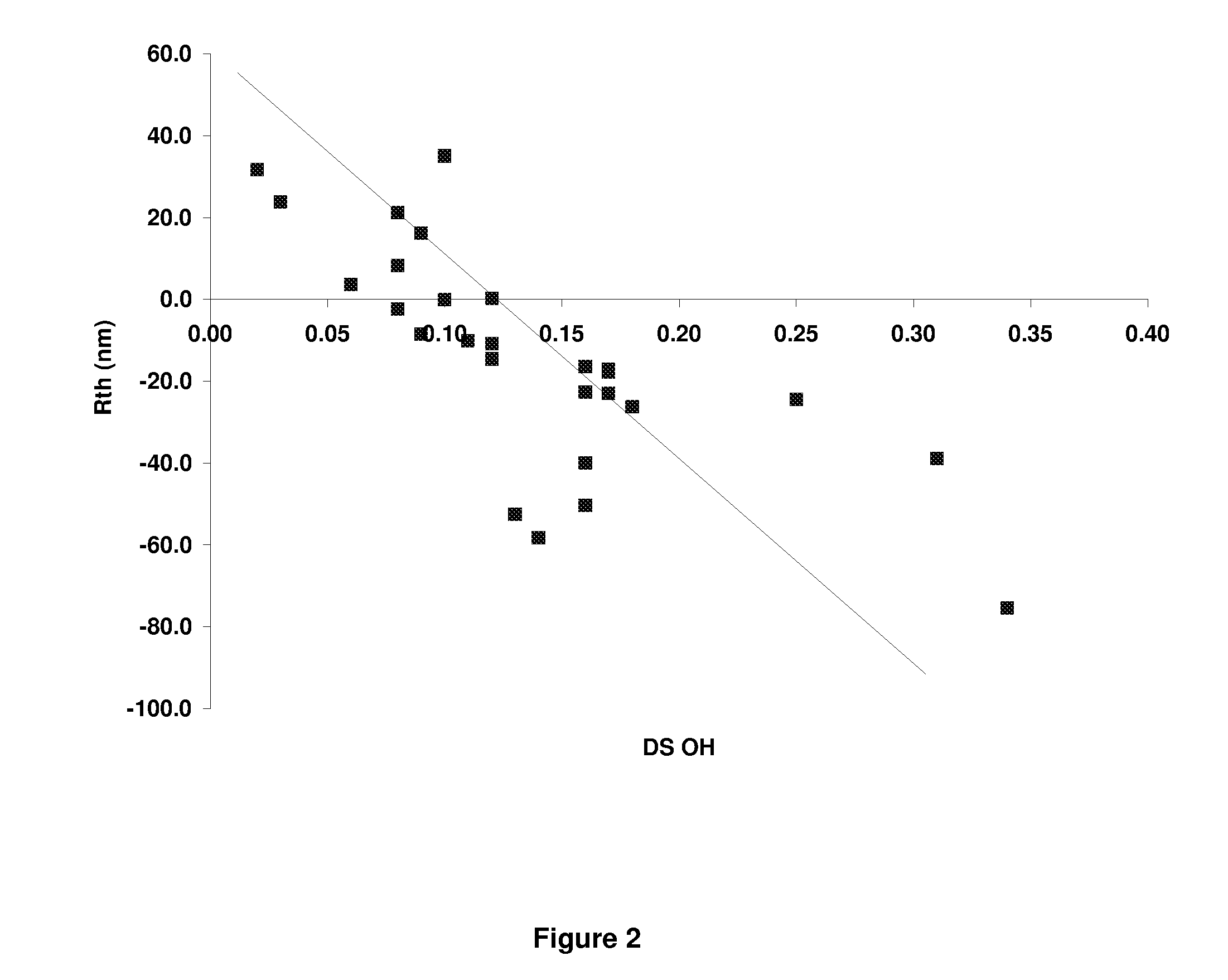

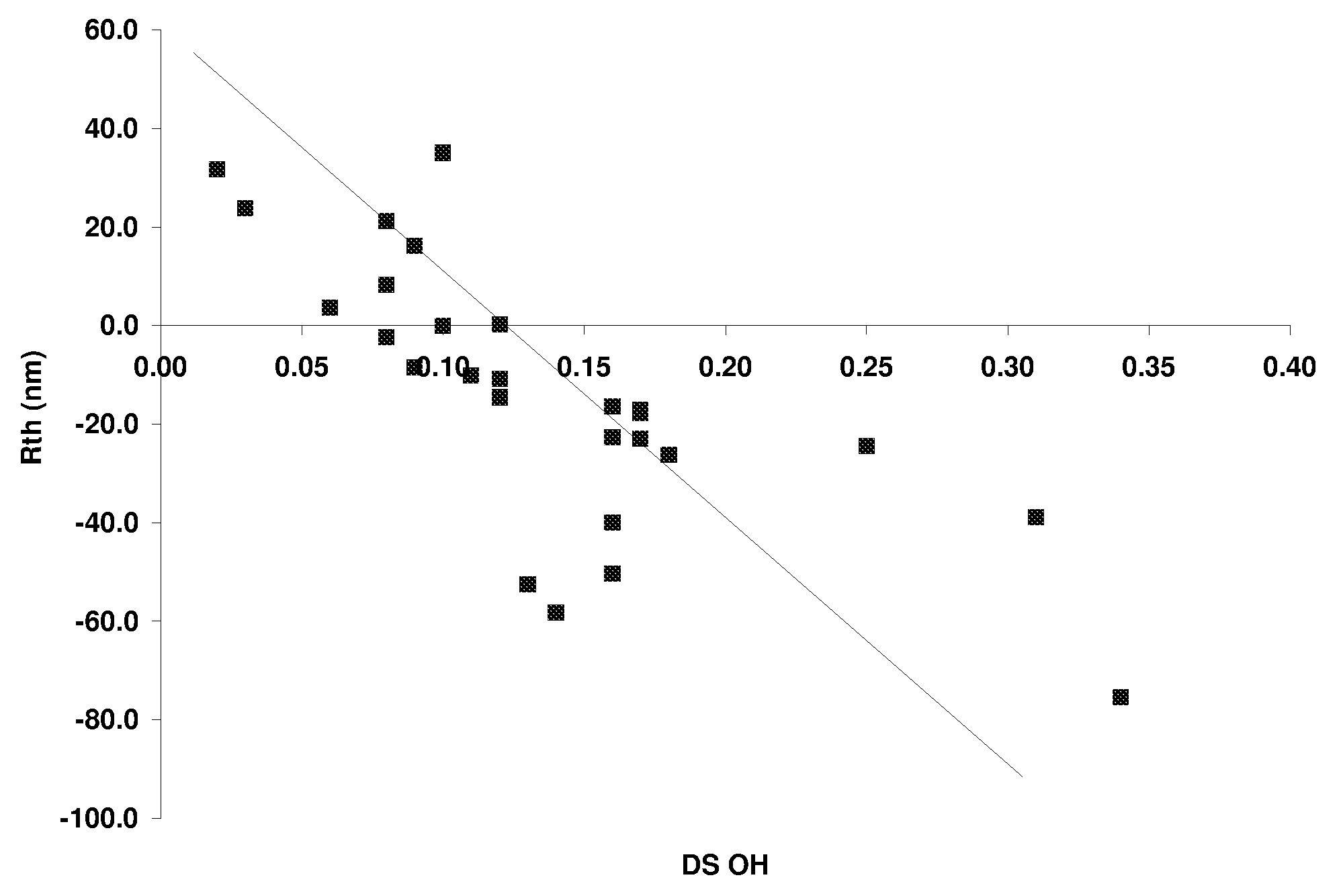

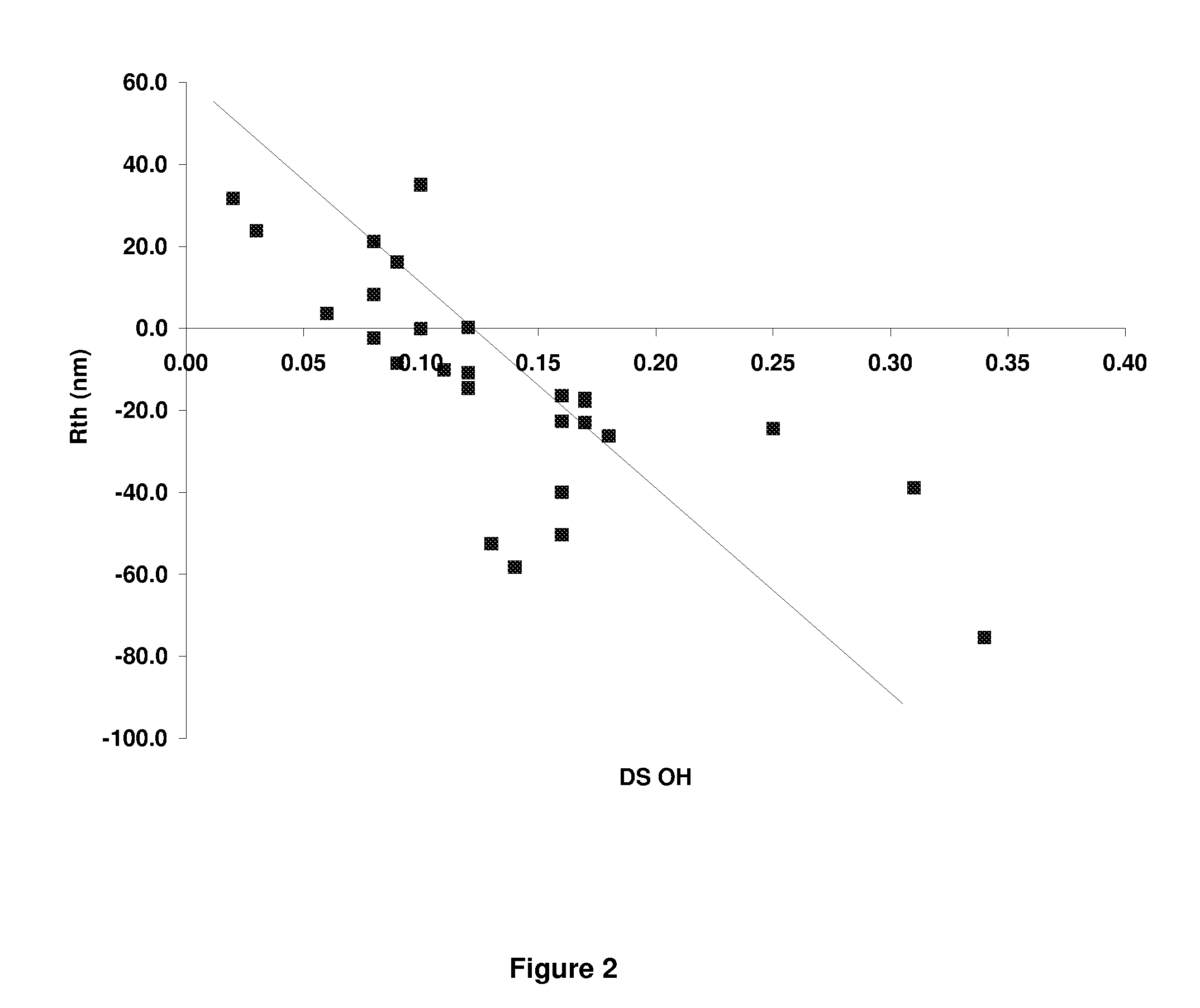

Cellulose Ester Compositions Having Low Bifringence and Films Made Therefrom Comprising a Plasticizer

The present invention relates to cellulose esters having low hydroxyl content for use in optical applications, such as liquid crystal display (LCD) films. Films made with low hydroxyl levels and a given ratio of non-acetyl ester to hydroxyl level have been found to have low intrinsic birefringence. Therefore, these films can be cast, molded, or otherwise oriented without an appreciable birefringence or optical distortion (i.e. retardation). Such features make these films useful in polarizer, protective, and compensator films as well as molded optical parts, such as lenses. Furthermore, it has also been found that resins of the present invention can also be made to have “+C plate” behavior either by melt or solvent based processing, a characteristic which is not typical of cellulose esters. Such +C behavior allows films to be produced having unique compensatory behavior. Other embodiments of the invention relate to methods melt casting films while minimizing birefringence formation. Another embodiment of the invention is directed to films made from the cellulose esters described herein further comprising a plasticizer.

Owner:EASTMAN CHEM CO

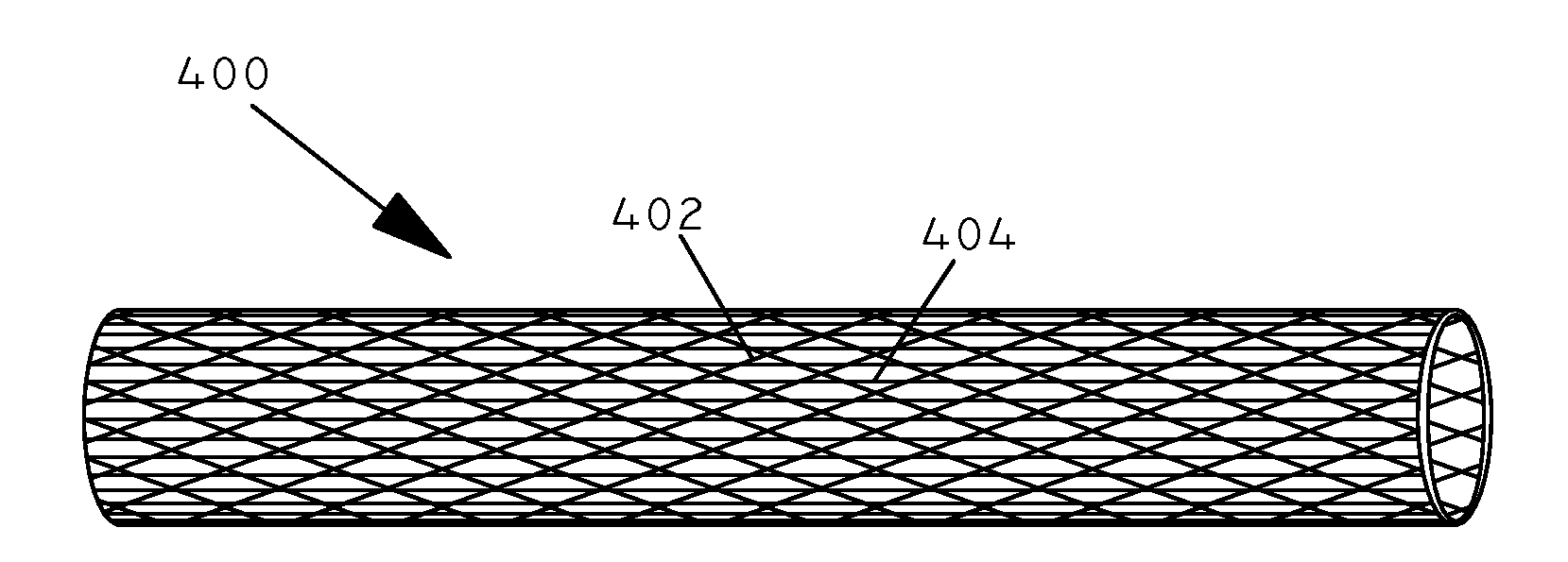

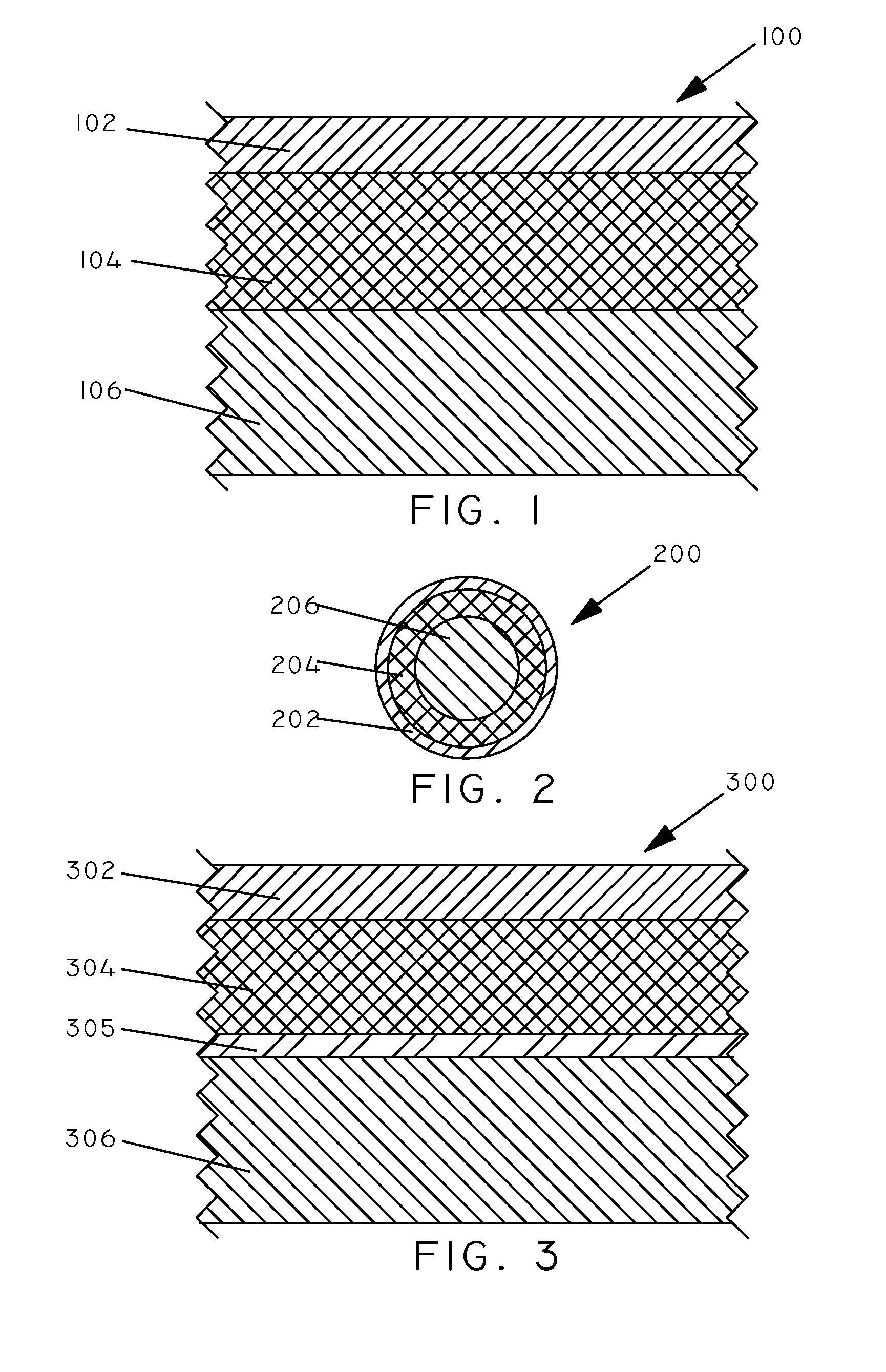

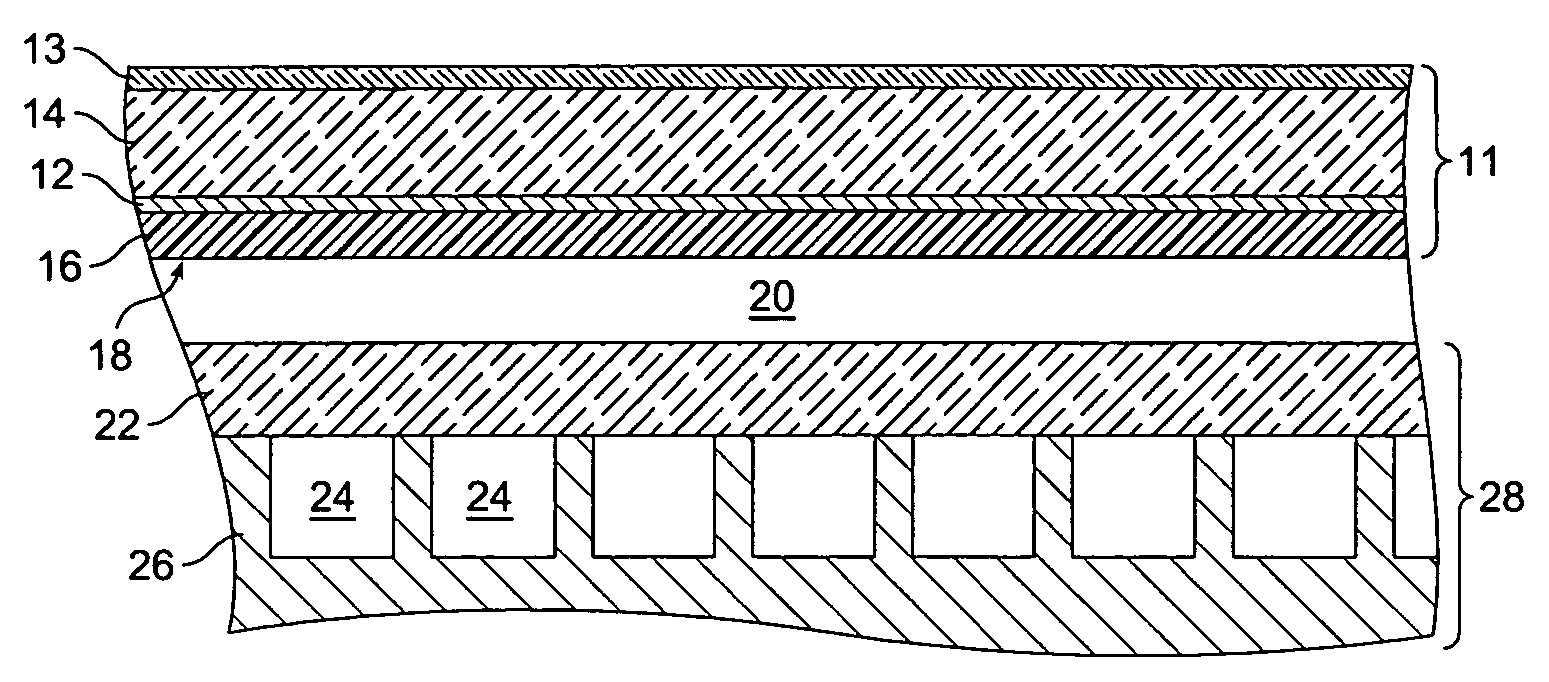

Multi-layered coatings and methods for controlling elution of active agents

Embodiments of the invention include multi-layered coatings for controlling the elution rates of active agents and methods. In an embodiment, the invention includes a method of applying an elution control coating to a substrate. The method can include depositing a coating solution onto the substrate to form a base layer. The method can also include selecting a desired concentration of the solvent based on a desired elution rate. The method can further include removing solvent from the base layer to reach a desired concentration of the solvent and depositing a layer of parylene on the base layer. In an embodiment, the invention can include a medical device including a substrate, a base layer, and a porous layer. The base layer can include a polymeric matrix and an active agent dispersed within the polymeric matrix. The porous layer can include parylene. Other embodiments are also included herein.

Owner:SURMODICS INC

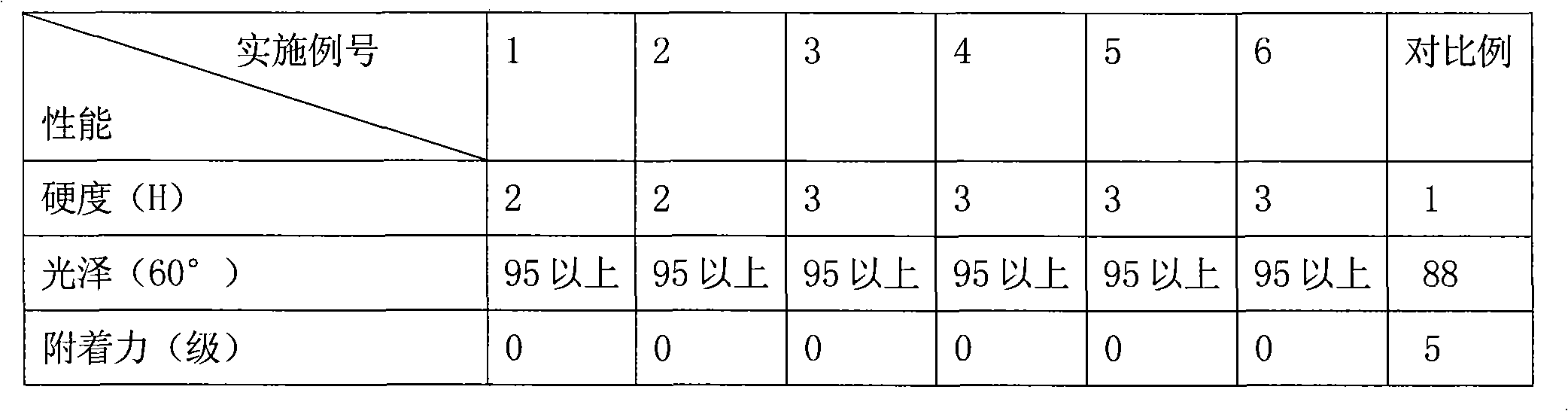

UV curing color decorative coating

InactiveCN101407651ASolve the problem of deep curingAvoid pollutionMulticolor effect coatingsPolyesterUltraviolet

The invention relates to an ultraviolet curing color decorative coating, the components of the coating and the parts by weight thereof are as follows: 5 to 25 parts of epoxy acrylate prepolymer, 5 to 30 parts of polyurethane acrylate prepolymer, 2 to 10 parts of polyester acrylate prepolymer, 15 to 70 parts of acrylate monomer, 1 to 10 parts of photoinitiator, 1 to 35 parts of pigment, 0.5 to 10 parts of dispersant and 0.1 to 2 parts of auxiliary agent, the acrylate monomer is a mixture of the monomer with bifunctionality and the monomer with high functionality, wherein, the mixture ratio of the monomer with high bifunctionality to the monomer with bifunctionality is 1: 0.3 to 8. Compared with an ultraviolet curing transparent varnish, the ultraviolet curing color decorative coating has stronger decorative effect and almost the same curing speed, paint film hardness, adhesion, paint film gloss, and the like; and compared with a traditional solvent based colored paint, the ultraviolet curing color decorative coating does not contain volatile organic solvent, thereby avoiding the pollution and greatly improving the production efficiency. The ultraviolet curing color decorative coating is applicable to the decoration of plastics, wood materials, metals and other base materials.

Owner:BAODING LUCKY POLYMER MATERIAL TECH DEV +1

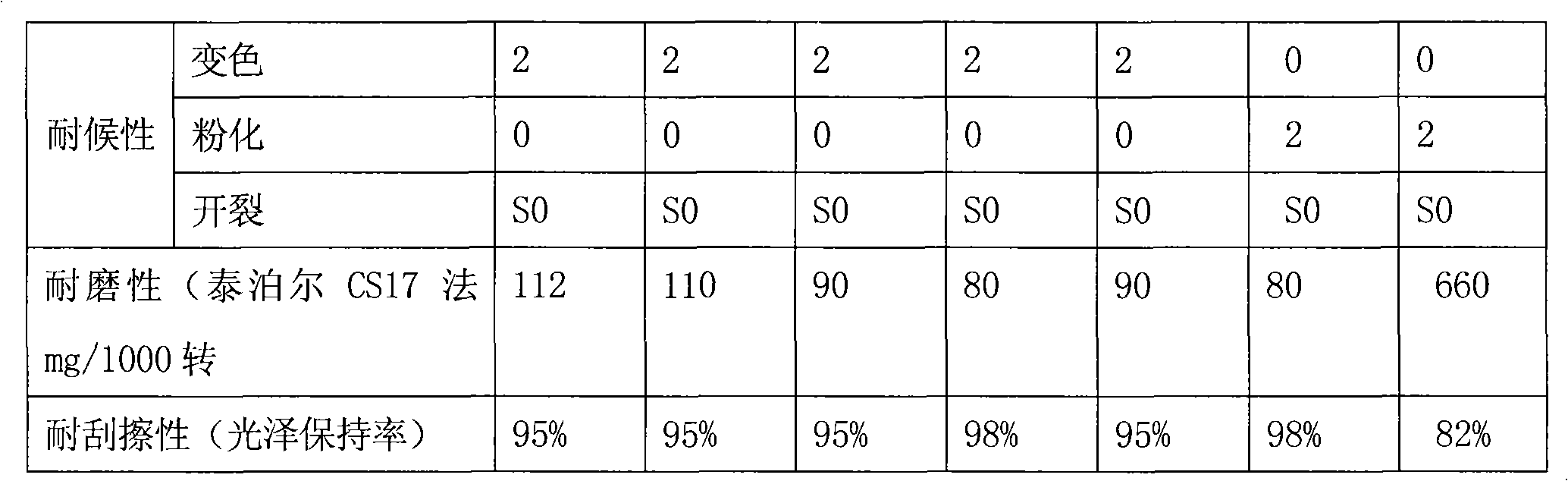

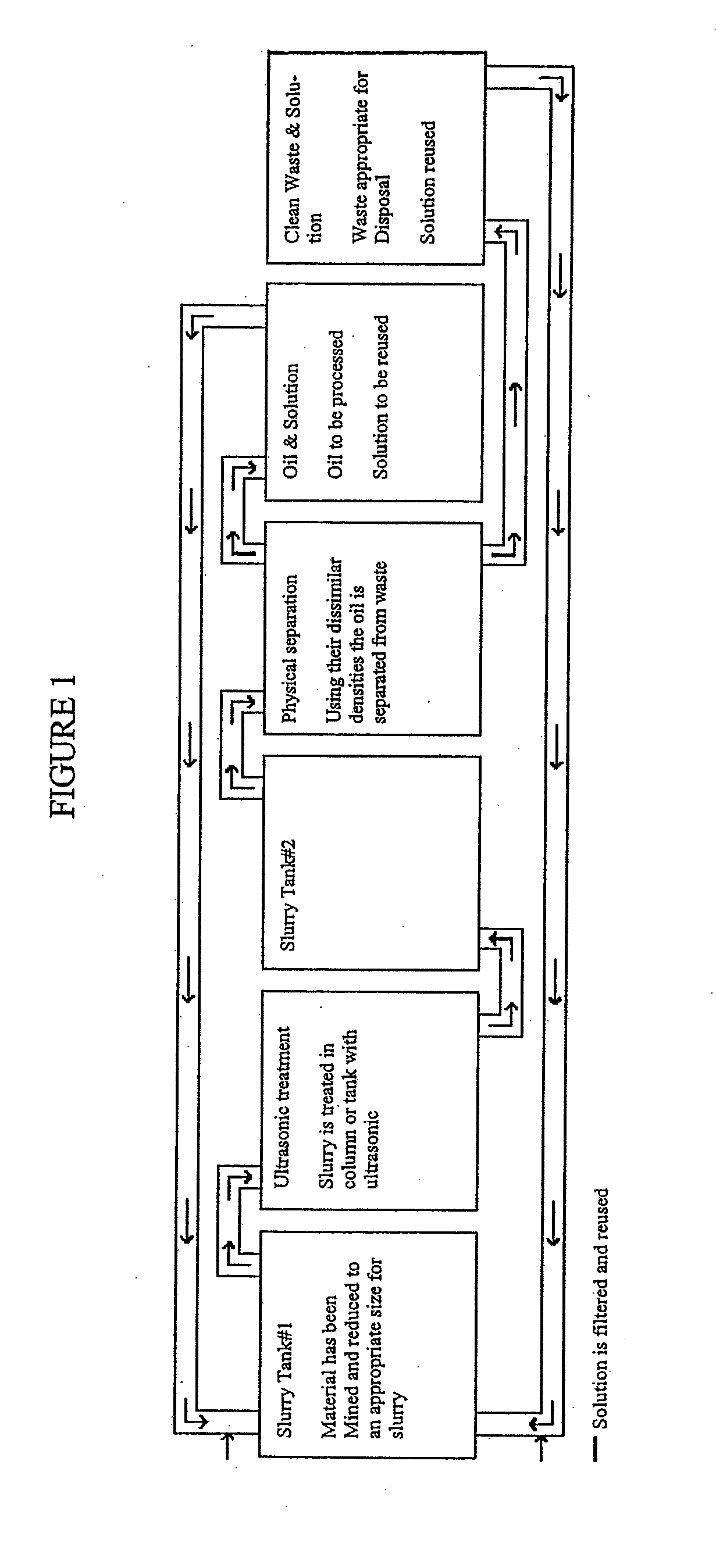

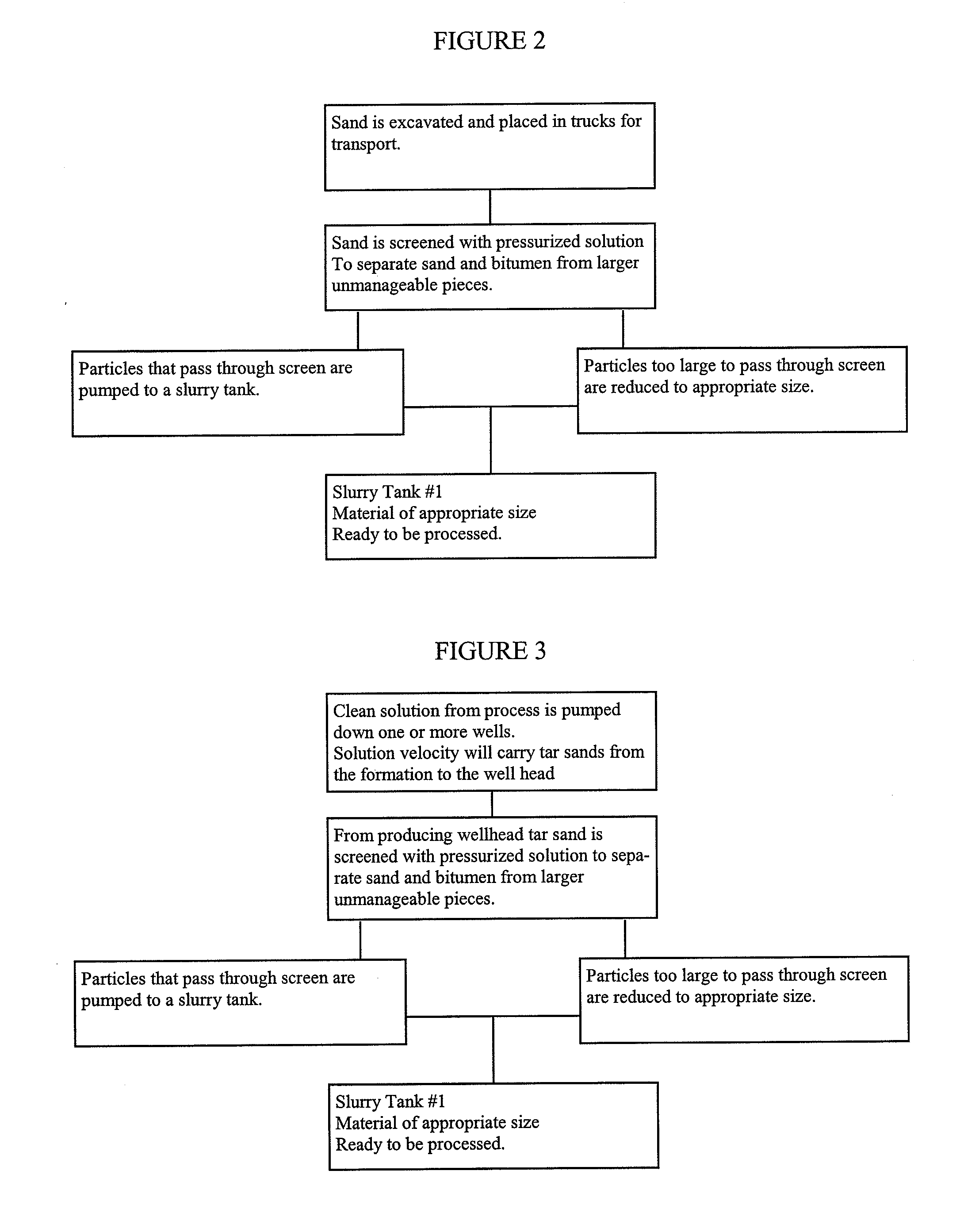

Method for extracting heavy oil and bitumen from tar sands

InactiveUS20080139418A1Removing both soluble and insoluble bitumenEfficient removalLiquid hydrocarbon mixture productionFlushingWater basedBatch processing

The use of high flash point low vapor pressure compositions for removal of crude oil deposits from tar sands by injection of products in situ or by removal of tar sands and batch processing. Processing equipment is designed for use on these compositions to maximize recovery of deposits and producing clean sand clays or other base materials for re-deposition without further treatment. The compositions consist of solvent based cleaners, solvent emulsion cleaners, and / or water based alkaline cleaners.

Owner:UNITED ENERGY CORP

Cellulose Ester Compositions Having Low Bifringence and Films Made Therefrom

The present invention relates to cellulose esters having low hydroxyl content for use in optical applications, such as liquid crystal display (LCD) films. Films made with low hydroxyl levels and a given ratio of non-acetyl ester to hydroxyl level have been found to have low intrinsic birefringence. Therefore, these films can be cast, molded, or otherwise oriented without an appreciable birefringence or optical distortion (i.e. retardation). Such features make these films useful in polarizer, protective, and compensator films as well as molded optical parts, such as lenses. Furthermore, it has also been found that resins of the present invention can also be made to have “+C plate” behavior either by melt or solvent based processing, a characteristic which is not typical of cellulose esters. Such +C behavior allows films to be produced having unique compensatory behavior. Other embodiments of the invention relate to methods melt casting films while minimizing birefringence formation.

Owner:EASTMAN CHEM CO

Dual-curing coating and preparation method thereof

InactiveCN102181192ACuring shrinkage is smallIncrease crosslink densityCoatingsInformation layerCoating system

The invention discloses a dual-curing coating. The coating contains ultraviolet curing resin monomers, a low polymer, a photo-initiator, polymer resins, an adjuvant and an organic solvent. In the invention, the dual-curing coating is prepared by synergistic copolymerization of an ultraviolet curing coating system and a solvent-based polymer system. The preparation method of the coating comprises the following steps: firstly thermocuring, and then processing information layers and photocuring at the same time; or firstly photocuring, then processing the information layers, and finally heating with an oven or infrared-heating for further cross-linking curing. Therefore, the dual-curing coating has better comprehensive performances such as fast curing speed, small film-coating cure shrinkage and high crosslinking density so as to achieve the characteristics of chemical corrosion resistance, strong wear resistance, strong high temperature resistance, excellent flexibitity, excellent adhesive force and the like; and the coating can be used for laser anti-counterfeit marks of plastics, cosmetic preparations, ceramic materials, glass, paper, leather, wooden products and metal products as well as production of pigment preparations and the like.

Owner:SHANGHAI HONGDUN ANTI COUNTERFEIT MATERIAL

Preparation method of waterborne polyurethane synthetic leather base

The invention relates to a preparation method of a waterborne polyurethane synthetic leather base. A waterborne polyurethane resin takes water as a dispersing medium, is nontoxic, environmentally-friendly, safe and inflammable and is an optimal substitute product for a solvent resin. However, the application of the waterborne polyurethane resin to synthetic leather is relatively hysteretic, and is mainly concentrated on surface finishing of the synthetic leather. The preparation method of the waterborne polyurethane synthetic leather base comprises the following steps of: designing a base fabric; pretreating; drying; soaking in waterborne polyurethane slurry; coating a waterborne polyurethane foamed coating; and drying. The product has the basic structure of a solvent type wet process synthetic leather base and has handfeel and physical properties close to those of the solvent type synthetic leather base; solvents are not used for processing in the entire production process; the preparation method can be applied to post-processing manufacturing of any synthetic leather product; and a waterborne polyurethane material is used for post-processing, so that the synthetic leather base can be used for manufacturing shoe leather, sofa leather, case leather, clothes leather and the like.

Owner:兰州科天水性科技有限公司

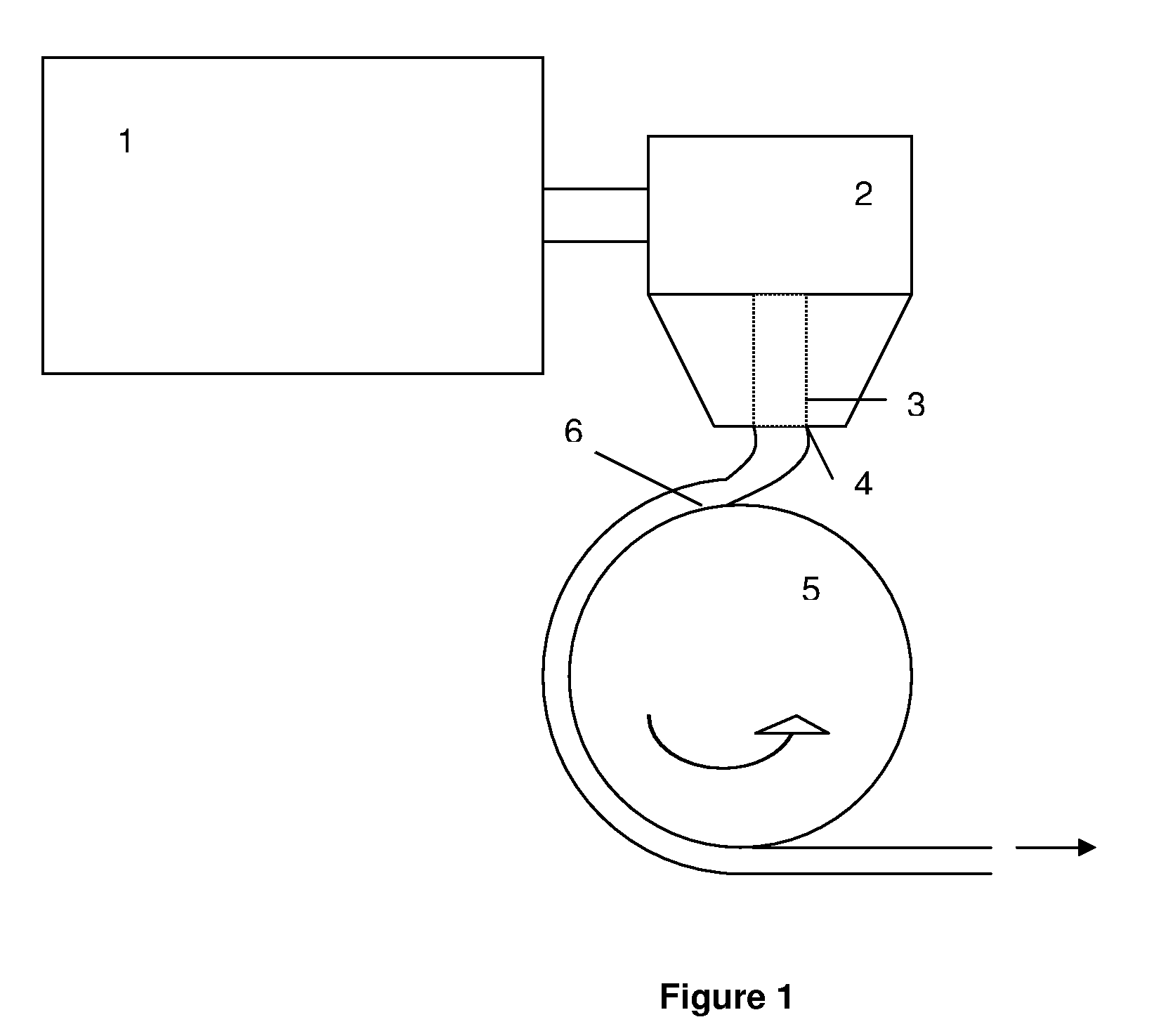

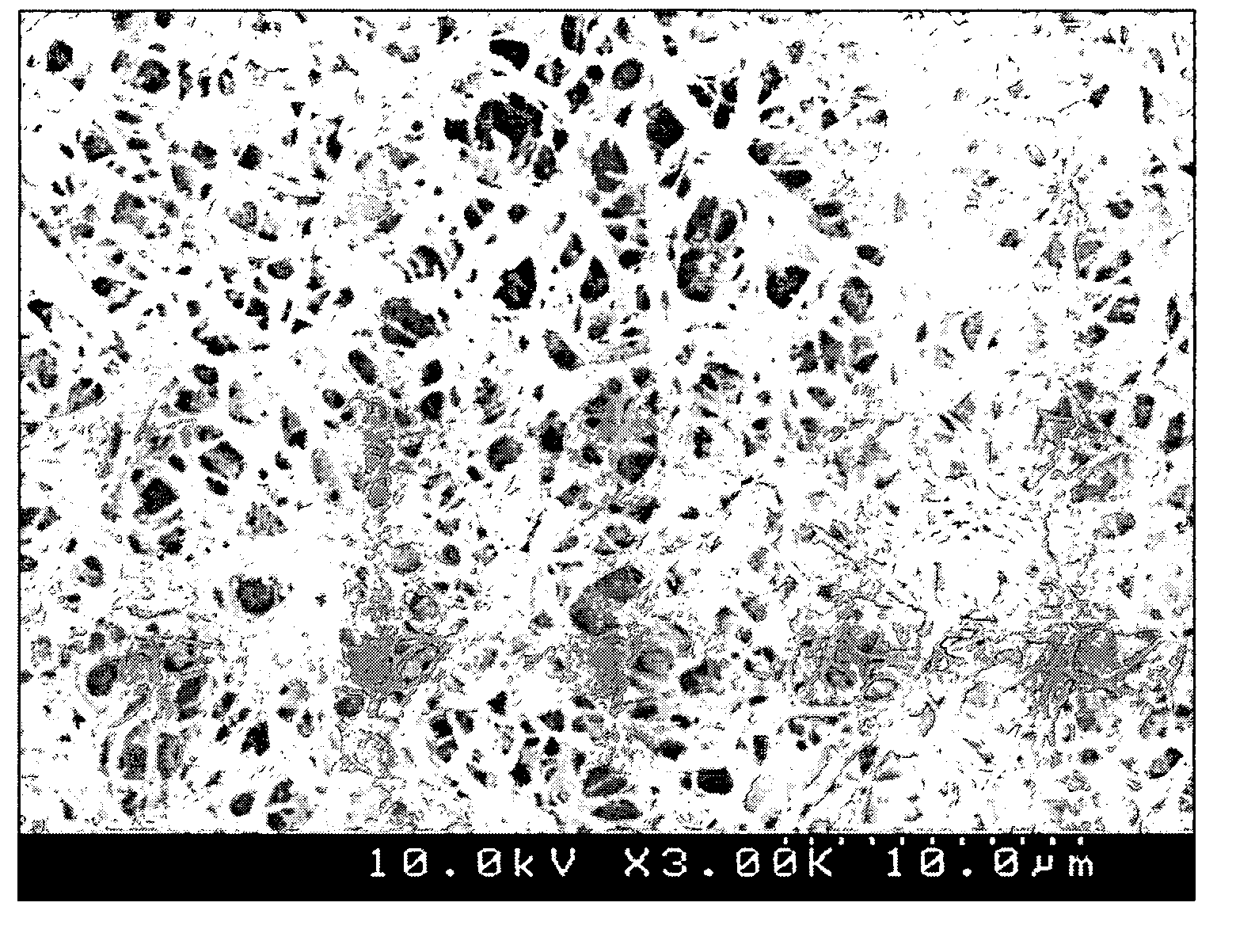

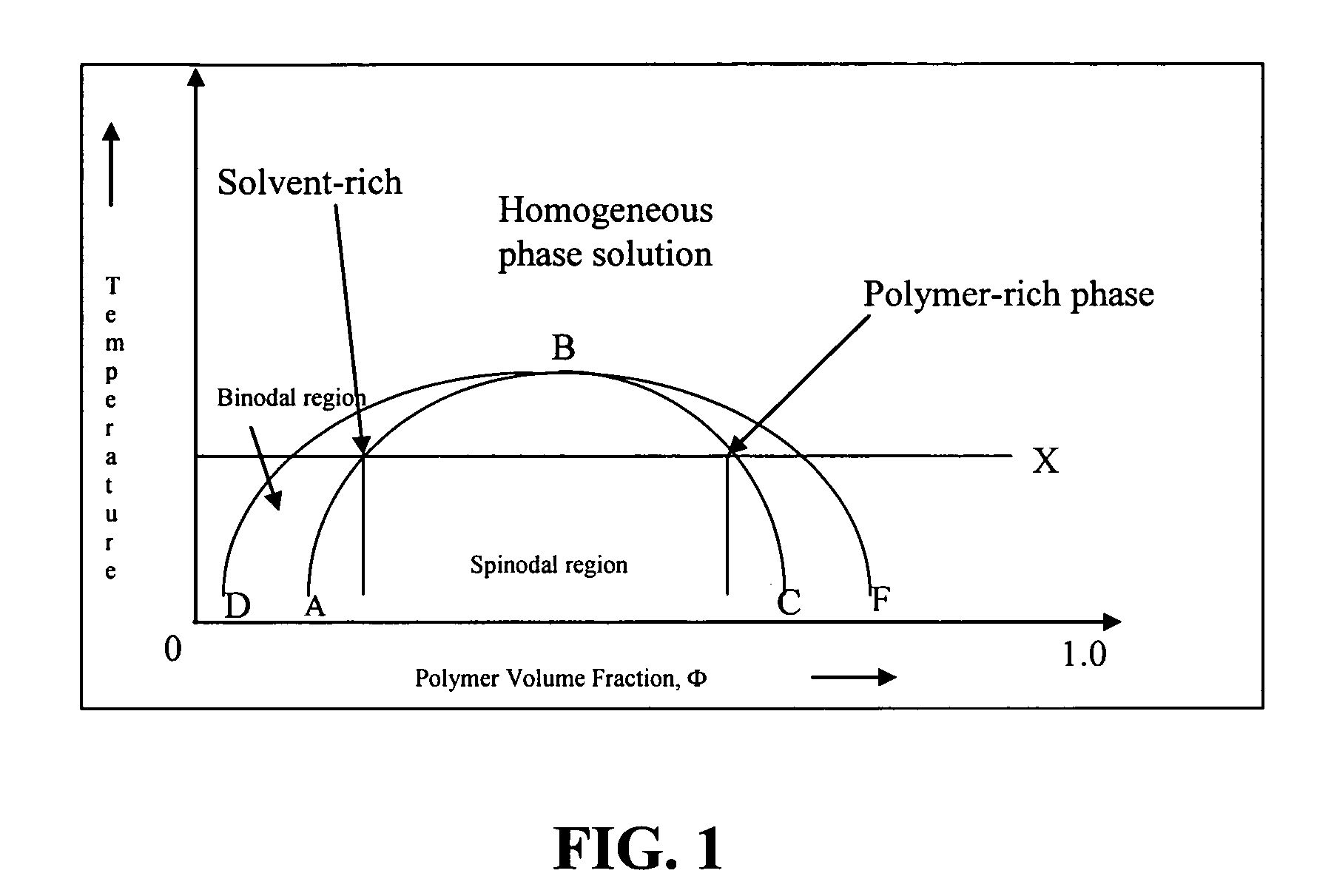

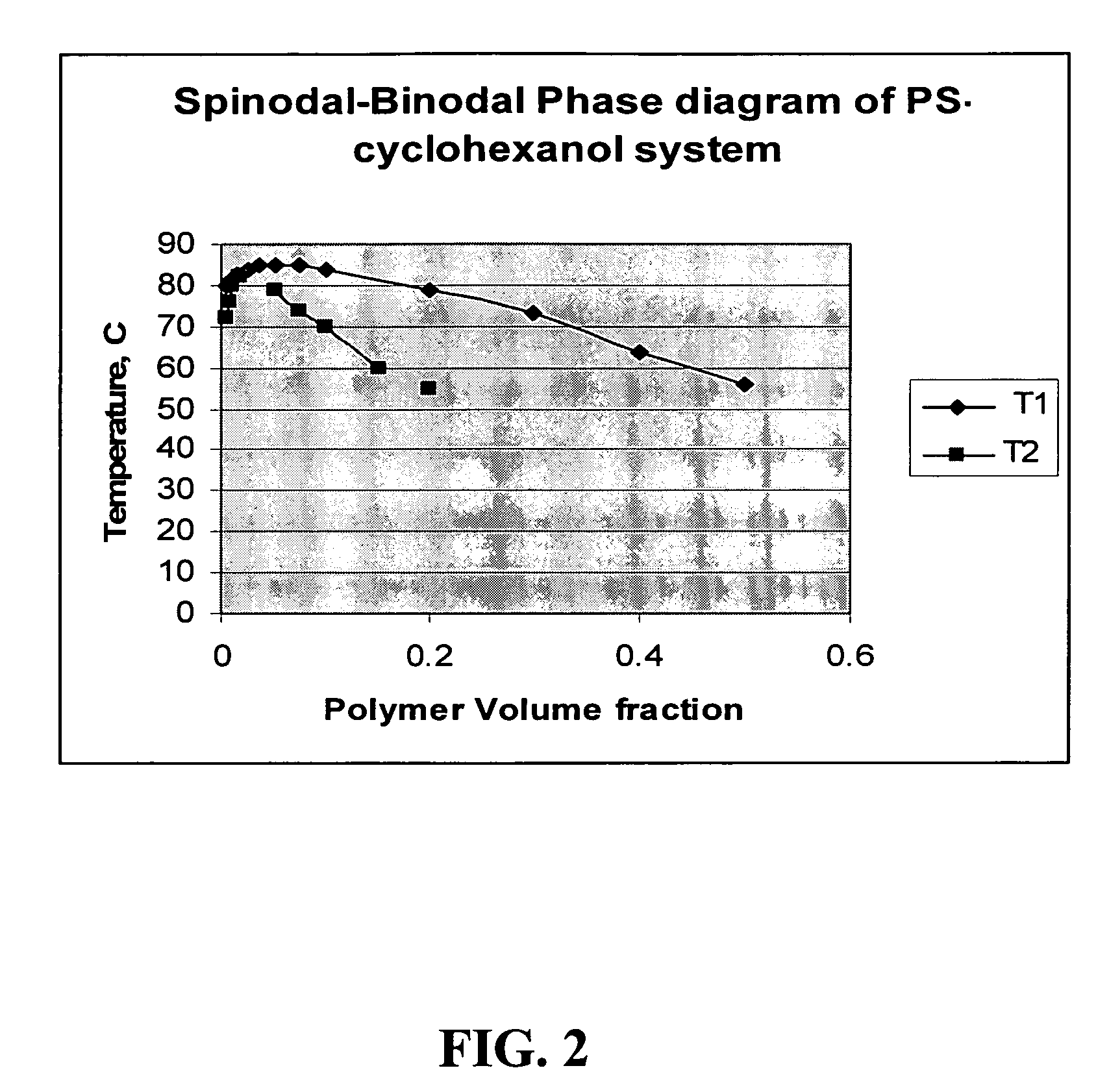

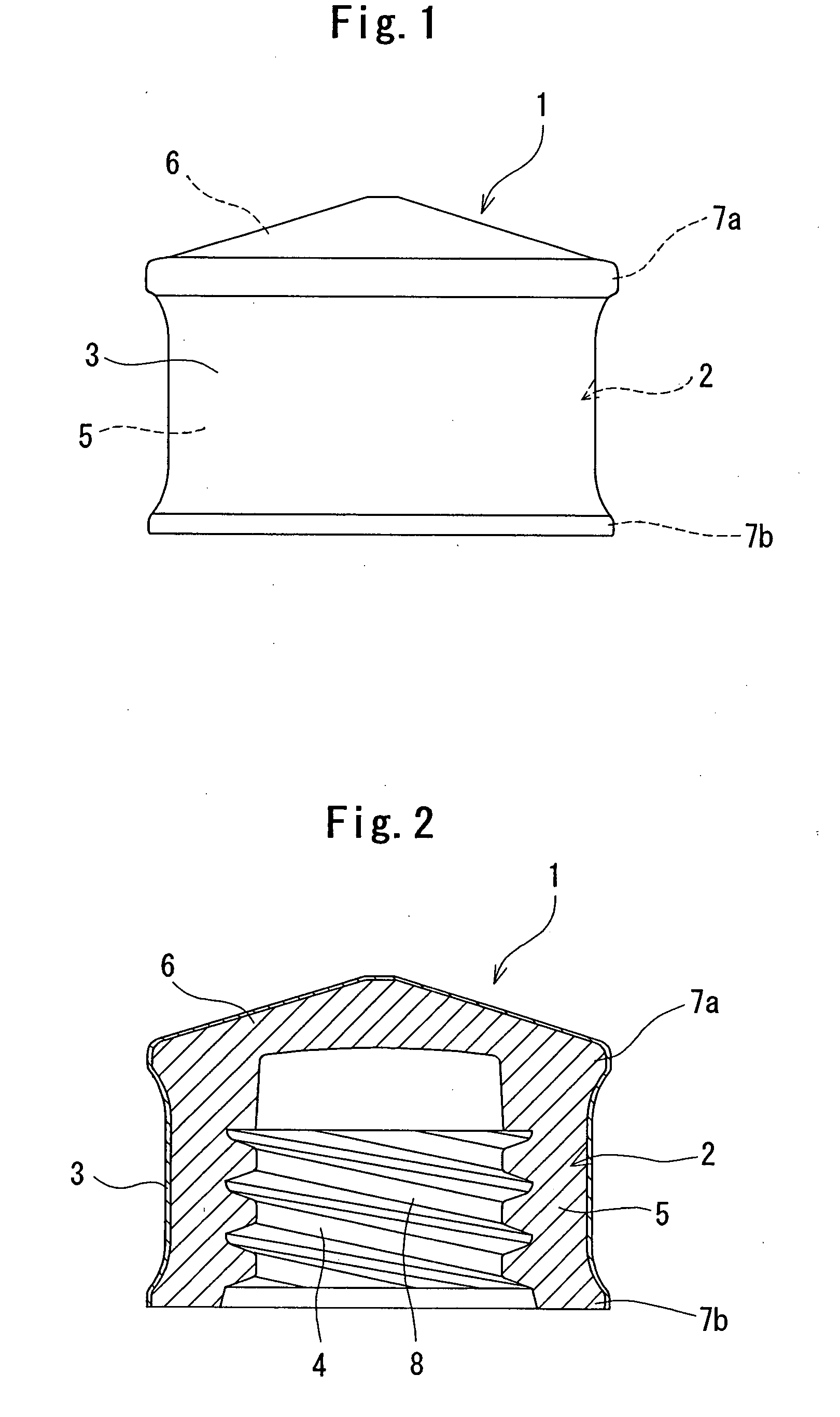

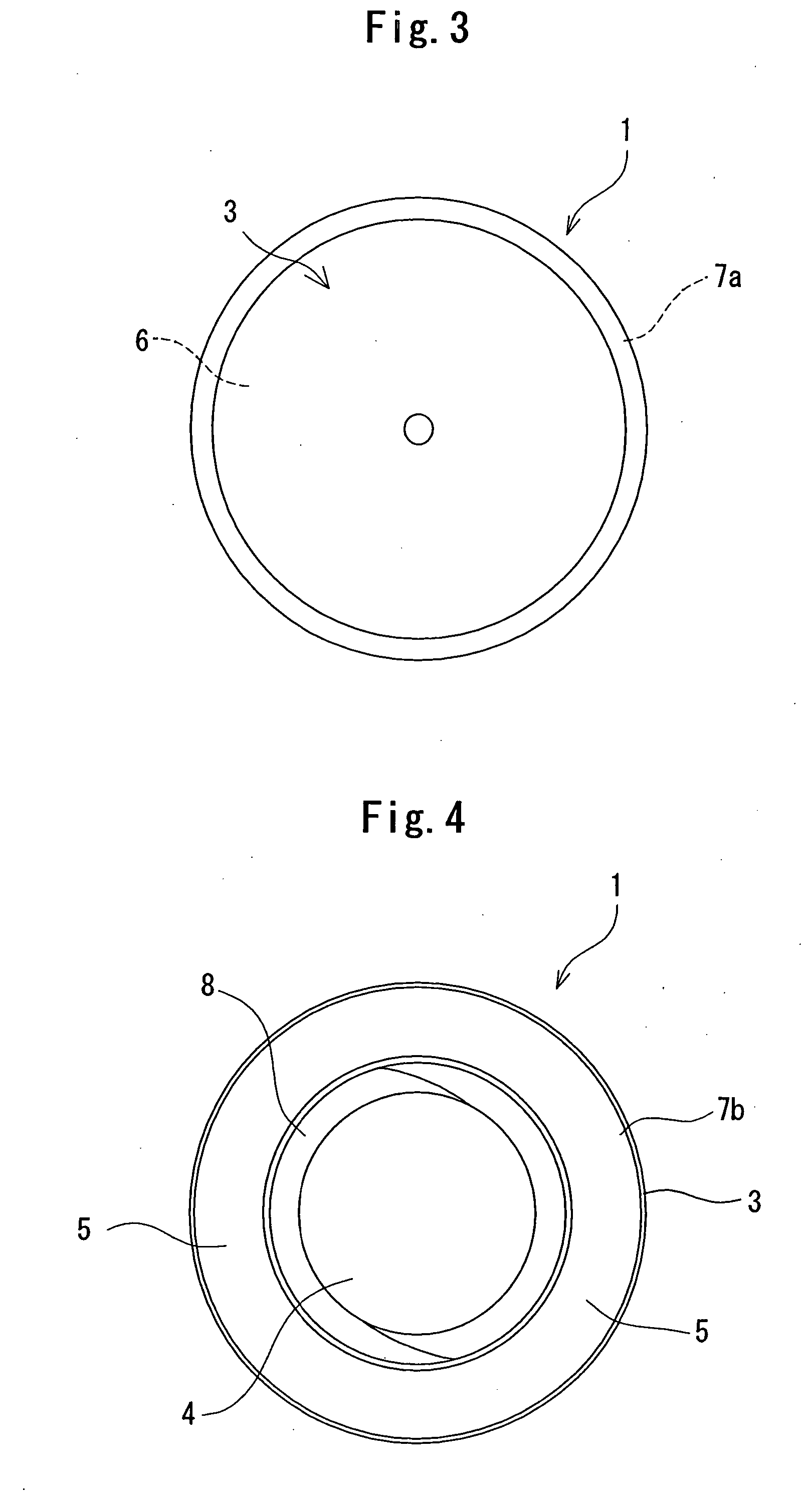

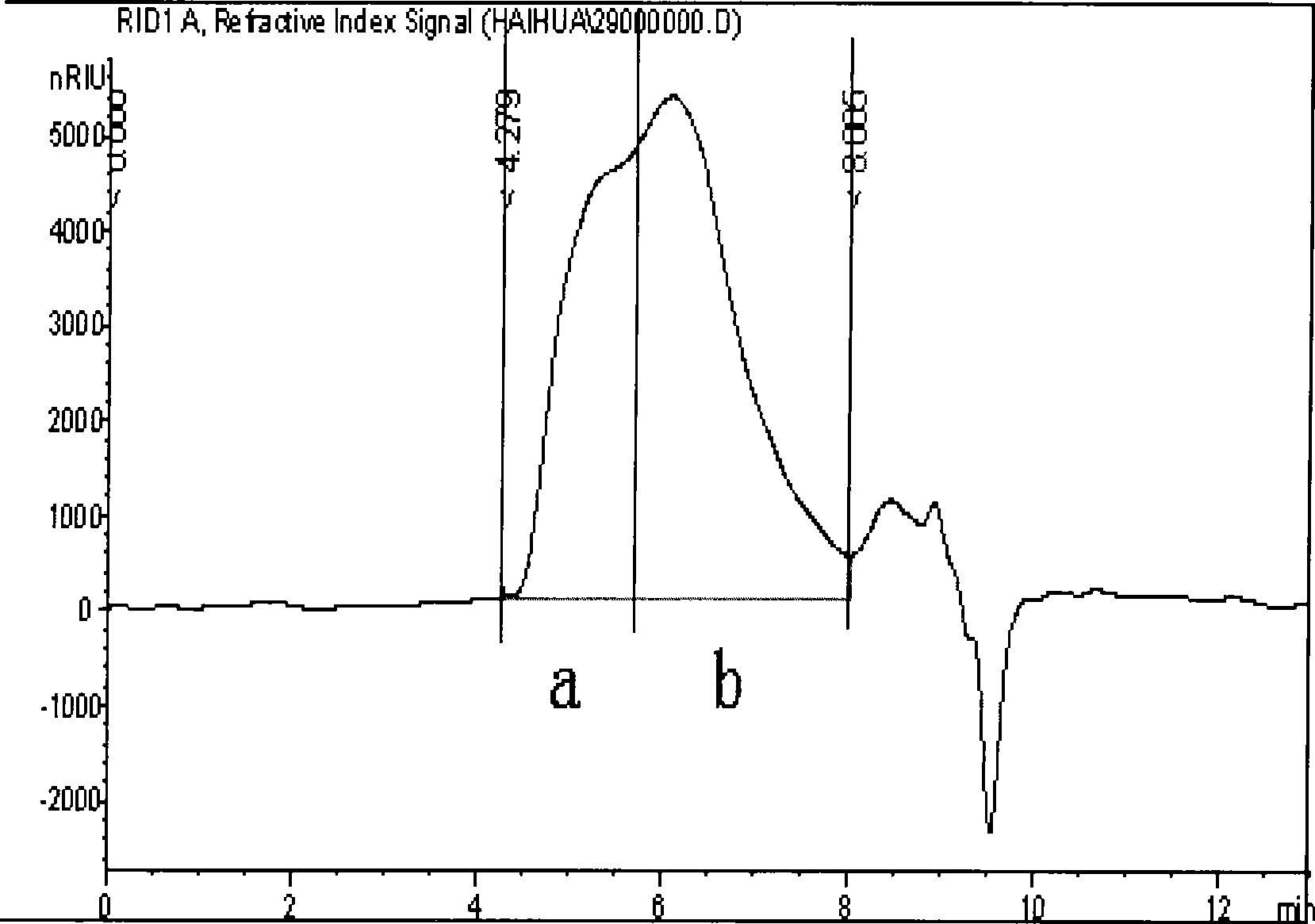

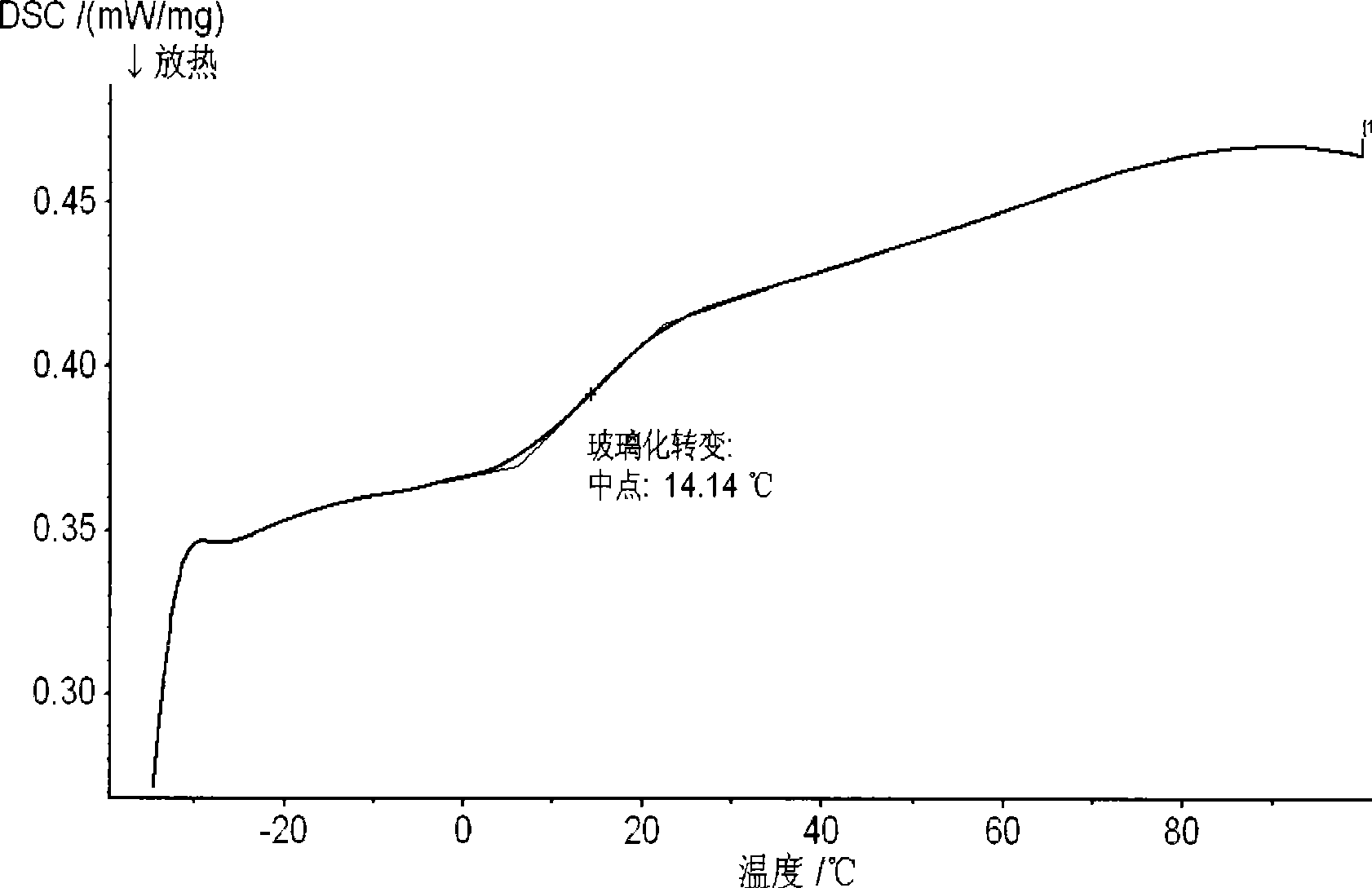

Method for manufacturing microporous CMP materials having controlled pore size

A method of manufacturing a chemical-mechanical polishing (CMP) pad comprises the steps of (a) forming a layer of a polymer resin liquid solution (i.e., a polymer resin dissolved in a solvent); (b) inducing a phase separation in the layer of polymer solution to produce an interpenetrating polymeric network comprising a continuous polymer-rich phase interspersed with a continuous polymer-depleted phase in which the polymer-depleted phase constitutes about 20 to about 90 percent of the combined volume of the phases; (c) solidifying the continuous polymer-rich phase to form a porous polymer sheet; (d) removing at least a portion of the polymer-depleted phase from the porous polymer sheet; and (e) forming a CMP pad therefrom. The method provides for microporous CMP pads having a porosity and pore size that can be readily controlled by selecting the concentration polymer resin in the polymer solution, selecting the solvent based on the solubility parameters of the polymer in the solvent polarity of solvent, selecting the conditions for phase separation, and the like.

Owner:CMC MATERIALS INC

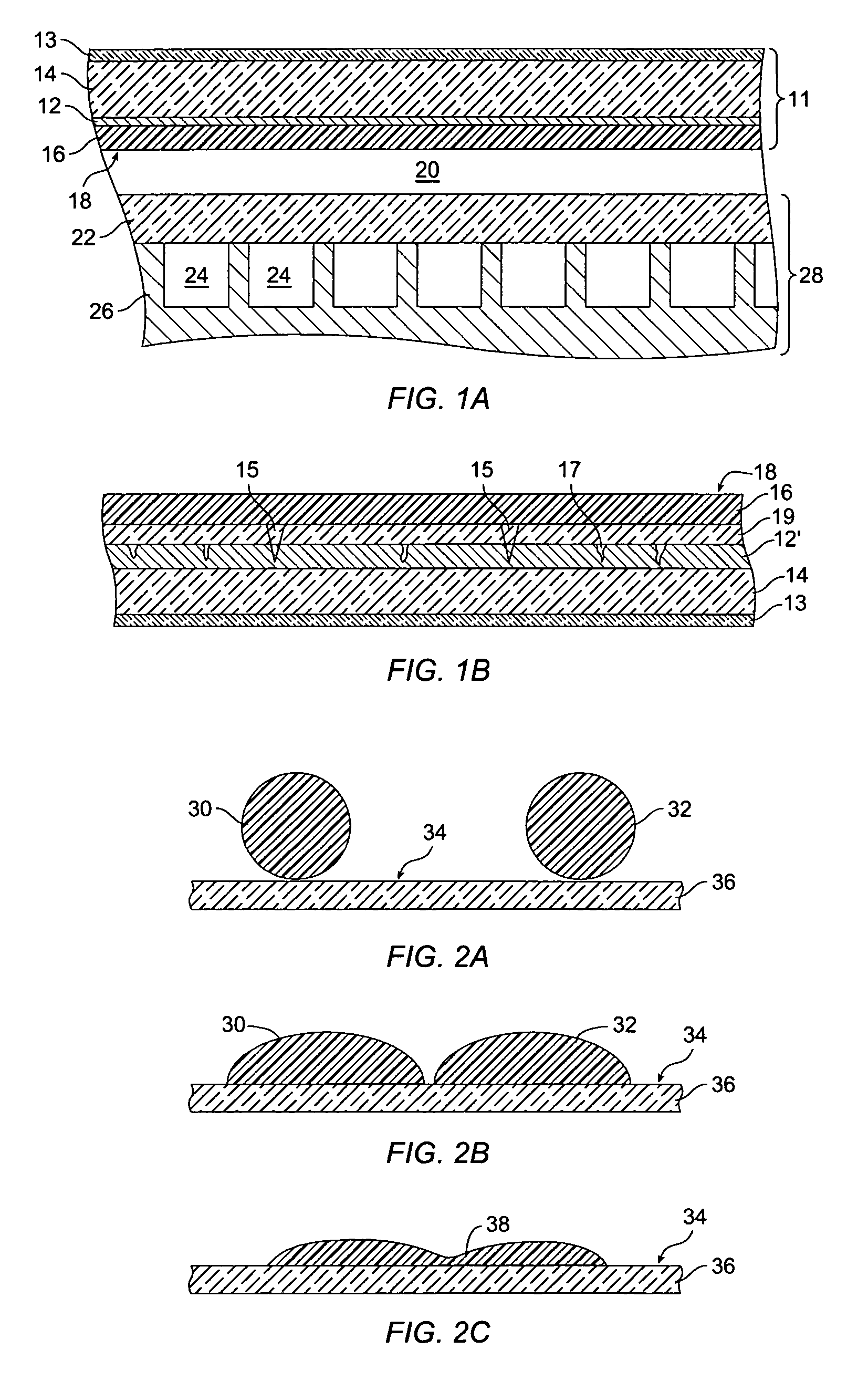

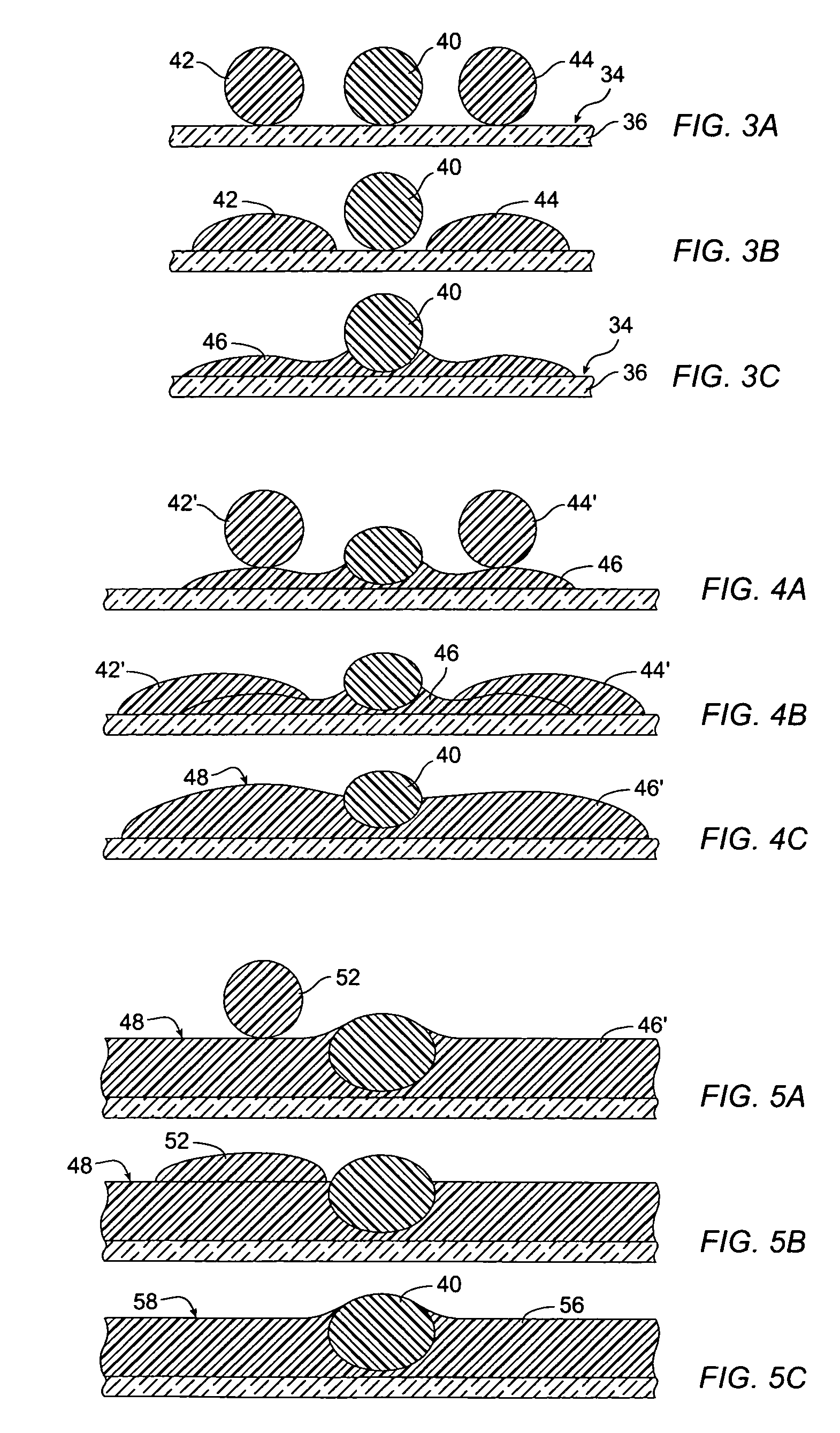

Dyed polymer coating for display panel

InactiveUS20050100690A1Improve color-balanceIncrease contrastRecord information storagePolyurea/polyurethane coatingsPolymer scienceSolvent based

An transmissive panel includes a polymer coating with a textured antireflective surface. Texturing of the surface is achieved in a variety of fashions. In some embodiments the polymer coating is embossed after application to the panel. In other embodiments, the polymer coating is solvent-based and develops a textured surface as a result differential shrinkage. In yet other embodiments, an aerosol of solvent-based polymer precursor is applied to the surface as a combination of high-viscosity droplets and low-viscosity droplets, portions of high-viscosity droplets extending above a film of polymer formed from low-viscosity droplets to provide a textured antireflective surface.

Owner:JDS UNIPHASE CORP

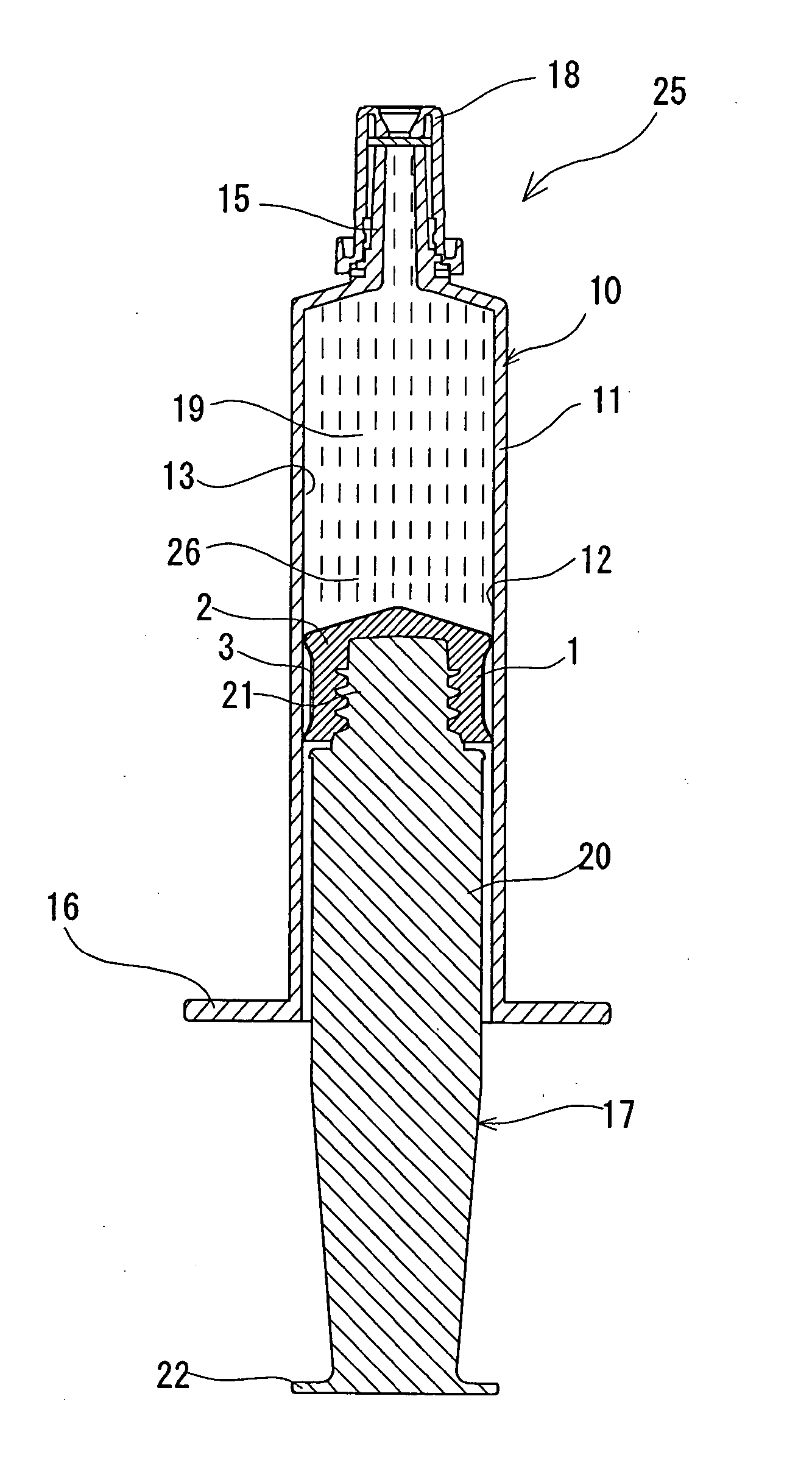

Medical appliance-coating composition and medical appliance

A medical appliance-coating composition contains a solvent-based silicone rubber, and in addition, carbon nanotubes, and fine particles of silicone resin. A medical appliance having a slidable coating film formed thereon moves in contact with an inner surface of a medical member or an inner surface of a lumen. The slidable coating film is disposed at a portion, of the medical appliance, which contacts the medical member or the lumen. The slidable coating film is comprised of silicone rubber, the carbon nanotubes and the fine particles of the silicone resin.

Owner:TERUMO KK

Method for developing multilayer imageable elements

InactiveUS6992688B2Recording apparatusSemiconductor/solid-state device manufacturingSolvent basedEngineering

A method for forming an image by imaging and developing a multi-layer imageable element, in which the developer is fresh developer and the developer is not reused, is disclosed. Much smaller variation in dot percentage is obtained when each imaged imageable element is developed in fresh developer than when the developer is reused to develop additional imaged imageable elements. The method is especially suited to the formation of images using stochastic screening. Either a solvent based developer or a high pH developer may be used.

Owner:KODAK POLYCHROME GRAPHICS

Compound epoxy flooring coating and preparation method thereof

InactiveCN101654583AHigh mechanical strengthImprove corrosion resistanceRosin coatingsEpoxy resin coatingsSolvent freeFirming agent

The invention relates to compound epoxy flooring coating adopting the mixture of epoxide resin and modified resin as a base material and further comprising organic solvent, dispersant, wetting agent, antifoaming agent, flatting agent, scratch resistance agent, pigment and stuffing as well as reactive diluent selected according to requirements. When in use, the coating is mixed and solidified withthe components of firming agent, accelerant, etc. By regulating the content of the components, the compound epoxy flooring coating of the invention can be used for manufacturing a solvent or solvent-free autolevelling epoxy floor. The compound epoxy flooring coating of the invention has favorable over-all properties, and not only has the characteristics of high mechanical strength, favorable anti-corrosion property, high adhesive force and good wear resistance property of the epoxide resin but also has the characteristics of good weather resistance, high decorative property and hardness and shock resistance of the modified resin; and the preparation method thereof is simple and practicable, is low-cost, and is suitable for mass preparation.

Owner:北京红狮科技发展有限公司

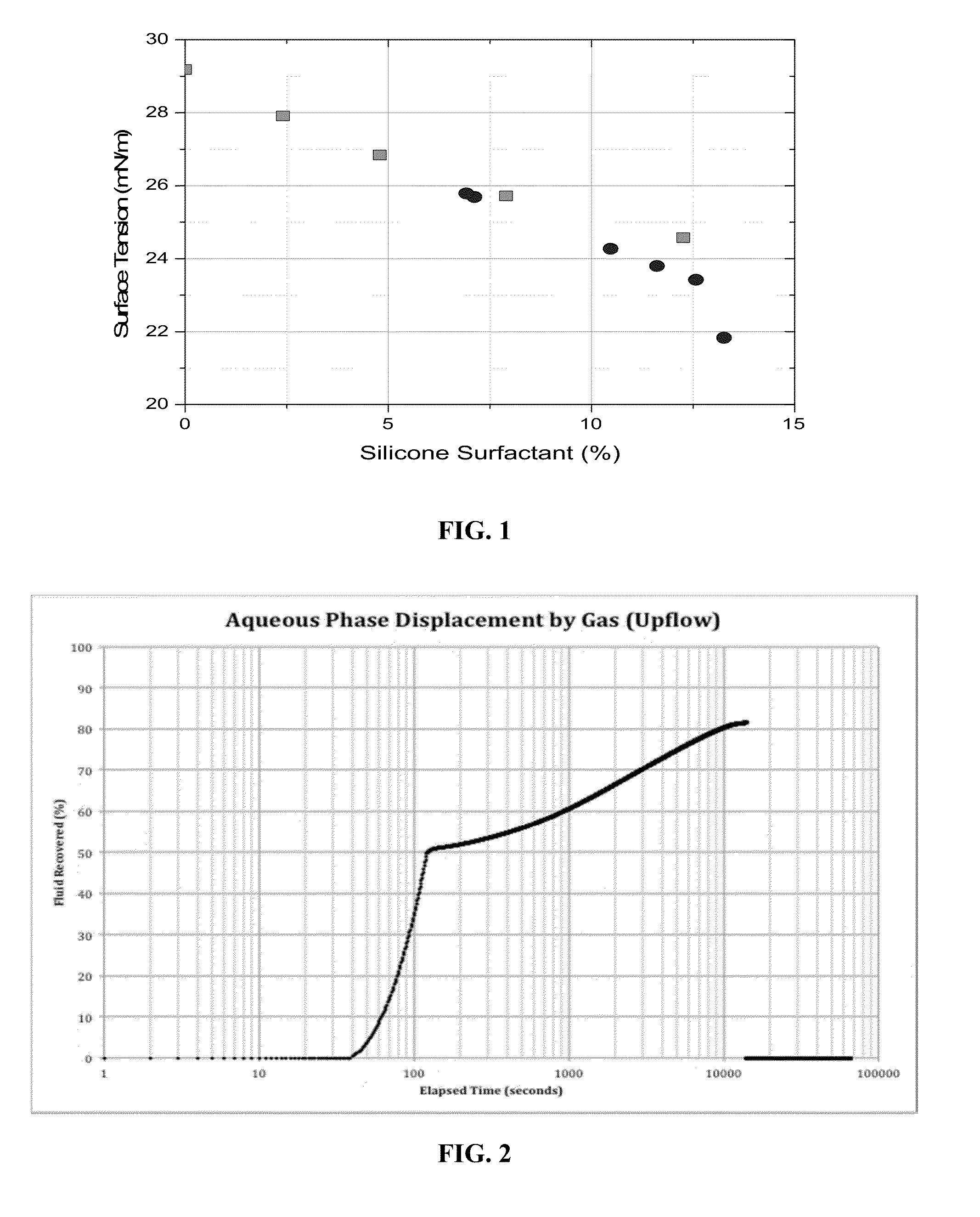

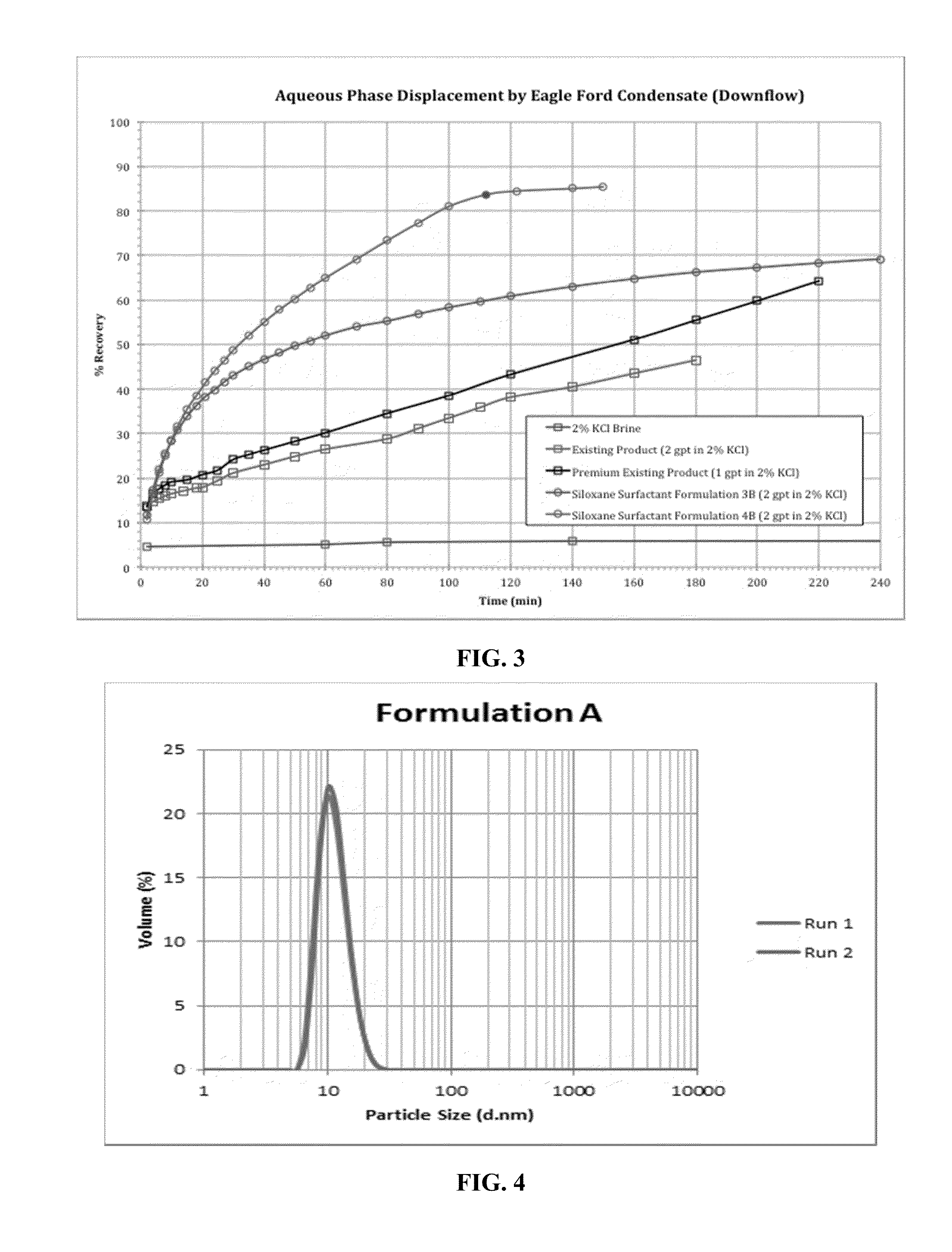

Siloxane surfactant additives for oil and gas applications

InactiveUS20140262288A1Improve propertiesImproved propertyFluid removalFlushingSolvent basedHydraulic fracturing

A well treatment additive includes a siloxane surfactant, a solvent and an aqueous phase. The solvent is preferably a terpene hydrocarbon. Also disclosed is a method for using the well treatment additive to form and enhance the properties of terpene solvent based additives useful for the treatment of oil and gas wells. Methods of using the novel well treatment additives include using the additives in a variety of well treatment processes including, but not limited to, acidizing operations, hydraulic fracturing operations, well remediation operations and water removal operations.

Owner:PNC BANK NAT ASSOC

Polyurethane-based pressure sensitive adhesives and methods of manufacture

Polyurethane-based pressure sensitive adhesives comprising the reaction product of: an isocyanate-reactive component comprising at least two isocyanate-reactive materials, an isocyanate-functional component; a reactive emulsifying compound; a chain capping agent and an optional chain extending agent. The adhesives, which are preferably pressure sensitive adhesives, can be prepared from 100% solids, waterborne or solventborne systems.

Owner:3M INNOVATIVE PROPERTIES CO

Solvent inkjet ink receptive films

InactiveUS6589636B2Decorative surface effectsDuplicating/marking methodsPolymer scienceSolvent based

In one aspect, the invention provides an image receptor medium which comprises an extruded image receptive layer that is receptive to solvent-based inkjet ink. Image receptive layers of the invention comprise a blend of an ink absorptive resin and a carrier resin. The ink absorptive resin is compatible with the carrier resin and had a Hildebrand Solubility Parameter within about 3.1 (MPa)1 / 2 of that of the solvent of the ink. In another aspect, the invention provides an image receptor medium which comprises a coextruded or extrusion coated image receptive layer and a core layer bonded together. In other aspects, the invention provides methods of printing images and methods of making an extrusion coated or coextruded image receptor medium.

Owner:3M INNOVATIVE PROPERTIES CO

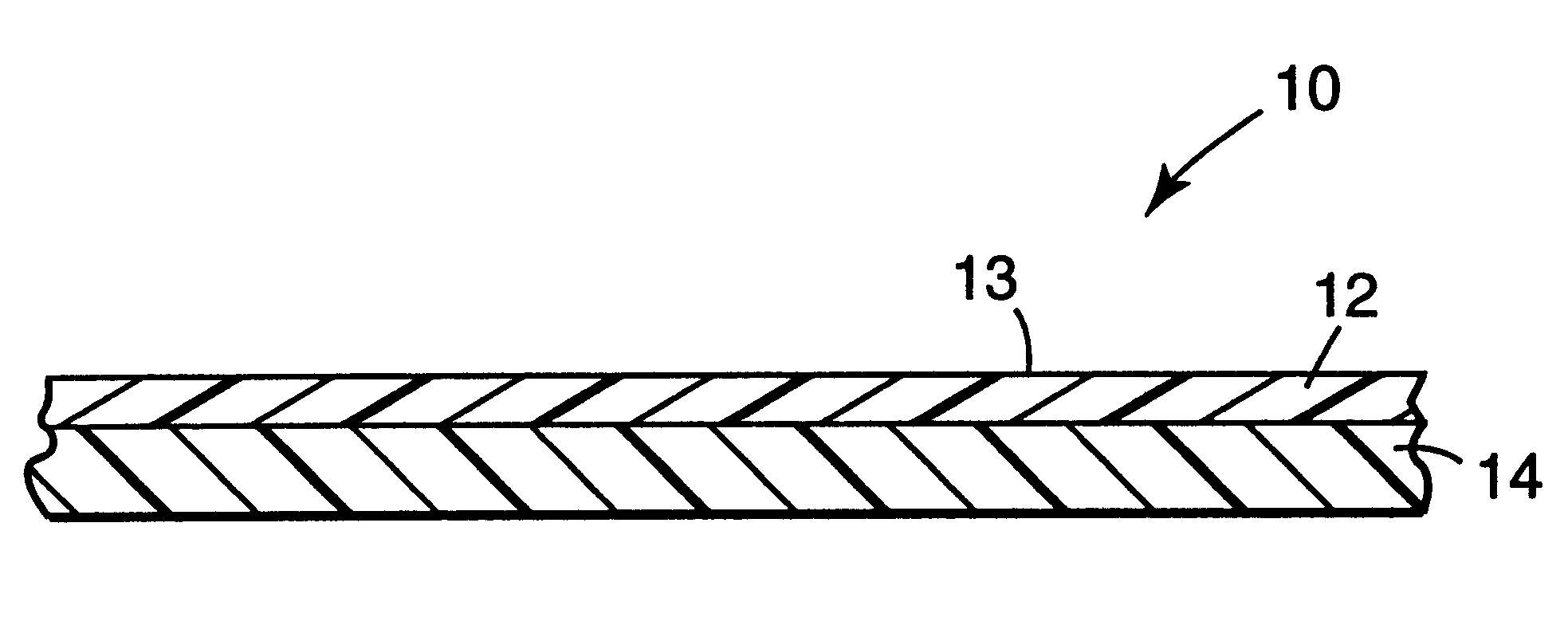

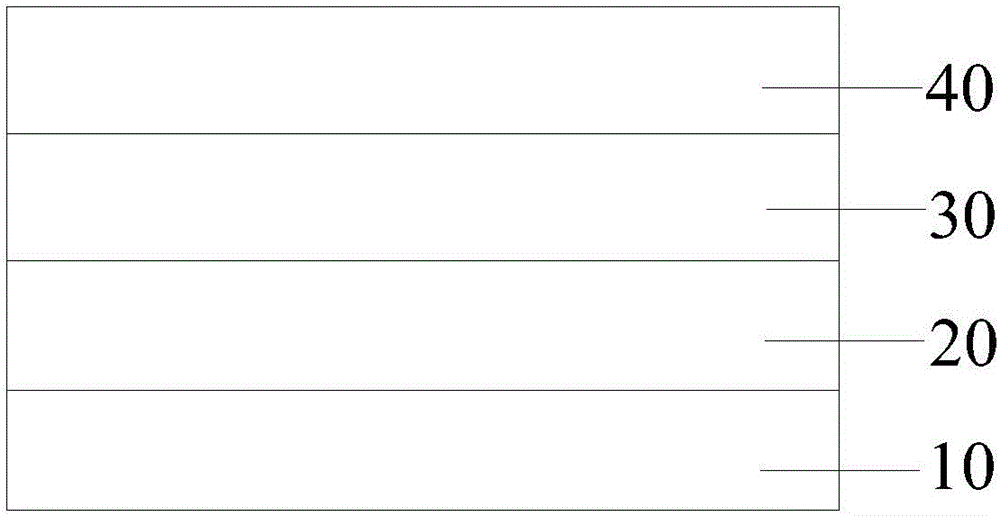

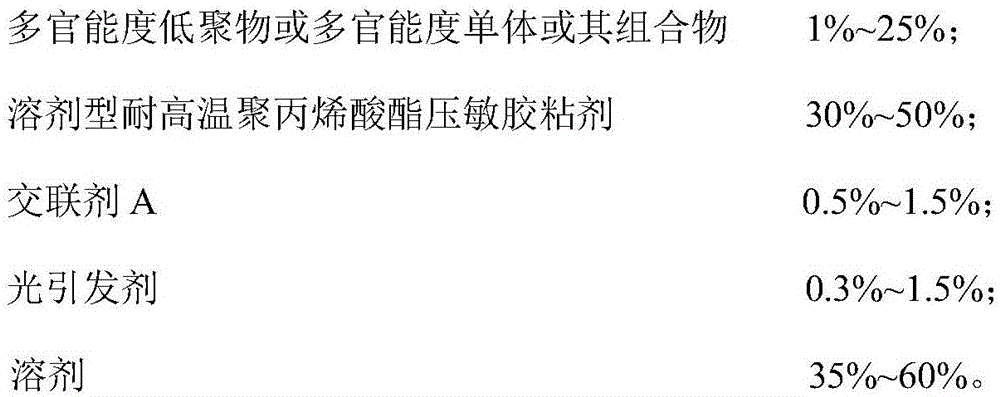

Heat-resistant UV visbreaking glue composition and UV visbreaking protective film

InactiveCN105778806AImprove peel forceSmall peeling forceFilm/foil adhesivesPolyureas/polyurethane adhesivesCross-linkTectorial membrane

The invention discloses a heat-resistant UV visbreaking glue composition and a UV visbreaking protective film prepared with this composition. This composition is made from the following materials according to parts by weight: 1-25% of a polyfunctional oligomer or polyfunctional monomer or its composition, 30-50% of a solvent type high-temperature-resistant polyacrylate pressure-sensitive glue, 0.5-1.5% of a cross-linking agent, 0.3-1.5% of a photo-initiator, and 35-60% of a solvent. The heat-resistant UV visbreaking protective film comprises a base (10), a bottom coating layer (20) applied to the surface of the base (10), a UV visbreaking glue layer (30) applied to the bottom coating layer (20), and a release film (40). The heat-resistant UV visbreaking protective film prepared herein can resist a high temperature of 120 DEG C and has the advantages of high UV pre-illumination release force, low UV post-illumination release force and no glue residue.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Conformable solvent-based bandage and coating material

ActiveUS20070041935A1Non-irritatingNot cause inflammationSurgical adhesivesSynthetic polymeric active ingredientsCyanoacrylateMedicine

Liquid hemostatic coating materials comprise a cyanoacrylate monomer and a solvent system comprising a volatile, non-reactive liquid that is non-stinging and non-irritating to a user. The material forms a coating or bandage in the form of a film that when applied and adhered to a surface or to the skin of a user inhibits the application surface from adhering to another surface.

Owner:ROCHAL PARTNERS

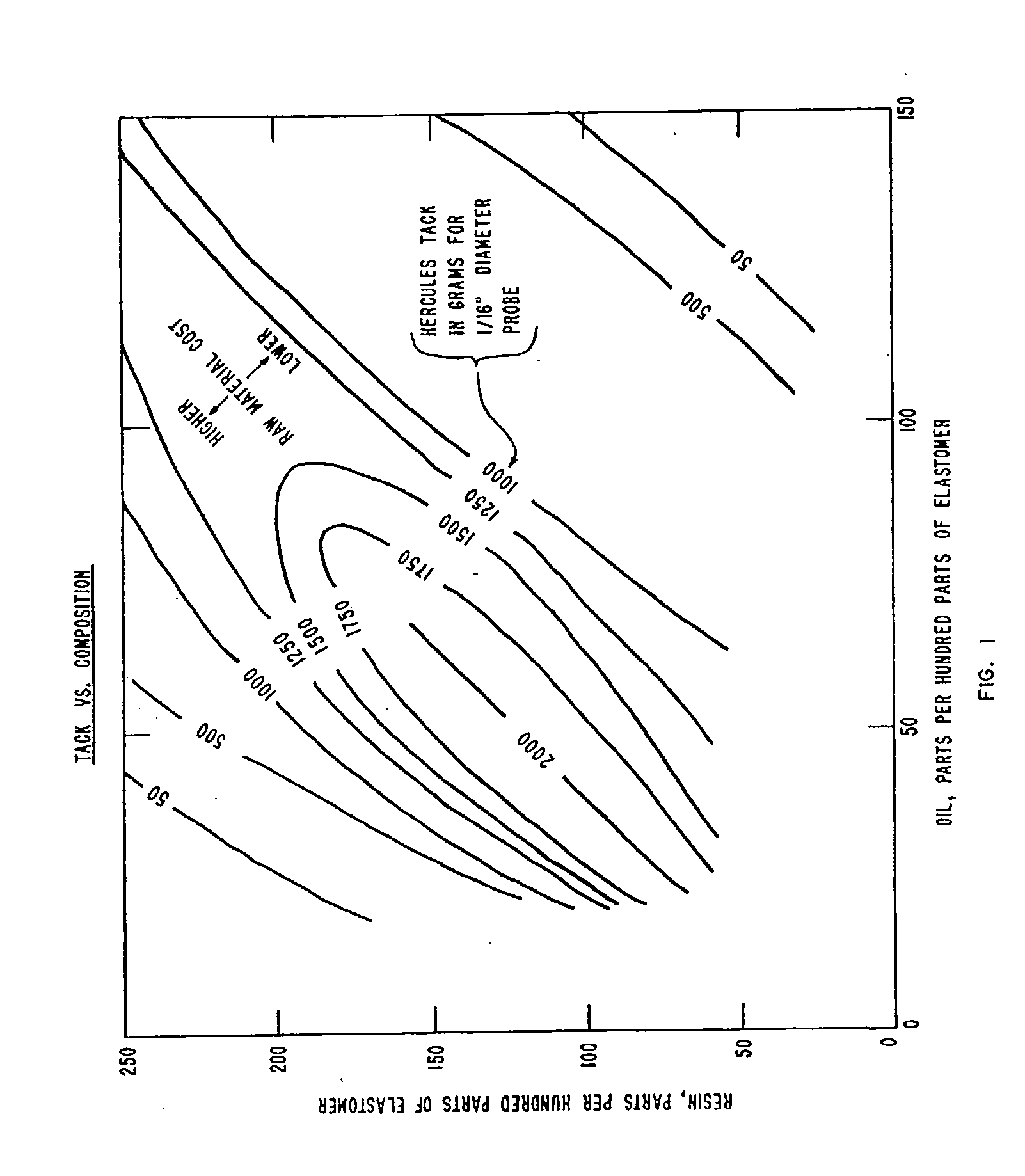

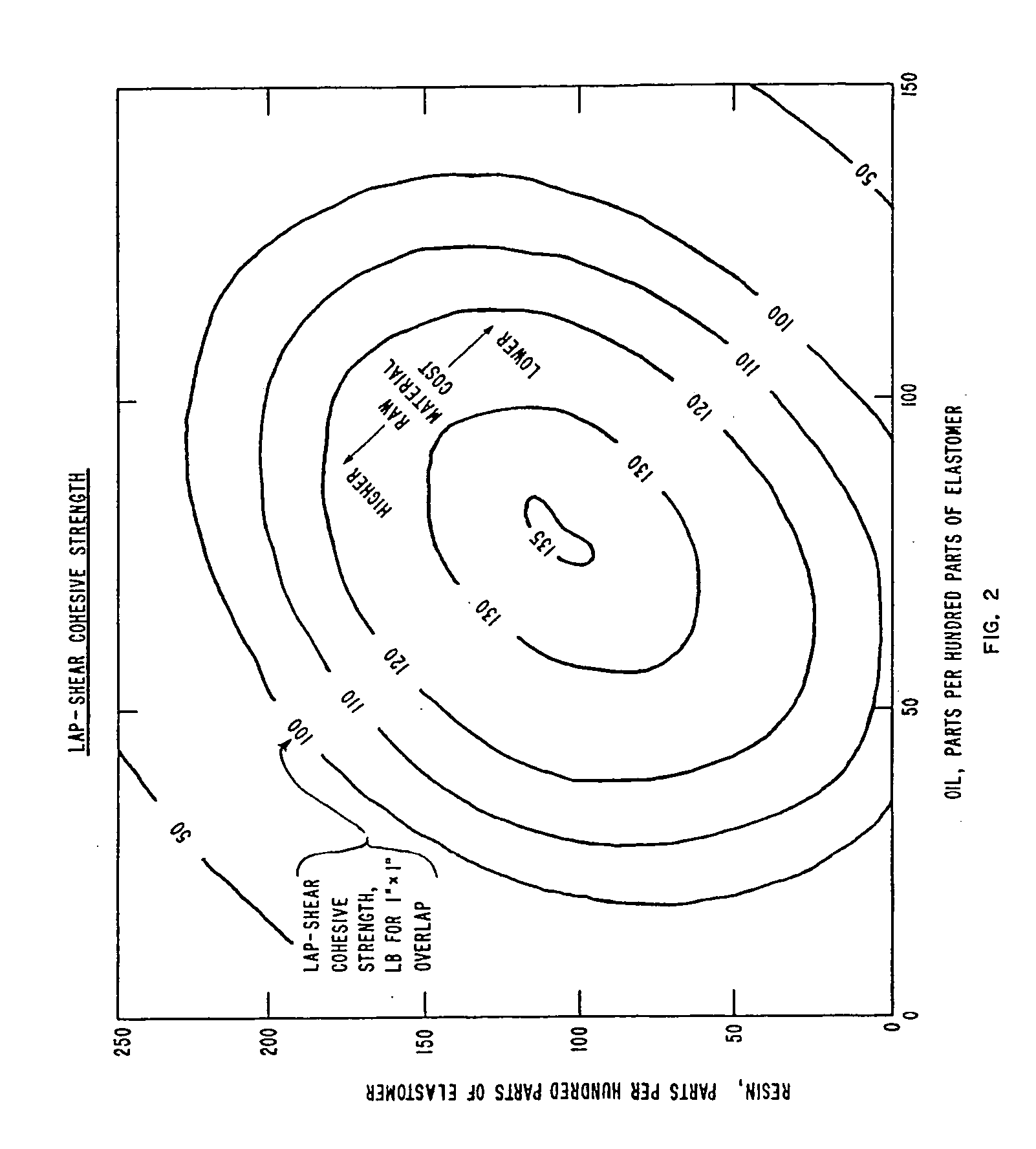

Solvent based, elastomeric coatings with lower VOC

The present invention relates to solvent based coatings which have a low level of volatile organics compounds (VOC) meeting California VOC regulations and which can be spray applied as a coating on a variety of surfaces. The coating formulation comprises a hydrogenated styrene / butadiene triblock copolymer, a hydrogenated styrene / butadiene diblock copolymer, at least one hydrocarbon solvent, at least one VOC exempt solvent, a midblock tackifying resin, and a pigment or filler. The relative amounts of solvent, tackifying resin and pigment are adjusted to obtain a solvent based, elastomeric coating having a VOC content of no more than 250 grams per liter and a viscosity no higher than 2,000 centipoise @ 25° C. as measured according to ASTM D2196.

Owner:ST CLAIR DAVID JOHN

Compositions for water-based and solvent-based sprayable gels and methods for making same

InactiveUS6838426B1Efficient removalCationic surface-active compoundsOrganic detergent compounding agentsWater basedBrick

The present invention is a sprayable gel cleaning composition and a method of making said sprayable gel cleaning composition. The gel stays on the stained surface until it is wiped off, unlike non-gelatinous compositions that have a very short surface contact time. The active agents of the sprayable gel cleaning composition are in contact with the stain for a longer period of time than other cleaners. The sprayable gel cleaning composition can be used to remove household and industrial spots and stains that are present on walls, cabinets, stove tops, doors, and trim. In addition, this invention can be used to clean concrete and brick, and remove caulk and paint from surfaces, as well as remove bug and tar stains present on automobiles, trucks, and other machinery and surfaces. The gelatinous composition may be water-based or solvent-based.

Owner:WEIMAN PROD

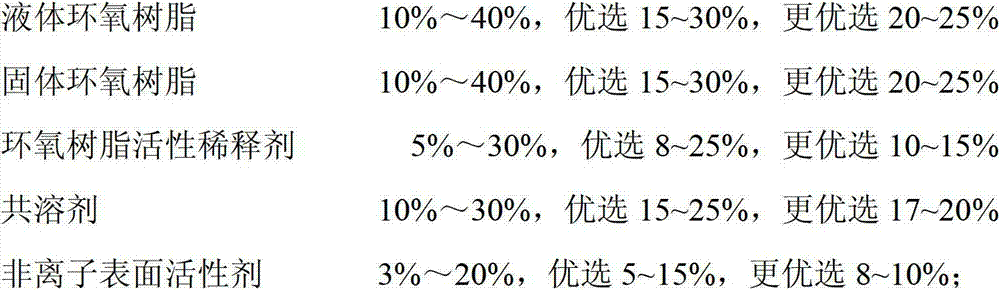

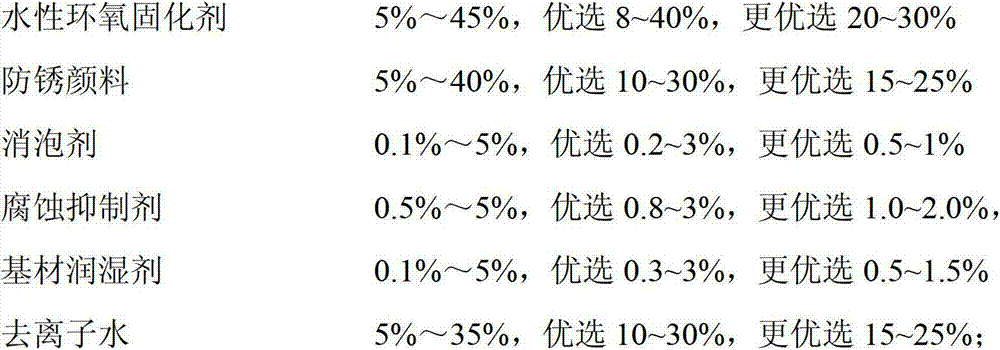

Room temperature fast-drying highly-anticorrosive two-component waterborne epoxy coating and preparation method thereof

ActiveCN103087612AImprove anti-corrosion performanceFast curingAnti-corrosive paintsEpoxy resin coatingsSurface-active agentsChemistry

The invention provides a room temperature fast-drying highly-anticorrosive two-component waterborne epoxy coating and a preparation method for the coating. The coating comprises A and B two components, wherein the A component consists of liquid epoxy resin, solid epoxy resin, an epoxy resin reactive diluent, a cosolvent, and a non-ionic surface active agent; the B component consists of a waterborne epoxy curing agent, an anticorrosive pigment, a foam killer, a corrosion inhibitor, a substrate wetting agent and de-ionized water, and during application, mass proportion of the A component to B component is 1:3-6. The coating is high in curing speed of coated film, the surface is dried in 30min at room temperature without being roasted; the coating has high early hardness, and the hardness can reach 3H in 48 hours; and in addition, the coating is good in thermal resistance stability, low in VOC (Volatile Organic Compound) content, excellent in anti-corrosion performance, and is capable of replacing a solvent type two-component epoxy coating to be applied to the anti-corrosion of a steel structure.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

Aqueous polyurethane dry process transform-film synthetic leather and manufacturing method thereof

InactiveCN102312378AHeating evenlySave heating energySynthetic resin layered productsTextiles and paperOrganic solventSolvent based

The invention which relates to an aqueous polyurethane dry process transform-film synthetic leather and a manufacturing method thereof belongs to the technical field of synthetic leathers and manufacturing methods thereof. The manufacturing method of the aqueous polyurethane dry process transform-film synthetic leather is characterized in that the manufacturing method comprises the following steps: 1, preparing a base cloth which treats a non-woven fabric as the skeleton; 2, coating a superficial layer, a foaming layer and a bonding layer on release paper to realize the dry process transform-film; 3, carrying out leather-paper separation after the paper-leather separation or slaking; and 4, examining and warehousing. Compared with solvent-based polyurethane, the aqueous polyurethane dry process transform-film synthetic leather has equivalent physical properties, and accords with application demands, environmentally friendly aqueous polyurethane is used, a product (the aqueous polyurethane dry process transform-film synthetic leather) contains no organic solvents which are harmful to environmental protection, a DMF recovery operation which is required in the production process of solvent-based products is reduced, the production process is simplified, and energy saving and environmental protection are realized, so the aqueous polyurethane dry process transform-film synthetic leather which adapts to foreign restrictive requirements on environment friendly polyurethane synthetic leathers and allows the production personnel demand, the damage to the personnel, and the production cost to be reduced has a strong market competitiveness.

Owner:YANTAI LIANCHENG POLYMER MATERIAL

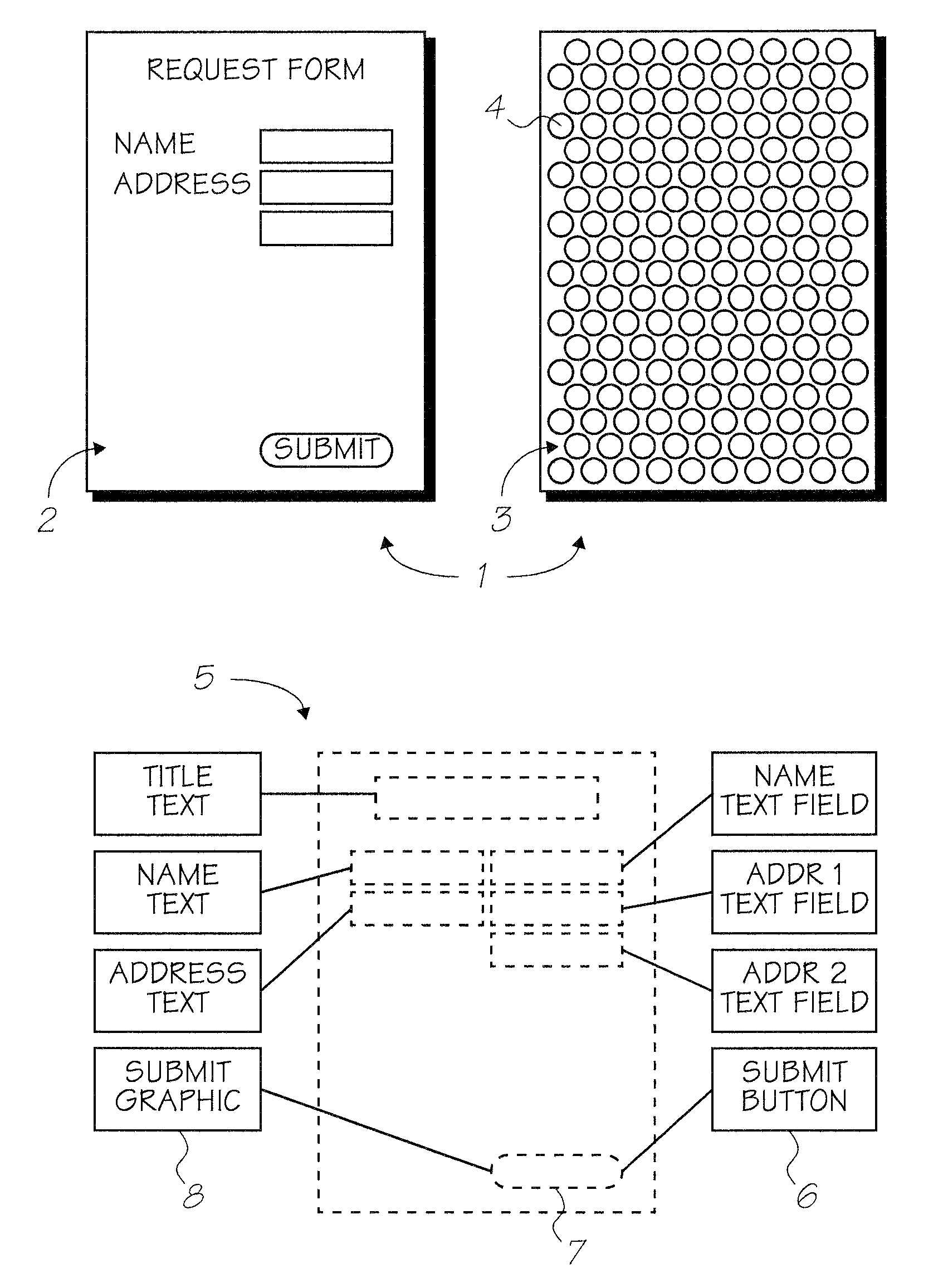

Secure Lottery Ticket Using Hybrid Construction

InactiveUS20120025516A1Minimizing overlapMinimizing blank spaceStampsOther printing matterWater basedSolvent based

Solvent-based and water-based scratch-off materials are employed as single layers on a lottery ticket to create a more resistant ticket construction that still provides a satisfactory play experience. In one embodiment, two different scratch-off inks on the play area of the ticket are employed, with the majority of the ink being a softer, solvent-based, formulation. The ink covering sensitive areas of the ticket includes a harder, water-based, formulation.

Owner:GTECH PRINTING CORP

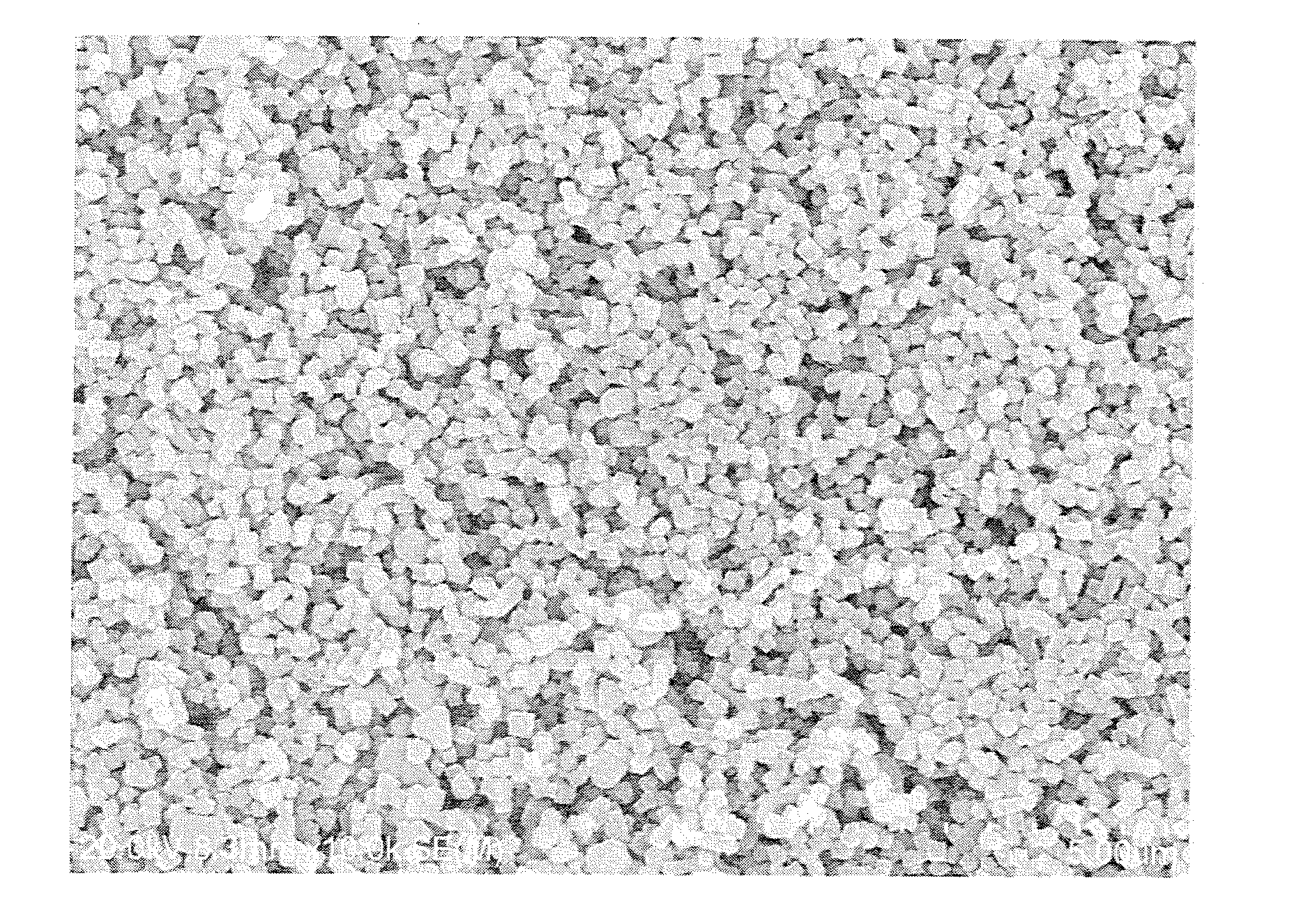

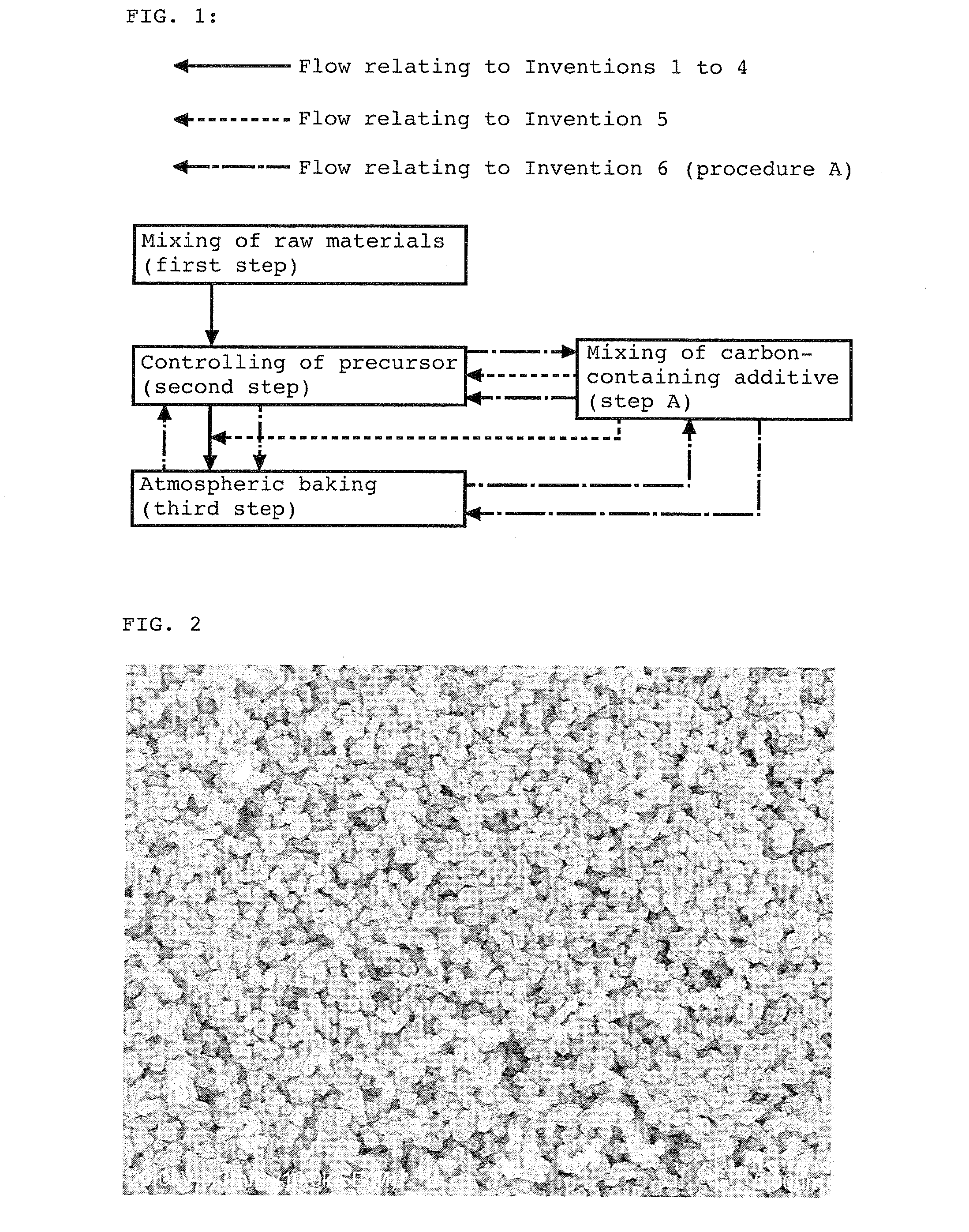

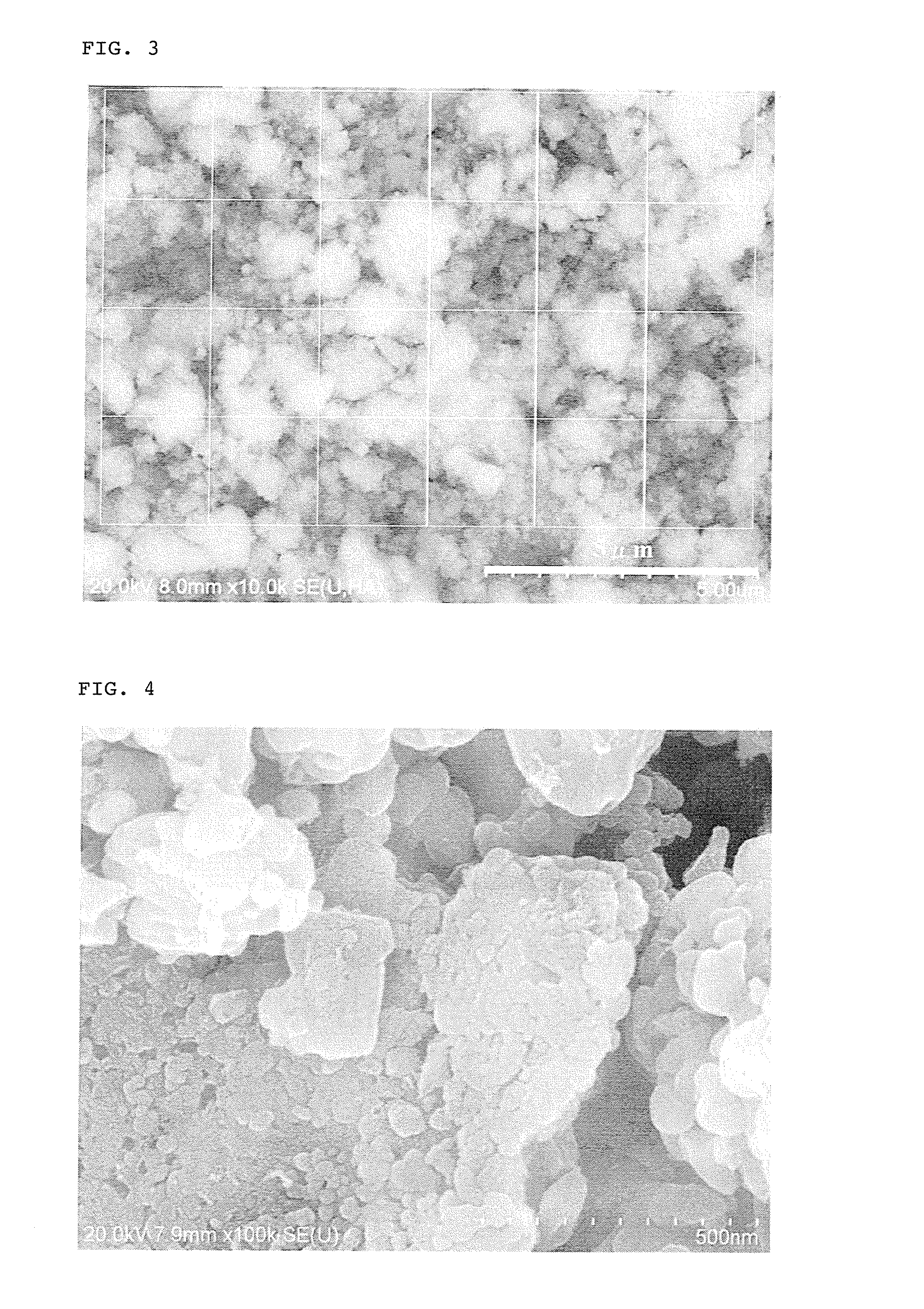

Process for producing lithium iron phosphate particles, lithium iron phosphate particles having olivine type structure, and positive electrode sheet and non-aqueous solvent-based secondary battery using the lithium iron phosphate particles

InactiveUS20110091772A1Low costReduce environmental burdenElectrode manufacturing processesPhosphatesOxygenOlivine

The present invention relates to a process for producing lithium iron phosphate particles having an olivine type structure, comprising a first step of mixing an iron oxide or an iron oxide hydroxide as an iron raw material which comprises at least one element selected from the group consisting of Na, Mg, Al, Si, Cr, Mn and Ni in an amount of 0.1 to 2 mol % for each element based on Fe, and a carbon element C in an amount of 5 to 10 mol % based on Fe, and has a content of Fe2+ of not more than 40 mol % based on an amount of Fe and an average primary particle diameter of 5 to 300 nm, with a lithium raw material and a phosphorus raw material; a second step of controlling agglomerates diameter in the resulting mixture is 0.3 to 5.0 μm; and a third step of sintering the mixture obtained in the second step in an inert gas or reducing gas atmosphere having an oxygen concentration of not more than 0.1% at a temperature of 250 to 750° C.

Owner:TODA IND

Ultrathin section steel structure fire-resisting paint and preparation thereof

The invention discloses an ultra-thin fireproof coating for a steel structure and a preparation method thereof. The coating has the characteristics of high gloss, good water resistance, strong adhesion force and so on of a solvent based ultra-thin fireproof coating, also has the advantages of water-based coatings by taking water as a medium, and satisfies the direction of developing low-pollution and environment-friendly coatings of the coating industry. The technical proposal comprises that the ultra-thin fireproof coating for the steel structure is prepared from the following components by weight portion: 10 to 35 portions of acrylic hybrid emulsion, 10 to 25 portions of dehydration and carbon-forming catalyst, 10 to 25 portions of carbon forming agent, 5 to 20 portions of foaming agent, 5 to 20 portions of flame retardant, 5 to 25 portions of pigment and filler, 3 to 10 portions of reinforcing agent, 5 to 10 portions of latent solvent, 1 to 5 portions of dispersant, 0.1 to 1 portion of foam killer, 0.2 to 2 portions of flatting agent, 0.2 to 2 portions of thickening agent, 1 to 5 portions of film forming additive, and the balance being water.

Owner:MARINE CHEM RES INST

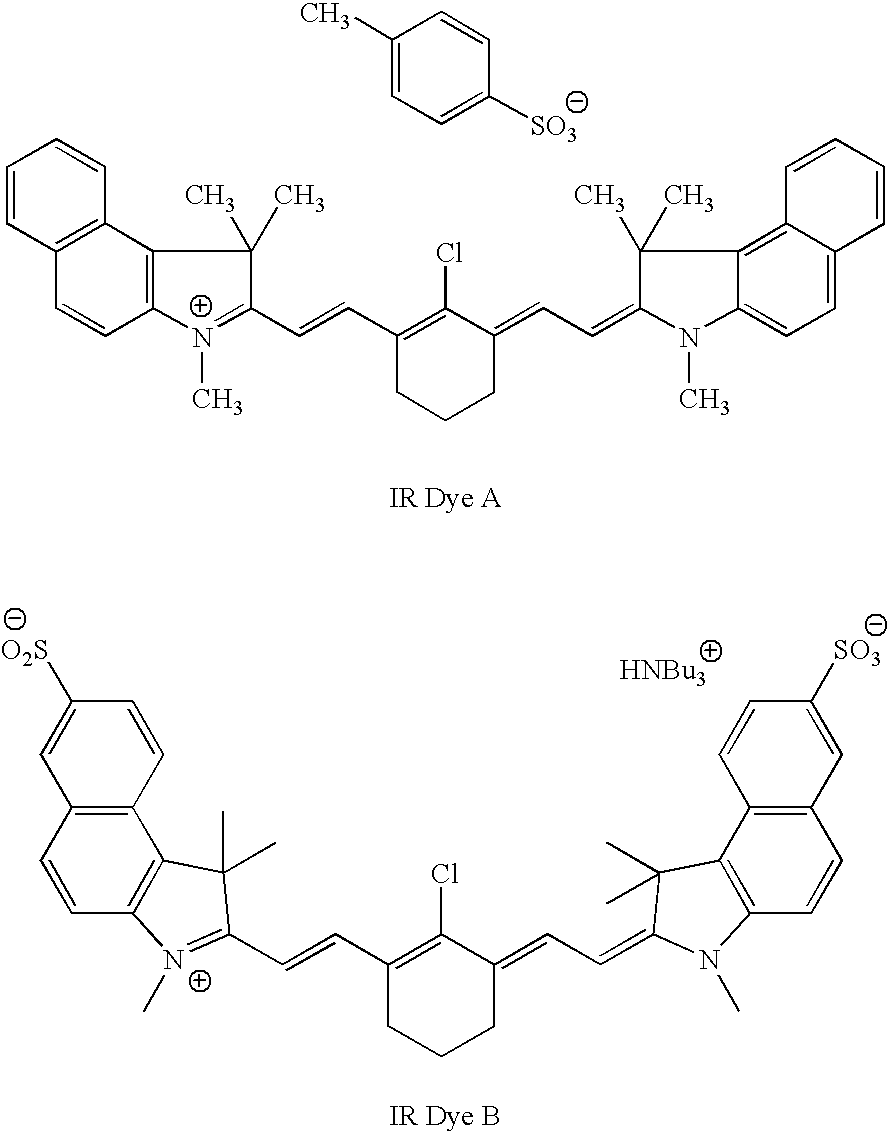

Alternative phthalocyanine dyes suitable for use in offset inks

A phthalocyanine phthalocyanine salt suitable for formulation in a solvent-based or oil-based ink vehicle is disclosed. The phthalocyanine comprises one or more sulfonate groups and a counterion of at least one sulfonate group is an ammonium cation comprising at least 15 carbon atoms. Ammonium salts of sulfonated gallium naphthalocyanines exemplify such phthalocyanine salts.

Owner:BASF SE

Solar module back veneer comprising non-solvent bonding layers and manufacturing method thereof

ActiveCN102569451AAvoid pollutionImprove performanceFinal product manufacturePhotovoltaic energy generationPolymer scienceAcrylic resin

The invention provides a solar module back veneer comprising non-solvent bonding layers. The solar module back veneer comprises: a base film layer, the bonding layers on two sides of the base film layer, a fourth thin layer and a fifth thin layer which are on another two sides of the bonding layers. The materials of the bonding layers are selected from one or more of the following components: polyethylene and a vinyl copolymer, polypropylene and modified polypropylene, thermoplastic polyurethane, acrylic resin and ABS series resin. The invention also provides a manufacturing method of the back veneer. According to the invention, a solvent adhesive can be completely avoided to be used. By using the method of the invention, pollution generated through volatilization and emission of the solvent to environment during a traditional back veneer manufacturing process can be avoided. Simultaneously, adhesive strength, ageing resistance, barrier performance and a long-term service ability can be increased. By using the non-solvent bonding layers, a fusion extrusion technology can be used during manufacturing the solar module back veneer, which substantially reduces production cost.

Owner:DSM SUNSHINE SOLAR TECH (SUZHOU) CO LTD

Multiple reversible color change microcapsule anti-counterfeiting material and preparation method and application thereof

InactiveCN101724392AHigh-speed emulsification and dispersionGood weather resistanceOther chemical processesLuminescent/fluorescent substance additionInfraredWater based

The invention discloses a multiple reversible color change microcapsule anti-counterfeiting material and a preparation method and applications thereof. The preparation method comprises the following steps: dissolving at least one of temperature-sensitive material, humidity sensitive material, ultraviolet excited fluorescence material and infrared excited fluorescence material in high boiling point solvent containing UV resistant agent and antioxidant, then adding emulsifier and protective colloid to obtain emulsion solution, and adopting the in-situ polymerization method to obtain the anti-counterfeiting material with microcapsule structure. The microcapsule structure of the invention can isolate the air and the wall of the microcapsule can reduce the light transmission, thus improving the weather resistance and light resistance of the anti-counterfeiting material and prolonging the use validity of the product. The material is a microcapsule aqueous solution so that the material is completely applicable to the coating method of the currently existing water-based paint, removes apprehensions in areas of safety, health and environmental protection, thoroughly solves the defect of the complicated solvent-based (oily material) coating and processing method, satisfies the anti-counterfeiting demand and can be applied in papers, cloth and film materials in large.

Owner:张世智

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com