Patents

Literature

170results about How to "Save heating energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

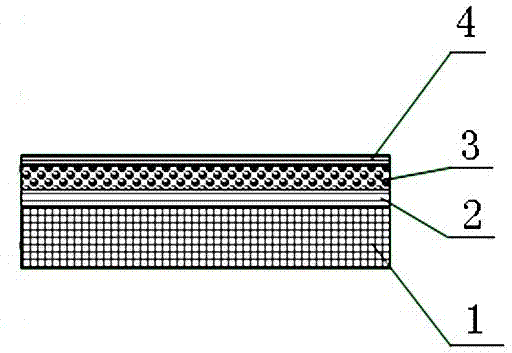

Aqueous polyurethane dry process transform-film synthetic leather and manufacturing method thereof

InactiveCN102312378AHeating evenlySave heating energySynthetic resin layered productsTextiles and paperOrganic solventSolvent based

The invention which relates to an aqueous polyurethane dry process transform-film synthetic leather and a manufacturing method thereof belongs to the technical field of synthetic leathers and manufacturing methods thereof. The manufacturing method of the aqueous polyurethane dry process transform-film synthetic leather is characterized in that the manufacturing method comprises the following steps: 1, preparing a base cloth which treats a non-woven fabric as the skeleton; 2, coating a superficial layer, a foaming layer and a bonding layer on release paper to realize the dry process transform-film; 3, carrying out leather-paper separation after the paper-leather separation or slaking; and 4, examining and warehousing. Compared with solvent-based polyurethane, the aqueous polyurethane dry process transform-film synthetic leather has equivalent physical properties, and accords with application demands, environmentally friendly aqueous polyurethane is used, a product (the aqueous polyurethane dry process transform-film synthetic leather) contains no organic solvents which are harmful to environmental protection, a DMF recovery operation which is required in the production process of solvent-based products is reduced, the production process is simplified, and energy saving and environmental protection are realized, so the aqueous polyurethane dry process transform-film synthetic leather which adapts to foreign restrictive requirements on environment friendly polyurethane synthetic leathers and allows the production personnel demand, the damage to the personnel, and the production cost to be reduced has a strong market competitiveness.

Owner:YANTAI LIANCHENG POLYMER MATERIAL

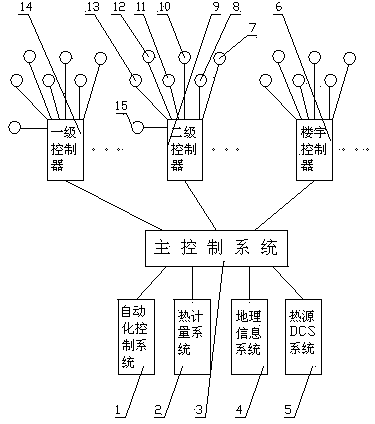

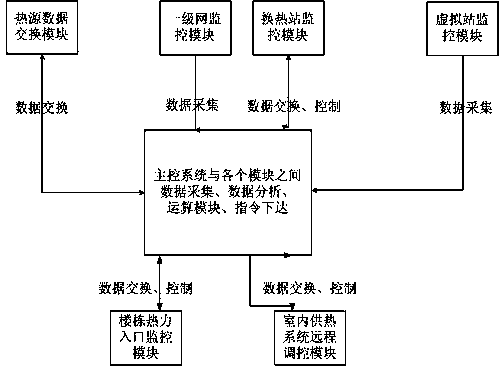

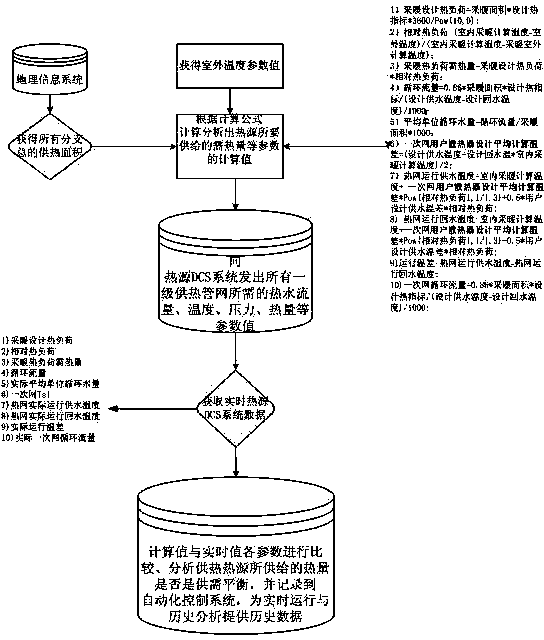

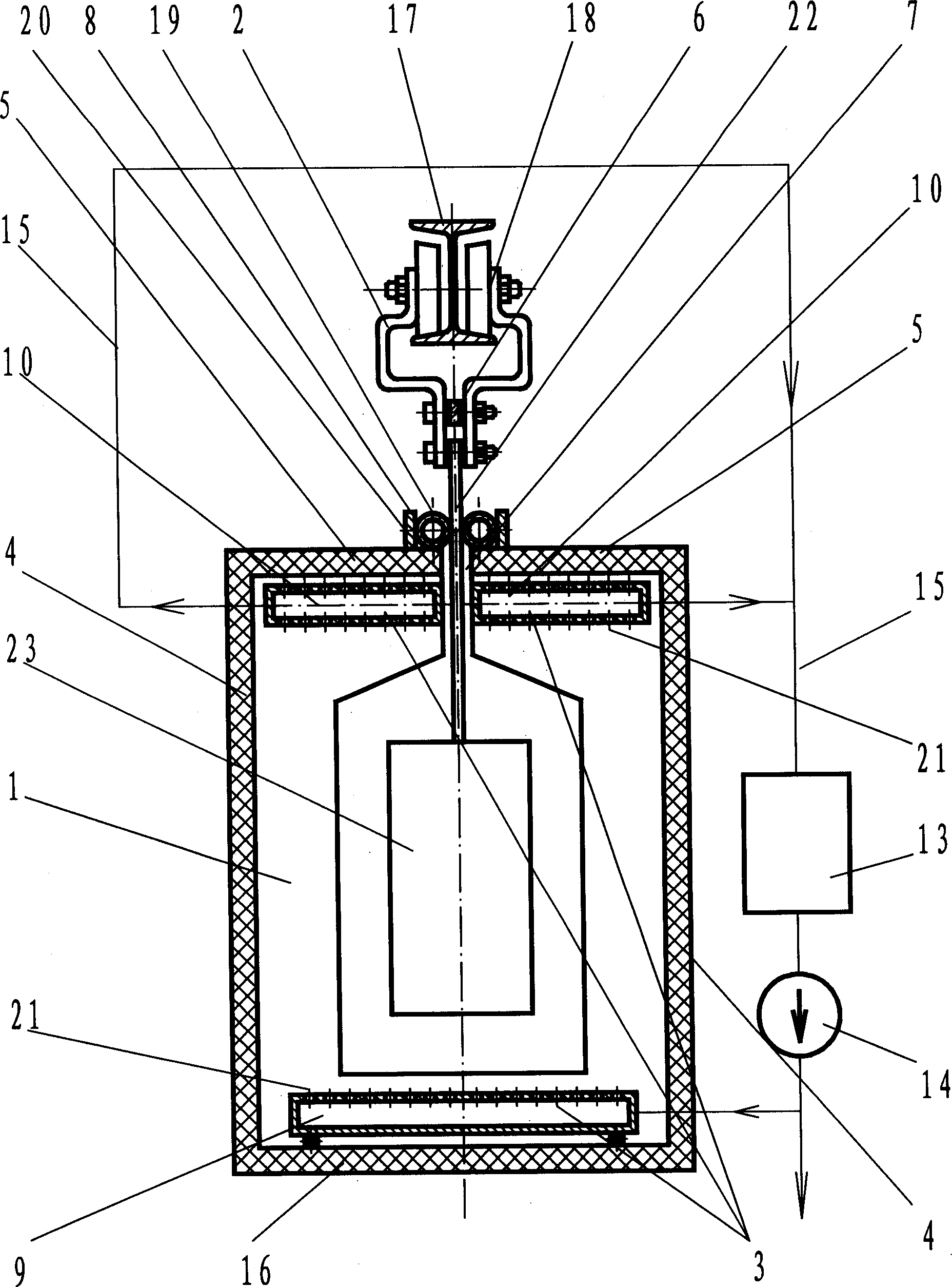

Intelligent heat supply network integrated system and control method thereof

ActiveCN104048347AReasonable controlEffective controlLighting and heating apparatusSpace heating and ventilation detailsFrequency changerControl system

The invention discloses an intelligent heat supply network integrated system and a control method of the intelligent heat supply network integrated system and relates to a city heating system and a control method of the city heating system. The system comprises a heat source, a heat supply dispatch initial station, a heat exchange station, a primary heat supply pipe network, a secondary heat supply pipe network and a building heat supply pipe network, a main control system, a primary controller, a secondary controller and a building controller are arranged, each stage of heat supply pipe network is provided with a heat meter, a pressure sensor, a temperature sensor and an electric adjusting valve, a circulation pump on the primary network and a circulation pump on the secondary network are respectively provided with a frequency converter, and the building controller, the primary controller and the secondary controller are connected with the main control system; the building controller is electrically connected with the electric adjusting valve of the building heat supply pipe network. The main control system obtains control parameters through the sensors on all the stages of pipe networks, and the working states of the heat supply pipe networks are adjusted and controlled according to the specific values between the parameters and designed values. According to the intelligent heat supply network integrated system, heat and water balance of the heat supply pipe networks is optimally controlled, no utilizable energy is wasted, and the intelligent heat supply network integrated system is green, capable of saving energy, environmentally friendly and beneficial for descendants.

Owner:山东国能智能科技有限公司

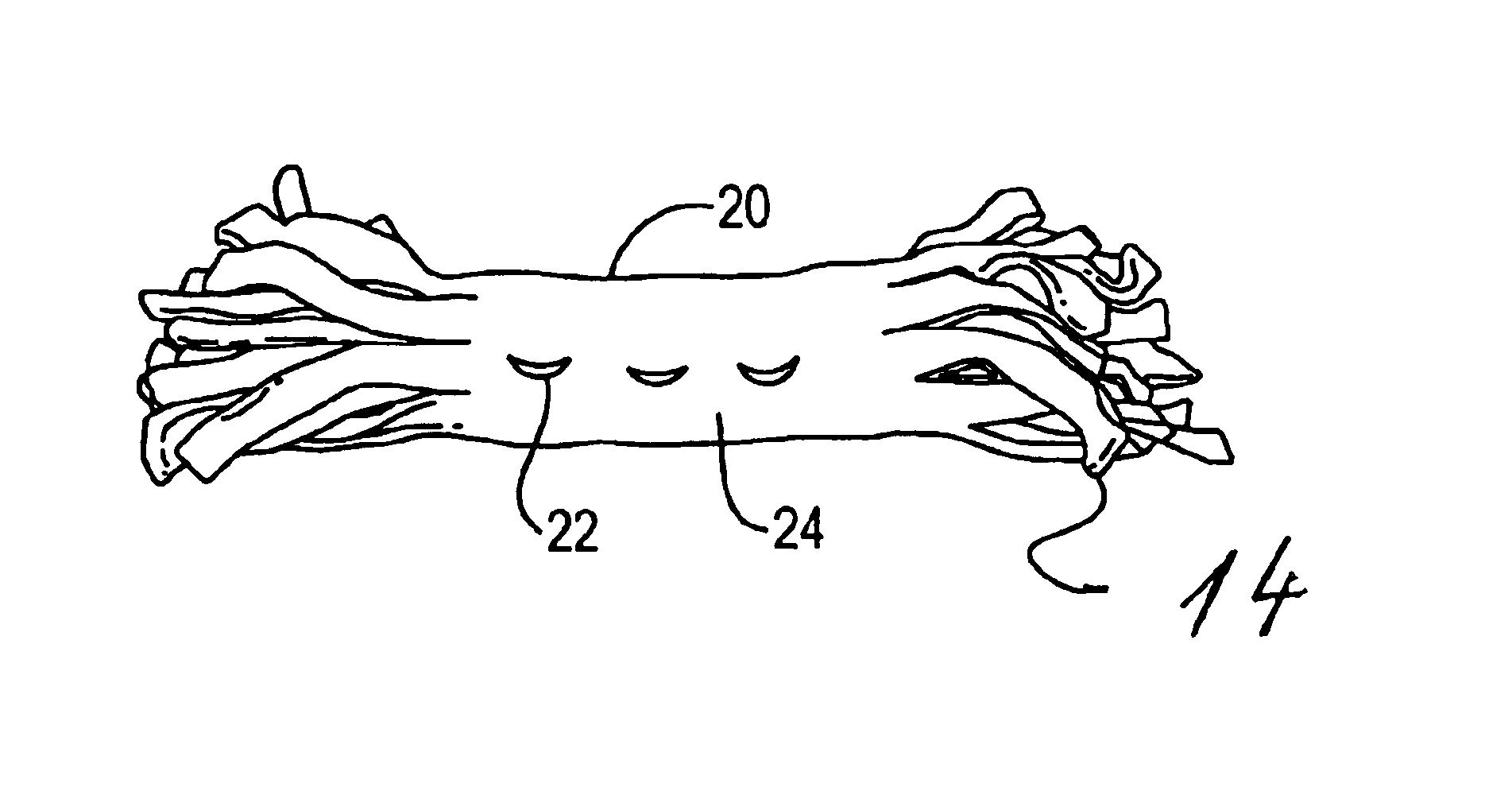

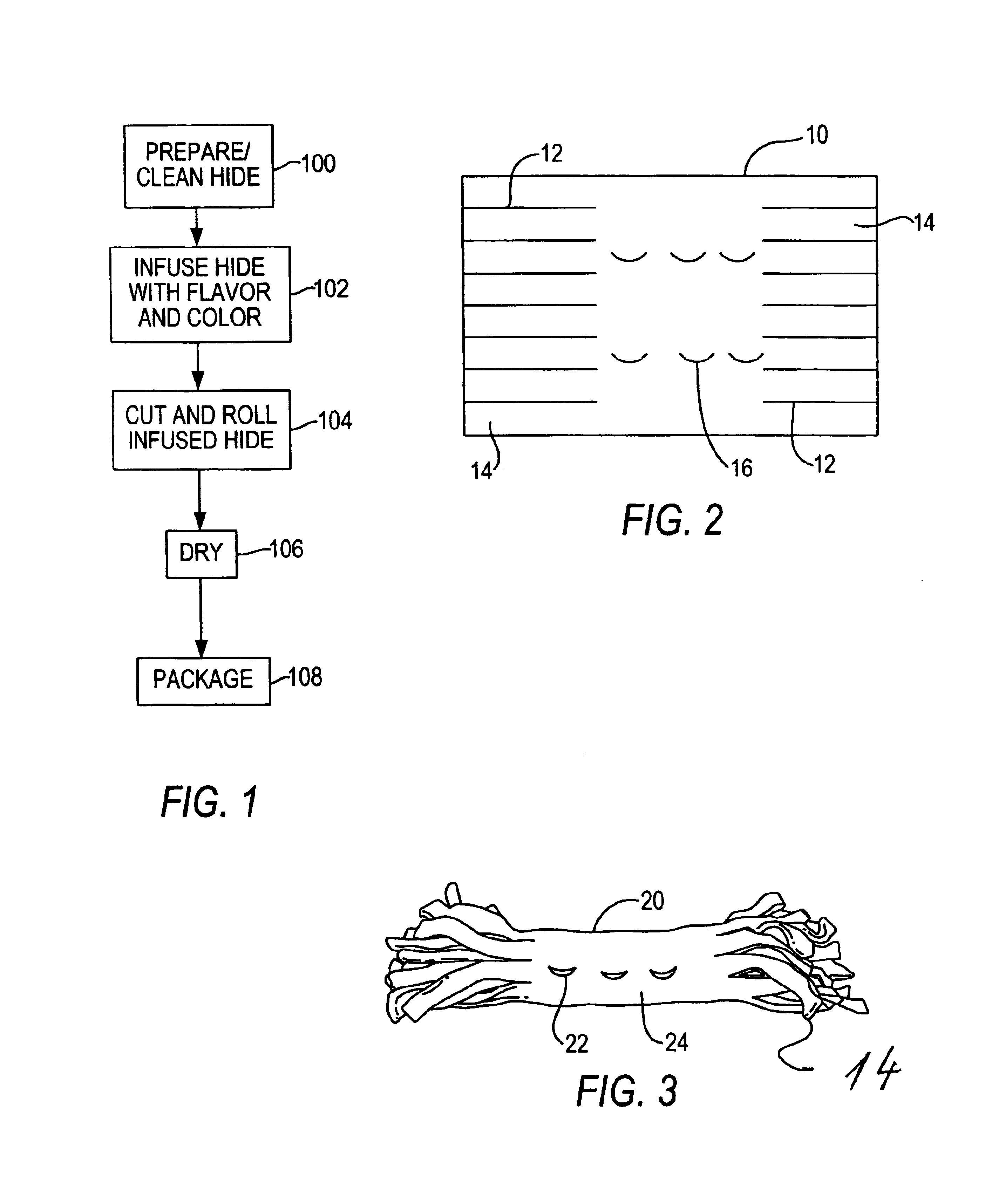

Dental chew roll and method of making the same

InactiveUS6935275B2Save heating energySave heating equipmentAnimal feeding stuffOther apparatusLarge animalEngineering

A dental dog chew roll is cut from a flavored and colored hide piece. The hide pieced is rolled to form into a cylindrical body with two ends, with strips of the hide extending from the cylindrical body. Optionally, cuts are made in the body to provide more surface area. Preferably, the hide piece is made from a large animal hide that is cleaned, infused with flavor and dried.

Owner:HARTZ MOUNTAIN THE

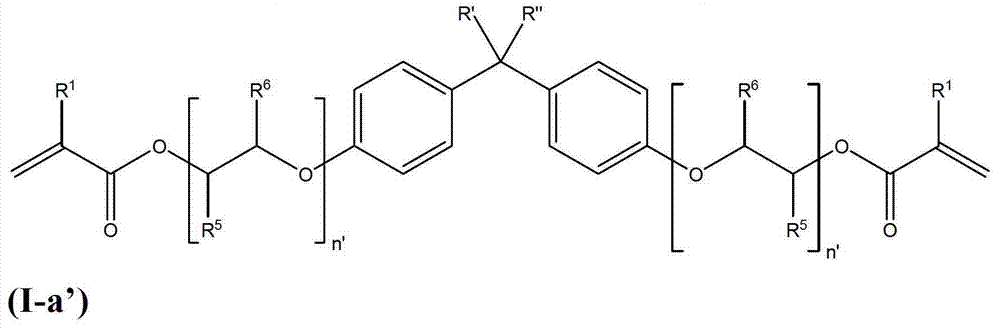

Low-temperature quick deemulsifying agent for water-containing wax-containing erude oil and its preparation method

InactiveCN1537924AFast dehydrationGood demulsification and dehydration effectHydrocarbon oil dewatering/demulsificationEpoxyOil processing

Owner:SHANDONG UNIV

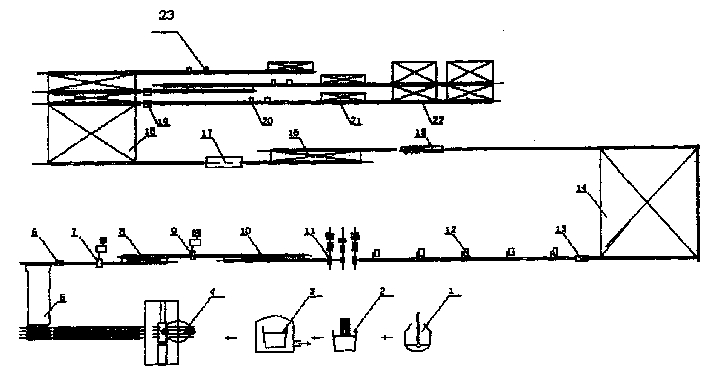

Short flow path manufacturing method of heavy rail

InactiveCN1589983AImprove pure qualityEliminate white spot defectsMetal rolling arrangementsEngineeringMolten steel

A short-flow technology for manufacturing the heavy rails with 50 m in length includes such steps as refining molten steel, conticasting, step heating, shaping rolling, fine rolling, sawing by needed size, prebending-cooling, straightening, and inspection. Its advantages are short technological flow, high quality of product and low cost.

Owner:ANGANG STEEL CO LTD

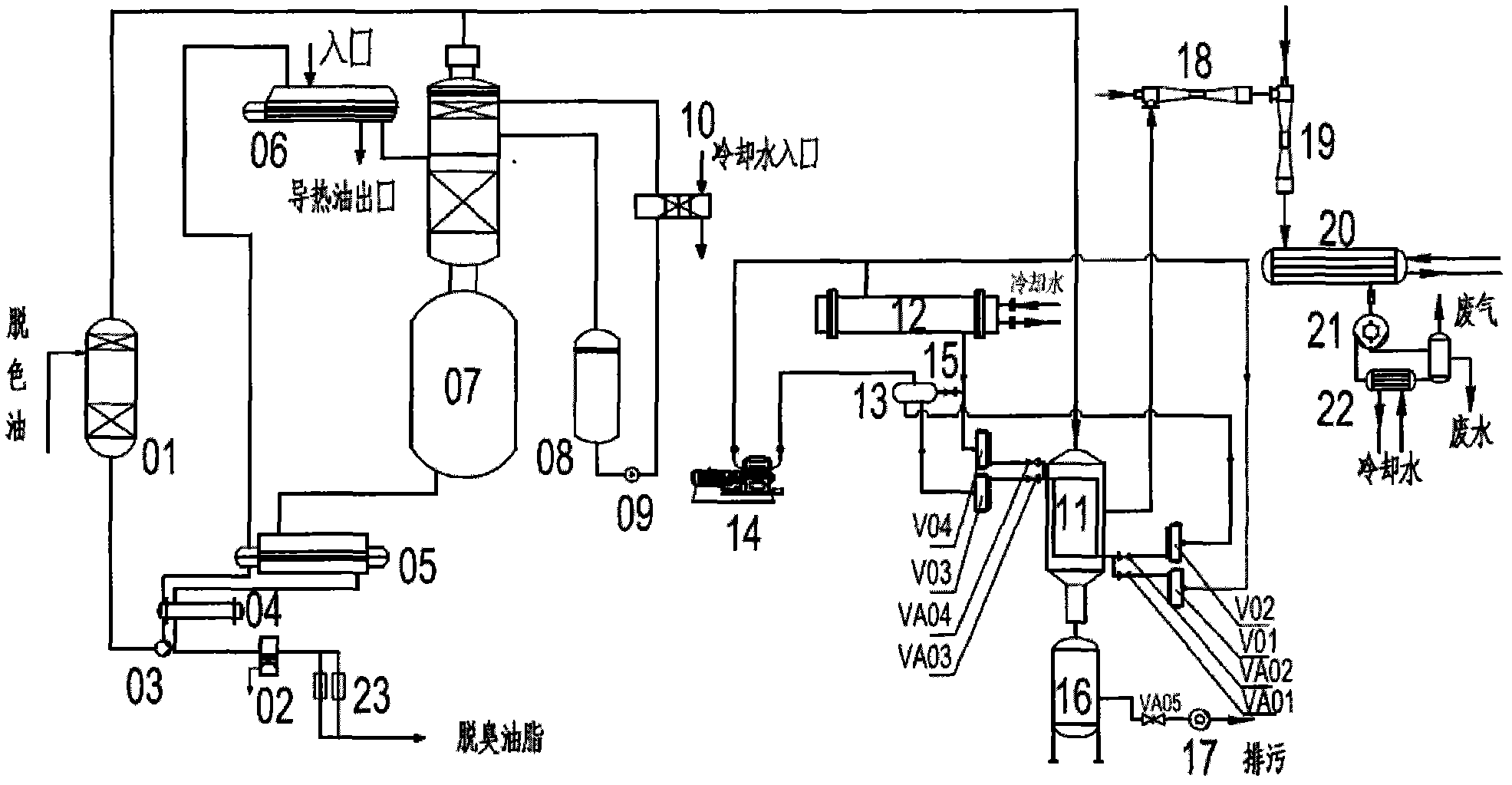

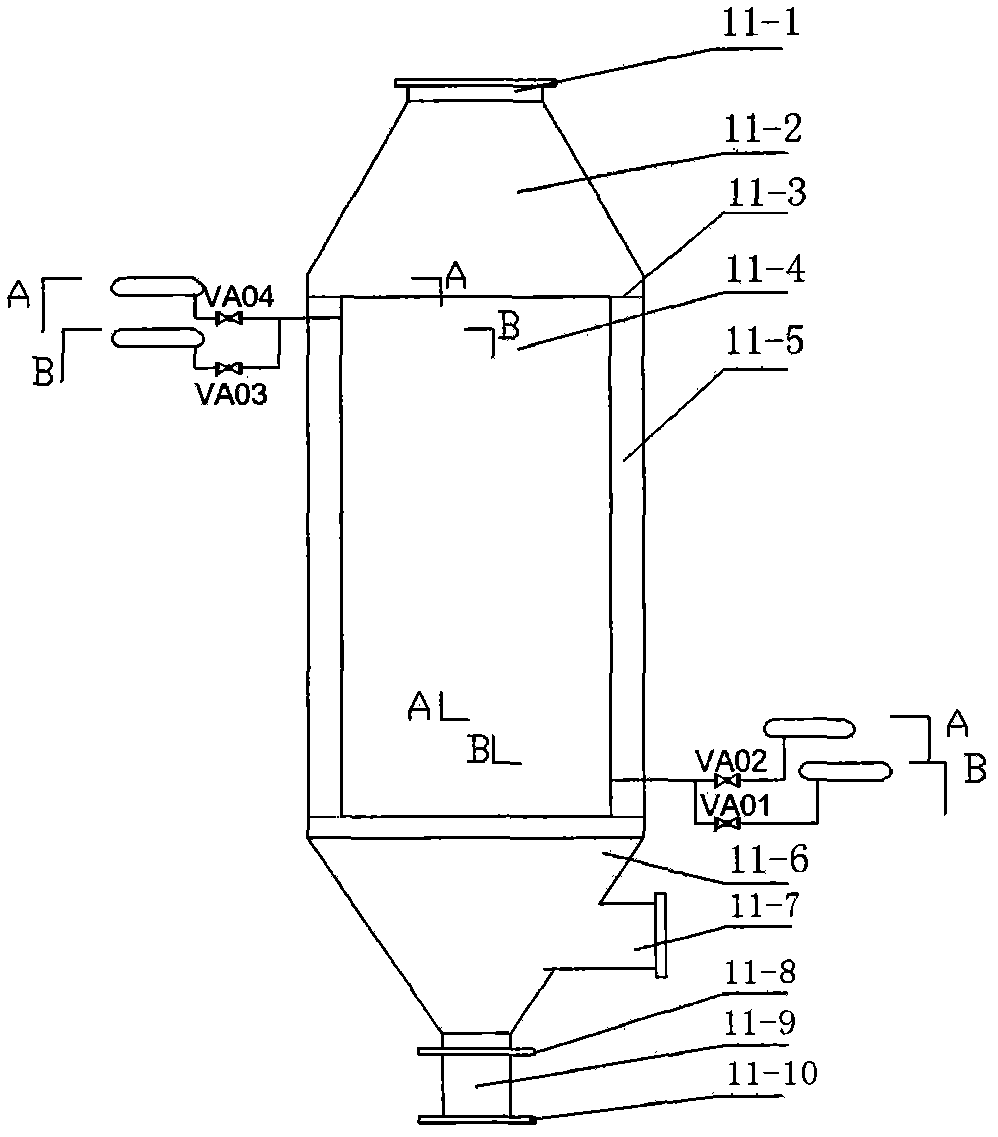

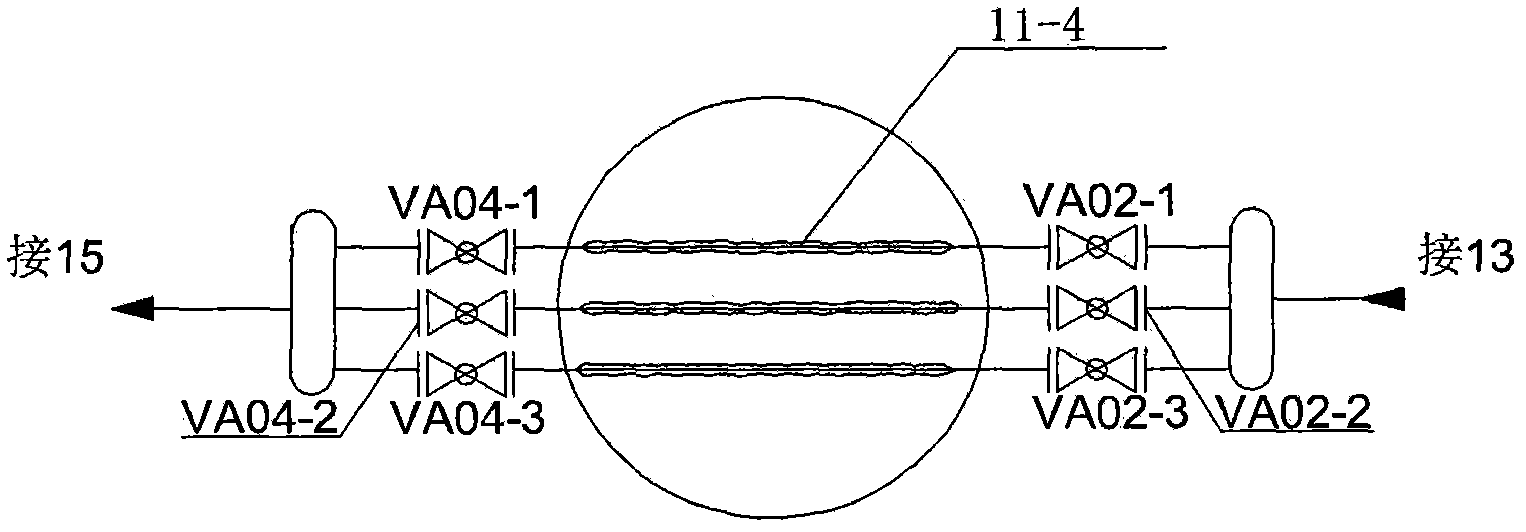

Freeze-condensing vacuum deodorizing method and equipment for fat and oil

The invention relates to a freeze-condensing vacuum deodorizing method for fat and oil. The method is characterized by comprising the following steps of: 1) preparing; 2) performing gassing to remove oxygen; 3) heating; 4) deodorizing; 5) cooling; and 6) freezing, trapping and melting. Equipment using the method is characterized by comprising the following units of: (1) a gassing unit; (2) a heating unit; (3) a deodorizing unit; (4) a fatty acid trapping unit; (5) a vacuum refrigeration unit; (6) a rear vacuum pump unit; and (7) a defrosting unit. When the method and the equipment are used for performing fat and oil deodorizing production, the method and the equipment have the advantages of greatly reducing heating energy, greatly reducing the using amount of injecting steam and the using amount of cooling water and improving production efficiency. Moreover, sealing treatment is performed on a system and no waste gas is discharged, so the method and the equipment also have the advantages of energy conservation, emission reduction, sanitation and environmental protection.

Owner:中机康元粮油装备(北京)有限公司

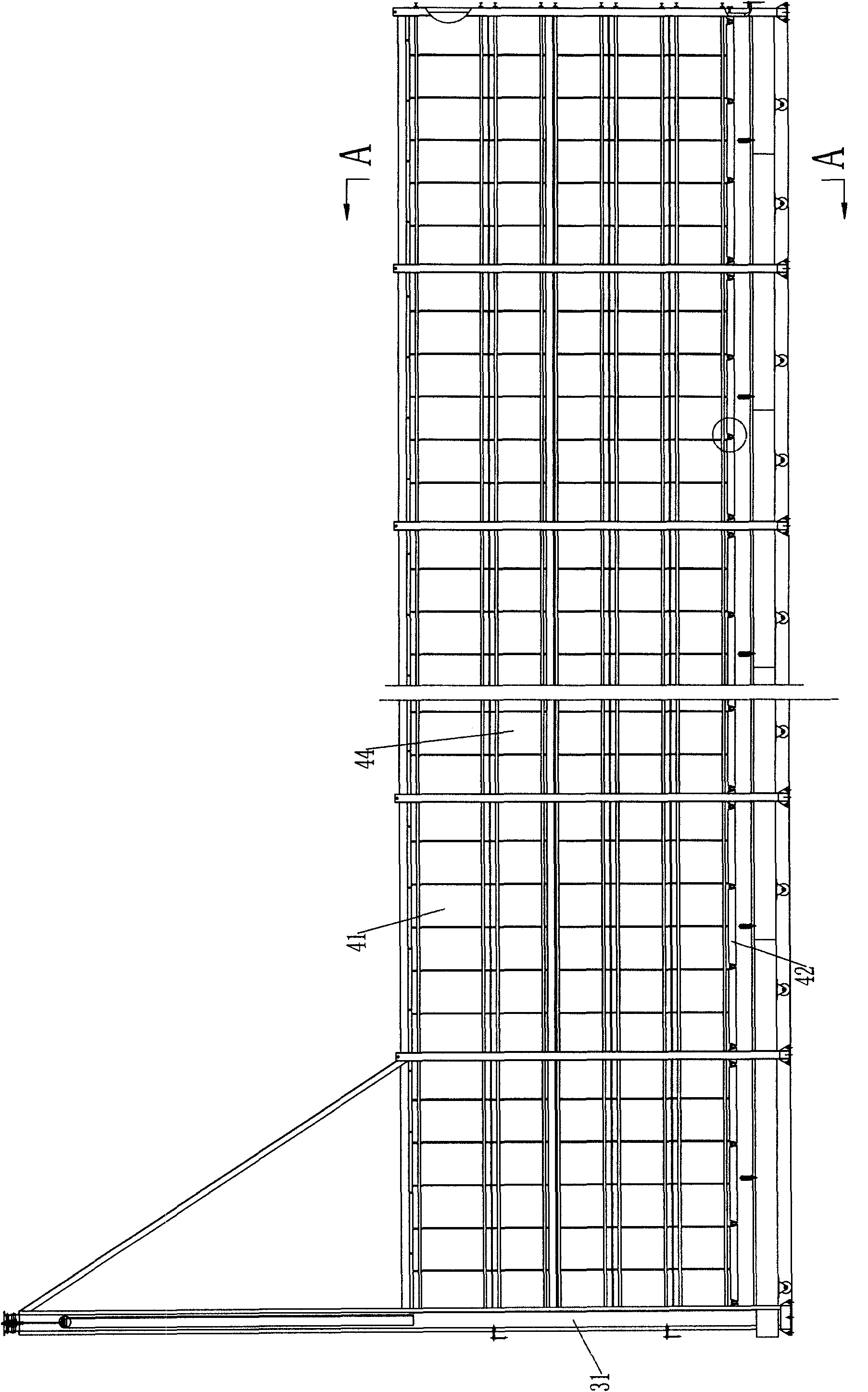

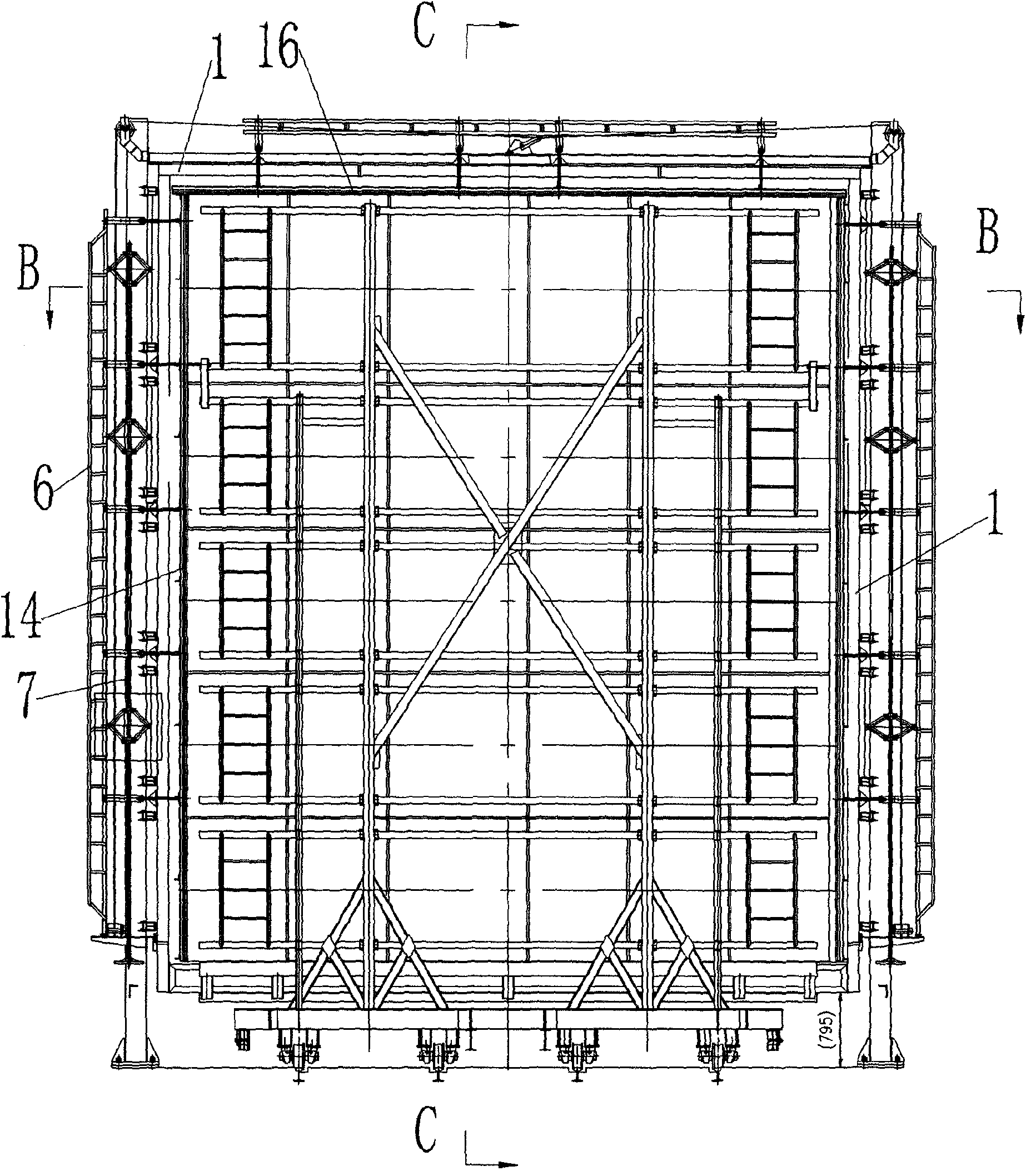

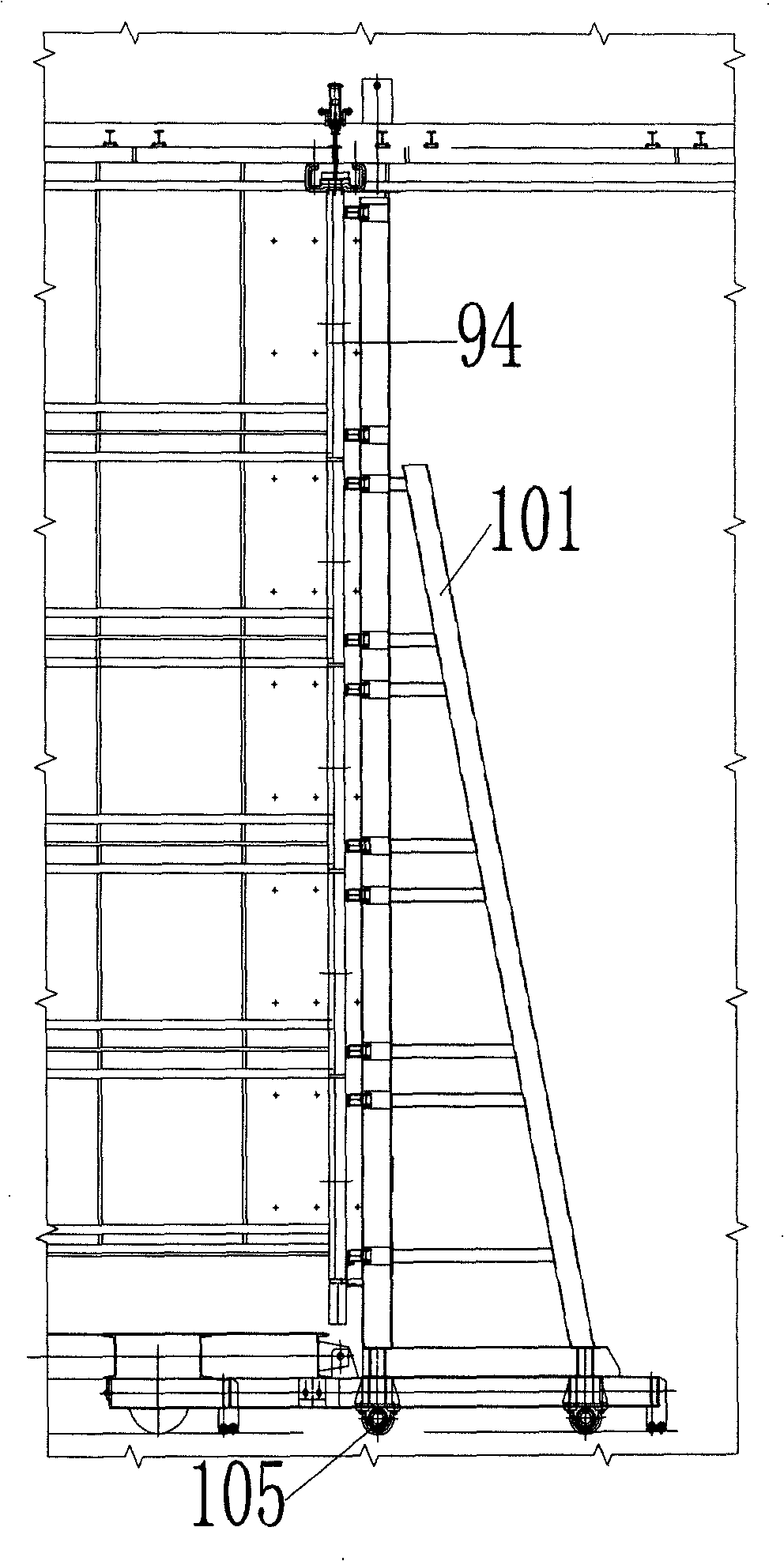

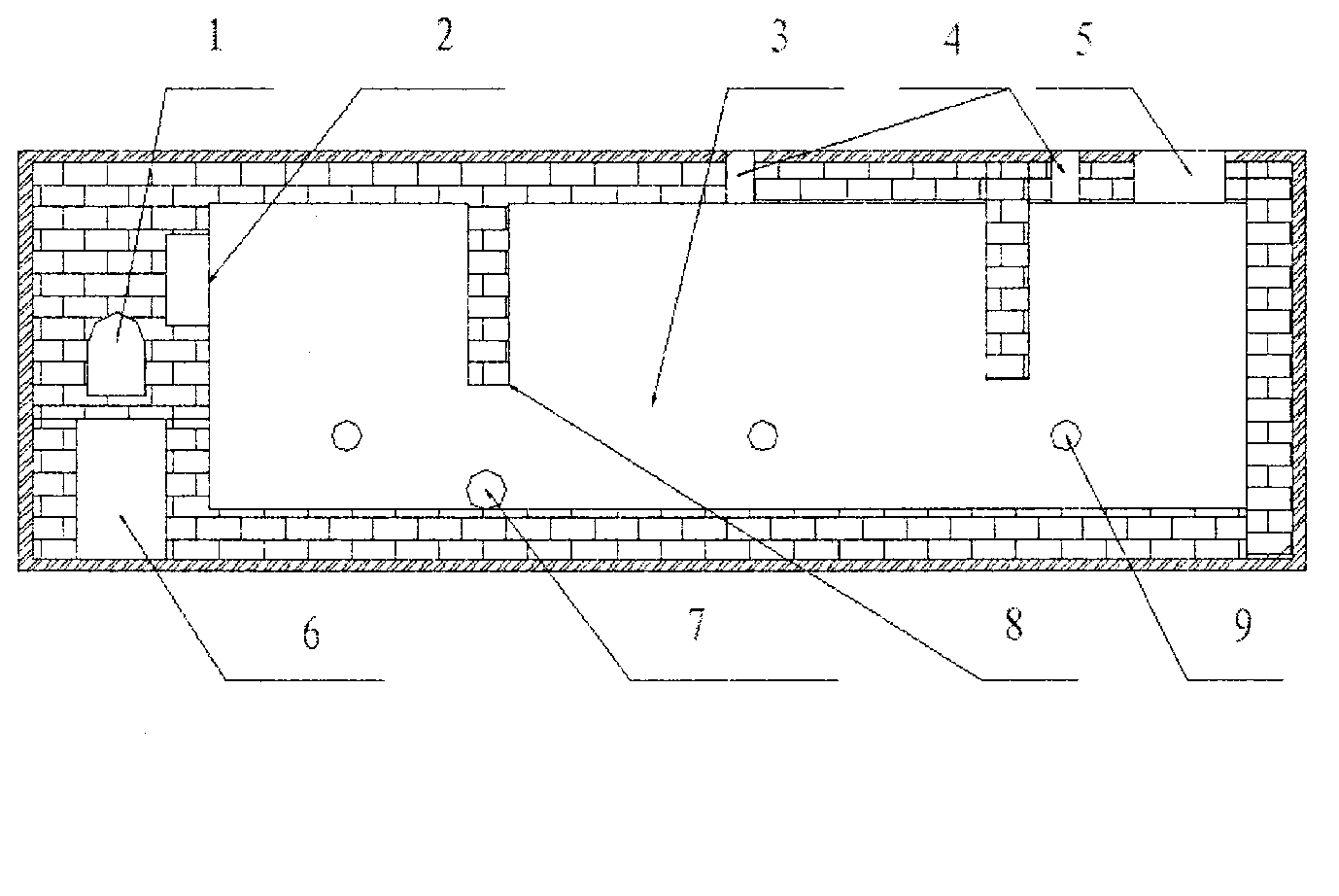

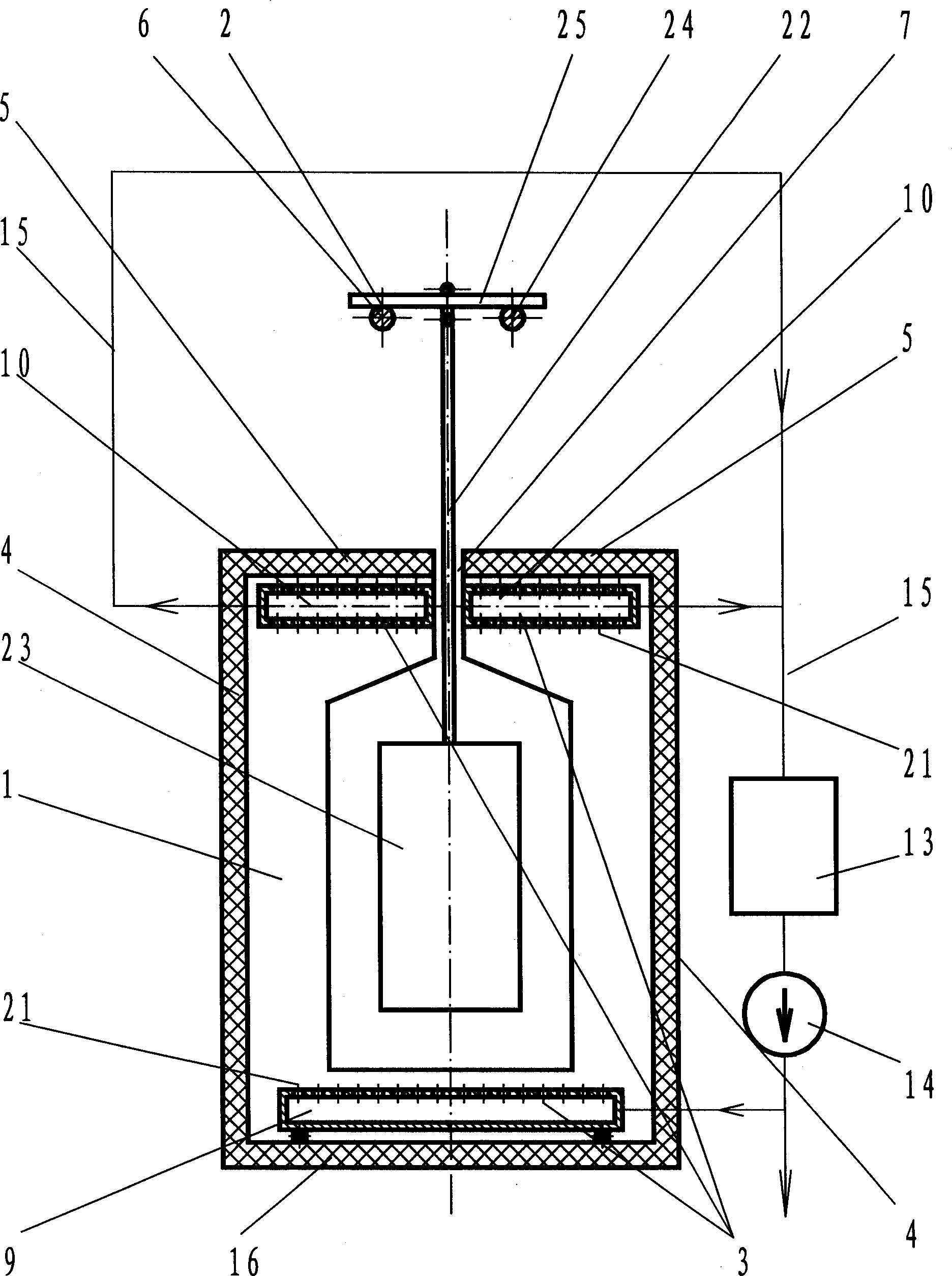

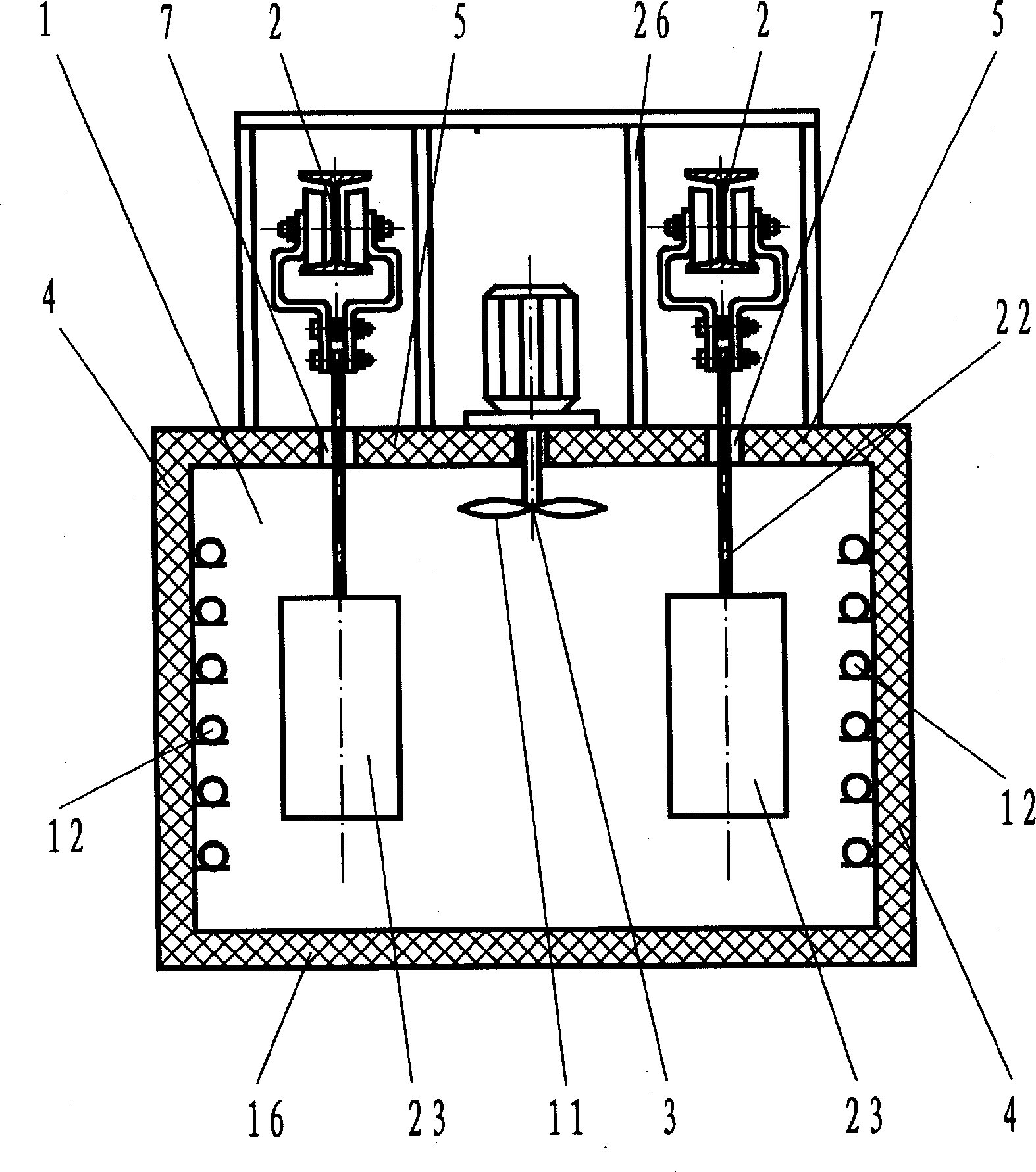

Trolley assembly annealing furnace

The invention aims to provide a trolley assembly annealing furnace capable of regulating a required heating space according to the length of equipment, which comprises a furnace body consisting of a combined heat preserving furnace wall and a heat preserving furnace base; the front part of the furnace body is provided with a furnace door moving up and down, while the rear part is provided with a rear wall; the wall on the inside of the furnace wall is provided with a heat source; a trolley is provided with a movable wall which is in sealing contact with the inside and the top of the furnace wall, and can divide a furnace chamber into a front section and a rear section; and the trolley assembly annealing furnace is characterized in that: the furnace wall is formed by combining and splicing a plurality of detachably connected heated board unit bodies; the heat source is a plurality of mutual independent electric heaters, and the heated board unit bodies are provided with connecting parts for connecting the electric heaters; and the trolley is formed by orderly connecting a plurality of independent trolley units.

Owner:NANJING BAOSE

Mineral dressing collector for poor hematite reverse flotation

InactiveCN101455995ASave heating energyReduce the amount of medicine usedFlotationChemistryPotassium hydroxide

The invention provides an ore-dressing agent for use in reverse flotation of lean hematite ore. The collecting agent is a potassium salt of the hydroxy fatty acid and has a chemical molecular formula of R1-C(OH)n1-C(OH)n2-COOK, wherein n1 ranges from 1 to 2, n2 ranges from 0 to 2, and R1 is preferably saturated or unsaturated hydrocarbons having 9 to 19 carbon atoms. According to a molecular design principle, the invention introduces hydroxyl functional groups to alpha positions and beta positions of a fatty acid mixture and adopts potassium hydroxide for saponification. The collecting agent has the advantages of reducing energy consumption due to preparation and use at the normal temperature, reducing use cost due to small dosage, reducing tailings grade during reverse flotation ore dressing operation by improving the technical indexes of reverse flotation, along with obvious economic effect.

Owner:ANSTEEL GRP MINING CO LTD

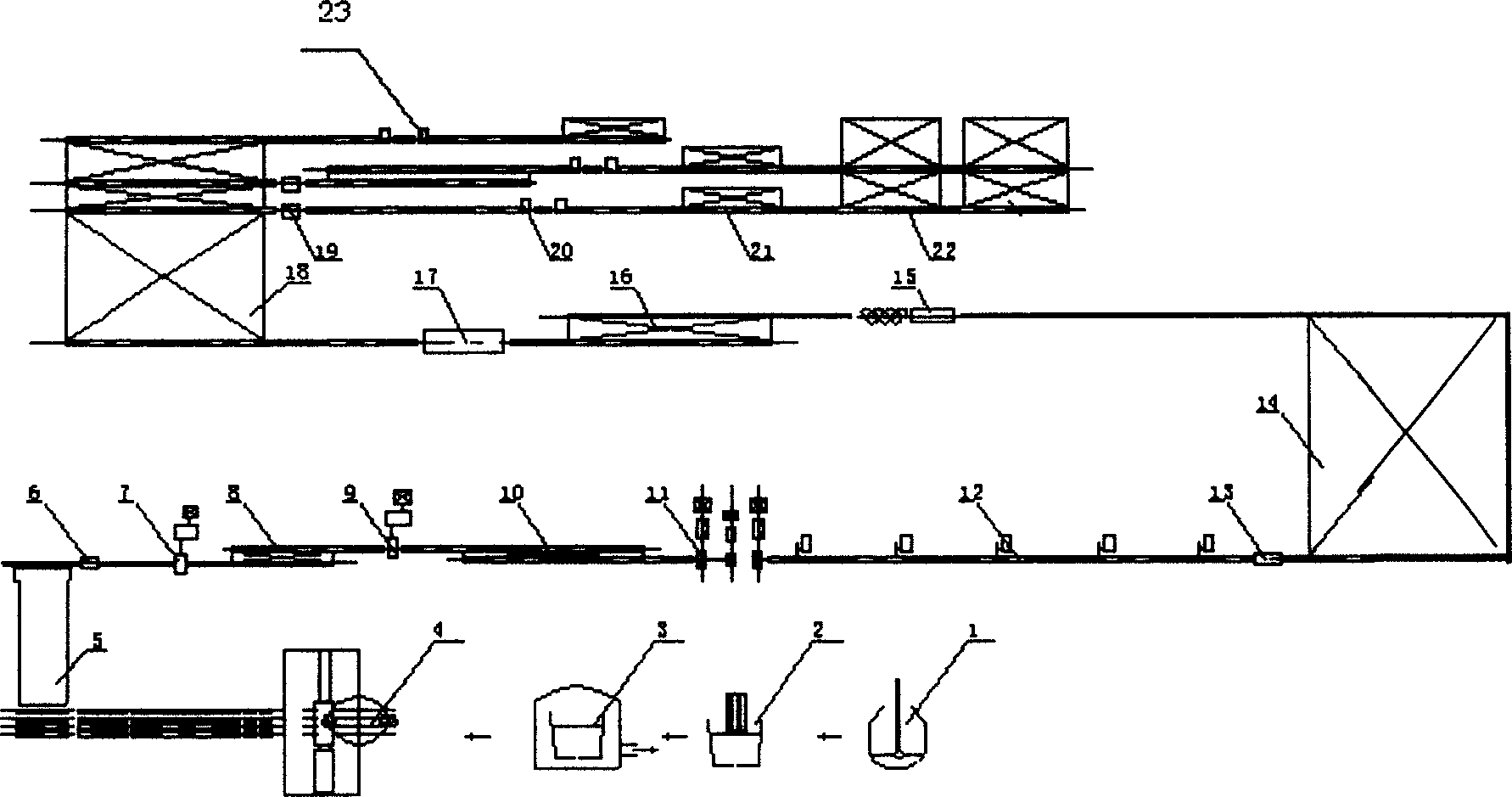

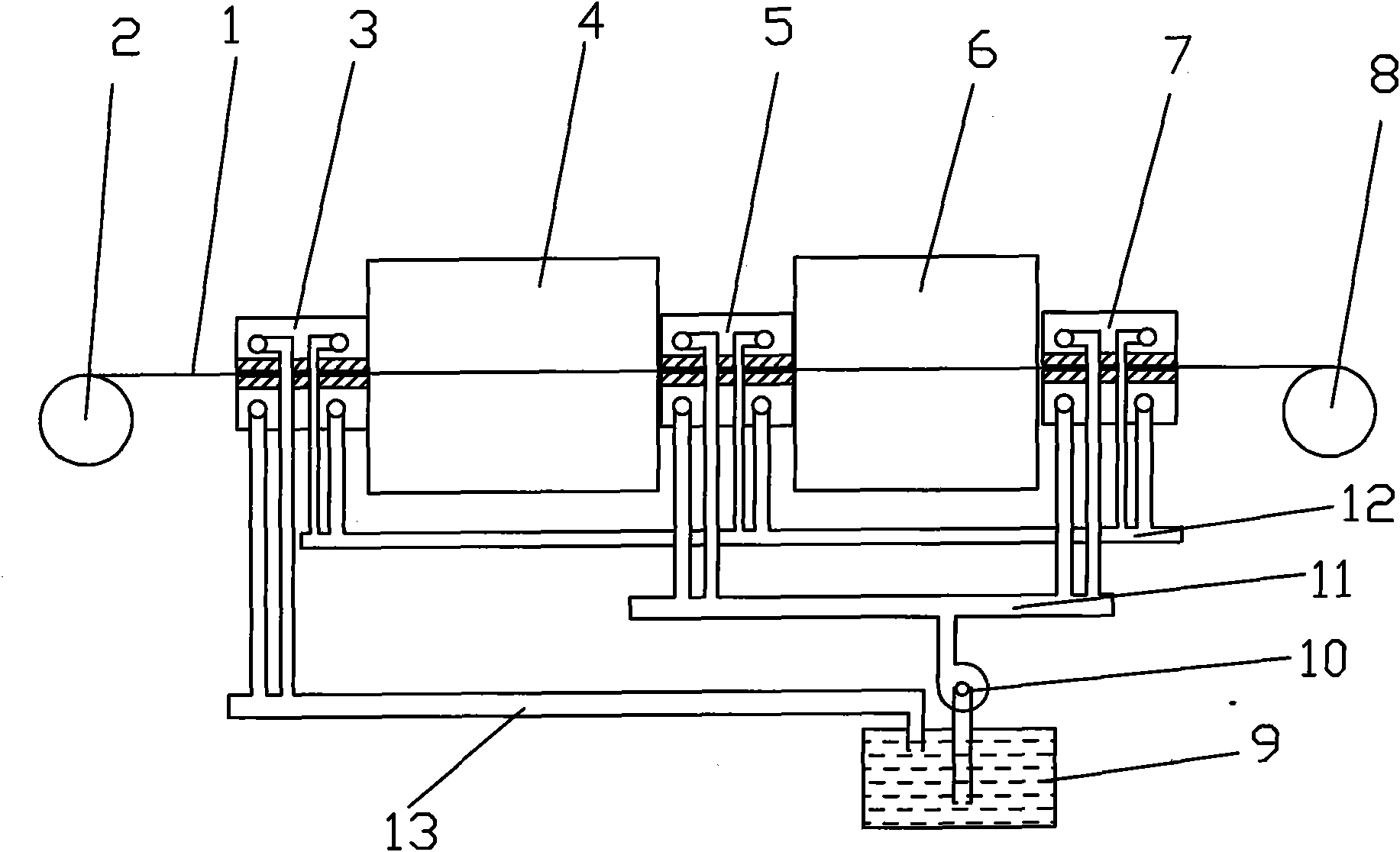

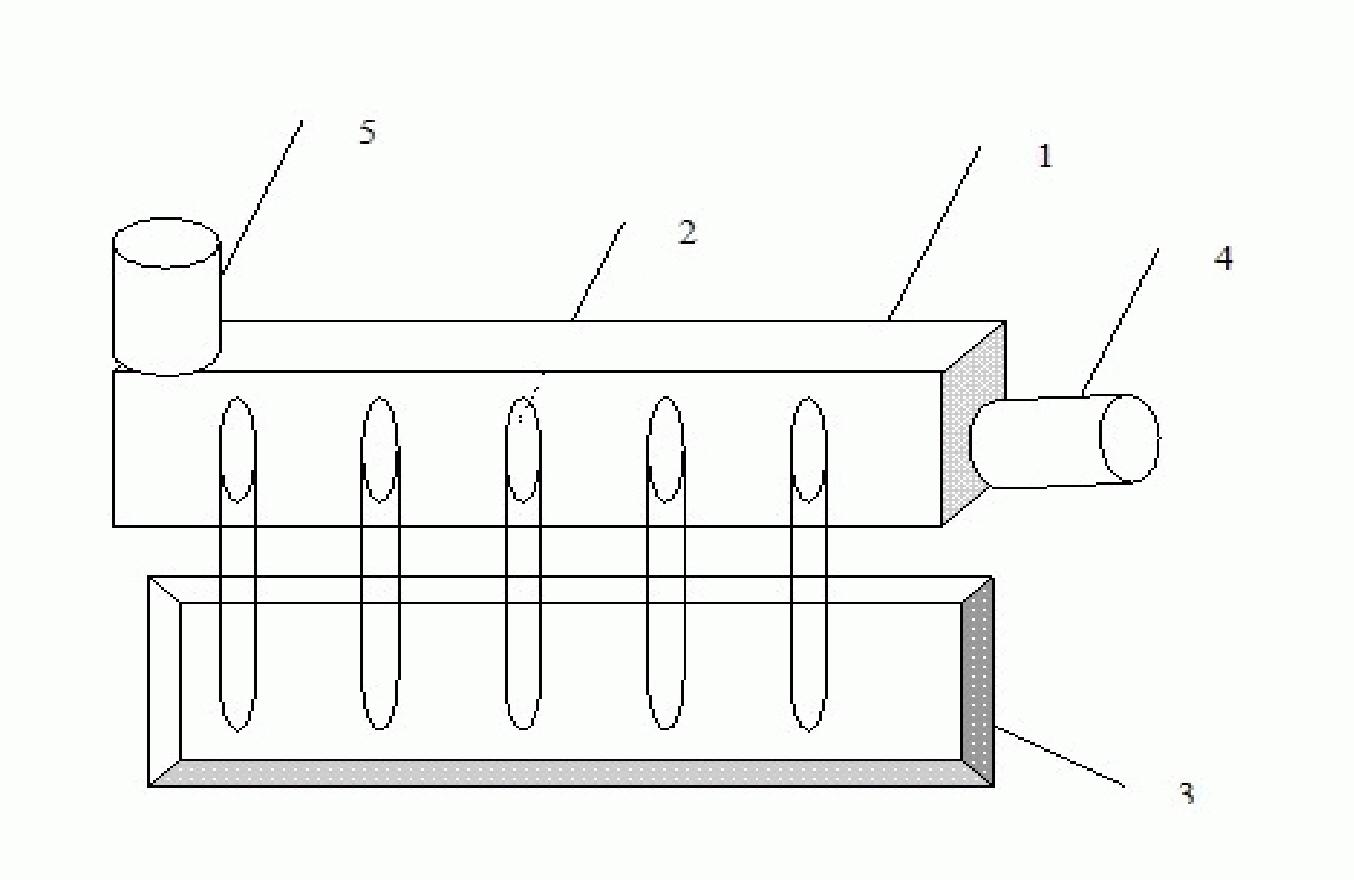

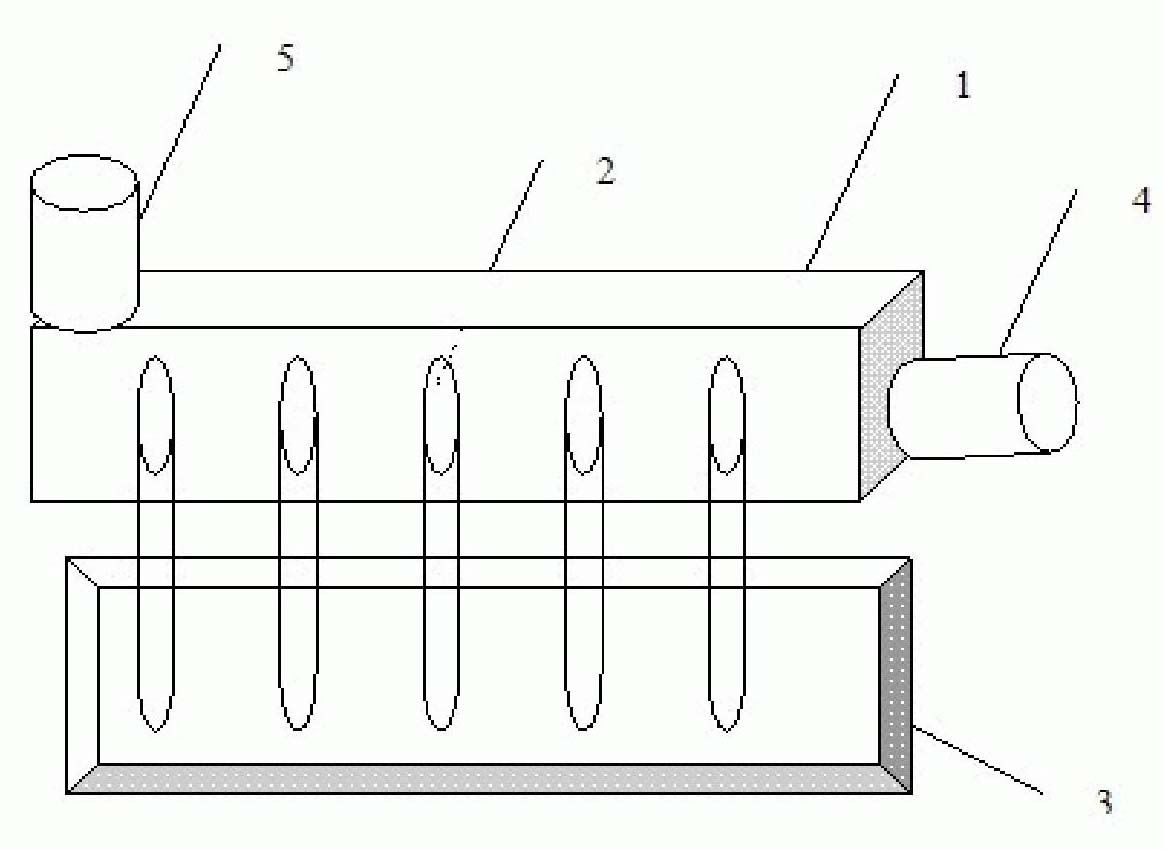

Waste heat utilization steel strip heat treatment system

ActiveCN101899562ASave heating energyReduce manufacturing costFurnace typesHeat treatment furnacesQuenchingSteel belt

The invention provides a waste heat utilization steel strip heat treatment system. The system comprises an unwinding wheel, a winding wheel and steel strips which are arranged between the unwinding wheel and the winding wheel, wherein a heating furnace and a tempering furnace which correspond to the steel strips are sequentially arranged between the unwinding wheel and the winding wheel; a quenching pressure plate is arranged between the heating furnace and the tempering furnace; a waste heat recovery pressure plate is arranged at the back of the tempering furnace; and a waste heat utilization pressure plate which corresponds to the quenching pressure plate and the waste heat recovery pressure plate are arranged in front of the heating furnace. The steel strips can be preheated by part of waste heat so as to save the heating energy of the steel strips and production cost.

Owner:ZHEJIANG BAINAI STEEL STRIP

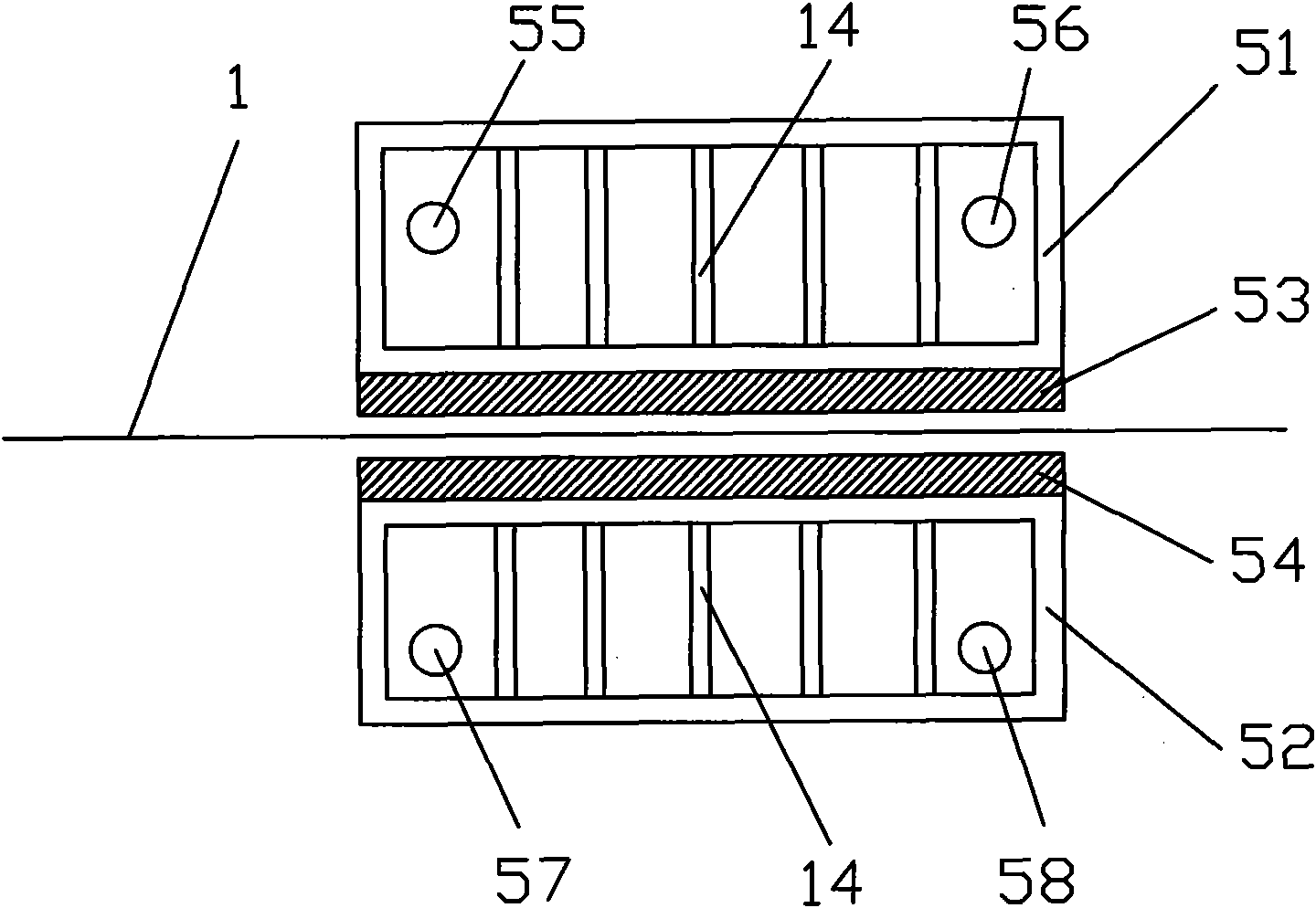

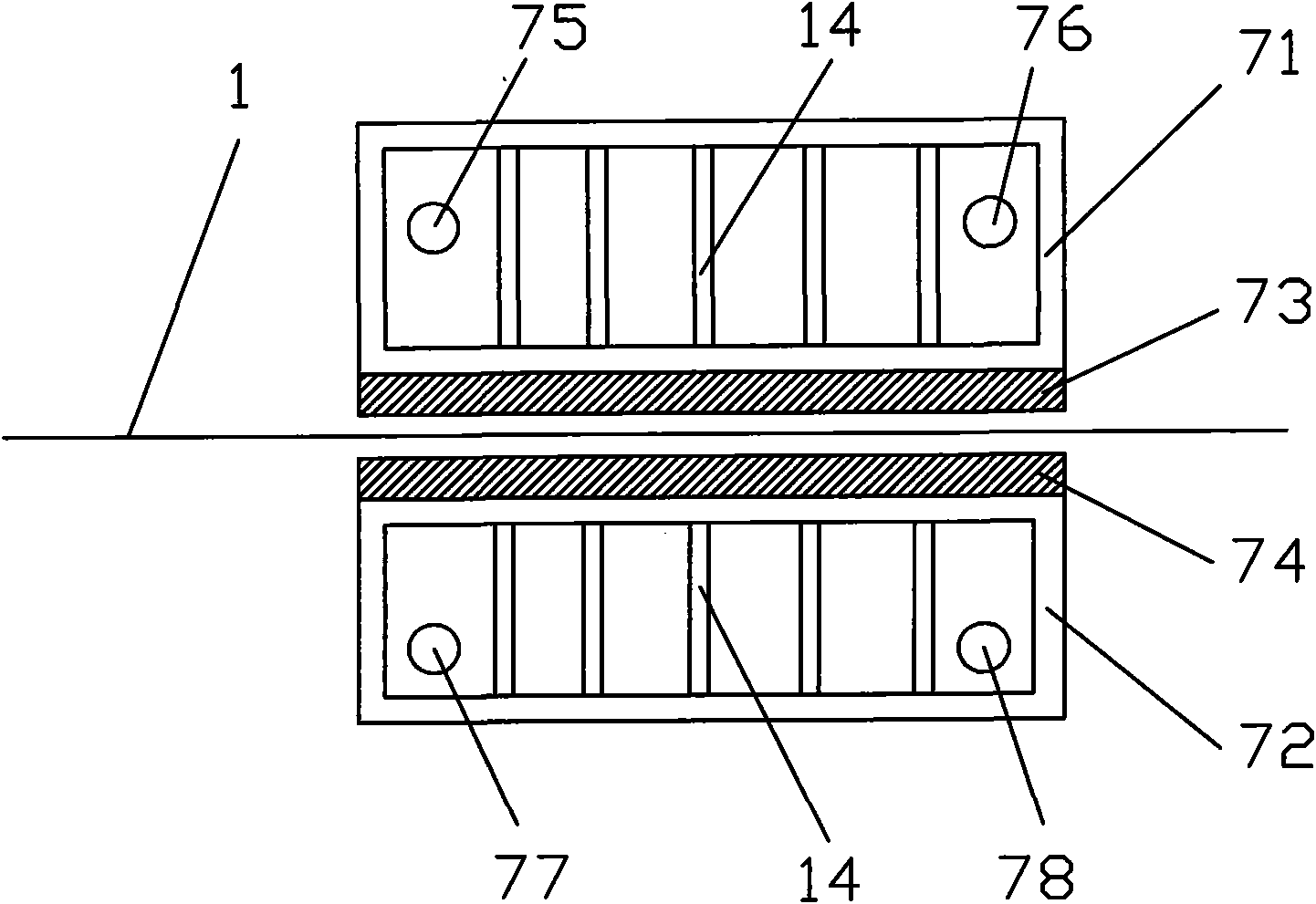

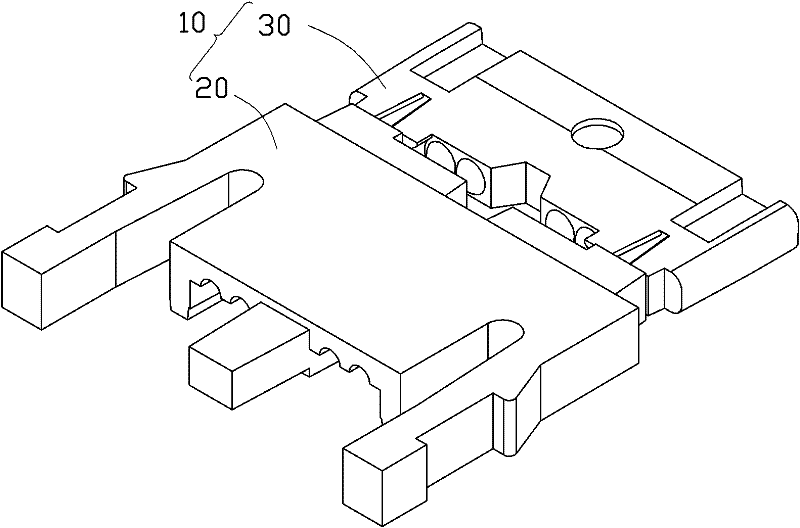

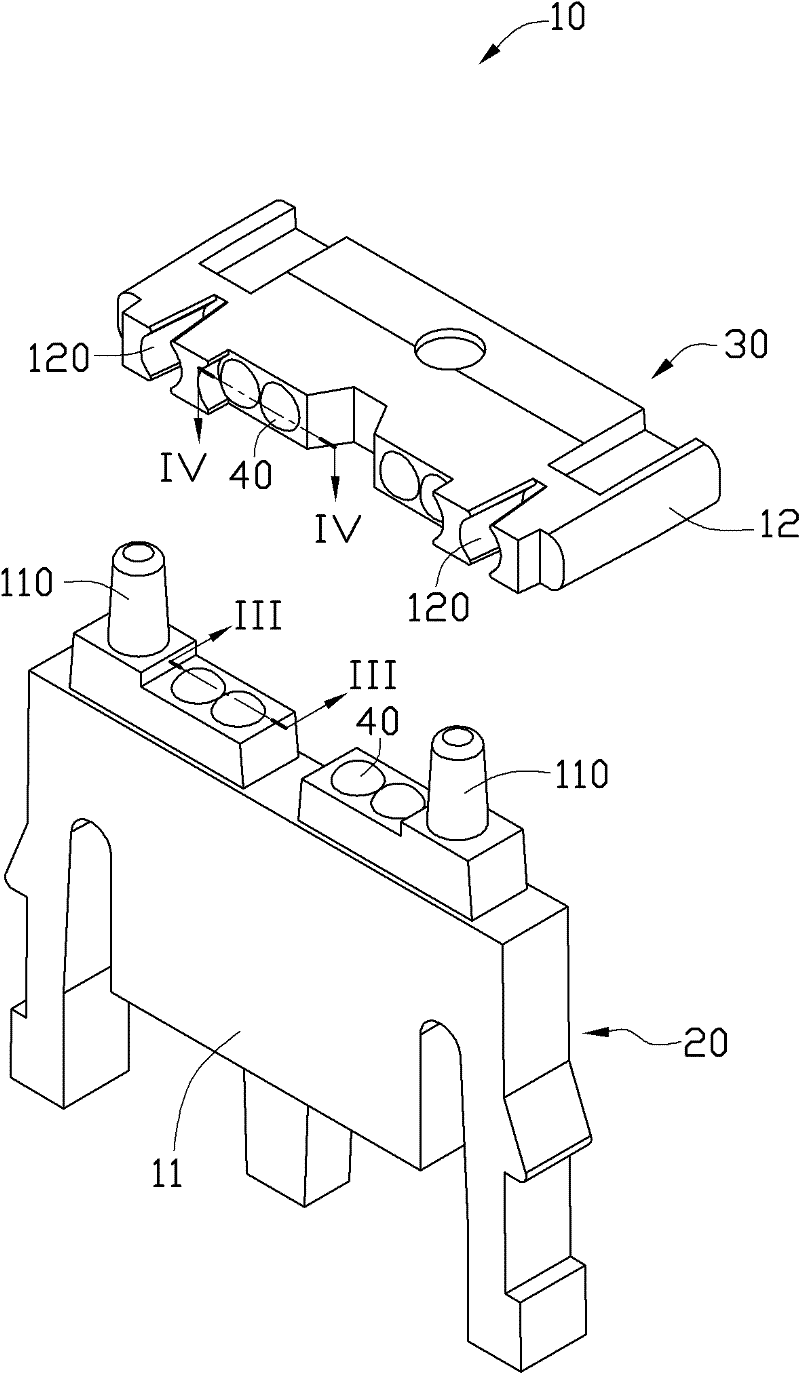

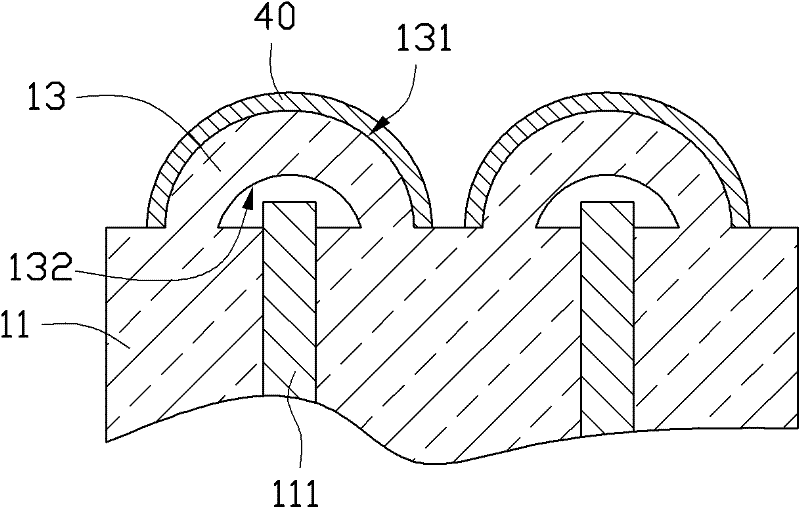

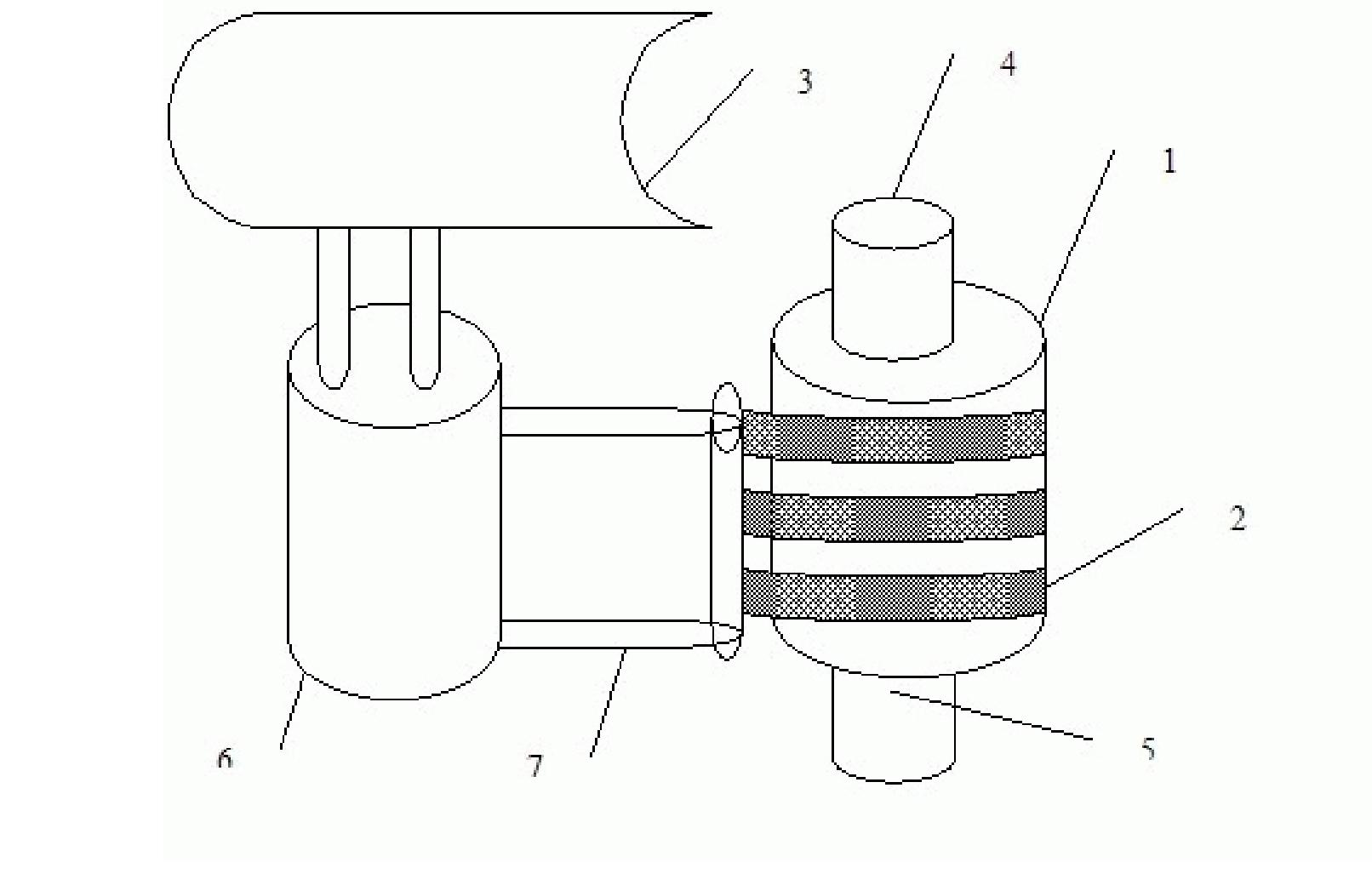

Optical fiber coupling connector and manufacturing method thereof

The invention relates to an optical fiber coupling connector and a manufacturing method of the optical fiber coupling connector. The optical fiber coupling connector comprises a plug body, a first lens embedded in the plug body, a socket body and a second lens embedded in the socket body, wherein the first lens comprises a first optical surface; the second lens comprises a second optical surface which is coupled with the first optical surface in an optical way; the plug body is molded with the first lens in an integral way by transparent plastic, and the socket body is also molded with the second lens in an integral way by the transparent plastic, wherein the melting point of the transparent plastic is lower than that of polyetherimide, and the fluidity of the transparent plastic is better than that of the polyetherimide; and the first optical surface and the second optical surface are respectively plated with a transparent film. After the optical fiber coupling connector is manufactured by the method, the optical characteristics of the optical fiber coupling connector can be maintained, and the production cost is greatly reduced.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

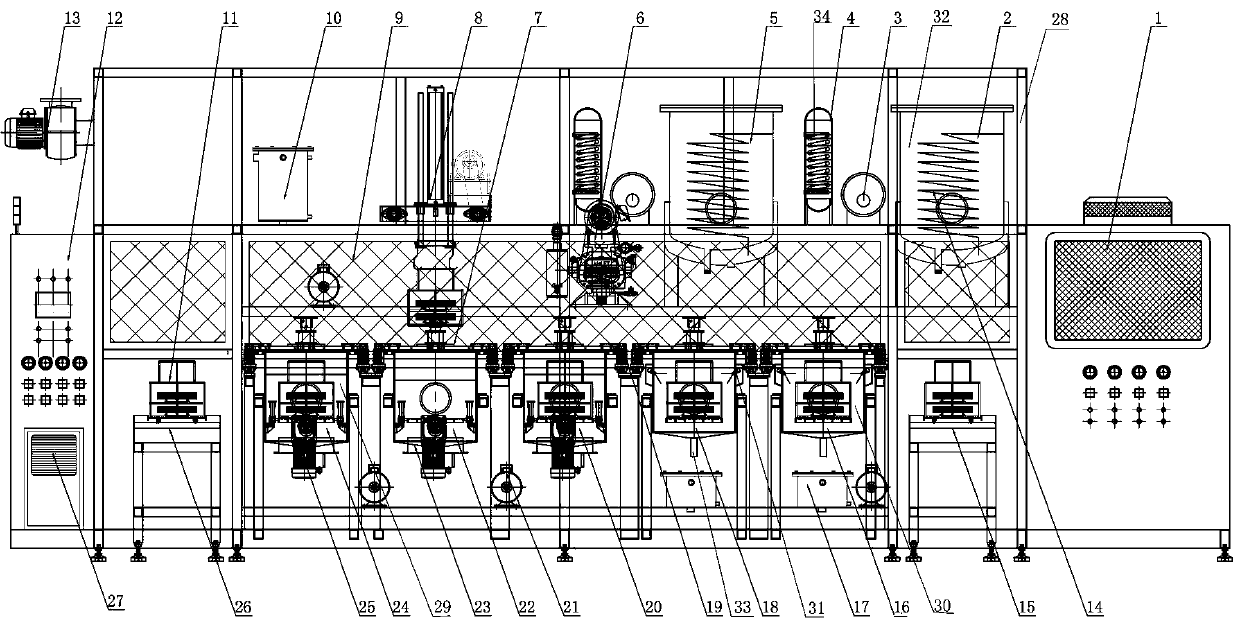

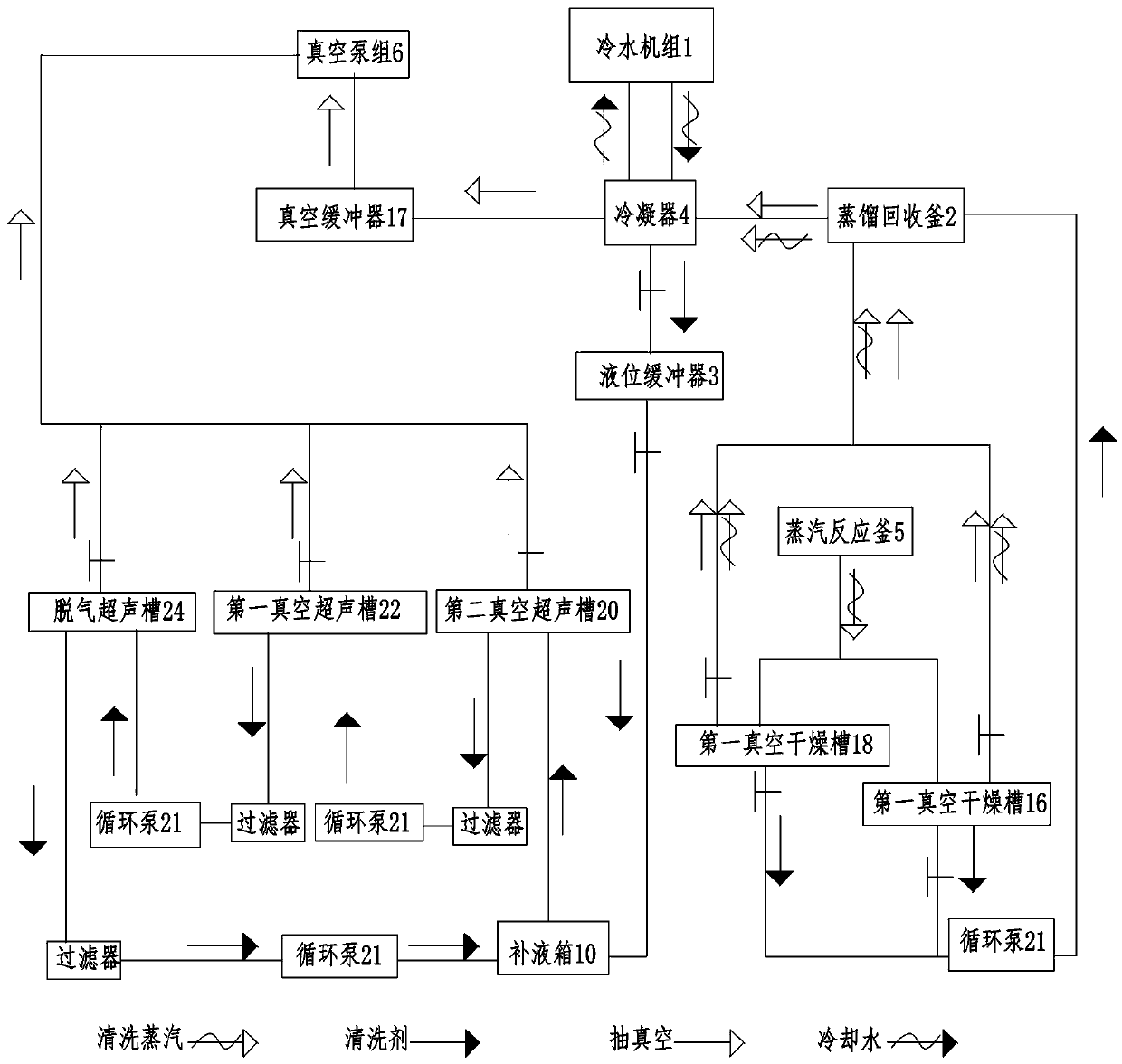

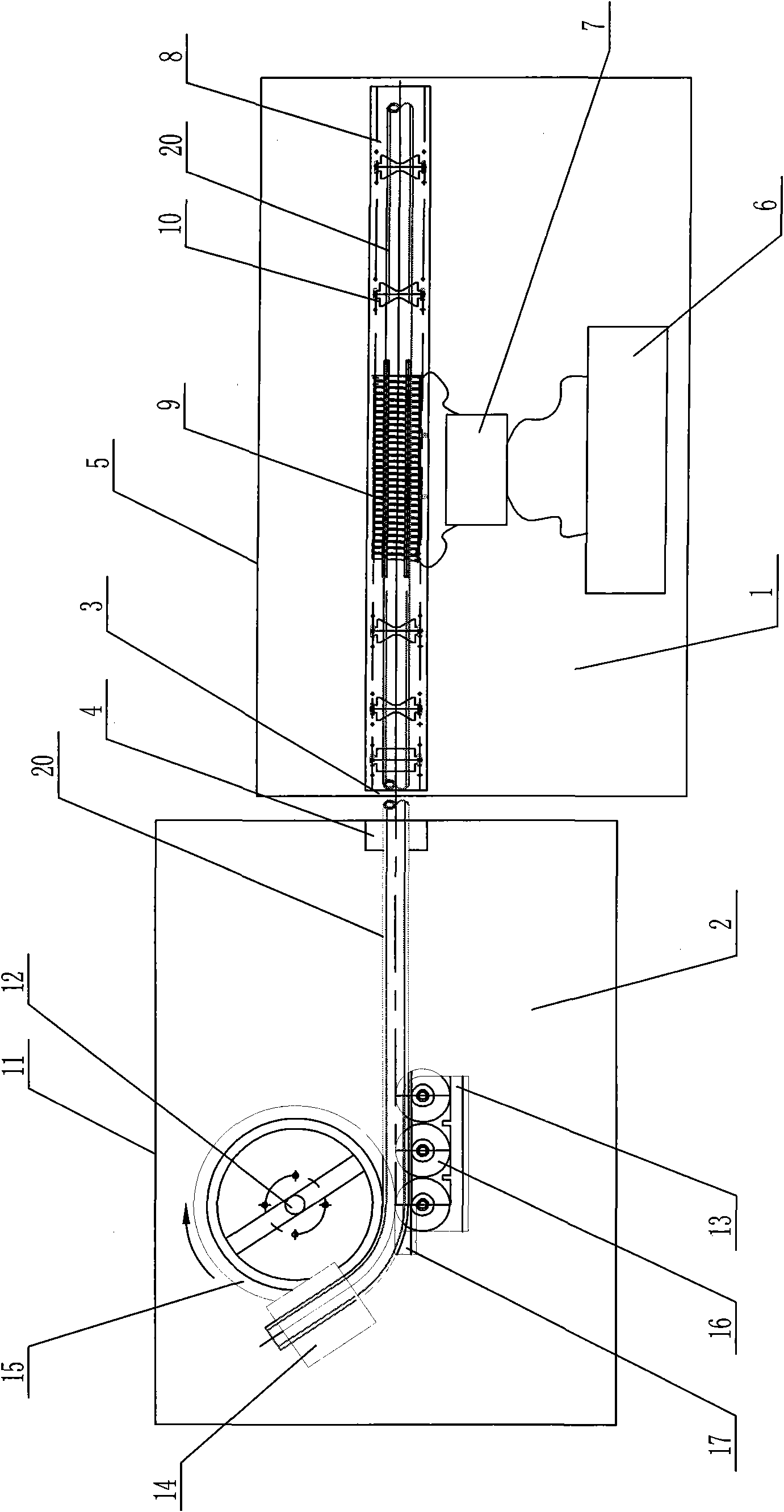

Multi-groove type vacuum hydrocarbon cleaning and drying machine for alloy stamping parts

PendingCN110894609ASolve turnover handling problemsReduce manual labor intensityCleaning using liquidsProcess engineeringVacuum pump

The invention discloses a multi-groove type vacuum hydrocarbon cleaning and drying machine for alloy stamping parts. An exhaust fan, an electric appliance control cabinet, a cabinet cooling air conditioner and a water chilling unit are installed outside a cabinet, observation windows are arranged in both the front and back sides, a feeding table and a discharging table are arranged at the two endsof the interior of the cabinet respectively, and an ultrasonic cleaning assembly and a vacuum drying assembly are sequentially installed between the feeding table and the discharging table. A carrying assembly is arranged over the feeding table, the ultrasonic cleaning assembly, the vacuum drying assembly and the discharging table; a liquid supplementing box, a vacuum pump set, a steam reaction kettle and a distillation recovery assembly are arranged over the carrying assembly; the ultrasonic cleaning assembly and the liquid supplementing box are circularly connected through a pipeline; the vacuum drying assembly, the distillation recovery assembly and the liquid supplementing box are in pipeline connection; and the vacuum pump set is connected with air exhaust ports of the ultrasonic cleaning assembly and the distillation recovery assembly. The cleaning and drying machine has the effects of being high in automation degree and little in pollution, and the problems that in the prior art, pollution is serious, the quality and efficiency are low, and labor intensity is large are solved.

Owner:ZHANGJIAGANG GANGWEI ULTRASONIC ELECTRONICS

Processing method for cold bending pipes by medium frequency heating

ActiveCN101623724AHeating evenlyHeating environmental protectionCoil arrangementsMetal-working feeding devicesMedium frequencyEngineering

The invention discloses a processing method for cold bending pipes by medium frequency heating, comprising the following steps: firstly, heating the part, which is required to be bent, of a pipeline to certain temperature by adopting the medium frequency heating mode, and then bending the pipeline. The method has the advantages that the design is reasonable, the heating effect is good, the work efficiency is high, the pipeline bending quality is good and the labor intensity of workers is reduced, and the method can provide good productivity benefits for the enterprises.

Owner:HENAN HUADIAN JINYUAN PIPING

Brazing powder for ultrasonic assisted brazing and brazing method

ActiveCN109759741AEnable low-temperature interconnectsSave heating energyWelding/cutting media/materialsSoldering mediaBiological activationCobalt

The invention provides brazing powder for ultrasonic assisted brazing and a brazing method. The brazing powder is prepared by uniformly mixing tin copper powder or tin silver copper powder, or powderof the tin copper powder mixed with the tin silver copper powder with any one kind, or any two kinds, or any three kinds, or any four kinds, or any five kinds of nickel powder, cobalt powder, copper powder, tin powder and titanium powder of active nanoparticles with the diameters being 1-1000nm according to the mass ratio being at most 20%. According to the brazing powder for ultrasonic assisted brazing and the brazing method, the temperature is low during welding, and the active nanoparticles are adopted; by oscillation heating of an ultrasonic generator, the metallurgical reaction between solder or the nanoparticles and a base material is promoted, the full-solid phase or semisolid state low-temperature interconnection of lead-free solder is realized, and the welding temperature is morethan 30% lower than conventional liquid phase interconnection; oscillating activation and friction generated by the ultrasonic generator can cause an oxidation film on the surface of the welding basematerial to be broken to achieve the effect of film removal, thus gas pollution from a welding flux is reduced, the welding pollution is less, and the joint quality is high.

Owner:CHONGQING UNIV OF TECH

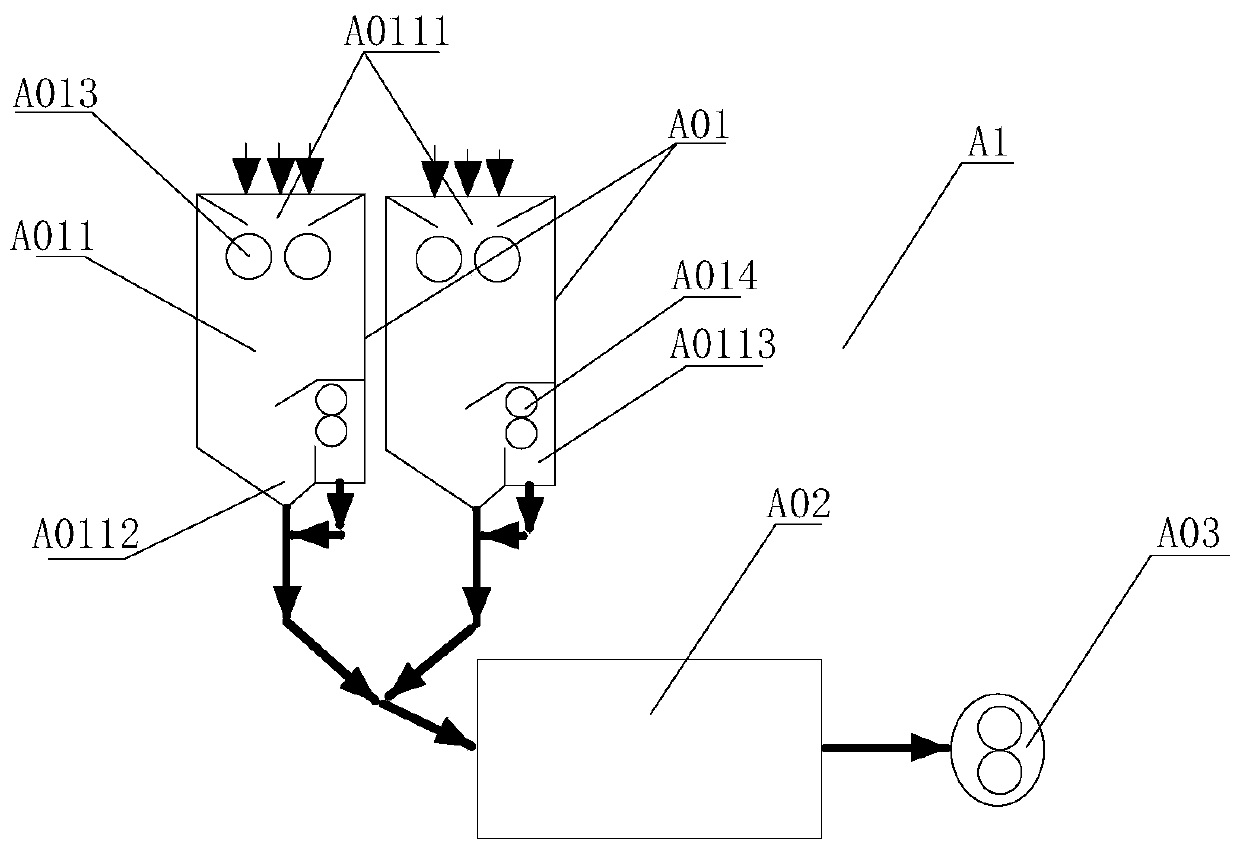

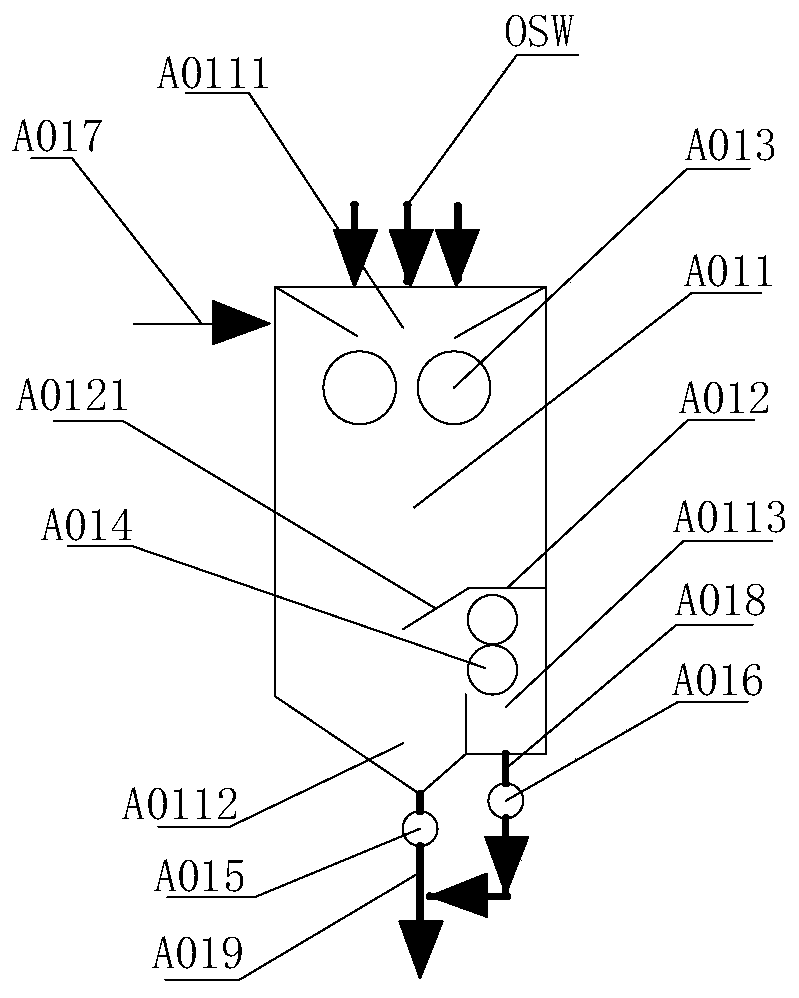

Process and equipment for continuously preparing nano carbon ball

The invention provides a process and equipment for continuously preparing nano carbon ball, wherein carbon-containing raw materials such as aromatic hydrocarbons heavy oil, coal tar, mixed benzene, coke-oven gas, anthracene oil, naphthalene oil, phenol oil, CH4 or C2H2 are applied; natural gas is used as fuel, and combusted with air through a heating stove to provide reaction heat for a cracking furnace; the other part of carbon-containing raw materials flows in a rate of 1000-3000 m3h-1, and is gasified and sprayed into the heated cracking furnace, simultaneously, catalyst and auxiliary agent are sprayed into the heated cracking furnace; raw materials undergo cracking reaction at the reaction temperature with isolation and dilution of protection gas; the product obtained from the cracking reaction is sent to a heat exchanger to be cooled by heat exchange; and solid nano carbon balls are obtained after being separated by a separator. The invention realizes continuous production of nano carbon material from gas by cracking reaction in the cracking furnace, is suitable for the application of a plurality of carbon raw materials with low cost for industry use, and utilizes heat which is by-product of raw materials to meet the need for keeping the reaction furnace temperature, and thus power consumption is reduced, production cost is saved, and nano carbon balls are prepared continuously with reduced cost.

Owner:乌鲁木齐西峰合创石油化工有限责任公司 +1

Easy compact asphalt mixing material and preparation method of easy compact asphalt mixing material

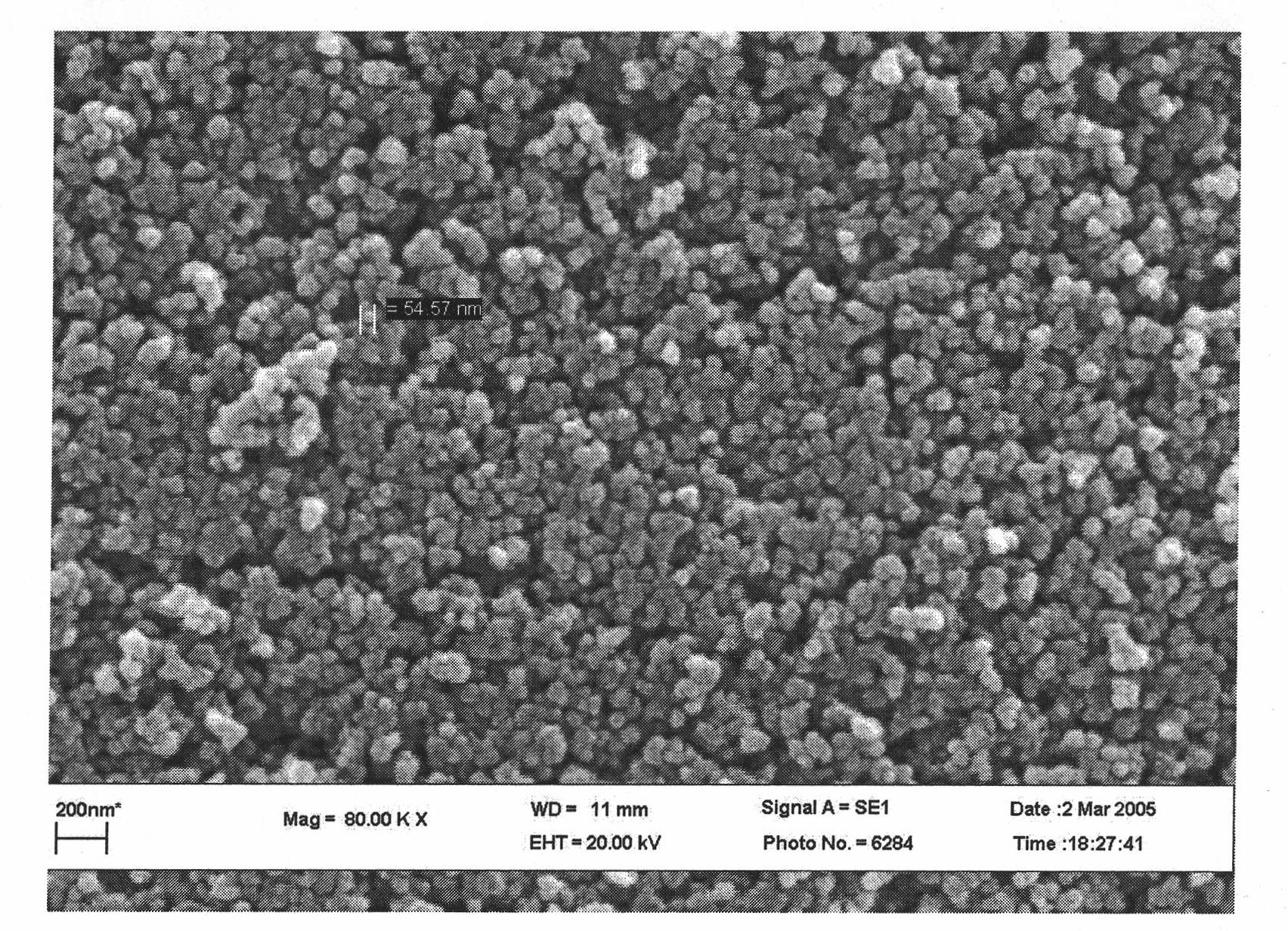

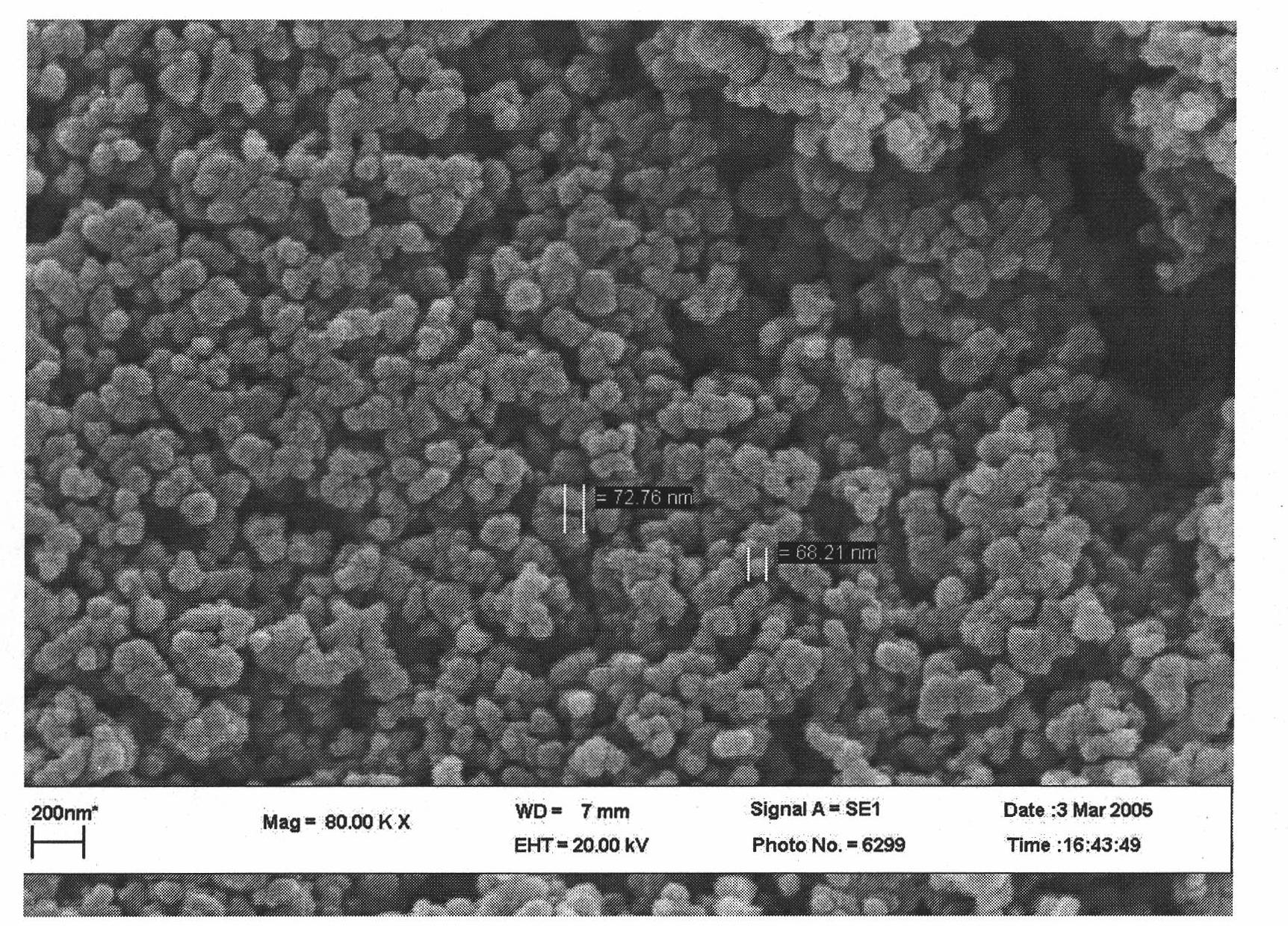

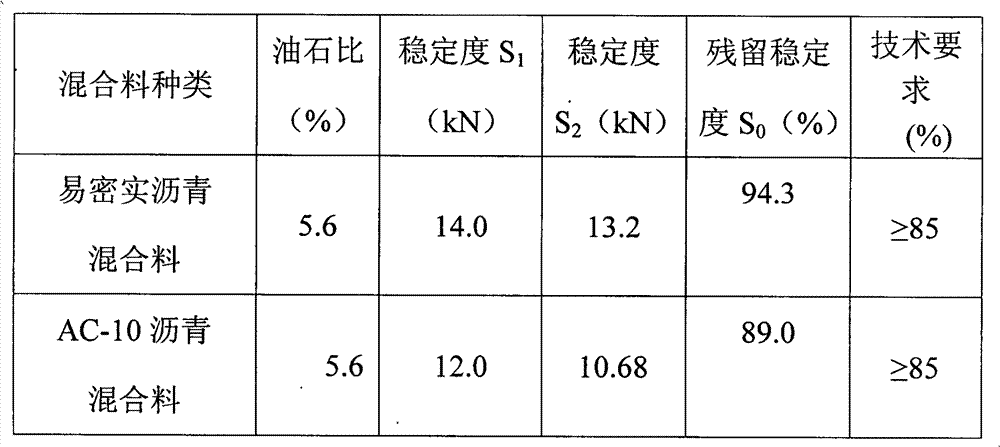

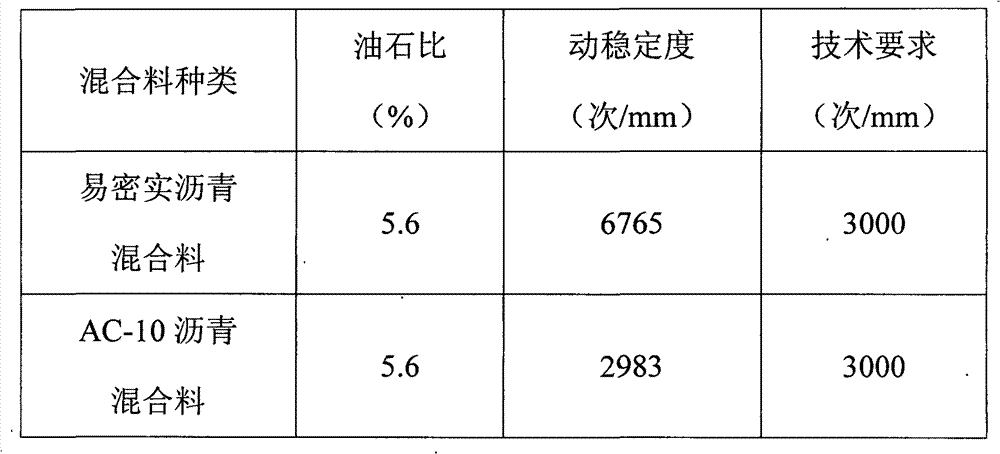

The invention discloses an easy compact asphalt mixing material and temperature and time control parameters in the preparation process of the easy compact asphalt mixing material. The easy compact asphalt mixing material comprises 100 parts of ore materials, 5.8 to 6.4 parts of modified asphalt, 0.2 to 0.3 parts of polyester fibers and 0.3 parts of easy compact agents, wherein the ore materials comprise the following ingredients in weight proportioning: 50 percent to 60 percent of 8-11mm macadam, 10 percent to 15 percent of 5-8mm macadam, 25 percent to 35 percent of manufactured sand and 3 percent to 8 percent of limestone ore powder. The ore materials are heated to 150 DEG C to 160 DEG C and is then subjected to dry stirring with polyester fibers for 5 to 10s, the modified asphalt is heated to 165 DEG C to 175 DEG C, the easy compact agents start to be sprayed after the modified asphalt is sprayed for 3s, the total time for spraying the asphalt and the easy compact agents is controlled to be within 13s, the ore powder is added after the wet stirring for 6s, the total time of the stirring and the mixing is not lower than 60s, the cylinder discharge temperature is controlled to 135 to 155 DEG C, and the easy compact asphalt mixing material is obtained. The mixing material is easy to compact, the rutting resistance capability is high, the construction temperature is reduced to 30 to 50 DEG C, heating energy sources are saved by about 22 percent, the emission of asphalt smoke and greenhouse gas such as CO2 is reduced, the effects of energy saving, emission reduction and environment protection are obvious, meanwhile, the construction quality is improved, the effective construction time is prolonged, and the work period is shortened.

Owner:中石化胜利建设工程有限公司

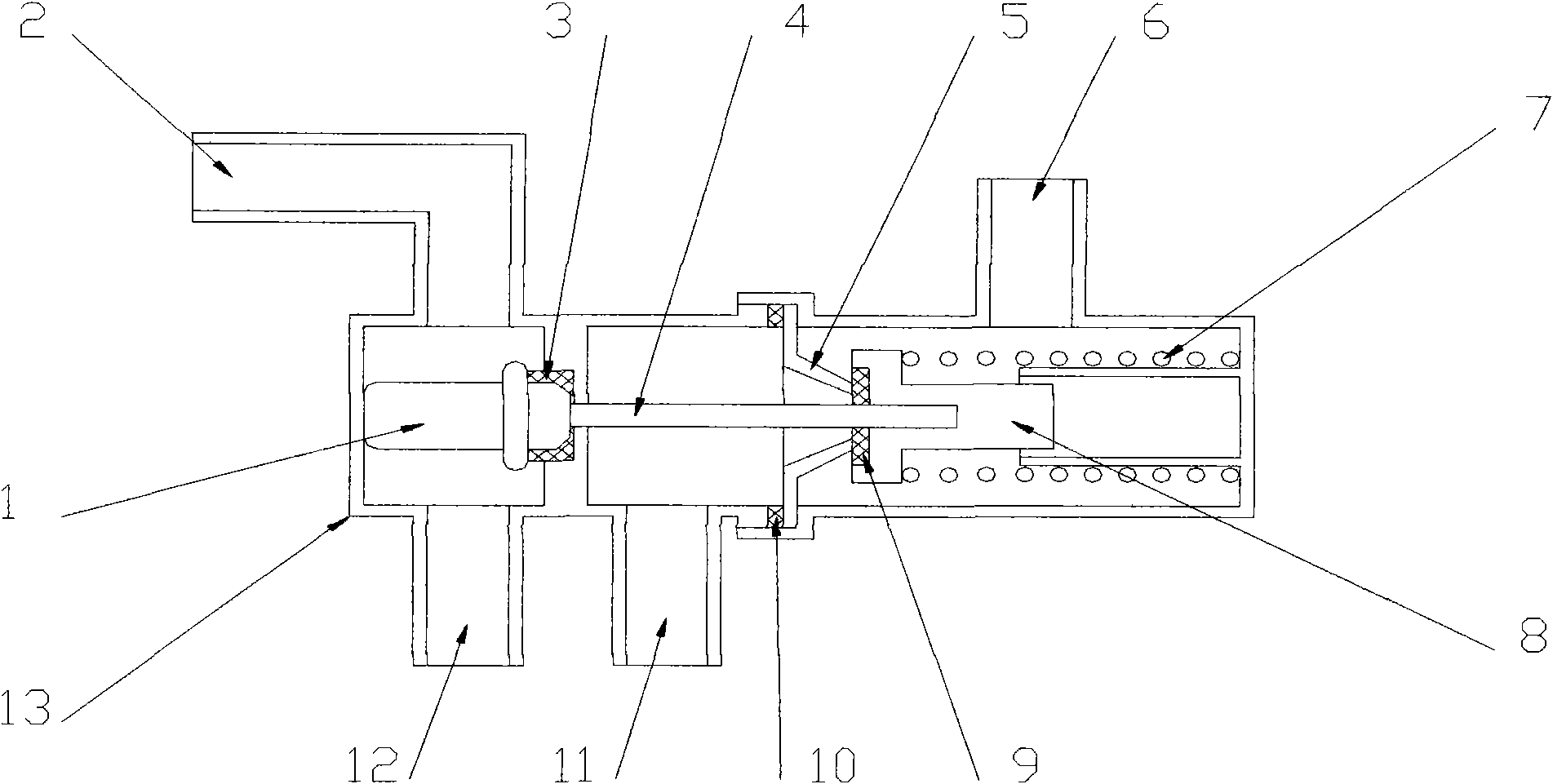

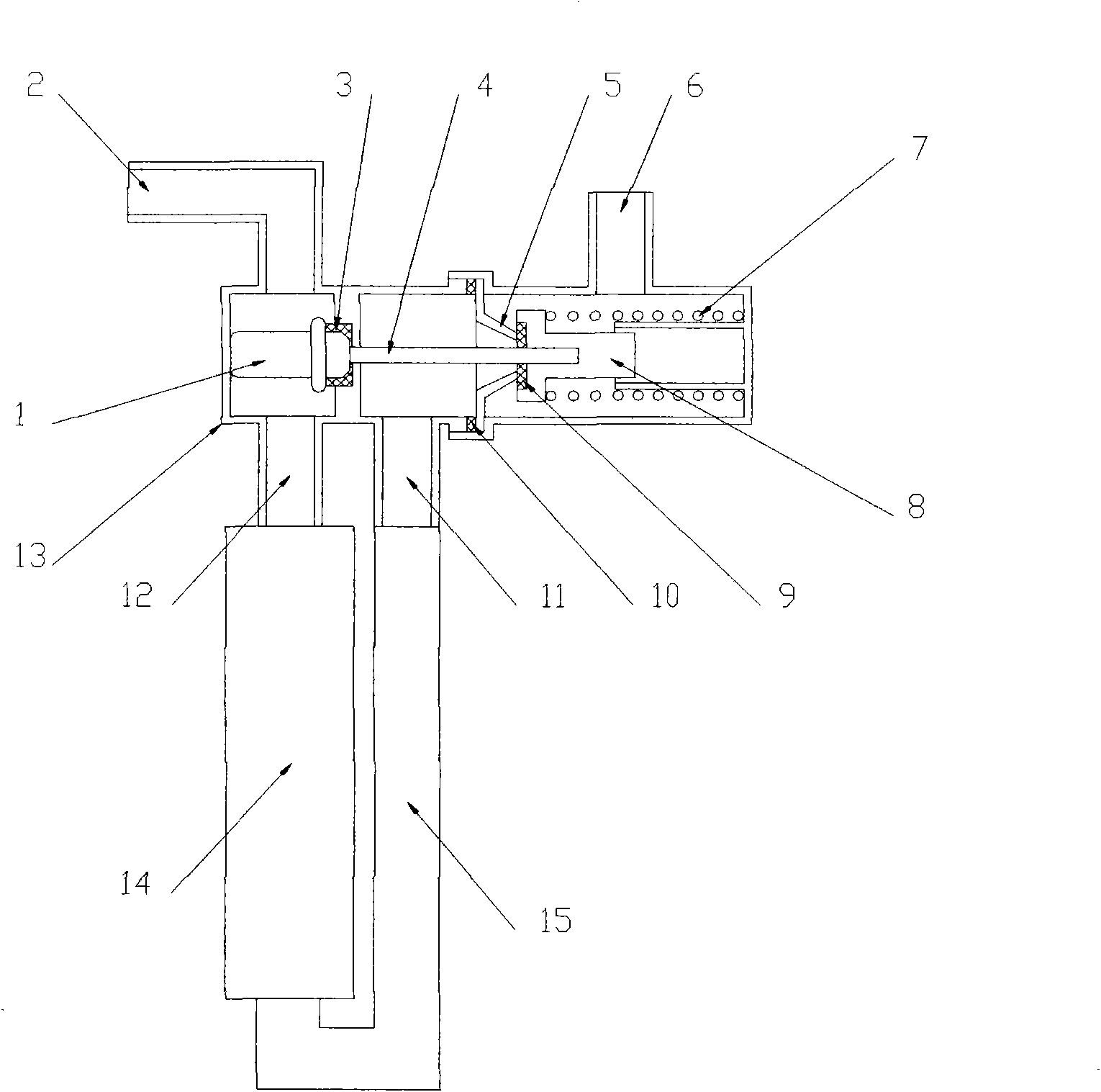

Temperature controlling valve

InactiveCN101629653ALow costImprove reliabilityOperating means/releasing devices for valvesValve members for heating/coolingTemperature controlInlet valve

The invention relates to a temperature controlling valve. A thermodynamic element sensitive to the temperature is arranged at a hot water outlet end for sensing the temperature of hot water; a control valve is arranged in a water inlet pipeline of a heating device; and the state of the thermodynamic element controls the state of the valve to realize the control on the temperature of the hot water. During heating the water by a heater, when the thermodynamic element senses that the temperature of the hot water reaches the designed outlet temperature, the thermodynamic element actuates to open a water inlet valve of the heater to make the hot water reach the designed temperature flow out of the heater; and when the heater stops heating, or the temperature of the hot water is lower than the designed temperature, the thermodynamic element actuates to close the water inlet valve of the heater to stop the hot water from flowing out. The state of the water inlet valve is controlled by the temperature of the hot water to realize the control on the temperature of the hot water. The temperature controlling valve has simple structure, low cost, high reliability and high control precision, and is suitable for various heating modes and the control of various temperatures of the hot water.

Owner:叶萍

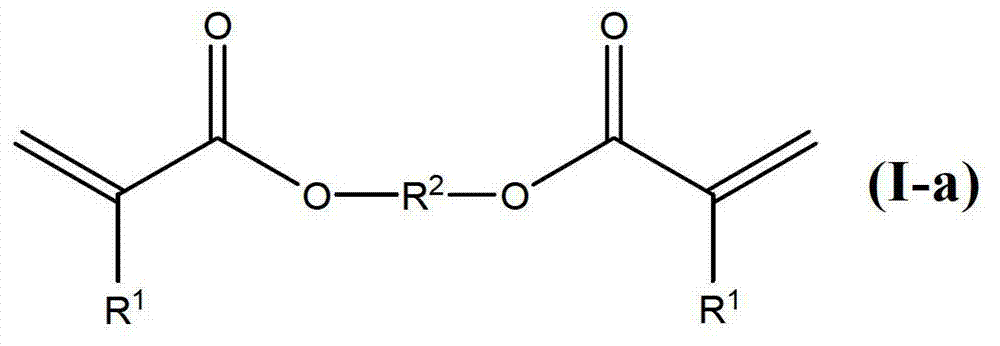

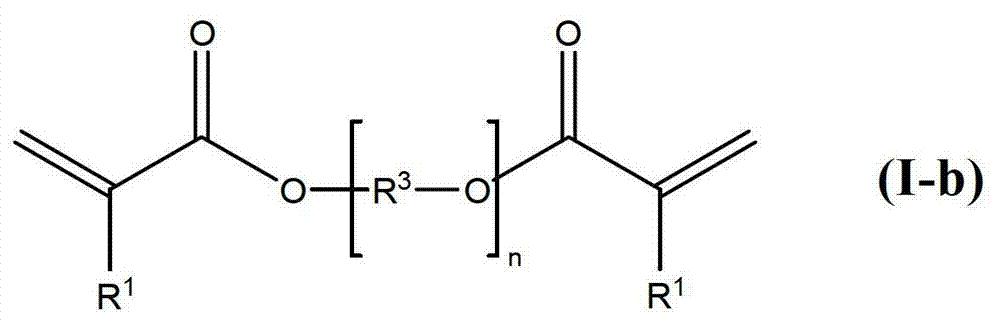

Two-part polyurethanes based on hyperbranched polymers

InactiveCN103080180ALong application periodShort application periodPolyurea/polyurethane coatingsPolymer scienceSide chain

The present invention relates to two-part polyurethane compositions. This two-part composition consists of a first pack (C1) and a second pack (C2). The first pack (C1) comprises at least one hyperbranched copolymer (HBC) having pending OH groups and which is prepared from at least one or more monomer(s) (M2) having at least two unsaturated C-C bonds and one or more monomer(s) (MH) having one unsaturated C-C bonds and one hydroxyl group in the presence of a cobalt (II) complex (CC). The second pack (C2) comprises at least one polyisocyanate (PI). It has been possible to offer a two-part polyurethane composition which has low viscosity, long pot life, fast cure, excellent weathering and UV resistance and is particularly suitable for the use as coating.

Owner:SIKA TECH AG

Method for producing pig iron and phosphate using ferro-phosphorus

InactiveCN102796838AIncrease the speed of oxidation reactionSave heating energyPhosphoric acidPhosphateReaction temperature

A method for producing pig iron and phosphate using ferro-phosphorus is characterized in that: the ferro-phosphorus is arranged in a reverberatory furnace, and performs quick air refining reaction with air or oxygen-rich air, thus the phosphor in the ferro-phosphorus is oxidized into P2O5 gas, and the reaction furnace gas is subjected to heat exchange, dust removal, and P2O5 hydration absorption to obtain rough phosphoric acid, and the rough phosphoric acid is refined and purified to obtain a technical grade phosphoric acid product. While the phosphorus element is oxidized, part of the ferro element is oxidized into ferric oxide, and then the ferric oxide is reacted with the newly-added ferro-phosphorus, thus the phosphorus element is oxidized into the P2O5 gas, and the ferric oxide is reduced into the ferro by phosphorus; when the phosphorus content in the iron solution in the reverberatory furnace is smaller than 4%, the iron solution is arranged in a converter and processed by pig iron smelting after adding refining agent such as burned lime powder as dephosphorization agent, and the eligible pig iron solution is then processed by injection moulding to obtain a pig iron product. The best material reaction temperature in the reverberatory furnace is 1300-1600 DEG C.

Owner:黄靖元

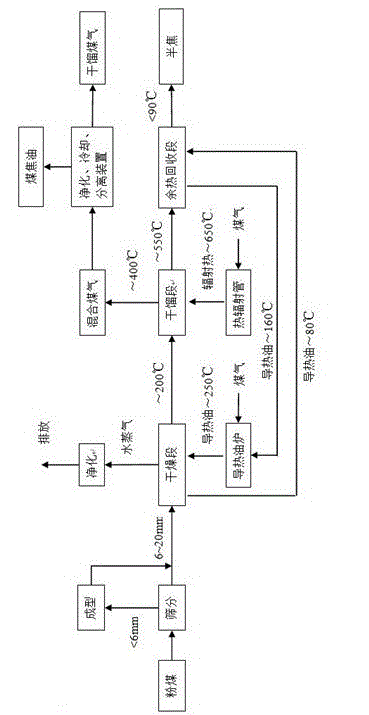

Zero-heat carrier powdered coal low-temperature dry distillation carbonization method

ActiveCN103333705AAvoid interactionStable working temperatureEnergy inputIndirect heating destructive distillationWaste heat recovery unitHeat carrier

The invention relates to a zero-heat carrier powdered coal low-temperature dry distillation carbonization method. The zero-heat carrier powdered coal low-temperature carbonization method is characterized by being carried out in a closed furnace body, carrying out drying and waste heat recovery on powdered coal by utilizing heat-conducting oil inside a heat-conducting oil furnace and carrying out carbonization and heating on the powdered coal by utilizing a gas-fired radiant pipe. The method is carried out according to the following five steps of: screening; pressing for forming; drying; carrying out carbonization; carrying out waste heat recovery. The method disclosed by the invention can realize that the carbonization treatment is carried out on the powdered coal with a diameter smaller than 20 mm and can be used for treating and utilizing the by-product generated in a carbonization process.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Cold crystallization production technology for low-cost high heat-resistance polylactic acid product

InactiveCN105732995AImprove efficiencyReduce manufacturing costCoatingsPolymer scienceInjection molding machine

The invention discloses a cold crystallization production technology for a low-cost high heat-resistance polylactic acid product, and belongs to the field of polylactic acid product processing.The cold crystallization production technology comprises the steps that a polylactic acid matrix is filled with talcum powder to obtain modified polylactic acid; a common cold mold injection molding machine is used for carrying out injection molding on the modified polylactic acid, and a polylactic acid injection molding product is obtained; then an assembly line infrared oven is used for carrying out cold crystallization process operation on the polylactic acid injection molding product, and then the high temperature-resistance polylactic acid product is obtained.The cold crystallization production technology for the polylactic acid product has the advantages of being high in production efficiency and low in production cost.

Owner:宁波高新区优合塑料制品有限公司

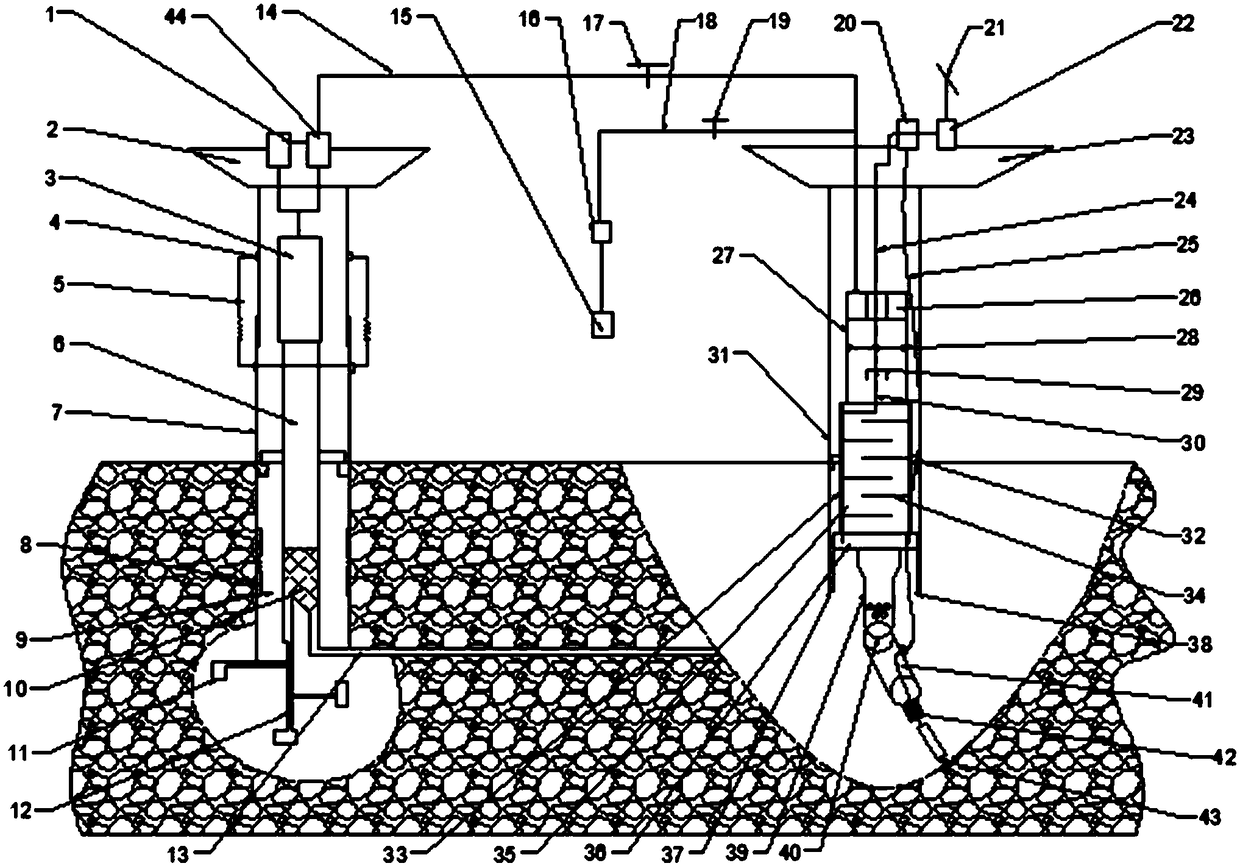

Natural gas hydrate exploitation method

The invention relates to the technical field of seabed shallow layer natural gas hydrate exploitation, in particular to a natural gas hydrate exploitation method. A water injection well and an exploitation well are arranged in the sea, a hydrate layer is heated by the water injection well, the water injection well communicates with the exploitation well communicate with each other on the water surface through a first water tube, thus, water drained from the exploitation well enters the water injection well, the exploitation well and the water injection well communicate with each other by the first pipe, thus, hot water separated from the exploitation well is injected into the water injection well again, part of hot water form hot cycle, namely low-temperature water which is injected into the water injection well at the very beginning is heated and injected into the hydrate layer, the hydrate layer is heated, thus, the temperature of a mixture collected by the exploitation well is high,water separated from the mixture is injected into the hydrate layer again, therefore, part of heating energy can be saved, heat loss is reduced, and the cost is saved.

Owner:SOUTHWEST PETROLEUM UNIV

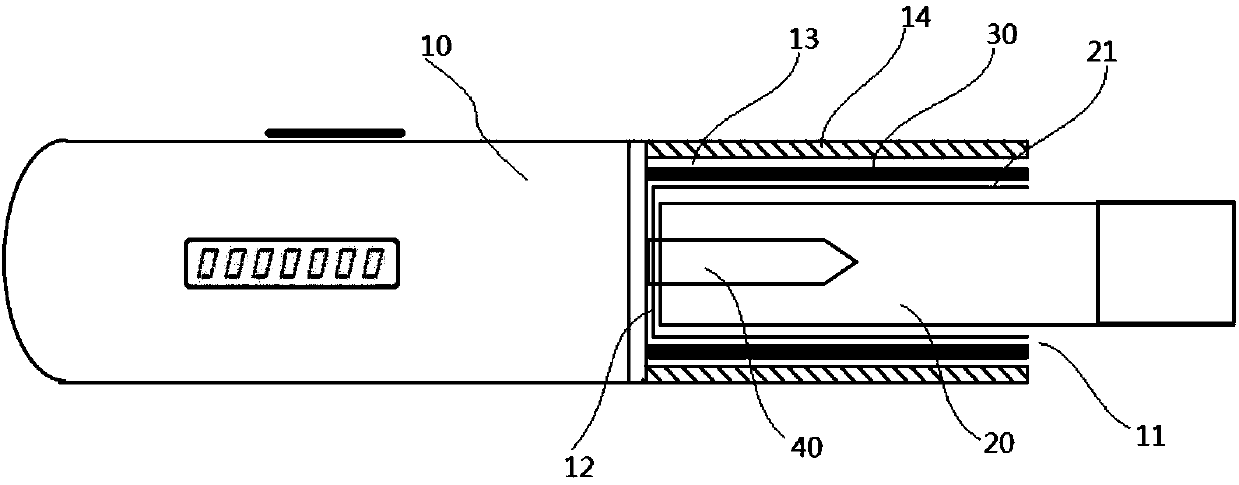

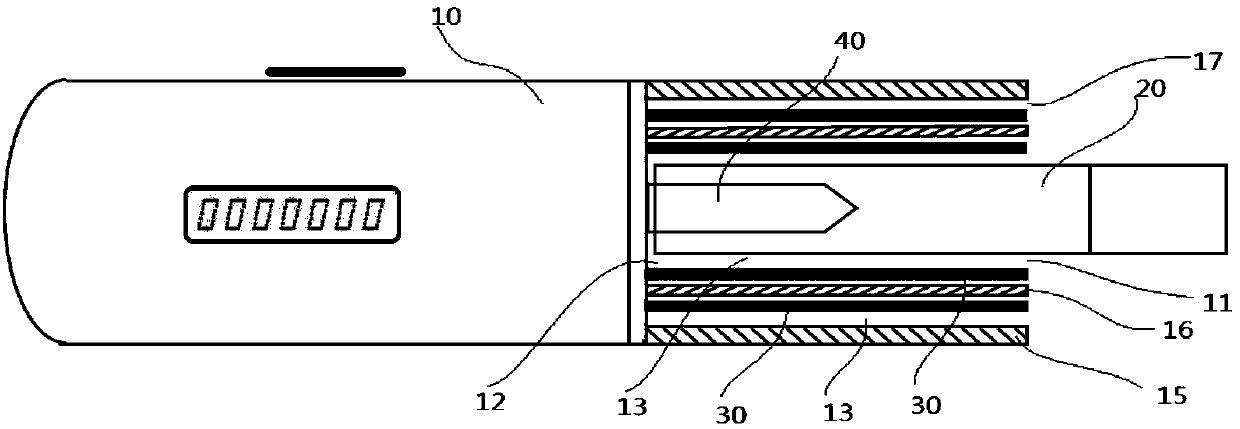

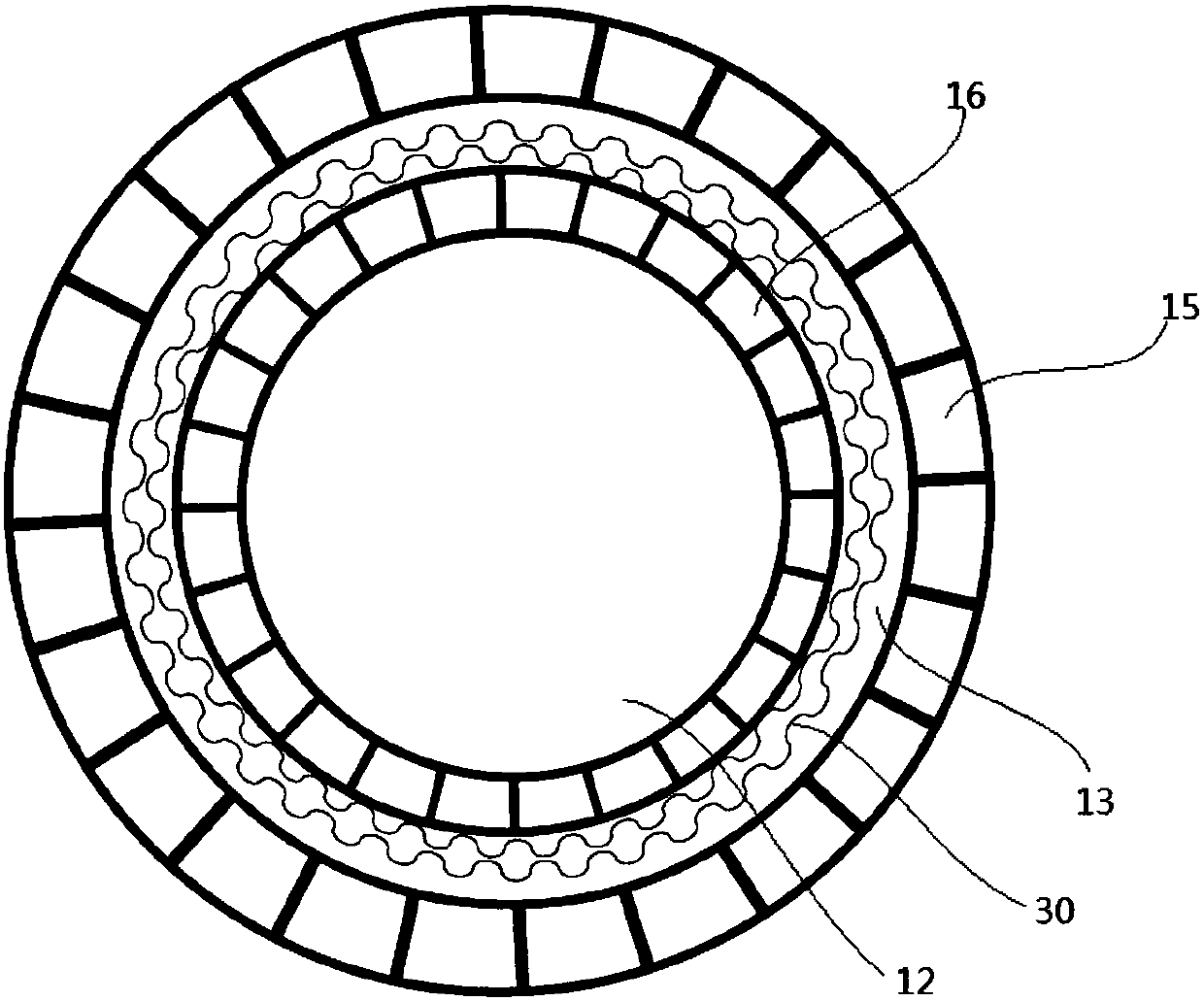

Smoking set

InactiveCN109645568AReduce the speed at which heat is dissipatedSave heating energyTobacco pipesTobacco devicesTransverse planeEngineering

The invention provides a smoking set, which comprises an elongated shell, a power source, an opening, a cavity and an airflow passage. The power source is arranged in the shell, the end of the shell is provided with the opening, the cavity extends along the shell from the opening longitudinally and used for cigarette storage, and the airflow passage extends longitudinally along a gap between a cigarette and the shell and internally provided with a blocking layer for weakening transverse air flowing. By arrangement of the blocking layer for weakening transverse air flowing in the airflow passage, outward heat diffusion is blocked while a tube wall cooling function is achieved; the blocking layer is intrinsically made from a heat insulation material, the speed of heat diffusion from the storage cavity to the tube wall is sharply decreased while air is partitioned into multiple parts; due to a large contact area between the blocking layer and the flowing airflow, intrinsic heat of the blocking layer and heat of the outer wall of the shell are effectively taken away by air flowing in smoking, so that cooling of the tube wall of the shell is realized.

Owner:SHENZHEN RUXIANGJU TECHCAL DEV LTD +1

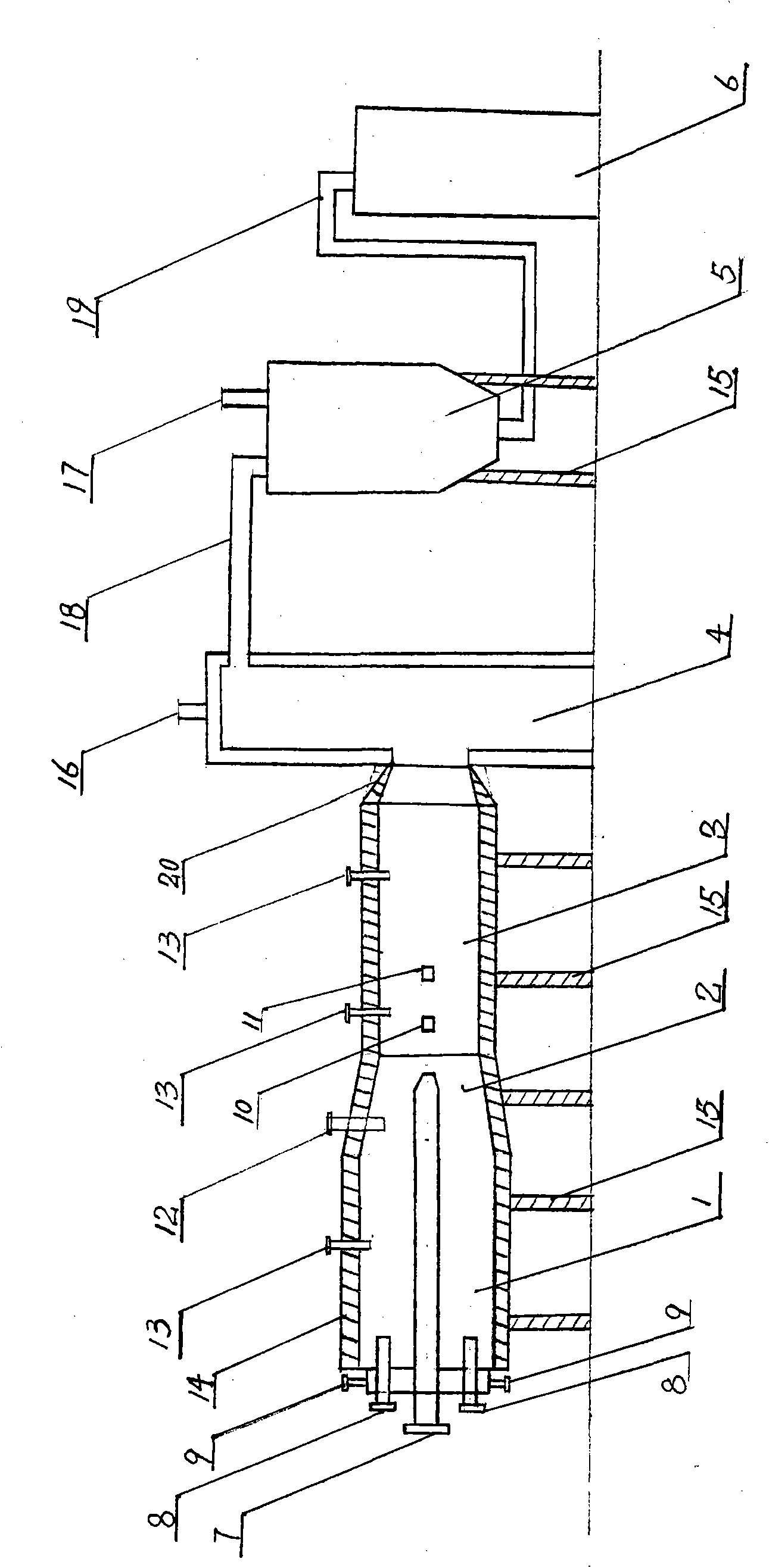

Coating drying solidifying forced convection heating furnace with suspending conveying workpiece device

InactiveCN1479068ASave heating energyDrying machines with progressive movementsHeating arrangementEngineeringForced convection

A heating furnace with forced convection for drying and solidifying the coated workpieces which are hung and delivered is composed of the heating furnace consisting of forced convection unit, side walls and top wall, and the hanging-delivering apparatus with delivering chain which can pass through the slit on top wall of heating furnace. Its advantage is high utilization rate of heat energy.

Owner:曹义东

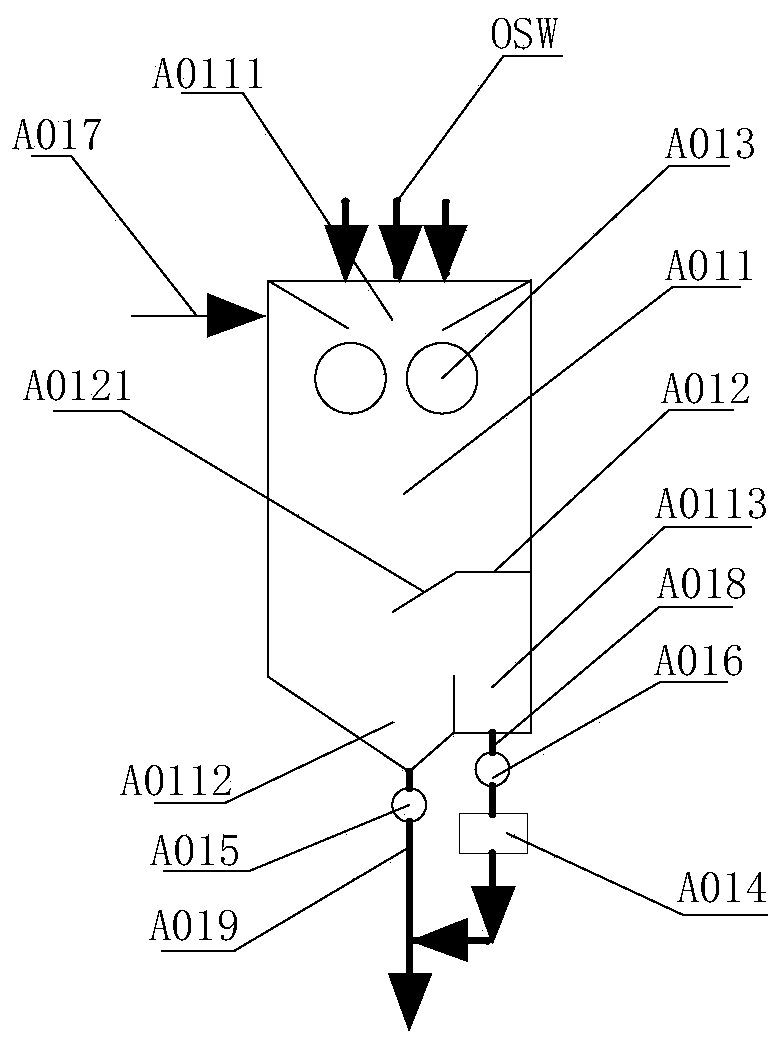

Organic solid waste pretreatment system and process and corresponding organic solid waste continuous hydrothermal treatment system and process

ActiveCN111346897ASave heating energyReduce energy costsWaste processingSolid waste disposalProcess engineeringEnvironmental engineering

The invention discloses an organic solid waste pretreatment system and process and a corresponding organic solid waste continuous hydrothermal treatment system and process. The organic solid waste pretreatment system comprises a weight sorting-smashing device and a ball milling device; the water weight sorting-smashing device comprises a sorting cavity and a second-stage smashing unit, separationof light materials and heavy materials can be achieved through the sorting cavity, smashing the light materials by the second-stage smashing unit is carried out to prepare primary mud, the ball milling device receives the primary mud and carries out ball milling to prepare mud containing impurities, the heavy materials separated by the sorting cavity can enter the ball milling device to be used asabrasive materials. The organic solid waste pretreatment system is simple and reasonable in structure, facilitates separation of light and heavy materials and utilization of heavy material waste, refines, homogenizes and fluidizes organic solid waste, can achieve organic solid waste synergism, high efficiency and continuous hydrothermal treatment, effectively prevents continuous hydrothermal technology blockage and the like, fully recovers heat energy in the technological process, and improves the utilization rate of organic solid waste, resource utilization of products can be realized, and obvious environment-friendly and economic benefits are obtained.

Owner:TSINGHUA UNIV

Polypropylene non-woven fabric waste recovery process

InactiveCN109082775AImprove recycling ratesSimple structureFilament forming substance formingMonocomponent polypropylene artificial filamentPulp and paper industryNonwoven fabric

The invention discloses a polypropylene non-woven fabric waste recovery process. The process sequentially comprises the steps that (1), non-woven fabric waste is delivered into a forcing feeding screwrod machine on the second floor through a collecting retracting box and roller tubes; (2), the waste is winded and squeezed by the forcing feeding screw rod machine, and pulling force is generated topull the waste into the feeding machine repeatedly, and the non-woven fabric waste is delivered into a heating tube to be heated and melted after squeezing and tearing are conducted; (3), melted waste material is uniformly mixed with raw material particles according to a certain ratio, and polypropylene fibers are prepared through a spinneret device; (4) the polypropylene fibers on which spinningis conducted are prepared into fiber layer through laying passing through a receiving device, a layer of polypropylene fiber is added to the fiber layer through a conveying belt, and non-woven fabricis prepared through hot pressing rolling; (5) rolled non-woven fabric is placed on a cutting machine to cut into non-woven fabric products with specific width dimensions. By means of the process, dried body mass is improved, and product yield is greatly improved.

Owner:杭州富阳雷讯科技咨询服务有限公司

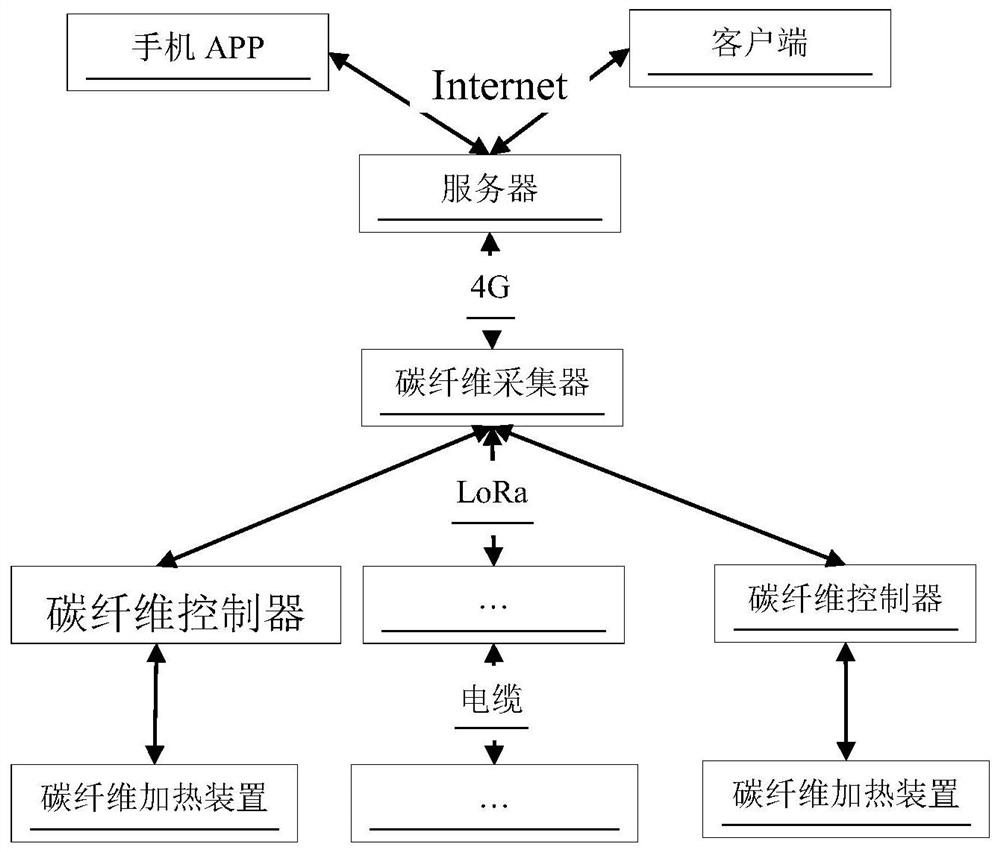

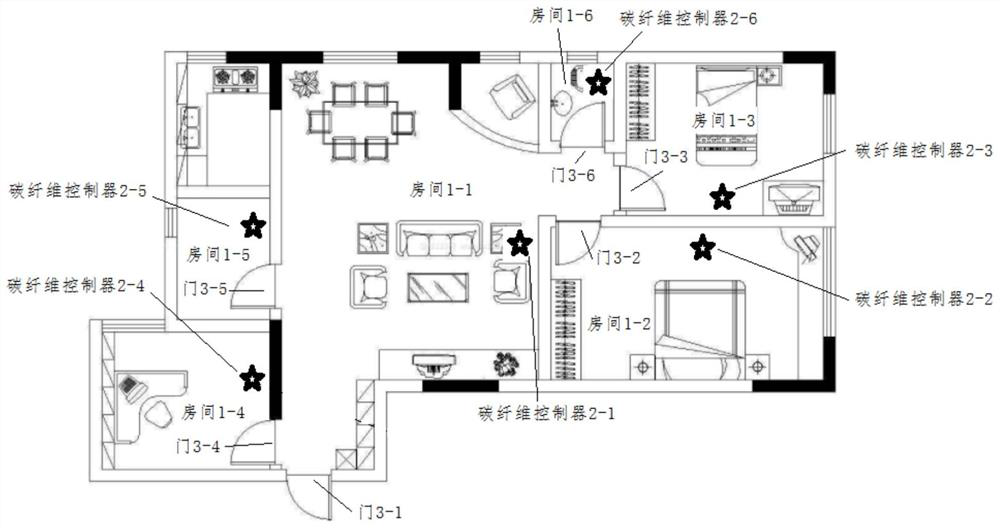

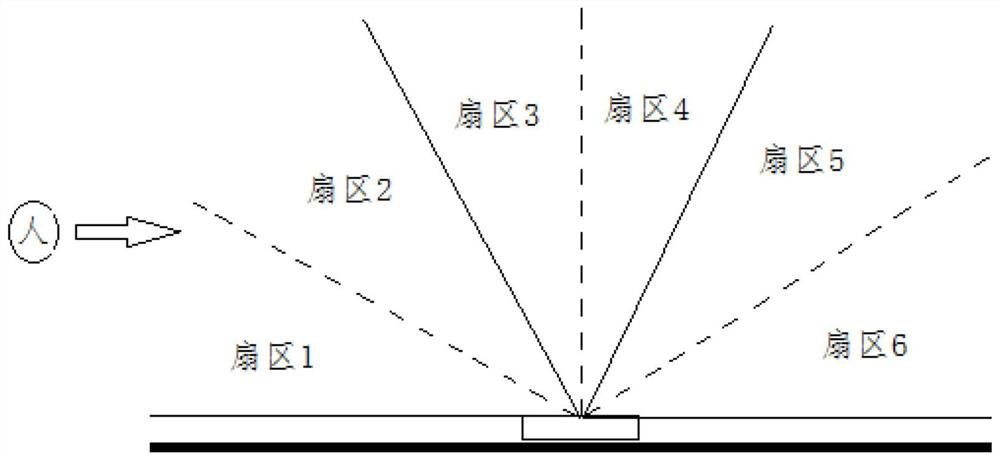

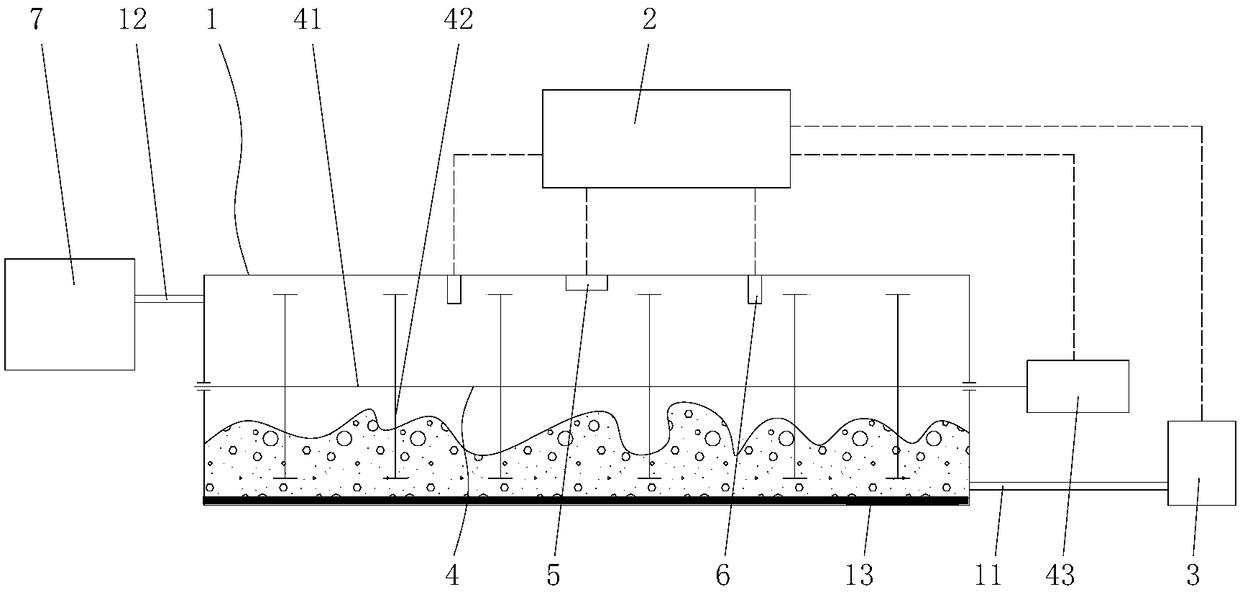

Heating control system based on human body moving detection

ActiveCN111678196AHeating economyHeating energy savingTransmission systemsLighting and heating apparatusFiberHuman body

The invention provides a heating control system based on human body moving detection. The heating control system comprises a server, a carbon fiber collector, carbon fiber controllers and a carbon fiber heating device. The server is in communication connection with the carbon fiber collector. The carbon fiber collector is in communication connection with the multiple carbon fiber controllers. Thecarbon fiber controllers are connected with the carbon fiber heating device. The carbon fiber controllers are used for measuring the indoor temperature, the human body moving state and the moving time. The server is used for conducting management, analysis and decision on data sent by the carbon fiber collector and recognizing vacant rooms and vacant rules so as to achieve low-temperature runningcontrol. The heating control system based on the human body moving detection has the beneficial effects that different vacancy time intervals and vacancy states of various rooms are detected, recognized and distinguished, the heating temperature of the rooms is controlled according to the vacancy rules, so that low-temperature running in the vacancy time intervals is achieved, normal heating in non-vacancy time intervals is achieved, and economical and energy-saving heating under comfortable heating conditions is ensured.

Owner:BEIJING FINE & CLEAN ENERGY

Solar heat pipe garbage drying equipment

InactiveCN101900477ADry fastContinuous dryingWaste processingSolar heat devicesThermal energyHeat pipe

The invention aims to provide solar heat pipe garbage drying equipment, which can realize the quick, uniform and continuous garbage drying at a stably-controlled temperature. In the equipment, a heat pipe is arranged in a garbage drying chamber to realize the stable, uniform, quick and continuous drying of garbage. Various solar collection techniques are used for collecting heat; the heat storage system is used for realizing heat storage; and the heat pipe arranged in the drying chamber is used for realizing the uniform, stable, possible and energy-saving heating of the garbage.

Owner:BEIJING WISWORD HI TECH

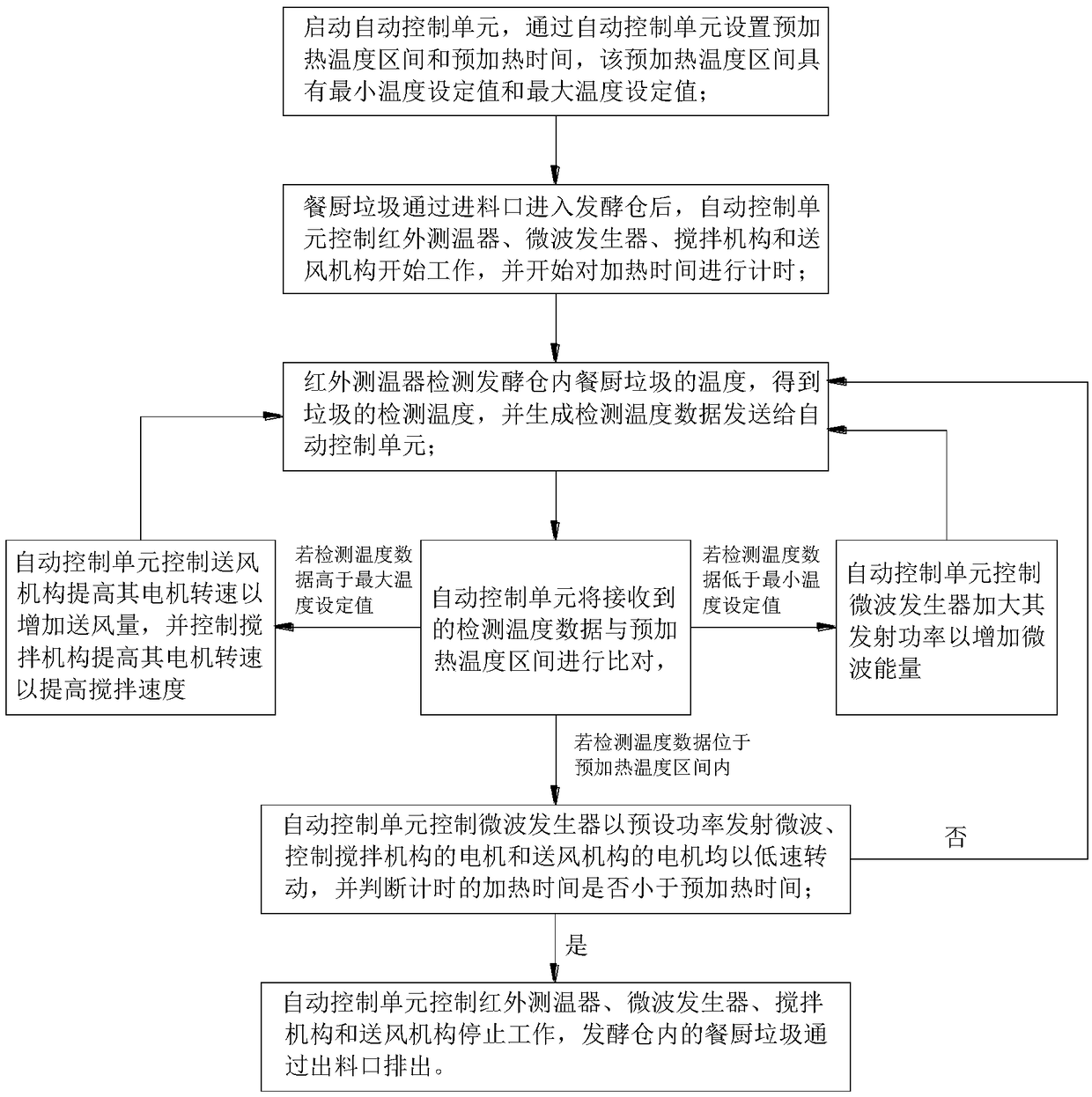

Kitchen waste fermentation heating system and control method thereof

PendingCN109401943AAdjustable temperatureUniform temperatureBioreactor/fermenter combinationsBiological substance pretreatmentsCold airMicrowave

The invention relates to a kitchen waste fermentation heating system and a control method thereof. The system comprises a fermentation chamber, an automatic control unit and an air feeding mechanism.A feed inlet, a discharge outlet, an air inlet and an air outlet are arranged on the fermentation chamber; the air feeding mechanism is communicated with the air inlet through an air inlet pipe, and is used for delivering fresh cold air into the fermentation chamber; the fermentation chamber is made from metal materials; a stirring mechanism for stirring kitchen waste, a microwave generator for heating the kitchen waste, and an infrared temperature detector for detecting the temperature of the kitchen waste are arranged in the fermentation chamber; the infrared temperature detector is connected with the input end of the automatic control unit, and is used for sending generated detected temperature data to the automatic control unit; the output end of the automatic control unit is connectedwith the microwave generator, the stirring mechanism and the air feeding mechanism, and the automatic control unit is used for respectively controlling the microwave generator, the stirring mechanismand the air feeding mechanism according to the received detected temperature data.

Owner:FUJIAN LONGMA ENVIRONMENTAL SANITATION EQUIP

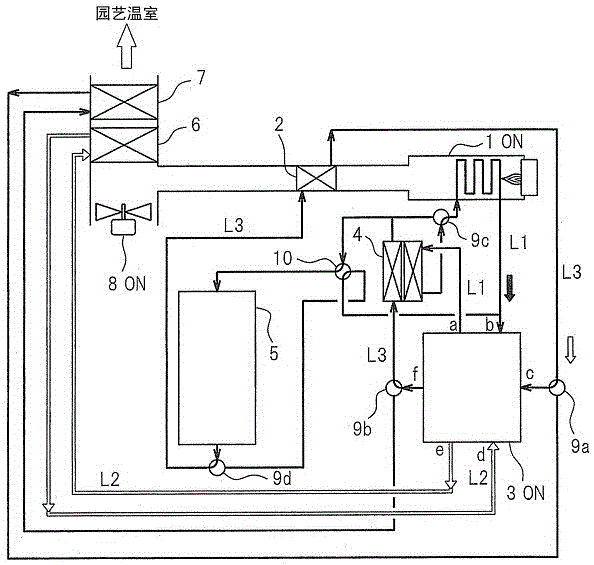

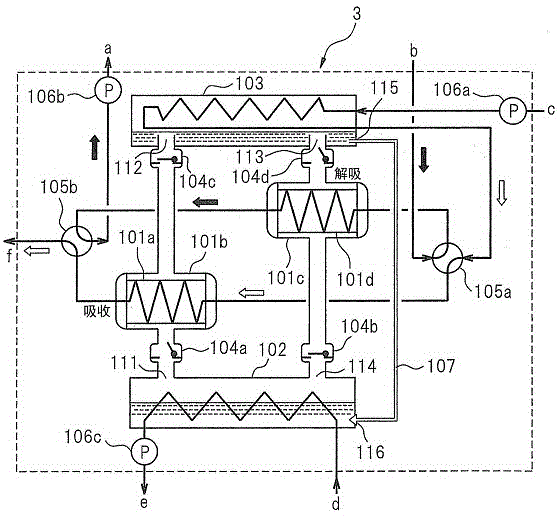

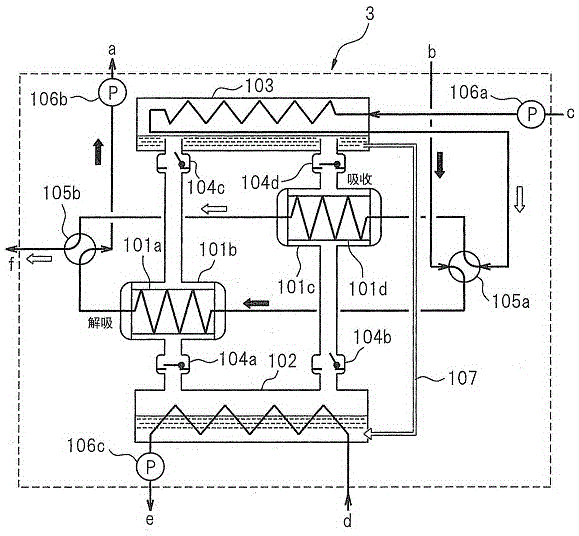

Carbon dioxide supply apparatus

The present invention discloses a carbon dioxide supply apparatus. The carbon dioxide supply apparatus is characterized by comprising a burner (1), a cooler (3) and a heat exchanger (6) for heat absorption. A fluid cooled by a cooling cycle of the cooler (3) flows through the heat exchanger (6) for heat absorption. The burner (1) comprises a combustion unit for combusting fuel; a first supply unit, wherein the first supply unit comprises an electric heater for heating the fuel to be supplied to the combustion unit and the first supply unit supplies the fuel heated by the electric heater to the combustion unit; and a second supply unit, wherein the second supply unit comprises a heat exchange unit for transferring heat of the combustion unit into heat for vaporization of the fuel, the second supply unit supplies the fuel heated by the heat exchange unit to the combustion unit, and the electric heater and the heat exchange unit are connected in parallel to the combustion unit.

Owner:LIUZHOU SHANTAI GAS

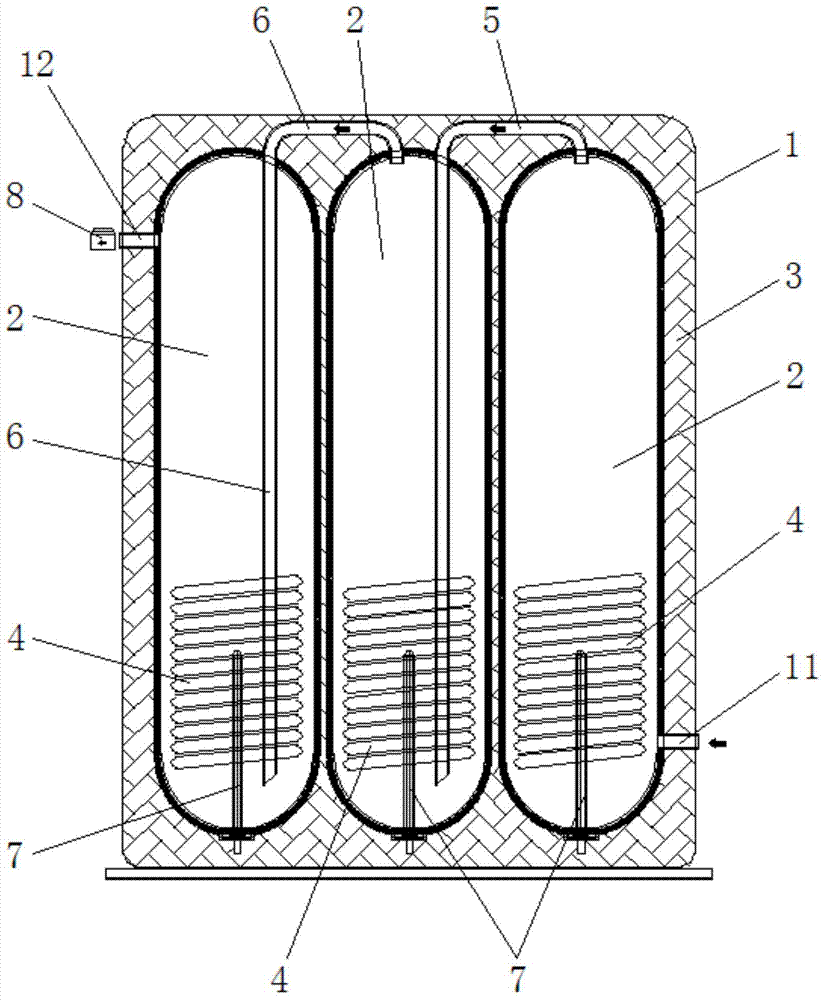

Multi-liner air energy water heater

InactiveCN104848541ASolve the problem of mixed waterIncrease usageFluid heatersInsulation layerPlastic materials

The invention provides a multi-liner air energy water heater. The multi-liner air energy water heater comprises a heat pump system, a control device and a water tank. The water tank comprises a shell, more than two liners and a heat insulation layer, wherein the liners are arranged in the shell, the heat insulation layer is filled in the shell and wraps the liners, the liners are arranged in the shell and communicated by serial honeycomb ducts, and a heating coil is arranged at the lower end of the inside of each liner. Thus, the problem of water mixing of the water tank is solved, and the multi-liner air energy water heater is high in hot water usage rate and energy saving and stable in heating. Meanwhile, the liners are provided with electric auxiliary heating rods and the heating coils for heating synchronically, heating is fast, water temperature is uniform and stable, and the problem that an air energy water heater is slow in temperature rise in the cold region or cannot be used normally is solved. The liners molded by PPR (pentatricopeptide repeats) plastic materials are water-tight, rust-free and anti-corrosion. In addition, by the rectangular external-mounting water tank, the problem that a conventional barrel type water tank cannot be mounted externally and is large in occupation area is solved, a water-electricity isolation switch is arranged at a water outlet, and using safety is high.

Owner:李新华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com