Patents

Literature

325results about How to "Fast dehydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

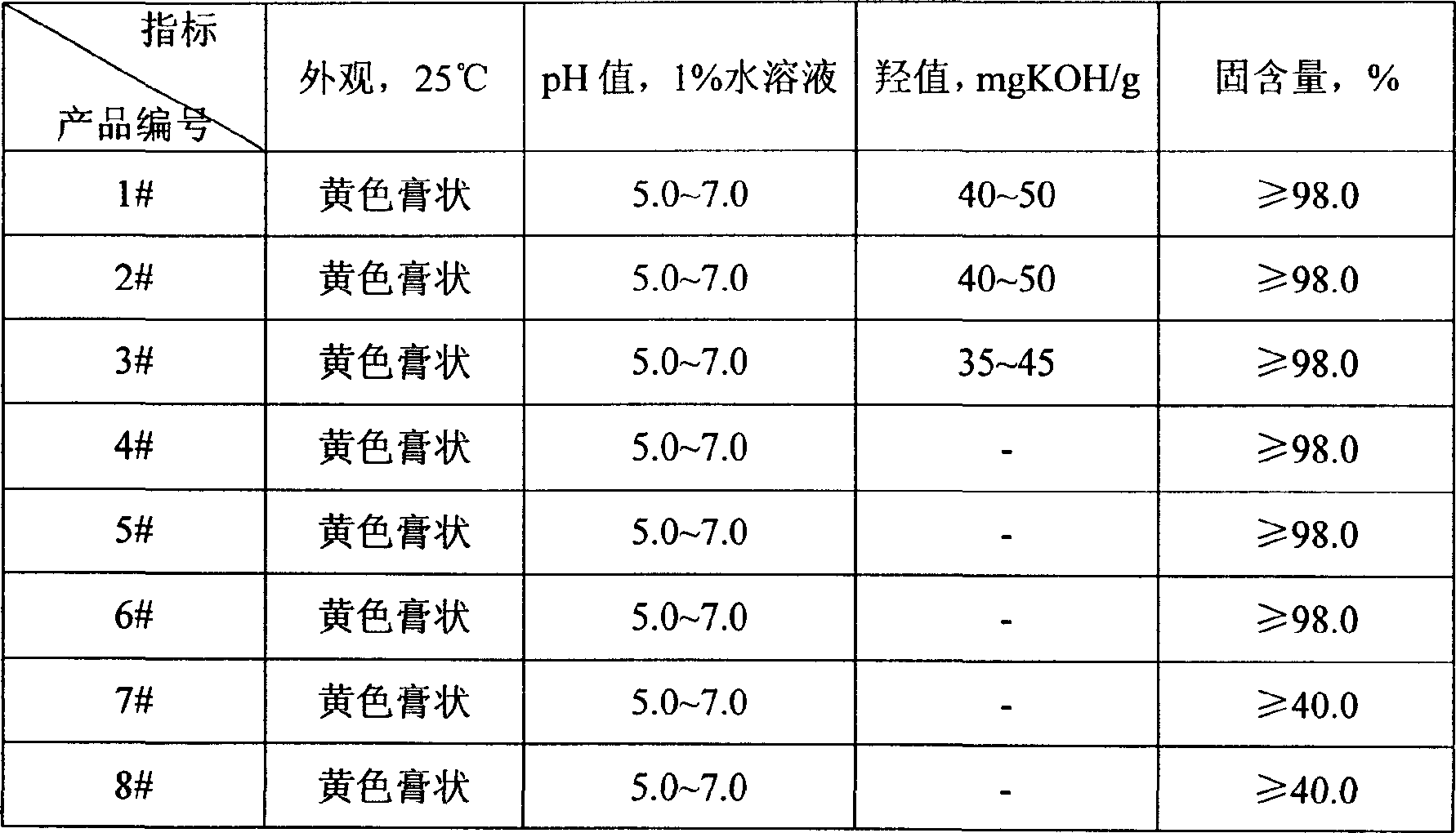

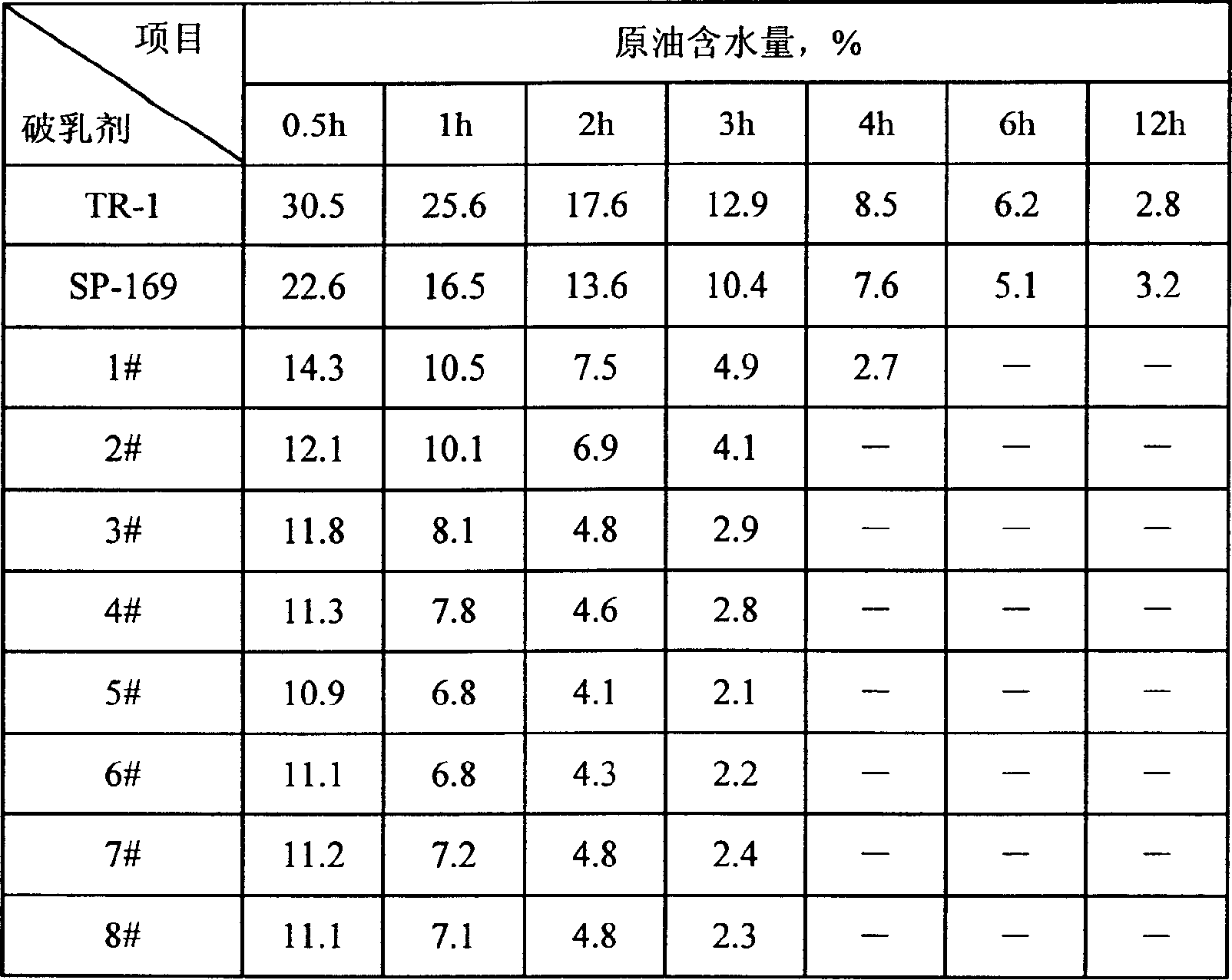

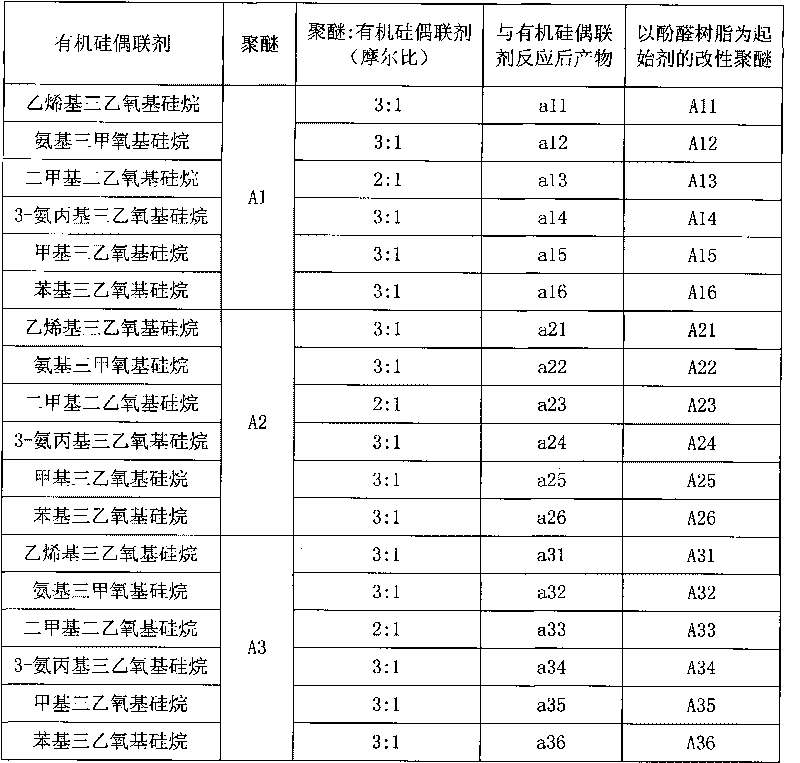

Thick oil demulsifier and its prepn

ActiveCN1810933ALow densityIncrease viscosityHydrocarbon oil dewatering/demulsificationEpoxyDemulsifier

The present invention is one kind of thick oil demulsifier and its preparation process, and belongs to the field of petrochemical technology. The present invention features that phenol-amine resin as the initial material is block polymerized with epoxy propane ad epoxy ethane under the action of catalyst to obtain stereo netted macromolecular polyether as the thick oil demulsifier. The polyether as the thick oil demulsifier may be further chain expanded for even high demulsifying effect. The thick oil demulsifier can reach the oil-water interface fast to lower the elasticity and viscosity of the interface film, speed the aggregation of liquid drops and demulsify effectively. The thick oil demulsifier has simple preparation process, is suitable for industrial production, and may be used in the efficient dewatering of oil field produced liquid with different water contents.

Owner:LIAONING OXIRANCHEM INC

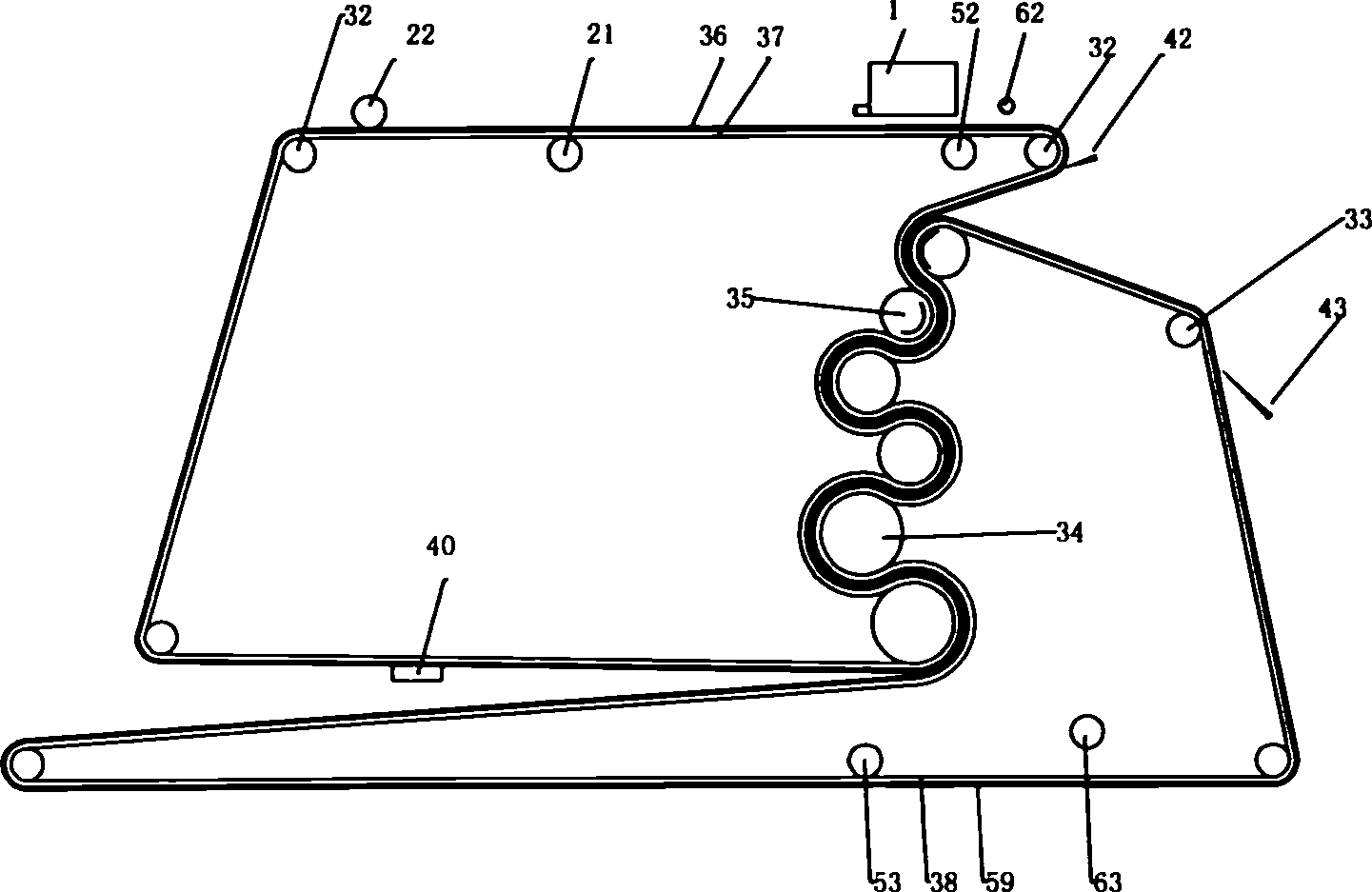

Belt type filter press

ActiveCN1879932AHigh filtration pressureHigh filter pressureMoving filtering element filtersEngineeringFilter press

The invention relates to a belt compress filter for dewatering the micro grains, wherein it is formed by a frame, a driver, a feeding device, a compress area and an auxiliary device; said compress area comprises a compress filtering roller and a filtering belt; the driver comprises a motor and a gear box; the auxiliary device comprises a tension roller, a scrape device, a water collector, a corrector, and a filter belt washer. The invention is characterized in that: the back of filter belt is lined with steel compress belt; the compress filtering rollers are compacted arranged. The invention can improve the filter pressure of compress filter to improve the balance point between the filter pressure and the filter resistance, to overcome the defects of present technique, while it can improve the dewatering efficiency and the yield.

Owner:ZHEJIANG HUAZHANG TECH

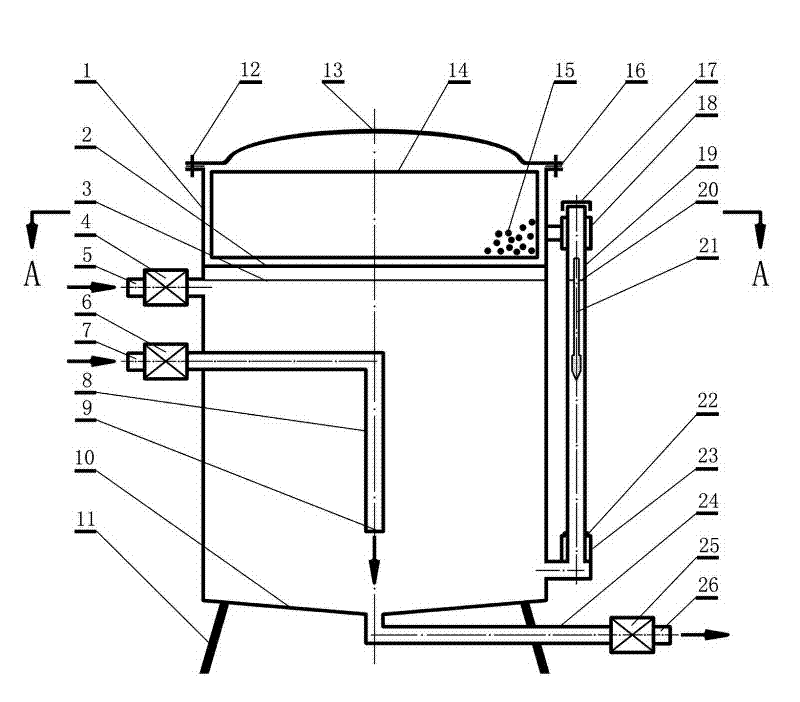

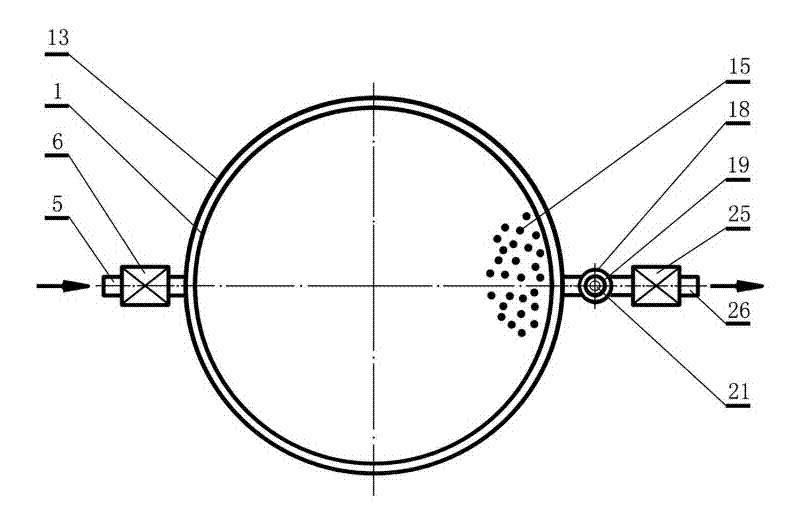

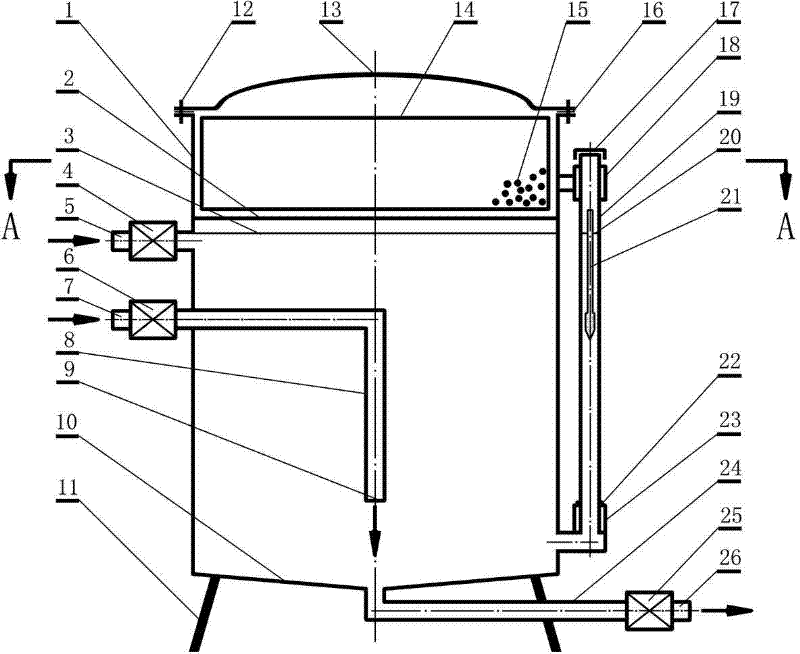

Dehydrating apparatus for alcoholic group bactericidal and fresh keeping liquid

InactiveCN102350092ASimple structureEasy to operateSolid sorbent liquid separationAlcoholInlet valve

The invention discloses a dehydrating apparatus for an alcoholic group bactericidal and fresh keeping liquid. A technical scheme has main points that the dehydrating apparatus for the alcoholic group bactericidal and fresh keeping liquid comprises a cylinder container, a cover plate, a connecting bolt, a feed inlet, a feed valve, a high pressure air inlet, a high pressure air inlet valve, a high pressure air pipeline, a web plate, a granular alcoholic group bactericidal and fresh keeping liquid desiccant, a stainless steel basket, a transparent glass tube, an alcohol meter, a transparent glass tube top cover, a glass tube support, a discharging pipe, a discharge valve, a discharge hole and a support. The dehydrating apparatus for the alcoholic group bactericidal and fresh keeping liquid has characteristics of simple structure, convenient operation and fast dehydrating speed; after dehydration, the alcoholic group bactericidal and fresh keeping liquid with an alcoholic strength less than 80 has an alcoholic strength higher than 99.0%. The dehydrating apparatus for the alcoholic group bactericidal and fresh keeping liquid can conduct continuous production according to batches; the granular alcoholic group bactericidal and fresh keeping liquid desiccant in a saturation state after absorbing water can be dried for reuse; besides the dehydrating apparatus is suitable for dehydrating of alcoholic group bactericidal and fresh keeping liquid and other alcoholic products.

Owner:南通沪联航海设备有限公司

Dewatering antirust oil

A dewatering antirust oil is prepared from mineral oil (85-93 mass%), antirust additive (4-8), dewatering additive (1-5), antioxidizing agent (0.5-2) and other additives (0.1-0.5). Iron and steel objects after treated have their surface adhered with antirust oil film. Its advantages include high dewatering speed (2-5 min) and long antirusting period (1-2 years).

Owner:蔡毓英

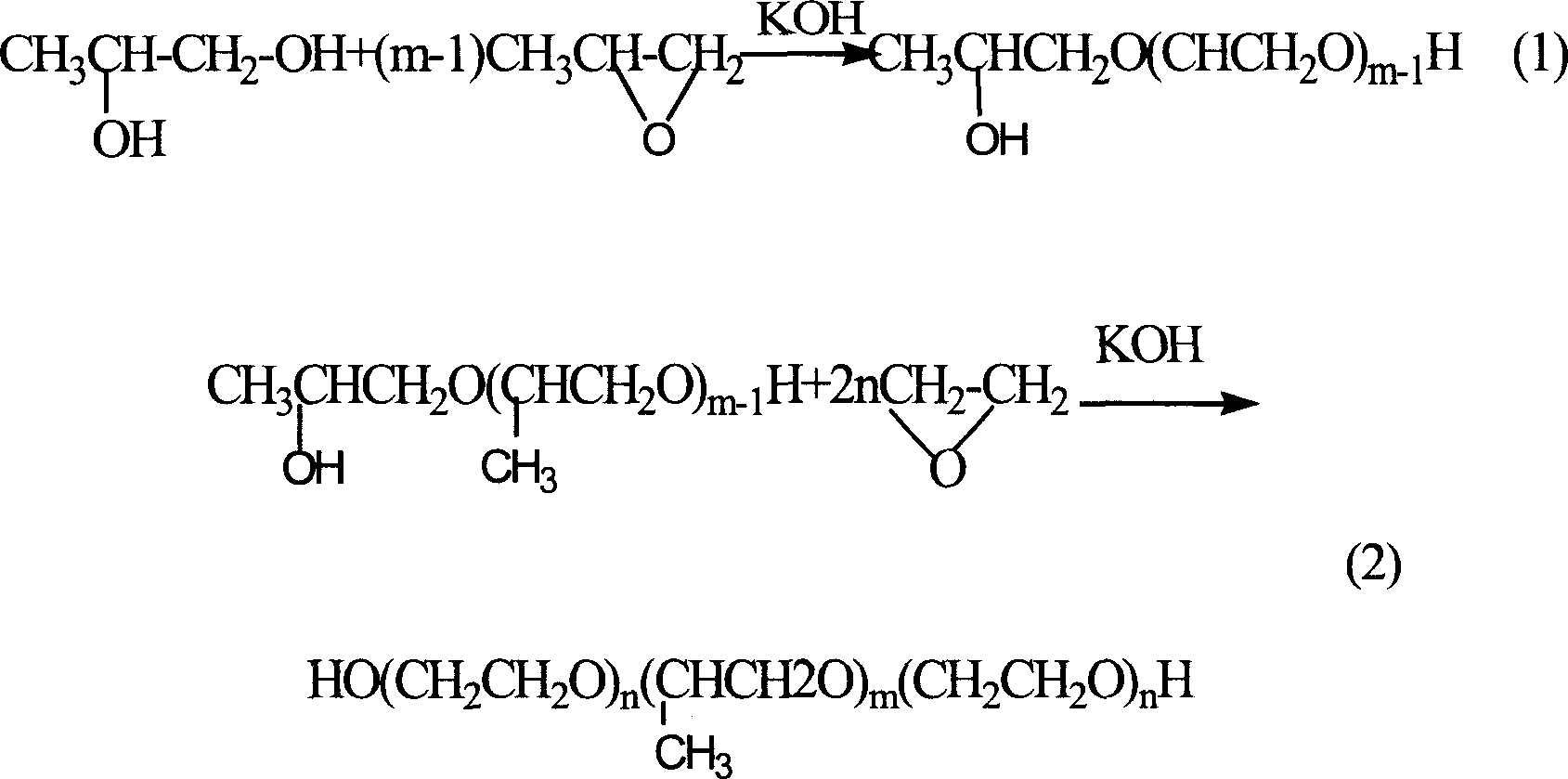

Low-temperature quick deemulsifying agent for water-containing wax-containing erude oil and its preparation method

InactiveCN1537924AFast dehydrationGood demulsification and dehydration effectHydrocarbon oil dewatering/demulsificationEpoxyOil processing

Owner:SHANDONG UNIV

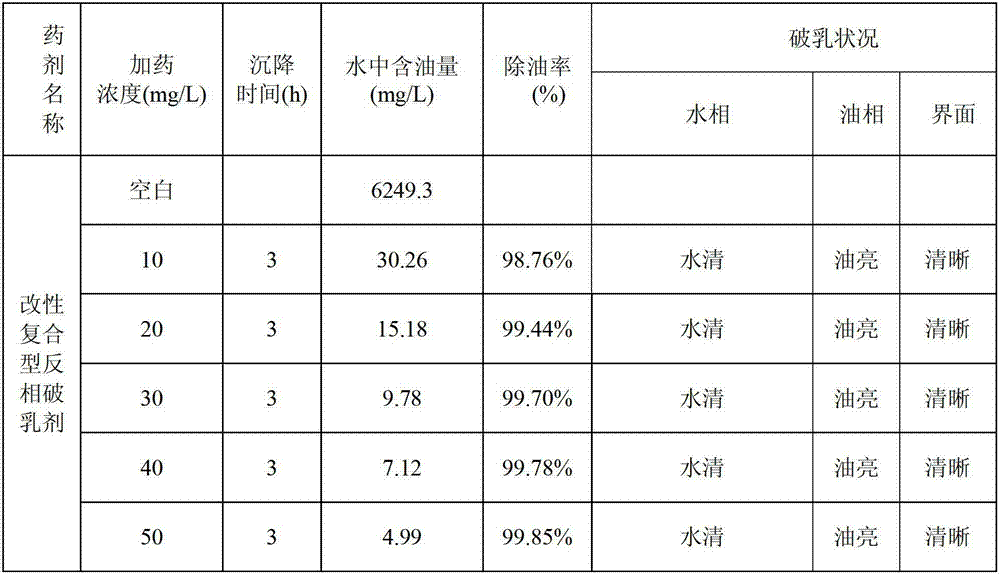

High-temperature sewage treatment reverse demulsifier of ultra-heavy oil

InactiveCN103086472ASimple technical routeMild reaction conditionsFatty/oily/floating substances removal devicesNon-miscible liquid separationCross-linkPotassium hydroxide

The invention discloses a high-temperature sewage treatment reverse demulsifier of ultra-heavy oil. The method comprises the following steps of preparing chlorinated polyether by taking propanetriol and epichlorohydrin as materials and boron trifluoride ether solution as an initiator; preparing cationic poly ether by placing the chlorinated polyether and trimethylamine in a high-pressure reactor; by taking carbinol as a solvent, and boron trifluoride diethyl etherate as the initiator, repeatedly and alternatively carrying out Michael addition reaction and amidation by ethanediamine, methyl acrylate and the like to prepare 3.0-generation dendritic macromolecule polyamide-amine; by taking polyethylene glycol and poly propylene glycol as materials, and potassium hydroxide powder as a catalyst, adding polypropylene glycol to prepare non-ionic polyether after the polyethylene glycol reacts a period of time; finally by taking 3.0-generation polyamide-amine as a cross-linking agent, preparing the modified composite polyamide-amine-polyether high-temperature sewage treatment reverse demulsifier of the ultra-heavy oil by compounding cationic polyether and non-ionic polyether.

Owner:KARAMAY SANDA NEW TECH +1

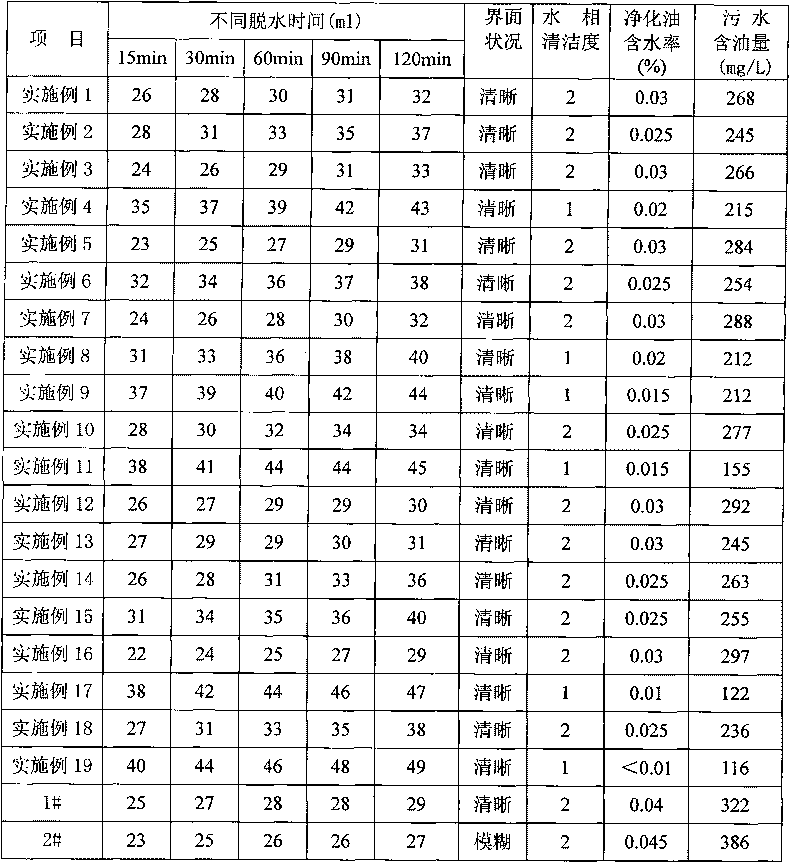

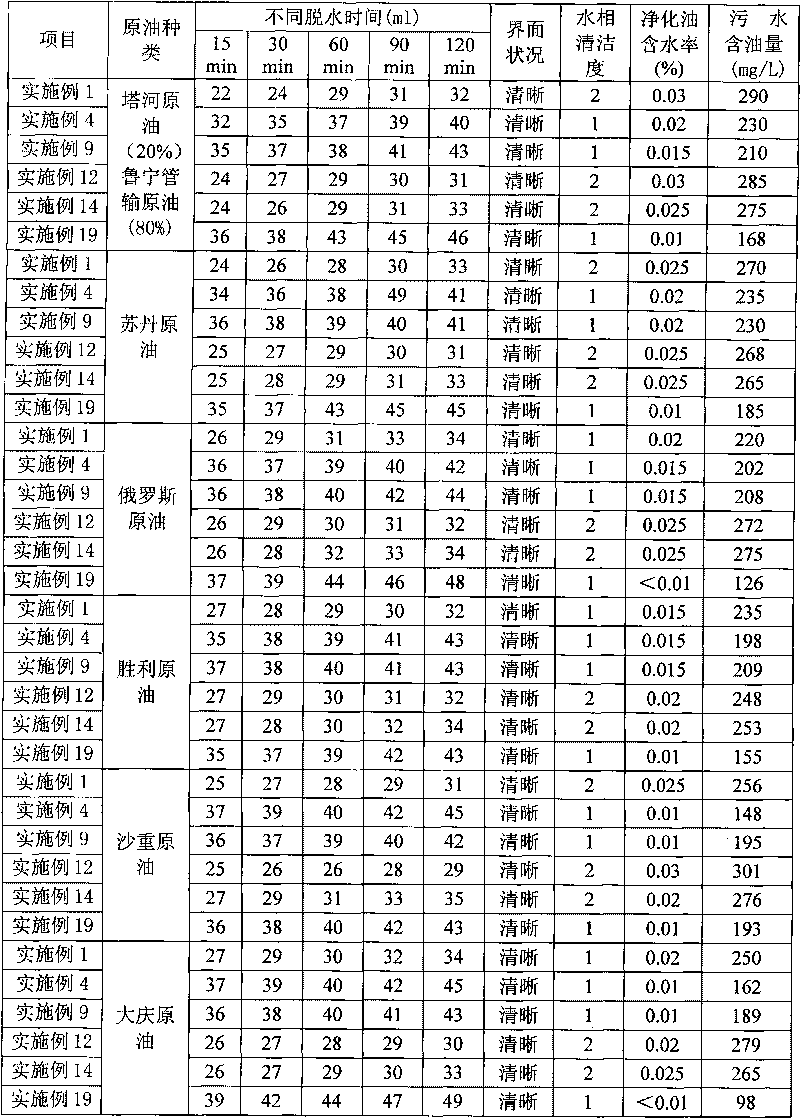

Multiple combination oil soluble demulsifier

ActiveCN101693846AImprove dehydration effectStrong broad spectrumDewatering/demulsification with chemical meansSodium phosphatesSolvent

The invention relates to a multiple combination oil soluble demulsifier which comprises 36-50 percent of demulsifier, 5-10 percent of surfactant containing fluorin and 40-59 percent of solvent, wherein the demulsifier comprises modified polyether taking phenolic resin as an initiator and modified polyether taking higher aliphatic alcohol as an initiator, and the weight ratio of the modified polyether taking the phenolic resin as the initiator to the modified polyether taking the higher aliphatic alcohol as the initiator is 0.8-3. The surfactant containing fluorin is preferably sodium perfluorous nonenyloxybenzenesulfonyl, perfluorous ethyldiethanolamine sodium phosphate or N-ethyl Perfluorooctanesulfonamide. The invention is mainly applied to atmospheric and vacuum process of a refinery with the operation temperature of 70-150 DEG C. When the use level is 3-30 ppm, the demulsifier has the advantages of good demulsifying effect, clear water and emulsion layers of demulsifying, high dehydration speed, low water content in purified oil, low oil content of water of dehydration, good broad spectrum activity and low cost.

Owner:金浦新材料股份有限公司

Method for preparing biomass solid molding fuel

InactiveCN102021057AReduce consumptionFast evaporationSludge treatment by de-watering/drying/thickeningBiofuelsCompression moldingMolding machine

The invention discloses a method for preparing biomass solid molding fuel, comprising the following steps of: (1) transferring waste residue and sludge from paper making and biomass dry powder into a batcher in proportion to obtain a mixture; (2) transferring the mixture obtained in the step (1) into a stirrer, fully stirring and breaking up the mixture; (3) conveying the mixture obtained in the step (2) into a dryer through a conveyor; (4) further reducing the water content of the mixture through the dryer and transferring the mixture into a distributing bin; (5) transferring the mixture into a molding machine, carrying out compression molding to obtain solid molding fuel and further reducing the water content of the solid molding fuel through screening, cooling and air-drying; and (6) transferring the solid molding fuel obtained in the step (5) into a mechanical packer to obtain a finished product. By effectively using the waste residue and the sludge from paper making and the biomass dry powder, the invention not only enables the waste residue and the sludge from paper making and the biomass dry powder to be treated, but also successfully produces the clean biomass solid molding fuel, and is beneficial to reduction of consumption of mineral energy.

Owner:NINGBO GUOHAI ENERGY TECH

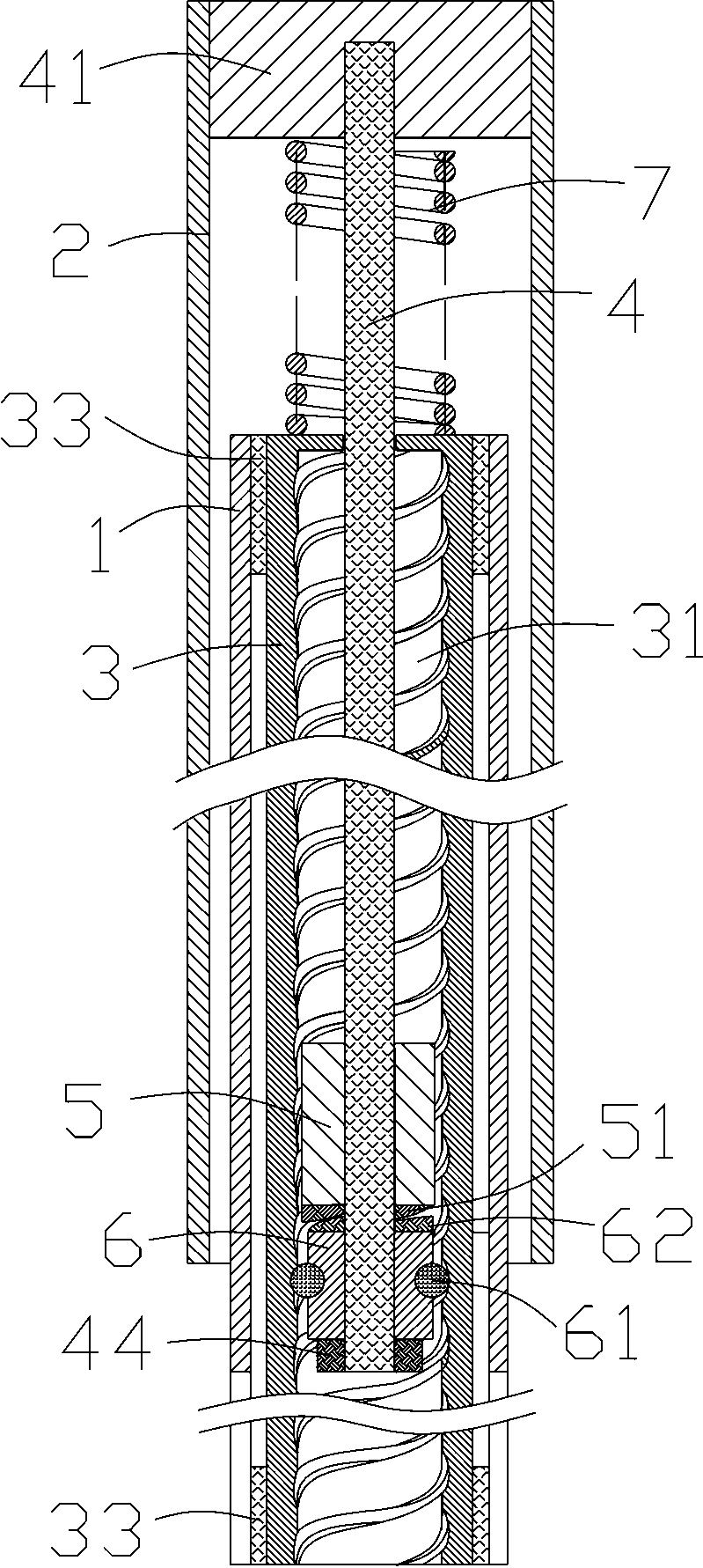

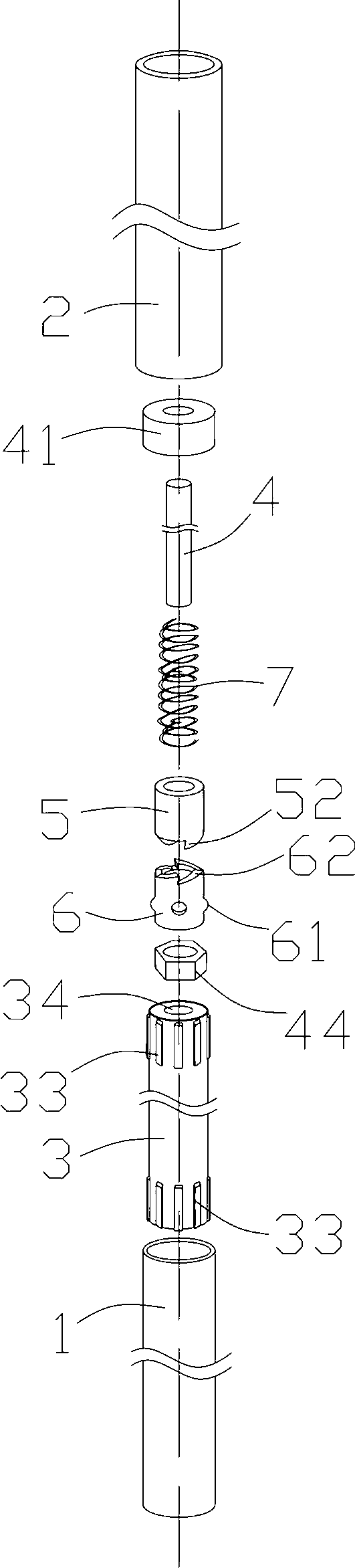

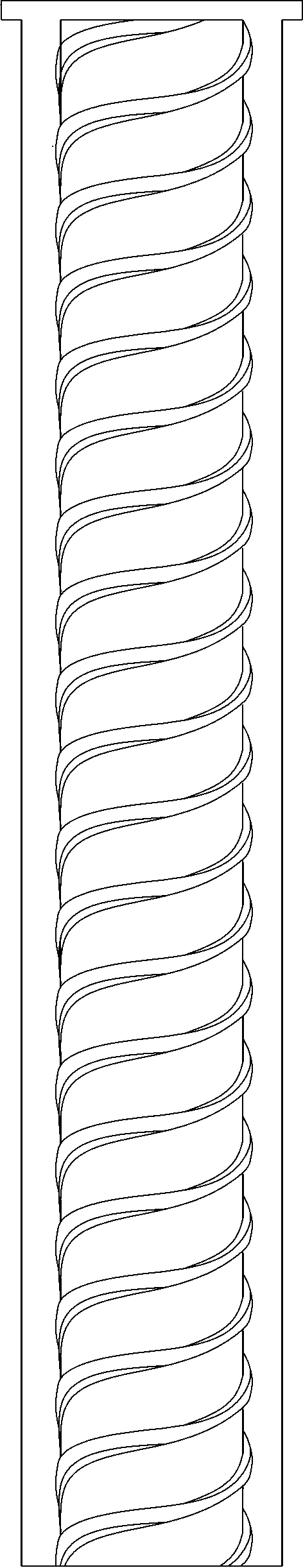

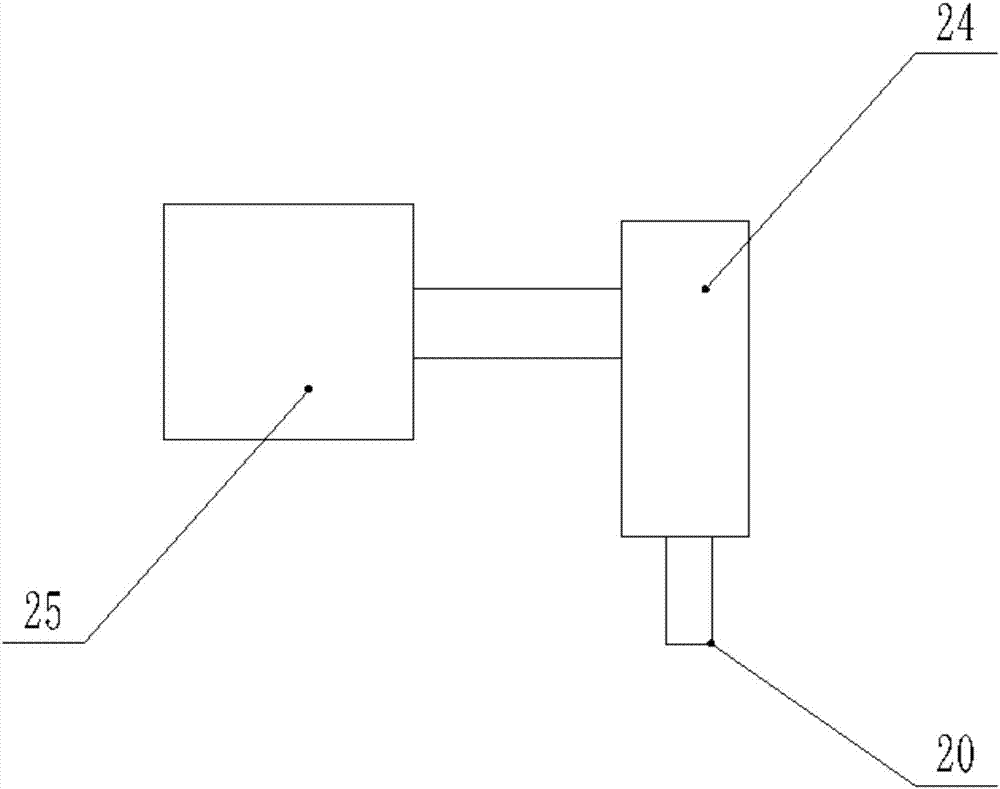

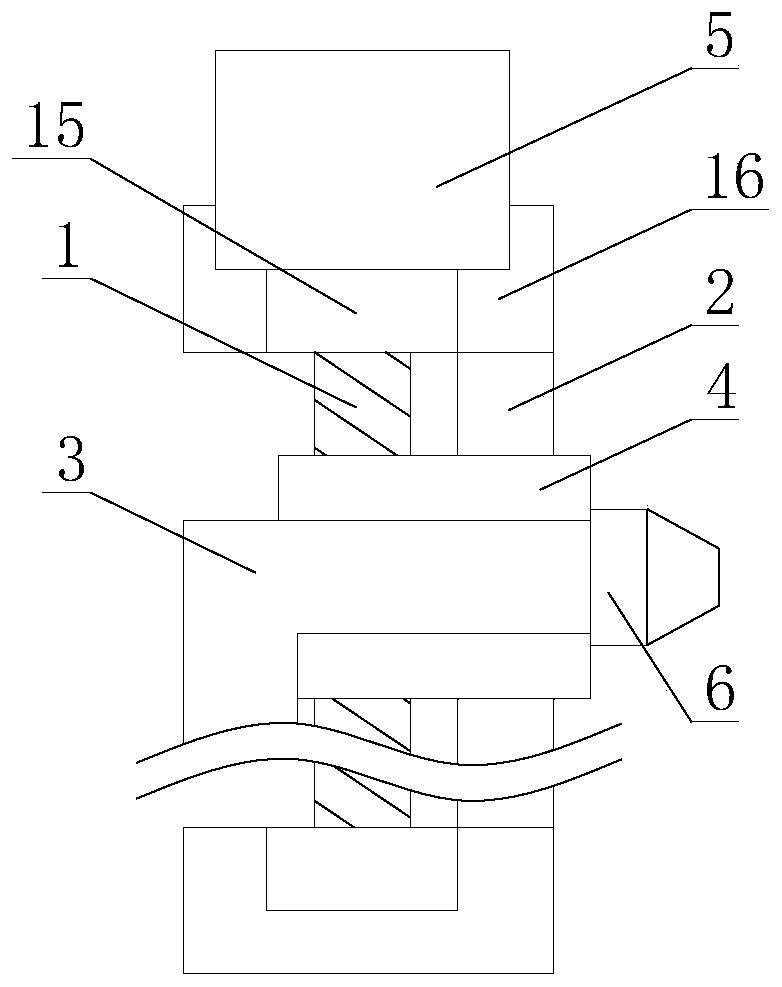

Manually-pressed type rotating mop rod

ActiveCN103120575ASimple structureFew partsCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention discloses a manually-pressed type rotating mop rod. The manually-pressed type rotating mop rod comprises an inner rod body, an outer rod body, a rotating sleeve, a guide shaft core, a rotating guide piece, a blocking portion and a braking portion. The inner rod body and the outer rod body are mutually connected in a sleeved mode. The rotating sleeve is arranged in the inner rod body and the inner wall of the rotating sleeve is provided with a spiral groove. The guide shaft core is arranged in the rotating sleeve, and the upper end of the guide shaft core is fixedly connected with the outer rod body. The rotating guide piece is sleeved at the lower end of the guide shaft core and capable of rotating along the guide shaft core. The blocking portion is arranged at the lower end of the guide shaft core and used for blocking the rotating guide piece from slipping off. The braking portion is capable of preventing the rotating guide piece from rotating. The rotating guide piece is capable of moving vertically in a small distance between the blocking portion and the braking portion. The manually-pressed type rotating mop rod is simple in structure, small in number of components, easy to assemble and high in production efficiency, and dewatering effect is improved greatly, and the phenomenon that a mop head idles can not happen in long-term use.

Owner:浙江美添乐家居用品股份有限公司

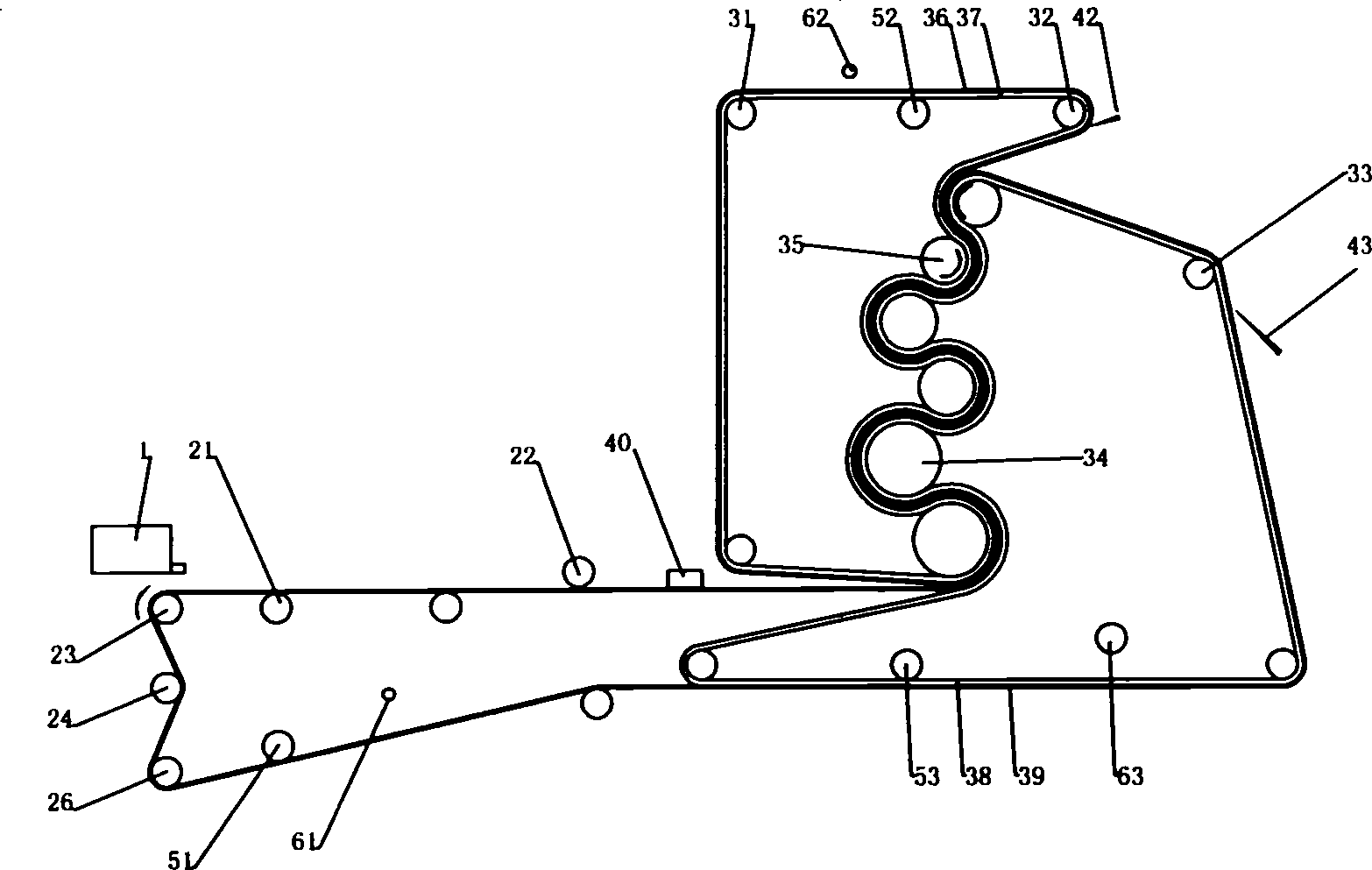

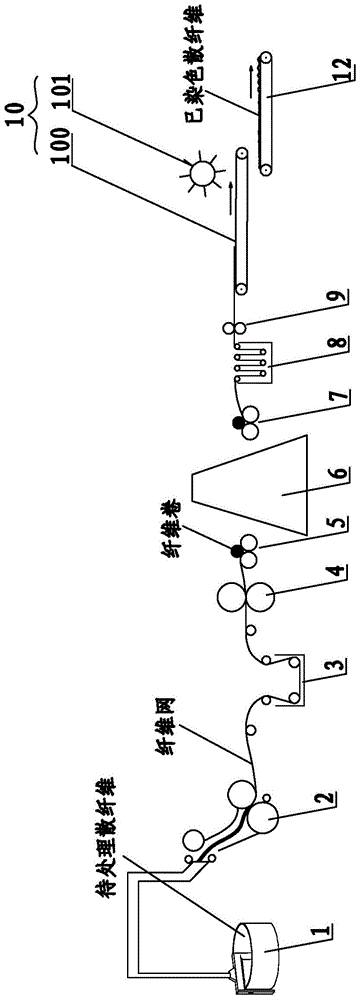

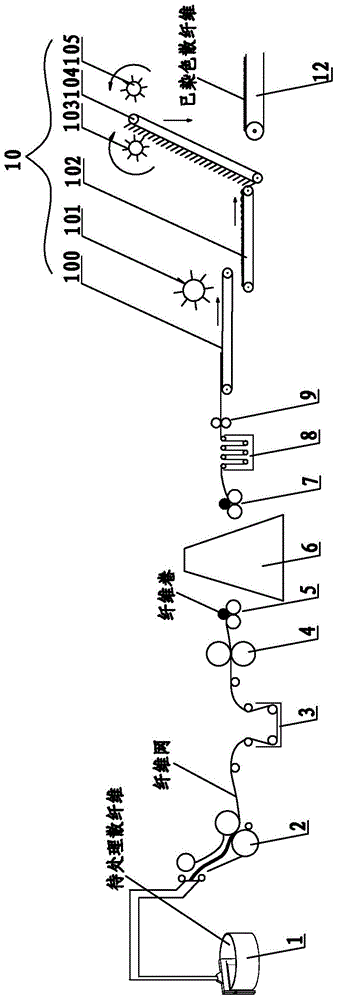

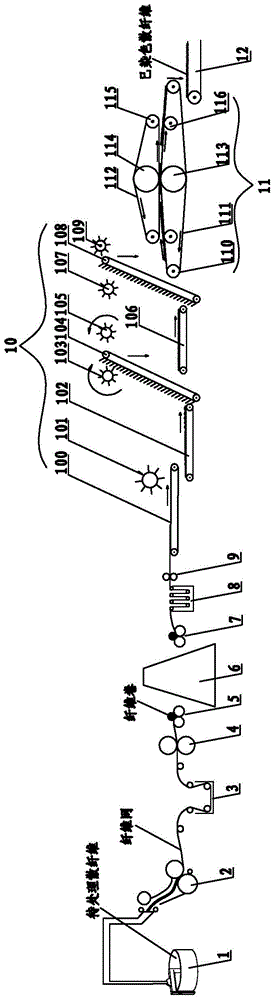

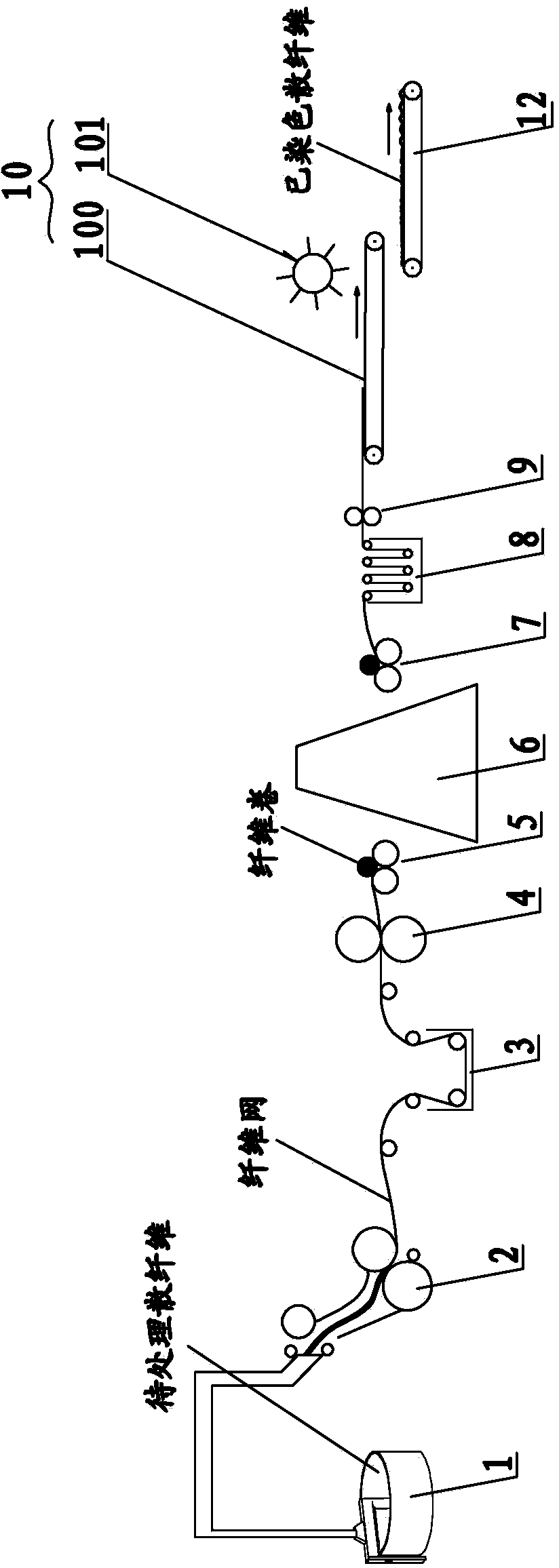

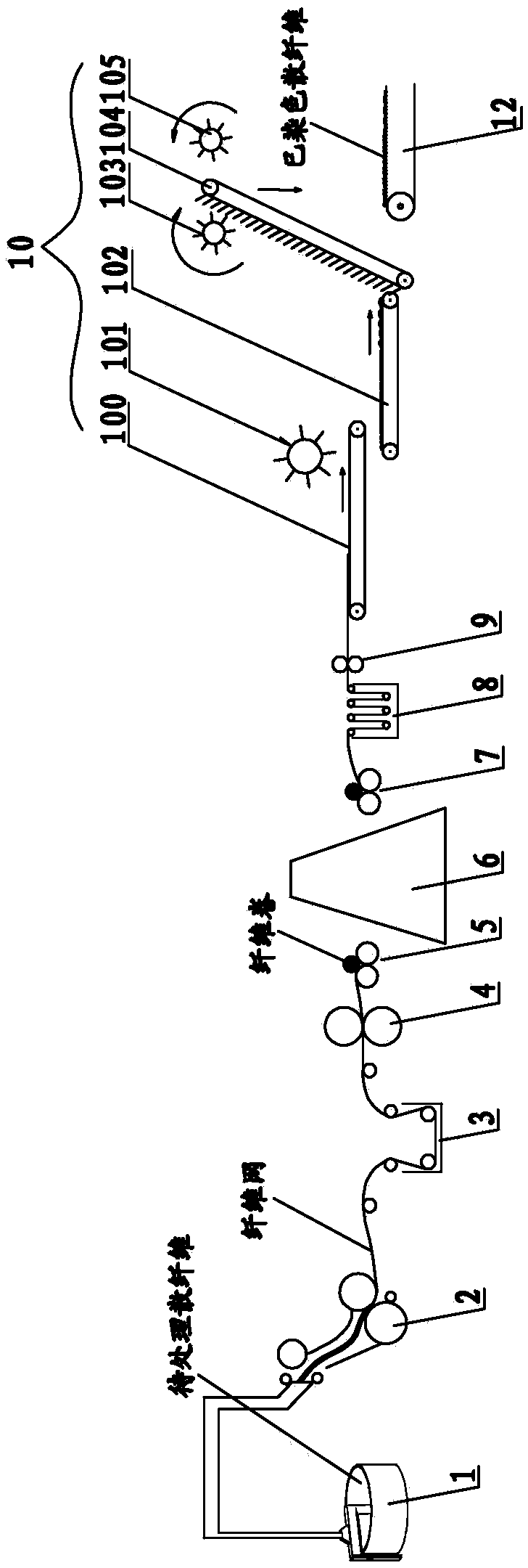

Loose fiber dyeing process

ActiveCN103911782AEvenly dyedConvey evenlyTextile treatment machine partsLiquid/gas/vapor fibres/slivers/rovings treatmentFiberPolymer science

The invention relates to a loose fiber dyeing process and belongs to technical field of fiber dyeing. The process sequentially includes: grabbing cotton, forming nets, soaking, mangling, forming rolls, cold piling, unrolling, washing, squeezing, splitting, spreading and drying. Squeezed loose fibers are fed to the spreading procedure after splitting, the loose fibers are squeezed at the squeezing force of 3-15kg / cm<2> under the premise of not damaging the fibers, the squeezed dyed fibers are directly fed through a lower conveying belt to an eight-cage dryer or a loose fiber high-frequency dryer for drying. By the process, the defects that continuous production cannot be performed and machining efficiency is low in conventional technologies are overcome, the defects that of uneven dyeing, low drying efficiency, large energy consumption and the like when the loose fibers are dried in a net structure are overcome, fiber damage is low during processing, and the quality of the finished fibers is guaranteed.

Owner:SHAOXING GUOZHOU TEXTILE NEW MATERIAL

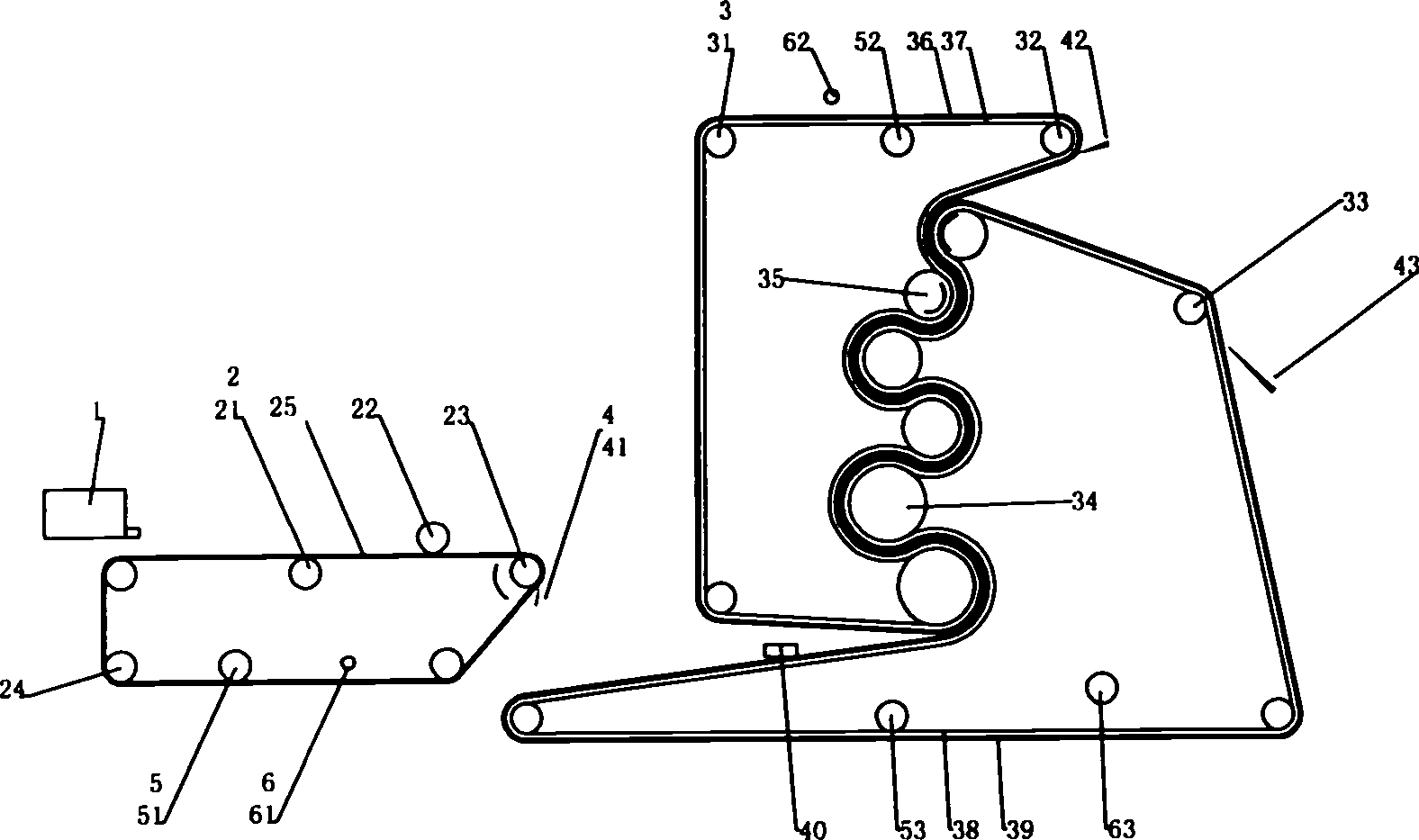

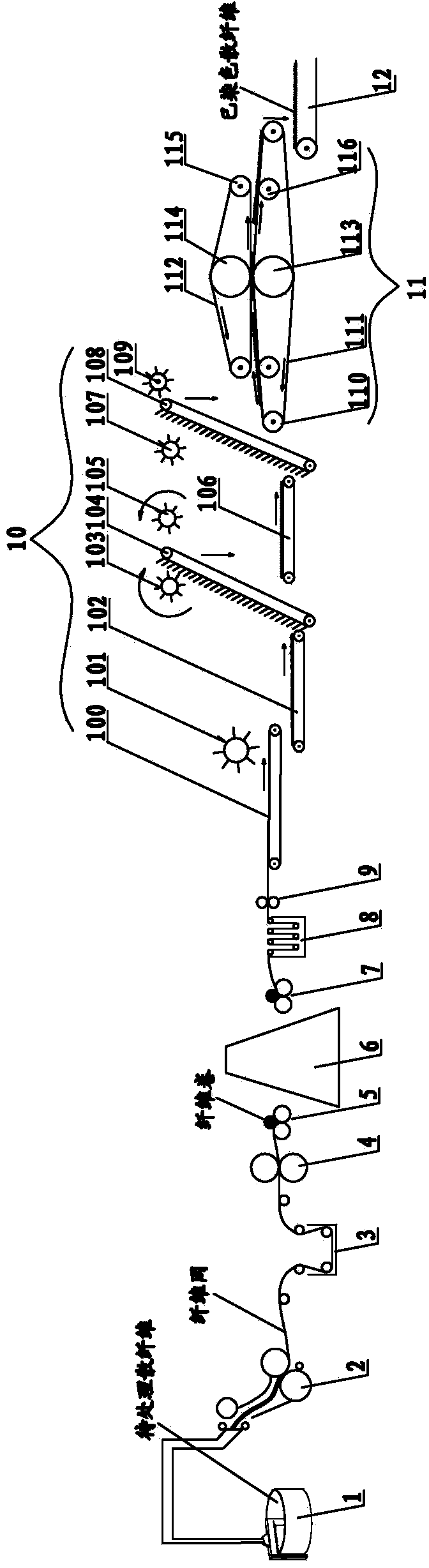

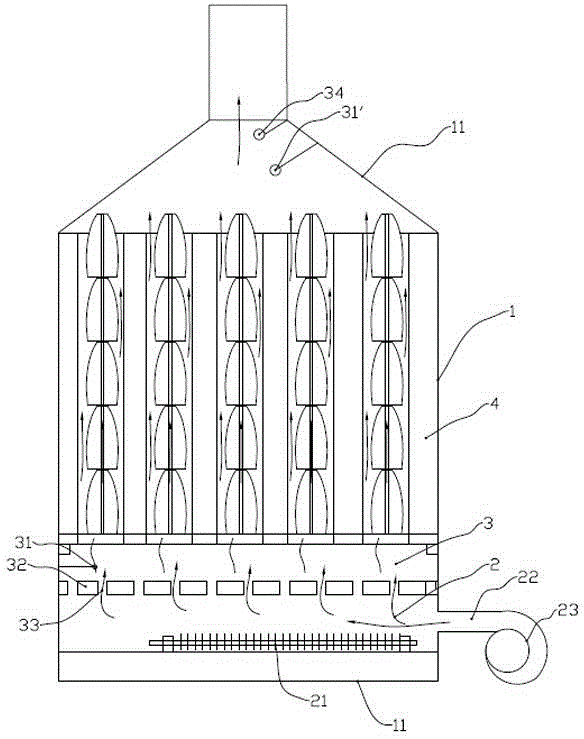

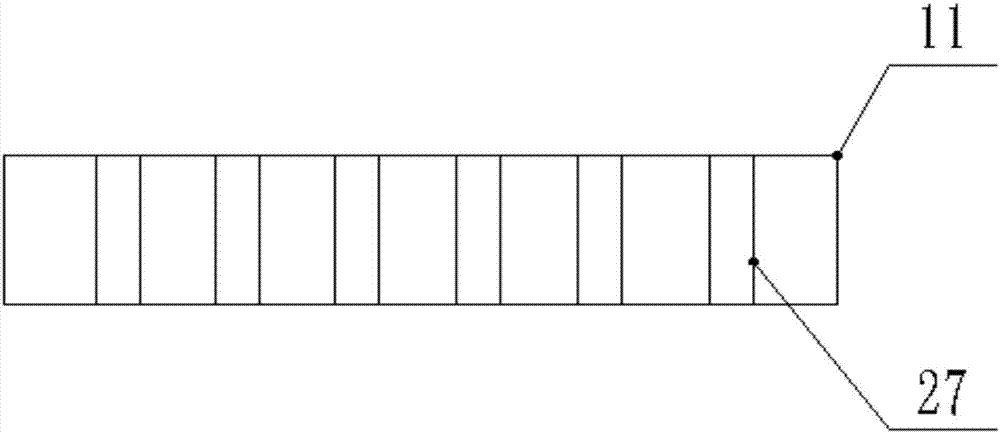

Loose stock dyeing device

ActiveCN103882637AEvenly dyedConvey evenlyTextile treatment machine partsLiquid/gas/vapor fibres/slivers/rovings treatmentFiberProcess efficiency

The invention relates to a loose stock dyeing device and belongs to the technical field of stock dyeing devices. The loose stock dyeing device comprises a cotton grabbing device, a net forming device, a steeping device, a mangle device, a coiling device, a cold-batch fixation device, a uncoiling device, a washing device, a squeezing device, a splitting device and a drying device, wherein the cotton grabbing device, the net forming device, the steeping device, the mangle device, the coiling device, the cold-batch fixation device, the uncoiling device, the washing device, the squeezing device, the splitting device and the drying device are sequentially arranged. A loose stock net after squeezing is sent to the splitting device to be split and sent to the drying device to be dried. According to the technical scheme, the defects that continuous production cannot be performed and processing efficiency is low in the prior art are overcome, and the defects that dyeing is uneven, drying efficiency is low and energy consumption is large in drying loose stock with a net-shaped structure are overcome. In the processing process, stock damage is little, and the quality of finished stock products is ensured.

Owner:SHAOXING GUOZHOU TEXTILE NEW MATERIAL

Sepiolite purification technique

ActiveCN101288857AEasy to control the degree of dispersionAvoid pollutionWet separationSlurryPollution

The invention provides a sepiolite purification process, belonging to the sepiolite purification process, which mainly solves the technical problems that the existing process can not continuously produce the sepiolite with higher purity on a large scale, etc. The key point of the technical proposal is that crude ore mixed water is poured into a multi-class mixing pool and mixed with multi-class by a slow-speed mixing machine to prepare the slurry, settled with multi-class by an overflow settlement trough, and settled with multi-class by a buffer settlement pool and separated to prepare sepiolite suspension; solid and liquid separation of the sepiolite suspension is carried out by a screen filter device; dehydration by a press filter machine and the drying are carried out so as to gain the product. The sepiolite purification process is convenient for controlling the dispersion degree of the pulp and continuous producing; the yield is greatly improved; the sepiolite purification process avoids the defect that the sepiolite is difficult to be separated from the water by the normal press filter machine; furthermore, no other filter aid is added, thus avoiding pulp pollution and greatly improving the dehydration speed. As the centrifuge is not adopted, the process can greatly reduce the energy consumption and increase the output. The sepiolite purification process can be widely applied to the processing and purification of various low-grade sepiolites.

Owner:湘潭海泡石科技有限公司

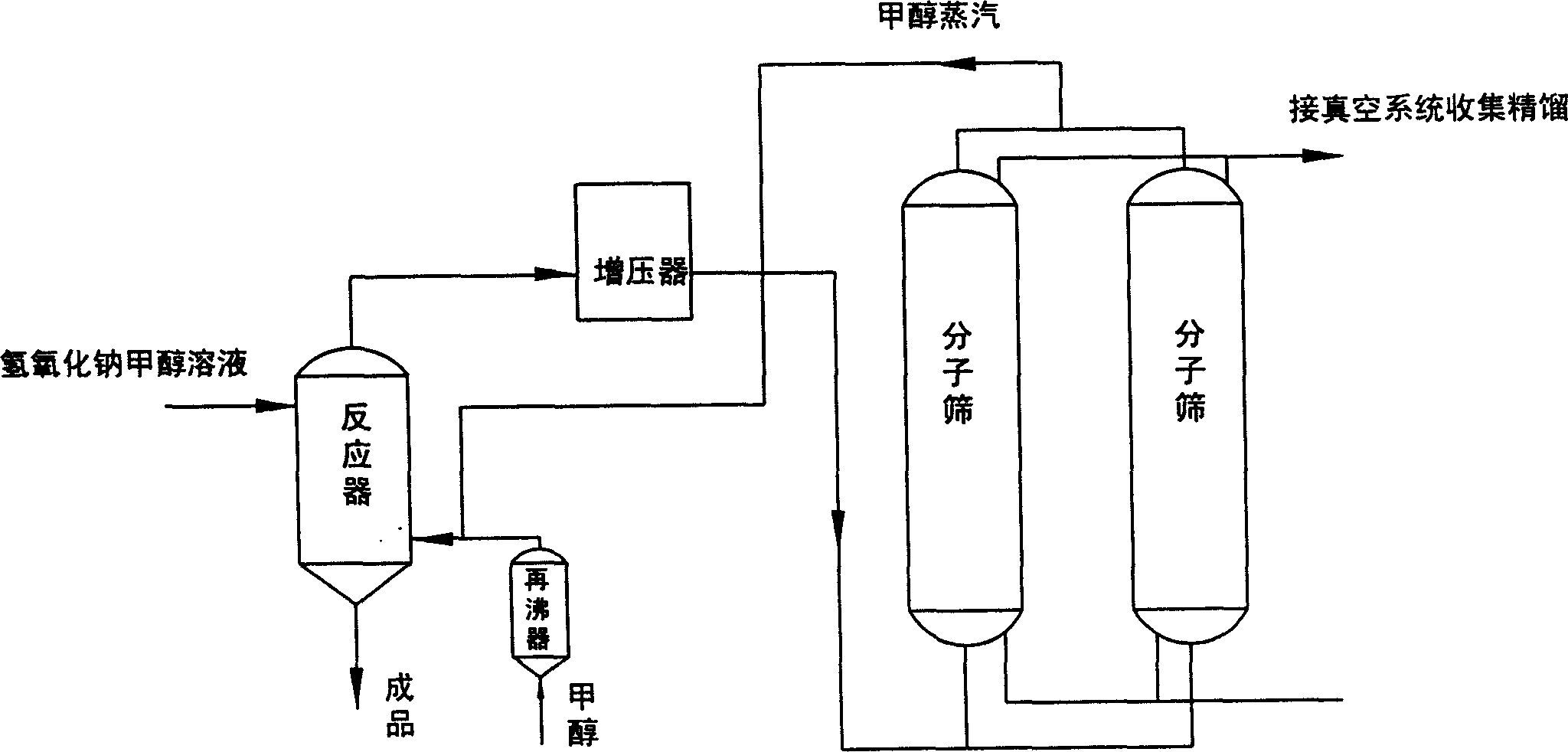

Technique of alkaline process for producing sodium methoxide/sodium ethylate

InactiveCN1626488AQuick responseContinuous responsePreparation of metal alcoholatesSodium methoxideMolecular sieve

A process for preparing sodium methoxde (or ethoxide) by alkali method includes reaction between excess methanol (or ethanol) and sodium hydroxide to obtain product, dewatering the vapour of methanol (or ethanol) by parallel two molecular sieves for alternative adsorption and desorption, and rectifying the solution of methanol (or ethanol) for reuse. Its advantage is no pollution.

Owner:于志波

Method for processing sludge resources

InactiveCN101671588AFast dehydrationReduce moisture contentSludge treatment by de-watering/drying/thickeningBiofuelsSludge cakeProcess engineering

The invention discloses a method for processing sludge resources. The method comprises the following steps: (1) evenly mixing the crushed dry plant-based wastes generated in the industrial and agricultural production with sludge cake with moisture content of 80wt%-85wt%; the moisture content of the mixture is lower than 55 wt%-60wt%; (2) the mixture is heated and dried until the moisture content thereof is 20 wt%-25wt%; (3) fuel particles are produced through a granulating machine; and (4) the fuel particles are used for heat supply for the drying step. Since the plant-based wastes provided with low moisture content and generated in the industrial and agricultural production are mixed with the sludge cake, the dehydration speed of the mixture in a drying apparatus is higher than that of the single sludge cake, the drying temperature is lower, and the heat consumption is less. The fuel particles obtained by the method can be taken as the energy resources to replace the fossil energy forsewage treatment, and simultaneously, the obtained heated steam also can be taken as resource to sell.

Owner:天津紫荆能源技术有限责任公司

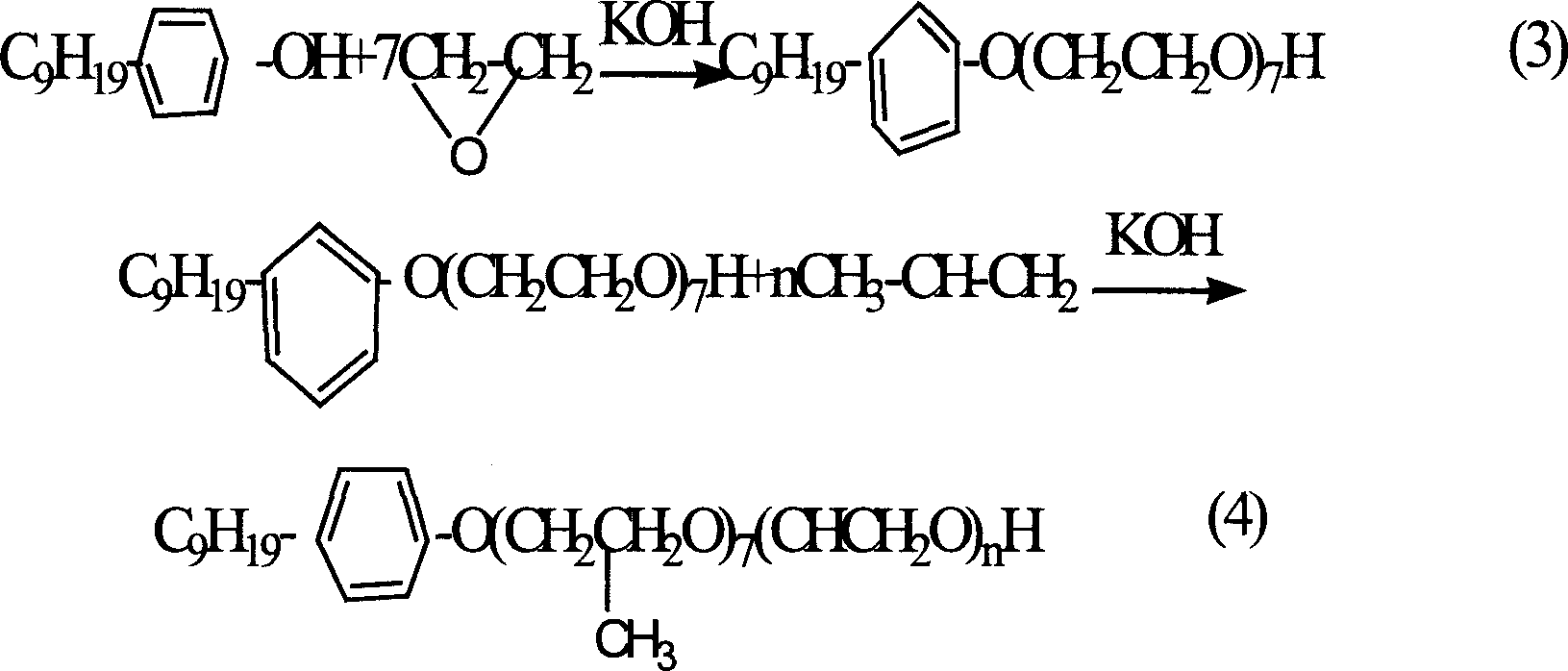

Highly efficient anti-phase emulsion breaker for thick oil pollution water processing

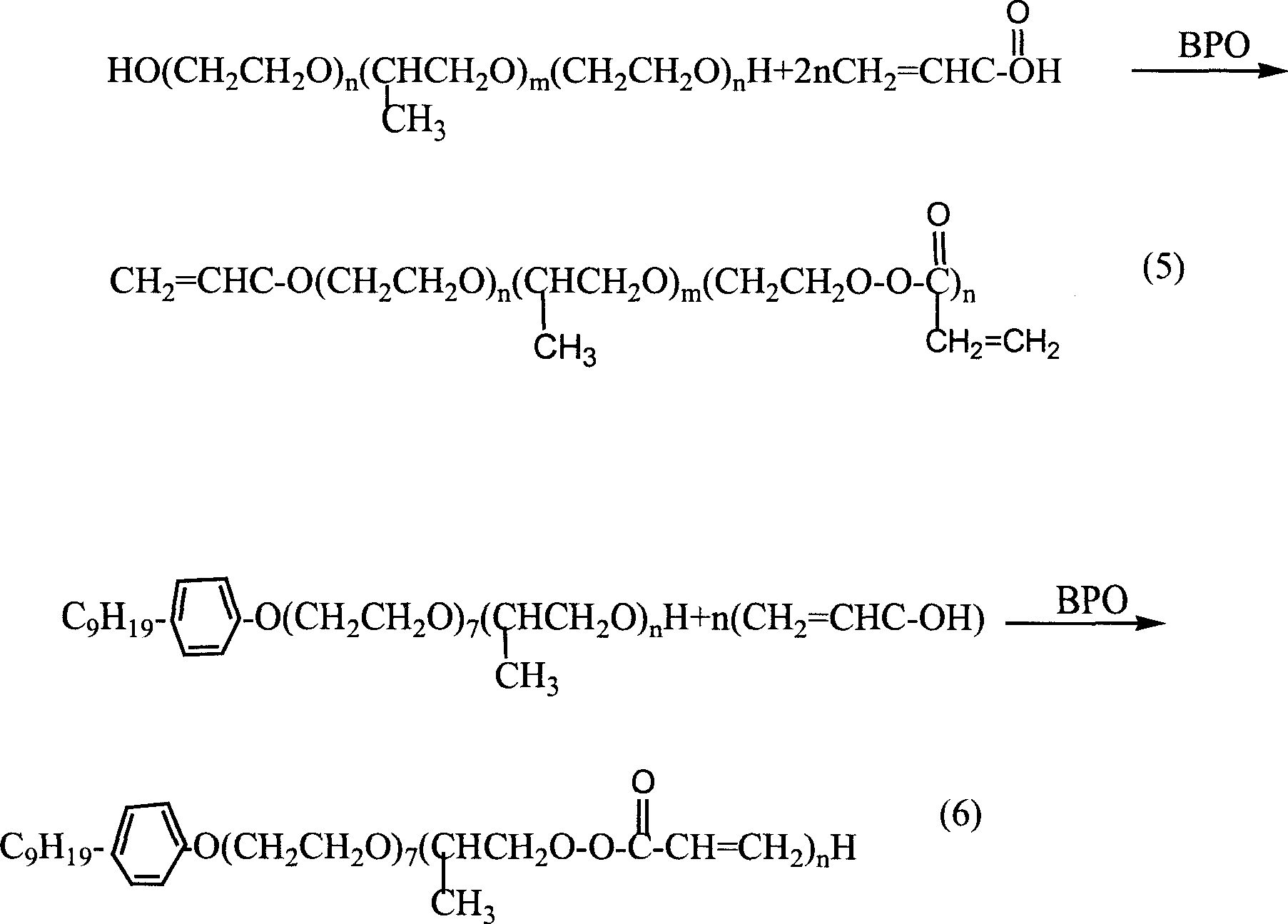

InactiveCN1966138AFast separationReduce oil contentTransportation and packagingMixingWater processingPhenol

The invention relates to a dense oil sewage treatment reverse-phase demulsifying agent, wherein the invention is characterized in that: it uses methyl glycol as initial agent, via catalyst, to process oxypropylation reaction, and process aggregation with epoxyethane, to generate methyl glycol polyether; uses nonyl phenol as initial agent, via catalyst, to react with epoxyethane to generate nonyl phenol ethoxy compound, then to be aggregated with epoxypropane, to generate alkyl phenol polyvinyl ether; then mixing two products, to process esterification with acroleic acid under acid condition, via initiator to process free group aggregation, to generate esterified product, then uses maleic acid to seal end, to generate acroleic acid modified macromolecule demulsifying agent. The invention has simple process, warm reaction, and high efficiency.

Owner:YANGTZE UNIVERSITY

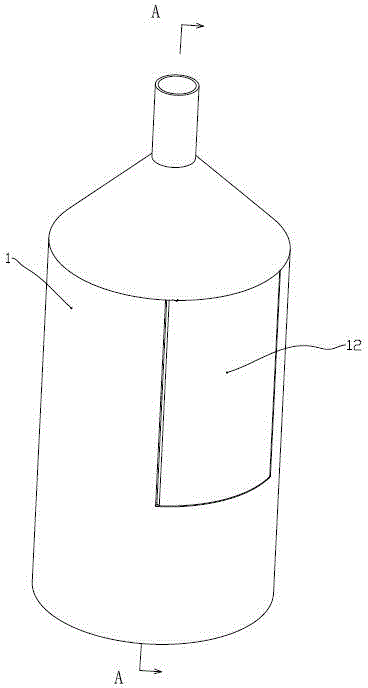

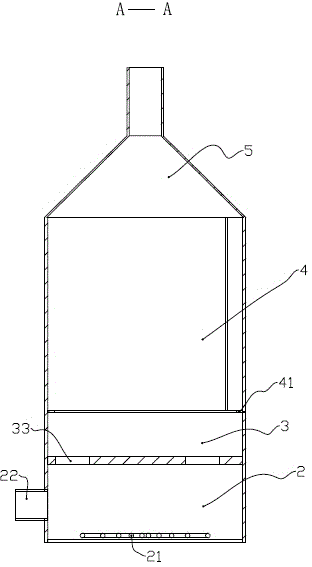

Corn ear fast air drying machine and method

InactiveCN103954103ADehydration fastImprove dehydration efficiencyDrying gas arrangementsDrying solid materialsLiquid-crystal displayEngineering

The invention relates to a corn ear fast air drying machine and method. The air drying machine comprises a drum body; end covers are arranged at the top and bottom of the drum body; a heating bin, a wind homogenizing bin, an air drying bin and an exhaust channel are sequentially arranged in the cavity in the drum from bottom to top; electric heating pipes are arranged at the bottom of the heating bin; a blast hole is formed in the drum body; a wind homogenizing plate is arranged between the heating bin and the wind homogenizing bin; a temperature sensor is arranged in the wind homogenizing bin; a turntable is placed at the inner wall of the air drying bin and is provided with through holes; the drum body is provided with a loading side door convenient to open; a flexible clamping plate is arranged at the inner wall of an air duct cylinder; a temperature sensor and a humidity sensor are arranged in the exhaust channel; a liquid crystal display panel is arranged at the outer part of the drum body. The invention also discloses an air drying method, air outlets for entering the air drying bin are arrayed in sequence, large-flow air flows are formed, the air flows can be used for air drying at inner and outer sides of corn ears, air drying can be fast formed and the air drying speed is improved by more than four times compared with the natural air drying speed.

Owner:MAIZE RES INST SHANDONG ACAD OF AGRI SCI

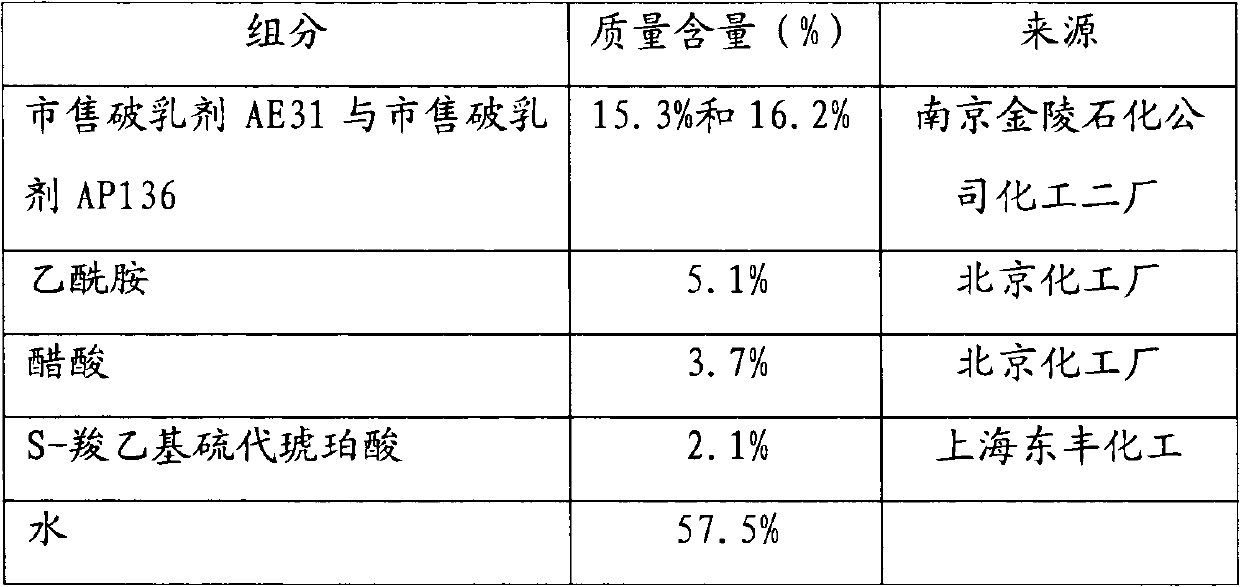

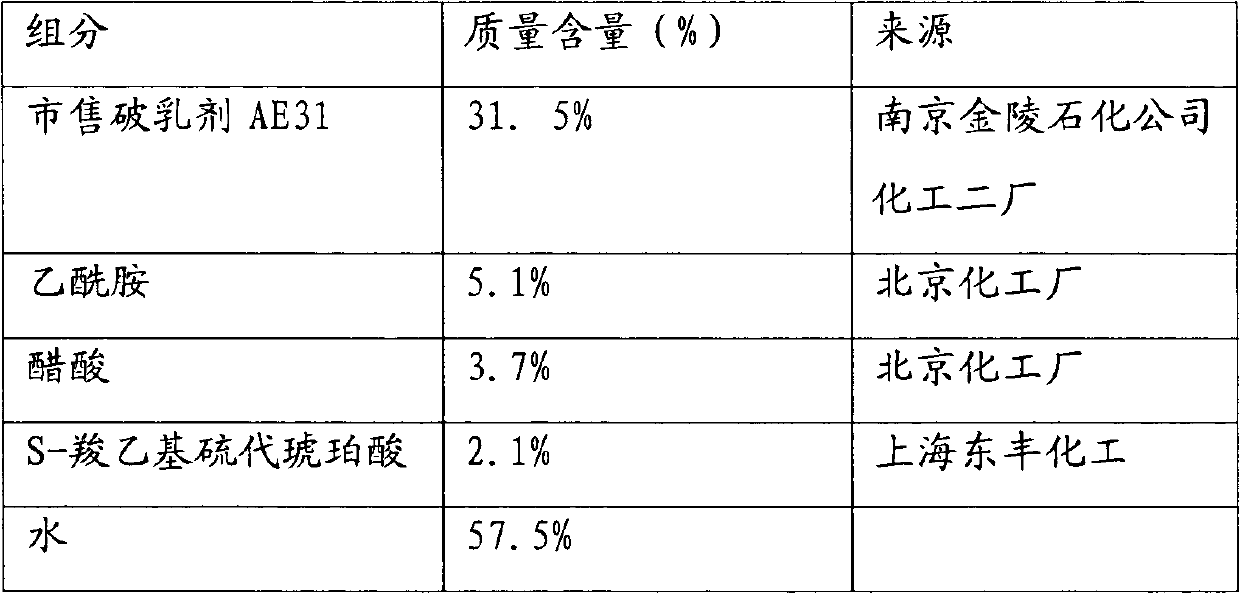

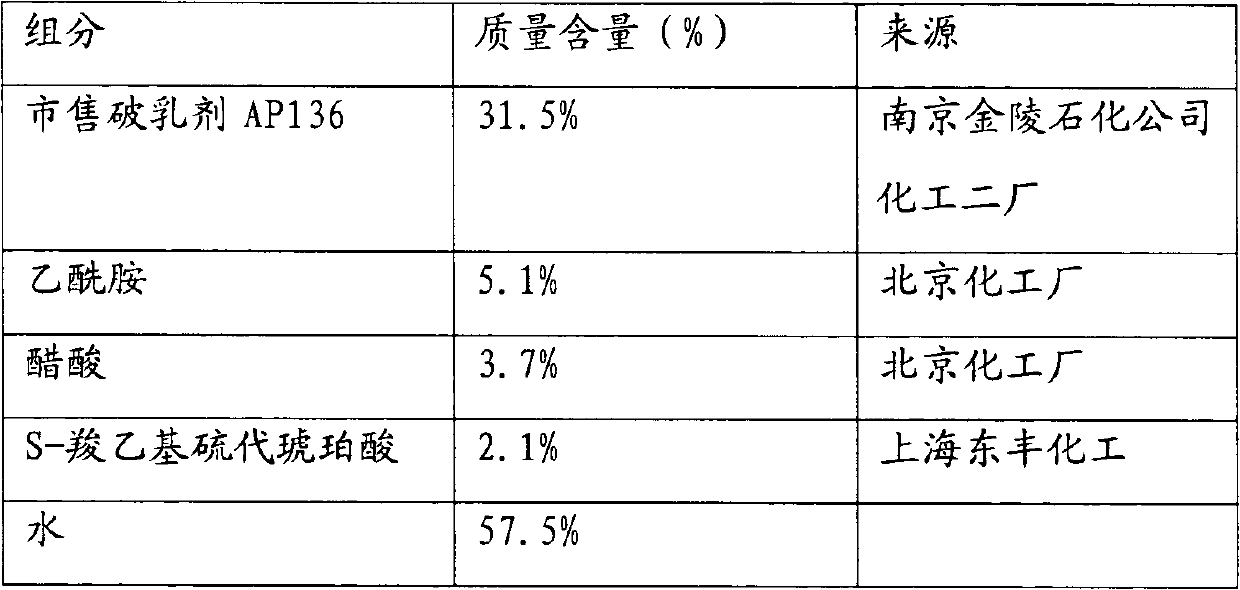

Composite demulsifying agent

ActiveCN103374386AFast dehydrationImprove dehydration rateDewatering/demulsification with chemical meansCarboxylic acidPolypropylene

The invention relates to a composite demulsifying agent. The composite demulsifying agent is a solution which comprises 5-60 parts of polyoxyethylene polypropylene oxide block polyether, 2-10 parts of primary amide, 1-20 parts of C2-C6 carboxylic acids and 20-90 parts of water in parts by mass. When being used for demulsifying high acid crude oil, the composite demulsifying agent has the characteristics of fast dehydration speed, high dehydration rate, low content of water phase and oil and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

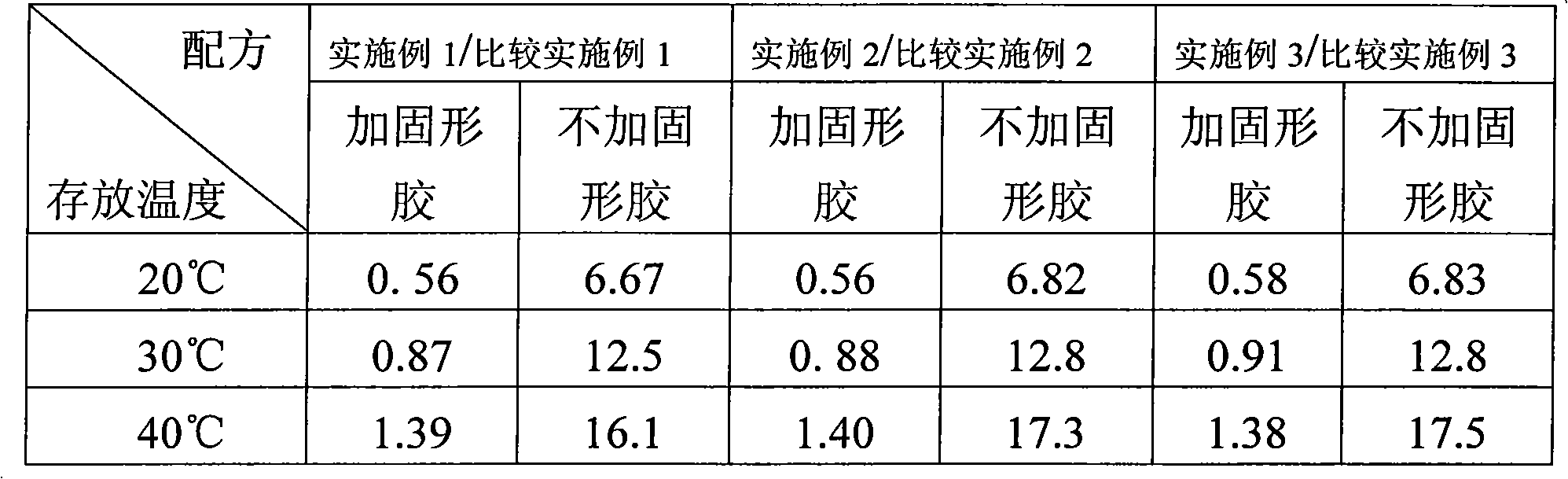

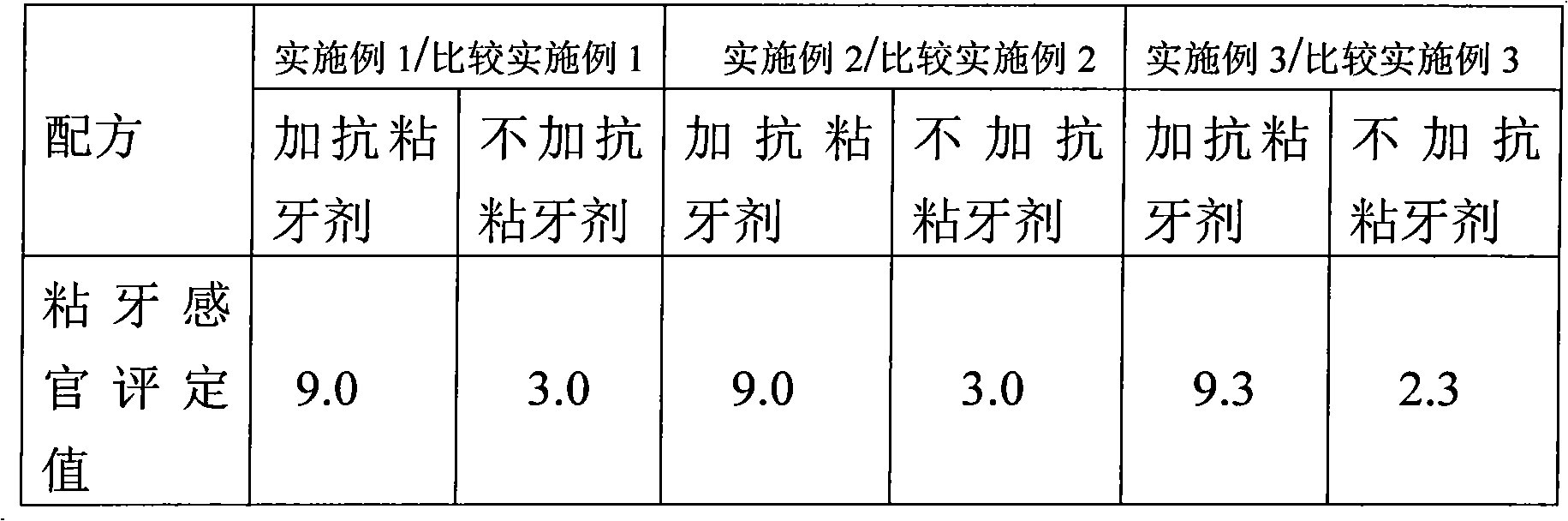

Solid honey candy and preparation method thereof

InactiveCN102058004AChange the curing characteristicsImprove product valueConfectionerySweetmeatsSucroseMicrowave

The invention relates to a solid honey candy and a preparation method thereof. The solid honey candy comprises the following components in percentage by weight: 100 percent of liquid pure honey, 3 to 6 percent of edible solid gum and 0.7 to 3 percent of teeth stick-resisting agent, wherein the edible solid gum is selected from arabic gum, konjac gum and pectin, and the teeth stick-resisting agentis selected from lecithin, sucrose fatty acid ester and water-soluble glycerol monostearate. The preparation method of the solid honey candy comprises the following steps of: weighing the components in a weight ratio, dissolving the edible solid gum and the teeth stick-resisting agent in hot water, adding the solution into the liquid pure honey, dehydrating the obtained mixed liquid by a vacuum microwave heating method to ensure that water content is below 3 percent, performing cast molding at the temperature of between 60 and 70 DEG C, cooling and demolding to obtain the solid honey candy. The honey content of the solid honey candy is above 90 percent; the color, aroma, taste and nutrients of the original liquid honey are basically not changed; a solid shape can be kept at room temperature; and the edible teeth stick-resisting agent is added into the formula, so that the solid honey candy is not sticky to teeth and has good mouthfeel during chewing. The preparation method is easy.

Owner:JIANGNAN UNIV

Processing method of bamboo shoots

InactiveCN103445106ASimple and efficient operationFast dehydrationFood preparationChemistryEdible oil

The invention discloses a processing method of bamboo shoots, and aims to provide a method for enabling the bamboo shoots to be well-cooked, facilitating drying the bamboo shoots and utilizing juice of the bamboo shoots. According to the technical scheme, the bamboo shoots are fumigated with high-temperature and high-pressure steam, the fumigated and well-cooked bamboo shoots are cooled, the cooled bamboo shoots are dewatered by a drying machine, the dewatered bamboo shoots are baked, the flowing juice of the dried bamboo shoots is mixed with edible oil for decocting seasoning. The processing method of the bamboo shoots, disclosed by the invention, comprises the following steps: (1) placing husked and cleaned bamboo shoots in a sealed fumigation pool, and discharging high-temperature and high-pressure steam from a steam boiler to fumigate the bamboo shoots so that the bamboo shoots are well-cooked; (2) cooling and fumigating the well-cooked bamboo shoots out of the pool; (3) dewatering the cooled bamboo shoots by the drying machine and collecting the juice of the bamboo shoots flowing out during drying; (4) baking the dewatered bamboo shoots; (5) mixing the collected juice of the bamboo shoots with the edible oil for decocting the seasoning. According to the technical scheme, the processing method is easy and convenient to operate, the dewatering speed of the dried bamboo shoots is high by using the processing method of the bamboo shoots, and the quality of the seasoning decocted from the juice of the bamboo shoots is good.

Owner:胡素芳

Dried fresh jujube slices and energy-saving process technology for differential pressure expansion drying

PendingUS20190269160A1Difficult to chewIncrease investmentFood coatingFood shapingFreeze-dryingDifferential pressure

A method for processing dried fresh jujube slices includes the following steps: preparing jujube slices, coring and removing stems, quick-freezing and retaining freshness of the jujube slices, thawing frozen jujube slices, protecting color treatment, expanding jujube slices under differential pressure, preparing superfine mixed seasoning powder, and coating of the superfine mixed seasoning powder. For one hand, this method solves problems that the dried fresh jujube slices will be deeply oxidized and brown when dried by the hot air at a high temperature of 90-110° C., the jujube slices with compacted cells will become harder and be difficult to chew because of 6-8 h rapid dehydration. On the other hand, it solves problems that exist in freeze drying at a vacuum degree of 1.3-13 Pa, and at a low temperature of −10-50° C., such as high energy consumption, long processing cycle, high equipment investment, small size of slices, and poor taste.

Owner:NINGXIA ZHONGXI JUJUBE IND LTD LTD +1

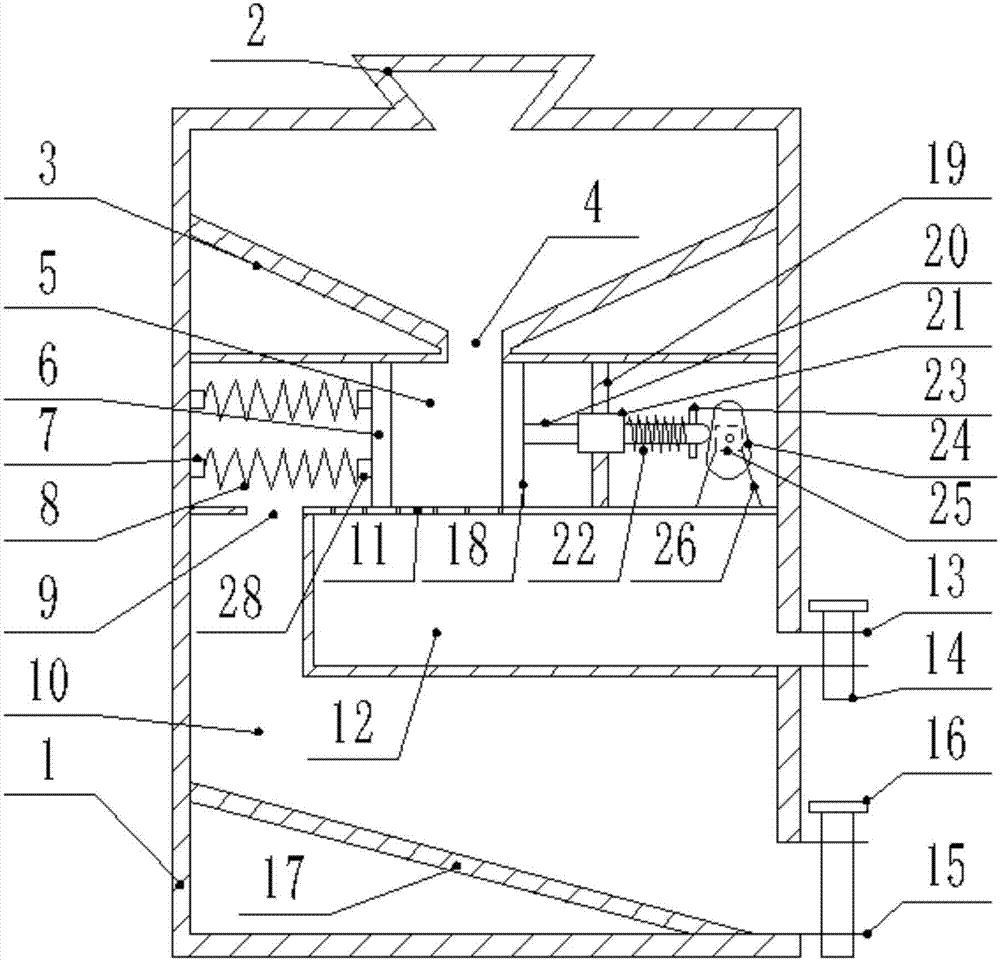

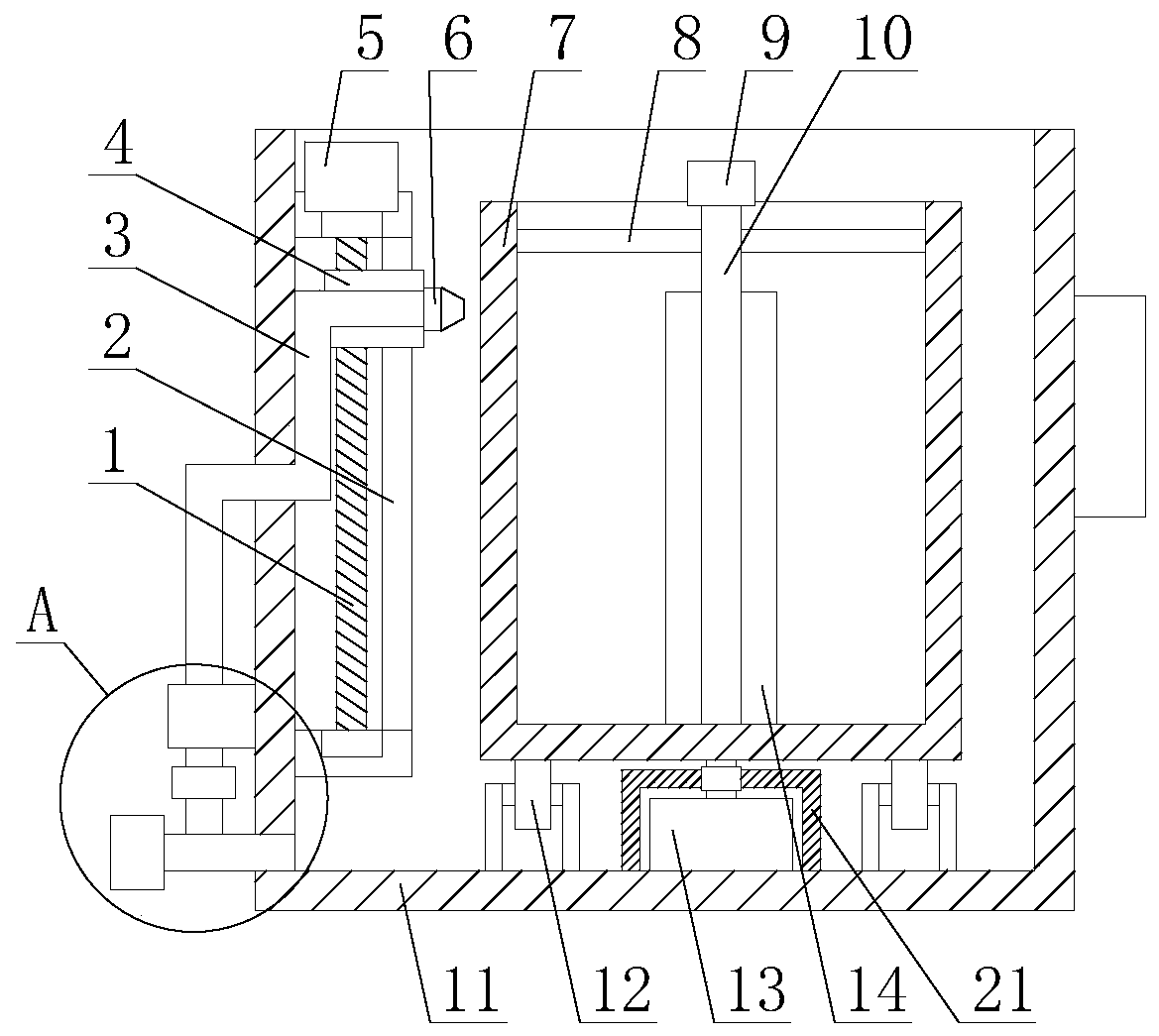

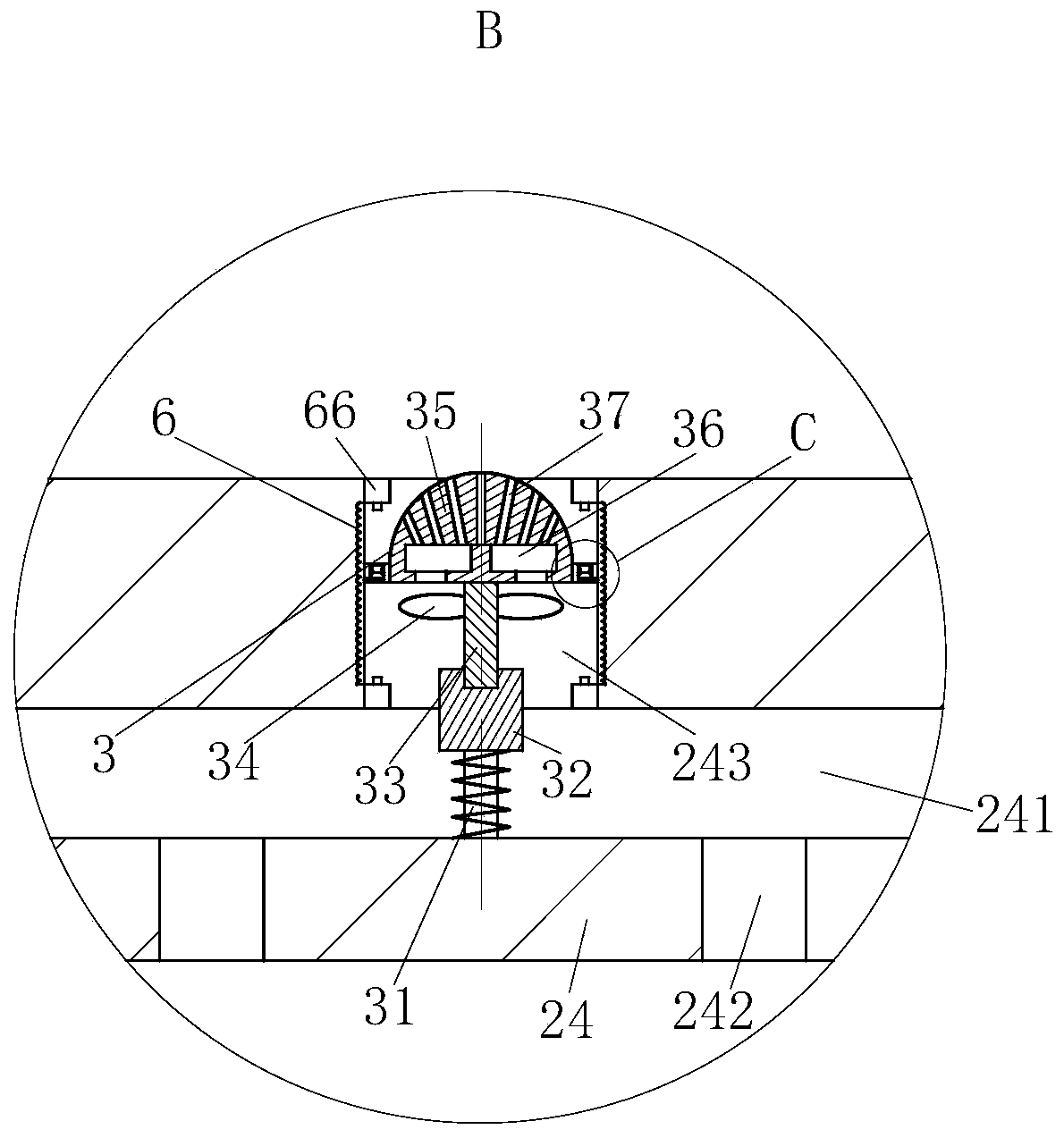

Cam-controlled faece dehydrating device

InactiveCN108002686AEasy to dehydrateFast dehydrationSludge treatment by de-watering/drying/thickeningEngineeringCam

The invention discloses a cam-controlled faece dehydrating device. The cam-controlled faece dehydrating device comprises a dehydration tank, wherein a hopper is connected to the middle of the top tankbody of the dehydration tank; first baffles are respectively connected to the inner walls of the left side and the right side of the upper part of the dehydrating tank; a first discharging opening isformed between the two first baffles; a dehydration chamber is arranged below the first discharging opening; a first extrusion plate is arranged on the left side of the dehydration chamber; second fixed blocks are fixedly connected to the upper end and the lower end of the left side of the first extrusion plate; first springs are connected to the left ends of the second fixed blocks; a first fixed block is connected to the left end of each first spring; a second discharging opening is formed below the first springs; a faece storing chamber is arranged below the second discharging opening; a second baffle is obliquely connected to the lower part of the faece storing chamber; a second discharging pipe is connected to the lower part of the tank body at the right side of the faece storing chamber; a second discharging valve is connected to the middle part of the second discharging pipe; a drainage board is arranged below the dehydration chamber. According to the cam-controlled faece dehydrating device disclosed by the invention, the faece dehydration effect is more obvious, the faece dehydration speed is increased and the working efficiency of faece dehydration is greatly improved.

Owner:ZHENGZHOU HAOEN ELECTRONICS INFORMATION TECH CO LTD

Processing method for raw materials of rattan plaited craft

InactiveCN105252621AExtended service lifeImprove securityWood treatment detailsReed/straw treatmentThree stageHot blast

The invention provides a processing method for raw materials of a rattan plaited craft. The processing method comprises the following steps that raw material rattan within a certain diameter range is obtained, the surface of the raw material rattan is polished and treated to be in the same diameter magnitude and the same length, and 30 rattan is bundled as a set; the bundled raw material rattan is placed in dehydration liquid for 8-12 hours to be soaked and dehydrated; the raw material rattan is washed with clean water to remove the dehydration liquid adhering to the surface after the dehydration; drying is conducted with hot-blast air, the drying is divided into three stages, and the rattan is dried to nine into dry; and the rattan is separated and tiled under the sunlight condition for 20-30 hours to complete the last-stage drying. According to the processing method for the raw materials of the rattan plaited craft, the anticorrosion and inflaming retarding processing treatments are conducted, so that the service life is long and the fireproof safety is high. The efficiency of dehydration of the adopted dehydrating and drying methods is high, and the disinfection treatment is conducted on the raw material rattan in the drying process, so that the batch production process is achieved.

Owner:安徽省丰蓼农业开发有限公司

Coal tar dehydrant and applications thereof

ActiveCN103361109AReduce dosageFulfil requirementsDewatering/demulsification with chemical meansSodium acetateAqueous solution

Provided are a coal tar dehydrant and applications thereof. The coal tar dehydrant is composed of, by weight, 0.08-0.1 part of first component and 1.5-5 parts of second component. The first component is composed of 30 wt.% of polyether, 50 wt.% of methanol and 20 wt.% of tap water. The second component is sodium acetate aqueous solution with a mass fraction of 40%. When the coal tar dehydrant is used to dehydrate coal tar, 1.6-5 kg of the dehydrant is added into 1 ton of coal tar. The dosage of the dehydrant is small, the water content of the coal tar can be reduced to below 3%, which satisfies coal tar finished product requirements. Compared to coal tar dehydrants in the prior art, the coal tar dehydrant is advantaged by rapid dehydration speed, high efficiency and low energy consumption.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Method for conditioning urban sludge by agent compounding

InactiveCN108083609AImprove dehydration effectCalorific valueSludge treatment by de-watering/drying/thickeningElectrochemical sludge treatmentDewatered sludgeMoisture

The invention discloses a method for conditioning urban sludge by agent compounding. The method comprises (1) adjusting pH through an acid solution, then adding iron powder and activated carbon powderinto sludge, carrying out full stirring mixing, starting an aeration device to condition and transferring a part of substances in the sludge into the liquid phase, (2) adding a persulfate into the sludge conditioned in the previous step, activating the persulfate through ferrous ions, oxidizing to break the sludge so that combined water, adsorbed water, interstitial water and free water in the sludge are partially separated, the dewaterability is improved and SCOD, proteins and polysaccharide in the sludge are increased, and (3) after sludge conditioning, carrying out mechanical dewatering toobtain dewatered sludge. The method can reduce the moisture content of the urban sludge from 97 to 99% to 55 to 60%, greatly reduce the specific resistance and volume of the sludge, greatly improve the combustion calorific value, realize harmlessness, stabilization, reduction and recycling of sludge and has a wide application prospect.

Owner:NANCHANG HANGKONG UNIVERSITY

Efficient centrifugal water extractor with cleaning function

InactiveCN110455042AGood energy saving effectImprove work efficiencyDrying solid materials without heatHollow article cleaningAir pumpPulp and paper industry

The invention relates to an efficient centrifugal water extractor with a cleaning function. The water extractor comprises a main body, a water extracting bucket, and a second motor; the water extracting bucket is arranged in the main body, the second motor is arranged on the inner wall of the bottom of the main body, the second motor is connected with the water extracting bucket, a cleaning mechanism and an extruding mechanism are further included, the cleaning mechanism comprises a sliding rod, a lifting block, a water pump, a driving assembly, a nozzle, a first pipeline, a second pipeline, avalve and two mounting plates, the extruding mechanism comprises a ventilation pipe, an air pump, and at least two air bags, and the driving assembly comprises a first motor and a screw. According tothe efficient centrifugal water extractor with the cleaning function, through the cleaning mechanism, the water extracting bucket can be cleaned, the probability that the water extracting bucket is blocked is reduced, the water extracting property of the water extracting bucket can be improved, through the extruding mechanism, cloth in the water extracting bucket can be extruded, the cloth waterextracting speed can be improved, and the work efficiency of the centrifugal water extractor can be improved.

Owner:李晓云

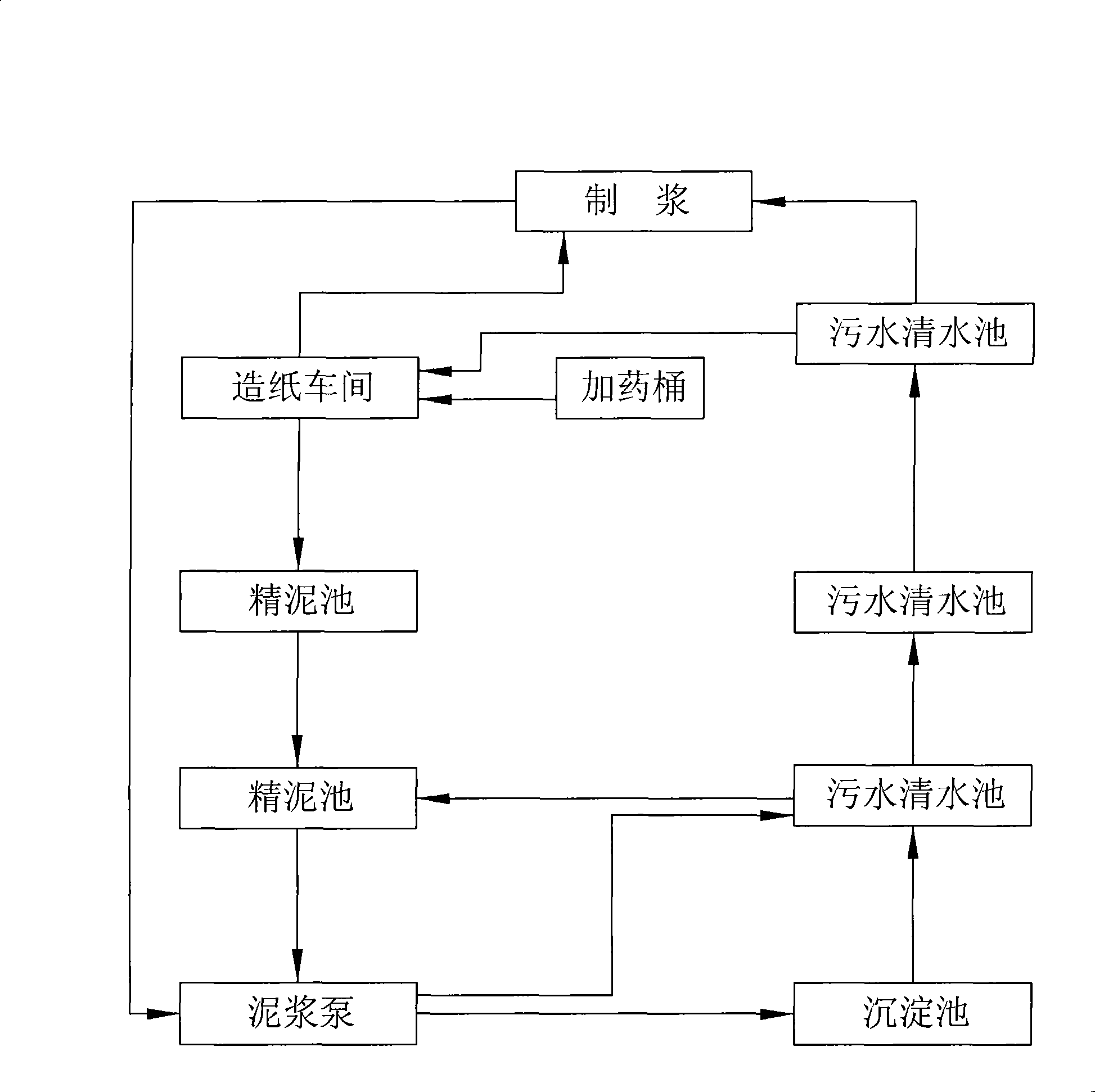

Zero discharge technology of paper making sewage disposal

InactiveCN101381135AReduce meshSave waterWater/sewage treatment by flocculation/precipitationFiberAfter treatment

Owner:许金平

Processing technology of vertical strip-shaped white tea

The invention discloses a processing technology of vertical strip-shaped white tea. The processing technology comprises: a, tea-picking; b, withering; c, fixing; d, tidying of the tea to make shape; e, drying; and f, fragment enhancement. The step of withering combines compound withering indoor and hot air withering, and the withering operation includes: putting the fresh leaves into a water sieve, placing the water sieve into a withering room, withering the tea for 20-30 min by indoor light, naturally withering the tea for 3-5h in the room, putting the tea into a withering groove to perform hot air withering for 10-30 min, and performing the repeated operation for 2-3 times to obtain the withering tea leaves with water content of 40-50%. The step of fragment enhancement includes adding the dried tea into a fragment enhancer, and maintaining the tea in the fragment enhancer for 4-5 min at 100-120 DEG C to obtain the finished product. The processing technology combines compound withering indoor and hot air withering, performs withering alternately, uses the light effectively, promotes the disappearance of browish-green and moisture and conversion of the inclusion, has a certain effect on improving the mellow mouthfeel of tea infusion, provides controllable environment for stably producing high-quality white tea, and can get rid of the restriction of unfavorable weather condition such as cloudy and rainy.

Owner:遵义黔七碗茶业有限公司

Chemical material finished product dehydration tank

ActiveCN109916155APrevent proliferationReduce moisture contentDrying gas arrangementsDrying machines with non-progressive movementsAir blowerDehydration

The invention belongs to the technical field of chemical machinery, in particular to a chemical material finished product dehydration tank comprising a frame body, a gas conveying mechanism, a diffusing mechanism, an air outlet mechanism, a dust removing mechanism, a circulation mechanism and a filtering mechanism; the gas conveying mechanism comprises a hot air blower, a gas conveying pipe and adispersing rod; the upper and lower ends of the dispersing rod are vertically and fixedly mounted on the upper and lower walls of the inner end of the frame body, the dispersing rod is internally provided with a dispersing groove, and the outer surface of the dispersing rod is evenly and fixedly connected with flow guide plates; the flow guide plates are arranged to be in a round cover shape, theflow guide plates are sealed through a circular pipe, a leaking hole is formed in the wall of the flow guide plate at the lowest end, and placing frames are arranged below the flow guide plates; the placing frames are arranged in round pipes, the inner sides of the placing frames are evenly and fixedly connected to the outer surface of the dispersing rod, and the lower walls of the placing framesare internally provided with gas separation grooves. The chemical material finished product dehydration tank is mainly used for solving the problems that an existing dehydration tank cannot completelydehydrate chemical materials, and energy is wasted in the dehydration process.

Owner:双键化工(泰兴)有限公司

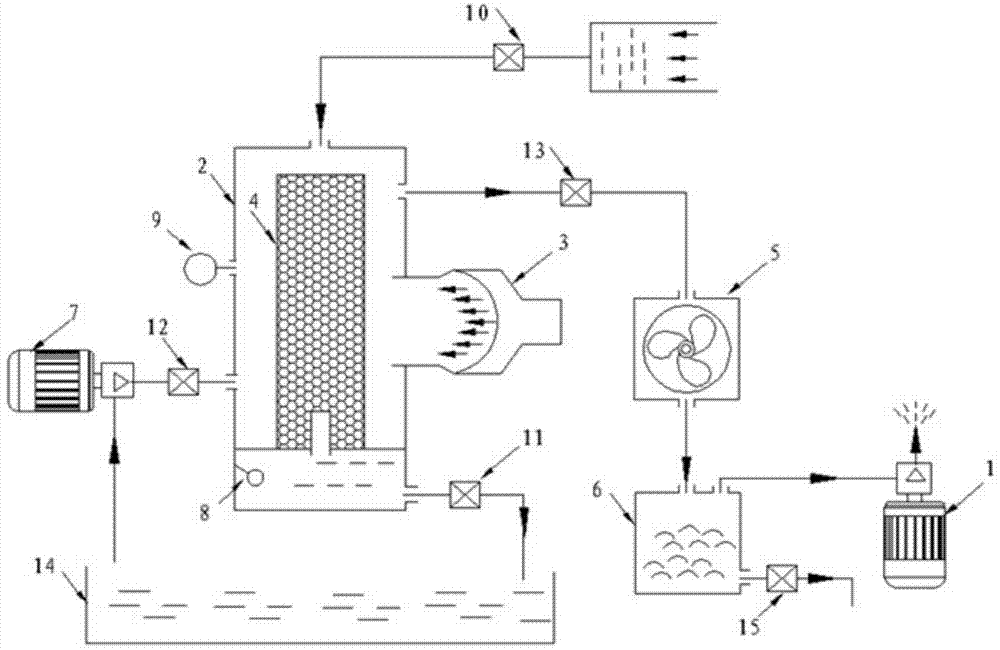

Lubricating oil vacuum microwave water removing device

InactiveCN104771933AFast dehydrationImprove work efficiencyIon-exchange process apparatusIon-exchanger regenerationMicrowaveOil water

The invention discloses a lubricating oil vacuum microwave water removing device. The lubricating oil vacuum microwave water removing device is provided with an adsorption water removing system, and the adsorption water removing system for drying a water adsorption filter element is arranged on a filtering tank body in the adsorption water removing system. Microwaves are used in the adsorption water removing system for heating adsorbed water in the water adsorption filter element, and the adsorbed water in the water adsorption filter element is pumped out under the vacuum negative pressure effect. Compared with the prior art, the device has the advantages that the water removing manner is proper, compared with an existing vacuum heating manner, the lubricating oil water removing speed can be improved by 3 times to 5 times, energy can be saved by more than 90 percent, and therefore the working efficiency is greatly improved; compared with traditional equipment, the size of the equipment is greatly reduced, the weight is small, and transportation and moving are convenient and rapid; the device is reasonable in structure, high in integrality, good in work reliability, few in part, and quite easy and convenient to assemble and maintain.

Owner:周建伟

Dehydrated dried bamboo shoots

InactiveCN107439672ABright colorInhibit the degree of browningFruits/vegetable preservation by dehydrationMicrowaveBamboo shoot

The invention discloses a dried dehydrated bamboo shoot, which relates to the technical field of bamboo shoot processing and comprises the following steps: (1) pretreatment; (2) air-drying treatment; (3) vacuum freezing treatment; (4) microwave drying; The dehydrated dried bamboo shoots, the color is close to fresh bamboo shoots, the properties are basically unchanged, the tissue is loose, the surface pores are large, and the taste is crisp and crisp.

Owner:NINGGUO MAOSHENG FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com