Composite demulsifying agent

A composite demulsifier and composite demulsification technology, applied in the field of composite demulsifiers, to achieve the effects of low oil content in the water phase, high dehydration rate, and fast dehydration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Preparation of demulsifier:

[0016] The corresponding demulsifier can be prepared by mixing the components in the table in proportion until uniform. Among them, the commercially available demulsifier AE31 is a di-block polyoxyethylene polyoxypropylene polyether, and the demulsifier AP136 is a tri-block polyoxyethylene polyoxypropylene polyether.

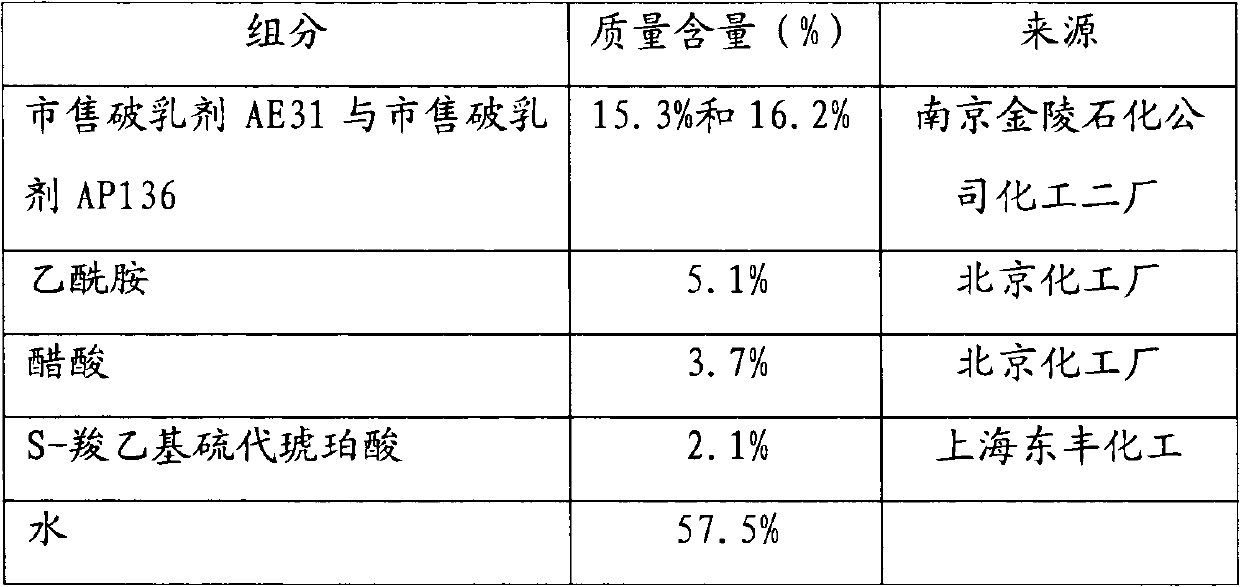

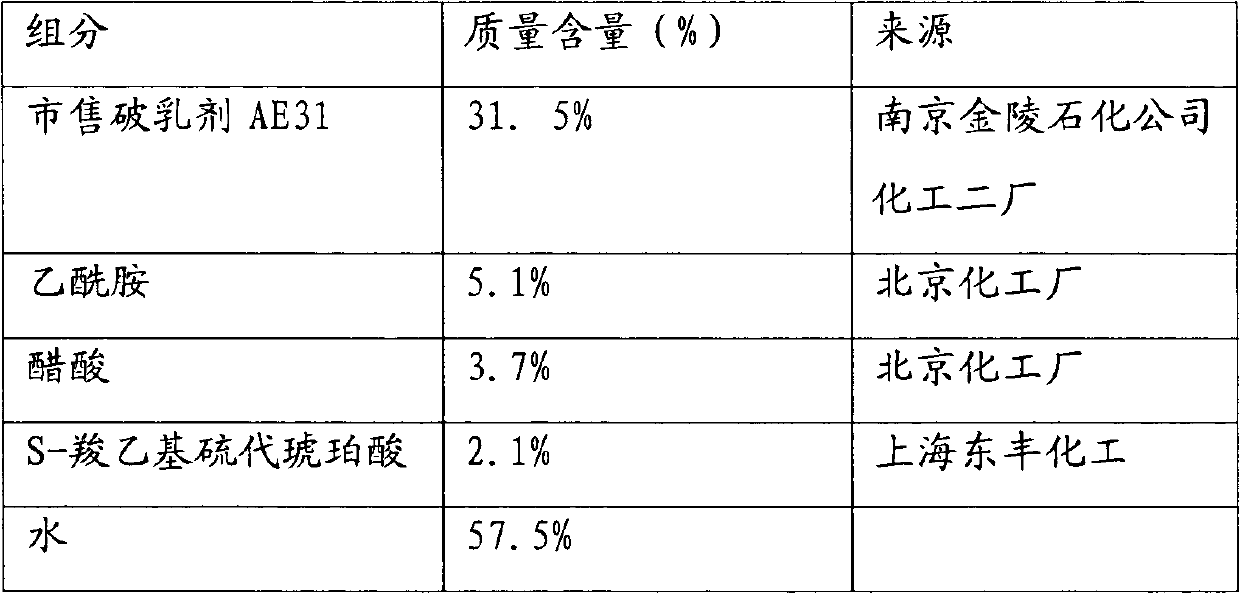

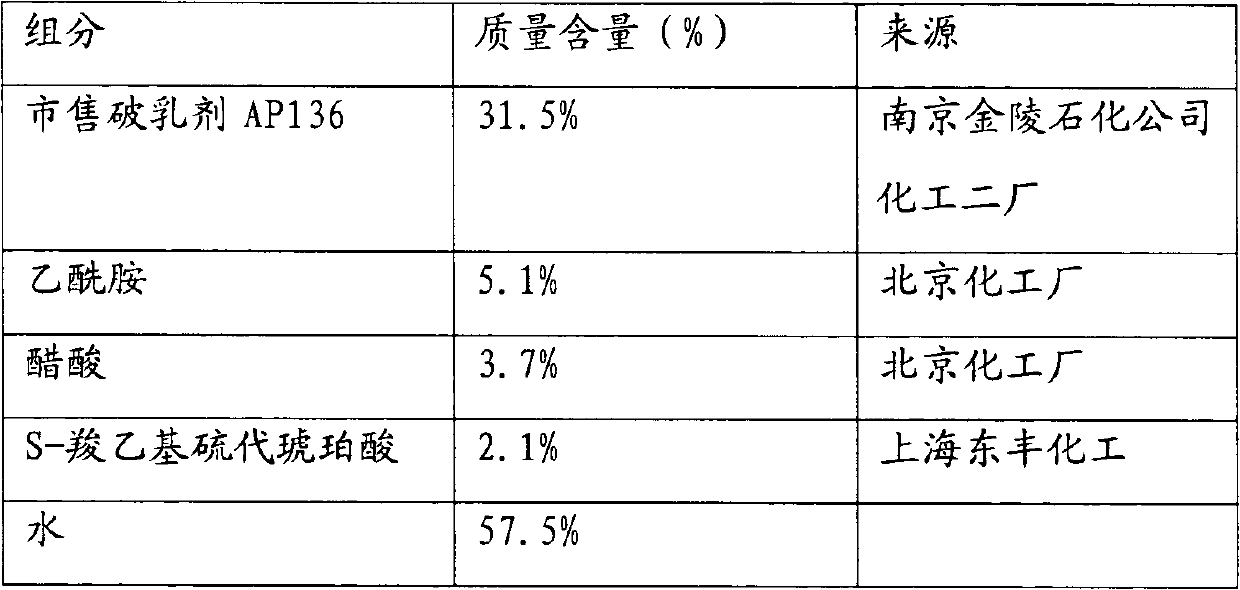

[0017] Table 1 Composition of Demulsifier 1

[0018]

[0019] Table 2 Composition of demulsifier 2

[0020]

[0021] Table 3 Composition of demulsifier 3

[0022]

Embodiment 2

[0024] Demulsifier evaluation test:

[0025] Demulsification tests were carried out using demulsifiers 1, 2 and 3. The oil used in the test is Quidou high-acid crude oil (with a density of 0.9220g / cm 3 , acid value is 2.19mgKOH / g), first preheating the raw material oil to 80°C, adding water (water injection is 10% by mass), demulsifier, fully mixed, placed in a constant temperature water bath at 80°C, and regularly observing the water content. The test results are shown in Table 4.

[0026] Table 4

[0027]

Embodiment 3

[0029] Preparation of demulsifier:

[0030] Prepared according to the method of Example 1.

[0031] The composition of table 5 demulsifier 4

[0032]

[0033] The composition of table 6 demulsifier 5

[0034]

[0035] The composition of table 7 demulsifier 6

[0036]

[0037] The composition of table 8 demulsifier 7

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com