Zero discharge technology of paper making sewage disposal

A papermaking sewage and zero discharge technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of zero sewage discharge and water source pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

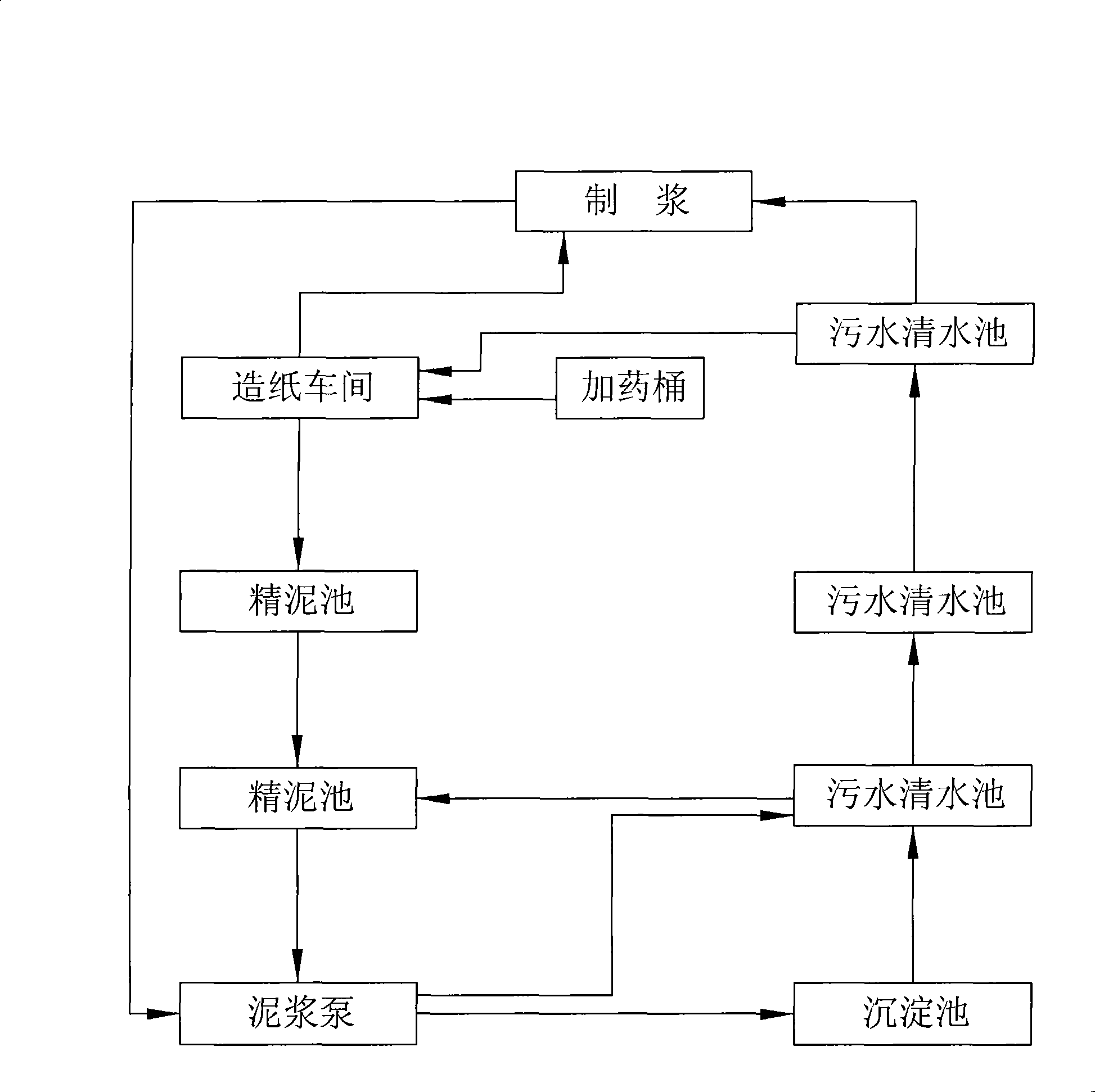

[0005] see figure 1 , this specific real-time mode adopts the following technical scheme: it comprises several fine mud pools 1, several sewage clear water pools 2, sedimentation tanks 3, mud pumps 4, absorbs water source from a sewage clean water pool 2 in the pulping process of papermaking, The papermaking workshop also draws water from the sewage clear water tank 2, and the dosing tank adds medicine to the papermaking workshop. Pool 2; the sewage discharged from the papermaking workshop is treated by two fine mud pools 1, and then pumped by the mud pump 4 into the sedimentation tank 3 and the sewage clean water pool 2. Part of the mud returns to the fine mud tank 1, and the rest of the sewage enters other sewage clear water tanks 2 to continue processing. The invention is mainly used for producing bobbin paper, does not require high bleaching degree, can reuse sewage, and truly achieves zero discharge of sewage. In the present invention, fiber separation and pressure siev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com